Patents

Literature

641 results about "Magnetic filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

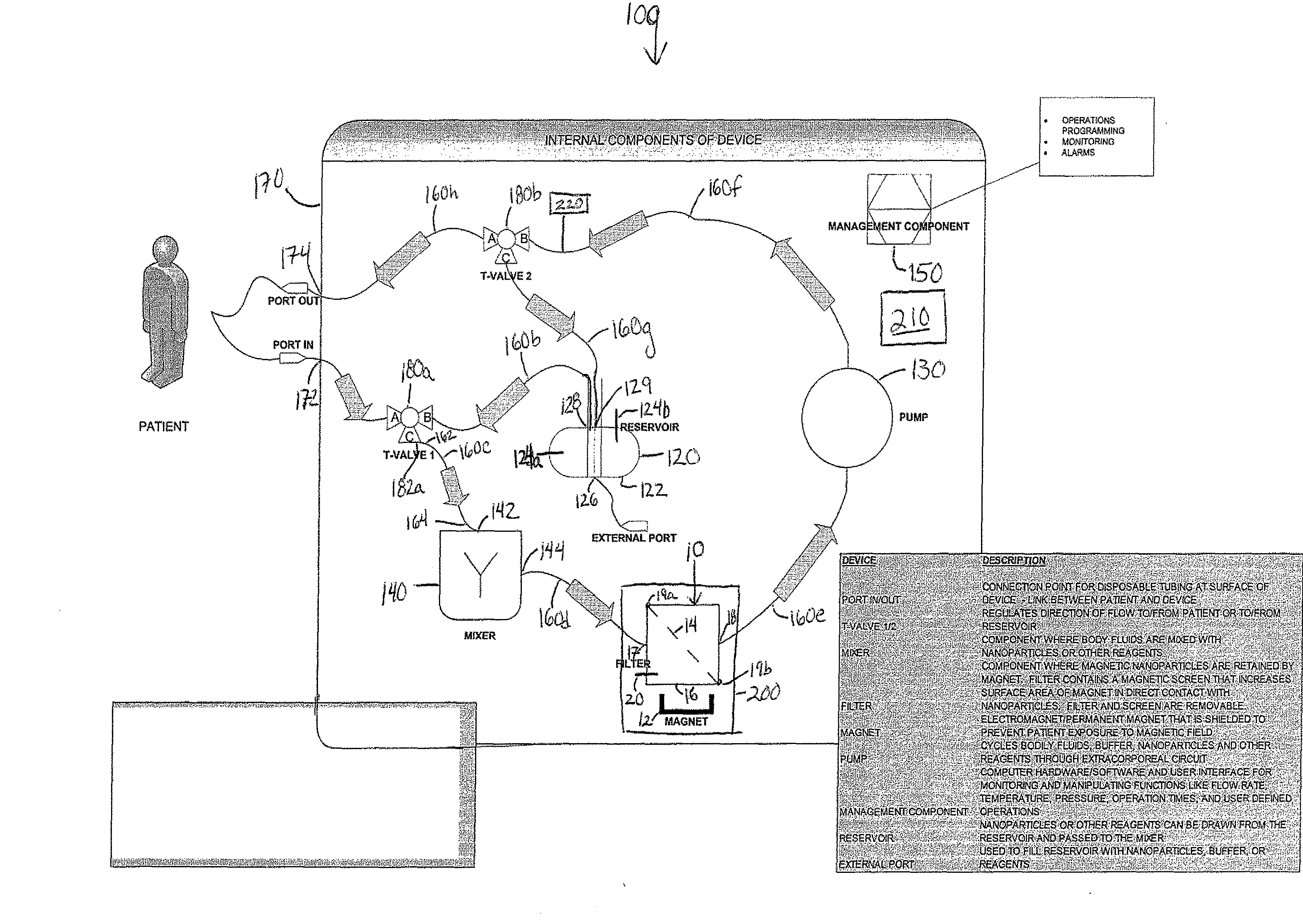

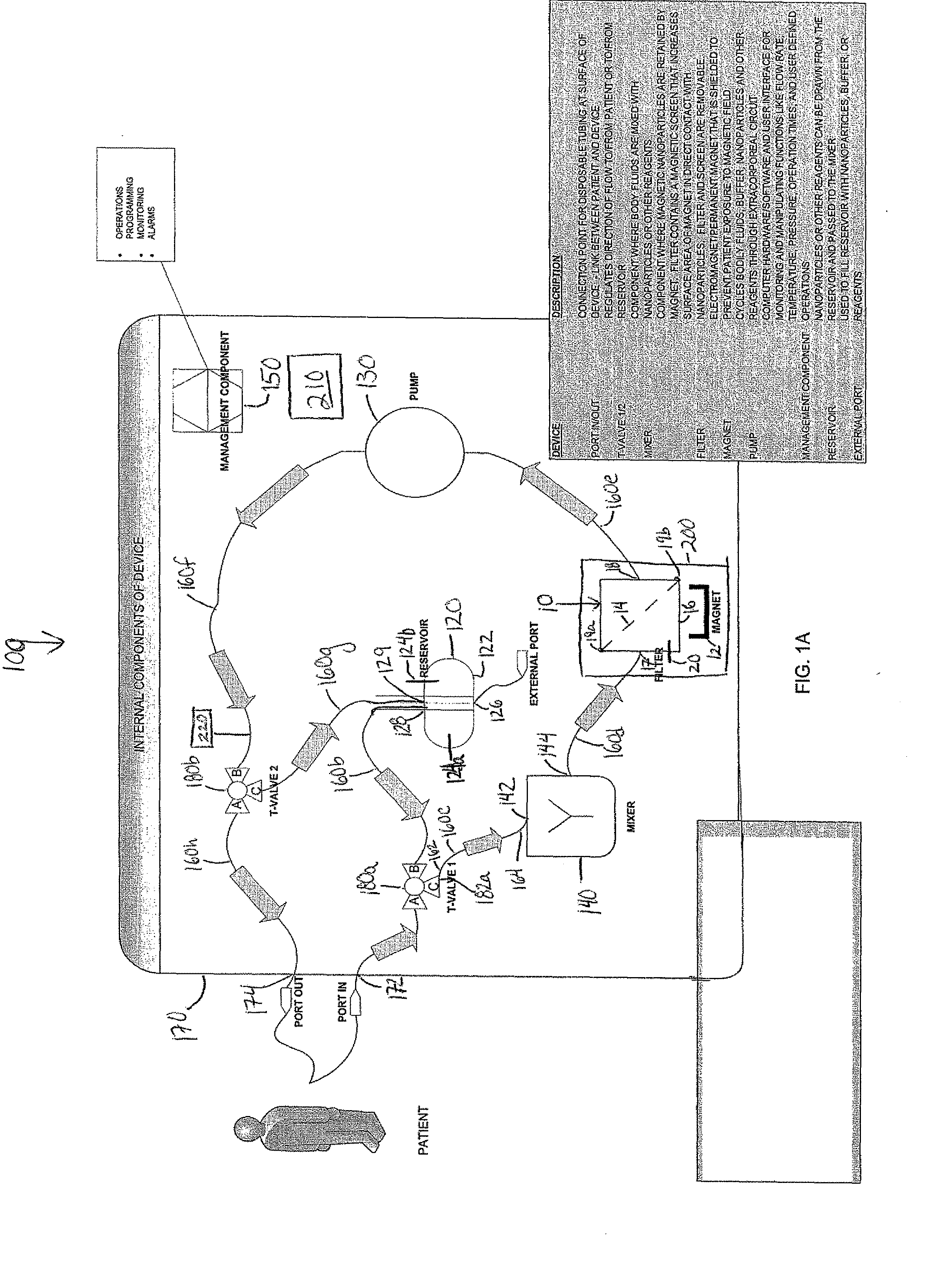

Device and method of using superparamagnetic nanoparticles in treatment and removal of cells

InactiveUS20110098623A1Simple methodAntibacterial agentsOther blood circulation devicesCancer cellFunctionalized nanoparticles

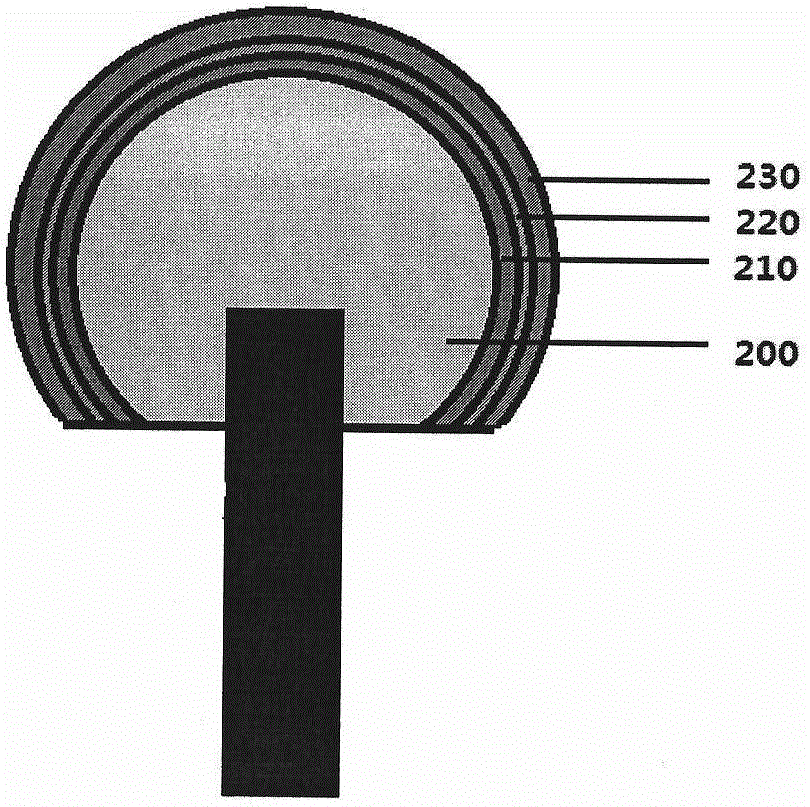

Methods and devices for selectively removing from a subject a target cell, pathogen, or virus expressing a binding partner on its surface are presented. In one embodiment, the device contains an excorporeal circuit, which includes, at least, a magnetic filter comprising a magnet and a removable, magnetizable substrate capable of capturing magnetic nanomaterials; and a pump in fluid communication with the magnetic filter, wherein the pump moves fluid through the excorporeal circuit. The magnet is capable of generating a magnetic field sufficient to capture magnetic nanomaterials in the magnetic field. In a preferred embodiment, the target cells are cancer cells and / or cells infected with pathogenic agents. The devices may be designed for extracorporeal or in vivo uses. Functionalized superparamagnetic nanoparticles are either mixed ex vivo with a biological fluid from the patient or injected into the patient. Then the biological fluid, which includes the nanoparticles is transported to the magnetic filter to remove any nanoparticles that are complexed to the target cells, pathogens, or virus, and any free nanoparticles. Optionally, the functionalized nanoparticles contain and deliver a therapeutic agent. In one embodiment, the therapeutic agent is released when the nanoparticle binds to the target cells, pathogens, or virus.

Owner:GEORGIA TECH RES CORP

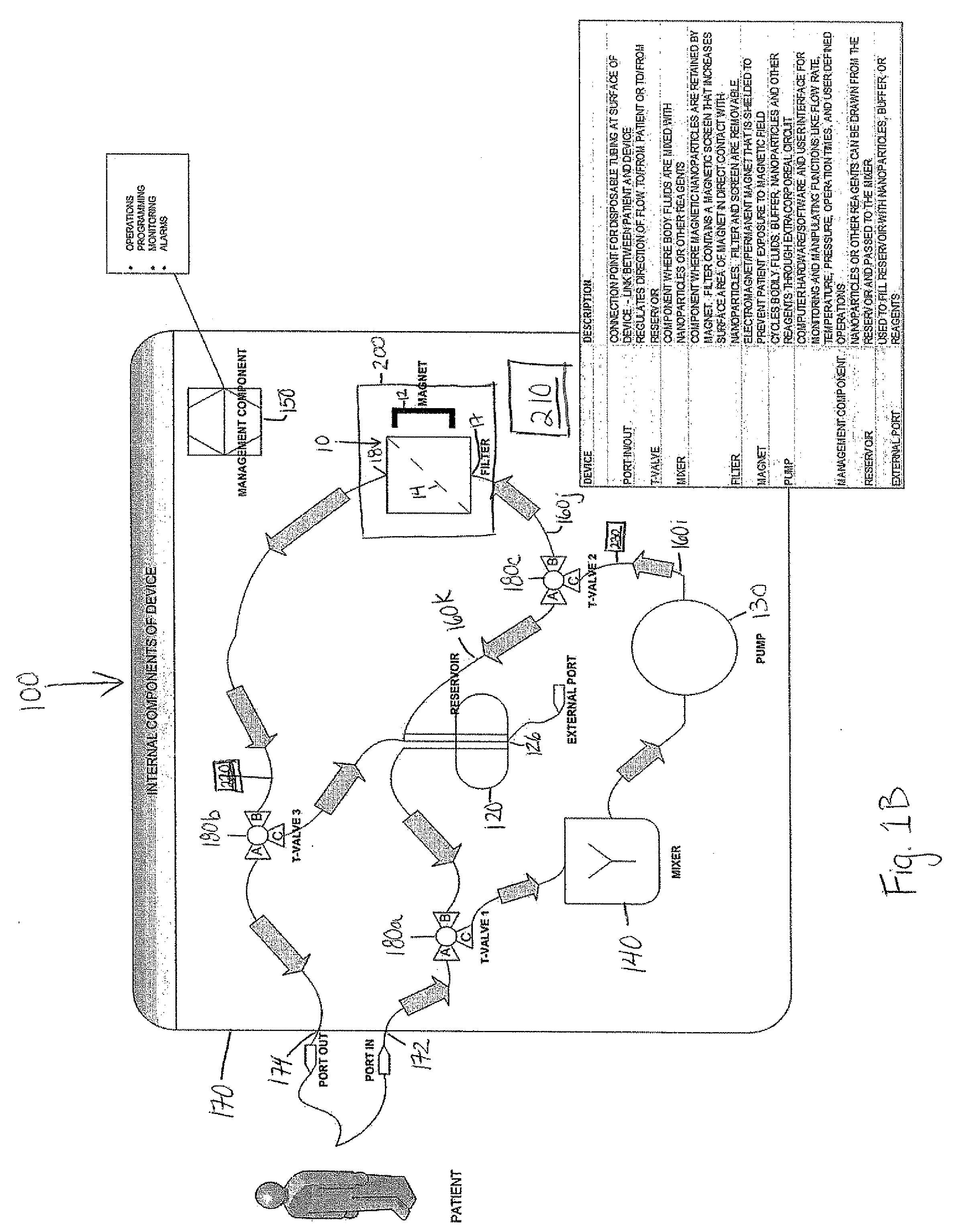

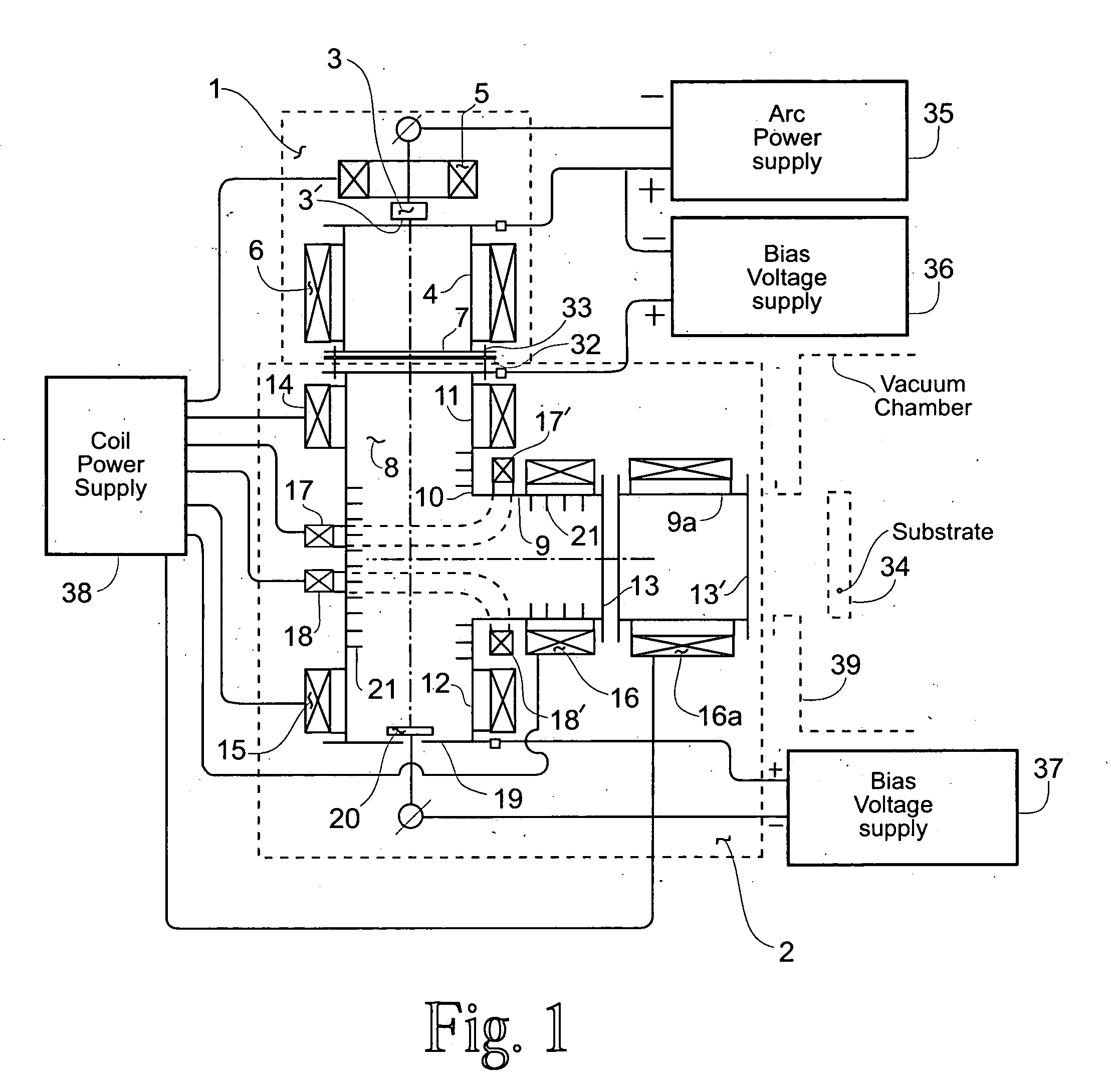

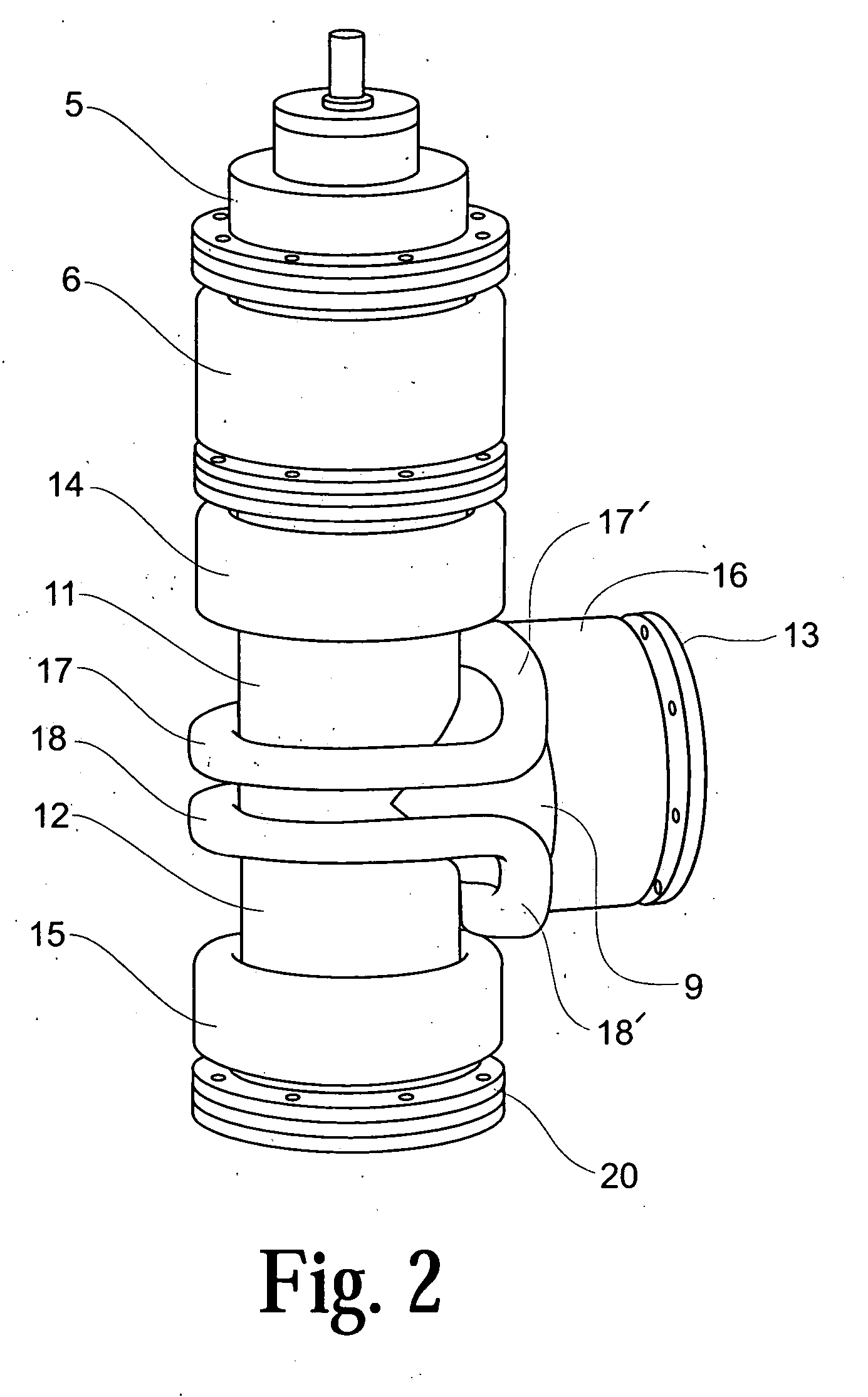

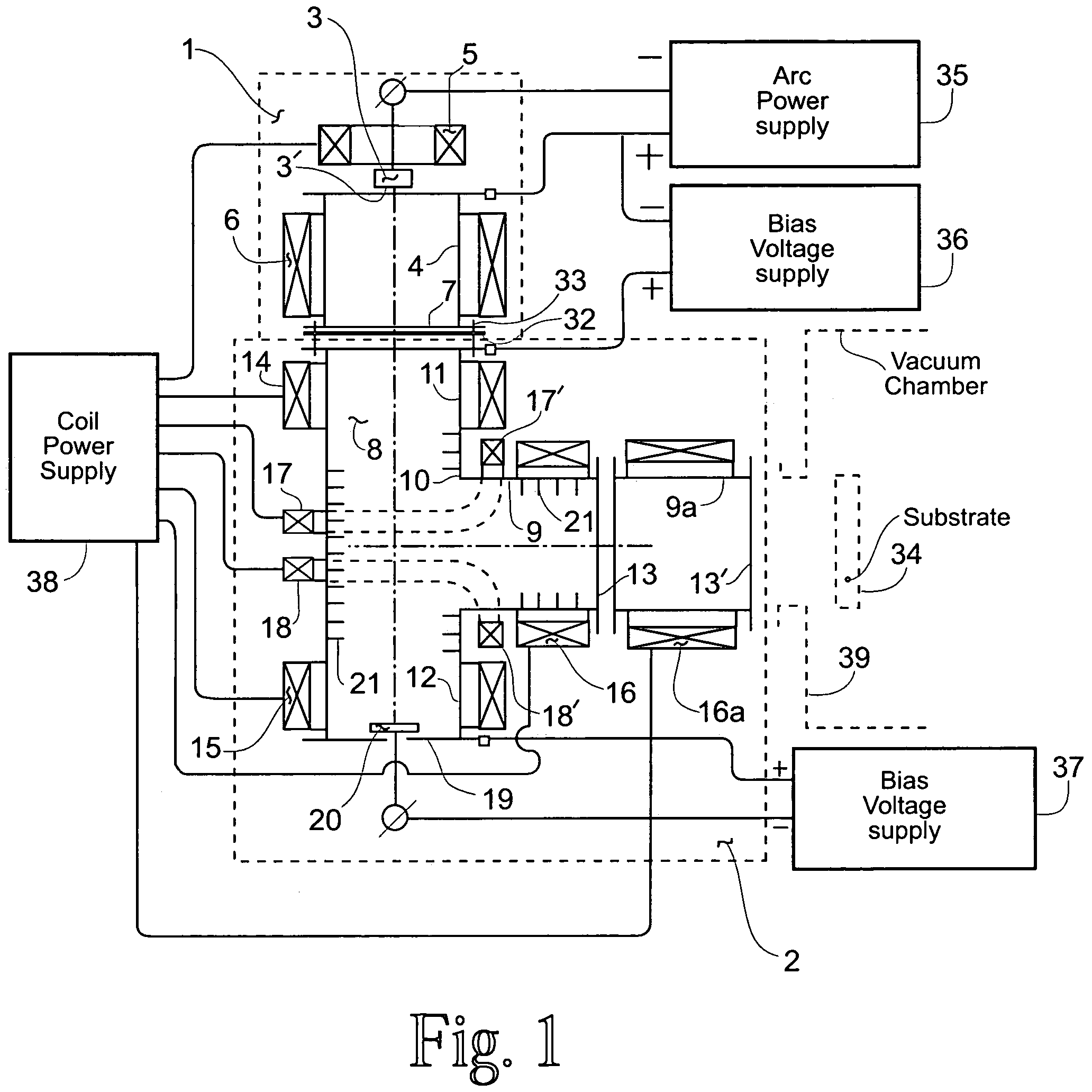

Filtered cathodic-arc plasma source

InactiveUS20070187229A1Reduction in kinetic ion energyImprove ion transmission efficiencyCellsElectric discharge tubesPlasma currentMagnetic flux

