Neutral rust-proof water-based cleaning agent and preparation method

A technology of water-based cleaning agent and cleaning aid, which is applied in the field of industrial cleaning and achieves the effect of wide range of use, easy biodegradation and disposal and discharge, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

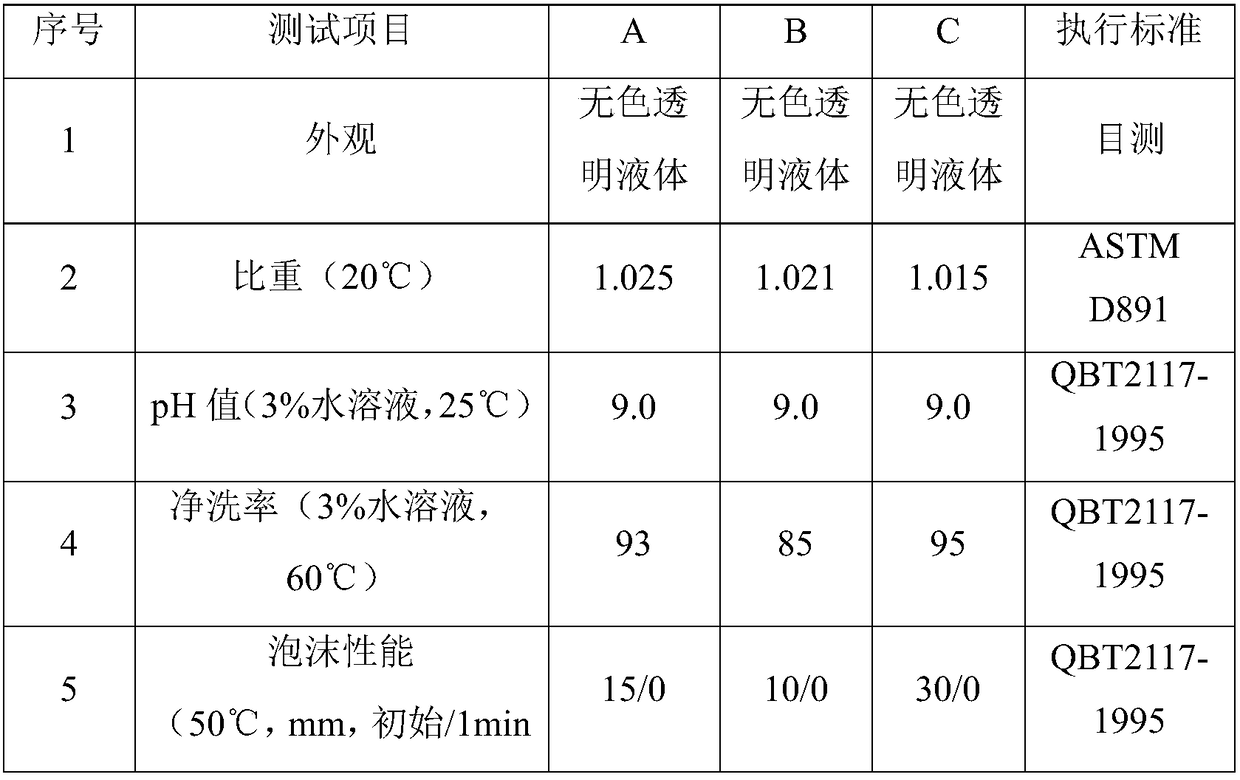

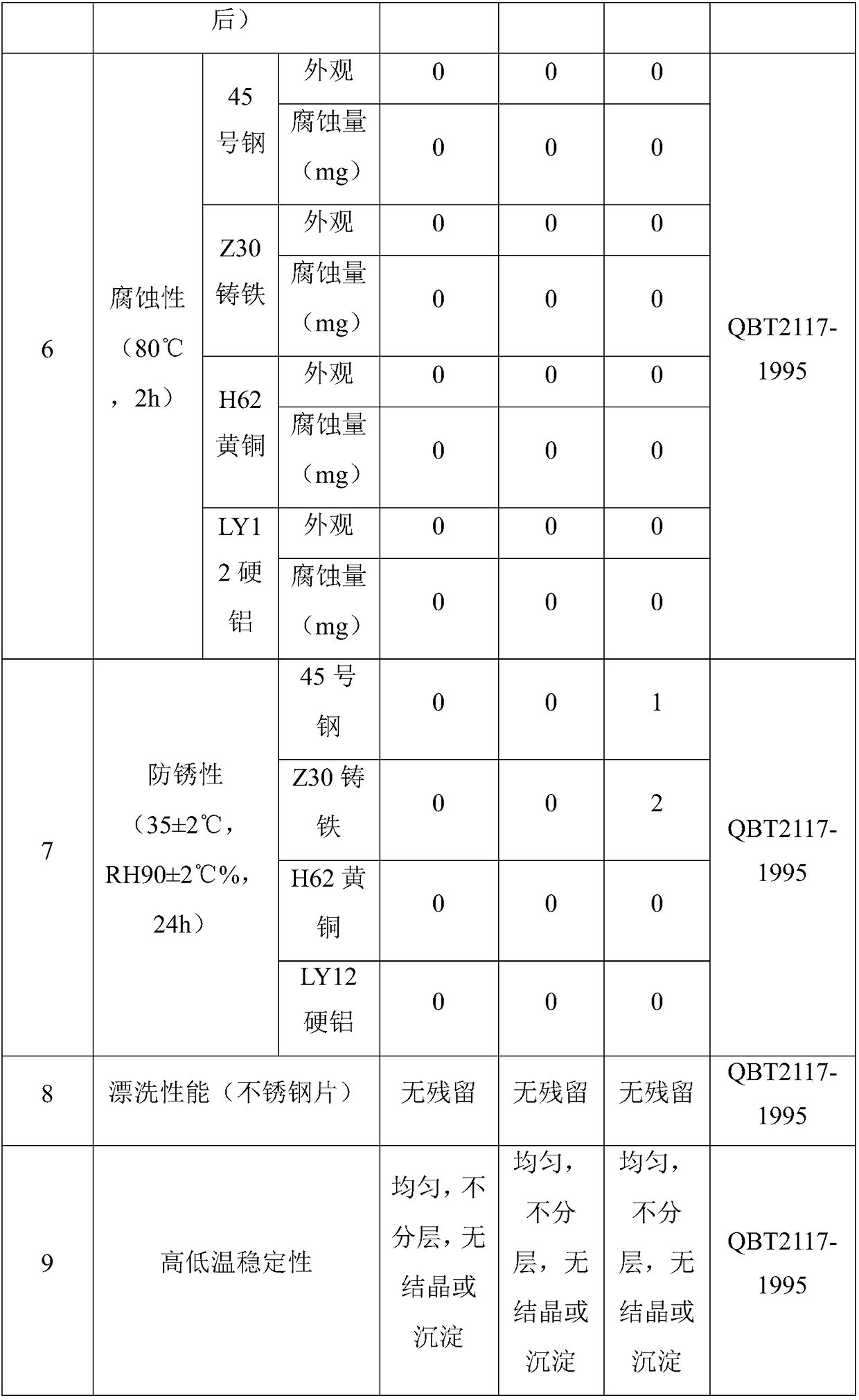

[0037] Embodiment 1 (antirust performance and cleaning performance balance):

[0038] Neutral anti-rust water-based cleaning agent A, comprising the following components in mass percent:

[0039] Phosphate-free cleaning aids: sodium benzoate 1%, sodium sulfate 2% and sodium carbonate 0.3%;

[0040] Metal corrosion inhibitor: 4.5%, MBT and TTA are mixed in a mass ratio of 1:1;

[0041] Surfactants: C10-14 Fatty Alcohol Polyoxyalkylene Ether 7.5%, C9-11 Pareth-3 5% and PEG-2 Cocoyl Methyl Ammonium Chloride 2.5%;

[0042] Solubilizer: triethanolamine 12%;

[0043] Defoamer: polydimethylsiloxane 0.1%;

[0044] Pure water 65.1%.

Embodiment 2

[0045] Embodiment 2 (strong antirust performance, weak cleaning performance):

