Patents

Literature

337 results about "Sound Absorber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microperforated polymeric film for sound absorption and sound absorber using same

Microperforated polymeric films and sound absorbers using such films are provided. The microperforated polymeric films may be relatively thin and flexible and may further include holes having a narrowest diameter less than the film thickness and a widest diameter greater than the narrowest diameter. The microperforated polymeric films of a sound absorber may also have relatively large free span portions, which, in certain embodiments, may vibrate in response to incident sound waves.

Owner:3M INNOVATIVE PROPERTIES CO

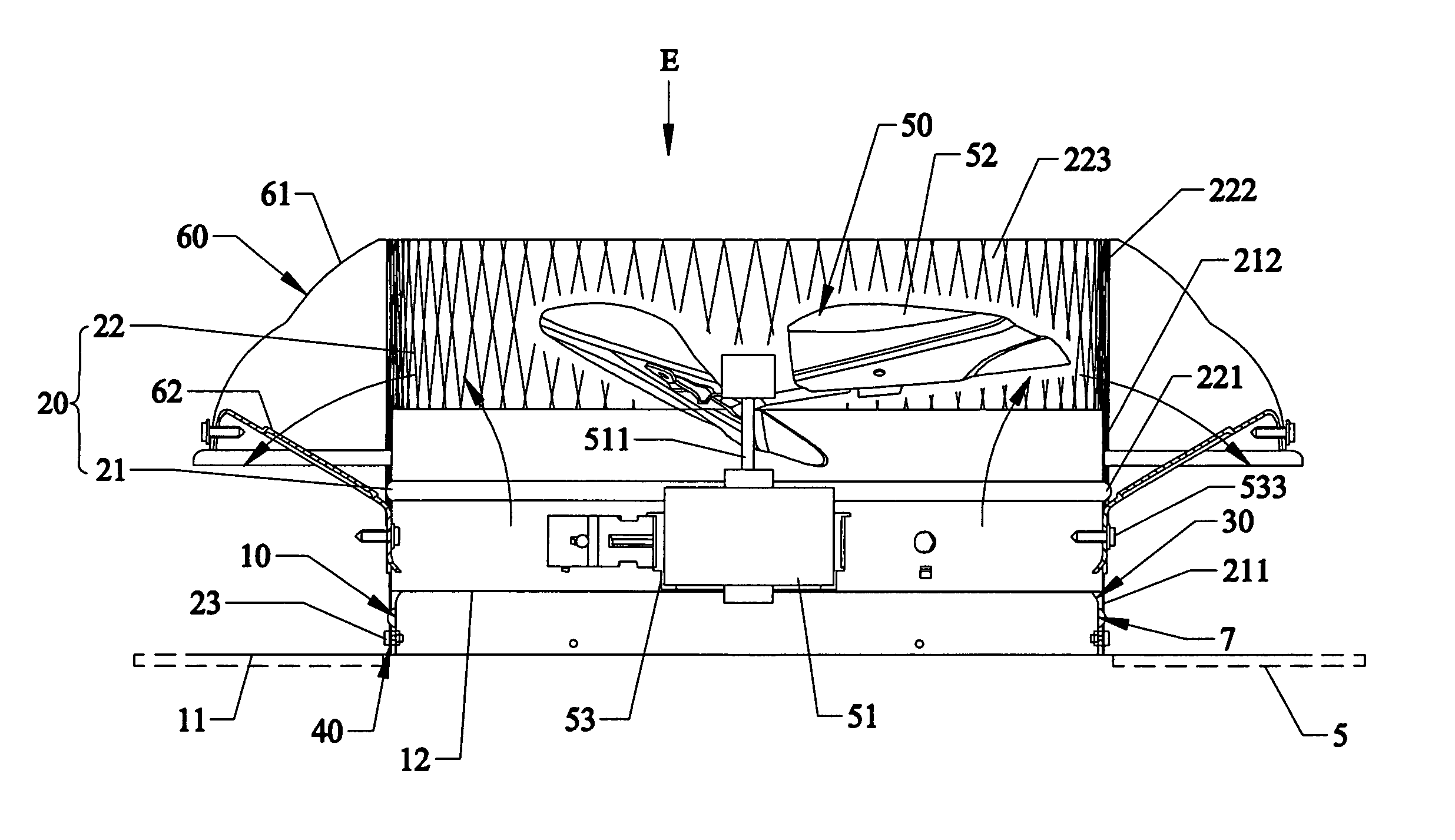

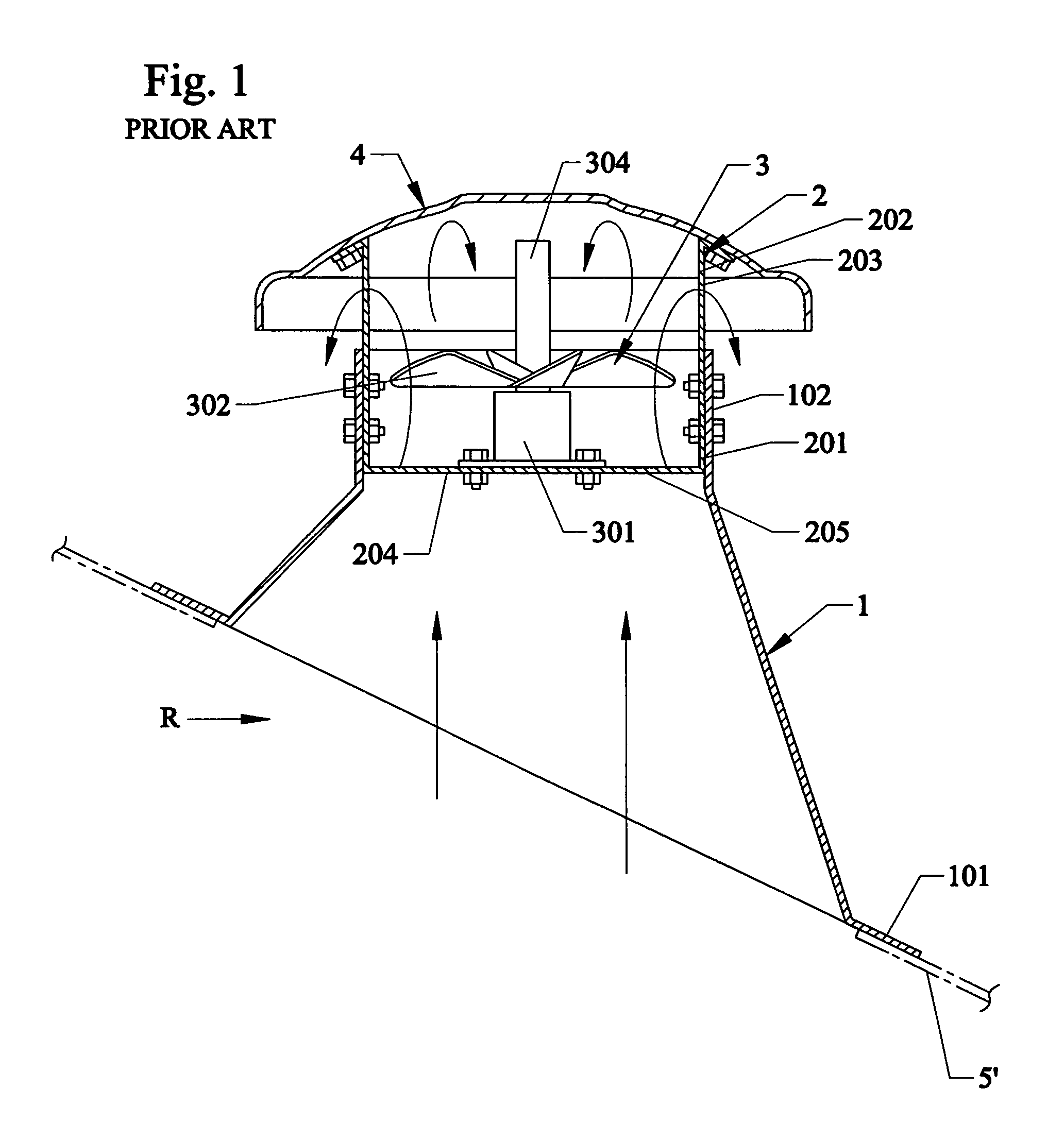

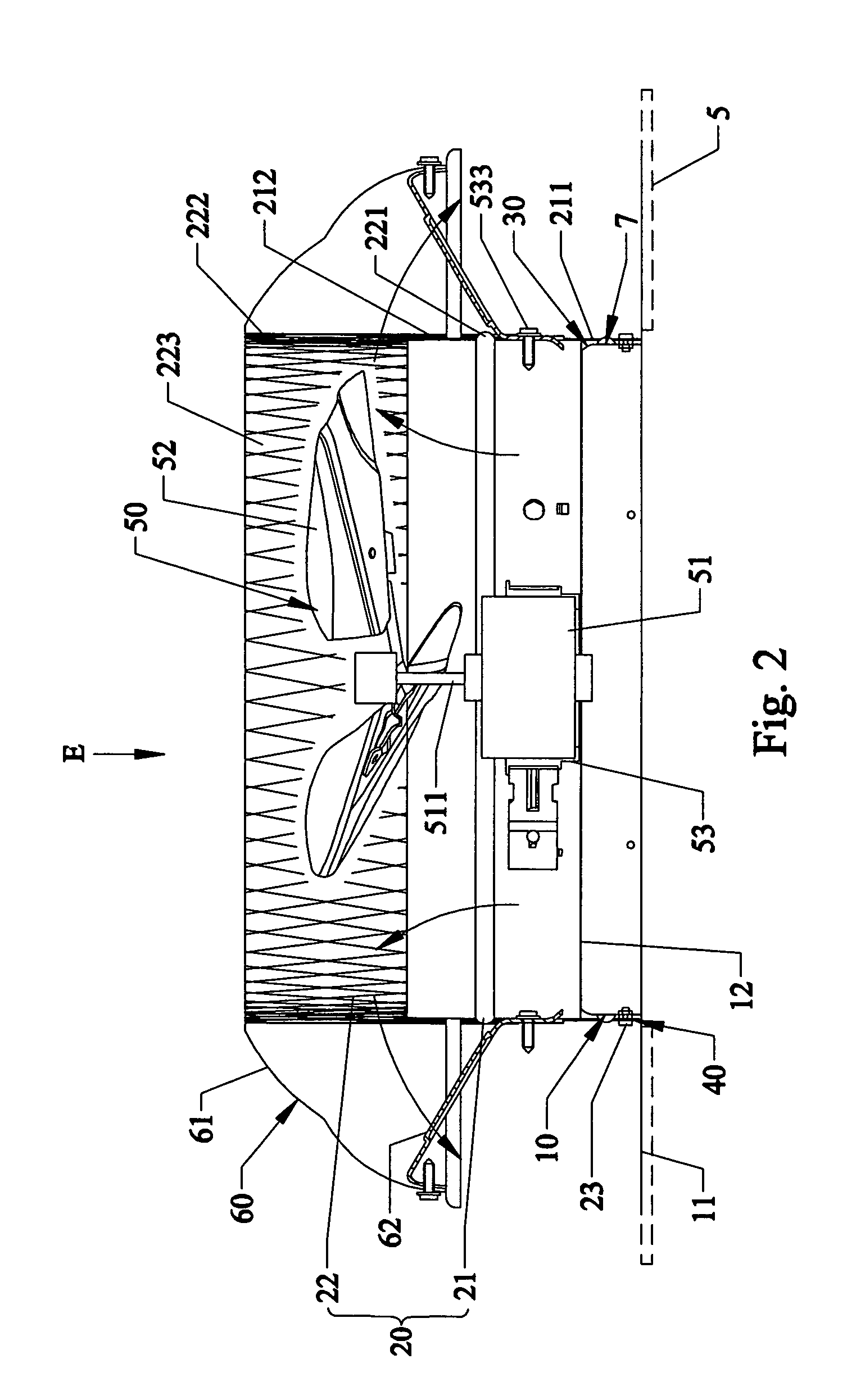

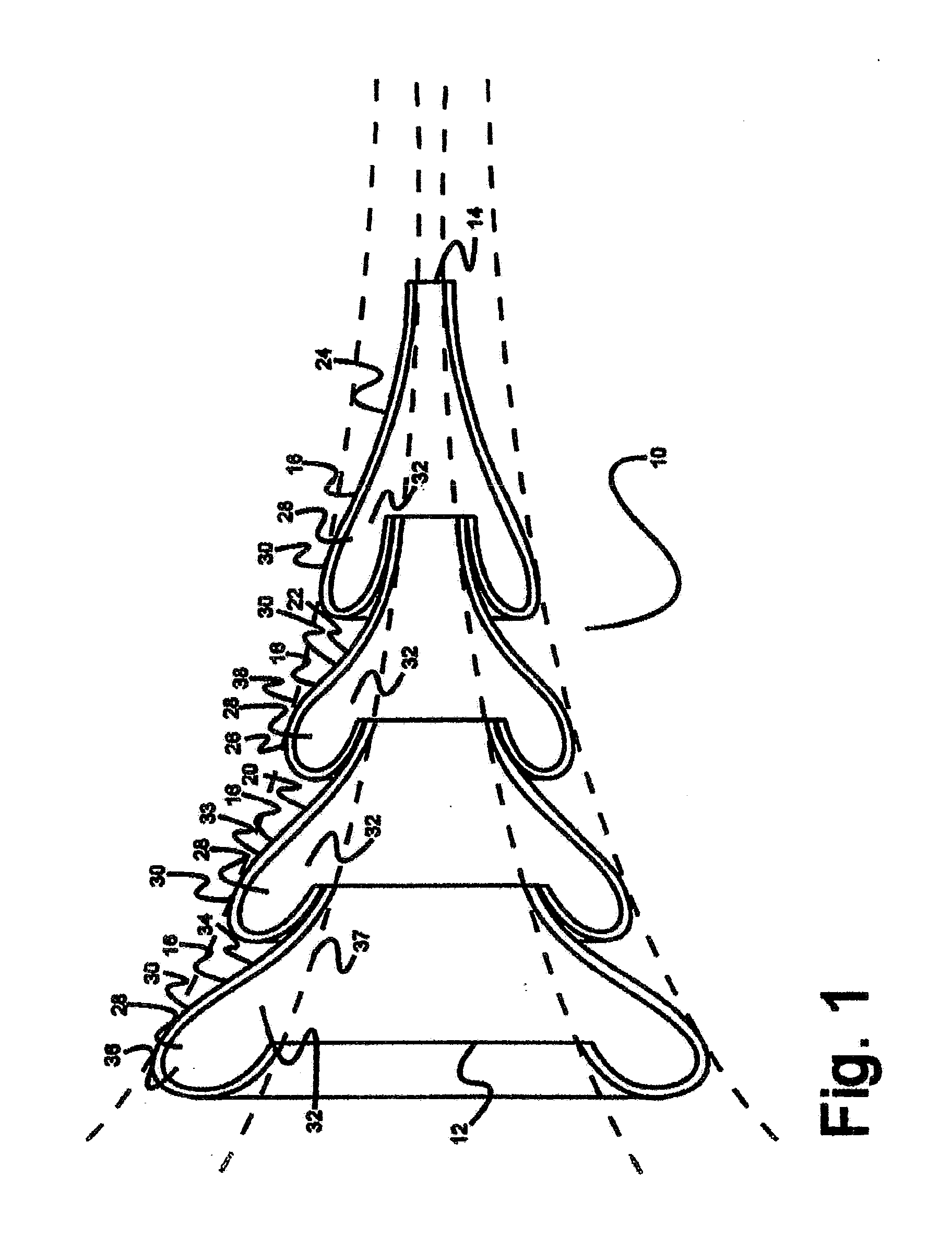

Air exhausting apparatus with draining passage

ActiveUS7677964B1Avoid enteringCombination devicesDispersed particle filtrationCouplingSound Absorber

An air-exhausting apparatus, device, method of assembly and use for an attic and rooftop fan, which prevents water intrusion into the housing. The fan can include a tubular base having a bottom side mounted on a roof of a room, and an upper end portion converging toward a top side of the base. A coupling sleeve unit has a first coupling end portion sleeved fixedly on the base and cooperating with the base to define an annular draining passage therebetween, and a second coupling end portion opposite to the first coupling end portion. A fan unit is mounted in the coupling sleeve unit, and is operable so as to exhaust air outwardly of the room via air holes in the second coupling end portion of the coupling sleeve unit. A cover unit includes a cover body disposed on the second coupling end portion of the coupling sleeve unit, and a supporting frame interconnecting fixedly the cover body and the coupling sleeve unit. Wear and / or sound absorbers can also be included.

Owner:CHIEN LUEN INDS

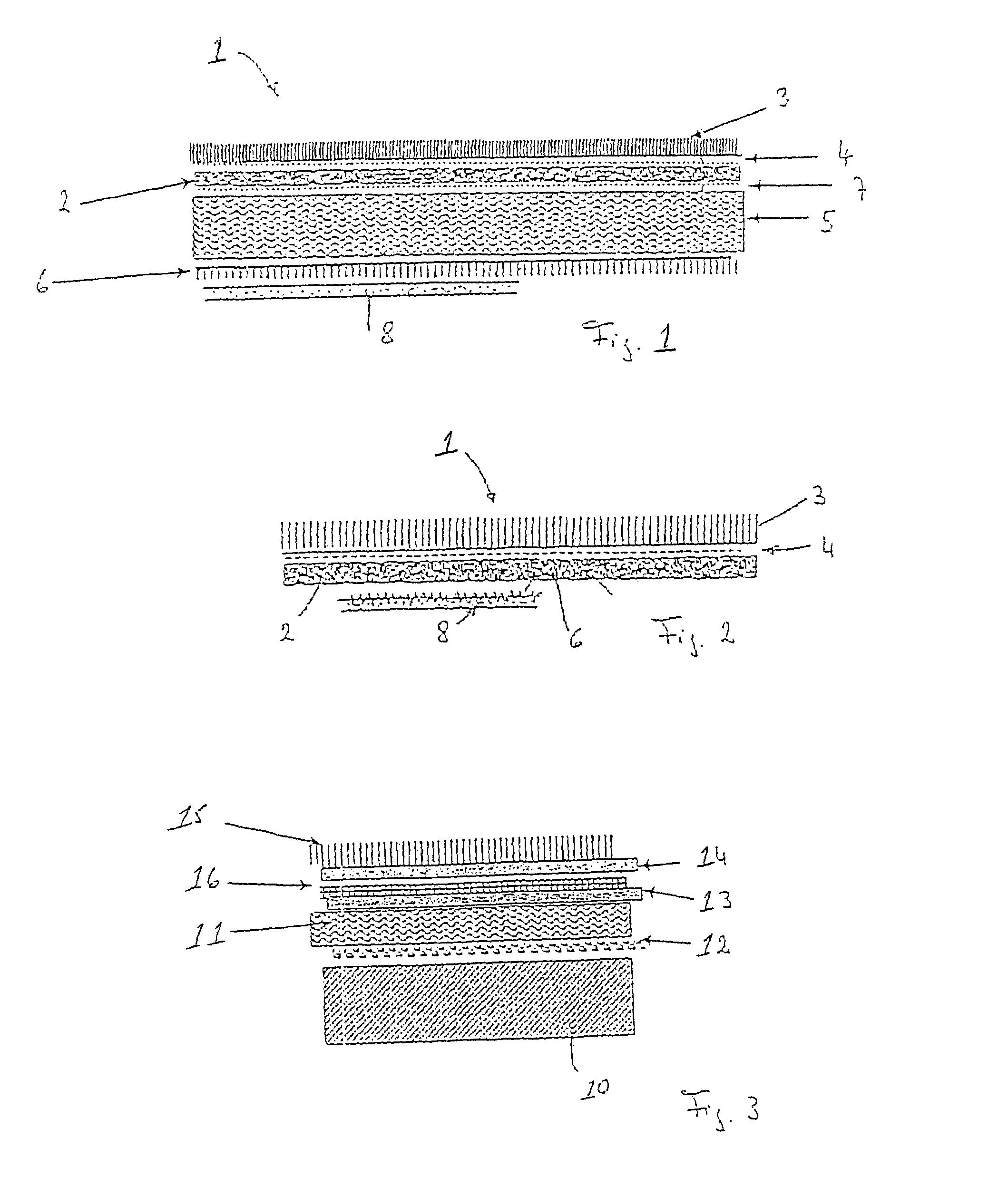

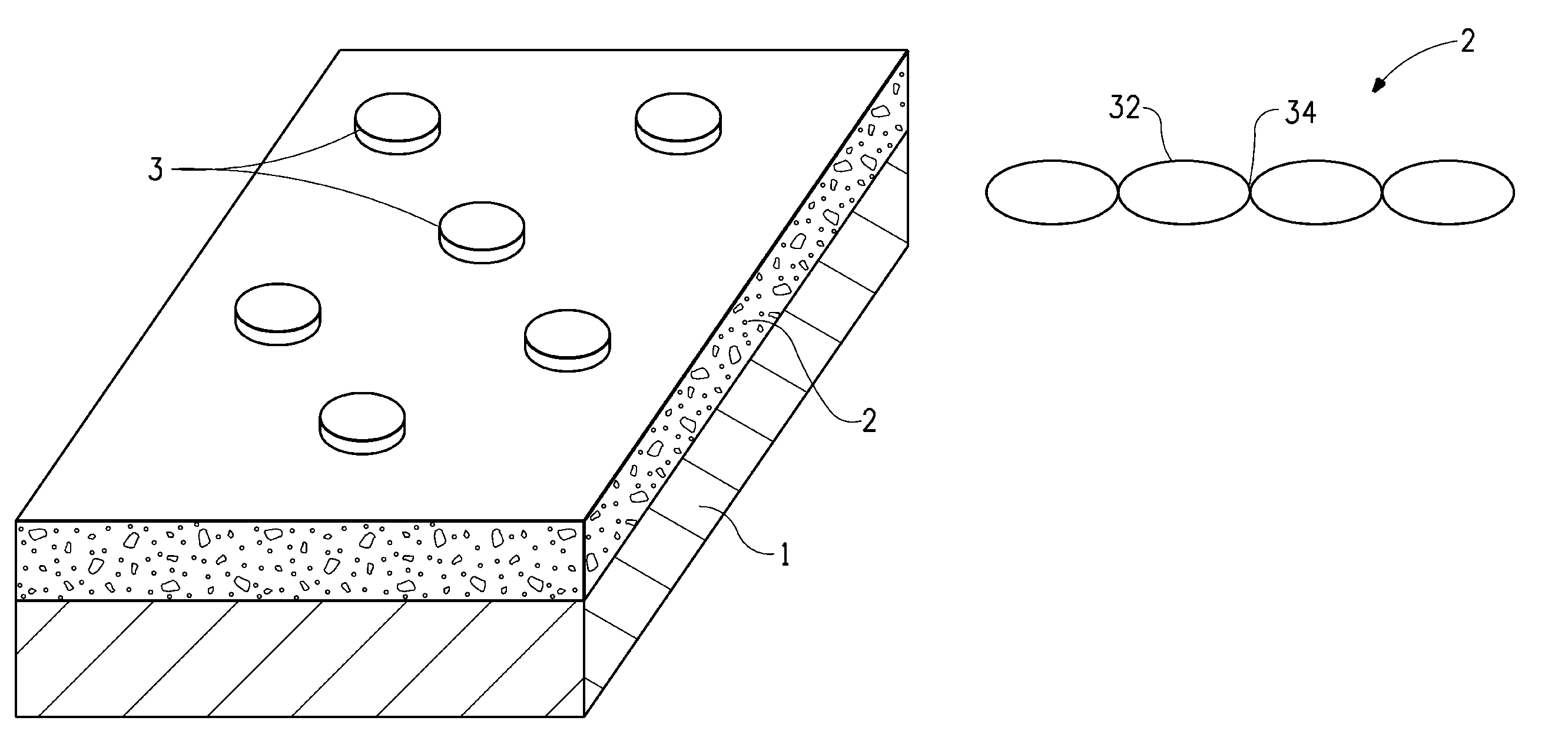

Five-layer sound absorbing pad: improved acoustical absorber

ActiveUS20040065507A1The process is simple and convenientDecreasing flexibilityWallsLayered productsEngineeringNatural fiber

An acoustical absorber, having the structure: scrim / film / batt / film / scrim. Preferably, the batt is made from about 60% to about 90% by weight natural fiber and about 10% to about 40% synthetic fiber. Also, a method of making the acoustical absorber is provided. Additionally, a method for acoustically insulating a structure with the acoustical absorber is provided. The method for acoustically insulating may include the steps of compressing the acoustical absorber to less than its original volume prior to installing the absorber and releasing the absorber from compression following the installing step, allowing the material to recover and to fill the void of the structure in which the absorber was placed.

Owner:ACOUSTEK NONWOVENS

Sound absorptive protective mat

InactiveUS6983822B2Improve acoustic propertiesNoise reduction installationsVehicle arrangementsEngineeringSound Absorber

