Patents

Literature

189 results about "Nonthermal plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

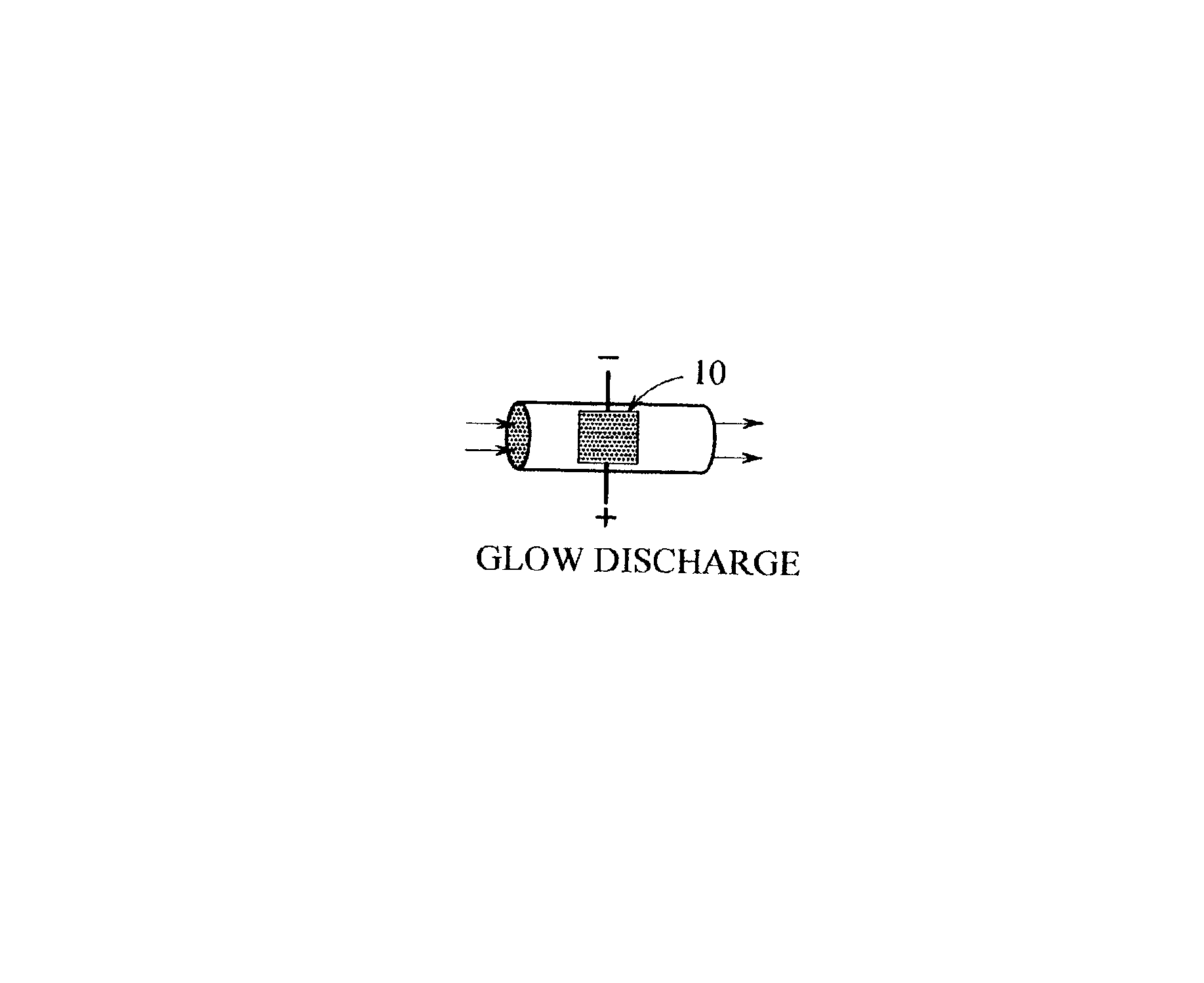

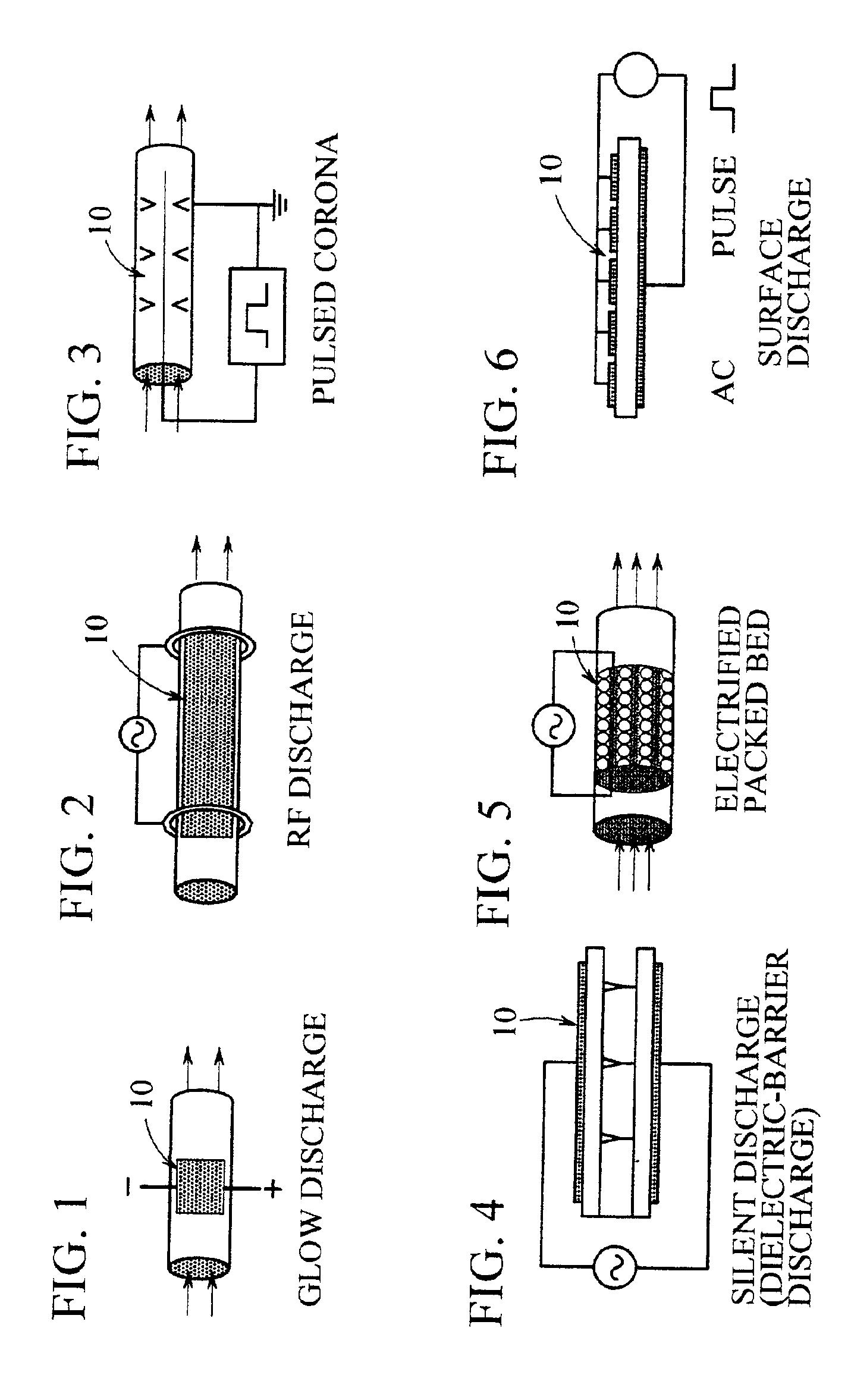

A nonthermal plasma, cold plasma or non-equilibrium plasma is a plasma which is not in thermodynamic equilibrium, because the electron temperature is much hotter than the temperature of heavy species (ions and neutrals). As only electrons are thermalized, their Maxwell-Boltzmann velocity distribution is very different than the ion velocity distribution. When one of the velocities of a species does not follow a Maxwell-Boltzmann distribution, the plasma is said to be non-Maxwellian.

No reduction with diesel fuel reformed by nonthermal hyperplasma

ActiveUS6957528B1Reduce NOxImprove performanceInternal combustion piston enginesExhaust apparatusOn boardExhaust fumes

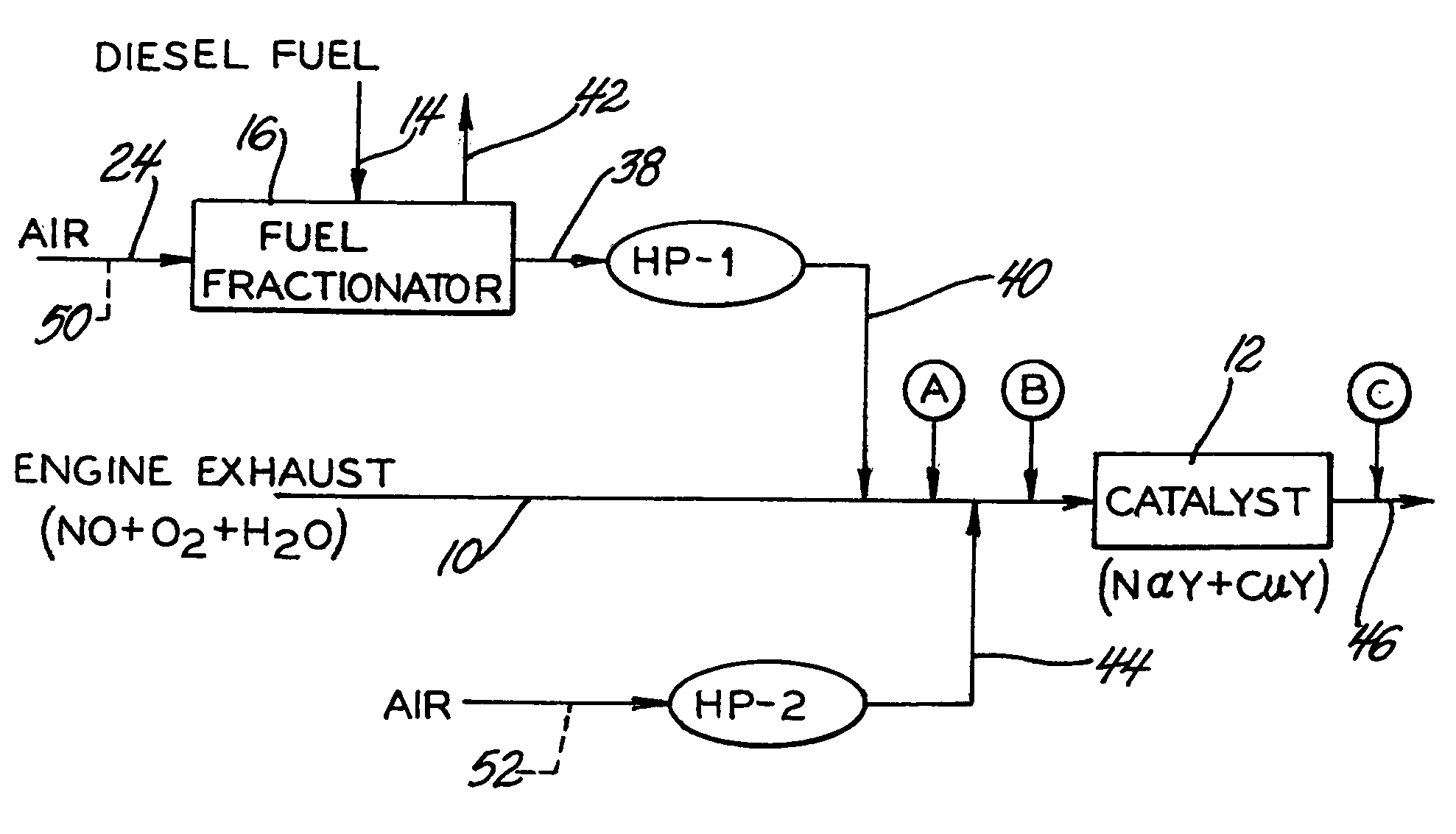

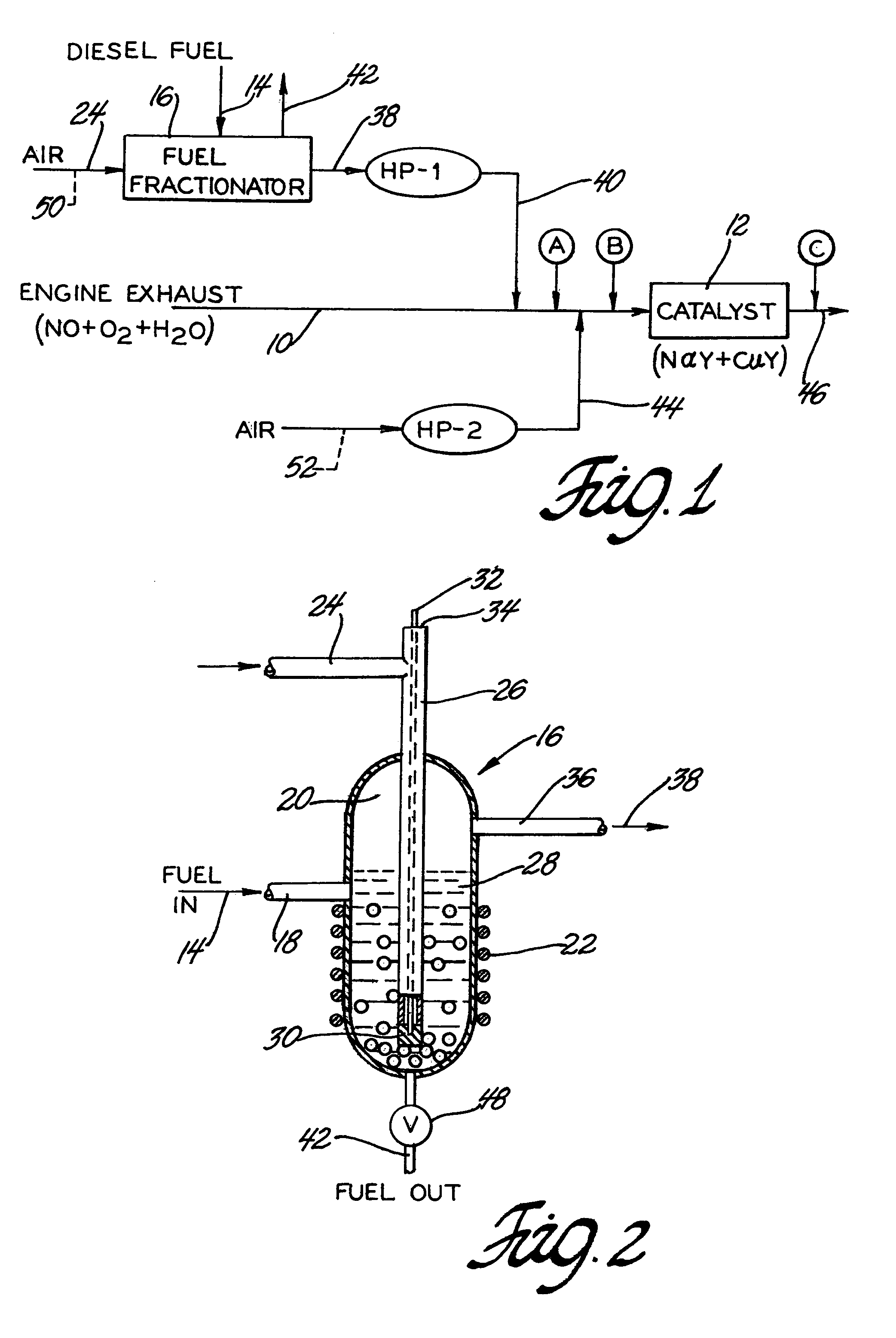

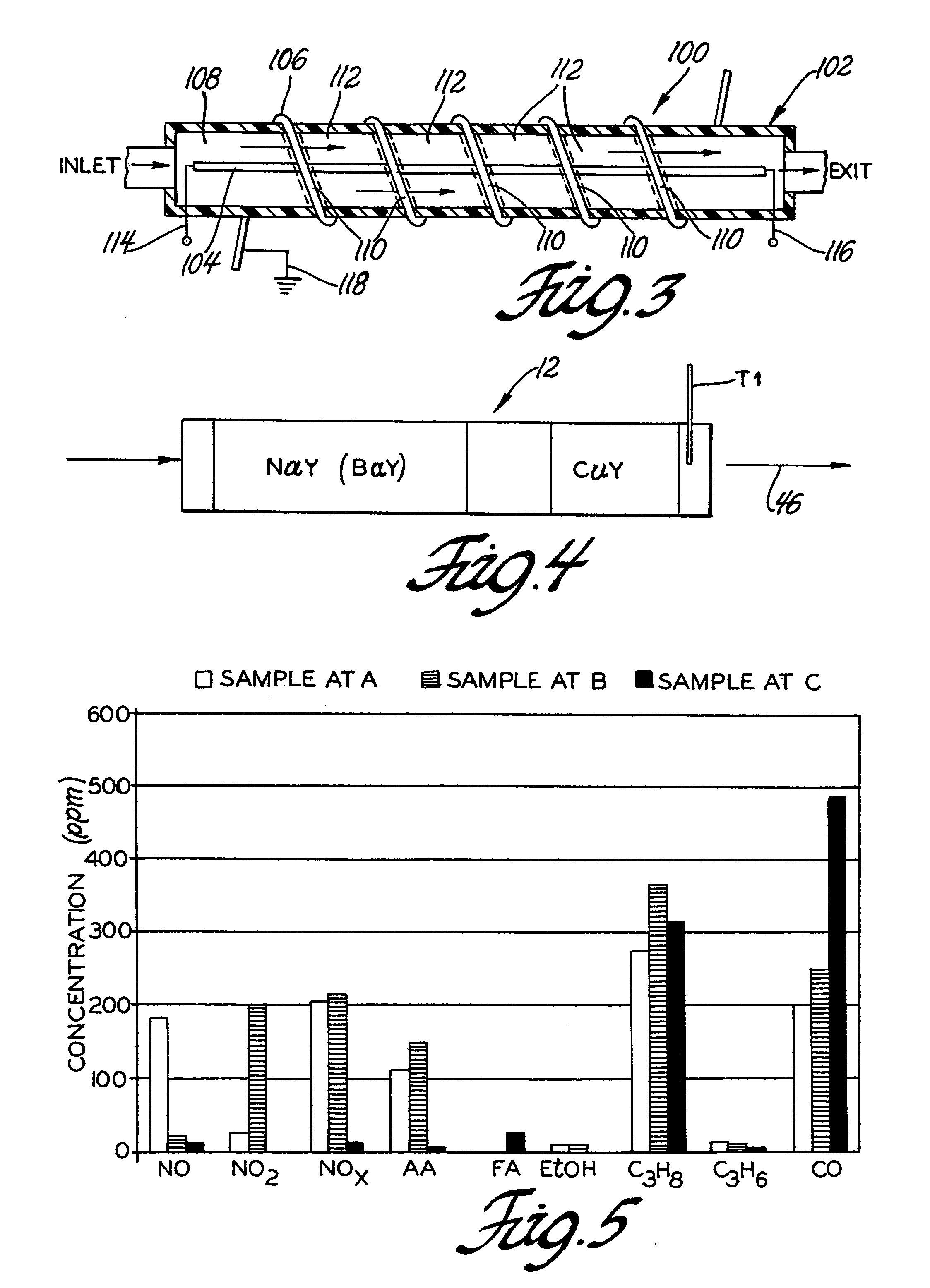

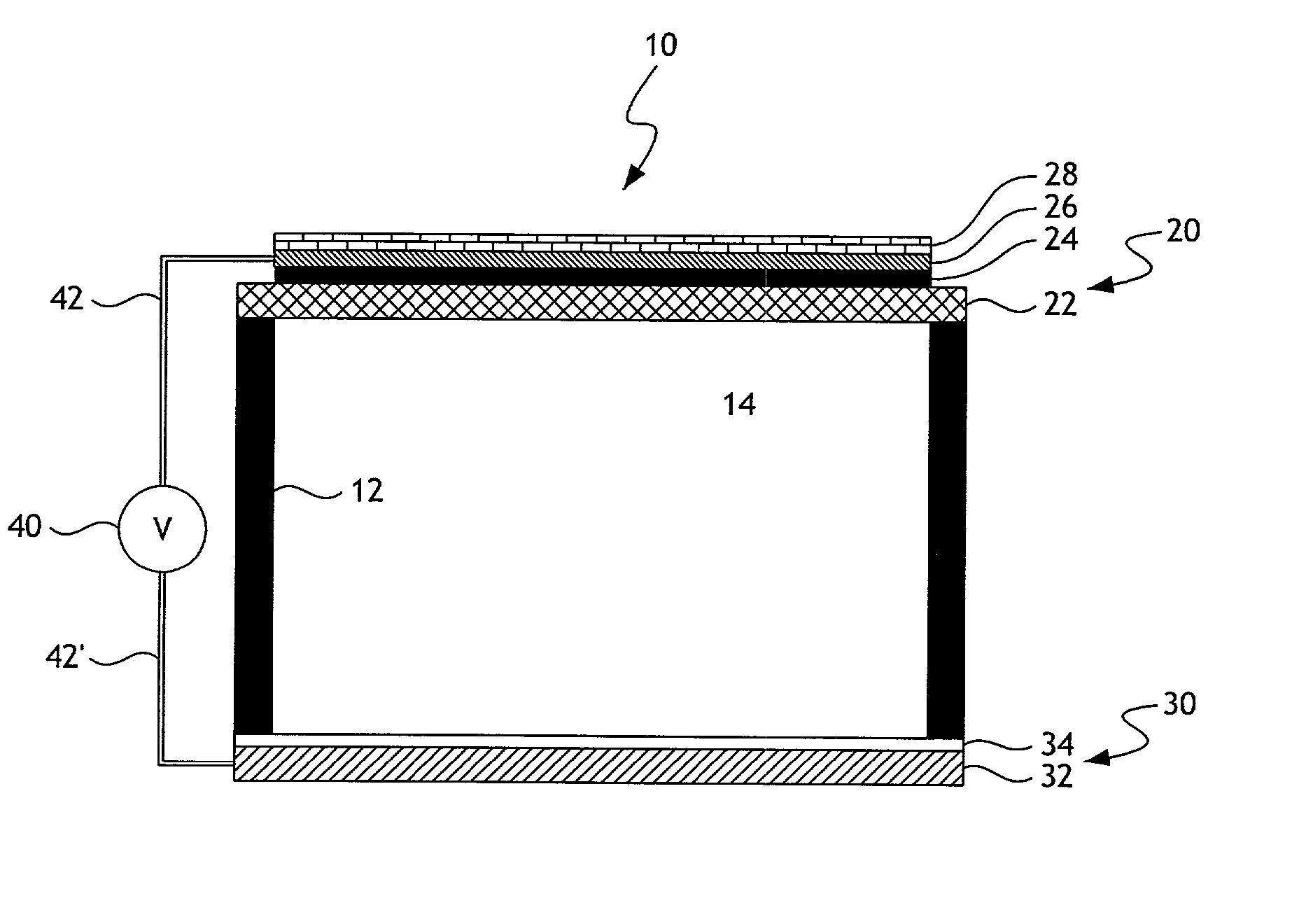

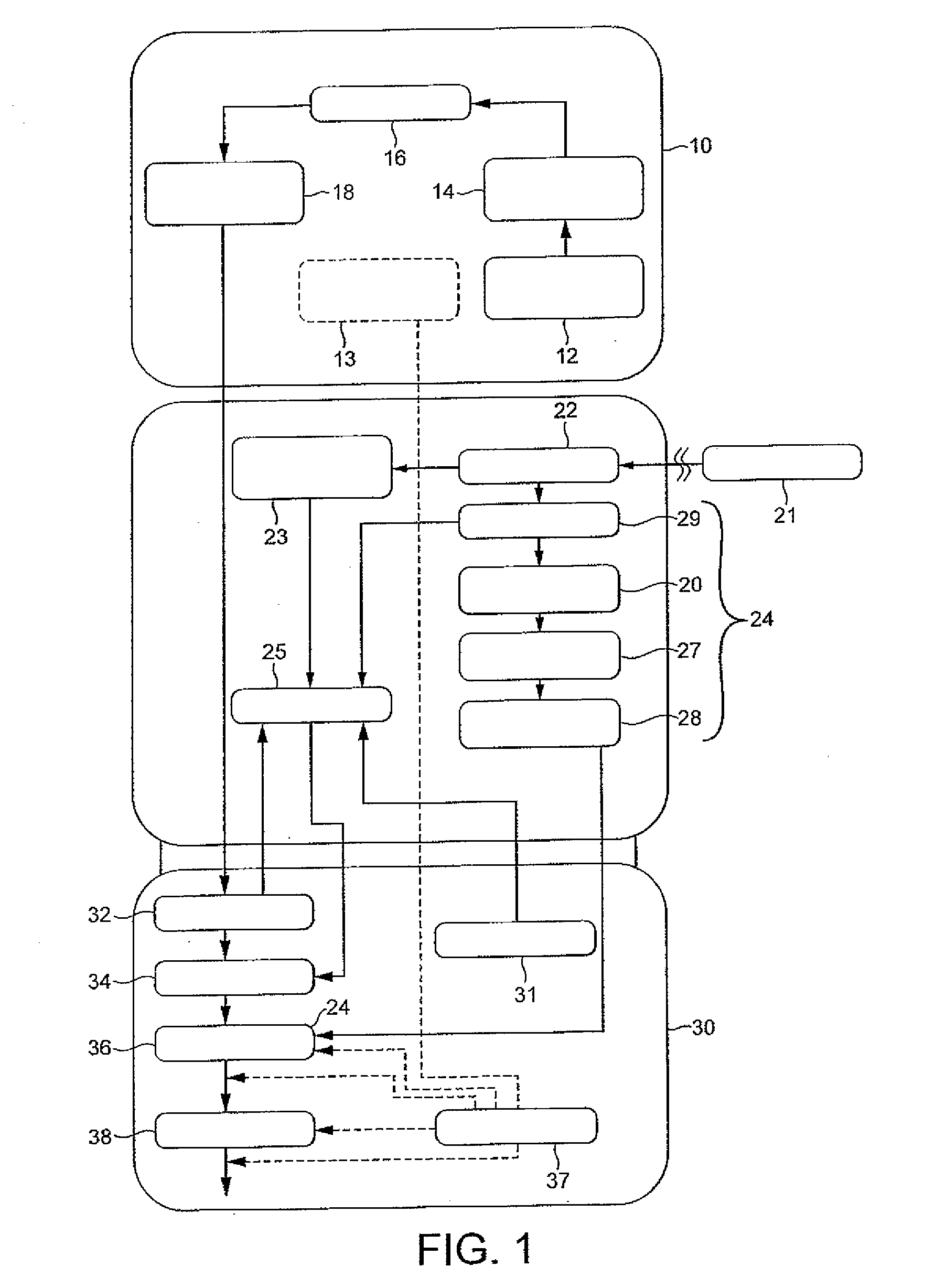

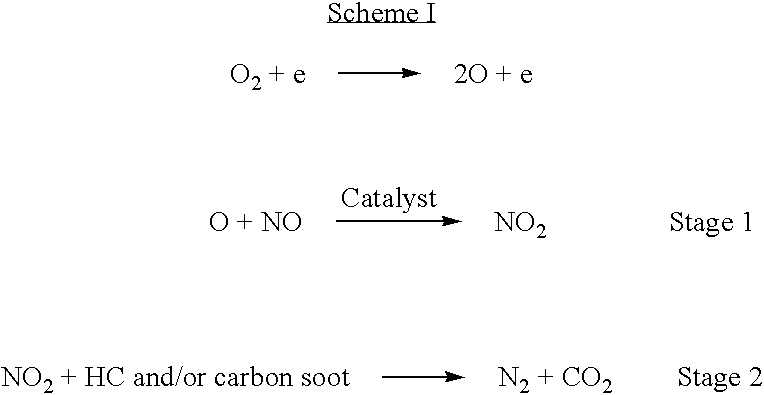

The reduction of NOx in diesel engine exhaust gas, typically at about 200° C. to 400° C., is accomplished using a dual bed NaY—CuY zeolite reduction catalyst. The effectiveness of the catalyst in reducing the nitrogen oxides is markedly increased by the separate and sequential additions of plasma reformed diesel fuel and ozone to the exhaust before it contacts the powdered catalyst. Reformed diesel fuel is obtained by withdrawing fuel from on-board storage, heating the withdrawn volume and stripping a more volatile fraction with air and passing the air / volatile diesel fuel fraction through a non-thermal plasma reactor. Ozone is obtained by blowing ambient air through a second non-thermal plasma reactor.

