Patents

Literature

34results about How to "To achieve the delivery effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

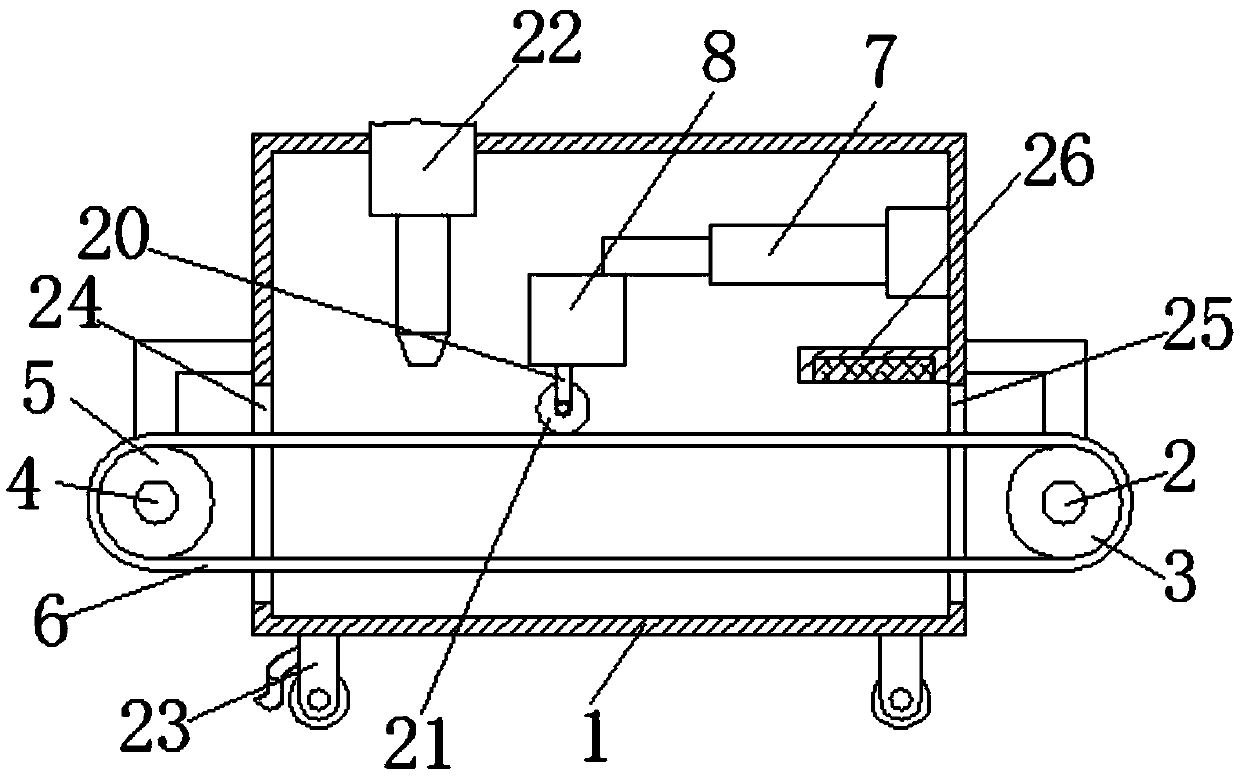

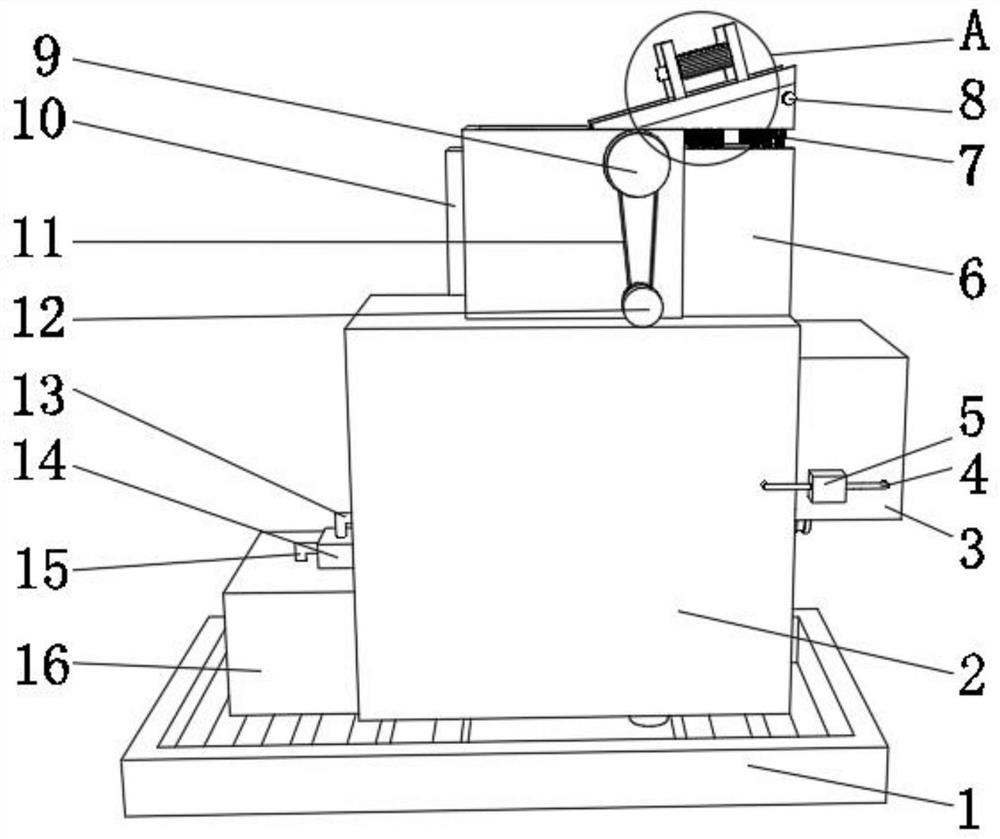

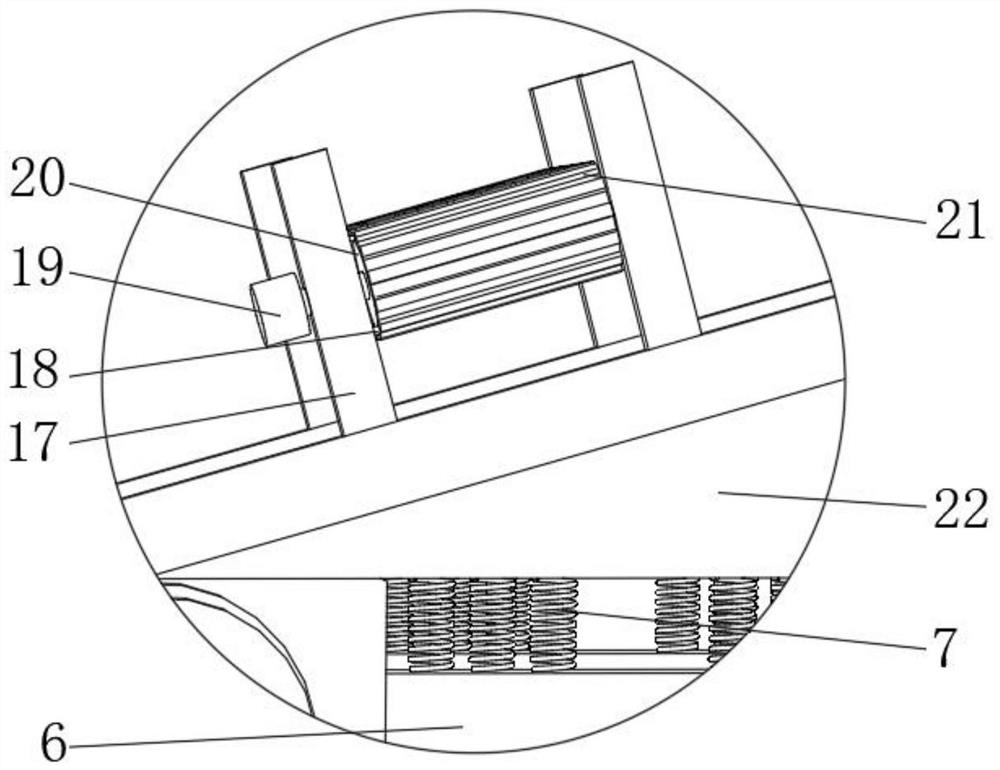

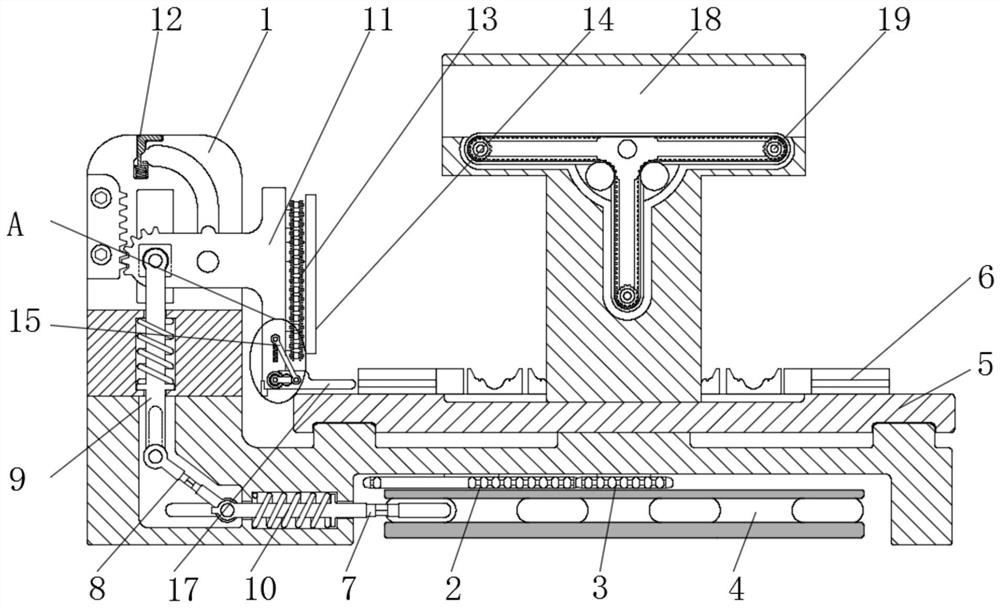

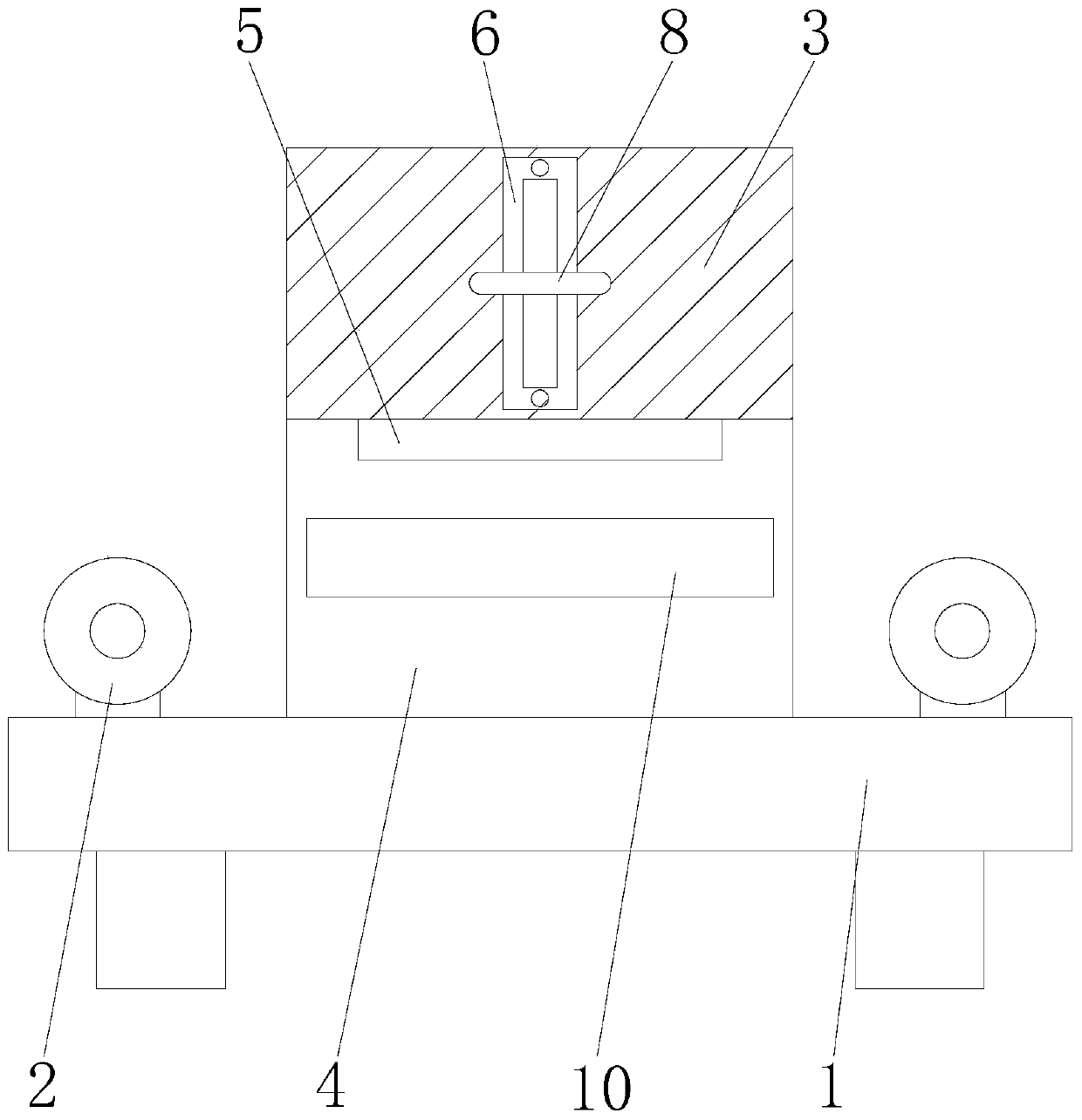

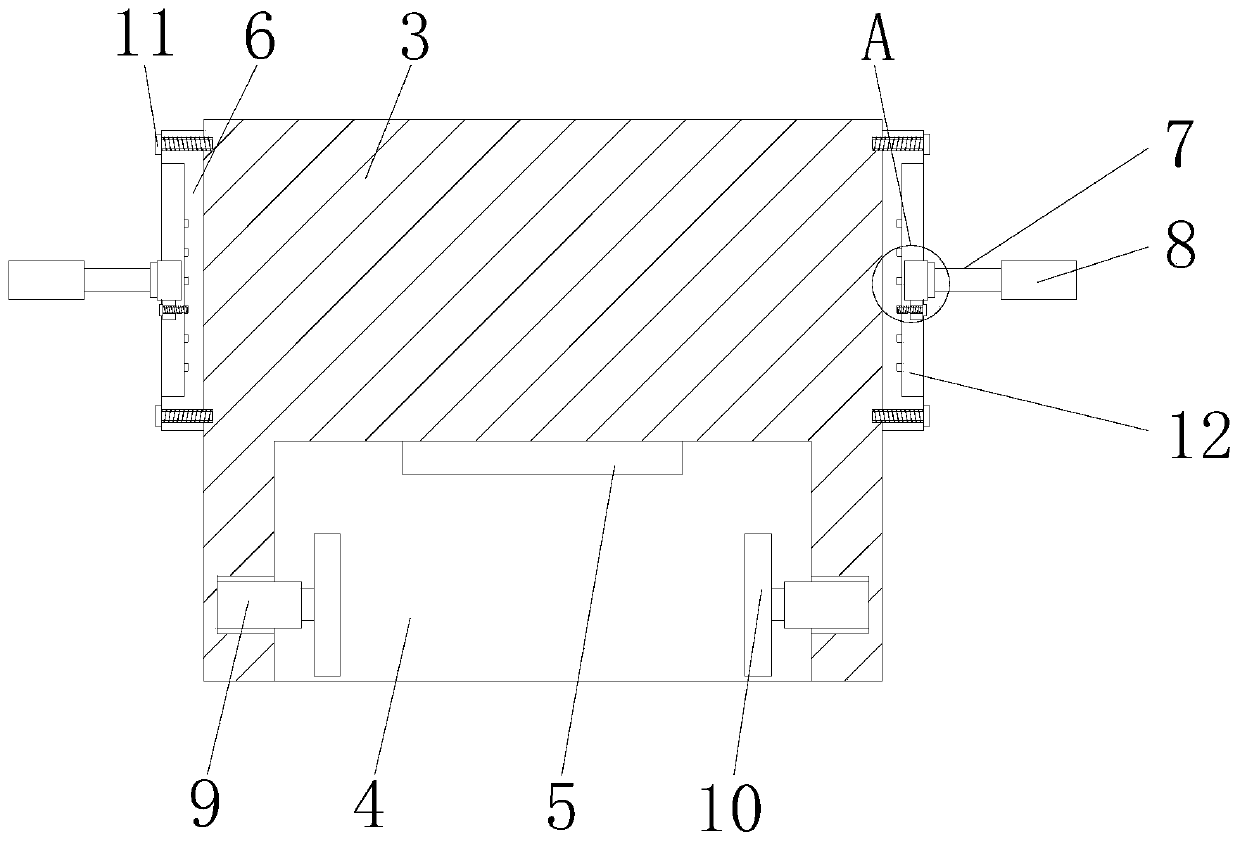

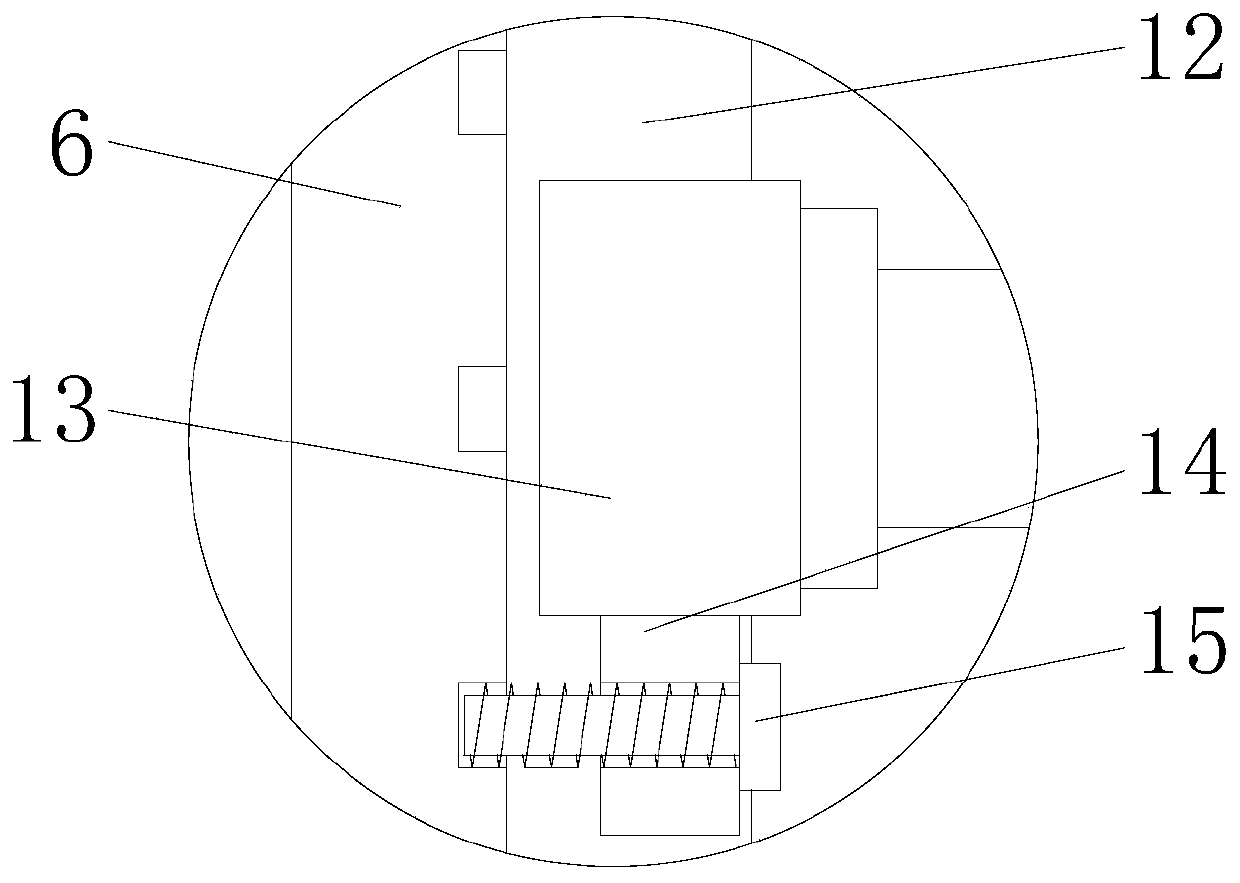

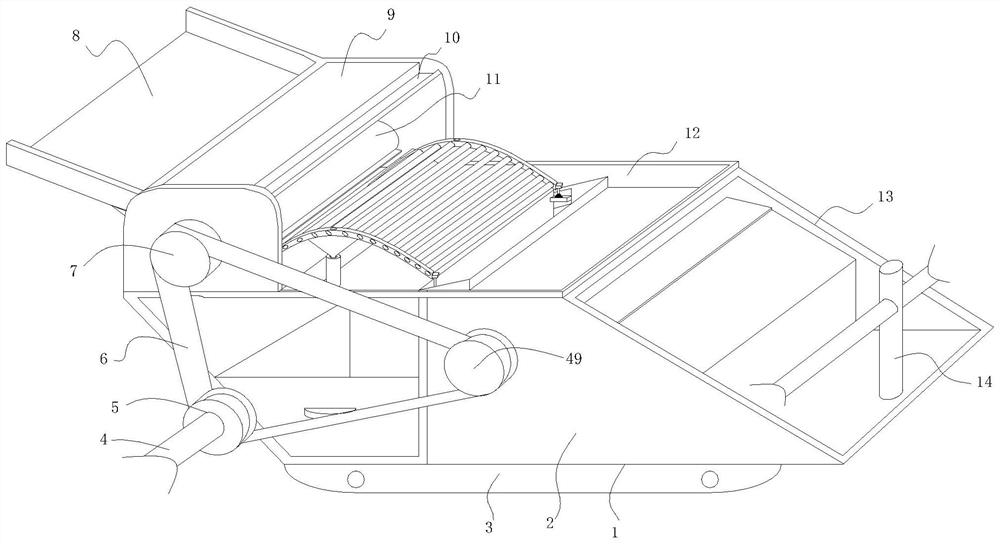

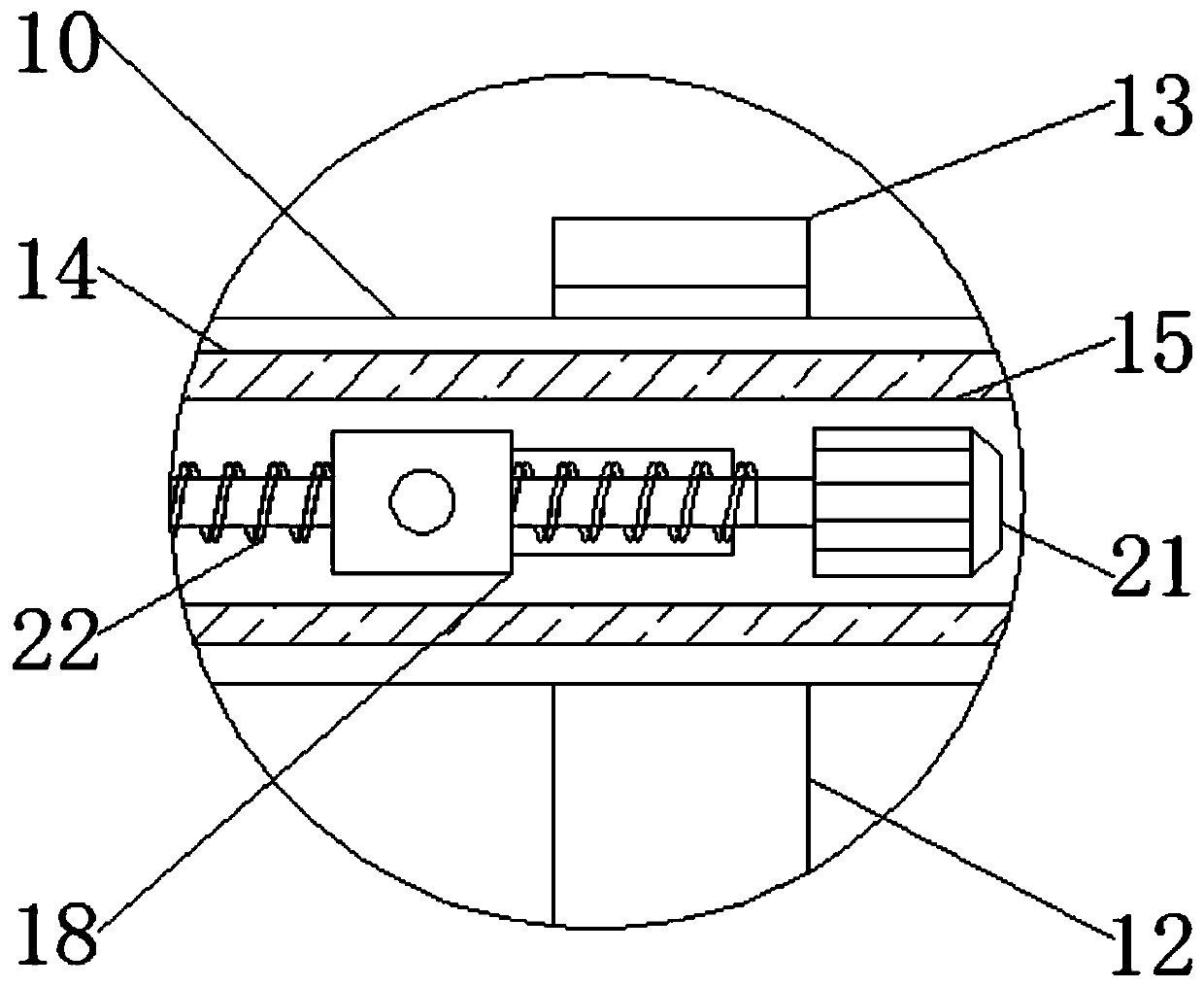

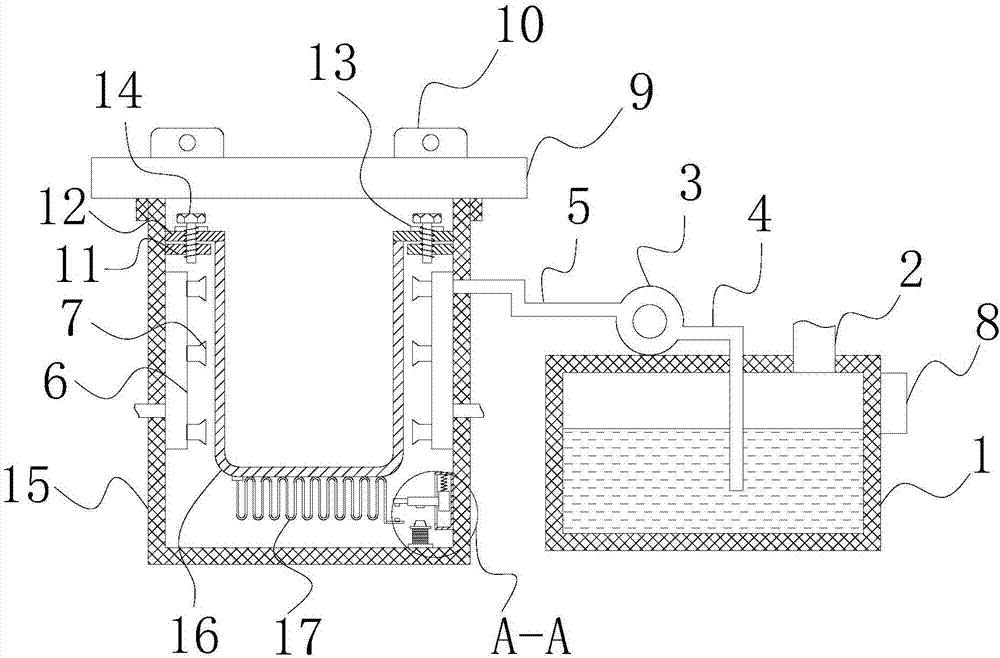

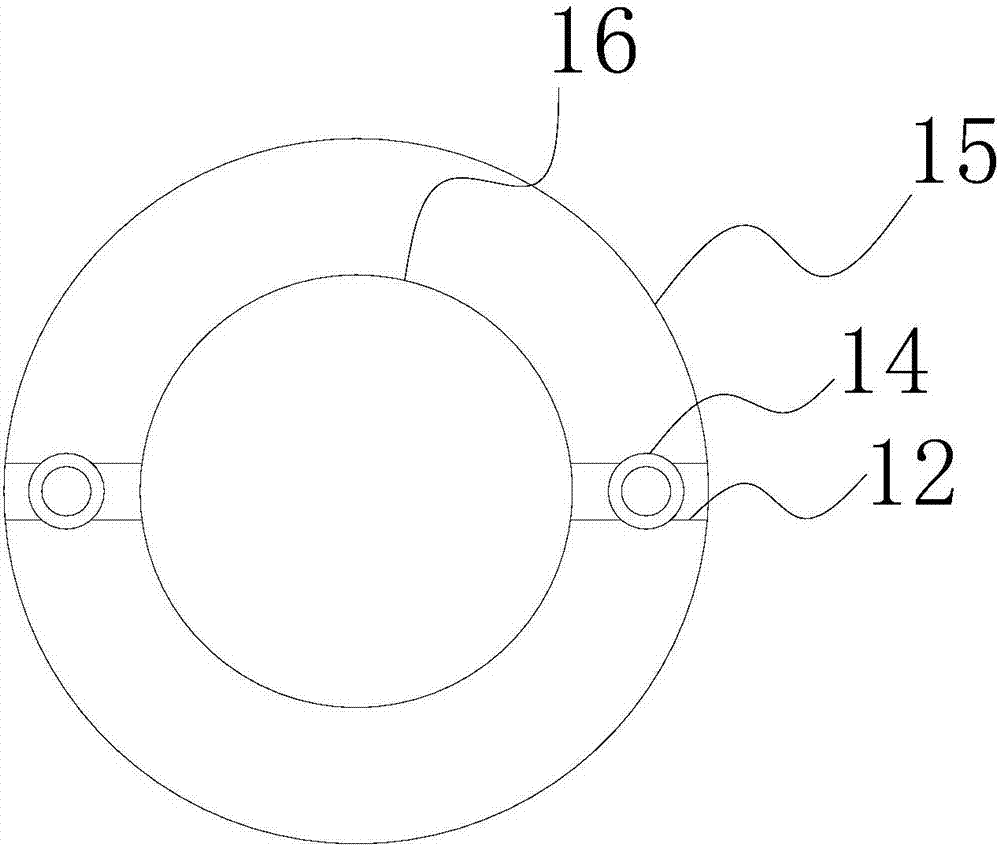

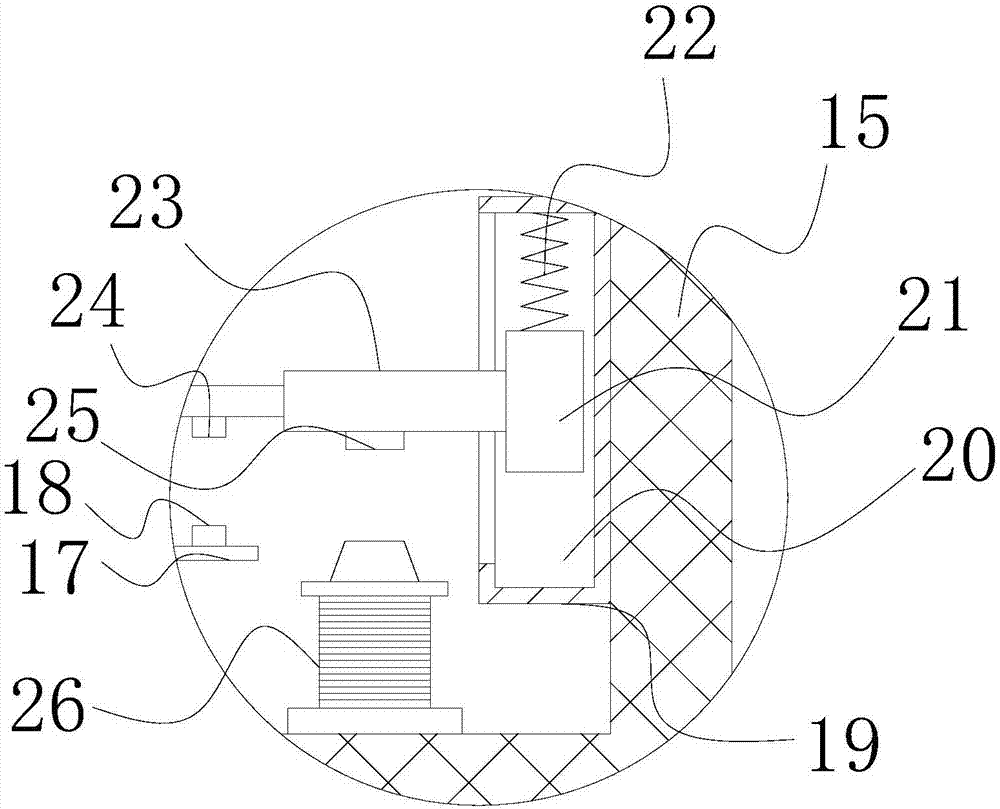

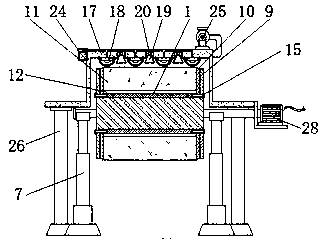

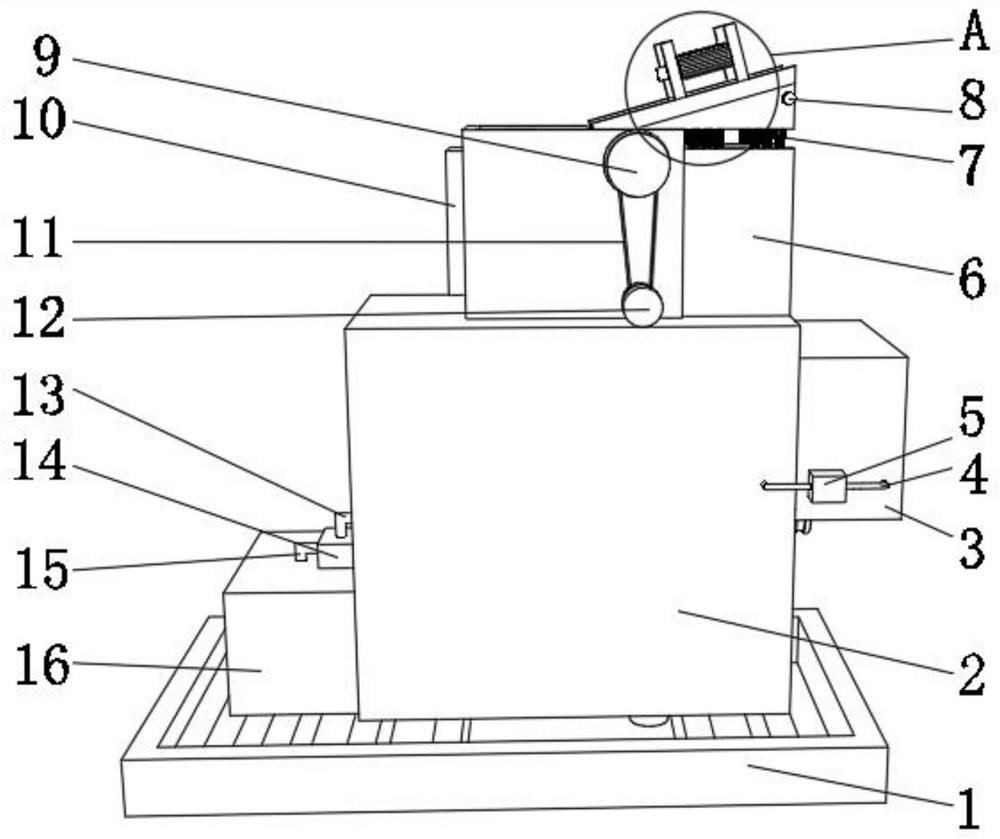

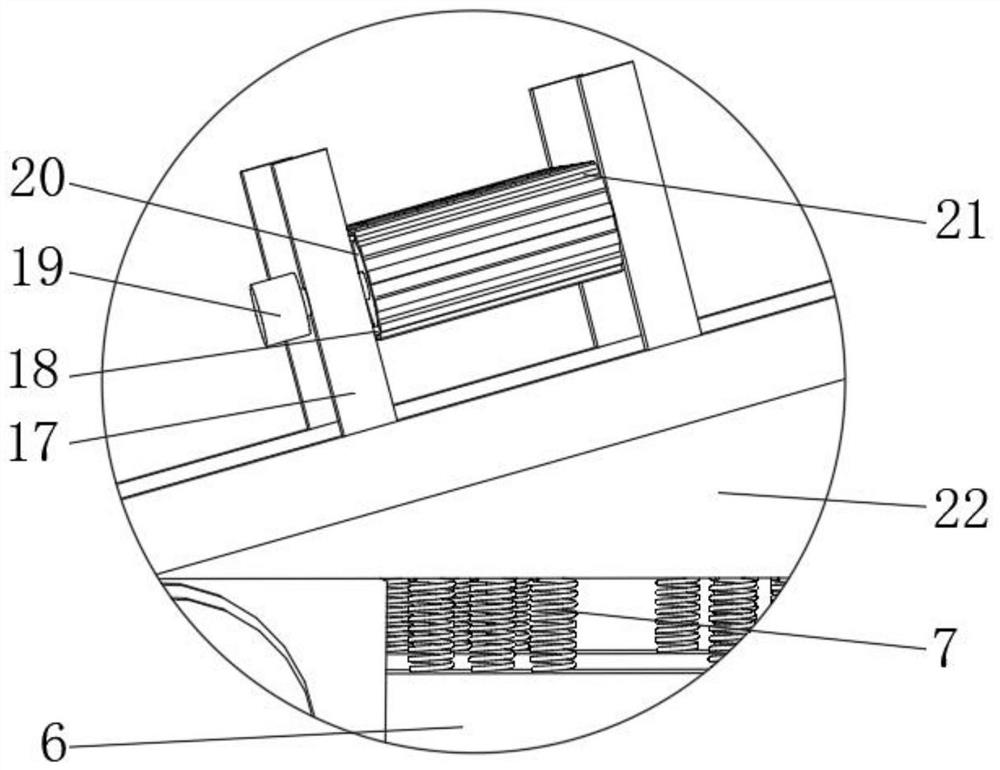

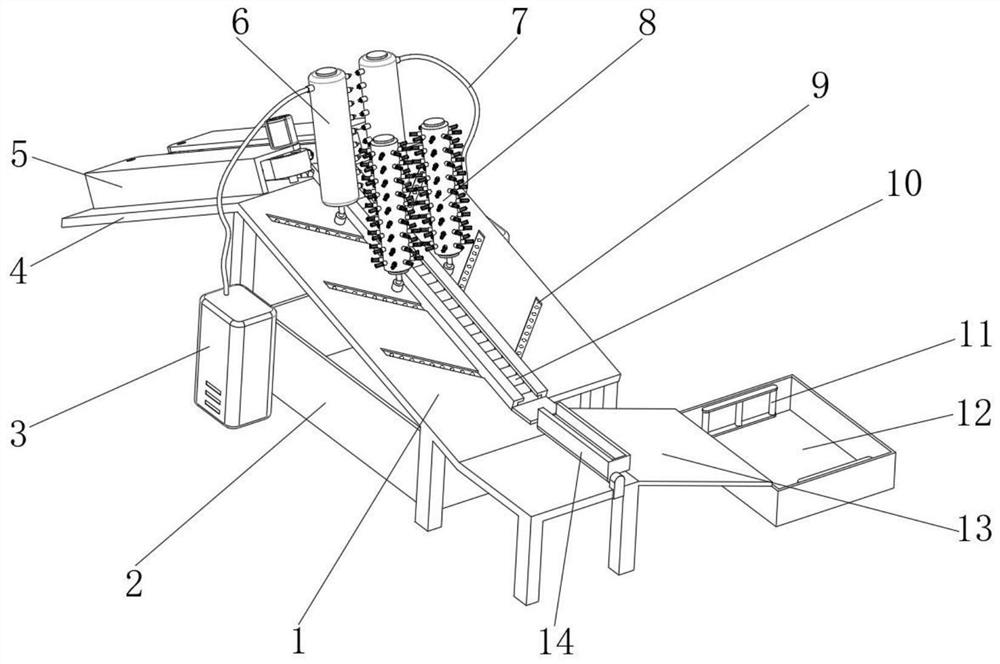

Improved plate gluing device

InactiveCN110653118ATo achieve the delivery effectGlue saves time and effortLiquid surface applicatorsCoatingsDrive wheelTransmission belt

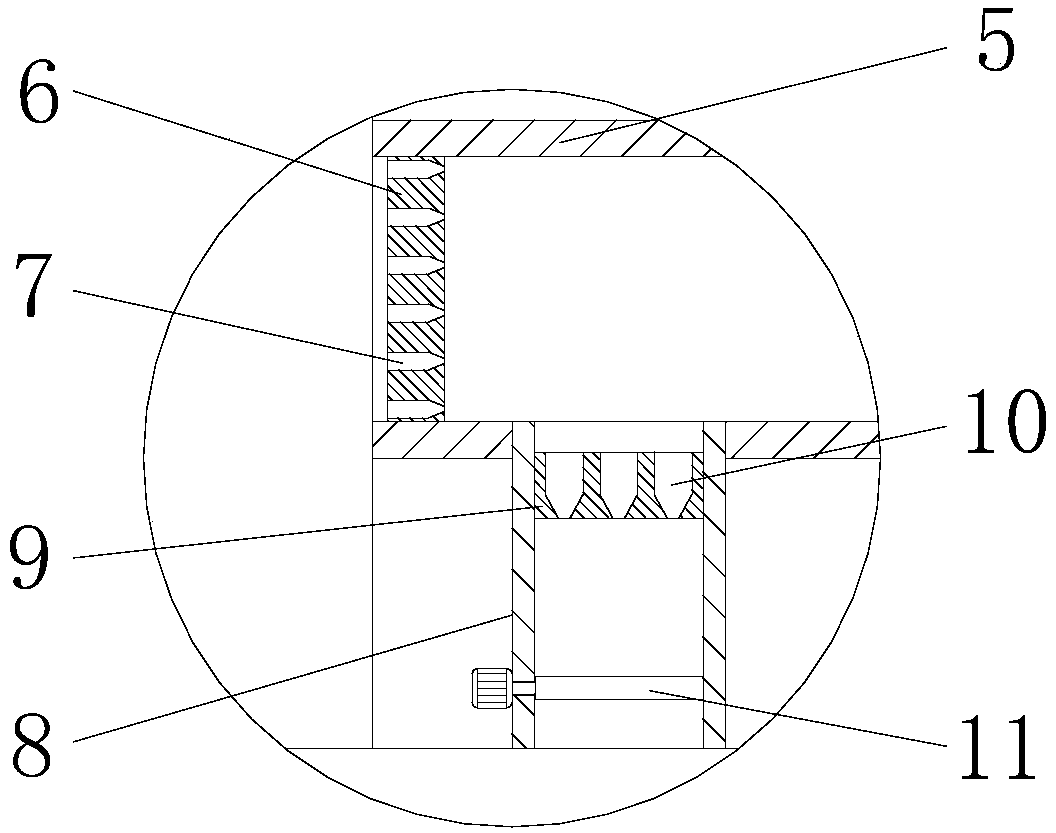

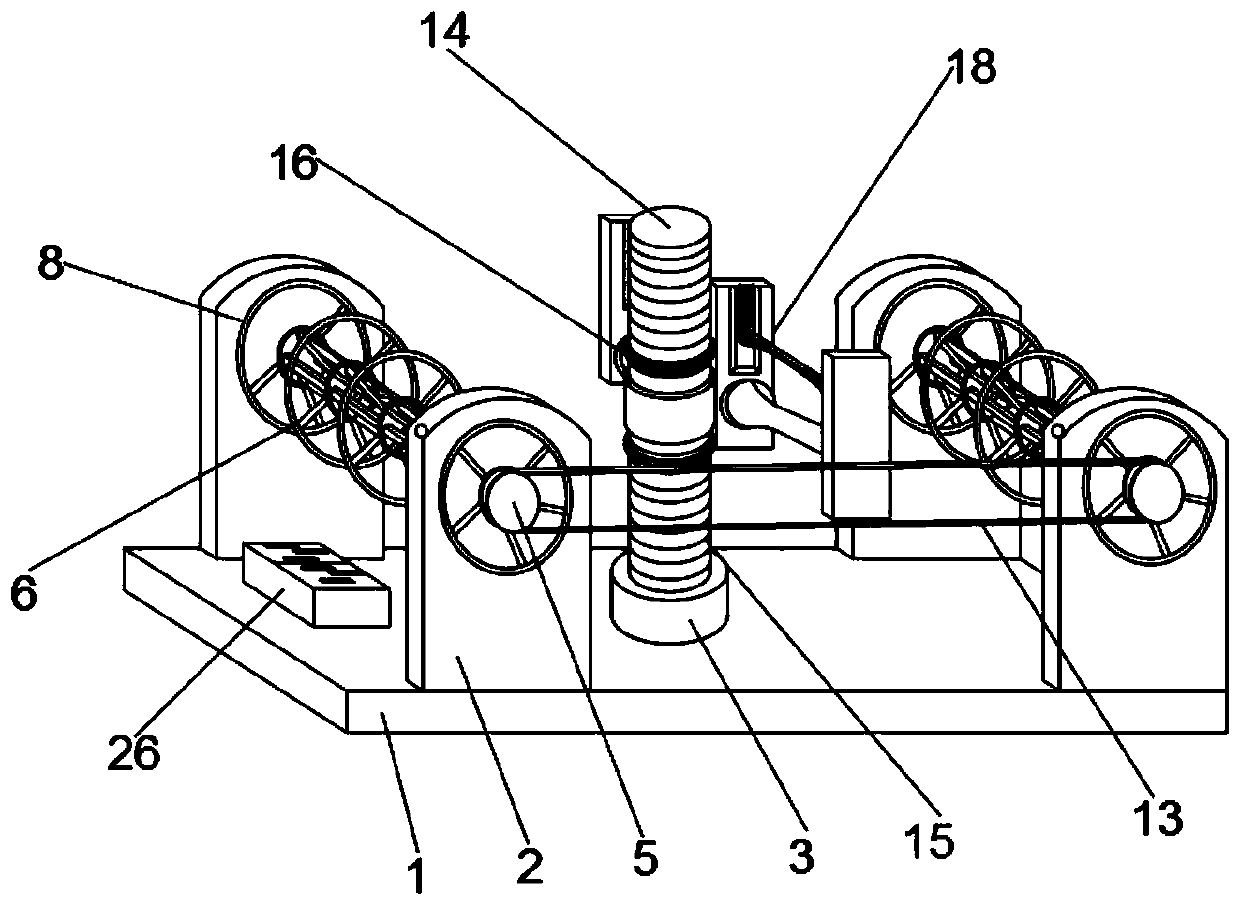

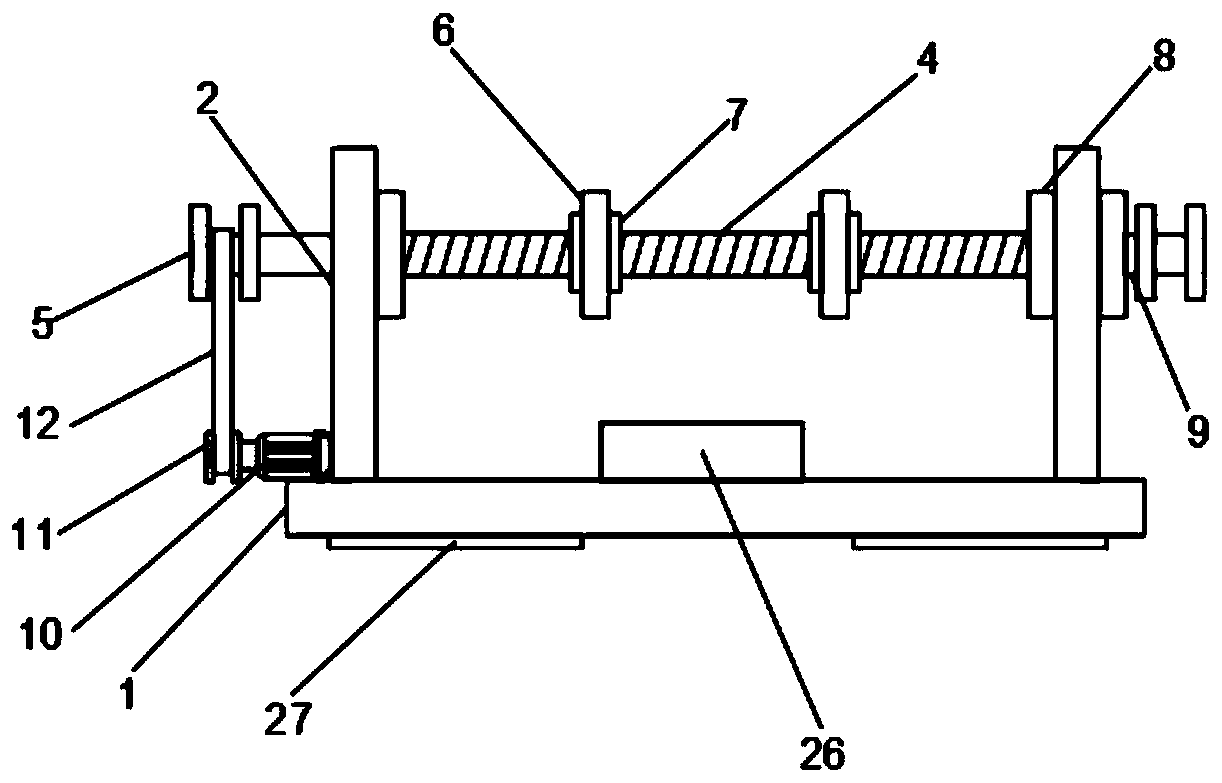

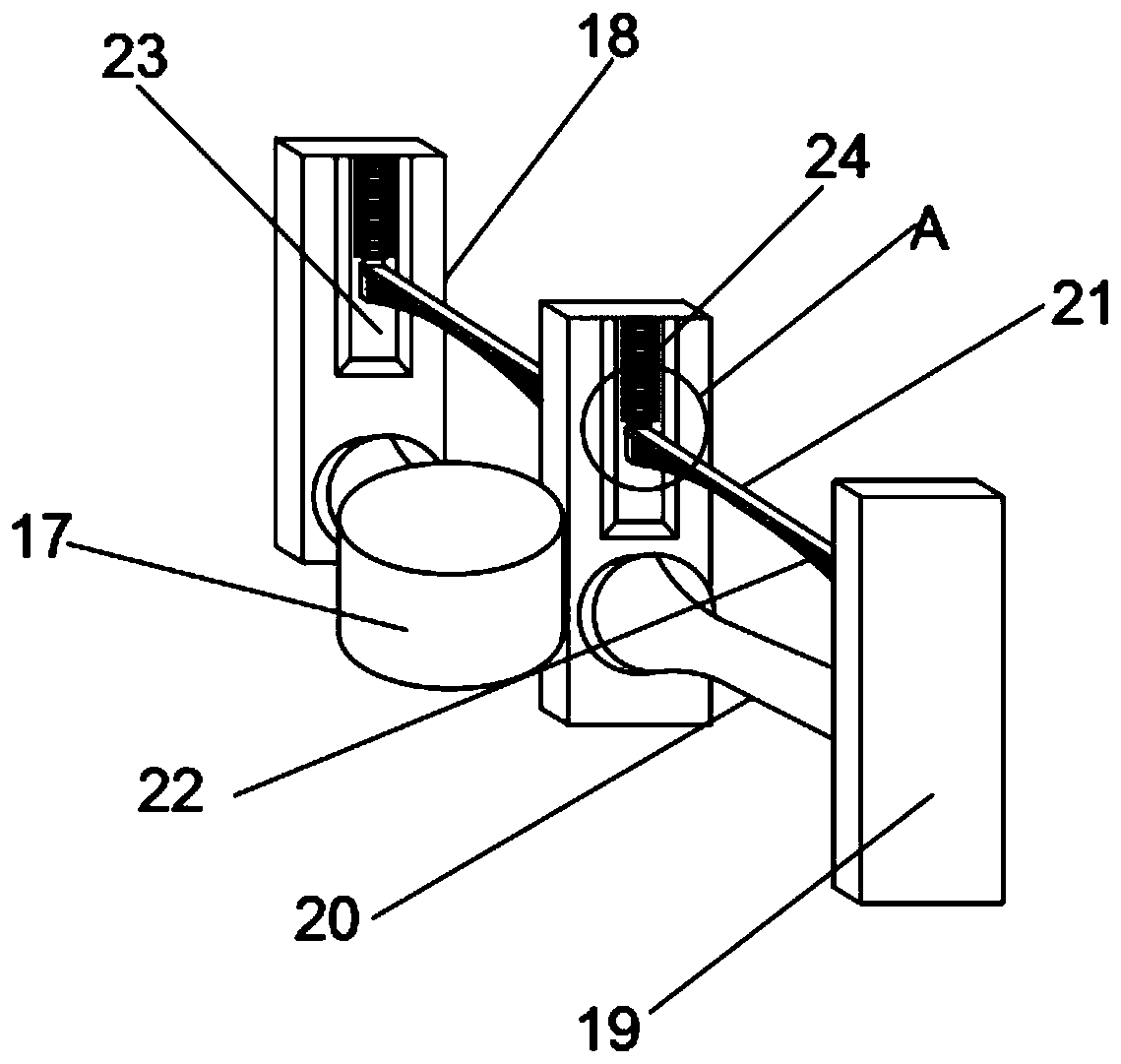

The invention discloses an improved plate gluing device. The device comprises a machine body, wherein a driving motor is fixedly connected to the right side of the machine body through a supporting plate, an output shaft of the driving motor is fixedly connected with a driving roller, the left side of the machine body is movably connected with a rotating rod through a supporting plate, the surfaceof the rotating rod is sleeved with a driven roller, and the surface of the driven roller is in transmission connection with the surface of the driving roller through a conveying belt. According to the device, through the cooperation of the driving motor, the driving roller, the rotating rod, the driven roller and the conveying belt which are arranged, the effect of conveying a wood plate is achieved, and through the cooperation of a rotating motor, a driving wheel, a rotating shaft, a driven wheel, a belt, a cam, a cam groove, a roller, a swing rod, a shaft pin, a fixing plate and a connecting rod which are arranged, the roller is used for gluing the plate, so that the time-saving and labor-saving effect during plate gluing is achieved, the working difficulty of the processing personnelis reduced, and the working efficiency of the processing personnel is improved.