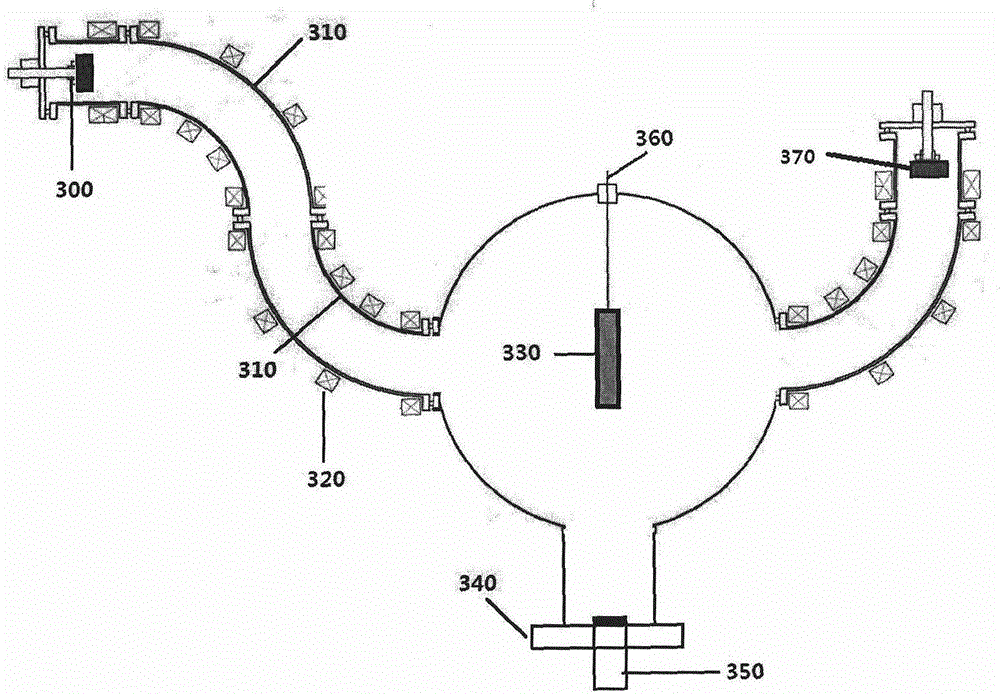

A filtered cathodic-arc plasma source of lower plasma losses and higher output plasma current to input current efficiency is disclosed. Plasma filtering is accomplished in a right angle bend magnetic filter arranged to include the effects of at least three added magnetic coils located at the right angle bend of the filter path. These magnetic coils and other filter attributes, including an array of transverse fins and a magnetic cusp trap in the filter path, achieve desirable magnetic flux paths, lower plasma collision losses and reduced undesired particle output from the plasma filter. Multiple cathode sources, multiple plasma output ports, Larmour radius influence, equipotential magnetic flux lines and electron / ion interaction considerations are also included in the plasma source. Application of the plasma source to film coating processes is included.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

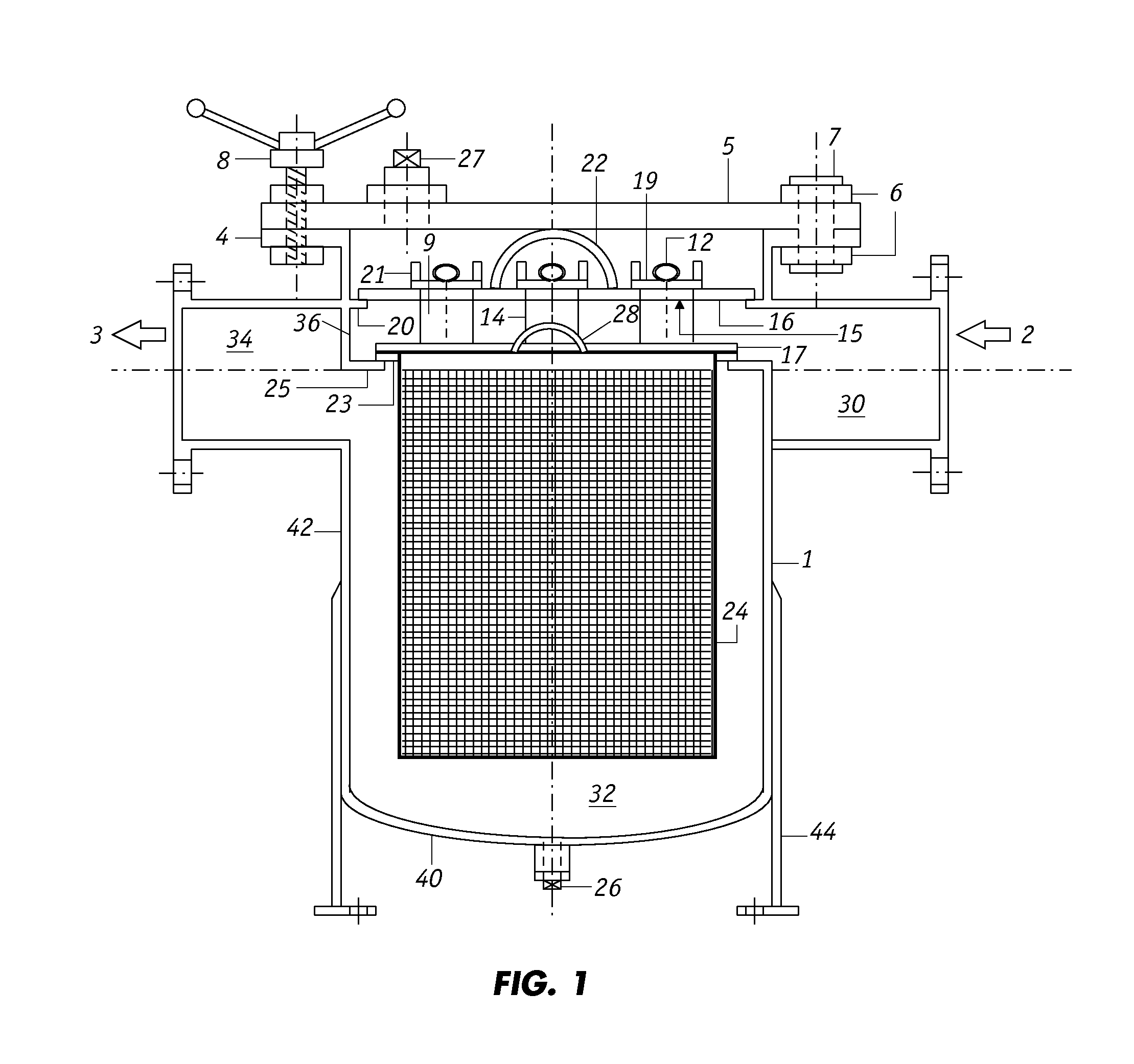

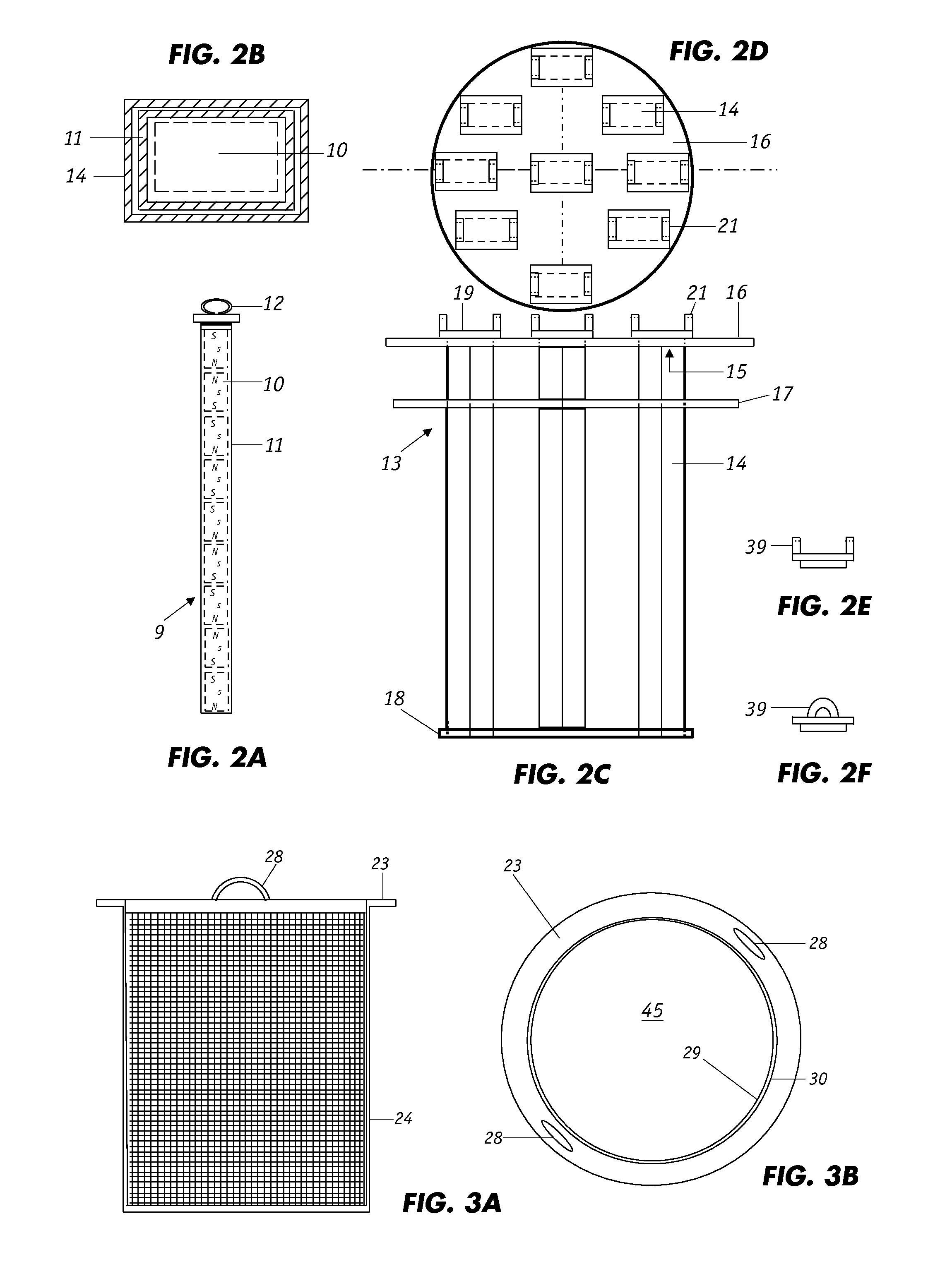

Magnetic filter

ActiveUS20070090055A1Excessive wearEliminates the magnetic field within the internal passageWater treatment parameter controlElectrostatic separationWorking fluidEngineering

A magnetic filter device capable of separating contaminant material from a working fluid. The device includes an inlet to allow fluid to flow into the device and an outlet to allow fluid to flow out of the device. The filter further includes an elongate magnetic core comprising at least four columns of magnets. At least two magnetic columns include a north polarity extending over the length of the columns and at least two columns have a south polarity extending substantially the length of the columns. The four columns are positioned lengthways around a central longitudinal axis of the core in alternating north and south polarity thereby generating a magnetic field of alternating high and low field intensity in the region around the magnetic core exterior.

Owner:ECLIPSE MAGNETICS

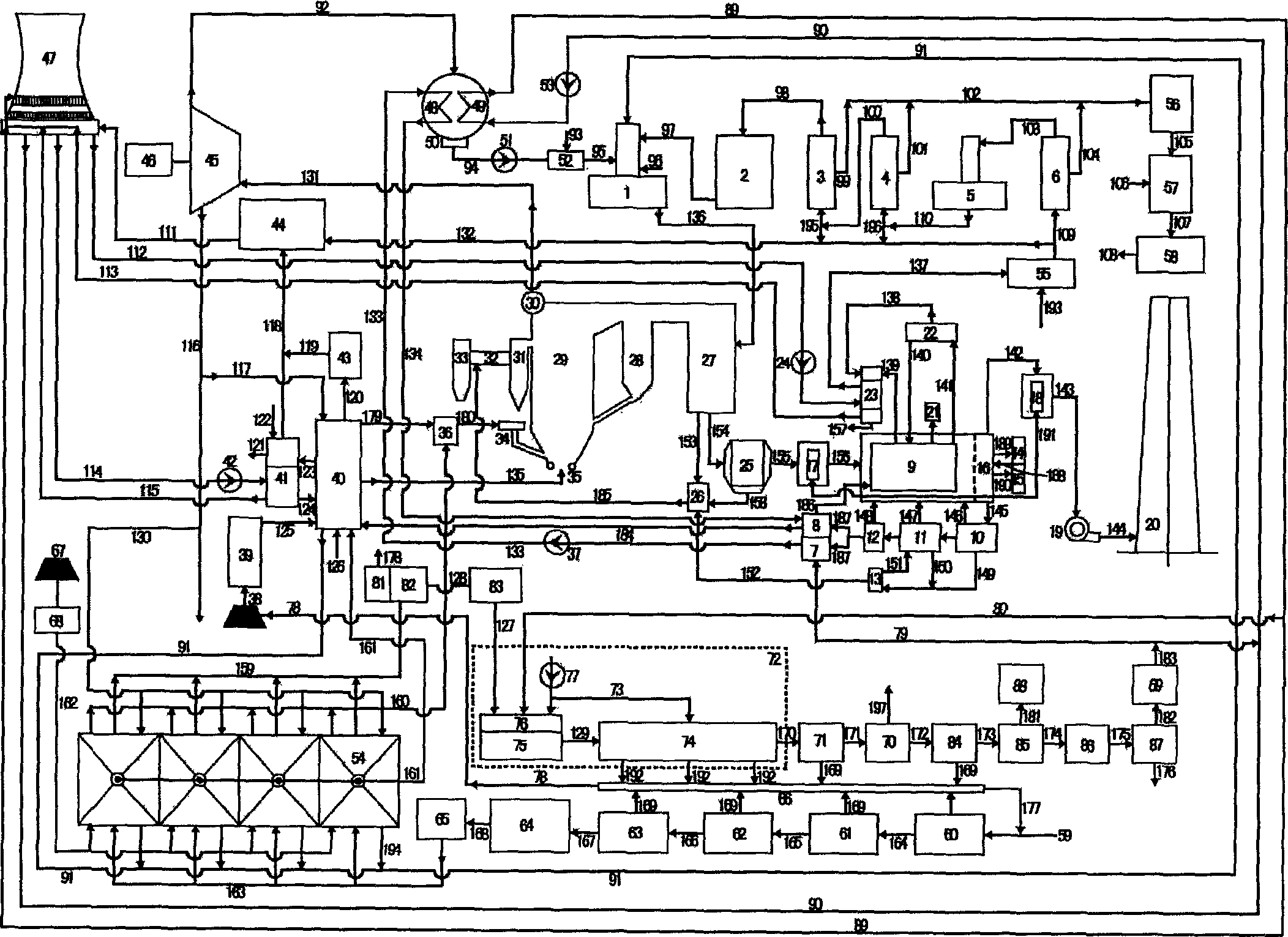

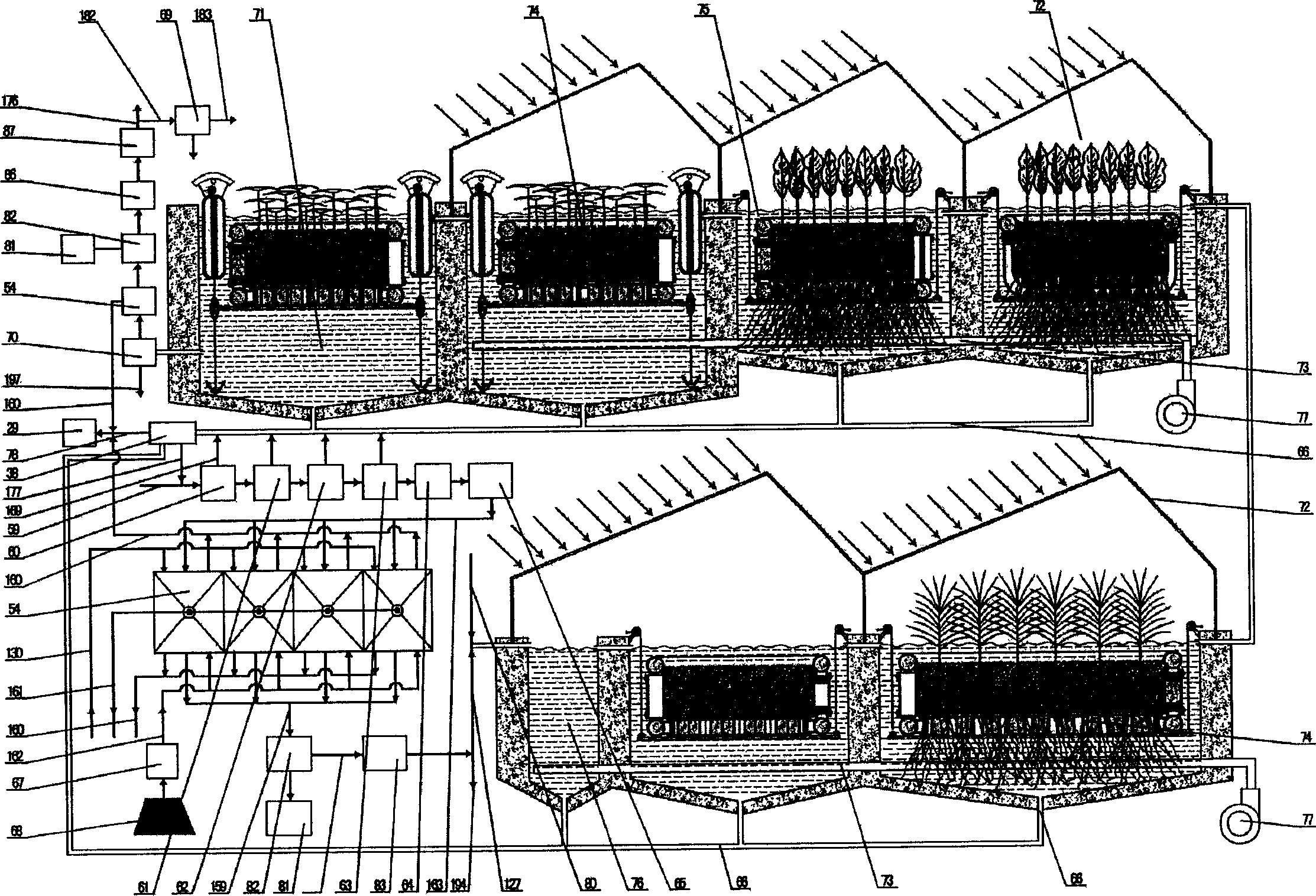

Sewage-refuse treatment clean-production system at the center of generating plant

InactiveCN1743284AImprove efficiencyComplete desulfurizationWater/sewage treatment by irradiationSolid waste disposalSteam condensationCoal

This sewage and garbage treatment system centrally designed for power plant includes sewage treatment unit, fuel processing unit, garbage combustion boiler, fly ash processing unit, smoke processing unit, the de-oxygenating draining steam of turbine steam-extraction heat-supply boiler and circulated water cooling unit. The effluent of sewage treatment unit with coal as filter is led into magnetic water strainer, and condensed water from the domestic garbage dehydration-drying condensed water-recovering combustion-supporting device is cleared by the coal filtration and normal water treatment system to feedback the circulated water-cooling system, the steam condensed water is heated and delivered into the de-oxygenating device. Treated sewage is introduced into multi-medium condenser and the distillation-desalination device; discharged smoke from fly ash incineration device is led into garbage combustion boiler; acid water discharged from distillation unit and alkaline water from coal filter are neutralized and discharged. Water distillation system and the circulation cooling water of the steam turbine condensator are led to the air- water cooling tower.

