Acoustic impedance adjusting device and method based on self-adaptive micro-perforated panel sound absorber

A technology of micro-perforated plates and adjustment devices, which is applied in the direction of sound-generating devices and instruments, and can solve the problems of increasing structural complexity, space distance limitation, increasing material and processing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings. The present invention is applicable to single-layer or multi-layer piezoelectric film micro-perforated sound absorbers:

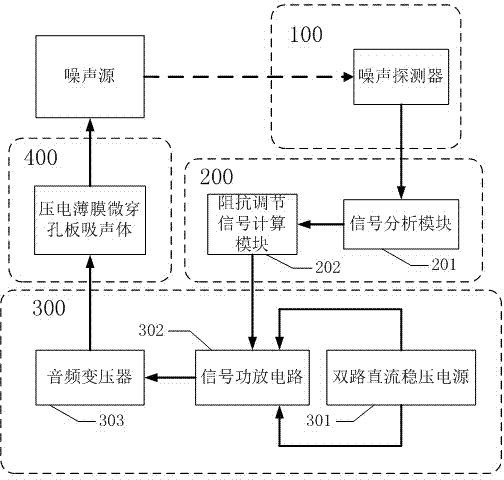

[0048] like figure 1 An acoustic impedance adjustment device based on an adaptive micro-perforated plate sound absorber is shown, the adjustment device includes a noise detector 100, an adaptive controller 200, a piezoelectric film driving circuit 300 and a piezoelectric film micro-perforated plate sound absorption Body 400. The adaptive controller 200 includes a signal analysis module 201 and an impedance adjustment signal calculation module 202 . The piezoelectric film driving circuit 300 includes a dual-channel DC regulated power supply 301 , a signal power amplifier circuit 302 and an audio transformer 303 . The dual-channel DC regulated power supply 301 is used to supply power to the signal power amplifier circuit 302 . The piezoelectric film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com