Owner:AUTONEUM MANAGEMENT AG

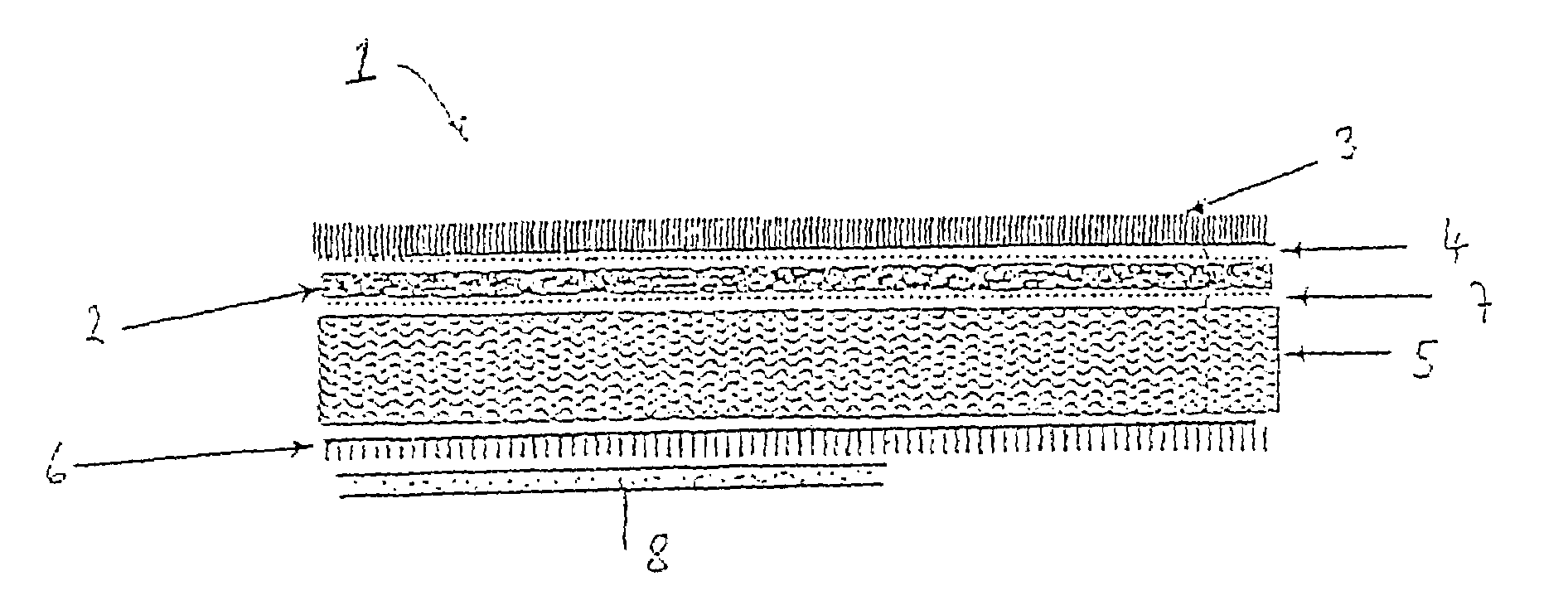

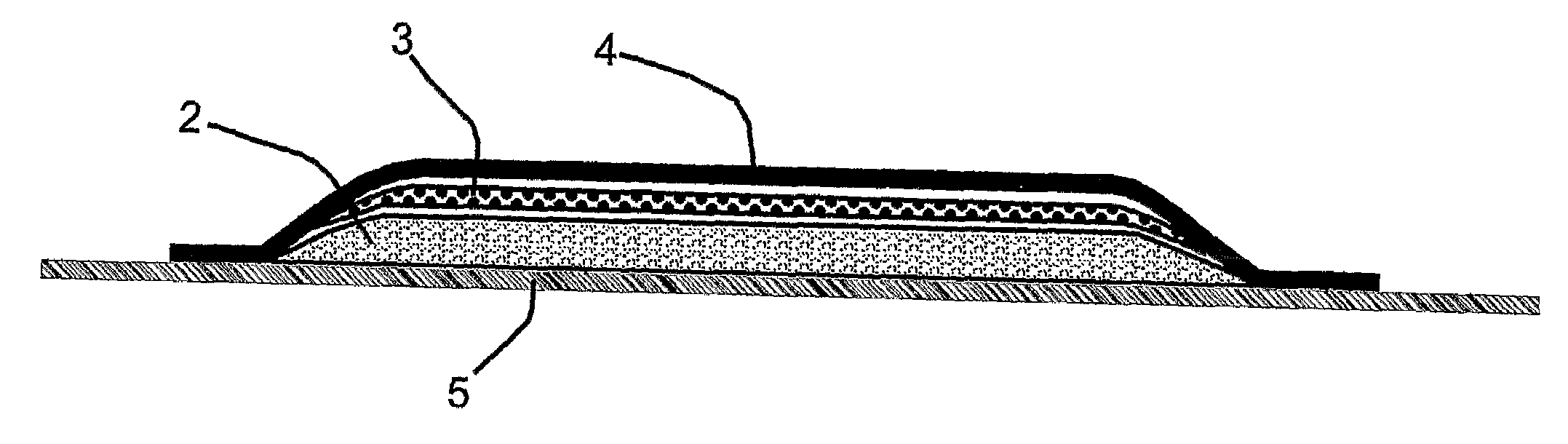

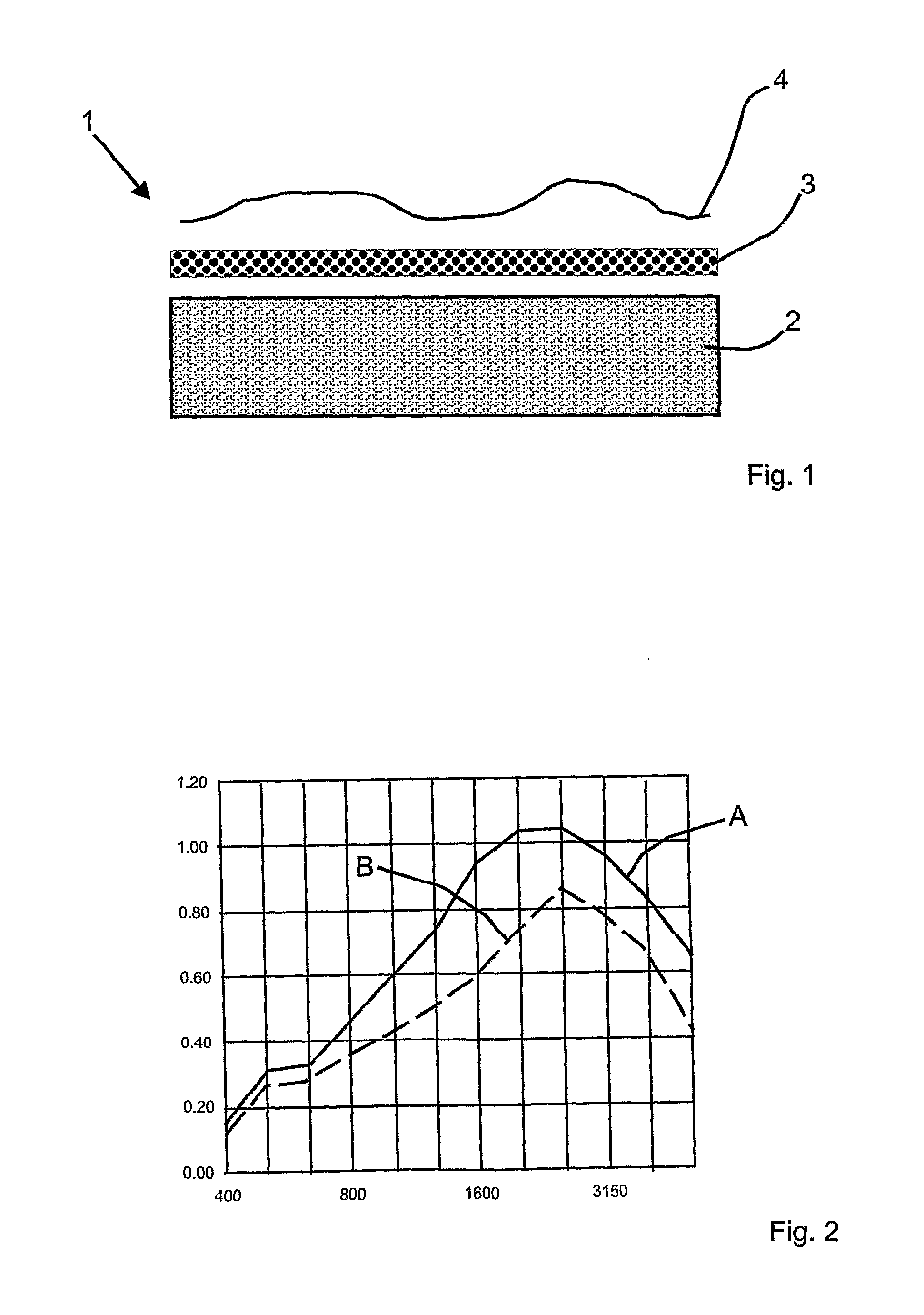

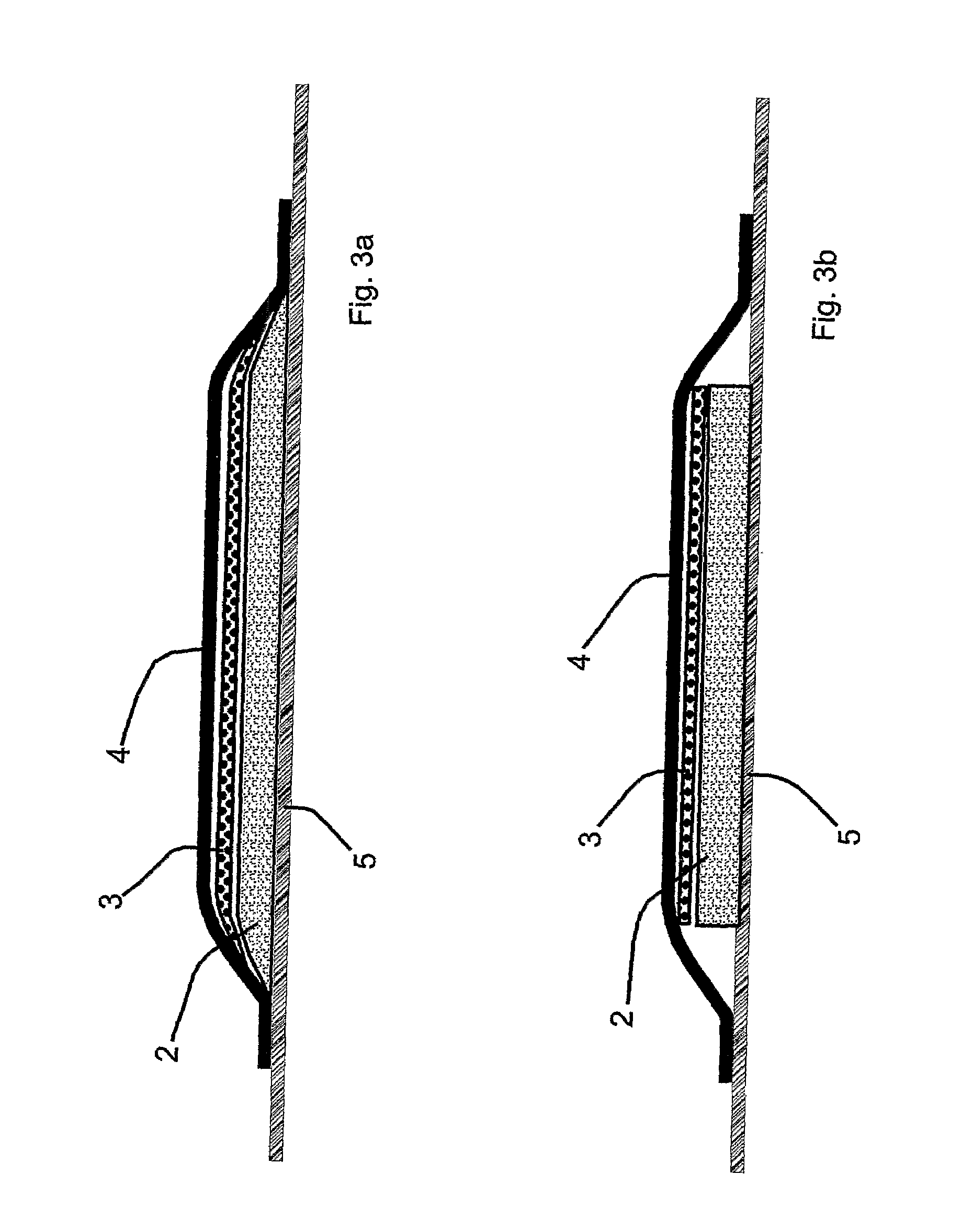

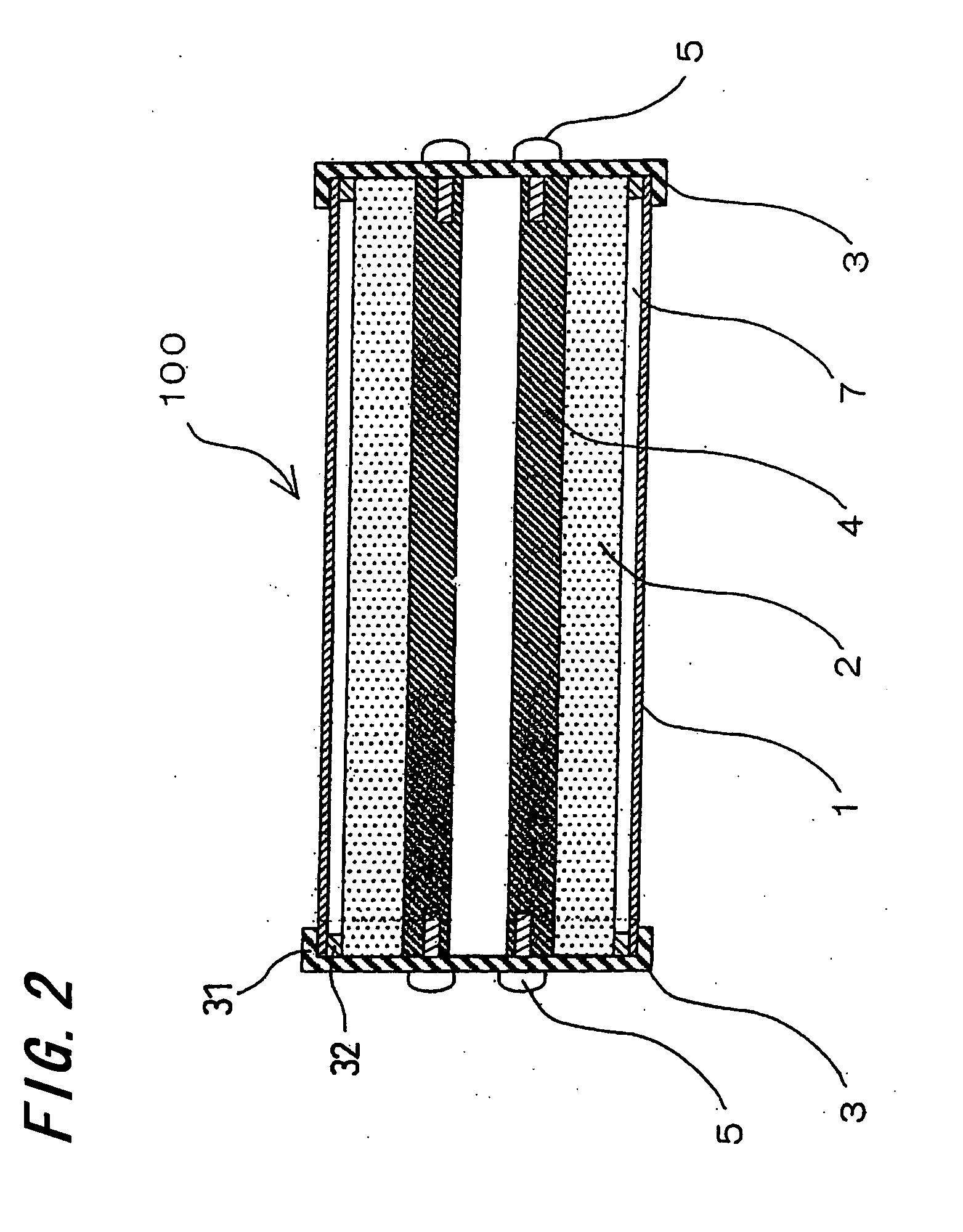

Sealed thin-multi-layer sound absorber

InactiveUS7677358B2Improve acoustic performanceWide frequency bandwidthWallsMachines/enginesEngineeringSound Absorber

The invention relates to a thin sound absorbing multi-layer assembly, which is intended, in particular, to reduce interior or exterior noise of a motor vehicle. The assembly according to the invention comprises at least three stacked layers consisting respectively of: a first layer (4) being impervious and having an area weight of between (20) to (100 g / m2); a second layer (3) having an air flow resistance of between (250) to (2500 Ns / m3) and an area weight of between (15) to (250 g / m2); a third layer (2) being an open pored, acoustic spring type layer having a thickness of between (2) to (30 mm) and an area weight of between (50) to (1000 g / m2).

Owner:RIETER TECHNOLOGIE AG

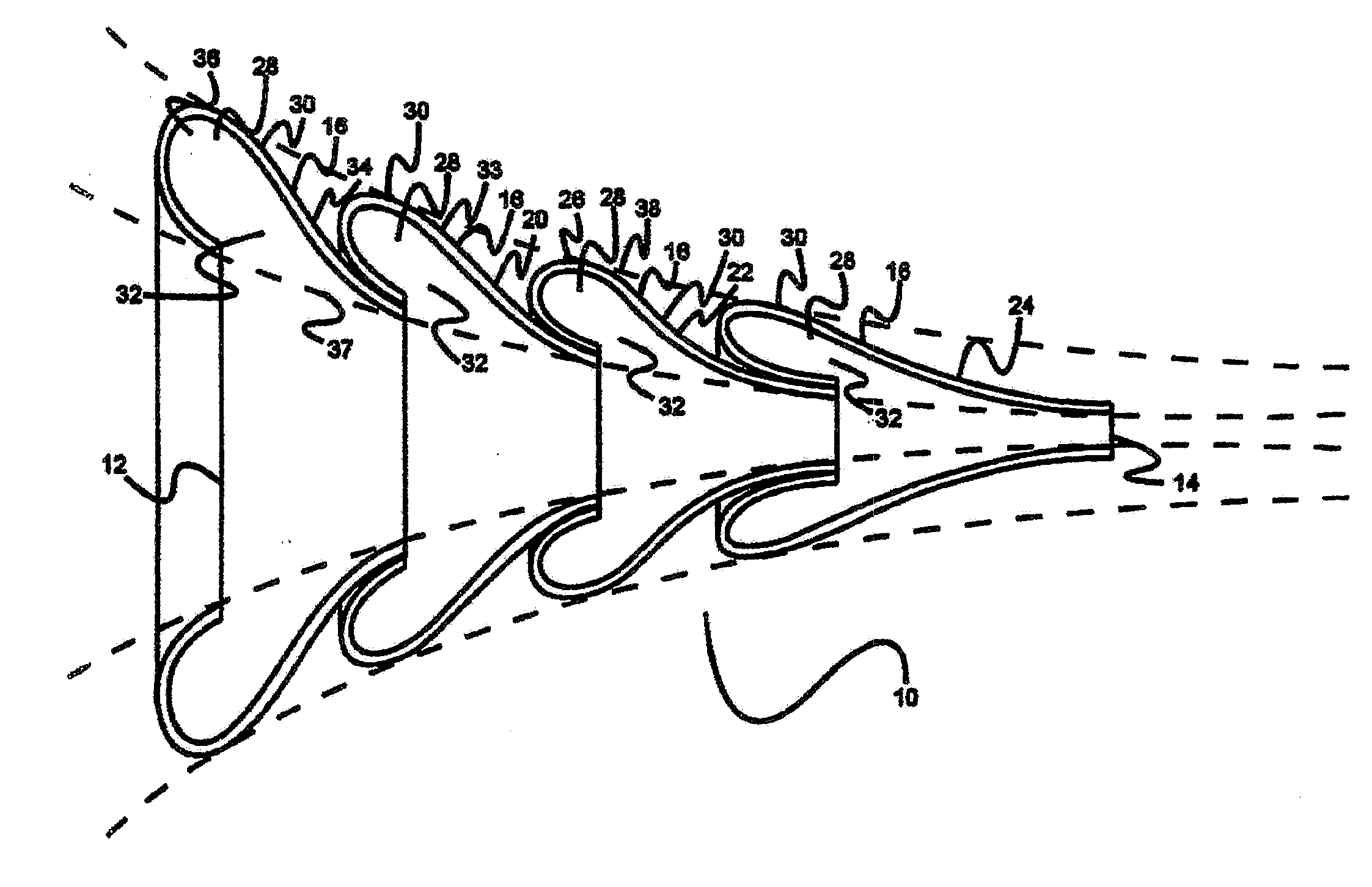

Channeling fluidic waveguide surfaces and tubes

InactiveUS20150337878A1Reduce fluid frictionReduce surfaceVehicle seatsVehicle body stabilisationJet engineEngineering

Waveguide or flow guide surfaces can improve the efficiency of fluid flow through tubes or over surfaces. When incorporated in a tube, the waveguides improve flow and function as sound absorbers making them useful in engine mufflers, firearm silencer / suppressors and jet engine exhaust attenuators. On surfaces, the waveguides can reduce fluid drag and find use on projectiles (e.g., bullets), airfoils for aircraft, and land borne vehicles. The waveguide array in either a tubular chamber or on a surface comprises a plurality of successive wave-like undulations inclined generally in the direction of flow and when employed in tubes extending inwardly to permit an unobstructed path for the fluid gas from entry to exit. The waves define annular wave cavities between their successive inwardly extending edges and the wall of the chamber with each cavity having a cavity mouth open to the unobstructed path. The waveguides are sized and spaced so that gas vortices are created within the cavities when gas flow occurs which vortices create a fluid boundary layer that assists the gas flow.

Owner:PARAFLUIDICS

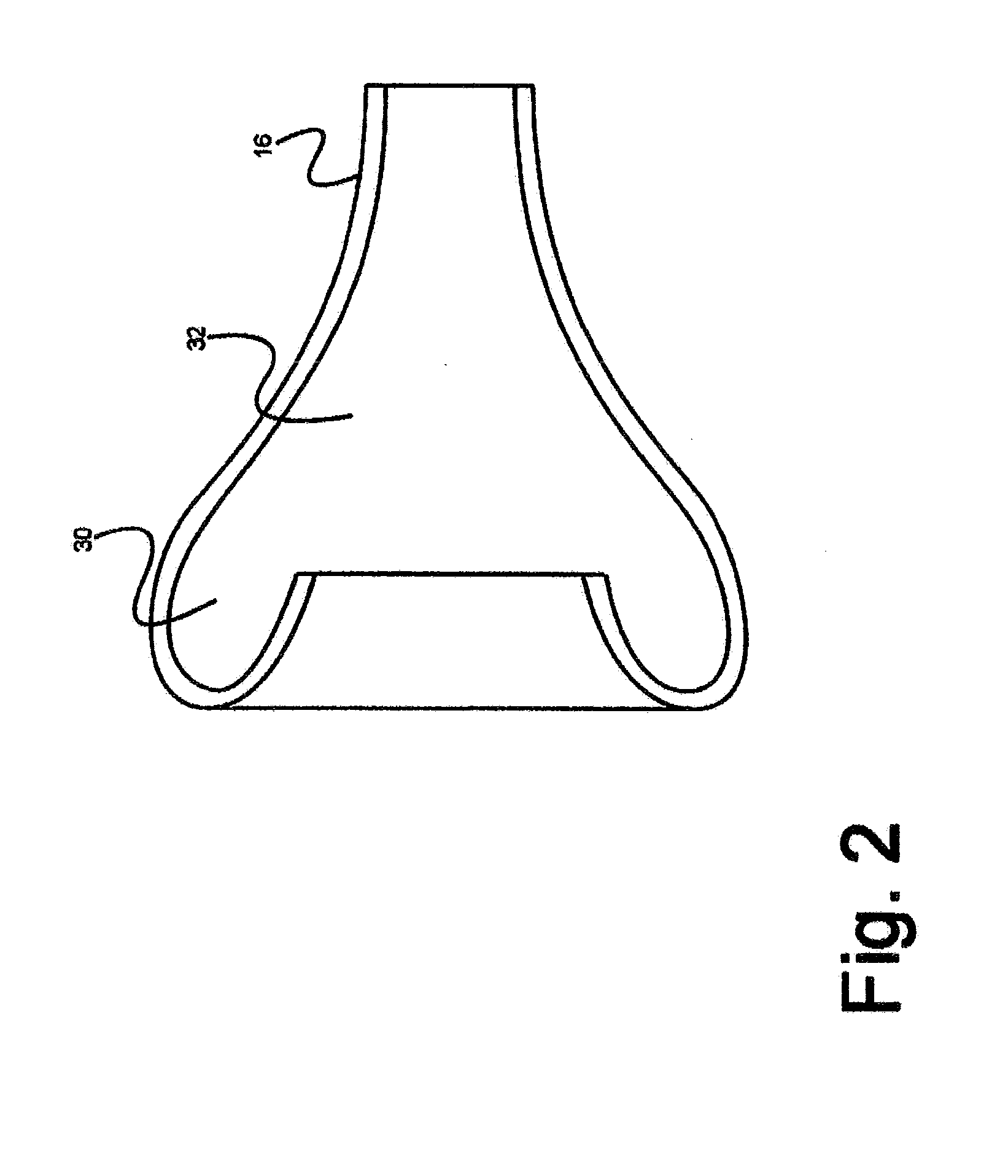

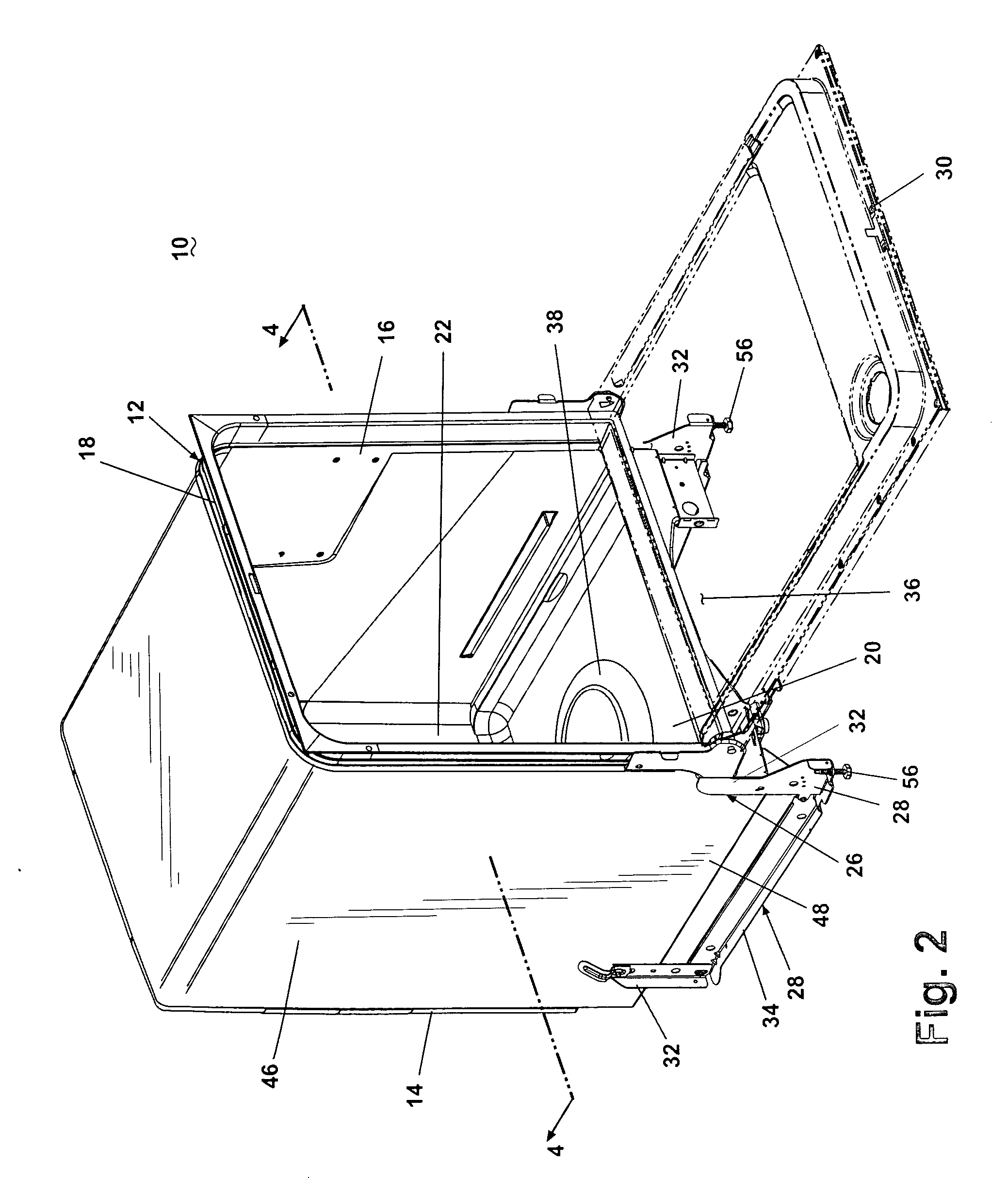

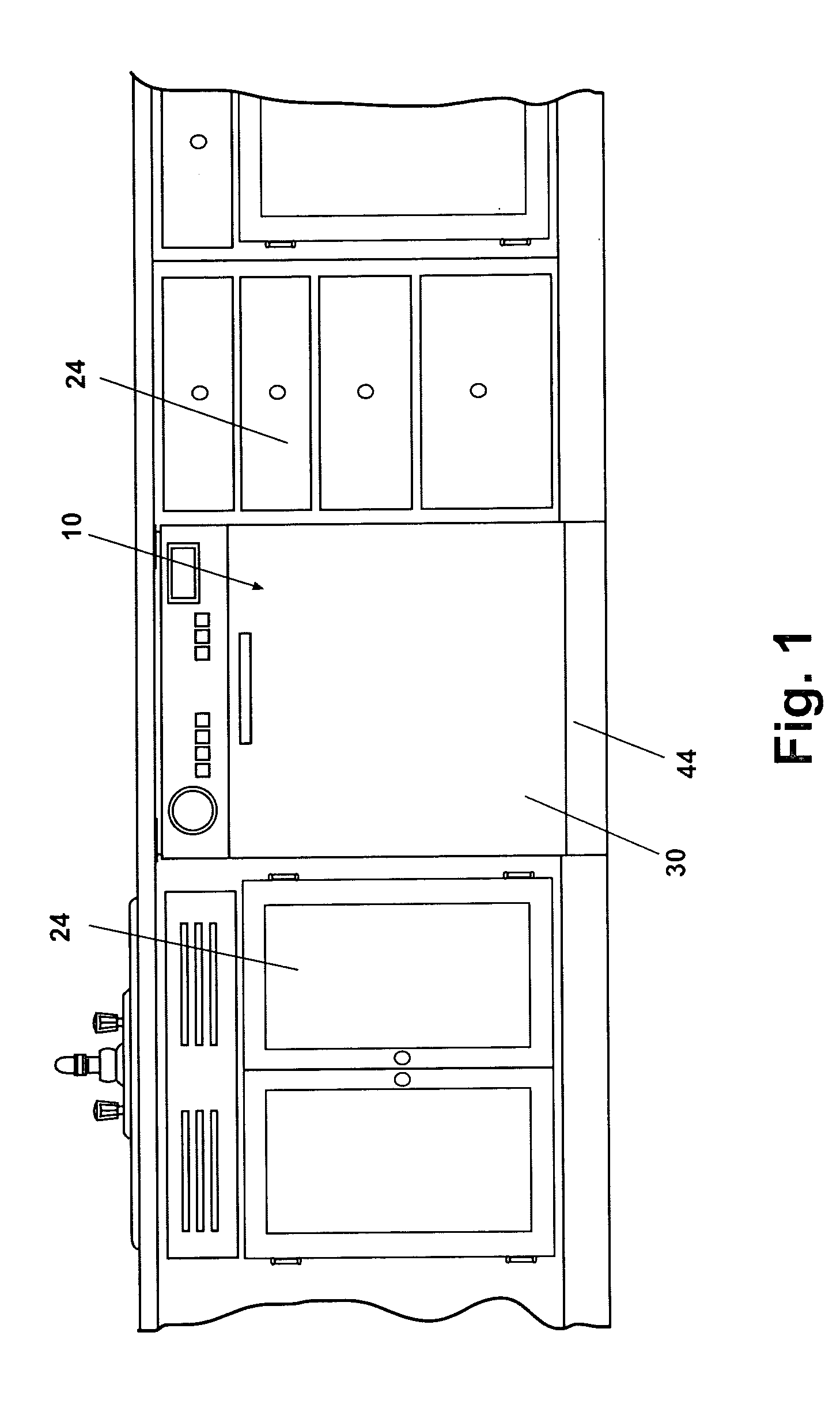

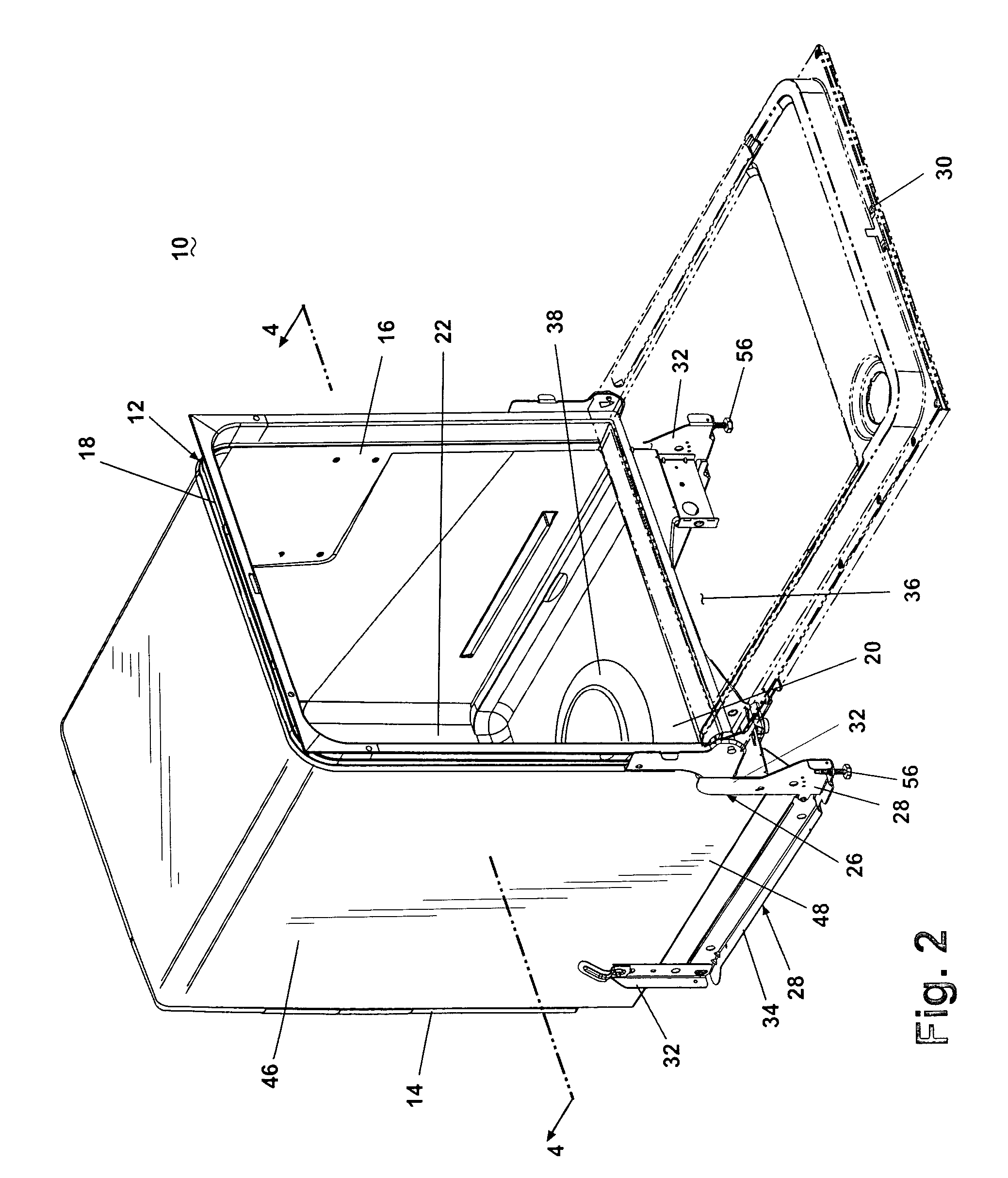

Dishwasher and motor cavity sound attenuator

ActiveUS20050092353A1Reduce the soundTableware washing/rinsing machine detailsElectrostatic cleaningSound AbsorberAcoustics

A dishwasher with a sound attenuator for attenuating the sound emanating from a motor cavity of the dishwasher. The sound attenuator comprising a sound absorber and a sound barrier. The sound absorber absorbing sound in the motor cavity with the sound barrier blocking the unabsorbed sound from escaping.

