Patents

Literature

3032results about How to "Improve working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

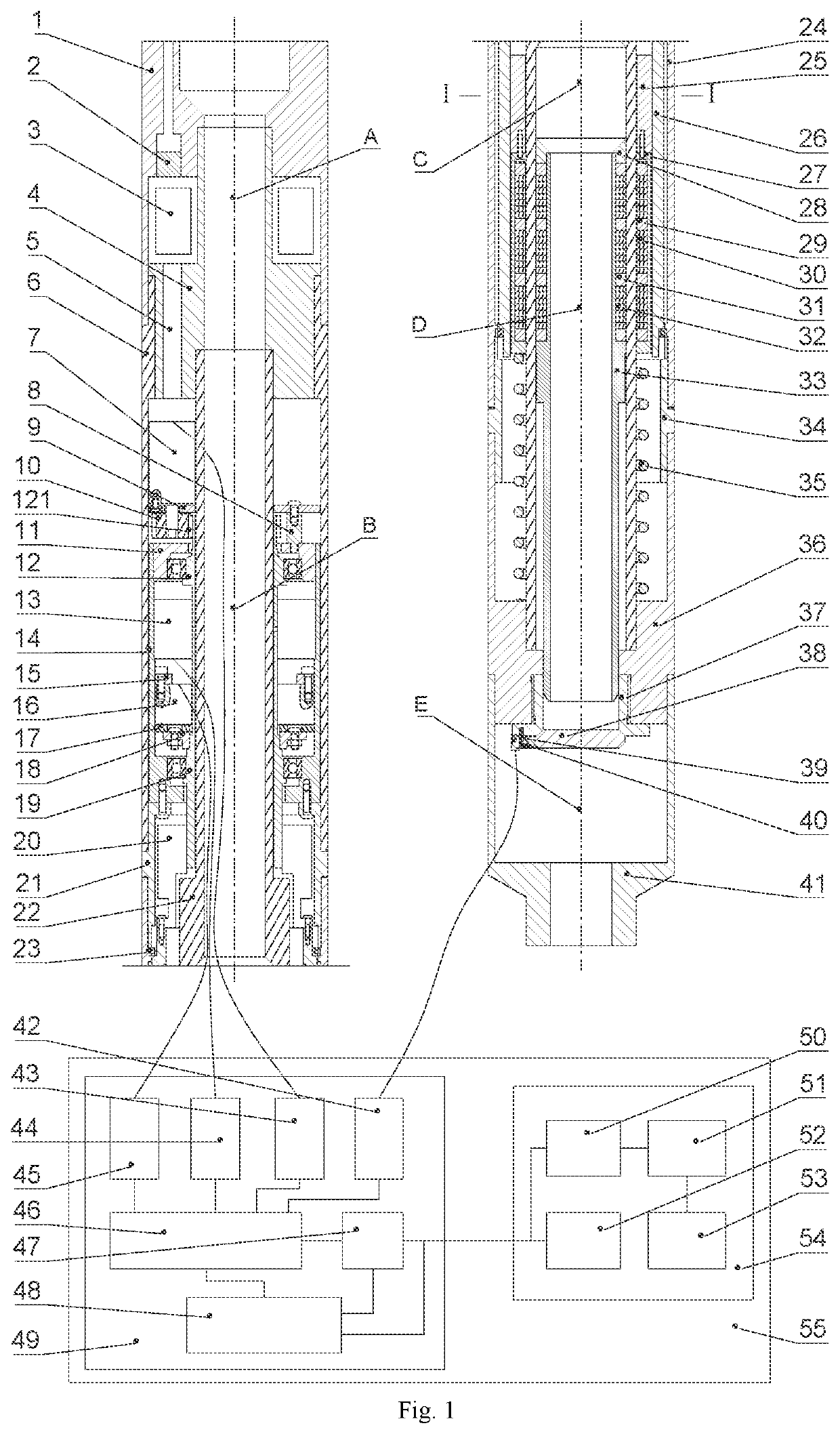

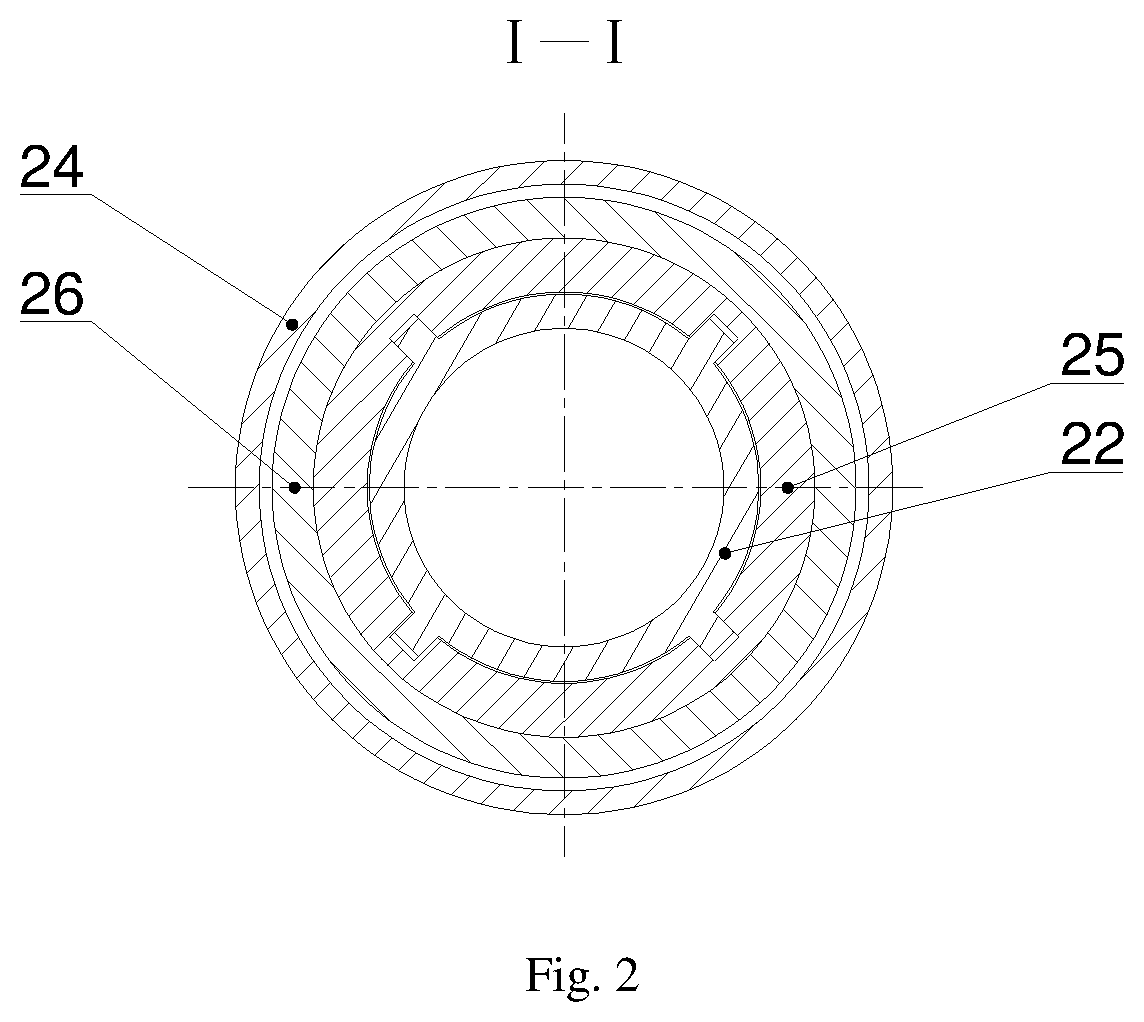

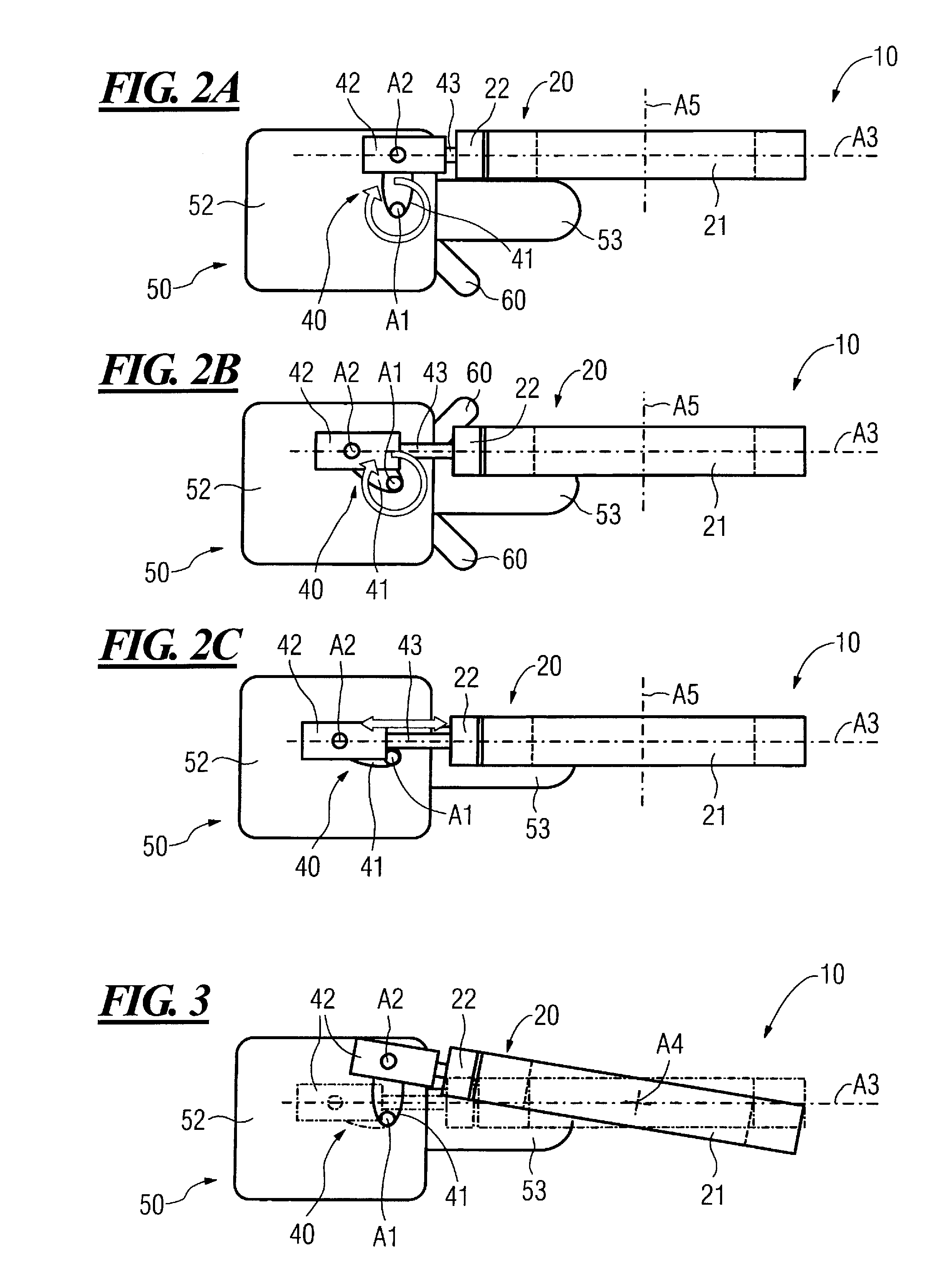

Fully-electrically driven downhole safety valve

ActiveUS10989019B2Improve response speedImprove working conditionsOperating means/releasing devices for valvesConstructionsControl systemMotronic

The present disclosure belongs to the field of petroleum engineering, in particular to a fully-electrically driven downhole safety valve. The fully-electrically driven downhole safety valve comprises a downhole safety valve mechanism and a downhole safety valve control system; wherein the downhole safety valve mechanism includes an electronic cabin module, a transmission control module, a motion conversion module, a magnetic coupling and spring module. and a valve module; the downhole safety valve control system includes a downhole comprehensive unit and an uphole comprehensive unit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

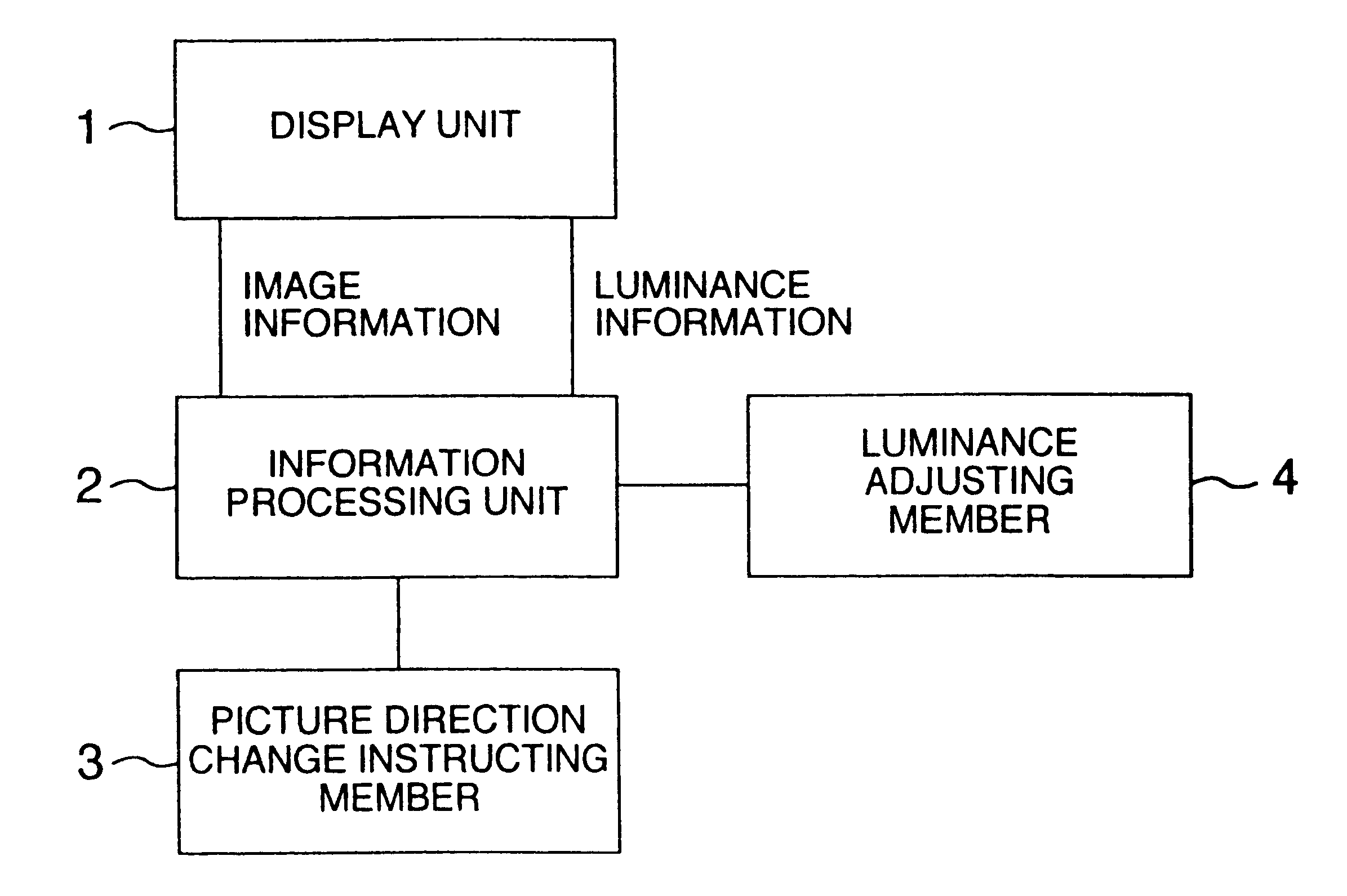

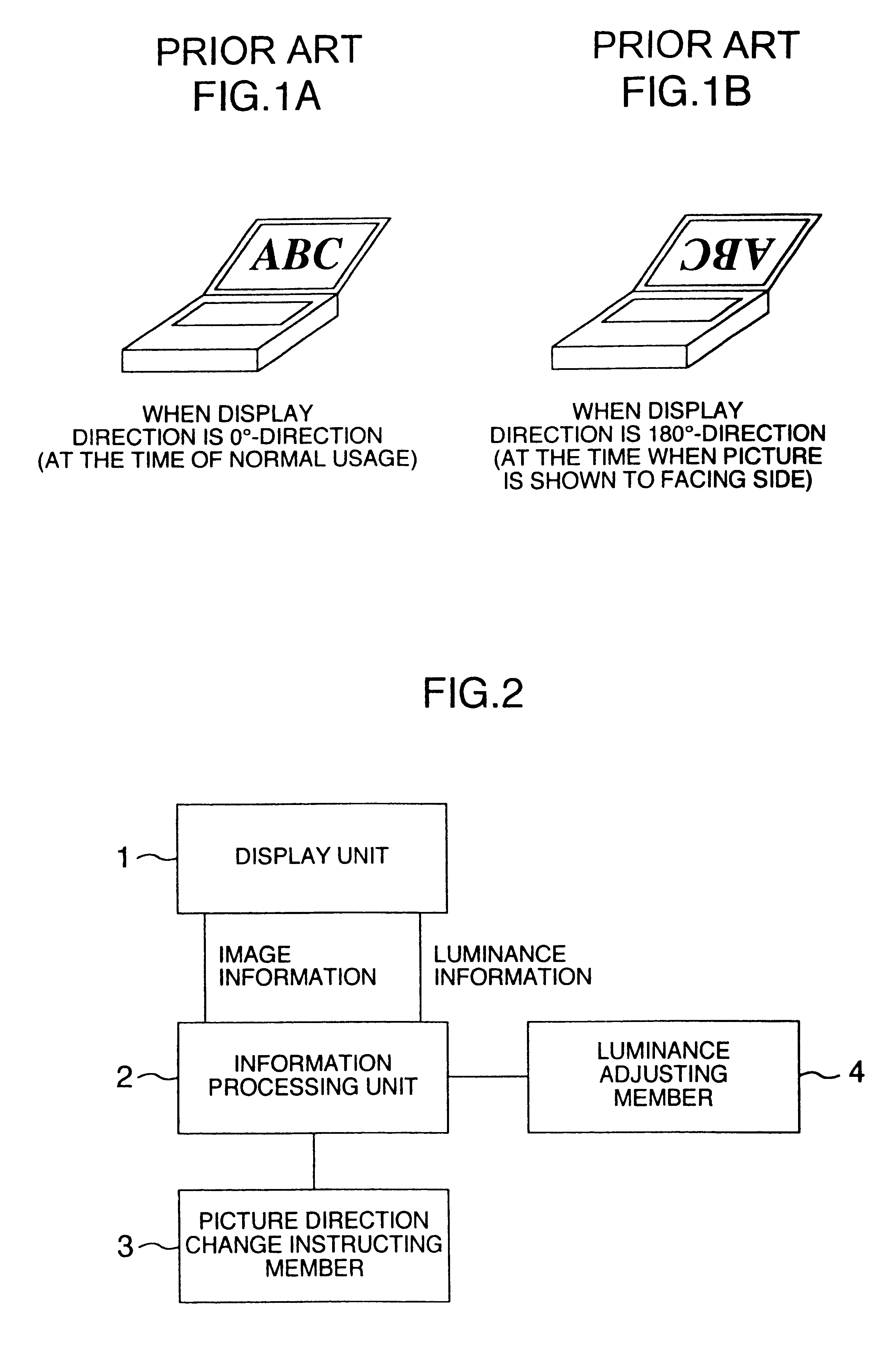

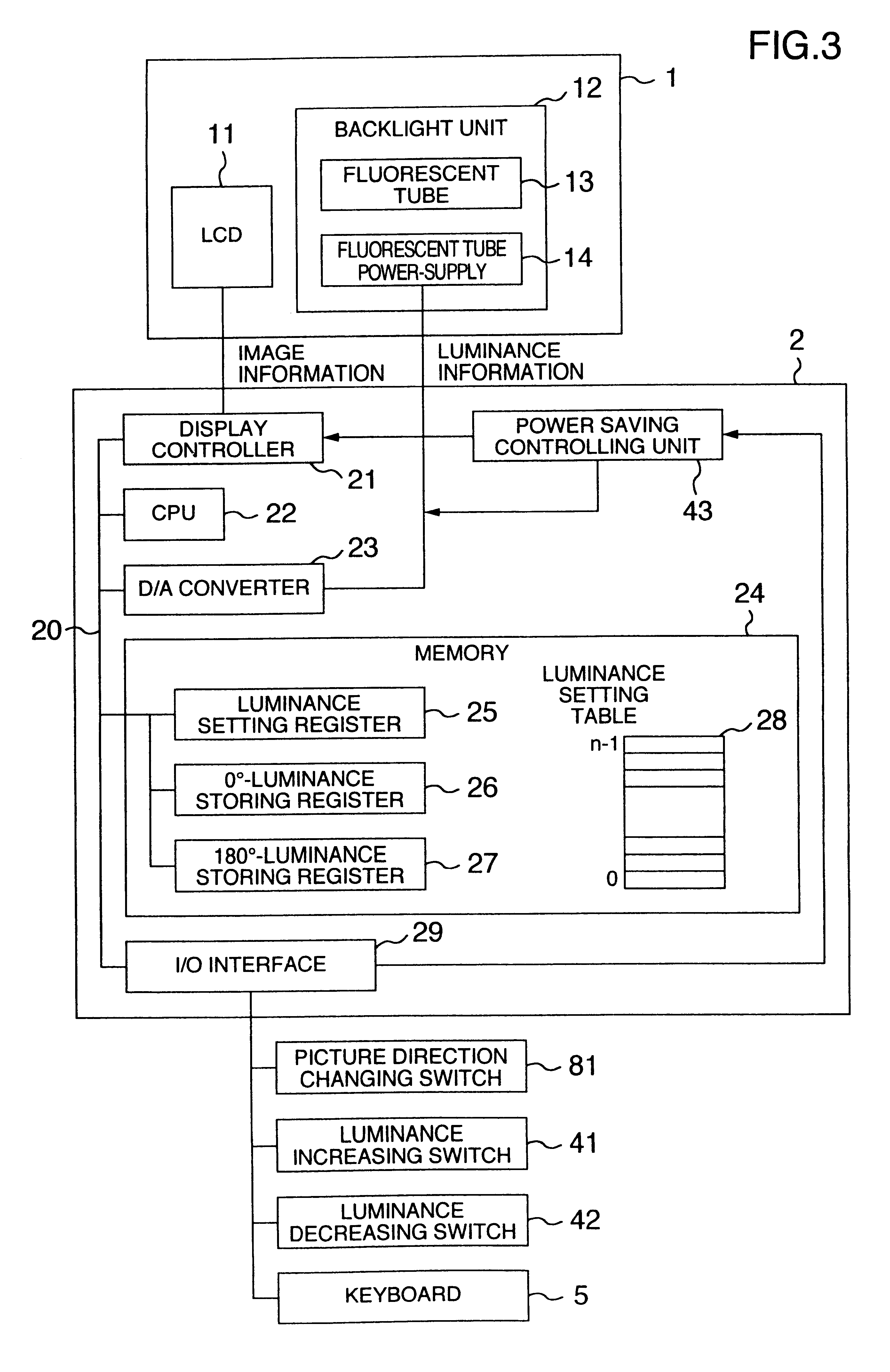

Liquid crystal display apparatus and its luminance control method

InactiveUS6693612B1Easy to seeIncrease impressionTelevision system detailsColor television detailsInformation processingLiquid-crystal display

The information processing apparatus equipped with a liquid crystal display apparatus that is usable in the face-to-face usage style. When the display direction is switched into the facing direction and in a normal usage state, the liquid crystal display apparatus exhibits an excellent visual recognizability and complicated operations are unnecessary. The image information, the picture direction of which has been inverted upside down, is outputted from the information processing unit 2 to the display unit 1 in such a manner as to be coupled with the picture direction change instructing member 3. At the same time, the luminance information at the time of the picture upside-down inversion, which has been set in advance into the luminance adjusting member 4, is supplied to the display unit 1 so as to change the luminance simultaneously with the picture inversion. At this time, the luminance of the display unit 1 at the time of the picture upside-down inversion is changed to a higher luminance, thereby making it possible to enhance the visual recognizability from the facing side.

