Patents

Literature

703results about How to "Reduce cleaning times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Portable high-temperature, high-pressure washing plant

InactiveUS6675437B1Reliable outputIncrease temperatureInternal combustion piston enginesRecuperative heat exchangersProcess engineeringThermal contact

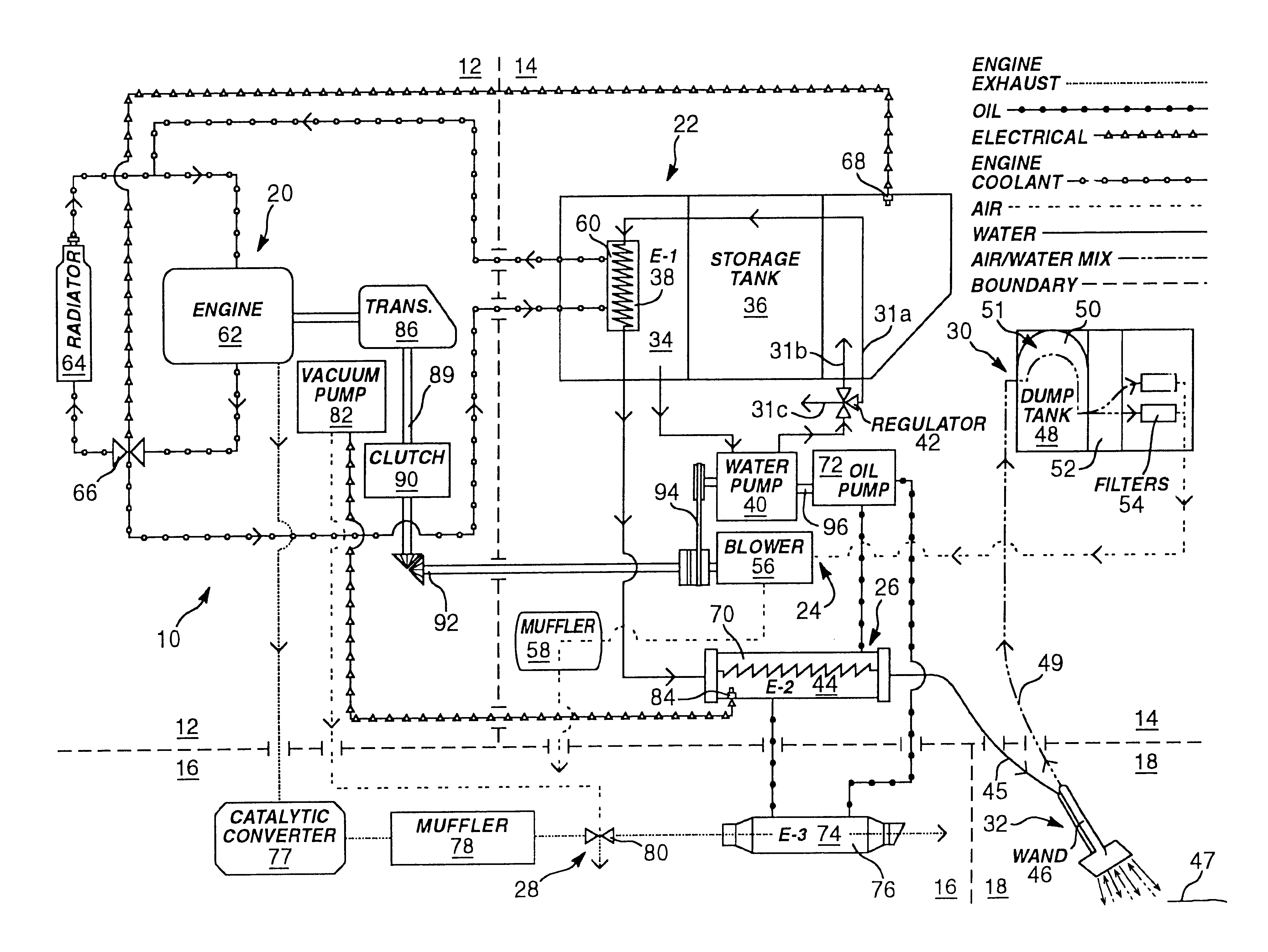

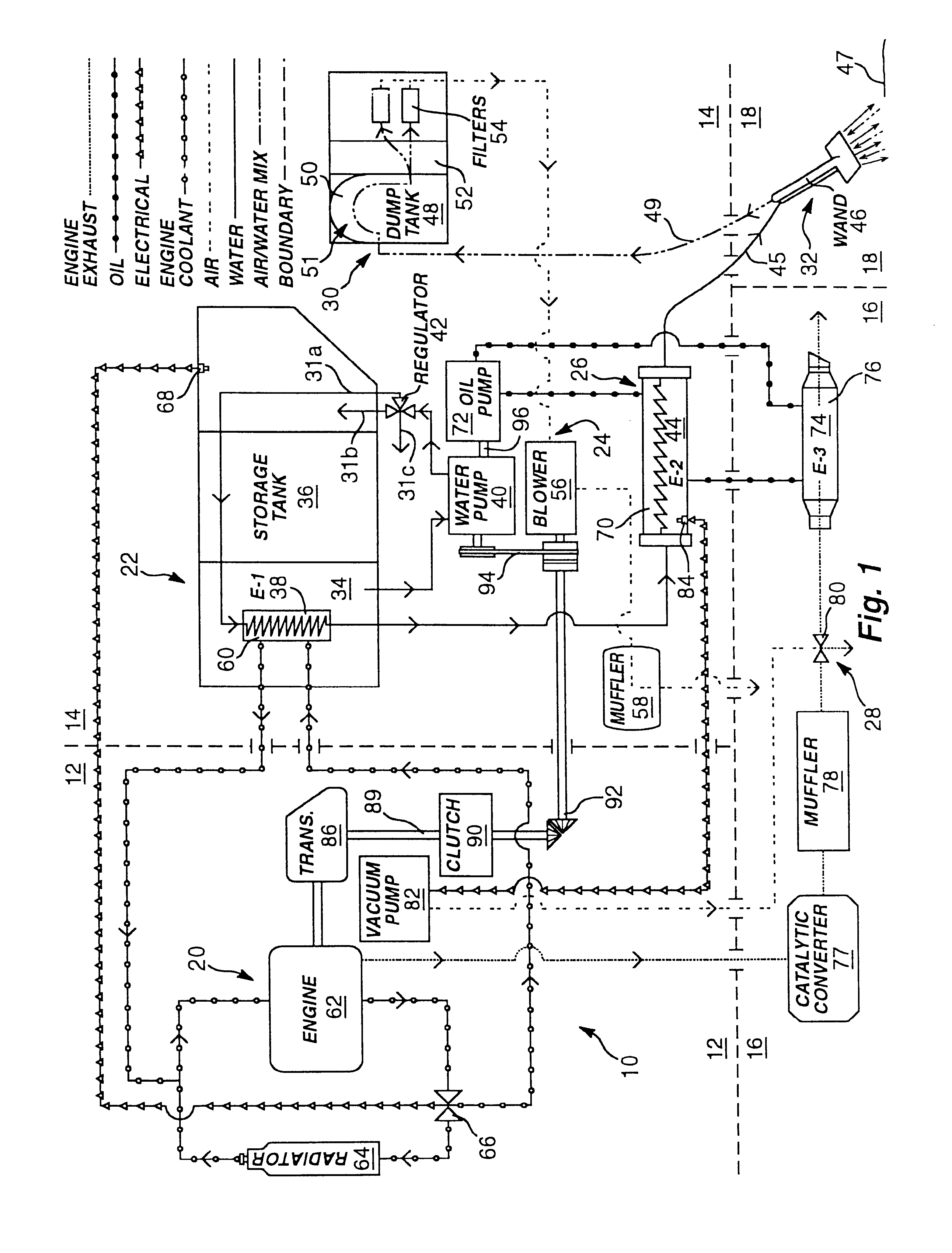

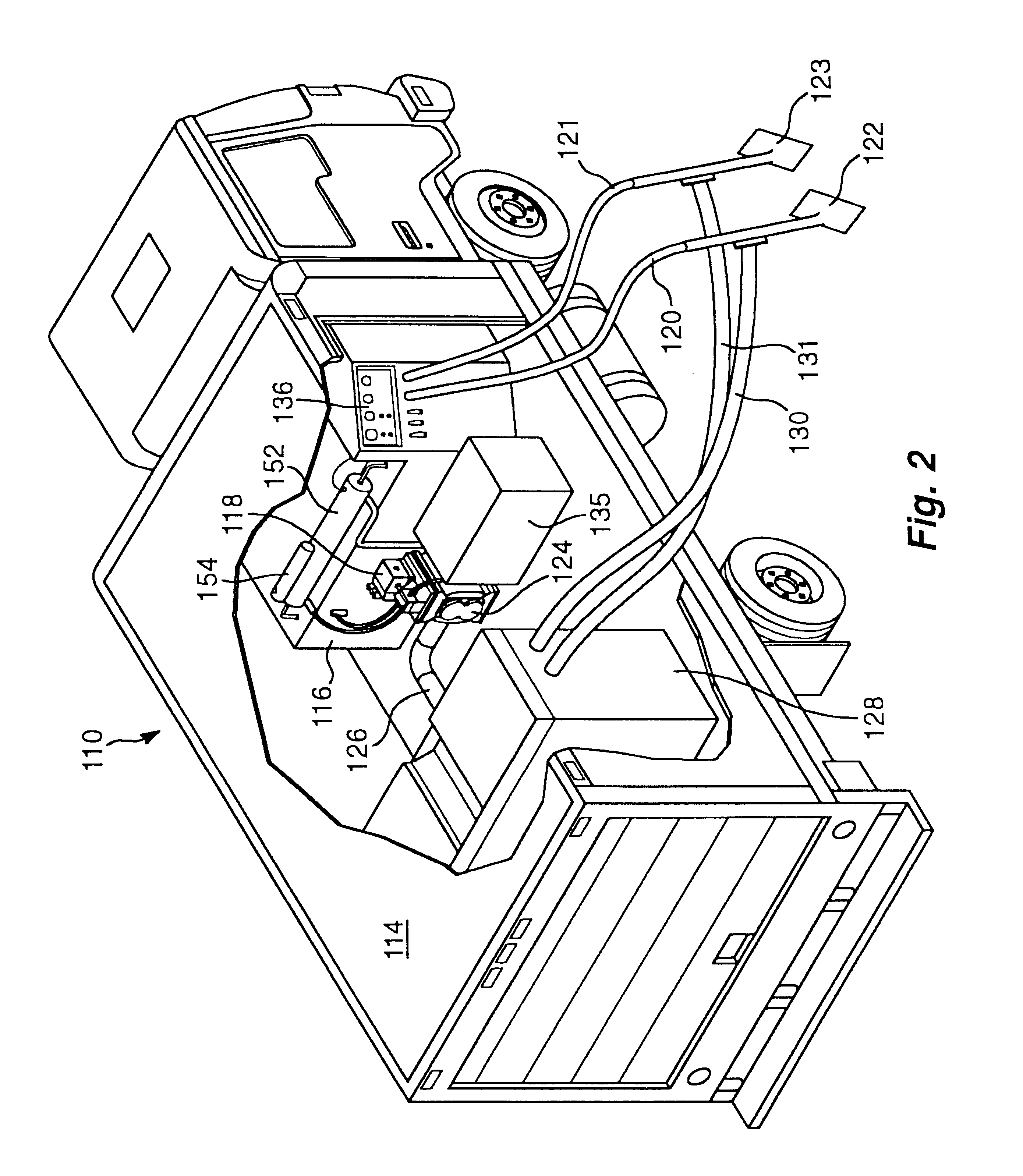

A washing system for high temperature cleaning applications, such as carpet-cleaning, is disclosed that provides a consistent cleaning fluid temperature. The washing system utilizes multiple heat exchangers and multiple heat paths. The heating and power source is provided by a medium duty, diesel cycle engine. Multi-stage heating involves heat transfer from the engine's coolant to the cleaning fluid and heat transfer from the exhaust of the engine to the cleaning fluid via an intermediate medium. The system also includes a fluid clutch used to engage a power takeoff from the engine to operate the pump and blower of the washing plant. A failsafe source cutoff diverts the exhaust flow from thermal contact with an intermediate heat transfer oil.

Owner:BLUE LINE EQUIP

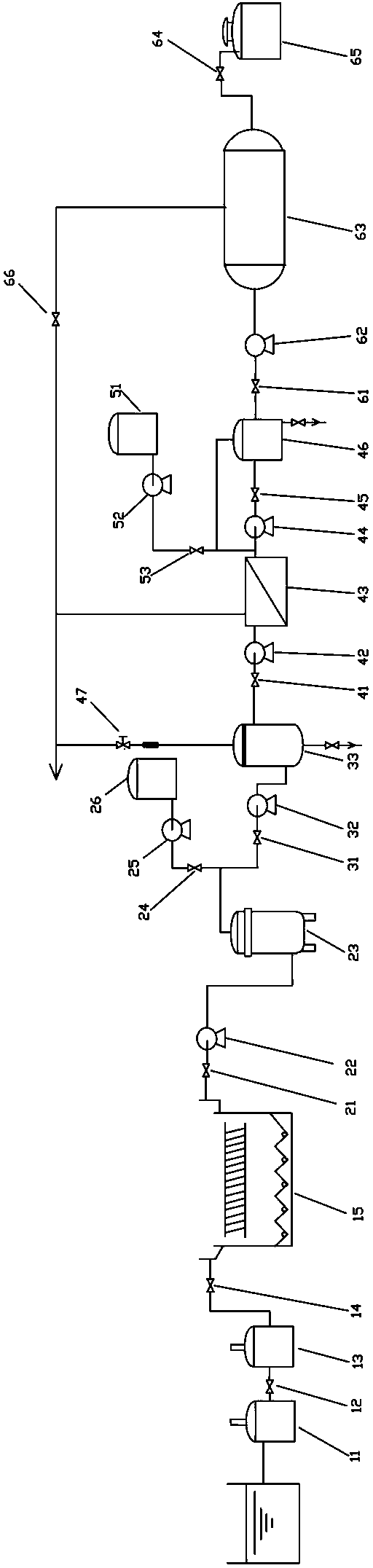

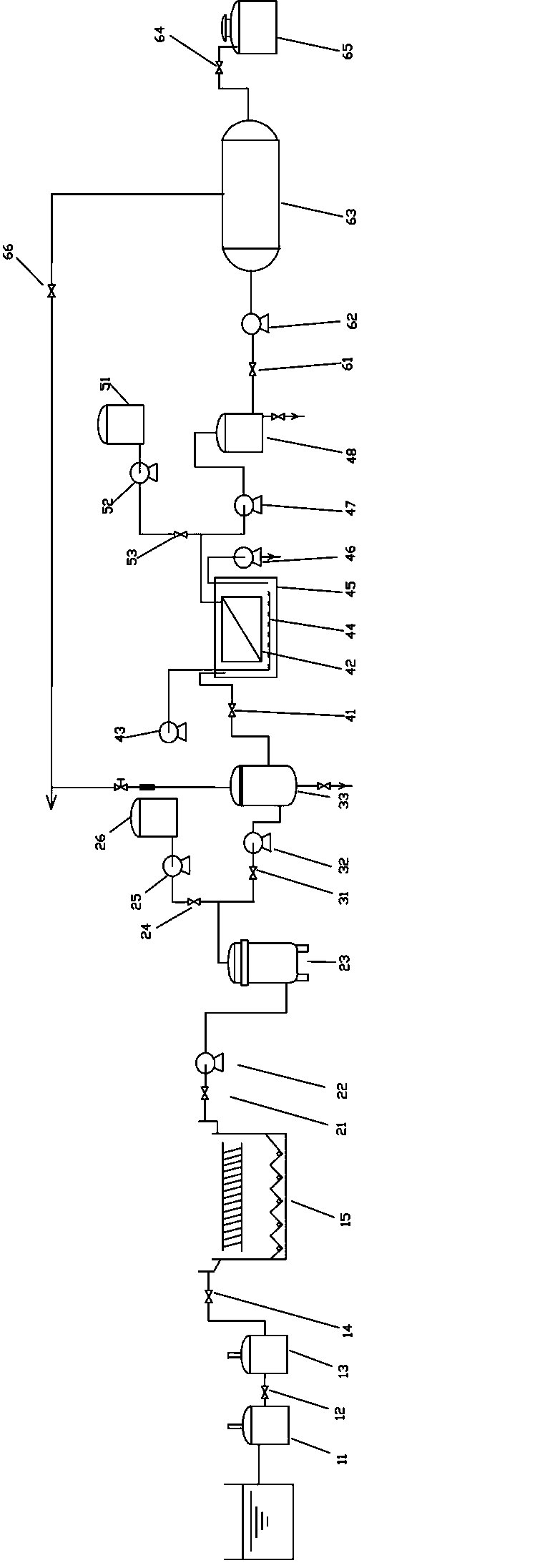

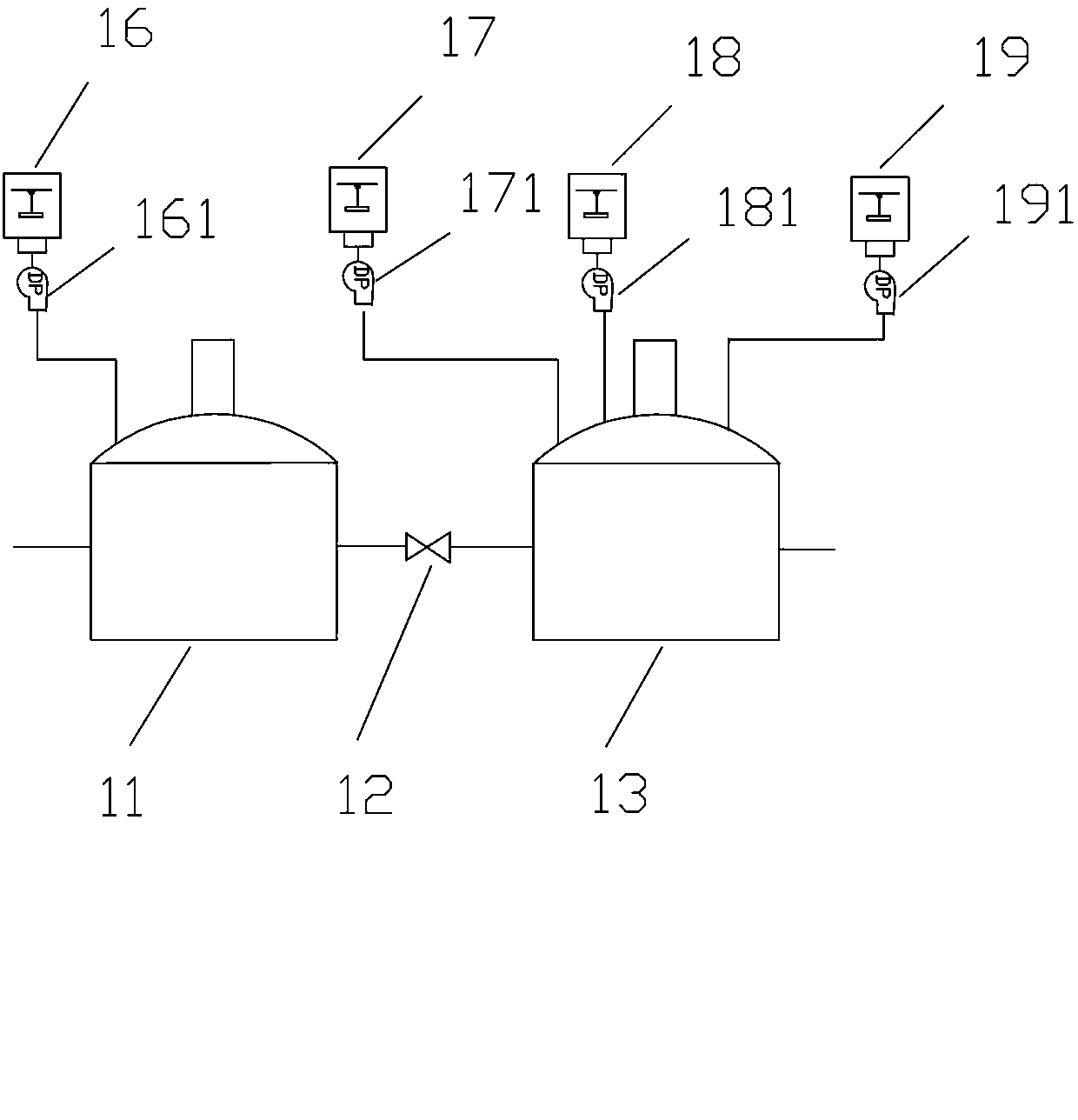

Biogas slurry concentrate and engineering preparation method

ActiveCN104058799AEasy to concentrateImprove throughputBio-organic fraction processingClimate change adaptationSolubilityResource utilization

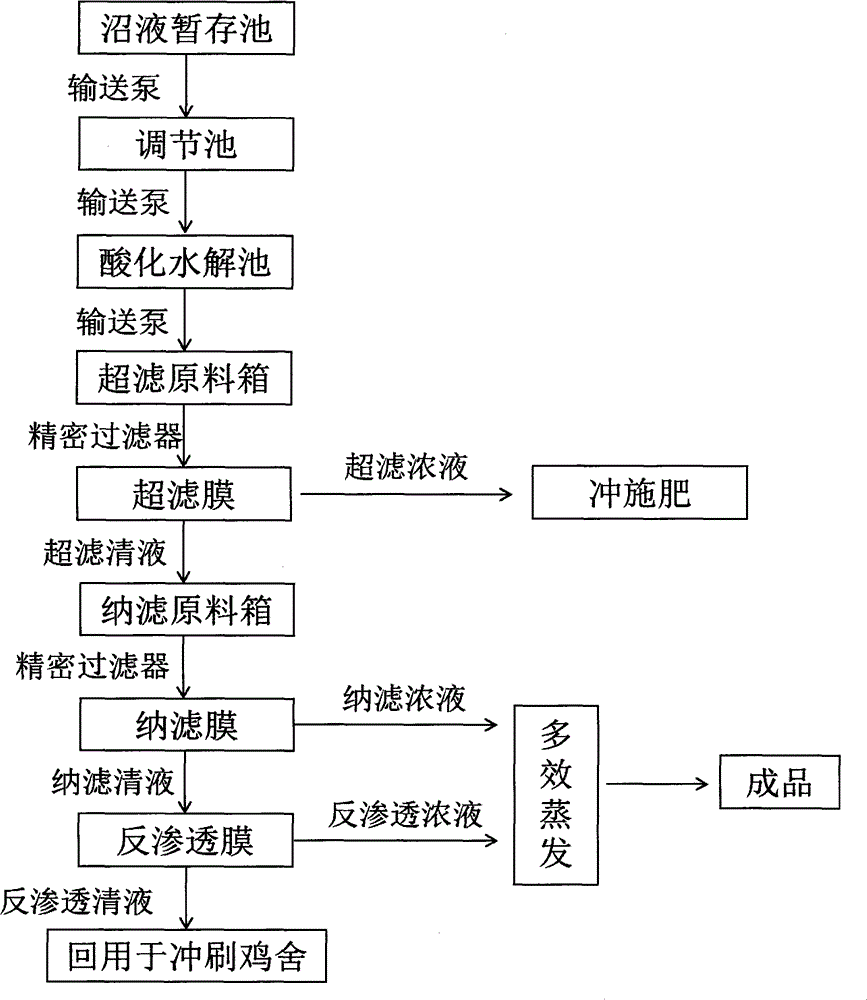

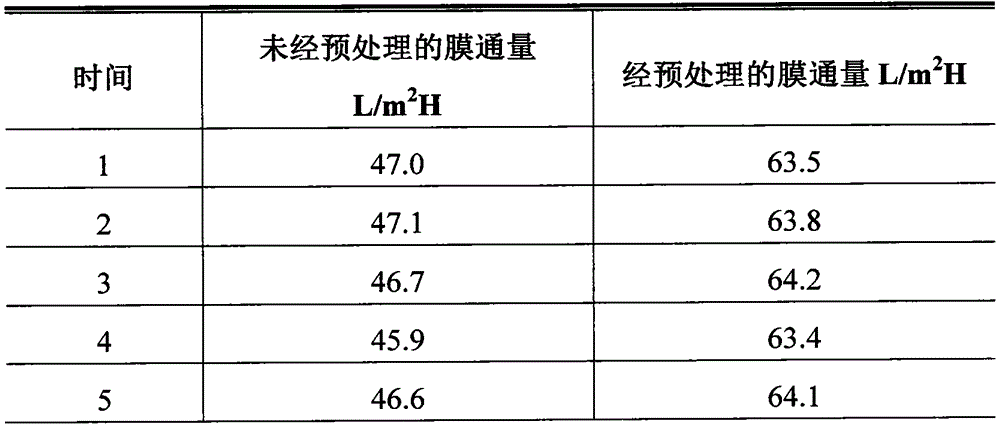

The invention relates to a biogas slurry concentrate and an engineering preparation method, which belongs to the technical field of biogas slurry resource utilization. The method comprises the following steps: pretreating a membrane of a chicken manure biogas slurry, passing the pretreated biogas slurry through an ultrafilter membrane of an inorganic ceramic membrane for filtering impurity, passing through a nanofiltration membrane and a reverse osmosis membrane for interception and condensation, and final removing solid insoluble particles in the biogas slurry, the macro-molecule substance which is difficult to be absorbed by the crops, high power concentrated biogas slurry organic micromolecule nutrients. The method overcomes of disadvantages of easy membrane obstruction, severe damage, difficult high power condensation, difficult engineering stable operation in prior art, the obtained biogas slurry concentrate finished product is nano level organic state micromolecule substance, has the advantages of comprehensive and balanced nutrition, good water solubility, strong permeability, high activity, and high practical application value.