Owner:GM GLOBAL TECH OPERATIONS LLC

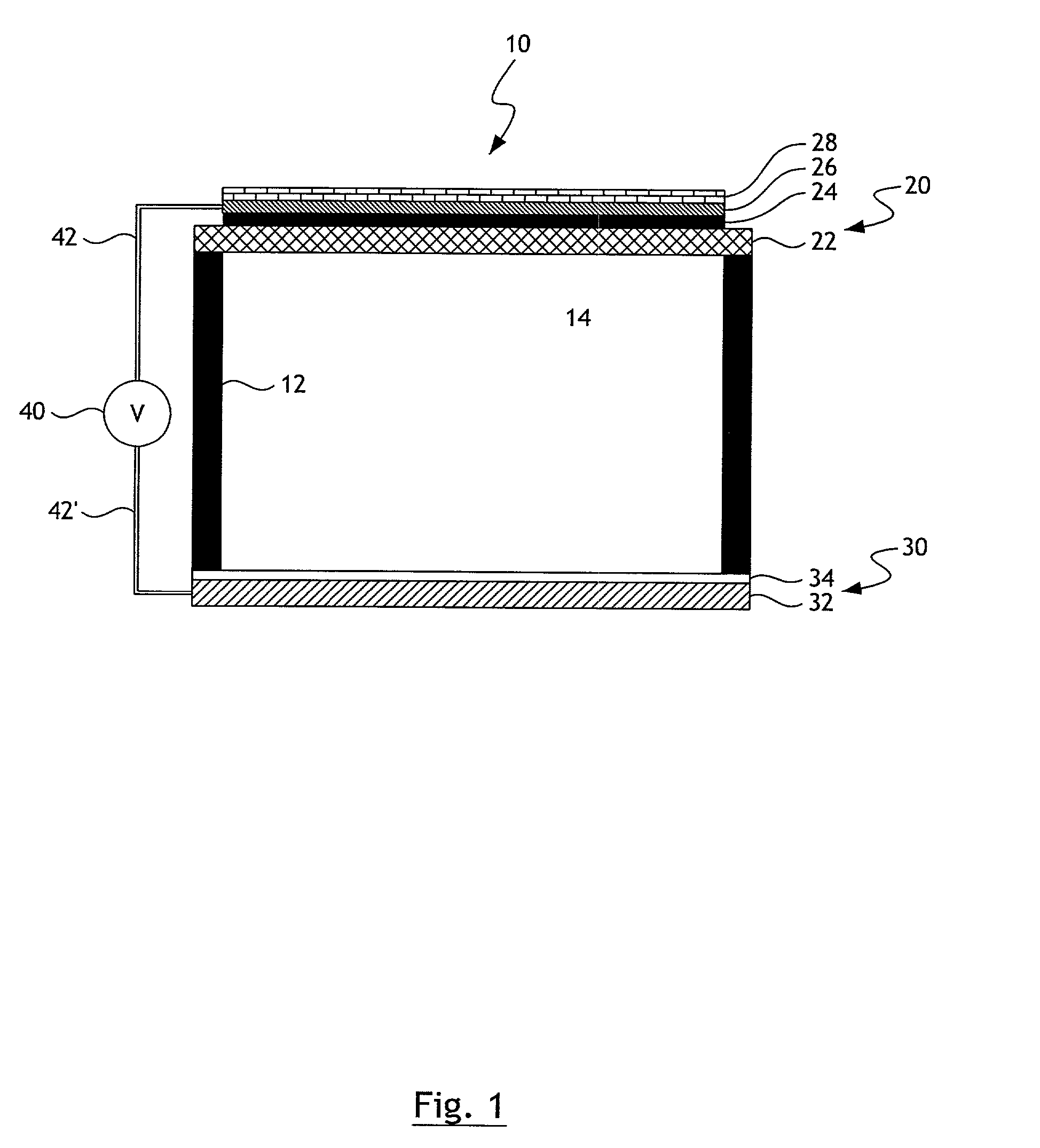

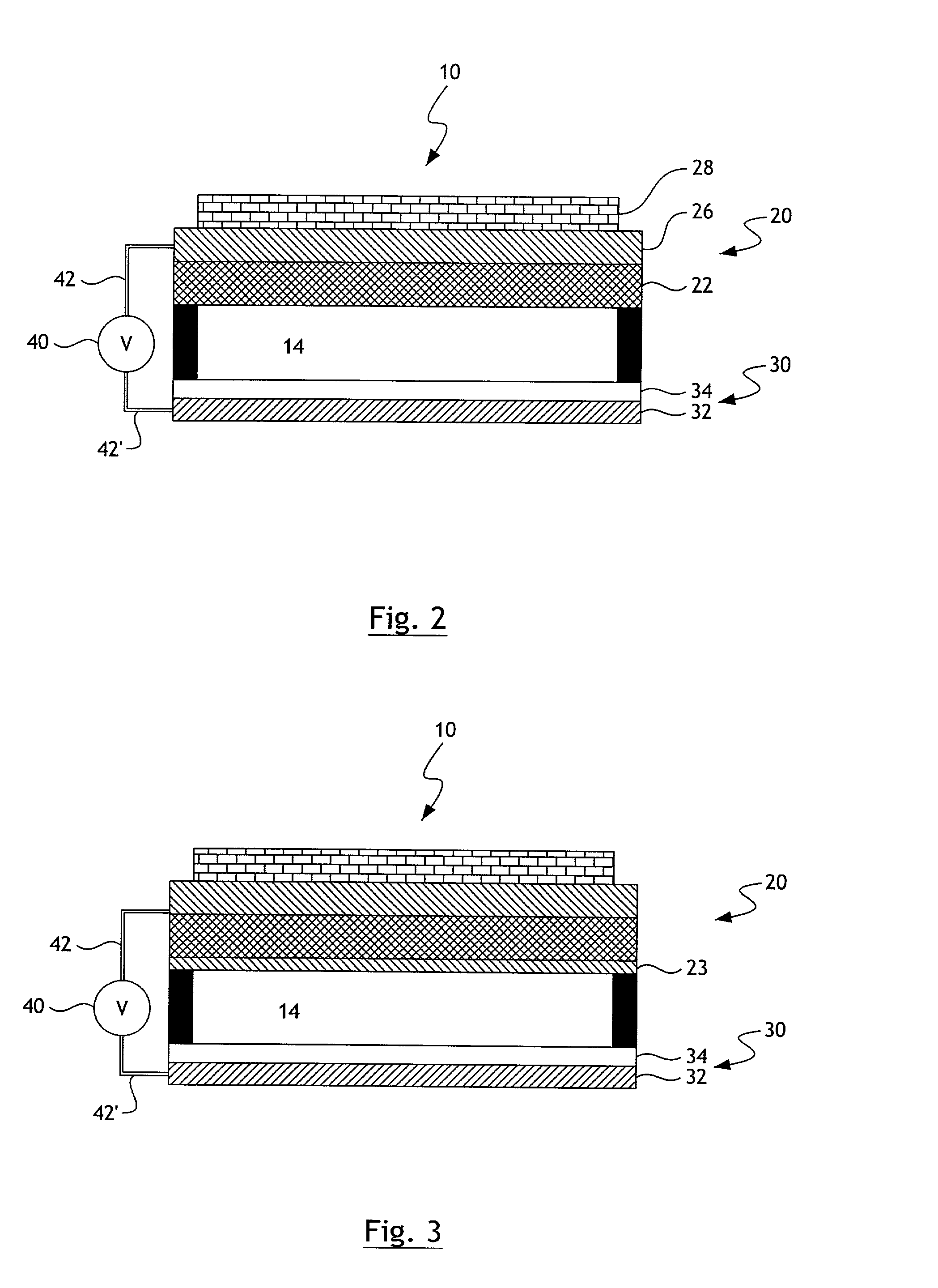

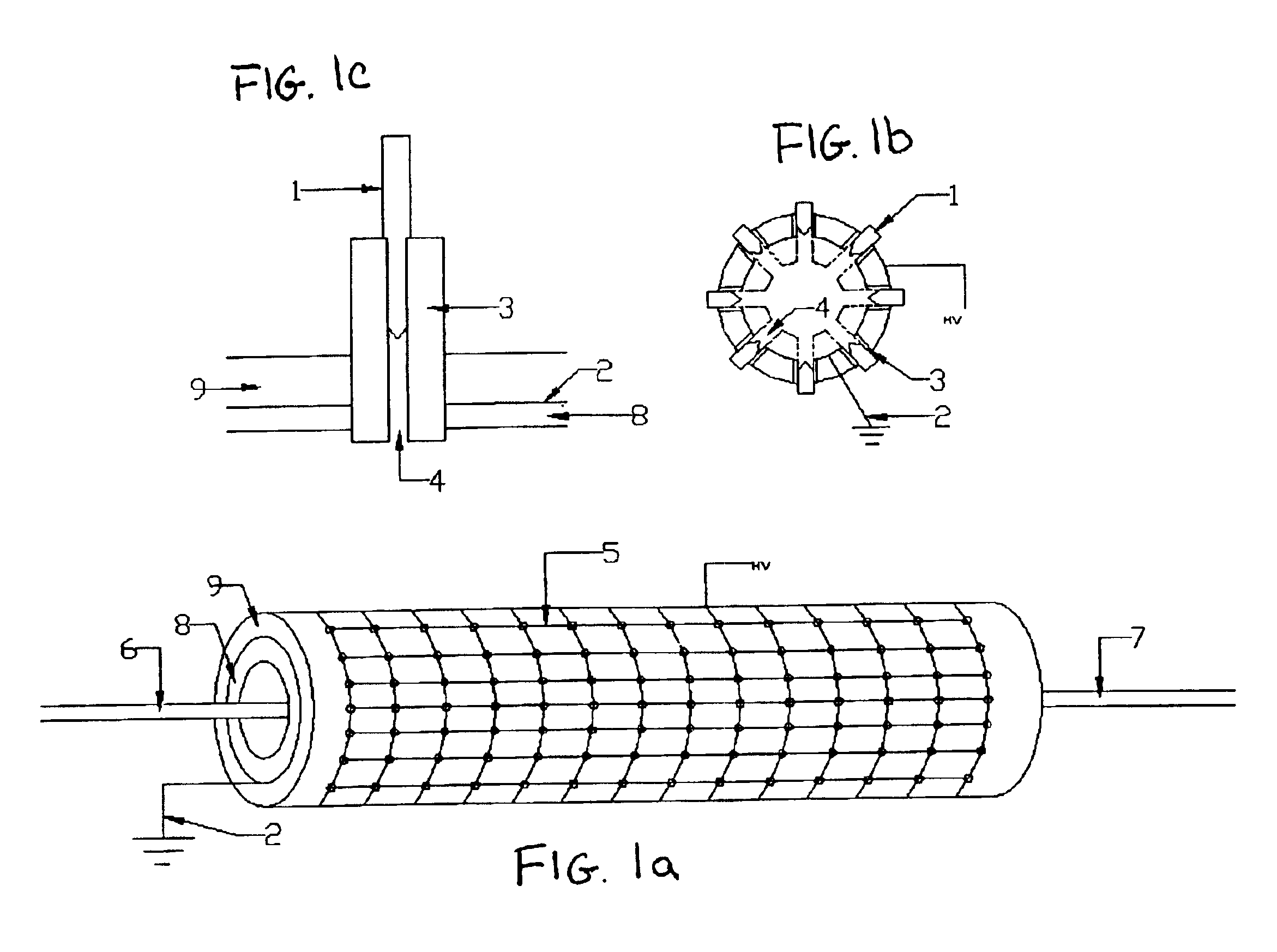

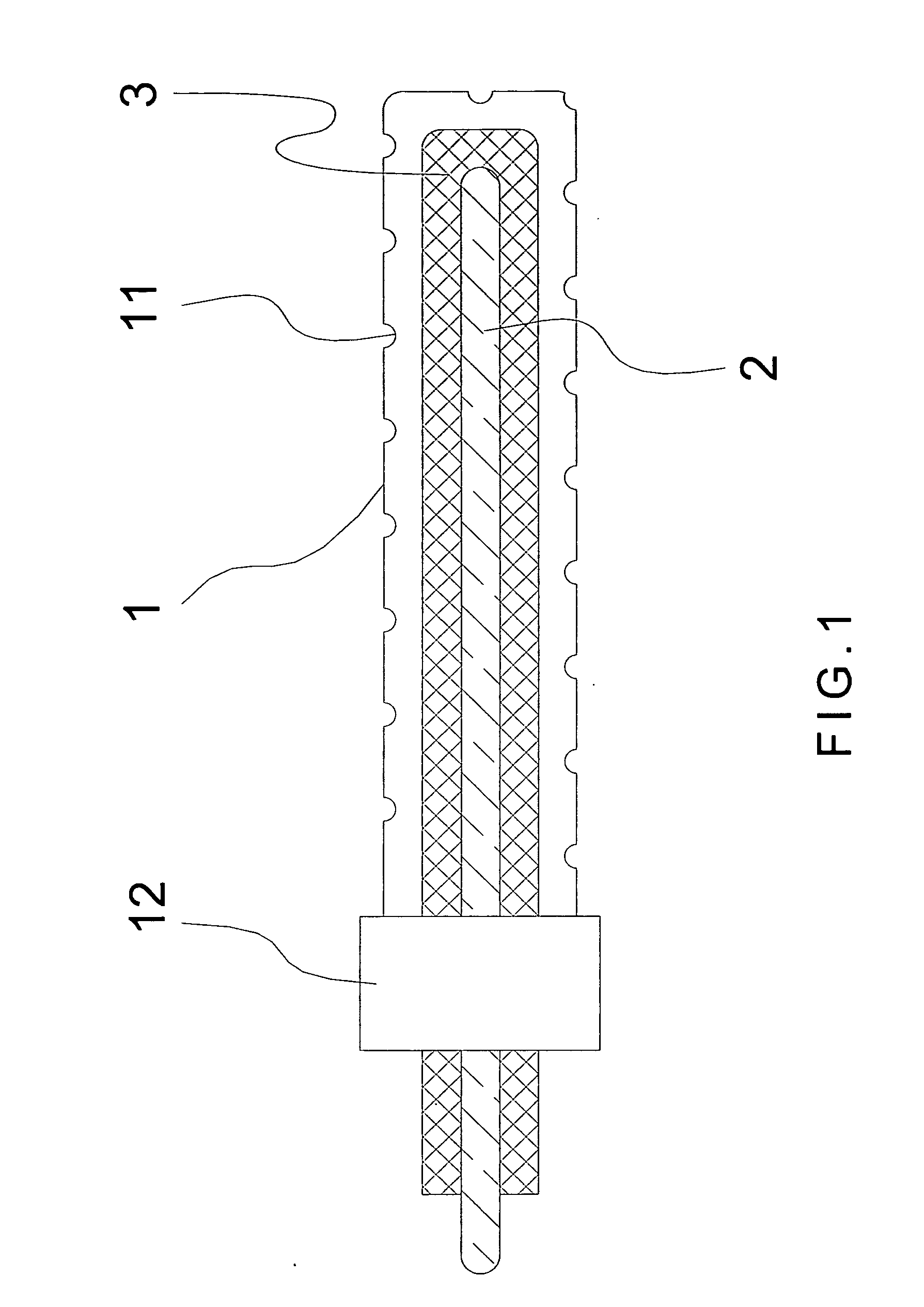

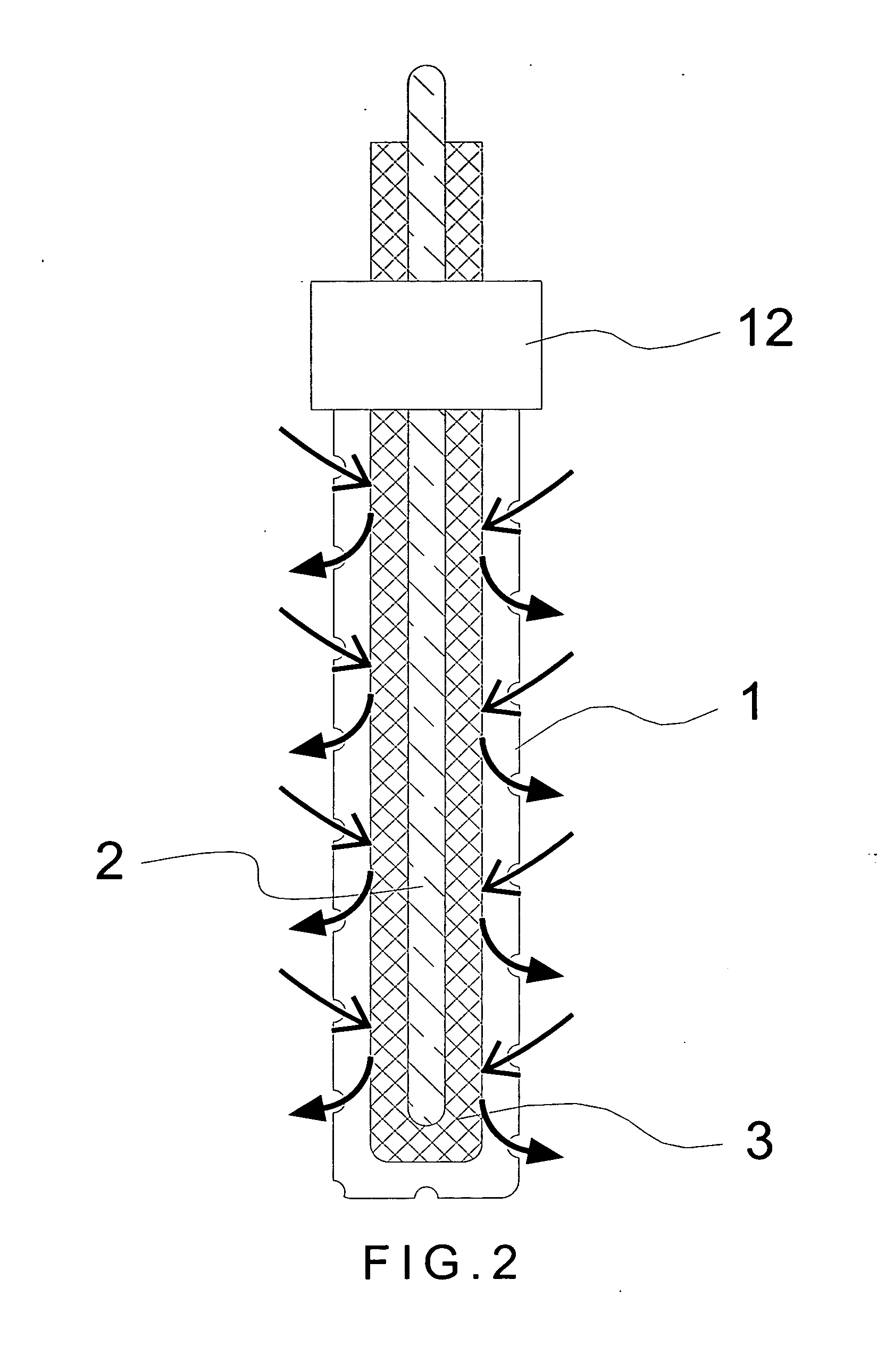

Dielectric barrier discharge plasma reactor cell

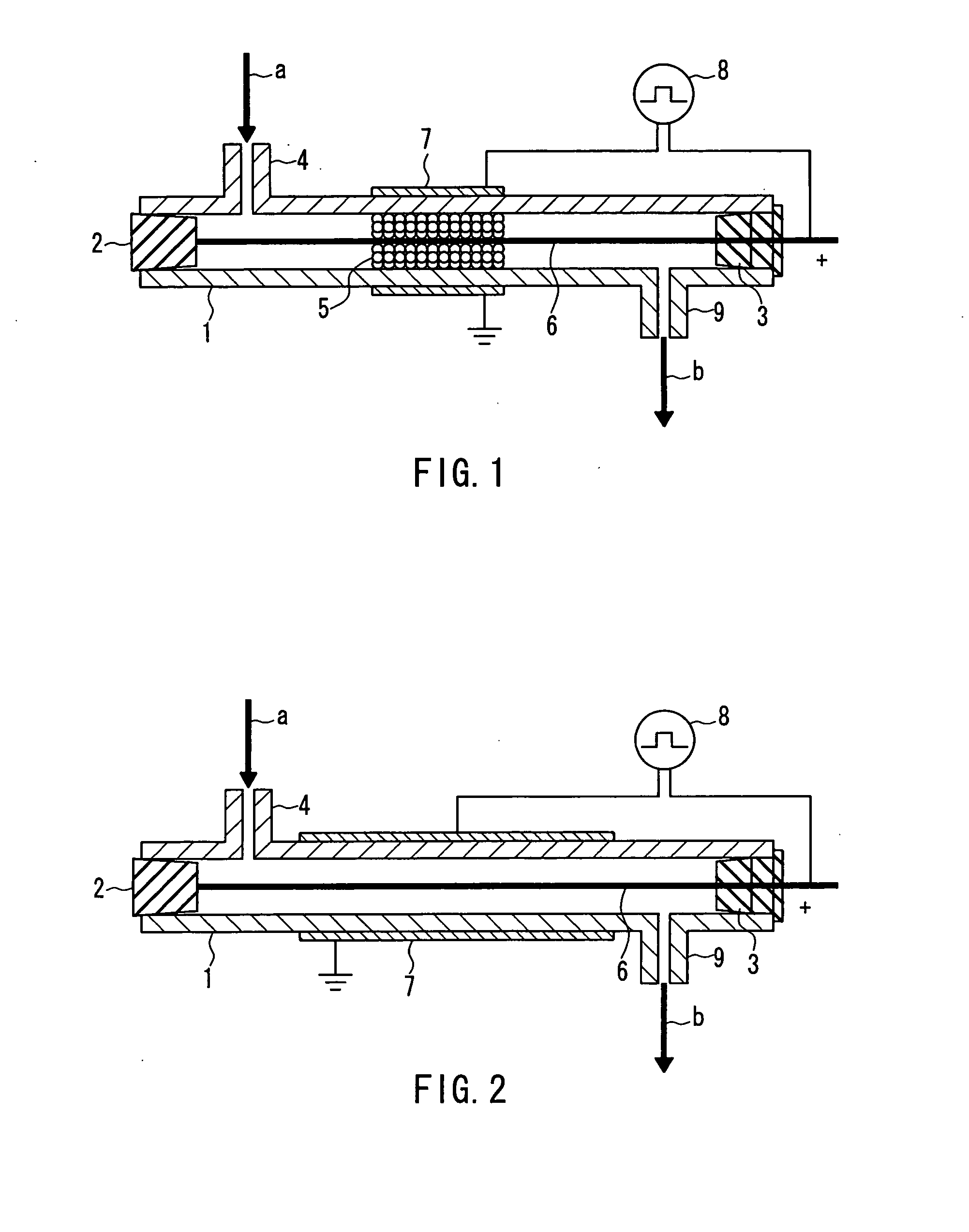

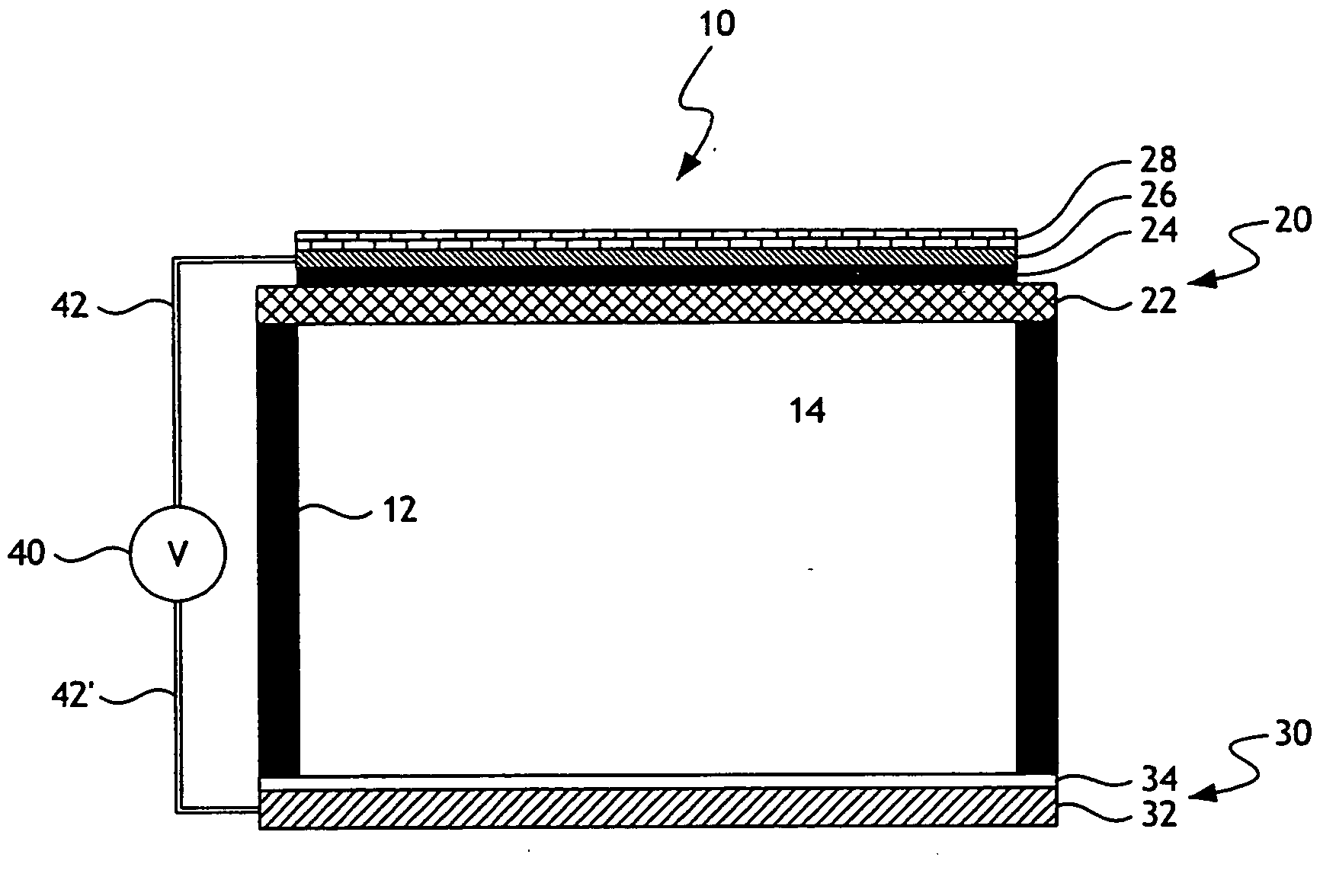

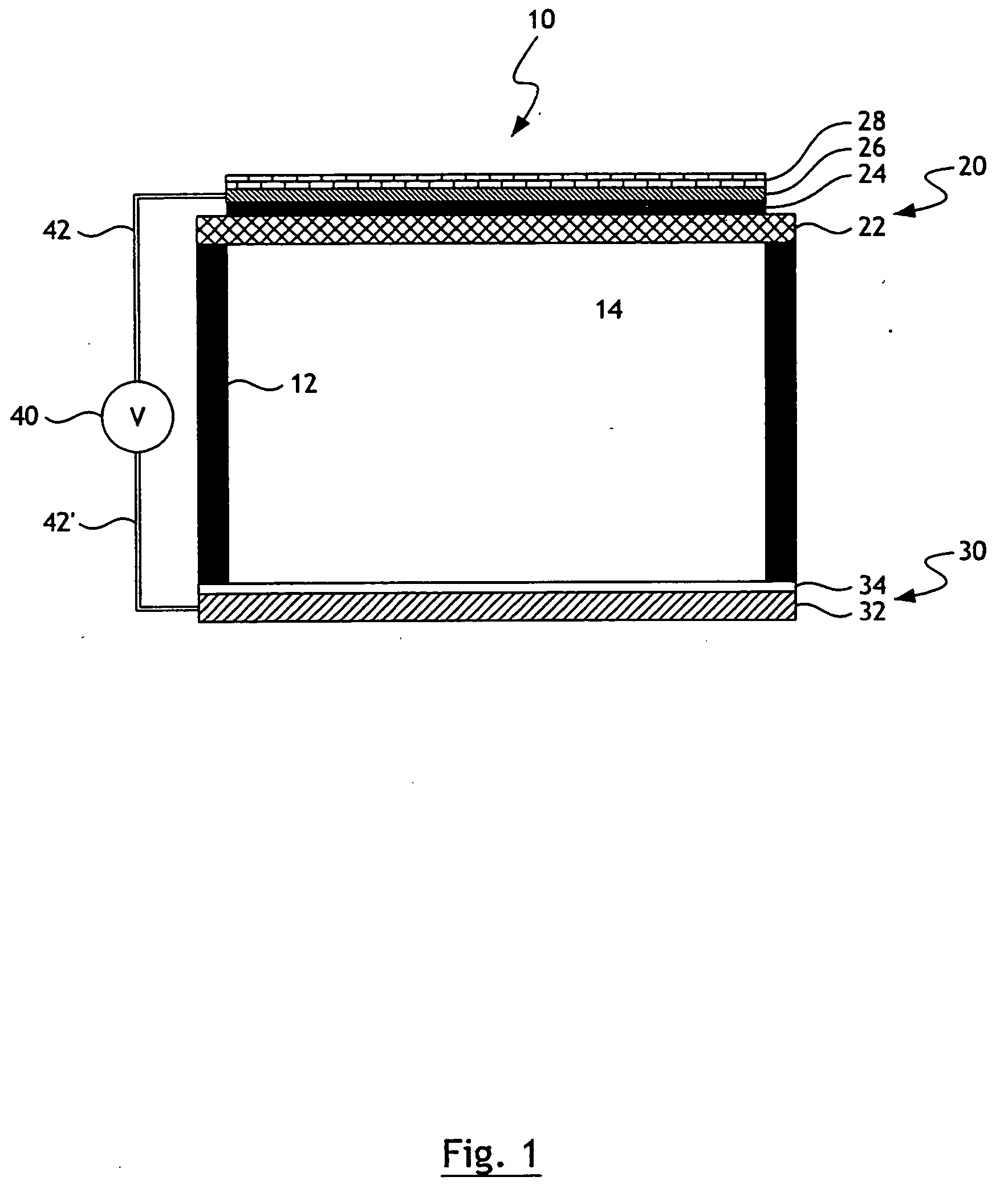

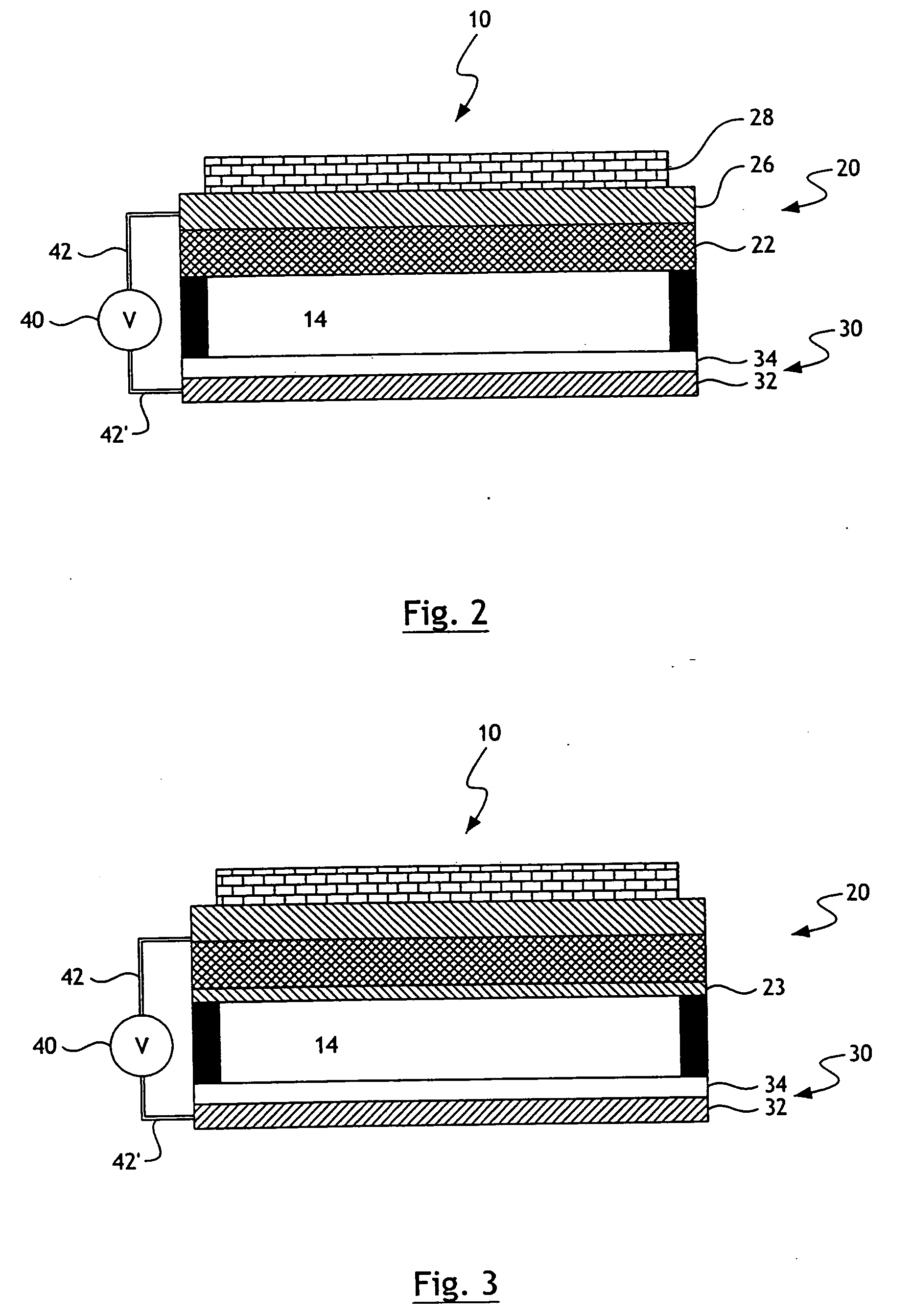

InactiveUS20030030374A1Gaseous chemical processesLighting and heating apparatusElectricityElectrical conductor

A dielectric barrier discharge plasma cell that generates a uniform, non-thermal plasma that is effective at neutralizing harmful agents. The cell is able to generate a uniform non-thermal plasma because it reduces arcing by controlling the distance between the conductor and dielectric, applying a low frequency alternating current voltage to the cell, and carefully applying the layers to the conductor and dielectric.

Owner:GTE GOVERNMENT SYST CORP

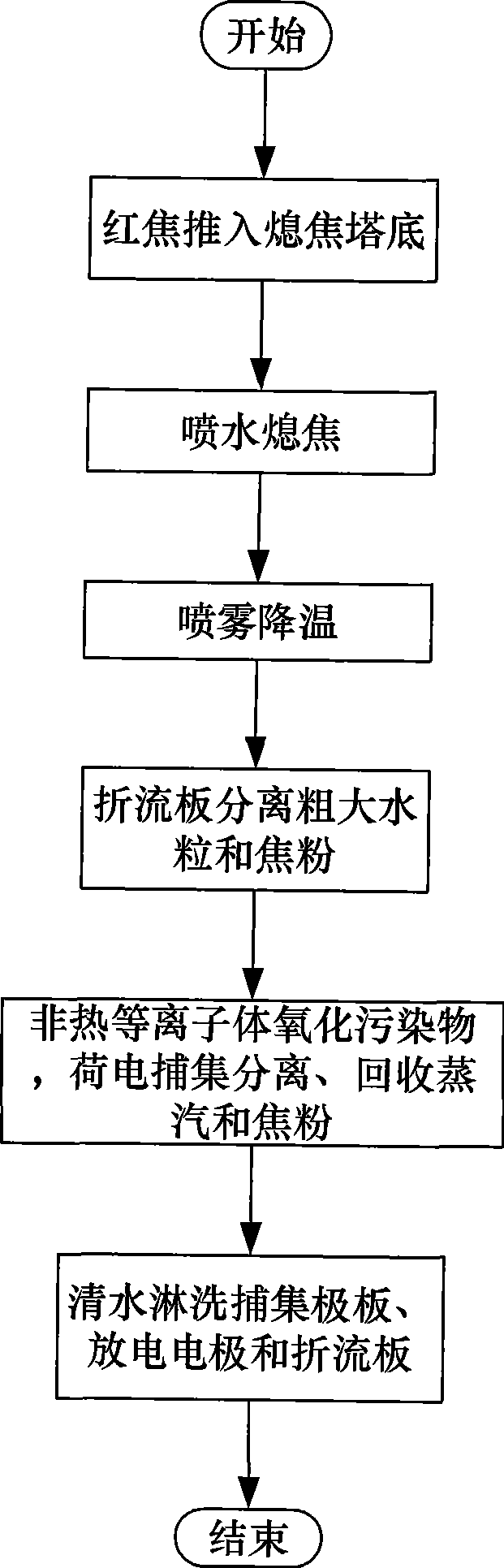

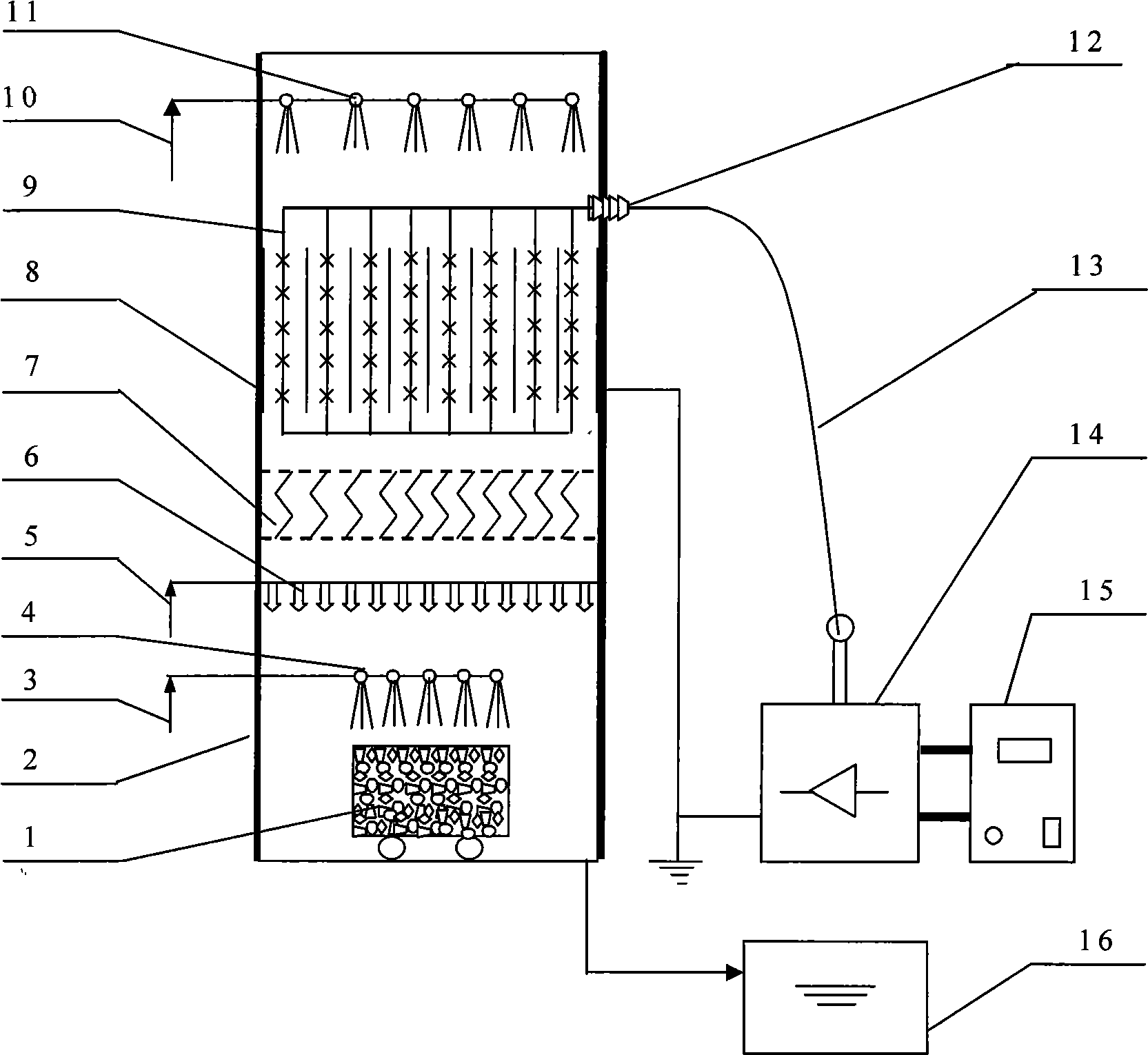

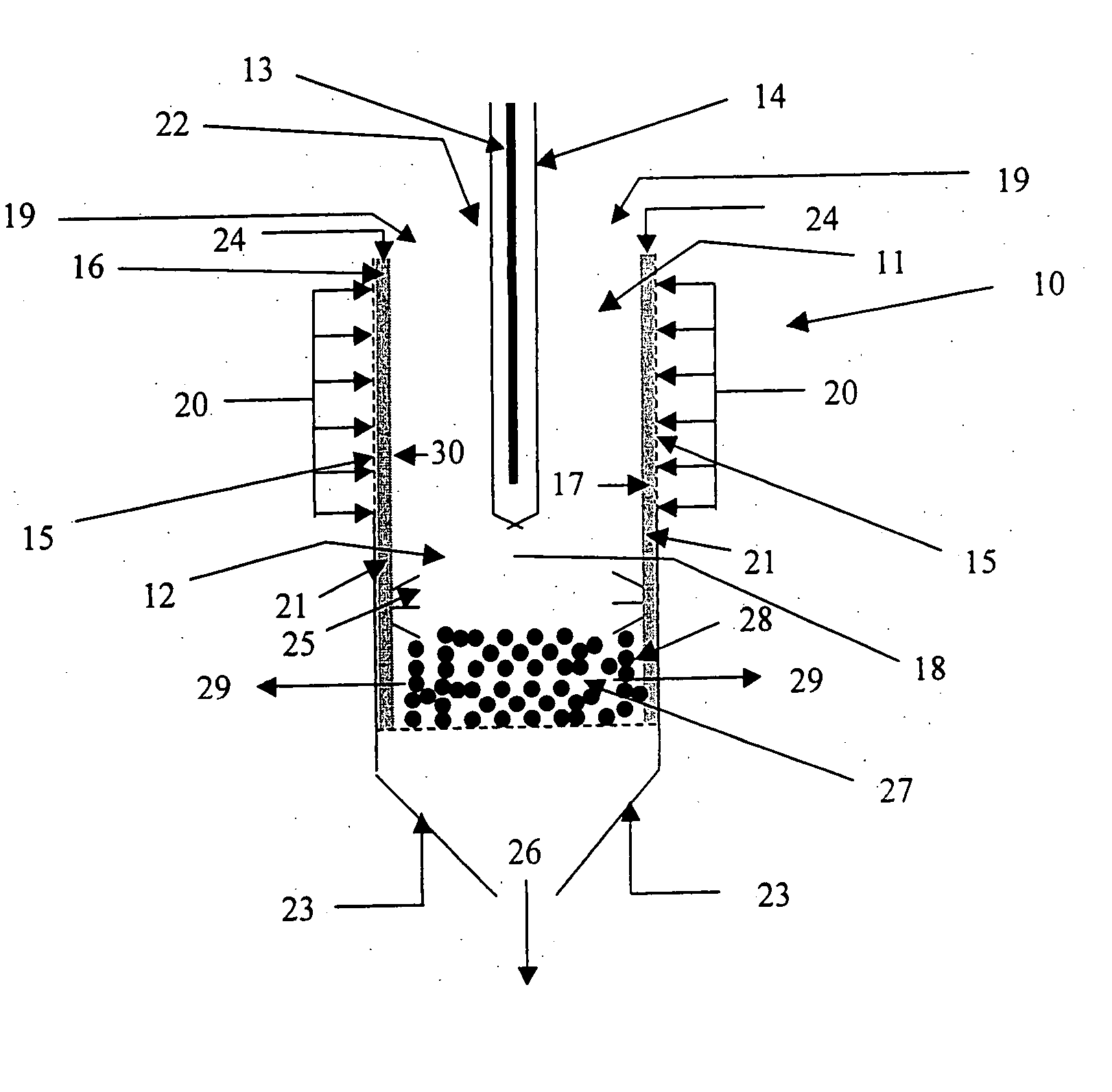

Wet coke-quenching aerial fog processing method and device based on non-thermal plasma injection

InactiveCN101486017AReduce the amount of pollutantsPrevent diverted emissionsCombination devicesCoke quenchingWater vaporHigh pressure

The invention discloses a method and a device for processing wet quenching coke gas fog on the basis of athermal plasma injection. The method comprises the following steps that: in the ascending process, the hot gas fog generated by wet quenching coke sequentially passes through three processing steps including spray cooling, pre-dedusting on a baffle plate and athermal plasma purification, and is cooled in a spray cooling area; the cooled gas fog enters a pre-dedusting area on the baffle plate where the thicker and bigger water particles and coke powder in the gas fog are separated from the gas fog and impact to the baffle plate under the action of inertia; the remaining gas fog continues to ascend and enter an athermal plasma purification area where organic components, ammonia nitrogen and cyanide in the gas fog are oxidized by the athermal plasma; the water particles and the coke powder are charged and are transferred to a trapping pole plate directionally under the action of a high voltage electric field; and then the gas flow after subjected to the athermal plasma purification area continuous to ascend to the top of a coke quenching tower to be discharged. After the processing steps, the contents of water vapor and the coke powder discharged outside after one ton of coke is produced are controlled to be less than 0.05 ton and 5 grams respectively, and the removal rate of the organic components, the ammonia nitrogen and the cyanide can reach more than 80 percent.

