Patents

Literature

690results about How to "Avoid uneven mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

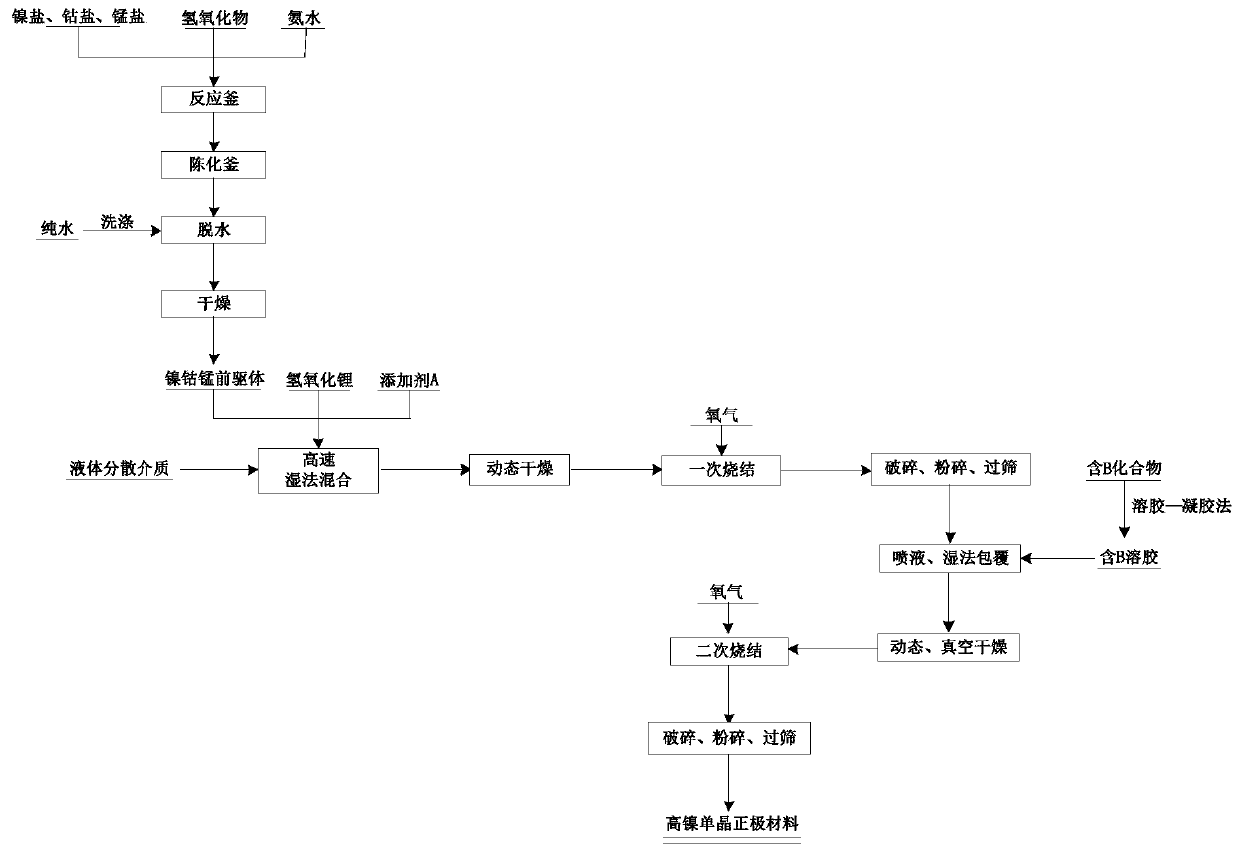

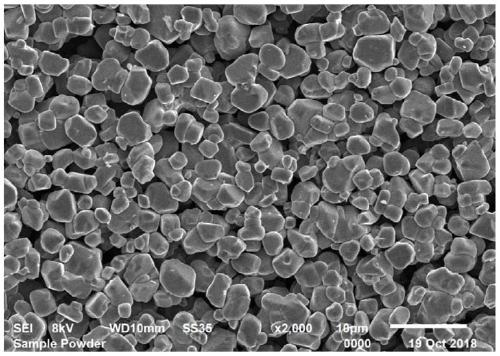

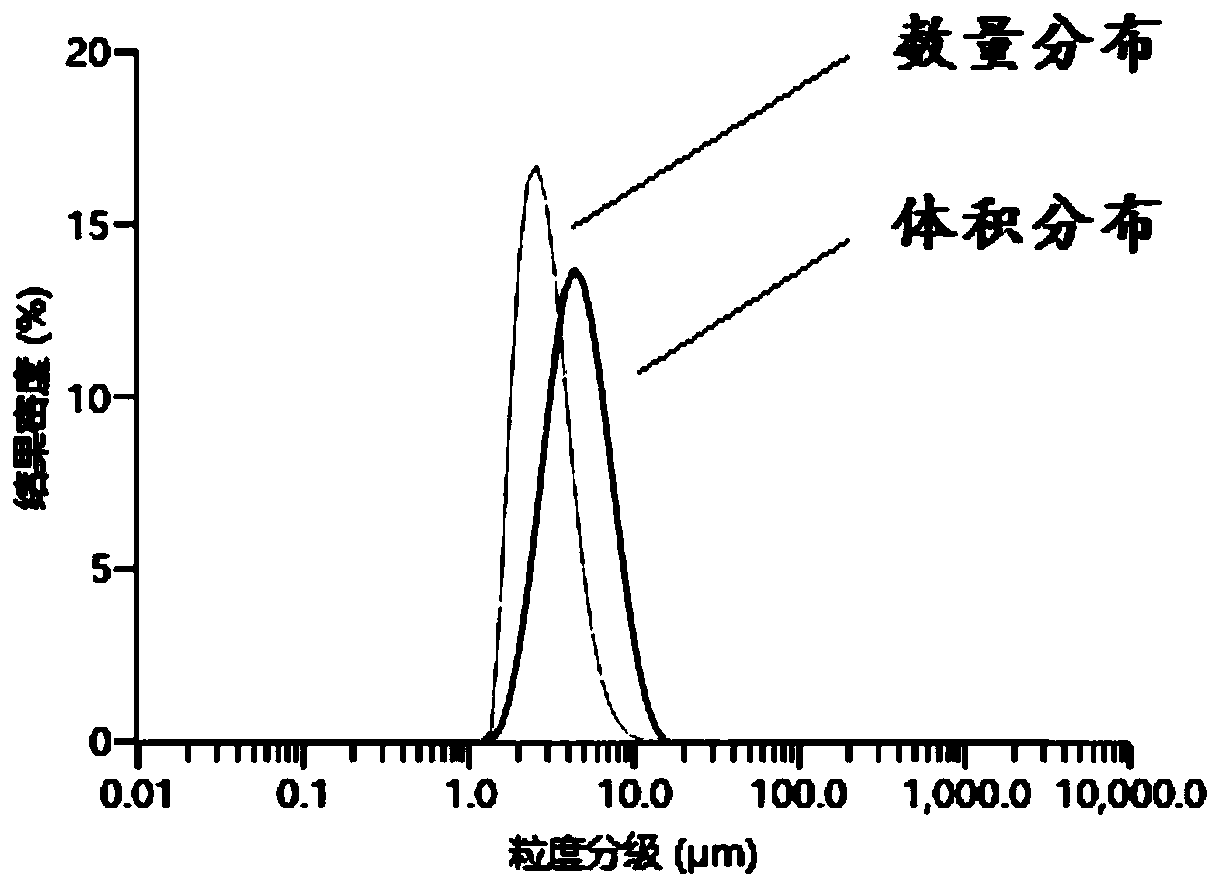

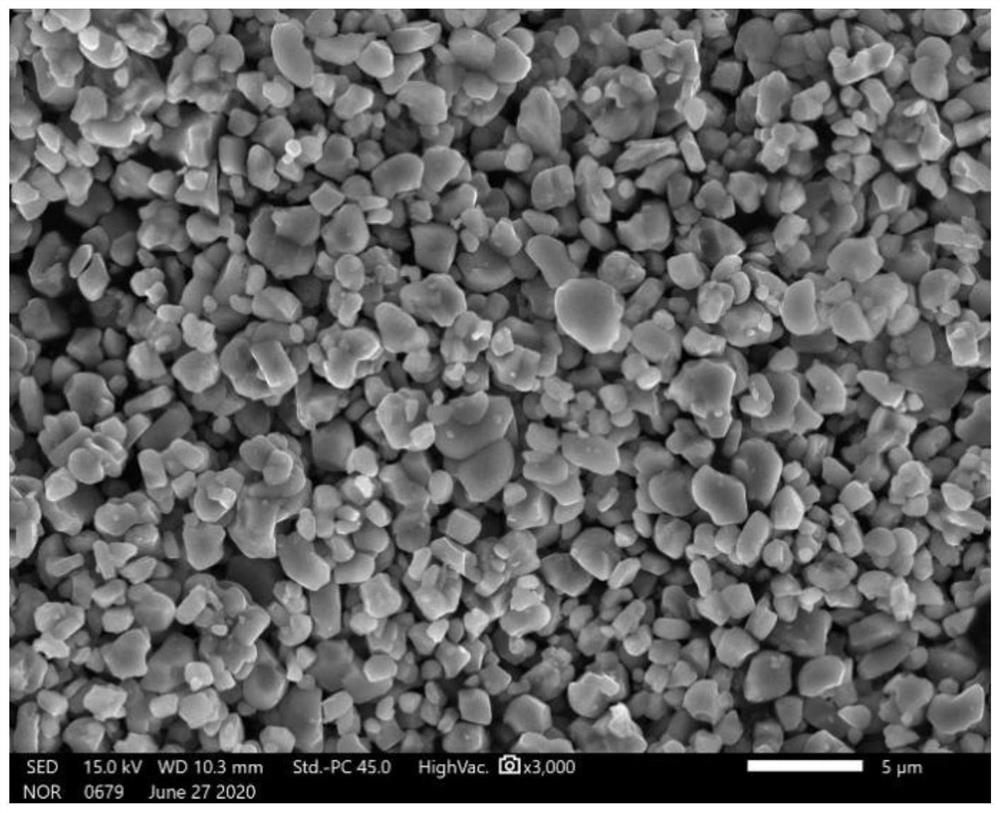

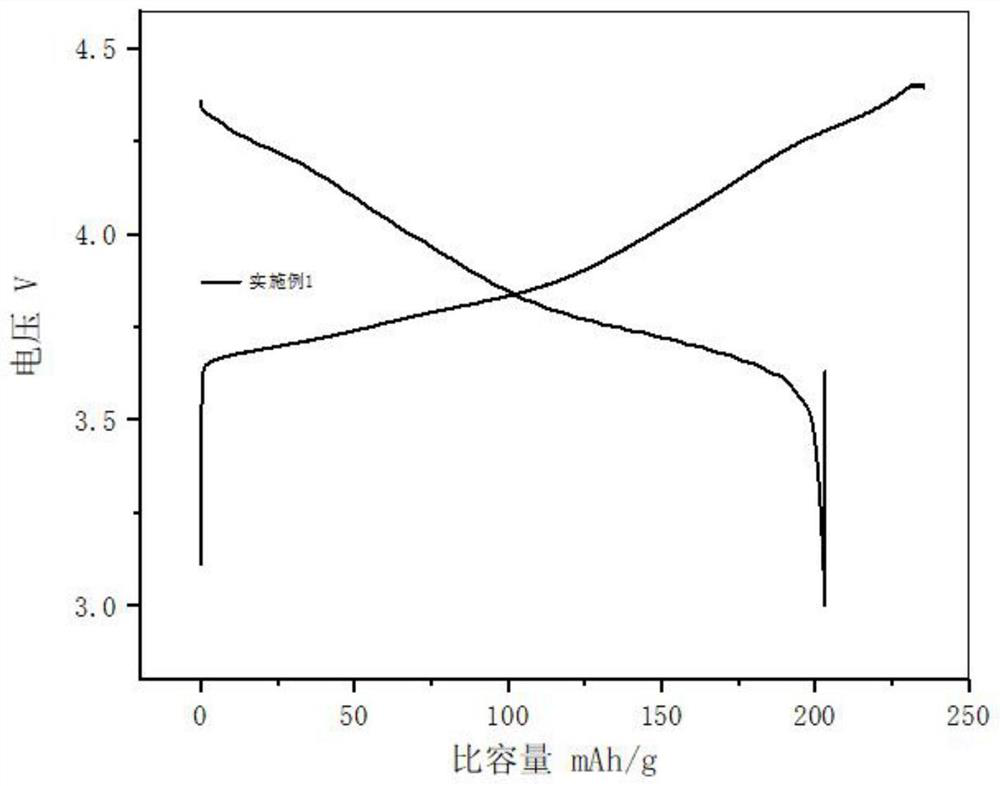

Method for preparing high-nickel long-cycle single-crystal lithium ion battery positive-pole material

InactiveCN110451585AImprove uniformityImprove stabilityCell electrodesSecondary cellsNickel saltLithium hydroxide

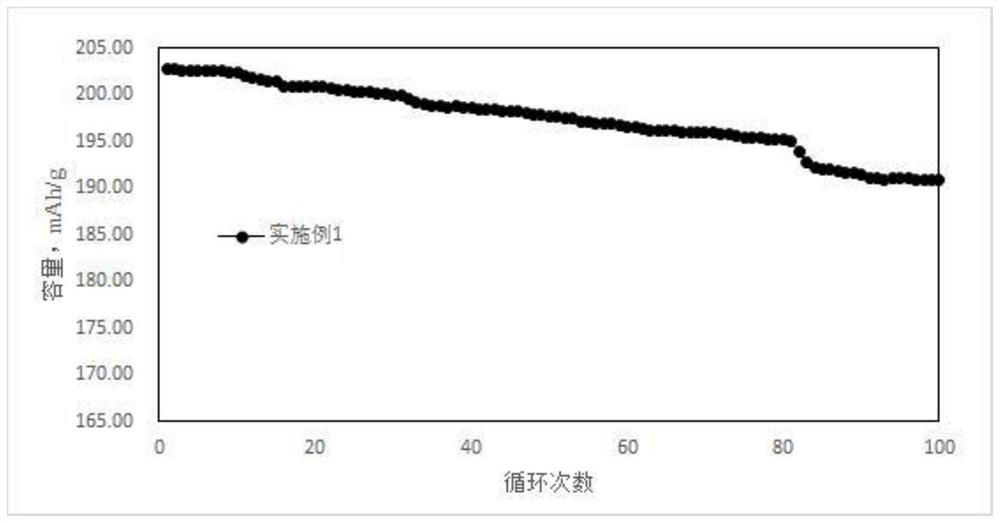

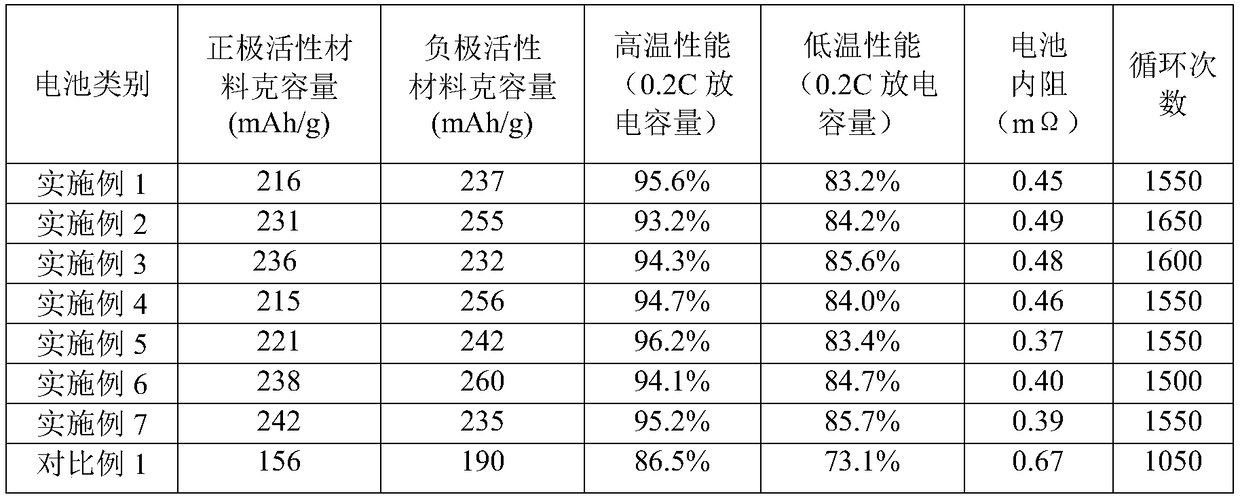

The invention relates to a method for preparing a high-nickel long-cycle single-crystal nickel-cobalt-manganese (NCM) lithium ion battery positive-pole material. The preparation method comprises the following steps: (1) mixing a soluble nickel salt, a cobalt salt, a manganese salt, an alkali metal hydroxide and ammonia water, and enabling the mixture to flow into a reaction kettle for constant-temperature coprecipitation to obtain a high-nickel NCM ternary precursor material; (2) uniformly mixing the high-nickel NCM ternary precursor, lithium hydroxide and an additive A in a wet high-speed mixing mode, carrying out drying, then carrying out primary sintering in an oxygen-enriched atmosphere to obtain a spherical high-nickel NCM ternary positive-pole material; (3) carrying out crushing, smashing and sieving to obtain a high-nickel NCM ternary positive-pole material; and (4) carrying out wet mixing and drying on the high-nickel NCM ternary positive-pole material with a coating agent B, carrying out secondary sintering in an oxygen-enriched atmosphere, and carrying out crushing, smashing and sieving to obtain the high-nickel single-crystal NCM lithium ion battery positive-pole material. The positive-pole material prepared by the method has the advantages of high capacity, good cycle performance, high compaction density and the like.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

