Patents

Literature

457 results about "Plasma beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

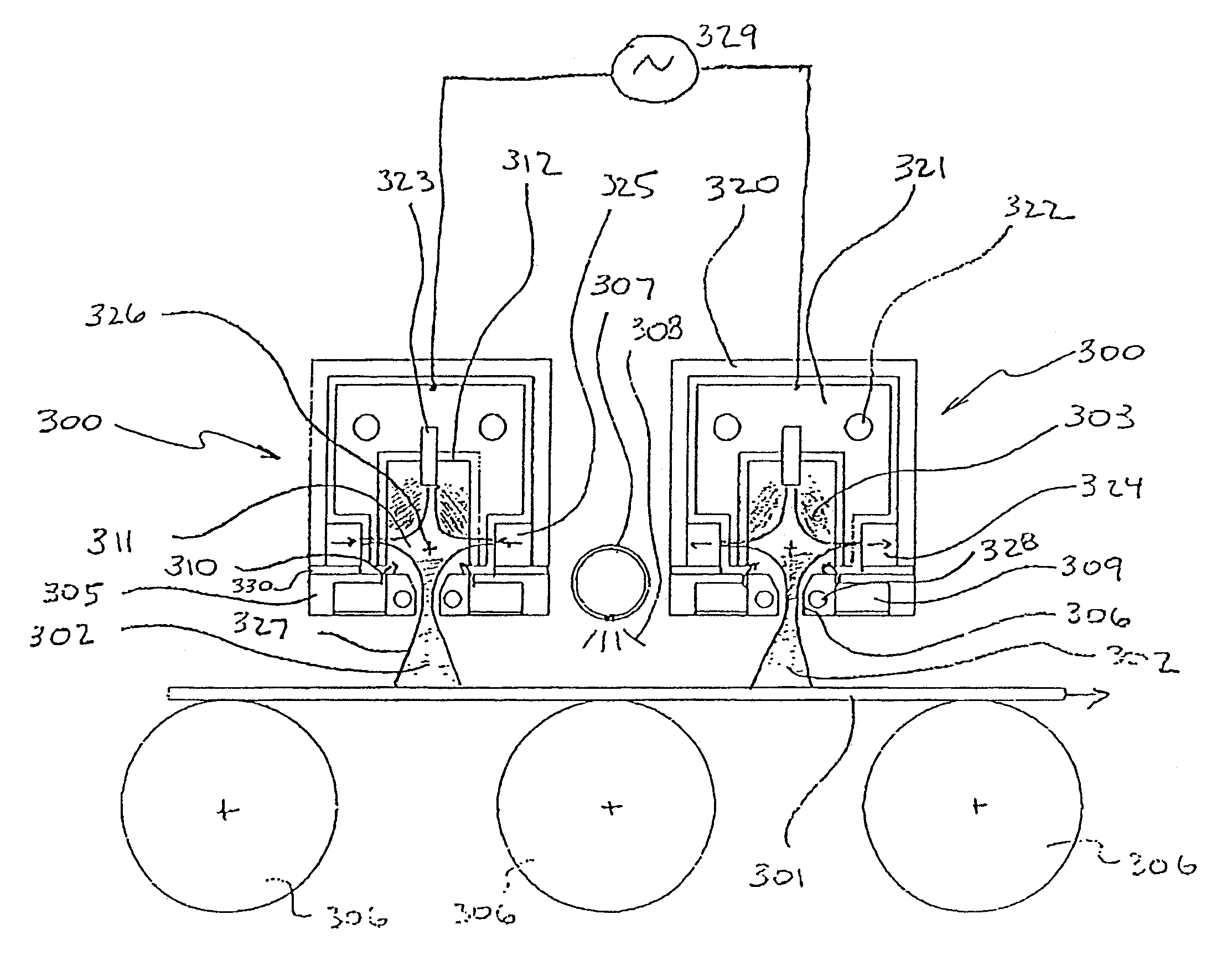

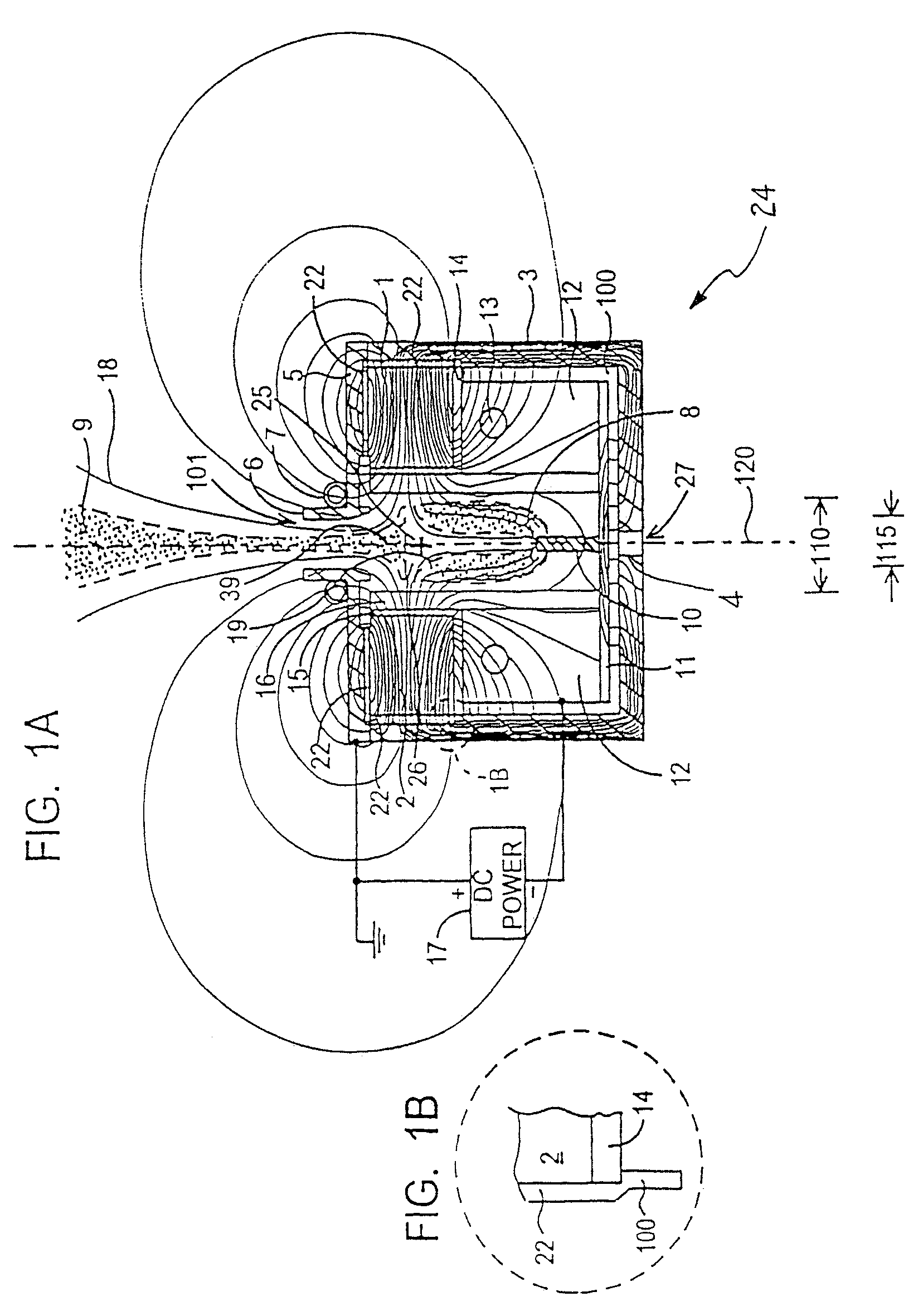

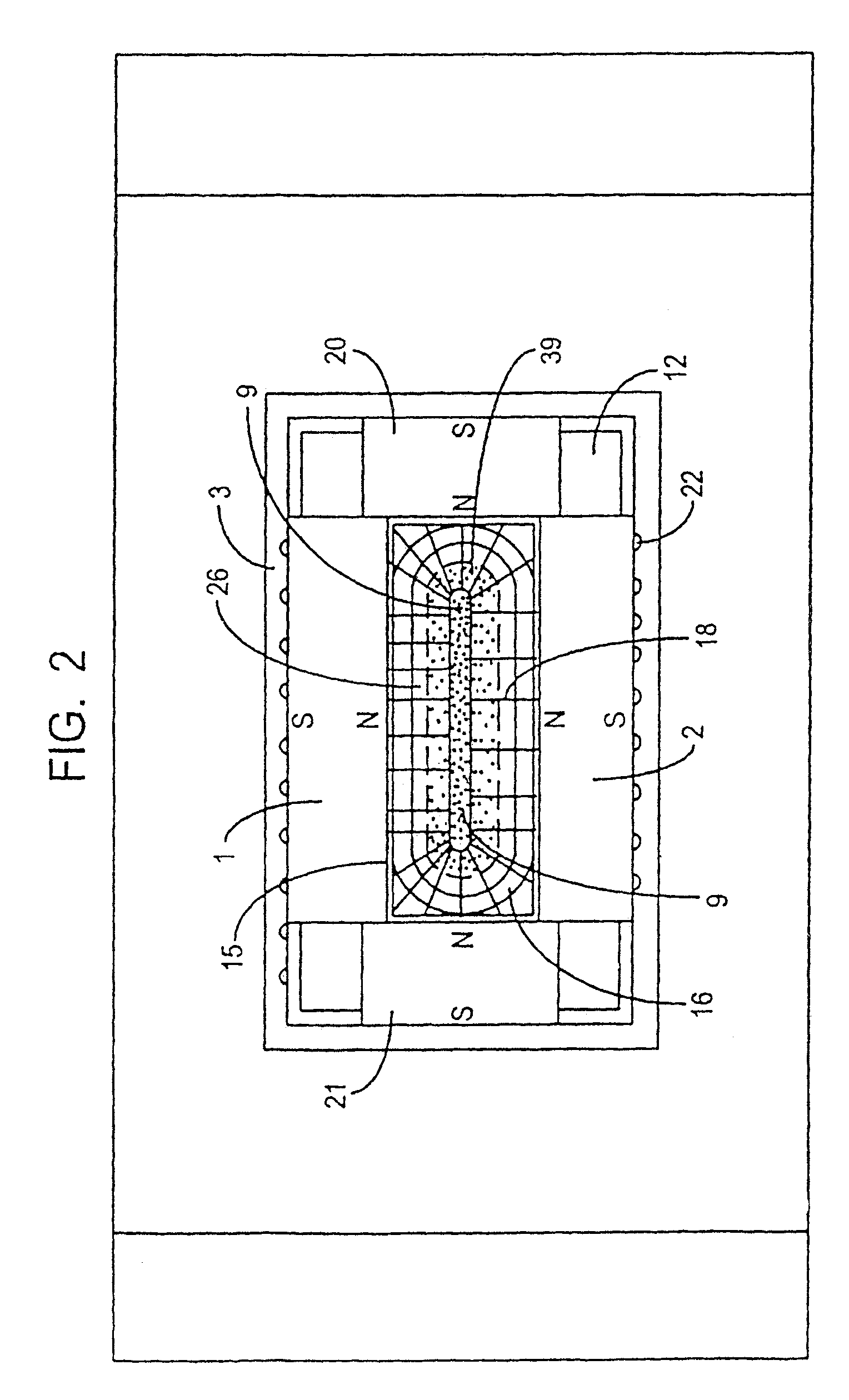

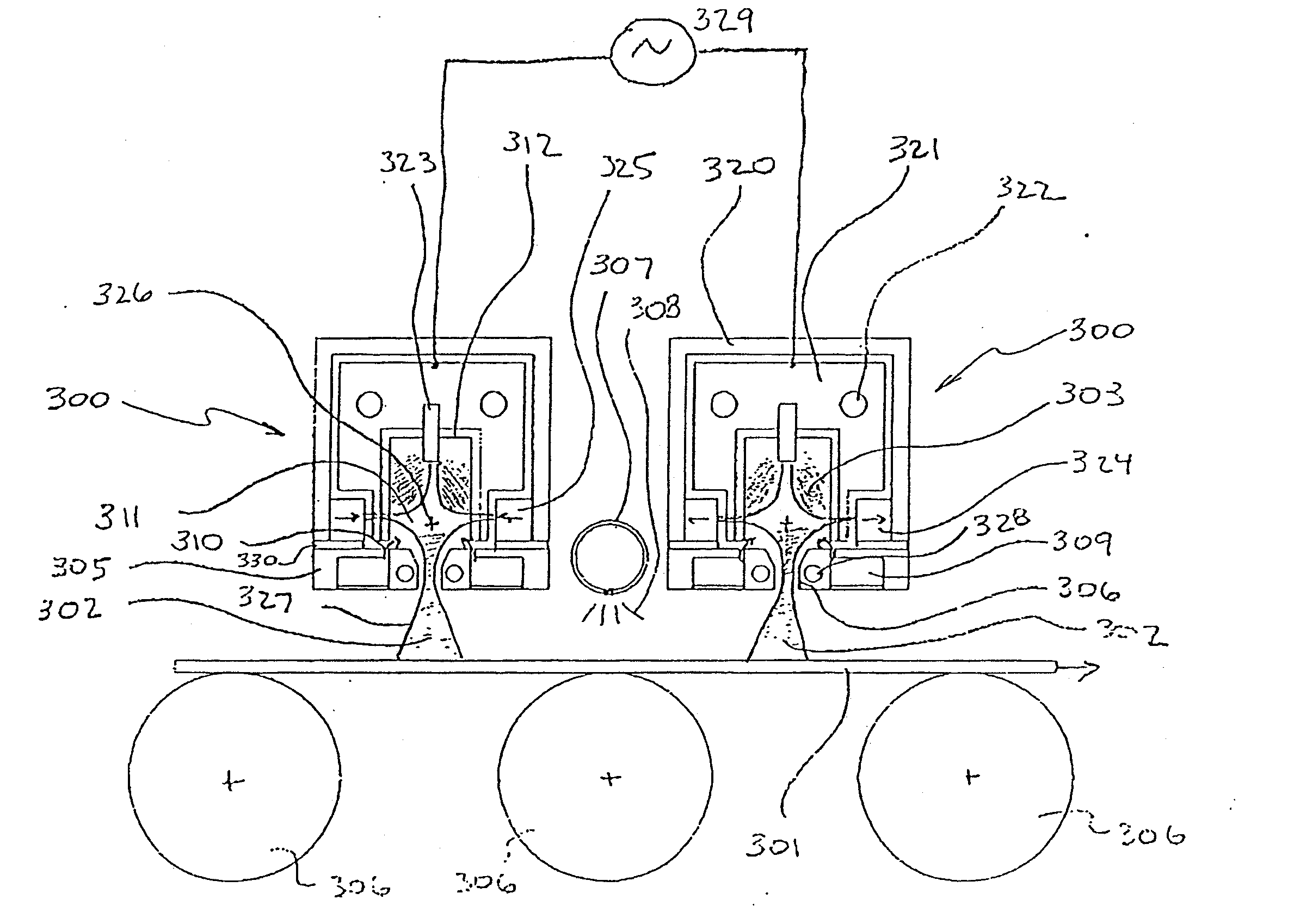

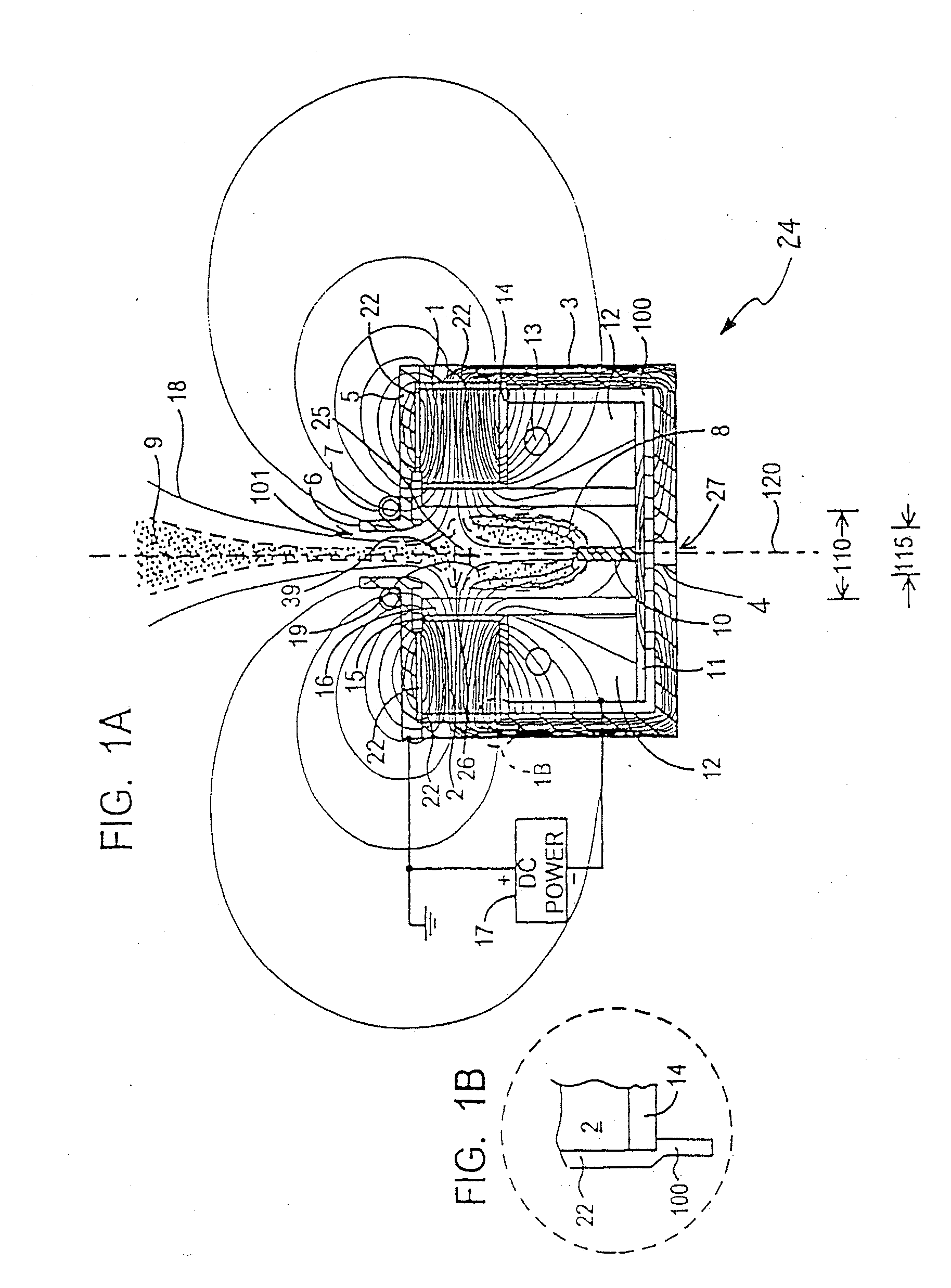

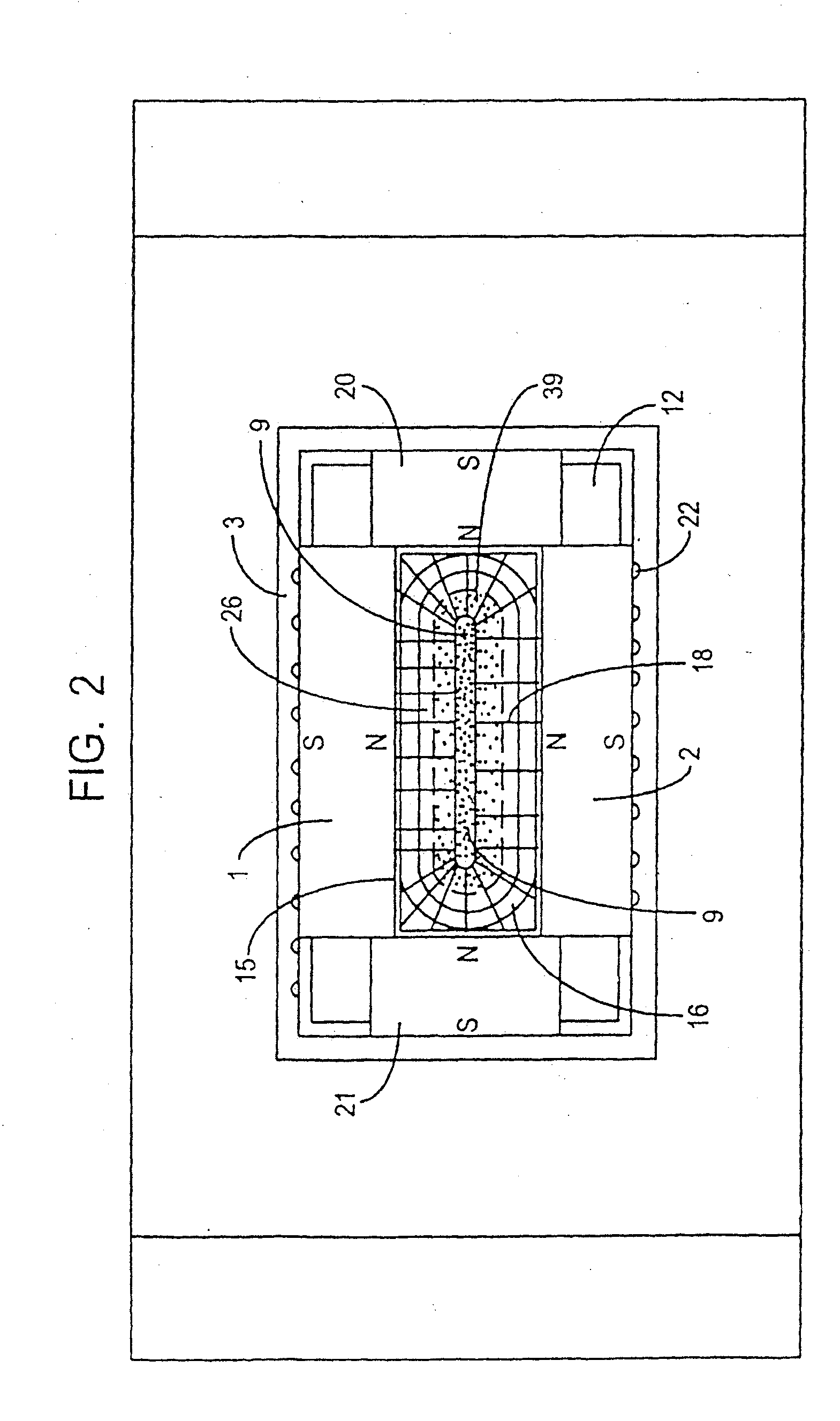

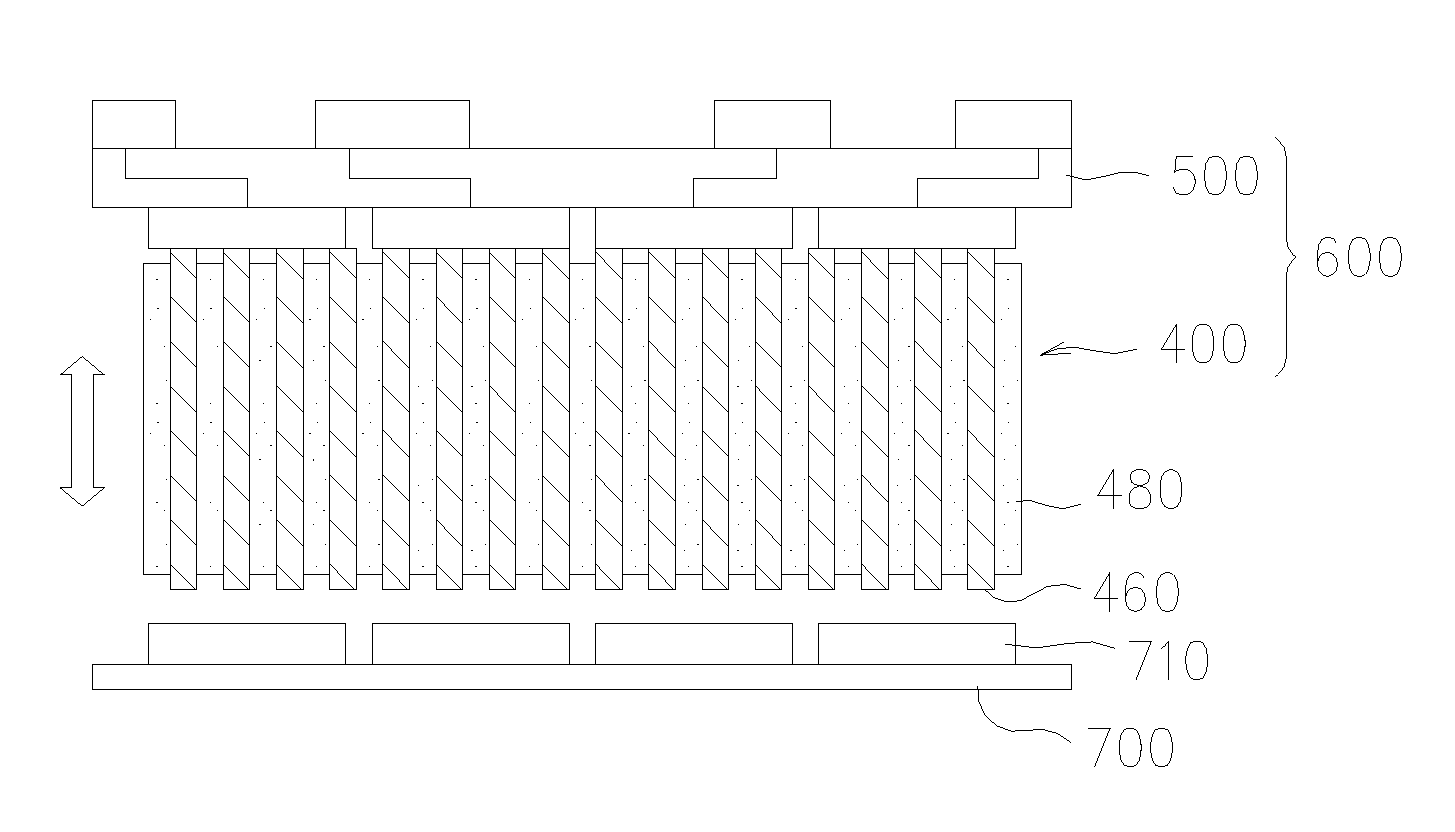

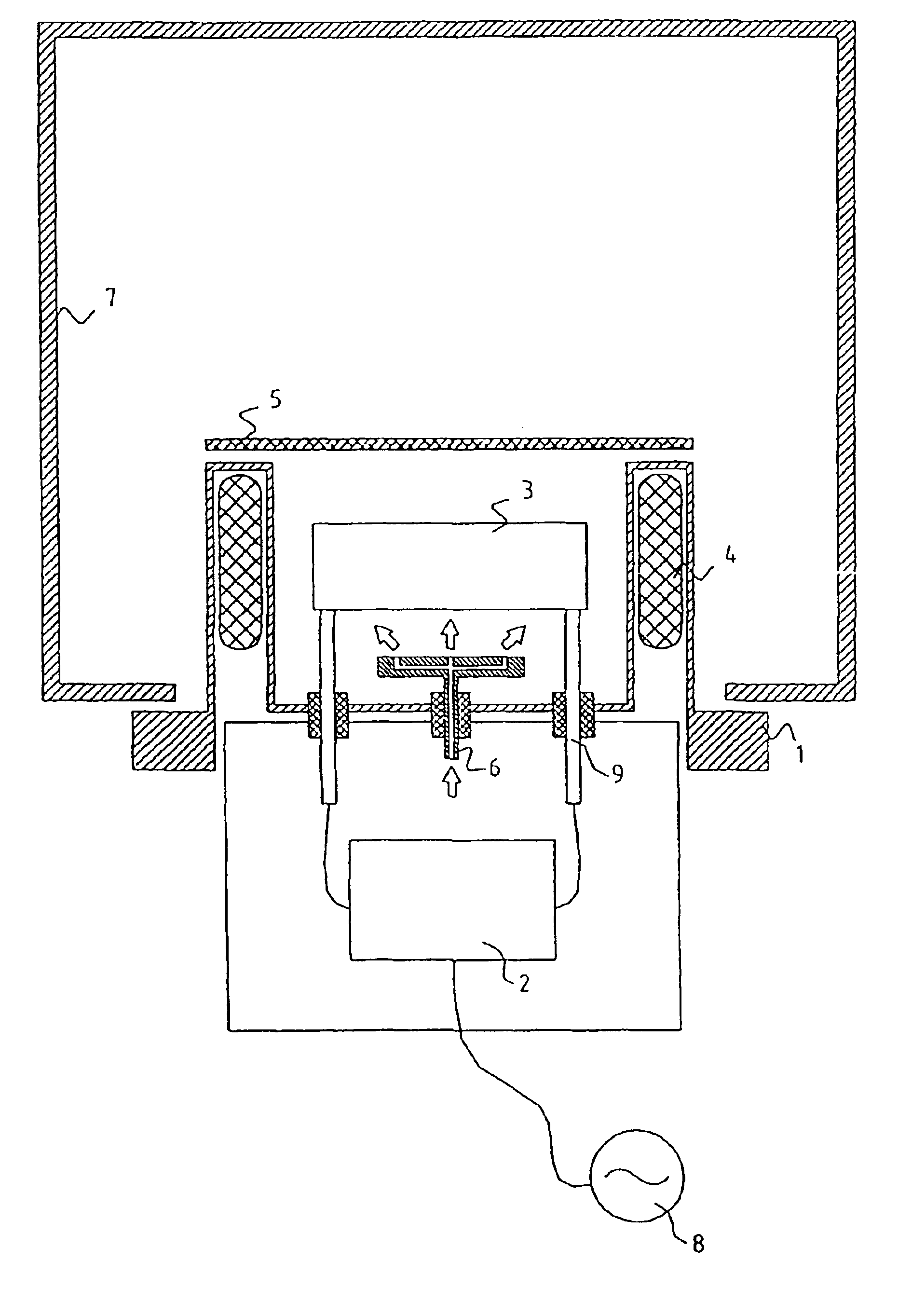

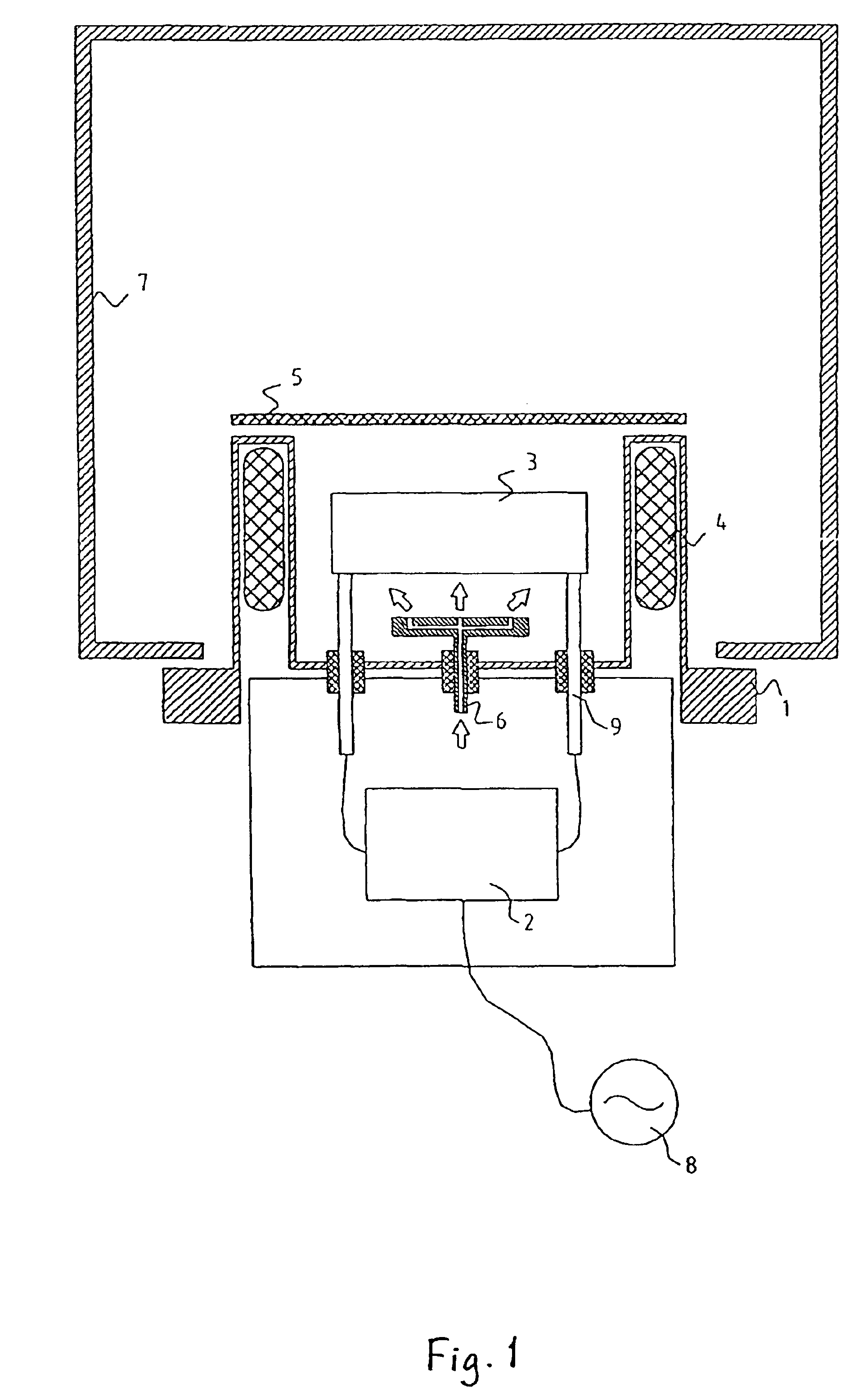

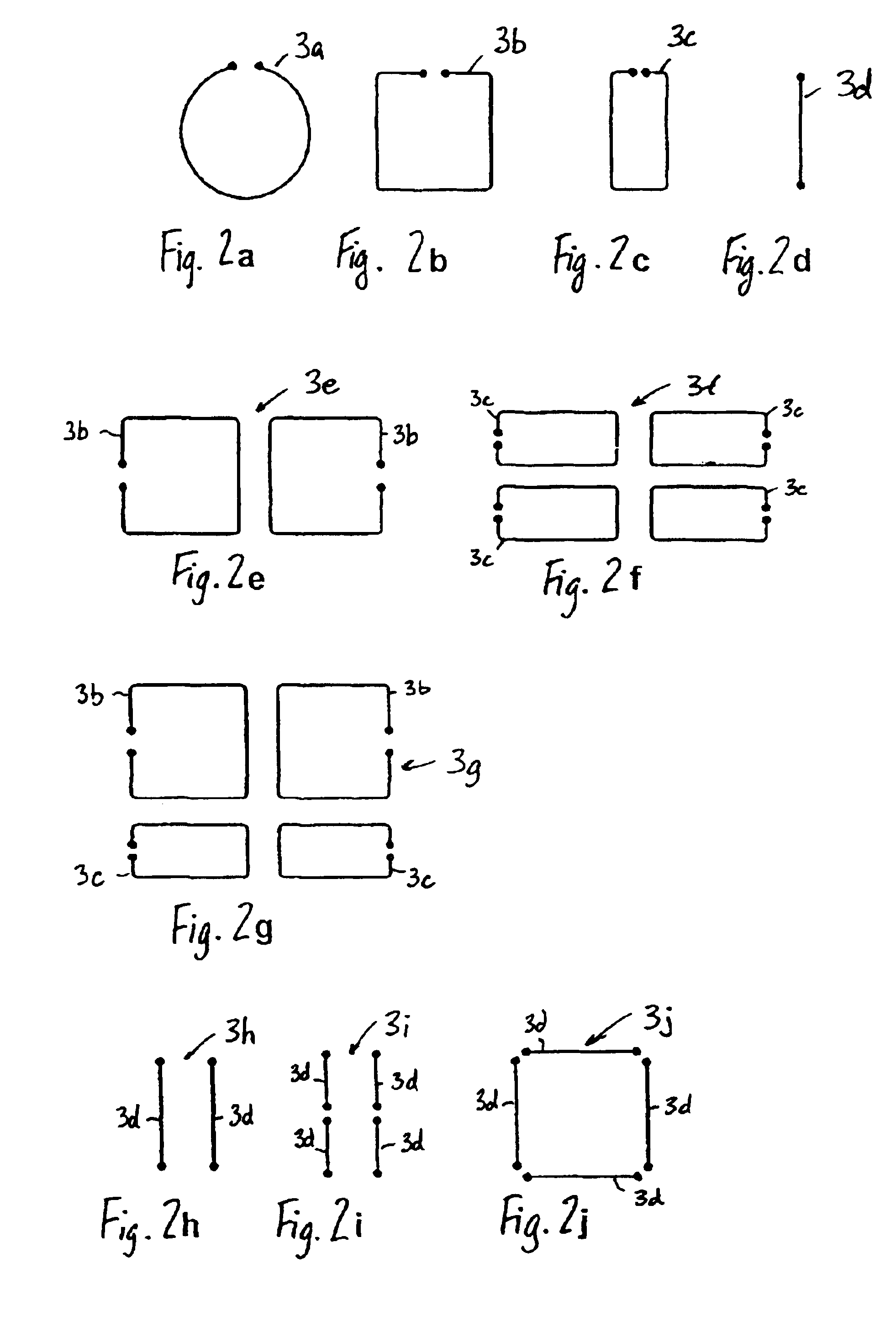

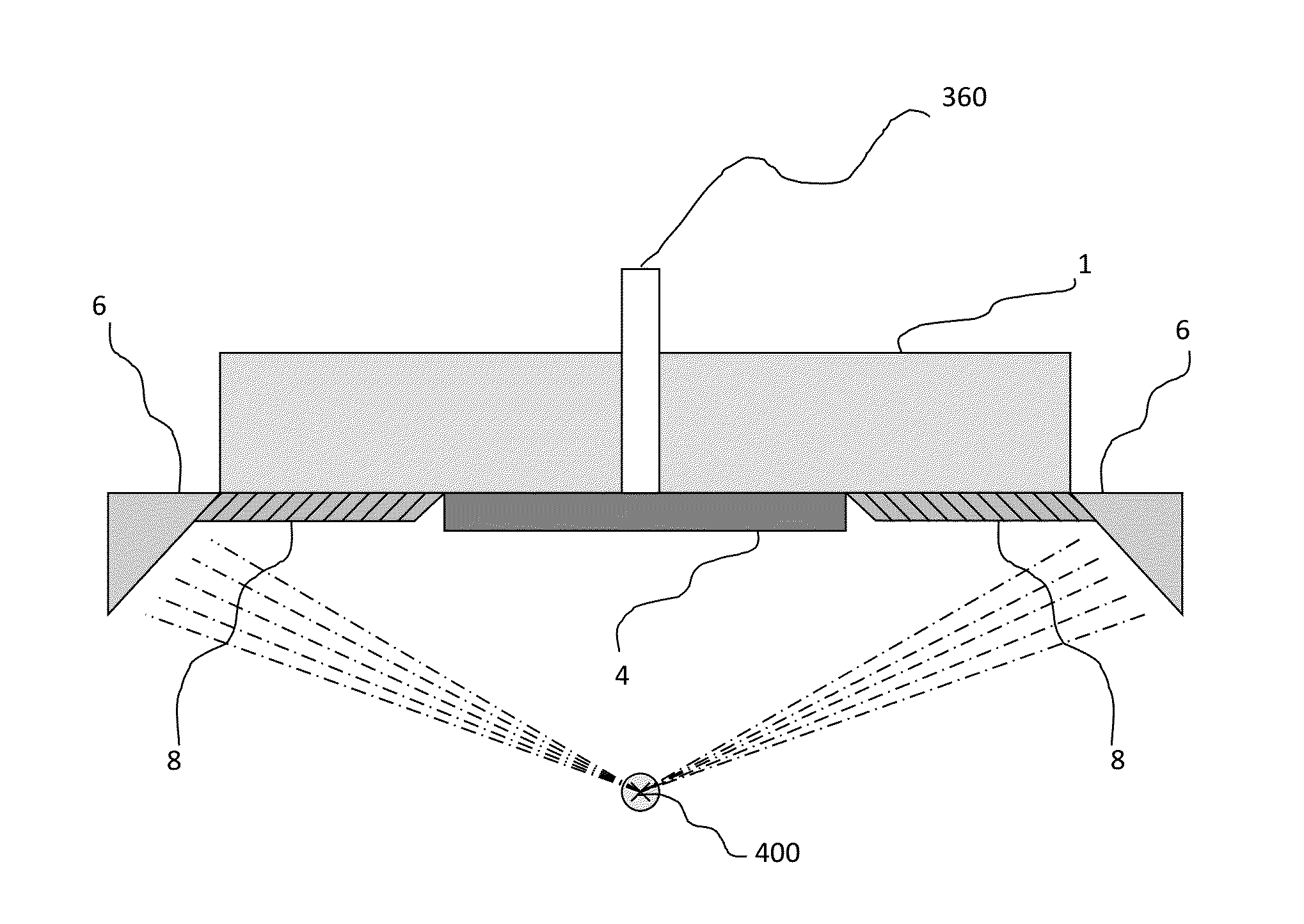

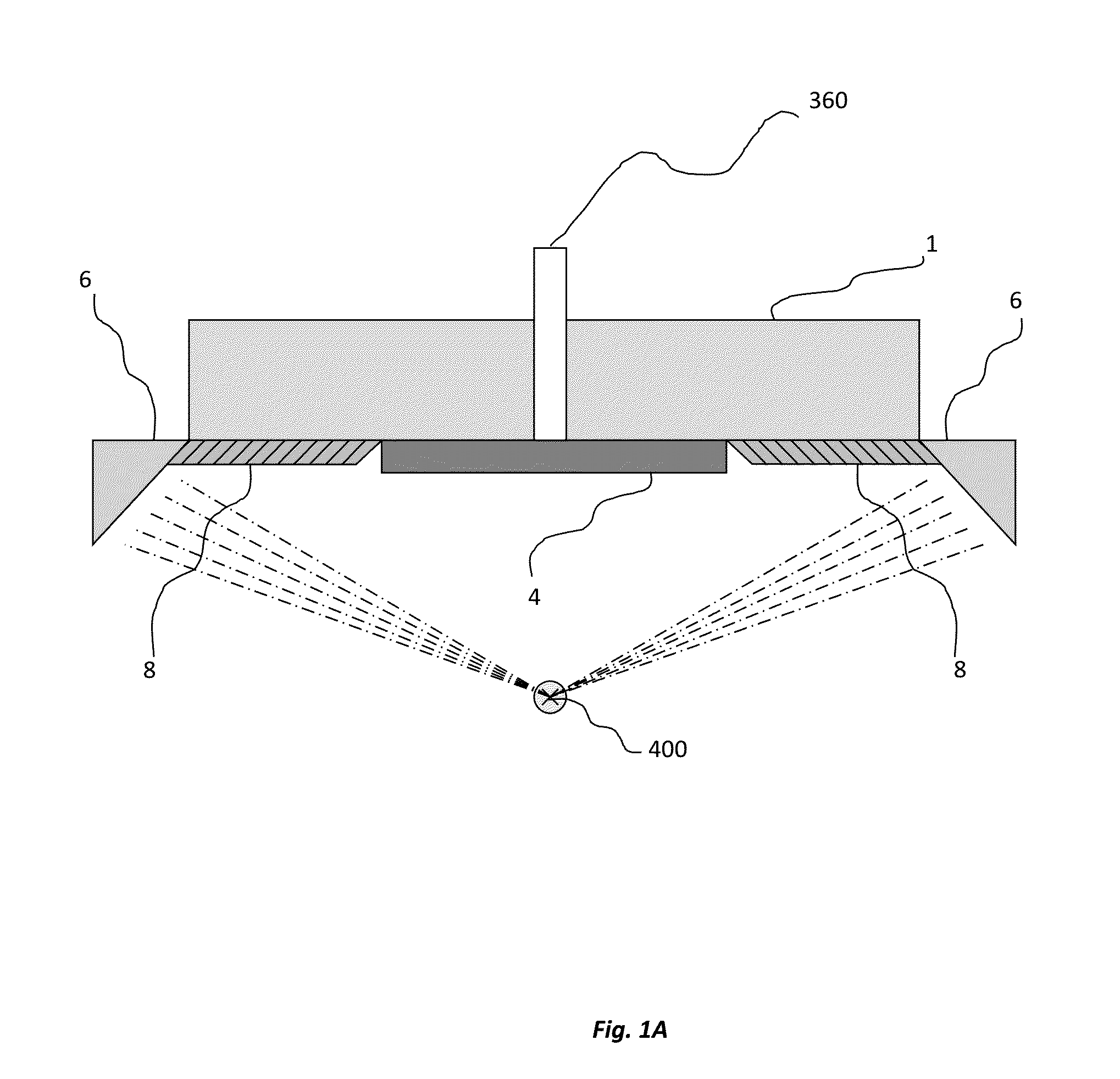

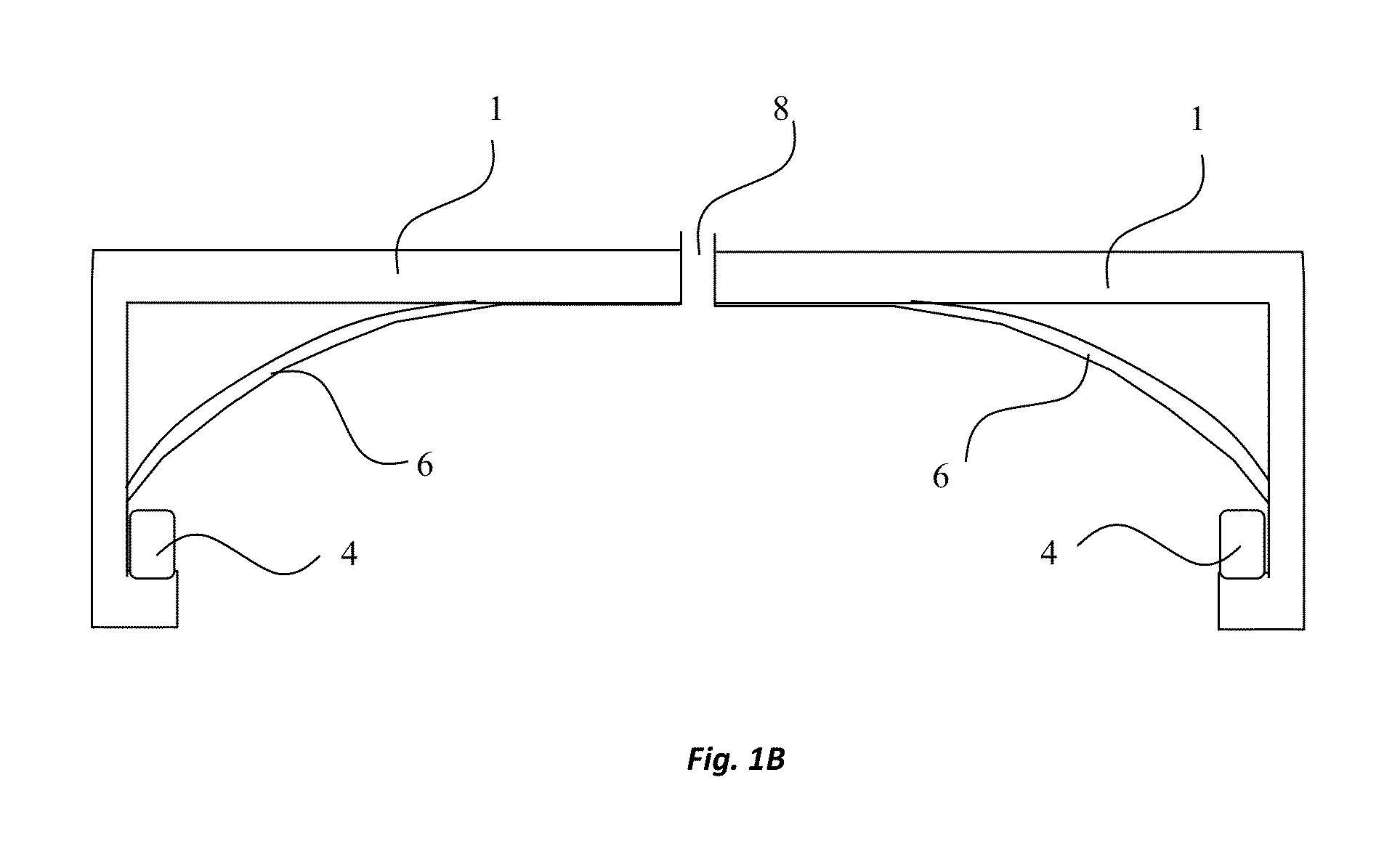

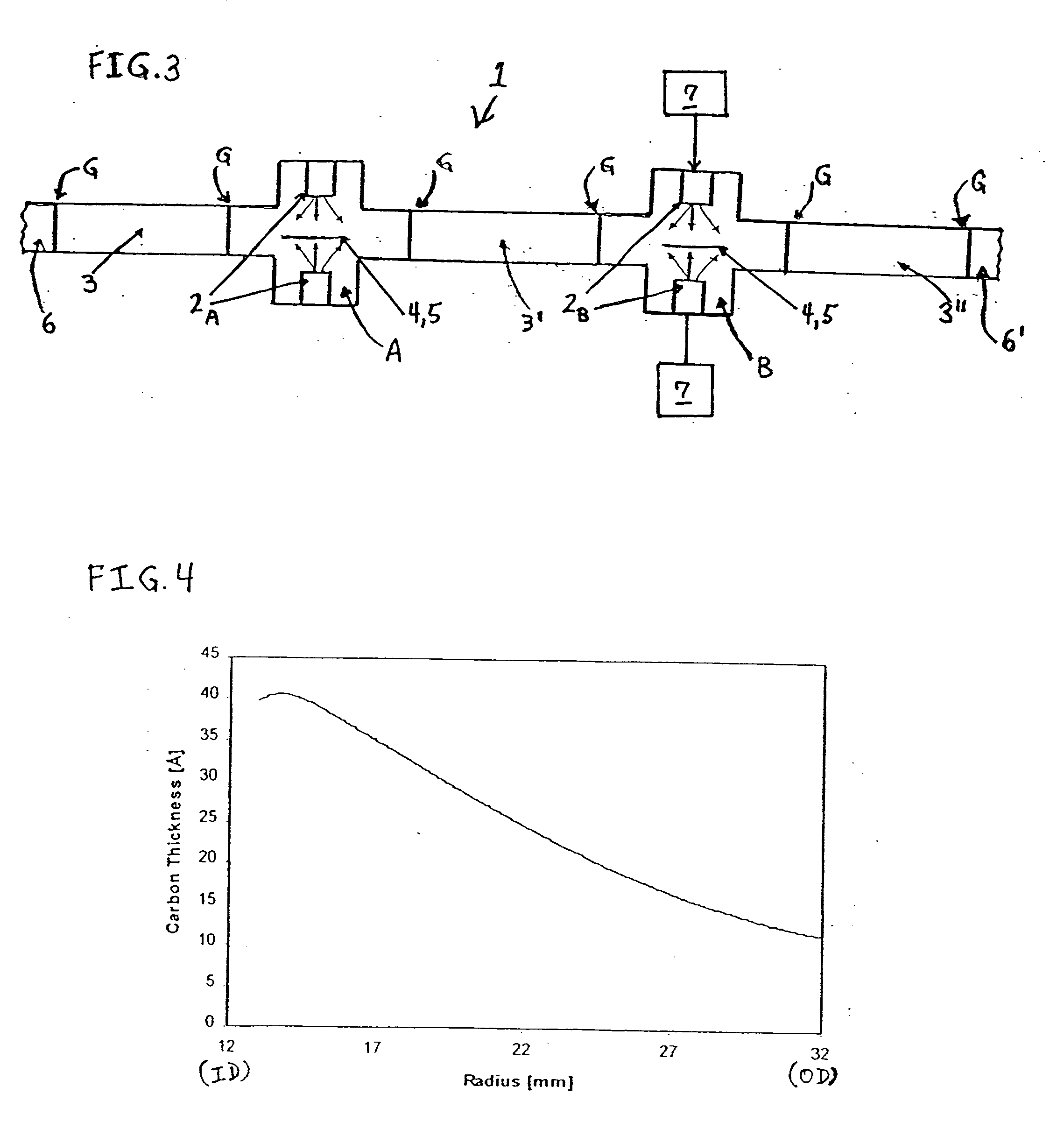

Dual plasma beam sources and method

A pair of plasma beam sources are connected across an AC power supply to alternatively produce an ion beam for depositing material on a substrate transported past the ion beams. Each plasma beam source includes a discharge cavity having a first width and a nozzle extending outwardly therefrom to emit the ion beam. The aperture or outlet of the nozzle has a second width, which second width is less than the first width. An ionizable gas is introduced to the discharge cavity. At least one electrode connected to the AC power supply, alternatively serving as an anode or a cathode, is capable of supporting at least one magnetron discharge region within the discharge cavity when serving as a cathode electrode. A plurality of magnets generally facing one another, are disposed adjacent each discharge cavity to create a magnetic field null region within the discharge cavity.

Owner:GENERAL PLASMA

Dual plasma beam sources and method

A pair of plasma beam sources are connected across an AC power supply to alternatively produce an ion beam for depositing material on a substrate transported past the ion beams. Each plasma beam source includes a discharge cavity having a first width and a nozzle extending outwardly therefrom to emit the ion beam. The aperture or outlet of the nozzle has a second width, which second width is less than the first width. An ionizable gas is introduced to the discharge cavity. At least one electrode connected to the AC power supply, alternatively serving as an anode or a cathode, is capable of supporting at least one magnetron discharge region within the discharge cavity when serving as a cathode electrode. A plurality of magnets generally facing one another, are disposed adjacent each discharge cavity to create a magnetic field null region within the discharge cavity.