Owner:MAXELL HLDG LTD

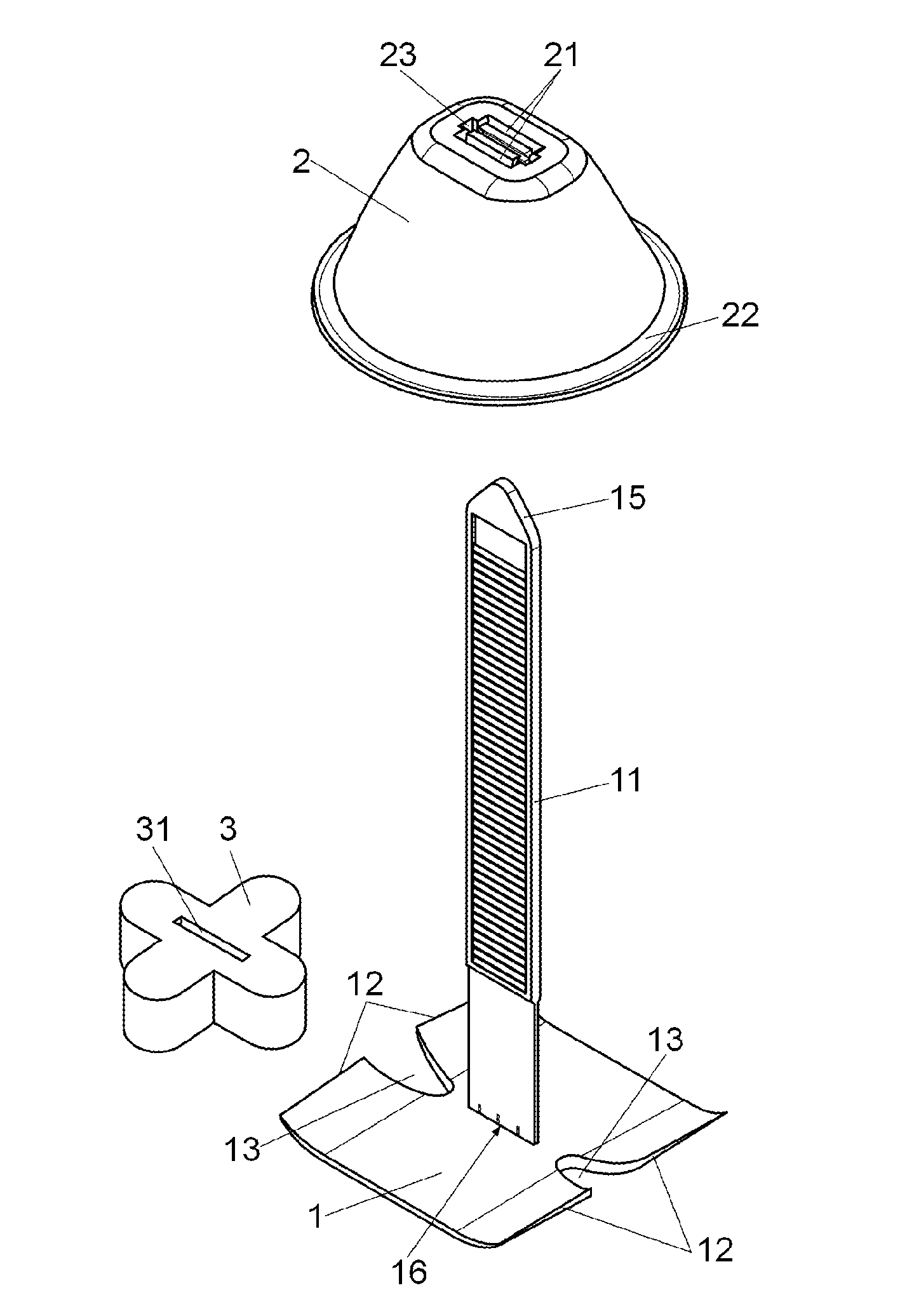

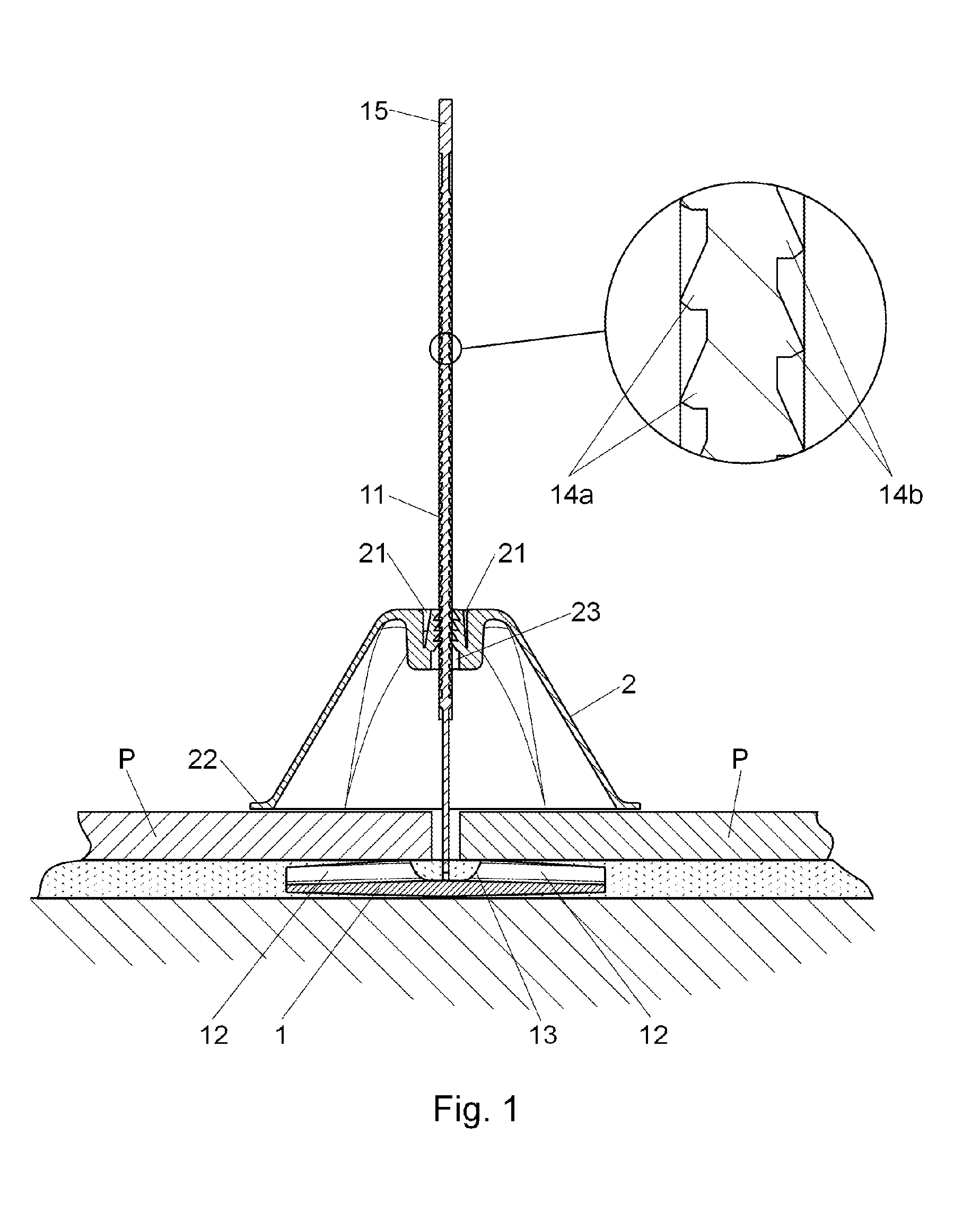

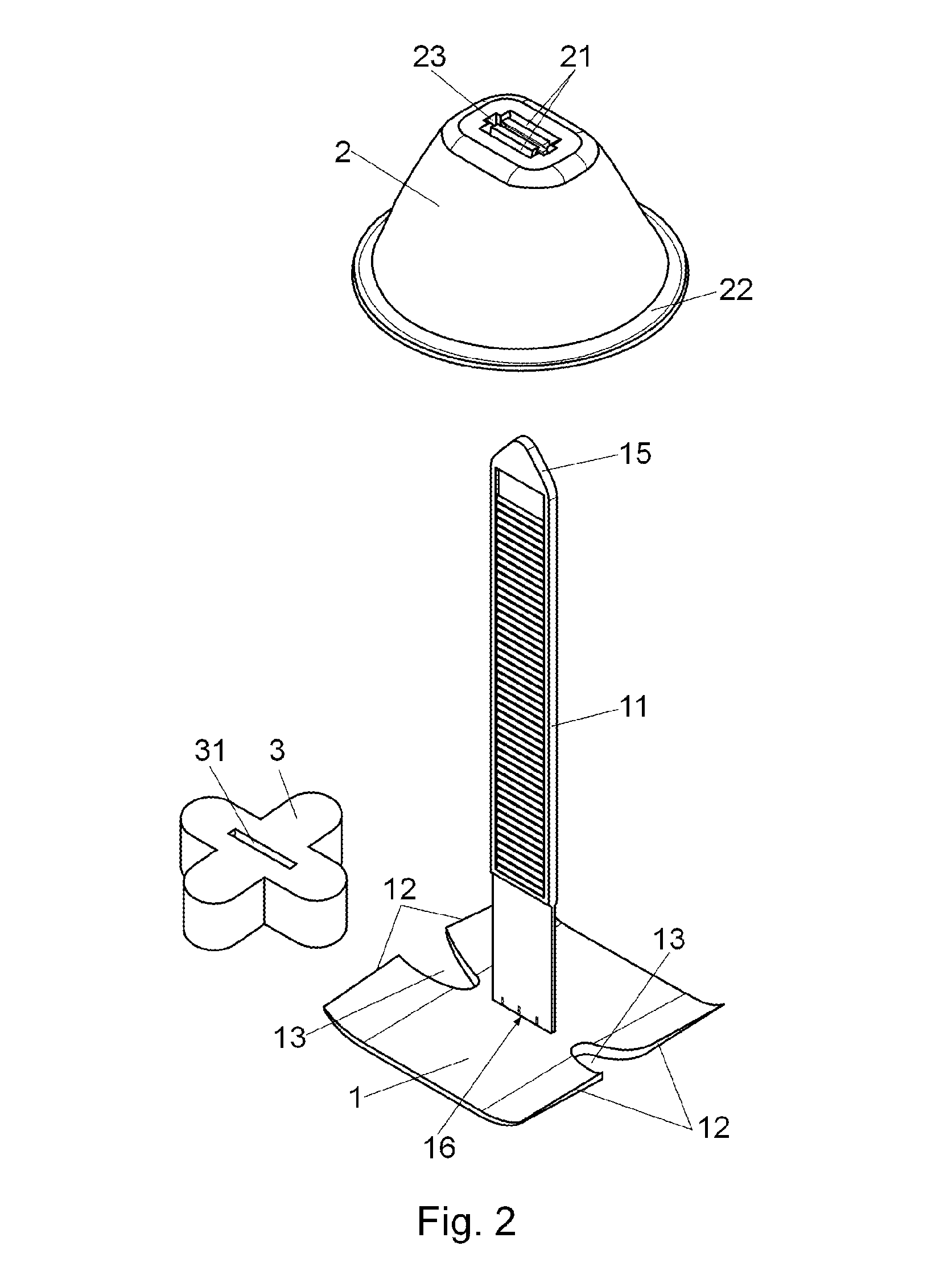

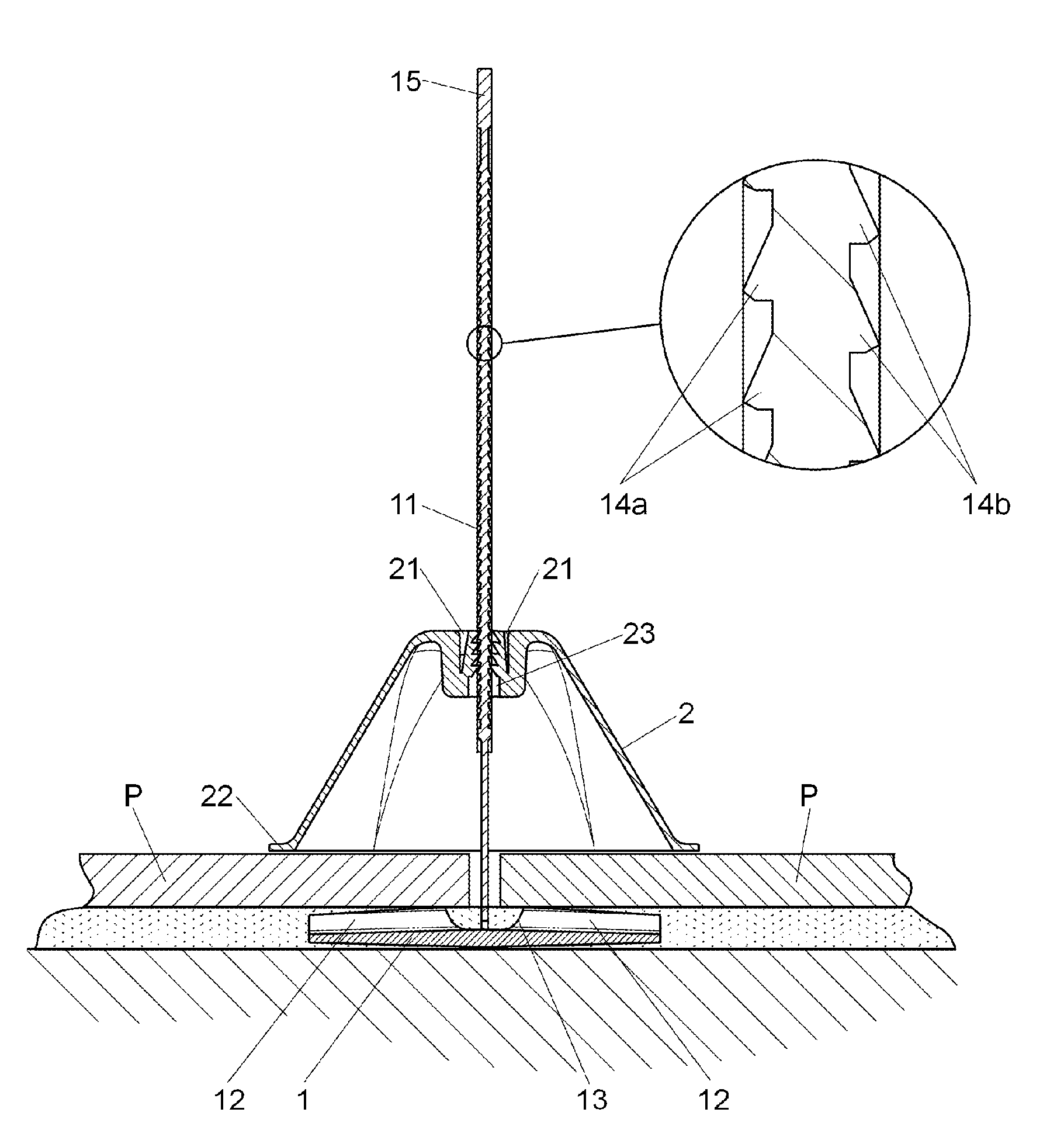

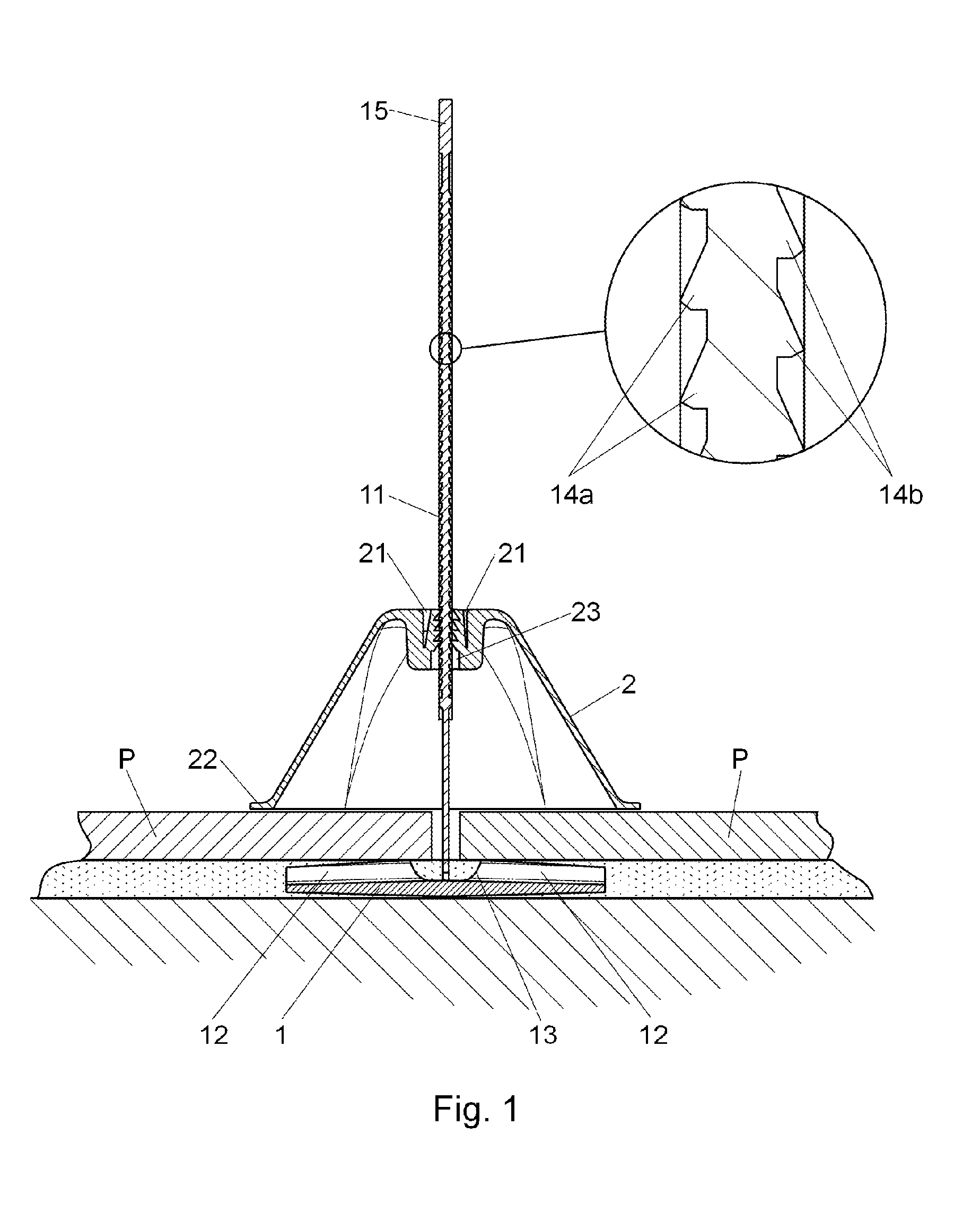

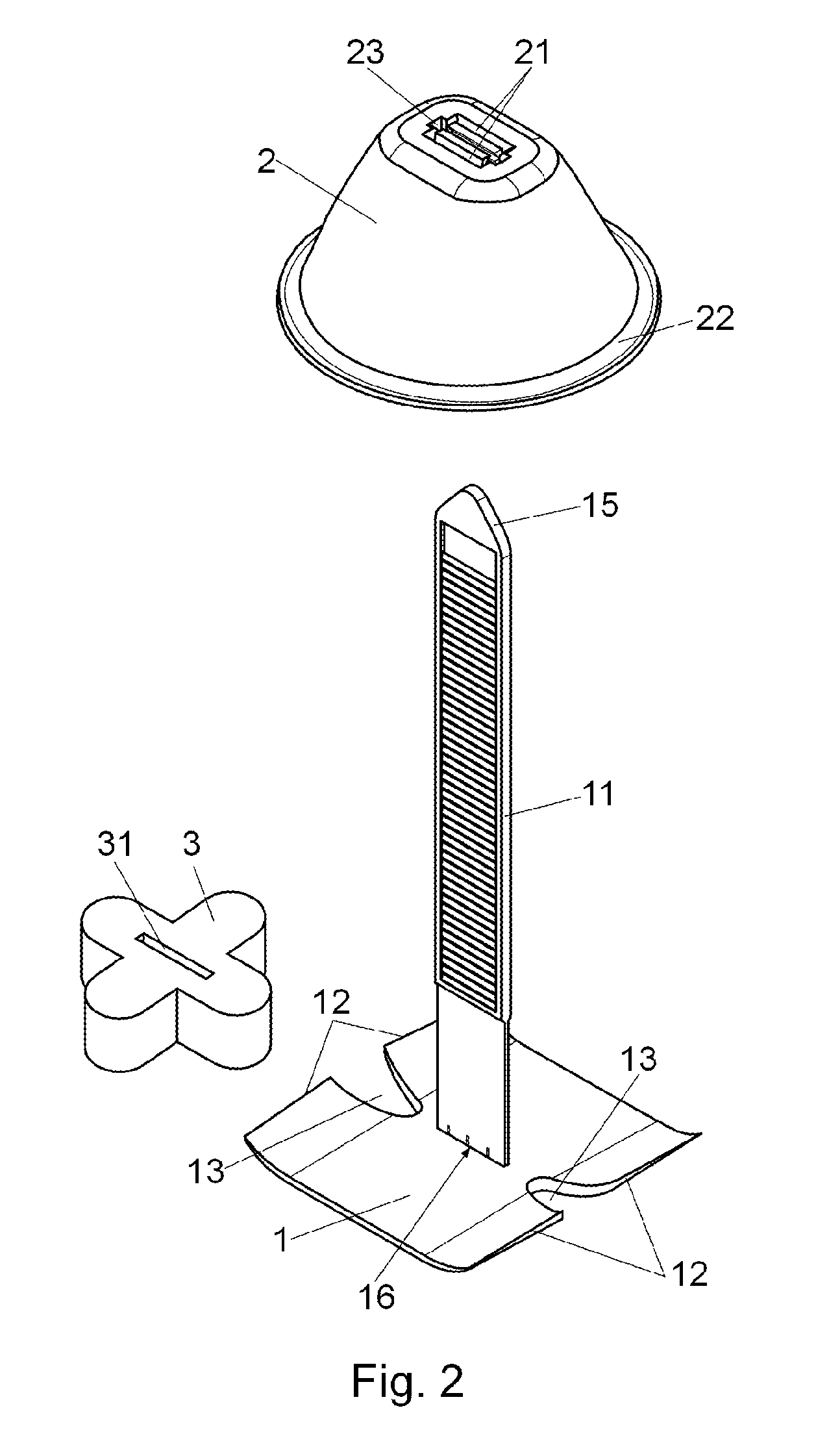

Levelling device for the placing of pieces for covering floors and similar

ActiveUS20100263304A1Shorten the timeImprove working conditionsCeilingsRoof toolsEngineeringHollow form

The device has a first lower substantially flat body, which has in its upper part a flexible post with a narrowed or weakened portion and a second upper body with the passage for receiving and securing said post. The flexible post, which has a rectangular cross section, has in its main surfaces respective mutually opposed toothings, which teeth are offset in the lengthwise direction and the passage of the second body has two latching pawls mutually opposed, so that in the operative position of the devices, the teeth of the flexible post engage in an alternate form with said latching pawls. The second body has a bell like hollow form with a lower widened contact mouth or border.