Owner:SHANDONG MINHE BIOTECHNOLOGY CO LTD

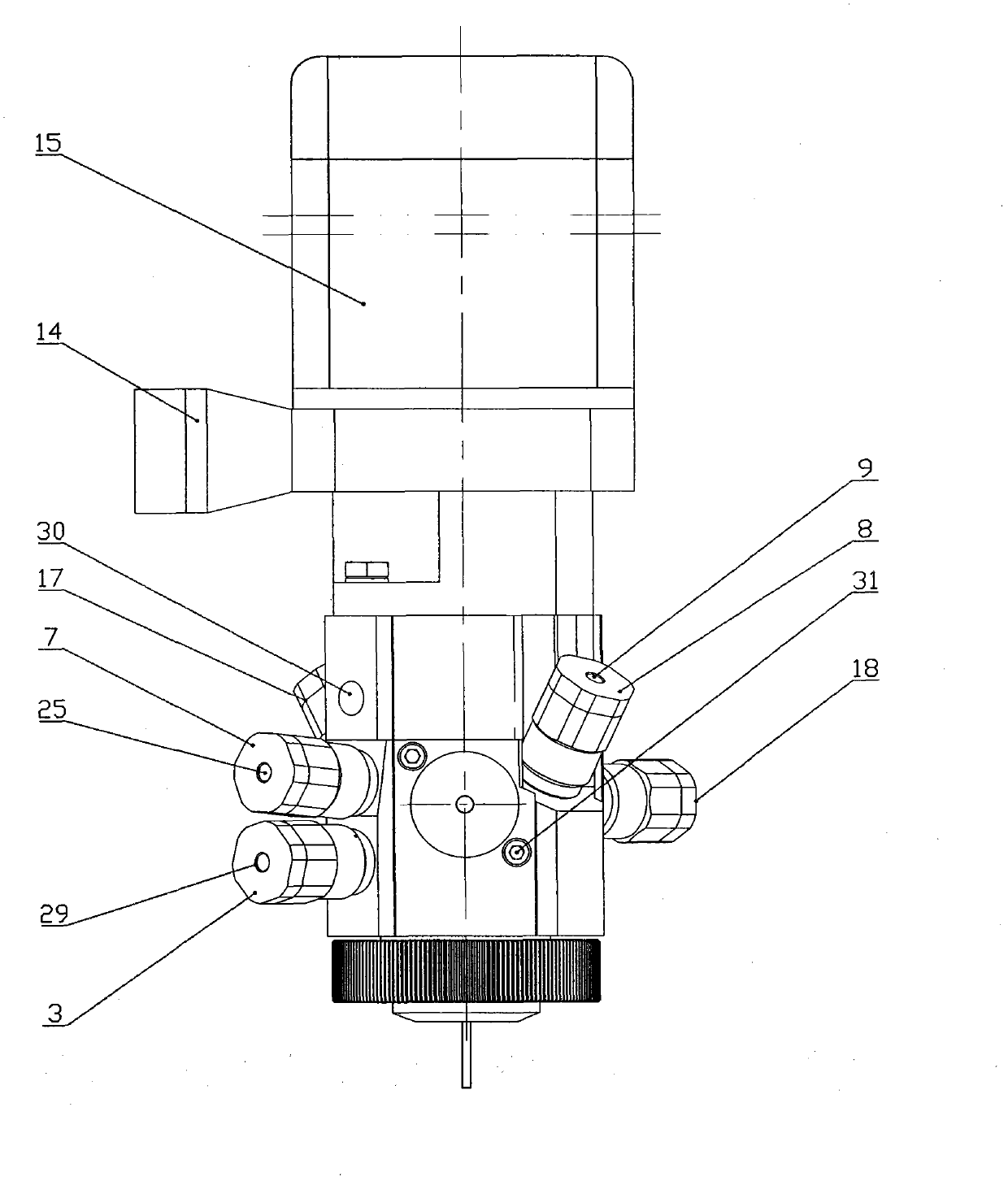

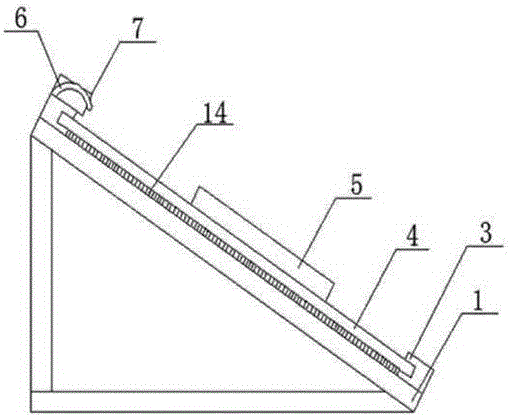

Water-cleaning gluing head for multi-component polyurethane needle valve

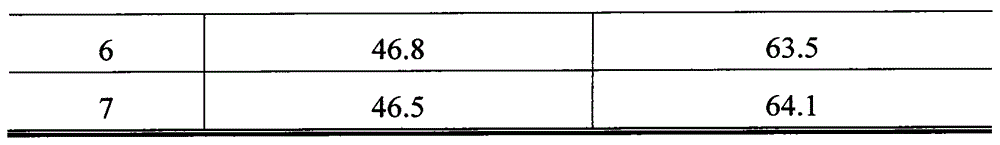

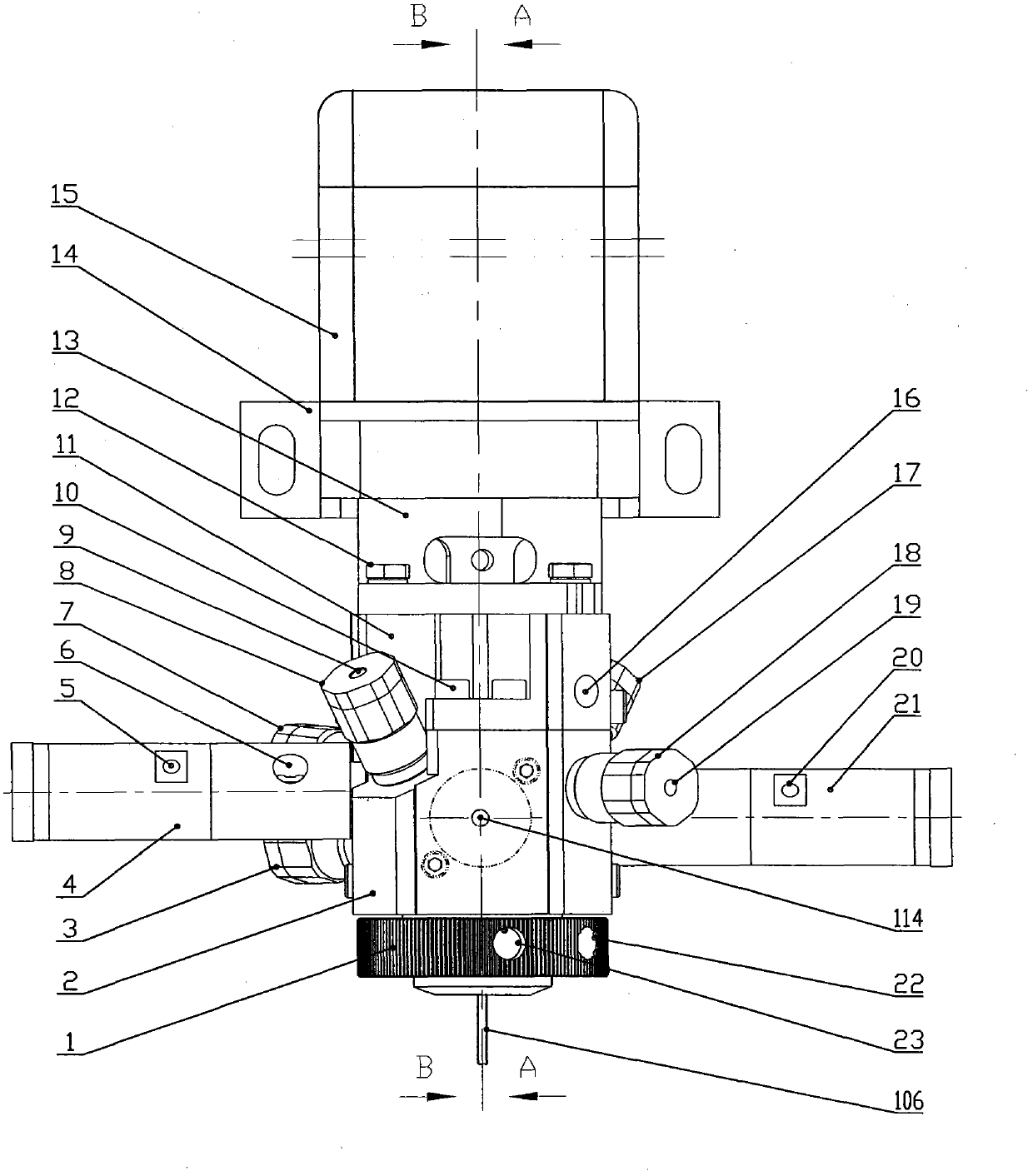

ActiveCN102601018ARemove threatEliminate pollutionLiquid surface applicatorsHollow article cleaningPhysical well beingEngineering

The invention relates to a water-cleaning gluing head for a multi-component polyurethane needle valve, in order to solve the problem that the traditional double-component polyurethane gluing head must be cleaned with a solvent and cannot be cleaned with water. The multi-component polyurethane water-cleaning gluing head comprises a motor, a transmission shaft, a stirring blade, a cup moving part, a valve base, a middle valve body, an upper valve body, a valve fixing plate, an component needle valve A, a component needle valve B, a water valve A, a water valve B, a water valve C, a water valve D and an air valve, wherein a cup base is connected with the valve base; a sealing ring A, a sealing ring B and a sealing ring C are mounted on an outer ring of a moving cup body; a check ring, a sealing circle and a sealing ring are mounted on an inner ring of the moving cup body; and a fixing sleeve is mounted between an ending opening on the cup base and the valve base. The manner of cleaning with water and then cleaning with compressed air is realized; the cleaning time is shortened; the threat to the health of operators and the environmental pollution caused by the solvent are eliminated; the structure is simple and compact; the mounting is convenient; the repairing is quick; and the stability is increased.

Owner:DALIAN HUAGONG INNOVATION TECH

Washing process for denim garment

ActiveCN104532592ANo effect on air qualityReduce storage pressureBiochemical fibre treatmentDry-cleaning apparatus for textilesChemical oxygen demandRoom temperature

The invention relates to a washing process for a denim garment. The washing process comprises the following steps: performing bio-enzyme de-sizing treatment in an amylase solution after performing denim garment fabric pre-treatment; performing enzyme washing by neutral enzyme powder; dehydrating and drying after cleaning with clean water; performing monkey wash on the fabric surface; performing neutralization treatment on the fabric which is subjected to monkey wash; adding a softening agent to perform softening treatment on the fabric; cooling the denim garment fabric to room temperature after dehydrating and drying, thereby completing washing on the denim garment. Compared with the prior art, the washing process has the advantages of quickly removing residual manganese ions, shortening the processing time, removing the color of a bleaching liquid, reducing the cleaning frequency, being low in sewage COD (chemical oxygen demand), and the like.

Owner:FIBER CHEM BIOLOGICAL CHEM

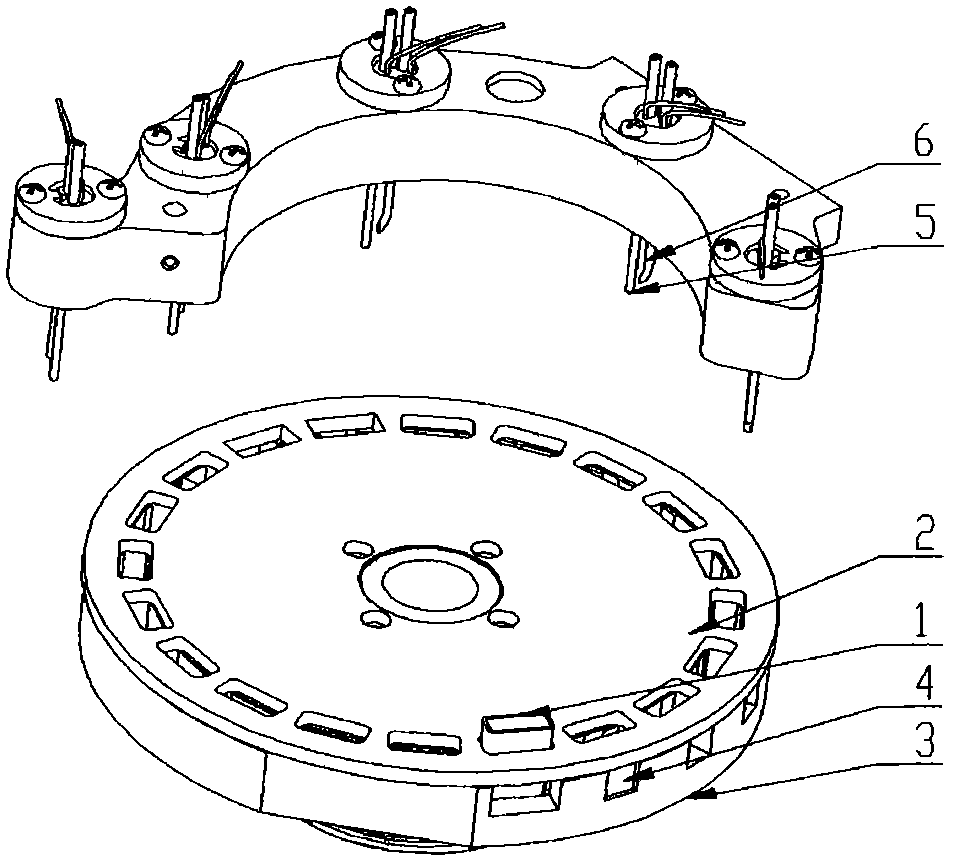

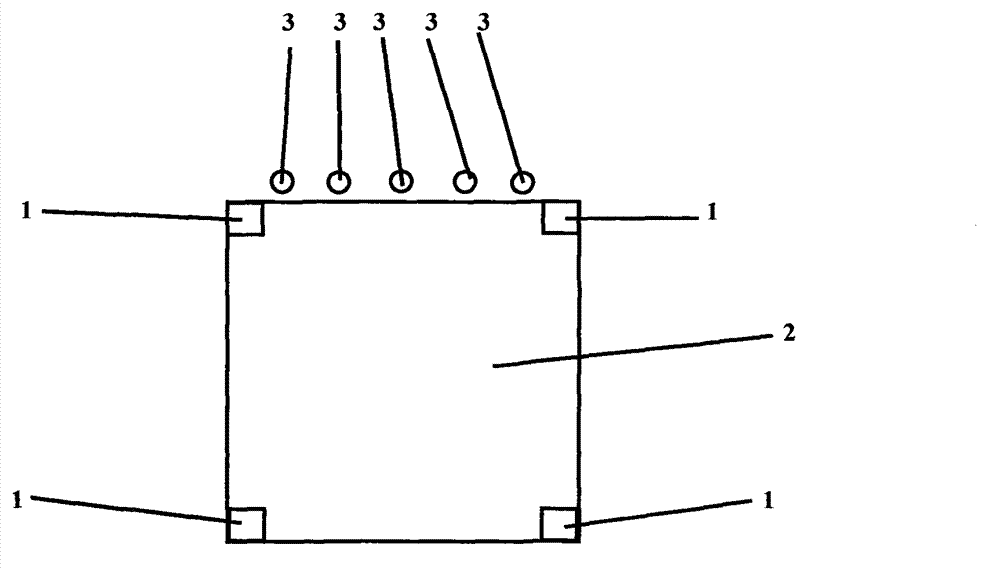

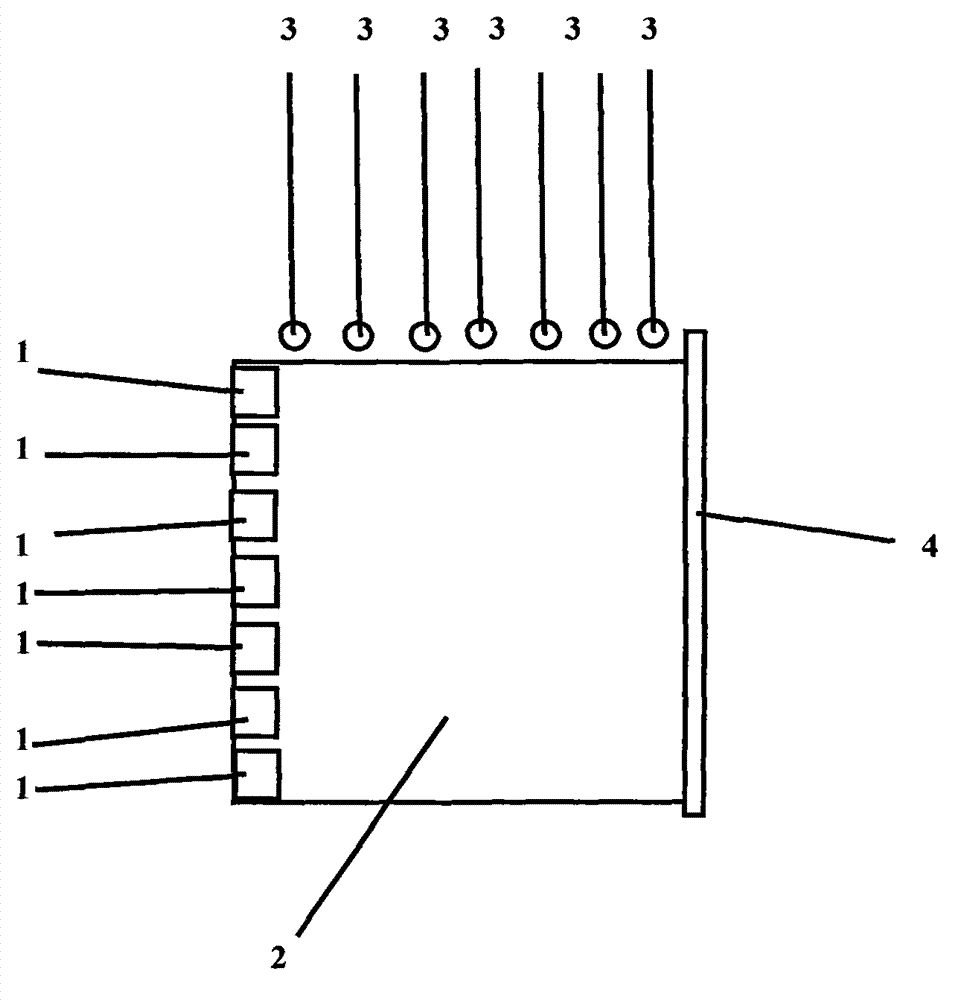

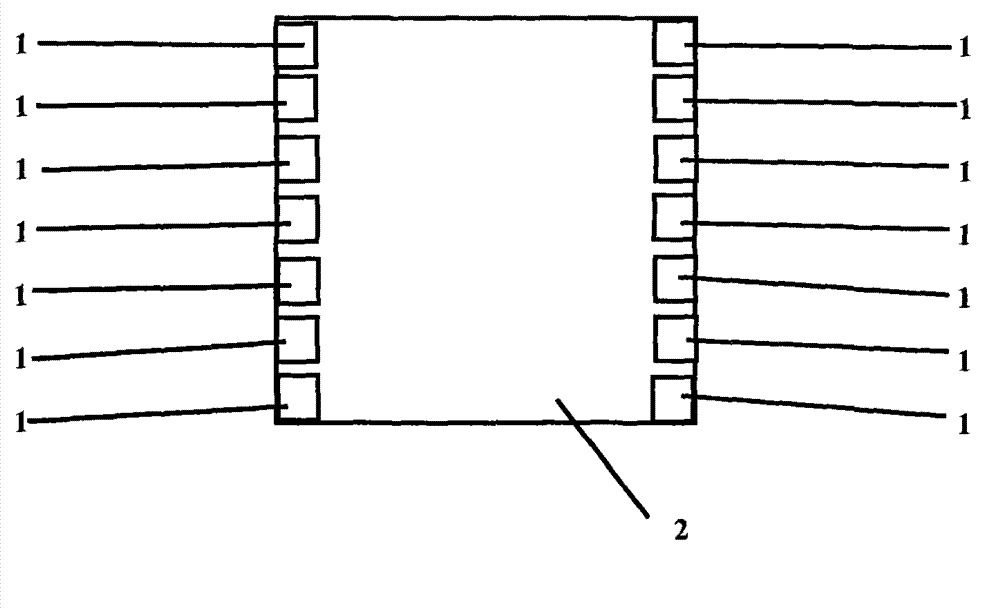

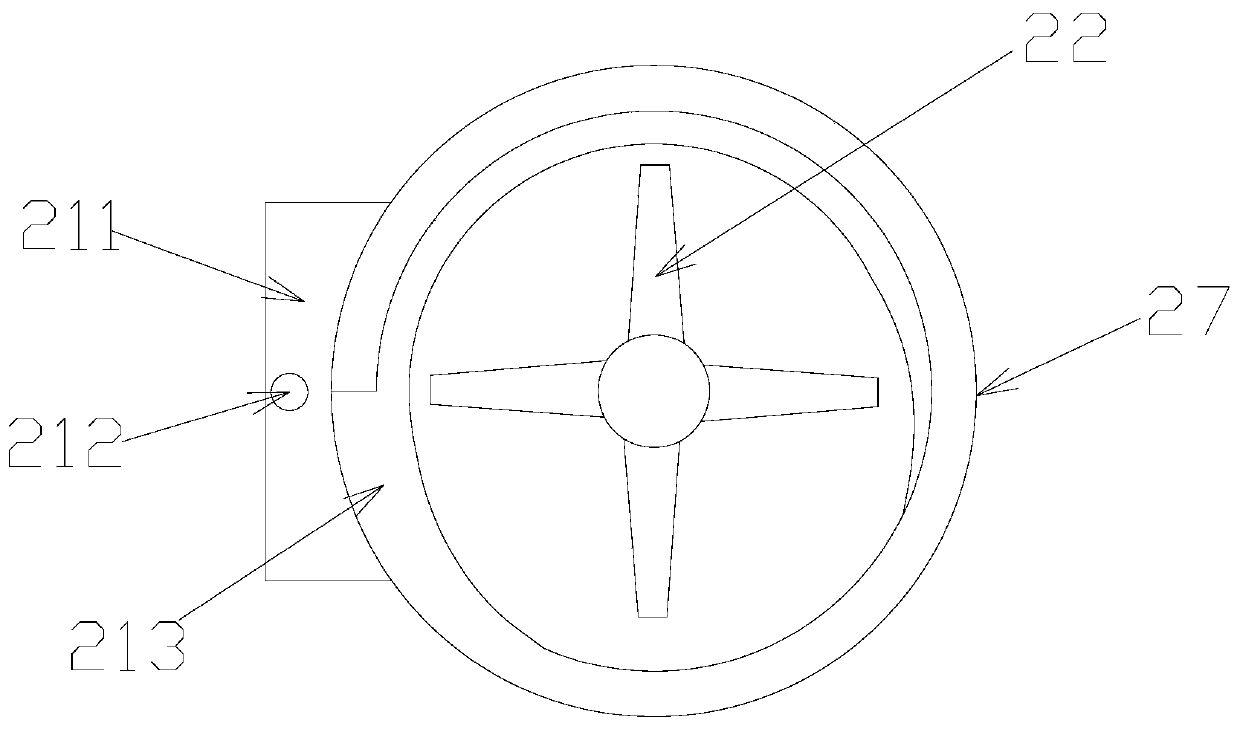

Reaction vessel for luminescence tester and cleaning and separating mechanism thereof

InactiveCN105891113AMultiple movesGuaranteed reliabilityMaterial analysis by optical meansBiological testingMagnetic beadBiochemical engineering

The invention discloses a reaction vessel for a luminescence tester and a cleaning and separating mechanism thereof. The reaction vessel is made of a transparent material and is flat, the opening of the reaction vessel is larger than the bottom of the reaction vessel, the reaction vessel is placed in a cleaning turnplate in the circumferential direction, the flat sides of the reaction vessel are in the circumferential direction, a suction pin and a drawing pin are arranged above the reaction vessel, and magnets used for magnetic separation are placed on the flat sides of the reaction vessel so as to attract magnetic bead particles to one side of the reaction vessel fast and prevent the magnetic bead particles from being sucked away by the suction pin during cleaning; to completely remove impurities, the magnets are placed on the two flat sides of the reaction vessel alternately to enable the magnetic beads to move to the other side from one side of the vessel during cleaning, impurities possibly precipitating under the magnetic beads are released, so that the reliability and repeatability of measurement results are guaranteed, the number of times of cleaning is reduced, and testing speed is increased.

Owner:HEFEI YUNTAO OPTOELECTRONICS TECH

Method for removing smelly substances in water

InactiveCN103121732APollution controlReduce concentrationWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisNano catalystHollow fibre

The invention discloses a method for removing smelly substances in water, which comprises the following steps: 1. preparing an inorganic nano catalyst, an organic high-polymer basal film material, additives, a solvent and the like into a film casting solution at certain temperature, and preparing a flat or hollow-fiber or tubular inorganic-organic hybrid photocatalytic separation film; and 2. putting the inorganic-organic hybrid photocatalytic separation film on a film filter unit, and filtering smelly-substance-containing water to be treated in a dead end filtering or cross-flow filtering mode under the conditions of a proper light source. The photocatalytic unit and the film separation unit which are mutually independent are organically fused into one unit for operation, and thus, the invention can simultaneously have the advantages of both photocatalysis and film separation. The method disclosed by the invention has the advantages of simple technique, no need of reagents, high operation reliability, compact equipment and easy automatic control; and the method can effectively remove smelly substances in water, reduce the film pollution, prolong the service life of the film, and lower the technological cost.

