Patents

Literature

99results about How to "Improve overcharge resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

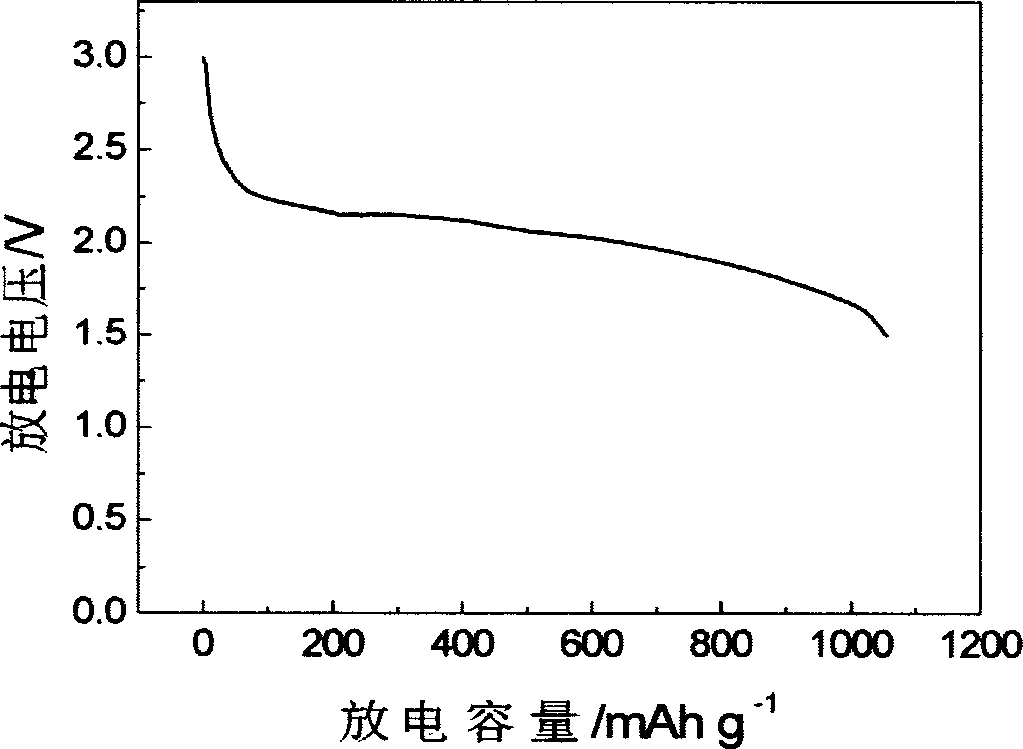

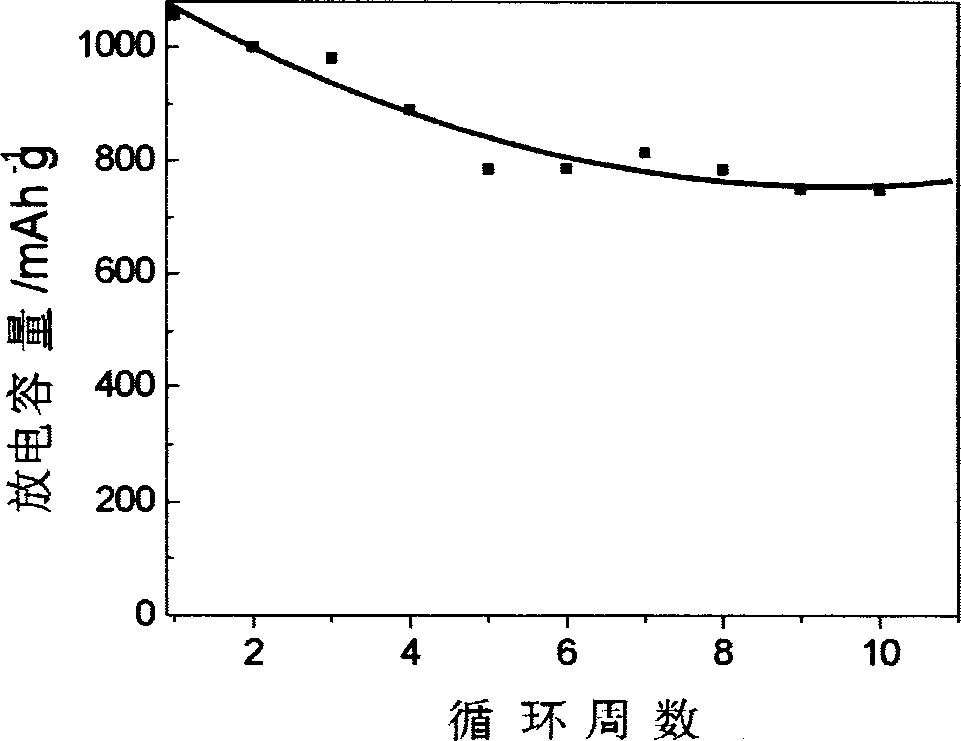

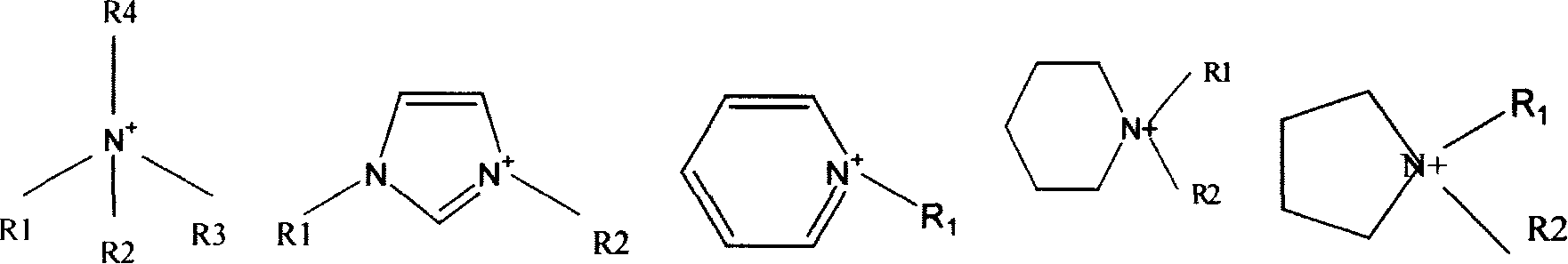

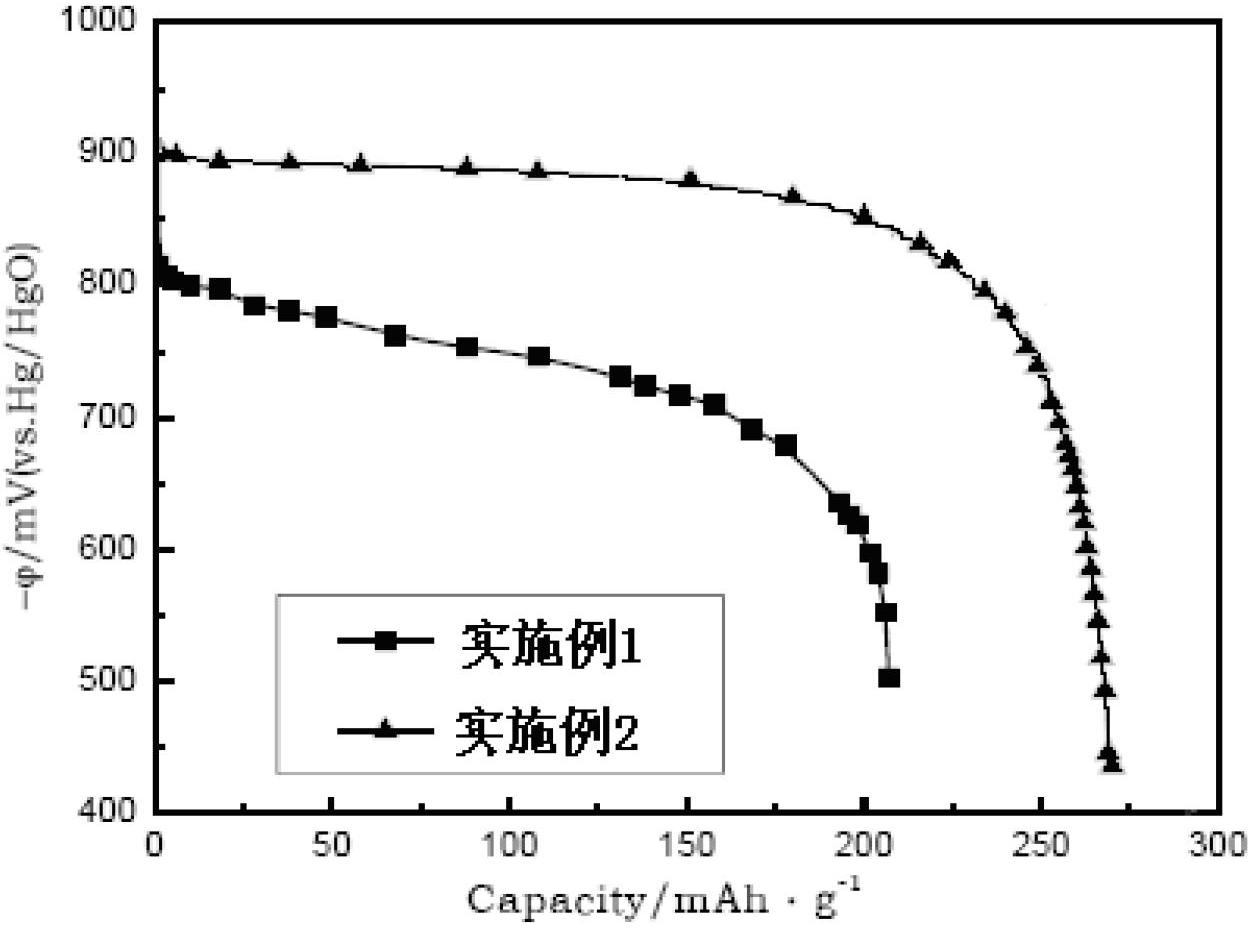

Lithium-sulphur battery electrolyte and chargeable lithium-sulphur battery thereof

InactiveCN1838469ASolve the dissolution lossImproved capacity characteristics and cycle lifeActive material electrodesLi-accumulatorsSolventSolubility

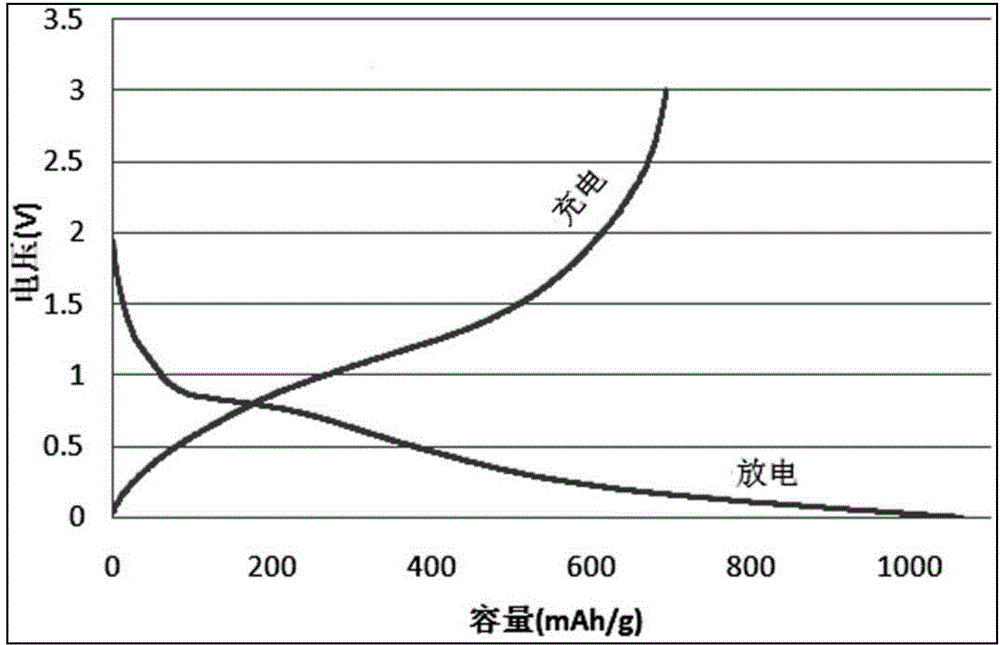

This invention relates to a lithium-sulfur buttery electrolyte and chargeable lithium-sulfur buttery, wherein the electrolyte uses one or more than one quaternary amine salt ion liquid as solvent to inhibit the soluble capability of the middle product polysulfide from electrode reaction in electrolyte, which improves the capacity and circle life of Li-S battery. Li-S battery used this electrolyte has many advantages, such as the reversible capacity is large, the circle capability is well, and it has nice safety capability and a bright application future.

Owner:WUHAN UNIV

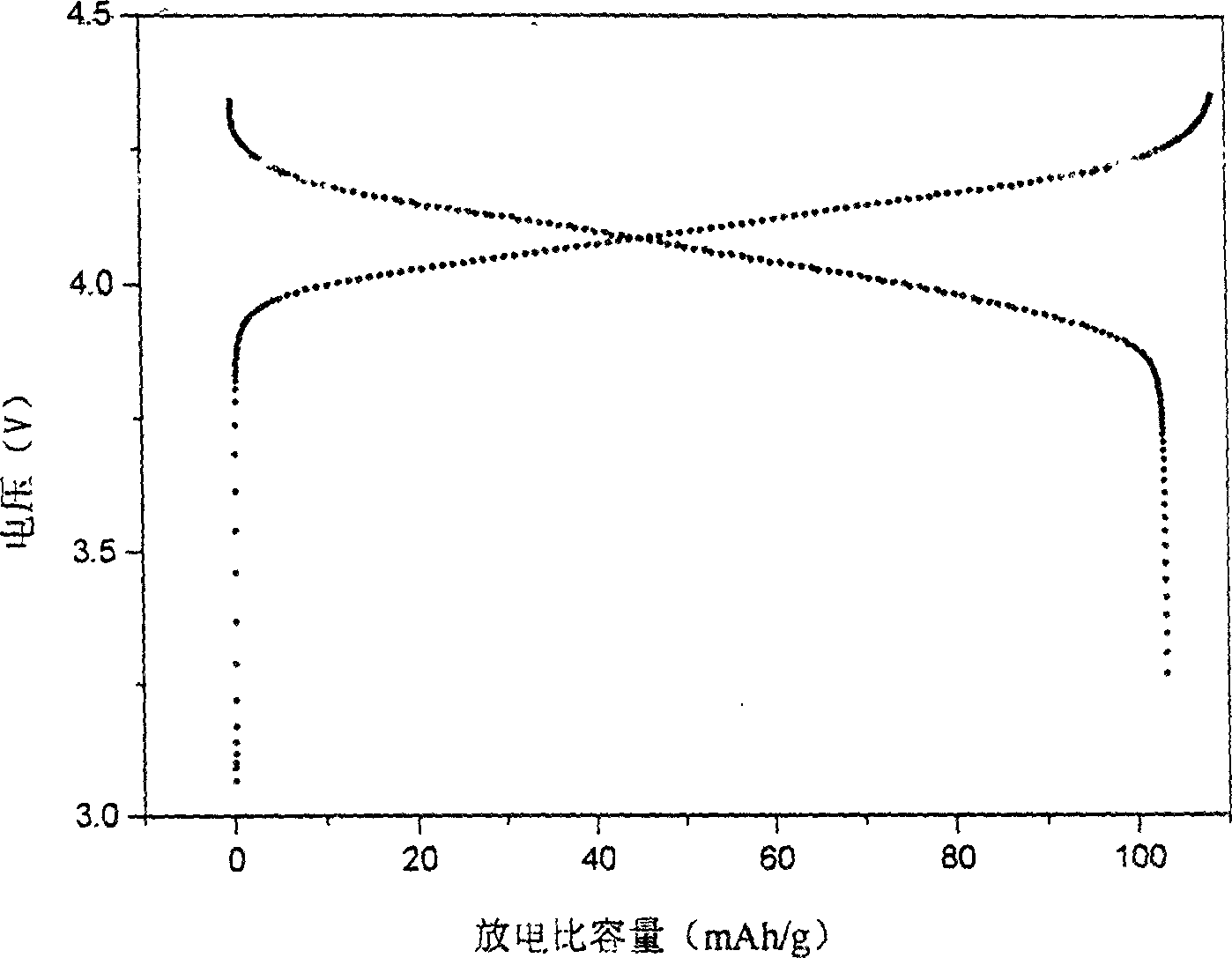

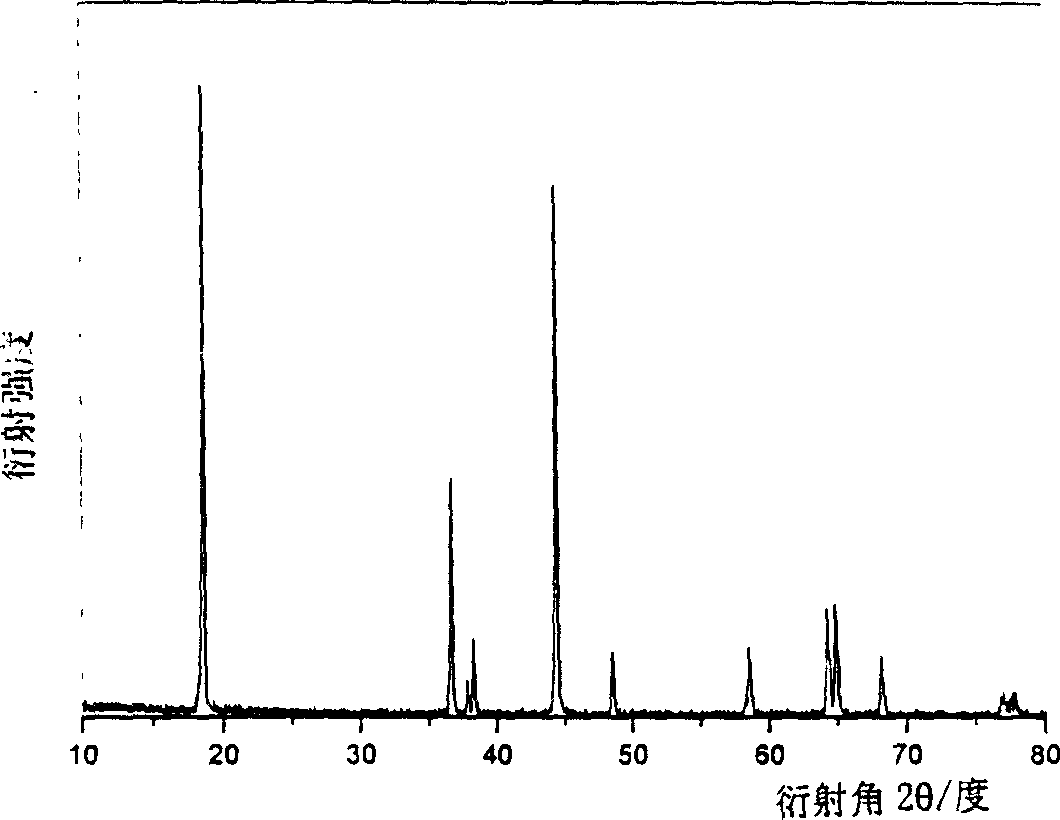

A positive electrode material for lithium secondary cell, and preparation and usage thereof

InactiveCN1595687AIncrease energy densityGood charge and discharge cycle performanceElectrode manufacturing processesIron compoundsLithiumManganese

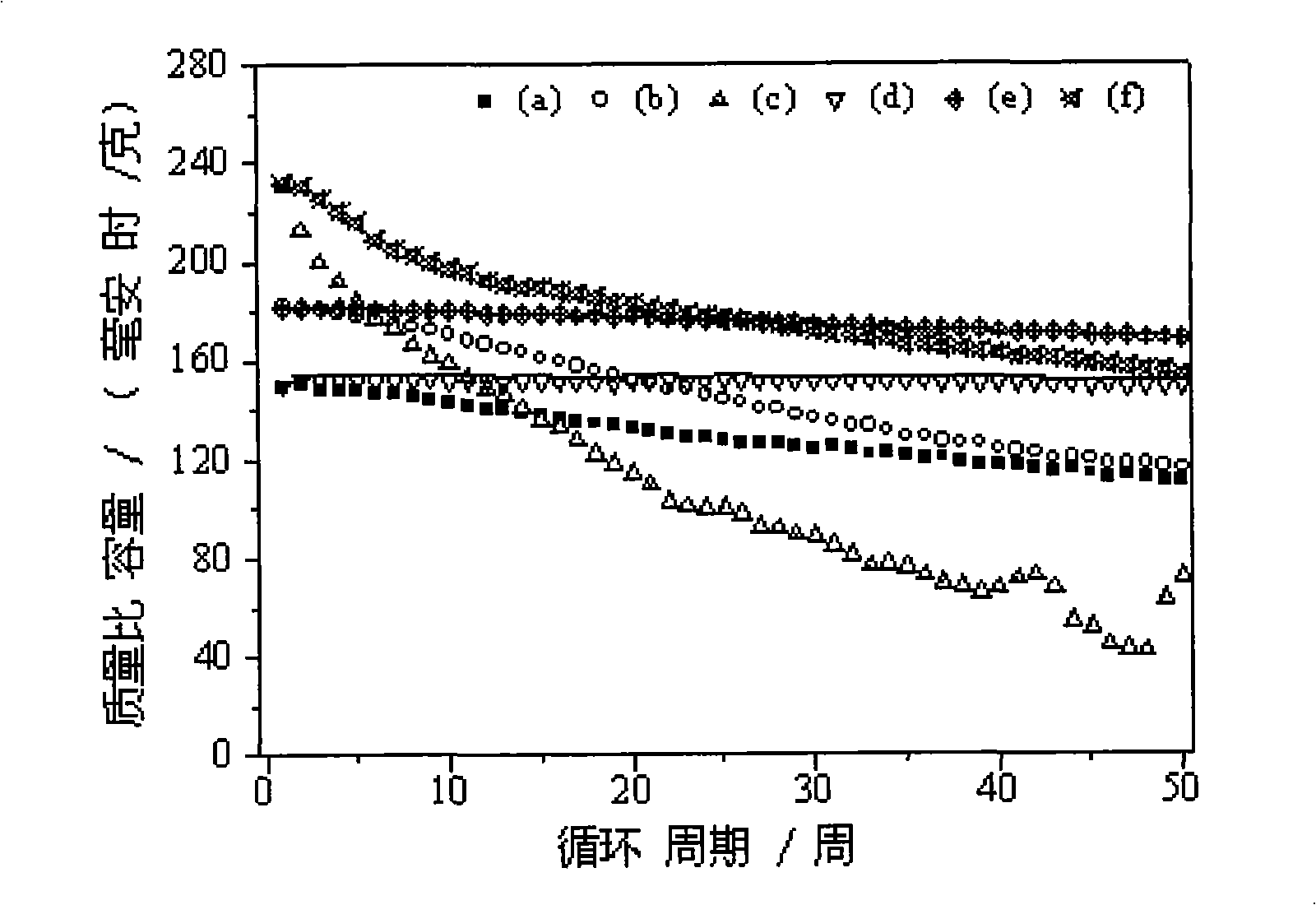

The invention relates to positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn2-zMzO4 (0<=z<=0.5.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Sr, Cr, Ga, Cu and Zn. The manufacturing method for positive electrode material of the lithium 1 secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