Owner:GENERAL PLASMA

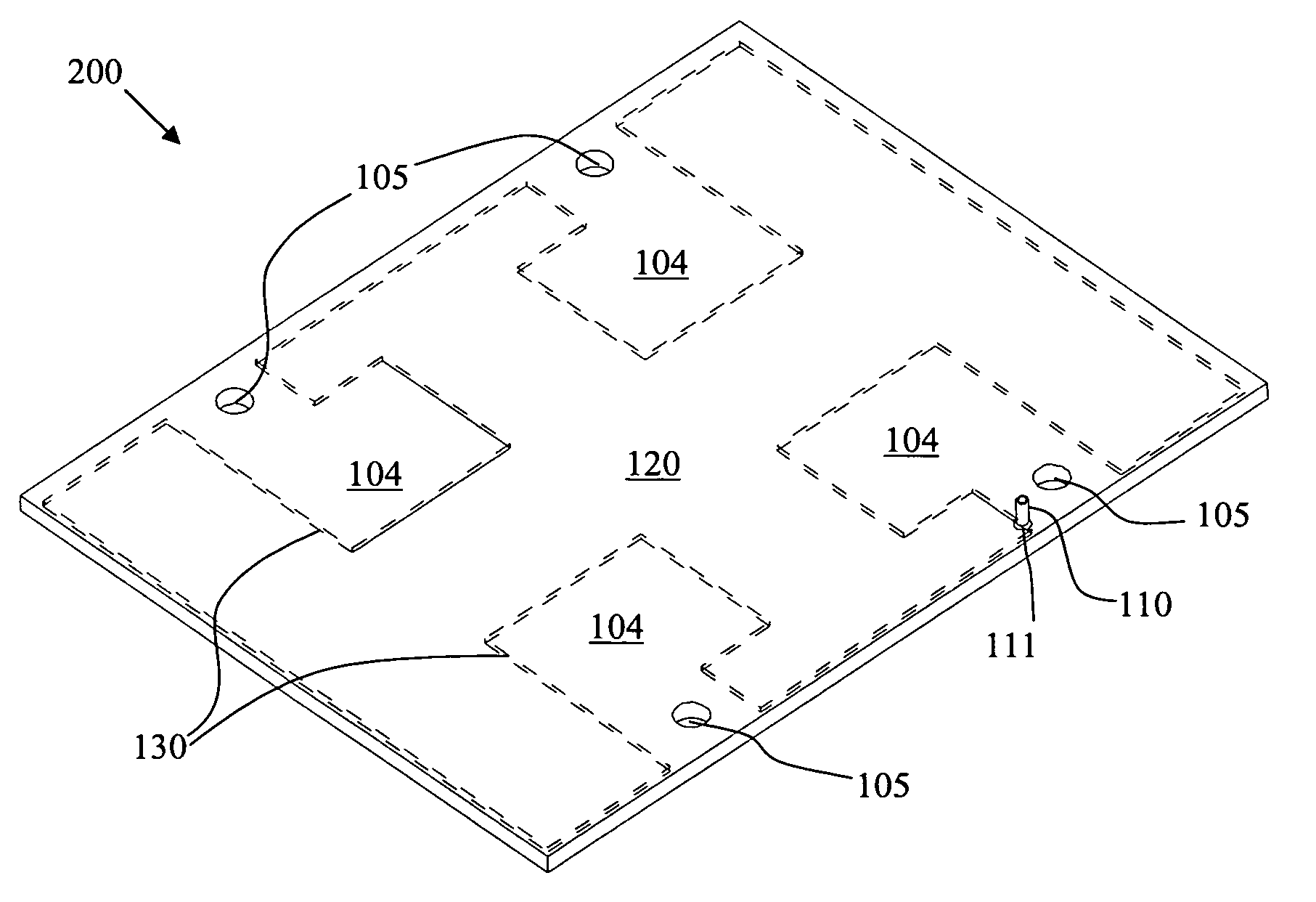

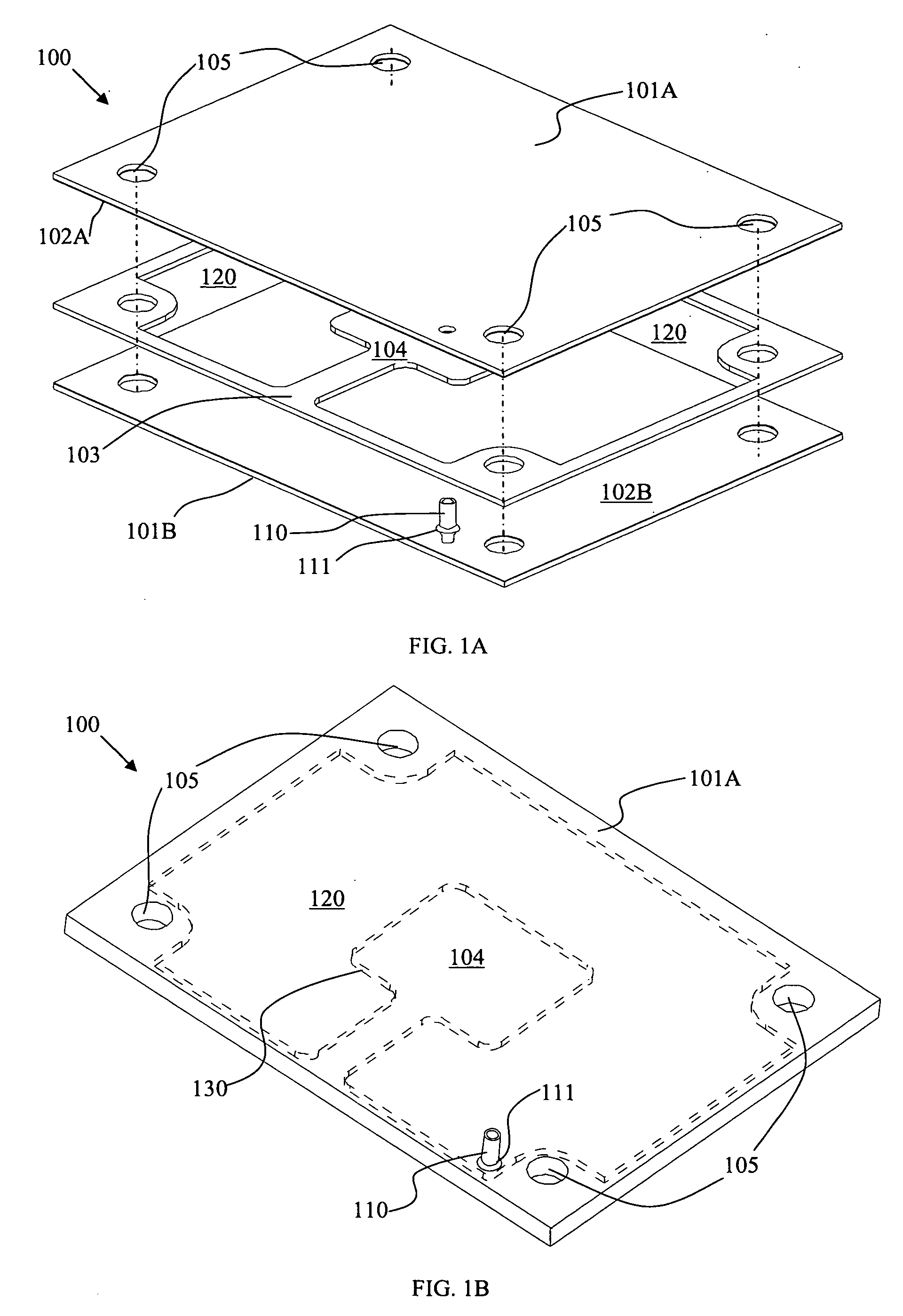

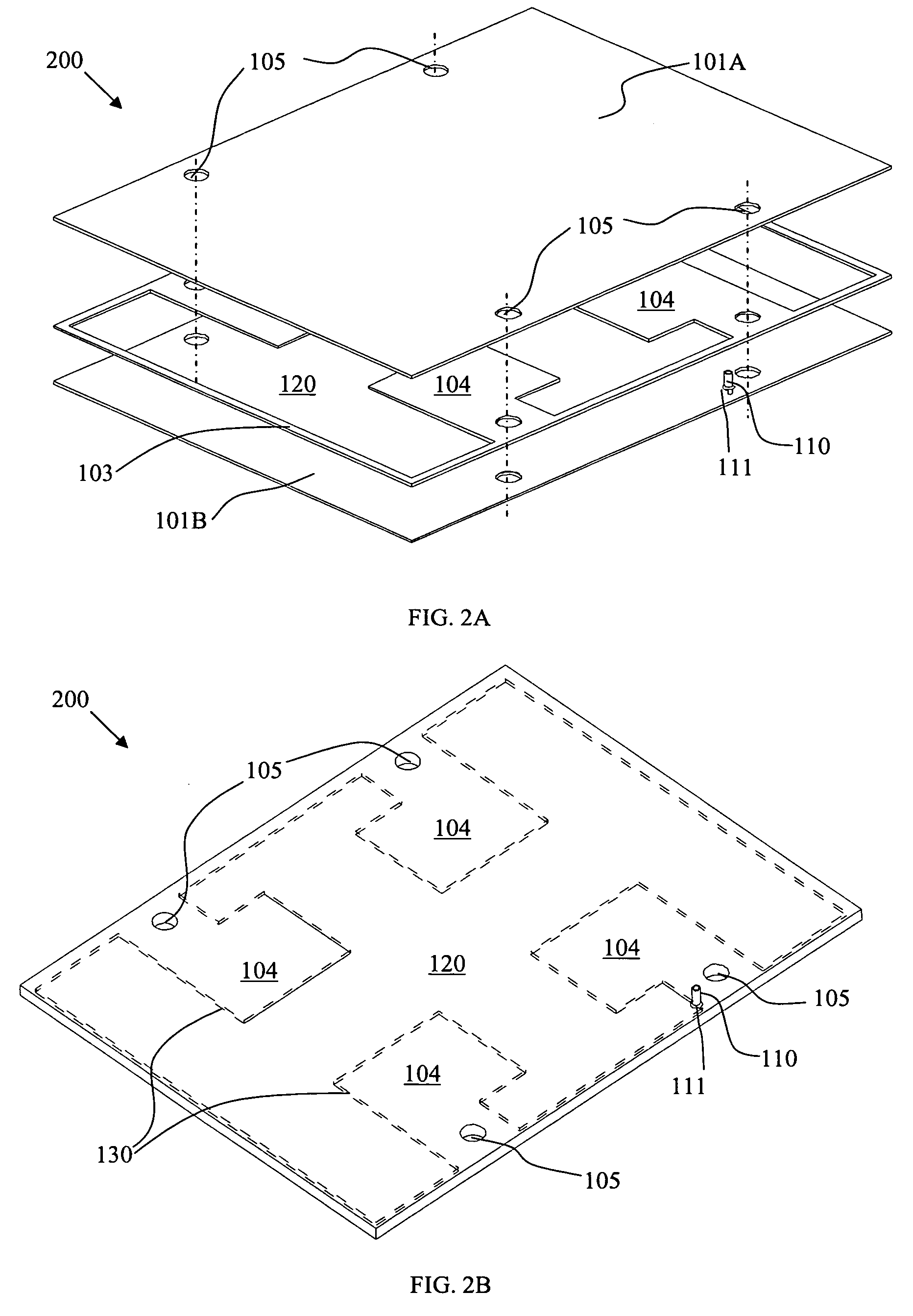

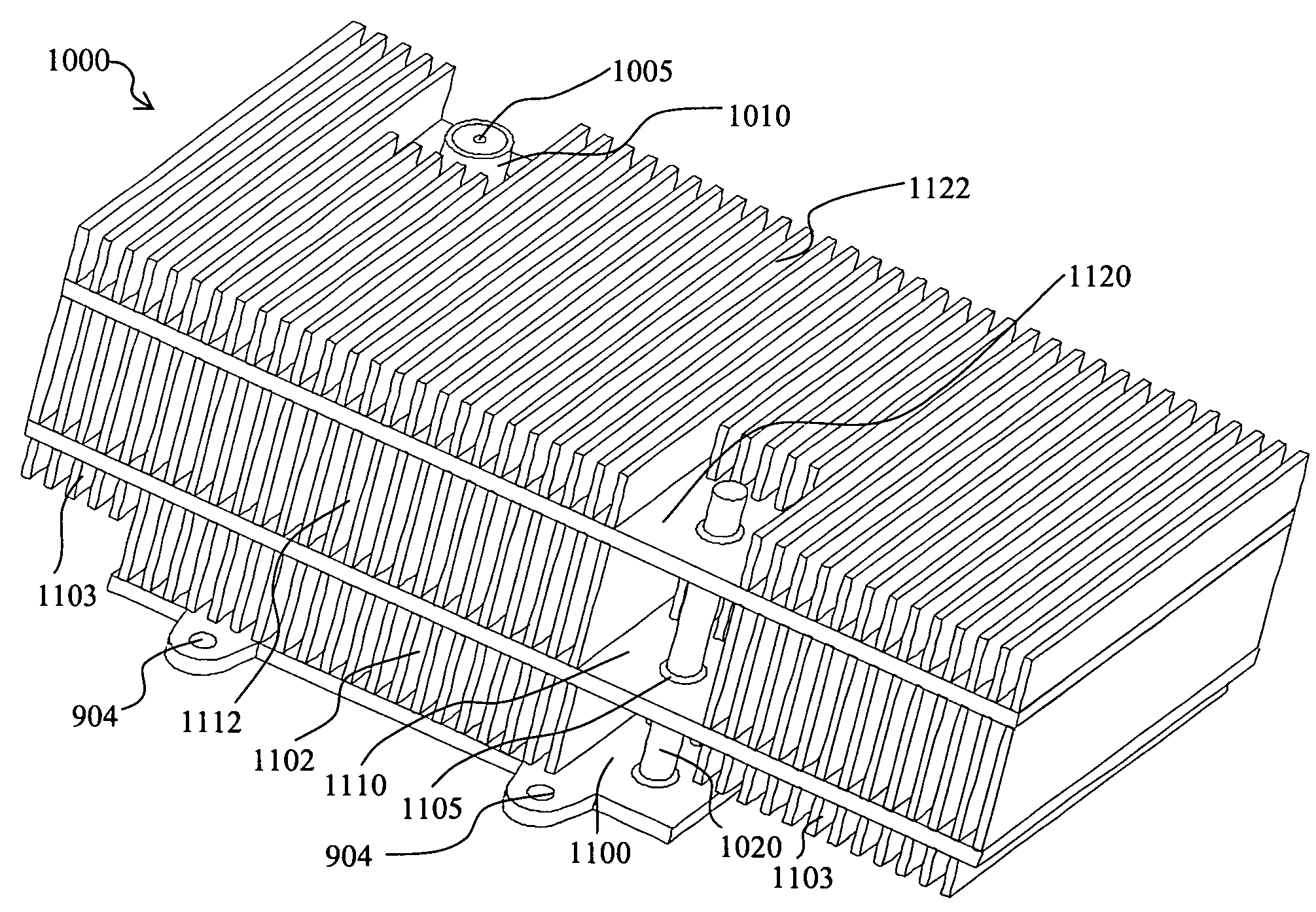

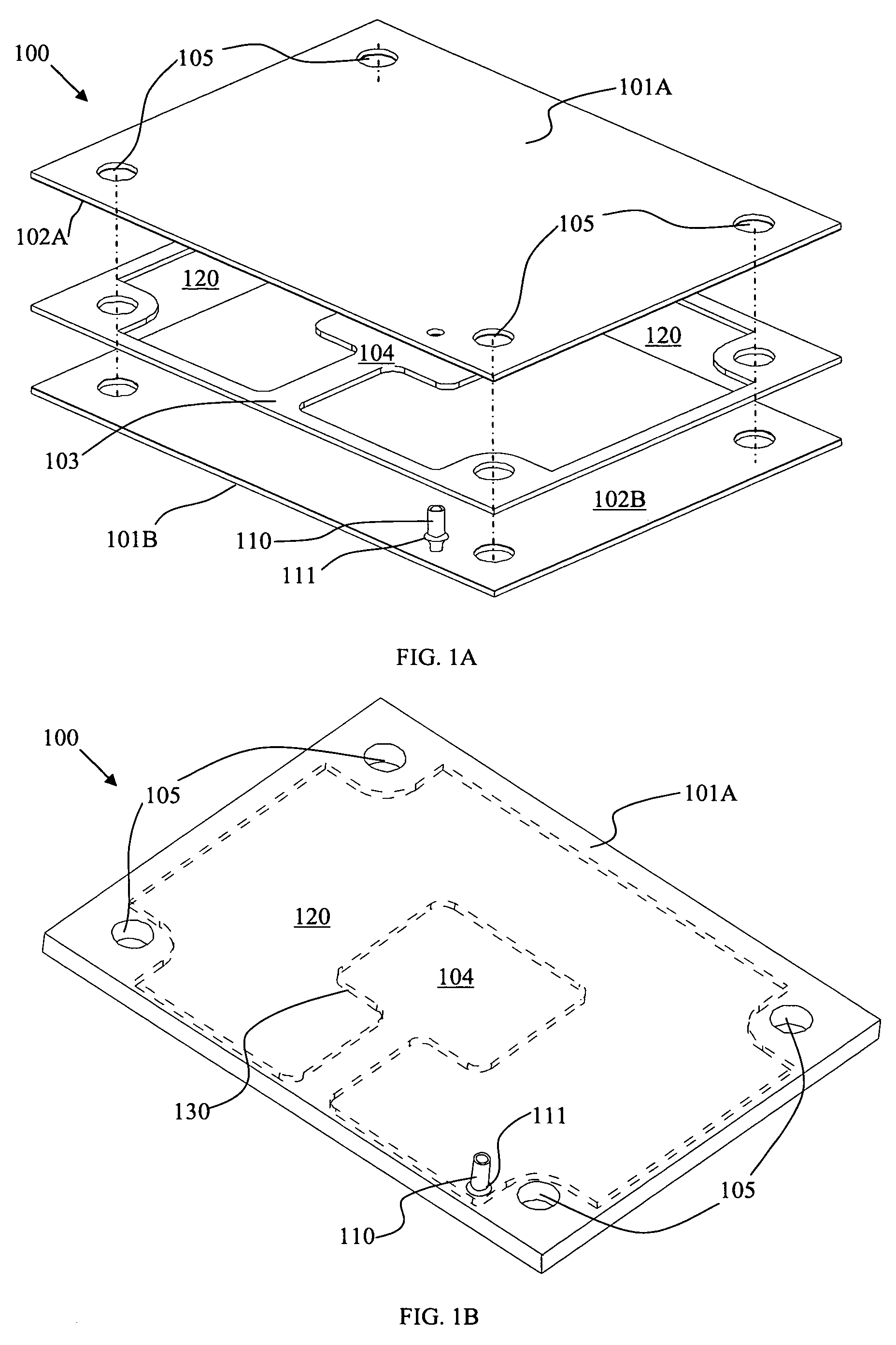

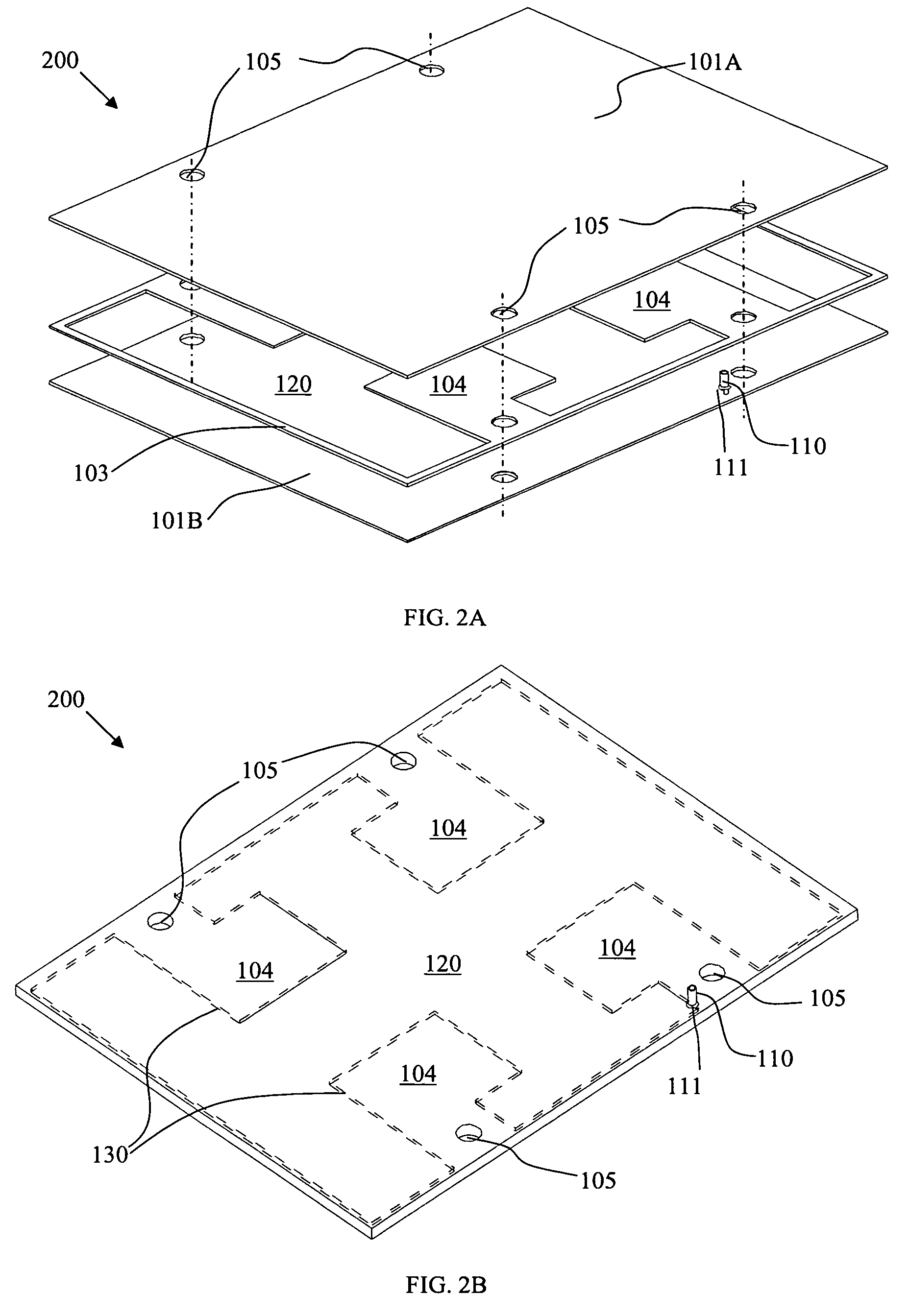

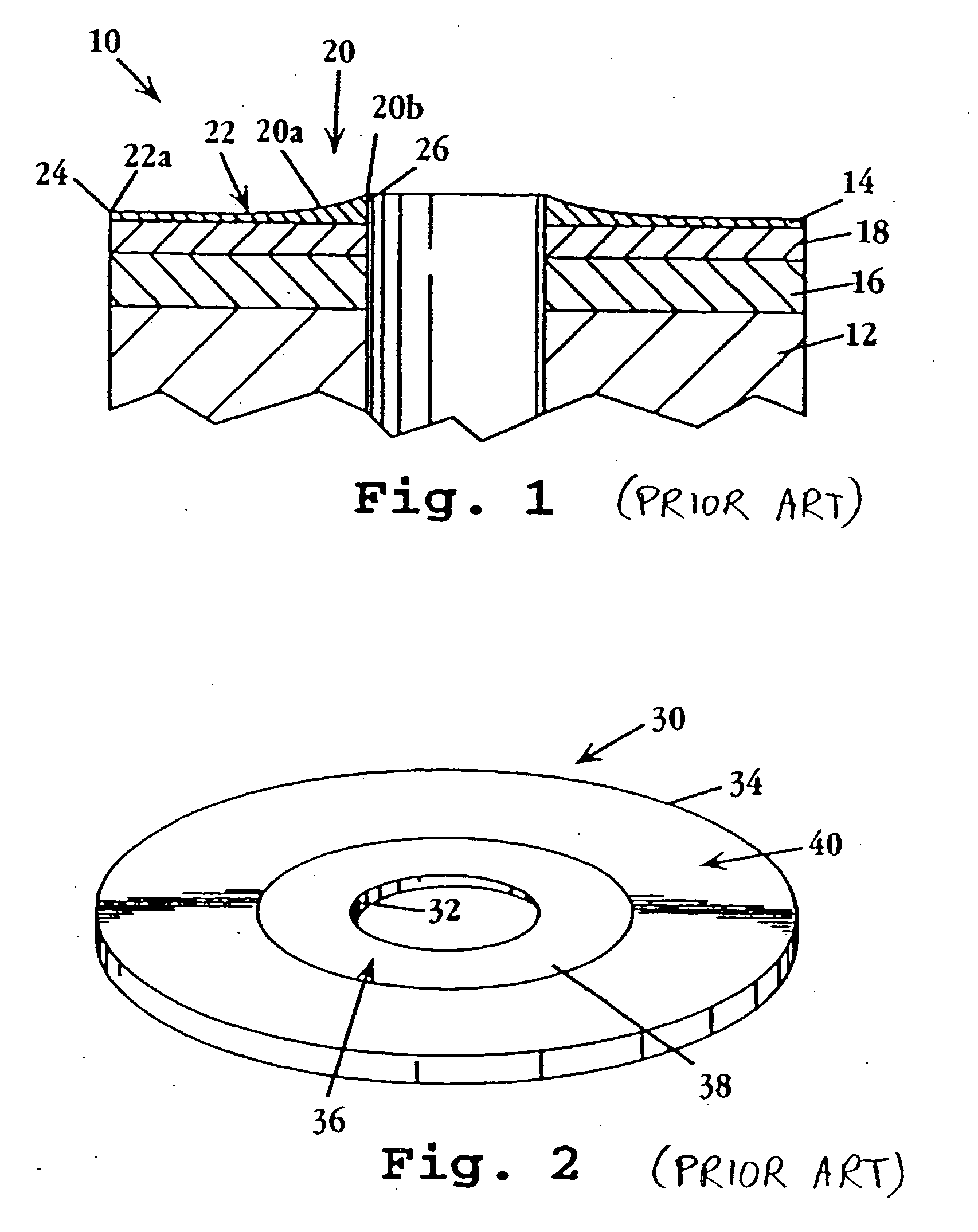

Nearly isothermal heat pipe heat sink and process for making the same

InactiveUS20060096740A1Mechanical stiffnessCost-effectiveSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

A nearly isothermal heat pipe heat sink is provided. The heat sink includes a flat heat pipe connected to one or more flat vapor chambers using a conduit and a heat pipe. The connected flat heat pipe and the flat vapor chambers form a common vapor domain. Fins are attached on the outer surfaces of the flat heat pipe and the flat vapor chambers. Various capillary structures are also provided for fabricating flat heat pipes. A panelized welding process is further provided for fabricating flat heat pipes or flat vapor chambers. The panelized welding process uses either friction stir welding (FSW) or plasma beam welding to transversely join the panels that form the flat heat pipes or the flat vapor chambers.

Owner:ZHENG WEN CHUN

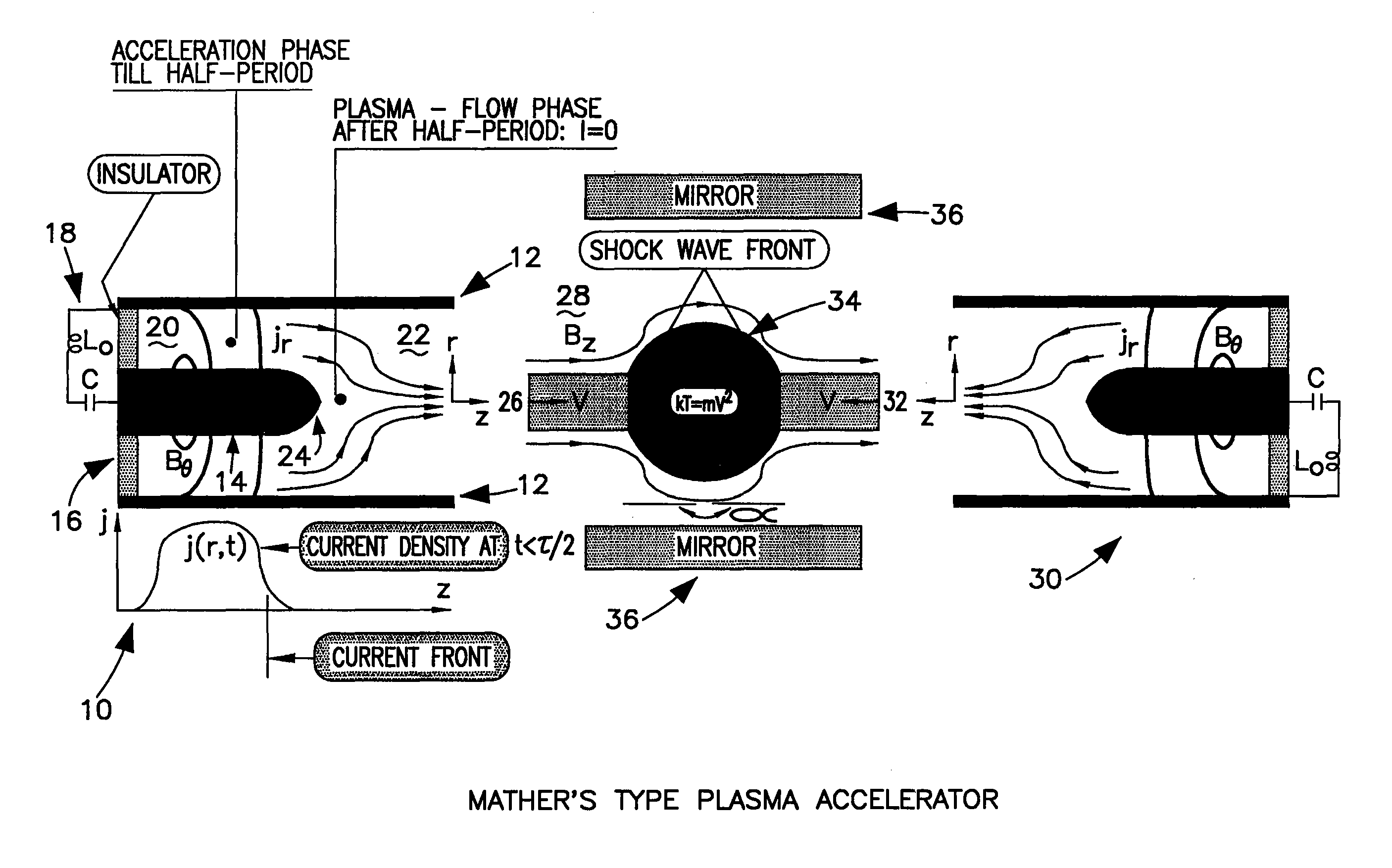

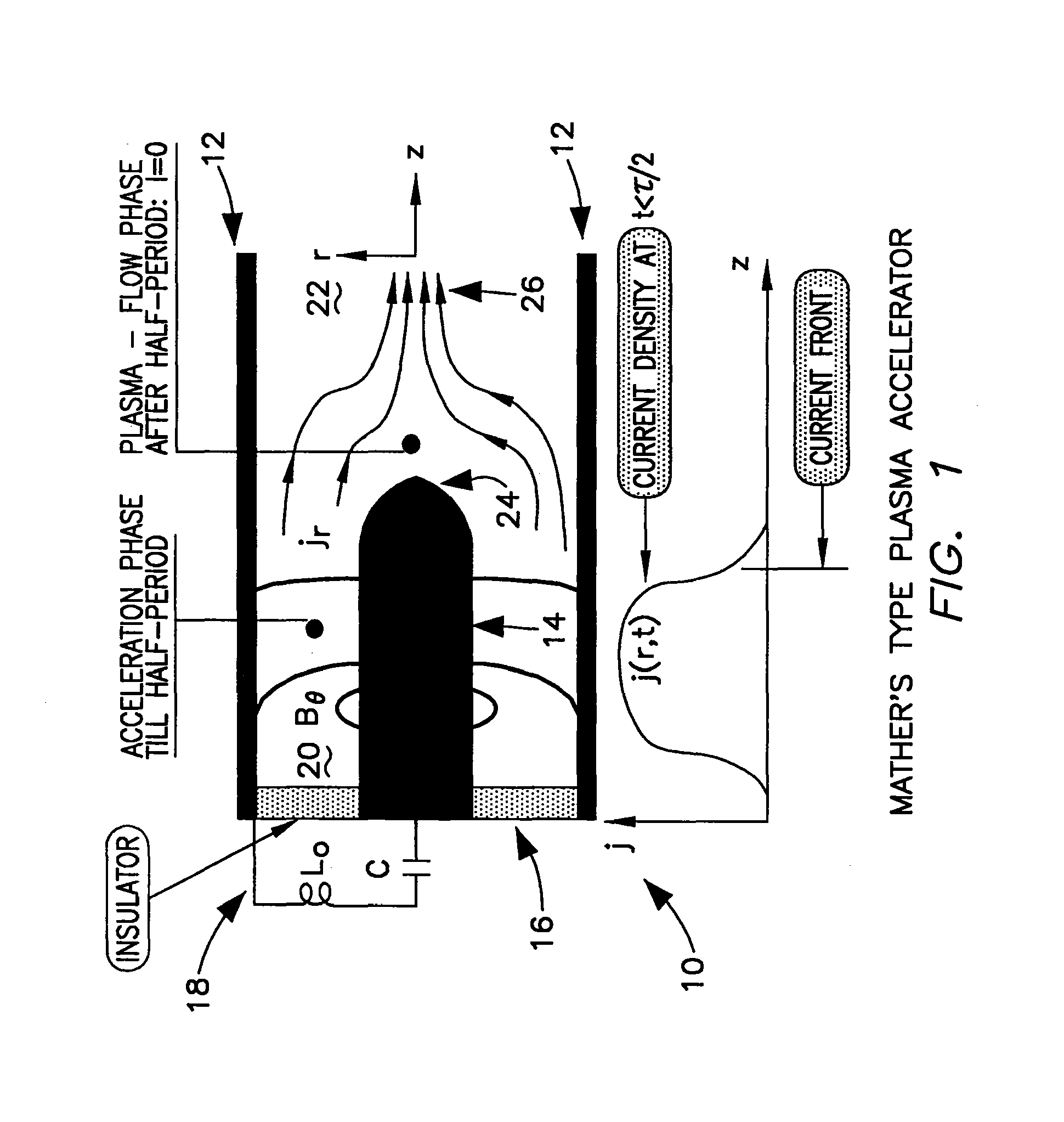

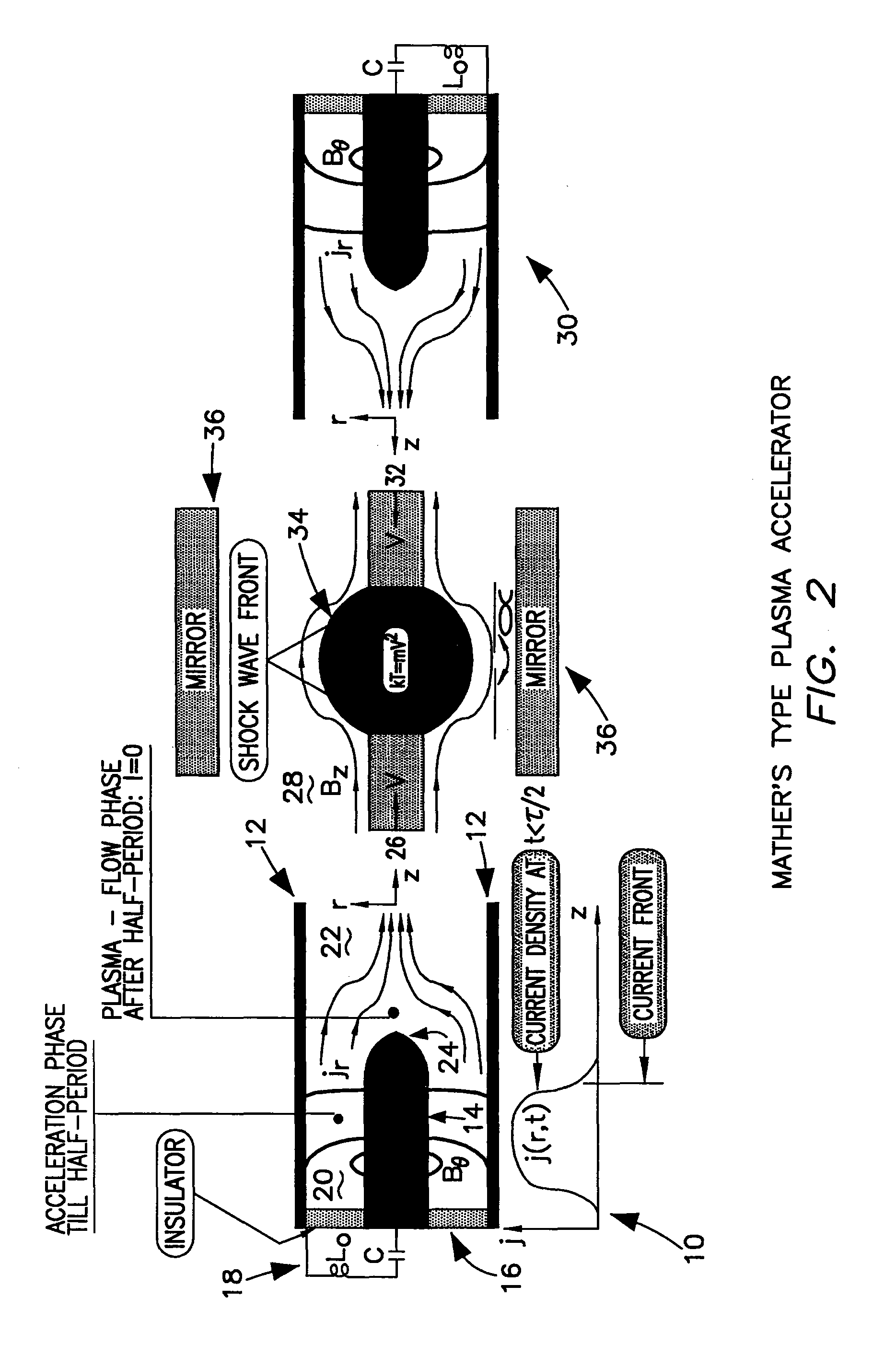

Method for generating extreme ultraviolet with mather-type plasma accelerators for use in Extreme Ultraviolet Lithography

InactiveUS7115887B1Radiation pyrometryX-ray tube with very high currentUltravioletElectromagnetic radiation

A device and method for generating extremely short-wave ultraviolet electromagnetic wave uses two intersecting plasma beams generated by two plasma accelerators. The intersection of the two plasma beams emits electromagnetic radiation and in particular radiation in the extreme ultraviolet wavelength. In the preferred orientation two axially aligned counter streaming plasmas collide to produce an intense source of electromagnetic radiation at the 13.5 nm wavelength. The Mather type plasma accelerators can utilize tin, or lithium covered electrodes. Tin, lithium or xenon can be used as the photon emitting gas source.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

High resolution plasma etch

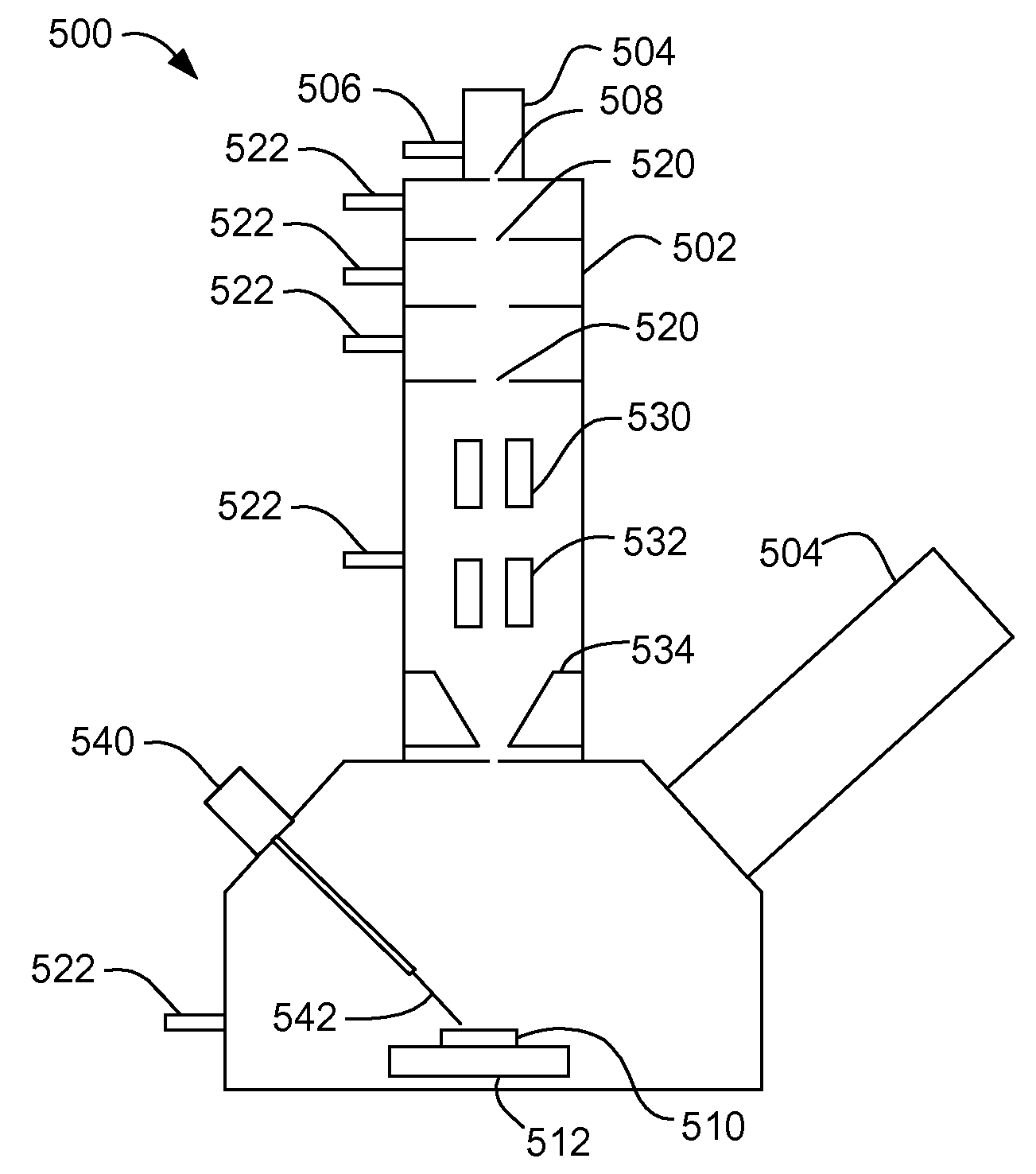

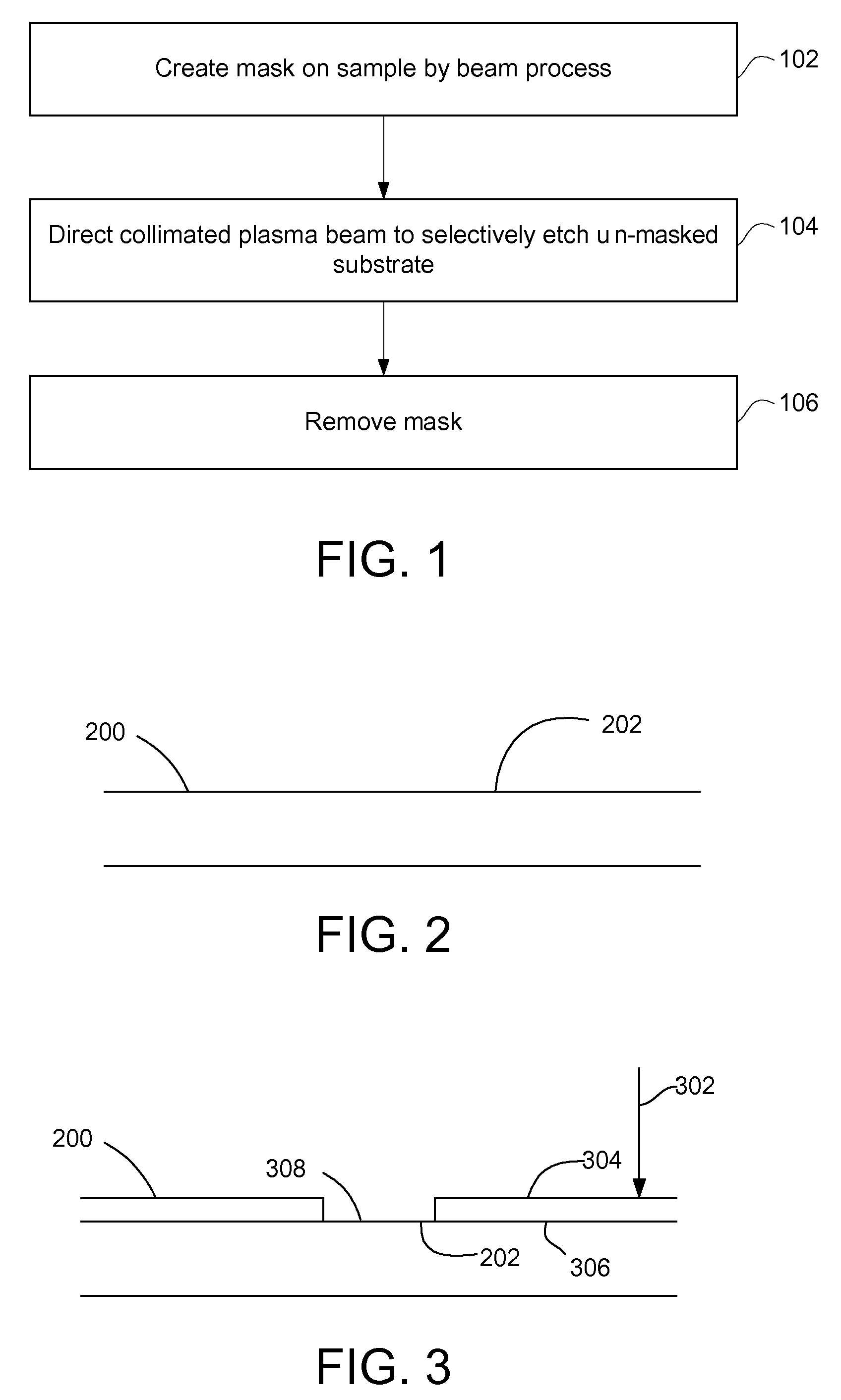

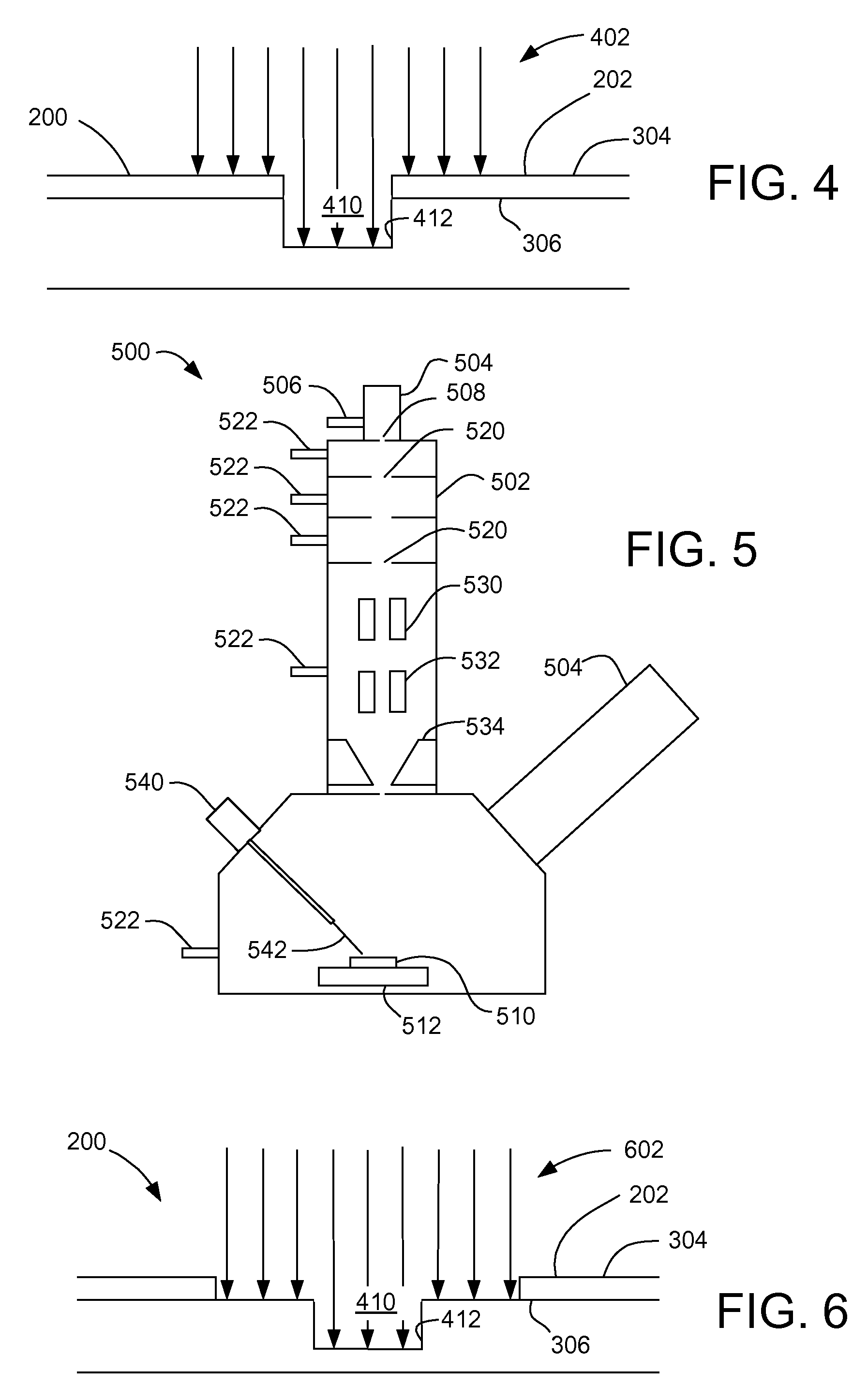

A method for fabrication of microscopic structures that uses a beam process, such as beam-induced decomposition of a precursor, to deposit a mask in a precise pattern and then a selective, plasma beam is applied, comprising the steps of first creating a protective mask upon surface portions of a substrate using a beam process such as an electron beam, focused ion beam (FIB), or laser process, and secondly etching unmasked substrate portions using a selective plasma beam etch process. Optionally, a third step comprising the removal of the protective mask may be performed with a second, materially oppositely selective plasma beam process.

