Patents

Literature

122results about How to "With anti-rust function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

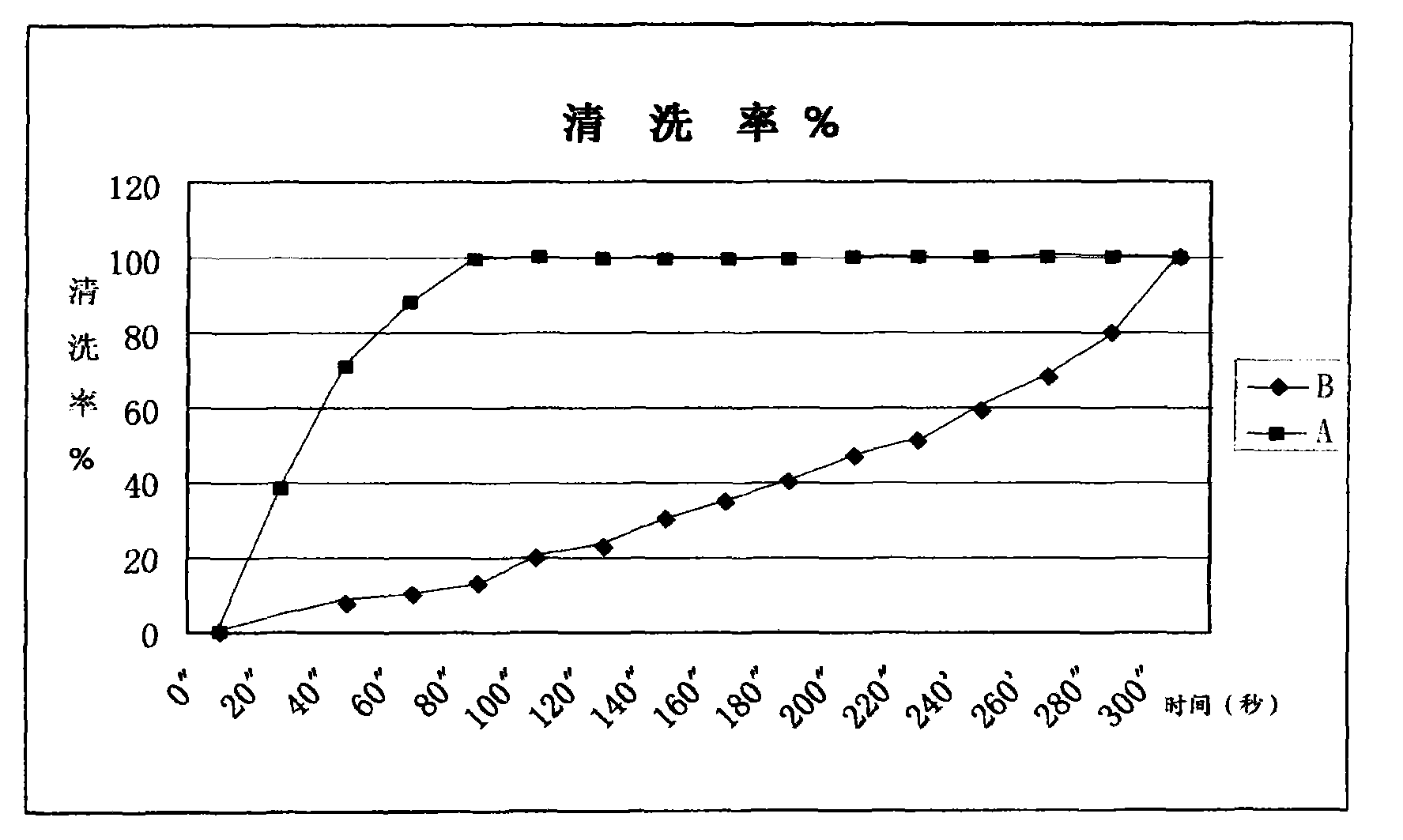

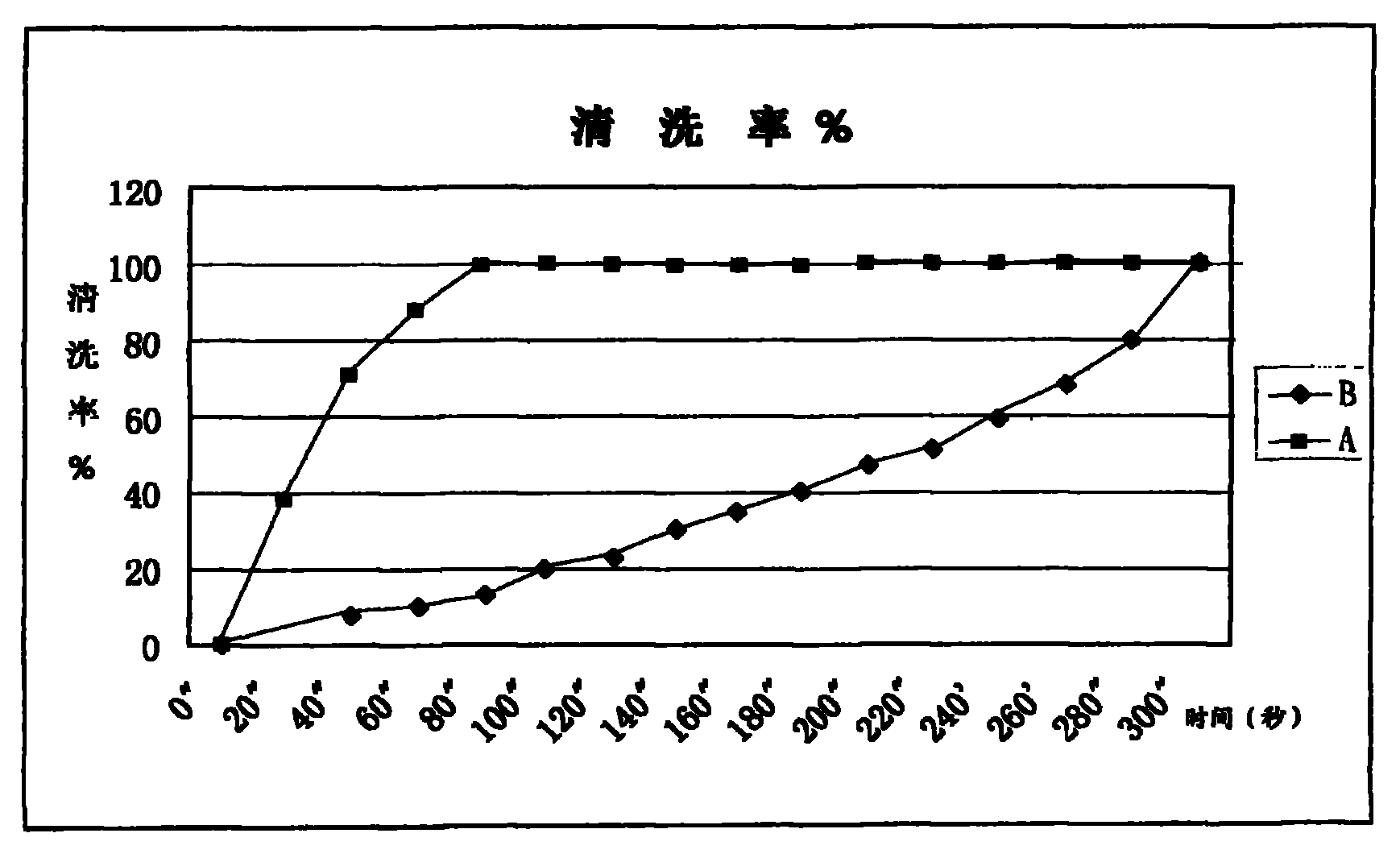

Water-based airplane surface cleaning agent and preparation method thereof

ActiveCN101955854AGood protectionThe formula is scientific and reasonableInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsIonChemistry

The invention relates to a water-based airplane surface cleaning agent, which is prepared by uniformly mixing the following components in percentage by weight: 21 to 30 percent of degradable surfactant, 5 to 7 percent of metal corrosion inhibitor, 0.3 to 2 percent of pH regulating agent, 1.7 to 5 percent of stabilizer, and the balance of deionized water. A preparation method comprises the following steps: (1) weighing the pH regulating agent, the degradable surfactant, the metal corrosion inhibitor, the stabilizer and the deionized water according to the ratio of weight percent; (2) adding the pH regulating agent, the metal corrosion inhibitor, the degradable surfactant and the stabilizer into the deionized water at the room temperature of between 23 and 25 DEG C; and (3) stirring the liquid at constant speed of 60 to 80r / min for 20 to 40 minutes to ensure that no bubble is generated in the liquid to prepare the cleaning agent after uniform mixing. The invention has scientific and reasonable formula and simple process without special equipment, and the cleaning agent has the advantages of strong cleaning capability, short cleaning time, low cost, high efficiency and is safe and reliable for use.

Owner:北京凯兰航空技术有限公司

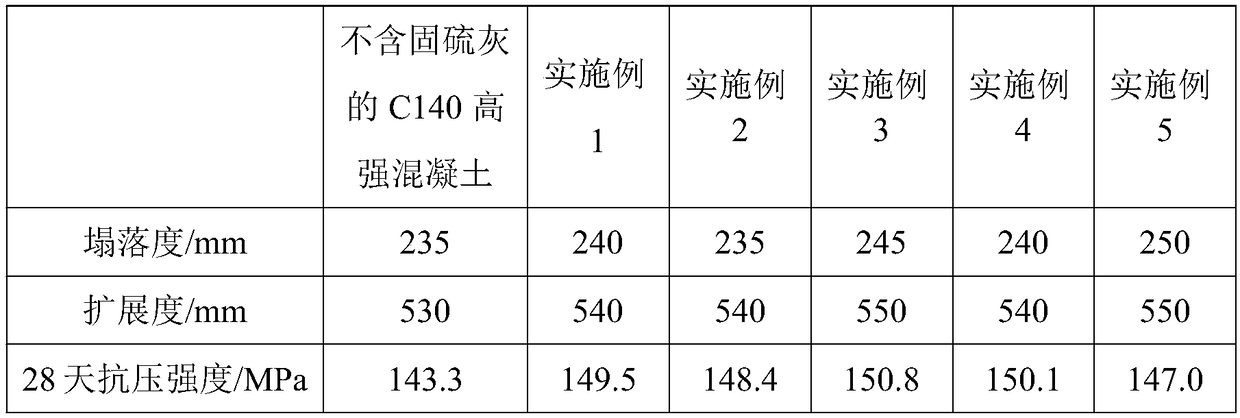

C140 high-strength concrete and preparation method thereof

The invention belongs to the field of concrete, and particularly discloses C140 high-strength concrete and a preparation method thereof. The concrete is prepared from the following materials in partsby weight: 490-570 parts of cement, 45-65 parts of coal ash, 100-120 parts of mineral powder, 65-85 parts of desulphurization ash, 20-40 parts of silica fume, 750-950 parts of coarse aggregate, 400-600 parts of fine aggregate, 5.5-7.5 parts of a water reducer, 10-20 parts of a corrosion inhibitor, 60-100 parts of fibers and 145-160 parts of water. The invention provides the C140 high-strength concrete; the concrete has a good slump, good extended degree, good compressive strength, and excellent comprehensive performance, and meanwhile, the problems of resource shortage of traditional cement admixtures of the mineral powder, the coal ash, the silica fume and the like, and limited resourced approaches and a low utilization rate of the desulphurization ash are solved.