[0046] Neutral anti-rust water-based cleaning agent B, comprising the following components in mass percent:

[0047] Phosphate-free cleaning aids: sodium benzoate 1%, sodium sulfate 2% and sodium carbonate 0.3%;

[0048] Metal corrosion inhibitor: 4.5%, MBT and TTA are mixed in a mass ratio of 3:1;

[0049] Surfactants: C10-14 Fatty Alcohol Polyoxyalkyl Ether 3%, C9-11 Pareth-3 2% and PEG-2 Cocoyl Methyl Ammonium Chloride 1%;

[0050] Solubilizer: triethanolamine 12%;

[0051] Defoamer: polydimethylsiloxane 0.1%;

[0052] Pure water 74.1%.

Embodiment 3

[0053] Embodiment 3 (weak antirust performance, strong cleaning performance):

[0054] Neutral anti-rust water-based cleaning agent C, comprising the following components in mass percent:

[0055] Phosphate-free cleaning aids: Sodium Benzoate 1%, Sodium Sulfate 2%, and Sodium Carbonate 0.3%

[0056] Metal corrosion inhibitor: 3%, MBT and TTA are mixed in a mass ratio of 2:1;

[0057] Surfactants: C10-14 fatty alcohol polyoxyalkyl ether 15%, C9-11 pareth-3 10% and PEG-2 cocomethyl ammonium chloride 5%;

[0058] Solubilizer: sodium xylene sulfonate 5%;

[0059] Defoamer: polydimethylsiloxane 0.1%;

[0060] Pure water 58.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com