Patents

Literature

76results about How to "To vibrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

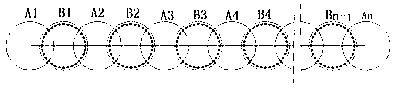

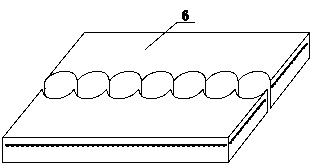

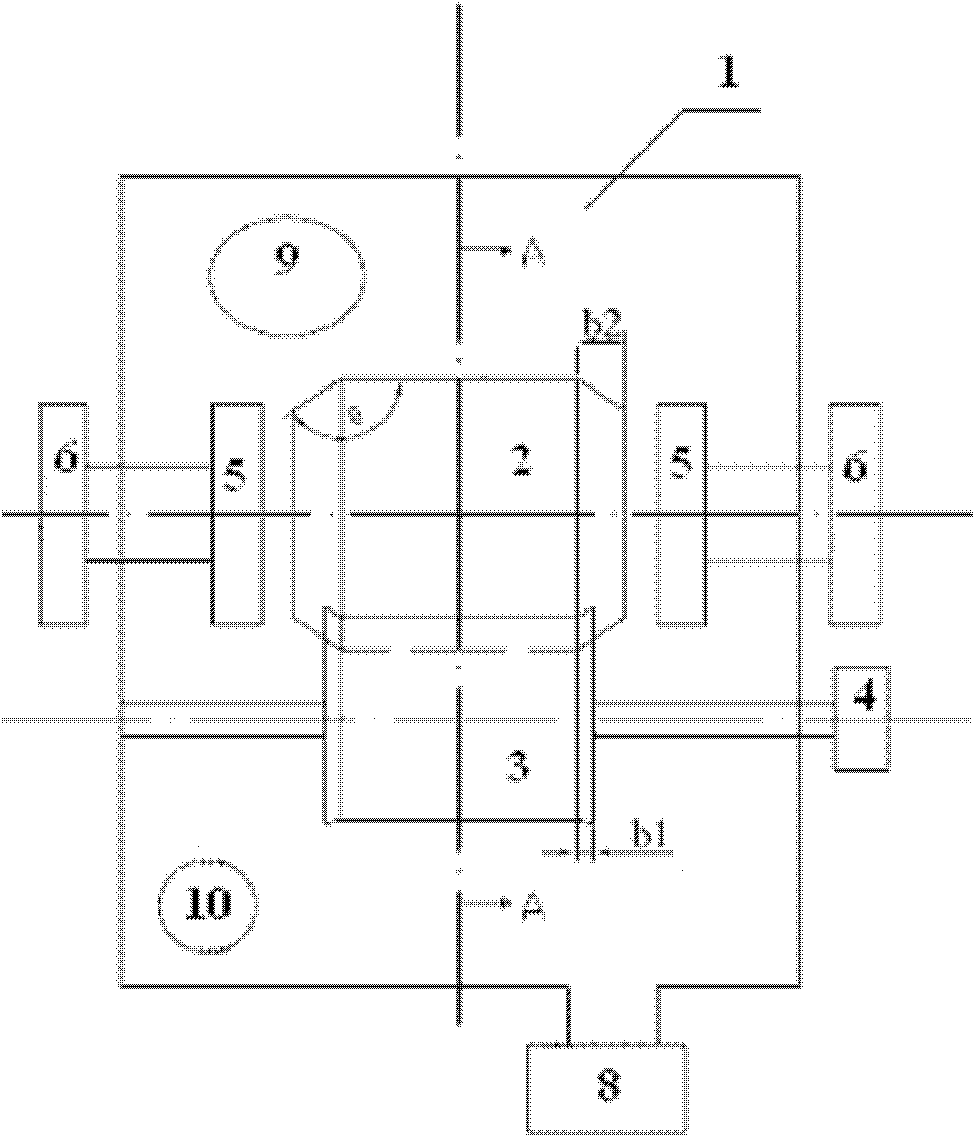

Construction method for vibrating sunken tube construction secant pile wall

InactiveCN103255764AFast constructionImprove work efficiencyBulkheads/pilesEngineeringStructural engineering

The invention discloses a construction method for a vibrating sunken tube construction secant pile wall, and belongs to the technical field of construction. The construction method comprises the construction steps: construction preparation, pile position measuring and unreeling, construction of a guide wall, vibrating and sinking casing pipes in position by using a vibrating sunken tube pile machine, construction of a first plain concrete pile, earth taking through an in-position rotary drilling rig, concrete pouring and casing pipe removing, construction of a second plain concrete pile, construction of a third plain concrete pile, construction of a first steel reinforcement cage concrete pile, construction of a second steel reinforcement cage concrete pile and the like. The steps are repeated in sequence until the completion of the secant pile walls. The construction method is fast in construction speed, the construction time of a single pile is about six hours, construction efficiency is improved, the casing pipes are pressed down and pulled off by using a vibration mode, a vibration function is performed on concrete poured underwater, the situation that the steel reinforcement cage floats upward is effectively controlled, the concrete is denser and solider, the quality of a pile body is higher, and the method is suitable for bracing engineering of foundation pits in suburbs, and is particularly suitable for the construction of the secant pile wall of the soil layer of silt, clay and sludge.