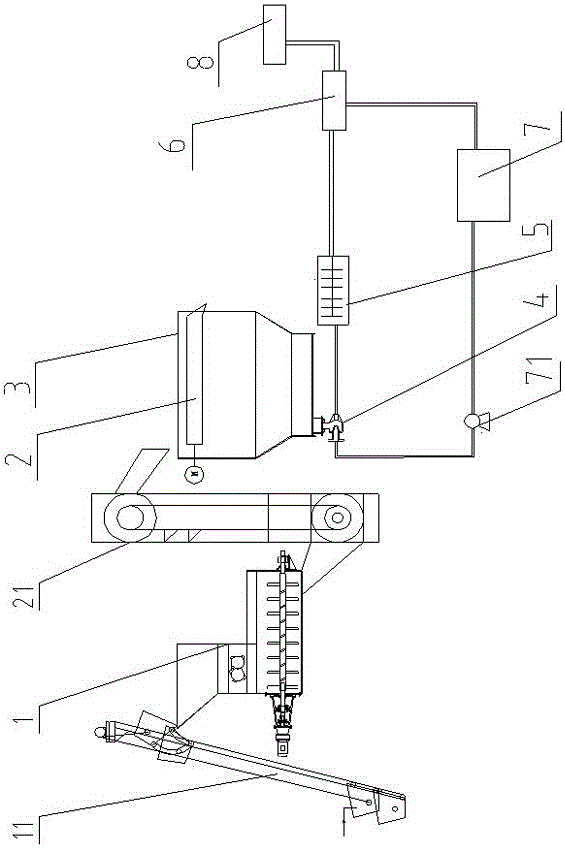

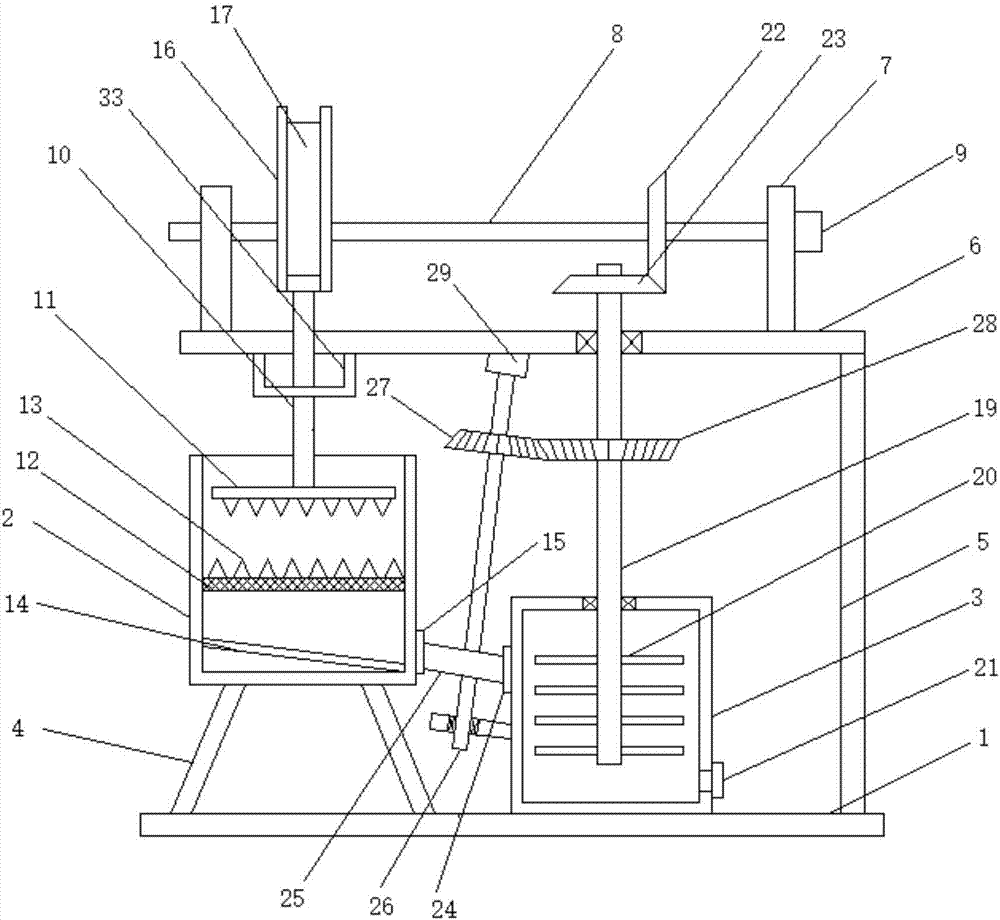

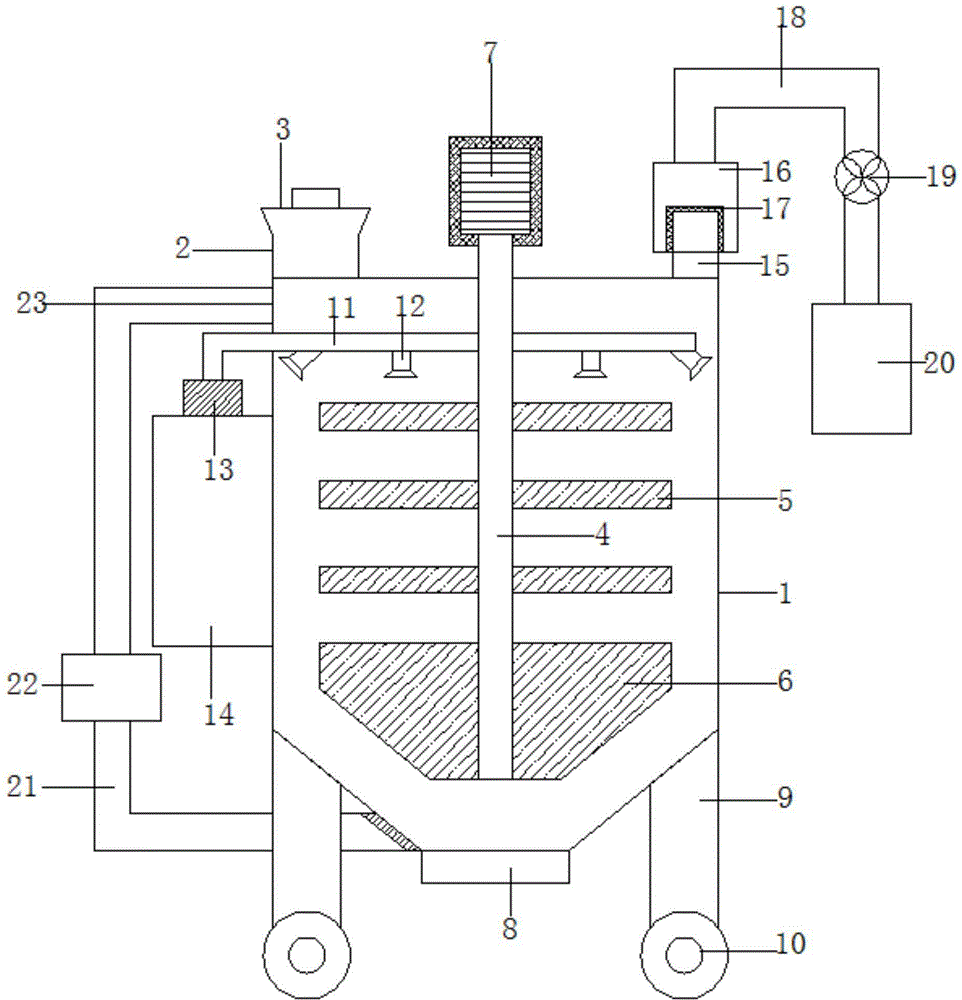

Oily sludge treatment system and treatment method thereof

PendingCN106746420AGood processing effectEasy to handleWaste water treatment from quariesSievingWater storageSludge

The invention discloses an oily sludge treatment system and a treatment method thereof. The treatment system comprises crushing equipment, a vibrating screen, a precipitation device, an ejector, a high-speed crushing device, a water storage device and separation device for separating oil, water and sludge, wherein the crushing equipment is used for primarily crushing oily sludge and is provided with an oil slick space and a first oil slick outlet which can be opened and closed; the vibration screen is located at the upper part of the precipitation device; the precipitation device is used for precipitating the screened oily sludge; the high-speed crushing device is used for crushing the oily sludge into fine particles; the precipitation device is sequentially connected with the ejector, the high-speed crushing device and the separation equipment; a water outlet of the water storage device is connected with a water inlet of the ejector. The treatment system can be applicable to dewatering of various oily sludges, meanwhile, the oil rate of the oily sludge can be reduced to below 3%, oil can be recovered to the maximal extent and secondary pollution of wastewater is not generated.

Owner:仇霞霞

Cast-in-situ fireproof material of fireproof door and manufacturing method of fireproof door

InactiveCN101519312APrevent agingAvoid problems with reduced fire performanceSolid waste managementFireproof doorsFiberAdhesive

The invention relates to a cast-in-situ fireproof material of a fireproof door and a manufacturing method of the fireproof door, in particular to a cast-in-situ inorganic gelled material of a fireproof door leaf and a fireproof door frame, comprising the following components by weight percent: 30-60 of magnesia; 17-50 of magnesium chloride solution; 0.5-3 of modifier; 0.1-1 of flock and 5-30 of fly ash, which are mixed to be a liquid inorganic gelled material. The invention has the advantages that the inorganic gelled material is manufactured by a cast-in-situ mode, and no adhesive or no prefabricated inner is needed, thereby the conditions of cracks, filling and uneven material mix in the prior art are avoided, and materials which can evaporate noxious gas after heating are completely cancelled; the inorganic gelled material containing a large amount of foam is filled in a framework, thereby the weight of the whole fireproof door is reduced, and the transportation and the installation efficiencies are greatly enhanced; the foam has good insulation effect, and the solidified foam in the fireproof material can further shrink after pressure processing so as to have complete filling, thereby enhancing the density of the fireproof door and greatly strengthening the fireproof performance.

Owner:HUNAN BDF ENERGY SAVING TECH

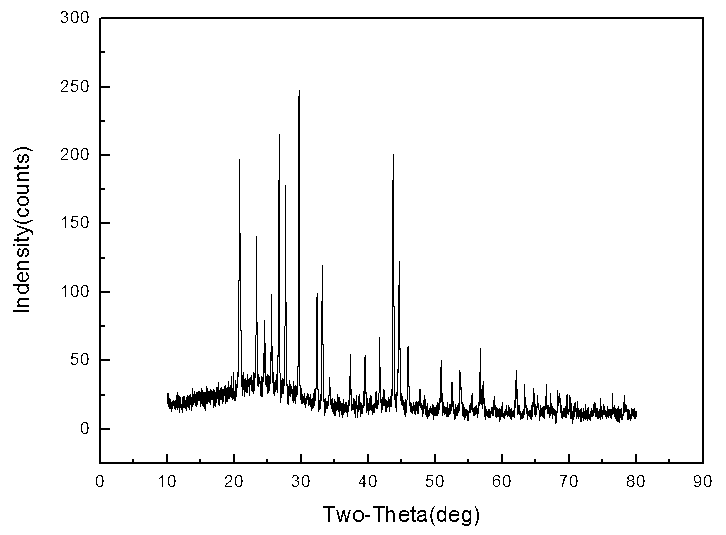

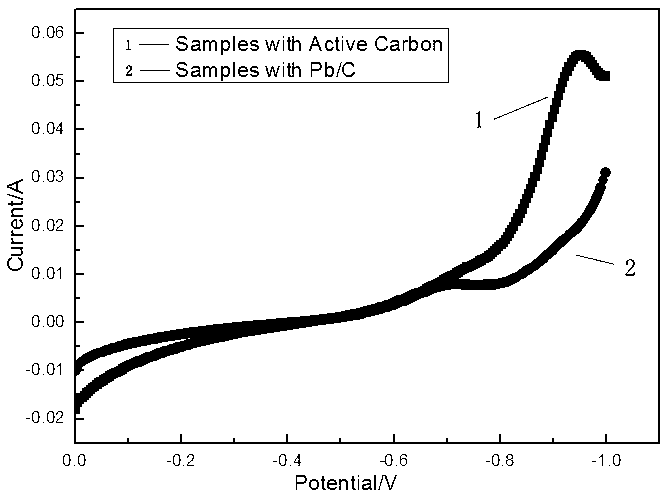

Lead/carbon composite for storage battery and preparation method of lead/carbon composite material

ActiveCN103137955AIncrease the proportionAvoid uneven mixingCell electrodesCarbon compositesCharge current

The invention discloses a lead / carbon composite for a storage battery. The lead / carbon composite is prepared from the following raw materials in percent by weight: 85-99.9 percent of lead-salt solution and 0.1-15 percent of conductive carbon material, wherein the lead salt solution is prepared from a soluble lead salt and deionized water, and the mol concentration of the lead salt solution is 0.1-0.8M. The invention also discloses a preparation method of the lead / carbon composite for the storage battery. The lead / carbon composite is substantially a conductive carbon material modified by lead oxide. Lead has the characteristics of low resistivity, high plasticity and high hydrogen evolution overpotential. The characteristics of the lead ensure that the hydrogen evolution overpotential of the carbon material after modified by PbO in a lead-acid battery is remarkably increased; and meanwhile the charging current occupied by partial hydrogen evolution reaction in a charging process is reduced, and the charging efficiency is increased.

