High-entropy rare-earth phosphate powder and preparation method thereof

A rare earth phosphate and rare earth nitrate technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of no research report on high-entropy rare earth phosphate ceramic powder, unsuitable for popularization and use, and complicated preparation methods. , to achieve the effect of low raw material cost, matching thermal expansion coefficient and high solid solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

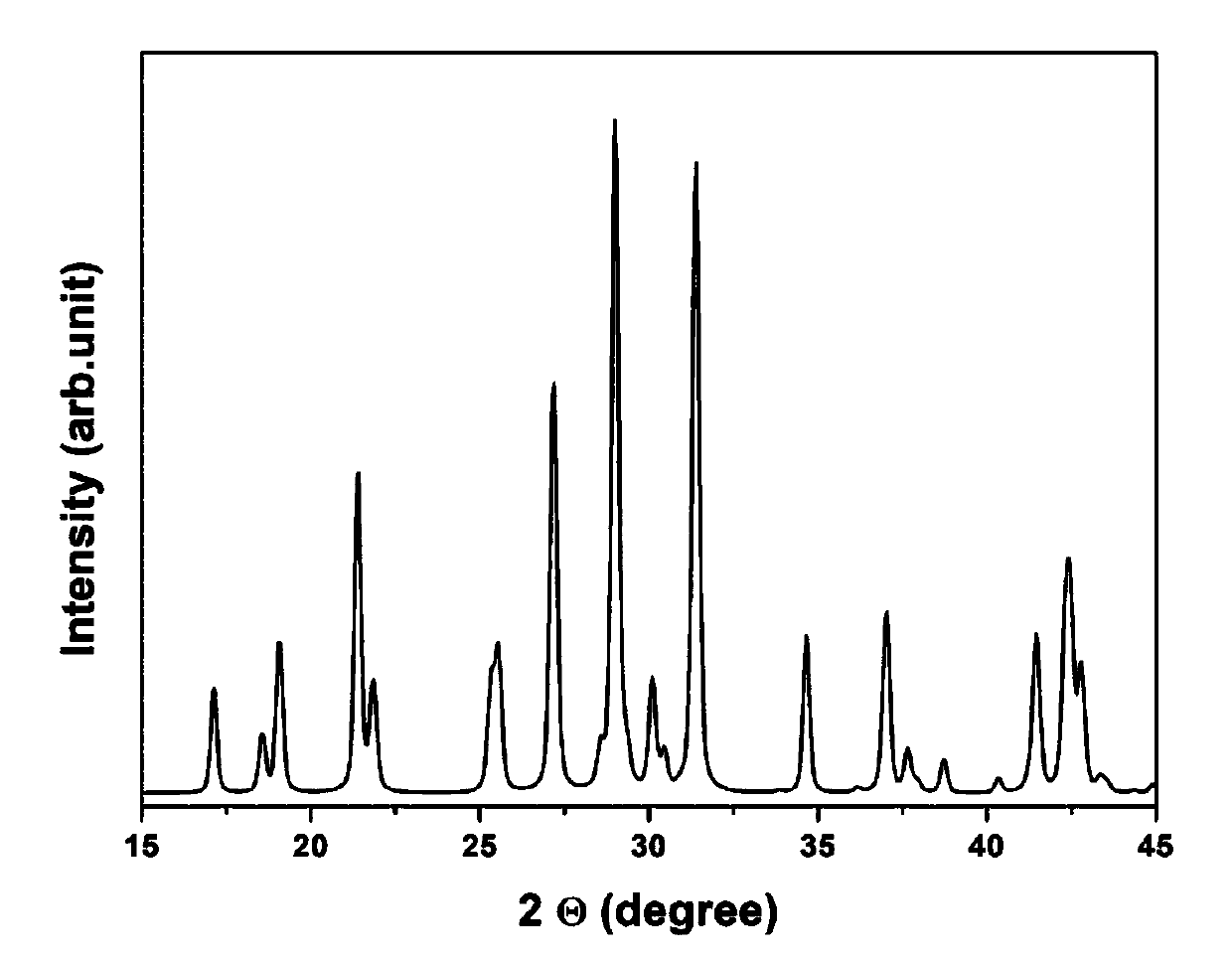

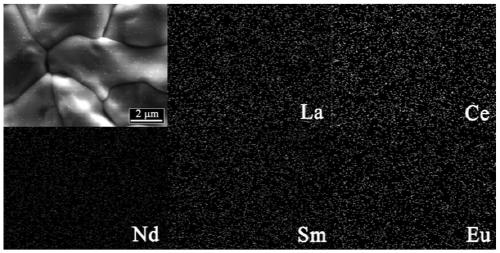

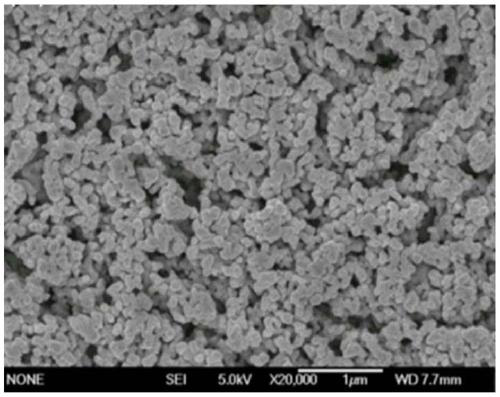

Embodiment 1

[0041] (1) Rare earth nitrate La(NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O, Nd(NO 3 ) 3 ·6H 2 O, Sm(NO 3 ) 3 ·6H 2 O, Eu(NO 3 ) 3 ·6H 2 O is weighed according to an equimolar ratio, the total amount of rare earth nitrates is 1mol, and the content of each rare earth nitrate is 0.2mol. Put the above raw materials in a beaker, add deionized water, and magnetically stir at a rate of 200r / min for 2h , forming a uniform and transparent solution to obtain a rare earth nitrate mixed solution;

[0042] (2) Adding a phosphoric acid solution with a mass concentration of 85% in the rare earth nitrate mixed solution, the amount of phosphoric acid is 1mol, and stirring continuously during the addition until a uniform precipitation is formed to obtain a precipitate;

[0043] (3) After the precipitate was filtered and washed 3 times, it was dried in a drying oven for 12 hours at a drying temperature of 40°C, then placed in a muffle furnace, and kept at a temperature of 1300°C for 2 ...

Embodiment 2

