Electronic information product detection platform

A detection platform and electronic information technology, applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve the problem of wasting labor and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

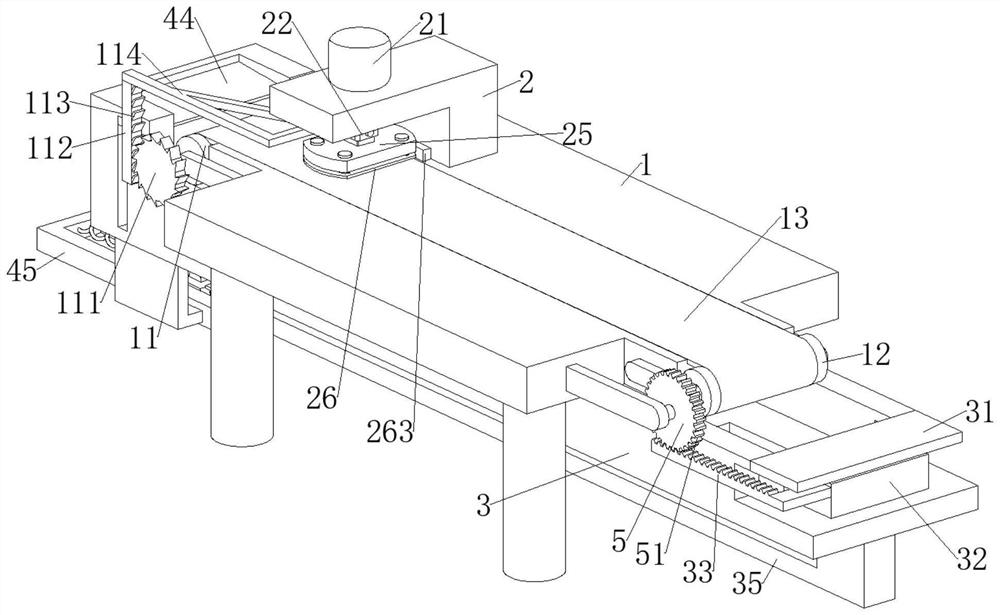

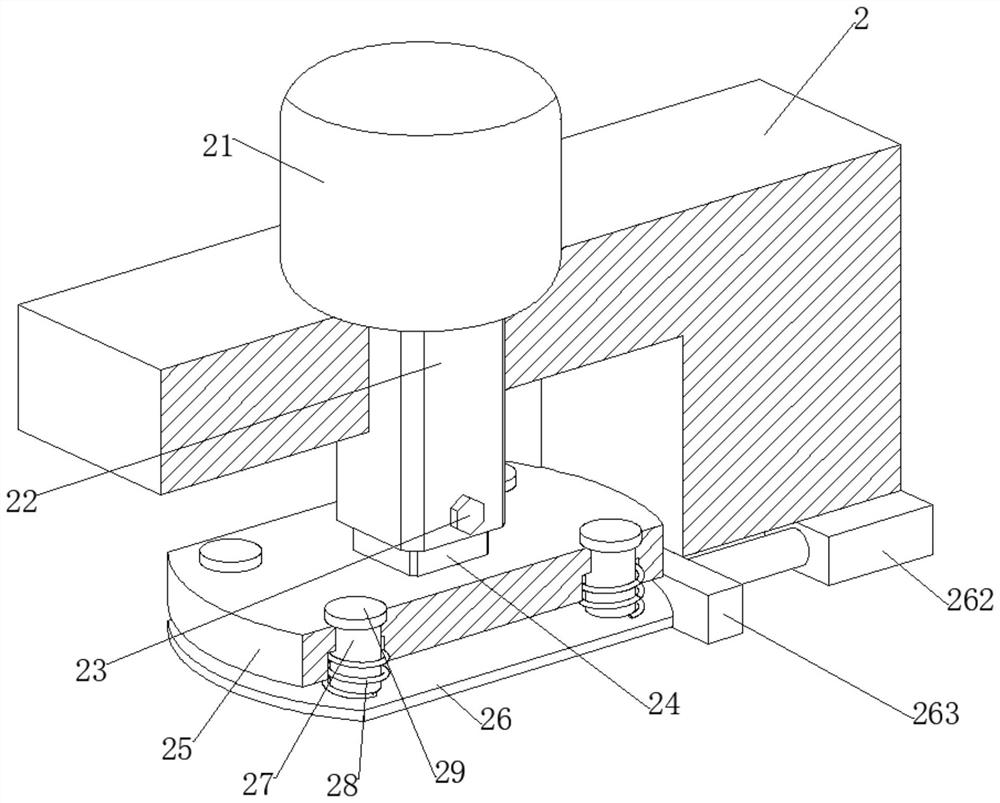

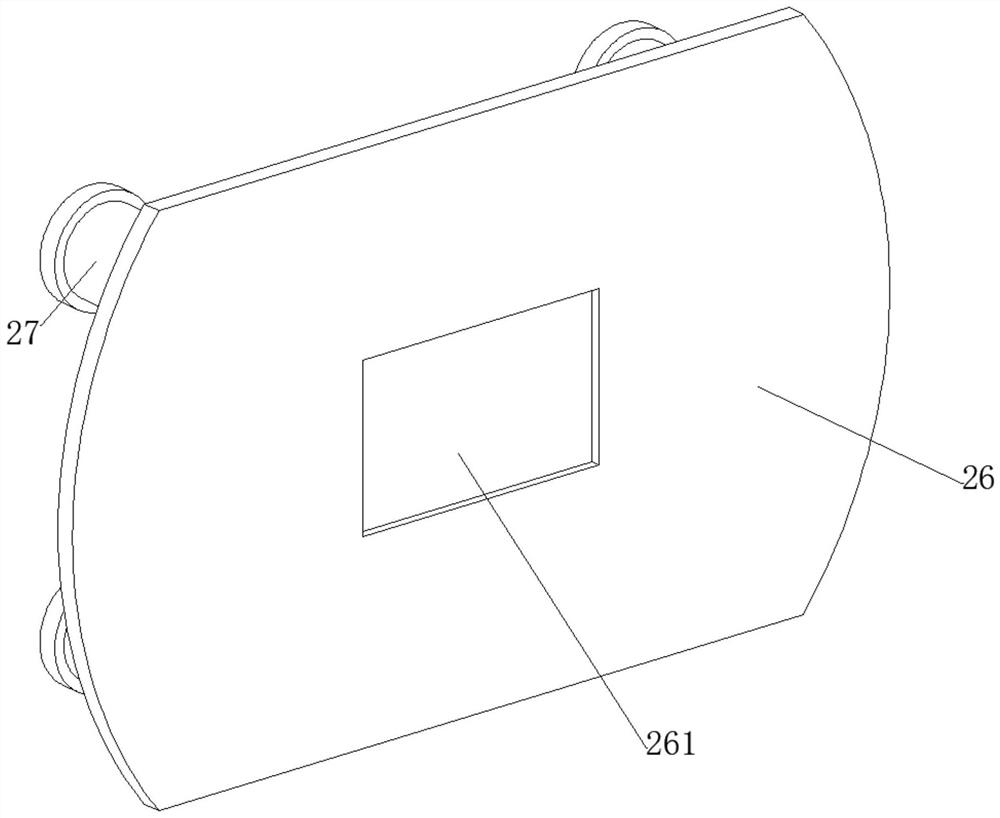

[0024] The present invention provides a technical solution: an electronic information product testing platform, comprising a workbench 1, a mounting frame 2 is fixedly connected to the workbench 1, a hydraulic press 21 is fixedly connected to the mounting frame 2, and an output end of the hydraulic press 21 is fixedly connected with a The rectangular cylinder 22, the mounting frame 2 is provided with a through hole that cooperates with the rectangular cylinder 22, the rectangular cylinder 22 is slidably connected with a rectangular rod 24, and the rectangular cylinder 22 is threadedly connected with a screw 23. A mounting plate 25 is fixedly connected to the bottom of the rod 24, and a guide rod 27 is slidably connected to the mounting plate 25. The guide rod 27 is separated from the limit ring 29 of the mounting plate 25 , a spring 28 is sleeved on the guide rod 27 , and two ends of the spring 28 are respectively abutted against the mounting plate 25 and the pressing plate 26 ...

Embodiment 2

[0029] On the basis of the first embodiment, further, the worktable 1 is provided with a conveying mechanism for conveying products. A conveyor belt 13 is provided between the first conveying roller 11 and the second conveying roller 12 and is connected by transmission through the conveying belt 13. The conveying mechanism