Owner:WHIRLPOOL CORP

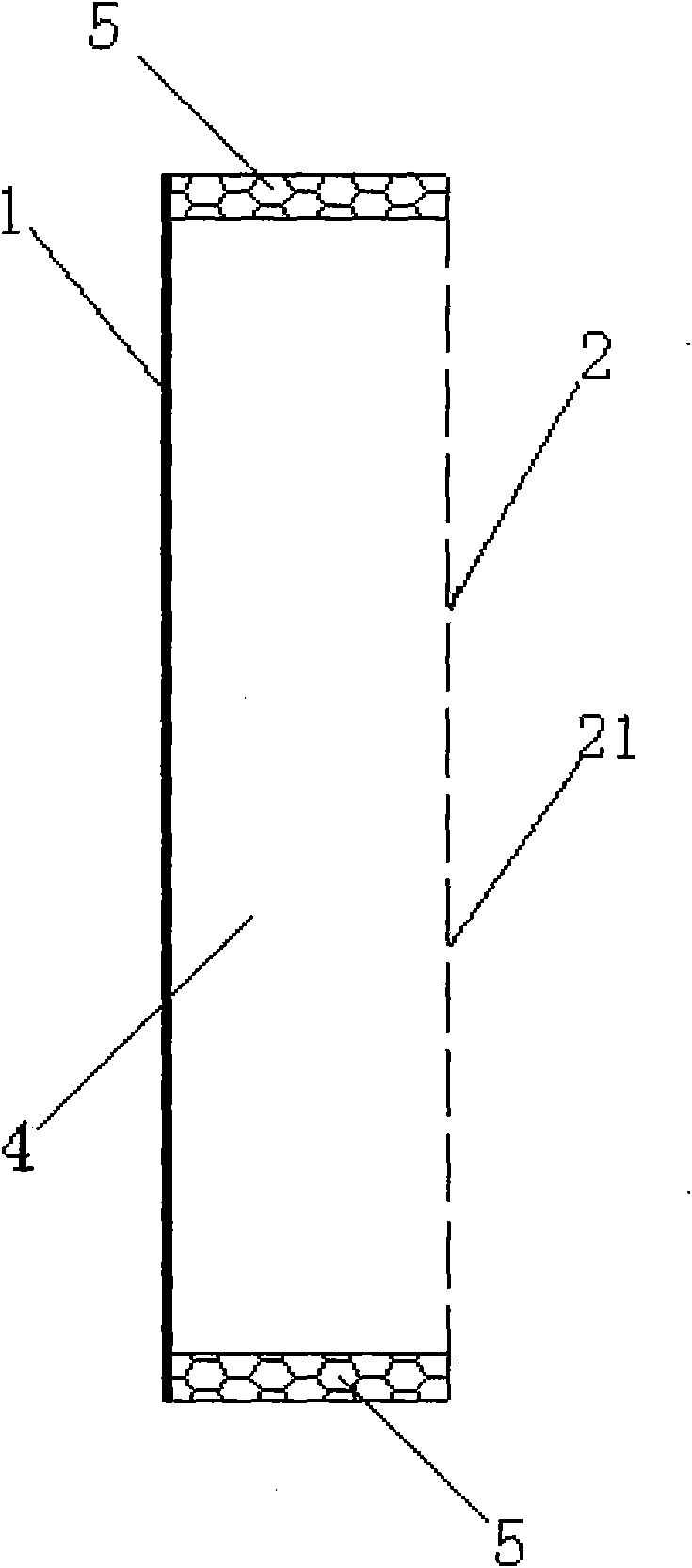

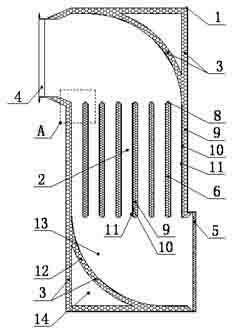

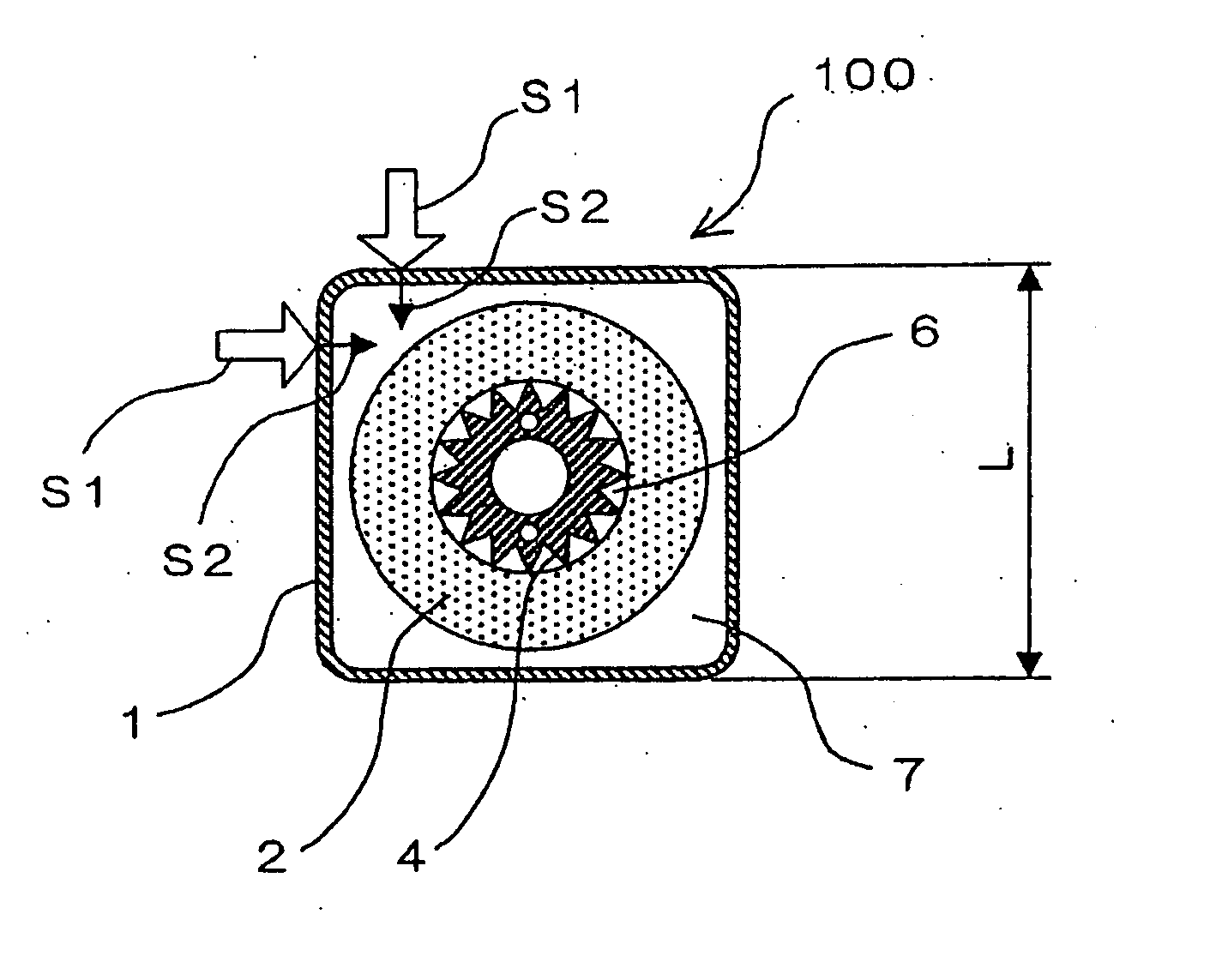

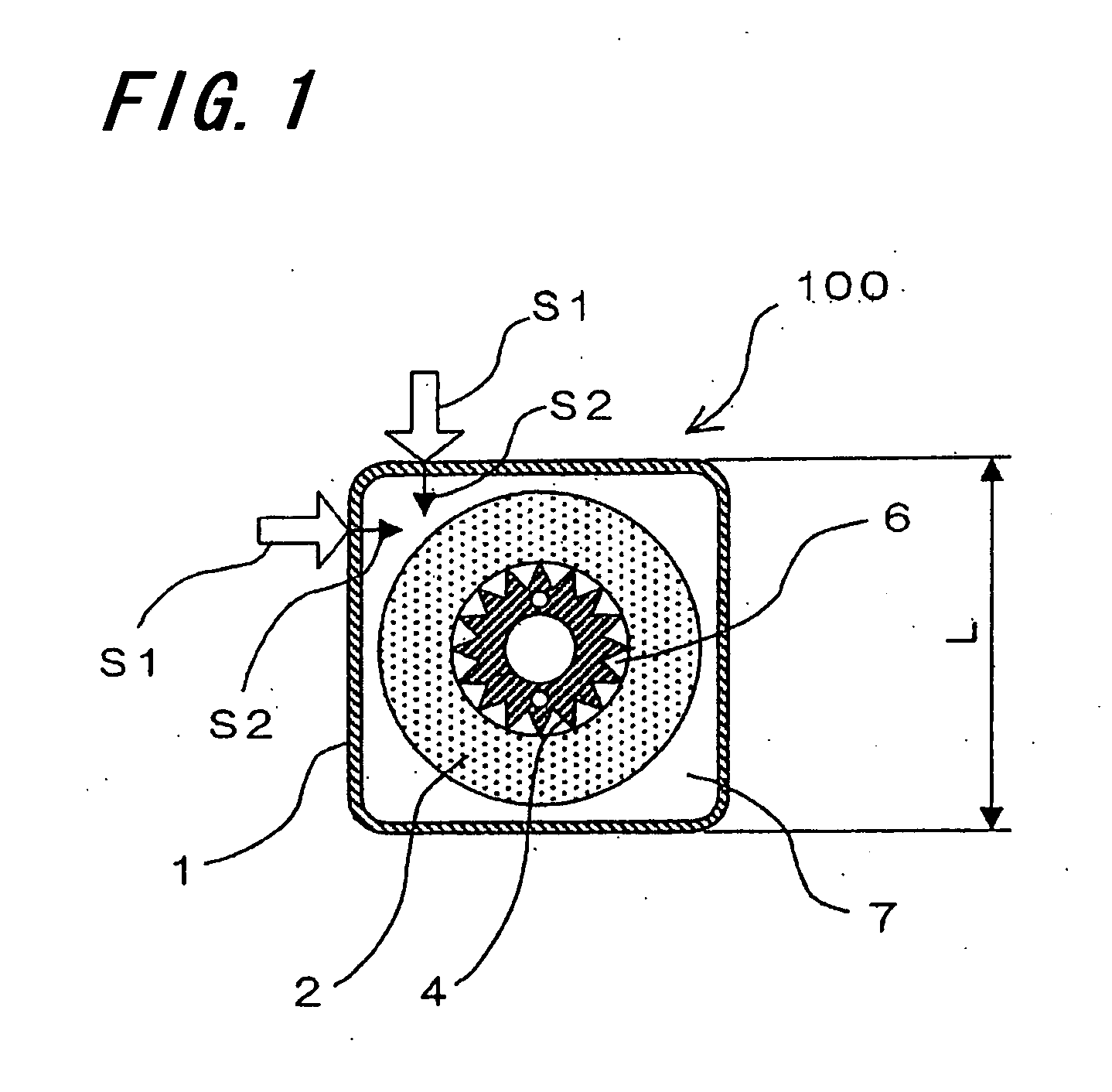

Micro-perforated plate with resonant sound absorption structure

ActiveCN102044239ASound absorption frequency bandwidthAutomatic distance adjustmentSound producing devicesSemi activePower noise

The invention relates to a micro-perforated plate with a resonant sound absorption structure. The micro-perforated plate with the resonant sound absorption structure is characterized by comprising a rigid wall, a micro-perforated plate and a cavity which is formed between the rigid wall and the micro-perforated plate, wherein the two ends of the rigid wall are connected with the two ends of the micro-perforated plate through a flexible or elastic material respectively. In the sound wave absorption process of the micro-perforated plate with the resonant sound absorption structure, the distancebetween the micro-perforated plate and the rigid wall can be automatically adjusted and a semi-active resonant sound absorption structure is formed in the cavity between the micro-perforated plate and the rigid wall along with the variation of sound wave frequency and the influence of vibrating air flow. Therefore, the micro-perforated plate with the resonant sound absorption structure has highersound absorption performance in a wider frequency range, the sound absorption frequency band of the micro-perforated plate with the resonant sound absorption structure is greatly expanded, and the defect of a narrower sound absorption frequency band of a sound absorber of the micro-perforated plate with a rigid structure can be overcome. The micro-perforated plate with the resonant sound absorption structure can be widely used for the sound absorber, mufflers and various sound absorption and insulation structures to treat a noise environment caused by air power noise.

Owner:北京绿创声学工程股份有限公司

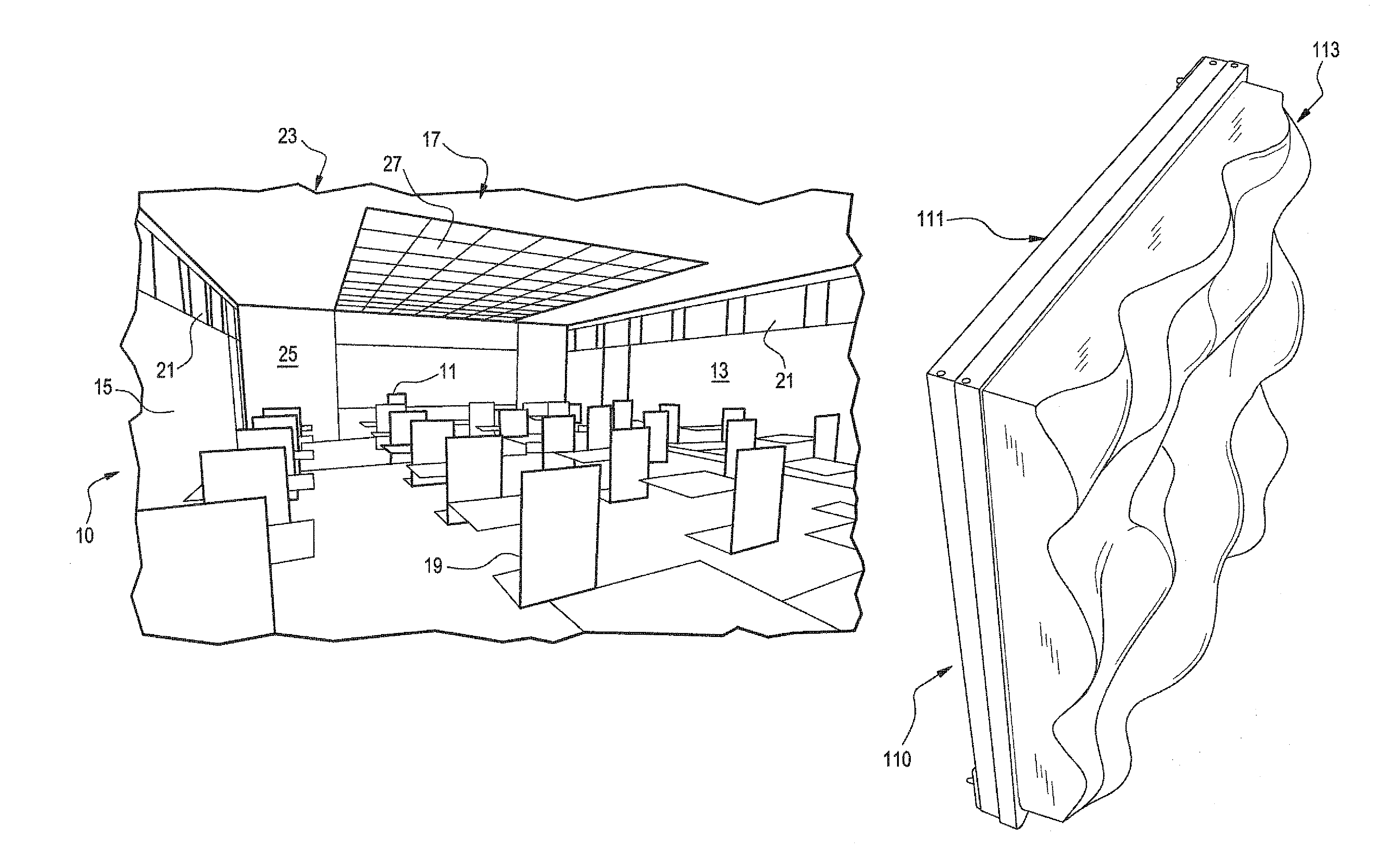

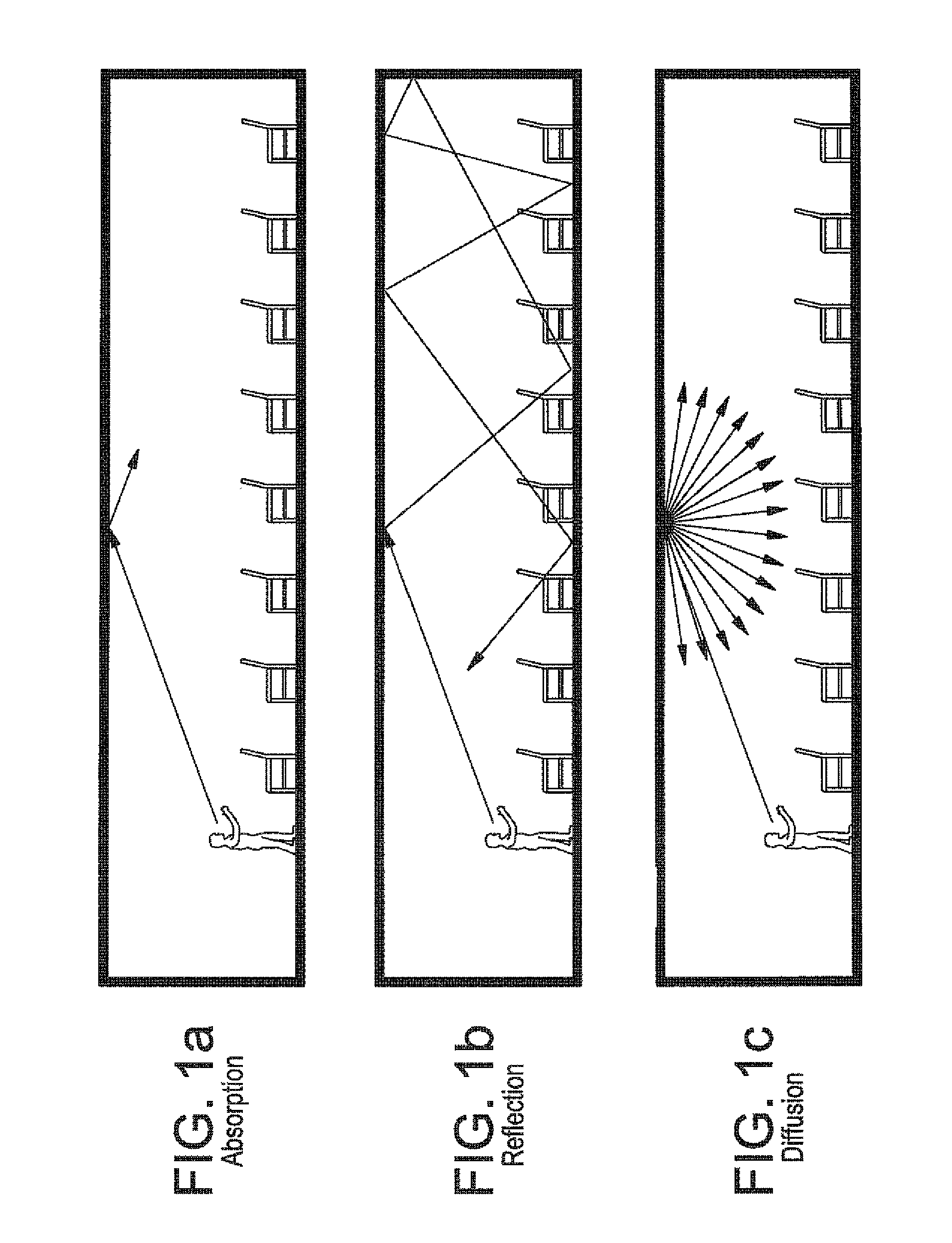

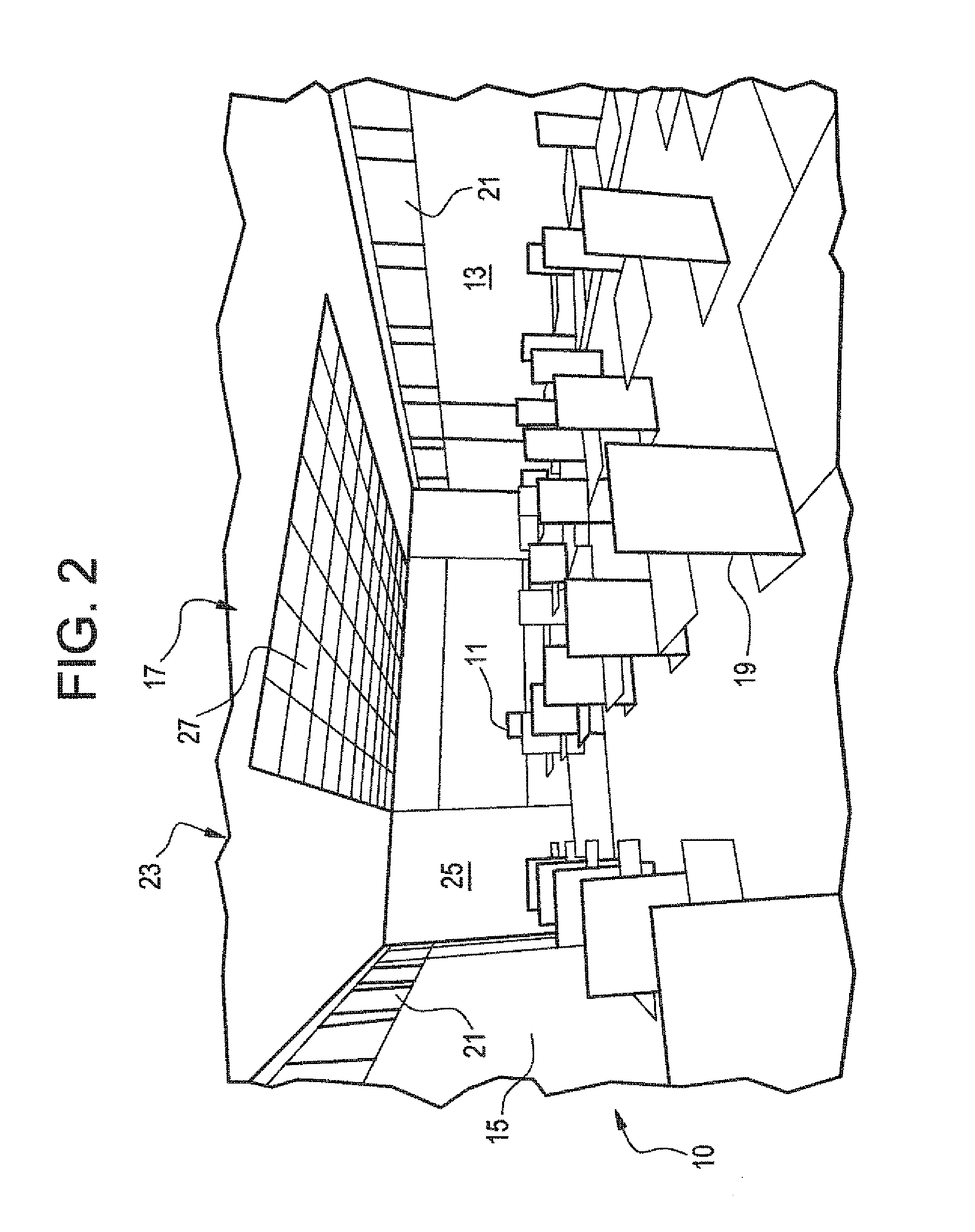

Combination light diffuser and acoustical treatment and listening room including such fixtures

Combination light diffusion with either sound diffusion or absorption is provided in a single lighting fixture, to provide uniform luminosity and sound control. The traditional flat light diffuser is replaced with a translucent acoustical element which either diffuses sound or absorbs the sound. The sound diffuser topology includes random surfaces, geometrical shapes, number theoretic diffusers or optimized rectilinear or curvilinear surfaces. The translucent sound absorber includes microperforated or microslit panels, as well as translucent fabrics and microperforated, translucent wood veneers.

Owner:DANTONIO PETER

Inorganic fiber mat, holding sealer, sound absorber, and method for manufacturing inorganic fiber mat

ActiveUS20090081455A1Improve working conditionsAmount of organic binder may be reduced more easilyExhaust apparatusLayered productsSound AbsorberFiber

Owner:IBIDEN CO LTD

Adiabatic sound absorber with high thermostability

InactiveUS20090252943A1Improve thermal insulation performanceHigh sound absorbencySynthetic resin layered productsNon-woven fabricsFiberDecomposition

Provided is a flexible adiabatic sound absorber with high thermal insulation performance and acoustic performance, particularly an adiabatic sound absorbing material that is suitable for a new severe requirement specification regarding aircrafts. The adiabatic sound absorber comprises mixing uniformly 20 to 80% of a high-thermostable inorganic fiber whose high-temperature strength is maintained at 1000° C. or more, 10 to 60% of a flame-retarded organic fiber whose thermal melting or decomposition temperature is 350° C. or more and 10 to 25% of an organic fiber having a low melting point and treating the obtained woolly felt with heating to transform the whole into the mat-form material of 8 to 50 mm in thickness.

Owner:FUJI MASCH MFG CO LTD

Dishwasher and motor cavity sound attenuator

ActiveUS7409959B2Tableware washing/rinsing machine detailsElectrostatic cleaningSound barrierSound Absorber

A dishwasher with a sound attenuator for attenuating the sound emanating from a motor cavity of the dishwasher. The sound attenuator comprising a sound absorber and a sound barrier. The sound absorber absorbing sound in the motor cavity with the sound barrier blocking the unabsorbed sound from escaping.

Owner:WHIRLPOOL CORP

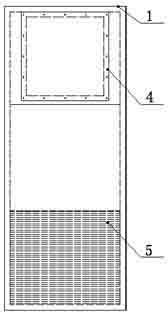

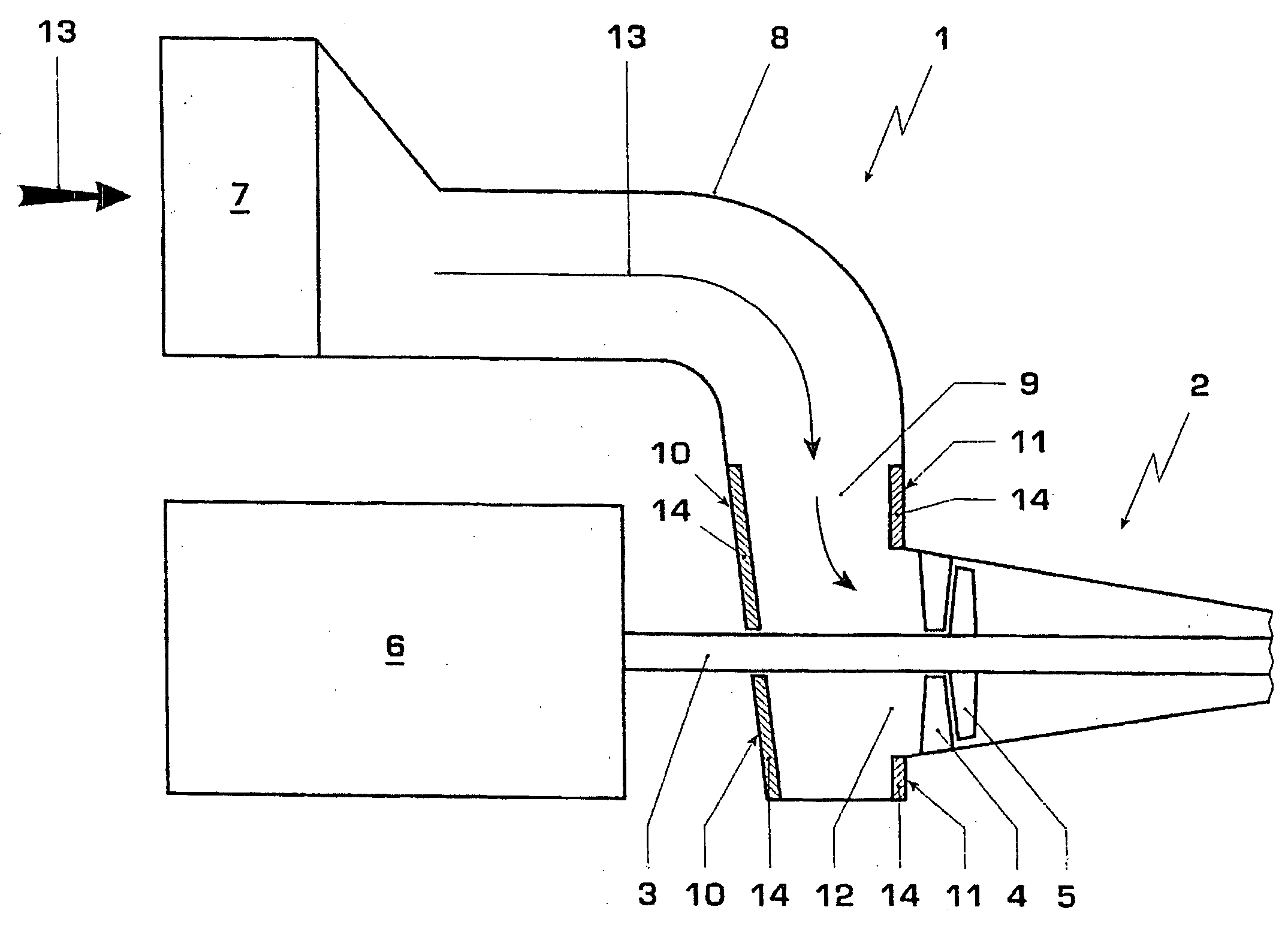

Impedance compound right-angled muffler

ActiveCN102522079AImprove aerodynamic performanceAdaptableSound producing devicesEngineeringAcoustic wave

The invention discloses an all-frequency sound absorption impedance compound right-angled muffler, which consists of a muffler shell, a resistive muffling structure, a right-angle resistive muffling structure, a flange port, and an air outlet louver. The invention is characterized in that the resistive muffling structure consists of plate type sound absorbers, axes of the plate type sound absorbers are arranged in parallel along an airflow direction; the right-angle resistive muffling structure consists of a cube and a cambered diversion sound absorber, wherein four sides are an inner wall of the muffler shell, one side is the resistive muffling structure, the other side is the air outlet louver or the air inlet flange port, and the cambered diversion sound absorber and the inner wall of the muffler shell together form a right-angle cavity. The inventive structure has good muffling performance and process performance; and the resistive muffling structure and the right-angled reactive muffling structures can be combined according to specific mounting conditions, and are highly adaptive.