Owner:FEI CO

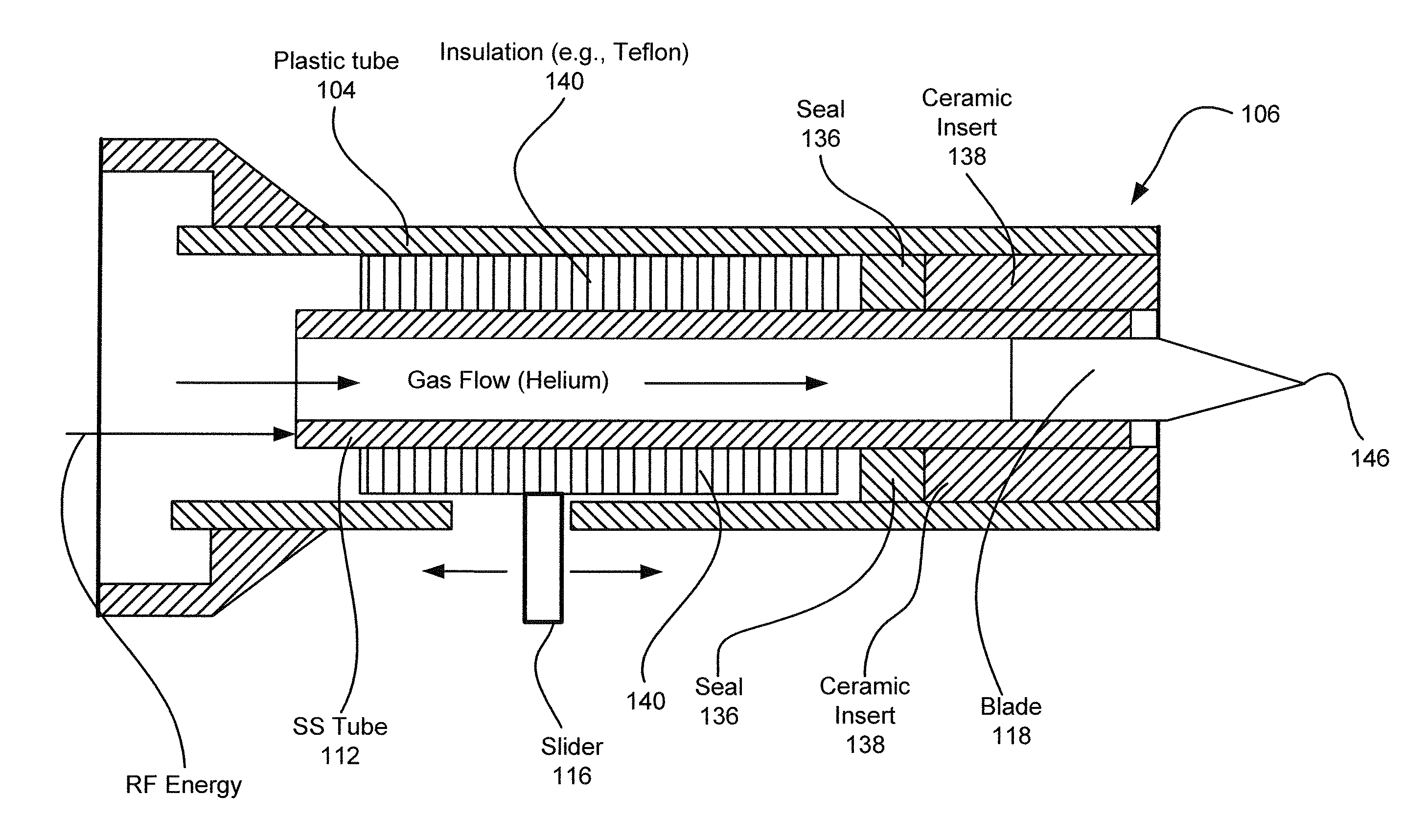

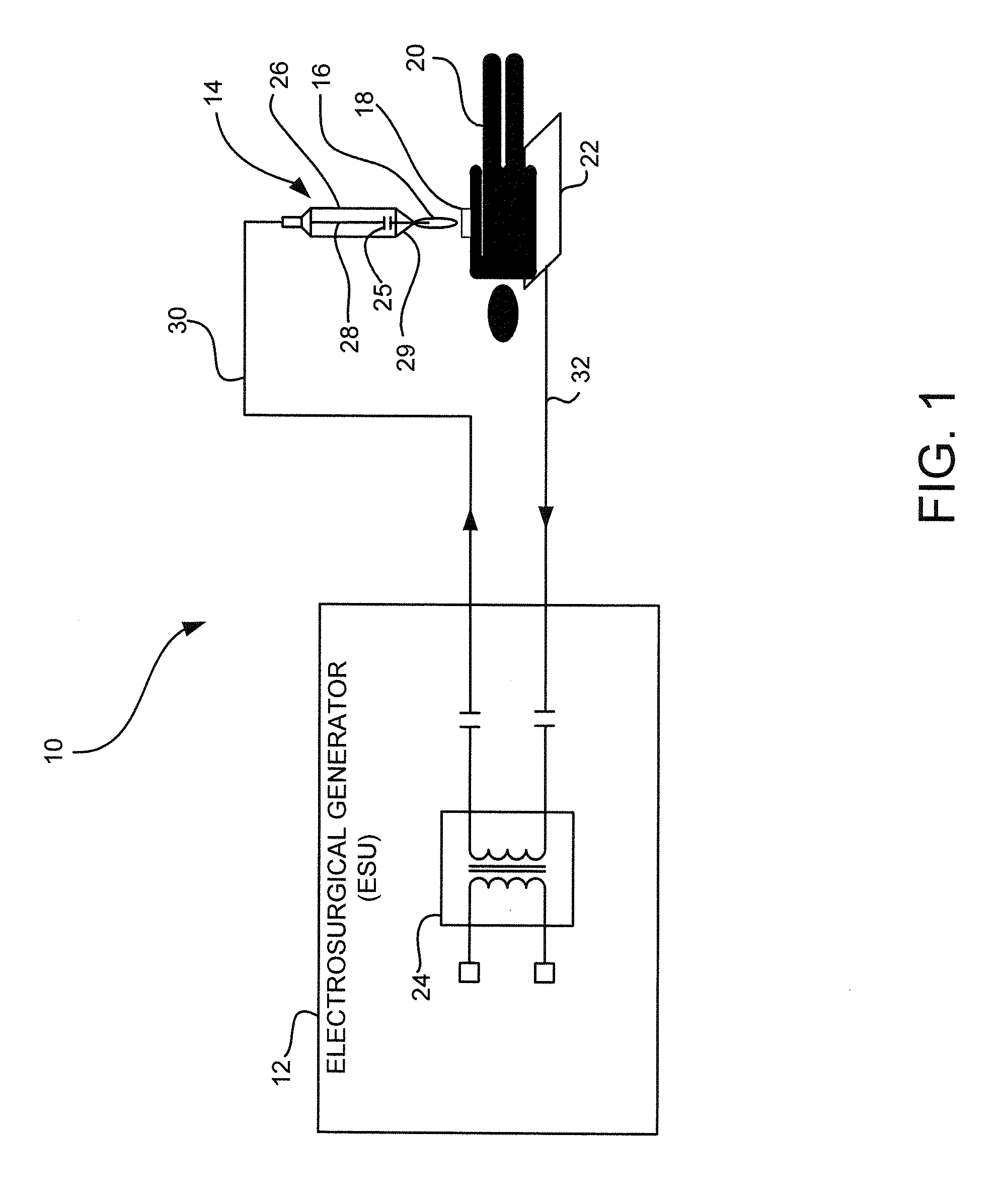

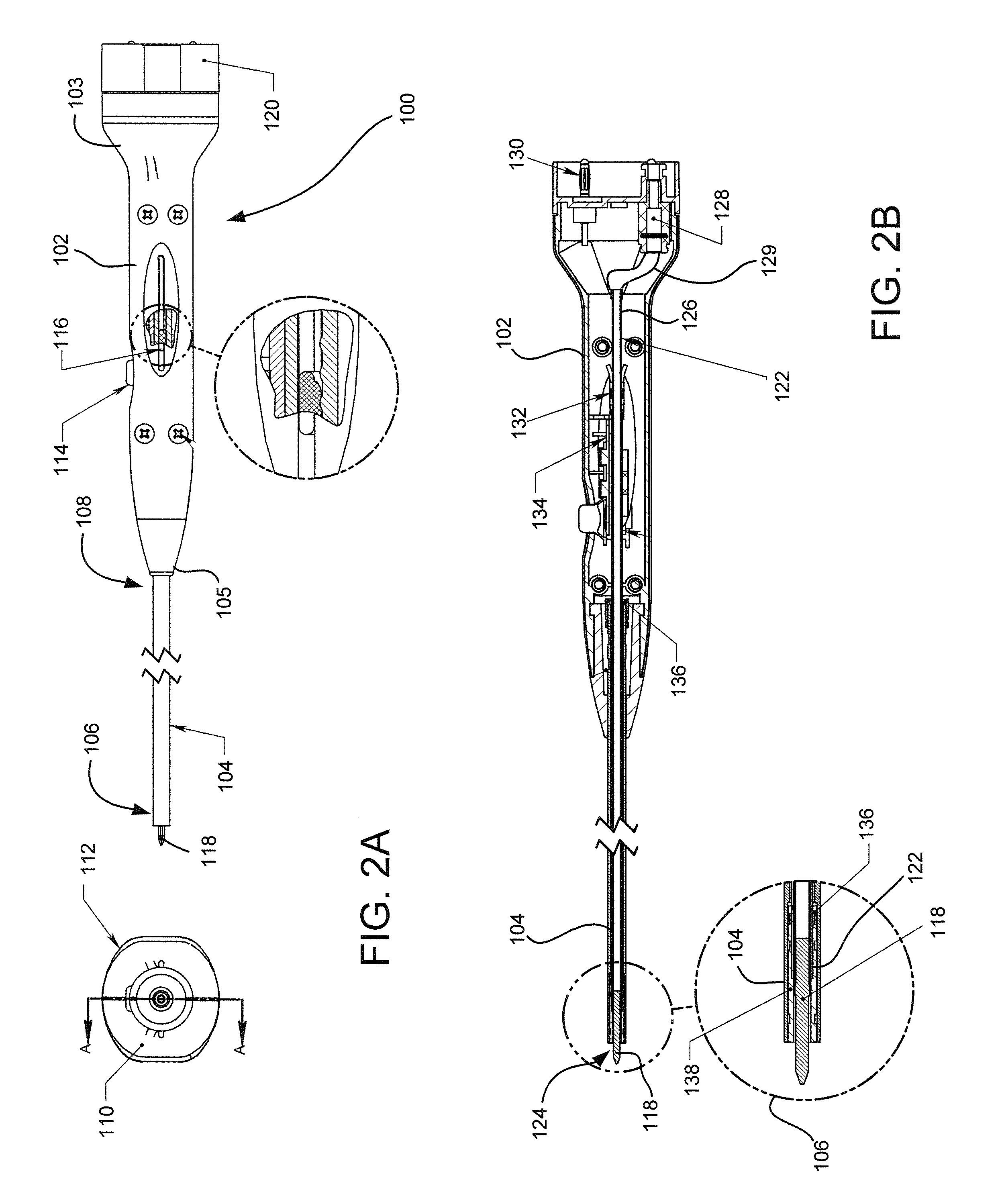

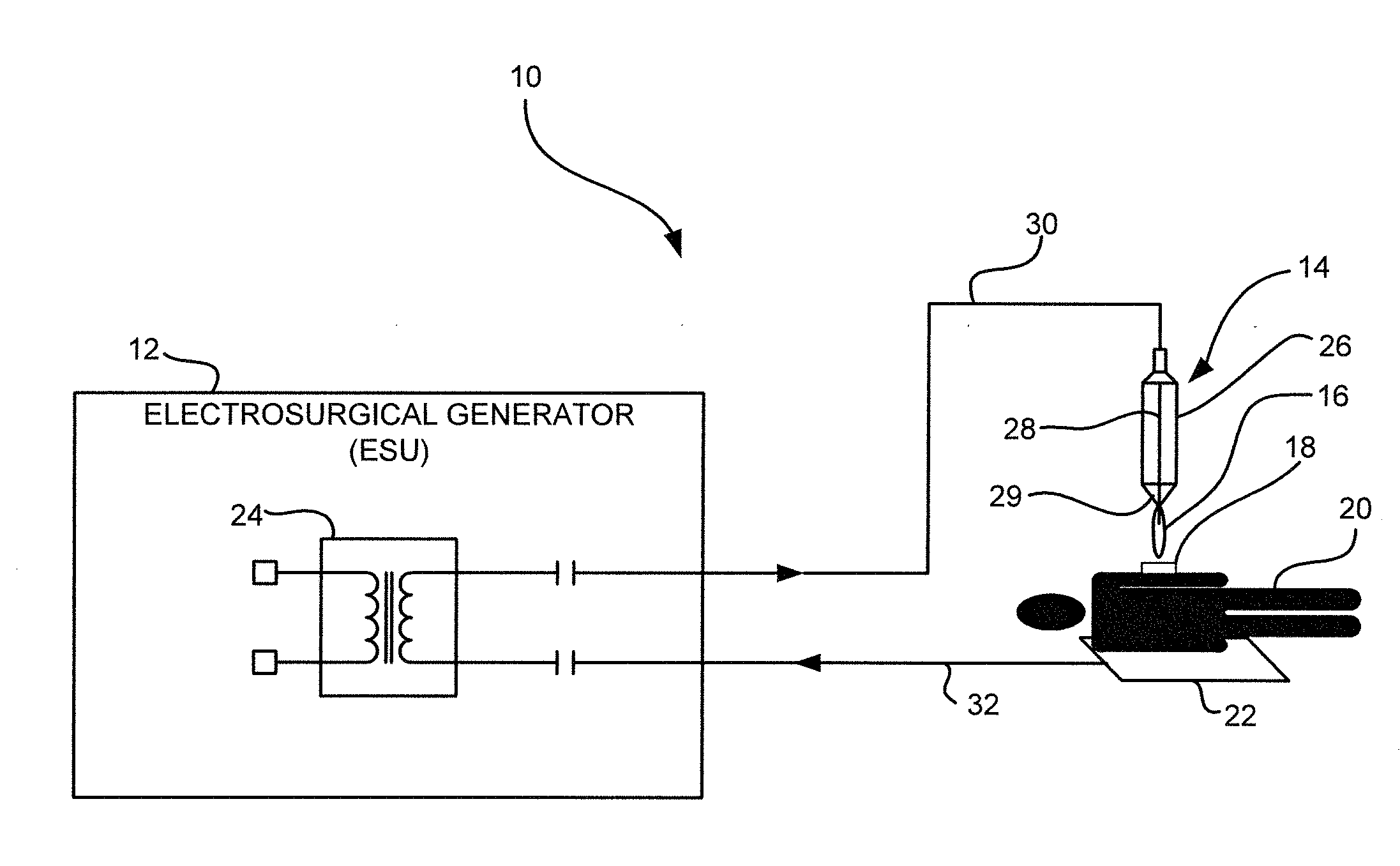

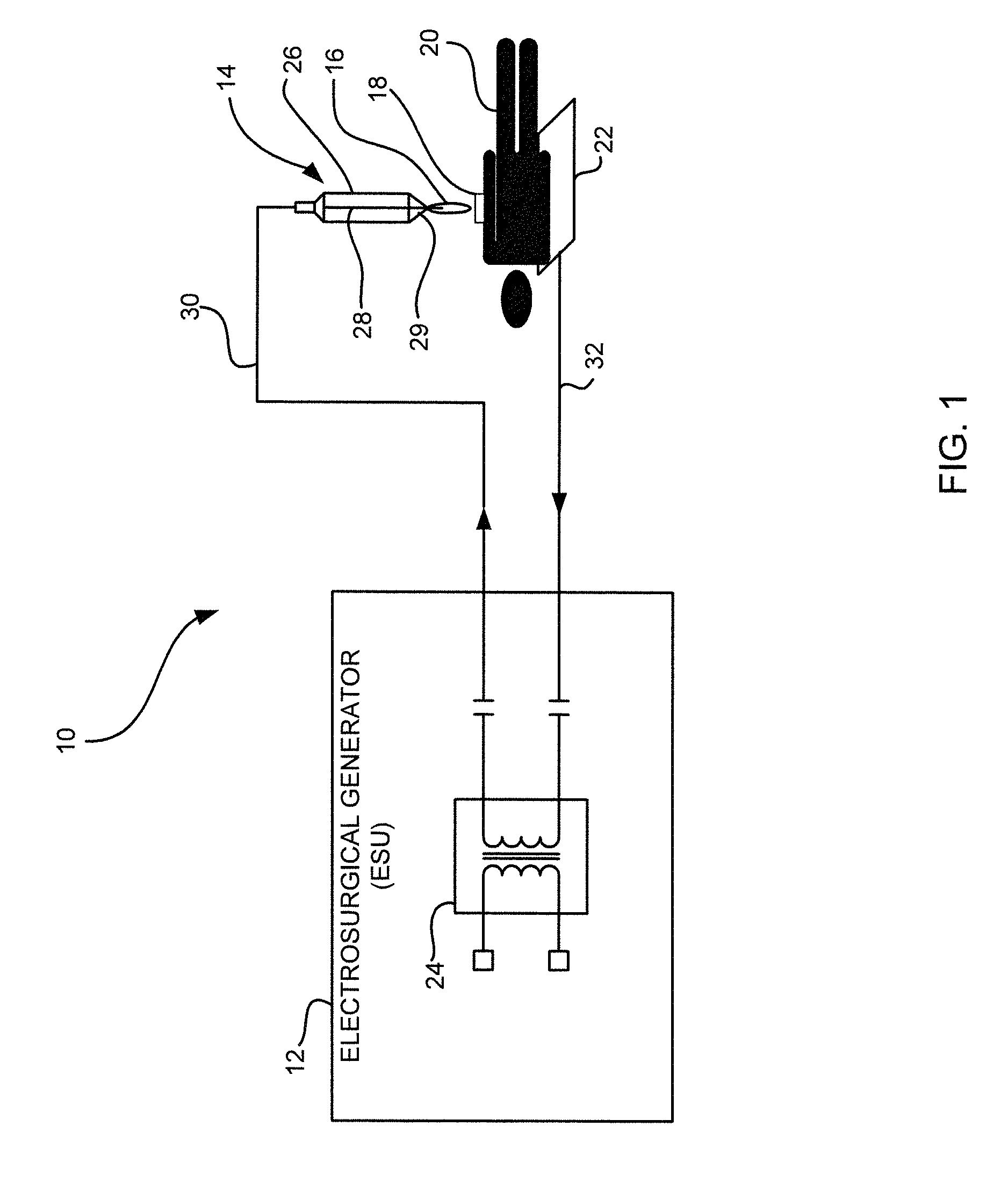

Electrosurgical apparatus with retractable blade

An electrosurgical apparatus with a retractable blade for use in cold plasma applications, electrosurgical cutting and mechanical cutting is provided. The electrosurgical apparatus employs a tip of the retractable blade as a sharp conductive point to generate a plasma beam or discharge. When the blade is retracted within the electrosurgical apparatus, it is electrically energized while an inert gas flows over it, producing a cold plasma discharge. In the de-energized state, the blade is advanced and used as a traditional, mechanical surgical blade.

Owner:BOVIE MEDICAL CORP

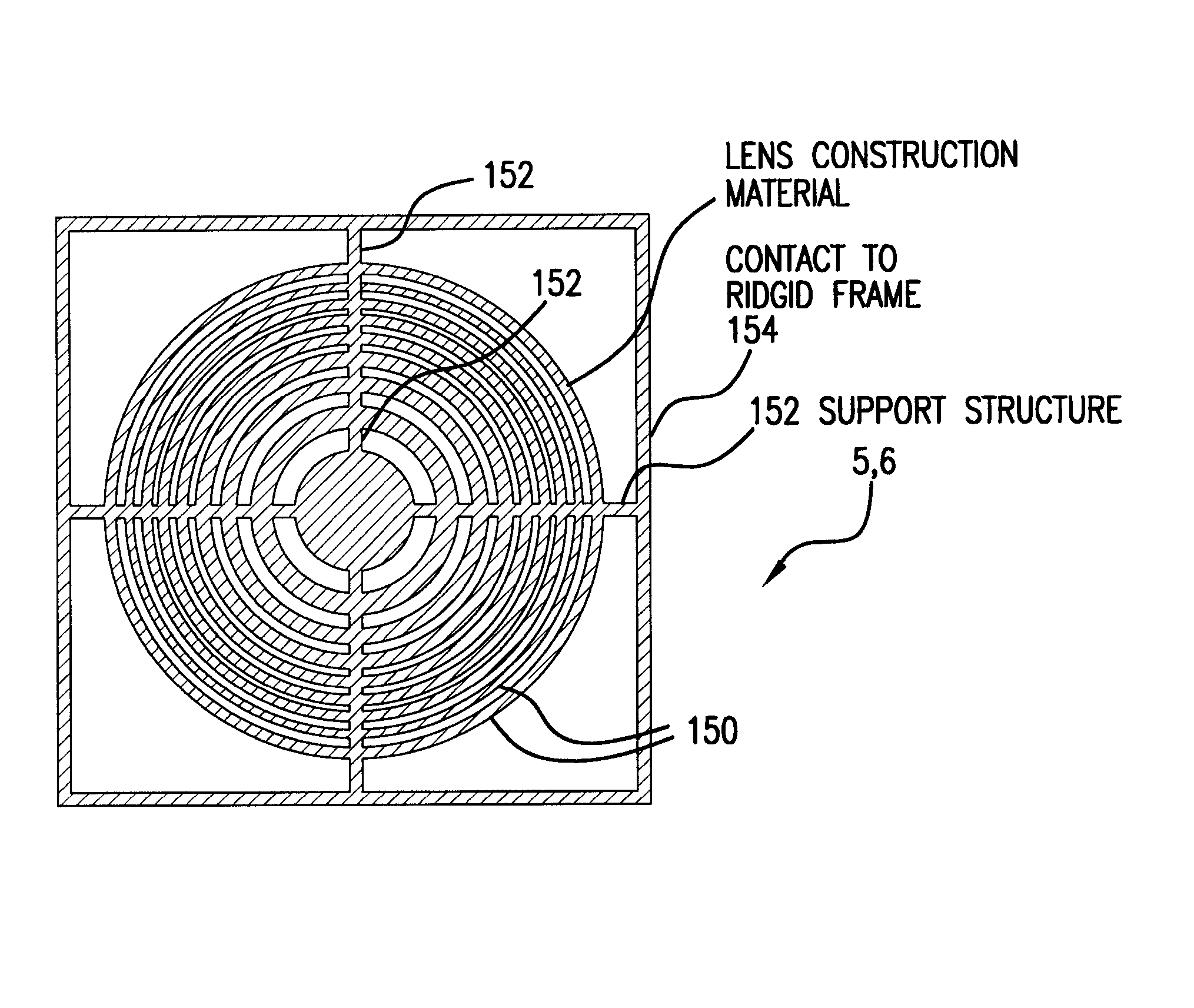

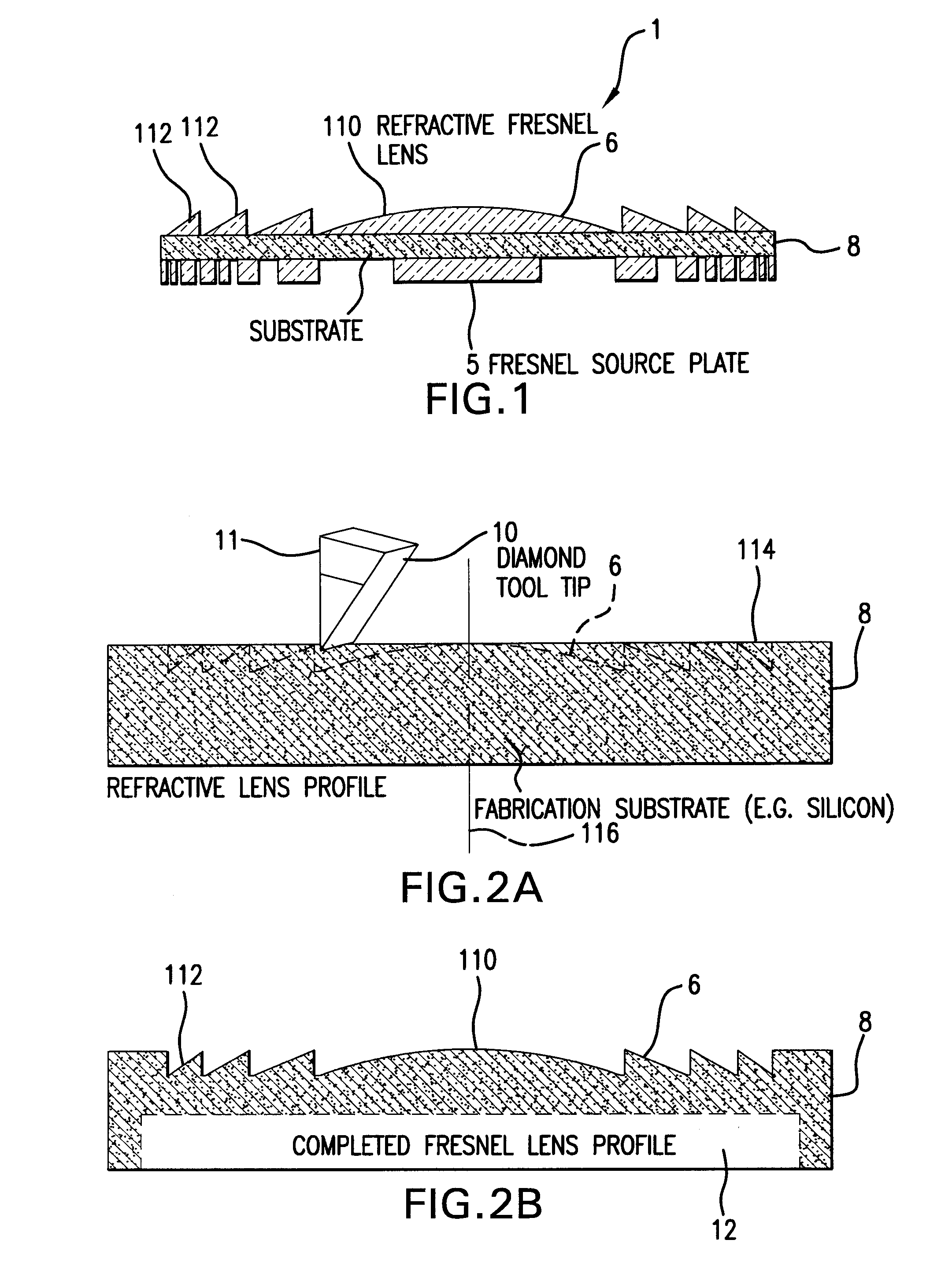

Fabrication Methods for Micro Compound Optics

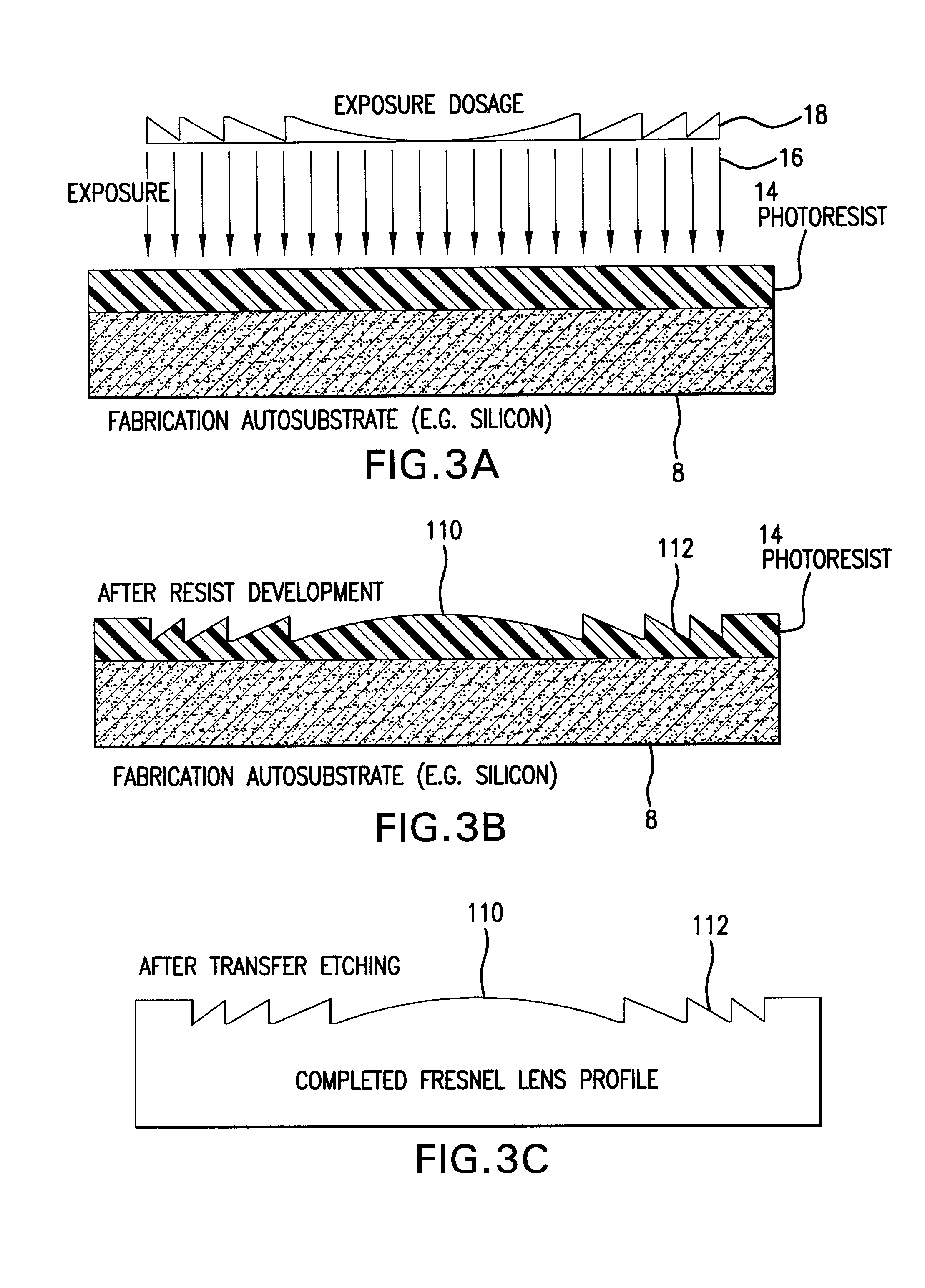

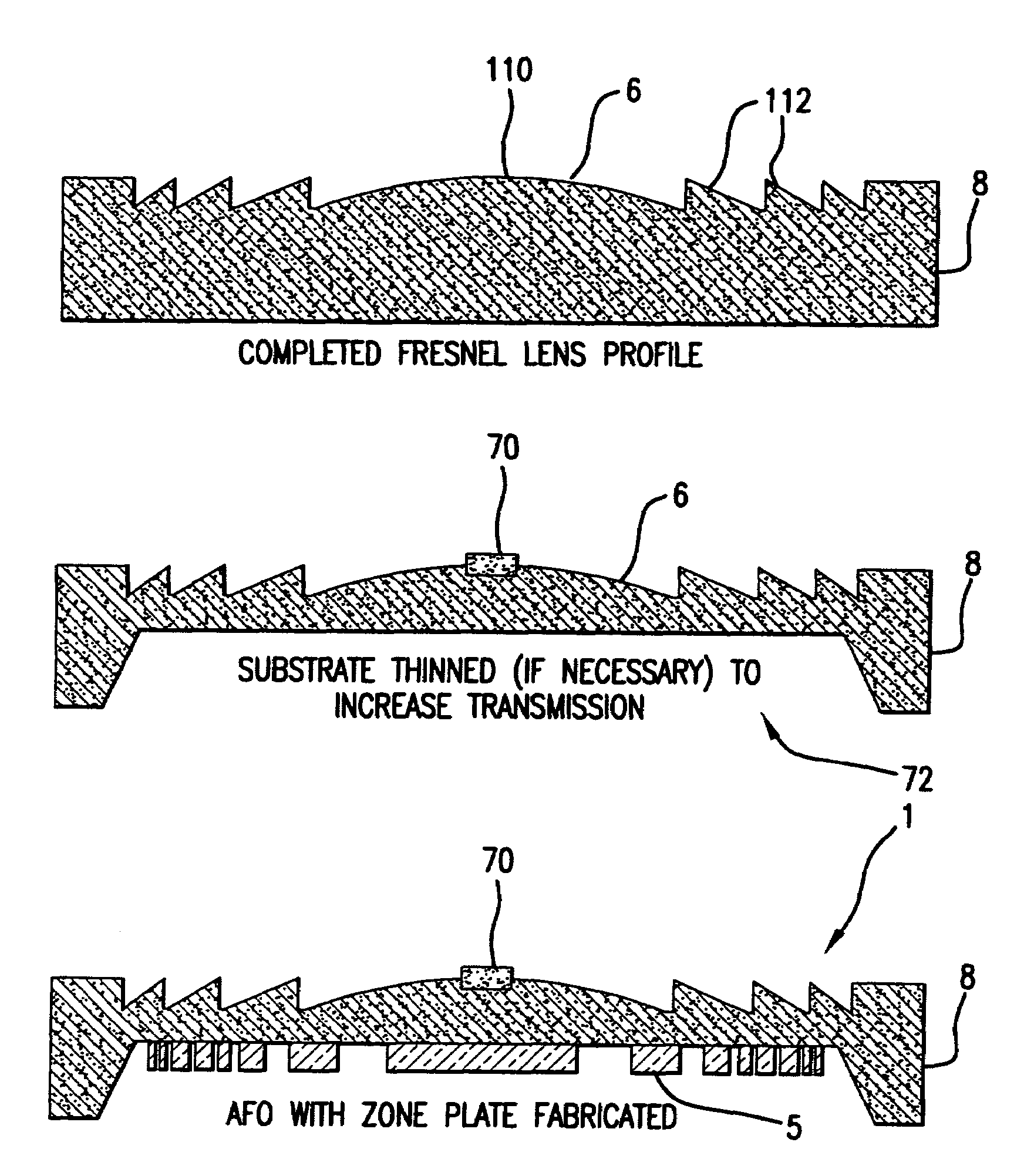

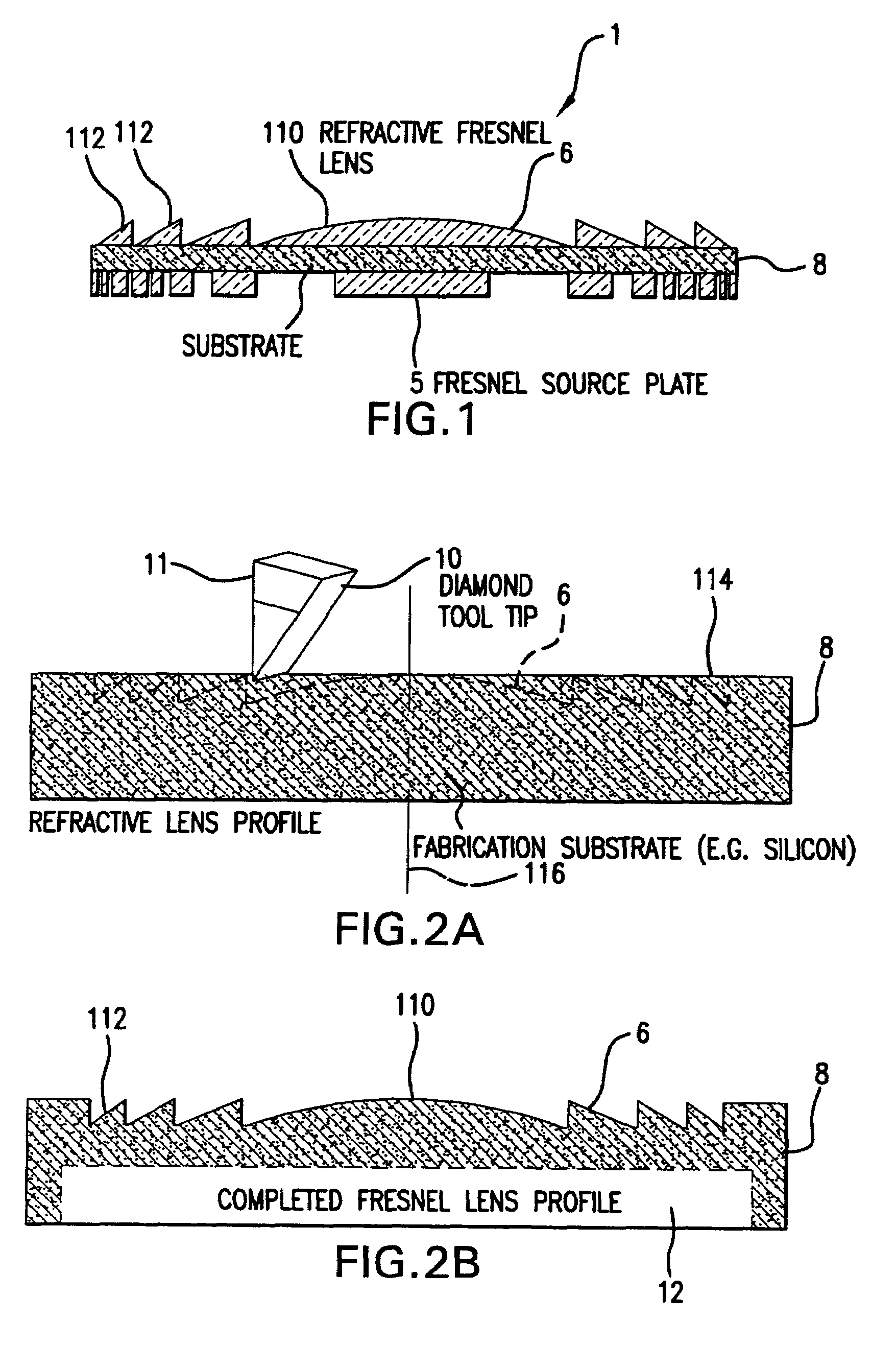

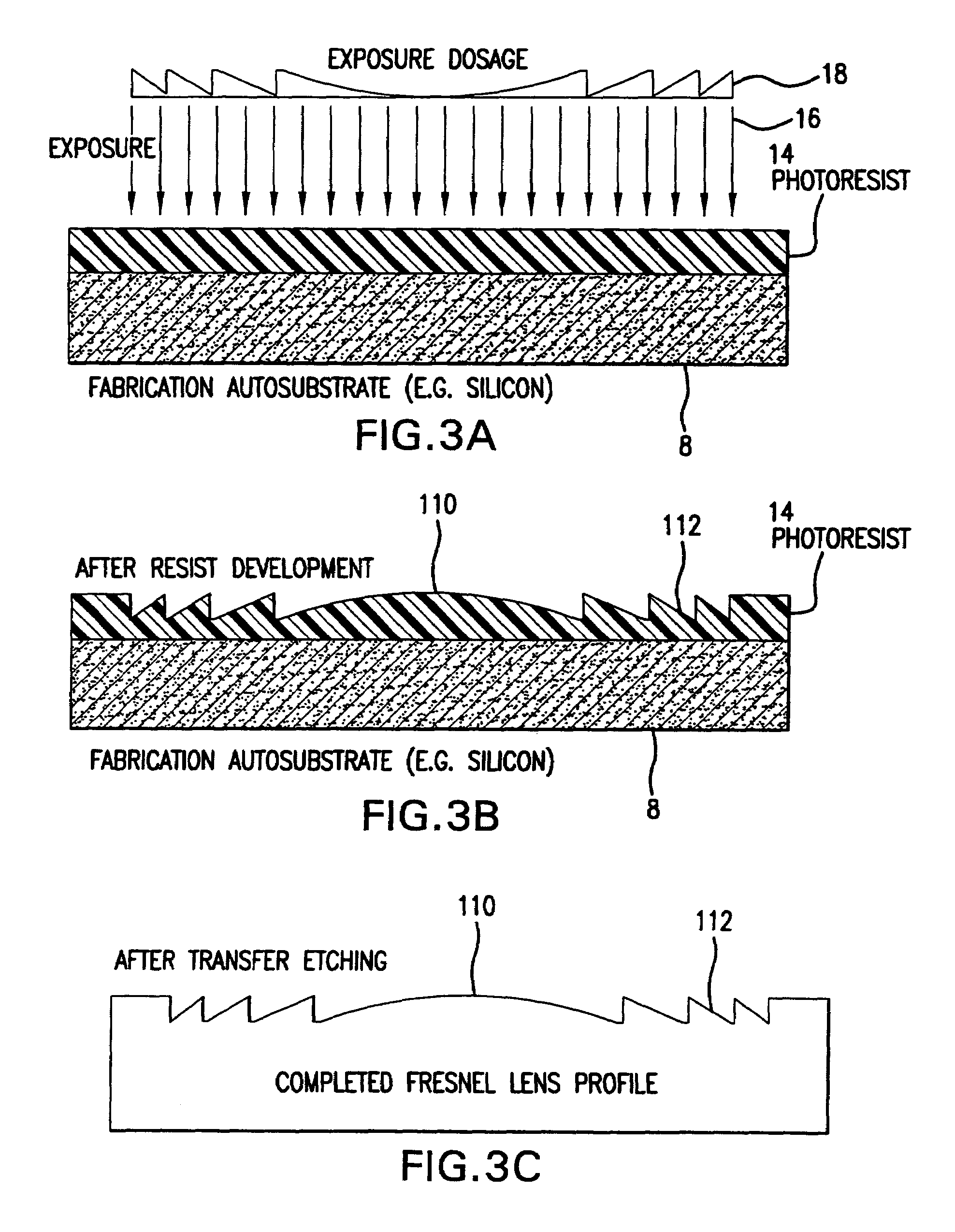

Methods for fabricating refractive element(s) and aligning the elements in a compound optic, typically to a zone plate element. The techniques are used for fabricating micro refractive, such as Fresnel, optics and compound optics including two or more optical elements for short wavelength radiation. One application is the fabrication of the Achromatic Fresnel Optic (AFO). Techniques for fabricating the refractive element generally include: 1) ultra-high precision mechanical machining, e.g,. diamond turning; 2) lithographic techniques including gray-scale lithography and multi-step lithographic processes; 3) high-energy beam machining, such as electron-beam, focused ion beam, laser, and plasma-beam machining; and 4) photo-induced chemical etching techniques. Also addressed are methods of aligning the two optical elements during fabrication and methods of maintaining the alignment during subsequent operation.