also includes a bracket 114 fixedly connected to the rectangular cylinder 22. The bracket 114 is fixedly connected with a vertical rod 112. The vertical rod A plurality of elastic pieces 113 arranged in a linear array are fixedly connected to the 112 , and a ratchet wheel 111 is fixedly connected to the first conveying roller 11 coaxially.

[0030] refer to figure 1When the rectangular tube 22 moves up and down, the bracket 114 fixedly connected to the rectangular tube 22 moves up and down synchronously with the rectangular tube 22, and the vertical rod 112 fixedly connected to the bracket 114 also moves up and down synchronously with the bracket 114. When t...

Embodiment 3

[0032] On the basis of the second embodiment, further, the conveying mechanism is provided with a drop test mechanism for detecting the drop resistance of the product. A horizontal plate 31 is fixedly connected, a push block 32 is slidably connected in the receiving groove 3, a rack 33 is fixedly connected to the push block 32, and a cylinder 5 is rotatably connected to the worktable 1. The complete teeth 51 meshed by the rack 33, the drop test mechanism also includes a rotating shaft 121 coaxially and fixedly connected to the second conveying roller 12, the end of the rotating shaft 121 close to the cylinder 5 is fixedly connected with a full-tooth gear 122, the cylinder 5 A non-complete gear 53 is fixedly connected to the inner coaxial. The inner side wall of the cylinder 5 is provided with half teeth 52 opposite to the teeth on the incomplete gear 53. The full-tooth gear 122 alternates with the incomplete gear 53 and One-half of the teeth 52 on the cylinder 5 mesh.

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com