Owner:徐宝安

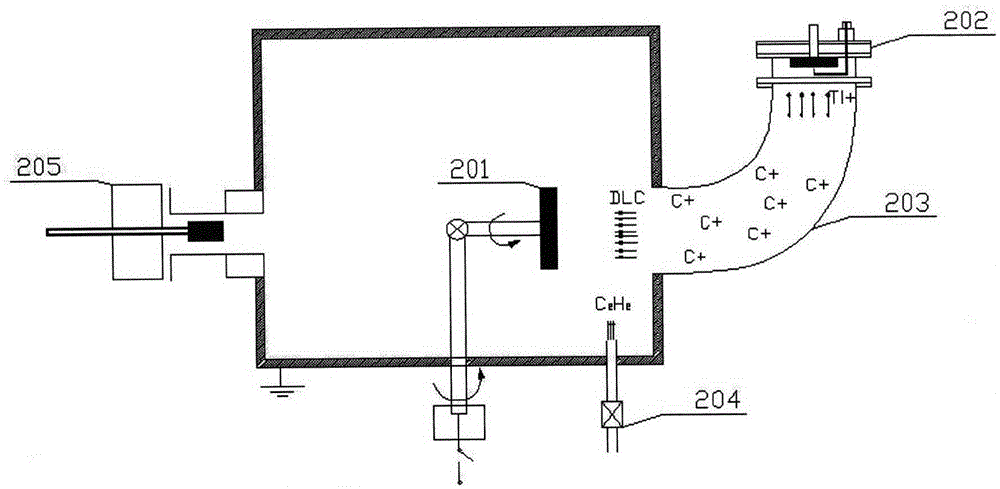

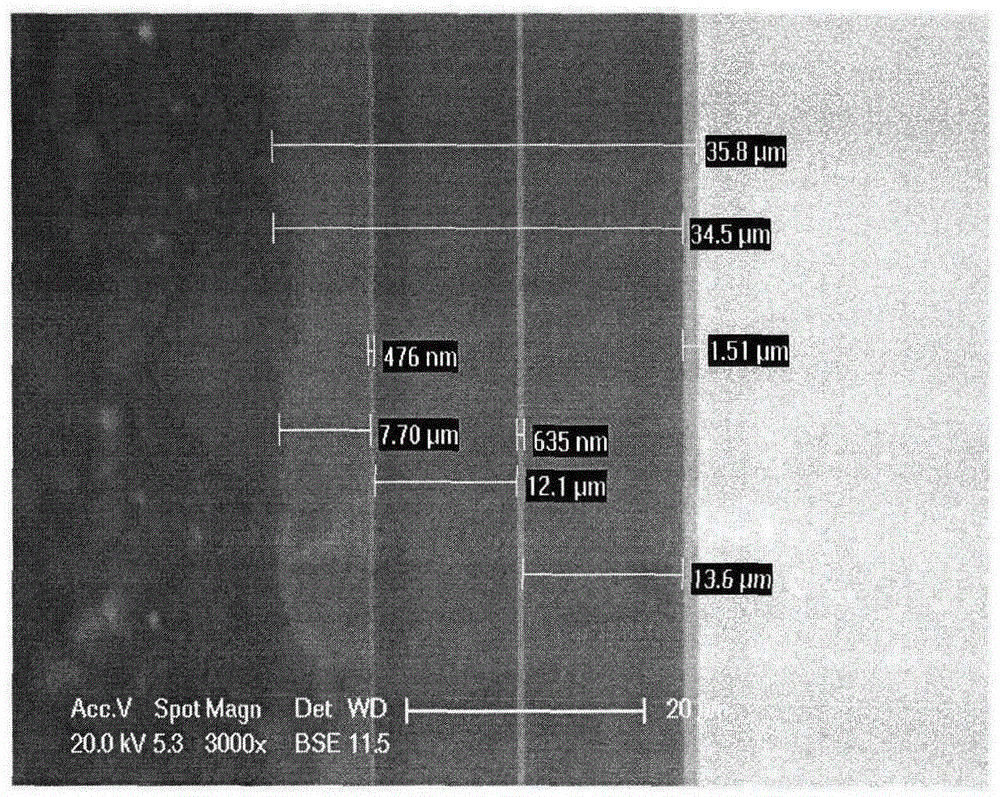

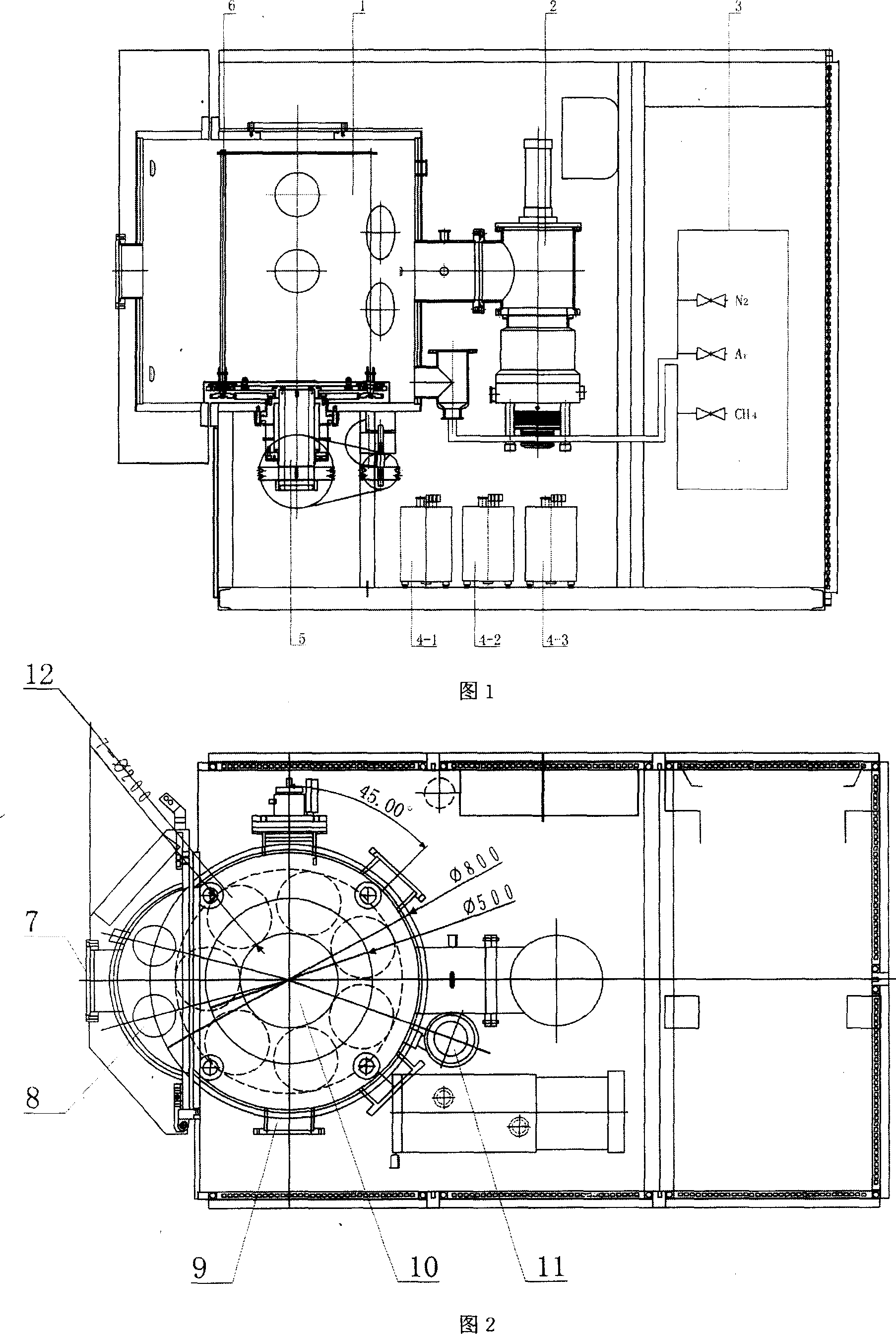

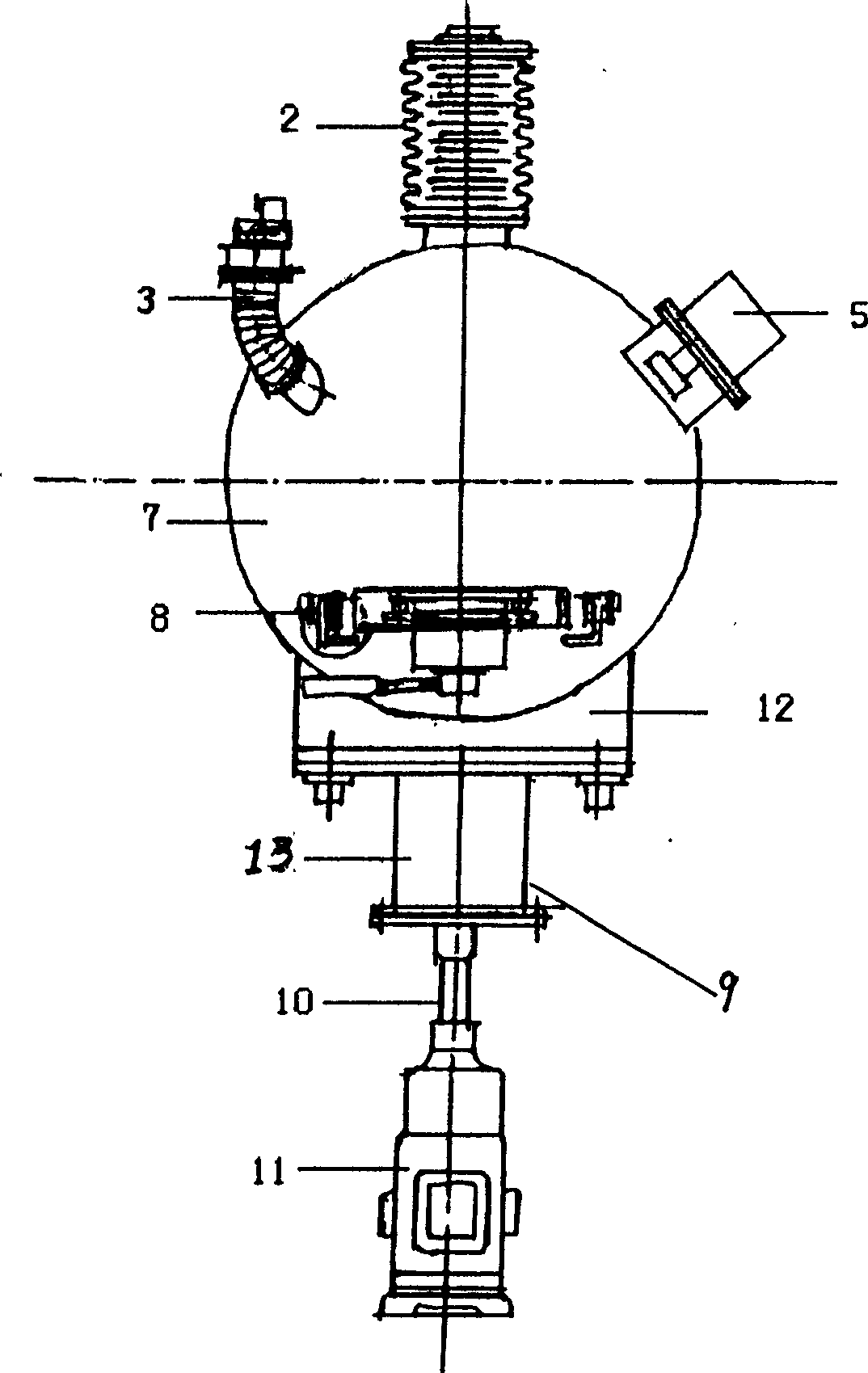

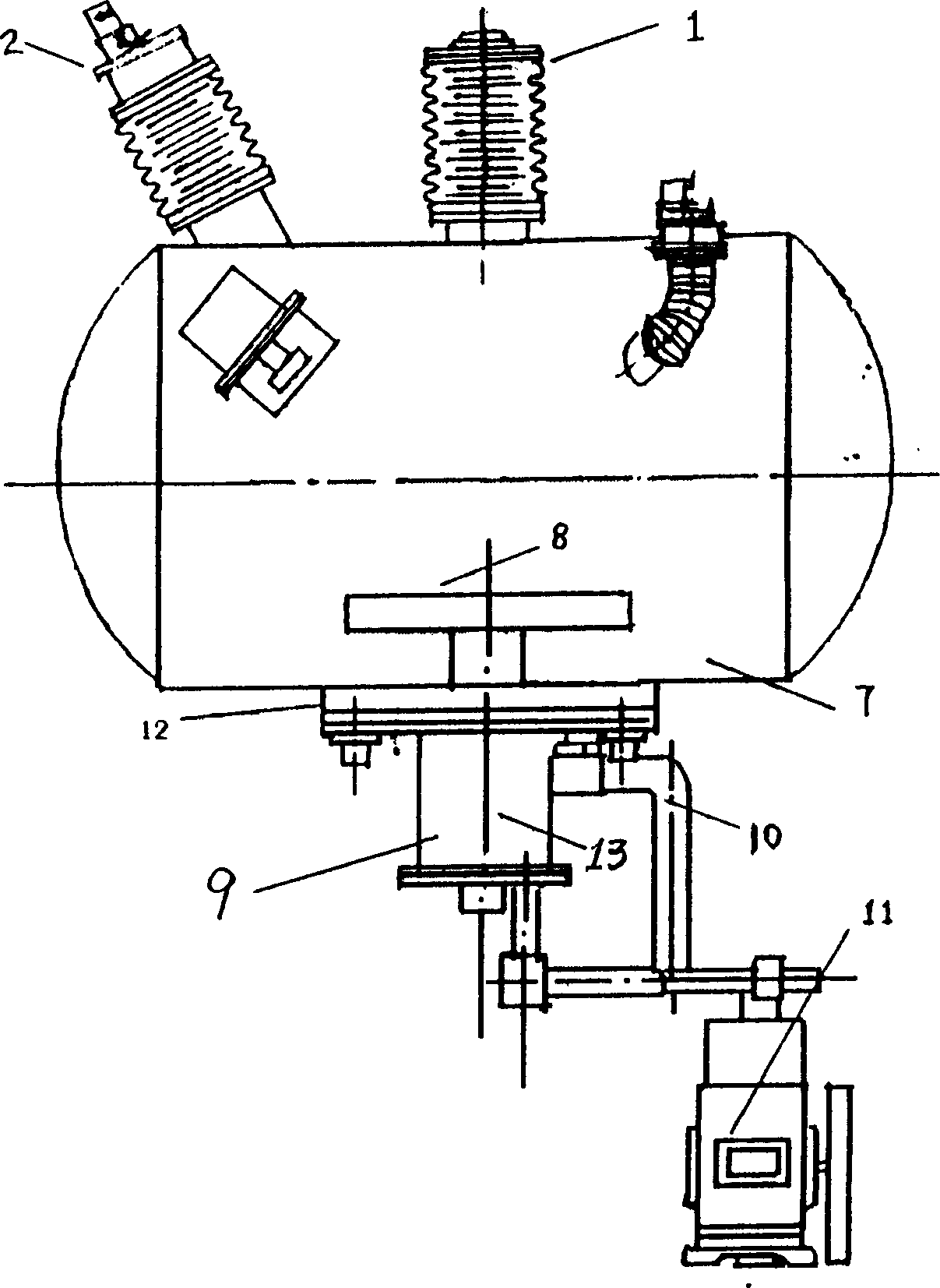

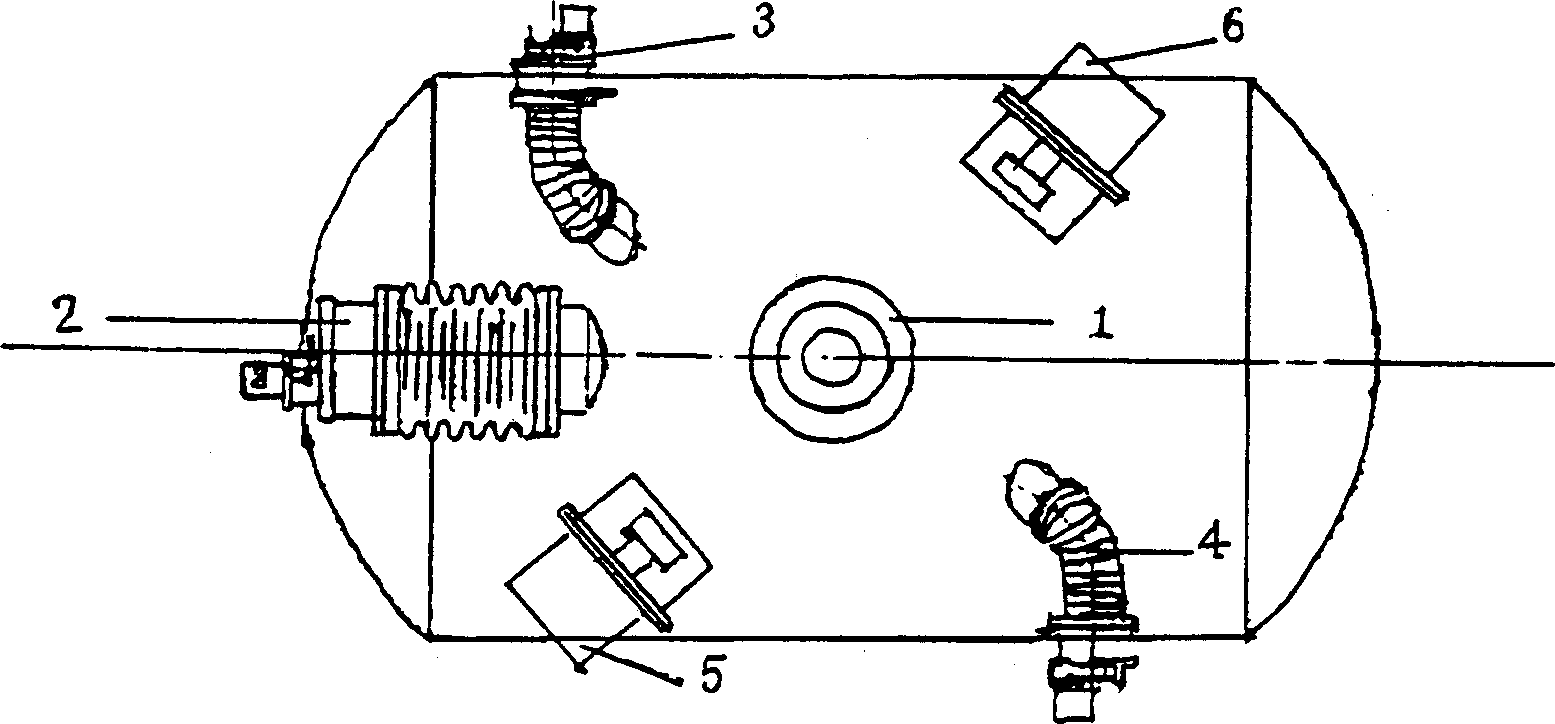

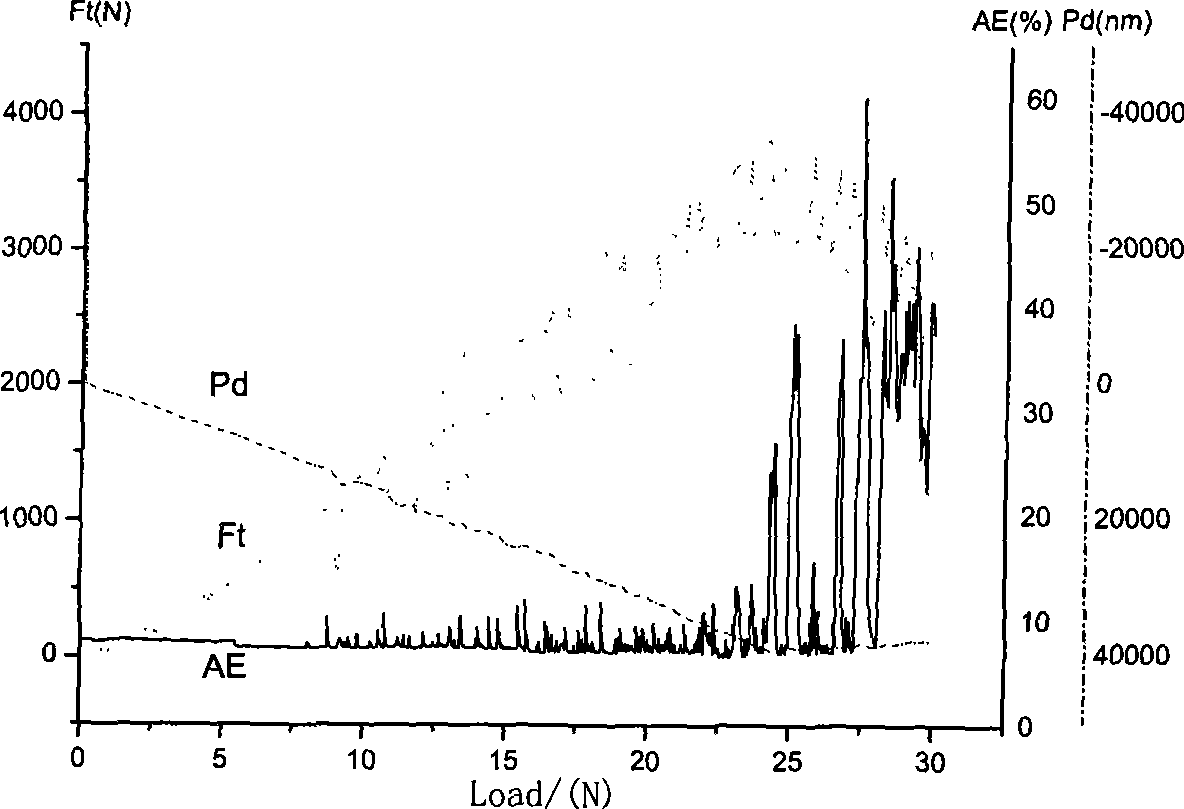

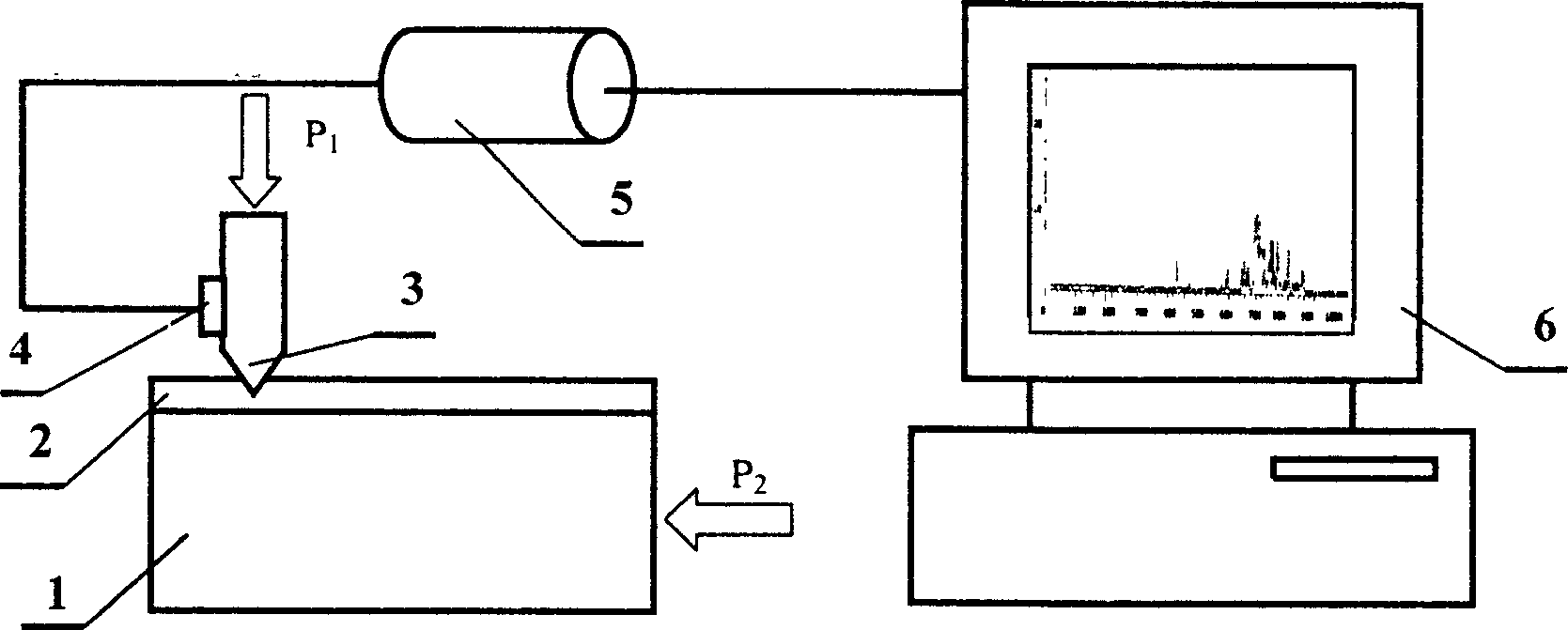

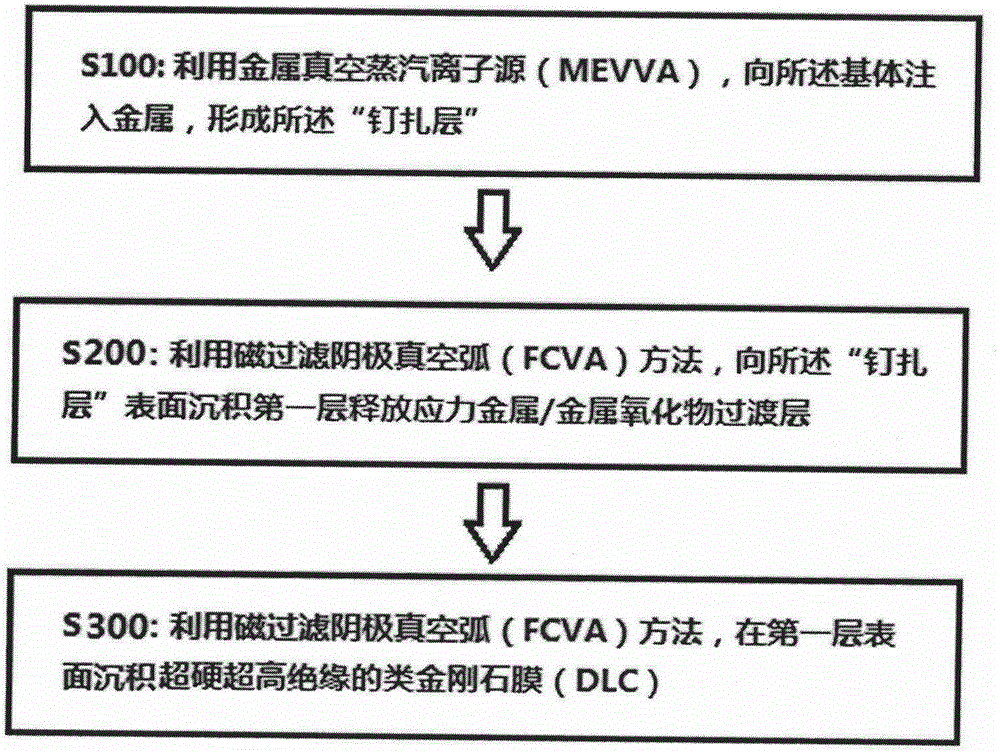

Method for preparing DLC (diamond-like carbon) thick films by means of efficient magnetic filter plasma deposition

ActiveCN105755442AEffective filteringFacilitate separate control of the ionization processVacuum evaporation coatingSputtering coatingCathodic arc depositionDiamond-like carbon

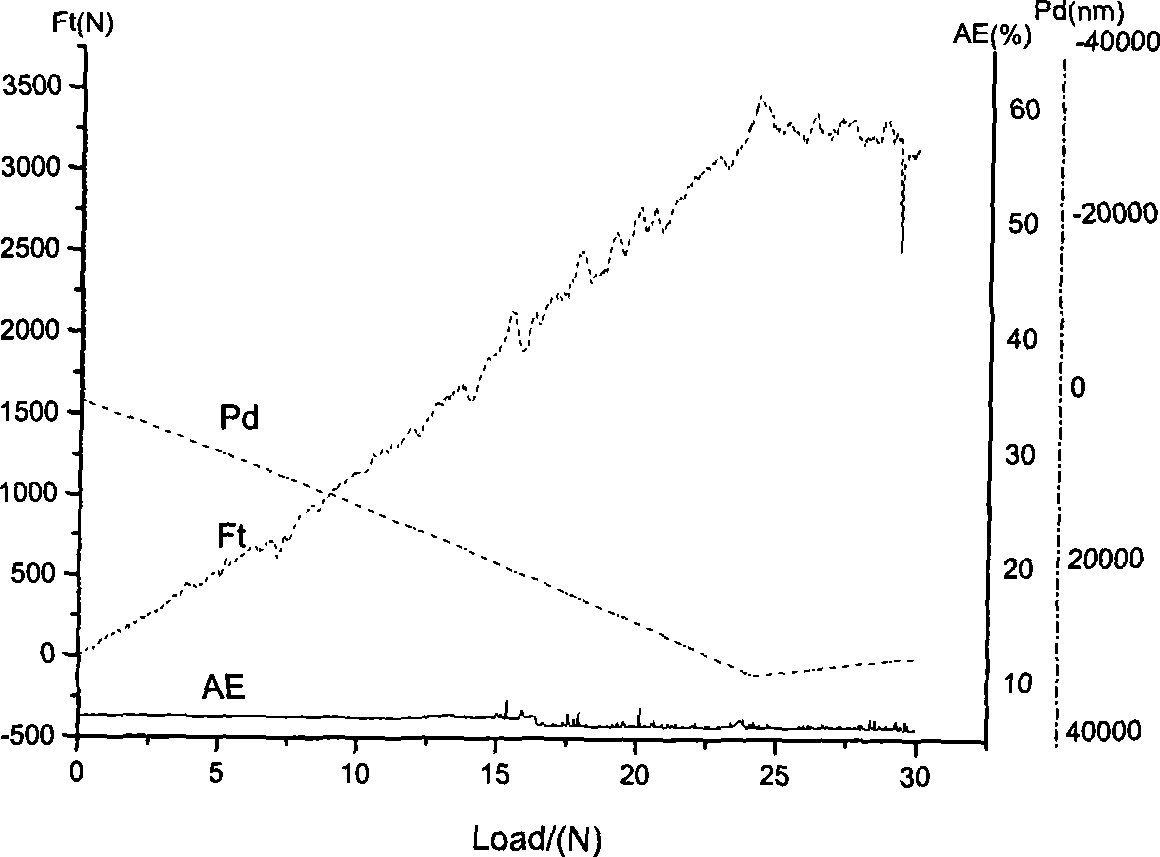

The invention discloses a method for preparing Metal carbide-inlaid Diamond-like Carbon (MC / DLC) films with the thicknesses larger than 30 micrometers, belongs to the field of preparation of hard abrasion-resistant coatings, and particularly relates to a technology for preparing MC / DLC thick films by the aid of magnetic filter plasma deposition processes.MC / DLC thick film structures comprise ion injection pinning layers, metal transition layers and the MC / DLC films.The method has the advantages that the DC / DLC films prepared by the aid of ion injection technologies, magnetic filter technologies and cathodic arc deposition technologies are high in binding force, the arc current intensity, the magnetic field intensity of bent pipes and the gas inflow of gas with carbon are controlled in deposition procedures, accordingly, the thicknesses, the hardness, the rub resistance and the abrasion resistance of the MC / DLC thick films can be optimized, and the high-quality MC / DLC thick films can be prepared by the aid of the method; magnetic filter plasma deposition equipment for implementing the method has proprietary intellectual property rights and is easy to operate, processes are mature, the MC / DC films can be produced on a large scale, and the method is suitable for deposition application to high-hardness abrasion-resistant coatings in all industrial components such as bearings of cutters.