Owner:XIAMEN JIADA GREEN CONSTRUCION ENG CO LTD

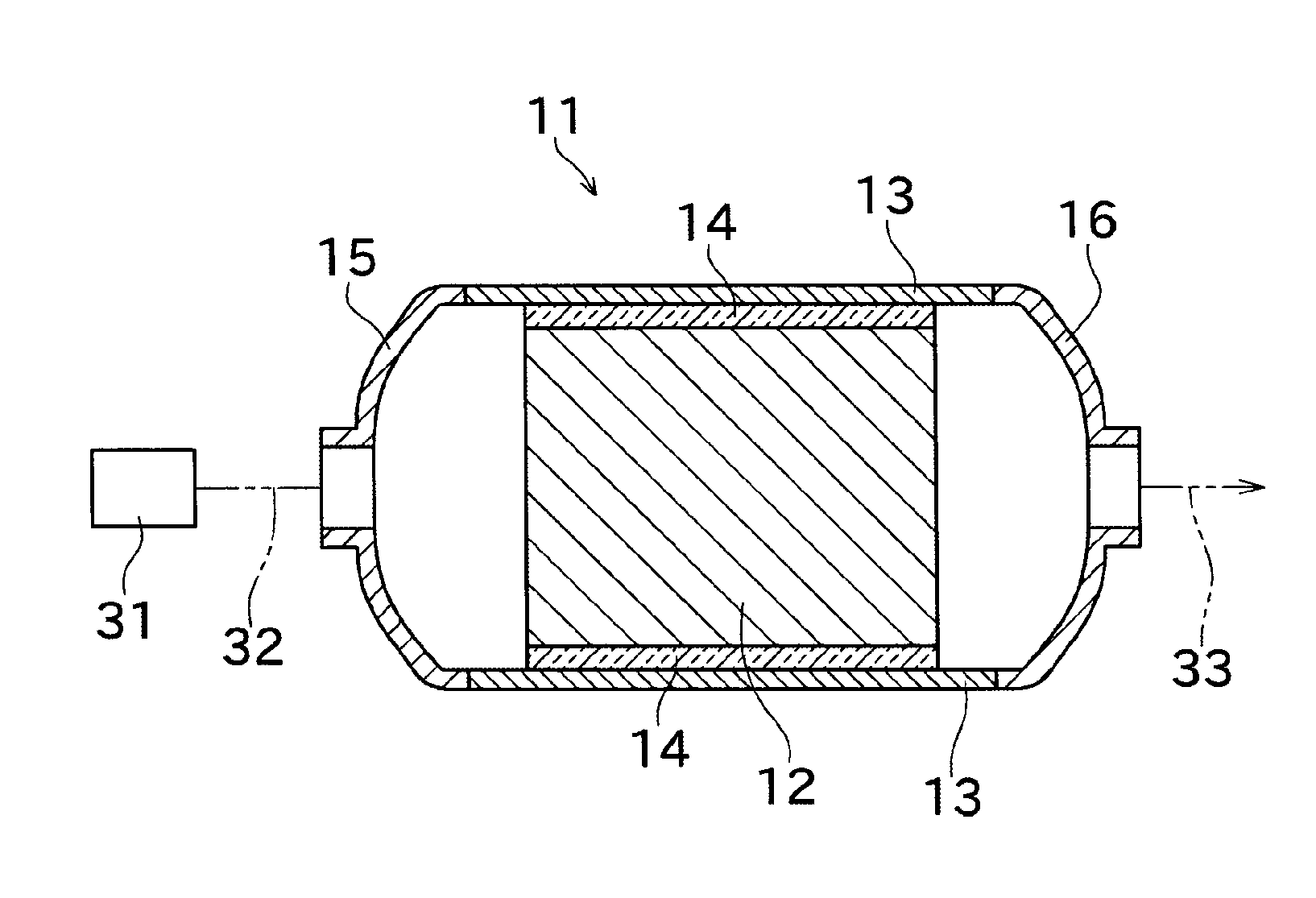

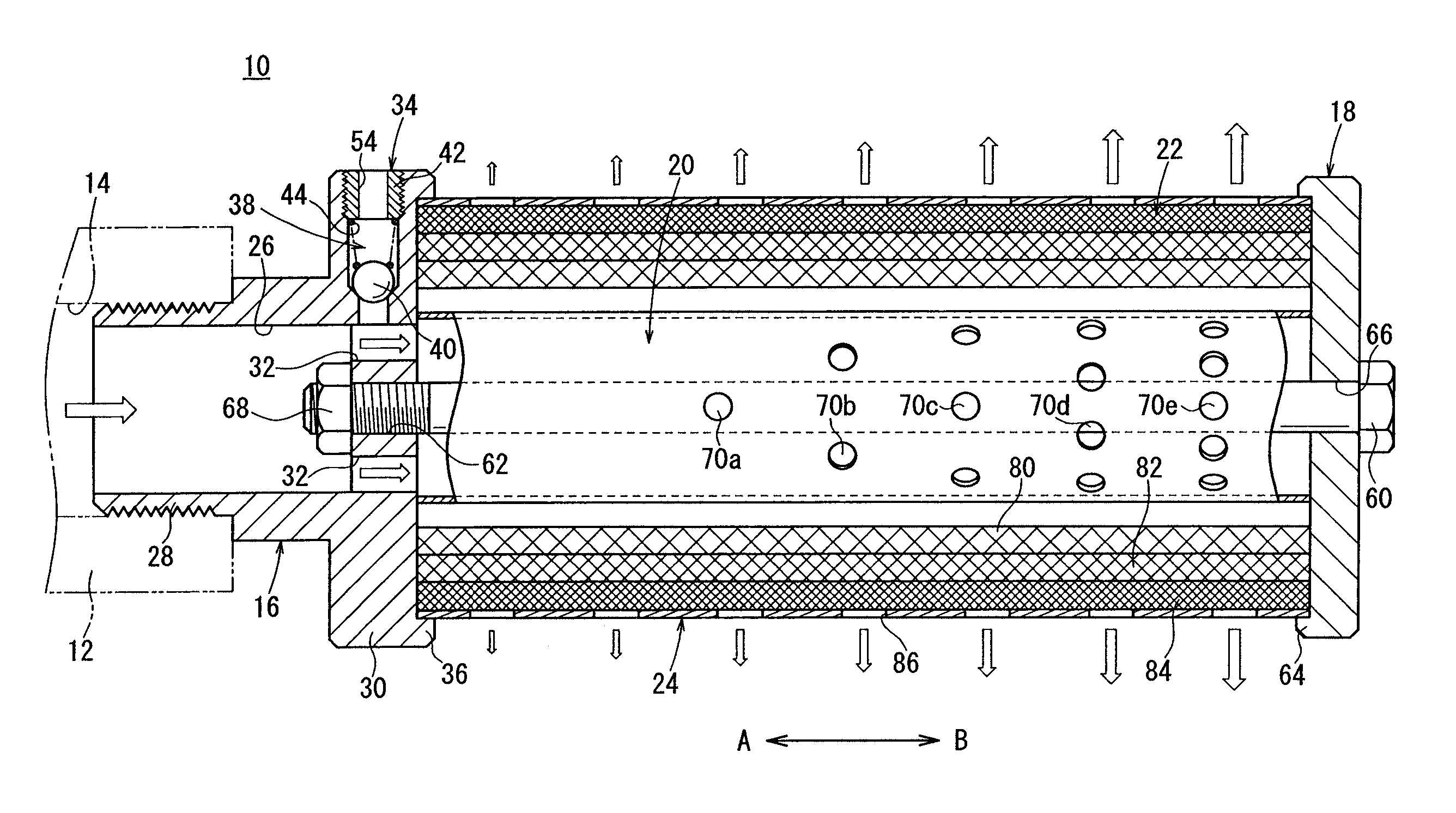

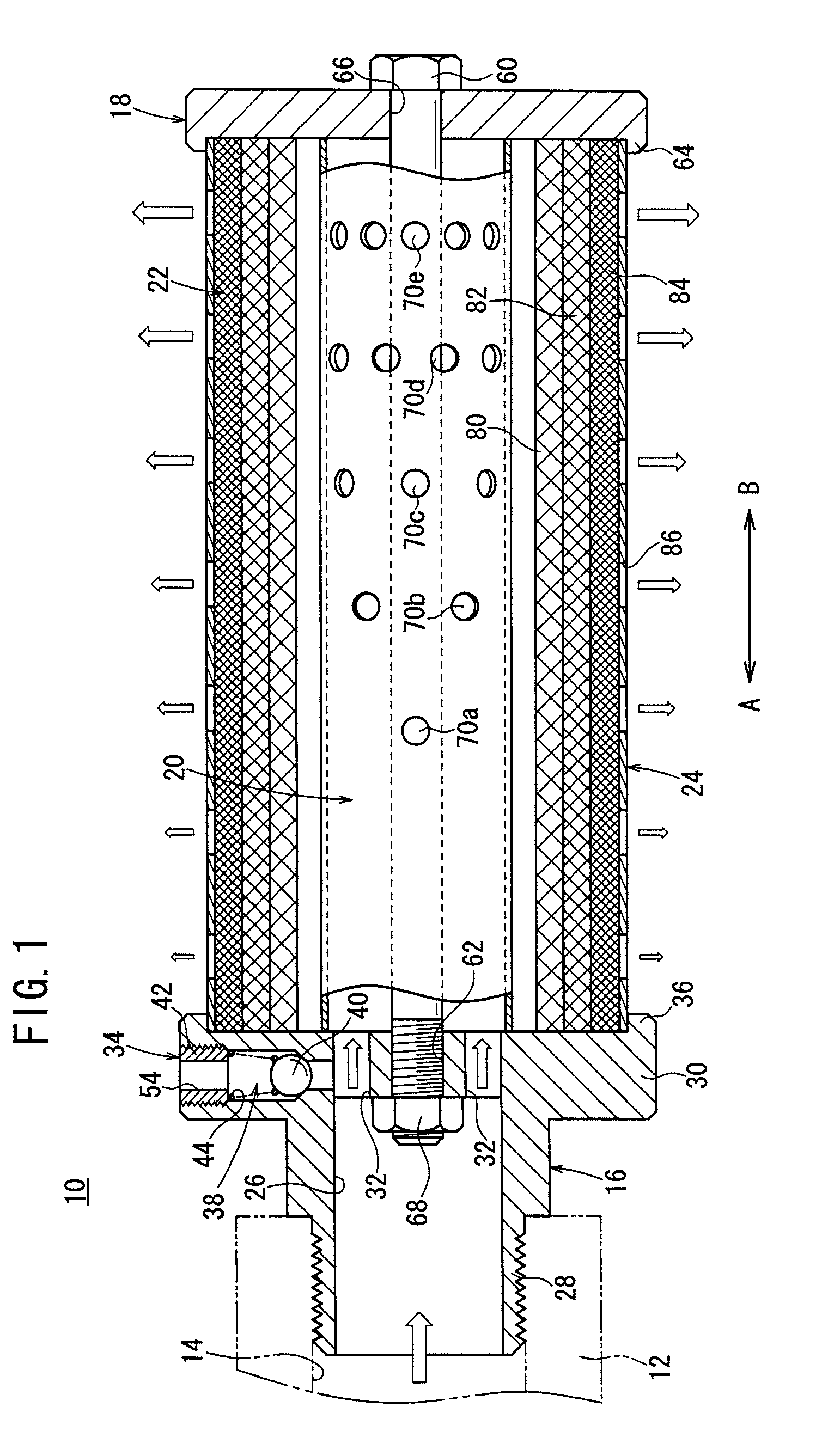

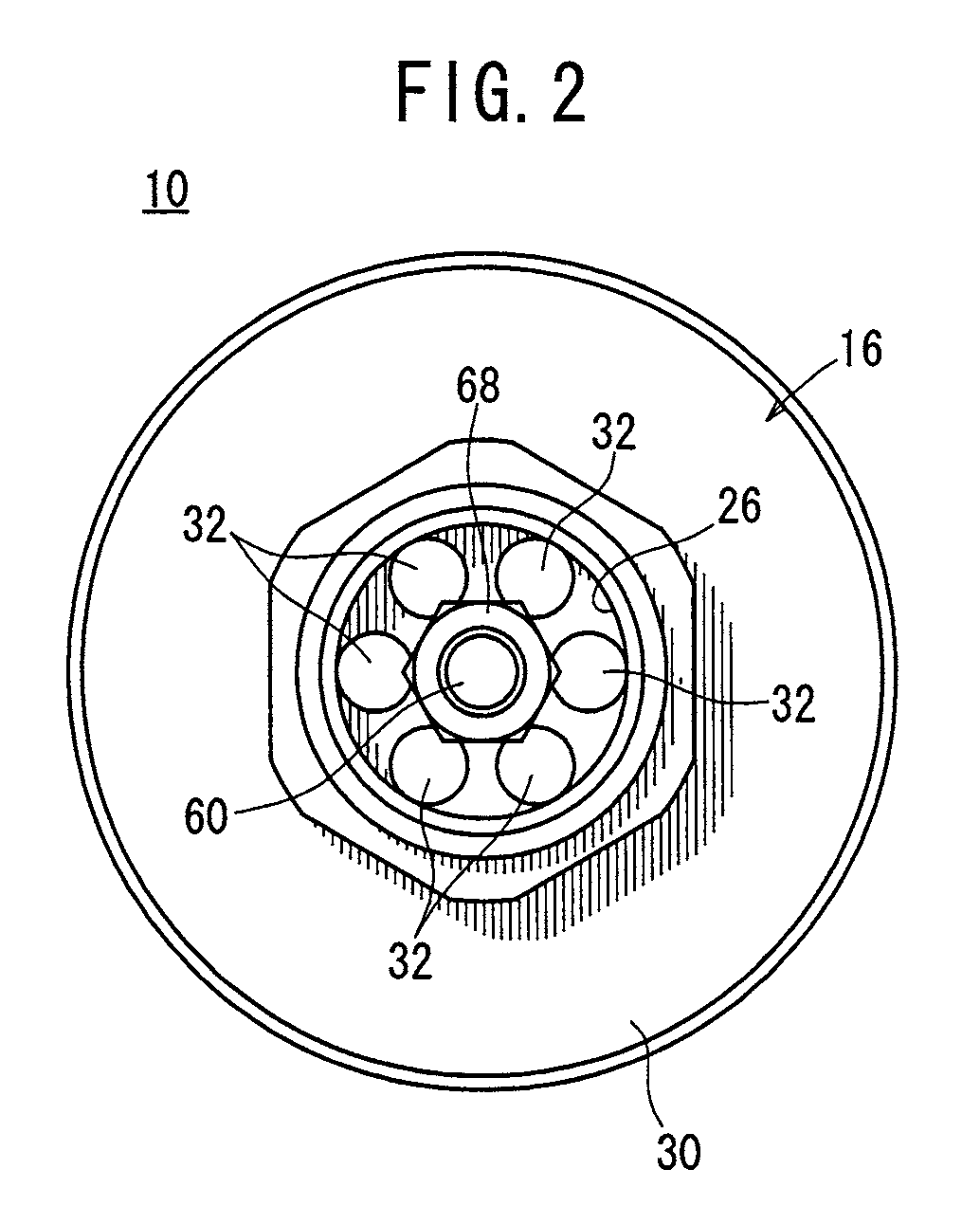

Silencer

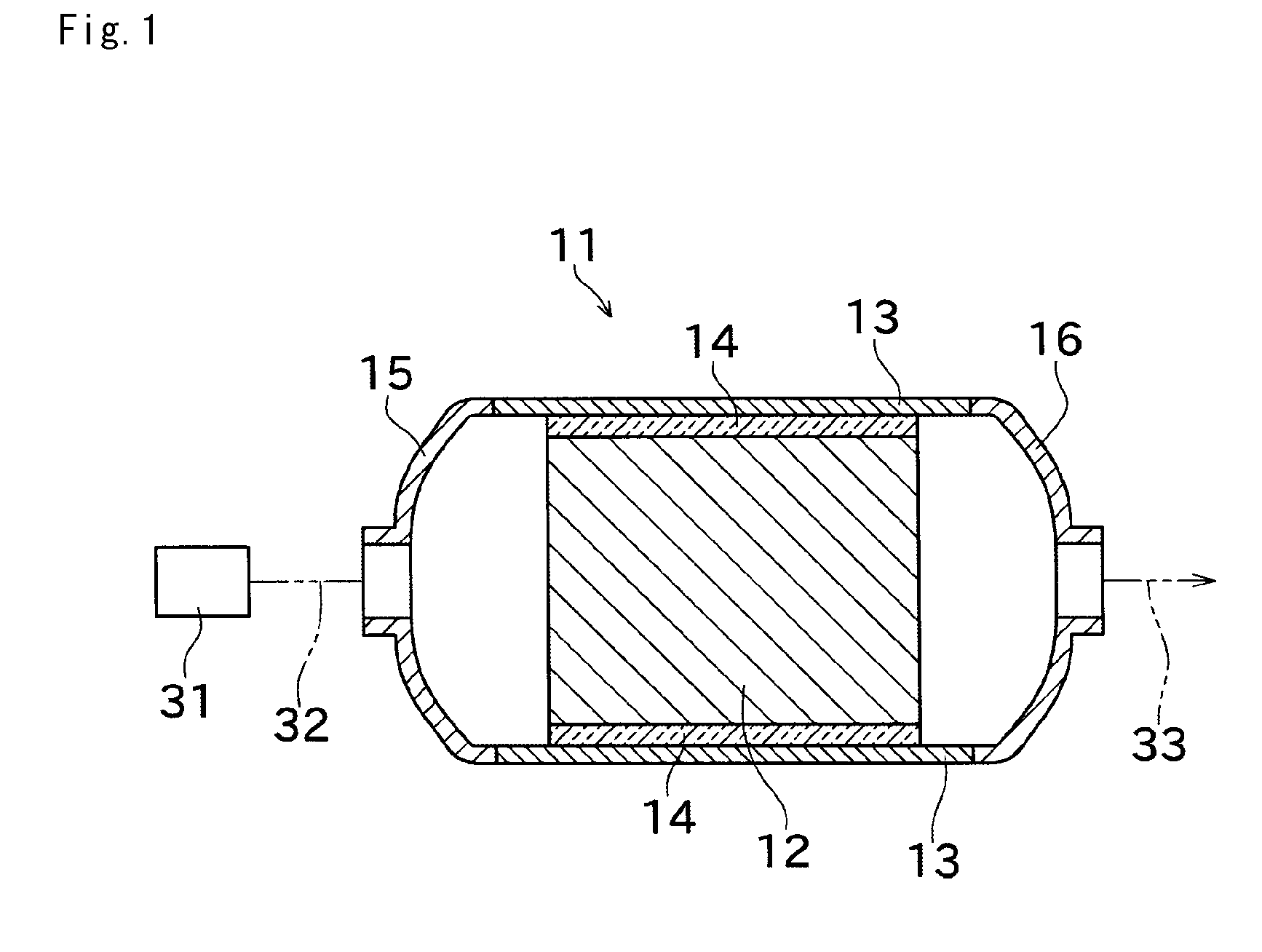

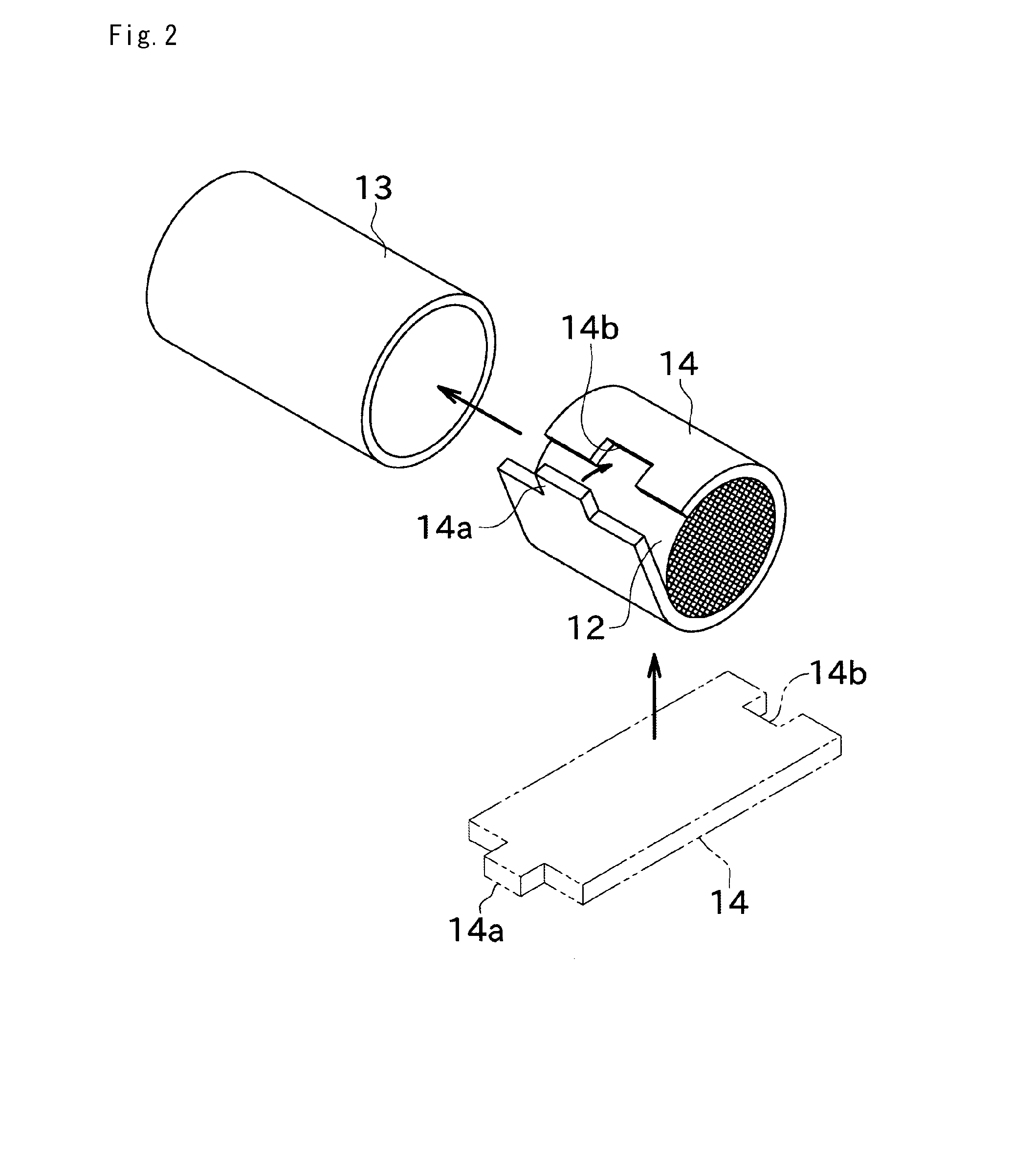

ActiveUS7753167B2Suppress generationAvoid it happening againInternal combustion piston enginesPositive displacement pump componentsEngineeringSound Absorber

A silencer includes a cylindrical member held between a body connected to an exhaust side of a fluid pressure device and a disk-shaped retaining member. A net-shaped sound absorber is disposed around an outer circumference of the cylindrical member. A pressure fluid flows from the body into the interior of the cylindrical member and is discharged toward the sound absorber through a plurality of first through fifth exhaust holes formed in the cylindrical member. Accordingly, dust in the pressure fluid is removed by the sound absorber, which is formed of a plurality of stacked filters, and further, the pressure fluid is discharged to the outside after exhaust noises have been absorbed by the sound absorber.

