Centrifugal rotating E-shaped carbon steel piece lining plastic device provided with heat preservation cover

A technology of a heat preservation device and a heat preservation cover, which is applied in the field of workpiece processing, can solve the problems such as the loose attachment of the plastic pipe and the inner wall of the E-shaped carbon steel part, and the poor plastic lining effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

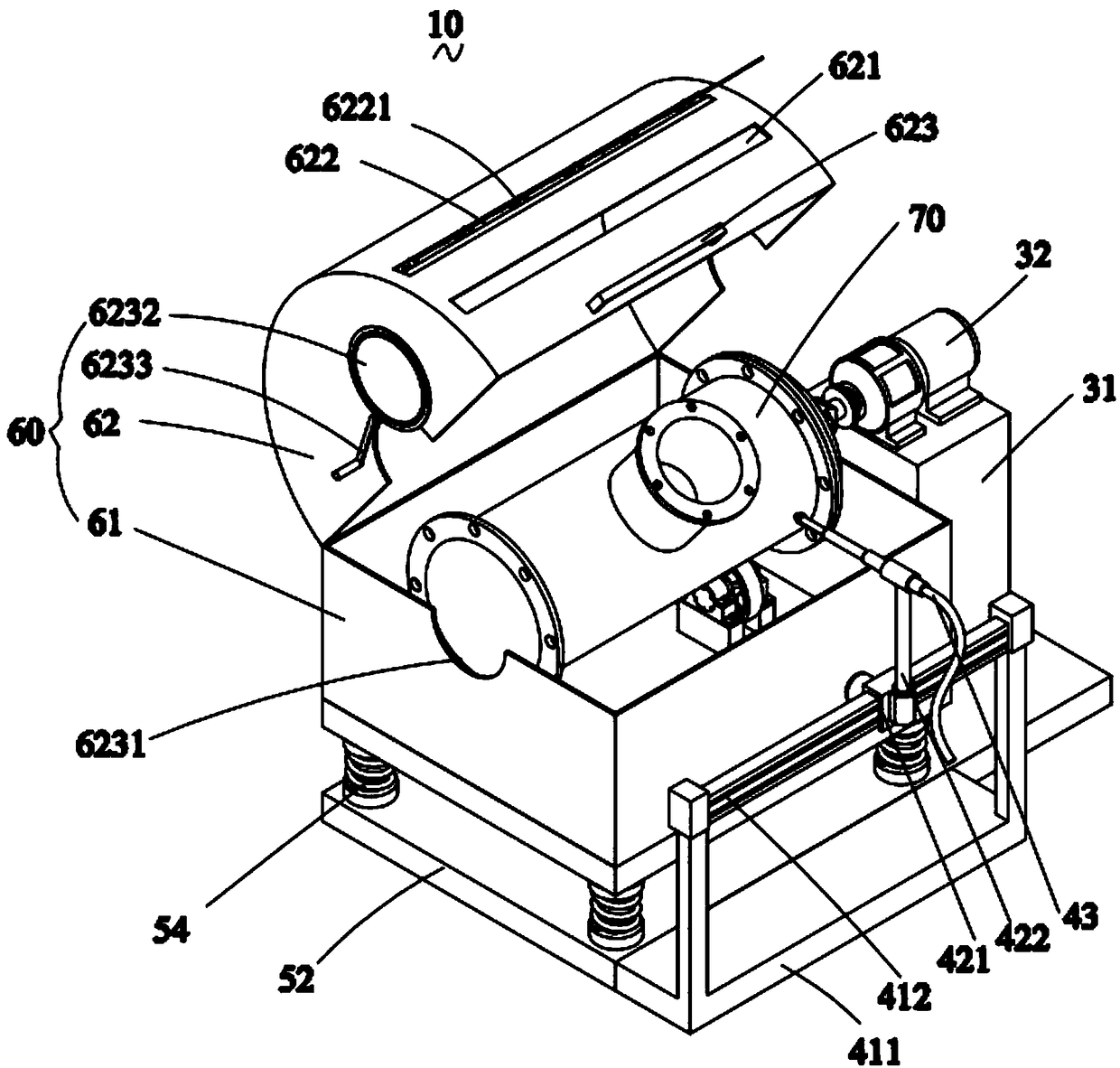

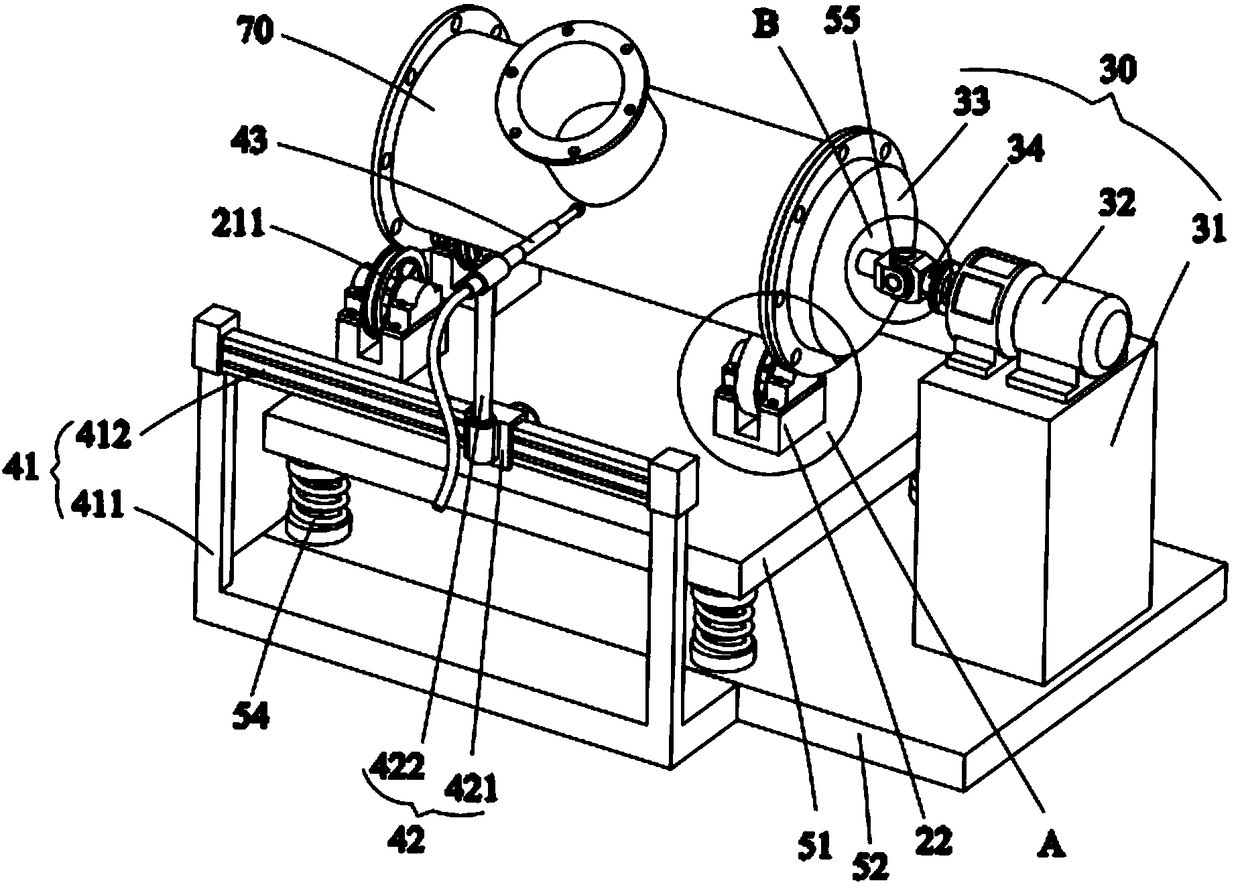