Owner:SHENZHEN CENT POWER TECH

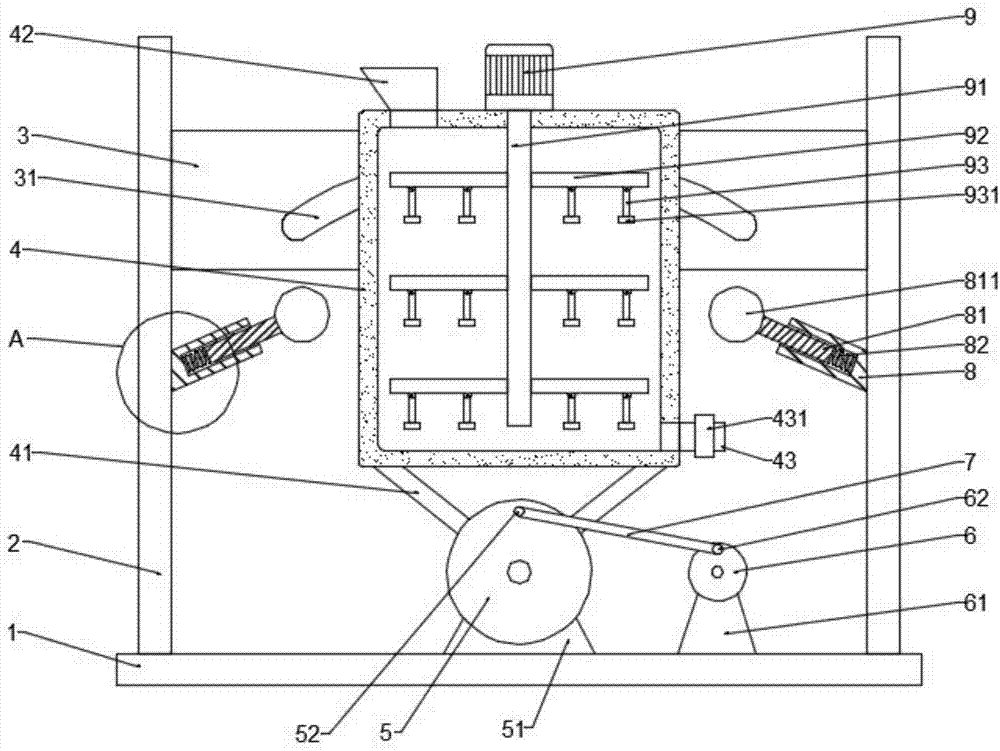

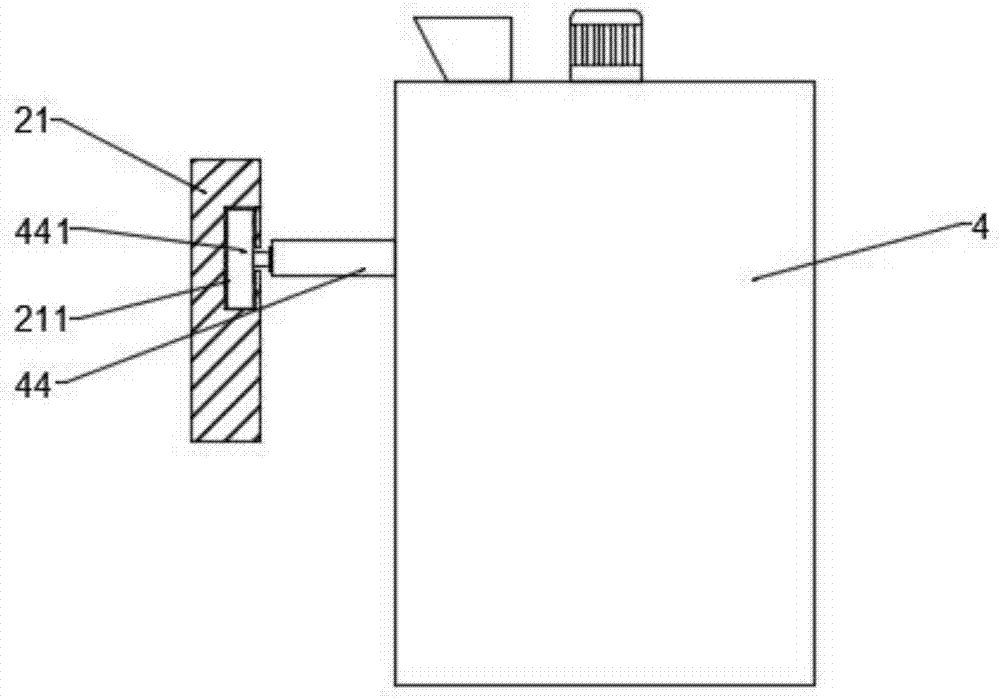

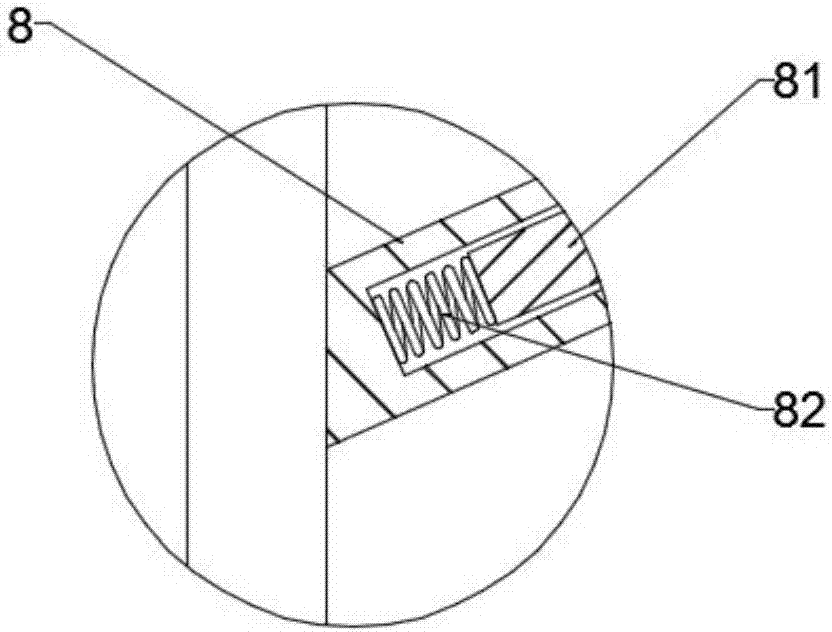

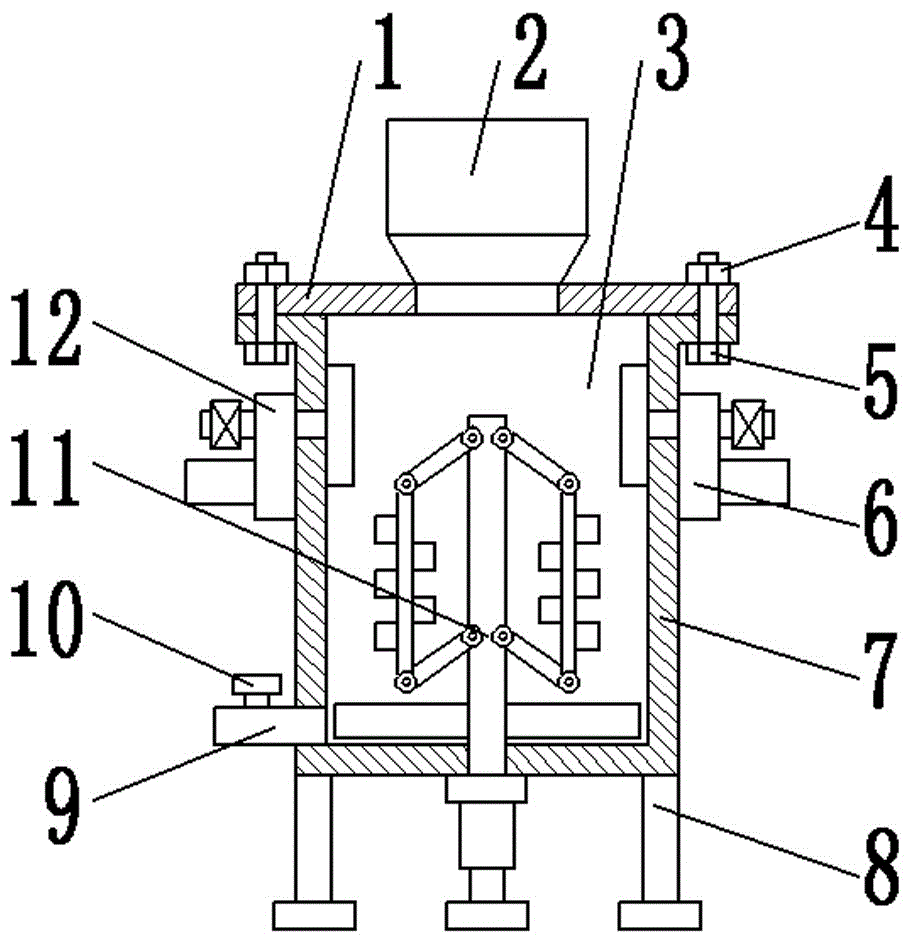

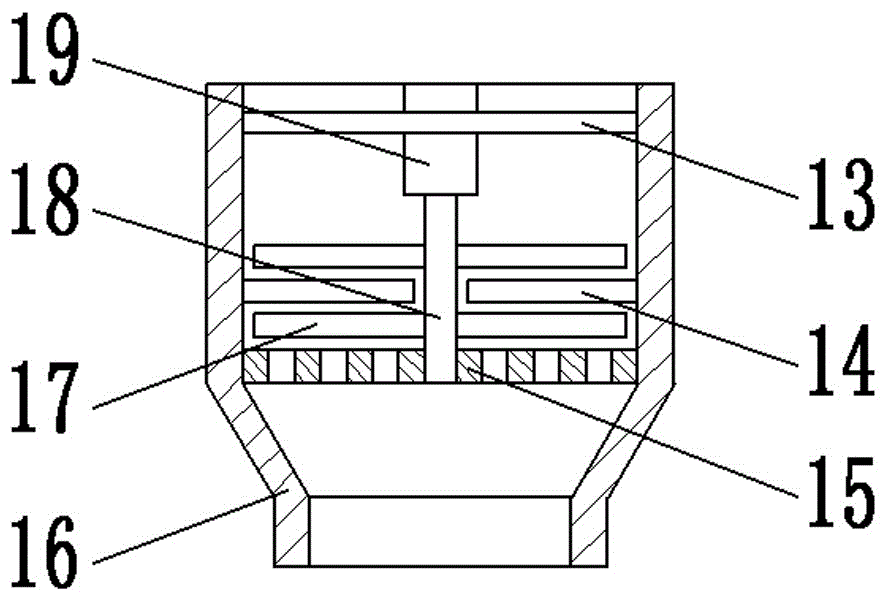

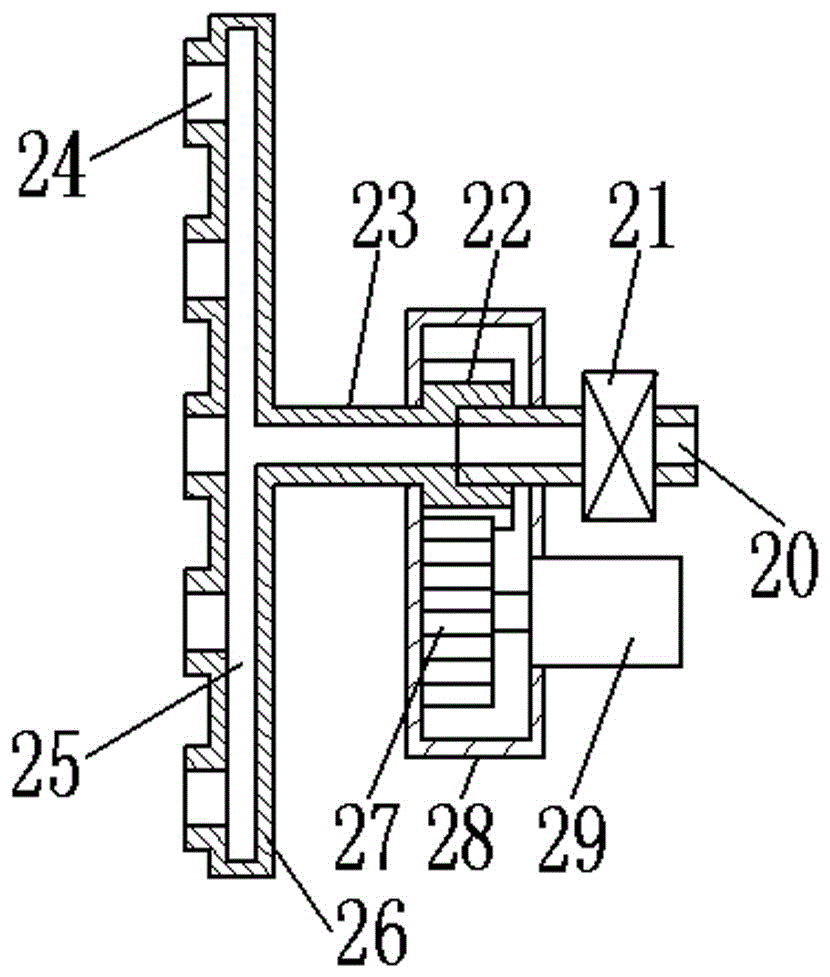

Oscillating-type efficient feed mixing device

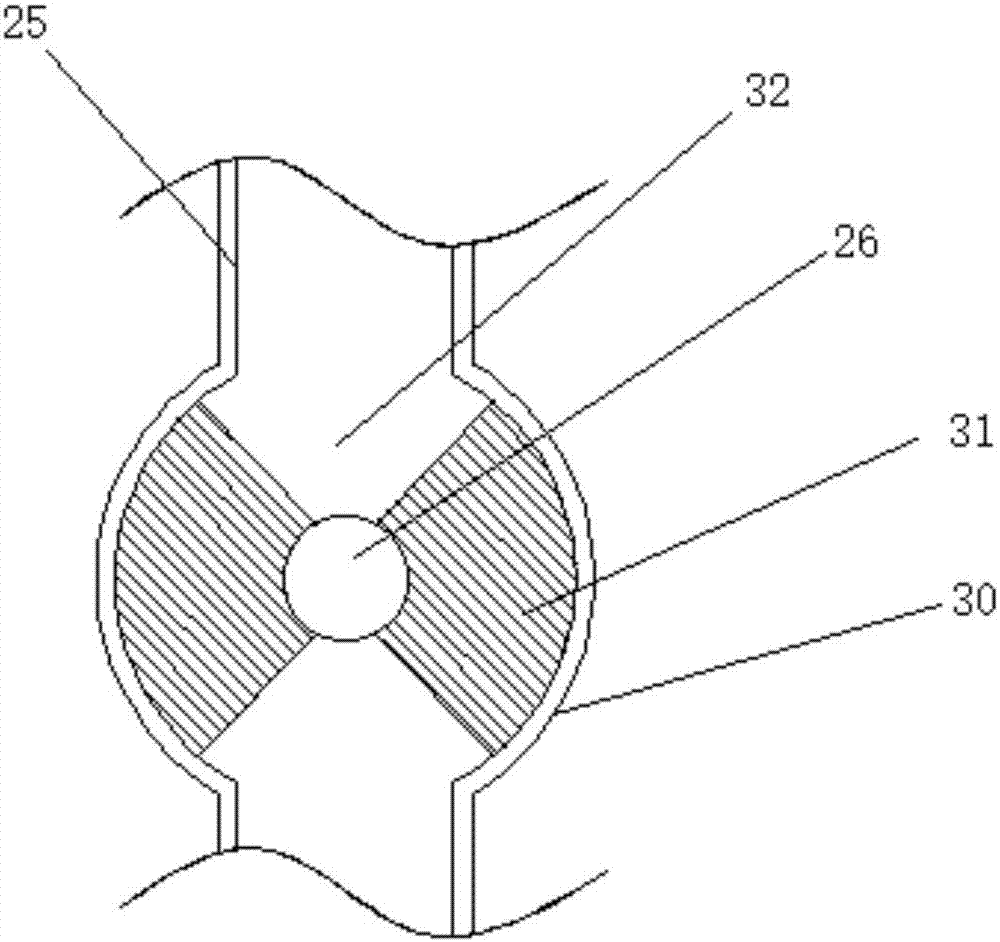

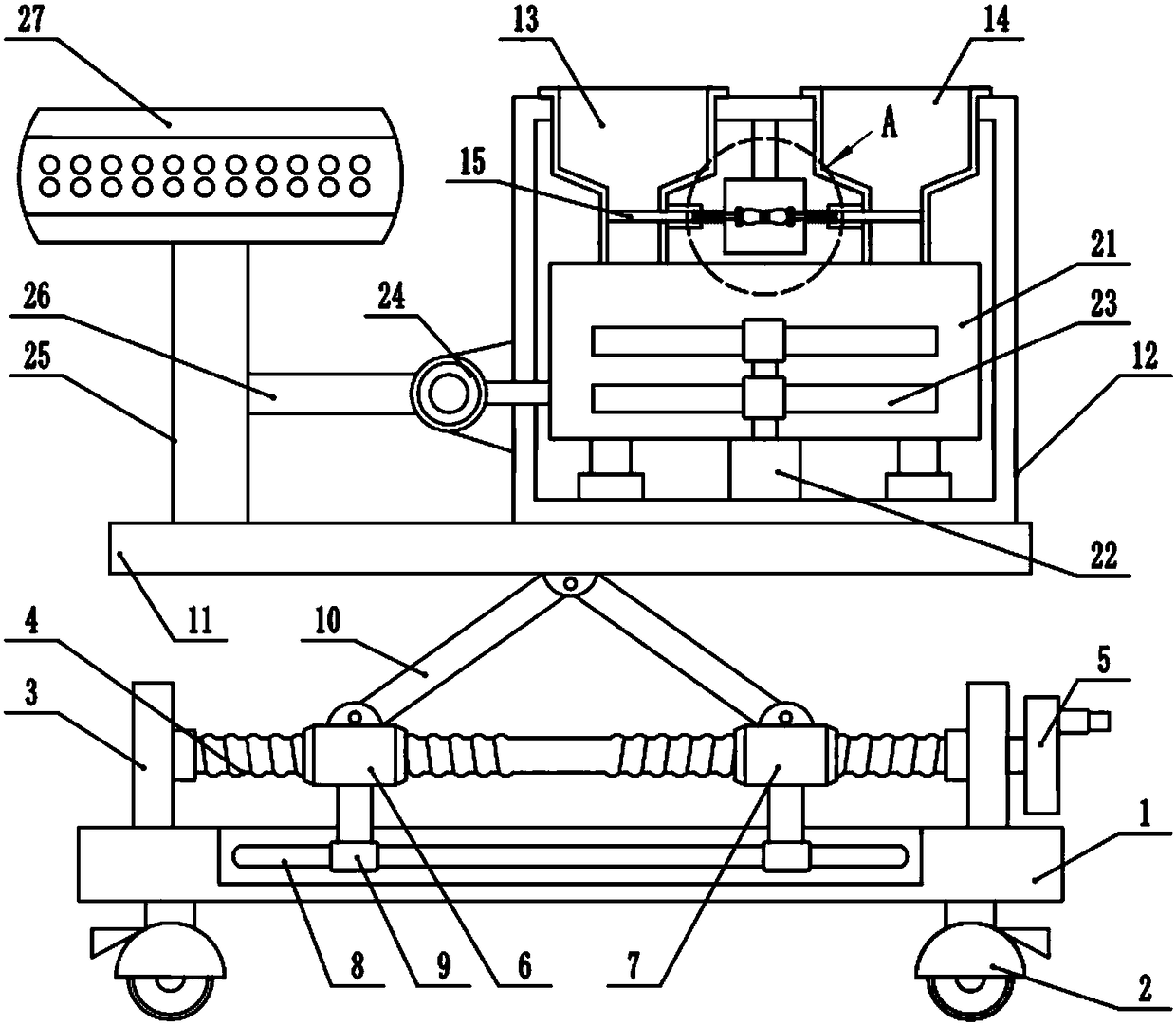

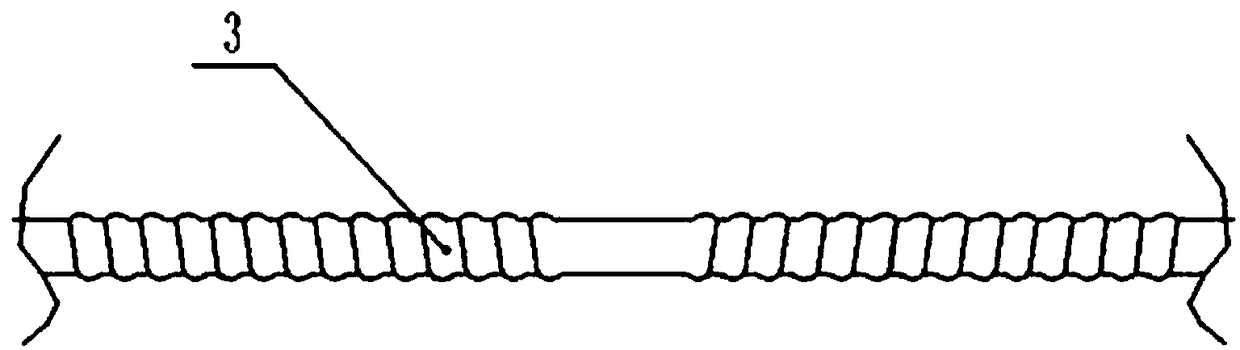

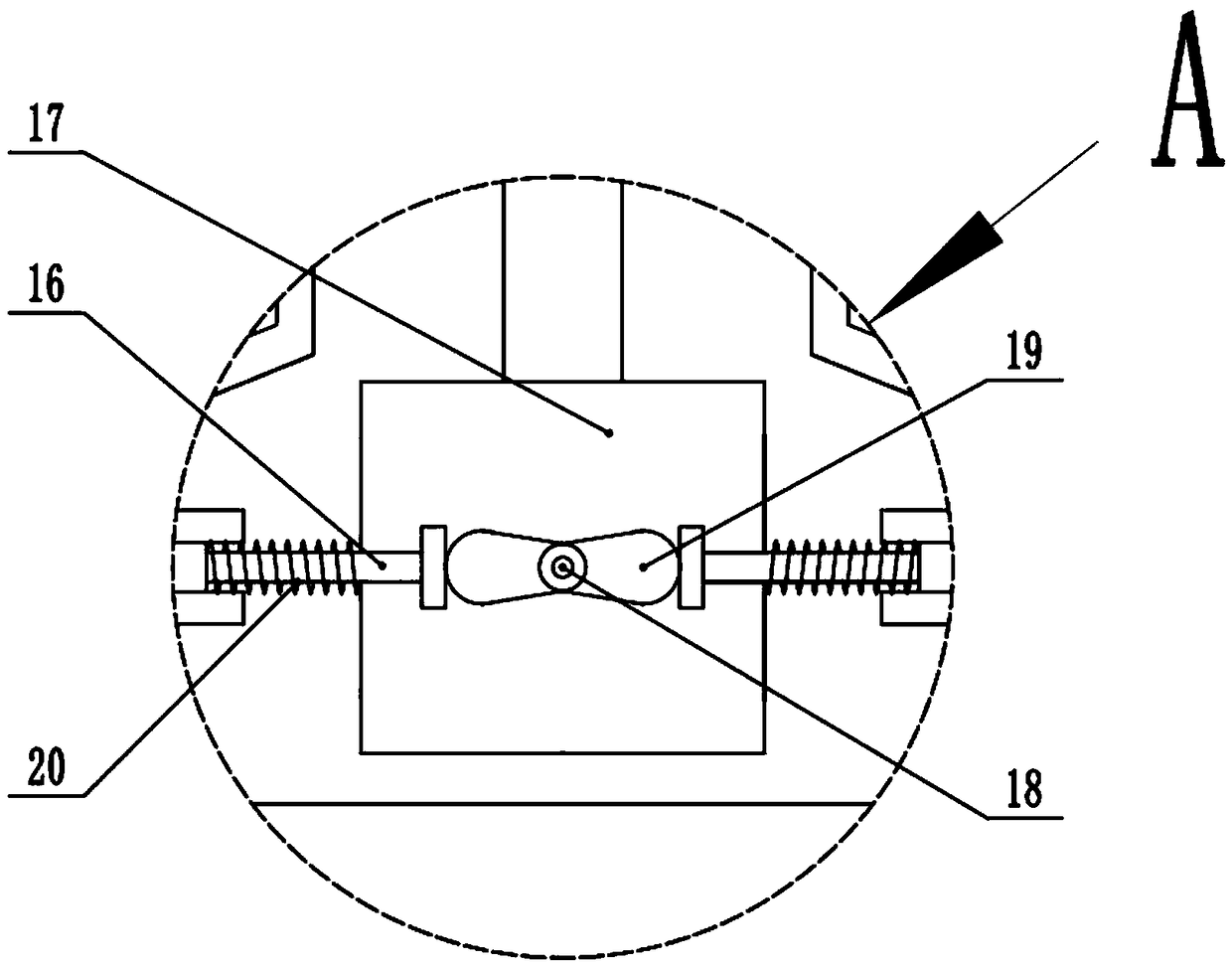

InactiveCN107469711AImprove swing stabilityImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingCircular discEngineering

Owner:罗娟

Efficient energy-saving feedstuff stirring machine

InactiveCN105169993AFalling smoothlyDrop savingsRotary stirring mixersMixer accessoriesBristleEngineering

The invention discloses an efficient energy-saving feedstuff stirring machine. The efficient energy-saving feedstuff stirring machine comprises a stirring barrel, an iron removing cavity and a spiral conveying barrel. A feeding hopper is arranged on the upper side of the stirring barrel, the lower side of the feeding hopper is connected with the iron removing cavity, a rotating shaft is horizontally arranged inside the iron removing cavity, magnetic iron pieces are symmetrically arranged on the outer wall of the rotating shaft in the vertical direction, and the seven pairs of magnetic iron pieces are arranged in the left-right direction. The bottom end of the iron removing cavity is connected with a feeding port in the lower side of the stirring barrel, a sieve is horizontally arranged on the upper side inside the stirring barrel, and the periphery of the sieve is installed on the inner wall of the stirring barrel through bolts. The magnetic iron pieces are rotated to remove iron of feedstuff sufficiently, the vibration sieve can make the feedstuff evenly fall, and therefore the stirring effect and efficiency are improved; a scraping cleaning bristle brush can scrap off the feedstuff adhering to the inner wall, waste of the feedstuff is avoided, a solar cell panel converts solar energy into electric energy so that the electric energy can be used for the stirring machine, in this way, energy is saved, continuous and even automatic discharging can be achieved, and the working efficiency of the stirring machine is improved.

Owner:林桂清

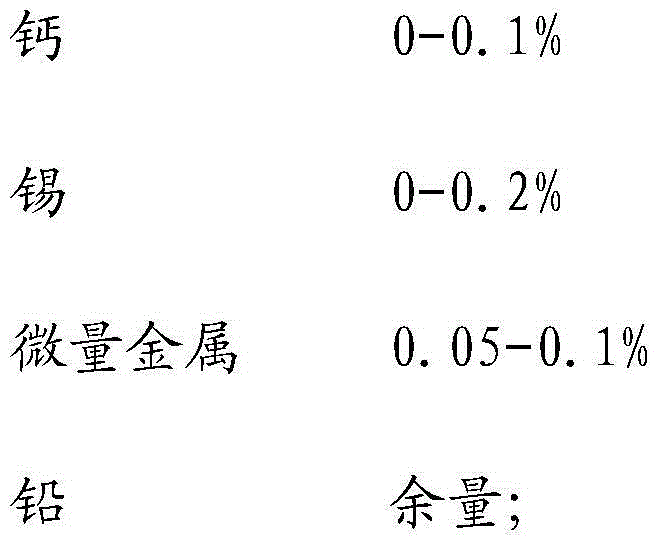

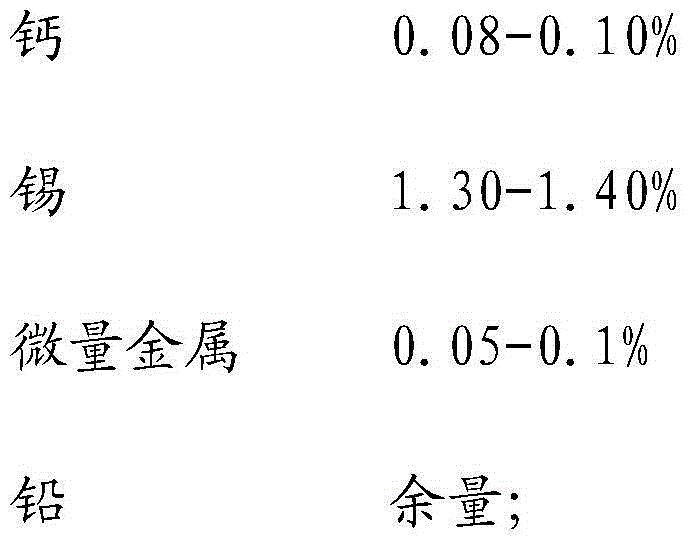

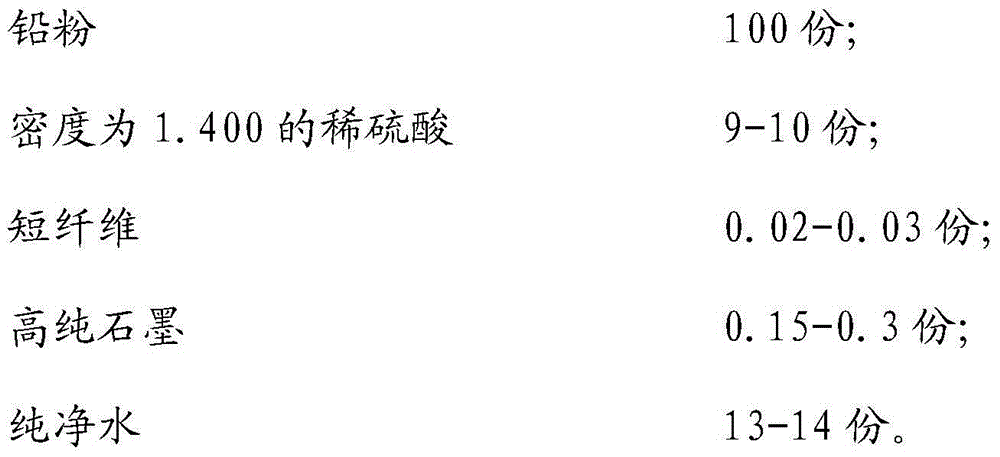

Lead-carbon battery for motorcycle and preparation method thereof

ActiveCN104835965AGood for high rate dischargeImprove charge acceptanceLead-acid accumulator electrodesFiberPower flow

The invention discloses a lead-carbon battery for a motorcycle. The lead-carbon battery comprises positive grid, a positive lead plaster coated on the positive grid, a negative grid and negative lead plaster coated on the negative grid, wherein the positive lead plaster is prepared from the following raw materials in parts by weight: 100 parts of lead powder, 9-10 parts of dilute sulfuric acid which is 1.400 in density, 0.02-0.03 part of short fiber, 0.15-0.3 part of graphite and 13-14 parts of purified water; and the negative lead plaster is prepared from the following raw materials in parts by weight: 100 parts of lead powder, 0.95-1.15 parts of expanding agent, 1-4 parts of complex carbon material, 7-8 parts of dilute sulfuric acid which is 1.400 in density, 0.015-0.025 part of short fiber and 11-14 parts of purified water. The positive and negative active substance utilization ratio of the prepared lead-carbon battery for the motorcycle is increased by 15-25 percent in comparison to a conventional battery. When the battery is started for discharging at large current at the multiplying power of 8-10 times, the output power is stable.