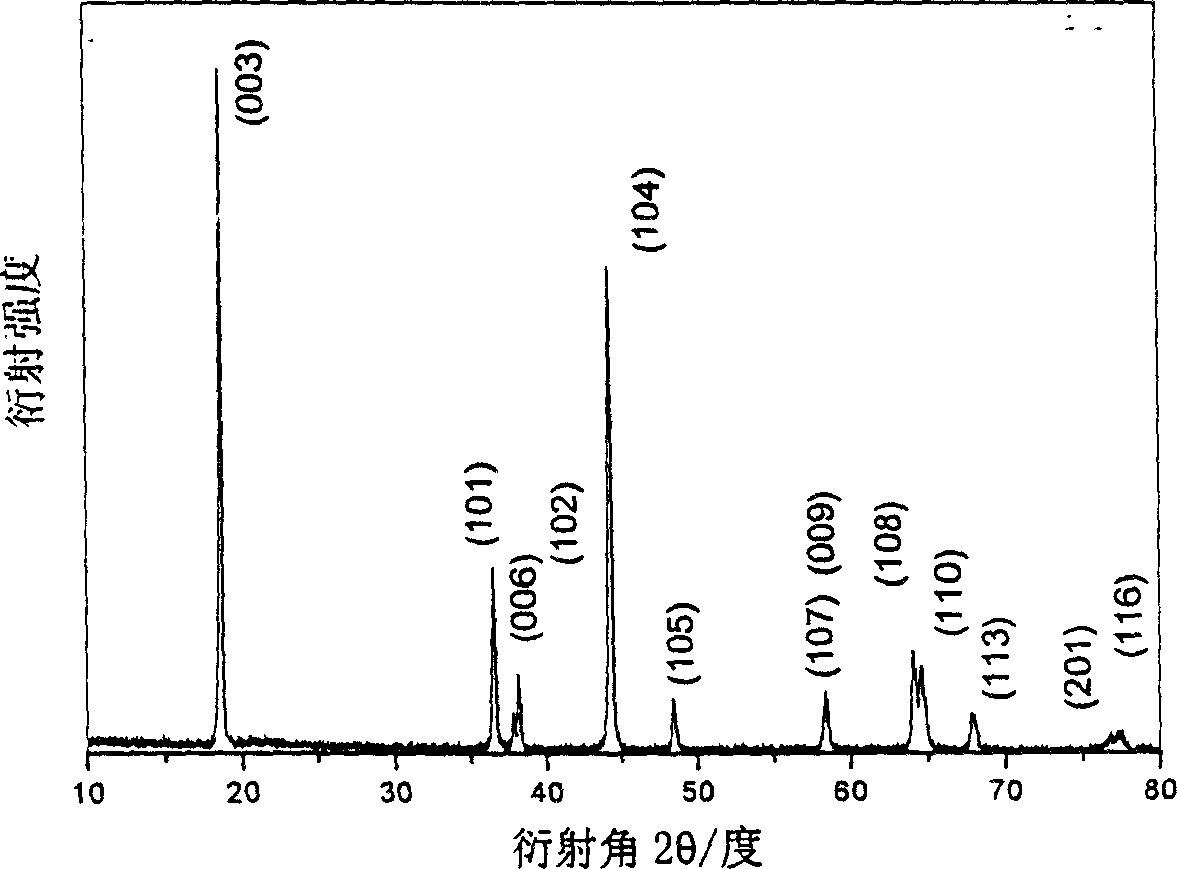

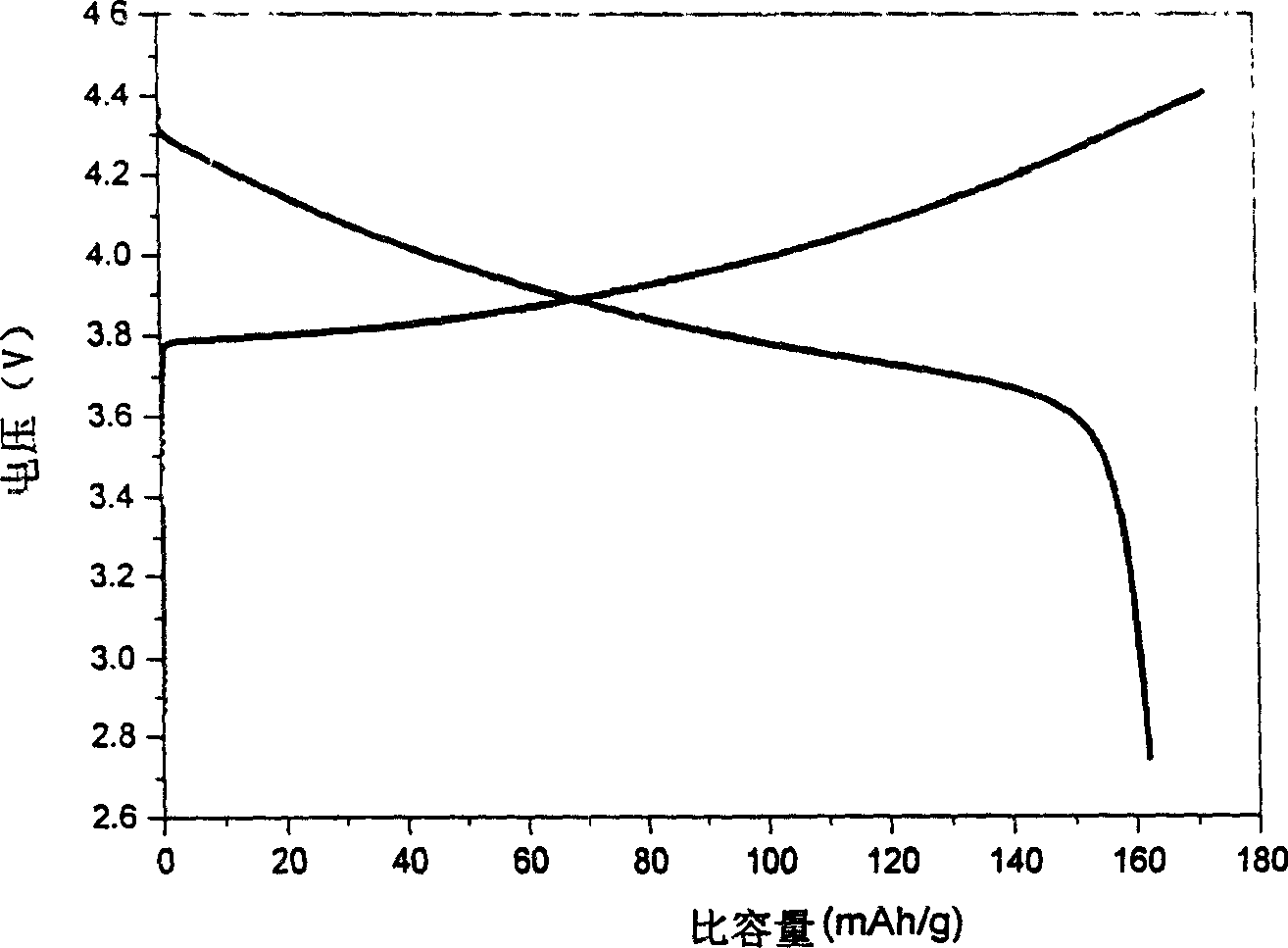

Positive electrode material of manganese series, and preparation and usage thereof

InactiveCN1595689AIncrease energy densityIncrease powerElectrode manufacturing processesSecondary cellsManganeseThermal stability

The invention relates to manganese department positive electrode material of a lithium secondary battery, which can combine with electrolyte solution or solid electrolyte, and negative electrode active material to form lithium secondary battery. Its characteristics are: the positive electrode material of lithium secondary battery is LiMn1-x-y NixMyO2(x is not less than 0.2 and not larger than 0.8, y is not less than 0 and not larger than 0.6, and x+y is not larger than 1.), M is chosen from Li, Mg, Co, Ni, Fe, Al, Cr. The manufacturing method for manganese department positive electrode material of the lithium secondary battery, includes preparation of usher containing Mn; decorate to the covering of usher particle containing Mn; mix with lithium salt and prepare particle; sintering and other steps. By decoration of the surface of particle to usher 6 of positive electrode containing Mn or active material itself, state of material or apparent condition of material can be changed and its capacity of powerful charge and discharge, cycle performance and thermal stability can be raised. The invention has notable advantages including low cost, capacity of powerful charge and discharge, super-long cycle performance, excellent safety, super-long circulation property and resistance to overcharge .

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

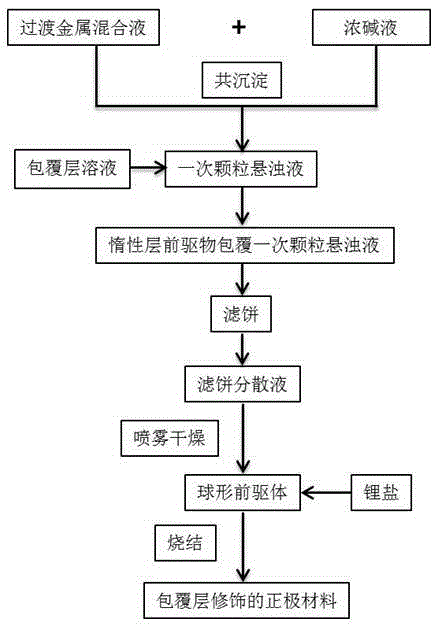

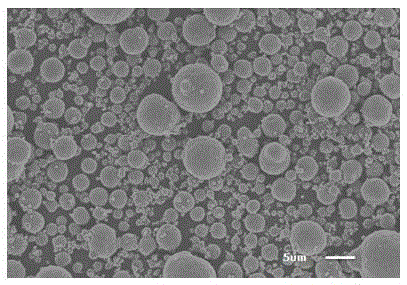

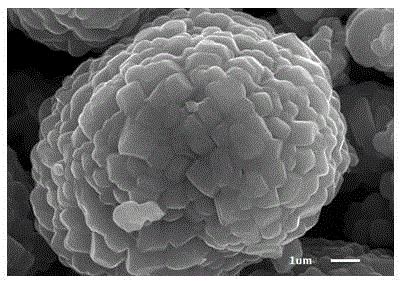

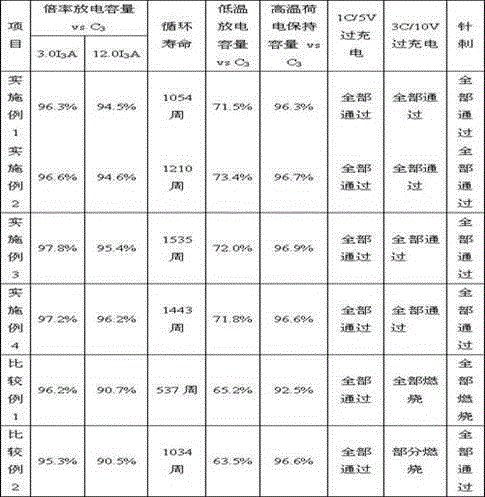

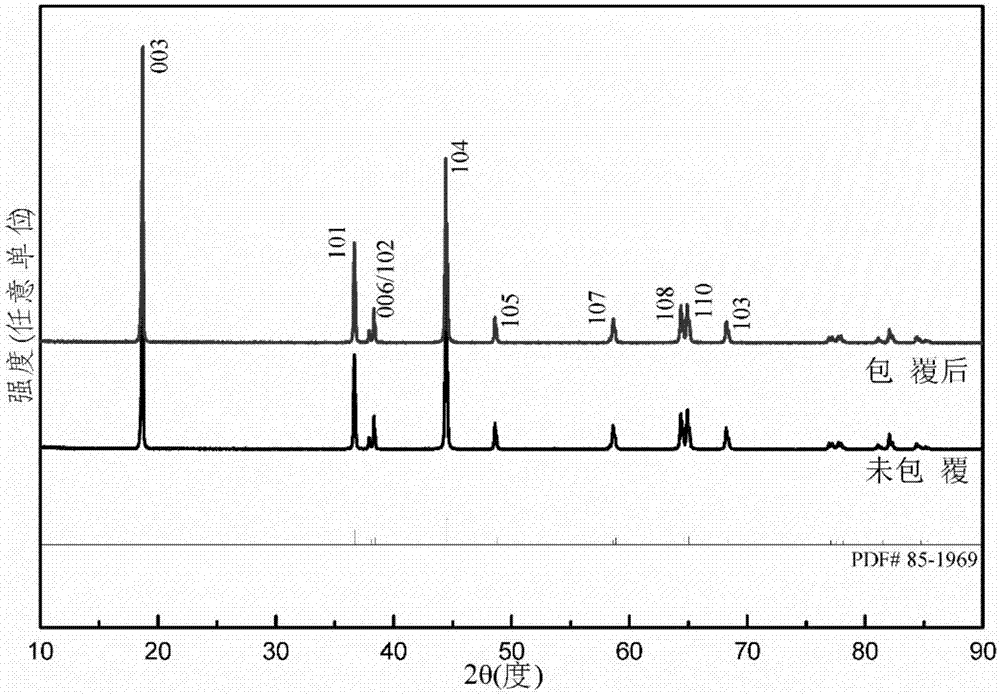

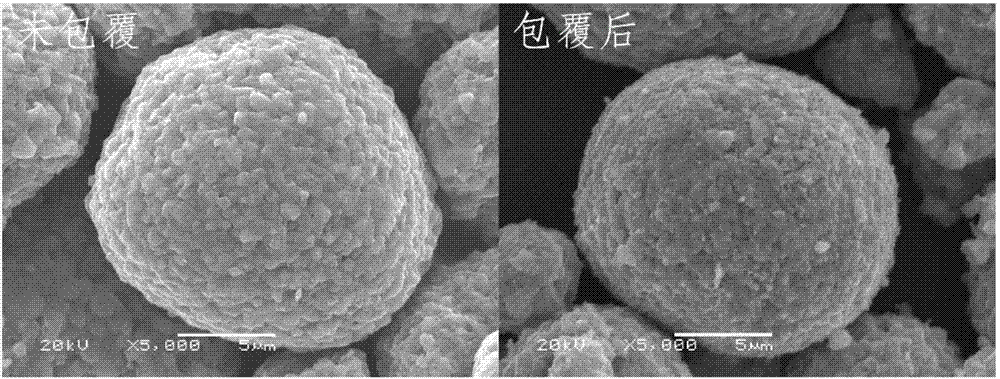

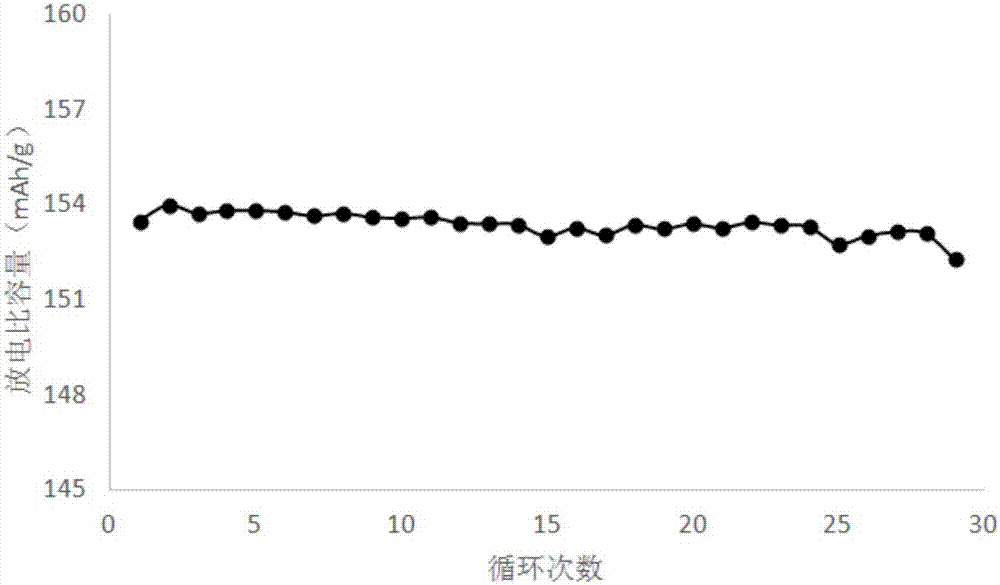

Long-cycle and high-safety power lithium ion battery positive electrode material and preparation method thereof

InactiveCN105406056AUniform dispersion and depositionEvenly dispersedCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention discloses a long- cycle and high-safety power lithium ion battery positive electrode material and a preparation method thereof. The positive electrode material can be shown as a general formula LiNi<(1-a-b-c)>CoMnM<c>O2.xLiM<1>O<y>, wherein a is greater than 0 and less than 1, b is greater than 0 and less than 1, a+b+c is greater than 0 and less tan 1, x is greater than 0 and less than 0.1, and y is greater than 1 and less than 5; LiNi<(1-a-b-c)>CoMnM<c>O2 is a primary active crystalline particle of the positive electrode material, and is a lithiated composite oxide composed of nickel cobalt manganese and doping element M; and the LiM<1>O<y> is a coating layer coating crystal boundary of the primary active crystalline particle and surface of a polycrystalline secondary particle. The positive electrode material provided by the invention has high stability of crystalline main body, surface and crystal boundary, has good compatibility with electrolyte and is not liable to generate side reaction. The material provided by the invention is used for batteries, has long cycle life, high over-charging resisting capability, good high temperature and high voltage performance and high integral safety, and is particularly suitable for power batteries.