Owner:浙江省地矿建设有限公司

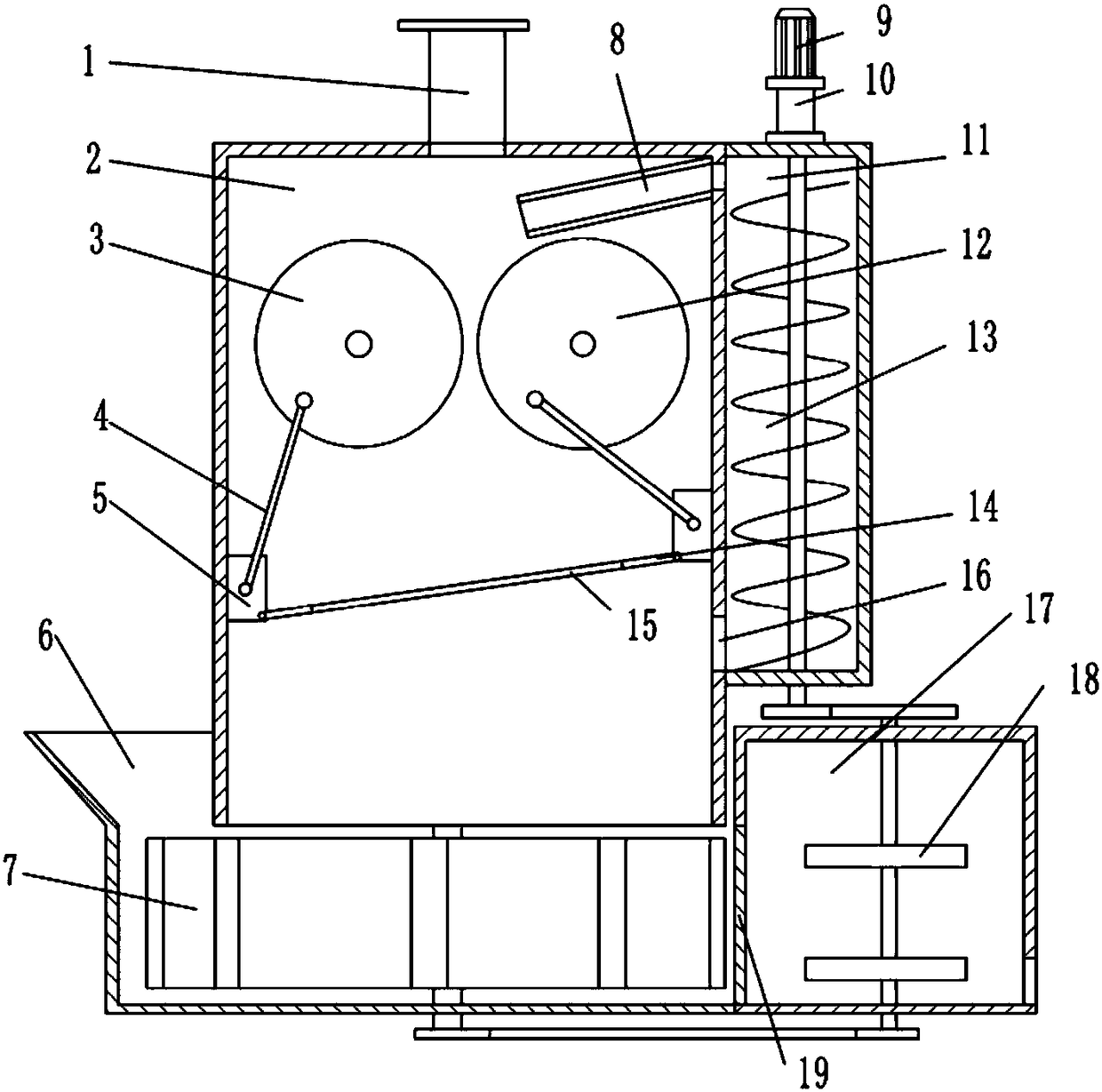

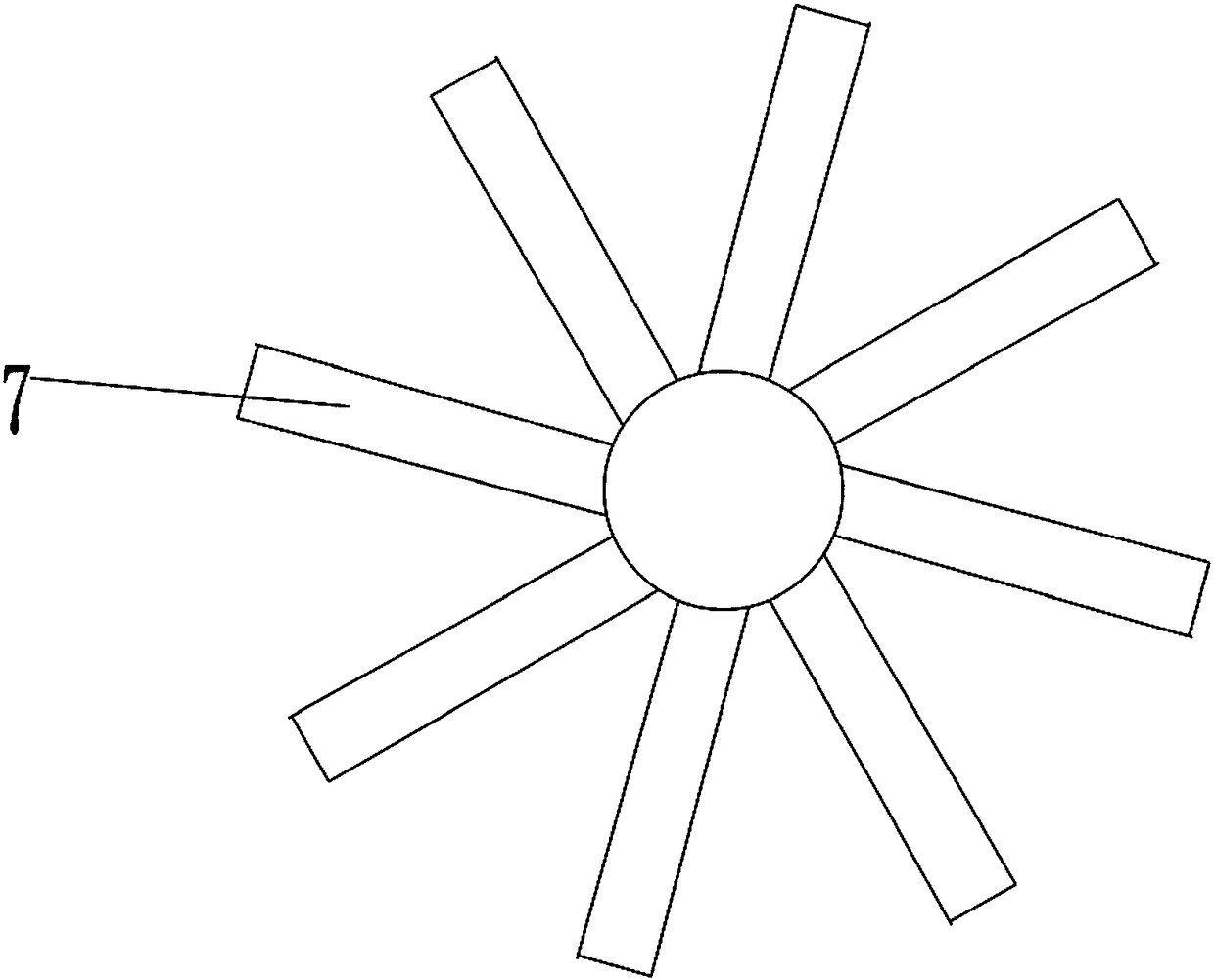

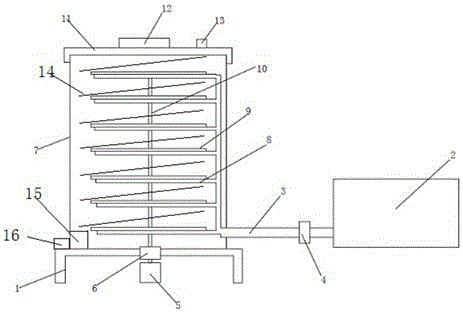

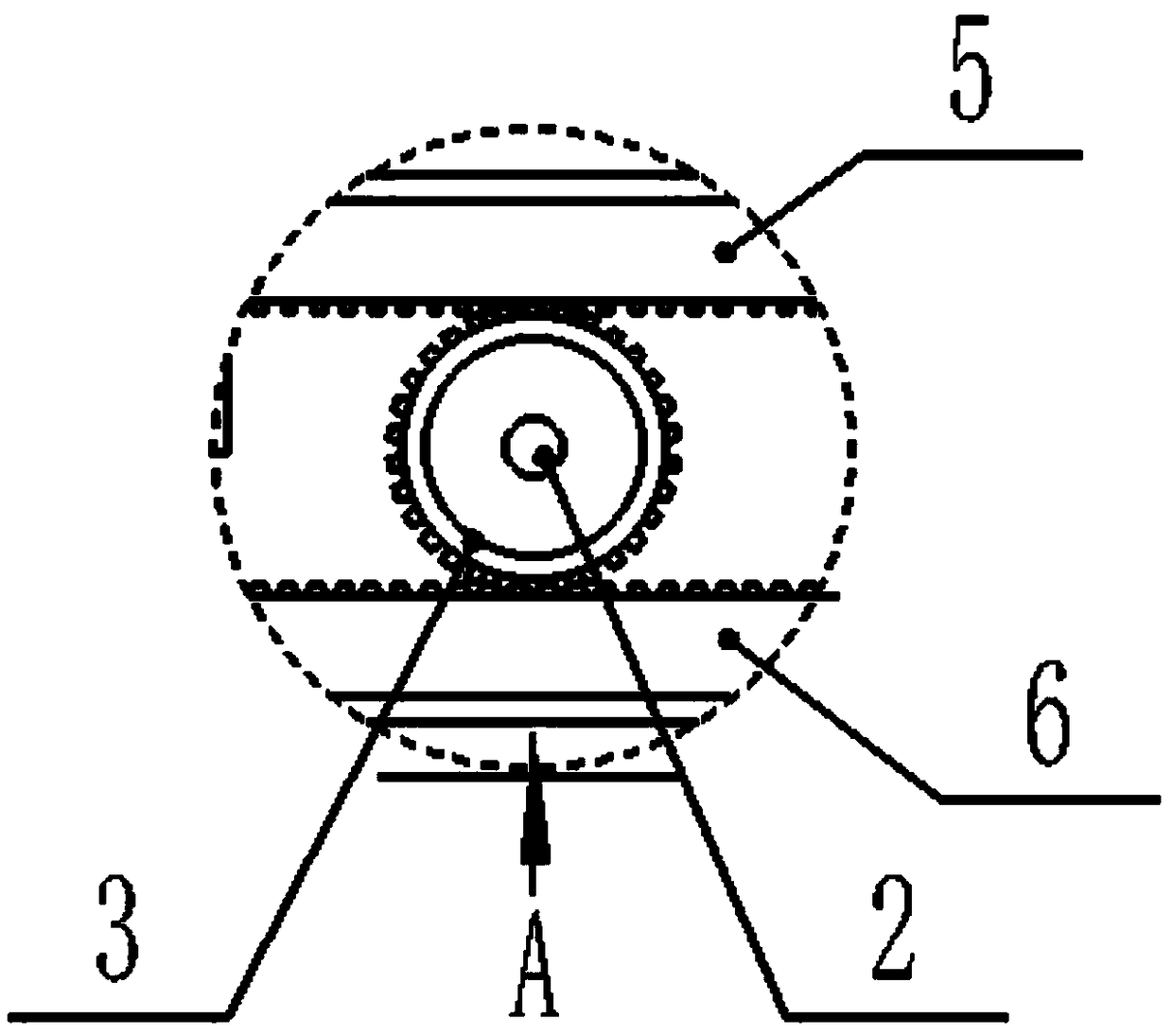

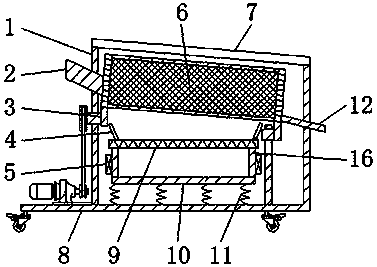

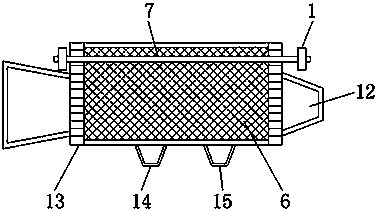

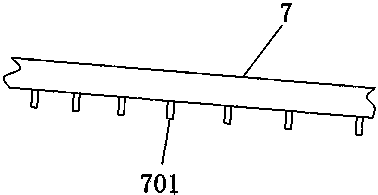

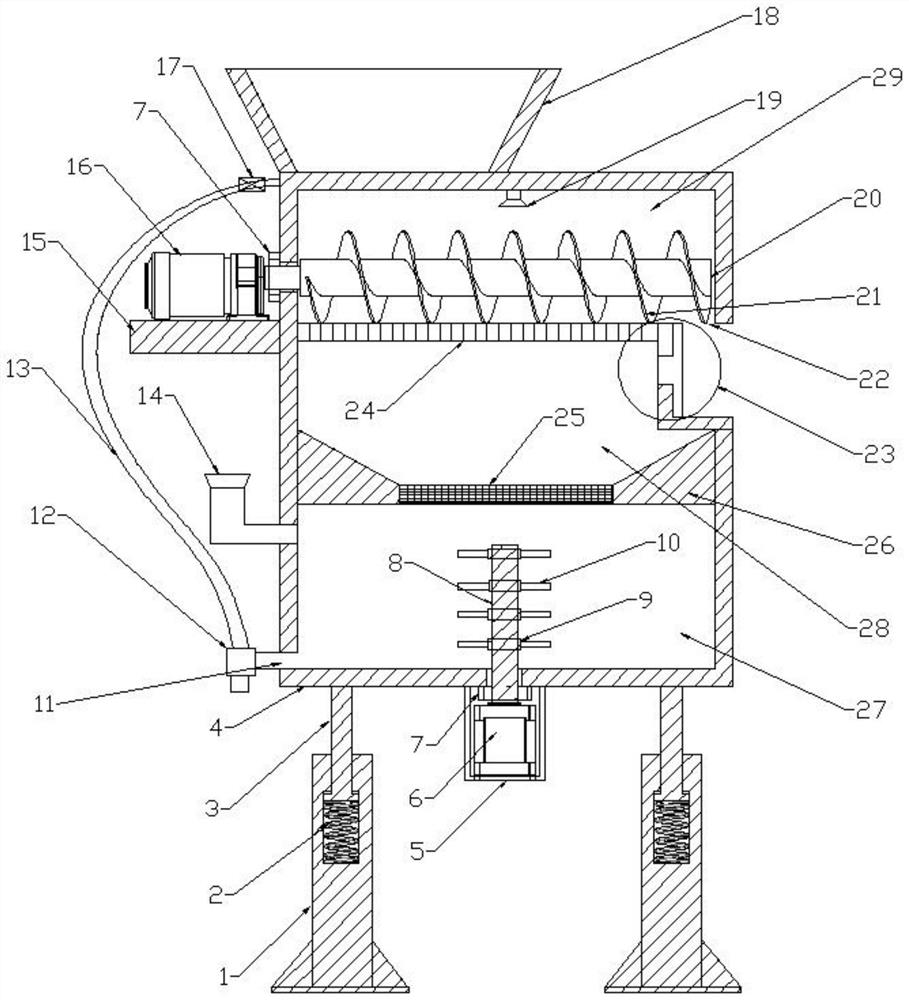

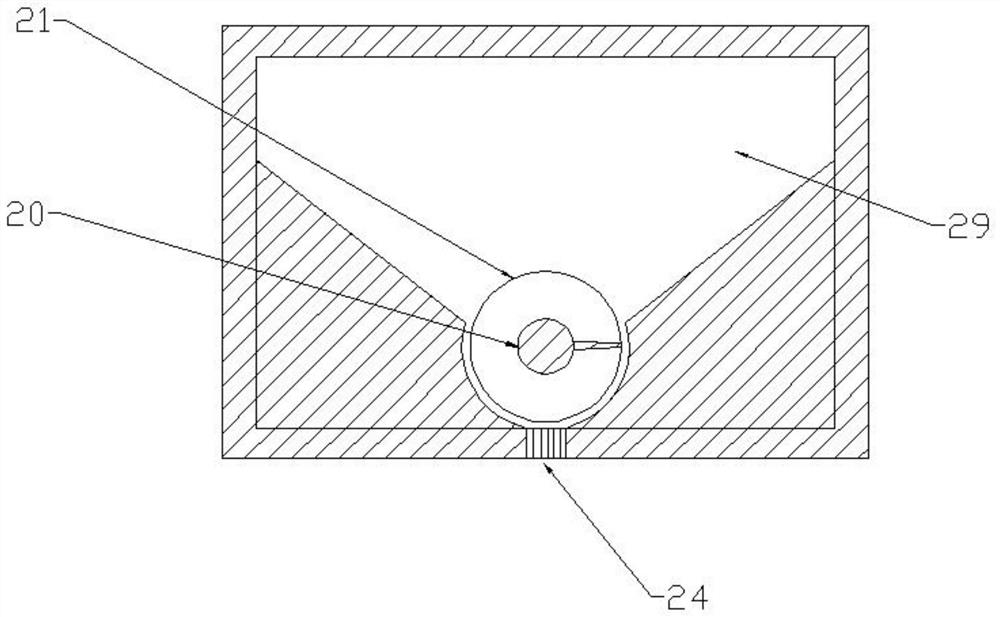

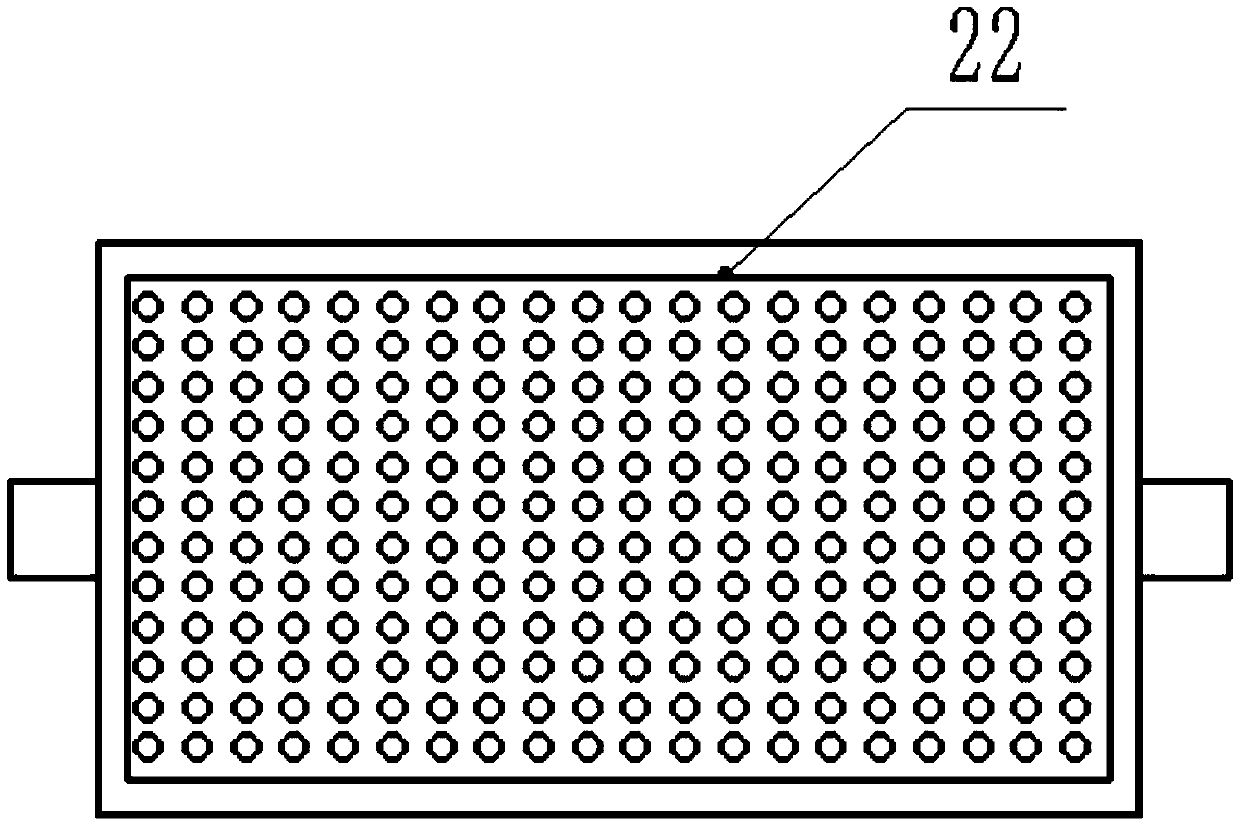

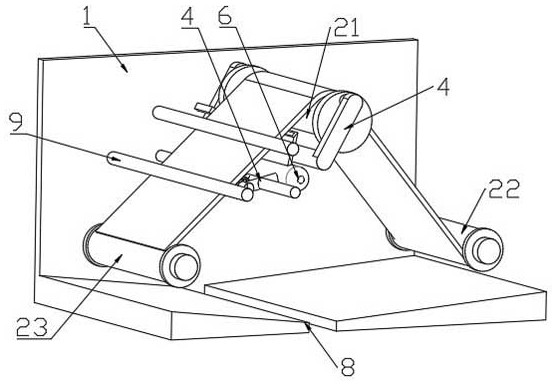

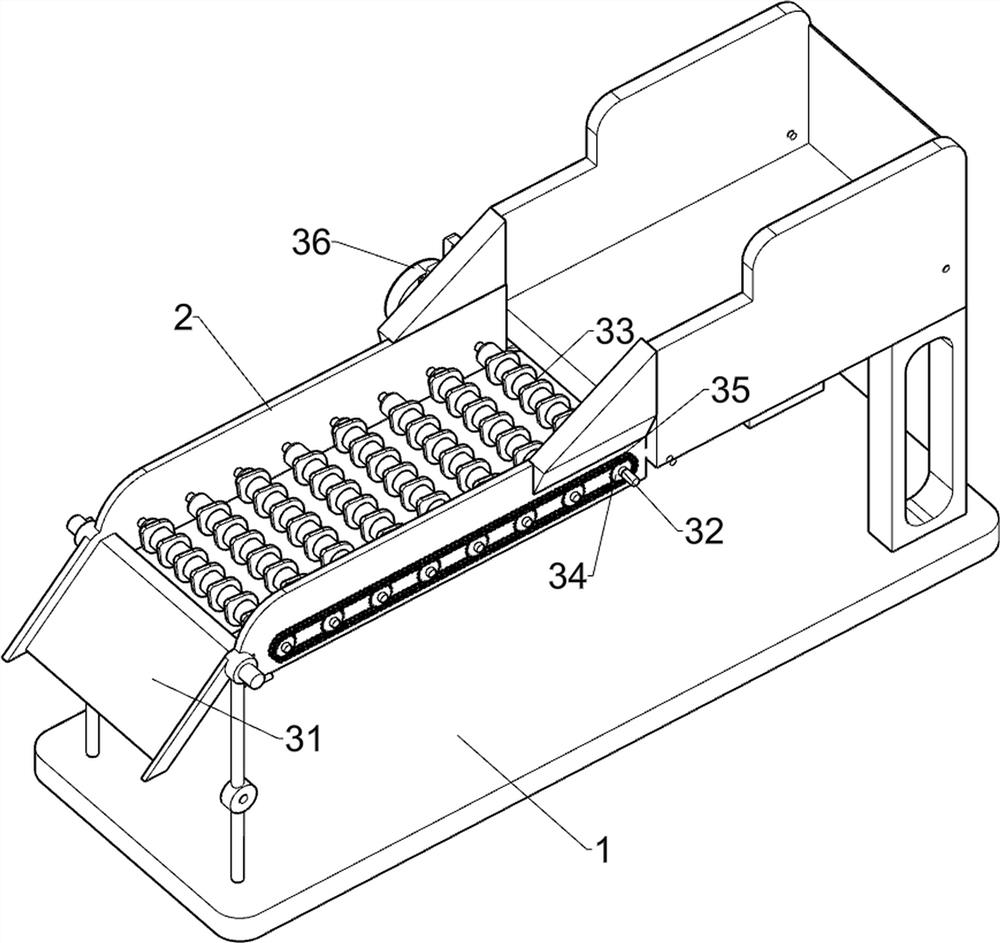

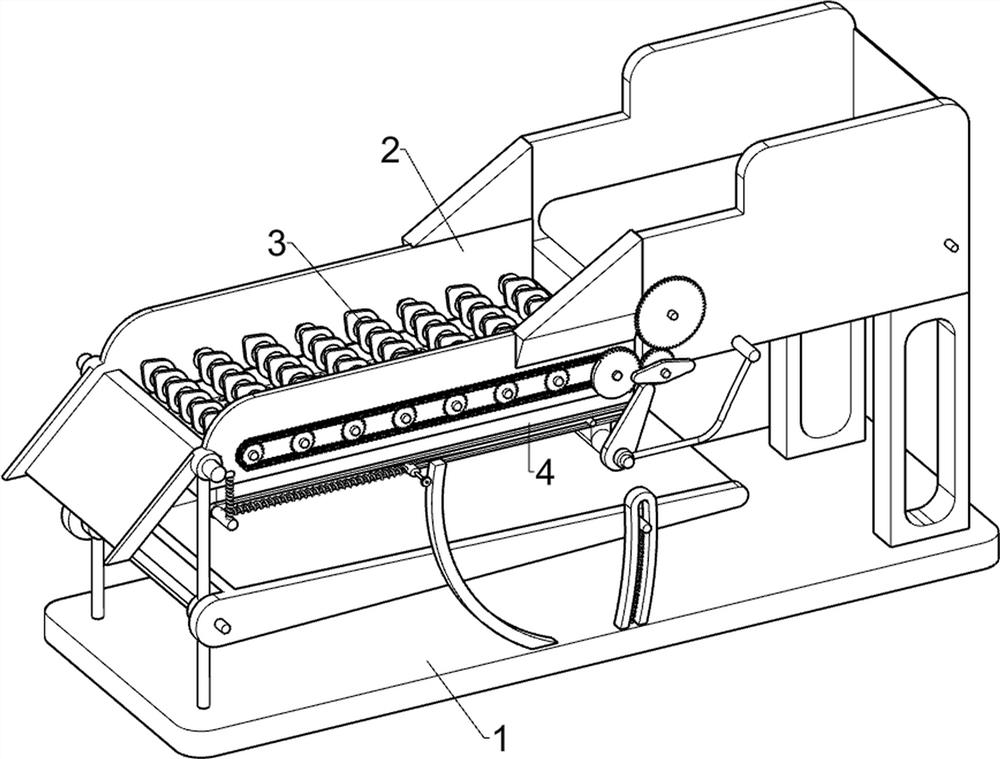

Drum type gravel separation equipment for construction site

InactiveCN107159550AAffect the sorting effectImprove sorting effectSievingGas current separationGear wheelElectric machinery

The invention relates to drum type gravel separation equipment for a construction site. The drum type gravel separation equipment comprises a conveying belt, a first bottom plate, a first motor, a sliding chute, a separation roller, a first separation net, a first belt wheel, a second motor, a second separation net, a second bottom plate, a first gravel outlet, a steel brush roller, a second gravel outlet and a third gravel outlet. The lower end of the conveying belt is arranged inside a gravel feeding hopper. The right end of the first bottom plate is connected with a fifth supporting rod through a fixing bolt. The sliding chute is arranged at the upper end of a sixth supporting rod. The two ends of the separation roller are provided with gear grooves. The first separation net is arranged on the outer surface of the separation roller. The second motor is fixedly connected with a second belt wheel through a speed reducer. According to the drum type gravel separation equipment for the construction site, the steel brush roller is arranged on the rear side of the separation roller, the effect that the separation roller is cleaned during operation is achieved, the first separation net is prevented from being blocked by gravel, and thus, the separation efficiency of the separation roller is improved.

Owner:安徽新兴翼凌机电发展有限公司

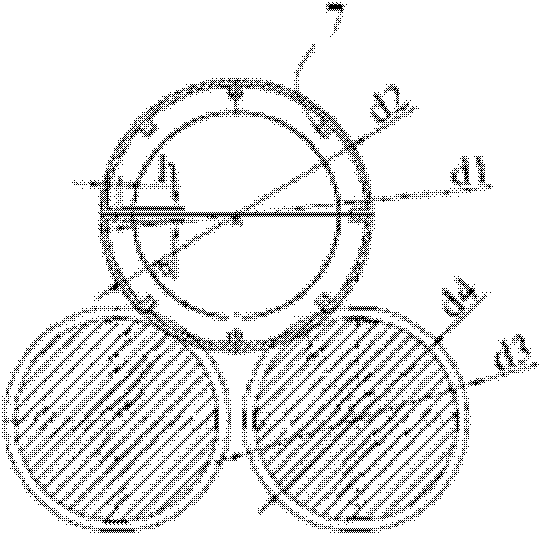

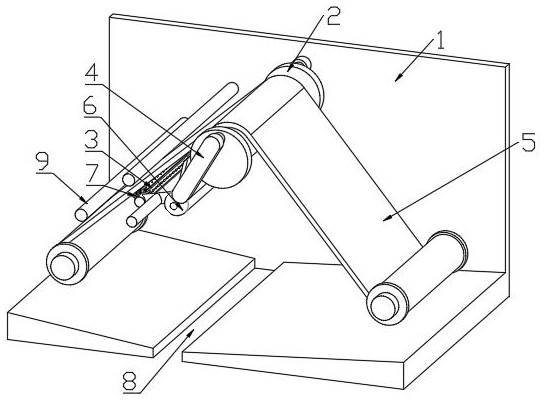

Target magnetron sputtering device and film coating method used for powder particle surface film coating

InactiveCN103160795ATo vibrateFully exposedVacuum evaporation coatingSputtering coatingOperational costsVacuum chamber

The invention provides a target magnetron sputtering device and a film coating method used for powder particle surface film coating. The target magnetron sputtering device comprises a vacuum chamber, a roller with openings at two ends, two support rollers, a motor, a speed regulation device, two magnetron sputtering target frames and a sputtering power source, wherein each support roller is provided with a limiting inclined face. The support rollers are connected with the speed regulation device. The roller is directly placed on the support rollers and driven to rotate through the support rollers. Target materials are arranged at the positions of the openings at the two ends of the roller. During magnetron sputtering film coating, a grinding ball and powder are simultaneously placed into the roller, the rotating speed of the motor is regulated, the grinding ball and powder particles in the roller are enabled to drop in a parabola mode, sputtering stream injected from the openings of the roller is deposited on the falling powder, and film with good evenness is obtained after a certain period of time. The target magnetron sputtering device and the film coating method used for the powder particle surface film coating are large in technological handling capacity, low in operational cost and suitable for industrial production.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

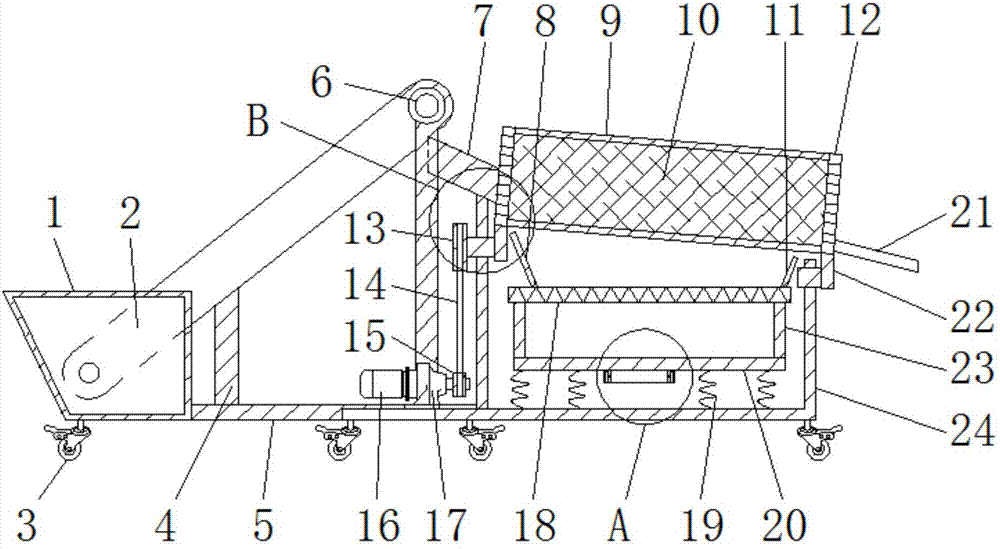

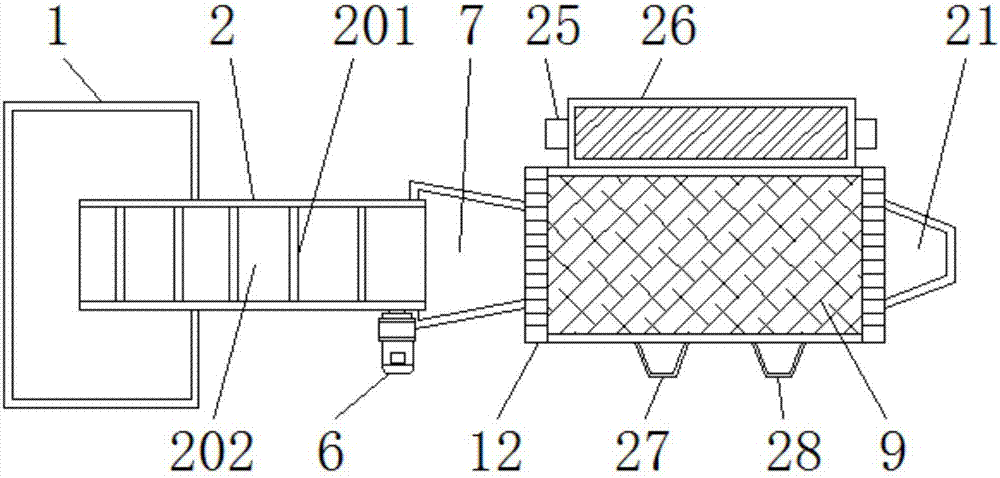

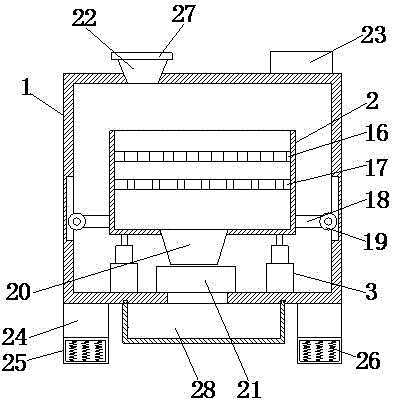

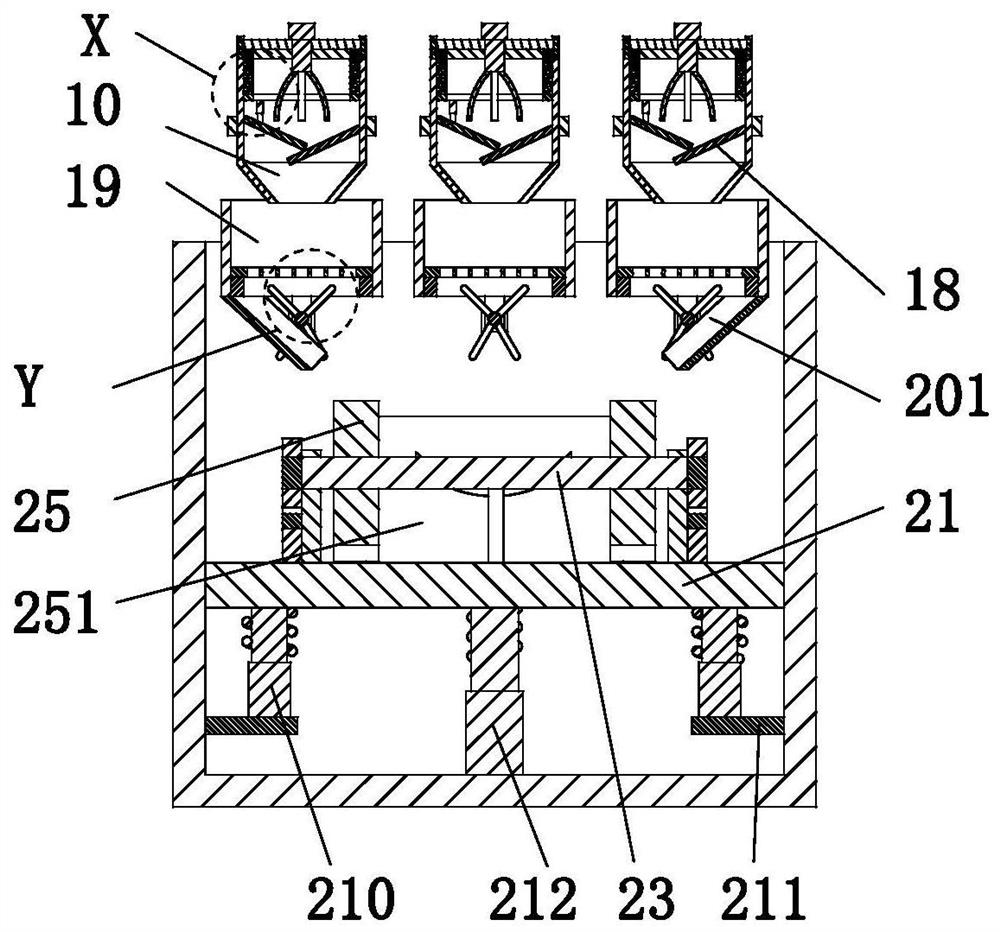

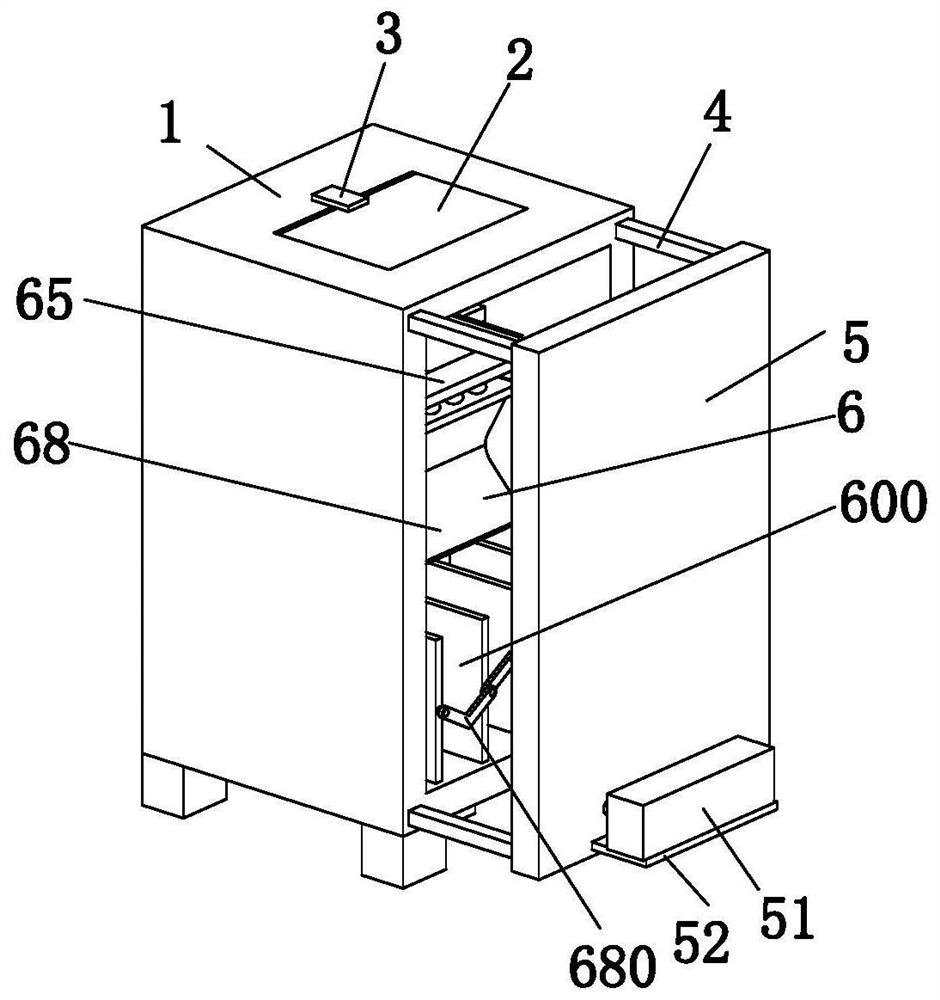

Heat-preservation material mixing device

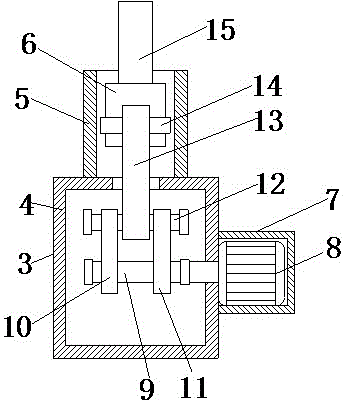

InactiveCN108057381ATo vibrateAvoid cloggingRotary stirring mixersTransportation and packagingMechanical engineeringCrankshaft

The invention belongs to the technical field of material mixing devices and in particular discloses a heat-preservation material mixing device which comprises a crushing part, a conveying part and a mixing part, wherein a first crushing roller and a second crushing roller are arranged inside a crushing bucket to crush raw materials; the first crushing roller, the second crushing roller, connectingrods and sliding blocks form a bias crankshaft sliding block mechanism; a filtering net is arranged between the two sliding blocks; a material circulation hole is formed in a side wall when the sliding blocks are moved to a lowest point; a circulation bucket with spiral conveying blades is mounted outside the material circulation hole; the circulation bucket is communicated with the upper part ofa crushing bucket; the conveying part is communicated with the lower end of the crushing part; the conveying part comprises a conveying bucket; a second feeding hole and shifting blades are arrangedinside the conveying bucket; the mixing part is communicated with the conveying part; the mixing part comprises a mixing bucket; stirring blades and a discharge hole are arranged inside the mixing bucket. By adopting the scheme of the invention, the problems that heat-preservation materials are not uniformly mixed and the stirring time is too long, are solved.

Owner:宁波得晴电器科技有限公司

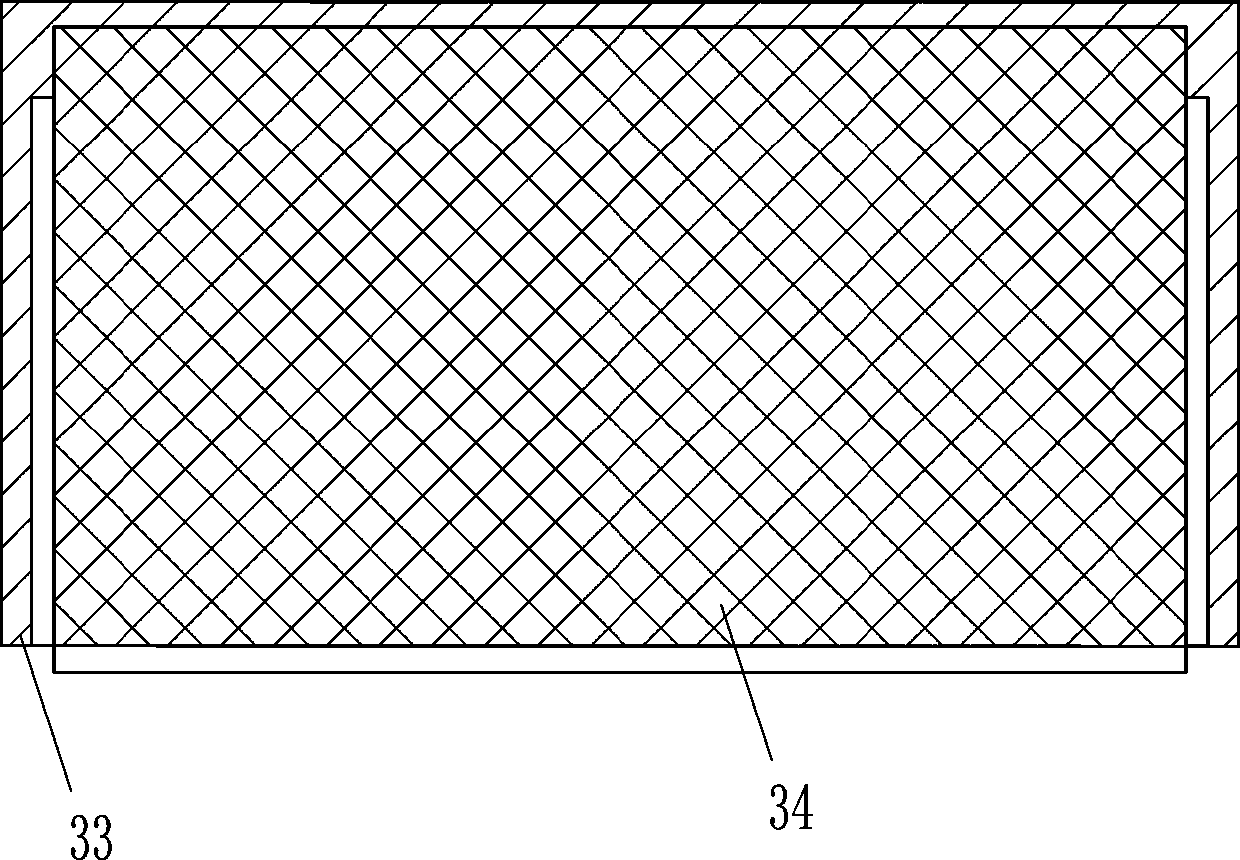

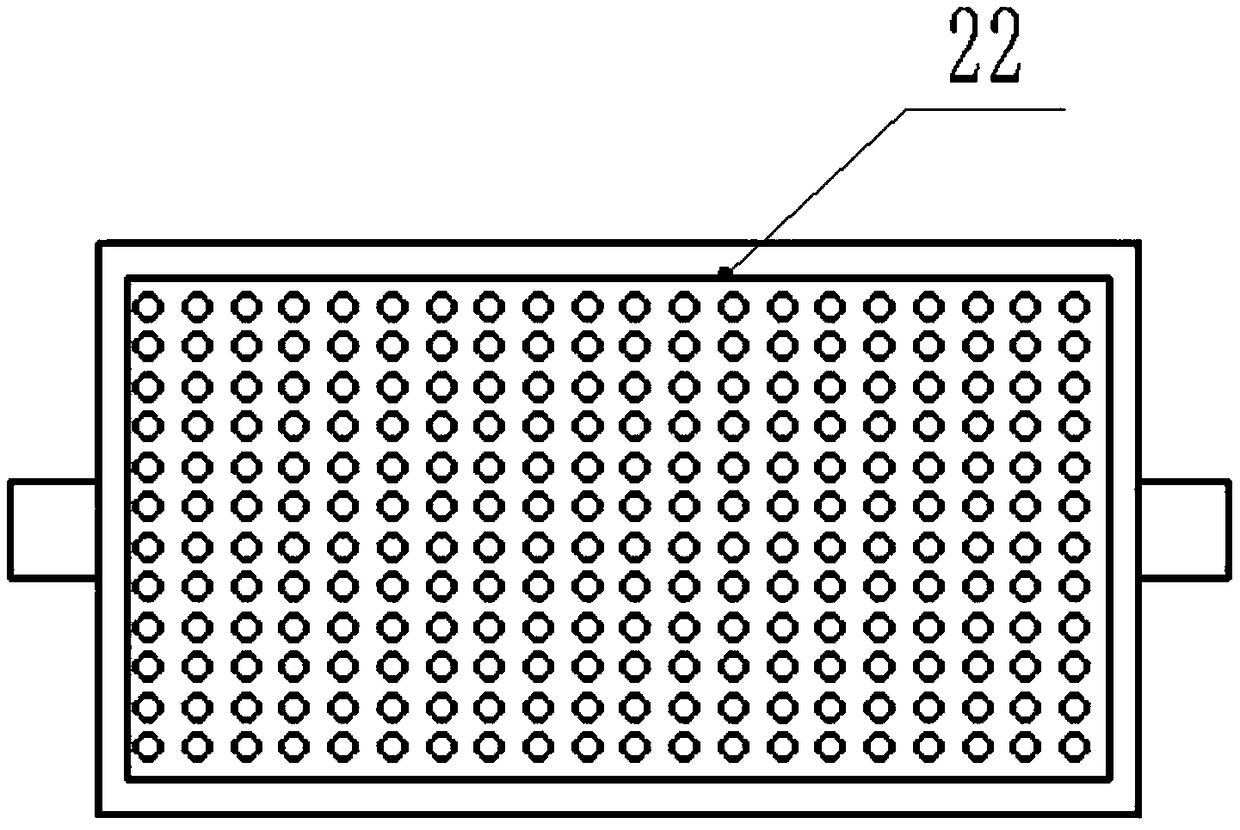

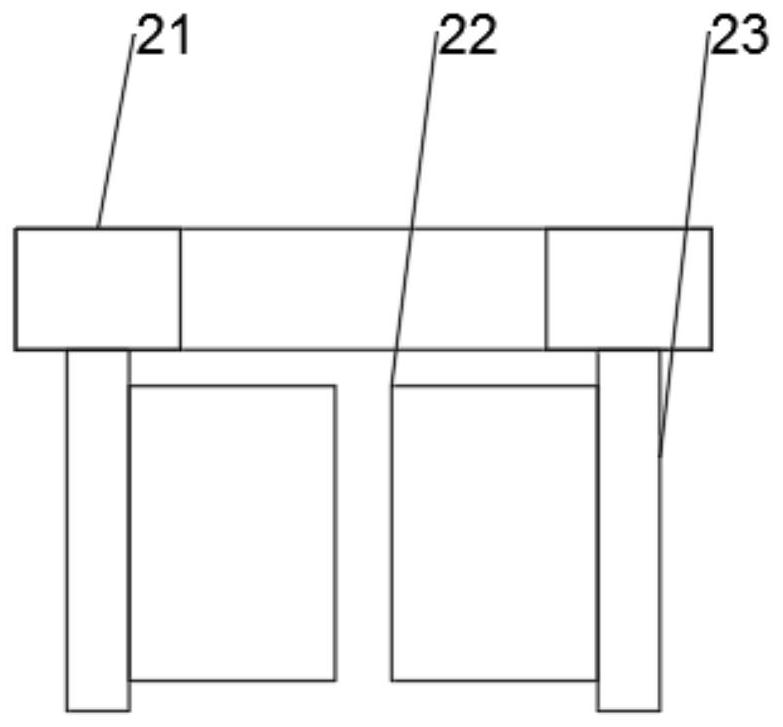

Plastic raw material production screening machine having vibrating screening function

InactiveCN106670099AWith vibration screening functionTo vibrateSievingScreeningScreening effectEngineering

The invention discloses a plastic raw material production screening machine having the vibrating screening function. The plastic raw material production screening machine having the vibrating screening function comprises a machine body. A screening box is arranged inside the machine body. The bottom of the inner wall of the machine body is symmetrically and fixedly connected with vibrating devices. Each vibrating device comprises a first supporting seat and a second supporting seat. The bottom of each second supporting seat is fixedly connected with the top of the first supporting seat. The connecting block is arranged inside the second supporting seat. A motor installation rack is fixedly connected to the back surface of each first supporting seat. The plastic raw material production screening machine having the vibrating screening function achieves the vibrating function on the screening box through the arrangement of motors, first connecting columns, first supporting plates, second supporting plates, second connecting columns, first ejecting rods and second ejecting rods, large-particle raw materials in plastic raw materials cannot block through holes of screening plates, the screening effect is improved, and the economic loss of a user is reduced.