Owner:XRADIA

Fabrication methods for micro compounds optics

InactiveUS7365909B2Semiconductor/solid-state device detailsSolid-state devicesDiamond turningLithographic artist

Methods for fabricating refractive element(s) and aligning the elements in a compound optic, typically to a zone plate element. The techniques are used for fabricating micro refractive, such as Fresnel, optics and compound optics including two or more optical elements for short wavelength radiation. One application is the fabrication of the Achromatic Fresnel Optic (AFO). Techniques for fabricating the refractive element generally include: 1) ultra-high precision mechanical machining, e.g,. diamond turning; 2) lithographic techniques including gray-scale lithography and multi-step lithographic processes; 3) high-energy beam machining, such as electron-beam, focused ion beam, laser, and plasma-beam machining; and 4) photo-induced chemical etching techniques. Also addressed are methods of aligning the two optical elements during fabrication and methods of maintaining the alignment during subsequent operation.

Owner:CARL ZEISS X RAY MICROSCOPY

Ion plasma beam generating device

ActiveUS6975073B2Reducing electron emissionWide range of fieldsElectric discharge tubesElectric arc lampsDopantWire grid

An electron beam device wherein a low temperature gaseous plasma is generated in a chamber divided by two parallel wire grids. A semiconductor wafer serves as a cathode drawing ions from the plasma to impinge on the wafer, generating secondary electrons that are accelerated toward an anode on the opposite side of the grids where a target resides. In order to have a beam with uniform cross-sectional flux characteristics, the semiconductor wafer is doped with a graded dopant concentration that promotes a uniform beam.

Owner:ADASTRA TECH

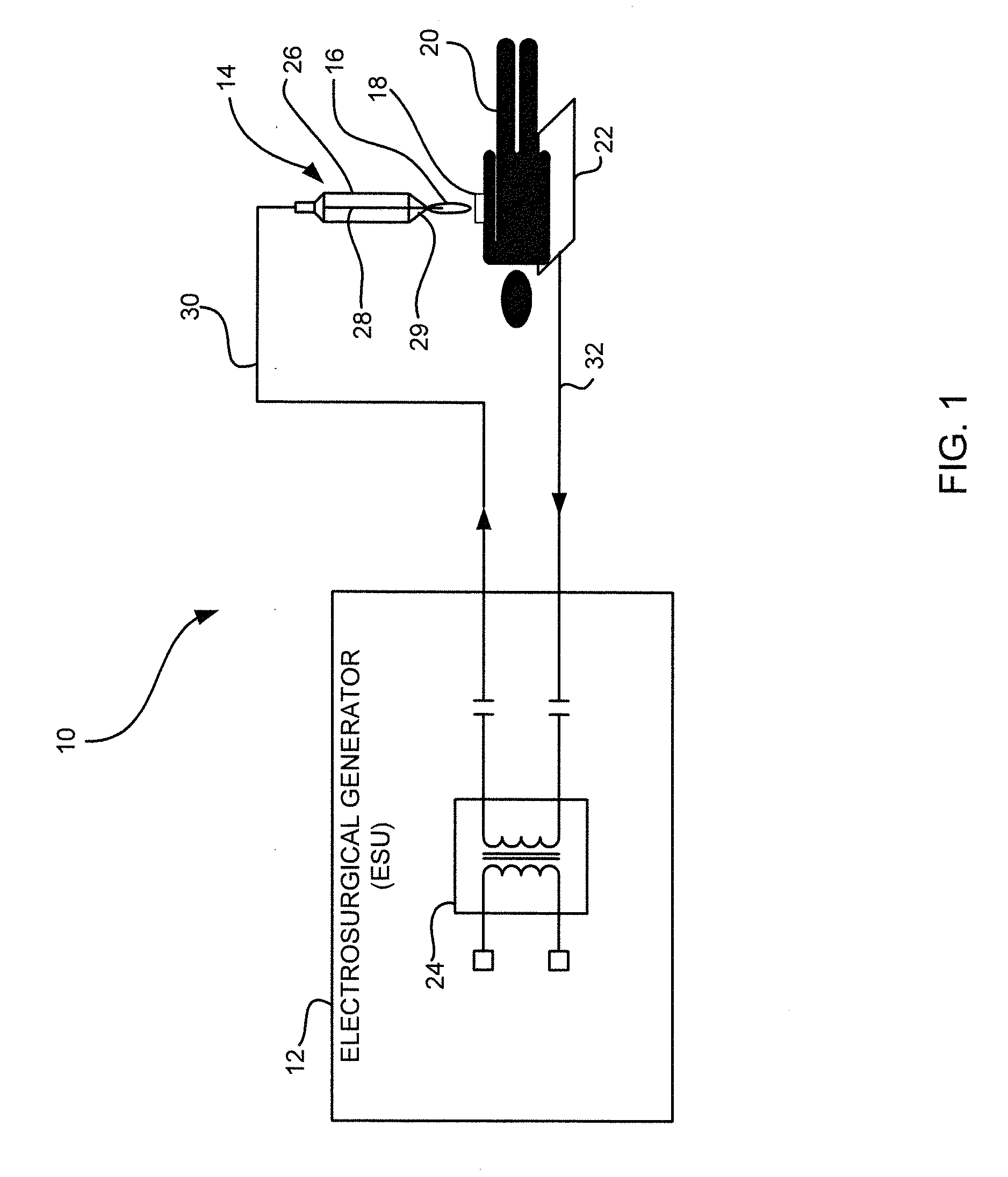

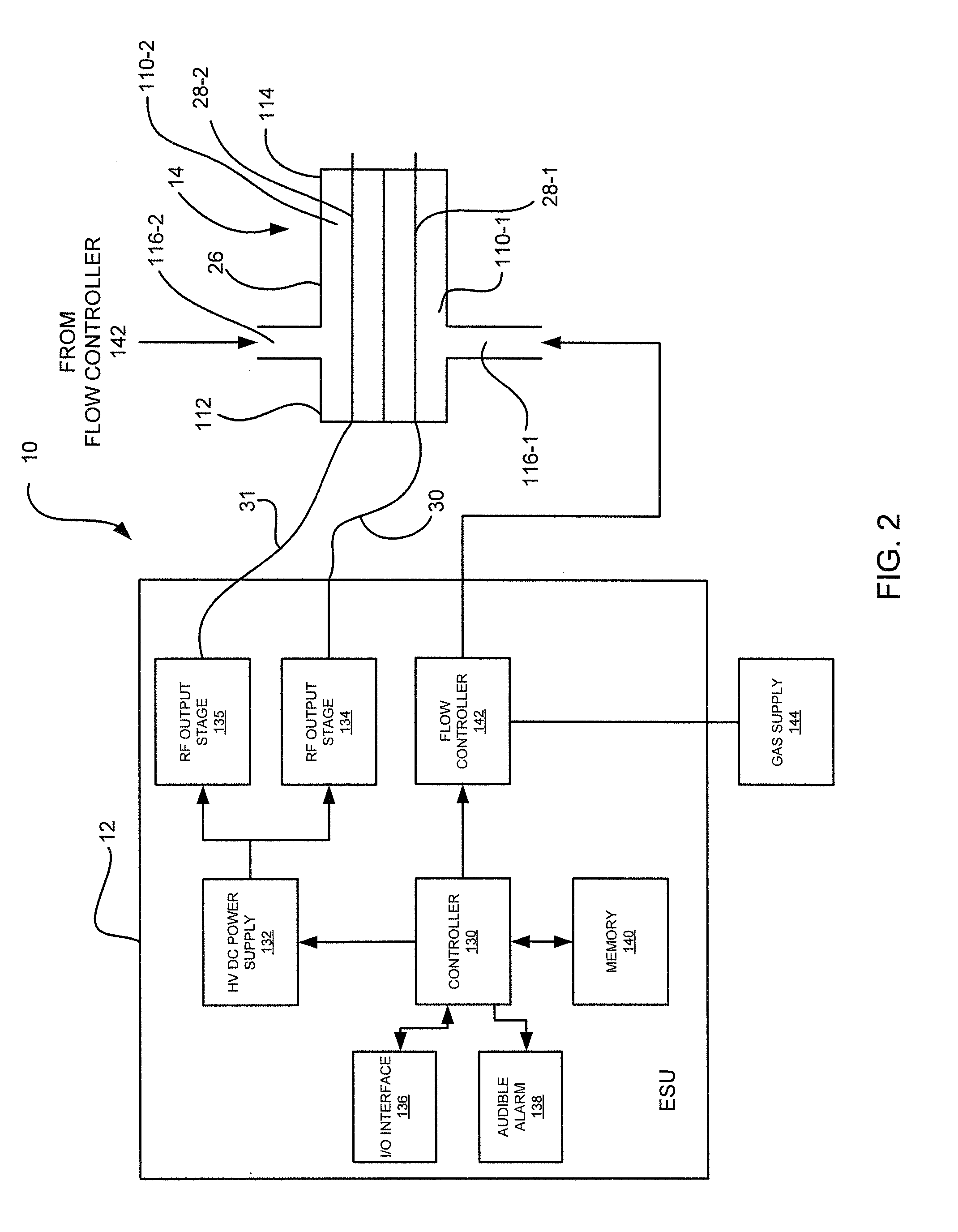

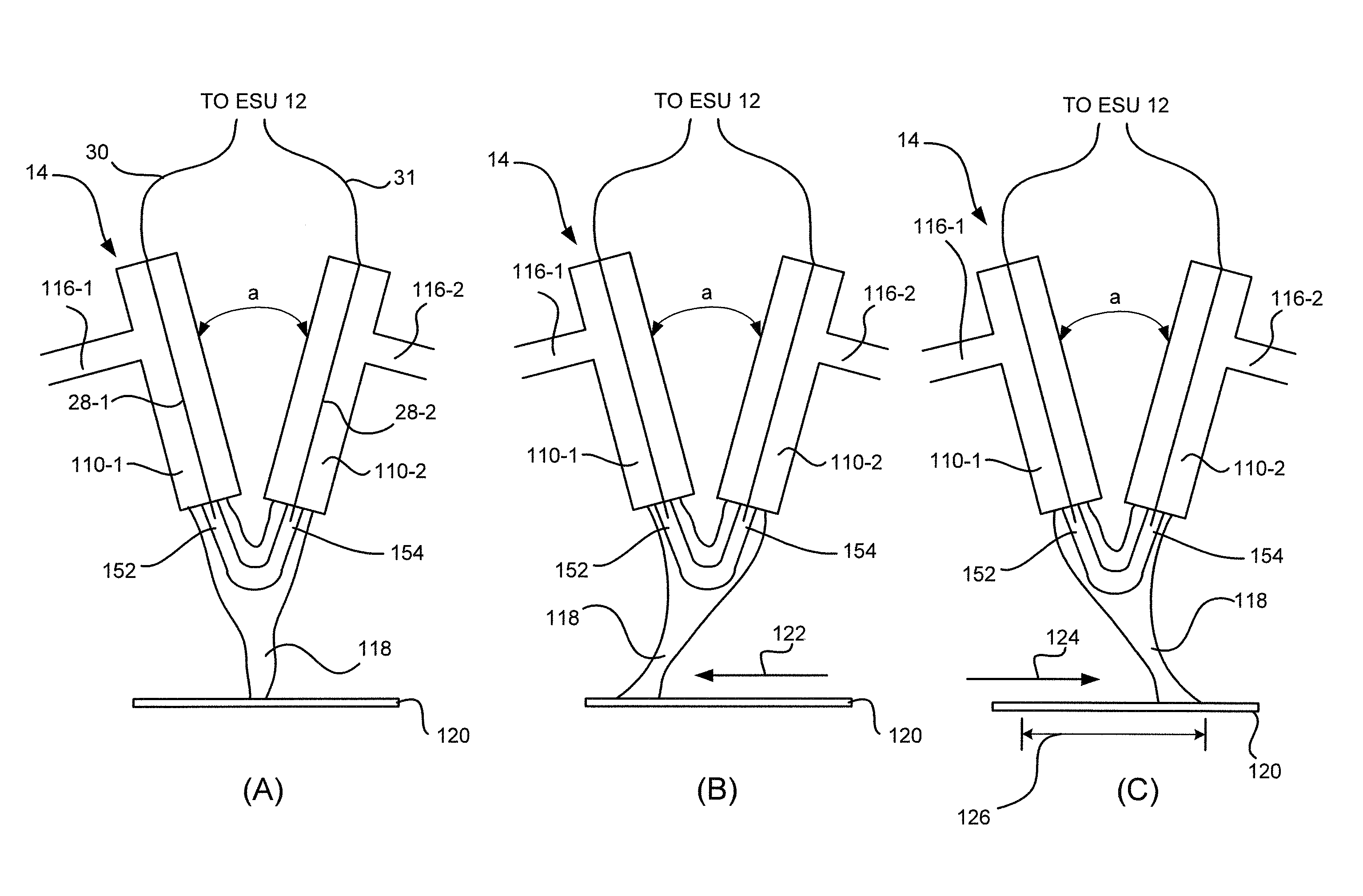

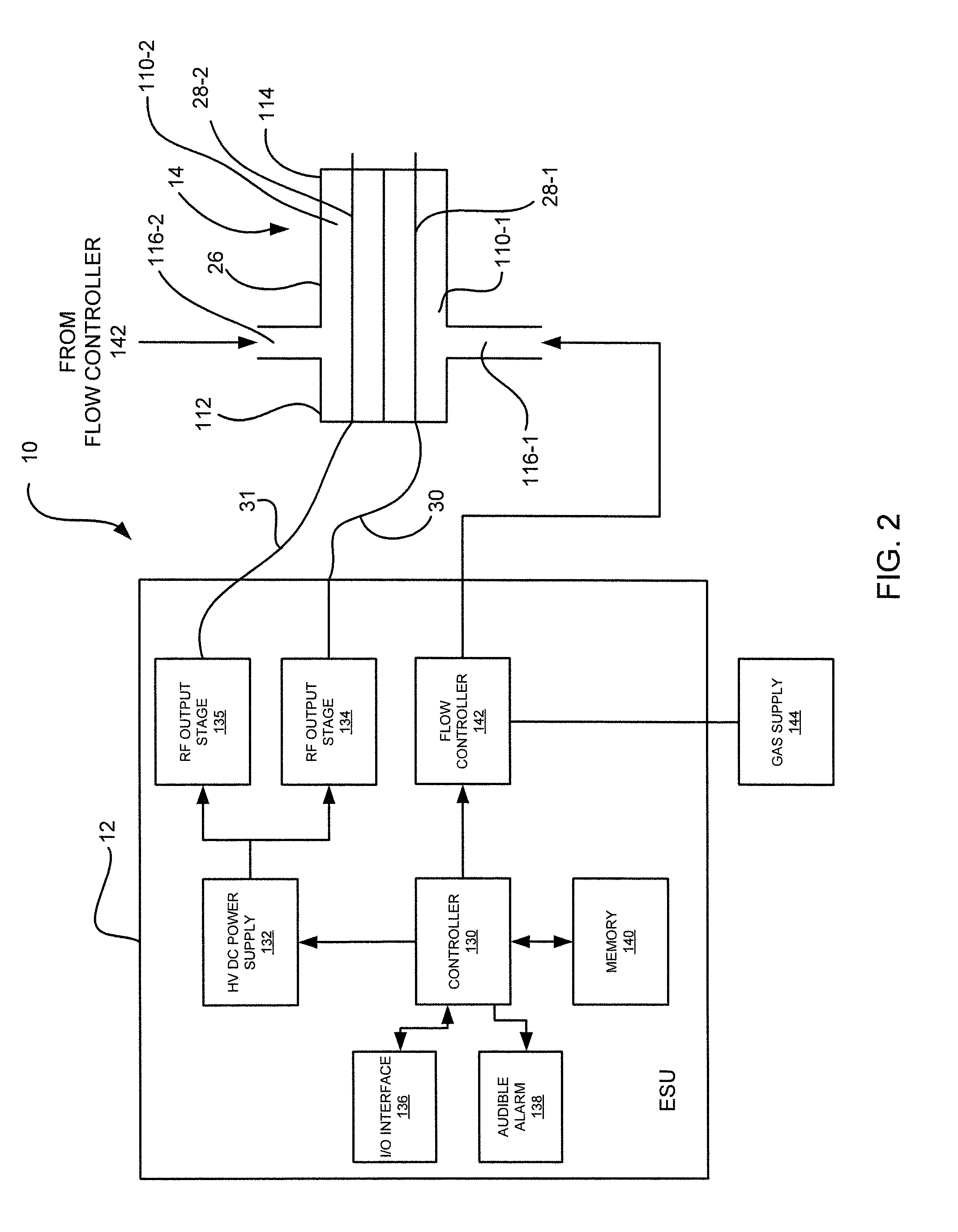

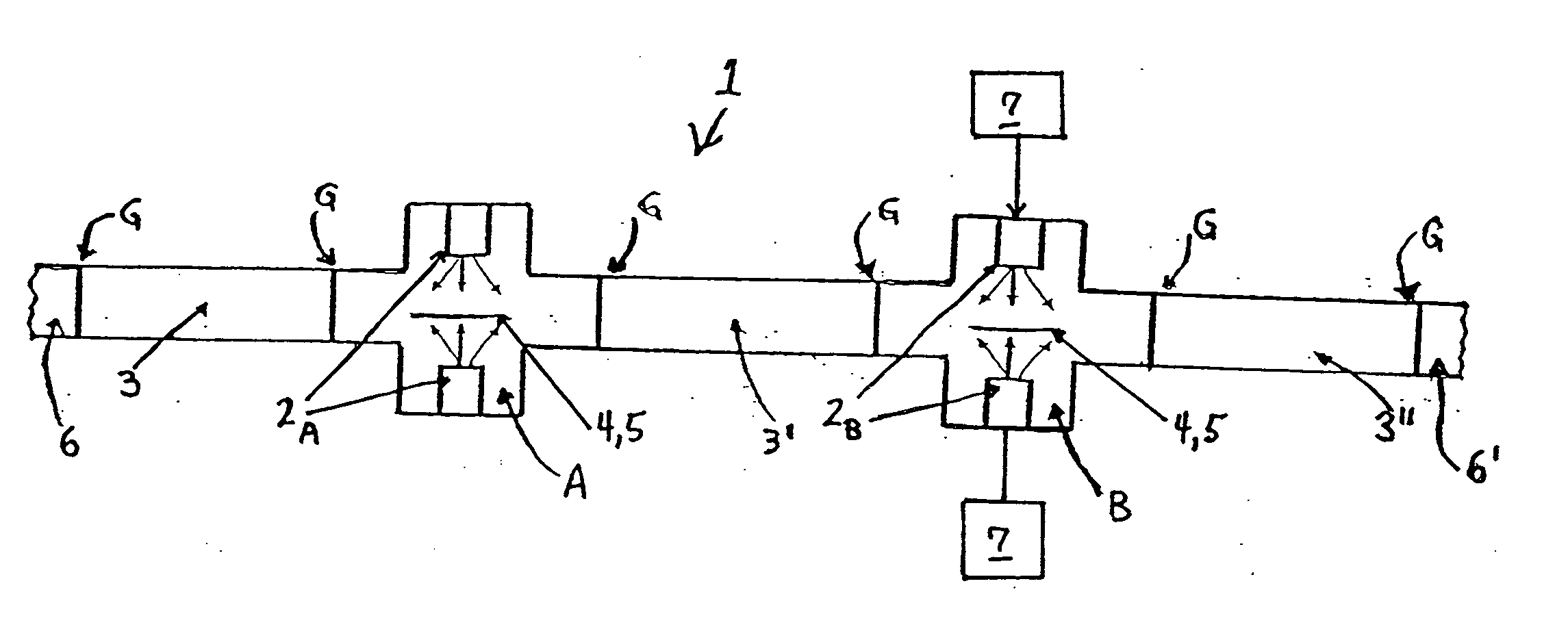

Electrosurgical apparatus to generate a dual plasma stream and method thereof

ActiveUS20110184408A1Small equivalent capacitanceGood effectSurgical instruments for heatingPlasma currentElectrosurgery

The present disclosure relates to an electrosurgical apparatus to generate a dual plasma stream to perform electrosurgery on a surgical site on a patient. The apparatus and method of the present disclosure generates a hot gas jet to a surgical site by generating two plasma beams that are electrically up to 180 degrees out of phase from each other. Since each beam uses the other beam to establish plasma currents at a load, the combined dual plasma stream can be used on non-conductive surfaces, e.g., a tissue at the surgical site. Furthermore, by applying different flow rates to the plasma beams, various scanning effects by the hot gas jet can be achieved.

Owner:BOVIE MEDICAL CORPORATION

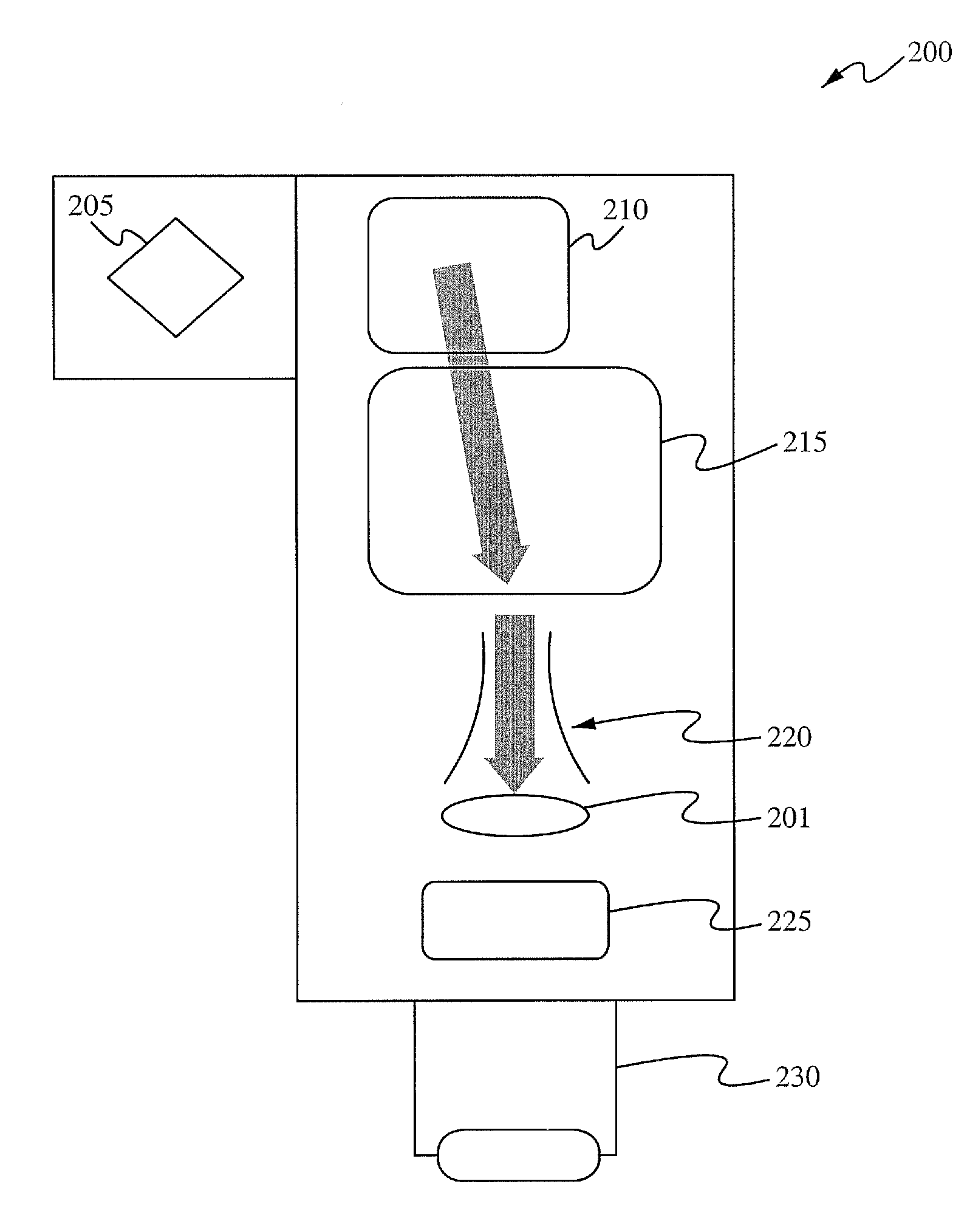

Application specific implant system and method for use in solar cell fabrications

ActiveUS20090309039A1Stability-of-path spectrometersBeam/ray focussing/reflecting arrangementsSolar cellSingle ion

Solar cells and other semiconductor devices are fabricated more efficiently and for less cost using an implanted doping fabrication system. A system for implanting a semiconductor substrate includes an ion source (such as a single-species delivery module), an accelerator to generate from the ion source an ion beam having an energy of no more than 150 kV, and a beam director to expose the substrate to the beam. In one embodiment, the ion source is single-species delivery module that includes a single-gas delivery element and a single-ion source. Alternatively, the ion source is a plasma source used to generate a plasma beam. The system is used to fabricate solar cells having lightly doped photo-receptive regions and more highly doped grid lines. This structure reduces the formation of “dead layers” and improves the contact resistance, thereby increasing the efficiency of a solar cell.

