Hydrogen storage alloy electrode for nickel-metal hydride battery

A hydrogen storage alloy and nickel-hydrogen battery technology, applied in the field of electrochemistry, can solve the problems of reduced overall performance, high internal pressure, reduced Ni-MH battery charge and discharge performance, cycle performance, etc., to achieve improved alkali resistance and high discharge The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

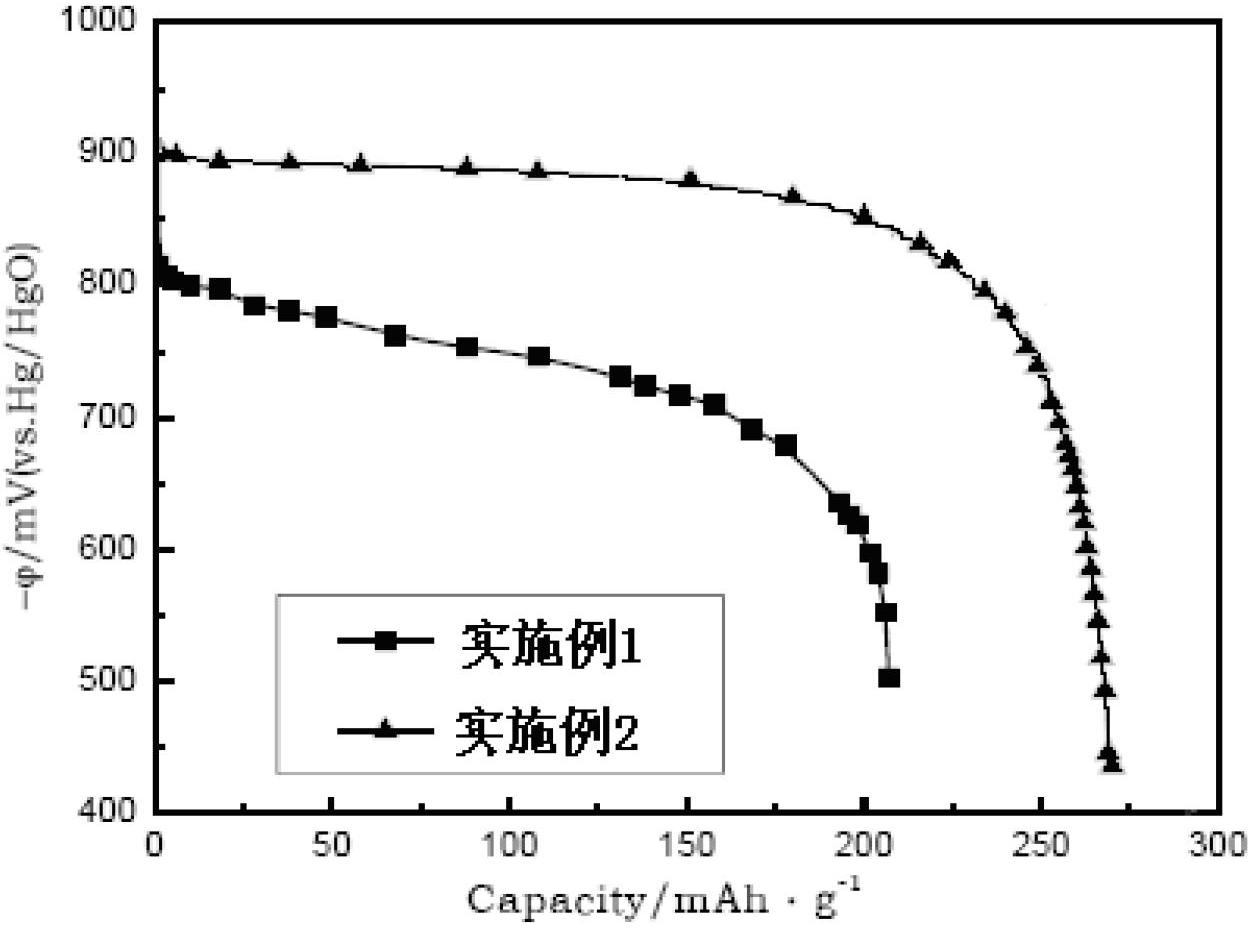

Embodiment 1

[0027] A hydrogen storage alloy electrode for a nickel-hydrogen battery, which is prepared as follows:

[0028] a. Pulping: LaNi with a weight ratio of 100:0.2:16 5 h 6 The hydrogen storage alloy powder, the iron phthalocyanine additive and the mixed binder are fully mixed and evenly obtained to obtain the negative electrode slurry;

[0029] b. Evenly coat the mixed negative electrode slurry on the negative electrode current collector (nickel-plated steel strip), put it in a vacuum drying oven, and dry at 70°C for 8 hours;

[0030] c. After rolling the dried pole piece to a thickness of 0.5mm, cut it to 80mm×40mm.

[0031] The mixed binder is 2wt% HPMC and 50wt% SBR, and the weight ratio of the two is 3:1.