Owner:成都宏基建材股份有限公司

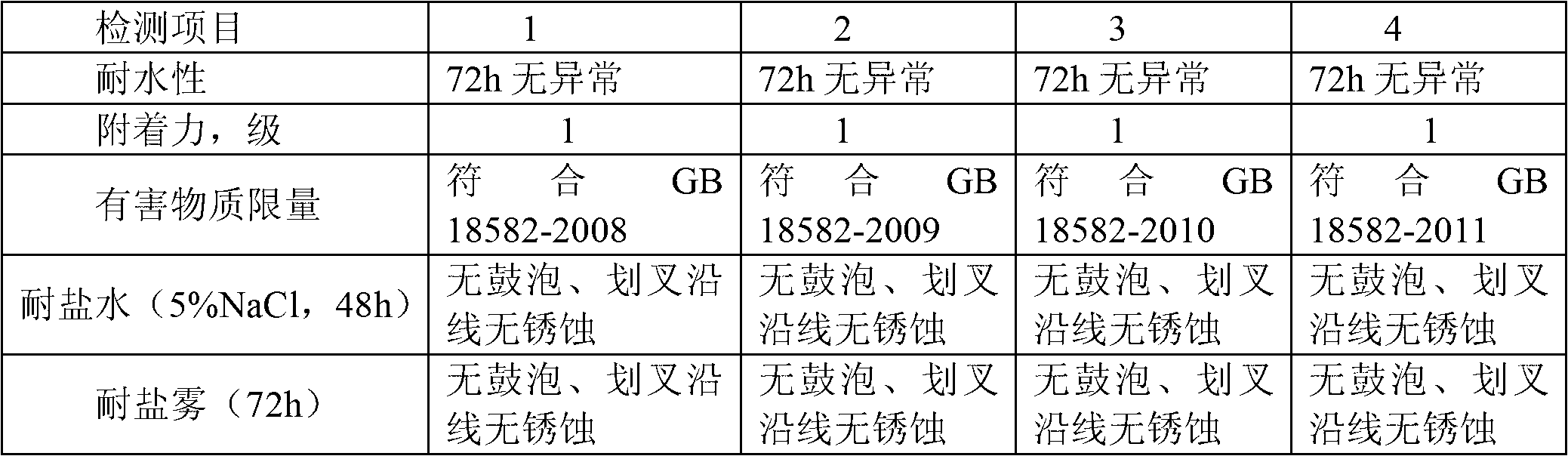

Water-based paint and preparation method thereof

InactiveCN102702871AAntibacterialMildew proofPolyurea/polyurethane coatingsEpoxy resin coatingsSodium acetateWater based

The invention relates to water-based paint, which comprises the following raw materials by part by weight: 52 to 55 parts of water, 0.5 to 0.7 part of sodium dodecyl sulfate, 30 to 70 parts of emulsion or aqueous dispersoid resin, 0.8 to 1 part of ammonia water, 0.1 to 0.2 part of defoamer, 0.05 to 0.1 part of sodium acetate, 0.5 to 5 parts of germicide, 0.1 to 1 part of corrosion inhibitor and 0.1 to 0.2 part of potassium peroxydisulfate. The invention further provides a preparation method for the water-based paint. The water-based paint is non-poisonous and harmless and causes little pollution to the environment. A coating formed by applying the water-based paint has high brightness and excellent firmness and resistance to crack, is hard to a certain extent, contains few VOCs and no heavy metal and have the functions of antibiosis and both mold and rust prevention. Therefore, the water-based paint is environmentally friendly and safe.

Owner:ANHUI JINDUN PAINT

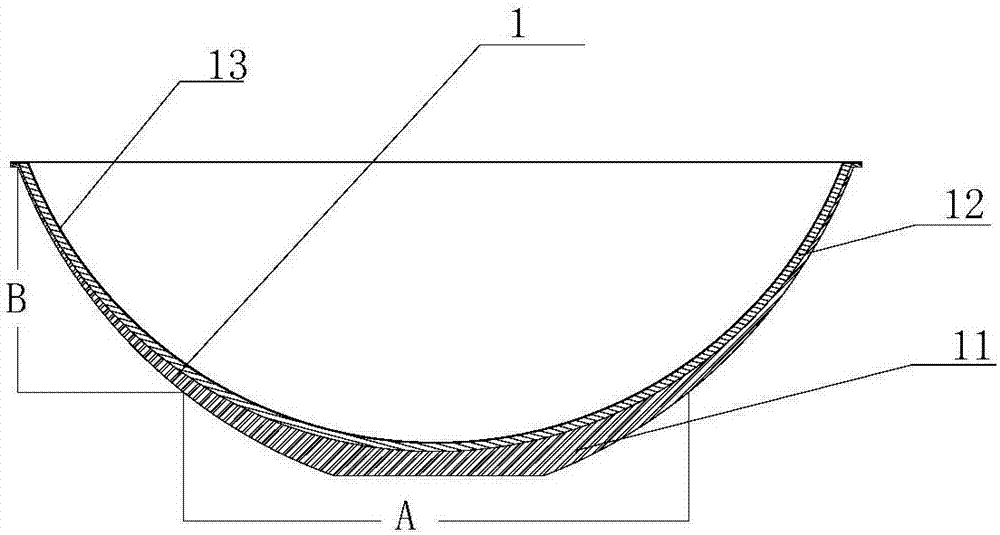

Smokeless cast iron wok and manufacturing method thereof

The invention discloses a smokeless cast iron wok and a manufacturing method thereof, and belongs to the field of kitchenware. The smokeless cast iron wok comprises a wok body, wherein the work body comprises an outer wok body, an inner wok body and a stainless steel coating; the outer wok body is cast from copper; the bottom of the outer surface of the outer wok body adopts a plane structure; the inner surface of the outer wok body and the outer surface of the inner wok body are combined in a fusion manner; the inner wok body is cast from cast iron; the bottoms of both the outer surface and the inner surface of the inner wok body adopt a circular-arc structure; the stainless steel coating is sprayed onto the inner surface of the inner wok body; and the stainless steel coating contains silicon, manganese, chromium, nickel, molybdenum, nitrogen, copper, cobalt, boron, carbon, niobium, calcium, phosphorus, sulfur and the balance of iron. The invention further provides the manufacturing method of the smokeless cast iron wok. The smokeless cast iron wok disclosed by the invention can be heated uniformly, can be prevented from generating smoke, is large in heated area and low in breakage possibility, and can be protected from rust erosion.

Owner:陆川县南发厨具有限公司

Rustproof rubber and manufacturing method thereof

The invention relates to a rubber material, and in particular to a rustproof rubber and a manufacturing method thereof. The rustproof rubber comprises by weight 45%-55% of a raw rubber, 3.0%-3.8% of an anti-rust agent, 0.7%-0.9% of an accelerant, 5.0%-7.0% of zinc oxide, 0.8%-1.2% of stearic acid, 5.0%-7.0% of DCP (dicumyl peroxide), 8.6%-9.6% of carbon black, 0.8%-1.2% of an antioxidant D and the balance of light calcium carbonate. When contacting with metal, the rubber provided by the invention can provide excellent rustproof protection to inhibit corrosion of metal and meanwhile avoid possible corrosion of the rubber during contact with the metal.

Owner:沈阳防锈包装材料有限责任公司

Oil dirt cleaning agent and preparation method thereof

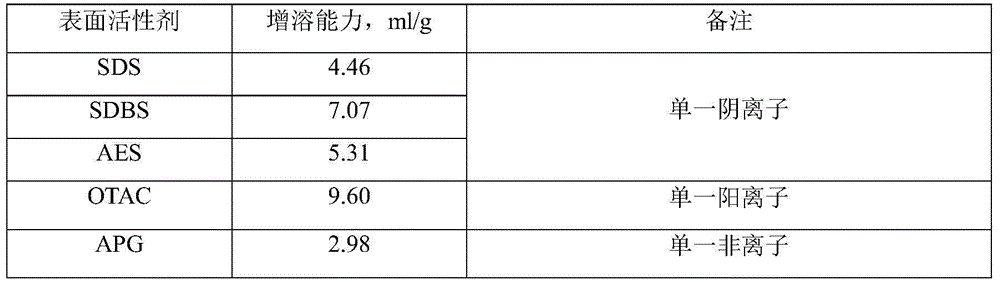

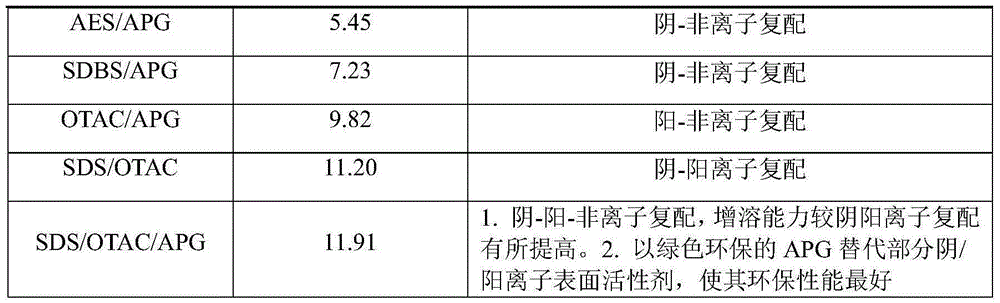

ActiveCN105154269AHigh economic valueEnhance solubilizationSurface-active non-soap compounds and soap mixture detergentsChemistryEnvironmental resistance

The invention provides an oil dirt powerful cleaning agent and a preparation method thereof. The oil dirt cleaning agent comprises the following components in parts by weight: 35-50 parts of oil, 21.5-53.5 parts of water, 1-5 parts of cationic surfactant, 1-5 parts of anionic surfactant, 1-5 parts of nonionic surfactant, 8-12 parts of cosurfactant n-butyl alcohol, 0-0.5 part of sodium chloride and 0.5-1 part of builder sodium tripolyphosphate. The oil dirt cleaning agent has the beneficial effects that the oil dirt cleaning agent uses compound microemulsion of the anionic / cationic surfactant with stronger solubilizing capacity and the nonionic surfactant with degradability as mother liquor and adopts several property assistants, so that the oil dirt cleaning agent achieves the advantages of rust prevention and decontamination, multiple reutilization of the lotion and environment friendliness, does not have limits to the oil content and has great economic value; meanwhile, the oil dirt cleaning agent also achieves diversification of cleaning objects, can be used for the materials, such as metals, glass, plastics, cloths, leather, ceramics and rubber and has a better application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Acid rust remover

ActiveCN101463481AThe formula is scientific and reasonableSimple production processSurface-active agentsWater soluble

The invention relates to an acidic rust remover which comprises the following components according to percentage by weight: 3%-10% of phosphate, 5%-10% of osmotic agent, 5%-10% of surface active agent, 1%-6% of pH conditioning agent and the balance of deionized water. The pH value of the acidic rust remover ranges from 10 to 12, and the acidic rust remover is colorless and transparent and has no penetrating odor. The acidic rust remover is highly efficient in cleaning a mechanical apparatus and can completely clear oil stains and rusty spots on the surface of the mechanical apparatus, prevent the rusty spots from being generated on the surface of the mechanical apparatus again, shorten the time for cleaning and improve the work efficiency; and the acidic rust remover is a water-soluble cleaning agent, hardly corrodes the apparatus, effectively reduces the production cost and is safe and reliable in use.