Owner:SMC CORP

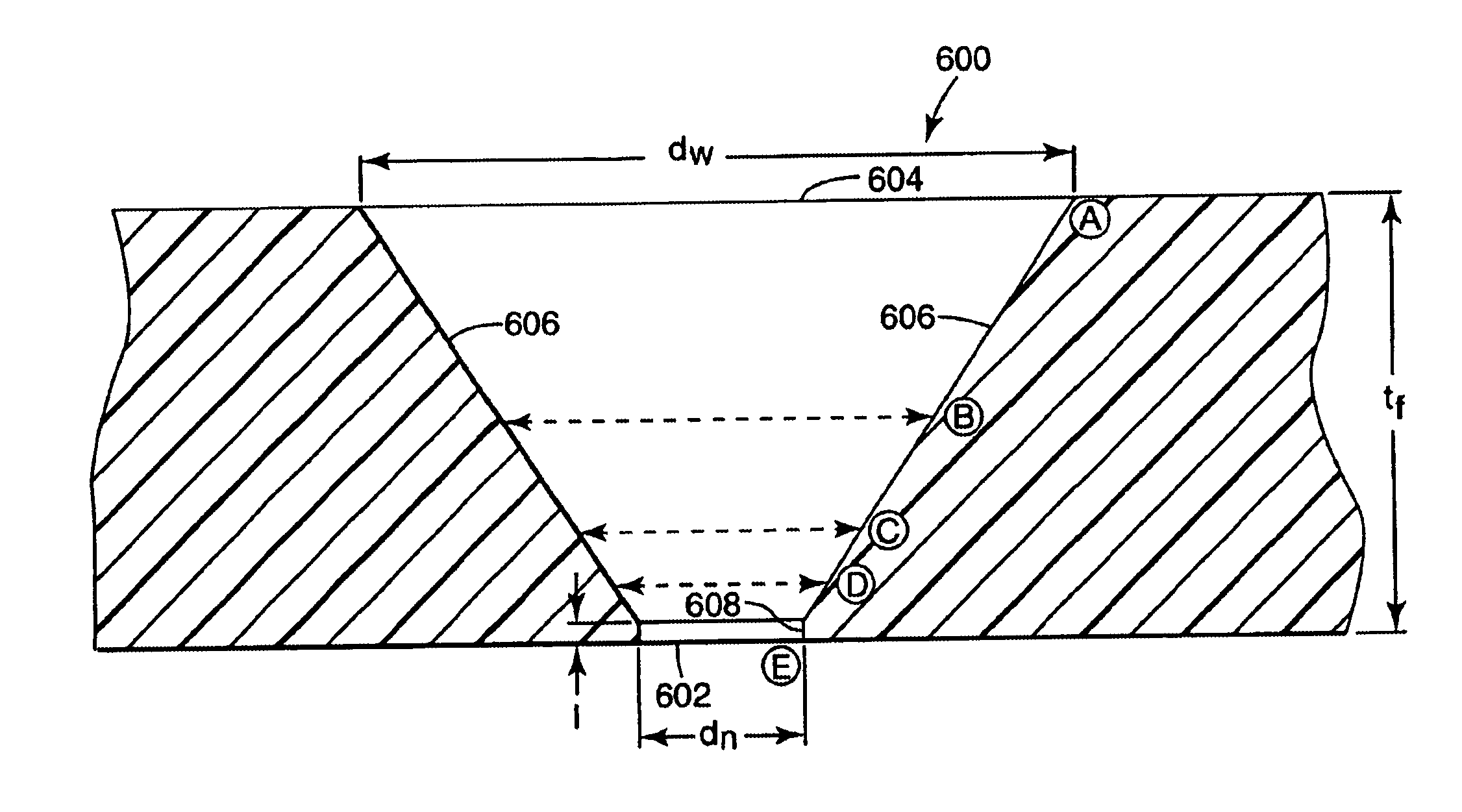

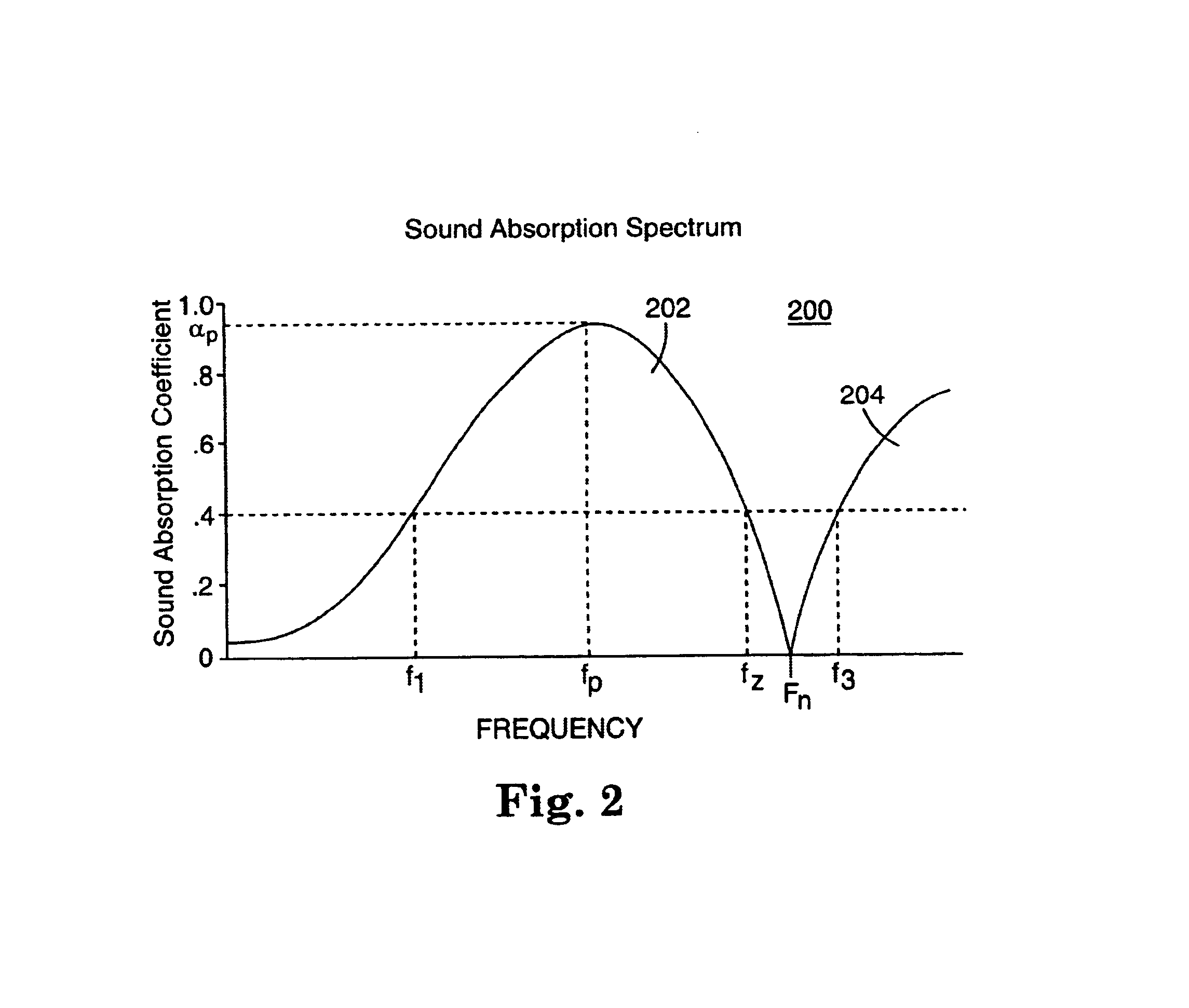

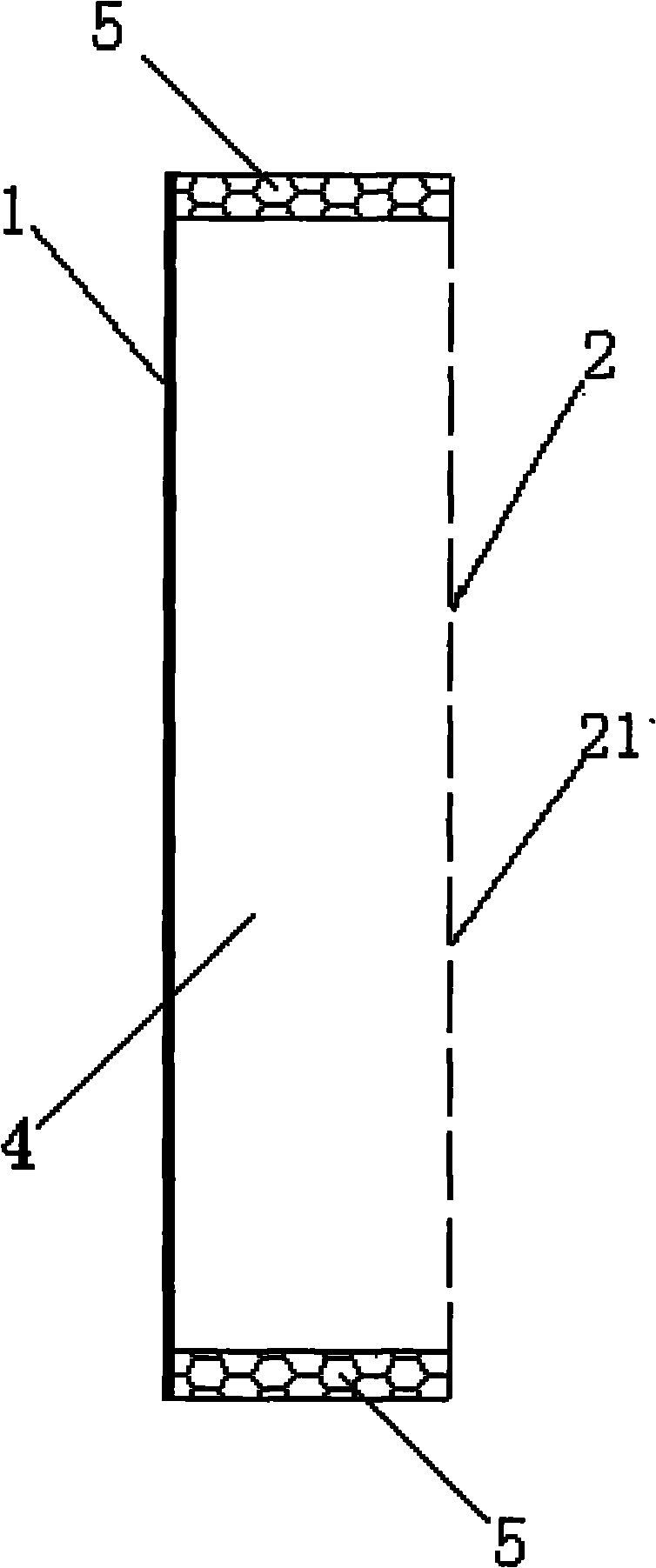

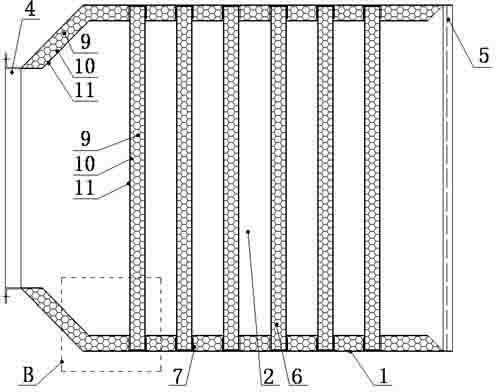

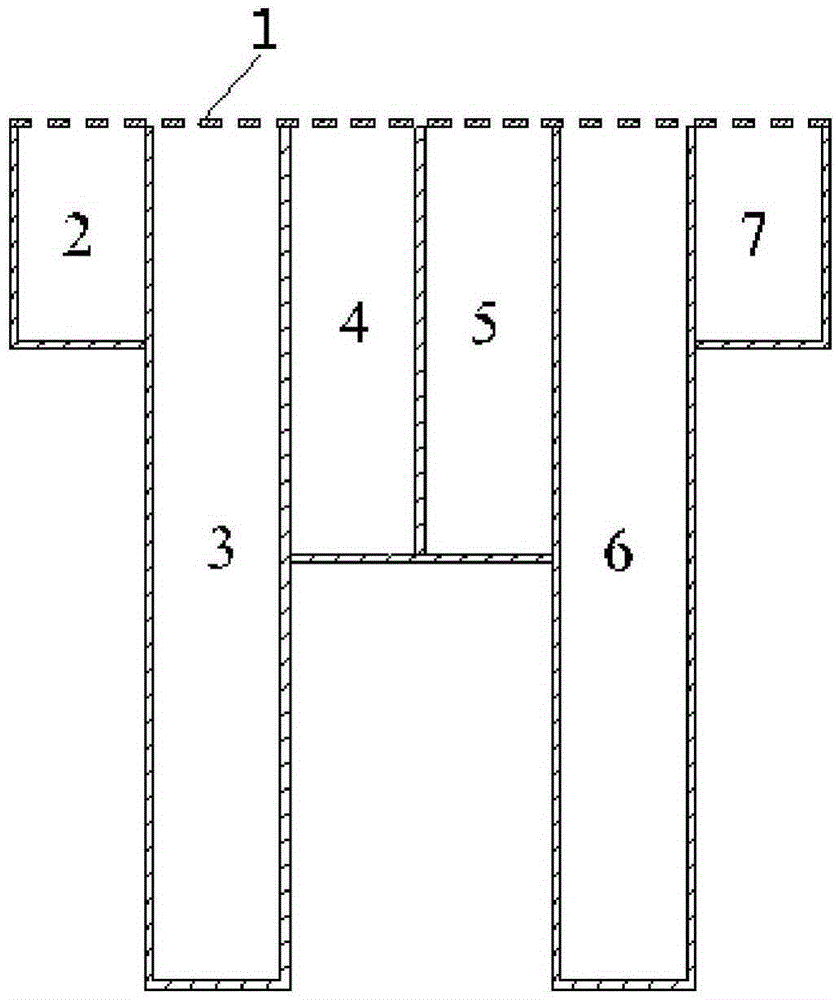

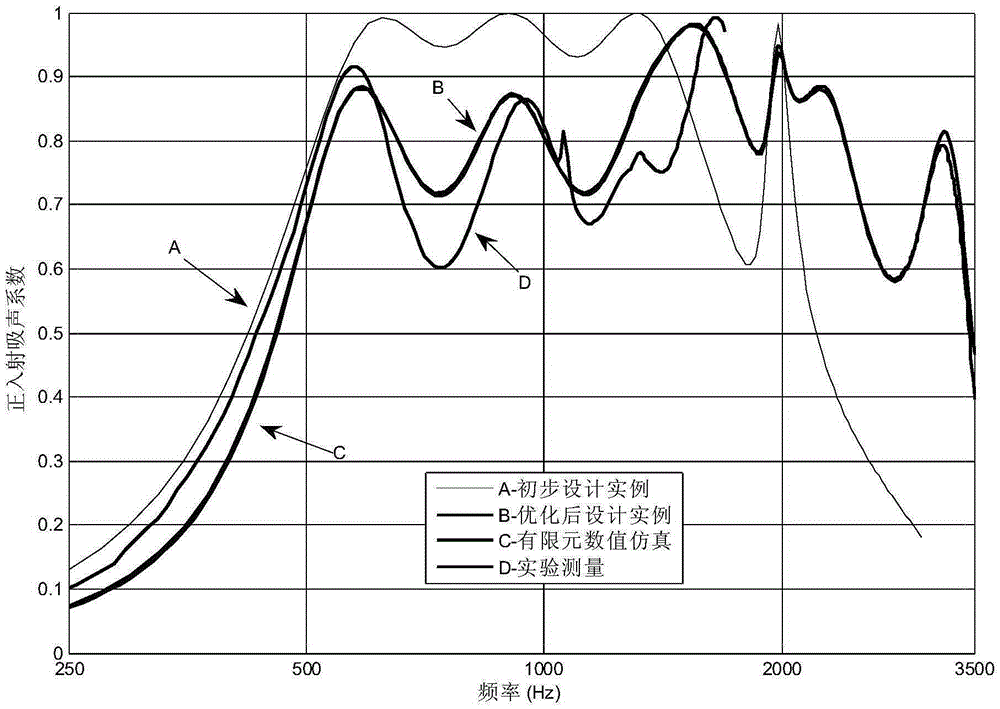

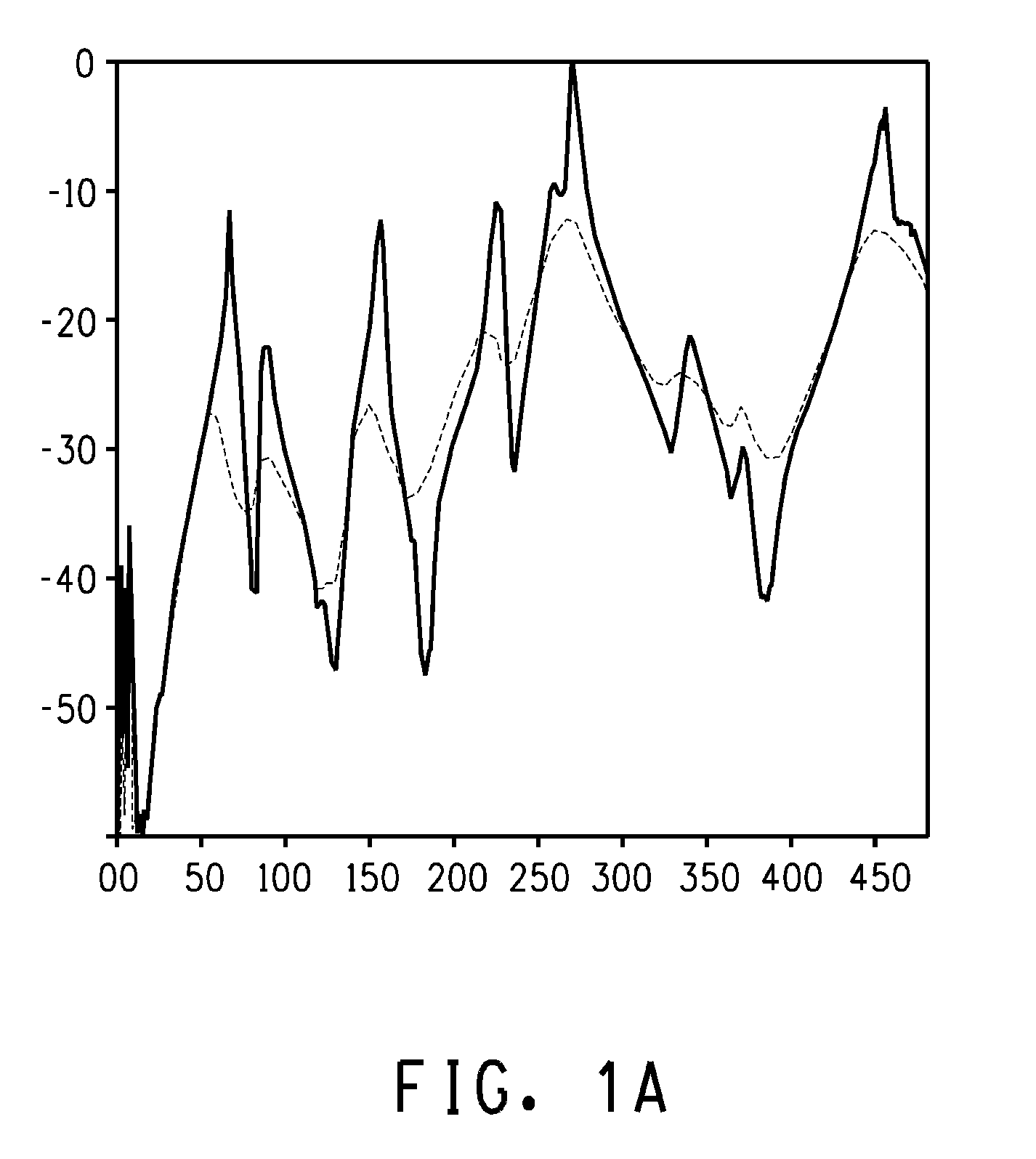

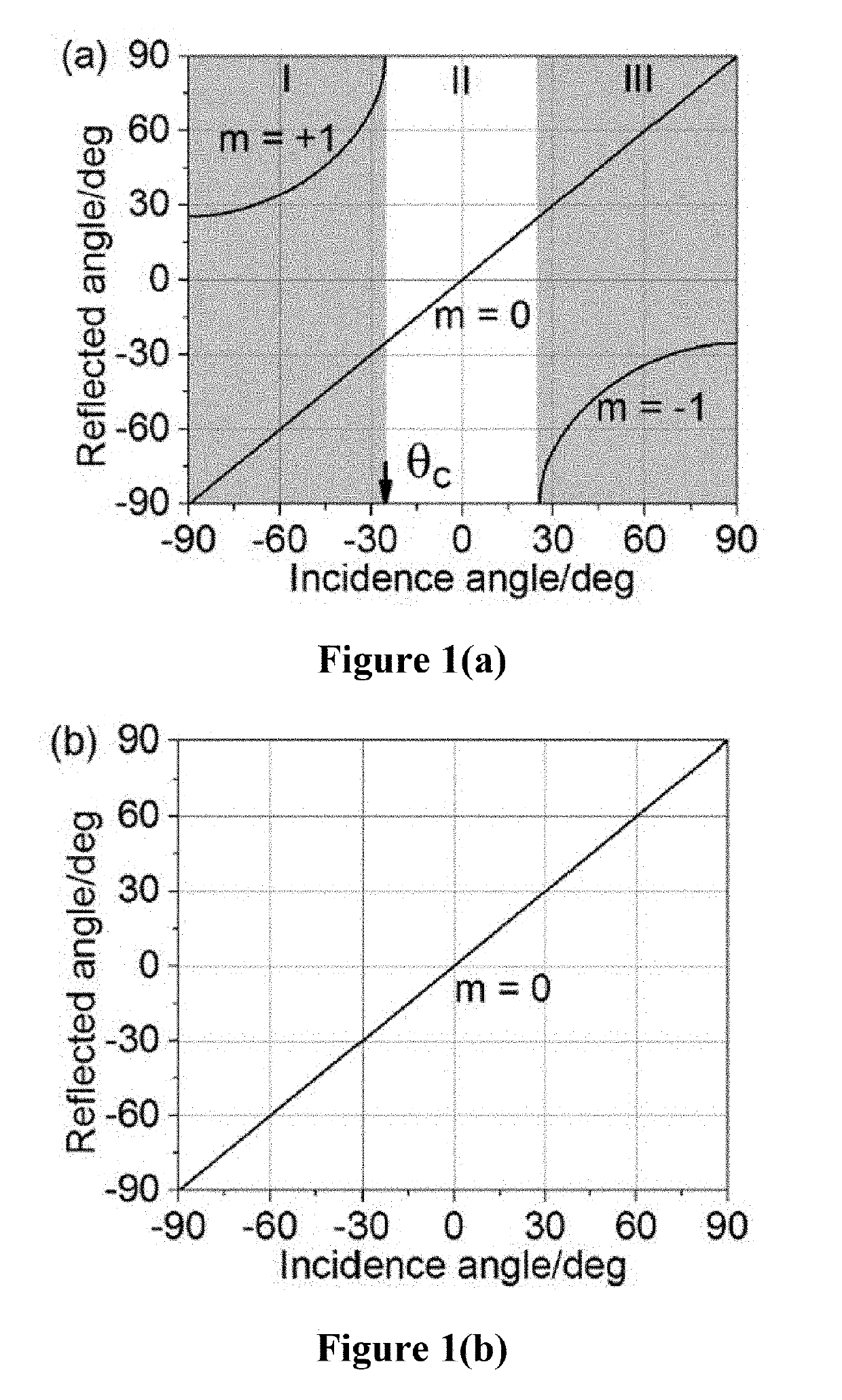

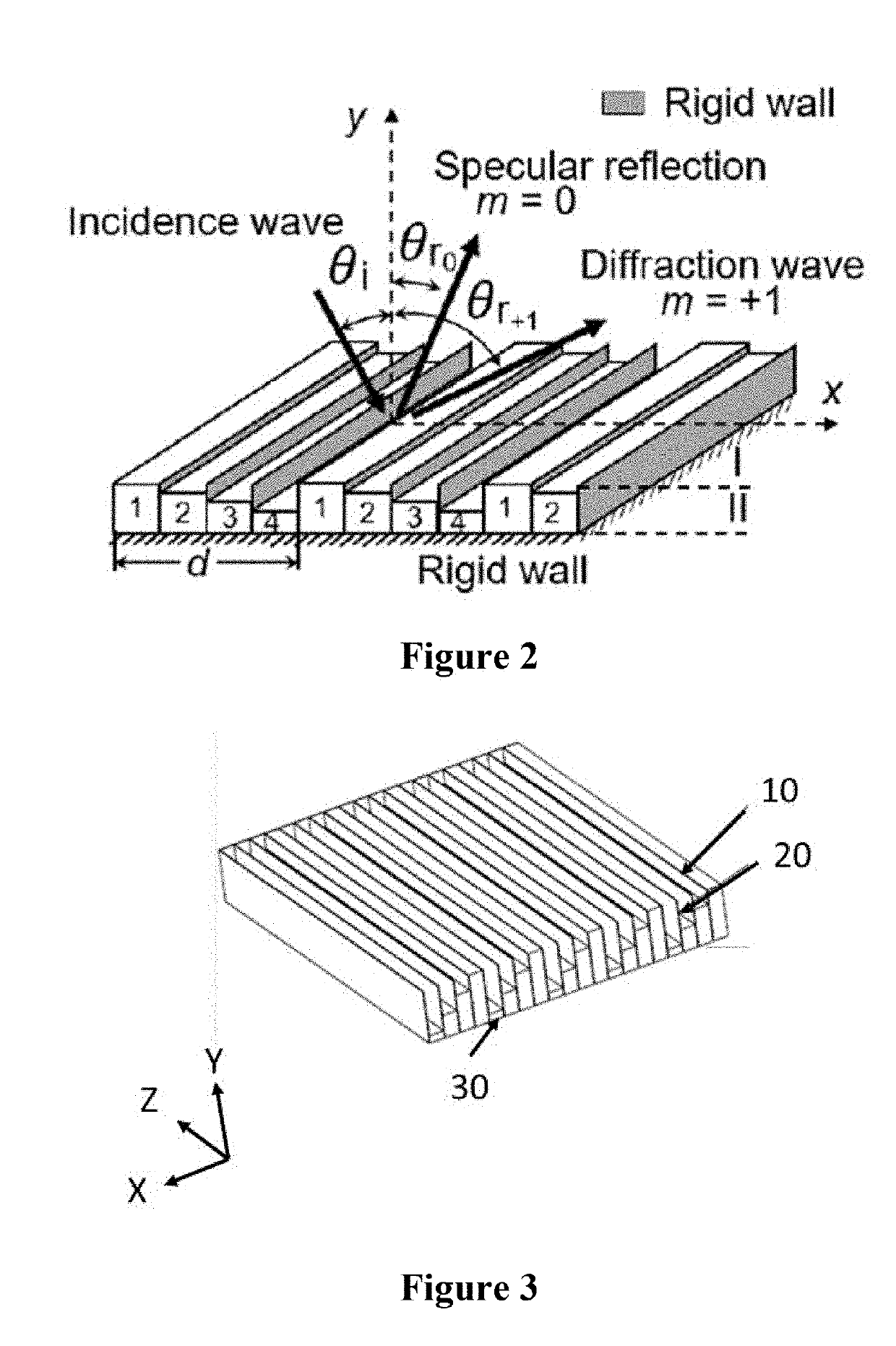

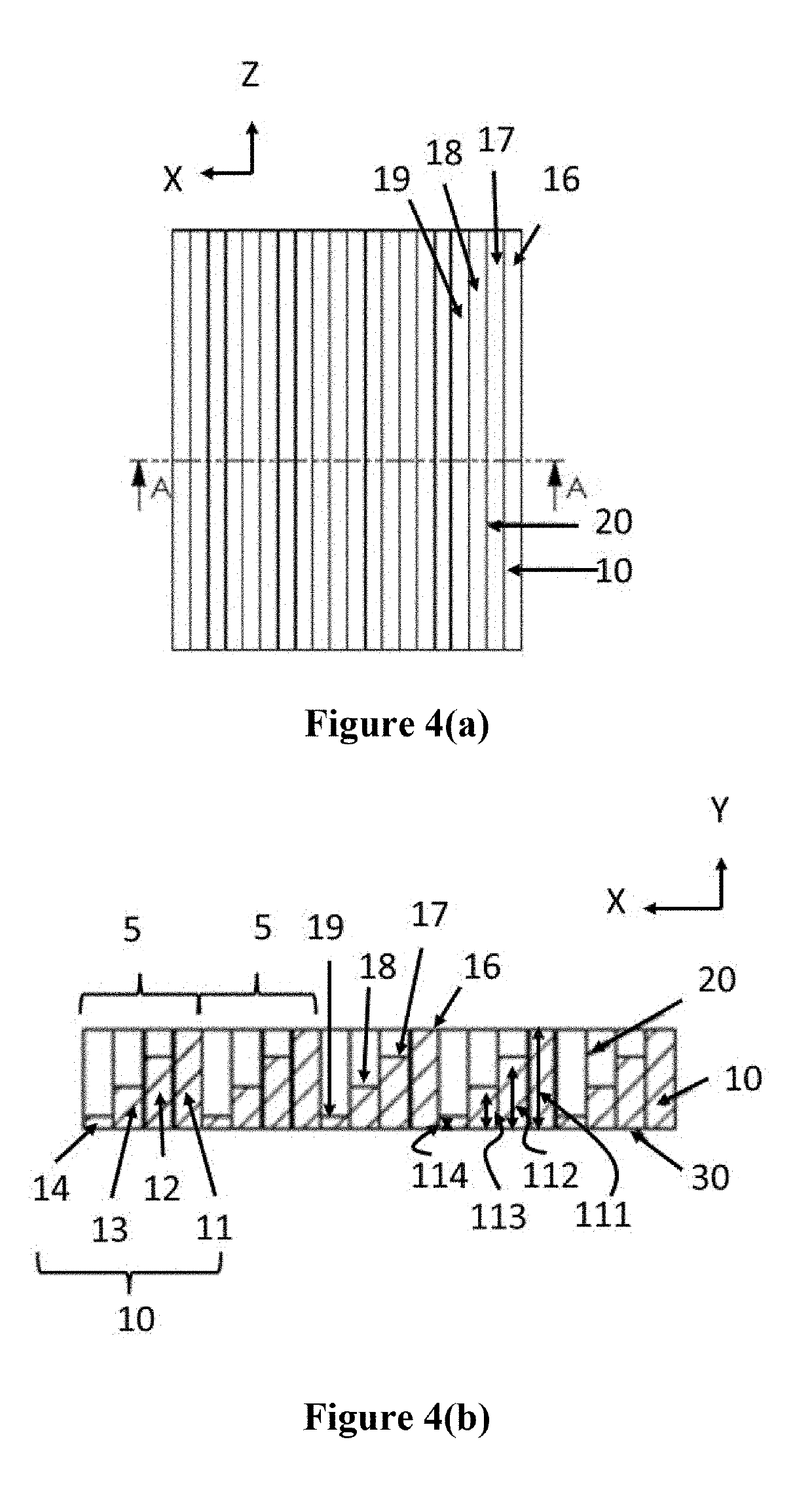

Broadband micro-perforated board sound absorber, absorber performance prediction method and absorber structure design method

ActiveCN105427853AHigh performance sound absorptionSave installation spaceGeometric CADSound producing devicesFrequency spectrumEngineering

The invention discloses a broadband micro-perforated board sound absorber, a sound absorber performance prediction method and a sound absorber structure design method. The sound absorber comprises a surface micro-perforated board and a back chamber with unequal periodicity depth, and the back chamber is used for expanding sound absorption bandwidth of the sound absorber. The performance prediction method is used for predicting a sound absorption coefficient frequency spectrum of the sound absorber, through finite element simulation and experiment measurement verification, the performance prediction method is accurate and reliable; the structure design method used for effectively realizing the broadband micro-perforated board sound absorber comprises steps that (1), a depth matrix of the periodic back chamber is designed on the basis of the secondary residual sequence combination arrangement theory; and (2), evaluation is realized on the basis of the performance prediction method, combination of parameters of the sound absorber are sequentially determined, including total sound absorber width of the periodic back chamber, depth of each sub back chamber, board thickness of the micro-perforated board, aperture and perforated percentage. Through the sound absorber performance prediction method and the sound absorber structure design method, the micro-perforated board sound absorber having the broadband sound absorption performance can be accurately, reliably and simply designed.

Owner:SOUTHEAST UNIV

Sound absorbing structure and sound chamber

ActiveUS8360201B2Effective absorptionReduce thicknessBuilding roofsCeilingsInternal pressureAcoustic wave

Owner:YAMAHA CORP

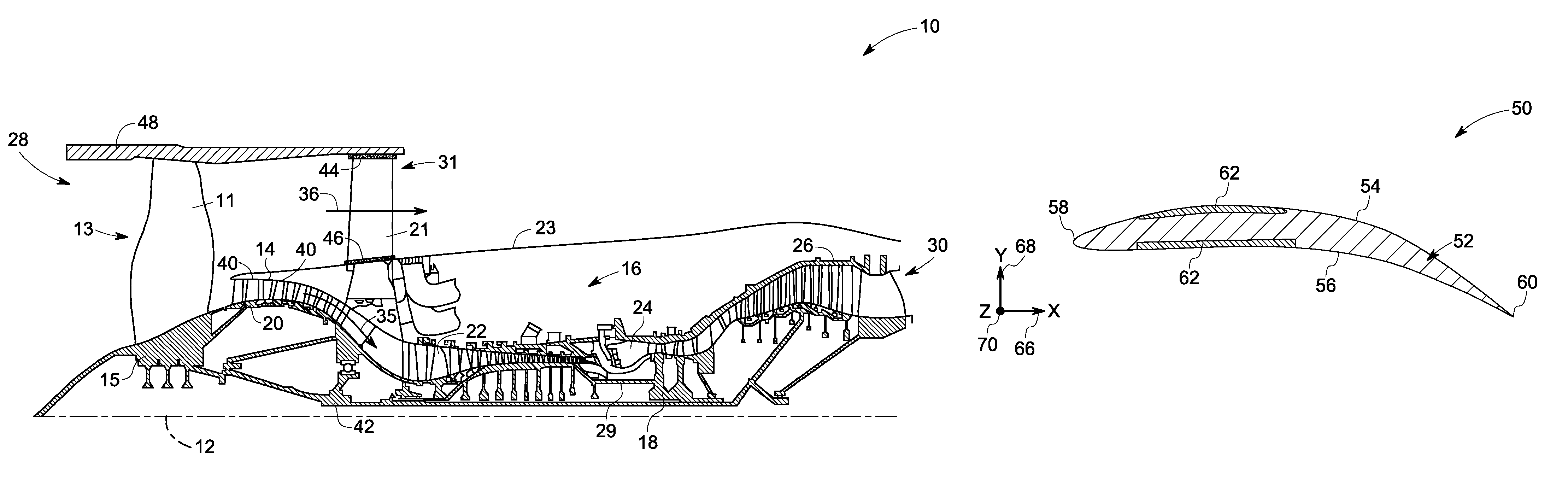

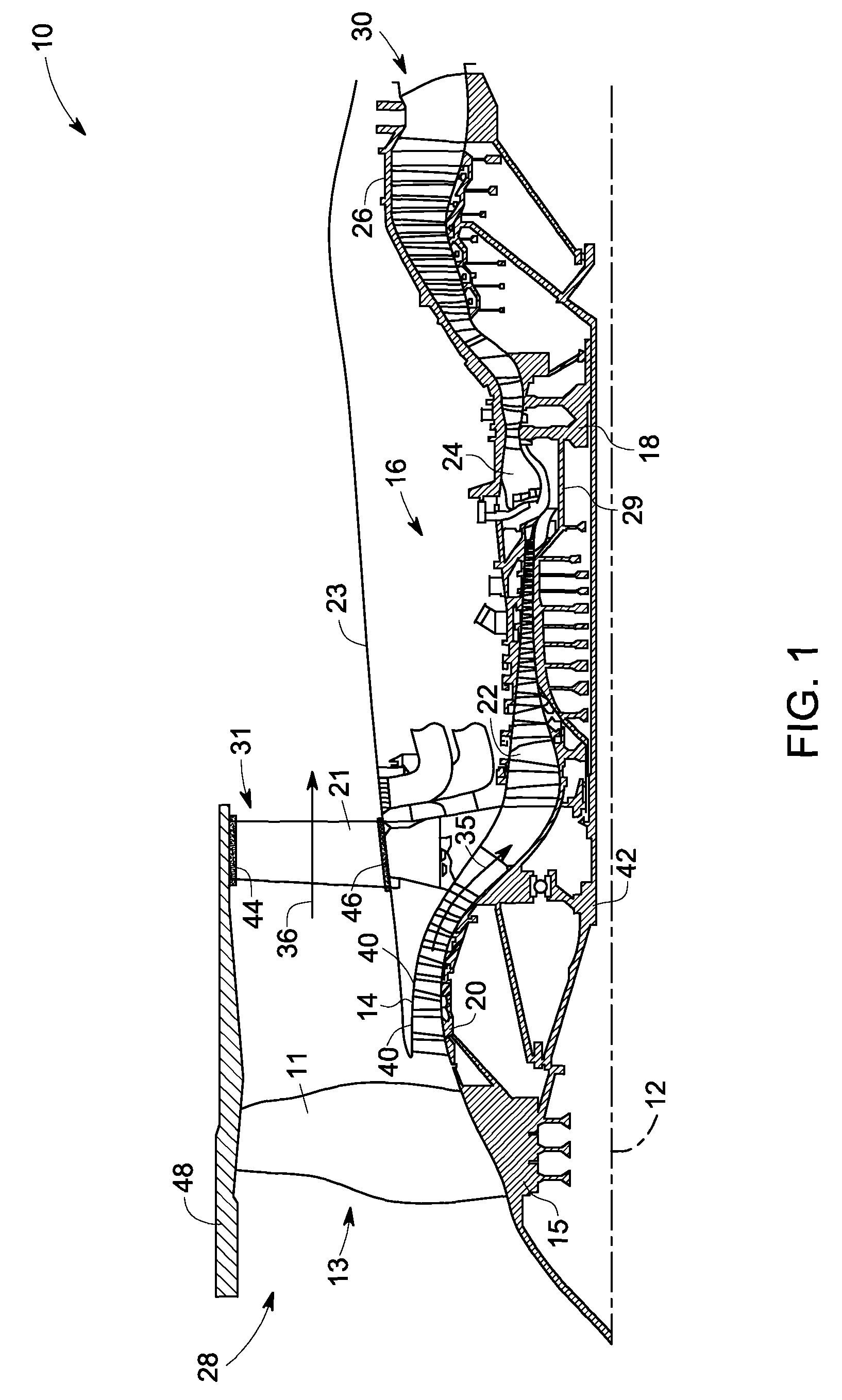

Combined acoustic absorber and heat exchanging outlet guide vanes

ActiveUS8333552B2Improve heat transfer performancePromote absorptionPump componentsEngine fuctionsSurface coolingAcoustic absorption

Owner:GENERAL ELECTRIC CO

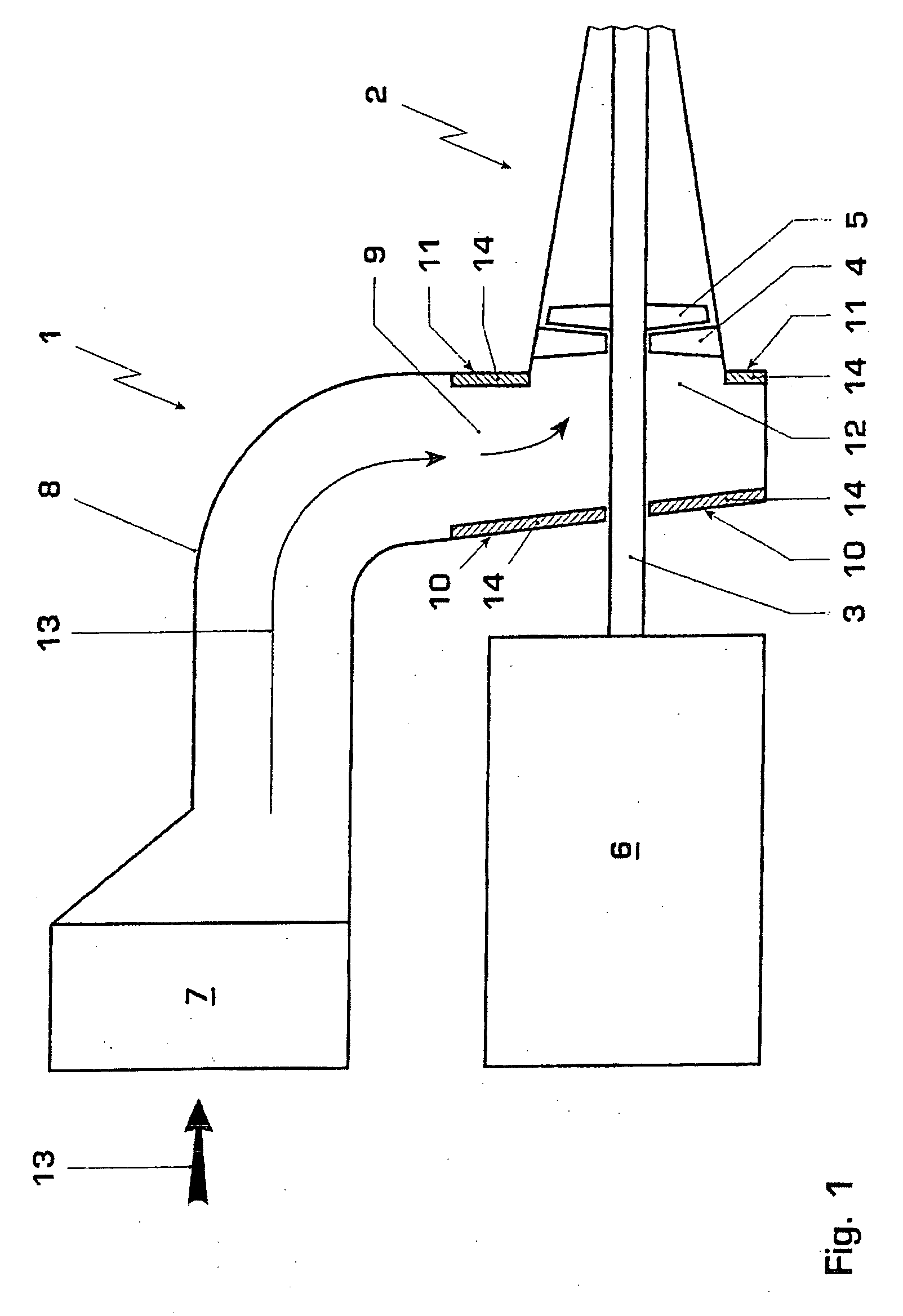

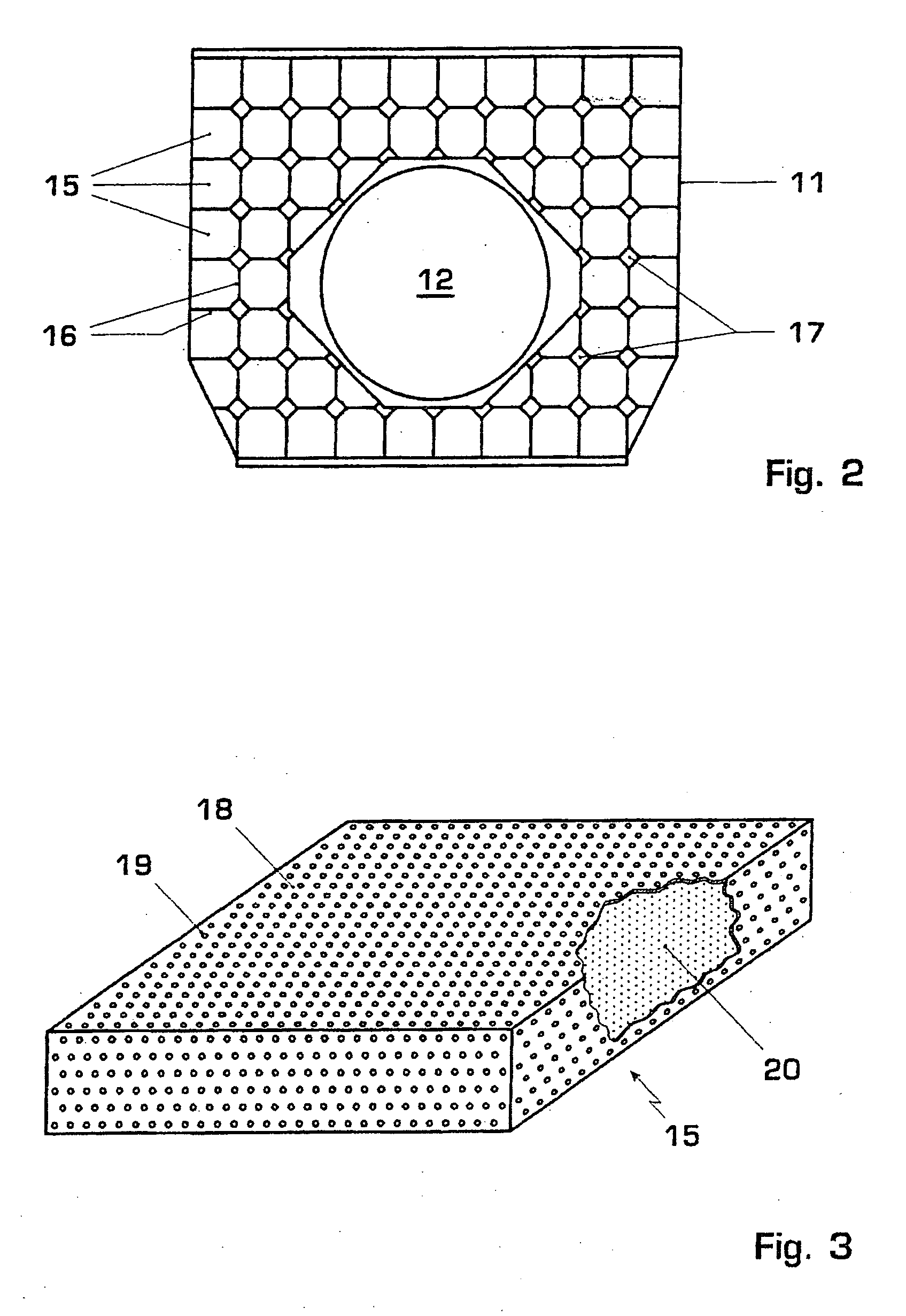

Sound absorber for gas turbine installations

InactiveUS20080202848A1Reliable silencing qualityEfficient silencingPump componentsEngine fuctionsSound AbsorberGas turbines

A device (1) for the feed of air to a compressor (2) of a gas turbine plant has an air inlet duct (8) and an air inlet chamber (9) which adjoins the air inlet duct. For the purpose of damping sound emissions of the compressor (2), a first and second inner wall (10, 11) of the inlet chamber (9) is at least partially lined by means of melamine foam. The invention is characterized by the advantages in that silencing is ensured both with wetness and with chemically aggressive conditions. The silencing device is consequently functionally reliable over an extended operating period.