Owner:WUXI HITXINCHENG POLYMER TECH

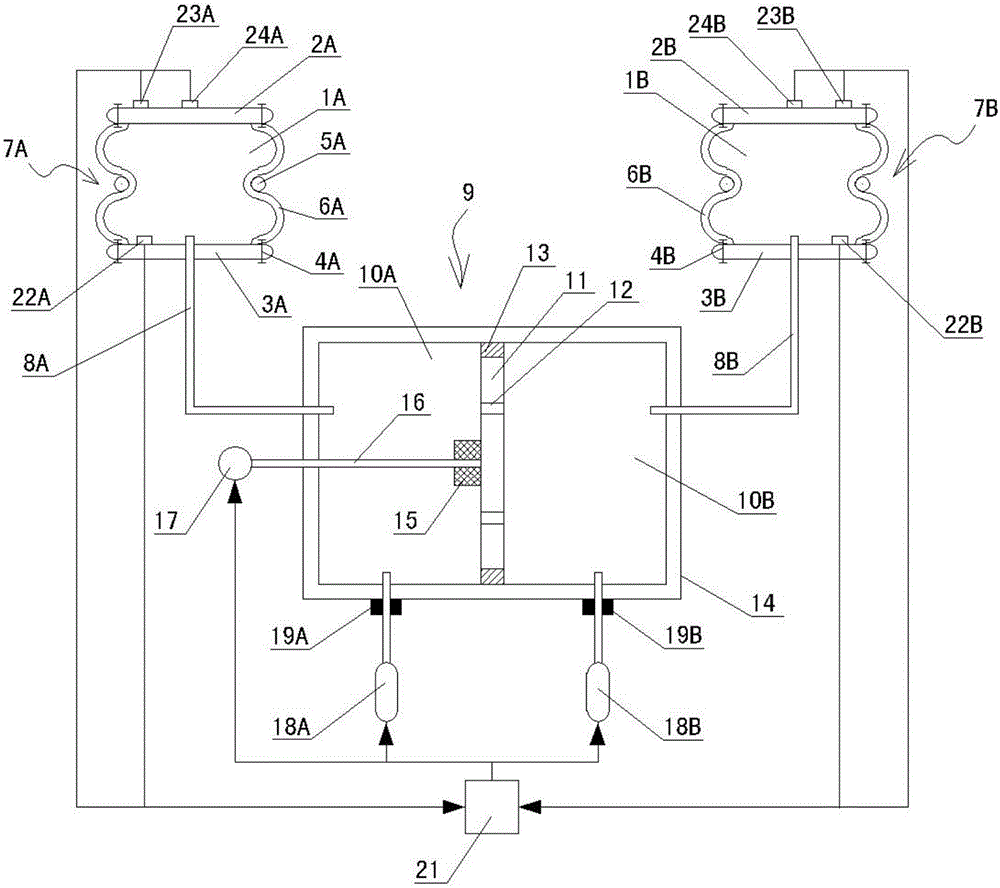

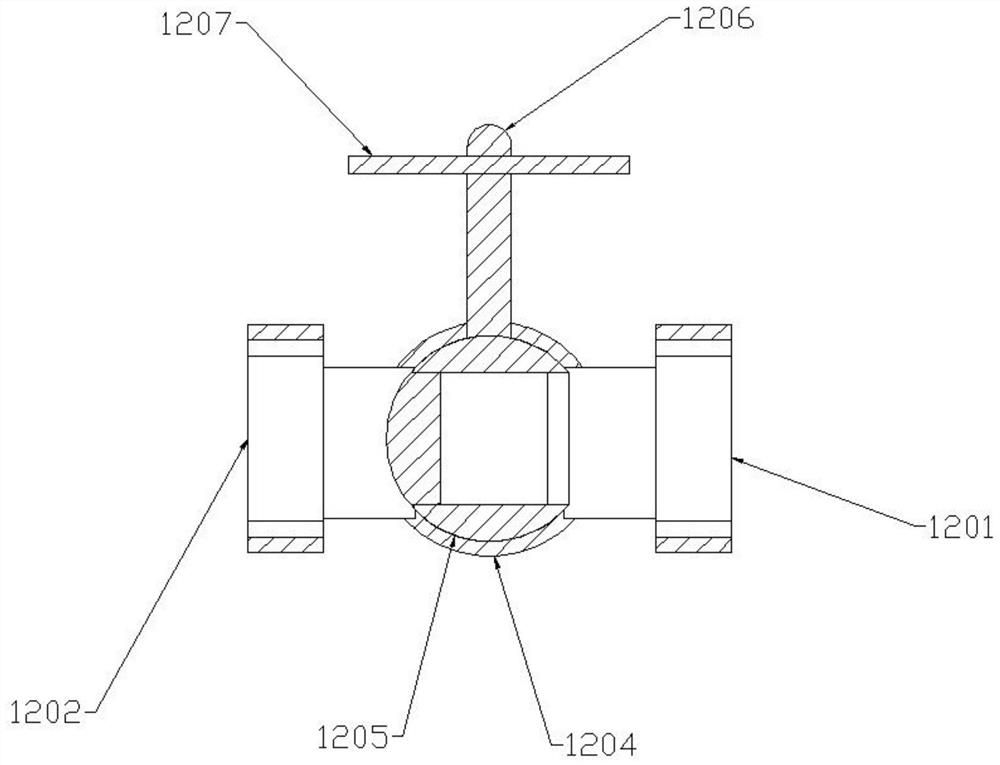

Dual air spring with shared additional air chamber and control method and application of dual air spring

ActiveCN105065544AOptimize layoutReduce the total massSpringsGas based dampersThermodynamicsAir spring

The invention discloses a dual air spring with a shared additional air chamber and a control method and application of the dual air spring. The dual air spring is characterized in that the dual air spring comprises a left air spring body and a right air spring body, and the shared additional air chamber and a controller used for controlling the working mode of the shared additional air chamber are arranged between the left air spring body and the right air spring body. The occupied space of the dual air spring is effectively reduced through the shared additional air chamber, the rigidity of the dual air spring can be controlled in real time according to the load displacement working condition of the air spring and the running work condition of an automobile, and the damping effect of the air spring is improved.

Owner:ANQING HUITONG AUTOMOTIVE PARTS

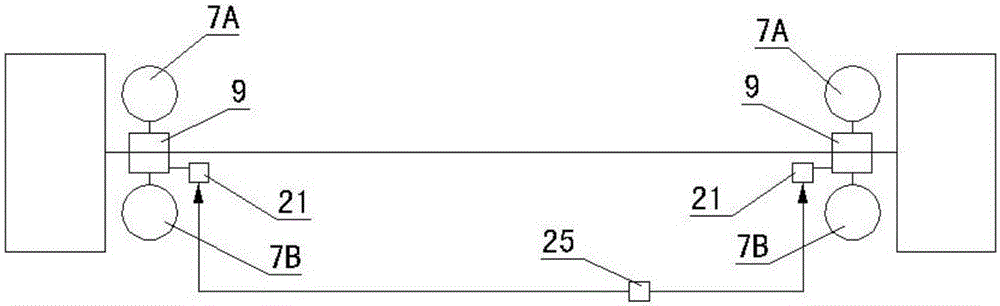

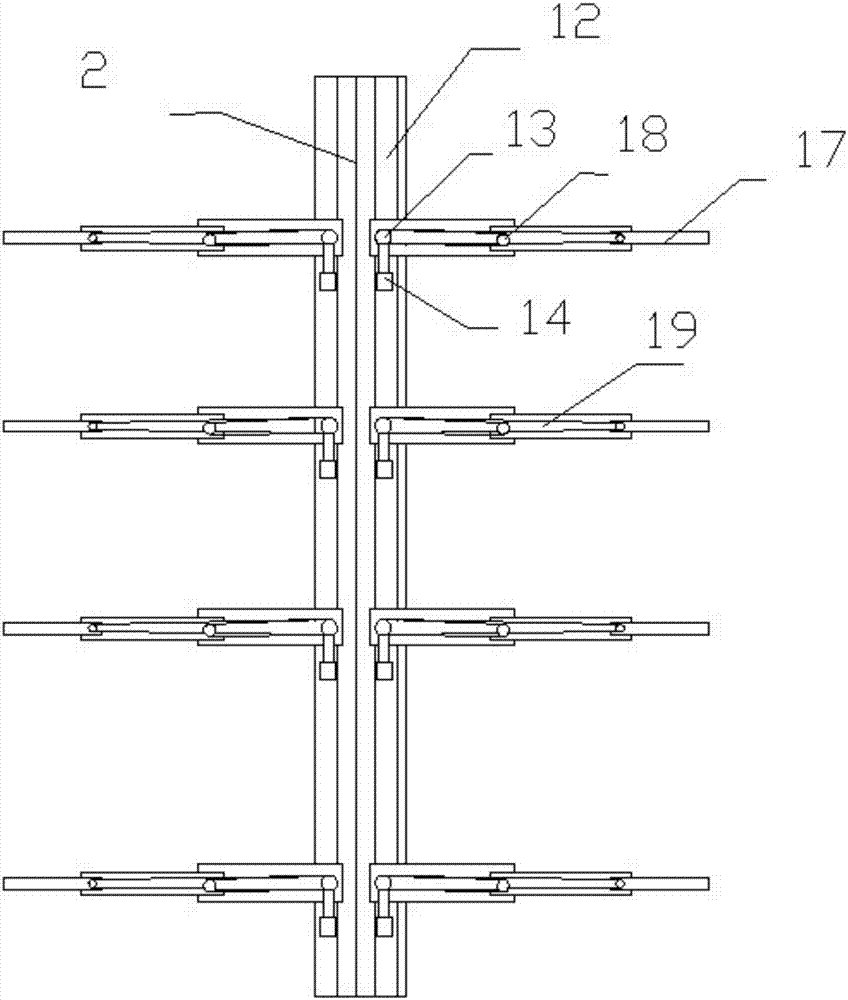

Exterior thermal-insulation and exterior decoration system for external wall and construction method therefor

The invention involves a insulating and finishing systems of the outer walls of buildings and its construction methods, particularly a low-cost, durable and safe insulating walls and it's more advanced construction methods. Said aim is achieved by the following technical methods: 1. pretreating the outer walls of buildings to making the outer walls binding with cement tightly. 2. fixing the decorative plate on the disposed walls using the stones dr-hanging technique, said decorative plate includes stone face brick, ceramic face brick and other decorative face brick for walls. The distance between walls and decorative face brick is given by designer. 3. Casting objects into the cavity formed between the outer walls and decorative face brick and reaching the construction requirement, the objects is prepared by mixing the light-weight insulation particles, cement and water. The light-weight insulation particles include polyphenyl foam particles, rock fiber particles, pearlstone particles and other insulating materials which can be processed into particles. The insulating walls constructed according the method has advantages such as the quality is durable and aesthetic, cost is low, process is simple and the construction period is short.

Owner:张伟生

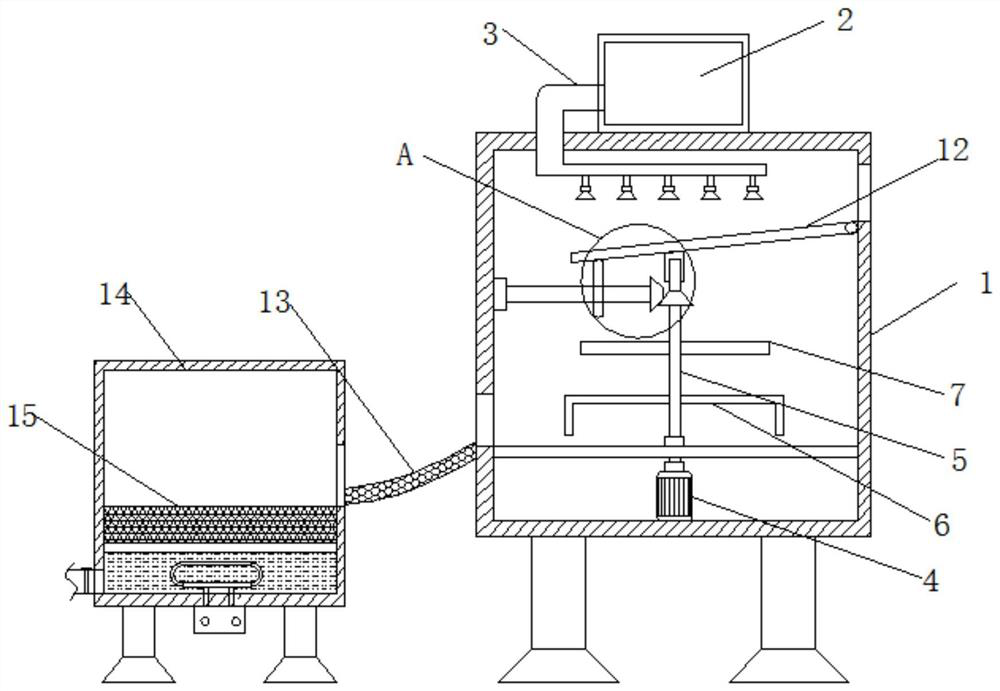

Pleurotus eryngii sterilization device

InactiveCN105724051AComprehensive sterilizationAvoid getting wetCultivating equipmentsMushroom cultivationEngineeringMechanical engineering

The invention discloses a pleurotus eryngii sterilization device, which comprises a steam sterilization tank, a high-temperature steam generator and a motor. The end is connected with a rotating shaft, the rotating shaft is vertically set, and the rotating shaft extends into the steam sterilization tank, and a plurality of grid plates are fixed on the rotating shaft. Bacteria bag, the present invention has simple and reasonable structure, convenient use and operation, high overall sterilization efficiency and good effect, so that each leaf can be fully sterilized, so the overall production efficiency is improved, and the overall operation of the equipment is stable and safe to use.

Owner:岑思

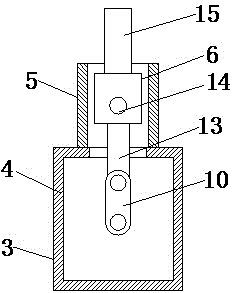

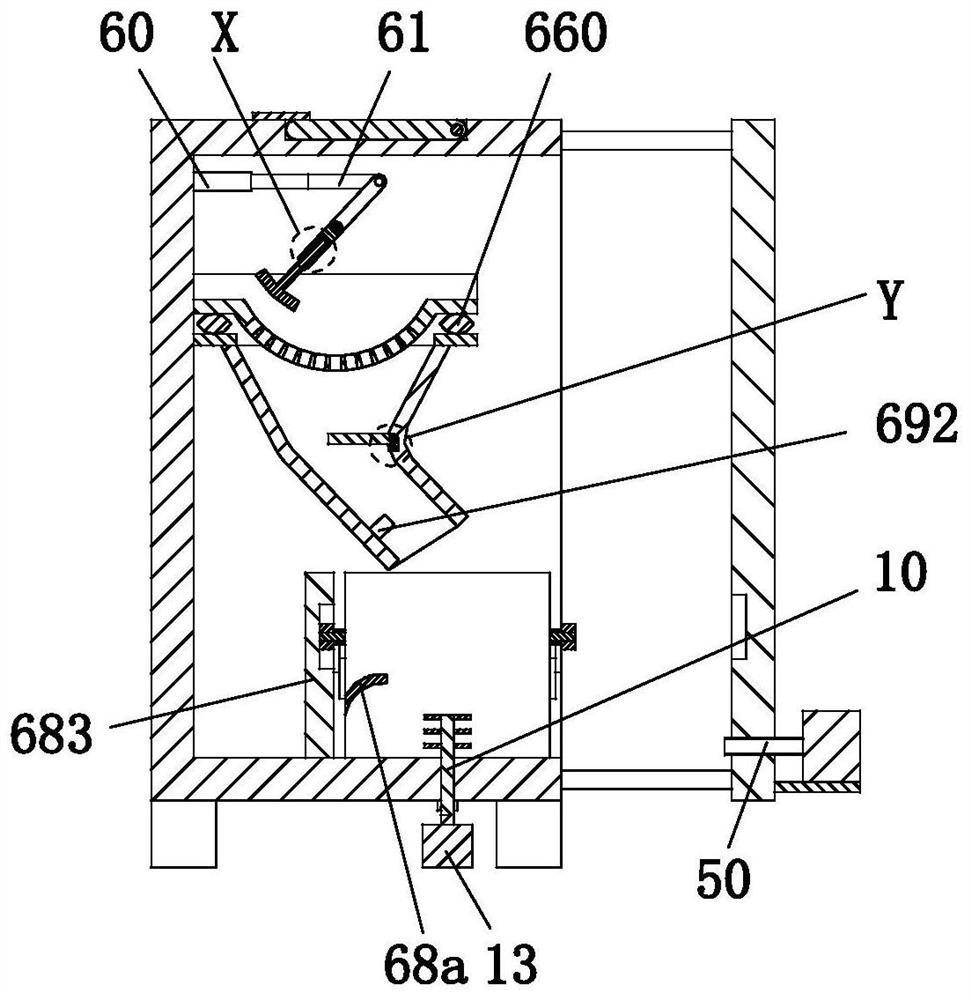

Table tennis ball cleaning device

InactiveCN112823831AIncrease profitSimple and novel structureBall sportsElectric machineryDrive motor

The invention discloses a table tennis ball cleaning device, relates to the field of ball cleaning, and provides the following scheme for solving the problems that table tennis balls are not thoroughly cleaned, shrunken table tennis balls cannot be recovered, use is affected, and materials are wasted, the table tennis ball cleaning device comprises a box body, and a water tank is installed at the top of the box body; a water pipe is fixedly connected to one side of the water tank, a driving motor is fixedly arranged on the inner wall of the bottom of the box body, an output shaft of the driving motor is fixedly connected with a rotating shaft, a stirring paddle is fixedly connected to the outer ring of the rotating shaft, a stirring rod is arranged above the stirring paddle, and a first bevel gear is fixedly arranged above the rotating shaft in a sleeving mode; and a second bevel gear is arranged above the first bevel gear. The table tennis ball cleaning device is simple and novel in structure, table tennis balls can be cleaned one by one and heated, the table tennis balls become round, the utilization rate is increased, the use hand feeling is improved, and the table tennis ball cleaning device is suitable for market popularization.

Owner:陕西信诺威体育用品有限公司

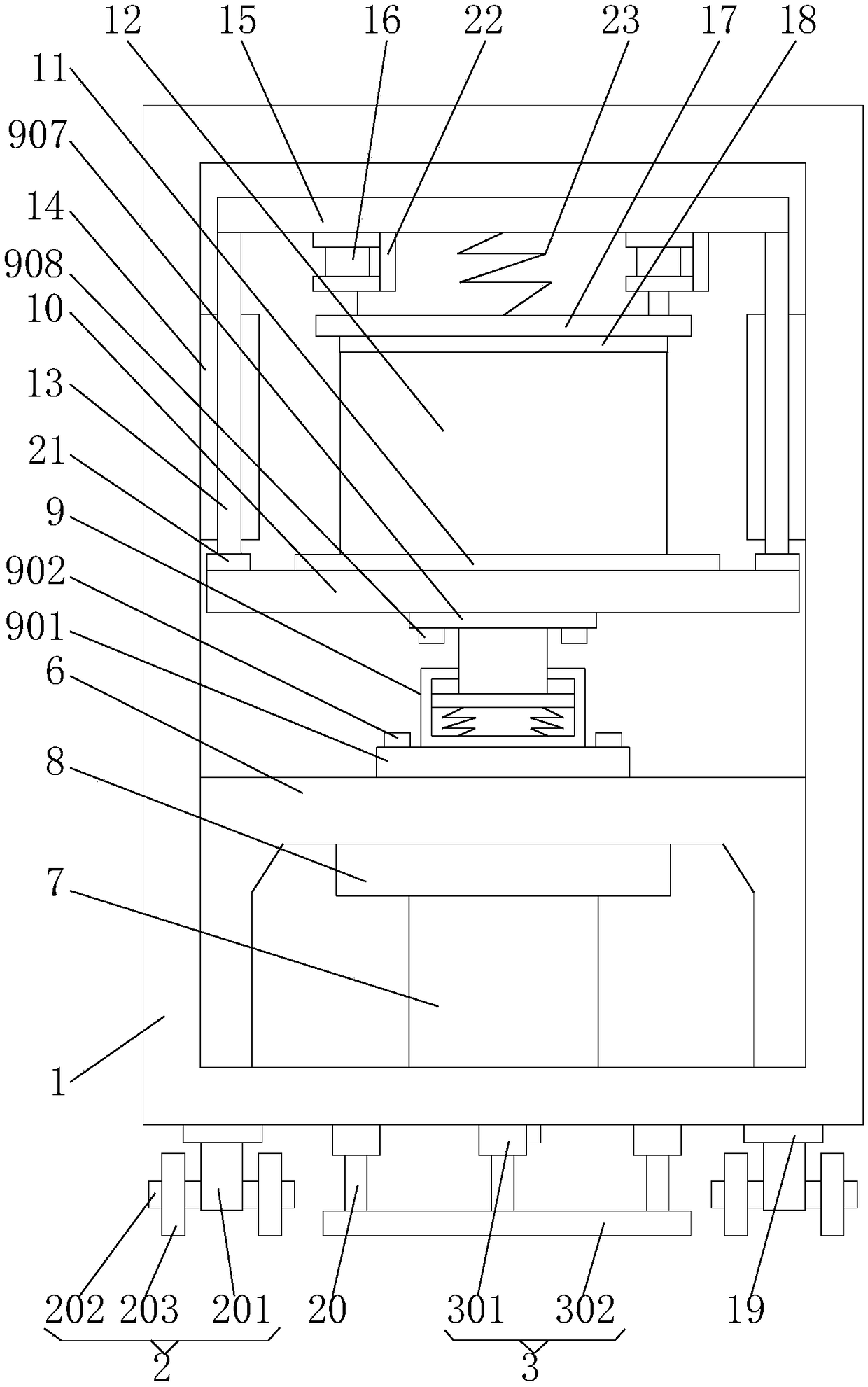

Plastic particle raw material screening machine

ActiveCN111070474AEasy to replace screenGood for decentralized collectionSievingScreeningPhysicsProcess engineering

The invention relates to screening machines, in particular to a plastic particle raw material screening machine in order to achieve the technical effects of being capable of carrying out preliminary screening and facilitating replacement of a mesh screen. The plastic particle raw material screening machine comprises a base, a discharge box, a screening device, a feed hopper, a material baffle, a handle, a first elastic part, a support and the like. The discharge box and the support are arranged on the top of the base. The screening device used for screening plastic particle raw materials is arranged on the top of the discharge box. The feed hopper is arranged on the top of the screening device. The material baffle is movably arranged at the discharge end of the feed hopper. The handle is connected to the material baffle. The handle penetrates through the screening device. The plastic particle raw material screening machine achieves the effects of being capable of carrying out preliminary screening and facilitating replacement of the mesh screen.