Owner:JIANGSU HAIXUN IND GROUP SHARE

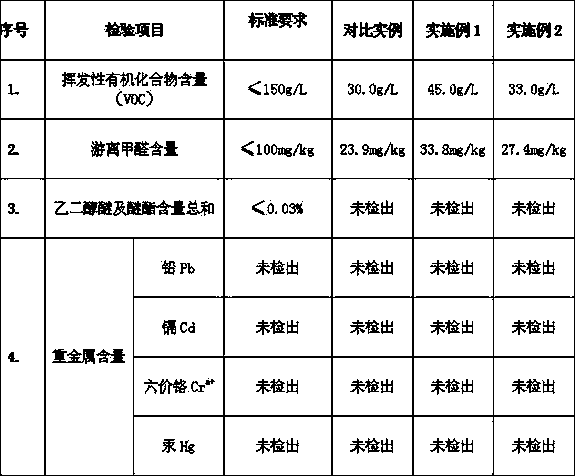

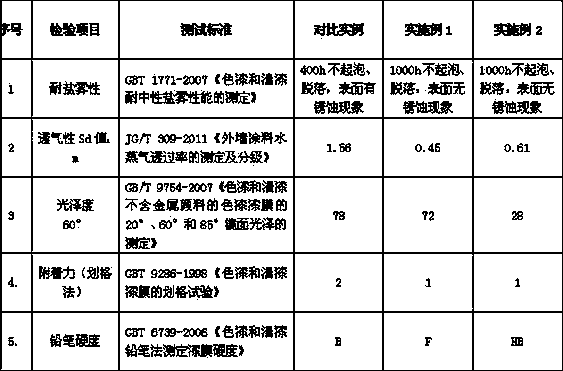

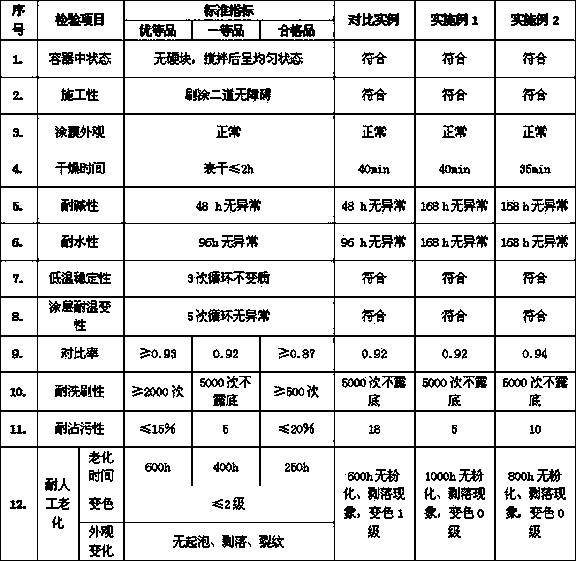

Water-based metallic paint with rustproof function for outer walls and preparation method thereof

ActiveCN103965726AWith anti-rust functionImprove waterproof performanceAnti-corrosive paintsWater basedEmulsion

The invention provides water-based metallic paint with a rustproof function for outer wall painting. The water-based metallic paint comprises the following components in parts by weight: 40-60% of silicone resin emulsion, 1-2% of film-forming agent, 10-20% of pearl pigment, 0.5-1% of flash-rust inhibitor, 0.3-0.6% of dispersant, 0.2-0.4% of wetting agent, 0.2-0.5% of defoaming agent, 0.3-1.0% of thickener, 0-5% of extinction powder and 25-35% of deionized water, wherein the silicone resin emulsion is water dilution type pure silicone resin emulsion, and the flash-rust inhibitor is modified zinc chelate. The water-based metallic paint provided by the invention has the advantages that the pure silicone resin emulsion is used as a film-forming agent, and meanwhile, the modified zinc chelate is added to the metallic paint and serves as the flash-rust inhibitor, so that a paint film has a good rustproof property, good stain resistance weather resistance and a very good decoration effect on outer walls and prolongs the service life of the walls relatively well. The invention aslo provides a preparation method with the rustproof function for the outer walls.

Owner:广东龙湖科技股份有限公司

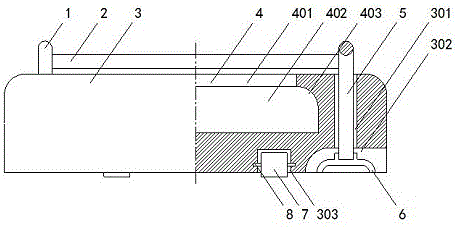

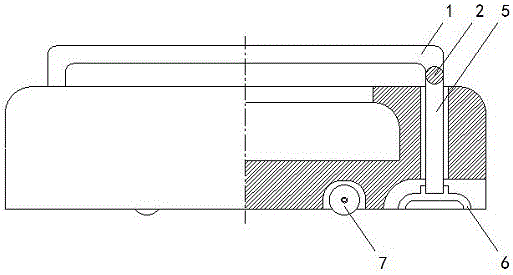

Overturning preventing and antirust movable type cleaning device for vessel deck

The invention discloses an overturning preventing and antirust movable type cleaning device for a vessel deck, and relates to the technical field of vessel equipment. The overturning preventing and antirust movable type cleaning device comprises first cross bars, second cross bars, a base, an accommodating cavity, vertical columns and suction cups, wherein a vertical column through hole is vertically formed in each of four top corners of the base; a horizontal suction cup cavity is formed in the bottom of each of the four top corners of the base; symmetrical rolling wheel cavities are formed in the bottom of the front side and the bottom of the rear side of the base; the accommodating cavity is formed in the center of the base; an accommodating cavity opening is formed in the top of the accommodating cavity, and communicates with a cavity body; an anti-overflowing wall is arranged on each of the four top corners of the top of the cavity body, and adopts the shape of an arc, and the openings of the arc-shaped anti-overflowing walls are downward; the first cross bars and the second cross bars are mutually connected to form a square; and each of vertical columns is connected to the end part of the corresponding first cross rod in the vertical direction, and is arranged in the corresponding vertical column through hole, and the bottom of each of the vertical columns is connected with the corresponding suction cup arranged in the corresponding suction cup cavity. The overturning preventing and antirust movable type cleaning device disclosed by the invention is ingenious in structure and convenient to use; and the overturning preventing and antirust movable type cleaning device can be effectively fixed on the surface of the deck and does not damage the deck, and the situation that liquid is overflowed is effectively prevented.

Owner:GUANGXI GAONONG MACHINERY

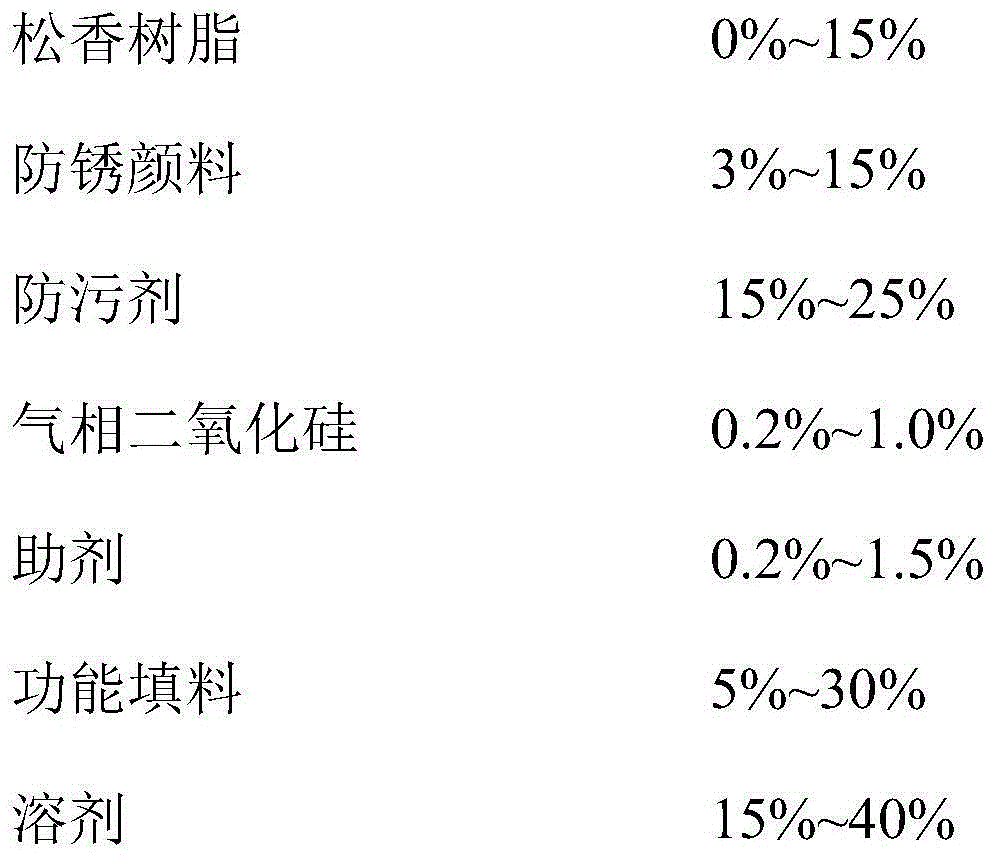

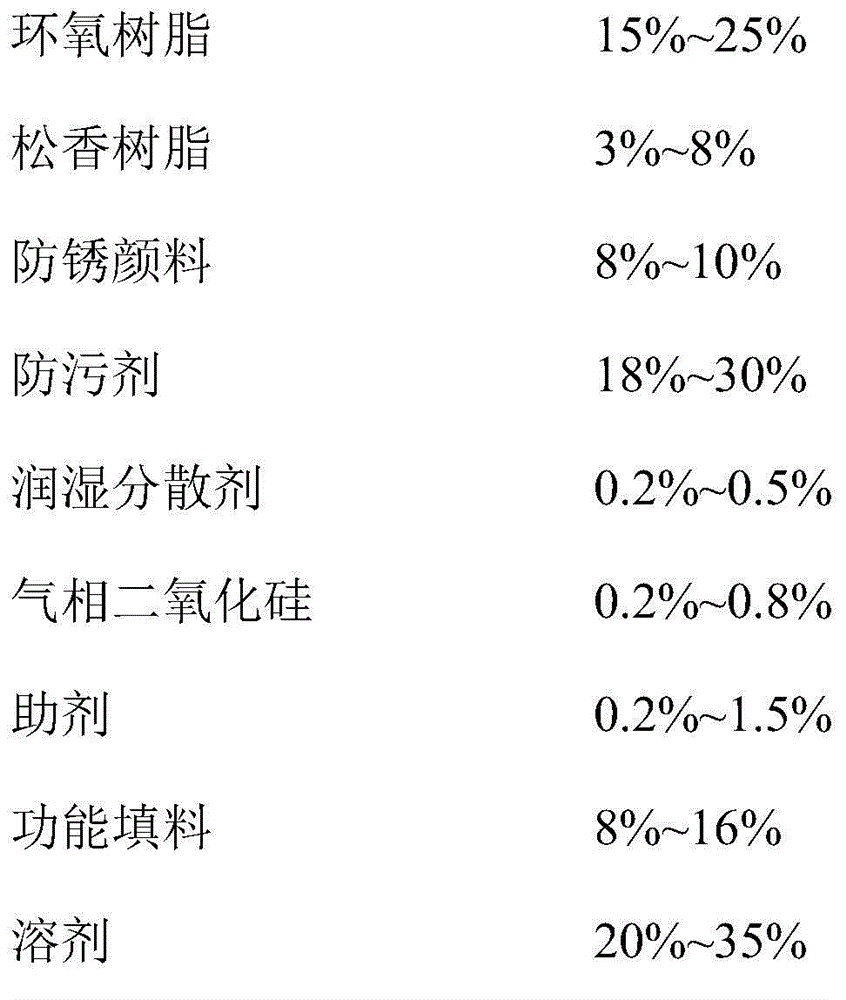

Contact type inshore fishing boat anti-fouling paint and preparation method thereof