Owner:BEIJING NORMAL UNIVERSITY

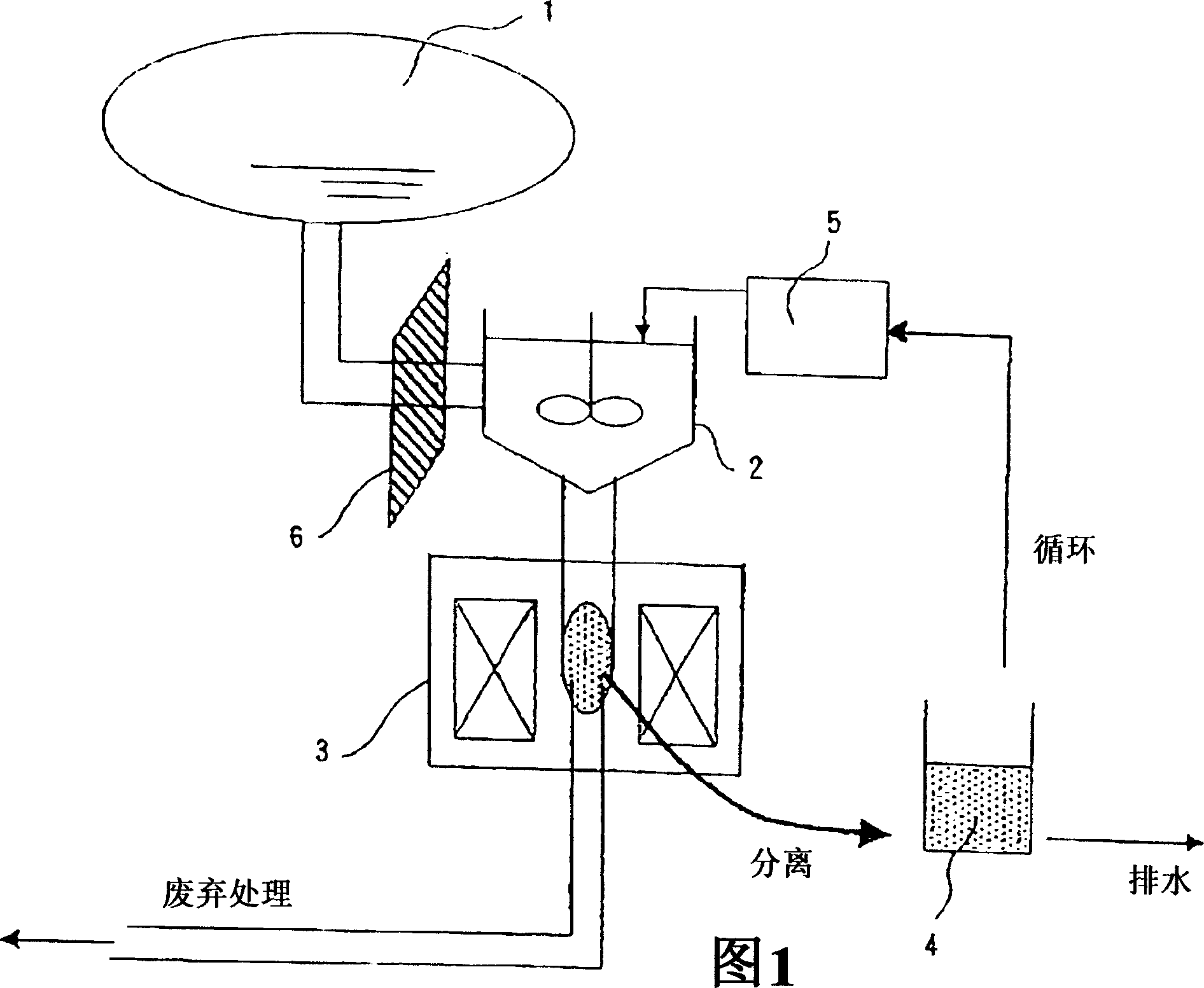

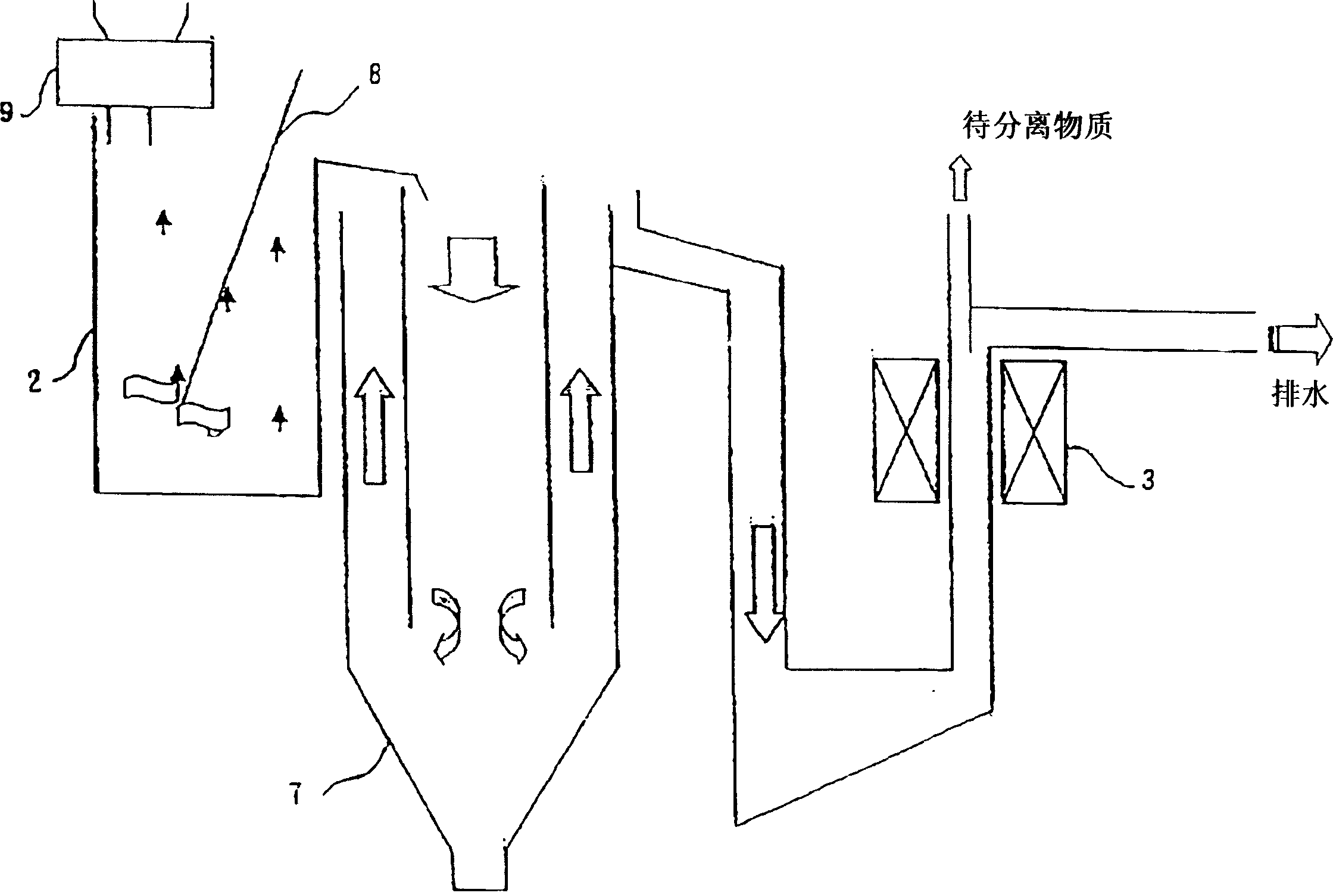

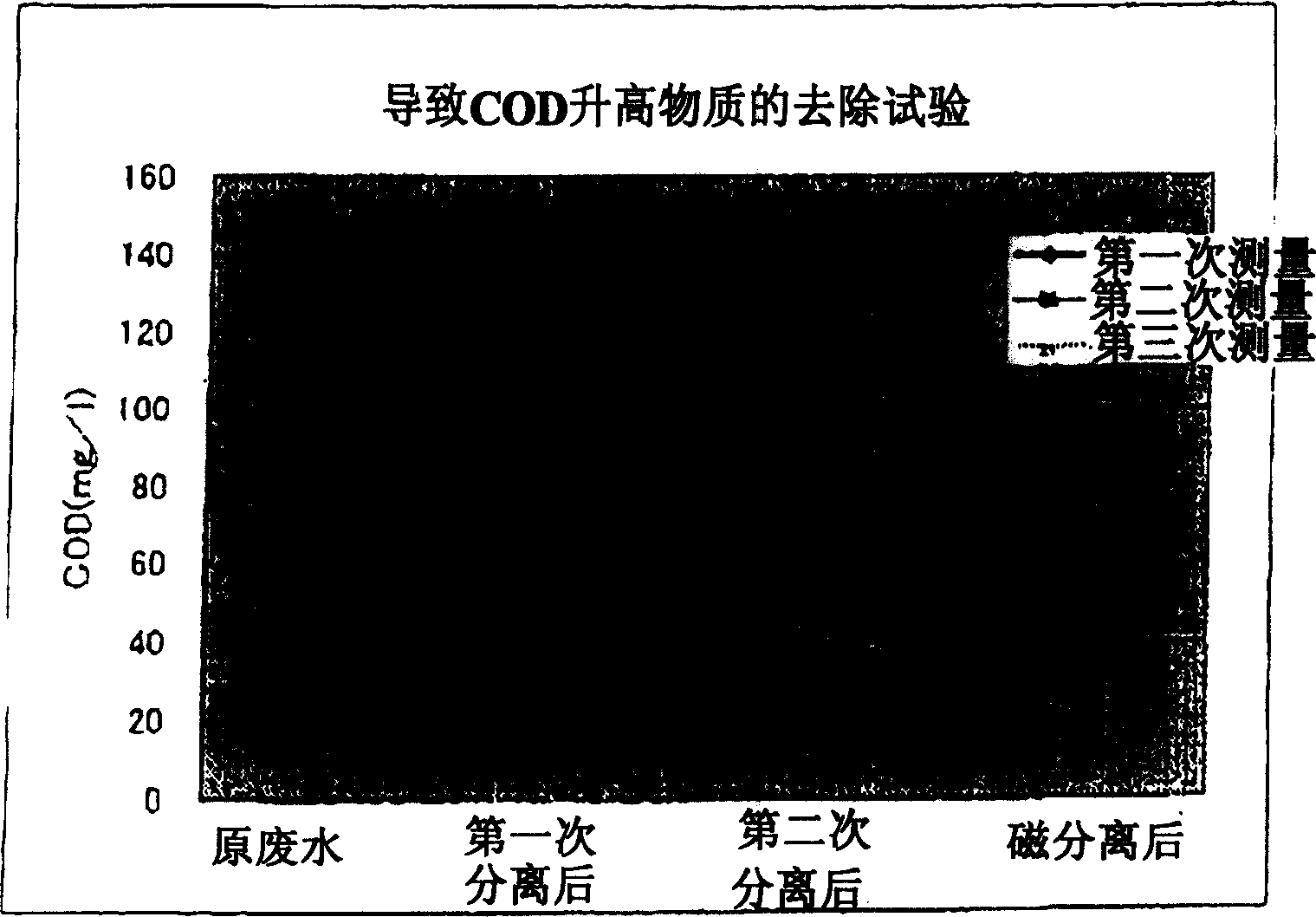

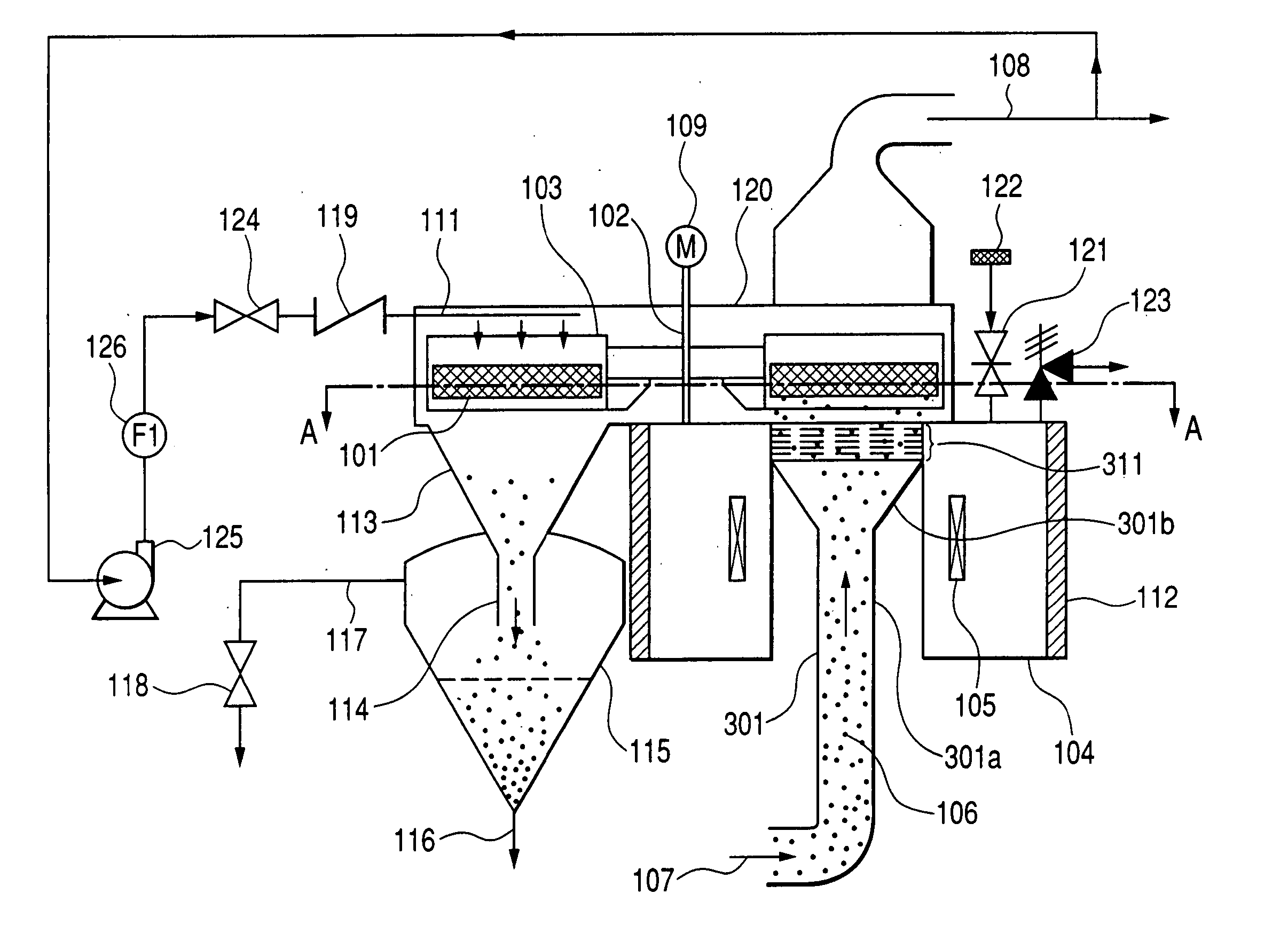

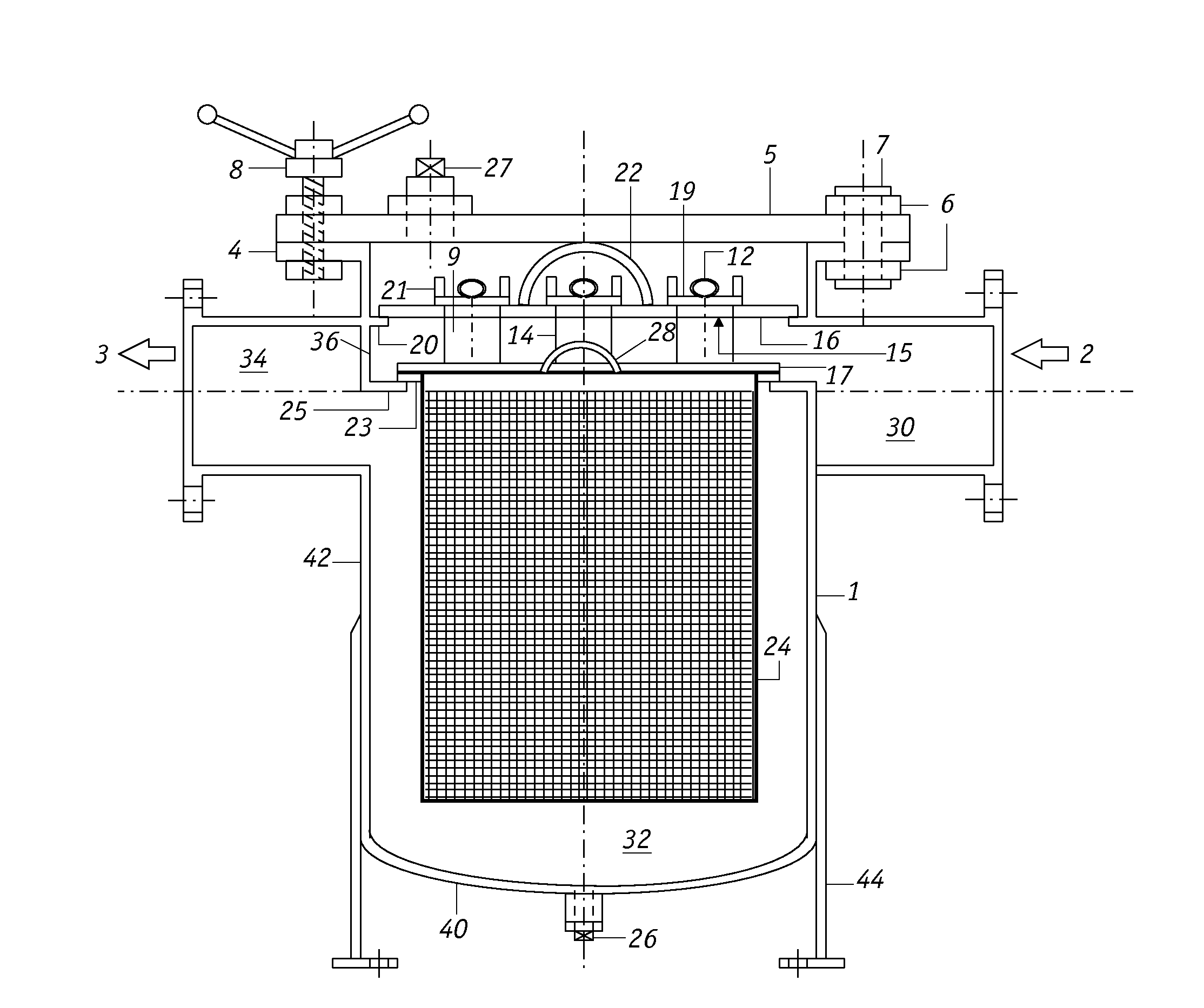

Waste water treatment system by superconductive magnetic separation

InactiveCN1697784ALow costSmall footprintTreatment using aerobic processesOpen gradient mangetic separatorsWater treatment systemMagnetic separator

An object of the invention is to provide a wastewater treatment system using a superconducting magnetic separator that can wash the magnetic filter efficiently. The system comprises in a bore of a superconducting magnet a removably built-up multiunit magnetic filter consisting of a plurality of single-unit magnetic filters. The multiunit magnetic filter has a total longitudinal length at least equal or greater than that of the superconducting magnet. During excitation of the superconducting magnet, a single-unit magnetic filter is removed from the upstream side (sewage side) of the multiunit magnetic filter by pushing in another single-unit magnetic filter from the downstream side (clean water side), and washed and returned to the downstream side again.

Owner:NIKI GLASS +2

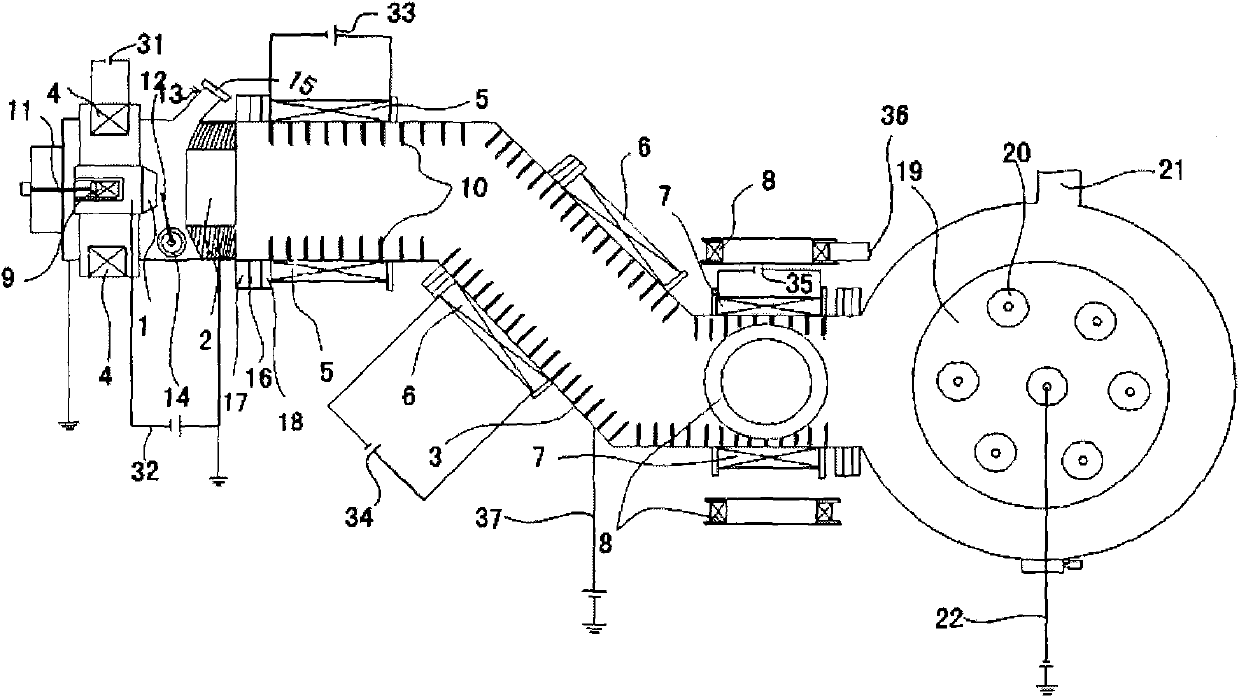

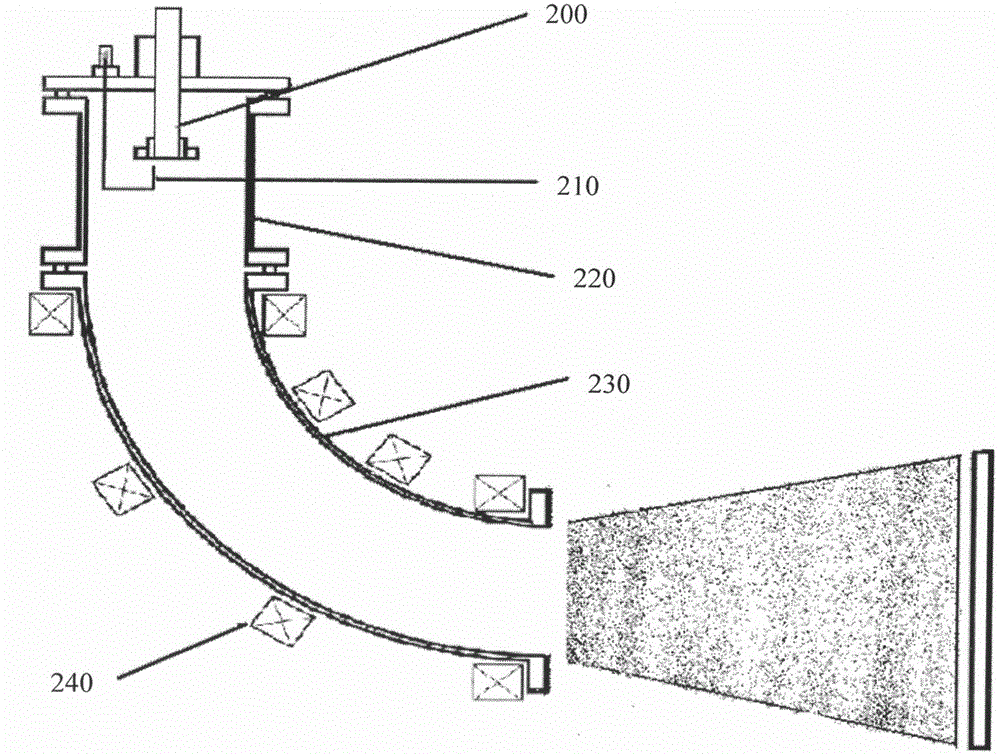

Cathodic vacuum arc source film depositing device and method for depositing film

ActiveCN101792895AIncrease deposition rateCompact structureVacuum evaporation coatingSputtering coatingEngineeringLarge particle

The invention discloses a cathodic vacuum arc source film depositing device which comprises a magnetic filtering part capable of transferring plasma at high speed and effectively filtering macro-large particles, wherein the magnetic filtering part comprises a tube body and a magnetic field generator which is arranged at the external periphery of the tube body; the tube body comprises an inlet end surface of the tube body and an outlet end surface of the tube body, at least one bent tube is arranged between the inlet end surface of the tube body and the outlet end surface of the tube body, and an included angle between the axial lines of the tube body at two sides of the bent tube is 135 degrees; and the introducing amount of inert gases in the device is 10-50sccm, and the vacuum degree is 1.0*10-5 to 5.0*10-5Torr after the device is vacuumized. Compared with the prior art, the cathodic vacuum arc source film depositing device of the invention can realize the purposes of effectively filtering macro-large particles and simultaneously transferring plasma at high speed, thereby improving the quality and the deposition rate of the film. The method of the invention can be used for depositing the film at high speed, the deposited film has compact structure, smooth surface and large uniform region area, and the method can be used for depositing high-performance ta-C films.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Hall Ion Source excitation magnetron sputtering enhancement magnetism filtration multi-arc ion composite coating method

InactiveCN101058870AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingPower flowIon bombardment

The invention discloses a making method of magnetic control sputtering reinforced typed magnetic filter multihead ion composite coater excited by Hall source, which comprises the following steps: extracting into vacuum; heating; exciting ion; plating; improving the connecting strength; obtaining the entire and compact film system for industrial need.

