Patents

Literature

40results about How to "To achieve the absorption effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

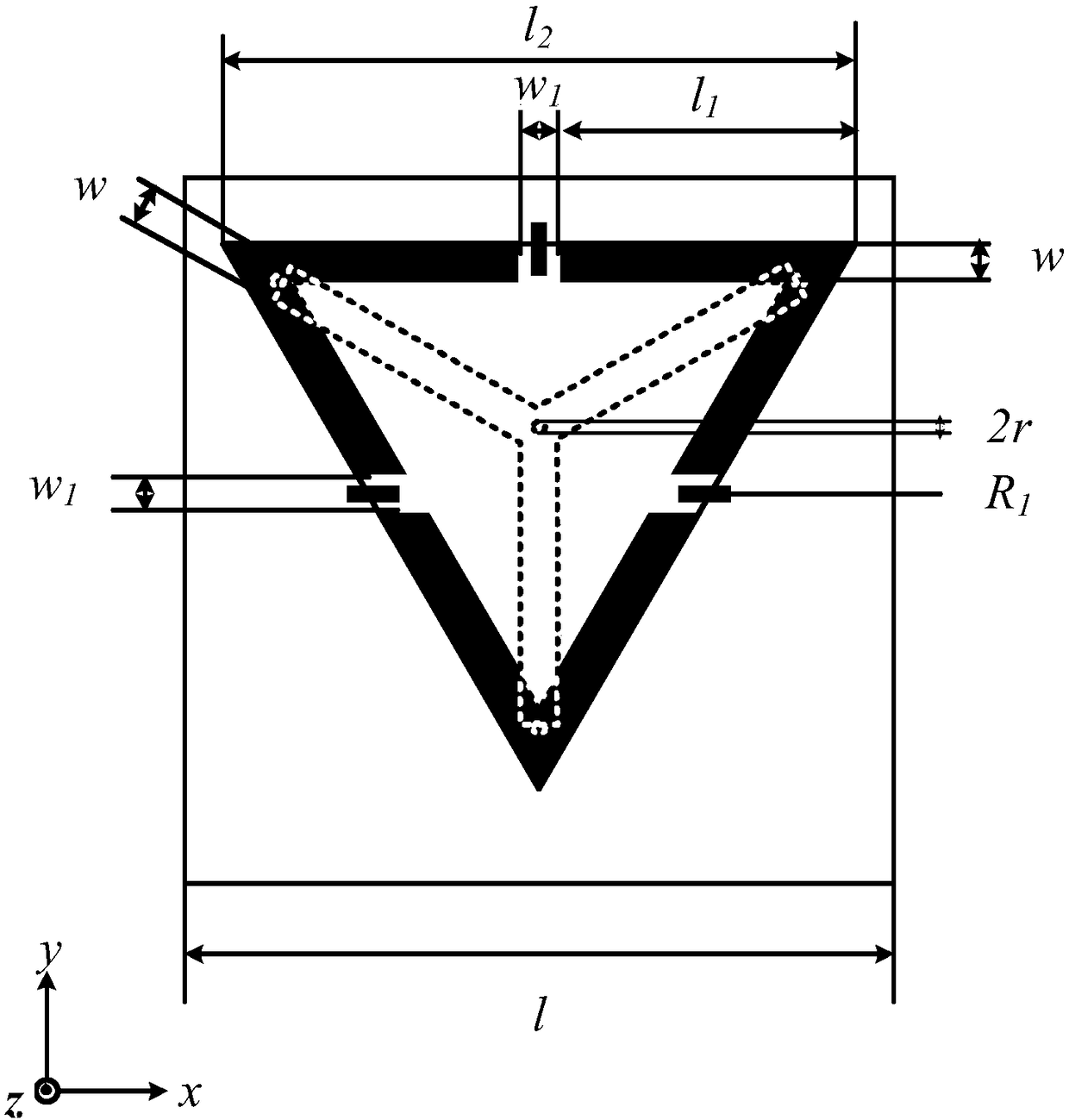

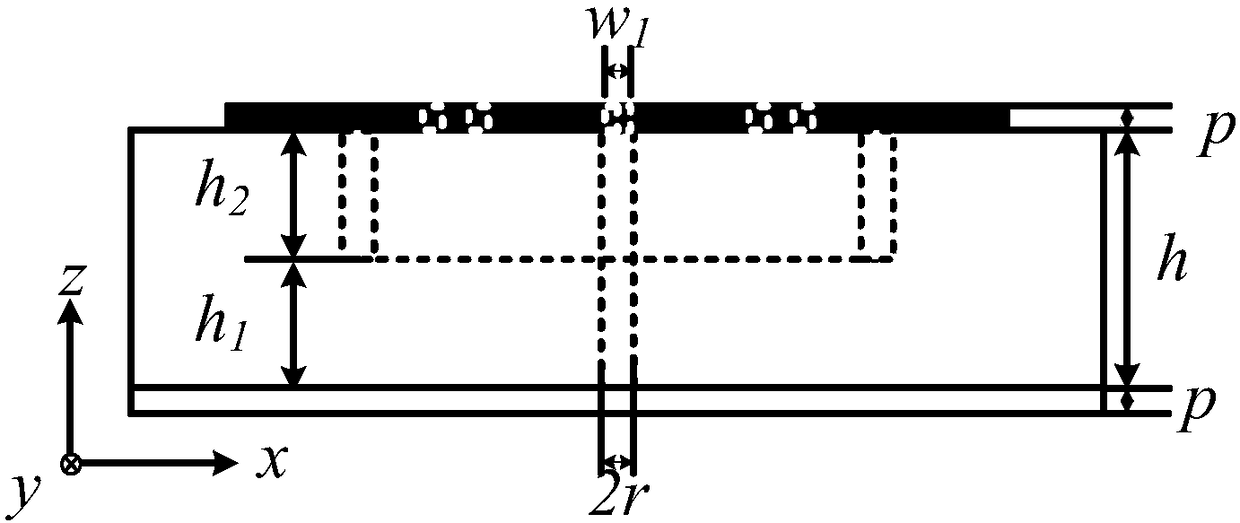

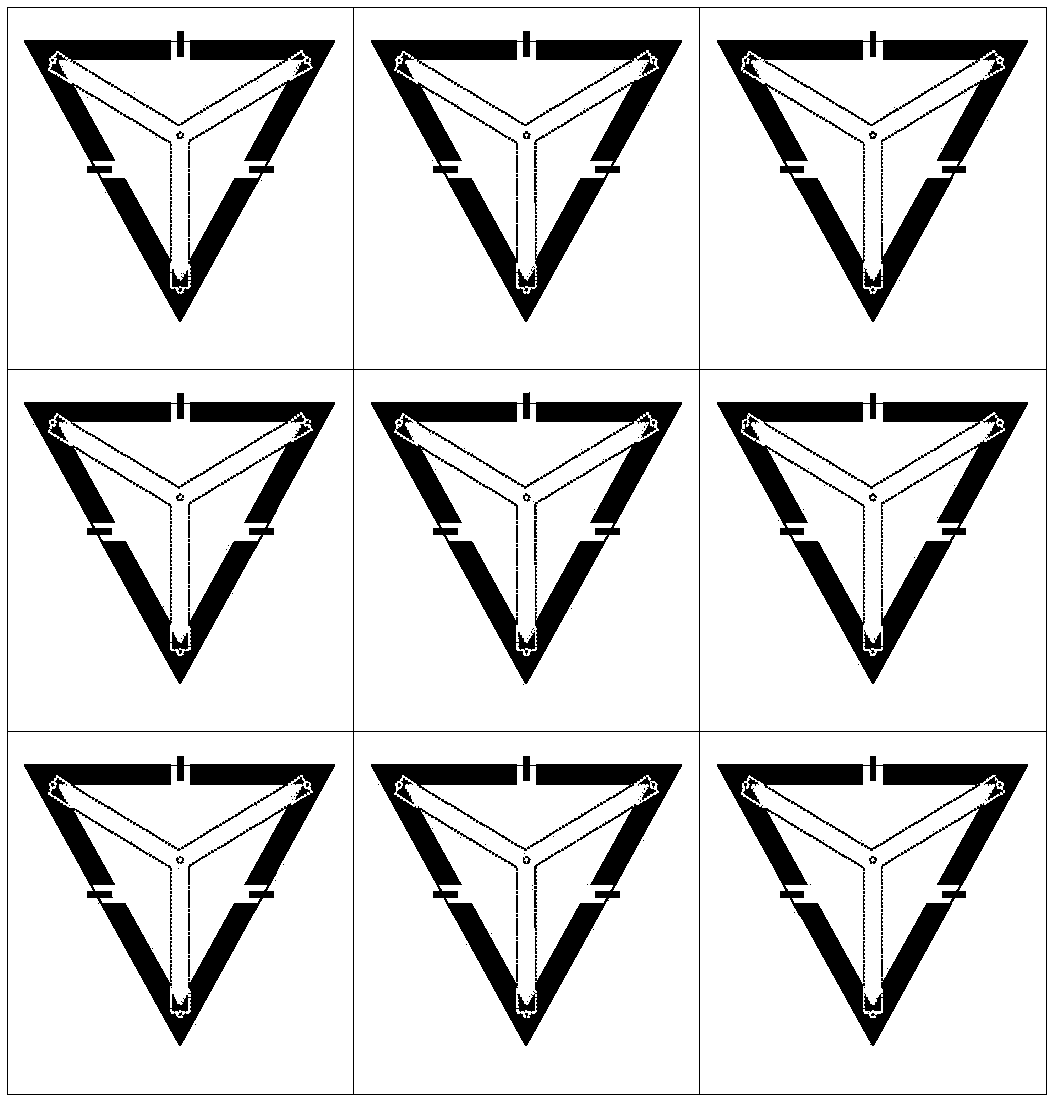

Multilayer structure plasma meta-material tunable ultrawide-band wave absorber

ActiveCN108183339APopular structureFlexible designAntennasOptical elementsDielectric substrateAbsorption effect

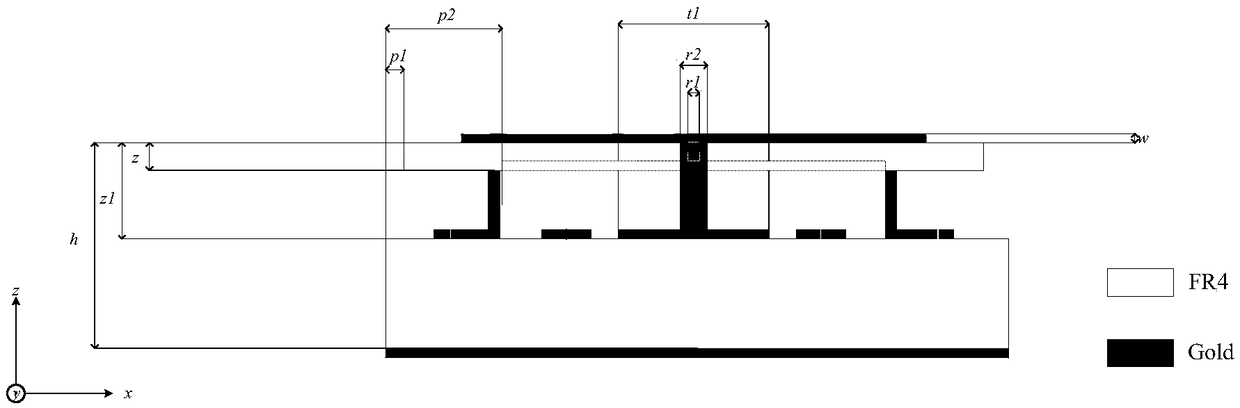

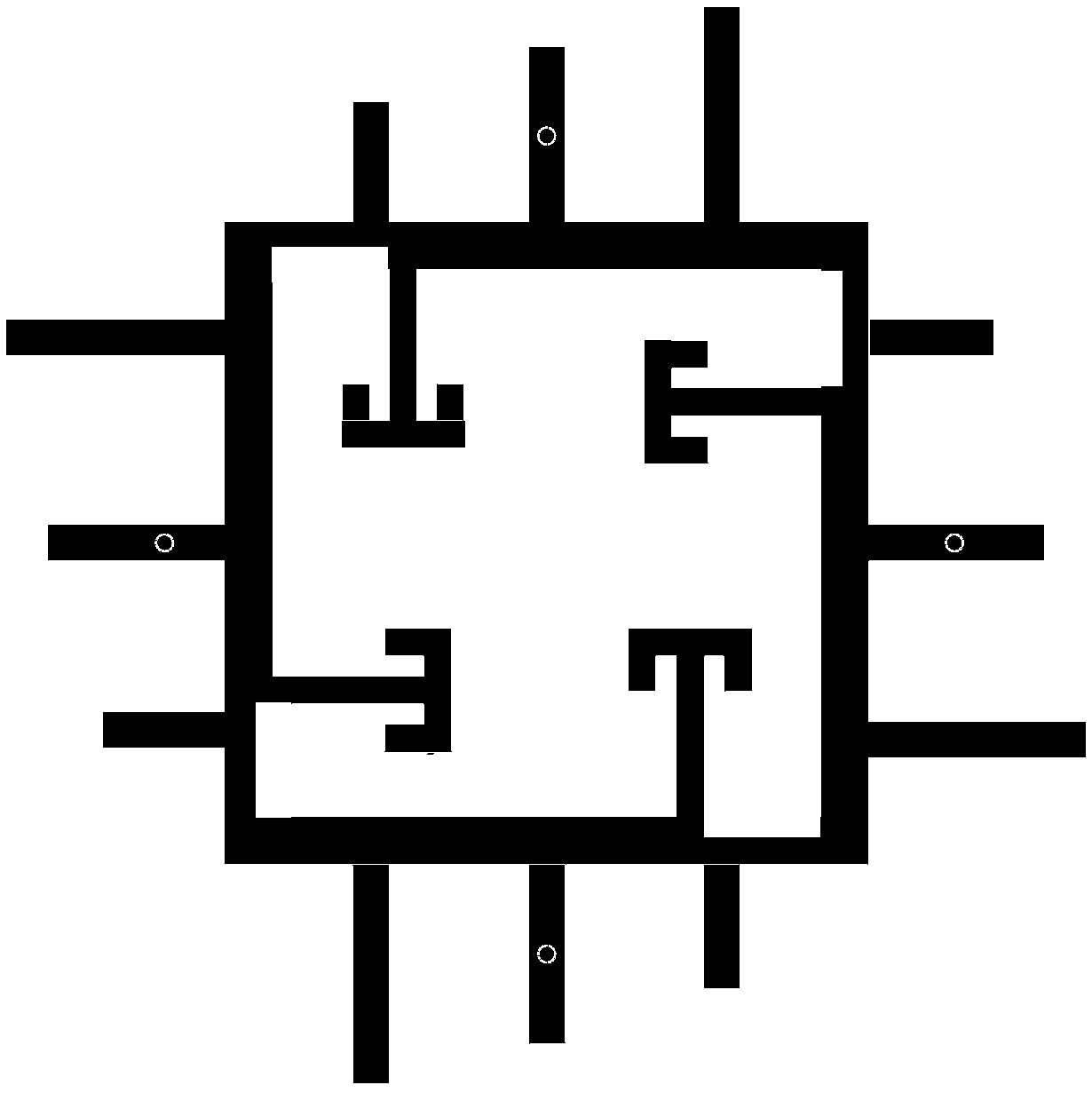

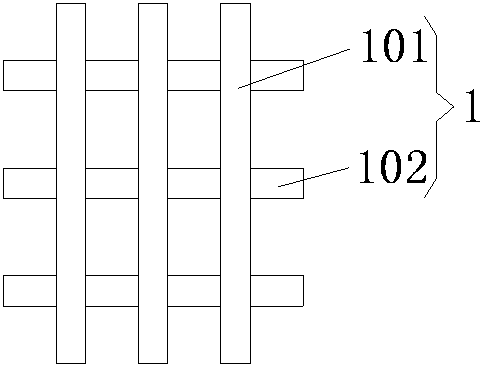

The invention discloses a multilayer structure plasma meta-material tunable ultrawide-band wave absorber of which the structure comprises a bottom metal reflecting plate, a dielectric substrate whichis arranged on the metal plate, solid state plasma resonant units which are arranged on the dielectric substrate, "Y"-shaped solid state plasma resonant units which are arranged in the dielectric substrate and solid state plasma columns which connect all the resonant units. The wave absorber has great absorbing effect for the TE polarized waves and controls the excitation area of the resonant units formed by the solid state plasma to realize excitation of different resonant units through programming so as to achieve the objective of dynamic regulation and control of different frequency of thewave absorber and realize ultrawide-band absorbing of the wave absorber; besides, the working frequency of the wave absorber can cover the whole Ku band under the condition of appropriate selection ofthe excitation area, and absorbing of low frequency electromagnetic waves can also be realized under the condition of small physical size.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