Owner:HUNAN SOUNDDON NEW ENERGY

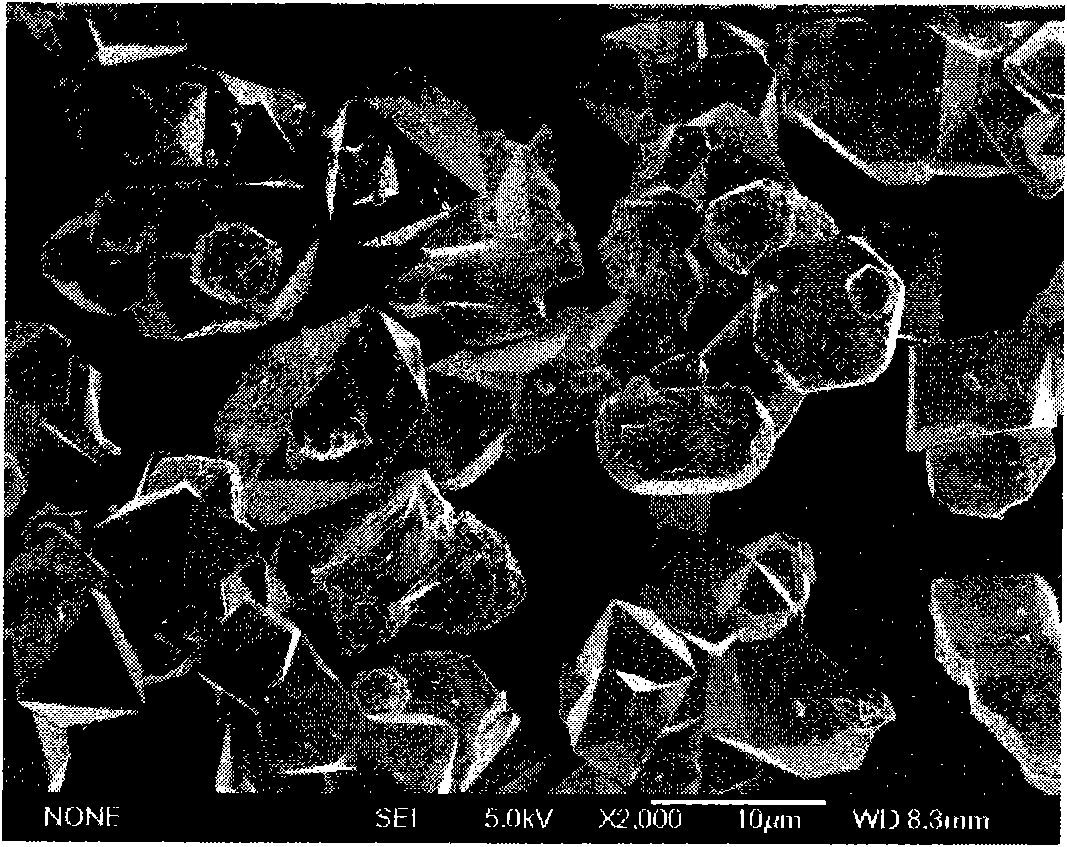

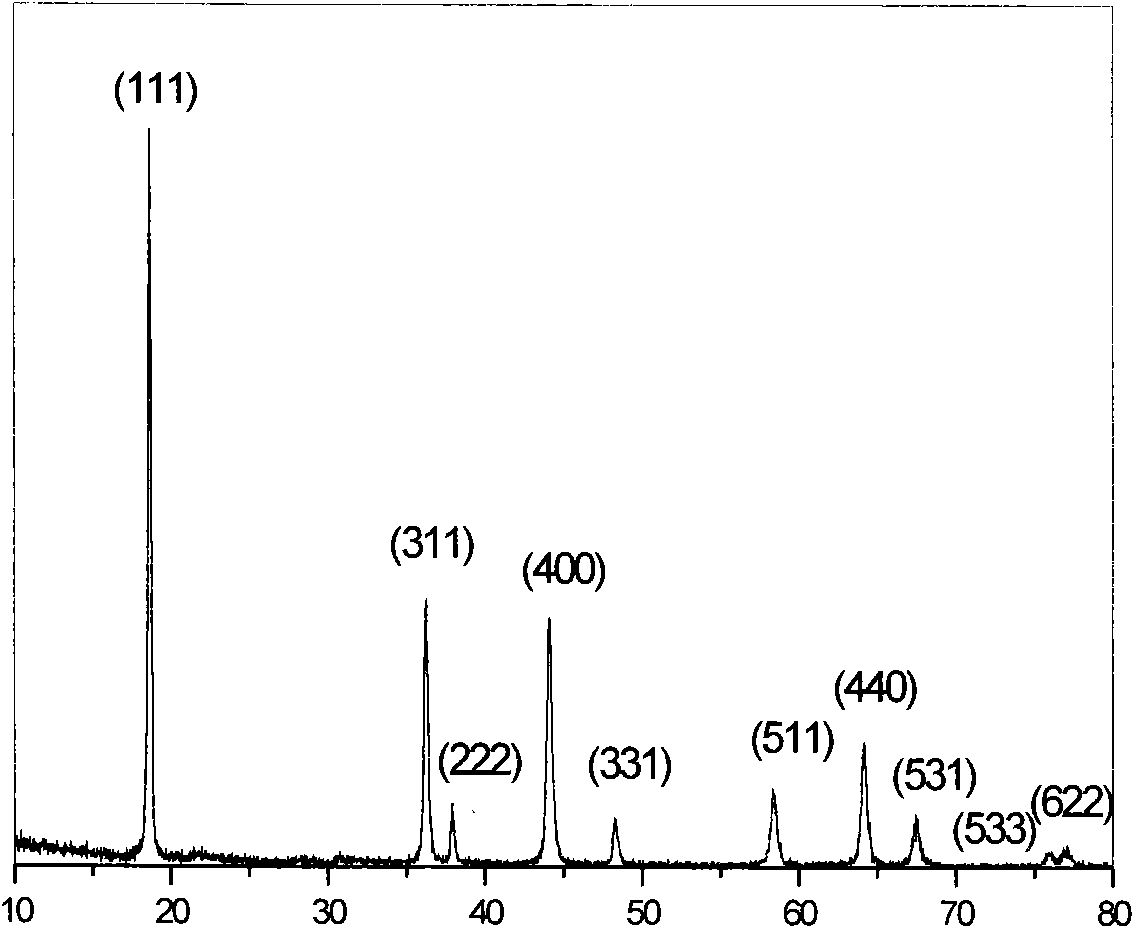

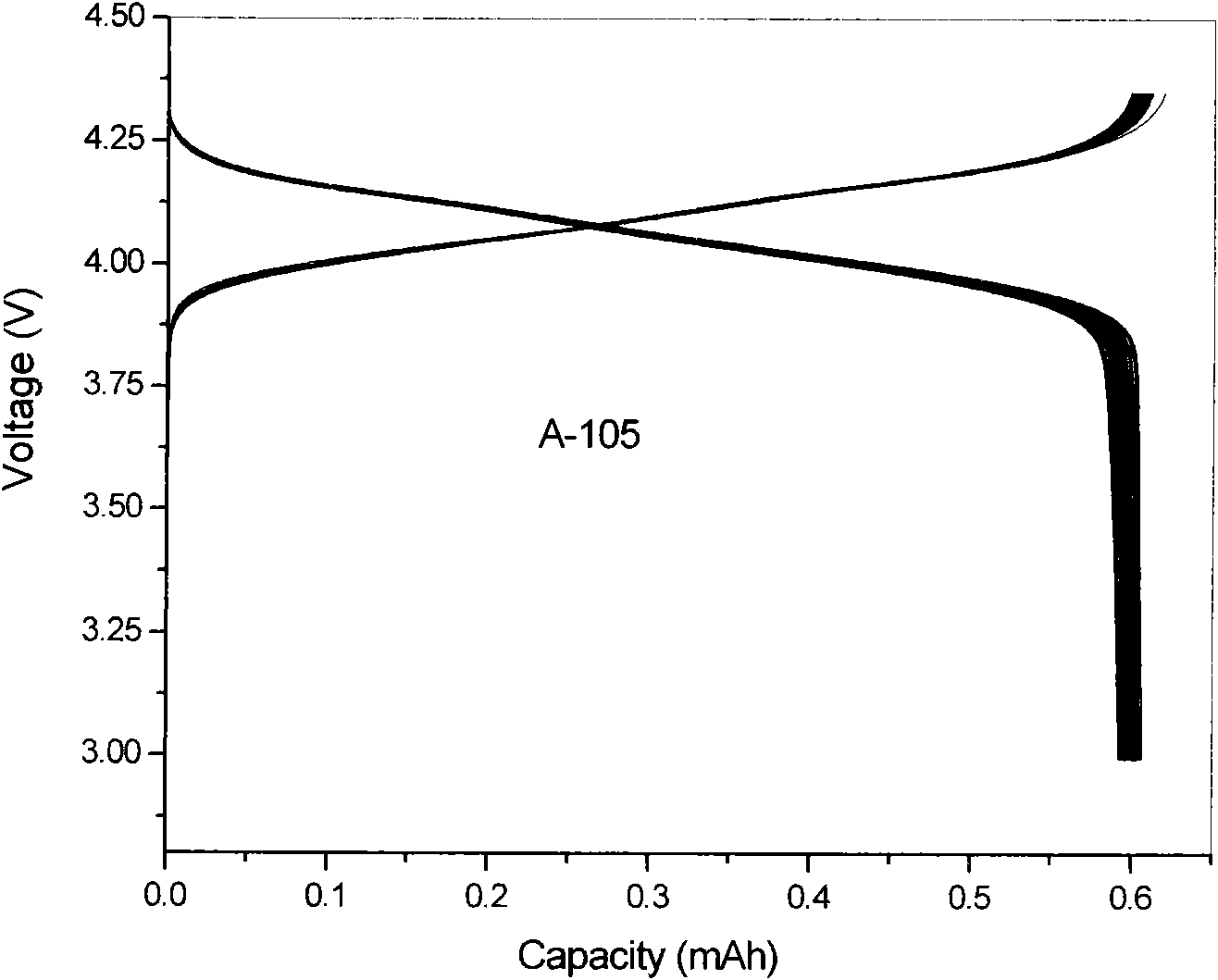

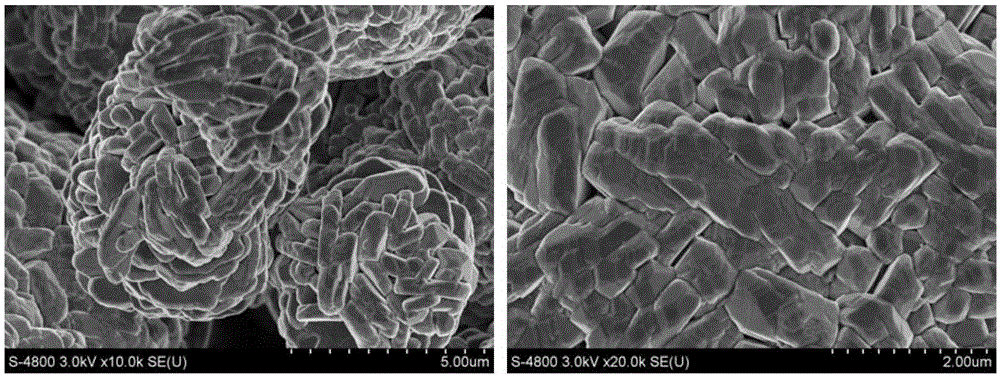

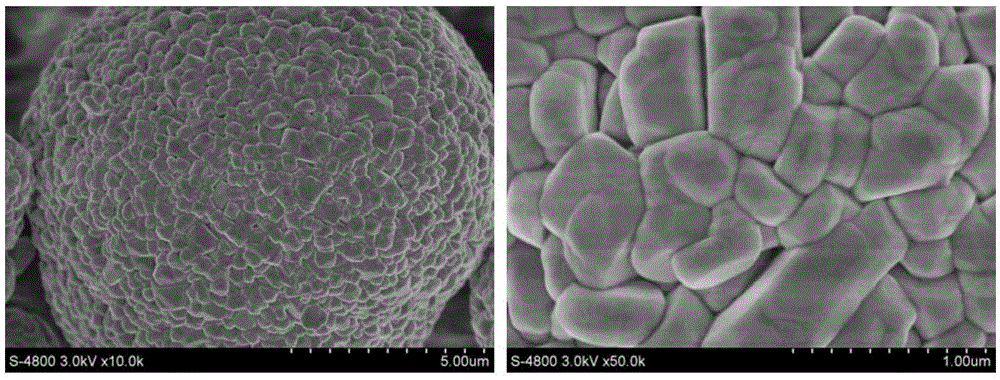

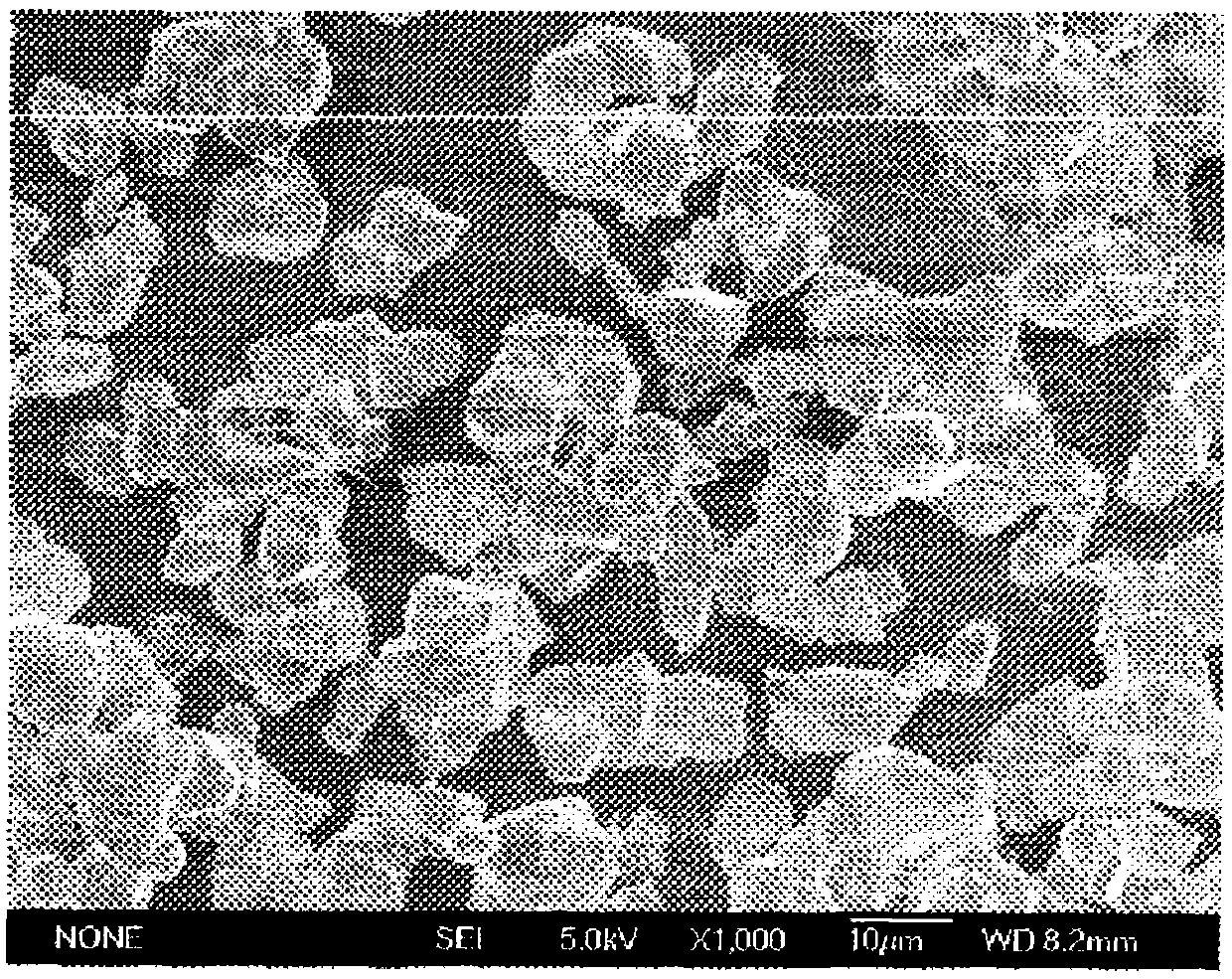

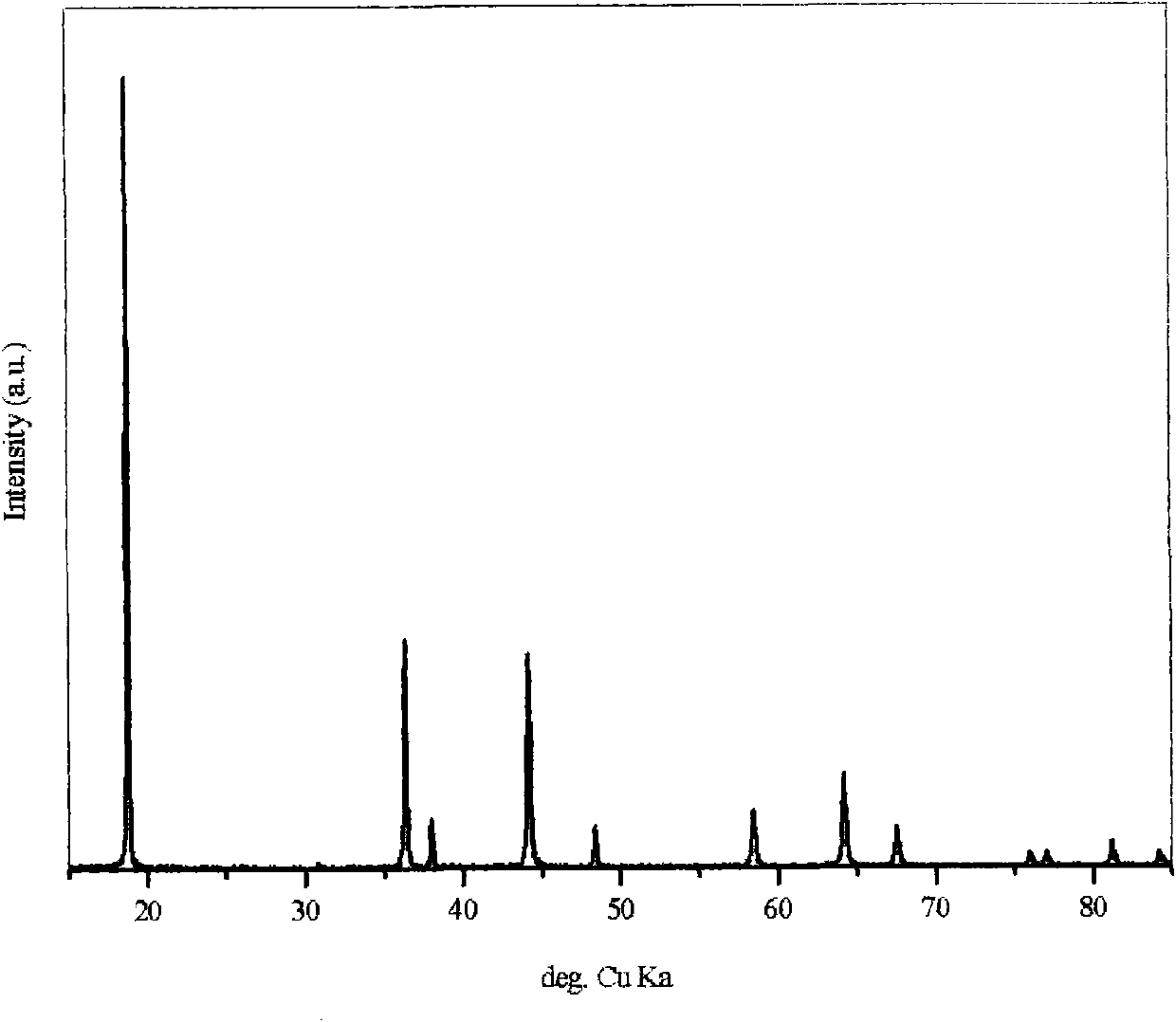

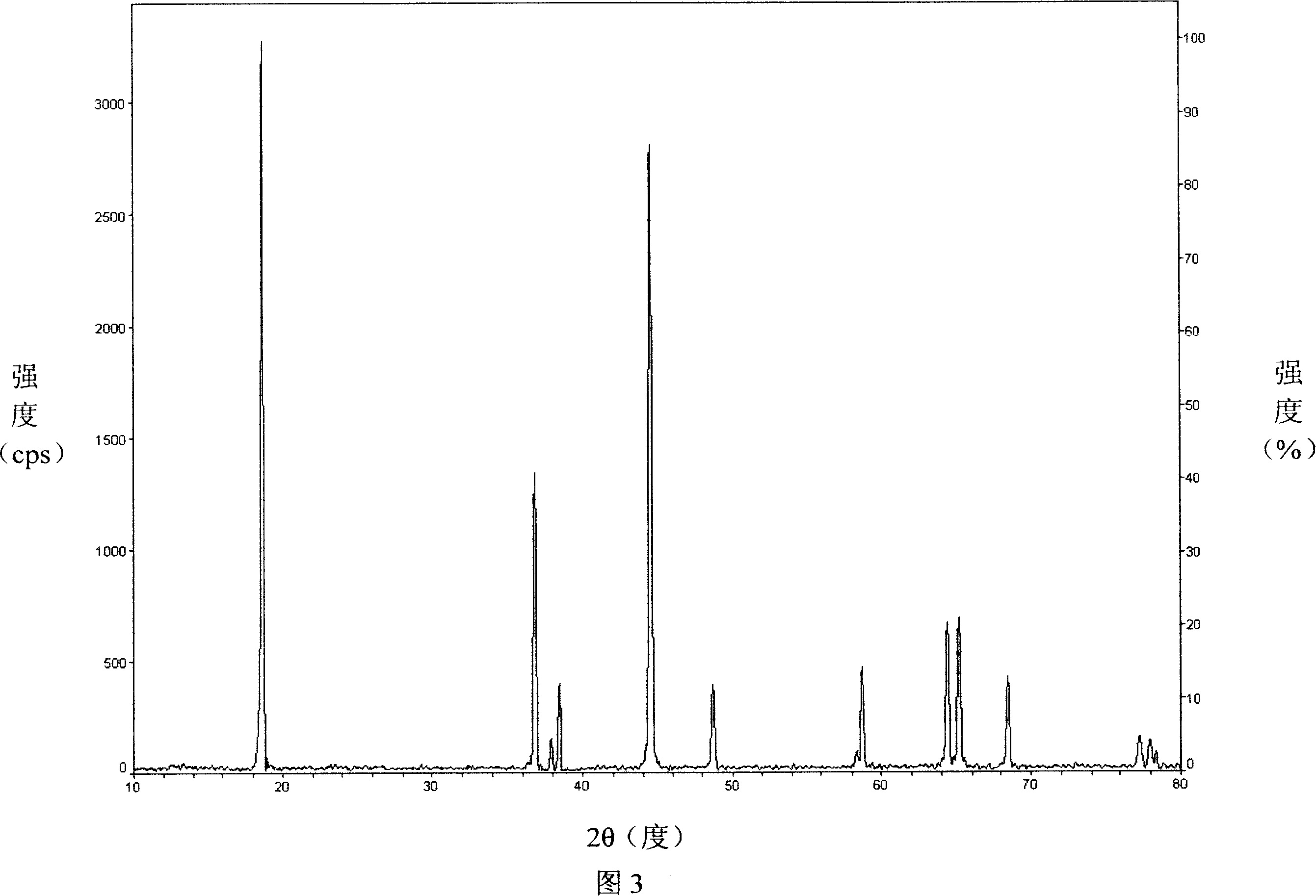

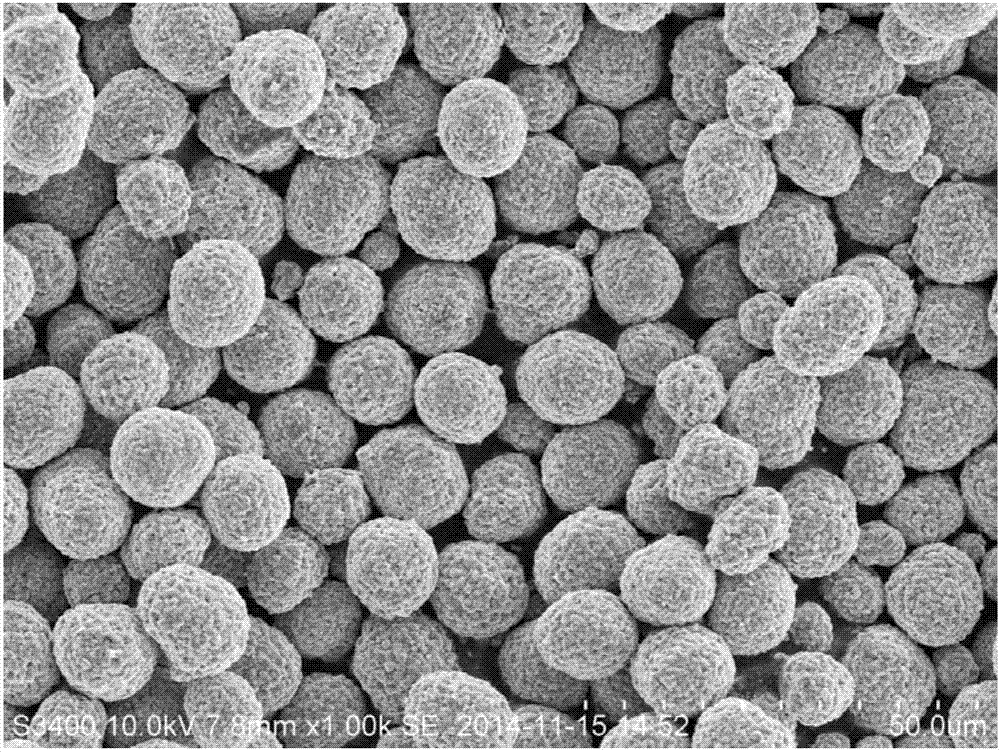

Micron single crystal granular anode material of lithium ion battery

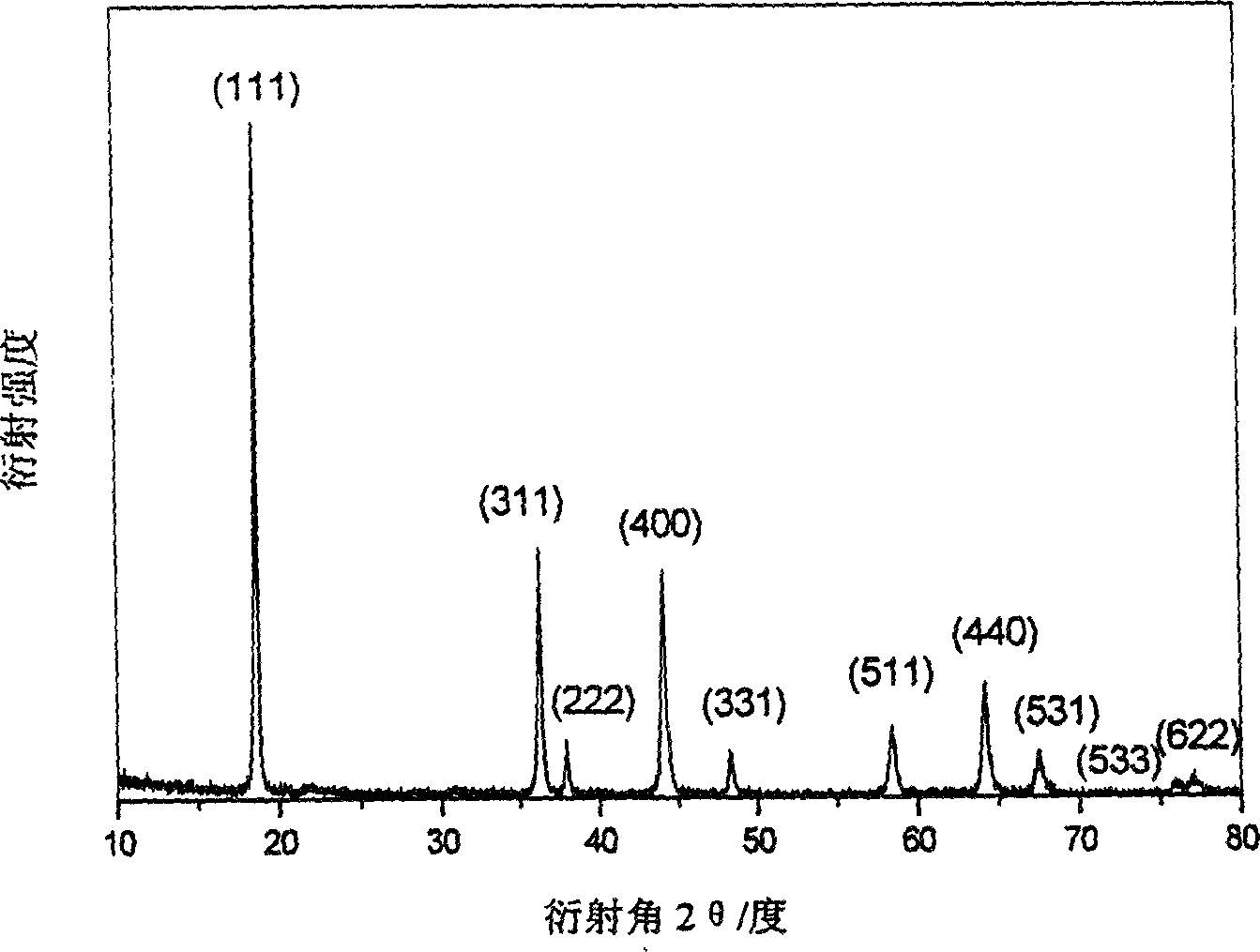

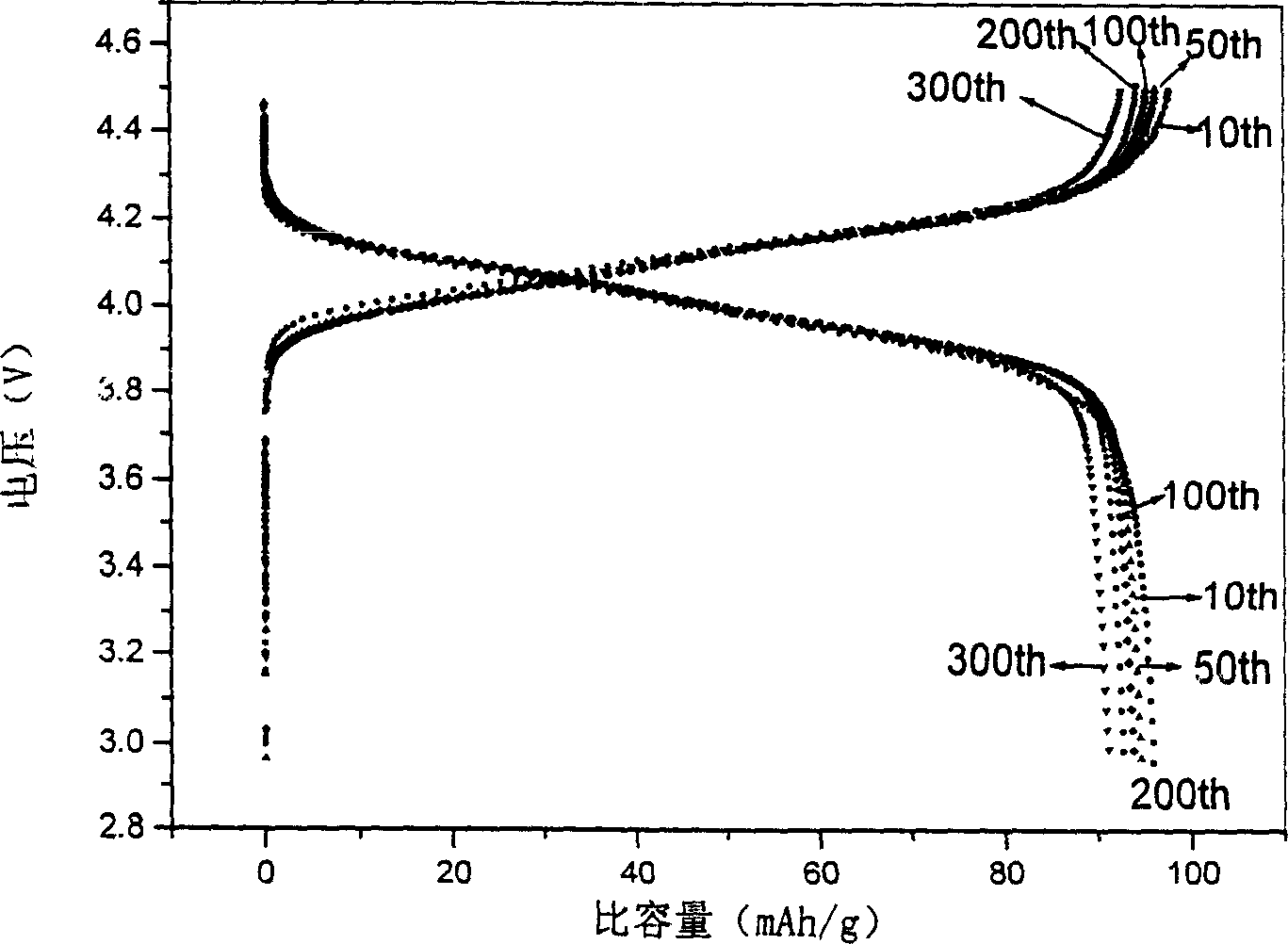

InactiveCN101587950AImprove high rate charge and discharge performanceImproved cycle life and high power output performanceAlkaline accumulatorsCell electrodesTemperature cyclingComposite oxide