[0047] (1) Rare earth nitrate La(NO 3 ) 3 ·6H 2 O, Y (NO 3 ) 3 ·6H 2 O, Nd(NO 3 ) 3 ·6H 2 O, Sm(NO 3) 3 ·6H 2 O, Eu(NO 3 ) 3 ·6H 2 O is weighed according to an equimolar ratio, the total amount of rare earth nitrates is 1mol, and the content of each rare earth nitrate is 0.2mol. Put the above raw materials in a beaker, add deionized water, and magnetically stir at a rate of 300r / min for 1h , forming a uniform and transparent solution to obtain a rare earth nitrate mixed solution;

[0048] (2) Adding a phosphoric acid solution with a mass concentration of 85% in the rare earth nitrate mixed solution, the amount of phosphoric acid is 1mol, and stirring continuously during the addition until a uniform precipitation is formed to obtain a precipitate;

[0049] (3) After the precipitate was filtered and washed 3 times, it was dried in a drying oven for 24 hours at a temperature of 30° C., then placed in a muffle furnace, and kept at a temperature of 1200° C. for 4 hour...

Embodiment 3

[0053] (1) Rare earth nitrate La(NO 3 ) 3 ·6H 2 O. YNO 3 ) 3 ·6H 2 O, Nd(NO 3 ) 3 ·6H 2 O, Yb(NO 3 ) 3 ·6H 2 O, Eu(NO 3 ) 3 ·6H 2 O is weighed according to an equimolar ratio, the total amount of rare earth nitrates is 1 mol, and the content of each rare earth nitrate is 0.2 mol. Put the above raw materials in a beaker, add deionized water, and magnetically stir at a rate of 120r / min for 4h , forming a uniform and transparent solution to obtain a rare earth nitrate mixed solution;

[0054] (2) Adding a phosphoric acid solution with a mass concentration of 85% in the rare earth nitrate mixed solution, the amount of phosphoric acid is 1mol, and stirring continuously during the addition until a uniform precipitation is formed to obtain a precipitate;

[0055] (3) After filtering and washing the precipitate for 3 times, dry it in a drying oven for 8 hours at 60°C, then place it in a muffle furnace, and keep it at 1150°C for 3 hours to obtain high-entropy rare earth p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com