Owner:INTEVAC

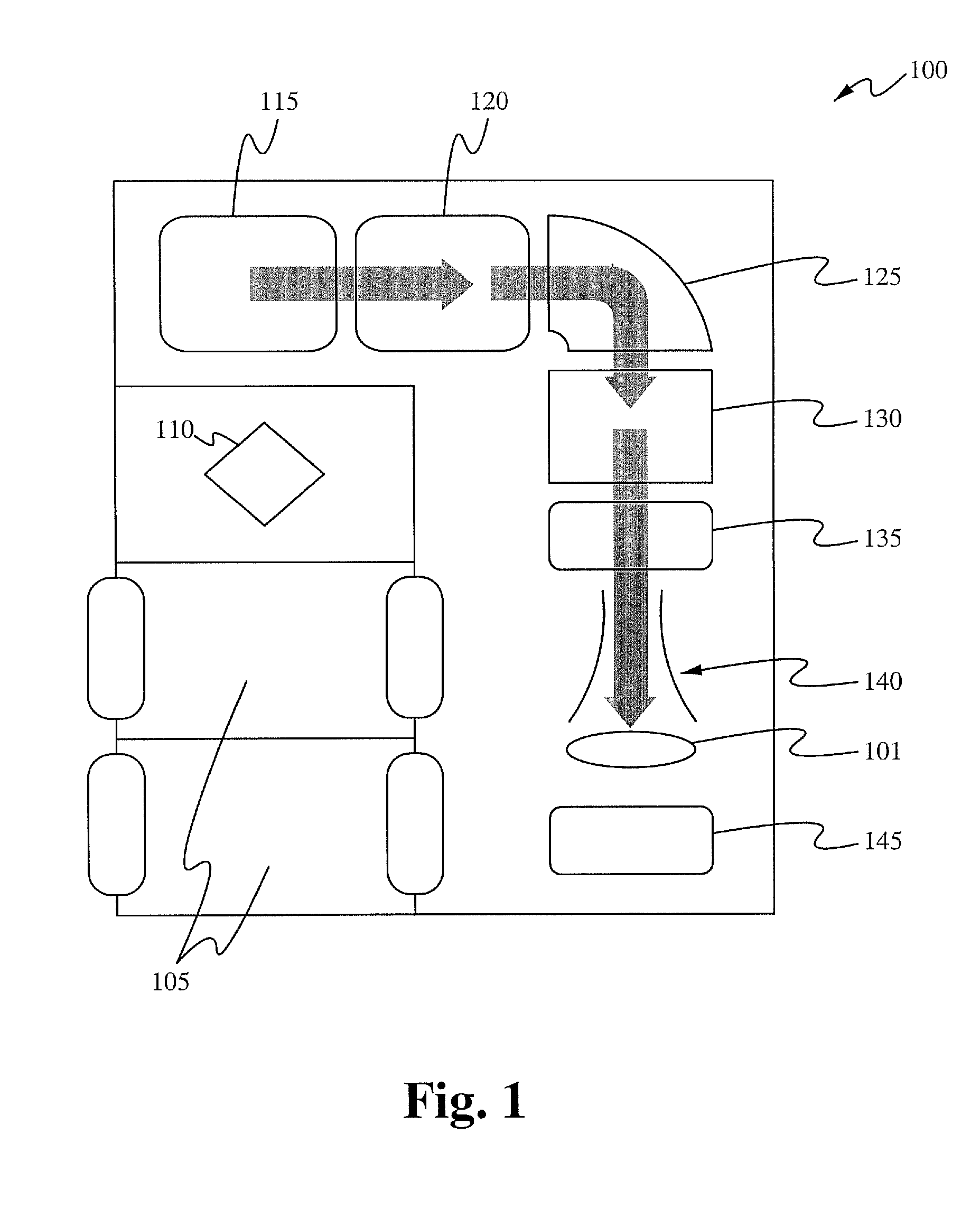

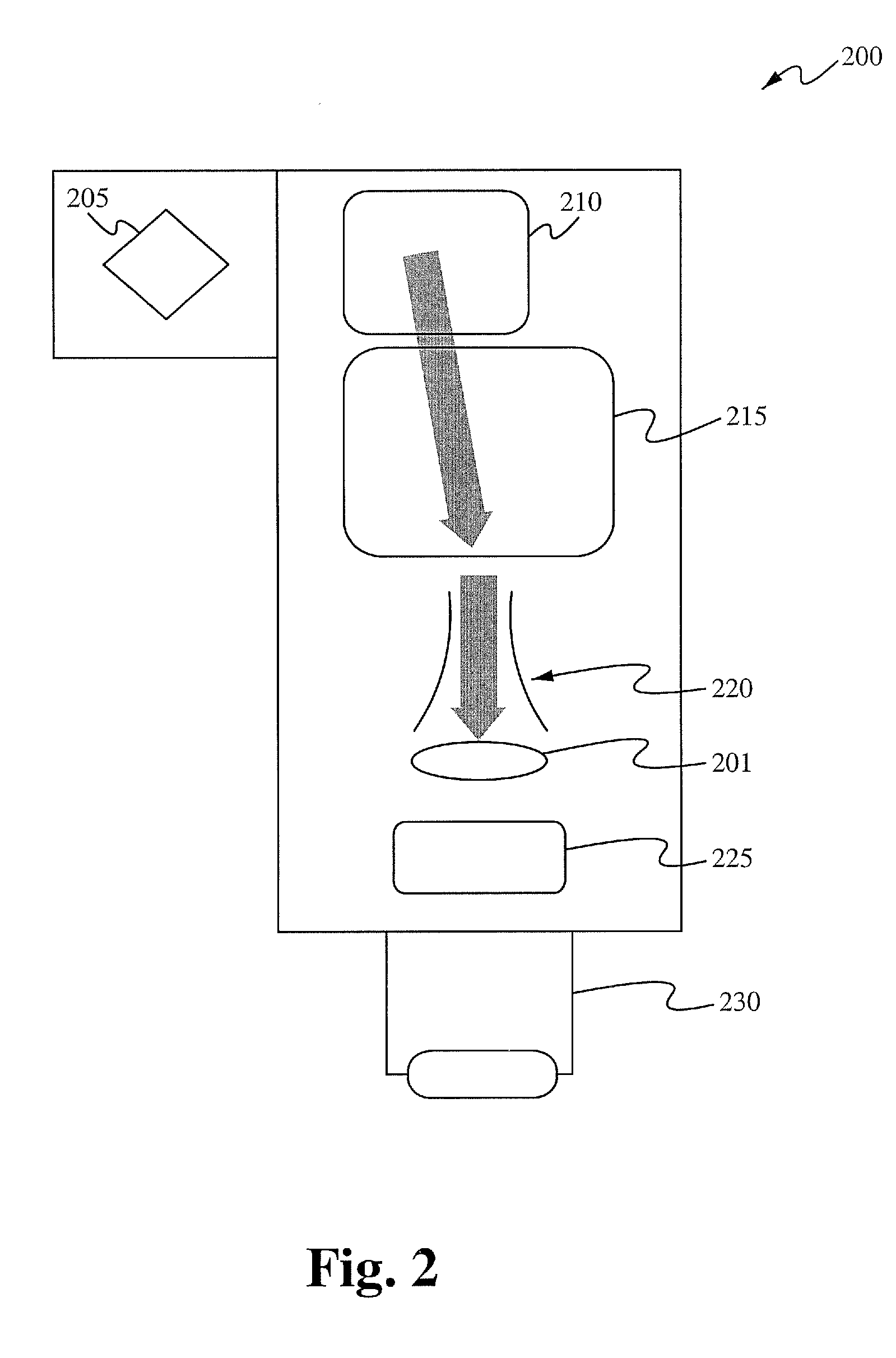

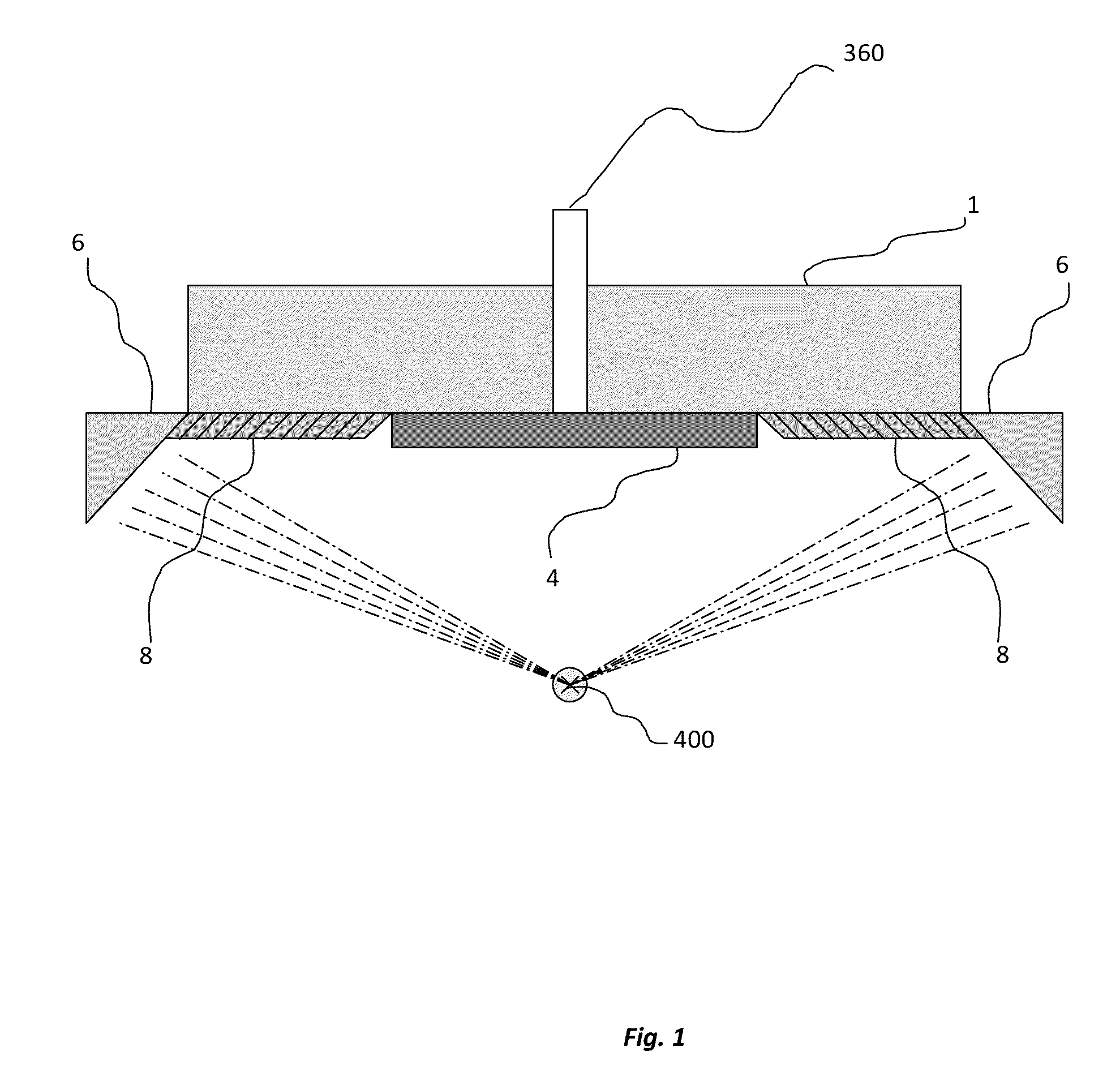

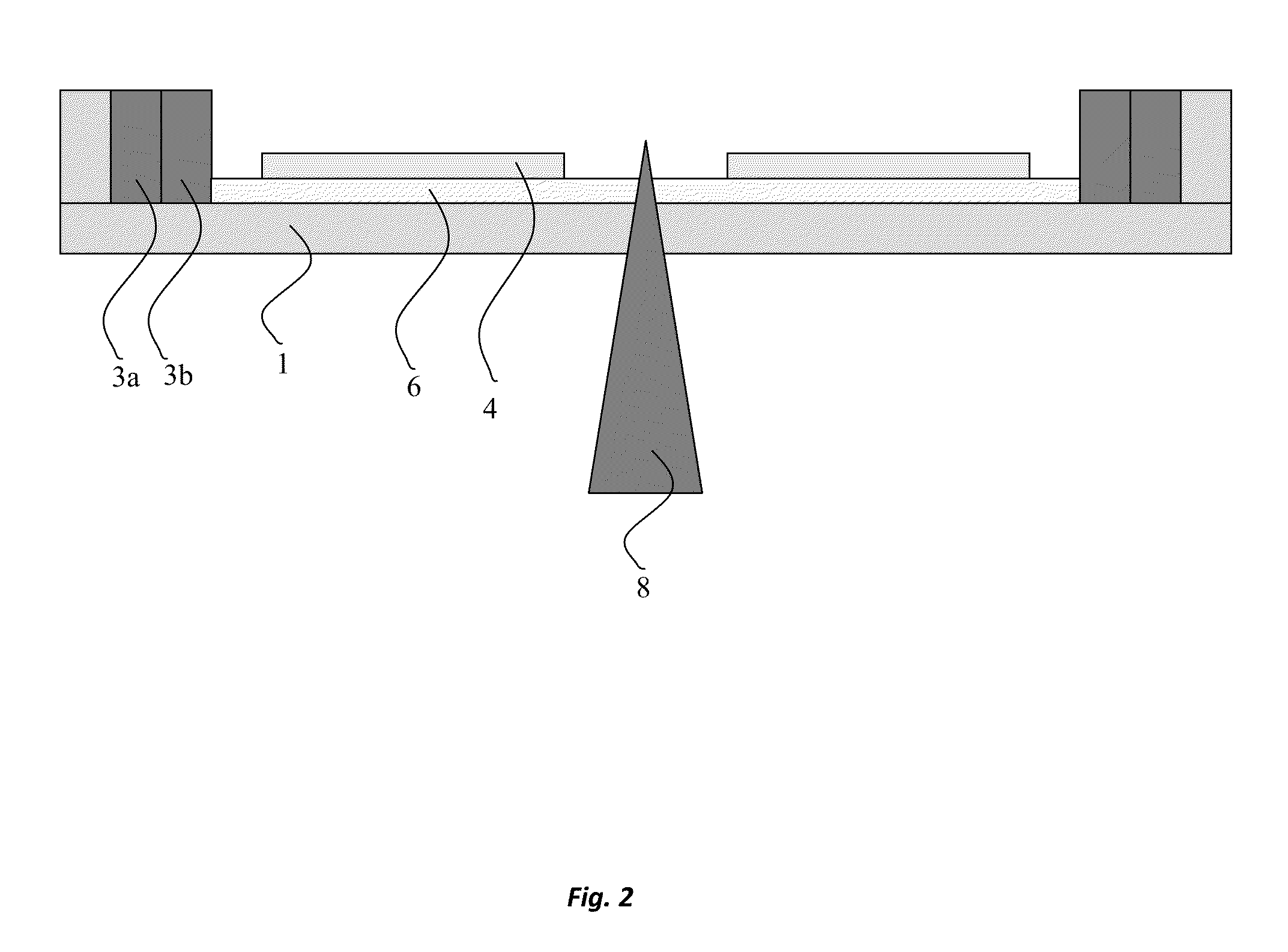

Dielectric deposition using a remote plasma source

InactiveUS20110226617A1Evenly distributedReduce thermal stressCellsElectric discharge tubesDielectricRemote plasma

A sputter deposition system comprises a vacuum chamber including a vacuum pump for maintaining a vacuum in the vacuum chamber, a gas inlet for supplying process gases to the vacuum chamber, a sputter target and a substrate holder within the vacuum chamber, and a plasma source attached to the vacuum chamber and positioned remotely from the sputter target, the plasma source being configured to form a high density plasma beam extending into the vacuum chamber. The plasma source may include a rectangular cross-section source chamber, an electromagnet, and a radio frequency coil, wherein the rectangular cross-section source chamber and the radio frequency coil are configured to give the high density plasma beam an elongated ovate cross-section. Furthermore, the surface of the sputter target may be configured in a non-planar form to provide uniform plasma energy deposition into the target and / or uniform sputter deposition at the surface of a substrate on the substrate holder. The sputter deposition system may include a plasma spreading system for reshaping the high density plasma beam for complete and uniform coverage of the sputter target.

Owner:APPLIED MATERIALS INC

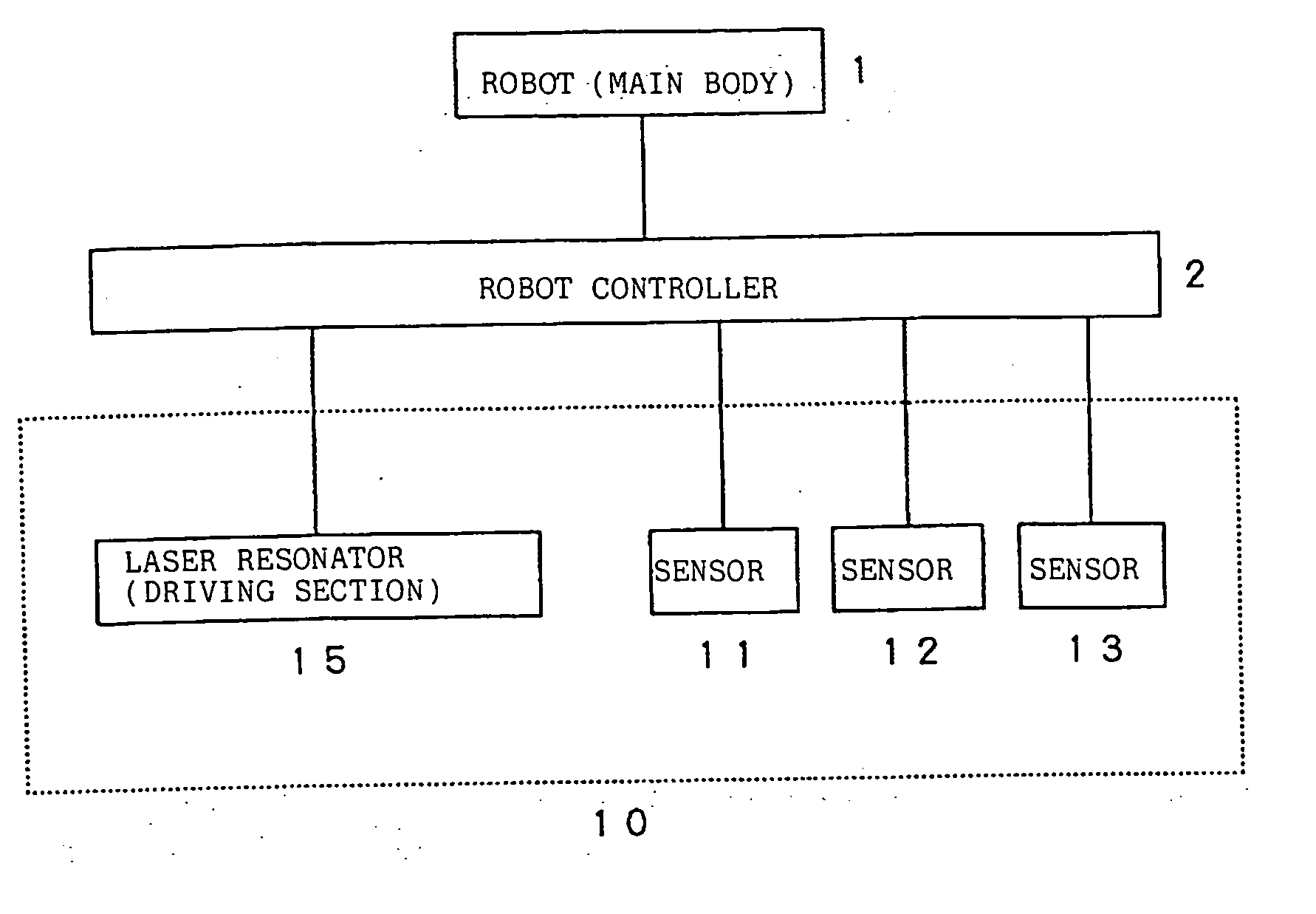

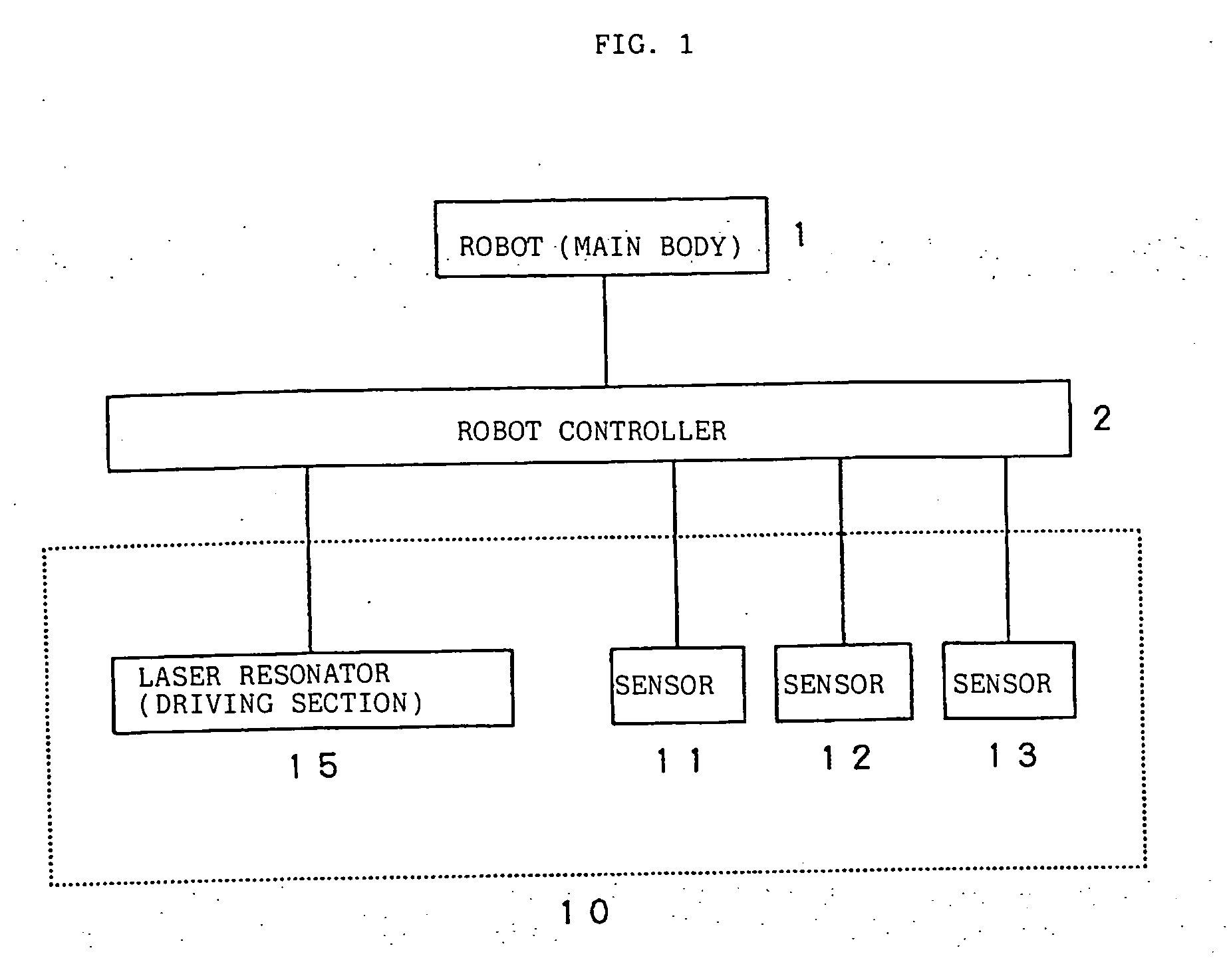

Laser welding unit

InactiveUS20050011867A1Improve accuracyImprove welding qualityLaser beam welding apparatusPlasma beamLaser beams

When a laser beam is irradiated from a laser welding torch onto a surface of a welding target workpiece, a plasma is generated. This plasma is introduced to an optical fiber, extracted by a filter-added half-silvered mirror, branched by half-silvered mirrors and a reflecting mirror, split by a bandpass filter, and detected by an optical sensor. Using a detection result of the optical sensor, a control for keeping the intensity or the temperature of a plasma beam constant is exercised.

Owner:FANUC LTD

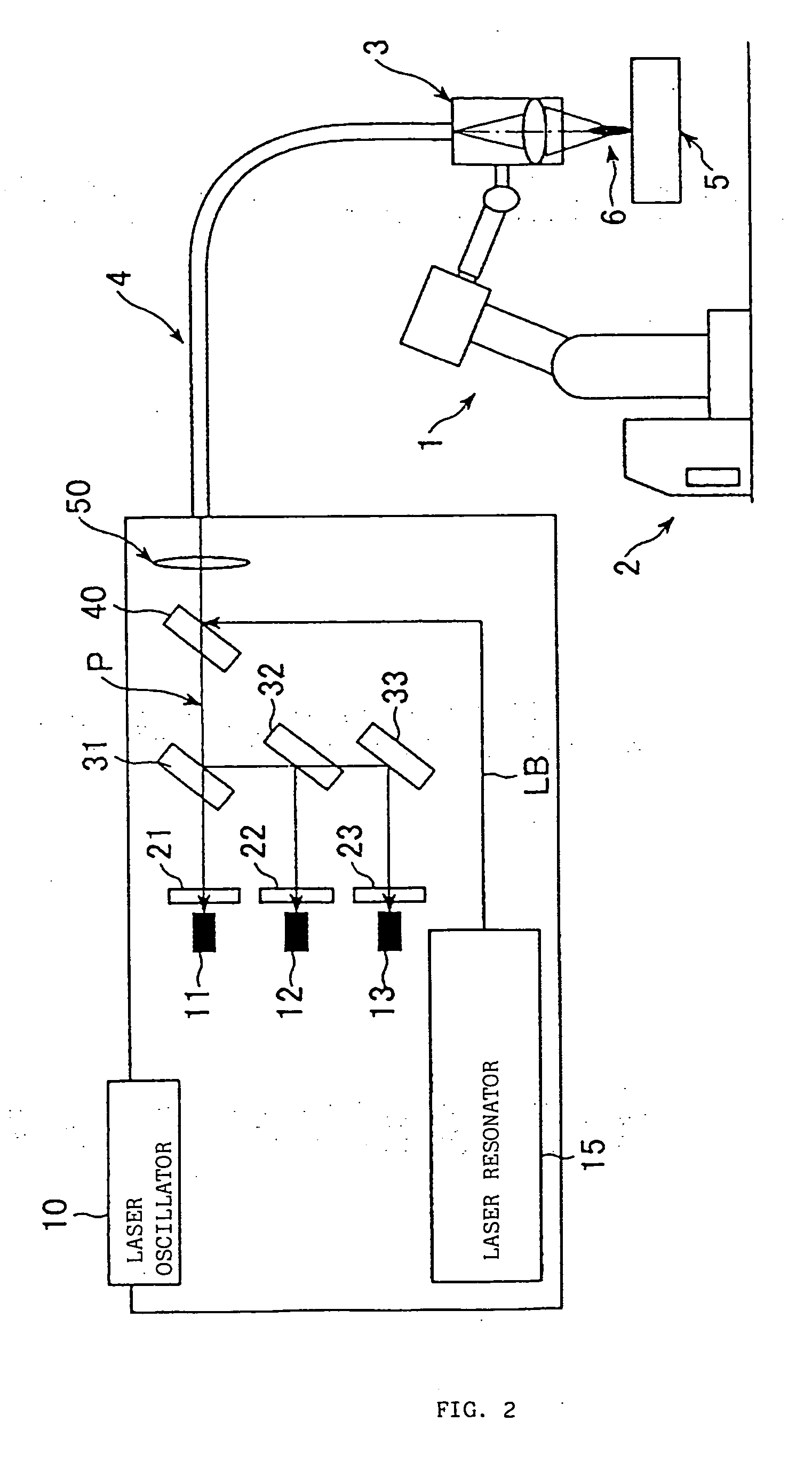

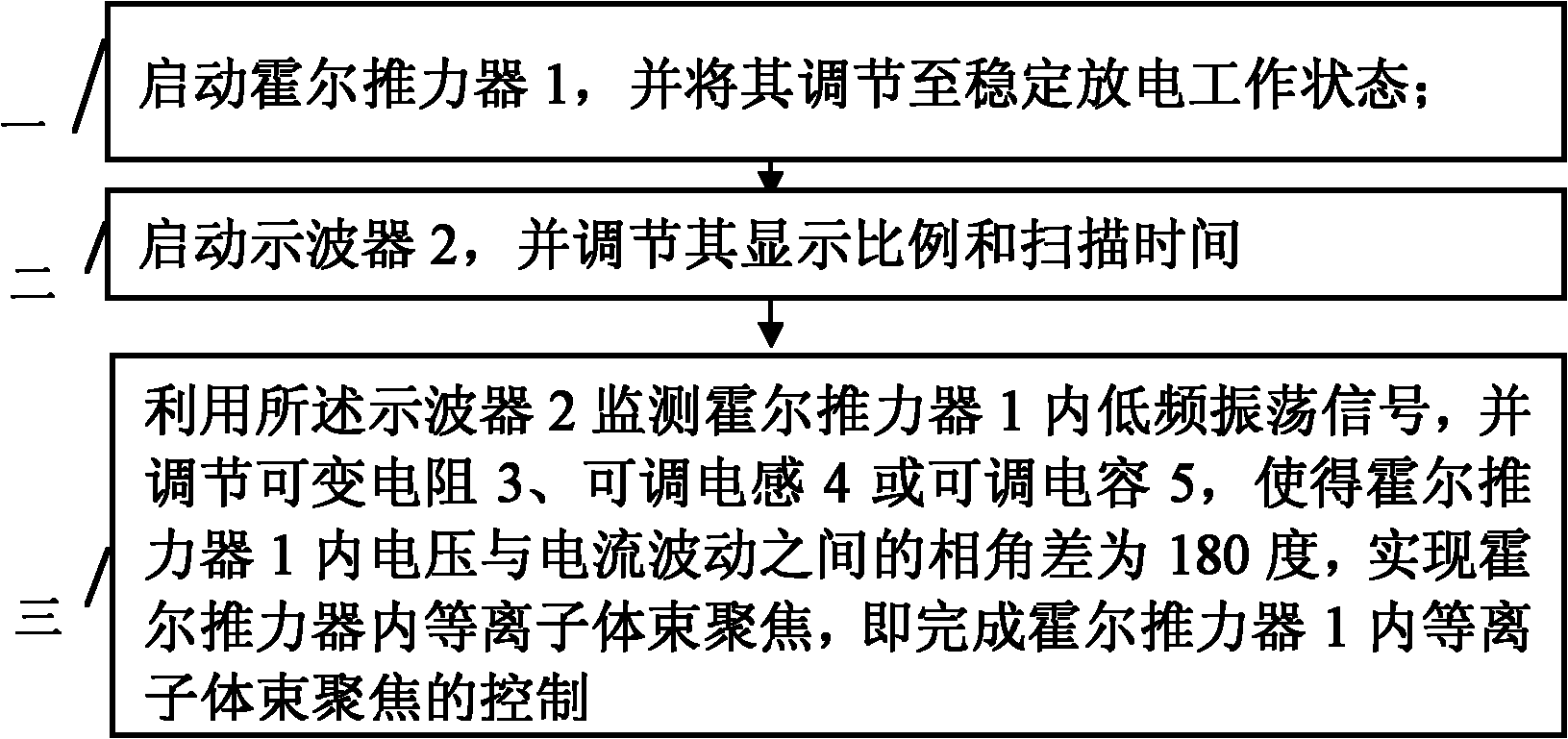

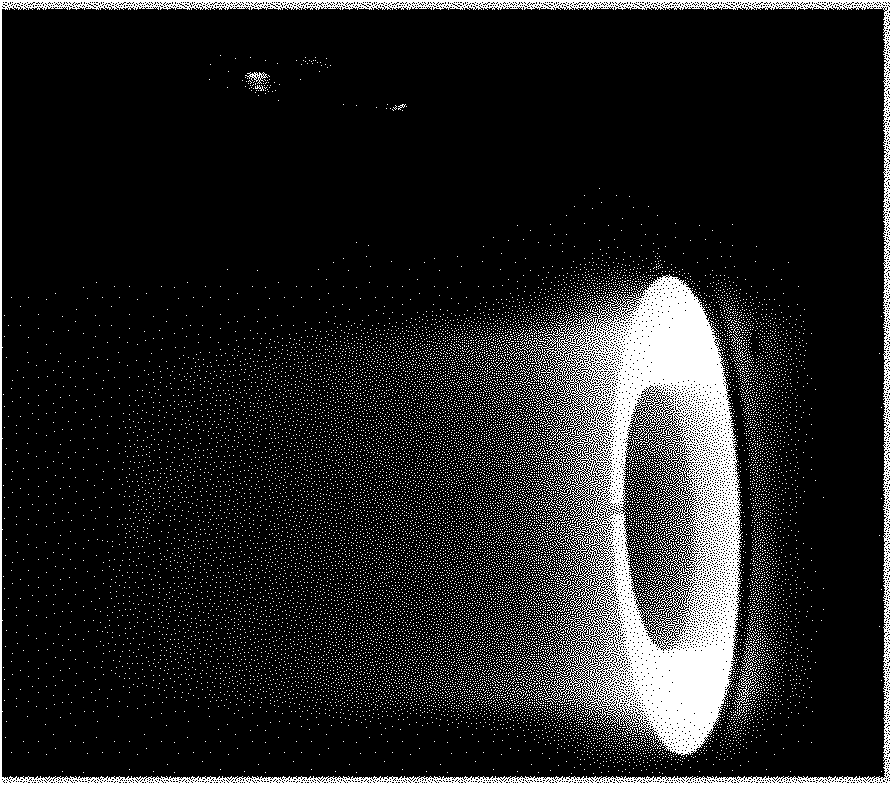

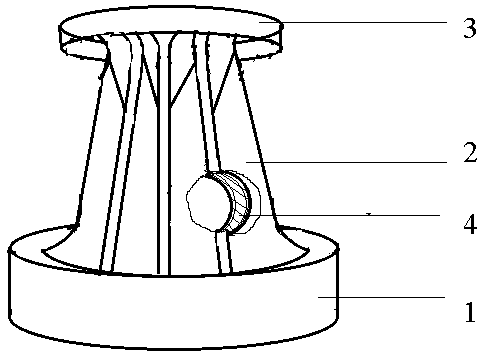

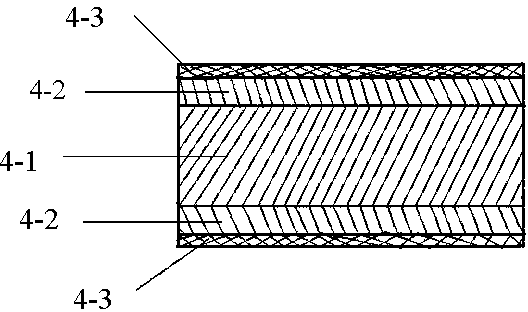

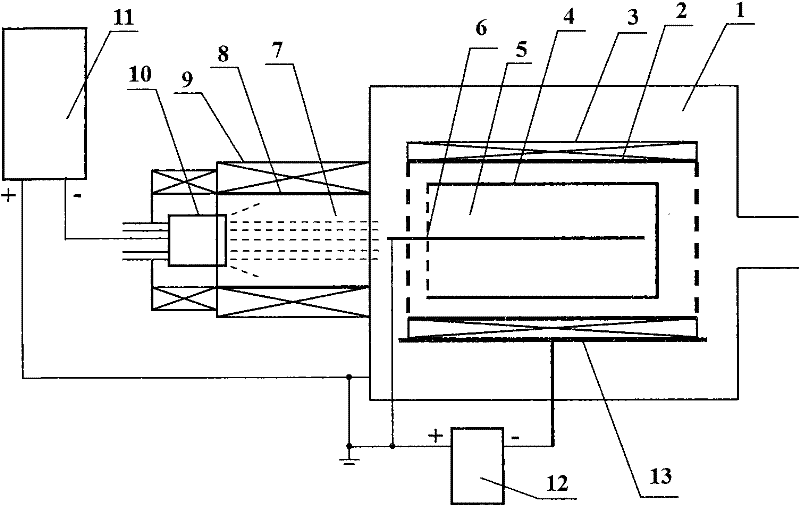

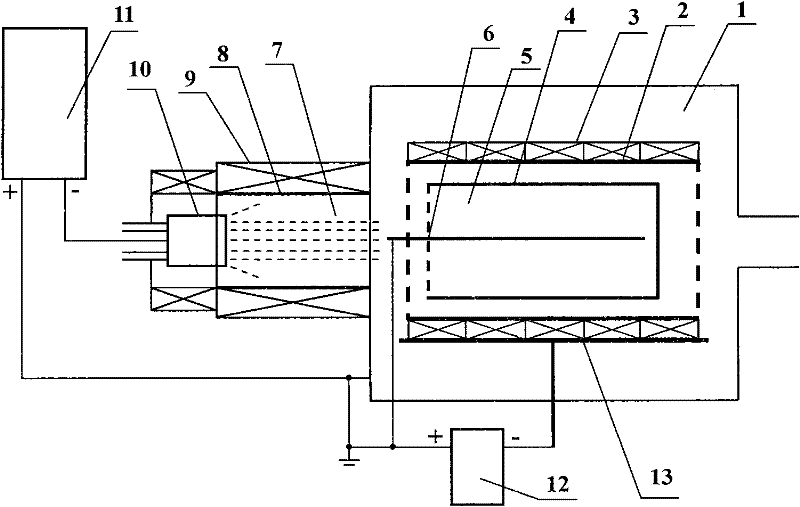

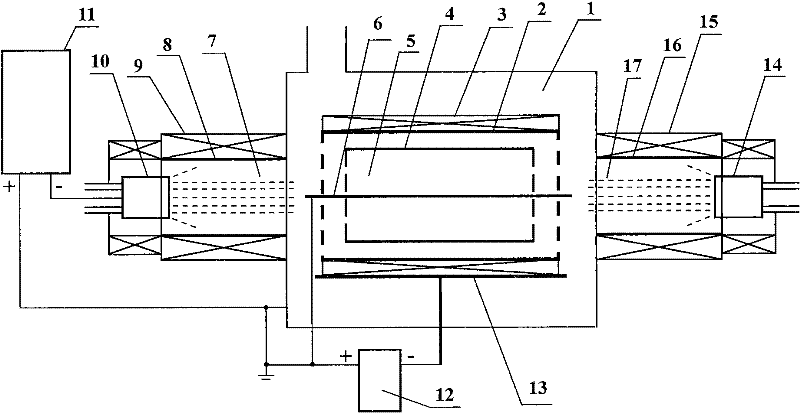

Outside loop control device and method for realizing plasma beam focusing in Hall thruster

InactiveCN101969737AAchieve focusEasy to implementNuclear energy generationMachines/enginesCapacitanceLoop control

The invention provides an outside loop control device and a method for realizing plasma beam focusing in a Hall thruster and relates to a plasma beam focusing technology in the Hall thruster. The device and method solve the problem that the calculation and adjustment are complex and the problem that the controllability is poor in the conventional method for realizing plasma beam focusing in a Hall thruster. The device of the invention comprises an externally powered loop system, an oscillograph, a variable resistor, an adjustable inductance and an adjustable capacitor. The method of the invention includes the following steps of: firstly, starting the Hall thruster and adjusting the Hall thruster to a stable discharge operational state; secondly, starting the oscillograph and adjusting the display scale and the scanning time of the oscillograph so as to clearly display low-frequency oscillation signal on the oscillograph; and finally, adjusting the value of the variable resistor, the adjustable inductance and the adjustable capacitor, keeping the phase-angle difference between the voltage and current fluctuation in the Hall thruster at 180 degrees so as to realize and control the plasma beam focusing in the Hall thruster. The device and the method are suitable for the plasma beam focusing in the Hall thruster.