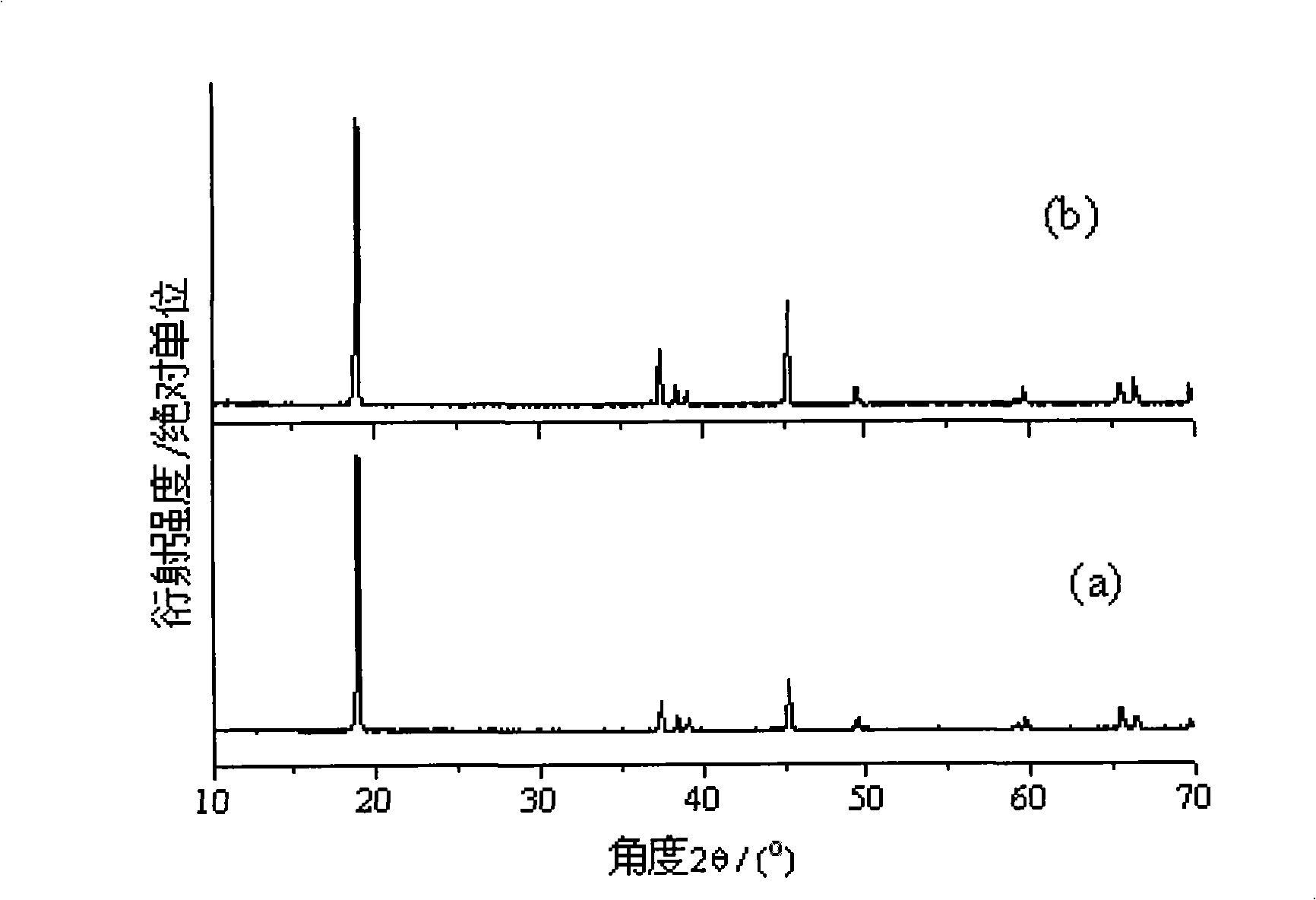

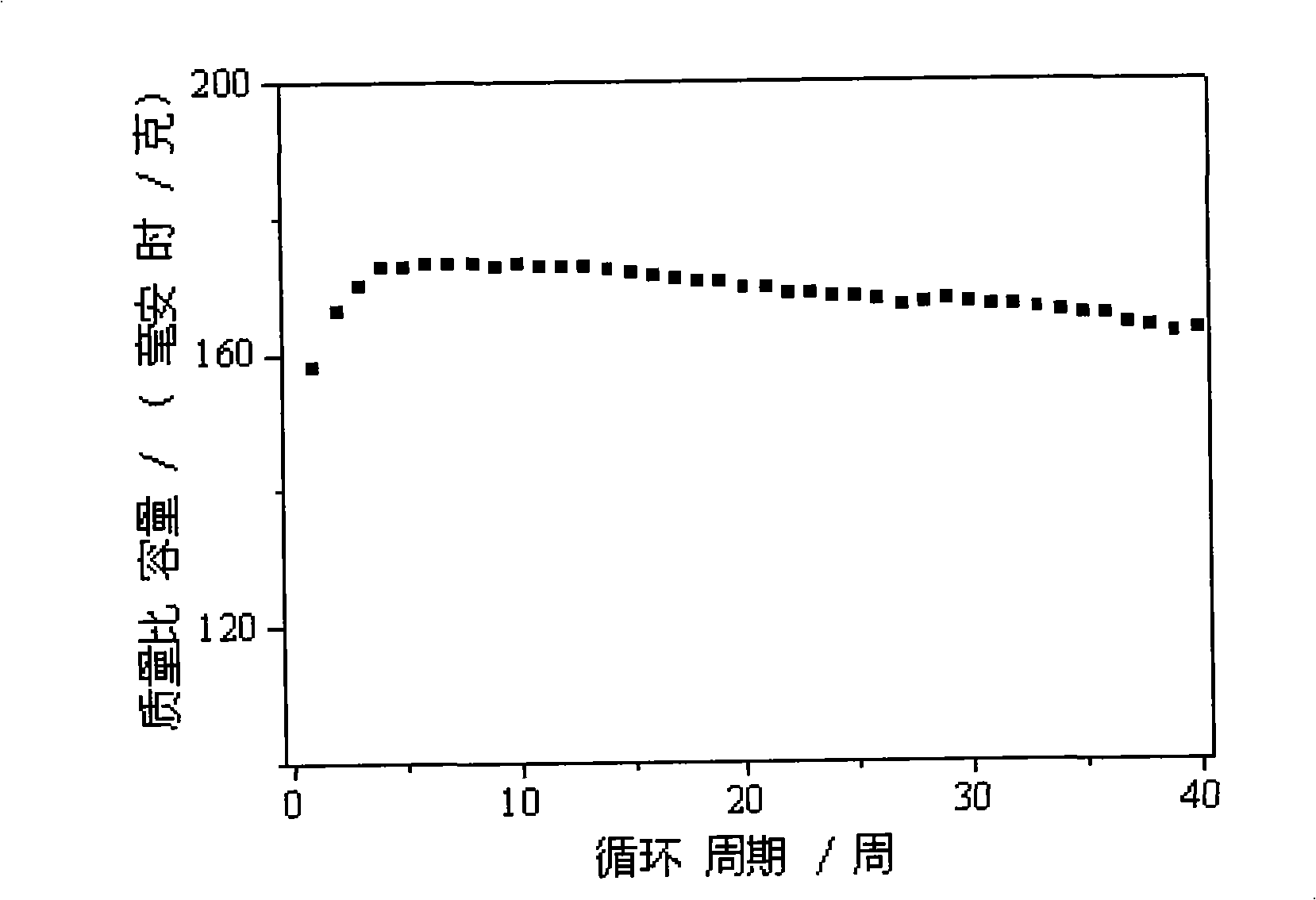

The invention relates to a micron single crystal modified normal spinel lithium manganate LiMn(2-z)MzO4 and a preparation method thereof, wherein z is more than or equal to 0 and is less than or equal to 0.5. The preparation method is characterized in that firstly, composite oxides of manganese and modified metal M are used as raw materials of preparation, the composite oxides are porous aggregates consisting of nanometer microcrystal, the average size of the aggregates is between 5 micrometers and 20 micrometers, and the specific surface of the composite oxides powder is more than 20m / g (measured by a BET method); secondly, the prepared modified lithium manganate material basically consists of micro regular octahedron single crystal, the average size of the single crystal granular is between 5 micrometers and 20 micrometers, the specific surface is lower and is less than 0.5m / g. In addition, the product has excellent physical and electrochemical properties, such as ultralow specific surface, reasonable granular size distribution, better electrode processing property and ultralong circulation service life, excellent multiplying power property, remarkable high-low temperature cycling and storage properties, and best safety, and can be widely used as the materials of an anode of the lithium ion battery, especially a power lithium ion battery.

Owner:QINGDAO LNCM

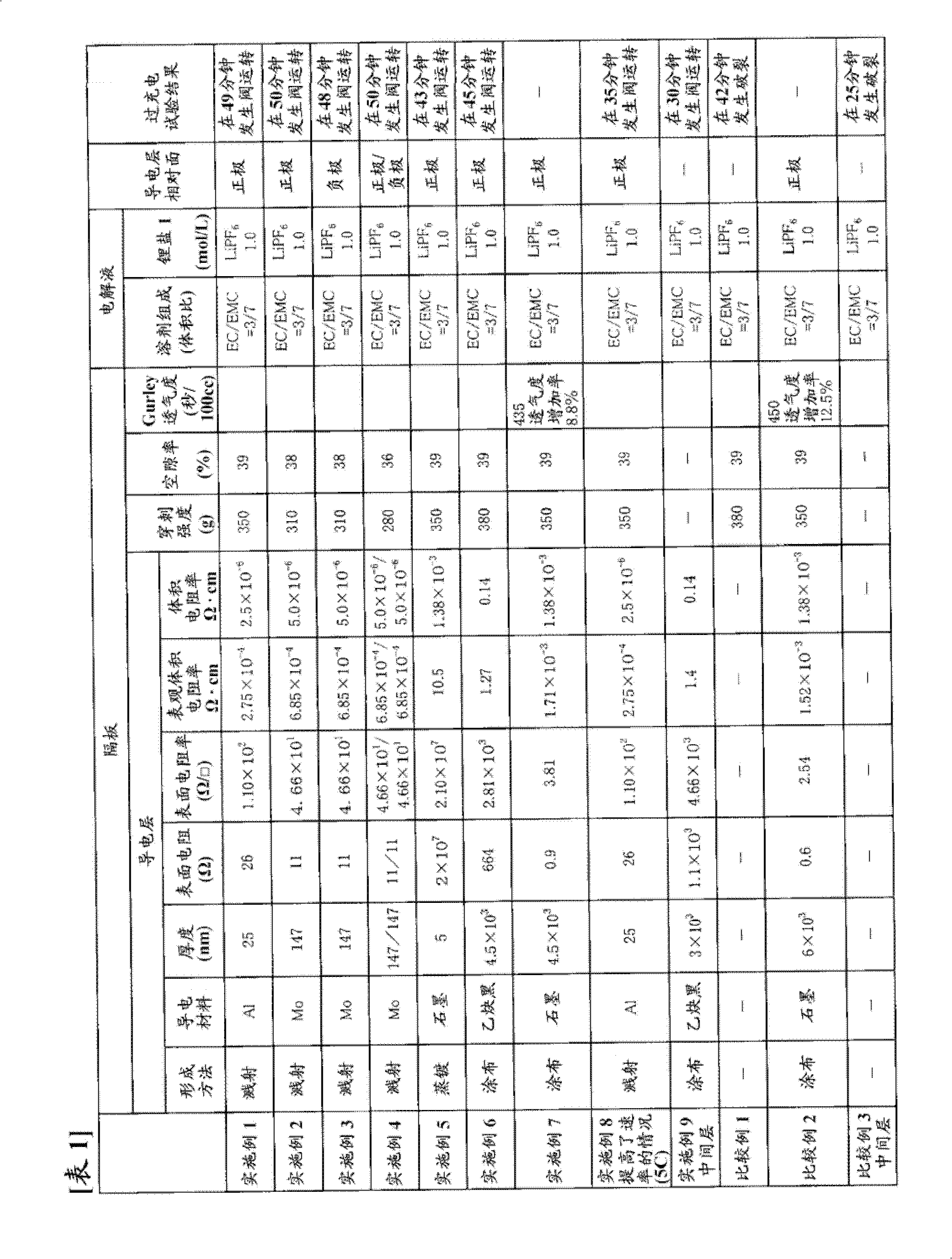

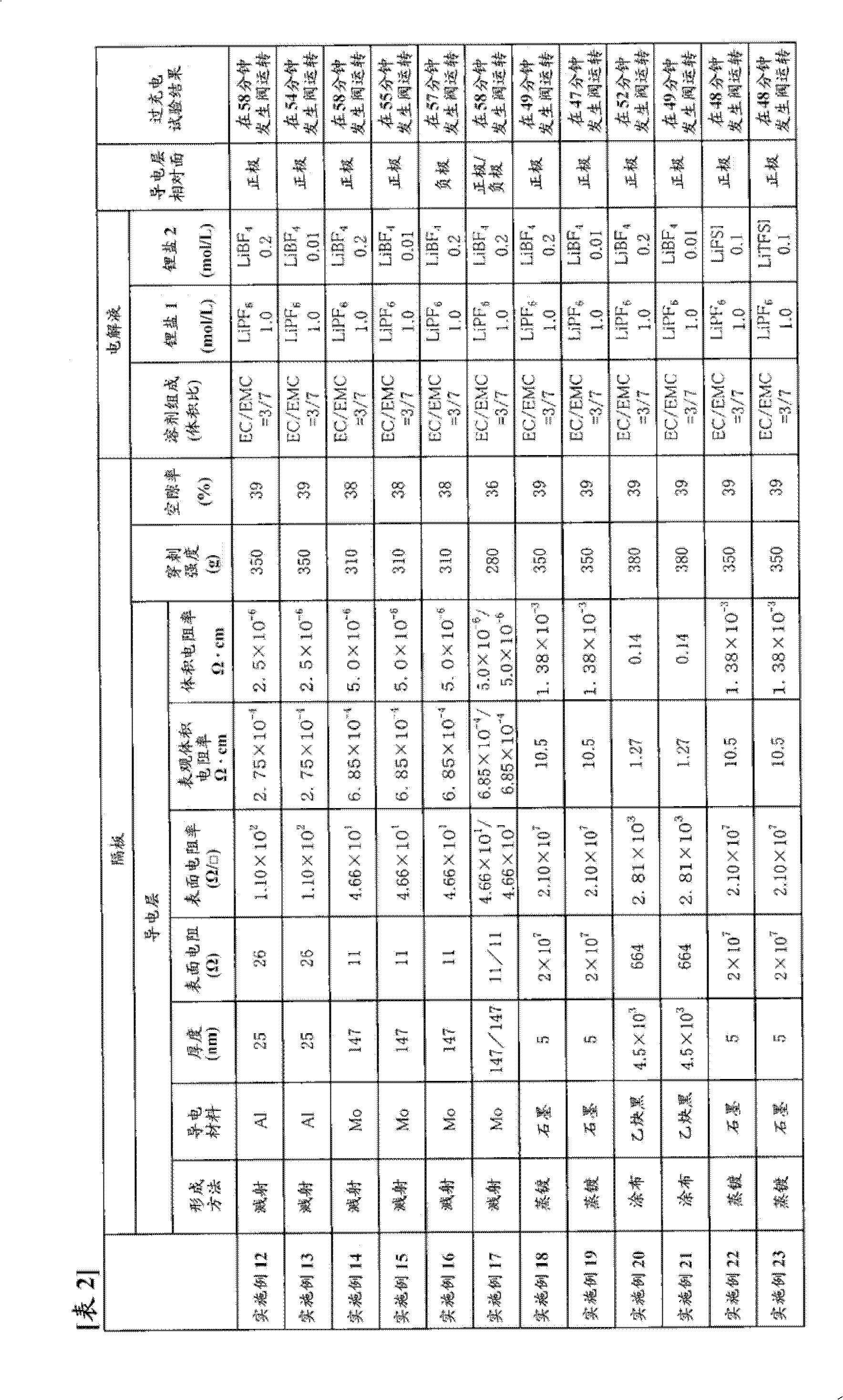

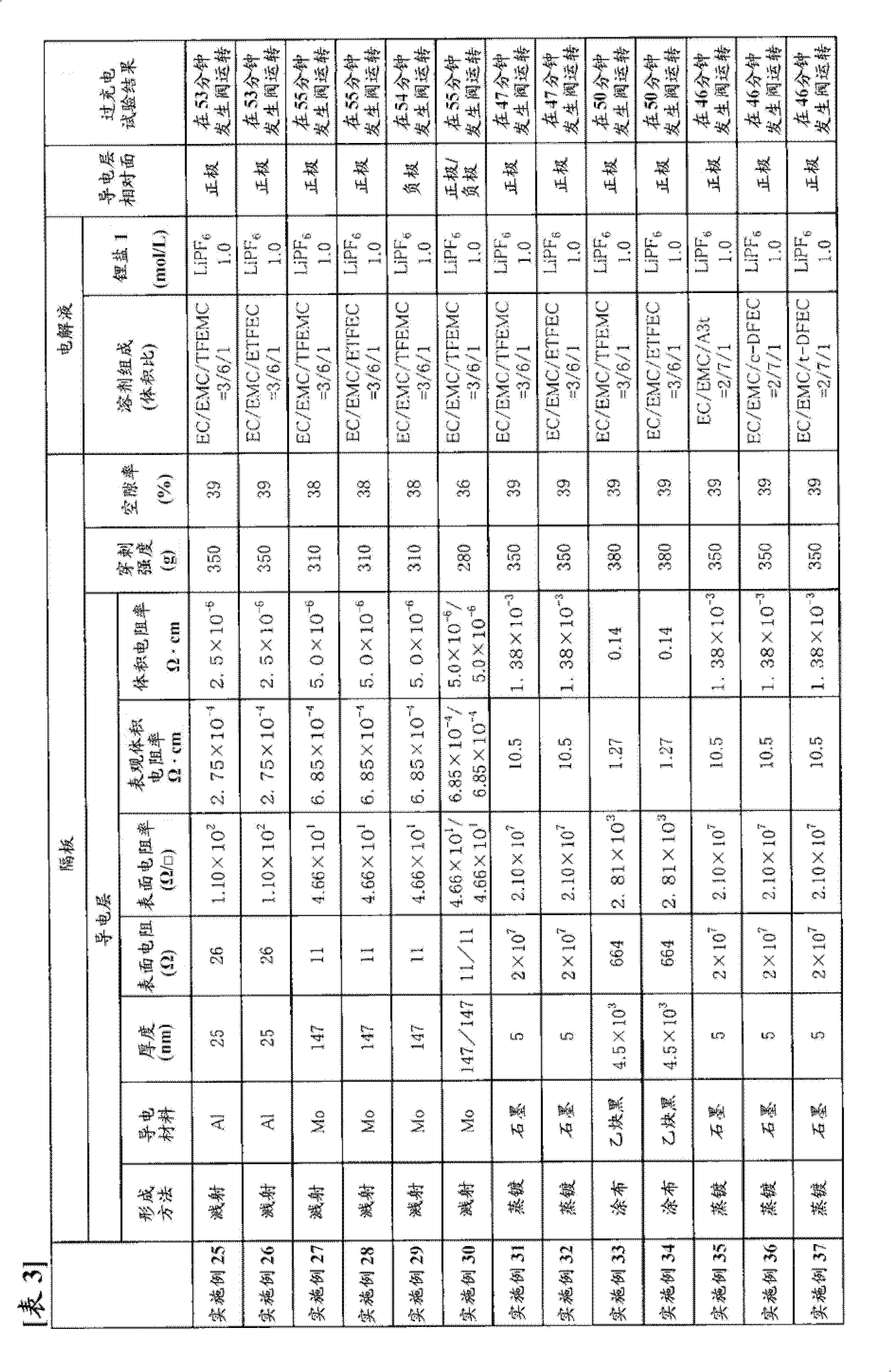

Separator for non-aqueous electrolyte secondary battery and non-aqueous electrolyte secondary battery

InactiveCN102498590AAvoid short circuitImprove overcharge resistanceCell seperators/membranes/diaphragms/spacersCell electrodesSolventNon aqueous electrolytes

The invention relates to a separator for a non-aqueous electrolyte secondary battery and a non-aqueous electrolyte secondary battery. The separator is for use in a non-aqueous electrolyte secondary battery provided with: positive and negative electrodes capable of occluding and discharging lithium; a separator; and a non-aqueous electrolyte including a non-aqueous solvent and an electrolyte. The separator comprises a conductive layer wherein (1) the apparent volume resistivity of the conductive layer is 1*10-4 Omega*cm to 1*106 Omega*cm, or (2) the apparent volume resistivity of the conductive layer is 1*10-6 Omega*cm to 1*106 Omega*cm, or (3) the surface electrical resistance of the conductive layer is 1*10-2 Omega to 1*109 Omega, and the film thickness of the conductive layer is less than 5 [mu]m.

Owner:MITSUBISHI CHEM CORP +1

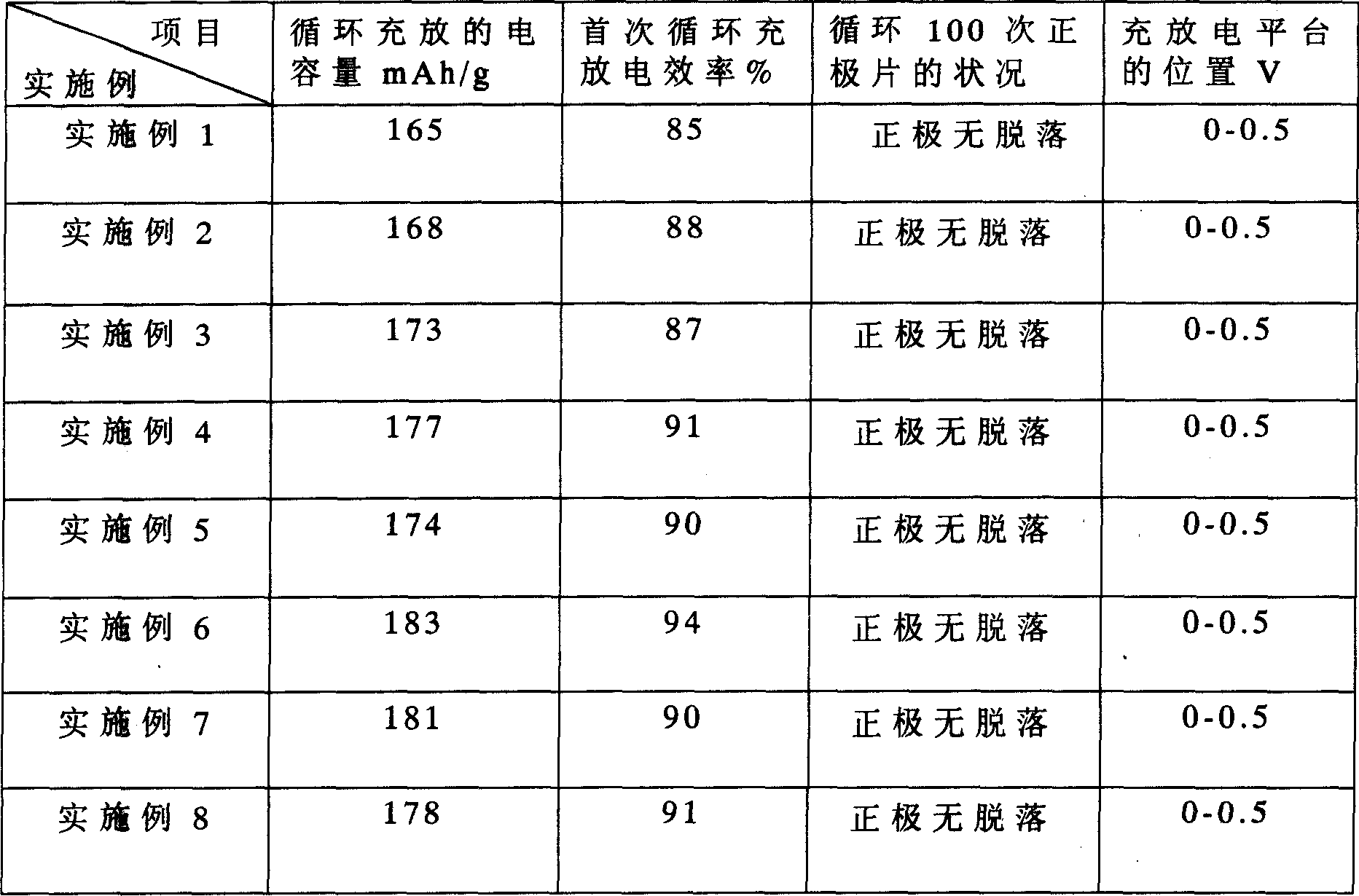

Method for processing ternary material by being clad with lithium ferric manganese phosphate

InactiveCN105406069AGood coating consistencyImprove consistencyCell electrodesSecondary cellsManganeseSlurry

The invention relates to a method for processing a ternary material by being clad with lithium ferric manganese phosphate. The invention belongs to the technical field of a cathode material of lithium ion batteries. The method for processing the ternary material by being clad with the lithium the ferric manganese phosphate comprises the steps of 1, preparation of LFMP precursor slurry: respectively weighing iron, manganese, lithium and phosphorus sources in proportion required by 0.1-100g LFMP, weighing 0-50g ascorbic acid, and adding a dispersion solvent, wherein the solid content is 10%-80%; 2, mixture of materials: weighing 100g ternary material with the constitute of Li(z)Ni(1-x-y)Co(x)Mn(y)O(2), or the mixture of two or more constitutes with the above proportion, adding the slurry, mixing the slurry and the mixture, and carrying out vacuum drying; 3, preparation of the ternary material / lithium ferric manganese phosphate composite cathode material: putting the materials into an argon protective atmosphere sintering surface, keeping warm at the temperature of 250-400 DEG C for 2-6h, then heating to 500-700 DEG C and keeping for 6-16h, cooling along with the furnace, and sieving. The method provided by the invention has the advantages of being simple in technology, convenient to operate, accordant in material performance, small in influence on cell capacity density, and being capable of improving safety performance of the ternary material.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Lithium ion battery anode material and preparation method thereof