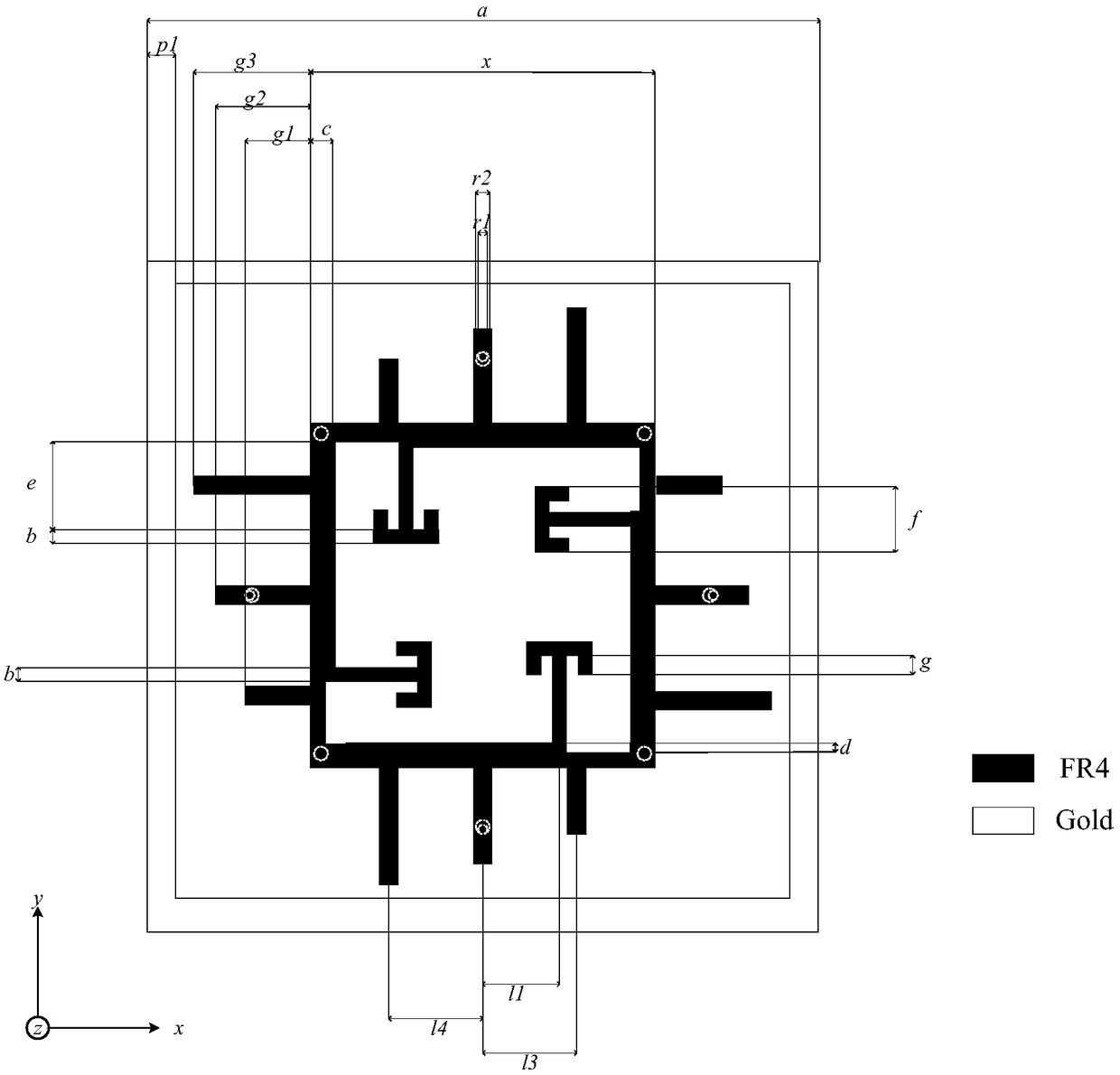

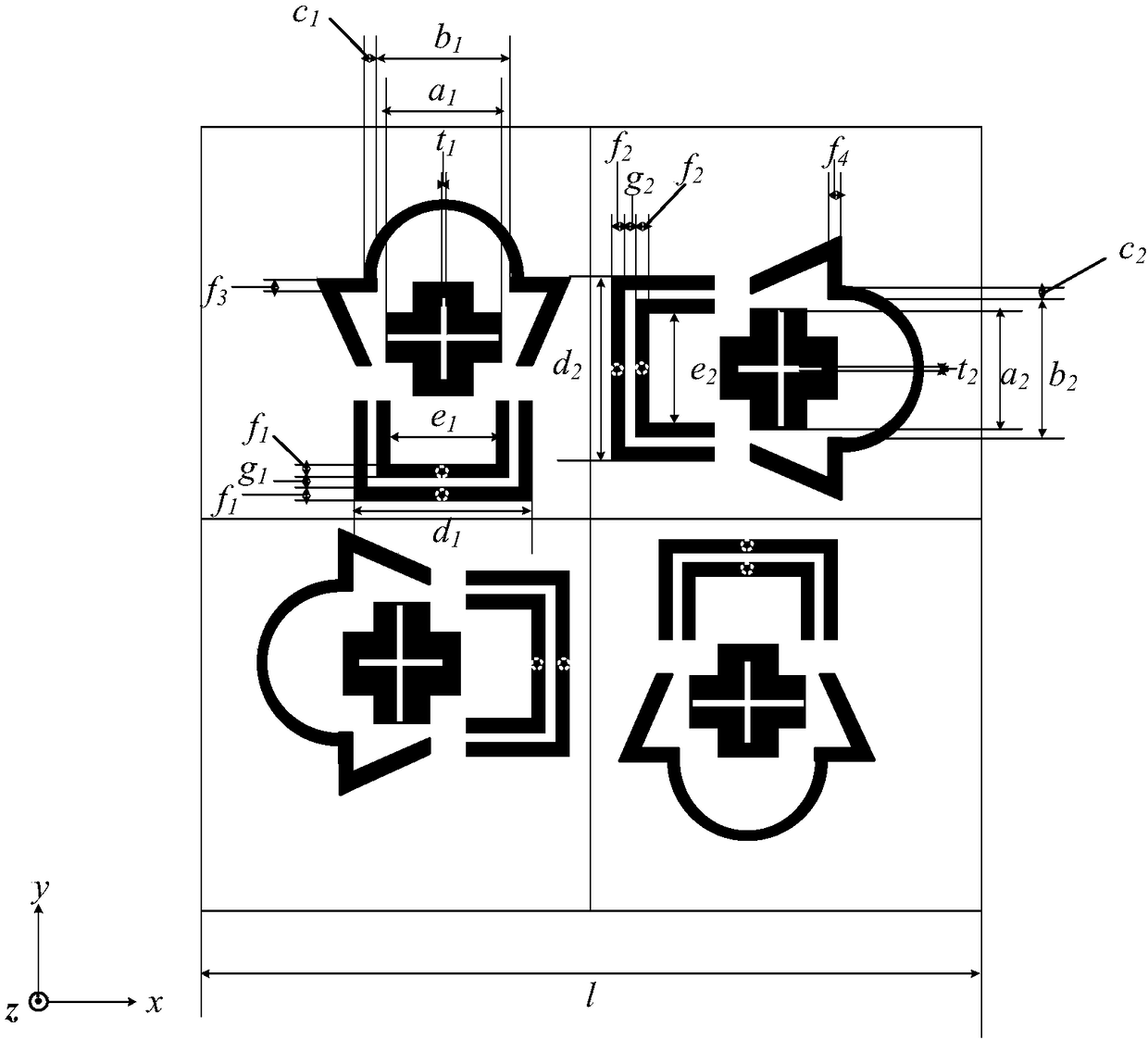

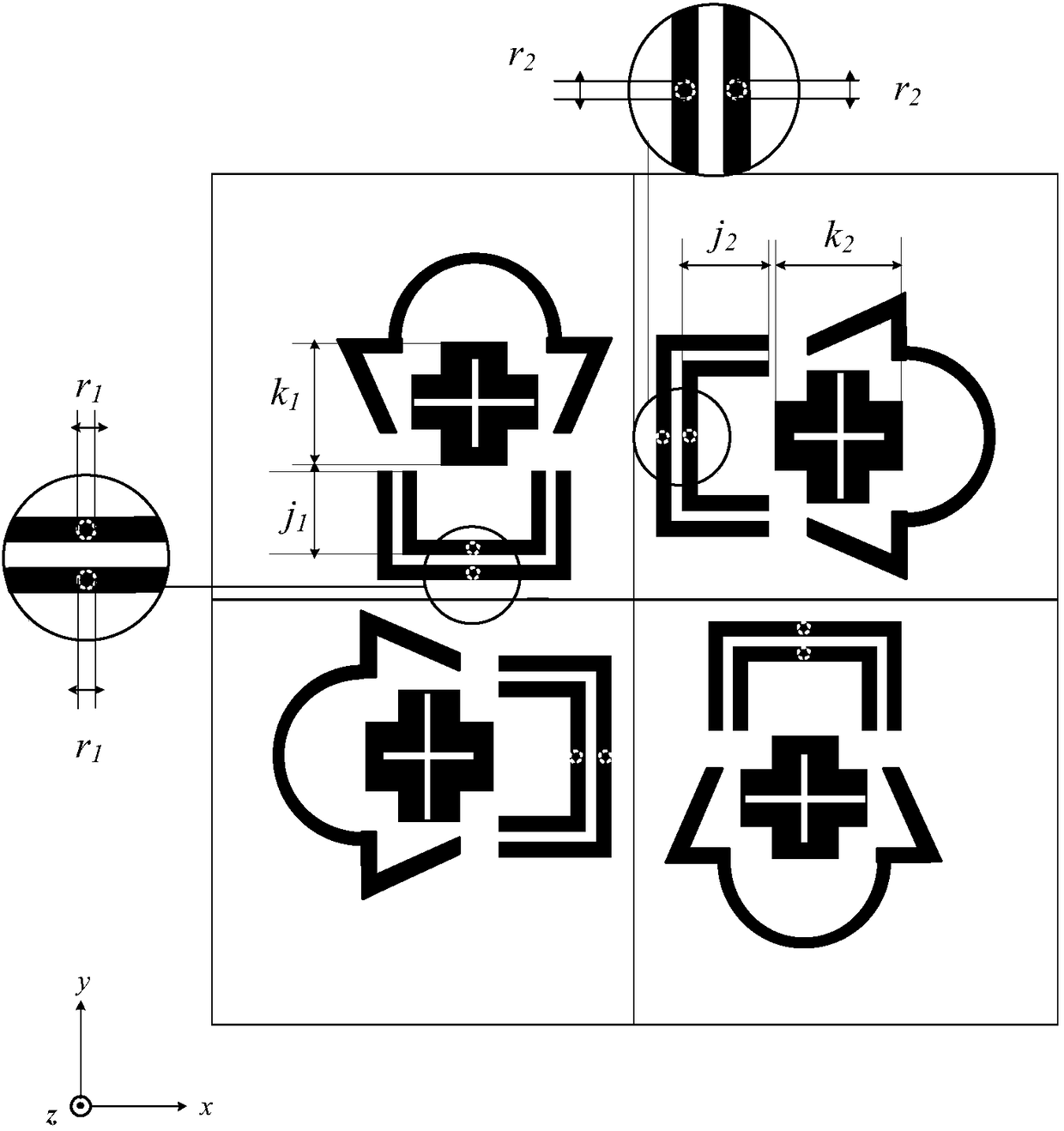

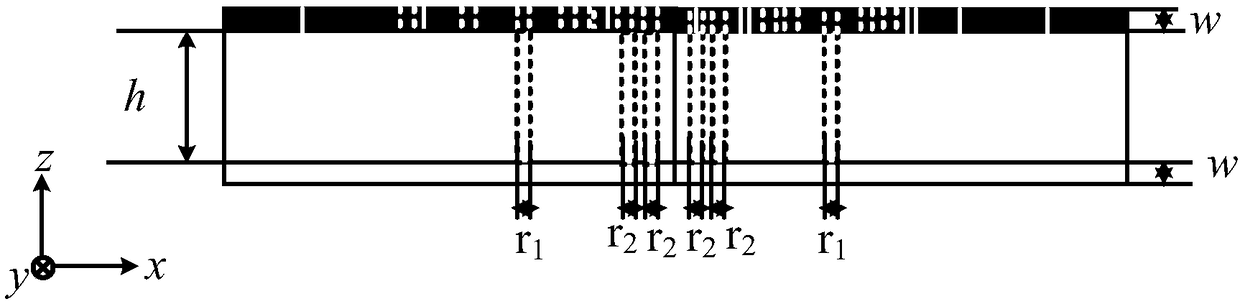

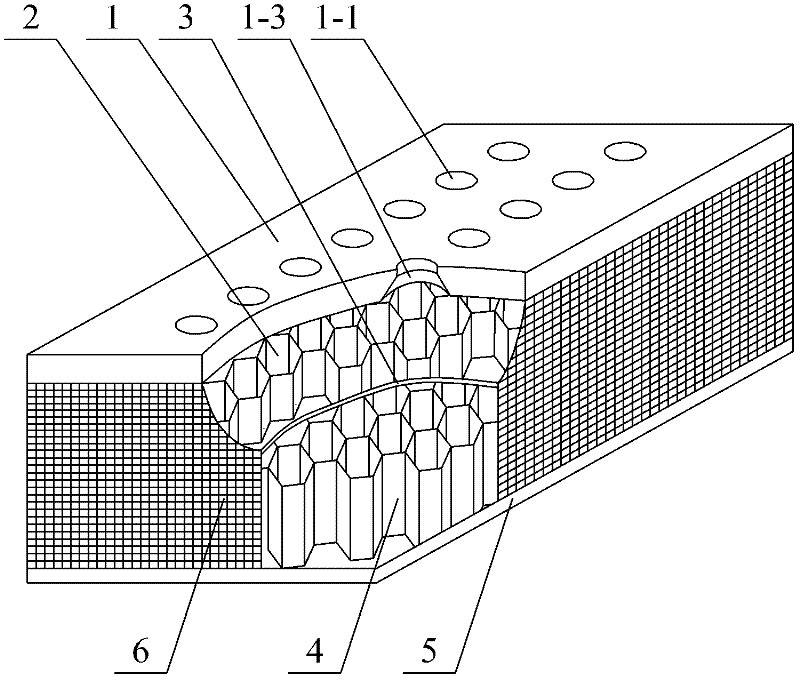

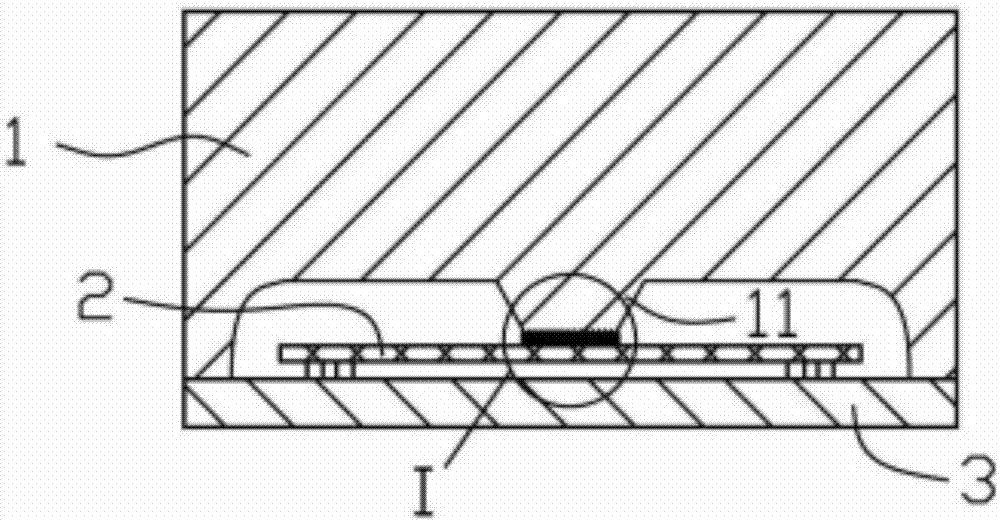

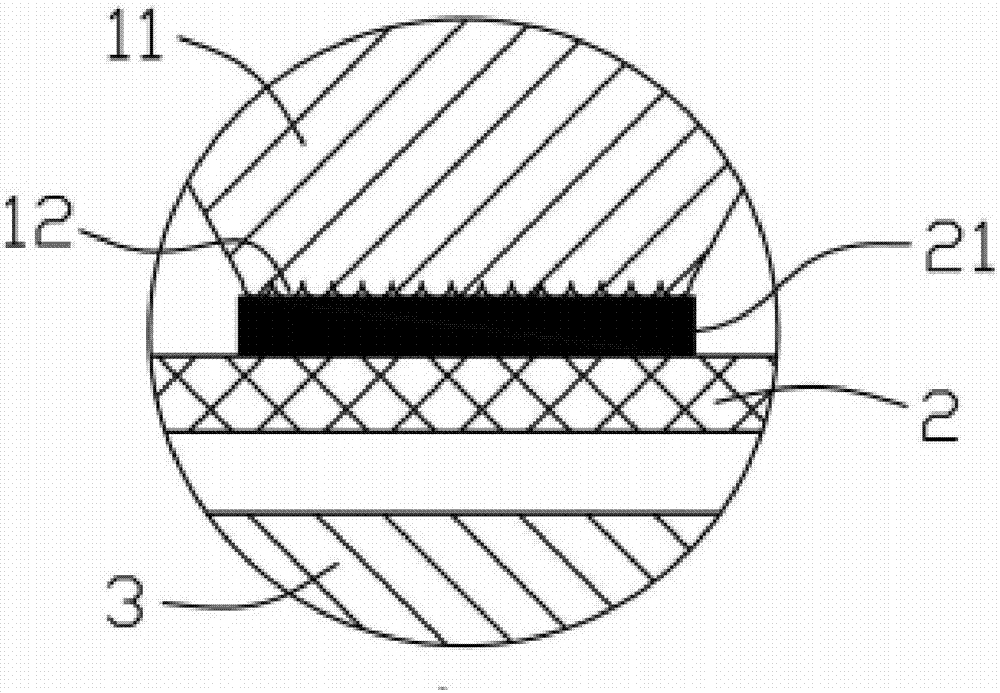

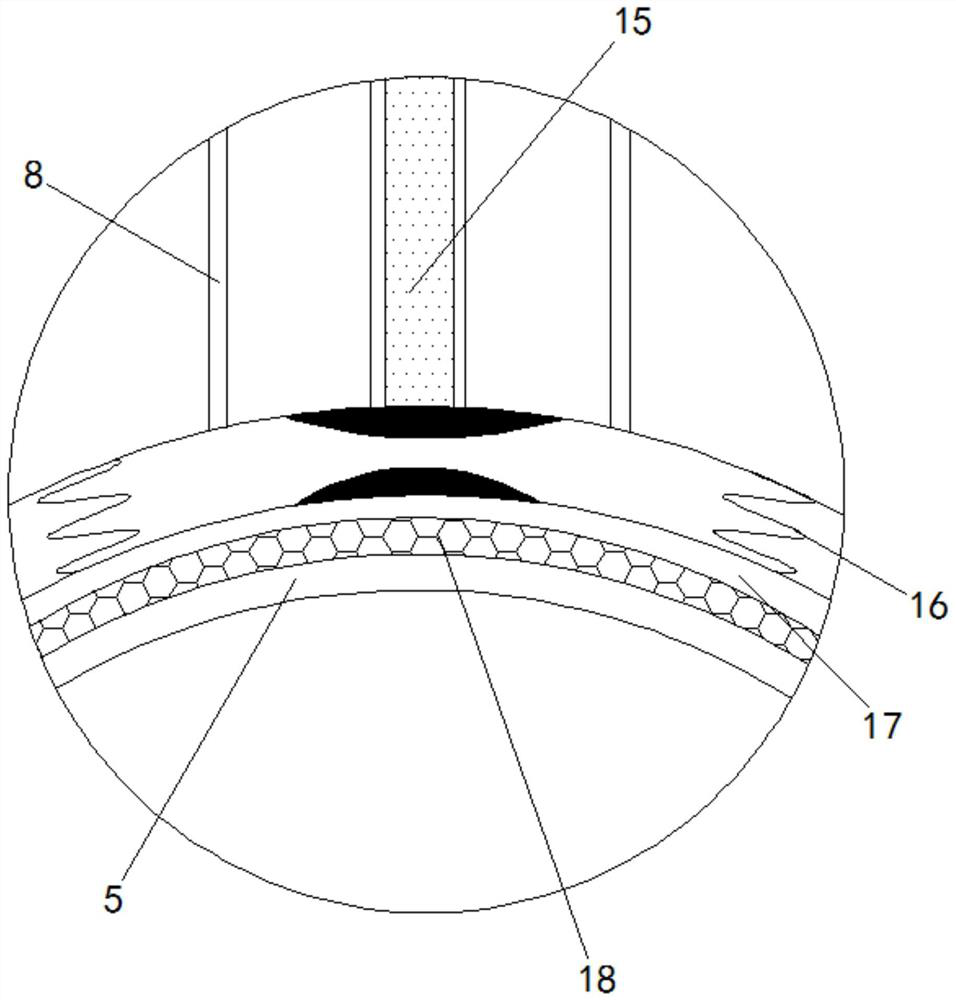

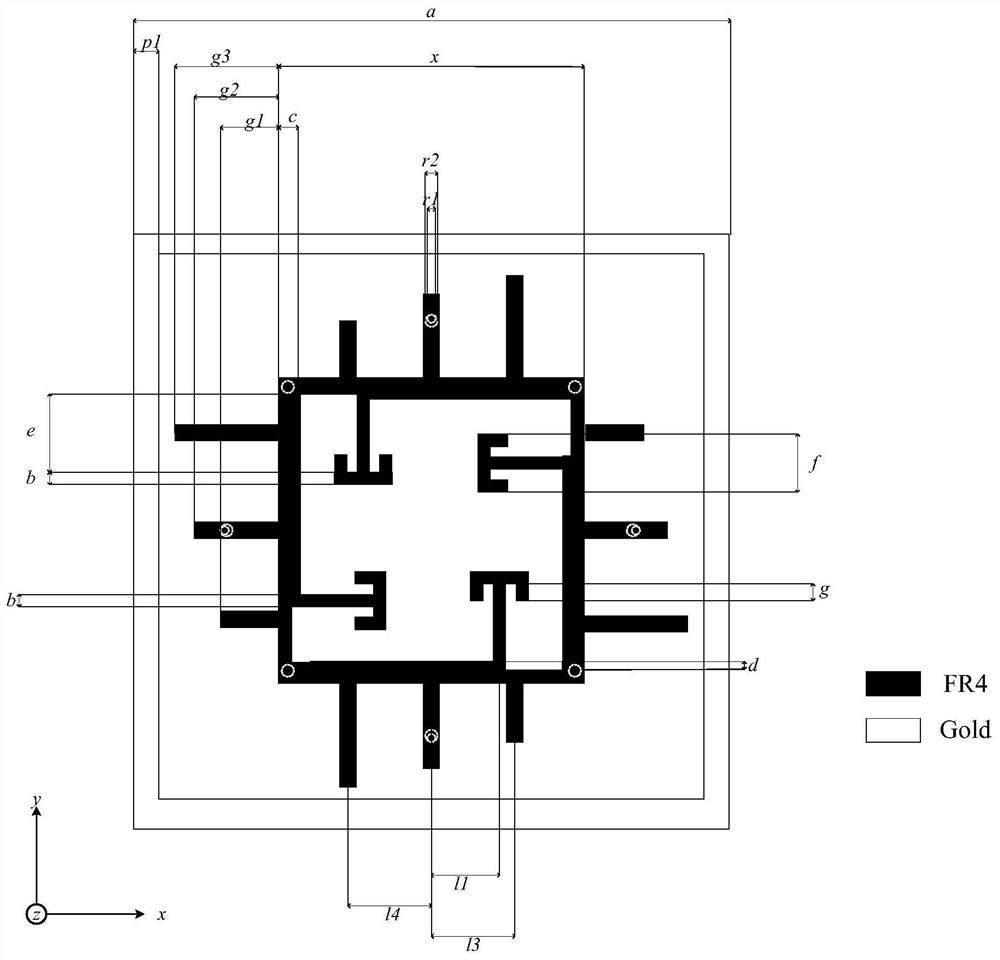

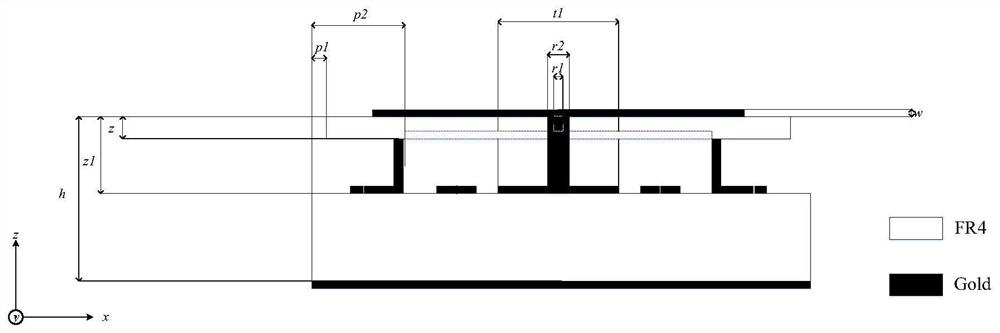

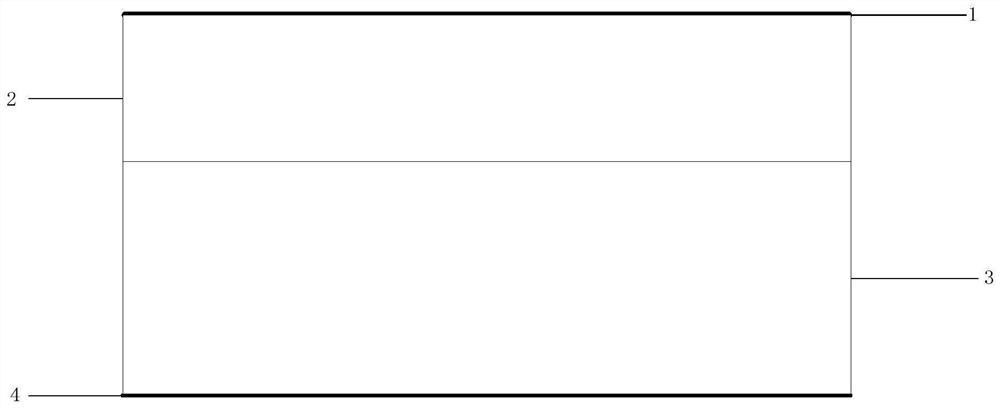

Multilayer structural and polarization insensitive ultra-wide band terahertz microwave absorbing device

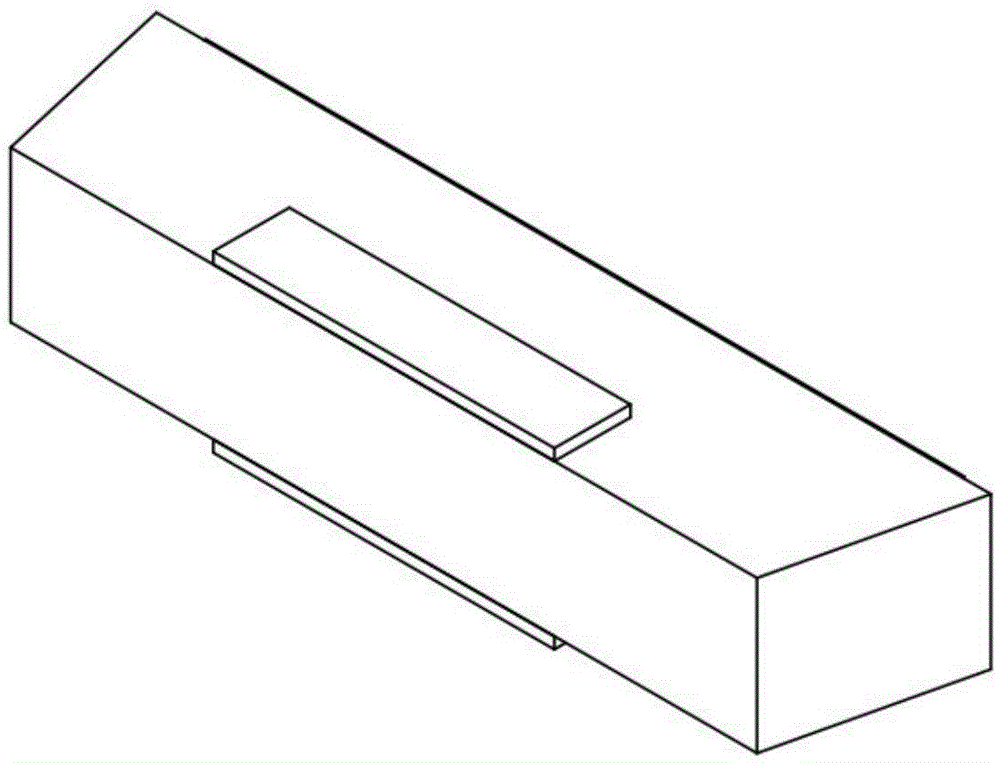

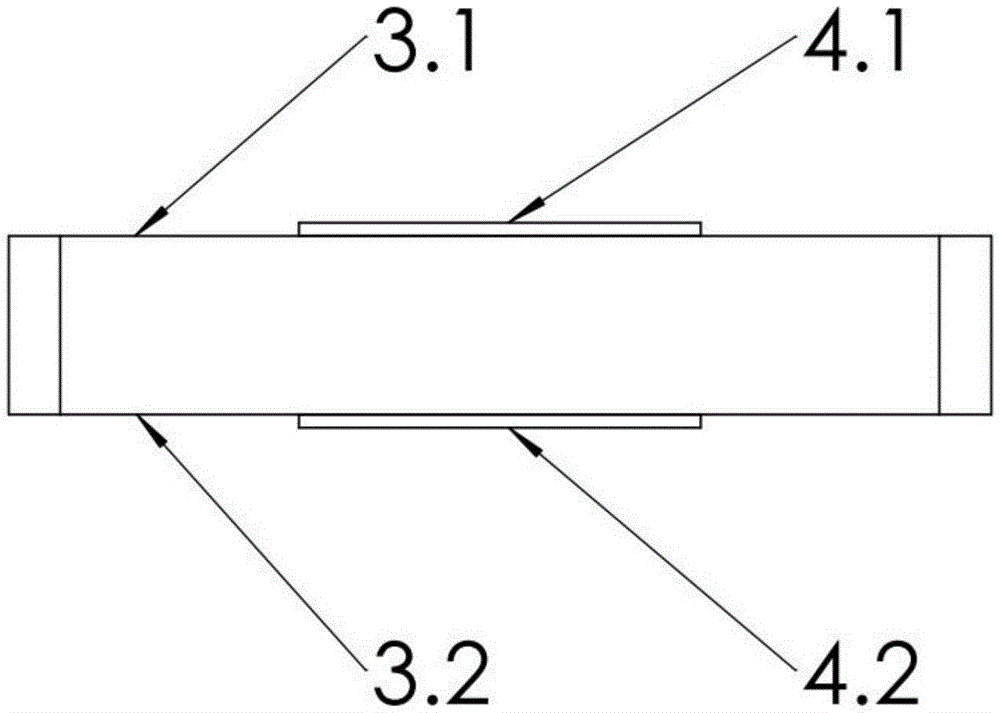

The invention a multilayer structural and polarization insensitive ultra-wide band terahertz microwave absorbing device. The microwave absorbing device includes a bottom reflecting plate and a cut medium substrate arranged above the bottom reflecting plate; a first resonance unit consisting of a layer of metal patches is arranged above the medium substrate; and the internal of the medium substrateis inlaid with a second resonance unit consisting of two layers of the metal patches. Through a design of a multilayer structure and the utilization of metals as a resonance material, wide band absorption effects can be achieved through the mutual resonance between layers, so that the absorption bandwidth of the microwave absorbing device can be expanded from wide band to ultra-wide band; and asthe structure of the microwave absorbing device has a symmetrical characteristic, the absorption property of the microwave absorbing device on TE polarized waves and TM polarized waves is basically the same, so that the microwave absorbing device can realize the ultra-wide band absorption effects on a THz wave band.

Owner:NANJING UNIV OF POSTS & TELECOMM

Method for suppressing parasitic oscillation in gain medium of grazing incidence plate strip

InactiveCN105529602AEnhanced parasitic oscillationsImprove absorption propertiesLaser detailsLaser technologyPulse energy

The invention relates to a method for suppressing parasitic oscillation in a gain medium of a grazing incidence plate strip. According to the method, a layer of dielectric material is plated on three non-light-through surfaces of the grazing incident plate strip, and the dielectric material shows the absorption characteristic on the parasitic oscillation of the gain medium. The method is simple and is wide in application range, and a better suppression effect on the parasitic oscillation is exerted. A plate strip crystal comprises six surfaces, the parasitic oscillation in the crystal can be enhanced by reflection or scattering of each surface, thus, an absorption medium is plated on all other surfaces except a pumping surface and a light through surface, and a parasitic oscillation loop is cut off to achieve an absorption effect. By the method, the parasitic oscillation of the gain medium with such structure can be effectively suppressed, the energy storage and the gain of the gain medium are improved, the amplified spontaneous radiation (ASE) of a system is reduced, and the output light pulse energy is improved. The method belongs to the technical field of laser.