Owner:GERMANS BOADA SA

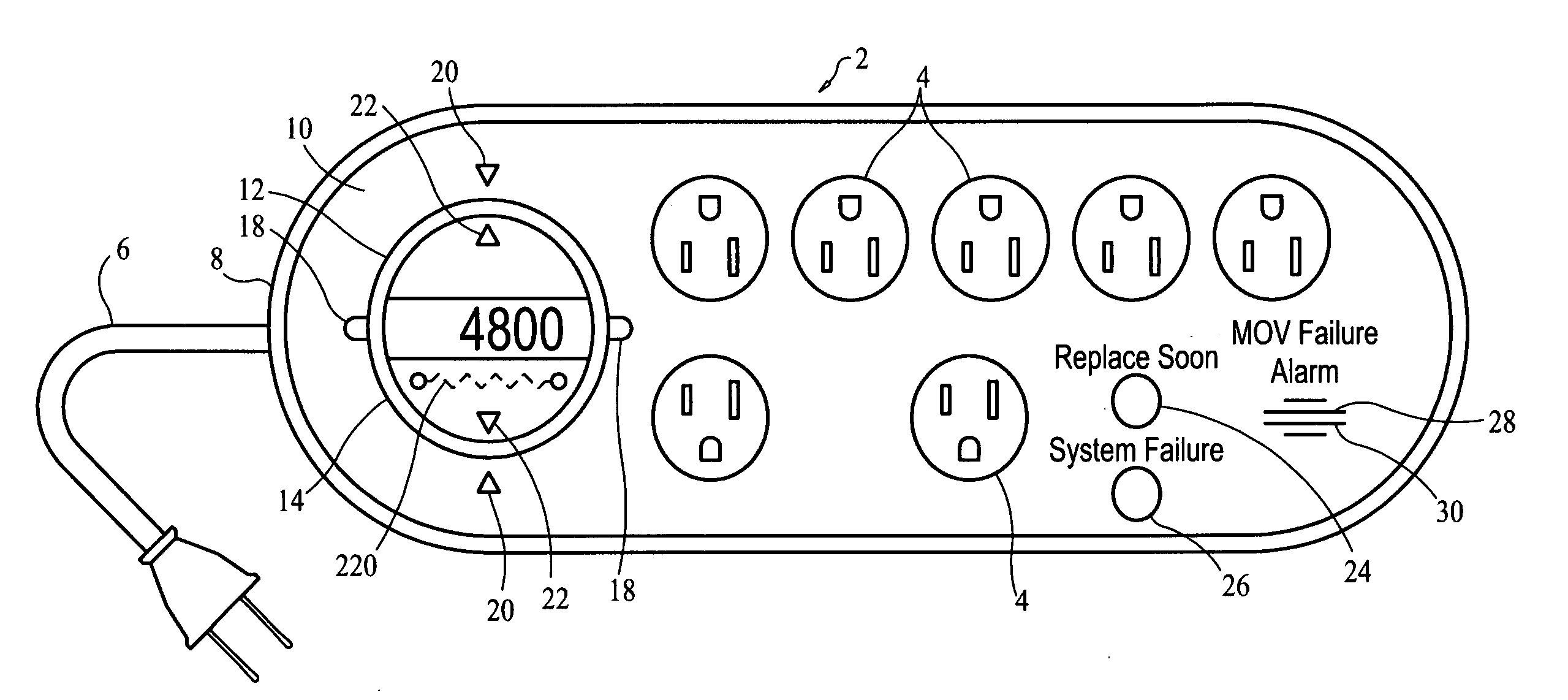

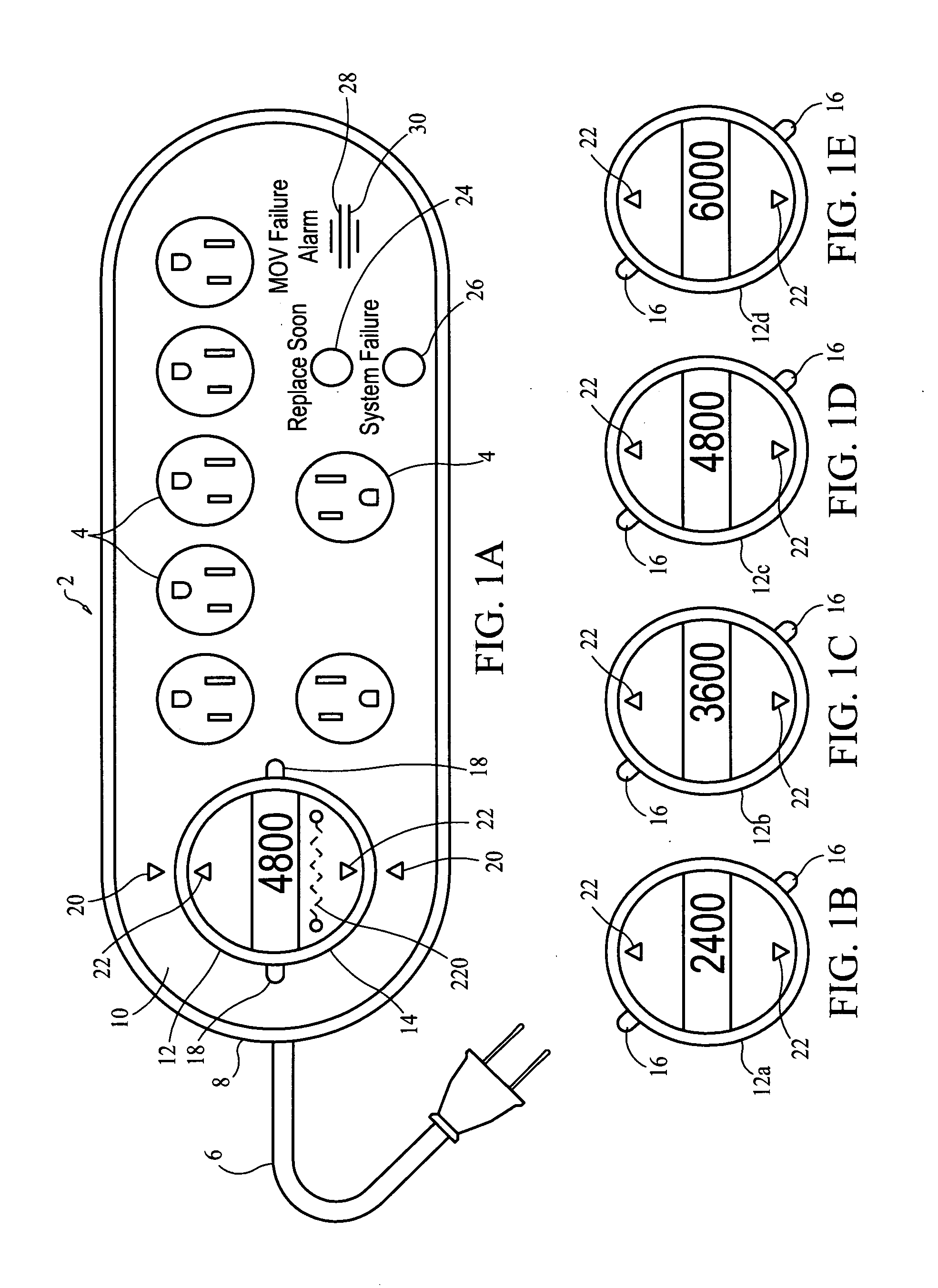

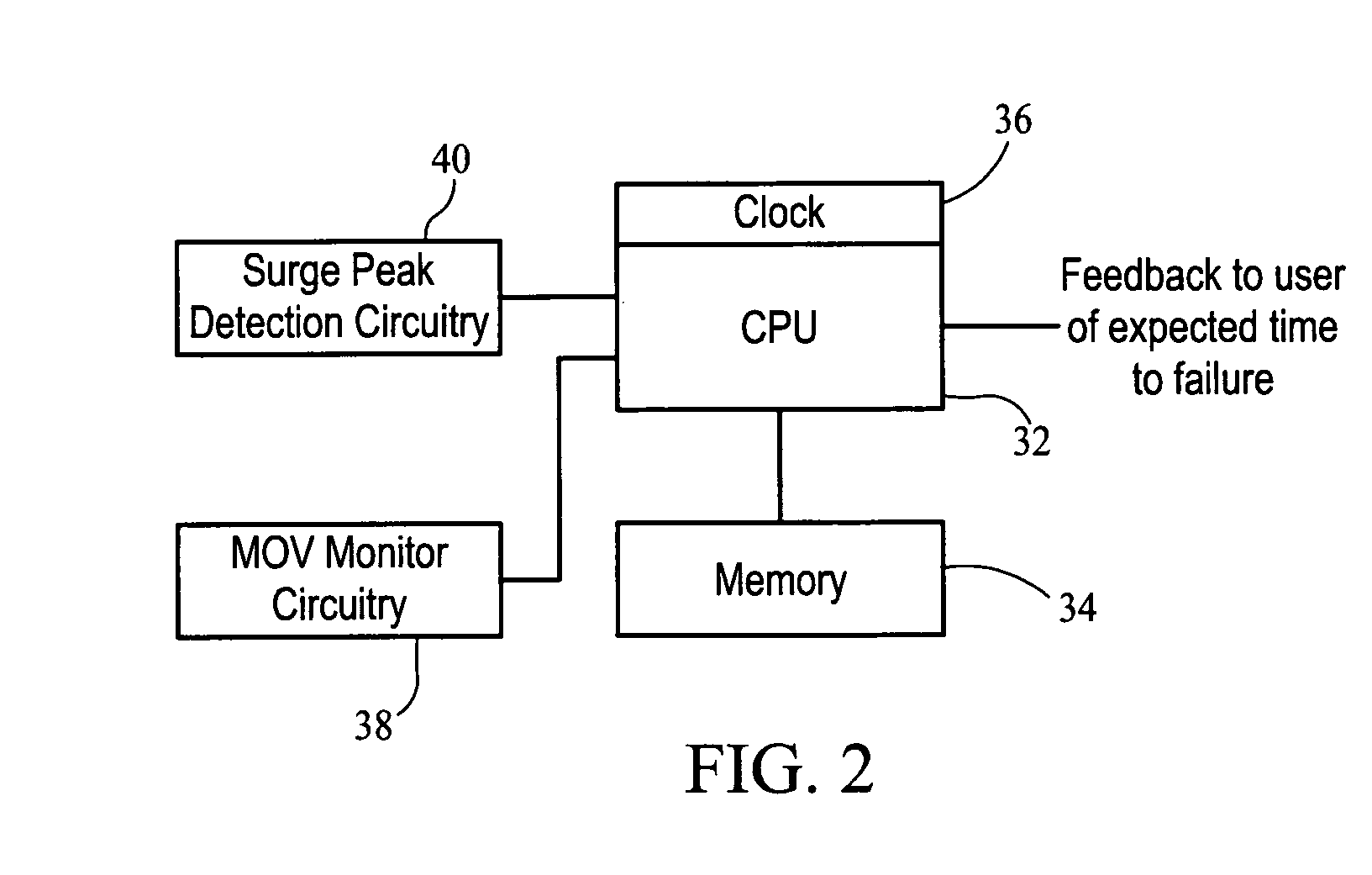

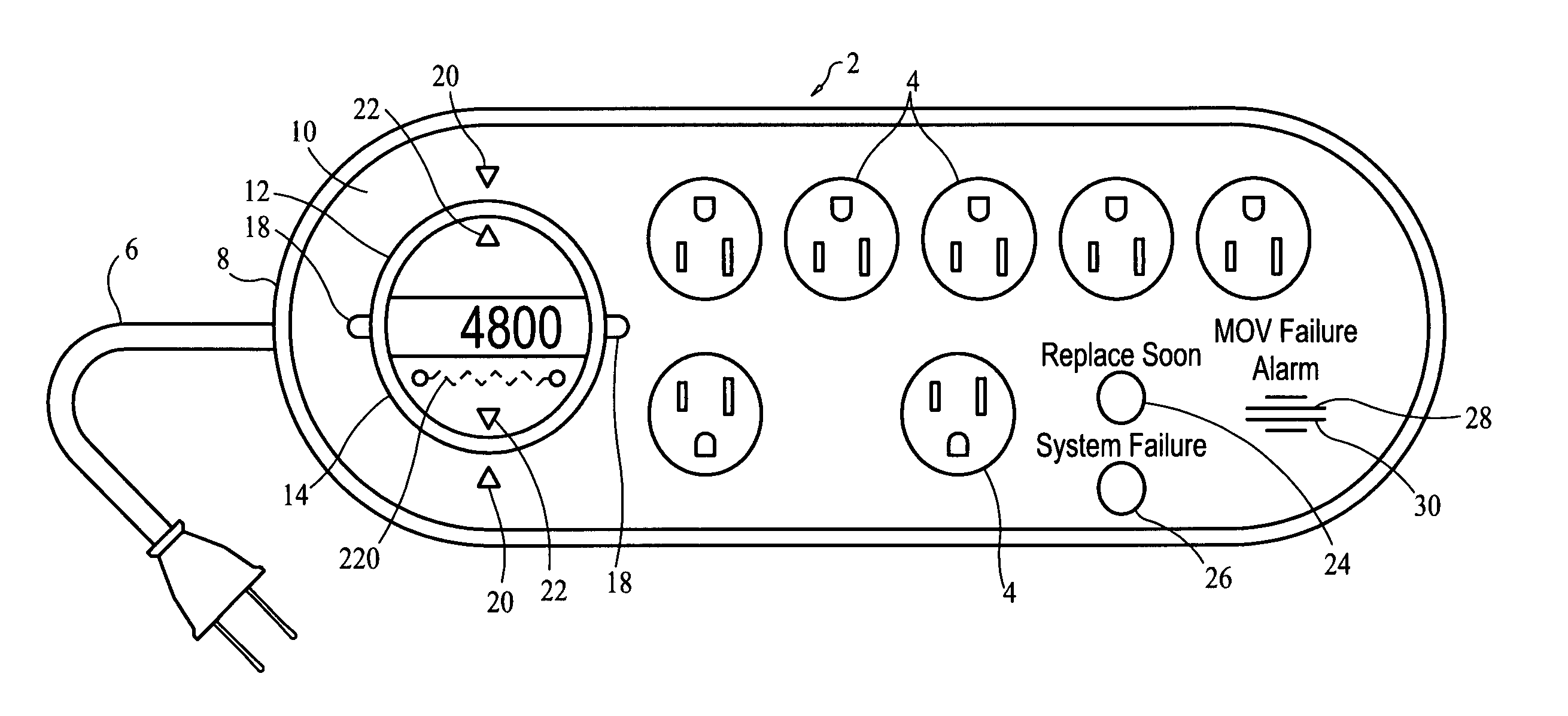

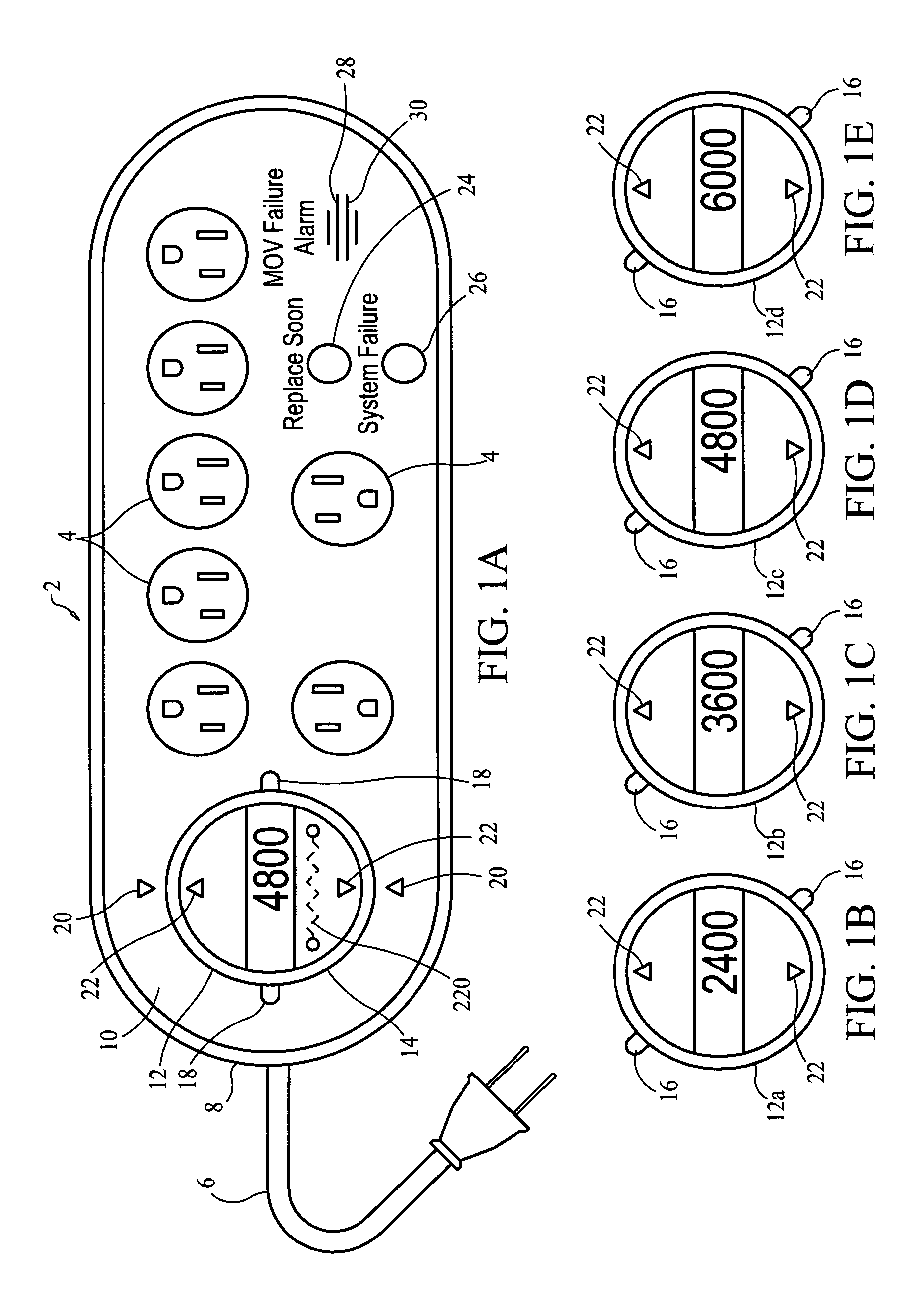

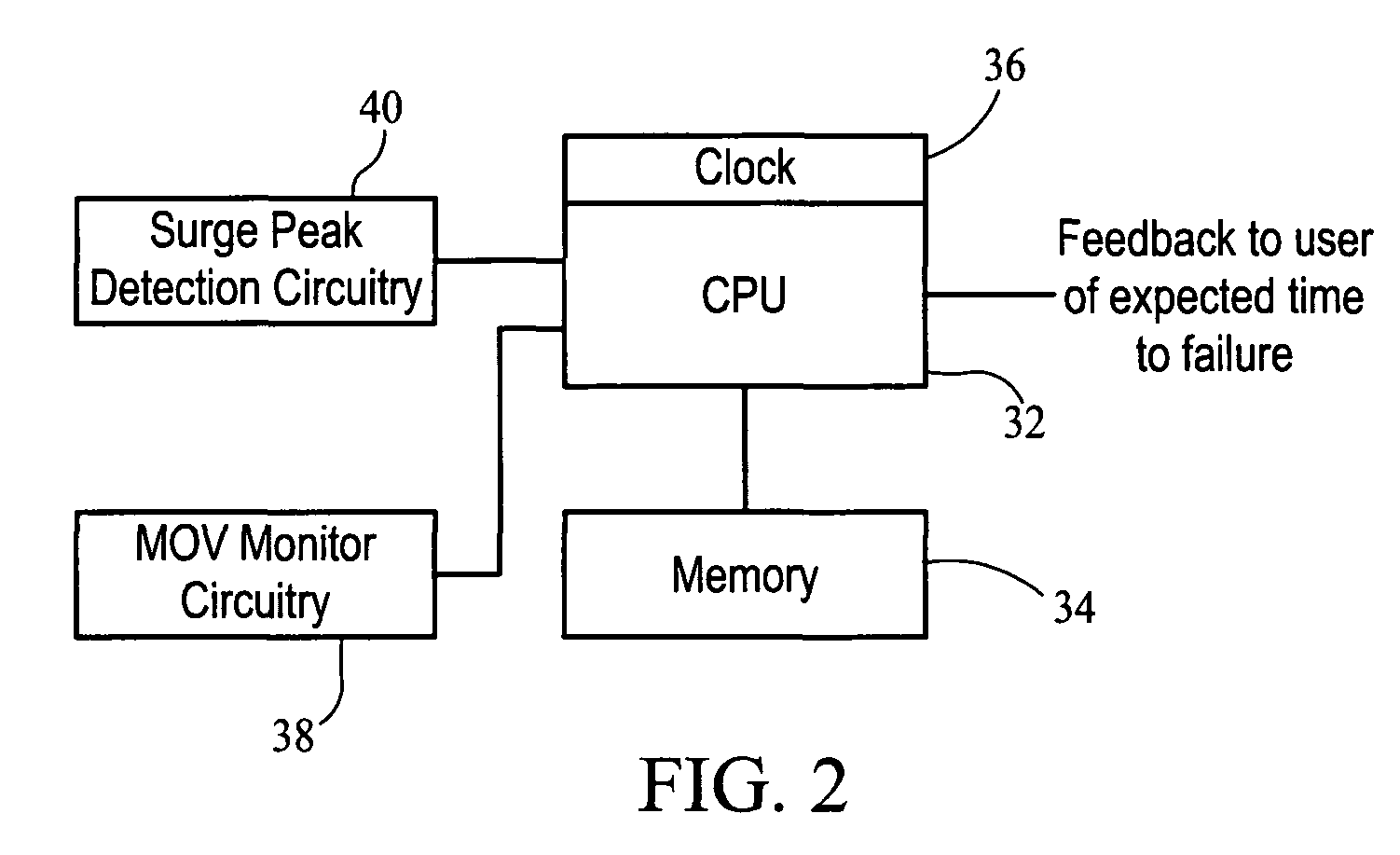

Home control protection system

InactiveUS20090207034A1Improve working conditionsStop workingEmergency protective arrangement detailsAlarmsProtection systemHome control

A home control protection system includes at least one surge protection strip having a plurality of power outlet receptacles, and a wall mountable central control unit that is in electrical communication with the at least one surge protection strip. The surge protection strip includes a replaceable surge protector module. The surge protection strip includes a circuit for detecting and counting the number of power surges which are shunted by the surge protector module, and compares the number of power surges with a predetermined threshold power surge number that corresponds to a predicted maximum number of power surges before failure of the surge protector module will occur.

Owner:VOXX INTERNATIONAL

Levelling device for the placing of pieces for covering floors and similar

Owner:GERMANS BOADA SA

Home control protection system

InactiveUS7961111B2Improve working conditionsStop workingEmergency protective arrangement detailsAlarmsComputer moduleProtection system

A home control protection system includes at least one surge protection strip having a plurality of power outlet receptacles, and a wall mountable central control unit that is in electrical communication with the at least one surge protection strip. The surge protection strip includes a replaceable surge protector module. The surge protection strip includes a circuit for detecting and counting the number of power surges which are shunted by the surge protector module, and compares the number of power surges with a predetermined threshold power surge number that corresponds to a predicted maximum number of power surges before failure of the surge protector module will occur.

Owner:VOXX INTERNATIONAL

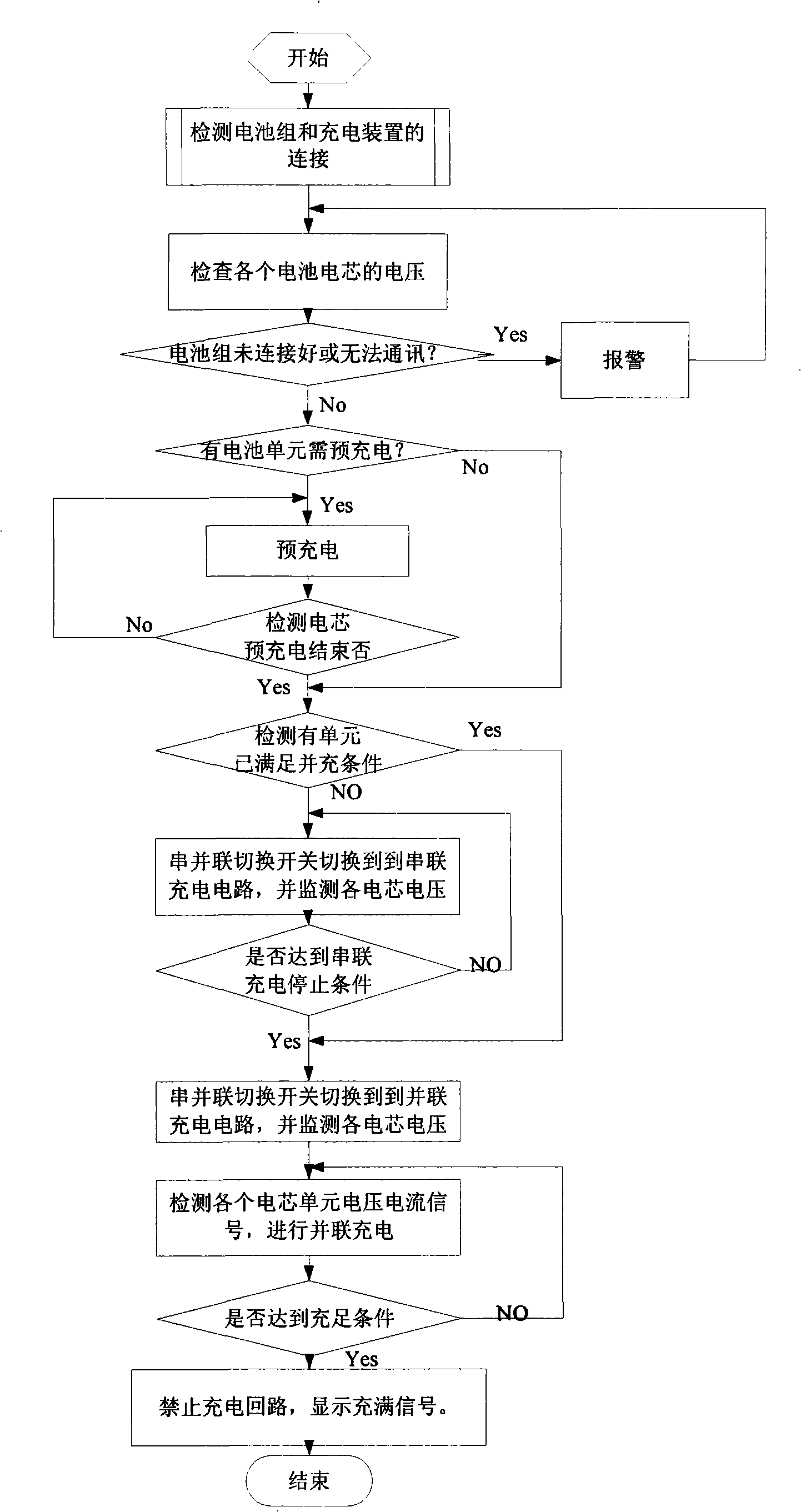

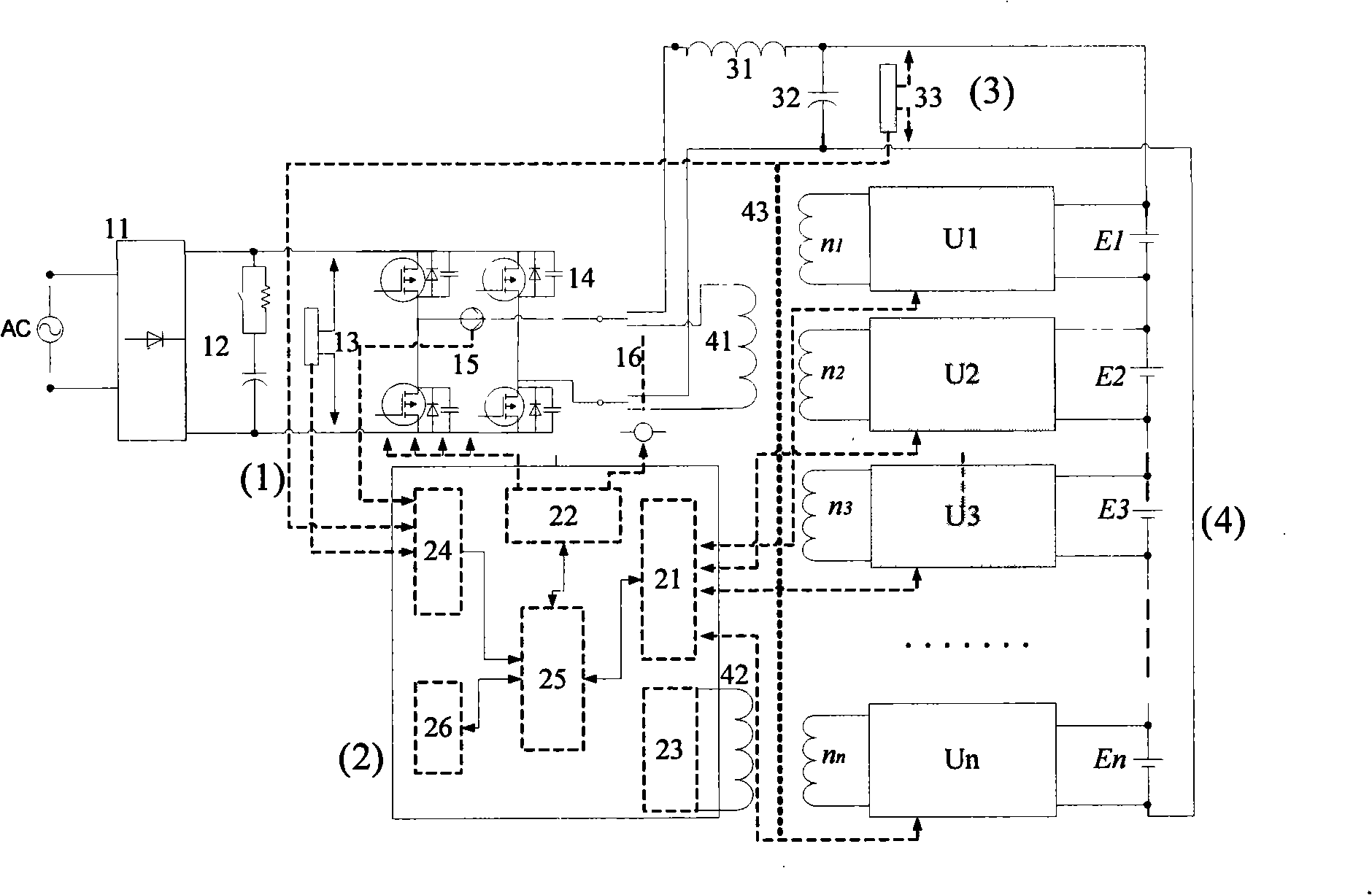

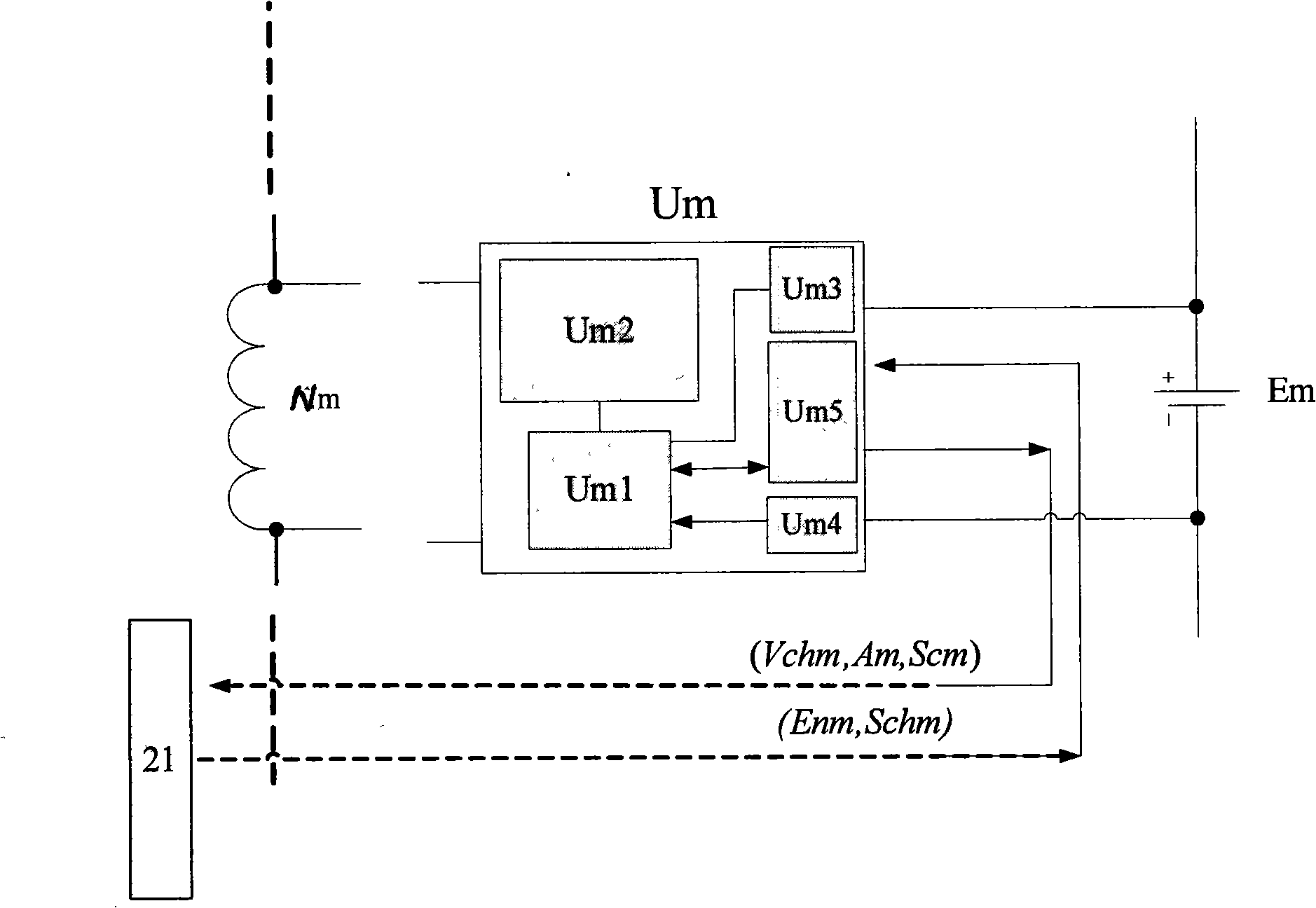

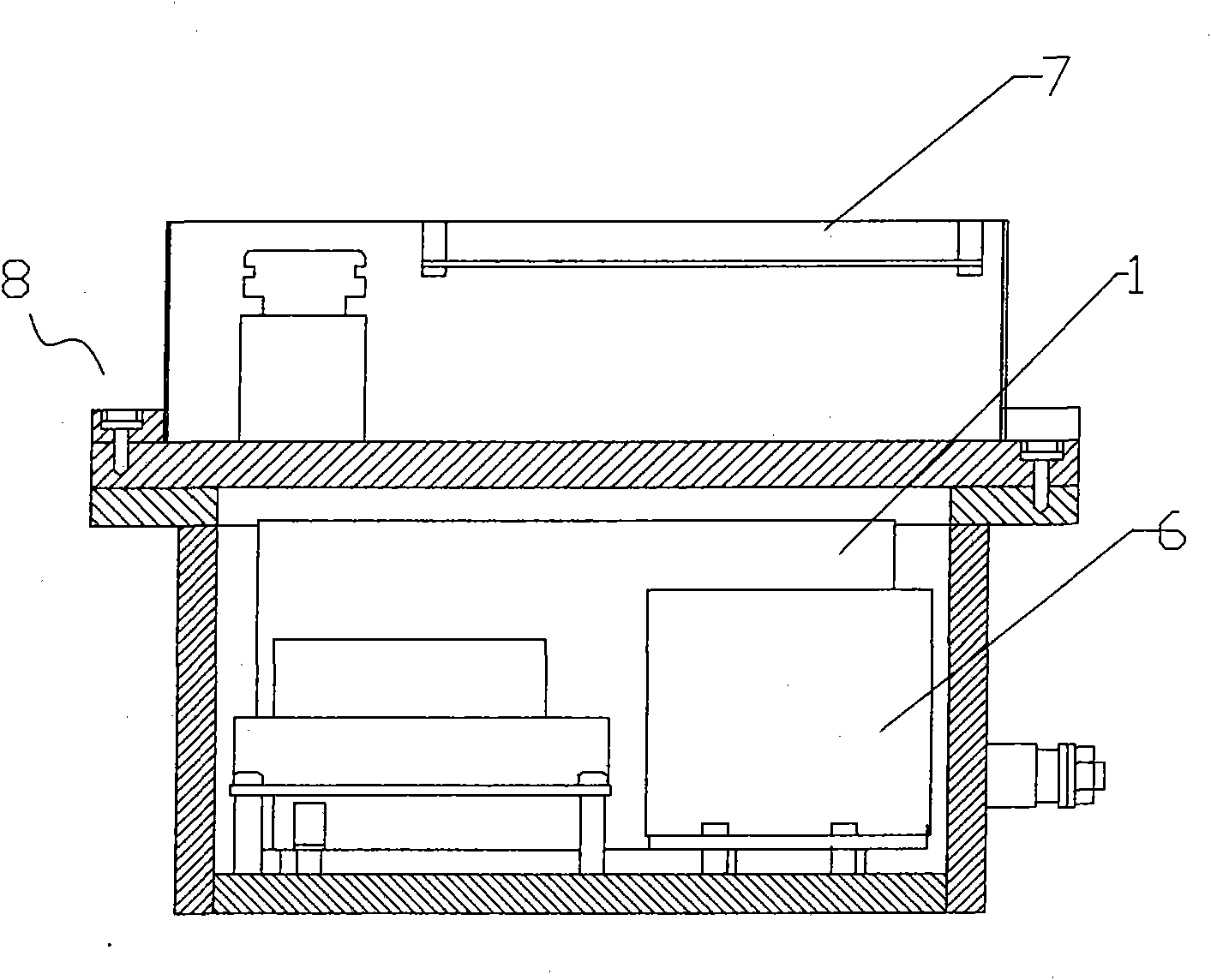

Serial and parallel switching and charging method and charging device for lithium dynamic battery unit