Owner:SHANGHAI JIAO TONG UNIV

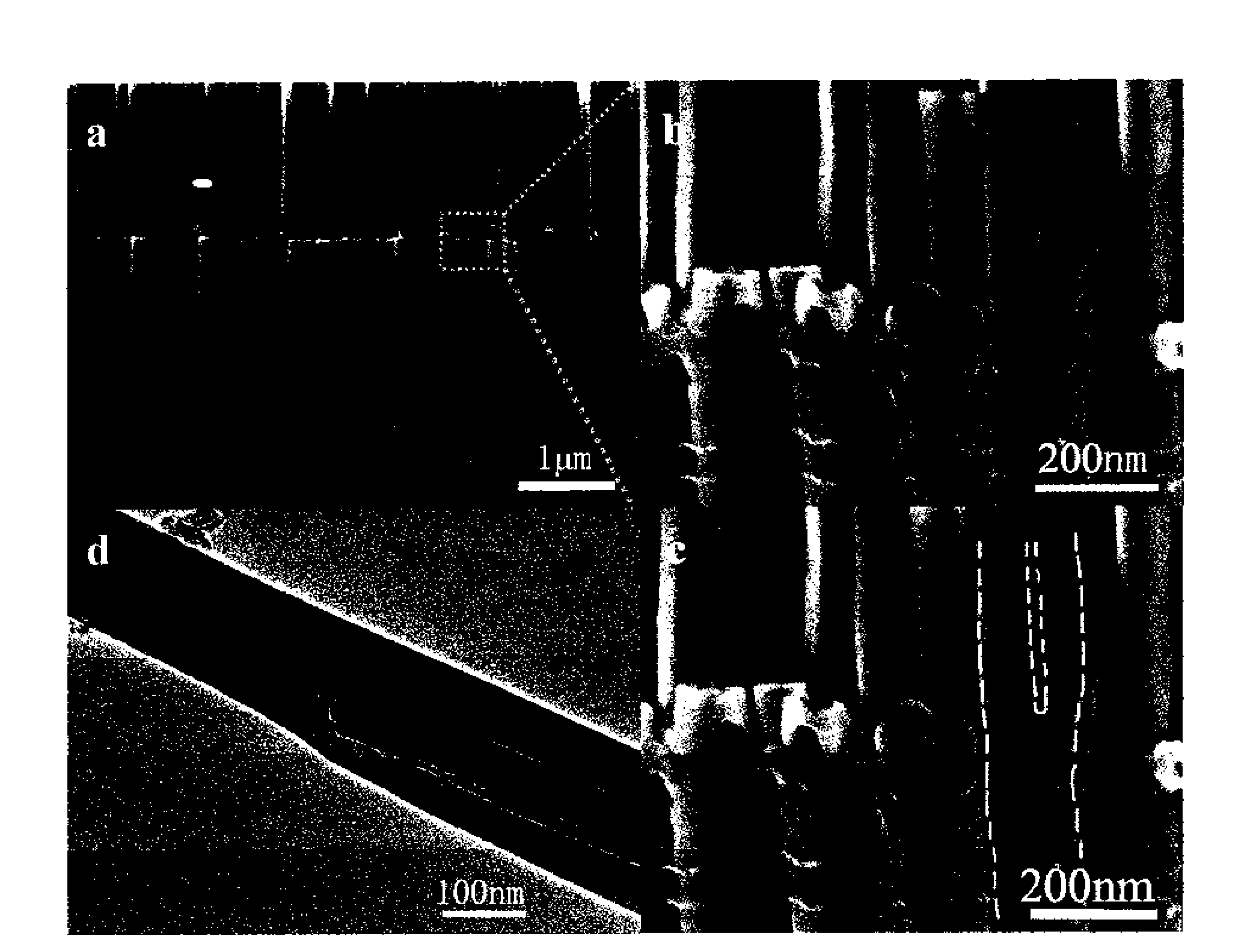

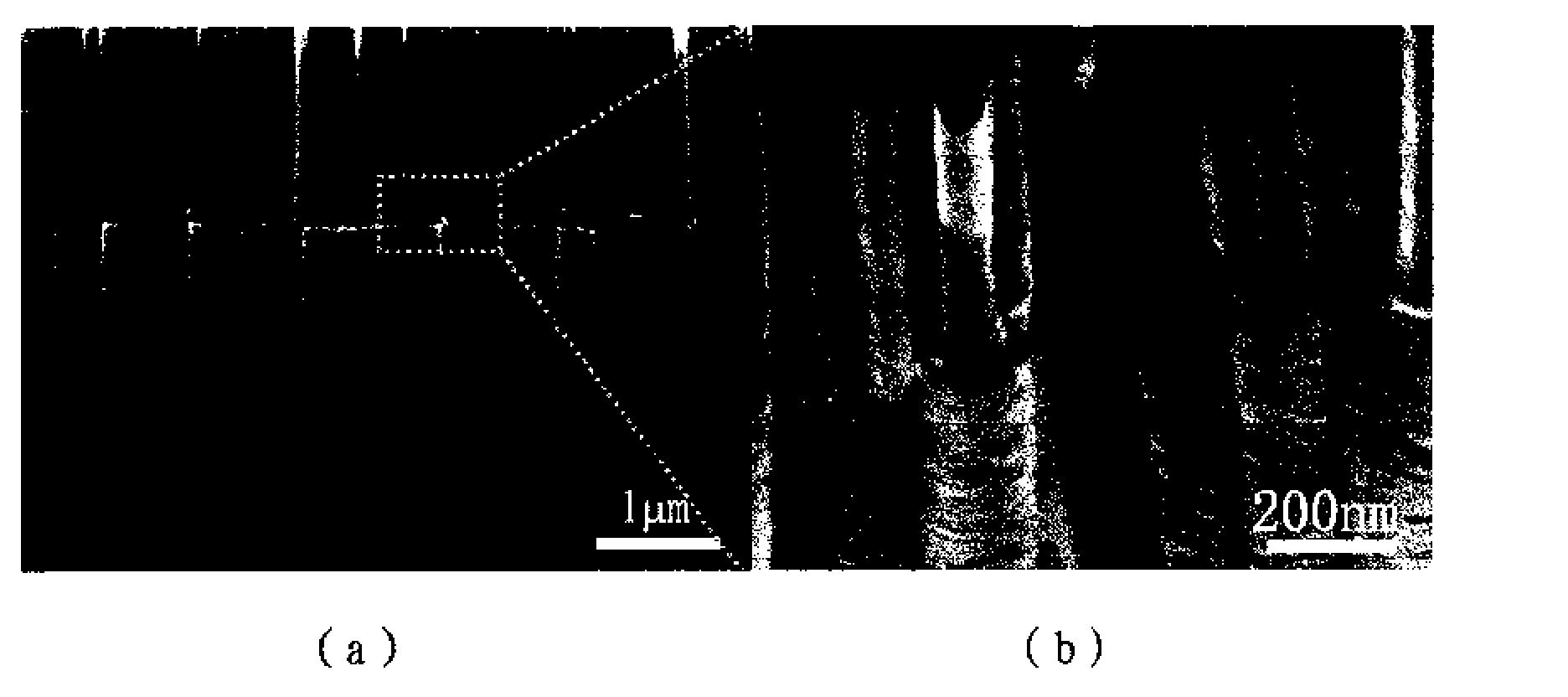

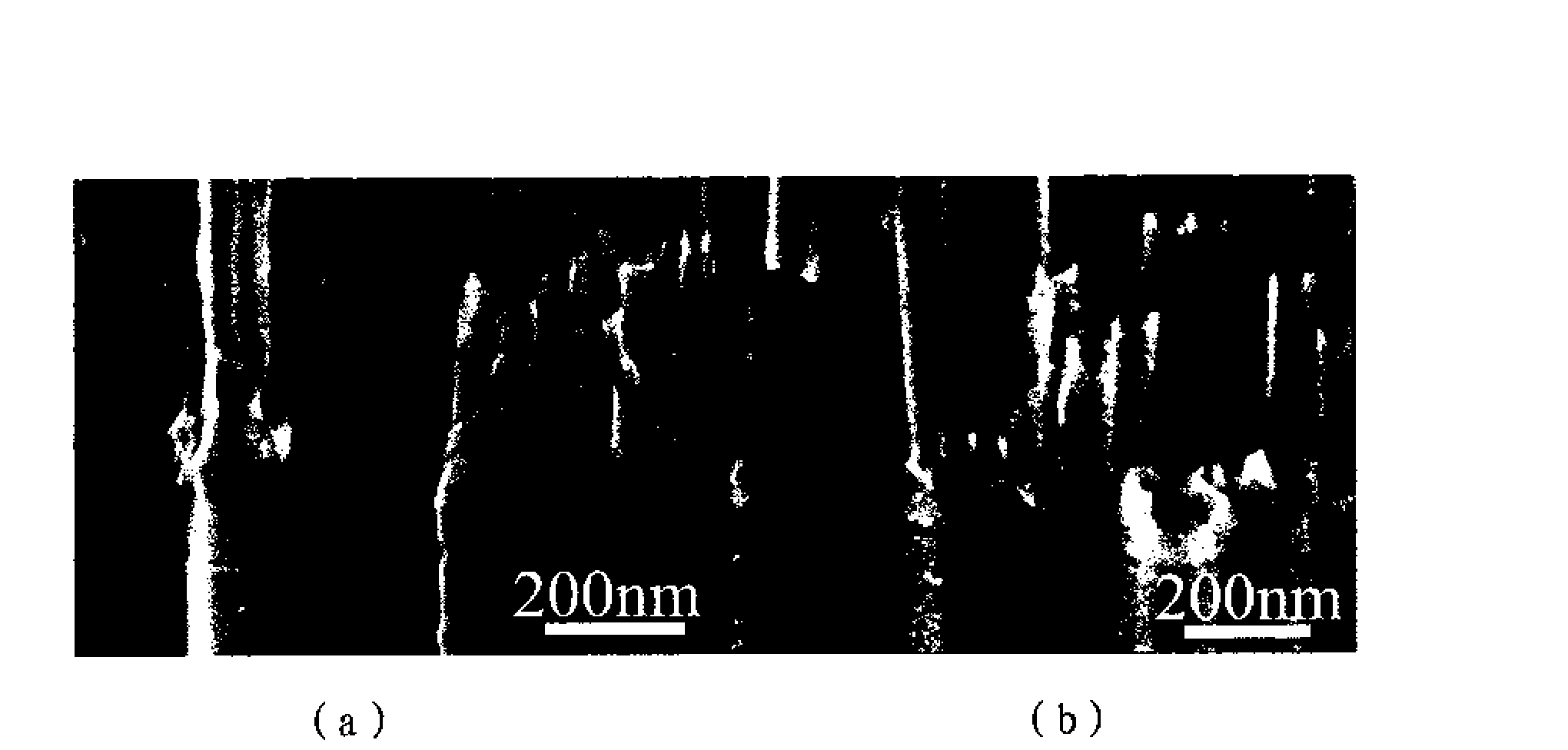

Branch controllable titanium dioxide nanotube array thin film and preparation method thereof

InactiveCN101660189ALarge adjustment rangeShape is easy to controlPolycrystalline material growthNanostructure manufacturePorosityDc voltage

The invention discloses a branch controllable titanium dioxide nanotube array thin film and a preparation method thereof. The thin film consists of an array of a titanium dioxide nanotube formed by connecting a main tube and a branch tube in series; the thickness of the thin film is 1-100mum, and the porosity factor is 40-60 percent. The preparation method comprises the following steps: preparinga main tube electrolyte according to the proportion that the mole ratio of ammonium fluoride to glycol to water is 0.05-0.15:17.7:0.015-0.025, and preparing a branch tube electrolyte according to theproportion that the mole ratio of hydrofluoric acid to glycol is 0.15-0.25:17.7; then firstly, putting one surface of a titanium sheet in the main tube electrolyte to serve as the anode; carrying outanode oxidization under the conditions that the DC voltage is 55-65V and the temperature is 0-35 DEG C for 0.5-6h; then using the glycol to clean the anode; subsequently, putting the surface which isanodized in the branch tube electrolyte to serve as the anode, and carrying out anode oxidization under the conditions that the DC voltage is 30-120V and the temperature is 0-35 DEG C for more than 30min, thereby preparing the thin film. The thin film can be widely used for fields of dye-sensitized solar cells, gas sensors, photolytic water hydrogen production and photonic crystal.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Cryo-concentration method of juice obtained by processing organisms

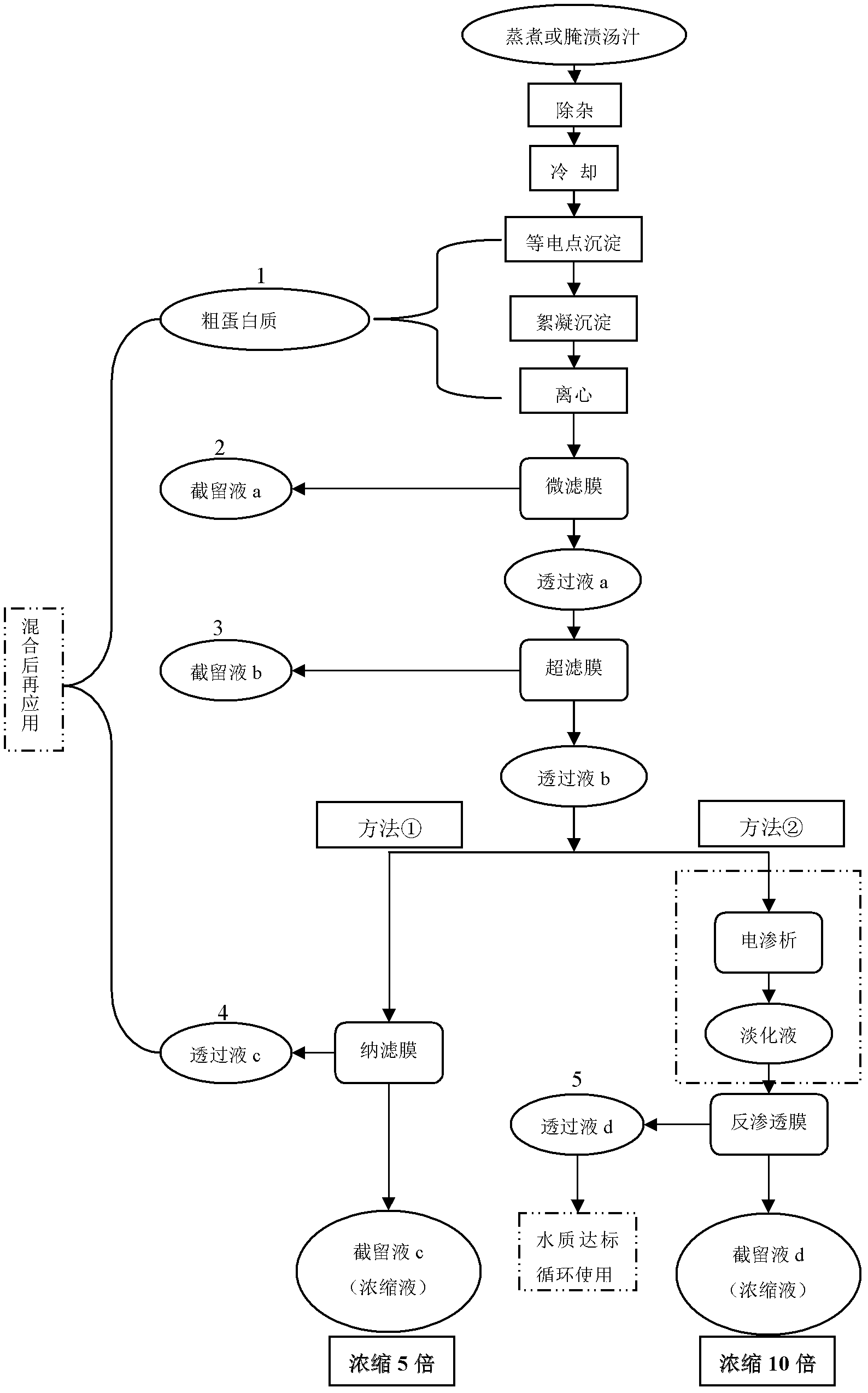

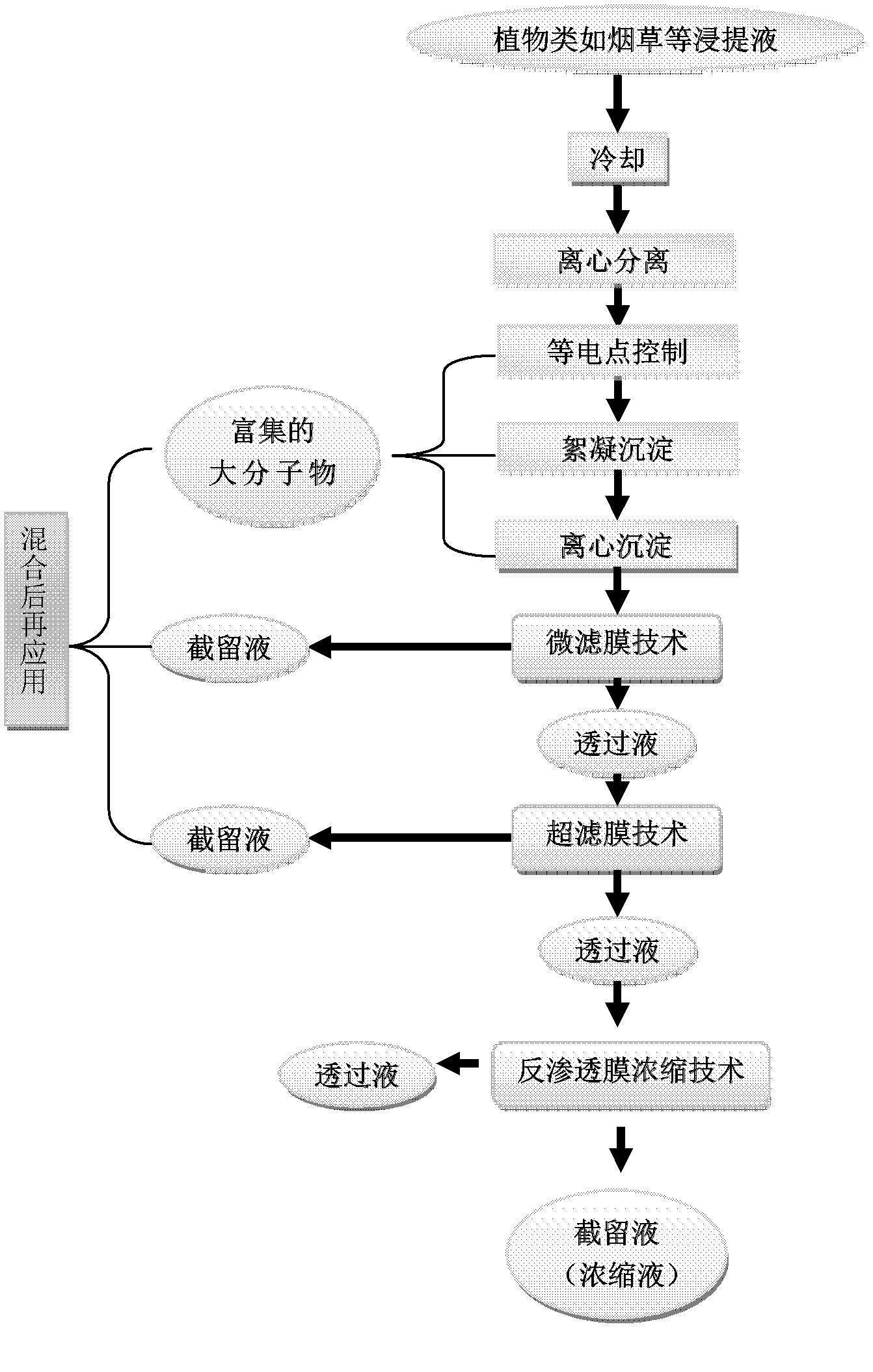

ActiveCN102657320AEmission reductionReduce pollutionTobacco treatmentFood preparationConcentration polarizationEnrichment methods

The invention discloses a cryo-concentration method of juice obtained by processing organisms, comprising the following steps: firstly pretreating the juice by using isoelectric precipitation, flocculation precipitation, centrifugal separation and the like to gather protein and reduce the protein content in the juice, so as to reduce the concentration polarization of membrane concentration; and then integratedly cascading membrane modules to concentrate small-molecule nutrient and flavor substances by fully utilizing the advantages of microfiltration, ultrafiltration, stepwise rejection of reverse osmosis, and desalination of electrodialysis to reduce osmotic pressure. The method is suitable for the juice obtained by processing organisms having a content of concentrated amino acid nitrogen being 5-100 mg / 100ml and has a wide application range. The method can not only concentrate and recover nutrient and flavor substances, transforms the juice into something valuable, raises the product additional values, reduces the discharge of food processing waste water, reduces environmental pollution, and can basically realize the basically complete recycling of the nutrient and flavor substances of the juice.

Owner:ZHEJIANG UNIV OF TECH

Culture method for Chinese honeybees

The invention belongs to the technical field of beekeeping and particularly relates to a culture method for Chinese honeybees. The culture method for the Chinese honeybees comprises the steps: S1. providing beehives; S2. carrying out hiving; S3. carrying out propagation period management; S4. carrying out bee colony queen breeding; S5. carrying out swarming; S6. carrying out bee colony merging; S7. carrying out honey-getting; S8. enabling bee colonies to live through summer and winter; S9. feeding the bee colonies and preventing bee theft; S10. carrying out disease and insect pest control on the Chinese honeybees; S11. disinfecting beekeeping equipment; S12. preventing and treating chaos bee clusters; and S13. preventing and treating swarming fever. According to the method, the provided beehives facilitate bee colony observation, swarming and merging and can help the bee colonies to safely live through summer, absconding is reduced, the beehives are warm in winter and cool in summer, the bee colonies have no need of migration, and feeding can be carried out at fixed points; the yield and quality of honey can be improved; and the culture method disclosed by the invention can be used for solving the difficult problems in a Chinese honeybee culture process that the colony population is small and the quantity of plant diseases and insect pests is large.

Owner:赵学智 +2

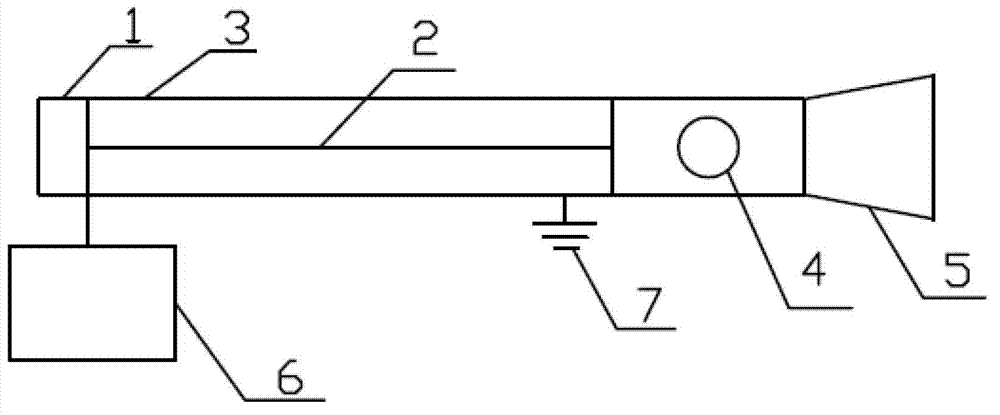

Method for detecting surface pollution degree through ultrasonic wave and cleaning pollution

InactiveCN103191886AGuaranteed cleanlinessReduce cleaning timesAnalysing solids using sonic/ultrasonic/infrasonic wavesCleaning using liquidsSurface cleaningUltimate tensile strength

The invention discloses a method for detecting the surface pollution degree through ultrasonic wave and cleaning the pollution. An ultrasonic transducer emits ultrasonic wave and receives the ultrasonic wave, and in pollution degree detection, the ultrasonic transducer emits sound surface wave with the frequency of F1, the sound surface wave is broadcasted along the cleaned surface and then is received by the ultrasonic transducer; when the pollution degree varies, the strength of the sound surface wave received by the ultrasonic transducer can be different, the strength of the output electric signals can be different, when the electric signals reach certain preset values, the ultrasonic transducer emits ultrasonic wave with the frequency of F2 to clean the surface, and after a period of cleaning, cleaning can be stopped for detecting again. By means of the method, the surface pollution degree can be detected ceaselessly, cleaning can be performed automatically according to the pollution degree, the surface can be always kept clean, damage to the surface can be reduced, and energy is saved.