Owner:BEIHANG UNIV

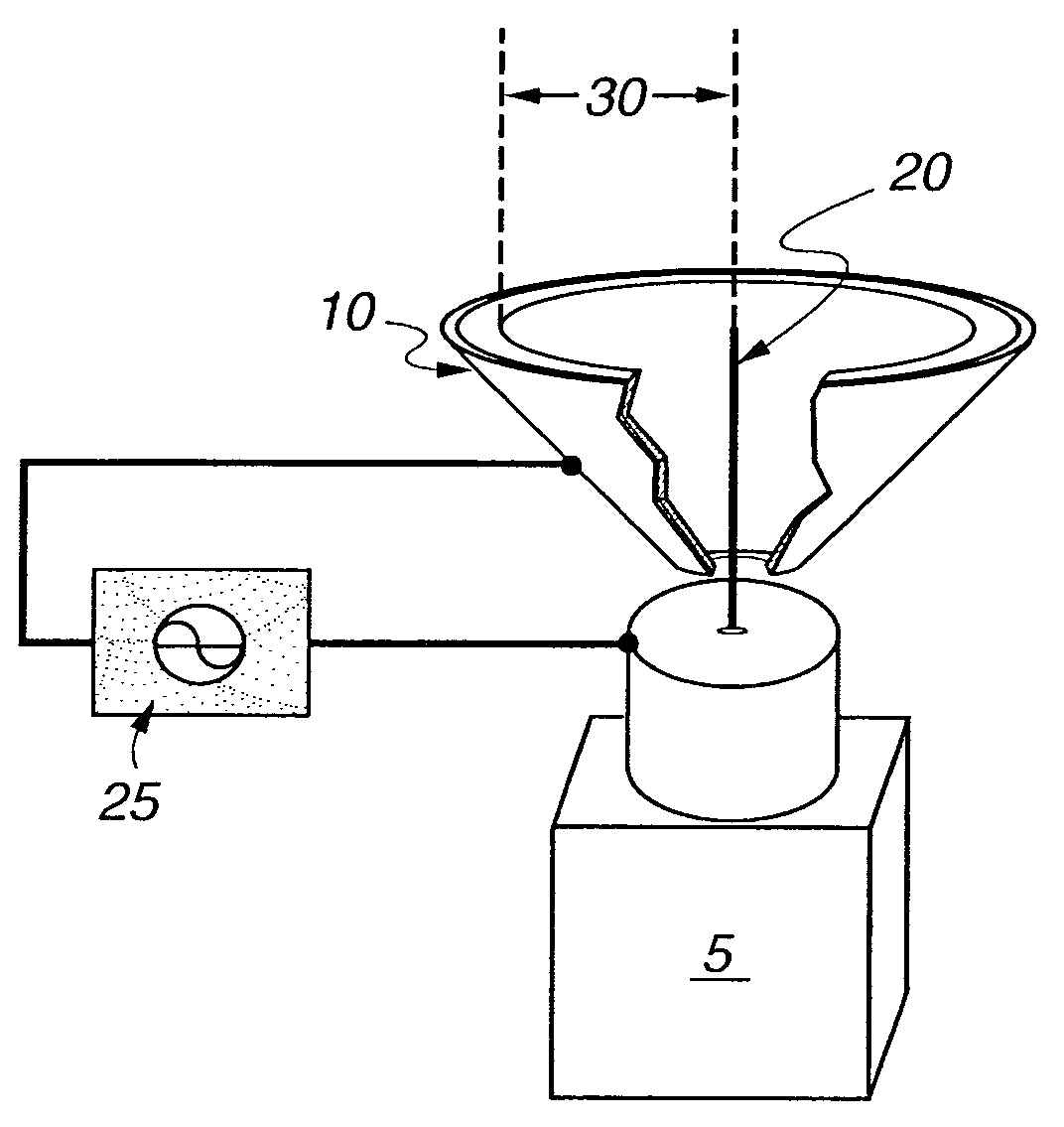

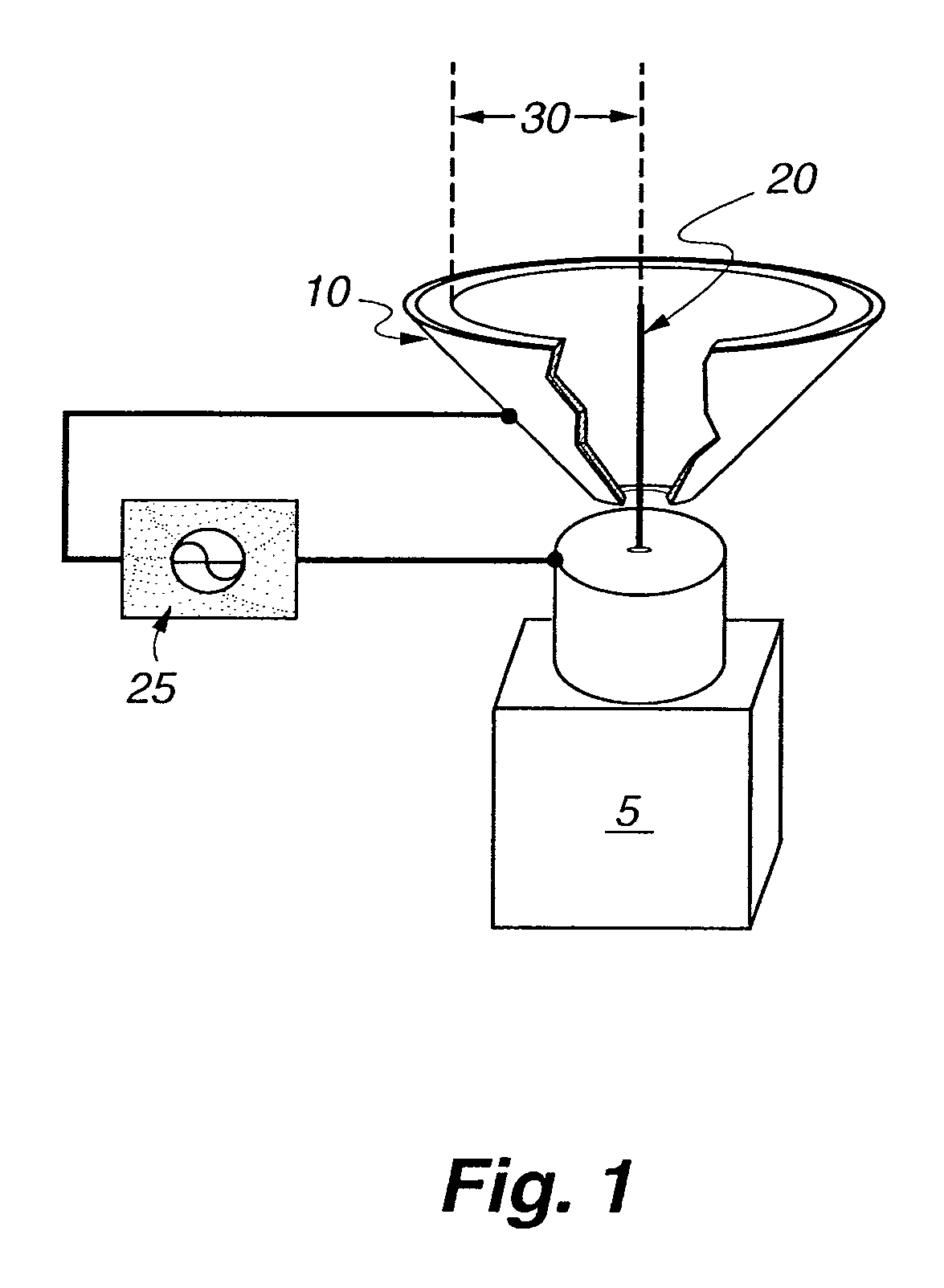

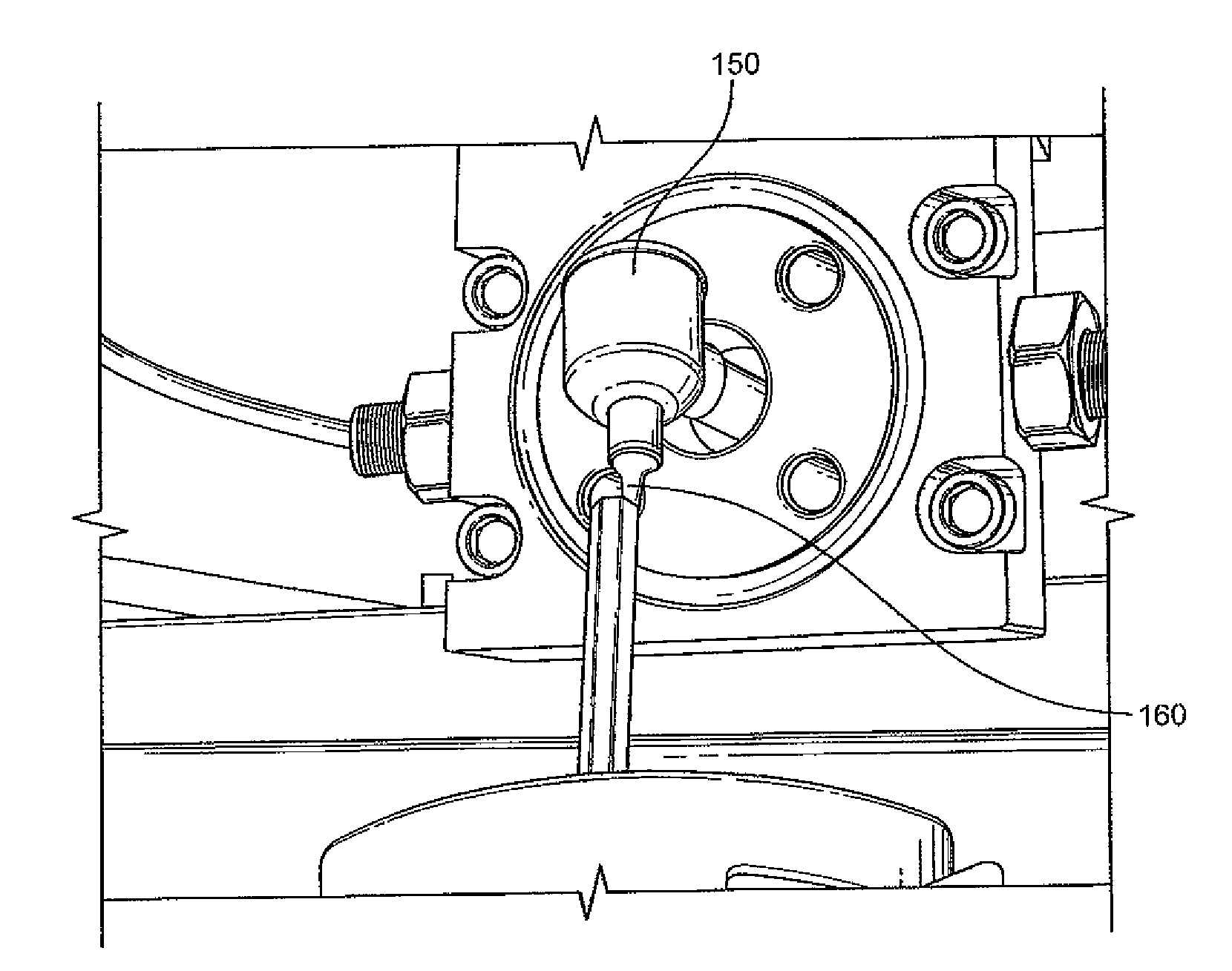

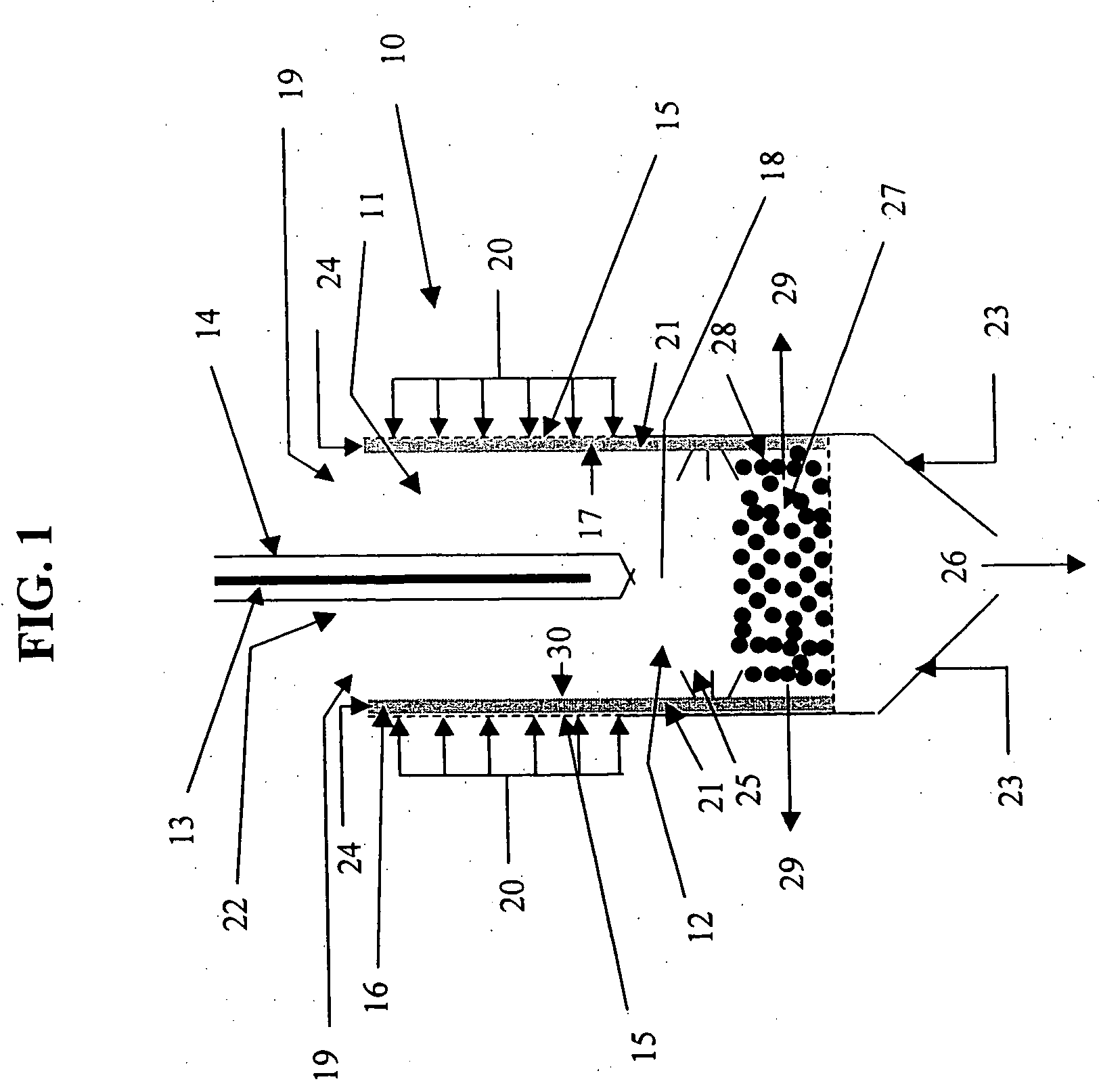

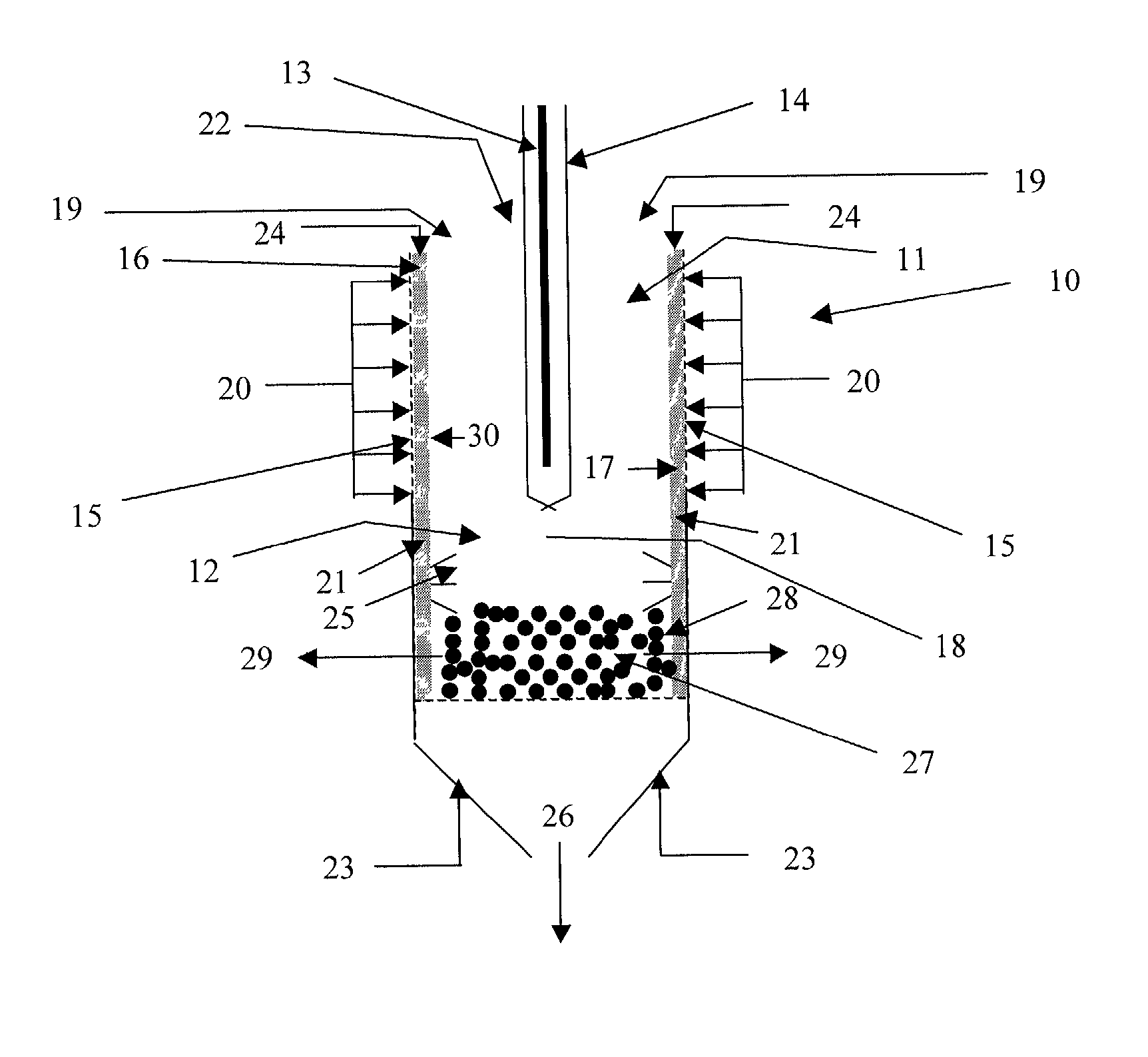

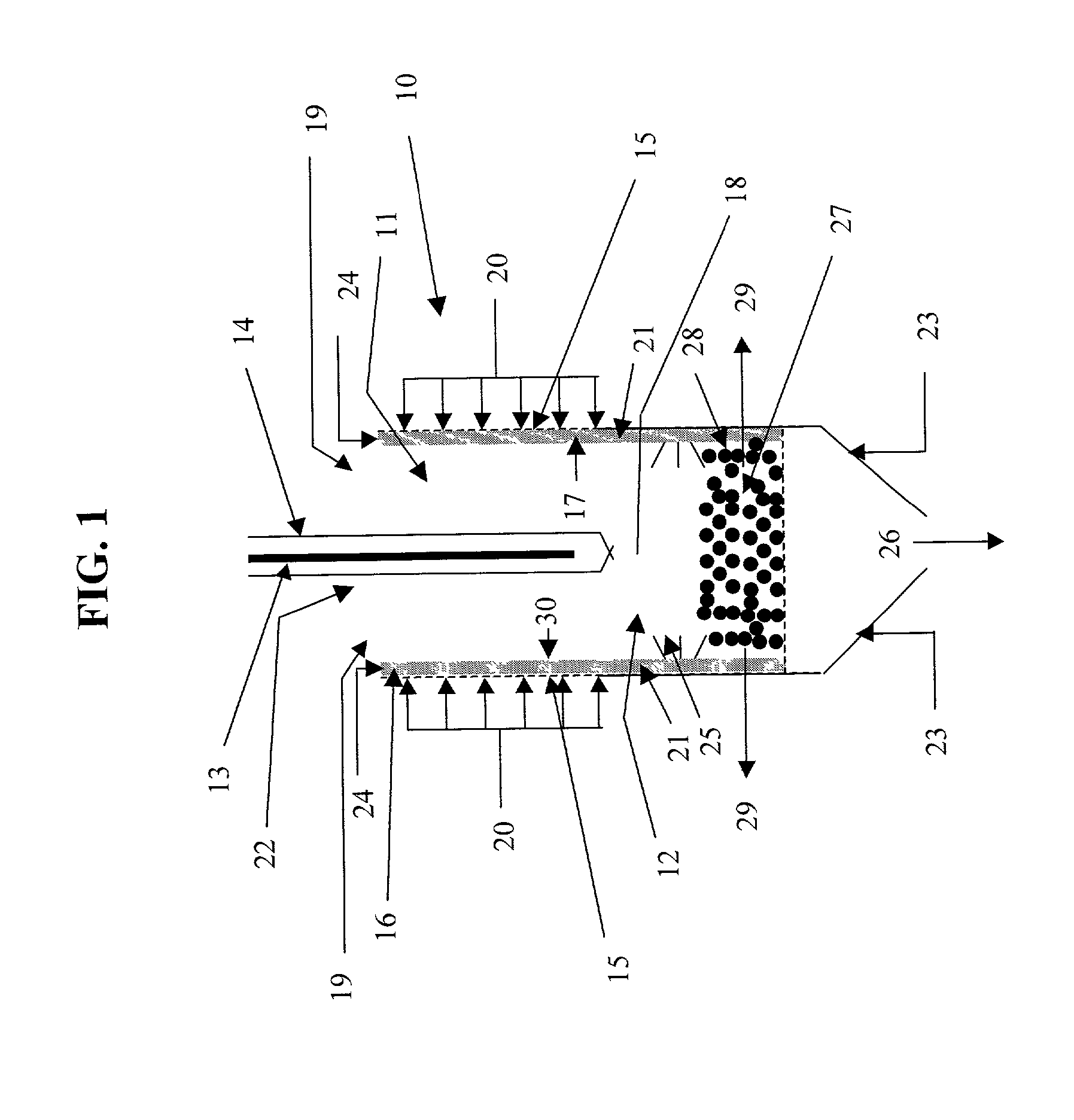

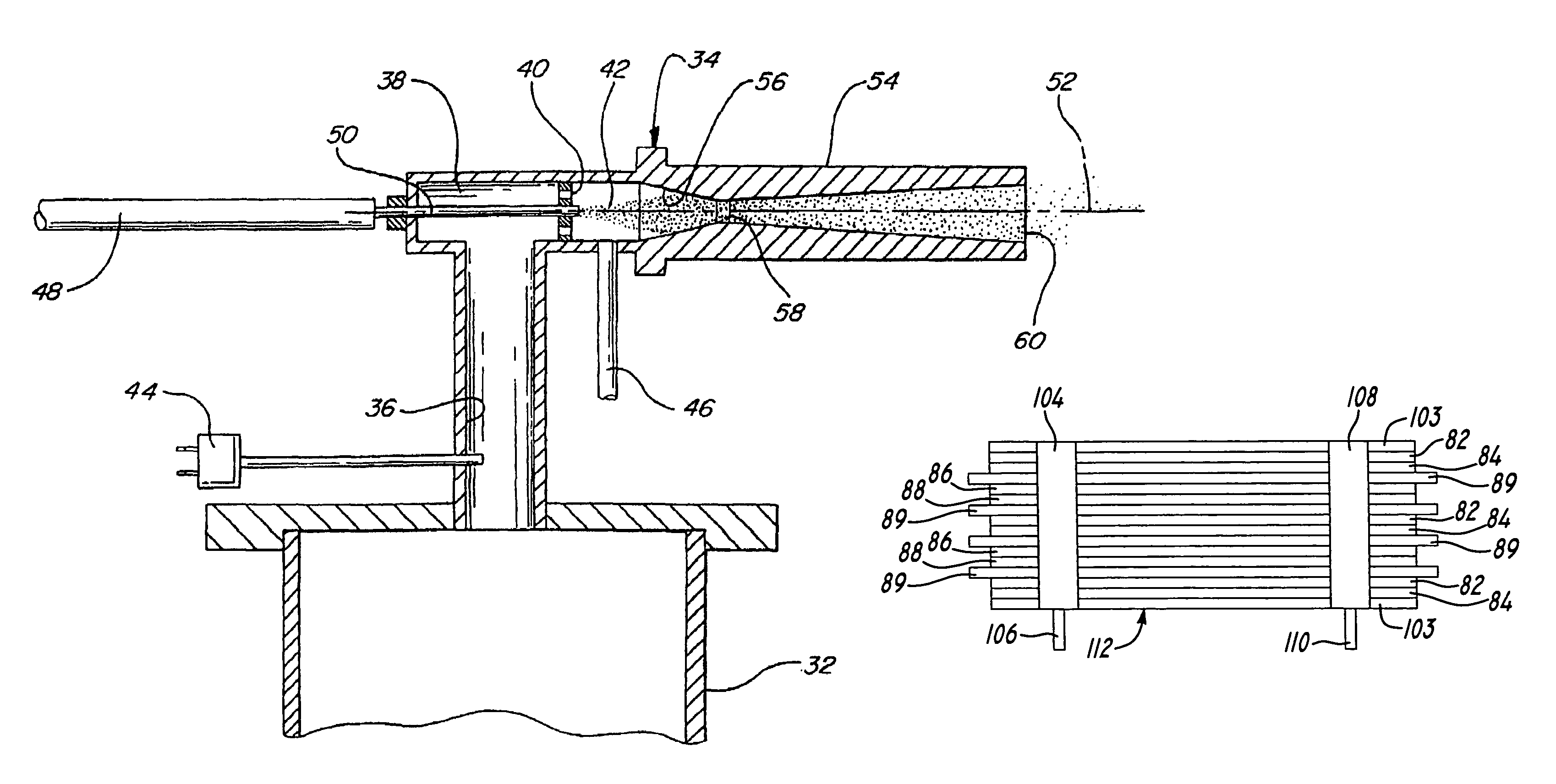

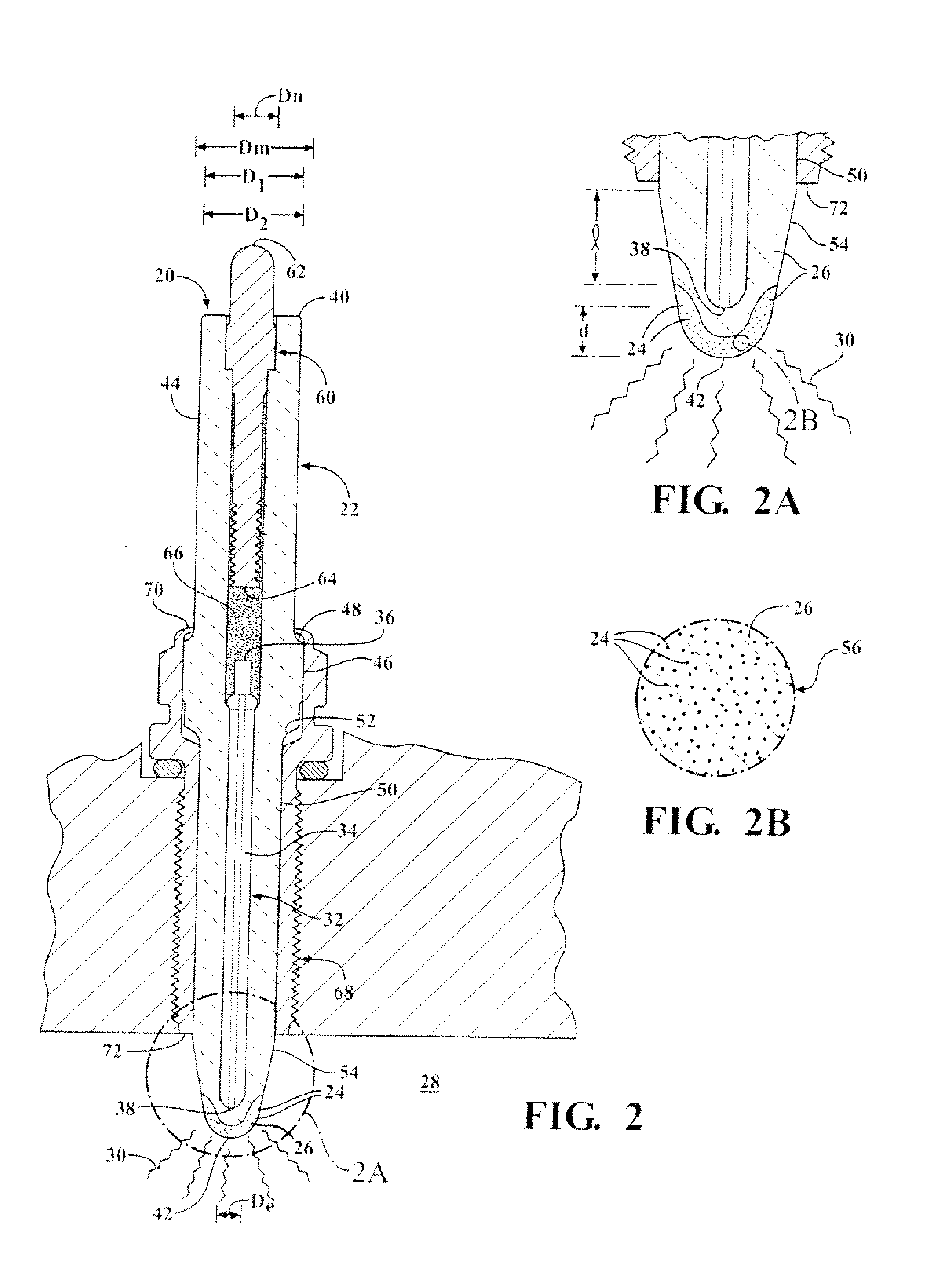

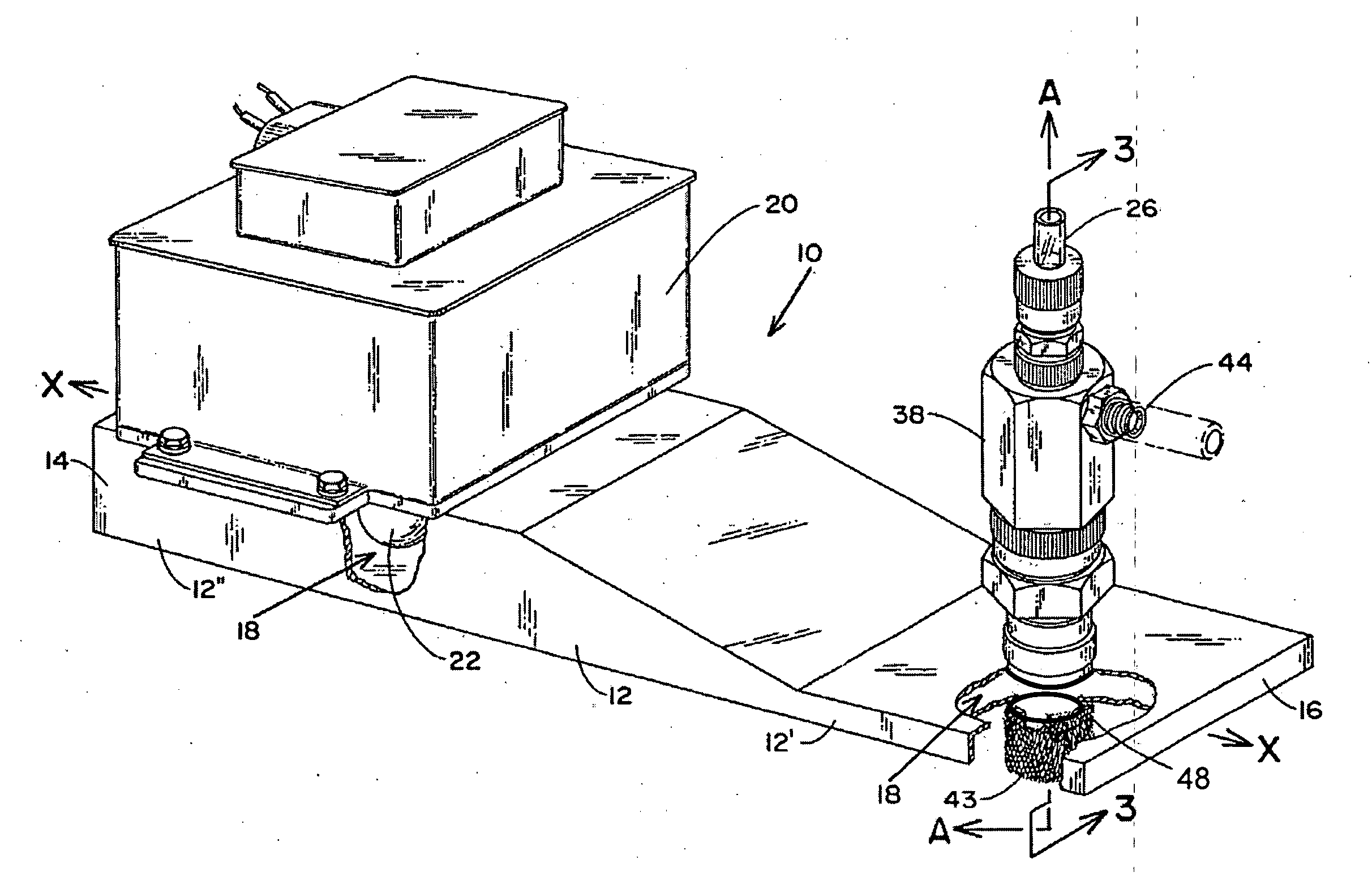

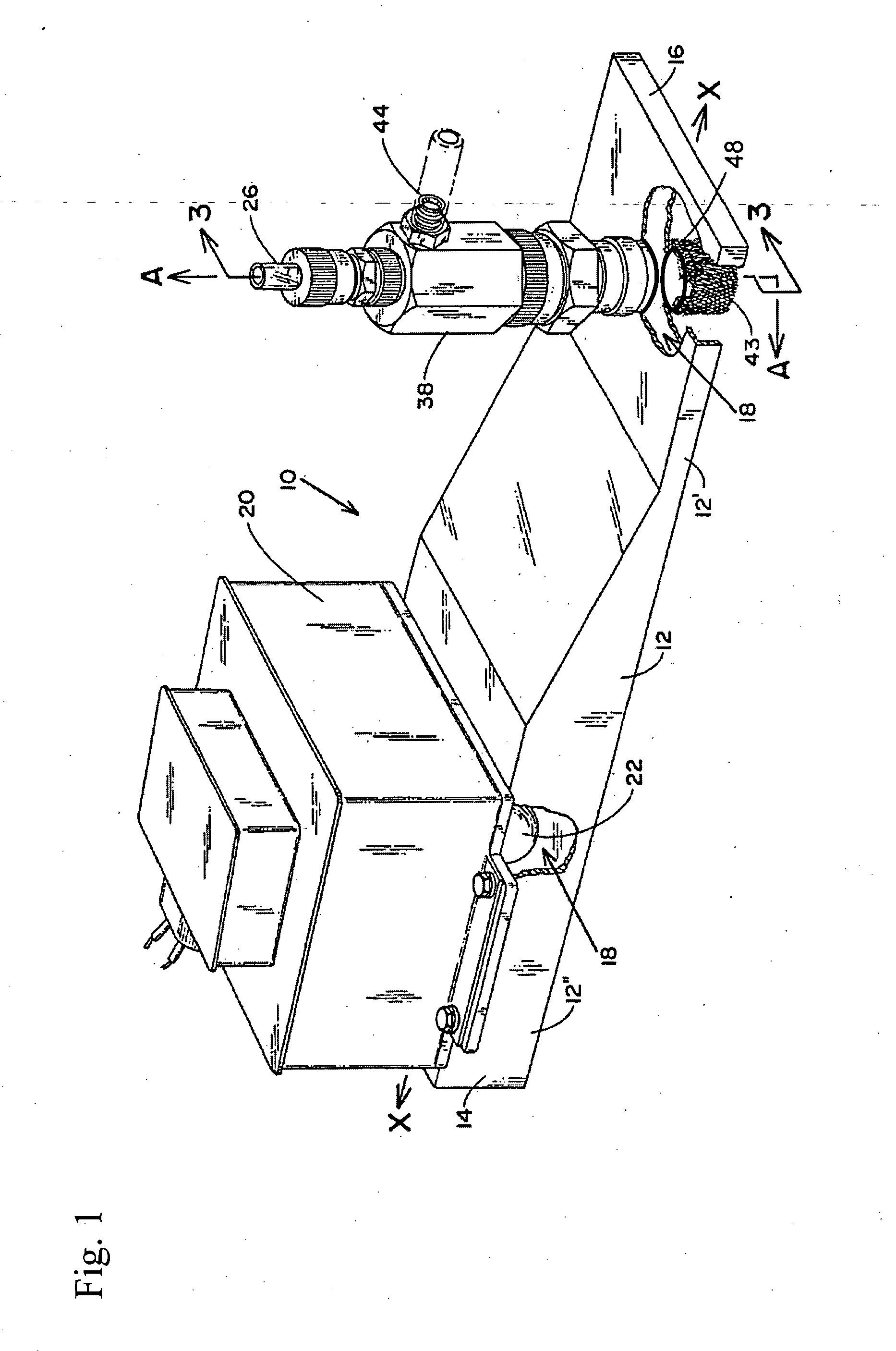

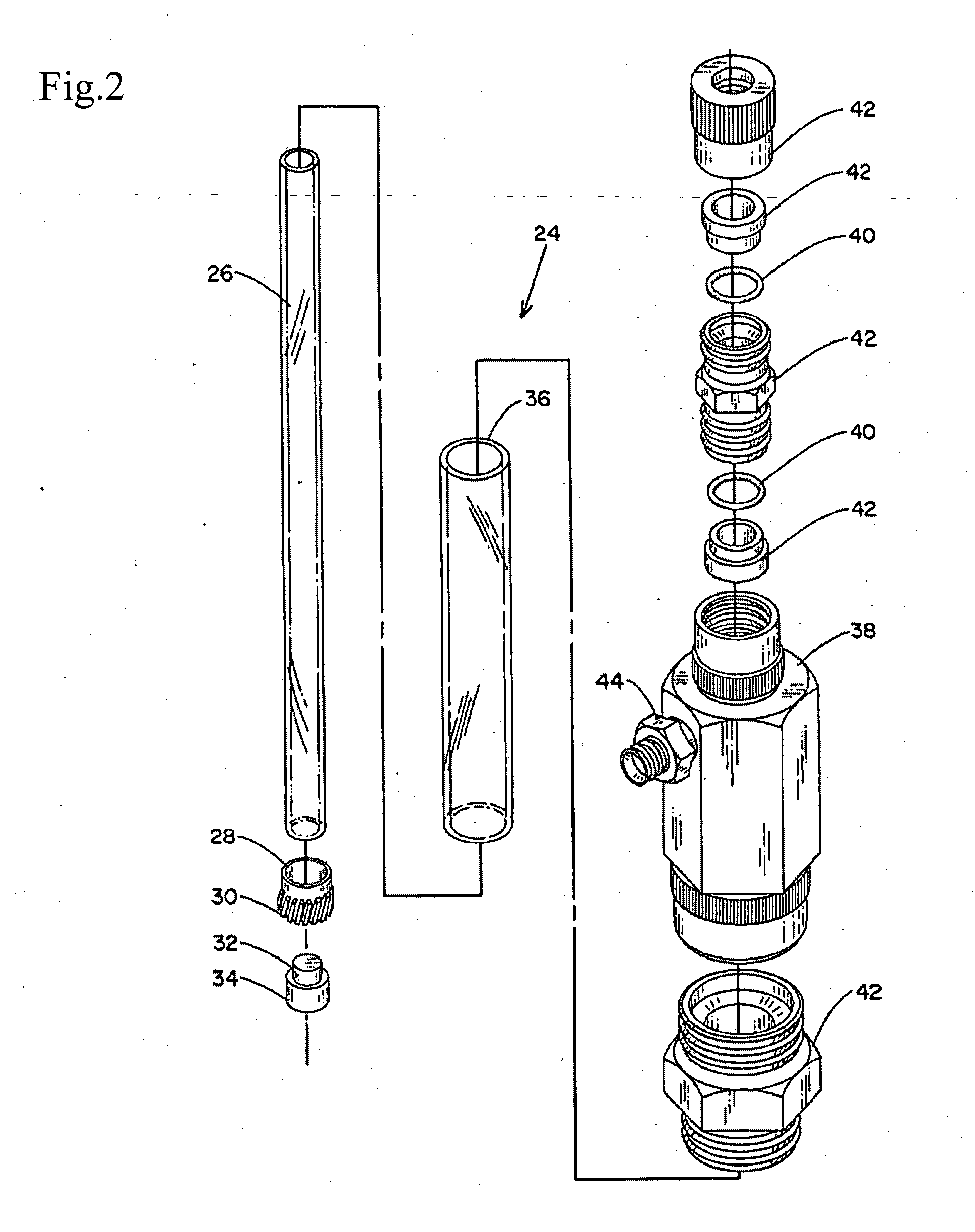

Fuel injector utilizing non-thermal plasma activation

A non-thermal plasma assisted combustion fuel injector that uses an inner and outer electrode to create an electric field from a high voltage power supply. A dielectric material is operatively disposed between the two electrodes to prevent arcing and to promote the formation of a non-thermal plasma. A fuel injector, which converts a liquid fuel into a dispersed mist, vapor, or aerosolized fuel, injects into the non-thermal plasma generating energetic electrons and other highly reactive chemical species.

Owner:LOS ALAMOS NATIONAL SECURITY

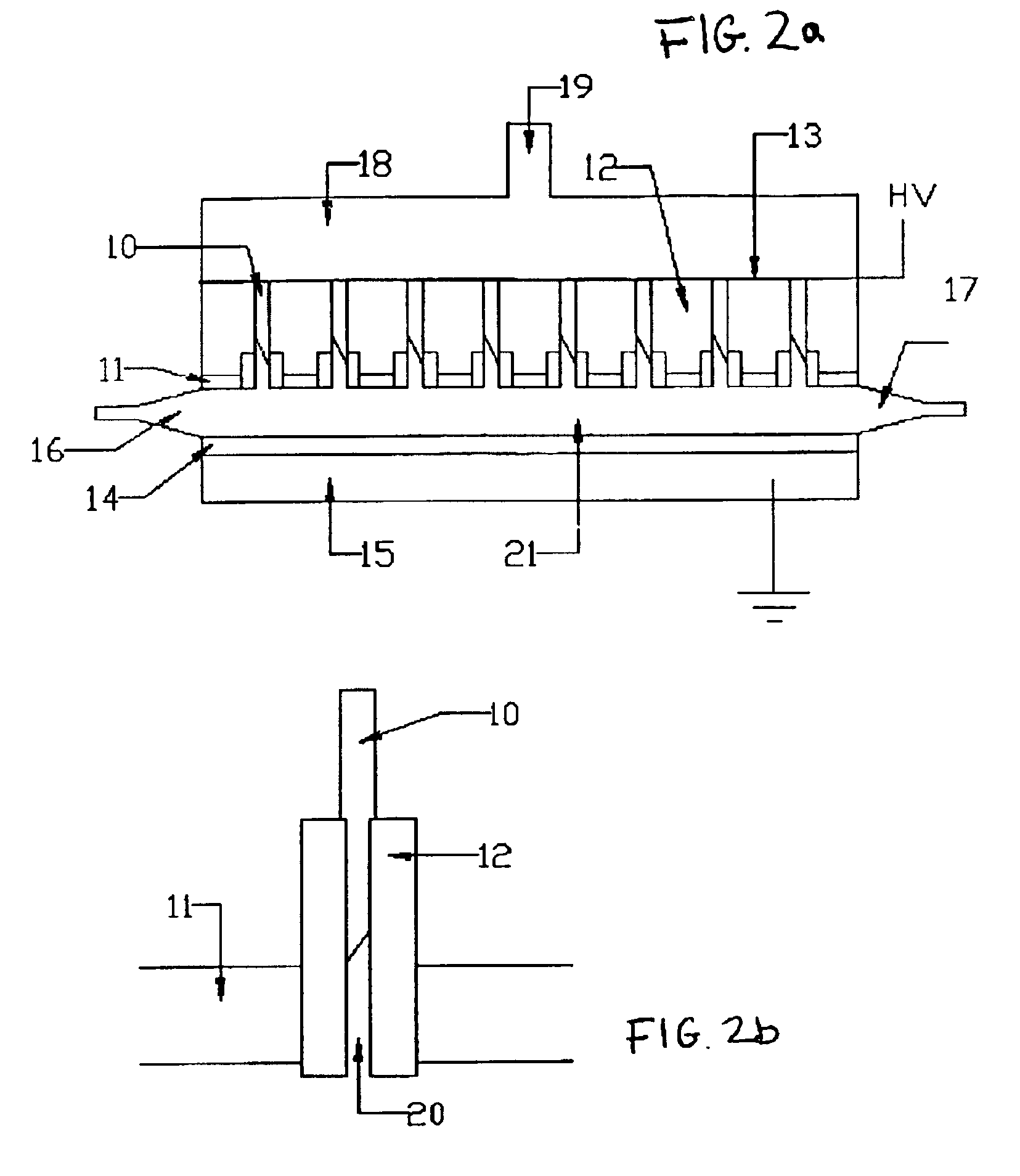

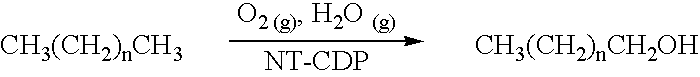

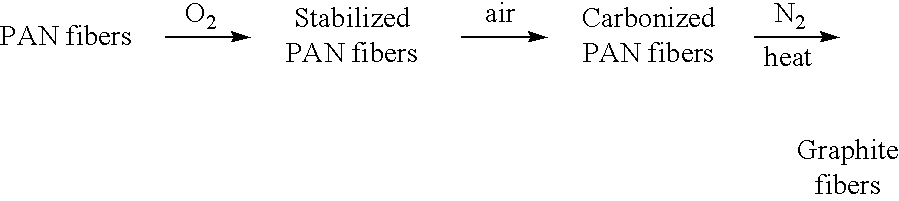

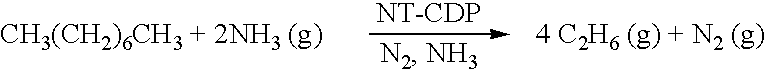

Chemical processing using non-thermal discharge plasma

InactiveUS6923890B2Simple processEnhanced water gas shiftingHydrogenMolecular sieve catalystsChemical treatmentFiber

A method for activating chemical reactions using a non-thermal capillary discharge plasma (NT-CDP) unit or a non-thermal slot discharge plasma (NT-SDP) unit (collectively referred to as “NT-CDP / SDP”). The NT-CDP / SDP unit includes a first electrode disposed between two dielectric layers, wherein the first electrode and dielectric layers having at least one opening (e.g., capillary or a slot) defined therethrough. A dielectric sleeve inserted into the opening, and at least one second electrode (e.g., in the shape of a pin, ring, metal wire, or tapered metal blade) is disposed in fluid communication with an associated opening. A non-thermal plasma discharge is emitted from the opening when a voltage differential is applied between the first and second electrodes. Chemical feedstock to be treated is then exposed to the non-thermal plasma. This processing is suited for the following exemplary chemical reactions as (i) partial oxidation of hydrocarbon feedstock to produce functionalized organic compounds; (ii) chemical stabilization of a polymer fiber (e.g., PAN fiber precursor in carbon fiber production; (iii) pre-reforming of higher chain length petroleum hydrocarbons to generate a feedstock suitable for reforming; (iv) natural gas reforming in a chemically reducing atmosphere (e.g., ammonia or urea) to produce carbon monoxide and Hydrogen gas; or (v) plasma enhanced water gas shifting.