InactiveCN101262140ALow costReduce volumeBatteries circuit arrangementsEmergency protective circuit arrangementsTransformerPre-charge

The invention discloses an Li traction battery series parallel change-over charging method and a charging device. The charging device comprises a power main loop comprising a rectifier circuit, a DC filtering capacitor, a pre-charging circuit, a voltage sensor, a switch bridge circuit, a charging current sensor and a series parallel change-over switch, a control circuit board comprising a parallel branch signal unit, a switch signal drive control unit, a coil signal circuit, a voltage current signal circuit, a control processor and a signal display unit, a serial charging circuit comprising a filter inductor, a filter capacitor and an output voltage sensor, and a parallel charging circuit comprising a primary coil, a feedback coil, an iron core, a plurality of secondary coils of a multi-winding transformer and a plurality of series parallel charging unit. The pre-charging, serial charging and parallel charging are carried out by the charging method according to a set pre-charging voltage value and an end voltage value. The method and the device provided by the invention reduce the cost and volume of charging devices, maintain the balance of charging capacity of every Li traction battery electrical core, ensure adequate protection and best working status for each battery unit and improve safety and service life cycle of Li traction battery.

Owner:刘云海 +2

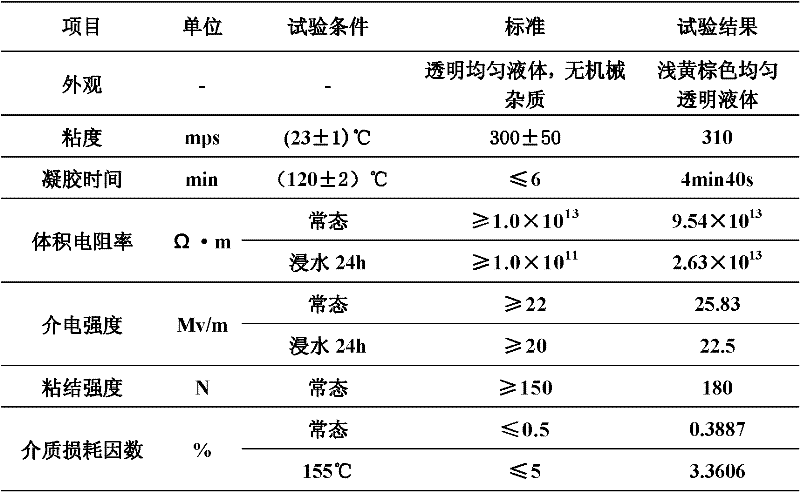

Environmentally-friendly type solvent-free impregnating resin and preparation method thereof

InactiveCN102225986AConservation TrendsPromote safe productionApplying solid insulationCoils manufactureLow voltageTransformer

The invention discloses an environmentally-friendly type solvent-free impregnating resin and a preparation method thereof. The impregnating resin comprises: 100 parts by weight of one or more high heat-resistant unsaturated polyester resins, 0 to 100 parts by weight of one or more modified epoxy resins, 50 to 200 parts by weight of one or more novel reactive diluents, 0.1 to 1 parts by weight of one or more polymerization inhibitors, 1.5 to 3.8 parts by weight of one or more initiators and 0 to 2 parts by weight of one or more auxiliary agents. Under the same work conditions, a baking time of the solvent-free impregnating resin is less than about one third of a baking time of the existing conventional solvent-free type impregnating resin utilized for middle and low voltage motors and transformers, and an energy consumption of the solvent-free impregnating resin is lower than about 25% of an energy consumption of the existing conventional solvent-free type impregnating resin middle and low voltage motors and transformers.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

High hardness ferritic stainless steel wearable surfacing flux-cored wire

InactiveCN101224527AOvercome the disadvantage of poor wear resistanceHigh hardnessWelding/cutting media/materialsSoldering mediaHigh carbonBoron carbide

The invention provides a high hardness ferrite stainless steel wearable flux-cored wire, which takes a low carbon steel H08A cold rolling thin steel strip as an external wrapper; furthermore, the wrapper is internally provided with a powder core which is composed of graphite, metal and alloy powder; the weight percentages of all ingredients of the powder core are 50-75% of high carbon ferrochrome, 10-16% of ferrovanadium, 6-10% of ferrotitanium, 2-10% of tungsten carbide, 2-3% of nickel powder, 1.5-2.5% of silver graphite, 1-3.5% of boron carbide, 1-2% of aluminium magnesium powder, 0-10% of metallic chromium, and the residual quantity of reduced iron powder; the filling proportion of the powder core is 46-50%; the invention adopts the technical proposal that high-content ferrovanadium and adequate alloy powders such as tungsten carbide and boron carbide, etc. are added into the flux-cored wire, changes the microstructure of the existing ferrite stainless steel flux-cored wire surfacing alloy, overcomes the shortages of poor wearability and ductility, and can be applied to submerged arc bead weld manufacture or repair of the parts which has high requirement of abrasion and the corrosion resistance of the wearable grain.

Owner:XIANGTAN UNIV

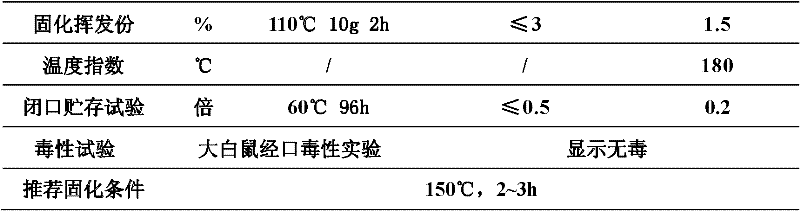

Film coating process for aluminium alloy wheel hub

InactiveCN101343740AReduce pollutionReduce energy consumptionVacuum evaporation coatingSputtering coatingPolyesterFilm coating

The invention discloses an aluminum alloy wheel hub coating technology. The aluminum alloy wheel hub coating technology comprises the procedures of oil removing, cleaning and drying, pre-treating, epoxy polyester powder spraying and solidifying, grinding I, methyl methacrylate-acrylate copolymer paint spraying and solidifying, grinding II, polybutadiene high temperature resistant insulating coating spraying and solidifying, vacuum cathode arc ion chromium plating and magnetism control sputtering aluminum plating, and polyurethane methacrylate light solidifying paint spraying and solidifying in sequence. The aluminum alloy wheel hub coating technology adopts dry electric plating to replace the traditional wet electric plating, the plating layer surface quality and the physical and chemical properties are approximately equivalent to the wet electric plated aluminum alloy wheel hub, the chromium consumption is reduced to about one fifth of the wet electric plating, the water consumption is reduced to about one seventh of the wet electric plating, precious nickel and copper are not utilized, the poisonous metal substance such as hexavalent chromium is not contained, the pollution to the environment is reduced, the energy, water and precious metal consumption is remarkably reduced, the technological flow is simplified, the production efficiency is enhanced, the heavy polishing working sequence is omitted, the working condition is remarkably improved, and the cost is reduced.

Owner:HUZHOU JINTAI PLATING IND

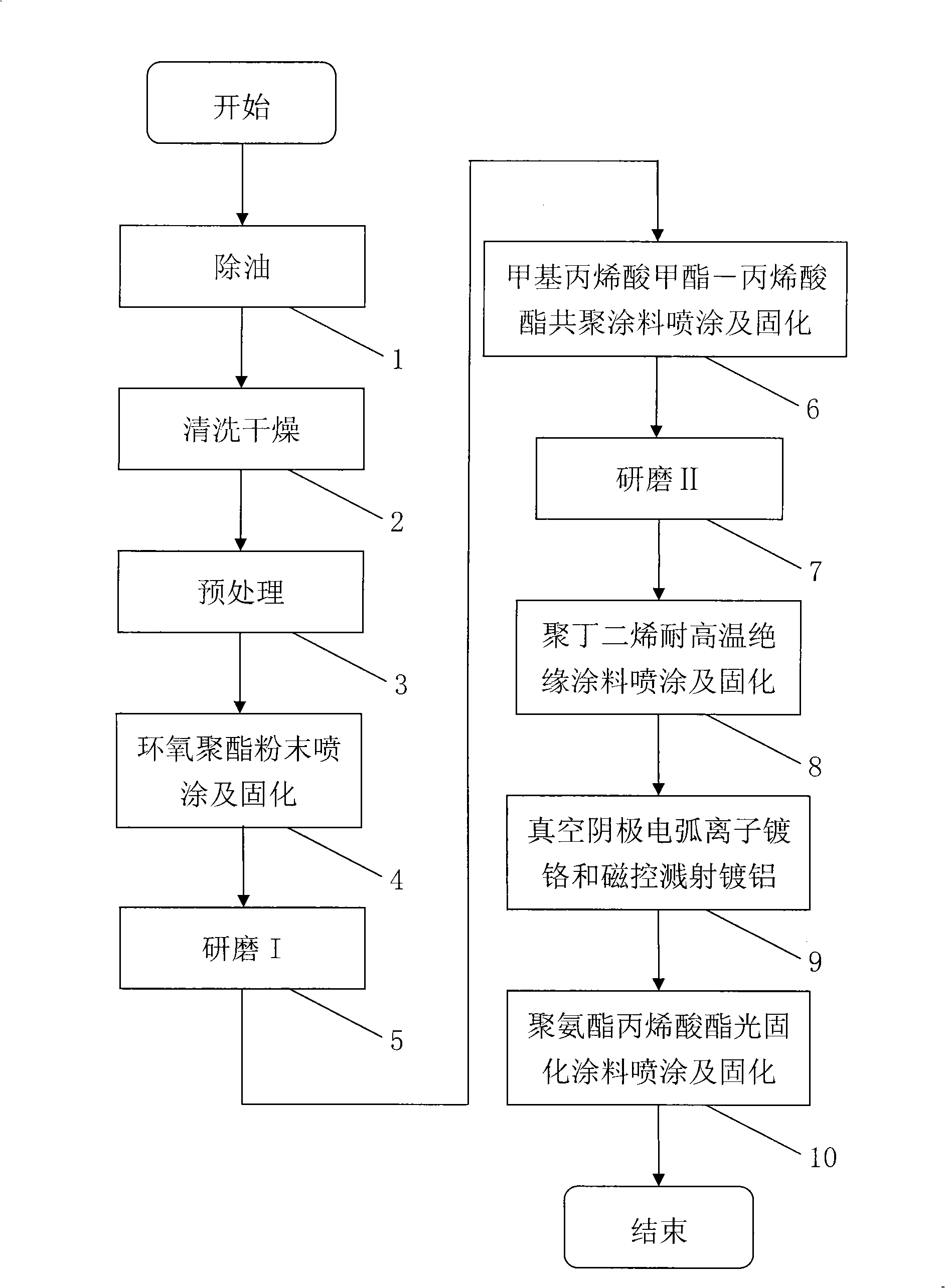

Intelligent dust concentration limit setting spray dust settling device, system and method

InactiveCN101915116AAvoid unnecessary wasteReduce Waterlogging ProblemsMining devicesDust removalLower limitControl signal

The invention discloses an intelligent dust concentration limit setting spray dust settling device. The device comprises a control unit, a dust concentration sensor, an electromagnetic valve and a sprinkler head, wherein the signal output end of the dust concentration sensor is connected with a signal input end of the control unit; a control signal output end of the control unit is connected with a control signal input end of the electromagnetic valve; and the control unit realizes spray control over the sprinkler head through the switching of the electromagnetic valve. In the device of the invention, the dust concentration limit is manually set; the spraying starts when the dust concentration limit exceeds an upper limit value and stops when the dust concentration limit is less than a lower limit value; and thus the meaningless waste of water resource is prevented, the water logging in roadways is reduced, the working conditions are improved and the health and the safety of mine workers are ensured. In addition, the invention also discloses an intelligent dust concentration limit setting spray dust settling system, so the remote on-line monitoring of the dust concentration can be realized; meanwhile, the invention also discloses an intelligent dust concentration limit setting spray dust settling method.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

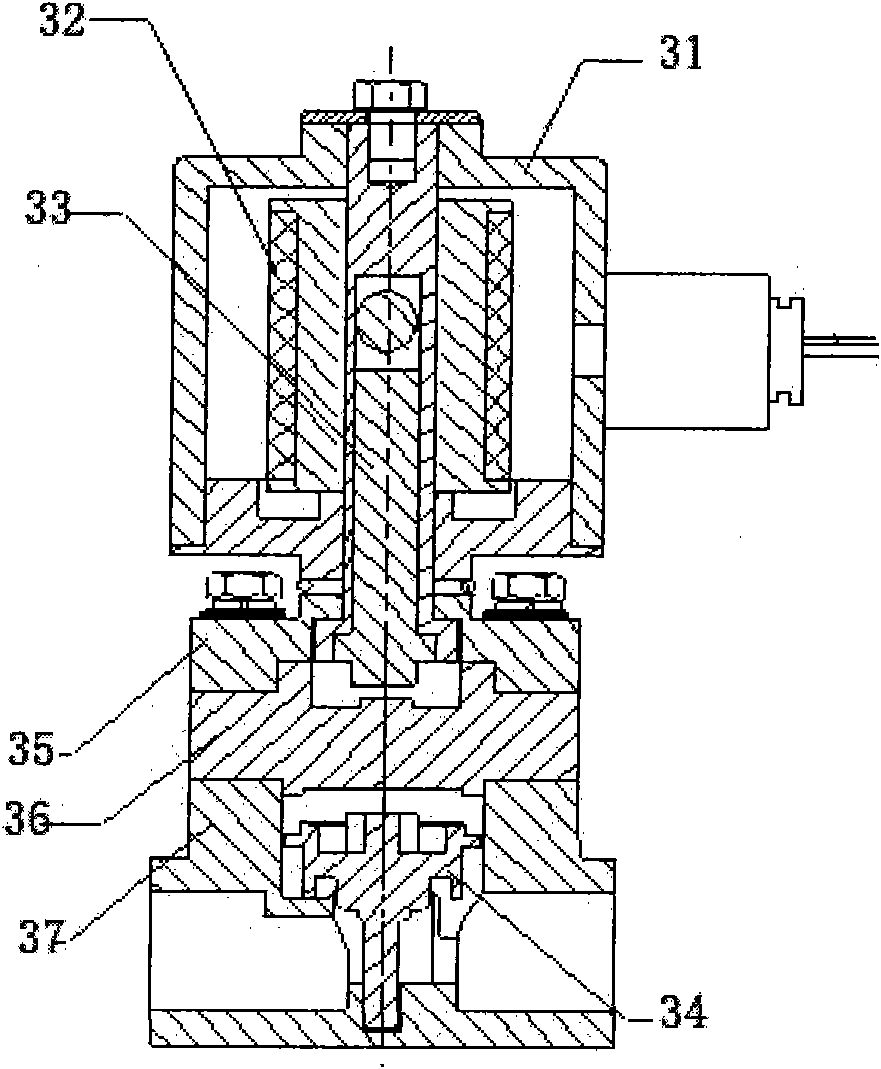

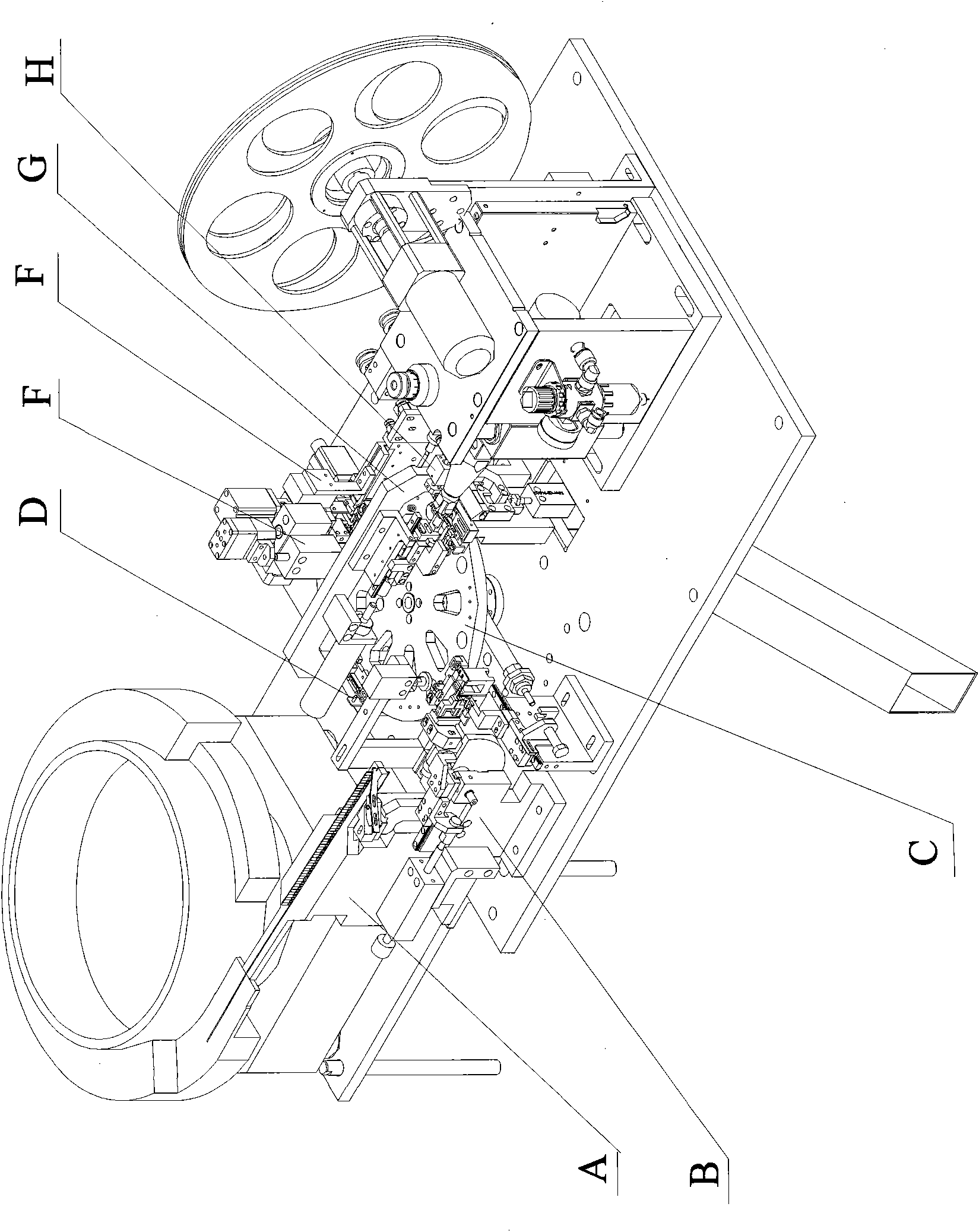

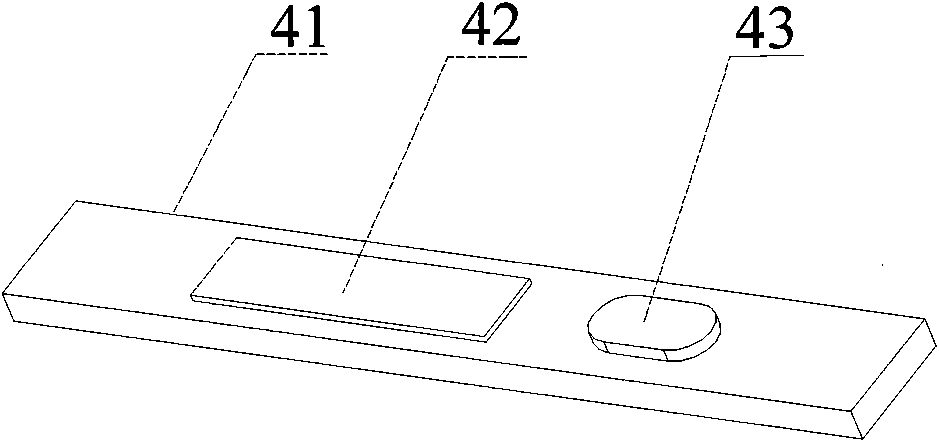

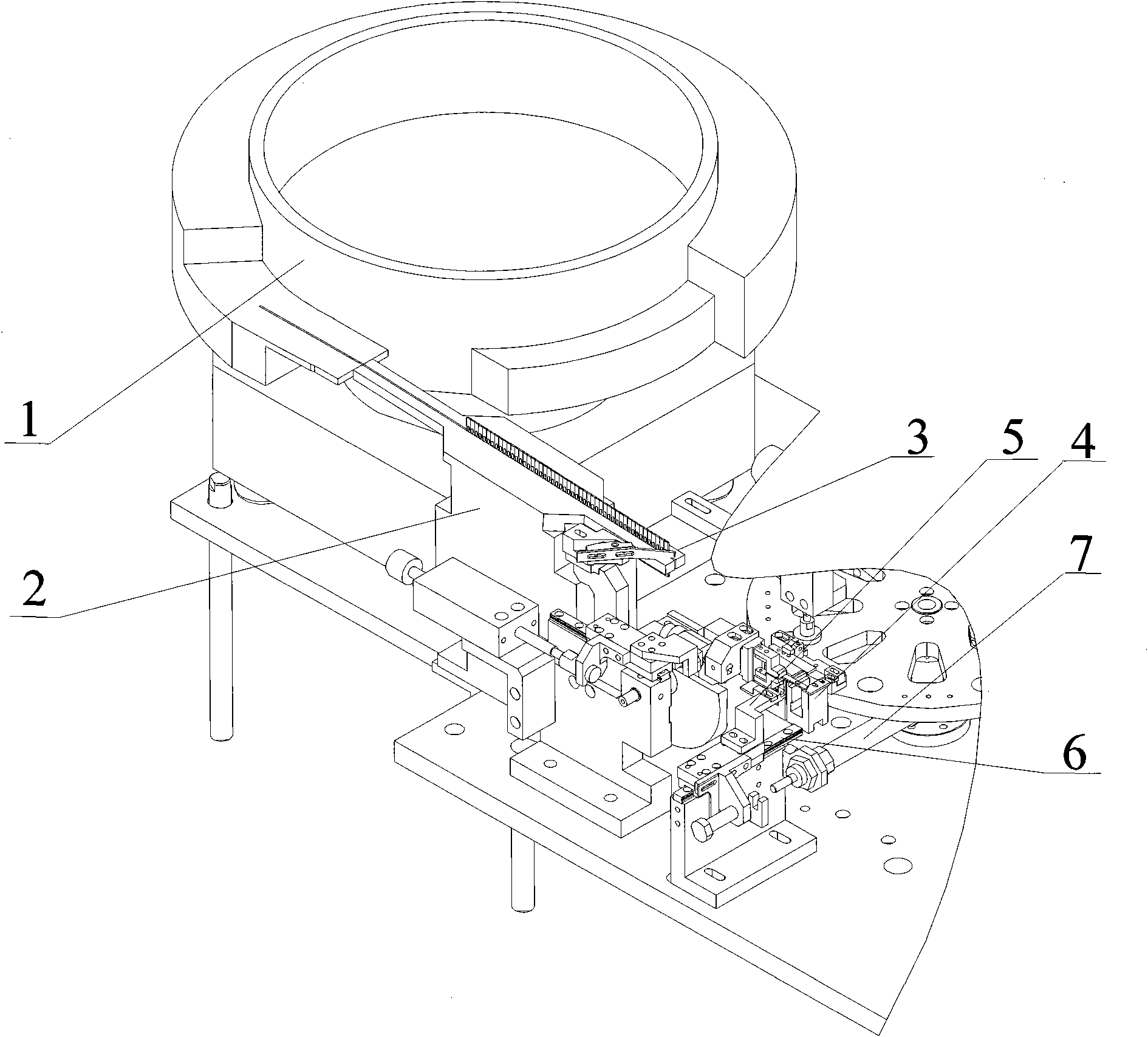

Automatic welding machine of aluminum-nickel compound piece of lithium ion battery cover plate

ActiveCN101913029AChange choresSave human effortWelding apparatusAutomatic controlUltrasonic welding

The invention provides an automatic welding machine of an aluminum-nickel compound piece of a lithium ion battery cover plate, consisting of a feeding mechanism A, a feeding turnover mechanism B, a turnplate mechanism C, a detection mechanism D, a nickel piece feeding mechanism E, a spot-welding machine F, an ultrasonic welding mechanism G, a banking mechanism H and an automatic control mechanism, wherein the feeding mechanism A, the feeding turnover mechanism B, the turnplate mechanism C and the detection mechanism D are arranged on the tabletop of the automatic welding machine; the nickel piece feeding mechanism E, the spot-welding machine F, the ultesonic welding mechanism G and the banking mechanism H are arranged on the turnplate mechanism C; the aluminum-nickel compound piece is placed on the lithium ion battery cover plate through the feeding mechanism A, the feeding turnover mechanism B, the turnplate mechanism C, the detection mechanism D and the nickel piece feeding mechanism E; and the lithium ion battery cover plate is automatically welded with the aluminum-nickel compound piece through the spot-welding machine F, the ultrasonic welding mechanism G and the banking mechanism H. The invention ensures that the whole process flow realizes the automation, changes the traditional mode for manually finishing miscellaneous work, librates the large amount of labor force, greatly improves the work conditions, greatly increases the yield, greatly reduces the manufacturing cost and simultaneously and effectively ensures the quality of products.