Owner:HENAN ZHONGBAO TECH

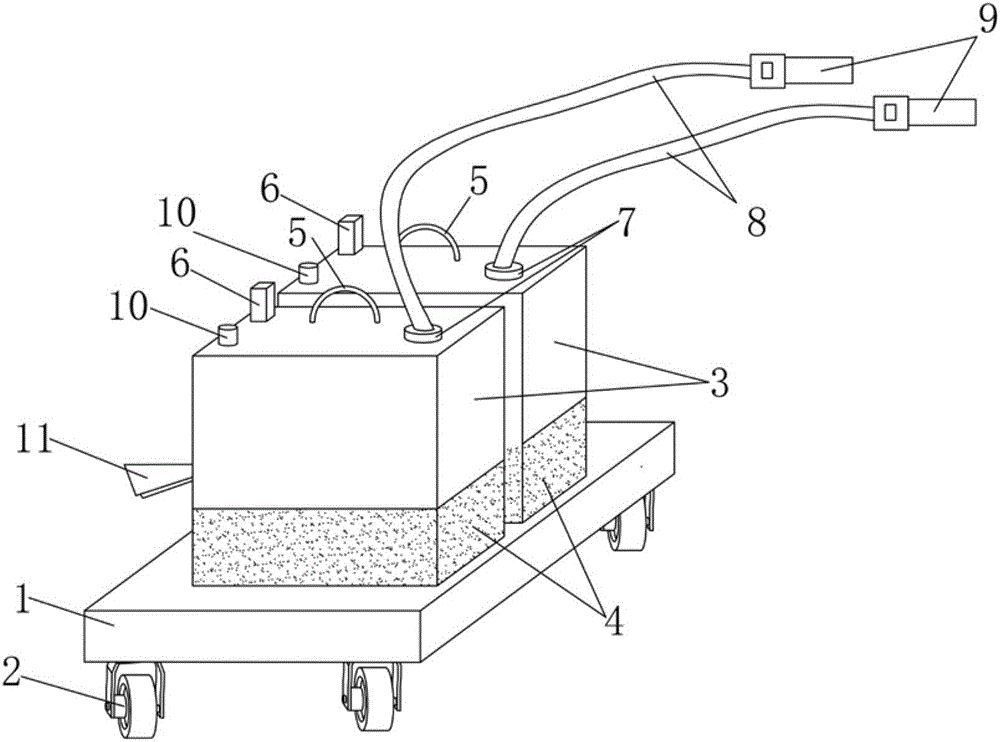

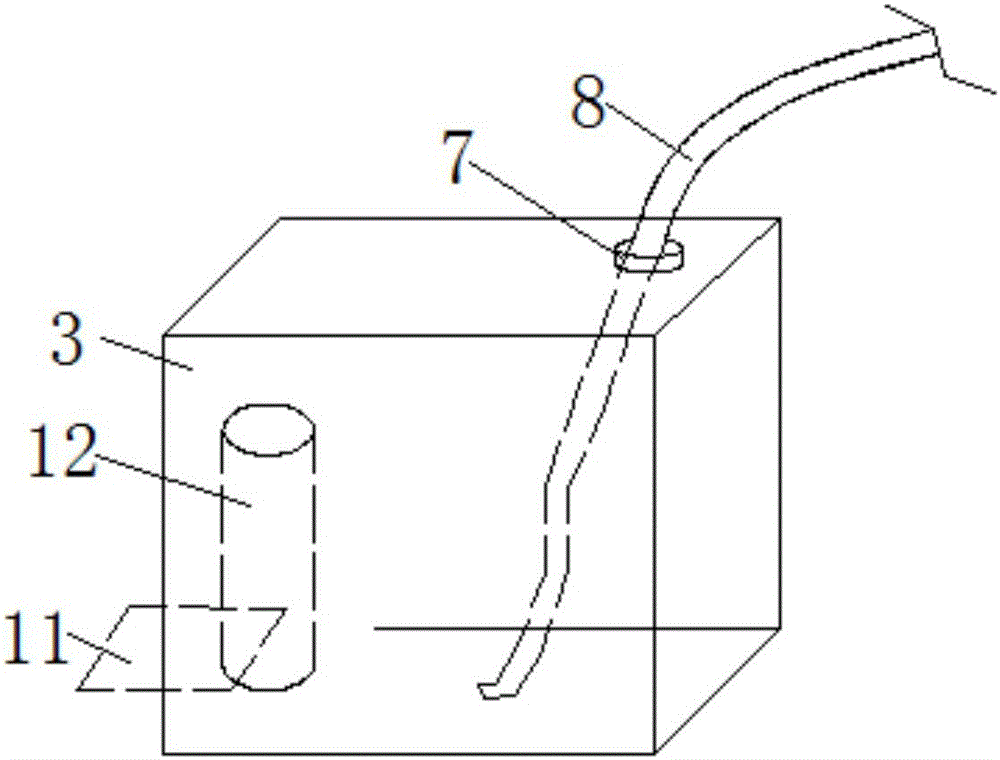

Compression type washing device for experimental analysis

InactiveCN105689350AIncrease storage capacityTo achieve the delivery effectHollow article cleaningCompression PumpEngineering

The invention relates to a compression type washing device for experimental analysis. The compression type washing device comprises a base, sliding wheels and a box; a handle, a pressure meter and a cover are fixedly installed at the top of the box; and the cover is provided with an infusion flexible pipe, and one end of the infusion flexible pipe extends into the box and is in contact with the inner wall of the bottom of the box. According to the compression type washing device for experimental analysis, the box is improved, the storage volume of a solvent is improved, and damage caused by too-large pressure in a container is avoided, different cleaning solvents can be contained, and the washing effect of different pollutants is achieved; a foot rest and a one-way valve compression pump are matched, so that the solvent conveying effect is achieved; through the base with the sliding wheels, convenience is brought to movement at will, and operation is easy and convenient; and filling can be carried out after the cover is opened, and time and labor are saved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

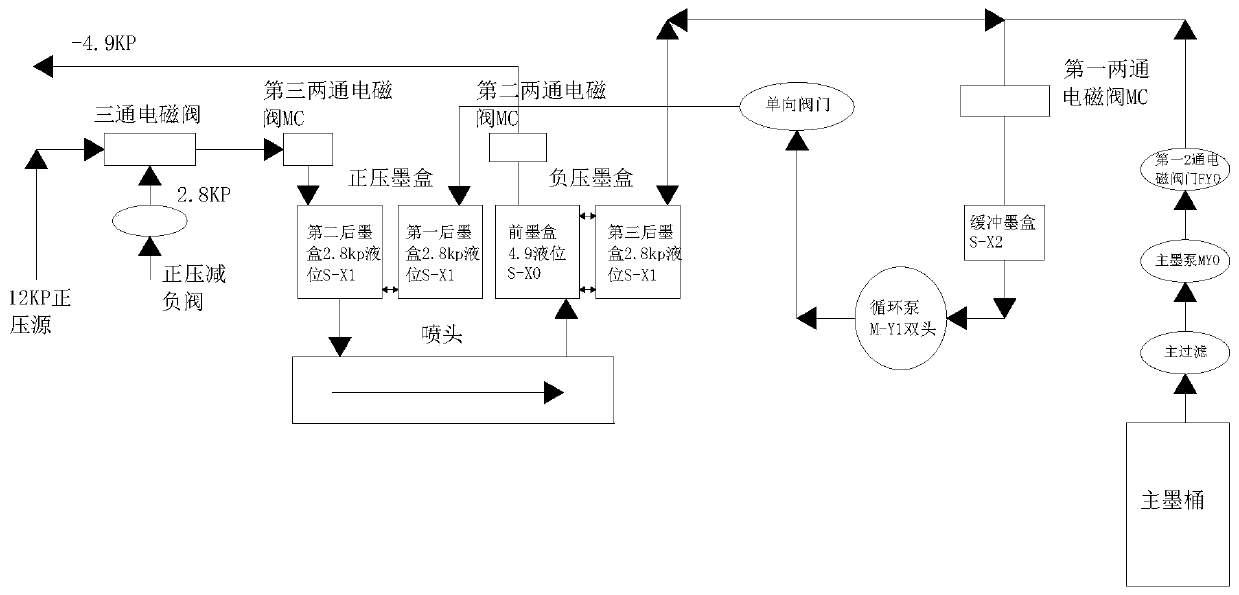

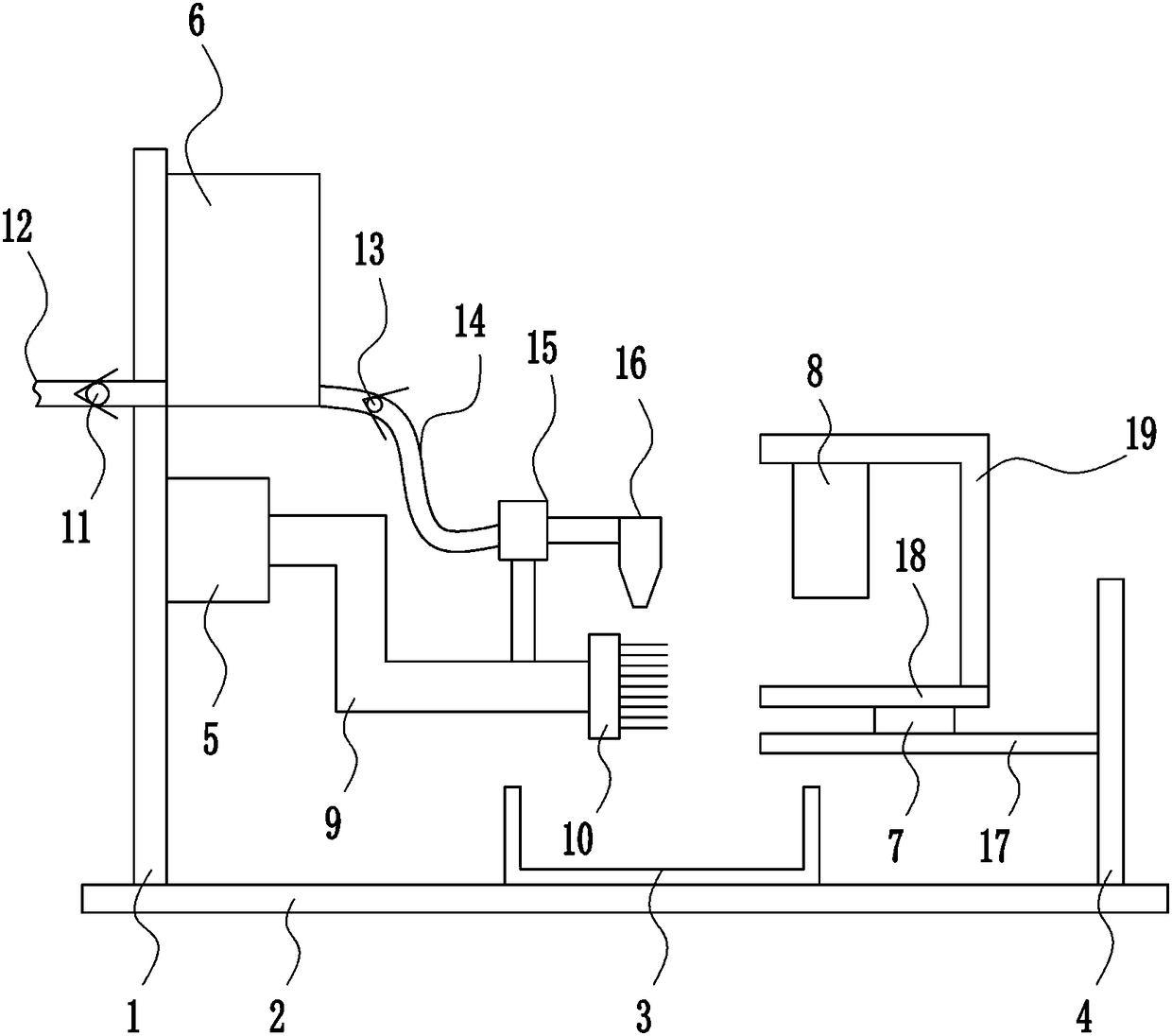

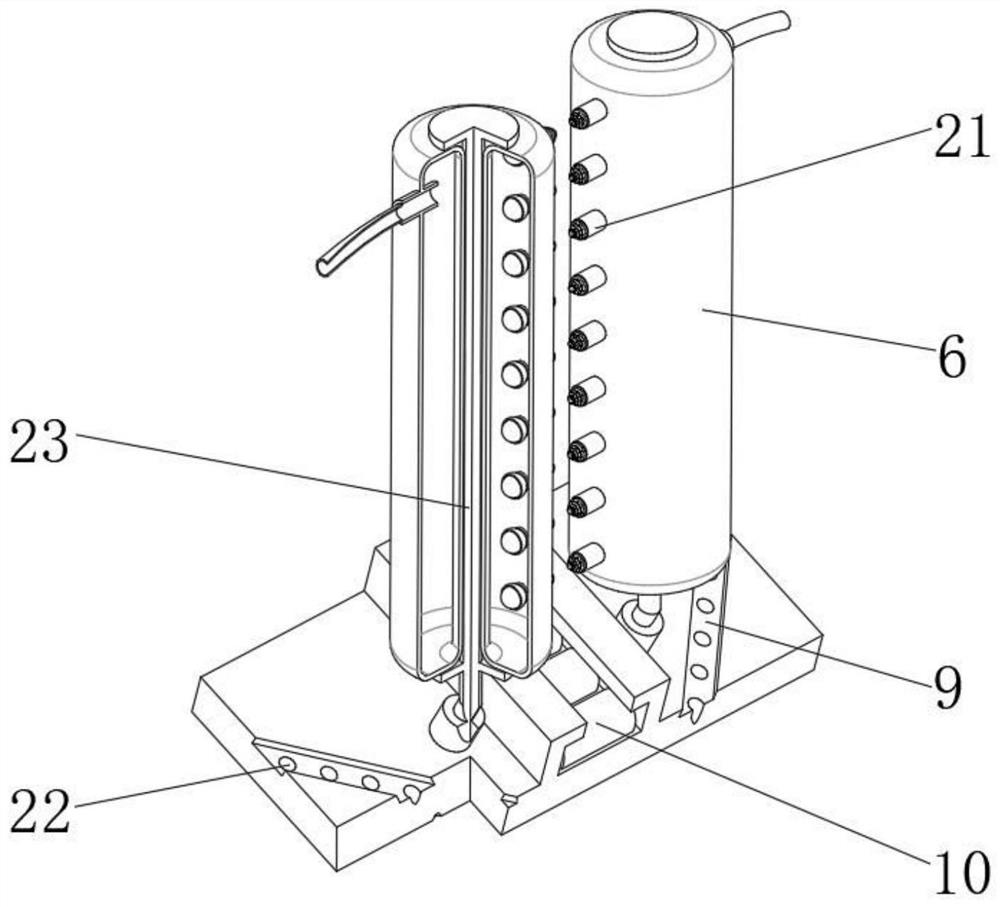

Positive pressure and negative pressure circulation system used for printing head and capable of ensuring stable digital printing

InactiveCN110978798ATo achieve the delivery effectRealize the buffering effectPrintingEngineeringDigital printing

The invention discloses a positive pressure and negative pressure circulation system used for a printing head and capable of ensuring stable digital printing. The positive pressure and negative pressure circulation system used for the printing head and capable of ensuring stable digital printing comprises a main ink bucket, wherein an output end of the main ink bucket is unidirectionally connectedwith an input end of a main ink pump MYO; an output end of the main ink pump MYO is unidirectionally connected with an input end of a first two-way electromagnetic valve FYO; an output end of the first two-way electromagnetic valve FYO is unidirectionally connected with an input end of a first two-way electromagnetic valve MC; and an output end of the first two-way electromagnetic valve MC is unidirectionally connected with an input end of a buffer ink box S-X2. According to the positive pressure and negative pressure circulation system used for the printing head and capable of ensuring stable digital printing, the effect of storing ink is achieved through the arrangement for the main ink bucket; the effect of conveying ink is achieved through the main ink pump MYO; the effect of connecting with the first two-way electromagnetic valve MC is achieved through the first two-way electromagnetic valve FYO; and the effect of connecting with the buffer ink box S-X2 and 2.8kp liquid level S-X1 of a third rear ink box. The circulation system is stable in ink channel and free from the case of ink lack, and facilitates people to print an object.

Owner:南通东川数码科技有限公司

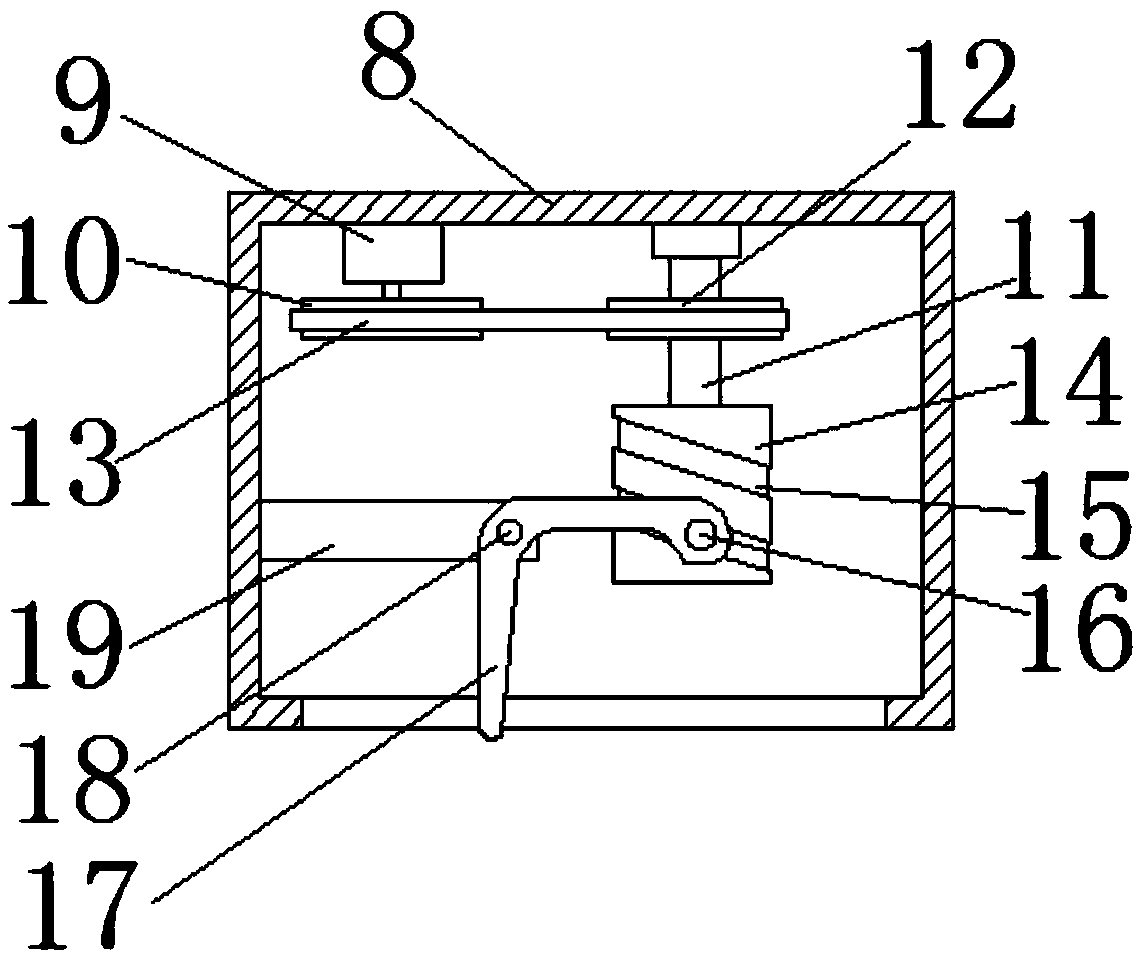

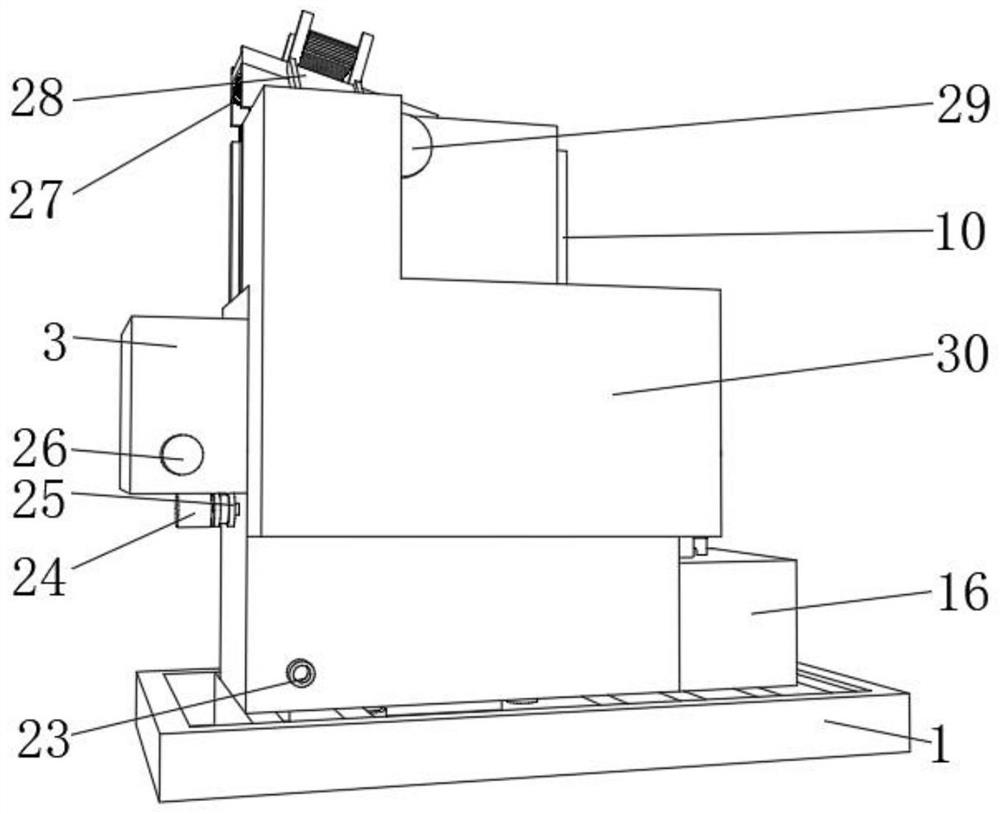

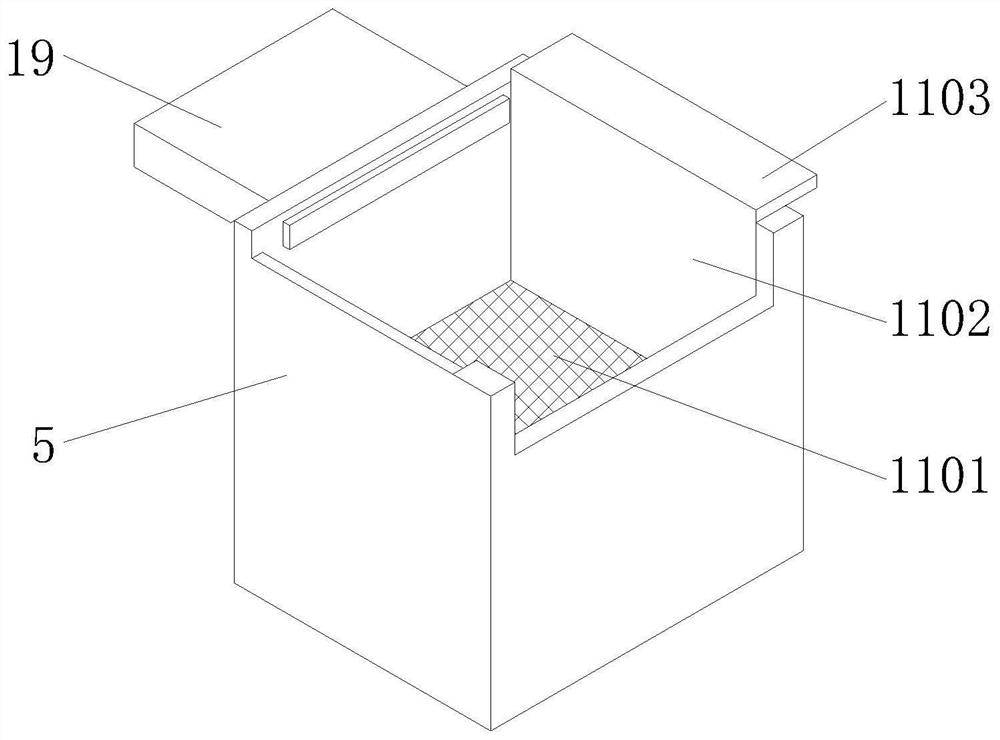

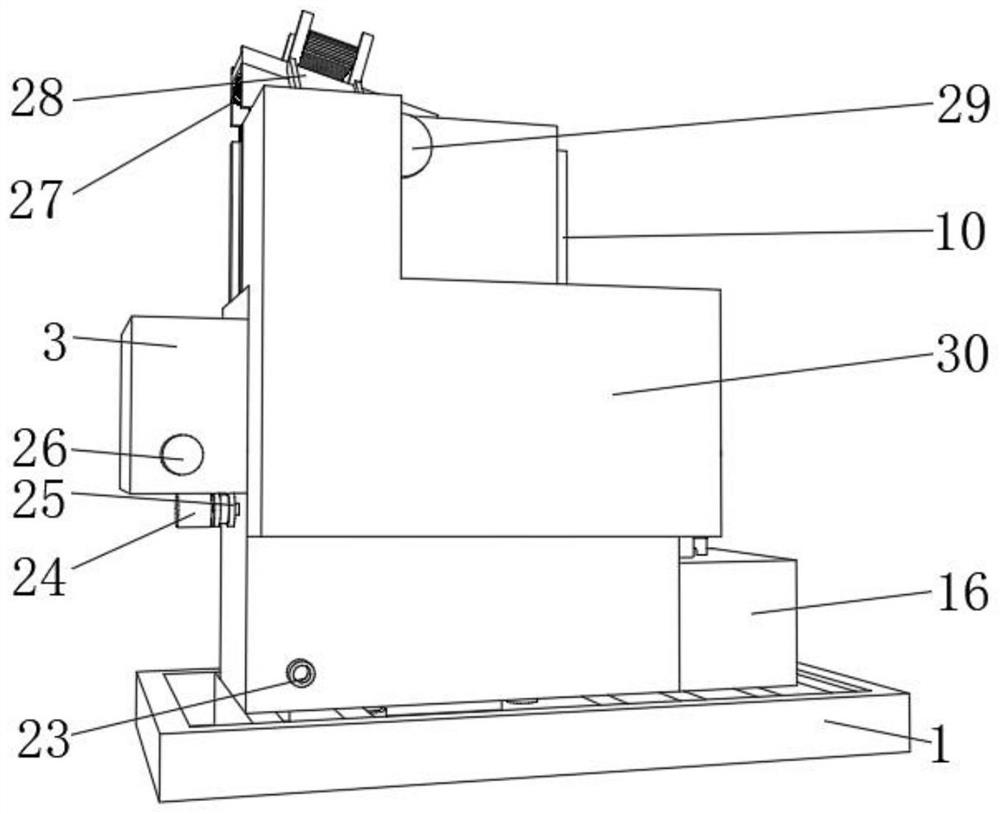

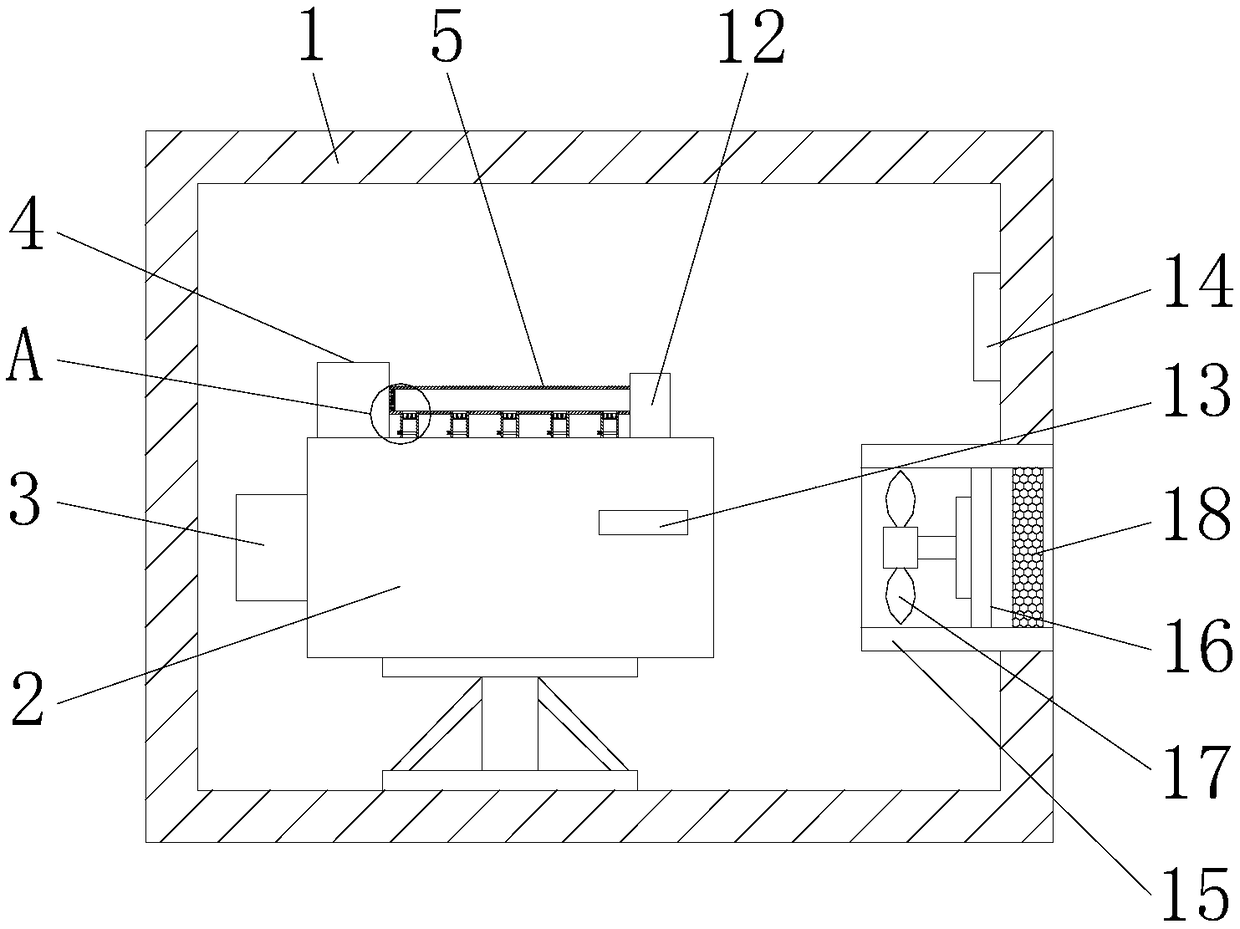

Environment-friendly solid waste treatment device

ActiveCN112495990ATo achieve the delivery effectAvoid cloggingSievingScreeningAir pumpElectric machinery

The invention discloses an environment-friendly solid waste treatment device, and relates to the technical field of solid waste treatment. The environment-friendly solid waste treatment device aims tosolve the problem that crushing is not sufficient enough. The environment-friendly solid waste treatment device specifically comprises a base, wherein a box body is fixed to the top of the base through bolts; a jaw type crushing mechanism is arranged on the inner wall of the top of the box body; a crushing box is fixed to the outer wall of the side, close to the crushing mechanism and provided with a filter plate box body, of the box body through bolts; a crushing mechanism is arranged in the crushing box; an air pump is fixed to the outer wall of one side of the crushing box through bolts; aconveying pipe is fixed to an air inlet and an air outlet of the air pump through threads; a secondary crushing mechanism is arranged in the box body; and a stirring mechanism is arranged on the inner wall of the bottom of the box body. According to the environment-friendly solid waste treatment device, the discharging condition of a feeding port is detected through an ultrasonic sensor, so thatthe ultrasonic sensor transmits an electric signal to a controller; and the controller controls a first motor to reduce the vibration frequency of a vibration screen, so that the feeding progress is slowed down, and then the phenomenon that the feeding port is blocked is avoided.