Owner:PLASMASOL CORP

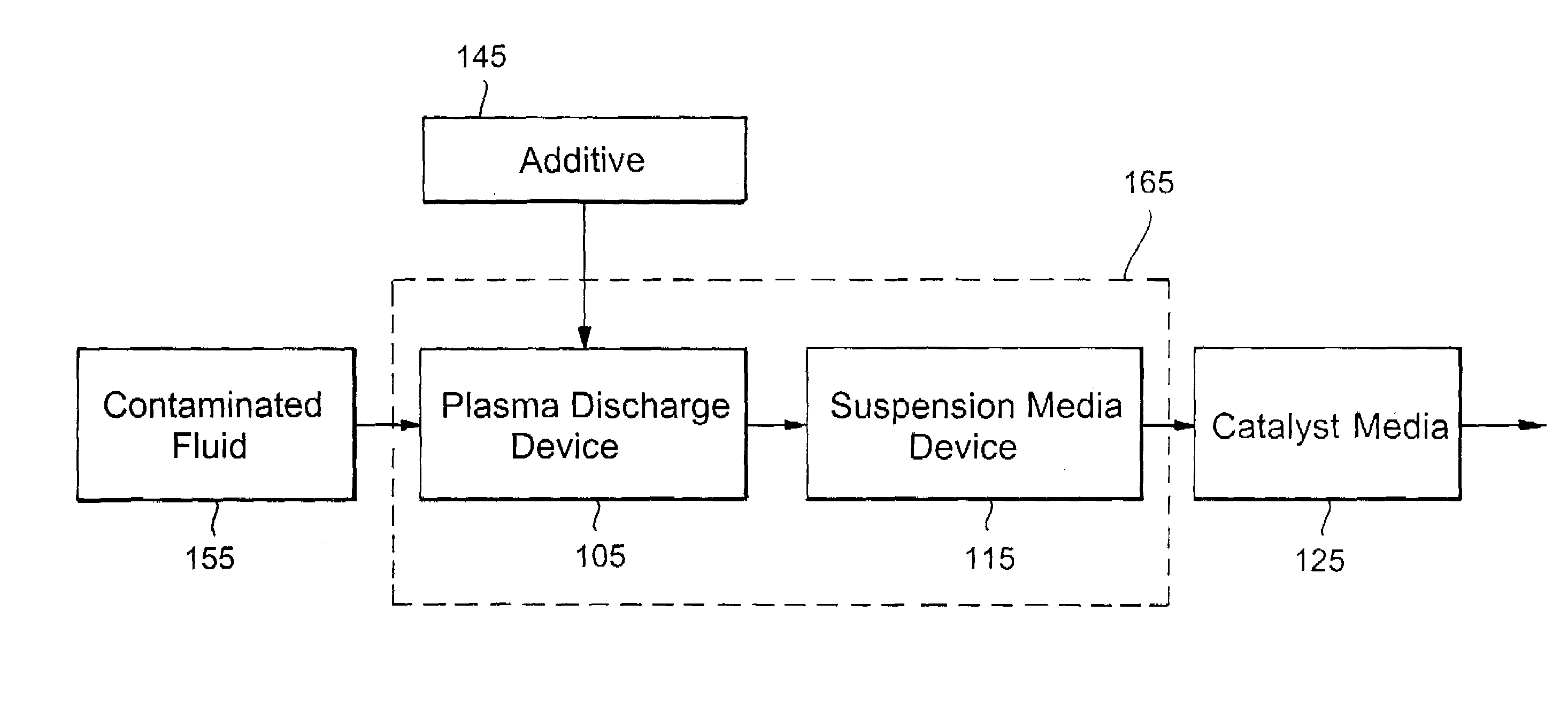

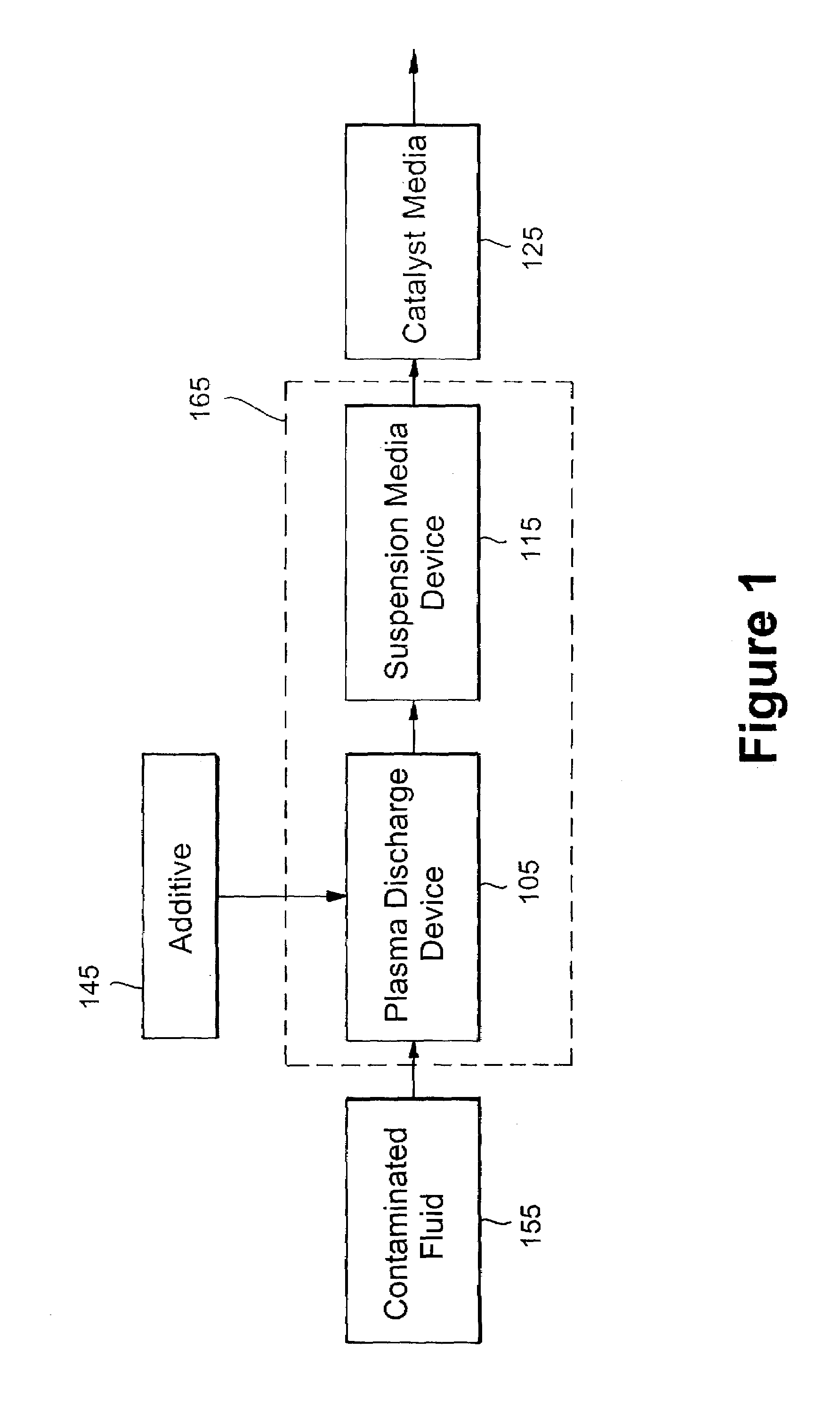

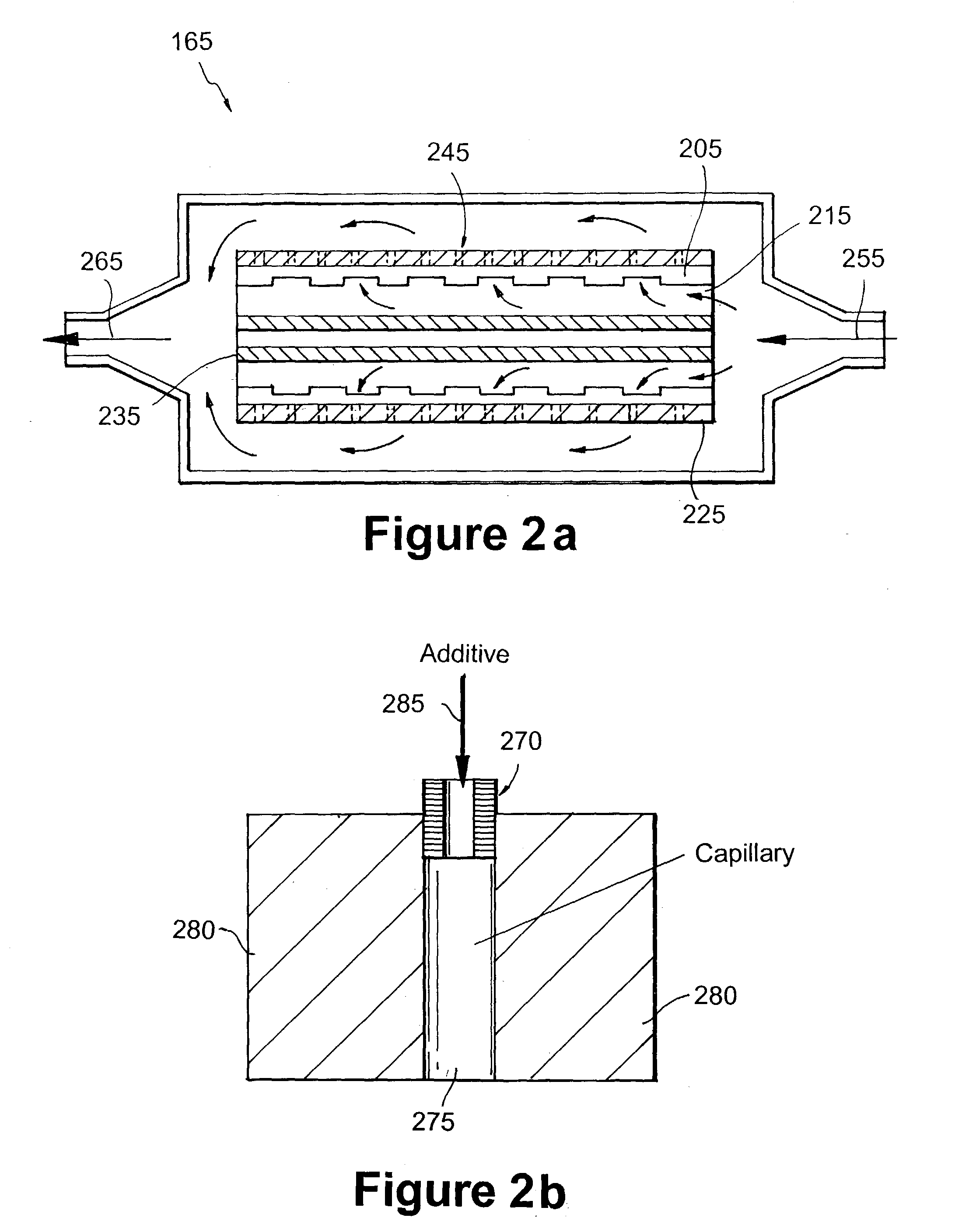

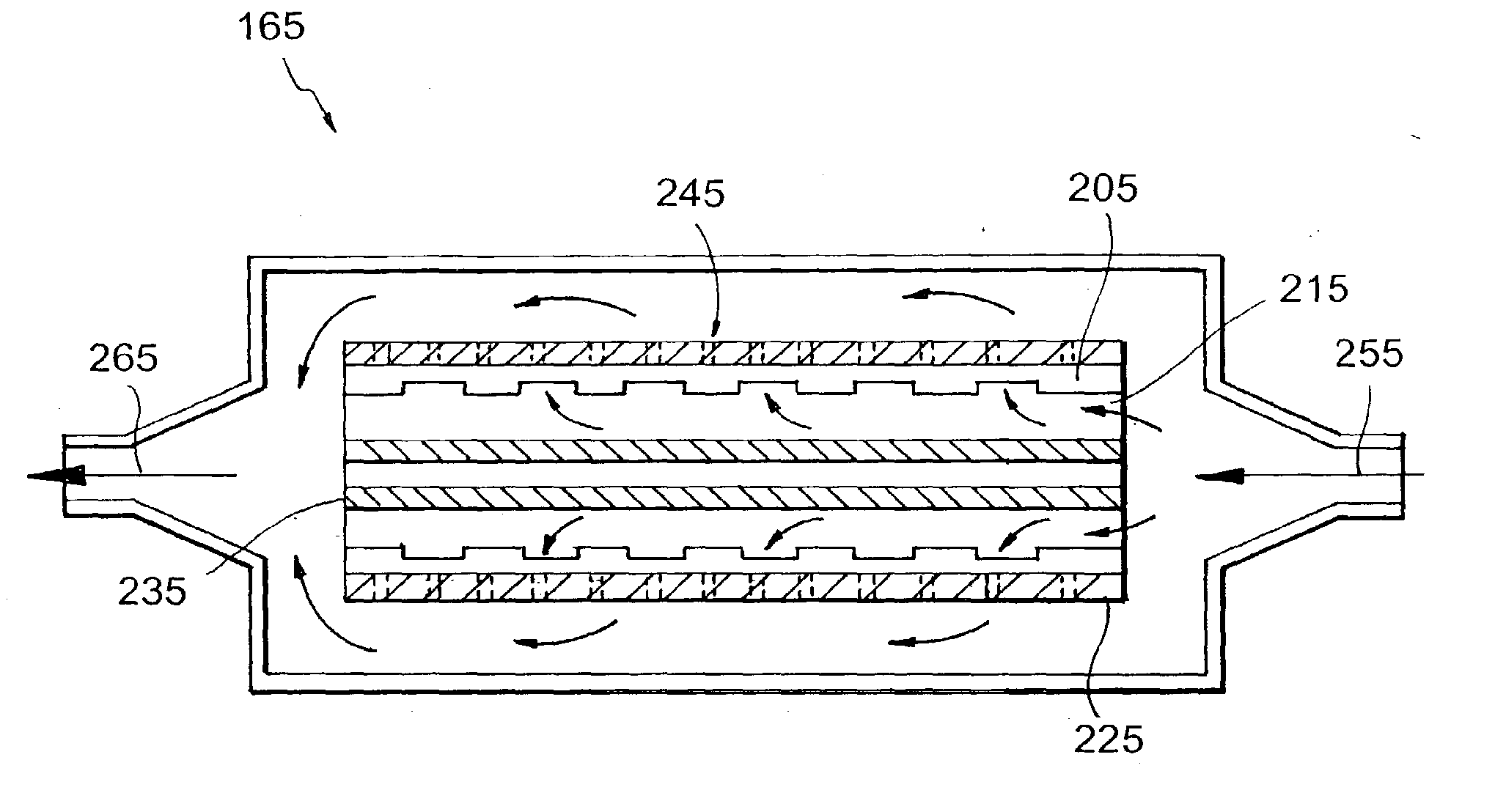

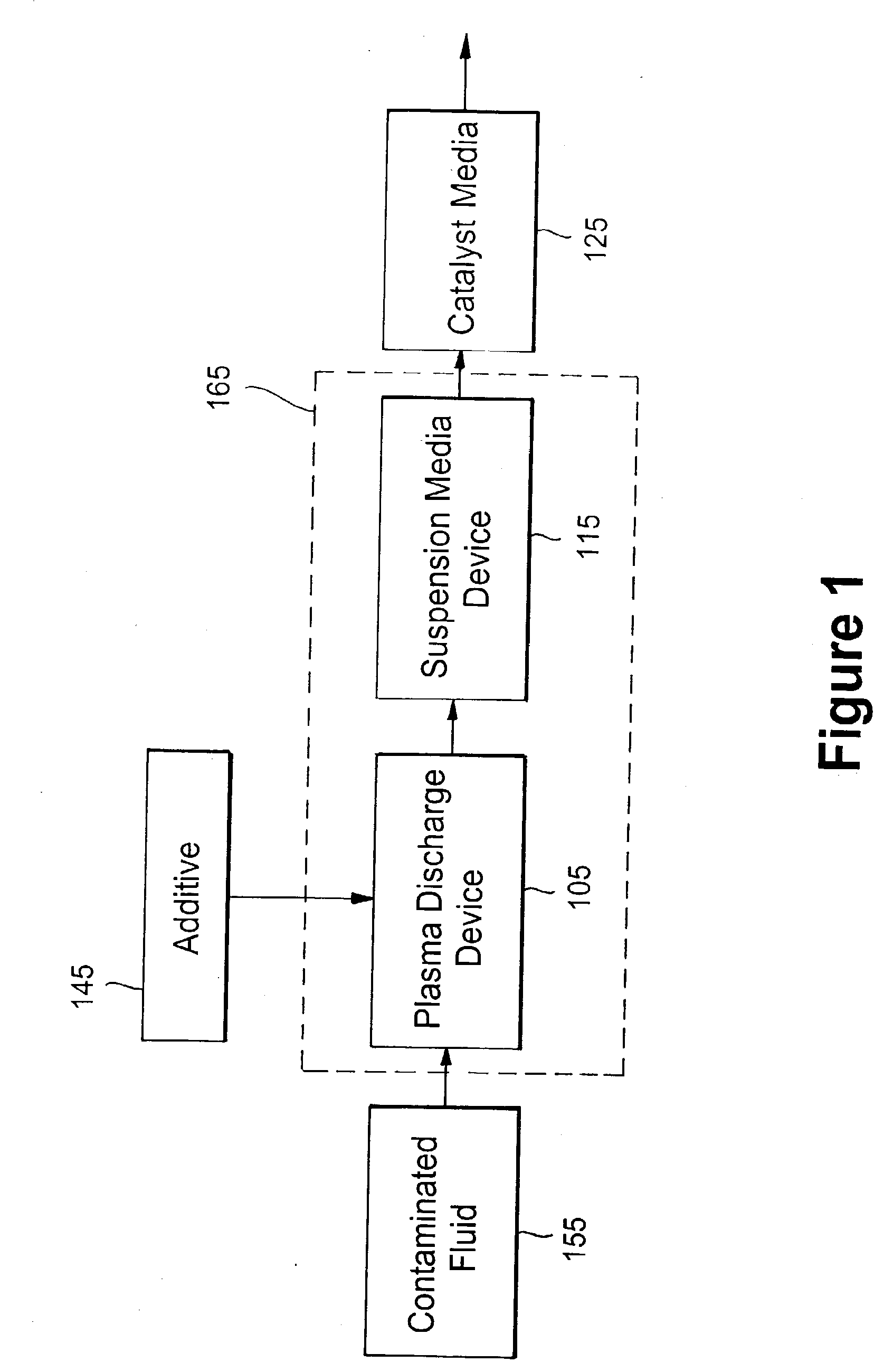

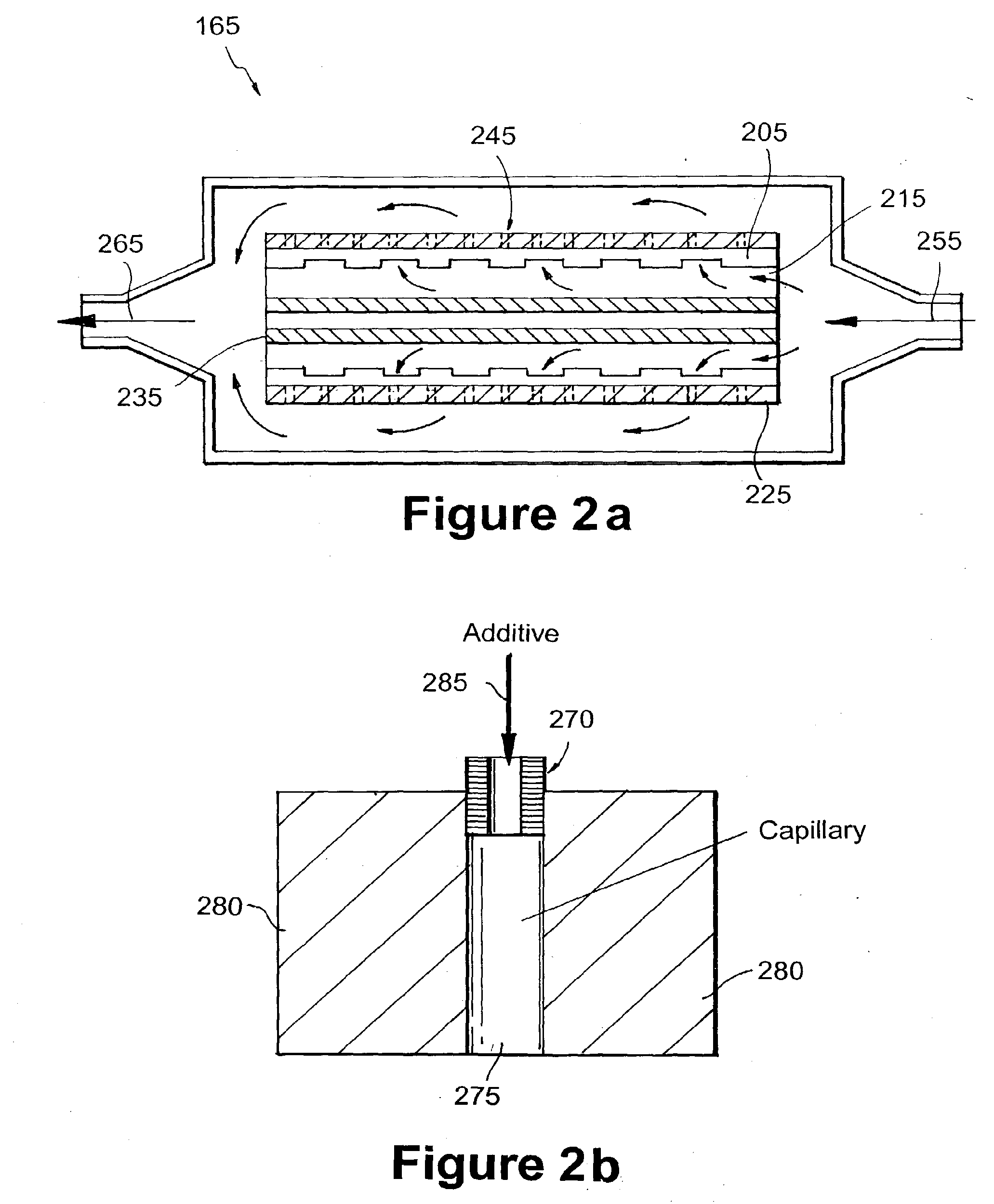

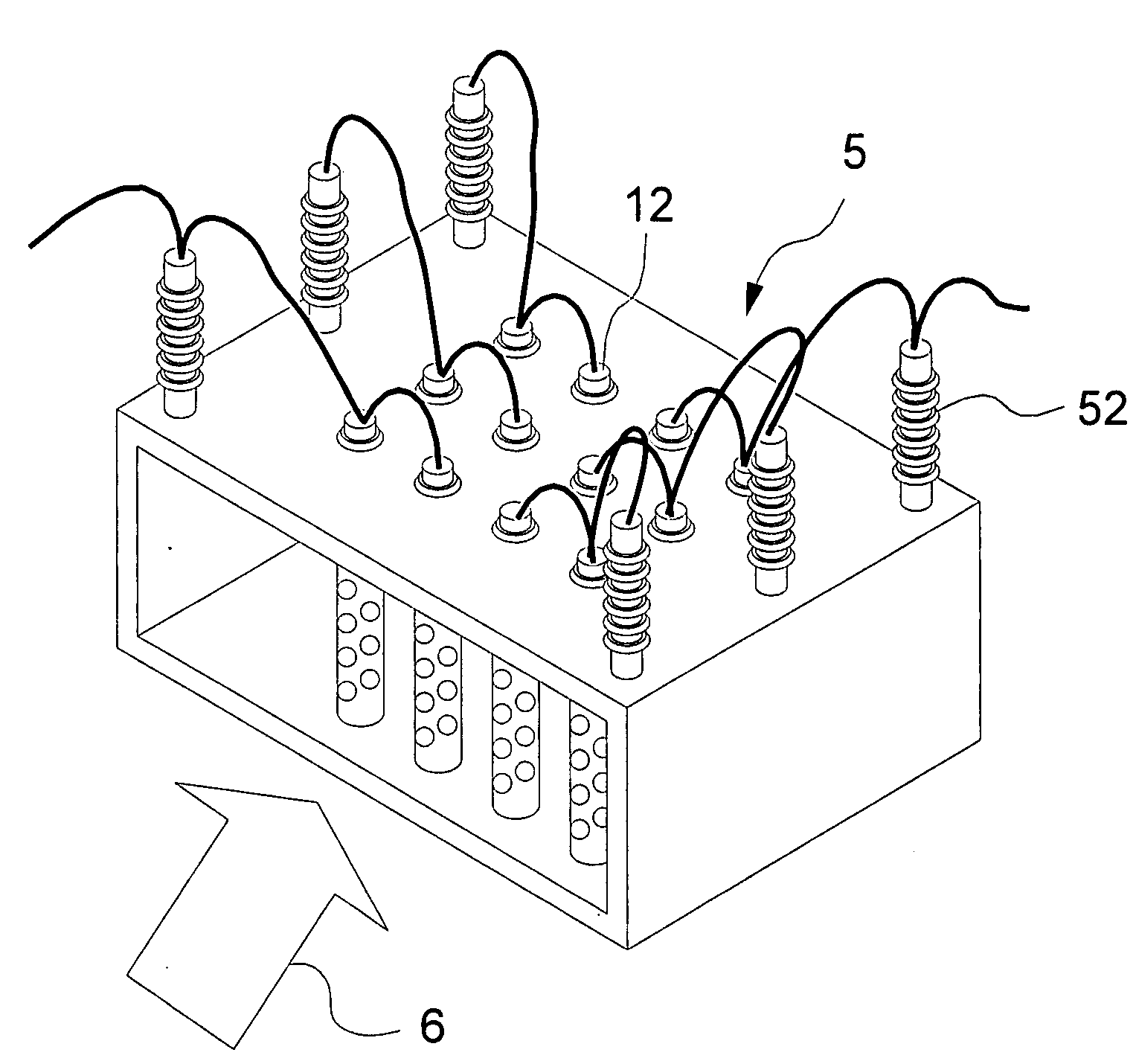

In situ sterilization and decontamination system using a non-thermal plasma discharge

InactiveUS7192553B2Improve sterilization efficiencyReduce healthMechanical apparatusGas treatmentElectricityParticulates

A sterilization and decontamination system in which a non-thermal plasma discharge device is disposed upstream of a suspension media (e.g., a filter, electrostatic precipitator, carbon bed). The plasma discharge device generates a plasma that is emitted through apertures (e.g., capillaries or slits) in the primary dielectric. Plasma generated active sterilizing species when exposed to contaminants or undesirable particulate matter is able to deactivate or reduce such matter in contaminated fluid stream and / or on objects. Thus, the undesirable contaminants in the fluid to be treated are first reduced during their exposure to the plasma generated active sterilizing species in the plasma region of the discharge device. Furthermore, the plasma generated active sterilizing species are carried downstream to suspension media and upon contact therewith deactivate the contaminants collected on the suspension media itself. Advantageously, the suspension media may be cleansed in situ. To increase the sterilization efficiency an additive, free or carrier gas (e.g., alcohol, water, dry air) may be injected into the apertures defined in the primary dielectric. These additives increase the concentration of plasma generated active sterilizing agents while reducing the byproduct of generated undesirable ozone pollutants. Downstream of the filter the fluid stream may be further treated by being exposed to a catalyst media or additional suspension media to further reduce the amount of undesirable particulate matter.

Owner:PLASMASOL CORP +1

In situ sterilization and decontamination system using a non-thermal plasma discharge

InactiveUS20080063577A1Improve sterilization efficiencyReduce healthMechanical apparatusGas treatmentDielectricParticulates

A sterilization and decontamination system in which a non-thermal plasma discharge device is disposed upstream of a suspension media (e.g., a filter, electrostatic precipitator, carbon bed). The plasma discharge device generates a plasma that is emitted through apertures (e.g., capillaries or slits) in the primary dielectric. Plasma generated active sterilizing species when exposed to contaminants or undesirable particulate matter is able to deactivate or reduce such matter in contaminated fluid stream and / or on objects. Thus, the undesirable contaminants in the fluid to be treated are first reduced during their exposure to the plasma generated active sterilizing species in the plasma region of the discharge device. Furthermore, the plasma generated active sterilizing species are carried downstream to suspension media and upon contact therewith deactivate the contaminants collected on the suspension media itself. Advantageously, the suspension media may be cleansed in situ. To increase the sterilization efficiency an additive, free or carrier gas (e.g., alcohol, water, dry air) may be injected into the apertures defined in the primary dielectric. These additives increase the concentration of plasma generated active sterilizing agents while reducing the byproduct of generated undesirable ozone pollutants. Downstream of the filter the fluid stream may be further treated by being exposed to a catalyst media or additional suspension media to further reduce the amount of undesirable particulate matter.

Owner:STEVENS INSTITUTE OF TECHNOLOGY +1

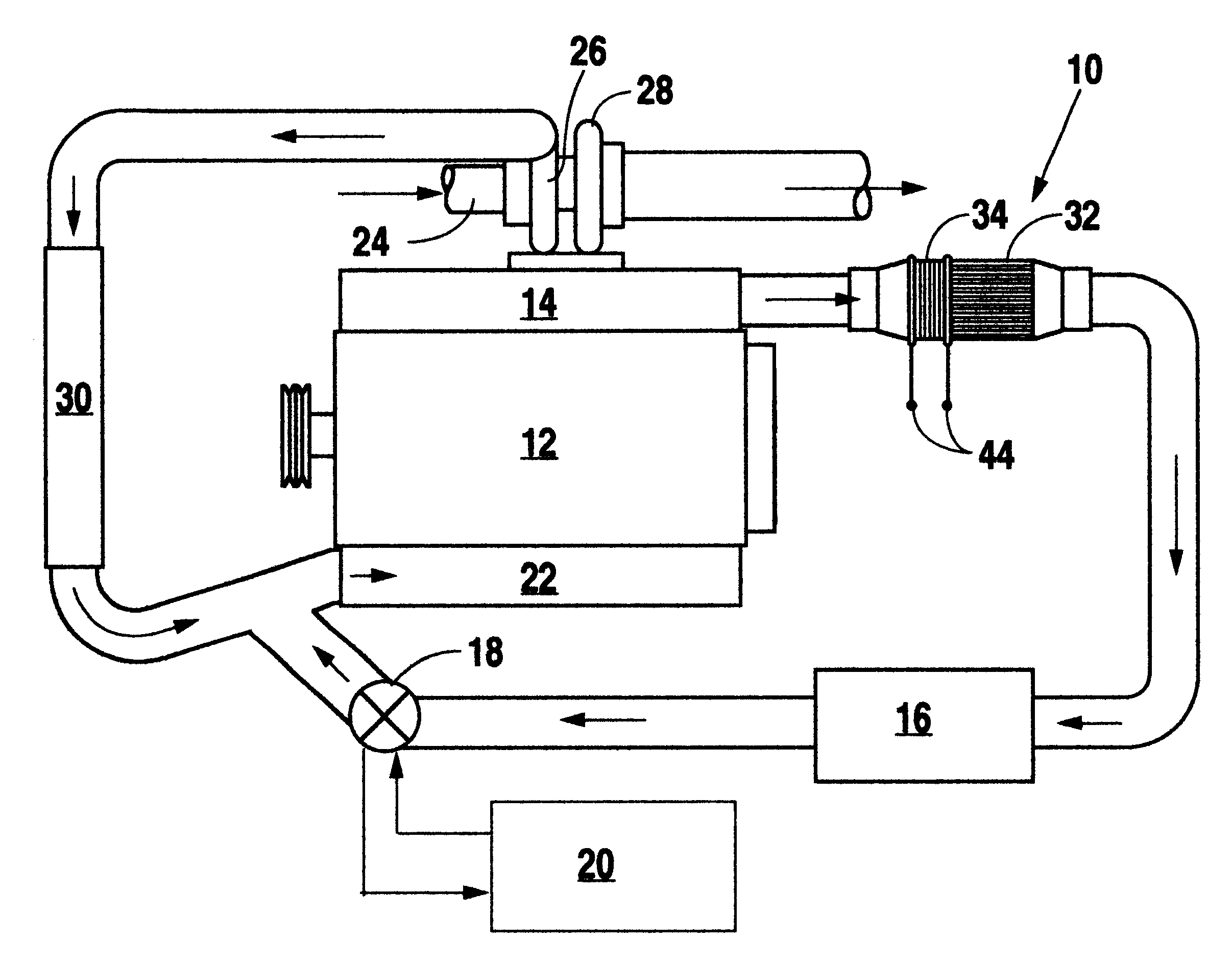

Method for generating a highly reactive plasma for exhaust gas aftertreatment and enhanced catalyst reactivity

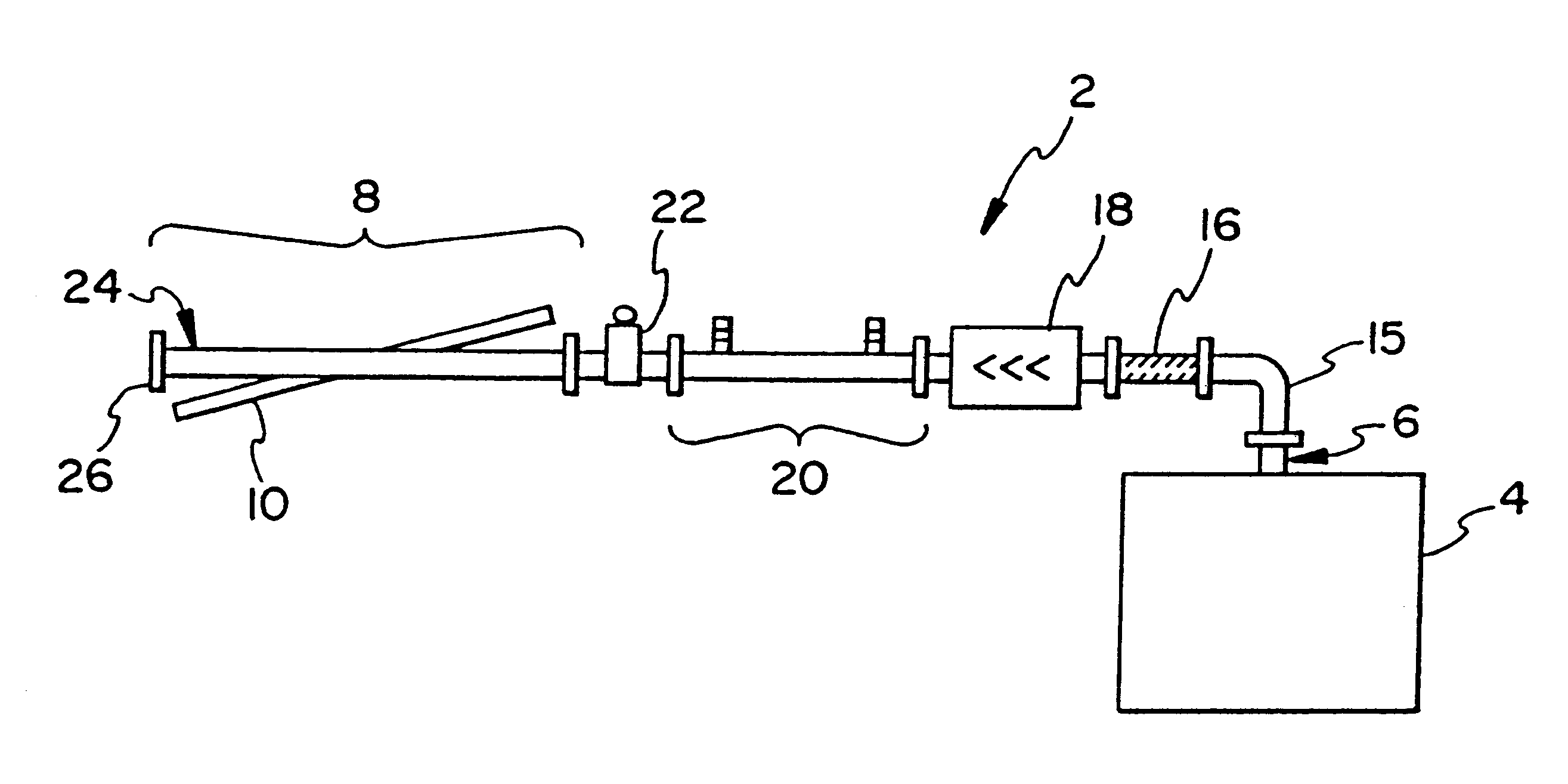

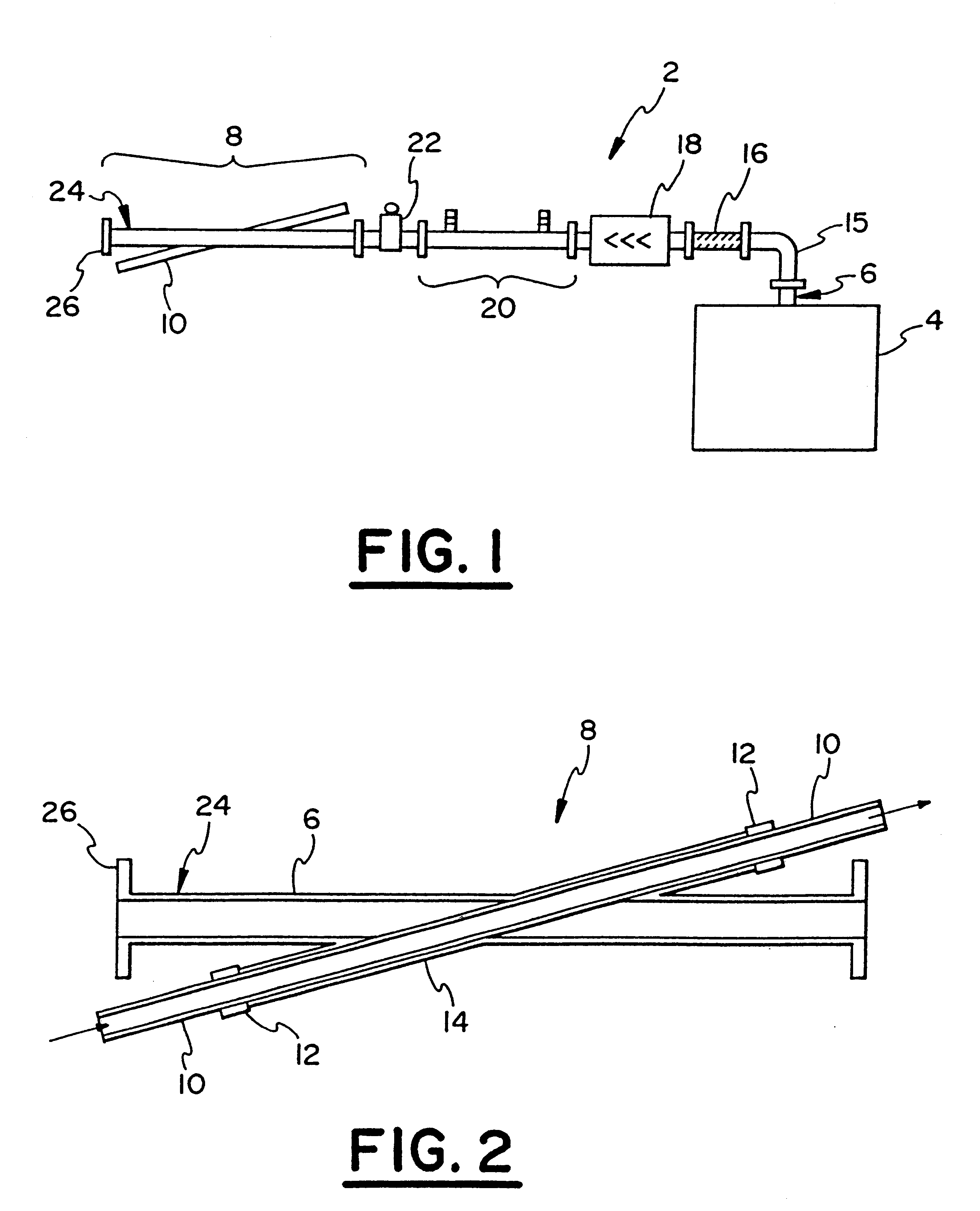

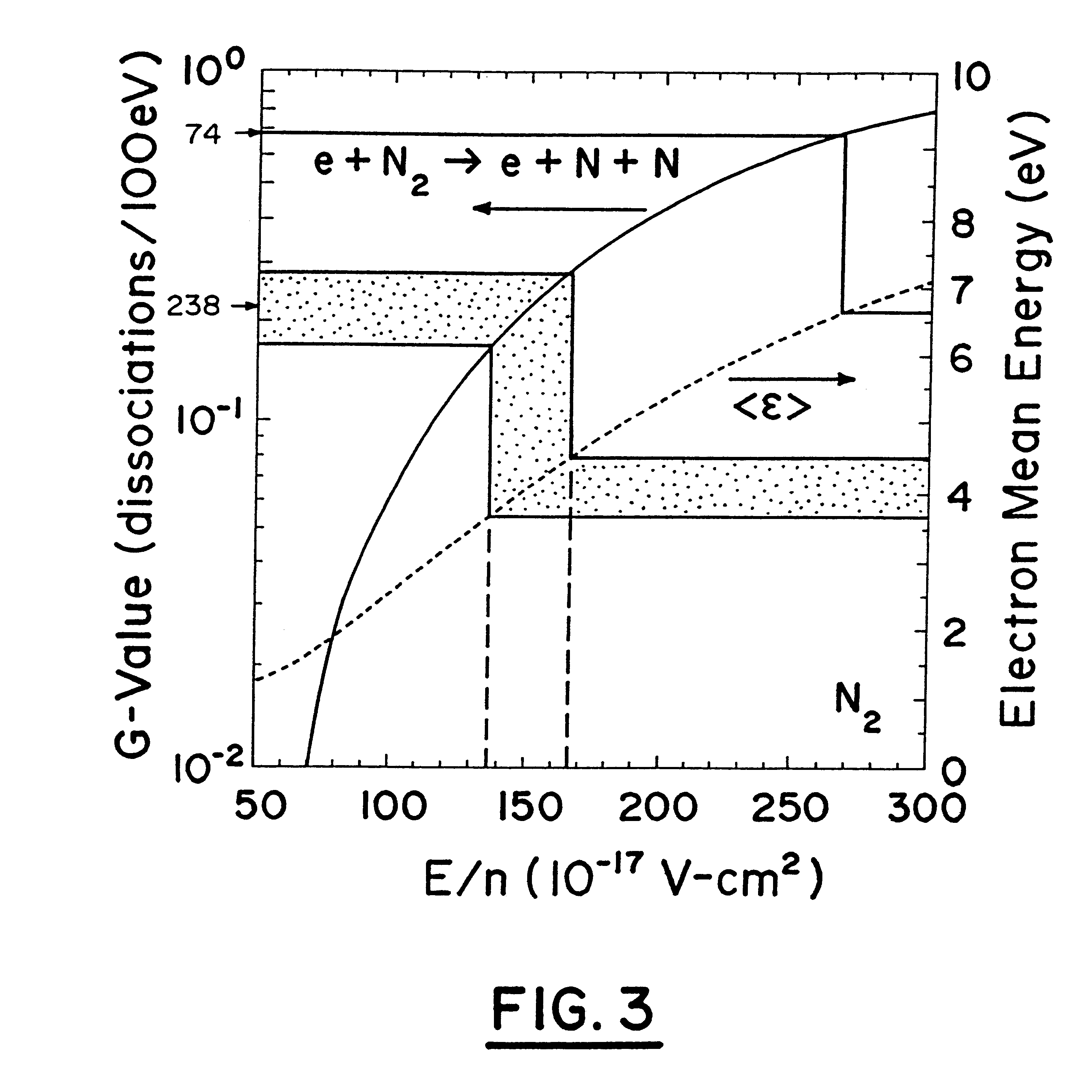

InactiveUS6190507B1Lower impedanceImprove responseInternal combustion piston enginesExhaust apparatusMicrowaveReactive plasma