Owner:HUNAN HUAHUI NEW ENERGY

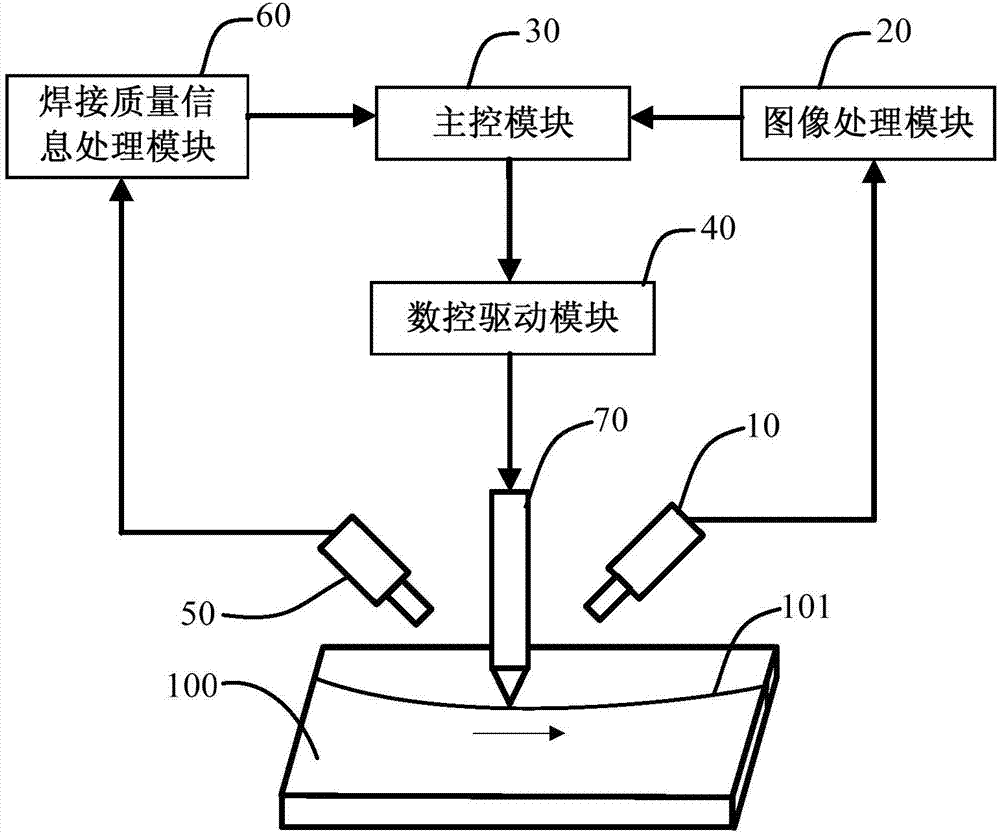

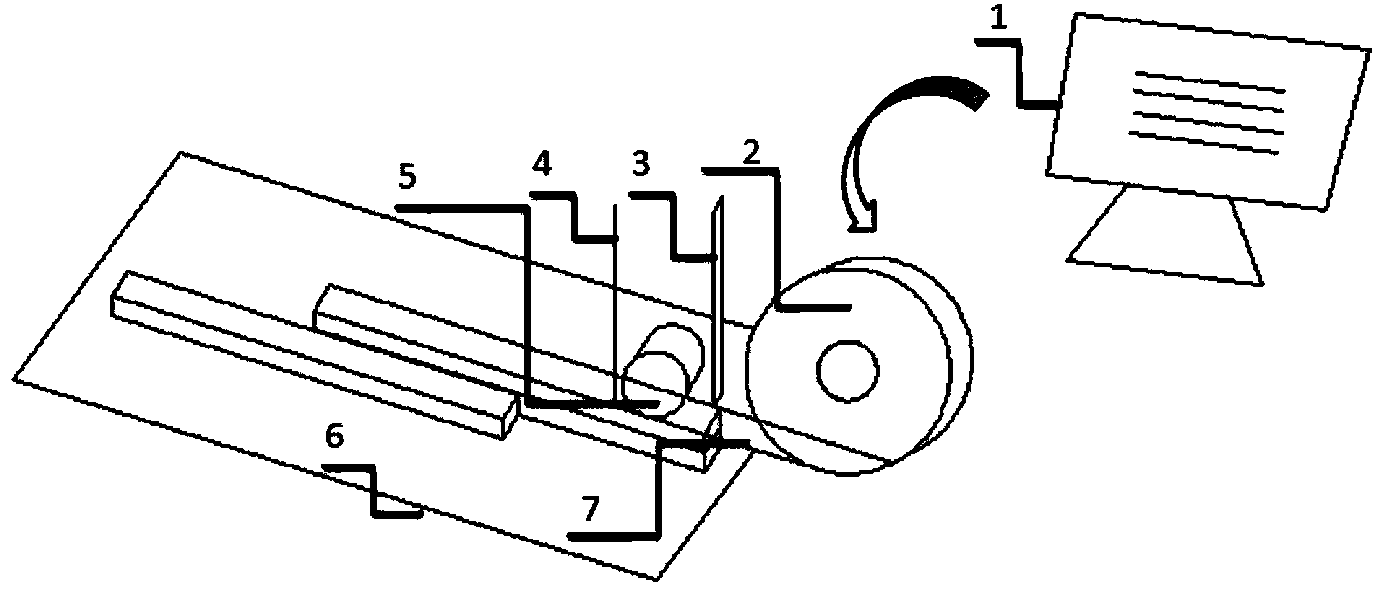

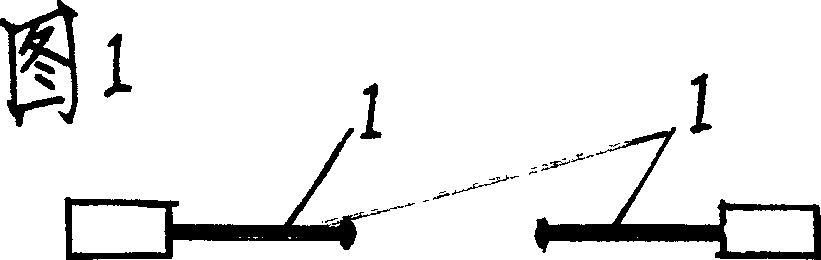

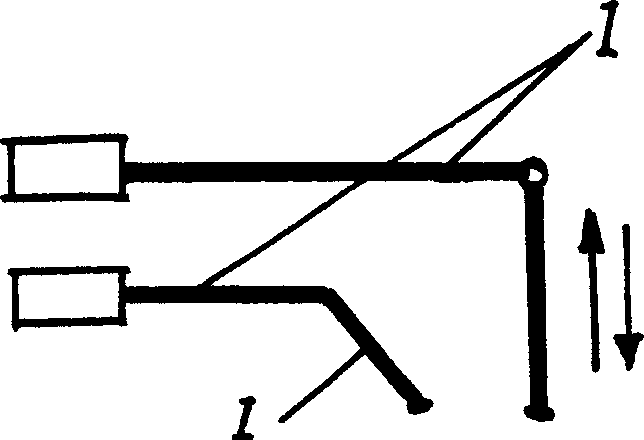

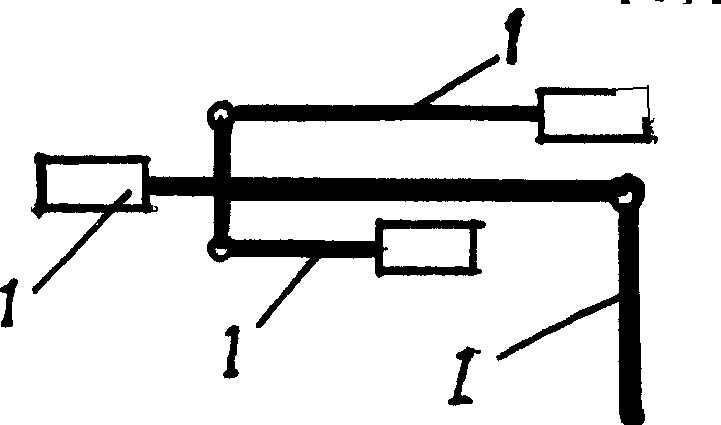

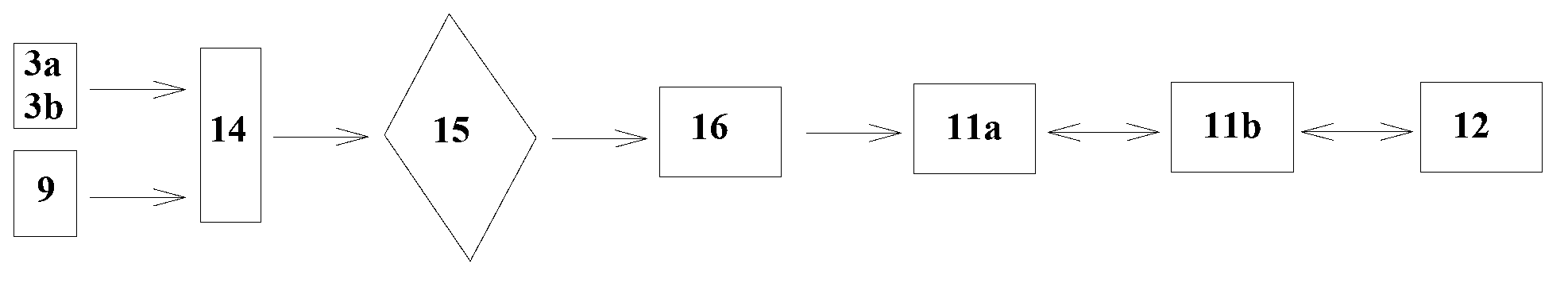

Welding seam tracking system and method of laser welding machine

ActiveCN103753015AImprove the level ofThe workload is reduced or even ignoredLaser beam welding apparatusNumerical controlSimulation

The invention discloses a welding seam tracking system of a laser welding machine. A CCD (Charge Coupled Device) visual sensor is used for converting collected light signals into image data which is output in a serial mode according to the time sequence to obtain a welding seam path image; an image processing module is used for preprocessing the welding seam path image, calculating the actual welding seam path width and tracking direction and combining with the obtained workpiece height through detection to output actual welding track data; a main control module is used for processing the actual welding track data and sending out a control instruction according to the processing result; a numerical control driving module is used for executing the control instruction of the main control module to drive a lase welding head, adjusting the position of the laser welding head and controlling the welding action of the welding head. According to the welding seam tracking system and method of the laser welding machine, the automatic laser welding is achieved, the deviation is small, the accuracy is high, the welding quality is good, and the like.

Owner:SHENZHEN GDLASER TECH CO LTD

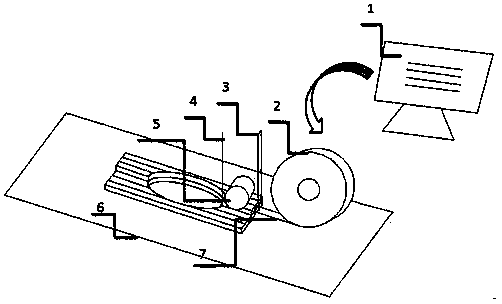

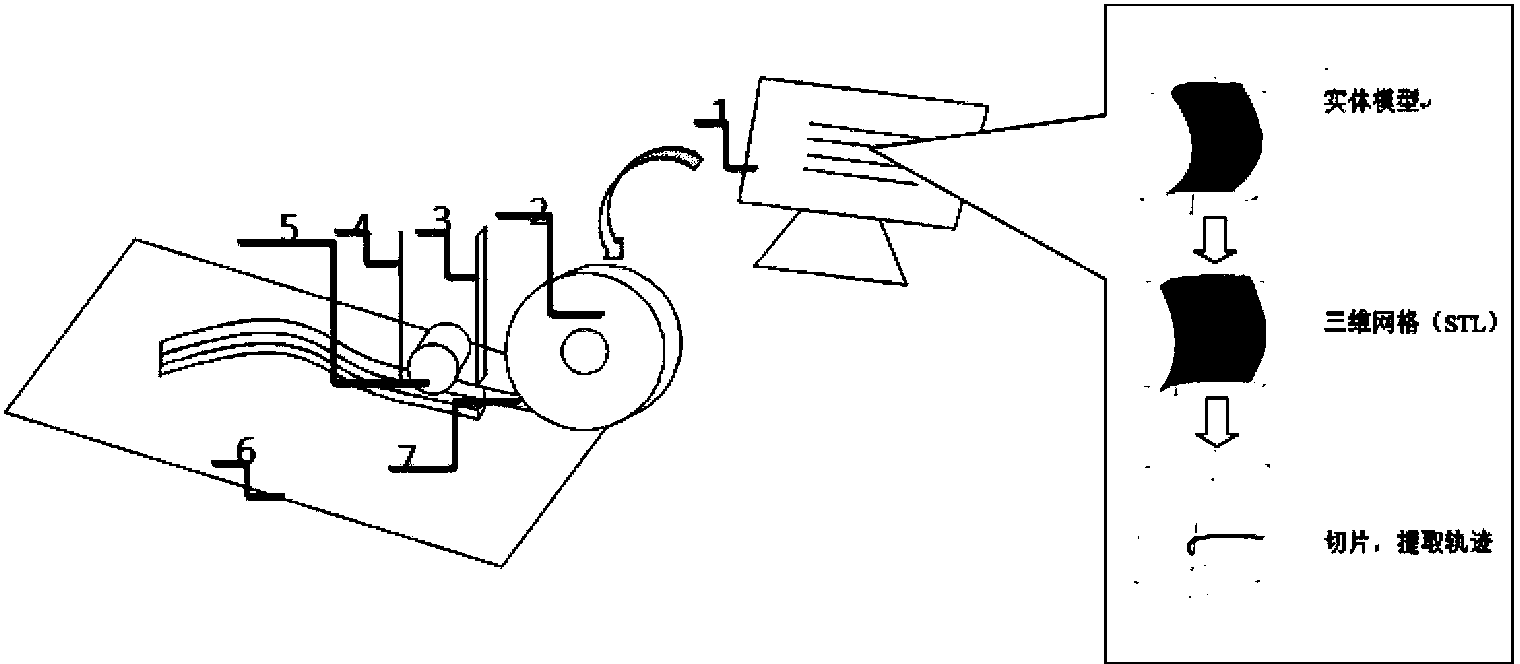

Metal part additive manufacturing method based on contour features

ActiveCN103350321ALow costImprove efficiencyAdditive manufacturing apparatusRoute planningProcess engineering

The invention discloses a metal part additive manufacturing method based on contour features, which comprises the following steps: 1, establishing a metal part CAD (Computer Aided Design) geometric model, and extracting an STL(Standard Template Library) model; 2, determining the manufacturing direction of the metal part according to the contour features and the complexity of the metal part, and carrying out the route planning on the part additive manufacturing; 3, rotationally slicing the STL model by using a layered slicing software, and generating a control command by a computer according to the contour information; 4, sending panel veneer with set width and thickness by a panel veneer feeding mechanism under the control of the control command, and shearing; and 5, finishing the welding of layers under the actions of heat generated by resistance welding or friction stirring welding as well as rolling, and meanwhile removing contour burrs through compounding the same-station milling, repeating the step 4 and the step 5, till finishing the forming of the whole part, and if not meeting the part precision requirement, adding the part finish machining step at last. Compared with the prior art, the manufacturing method has the advantages of less process, high forming quality, short manufacturing period, low cost and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Working device setted on one place and engineering machinery using it

InactiveCN1831253AShorten the timeImprove operational skillsMechanical machines/dredgersVehiclesState of artEngineering

The invention is a working device arranged in some place, composed of two or above working devices arranged in some place, back-to-back, side-arranged, opposite, staggered, side-by-side, up and down, rotatable, inclinable, turnable, movable, liftable or in other form. And an engineering machine applying it is composed by arranging it in corresponding position on a corresponding vehicle or chassis or connecting it with the correspond position. And it can compose various engineering machines by various vehicles or chassises, compact, multifunctional, low-cost, high-efficiency and energy-saving, and having strong practicality.

Owner:姚实现

Sublevel open-stoping mining method with subsequent backfilling for long-hole caving in thin ore bodies

InactiveCN104453901APlay the role of supplementary prospectingFlexibilityUnderground miningSurface miningMaterials scienceDeep hole

The invention discloses a sublevel open-stoping mining method with subsequent backfilling for long-hole caving in thin ore bodies. The sublevel open-stoping mining method with subsequent backfilling is characterized by comprising the following steps: arranging ore blocks along the orientation of the ore bodies, and dividing the ore block into ore chambers and ore pillars; dividing the ore blocks into segments in a vertical direction by sublevel drilling gate ways with an interval of 15-20m; drilling upward parallel or fan-shaped and downward parallel or fan-shaped medium-depth holes in the sublevel drilling gate ways to recover, wherein different sublevel caving sequences can be adopted according to the stabilization condition of the hanging wall surrounding rocks of the ore bodies; laterally loading ores by using a carry scraper from a bottom trench; locally anchoring the unstable areas of the hanging walls of the ore bodies, and drilling the anchored holes along with the caved holes; after the ores are recovered from the ore chambers, recovering the ore pillars according to the condition of the adjacent ore blocks, and finally filling goaf with waste rocks. The method has the prominent effects of good labour conditions, safety in working, high operation efficiency and high production capacity, and can realize intensified mining and ore mucking, and effectively control ore losses and dilution rate.

Owner:GUANGXI UNIV

Method for preparing solventless unsaturated polyester-imide wire coating enamel

InactiveCN101514276AHigh temperature resistantEnergy saving and environmental protectionPlastic/resin/waxes insulatorsCoatingsImideAcid value

The invention relates to a method for preparing solventless unsaturated polyester-imide wire coating enamel. The method comprises preparation of unsaturated polyester-imide and processing of paint mixing, wherein the unsaturated polyester-imide is prepared by the following steps: first step, adding polylol, dibasic acid or estolide into a reaction kettle according to a mol ratio of 1.05-1.5:1; stirring and heating the mixture to a temperature of between 160 and 170 DEG C; preserving the heat for 0.5 to 2 hours; and slowly heating the mixture to a temperature of between 200 and 205 DEG C until the acid value is no less than 50 mg KOH / g; and second step, cooling the mixture to a temperature of between 110 and 120 DEG C, adding trimellitic anhydride and diamine with the mol ratio of 2:1, and preserving the heat at a temperature of between 130 and 150 DEG C until the material is transparent; and after 1 hour of heat preservation, slowly heating the material to a temperature of between 200 and 205 DEG C until the acid value is no less than 30 mg KOG / g. Machine winding dipped by the solventless resin has the advantages of small volatilization loss, high filling rate, few times of paint dipping, short baking time, strong binding power, excellent performance of electrical appliance, environmental pollution reduction, and the like.

Owner:上海新天和树脂有限公司 +1

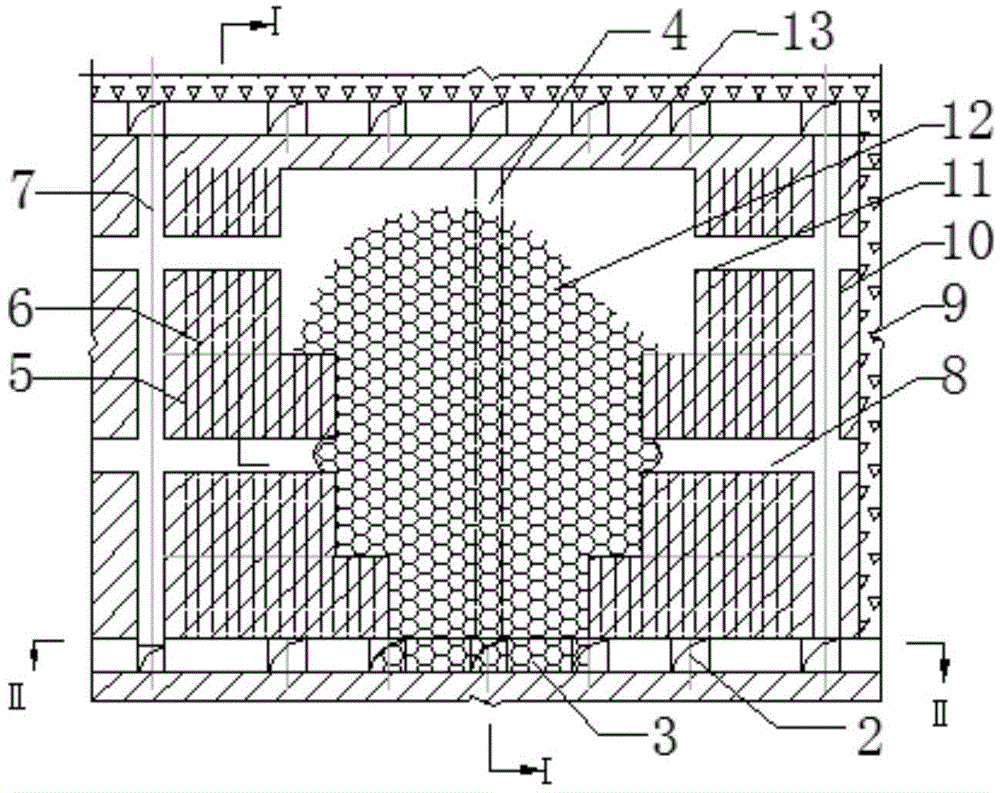

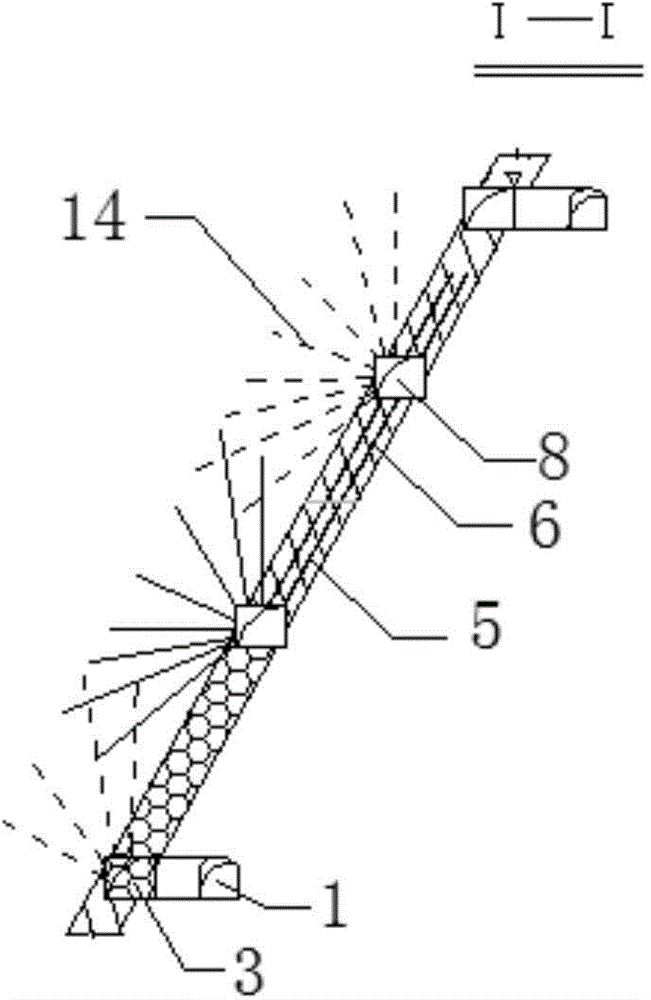

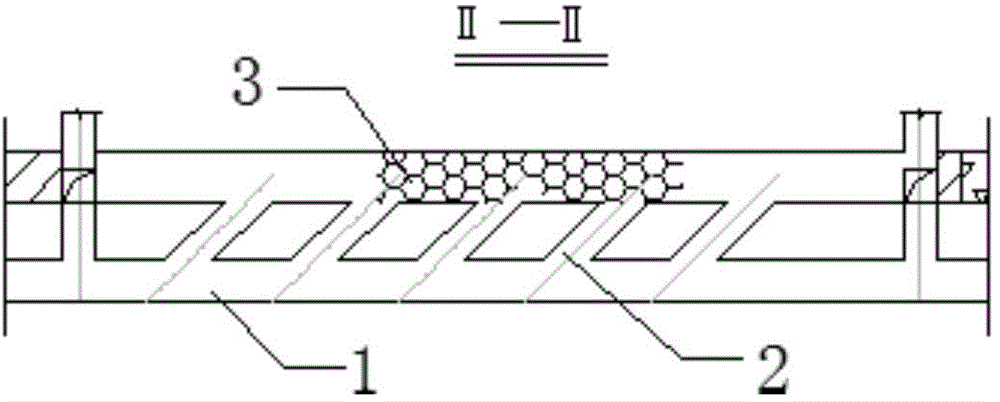

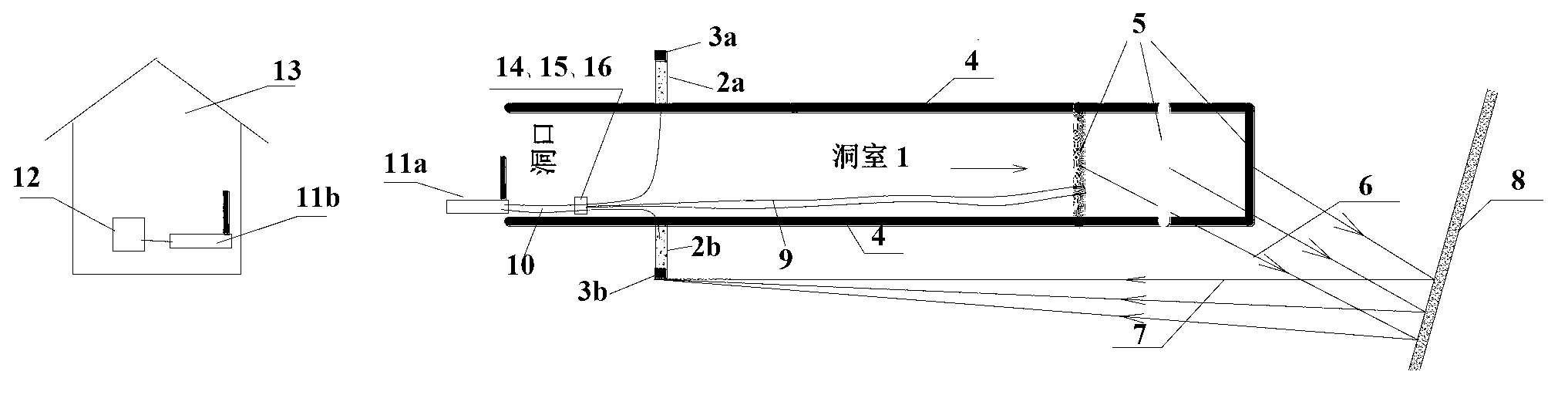

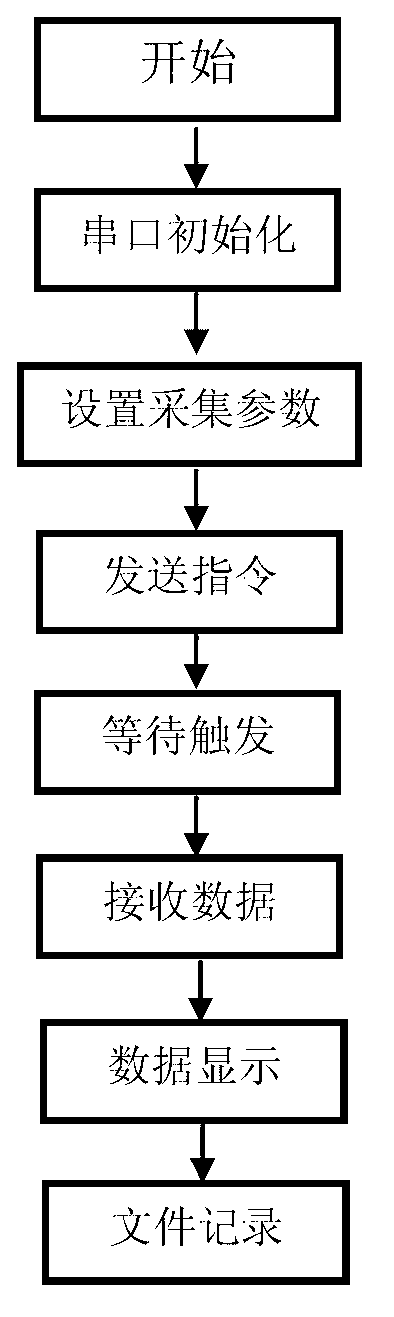

Method and device for tunnel advance geology forecast with tunnel face blasting as focus