Owner:QINGYUAN KAIJIE POWER SUPPLY CO LTD

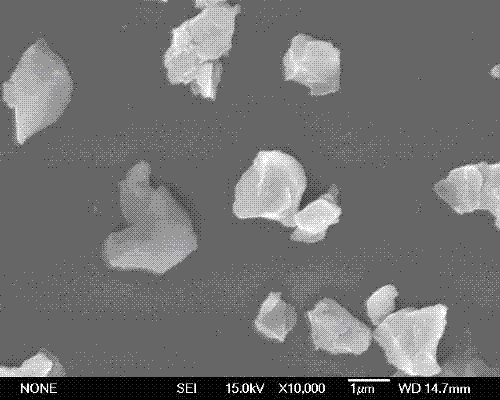

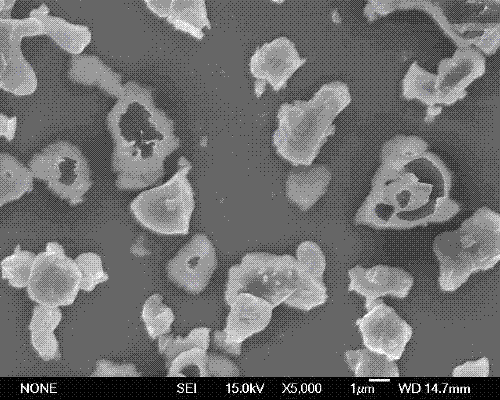

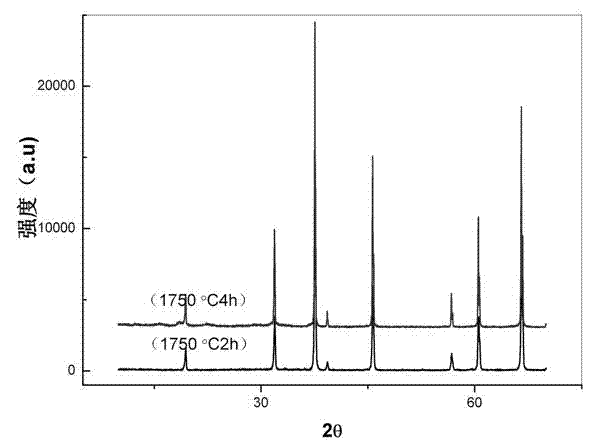

Process for preparing gamma-AlON powder by chemical coprecipitation and carbothermal reduction method

The invention relates to a process for preparing gamma-AlON powder by chemical coprecipitation and a carbothermal reduction method, belonging to the synthesis and processing field of ceramic material powder. The process is characterized by comprising the following steps: carrying out precipitation reaction based on aluminium nitrate, urea and nano carbon black as raw materials, polyethylene glycol (PEG) as a dispersing agent and ammonium bicarbonate as a precipitator so as to obtain a precursor; precipitating and washing the precursor, drying and then grinding, and processing for 2-4 hours under the protective condition of nitrogen with 700 DEG C; insulating for 2-4 hours at the temperature of 1750 DGE C under the condition that the flow of nitrogen is 0.5L / min; and naturally cooling in air, then decarbonizing at the temperature of 700 DEG C so as to finally obtain the pure AlON powder with a particle size of 1-4 mu m and the grain size of the powder is uniform.

Owner:SHANGHAI UNIV

Integrated crushing, stirring and mixing device for construction coating particles

InactiveCN107442031AAvoid affecting useMix in timeTransportation and packagingMixer accessoriesDrive shaftArchitectural engineering

The invention discloses an integrated crushing, stirring and mixing device for construction coating particles, which comprises a bottom plate, a crushing groove and a mixing box, wherein a driving shaft is mounted on a support rack; one end of the driving shaft is connected with a driving motor arranged on the support rack; a vertical upward pressure rod is arranged at a port of the crushing groove; a crushing pressure plate is arranged at the lower end of the pressure rod; a sieve plate is arranged in the crushing groove; a material inlet is formed in a side wall, close to the crushing groove, of the top end of the mixing box, and connected with a material outlet by a material guide channel; a stirring shaft is arranged in the crushing groove; the upper end of the stirring shaft is connected with the driving shaft by a gear mechanism; a plurality of stirring and mixing rods arrayed in a circular ring manner are arranged at the lower end of the stirring shaft; and a discharge port is formed in a side wall of the bottom end of the mixing box. The device is simple in structure, higher in processing and production efficiency, better in linkage, stable in transmission, uniform and sufficient in mixing, easy and simple to operate and higher in practicability, and can simultaneously perform crushing and mixing.

Owner:林红英

All-directional nutrient solution spraying device for hydraulic engineering irrigation

InactiveCN108112332AImprove the cultivation effectImprove the mixing effectTransportation and packagingRotary stirring mixersFixed frameEngineering

The invention discloses an all-directional nutrient solution spraying device for hydraulic engineering irrigation. The all-directional nutrient solution spraying device comprises a base, a firs screwrod, a support platform and a mixing tank, wherein a first material storage tank and a second material storage tank are symmetrically arranged at the left and right parts on the upper side of the fixed frame, and liquid baffles are mounted on liquid outlets in the lower parts of the first material storage tank and the second material storage tank in a sliding manner; and an annular liquid sprayinghead is further mounted at the upper end of a guide pipe in a threaded manner. By utilizing the liquid baffles, the liquid outlets of the first material storage tank and the second material storage tank are intermittently blocked, and a nutrient solution and a water solvent are intermittently discharged into the mixing tank to be stirred and mixed, so that the mixing effect between the nutrient solution and the water solvent is greatly improved, and a non-uniform mixing phenomenon is avoided; and by utilizing the annular liquid spraying head, the spraying range is relatively large.

Owner:浦江县宏创科技开发有限公司

Preparation technology of UO2-graphene composite fuel

ActiveCN107342110AEvenly dispersedEvenly distributedNuclear energy generationReactors manufactureNuclear reactor coreNuclear reactor

The invention belongs to the field of preparation of nuclear reactor fuels, and provides a preparation technology of a UO2-graphene composite fuel pellet in order to solve the problems of uneven physical mixing, low production efficiency and high production cost existing in existing preparation technologies of a UO2-graphene composite fuel and low density of fuels prepared through other sintering technologies. The technology mainly comprises the following steps: 1, synthesizing UH3 powder; 2, synthesizing a uranyl nitrate solution; 3, synthesizing (NH4)2U2O7-graphene composite powder; 4, synthesizing UO2-graphene composite powder; 5, mixing the UO2-graphene composite powder with the UH3 powder; 6, carrying out cold press molding to form a green body of the fuel pellet; and 7, carrying out pressureless sintering to form the fuel pellet. The technology adopting a chemical method has the advantages of high production efficiency and low cost, and solves the problems of uneven elements and low density of the composite fuel, the relative density of the prepared composite fuel is about 95%, and the composite fuel has excellent thermophysical performances.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

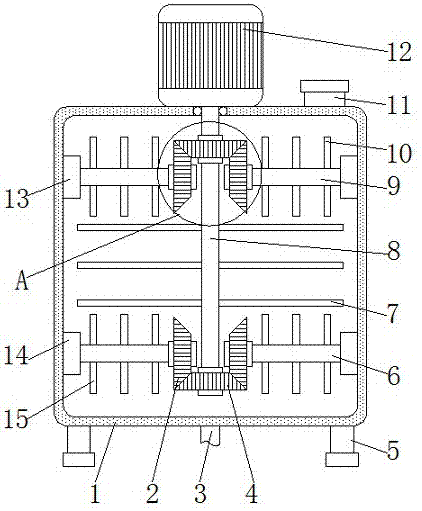

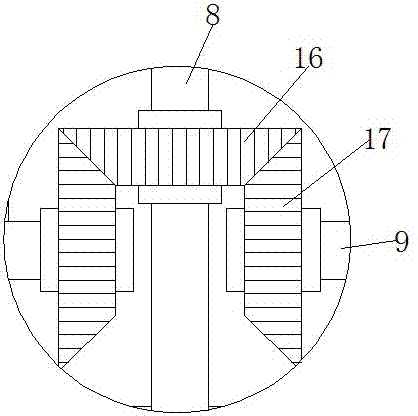

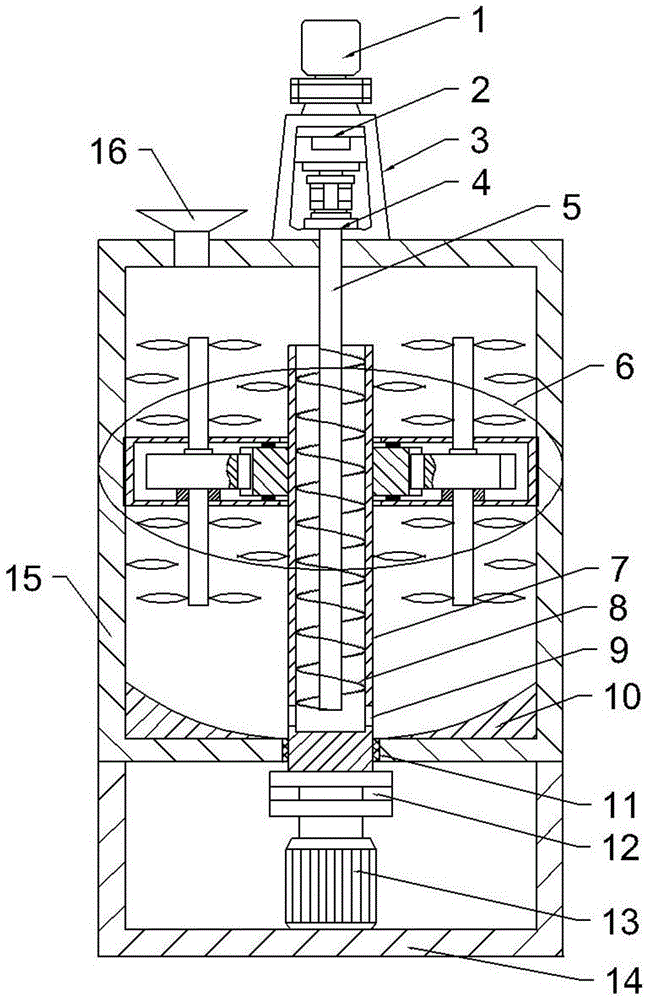

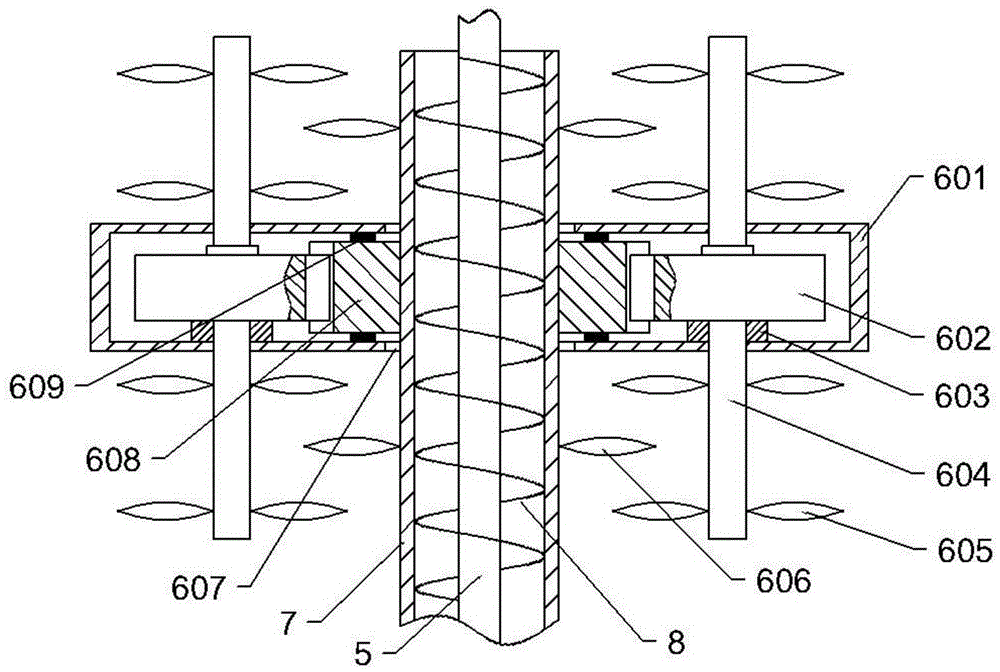

Stirring machine for food processing

InactiveCN107281945AAvoid uneven mixingStir wellRotary stirring mixersTransportation and packagingPulp and paper industryFood processing

The invention discloses a stirring machine for food processing. The stirring machine comprises a stirring tank, wherein a motor is fixedly connected at the top of the stirring tank; a rotary shaft is fixedly connected at the output end of the motor; the bottom of the rotary shaft penetrates through an inner cavity of the stirring tank and is sleeved with a first driving bevel gear; first driven bevel gears are arranged on two sides of the first driving bevel gear and meshed with the two sides of the first driving bevel gear. The stirring tank, the first driven bevel gears, a discharging pipe, the first driving bevel gears, supporting legs, a first stirring shaft, third stirring rods, the rotary shaft, a second stirring shaft, second stirring rods, a feeding pipe, the motor, second bearing blocks, first bearing blocks, first stirring rods, second driving bevel gears and second driven bevel gears are matched in use, the problem of uniform stirring of existing stirring machines for food processing is solved, the stirring machine for food processing has the advantage of uniform stirring and worth popularization, and the practicability of the existing stirring machines for food processing is improved.

Owner:吴亚伟

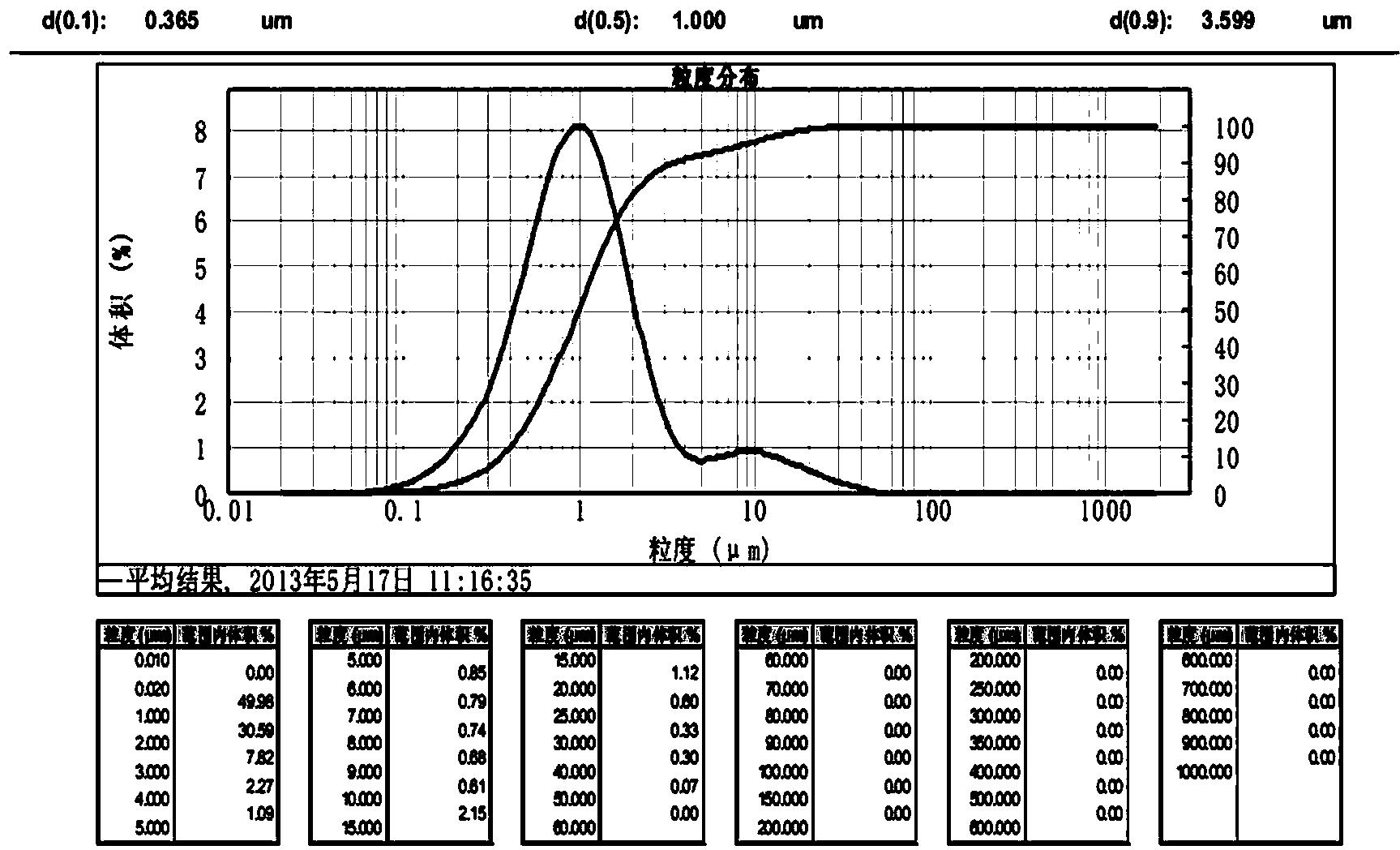

Preparation method of ultrafine tungsten carbide powder

ActiveCN103408015AImprove uniformityAvoid uneven mixingTungsten/molybdenum carbideTungstenCarbon black

The invention relates to a preparation method of ultrafine tungsten carbide powder. A mixture of ultrafine tungsten powder, carbon black and ultrafine tungsten carbide powder used as an initial reactant is subjected to carbonization reaction in a non-oxidizing atmosphere to prepare the ultrafine tungsten carbide powder. The ultrafine tungsten carbide powder prepared by the method has the advantages of small particle size, uniform particle size distribution, favorable dispersity, no pellet and high combined carbon content; and the production technique can easily control the quality and can implement mass production.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