Owner:BEIJING UNIV OF TECH

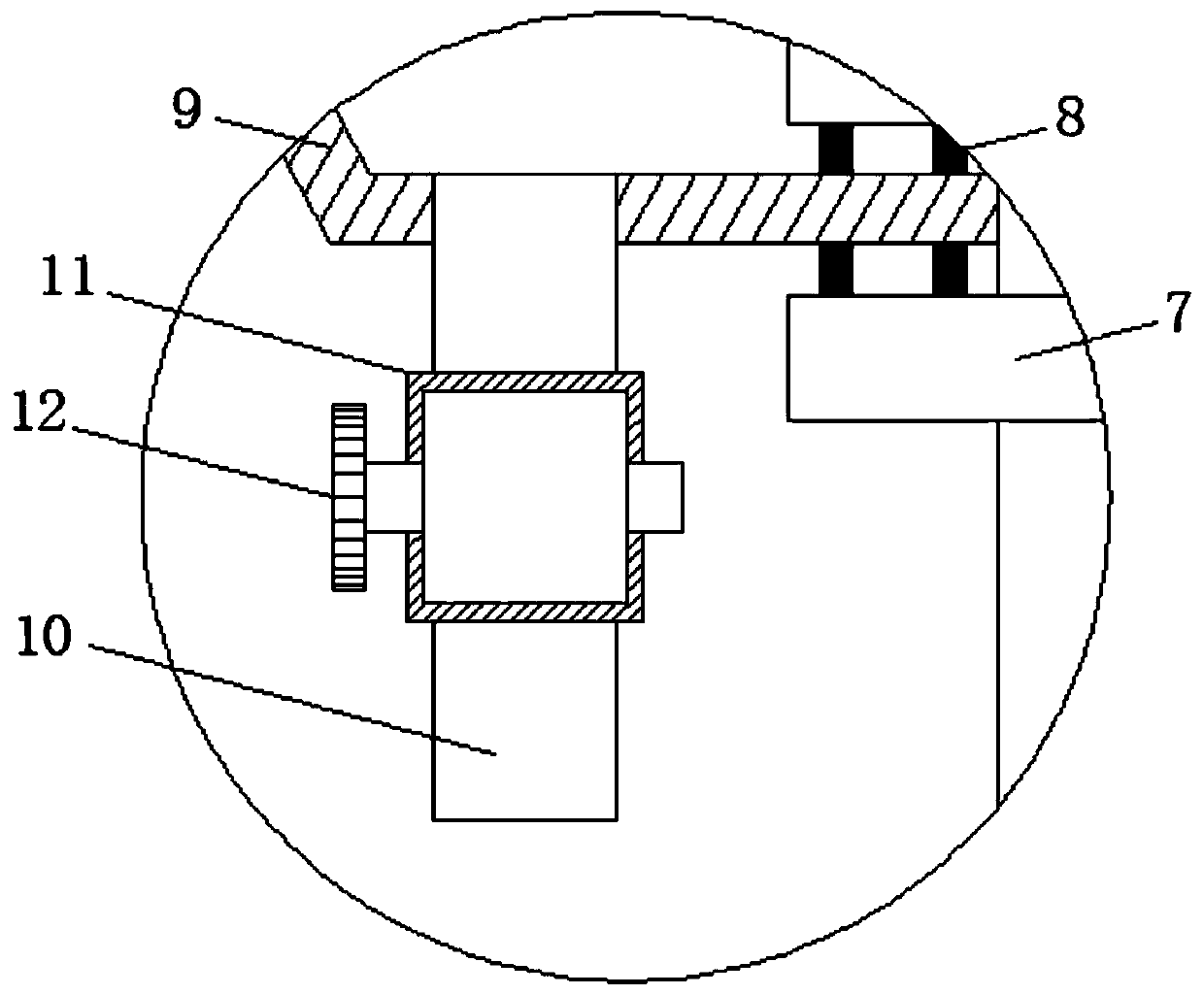

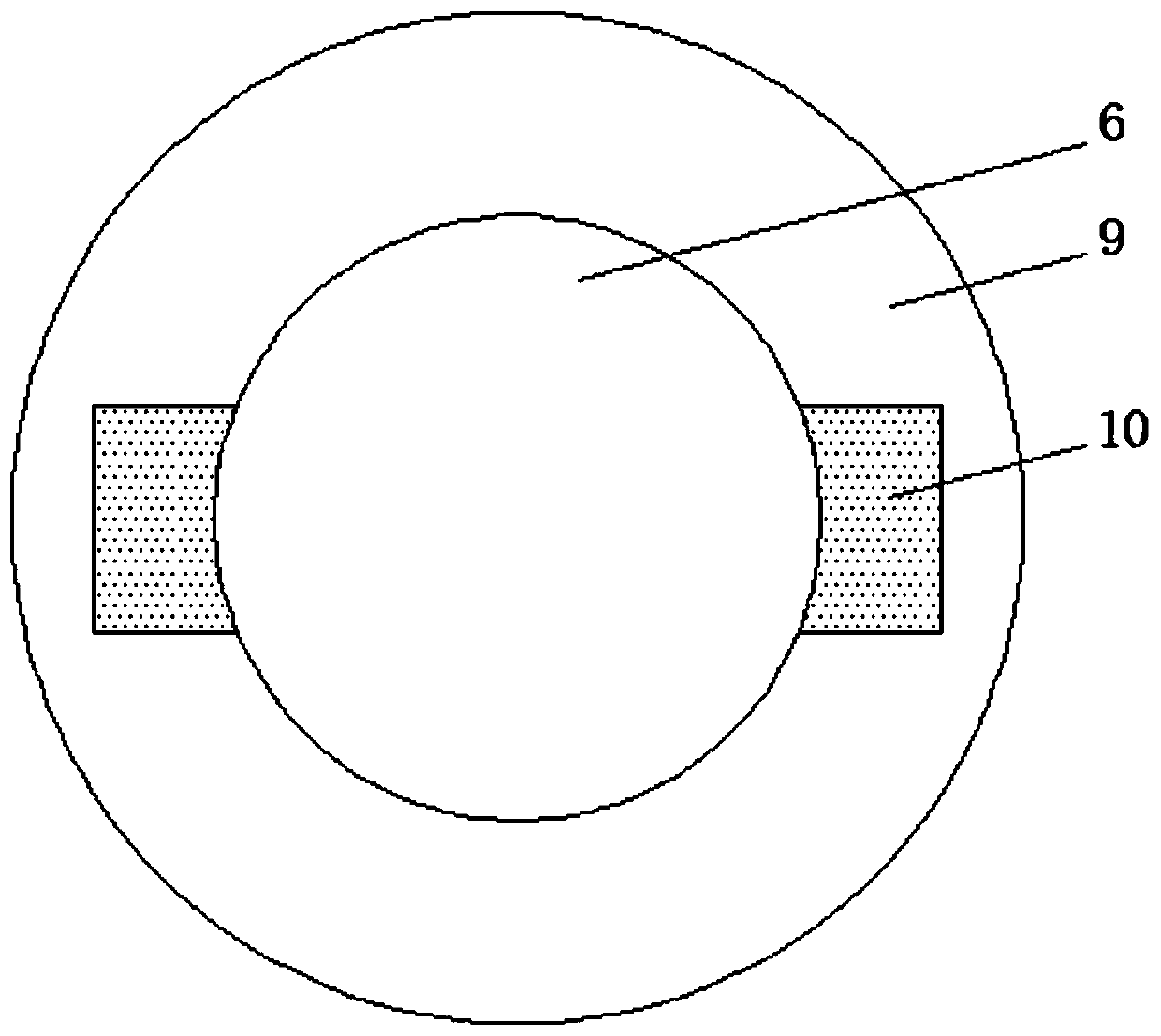

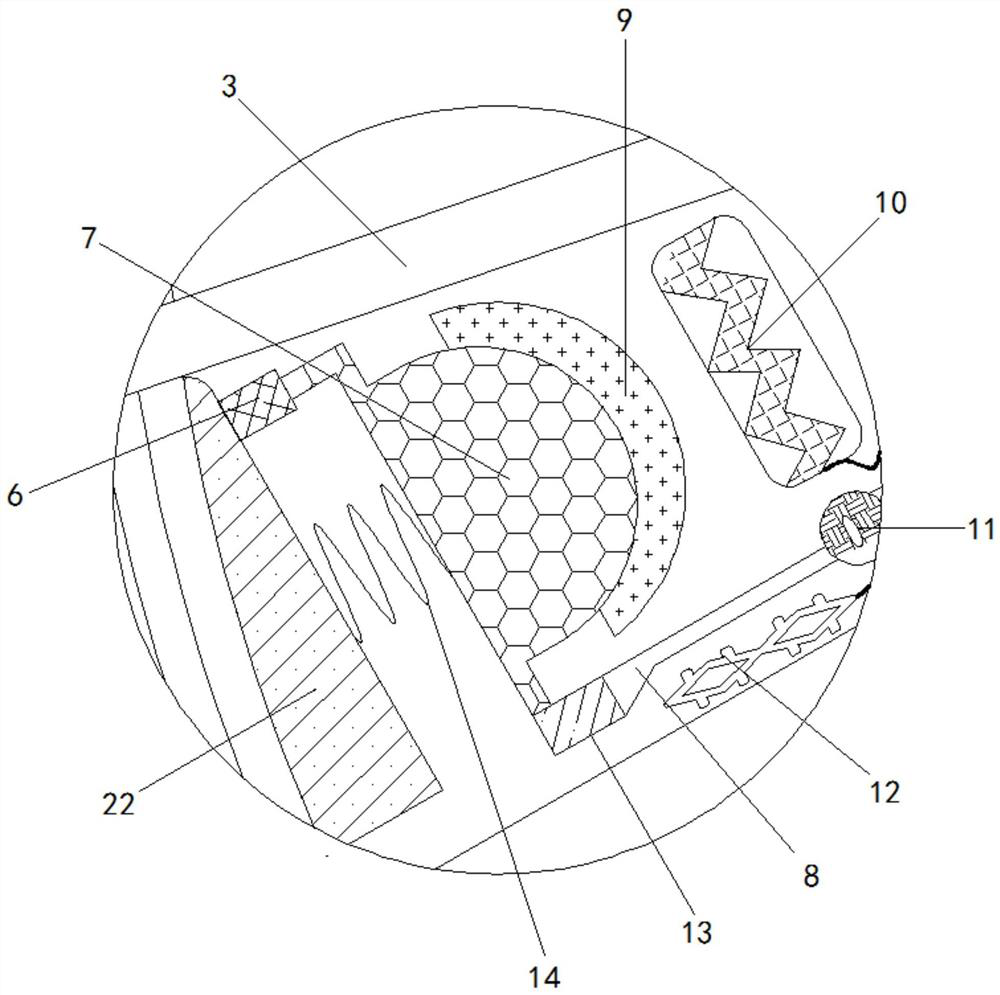

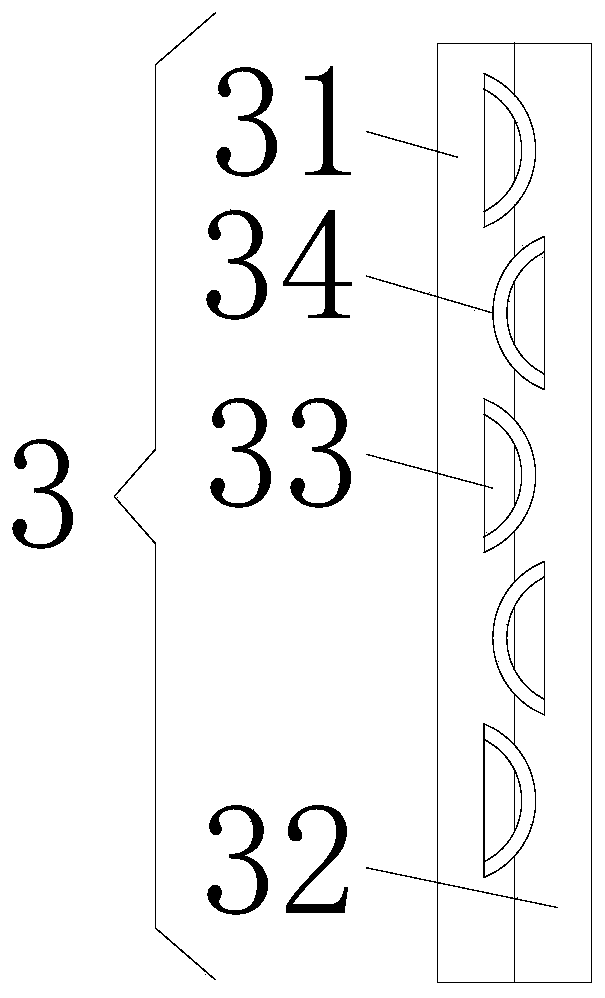

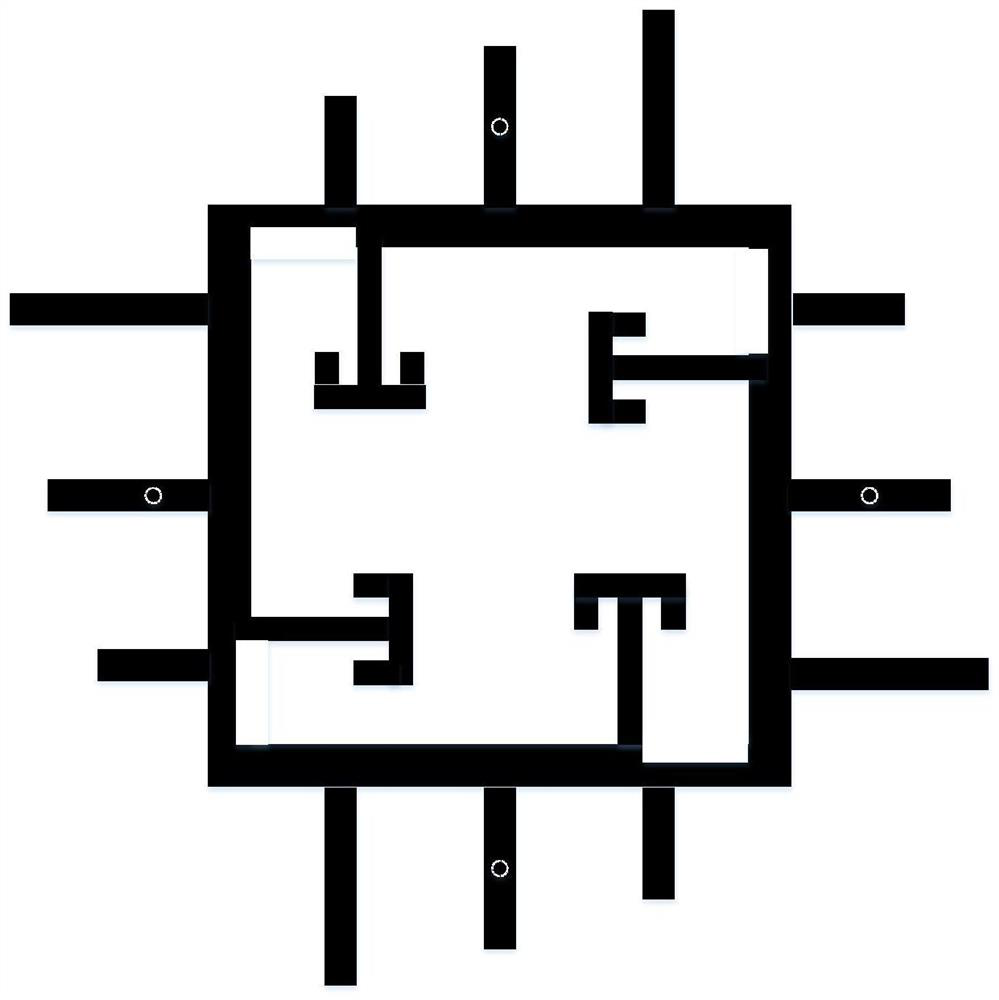

Crown-shaped regulable plasma meta-material broadband wave absorber

ActiveCN108183338APromote absorptionTo achieve the absorption effectAntennasOptical elementsExcited stateDielectric substrate

The invention discloses a crown-shaped regulable plasma meta-material broadband wave absorber of which the structure comprises a bottom metal reflecting plate and a dielectric substrate and solid state plasma resonant units which are arranged on the bottom metal reflecting plate. The solid state plasma resonant units have two working states: the excited state and the non-excited state. The plasmameta-material broadband wave absorber has great absorbing effect for the TE polarized waves and the TM polarized waves and controls the excitation area of the resonant units formed by the solid stateplasma to realize excitation of different resonant units through programming so as to achieve the objective of dynamic regulation and control of different frequency of the wave absorber and realize broadband absorbing of the wave absorber; besides, the working frequency of the wave absorber can cover the whole X band under the condition of appropriate selection of the excitation area.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

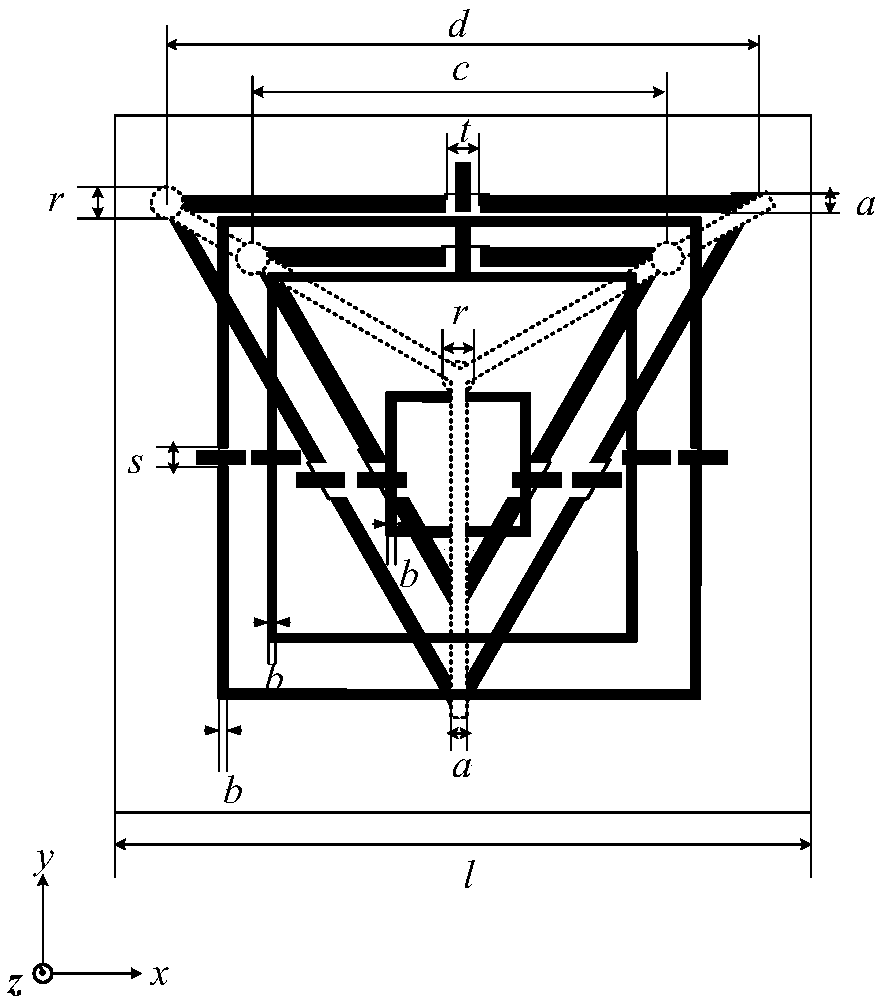

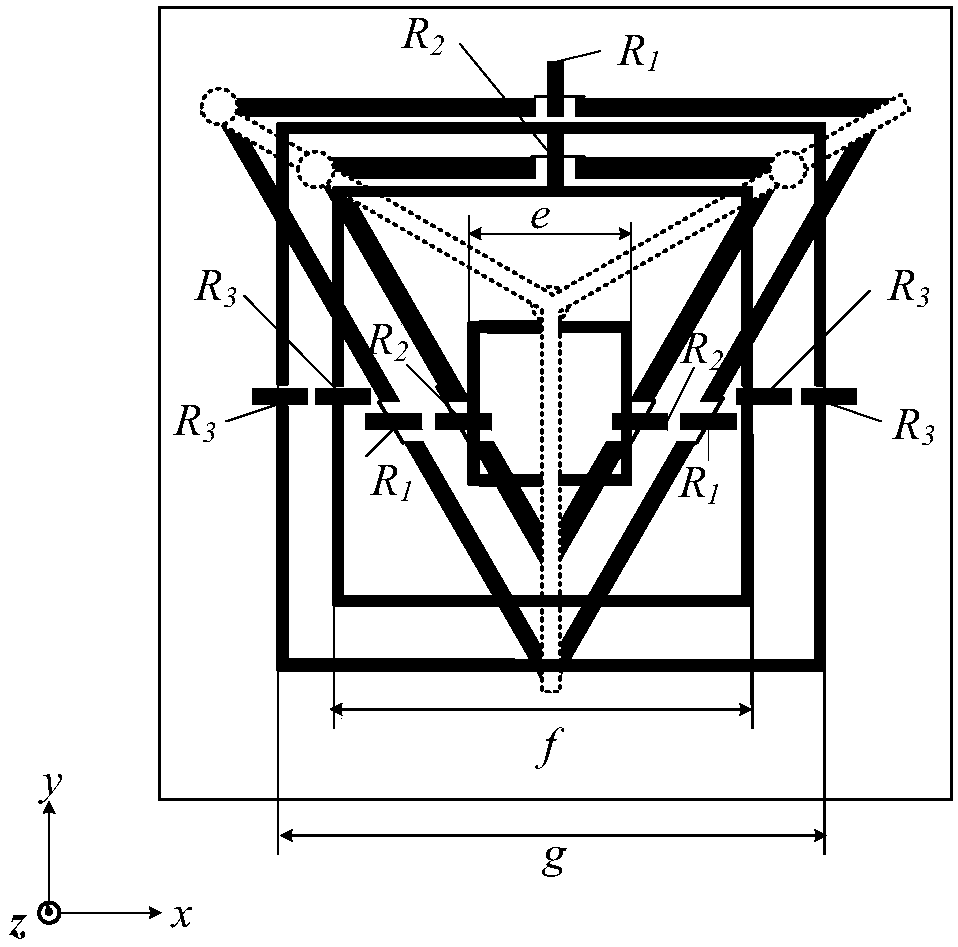

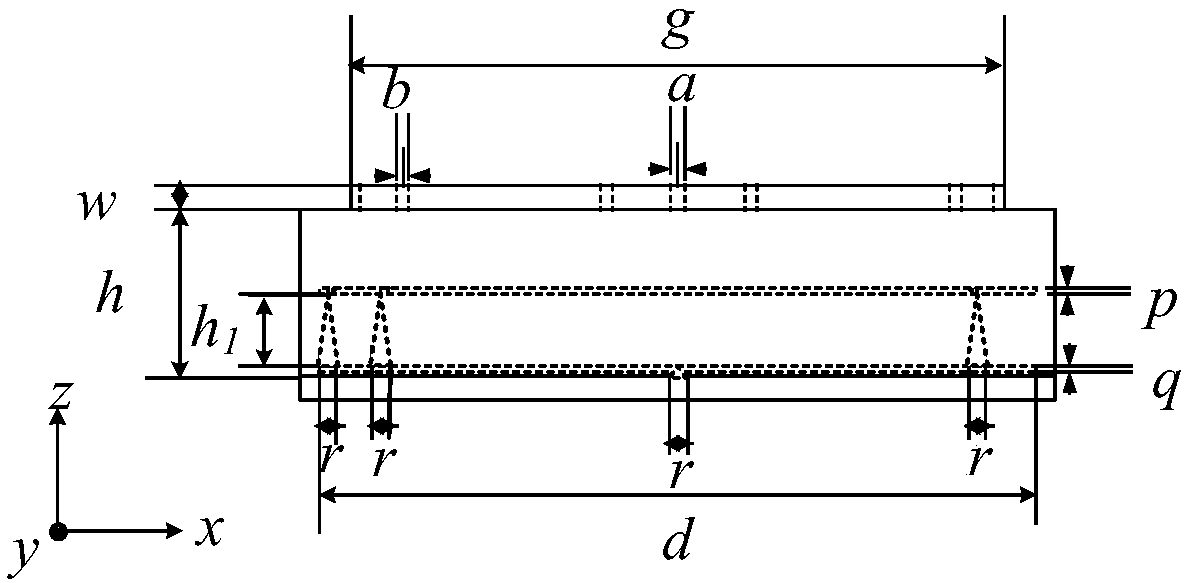

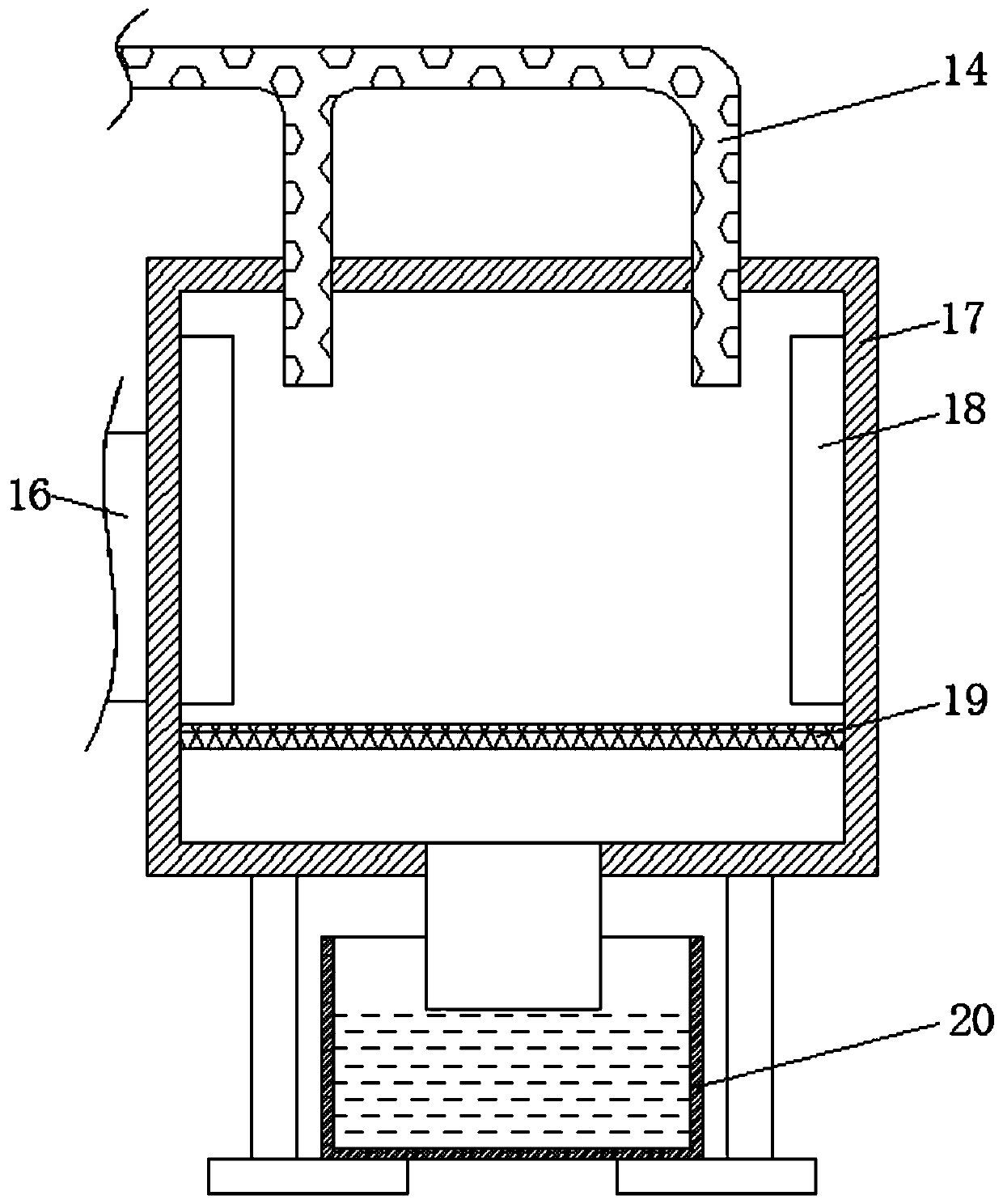

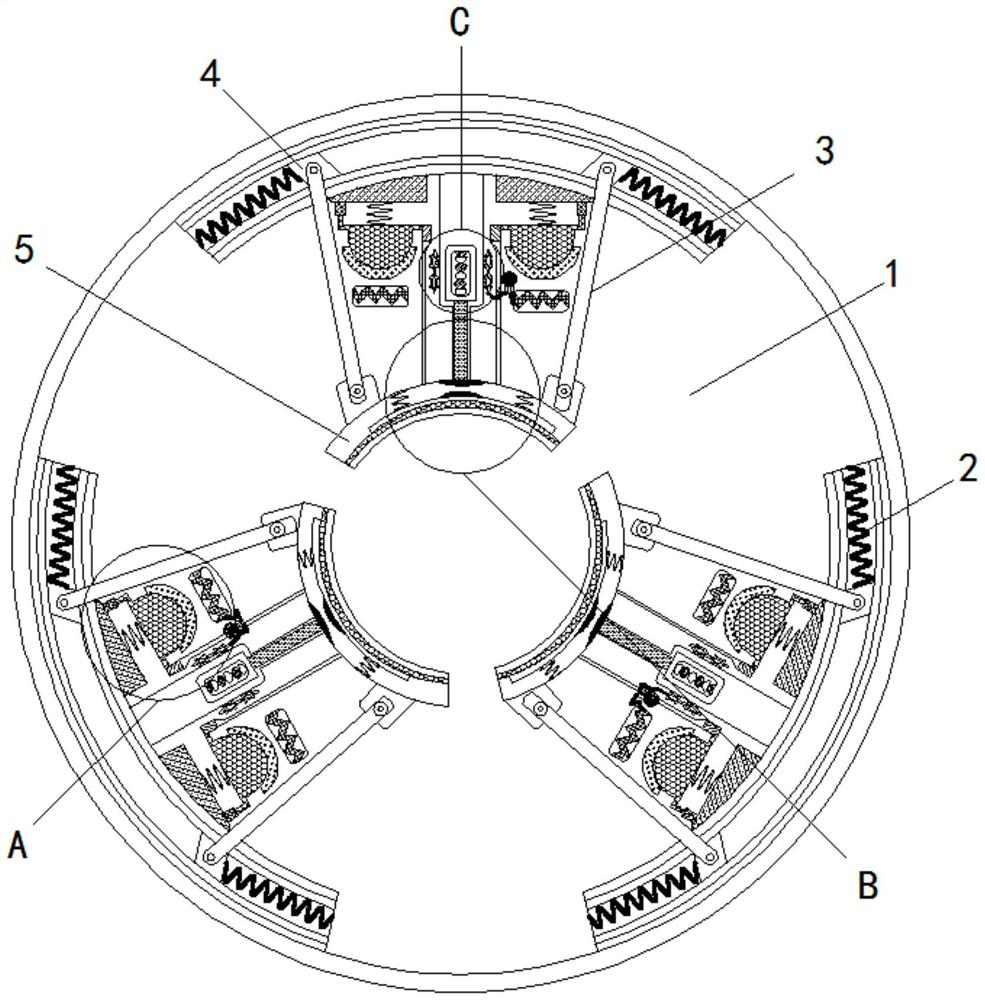

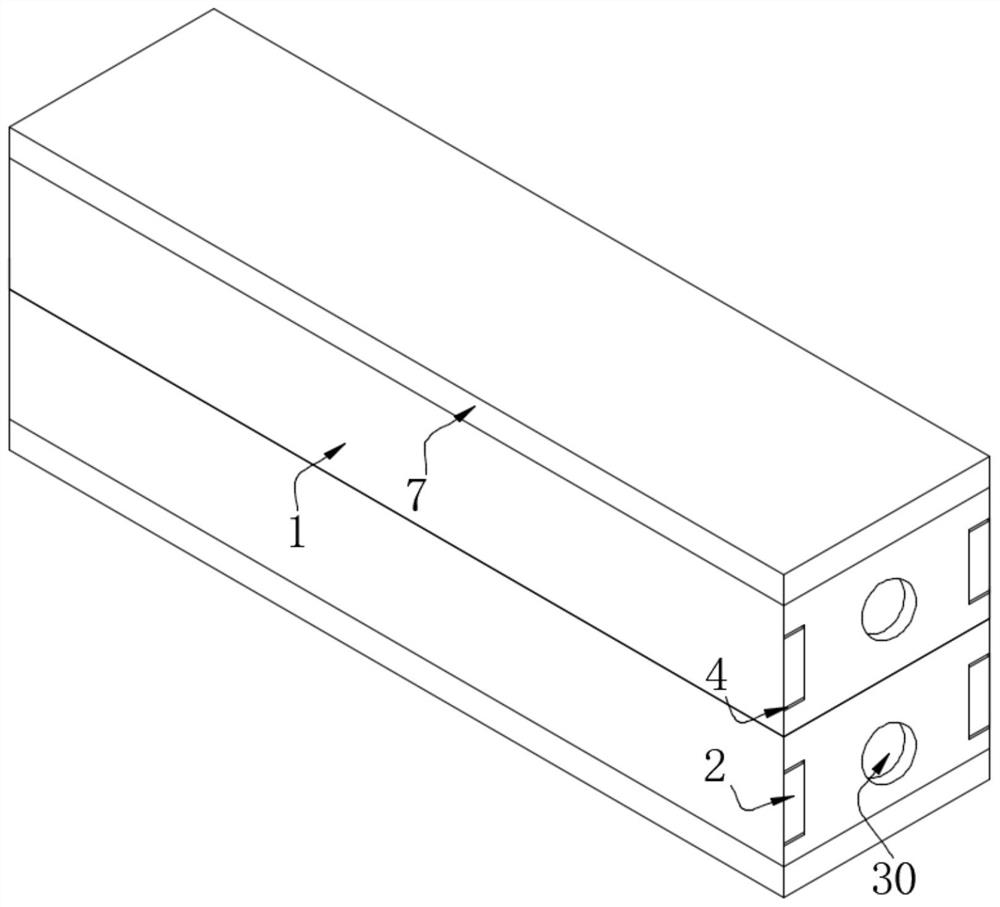

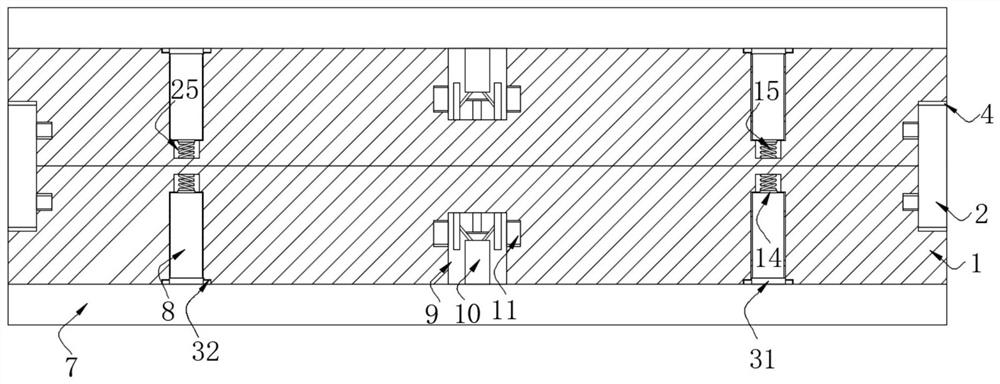

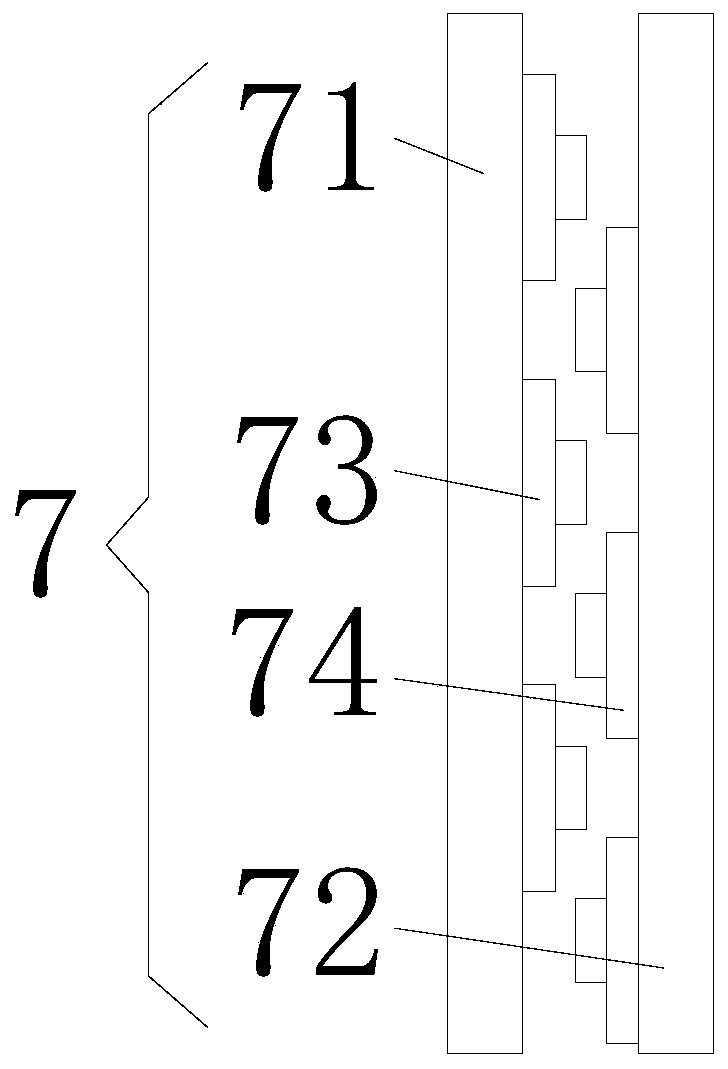

Tunable ultra wide band wave absorption device for multi-layer bracket structure

ActiveCN108183341ATo achieve the absorption effectRealize dynamic regulationAntennasOptical elementsElectrical resistance and conductanceDielectric substrate