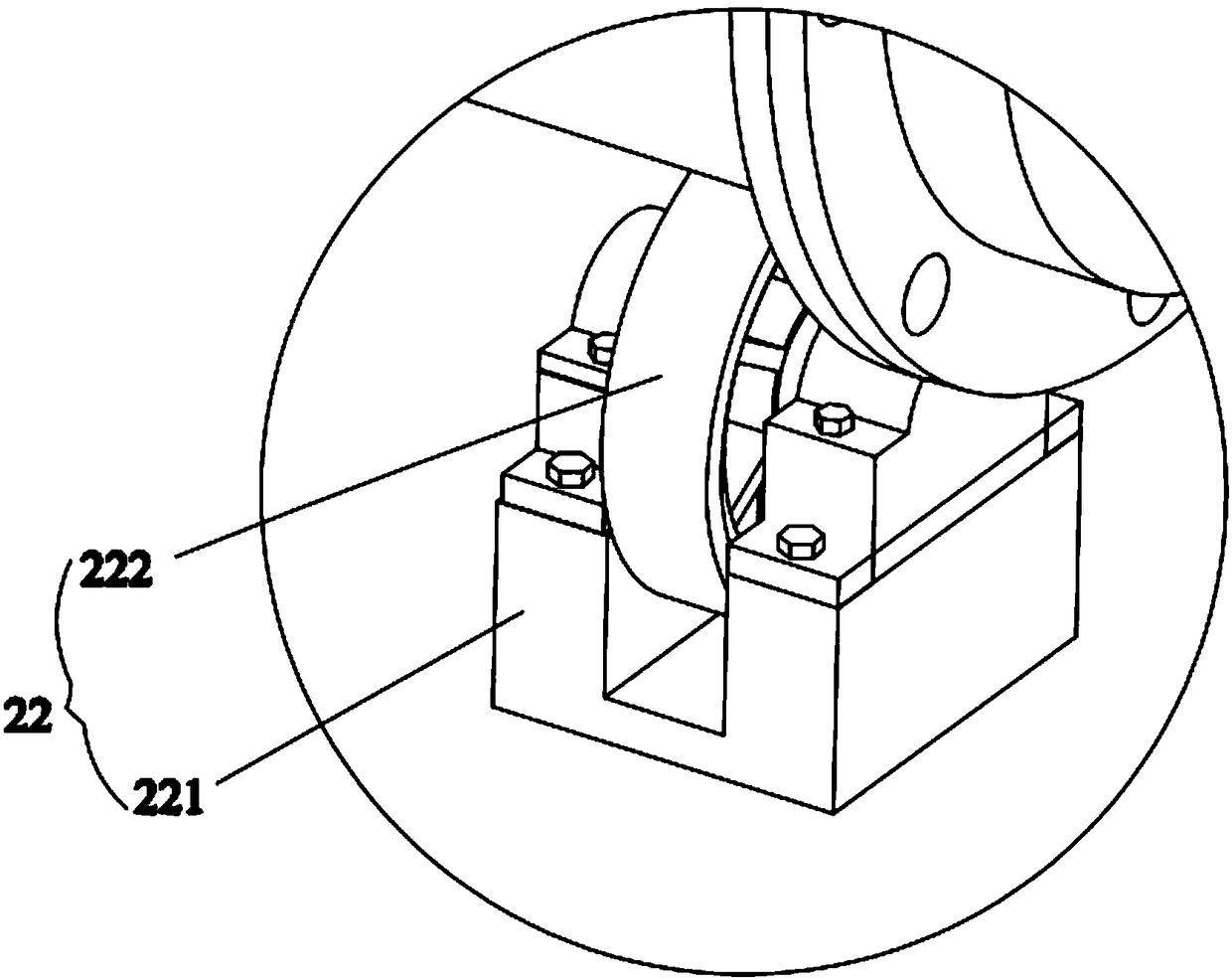

[0023] Please see Figure 1 to Figure 8, the embodiment of the present invention provides a centrifugally rotating E-shaped carbon steel piece 70 plastic lining device 10, which is used to line the E-shaped carbon steel piece 70, including a supporting device, a driving device 30, a heating device, a vibrating device 50 and The heat preservation device 60, the support device is arranged on the bottom of the E-shaped carbon steel part 70, plays a supporting role to the E-shaped carbon steel part 70, and the driving device 30 is arranged on one side of the E-shaped carbon steel part 70 to drive the E-shaped carbon steel part The part 70 is centrifugally rotated, and the heating device is arranged near the outer wall of the E-shaped carbon steel part 70 to heat the E-shaped carbon steel part 70, so that the polyethylene powder sticking on the inner wall of the E-shaped carbon steel part 70 is melted to The E-shaped carbon steel part 70 is lined with plastic, and the vibration dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com