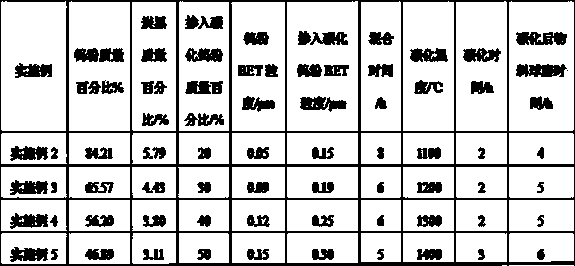

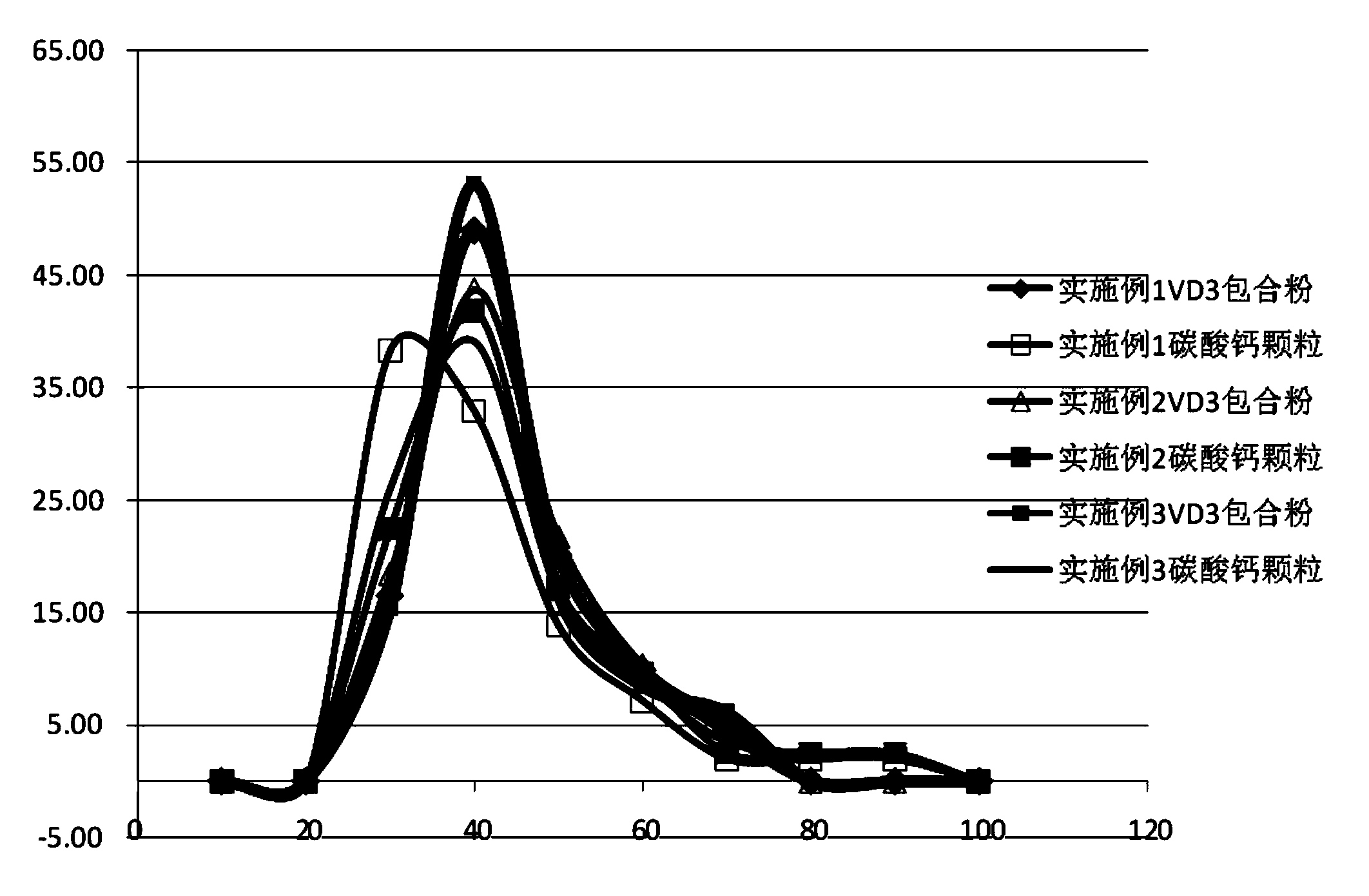

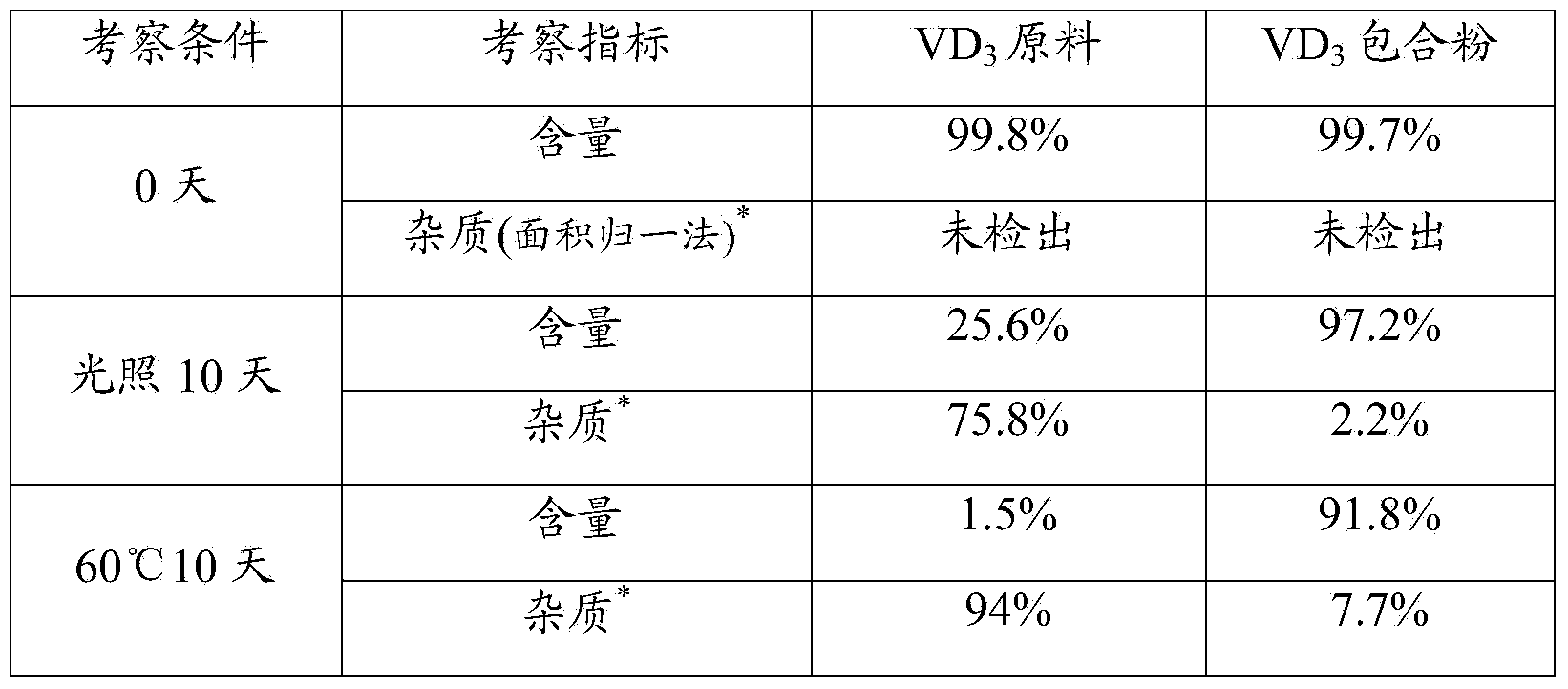

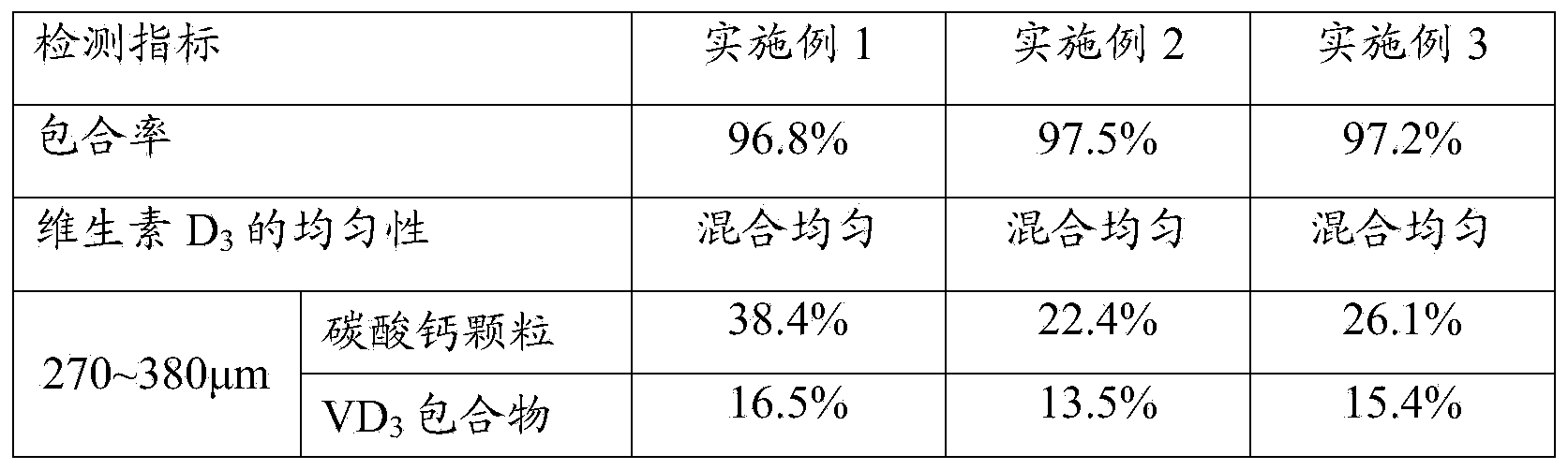

Calcium carbonate D3 granula and preparation method thereof

ActiveCN103463126AImprove stabilityFix stability issuesOrganic active ingredientsMetabolism disorderVitaminBeta-Cyclodextrins

The invention discloses a calcium carbonate D3 granula and a preparation method thereof. The calcium carbonate D3 granula is prepared by mixing calcium carbonate granules and beta-cyclodextrin inclusion powder of vitamin D3, wherein the grain size distribution of the calcium carbonate granules is consistent with that of beta-cyclodextrin inclusion powder granules of vitamin D3; the weight ratio of beta-cyclodextrin inclusion powder of vitamin D3 to the calcium carbonate granules is 4 / 10,000 to 5.7 / 1,000. By adopting the preparation method, the problems due to the stability of vitamin D3 and non-uniform mixing can be solved; the preparation process is simple; the calcium carbonate D3 granula is easily stored and has a long shelf life; the dosage is easily mastered; the calcium carbonate D3 granula is suitable for companies of various scales to produce and has a huge business prospect.

Owner:GUIZHOU LIANSHENG PHARMA

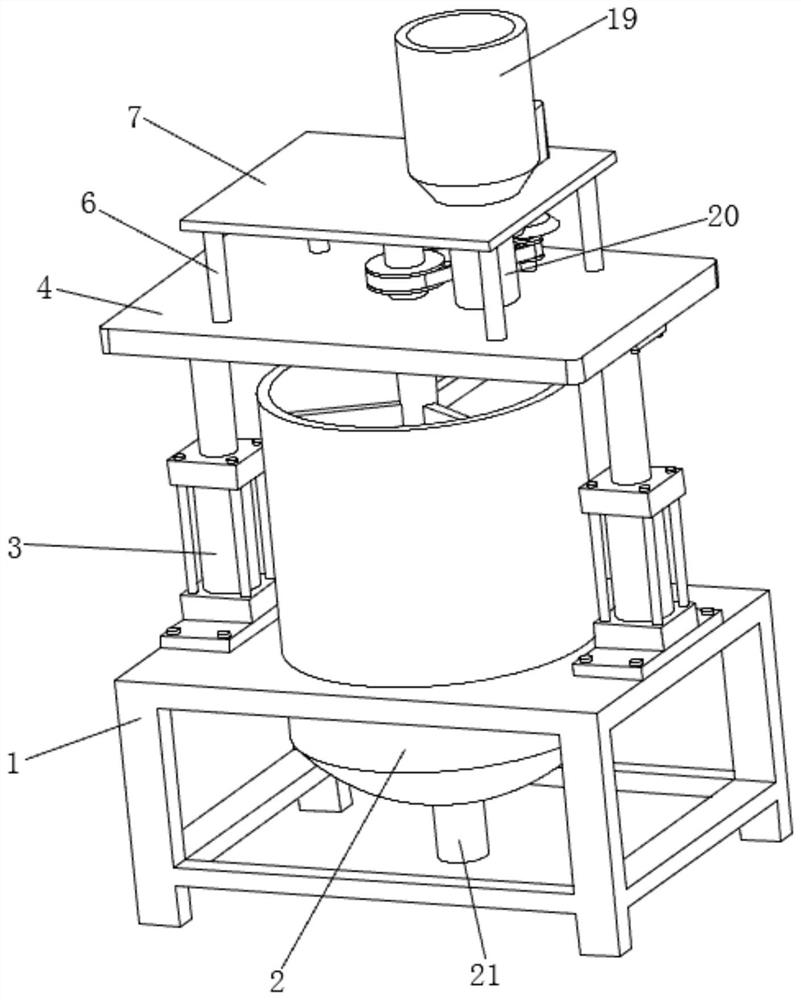

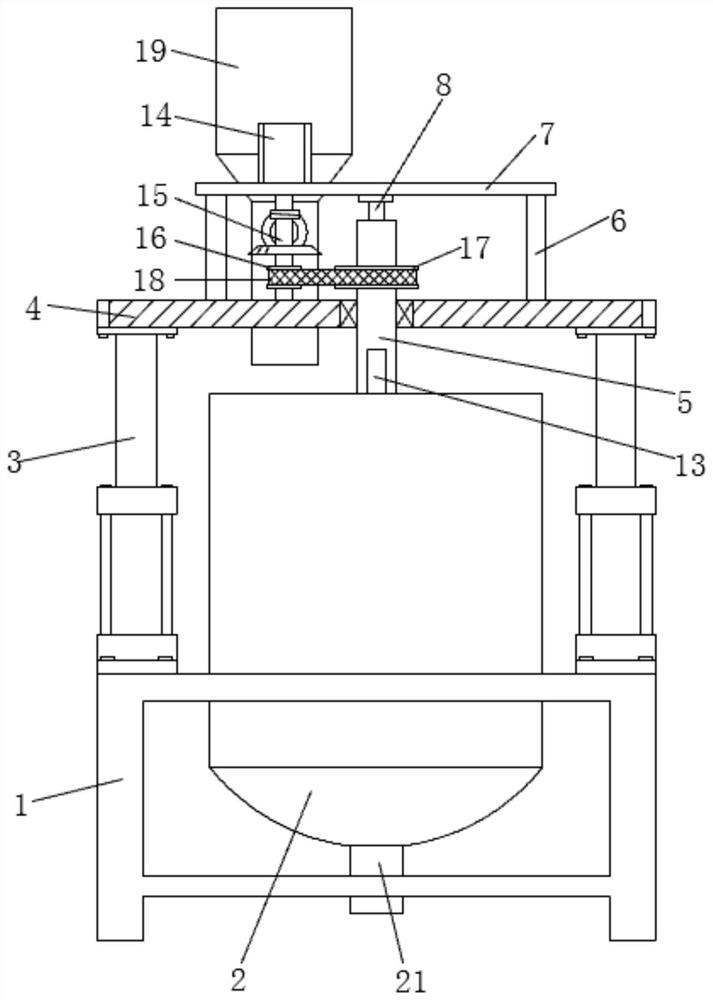

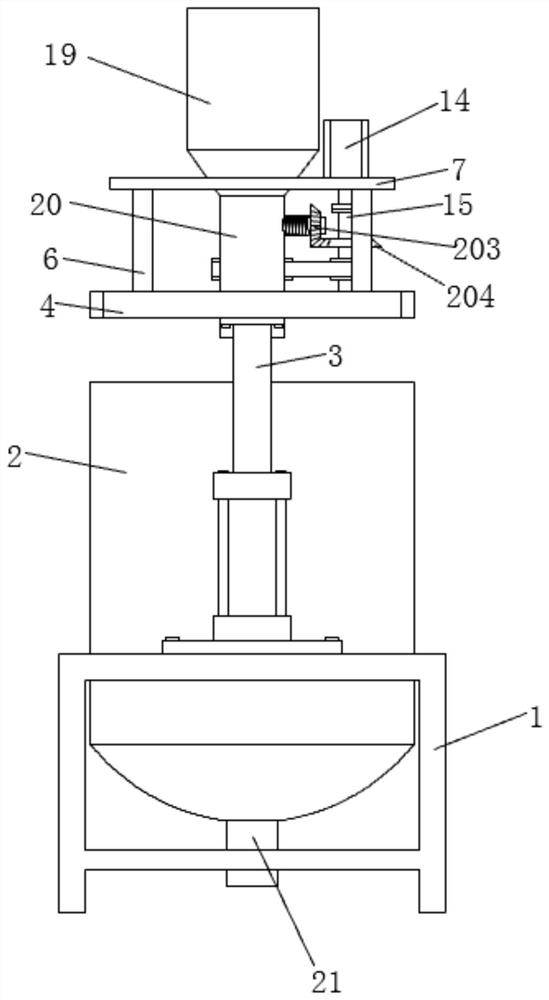

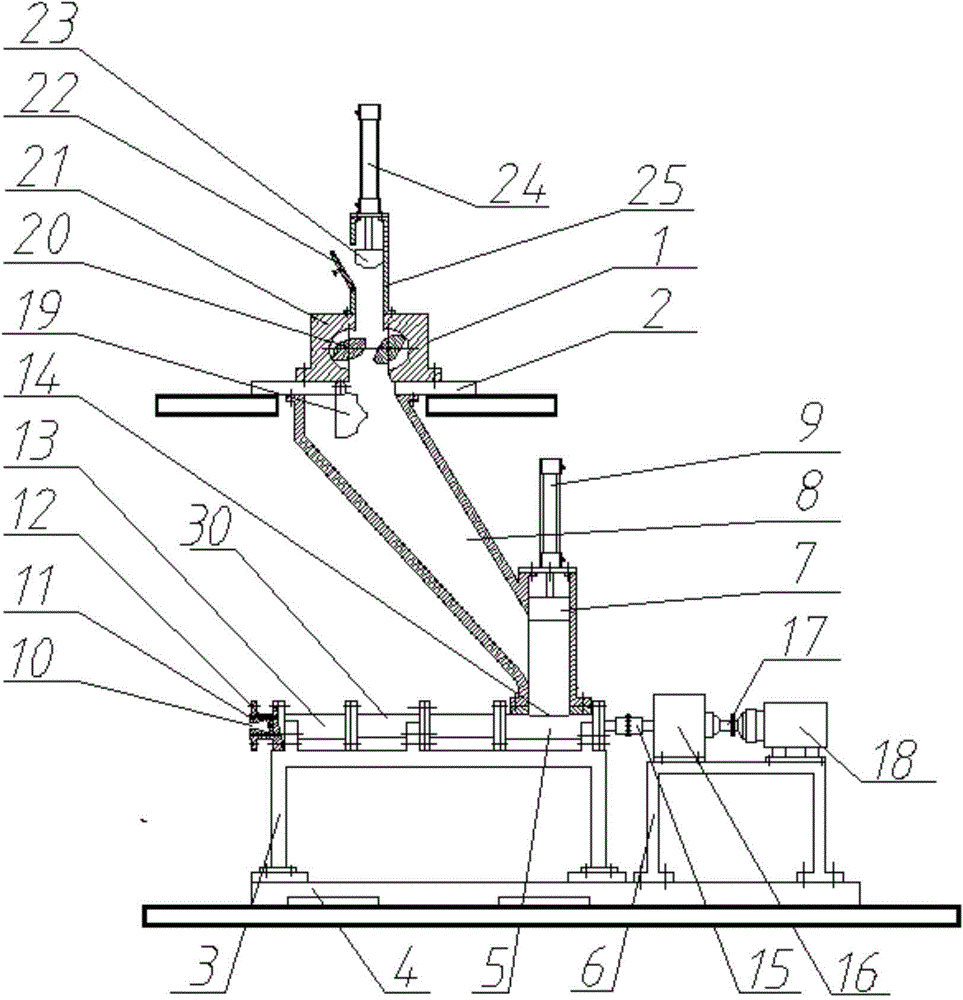

Solid and liquid mixing and reacting apparatus with solid material breaking device

InactiveCN106540645AAvoid uneven mixingStir wellRotary stirring mixersTransportation and packagingEngineeringKnife blades

The invention provides a solid and liquid mixing and reacting apparatus with a solid material breaking device. The apparatus comprises a tank body and an upper cover; a mixing chamber is arranged in the tank body; the upper cover is provided with the solid material breaking device; the solid material breaking device comprises a breaking tank, a breaking motor, a breaking rotation shaft, rotating cutter blades and a fixed cutter blade; a first liquid material feeding device and a second liquid material feeding device are arranged on the sidewall of the top of the tank body; each of the first liquid material feeding device and the second liquid material feeding device comprises a transmission box, a rotating motor, a liquid feeding tube and a rotating spray disc; a stirring device is arranged in the mixing chamber; the stirring device comprises a stirring motor, a stirring shaft, first rotating rods, fixed rods, second rotating rods and a scraper plate; a solid material is broken through the solid material breaking device; and the material is fully stirred through the stirring device to realize reaction acceleration.