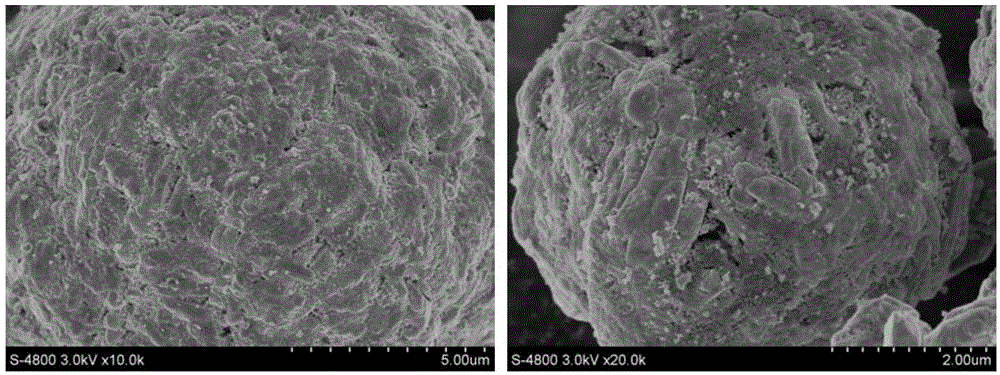

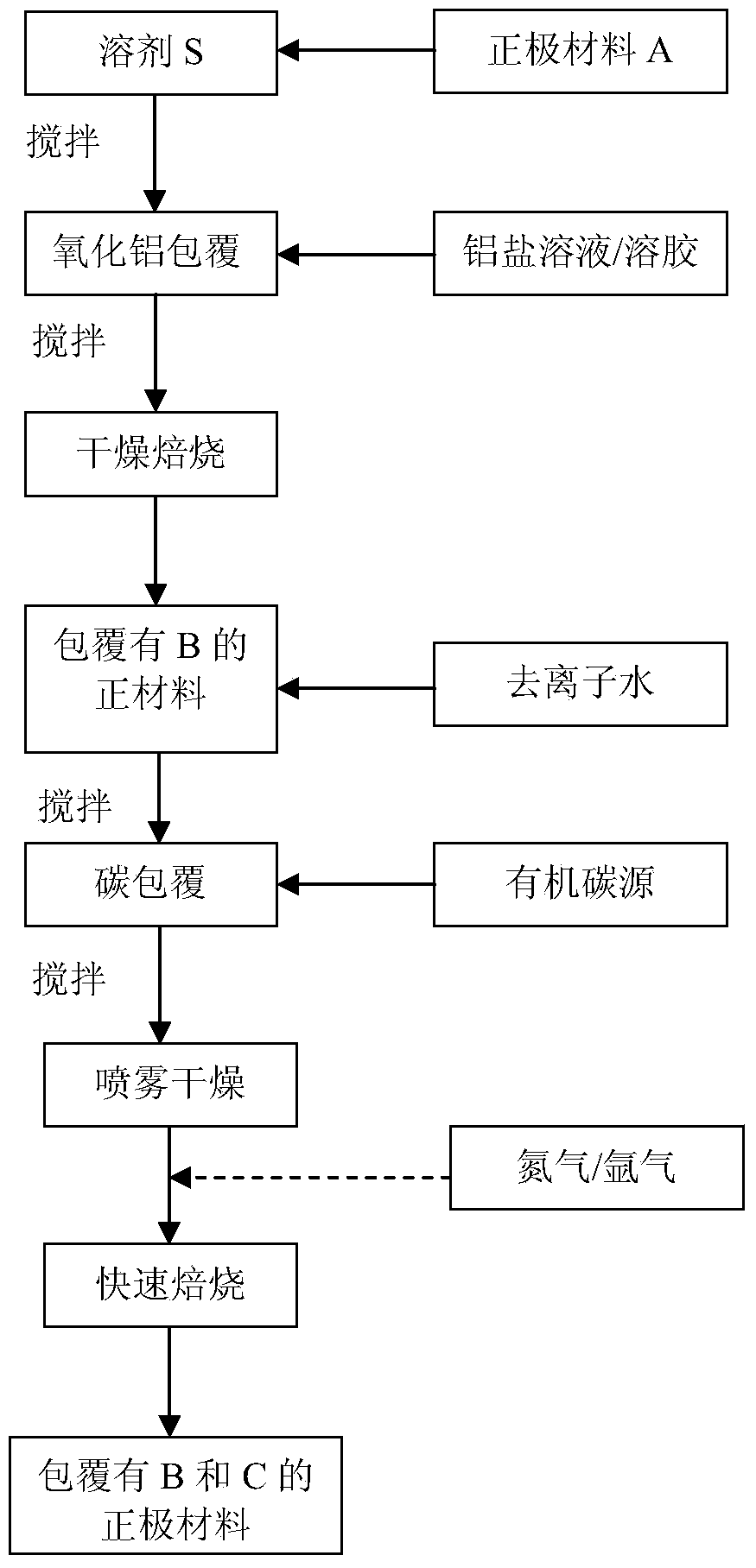

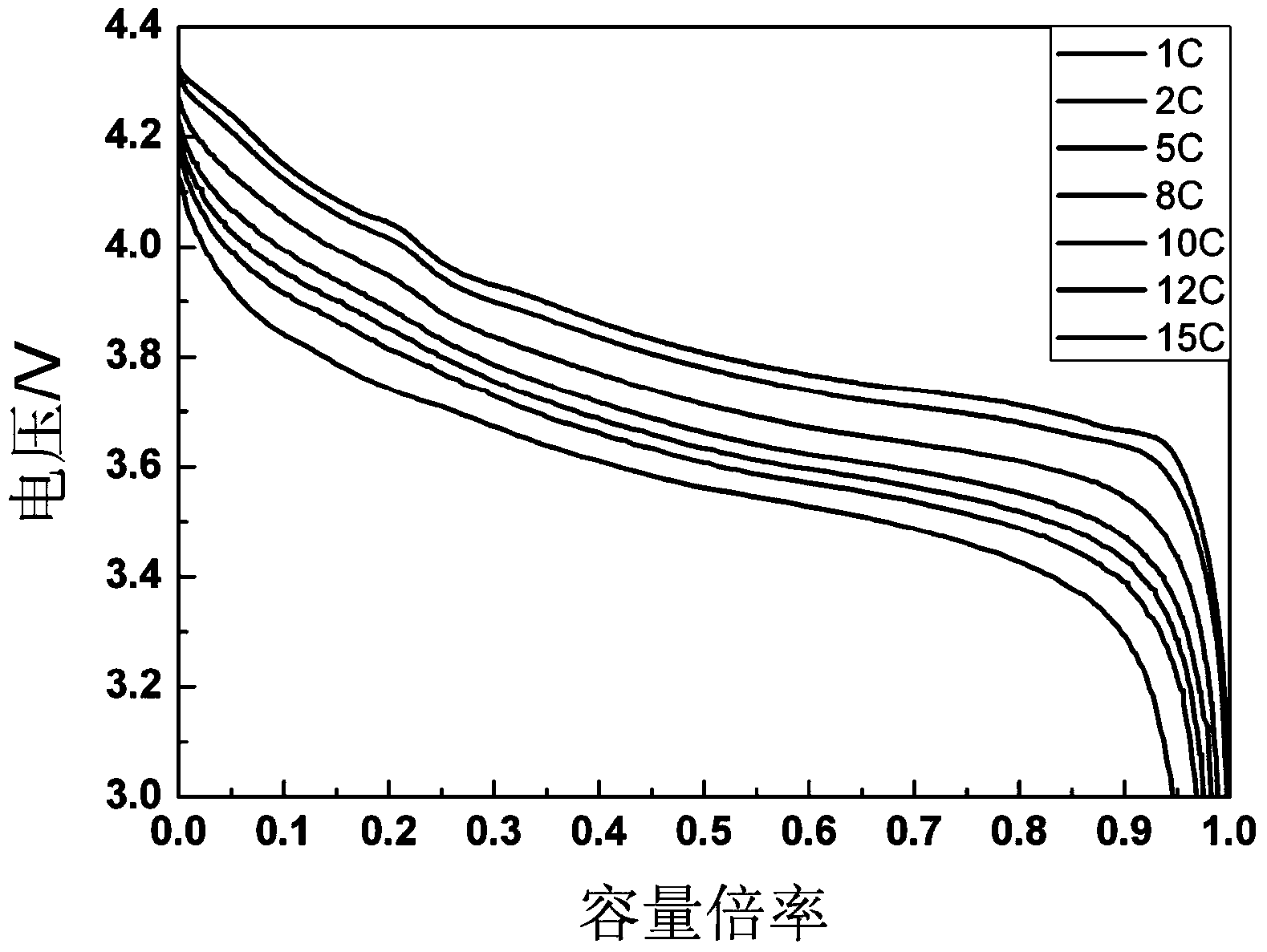

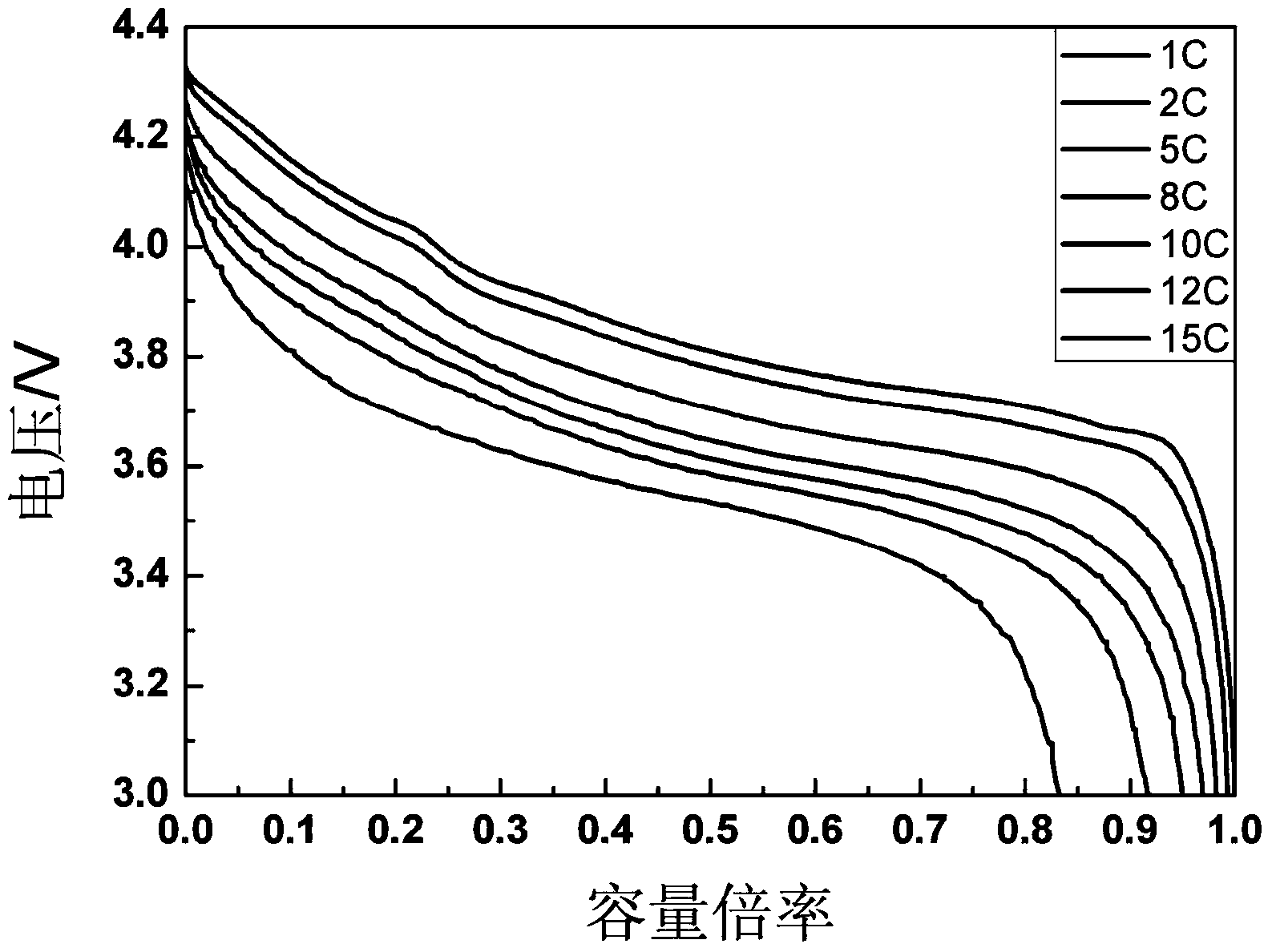

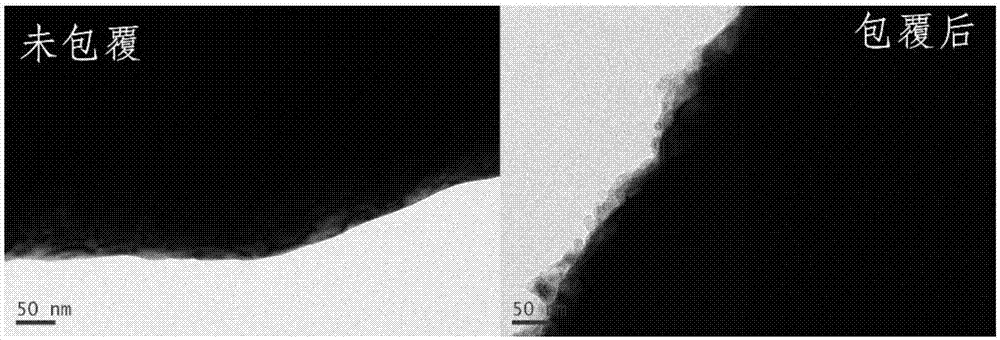

ActiveCN103647073AAvoid metal reductionQuick releaseElectrode thermal treatmentSecondary cellsCarbon coatingCarbon source

The invention discloses a preparation method of a lithium ion battery anode material. The method is characterized in that the outer surface of the existing lithium ion battery anode material is sequentially coated with an aluminum oxide layer and a carbon layer, wherein the coating condition is liquid-phase coating, in the coating process of the aluminum oxide, the addition sequence of the existing lithium ion battery anode material and aluminum salt is adjusted, and the coating substance organic aluminum salt is added under the continuously stirring condition, so that a hydrolytic product is uniformly adsorbed onto the surface of an active substance. The carbon coating is carried out through a spray drying and rapid sintering way in the inert gas atmosphere, so that the problems that the metal is reduced due to the high-temperature carbon coating and the organic carbon source is difficultly carbonized in low temperature can be avoided. The invention also discloses a lithium ion battery anode material prepared through the method. The energy density and power density of the battery can be remarkably improved, and the cycling performance, the capacity retention rate and the safety performance of the battery can be improved.