Owner:仁净(江苏)集成系统科技有限公司

Device for collecting and processing fish excrement in environmentally friendly aquaculture net lift car

InactiveCN108077143APrevent escapeNo movement effectClimate change adaptationWaste water treatment from animal husbandrySurface mountingPulp and paper industry

The invention discloses a device for collecting and processing fish excrement in an environmentally friendly aquaculture net lift car. The device comprises a hollowed-out culturing box, a first motor,a collection box and a second motor, a collection cylinder is welded at the bottom end of the hollowed-out culturing box, a collection cylinder connector is installed at the bottom end of the collection cylinder, a delivery pipe connector is sleeved on the outer surface of the collection cylinder connector, the delivery pipe connector and the collection cylinder connector are mutually clamped andfixed through clamping teeth, the delivery pipe connector is connected with a delivery pipe, the other end of the delivery pipe is connected with a first water pump input port, the first water pump input port is installed on one side of the first water pump, the collection box is installed on one side of the first water pump, a stop block is installed on the interior surface of the collection box, a filter groove is clamped on the stop block, active carbon is arranged at the bottom end of the filter groove, and a filter screen is arranged at the bottom end of the active carbon. A floatation cylinder is adopted to float a hollowed-out culturing net to limit culturing, and a draw-out filter mode is used for removing redundant fish excrement in a water body.

Owner:湖州南浔超联水产养殖有限公司

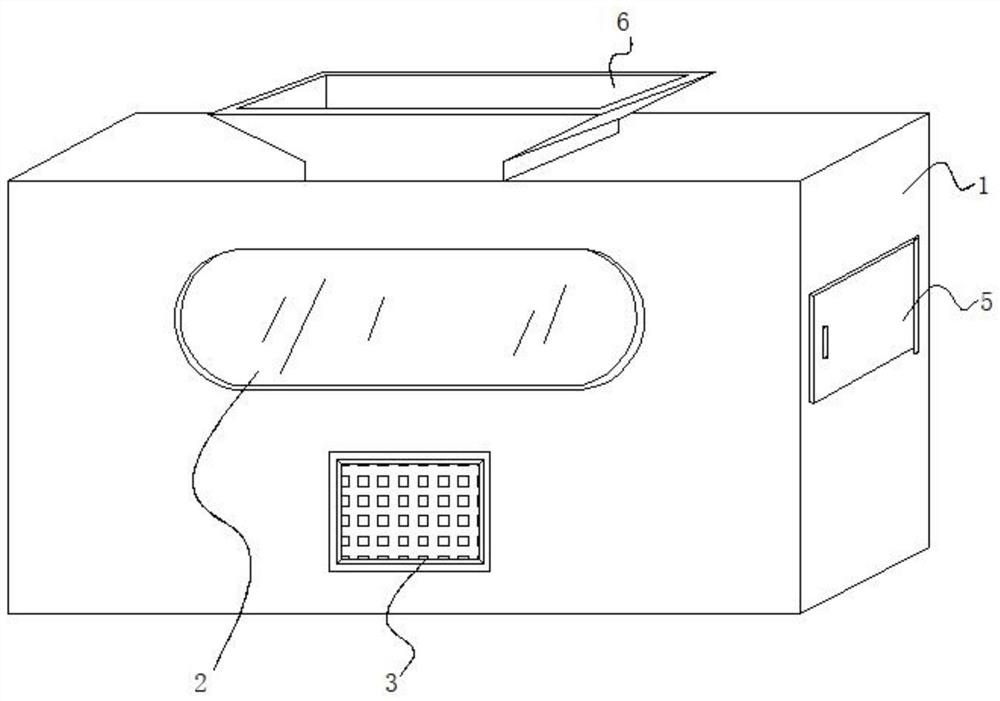

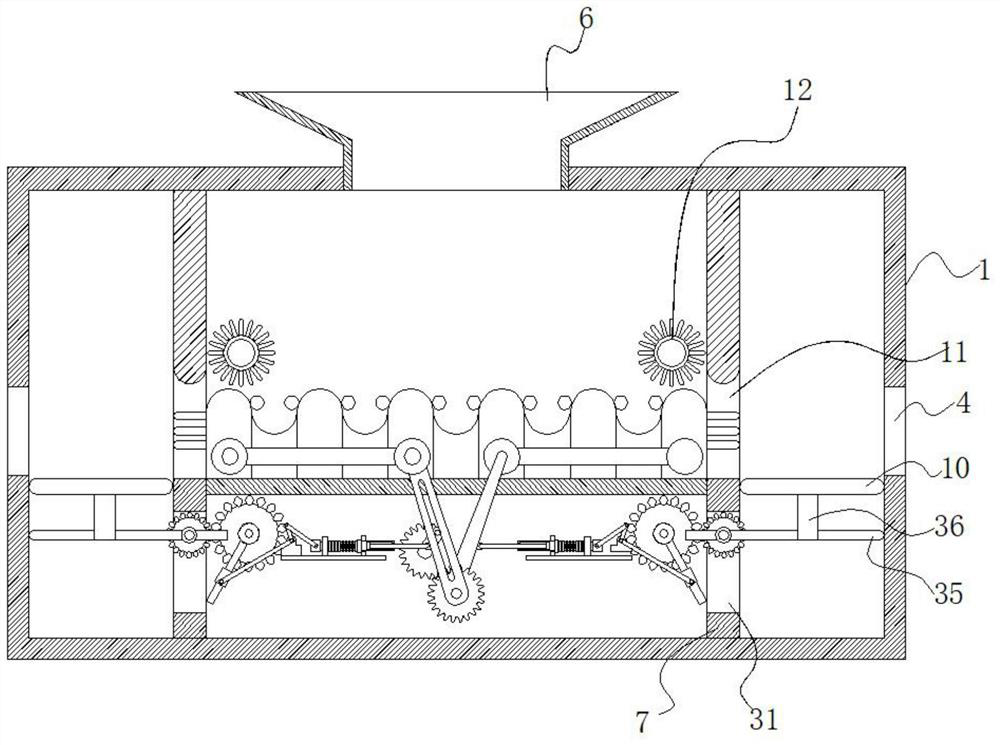

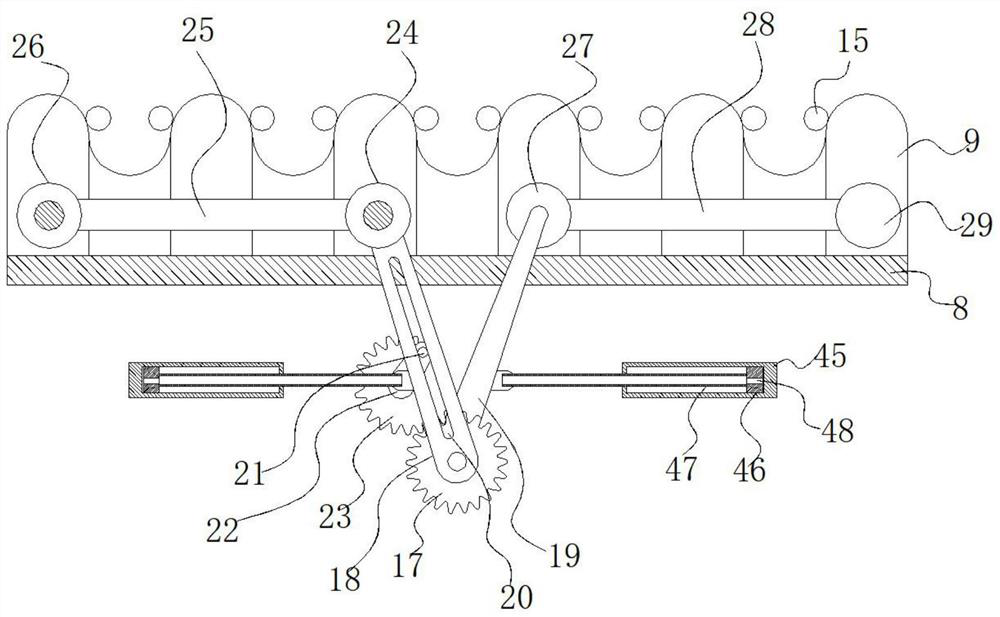

Wave-groove-based crushing type electronic technology waste product disassembling and recycling device

PendingCN113953300AAchieve tiltDismantling is effectiveTransportation and packagingSolid waste disposalWaste productEngineering

The invention discloses a wave-groove-based crushing type electronic technology waste product disassembling and recycling device which comprises a box body. An observation window is arranged in the center of the upper portion of the front face of the box body, an operation panel is arranged below the observation window, discharging windows are formed in the upper portions of the two sides of the box body, and a feeding hopper is arranged in the center of the top of the box body; supporting columns are arranged at the two sides in the box body correspondingly, a partition plate transversely penetrates through the lower portion between the supporting columns, a movable corrugated folding plate is arranged at the top of the partition plate, a driving mechanism is arranged in the middle of the lower portion of the partition plate, power mechanisms are arranged at the two sides of the driving mechanism correspondingly, and angle-adjustable plates are arranged on the power mechanisms correspondingly; and the angle-adjustable plates are located between the supporting columns and the inner wall of the box body and located at the bottoms of the inner sides of the discharging windows, hollowed-out upper through holes are formed in the middles of the supporting columns, waste electronic products can be disassembled and recycled conveniently, and waste and environment pollution are avoided.