InactiveCN104693970AGood antifouling performanceGood anti-corrosion performanceAntifouling/underwater paintsRosin coatingsSolventPesticide

The invention discloses contact type inshore fishing boat anti-fouling paint and a preparation method thereof. The contact type inshore fishing boat anti-fouling paint comprises a component A and a component B, wherein the component A comprises the following components in percentage by weight: 10%-30% of epoxy resin, 0-15% of rosin resin, 3%-15% of anti-rusting pigments, 15%-25% of an anti-fouling agent, 0.2%-1.0% of fumed silica, 0.2%-1.5% of an aid, 5%-30% of functional pigments and 15%-40% of a solvent; the component B comprises the following components in percentage by weight: 60%-100% of an epoxy curing agent and 0-40% of a solvent. The contact type inshore fishing boat anti-fouling paint has the advantages that the anti-fouling paint does not contain internationally forbidden pesticide poisons such as organic tributyltin (TBT) and dichlorodiphenyltrichloroethane (DDT); the manufacturing and construction environments are relatively good, the poisons and resin emitted to ocean are reduced; the contact type inshore fishing boat anti-fouling paint is environmentally friendly and is non-toxic to the environment.

Owner:上海华谊精细化工有限公司上海开林造漆厂

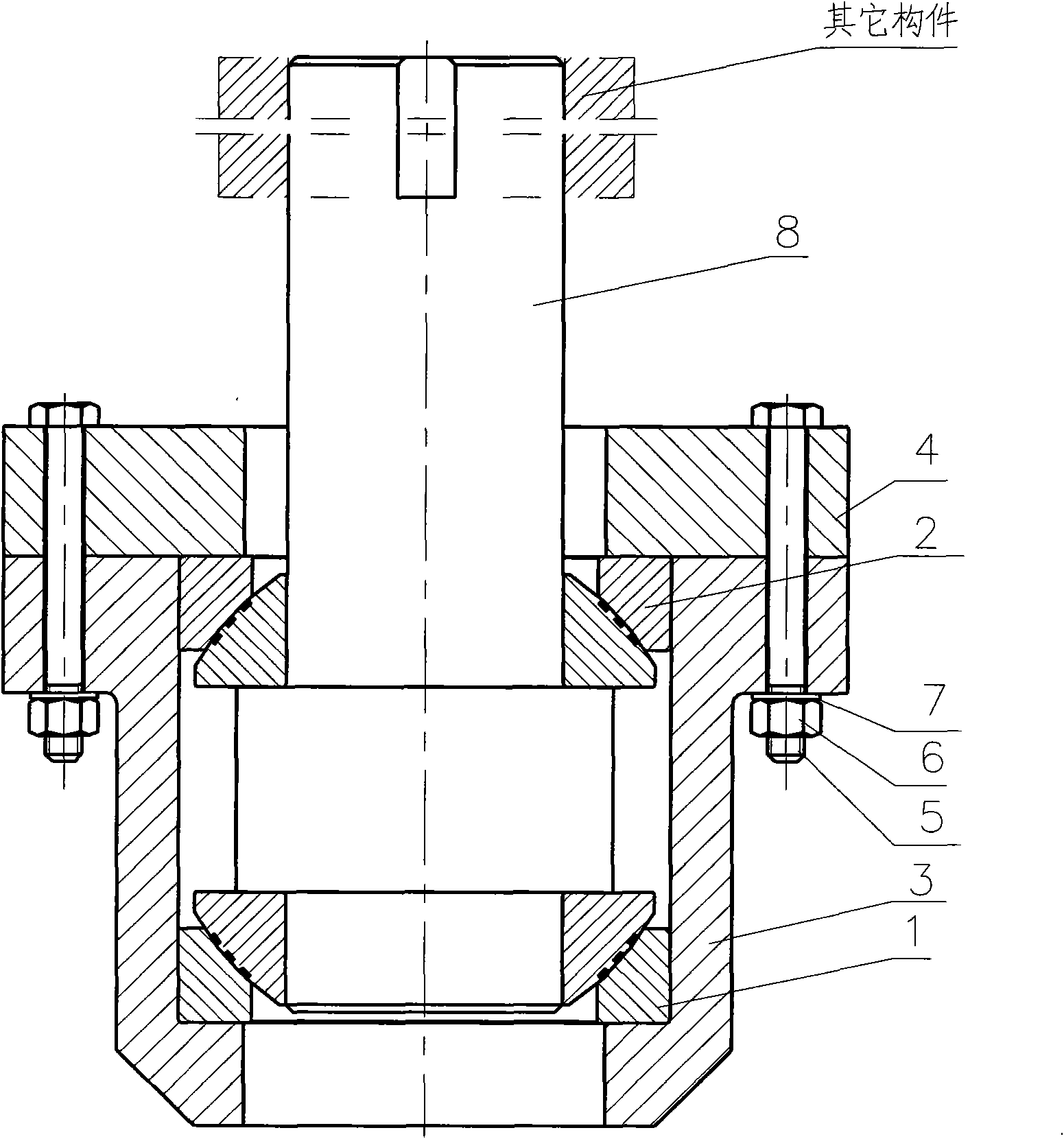

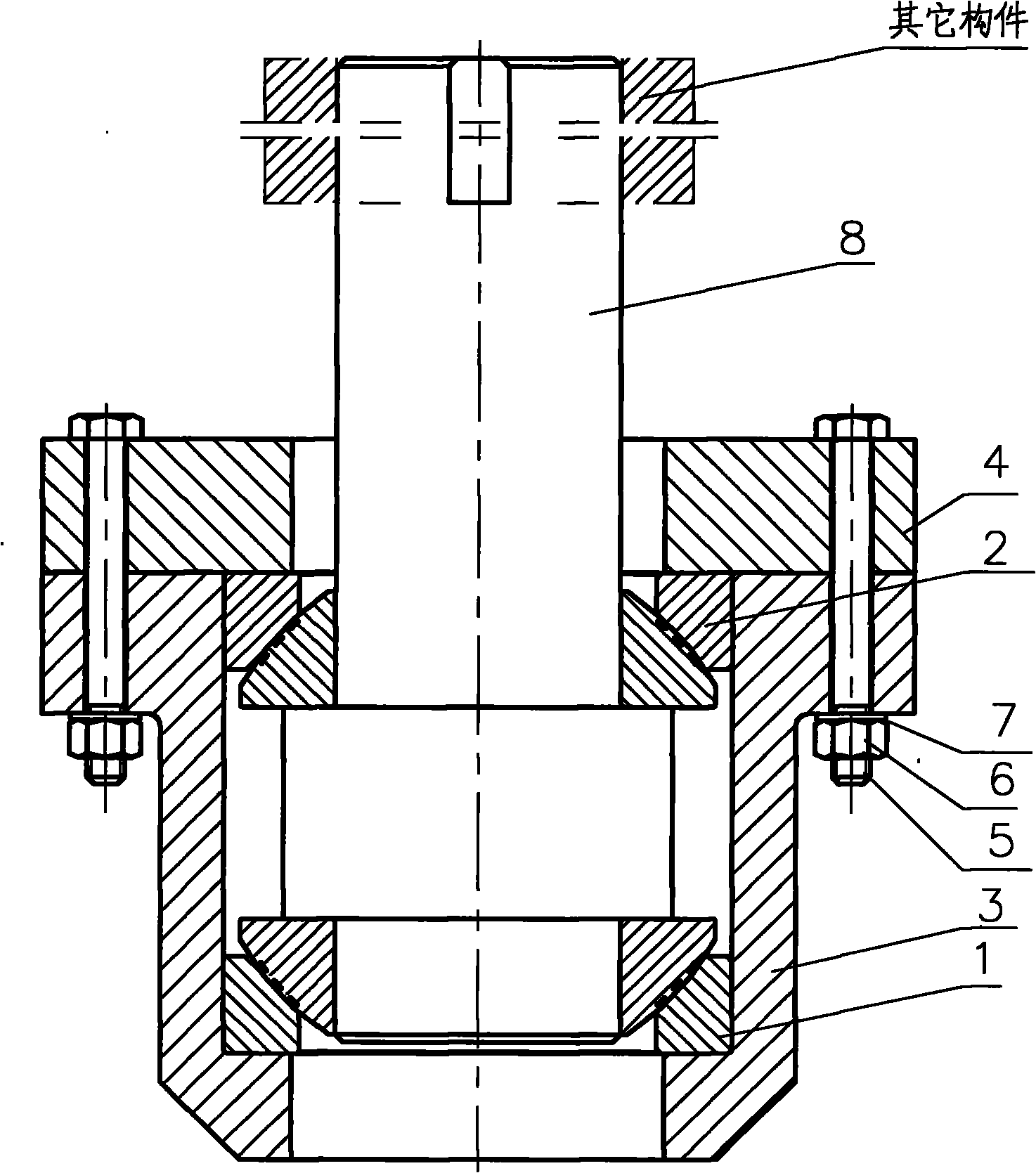

Hardware universal hinging unit

InactiveCN101806325AWith anti-rust functionEffective removalYielding couplingShear forceBending moment

The invention discloses a hardware universal hinging unit, which consists of a pair of thrust articulated bearings, a mandrel, a fixed base, a fixed cover plate, a bolt, a nut and a washer. The pair of thrust articulated bearings are matched and connected with the mandrel; housing washer excircles of the pair of thrust articulated bearings are matched with an inner bore of the fixed base; the fixed cover plate is pressed on the housing washer of one of the thrust articulated bearings and locked with each other through the bolt, the nut and the washer to form the hinging unit; a fitting surface between the thrust articulated bearings and the housing washer is a spherical surface and the two can be relatively rotated, so a member connected with the other end of the mandrel and a member connected with the end of the fixed base can be rotated in all directions in the circumference; a hinging function node with multi-direction rotation is realized, surface outer shearing force or additional bending moment loaded on the hardware can be effectively unloaded, and the safety of a building element is ensured; and the thrust articulated bearings are made of stainless steel, so the hardware universal hinging unit has a rust-proof function.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