Owner:ANHUI NORMAL UNIV

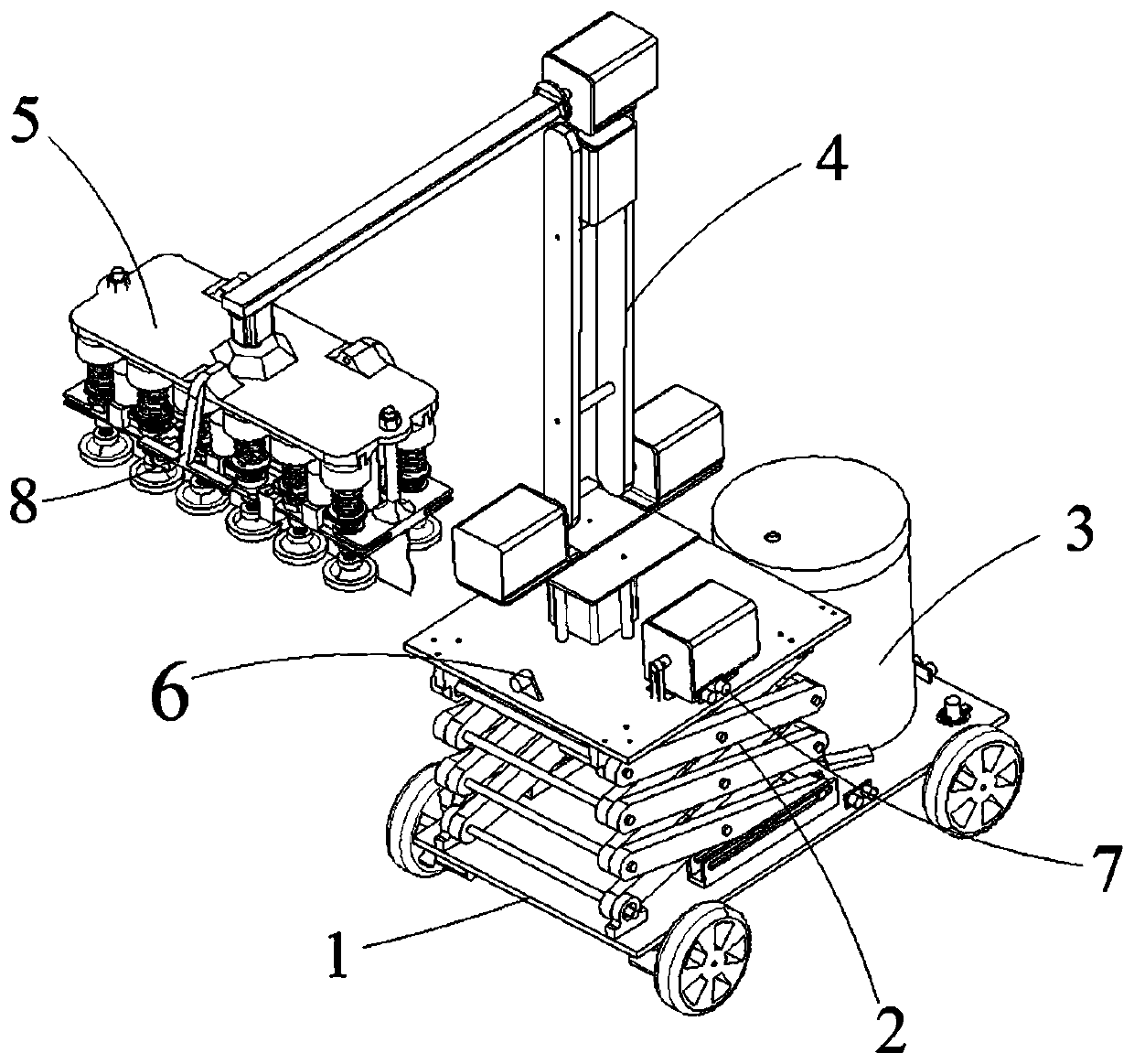

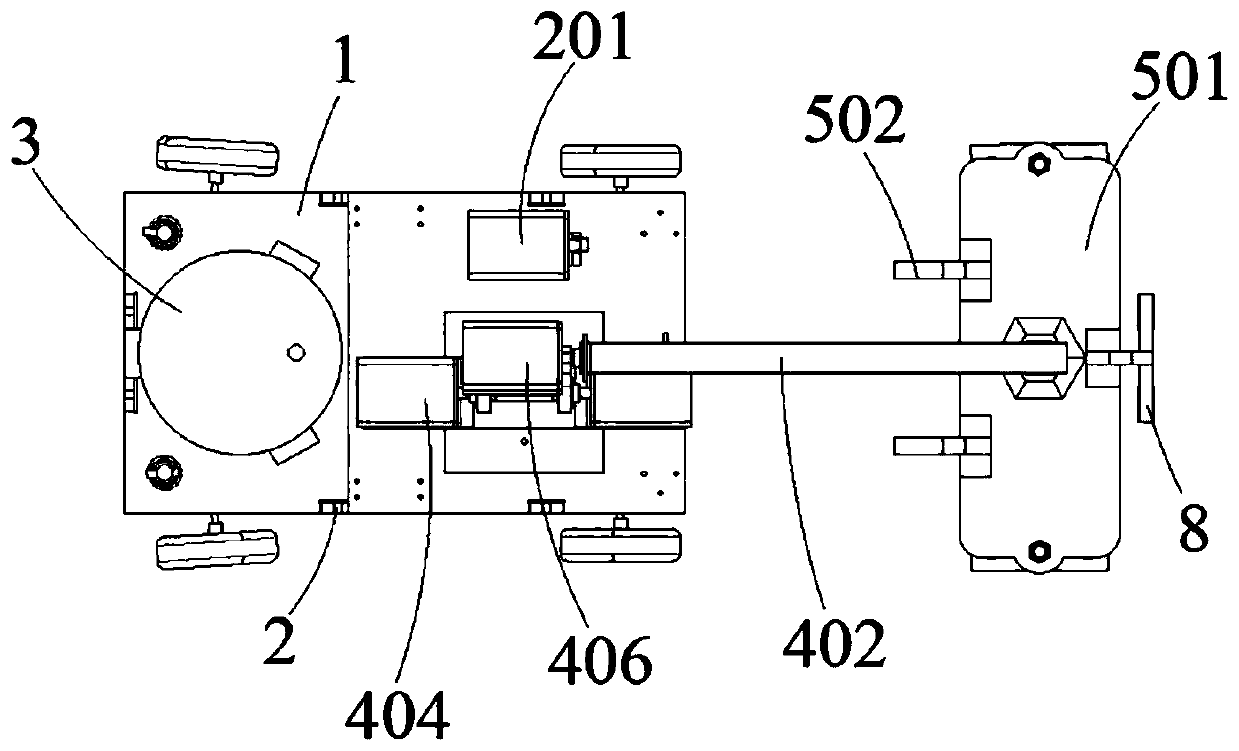

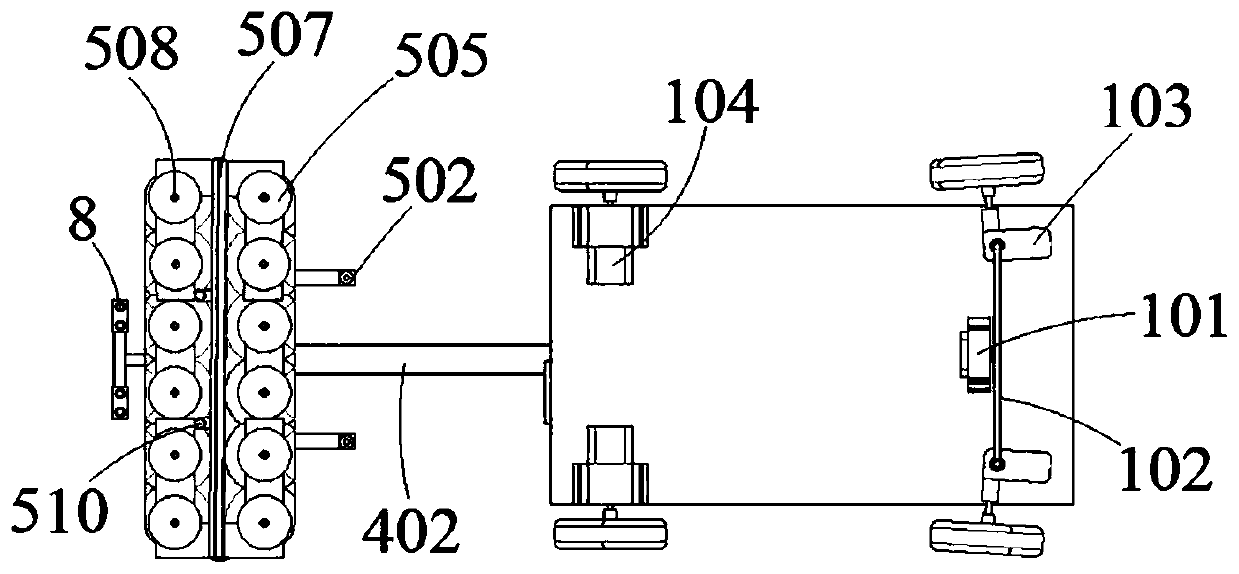

Vehicle cleaning robot

ActiveCN110216690AFully automatedImprove cleaning efficiencyCleaning apparatus for vehicle exteriorsManipulatorManipulatorUltimate tensile strength

The invention relates to the technical field of vehicle cleaning equipment, and particularly relates to a vehicle cleaning robot. The vehicle cleaning robot comprises a travelling chassis, a lifting platform arranged above the travelling chassis, a manipulator arranged on the lifting platform, and a scrubbing assembly arranged at an operation end of the manipulator. The vehicle cleaning robot further comprises an image acquisition device, a distance monitoring device and a control device. With the adoption of the vehicle cleaning robot, the automation of vehicle cleaning working is realized, and the labor intensity of the vehicle cleaning working is reduced; and in addition, the vehicle cleaning robot is capable of analyzing the dimensions of a vehicle to be cleaned and planning the running track of the scrubbing assembly before the cleaning working, and in this way, the cleaning efficiency of the vehicle cleaning robot is increased, and on the other hand, the overall running track length of the scrubbing assembly in the cleaning process is reduced, so that consumption for water is reduced.

Owner:GUANGZHOU UNIVERSITY

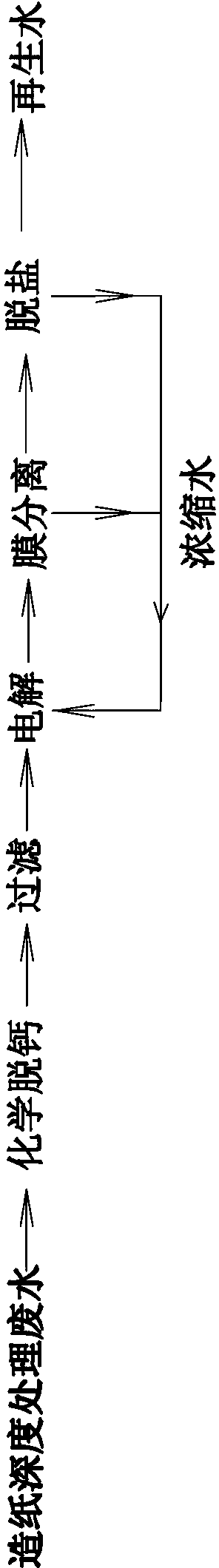

Recycling device used for papermaking advanced treatment wastewater and based on chemical decalcification

InactiveCN103253838AEmission reductionReduce wasteGeneral water supply conservationMultistage water/sewage treatmentElectrolysisMembrane technology

The invention discloses a recycling device used for papermaking advanced treatment wastewater and based on chemical decalcification. The recycling device comprises a chemical decalcification system, a filter system, an electrolysis system, a membrane separation system and a desalting system, wherein the chemical decalcification system is equipped with a dosing system, and the membrane separation system is one of an ultrafiltration system and an MBR (Membrane Bio-Reactor) system. The recycling device combines a chemical decalcification technology, an electrochemical technology and a membrane technology, and 70-85% of the papermaking advanced treatment wastewater can be regenerated and recycled after treated, so that wastewater discharge is reduced; environmental pollution due to the wastewater is avoided; waste of a water resource is reduced; the cost of the regenerated circulating water can be lower than that of tap water; and the recycling device is economical and reasonable, generates better economic benefits, lowers a water consumption index and a wastewater discharge index per ton of paper greatly, and raises economic and technical indexes of an enterprise.