Owner:西安宇杰表面工程有限公司

Ion implanted composite coating film apparatus

InactiveCN1472360AVersatilityReduce manufacturing costVacuum evaporation coatingSputtering coatingVacuum pumpingIntermediate frequency

A composite ion implantation plating equipment is composed of 6 ion source (gas ion source, metal ion source, DC magnetically controlled sputter target source, MF-pulse magnetically controlled sputter target source and two DC magnetic filter arc ion source), a vacuum chamber containing a multi-purpose bench, and a vacuumizing system for said vacuum chamber.

Owner:SHANGHAI JIAO TONG UNIV +1

RF system, magnetic filter, and high voltage isolation for an inductively coupled plasma ion source

ActiveUS20140077699A1Improved magnetic filteringHigh voltageParticle separator tubesElectric arc lampsCapacitanceInductively coupled plasma

In a plasma ion source having an induction coil adjacent to a reactor chamber for inductively coupling power into the plasma from a radio frequency power source and designed for negative and positive ion extraction, a method for operating the source according to the invention comprises providing radio frequency power to the induction coil with a RF amplifier operating with a variable frequency connected to a matching network mainly comprised of fixed value capacitors. In this device the impedance between the RF power source and the plasma ion source is matched by tuning the RF frequency rather than adjusting the capacitance of the matching network. An option to use a RF power source utilizing lateral diffused metal oxide semiconductor field effect transistor based amplifiers is disclosed.

Owner:OREGON PHYSICS

TiAlN/TiN for tool and mould material surface and preparation thereof

InactiveCN101435070AExtended service lifeImprove wear resistanceLayered productsVacuum evaporation coatingAutomatic controlWear resistance

The invention discloses a magnetic filtration TiAlN / TiN thin film on the surface of tool and die material and a preparation method thereof. A layer of magnetic filtration TiN thin film is firstly plated on the surface of the tool and die material by adopting a magnetic filter, then a layer of magnetic filtration TiAlN thin film is plated, and the total thickness of double layers of thin films is 1 to 4 Mu m. The magnetic filtration TiAlN / TiN thin film has short preparation time, low cost and good wear resistance, is beneficial to prolonging the service life of the tool and die; and the processing quality of the plated film is high, the preparation technique is simple, the operation is easy and the plating process adopts electrical and mechanical automatic control.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

Magnetic filter and magnetic filtering assembly

InactiveUS20100294706A1Easy to cleanCorrosion resistanceWater/sewage treatment by magnetic/electric fieldsMagnetic separationEngineeringMagnetic filter

A reusable magnetic device for the extraction of ferrous particles from a body of fluid, wherein the device comprises a plurality of magnets and soft ferrous metal spacers arranged in an alternating sequence to form a stack, adjacent magnets being arranged with like poles facing, a non-magnetic and non-ferrous end piece terminally disposed at a first end of the stack, and a non-magnetic housing that contains the magnets, the spacers and the end piece. The magnetic device can be installed in a vessel to provide a fluid filtering assembly.

Owner:SIMONSON ROGER M

Method for filtering Fischer-Tropsch synthesized heavy wax

The invention discloses a method for filtering Fischer-Tropsch synthesized heavy wax. The method is as follows: feeding heavy wax extracted from a Fischer-Tropsch synthesized reactor into a high-gradient magnetic filter to adsorb and remove the iron-based catalyst in the heavy wax, and then entering a device of next procedure. The method of the invention adopts the high-gradient magnetic filter to adsorb and remove the iron-based catalyst in the heavy wax, the flow is simple and is convenient for operation, and the material consumption is lower, no waste residue is generated, thereby avoiding the occurrence of secondary pollution. Meanwhile, the filtering result is obvious, which can be up to more than 99. 5%, the device energy consumption is the lowest in the country, thereby being worth promotion and application.

Owner:中国石油集团工程设计有限责任公司抚顺分公司 +1

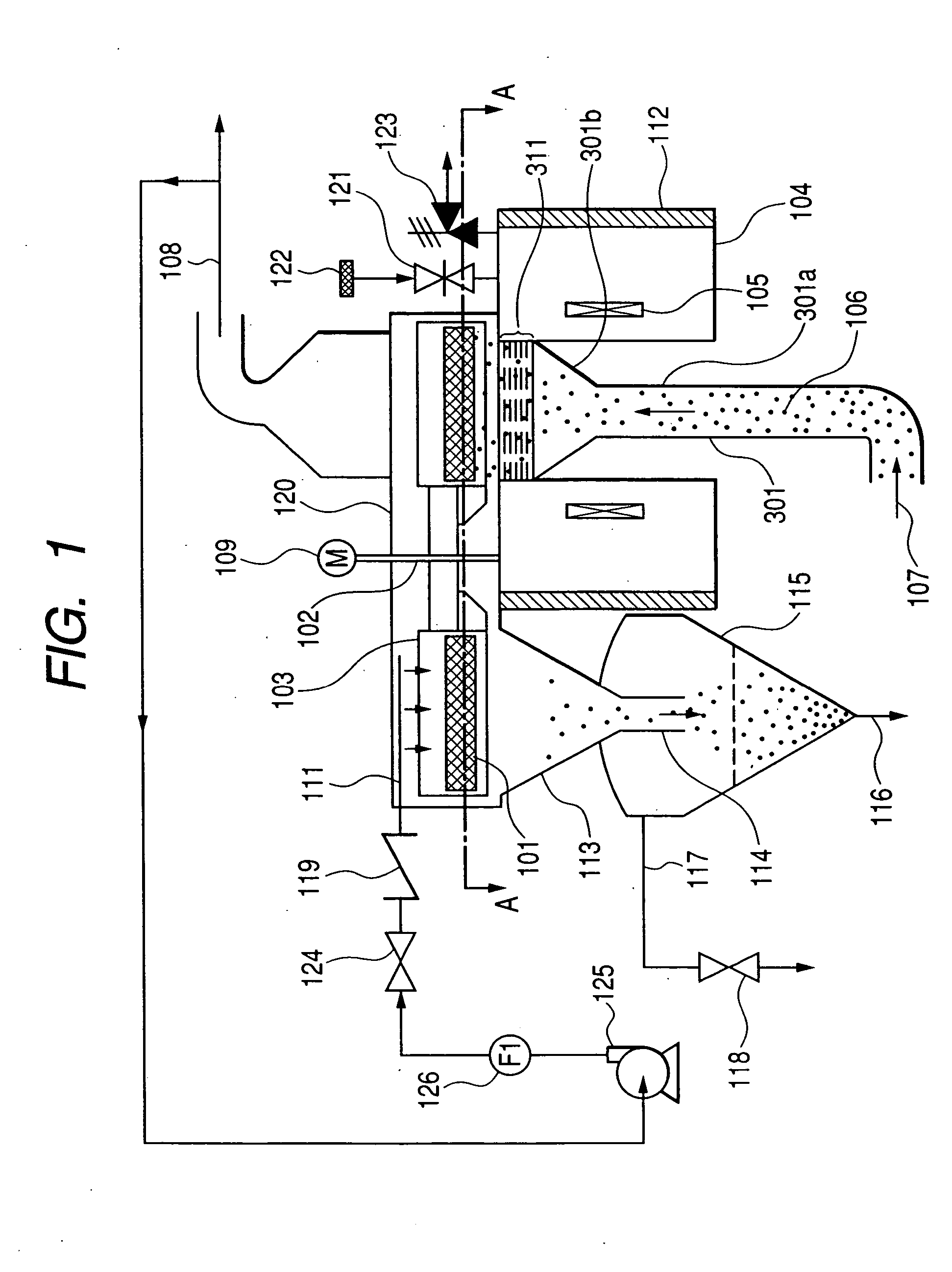

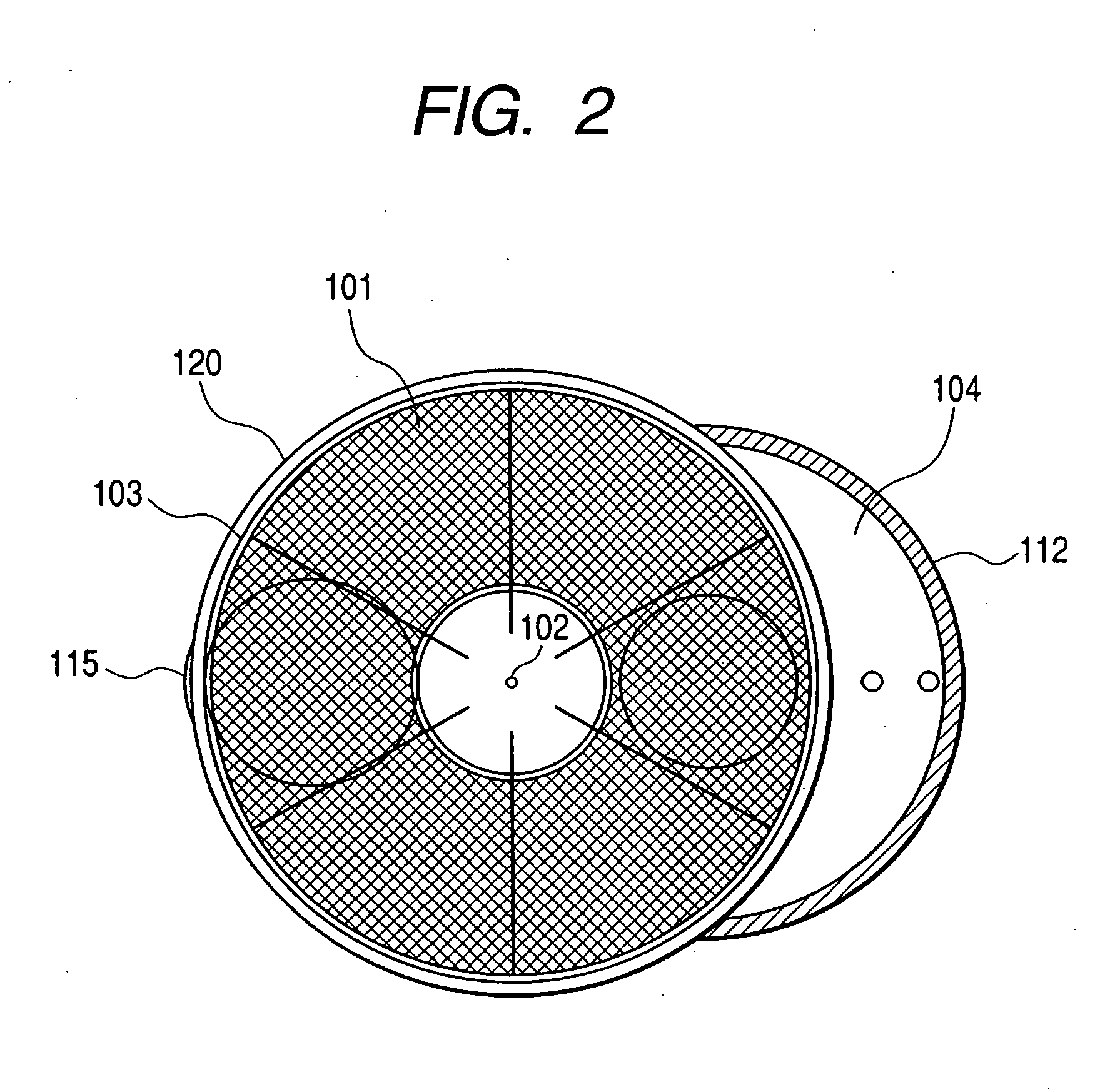

Magnetic separation unit and water purification system

InactiveUS20050126976A1Increase the magnetic field strengthLow magnetic separation performanceSludge treatment by de-watering/drying/thickeningOther chemical processesWater channelMagnetic separator

A magnetic separation unit can prevent any magnetic flocs deposited on an inner wall of a water passing pipe from closing a water channel for stabilizing a magnetic separation performance and reduce cost by a small-diameter portion of the water passing pipe. The magnetic separation unit has an air-core solenoid type magnet provided around the water passing pipe guiding, from a lower side, treated water including magnetic flocs in which contaminants and magnetic particles are flocculated, a rotating disc type magnetic filter case provided above the air-core solenoid type magnet for attracting the magnetic flocs in the treated water supplied from the water passing pipe and flushing means for flushing the matrixes to which the magnetic flocs are attracted. The water passing pipe has a small-diameter pipe positioned in the air-core solenoid type magnet, and an enlarged pipe enlarged from the small-diameter pipe toward a water passing part of the rotating disc type magnetic filter case.

Owner:HITACHI TSUCHIURA ENJINIARINGU +1

TiN two-layer film cladding for cutting tool material surface and its preparing method

InactiveCN1850402AImprove the interface binding forceLow costVacuum evaporation coatingSputtering coatingMicrometerTotal thickness

The present invention discloses a TiN double-layer film coat on the surface of cutting tool material and its preparation method. Its preparation method includes the following steps: firstly, adopting magnetic filter to electroplate a layer of nano-grade particle TiN film on the surface of cutting tool material, then adopting general multiple-arc electroplating process to electroplate a layer of micrometer-grade granule TiN film, in which nano-grade TiN particle size is 40-100 nm, film thickness if 50-300 nm, micrometer-grade TiN granule size is 0.5-1 micrometer, total thickness of double-layer film is 2-5 micrometers.

Owner:SOUTH CHINA UNIV OF TECH

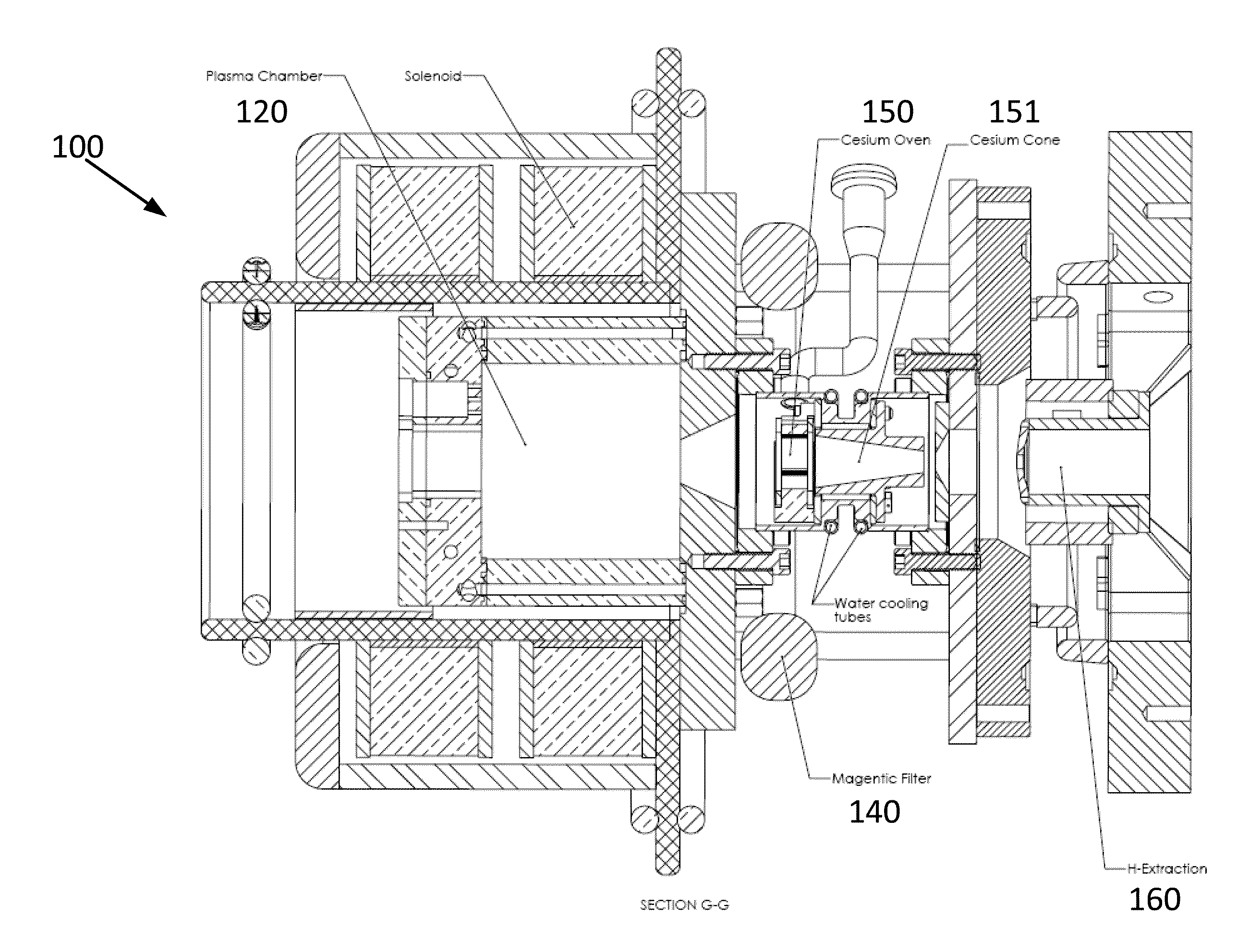

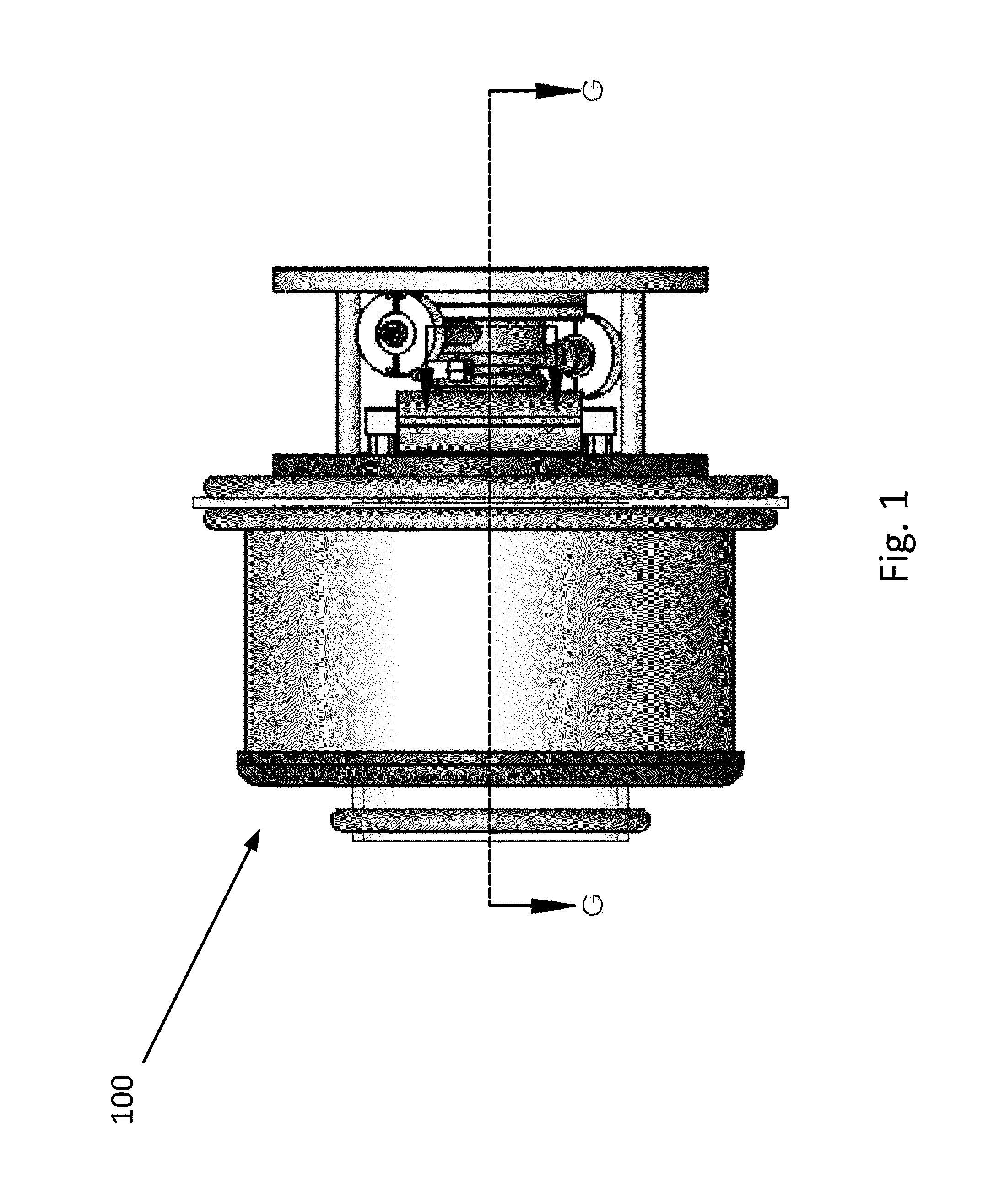

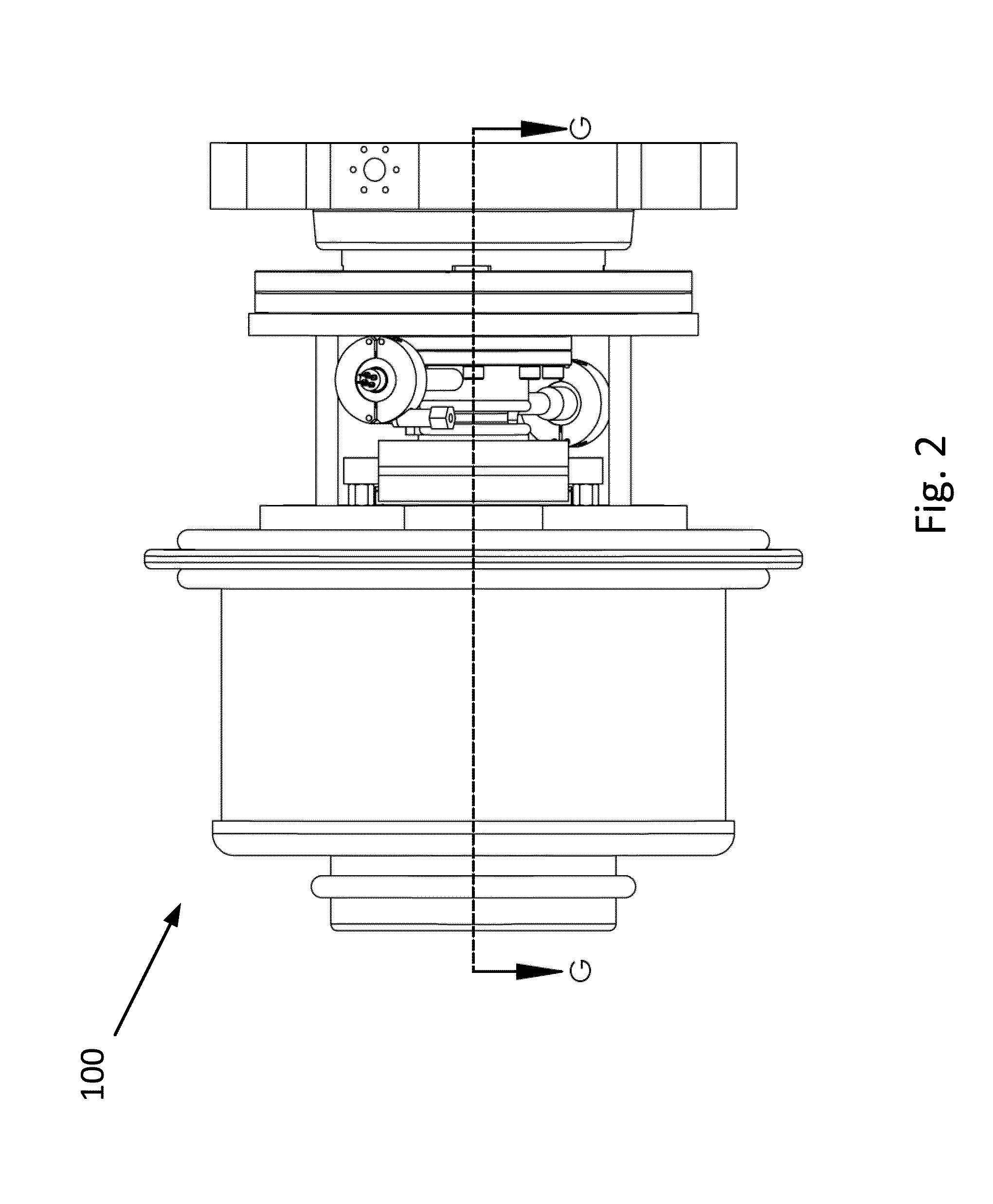

High reliability, long lifetime, negative ion source

A negative ion source includes a plasma chamber, a microwave source, a negative ion converter, a magnetic filter and a beam formation mechanism. The plasma chamber contains gas to be ionized. The microwave source transmits microwaves to the plasma chamber to ionize the gas into atomic species including hyperthermal neutral atoms. The negative ion converter converts the hyperthermal neutral atoms to negative ions. The magnetic filter reduces a temperature of electrons provided between the plasma chamber and the negative ion converter. The beam formation mechanism extracts the negative ions.