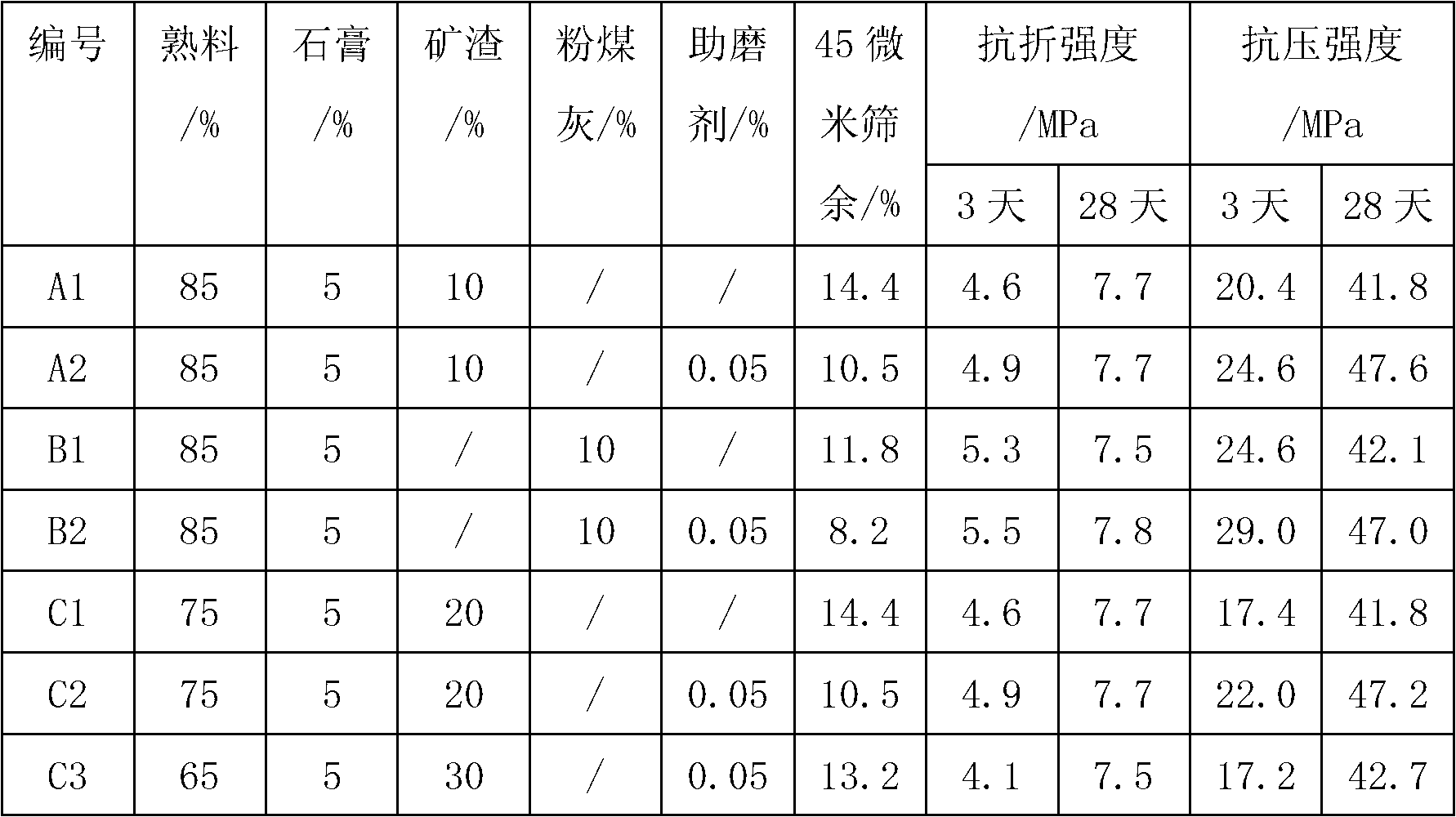

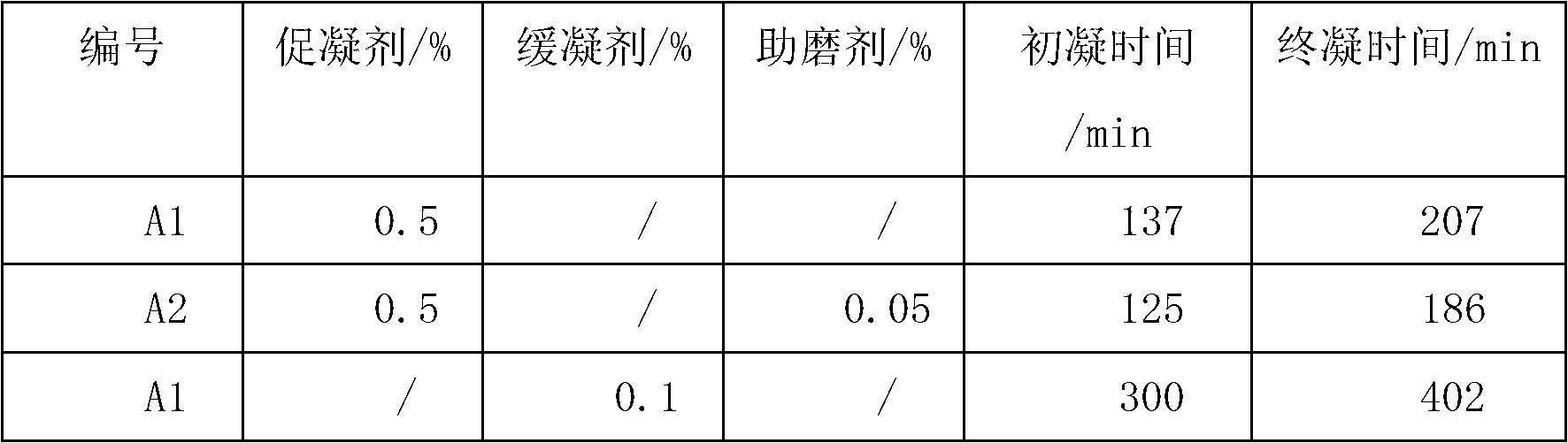

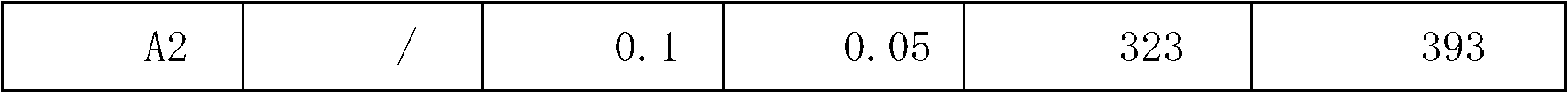

Reinforced type cement grinding aid and preparation method thereof

The invention discloses a reinforced type cement grinding aid and a preparation method thereof. The reinforced type cement grinding aid disclosed by the invention is prepared from triethanolamine, ethylene glycol, naphthalene-based superplasticizer, sodium oleate and water. The reinforced type cement grinding aid disclosed by the technical field has the functions of grinding aiding, improving the strength of the cement in different age periods and enhancing the anti-rust capability of the reinforced concrete; and moreover when the cement produced by using the reinforced type cement grinding aid, reinforcing steel bars of the concrete are prevented from rust.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Cleaning agent for bearing and bearing seat for pump

The invention discloses a cleaning agent for a bearing and a bearing seat for a pump, and relates to the technical field of equipment maintenance. The cleaning agent is made of following raw materials including, by weight, 15 parts to 20 parts of ore soil, 10 parts to 15 parts of hydrogenated rosin, 10 parts to 15 parts of asbestos wool, 8 parts to 11 parts of tea seed powder, 6 parts to 9 parts of washing powder, 6 parts to 9 parts of stearic acid, 4 parts to 8 parts of cinerite, 3 parts to 6 parts of polyaspartic acid, 3 parts to 6 parts of sodium salicylate, 2 parts to 4 parts of soda ash, 1 part to 2 parts of aluminum powder, 0.5 part to 1 part of borax, 0.2 part to 0.3 part of a silane coupling agent and 200 parts to 250 parts of ethyl alcohol. The cleaning agent is convenient to use, and during use, a user only needs to dip a few cleaning agent by duster cloth to wipe the bearing and the bearing seat; and dirt attached to the surfaces of the bearing and the bearing seat can be thoroughly removed, the bearing and the bearing seat have the antirust function after being wiped, the phenomenon that the bearing and the bearing seat act with water or oxygen in environment to generate the corrosion phenomenon is avoided, the service life of the bearing and the bearing seat is prolonged, and therefore normal running of the pump is ensured.