The invention discloses a tunable ultra wide band wave absorption device for a multi-layer bracket structure. The tunable ultra wide band wave absorption device structurally comprises a bottom layer metal reflecting plate, a dielectric substrate above the metal plate, three square ring plasma resonance structures on the dielectric substrate, tree branch-shaped solid plasma resonance units in the dielectric substrate, triangular annular plasma resonance units among which resistors are connected in a spanning manner and conical solid plasma resonance units which are connected with the resonancestructures, wherein resistors are connected between two square rings in the spanning manner. The absorption device has very good absorption effect to TE polarized waves and controls an excitation region of the resonance units formed by solid plasmas through a programming manner, so that excitation to different resonance units can be realized, the purpose of dynamically regulating different frequencies of the absorption device is achieved, and ultra wide band absorption of the wave absorption device is realized; and in addition, the working frequency of the wave absorption device can cover multiple electromagnetic wave bands under the condition of proper selection of the excitation region, and absorption of lower frequency electromagnetic waves can also be realized in lower physical size.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

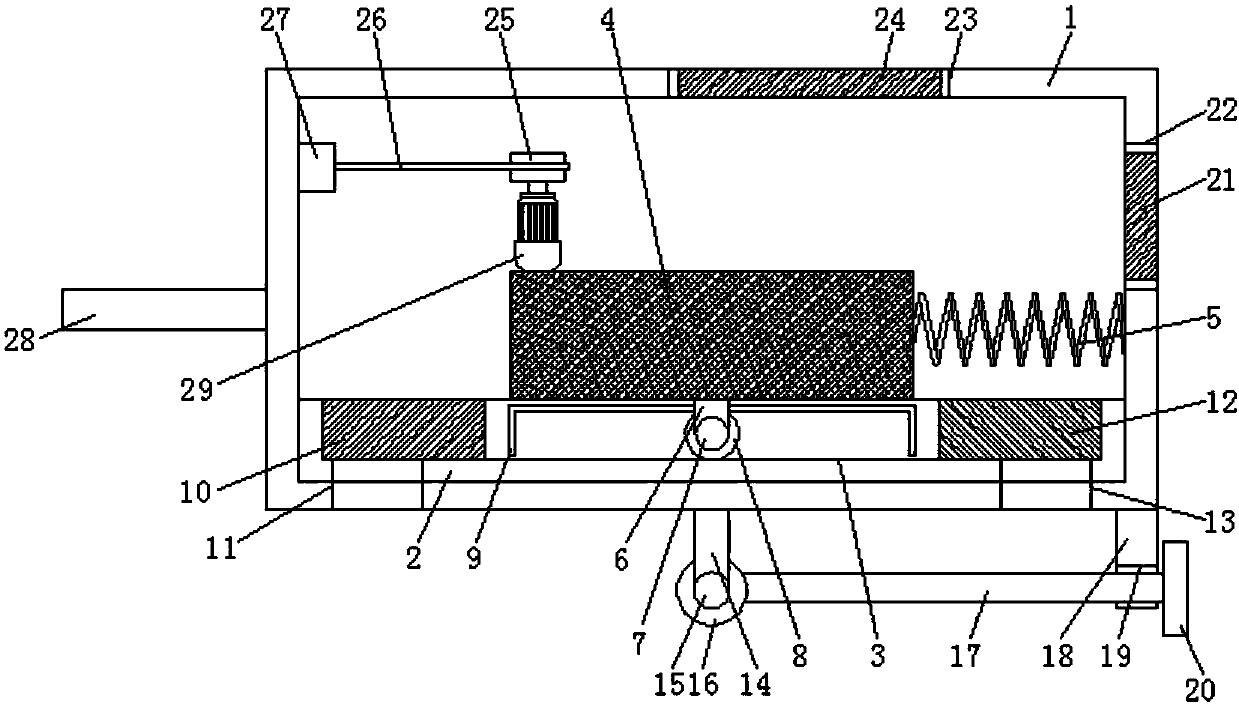

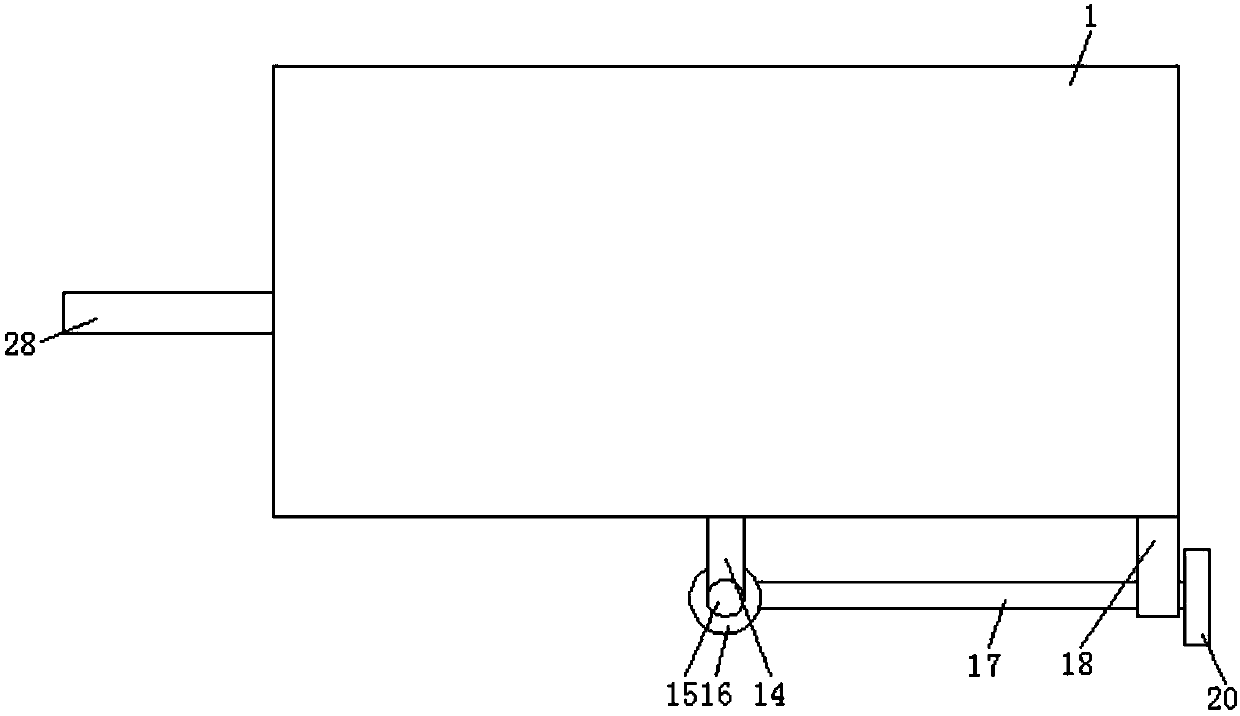

Waterproof coal mine methane detection instrument

InactiveCN107764942ATo achieve the absorption effectPrevent fallingGas analyser construction detailsEngineeringCoal mine methane

The invention provides a waterproof coal mine methane detection instrument and relates to the field of coal mine methane detection instruments. The waterproof coal mine methane detection instrument includes a casing, the left side of the casing is fixedly connected with an insertion rod, the inner bottom wall of the casing is fixedly connected with a bottom plate, and the upper surface of the bottom plate is lapped with an instrument body. The upper surface of the bottom plate is provided with a chute, and the lower surface of the instrument body is fixedly connected with a wheel bar inside the chute, and the end of the wheel bar away from the instrument body is fixedly connected with a wheel shaft. The waterproof coal mine methane detection instrument, through the first isolation layer and the second isolation layer respectively arranged inside the first opening and the second opening, prevents the gravel from falling into the inside of the shell when the mine is mining, and passes through the The first sponge block cooperates with the second sponge block to achieve the effect of absorbing moist water vapor and water droplets, and through the contraction function of the spring, the effect of driving the extrusion rod to squeeze the second sponge block to the right is achieved.

Owner:镇江市南方工矿器材有限公司

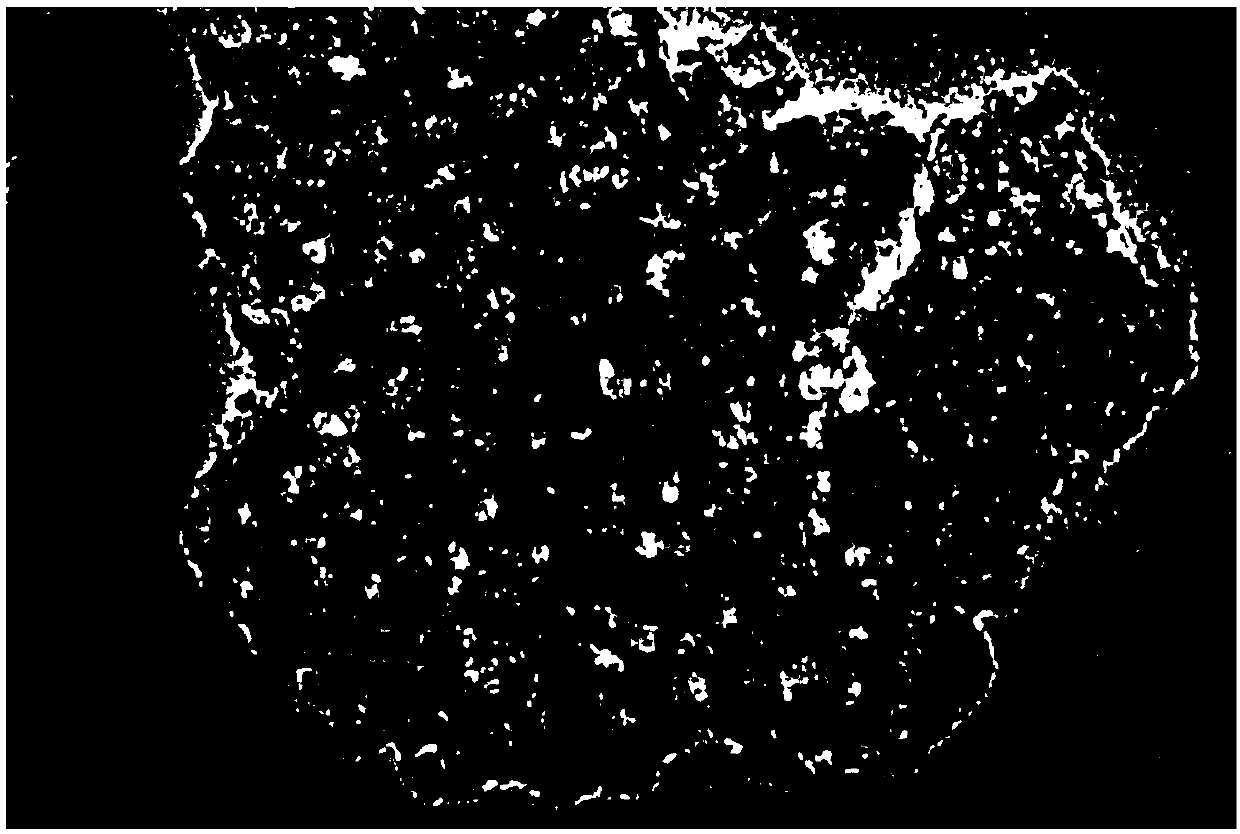

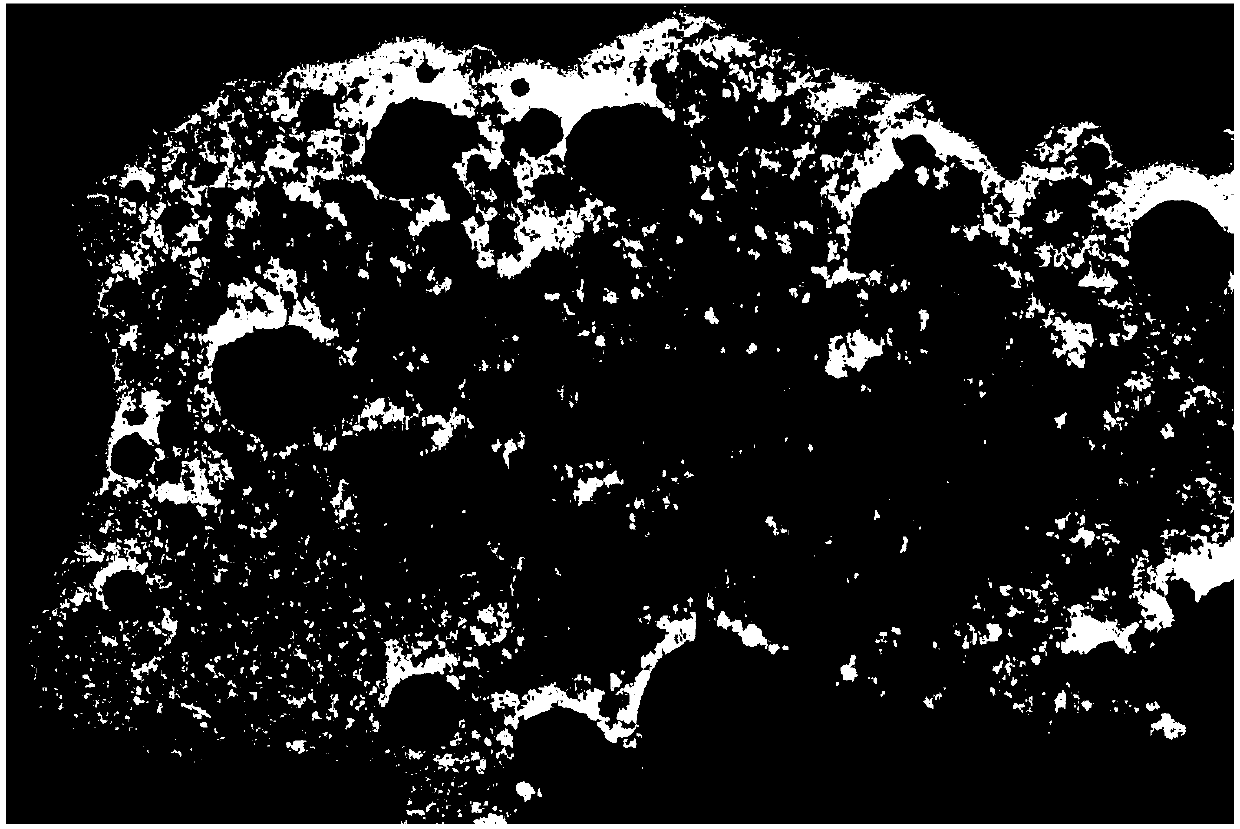

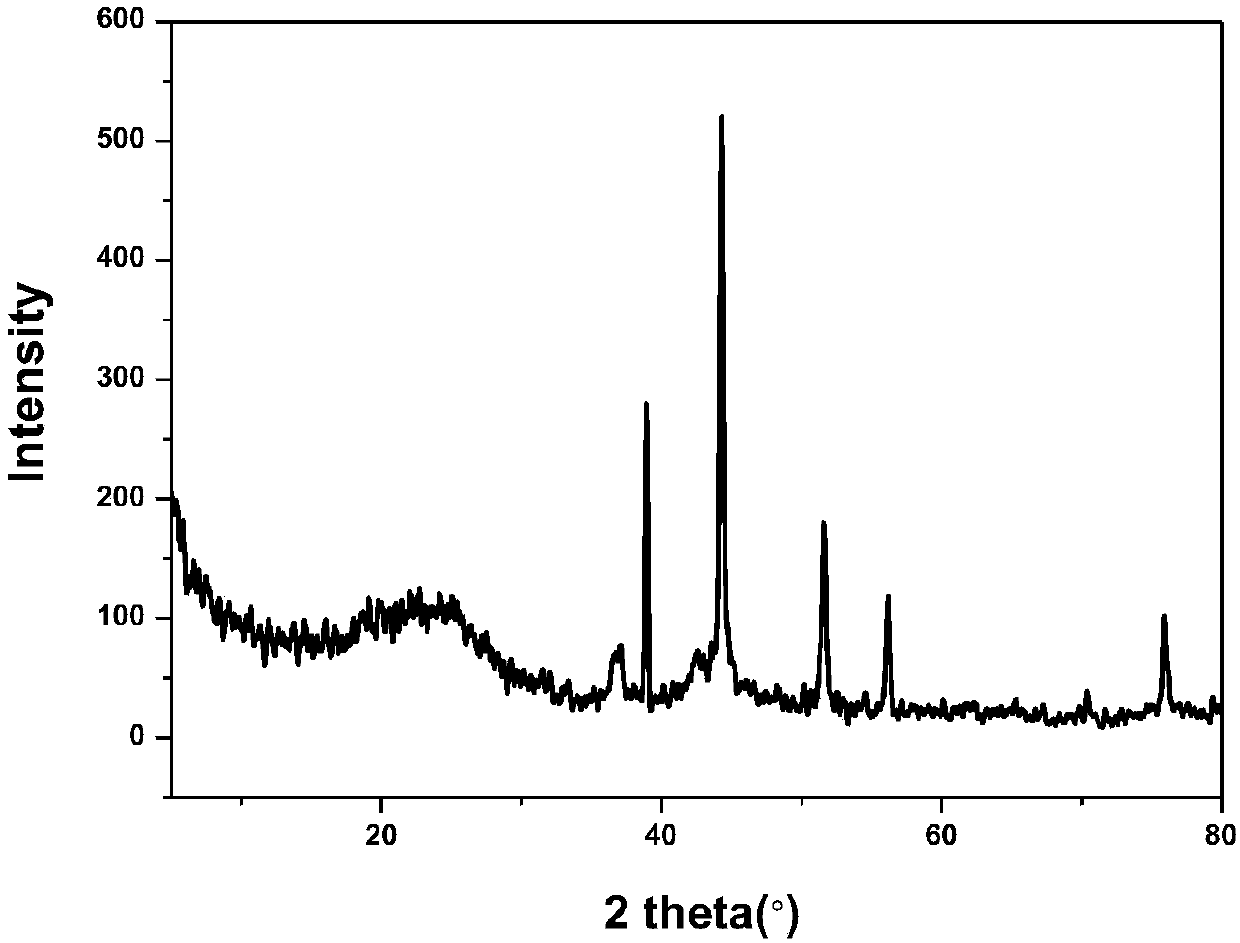

Shower nozzle-structured mesoporous carbon and nanometer cobalt compound and preparation method and application thereof

ActiveCN108024493AWith dielectric lossWith magnetic lossMagnetic/electric field screeningCarbon preparation/purificationDielectric lossNanometre

The invention provides a shower nozzle-structured mesoporous carbon and nanometer cobalt compound, wherein nanometer cobalt is embedded in mesoporous carbon pores. By enabling magnetic nanometer metalcobalt particles to be embedded in mesoporous carbon pores, dielectric loss and magnetic loss on electromagnetic wave are achieved, and wave-absorption strength and loss frequency band can be controlled easily, so that the electromagnetic wave absorption effect is improved effectively; meanwhile, metal cobalt is high in mass and harmful to a human body; and by enabling a few nanometer cobalt particles to be embedded in mesoporous carbon pores, and compared with a cobalt material, the wave absorption effect is ensured, and lighter weight, higher safety and plasticity are achieved, so that thecompound can be widely doped to various electromagnetic wave absorption materials.

Owner:GUANGDONG UNIV OF TECH

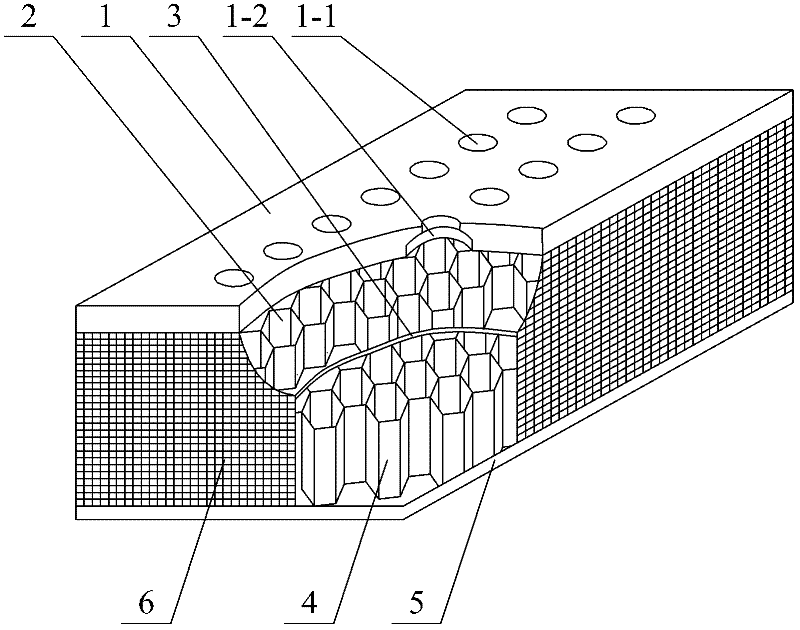

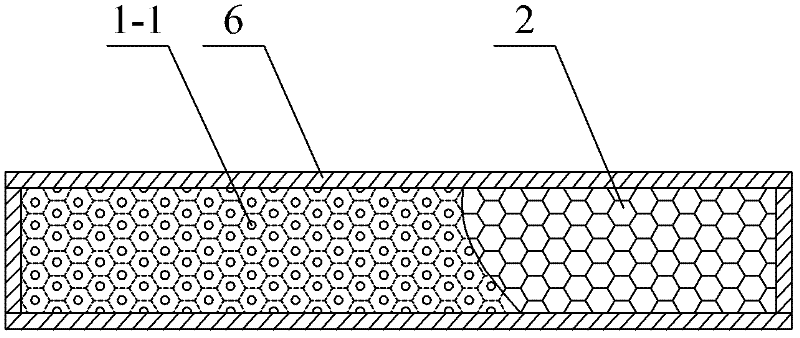

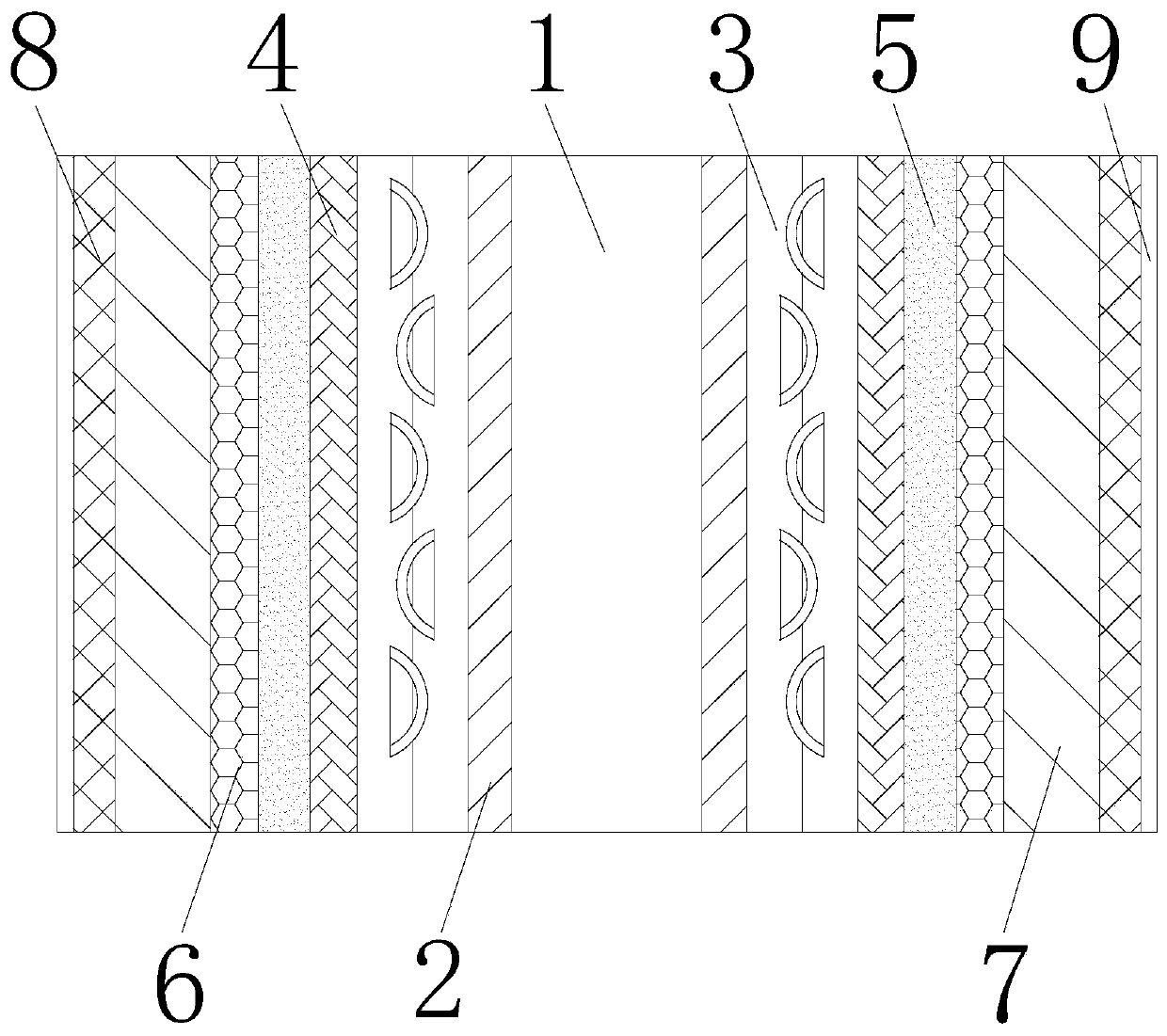

Variable cross-section perforated double-layer sandwich broadband sound-absorbing panel

InactiveCN102294847ATo achieve the absorption effectLightweight and high strengthPaper/cardboard layered productsArchitectural acousticsCell cavity

The variable cross-section perforated double-layer sandwich broadband sound-absorbing panel relates to a sound-absorbing panel. In order to solve the problem that the existing wooden sound-absorbing panels have a narrow sound-absorbing frequency band. The panel, the upper core layer, the thin paper layer, the lower core layer and the back panel are bonded together from top to bottom in sequence. There are multiple through holes uniformly distributed along the thickness direction on the panel, and each through hole consists of a small diameter round hole. Composed of large-diameter round holes or conical holes, small-diameter round holes are set on the front of the panel, large-diameter round holes or conical holes are set on the back of the panel, and the diameter of the small-diameter round hole is equal to the diameter of the small end of the conical hole. The upper and lower core layers are both honeycomb core layers. The honeycomb core layer is composed of multiple hexagonal cylinders spliced together. The inner cavity of each hexagonal cylinder is a honeycomb cavity. The multiple honeycomb cavities on the upper core layer communicate with the multiple honeycomb cavities on the lower core layer and the multiple through holes on the panel. The invention is used for indoor places where architectural design has higher requirements on acoustics.