[0032] The iron phthalocyanine is prepared by the following method:

[0033] a, phthalic anhydride, urea, (NH 4 ) 2 MoO 4 , mix well, heat up to 220°C, add FeCl 2 4H 2 O, react to get crude product; Described phthalic anhydride, urea, (NH 4 ) 2 MoO 4 , FeCl 2 ...

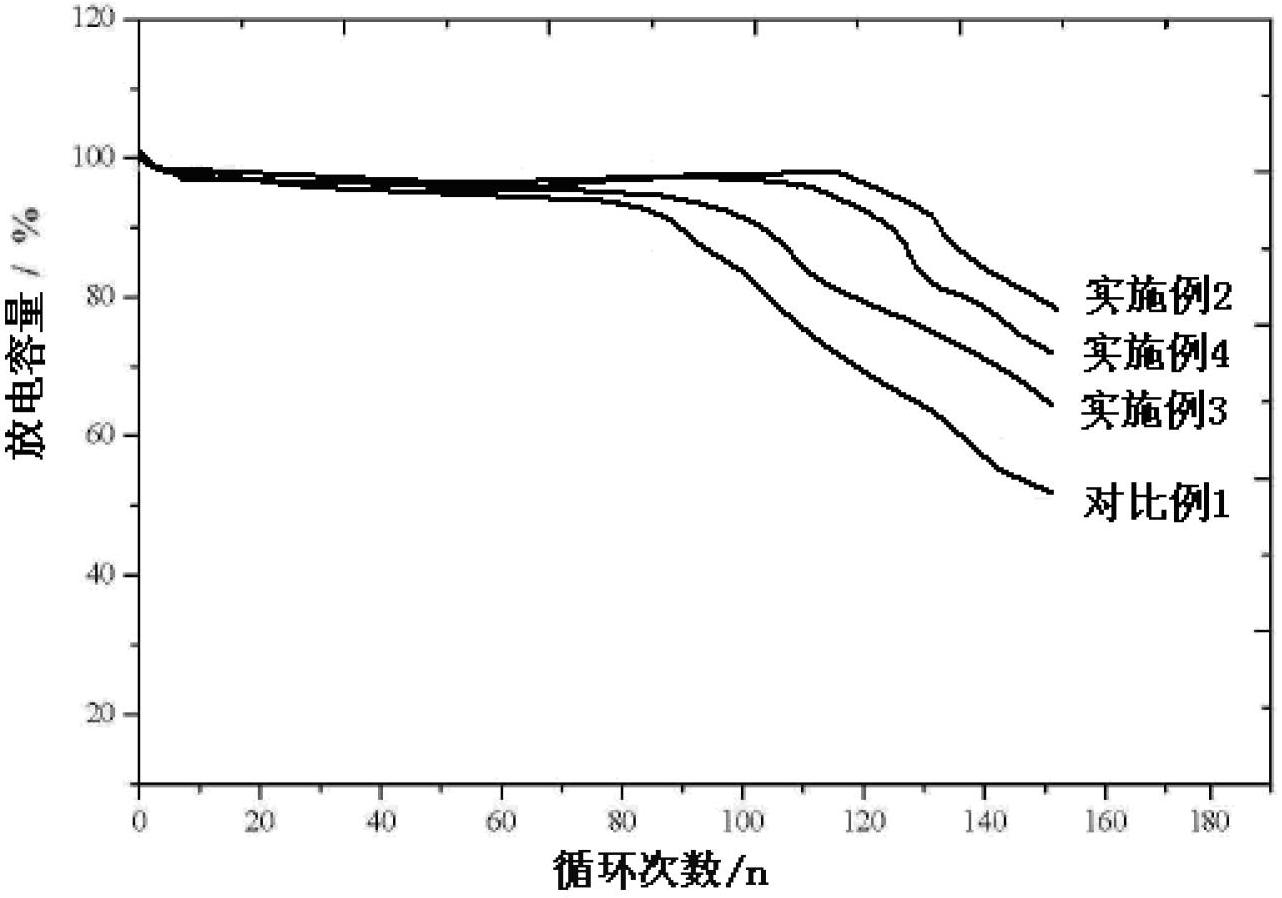

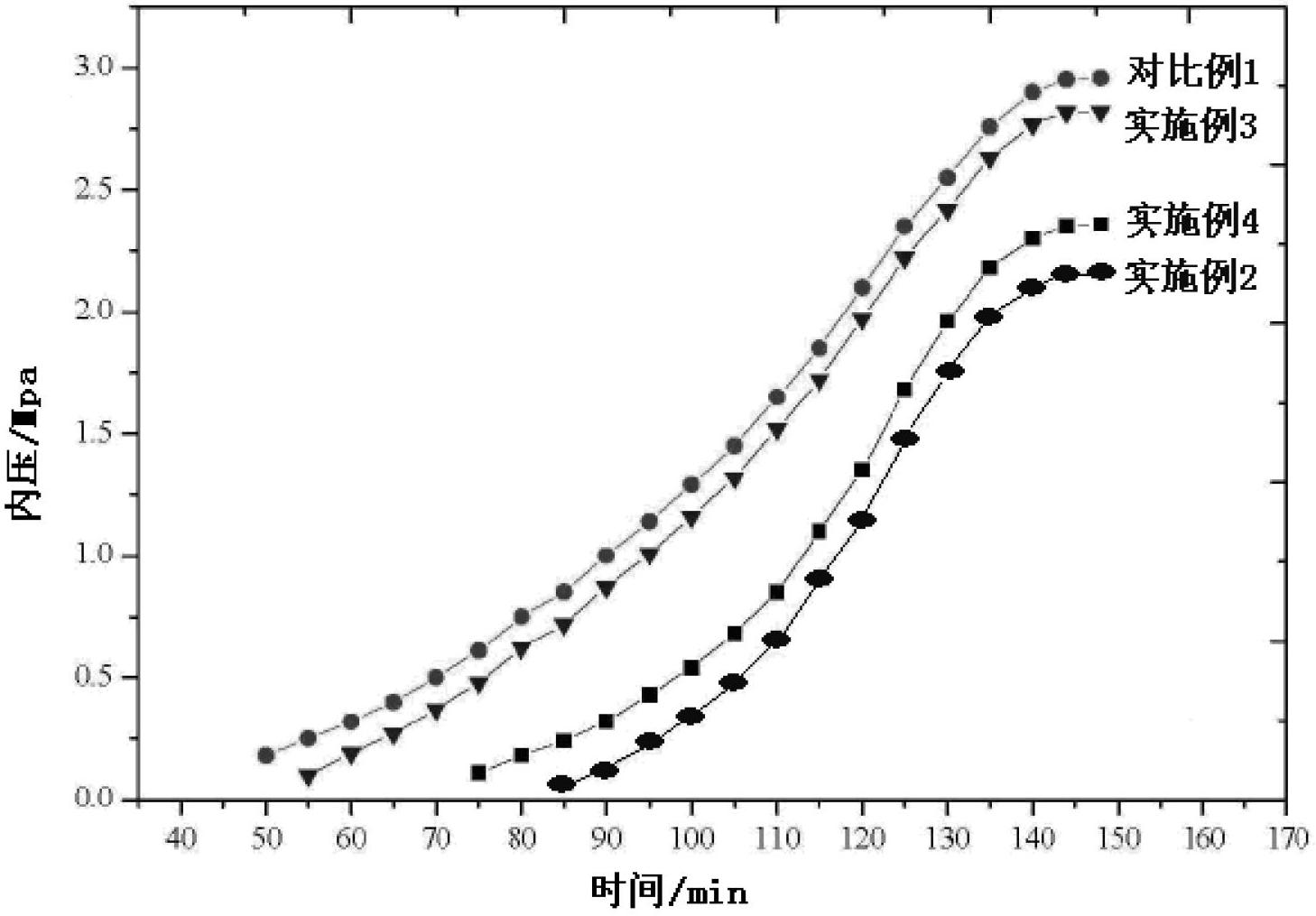

Embodiment 2

[0036] A hydrogen storage alloy electrode for a nickel-hydrogen battery, which is prepared as follows:

[0037] a. Pulping: LaNi with a weight ratio of 100:0.2:16 5 h 6 The hydrogen storage alloy powder, the iron phthalocyanine additive and the mixed binder are fully mixed and evenly obtained to obtain the negative electrode slurry;

[0038] b. Evenly coat the mixed negative electrode slurry on the negative electrode current collector (nickel-plated steel strip), put it in a vacuum drying oven, and dry at 70°C for 8 hours;

[0039] c. After rolling the dried pole piece to a thickness of 0.5mm, cut it to 80mm×40mm.

[0040] The mixed binder is 2wt% HPMC and 50wt% SBR, and the weight ratio of the two is 3:1.

[0041] The LaNi 5 h 6 The hydrogen storage alloy powder is LaNi coated with cobalt 5 h 6 Hydrogen storage alloy powder.