Owner:ANHUI SANHUAN PUMP

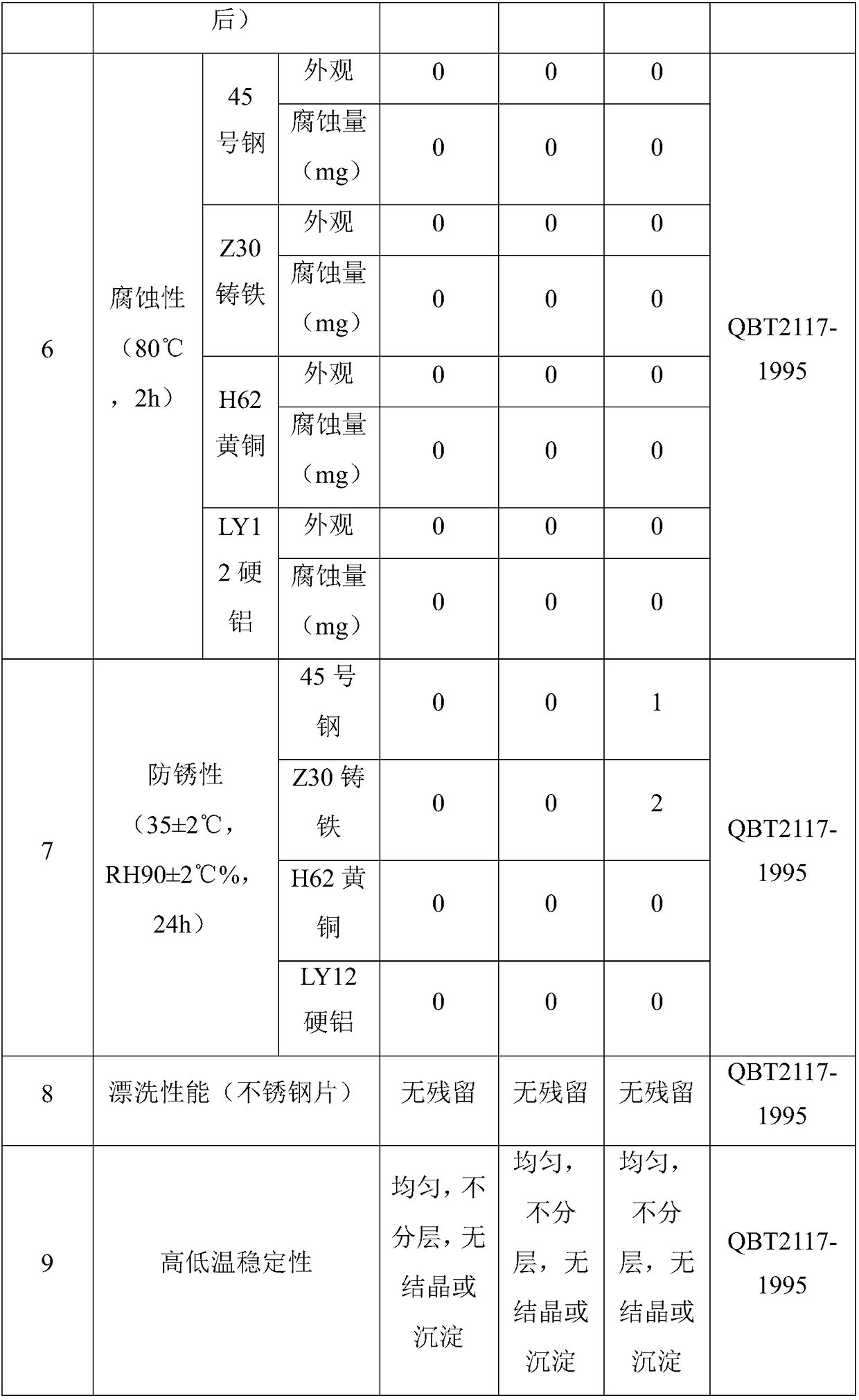

Multifunctional antirust corrosion-inhibiting agent

The present invention relates to a multifunctional preparation for rust prevention and corrosion inhibition, which is prepared by the following method: 1) first add 597g of water into a 1000ml beaker, then add 217g of metal corrosion inhibitor, and stir for 3-4 hours at room temperature; 2) add 83g of borate coupling agent, stirred at room temperature for 1-1.5 hours; 3) Finally, 103g of titanate coupling agent was added, stirred for 2-3 hours to obtain the antirust and corrosion inhibitor. The antirust performance of the present invention is carried out according to the antirust test standard, and there is no rust on the inner metal surface within 24 hours, and there is no change on the surface. After using the present invention, the paint adhesion is significantly enhanced. According to the cross-cut test standard of GB / T 9286-1998 paint and varnish paint film, the paint film adhesion grade is 0 grade. The invention has excellent corrosion inhibition function, and the pure hydrochloric acid is added in a ratio of 0.3-0.5%, which can effectively prevent metal over-corrosion.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

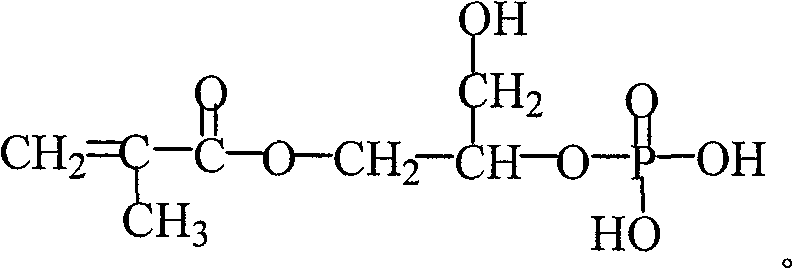

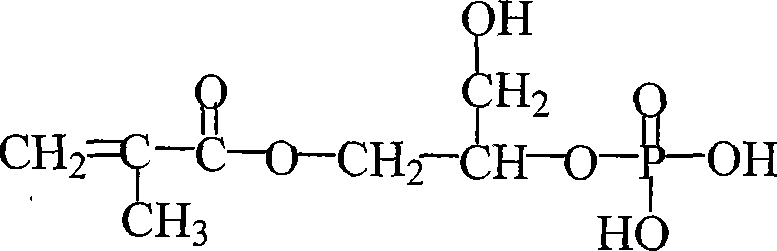

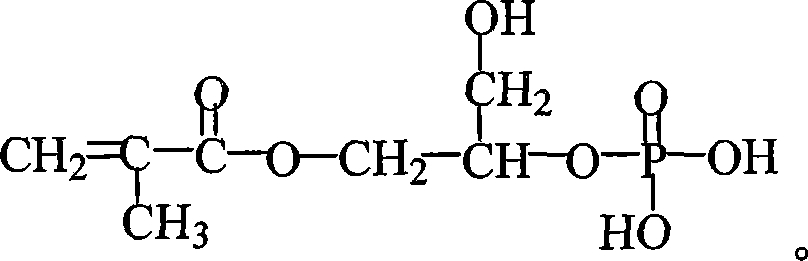

Reactive phosphoric acid esters emulsifying agents and method for preparing same

InactiveCN101284846BImprove antistatic performanceGood emulsifying effectTransportation and packagingMixingMethacrylatePhosphoric Acid Esters

The invention relates to a reaction-type phosphate ester-class functional emulsifying agent and a method for making the same. The chemical structure of the reaction-type phosphate ester-class functional emulsifying agent is as above. The functional emulsifying agent, adopting epoxypropyl methacrylate and phosphoric acid as raw material, acetone as reaction medium and hydrochinone as polymerization inhibitor, is obtained after solvent is removed through vacuum distillation when reaction is finished at a lower temperature. The functional emulsifying agent not only has the advantages of ordinaryfunctional emulsifying agent, but also has an anti-rust function. Therefore, the method provides an emulsifying agent with outstanding performances for the development of aqueous anti-rust paint, andhas tremendous application value.

Owner:NORTHWEST NORMAL UNIVERSITY

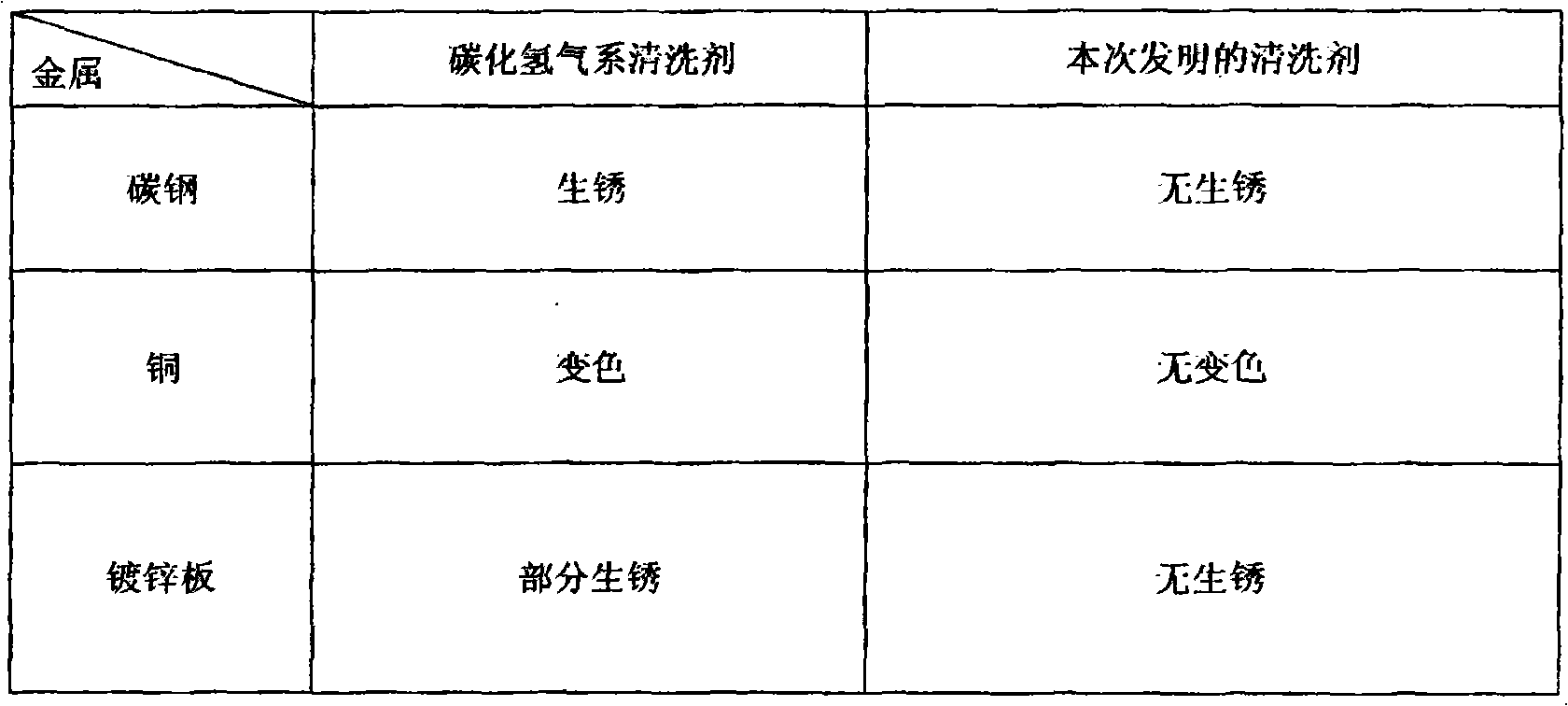

Neutral rust-proof water-based cleaning agent and preparation method

The invention provides a neutral rust-proof water-based cleaning agent. A raw material of the agent contains a phosphorus-free cleaning auxiliary agent, a metal corrosion inhibitor, a surfactant, a solubilizer, a defoaming agent and water. The invention further provides a preparation method of the neutral rust-proof water-based cleaning agent. According to the neutral rust-proof water-based cleaning agent, foam is low, a plurality of cleaning modes such as spray cleaning, ultrasonic cleaning and bubbling cleaning can be adopted, the application range is wide, the use method is flexible and diversified, the good cleaning effects on grinding oil, cutting fluid, metal powder and the like in the production and processing processes of various metal devices are realized, no influence is generated on subsequent surface treatment, and a certain rust-proof function is achieved; and the cleaning agent is easy to biodegrade and process and discharge, the compatibility with different metals is better, the cleaning and rust-proof performance are very high, the preparation process is simple, the preparation difficulty is reduced, and the manpower requirement is reduced.

Owner:长沙艾森设备维护技术有限公司

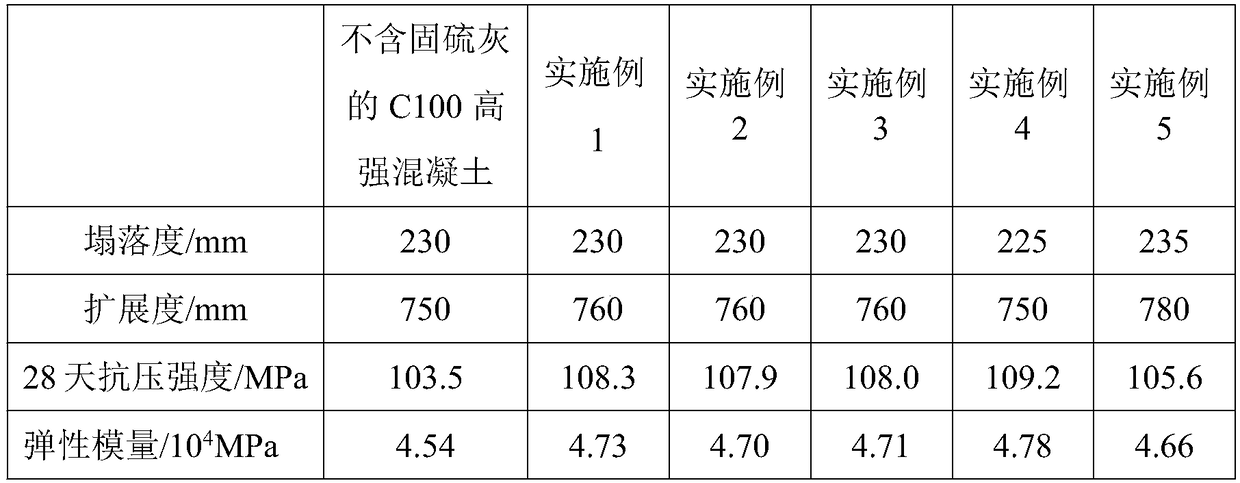

C100 high-strength concrete and preparation method thereof

InactiveCN109020401AReduce water demandReduce Microstructural DefectsHigh strength concreteWater reducer

The invention belongs to the field of concrete, and particularly discloses C100 high-strength concrete and a preparation method thereof. The concrete is prepared from the following materials in partsby weight: 420-470 parts of cement, 90-120 parts of mineral powder, 30-40 parts of coal ash, 60-70 parts of desulphurization ash, 970-1010 parts of coarse aggregate, 650-670 parts of fine aggregate, 4.5-6.5 parts of a water reducer, 5-15 parts of a corrosion inhibitor and 120-130 parts of water. The invention provides the C100 high-strength concrete; the concrete has a good slump, good extended degree, good compressive strength and elasticity modulus, and excellent comprehensive performance, and meanwhile, the problems of resource shortage of traditional cement admixtures of the mineral powder, the coal ash and the like, and limited resourced approaches and a low utilization rate of the desulphurization ash are solved.