Owner:EVE ENERGY CO LTD

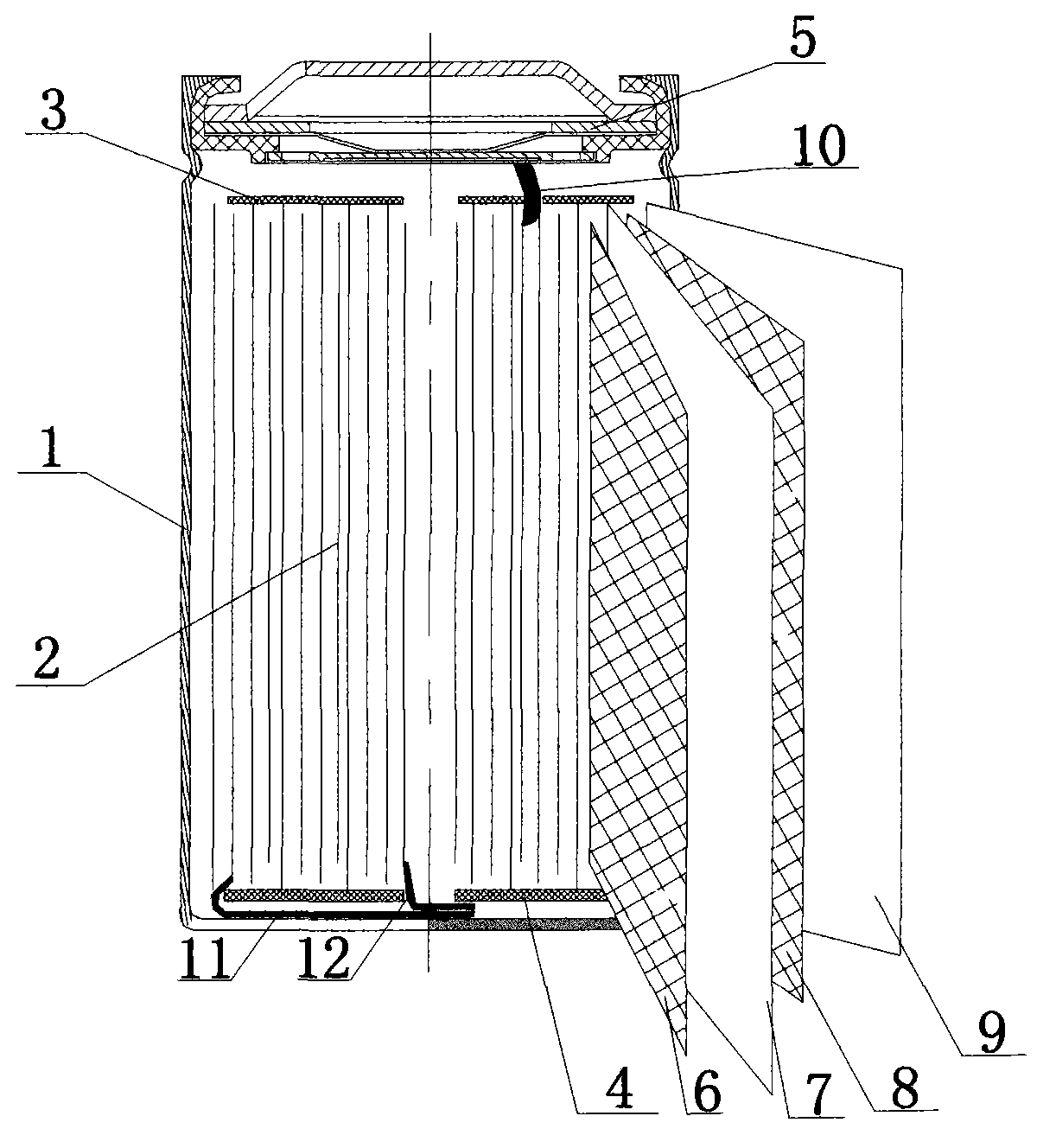

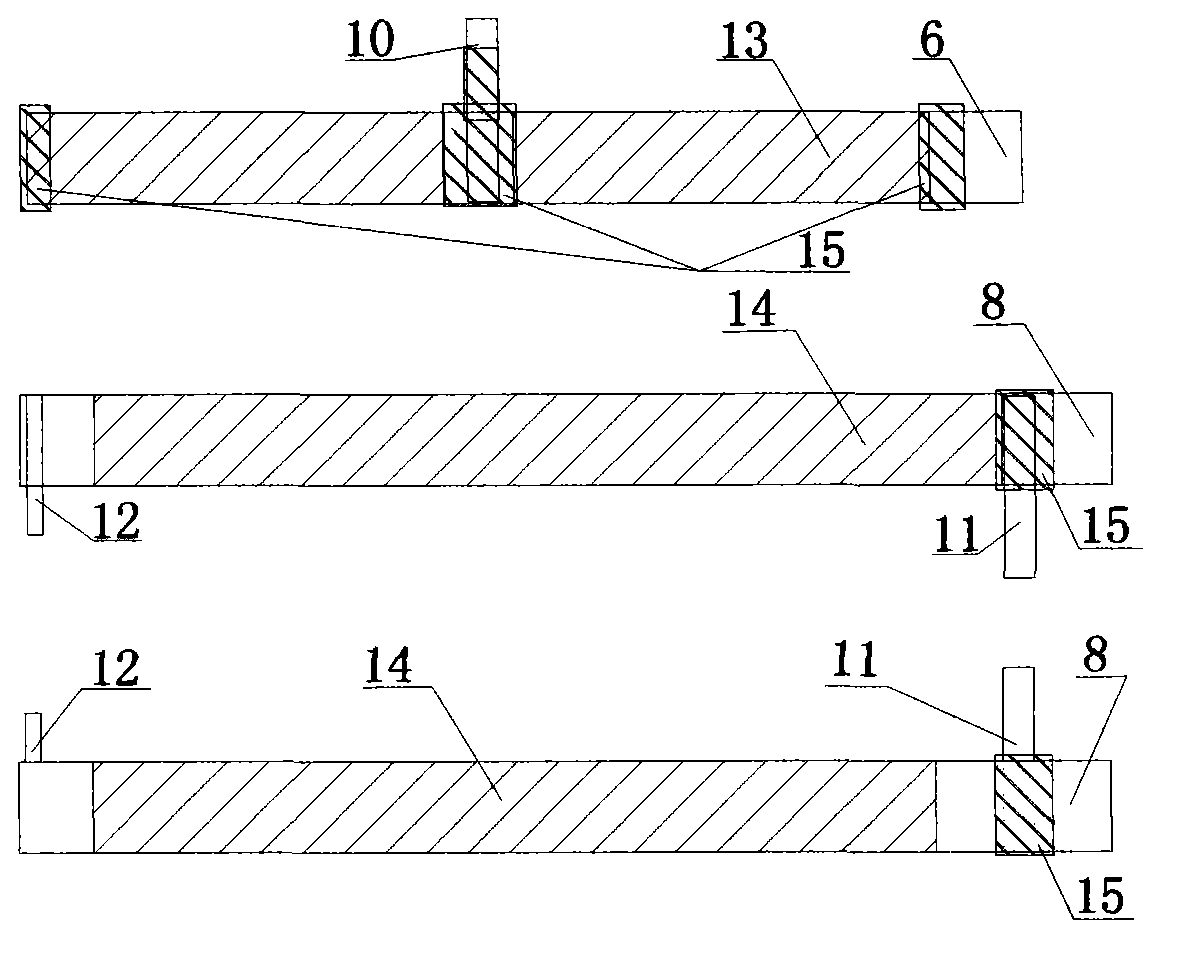

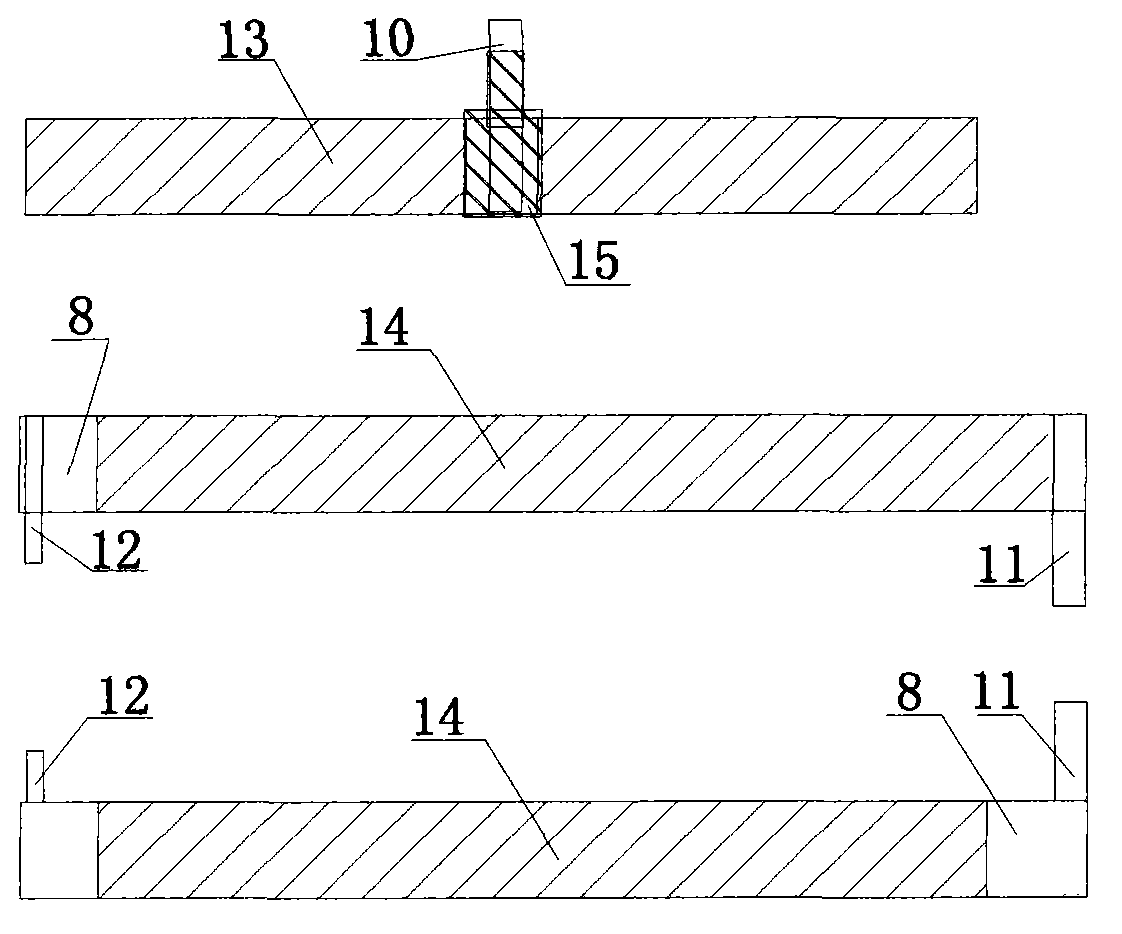

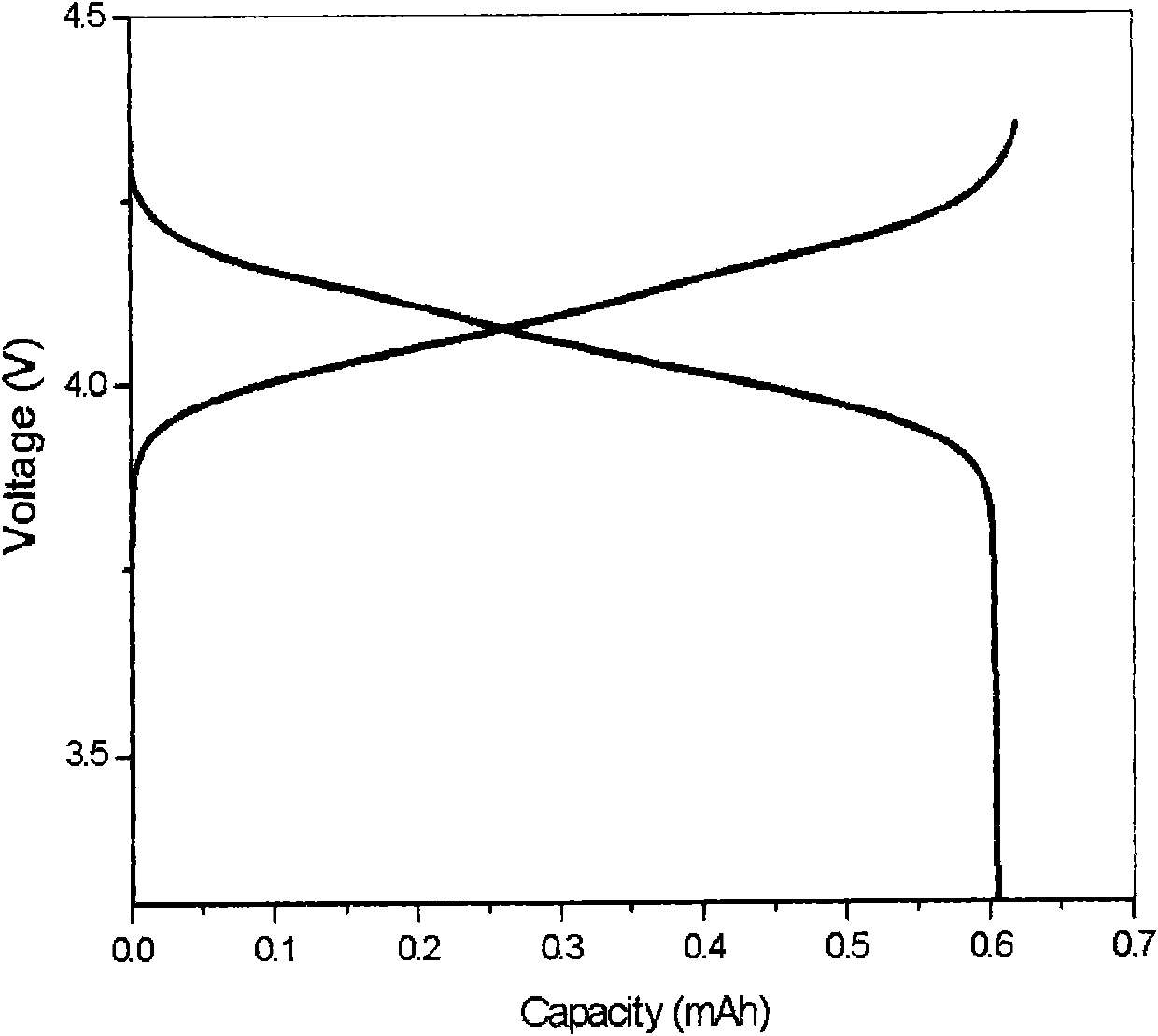

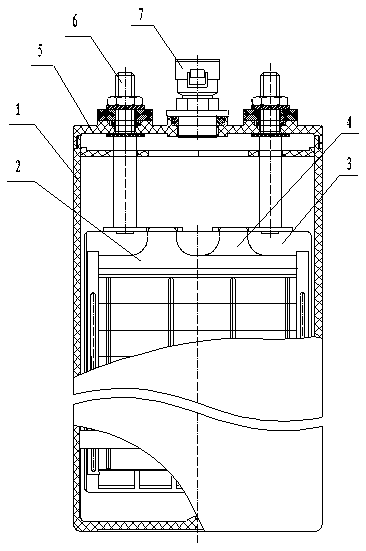

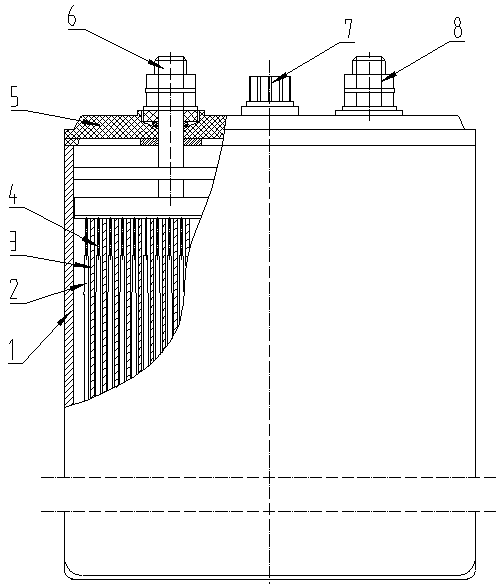

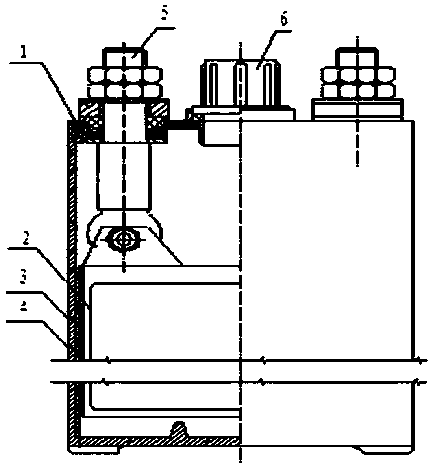

Lithium nickel cobalt manganate cylindrical high-rate battery and preparation method thereof

ActiveCN103413975AIncrease productivityImprove overcharge resistanceFinal product manufactureCell component detailsHigh rateAdhesive

The invention belongs to a high-safety lithium nickel cobalt manganate cylindrical high-rate battery and a preparation method thereof. The battery comprises a nickel-plated steel case and a lithium ion battery cell in the nickel-plated steel case, wherein an upper insulating strip and a lower insulating strip are respectively arranged at the upper part and the lower part of the lithium ion battery cell; a cap is arranged on a mechanical seal port in the upper part of the nickel-plated steel case; the lithium ion battery cell comprises a positive plate, a first diaphragm, a negative plate and a second diaphragm which are superposed in sequence and reeled; by setting the positions of a positive pole leading-out end and a negative pole leading-out end and setting the sticking position and manner of a high-temperature adhesive tape, the battery production efficiency can be effectively improved and defects in a processing procedure can be reduced; as the first diaphragm and the second diaphragm are used in combination and electrolytes containing special additives are selected and used to coordinate with one another, the destructive safety performance test of the battery is 100% qualified. The battery has the advantages that the assembly is simple, the yield is high, the cycle performance is good, and the safety performance of resistance to overcharge, short circuit, needling, squeezing, impact and the like can be improved.

Owner:河南比得力高新能源科技有限公司

LiMn2-xMxO4.yLiAlO2 as anode material for lithium ion battery

The invention relates to a solid solution for a lithium ion battery with a positive spinel structure having the formula LiMn2-xMxO4.yLiAlO2 (0<=0.1, 0<y<0.5), wherein, M is one or more selected from Mg, Ca, Co, Ni, Cr and Zn. The solid solution can be used as an anode material for the lithium ion battery, characterized in that: the lithium-containing solid solution has good processability of electrodes, super long cycle lifetime, excellent multiplying performance, extraordinary high and low temperature cycle and storage performance and great safety performance, and can be widely used as anode materials for lithium ion batteries, especially for dynamic lithium ion batteries.

Owner:QINGDAO LNCM

Preparation method of ternary compound potassium ion battery plus plate material

ActiveCN1956242AAvoid local overconcentrationIncrease contactElectrode manufacturing processesLithium compoundsLithium compoundSolvent

A method for preparing positive electrode material of ternary composite Li ion cell includes mixing soluble compound of Ni and Mn as well as Co to be transition metal soluble, filling certain amount of ammonia water in reactor then adding transition metal solution into reactor by ejecting gun and pumping mixed liquid of ammonia and sodium hydroxide into reactor by precipitation then wet-mixing it with Li compound, sintering mixture of presoma and Li compound with high temperature under oxygen atmosphere then grinding sintered material to obtain positive electrode material.

Owner:BYD CO LTD

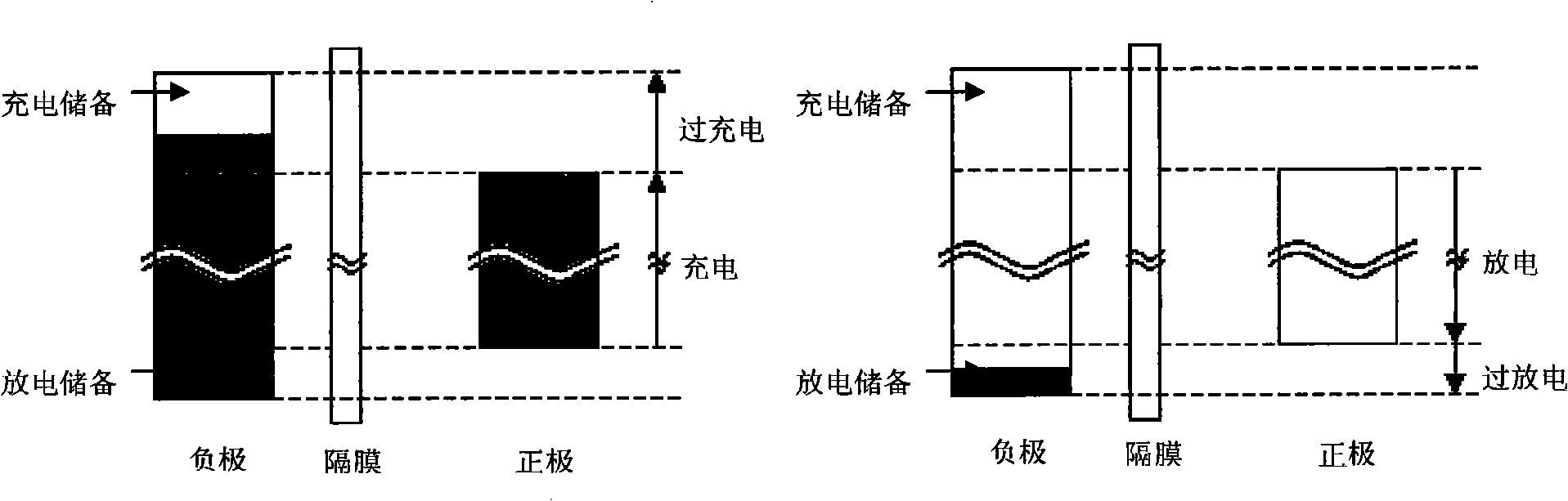

High safety, high power lithium ion power battery

InactiveCN101000971AImprove overcharge resistanceImprove thermal stabilityFinal product manufactureSecondary cellsPower batteryOrganic solvent

This invention relates to the lithium ion batteries with high security and high power for electric bicycles, which is composed of the first anode film, the first cathode film, the second anode film, the second cathode film, separator, electrolyte and battery shell, and the batteries have the laser welding seal. The electrolyte is made of LiPF6, organic solvents, sufficient additive cyclohexyl benzene and flame retardant additive three beta TCEP. The cover of battery is installed with the injecting holes and explosion-prevented films. The winding order from inside to outside of battery core is the first anode film, separator, the first cathode film, separator, the second anode films, separator, the second cathode film, separator.

Owner:TIANJIN UNIV

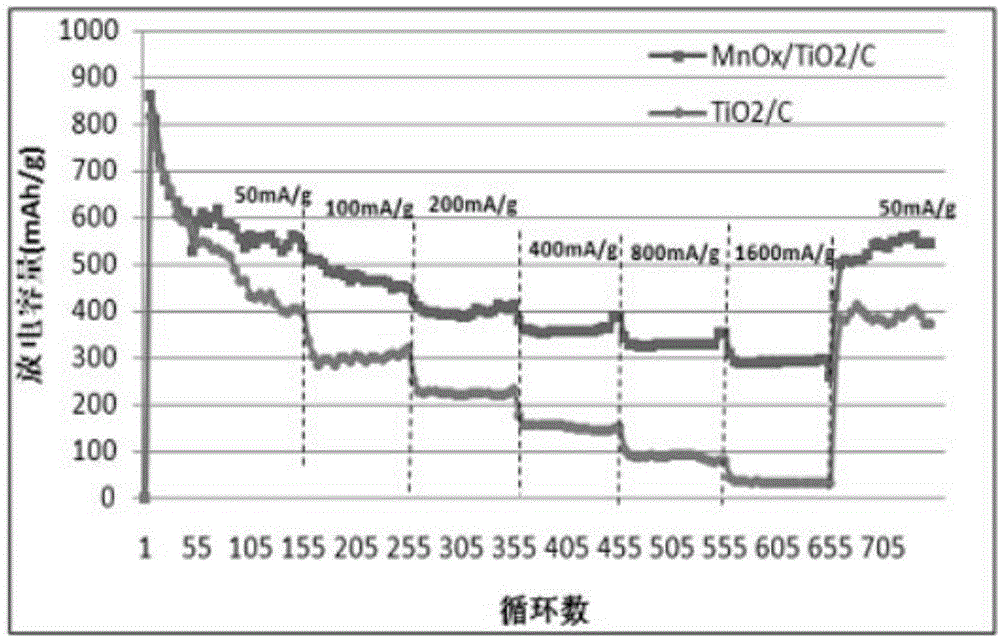

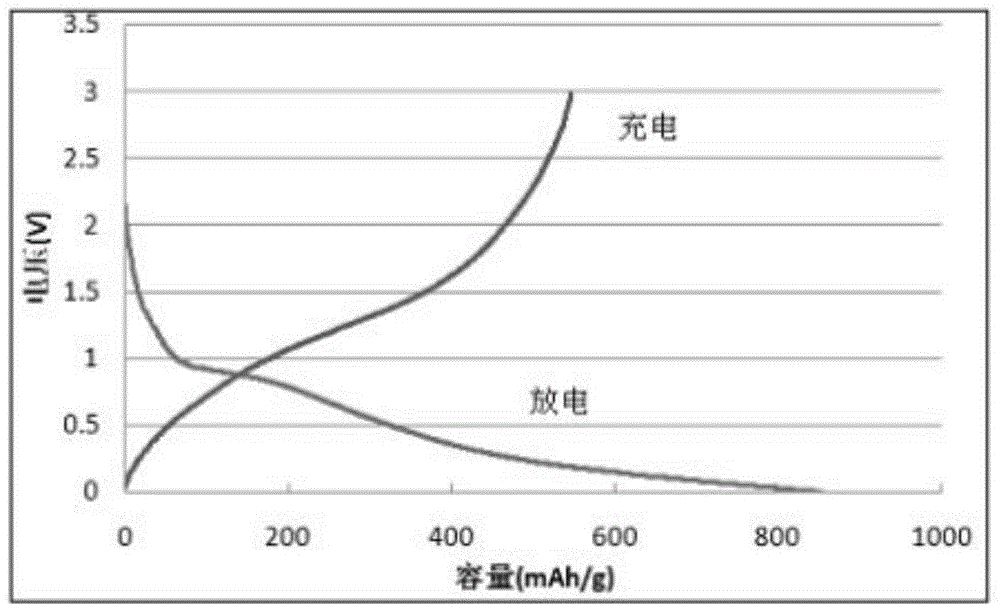

Preparation method of nano-composite membrane electrode material

InactiveCN104868100AIncrease electrochemical potentialImprove cycle performanceMaterial nanotechnologyCell electrodesFiberManganese

The invention discloses a preparation method of a nano-composite membrane electrode material. The preparation method comprises the following steps: (1) dissolving a precursor of manganese, a precursor of titanium and a precursor of carbon in an organic solvent to prepare a spinning solution; (2) performing electrostatic spinning on the spinning solution to obtain a nano-fiber material; and (3) after performing pre-oxidation treatment on the nano-fiber material, performing carbonization treatment in an inert atmosphere to obtain the required nano-composite membrane electrode material. The MnOx / TiO2 / C nano-fiber composite membrane electrode material prepared by the preparation method is excellent in performance, nano particles of MnO2 and TiO2 are distributed on carbon nanofibers with good electric conductivity and porous structure in a mutually interlaced manner, and crystal structures of MnO2 and TiO2 nano particles affect each other and the MnO2 and TiO2 nano particles coordinately distribute on the carbon nanofiber membrane , so that the intercalation and deintercalation efficiency of lithium is improved, and the cycle performance and rate performance of the electrode material are improved; and moreover, the porous structure of the carbon nano-fibers provides a passage for the intercalation and deintercalation of lithium ions, and the electric conductivity is improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Lithium ionic cell composite positive pole material coated by orthosilicate

InactiveCN101308926AImprove overcharge resistanceImprove thermal stabilityElectrode manufacturing processesChemical/physical/physico-chemical processesLithiumDissolution

A composite lithium ion battery anode material coated with orthosilicate and the preparation method thereof are disclosed, belonging to battery electrode material field and the preparation method field. The formula of orthosilicate is MSiO4(M is Mn,LiCo, LiFe) and the orthosilicate contains 0.1%-5.0% the mass of the electrode material. The preparation method of the composite anode material includes the following steps: firstly, preparing orthosilicate sol; adding the target anode material into the orthosilicate sol and mix the two thoroughly; drying and baking the mixture; in this way, coated and modified anode material can be obtained. The anode material is greatly improved in over-charging resistance and thermal stability while not reduced in specific capacity. Furthermore, the preparation method is simple in technique and convenient to operate and can effectively avoid the dissolution of the lithium ions and is easy to realize in large scale industrial production.