Owner:梅新星

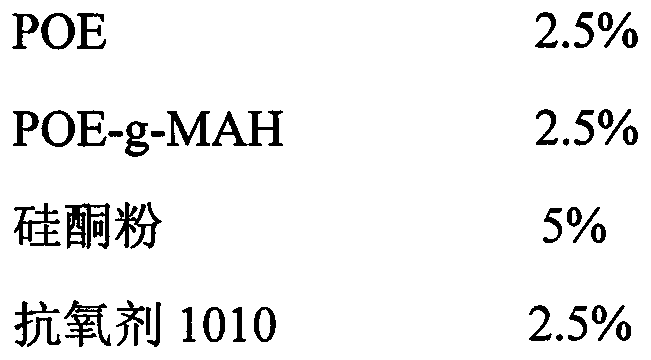

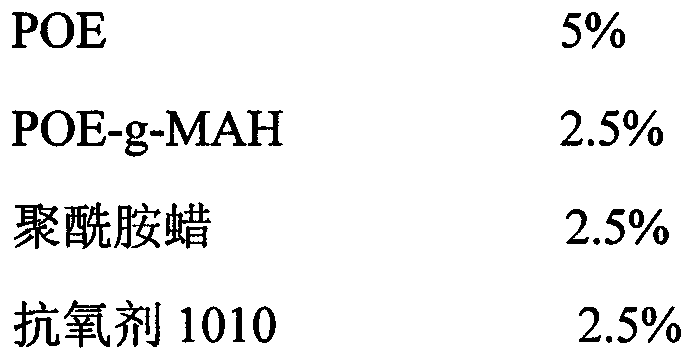

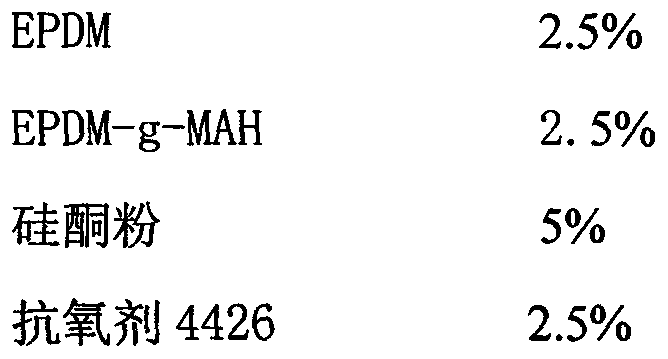

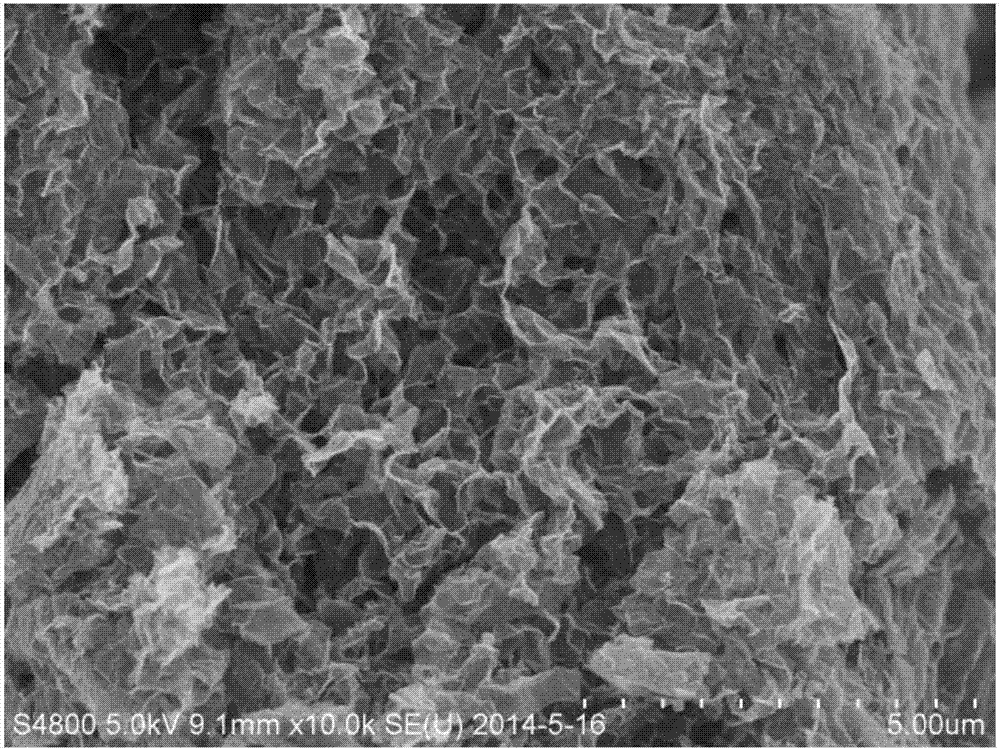

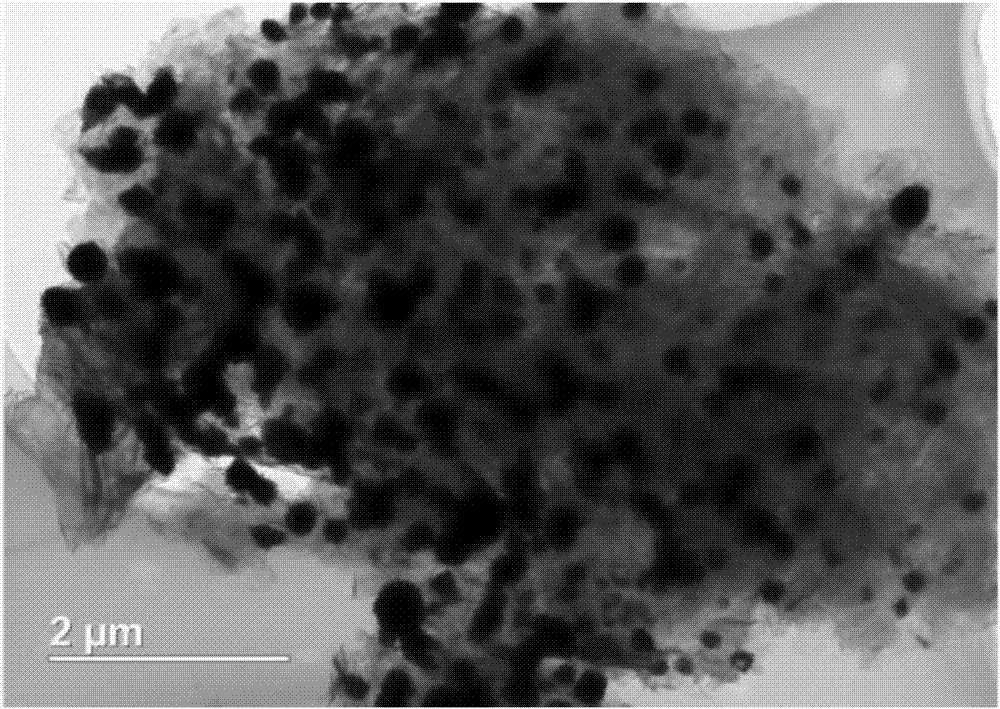

High-performance polyamide/samarium-iron-nitrogen magnetic composite material and preparation method thereof

The invention relates to a method for preparing a high-performance polyamide / samarium-iron-nitrogen magnetic composite material. The method comprises the following steps: first, extruding polyphenylene sulfide resin serving as a matrix, a toughening agent, a lubricating agent, an antioxidant and the like together by using a twin-screw extruder to prepare a multifunctional master batch; second, extruding samarium-iron-nitrogen which is subjected to surface treatment and the master batch which is prepared in the first step to prepare the magnetic composite material. The polyamide / samarium-iron-nitrogen magnetic composite material prepared by the method has high fluidity, high magnetic performance and good mechanical properties, and is suitable for producing devices by an injection molding method. The method has the advantages of simple preparation process, low equipment requirement and applicability to industrial production.

Owner:杭州海声科技有限公司

Lead-carbon super battery anode material and preparation method thereof

The invention provides a lead-carbon super battery anode material which is a graphene / Pb nano composite material. The lead-carbon super battery anode material is prepared by mixing a lead salt solution with a graphite oxide solution, carrying out hydrothermal reaction, and then carrying out macro body freeze drying and burning. The lead-carbon super battery anode material is prepared from 91 to 99.5 percent of lead and 0.5 to 9 percent of graphene. The lead salt solution is prepared by dissolving soluble lead salt into deionized water; the soluble lead salt is one or several of lead-containing nitrate, acetate, carbonate, hydrochloride, sulfate and complex salt. The invention further provides a preparation method of the lead-carbon super battery anode material. The preparation method provided by the invention has the advantages of high efficiency, environmental friendliness, high uniformity and the like; the prepared lead-carbon super battery anode material is high in uniformity, high in stability and wide in application prospect.

Owner:江苏强劲新能源科技有限公司

Diamond powder stirring and mixing device

InactiveCN112076655AIncrease the mixing areaAvoid uneven mixingTransportation and packagingRotary stirring mixersElectric machineryEngineering

The invention discloses a diamond powder stirring and mixing device comprising a stirring tank with an opening in the top, the stirring tank is plugged into the center of the inner cavity of a base; supporting columns are symmetrically and fixedly connected to the left side and the right side of the top of a base; a cover plate is fixedly connected to the tops of the supporting columns, and threesets of first hinge seats are fixedly connected to the outer wall, located below the cover plate, of a stirring shaft in the axial direction; and a first stirring rod is hinged to one end, away from the stirring shaft of each first hinge seat. The stirring shaft, the first stirring rods and a second stirring rod can be driven to rotate through a rotating motor, so that materials in the stirring tank are stirred, and the sliding block slides up and down along a reciprocating screw rod in a reciprocating mode; connecting rods drive the first stirring rods to swing up and down at an angle for stirring, so that the stirring areas of the first stirring rods and the second stirring rod are larger, the mixing effect is better, and uneven mixing caused by inertia centrifugal force generated by materials under the stirring action of the stirring shaft and the stirring rods can be avoided; therefore, the mixing effect can be further improved.

Owner:南安市鄂丰机械有限公司

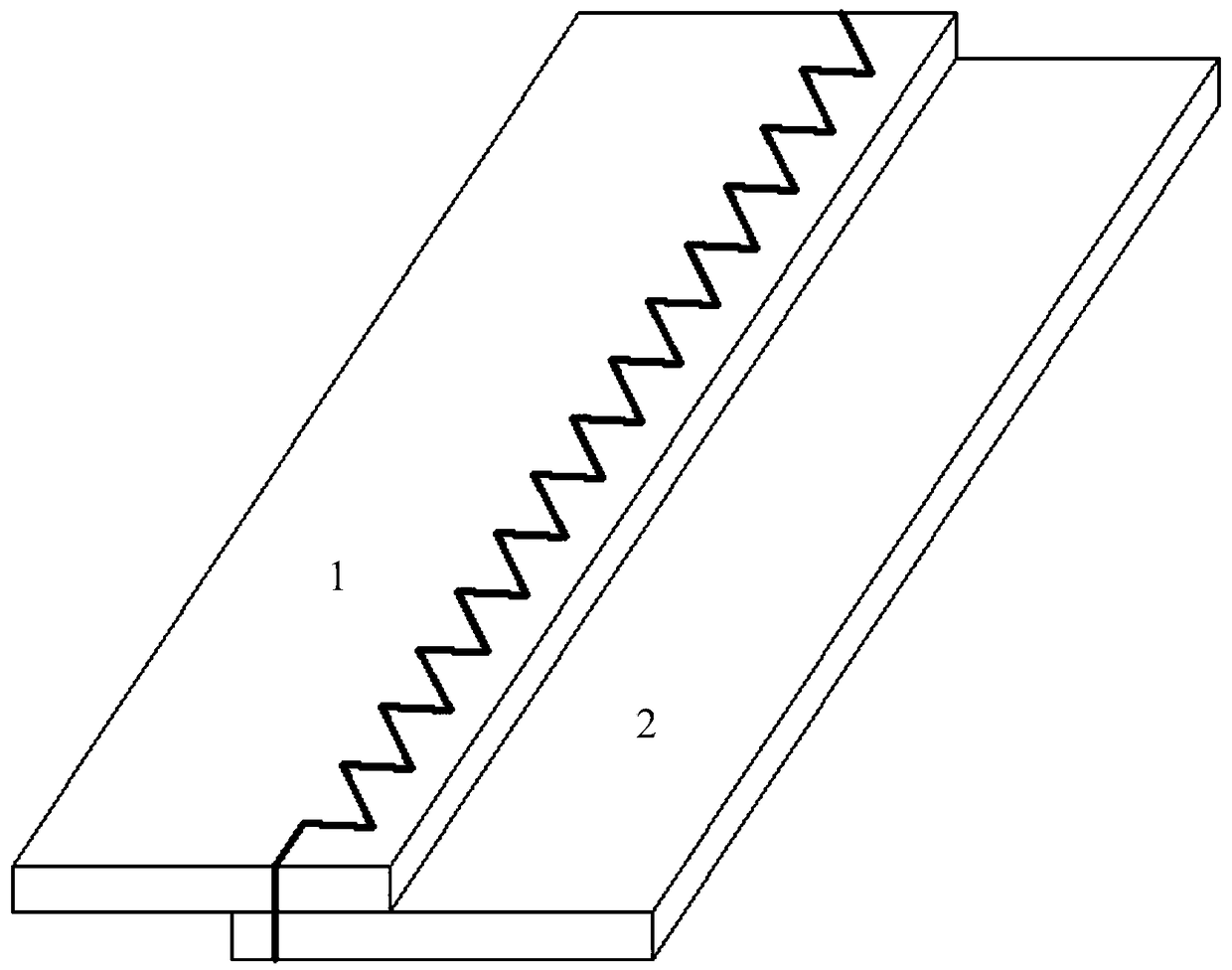

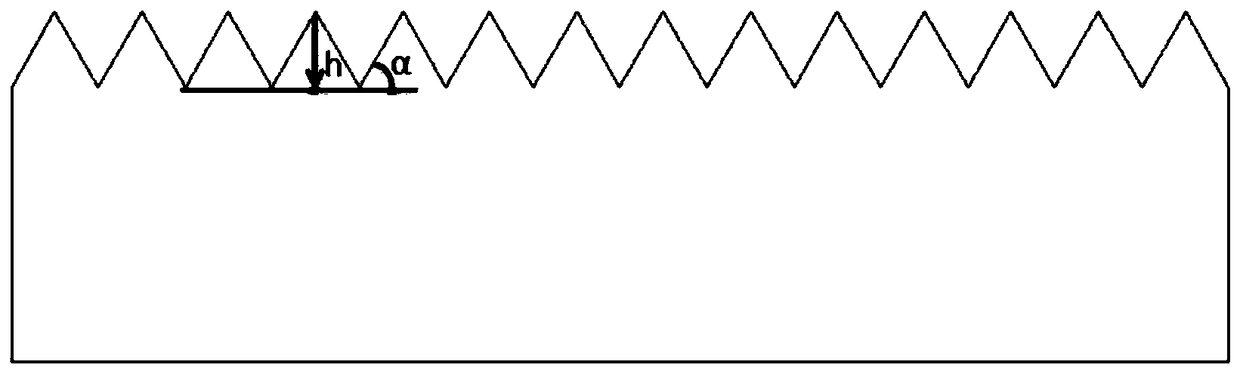

Titanium-steel dissimilar metal structure and manufacturing method thereof

ActiveCN108817647AHigh strengthHigh tensile strengthWorkpiece edge portionsNon-electric welding apparatusRelative motionEngineering

The invention provides a titanium-steel dissimilar metal structure and a manufacturing method thereof. The meshing-corresponding sawtooth structure with high integrating degree is obtained by a stacking-and-lapping mode; a composite plate is obtained by meshing-connection; and high-quality welding of titanium-steel dissimilar metal is achieved by a stirring-friction welding method. The influence on the performance of a dissimilar metal stirring-friction welding connector by deviation is not necessarily to be considered; and asymmetry of a forward side and a backward side in the traditional butt joint process is eliminated. The sawtooth meshing structure is adopted, and therefore action of welding force on materials during the welding process is improved to assist material smashing, the linear contact area of the dissimilar metal is increased, relative movement distance of metal atoms is shortened so that more atoms can move under the same energy, the mutual flow and mutual mixing capacity of the dissimilar metal materials can be improved, the problem of nonuniform connector tissue mixing is avoided, interlocking mixing of weld joint materials is improved, and strength of the connector is greatly improved.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method of cobalt-free positive electrode material

InactiveCN112133903AAchieve decobaltizationExcellent H2Secondary cellsPositive electrodesNickel saltLithium hydroxide

The invention discloses a preparation method of a cobalt-free positive electrode material, which comprises the following steps of: (1) preparing of a cobalt-free positive electrode material precursor:(1a) mixing a nickel salt solution and a manganese salt solution, adding a nano additive, and carrying out ultrasonic treatment; (1b) in a nitrogen atmosphere, adding the mixed solution into a reaction kettle, then adding a mixed alkali solution of strong alkali and ammonia water, adjusting the pH value to 9-12 and the reaction temperature to 40-60 DEG C, and washing, filtering and drying after the reaction is finished; and (2) high-temperature sintering: uniformly mixing lithium hydroxide with the powder obtained in the step (1b), calcining at a constant temperature of 700-1000 DEG C for 5-20 hours, and naturally cooling to obtain the cobalt-free positive electrode material. The method can be used for preparing a series of cobalt-free substitutes of NMC and NCA cathode materials, is simple in process, uniform in particle distribution, large in specific discharge capacity and good in cycle performance, realizes cobalt removal of the cathode materials, and reduces the cost.

Owner:陕西红马科技有限公司

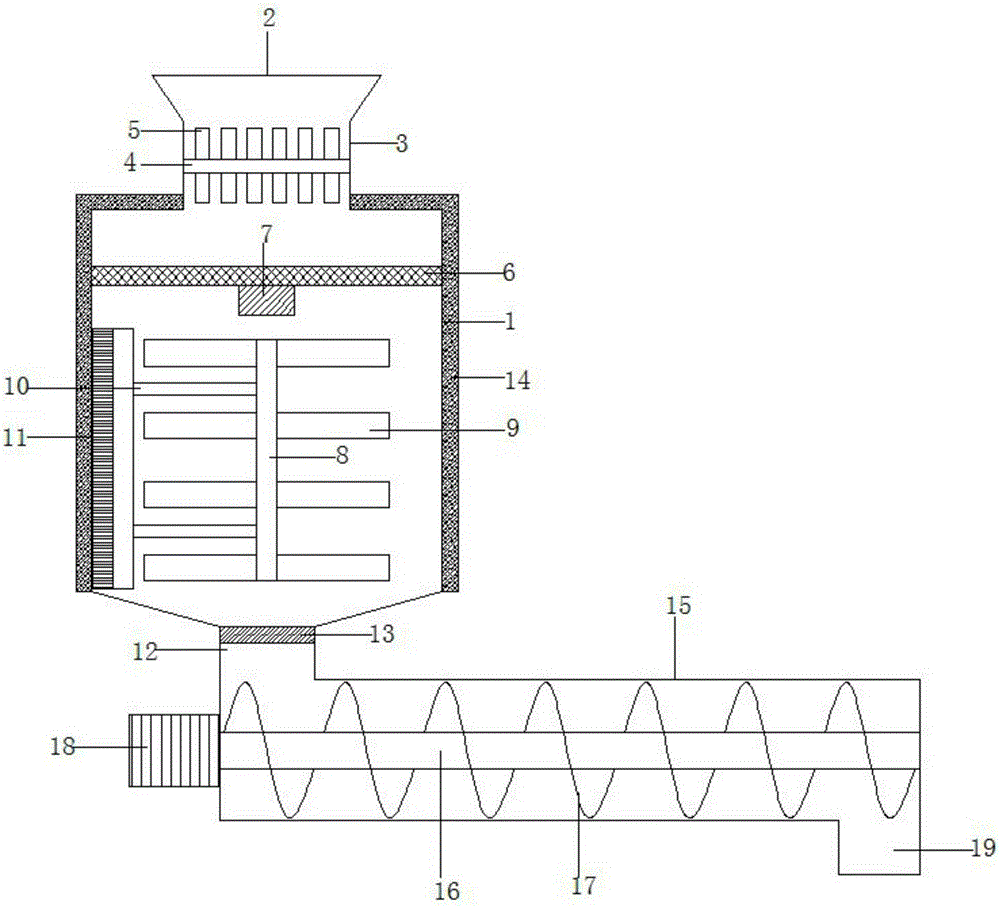

Vertical type mixer for producing ceramics

InactiveCN104923102AAvoid pollutionSave raw materialsDispersed particle filtrationRotary stirring mixersCeramicEngineering

The invention discloses a vertical type mixer for producing ceramics. The vertical type mixer comprises a mixing cylinder, cleaning nozzles and a circulation material conveying pump, wherein a feeding funnel is disposed at the left end of the mixing cylinder, a cover plate is disposed at the top end of the feeding funnel, a rotary shaft is vertically disposed at the axis inside the mixing cylinder, mixing blades are disposed on the upper outer wall of the rotary shaft in a left-right symmetry manner, and a mixing plate is fixed on the lower side of the rotary shaft. The vertical type mixer has the advantages that the mixing blades and the mixing plate jointly mix materials, the materials at the bottom are pumped into the top of the mixing cylinder in a circulation manner for mixing, uneven mixing caused by the fact that the materials at the bottom cannot be stirred, self-cleaning of the interior of the mixing cylinder can be achieved, manual cleaning is not needed, time and labor are saved, the mixing cylinder can be used conveniently next time, dust leakage during mixing can be avoided by the cover plate on the feeding funnel, dust produced during mixing can be recycled, dust pollution is avoided, and raw materials are saved.

Owner:顾马飞

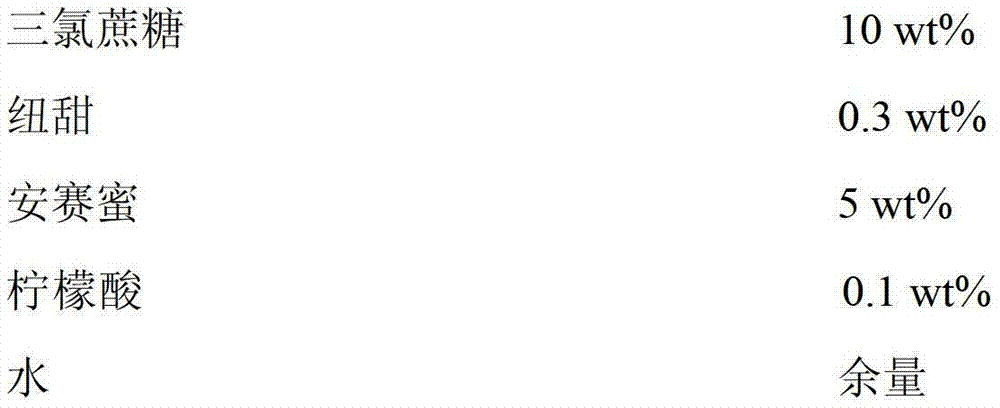

Liquid composite high-intensity sweeter and preparation method thereof

The invention discloses a liquid composite high intensity sweeter comprising sweet substances and a solvent. Based on the weight of the sweeter, the sweet substances are one or a plurality of the following components: 0.1-3wt% of aspartame, 0.1-30wt% of sucralose, 0.1-30wt% of acesulfame potassium and 0.01-10wt% of neotame. In addition, the invention further discloses a method for preparing the liquid composite high intensity sweeter. The liquid composite high intensity sweeter is obtained by dissolving the sweet substances into the solvent, not only has the similar sweet taste to sucrose and several times to thousandfold higher sweetness than sucrose, is mixed uniformly, and has no particles remained; the product quality and the convenience in use are beneficially improved, and the actual requirements of production and consumption are well satisfied; and meanwhile, the method for preparing the sweeter provides an effective guarantee for the quality and the edible safety of sweeter products.