Owner:成都宏基建材股份有限公司

C80 high-strength concrete and preparation method thereof

InactiveCN109020403AReduce water demandReduce Microstructural DefectsHigh strength concreteWater reducer

The invention belongs to the field of concrete, and particularly discloses C80 high-strength concrete and a preparation method thereof. The concrete is prepared from the following materials in parts by weight: 400-450 parts of cement, 75-95 parts of mineral powder, 30-40 parts of coal ash, 45-65 parts of desulphurization ash, 950-1100 parts of coarse aggregate, 650-750 parts of fine aggregate, 3-5parts of a water reducer, 5-15 parts of a corrosion inhibitor and 130-145 parts of water. The invention provides the C80 high-strength concrete; the concrete has a good slump, good extended degree, good compressive strength, and excellent comprehensive performance, and meanwhile, the problems of resource shortage of traditional cement admixtures of the mineral powder, the coal ash and the like, and limited resourced approaches and a low utilization rate of desulphurization ash are solved.

Owner:成都宏基建材股份有限公司

Water-soluble metal cleaner and manufacturing method thereof

The invention discloses a water-soluble metal cleaner, which comprises the following raw materials in parts by weight: 5-10 parts of monohydric alcohol, 1-1.5 parts of sodium carbonate, 10-30 parts of dipropylene glycol monomethyl ether, 30-50 parts of ethylene glycol monobutyl ether, 0.5-5 parts of morpholine and 5-20 parts of water, wherein, ethanol is preferred as the monohydric alcohol, and the pH value of 7-11 is preferred in the invention. The invention improves the traditional formulation to use alkanolamine, monohydric alcohol or fatty alcohol substances as the raw materials, and does not contain compounds harmful the environment. The invention has the advantages of simple manufacturing process, short time for cleaning the metal surface, good cleaning effect and favorable rust resistance.

Owner:金福东

Detergent for removing oil stains on surface of metal

The invention relates to a detergent for removing oil stains on the surface of a metal and belongs to the technical field of industrial detergents. The detergent for removing oil stains on the surface of the metal is prepared from the following components in parts by weight: 20-30 parts of Chinese honeylocust fruit extract, 10-20 parts of sodium metasilicate, 5-20 parts of sodium phosphate, 20-35 parts of oleic acid, 20-40 parts of triethanolamine, 5-15 parts of polyoxyethylene fatty acid, 5-10 parts of sucrose fatty acid ester, 5-15 parts of sodium lauryl sulfate, 10-15 parts of acetone, 10-15 parts of methyl cellulose, 5-10 parts of banana skin extract, 5-10 parts of polyetherimide, 5-10 parts of active black phosphorene powder, 5-10 parts of a carbon nanotube, 0.5-2 parts of a defoamer and 70-90 parts of deionized water. The detergent provided by the invention can quickly and effectively remove oil stains, has a very strong cleaning effect on mechanical oil, antirust oil, mineral oil and animal and plant oil, is little in foam, and has a certain anti-rust function on metals.

Owner:NANTONG KEXING CHEM

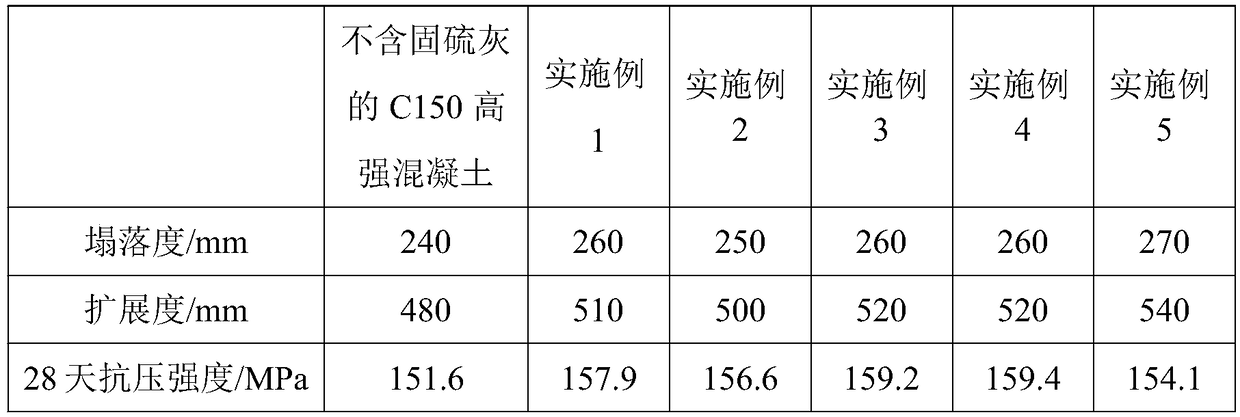

C150 high-strength concrete and preparation method thereof

The invention belongs to the field of concrete and particularly discloses C150 high-strength concrete and a preparation method thereof. The concrete consists of the following materials in parts by weight: 500 to 580 parts of cement, 45 to 65 parts of coal ash, 110 to 130 parts of ore powder, 65 to 85 parts of solid sulfur ash, 20 to 40 parts of silicon ash, 750 to 950 parts of crude aggregate, 400to 600 parts of fine aggregate, 5.5 to 7.5 parts of water reducer, 10 to 20 parts of corrosion inhibitor, 100 to 150 parts of fiber and 145 to 165 parts of water. The C150 high-strength concrete provided by the invention has good slump degree, expansion degree and compressive strength, has excellent comprehensive property, and overcomes the problems of shortage of the traditional cement admixtureresources such as the ore powder, the coal ash and the silicon ash, limited recycling route of the solid sulfur ash and low utilization rate of the solid sulfur ash.