Owner:NORTHEAST FORESTRY UNIVERSITY

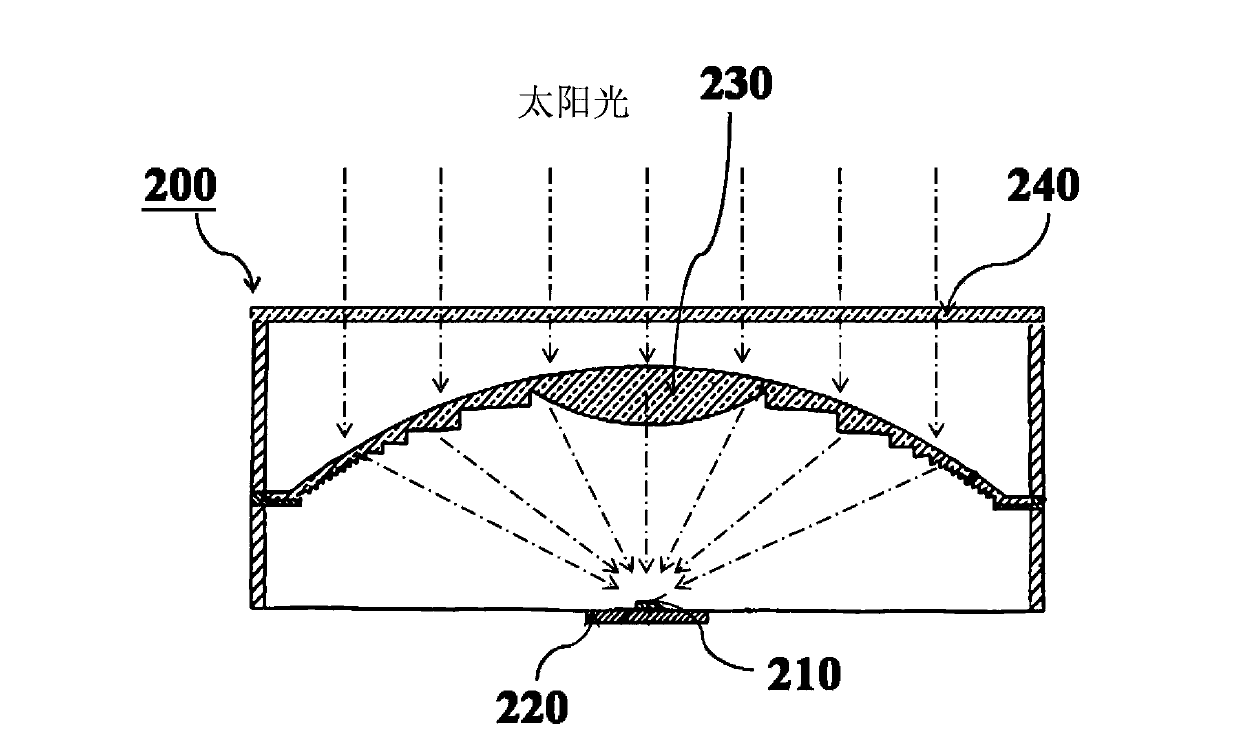

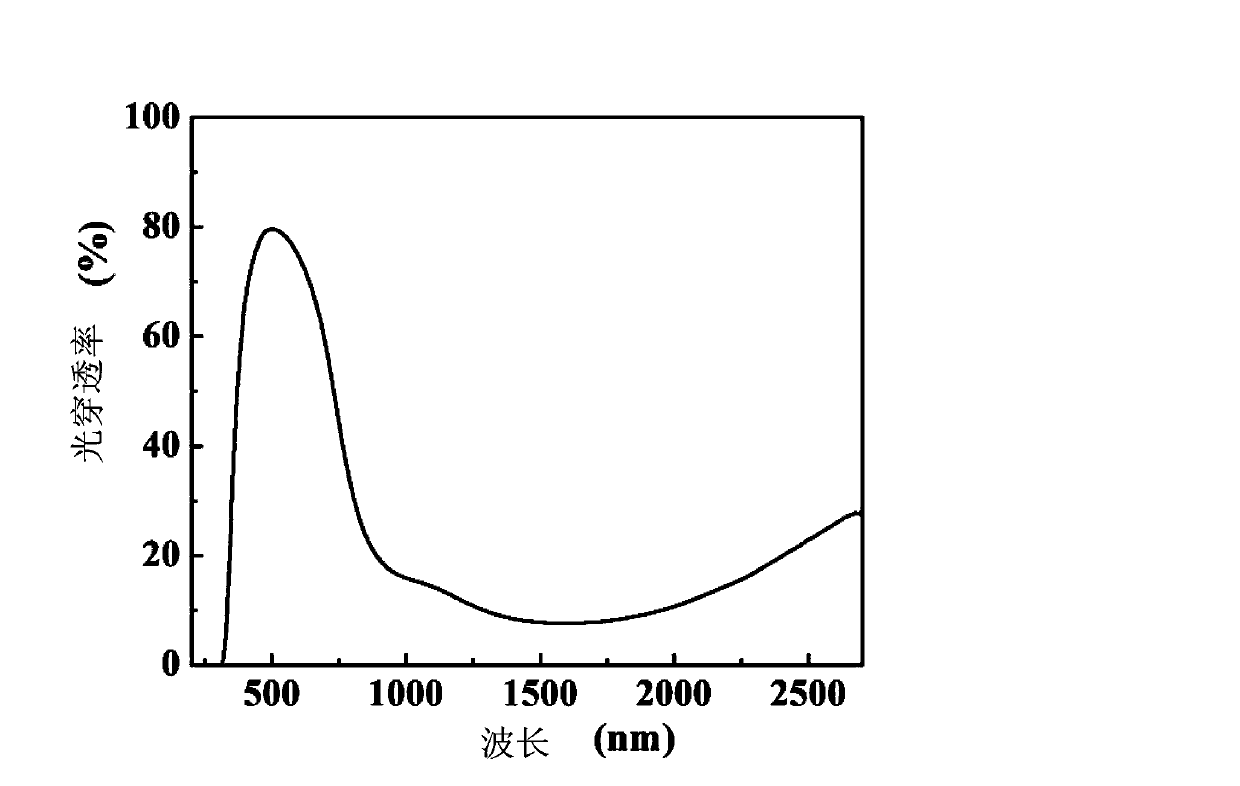

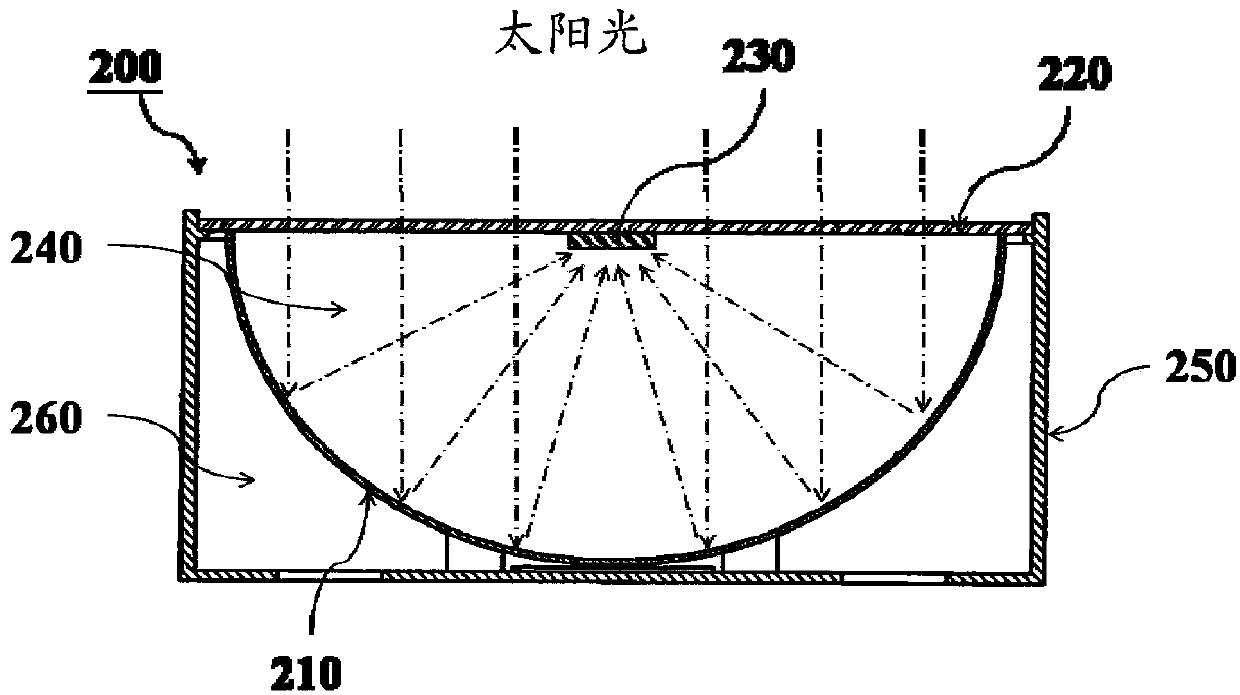

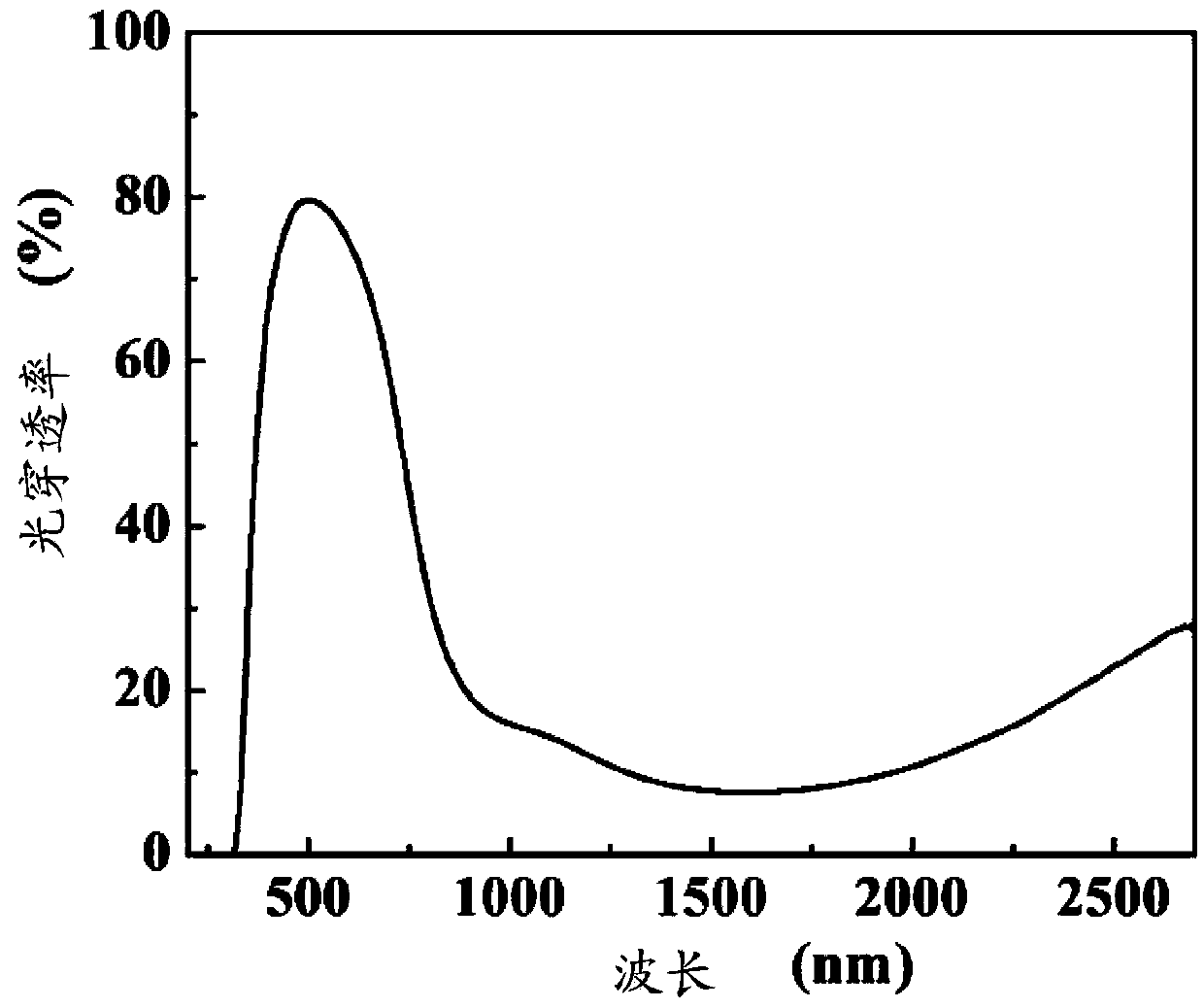

Condensing type soler battery module with lower calorific value

InactiveCN103378207ASave energyReduce heatFinal product manufacturePhotovoltaic energy generationOptical radiationThermodynamics

The invention relates to a condensing type soler battery module with lower calorific value. The soler battery module with lower calorific value comprises a solar battery chip, a circuit supporting plate, a collecting lens and an infrared isolation element. The product provided by the invention can effectively reduce heat source generated by infrared irradiation, in order to eleminate the problem that the condensing type soler battery module has an excessive temperature; moreover, the infrared isolation elemt has has a simple processing method, thereby effectivly reducing production cost.

Owner:NANMAT TECH

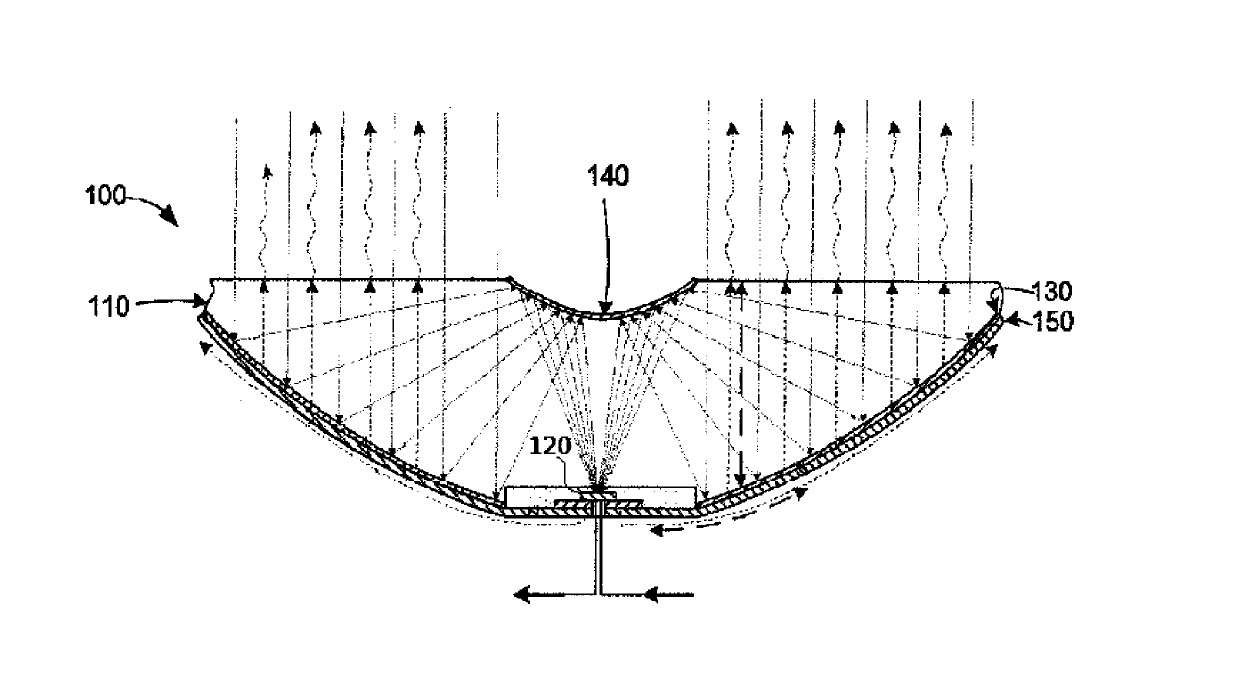

Reflection type condensed light type solar battery module

InactiveCN103378206AReduce heatReduce manufacturing costPhotovoltaic energy generationSemiconductor devicesEngineeringSolar battery

The invention relates to a reflection type condensed light type solar battery module, and the solar battery module contains a reflection type collecting lens, an infrared isolation element and a solar battery chip. The product provided by the invention can effectively reduce heat energy generated by infrared light wave length energy and eleminate the problem that the condensed light type solar battery module has a very high temperature.

Owner:NANMAT TECH

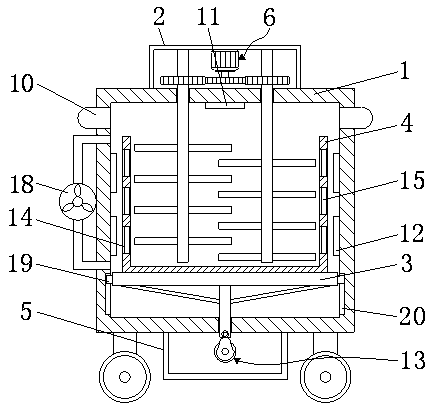

Agricultural machinery grain drying treatment device

InactiveCN109442923ATo achieve the shaking effectTo achieve the effect of placementDrying gas arrangementsDrying solid materialsAgricultural engineeringAgricultural machinery

The invention discloses an agricultural machinery grain drying treatment device. The agricultural machinery grain drying treatment device comprises a box body, the top of the box body is fixedly connected with a first placing box, the box body is internally and fixedly connected with a fixed plate, the top of the fixed plate is fixedly connected with a storing box, the bottom of the box body is fixedly connected with a second placing box, the first placing box is internally and fixedly connected with a stirring mechanism, and the back face of the box body is fixedly connected with a collectionbox. According to the agricultural machinery grain drying treatment device, by means of the arrangements of the fixed plate and the storing box, the effect of placing grain is achieved; by means of the stirring mechanism, the effect of stirring the grain is achieved; by means of a first air fan and the collection box, the effect of absorbing dust generated by the grain is achieved; by means of adust sensor, the effect of detecting the dust is achieved; by means of heating blocks, the effect of generating heat is achieved; by means of a stretching and contracting mechanism, the effect of driving the storing box to shake is achieved; and by means of the agricultural machinery grain drying treatment device, the grain can be effectively dried, and the agricultural machinery grain drying treatment device is convenient to use for people.

Owner:叶敬梓

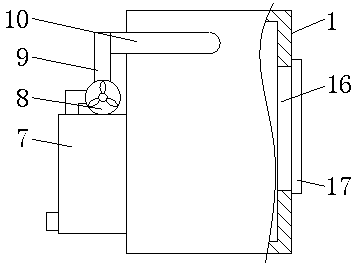

Instrument surface dust removal device based on centrifugal separation principle

InactiveCN111346464ATo achieve the absorption effectTo achieve the effect of complete dust removalCombination devicesDirt cleaningDust controlElectric machinery

The invention relates to the technical field of instruments and meters. The invention further discloses an instrument surface dust removal device based on the centrifugal separation principle. The instrument surface dust removal device comprises a centrifugal box body, supporting legs are movably connected to the left side and the right side of the bottom end of the centrifugal box body; a material taking opening is formed in the bottom end of the centrifugal box body; a rotating shaft is movably connected to the right end, close to the material taking opening, of the middle of a bottom side plate of the centrifugal box body; the bottom end of the rotating shaft is movably connected with a motor; the end, away from the motor, of the rotating shaft is movably connected with a material distribution block. The outer surface of the middle part of the rotating shaft is movably connected with a positioning block; the bottom end of the positioning block is movably connected with a connectingrod; according to the instrument surface dust removal device based on the centrifugal separation principle, through cooperative use of a dust removal box body, the metal block, a filter screen, a water tank and other structures, the effect that dust obtained after dust removal is absorbed is achieved, and through cooperative use of the material block, the positioning block, the connecting rod, a conical barrel and other structures, the effect of complete dust removal is achieved.

Owner:吴小毛

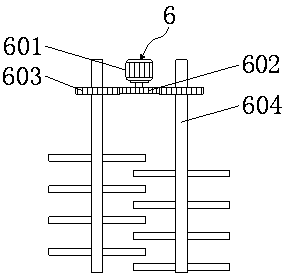

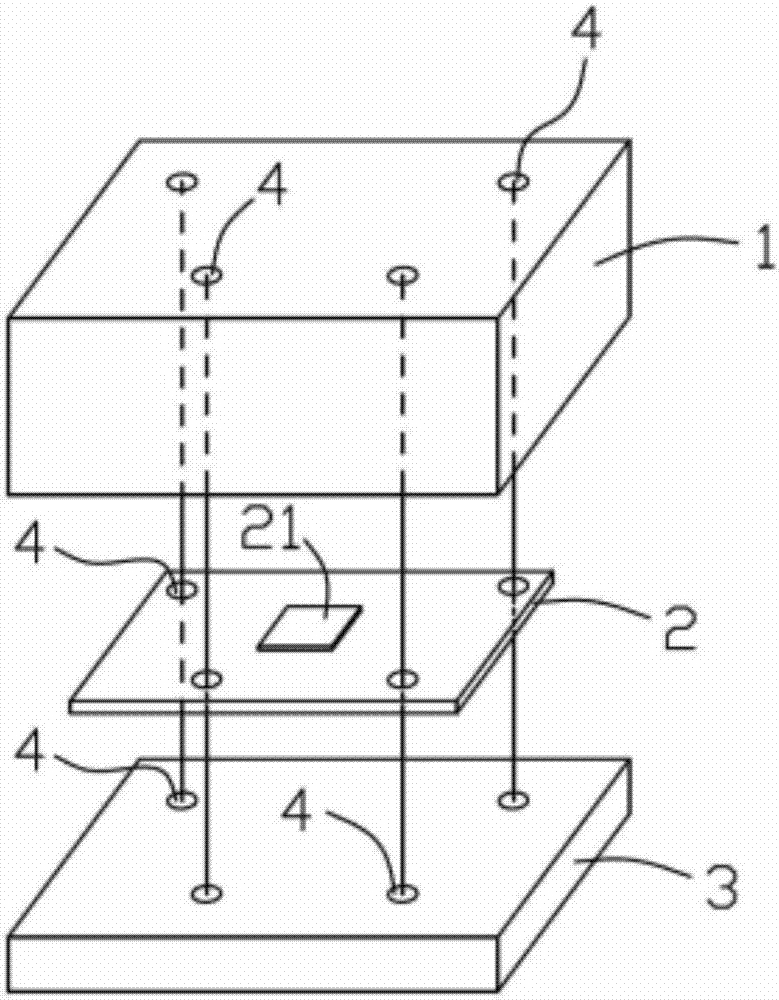

Intelligent household mute central control machine case

PendingCN107995831AReduce noiseImprove system stabilityScreening casingsCooling/ventilation/heating modificationsComputer caseManufacturing engineering

The invention relates to an intelligent household mute central control machine case. The intelligent household mute central control machine case includes an upper-layer case cover, a middle-layer control mainboard and a lower-layer case bottom; the upper-layer case cover, the middle-layer control mainboard and the lower-layer case bottom are all provided with matched installation holes, a core processor is arranged on the control mainboard, the upper-layer machine case is internally provided with a boss matched with the core processor, the boss is provided with a heat-radiating bulge arrangedin a large area, and the heat-radiating bulge is tightly attached to the core processor. The inner surfaces of the upper-layer case cover and the lower-layer case bottom are covered with electromagnetic shielding material layers.