Owner:ANSALDO ENERGIA IP UK LTD

Ultrasonic transducer

ActiveUS7548014B2Increase sound pressureGood reverberationPiezoelectric/electrostrictive microphonesPiezoelectric/electrostriction/magnetostriction machinesAdhesiveSound Absorber

An ultrasonic transducer includes a cylindrical cap member having a bottom. A piezoelectric element is bonded to the inner side of a bottom portion of the cap member using a conductive adhesive or other suitable adhesive. An inner frame made of a material having an acoustic impedance greater than that of the cap member is fitted into the cap member so as to be in contact with a side portion, including the end portion, of the cap member. Through-holes are provided in the side portion of the inner frame. Lead wires are connected to the piezoelectric element and the inner frame, respectively. A sound absorber and a damper are inserted into the inner frame. The damper is in direct contact with the side portion of the cap member via the through-holes of the inner frame.

Owner:MURATA MFG CO LTD

Five-layer sound absorbing pad: improved acoustical absorber

An acoustical absorber, having the structure: scrim / film / batt / film / scrim. Preferably, the batt is made from about 60% to about 90% by weight natural fiber and about 10% to about 40% synthetic fiber. Also, a method of making the acoustical absorber is provided. Additionally, a method for acoustically insulating a structure with the acoustical absorber is provided. The method for acoustically insulating may include the steps of compressing the acoustical absorber to less than its original volume prior to installing the absorber and releasing the absorber from compression following the installing step, allowing the material to recover and to fill the void of the structure in which the absorber was placed.

Owner:ACOUSTEK NONWOVENS

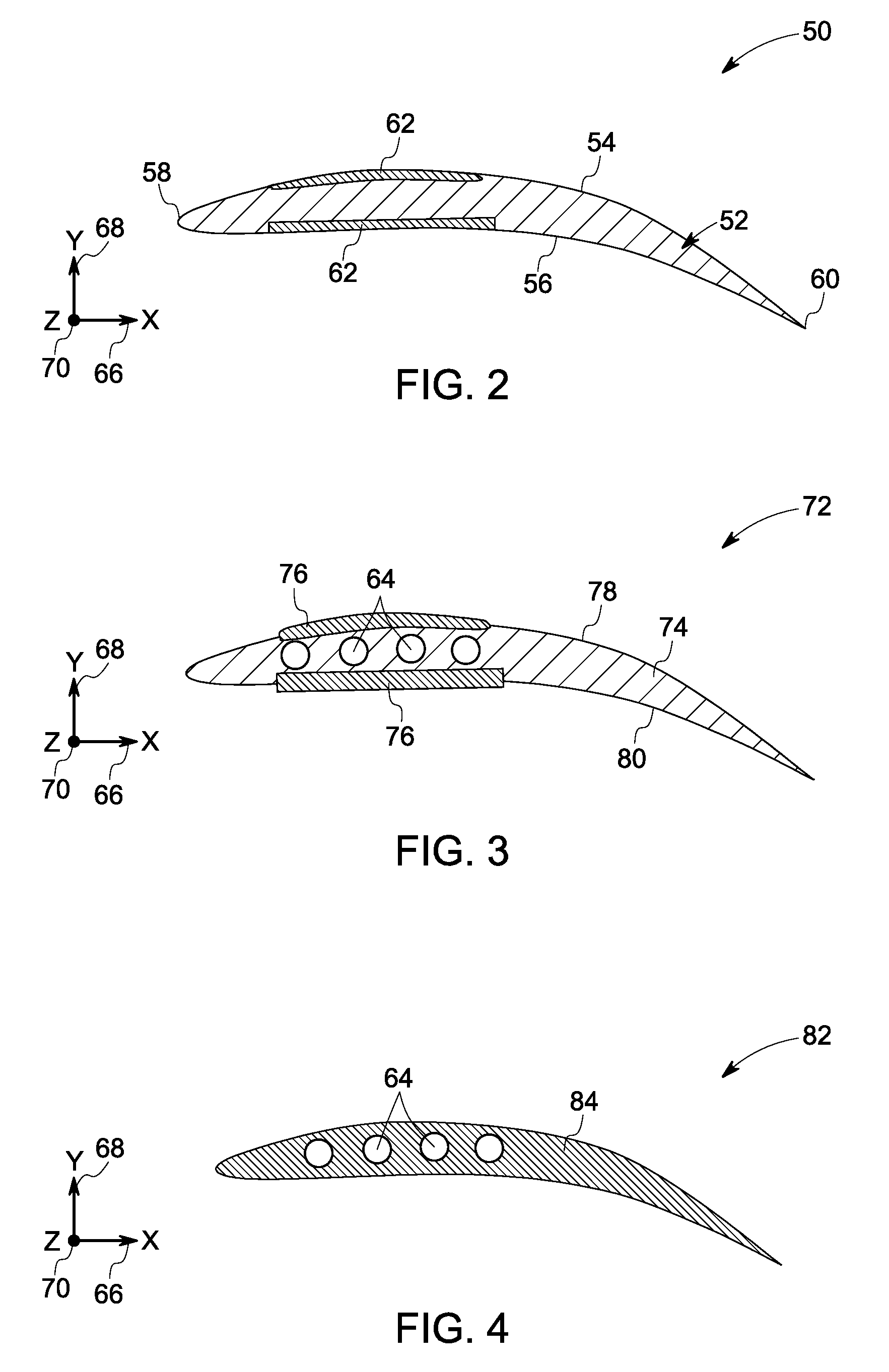

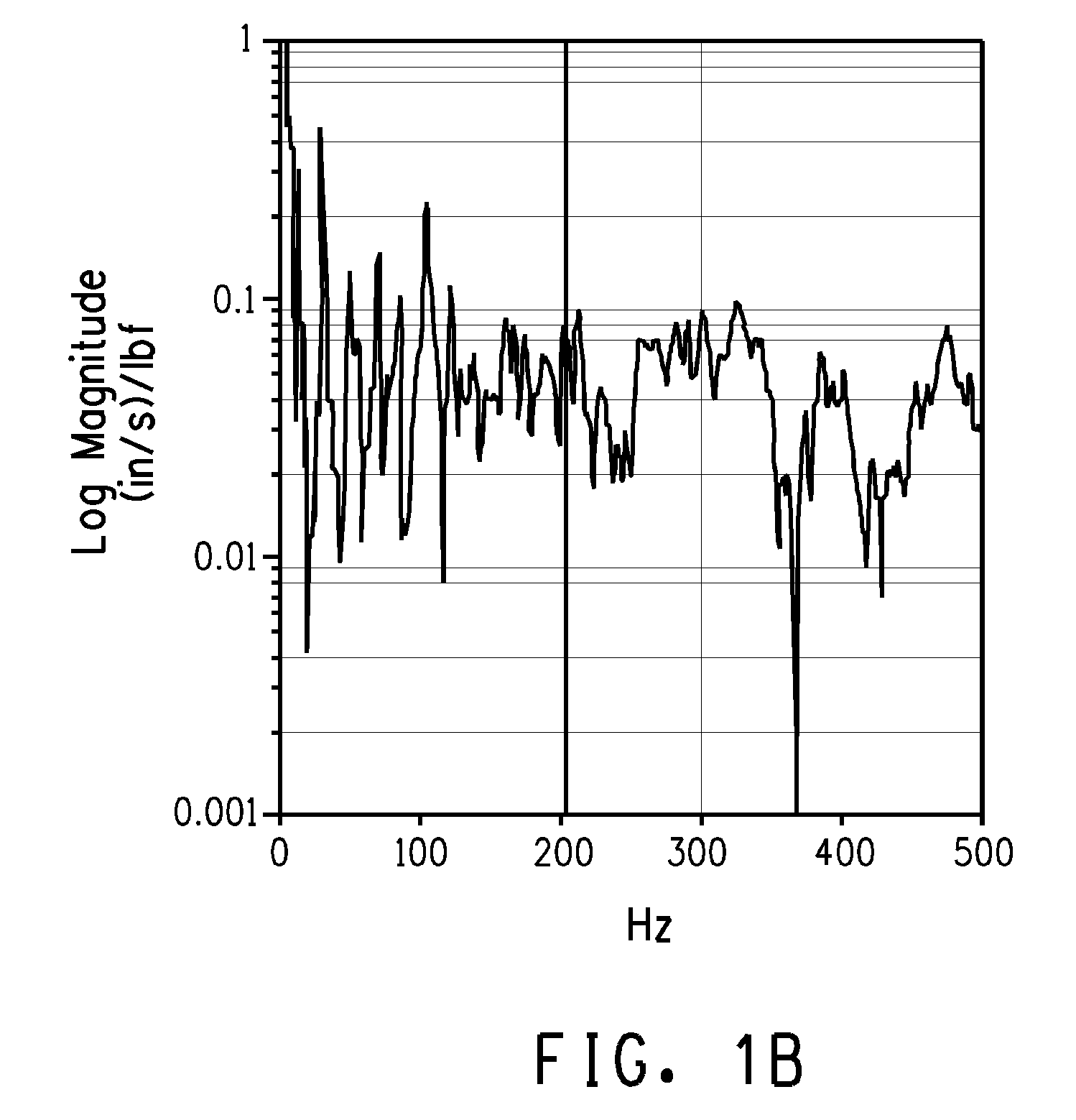

Broadband passive distributed tuned vibration and acoustic absorber for modally dense structures

A passive distributed vibration absorber that utilizes multiple discrete mass elements and a viscoelastic layer and that effectively attenuates vibration in modally dense structures excited by a broadband input noise excitation and is tunable to multiple natural frequencies in such modally dense vibrating structures including low frequencies

Owner:DUPONT SAFETY & CONSTR INC

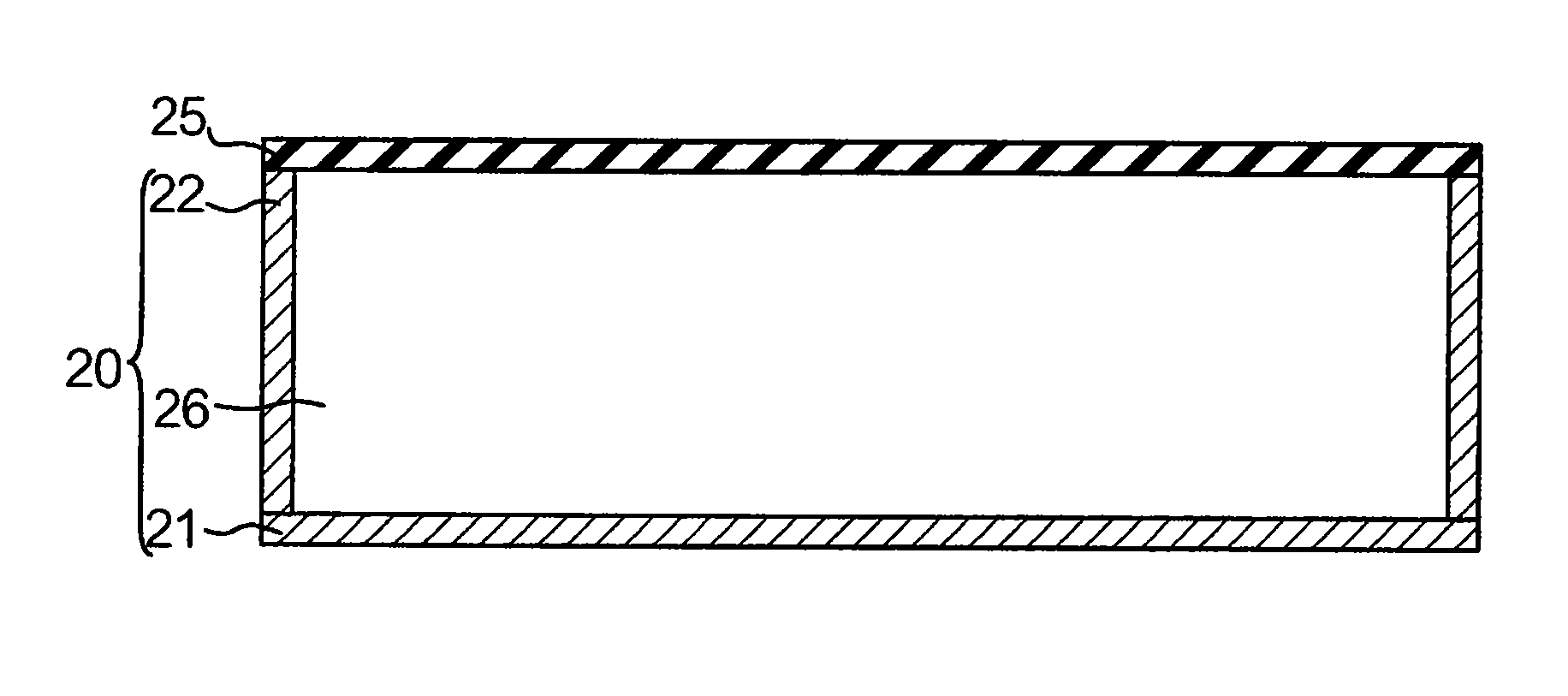

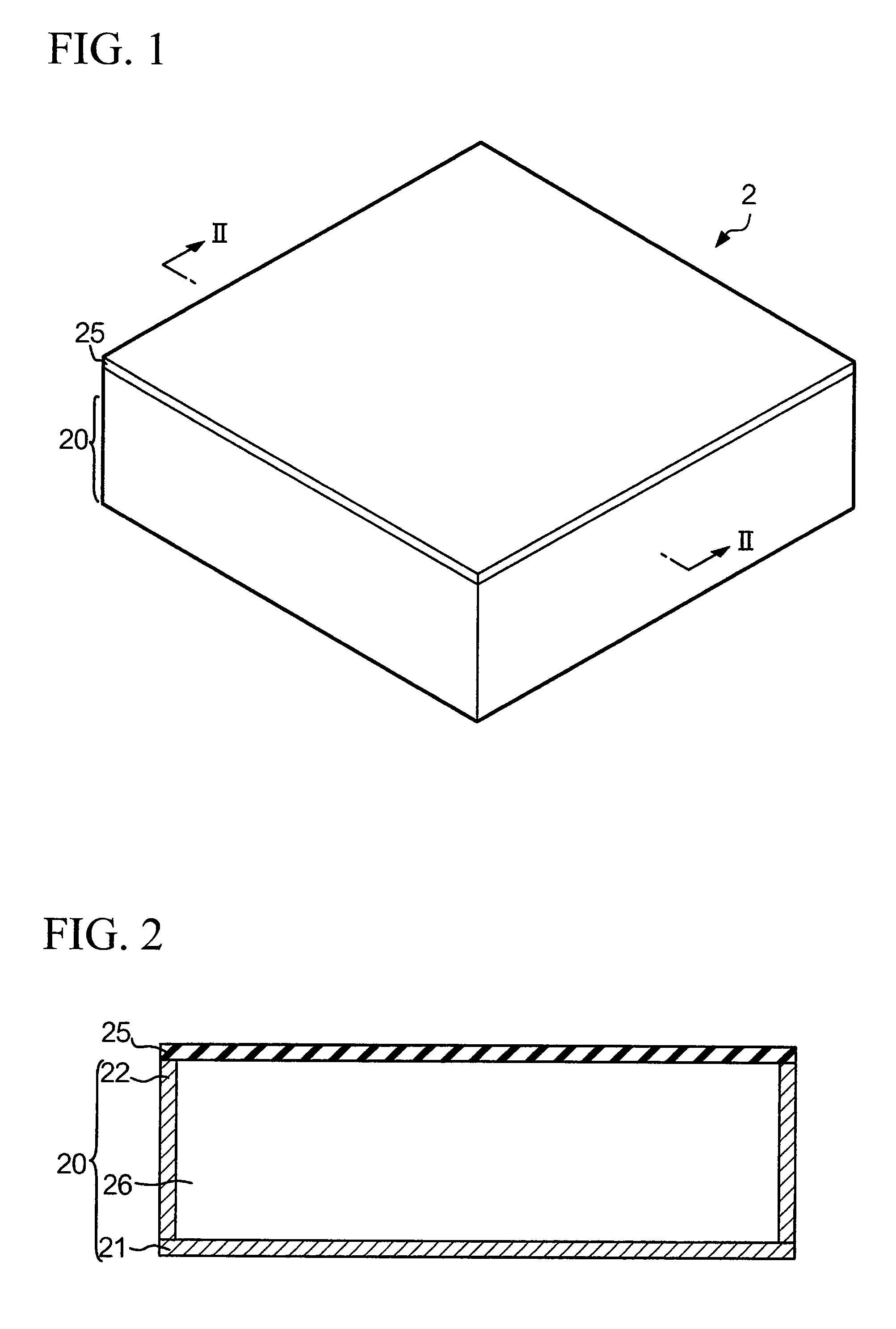

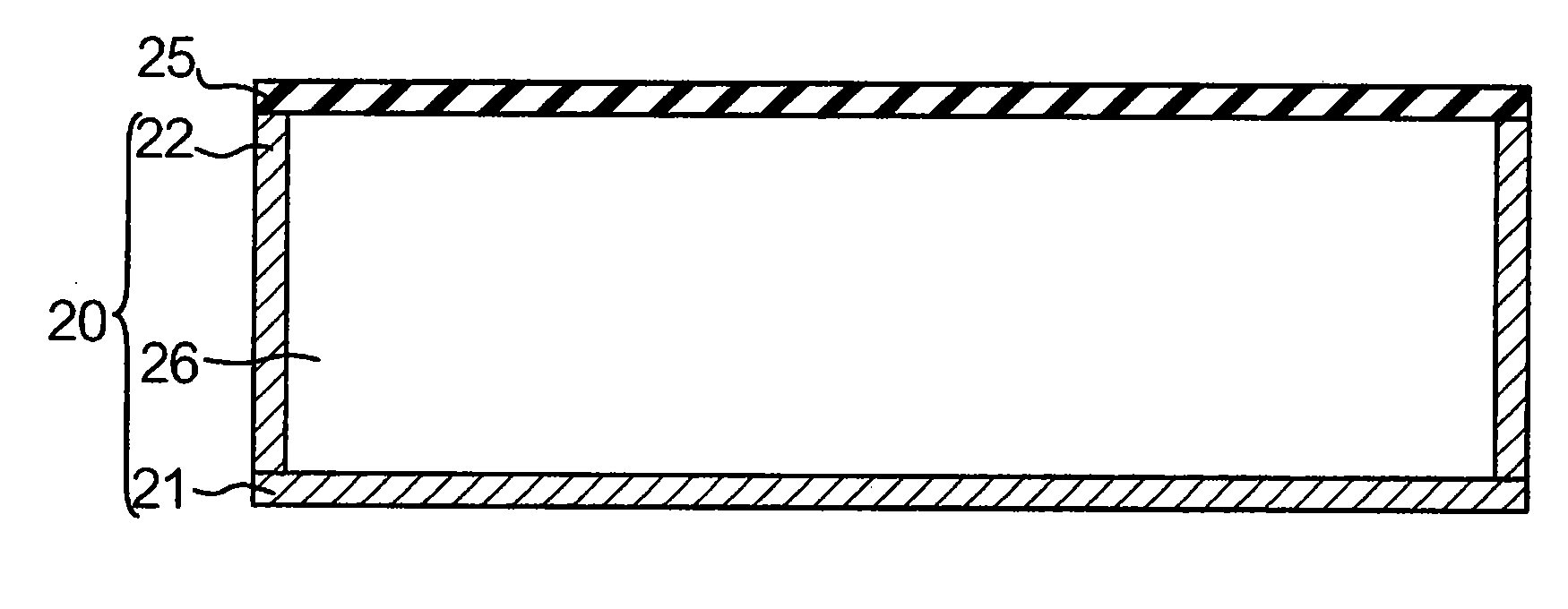

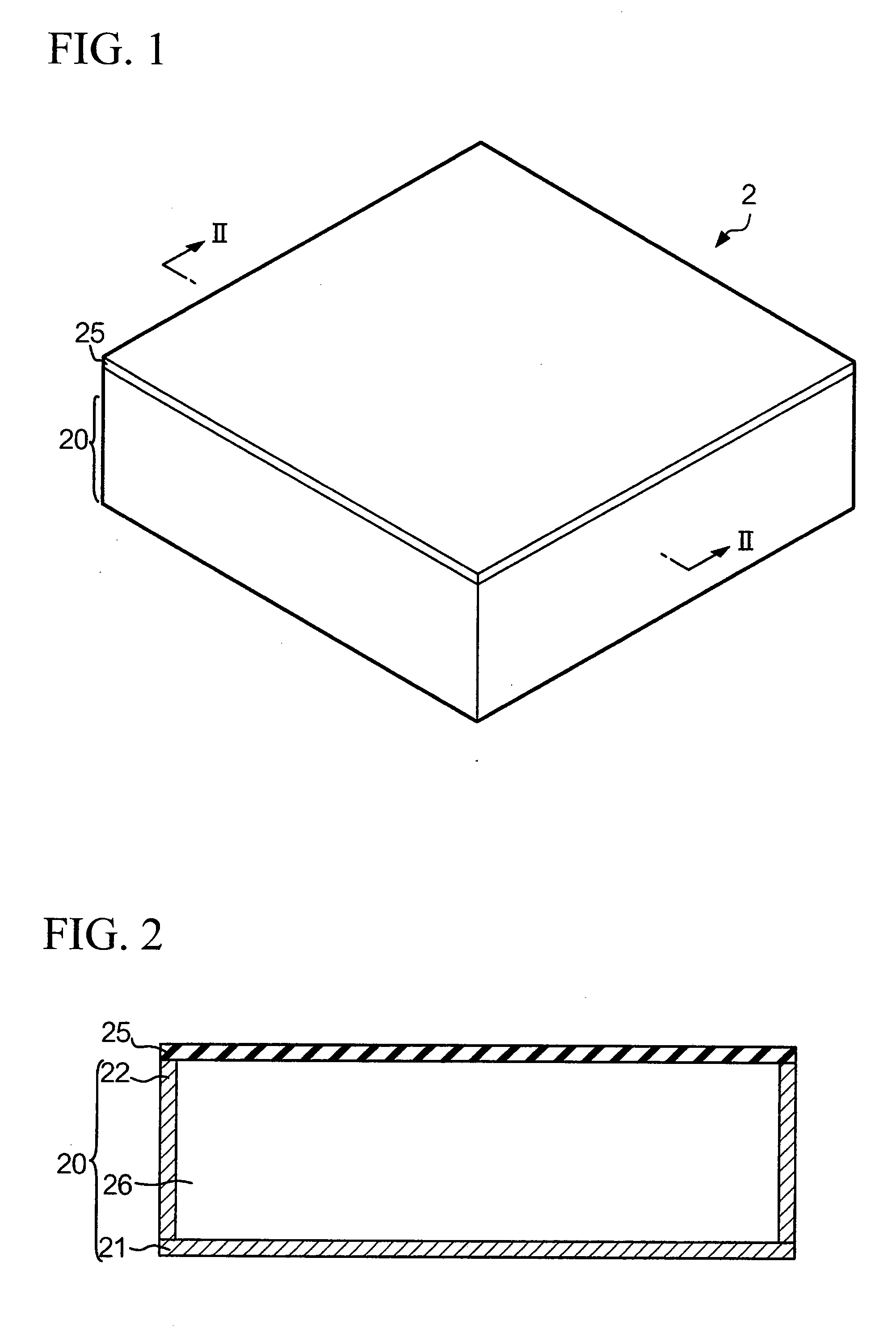

Sound absorbing structure and sound chamber

ActiveUS20090120717A1Effective absorptionReduce thicknessBuilding roofsCeilingsInternal pressureEngineering

A sound absorber is formed by covering the opening of a housing with a vibration member having a flat shape or a film shape so as to define an air layer therebetween. The sound absorber is attached to the wall of a room such that the vibration member is positioned opposite to the wall with a prescribed space therebetween. Sound generated in the room particularly in low frequencies enters into the space between the vibration member and the wall so as to cause vibration of the vibration member due to the pressure difference between the sound pressure applied to the space and the internal pressure of the air layer, thus consuming energy of sound waves. Thus, it is possible to efficiently absorb low-frequency sound with a reduced thickness of the air layer.

Owner:YAMAHA CORP

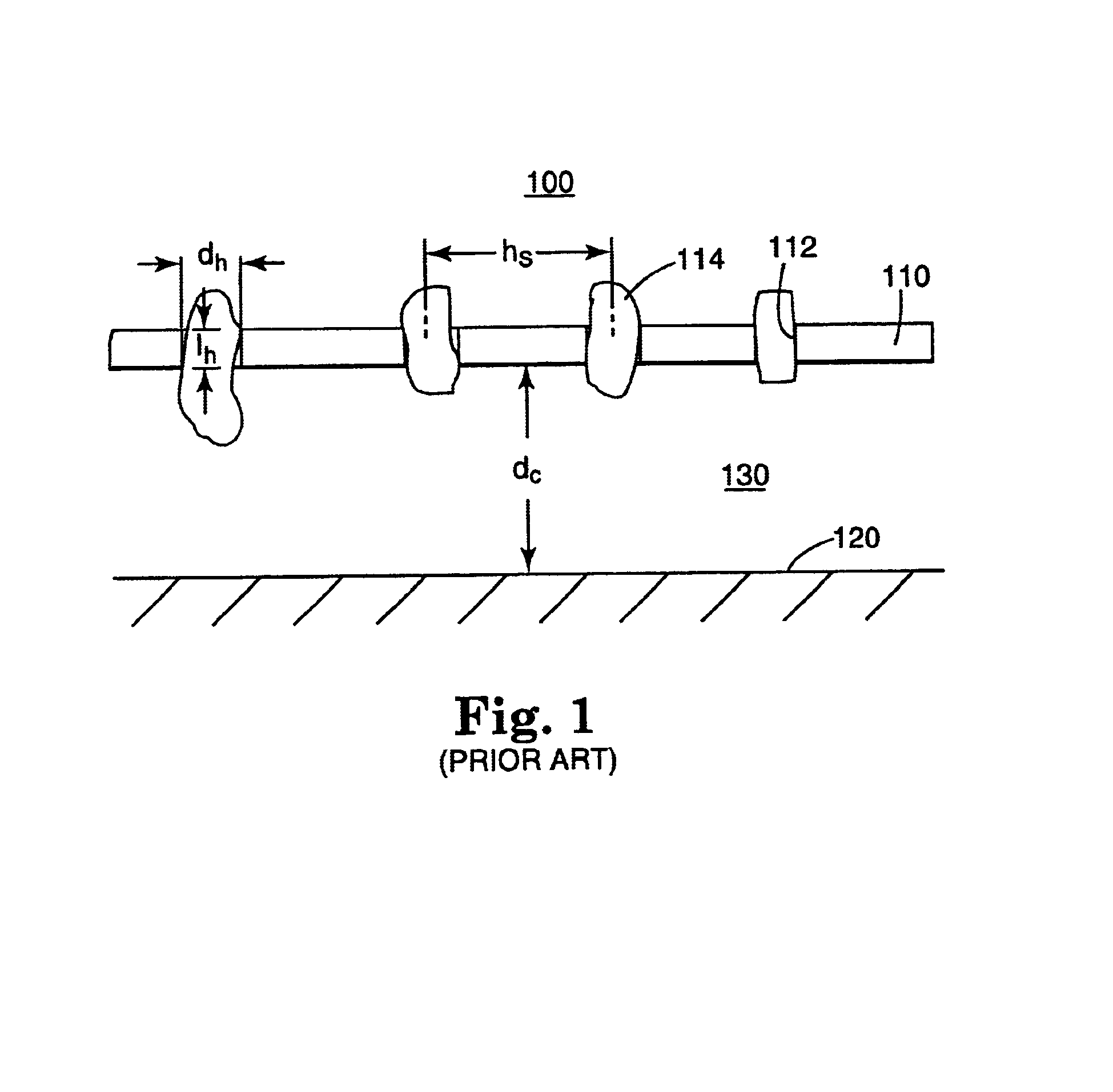

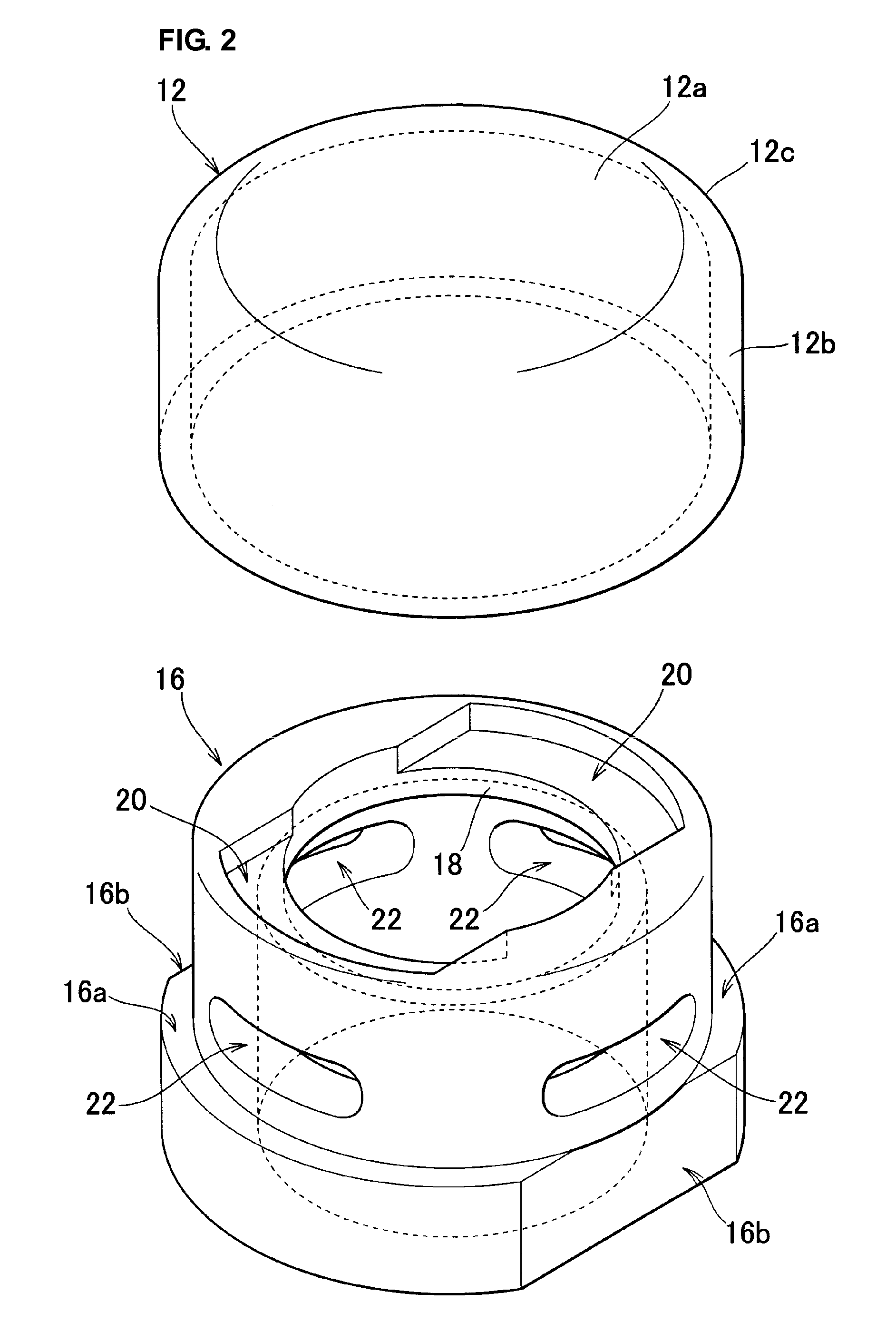

Sound absorber and sound absorbing device

InactiveUS20060260870A1Promote absorptionAttenuate sound wavesCeilingsNoise reduction constructionFiberEngineering

A sound absorber according to the present invention comprises: a tubular porous sheath with a non-circular cylindrical cross-section; a circular cylindrical soft fiber sound absorbent disposed inside the porous sheath in partial contact or non-contact with the porous sheath with the longitudinal direction thereof aligned with the longitudinal direction of the porous sheath; and a bar-like core with a non-circular cylindrical cross-section disposed inside the soft fiber sound absorbent in a partial contact or non-contact with the soft fiber sound absorbent with the longitudinal direction thereof aligned with the longitudinal direction of the soft fiber sound absorbent. A sound absorbing device according to the present invention comprises a plurality of the sound absorbers arranged side by side at specific intervals in two or more rows in a staggered configuration. Alternately, a plurality of sound absorbers having a generally isosceles trapezoidal cross-section are arranged in a row with the upper and lower bases of the isosceles trapezoidal cross-sectional shape thereof exposed to the outside alternately.