Owner:SHINE TECH LLC

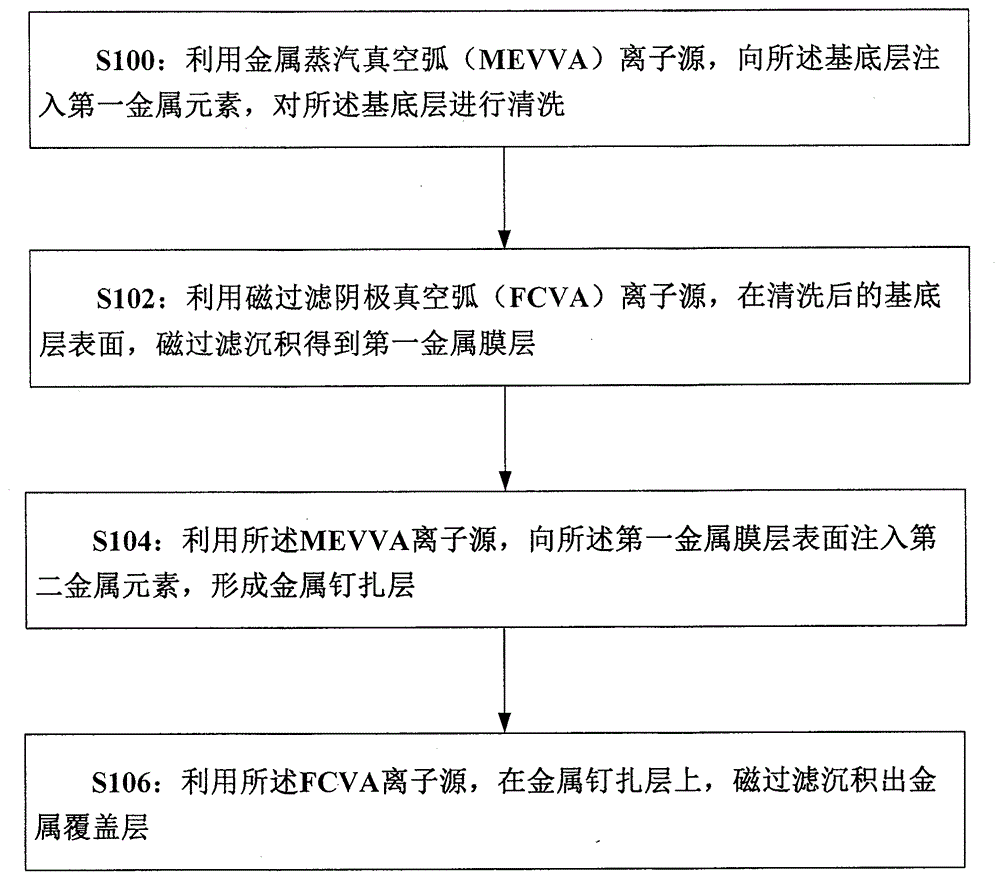

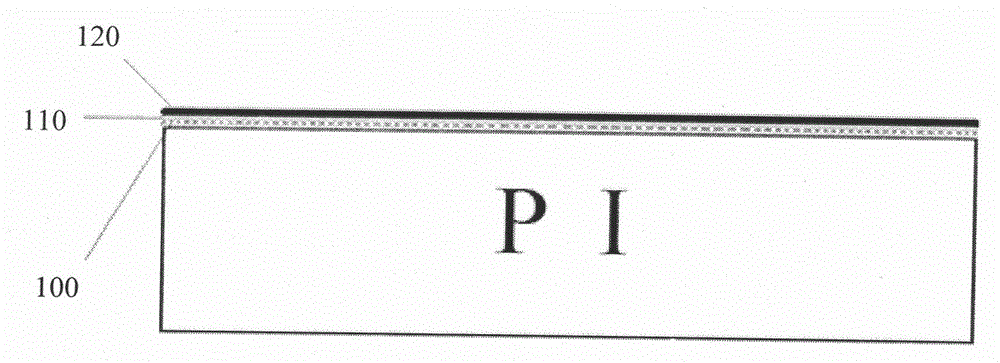

Making methods and apparatuses of flexible substrate circuit board and metal pinning layer

ActiveCN104372295AImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingMetalMaterials science

The invention discloses making methods and apparatuses of a flexible substrate circuit board and a metal pinning layer. The making method of the metal pinning layer comprises the following steps: injecting a first metal element into a substrate layer by using a metal vapor vacuum arc (MEVVA) ion source, and cleaning the substrate layer; carrying out magnetic filtering deposition on the surface of the cleaned substrate layer by using a magnetic filtered cathodic vacuum arc (FCVA) ion source to obtain a first metal film; and injecting a second metal element to the surface of the first metal film by using the MEVVA ion source to form the metal pinning layer. The metal pinning layer and the flexible substrate circuit board made by adopting the making methods and the apparatuses have very high bonding force and peeling resistance.

Owner:BEIJING NORMAL UNIVERSITY

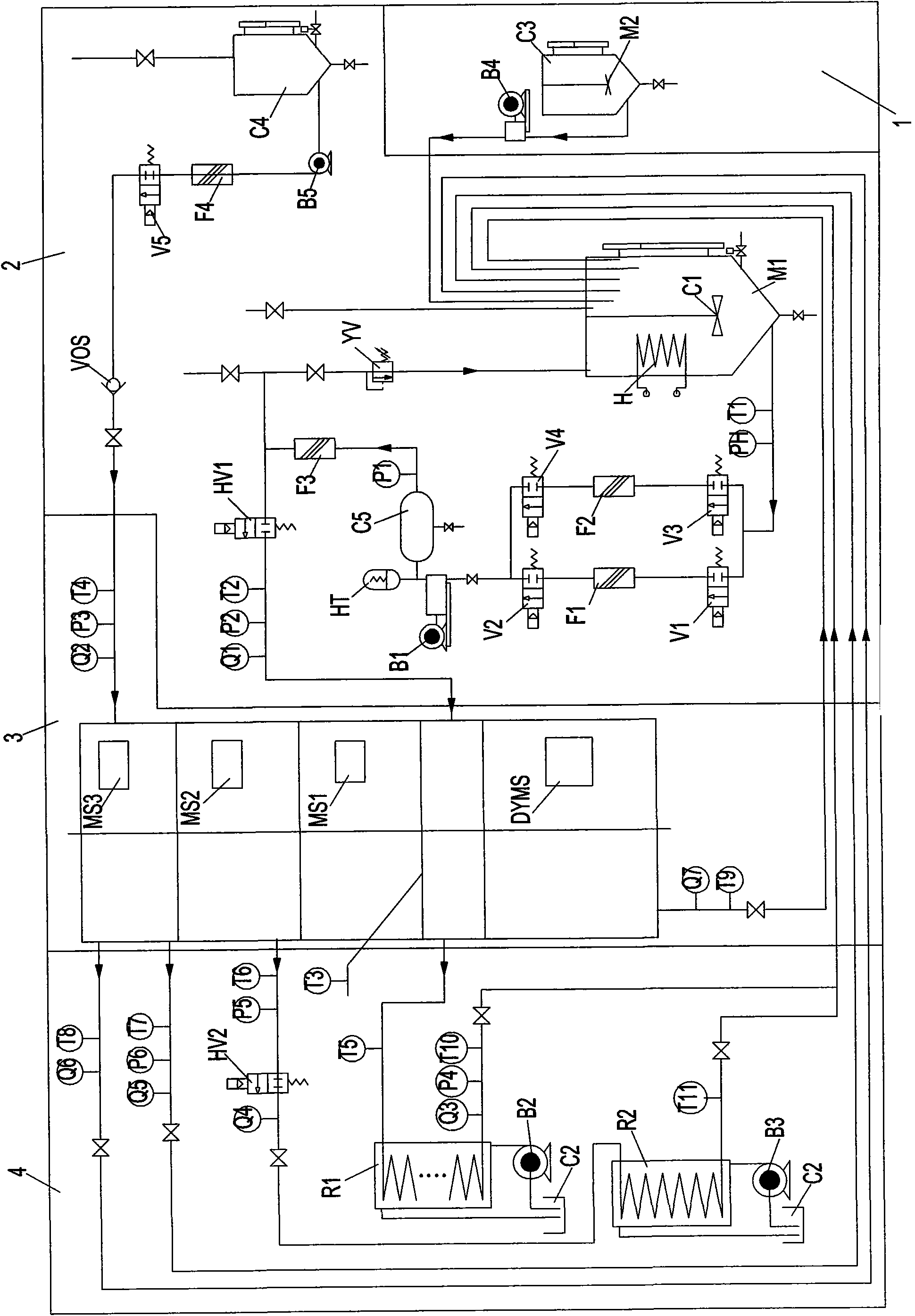

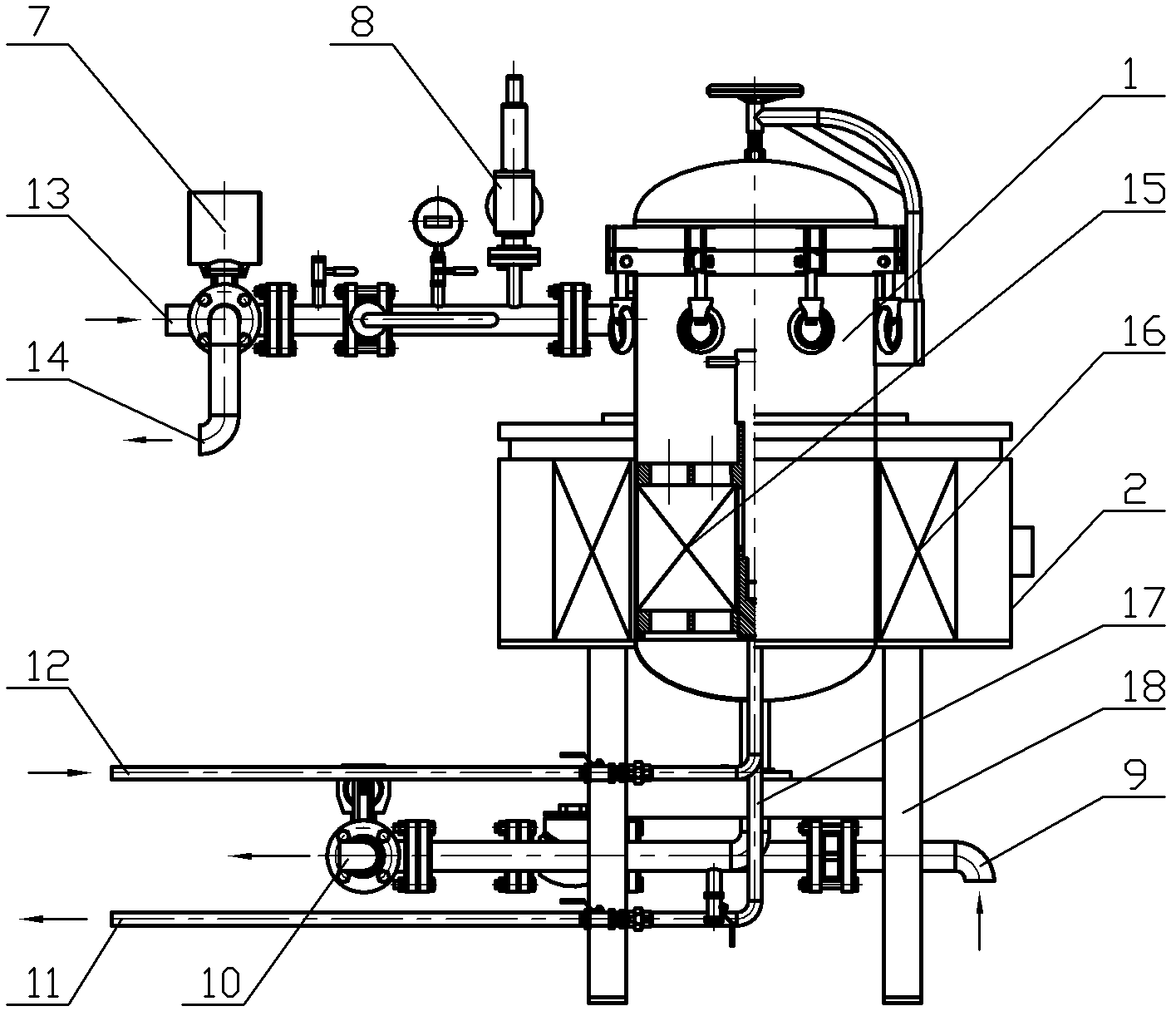

Mechanical seal test system for nuclear main pump

ActiveCN101639396ARealize stepless speed regulationAchieving a soft startFluid-tightness measurement using fluid/vacuumBuffer tankSystem pressure

The invention discloses a mechanical seal test system for a nuclear main pump, which is characterized in that the system comprises a medium concentration control zone, an injection medium processing zone, a frame zone and a reflux medium post processing zone. A test main shaft is used as a driven component in the frame zone; the test shaft is provided with a fluid static pressure seal or a fluid dynamic pressure seal or a fluid dynamic-static pressure combined seal. In the injection medium processing zone, a seal medium flow passage located between a low pressure container and a system seal cavity is respectively provided with a high pressure pump, a high pressure buffer tank and an energy accumulator, which are connected in series with a switchable magnetic filter, an organic filtering film and used,for providing a system pressure source; in the reflux medium post processing zone, a long pipe throttling cooler with a back pressure value is arranged at an outlet of the system seal cavity. The invention not only can simulate a fluid static pressure mechanical seal test for the nuclear main pump, but also can simulate a fluid dynamic pressure mechanical seal test for the nuclear mainpump, at the same time, the invention further can simulate a fluid dynamic-static pressure combined mechanical seal test for the nuclear main pump.

Owner:HEFEI GENERAL MACHINERY RES INST

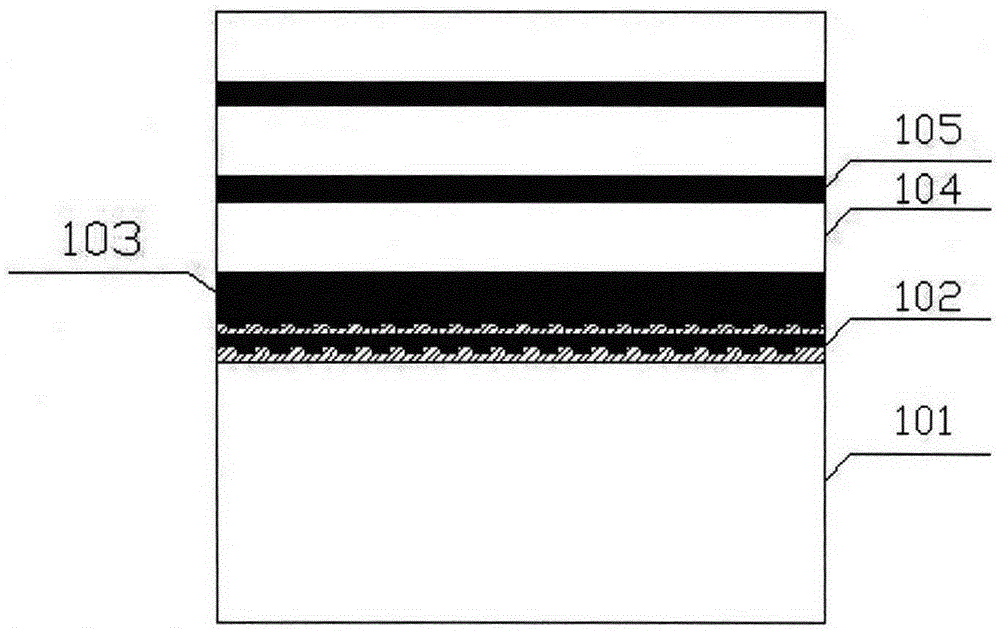

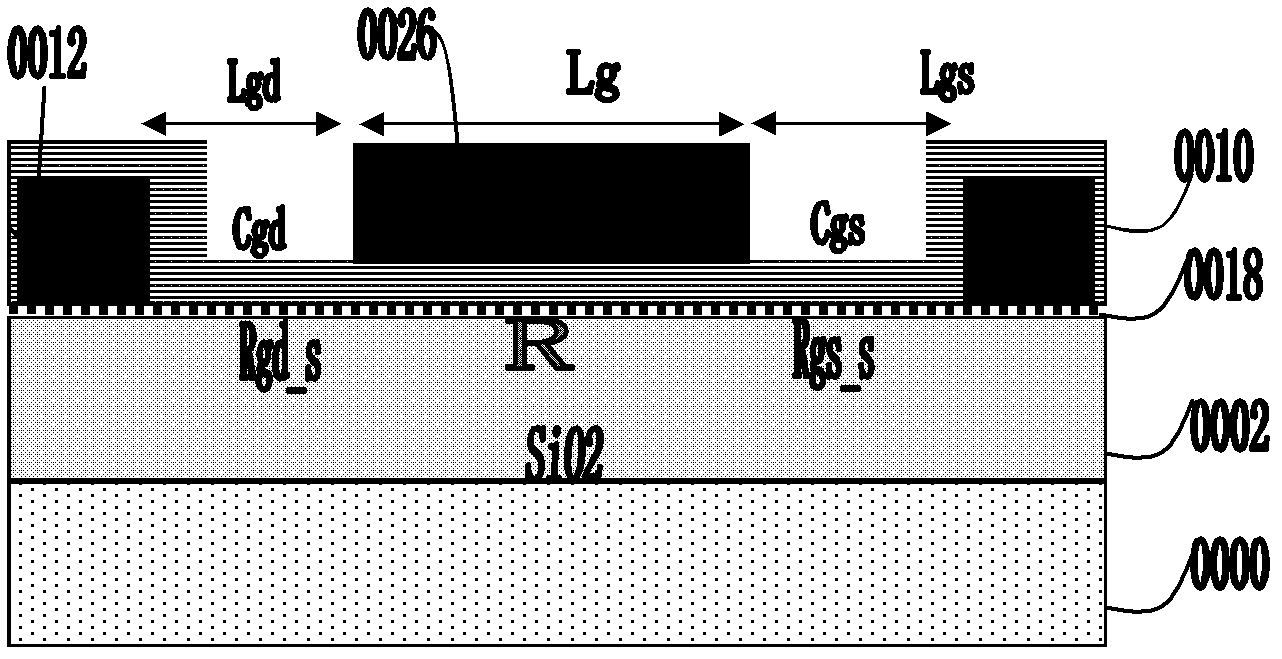

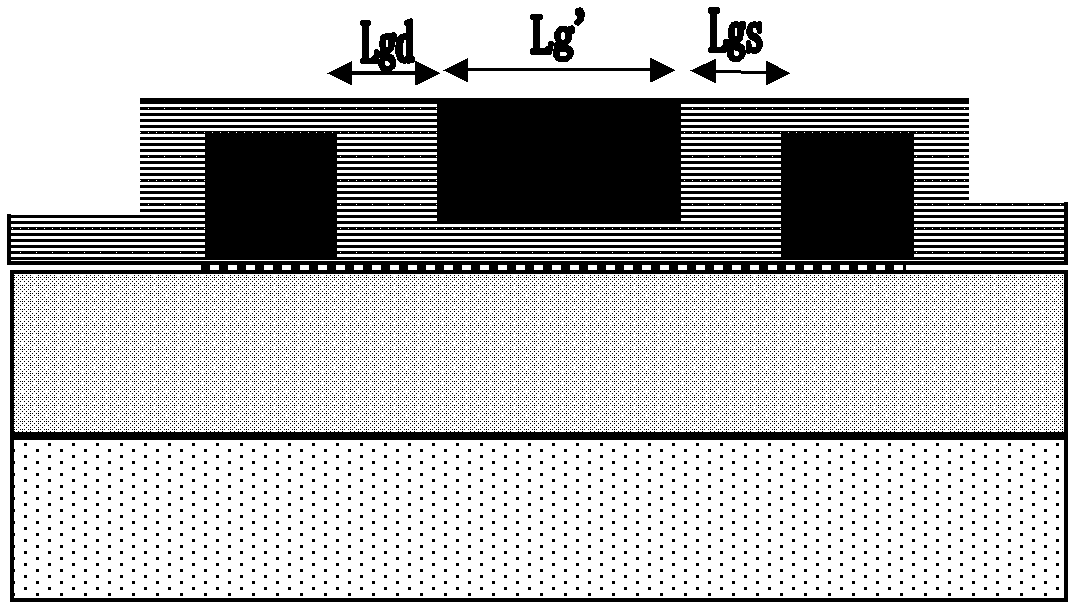

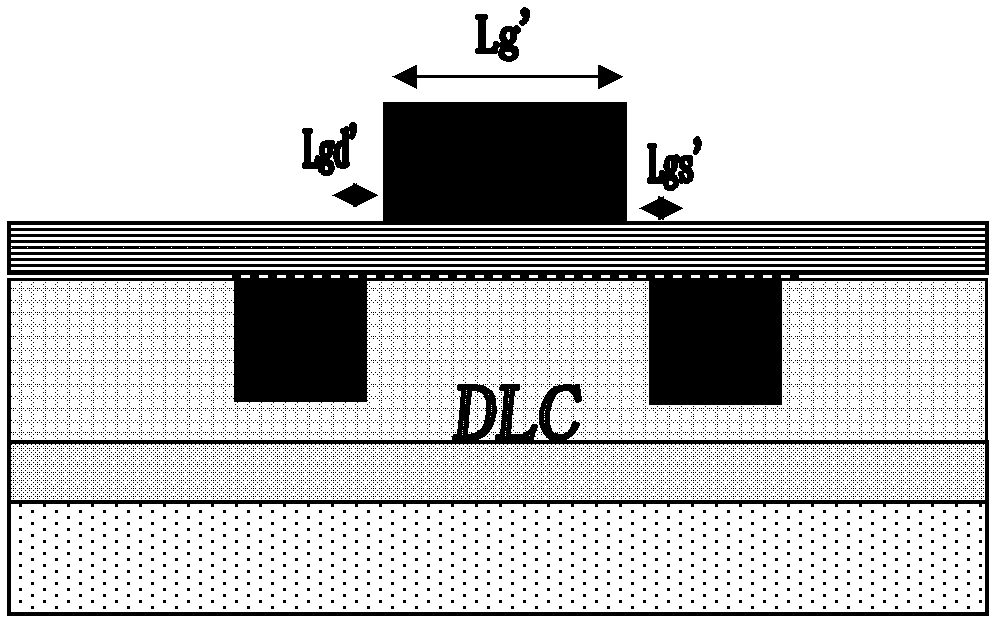

Source-drain buried graphene transistor device on diamond-like carbon substrate and manufacture method

InactiveCN103000669ALower channel resistanceReduce horizontal spacingSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricDiamond-like carbon

A source-drain buried graphene transistor device on a diamond-like carbon substrate and a manufacture method are applicable to radio frequency communication. The manufacture method includes: firstly, depositing a layer of diamond-like carbon amorphous carbon smooth in surface and stable in chemical property on the substrate by the aid of a magnetic filtered cathode vacuum arc system; secondly, etching a source trench and a drain trench on the diamond-like carbon amorphous carbon insulating layer and filling electrode metal into the trenches; thirdly, planarizing and cleaning the surface of the substrate prior to transferring graphene grown by a chemical vapor deposition method to the cleaned substrate; fourthly, growing gate insulating dielectric by an atomic layer deposition method and sputtering gate electrode metal; and finally, forming a metal gate by means of reactive ion etching and depositing low-K insulating dielectric to protect the device. Carrier mobility of a graphene transistor is high, and the source-drain buried structure is capable of decreasing the graphene length of a region uncovered by the gate, so that gate-source capacitance, gate-drain capacitance and channel resistance are reduced, and high-frequency performance and efficiency of the graphene transistor are improved. The source-drain buried graphene transistor device can be widely applied to small-sized high-frequency graphene integrated circuits.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