Owner:BEIJING UNIV OF CHEM TECH

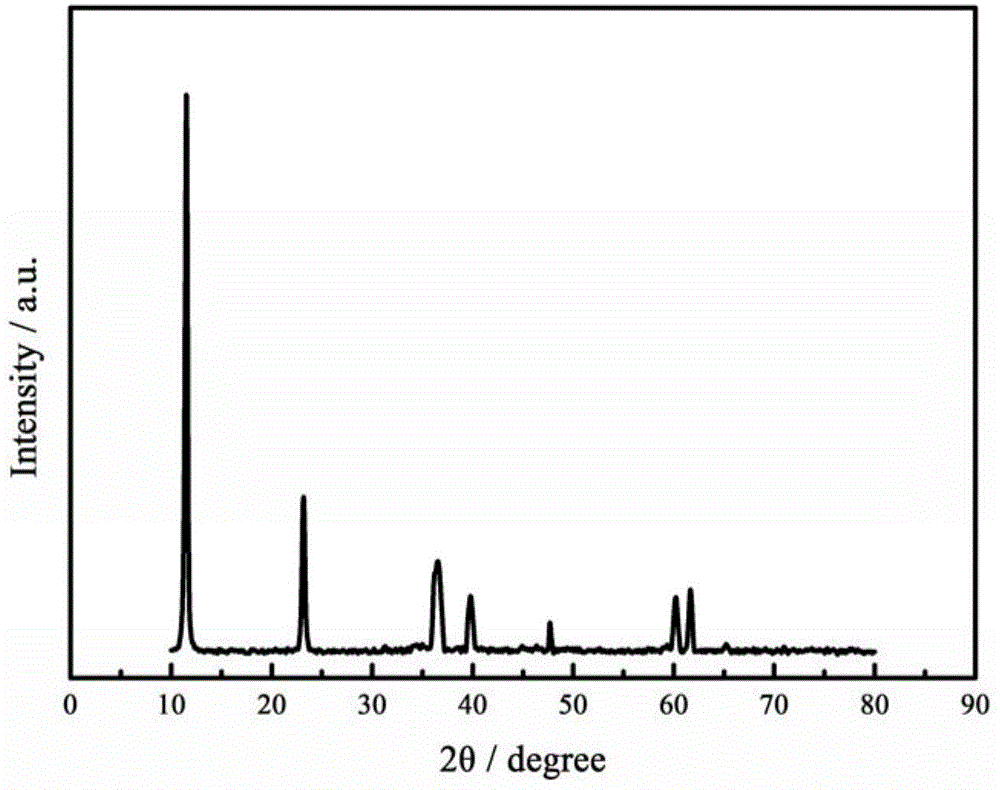

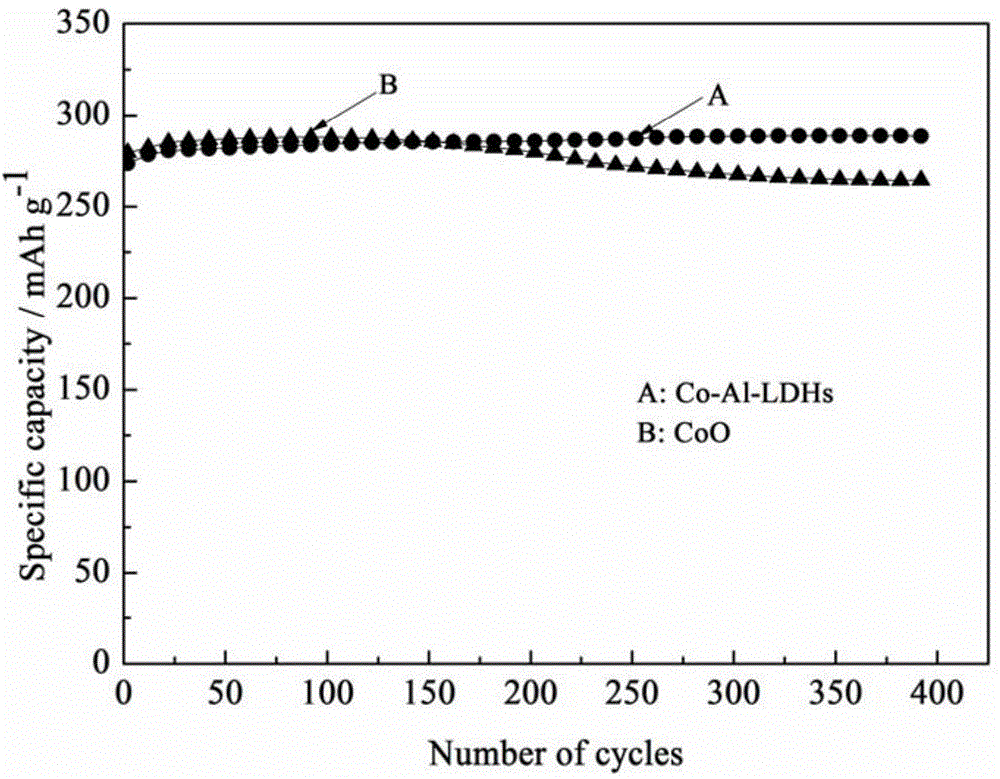

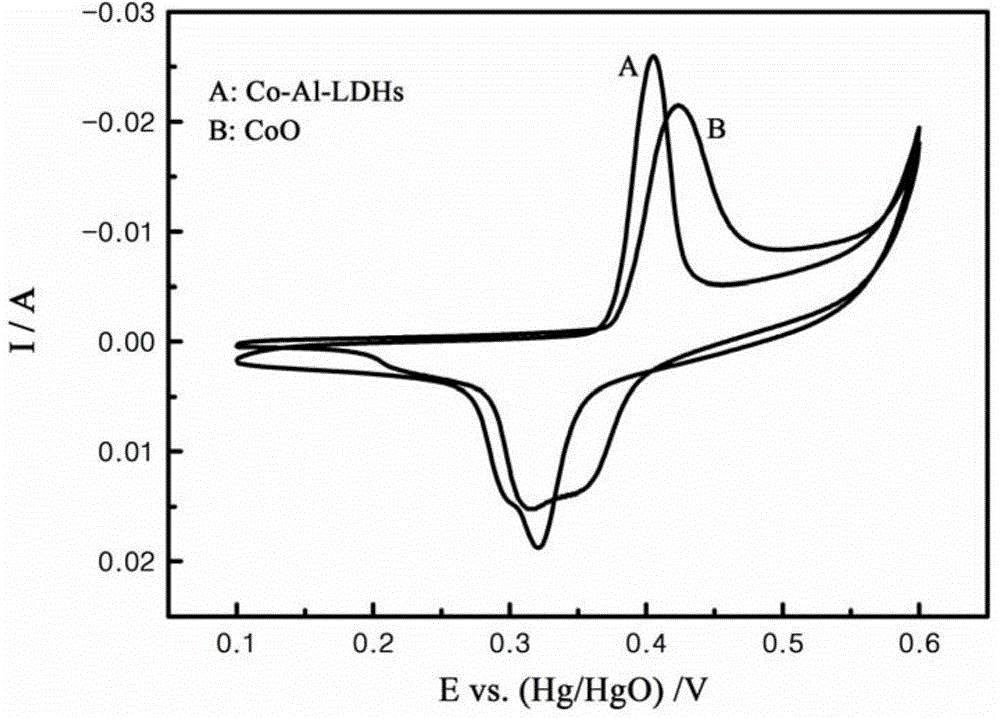

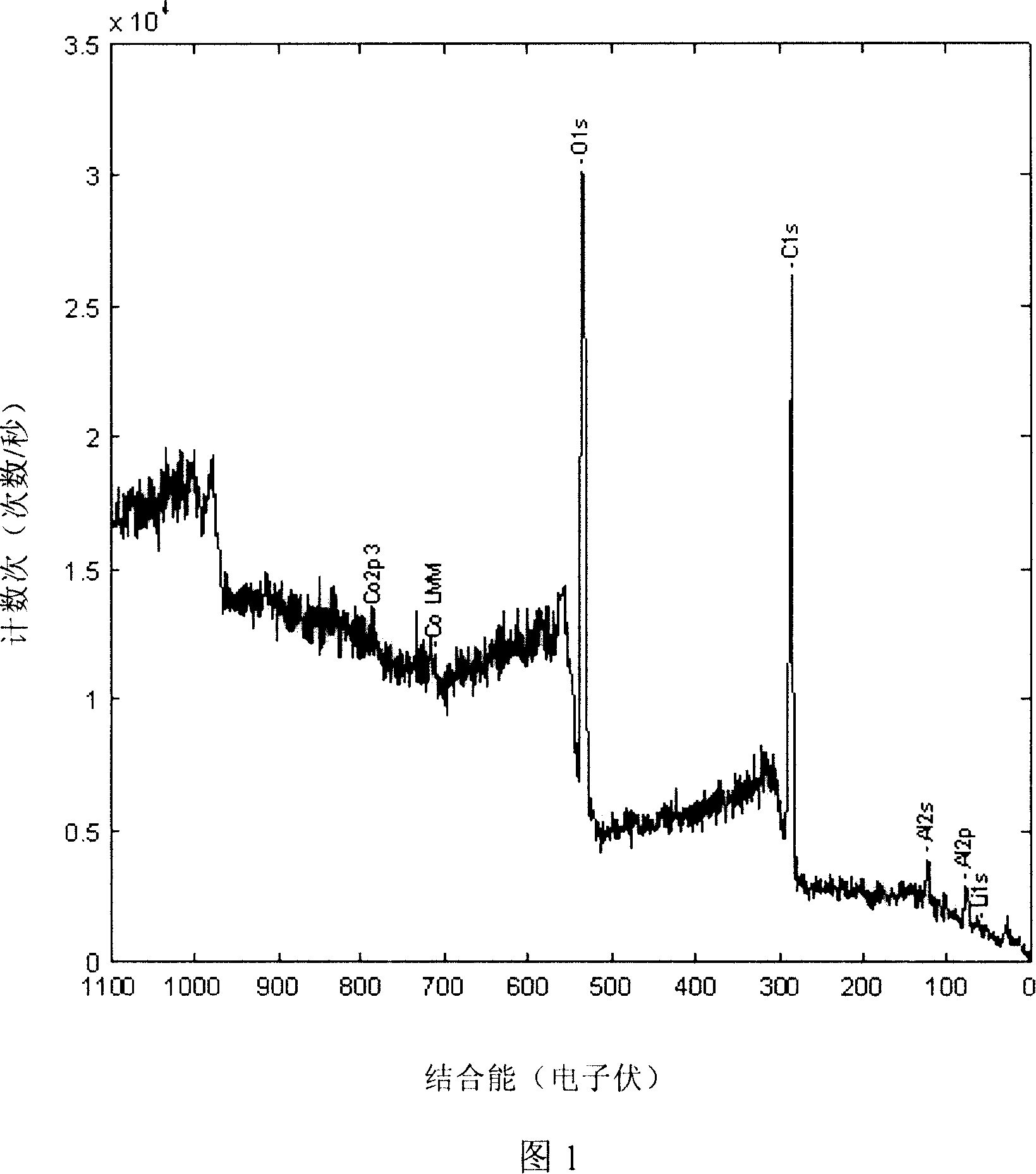

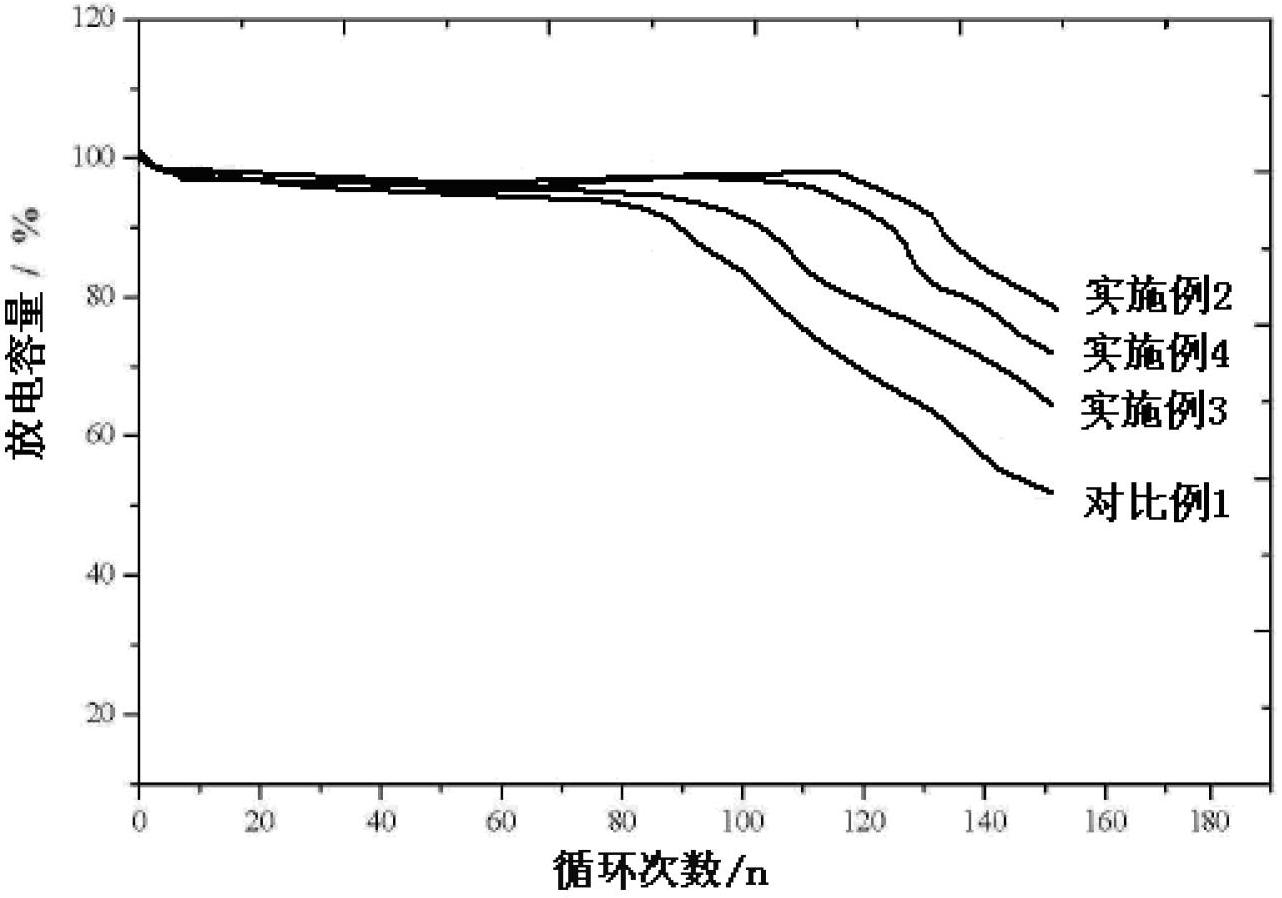

Method for preparing nickel positive electrode of nickel-metal hydride secondary battery by using cobalt-aluminum hydrotalcite and application thereof

InactiveCN104466122AThe synthesis process is simpleMild conditionsAlkaline accumulator electrodesNickel accumulatorsAdhesiveNickel oxide hydroxide

The invention discloses a method for preparing a nickel positive electrode of a nickel-metal hydride secondary battery by using cobalt-aluminum hydrotalcite. The method is characterized by comprising the following steps: a, mechanically mixing 30-40 parts by weight of cobalt-aluminum hydrotalcite, 50-60 parts by weight of nickelous hydroxide, 5-10 parts by weight of conductive agents to obtain a nickel-metal hydride battery positive electrode material mixture; b, adding dispersing agent solutions into the positive electrode material mixture in the step (a); ball-milling and adding adhesives for performing ball-milling for 3-5 hours to obtain a nickel positive electrode material with uniform mixing; and c, uniformly tabletting the nickel positive electrode material in the step (b) on current collector foam nickel and drying at the temperature of 60-200 DEG C, and cutting to obtain nickel positive electrode pole pieces. According to the nickel electrode of the nickel-metal hydride secondary battery, cobalt-aluminum hydrotalcite is used as an additive, the performance of the battery can be obviously improved, the capacity density and the power density of the battery can be improved, the charging / discharging cycle life of the battery is prolonged, the over-charging resistance capability is improved, and the self-discharging is reduced.

Owner:付春平

Method of lithium ion secondary battery anode active compound coating oxide layer

ActiveCN101118962AImprove overcharge resistanceImprove cycle performanceElectrode manufacturing processesChemical/physical/physico-chemical processesSolventOxygen

The present invention relates to a method for covering oxygen oxide layer on active matter of positive pole of lithium ion secondary battery. Wherein, the method comprises the steps as follows: adding acid matters in the mixture of oxysalt aqueous solution of amphoteric element and positive active matters; adjusting the PH value of the mixture making the oxygenic acid radical falling down; separating, washing, drying and calcining the gained solid product. Compared with the prior art, the invention does not need the process of evaporating a plurality of menstruum so as to reduce energy consumption and lower cost, cause slight pollution and assure safety. The battery produced by the present invention has favorable circle performance and overcharge durability.

Owner:BYD CO LTD

High-capacity long-service-life double-bag nickel-hydrogen battery

ActiveCN108767233AEasy to optimizeImprove structural stabilityFinal product manufactureCell electrodesInternal resistanceLiquid state

The invention discloses a high-capacity long-service-life double-bag nickel-hydrogen battery. A battery pole plate consists of a bag type nickel positive electrode plate, a bag type hydrogen storage alloy negative electrode pole plate and a multilayer composite membrane or separation electrode grid positioned between the bag type nickel positive electrode plate and the bag type hydrogen storage alloy negative electrode pole plate; an electrode material of the bag type nickel positive electrode plate is prepared from positive electrode active materials, conducting agents, additives and bondingagents; an electrode material of the bag type hydrogen storage alloy negative electrode pole plate is prepared from hydrogen storing alloy powder, conducting agents and bonding agents; electrolyte isa KOH alkaline solution containing additives in a rich liquid state. Through positive and negative electrode formula optimization, electrolyte formula optimization, electrode preparation method process improvement and separation plate optimization selection, the electrode structure of the positive and negative electrodes is greatly optimized; the utilization rate of positive and negative electrodeactive substances is improved; the internal resistance of the battery is optimized and reduced; the chalking resistant and anticorrosion capability of negative electrode hydrogen storage alloy is improved; the low-temperature performance of the battery is improved; the cycle service life of the battery is prolonged.

Owner:河南省恒明新能源有限公司

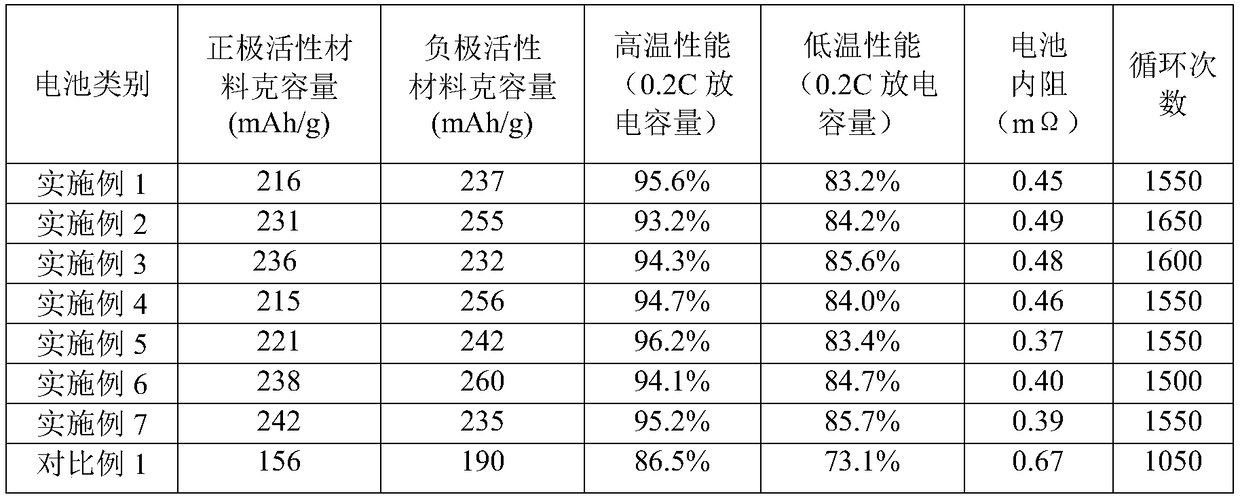

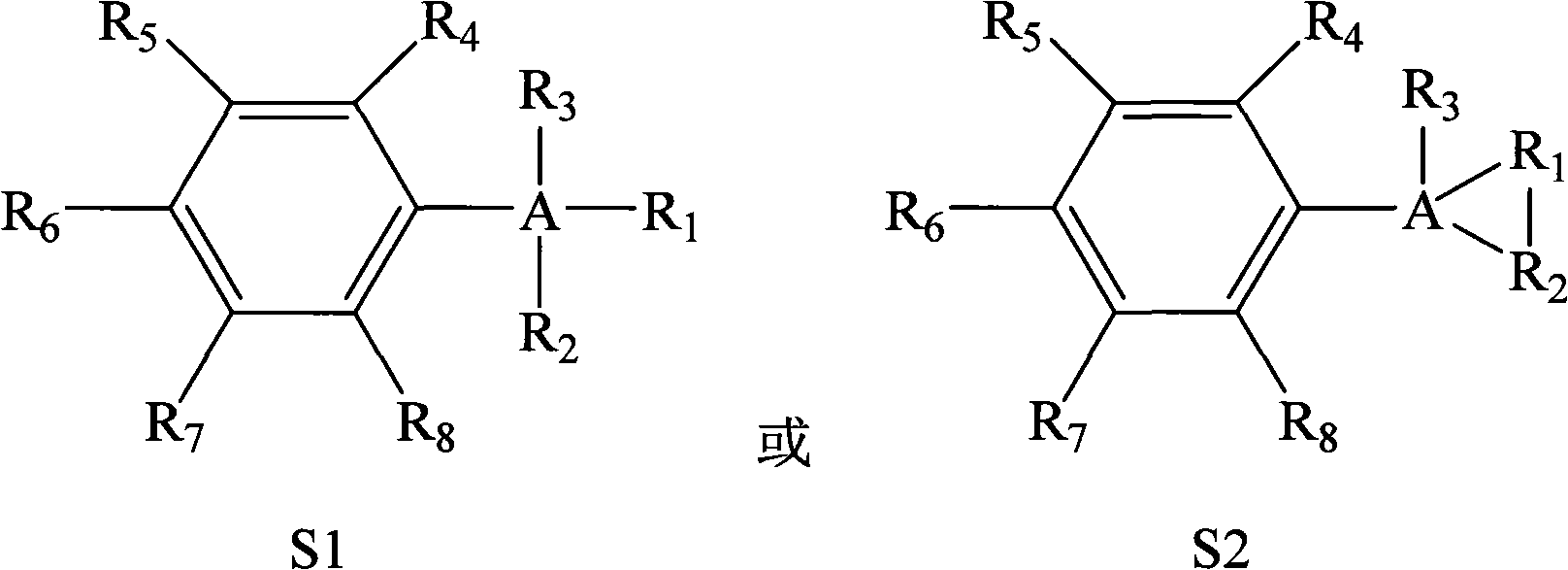

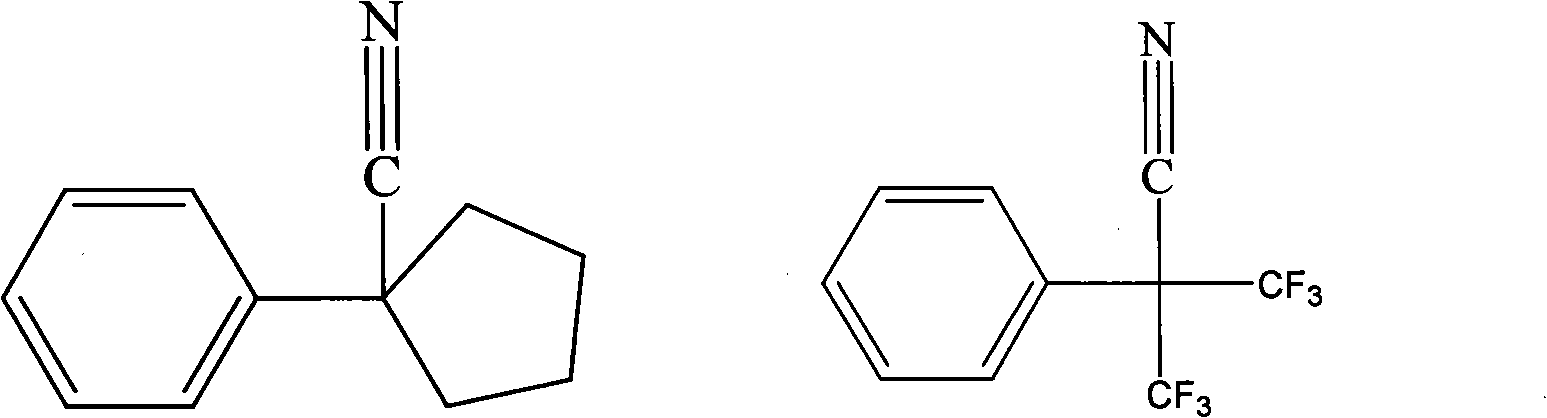

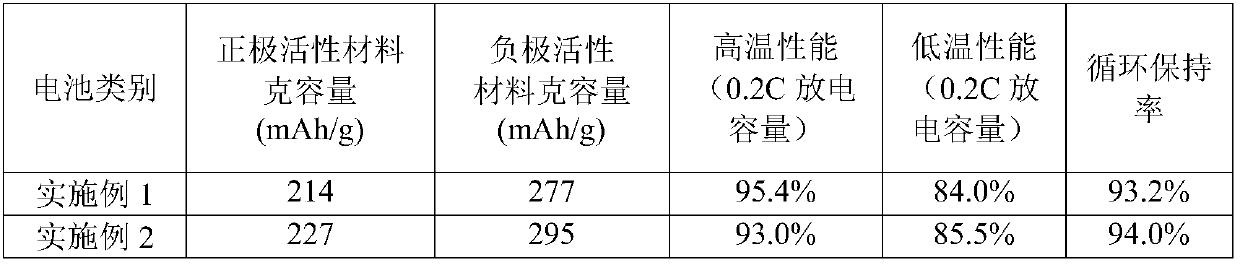

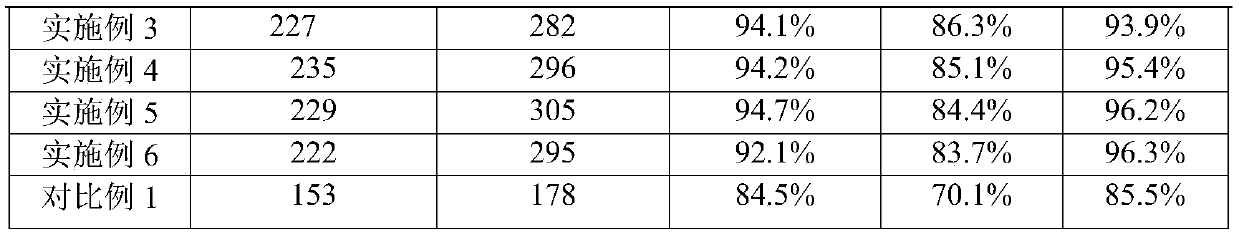

Lithium ion battery containing additives

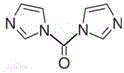

ActiveCN105428703AHigh magnificationGood low temperatureSecondary cellsPhysical chemistryLithium-ion battery

The invention provides a lithium ion battery containing additives. The lithium ion battery is characterized in that the lithium ion battery contains organic additives, and the additives mainly act on a lithium ion negative electrode or a negative electrode process; the organic additives are at least two selected from N,N-carbonyl diimidazole (CDI) or derivatives of N,N-carbonyl diimidazole, or at least two selected from N,N-carbonyl diimidazole (CDI) and derivatives of N,N-carbonyl diimidazole (CDI). The addition amount is 0.01%-5% of a battery adding electrolyte or a negative electrode material. The usage method is as follows: N,N-carbonyl diimidazole (CDI) and derivatives of N,N-carbonyl diimidazole (CDI) are dissolved in a lithium ion battery electrolyte solvent, then mixed dissolving in the lithium ion battery electrolyte or respective addition of the lithium ion battery electrolyte is carried out, or N,N-carbonyl diimidazole (CDI) or derivatives of N,N-carbonyl diimidazole (CDI) is dissolved in a solvent of the negative electrode process of the lithium ion battery, and then the additive is distributed in the battery negative electrode uniformly along with the negative electrode substance. The additive can raise the electric performances and safety performances of the lithium ion battery greatly.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

Battery and cathode composition thereof

ActiveCN101777650AReduce dosageReduce rateLead-acid accumulatorsLead-acid accumulator electrodesFiberSodium lignosulfonate

The invention discloses a battery and a cathode composition thereof. The composition comprises the following components in percentage by weight: 80.8-82.6 percent of lead powder, 0.13-0.17 percent of carbon black, 0.06-0.1 percent of sodium lignosulfonate, 0.39-0.43 percent of humic acid, 0.1-0.13 percent of oxygen resistant agent, 0.32-0.5 percent of barium sulfate, 0.03-0.05 percent of short fiber, 7.1-8.0 percent of sulfuric acid and 8.9-9.9 percent of pure water. In the invention, the battery has high over-charge and over-discharge resistance and prolonged service life, and reserves simultaneously the advantages of high capacity, good large-current discharge performance, good low-temperature characteristic, and the like.

Owner:GUANGZHOU KAIJIE POWER SUPPLY INDAL

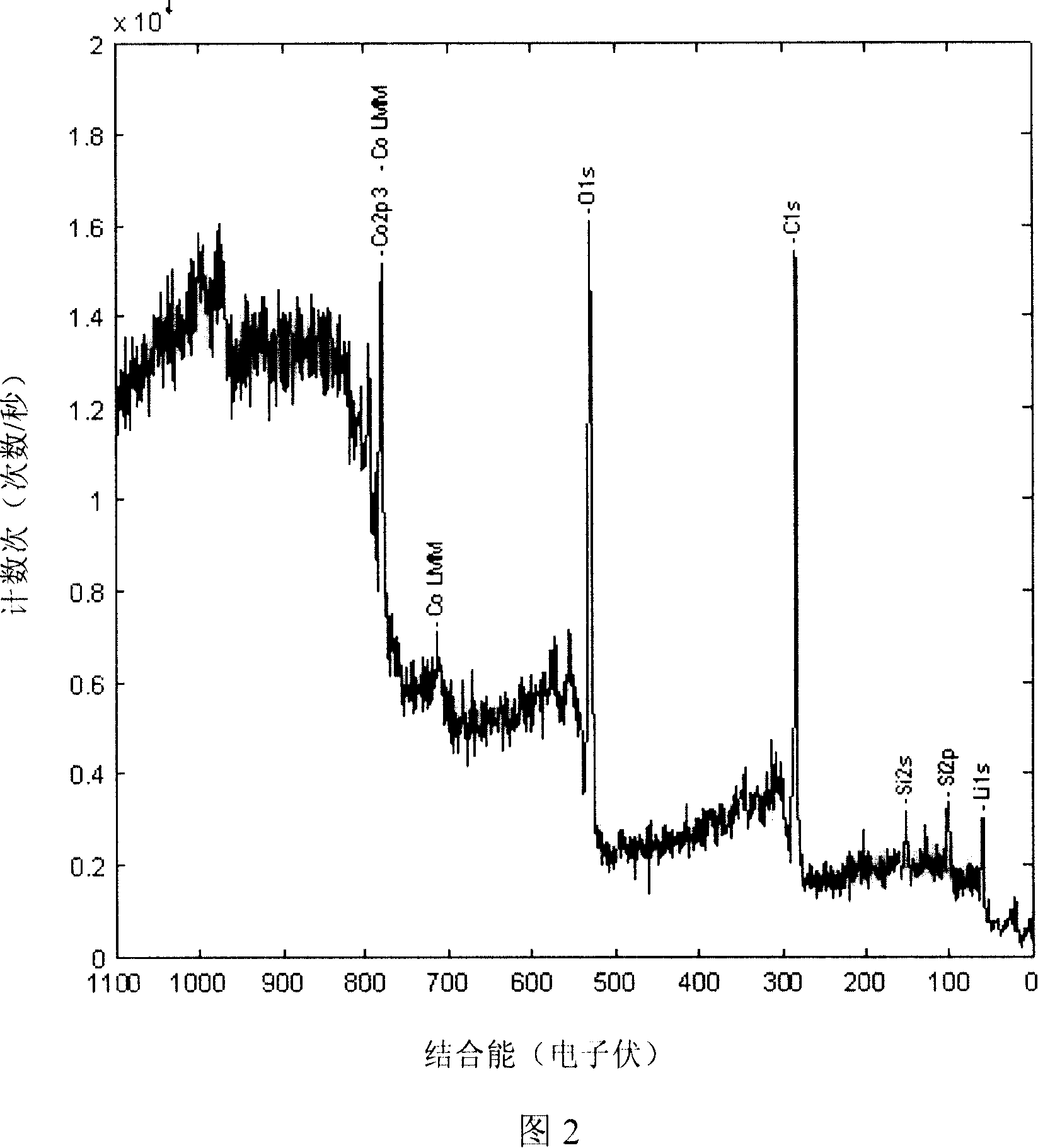

Nickel-based material, preparation method of nickel-based material, and lithium ion battery

InactiveCN106876697AImprove stabilityImprove thermal stabilityCell electrodesSecondary cellsOrganic solventSilanes

The invention provides a nickel-based material. The nickel-based material comprises a core material represented by the FORMULA (I) and a Li<4>SiO<4> coating layer coated on the surface of the core material. The invention further provides a preparation method of the nickel-based material. The preparation method of the nickel-based material comprises the following steps of: mixing methyl silane with an organic solvent, then, adjusting the pH value, and reacting to obtain coating liquid; mixing the coating liquid with a precursor material represented by the FORMULA (II) to stir, so that an initial nickel-based material is obtained; and, performing high-temperature solid-phase reaction after mixing the initial nickel-based material with lithium salt, so that the nickel-based material is obtained. Li<4>SiO<4> is coated on the surface of the core nickel-based material; the obtained nickel-based material is used as the cathode material; and thus, a lithium ion battery has better cycle performance and rate capability.

Owner:四川浩普瑞新能源材料股份有限公司

Preparation method of high capacity lithium ion battery lithium cobalt manganese nickel oxide positive electrode material

InactiveCN1514502AHigh reversible specific capacityPromote circulationElectrode thermal treatmentActive material electrodesManganeseLithium-ion battery

The method consists of procedures of solid phase synthesis and burning in high temperature including following steps. (1) According to lithium: cobalt, manganese, nickel=1-1.1 : 1 (atomic ratio), and cobalt : manganese : nickel=1:1:1, polyacrylamide and neodymia are added into even mixed sources of cobalt, manganese, nickel. The above admixture is mixed round evenly till it becoming colloid. (2) Baking drys the said colloid for 30 hr. under 150 deg.C, and ball milling is carried out till powder is passed through sieve. (3) With being preburned for 10 hr. at 300-450 deg.C, the said powder is cooled to room temperature. (4) Product is obtained after fine ball milling the preburned powder, passing through sieve, burning and sifting the powder by 300 screen mesh again. Comparing with prior art, the invented method adds polyacrylamide and neodymia as well as preburning step so as to possess features of high specific capacity, good cycle performance and pollution-free.