InactiveCN103217703AImprove signal-to-noise ratioUnfavorable Geological Body ForecastSeismic signal receiversCopper wireEngineering

Provided are a method and a device for tunnel advance geology forecast with tunnel face blasting as a focus. The method comprises the steps of (1) drilling holes on two lateral walls at the inlet position in a tunnel; (2) filling a coupling agent into the drilled holes, and attaching weave detectors to the walls of the drilled holes; (3) winding a trigger circuit copper wire on cartridged explosive, and placing the cartridged explosive into a blasted hole of the tunnel face; (4), enabling two three-component weave detectors buried in a tunnel hole to receive reflective earthquake wave signals; (5) sending the signals to an amplifier after the signals are selected by a multi-way switch; (6) enabling the amplifier to amplify the signals and then transmit the signals to an analog / digital (A / D) converter through wireless transmission; (7) enabling a wireless communication module of a control chamber to receive a wireless signal and then transmit the wireless signal to a host, and recording the signal; and (8) achieving geology forecast through an processing program installed in the host. The device comprises signal acquisition, wireless communication and control and a data analyzing system. The method is simple, easy and low in cost, can be used for advance geology forecast of tunnels, holes and roadway underground spaces, and achieves automation and normalization of geology forecast.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

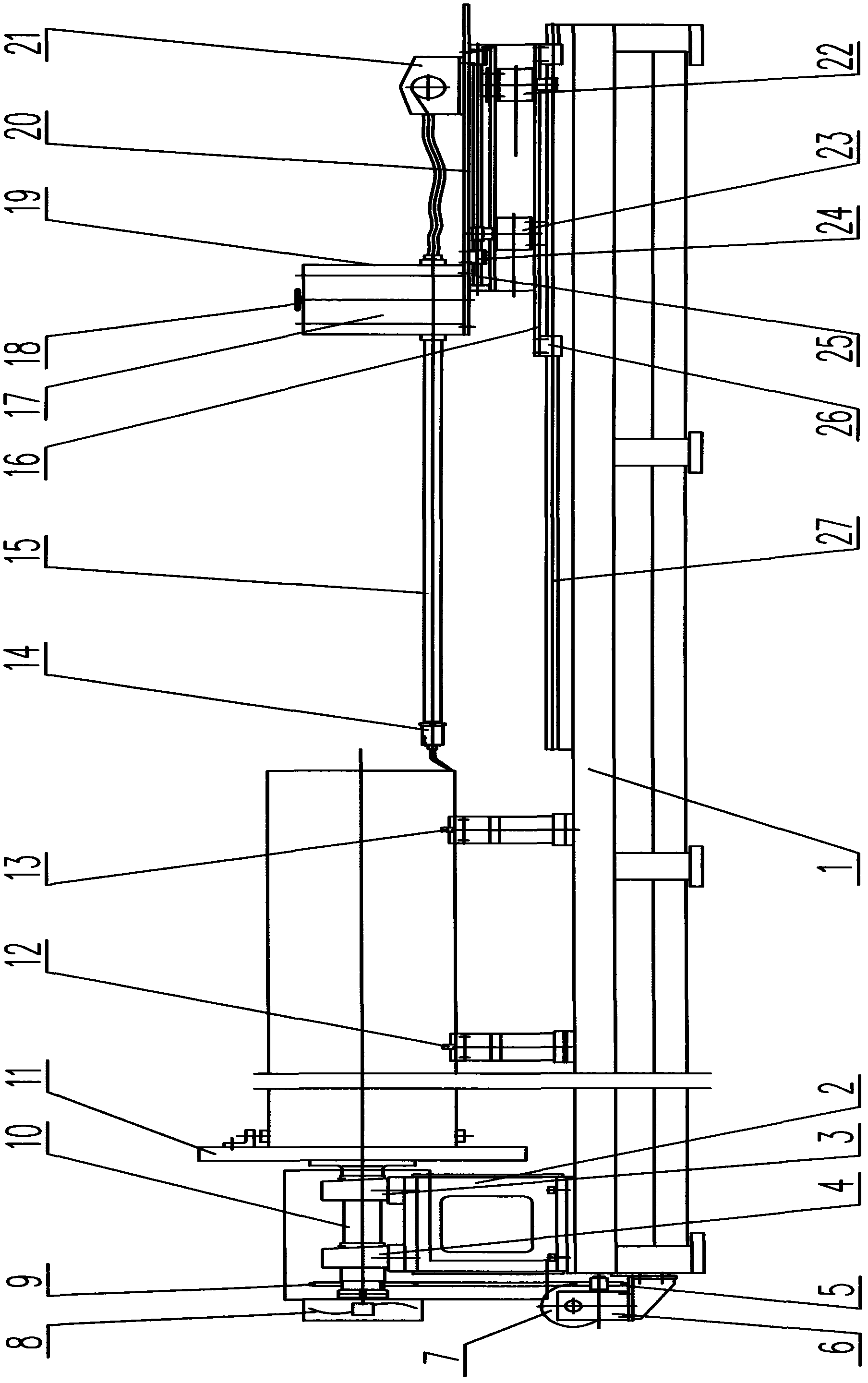

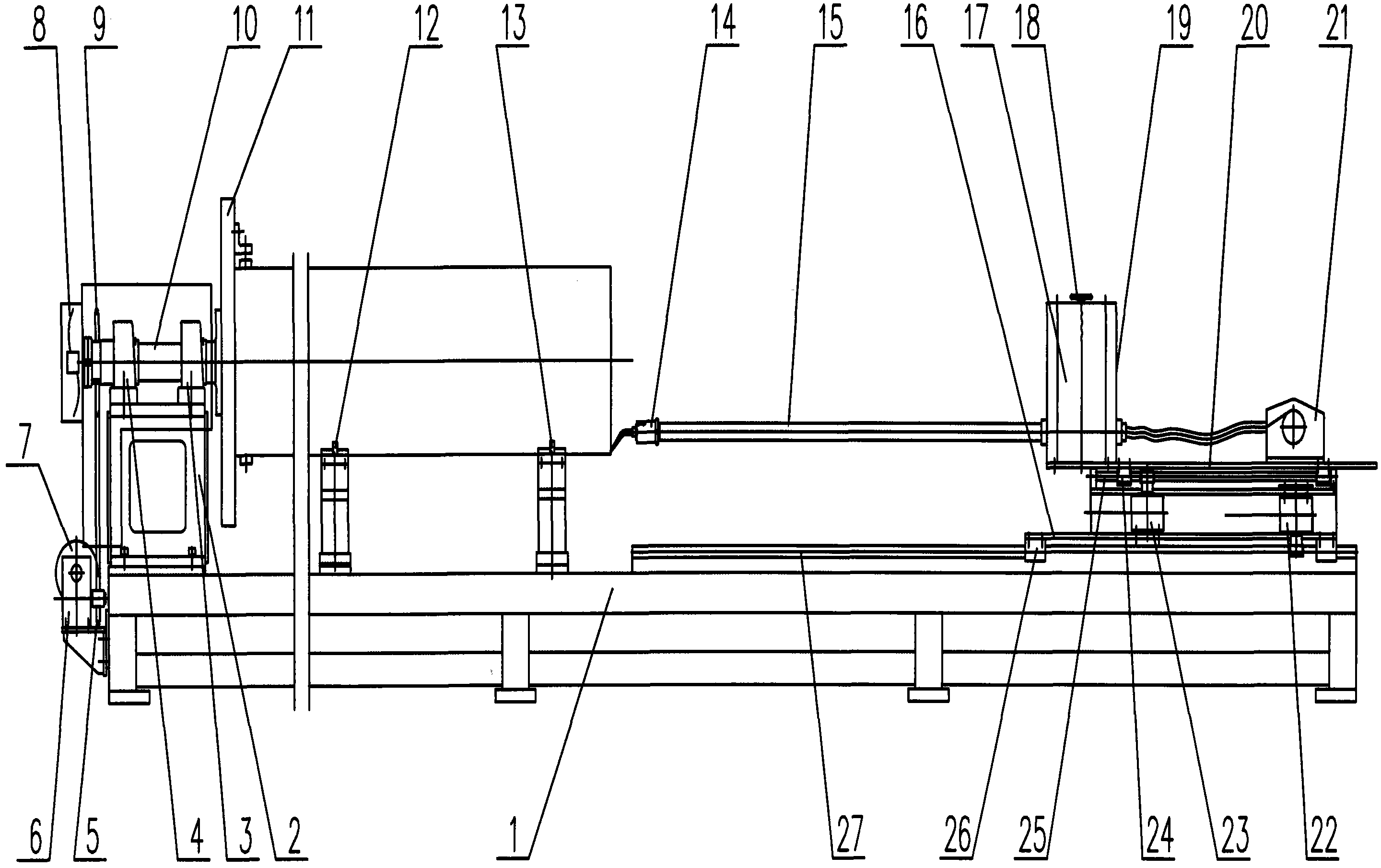

Automatic build-up welding equipment for abrasion-resistant layer on inner wall of pipeline and automatic build-up welding method

InactiveCN102049594ASmooth and reliable rotation speedGuaranteed uptimeWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlWelding power supply

The invention discloses automatic build-up welding equipment for an abrasion-resistant layer on an inner wall of a pipeline and an automatic build-up welding method for realizing efficient automatic production of high abrasion-resistant composite conveying pipelines. The equipment comprises a host, a direct-current gas protective welding power supply, a protective gas storage tank and a control box with a built-in automatic control device; one end of a base is provided with a head, a main shaft, a chuck and an adjustable roller bracket; the other end of the base is provided with a welding gun running execution device, and the device comprises a driving and reversing platform, a swing platform, a welding gun lifting mechanism, a wire feeder and a welding gun; the front end of the welding gun is provided with a welding torch, and a welding wire and a protective gas conveying pipe are communicated to the front end of the welding gun; the anode of the welding power supply is connected with the welding torch, and the cathode of the welding power supply is connected with a workpiece; and the moving parts are driven by a step motor through the automatic control device. The operation process comprises early preparation, parameter setting, welding and reset stopping; and by setting control parameters, the execution parts run according to the set parameters to form build-up welding layers tightly arranged and uniformly distributed in a spiral motion locus.

Owner:济南杰瑞复盛机电设备有限公司

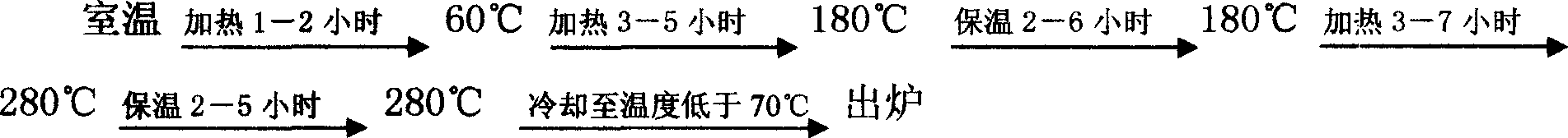

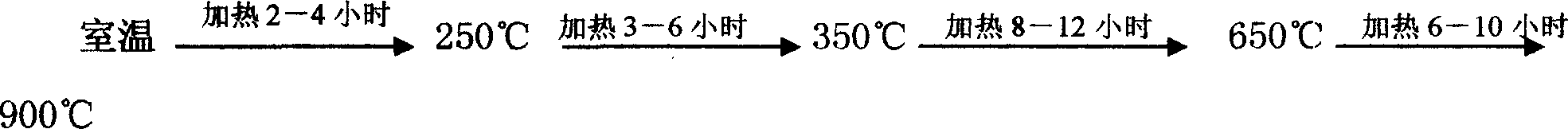

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

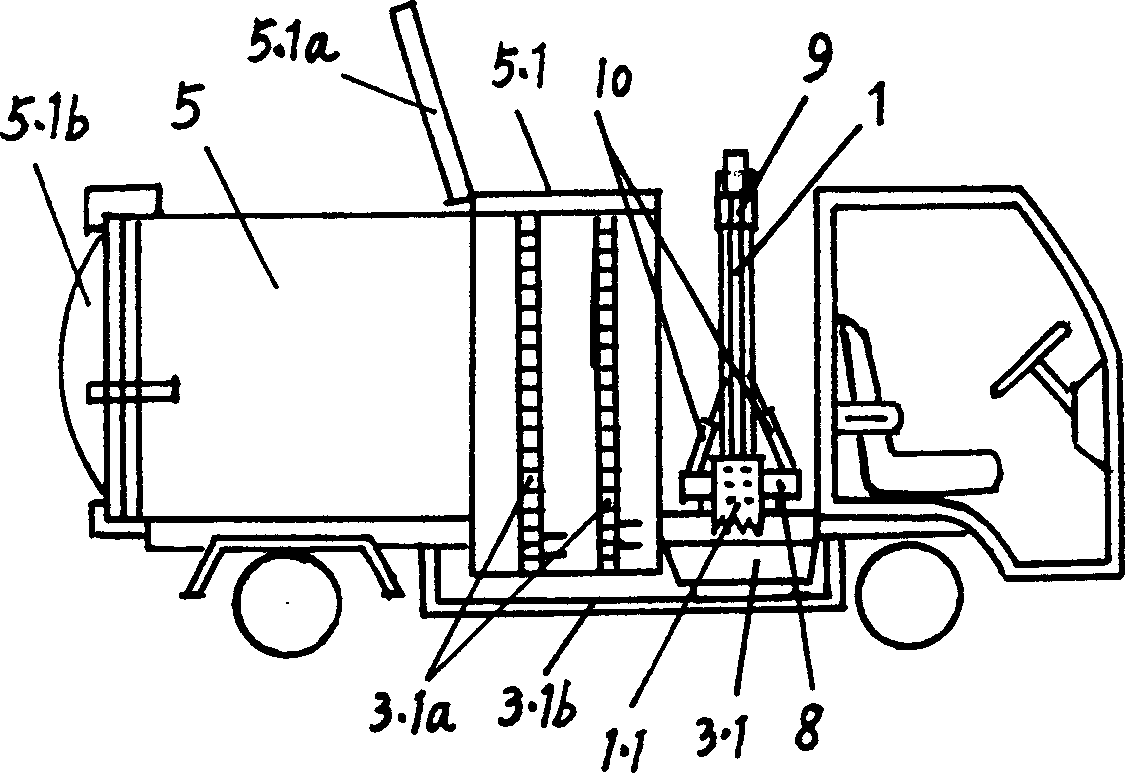

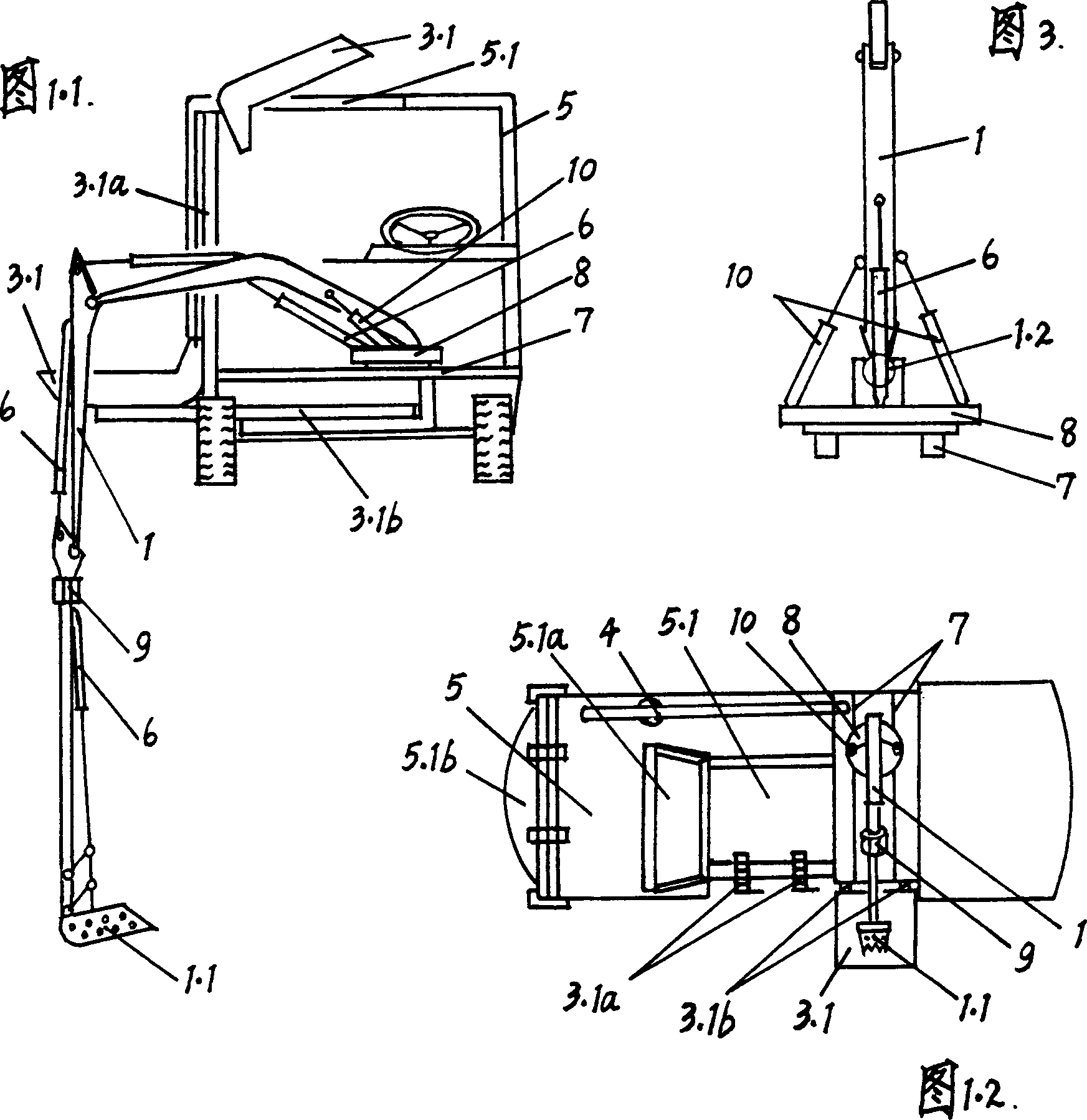

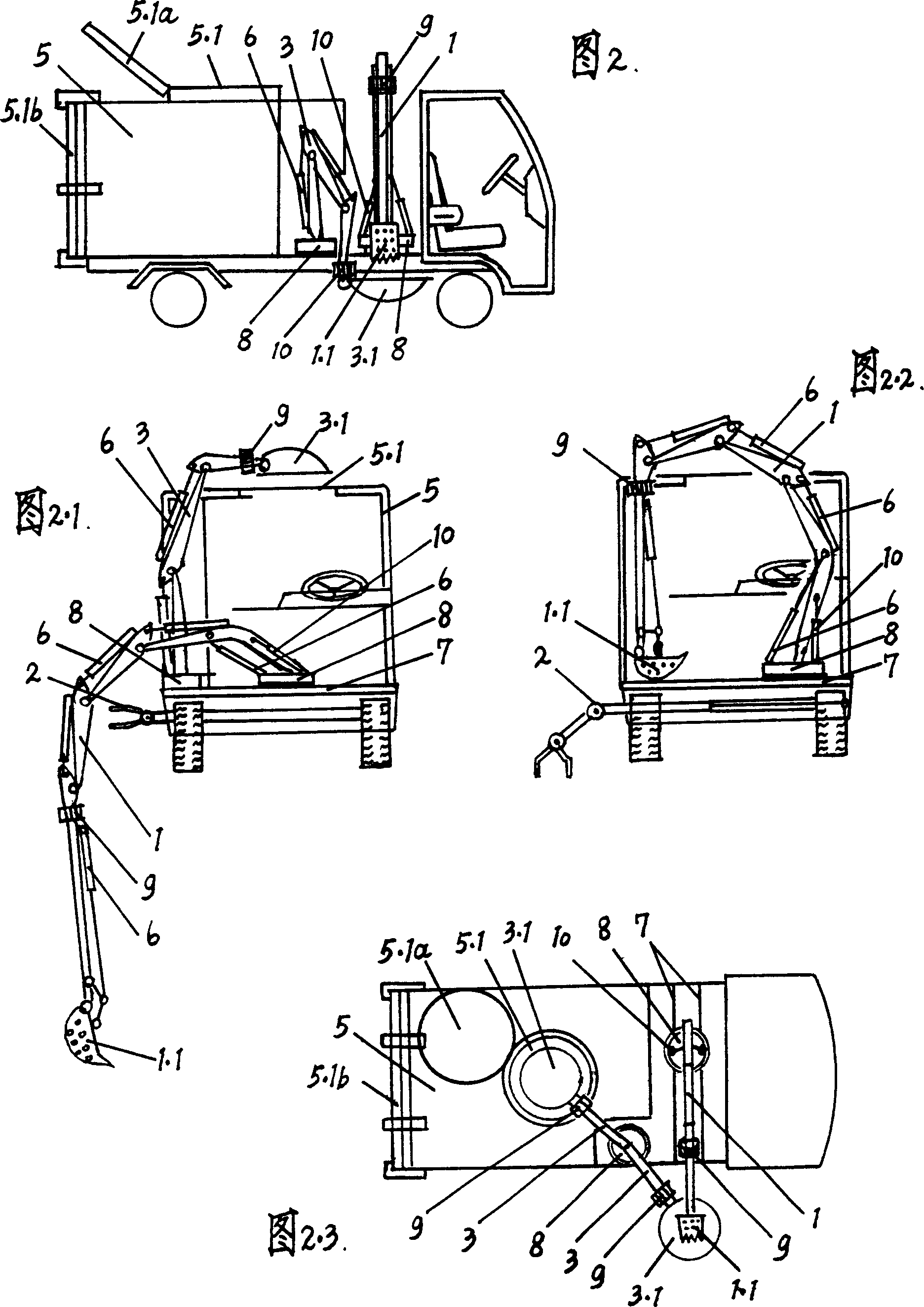

New type versatile sanitation vehicle, versatile cars, excavator, and mechanical arm

InactiveCN1519434AReduce labor intensityImprove working conditionsSoil-shifting machines/dredgersRoad cleaningAutomatic controlSpherical joint

A multi-purpose vehicle used as ordinary car, environmental sanitation car and digger is composed of main vehicle body, digger, grasp mechanism, load-bearing unit, sucking unit, sprinkler, and hoister. Said digger can also be installed to ship. A mechanical arm is also disclosed, which features that it has spherical joint, both axial and radial rotary unit, and the drivers in both direction of an arm segment.