Owner:深圳集科信电子塑胶有限公司

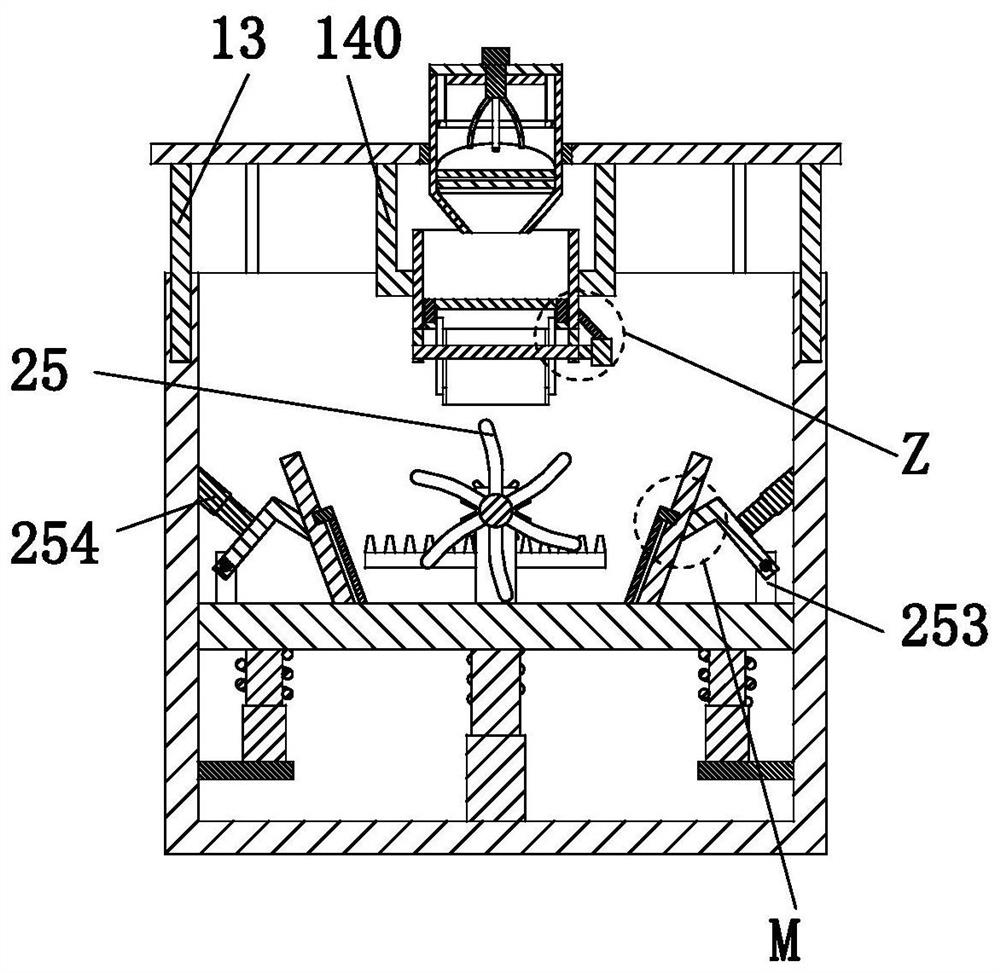

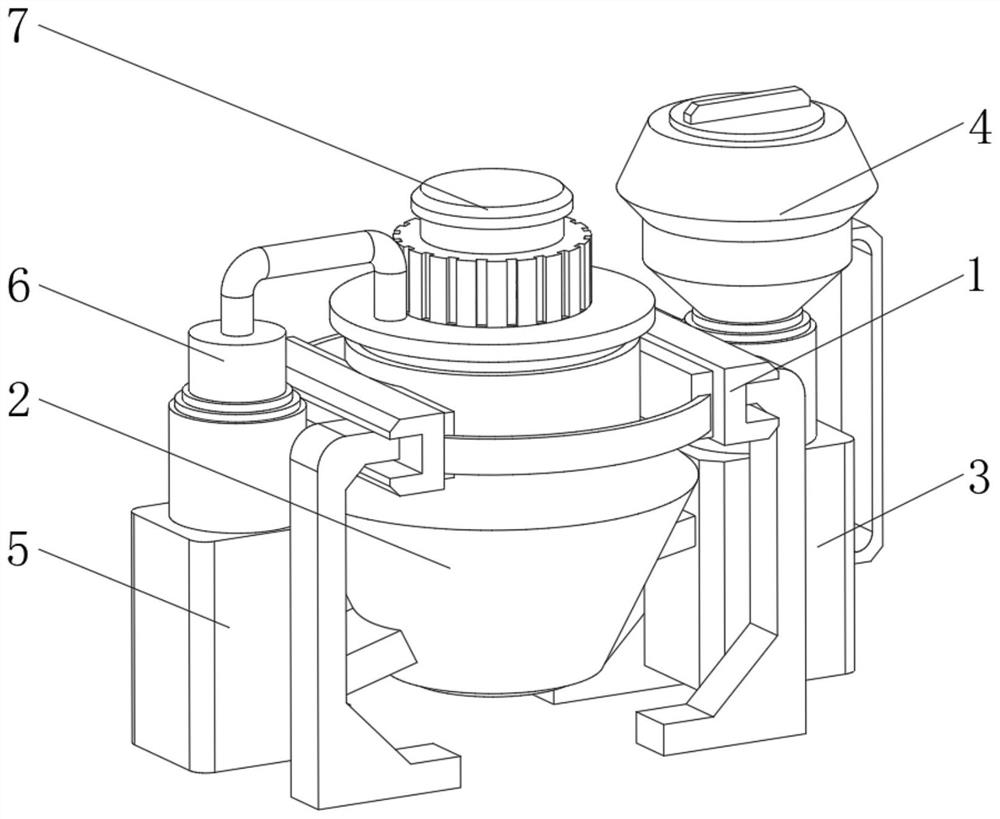

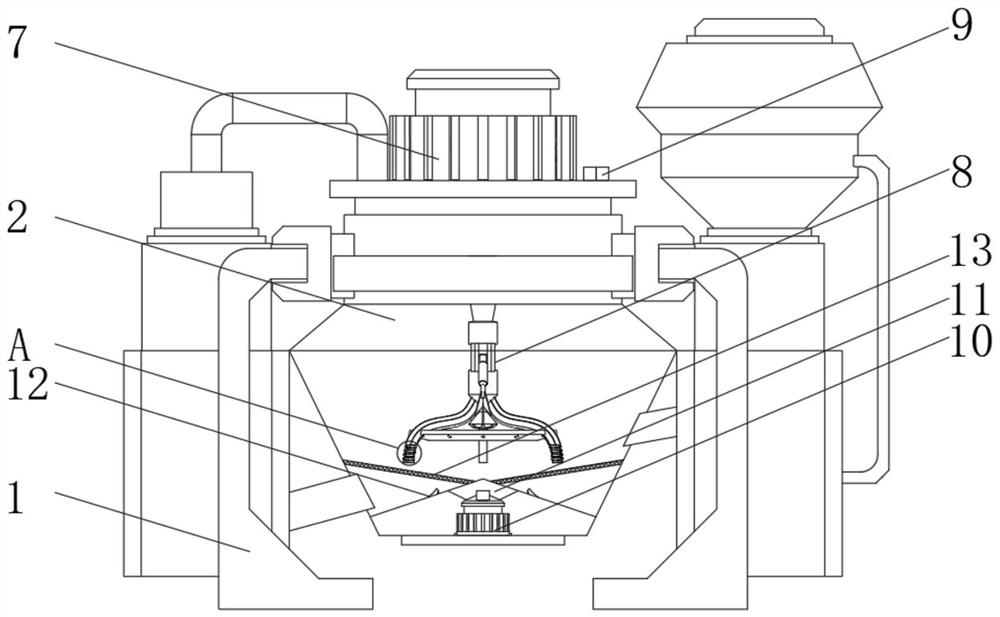

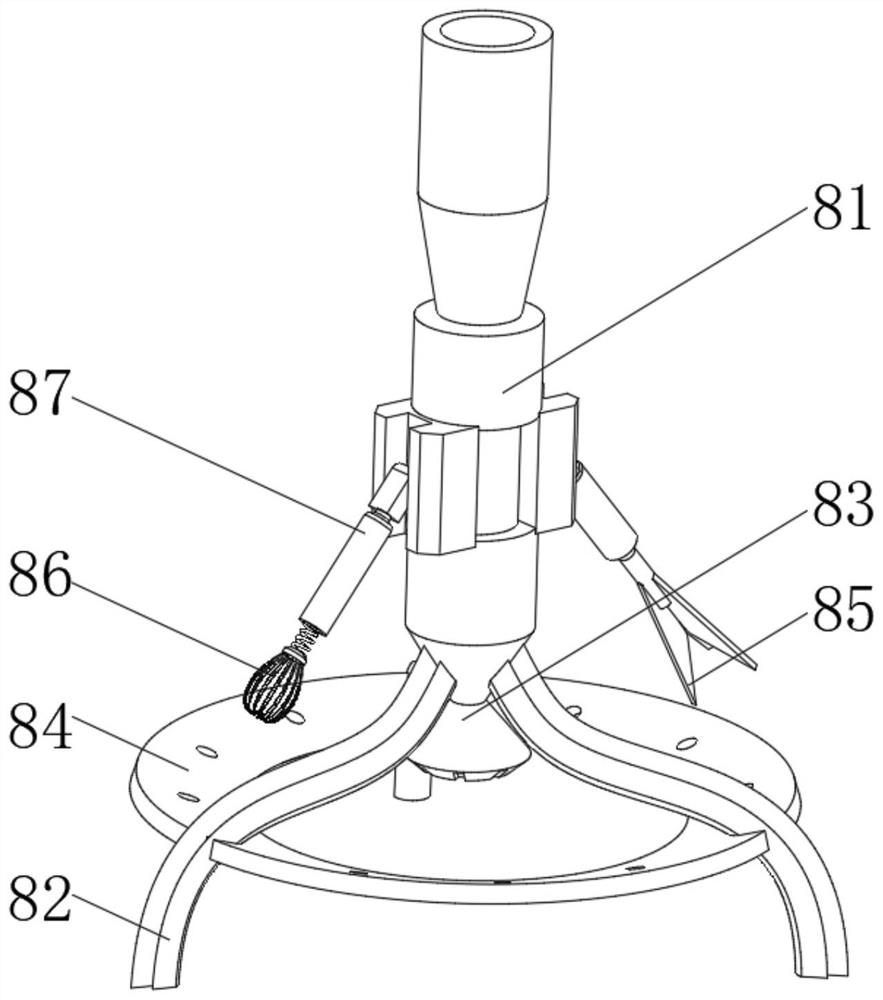

Stirring equipment for producing dry-mixed mortar

InactiveCN111906942AImprove the mixing effectCause productivitySievingScreeningBLENDER/MIXERProcess engineering

The invention relates to stirring equipment for dry-mixed mortar production. The stirring equipment comprises a feeding mechanism and a stirring mechanism, wherein the lower end of the feeding mechanism is connected with the upper end of the stirring mechanism in a sliding fit mode, and the lower end of the stirring mechanism is installed on an existing working ground. According to the stirring equipment, dry-mixed mortar stirring production is carried out by adopting a design concept of combining multiple stirring structures, and an arranged boosting group can play a role in centralizing rawmaterials, so that the mixing and stirring effect of the structure playing a stirring role in the stirring mechanism on the raw materials can be improved; and the phenomena of low single-time production capacity and poor quality caused by edge concentration of the raw materials can be avoided; and meanwhile, the arranged feeding mechanism can achieve single-time storage and multi-time quantitativefeeding of the raw materials, and the stirring equipment is convenient to periodically clean due to the detachability of the feeding mechanism.

Owner:盛亚明

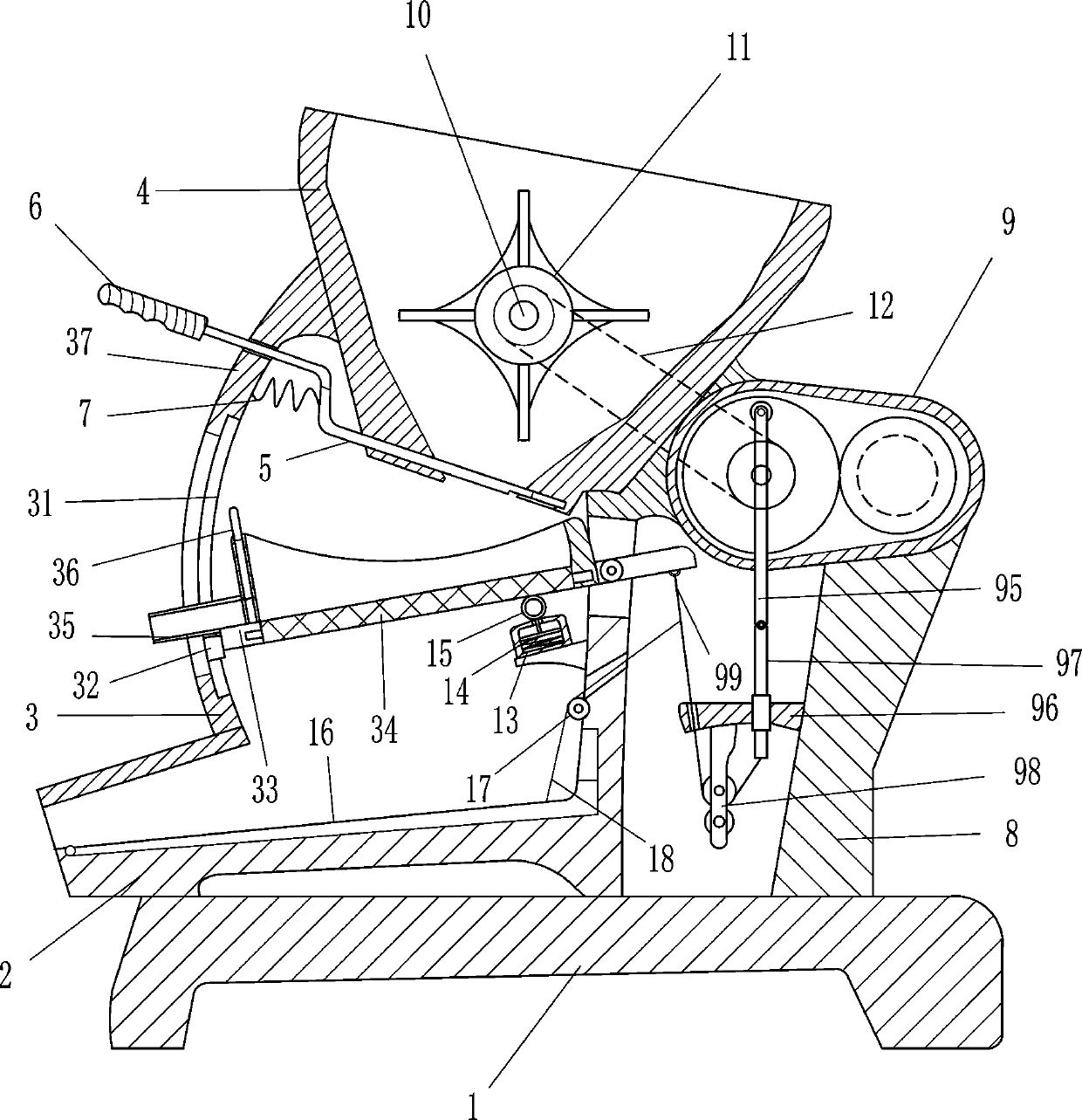

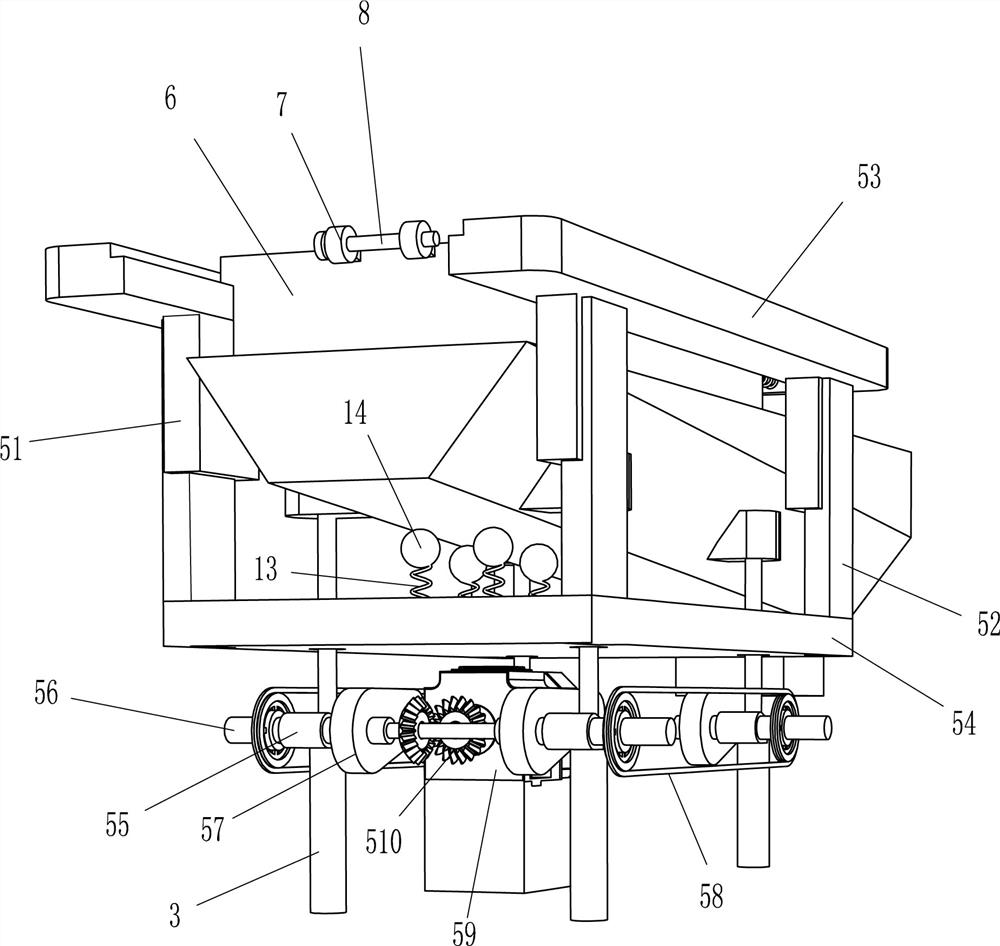

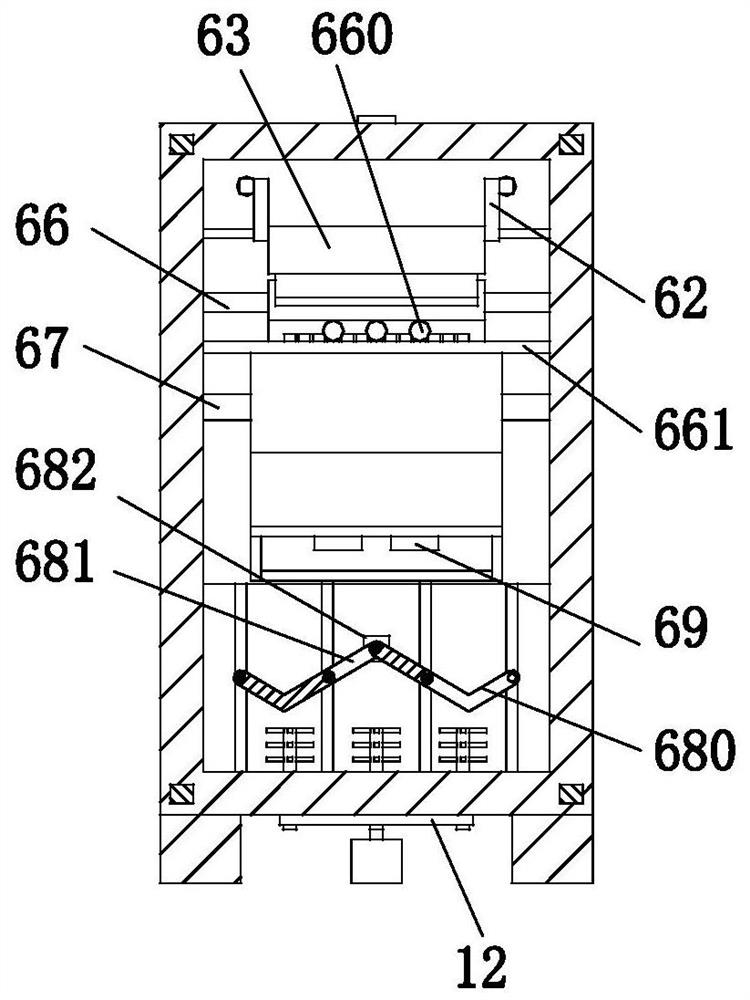

Gear driving and vibrating type high-quality soybean screening device for agriculture

InactiveCN108714556ASpeed up screeningImprove efficiencySievingScreeningElectric machineryDrive motor

The invention discloses a gear driving and vibrating type high-quality soybean screening device for agriculture. The high-quality soybean screening device comprises a base, a first drive motor, a lifting sliding plate, a screening box, a first screening plate and a second screening plate. The other end of a crankshaft is installed on a connecting plate in a rotating manner through a bearing. The crankshaft is provided with shaft sleeves. A first connecting rod and a second connecting rod are welded to the lower sides of the shaft sleeves on the left side and the right side correspondingly. Thesecond screening plate and the first screening plate are connected to the lower end of the first connecting rod and the lower end of the second connecting rod correspondingly. The other end of the first screening plate and the other end of the second screening plate are installed on the inner wall of the right side of the interior of the screening box in a hinged manner. According to the high-quality soybean screening device, by indirectly driving the screening box to ascend or descend, the function of vibrating the screening box is achieved, the soybean screening speed is increased greatly,meanwhile, power is supplied to enable a second drive motor to begin to rotate, the second drive motor drives the crankshaft to begin to rotate, thus the first screening plate and the second screeningplate are driven to begin to swing and screen, and the soybean screening speed of the first screening plate and the second screening plate is further increased.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