Owner:XINXIANG ZHONGKE SCI&TECH

Nickel-hydrogen battery and preparation method for anode material

ActiveCN101320805AReduce the effective capacity ratioReduce design capacityElectrode manufacturing processesFinal product manufactureCapacitancePartial oxidation

A nickel-hydrogen battery and a production method for positive pole material of the nickel-hydrogen battery are disclosed, the method comprises the following steps of: 1) production of the positive pole, at first, the surface of spherical nickel hydroxide as positive pole active substance is covered with a gamma-CoOOH covering layer, then the spherical nickel hydroxide whose surface is covered with the gamma-CoOOH is partially oxidized, average chemical valence of the nickel after oxidization is controlled as 2.08-2.20; 2) production of the negative pole, proportion of the capacitance of the negative pole to the capacitance of the positive pole is (1.15-1.25):1; 3) assembly for the negative pole, the positive pole and membrane; 4) formation of the battery, 0.05C-0.2C of current is adopted to activate the battery for 3 to 10 weeks with charge and discharge capacitances during each week being between 30% and 100%, and the current amount of the battery at the time of discharging in the first week is discharged to zero. The positive pole uses the partially-oxidized spherical nickel hydroxide whose surface is covered with the gamma-CoOOH, when the designed capacitance proportion of the positive and negative poles is fixed, the designed capacitance of the negative pole can be reduced correspondingly, powder applying amount of the negative pole is lessened, manufacturing cost of the battery is saved, and the battery is able to maintain the characteristics of long service life and resistance to overcharge.

Owner:SHENZHEN HIGHPOWER TECH CO LTD

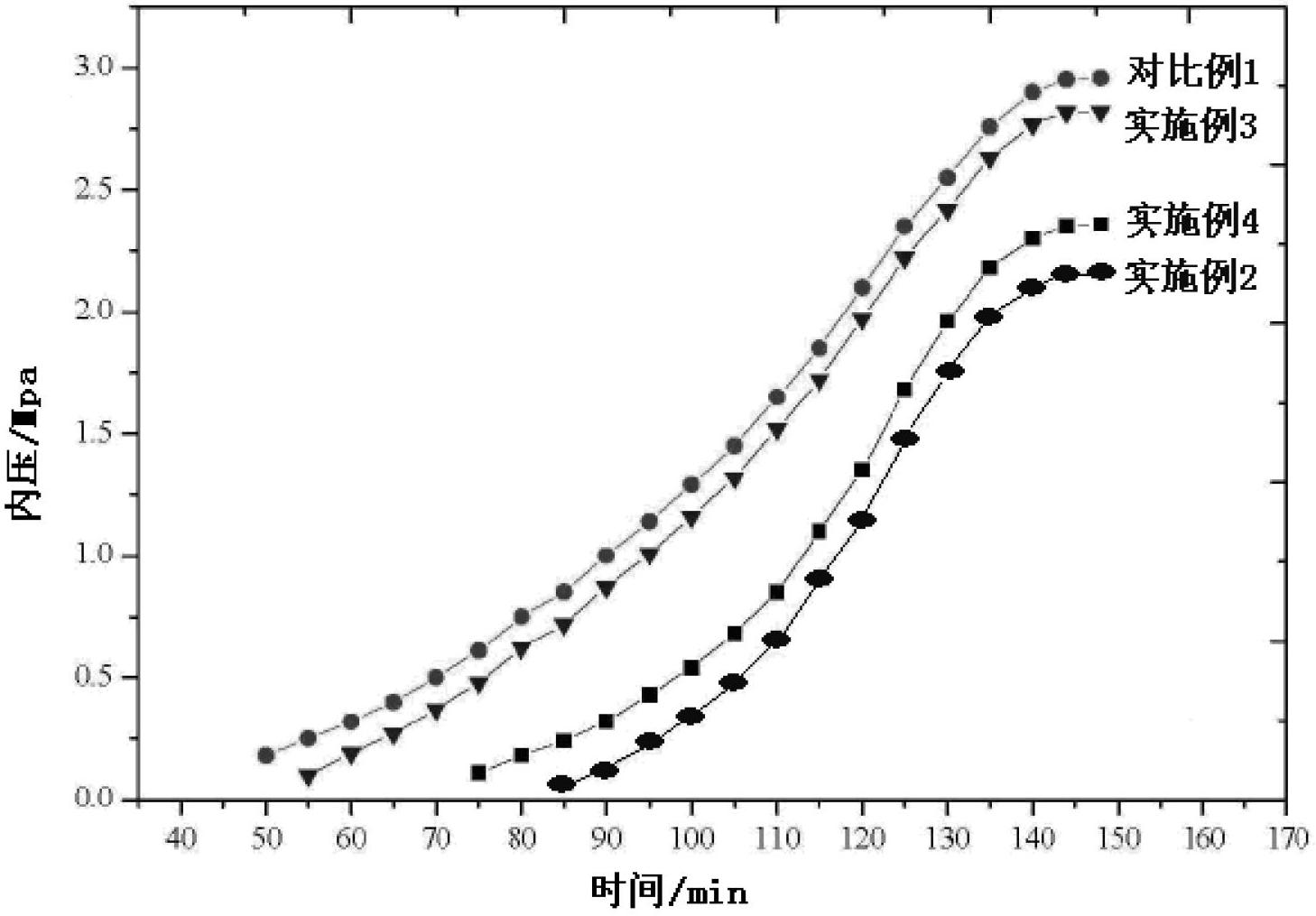

Zinc negative pole used for secondary zinc-nickel battery and preperative method and secondary zinc-nickel battery containing the same zinc negative pole

InactiveCN1812164AImprove overcharge resistanceReduce internal pressureNegative electrodesAlkaline accumulator electrodesInternal pressureTransmission channel

This invention relates to a kind of zinc cathode of secondary zinc nickel battery and the producing method, as well as secondary zinc nickel battery using the zinc cathode. The said zinc cathode concludes current-collecting body and cathode active materials coated on the current-collecting body. The characters are: the said cathode active materials have zinc oxide, adhesive and electrical conducting porous hydrophobic particles. The said electrical conducting porous hydrophobic particles, which are carbon black absorbing hydrophobic materials, are evenly distributed in the said cathode active materials of zinc cathode. Thus, this invention can provide transmission channel for oxygen which makes oxygen not only can compound on electrode surface, but can also go deep into the interior of electrode to compound. It makes efficiency of zinc cathode compounding oxygen greatly increased. The internal pressure of battery can be greatly decreased so as to greatly improving anti-surcharge ability of zinc nickel battery.

Owner:BYD CO LTD

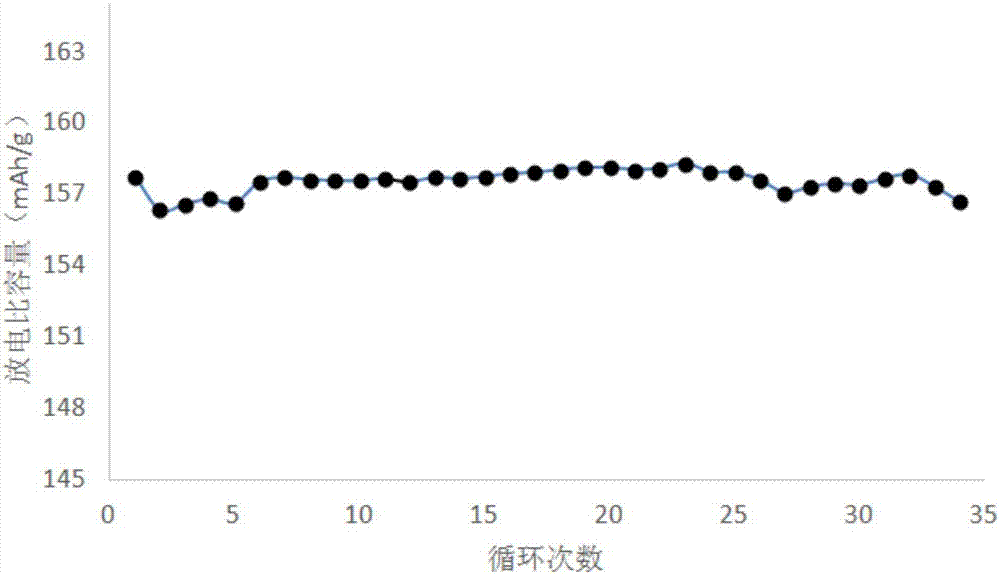

Preparation method of lithium nickel manganese cobalt positive electrode material, lithium ion battery positive electrode material and lithium ion battery

ActiveCN107464929AImprove product qualityEnsure consistencyCell electrodesSecondary cellsAqueous solutionNickel

The invention belongs to the technical field of a lithium ion battery, and relates to a preparation method of a lithium nickel manganese cobalt positive electrode material, a lithium ion battery positive electrode material and a lithium ion battery. The preparation method of the lithium nickel manganese cobalt positive electrode material, provided by the invention, comprises the following steps of preparing a ternary material precursor aqueous solution with weight concentration being 45-60%; preparing a lithium source compound aqueous solution with weight concentration being 20-30%; sending the ternary material precursor aqueous solution and the lithium source compound aqueous solution to an agitator by a pump, and performing uniform mixing and stirring to obtain a suspension liquid; performing spray drying on the suspension liquid to obtain lithium mixed powder; and sintering the lithium mixed power to obtain the lithium nickel manganese cobalt positive electrode material. By the preparation method, the mixing efficiency of a precursor and a lithium source compound and the mixed grain uniformity can be improved; and meanwhile, the preparation method is convenient to operate and easy to control and is moderate in reaction condition, and the prepared positive electrode material has excellent electrochemical performance.

Owner:NORTHERN ALTAIR NANOTECH CO LTD

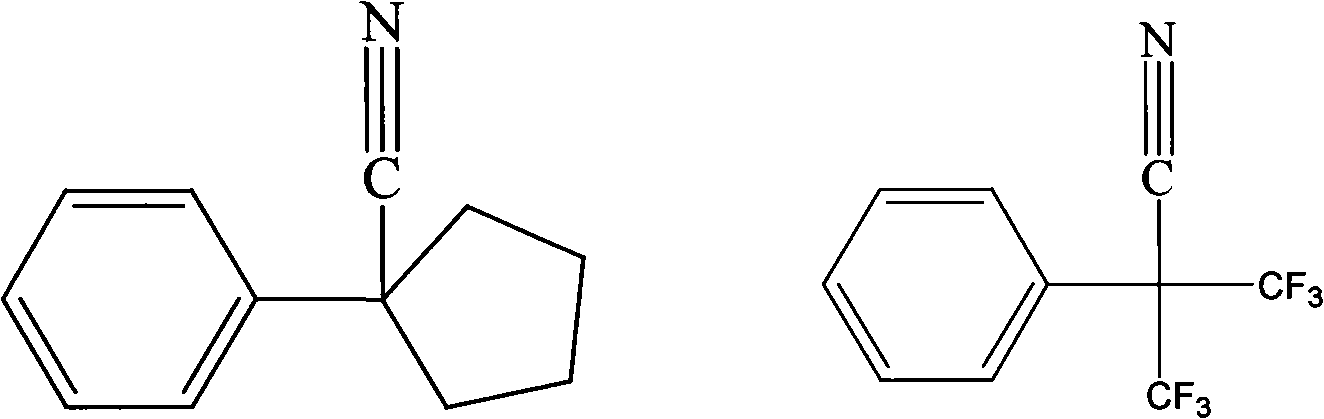

Electrolyte solution capable of improving over-charge safety performance of lithium battery

InactiveCN101841062AImprove overcharge safety performanceImprove overcharge resistanceOrganic electrolyte cellsSecondary cellsOrganic solventMass ratio

The invention discloses an electrolyte solution capable of improving over-charge safety performance of a lithium battery, which comprises following four types of components: (A) lithium salt, (B) organic solvent of carbonic esters and / or ethers, (C) over-charge safety additive and (D) other functional additives, wherein the composition of the solution can be written into A+B+C+D; the molar concentration range of the (A) lithium salt in the electrolyte solution is 0.001-2 mole / L; the mass ratio range of the (C) over-charge additive in the electrolyte solution is 0.01-30%, the molar concentration range of the (D) other functional additives in the electrolyte solution is 0-0.5 mole / L. The electrolyte solution can be applied to a lithium primary battery, a lithium secondary battery and a lithium ion battery.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

Large-capacity double-bag type iron-nickel battery

ActiveCN108682901AImprove overcharge resistanceExcellent rate performanceFinal product manufactureAlkaline accumulators manufactureEngineeringElectrolyte

The invention discloses a large-capacity double-bag type iron-nickel battery. A battery pole plate is composed of a bag type nickel positive pole plate, a bag type iron negative pole plate and a multilayered composite diaphragm or isolation grid located between the bag type nickel positive pole plate and the bag type iron negative pole plate; an electrode material of the bag type nickel positive pole plate is composed of a positive pole active material, a conducting agent, an additive and a binding agent; an electrode material of the bag type iron negative pole plate is composed of iron-basedoxide powder, a conducting agent, an additive and a binding agent; electrolyte is an alkaline solution which is at a barren liquor state and contains the additive. According to the large-capacity double-bag type iron-nickel battery disclosed by the invention, a formula of positive and negative poles is optimized, a formula of the electrolyte is optimized and a battery structure is adjusted, so that the charging and discharging performance, and circulating performance of the novel iron-nickel battery are improved; furthermore, the battery also has the advantages of high charging and dischargingvoltage platform, good over-charging and over-discharging resisting performance, low cost and the like.

Owner:河南省恒明新能源有限公司

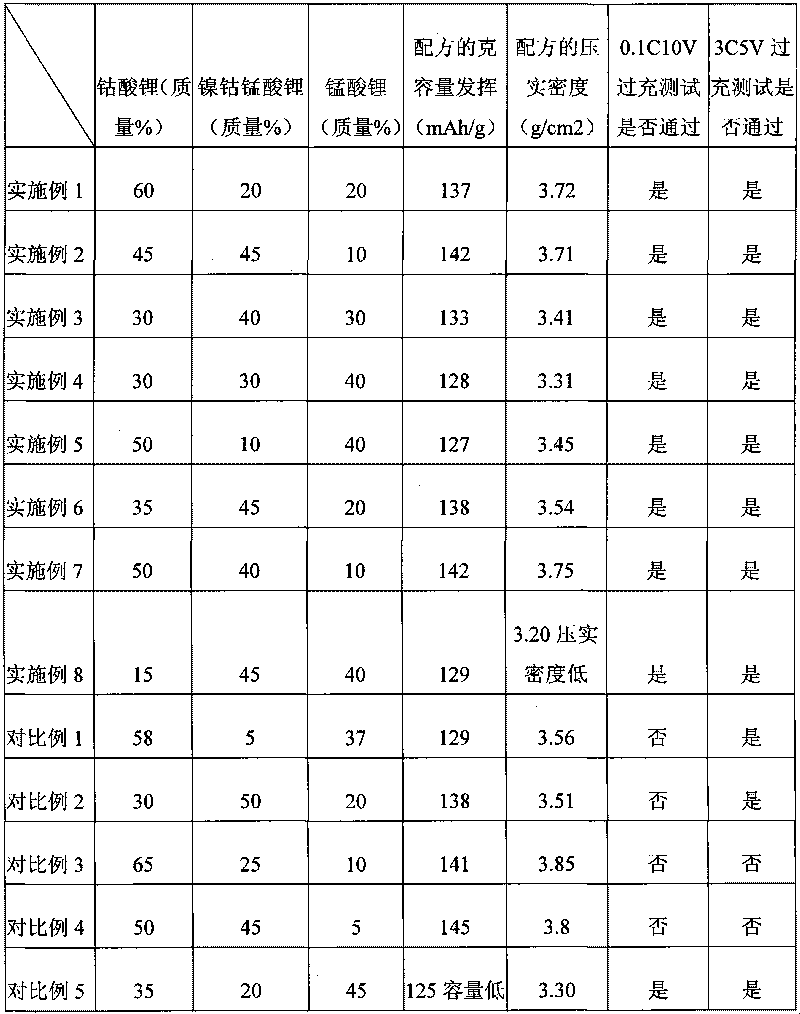

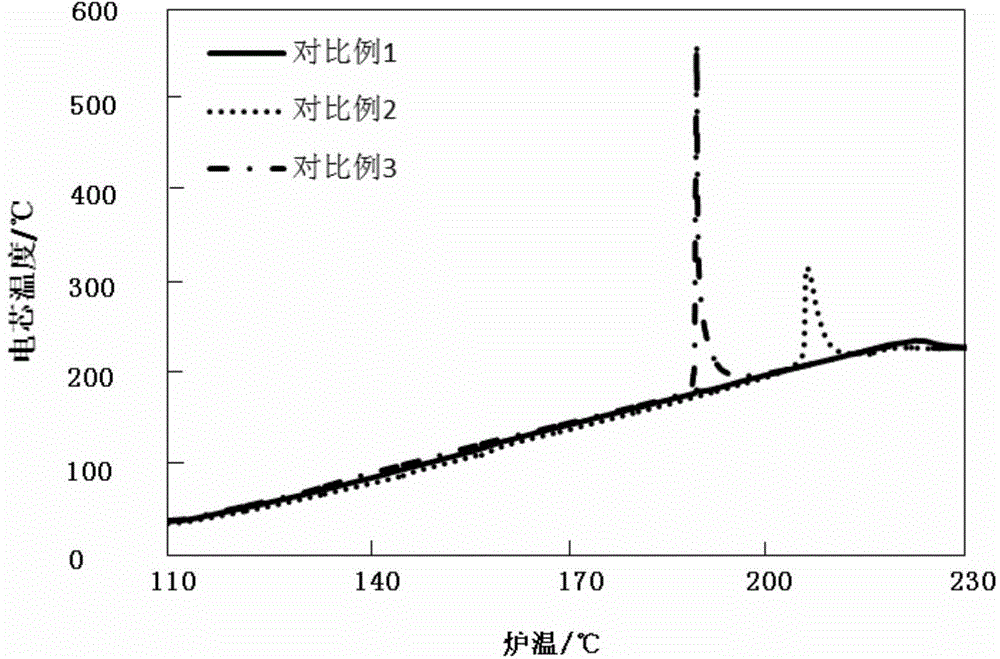

Lithium ion battery anode material and lithium ion battery prepared therefrom

InactiveCN101740765AImprove overcharge resistanceNo reduction in capacityCell electrodesSecondary cellsSpinelManganate

The invention discloses a lithium ion battery anode material and a lithium ion battery prepared therefrom. The anode material comprises15-60% by weight of lithium cobaltate, 10-45% by weight of nickel-cobalt lithium manganate and 10-40% by weight of spinel lithium manganate,. The lithium ion battery anode material prescription and the lithium ion battery made from the material prescription can improve the overcharge property resistance of the lithium ion battery and can not decrease the capacity of the lithium ion battery.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

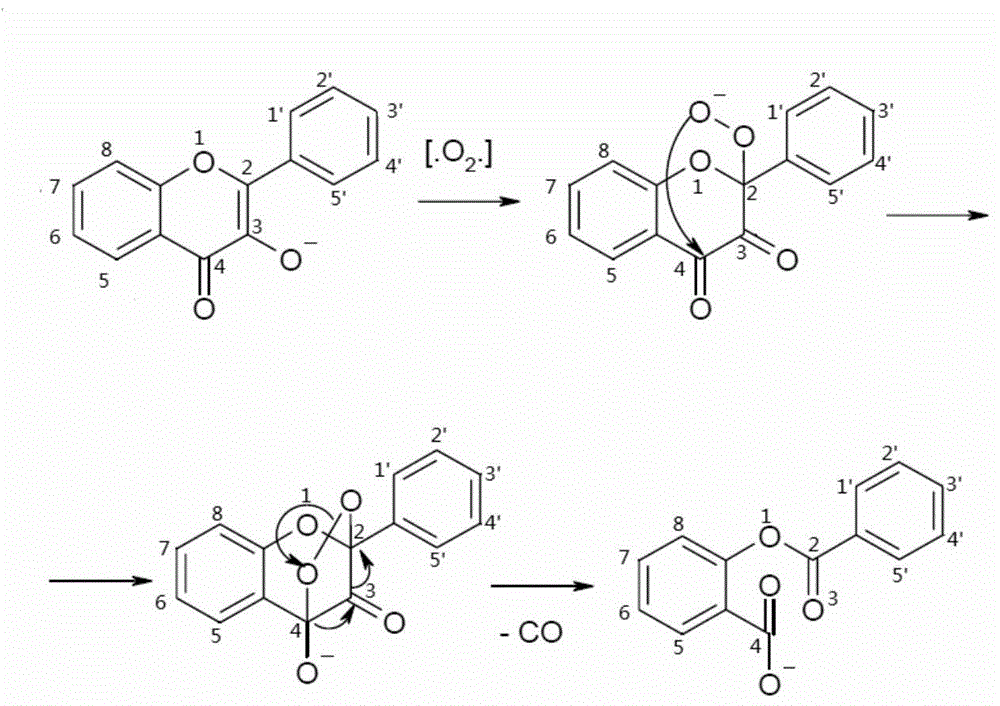

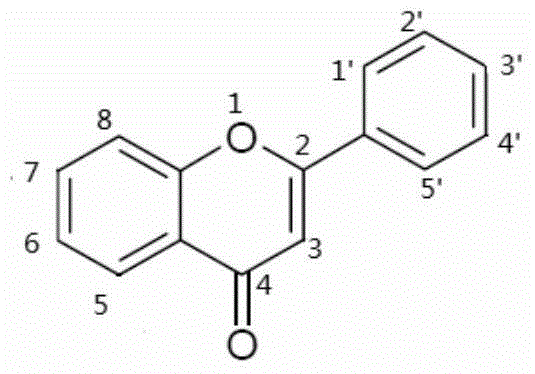

Lithium ion battery

ActiveCN106299507AImprove overcharge resistanceSolve thermal failureCell electrodesSecondary cells charging/dischargingArylHalogen

The invention provides a lithium ion battery. The lithium ion battery comprises a positive pole piece, a negative pole piece, an isolating film spaced between the positive pole piece and the negative pole piece, and an electrolyte solution. A positive electrode film piece also includes a positive electrode additive; the positive electrode additive is lithium carbonate; the electrolyte solution also includes an electrolyte solution additive; the electrolyte solution additive includes flavonoids and has the following chemical formula described in the specification, wherein H at 3, 5, 6, 7, 8, 1', 2', 3', 4' and 5' sites is independently substituted by functional groups substituted by phenolic hydroxyl, hydroxyl, alkyl, alkoxy, carboxyl, amino, aryl or halogen. The lithium ion battery effectively solves the problem of thermal failure of a lithium ion battery caused by side reactions of lithium carbonate in a positive pole piece under a condition of high temperature, and at the same time, the lithium ion battery has relatively good overcharge resistant performance.

Owner:CONTEMPORARY AMPEREX TECH CO

Hydrogen storage alloy electrode for nickel-metal hydride battery

InactiveCN102683711AImprove alkali resistanceImprove discharge capacityAlkaline accumulator electrodesIron phthalocyanineMethyl cellulose

The invention discloses a hydrogen storage alloy electrode for a nickel-metal hydride battery. The hydrogen storage alloy electrode comprises a cathode collector and a cathode active substance slurry coated on the cathode collector, wherein the cathode active substance is composed of LaNi5H6 hydrogen storage alloy powder, iron phthalocyanine additive and mixed adhesive at a weight ratio of 100:(0.1-1.0):(15-20); the mixed adhesive is composed of HPMC (Hydroxy Propyl Methyl Cellulose) with a weight percentage concentration of 2% and SBR (Styrene Butadiene Rubber) with a weight percentage concentration of 50%; the weight ratio of HPMC to SBR is (2-5):1; and the LaNi5H6 hydrogen storage alloy powder is cobalt-cladding LaNi5H6 hydrogen storage alloy powder. Compared with the prior art, the hydrogen storage alloy electrode for the nickel-metal hydride (Ni-MH) battery provided by the invention has the advantages that the inner voltage of the battery is obviously reduced, the discharge capacity is higher and the overcharging resistance and the cycle performance are excellent.

Owner:SHANGHAI YAOYU INDAL

High-capacity double-bag type zinc-nickel secondary battery and preparation method thereof

ActiveCN108878806AEasy to optimizeImprove high temperature performanceFinal product manufactureAlkaline accumulator electrodesAgricultural engineeringZinc

The invention discloses a high-capacity double-bag type zinc-nickel secondary battery and a preparation method thereof, wherein a battery polar plate group consists of a bag type nickel positive plate, a bag type zinc negative plate and a multilayer composite diaphragm positioned between the bag type nickel positive plate and the bag type zinc negative plate; the electrode material of the bag typenickel positive plate is composed of a positive electrode active material, a conductive agent, an additive and a binding agent; the electrode material of the bag type zinc negative plate is composedof a negative active material, a conductive agent, an additive and a binding agent; an electrolyte is an alkaline solution containing additives. According to the secondary battery, the formula of thepositive and negative electrodes and the formula of the electrolyte are optimized and the structure of the battery is adjusted, so that the charge and discharge performance and the cycle performance of the novel zinc-nickel secondary battery are improved, and the application requirements in the industrial field can be further met.

Owner:HENAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com