Owner:陈雨裳

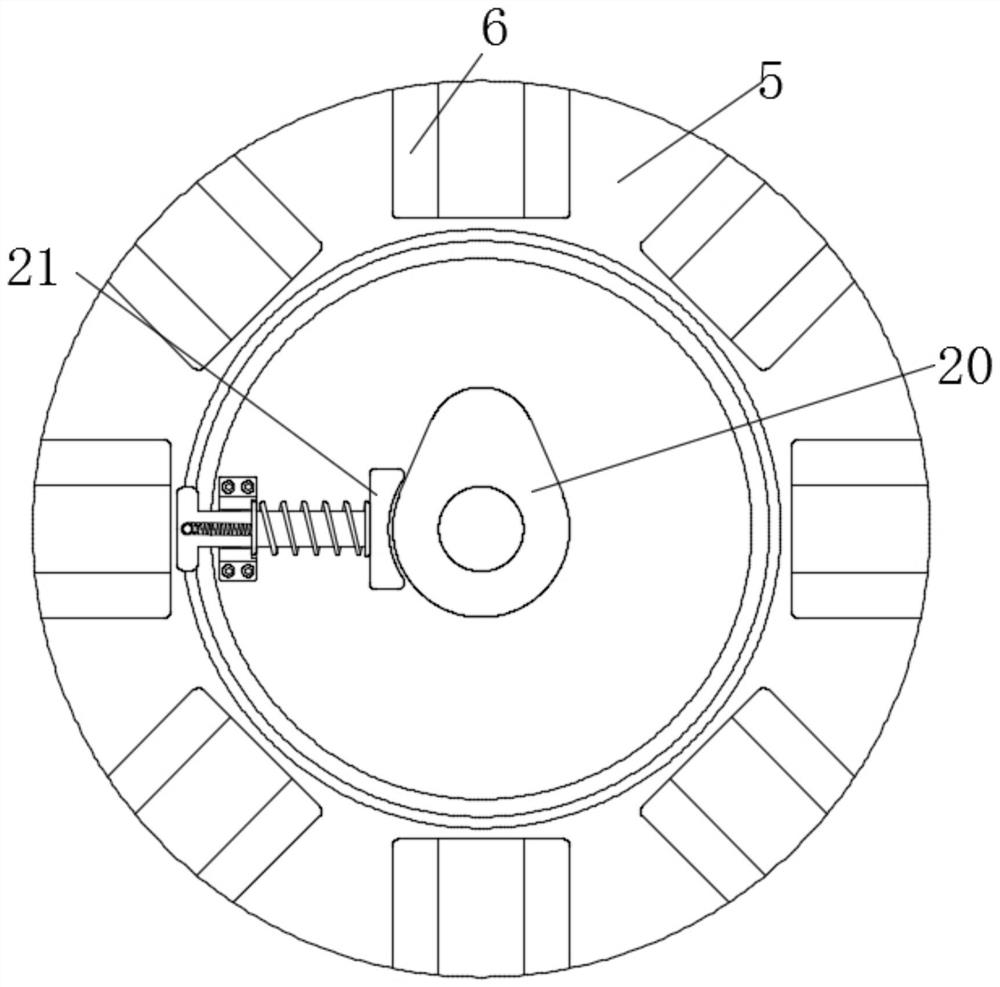

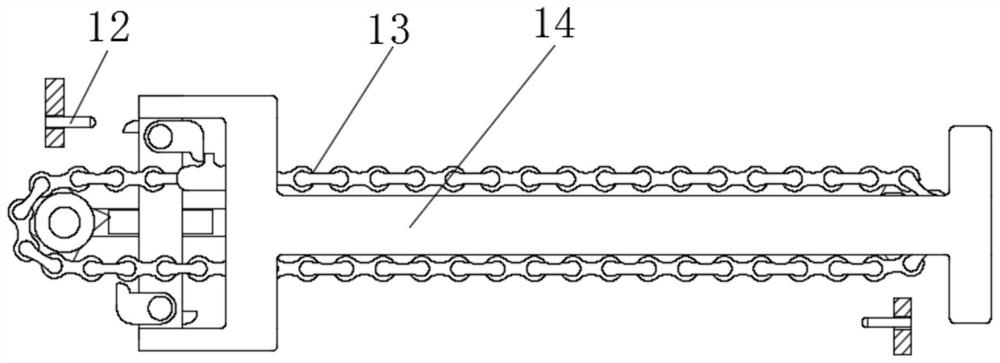

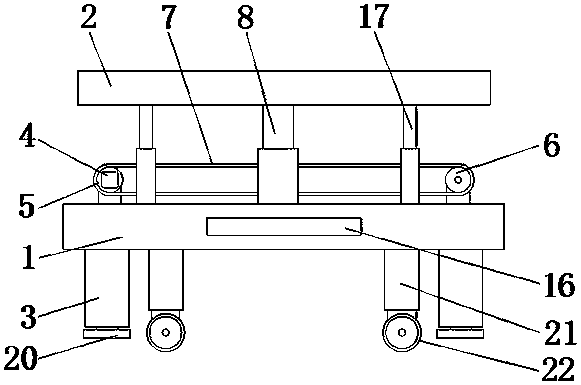

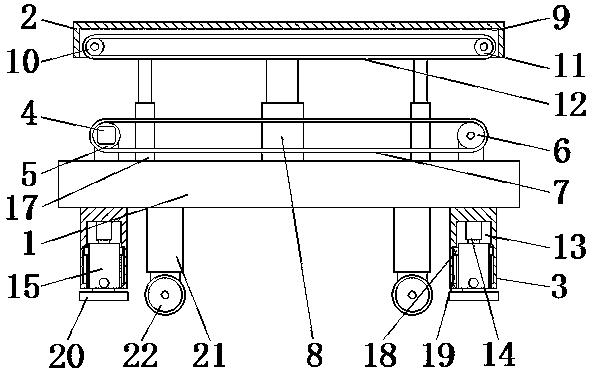

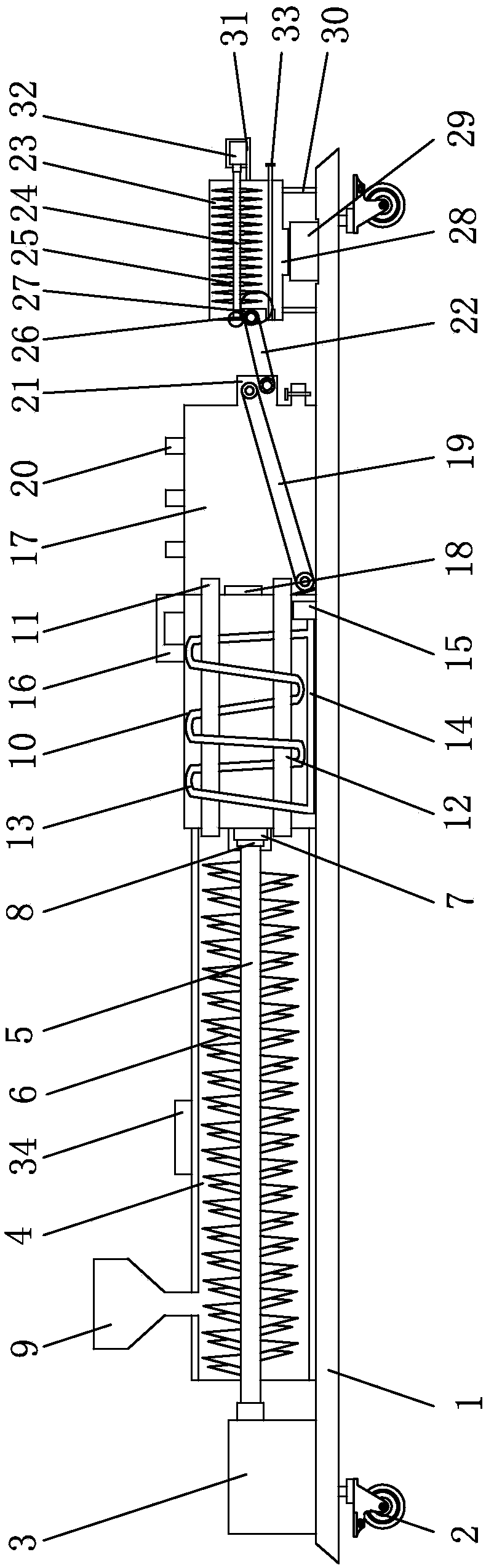

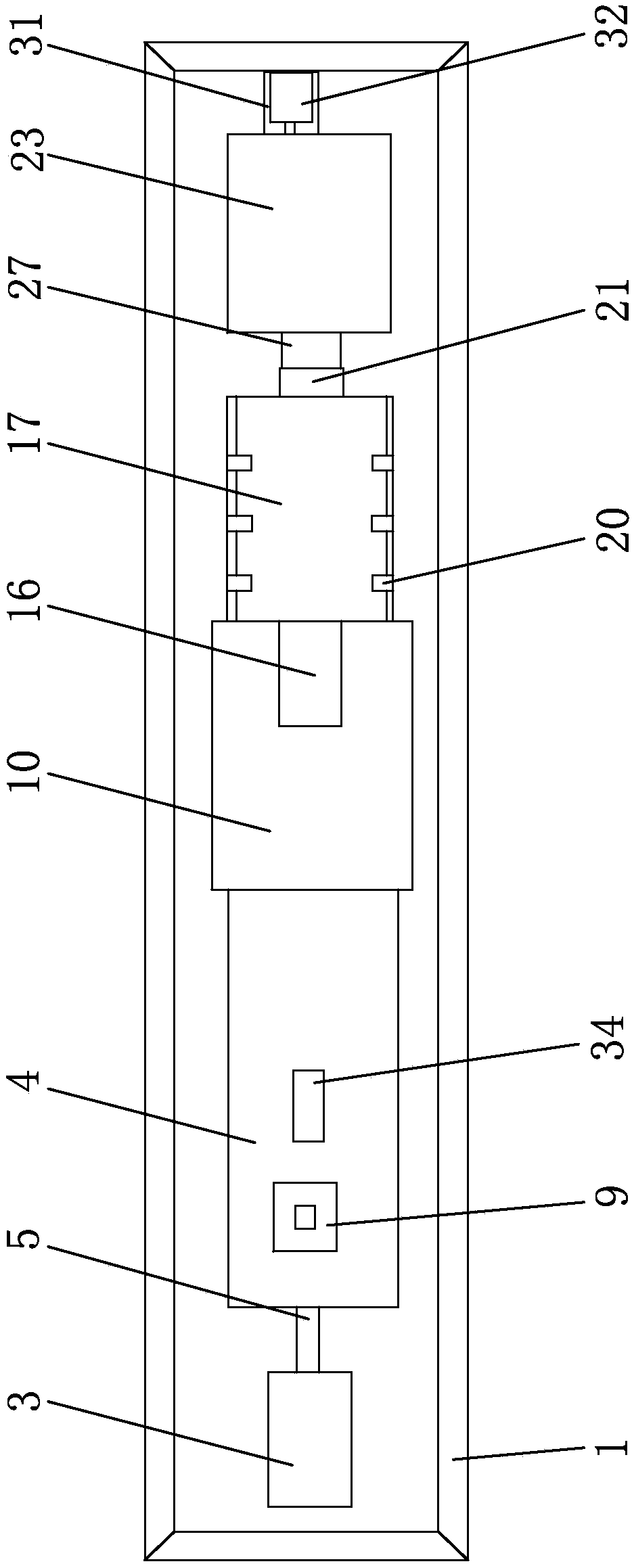

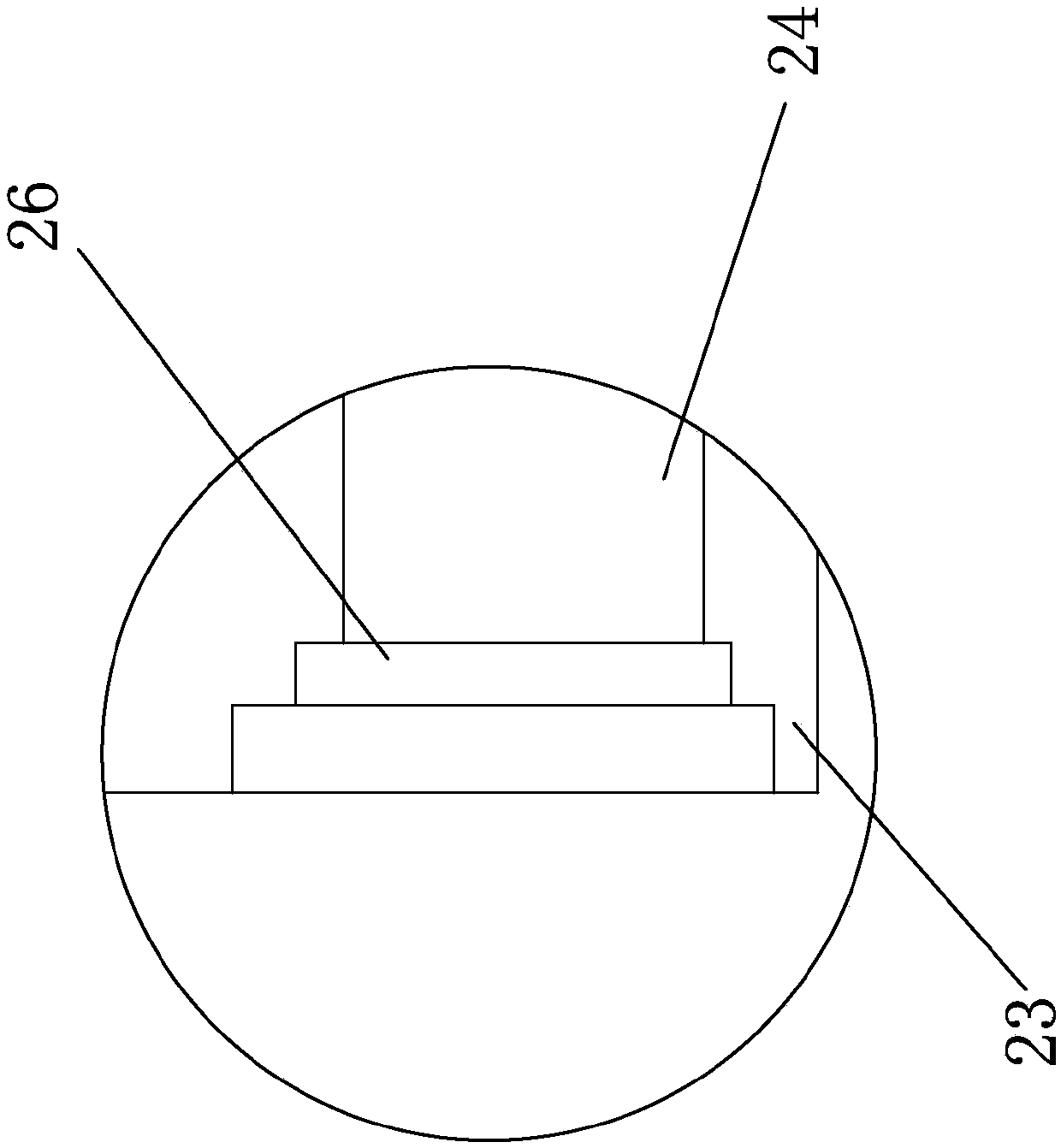

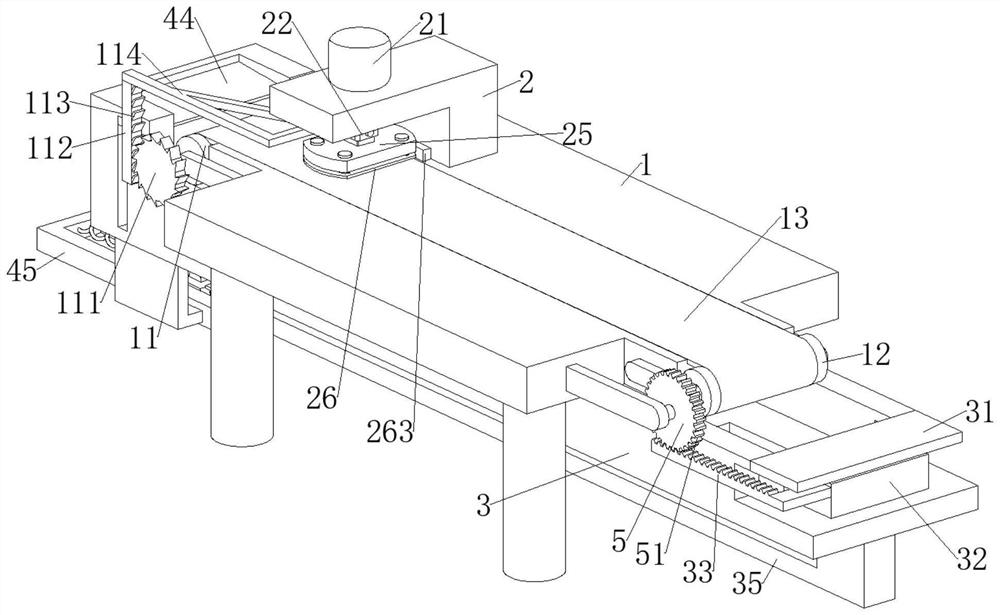

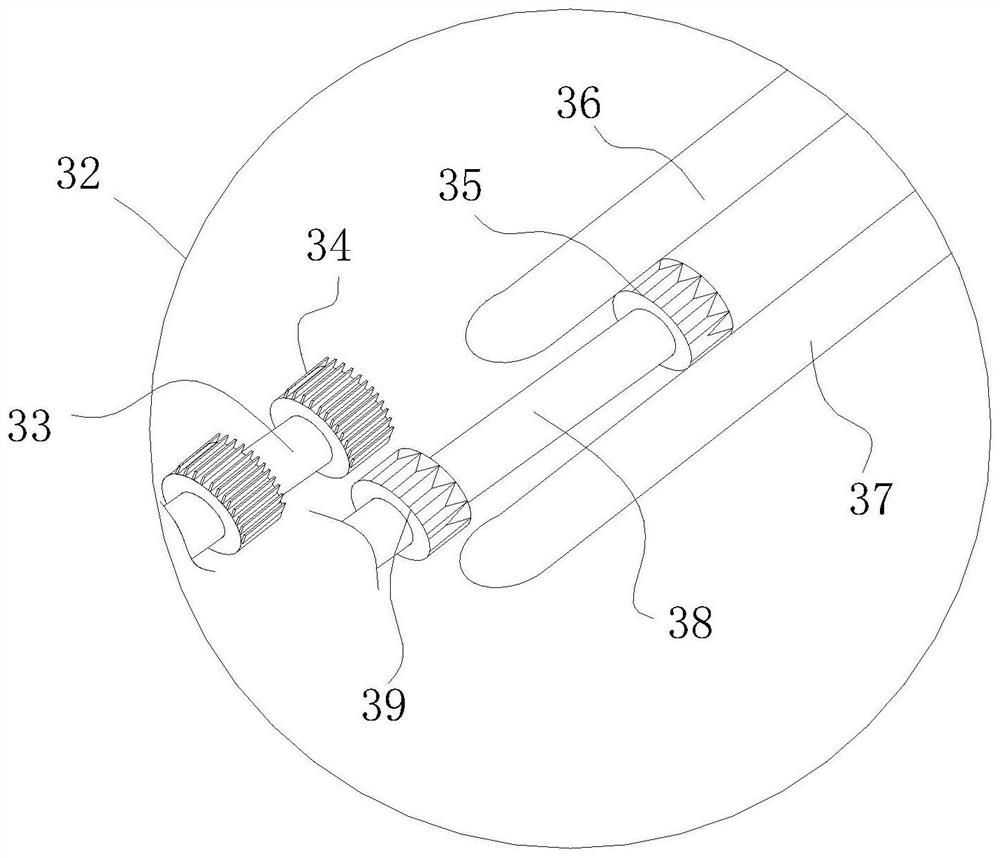

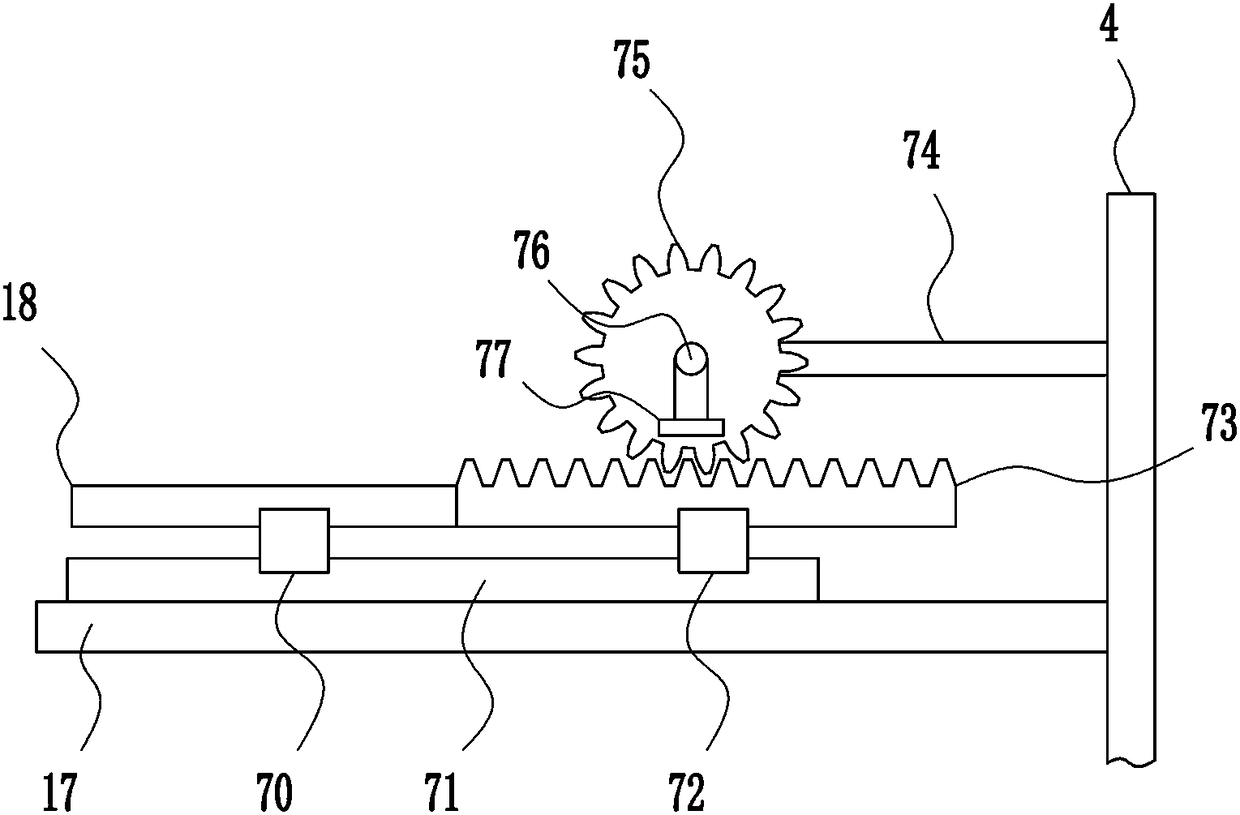

Energy-saving and environmental-friendly part successive feeding and recycling machining mechanism

InactiveCN113895877ATo achieve the delivery effectAchieve the effect of automatic transfer processing outputConveyor partsRotary conveyorsGear driveGear wheel

The invention relates to the technical field of hardware machinery, and discloses an energy-saving and environmental-friendly part successive feeding and recycling machining mechanism. The mechanism comprises a rack, the bottom of the rack is rotationally connected with a tooth-missing gear and an intermittent gear, the bottom of the intermittent gear is fixedly connected with an intermittent cam, and the top of the intermittent gear is fixedly connected with a rotating disc. A placing frame is fixedly connected to the top of the rotating disc, a top extension rod is slidably connected to the interior of the rack, a connecting rod is rotatably connected to the left side of the top extension rod, and a jacking rod is rotatably connected to the top of the connecting rod. According to the energy-saving and environmental-friendly part successive feeding and recycling machining mechanism, the intermittent gear is driven to rotate through the tooth-missing gear, the intermittent gear drives the top extension rod to move through the intermittent cam, the top extension rod drives the jacking rod to move through the connecting rod, the jacking rod drives a rotating frame to rotate, the rotating frame drives a rotating plate to move and rotate, and through cooperative use of a rotating chain wheel, a top extension plate and other mechanisms, the effect of automatically and intermittently conveying parts is achieved.

Owner:高洪利

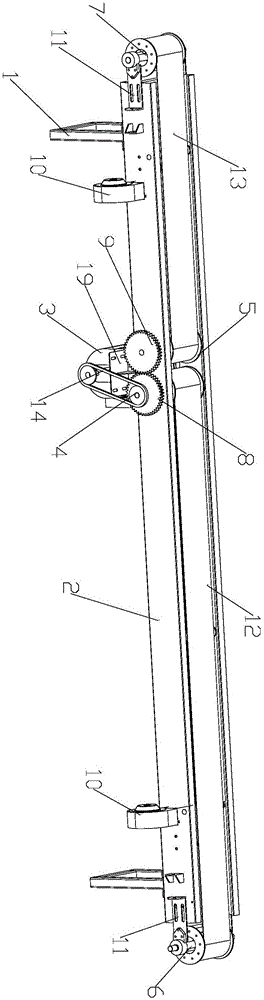

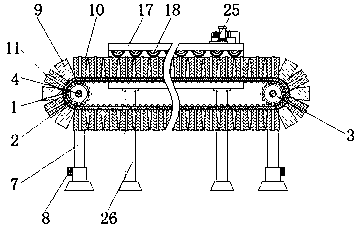

Conveying device with good flatness for straw plates

InactiveCN108706290ATo achieve the delivery effectTo achieve the mobile effectConveyorsDrive wheelEngineering

The invention discloses a conveying device with good flatness for straw plates. The conveying device comprises a base, wherein the top of the base is movably connected with a fixed plate; the two sides of the bottom of the base are fixedly connected with first supporting legs; the left side of the top of the base is equipped with a motor; the rotary shaft of the motor is fixedly connected with a first drive wheel; and the right side of the top of the base is movably connected with a first driven wheel. According to the conveying device disclosed by the invention, the first drive wheel, the first driven wheel and a first conveyor belt are arranged for conveying the straw plates; a firs electric telescopic pole drives the fixed plate to move; the effect of assisting the first conveyor belt to horizontally convey the straw plates is achieved through a second drive wheel, a second driven wheel and a second conveyor belt; levelness of the base is detected through a level gauge; the effect of regulating levelness of the base is achieved through a second electric telescopic pole and second supporting legs; and the straw plates can be horizontally conveyed, so that use of people is convenient.

Owner:许昌亚丹生态家居有限公司

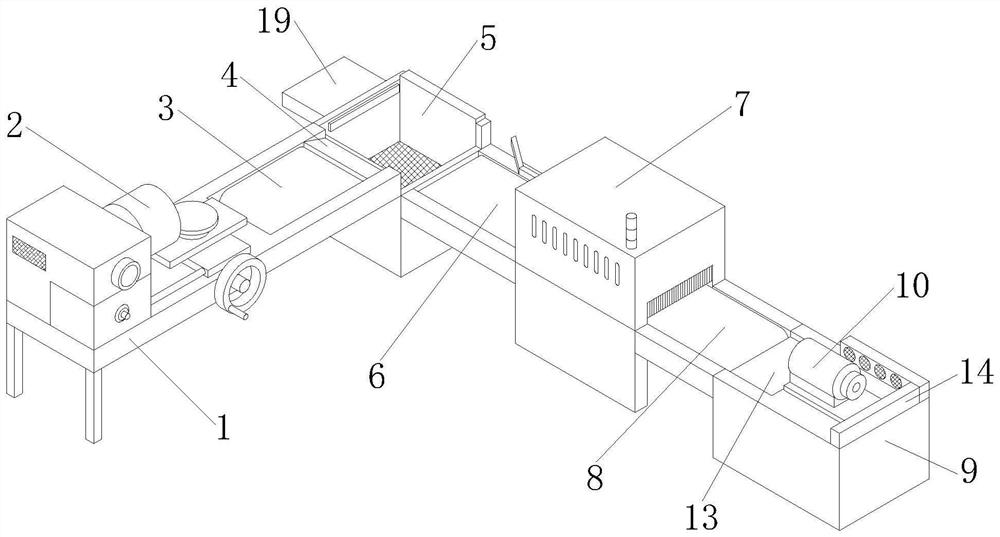

Polyethylene pipeline production equipment

PendingCN107639801AImprove cooling effectReduce cooling effectTubular articlesElectrical connectionCooling chamber

The invention provides polyethylene pipeline production equipment which comprises a base, a vacuum cooling chamber, a sprinkling chamber and a segmenting chamber. Castors are arranged at the bottom ofthe base, a first motor is arranged at the left end of the top of the base, a material barrel is arranged at the left end of the top of the base and arranged on the right side of the first motor, a feeding bucket and a controller are both arranged at the top outside the material barrel, the controller is arranged on the right side of the feeding bucket, the first motor and the controller are in electrical connection, a screw is arranged in the material barrel, the left end of the screw extends to the outside of the material barrel to be movably connected with an output end of the first motor,a fixing plate is arranged on the right side wall in the material barrel, and the right end of the screw is movably connected with the fixing plate through a first bearing. The polyethylene pipelineproduction equipment is mounted on the base and can be moved due to arrangement of the castors, and multiple processing procedures are set in the equipment.

Owner:海宁亚大塑料管道系统有限公司

New energy automobile oil way pipe fitting connector rapid manufacturing production process

InactiveCN113427218ATo achieve the delivery effectPrevent stackingOther manufacturing equipments/toolsConveyor partsNew energyPipe fitting

The invention belongs to the technical field of pipe fitting manufacturing, and particularly relates to a new energy automobile oil way pipe fitting connector rapid manufacturing production process. A first operation table is included, a cutting machining device is arranged at the top of the first operation table, and a first conveying belt is movably connected to an inner cavity of the first operation table. A chute is formed in the right side of the first operation table. The problems are solved that in an existing pipe fitting connector production process, a plurality of workers are needed for operation, the workers operate frequently for a long time, the production speed of the workers can be affected, the labor cost is increased, manual operation cannot be effectively reduced in the operation processes of cleaning, drying and the like, in the transportation process, parts cannot be effectively guided and throttled, the situation that the parts are extruded and fall off is liable to be caused by excessive conveying of the parts, the use cost is increased, a large amount of dust and raised dust are caused during grinding and are inconvenient to absorb, and thus the bodies of the workers are injured.

Owner:韩曦

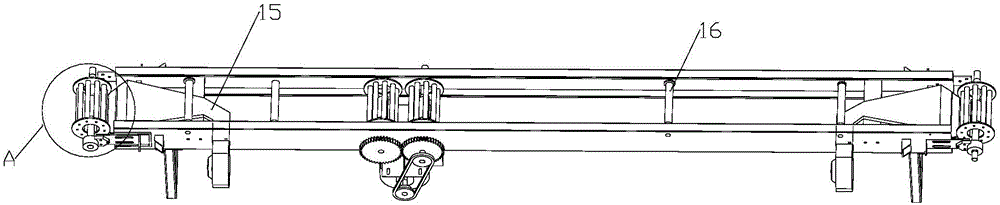

Different-direction conveying machine

InactiveCN105035625ARealize the function of different direction conveyingTo achieve the delivery effectConveyorsMotor driveEngineering

The invention discloses a different-direction conveying machine. The different-direction conveying machine comprises landing legs, two side beams, a motor, a motor installation seat board, an active roll shaft, a driven roll shaft, a first passive roll shaft, a second passive roll shaft, an active gear, a passive gear, a first belt, a second belt and roll shaft installation base plates. The side beams are installed on the landing legs, the motor is installed below the side beams through the motor installation seat board, the motor is arranged on the joint of the first belt and the second belt, the first passive roll shaft and the second passive roll shaft are fixed at the two sides of the side beams through the roll shaft installation base plates, the motor drives the active roll shaft to move through the belts, the active gear and the passive gear are installed on the active roll shaft and the driven roll shaft respectively, the active roll shaft and the driven roll shaft conduct transmission through the gears, the first belt is installed between the active roll shaft and the first passive roll shaft, and the second belt is installed between the driven roll shaft and the second passive roll shaft. The different-direction conveying machine is simple in structure, and by means of the two belts, the different-direction conveying function is achieved.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

Cloth inspecting machine for automobile trim fabrics

InactiveCN110219159ATo achieve the delivery effectTo achieve the detection effectInspecting textilesComputer engineering

The invention discloses a cloth inspecting machine for automobile trim fabrics. The cloth inspecting machine comprises a base. Rollers are movably connected to two sides of the top of the base. A support plate is fixedly connected to the center of the top of the base. A through hole is formed in the bottom of the surface of the support plate. A lighting lamp is fixedly connected to the top of an inner cavity of the through hole. Connection plates are fixedly connected to front and back sides of the support plate. Support rods are slidably connected to the surfaces of the connection plates. Thecloth inspecting machine has the advantages that the rollers are arranged to convey the trim fabrics; through the support plate and the through hole, the trim fabrics are conveniently moved; throughthe lighting lamp, the trim fabrics are inspected; through the support rods, a reflector is supported; through the reflector, the fabrics on the rear side are displayed to help workers check; the cloth inspecting machine helps the workers check the fabrics on the rear side, is convenient for different workers to use, and brings convenience to people.