Owner:TECHNO (FUJIAN) FOOD INGREDIENTS CO LTD

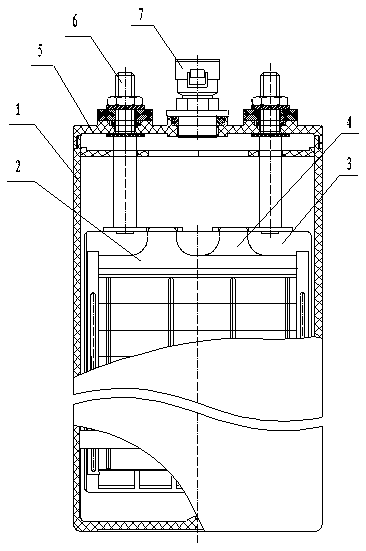

High-capacity long-service-life double-bag nickel-hydrogen battery

ActiveCN108767233AEasy to optimizeImprove structural stabilityFinal product manufactureCell electrodesInternal resistanceLiquid state

The invention discloses a high-capacity long-service-life double-bag nickel-hydrogen battery. A battery pole plate consists of a bag type nickel positive electrode plate, a bag type hydrogen storage alloy negative electrode pole plate and a multilayer composite membrane or separation electrode grid positioned between the bag type nickel positive electrode plate and the bag type hydrogen storage alloy negative electrode pole plate; an electrode material of the bag type nickel positive electrode plate is prepared from positive electrode active materials, conducting agents, additives and bondingagents; an electrode material of the bag type hydrogen storage alloy negative electrode pole plate is prepared from hydrogen storing alloy powder, conducting agents and bonding agents; electrolyte isa KOH alkaline solution containing additives in a rich liquid state. Through positive and negative electrode formula optimization, electrolyte formula optimization, electrode preparation method process improvement and separation plate optimization selection, the electrode structure of the positive and negative electrodes is greatly optimized; the utilization rate of positive and negative electrodeactive substances is improved; the internal resistance of the battery is optimized and reduced; the chalking resistant and anticorrosion capability of negative electrode hydrogen storage alloy is improved; the low-temperature performance of the battery is improved; the cycle service life of the battery is prolonged.

Owner:河南省恒明新能源有限公司

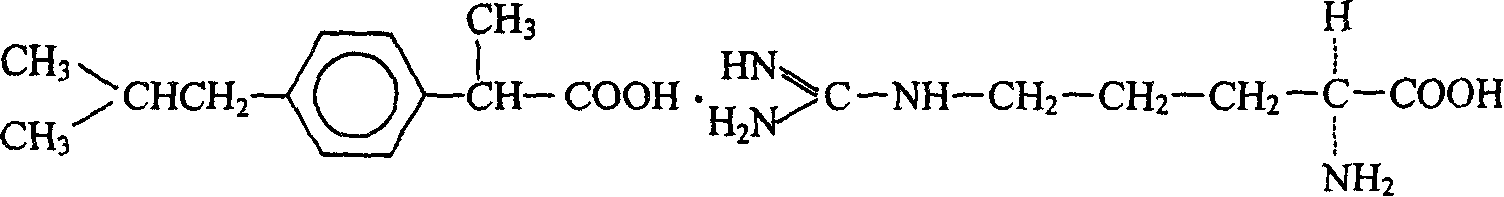

Method for preparing ibuprofen arginine

ActiveCN101190889AReduce synthesis process steps and reaction equipmentShort production processOrganic chemistryOrganic compound preparationSolventChemistry

The invention discloses a preparation method of an arginine ibuprofen salt. The method is that ibuprofen is adopted to dissolve into ethanol with 95 percent concentration and added with solid arginine while stirring, and then heated to 40 to 80 DEG C, stirred for 15 to 60 minutes, after reaction, cooled to room temperature and crystallized. The preparation method of the invention adopts that the solid arginine is directly added to the ibuprofen solution and no solvent is added before the solid arginine addition, thus shortening production technique steps and reducing reaction equipment. The process that directly crystallization from mother liquid in room temperature, need not be added with other solvent to dilute, thus reducing consumption of solvent and kinds, shortening production technique flow; as the solvent can be recycled and reused, thus reducing production cost and saving energy.

Owner:安徽华辰制药有限公司

Circulating material stirring and mixing device

InactiveCN105413560AImprove the mixing effectAvoid uneven mixingTransportation and packagingRotary stirring mixersCouplingEngineering

The invention discloses a circulating material stirring and mixing device. The circulating material stirring and mixing device comprises a stirring shell, a transmission device, a machine frame and a rotating shaft. The transmission device is fixed to the top end of the stirring shell through the machine frame and connected with the rotating shaft located inside the stirring shell. A spiral lifting blade is arranged on the rotating shaft, a lifting shell is arranged outside the spiral lifting blade and is hollow, the upper end of the lifting shell is open, and the lower end of the lifting shell is closed and connected with a motor located below the stirring shell through a coupling. A sealing ring is arranged at the portion where the lifting shell is in contact with the stirring shell, and an in-out opening is formed in the lower portion of the lifting shell. A stirring device is arranged on the outer side wall of the upper portion of the lifting shell. The circulating material stirring and mixing device has the advantages that structural design is reasonable; materials can be forcedly circulated, the problem that the materials at the bottom are unevenly mixed is solved, and the stirring and mixing effect on the materials is better.

Owner:TAISHAN MEDICAL UNIV

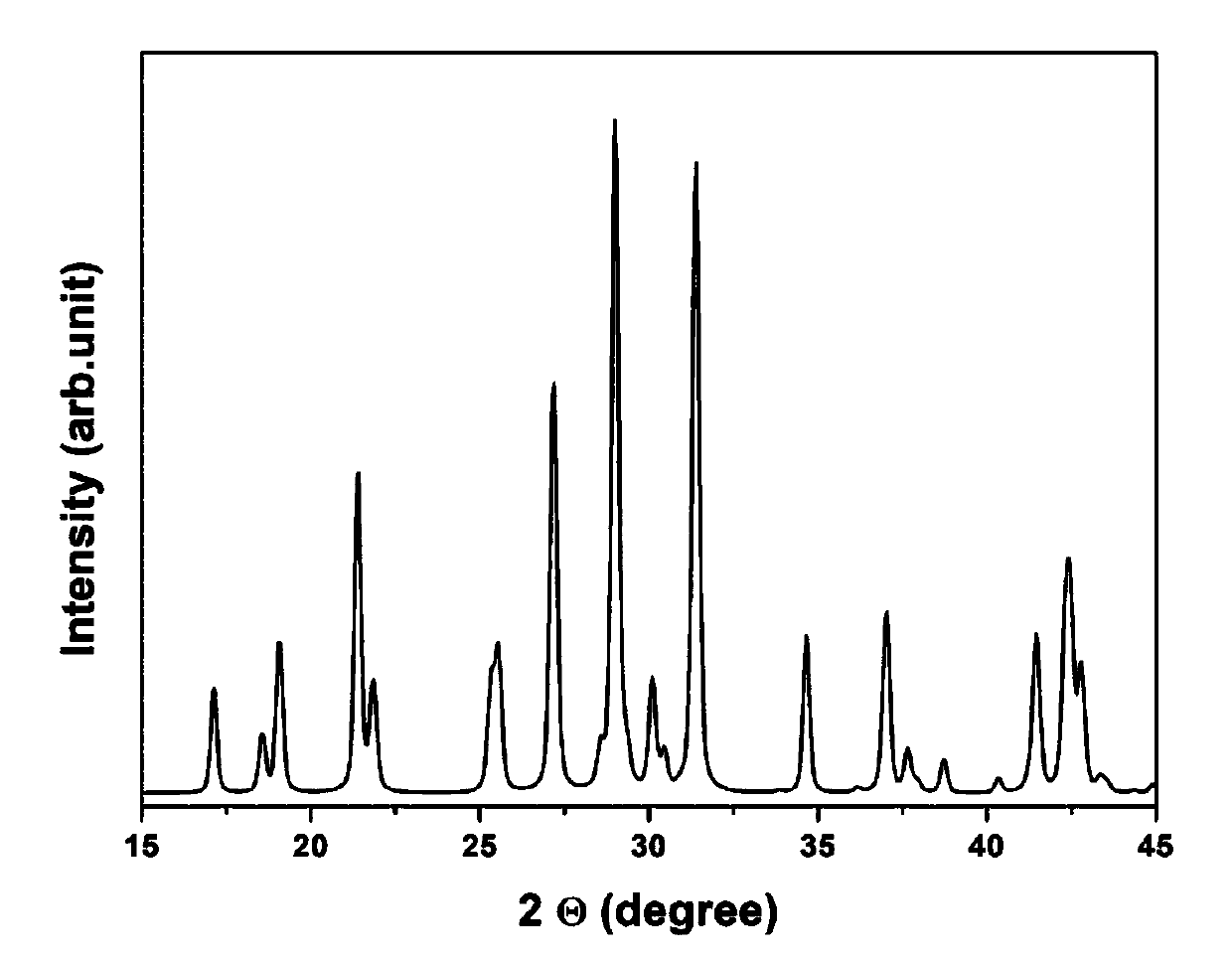

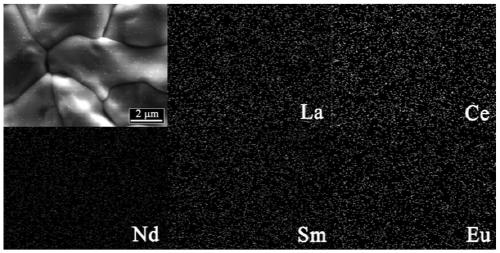

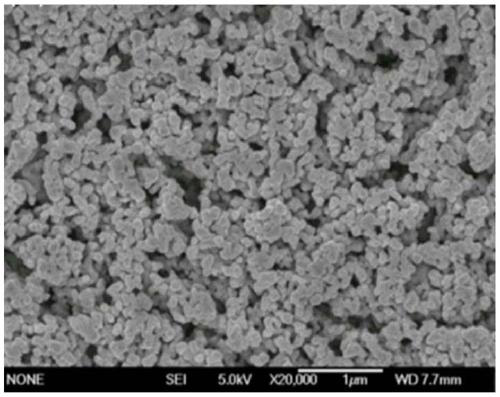

High-entropy rare-earth phosphate powder and preparation method thereof

The invention relates to the technical field of high-temperature ceramic material coatings, and particularly relates to high-entropy rare-earth phosphate powder and a preparation method thereof. The high-entropy rare-earth phosphate powder disclosed by the invention has a chemical formula as the follows (La0.2Ce0.2Nd0.2Sm0.2Eu0.2)PO4, (La0.2Y0.2Nd0.2Sm0.2Eu0.2)PO4, (La0.2Y0.2Nd0.2Yb0.2Eu0.2)PO4 or(La0.2Ce0.2Y0.2Yb0.2Er0.2)PO4. The high-entropy rare-earth phosphate powder has the advantages of high solid solubility, no impurity phase, low material heat conductivity, good high-temperature stability and adjustable expansion coefficient, can be used as a thermal barrier / environment barrier coating material of an Al<2>O<3f> / Al<2>O<3> composite material, and can also be used as a high-temperature heat insulation material. The preparation method of the high-entropy rare-earth phosphate powder provided by the invention is simple in process and low in calcining temperature.

Owner:淄博星澳新材料研究院有限公司

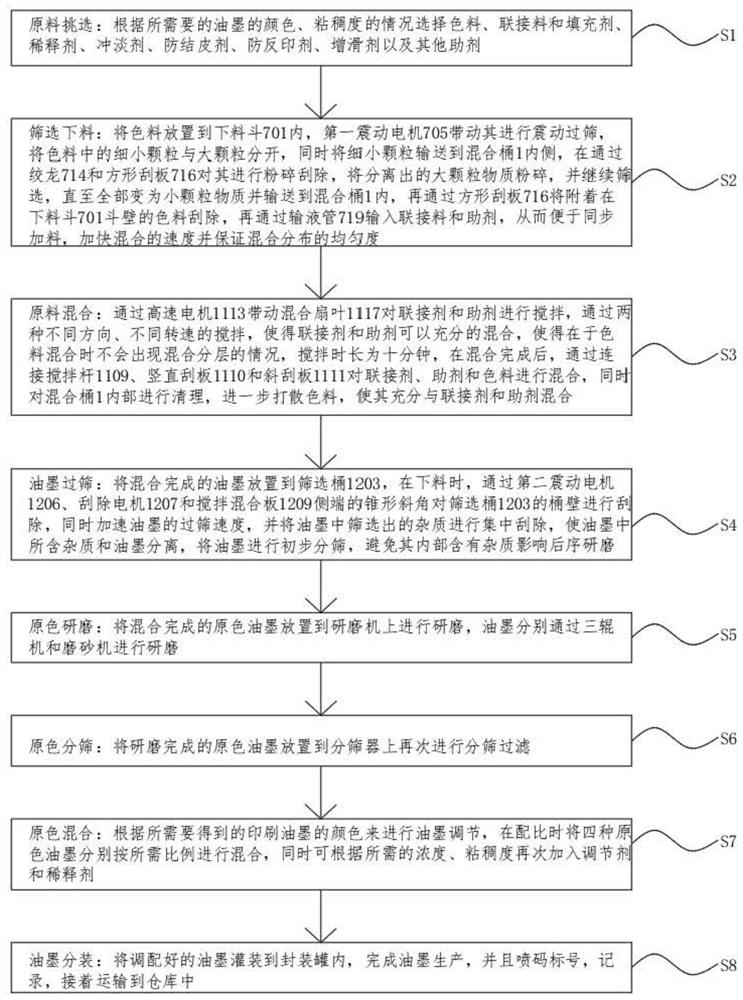

Preparation method of uniformly distributed ink for color printing

InactiveCN112473508AScientific and reasonable structureSafe and convenientRotary stirring mixersTransportation and packagingColor printingEngineering

The invention discloses a preparation method of uniformly distributed ink for color printing. A blanking hopper is placed on the inner side of a feeding port, hollow supporting blocks are welded to the two ends of the blanking hopper, first vibration springs are welded to the bottom ends of the hollow supporting blocks, one end of the blanking hopper is connected with a first vibration motor, anda fine screen is clamped to the inner side of the blanking hopper, a lifting motor is installed at the top end of a fixed installation frame, a linkage gear is connected with an auger in a welded modethrough a linkage rod, a square scraping plate is placed on the inner side of the blanking hopper, and pigment placed in the blanking hopper is screened and blanked through the vibration springs andthe vibration motor, therefore the pigment is filtered, and meanwhile lifting smashing is conducted through the auger and a lifting supporting plate, and the situation that in the blanking process, large-particle pigment blocks meshes is avoided, pigment particles become small and accordingly are more effectively mixed with a solvent, the pigment is scraped off through a scraper blade, and the situation that due to one-time large-amount blanking, uneven mixing is caused is avoided.