Owner:NAGATA KOSAKUSHO CO LTD

Production method of centrifugal glass cotton-like fiber

InactiveCN103130410ALow densityLow thermal conductivityGlass making apparatusChemical reactionCentrifugation

The invention discloses a production method of a centrifugal glass cotton-like fiber. According to the production method of the centrifugal glass cotton-like fiber, materials of quartz sands, orthoclases, limestones, glass cullet, soda ashes, borax and the like are adopted, the materials are mixed in a reasonable proportion, glass liquids can be obtained after physical and chemical reactions through kiln high-temperature melting, and short glass fiber cotton aggregates can be thrown out through high-speed centrifugal injection. Material produced through the production method of the centrifugal glass cotton-like fiber has the advantages of being small in density, low in heat conductivity, high in acoustic absorptivity, flame-resistant, frost-resistant, and not prone to decay. The material is ideal heat preservation and heat insulation material, and is mainly used in the heat insulation process of building rail structures, industrial equipment, and pipe networks, and fireproofing and the like of the buildings. The material can further used as a sound absorber which absorbs and eliminates sounds, sound-absorbing barriers, sound-absorbing wall faces and the like.

Owner:吴振华

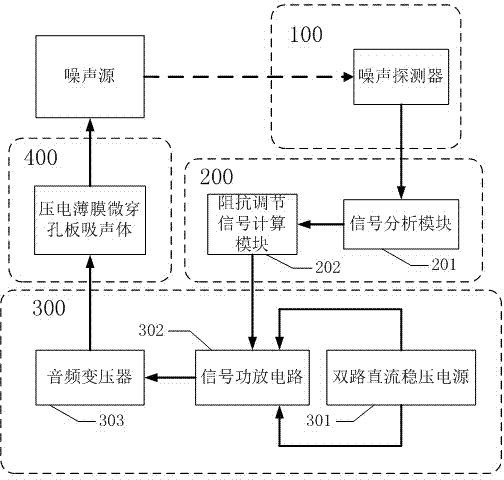

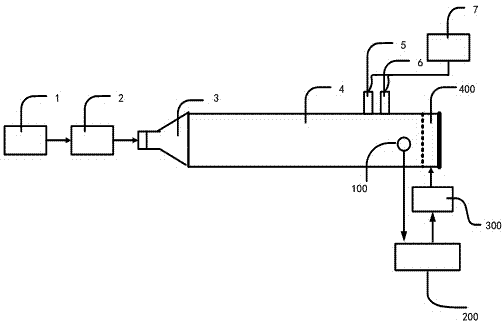

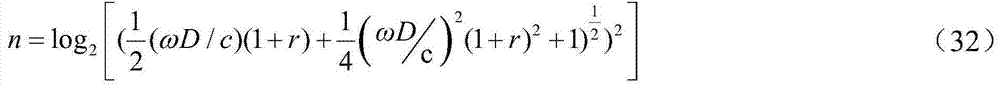

Acoustic impedance adjusting device and method based on self-adaptive micro-perforated panel sound absorber

InactiveCN104715749AReal optimized sound absorption coefficientReal optimized frequency bandSound producing devicesElectricityResonance

The invention relates to an acoustic impedance adjusting device and method based on a self-adaptive micro-perforated panel sound absorber. The acoustic impedance adjusting device comprises a noise detector, a self-adaptive controller, a piezoelectric film drive circuit and a piezoelectric film micro-perforated panel sound absorbing body. According to the acoustic impedance adjusting method, according to incidence noise source signals detected by the noise detector in real time, the self-adaptive controller is utilized for analyzing frequency and sound pressure of the signals, the piezoelectric film drive circuit is controlled to output optimized excitation voltage to drive a piezoelectric film micro-perforated panel to generate certain vibrating speed, and then acoustic impedance of the sound absorber is changed. According to the device and the method, a sound absorbing coefficient of a resonance sound absorbing structure of the micro-perforated panel can be optimized in real time, an effective sound absorbing frequency band of the resonance sound absorbing structure of the micro-perforated panel is greatly expanded, and noise can be reduced according to needs.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

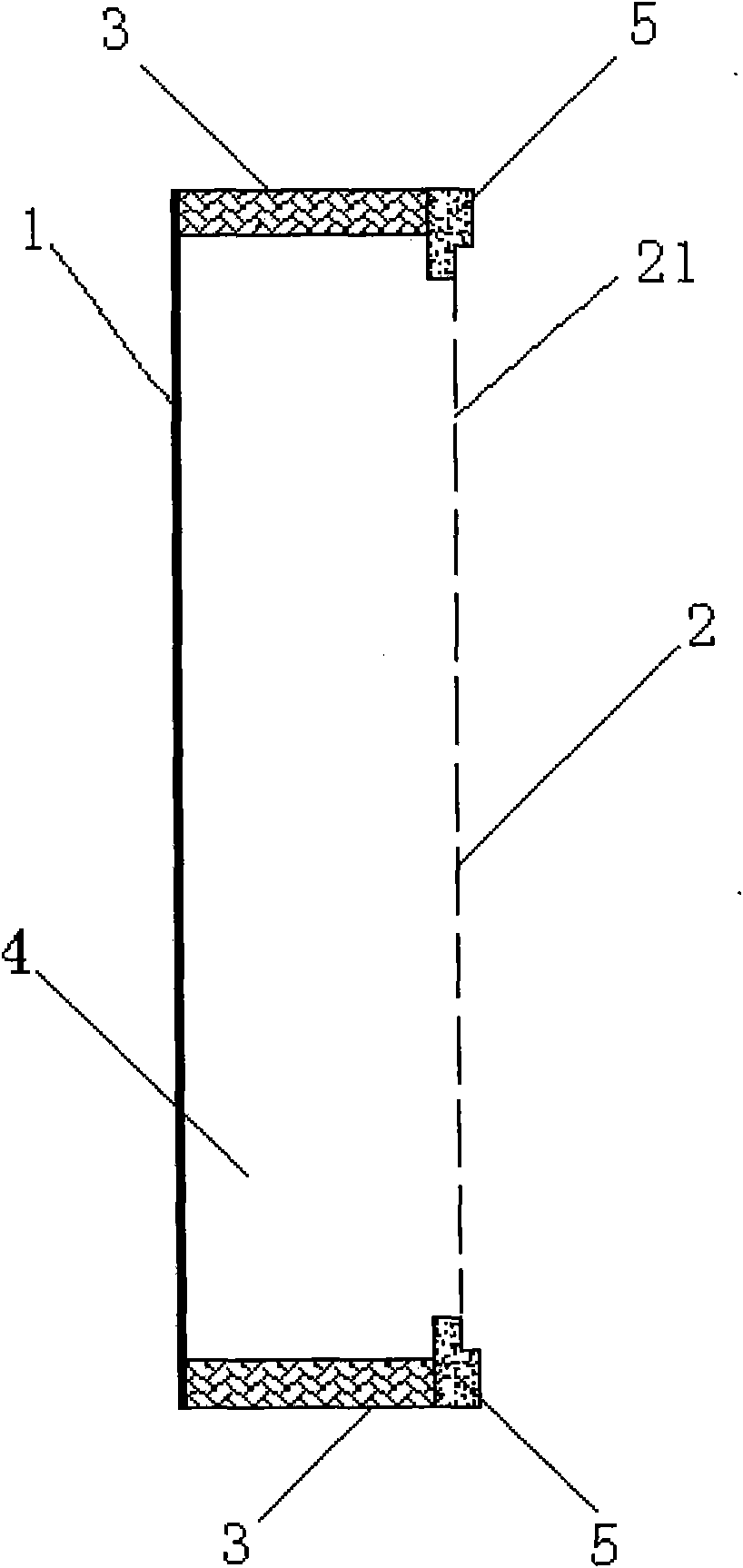

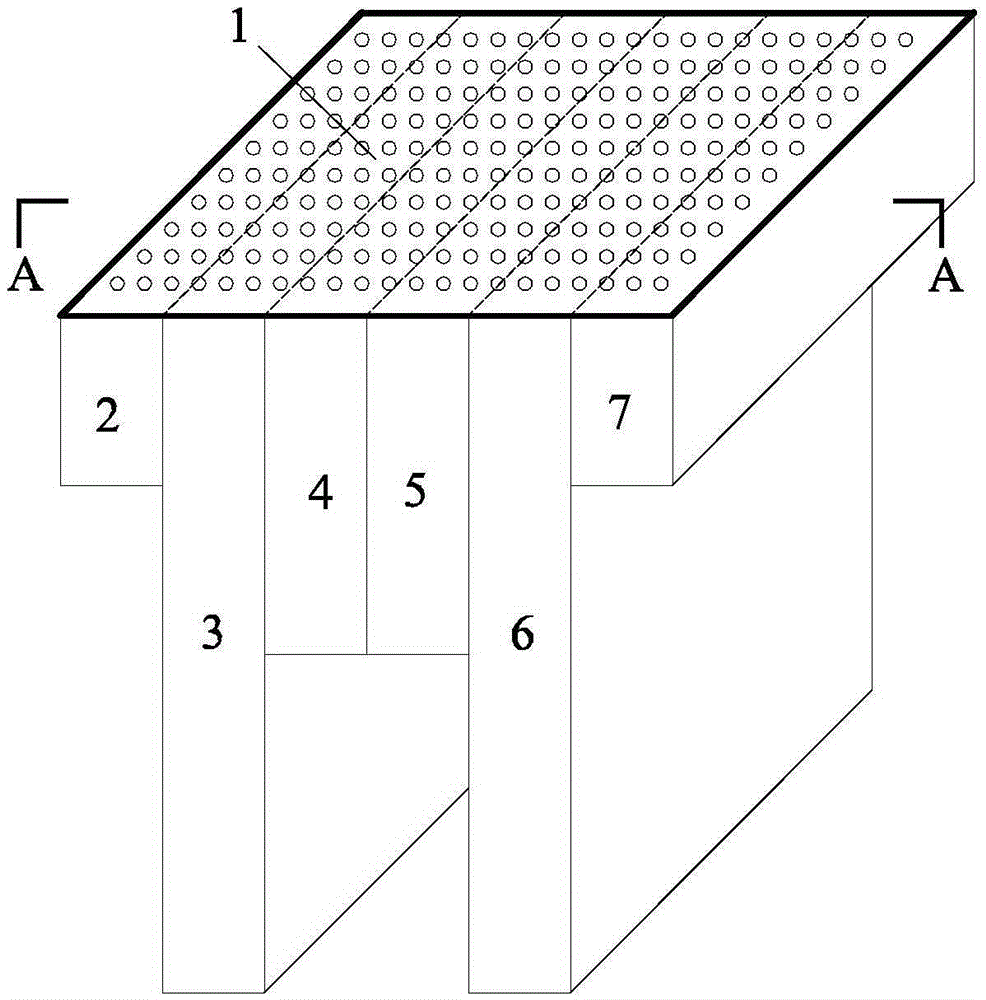

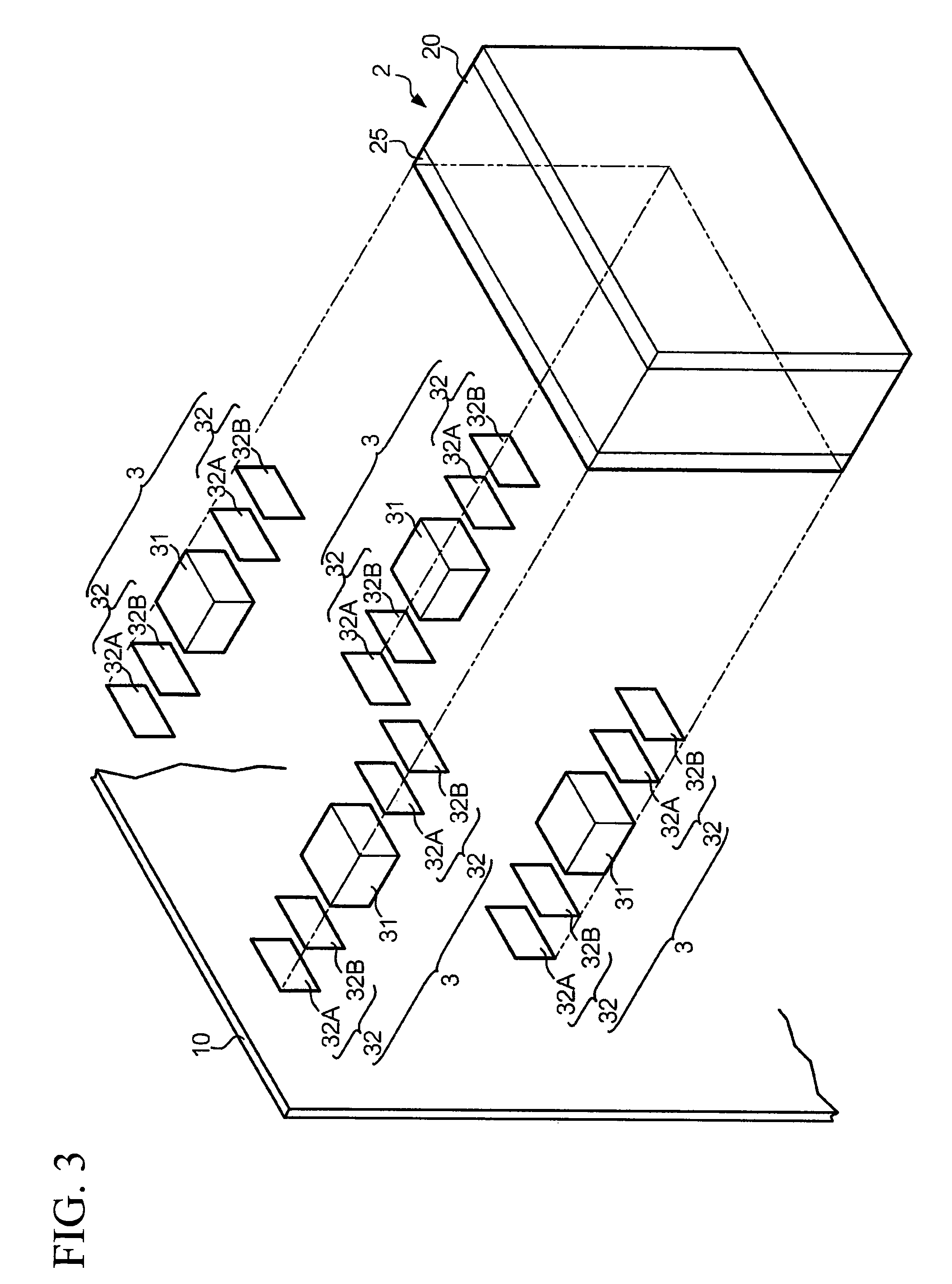

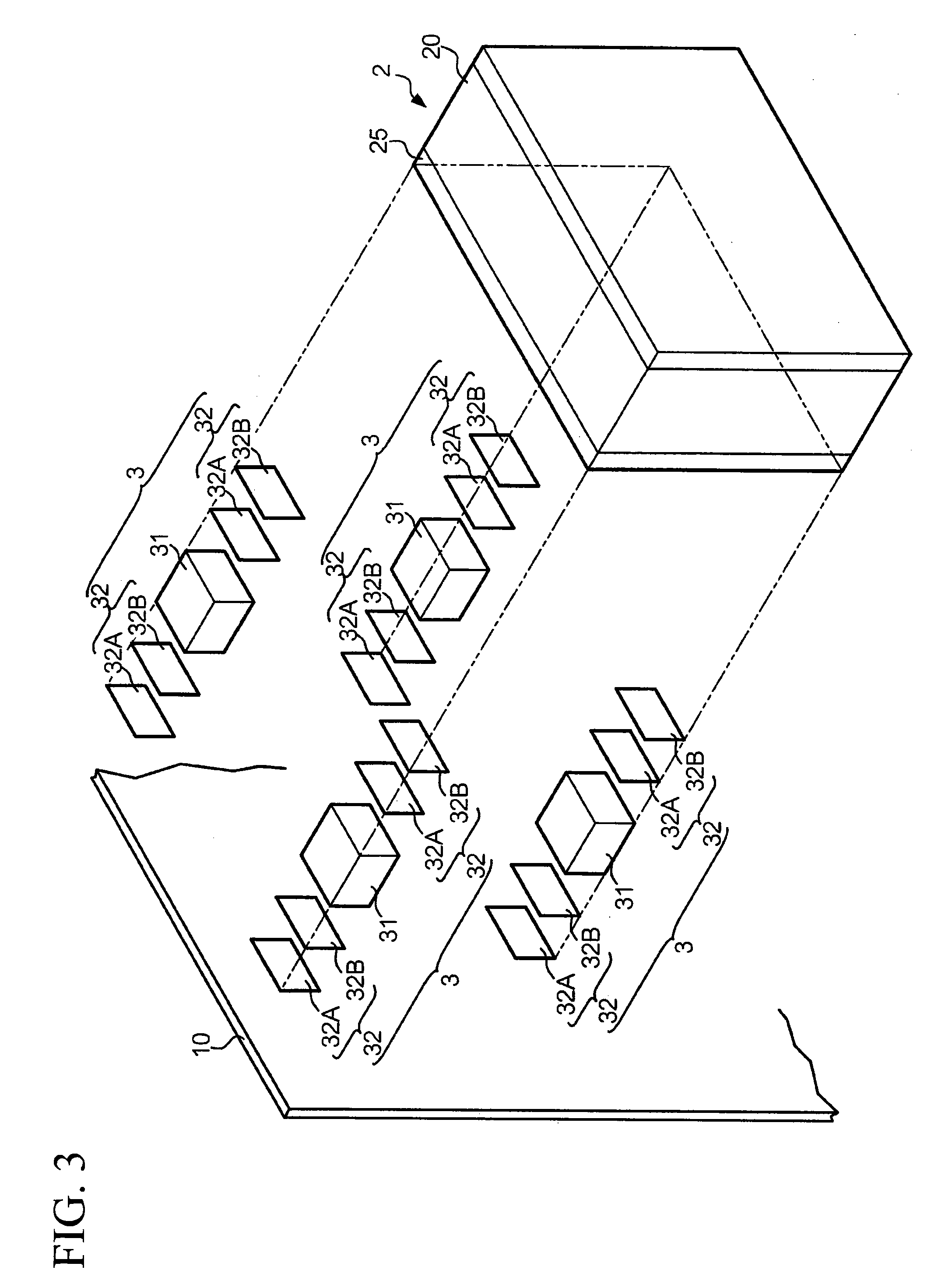

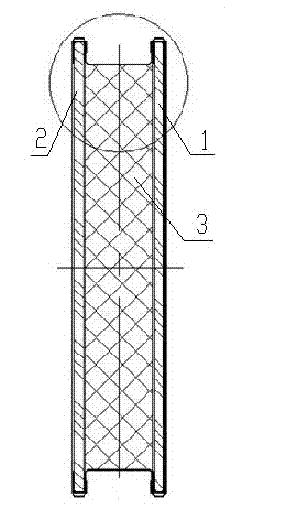

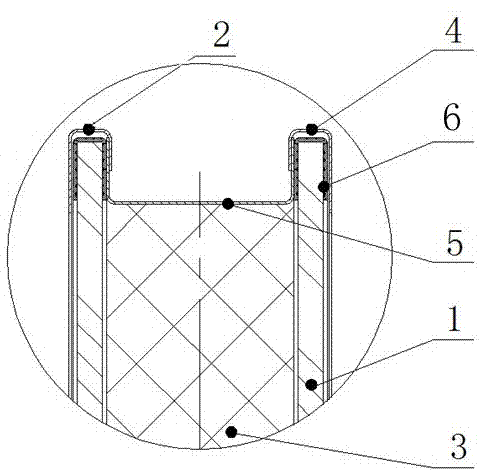

Sound insulation module and sound absorption and insulation composite structure of embedded truss structure with sound insulation module

ActiveCN102828564AEliminate gapsPrevent structural sound leakageWallsSound proofingEngineeringSound Absorber

The invention discloses a sound insulation module which comprises a first sound insulation board (1), a second sound insulation board (2) and sound absorbers (3) arranged between the two sound insulation boards or attached and connected to the surface of the first sound insulation board (1) or second sound insulation board (2). The invention also discloses a sound absorption and insulation composite structure of an embedded truss structure with the sound insulation module. The sound absorption and insulation composite structure comprises truss uprights (9) being embedded in uprights (8) of a plant and being capable of being fixed to the ground, embedded bottom cross beams between bottoms of the truss uprights (9), and a #-shaped truss structure formed by transverse support trusses (11) fixedly connected with the truss uprights (9), and grooves of the sound insulation module are embedded and sleeved on the truss uprights (9) and positioned between the embedded bottom cross beams and the transverse support trusses (11). The insulation composite structure eliminates a gap of a wall body to realize the cutting-off an acoustic bridge, and is good in wall body rigidity and simple in installation procedure.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

Sound absorber with stair-stepping structure

A sound absorber can include a back wall, a plurality of absorber elements disposed on the back wall and arranged periodically in a first direction, and a plurality of frames disposed between the plurality of absorber elements. The plurality of absorber elements can make a periodic meta-surface due to a different thickness. The plurality of absorber elements can be made of a porous material.

Owner:THE HONG KONG UNIV OF SCI & TECH

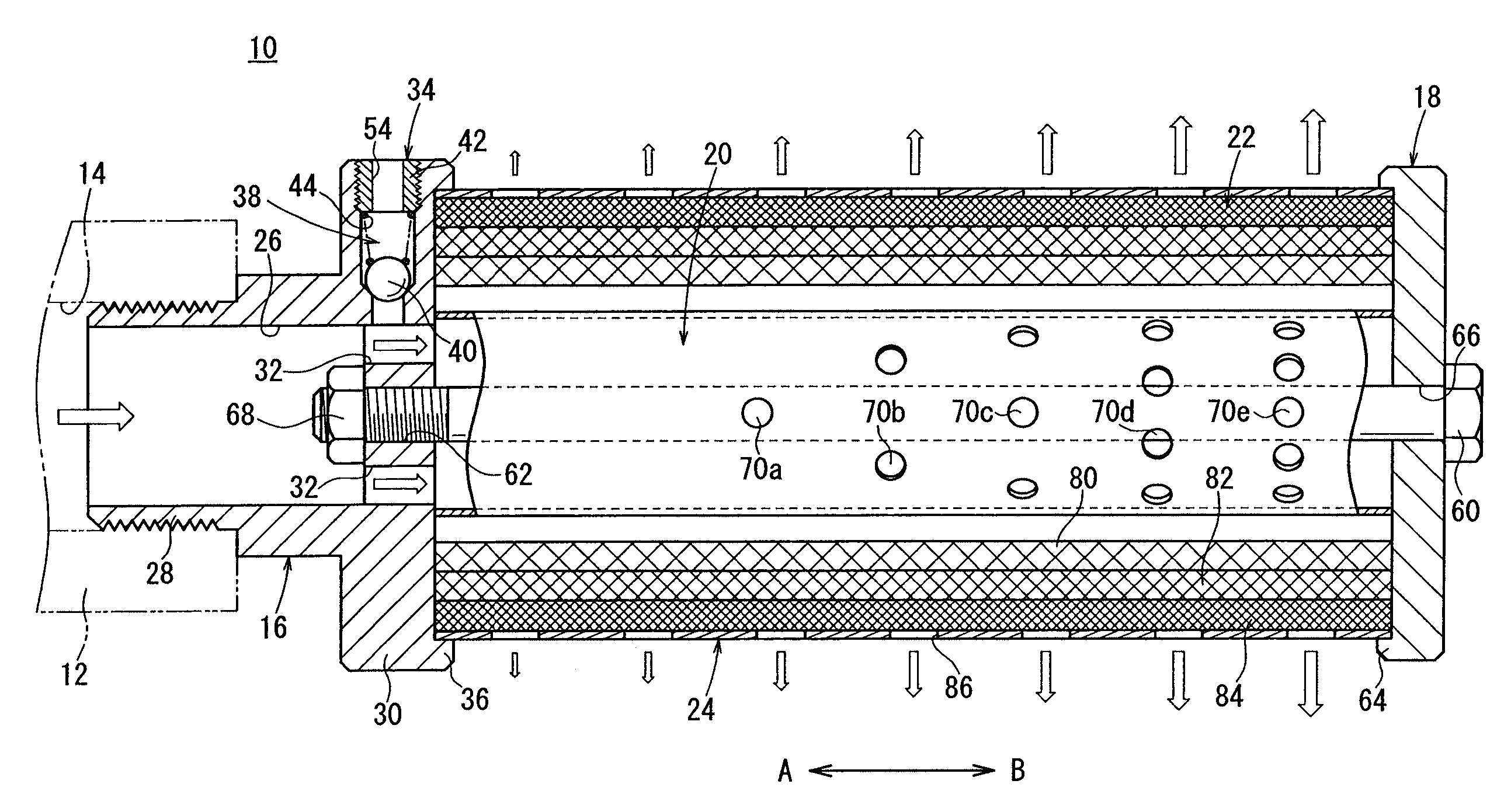

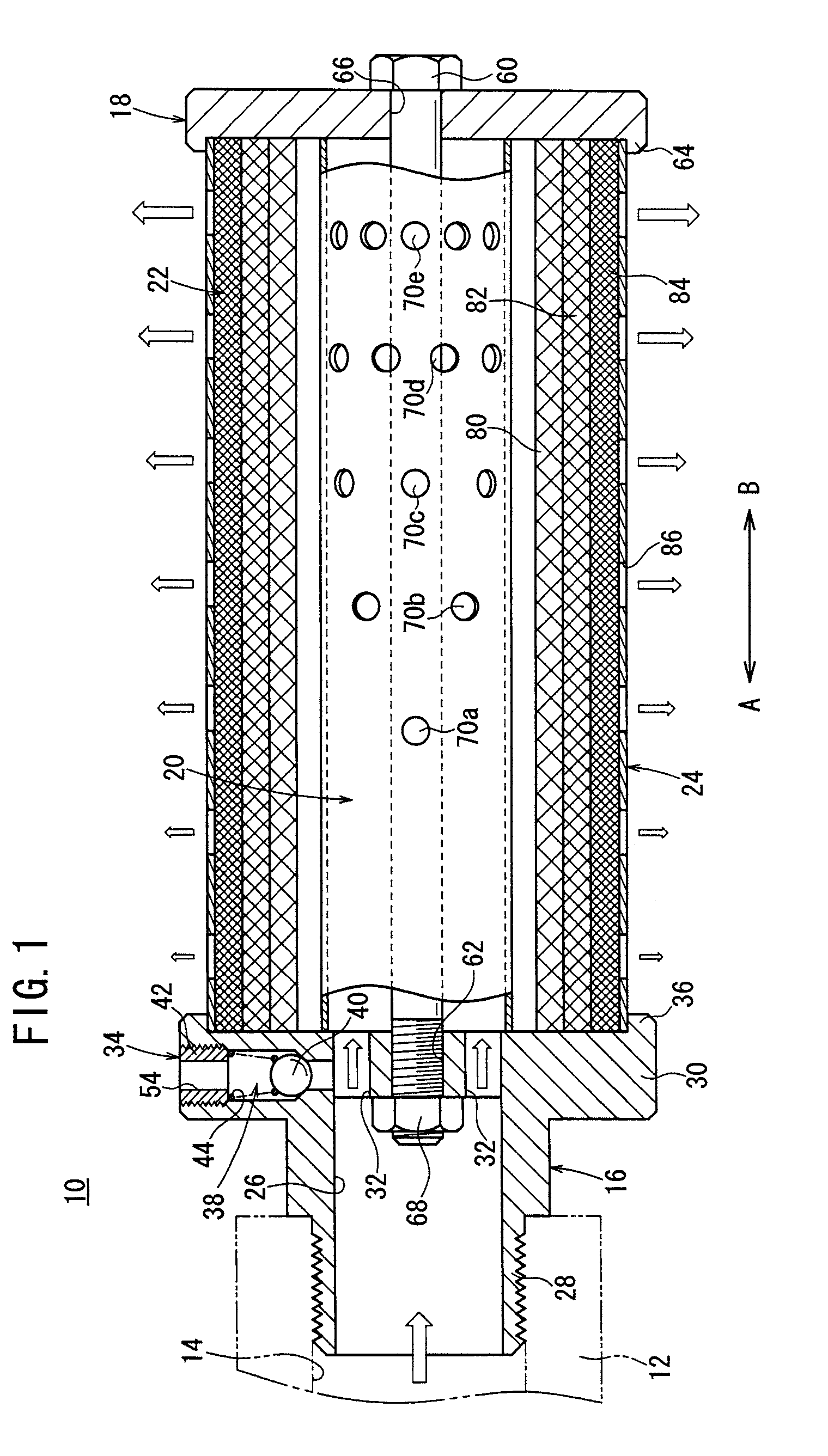

Silencer

ActiveUS20090266643A1Suppress generationReduce exhaust noiseInternal combustion piston enginesPositive displacement pump componentsEngineeringSound Absorber

A silencer includes a cylindrical member held between a body connected to an exhaust side of a fluid pressure device and a disk-shaped retaining member. A net-shaped sound absorber is disposed around an outer circumference of the cylindrical member. A pressure fluid flows from the body into the interior of the cylindrical member and is discharged toward the sound absorber through a plurality of first through fifth exhaust holes formed in the cylindrical member. Accordingly, dust in the pressure fluid is removed by the sound absorber, which is formed of a plurality of stacked filters, and further, the pressure fluid is discharged to the outside after exhaust noises have been absorbed by the sound absorber.