Owner:JIANGSU TIANYUAN NEW MATERIAL CO LTD

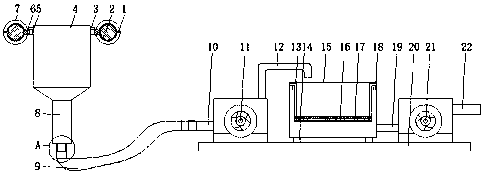

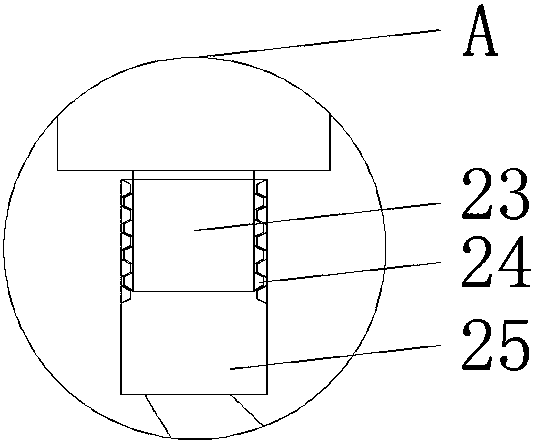

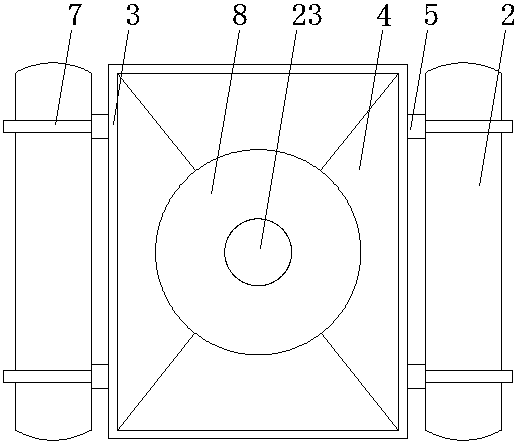

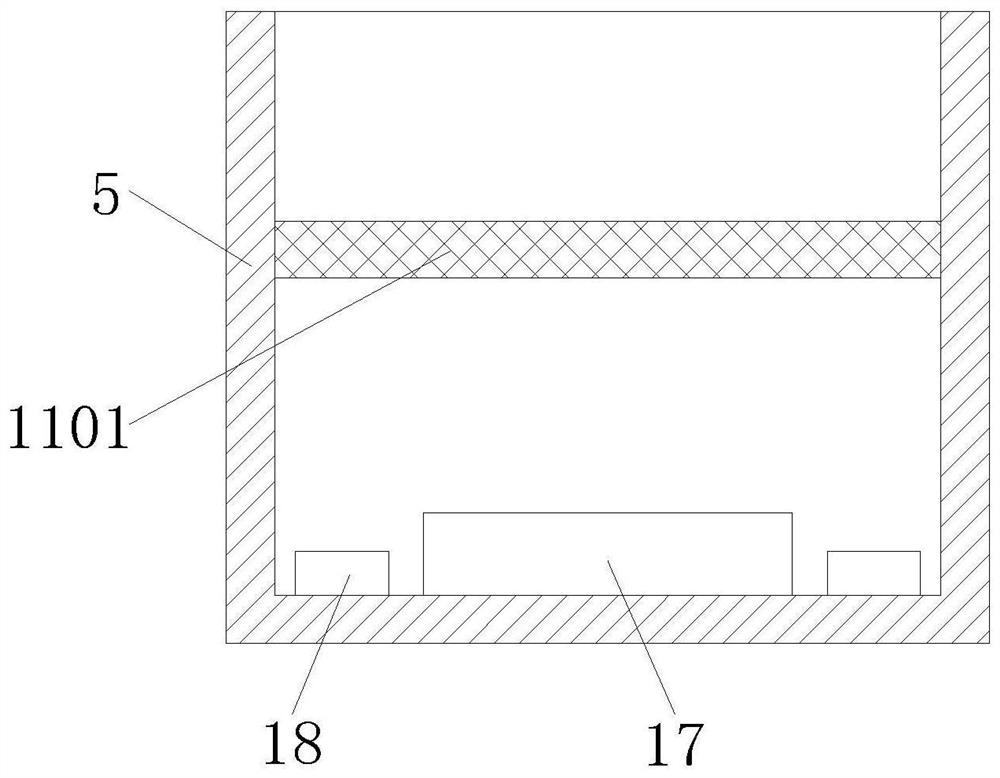

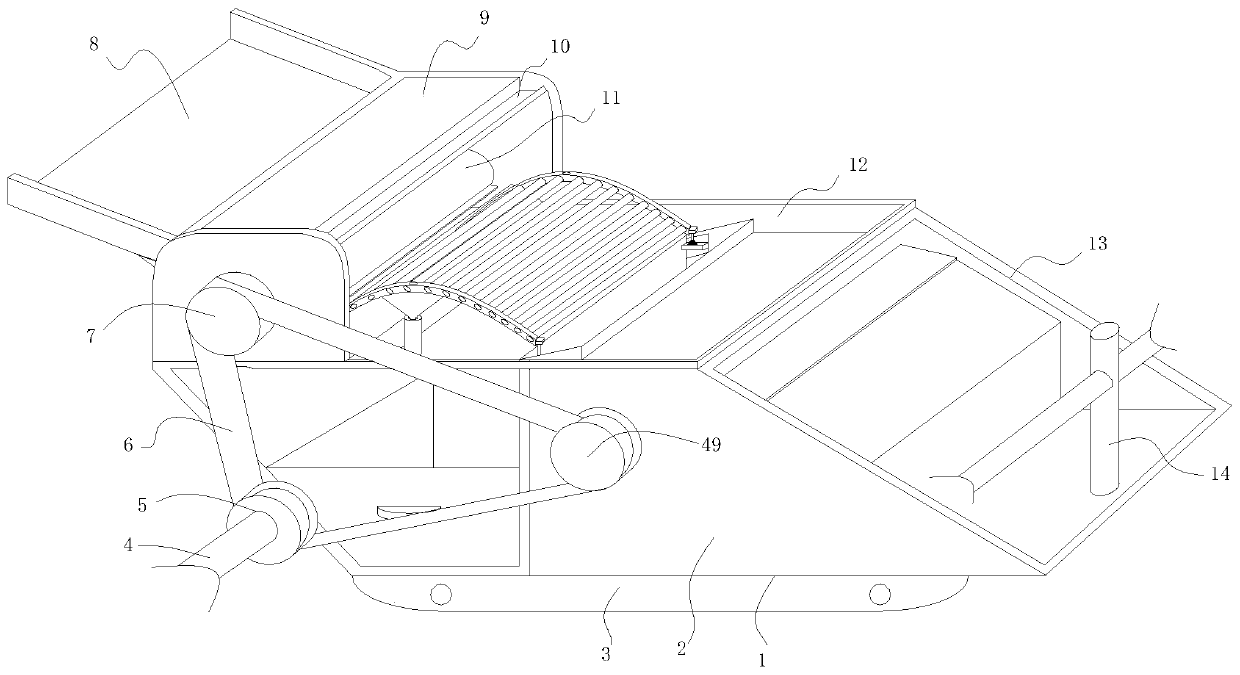

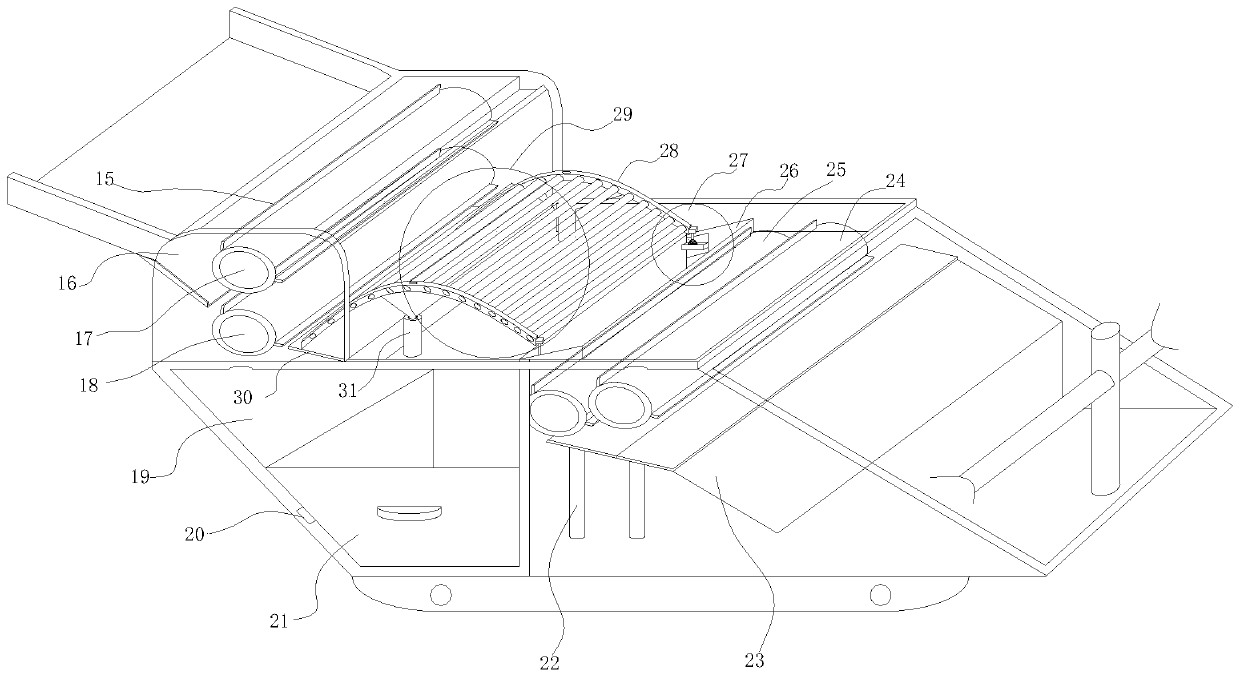

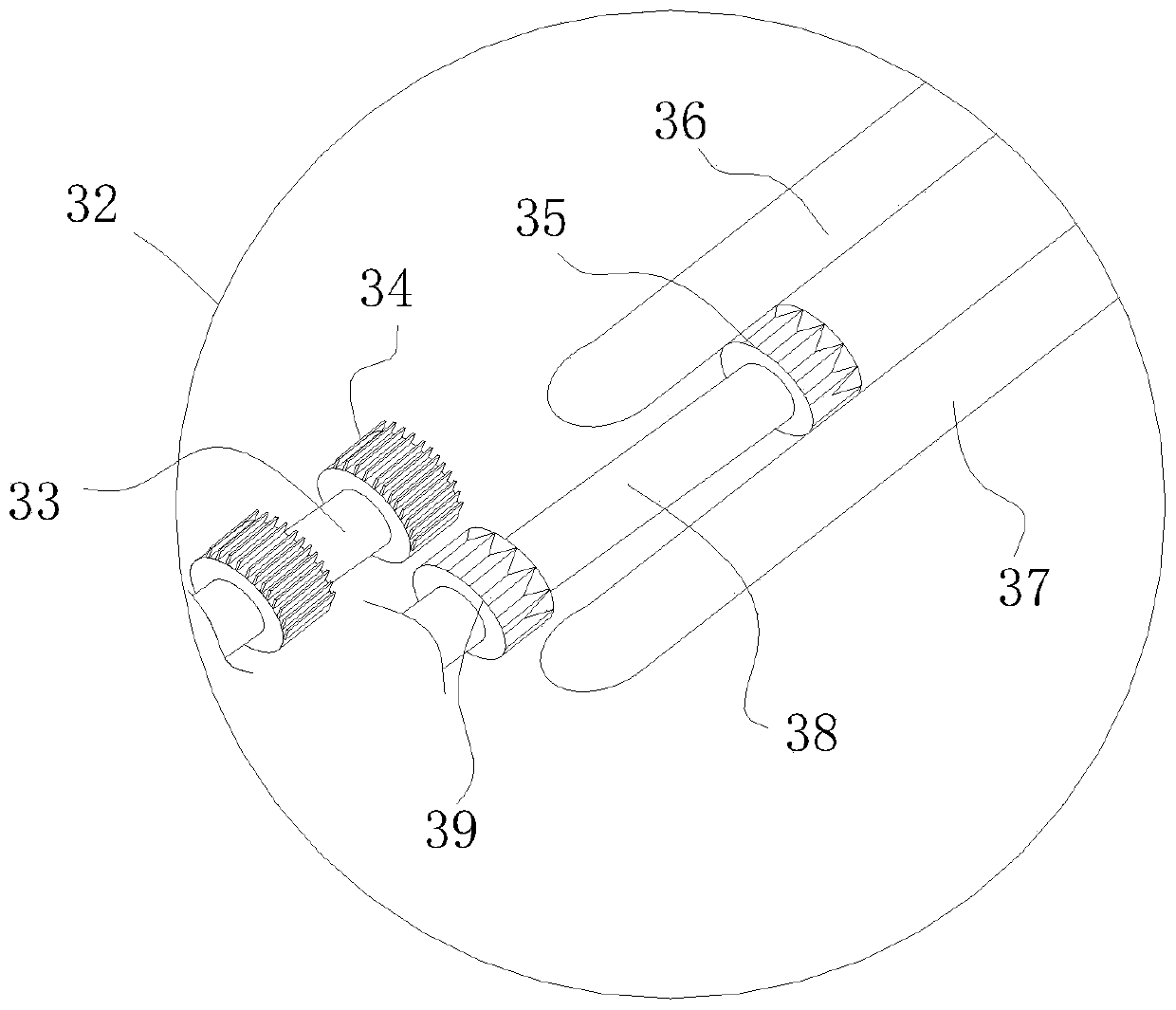

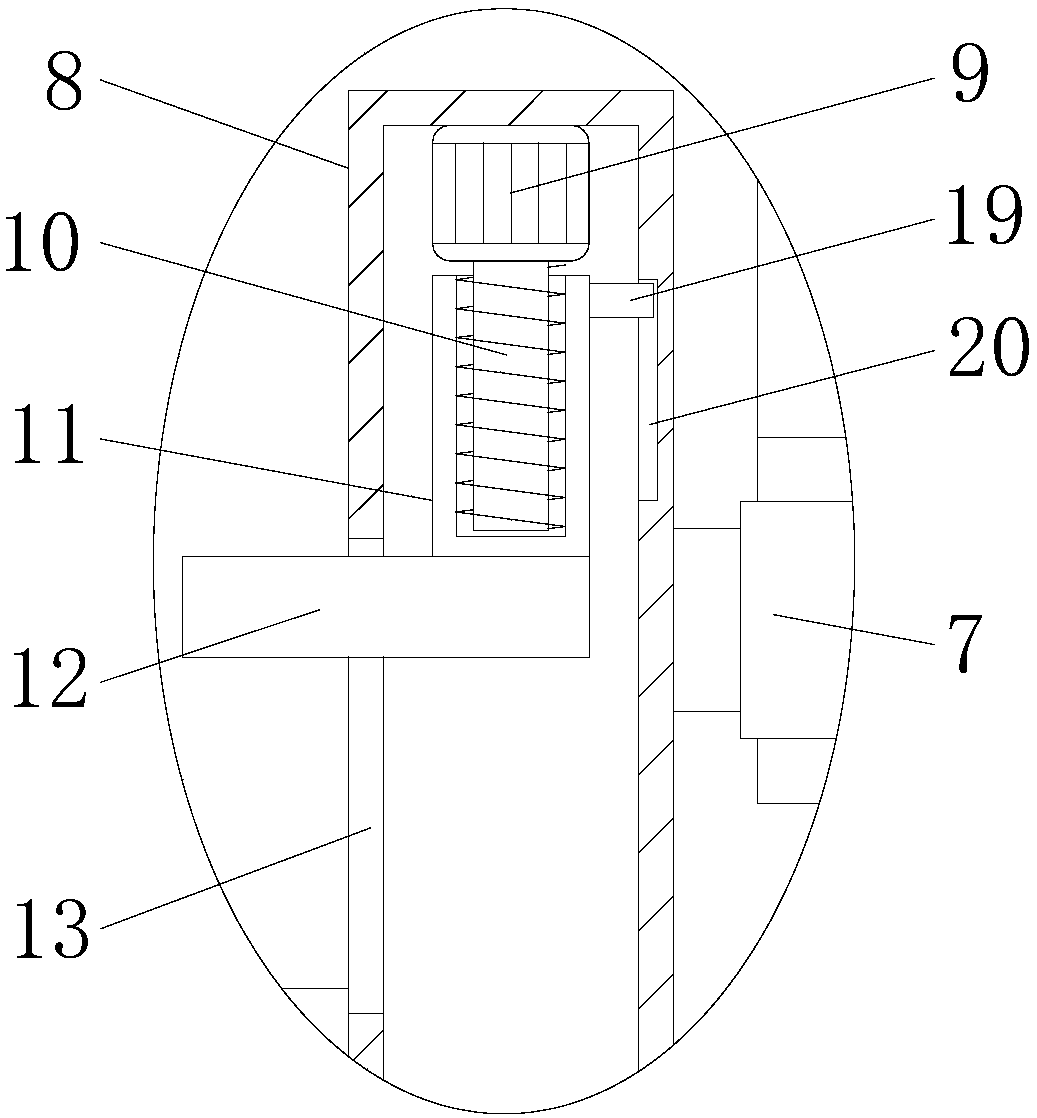

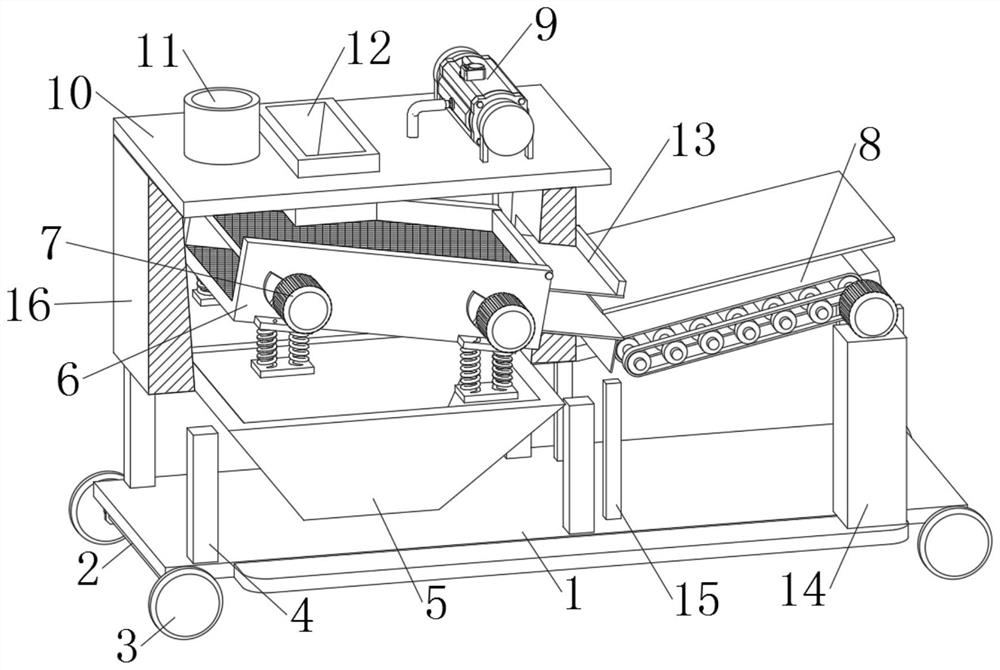

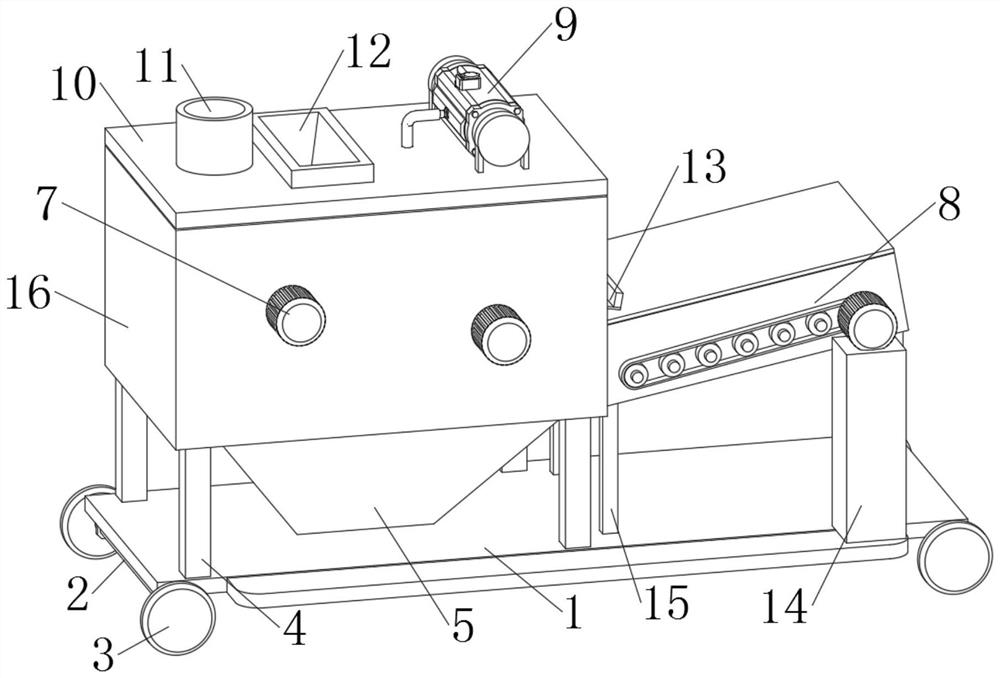

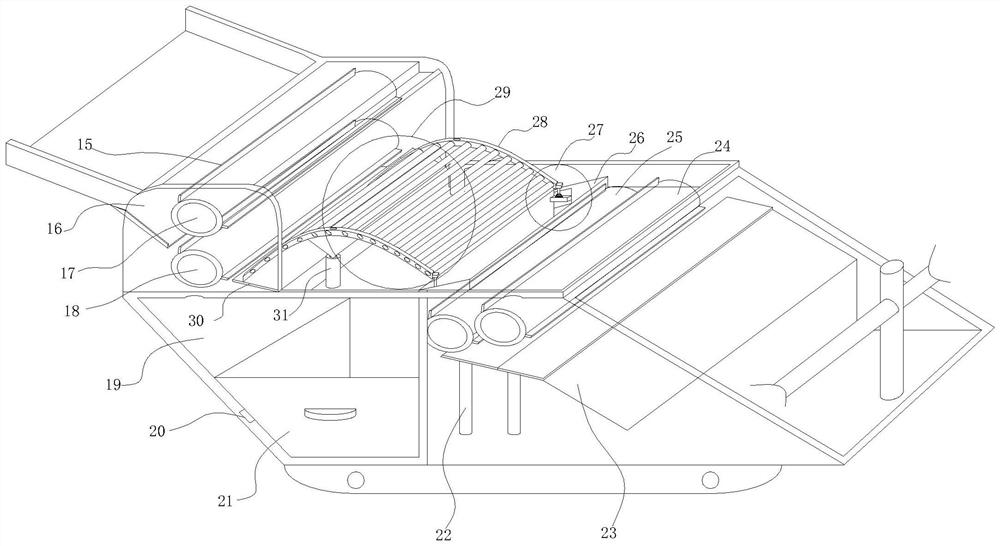

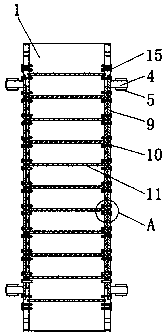

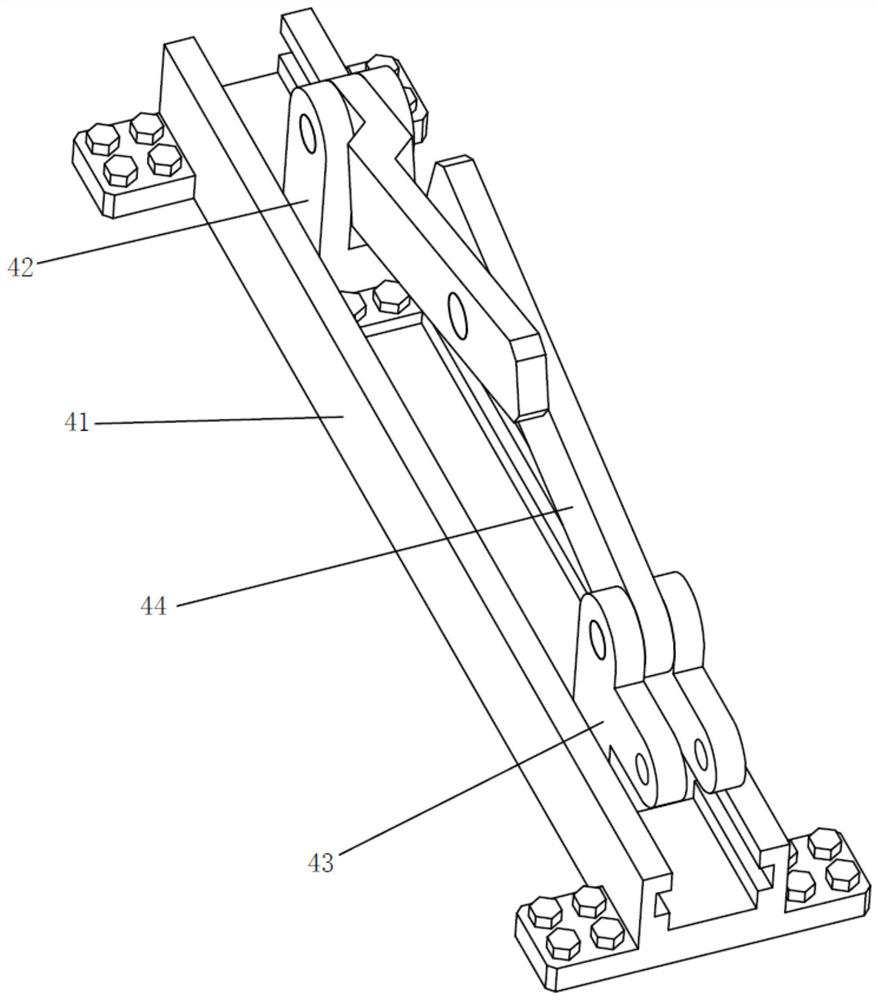

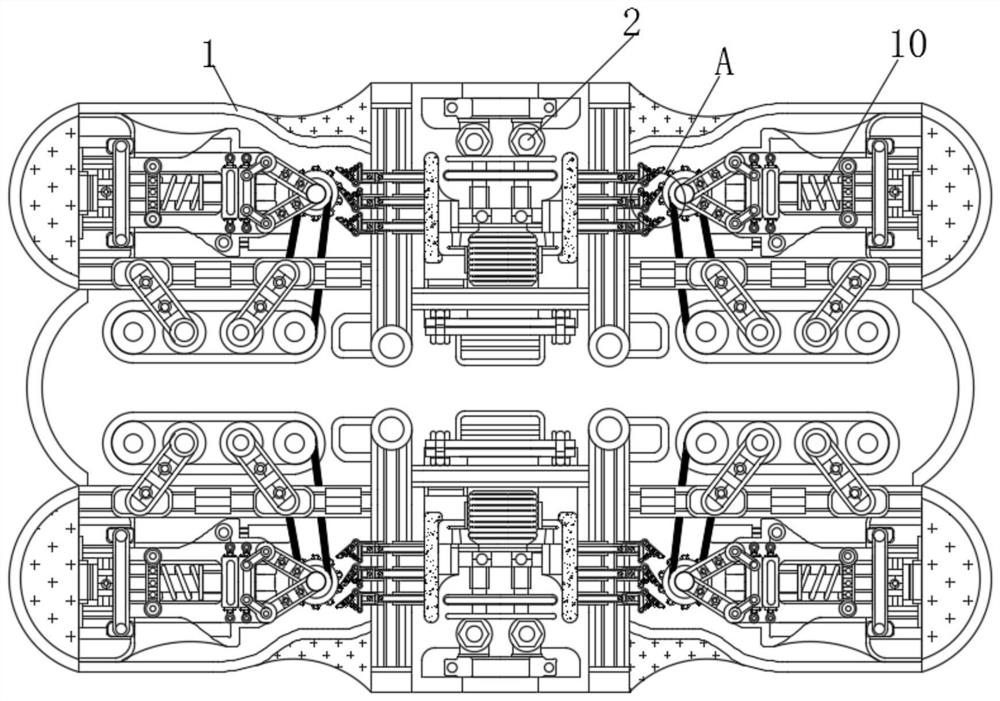

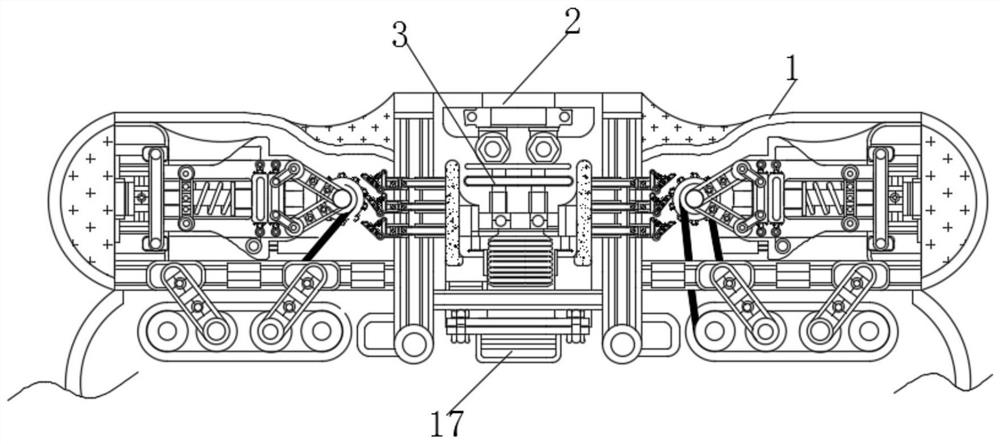

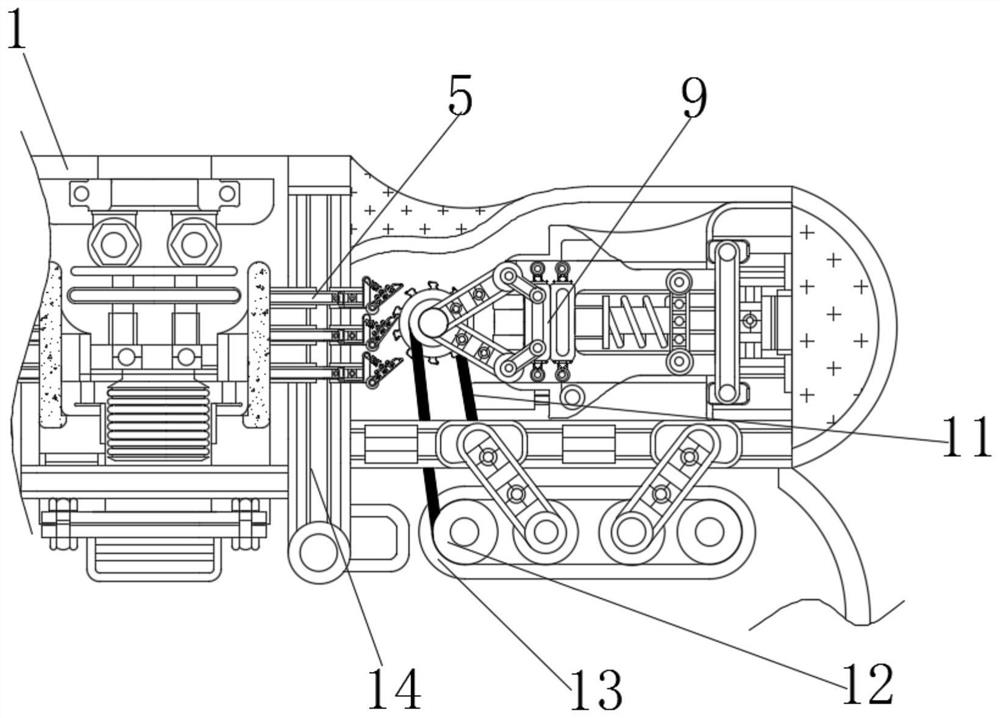

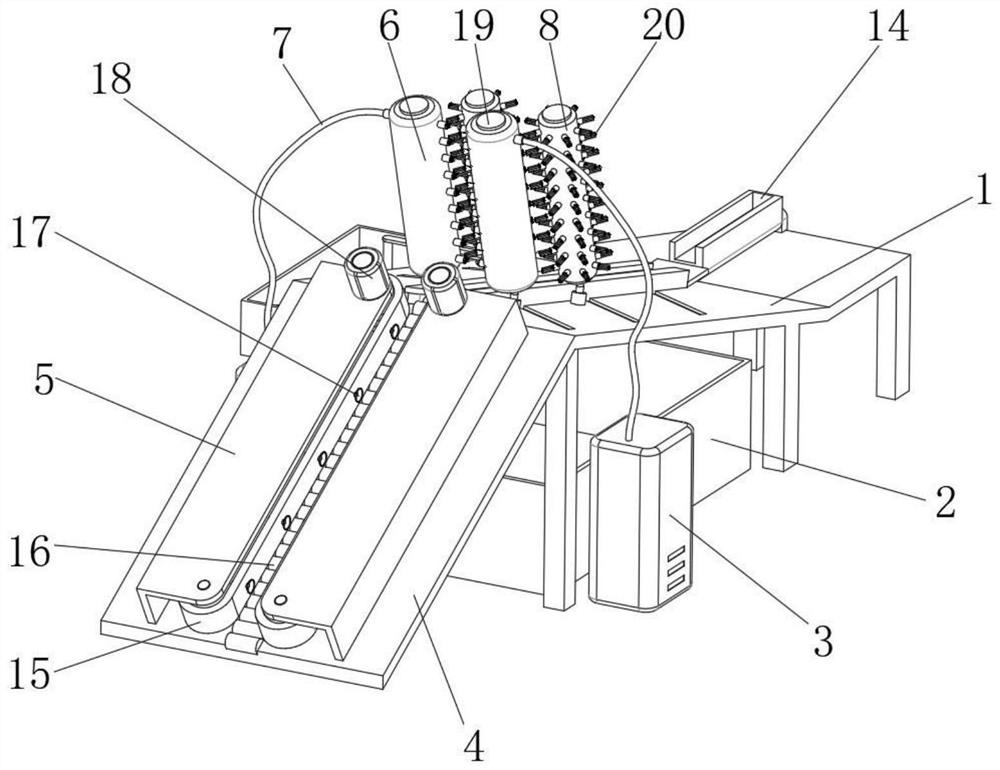

Continuous kenaf decorticator

The invention relates to the technical field and discloses a continuous kenaf decorticator. The problem is solved that kenaf is longer than common hemps but is not firmer than common hemp peels, so that when the kenaf is operated, kenaf peel is too long and break when being pulled, a mechanism at the discharge end is stuck due to broken kenaf peel, the decorticator needs to be maintained for operation, the quality effect of kenaf beating is influenced, and the kenaf stalk collecting problem during separation. According to the continuous kenaf decorticator, a large rolling compaction roller anda small rolling compaction roller which are arranged at the bottom of an inclined groove opening are used for secondary crushing of materials which do not fall off, and the crushed kenaf stalks are discharged into a collection box, so that secondary crushing of the kenaf is achieved, and the non-crushed kenaf is prevented from coming out with the kenaf stalks.

