Heat dissipation graphene composite decorative plate and manufacturing method

A technology of composite materials and composite material layers, which is applied in the field of graphene composite material decorative panels and manufacturing, can solve problems such as inability to dissipate heat, and achieve the effects of increasing functionality, increasing flexibility, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

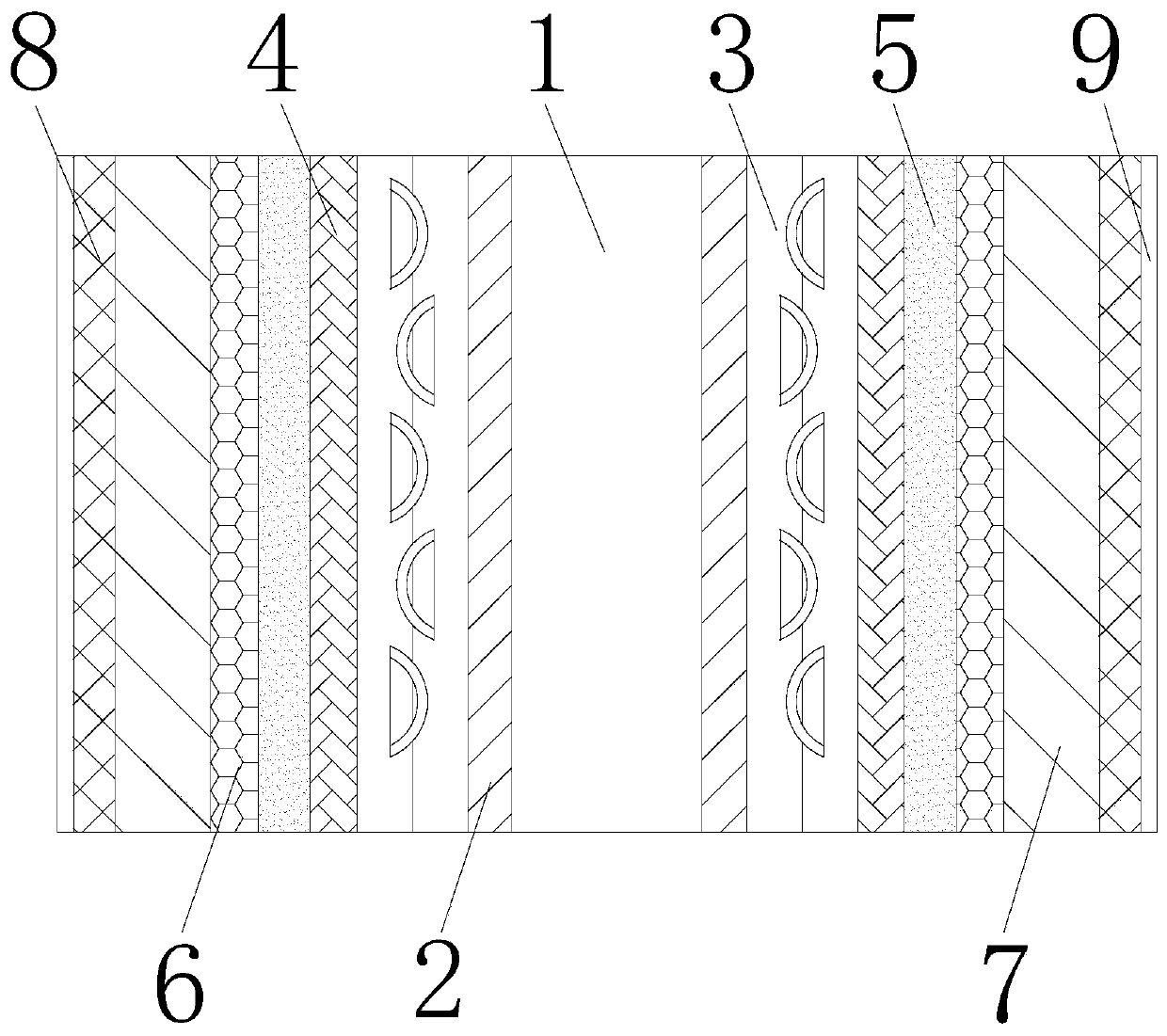

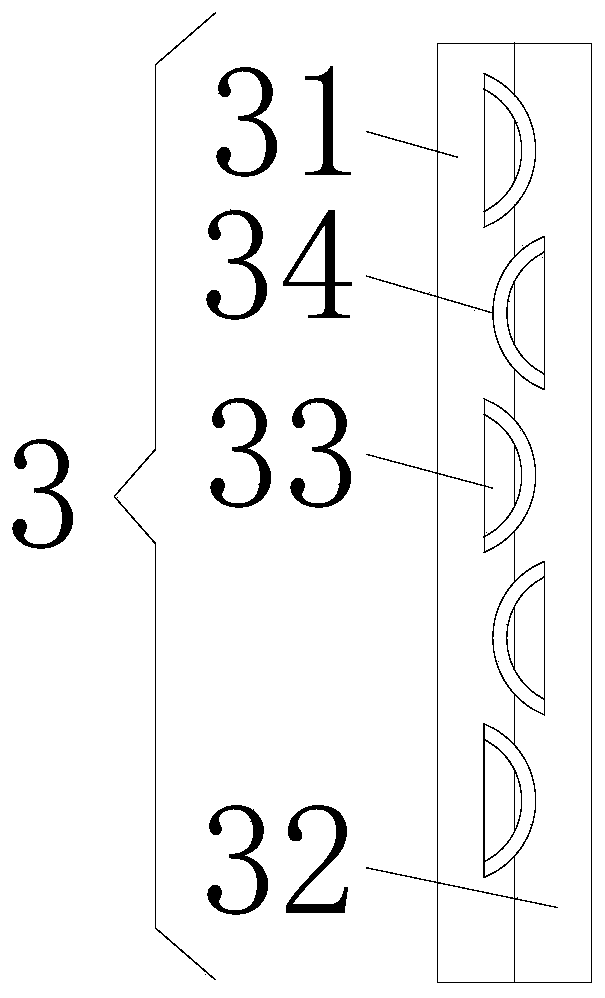

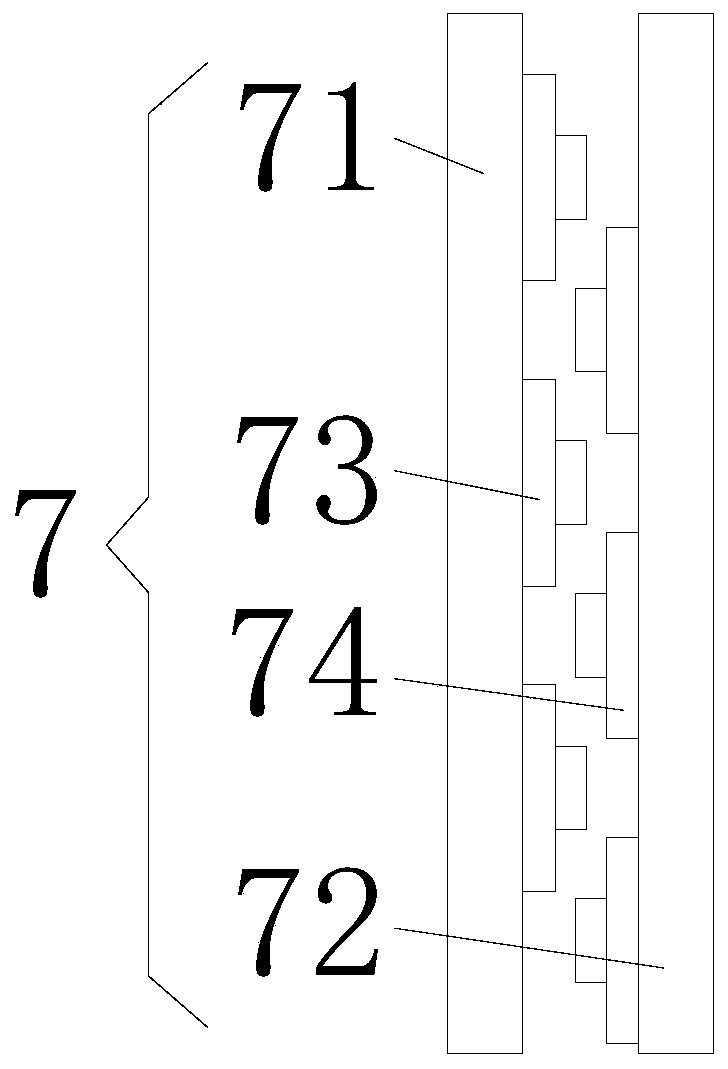

[0041] First, the resin layer 2 is applied on the surface of the substrate 1, and then the first support plate 33 and the second support plate 34 are respectively welded on the first graphene layer 31 and the second graphene layer 32. machine, the first support plate 33 and the second support plate 34 are pressed together, and then the heat conduction layer 4 is bonded on the first graphene composite material layer 3, and the plant fiber layer 5 is also bonded to the silicon-calcium plate layer 6 , and then the first support copper plate 73 and the second support copper plate 74 are fixed on the third graphene layer 71 and the fourth graphene layer 72, and the first support copper plate 73 and the second support copper plate 74 are also staggered and engaged, Carry out pressing by pressing machine, then decorative plate layer 8 is fixed on the second graphene composite material layer 7, also is brushing waterproof layer 9 on the surface of decorative plate layer 8 simultaneousl...

Embodiment 2

[0043] In embodiment one, add the following steps;

[0044] When the pressing machine is pressing the plates, the time can be set to 2-4 hours.