Owner:BOYING XIAMEN SCI & TECH

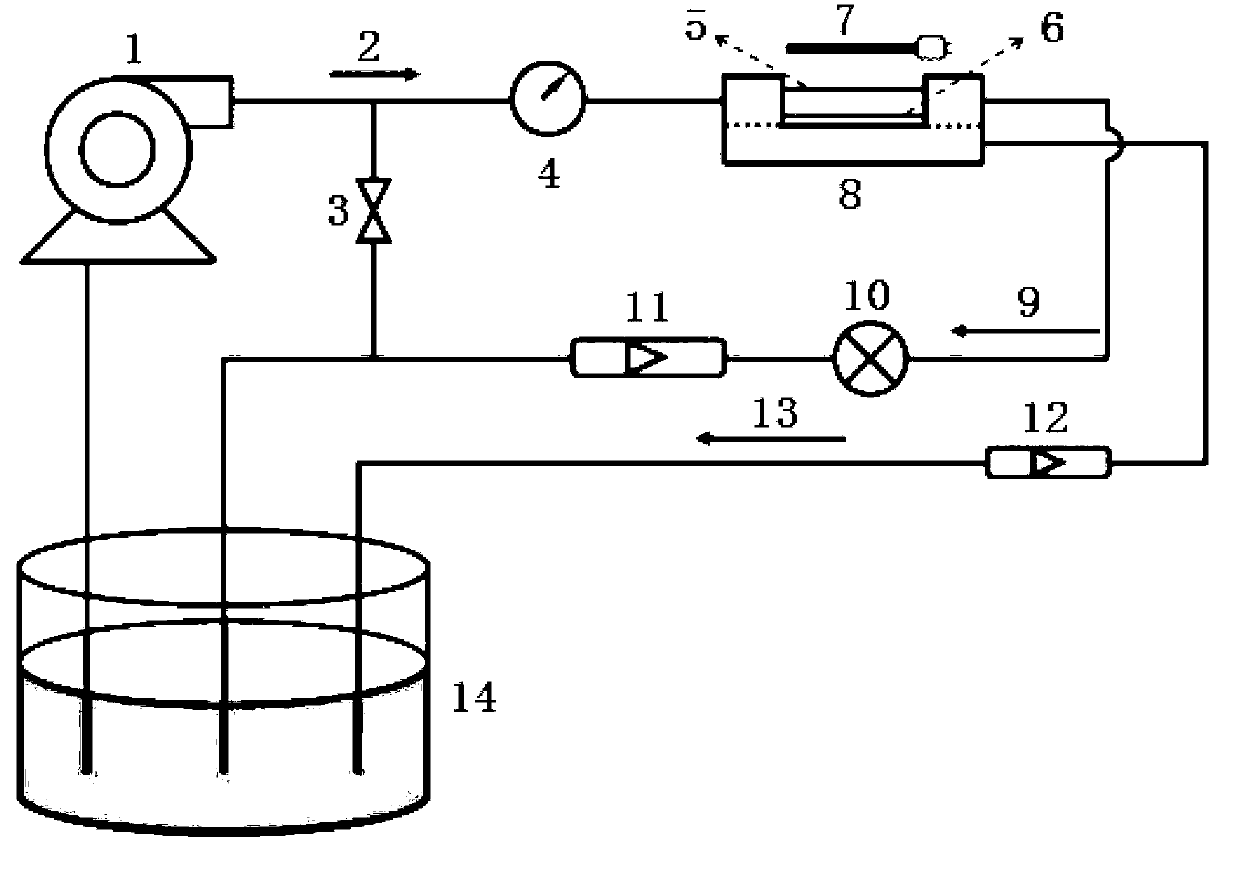

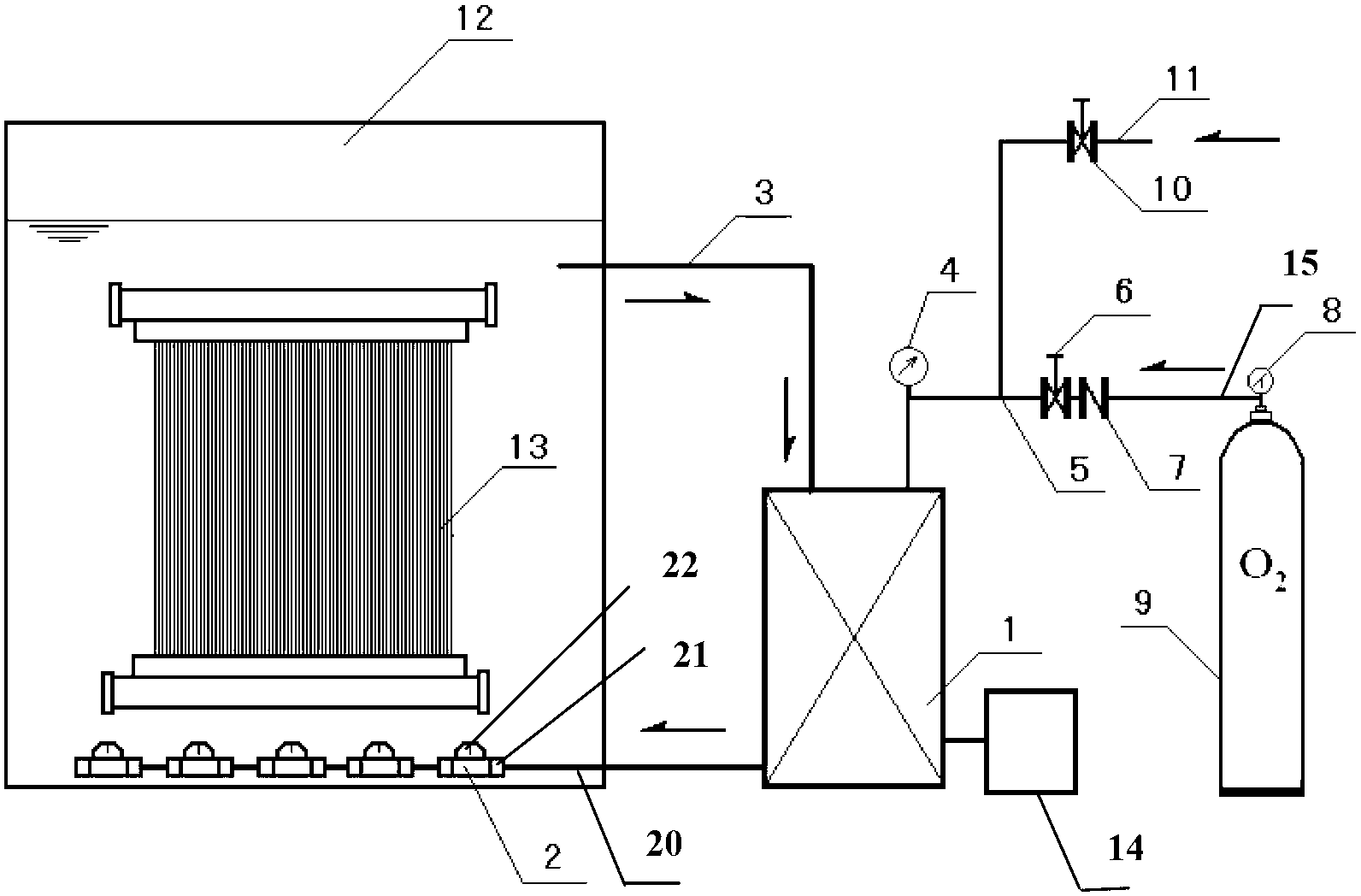

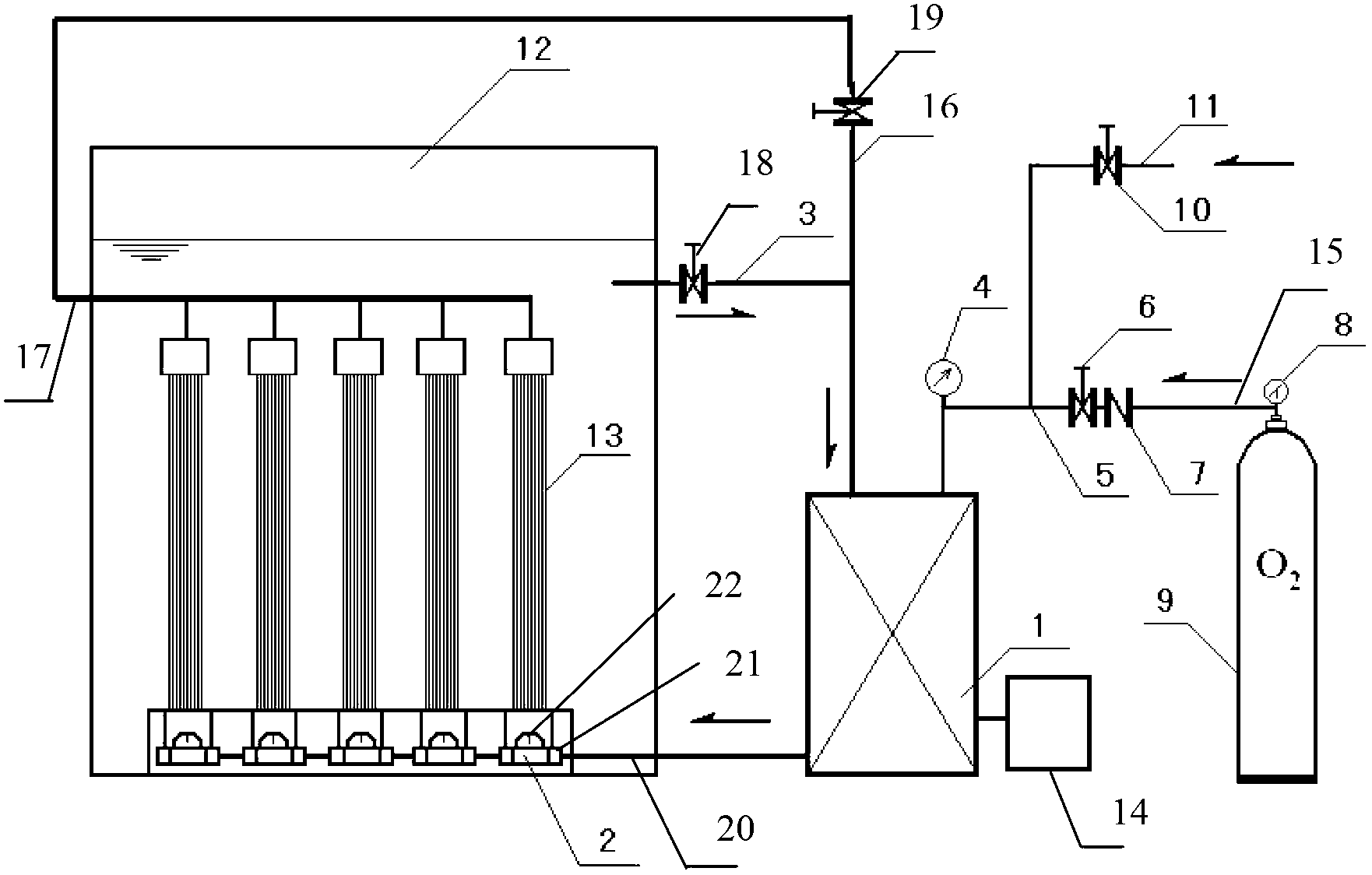

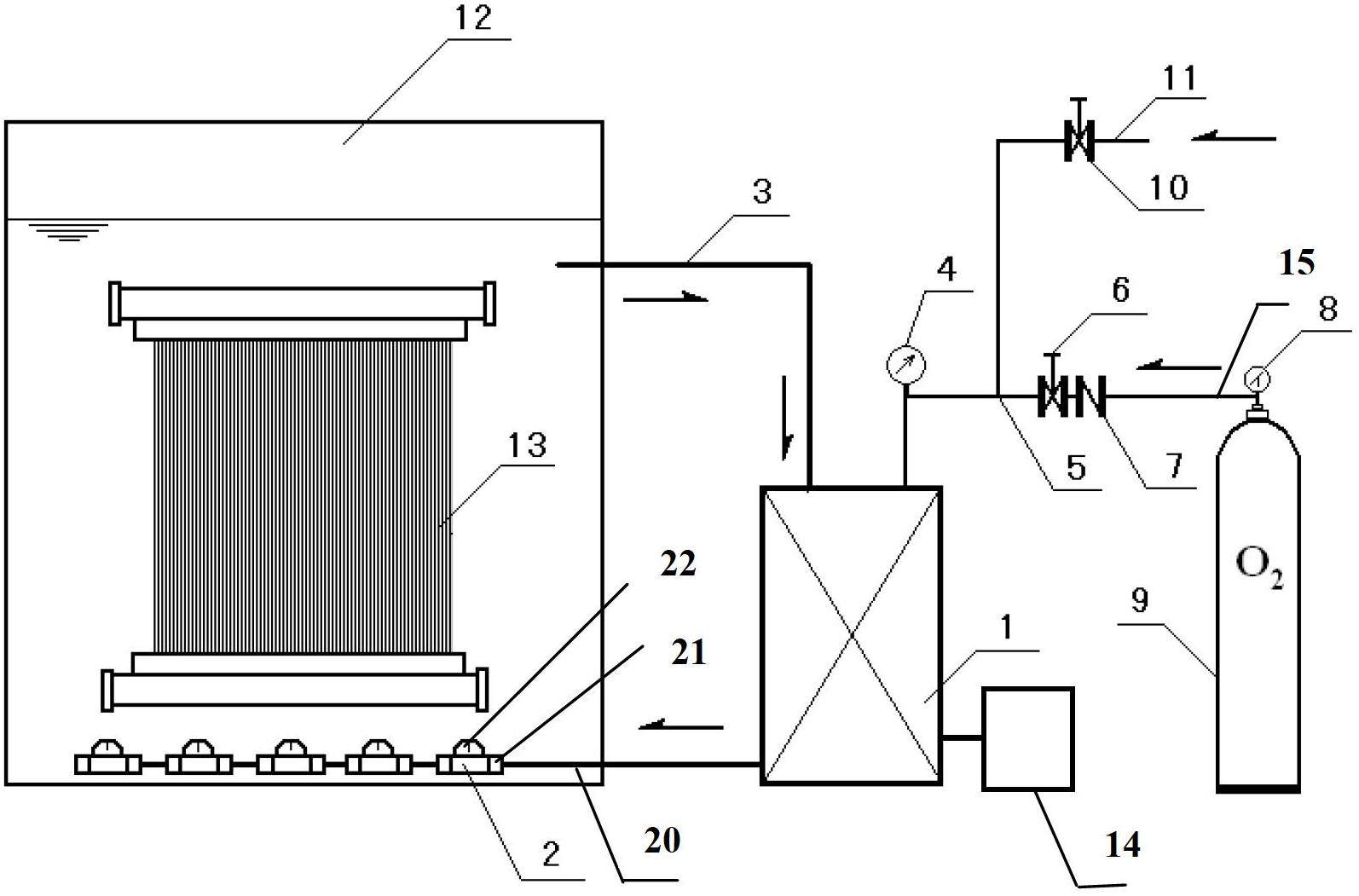

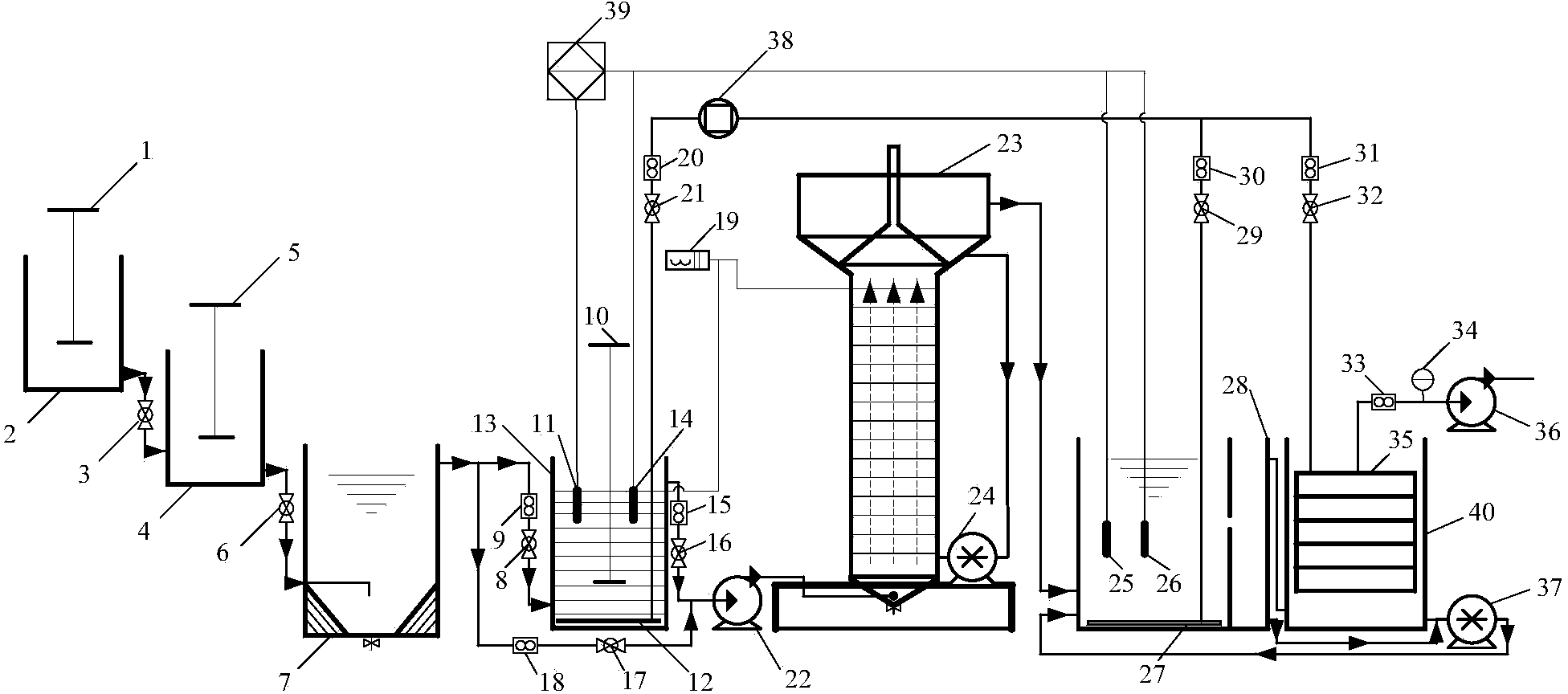

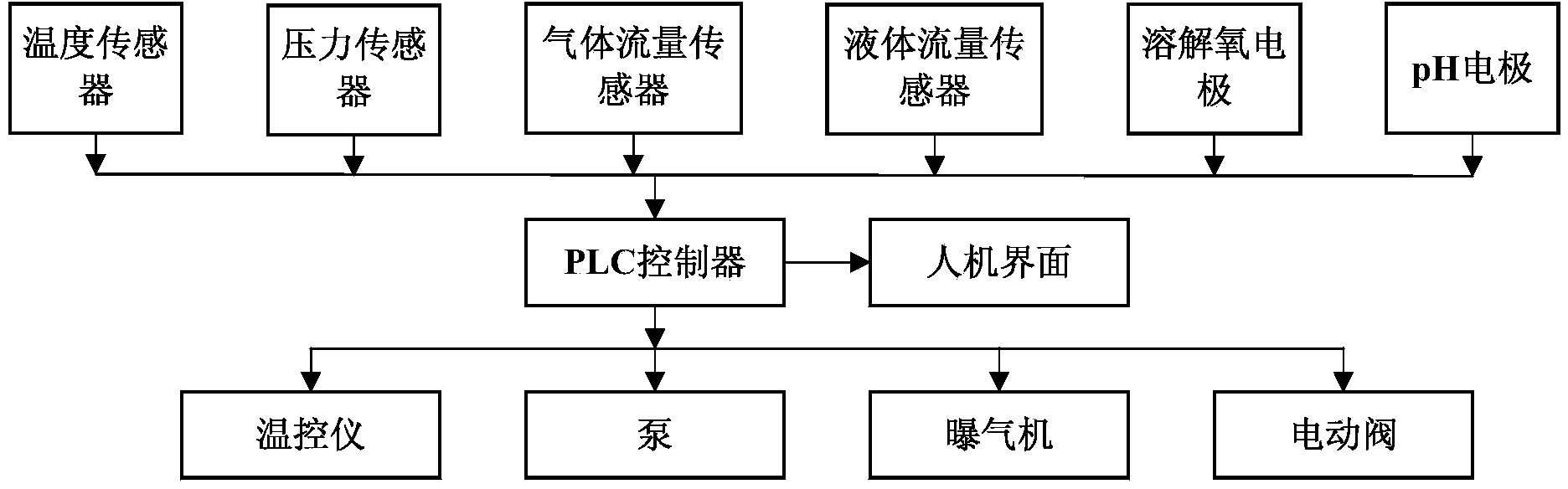

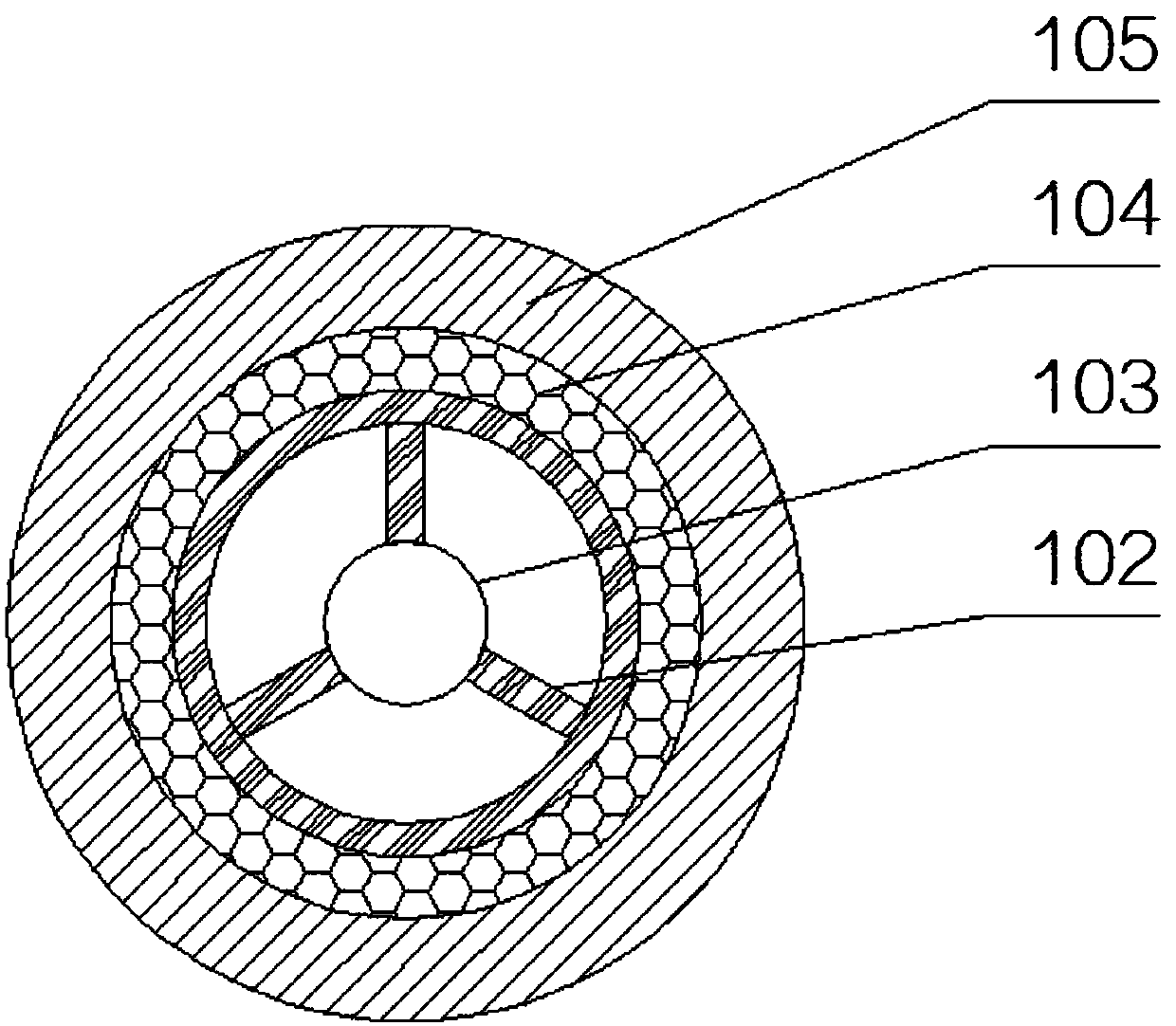

Membrane cleaning device applicable to submerged membrane bioreactor

ActiveCN102698607AReduce energy consumptionEasy to installSemi-permeable membranesSustainable biological treatmentMicrometerWater flow

The invention provides a membrane cleaning device applicable to a submerged membrane bioreactor. A micrometer and nanometer air bubble generator is used for replacing the traditional perforated aerator pipe, high-pressure water flows rich in micrometer-scale and nanometer-scale air bubbles are generated in the membrane bioreactor, while necessary oxygen for the microbial reaction is supplied, a good flushing effect is realized on a membrane assembly. The membrane cleaning device comprises the micrometer and nanometer air bubble generator and an oxygen supply system, wherein the micrometer and nanometer air bubble generator comprises a micrometer and nanometer air bubble generator host and aeration heads, an air dissolving device and a booster pump connected with the air dissolving device are arranged in the host, an air inlet of the air dissolving device is connected with the oxygen supply system, a water inlet of the air dissolving device is communicated with the membrane bioreactor, a water outlet of the air dissolving device is connected onto a plurality of aeration heads arranged in the membrane bioreactor through connecting pipelines, the aeration heads are uniformly arranged at the lower end of the membrane assembly arranged in the membrane bioreactor, and the directions of high-pressure water flows flowing out from the water outlets of all of the aeration heads are parallel to or tangent to the solid-liquid interface of a membrane of the membrane assembly.

Owner:BEIJING ZHONGNONG TIANLU MICRO NANO BUBBLE WATER S&T

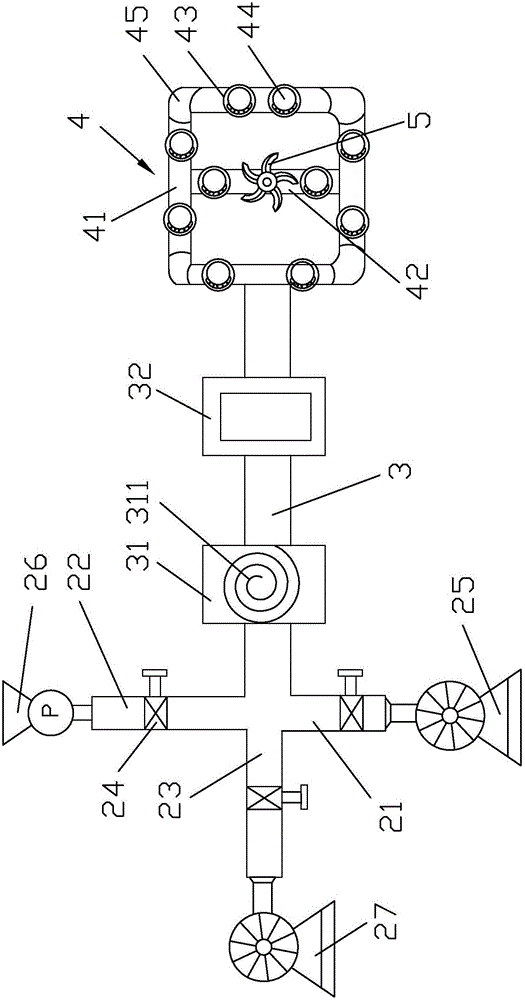

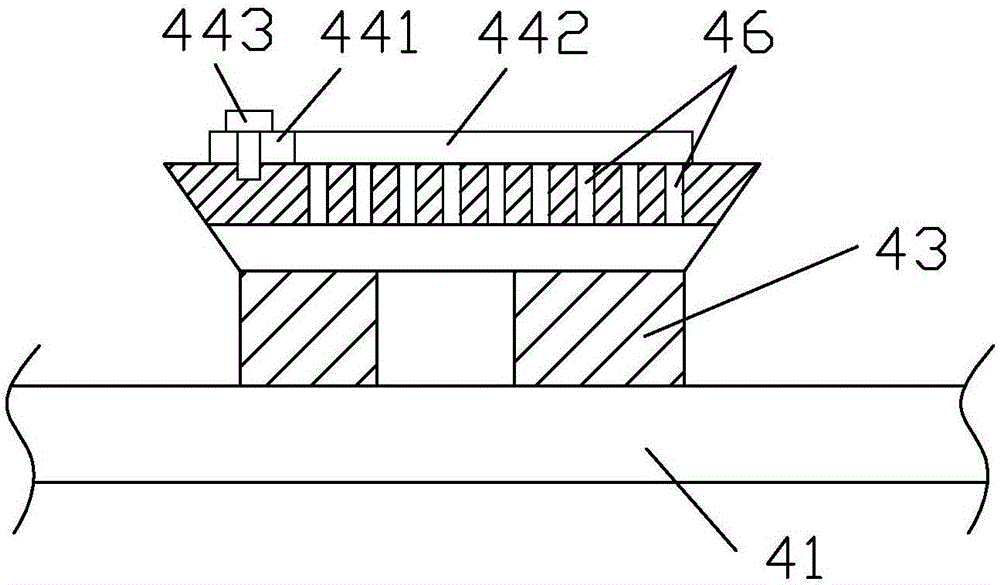

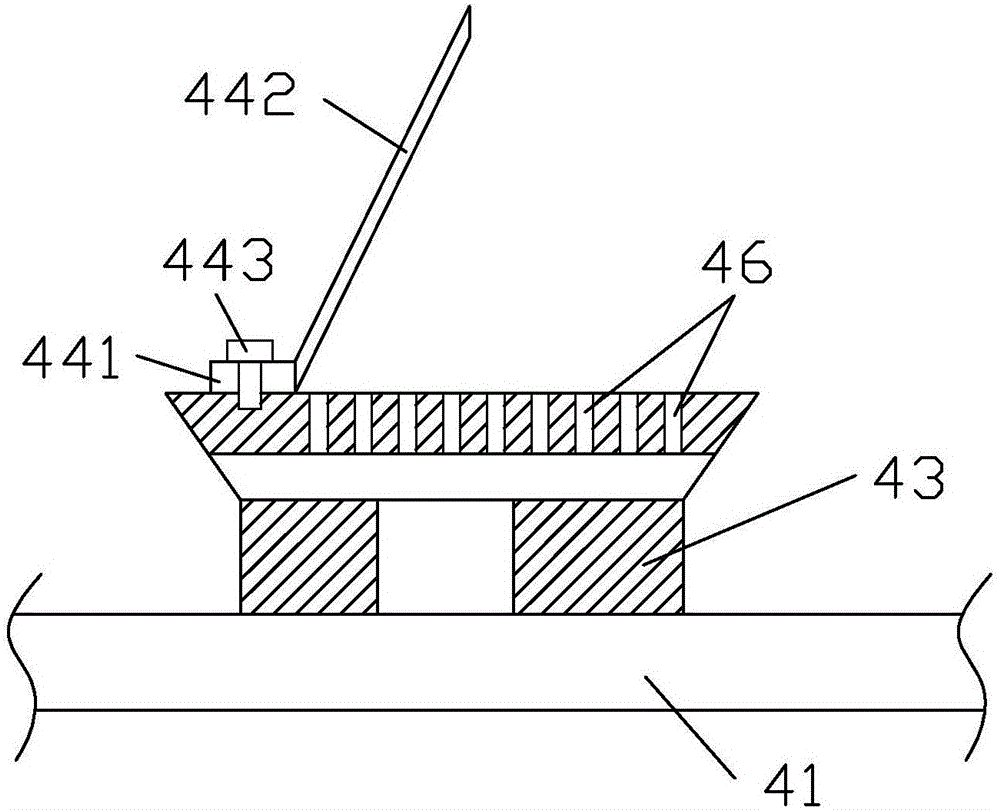

Landscape river aeration device and aeration method

ActiveCN106045077AIncrease surface areaIncrease profitTreatment using aerobic processesWater aerationSolubilityImpeller

The invention mainly discloses a landscape river aeration device and aeration method. The technical scheme is as follows: the device comprises a mounting rack, a gas inlet unit, a main pipeline, an aeration pipe and a rotary impeller, wherein the main pipeline is connected with a gas-liquid mixture and a bubble generator; the gas inlet unit comprises an air inlet pipe, a high-pressure water inlet pipe and an oxygen gas inlet pipe; the aeration pipe is composed of four aeration branch pipes which communicate with each other end to end; a connecting pipe is arranged between the two aeration branch pipes which are symmetrically arranged; the rotary impeller is installed on the connecting pipe; and the aeration branch pipes and connecting pipes are respectively provided with a sprayer on which a diaphragm is covered. The method comprises bubble aeration and surface aeration, has the advantages of simple installation, stable structure, favorable firmness and reasonable design, and is beneficial to implementing large-scale high oxygen solubility of the water body and enhancing the oxygen dissolution efficiency. By arranging the diaphragms, the aeration pores can not be easily blocked, thereby prolonging the service life of the aeration pipe, reducing the cleaning frequency and lowering the maintenance cost.

Owner:杭州市城市土地发展有限公司

Recycling method of papermaking advanced treatment wastewater based on chemical decalcification

InactiveCN103265133AOvercoming processingOvercome costsGeneral water supply conservationMultistage water/sewage treatmentElectrolysisDesalination

The invention discloses a recycling method of papermaking advanced treatment wastewater based on chemical decalcification. The recycling method comprises the following steps of chemical decalcification, filtering, electrolysis, membrane separation (ultra-filtration / MBR) and desalination. By combination of a chemical decalcification technology, an electrochemical technique and a membrane technology, 70-85% of papermaking advanced treatment wastewater can be recycled after being processed. Thus, wastewater emission is reduced; environmental pollution of the wastewater is avoided; waste of water resources is reduced; and the cost of regenerated circulating water is lower than the price of running water. Therefore, the recycling method is economical and reasonable; good economic benefit is generated; water consumption targets of tons of paper and wastewater discharge targets are greatly reduced; and the economic and technical indexes of enterprises are improved.

Owner:BOYING XIAMEN SCI & TECH

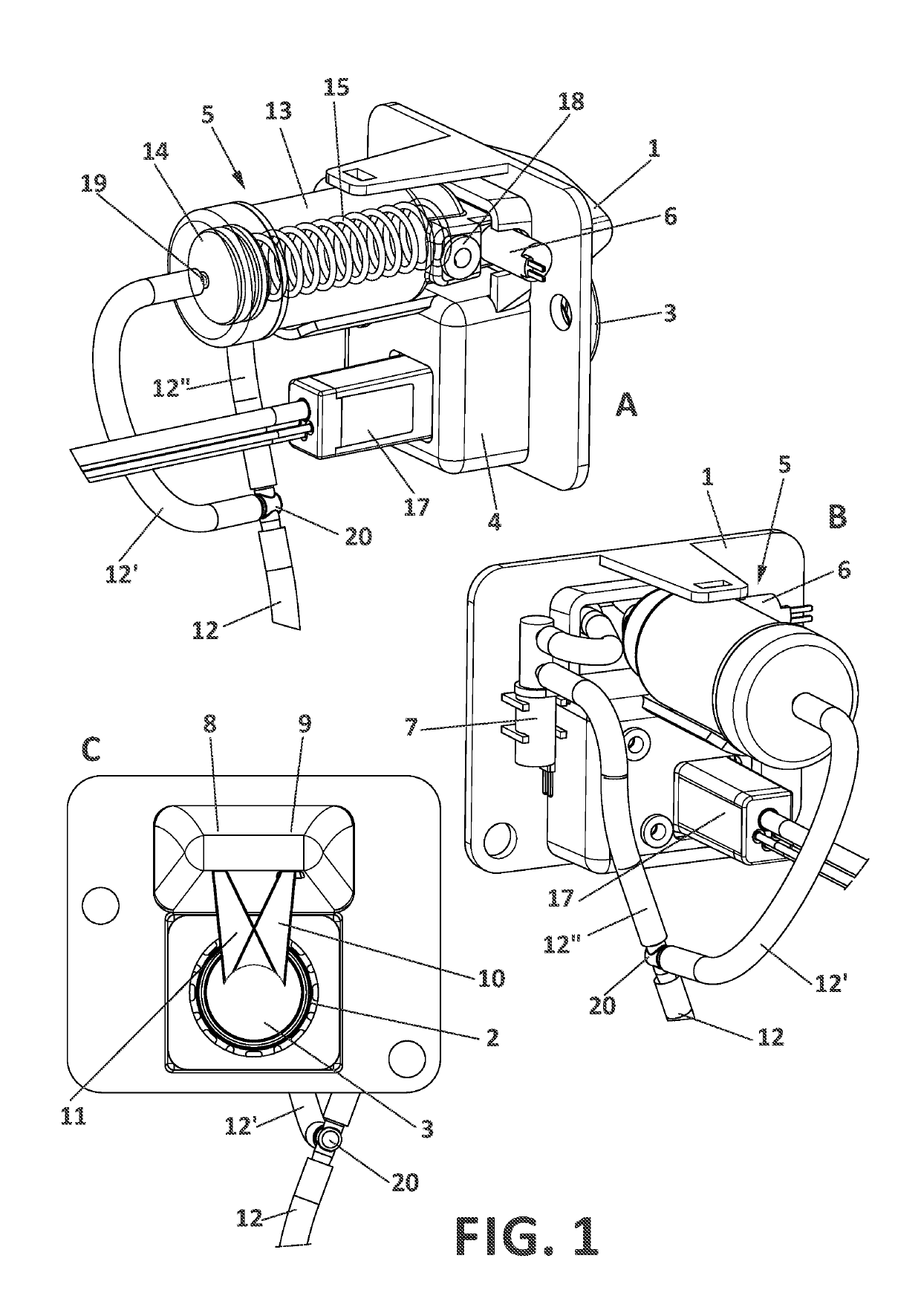

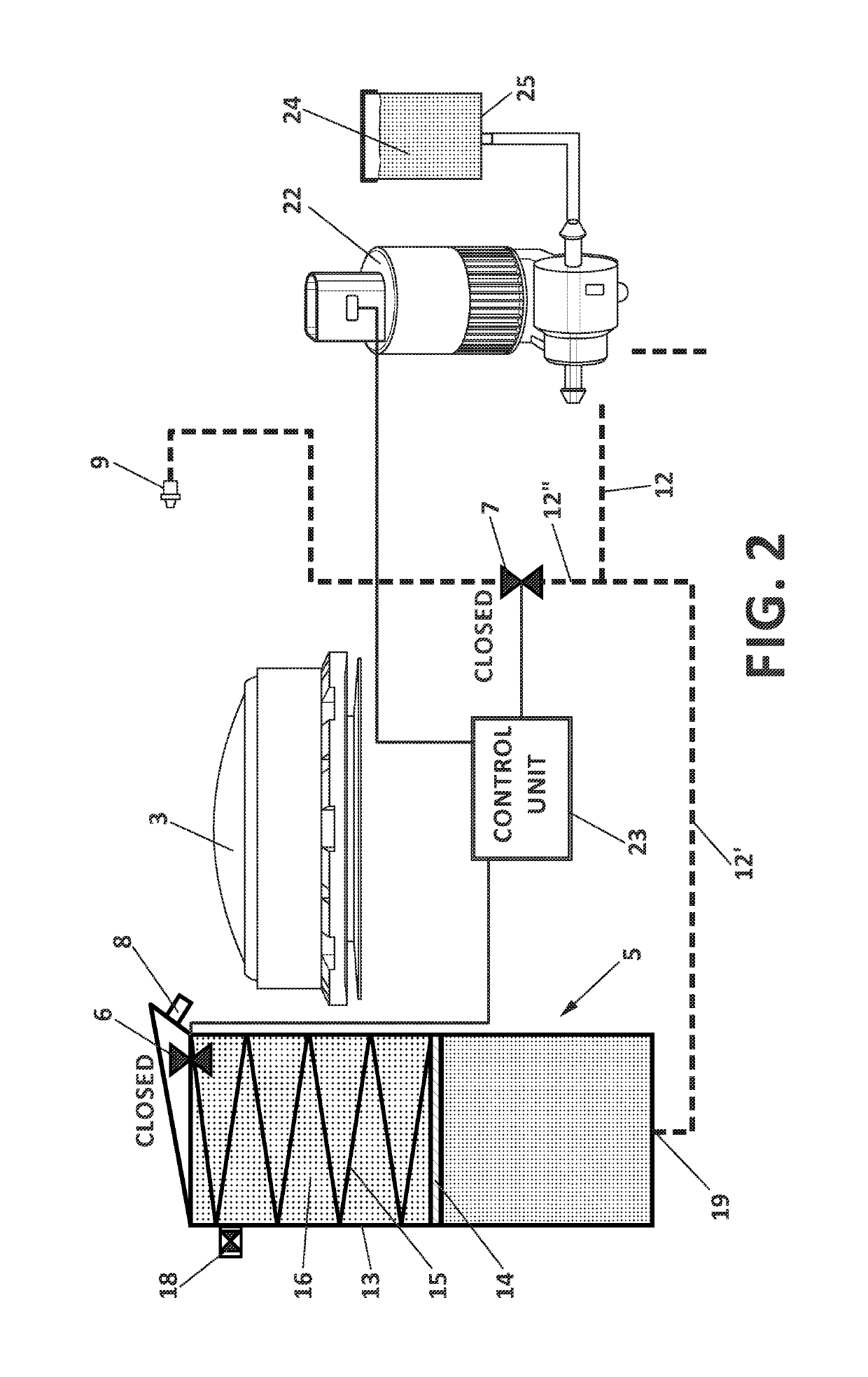

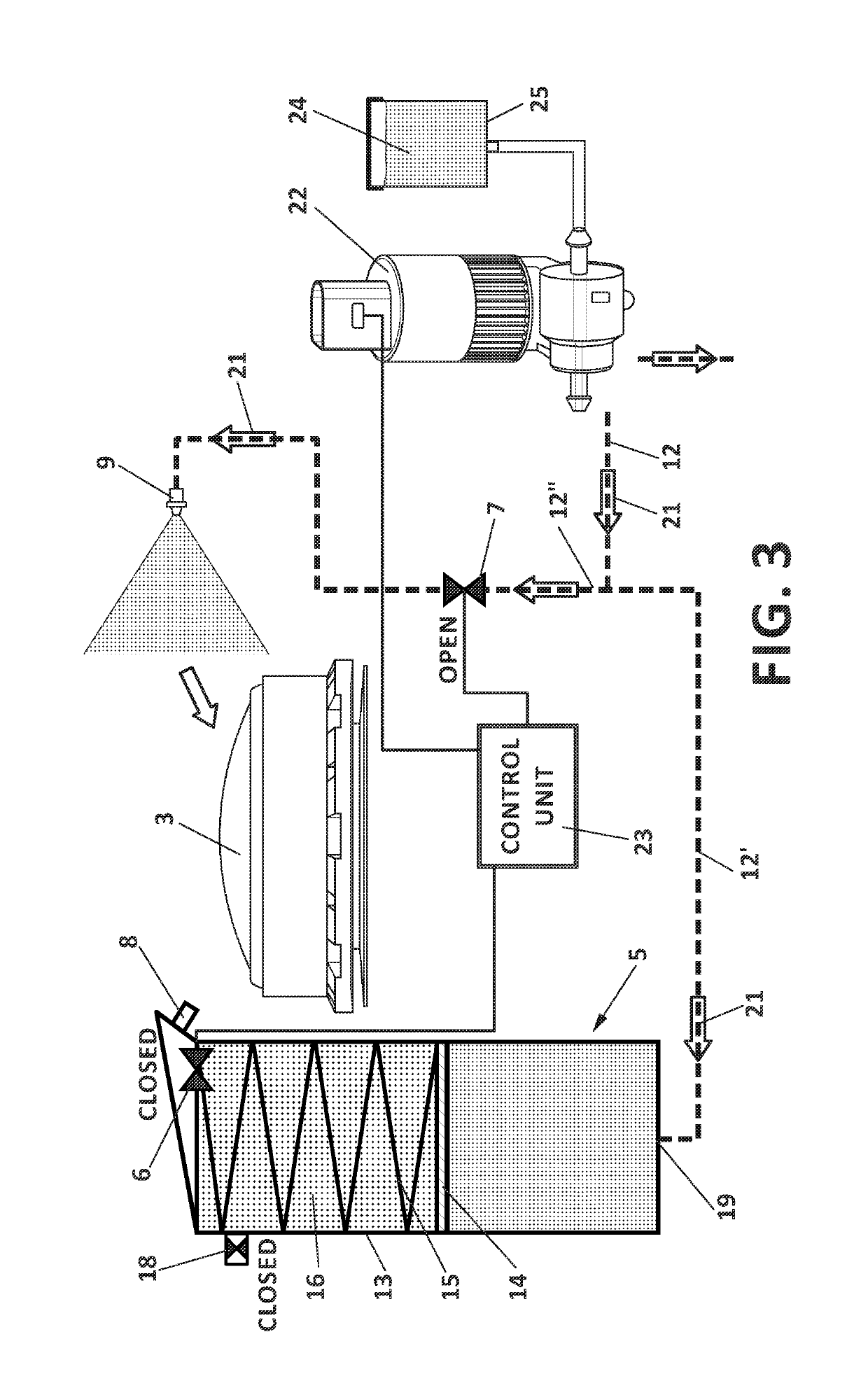

System and method for cleaning a vehicle-mounted optic lens

ActiveUS10286877B2Reduce in quantityCompletely processedVehicle cleaningCleaning using liquidsCamera lensAir pump

The present invention refers a system and a method for automatically cleaning an optic lens mounted on a vehicle, by spraying a washing liquid to remove any type of dirt from the lens such as a clear image or optic signal can be captured anytime, where an air pump is provided including a variable volume compression chamber to pressurize a volume of air, and a washing liquid conduit is communicated with a liquid nozzle and with the air pump, such as the air pump can be operated by the flow of pressurized washing liquid, such as the same flow of pressurized washing liquid is used to clean the optic surface, and to operate the air pump and generate a blast of air to blow off any liquid drop from the optic lens.