Owner:朱明君

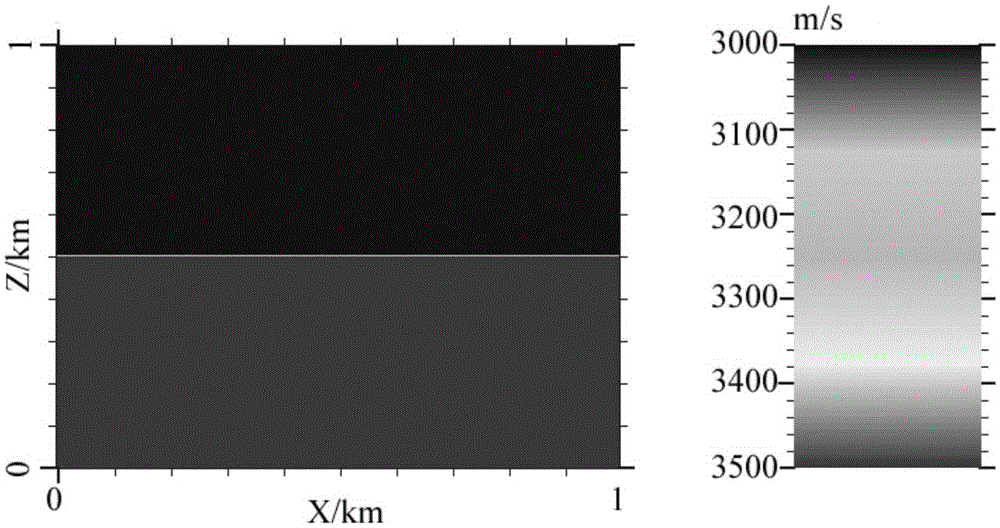

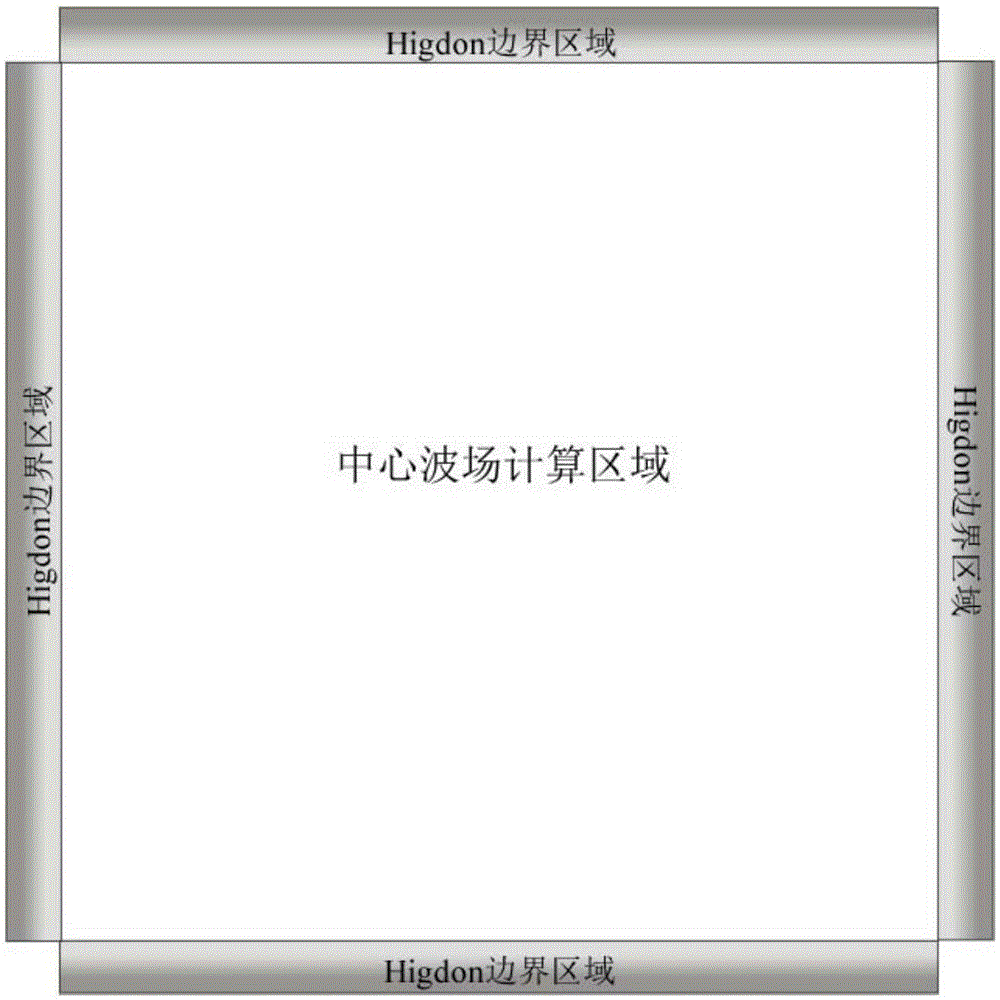

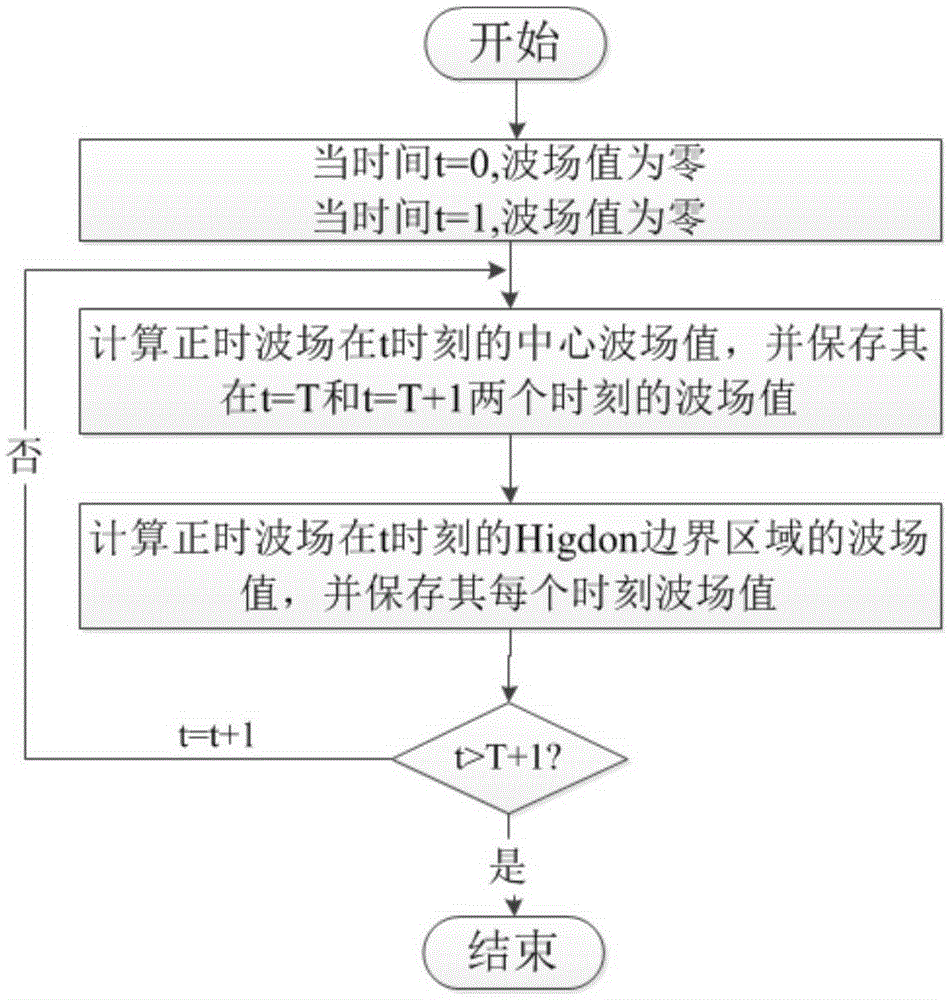

Sound wave reverse time migration method based on Higdon third-order boundary condition

InactiveCN105242310ATo achieve the purpose of absorption attenuationSmall amount of calculationSeismic signal processingReverse timeContinuation

The invention relates to a sound wave reverse time migration method based on a Higdon third-order boundary condition, and belongs to the field of seismic exploration migration imaging. The sound wave reverse time migration method has the specific steps of: step 1, carrying out continuation of a correct time wave field by taking seismic wavelets as correct time disturbance, saving central wave field values at the last two moments, and calculating and saving a wave field value in a boundary region based on the Higdon third-order boundary condition; step 2, carrying out continuation of a reverse time wave field by taking seismic records as reverse time disturbance, and reconstructing a central wave field value of the correct time wave field by utilizing the saved central wave field values and the wave field value of the boundary region; step 3, and multiplying a correct time wave field value and a reverse time wave field value at each point, regarding the result as an imaging value of the point, and adding the imaging values of all moments to obtain a final imaging value of the point. The sound wave reverse time migration method eliminates boundary reflection by utilizing the Higdon third-order boundary condition, achieves the reconstruction of the correct time wave field based on boundary storage of the boundary condition, can effectively reduce memory consumption of conventional reverse time migration, and has higher imaging precision.

Owner:OCEAN UNIV OF CHINA

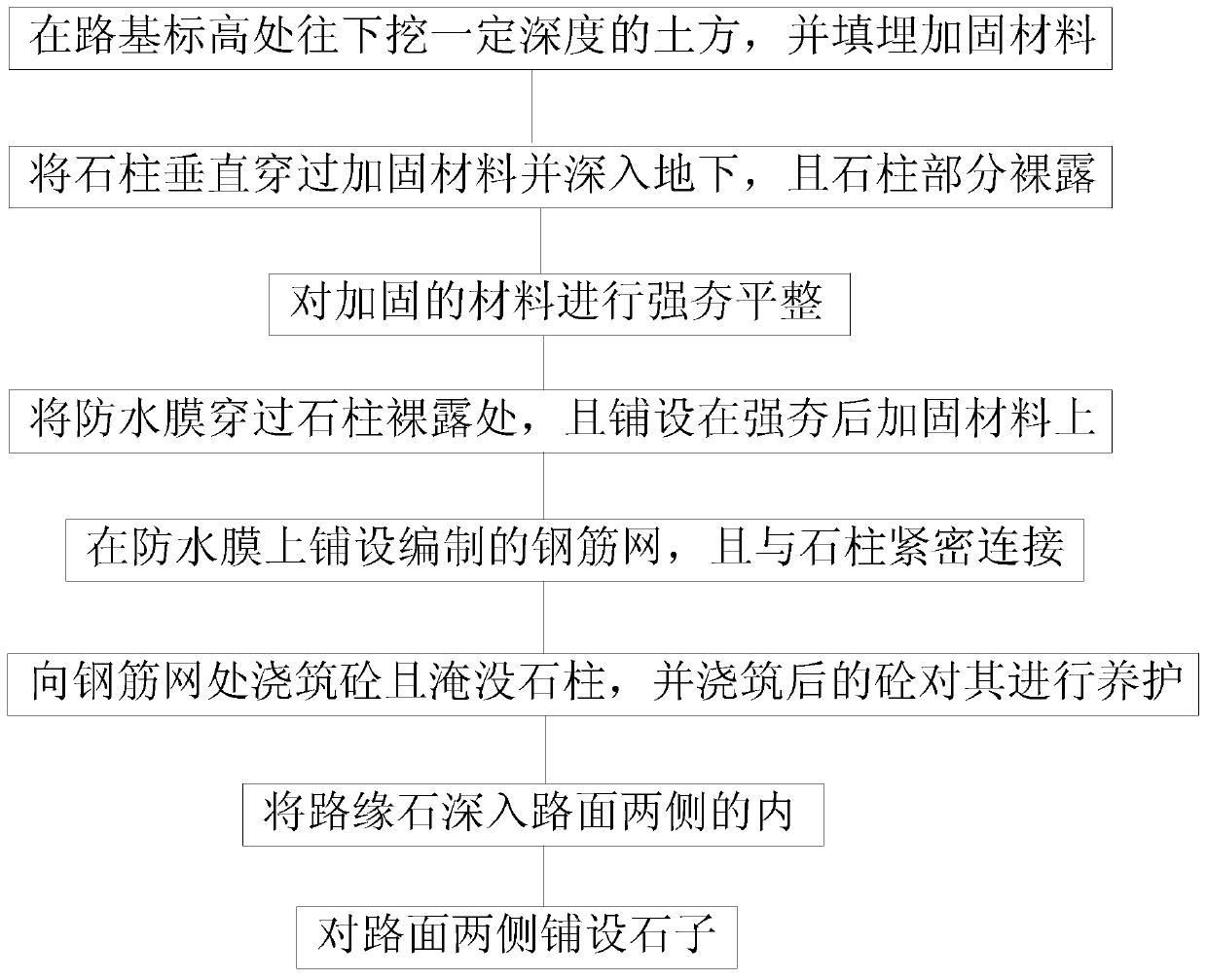

Settlement prevention construction method for highway

The invention discloses a settlement prevention construction method for a highway. The method comprises the following steps of downwards digging earthwork with a certain depth at a roadbed elevation,and packing a reinforcing material; vertically penetrating a stone column through the reinforcing material and enabling the stone colume to go deep into the ground, and exposing a part of the stone column; carrying out dynamic compaction and leveling on the reinforcing material; enabling a waterproof film to penetrate through the exposed part of the stone column and laying the waterproof film on the reinforcing material after dynamic compaction; laying a woven reinforcing mesh on the waterproof film to be tightly connected to the stone column; pouring concrete at the reinforcing mesh and submerging the stone column, and maintaining the poured concrete; enabling kerbs to go deep into two sides of the pavement; and laying stones on the two sides of the pavement. According to the settlement prevention construction method for the highway, the waterproof film is laid at the deep roadbed, so that the erosion of rainwater on the deep roadbed is avoided, and thus sedimentation is avoided; andthe stones are arranged, so that the erosion of the rainwater to the roadbed is reduced, and meanwhile, the vibration of the pavement is reduced, and thus the pavement can be used for a long time.

Owner:NANCHANG RAILWAY ENG CO LTD OF CHINA RAILWAY 24TH BUREAU GRP CO LTD +1

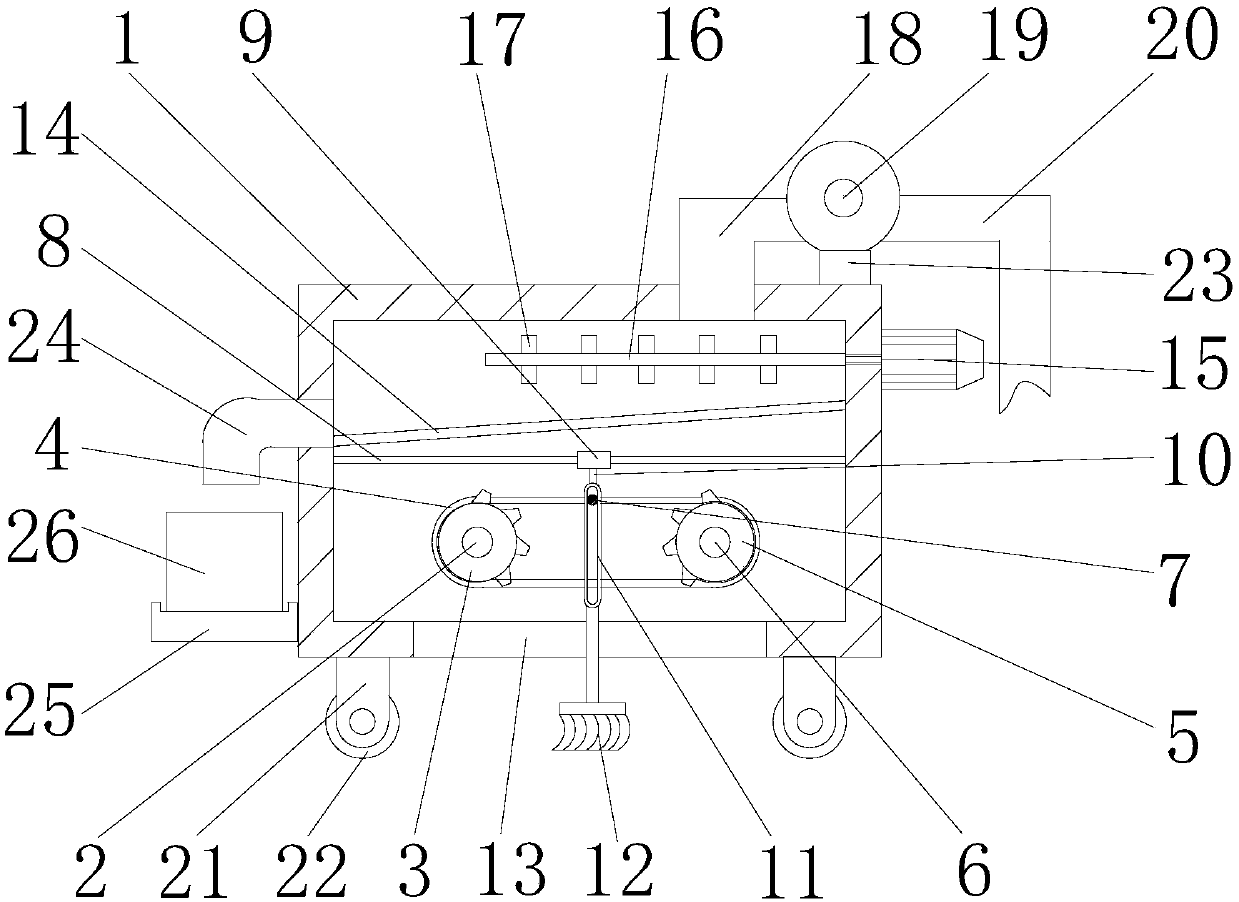

Garden fallen leaf sweeping device

InactiveCN107687147ATo achieve the absorption effectImprove work efficiencyRoad cleaningGrain treatmentsGear wheelGreening

The invention discloses a device for cleaning fallen leaves for gardens, which comprises a machine body, a first motor is fixedly connected to the bottom of the inner cavity of the body, an output shaft of the first motor is fixedly connected to a driving gear, and the surface of the driving gear A driven gear is connected through a chain transmission, and a rotating rod is fixedly connected to the axis center of the back of the driven gear, and the back of the rotating rod is movably connected to the inner wall of the body through a bearing, and a sliding shaft is fixedly connected to the surface of the chain . The present invention achieves the advantages of left and right movement by arranging the cooperation of the first motor, driving gear, chain, driven gear, rotating rod, sliding shaft, sliding rod, sliding sleeve, connecting rod, annular groove plate, broom and through groove, So as to achieve the effect of saving time and labor, the cooperation of the air outlet pipe, the fan and the air inlet pipe can achieve the effect of absorbing the fallen leaves, which brings convenience to the greening personnel, improves the work efficiency of the greening personnel, and contributes to the improvement of the garden environment. greening.

Owner:叶侃

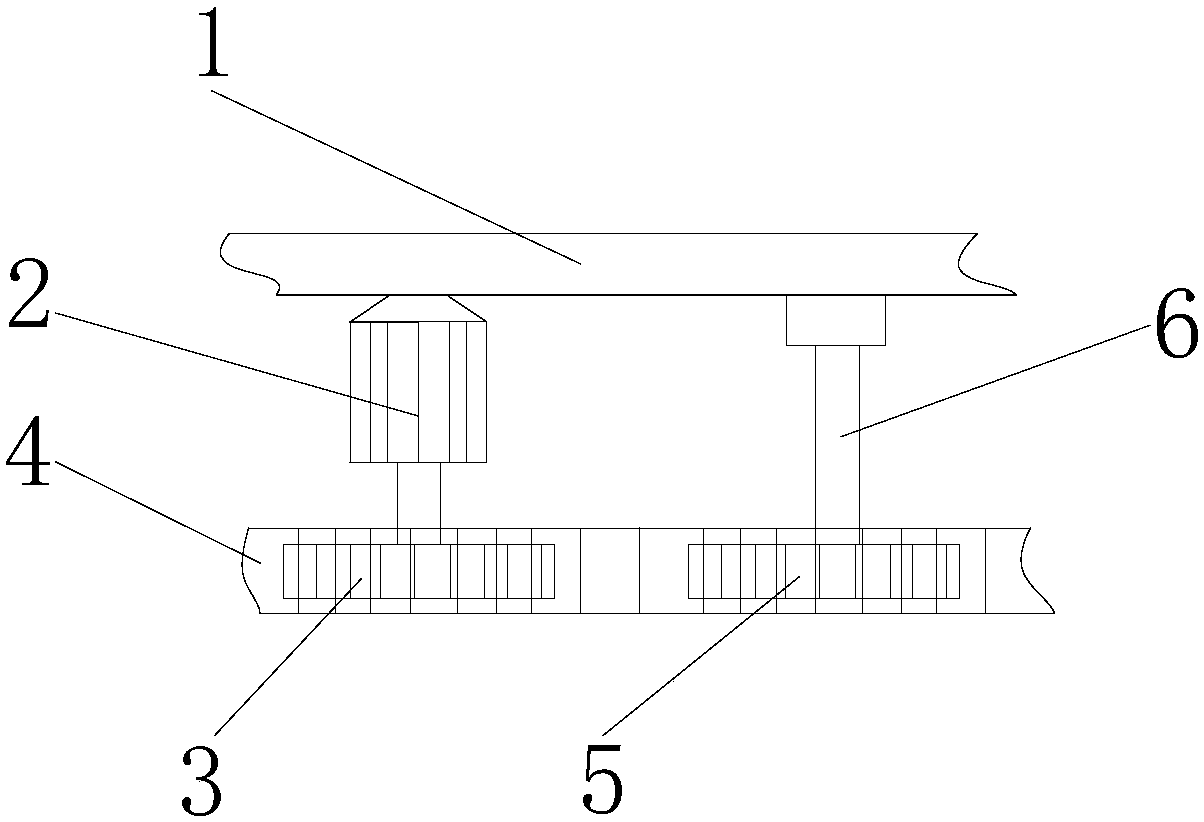

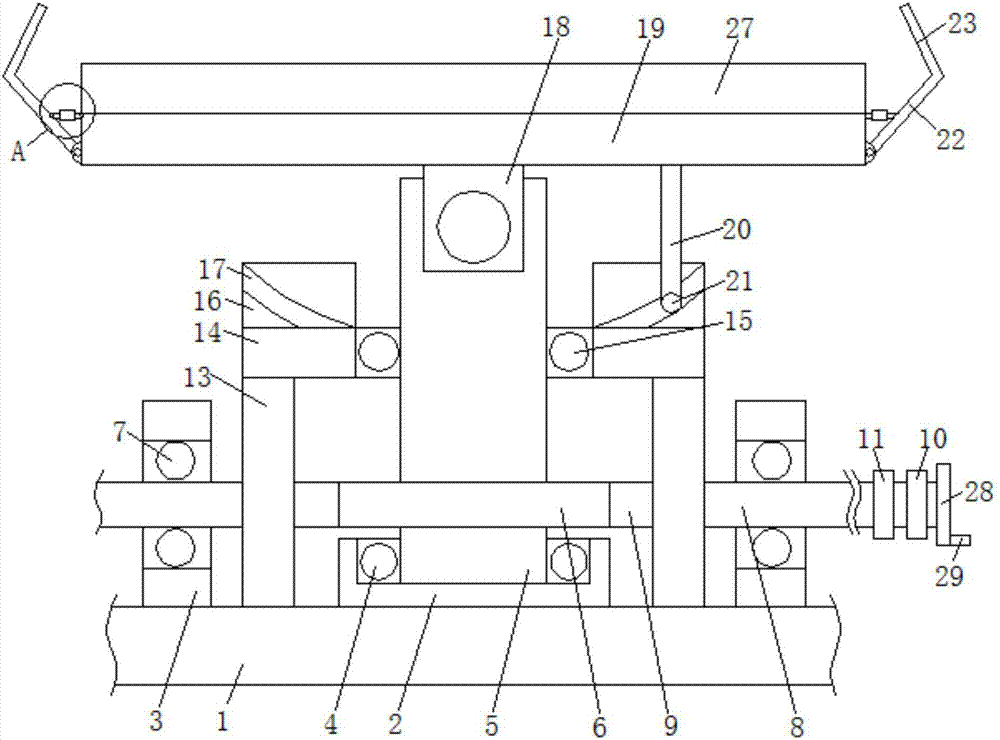

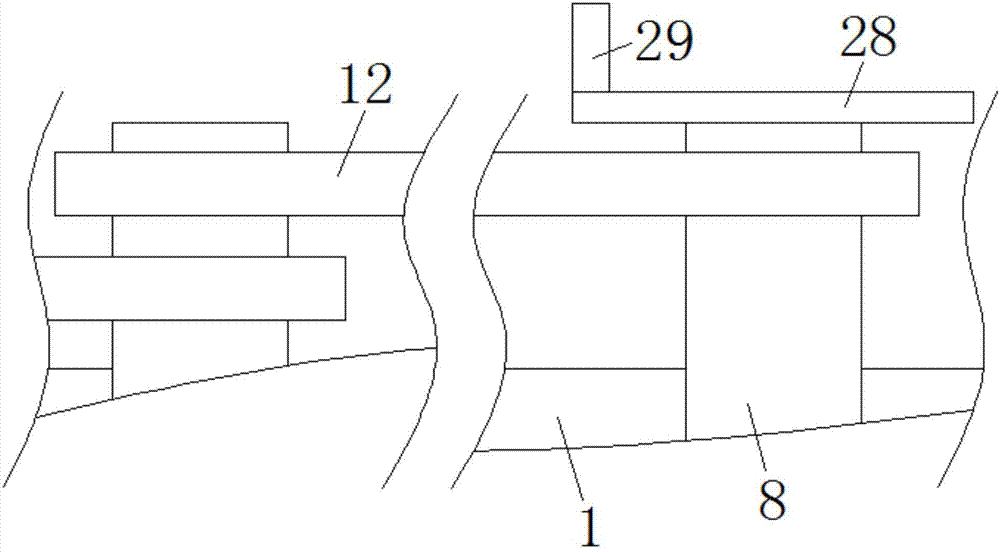

Welding, sealing clamping device for shock absorber

PendingCN112355560AControl the effect of stretchingChange the working voltageWelding/cutting auxillary devicesAuxillary welding devicesMagnetic tension forceDielectric plate

The invention relates to the technical field of shock absorber welding, and discloses a welding, sealing and clamping device for a shock absorber. The device comprises a fixed base, compression springs are fixedly connected to the inner wall of the middle of the fixed base, sliding blocks are movably connected to the inner wall of the middle of the fixed base, pressing rods are movably connected to the front faces of the sliding blocks, clamping bases are fixedly connected to the inner sides of the pressing rods, and purification cavities are formed in the middle of the fixed base. According to the welding, sealing and clamping device for the shock absorber, the clamping bases drive push rods to move, the push rods drive movable blocks to move, through cooperative use of dielectric plates,positive plates and negative plates, the effect of controlling air bags to stretch and retract is achieved, and electromagnets are powered on to generate magnetic force repelling magnetic blocks; andwhen a shock absorption barrel is welded, due to the fact that high temperature is generated during welding piece welding, bimetallic strips on the inner walls of the clamping bases are heated to generate deformation and bending, at the moment, the electromagnets are powered off, the air bags expand under the action of reset springs, and gas generated during welding is sucked into the purification cavities through gas suction pipes.

Owner:王哲涵

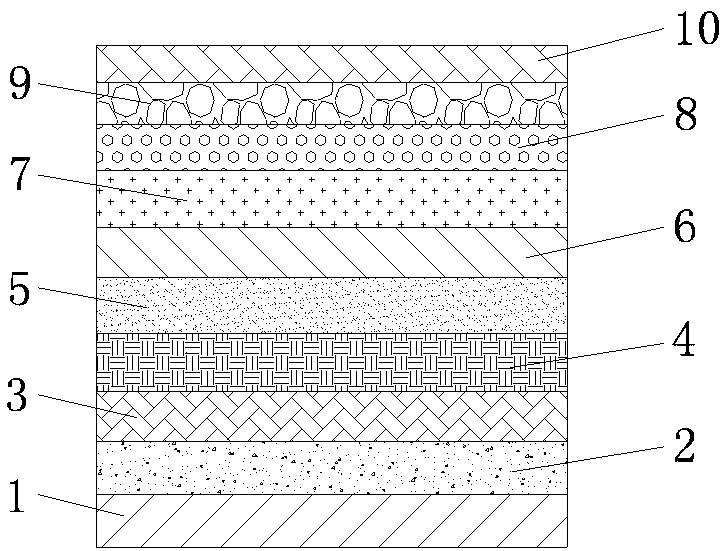

Moisture-permeable anti-bacteria and anti-ultraviolet bamboo fiber fabric

InactiveCN110682617ATo achieve the absorption effectMany functionsSynthetic resin layered productsCellulosic plastic layered productsFiberChemistry

The invention discloses moisture-permeable anti-bacteria and anti-ultraviolet bamboo fiber fabric. The moisture-permeable anti-bacteria and anti-ultraviolet bamboo fiber fabric comprises a base fabriclayer. A breathable layer is arranged at the top of the base fabric layer, and a reinforcing layer is arranged on the side, away from the base fabric layer, of the breathable layer. A moisture-absorbing layer is arranged on the side, away from the breathable layer, of the reinforcing layer, a waterproof and breathable layer is arranged on the side, away from the reinforcing layer, of the moisture-absorbing layer, and an anti-ultraviolet layer is arranged on the side, away from the moisture-absorbing layer, of the waterproof and breathable layer. According to the moisture-permeable anti-bacteria and anti-ultraviolet bamboo fiber fabric, the effect of forming the bamboo fiber fabric is achieved by the base fabric layer, the breathable effect is achieved by the breathable layer, the effectsof increasing the strength of the fabric and preventing wrinkling are achieved by the reinforcing layer, the moisture-absorbing effect is achieved by the moisture-absorbing layer, the waterproof and breathable effects are achieved by the waterproof and breathable layer, the anti-ultraviolet effect is achieved by the anti-ultraviolet layer, and the effect of ultraviolet absorption is achieved by anabsorbing layer. The bamboo fiber fabric has multiple functions and can meet requirements of people.

