Wet coke-quenching aerial fog processing method and device based on non-thermal plasma injection

A non-thermal plasma and treatment method technology, applied in the field of energy saving and environmental protection, can solve the problems of lack of purification effect of polycyclic aromatic hydrocarbon pollutants, separation, recovery of steam and low efficiency of coke powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

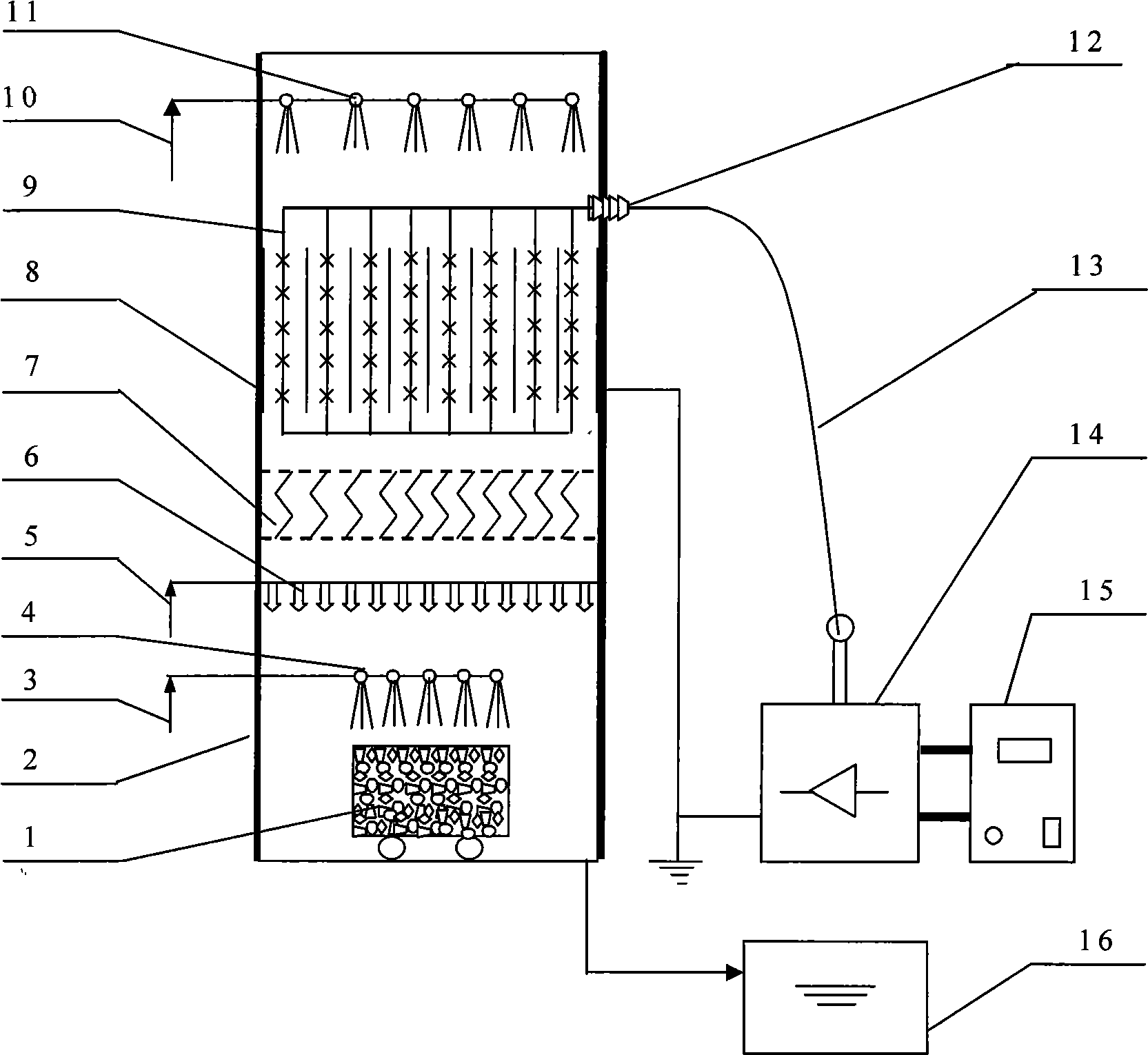

[0024] The specific implementation of the method and device for purifying quenched gas mist and recovering steam by injecting non-thermal plasma according to the present invention will be described below with reference to the accompanying drawings.

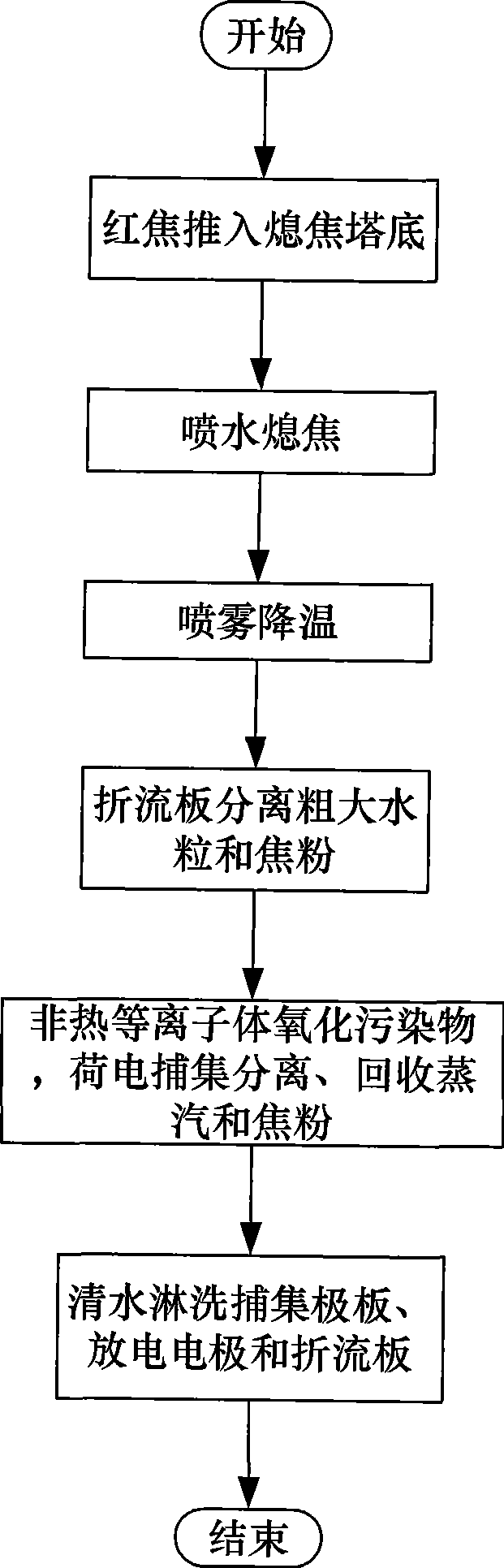

[0025] Such as figure 1 , figure 2 As shown, when the coke quenching car 1 enters the coke quenching tower 2, the coke quenching and coke quenching aerosol treatment system starts to work. The coke quenching water is transported to the nozzle 4 through the water pipe 3. After the coke quenching water is sprayed to the red coke, it quickly absorbs heat and part of it is converted into hot steam. At the same time, the hot steam also induces the outside air to enter the coke quenching tower 2. Under the buoyancy of hot steam and induced air, a stream of steam, outside air, coke powder and water particles, as well as polycyclic aromatic hydrocarbons, volatile phenols, ammonia nitrogen and cyanide volatilized from coke quenching wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com