A method for non-thermal plasma aftertreatment of exhaust gases the method comprising the steps of providing short risetime (about 40 ps), high frequency (about 5G hz), high power bursts of low-duty factor microwaves sufficient to generate a dielectric barrier discharge and passing a gas to treated through the discharge so as to cause dissociative reduction of the exhaust gases. The invention also includes a reactor for generating the non-thermal plasma.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

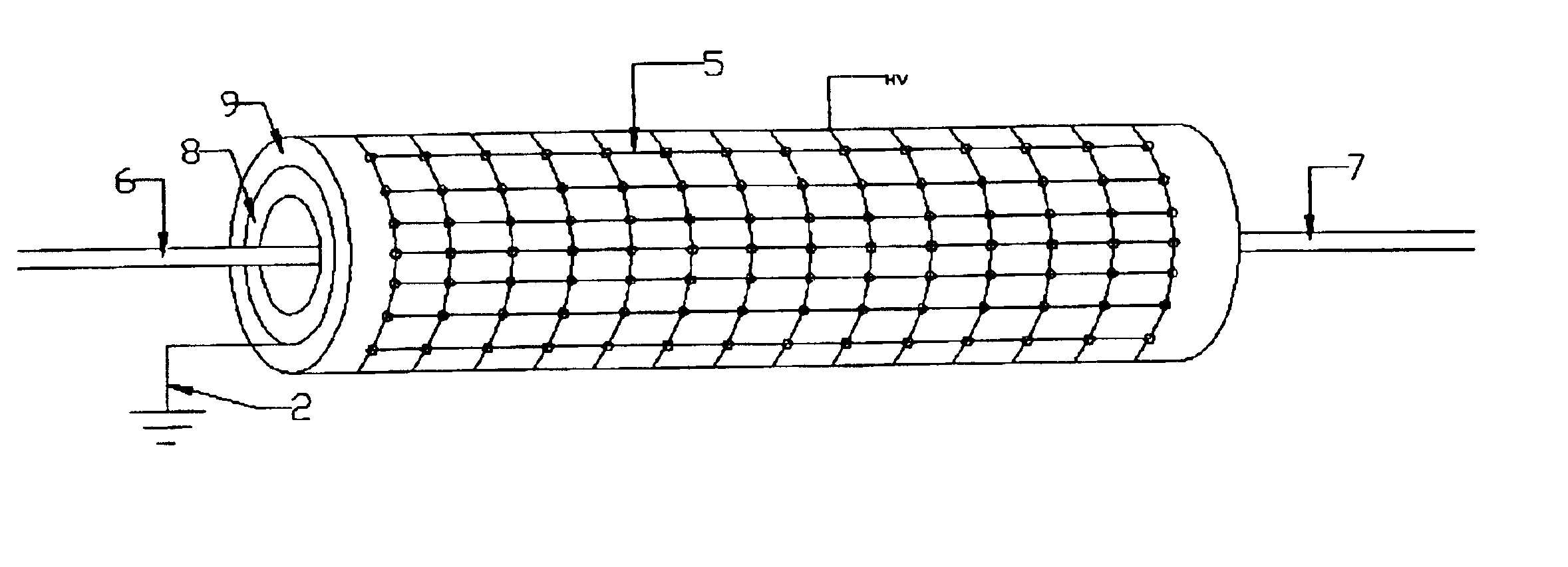

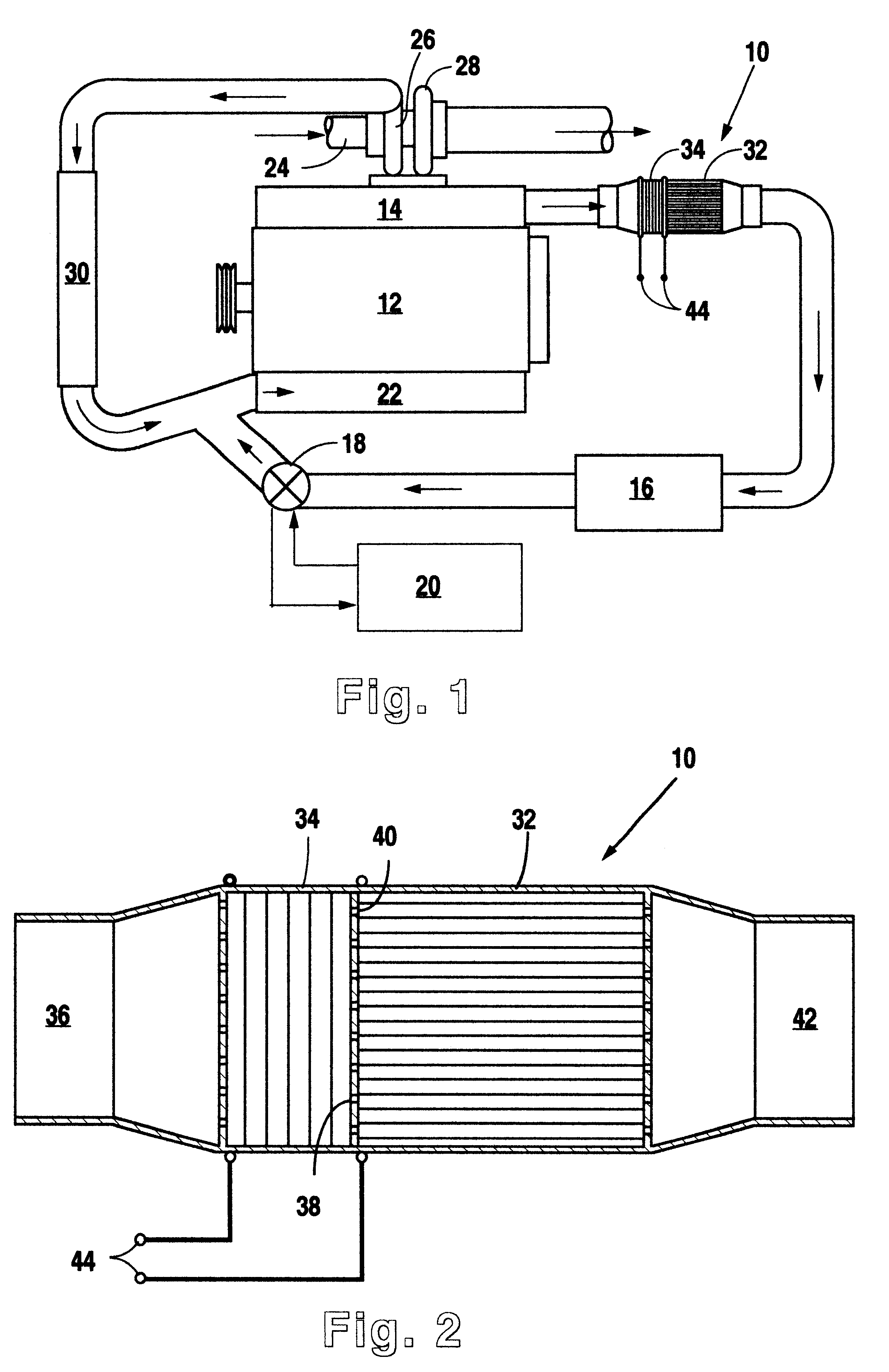

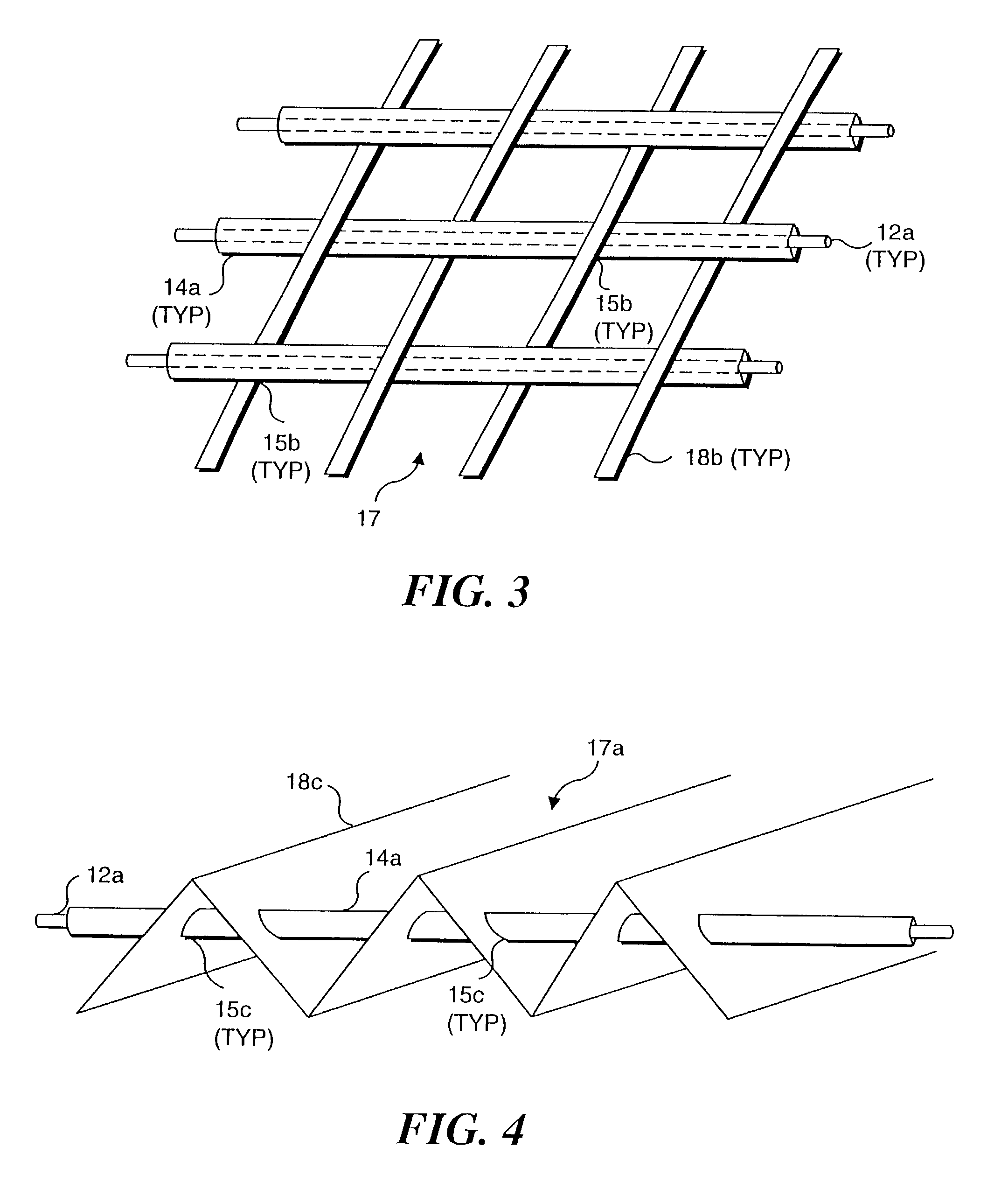

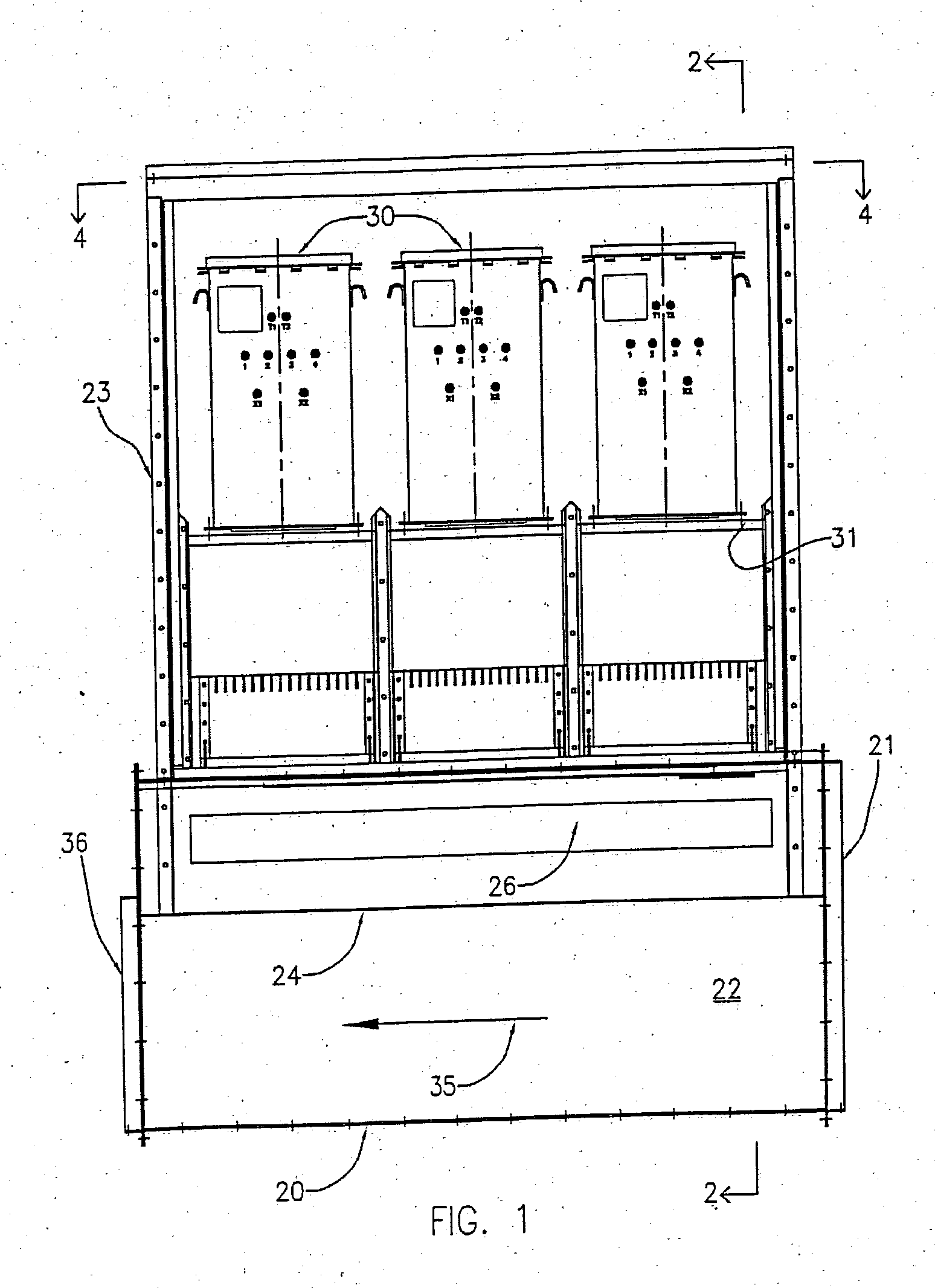

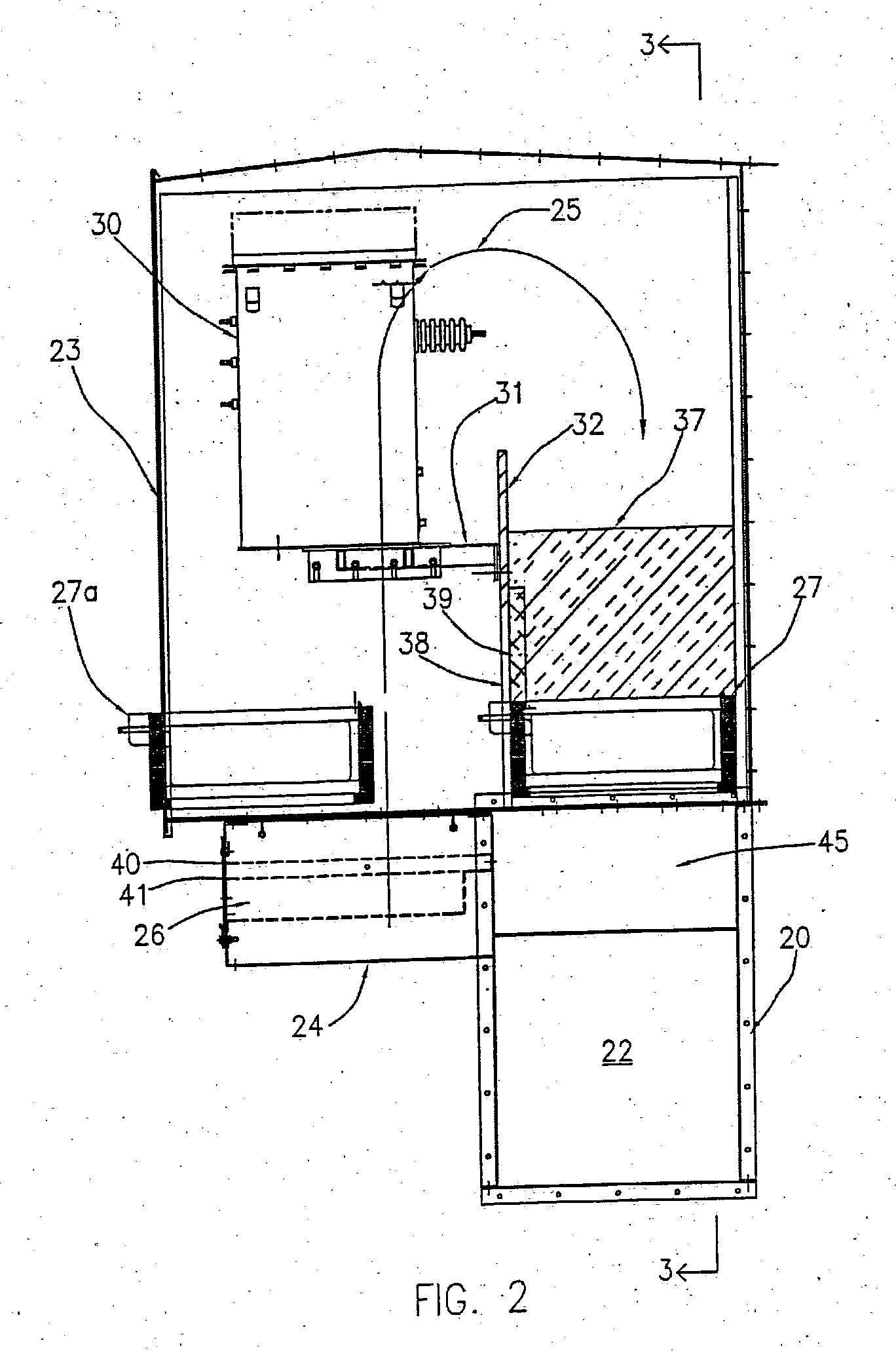

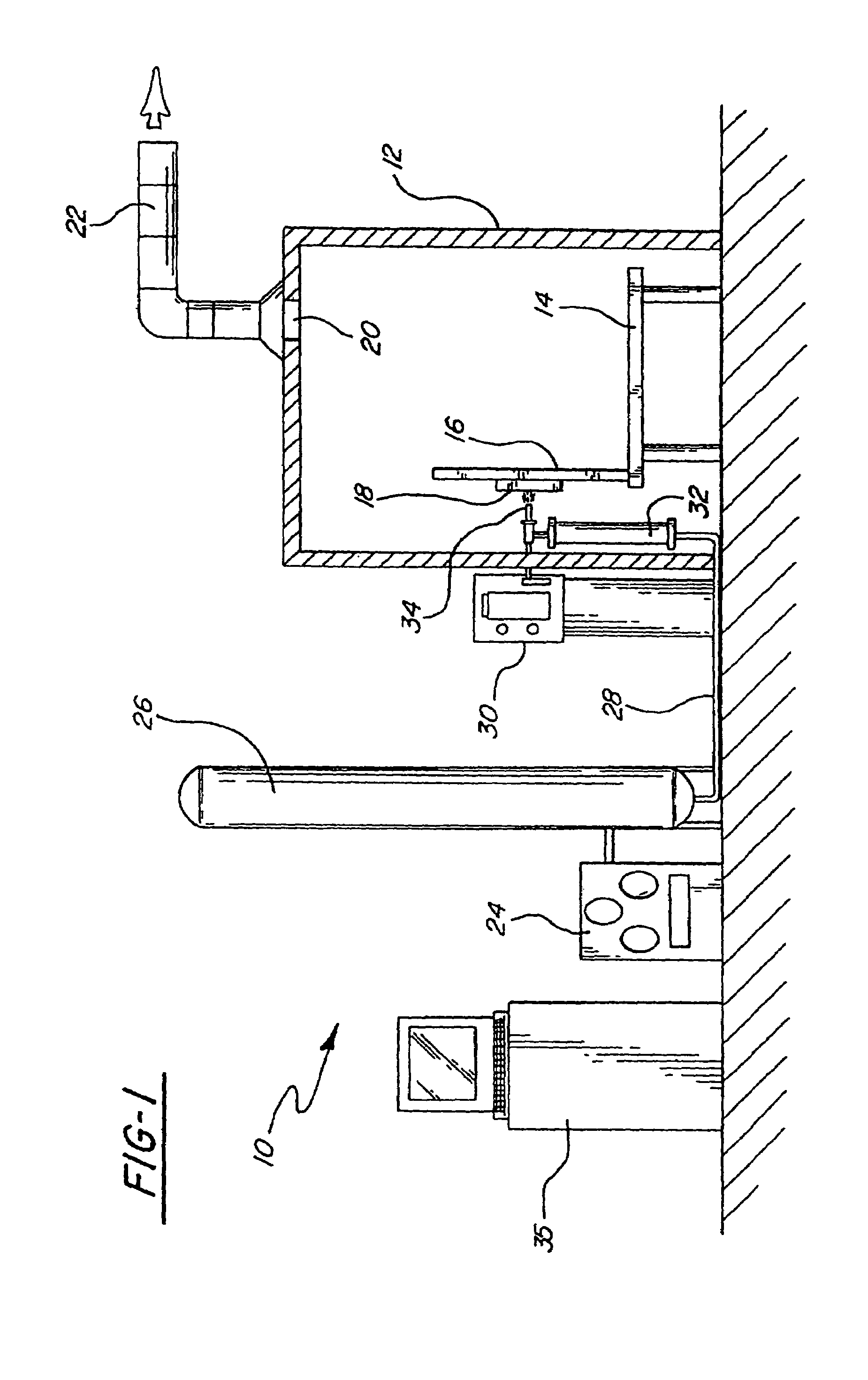

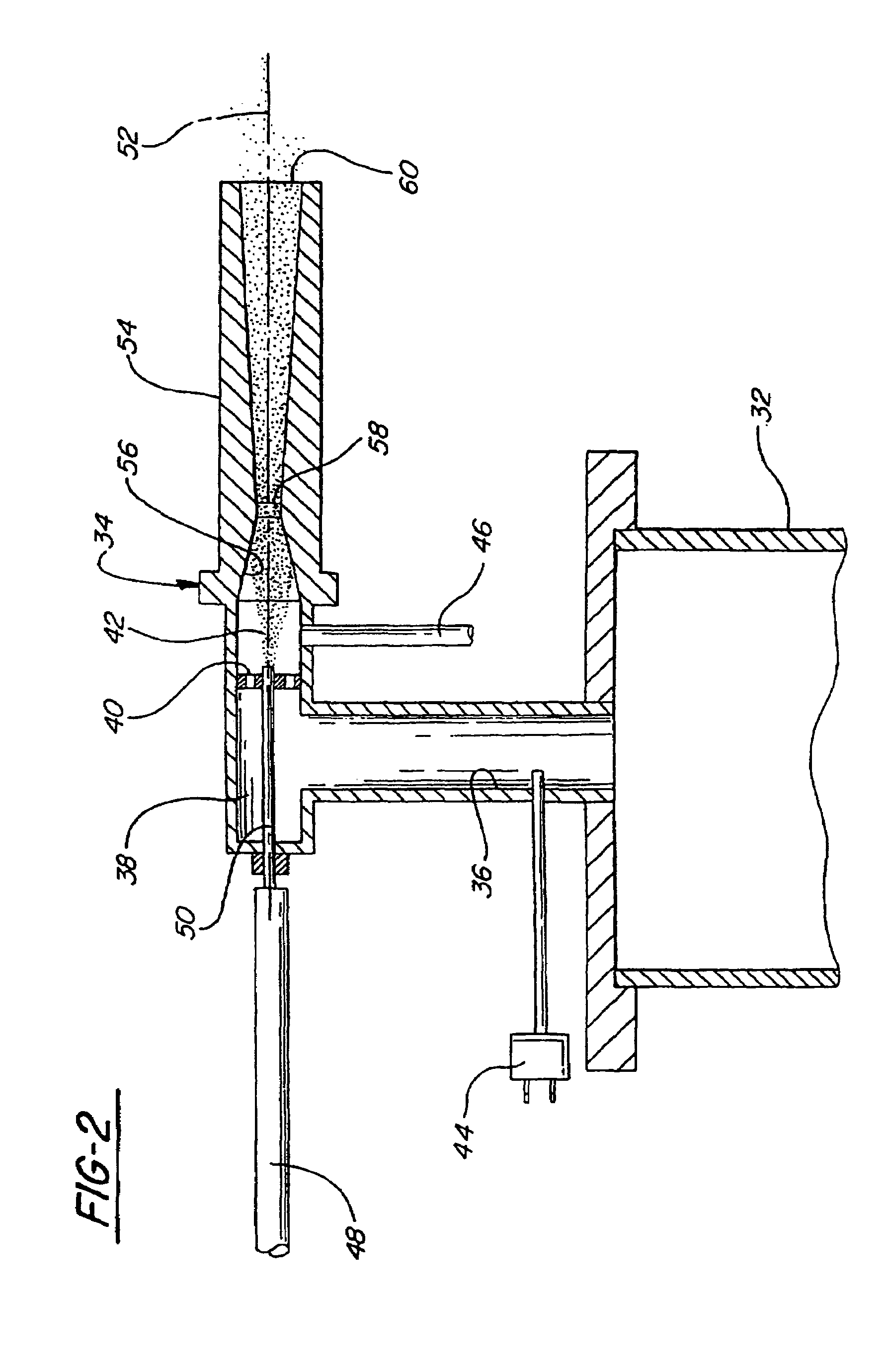

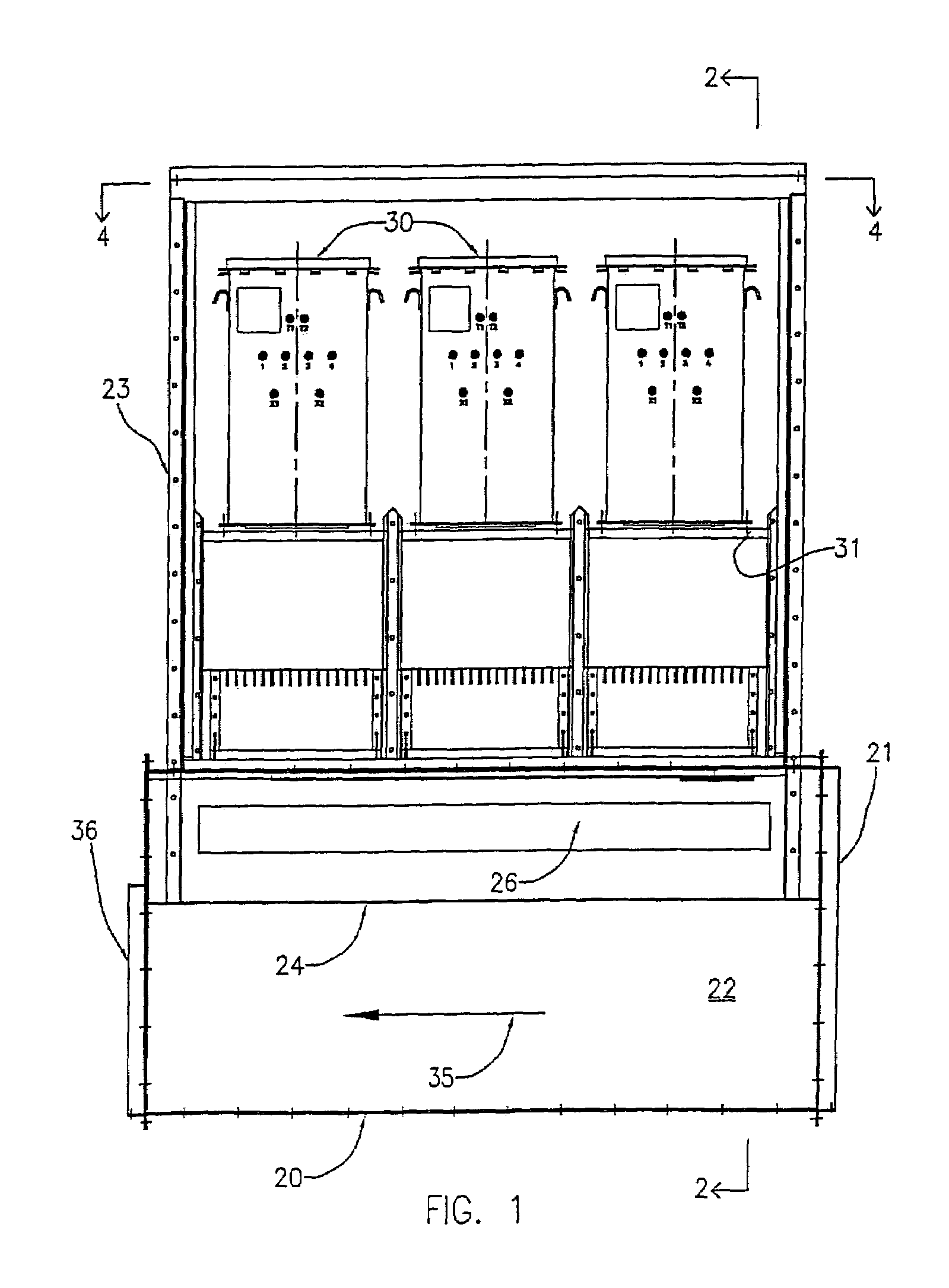

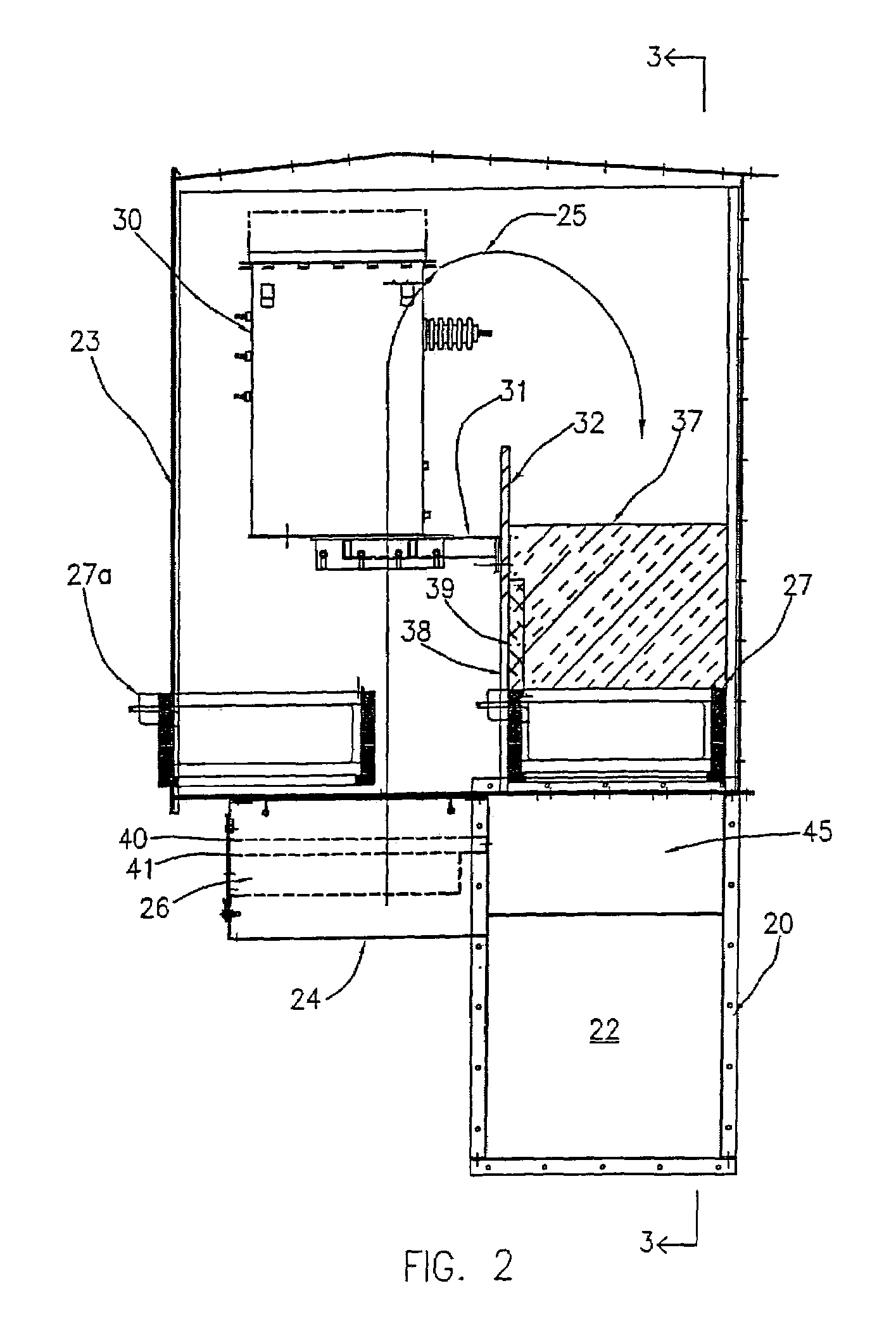

Exhaust gas recirculation filtration system

InactiveUS6474060B2Non-fuel substance addition to fuelInternal combustion piston enginesExternal combustion engineFiltration

A filtration system adapted to prevent diesel soot carried with recirculated exhaust gas from being recirculated through internal combustion engine. The filtration system provides continuous elimination of soot, thus reducing its negative impact on engine life, lubrication oil quality, and on components in the exhaust gas recirculation system. The filtration system comprises a non-thermal plasma generator that periodically, or continuously, oxidizes carbon deposited, or trapped, within a carbon filter disposed downstream of the non-thermal plasma generator.

