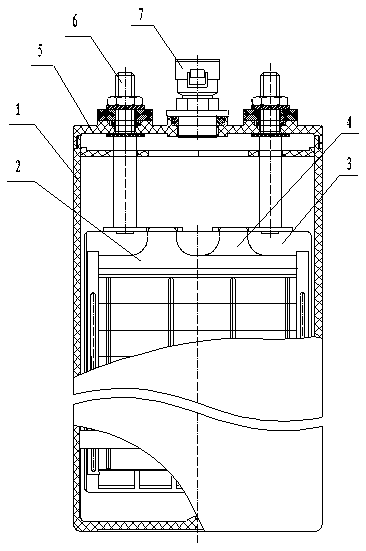

High-capacity long-service-life double-bag nickel-hydrogen battery

A nickel-hydrogen battery, long-life technology, applied in the direction of nickel storage battery, secondary battery, battery electrode, etc., can solve the problems of easy thermal runaway, unsafe, difficult to prepare large-capacity batteries, short cycle life, etc., to improve the powder resistance Chemical and anti-corrosion ability, improve the utilization rate of active material, improve the effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

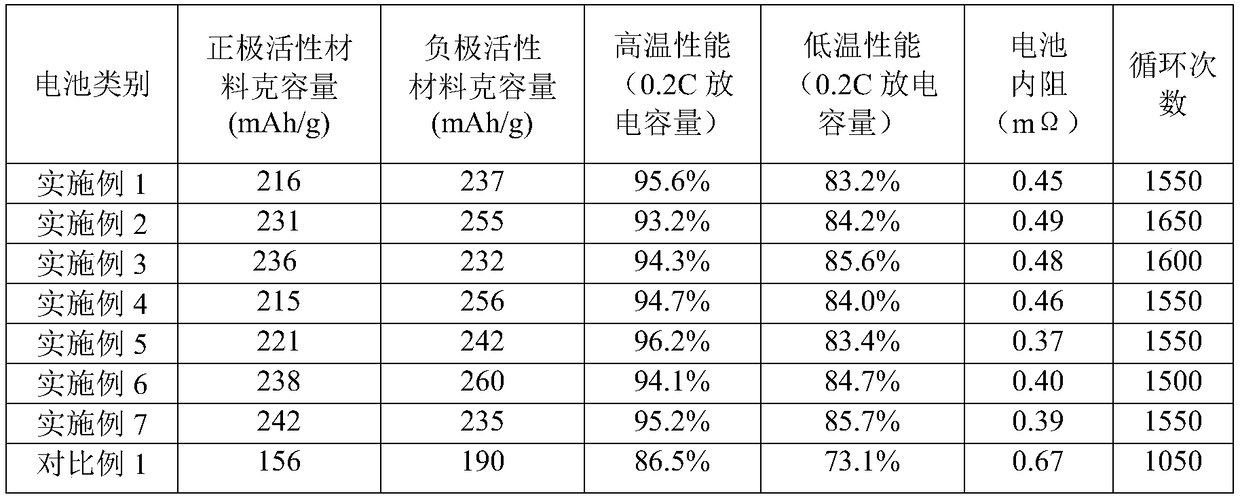

Examples

Embodiment 1

[0027] [Ni 0.8 al 0.2 co 0.05 (OH) 2 ]·[(BO 2 - ) z mH 2 O] Preparation of cathode active materials

[0028] First, nickel chloride is made into a nickel salt solution with a molar concentration of 1.8mol / L with deionized water that removes carbon dioxide, and aluminum sulfate and cobalt sulfate are dissolved in a molar ratio of 0.8:0.2:0.05 in the molar ratio of nickel, aluminum, and cobalt. In the sodium hydroxide solution with a concentration of 4mol / L, under the protection of inert gas nitrogen, slowly add the nickel salt solution dropwise into the reaction kettle equipped with the composite alkaline solution, the reaction temperature is 55°C, and the pH of the final reaction mixture is = 10.5, after the completion of the reaction, age the mother liquor at 55°C for 36h, then filter; dry the filter cake at 125°C for 2h, and grind it into powder, pass through a 200 mesh sieve for later use, transfer 8g of the obtained powder to the prepared mole In a sodium metaborat...

Embodiment 2

[0037] [Ni 0.9 al 0.1 Ca 0.05 (OH) 2 ]·[(CO 3 2- ) z mH 2 O] Preparation of cathode active materials

[0038] First, use deionized water to remove carbon dioxide to form a nickel salt solution with a molar concentration of 2.0 mol / L, and dissolve aluminum sulfate and calcium chloride in a molar ratio of 0.9:0.1:0.05. In the sodium hydroxide solution with a concentration of 5mol / L, the nickel salt solution is slowly added dropwise to the reaction kettle equipped with the composite alkaline solution, the reaction temperature is 55°C, and the pH of the final reaction mixture is 10.5. After the reaction is completed, The mother liquor was aged at 55°C for 36 hours, and then filtered; the filter cake was dried at 125°C for 1 hour, and ground into powder, and passed through a 200-mesh sieve to obtain Ni 0.9 al 0.1 Ca 0.05 (OH) 2 ]·[(CO 3 2- ) z mH 2 O powder samples.

[0039] will Ni 0.9 al 0.1 Ca 0.05 (OH) 2 ]·[(CO 3 2- ) z mH 2 O adopts the method same as e...

Embodiment 3

[0047] [Ni 0.7 al 0.3 Y 0.05 (OH) 2 ]·[(Cl - ) z mH 2 O] Preparation of cathode active materials

[0048] First nickel chloride is made into a nickel salt solution with a molar concentration of 2.0mol / L with deionized water that removes carbon dioxide, and aluminum chloride and yttrium chloride are dissolved in a ratio of 0.7:0.3:0.05 with the molar ratio of nickel, aluminum, and yttrium. into a sodium hydroxide solution with a molar concentration of 3 mol / L, and under the protection of inert gas nitrogen, slowly drop the nickel salt solution into a reaction kettle equipped with a composite alkaline solution, the reaction temperature is 60°C, and the mixture is finally reacted pH=11, after the completion of the reaction, the mother liquor was aged at 70°C for 48h, then filtered, the filter cake was dried at 125°C for 2h, and ground into powder to obtain [Ni 0.7 al 0.3 Y 0.05 (OH) 2 ]·[(Cl - ) z mH 2 O] Powder samples.

[0049] Preparation of pocket nickel positiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com