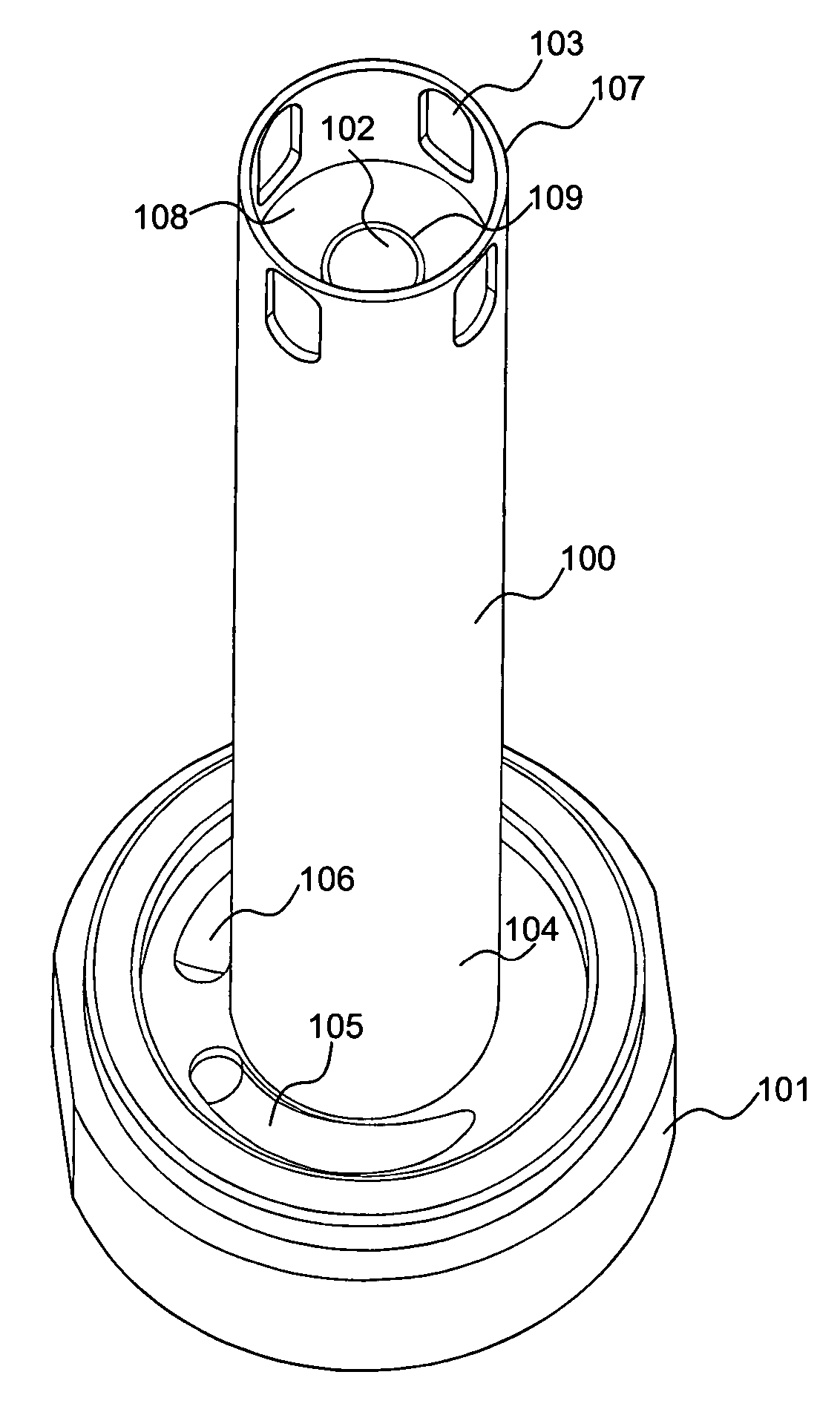

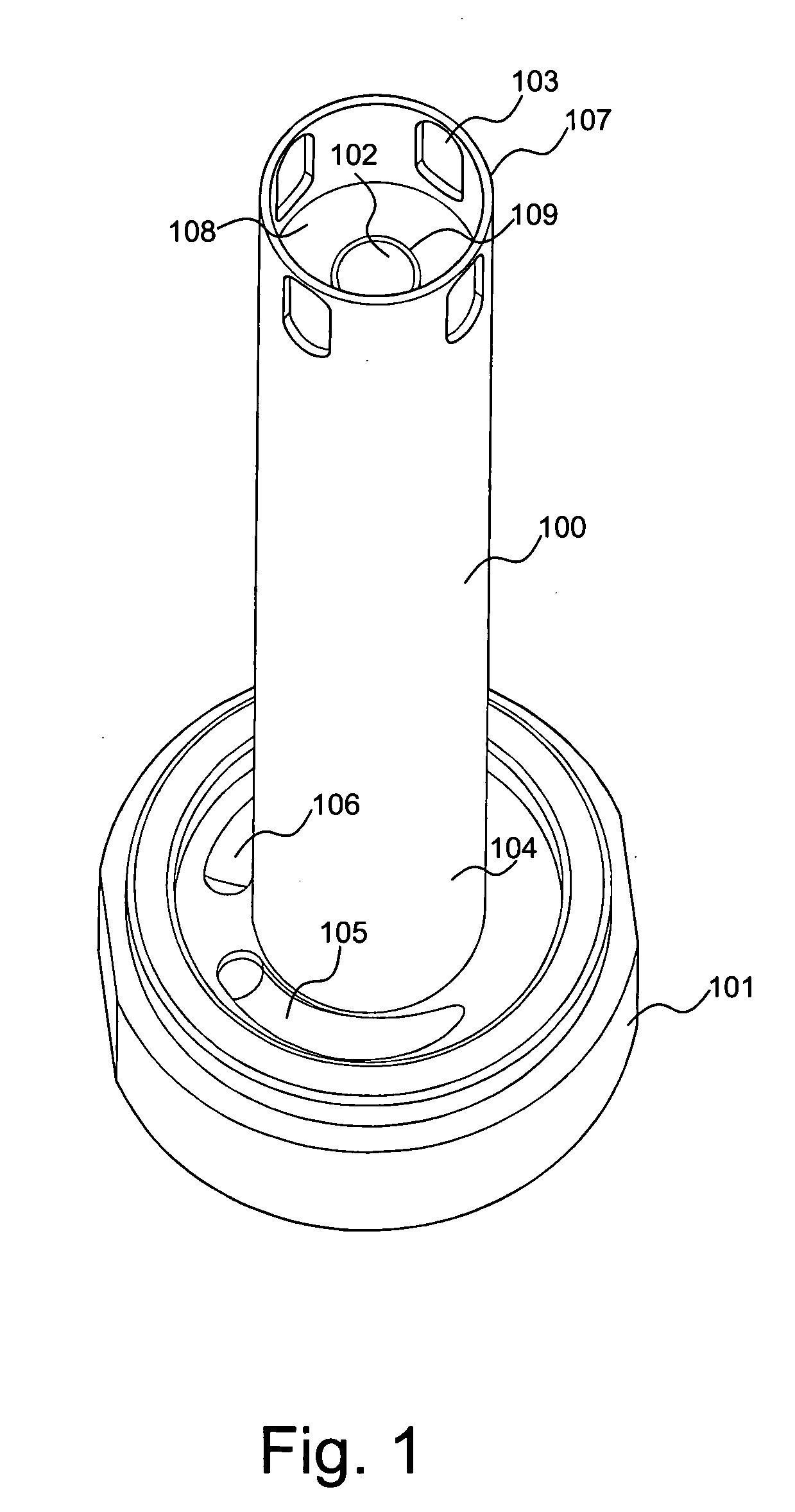

Magnetic Filter for Refining and Chemical Industries

ActiveUS20130240455A1Easy to separateElectrostatic separationWater/sewage treatment by magnetic/electric fieldsChemical industrySludge

A magnetic filter employs a magnetic core assembly that incorporates a plurality of exchangeable holder sleeves, each enclosing permanent magnets. Neither the sleeves nor magnetic bars are mechanically fixed to the filter housing. The magnet bars and holder sleeves are individually accessible. The number of holder sleeves in the magnetic core assembly is flexible. The magnetic filter in equipped with a screen that partially encloses the elongated holder sleeves to treat streams that contain degradation sludge, iron containing particles or flakes, and non-magnetic polymeric materials. In operation, a feed stream initially contacts the magnetic core assembly where paramagnetic contaminants become deposited onto the exterior surface of the holder sleeves under direct influence of strong magnetic field generated by the magnet bars. The mesh screen cylinder subsequently captures non-magnetic and weakly magnetic contaminants of a certain size before the cleaned stream exits the magnetic filter.

Owner:CPC CORPORATION +1

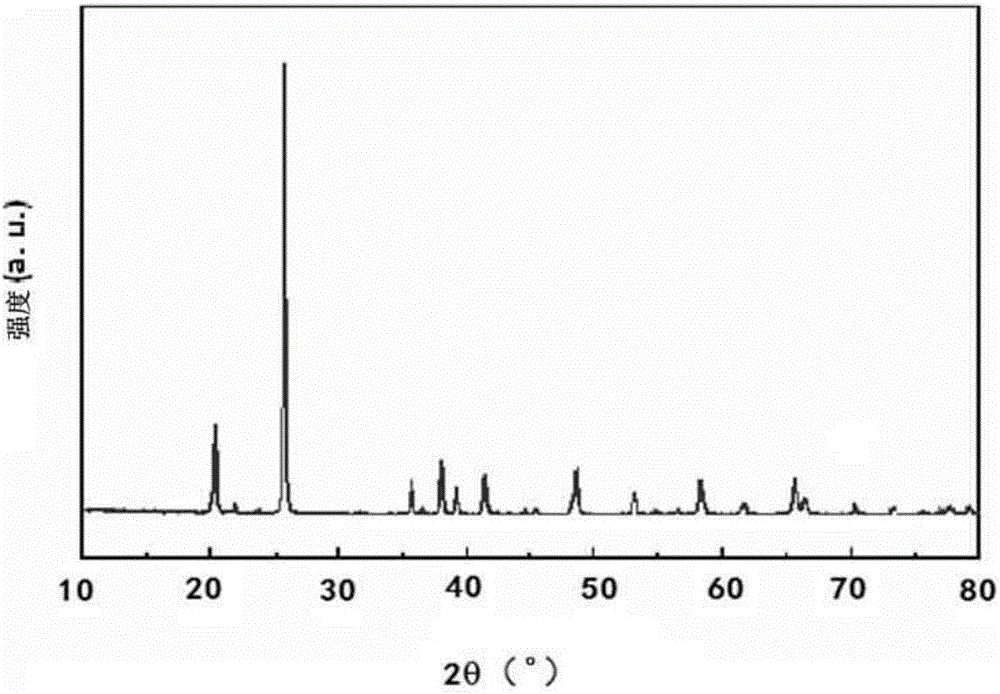

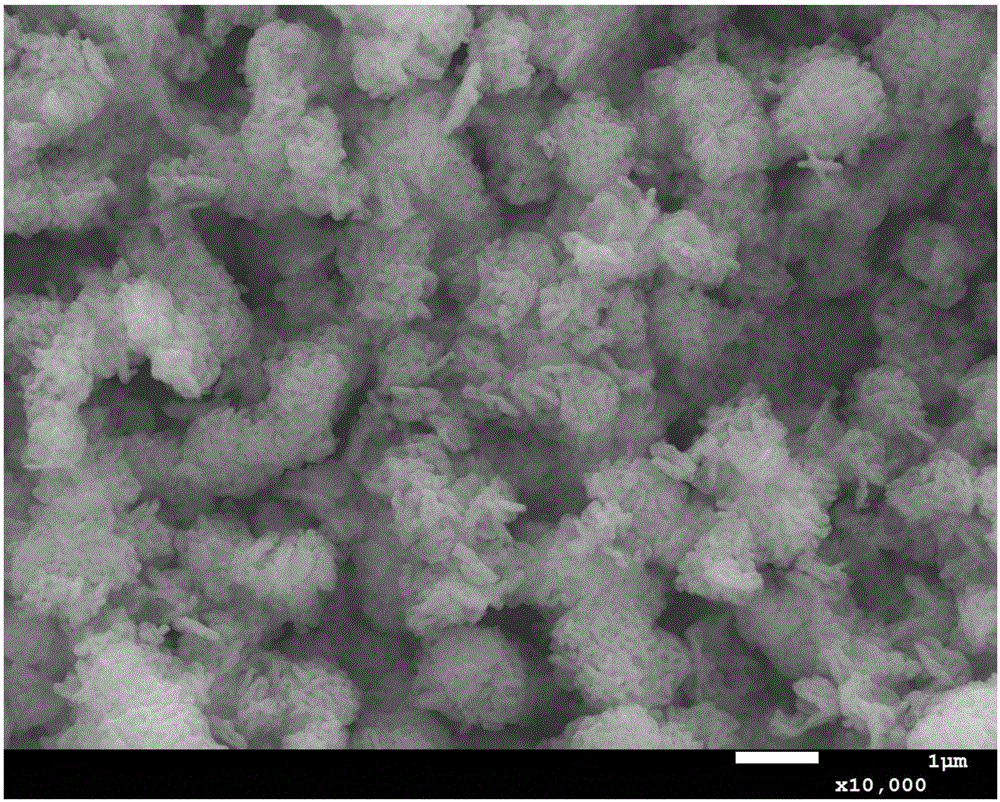

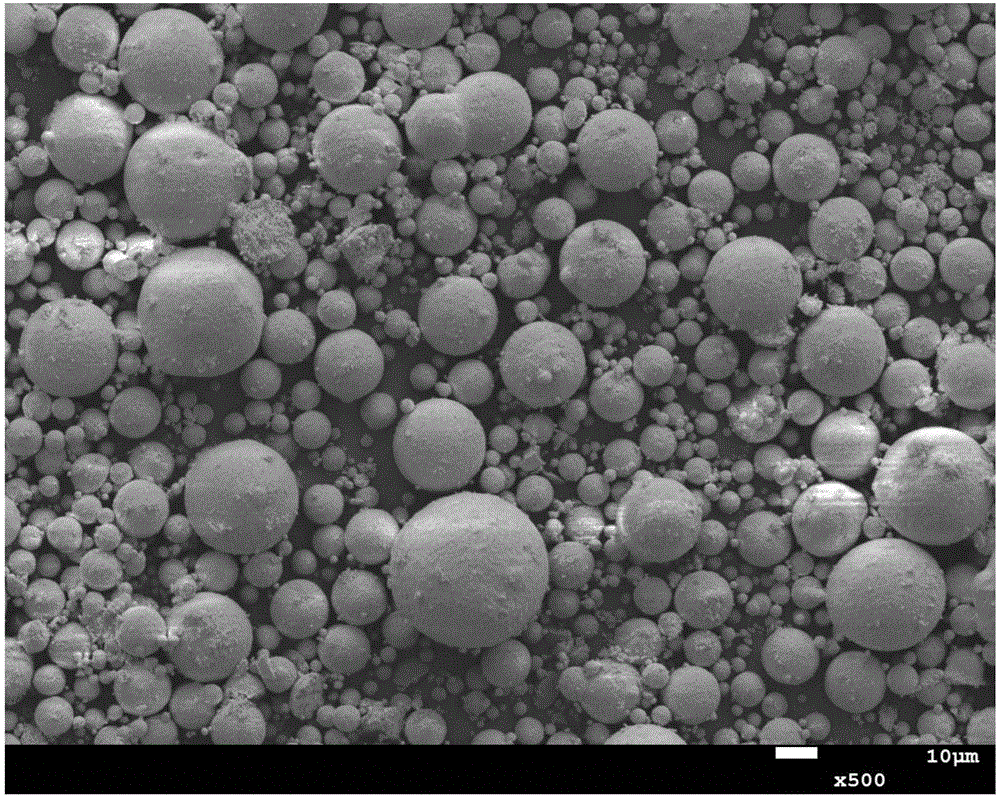

Preparation method of nano spherical ferric phosphate as well as nano ferric phosphate prepared by the method, lithium ferric phosphate and lithium battery

ActiveCN107522188AControllable particle sizeUniform particle size distributionCell electrodesNanotechnologyPhosphate productLithium-ion battery

The invention discloses a preparation method of nano spherical ferric phosphate as well as nano ferric phosphate prepared by the method, lithium ferric phosphate and a lithium battery. The method comprises the following steps: mixing: dropwise adding a mixed solution consisting of a phosphorus source compound solution and an oxidant solution into a soluble ferrous compound solution, adding a nano spherical control agent, and stirring and mixing; reacting: stirring at 50 to 100 DEG C under a refluxing condition, and reacting for 5 to 10 h; filtering: magnetically filtering the mixed solution after the reaction by adopting a high magnetic filter, press filtering the filtered solution, and obtaining a ferric phosphate crude product; and calcining: calcining for 24h at 650 to 850 DEG C under the protection of inert gas, and cooling to obtain a final ferric phosphate product. By adopting the method, the morphology of the ferric phosphate product can be controlled, and the performance of the lithium ferric phosphate can be improved.