Owner:姚实现

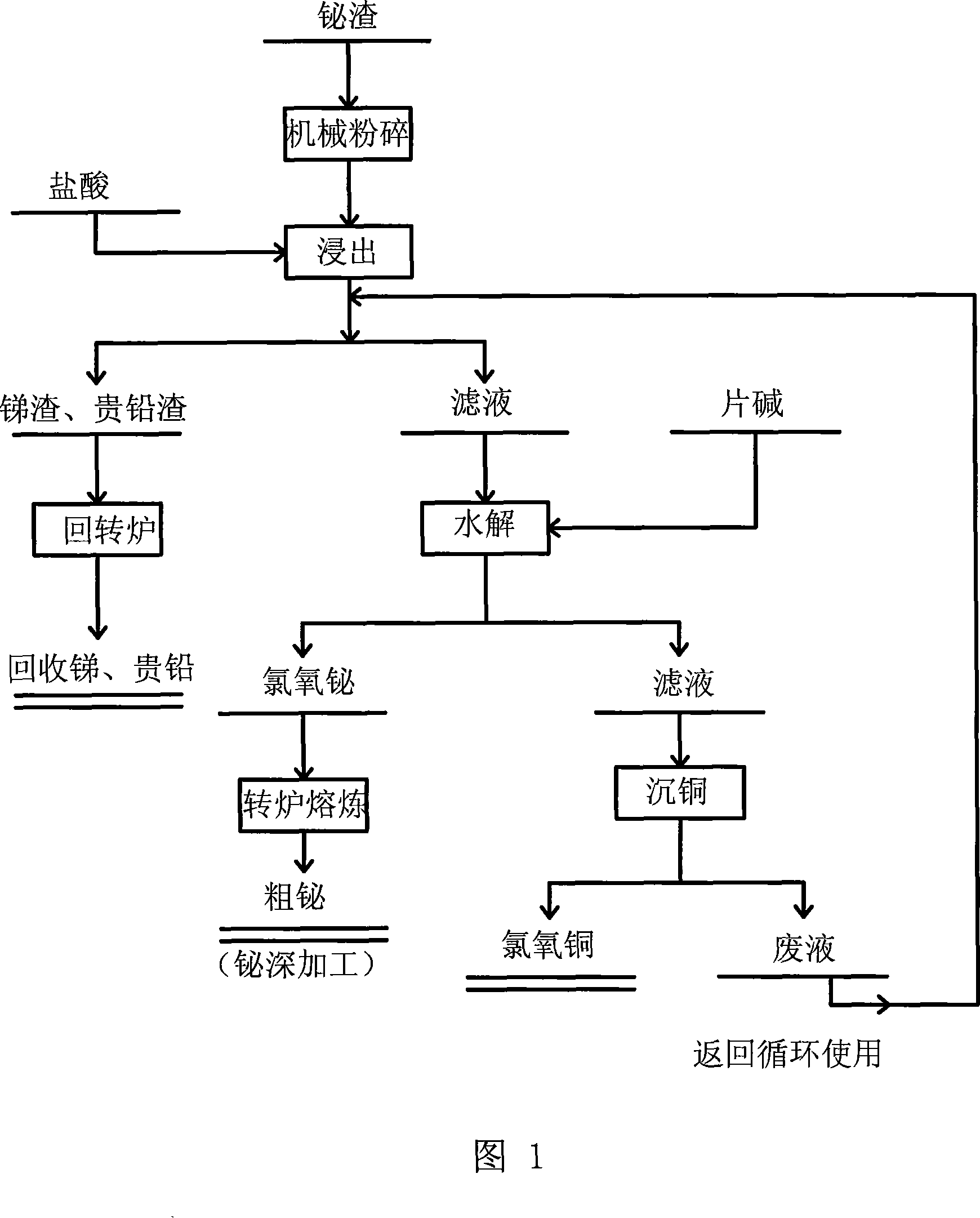

Technique for reclaiming smelting refined bismuth from bismuth slag

InactiveCN101082084AHigh recovery rateAdaptableProcess efficiency improvementPregnant leach solutionSlag

The present invention is process of recovering and smelting bismuth from bismuth slag, and belongs to the field of combined wet and pyrogenic non-ferrous metal smelting technology. The process includes the first wet leaching of bismuth slag with hydrochloric acid, precipitating leaching liquid to obtain bismuth oxychloride, reducing smelting to obtain coarse bismuth product, refining to obtain refined bismuth product, precipitating Cu from the bismuth extracting filtrate, and returning the used liquid to the leaching step. The present invention has high material adaptability, high metal recovering rate and environment friendship.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Preparation and method for drying sludge through deep dehydrating

InactiveCN102229464AImplement processing reduction requirementsNo noiseSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentMechanical pressDewatered sludge

The invention relates to a preparation and a treatment method, and especially relates to a preparation and a method for drying sludge through deep dehydrating. The preparation comprises: 0.000002 to 0.00001 parts of an organic polymeric flocculants, 0.00025 to 0.0025 parts of a coagulating modifier, 0.0005 to 0.00375 parts of a sterilizing deodorant, and 0.00025 to 0.0025 parts of a nucleating converting agent. The method comprises the following steps: a sludge gravity thickening initial dehydrating step, a sludge regulating step, a mechanical press-filtrating step, and a filtrate refluxing step. With the preparation and the method provided by the present invention, sludge deep dehydrating processes can be carried out in series, processing efficiency can be improved, and energy consumption can be reduced. The controllability of the method is high. With the method, recycling is realized.

Owner:ZHEJIANG JIEFENG ENVIRONMENTAL PROTECTION TECH ENG COMPANY

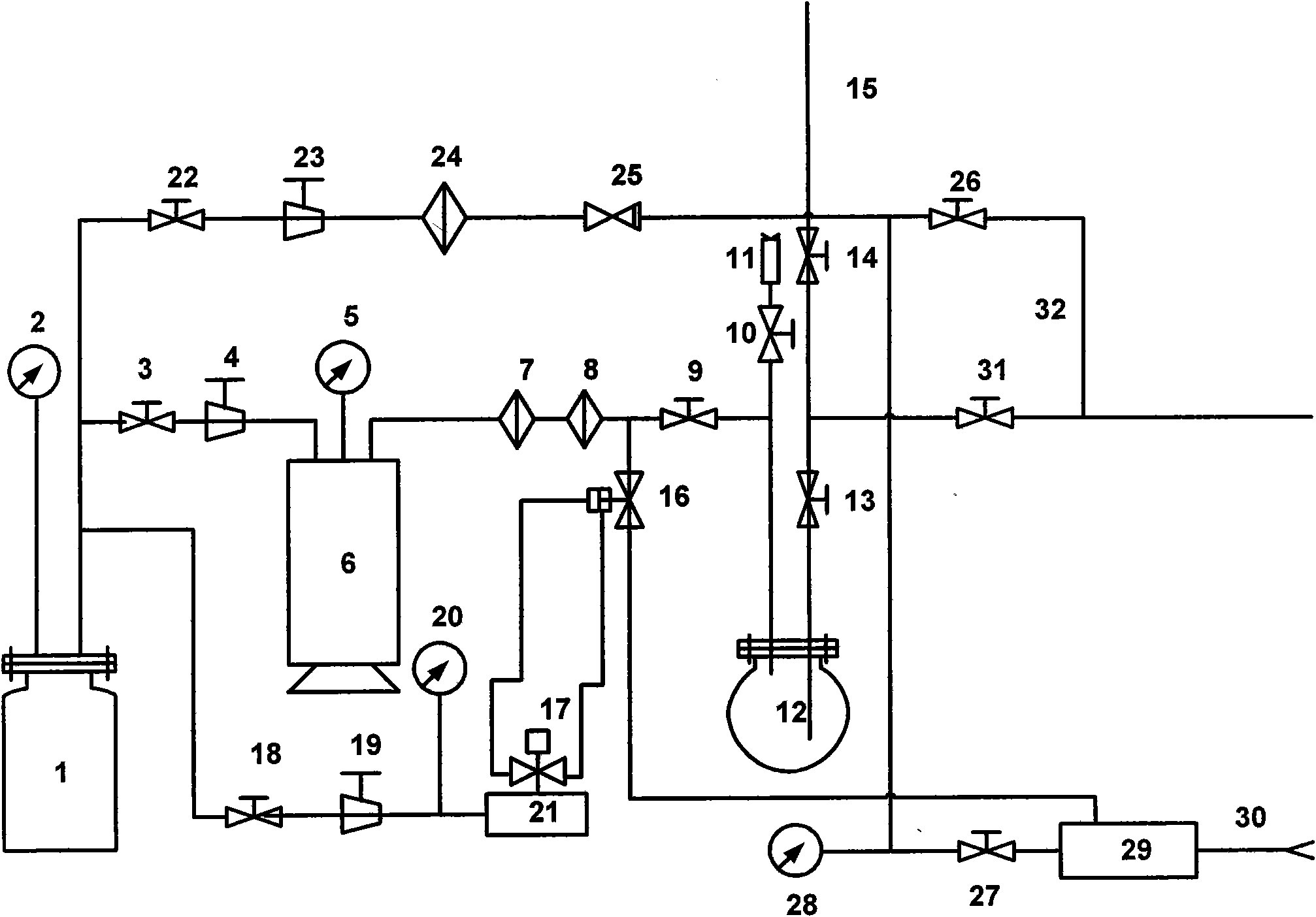

Pressure stability control device supplied with constant voltage by propellant

InactiveCN101539069AStable flowImprove working conditionsRocket engine plantsBuffer tankHigh pressure

The invention provides a pressure stability control device supplied with constant voltage by a propellant, in particular comprising a high-pressure air supply device, a supercharging device, a control gas device, a blowing device and a liquid propellant supplying device. The high-pressure air supply device supplies high-pressure air. The supercharging device supercharges a propellant storage tank to extrude the propellant to enter a feeding pipeline, and a supercharging buffer tank can stabilize the pressure of pressurized gas. The blowing device is in charge of filling the clearing of pipeline propellant. The control gas device provides control gas for the system. The pressure of pressurized gas can be always kept constant by the pressure stability control device supplied with constant voltage by the propellant, thereby continuously supplying liquid propellant in testing, and satisfying the principle of slow supercharging and preventing collapse of the feeding pipeline due to too fast pressurizing in pressurization.

Owner:BEIHANG UNIV

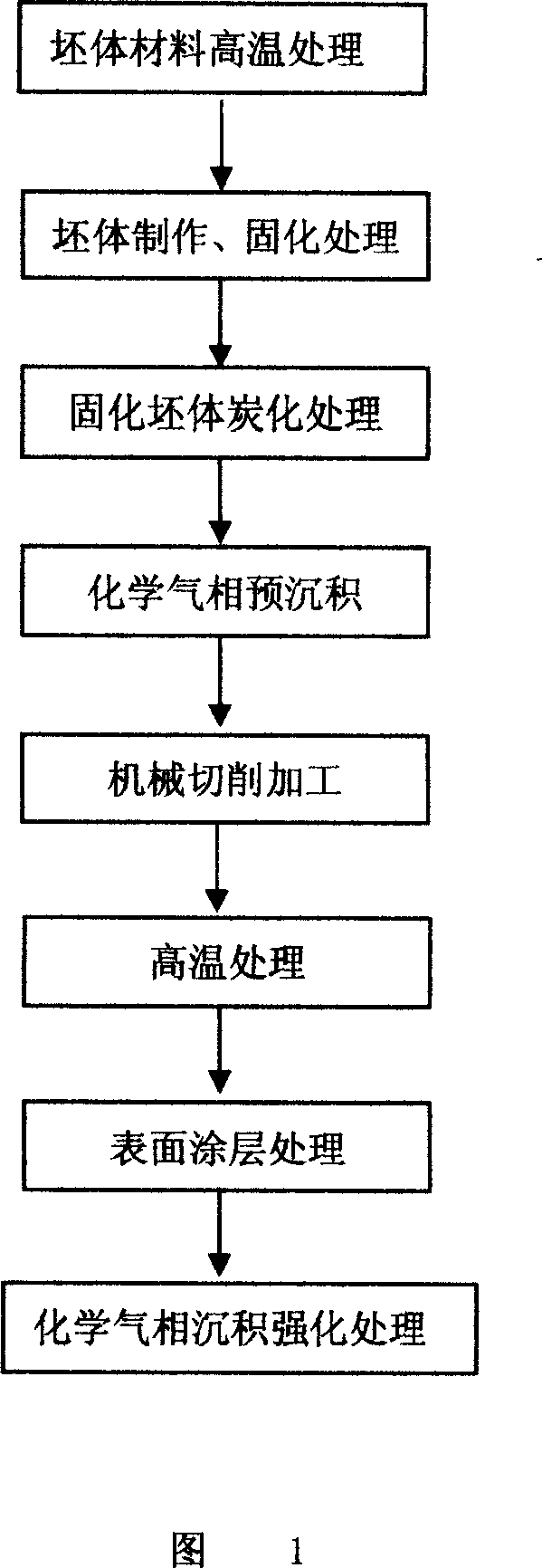

Production method of high purity cured charcoal felt silicon crystal growth oven

InactiveCN1994972AGuaranteed shape retentionMeet the use requirementsAfter-treatment apparatusBy pulling from meltGas phaseMetal impurities

The invention discloses a making method of high-purity solidified carbon cushion in the silicon crystal growing stove, which is characterized by the following: selecting flexible cushion with low metal impurity as blank material; disposing under high temperature to form graphite cushion; using graphite cushion as blank; solidifying the blank to shape with evenly permeable hardener; carbonizing the blank; proceeding chemical gas-phase deposition for blank; cutting part of element surface mechanically; disposing blank under high temperature; removing metal impurity and volatile substance; coating the working piece; strengthening the element surface; improving the corrosion resistant of blank surface.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

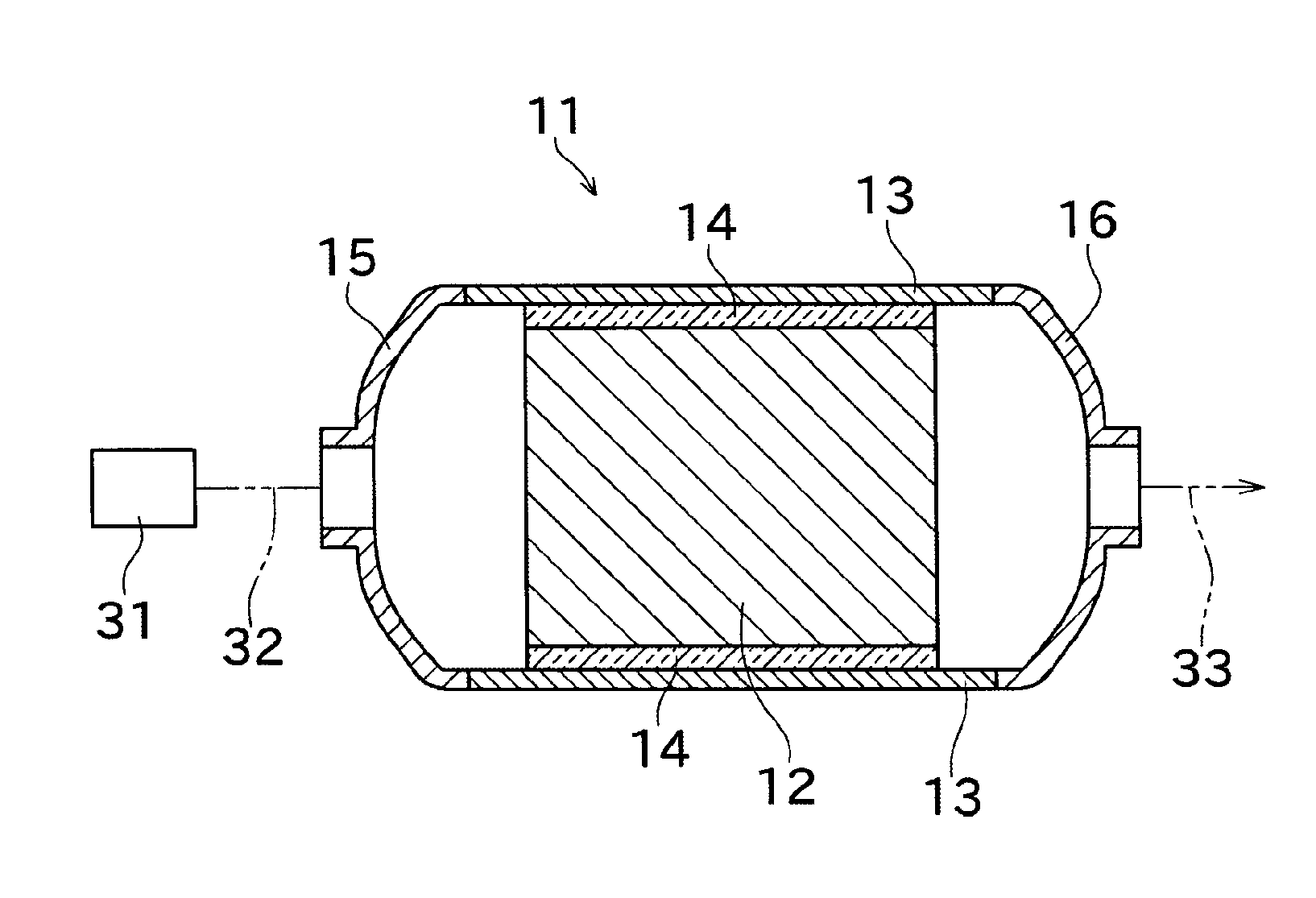

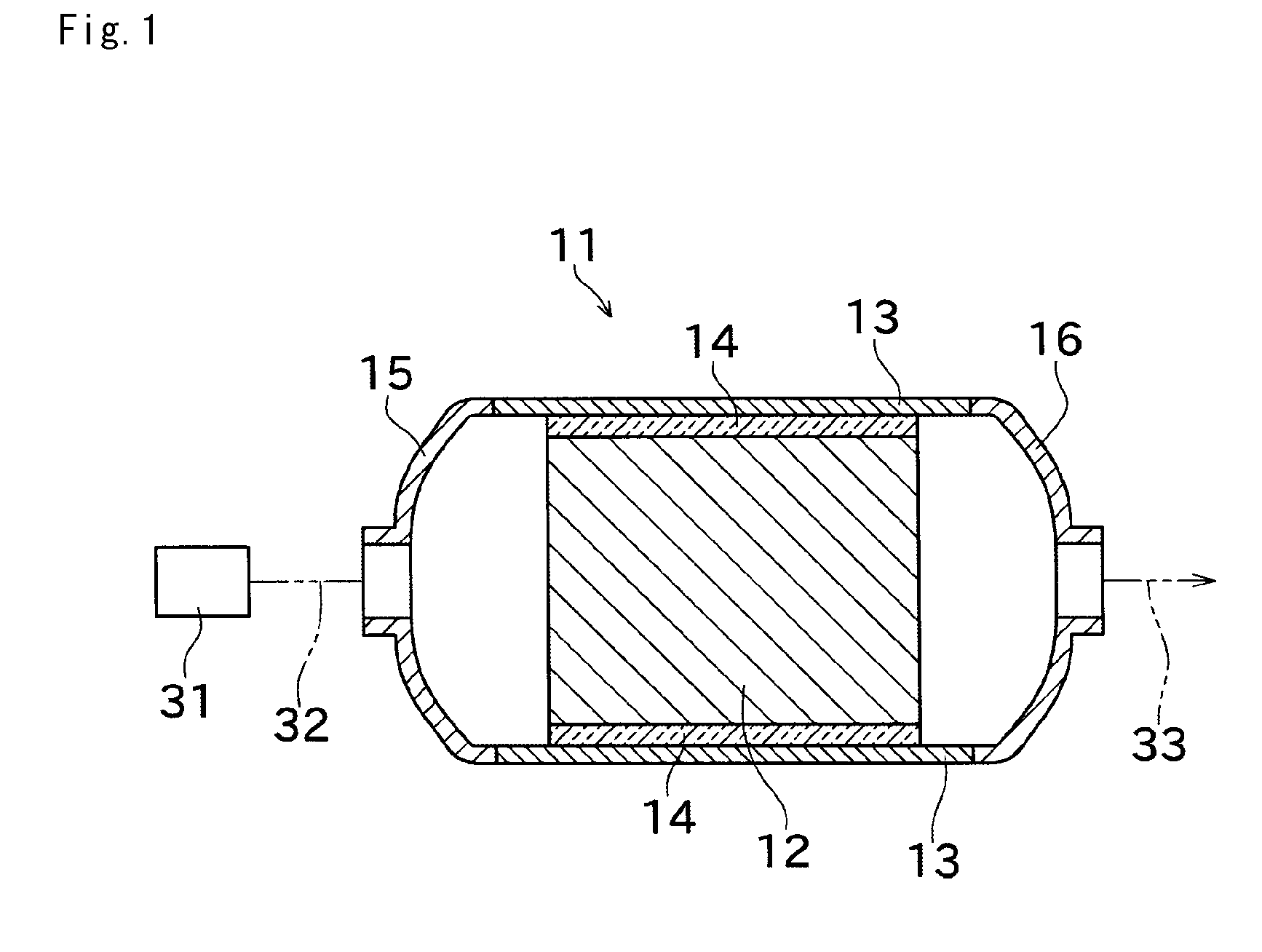

Inorganic fiber mat, holding sealer, sound absorber, and method for manufacturing inorganic fiber mat

ActiveUS20090081455A1Improve working conditionsAmount of organic binder may be reduced more easilyExhaust apparatusLayered productsSound AbsorberFiber

Owner:IBIDEN CO LTD

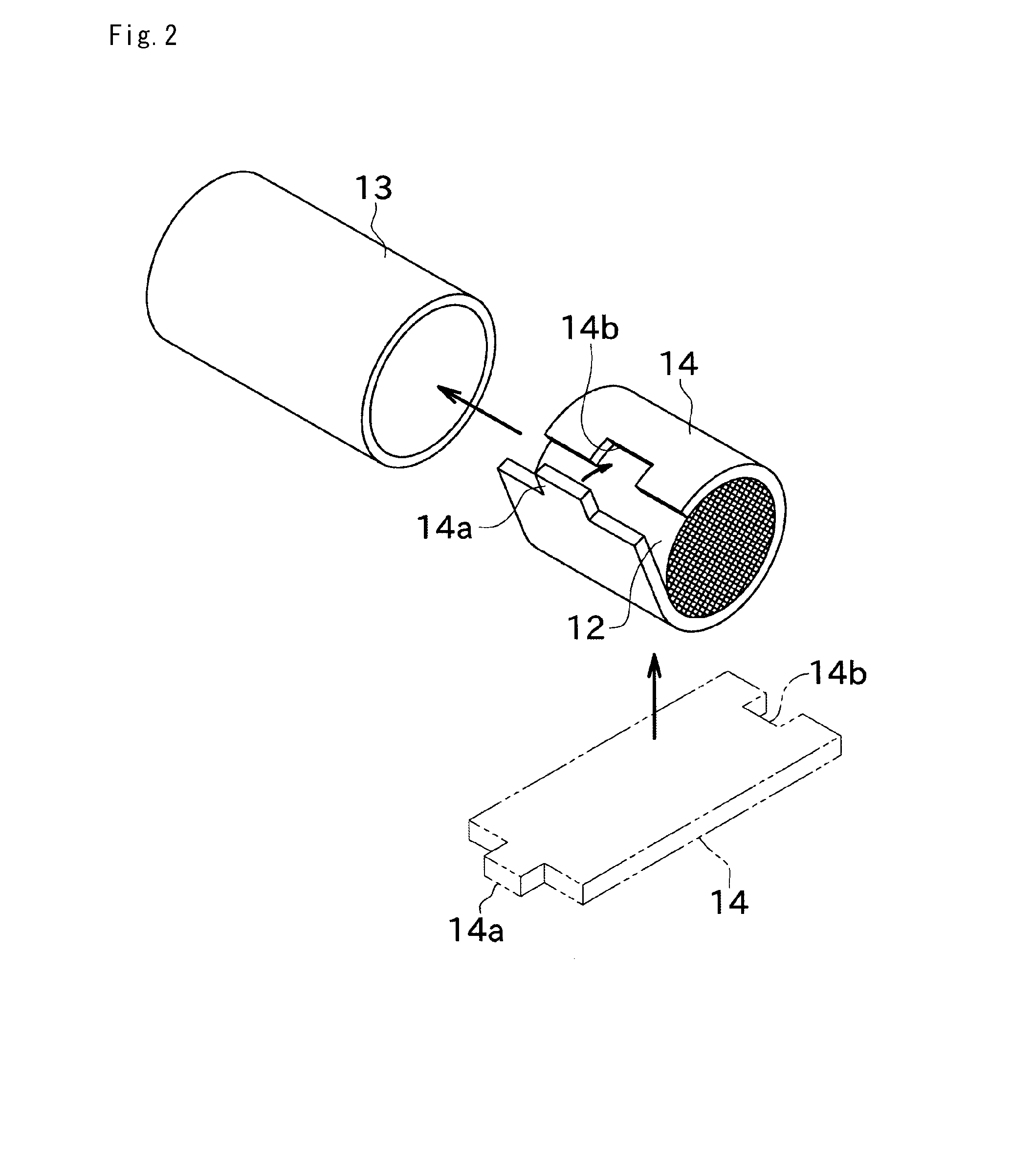

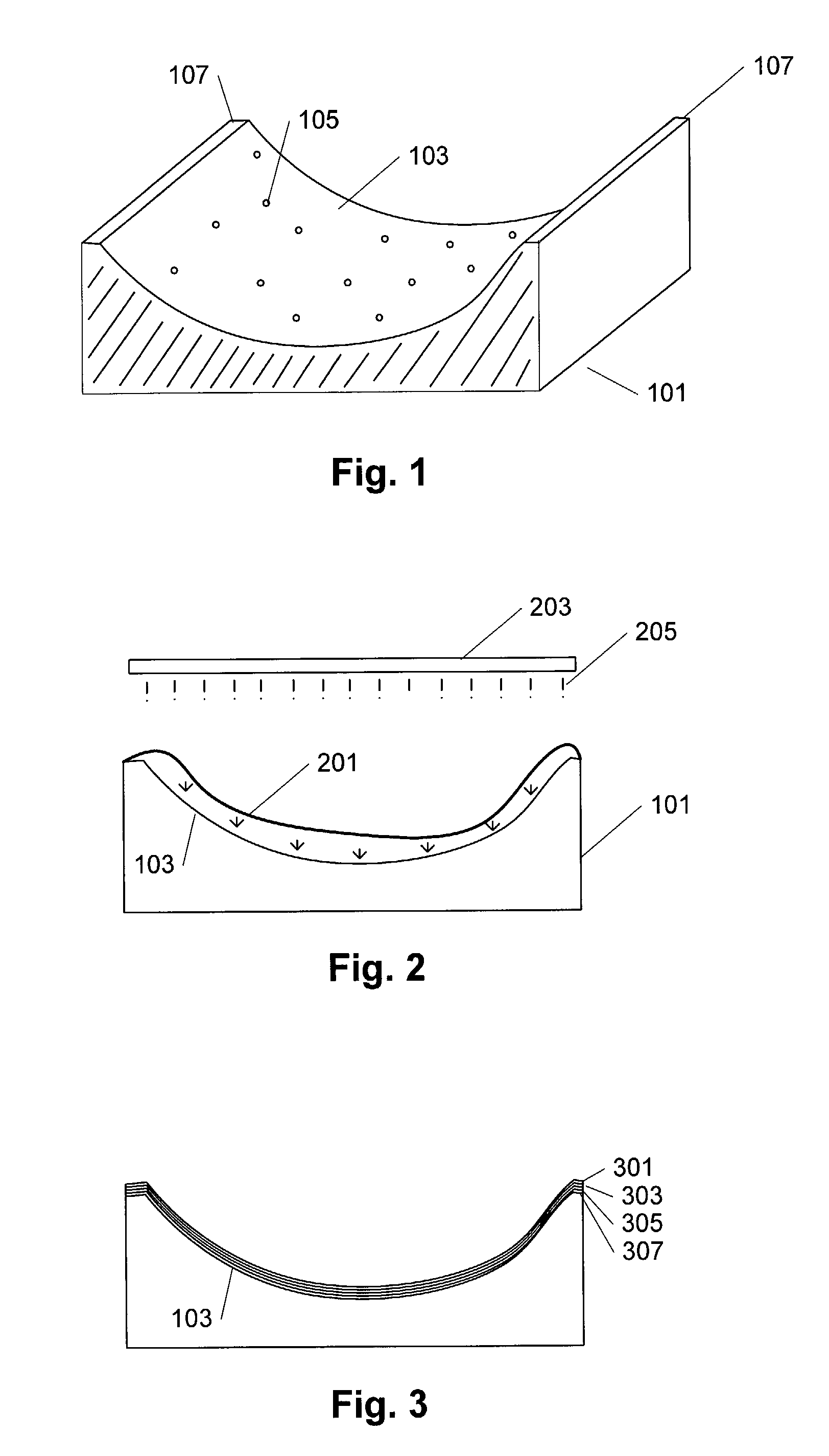

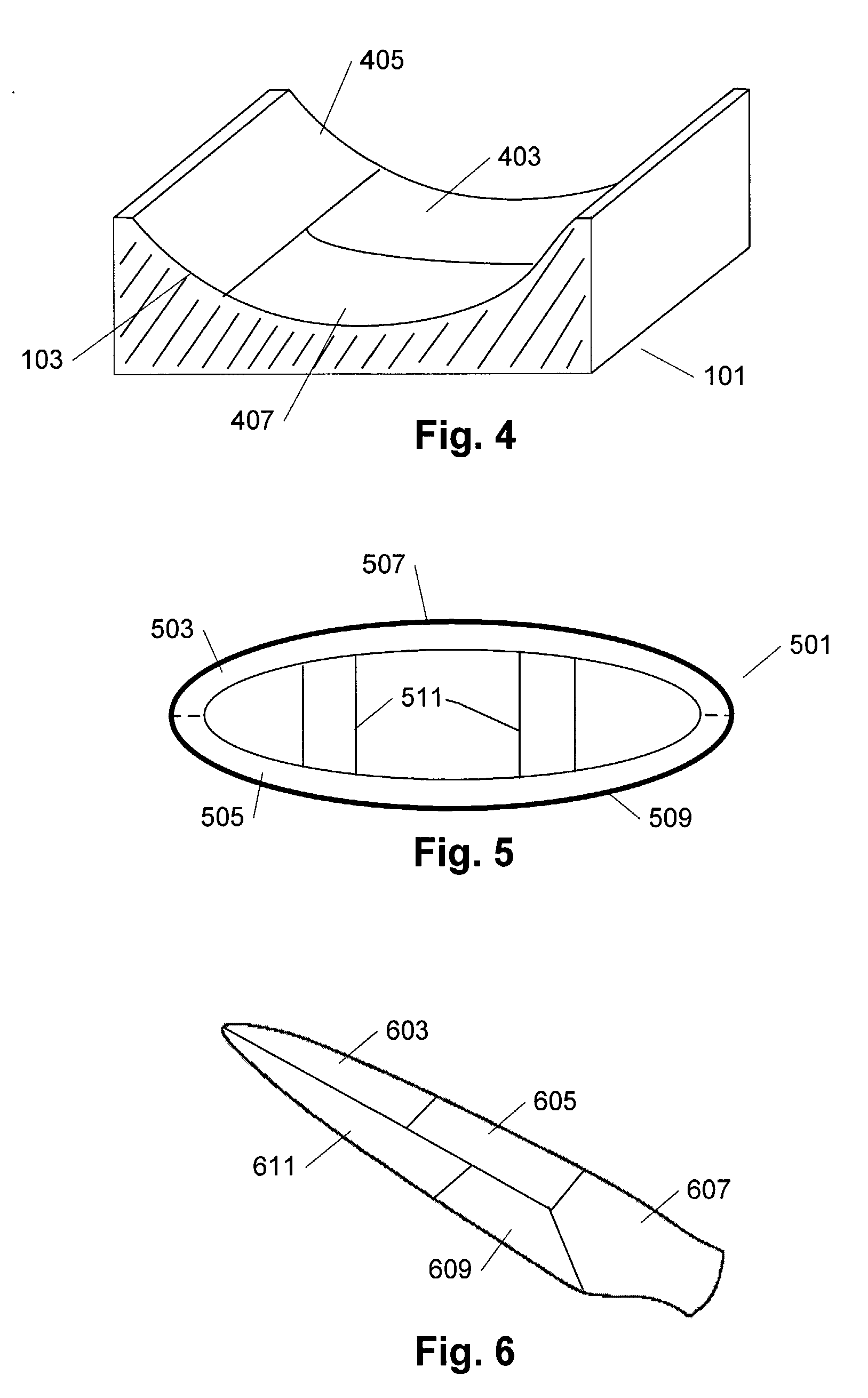

Method of Manufacturing a Fibre-Reinforced Part for a Wind Power Plant

ActiveUS20080304971A1Improve working conditionsMore to physical impactEngine manufacturePump componentsPower stationEngineering

The invention relates to a method of manufacturing fibre-reinforced parts for a wind power plant such as eg a blade, wherein the method comprises laying out a first, outermost layer of film in the interior surface of an open mould; following which different layers are arranged on top of the first layer, comprising layers of fibre material; and wherein resin is applied for joining the laid-out layers to each other. By use of a film for the outermost layer a moulding process results that provides a major improvement of the working conditions. A further advantage is also that, compared to the use of gelcoat, a surface is accomplished which is more resistant to physical influences in the form of eg cyclical stresses on the element. The invention also relates to a fibre-reinforced part for a wind power plant, eg a blade, wherein the part is structured from a first, outermost layer, and also to a blade for a wind power plant and comprising a fibre-reinforced part according to the invention.