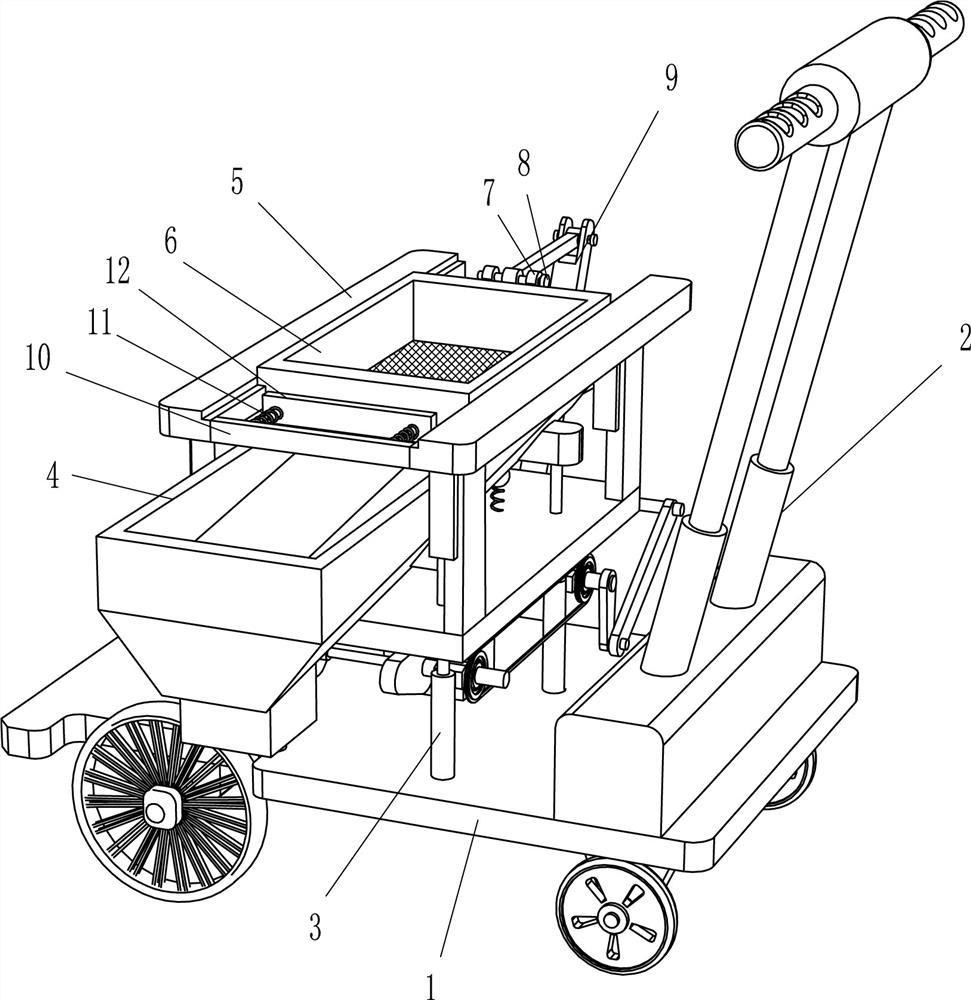

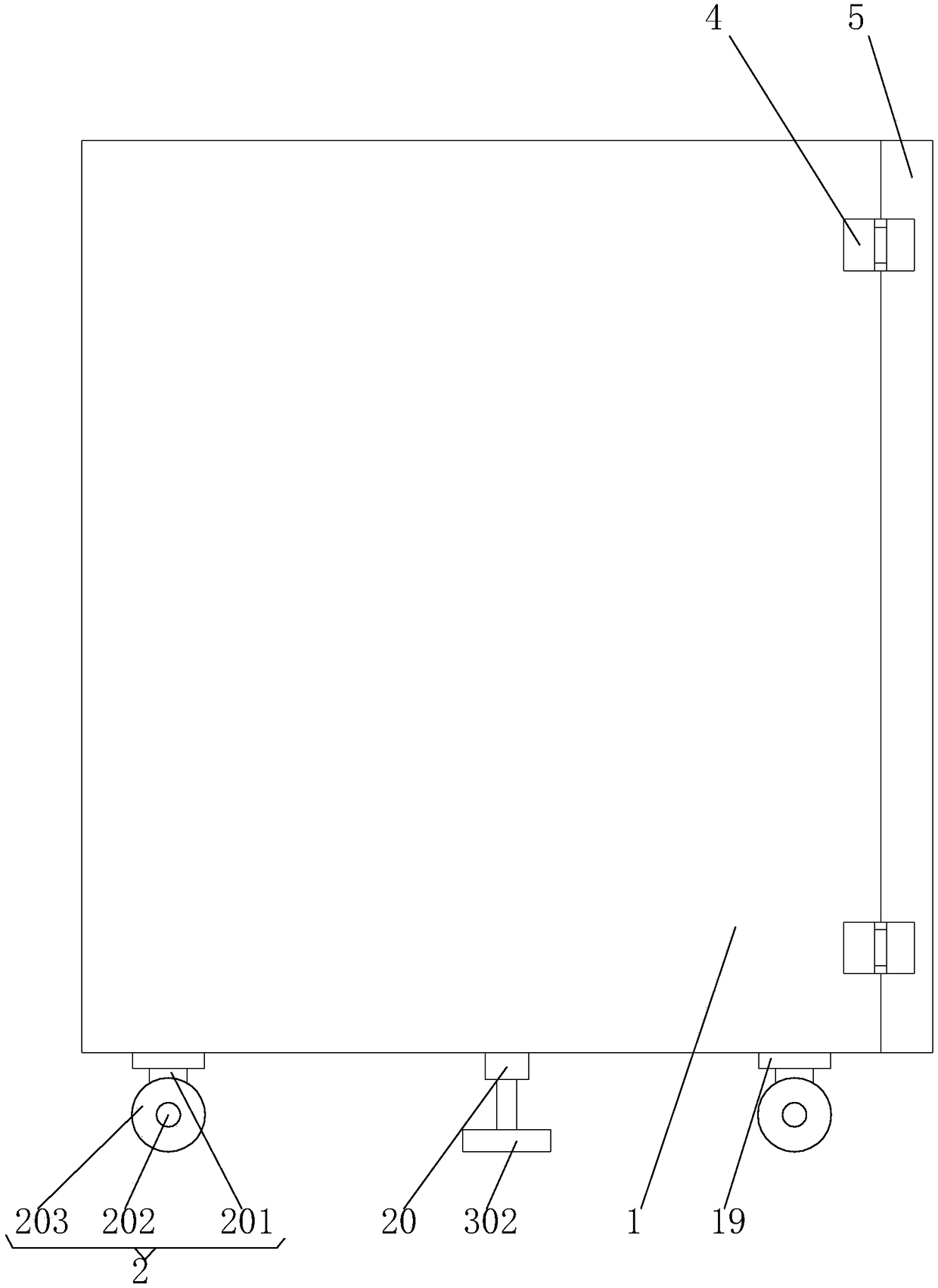

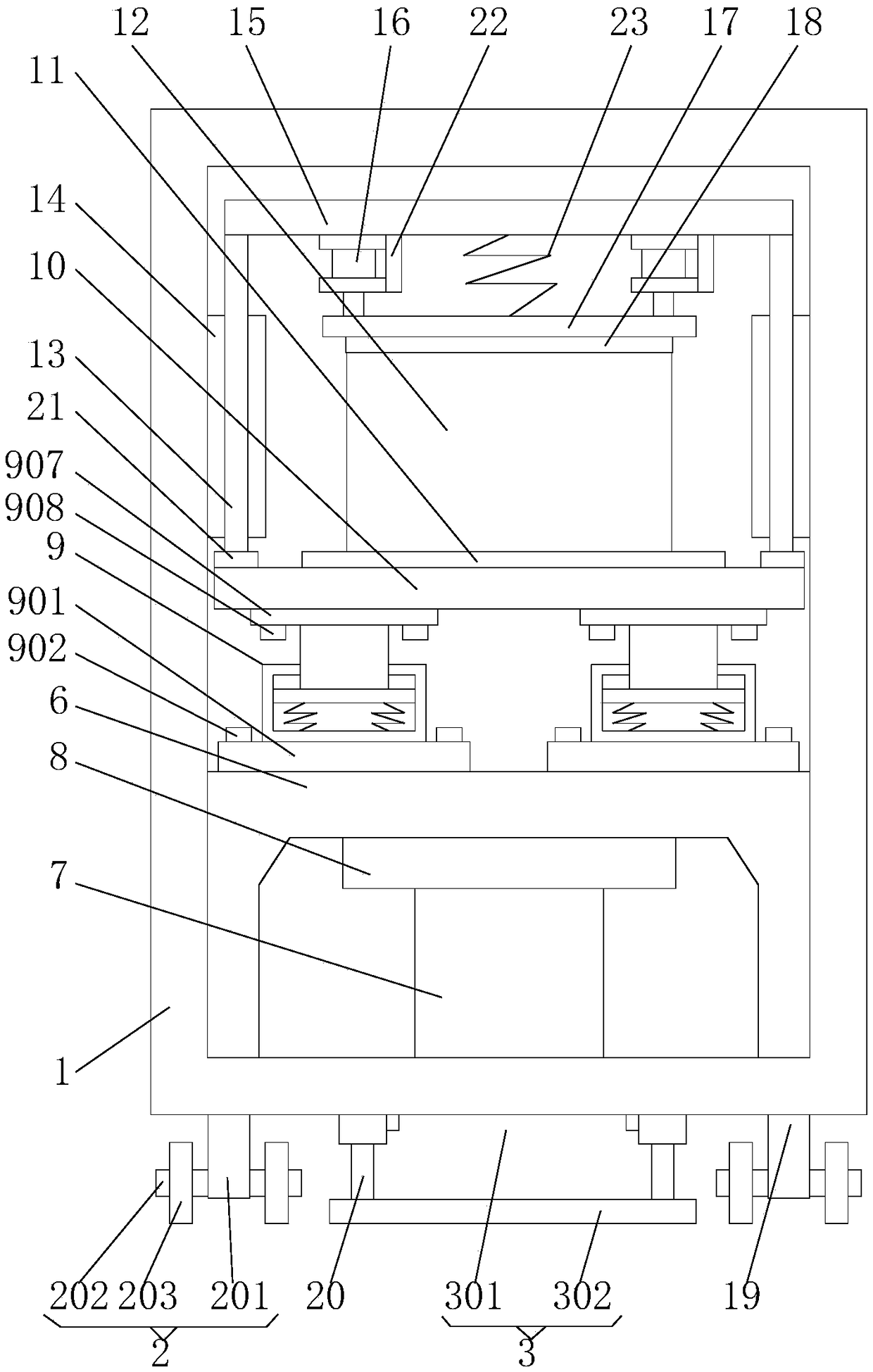

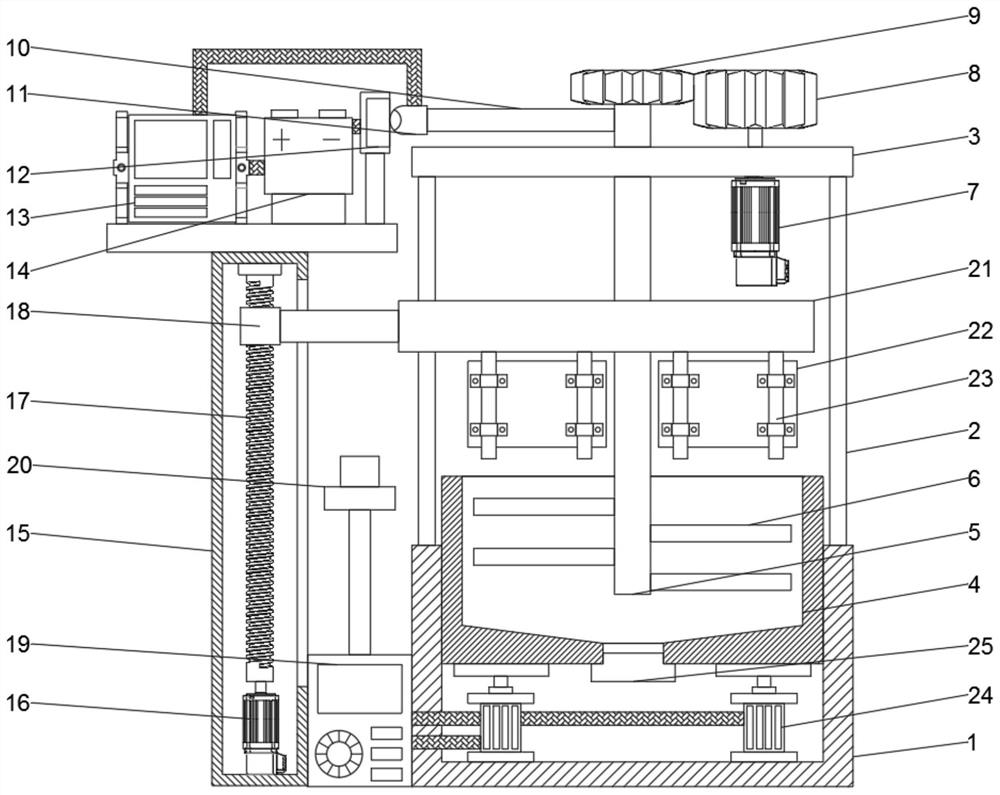

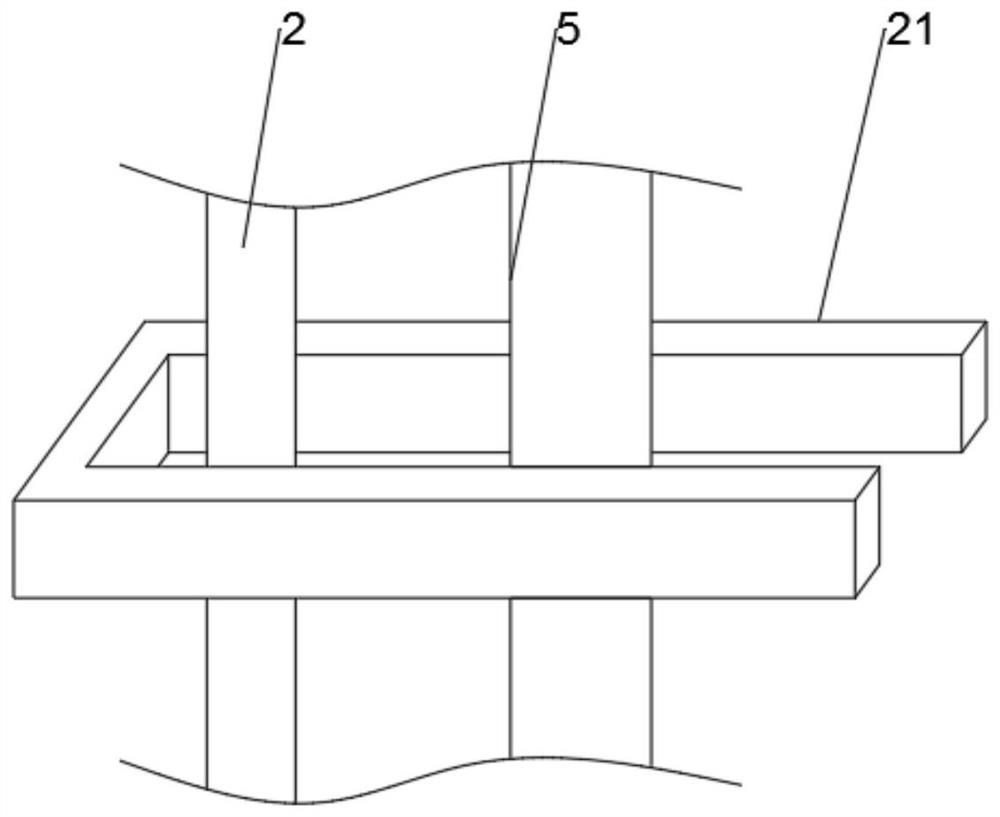

Building sand screening device

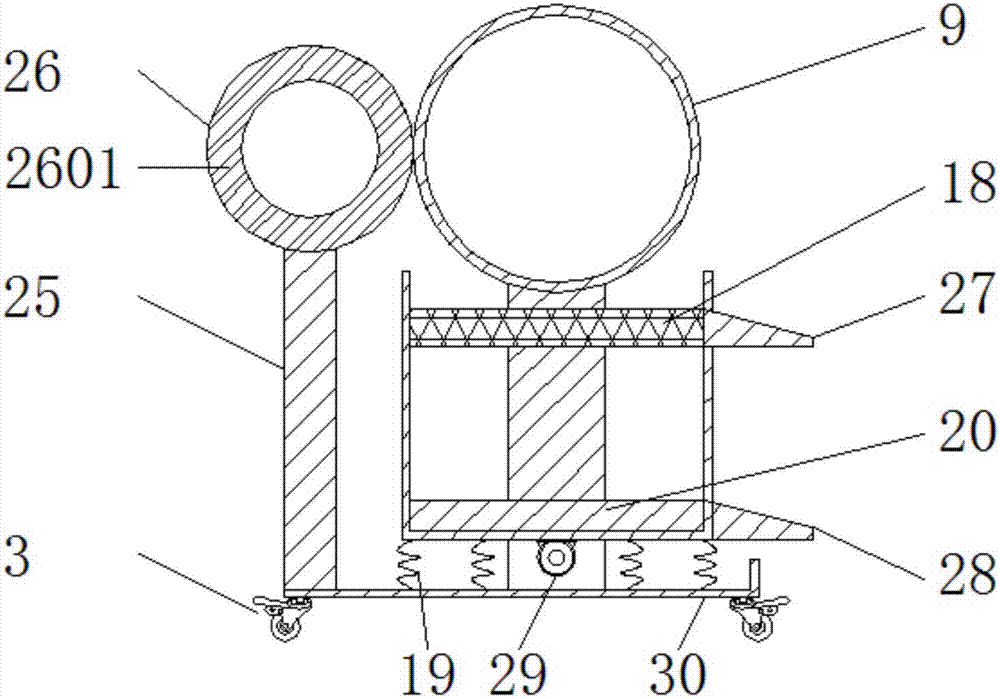

ActiveCN111701852AEasy to moveQuick filterSievingScreeningArchitectural engineeringStructural engineering

The invention belongs to the technical field of building processing equipment, and particularly relates to a building sand screening device. The technical problem is how to provide the building sand screening device which is convenient to move and realizes rapid screening. The building sand screening device comprises a trolley frame, guide columns, a dropping hopper, an up-down vibrating mechanism, a screening frame, insertion sleeves, insertion rods and a swing mechanism, wherein the four guide columns are arranged at the top of the trolley frame and combined into a rectangle, the dropping hopper is arranged at the tops of the four guide columns, the up-down vibrating mechanism is arranged on the four guide columns, the screening frame is arranged on the up-down vibrating mechanism and located over the dropping hopper, the insertion sleeves are symmetrically arranged on one side wall of the screening frame, the insertion rods are arranged in the insertion sleeves in an inserted manner, and the up-down vibrating mechanism is provided with the swing mechanism for shaking the screening frame horizontally. The building sand screening device achieves the effects of being convenient tomove and realizing rapid screening.

Owner:廖秀红

Gravel screening machine on construction site

InactiveCN107583857AAvoid cloggingImprove screening efficiencySievingScreeningEngineeringMechanical engineering

The invention discloses a gravel screening machine on construction site. The gravel screening machine comprises a feeding port, baffles, a vibration motor, a water pipe, a first discharging port and asecond discharging port, wherein the feeding port is formed in the left end of a first sieve; the baffles are welded at the two ends of a second sieve; the vibration motor is arranged on the outer side of a connecting plate; the water pipe is arranged above a support rod; a base plate is arranged above the base through a spring; the first discharging port is formed at the right end of the first sieve; gears are arranged at the two ends of the first sieve; the second discharging port is formed on the front side of the second sieve. In the gravel screening machine on construction site, the water pipe is arranged above the first sieve and a water jetting port is formed on the water pipe, so that the function of humidifying the gravel in the first sieve can be achieved and the surrounding environment can be prevented from being polluted by the dust in the gravel, and meanwhile, the water jetting port is capable of washing the gravel on the first sieve and preventing the first sieve from being plugged by the gravel and is beneficial to the increasing of the screening efficiency of the screening machine.

Owner:徐爱华

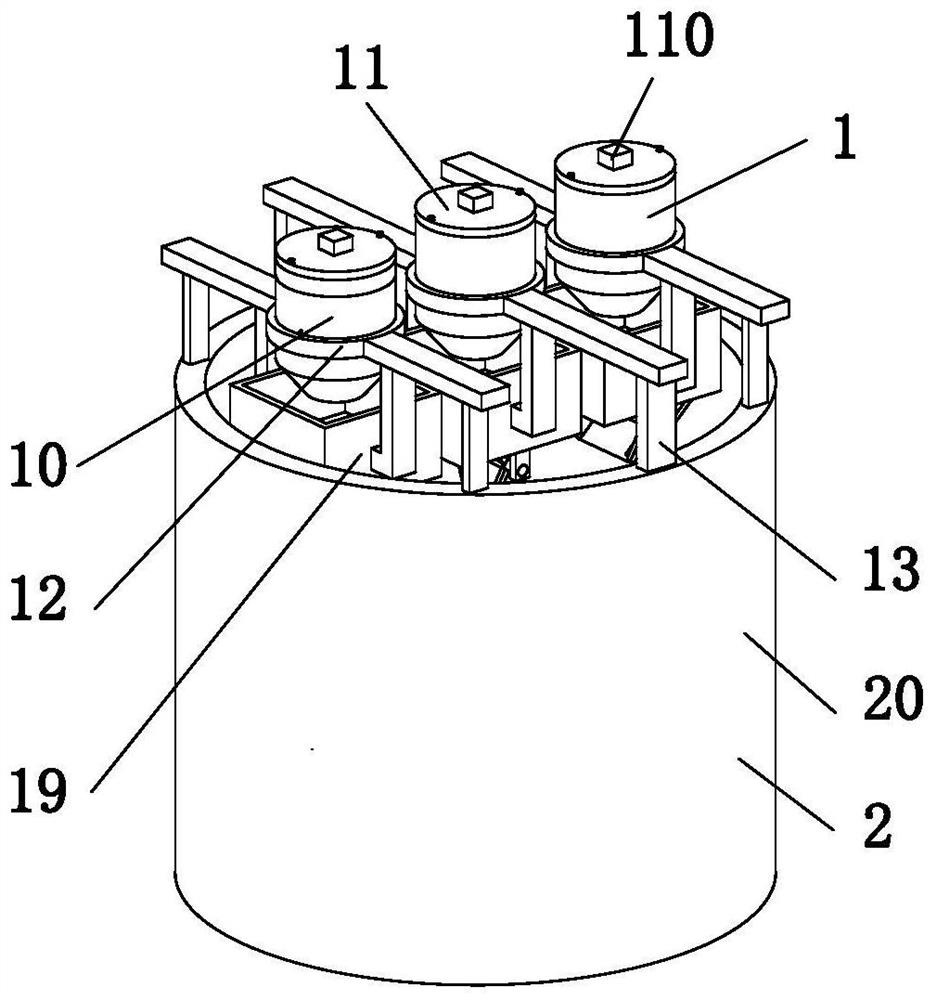

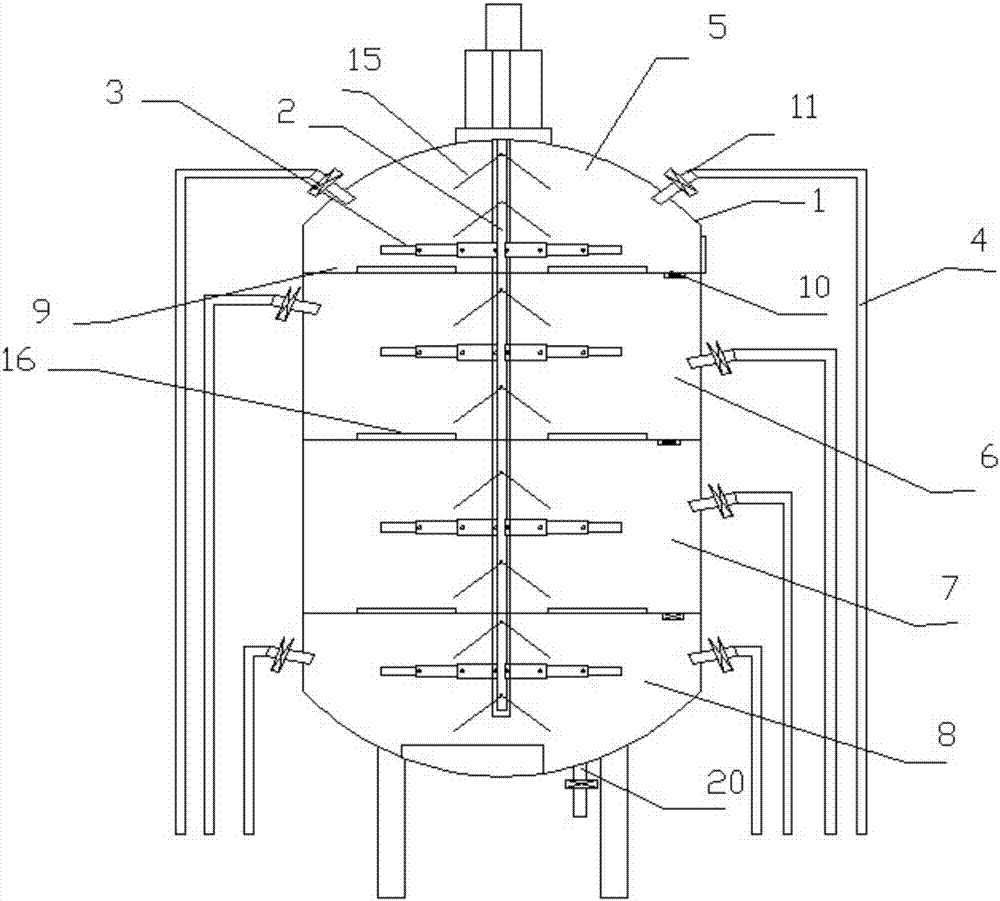

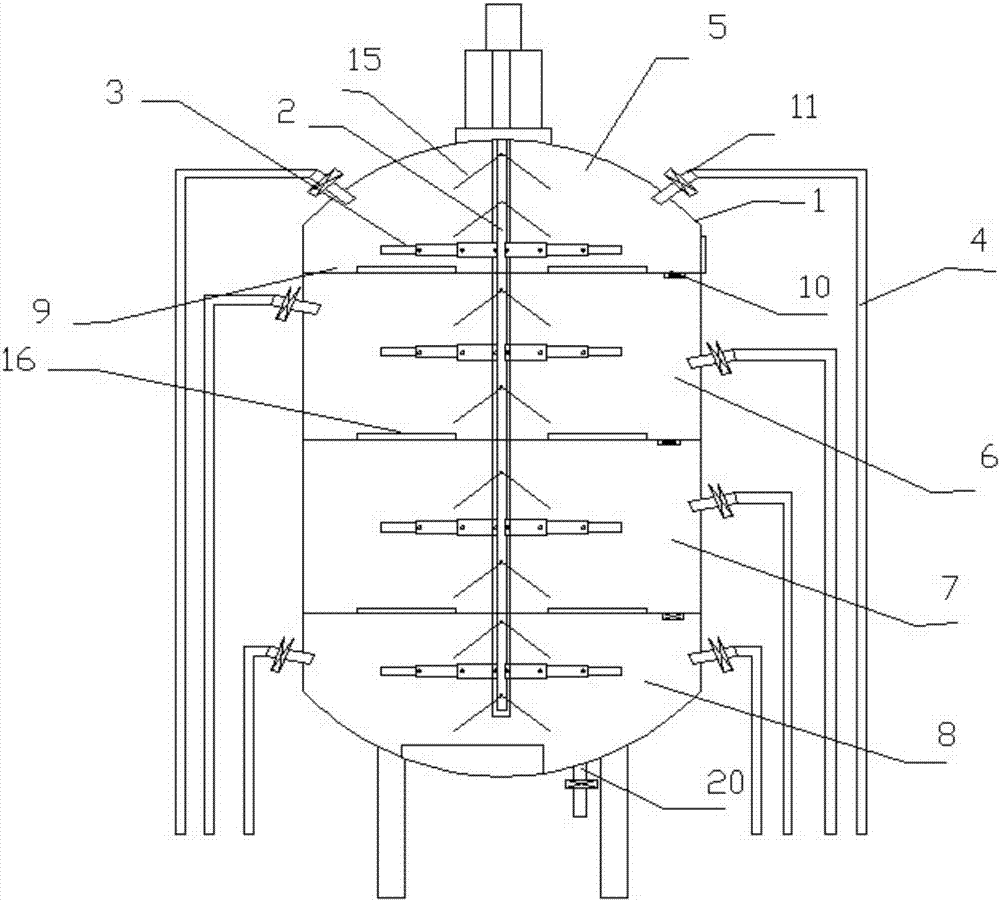

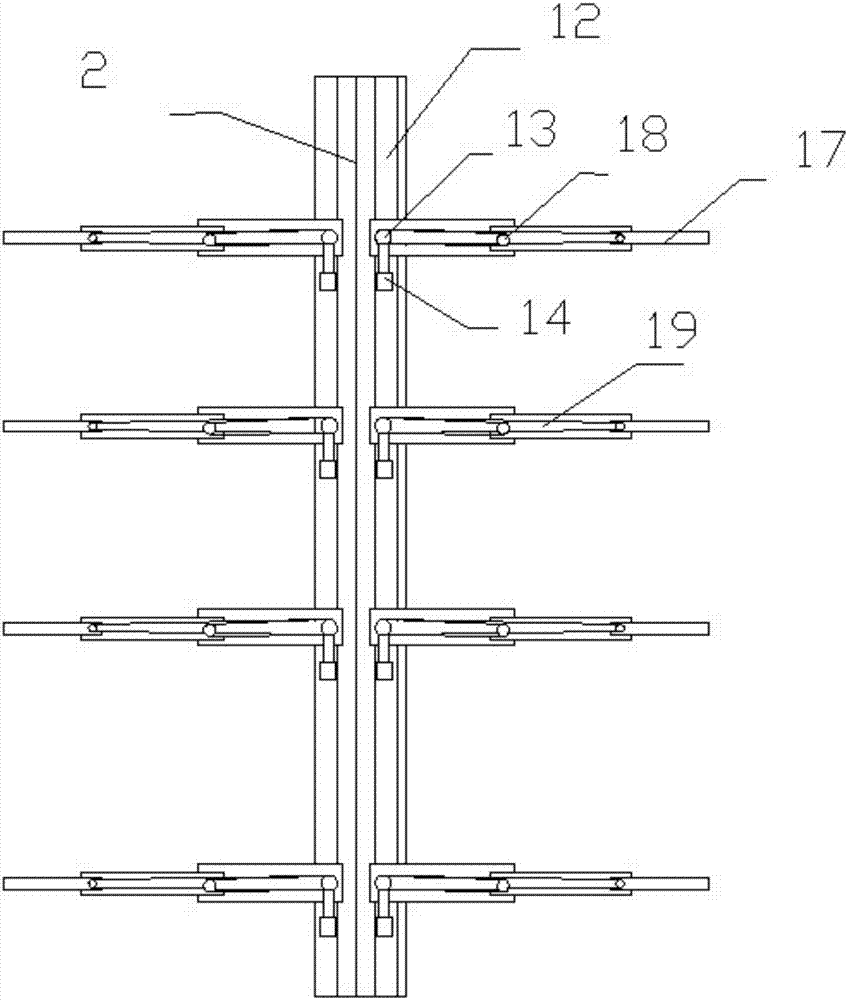

Automatic feeding reaction kettle for producing liquid barium-zinc heat stabilizer

PendingCN107252669AIncrease productivityImprove feeding efficiencyChemical/physical/physico-chemical stationary reactorsFeed devicesEngineeringZinc

The invention discloses an automatic feeding reaction kettle for producing a liquid barium-zinc heat stabilizer. The automatic feeding reaction kettle comprises a shell and a mixing device, wherein the mixing device comprises a mixing shaft and a blade; the blade is fixedly arranged on the mixing shaft; the mixing shaft extends into the shell; the shell is divided into four layers, which are a top layer, an upper middle layer, a lower middle layer and a bottom layer separately; the mixing shaft penetrates through the top layer, the upper middle layer, the lower middle layer and the bottom layer; a feeding hole is formed in each layer; the feeding holes are connected with delivery pipes; the delivery pipe connected with the feeding hole in the top layer is connected with a water suction pump; one end of the delivery pipes connected with the feeding hole in the upper middle layer is connected with the water suction pump and the other one is connected with a blast blower; the delivery pipe connected with the feeding hole in the lower middle layer is connected with the blast blower; the delivery pipe connected with the feeding hole in the bottom layer is connected with the blast blower. The automatic feeding reaction kettle for producing the liquid barium-zinc heat stabilizer is capable of automatically feeding, and is simple in feeding, time-saving and labor-saving, and the production efficiency is improved.