Owner:HARBIN INST OF TECH

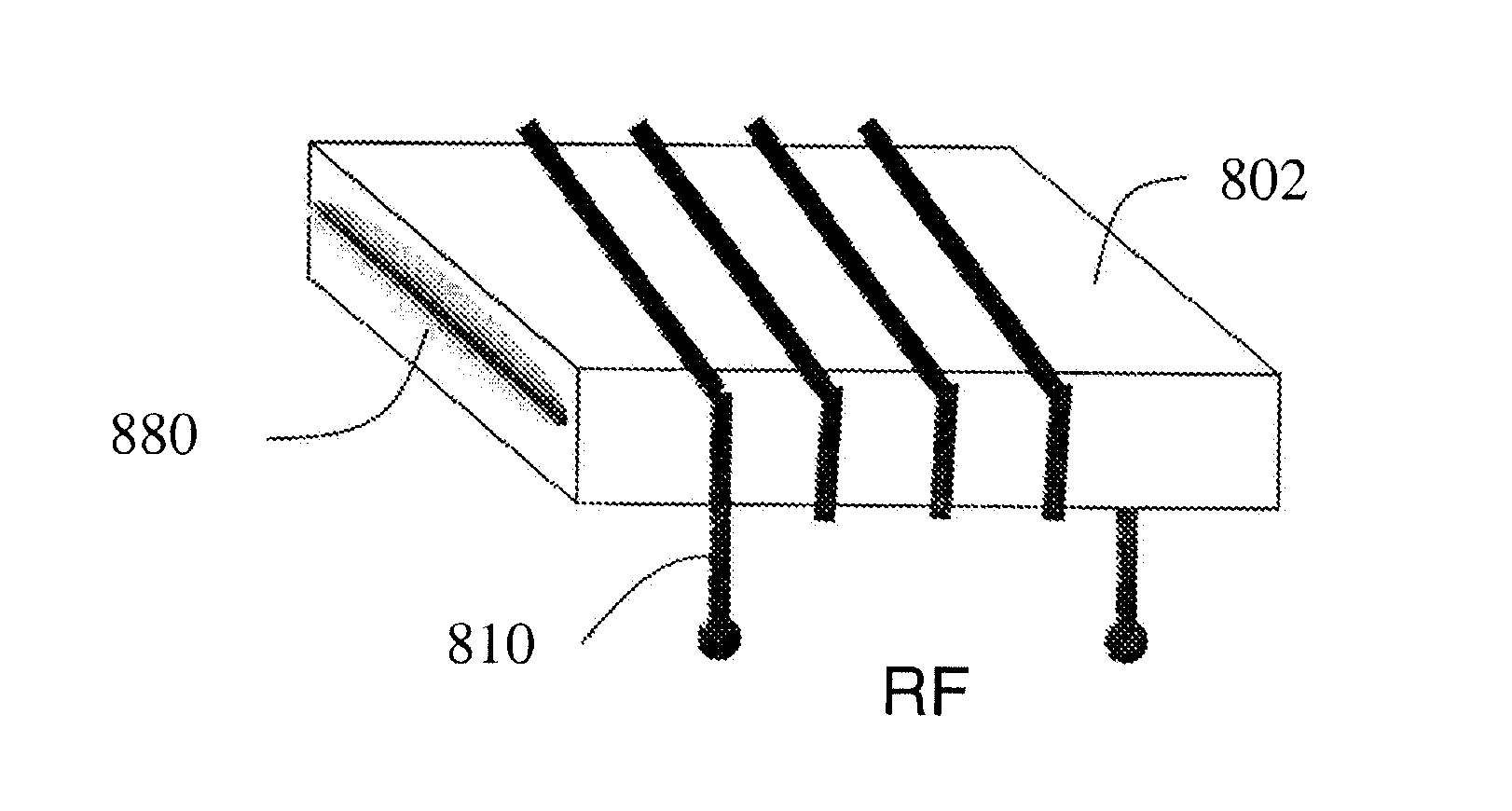

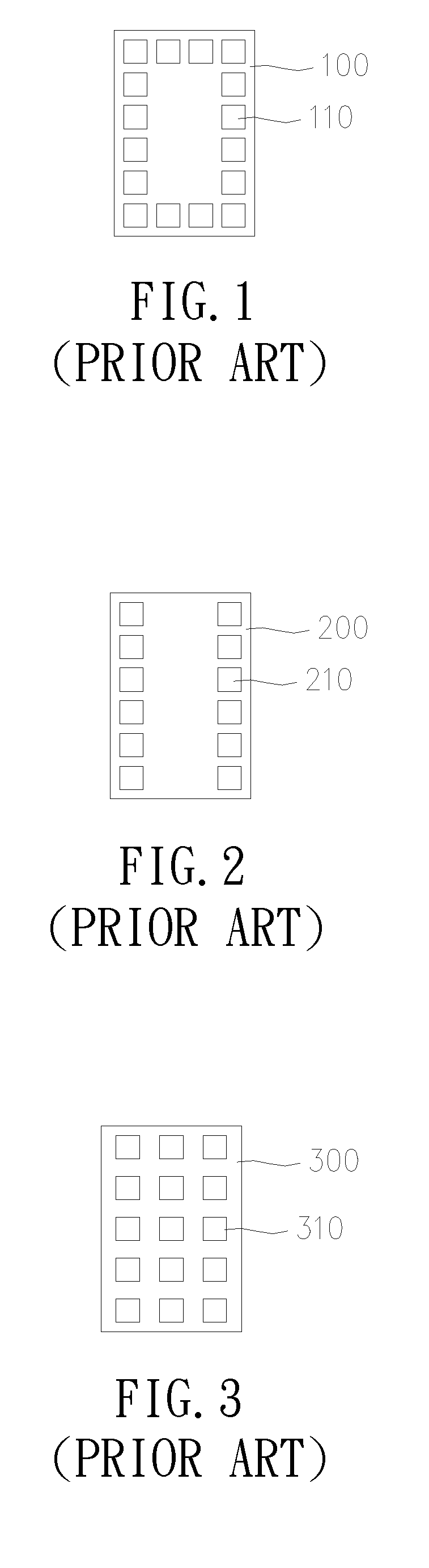

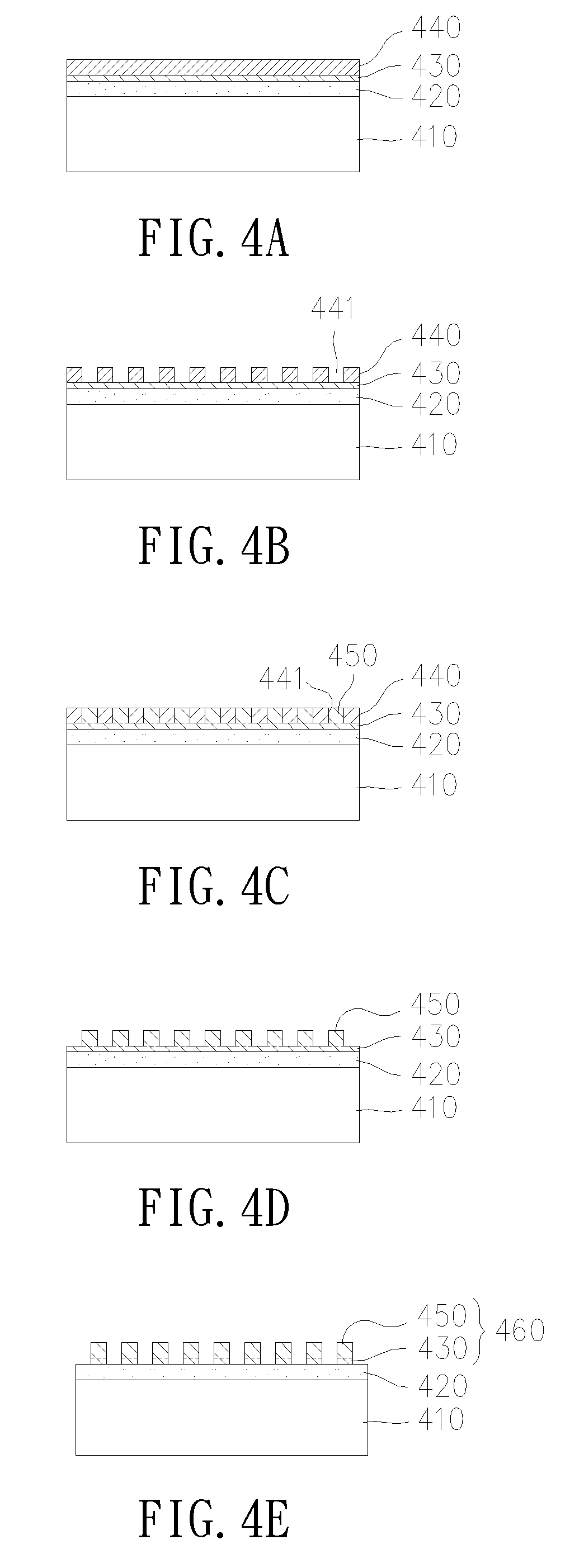

Method for making a conductive film and a probe card using the same

InactiveUS20090091343A1Large area detection abilityEasy maintenanceLine/current collector detailsElectrical measurement instrument detailsDielectricProbe card

A method for manufacturing a conductive film as well as the structure thereof and a probe card using the same are provided in the invention. The conductive film is substantially a stacked structure of a specific thickness formed by the adhering and stacking of at least an substrate in a vacuum environment by the use of surface processing and mechanical healing whereas each substrate has an array of metal micro-threads formed thereon, in which the plural metal micro-threads, each being wrapped in an insulating film, are arranged on the substrate to form the array in a unidirectional and single-layered manner by the use of a LIGA process and polymer thin film technology. In an exemplary embodiment, the insulating film can be a polymer thin film of high dielectric constant, being made of a material such as polydimethylsiloxane (PDMA) or polyimide (PI); and the metal micro-thread is made of a high conductivity and high strength Ni—Co alloy. Moreover, the so-formed conductive film can be cut into any desired dimensions by the use of an energy beam, such as laser beam, ion beam and plasma beam, etc. while combining the conductive film with a panel so as to be used for forming a probe card with large area detection ability that is low-cost, ease-to-maintain and capable of being adapted for wafers of various bonding pad arrangements.

Owner:IND TECH RES INST

Electrosurgical apparatus to generate a dual plasma stream and method thereof

ActiveUS8795265B2Small equivalent capacitanceGood effectSurgical instruments for heatingPlasma currentElectrosurgery

The present disclosure relates to an electrosurgical apparatus to generate a dual plasma stream to perform electrosurgery on a surgical site on a patient. The apparatus and method of the present disclosure generates a hot gas jet to a surgical site by generating two plasma beams that are electrically up to 180 degrees out of phase from each other. Since each beam uses the other beam to establish plasma currents at a load, the combined dual plasma stream can be used on non-conductive surfaces, e.g., a tissue at the surgical site. Furthermore, by applying different flow rates to the plasma beams, various scanning effects by the hot gas jet can be achieved.

Owner:BOVIE MEDICAL CORPORATION

Nearly isothermal heat pipe heat sink

InactiveUS7677299B2Mechanical stiffnessCost-effectiveSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat sink

A nearly isothermal heat pipe heat sink is provided. The heat sink includes a flat heat pipe connected to one or more flat vapor chambers using a conduit and a heat pipe. The connected flat heat pipe and the flat vapor chambers form a common vapor domain. Fins are attached on the outer surfaces of the flat heat pipe and the flat vapor chambers. Various capillary structures are also provided for fabricating flat heat pipes. A panelized welding process is further provided for fabricating flat heat pipes or flat vapor chambers. The panelized welding process uses either friction stir welding (FSW) or plasma beam welding to transversely join the panels that form the flat heat pipes or the flat vapor chambers.

Owner:ZHENG WEN CHUN

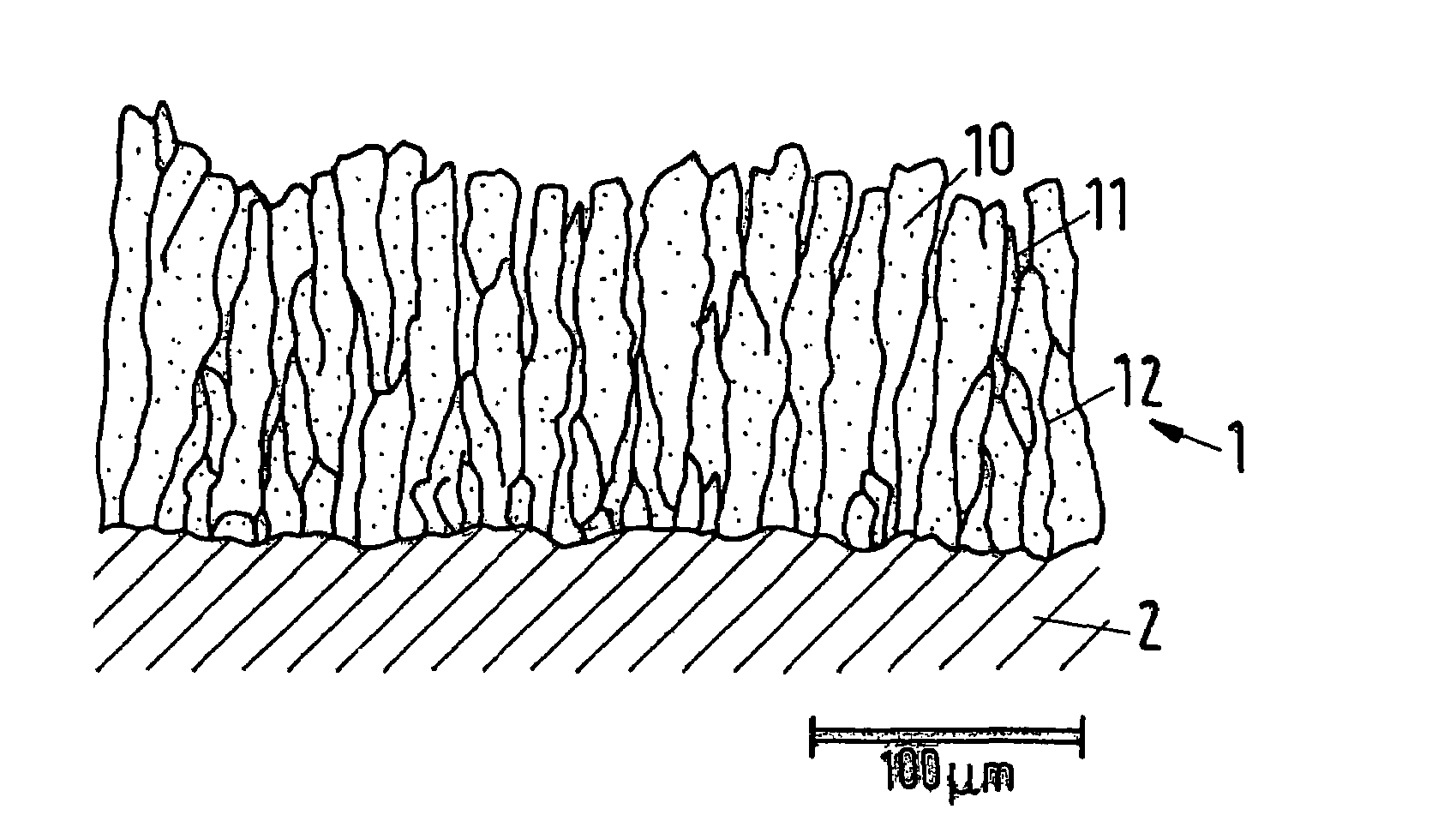

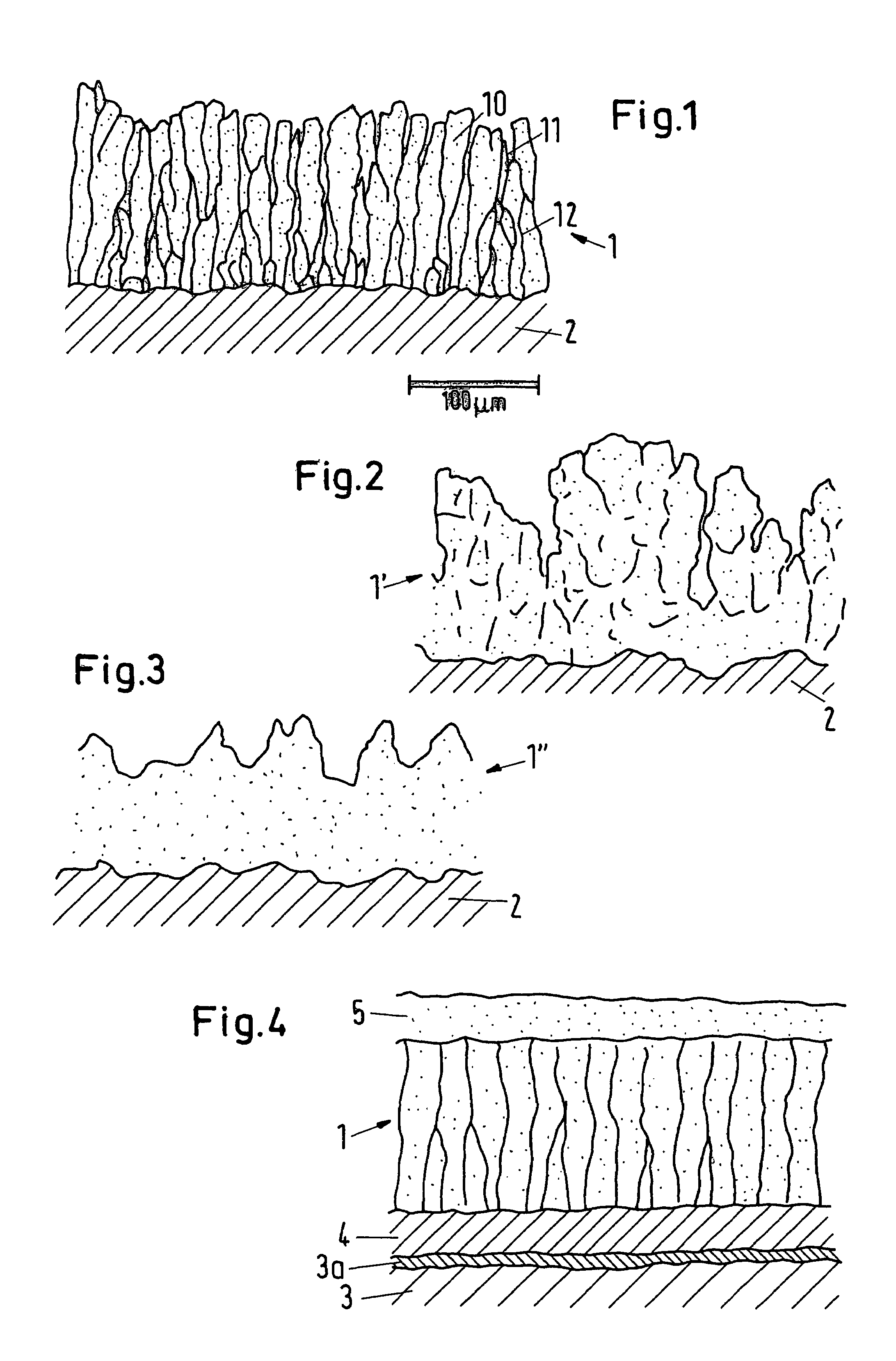

Plasma spraying method

InactiveUS7678428B2Short processing timeMolten spray coatingVacuum evaporation coatingGas phaseProduct gas

A method of forming a thermally insulating layer system on a metallic substrate surface is disclosed. The method includes: forming a plasma beam; introducing a coating material in the form of a powder having particles in the range between 1 and 50 μm, carried by a delivery gas into the plasma beam, so as to form a powder beam; defocusing the powder beam by using the plasma beam with a sufficiently high specific enthalpy and by maintaining a process pressure between 50 and 2000 Pa for at least partially melting and vaporizing at least 5% by weight of the powder, so as to form a vapor phase cloud; and forming from the vapor phase cloud onto the metallic substrate surface an insulating layer, being a part of the insulating layer system, having an anisotropic columnar microstructure having elongate particles; wherein the anisotropic columnar microstructure is aligned substantially perpendicular to the metallic substrate surface and low-density transition regions with little material delimit the elongate particles relative to one another.

Owner:SULZER METRO AG

Induction-cladded gradient hard composite material coating technique

ActiveCN104894558AOvercome limitationsImprove thermal shock resistanceMolten spray coatingSurface engineeringCrack free

The invention discloses an induction-cladded gradient hard composite material coating technique, and belongs to the technical field of material surface engineering. The surface of a metal part is pre-coated with a gradient coating, a hard phase and a metal phase of the gradient coating are composited, the pre-coating has element gradient distribution that the content of the hard phase increases gradually from an inner layer to an outer layer, the volume percent of the hard phase ranges from 0% to 90%, the pre-coating is inductively heated and re-melted in a protective atmosphere, and a continuous gradient hard composite material coating, which is combined with the base body interface of the metal part and is compact and flawless, is formed through mutual diffusion of the layers. By the gradient hard composite material pre-coating, the problems such as overhigh heat stress caused by conventional metallurgical bonding of induction-cladded hard coatings, concentrated coating impact heat stress caused by cladding of laser beams, electron beams and plasma beams and base body structure degradation caused by overall coating heating, brazing and sintering of the part are solved; the continuous gradient hard composite material coating meets requirements on high performance such as wear, corrosion and impact resistance of the part.

Owner:DALIAN UNIV OF TECH

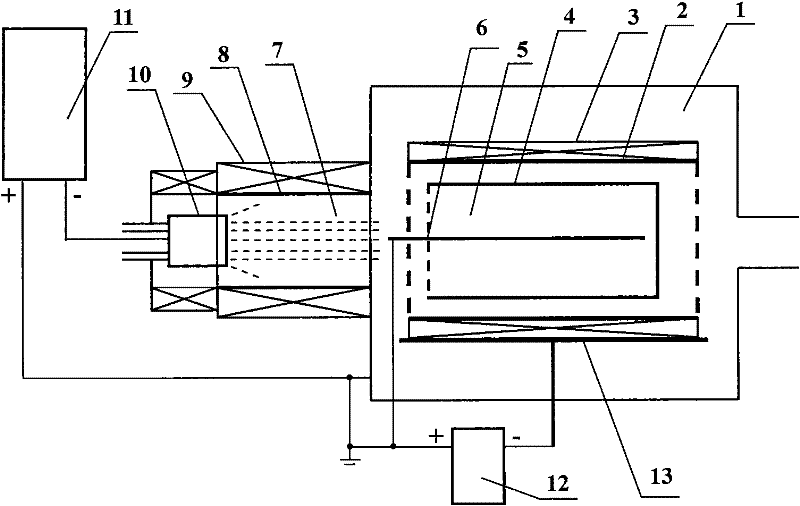

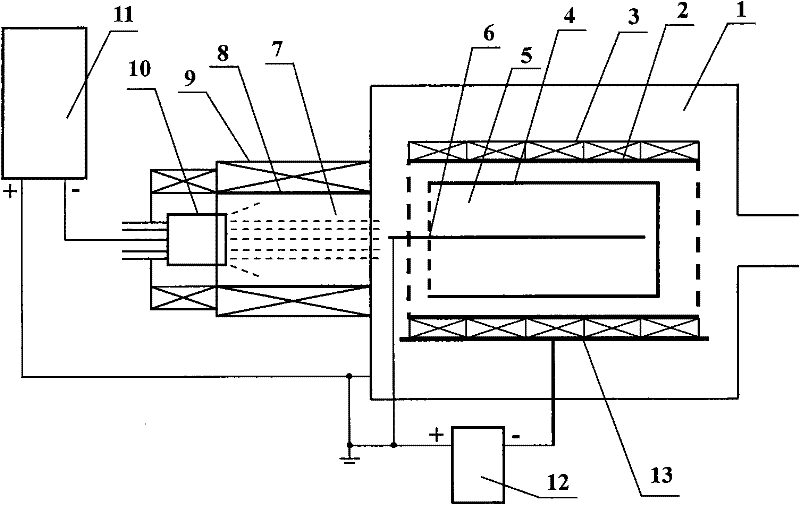

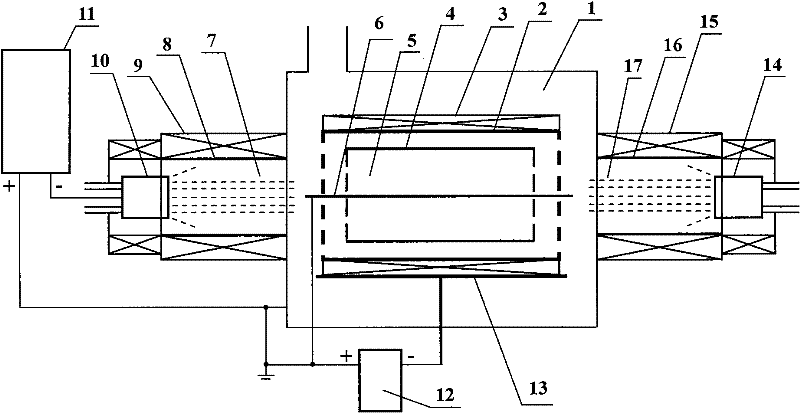

Method for plating inner surface of long tube through arc ion plating with magnetic field and electric field enhancement

InactiveCN102345101AGuaranteed Utilization EfficiencyEasy Control FocusVacuum evaporation coatingSputtering coatingTransmission channelVacuum chamber

The invention which belongs to the field of material surface modification relates to a method for plating the inner surface of a long tube through arc ion plating with magnetic field and electric field enhancement. The method is characterized in that: the movement locus of a plasma beam is constrained and controlled by a magnetic field in the process of arc ion plating, two sets of magnetic fieldgeneration apparatuses are arranged in an arc ion plating deposition apparatus, one set is arranged on a plasma transmission channel outside a vacuum chamber, the plasma beam is focused with the magnetic field to constrain the cross section diameter and the transmission efficiency of the plasma beam in transmission, and the other set is arranged on the outer side of a tubular workpiece in the vacuum chamber to guide the plasma beam to diffuse along the axial direction of the center of the tubular workpiece; and electric field enhancement is utilized in the arc ion plating because the electricfield allows the accelerated directional flow of the plasma to be realized, and the electric field enhancement is realized through arranging a pulse electric field in the workpiece. By utilizing the constraint and the control of the magnetic field and the electric field to the plasma beam, a purpose that the plasma deposites the film on the inner surface of the tube is realized, so the method is suitable for plating the inner surface of tubular workpieces which is used as a service surface.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for enhancing blade surface of metal hydraulic turbine runner by combining electrical sparkle deposition and plasma cladding

InactiveCN103834893AImprove wear resistanceHigh hardnessMolten spray coatingWear resistantShock resistance

The invention relates to a method for enhancing blade surface of a metal hydraulic turbine runner by combining electrical sparkle deposition and plasma cladding. The method can be used for effectively solving the problems of poor surface hardness, wear resistance, corrosion resistance, shock resistance and the like of a blade of the hydraulic turbine runner and prolonging of the service life of the metal hydraulic turbine runner. The method comprises the following steps: cladding the blade surface of the hydraulic turbine runner with alloy powder by using inoxidizability plasma beams so as to form an alloy coating, and then depositing WC (Wolfram Carbide) ceramic hard alloy by using electrical sparkles on the basis of the plasma cladding coating so as to form an electrical sparkle deposition and plasma cladding combined composite coating. The method is simple and practicable; the formed electrical sparkle deposition and plasma cladding combined composite coating is firmly bonded with a matrix and is large in thickness; a bade is high in hardness, good in compactness and wear-resisting property and long in service life; the composite coating gives play to the advantages of low cost, good wear-resistant anti-corrosion performance, high hardness and strength and excellent wear resistance of iron-nickel alloy.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

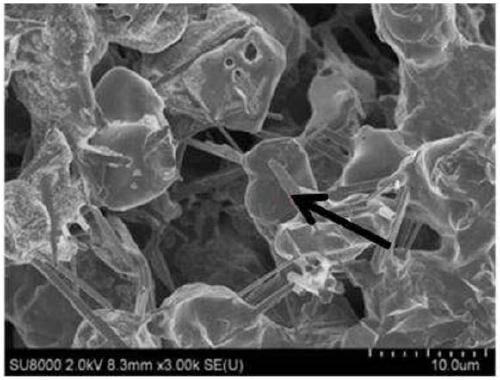

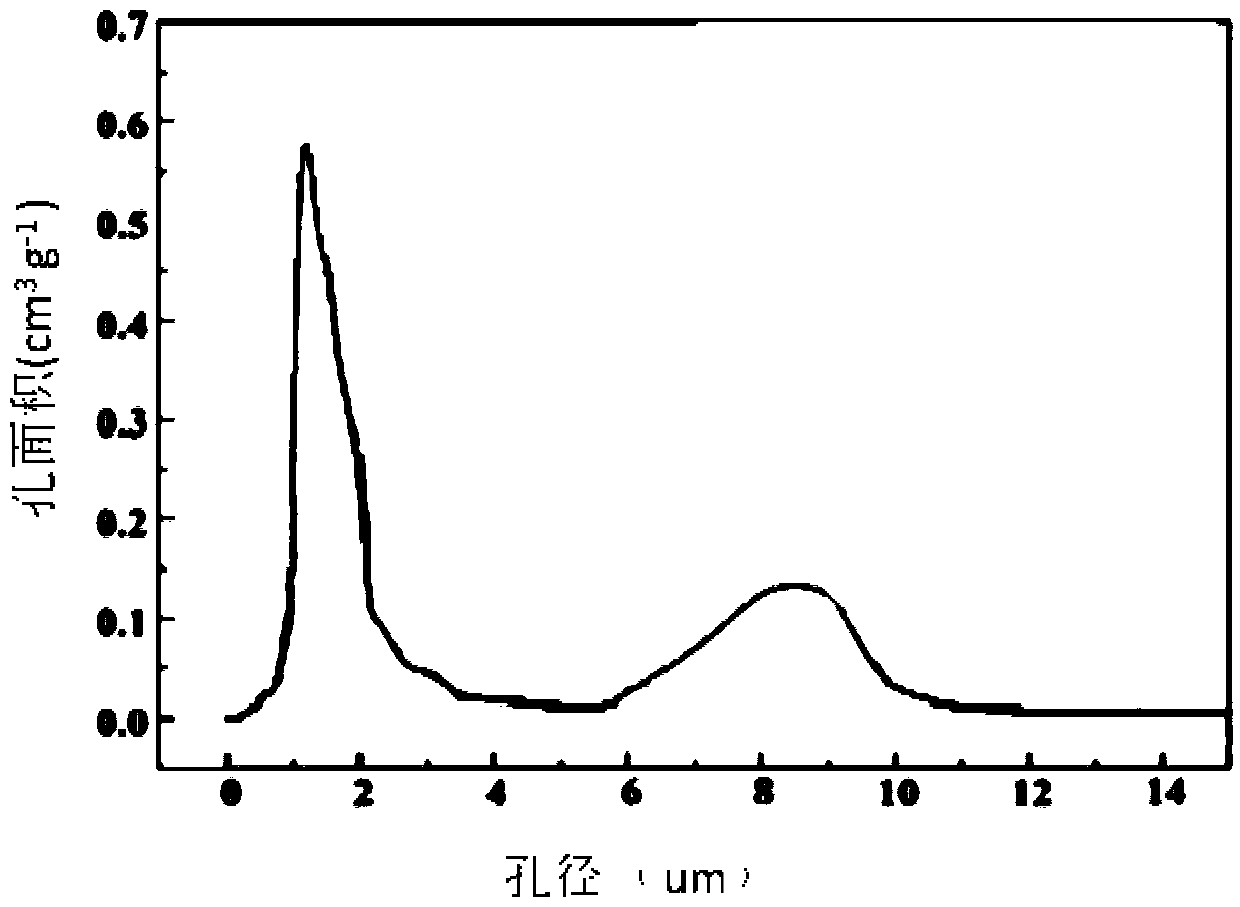

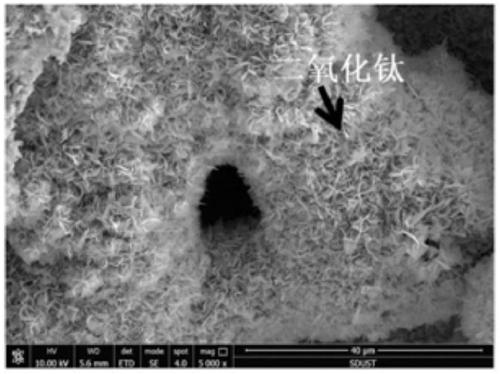

Porous ceramic membrane material for photo-thermal sea water desalination and preparation method and application

ActiveCN109530688AEnhanced light-to-heat conversionImprove catalytic purification effectGeneral water supply conservationWater treatment compoundsWater desalinationChemical synthesis

The invention discloses a porous ceramic membrane material for photo-thermal sea water desalination and a preparation method and application. The preparation method comprises the steps that a porous ceramic membrane foam board is used as a carrier, a nanometer heterostructure layer is synthesized on the carrier through a hydrothermal method, and a porous ceramic heterostructure membrane containingTiO2 on the surface is obtained through further calcination; and the pore diameter of the porous ceramic membrane foam board is 0.1-4.0 [mu]m, and the porosity is 30%-75%. According to the porous ceramic membrane material for the photo-thermal sea water desalination and the preparation method and the application, plasma beam heating control and chemical synthesis are combined, a porous ceramic membrane / nanometer oxide TiO2 heterostructure membrane with a controllable porous structure is prepared, the proportion of a pore forming agent and the technology parameters of plasma beam scanning heating are changed, ceramic foam boards with various porosities and pore diameters are obtained, a gradient structure can be assembled according to actual requirements, and photo-thermal conversion and sea water desalination multifunction application are realized.