Owner:SOUTHWEST RES INST

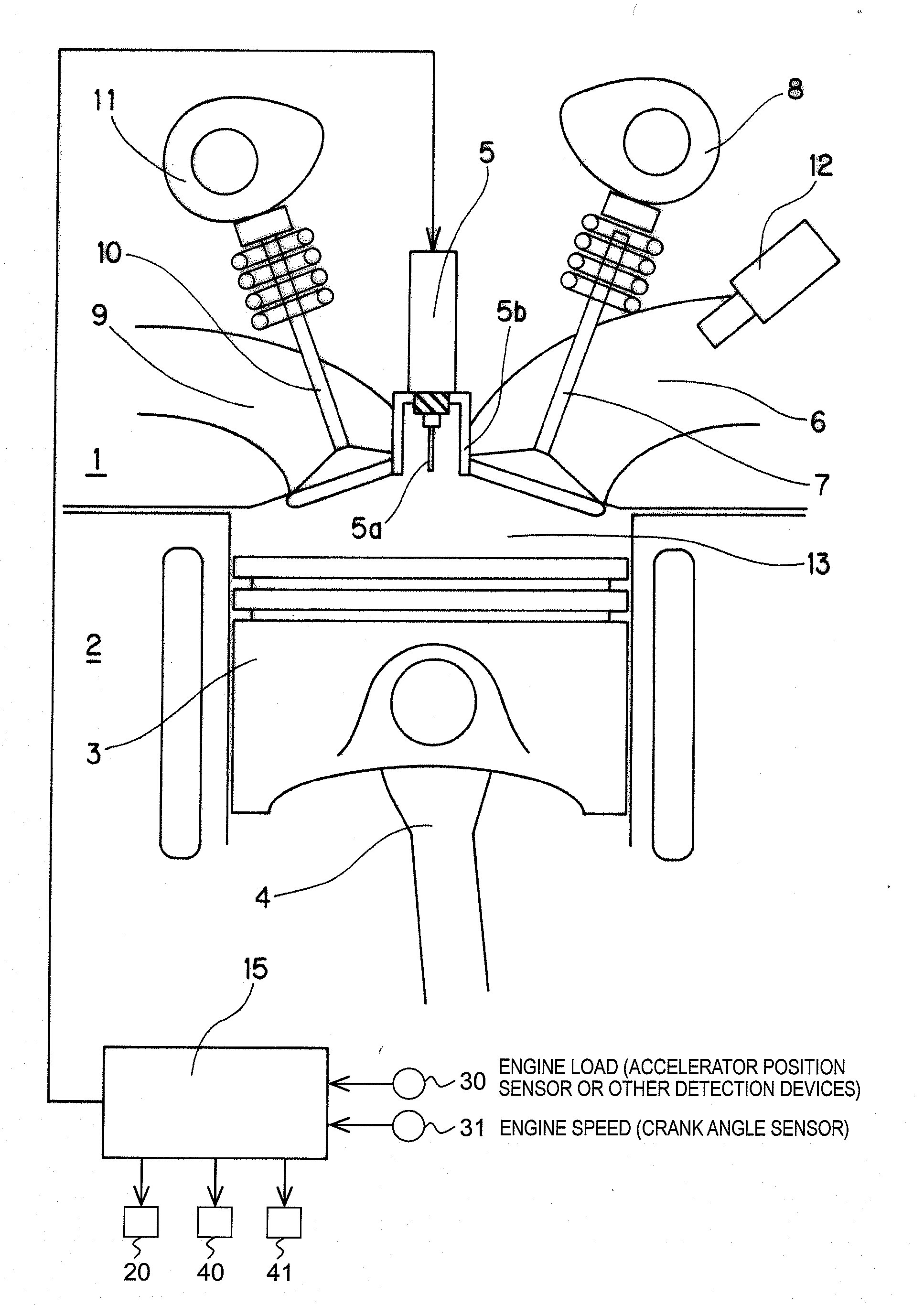

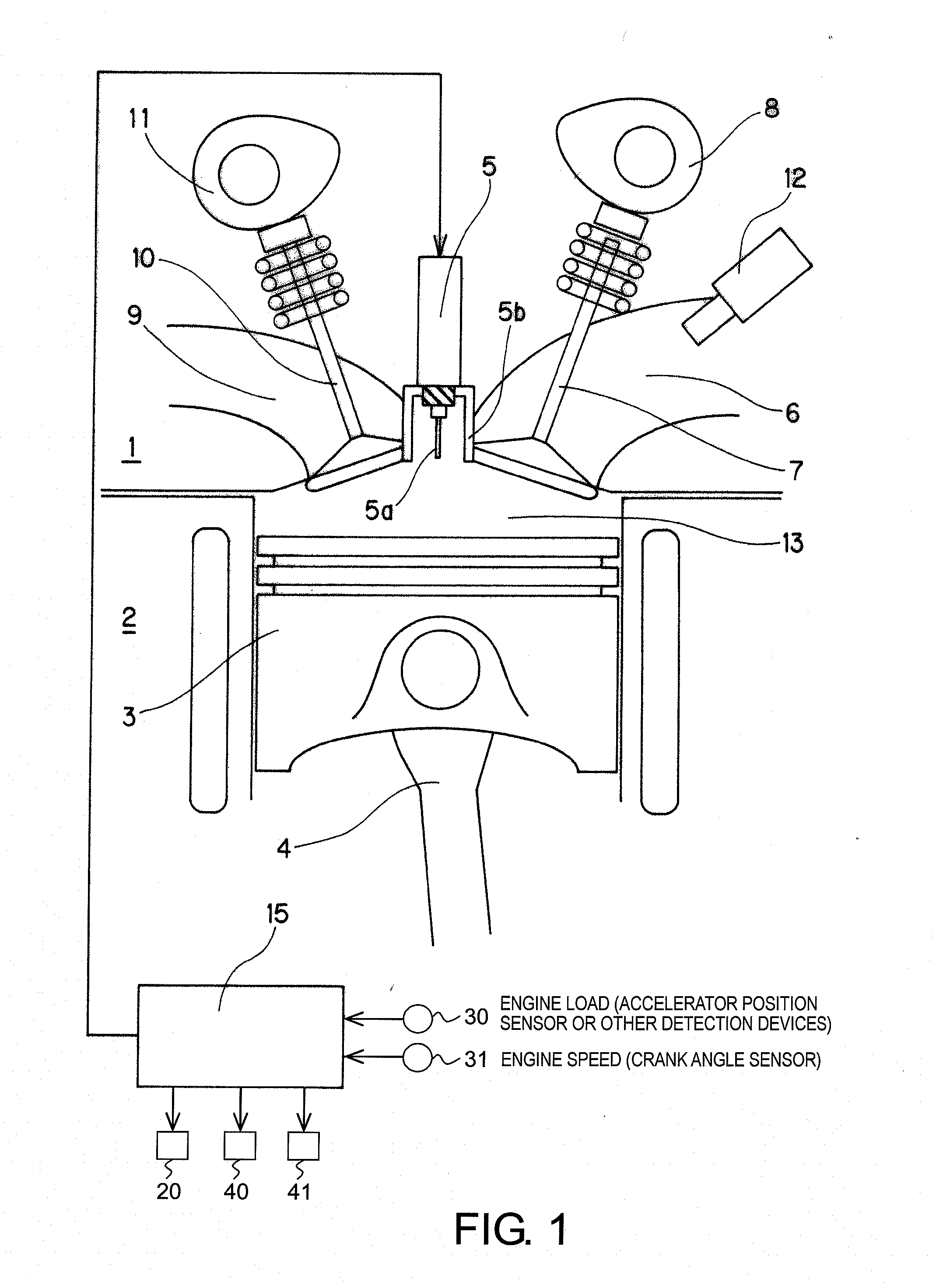

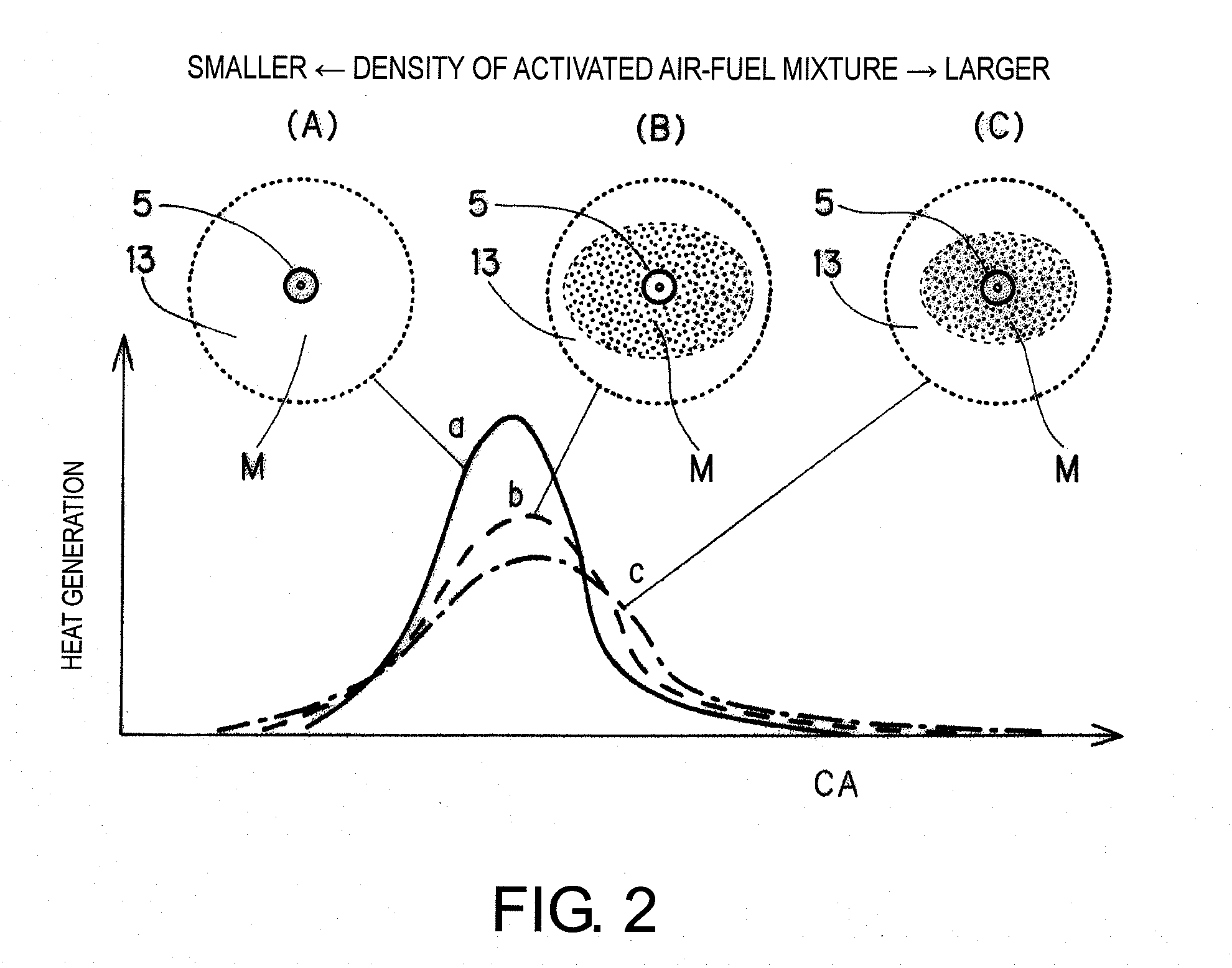

Internal combustion engine and combustion control method

InactiveUS20070266979A1Low degree of freedomReduce the impactSparking plugsValve arrangementsCombustion chamberElectric discharge

An internal combustion engine is provided that basically comprises a combustion chamber, an electric discharge unit and a controller. The combustion chamber receives a mixture of fuel and air that is caused to undergo compression self ignition. The electric discharge unit is provided inside the combustion chamber to generate an electric discharge for conducting combustion inside the combustion chamber. The controller is configured to control a voltage applied to the electric discharge unit. The controller is configured to control the electric discharge unit such that a non-thermal plasma can be formed without incurring a transition to arc discharging, and to control the quantity and distribution of an activated air-fuel mixture inside the combustion chamber in accordance with an operating condition of the internal combustion engine.

Owner:NISSAN MOTOR CO LTD

Active gases and treatment methods

InactiveUS20120064016A1Optimise populationNegative side effectCosmetic preparationsBiocideKryptonNoble gas

A method of making an active gas by generating a glow discharge, non-thermal plasma, in a gas mixture of a carrier gas and a more readily ionisable gas. The gas mixture is exposed to water vapour at or downstream from the generator to form the active gas. The gas mixture includes helium as the carrier gas and up to 40% by volume of at least one noble gas such as argon, krypton, or xenon as the more readily ionisable gas. The gas mixture is ejected at a temperature between 5° C. to 42° C. The active gas may be used for oral treatment such as cosmetic whitening of teeth, medical or non-clinical cleaning of teeth or for cleaning laundry or dishwashing items.

Owner:LINDE AG

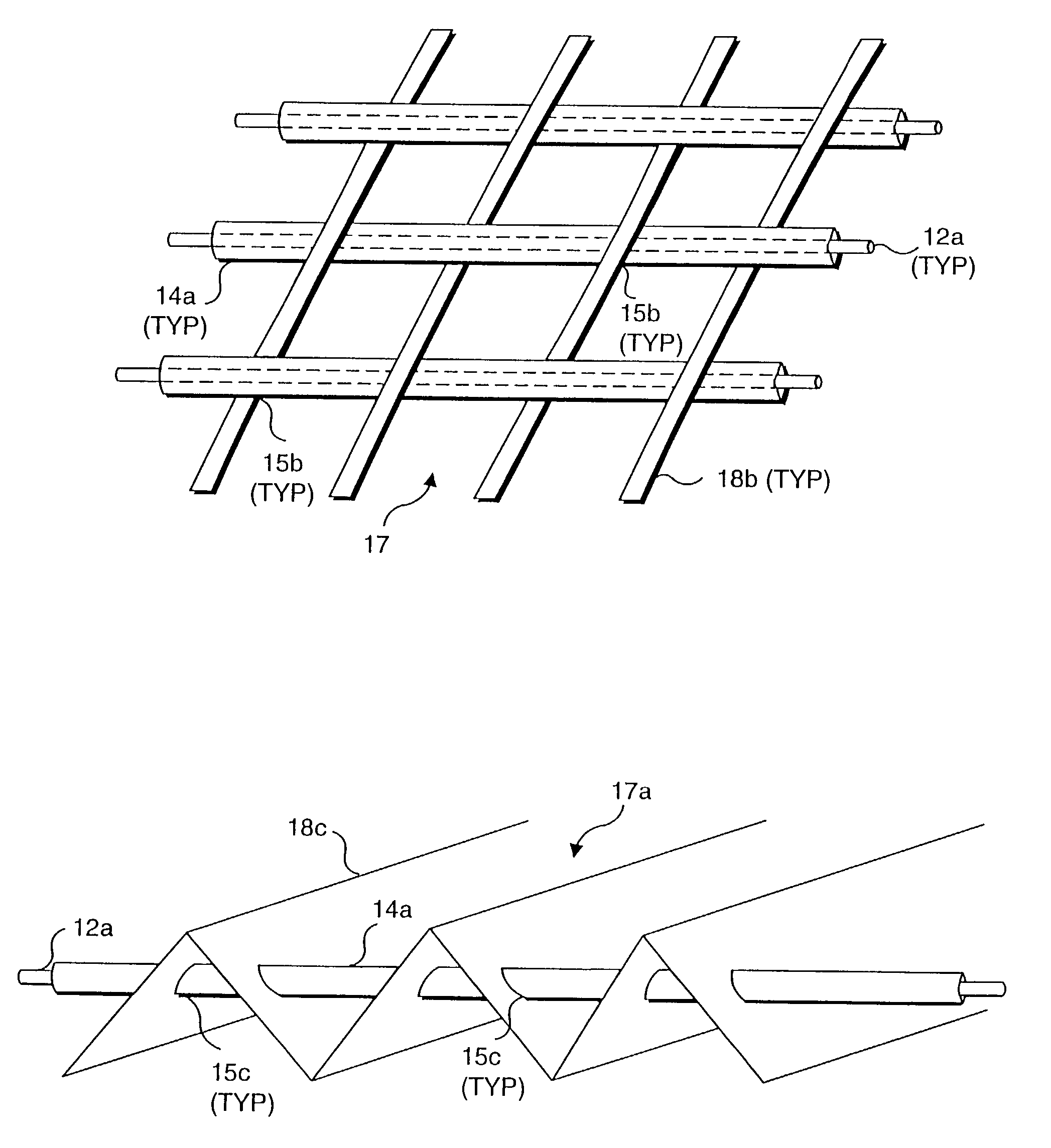

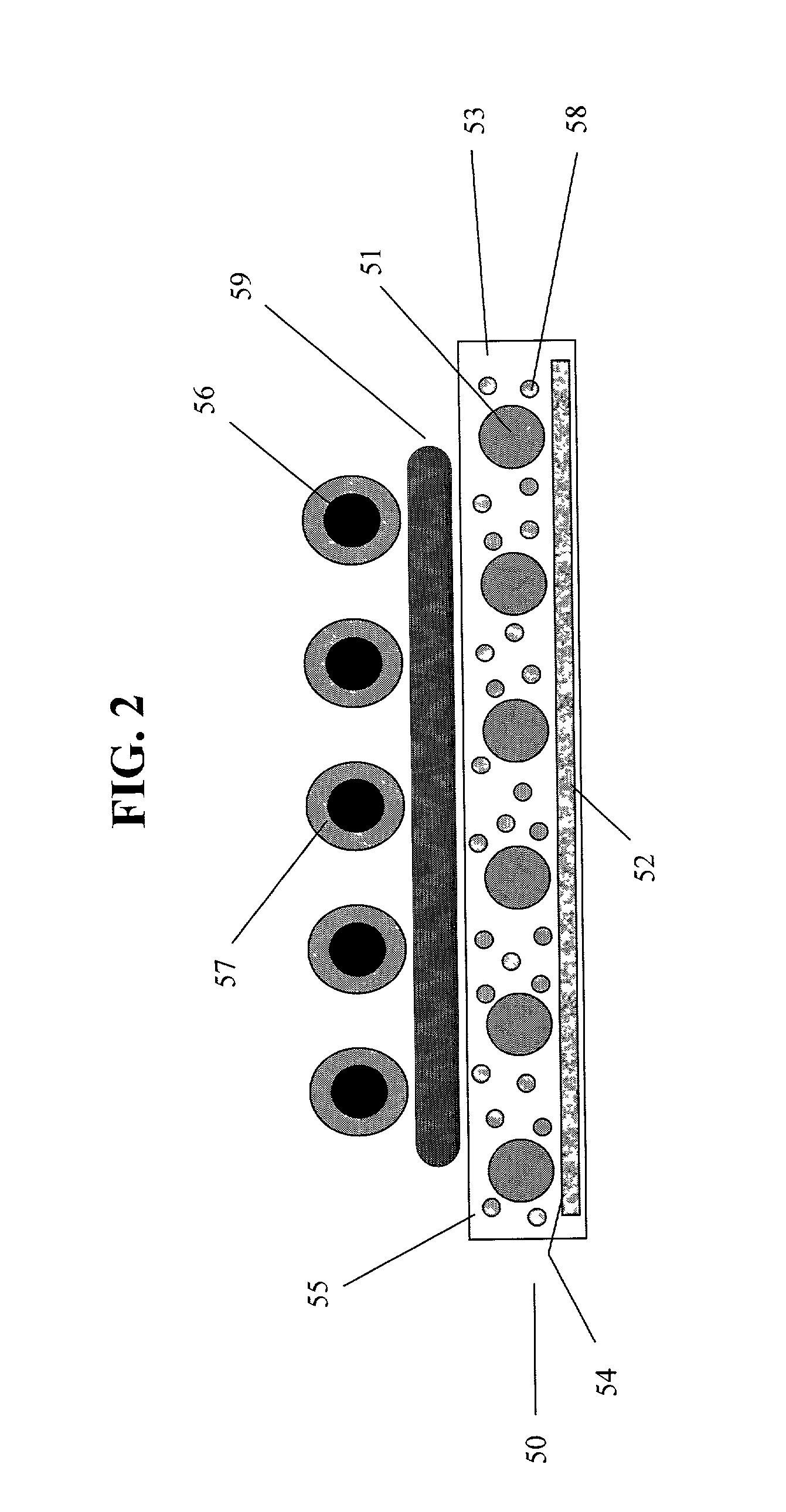

Decontamination of fluids or objects contaminated with chemical or biological agents using a distributed plasma reactor

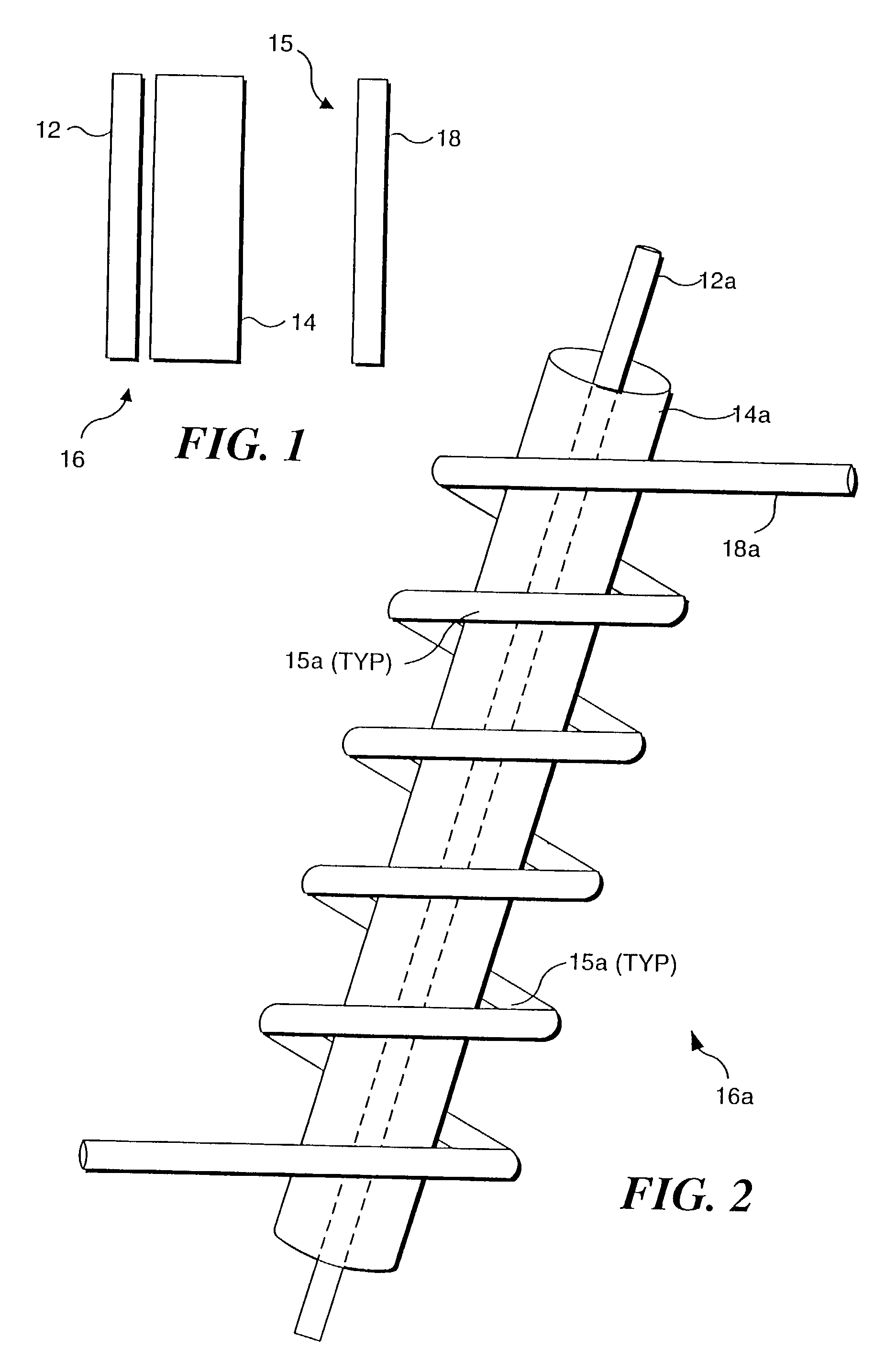

InactiveUS7037468B2Dispersed particle separationContaminated soil reclamationElectrical conductorCorona discharge

Apparatus and method for using a non-thermal plasma or corona discharge generated at multiple points and distributed to decontaminate surfaces and objects contaminated with chemical or biological agents. The corona discharge can be generated using very short high voltage pulses. The pulsed corona discharge can be directed at a contaminated surface through the unbraided strands at an end of a dielectric covered conductor. Another pulsed discharge embodiment incorporates a primary coil surrounding a chamber having a void filled with a plurality of secondary coils. A silent corona discharge can be generated using a variety of different configurations of a dielectric coated electrode and a bare electrode. The silent discharge is produced at all intersections between the dielectric covered electrode and the bare electrode. In one embodiment the apparatus comprises a blanket-like structure that is useful for decontaminating surfaces or decontaminating a fluid passing between spaced-apart bare electrodes.

Owner:FLIR DETECTION

Exhaust gas recirculation filtration system

InactiveUS20010042372A1Internal combustion piston enginesNon-fuel substance addition to fuelExternal combustion engineFiltration

A filtration system adapted to prevent diesel soot carried with recirculated exhaust gas from being recirculated through internal combustion engine. The filtration system provides continuous elimination of soot, thus reducing its negative impact on engine life, lubrication oil quality, and on components in the exhaust gas recirculation system. The filtration system comprises a non-thermal plasma generator that periodically, or continuously, oxidizes carbon deposited, or trapped, within a carbon filter disposed downstream of the non-thermal plasma generator.

Owner:SOUTHWEST RES INST

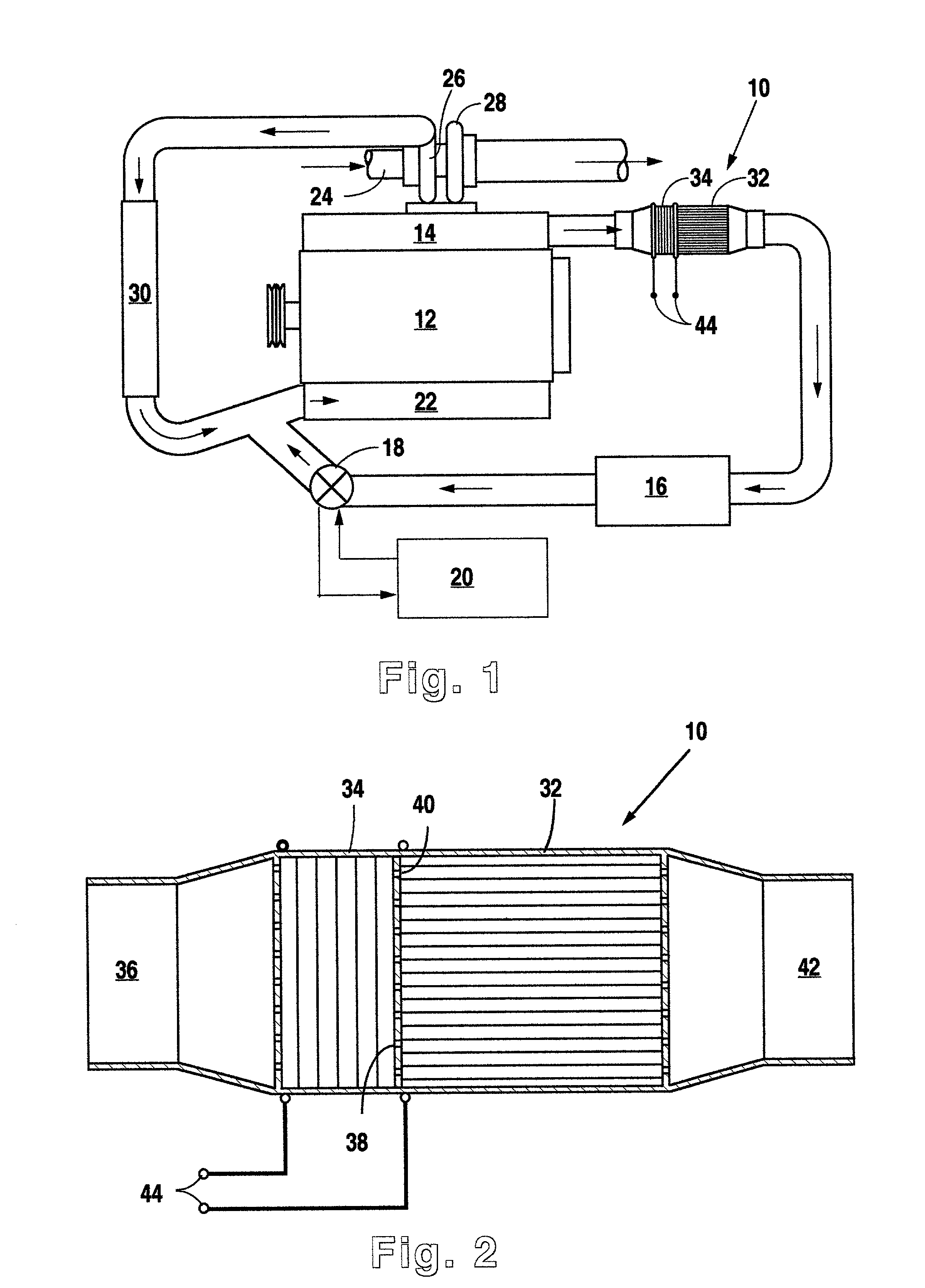

Method and apparatus for treating exhaust gas

InactiveUS20070071657A1Component can be removedHigh activityCombination devicesNitrogen compoundsNitrogen plasmaElectric discharge

A method for treating exhaust gas includes: adsorbing target components in the exhaust gas with an adsorbent (5); introducing a nitrogen gas with an oxygen concentration of 10 vol % or less and a purity of 90 vol % or more into the adsorbent (5); and applying (6, 7, 8) nonthermal plasma to the adsorbent (5). After the adsorbent (5) adsorbs the target components in the exhaust gas, the nitrogen gas is introduced into the adsorbent (5), and then an electric discharge is generated so that the nonthermal plasma of the nitrogen gas is applied to the adsorbent (5) and causes desorption of the target components and regeneration of the adsorbent (5). This method can remove the target components effectively from oxygen-containing exhaust gas by using nitrogen gas plasma with high activity as a result of ionization of a nitrogen gas and combining adsorption, desorption by the nitrogen gas plasma, and nitrogen plasma treatment.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY

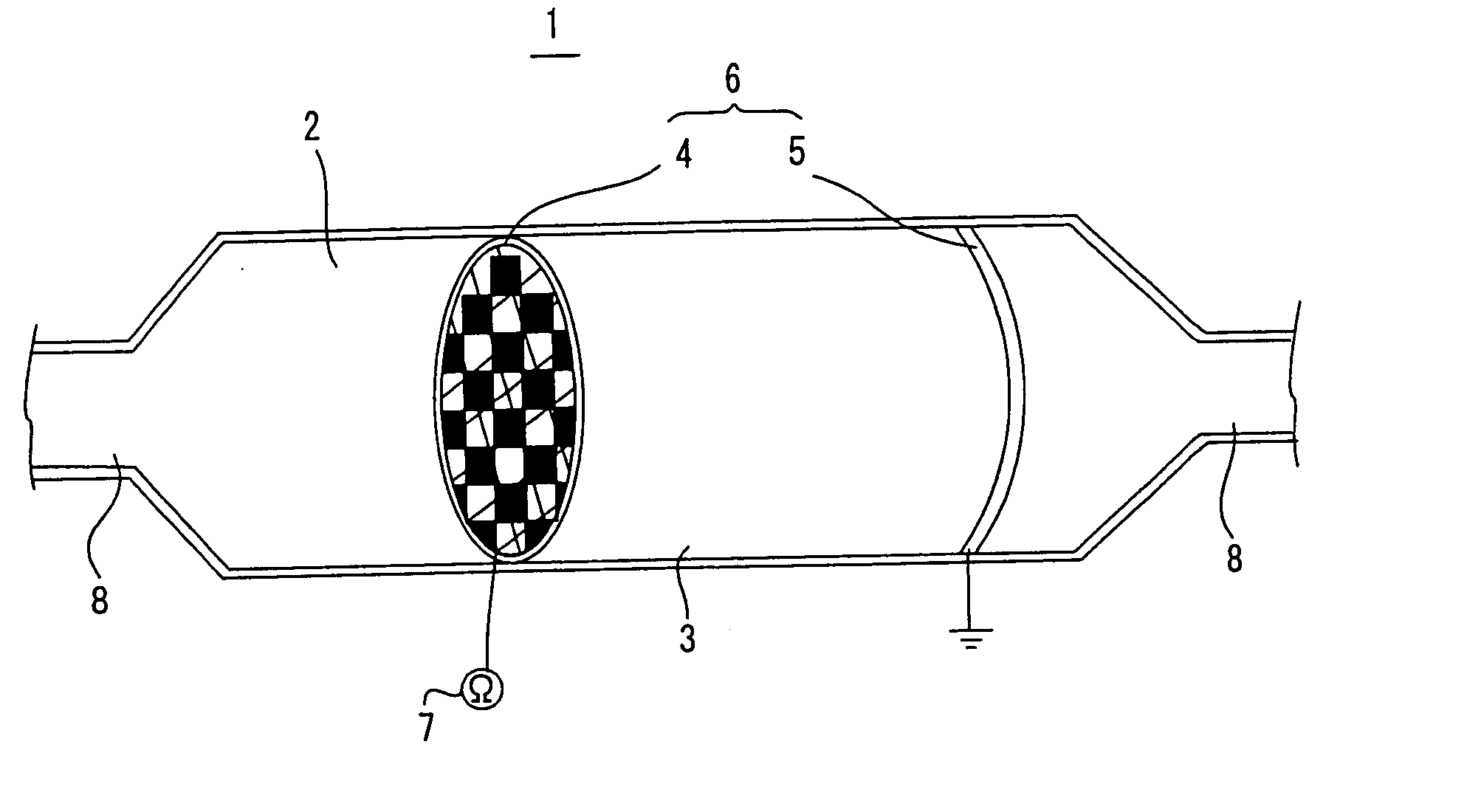

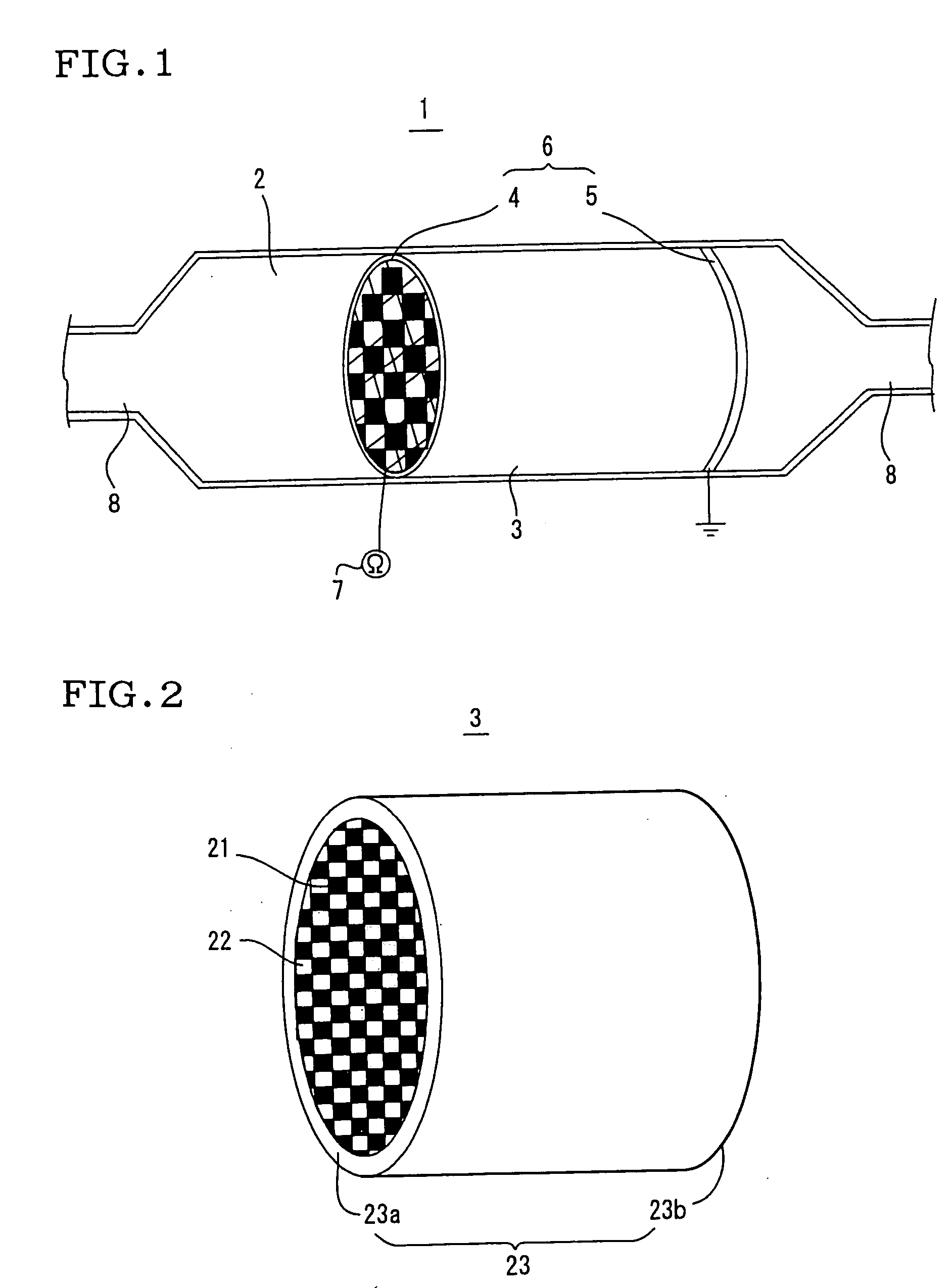

Exhaust gas treating apparatus

InactiveUS20050229564A1Weaken energyCombination devicesAuxillary pretreatmentParticulatesNitrogen monooxide

The present invention is characterized in that a casing 2 connected to an exhaust system 8, a honeycomb filter 3 placed in the inside of the casing 2, the honeycomb filter having a plurality of cells partitioned by partition walls, and plasma generation electrodes 6 placed being faced each other by sandwiching the honeycomb filter there are included, particulate matter contained in an exhaust gas is collected by the honeycomb filter 3, nitrogen monoxide contained in the exhaust gas is oxidized to nitrogen dioxide by nonthermal plasma generated between a pulse electrode 4 and an earth electrode 5 constituting the plasma generation electrodes 6, combustible materials in the particulate matter collected and deposited on the surface of the partition walls are removed through oxidation by the nitrogen dioxide produced. As a result, the honeycomb filter 3 can be regenerated.

Owner:NGK INSULATORS LTD +2

Dielectric barrier discharge plasma reactor cell

InactiveUS20050179395A1Simple and cost-effectiveImprove efficiencyGaseous chemical processesElectric discharge tubesElectricityElectrical conductor

A dielectric barrier discharge plasma cell that generates a uniform, non-thermal plasma that is effective at neutralizing harmful agents. The cell is able to generate a uniform non-thermal plasma because it reduces arcing by controlling the distance between the conductor and dielectric, applying a low frequency alternating current voltage to the cell, and carefully applying the layers to the conductor and dielectric.

Owner:GTE GOVERNMENT SYST CORP

Processes and apparatuses for treating halogen-containing gases

InactiveUS20040131524A1Decreasing and eliminating amountReduce corrosionCellsGas treatmentHalogenLiquid water

There are disclosed various processes, apparatuses and systems for treating a halogen-containing gas such as F2 that involve generating a plasma in order to reduce chemically the halogen-containing gas into products that are more environmentally manageable. According to a particular embodiment, a reducing agent is mixed with the halogen-containing gas to produce a feed gas mixture and a non-thermal plasma is generated in the feed gas mixture in the presence of liquid water.