Owner:成都宏基建材股份有限公司

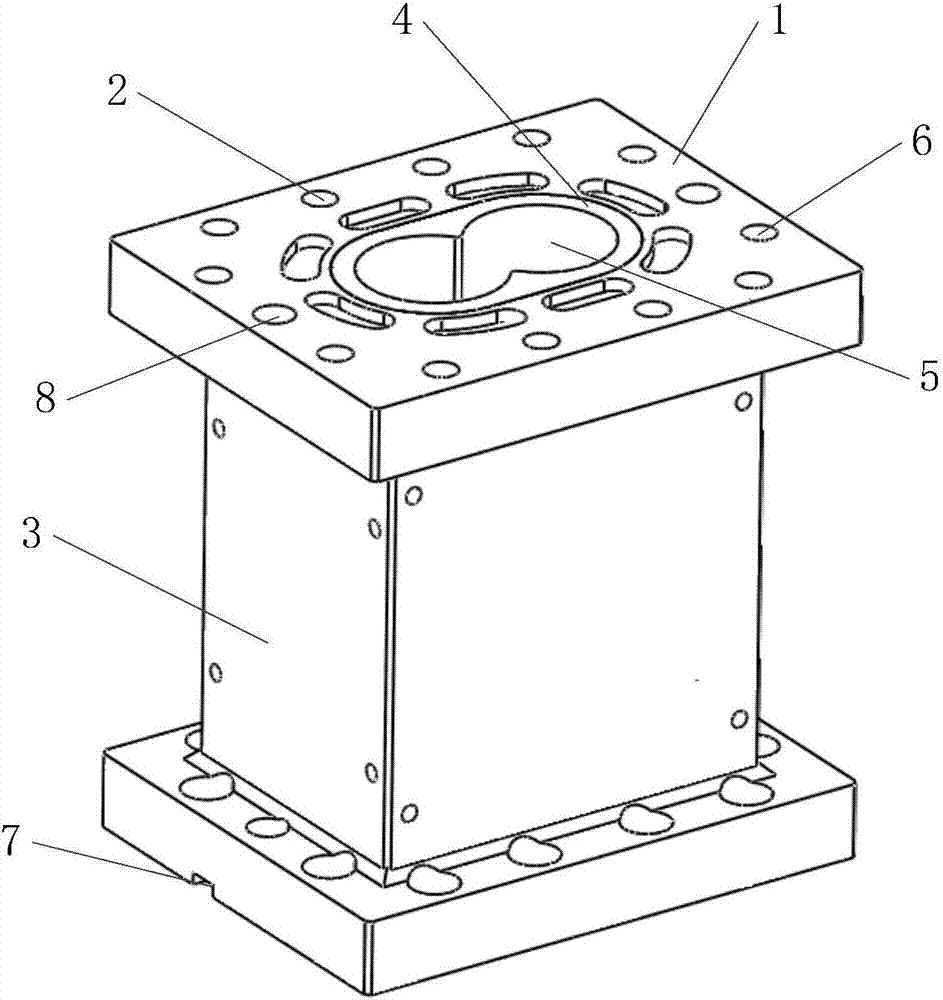

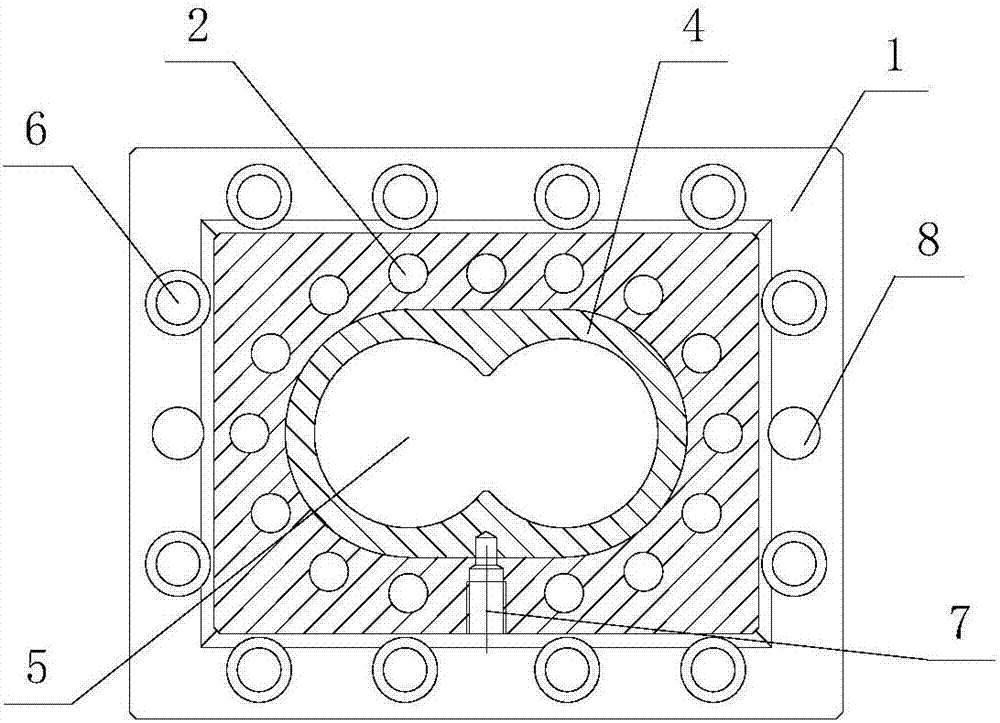

Double-metal machine barrel machining process

The invention discloses a double-metal machine barrel machining process. The double-metal machine barrel machining process comprises the following steps: (1) milling and grinding an outer sleeve of amachine barrel; (2) drilling a tapping water channel hole, a water charging hole and a water discharging hole in the outer sleeve of the machine barrel, welding sealing plates and machining water channels at the four sides of the outer sleeve of the machine barrel, and performing a leakage test after the water channels are machined; (3) machining a waist round hole in the center of the outer sleeve of the machine barrel, and pressing a steel sleeve into the waist round hole by means of hot charging; (4) machining an 8-shaped hole in the steel sleeve; and (5) performing finish-milling on the four sides by adopting a fly-cutter, performing finish-milling on a shoulder surface by adopting an alloy end mill, polishing the two end faces of the outer sleeve of the machine barrel by means of plane abrasion, and drilling each screw hole, each thread hole, each locking hole, each probe hole and each pin hole. The double-metal machine barrel machining process disclosed by the invention is simplein a machining process; a machined product is relatively high in wear resistance and corrosion resistance; the service life of a double-metal machine barrel is prolonged; and the production cost is lowered.

Owner:都江堰市江宁机械有限公司

Non-phosphorus metal cleaner

The invention discloses a non-phosphorus metal cleaner, belonging to the field of cleaners in mechanical industry. The non-phosphorus metal cleaner is composed of the following raw materials in percentage by weight: 20-30% of sodium carbonate, 8-10% of gluconic acid, 6-10% of dodecylbenzene sulfonic acid, 0.5-1.5% of sodium benzoate, 2-3% of peregal, 1-3% of benzotriazole, 2-4% of sodium hydroxide and the balance of water. The non-phosphorus metal cleaner is free of phosphorus and environment-friendly, can be used for cleaning ferrous metals and nonferrous metals in industry, and has the advantages of short cleaning time, favorable cleaning effect, no corrosion on parts, antirust function and low cost.

Owner:北京泽凯恩派航空材料有限公司

Environment-friendly water-based coating

InactiveCN106967317AReduce pollutionIncrease brightnessAntifouling/underwater paintsPaints with biocidesWater basedSodium acetate

The invention discloses environment-friendly water-based coating which comprises the components of, by weight, 15-20 parts of acrylic acid modified emulsion, 15-25 parts of acetoacetoxy ethyl methacrylate, 20-25 parts of water-based amino resin, 15-25 parts of rheological modified resin, 10-15 parts of modified aluminium powder, 5-15 parts of deionized water, 20-30 parts of rare earth aluminate, 3-6 parts of water-based organic silicon defoamer, 3-9 parts of water-based organic silicon flatting agent, 25-35 parts of water-based amine epoxy hardener, 20-25 parts of mussel attachment protein, 10-20 parts of aluminum antirust pigment, 10-15 parts of sodium acetate, 9-15 parts of dispersion resin, 15-20 parts of sodium dodecyl sulfate, 25-35 parts of epoxy resin and 15-30 parts of epoxypropane butyl ether.

Owner:德阳森华涂料化工有限公司

A prestressed hollow concrete square pile and its forming method

InactiveCN104018498BWith anti-rust functionAvoid the disadvantages of high pile damage rateCeramic shaping apparatusBulkheads/pilesPre stressCentrifugation

The invention discloses a prestress hollow concrete square pile which comprises a pile body, a circular through hole formed in the center of the pile body, a reinforcement cage, concrete and metal end plates. The metal end plates are arranged at the two ends of the pile body and are connected with the reinforcement cage. A stirrup of the reinforcement cage is welded to a main rib in a spiral-surrounding mode. The pile is characterized in that rust protection liquid is added into the concrete square pile. The invention further discloses a forming method of the prestress hollow concrete square pile. The method is characterized in that during a centrifugation forming process in which the concrete is placed into a centrifugation forming mould, the concrete is added, then the rust protection liquid is added, and then centrifugation forming is carried out. The prestress hollow concrete square pile has a rust protection function and is good in rust protection effect, and during storing, rust protection time can reach 2-3 years. According to the forming method of the pile, rust protection agents are added in the centrifugation forming step, the hollow concrete square pile can be generated, the production method has the advantages of being simple, burdens are avoided, operation is easy, and production efficiency reaches at least 95%-98%.

Owner:NANTONG ZHONGJI PILE

Cleaning agent for oil stain on electronic device

InactiveCN101463297ASimple production processStrong cleaning abilitySurface-active detergent compositionsChemistrySurface-active agents

The invention relates to an oil stain washing agent for an electronic device. The oil stain washing agent comprises the following compositions by weight percentage: 3 to 10 percent of silicate, 5 to 10 percent of phosphate, 5 to 10 percent of a surface active agent, 1 to 6 percent of a pH conditioning agent, 10 percent of polyoxyethylene, 2 to 5 percent of alkylphenol ether, and the balance being de-ionized water. The oil stain washing agent has the advantages that: 1) the washing agent does not contain nitrite which is harmful to human body and environment, and the surface of a part which is washed by the washing agent can form a compact protective film, thereby ensuring that the washed part has a function of rust prevention; 2) the washing agent has a simple production process by mixing the raw materials at normal temperature without special equipment, has strong washing capability and short washing time, saves labor power and time, and has efficacy of rust removal and rust prevention; and 3) the washing agent is water soluble, and waste fluid after washing is convenient for treating and discharging, and accords with the requirement of environmental protection.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Cleaning agent for grease removal

InactiveCN107354041AEfficient removalEasy to cleanSurface-active non-soap compounds and soap mixture detergentsVegetable oilSucrose

The invention relates to a cleaning agent for grease removal, and belongs to the technical field of industrial cleaning agents. The cleaning agent for grease removal is prepared from the following components in parts by weight: 10 to 20 parts of saponin extract, 5 to 20 parts of sodium carbonate, 10 to 20 parts of sodium phosphate, 5 to 15 parts of oleic acid, 10 to 20 parts of diethanol amine, 5 to 15 parts of sodium aliphatate, 2 to 8 parts of sucrose fatty acid ester, 5 15 parts of sodium dodecyl benzene sulfonate, 10 to 15 parts of ethyl alcohol, 5 to 15 parts of cellulose methyl ether, 2 to 5 parts of shaddock peel extract, 2 to 10 parts of polyetherimide, 3 to 6 parts of active silver nanoparticles, 5 to 8 parts of graphene oxide, 0.5 to 2 parts of defoaming agent and 50 to 80 parts of deionized water. The cleaning agent of the invention can quickly and effectively remove grease, has a strong cleaning effect on machine oil, anti-rust oil, mineral oil and animal and vegetable oil, has low foam and has a certain anti-rust function to metal.

Owner:NANTONG KEXING CHEM

Acid rust remover

ActiveCN101463481BThe formula is scientific and reasonableSimple production processPhosphateWater soluble

Owner:JIANGSU HAIXUN IND GROUP SHARE

Method for making ecological boiler

The invention provides a method for making an ecological boiler. The method comprises the following steps: heating ductile cast iron to 1,500-1,650 DEG C, melting into molten iron, pouring the molten iron into a die of the ecological boiler, and cooling to form a boiler blank; placing the cooled boiler blank into an electric furnace for heating, stopping heating when the heating temperature reaches 980-1,050 DEG C, preserving heat for 5-10 minutes, taking the boiler blank out of the electric furnace, and naturally cooling in the air to the room temperature; polishing the inner side surface of the boiler blank, and removing slag on the inner side surface of the boiler blank till the surface become smooth. Since the ecological boiler is made of the ductile cast iron which is high in toughness, the ecological boiler is prevented from being broken and deformed; the ductile cast iron can be used for conducting heat rapidly and is heated uniformly, and heat can be transferred rapidly during use of the made ecological boiler, thereby preventing the temperature of the inner side surface of the boiler body from getting too high, preventing the oil temperature from reaching a smoke point and realizing a smoke-free effect. The made ecological boiler is free from a chemical coating and ceramics falling, and has a rust prevention function.

Owner:福建南安市鑫鼎厨具有限公司

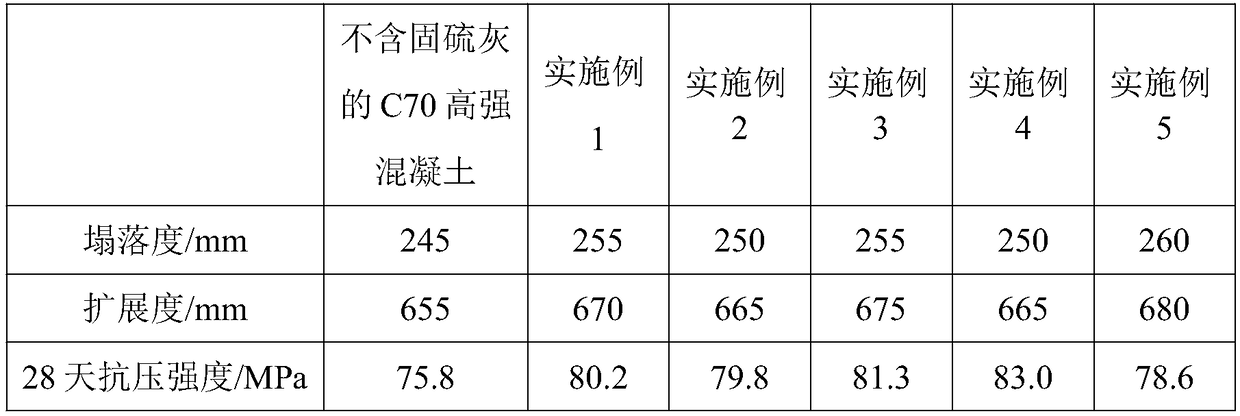

C70 high-strength concrete and preparation method thereof

InactiveCN109020400AStimulate latent activityElicitor can stimulate latent activityHigh strength concreteWater reducer

The invention belongs to the field of concrete, and particularly discloses C70 high-strength concrete and a preparation method thereof. The concrete is prepared from the following materials in parts by weight: 365-415 parts of cement, 70-90 parts of mineral powder, 25-35 parts of coal ash, 40-60 parts of desulphurization ash, 950-1100 parts of coarse aggregate, 650-800 parts of fine aggregate, 3-4.5 parts of a water reducer, 5-12 parts of a corrosion inhibitor and 125-145 parts of water. The invention provides the C70 high-strength concrete; the concrete has a good slump, good extended degree,good compressive strength, and excellent comprehensive performance, and meanwhile, the problems of resource shortage of traditional cement admixtures of the mineral powder, the coal ash and the like,and limited resourced approaches and a low utilization rate of the desulphurization ash are solved.

Owner:成都宏基建材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com