Micro-perforated plate with resonant sound absorption structure

A micro-perforated plate and resonant sound-absorbing technology, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of inconvenient production and use, and achieve the effect of widening the sound-absorbing frequency band and high sound-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

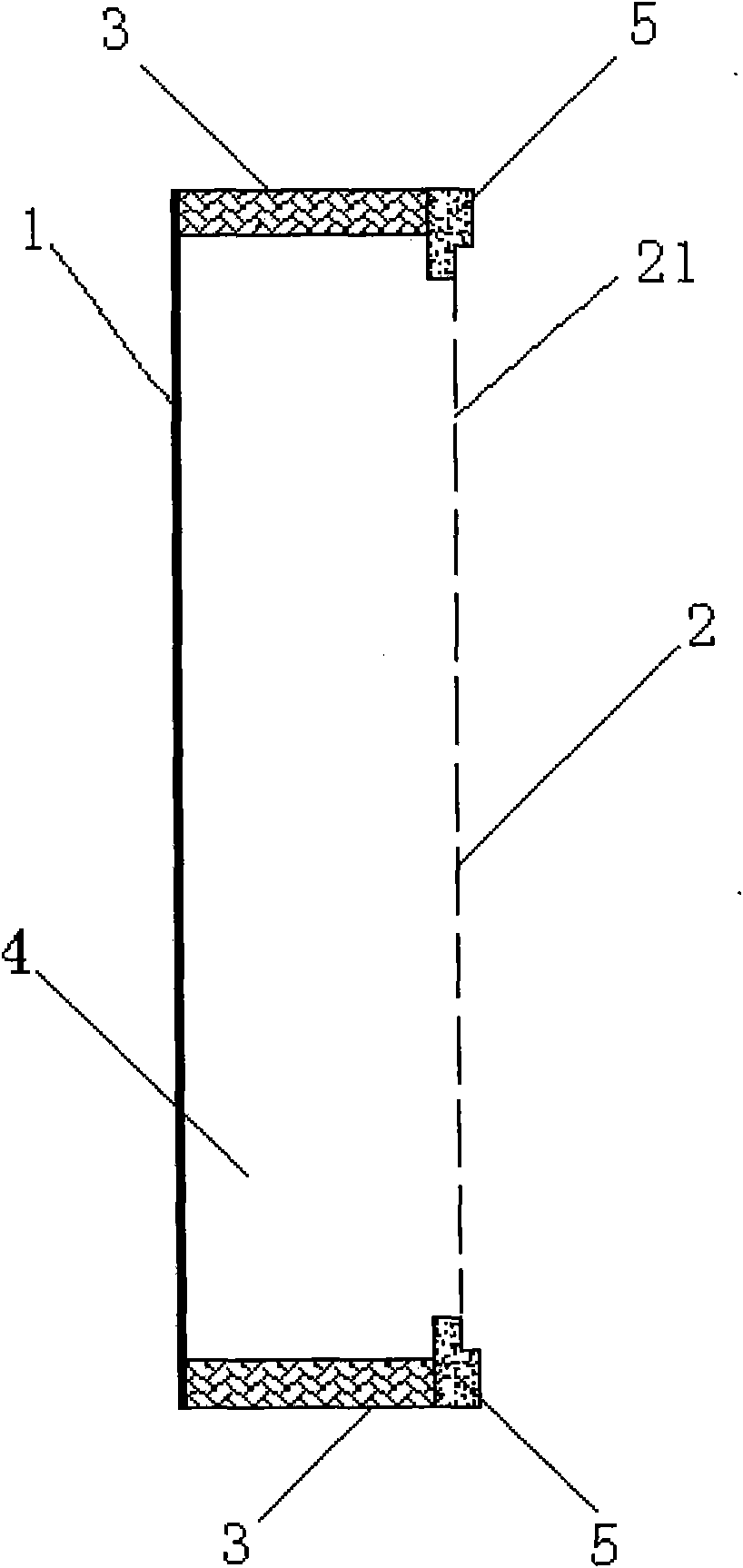

[0013] Such as figure 1 As shown, the micro-perforated plate with a resonant sound-absorbing structure in Embodiment 1 includes a rigid wall 1, a micro-perforated plate 2, two rigid sides 3 arranged at both ends of the rigid wall 1, and between the rigid wall 1 and the micro-perforated plate 2 The cavities 4 and flexible or elastic materials 5 respectively provided at both ends of the micro-perforated plate 2 are used to connect the rigid sides 3 . The composition of the flexible or elastic material 5 includes materials such as polymer flexible sound-absorbing materials, springs and soft rubber, forming a flexible or elastic connection between the micro-perforated plate 2 and the rigid side 3 .