Owner:LM GLASSFIBER

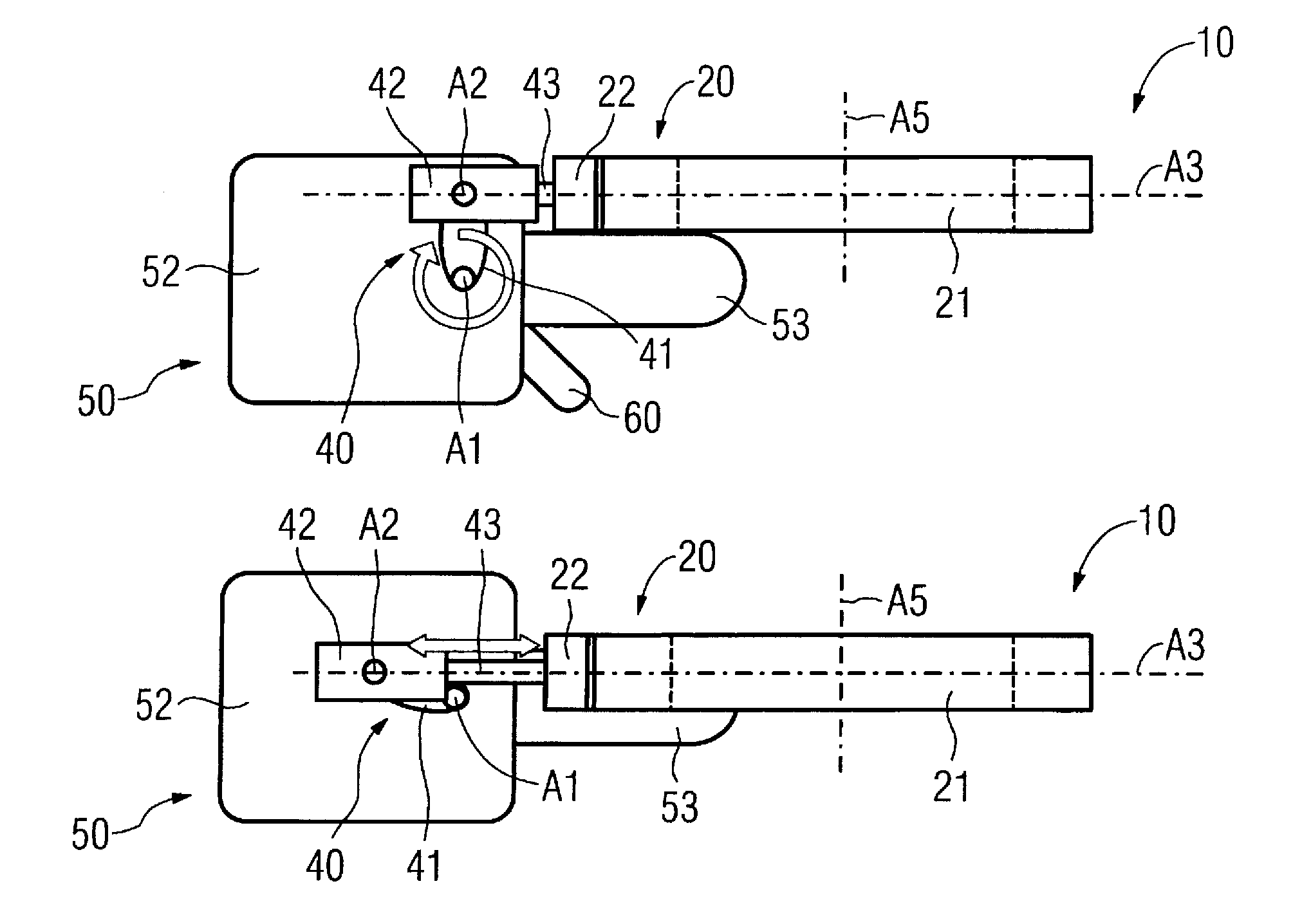

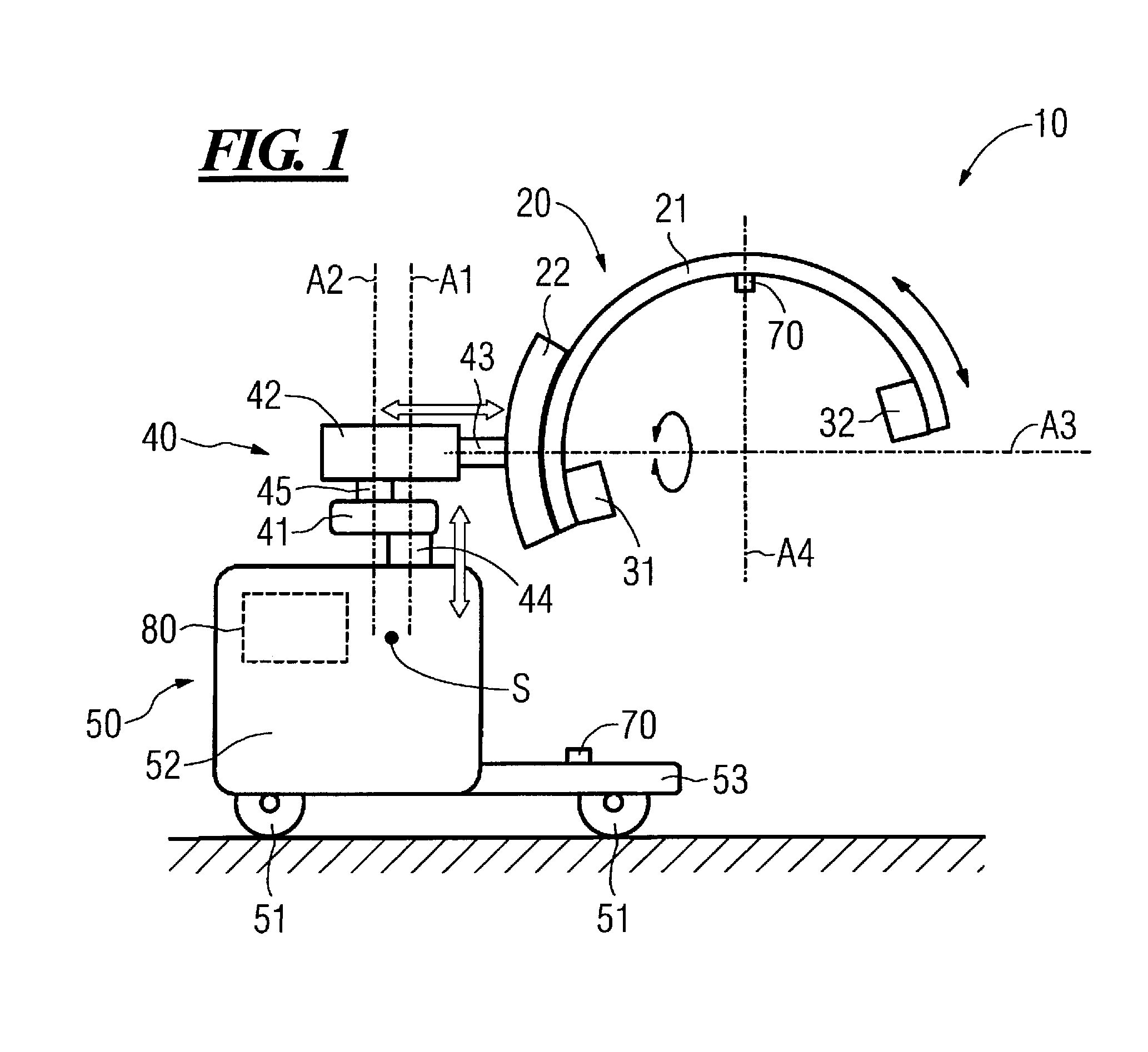

X-ray recording device with an X-ray detector and an X-ray emitter

InactiveUS7597473B2Low costSpace-saving and as stableX-ray apparatusRadiation diagnosticsRotational axisSoft x ray

An X-ray recording device has an X-ray detector and an X-ray emitter aligned with one another on a mobile supporting device, the supporting device being supported by retainer on a stand unit and being displaceable along a horizontal translation axis and / or vertical translation axis. The retainer has only one first pivoting arm rotatably mounted on the stand unit for rotation around a first vertical rotational axis and only one second pivoting arm rotatably mounted on the first pivoting arm for rotation around a second vertical rotational axis. This X-ray recording device allows an alteration to the recording range to be undertaken at reduced cost and with a space-saving and stable configuration.

Owner:SIEMENS AG

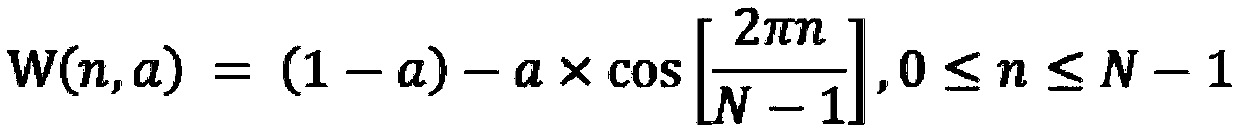

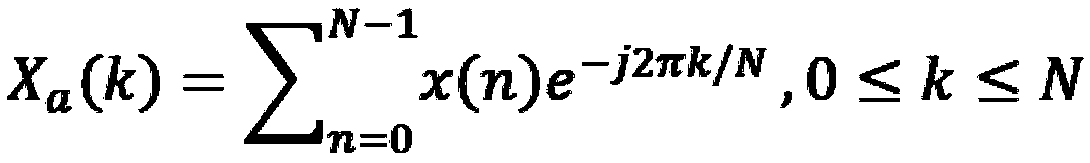

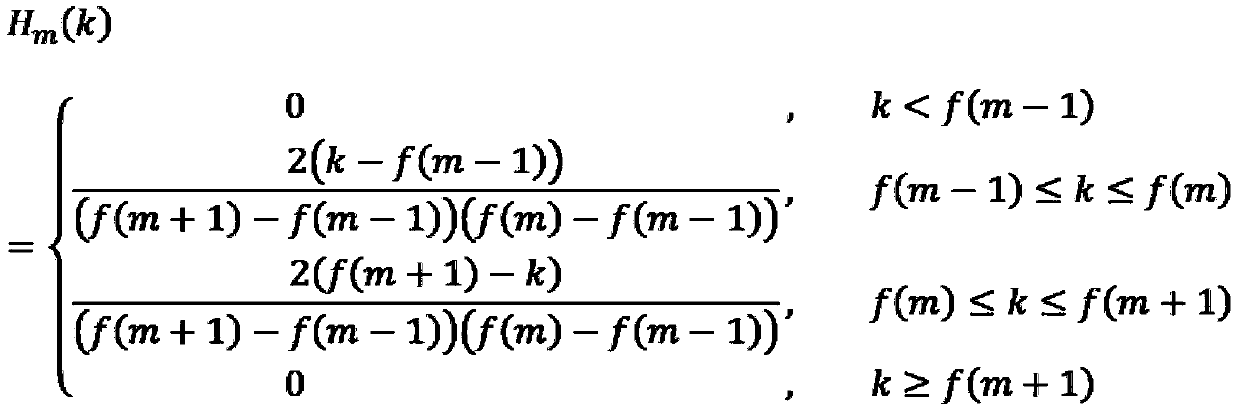

Method for identifying sound fault based on mel energy spectrum and convolution neural network

ActiveCN109599126ASave time at workSave human effortSpeech analysisTime domainFast Fourier transform

The invention discloses a method for identifying a sound fault based on a mel energy spectrum and a convolution neural network. The method comprises the following steps: first, performing pre-emphasison initially input audio data; then, performing framing and windowing processing on the data; after that, performing fast Fourier transform on framed and windowed data; extracting energy features ona frequency domain, processing an energy spectrum by using a set of mel-scale triangular filter banks; and after that, converting the data into a Mel energy spectrum by using energy in different frequency domains corresponding to each frame as a Y axis, and different frames in a time domain as an X axis. After that, the energy spectrum needs to be further framed to adapt to an input of a CNN (convolution neural network). Each frame is a sample, and one-hot coding of a label corresponding to each sample is used as an output of the CNN to train a CNN model until a network training error reachesthe minimum. During prediction, a probability value of each type of label is output, and a label with the largest probability value is taken as a final discrimination result.

Owner:广州丰石科技有限公司

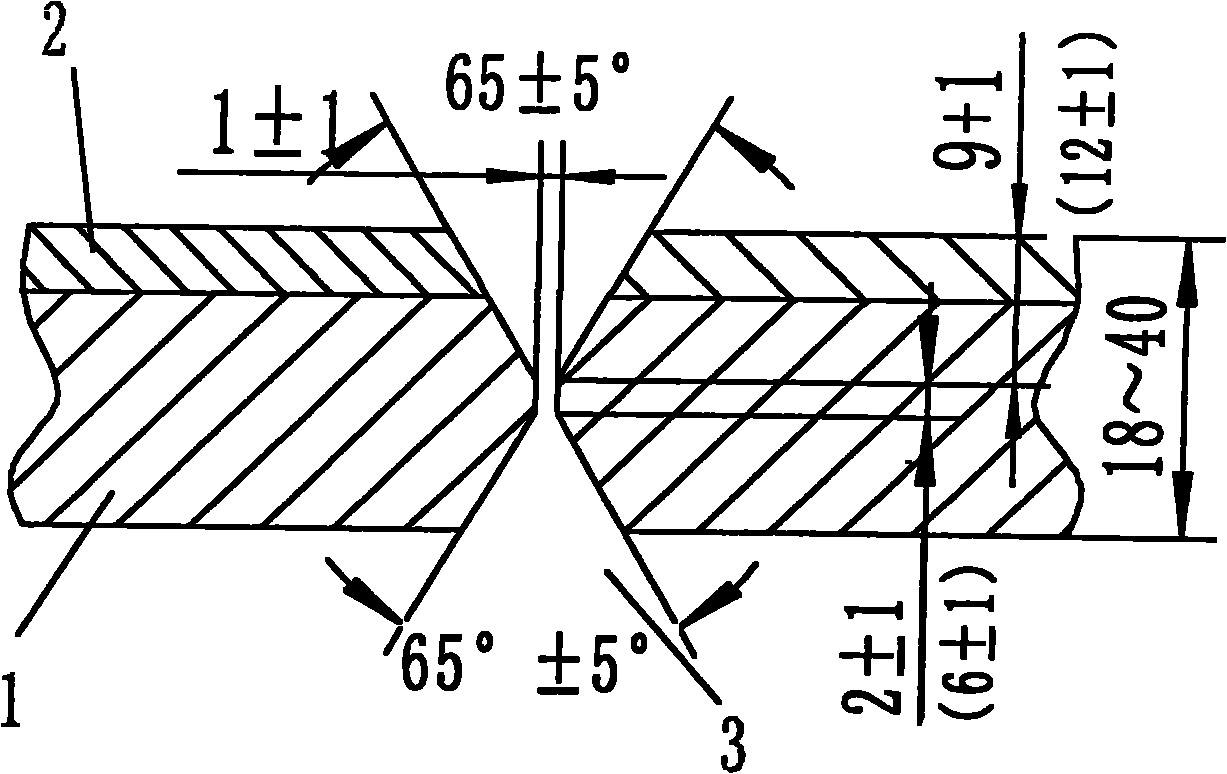

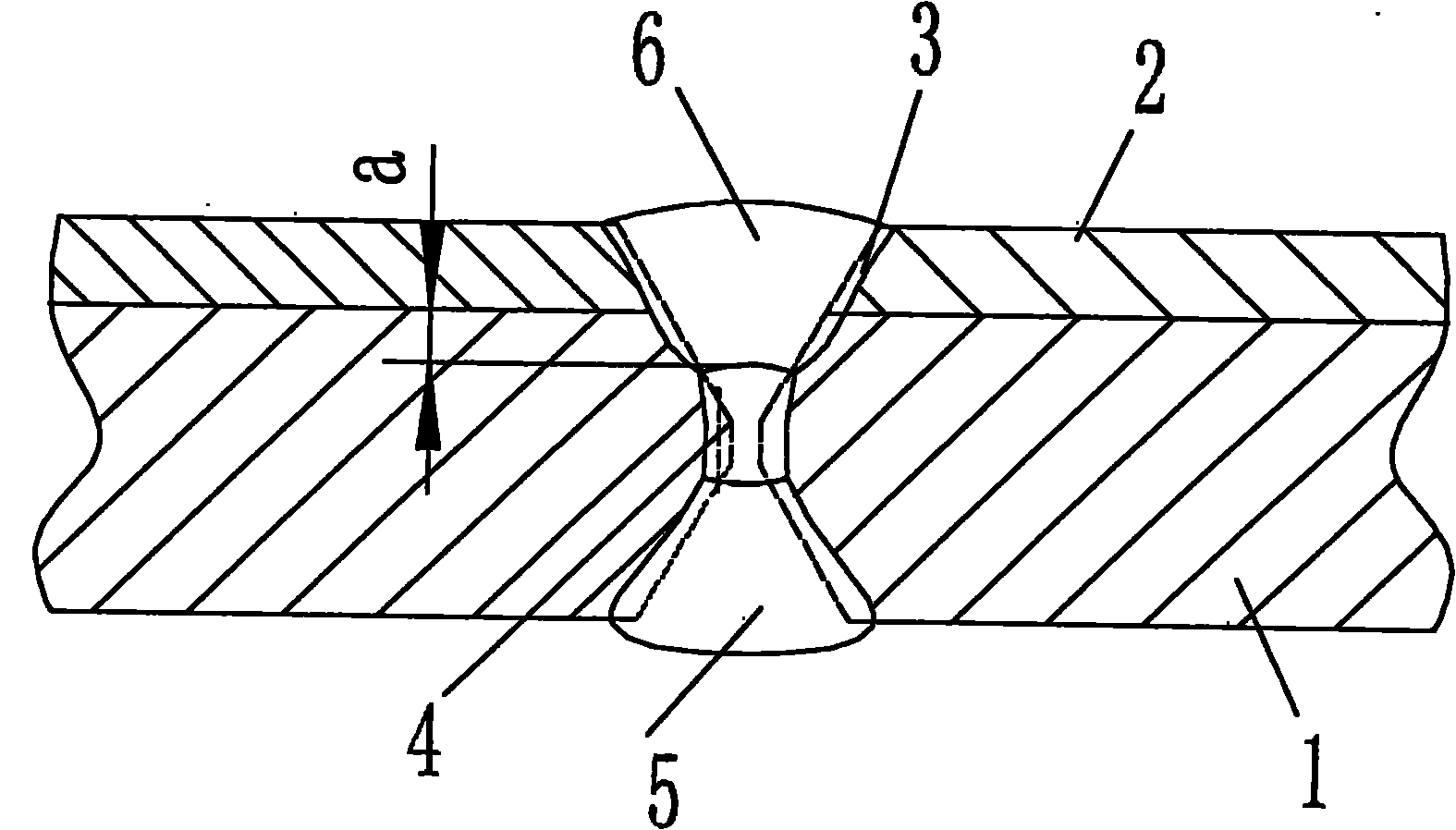

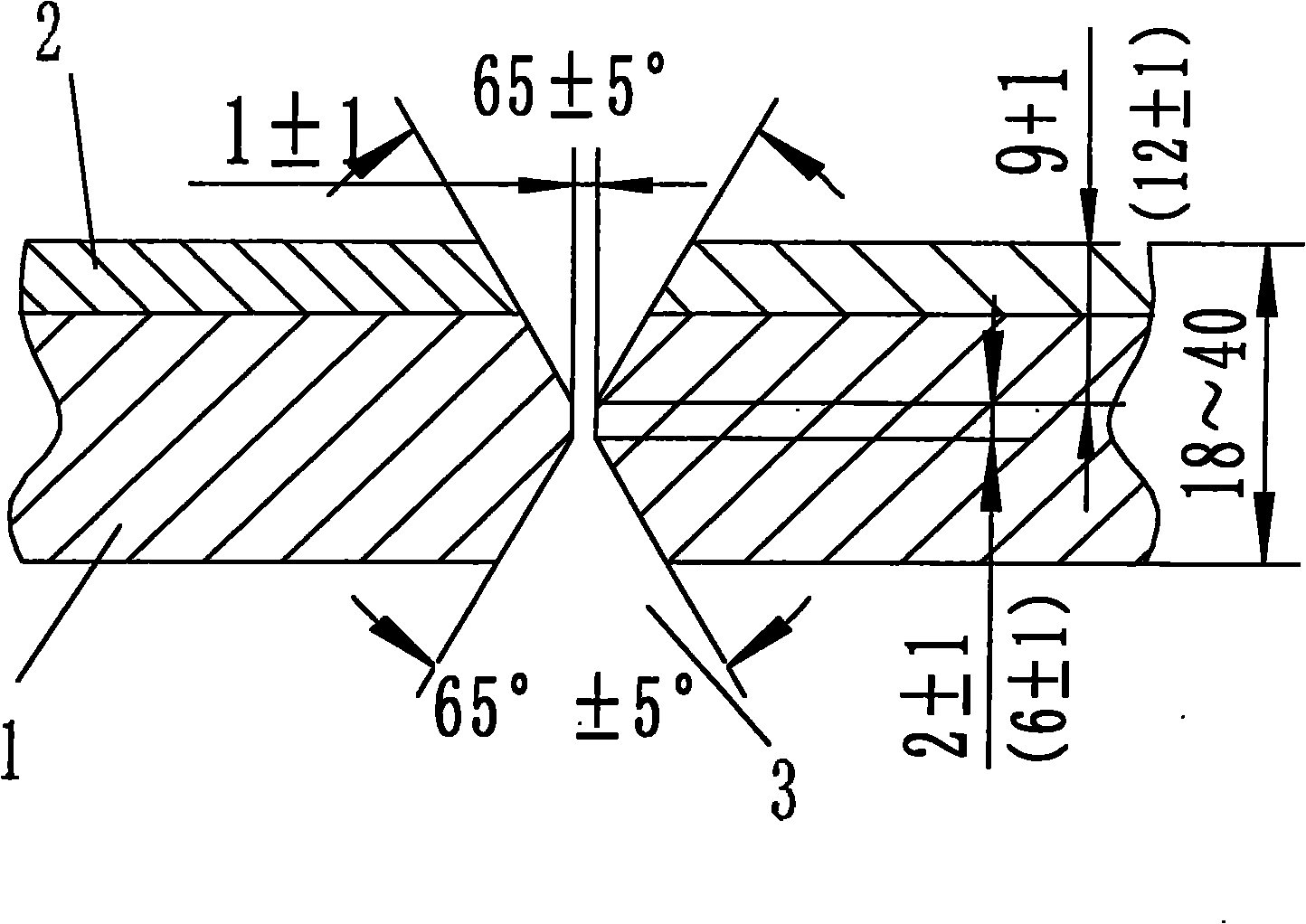

Submerged-arc welding process of stainless steel composite steel plate

ActiveCN101774068AReduce labor intensityReduce manufacturing costArc welding apparatusWelding/soldering/cutting articlesCurrent rangeVoltage range

The invention discloses a submerged-arc welding process of a stainless steel composite steel plate, which has the advantages that the labour intensity of welders can be effectively reduced, the labour condition, production efficiency and the welding quality are improved, the production cost is reduced, and the like. The invention comprises the following processes of: (1) processing a groove, i.e., processing the welding end of the stainless steel composite steel plate to be welded into a groove; (2) using the weld bead in the middle part of the groove as a bottoming weld line, using the weld bead at the upper part of the base layer bottoming weld line close to the stainless steel composite steel plate composite layer as the multicoat weld line and using the weld bead at the lower part of the base layer bottoming weld line as the base layer filling cap weld; (3) welding the base layer bottoming weld line by a traditional process; (4) welding the base layer filling cap weld by a traditional process; and (5) welding the multicoat weld line, wherein the welding current ranges from 350A to 400A, the welding voltage ranges from 28V to 30V and the welding speed ranges from 40cm / min to 50cm / min.

Owner:LUXI IND EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com