Owner:宁波索思机械设计有限公司

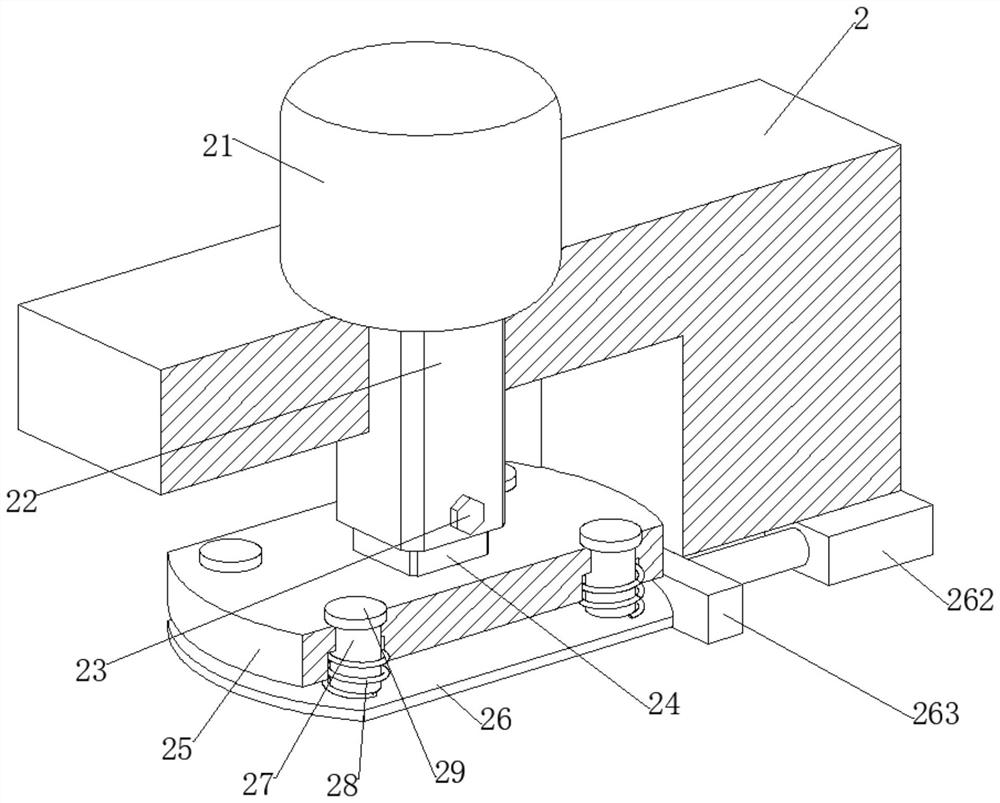

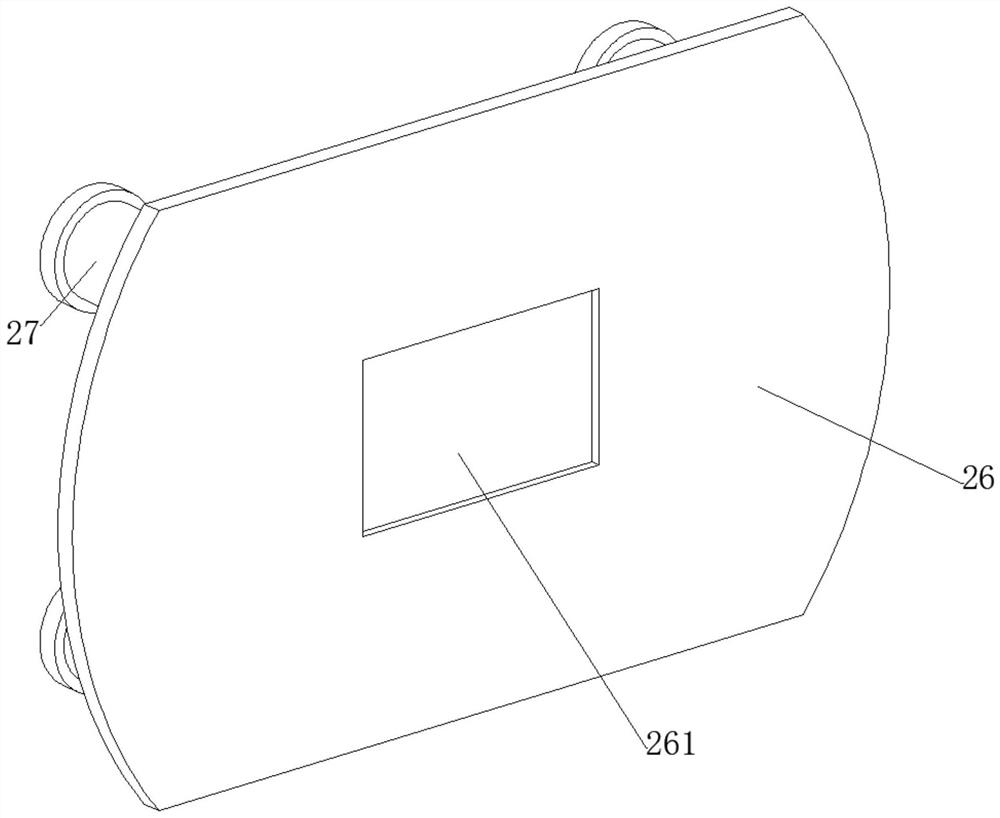

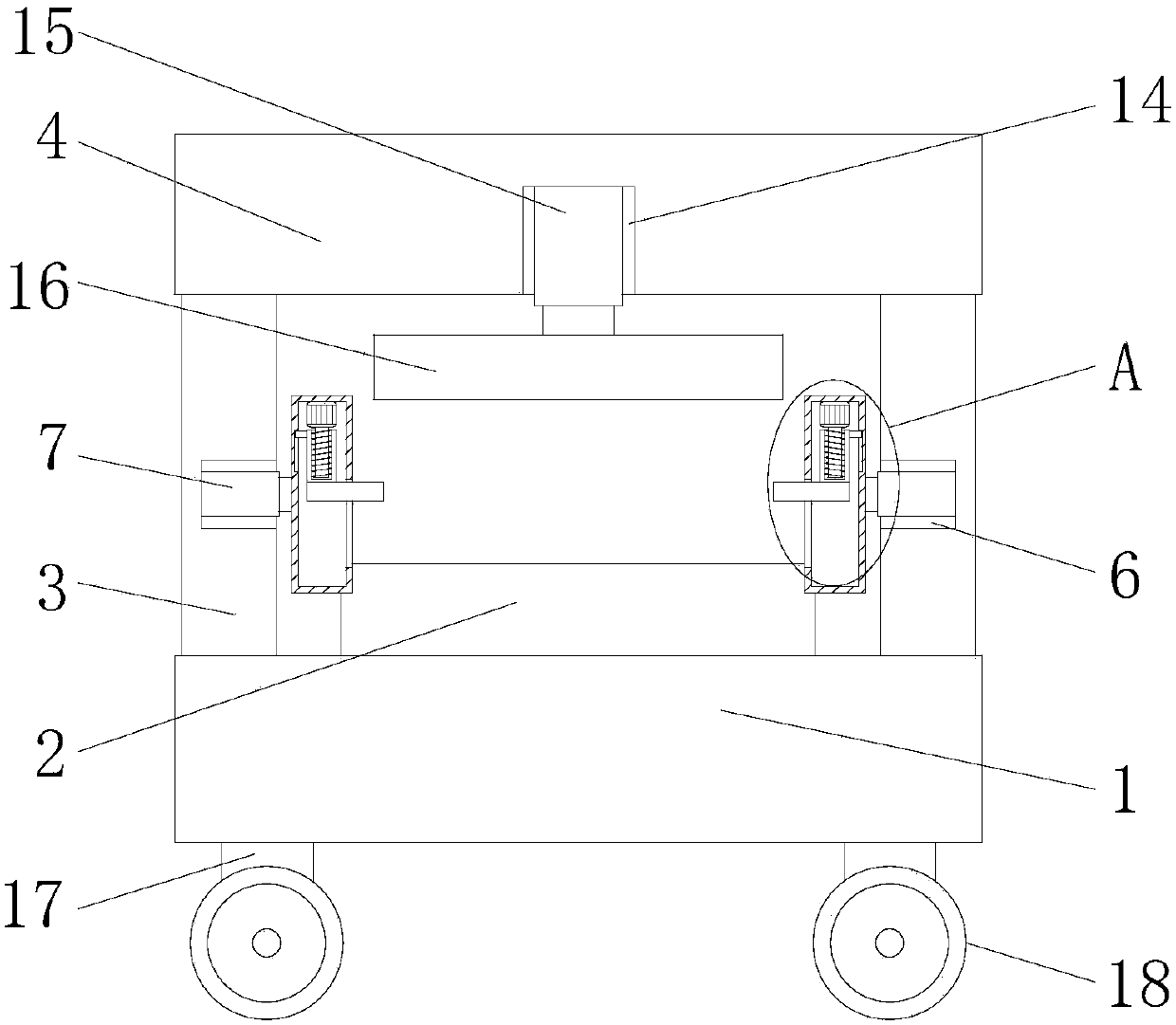

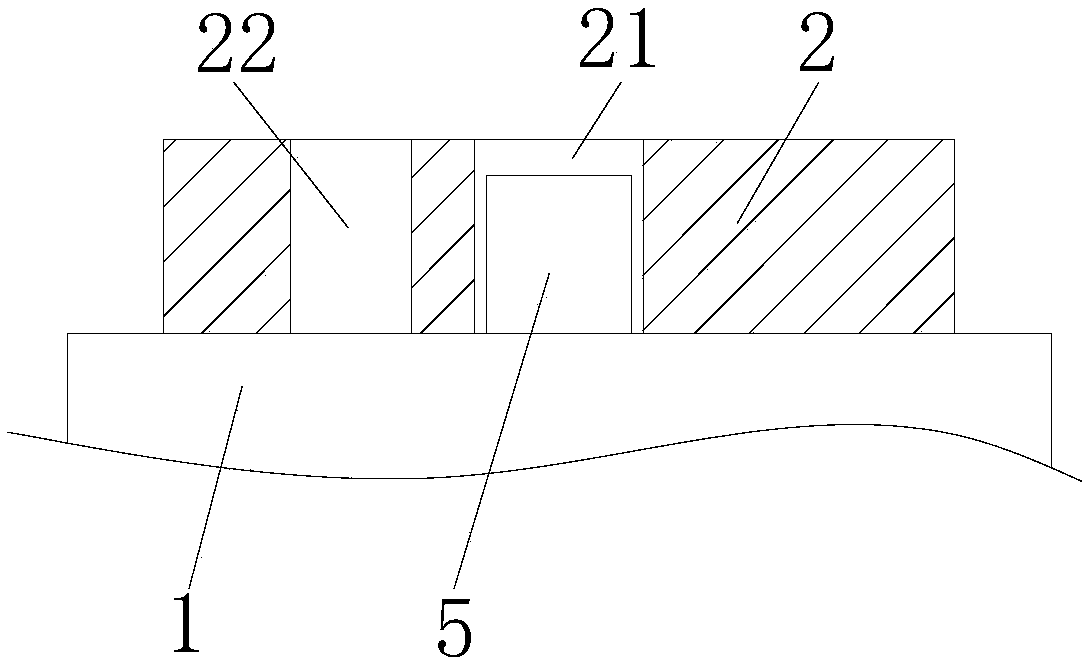

Electronic information product detection platform

InactiveCN114871129AAchieve the effect of eliminatingTo achieve the delivery effectSortingShock testingEngineeringMachine

The invention discloses an electronic information product detection platform, and belongs to the field of electronic information product detection.The electronic information product detection platform comprises a workbench, a mounting frame is fixedly connected to the workbench, a hydraulic machine is fixedly connected to the mounting frame, a mounting plate is fixedly connected to the bottom of a rectangular rod, and a guide rod is slidably connected to the mounting plate; the bottom of the guide rod is fixedly connected with a pressing plate for detecting the assembly firmness of a product, the top of the guide rod is fixedly connected with a limiting ring for preventing the guide rod from being separated from the mounting plate, the guide rod is sleeved with a spring, and the two ends of the spring abut against the mounting plate and the pressing plate respectively. By arranging the pressing plate and the pressure sensor, the effect of removing unqualified products is achieved, by arranging the conveying mechanism, the effect of conveying the to-be-monitored products is achieved, and by arranging the falling test mechanism, the effect of detecting the assembly degree of the products after falling is achieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Lining stainless steel strip plate shearing machine

InactiveCN110394492ATo achieve the delivery effectReach the limit effectShearing machinesShearing machine accessoriesThreaded pipeArchitectural engineering

The invention discloses a lining stainless steel strip plate shearing machine. The lining stainless steel strip plate shearing machine comprises a base, wherein a fixing plate is fixedly connected tothe axis position of the top of the base; two sides of the top of the base are fixedly connected with supporting rods; the tops of the supporting rods are fixedly connected with a supporting plate; and a first shearing plate is fixedly connected to the top of the base and positioned inside the fixing plate. According to the lining stainless steel strip plate shearing machine, a steel strip can beconveyed through the fixing plate; a clamping plate can be driven to move through an electric telescopic rod; the steel strip can be limited through the clamping plate; a threaded rod can be driven torotate through a motor; a pressing plate can be driven to move through the threaded rod and a threaded pipe; the steel strip can be fixed through the pressing plate; a second shearing plate can be driven to move through an air cylinder; the steel strip can be sheared through the first shearing plate and the second shearing plate; and the lining stainless steel strip plate shearing machine is capable of shearing and fixing the steel strips of different sizes and convenient to use for people.

Owner:JIANGSU SHUNLONG PIPE TECH CO LTD

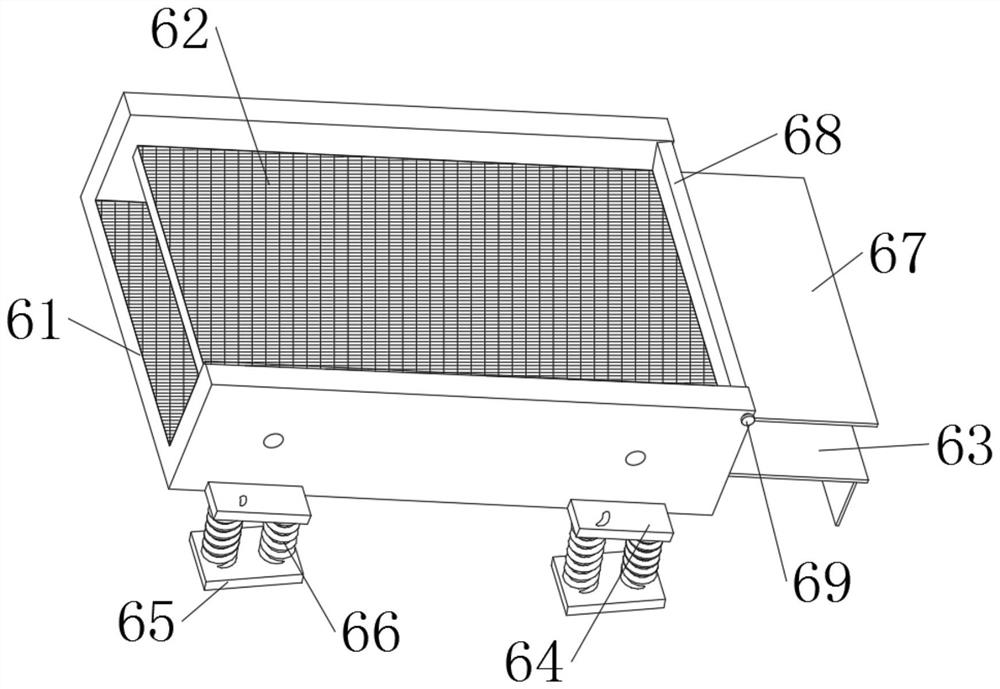

Pulse environment-friendly vibration cleaning sieve

InactiveCN113231301ATo vibrateQuick screeningSievingConveyorsClassical mechanicsStructural engineering

The invention discloses a pulse environment-friendly vibration cleaning sieve comprising a base, connecting shafts are arranged on the left portion and the right portion of the lower end of the base correspondingly, movable wheels are movably installed at the front ends and the rear ends of the two connecting shafts correspondingly, and two sets of supporting columns are fixedly installed on the left portion and the middle portion of the upper end of the base correspondingly. A processing box is fixedly installed at the upper ends of the two sets of supporting columns jointly, vibration devices are installed on the left portion and the right portion of the front end of the processing box in a penetrating mode, a vibration assembly is arranged in the processing box, a cover plate is fixedly installed at the upper end of the processing box, an air inlet is formed in the left portion of the upper end of the cover plate, and a feeding port is formed in the left side of the upper end of the cover plate. A pulse assembly is fixedly installed at the right portion of the upper end of the cover plate. According to the pulse environment-friendly vibration cleaning sieve, the grain screening effect can be improved under mutual cooperation of the vibration assembly and the vibration devices, meanwhile, the dust cleaning efficiency can be improved, and grain conveying can be improved.

Owner:安徽华宇机械制造有限公司

A continuous kenaf denumbing machine

ActiveCN109819766BTo achieve the delivery effectReach nestingMowersEngineeringMechanical engineering

The invention relates to the technical field, and discloses a continuous kenaf denumbing machine. The invention solves the problem of kenaf, the length of this type of hemp is longer than that of ordinary hemp, but it is not as strong as ordinary hemp skin, which leads to fracture when pulling because the kenaf is too long during operation, and the kenaf after beating is finished. The hemp skin causes the mechanism of the discharge end to be stuck, and the equipment needs to be repaired before it can be operated, which affects the quality of the hemp beating and the collection of hemp rods when they are detached. The present invention is arranged at the bottom of the inclined slot The large rolling roller and small rolling roller carry out secondary crushing of the materials that have not fallen, and discharge the broken hemp stalks into the collection box, achieving the secondary crushing of kenaf and avoiding the unbroken kenaf Hemp comes out with hemp stalks.

Owner:宁波索思机械设计有限公司

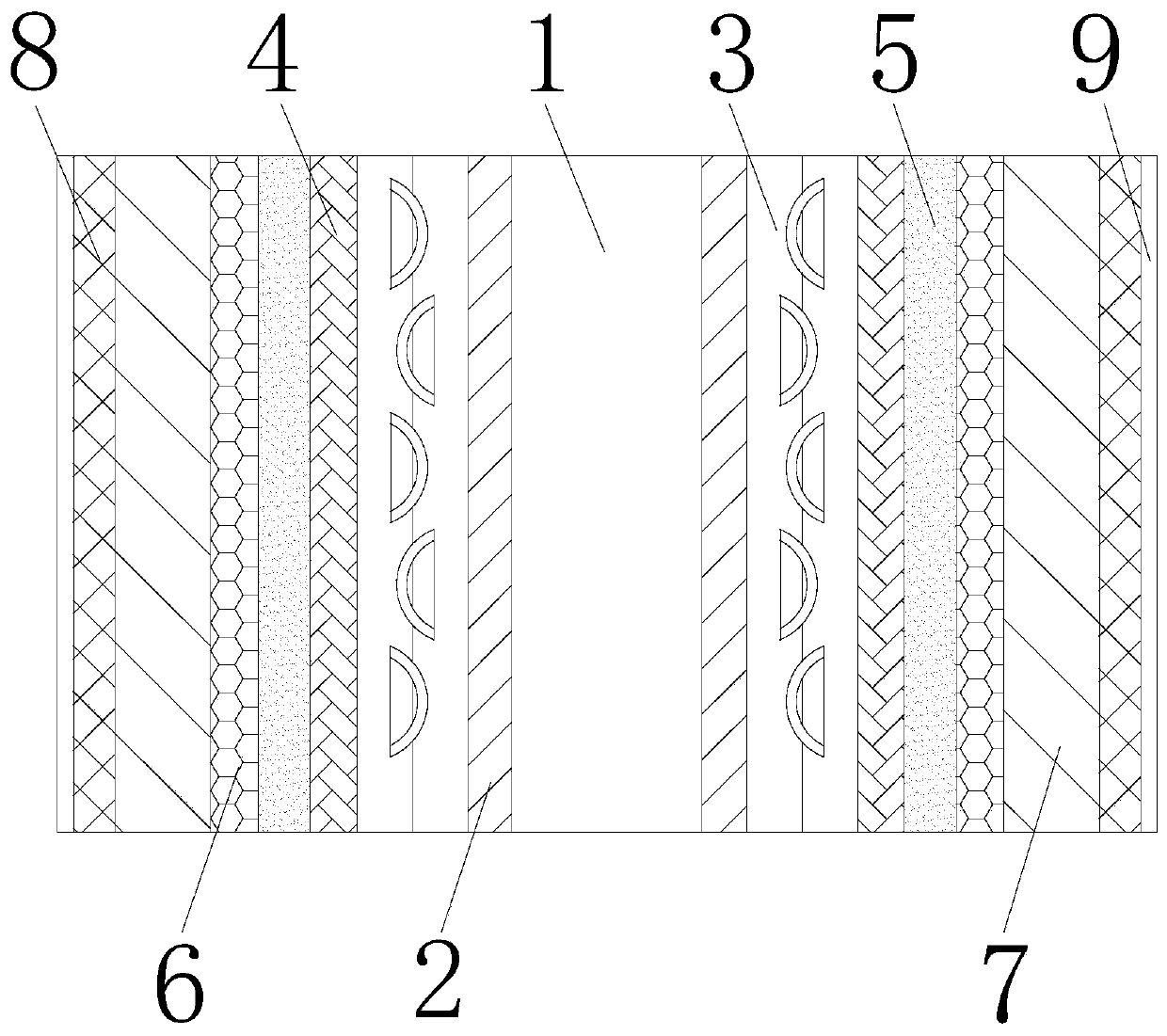

Heat dissipation graphene composite decorative plate and manufacturing method

InactiveCN110328918ATo achieve the protective effectTo achieve the absorption effectConveyorsSpraying apparatusCalcium silicateGraphene

The invention discloses a heat dissipation graphene composite decorative plate and a manufacturing method. The heat dissipation graphene composite decorative plate includes a base plate, the surface of the base plate is sleeved with a resin layer, one end of the resin layer far from the base plate is equipped with a first graphene composite material layer, one end of the first graphene composite material layer is provided with a heat conduction layer, and one end of the heat conduction layer far from the first graphene composite material layer is provided with a plant fiber layer. The base plate is disposed to reach the effect composing the decorative plate, through the resin layer, the effect of protecting the base plate can be reached, by means of the first graphene composite material layer, the effect of absorbing the heat on the base plate can be achieved, through the heat conduction layer, the effect of guiding the heat in the first graphene composite material layer out can be realized, through the plant fiber layer and a calcium silicate board layer, the function of the decorative plate can be increased, and by means of the plant fiber layer, the softness of the decorative plate can be increased. The decorative plate can dissipate the internal heat, and is convenient for people to use.

Owner:常州华祥碳材料科技有限公司

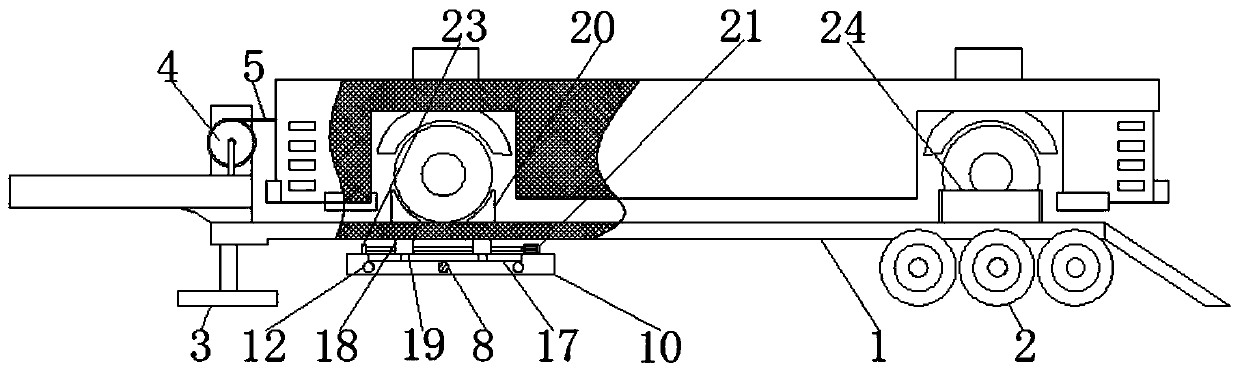

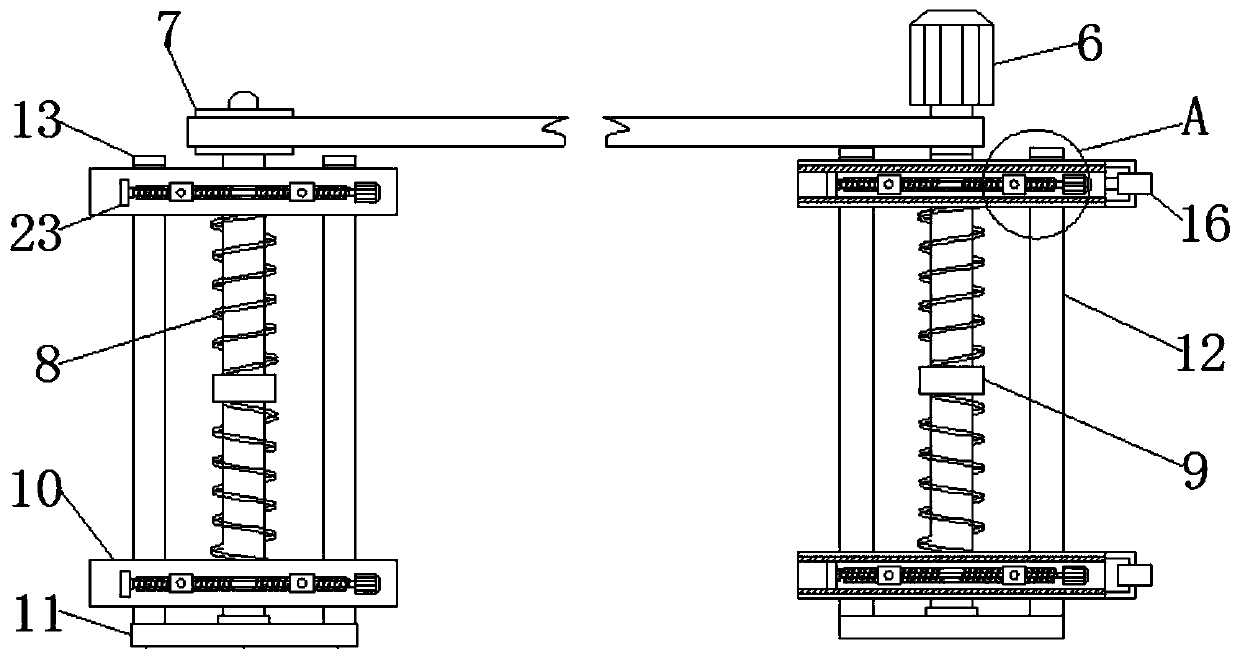

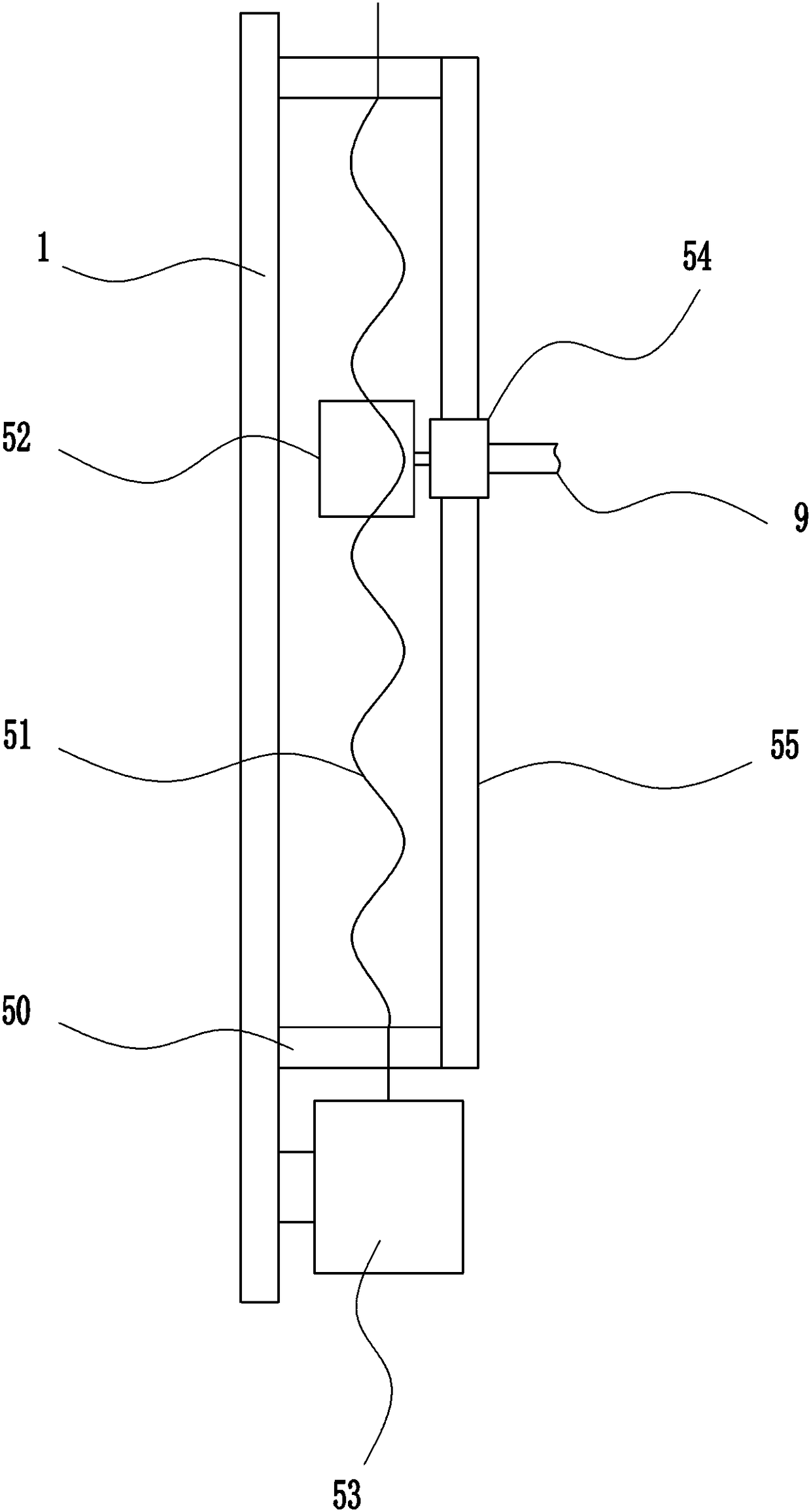

An easily adjustable shore-based conveying device for wharf vehicles

ActiveCN108974982BTo achieve the delivery effectItem transportation vehiclesLoading/unloadingElectric machineryTransportation technology

The invention discloses a conveniently-adjustable dock vehicle shore-based conveying device and relates to the technical field of dock vehicle transportation. The conveniently-adjustable dock vehicleshore-based conveying device comprises a vehicle body, the right of the bottom of the vehicle body is provided with wheels, the left of the bottom of the vehicle body is provided with a lifting control device, the left of the top of the vehicle body is provided with a motor-driven traction wheel outside which traction ropes are arranged, and the bottom of the vehicle body is fixedly connected witha first motor. By means of the structural design of the first motor, a rotary wheel, a first threaded rod, a limiting block, a moving plate, a fixed plate, a fixing rod, a connecting plate, a slidingrail, a sliding plate, an electric pushrod, a sliding groove, a moving block, a slider, a first clamping block, a second motor, a second threaded rod, a vertical plate and a second clamping block, the conveniently-adjustable dock vehicle shore-based conveying device solves the problem that dock vehicle shore-based conveying devices cannot be conveniently adjusted according to dock vehicle in different sizes.

Owner:ZHEJIANG OCEAN UNIV

Industrial furnace hearth cooling device

InactiveCN107024119AImprove stabilityAchieve storage effectFurnace typesFurnace coolingReservoir effectWater pipe

The invention discloses an industrial furnace hearth cooling device, which comprises a tank body, an inner tank is arranged inside the tank body, a cooling box is arranged on the right side of the tank body, and the top of the right side of the cooling box is connected with an inlet The liquid pipe, the top of the cooling tank and the left side of the liquid inlet pipe is fixedly connected with a water pump, the water inlet of the water pump is connected with the water inlet pipe, and the end of the water inlet pipe away from the water inlet of the water pump runs through the cooling box and extends to the cooling tank. Inside the box, the water outlet of the water pump is communicated with an outlet pipe. The present invention achieves the effect of storing the cooling liquid through the setting of the cooling box, and achieves the effect of transporting the cooling liquid through the setting of the water pump, and achieves the effect of transporting the cooling liquid into the cooling pipe through the setting of the water outlet pipe. The effect of spraying to cool the surface of the inner tank is solved, and at the same time, it solves the problem that the furnace cannot be cooled quickly and the work efficiency is reduced.

Owner:CHANGXING CAZENOVE FUNANCE IND CO LTD

Electric automatization food conveying device convenient to convey different forms of food materials

InactiveCN109368140AAvoid pollutionPrevent fallingConveyorsSupporting framesEngineeringConveyor belt

Owner:GUANGDONG OCEAN UNIVERSITY

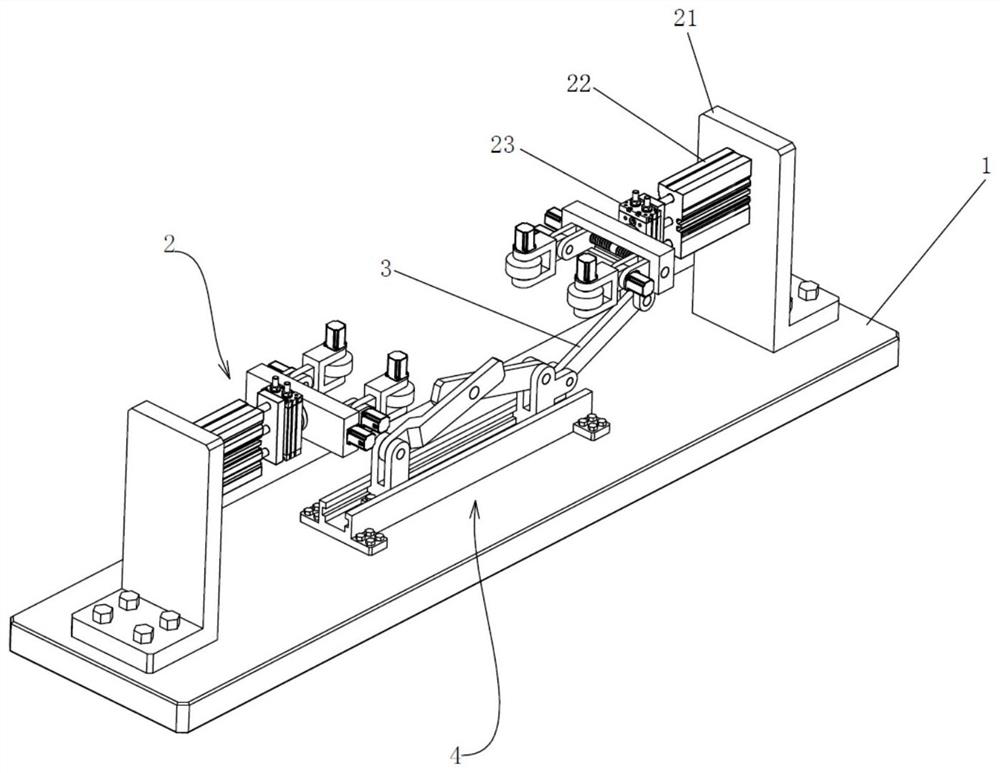

A stamping die waste material discharge mechanism and its stamping die

ActiveCN110899544BReach deliveryTo achieve the delivery effectEjection devicesStampingWaste material

The invention provides a stamping die waste material discharge mechanism and its stamping die, including a bottom plate, a conveying mechanism, a connecting rod and a lifting mechanism. Cylinder, the installation frame is installed on the power output end of the rotary cylinder, and there are two sliders Ⅰ installed in the installation frame. In the middle of the conveying mechanism, one of the two-axis cylinders in the conveying mechanism is hinged with the movable components in the lifting mechanism through connecting rods. The conveying effect is achieved through the contact between the roller and the side of the waste material, and the rotating installation of the mounting frame and the rotating installation of the roller mounting frame enable the roller to fit on the upper end surface of the waste material, thereby realizing the conveying of waste materials of different thicknesses. And the lifting mechanism can jack up the waste material to avoid the adhesion between the waste material and the mould.