[0045] First, the resin layer 2 is applied on the surface of the substrate 1, and then the first support plate 33 and the second support plate 34 are respectively welded on the first graphene layer 31 and the second graphene layer 32. machine, the first support plate 33 and the second support plate 34 are pressed together, and then the heat conduction layer 4 is bonded on the first graphene composite material layer 3, and the plant fiber layer 5 is also bonded to the silicon-calcium plate layer 6 , and then the first support copper plate 73 and the second support copper plate 74 are fixed on the third graphene layer 71 and the fourth graphene layer 72, and the first support copper plate 73 and the second support copper plate 74 are also staggered and engaged, Carry out pressing by pressing machine, then decorative plate layer 8 is f...

Embodiment 3

[0047] In embodiment two, add following steps again;

[0048] The thickness of the first graphene composite material layer 3 is 1-3 nanometers, and the thickness of the first support plate 33 and the second support plate 34 is 300-600 microns.

[0049] First, the resin layer 2 is applied on the surface of the substrate 1, and then the first support plate 33 and the second support plate 34 are respectively welded on the first graphene layer 31 and the second graphene layer 32. machine, the first support plate 33 and the second support plate 34 are pressed together, and then the heat conduction layer 4 is bonded on the first graphene composite material layer 3, and the plant fiber layer 5 is also bonded to the silicon-calcium plate layer 6 , the thickness of the first graphene composite material layer 3 is 1-3 nanometers, and the thickness of the first support plate 33 and the second support plate 34 is 300-600 microns, then the first support copper plate 73 and the second suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com