Owner:FICO TRANSPAR

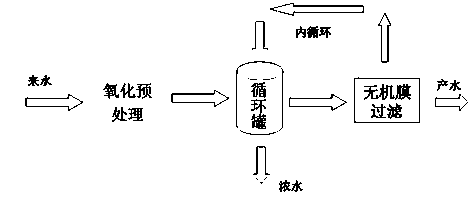

Treatment method for oil field polymer-bearing wastewater

ActiveCN104071919AExtended operating cycleReduce cleaning timesWaste water treatment from quariesMultistage water/sewage treatmentWater qualityCross-flow filtration

Owner:JIANGSU JIUWU HITECH

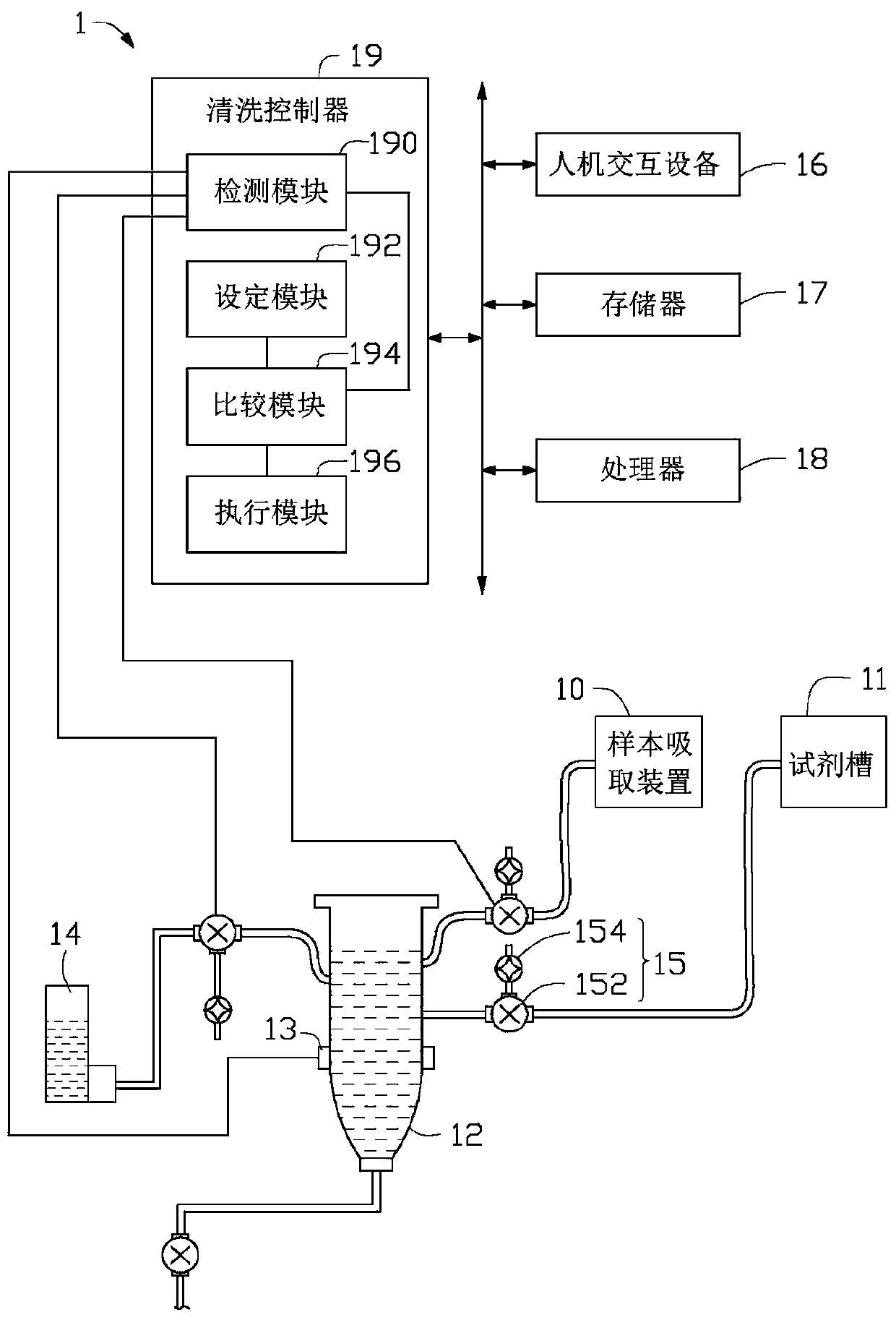

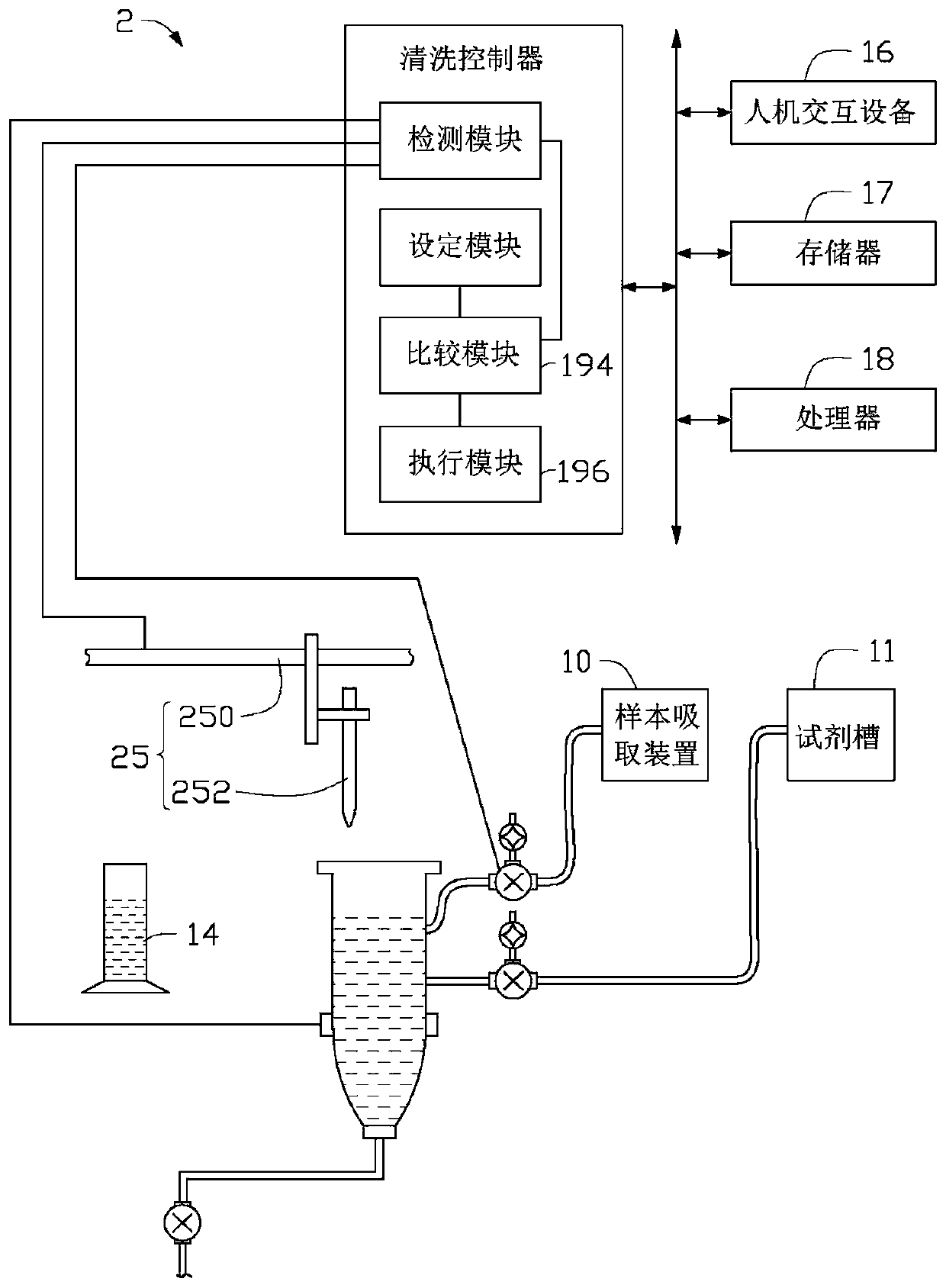

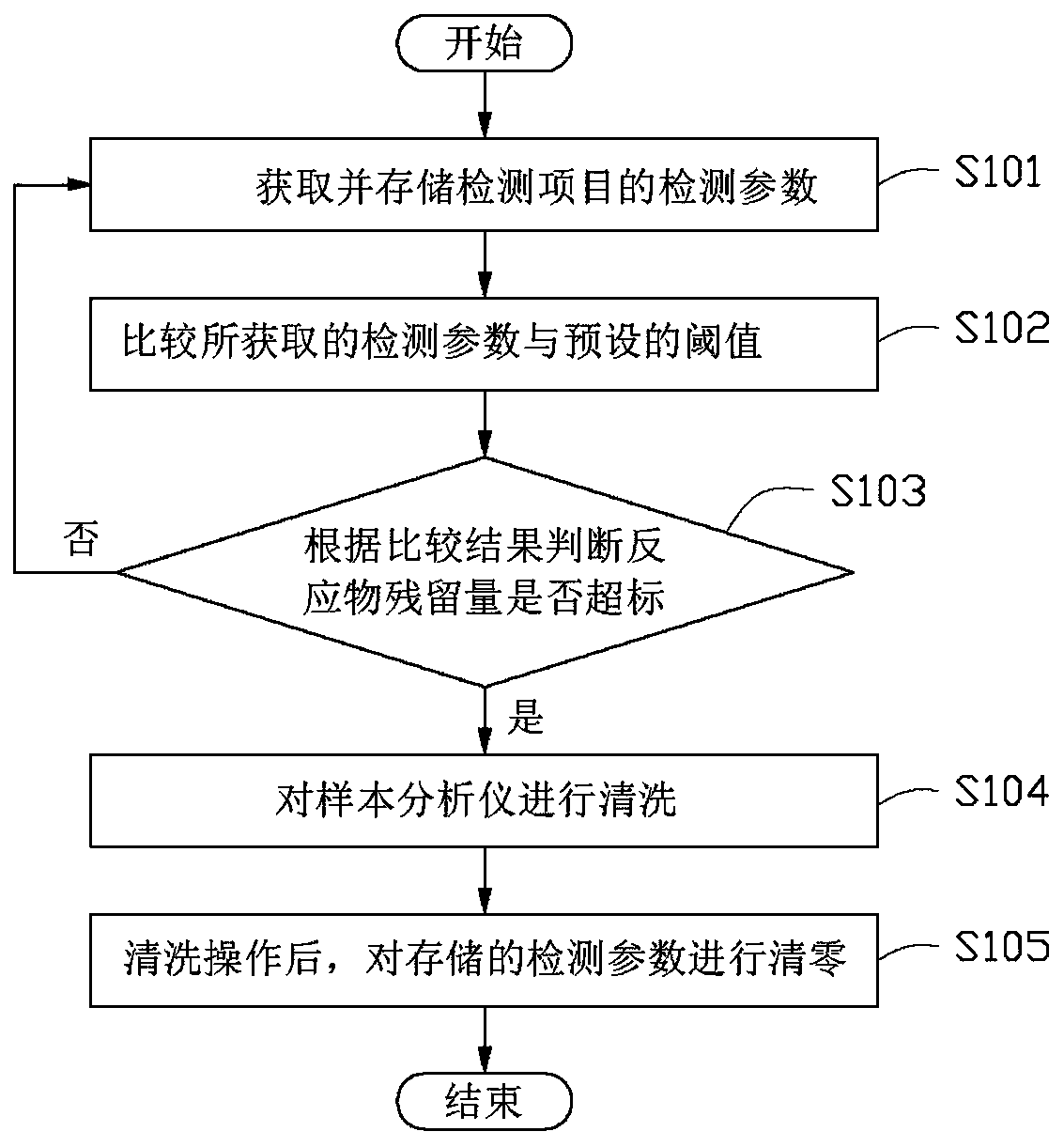

Sample analyzer and cleaning control method thereof

ActiveCN107643410ADoes not affect test resultsReduce cleaning timesMaterial analysisLiquid storage tankEngineering

The present invention relates to a sample analyzer, which comprises a sample suction device, a reaction cell, a detector, a cleaning liquid storage tank, a liquid transmission device and a cleaning controller, wherein the sample suction device sucks and conveys a sample to be tested to the reaction cell so as to be subjected to a measurement reaction, the detector detects the detection items of the reactant generated by the measurement reaction, a cleaning solution is stored in the cleaning liquid storage tank, and the cleaning controller is separately connected to the sample suction device and the detector so as to obtain detection parameters, determines whether the residual reactant exceeds a standard according the detection parameters, and controls the liquid transmission device to suckthe cleaning solution from the cleaning liquid storage tank so as to perform cleaning operation when the residual reactant exceeds the standard. The invention further relates to a cleaning control method of the sample analyzer.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

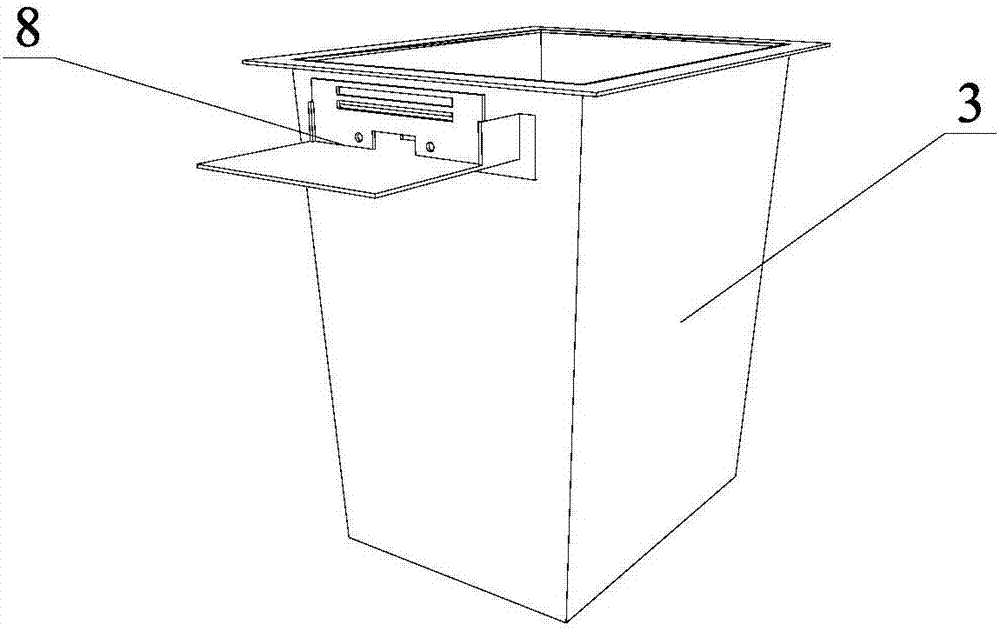

Garbage leachate treating device

InactiveCN103539319ASensitive controlEasy to manageTreatment using aerobic processesMultistage water/sewage treatmentLitterWater quality

The invention belongs to the technical field of waste water treatment and particularly relates to a garbage leachate treating device. By virtue of the garbage leachate treating device, an adsorption-coagulation-nitrosation-anaerobic ammonium oxidation-aerobic treatment-membrane bioreactor combined process can be applied to the treatment of garbage leachate. The garbage leachate treating device comprises the following three parts: a. a pretreatment part which is formed by means of sequentially connecting an adsorption tank, a coagulation tank and a sedimentation tank; b. a denitrification part which is formed by a nitrosation reactor and an anaerobic ammonium oxidation reactor; and c. a main body treatment part which is formed by an aerobiotic tank and a membrane tank. Aiming at the water quality characteristics of the garbage leachate, the garbage leachate treating device organically combines a physicochemical treatment unit and a biological treatment unit; simultaneously the treating device is transformed reasonably and has the advantages of short and compact technological process, high treatment efficiency, low energy consumption, long membrane-component service life, and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Improved method of reclaimed water treatment technology for effectively prolonging service lifetime of film

InactiveCN101274219ASimple processReduce processing stepsSemi-permeable membranesWater/sewage treatment by magnetic/electric fieldsReclaimed waterWater quality

The invention relates to a novel improved process for intermediate water reuse. Aiming at the shortages of traditional process in pre-processing process of film separation technique, the improved process adopts secondary magnetic separation technique and corresponding magnetic filter devices to replace traditional filter process and devices, and adds magnetic seeds and flocculant, which are taken as the pre-processing technique and devices of the film separation technique. Contaminations in wastewater pre-disposed by the improved process can be basically removed, the water quality requirement of film separation water intake is complied with, the miro-filtration, ultra-filtration, nano-filtration and pressure of reverse osmosis film are greatly lightened, the service life of the film is prolonged, and the cost of intermediate water reuse disposal is reduced.

Owner:郭玉同

Water washing process for denim clothes

InactiveCN106968102AReduce storage pressureQuick removalDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsHigh concentrationDenim

The invention provides a water washing process for denim clothes. The water washing process comprises the following steps: performing pretreatment, enzyme washing, ferment washing, water washing, primary dewatering, primary drying, monkey washing, neutralization treatment, softening, secondary dewatering and secondary drying on the denim clothes, and obtaining a water-washed finished product. The water washing process has the beneficial effects that no odor is generated during neutralizing reduction, so that the air quality in a working environment is not affected; by the use of a high-concentration product, the use amount is small, and the warehousing pressure of a factory is relieved; residual manganese ions can be quickly removed, and thetreatment time is shortened; the color of bleaching liquid can be removed; the number of cleaning times is reduced, and the sewage treatment pressure is relieved; the sewage COD is low; the sand level is clear, and the class of the denim clothes is improved.

Owner:FANCHANG QINGXIN WASHING CO LTD

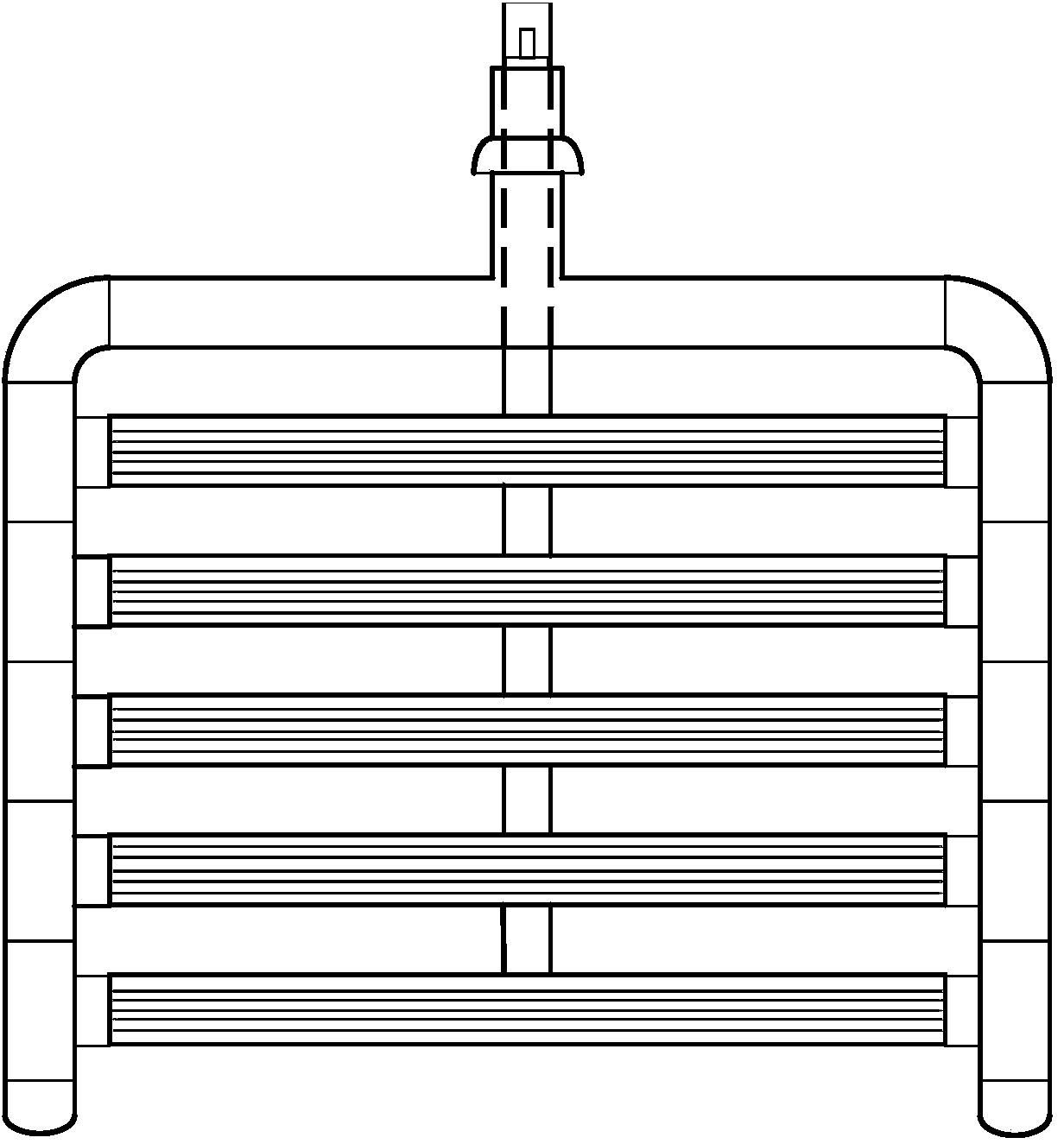

On-water garbage collection ship

InactiveCN104002934AAdjust transmission speed in timeImprove efficiencyWaterborne vesselsSpecial purpose vesselsMarine engineeringShore

The invention discloses an on-water garbage collection ship, comprising a ship body, a transporting device and a storage box, wherein the transporting device is mounted on the front end of the ship body, the storage box is placed at the middle part of the ship body, a conveying frame is connected onto the ship body through a support frame and a support oil cylinder, a roller is fixed on the conveying frame, the roller is sleeved with a conveying belt, and a variable frequency motor is connected with the roller. One end of a compression oil cylinder is mounted in the box close to one side of the front end of the ship body while the other end of the compression oil cylinder is connected with a compression plate, an upper sealing plate is mounted above the box, and the base plate is fixedly mounted below the box. A water groove is arranged below the base plate and communicated to the outside of the ship body. The on-water garbage collection ship can adjust the conveying speed of the conveying belt in time according to the collection quantity of the garbage, which is energy-saving, and can compress the collected garbage on the ship, thus reducing storage space and times for clearing on shore, and improving work efficiency.