Owner:德清县东来化学有限公司

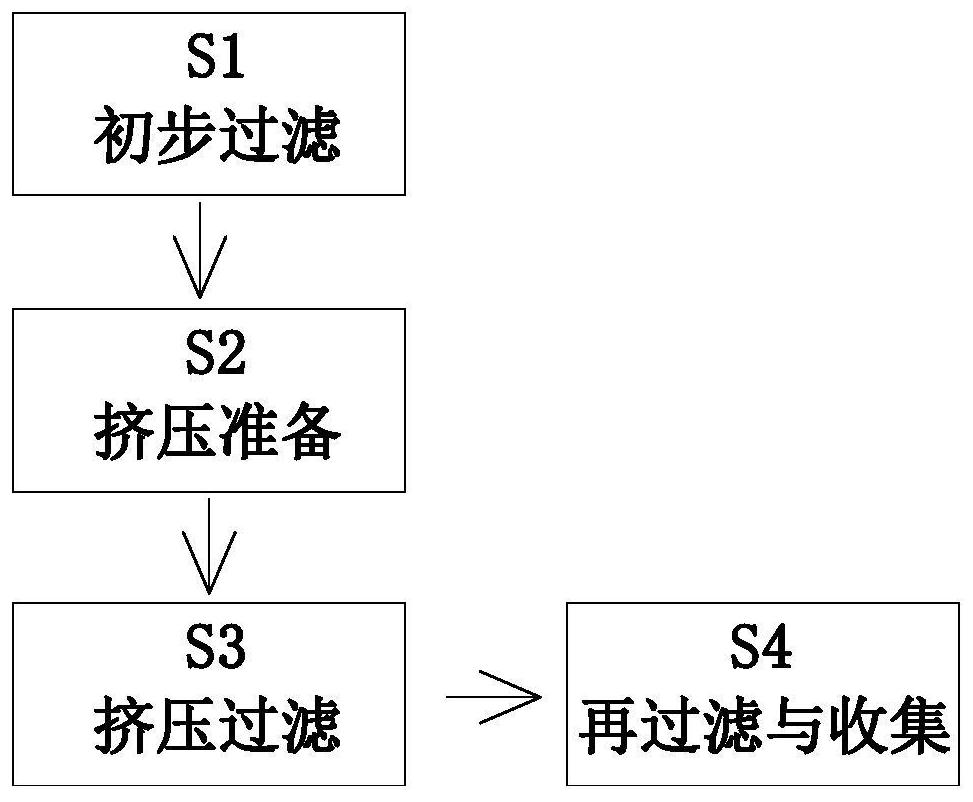

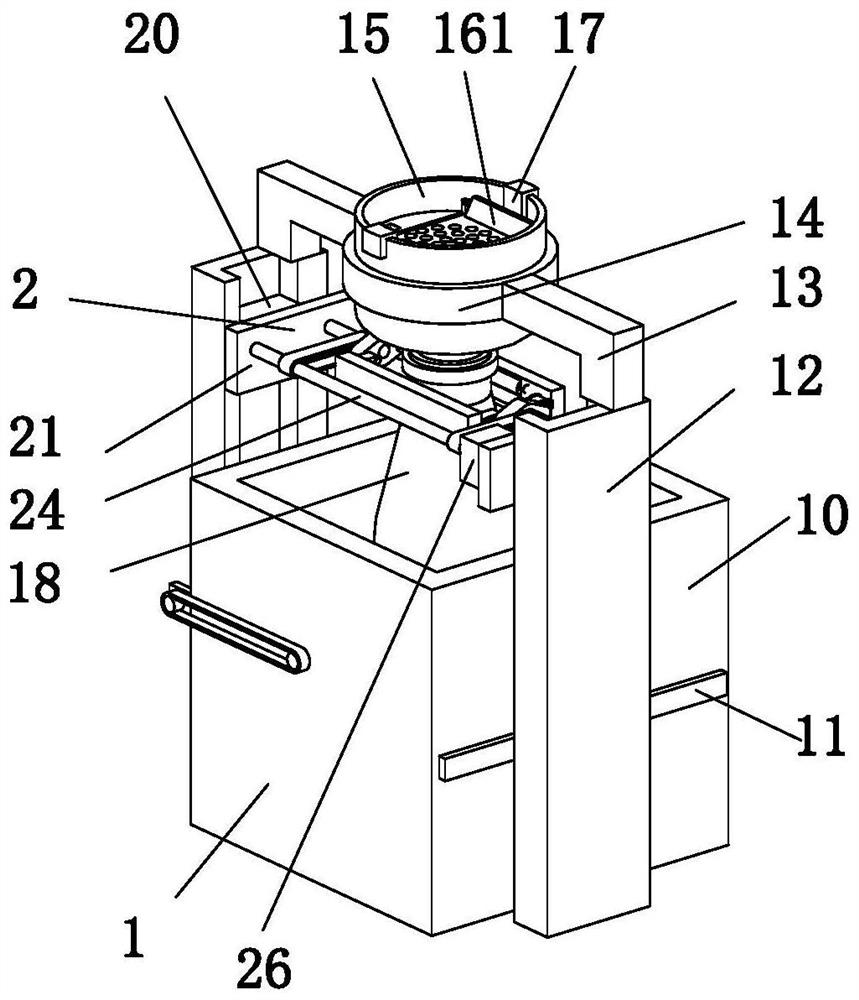

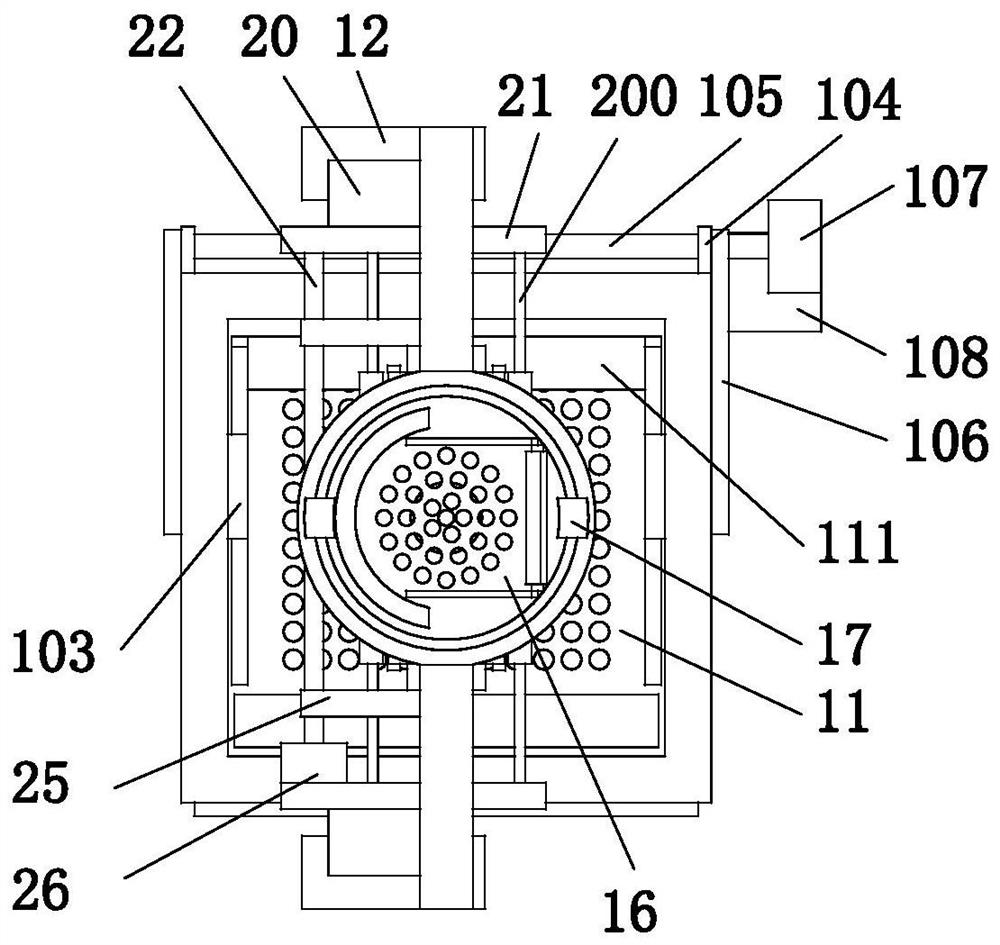

Collected rubber raw material preprocessing method

ActiveCN111823442AIncrease the degree of filtrationImprove the fineness of filtrationProcess engineeringIndustrial engineering

The invention relates to a collected rubber raw material preprocessing method. A collected rubber raw material preprocessing device is used by the collected rubber raw material preprocessing method. The collected rubber raw material preprocessing device comprises a collecting and filtering mechanism and an extrusion mechanism. The lower end of the collecting and filtering mechanism is installed onthe existing working ground in a sliding fit mode, and the extrusion mechanism is arranged at the upper end of the collecting and filtering mechanism. According to the collected rubber raw material preprocessing method, the design concept of the combination of multiple filtering structures is adopted to preprocess collected rubber raw materials, the filtering degrees of the arranged multiple filtering structures are improved in sequence, and then the whole filtering degree of the rubber raw materials is greatly improved. Meanwhile, the extrusion mechanism can fulfill the function that the airand the rubber raw materials are extruded to generate the pressure so as to conduct secondary filtering operation on the rubber raw materials, and the filtering refinement degree of the rubber raw materials can be greatly improved by the function.

Owner:日照宏达橡胶股份有限公司

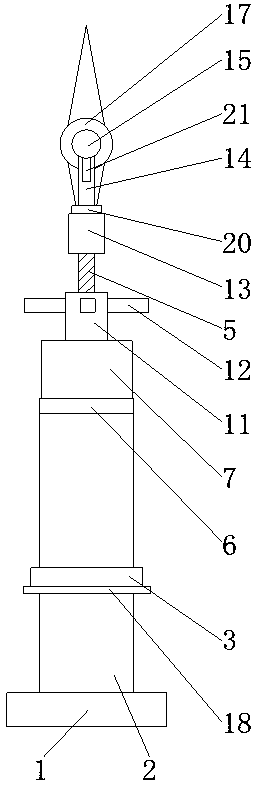

Single-column type offshore power generation device

ActiveCN108953042AAvoid obstructionGuaranteed uptimeBatteries circuit arrangementsWind motor supports/mountsWind forceSlide plate

The invention discloses a single-column type offshore power generation device. The single-column type offshore power generation device comprises a foundation block, wherein sliding plates are fixedlyconnected to the left side and the right side of the top of the foundation block, sliding sleeves are movably connected to the surfaces of the sliding plates, the two sliding sleeves are fixedly connected through a fixing plate, a threaded rod is fixedly connected to the middle point of the top of the fixing plate, and the tops of the two sliding plates are fixedly connected through a placing plate. According to the single-column type offshore power generation device, the sliding plates, the sliding sleeves, the fixing plate, the threaded rod, the placing plate, a connecting base, a sliding block, balls, a fastening bolt, a threaded sleeve, a rotating handle and a fixing sleeve are arranged to be matched with a supporting column, so that the height of the single-column type marine power generation device can be adjusted, the height can be adjusted in time according to the water level of the seawater, the obstruction of the water level to a fan blade is avoided, and therefore normal operation of the single-column type offshore wind power generation is guaranteed.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

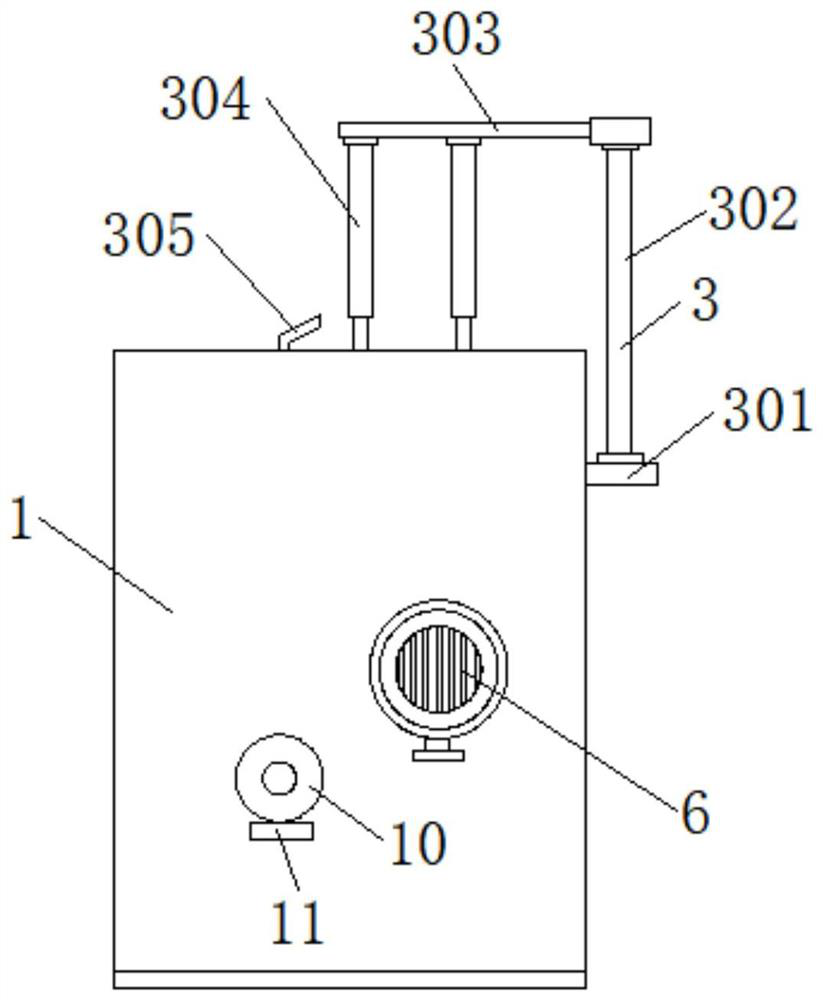

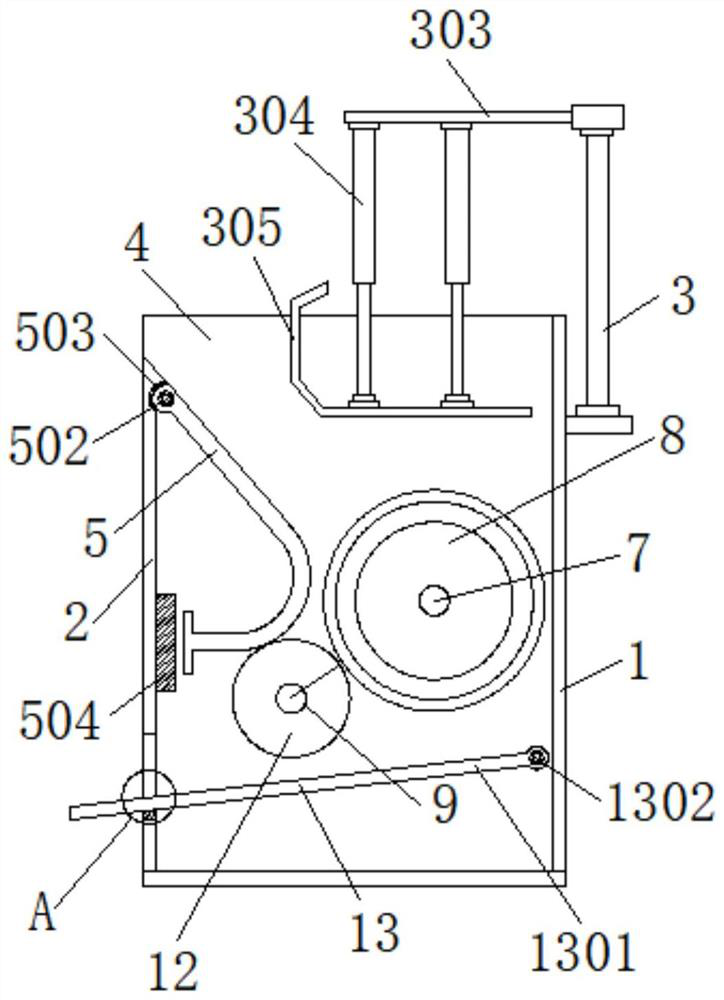

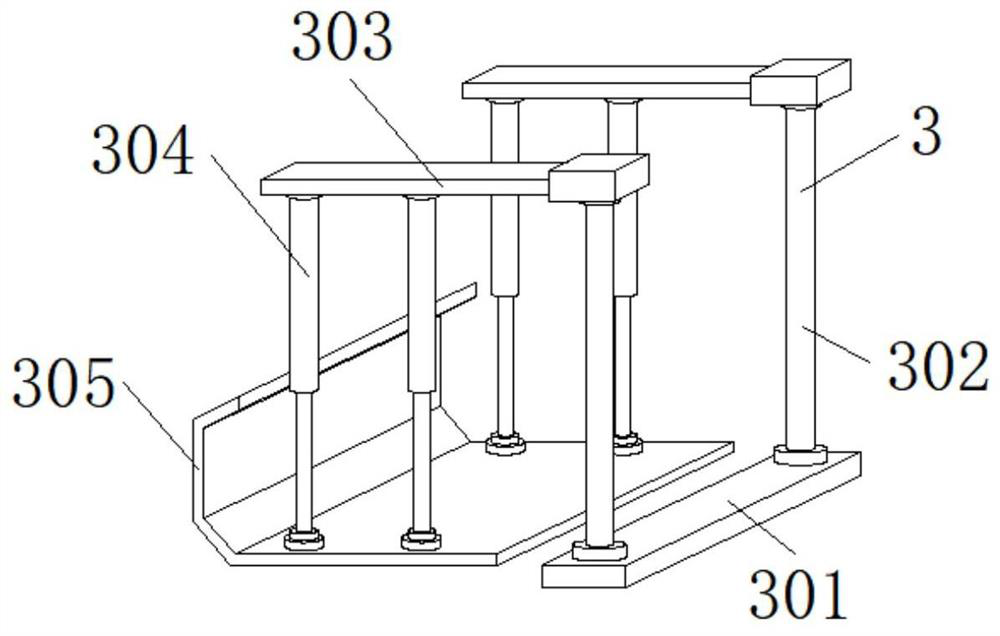

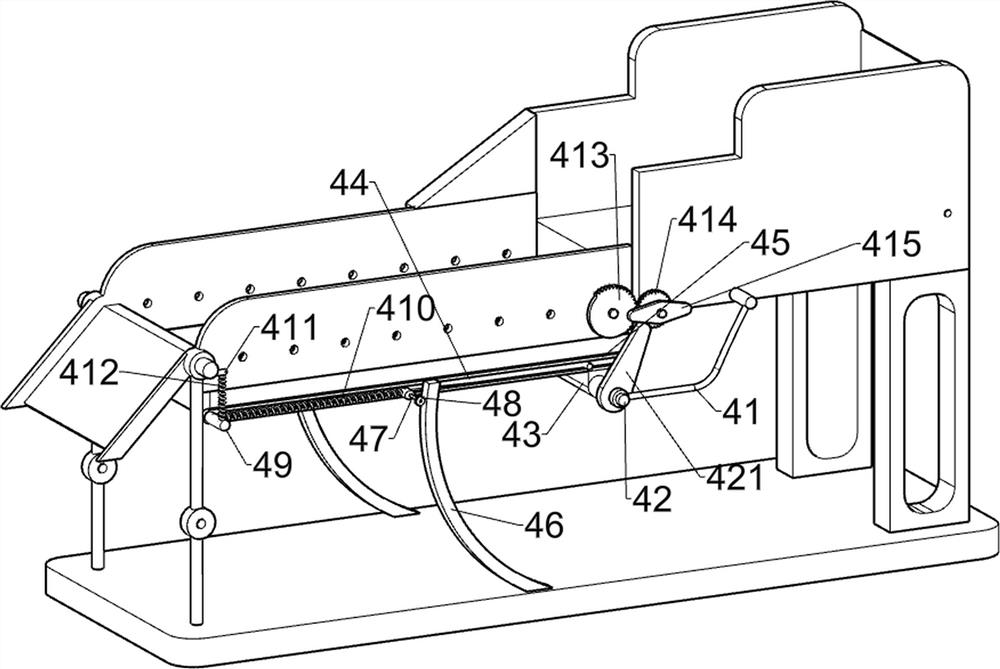

Sewage treatment equipment for automobile cleaning and using method thereof

InactiveCN112174365AGuaranteed not to pile upTo vibrateSpecific water treatment objectivesTreatment involving filtrationActivated carbon filtrationElectric machinery

The invention discloses sewage treatment equipment for automobile cleaning and a using method thereof. The sewage treatment equipment comprises a box body and supporting legs, wherein the box body comprises a disinfection chamber, a purification chamber and a separation chamber, supporting rods are fixed to the two ends of the lower portion of the box body, springs are arranged in the supporting legs, a motor base a is installed at the bottom of the box body, a motor a is fixed to the motor base a, the output end of the motor a is connected with a stirring rod, a lantern ring is fixed to the stirring rod, stirring fan blades are installed on the lantern ring, a water outlet and a feeding port are formed in the disinfection chamber, drainage plates are arranged on the two sides of the purification chamber, an activated carbon filter screen is fixed between the drainage plates, a screw rod is fixed to the left side of the separation chamber, screw blades are arranged on the surface of the screw rod, the left side of the screw rod is connected with a motor b outside the box body, a spray head and a first water inlet are arranged at the upper end of the separation chamber, and the spray head is connected with a water outlet pipe. According to the invention, the separation of sewage and dirt is greatly accelerated, and the purification effect of the sewage is effectively improved.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