Owner:苏州恒可鸣纺织有限公司

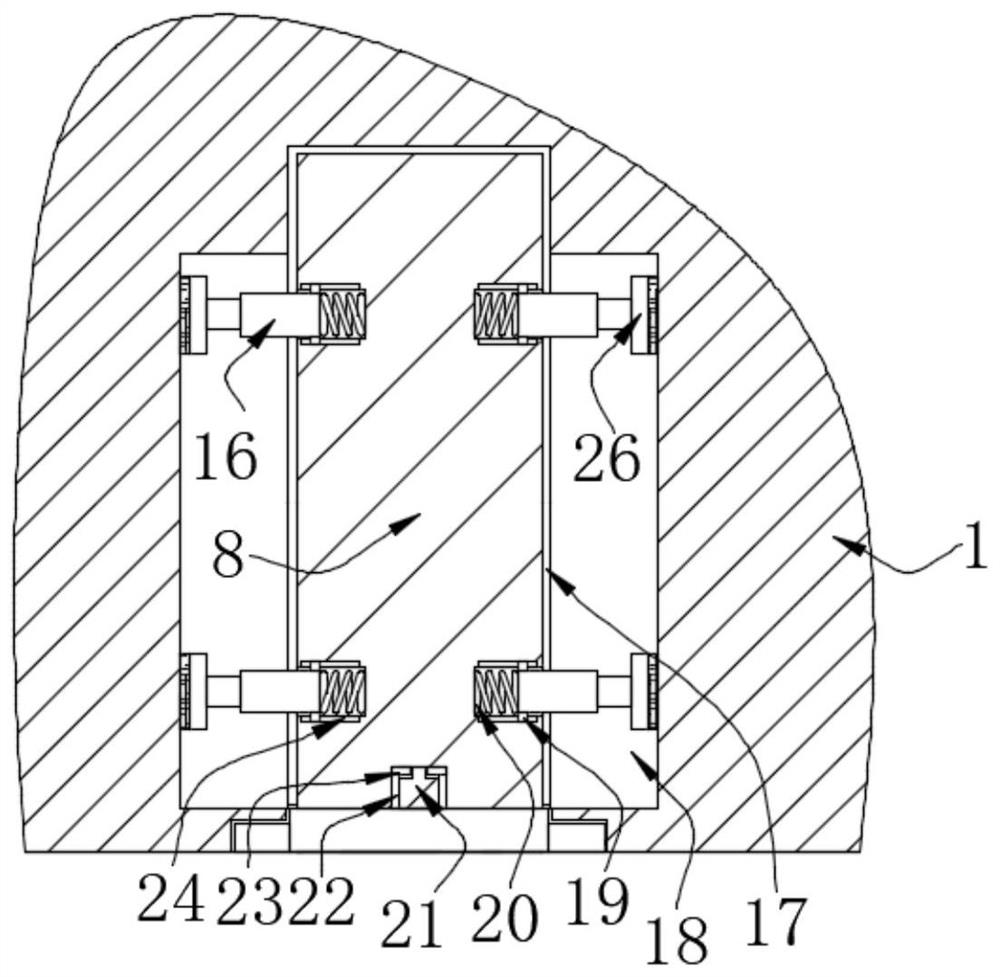

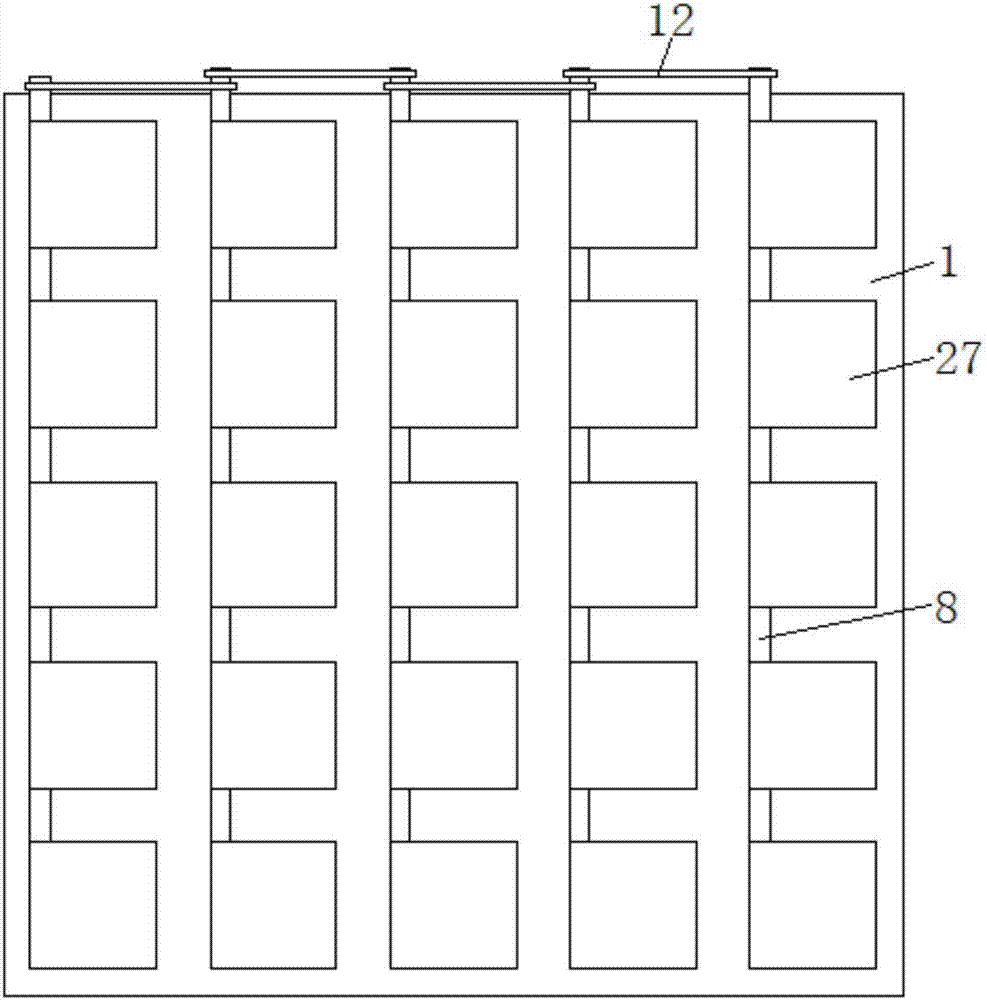

Component type timber structure building energy absorption and shock absorption structure

PendingCN112392316AImprove shock absorptionTo achieve the absorption effectProtective buildings/sheltersShock proofingEnergy absorptionMechanical engineering

The invention discloses a component type timber structure building energy absorption and shock absorption structure. The component type timber structure building energy absorption and shock absorptionstructure comprises two first plate bodies, two third grooves and two fourth grooves are symmetrically formed in the two first plate bodies correspondingly, the fourth grooves communicate with the third grooves, first springs are welded to the inner side walls of the fourth grooves, connecting plates are welded to one ends of the first springs, and supporting rods are attached to the tops of theconnecting plates. According to the component type timber structure building energy absorption and shock absorption structure, the supporting rods and first rod bodies are extruded through second plate bodies, so that the first springs are extruded, the supporting rods drive sleeves and T-shaped inner rods to move, the sleeves and the T-shaped inner rods drive third plate bodies to slide in the first sliding grooves so as to consume part of vibration force, and the shock absorption effect of the first plate bodies is improved; and the two connecting rods are extruded through the first rod bodies, so that the magnetic force between magnet plates and magnet blocks further consumes part of the vibration force, and therefore the effect of absorbing the vibration force is achieved, and the shock absorption effect of the first plate bodies is further improved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

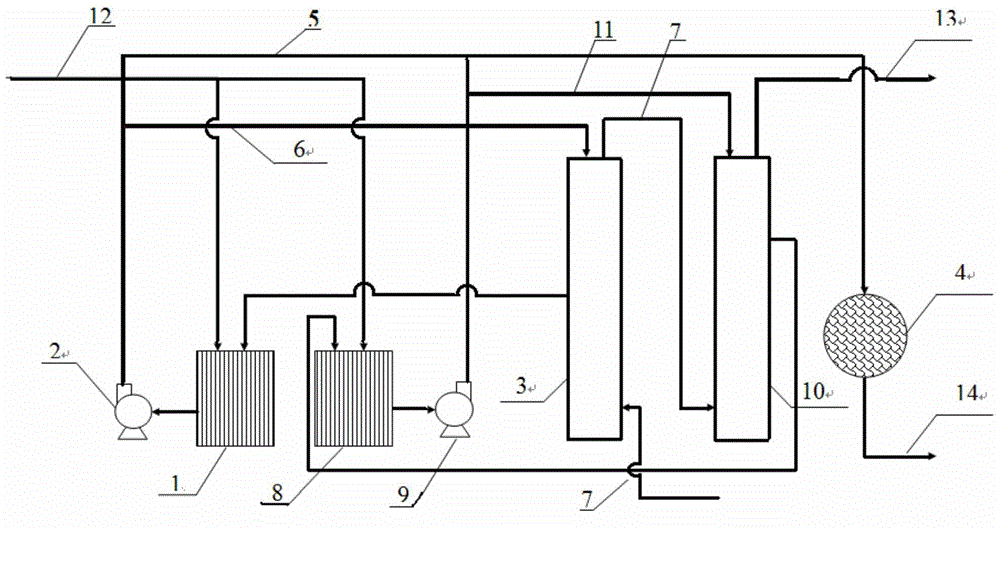

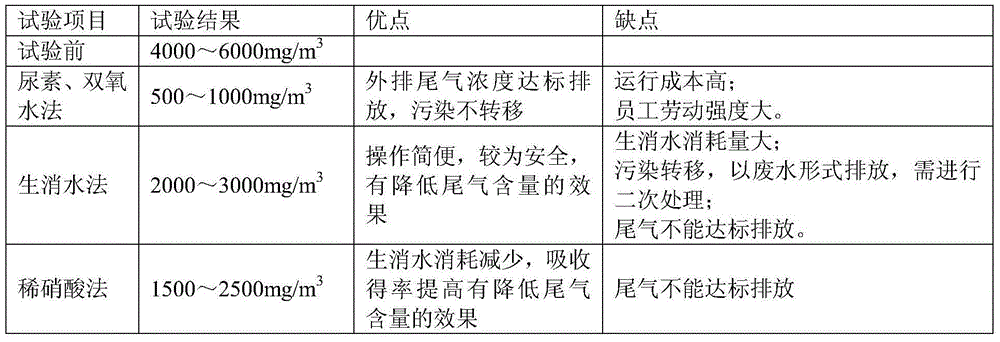

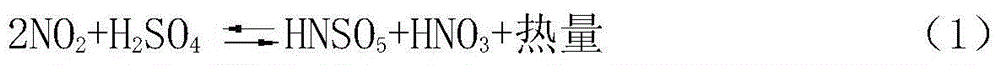

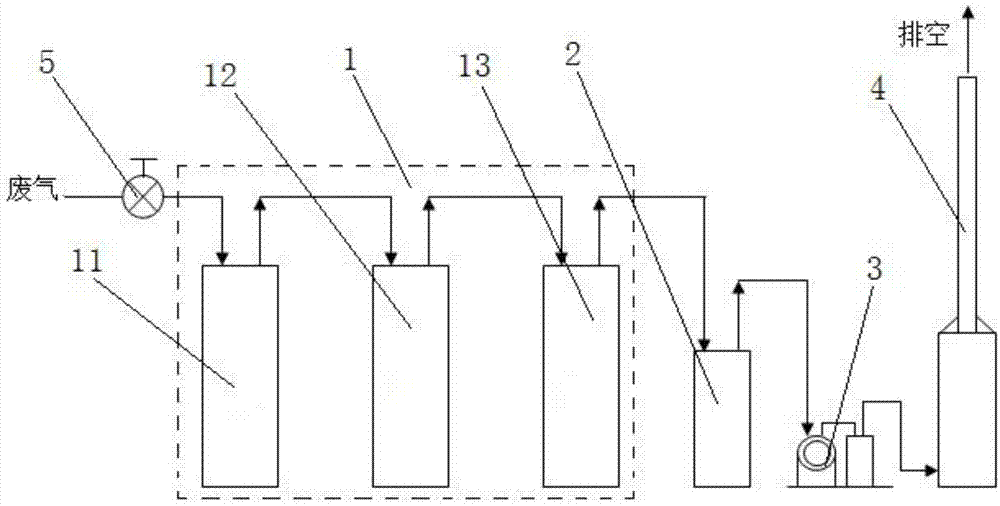

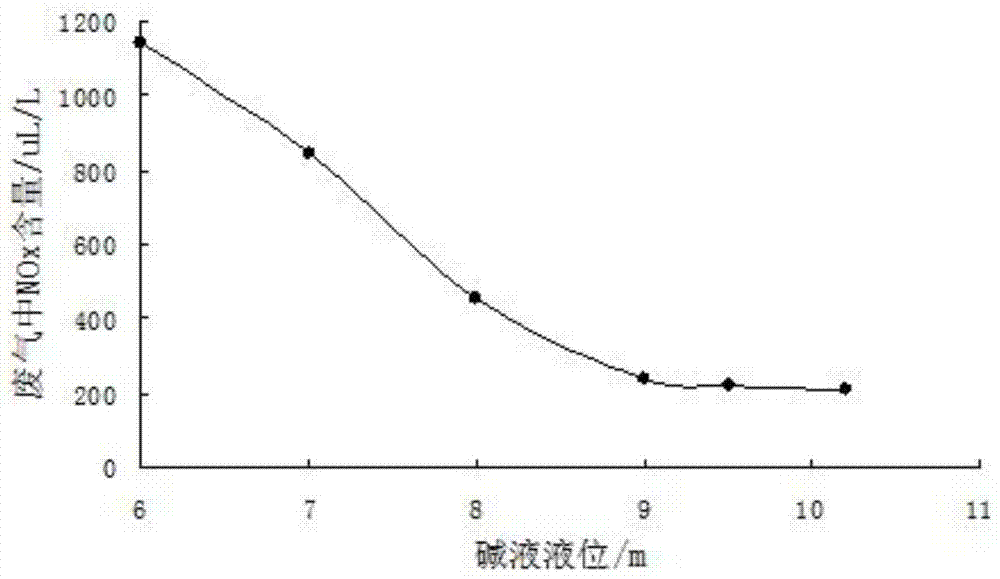

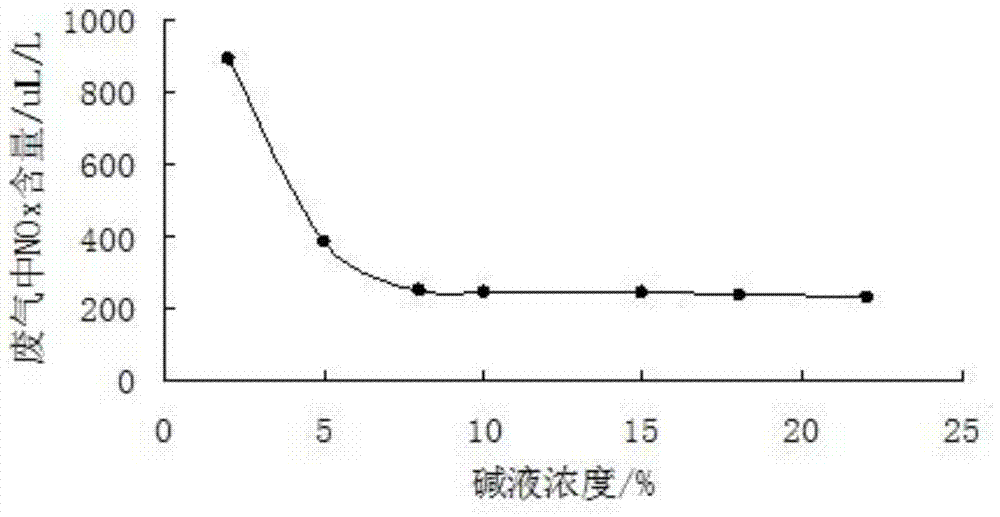

Device and method for reducing concentration of nitrogen oxide in discharged tail gas of explosive powder production line

InactiveCN104607025ASolve the cost-prohibitive problemReduce lossesDispersed particle separationLower limitProduction line

The invention discloses a device and method for reducing the concentration of nitrogen oxide in the discharged tail gas of an explosives powder production line. According to the device for reducing the concentration of nitrogen oxide in the discharged tail gas of the explosives powder production line, different circulation tanks are respectively communicated with a concentrated sulfuric acid pipeline, different circulation pumps and different tail gas decomposition towers of a nitric-sulfuric acid concentration procedure. Sulfuric acid is determined as the lower limit of the concentration of an absorbent, and circulated acid can be exchanged in time, so that the expected effect in absorbing the nitrogen oxide by using the concentrated sulfuric acid can be ensured, and the reduction of the concentration of the concentrated sulfuric acid, caused by circulation and absorption, is avoided. By adopting the device and the method, the nitrogen oxide absorption effect equivalent to those of a urea and hydrogen peroxide method and a pressurized absorption method can be achieved, the content of the nitrogen oxide in the waste gas can be reduced to be less than 500mg / m<3>, and moreover, the difficulty that the cost is too high in the operation process of the urea and hydrogen peroxide method and the pressurized absorption method is solved.

Owner:GANSU YINGUANG CHEM IND GRP CO LTD

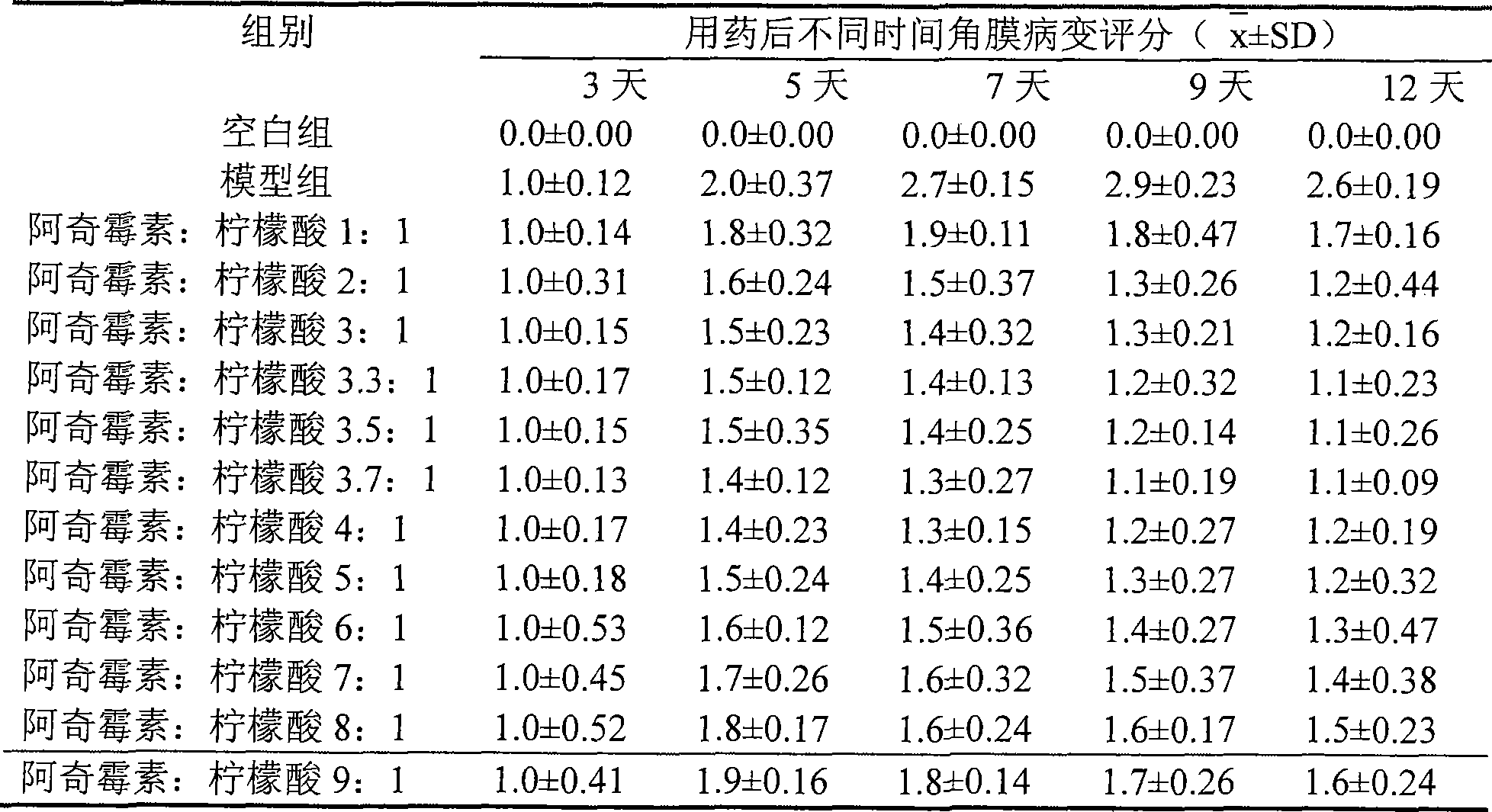

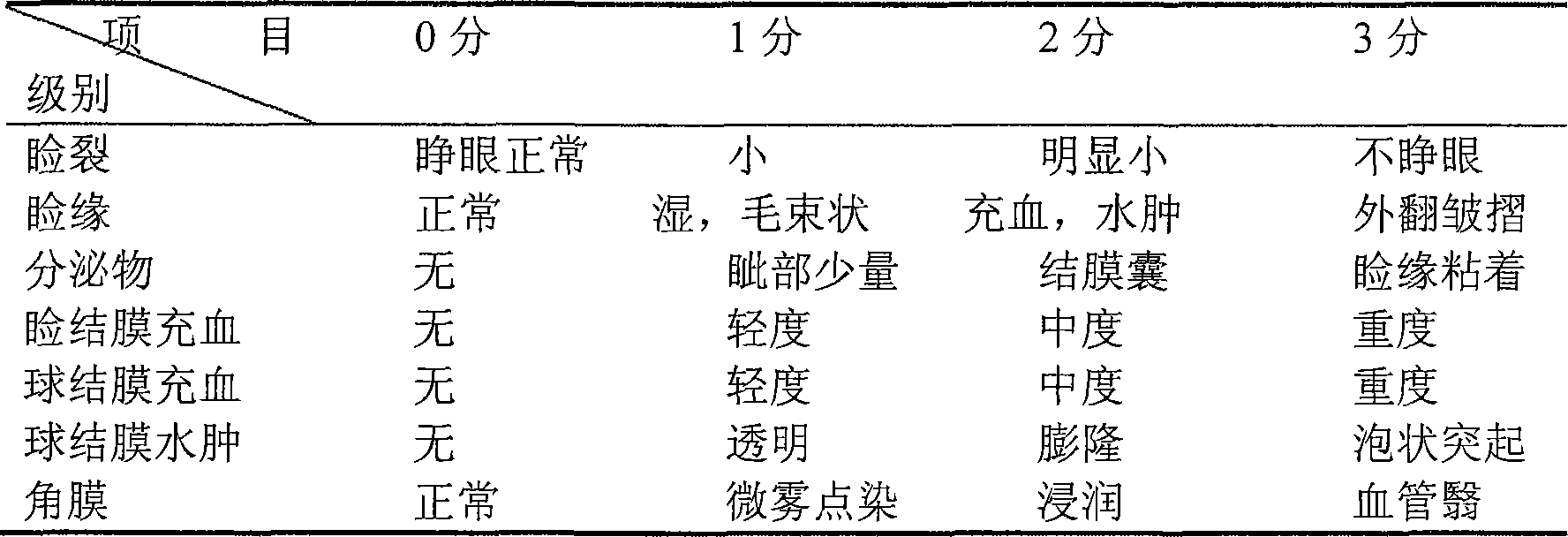

Azithromycin ophthalmic gel preparation composition and preparation and application thereof

InactiveCN101234079ATo achieve the absorption effectSolve the shortcomings of not easy to dissolveOrganic active ingredientsSenses disorderDiseaseAzithromycin

The invention discloses a novel composition of an ophthalmic Azithromycin gel preparation, a preparation method thereof and applications thereof. The researcher of the invention combines appropriate auxiliary materials with the combination of Azithromycin and citric acid to prepare the ophthalmic Azithromycin gel preparation; the combination of the Azithromycin and the citric acid in the invention can achieve better absorption of the Azithromycin, which resolves the problem that the Azithromycin is difficult to dissolve; meanwhile, the manufactured gel preparation can ensure that the drug have prolonged effects on lesion location to realize full absorption of the drug. The ophthalmic Azithromycin gel preparation of the invention has obvious pharmacological action and outstanding effects on treatment of such ophthalmic diseases as conjunctivitis, keratitis, trachoma, dacrocystitis, etc.

Owner:迈洋致达(北京)科技有限公司

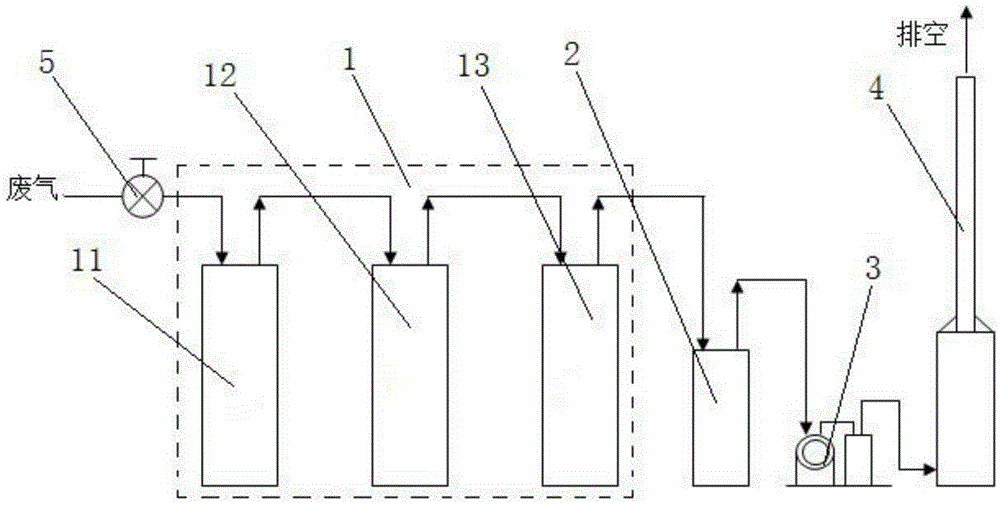

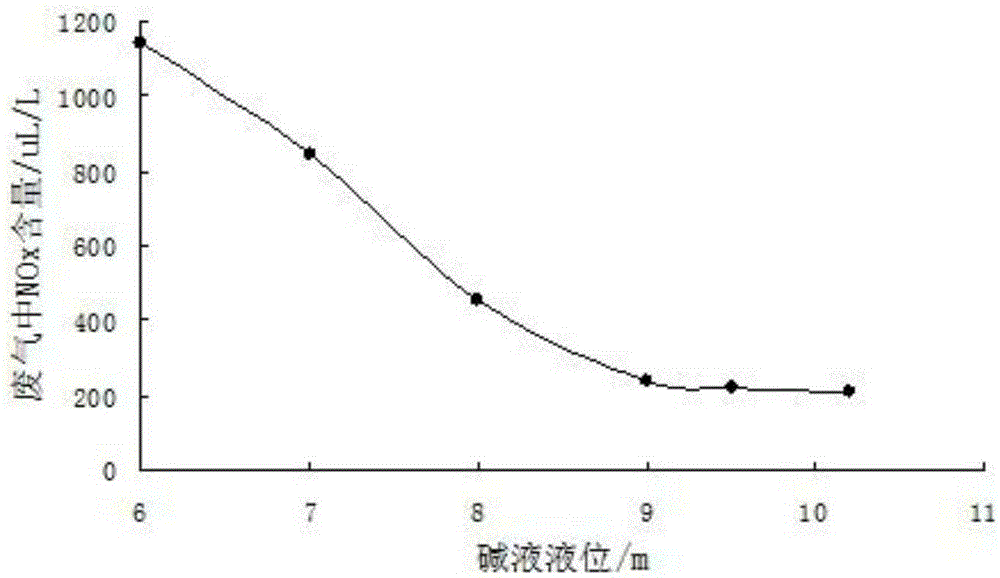

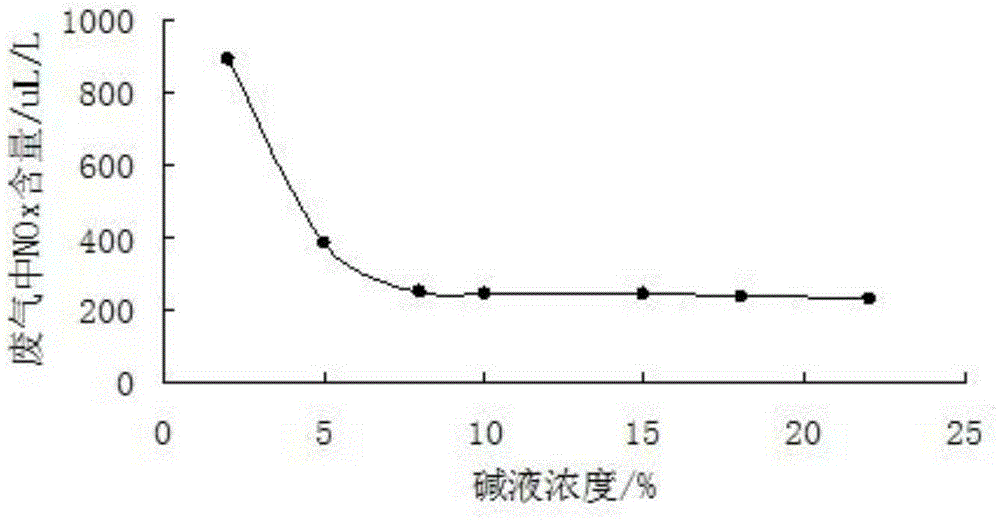

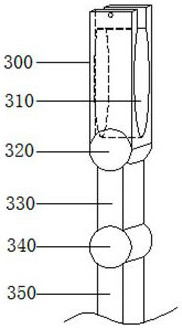

Molybdenum disulfide production waste gas treatment device and method

ActiveCN103894052BCause corrosionDoes not affect absorptionDispersed particle separationBuffer tankTower

The invention relates to a device for processing waste gas from molybdenum disulfide production. The device comprises an alkali tank, a buffer tank, a vacuum pump and an emptying tower which are sequentially connected through pipelines, wherein the alkali tank comprises an alkali tank 1#, an alkali tank 2# and an alkali tank 3# which are sequentially connected through pipelines. The method comprises the steps of enabling the waste gas to sequentially flow through an NaOH solution in the alkali tank 1#, the alkali tank 2# and the alkali tank 3# to absorb a great amount of NOx and a small amount of volatile HCl and HF in the waste gas, absorbing the small amount of NOx by virtue of urea in the buffer tank, and discharging the processed gas through the emptying tower. According to the device, the waste gas is directly absorbed and processed by virtue of NaOH, and the tail gas is supplementarily absorbed by virtue of the urea, so that an absorption effect cannot be influenced due to the crystallization of alkali liquid after the device is used for a long time; besides, the alkali tank and the buffer tank are antiseptic by virtue of a rubber lining technique, and the vacuum pump is arranged behind the buffer tank, the vacuum pump cannot be corroded by the processed waste gas, and the utilization rate of equipment is improved.