[0014] In this embodiment, the rigid wall 1 is mostly a conventional rigid material, which is used to support the micro-perforated plate with a resonant sound-absorbing structure, and if necessary, a supporting framework needs to be provided inside the rigid wall 1 . The materials of...

Embodiment 2

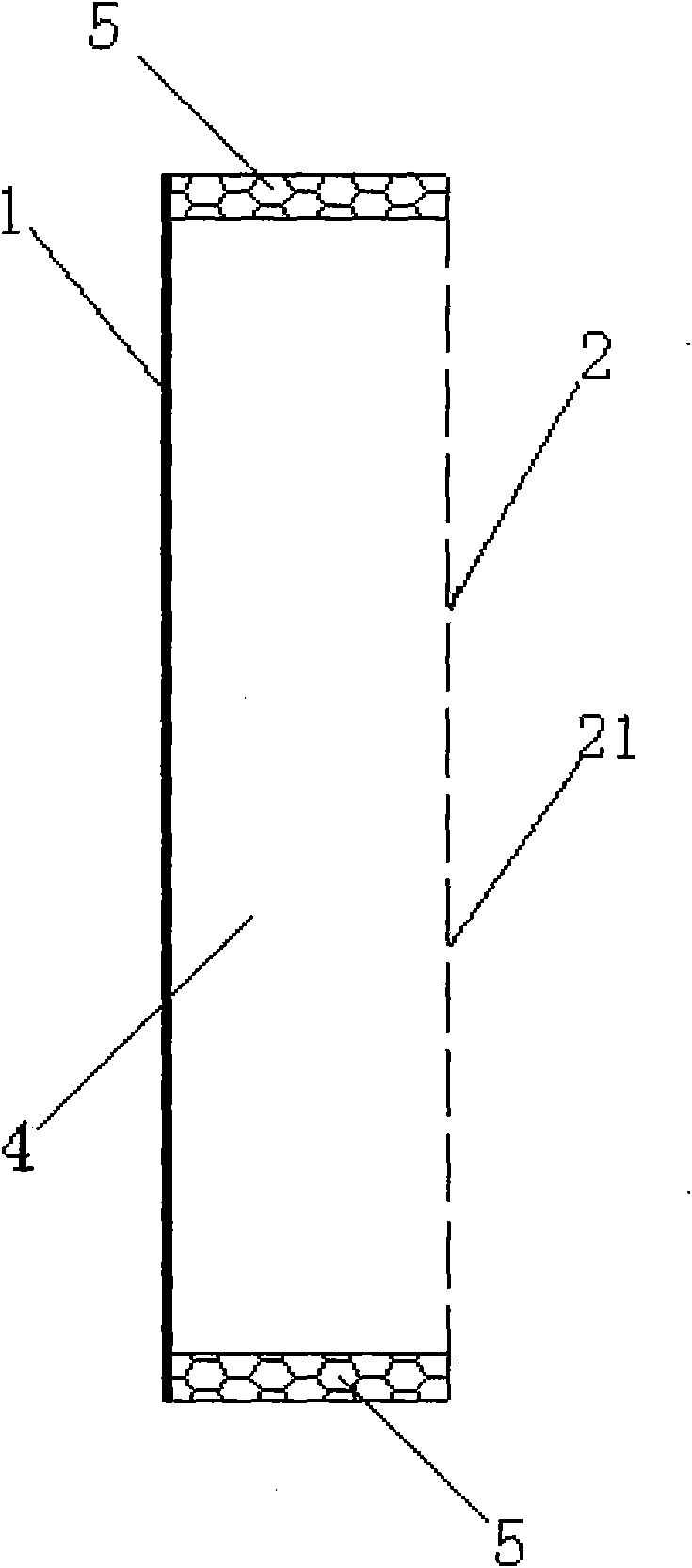

[0017] Such as figure 2 As shown, the micro-perforated plate with a resonant sound-absorbing structure in Embodiment 2 includes a rigid wall 1, a micro-perforated plate 2, a cavity 4 between the rigid wall 1 and the micro-perforated plate 2, and the two ends of the rigid wall 1 are connected to the The two ends of the corresponding micro-perforated plates 2 are directly connected by flexible or elastic materials 5 . The composition of the flexible or elastic material 5 includes polymer flexible sound-absorbing materials, springs, soft rubber and other materials, forming a flexible or elastic connection between the micro-perforated plate 2 and the rigid side 3 .

[0018] In this embodiment, the rigid wall 1 is mostly a conventional rigid material, which is used to support the micro-perforated plate with a resonant sound-absorbing structure, and if necessary, a supporting framework needs to be provided inside the rigid wall 1 . The materials of the micro-perforated plate 2 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com