Owner:张钰

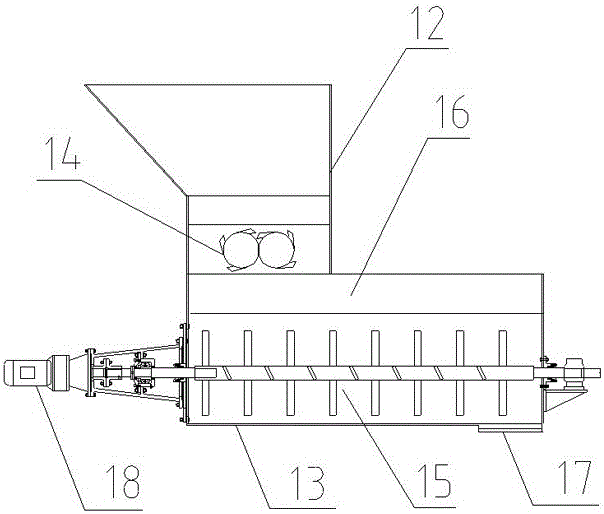

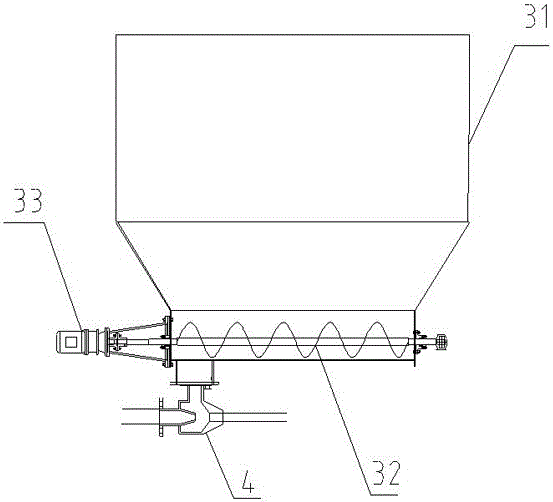

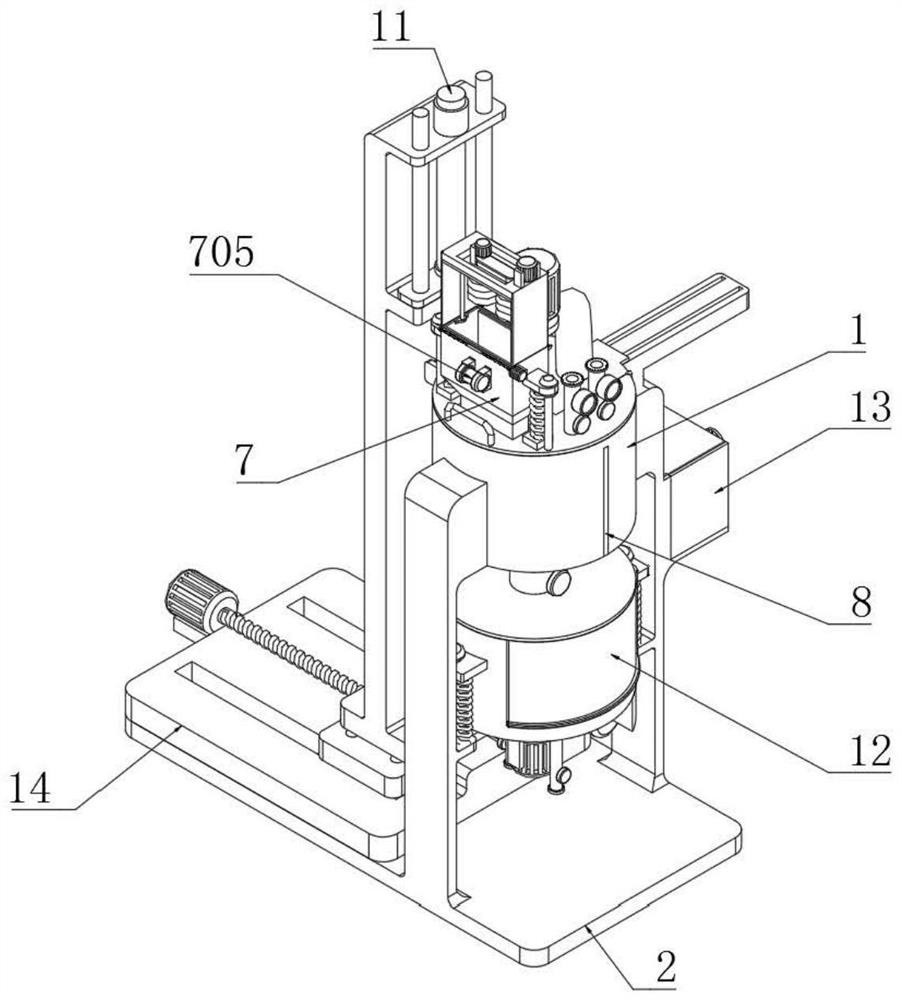

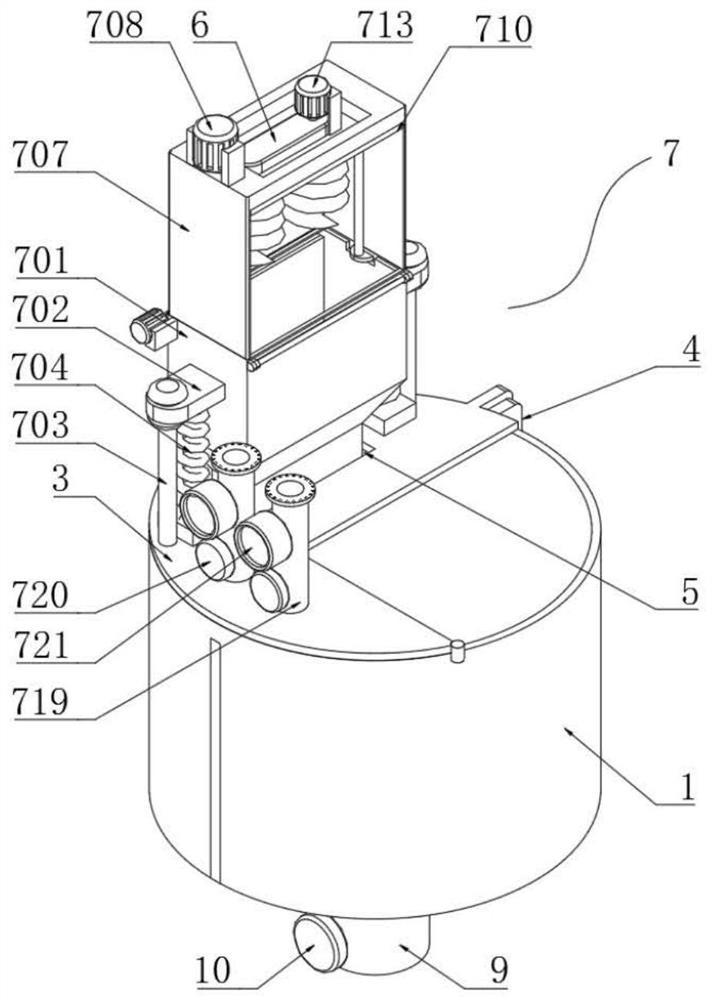

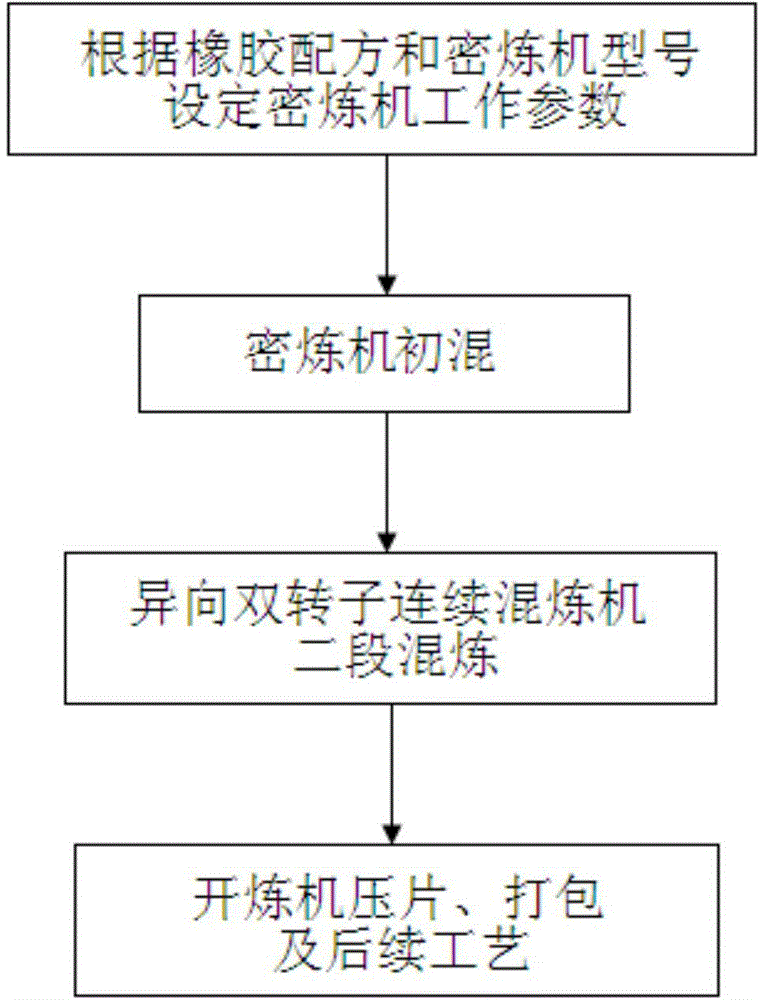

Continuous serial-type rubber mixing method

The invention belongs to the technical field of a processing method of rubber forming, and relates to a continuous serial-type rubber mixing method. The method comprises the steps of calculating the mass of each material and setting working parameters of an internal mixer according to a specific model of the internal mixer and a production formula of rubber compound; mixing matrix adhesive and various accessory ingredients in the internal mixer, and discharging the formed primary mixed rubber into a storage hopper when the temperature of the rubber reaches 95+ / -5 DEG C; pressing the primary mixed rubber into an opposite-direction dual-rotor continuous internal mixer by adopting a pressure weight through a feeding opening, carrying out the temperature-control two-sectional mixing for the primary mixed rubber by virtue of the cooperation of five sections of cooling passages, and discharging a formed semi-finished product rubber sheet through a discharging opening; adding an accelerator and sulfur after the semi-finished product rubber sheet is pressed by an open mill, and then carrying out the subsequent relevant process and test comparison analysis. By adopting the method, the continuity of the mixing technology is realized, non-uniformity for mixing small materials and rubber can be avoided, the production efficiency is improved, the quality of rubber products can be guaranteed, the energy loss in the mixing process can be reduced, and the manpower and material resource can be saved.

Owner:QINGDAO UNIV OF SCI & TECH

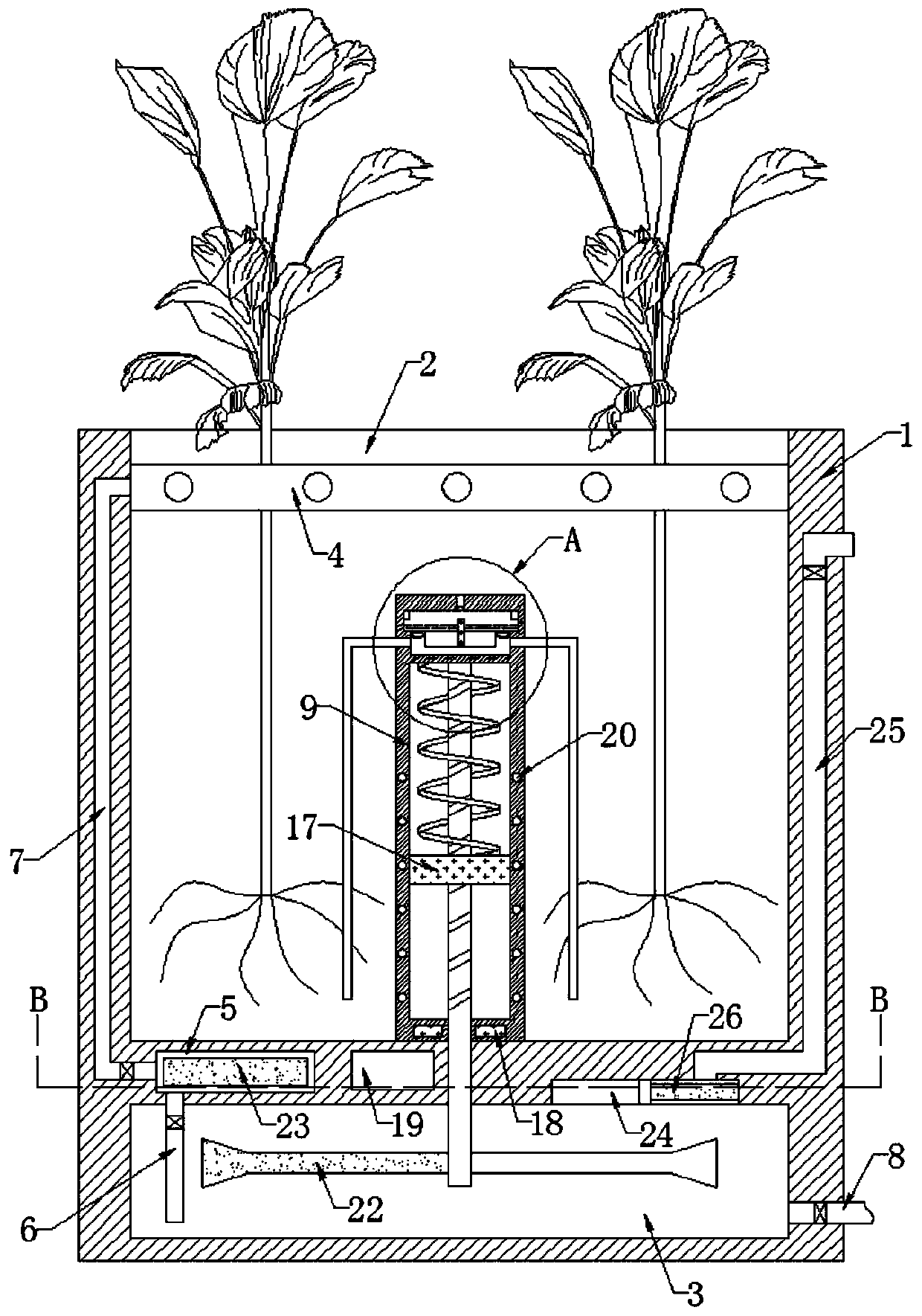

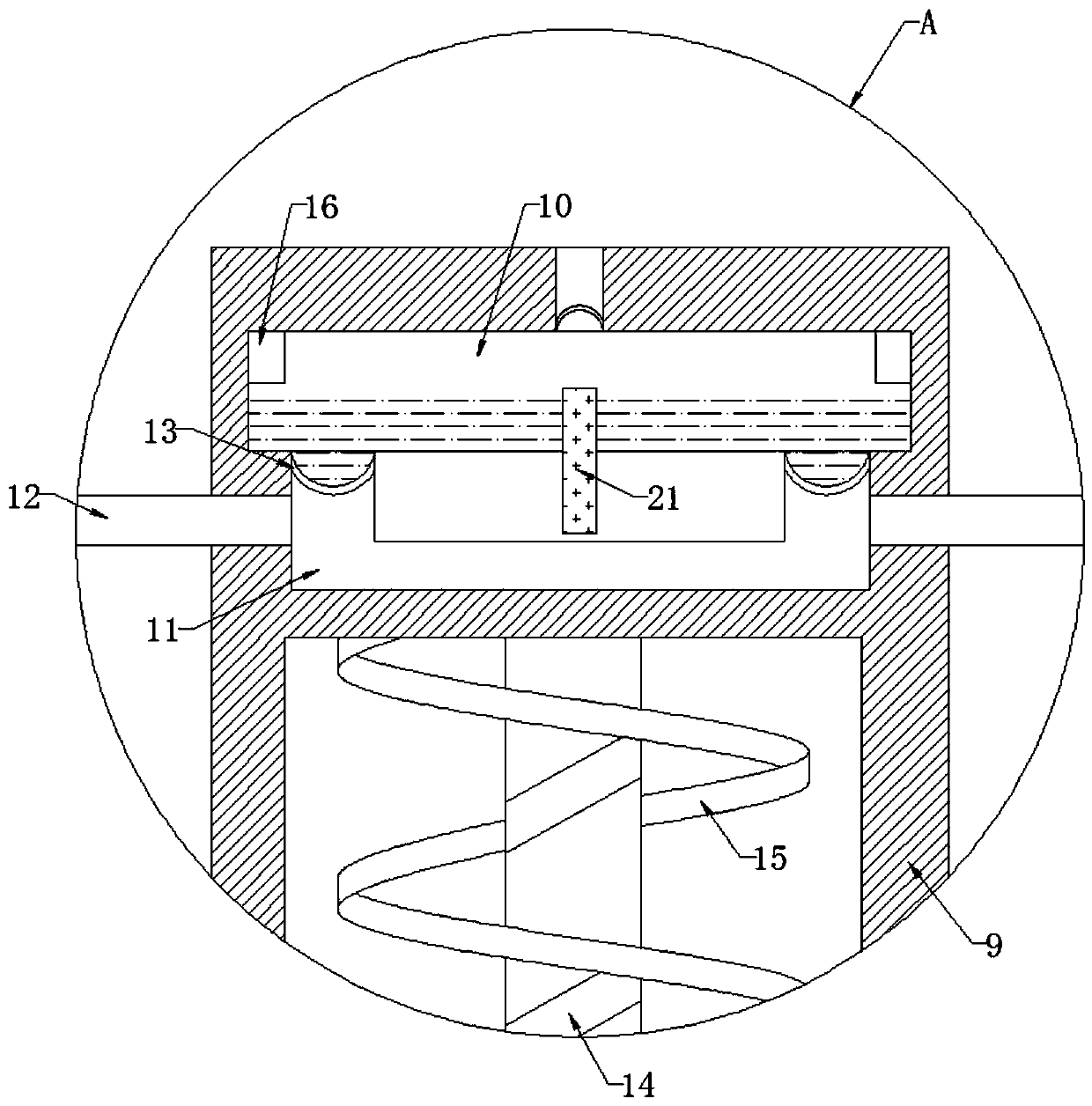

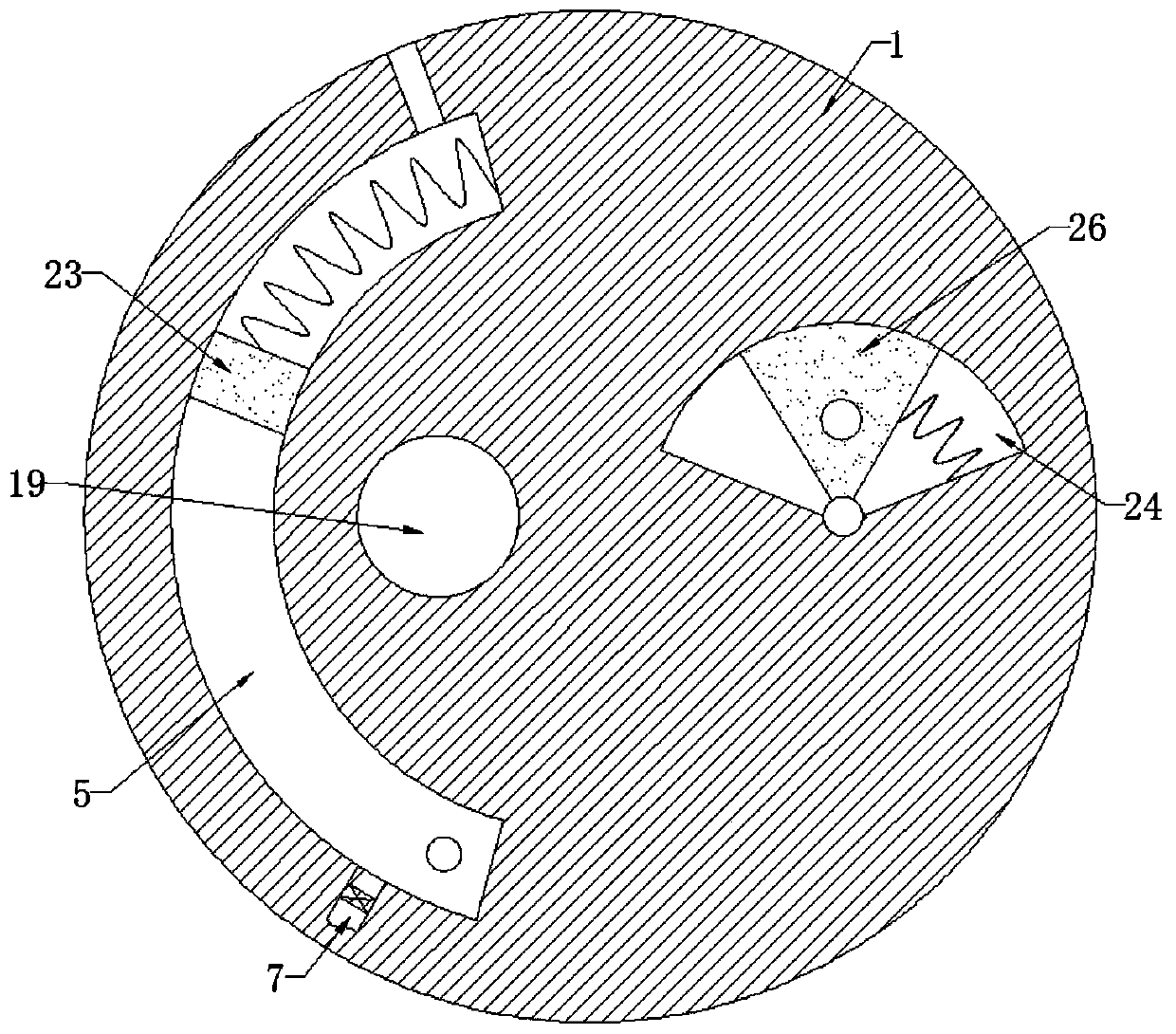

Potted plant cultivation system for overpass in municipal construction

InactiveCN111587704AIncrease watering frequencyGuaranteed normal growthBatteries circuit arrangementsSelf-acting watering devicesAgricultural engineeringAgricultural science

The invention discloses a potted plant cultivation system for an overpass in municipal construction. The potted plant cultivation system comprises a pot body, wherein a planting groove is formed in the upper end of the pot body; a water storage cavity is formed in the lower end of the pot body; a water spraying pipe is fixedly connected to the upper portion of the inner wall of the planting groove; an arc-shaped cavity is formed in the top in the water storage cavity; and the inner wall of the arc-shaped cavity is fixedly connected with a magnetic sliding plug through a spring. After the temperature in the soil of the planting groove rises, evaporation liquid evaporates to drive an elastic plate to bulge, so that a circuit between two conductive blocks and an annular magnet is connected, the annular magnet is heated, the annular magnet is demagnetized when the temperature rises to the Curie point of the annular magnet, and a magnetic sliding block rises under the driving of a reset spring to drive a lead screw to rotate; and then stirring blades are driven to continuously sweep over the magnetic sliding plug, so that the magnetic sliding plug sprays water in the water storage cavity into a water spraying pipe, and water can be automatically added into the planting groove according to the temperature of soil in the planting groove.

Owner:徐纯

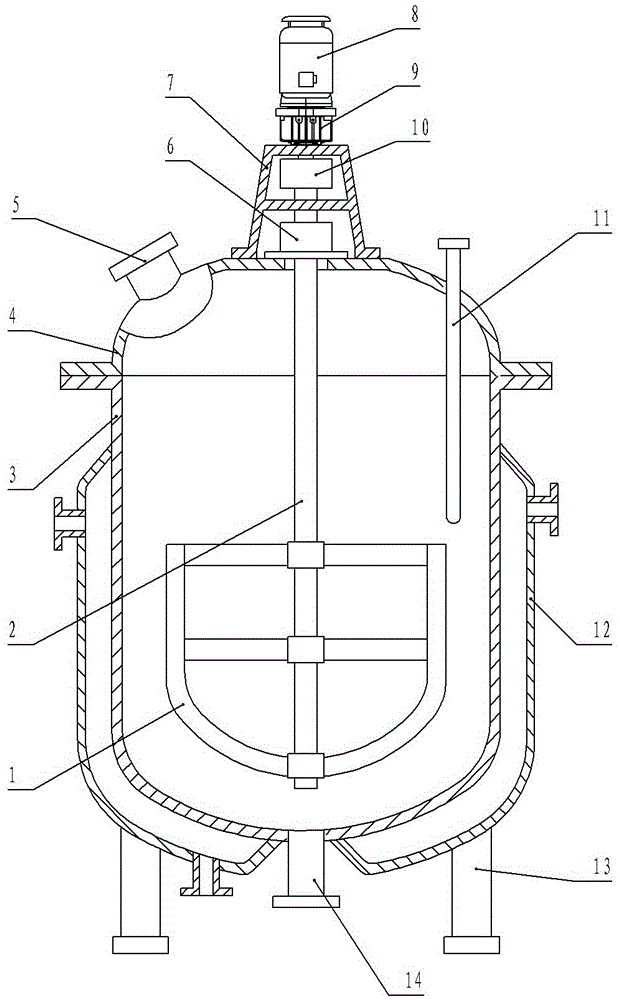

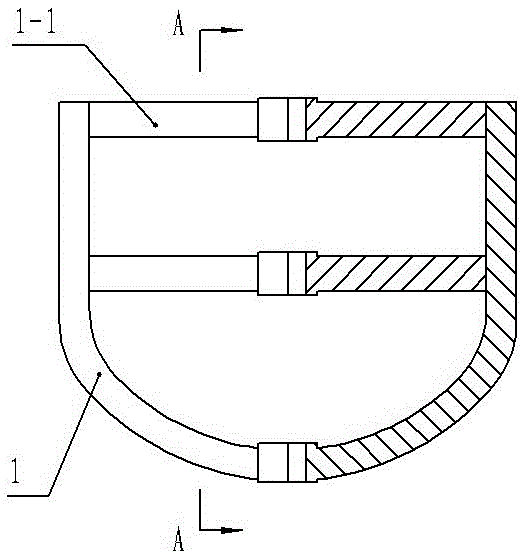

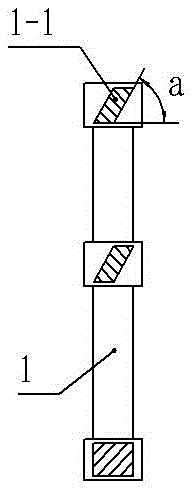

Reactor

InactiveCN103406085BWell mixedAvoid uneven mixingRotary stirring mixersTransportation and packagingVertical mixingProcess engineering

Owner:GUANGXI ZHONGCHANG RESIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com