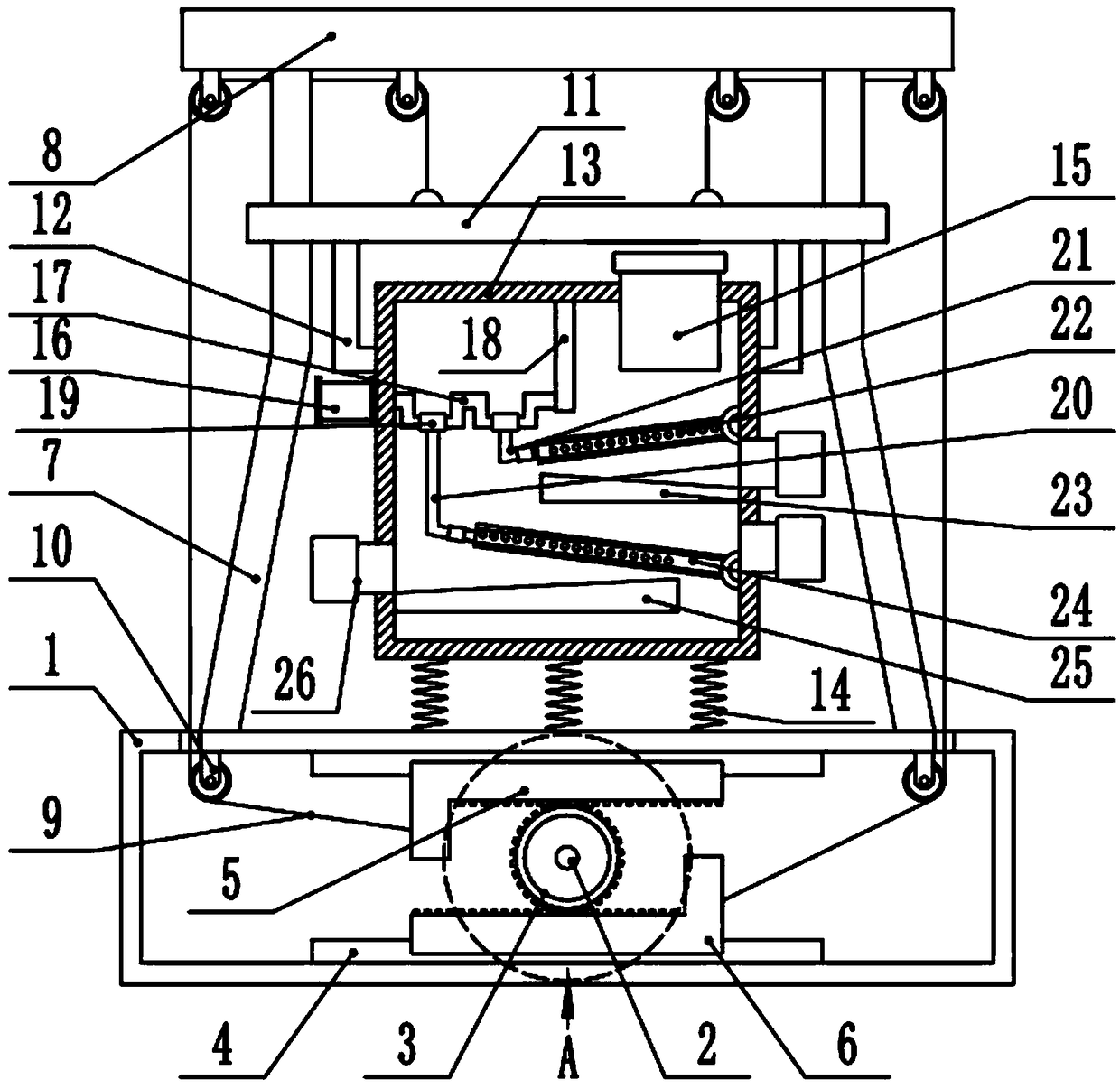

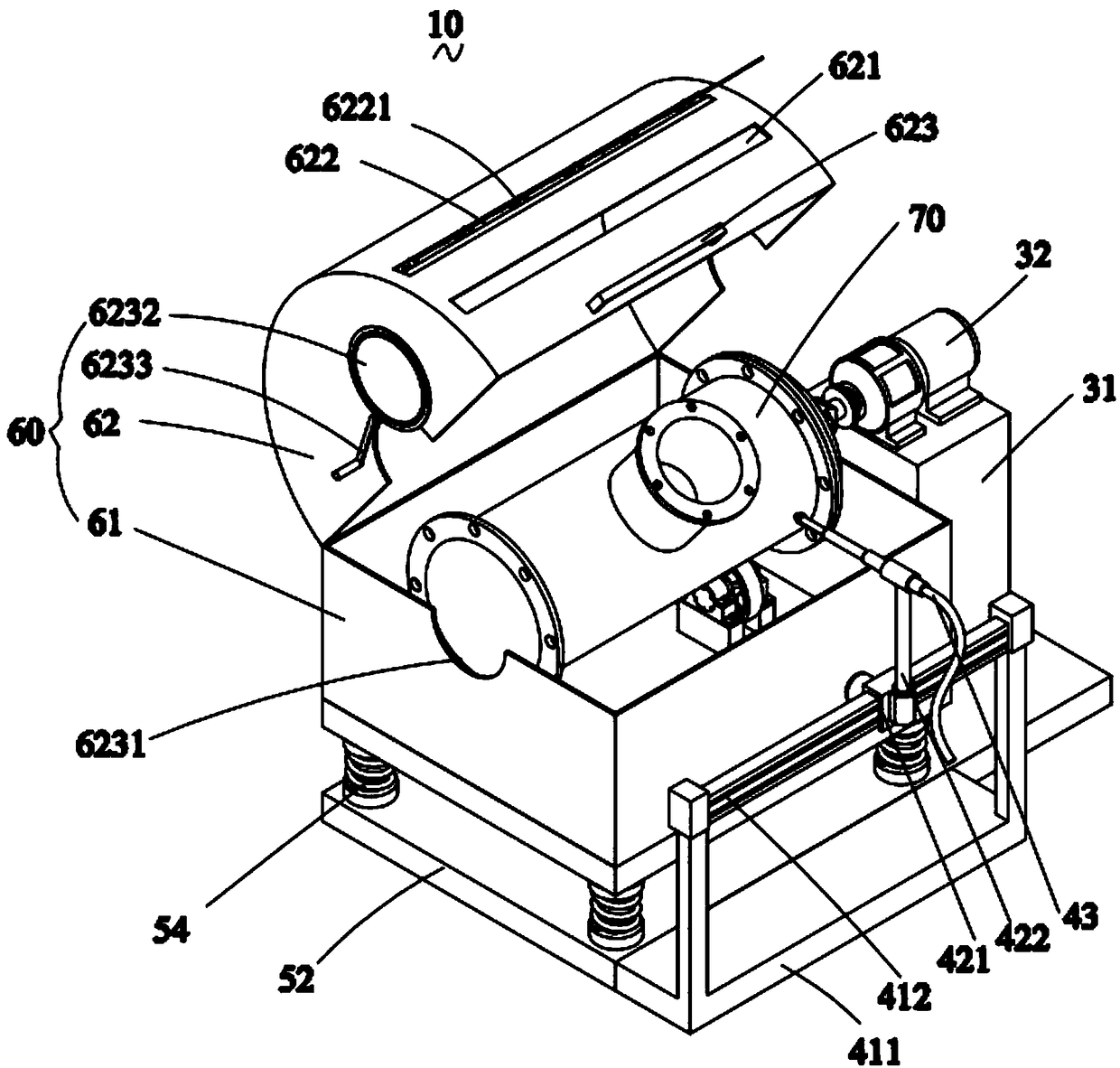

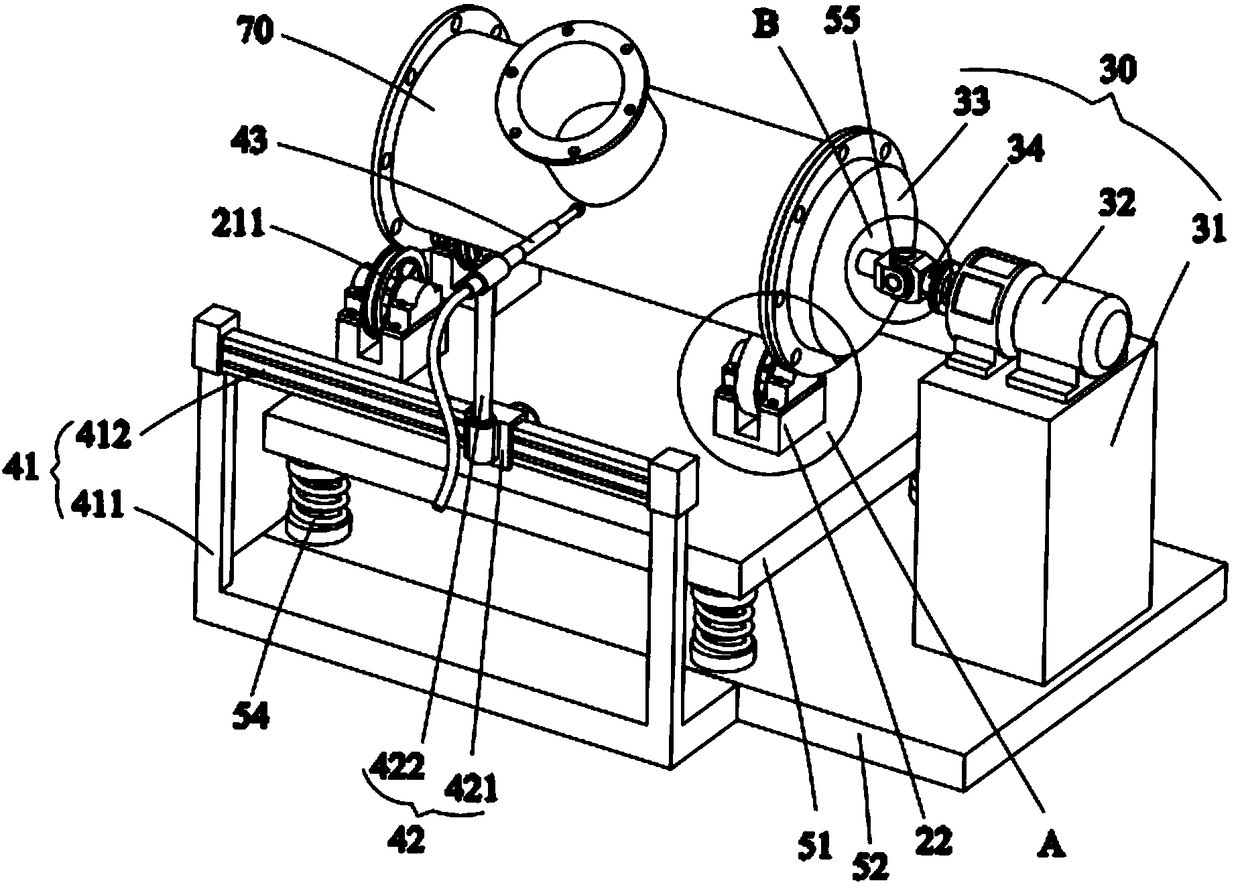

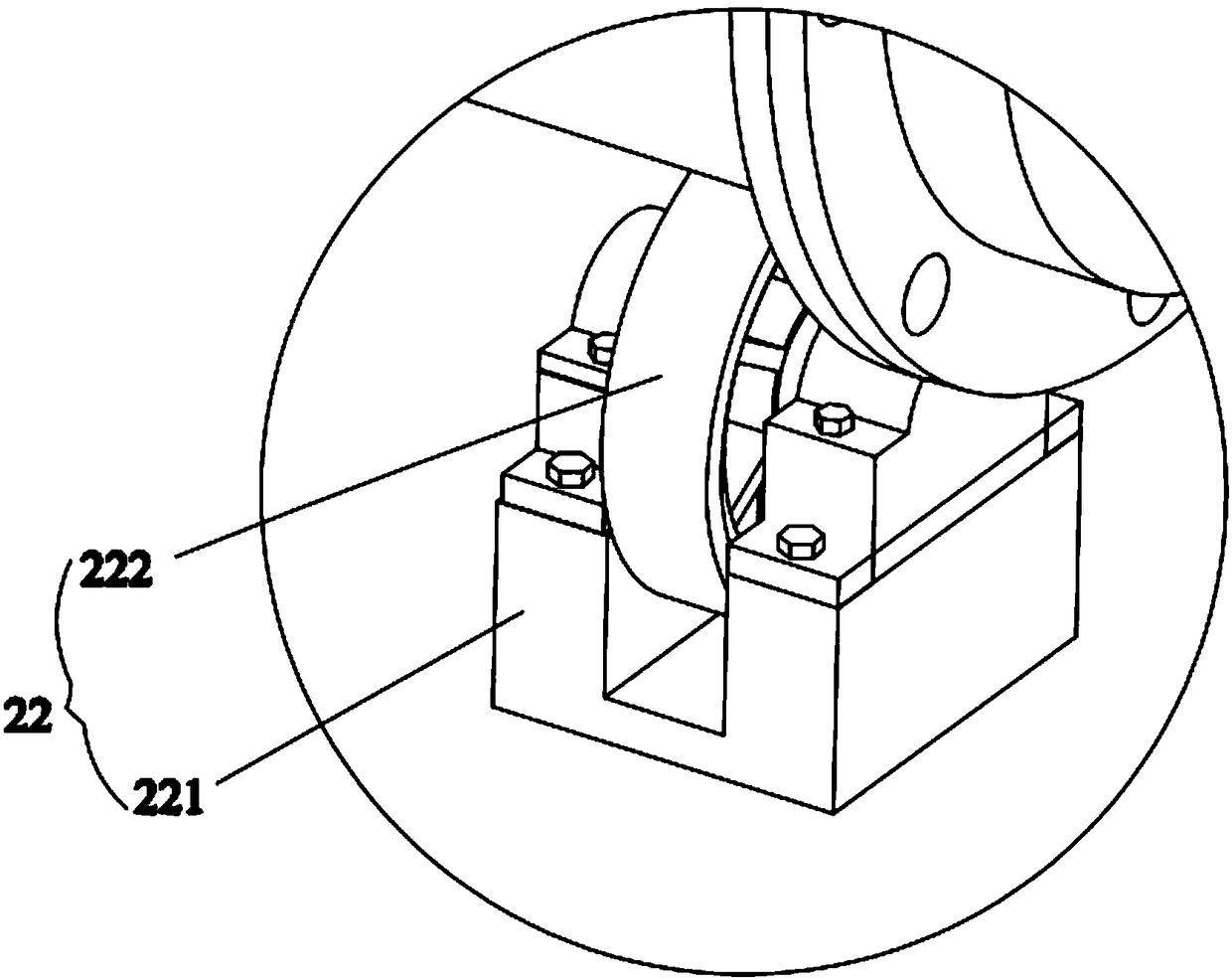

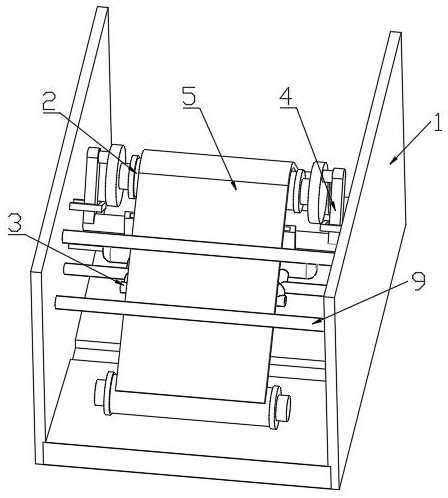

Centrifugal rotating E-shaped carbon steel piece lining plastic device provided with heat preservation cover

ActiveCN108499814AImprove corrosion resistanceImprove insulation performanceLiquid surface applicatorsCoatingsCarbon steelMaterials science

The invention relates to a centrifugal rotating E-shaped carbon steel piece lining plastic device provided with a heat preservation cover, and belongs to the technical field of workpiece processing. The device is provided with a supporting device, a driving device, a heating device, a vibrating device and a heat preservation device to plastic-line an E-shaped carbon steel piece so as to increase the corrosion resistance, insulation performance and the like of the E-shaped carbon steel piece. The supporting device is arranged at the bottom of the E-shaped carbon steel piece to support the E-shaped carbon steel piece; the driving device is arranged at one side of the E-shaped carbon steel piece to drive the E-shaped carbon steel piece to rotate centrifugally; the heating device is arranged near the outer side wall of the E-shaped carbon steel piece to heat the E-shaped carbon steel piece so as to melt polyethylene powder adhered and sprayed on the inner wall of the E-shaped carbon steelpiece to plastic-line the E-shaped carbon steel piece; the vibrating device is arranged at the bottom of the supporting device to vibrate the E-shaped carbon steel piece during the rotation of the E-shaped carbon steel piece to adhere polytetrafluoroethylene powder on the inner wall of the E-shaped carbon steel piece more firmly; and the heat preservation device is used for heat preservation of the E-shaped carbon steel piece so as to improve the plastic-lining efficiency.

Owner:宁夏金梯氟塑防腐设备有限公司

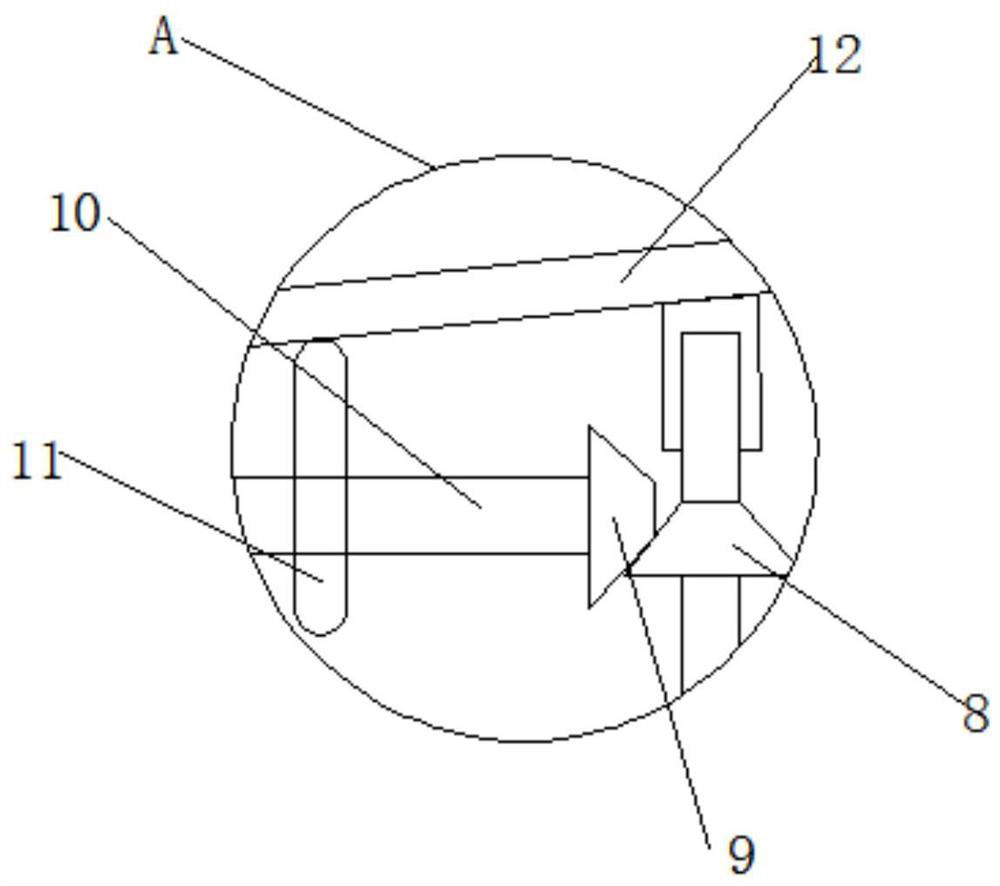

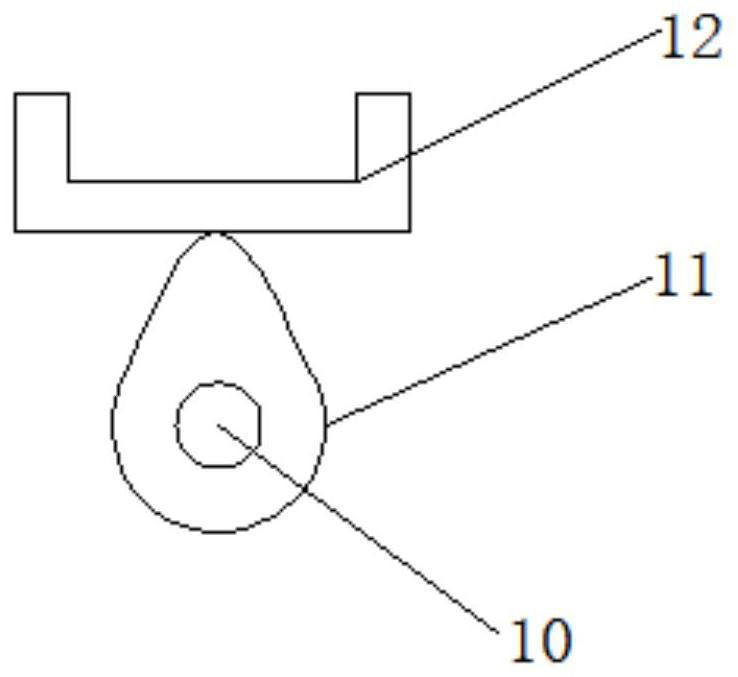

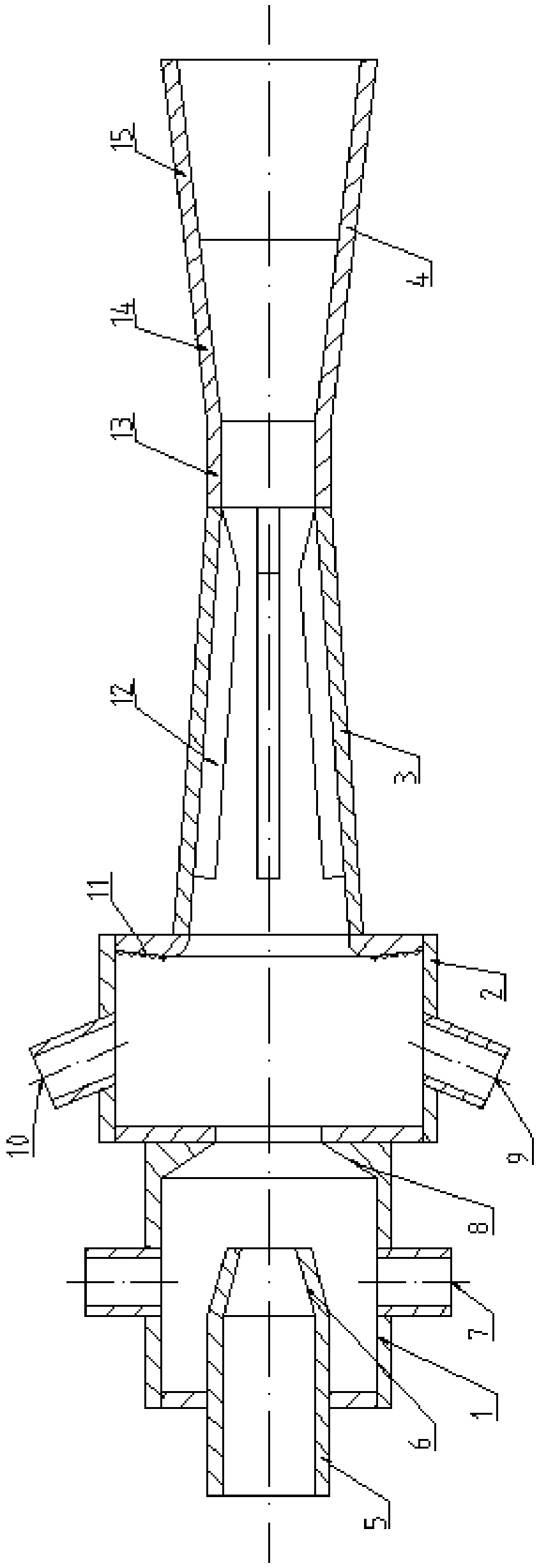

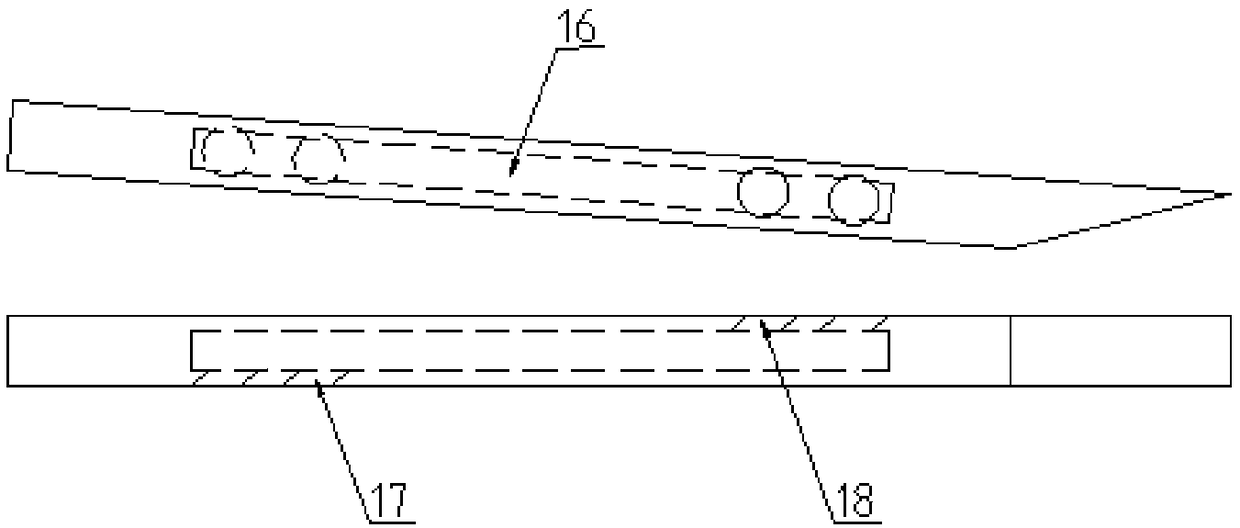

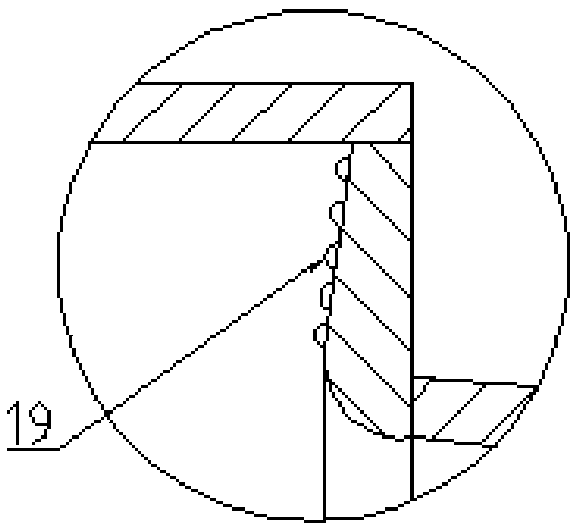

Gas-liquid mixing type jet injection device

PendingCN108970825AReduce shockReduces liquid build-up problemsLiquid spraying apparatusSustainable biological treatmentLiquid pressureEngineering

A gas-liquid mixing type jet injection device comprises a first mixing cavity (1), a second mixing cavity (2), a tapered shrinkage portion (3) and a diffusion portion (4) in sequentially adjacent connection. The first mixing cavity is peripherally provided with one or more gas suction inlets (7), and a water inlet (5) is positioned in the center of the first mixing cavity. The second mixing cavity(2) is peripherally provided with one or more treating fluid inlets (9) and a compressed gas inlet (10). The gas-liquid mixing type jet injection device is characterized in that a plurality of rectifying plates (12) are arranged on the inner peripheral wall of the tapered shrinkage portion (3) and internally provided with buffer cavities (16), and one side of each rectifying plate is provided with one or more inlet holes (17) while the other side is provided with one or more outlet holes (18). The gas-liquid mixing type jet injection device has advantages that problems of liquid impact and wall attachment of liquid in flow gathering of the tapered shrinkage portion can be reduced, design of the buffer cavities enables appropriate increasing of the pressure of liquid in a cavity of the tapered shrinkage portion during flow gathering, and a certain pressure increasing effect is achieved.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH +1