Owner:JINDUICHENG MOLYBDENUM CO LTD

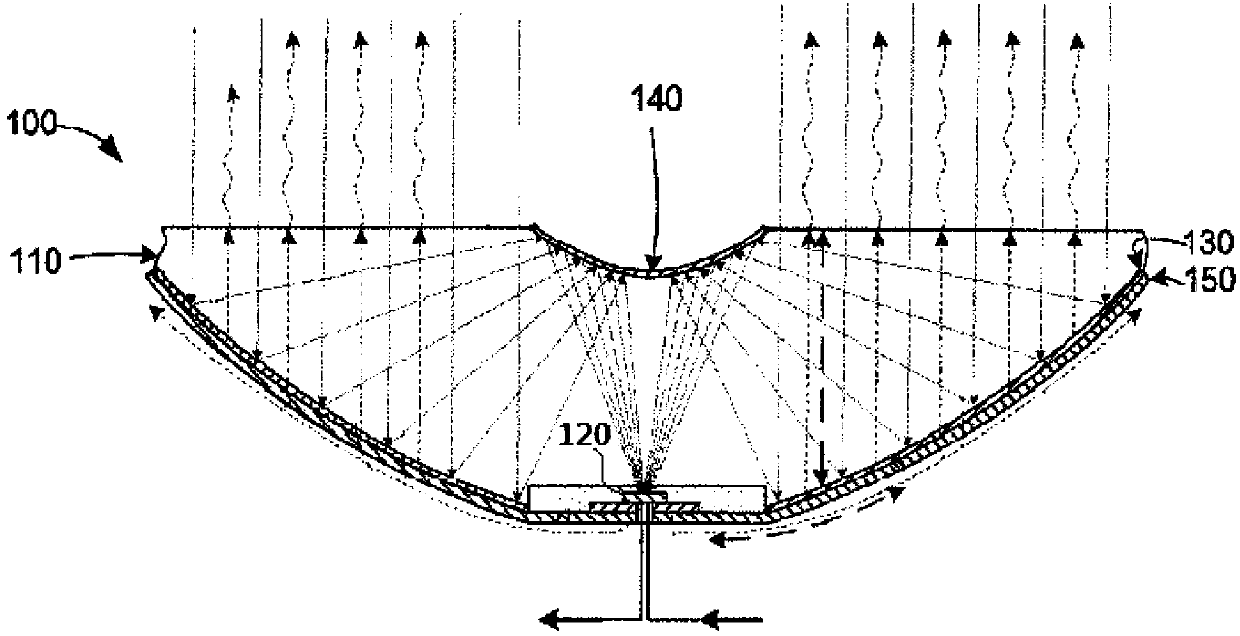

Efficient solar power station

InactiveCN107248839AAchieve the effect of rotationTo achieve the effect of up and downPhotovoltaic supportsSolar heat devicesPower stationEngineering

The invention discloses an efficient solar power station. The solar power station comprises an installation base top, wherein the upper surface of the installation base top is fixedly connected with an installation base and a bearing seat, the upper surface of the installation base is fixedly connected with a first bearing, the inner ring of the first bearing is fixedly connected with a rotary support column, the surface of the rotary support column is fixedly connected with a worm gear, and the interior of the bearing seat is fixedly connected with a second bearing. According to the efficient solar power station, the rotary support column can rotate so as to drive a solar panel to rotate circumferentially, so that an installation board can ascend and descend so as to drive the solar panel to ascend and descend axially, solar energy around the solar panel is collected and reflected to the solar panel to be absorbed; and a first light collecting board and a second light collecting board are adjusted in reflection angle, so that the solar absorption and use ratio of the solar panel is improved.

Owner:长兴澳蓝电力科技有限公司

Heat dissipation graphene composite decorative plate and manufacturing method

InactiveCN110328918ATo achieve the protective effectTo achieve the absorption effectConveyorsSpraying apparatusCalcium silicateGraphene

The invention discloses a heat dissipation graphene composite decorative plate and a manufacturing method. The heat dissipation graphene composite decorative plate includes a base plate, the surface of the base plate is sleeved with a resin layer, one end of the resin layer far from the base plate is equipped with a first graphene composite material layer, one end of the first graphene composite material layer is provided with a heat conduction layer, and one end of the heat conduction layer far from the first graphene composite material layer is provided with a plant fiber layer. The base plate is disposed to reach the effect composing the decorative plate, through the resin layer, the effect of protecting the base plate can be reached, by means of the first graphene composite material layer, the effect of absorbing the heat on the base plate can be achieved, through the heat conduction layer, the effect of guiding the heat in the first graphene composite material layer out can be realized, through the plant fiber layer and a calcium silicate board layer, the function of the decorative plate can be increased, and by means of the plant fiber layer, the softness of the decorative plate can be increased. The decorative plate can dissipate the internal heat, and is convenient for people to use.

Owner:常州华祥碳材料科技有限公司

A polarization-insensitive ultra-broadband terahertz absorber with multilayer structure

The present invention is a polarization-insensitive ultra-broadband terahertz wave absorber with a multi-layer structure, comprising a bottom reflection plate and a tailored dielectric substrate arranged above it, and a layer of metal patch is arranged above the dielectric substrate The first resonant unit of the dielectric substrate is embedded with a second resonant unit composed of two layers of metal patches. The invention adopts multi-layer structure design, uses metal as resonant material, and achieves broadband absorption effect through mutual resonance between layers. The absorption bandwidth of the absorber is expanded from broadband to ultra-wideband. And because the structure of the absorber has symmetry, the absorption performance of the absorber for TE polarized waves and TM polarized waves is basically the same. The absorber can realize ultra-broadband absorption effect in the THz band.

Owner:NANJING UNIV OF POSTS & TELECOMM

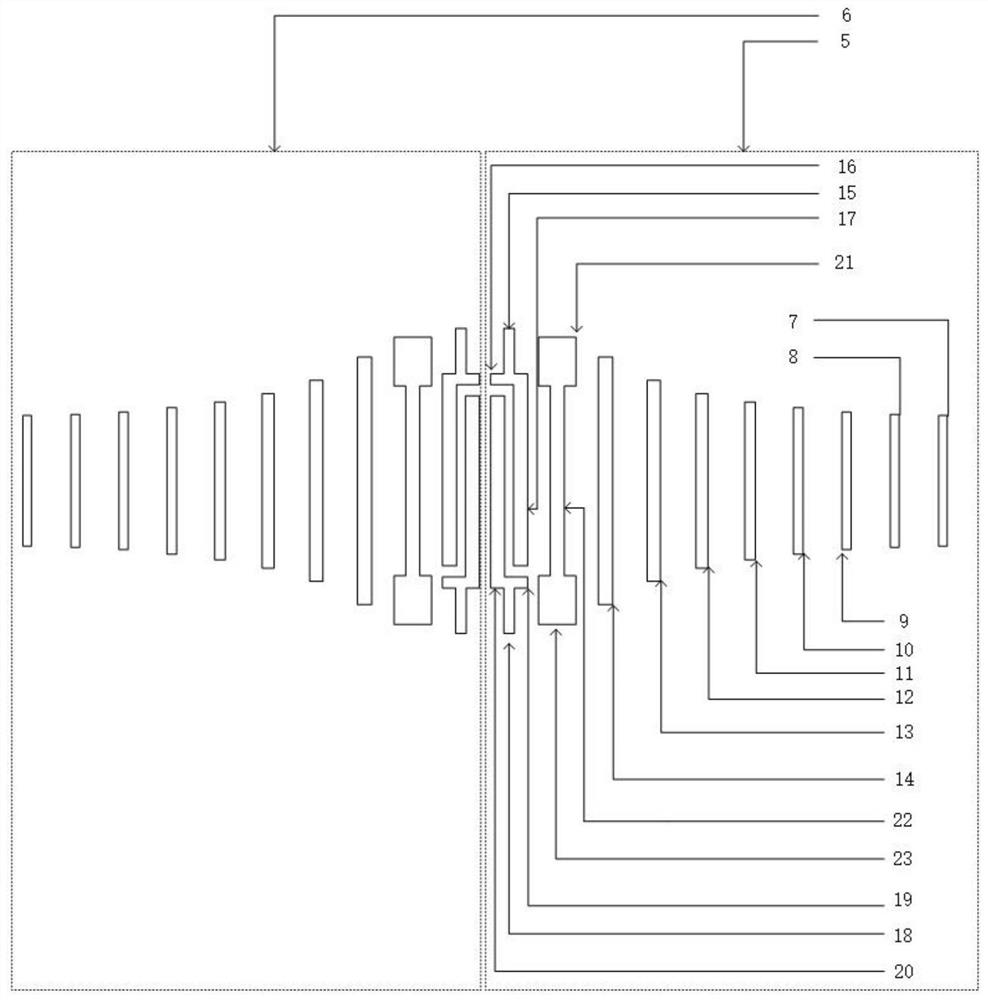

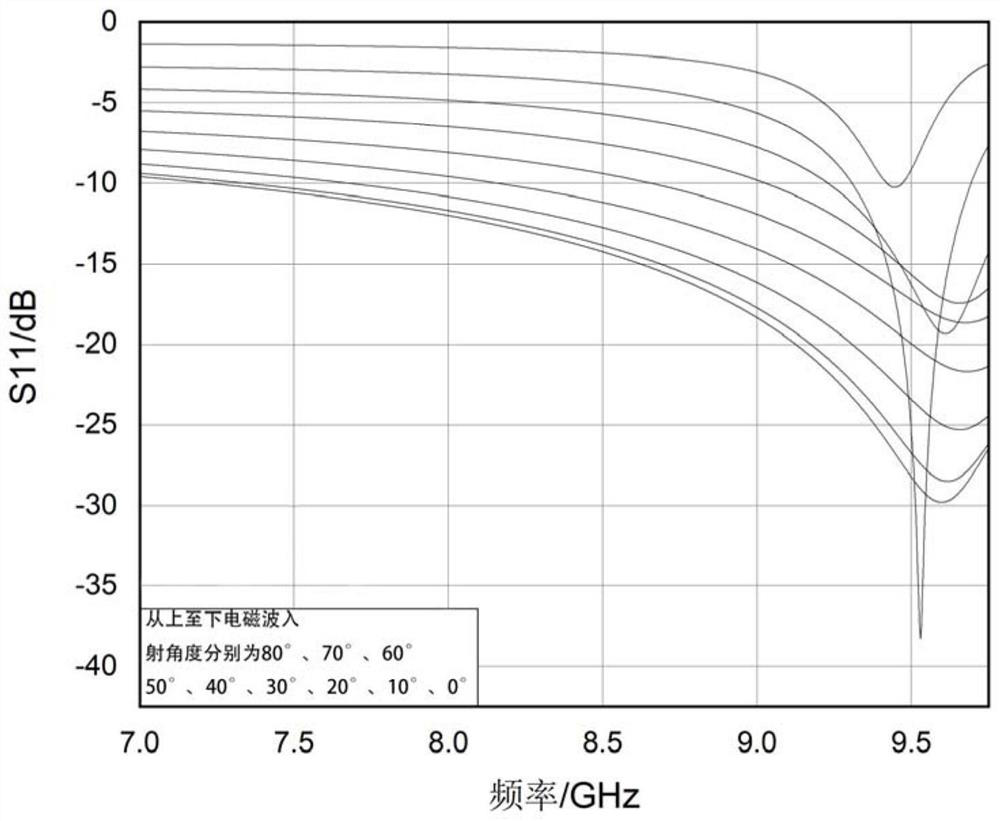

Electromagnetic absorption structure with wide incident angle

ActiveCN113381200ATo achieve the absorption effectPromote absorptionAntennasDielectric lossEngineering

The invention discloses an electromagnetic absorption structure with a wide incident angle. The electromagnetic absorption structure comprises an ITO pattern layer, a substrate, a dielectric loss layer and a good conductor layer which are stacked from top to bottom, wherein the substrate, the dielectric loss layer and the good conductor layer are rectangular plates, the substrate, the dielectric loss layer and the good conductor layer completely coincide from top to bottom, the ITO pattern layer is composed of a first ITO structure and a second ITO structure, the first ITO structure comprises fourteen rectangular ITO and an I-shaped ITO, the second ITO structure is located on the left side of the first ITO structure, and the second ITO structure and the first ITO structure are of a bilateral symmetry structure. According to the invention, the TE-mode electromagnetic wave absorbing effect is good when the incident angle ranges from 0 degree to 80 degrees, wherein when the incident angle of the TE-mode electromagnetic wave ranges from 0 degree to 70 degrees, the electromagnetic wave absorbing rate at the frequency point 9.5 GHz is stabilized to be 98% or above, and when the incident angle ranges from 70 degrees to 80 degrees, the TE-mode electromagnetic wave absorbing rate at the frequency point 9.5 GHz is stabilized to be 90% or above.

Owner:NINGBO UNIV

Industrial solid waste degradation device for geopolymer-based foam light soil production

PendingCN113732022AIncrease the rate of degradationShorten degradation timeSolid waste disposalCement productionIndustrial wasteWaste material

The invention discloses an industrial solid waste degradation device for geopolymer-based foam light soil production, and relates to the technical field of industrial solid degradation. The industrial solid waste degradation device comprises an industrial waste degradation device, a degradation box body, a material distribution humidifier, a pressurizer, a funnel crusher, a dust collector and a discharge port, wherein the industrial waste degradation device comprises the degradation box body, the top surface of the degradation box body is fixedly connected with the material distribution humidifier, and the outer surface of the right side of the material distribution humidifier is fixedly connected with the pressurizer. According to the device, falling solid waste is roughly and equally divided to the two sides through a material distribution head, then stirring blades are rotated through a rotator to shake and scatter the waste, biodegradation water is sprayed to the interior through a spray head in cooperation with a water suction pipe, the waste and liquid are mixed, the characteristic that the waste is roughly and equally divided is achieved, the problem of insufficient contact between excessive degradation liquid is solved, and the effect of uniformly dividing industrial solid waste and uniformly fusing the industrial solid waste is achieved.

Owner:广西北投交通养护科技集团有限公司

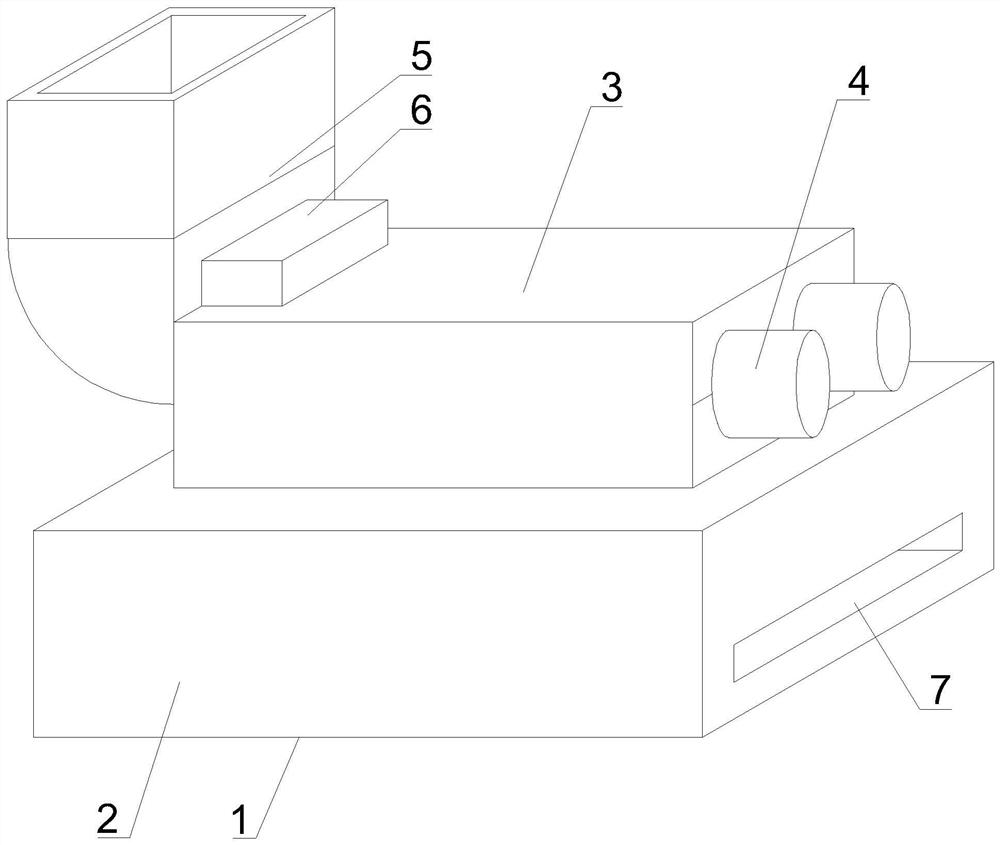

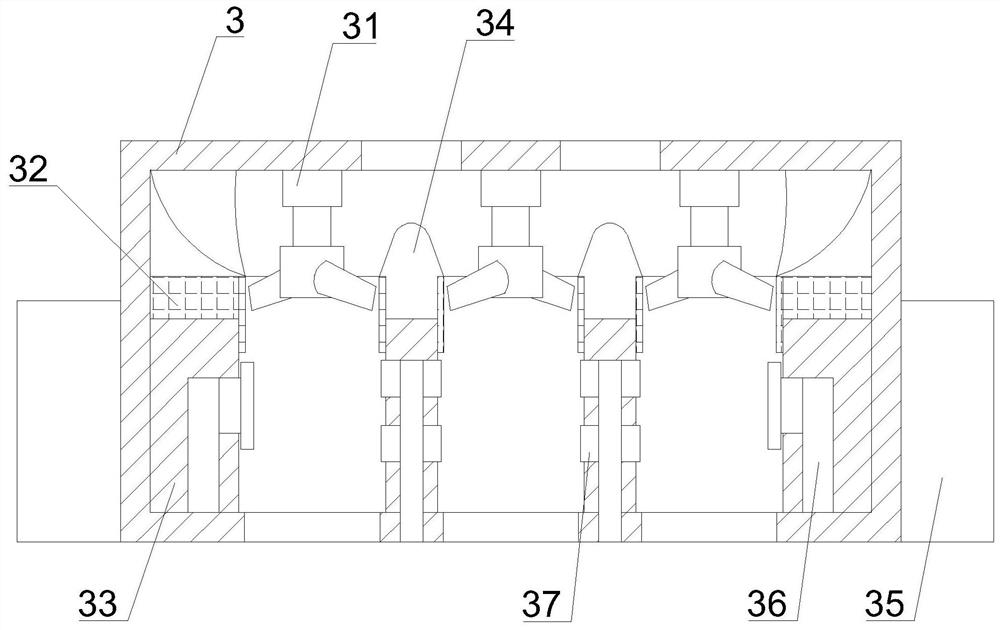

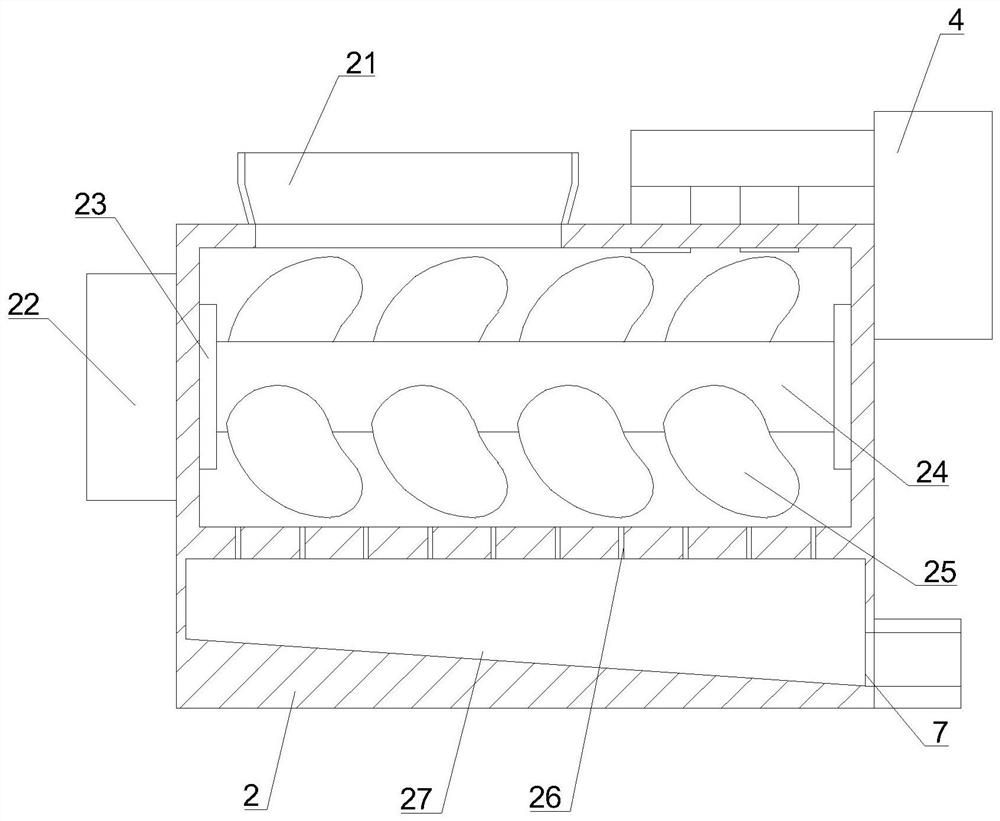

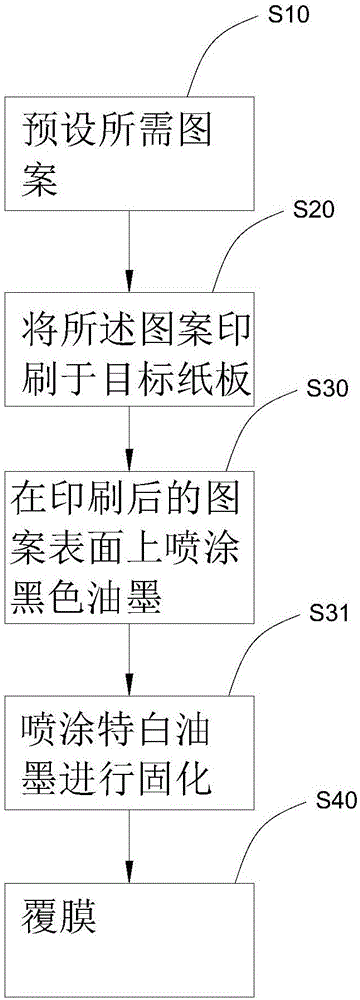

Spraying method for infrared anti-counterfeit label

InactiveCN106671633ATo achieve the absorption effectLow costStampsDuplicating/marking methodsInfraredEngineering

The invention provides a spraying method for an infrared anti-counterfeit label and relates to the printing field. The spraying method comprises the following steps: presetting patterns to be printed; printing the patterns on a target paper board; spraying the surfaces of the printed patterns with a black ink; and laminating. Through the scheme, a fixed first baffle is arranged on a wind-up roller; the printed anti-counterfeit patterns are sprayed with the black ink, and the light absorption effect of the black ink is utilized to achieve an absorption effect on infrared rays emitted by a spectroscopic detector, so that the successful detection effect is achieved; and the method does not need special inks, so that the cost is greatly lowered.

Owner:赵华

Steel belt surface dust removal device for slitting machine production line

PendingCN112337896AImprove cleanlinessIncrease flexibilityCleaning using gasesMaintainance and safety accessoriesDust controlWorking environment

The invention belongs to the technical field of slitting machine accessories, and particularly relates to a steel belt surface dust removal device for a slitting machine production line. The steel belt surface dust removal device comprises an outer frame, an inner bin, a support and a dust collector, wherein the interior of the outer frame is integrally connected with the inner bin, the right sidewall of the inner bin is fixedly connected with the support through screws, and the top of the support is connected with the dust collector in a sleeved mode. According to the steel belt surface dustremoval device for the slitting machine production line, through combined application of the accessories, a shearing table of a slitting machine is combined in the outer frame, the dust collector combined by the support is arranged on the side face of the outer frame, and the support can be matched with a main shaft and an auxiliary shaft to change the angle so as to adjust the dust collector, sothat the flexibility is high; and a vertical net is combined at the bottom of a dust collection plate of the dust collector, after a steel belt enters the shearing table, a variable frequency controller can be used for starting to extract dust on the surface of the steel belt and scraps generated in the shearing process, and the suction effect can be achieved in the shearing process, so that thecleanliness of the working environment is guaranteed, and the working efficiency is improved.

Owner:浙江精鑫金属材料股份有限公司

Device and method for processing waste gas from molybdenum disulfide production

ActiveCN103894052ACause corrosionDoes not affect absorptionDispersed particle separationBuffer tankProduct gas

The invention relates to a device for processing waste gas from molybdenum disulfide production. The device comprises an alkali tank, a buffer tank, a vacuum pump and an emptying tower which are sequentially connected through pipelines, wherein the alkali tank comprises an alkali tank 1#, an alkali tank 2# and an alkali tank 3# which are sequentially connected through pipelines. The method comprises the steps of enabling the waste gas to sequentially flow through an NaOH solution in the alkali tank 1#, the alkali tank 2# and the alkali tank 3# to absorb a great amount of NOx and a small amount of volatile HCl and HF in the waste gas, absorbing the small amount of NOx by virtue of urea in the buffer tank, and discharging the processed gas through the emptying tower. According to the device, the waste gas is directly absorbed and processed by virtue of NaOH, and the tail gas is supplementarily absorbed by virtue of the urea, so that an absorption effect cannot be influenced due to the crystallization of alkali liquid after the device is used for a long time; besides, the alkali tank and the buffer tank are antiseptic by virtue of a rubber lining technique, and the vacuum pump is arranged behind the buffer tank, the vacuum pump cannot be corroded by the processed waste gas, and the utilization rate of equipment is improved.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com