Owner:GUIPING DAZHONG SHIP REPAIR MFR YARD

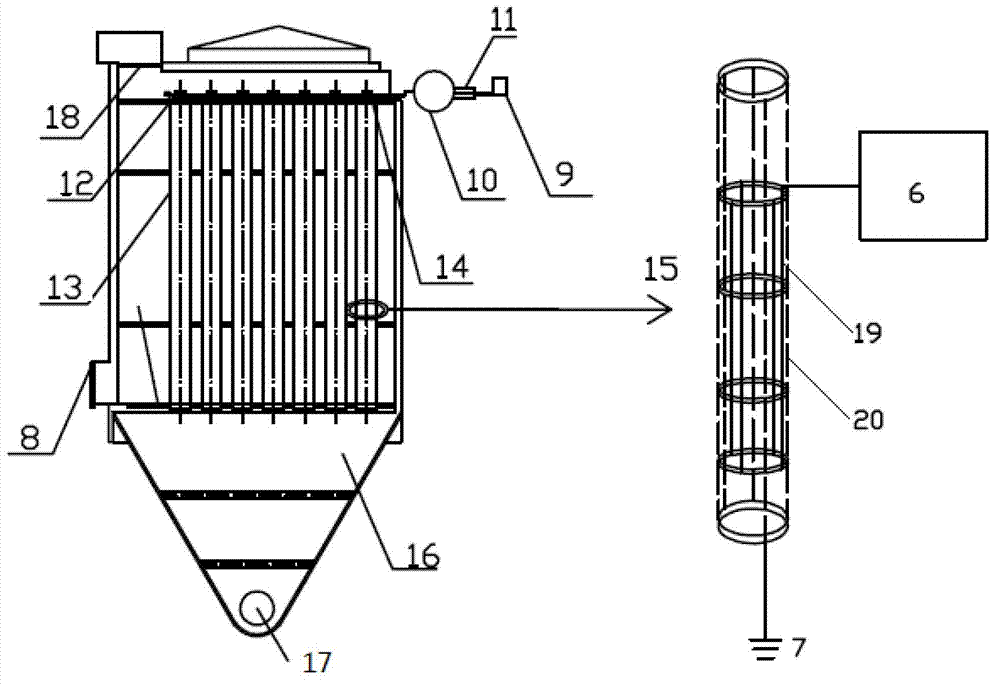

Superfine particulate matter purifying device

ActiveCN102772971AImprove charging effectIncrease the condensation effectCombination devicesAuxillary pretreatmentParticulatesElectrocoagulation

A superfine particulate matter purifying device comprises a gas discharge-electrocoagulation device and a static enhance bag type dedusting integrated device. The gas discharge-electrocoagulation device comprises an air flow inlet (1), a corona wire (2), a gas discharge tube (3), an air flow outlet divergent pipe (5), a direct current power supply (6) and a grounding electrode (7), and the static enhance bag type dedusting integrated device comprises an air inlet (8), a magnetic valve (9), an air pocket (10), a pulse valve (11), a jetting pipe (12), a filtering bag (13), a jetting hole (14), a dust skeleton (15), a dust hopper (16), a spiral dust discharge valve (17), wires (19) and ground wires (20). The air flow inlet is arranged at one end of the gas discharge tube, the other end of the gas discharge tube is connected with the air flow outlet divergent pipe, the dust skeleton is formed by distributing the wires and the ground wires in a vertical direction at intervals, and the superfine particulate matter purifying device is suitable for smoke dust removing and particularly superfine dust purifying devices for particulate matter (PM) below 2.5.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

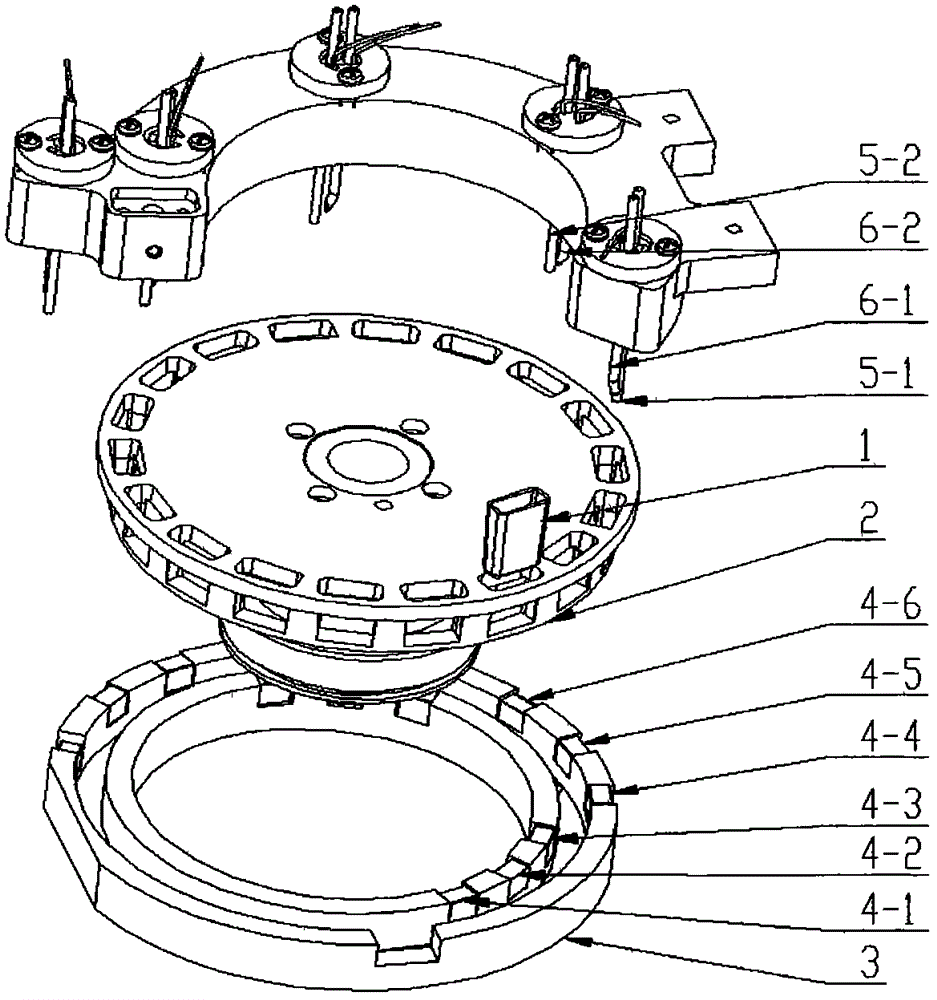

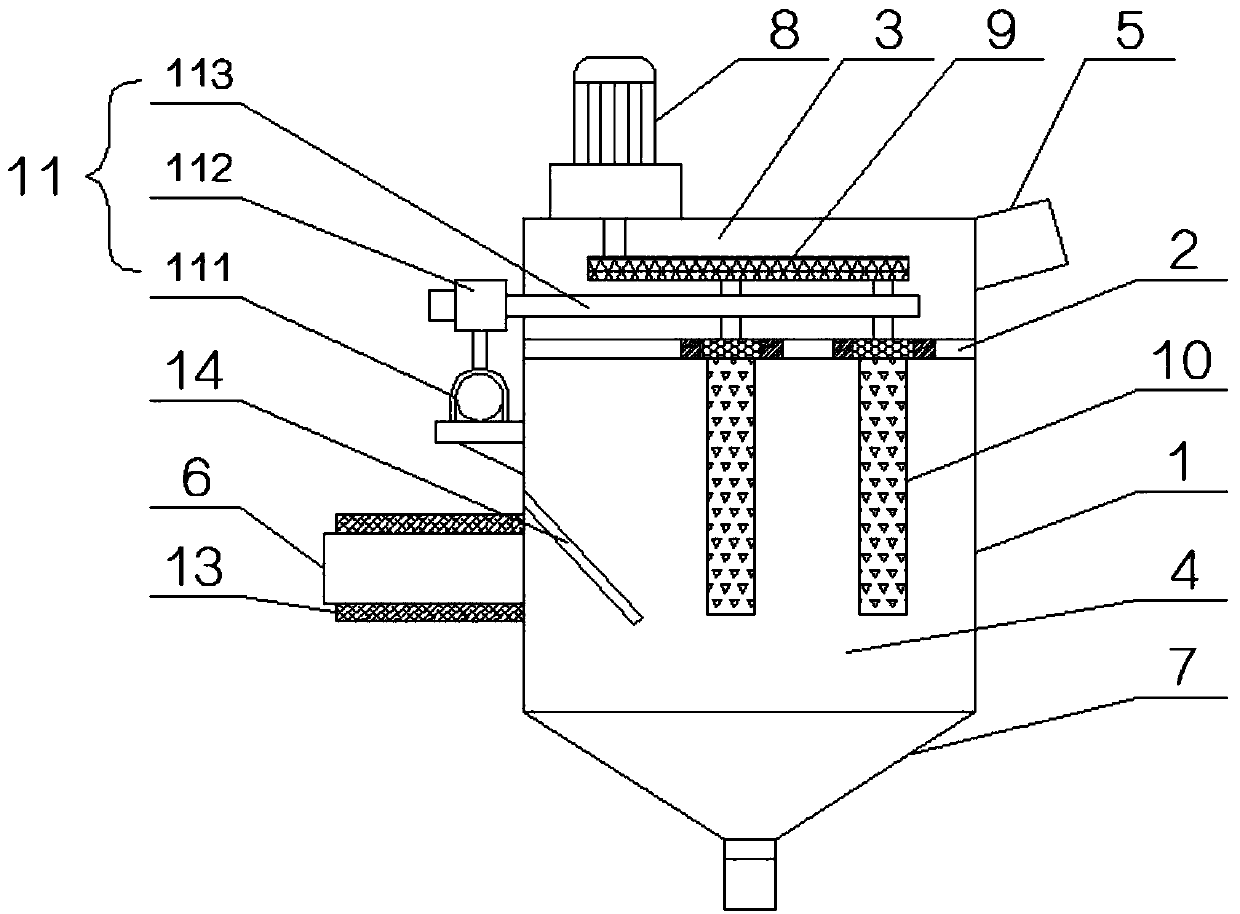

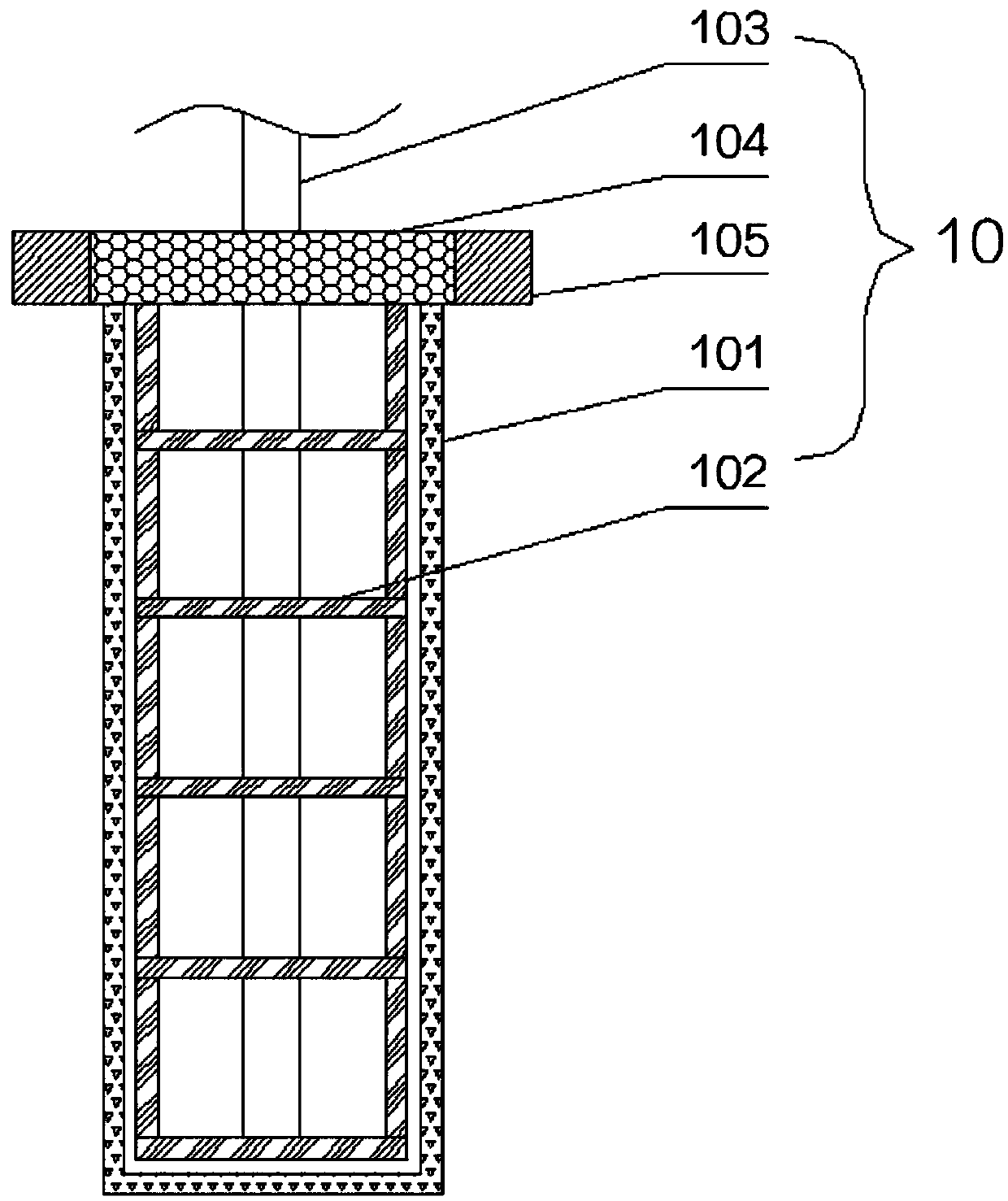

Self-rotation type bag type dust collector

PendingCN108031200AExtended service lifeReduce cleaning timesCombination devicesDispersed particle filtrationEngineeringLow speed

The invention discloses a self-rotation type bag type dust collector, which comprises a tank body and a clapboard arranged in the tank body. The clapboard divides the inner part of the tank body intoan air purification chamber and a dust filtration chamber; the air purification chamber is located above the dust filtration chamber; an air outlet is formed in the air purification chamber; an air inlet is formed in the dust filtration chamber; an ash bucket is arranged on the bottom part of the dust filtration chamber. The self-rotation type bag type dust collector further comprises a power mechanism, a transmission mechanism and a plurality of self-rotation type filter bag components, wherein the power mechanism is arranged on the air purification chamber; the self-rotation type filter bagcomponents are arranged on the clapboard; the power mechanism is connected with the self-rotation type filter bag components through the transmission mechanism. According to the self-rotation type bagtype dust collector provided by the invention, the power mechanism drives a filter bag to self-rotate at low speed, so that the filter bag can be utilized maximally, the nonuniformity of dust accumulated on the surface of the filter bag is avoided, the dust collection efficiency and the service life of the filter bag are improved, the times for deashing the filter bag is reduced, and meanwhile, the rotated filter bag can also throw way partial dust by depending on a centrifugal force.

Owner:江西银杉白水泥股份有限公司

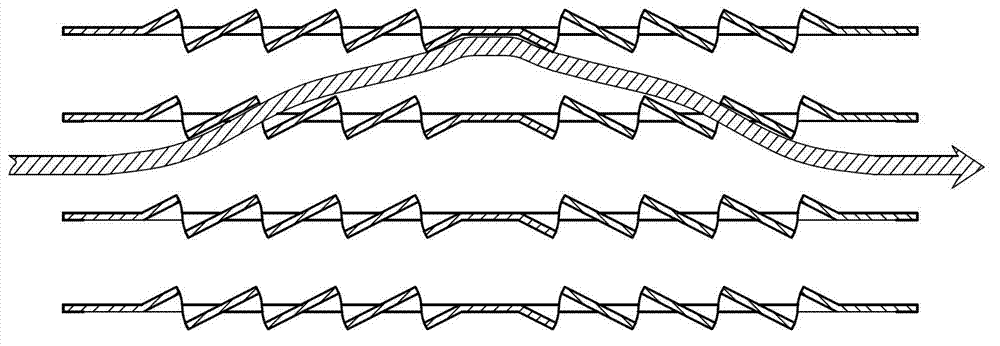

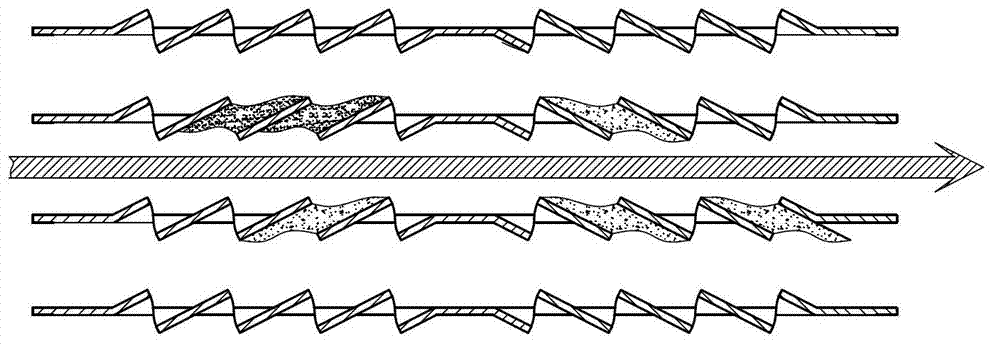

Louver fin and heat exchanger adopting louver fins

ActiveCN102767982APrevent gray cloggingExtended service lifeEvaporators/condensersTubular elementsEngineeringMicro heat exchanger

The invention discloses a louver fin and a heat exchanger adopting the louver fins, in particular to a microchannel heat exchanger, and solves the technical problem that fins of the conventional heat exchanger have high possibility of ash clogging, resulting in lowered performances of the heat exchanger. The louver fin provided by the invention includes a base sheet and louvered fins formed on the base sheet, wherein an air flow passage is formed between the adjacent louvered fins; and flow guide projections are arranged on the base sheet, and correspond to air inlets of the air flow passages. The louver fin provided by the invention can be applied to various heat exchangers and microchannel heat exchangers in the field of household / commercial air conditioners, can remarkably improve the ash accumulation of the air side of the heat exchanger, and improves the heat exchange performance of heat exchangers, particularly the microchannel heat exchangers.

Owner:珠海盾安热工科技有限公司

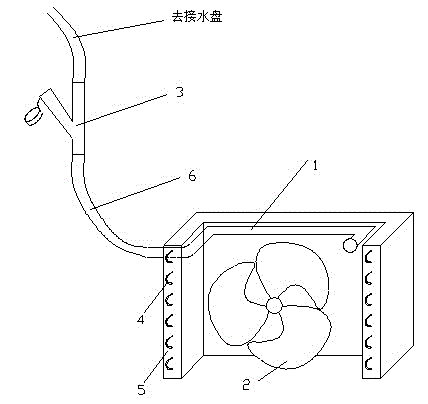

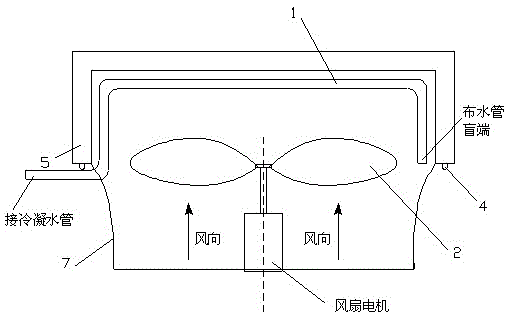

Cleaning and energy-saving device for househould air conditioner outer unit condenser

ActiveCN102878624ASimple structureEasy to operateLighting and heating apparatusAir conditioning systemsWater dischargeEvaporation

A cleaning and energy-saving device for a househould air conditioner outer unit condenser comprises a condenser pipe in an air conditioner outer unit, wherein a blowing-type axial flow fan is arranged on the inner side of the condenser pipe, a condensed water distribution pipe is arranged at the upper part of the space between the condenser pipe and a fan, one end of the condensed water distribution pipe is a blind pipe, the other end of the condensed water distribution pipe is connected with an air conditioner condensed water discharge pipe, a three-way pipe is connected onto an indoor pipe section of the condensed water discharge pipe, the condensed water discharge pipe is communicated with a water receiving tray, atomization spray holes which are uniformly distributed are formed in the lower positions of the water distribution pipe, which are close to a condenser pipe side, so that the condensed water is uniformly sprayed onto the heat exchange fins of the condenser pipe, and the gasification latent heat which is generated by water evaporation is utilized for enhancing heat exchange. When the air conditioner normally works, the condensed water can be guided to the water distribution pipe and is sprayed onto the heat exchange fins for enhancing heat exchange; and when the condenser water is cleaned, and a close cover of an opening end of the three-way pipe is opened to be filled with clean water or is connected with tap water, and is matched with the fan for cleaning the condenser pipe. The device has the characteristics of simplicity in structure, convenience in use, low cost and convenience in popularization.

Owner:DONGYING JINYILAI PETROLEUM MACHINERY

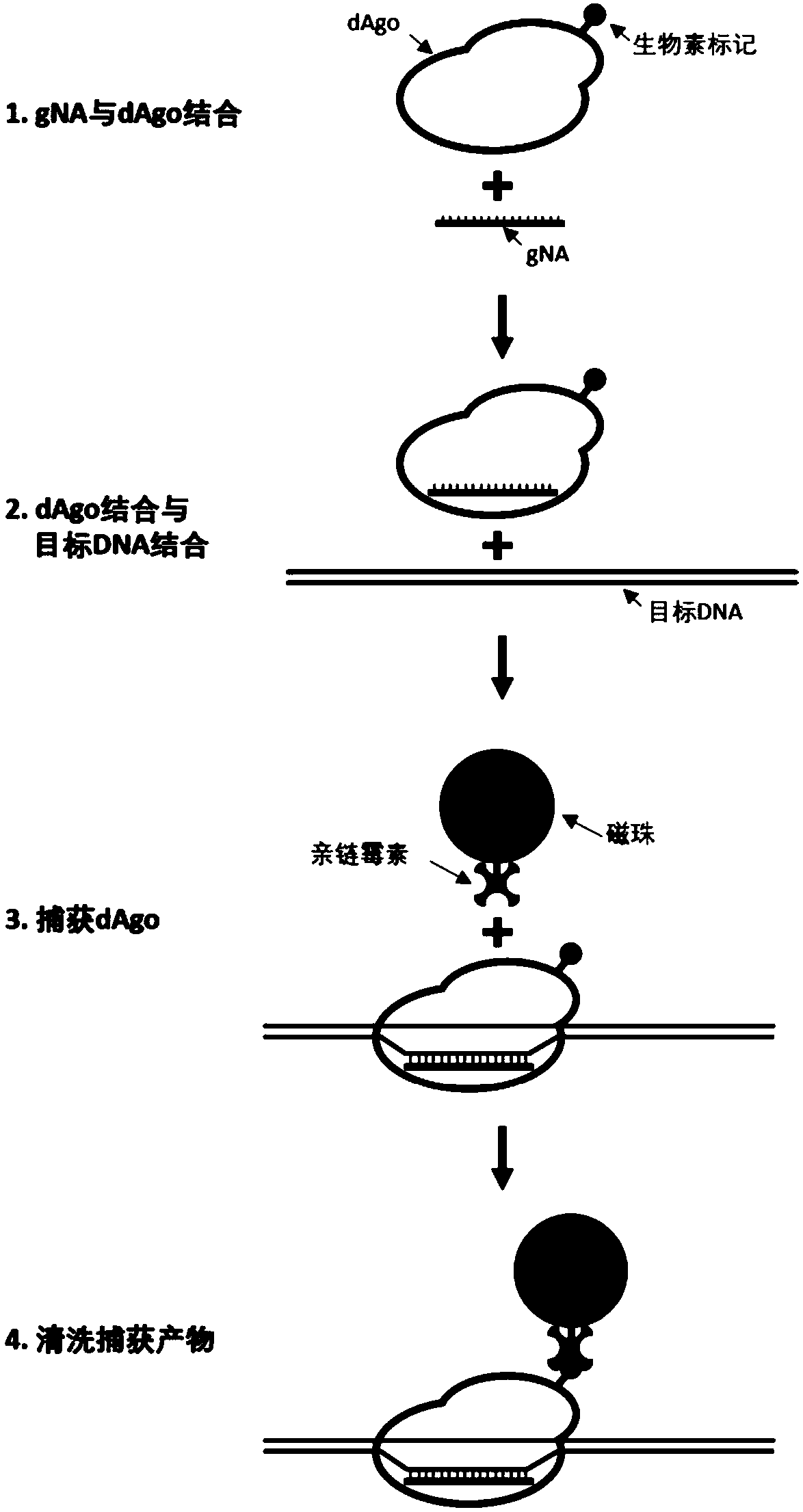

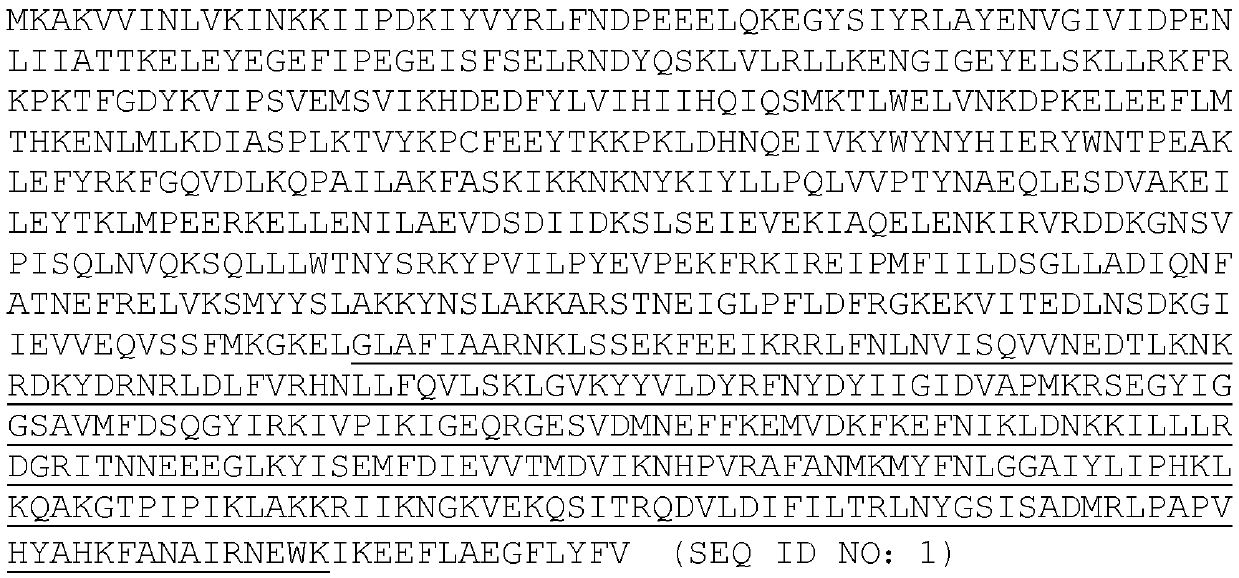

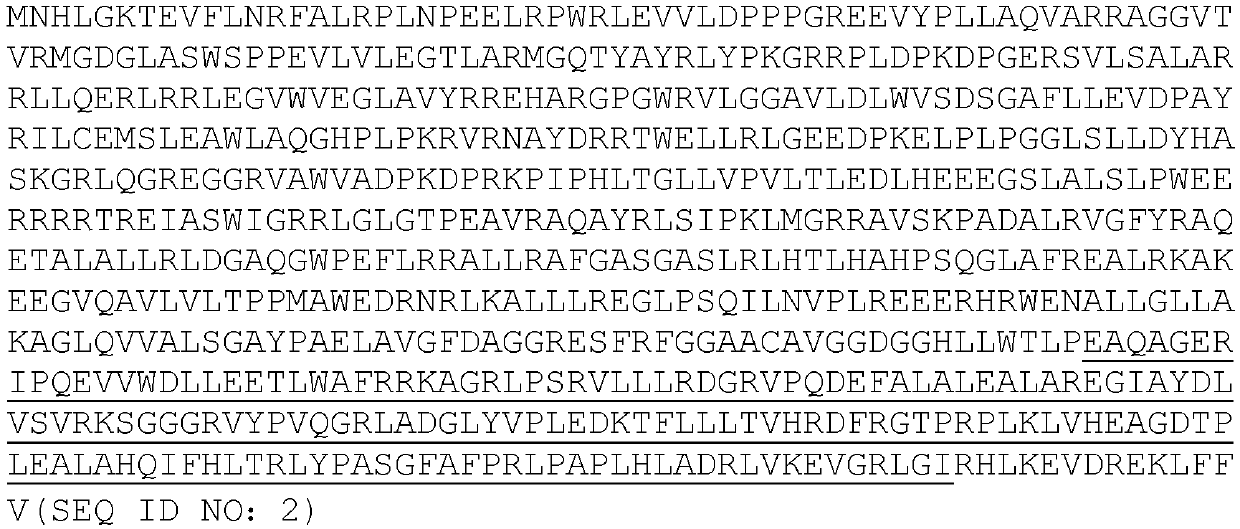

Argonaute protein mutant and application thereof

ActiveCN110229799APromote enrichmentReduce lossesFusion with RNA-binding domainNucleotide librariesTernary complexMutant

The present invention relates to an Argonaute protein mutant which lacks DNA cleavage activity, but has DNA binding activity. The mutation of the mutant is located in a PIWI domain. The invention alsorelates to application of the protein mutant particularly in the enrichment of target DNA and in the construction of a sequencing library. Therefore, the present invention also relates to a method for enriching the target DNA. The method comprises the steps of: (a) designing a leader sequence for a specific sequence in the target DNA; (b) combining the mutant, the leader sequence and the target DNA according to the present invention to obtain a mutant-leader sequence-target DNA ternary complex; (c) capturing the mutant-leader sequence-target DNA ternary complex through a capture medium; and (d) isolating the target DNA from the captured mutant-leader sequence-target DNA ternary complex to obtain enriched target DNA.