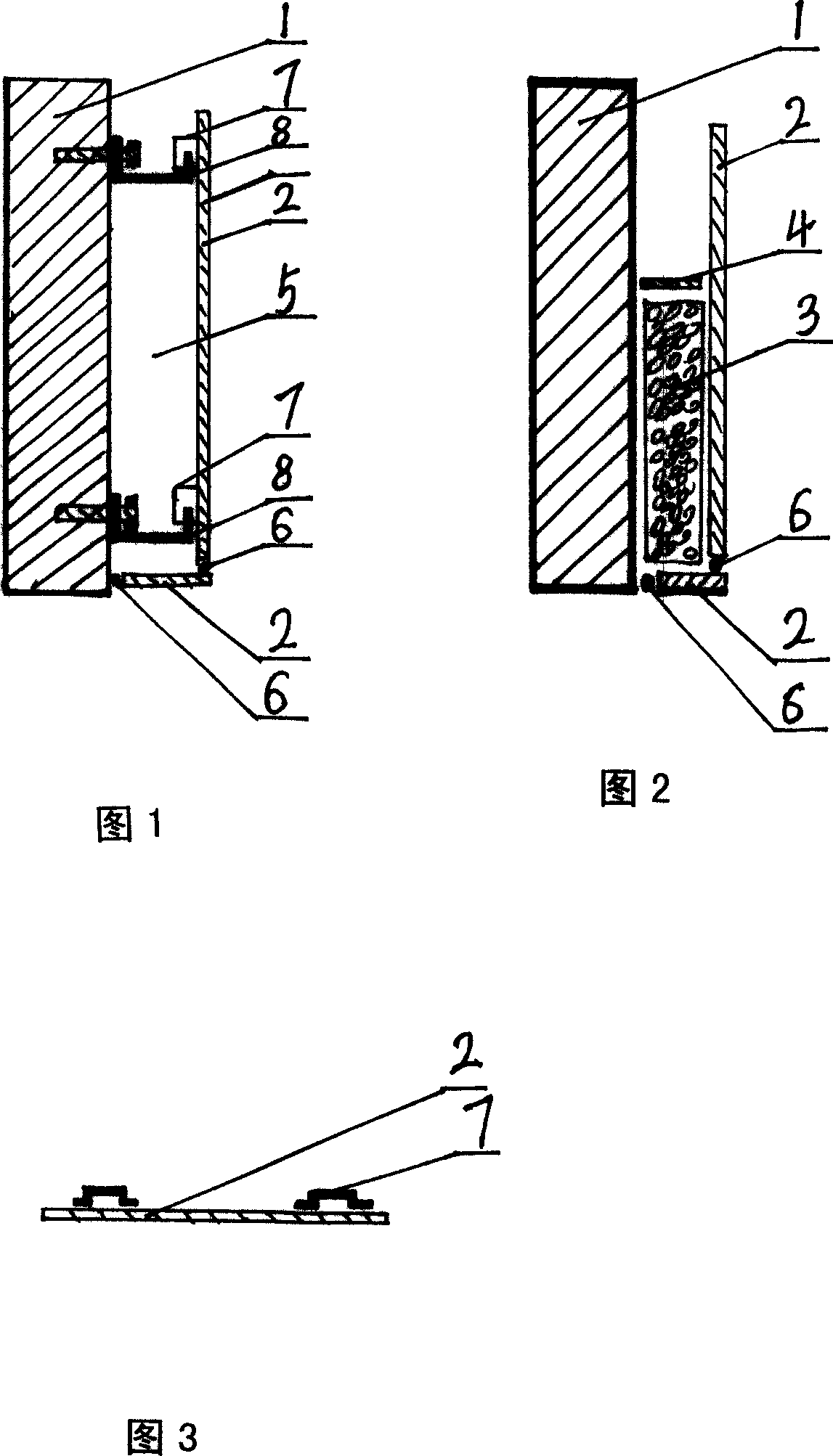

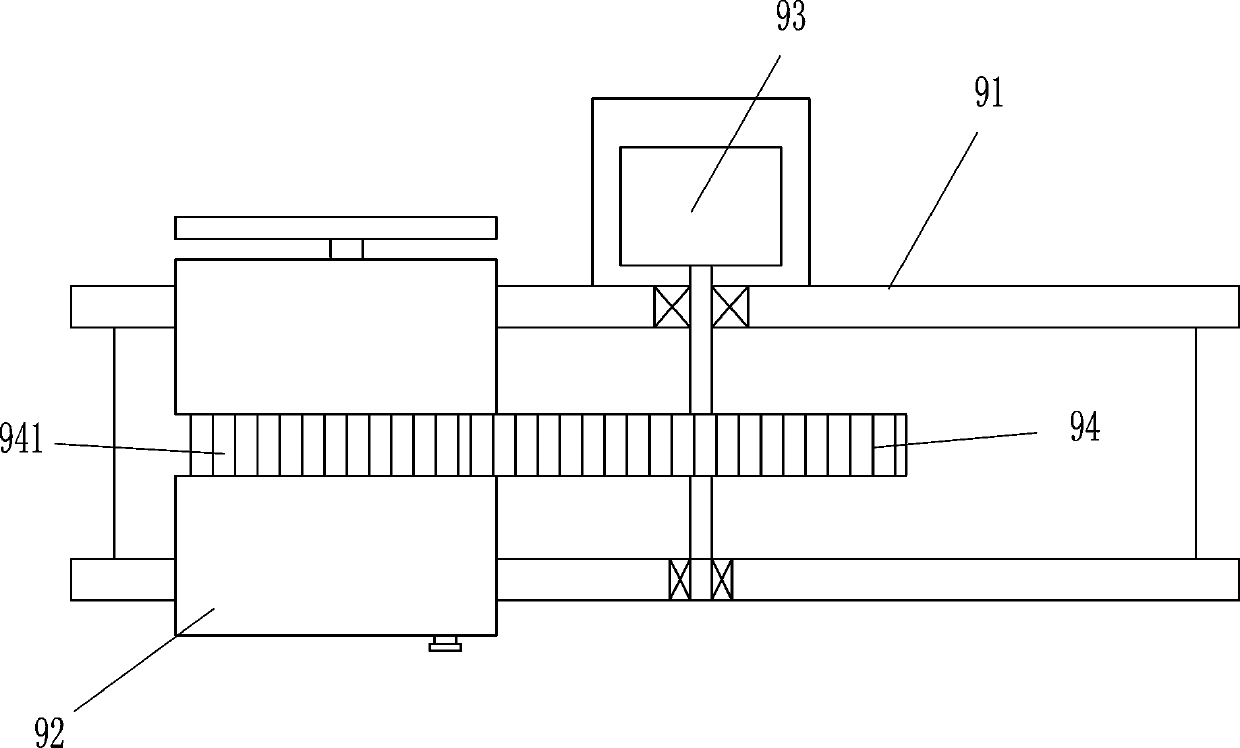

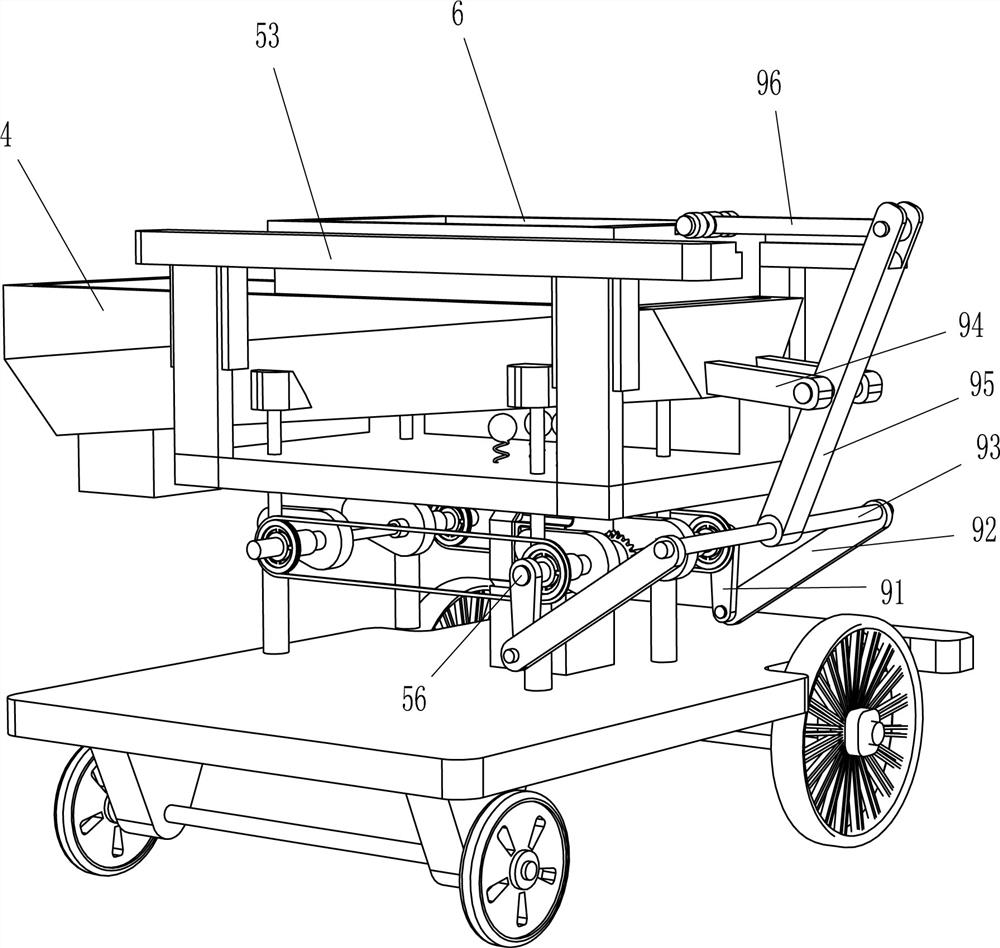

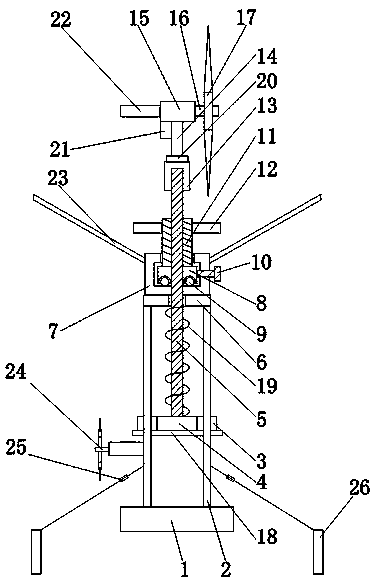

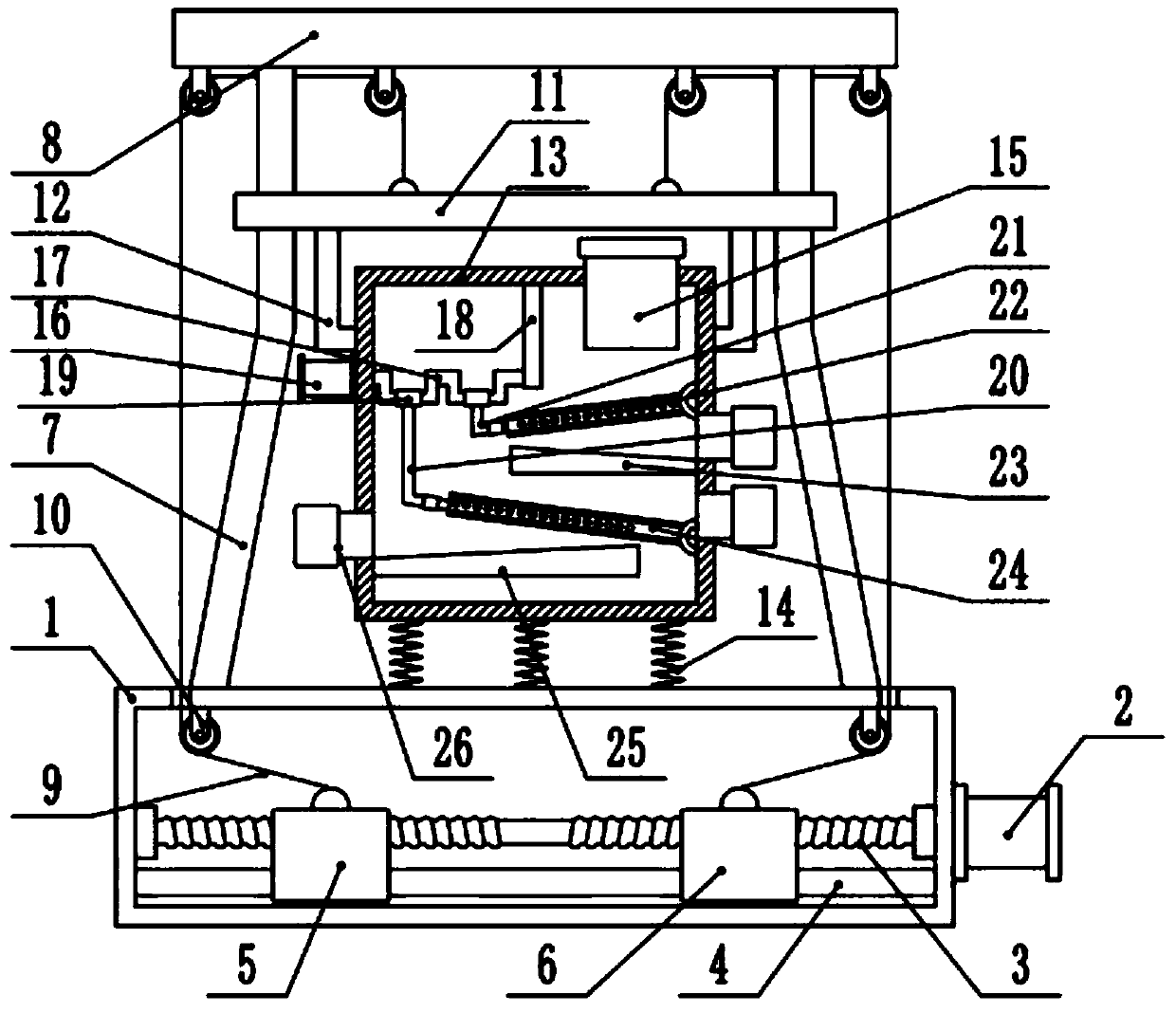

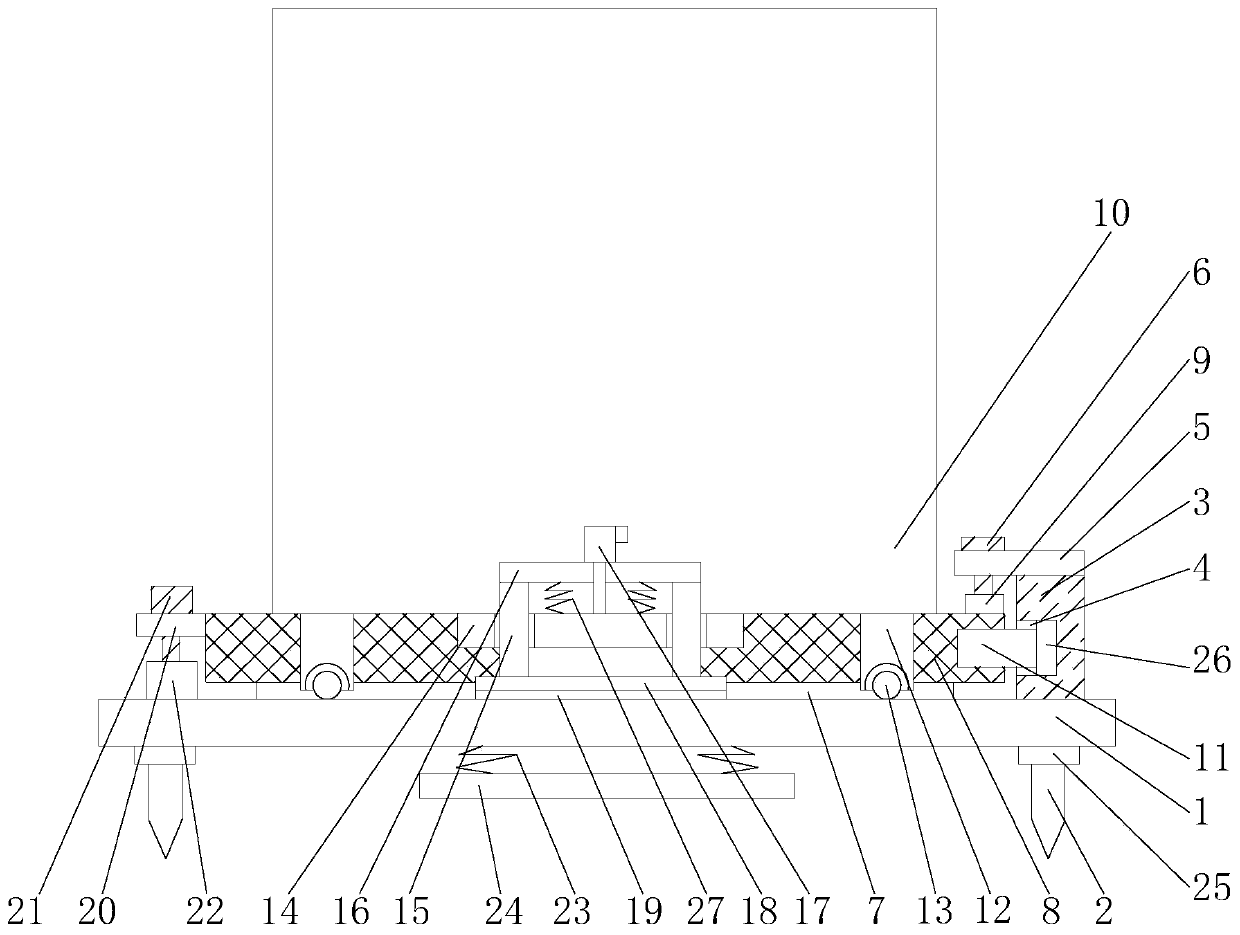

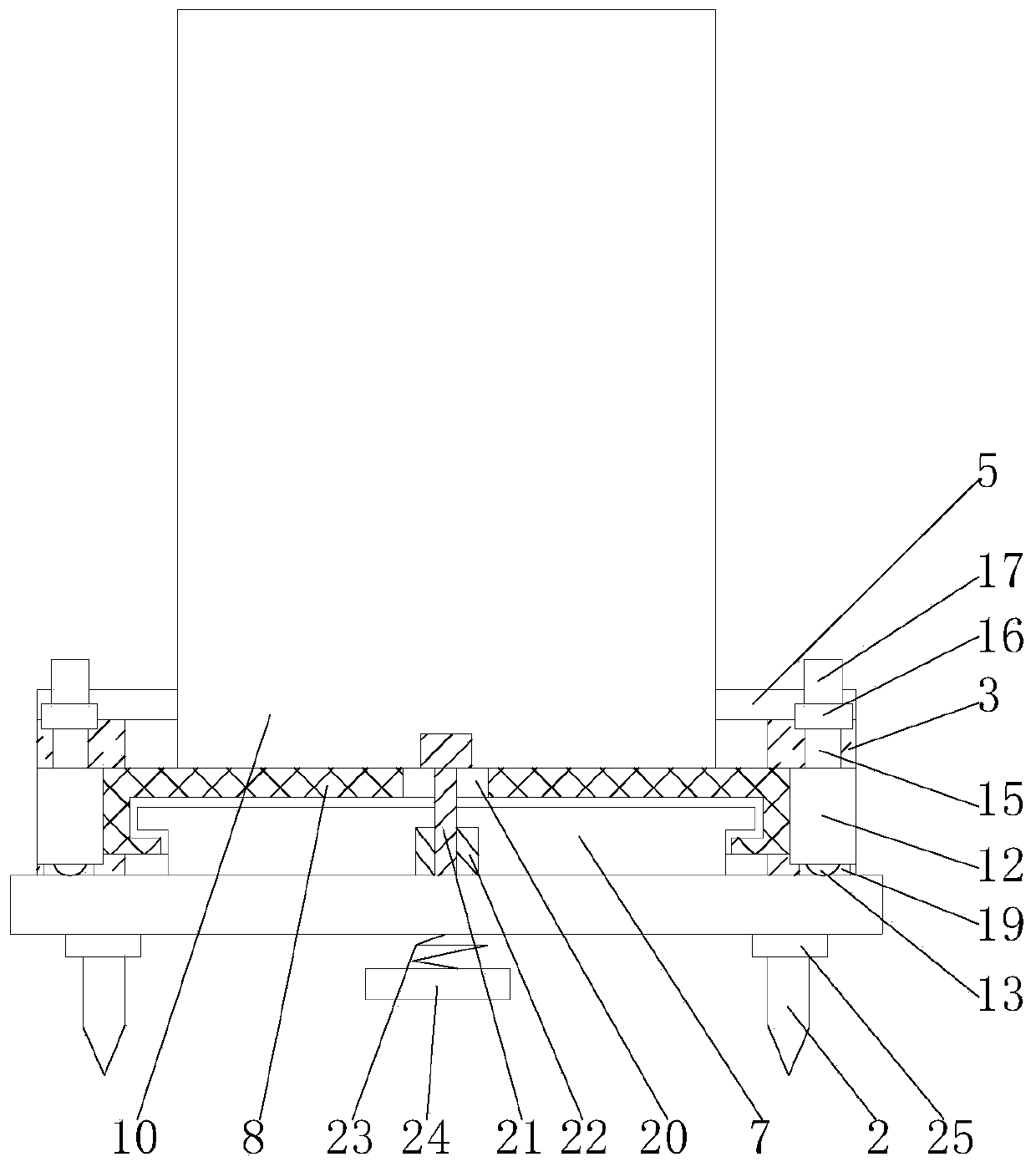

Lead-screw-driven vibrating type agricultural high-quality soybean screening device

InactiveCN108672285ASpeed up screeningImprove efficiencySievingScreeningElectric machineryDrive motor

The invention discloses a lead-screw-driven vibrating type agricultural high-quality soybean screening device. The lead-screw-driven vibrating type agricultural high-quality soybean screening device comprises a base, a first drive motor, a lifting slide plate, a screening box, a first screening plate and a second screening plate, wherein the other end of a crankshaft is rotatably mounted on a connecting plate through a bearing; shaft sleeves are arranged on the crankshaft; the lower sides of the shaft sleeves at left and right sides are separately welded with a first connecting rod and a second connecting rod; the lower end of the first connecting rod and the lower end of the second connecting rod are connected with a second screening plate and a first screening plate separately; and the other end of the first screening plate and the other end of the second screening plate are both hinged to and mounted on the inner wall of the right side inside the screening box. The screening box isindirectly driven to ascend or descend for vibrating the screening box, so that soybean screening speed is greatly increased; and meanwhile, a second drive motor is electrified to start to rotate, andthe second drive motor drives the crankshaft to start to rotate, so that the first screening plate and the second screening plate are driven to start to swing and screen, and therefore, screening speed of soybeans on the first screening plate and the second screening plate is further increased.

Owner:FUJIAN FUXIN AGRI TECH DEV CO LTD

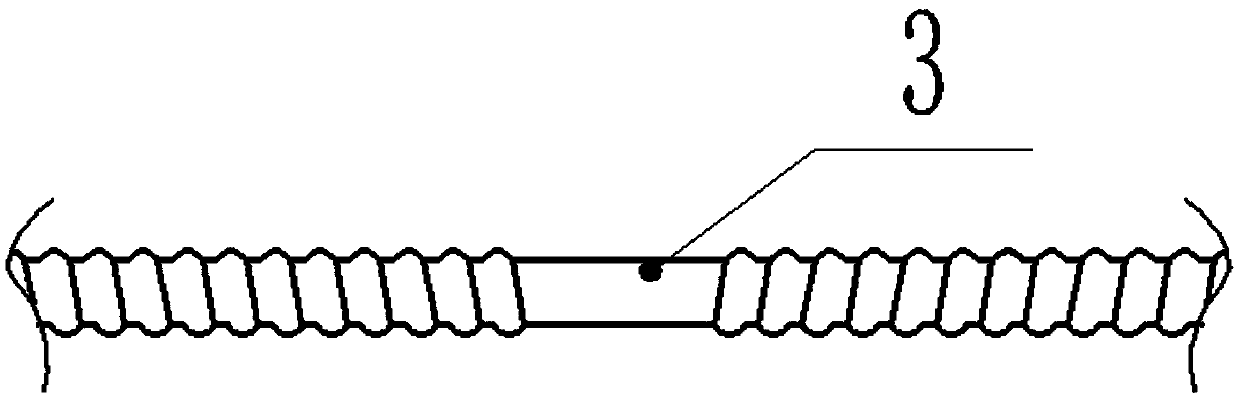

Textile fabric singeing device

ActiveCN113403788AGuaranteed singeing effectEasy to cleanMechanical cleaningPressure cleaningStructural engineeringMechanical engineering

The invention discloses a textile fabric singeing device which comprises an oven, a singeing transmission assembly and an impact ash removal assembly. The singeing transmission assembly comprises a first singeing wheel, a second singeing wheel and a guide wheel; the first singeing wheel and the guide wheel are symmetrically and rotatably installed in the oven; the second singeing wheel is rotatably installed between the first singeing wheel and the guide wheel; the impact ash removal assembly is rotatably installed in the oven and comprises an elastic shaft, connecting rods and impact wheels; the two ends of the elastic shaft are rotatably connected with the inner walls of the two opposite sides of the oven; the two connecting rods are symmetrically and vertically connected onto the elastic shaft; the two ends of the impact wheels and the two connecting rods are rotatably connected with deflection impact assemblies; and the deflection impact assemblies are fixedly installed at the two ends of the first singeing wheel in a limiting manner. According to the textile fabric singeing device provided by the invention, in the singeing process, the textile is subjected to vibration ash removal, so that the condition of the textile is improved; and meanwhile, the subsequent manual cleaning step is omitted, so that the processing efficiency is improved.

Owner:南通吉利新纺织有限公司

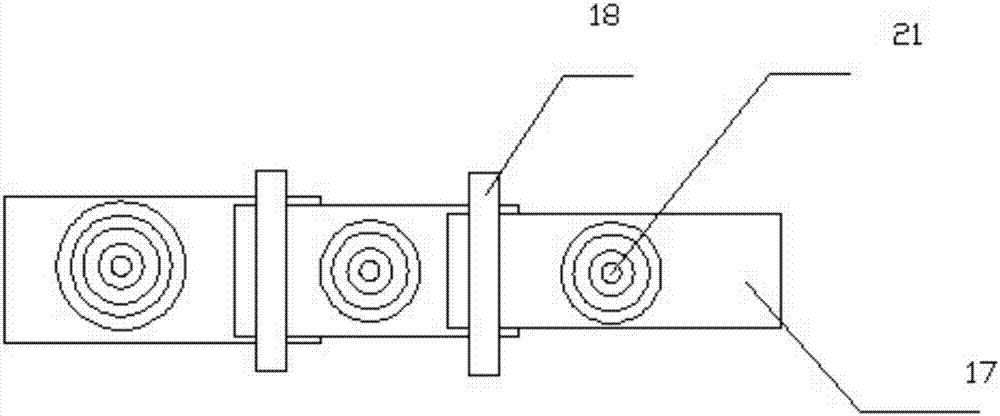

Reaction kettle for producing liquid barium-zinc heat stabilizer

PendingCN107213860AIncrease productivityImprove feeding efficiencyChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesElectrical resistance and conductanceHeat resistance

The invention discloses a reaction kettle for producing liquid barium-zinc heat stabilizer, which comprises a shell, an agitator, and a heater, the agitator comprises an agitating shaft and blades, the blades are fixed on the agitating shaft, the agitating shaft extends into the shell, a feed inlet and a discharge outlet are arranged on the shell, the heater is embedded in the blades, the heater comprises heating resistance wires and wires, the heating resistance wires are coiled in the blades, the wires are connected to a power supply, the agitating shaft is provided with vertical slide ways, the blades are fastened in the vertical slide ways by means of sliding shafts, pneumatic cylinders are mounted on the agitating shaft, and the other ends of the pneumatic cylinders are connected to the sliding shafts of the blades. When the reaction kettle for producing liquid barium-zinc heat stabilizer disclosed by the invention is utilized to prepare liquid barium-zinc heat stabilizer, the agitator can move up and down, consequently, substances can be promoted to be uniformly heated, reaction is thorough, the heat preservation time is shortened, and the production efficiency is increased.

Owner:德清县东来化学有限公司

Multipurpose ore material comprehensive crushing device

InactiveCN112121892AClose contactImprove work efficiencyGrain treatmentsElectric machineryStructural engineering

The invention discloses a multipurpose ore material comprehensive crushing device, and belongs to the technical field of ore crushing. The multipurpose ore material comprehensive crushing device comprises a crushing box, wherein a side plate is arranged at one side of the crushing box, an extrusion assembly is fixedly arranged at the top end of one side of the crushing box, a feeding assembly is arranged at the top end of the side, close to the extrusion assembly, of the side plate, a plurality of sets of mounting frames are evenly arranged at one end of the crushing box, a first motor is arranged at the top of one of the plurality of sets of mounting frames, and a first rotating shaft penetrating to one side of the interior of the crushing box is arranged at the output end of the first motor. According to the multipurpose ore material comprehensive crushing device, when materials fall on the top of an inclined plate, the inclined plate is impacted, so that the inclined plate inclinesdownwards with a hinge pin as the base point, and extrudes an elastic cushion, and the elastic cushion deforms, and generates reverse elastic potential energy, so that the inclined plate is returned under the action of the elastic potential energy, and continuously, the inclined plate shakes up and down with the hinge pin as the base point, and achieves the vibration effect, so that the inclined plate can discharge materials more quickly.

Owner:漳州市德睿机械设备有限公司

Classification treatment device for construction waste

ActiveCN112264301AEasy to classifyTo vibrateSievingGas current separationStructural engineeringProcess engineering

The invention relates to a treatment device, in particular to a classification treatment device for construction waste. The classification treatment device for construction waste is convenient to operate, high in classification efficiency and convenient for collecting, and then the problems existing in the prior art are solved. The classification treatment device for construction waste comprises abottom plate, a separation mechanism and a screening mechanism, wherein racks are arranged on the bottom plate; the separation mechanism is arranged between the racks; and the screening mechanism isarranged between the bottom plate and the racks. By starting a servo motor, rotation of first rotating rods is realized, then rotation of rotating blocks and left-right movement of a screening frame are carried out at the same time through cooperation of the separation mechanism and the screening mechanism, and thus the classification of construction waste is facilitated; and the screening frame continuously moves left and right, so that circular blocks continuously extrude arc-shaped blocks, then the vibration of the screening frame can be realized, and thus the screening frame is prevented from being blocked.

Owner:瑞泰环保装备有限公司

Fixed installation device of geothermal energy equipment

InactiveCN110726041AReduce installation difficultyEasy to installLighting and heating apparatusGeothermal energy generationStructural engineeringMechanical engineering

The invention discloses a fixed installation device of geothermal energy equipment. The fixed installation device comprises a base, two fixing piles are correspondingly and symmetrically arranged on the left and right sides of the bottom of the base, two limiting plates are symmetrically arranged on the right side of the top of the base, limiting grooves are formed in the left sides of the limiting plates, first fixing plates are fixedly connected to the tops of the limiting plates, first fixing bolts are arranged on the left sides of the tops of the first fixing plates, a sliding rail is fixedly connected to the top of the base, and a sliding block is slidably connected to the surface of the sliding rail. According to the fixed installation device, the base, the limiting plates, the firstfixing plates, the first fixing bolts, the sliding rail, the sliding block, a first threaded sleeve, a limiting pin, a supporting column, a ball, an electric pushing rod, a second fixing plate, a second fixing bolt and a second threaded sleeve are mutually matched, the fixed installation device of the geothermal energy equipment is conveniently installed, the installation difficulty of the installation personnel for a main body of the geothermal energy equipment is lowered, the installation time of the installation personnel is shortened, and the working efficiency of the installation personnel is improved.

Owner:宁波市汇正智能科技有限公司

Coal chemical gasification furnace

ActiveCN112063420ATo vibrateReduce cloggingGasification processes detailsSolid fuel combustionThermodynamicsCombustion

The invention relates to a coal chemical gasification furnace which comprises a furnace body, a feeding port plate, a limiting plate, a drawing rod, a front door and a processing mechanism, the furnace body is installed on the existing working ground, a feeding through groove is formed in the middle of the upper end of the furnace body, and the feeding port plate is installed between the left inner side wall and the right inner side wall of the feeding through groove through pin shafts; a limiting plate is installed at the rear end of the upper end face of the feeding port plate, the lower endof the limiting plate is connected with the upper end face of the furnace body in a sliding fit mode, and drawing rods are installed on the front end face of the furnace body in a sliding fit mode inan up-down symmetrical manner and are arranged in a bilateral symmetry mode, and the front end face of the drawing rods is connected with the rear end face of the front door, the rear end of the front door is connected with the front end of the furnace body in a sliding fit mode, the processing mechanism is arranged in the furnace body, and the arranged processing mechanism can achieve multi-cavity separate stacking combustion of fuel so that the probability of insufficient combustion of the fuel due to excessive stacking is reduced, and then the utilization rate of the fuel is increased.

Owner:SUZHOU HAILU HEAVY IND

Fixing device capable of increasing bearing capacity of support in communication equipment box

InactiveCN109121341AEasy to supportAvoid damageCasings/cabinets/drawers detailsSupport structure mountingEngineeringActual weight

The invention discloses a fixing device capable of increasing the bearing capacity of a support in a communication equipment box, which comprises a box body, and is characterized in that both left side and the right side of the bottom of the box body are symmetrically provided with two moving devices, the bottom of the box body is provided with a limiting device at the position among the four moving devices, the front of the box body is articulated with a box door through hinges, the bottom of the inner wall of the box body is provided with a support beam, and the bottom of the inner wall of the box body is fixedly connected with a support column located inside the support beam. The fixing device for the support in the communication equipment box can adjust the number of the bearing devices according to the actual weight of communication equipment through the mutual cooperation of the box body, a bearing device, a base plate, first fixing bolts, a base, a first buffer spring, a supportsliding block, a connecting column, a top plate, second fixing bolts, a support plate, a lower anti-slip pad and communication equipment, thereby being convenient for easily supporting the communication equipment, avoiding damages of the communication equipment and the support, and avoiding unnecessary economic losses.

Owner:淮北雷德机电科技有限公司

Microbial carbon-based fertilizer preparation mixing device for preventing tobacco plant root rot

ActiveCN112156700ATo vibrateAvoid uneven mixingShaking/oscillating/vibrating mixersRotary stirring mixersPlant rootsAgricultural engineering

The invention discloses a microbial carbon-based fertilizer preparation mixing device for preventing tobacco plant root rot. The device comprises an outer box body, an inner box body and a cleaning mechanism, a supporting rod is fixedly connected to the top end of the outer box body, a top plate is fixedly connected to the top end of the supporting rod, and a stirring mechanism is arranged on thetop plate. According to the microbial carbon-based fertilizer preparation mixing device for preventing tobacco plant root rot, through cooperation of the outer box body, the inner box body, the cleaning mechanism and the like, when the device conducts mixing and stirring, a stirring rod can be cleaned in a stirring gap, a telescopic air cylinder can be automatically started, and the telescopic aircylinder can vibrate an internal fertilizer while pushing the inner box body to ascend and descend, so that the internal fertilizer can be overturned, uneven mixing caused by sinking to the bottom isprevented, and the problems that after stirring is conducted for a certain time, the fertilizer adhering to the stirring rod can be extruded very firmly, much time and effort need to be consumed during cleaning, and the labor amount of workers is increased are solved.

Owner:HENAN AGRICULTURAL UNIVERSITY

Solvent mixing device for petroleum asphalt production

InactiveCN113926360AAvoid stickingGuaranteed excellent performanceTransportation and packagingMixer accessoriesThermodynamicsMechanical engineering

The invention discloses a solvent mixing device for petroleum asphalt production. The solvent mixing device specifically comprises a working frame which is provided with a supporting rack body, a butt joint mounting frame arranged above the working frame, and a supporting foot stool arranged at the bottom of the working frame; a mixing box which is provided with a mixing box body and a butt joint sleeve frame arranged on the side of the upper part of the mixing box; and a pretreatment box which is provided with a side treatment box body and a drainage pipe arranged on the inner side of the pretreatment box. The invention relates to the technical field of petroleum asphalt production. According to the solvent mixing device for petroleum asphalt production, the problems that a solvent cannot be mixed and stirred in multiple directions, and the produced solvent is non-uniformly mixed and is easy to adhere during mixing are solved, a device arranged at the bottom of the mixing box is matched with an internal mixer, so that the solvent at the bottom can be prevented from adhering, and the solvent can be uniformly mixed and rolled to flow upwards again during high-speed rotation.

Owner:吴长安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com