Owner:BATTELLE MEMORIAL INST

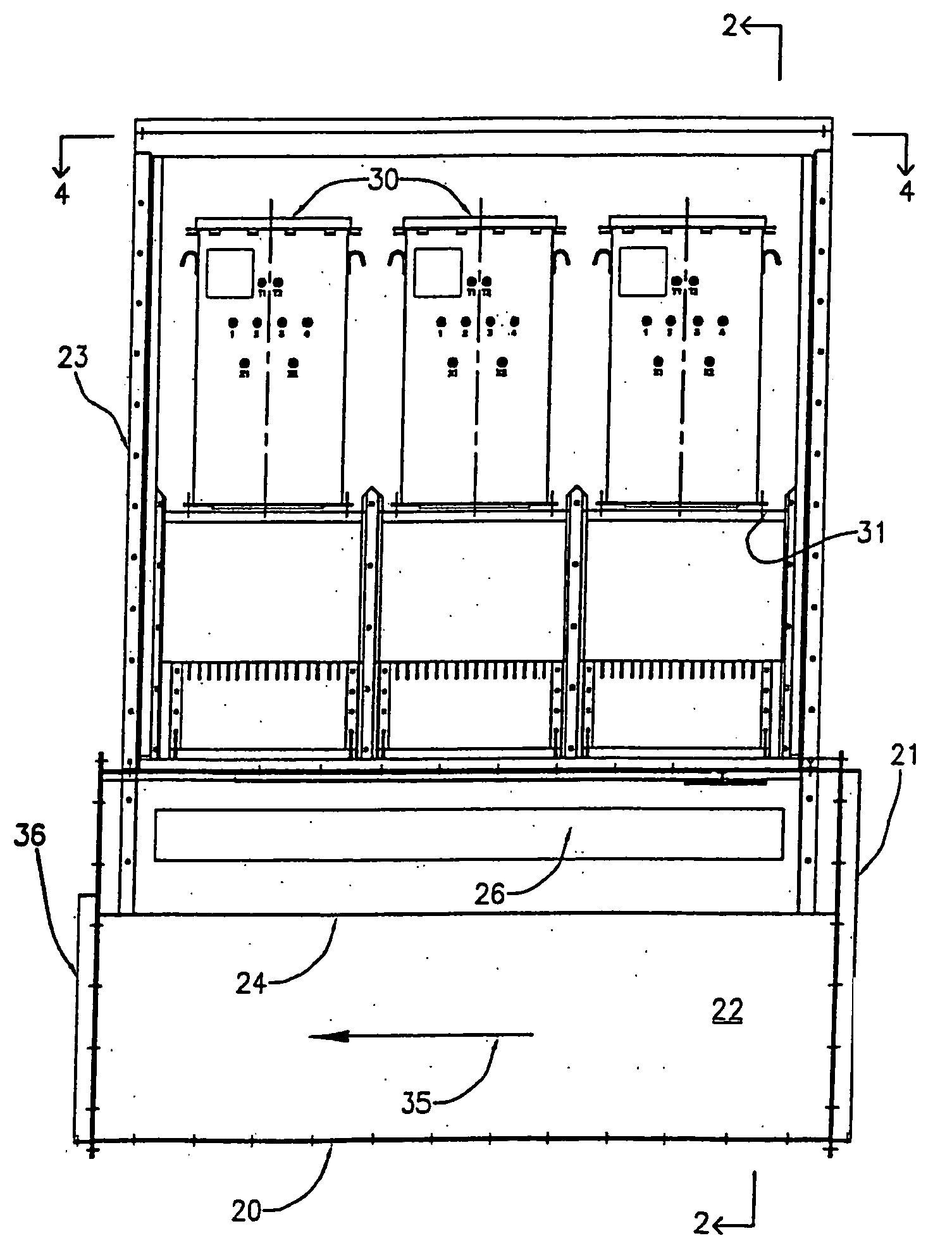

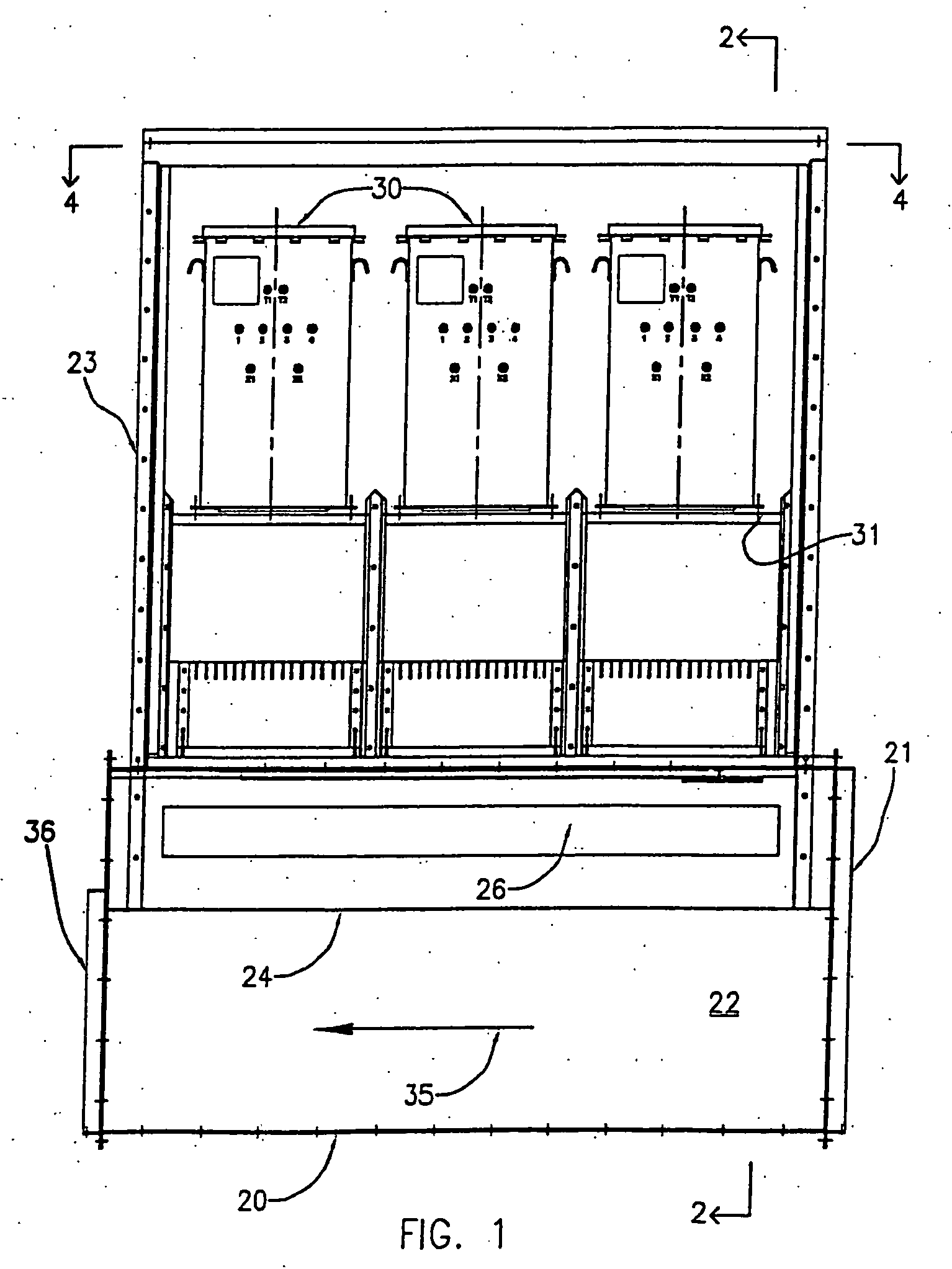

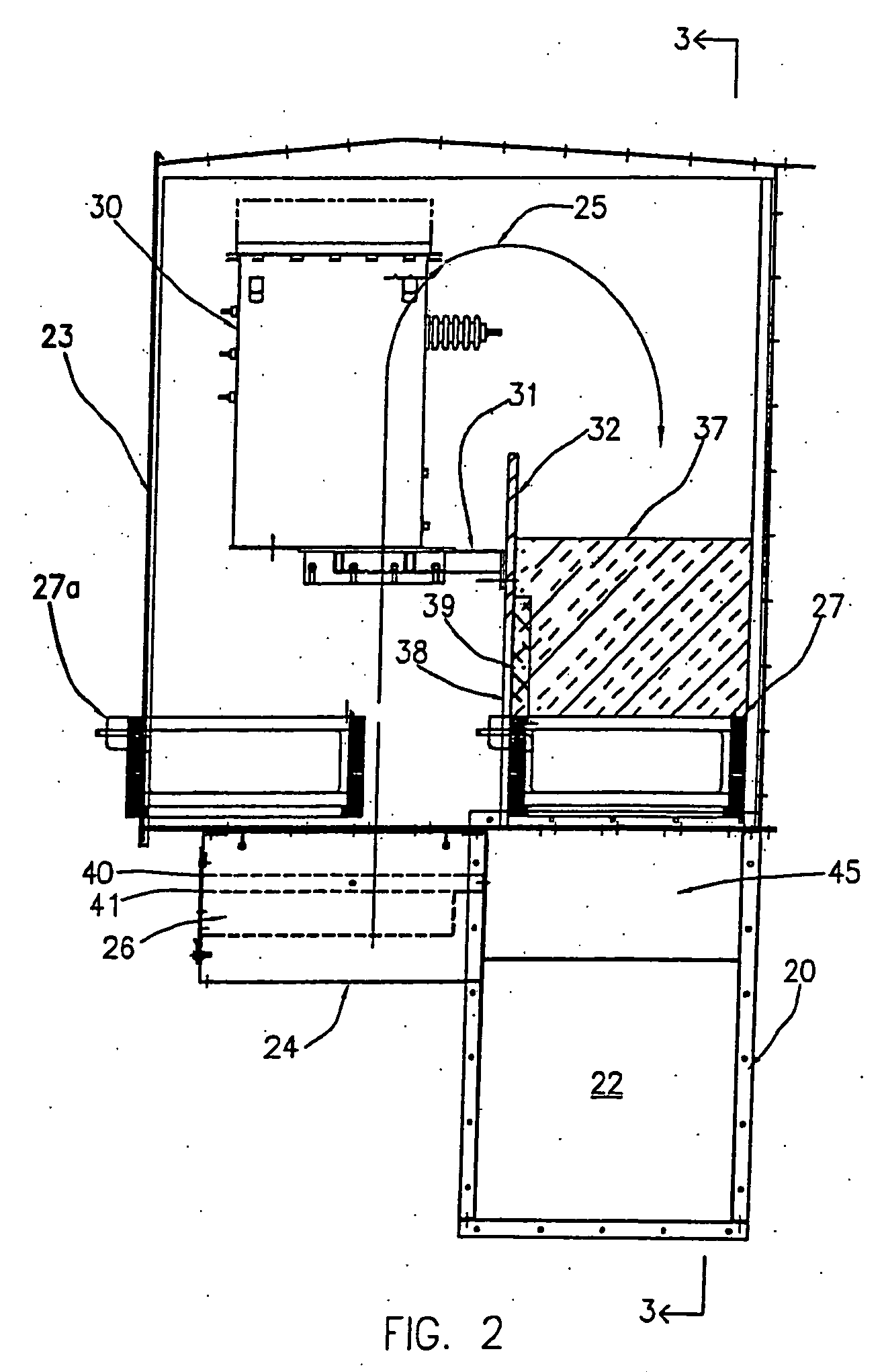

Apparatus and method for the treatment of odor and volatile organic compound contaminants in air emissions

ActiveUS20050023128A1Not to damageLarge capacityGas treatmentDispersed particle separationHermetic sealCompound (substance)

An odor removal system to neutralize odors and VOC emissions released into the environment by commercial and / or industrial air streams utilizes Non-Thermal Plasma (NTP) to create a range of Reactive Oxygen Species (ROS) to cause the oxidation and / or reduction of odor causing molecules and VOC's. The ROS is generated by drawing atmospheric and / or odorous air through a Dielectric Barrier Discharge Plasma Generation Cell (DBDPGC). The gas is activated by passing it through the non-thermal plasma field in the DBDPGC, producing the ROS that are then immediately mixed into the odorous gas stream to be treated, or if it is the odorous gas that is passing through the NTP field, it is inherently mixed. When large volumes of gas, and / or extremely high odor load in combination with large gas volumes must be treated, multiple units can be combined in parallel to treat the gas. The DBDPGC has hermetically sealed hot electrodes and may be used in other applications.

Owner:IONO2X ENG

Processes and apparatuses for treating halogen-containing gases

InactiveUS20030012718A1Decreasing and eliminating amountReduce corrosionGas treatmentSolvent extractionHalogenLiquid water

There are disclosed various processes, apparatuses and systems for treating a halogen-containing gas such as F2 that involve generating a plasma in order to reduce chemically the halogen-containing gas into products that are more environmentally manageable. According to a particular embodiment, a reducing agent is mixed with the halogen-containing gas to produce a feed gas mixture and a non-thermal plasma is generated in the feed gas mixture in the presence of liquid water.

Owner:BATTELLE MEMORIAL INST

Method for securing ceramic structures and forming electrical connections on the same

InactiveUS7335341B2Pretreated surfacesEnergy based chemical/physical/physico-chemical processesElectricityAdhesive

Owner:FLAME SPRAY IND

Apparatus and method for the treatment of odor and volatile organic compound contaminants in air emissions

Owner:IONO2X ENG

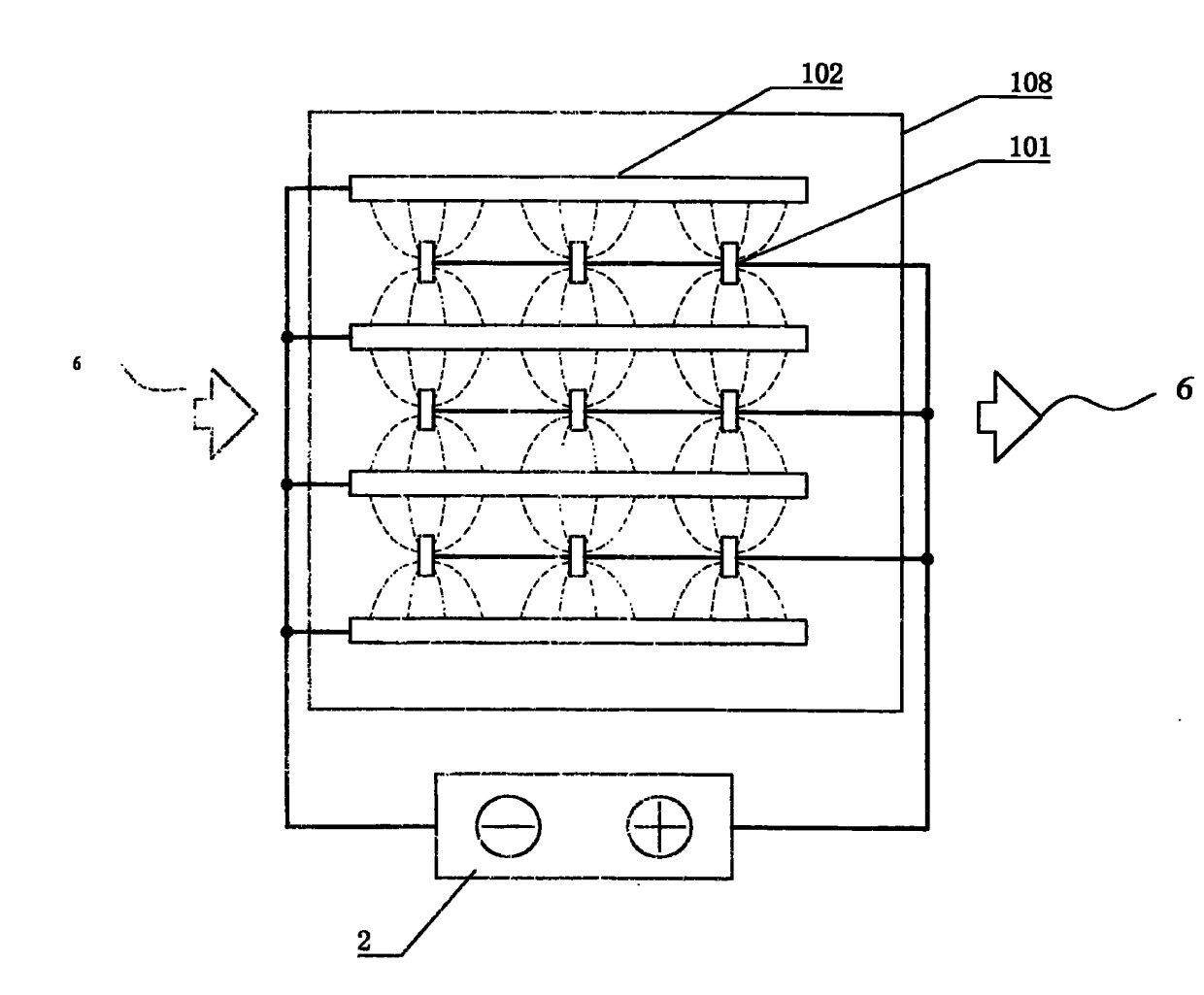

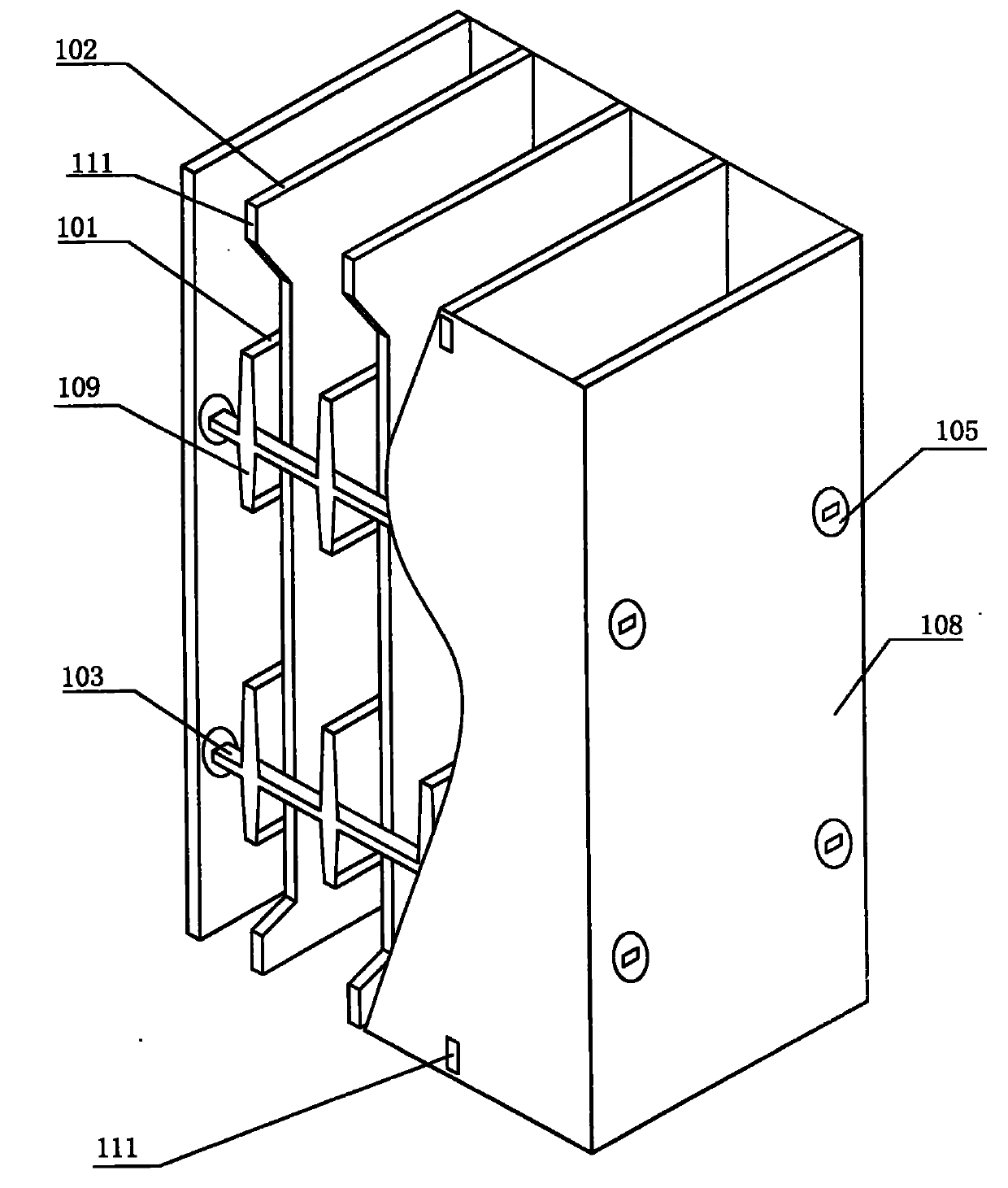

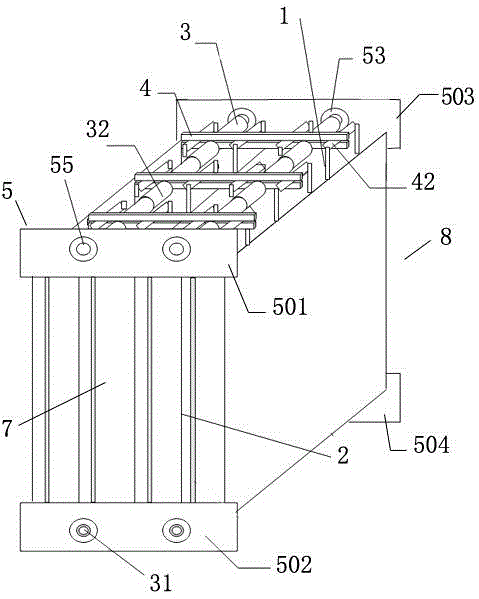

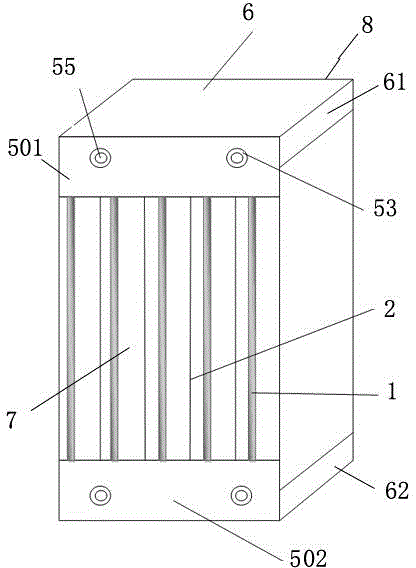

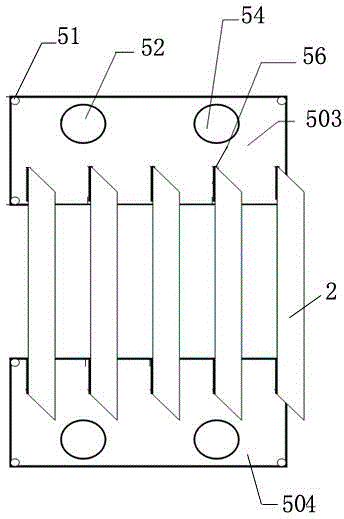

Metal strap-plate structure reactor

ActiveCN101920224AStable structureImprove insulation performanceGas treatmentDispersed particle separationCore componentCorona discharge

The invention belongs to the technical field of air disinfection and purification and relates to a metal strap-plate structure reactor comprising positive electrodes, negative electrodes and a housing, wherein each positive electrode is positioned between the two neighboring negative electrodes, and the housing is provided with an air inlet and an air outlet. The metal strap-plate structure reactor is characterized in that the positive electrodes are arranged in the same plane by a plurality of oxidization-resistance metal straps and arranged in parallel by equal distance to form an assembly, and the negative electrodes are made of aluminum plates or stainless steel plates; and both ends of each positive electrode are respectively fixed on a microdischarge-preventing conducting rail, and both ends of the microdischarge-preventing conducting rail are fixed with the housing through an insulating connector. The metal strap-plate structure reactor effectively prevents the microdischarge phenomena of the positive electrodes, prolongs the service life of the metal straps, enhances the concentration of plasma generated by the reactor, improves the air disinfecting and purifying efficiency and has energy saving. The aluminum plate surfaces of the negative electrodes are coated with TiO2 so that the reactor has the effect of yielding twice the result with half the effort. The reactor is a core component of a non-thermal plasma air disinfecting purifier and is a regenerated product of a sawtooth-shaped or needle-point-shaped reactor with nonuniform corona discharge.