Owner:SHANDONG UNIV OF SCI & TECH

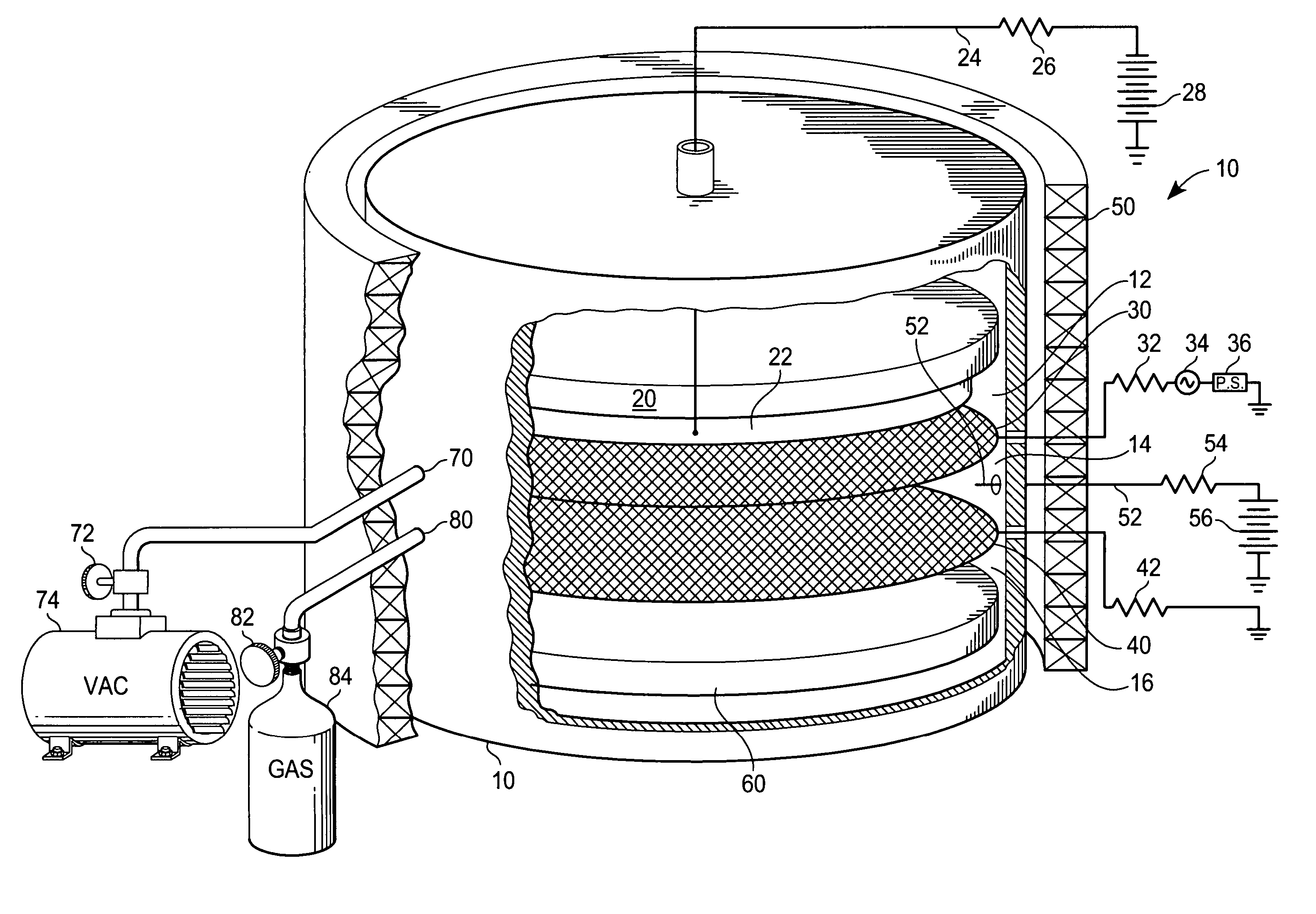

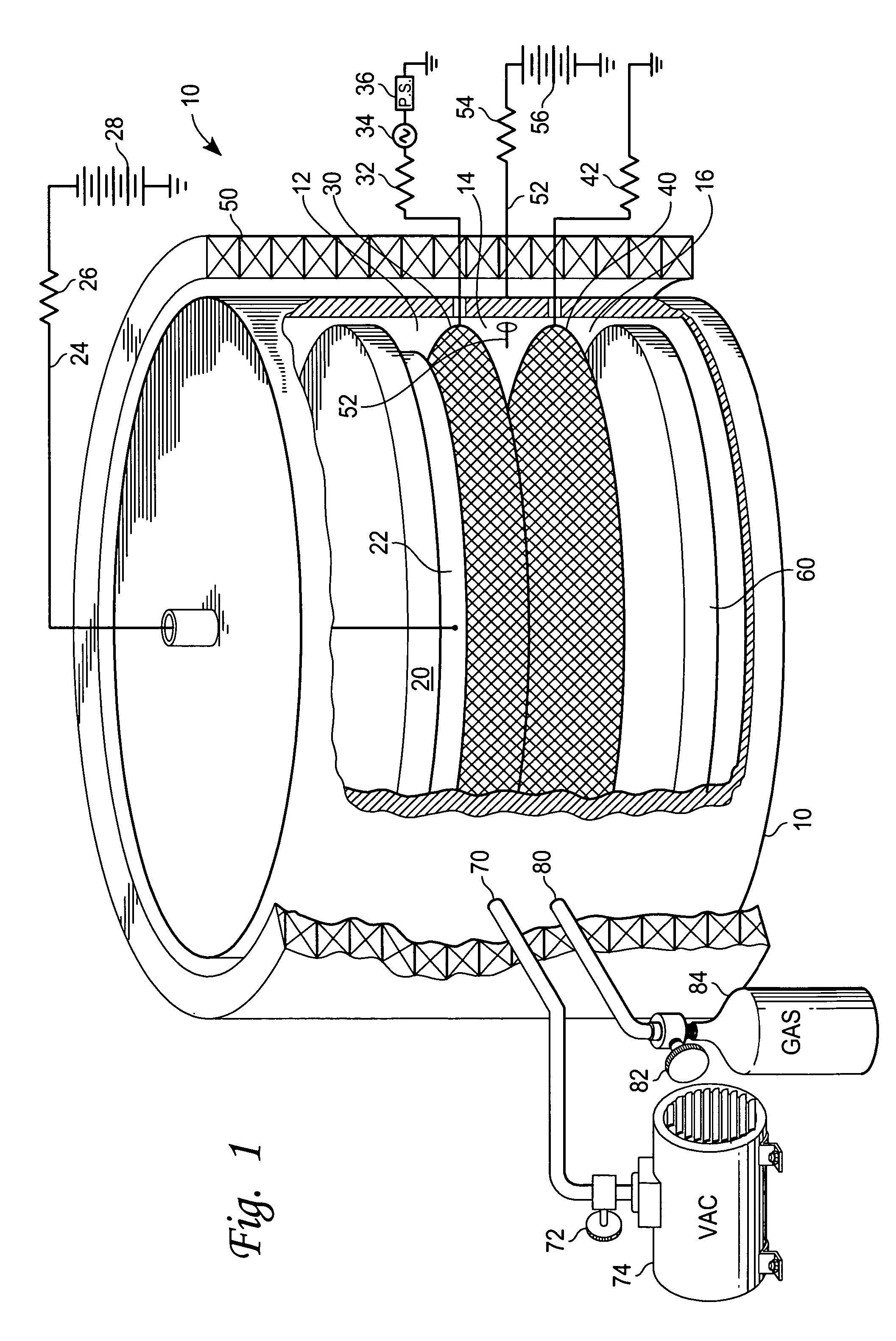

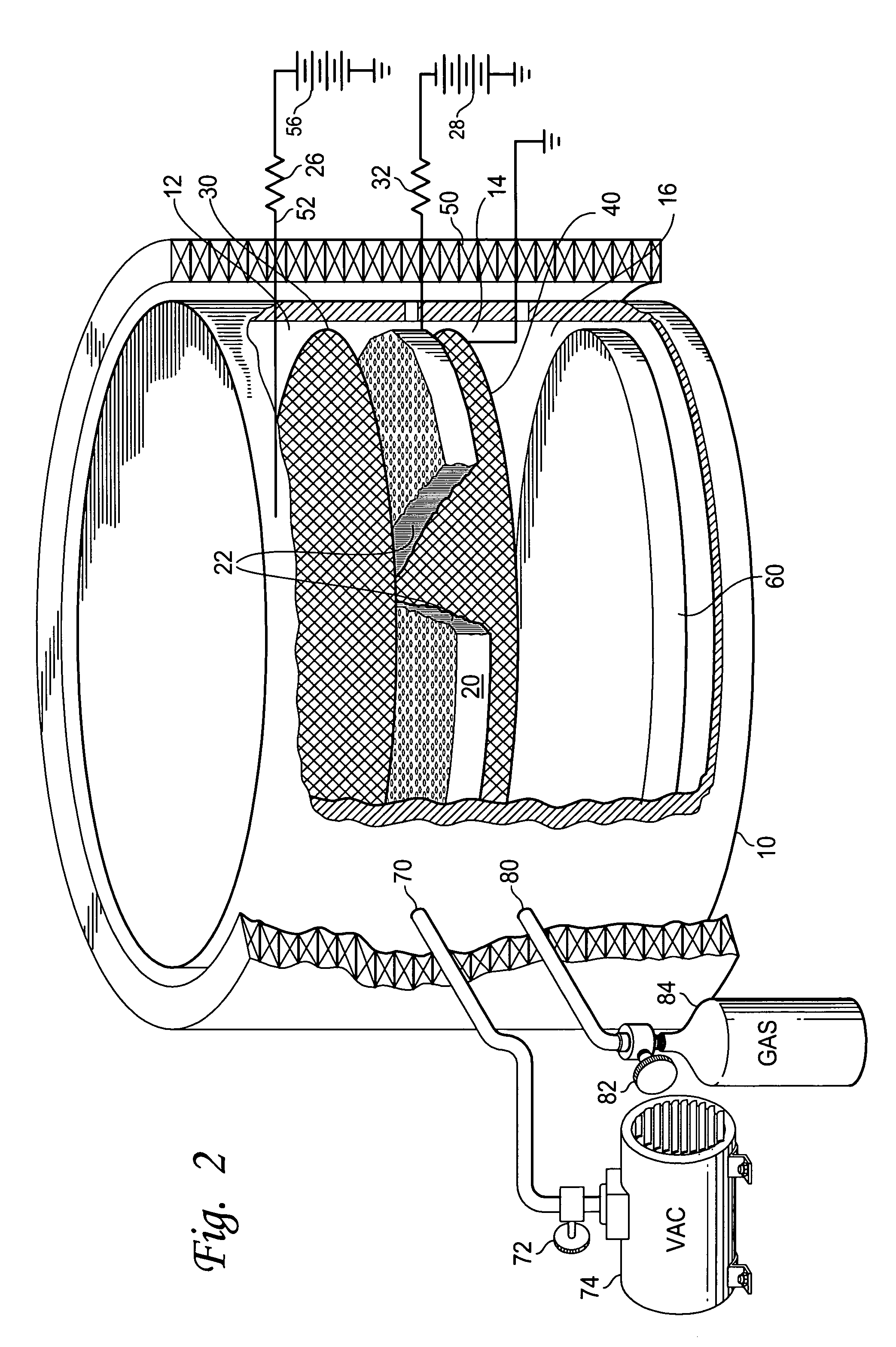

High frequency plasma source

InactiveUS6936144B2Improve versatilityImprove functionalityCellsElectric discharge tubesDistribution systemField coil

A high frequency plasma source includes a support element, on which a magnetic field coil arrangement, a gas distribution system and a unit for extraction of a plasma beam are arranged. Additionally a high frequency matching network is arranged within the plasma source.

Owner:CCR GMBH BESCHICHTUNGSTECH

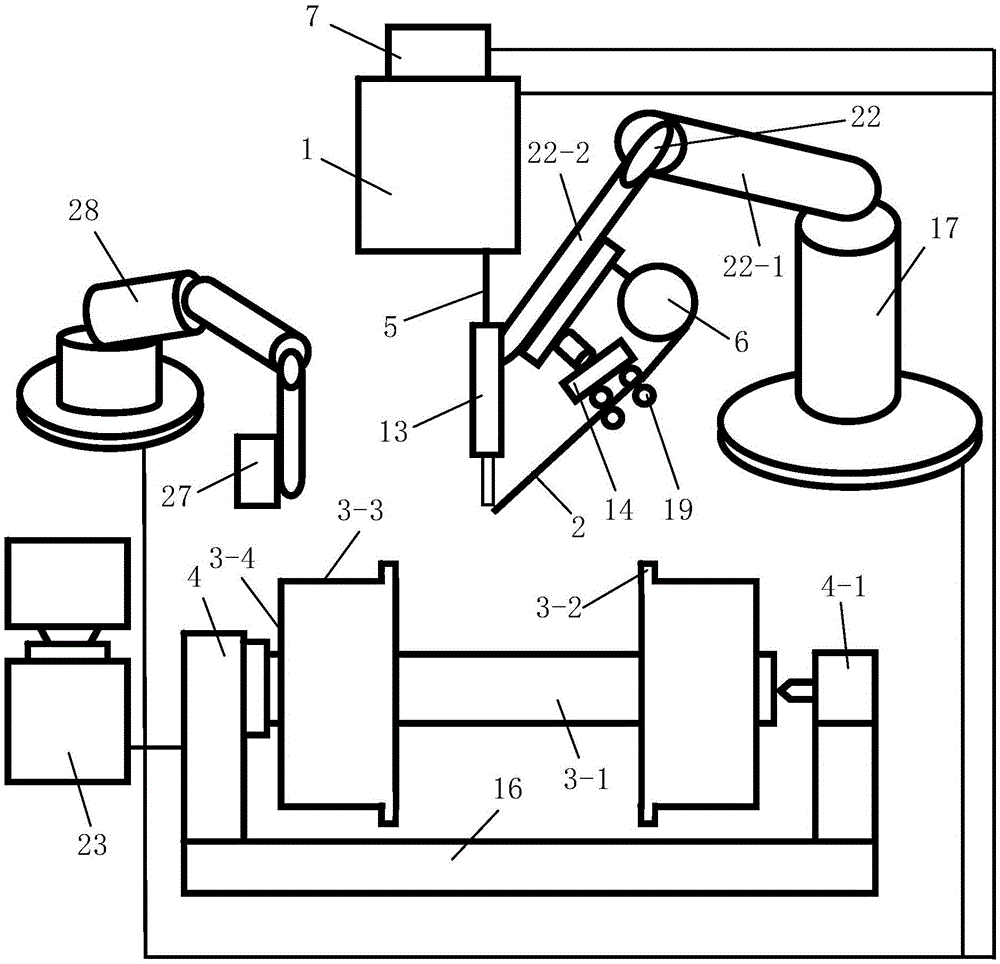

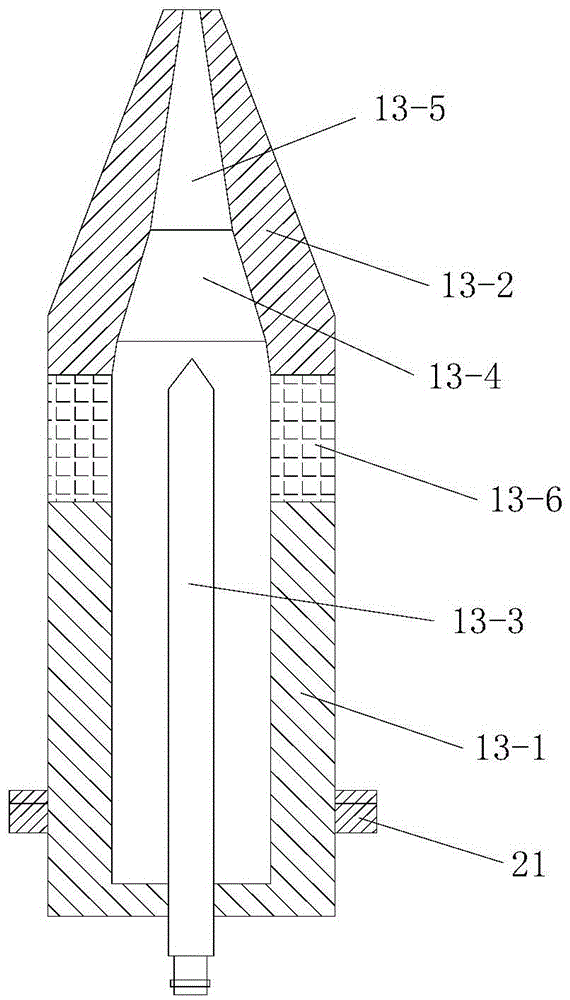

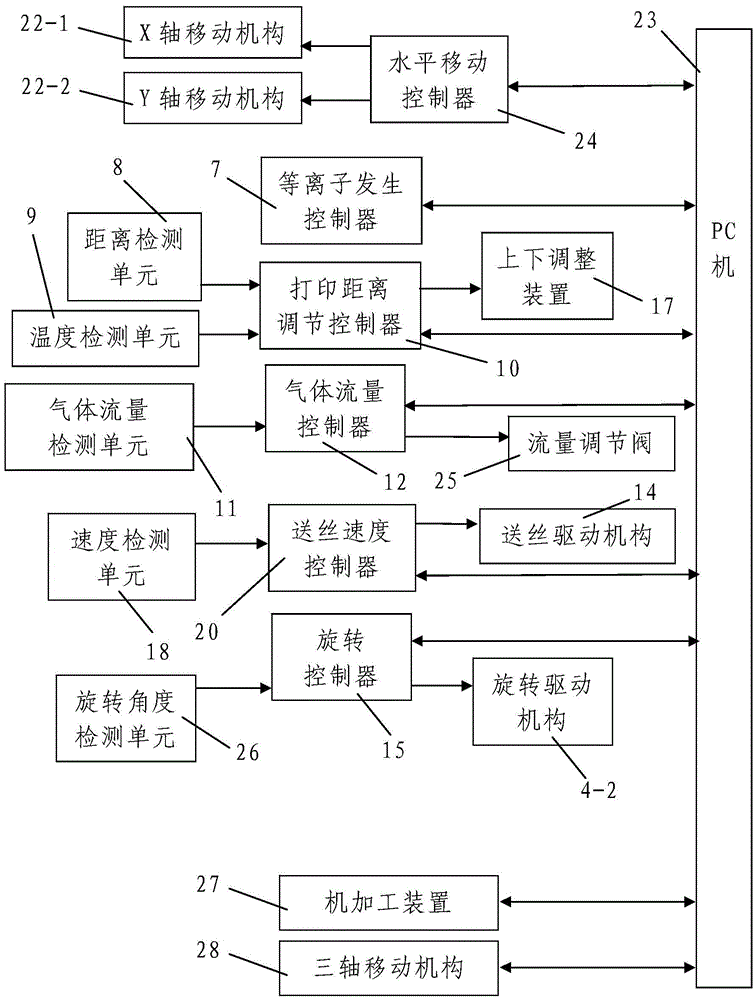

Plasma 3D fast forming and remanufacturing method and equipment of train wheels

InactiveCN105522155ASimple structureReasonable designAdditive manufacturing apparatusIncreasing energy efficiencyMonitoring systemPlasma generator

The invention discloses a plasma 3D fast forming and remanufacturing method and equipment of train wheels. The equipment comprises a monitoring system, a plasma beam machining system, a machining device for machining to-be-repaired train wheels, a three-axis moving mechanism for driving the machining device to move and a horizontal printing platform for placing the to-be-repaired train wheels. The plasma beam machining system comprises a plasma generator, a gas supply device, a feeding device and a printing positioning adjusting device. The monitoring system comprises a horizontal movement controller, a temperature detecting unit, a distance detecting unit, a printing distance adjusting controller and a rotation controller, wherein the temperature detecting unit and the printing distance adjusting controller form a temperature adjusting and control device. The method includes the steps of firstly, detecting train wheel defects; secondly, repairing the train wheels. The plasma 3D fast forming and remanufacturing method and equipment has the advantages that the equipment is reasonable in design, simple to operate, high in efficiency, good in use effect and high in repairing efficiency, a closed forming room is not needed, the repairing process is directly performed under an atmospheric environment, and the repaired train wheels are good in quality.

Owner:SINOADDITIVE MFG EQUIP CO LTD

Method for controlling biological processes in microorganisms

ActiveUS20160023183A1Function increaseBioreactor/fermenter combinationsElectrotherapyMicroorganismBlood plasma

The present invention discloses a method for providing at least one biological effect in at least one microorganism. The aforementioned method comprises steps of: (a) providing a system for administering modified plasma; (b) providing a substrate hosting said at least one microorganism; and (c) administering the generated modified plasma beam in a predetermined pulsed manner to said substrate hosting said at least one microorganism to provide said at least one biological effect to said at least one microorganism. The present invention further provides a system thereof.

Owner:ORTERON T O

Thickness gradient protective overcoat layers by filtered cathodic arc deposition

InactiveUS20050249983A1Simple methodApparatus is enlargedCellsProtective coatings for layersCathodic arc depositionMaterials science

Owner:SEAGATE TECH LLC

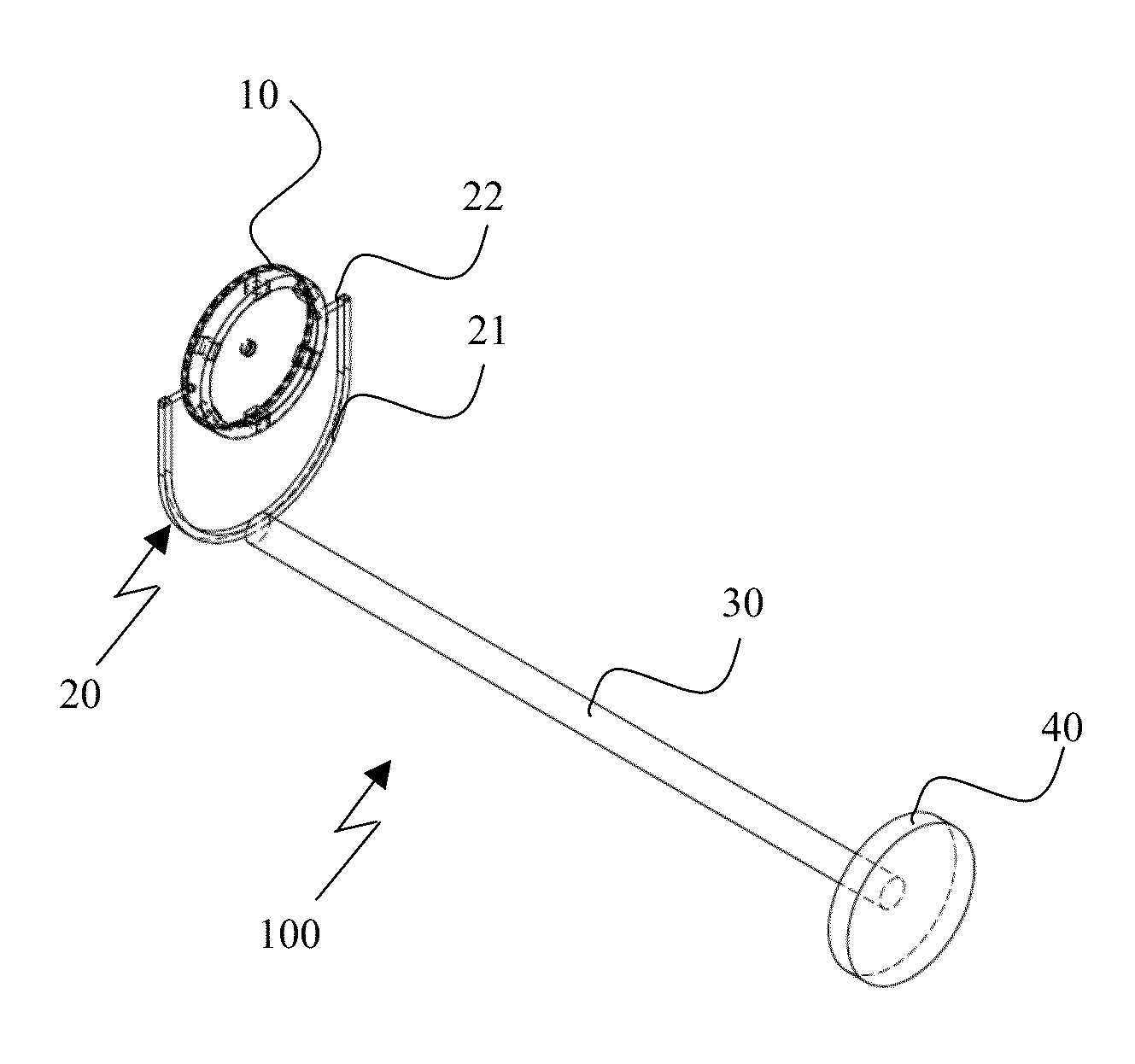

Physical means and methods for inducing regenerative effects on living tissues and fluids

ActiveUS8896211B2Promote functional recoveryElectric discharge tubesContaminated soil reclamationBody fluidNonthermal plasma

The present invention discloses a system for the administration of a plasma modified field (PMF) to a subject comprising: (a) a non thermal plasma (NTP) emitting source for emitting a plasma beam; (b) a plasma modified field coupling mechanism (PMFCM) comprising a plasma beam dish having at least one opening for the passage of said plasma beam; said plasma beam dish having a first surface and a second opposite surface; and (c) a controller for controlling said PMFCM. In a main aspect of the invention, said first surface of said plasma beam dish is mounted with: (i) at least one coupling element selected from the group consisting of: (1) at least one ferroelectric element for providing said field; (2) at least one ferromagnetic element for providing said field; (3) at least one piezoelectric element for providing said field; and (4) at least one piezomagnetic element for providing said field; and (ii) at least one reflecting element. In a further main aspect, the PMFCM and said controller are configured to adjust any of said at least one coupling and reflecting element in a predetermined manner thereby providing said PMF for inducing a therapeutic or regenerative or beneficial effect on said subject. The present invention further discloses methods and use of the aforementioned system.

Owner:ORTERON T O

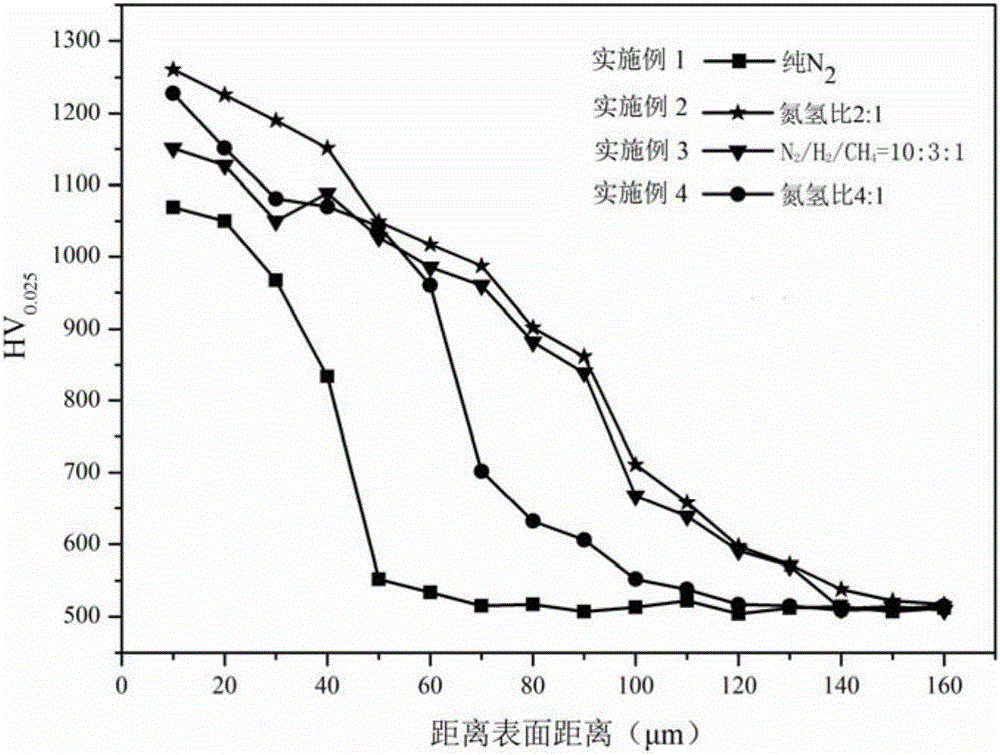

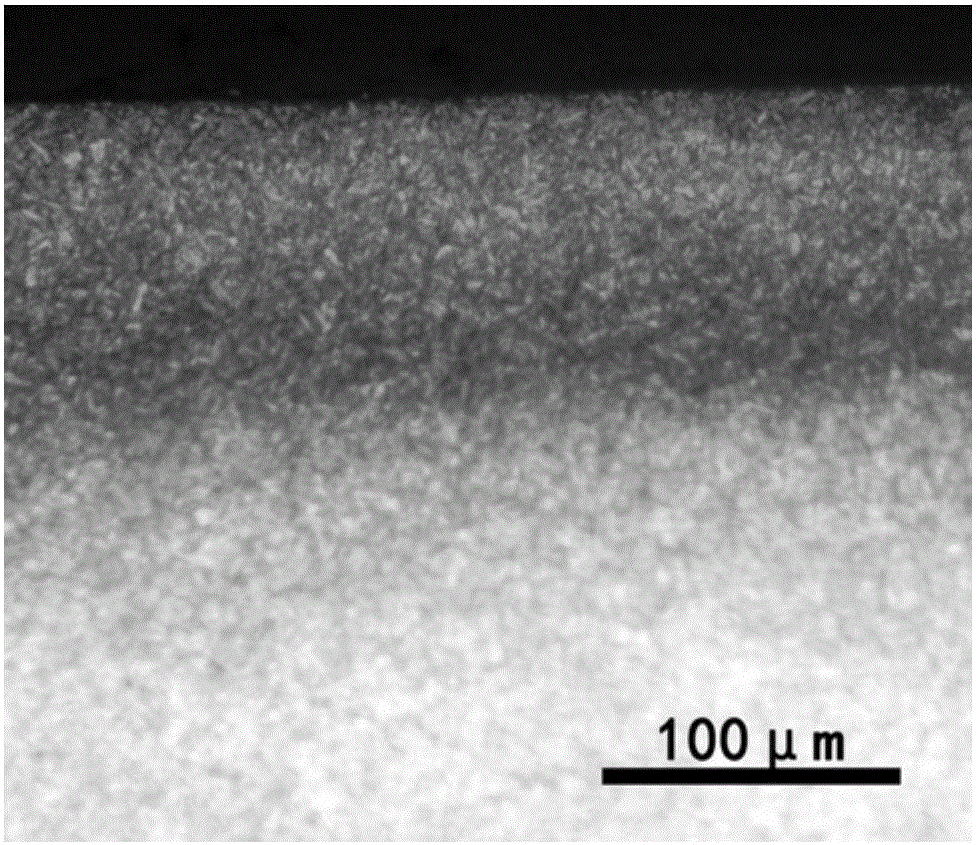

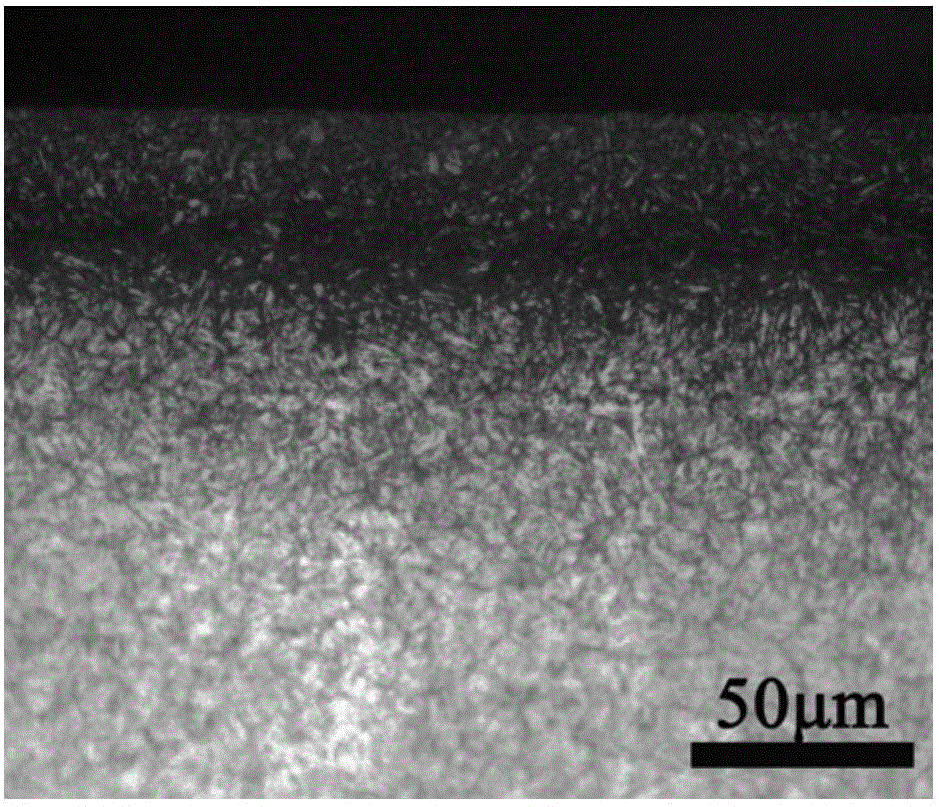

Method for conducting low-temperature efficient rapid ion nitriding on surface of steel workpiece

ActiveCN105839046AIncrease ionization rateReduce the voltage of the glow dischargeSolid state diffusion coatingCleansing AgentsVacuum chamber

The invention discloses a method for conducting low-temperature efficient rapid ion nitriding on the surfaces of a steel workpiece. The method includes the steps that a metal cleaning agent is adopted to remove oil stains on the surface of the workpiece, the pretreated workpiece is fixed to a workpiece rack, a door of a vacuum chamber is closed, and the workpiece rack is started to rotate; the vacuum chamber is pumped until the background vacuum is lower than 1*10<-2> Pa; an assisting heating device is started, the vacuum chamber containing the workpiece is heated to the temperature of 150-200 DEG C; argon is introduced in, a plasma beam is obtained through a hollow cathode ion source, the furnace wall of the vacuum chamber is an anode, and the workpiece rack is a cathode; working gas is introduced, and direct-current bias voltage of 600-800 V is applied to the workpiece; high-ionization-rate plasma containing the working gas is obtained, and the whole test sample is covered with the plasma; and the thickness of a nitriding layer is controlled. The growth rate of the nitriding layer can reach 30-50 micrometers per hour.

Owner:SOUTH CHINA UNIV OF TECH +1

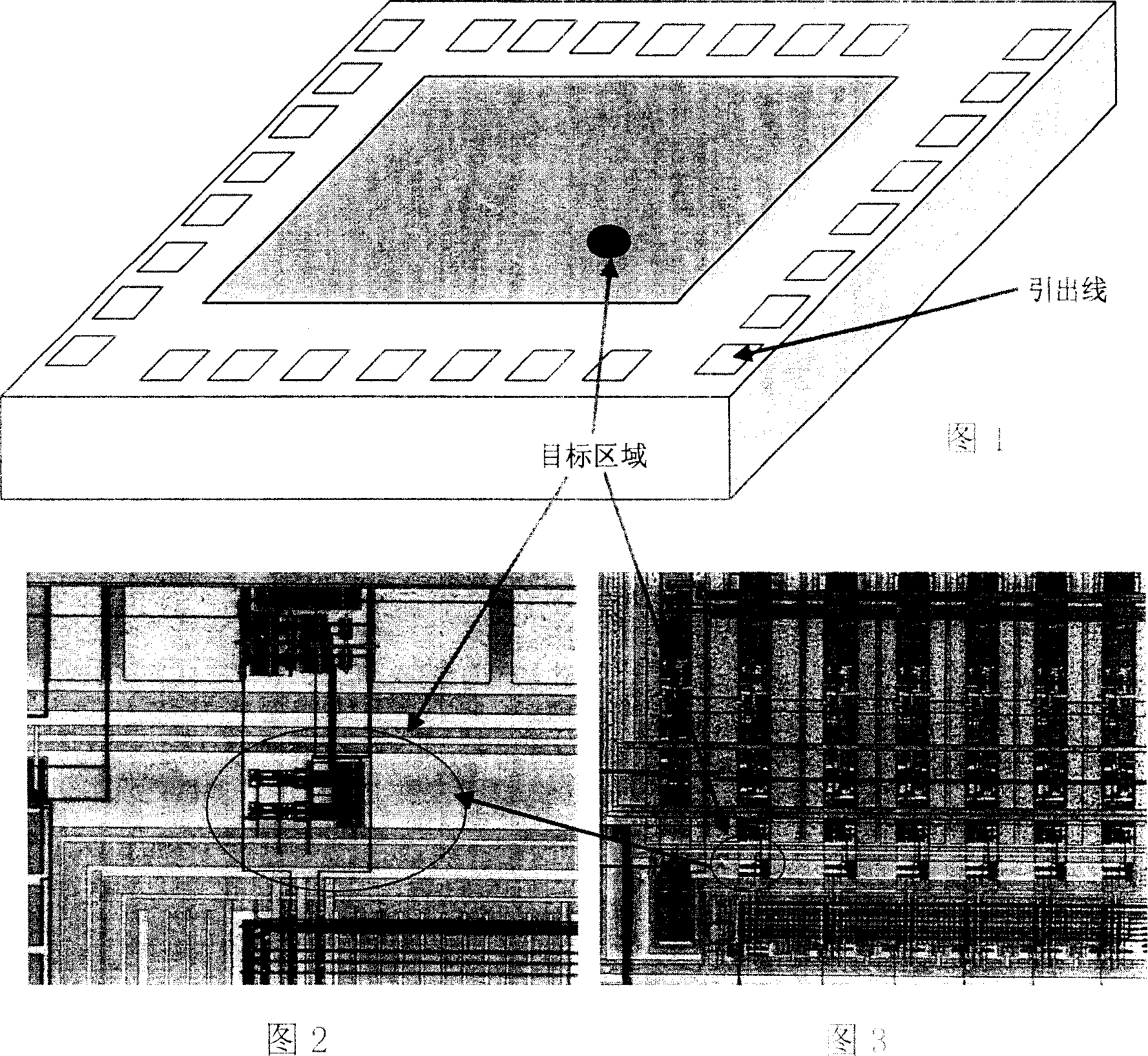

Method for focus plasma beam mending with precisivelly positioning

InactiveCN1941276APrecise positioningEasy to pick upSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingTransmission microscopyIon beam

The invention is concerned with the method that can locate the focusing ion beam to repair the location accurately, it is: locates the aiming area by the optics transmission microscope coordinating with the laser mark, the optics transmission microscope can show the circuitry structure directly by penetrating passive layer, the traditional method uses focusing ion beam imaging that can only show the outer layer situation of the sample, so the invention can locate the repair position of the focusing ion beam. The invention is: the laser energy of mark on the dope is lower that cannot damage the material of the sample. Moreover, the dope can be chemical reagent, such as acetone, that can be easy to scour off and daub times without number, and cannot affect the following steps.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Magnetic field for plating on inner wall of long pipe and field-enhanced arc ion plating device

ActiveCN102345097AGuaranteed Utilization EfficiencyParameters are adjustable and convenientVacuum evaporation coatingSputtering coatingTransmission channelVacuum chamber

The invention, belonging to the field of surface modification on materials, relates to a magnetic field for plating on inner wall of long pipe and a field-enhanced arc ion plating device, characterized in that: the magnetic field is used to restrain and control the plasma beam motion trail in the arc ion plating process, two sets of magnetic field generators are arranged in an arc ion plating deposition device, one set is arranged on the plasma transmission channel outside a vacuum chamber for using the magnetic field to focus the plasma beam and restrain the diameter of cross section and transmission efficiency when transmitting the plasma beam, and the other set is arranged on the outside of a tubular workpiece in the vacuum chamber for guiding the plasma beam to diffuse along with the central axial direction of the tubular workpiece; field enhancement is used in arc ion plating for using the magnetic field to realize accelerated directional flow of plasma, a pulsed electric field is arranged in the workpiece; the magnetic field and electric field are used to restrain and control the plasma beam, so as to realize the coating deposition of the plasma on the inner wall of the tube. The invention is suitable for depositing coatings on the inner wall of tubular workpiece which is used as the service surface.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com