Owner:BERRYGENOMICS CO LTD

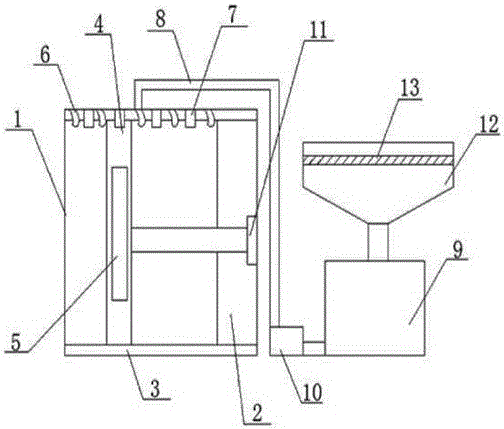

Automatic solar panel cleaning device for photovoltaic plant

InactiveCN106583301AReduce cleaning timesImprove cleaning efficiencyDrying gas arrangementsPhotovoltaicsHydraulic cylinderPhotovoltaic power station

The invention discloses an automatic solar panel cleaning device for a photovoltaic plant. The automatic solar panel cleaning device comprises a solar panel and a water storage box; two sliding rails are arranged at the upper end and the lower end of the front side of the solar panel; a cleaning plate is arranged between the two sliding rails; a brush is arranged on the lower side of the cleaning plate; a dust suction device is arranged on the upper side of the cleaning plate; a mounting plate is arranged on the right side of the solar panel and is provided with a hydraulic cylinder; the left end of the hydraulic cylinder is connected with the right side of the cleaning plate; a plurality of nozzles and air blowers are uniformly arranged on the front side of the sling rail at the upper end; the upper end of the water storage box is connected with a water collection bucket which is internally provided with a filter screen; the water storage box is connected with a water pump through a water passing pipe; and the water outlet end of the water pump is connected with the nozzles through the water passing pipe separately. The automatic solar panel cleaning device is simple in structure, convenient to use, high in cleaning efficiency and good in cleaning effect and prolongs the service life of the solar panel.

Owner:ZHEJIANG DIYE AGRI EQUIP

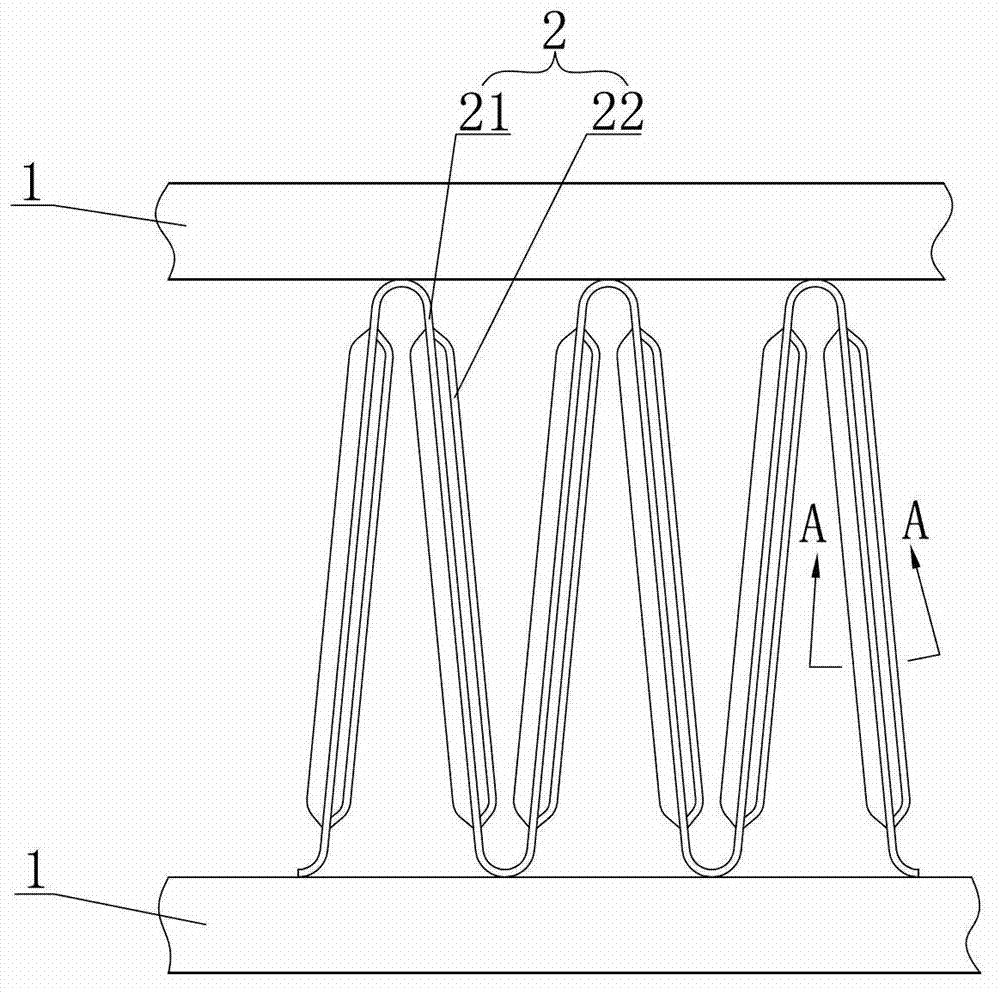

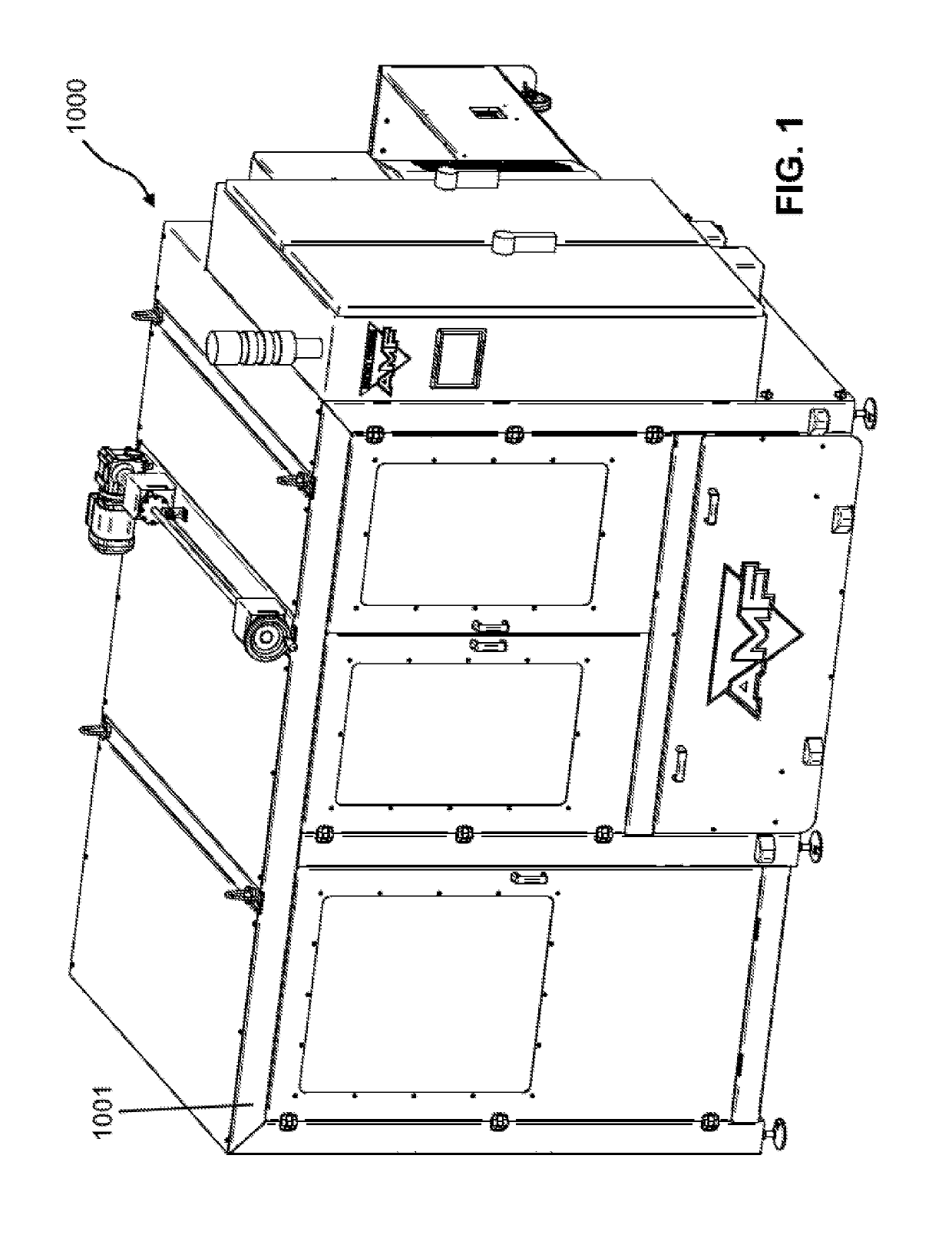

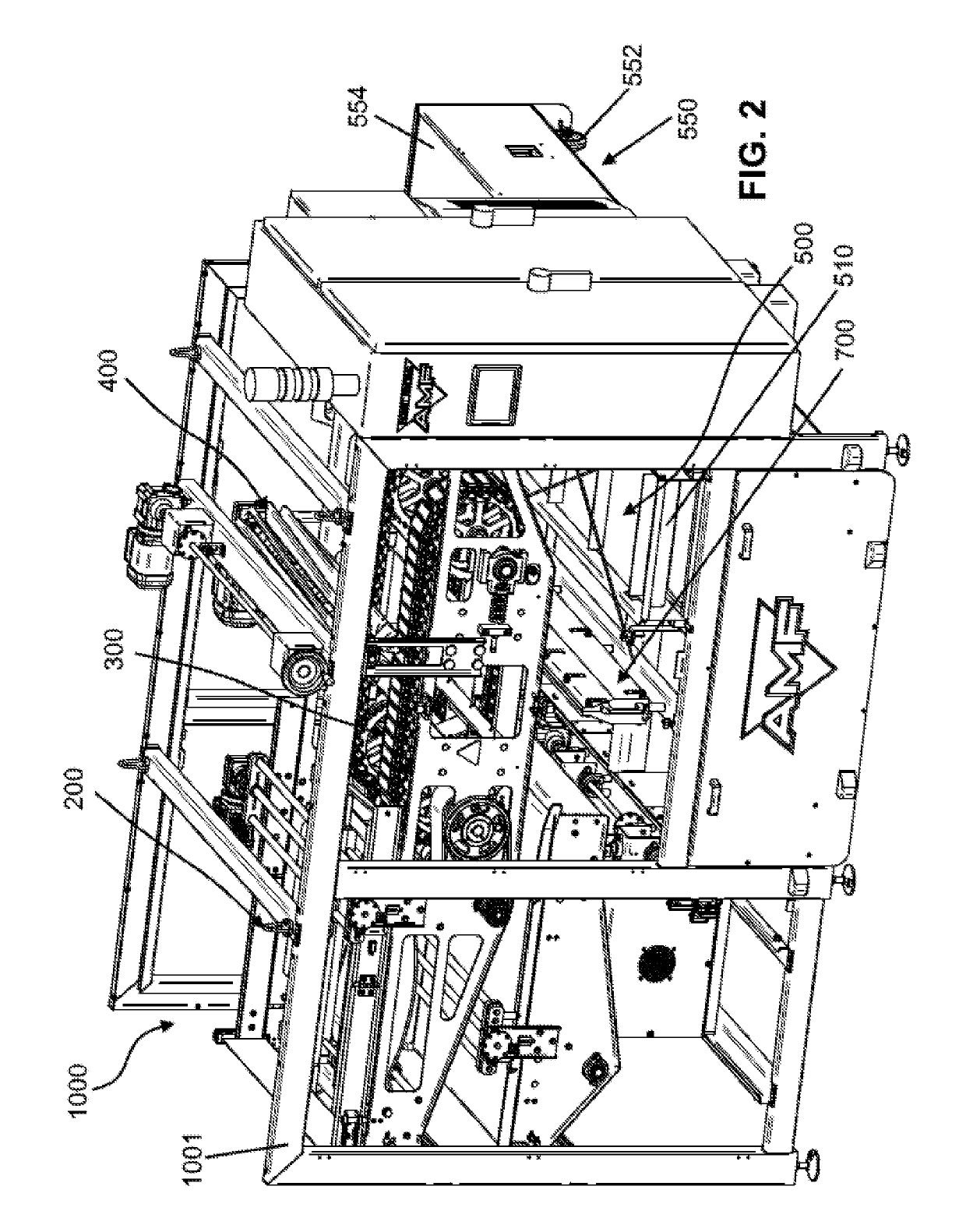

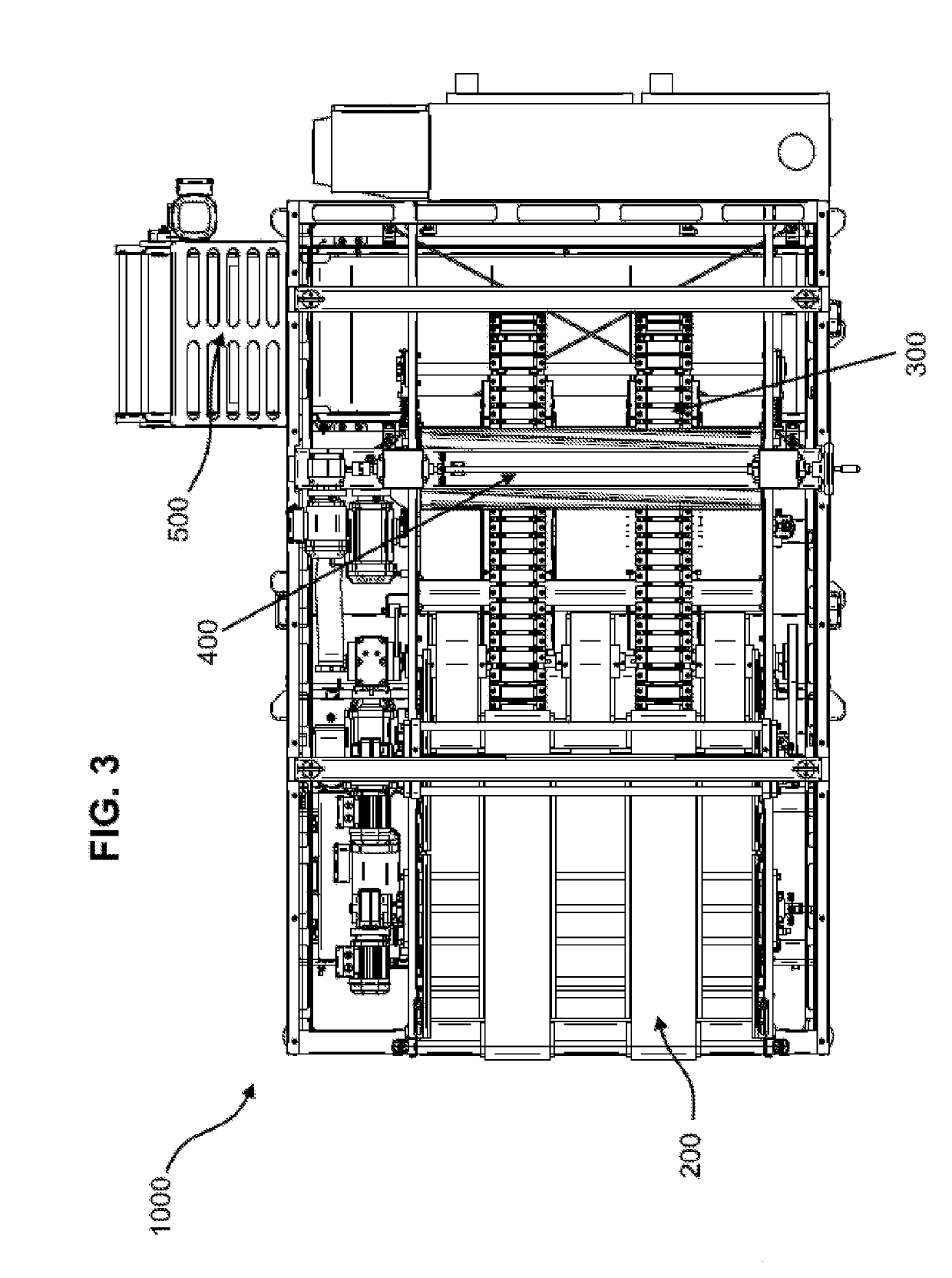

Pan Cleaner System and Method

ActiveUS20190090718A1Less cleaningReduce delaysConveyorsWashing processesWaste managementProcess engineering

The present invention relates to a pan cleaner system. The pan cleaner system comprises a main frame adapted to house a supply system, an inverting system and a cleaning system. The supply system, the inverting system and the cleaning system are configured to form a synchronized continuous functional line beginning by the supply system receiving a pan to be cleaned and ending by the cleaning system releasing a clean pan. The supply system comprises a first conveyor adapted to guide the pans towards the inverting and the cleaning systems. In one embodiment, the inverting system comprises a second conveyor adapted to magnetically hold the pans during the transport and the cleaning process. The pan cleaner system further comprises a releasing system adapted to release the pans from the magnetic conveyor once the cleaning process has been completed.

Owner:AMF AUTOMATION TECH CO OF CANADA

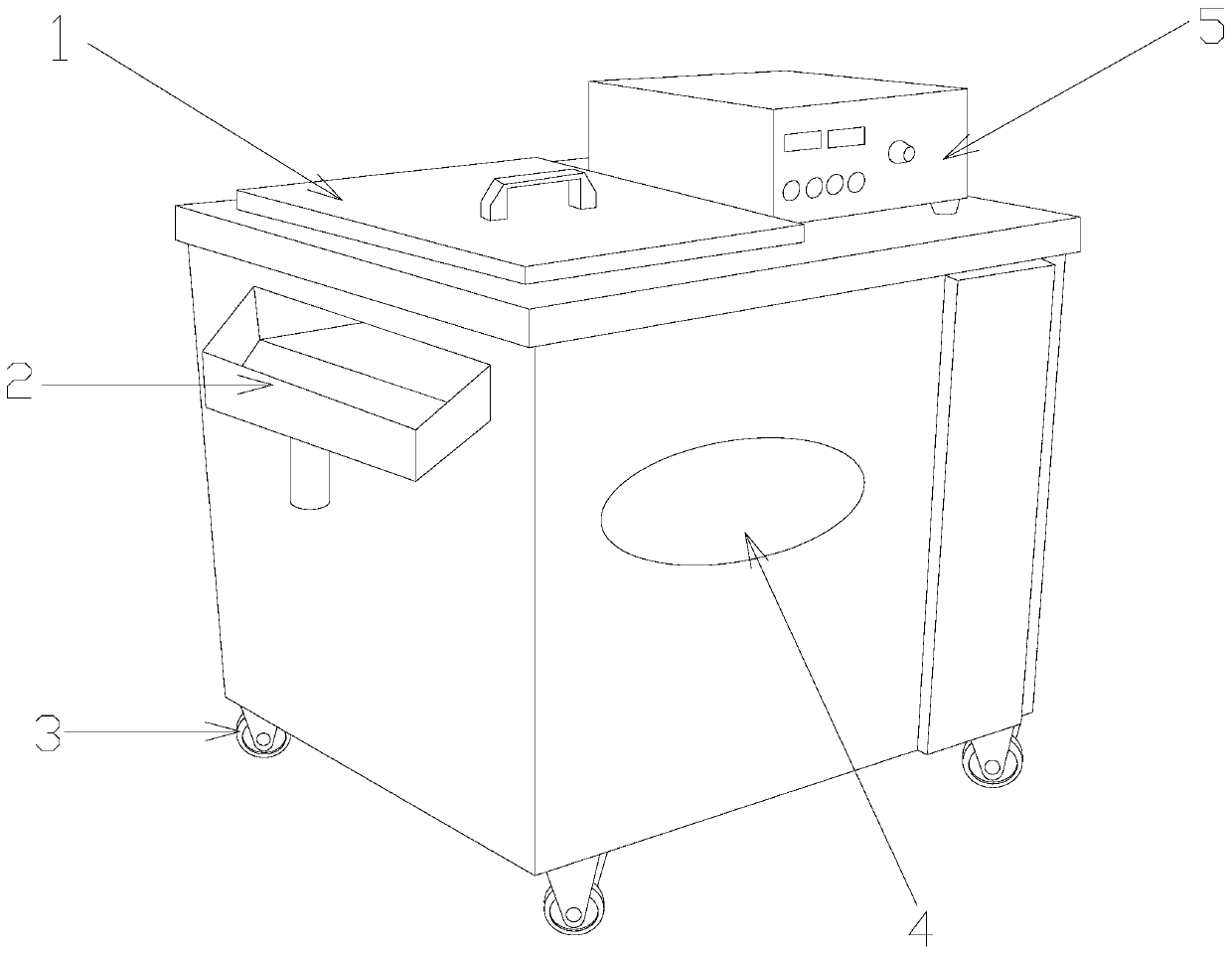

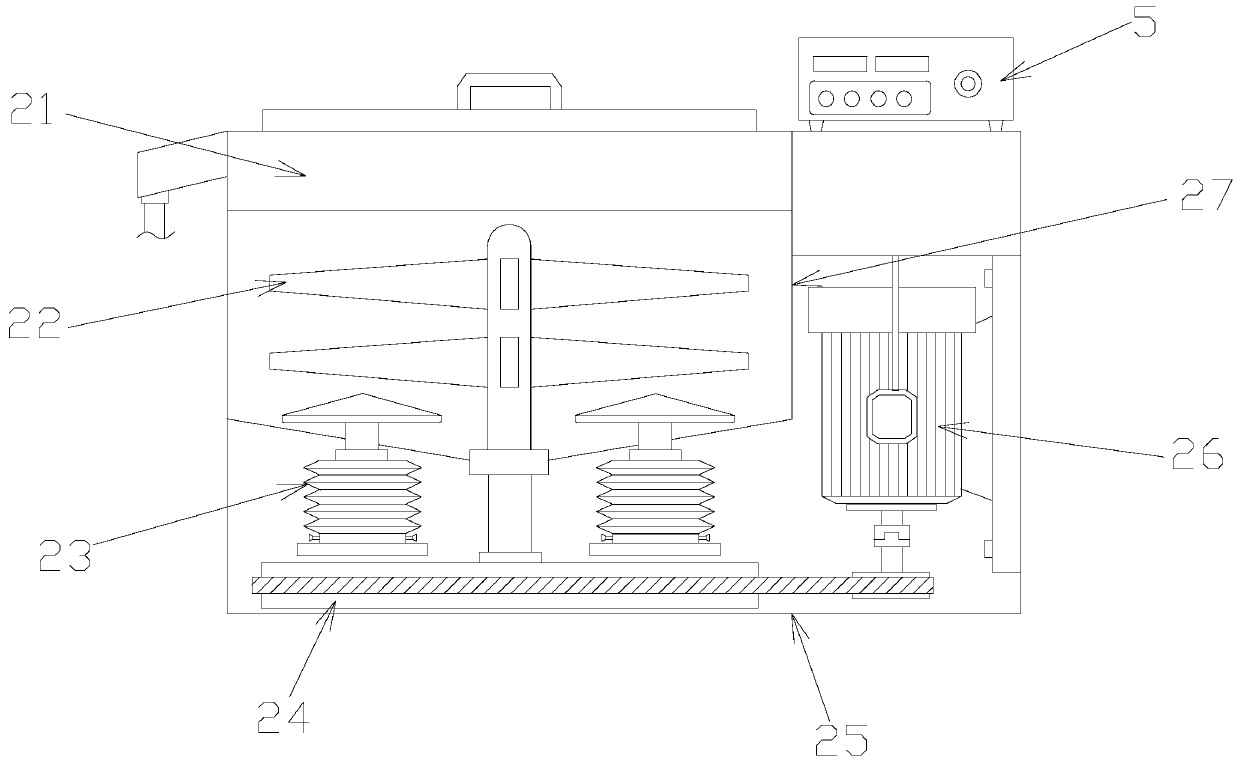

Bearing cleaning machine using bubble enhancement reaction

ActiveCN109865708APromote sheddingImprove cleaning effectCleaning using liquidsMachine controlAir bubble

The invention discloses a bearing cleaning machine using a bubble enhancement reaction. The bearing cleaning machine structurally comprises a splashing proof sealing cover, a cleaning machine main body, universal moving wheels, a product nameplate and a cleaning machine control machine. The bearing cleaning machine is combined with a bubble generating structure through a grease collecting structure, when a bearing is put into the cleaning machine to be cleaned, bubbles can be generated in the cleaning machine through the bubble generating structure, the overturning effect is generated throughthe bubbles and a cleaning solution, thus balls in the bearing rotates, and thus attachments on the surface of the bearing are dropped off; meanwhile the grease floating at the top of the cleaning solution can be effectively collected to be treated centrally, the situation that the grease at the top of the cleaning solution is attached on the surface of the bearing after being sunk when water is discharged from the cleaning machine, and the cleaning effect of the cleaning machine is effectively improved.

Owner:莆田市松尚家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com