Owner:SMC CORP

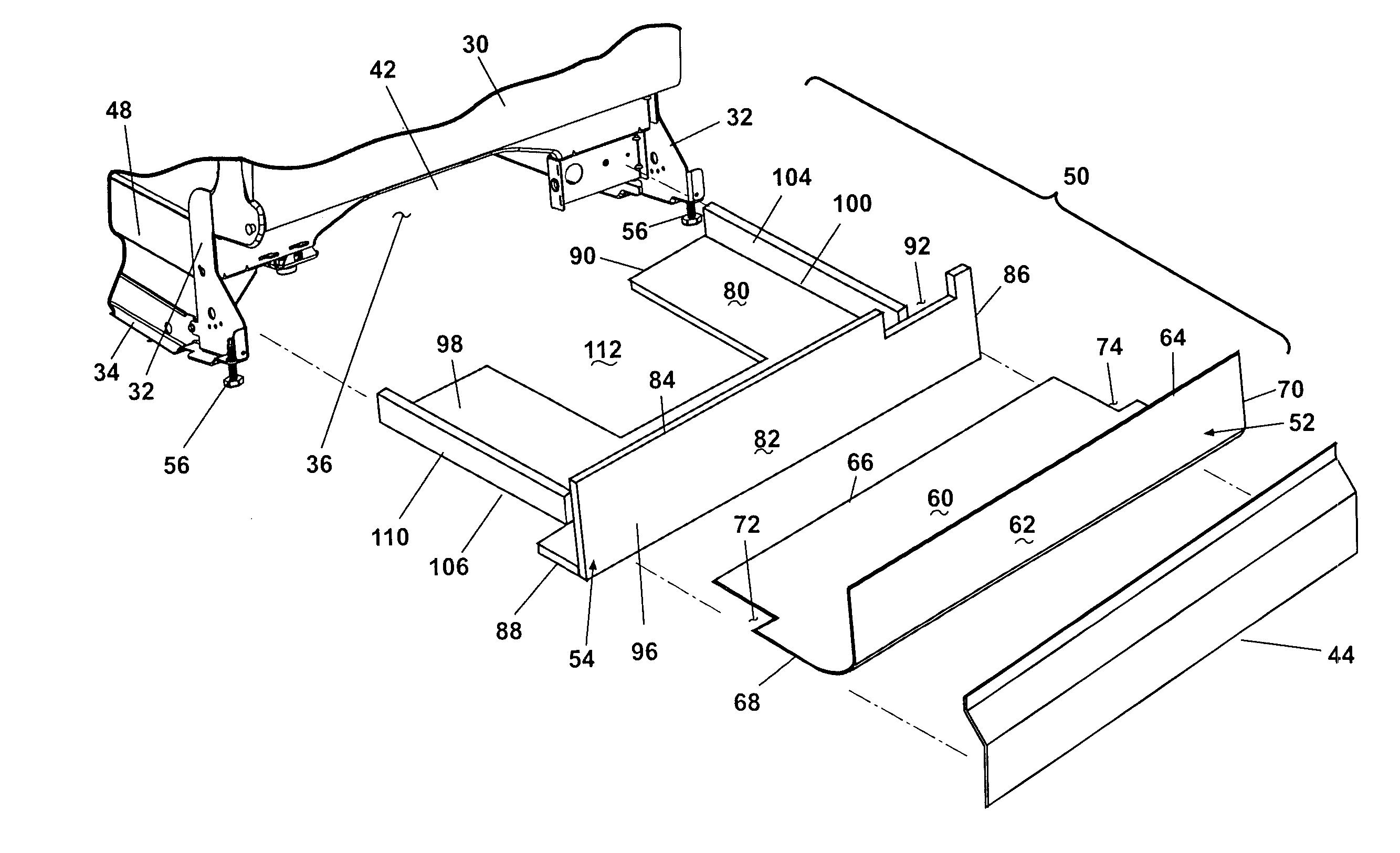

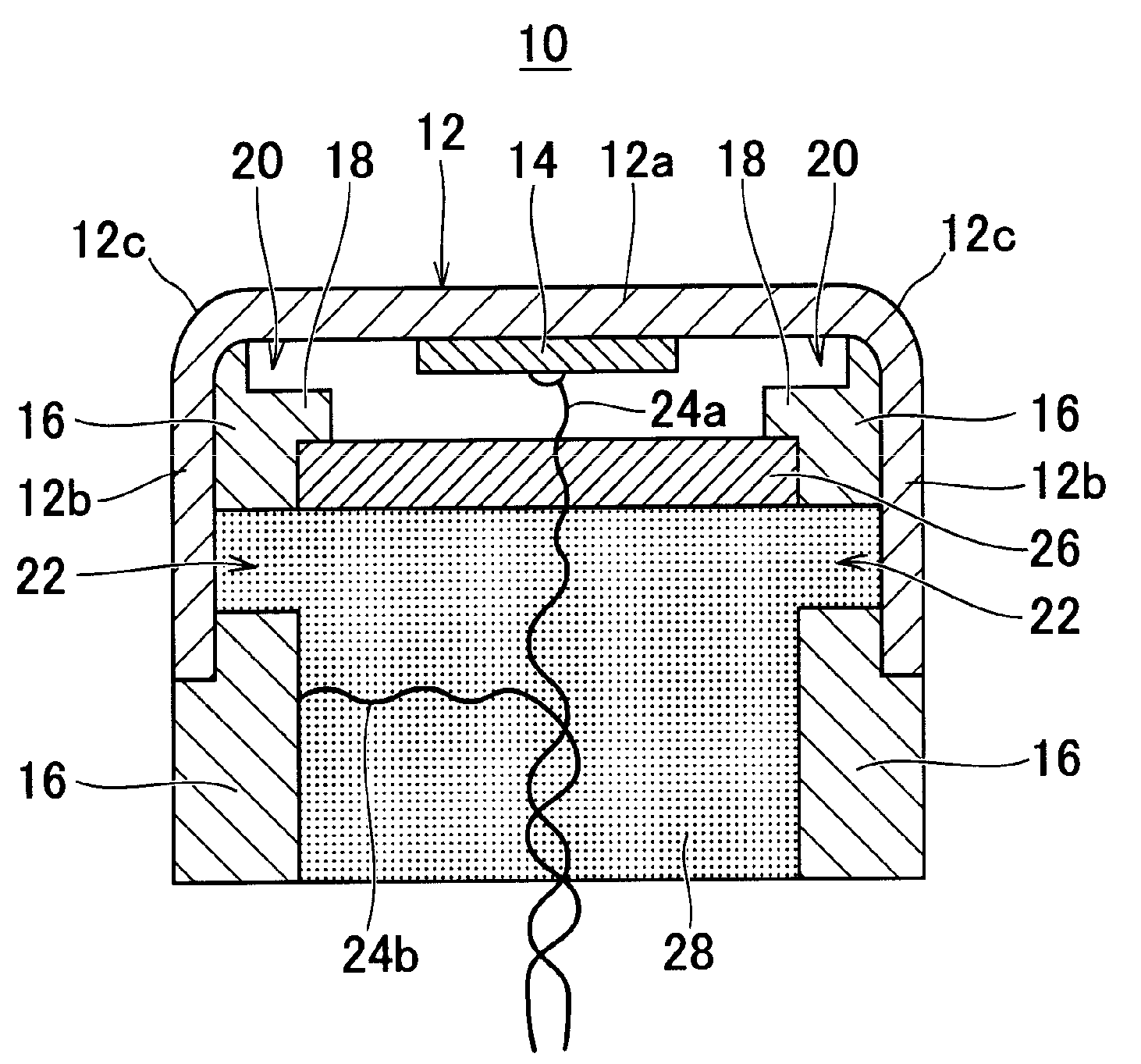

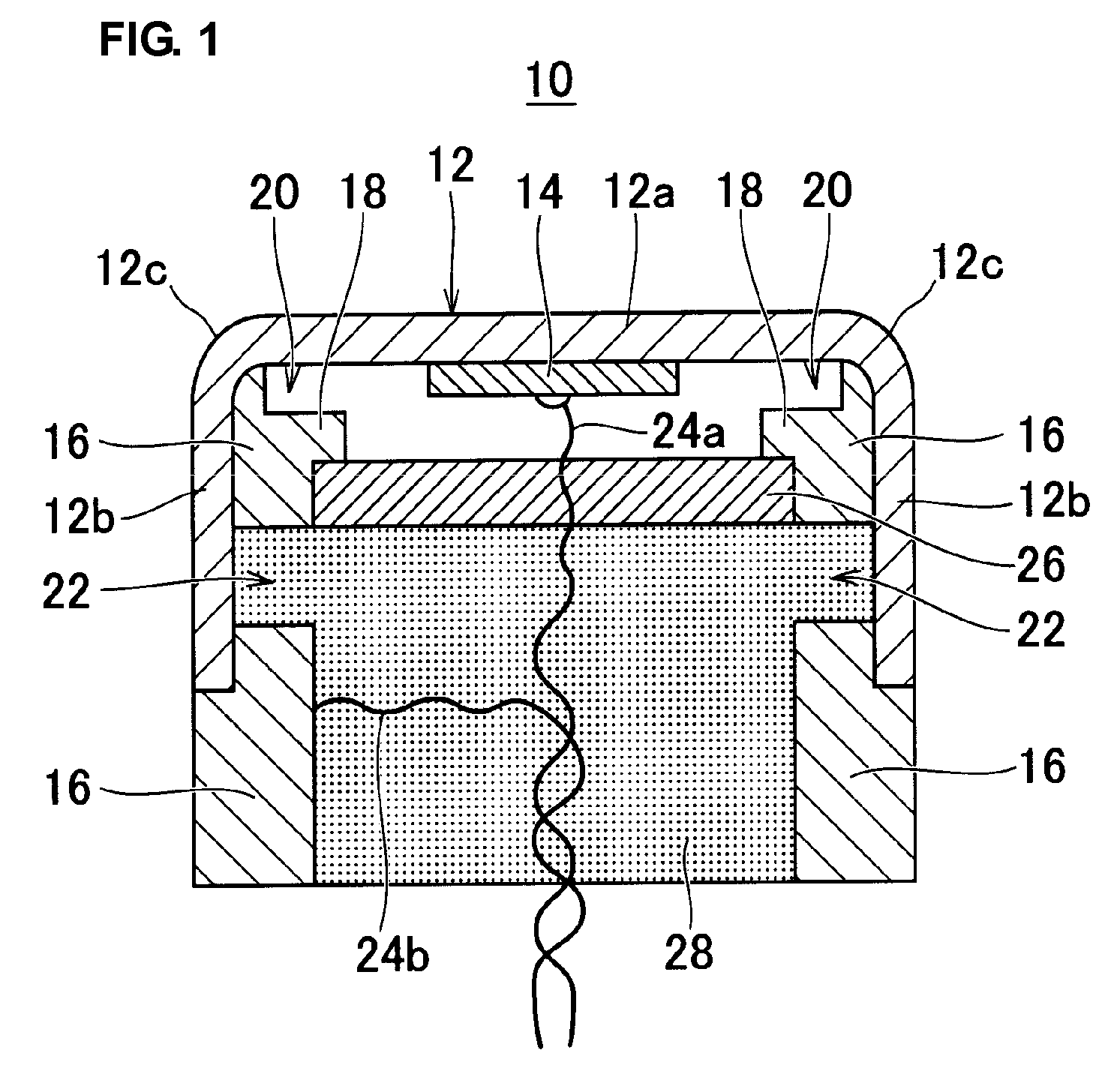

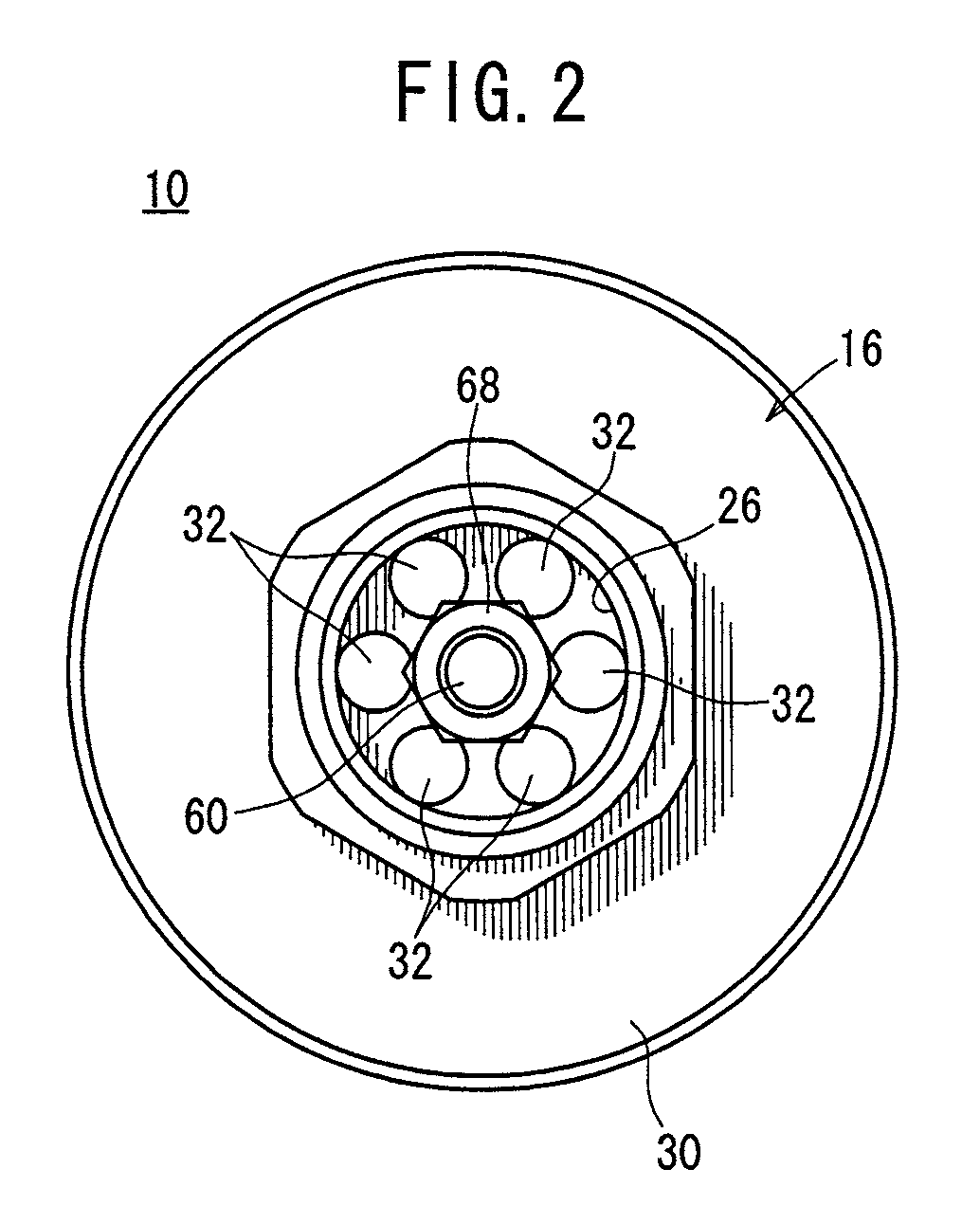

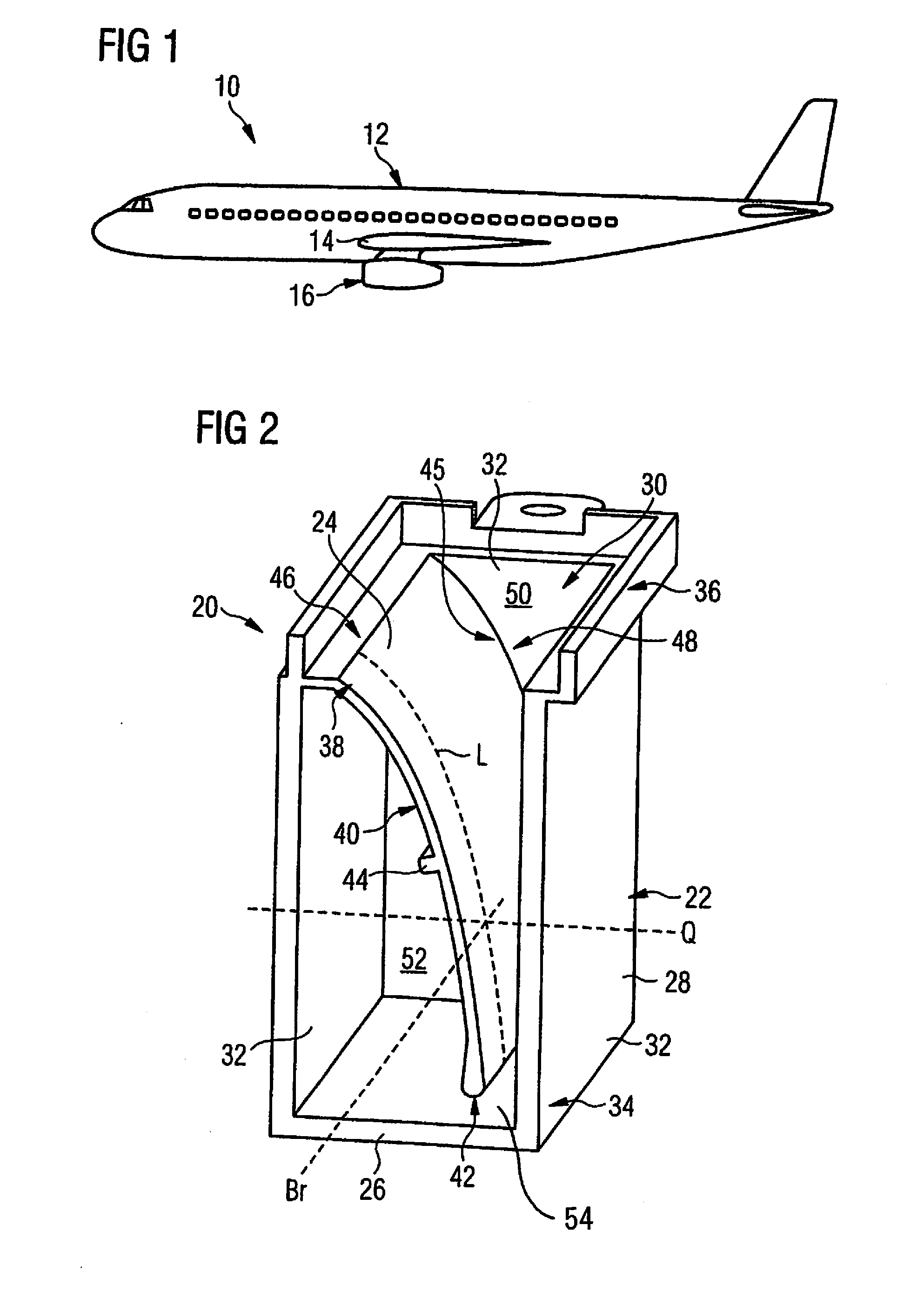

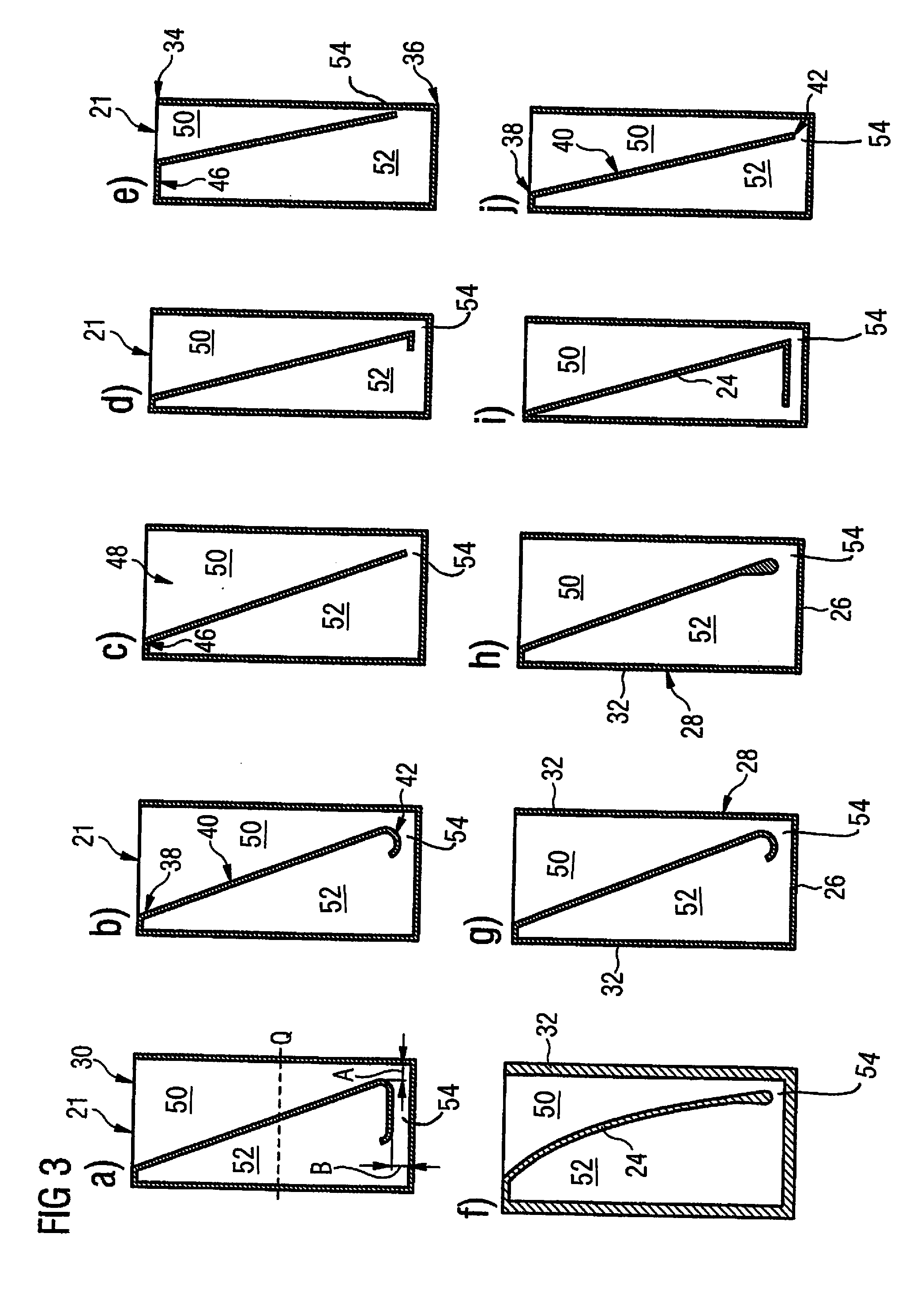

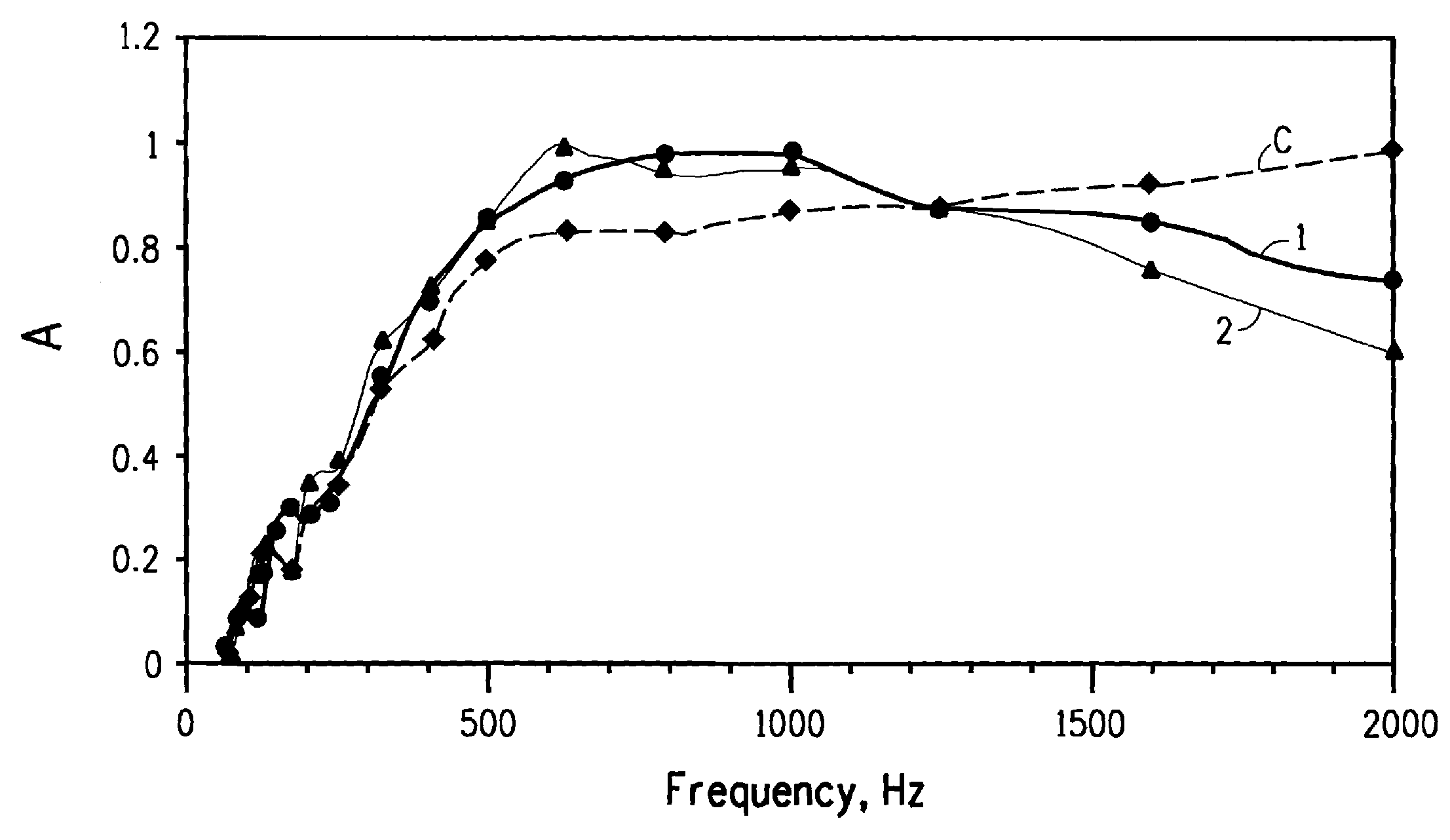

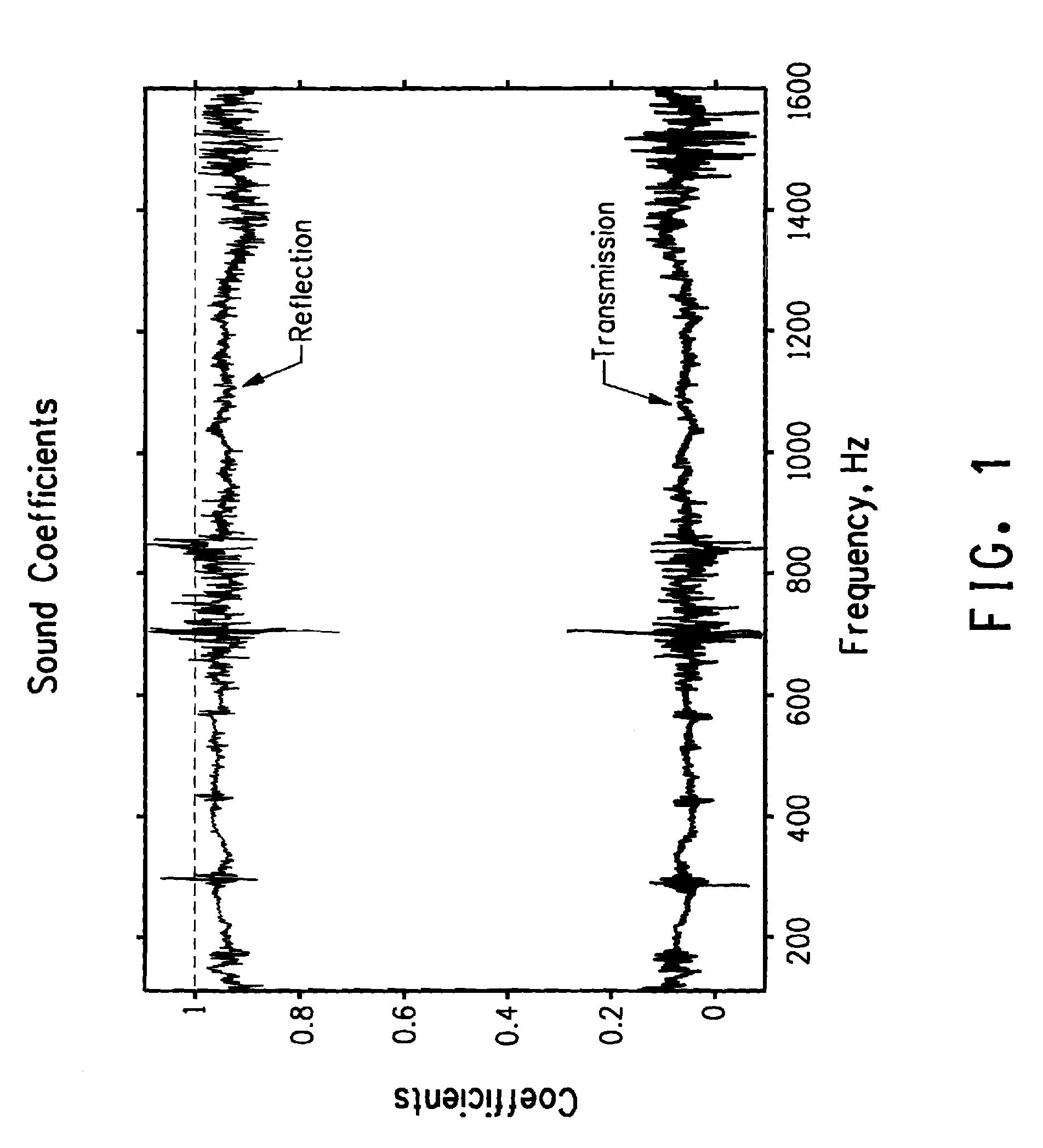

Sound absorber, sound absorber assembly and an engine with a sound absorber assembly

ActiveUS20150060194A1Good adhesionEasy disposalEngine manufactureEngine fuctionsEngineeringSound Absorber

A sound absorber comprising a base body and a tongue (24). The base body has a bottom plate, a wall enclosing the bottom plate and an opening enabling the entry of air into the base body. The tongue has a fixed end, a free end and a central portion disposed between the fixed and the free end. The free end of the tongue is spaced from the wall and the bottom plate, and the central portion of the tongue is disposed to extend at least partially straight along a width direction. Furthermore, a sound absorber assembly can include at least two sound absorbers, and an engine, in particular, for an aircraft, comprising such a sound absorber and / or such a sound absorber assembly.

Owner:AIRBUS DEFENCE & SPACE +1

Acoustic absorber with barrier facing

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com