Owner:ZHEJIANG TIANQING ENVIRONMENTAL PROTECTION TECH CO LTD

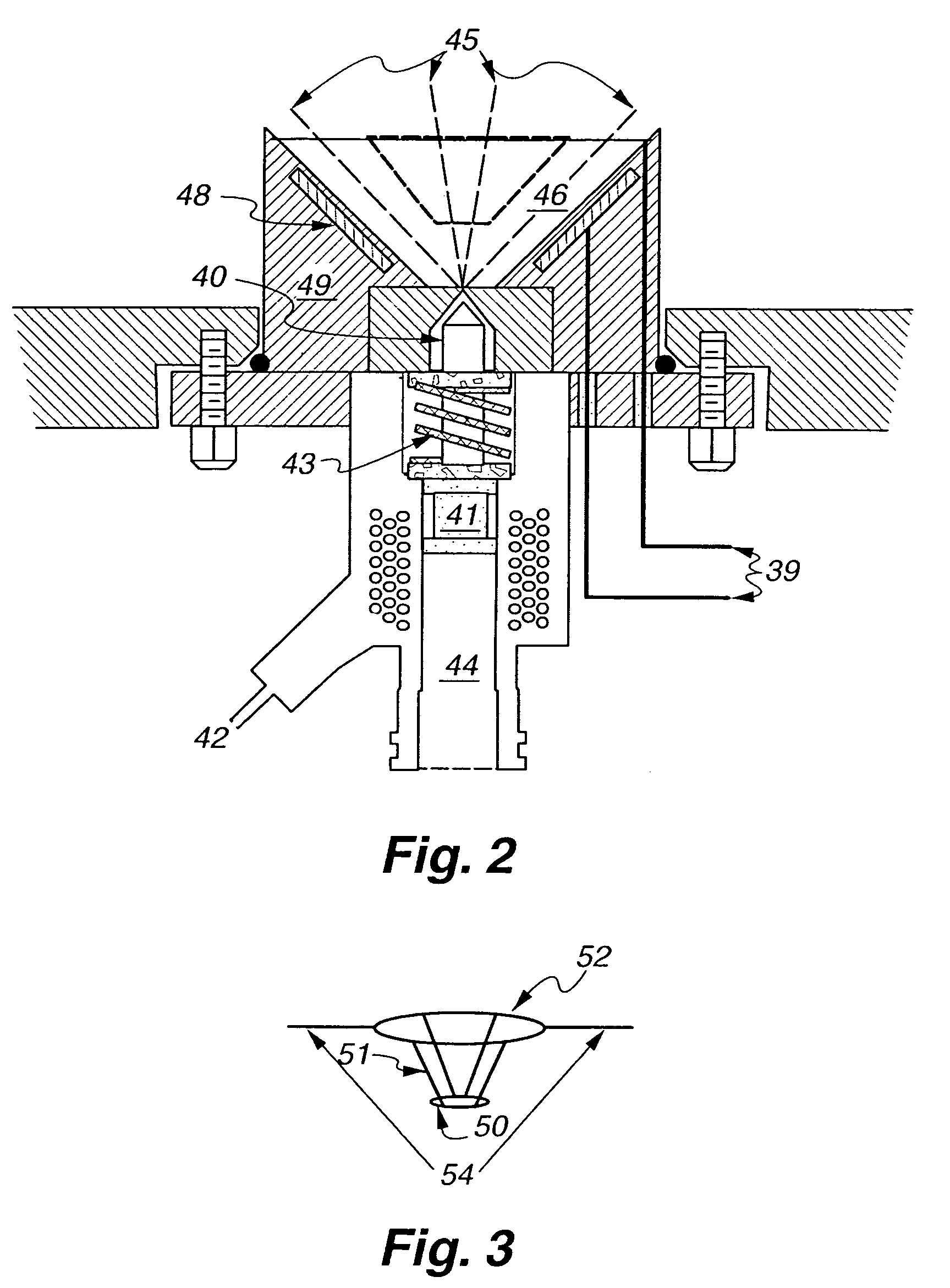

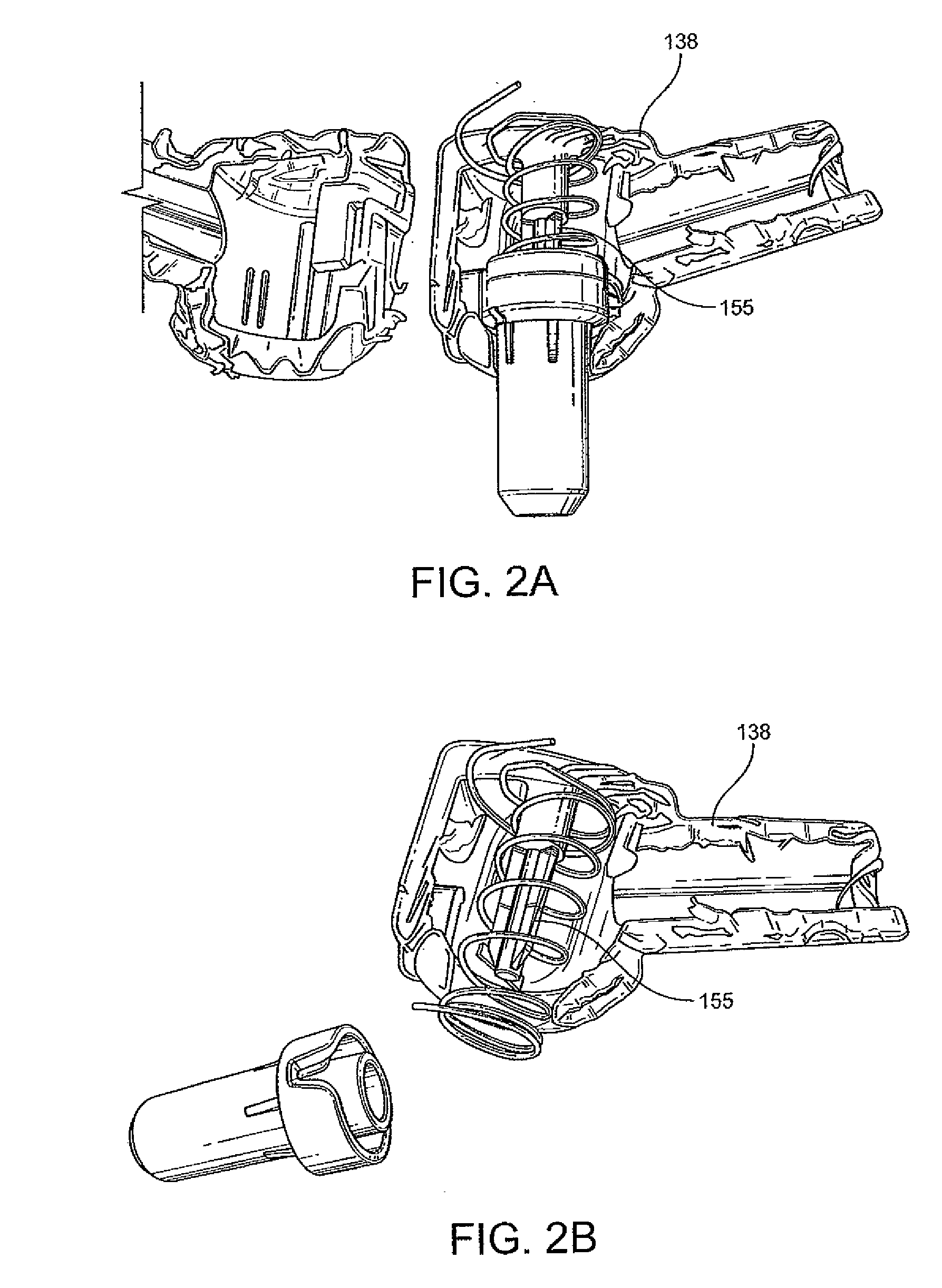

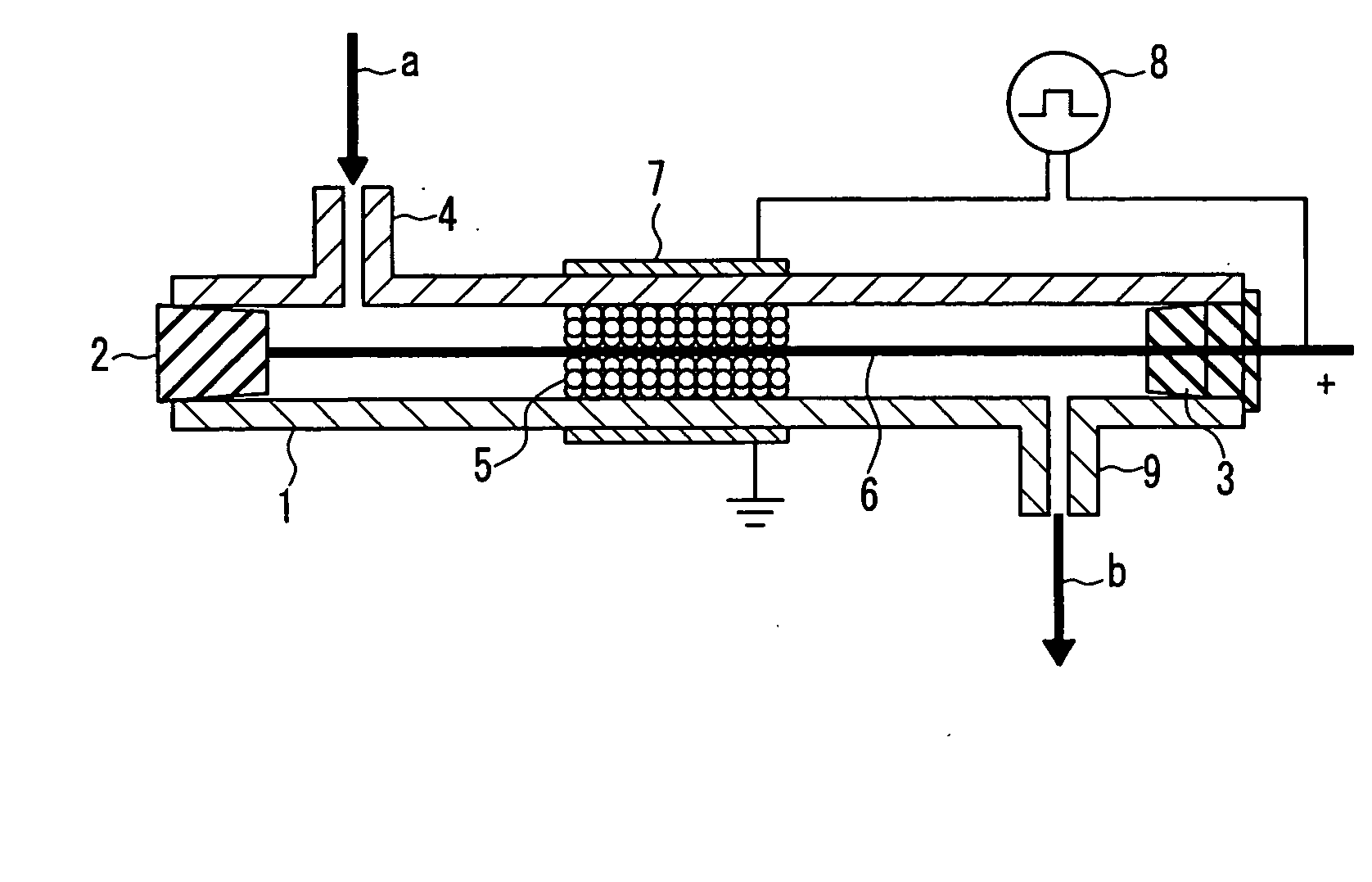

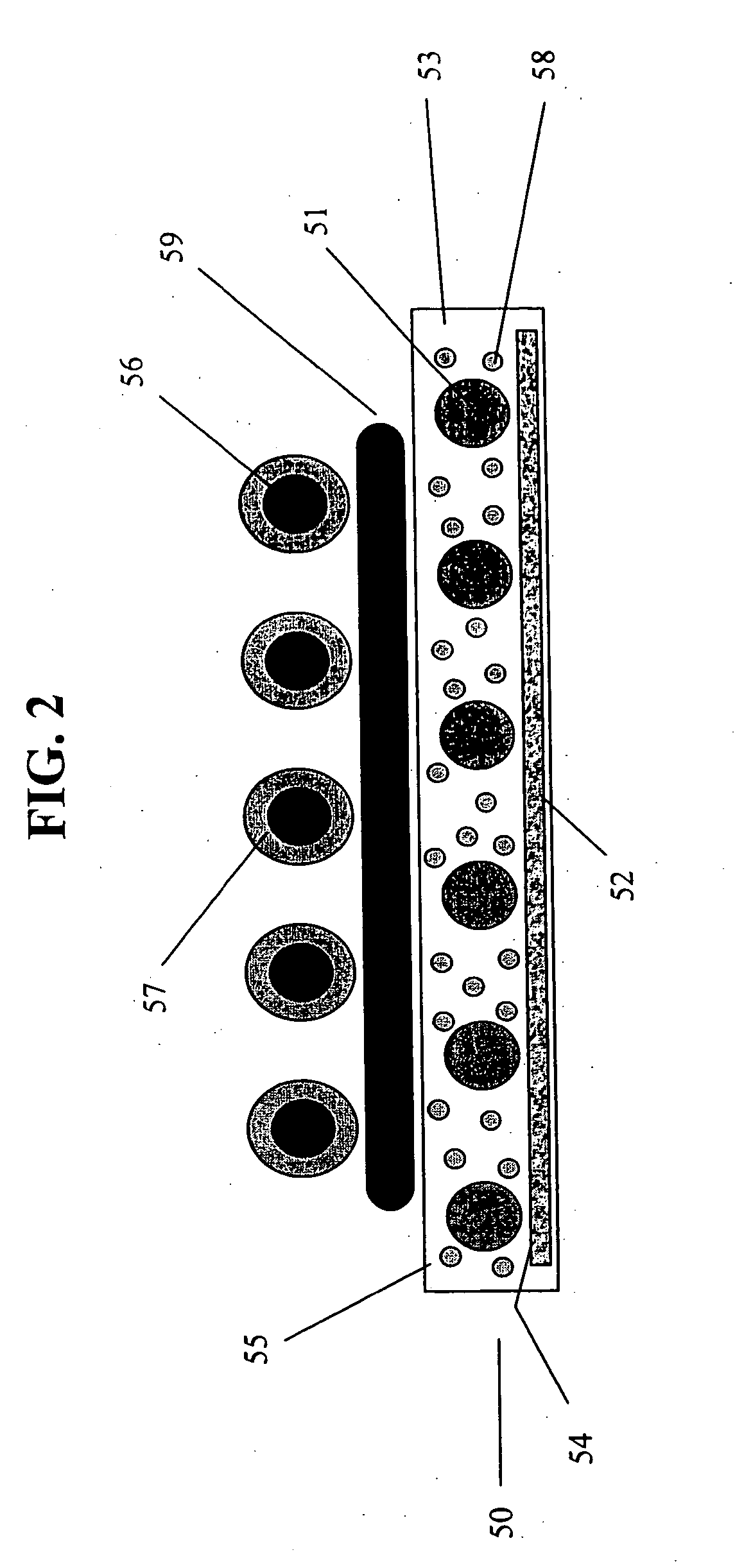

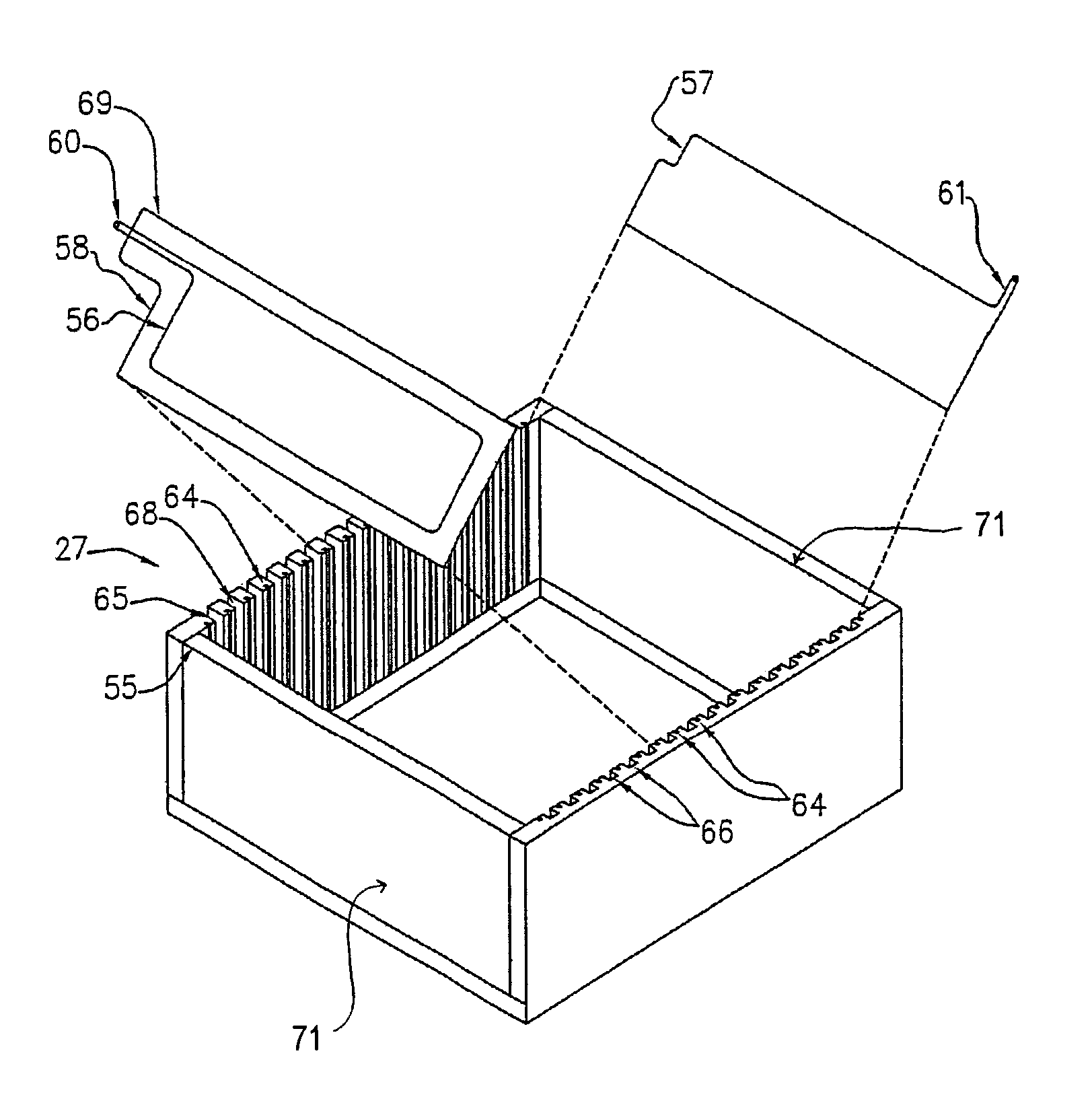

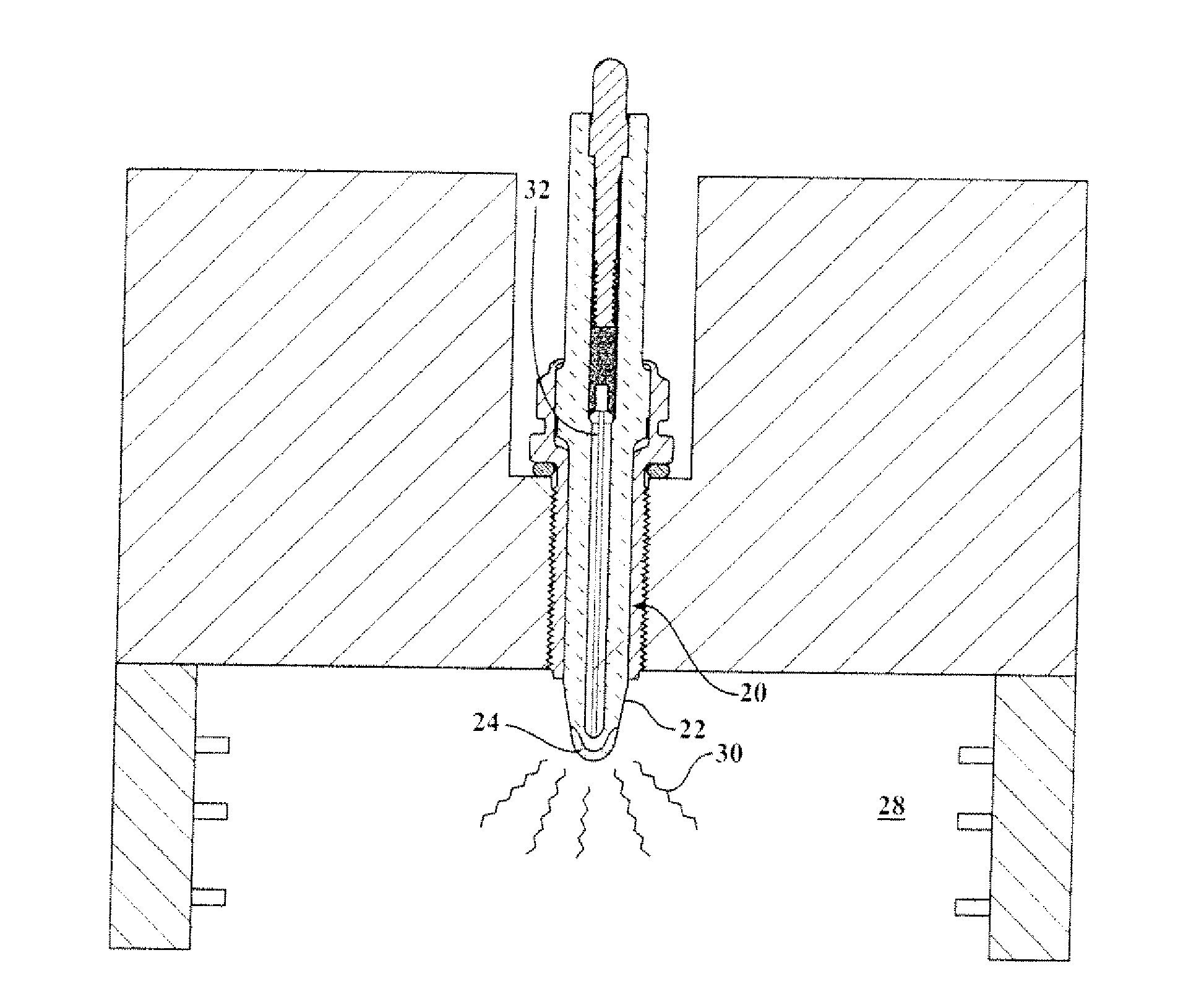

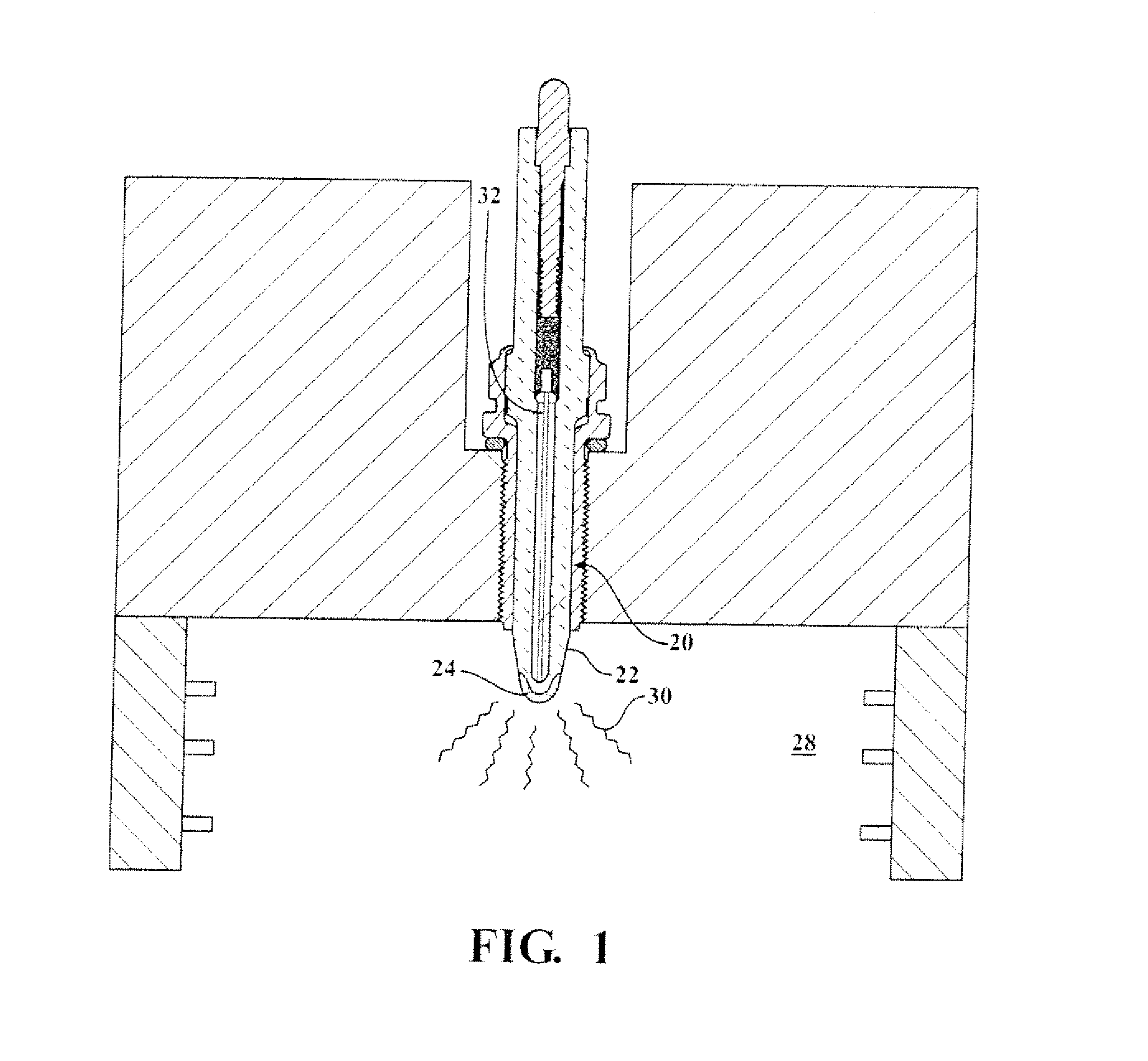

Non-thermal plasma ignition arc suppression

ActiveUS20120112620A1Eliminates arcingReduces arcingSpark gapsEngine ignitionCombustion chamberEngineering

An igniter (20) of a corona ignition system emits a non-thermal plasma in the form of a corona (30) to ionize and ignite a fuel mixture. The igniter (20) includes an electrode (32) and a ceramic insulator (22) surrounding the electrode (32). The insulator (22) surrounds a firing end (38) of the electrode (32) and blocks the electrode (32) from exposure to the combustion chamber (28). The insulator (22) presents a firing surface (56) exposed to the combustion chamber (28) and emitting the non-thermal plasma. A plurality of electrically conducting elements (24) are disposed in a matrix (26) of the ceramic material and along the firing surface (56) of the insulator (22), such as metal particles embedded in the ceramic material or holes in the ceramic material. The electrically conducting elements (24) reduce arc discharge during operation of the igniter (20) and thus improve the quality of ignition.

Owner:FEDERAL MOGUL IGNITION

Chemical processing using non-thermal discharge plasma

A method for activating chemical reactions using a non-thermal capillary discharge plasma (NT-CDP) unit or a non-thermal slot discharge plasma (NT-SDP) unit (collectively referred to as "NT-CDP / SDP"). The NT-CDP / SDP unit includes a first electrode disposed between two dielectric layers, wherein the first electrode and dielectric layers having at least one opening (e.g., capillary or a slot) defined therethrough. A dielectric sleeve inserted into the opening, and at least one second electrode (e.g., in the shape of a pin, ring, metal wire, or tapered metal blade) is disposed in fluid communication with an associated opening. A non-thermal plasma discharge is emitted from the opening when a voltage differential is applied between the first and second electrodes. Chemical feedstock to be treated is then exposed to the non-thermal plasma. This processing is suited for the following exemplary chemical reactions as (i) partial oxidation of hydrocarbon feedstock to produce functionalized organic compounds; (ii) chemical stabilization of a polymer fiber (e.g., PAN fiber precursor in carbon fiber production; (iii) pre-reforming of higher chain length petroleum hydrocarbons to generate a feedstock suitable for reforming; (iv) natural gas reforming in a chemically reducing atmosphere (e.g., ammonia or urea) to produce carbon monoxide and Hydrogen gas; or (v) plasma enhanced water gas shifting.

Owner:PLASMASOL CORP

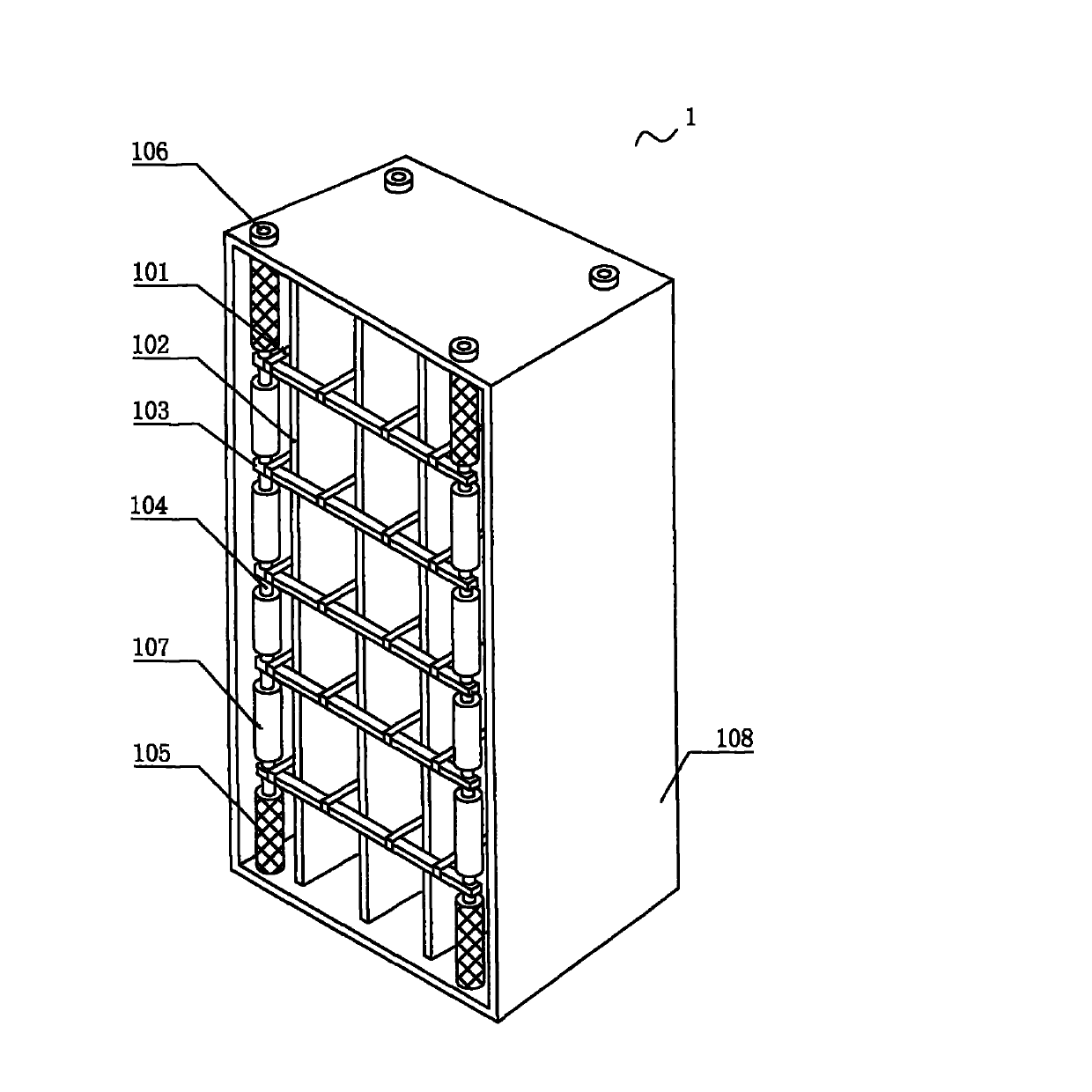

Non-thermal plasma air-purifying and disinfecting reactor

InactiveCN104127907AImprove purification effectFlexible and convenient installationDispersed particle separationDeodrantsEngineeringMetal

The invention relates to a non-thermal plasma air-purifying reactor which comprises a housing, a positive electrode, a negative electrode, an external draught fan and a power supply, wherein the positive electrode is arranged between two adjacent negative electrode plates, is in insulating connection with the two adjacent negative electrode plates, and is equipped with an air inlet and an air outlet at the same time, wherein a distance between the positive and the negative electrodes is not smaller than twice a power-generation distance; the positive electrode is fixed on an insulation piece by a positive electrode connection piece; the insulation piece comprises insulation rings; the positive electrode comprises n metal belt groups which are fixed on the positive electrode connection piece, each metal belt group is arranged between two adjacent negative electrode plates, and the metal belt groups are formed by arranging oxidization-resistant metal wires or metal belts at equal distance in the same plane; (n+1) rows of negative electrode plates which are arranged in parallel with the ventilating direction of the reactor are fixed on the reactor housing by negative electrode connecting plates to form the negative electrode; the negative electrode plates are detachably arranged on the negative electrode connecting plates; through holes in which the insulation piece is embedded are formed on the negative electrode connecting plates; and the insulation rings are embedded in the through holes. The non-thermal plasma air-purifying reactor disclosed by the invention greatly improves the purifying effect.

Owner:上海侃亿诺纺织品有限公司

Dielectric barrier discharge cell with hermetically sealed electrodes, apparatus and method for the treatment of odor and volatile organic compound contaminants in air emissions, and for purifying gases and sterilizing surfaces

ActiveUS20060251550A1Adjustable levelGas treatmentDispersed particle separationRubber materialAir emission

A Dielectric Barrier Discharge Plasma Generation Cell includes a plurality of hot electrodes interspersed with a plurality of ground electrodes whereby a power supply connected between the hot and ground electrodes creates a non-thermal plasma between the electrodes. The hot electrodes are hermetically sealed by a rubber material such as a siloxane material surrounding portions of the hot electrodes. The cells are useful in odor removal systems to neutralize odors and VOC emissions in commercial and / or industrial air streams and in gas purification and sterilizing systems which utilizes Non-Thermal Plasma (NTP) to create a range of Reactive Oxygen Species (ROS) to cause the oxidation and / or reduction of odor causing molecules, VOC's, and other contaminants. Where a plurality of cells are electrically connected in parallel, shorts in a cell can be detected by sensing the difference in currents feed to each of the plurality of cells.

Owner:IONO2X ENG

Non-thermal plasma reactor gas treatment system

A gas treatment system and method for using the same is disclosed. The gas treatment system, comprises: a non-thermal plasma reactor; and a catalyst composition disposed within said non-thermal plasma reactor, said catalyst composition comprising a MZr4(PO4)6, wherein M is a metal selected from the group consisting of platinum, palladium, ruthenium, silver, rhodium, osmium, iridium, and combinations comprising at least one of said foregoing metals. The process comprises exposing said gas to a plasma field and to the catalyst composition.

Owner:UMICORE AG & CO KG

Non-thermal plasma generator device

Owner:GOLKOWSKI CZESLAW

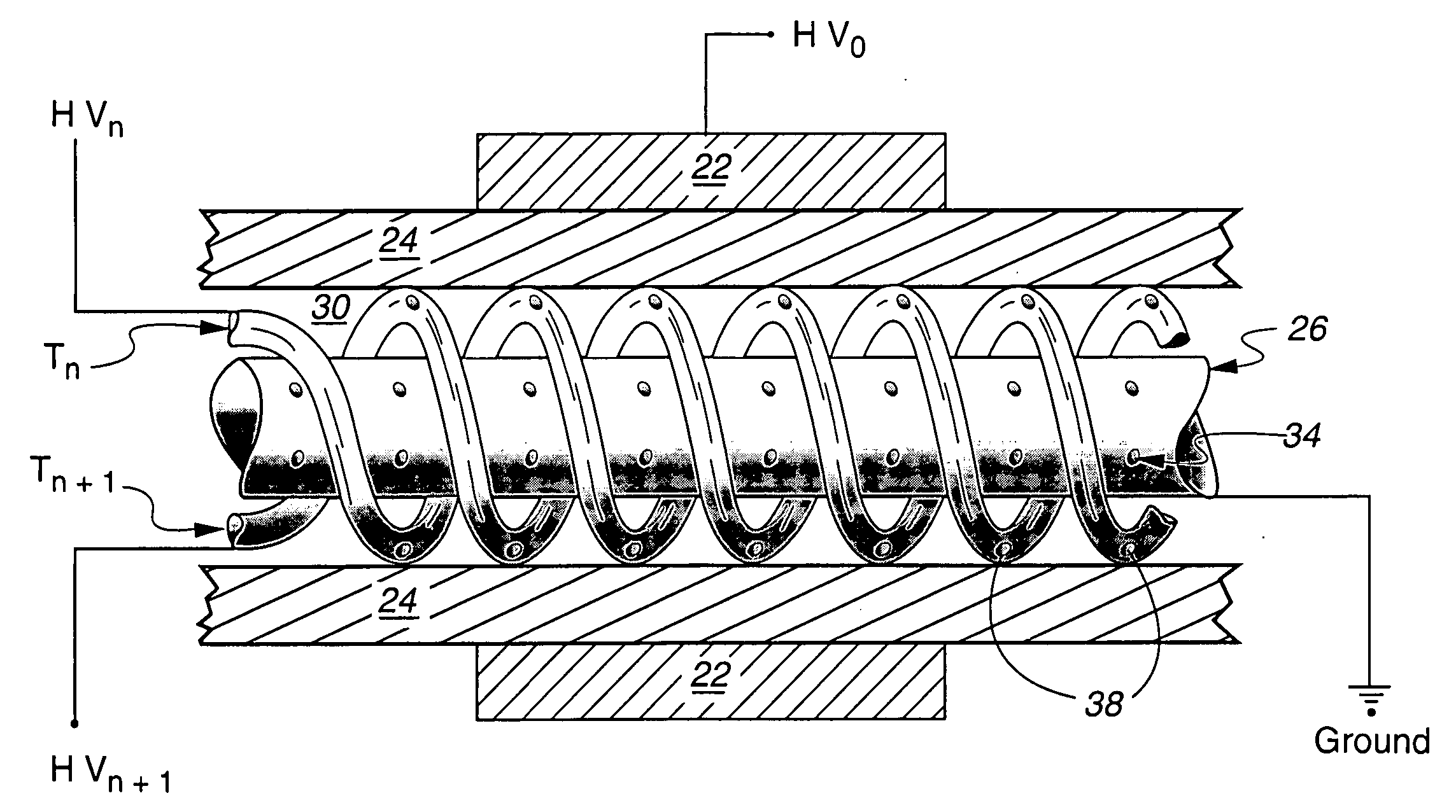

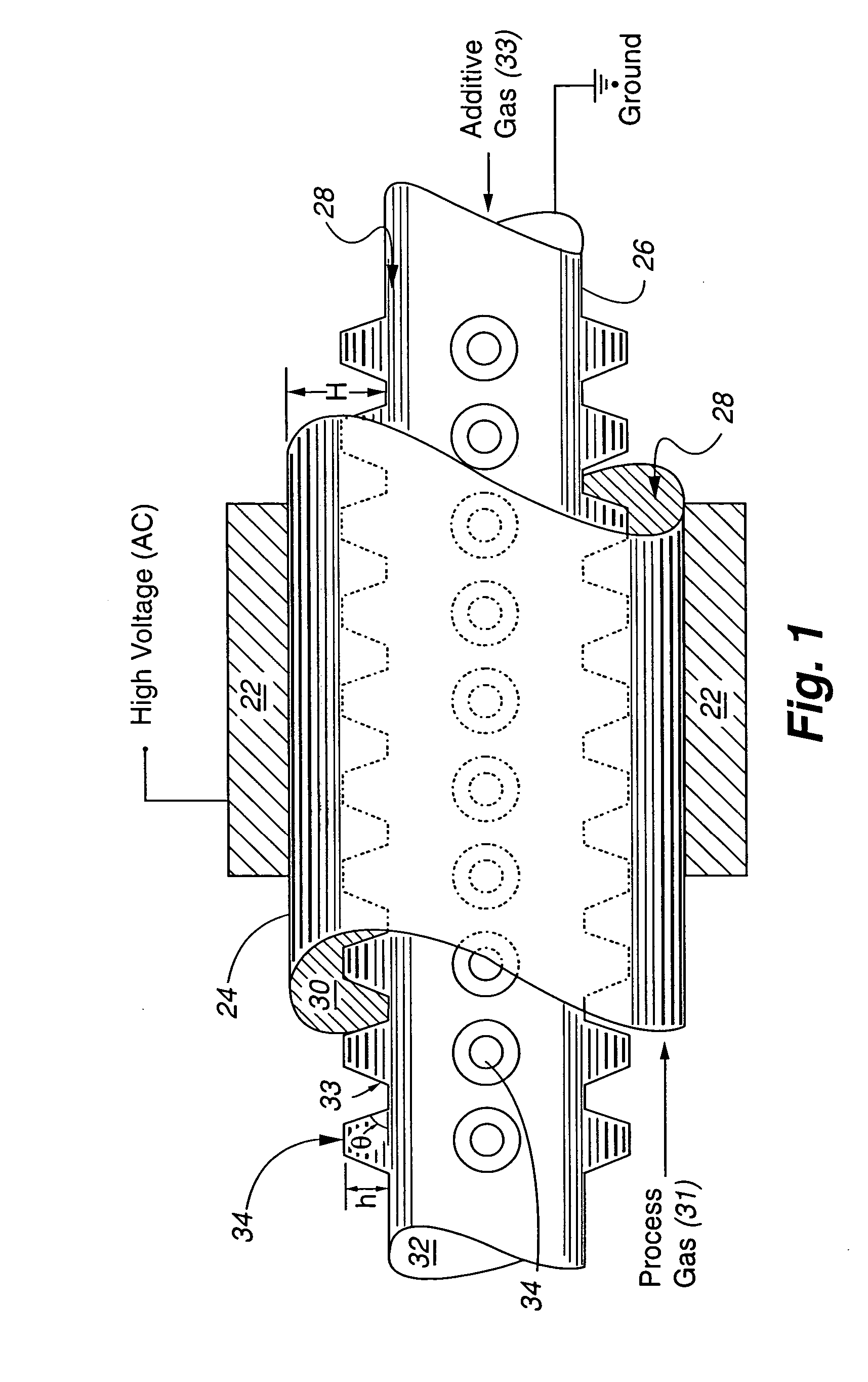

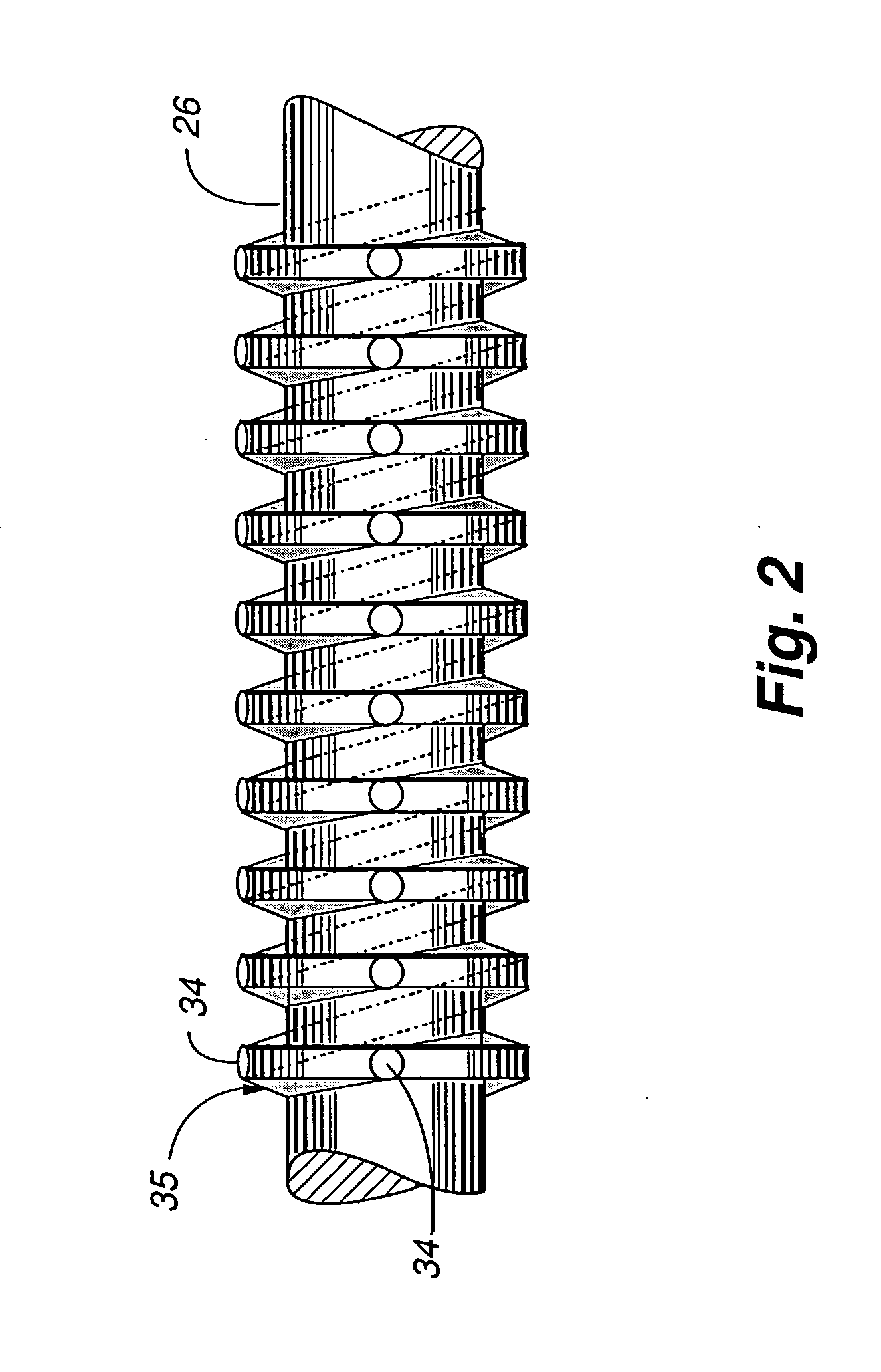

Field-enhanced electrodes for additive-injecton non-thermal plasma (NTP) processor

The present invention comprises a field enhanced electrode package for use in a non-thermal plasma processor. The field enhanced electrode package includes a high voltage electrode and a field-enhancing electrode with a dielectric material layer disposed in-between the high voltage electrode and the field-enhancing electrode. The field-enhancing electrode features at least one raised section that includes at least one injection hole that allows plasma discharge streamers to occur primarily within an injected additive gas.

Owner:LOS ALAMOS NATIONAL SECURITY

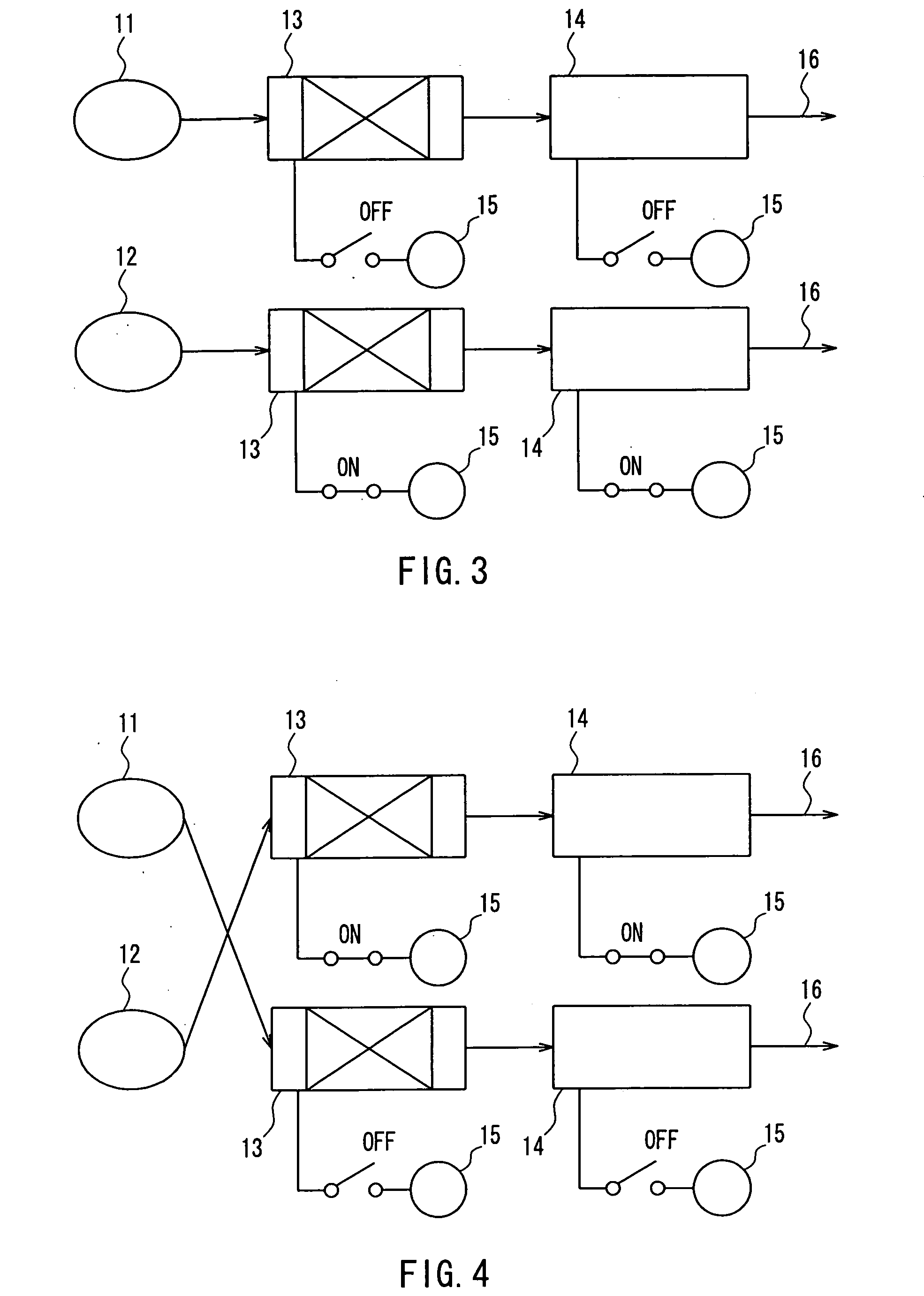

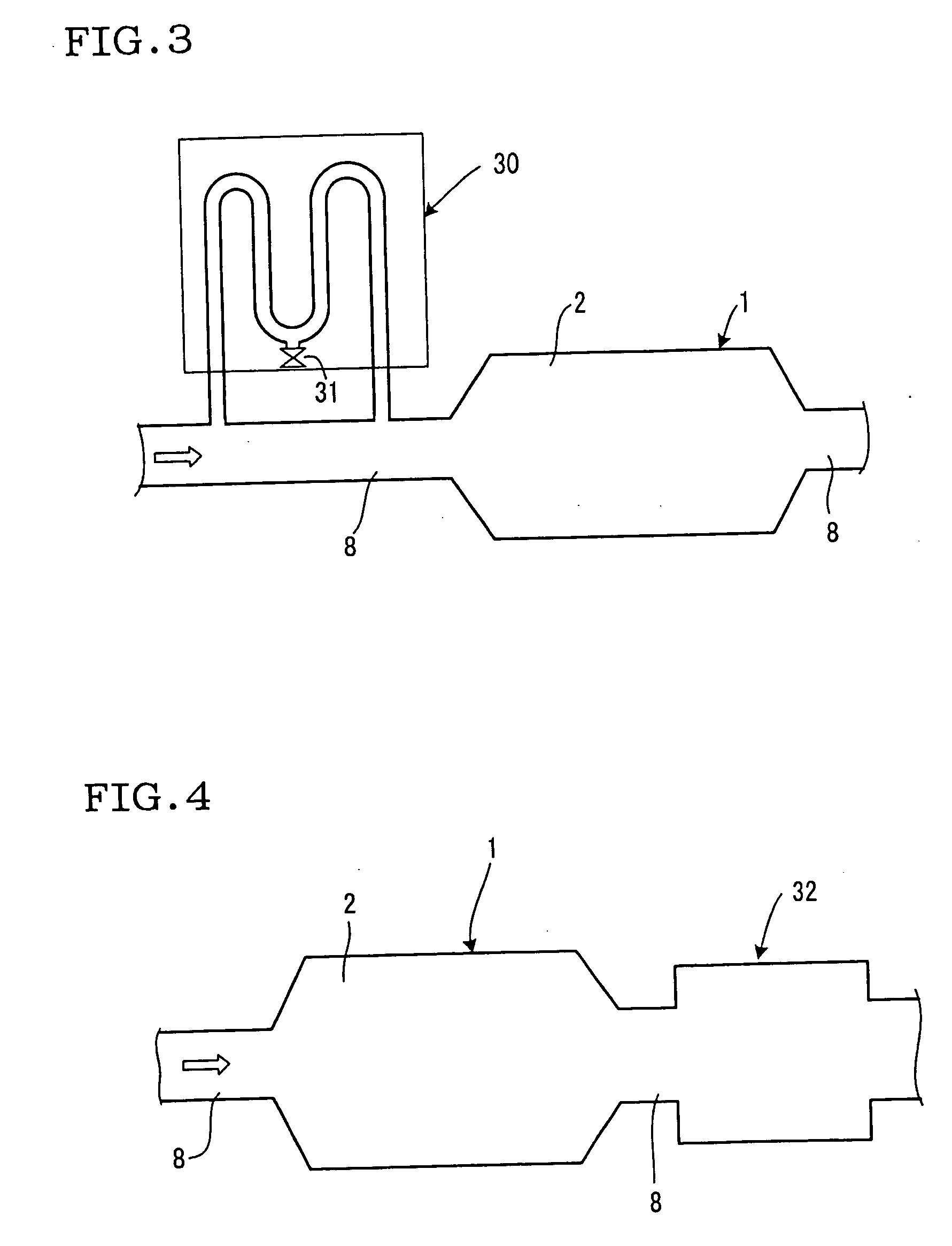

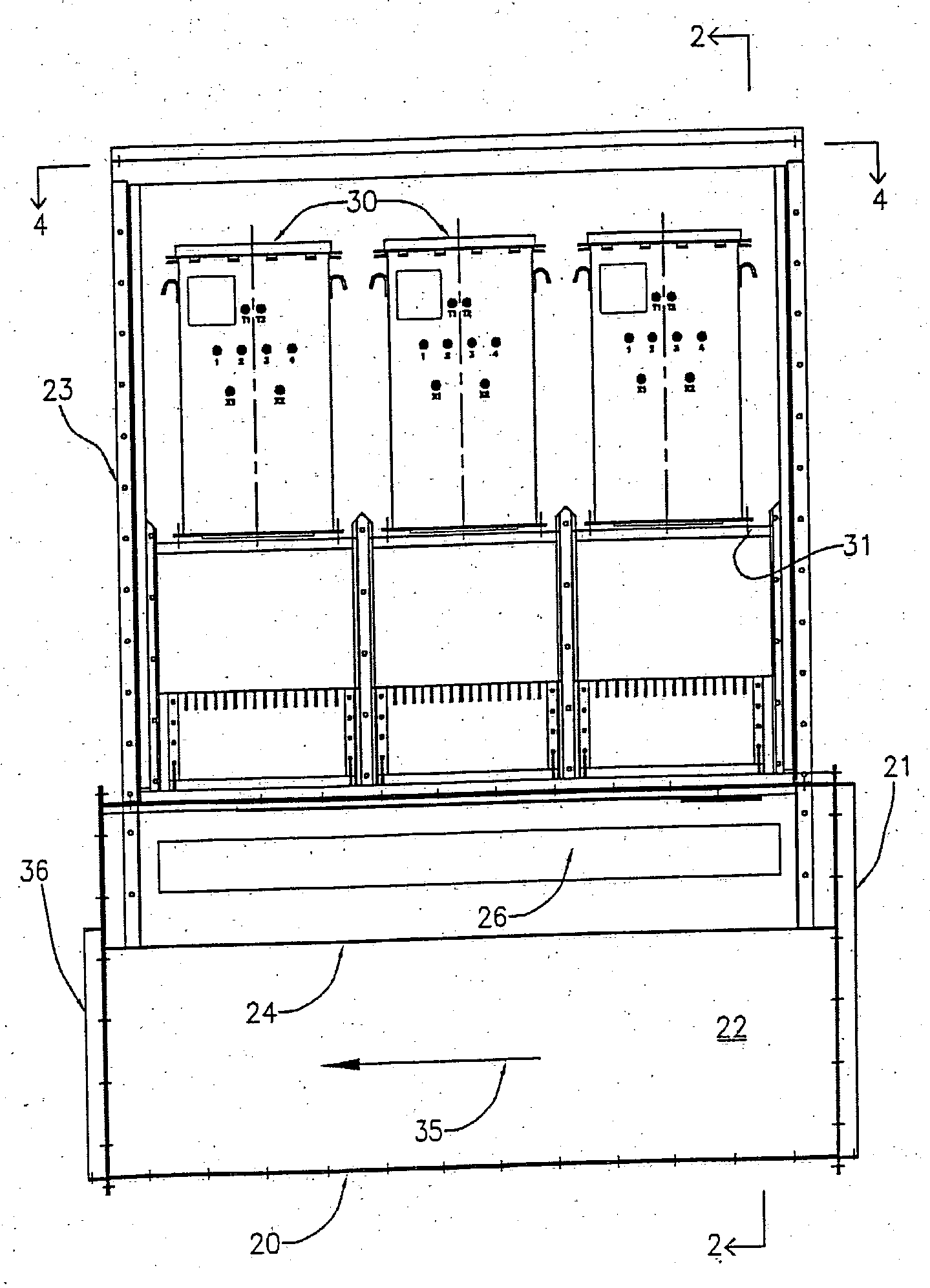

Lateral-flow waste gas treatment device using nonthermal plasma

InactiveUS20080131333A1Easy to assembleLow costCombination devicesGas treatmentDielectricProcess engineering

A lateral-flow dielectric barrier discharging reactor unit is designed to effectively process waste gas. Nonthermal plasma is obtained through high voltage gas breakdown for processing the waste gas. Reactor units can be arranged and integrated in a serial and / or parallel way with flow uniformity and smoothness for processing a great amount of waste gas with merits of simplicity and low cost.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com