Owner:昆山日腾精密模具科技有限公司

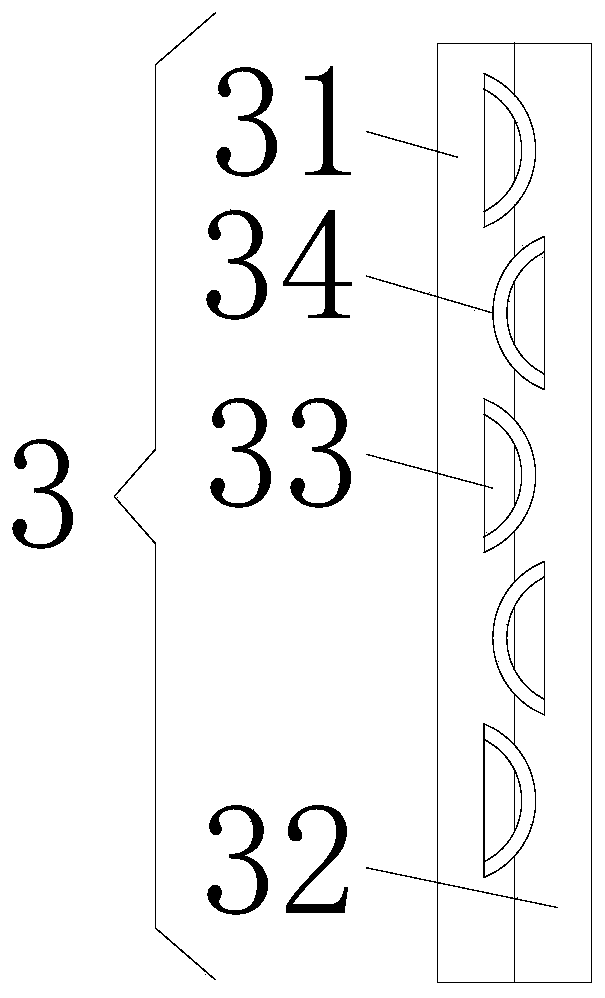

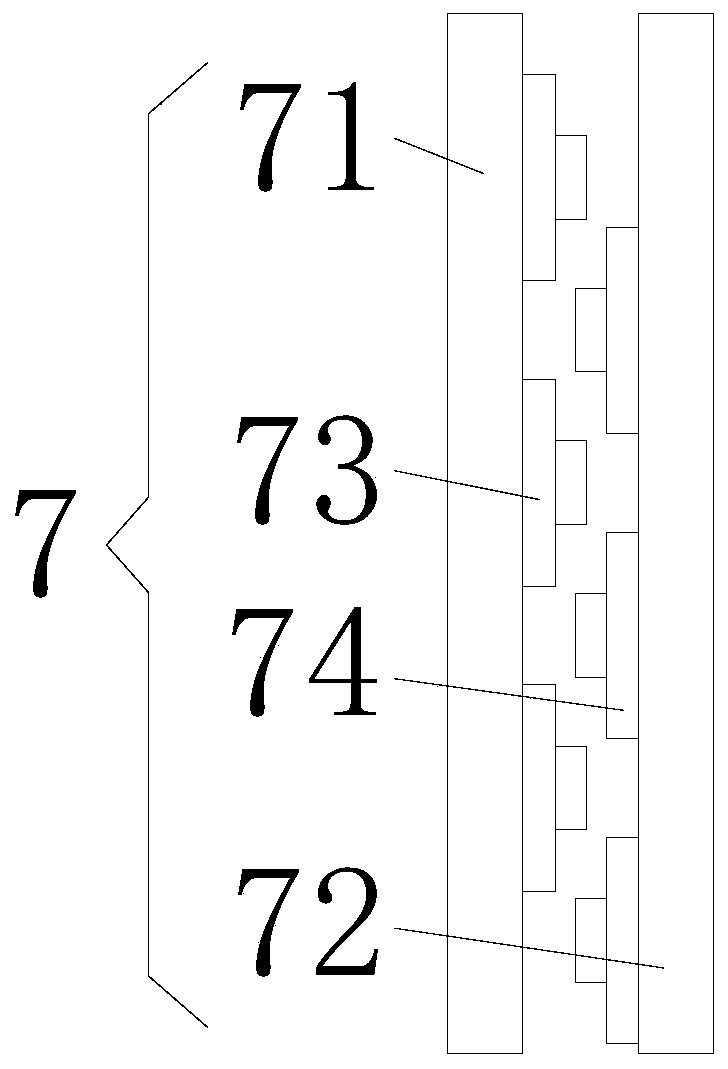

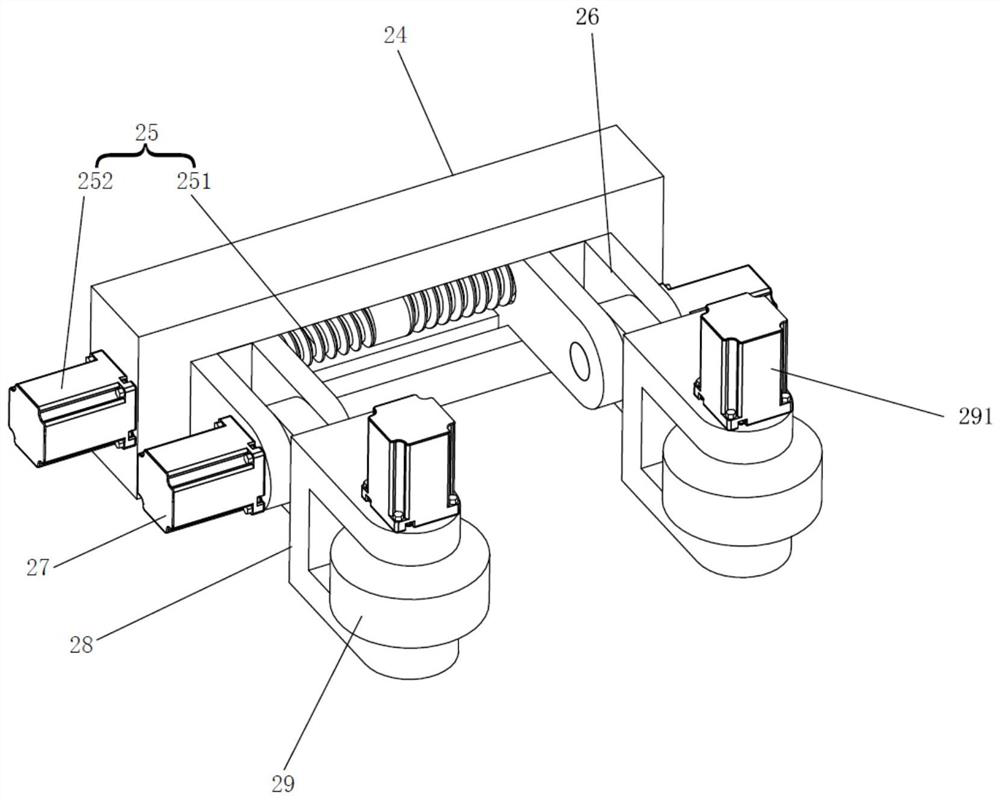

A kind of rapid gluing equipment for magazine perfect binding

ActiveCN107031225BTo achieve the delivery effectAdjustable positionBookbinding adhesiveEngineeringWireless

The invention relates to a rapid glue application device, in particular to a rapid glue application device for magazine perfect binding. The rapid glue application device for magazine perfect binding aims to achieve the technical effects of being convenient to operate, high in glue application efficiency and uniform in glue application. The rapid glue application device for magazine perfect binding comprises a left frame, a base plate, a collecting frame, a right frame, a first moving device, a glue conveying device, a second moving device, a lifting device, a fixing frame, a brush, a first one-way valve and the like. The left frame is welded to the left side of the top of the base plate, the first moving device is arranged in the middle of the right side of the left frame, a fixing frame is welded to the first moving device, and a brush is welded to the right end of the fixing frame. According to the rapid glue application device for magazine perfect binding, through control over steering of a first motor, a nut drives a guide sleeve to move frontwards and backwards, and the glue application efficiency is improved; and rotation of a second motor is controlled, and a first gear and a second gear are meshed with each other.

Owner:肥城新华印刷有限公司

An environmentally friendly solid waste treatment device

ActiveCN112495990BTo achieve the delivery effectAvoid cloggingSievingScreeningAir pumpElectric machinery

Owner:仁净(江苏)集成系统科技有限公司

Environment-friendly device for protecting processing personnel during printing of corrugated board

ActiveCN112895708ATo achieve the delivery effectAutomatic delivery effectOther printing apparatusPrinting press partsEngineeringStructural engineering

The invention relates to the technical field of corrugated boards, and discloses an environment-friendly device for protecting processing personnel during printing of a corrugated board. The environment-friendly device comprises a shell, the upper end of the shell is movably connected with a pushing column, the lower end of the pushing column is fixedly connected with a connecting mechanism, and the right end of the connecting mechanism is fixedly connected with a clamping block; and the right end of the clamping block is fixedly connected with a moving rod, the right end of the moving rod is movably connected with an extension spring, the right end of the extension spring is movably connected with an ejector rod, the right end of the ejector rod is movably connected with a rotating wheel, and the right end of the rotating wheel is movably connected with a guide block. A rotating disc rotates, then a pushing mechanism is driven by a connecting rotating disc to rotate, the outer surface of the pushing mechanism is adhered, so that the corrugated boards are driven to move, and the corrugated boards are automatically driven to automatically move to the lower end of a printing mechanism when printing is finished; and therefore, the effect of automatically conveying the corrugated boards is achieved.

Owner:泸州市一圣鸿包装有限公司

Environment-friendly municipal building construction baffle cleaning device and using method thereof

InactiveCN113231367AAvoid wastingImprove reliabilityCleaning using toolsCleaning using liquidsArchitectural engineeringMechanical engineering

The invention discloses an environment-friendly municipal building construction baffle cleaning device and a using method thereof, and relates to the technical field of baffle cleaning devices. In order to facilitating saving of water for cleaning, the environment-friendly municipal building construction baffle cleaning device comprises a cleaning frame, a rail allowing a baffle to slide is installed on the outer wall of the top of the cleaning frame, first supporting rollers which are evenly distributed are rotatably installed in the rail, a flushing mechanism and a brushing mechanism are installed on the outer wall of the top of the cleaning frame through installation rods, and the flushing mechanism and the brushing mechanism are located at the two sides of the rail. The using method of the device comprises the following steps that a user places the baffle on a second supporting pin roller between two conveying belts, and suction cups are sucked to the two sides of the baffle. According to the device, by arranging a water spraying barrel, a connecting rod, a packing head and other structures, water can be automatically sprayed in the sliding process of the baffle, and the water spraying position is determined by the position in contact with the baffle, so that the phenomenon of water waste is effectively avoided, and the reliability and the environmental protection property are improved.

Owner:武汉合创四联科技发展有限公司

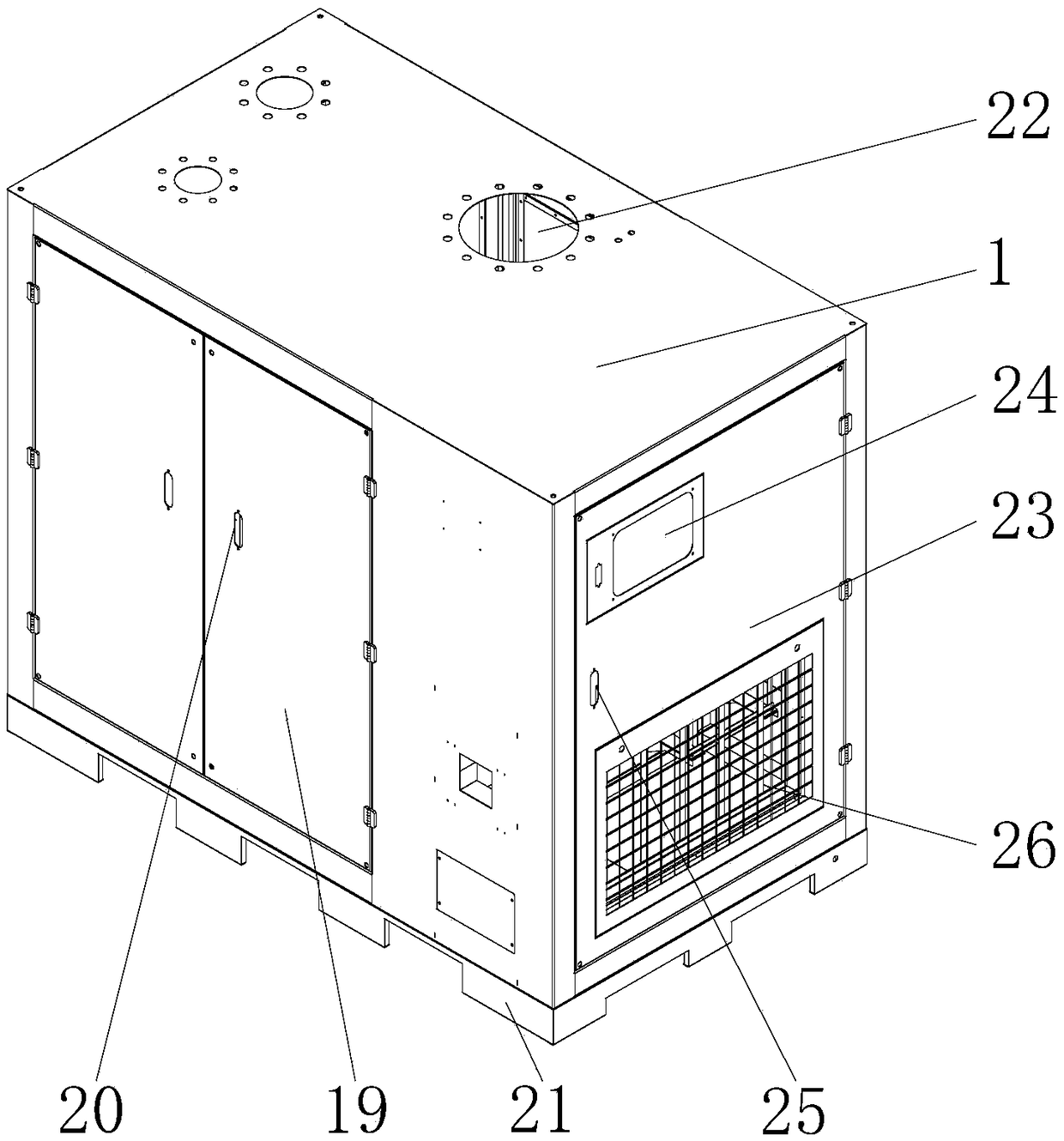

Rapid cooling structure for magnetic suspension air blower

PendingCN109488642ATo achieve cooling effectEasy accessPump componentsPump controlEngineeringAir blower

The invention discloses a rapid cooling structure for a magnetic suspension air blower. The rapid cooling structure comprises a box body and a magnetic suspension air blower body. The left side of themagnetic suspension air blower body communicates with an air inlet pipe. The left side of the top of the magnetic suspension air blower body communicates with a first air outlet pipe. The right sideof the first air outlet pipe communicates with a first connection pipe. According to the rapid cooling structure, by arranging the magnetic suspension air blower body, the effect of gas conveying is achieved; by means of the first air outlet pipe, the effect of discharging gas is achieved; by means of a first connection pipe and a second connection pipe, the effect of cooling the magnetic suspension air blower is achieved; by means of a first fixed plate and a first through hole, the gas in the first air outlet pipe can conveniently enter the first connection pipe, and the effect of controlling the gas inflow is also achieved at the same time; and by means of a second fixed plate and a second through hole, the gas in the magnetic suspension air blower can conveniently enter the second connection pipe. By means of the cooling structure, the magnetic suspension air blower can be effectively cooled.

Owner:河南迪诺环保科技股份有限公司

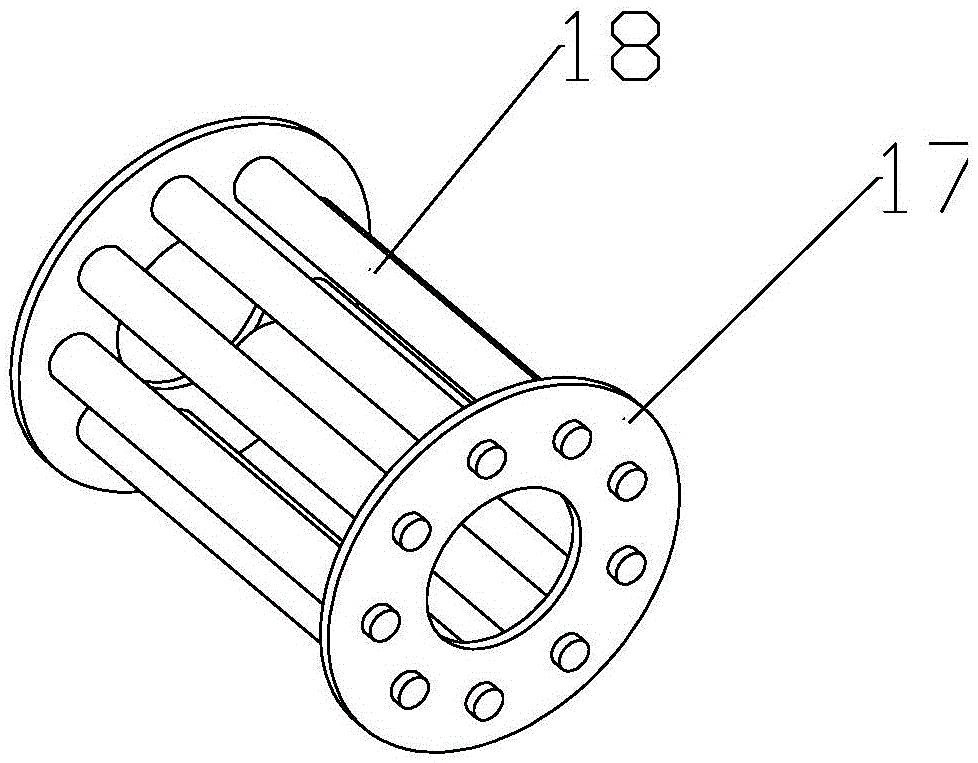

Conveying line tool plate for cable machining

InactiveCN111547571ATo achieve the delivery effectReduce labor intensityFilament handlingCircular discElectric machinery

The invention discloses a conveying line tool plate for cable machining, and belongs to the technical field of cable conveying. The conveying line tool plate comprises a mounting plate, fixing framesmounted at the positions close to the two ends of the mounting plate and a rotating disc arranged between the two sets of fixing frames, the fixing frames are integrally formed on the upper surface ofthe mounting plate, rotating threaded rods are installed between any set of fixing frames, second fixing discs are integrally formed at the two ends of the rotating threaded rods, bearings are connected to the two ends of the rotating threaded rods, and the bearings penetrate through the two sides of the fixing frames correspondingly and are connected with first belt pulleys correspondingly. According to the conveying line tool plate, by starting a motor to rotate, a cable on the rotating threaded rod at one end of the mounting plate is conveyed to the rotating threaded rod at the other end of the mounting plate, so that the effect of conveying the cable is achieved, the labor intensity of workers is reduced, and the processing efficiency of the cable is greatly improved.

Owner:KUNSHAN XINGHONGMENG ELECTRONICS CO LTD

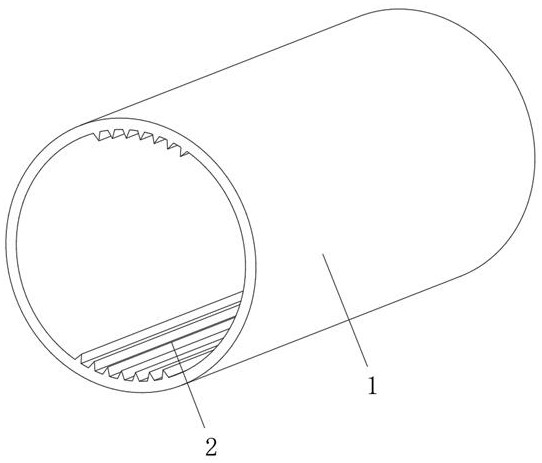

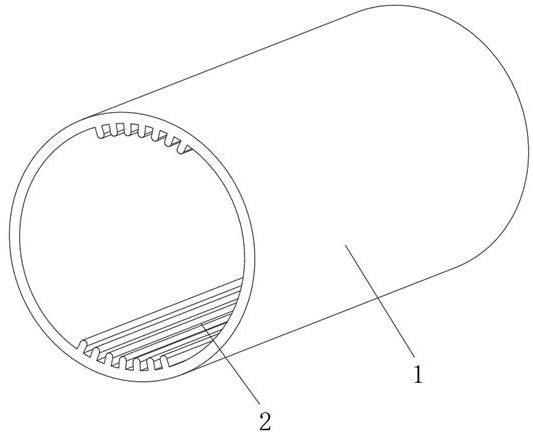

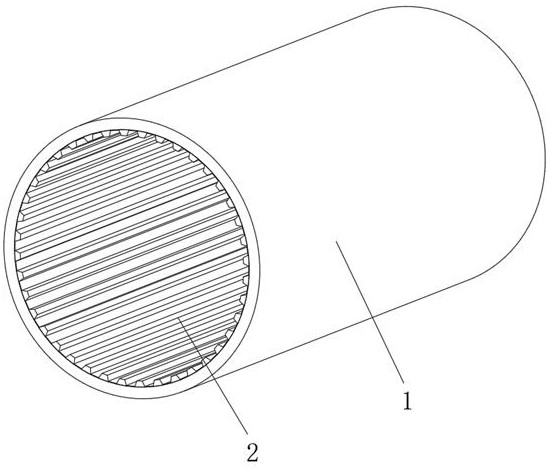

Ultra-thin interval tooth grooved pipe with large radius-thickness ratio

PendingCN113775841AIncrease the longitudinal forceImprove circulation ratePipe elementsCouplingsEngineeringPipe

The invention provides an ultra-thin interval tooth grooved pipe with a large radius-thickness ratio, and relates to the technical field of grooved pipes. The grooved pipe comprises a pipe body and interval teeth, wherein the pipe body is divided into four equant quadrant areas according to a cross-section horizontal line and a plumb line; at least one quadrant of the four quadrant areas of the pipe body is provided with the interval teeth; the tooth thickness of the interval teeth ranges from 0.031 mm to 0.065 mm; the wall thickness of the pipe body ranges from 0.082 mm to 0.122 mm; the pipe body can be in a flat pipe shape, and the interval teeth are symmetrically and evenly arranged on the inner wall of the flat-pipe-shaped pipe body; the interval teeth can be in a flat shape, the tooth thickness of the interval teeth is 0.039 mm, and the wall thickness of the pipe body is 0.093 mm; and the interval teeth can be in a convex shape, the tooth thickness of the interval teeth is 0.065 mm, and the wall thickness of the pipe body is 0.082 mm. According to the grooved pipe, the defects that a traditional grooved pipe is single in size and shape and has certain limitation in use, and when transverse force and longitudinal force borne by the grooved pipe are not uniform, the grooved pipe is prone to deformation, and normal use of the grooved pipe is affected are overcome.

Owner:江西耐乐科技协同创新有限公司 +2

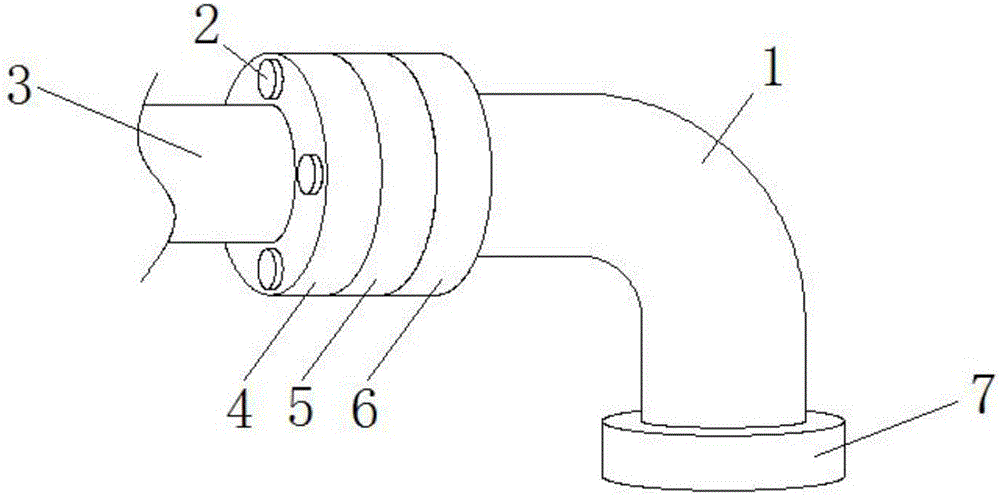

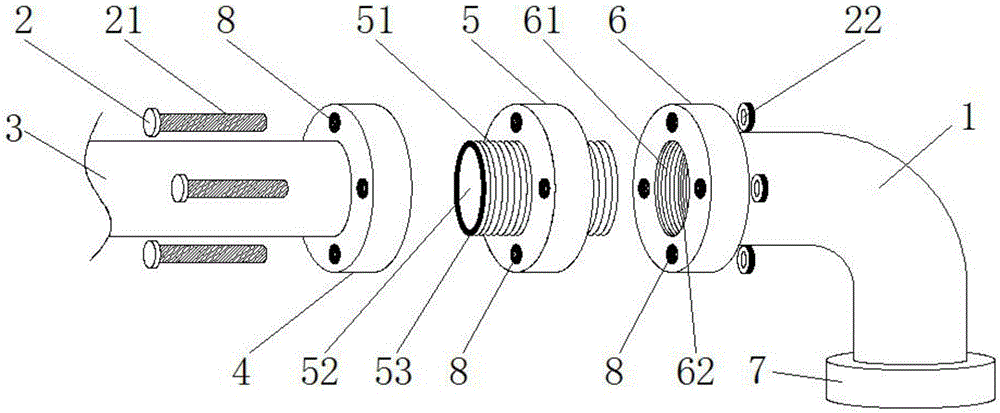

Lateral movement sprinkler water inlet bend rapid replacement rotation device

InactiveCN106764178ATo achieve the delivery effectImprove sealingFlanged jointsWatering devicesWater sourceEngineering

The invention discloses a lateral movement sprinkler water inlet bend rapid replacement rotation device which comprises a bend, a connecting piece, a water inlet pipe and a middle connecting piece. A second flange is fixedly welded to one side of the bend, a third flange is fixedly welded to the bottom of the bend, a first flange is fixedly welded to one side of the water inlet pipe, and the first flange and the second flange are fixedly connected through the middle connecting piece; and connecting pipes are arranged on the two sides of the middle connecting piece, and outer threads are arranged on the outer walls of the connecting pipes. According to the lateral movement sprinkler water inlet bend rapid replacement rotation device, the water inlet pipe is connected with a water source, the third flange is connected with an irrigation device, the bend and the water inlet pipe are fixedly connected through the middle connecting piece, and therefore the conveying effect is achieved; and a sealing ring is used for improving the leakproofness, during disassembling, fixing nuts are disassembled, the connecting pieces are taken down, the middle connecting piece is rotated, and then the bend and the water inlet pipe can be separated. The lateral movement sprinkler water inlet bend rapid replacement rotation device is reasonable in structure, relatively convenient to mount and demount and good in leakproofness, the working efficiency is effectively improved, and cost is saved.

Owner:ANHUI IRRITECH AGRI EQUIP DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com