[0042] The iron phthalocyanine is prepared by the following method:

[0043] a, phthalic anhydride, urea, (NH 4 ) 2 MoO 4 , mix well, heat ...

Embodiment 3

[0046] A hydrogen storage alloy electrode for a nickel-hydrogen battery, which is prepared as follows:

[0047] a. Pulping: LaNi with a weight ratio of 100:0.1:15 5 h 6 The hydrogen storage alloy powder, the iron phthalocyanine additive and the mixed binder are fully mixed and evenly obtained to obtain the negative electrode slurry;

[0048] b. Evenly coat the mixed negative electrode slurry on the negative electrode current collector (nickel-plated steel strip), put it in a vacuum drying oven, and dry at 70°C for 8 hours;

[0049] c. After rolling the dried pole piece to a thickness of 0.5mm, cut it to 80mm×40mm.

[0050] The mixed binder is 2wt% HPMC and 50wt% SBR, and the weight ratio of the two is 2:1.

[0051] The LaNi 5 h 6 The hydrogen storage alloy powder is LaNi coated with cobalt 5 h 6 Hydrogen storage alloy powder.

[0052] The iron phthalocyanine is prepared by the following method:

[0053] a, phthalic anhydride, urea, (NH 4 ) 2 MoO 4 , mix well, heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com