Owner:YOSHIHIRO COMM EQUIP GRP CO LTD

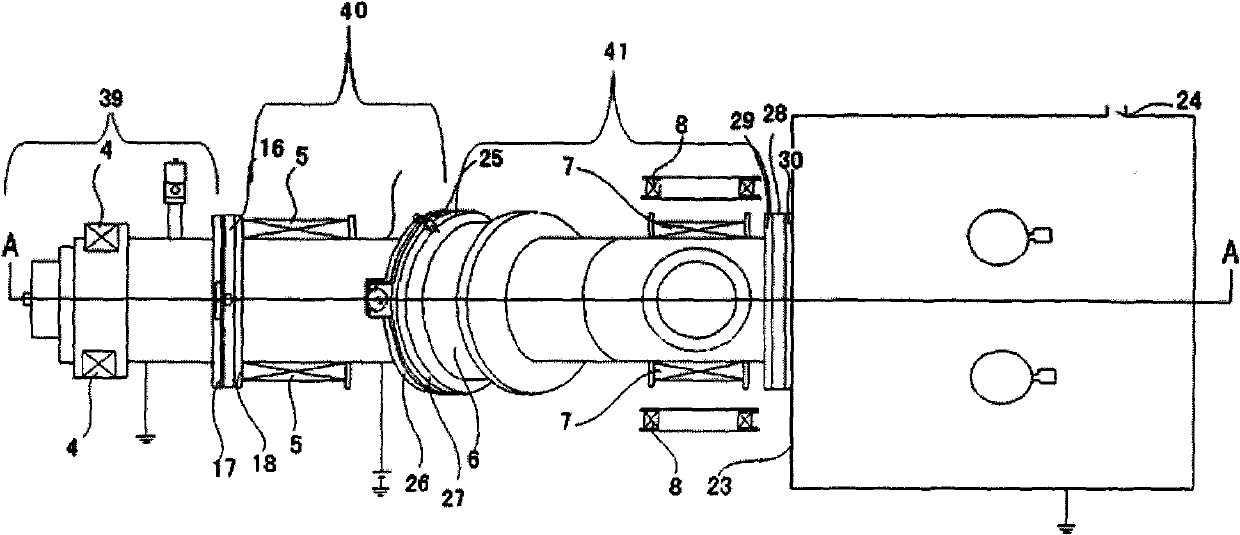

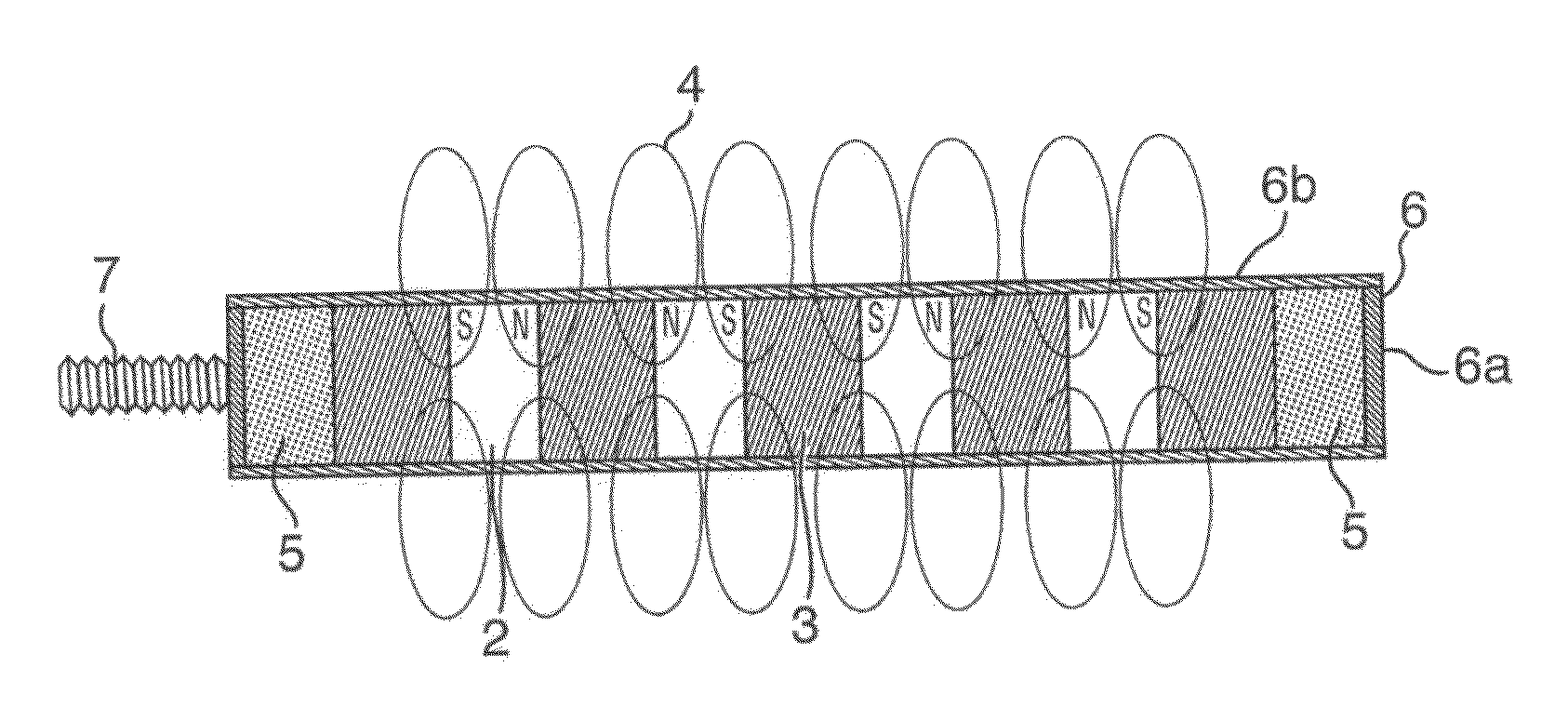

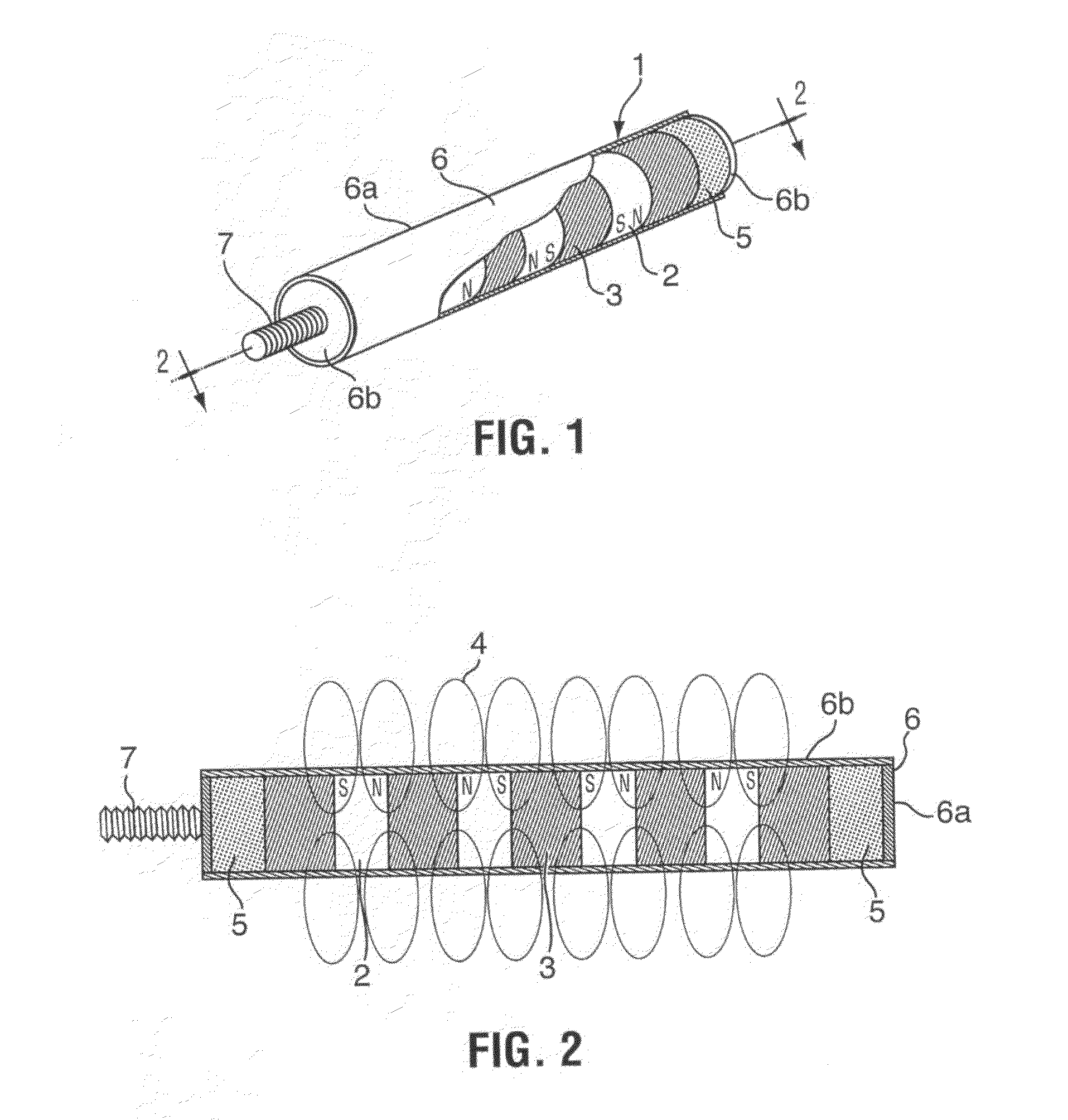

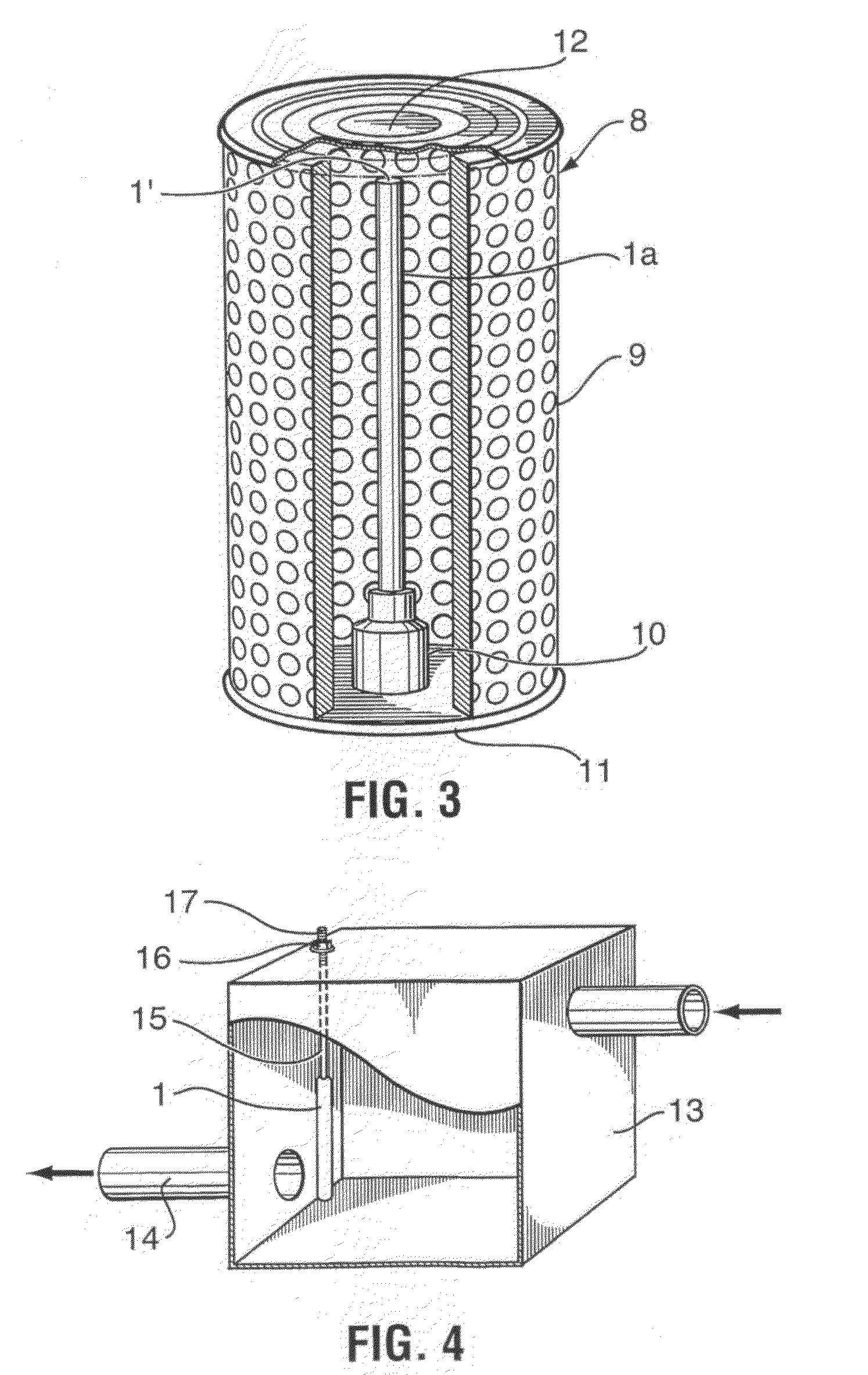

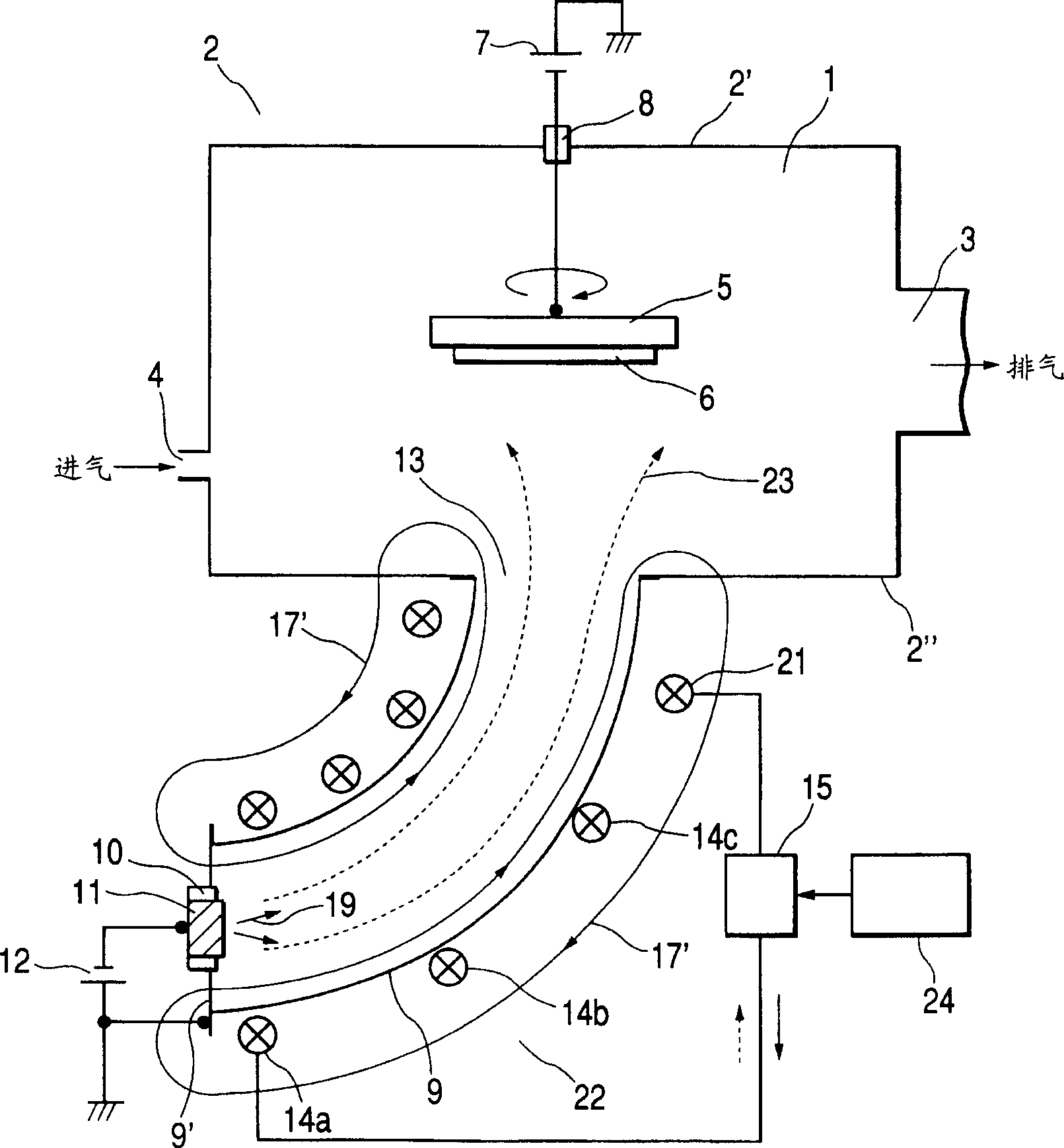

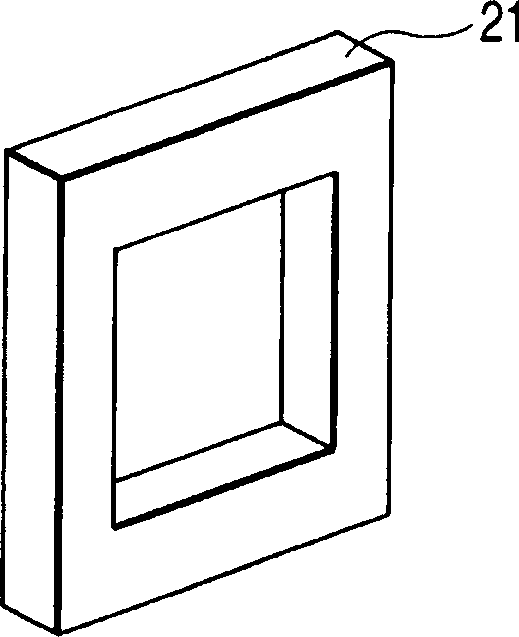

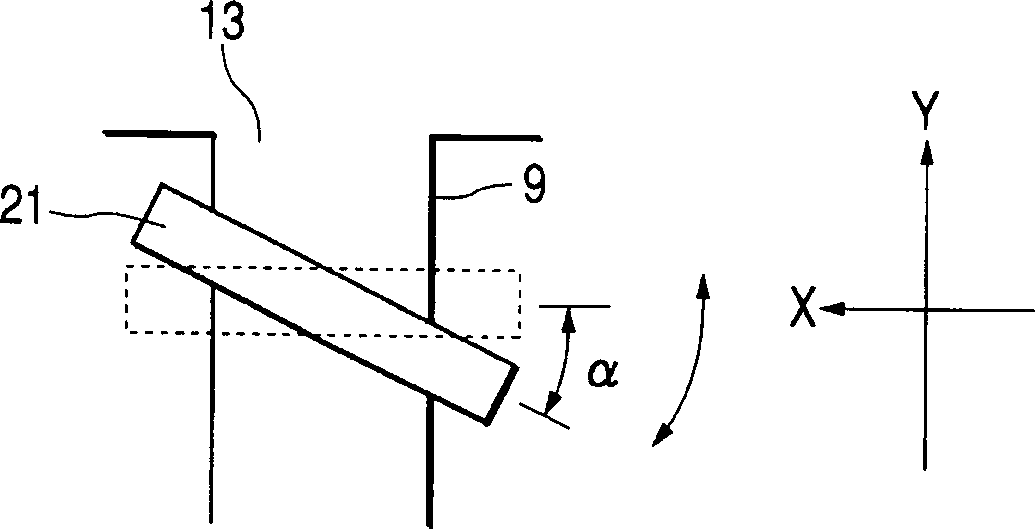

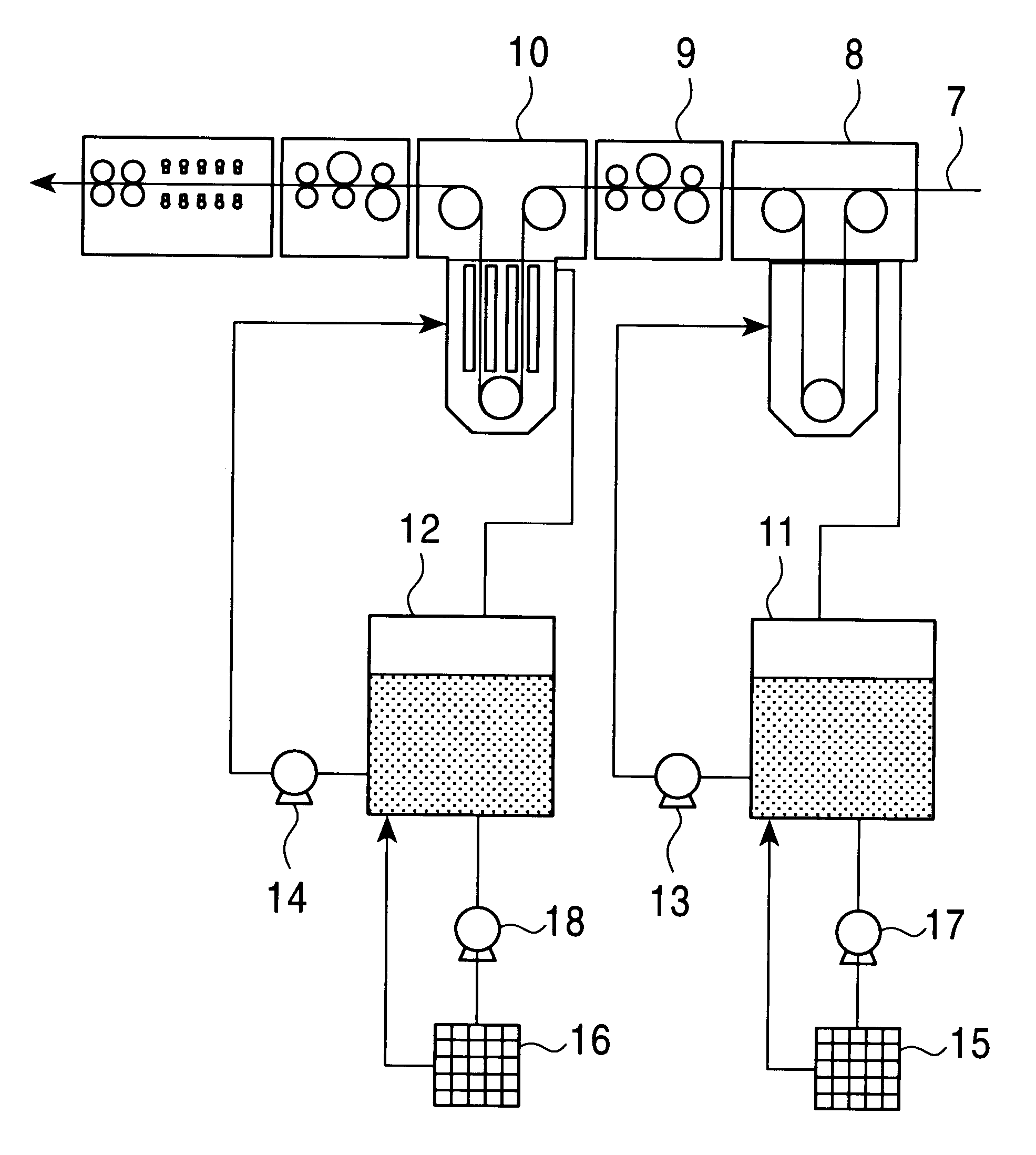

Method and device for vacuum arc vapour deposition

To prevent the film forming characteristic deterioration by a magnetic field of a magnetic filter to thereby make vacuum arc vapor deposition uniform, in the invention, plurality of magnets includes a terminal magnet closest to a plasma injection hole located at the other end of duct and specified magnets. The terminal magnet located closest to plasma injection hole may be set to incline to a plasma injection plane of the plasma injection hole. Further, at lease one of specified magnets may be inclined to the plasma injection plane. Further more, at least one of magnetic field generating coils may be formed with a plurality of electromagnetic coils, which are inclined at different angles with respect to a cross section of the duct. One of electromagnetic coils may be selectively energized by current on a basis of setting and controlling of deflection magnetic field generated by the magnetic filter.

Owner:NISSIN ELECTRIC CO LTD

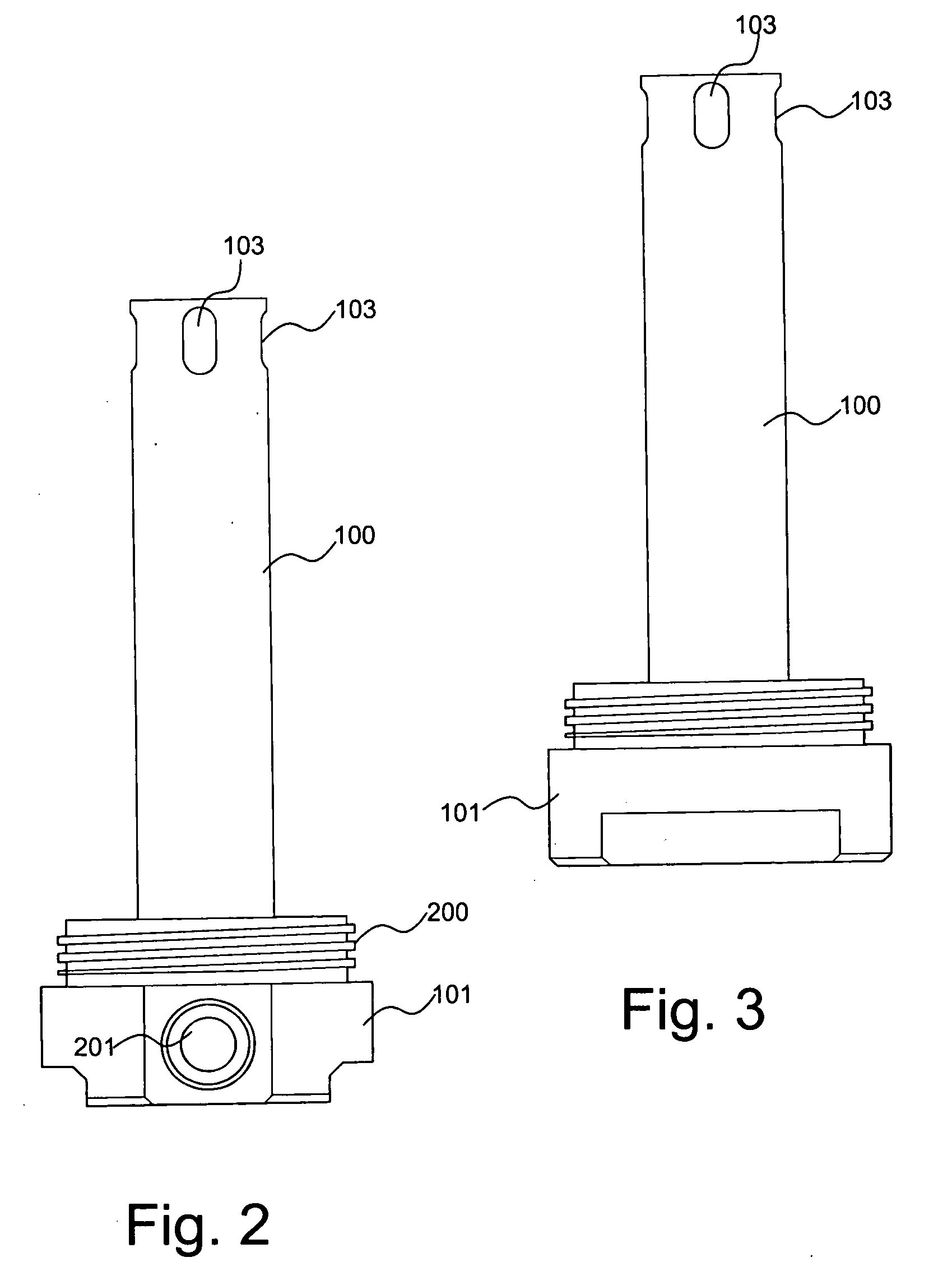

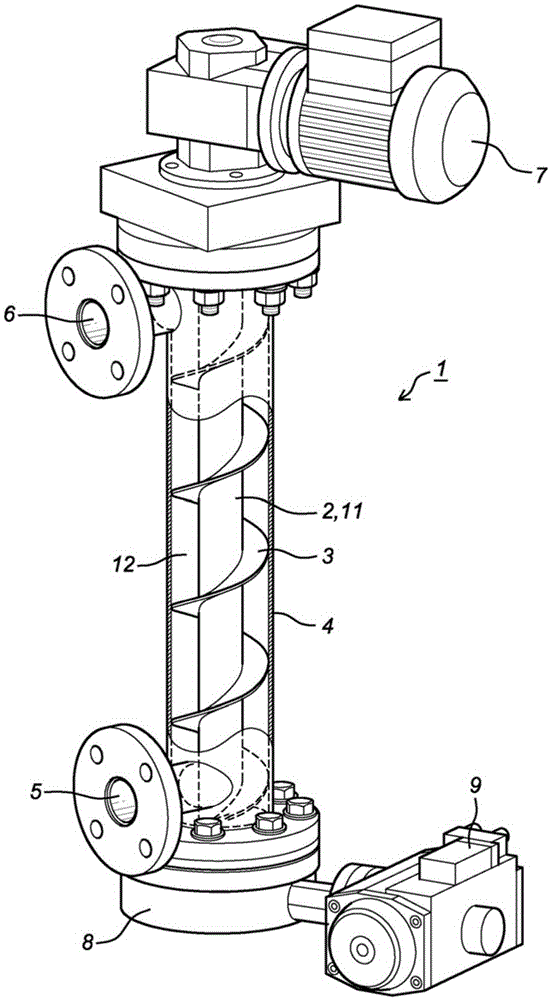

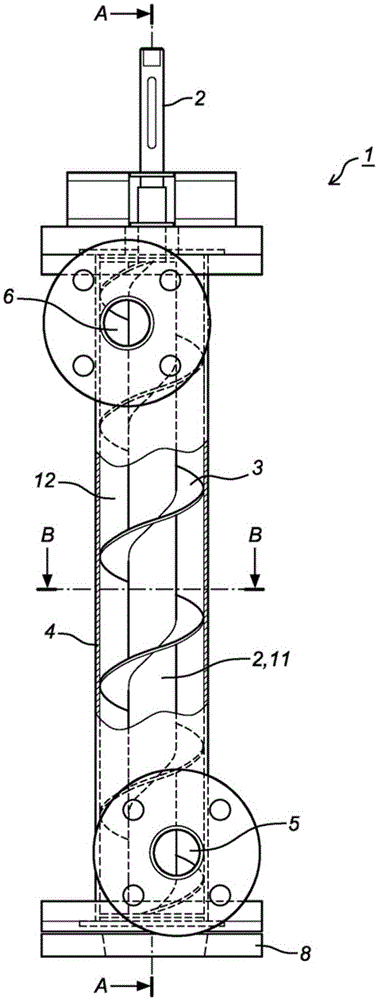

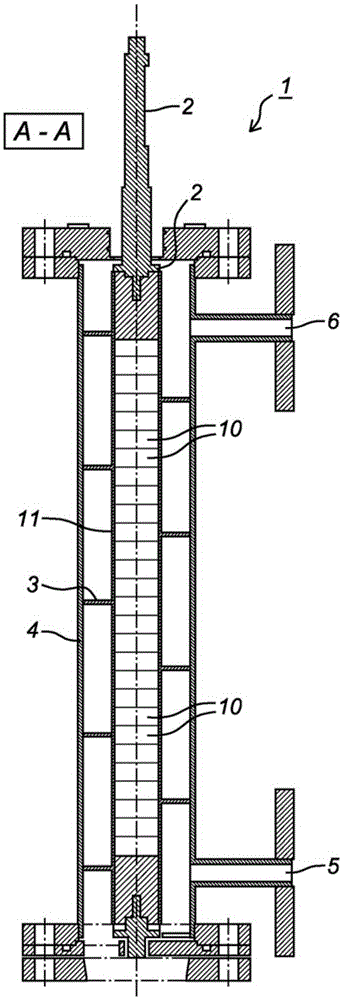

Filter device and method for removing magnetizable particles from a fluid

ActiveCN105392566AEasy to joinSimple structureHigh gradient magnetic separationElectrostatic separationEngineeringMagnetic filter

The invention relates to an improved magnetic filter device (1) for separating a fluid and magnetizable particles. The invention also relates to a method for separating a fluid and magnetizable particles, particularly by making use of a device (1) according to the invention.

Owner:艾瑟林解决方案责任有限公司

Method and equipment for prolonging life of push rod component in aerospace relay

ActiveCN105755443AImprove bindingHigh peel strengthVacuum evaporation coatingSputtering coatingWear resistantBinding force

The invention discloses method and equipment for prolonging the life of a push rod component in a sealed relay. In the method, a superhard wear-resistant film layer with good insulating property is deposited on the surface of a push ball in the push rod component by a low-energy ion beam technology; and the film is prepared by the following steps: injecting a layer of metal 'pinning layer' capable of improving binding force of the film into glass surface by a metal vapor vacuum arc (MEVVA) ion source method; depositing a first metal film transition layer for releasing internal stress on the metal 'pinning layer' by a magnetic filtered cathodic vacuum arc (FVCA) deposition method; and depositing a superhard wear-resistant DLC layer on the first transition layer by the magnetic FVCA deposition method, wherein the total thickness of the film is 0.1-5 microns. Through the invention, the life of the push ball in the push rod component of the sealed relay can be obviously prolonged by depositing the superhard DLC film on the push rod component of the sealed relay.

Owner:BEIJING NORMAL UNIVERSITY

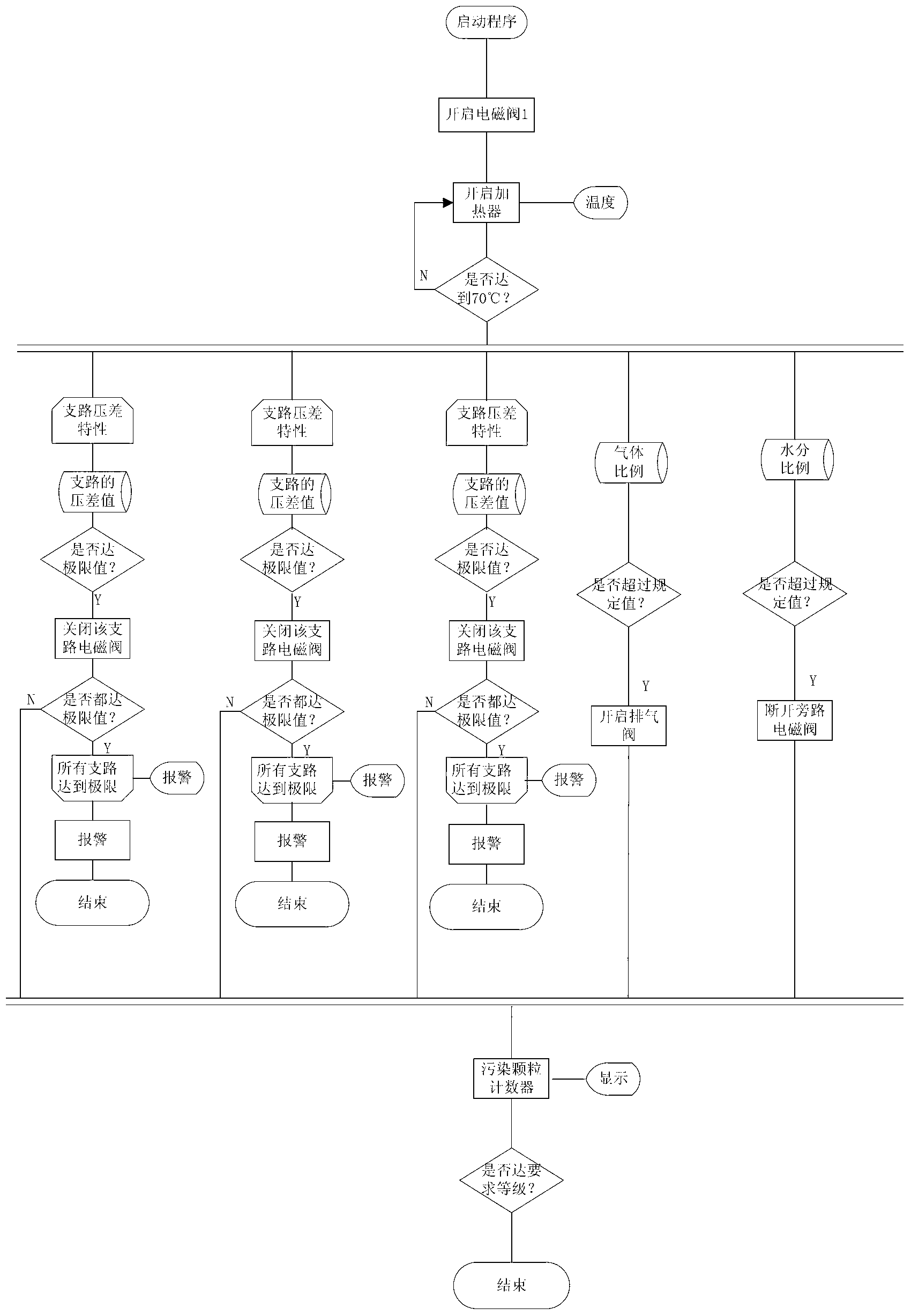

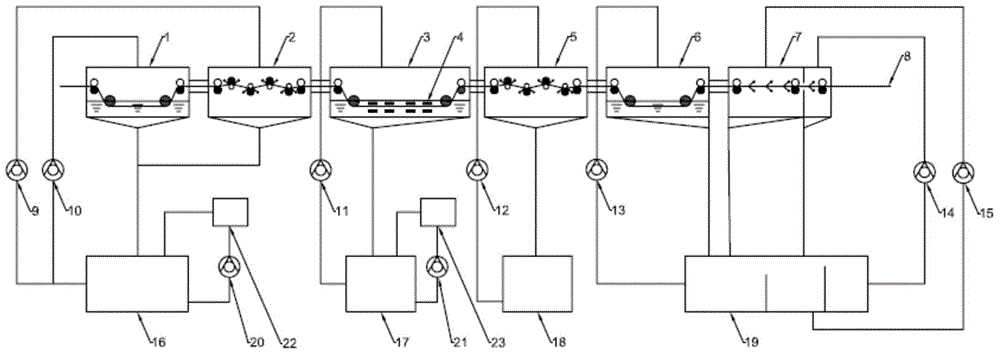

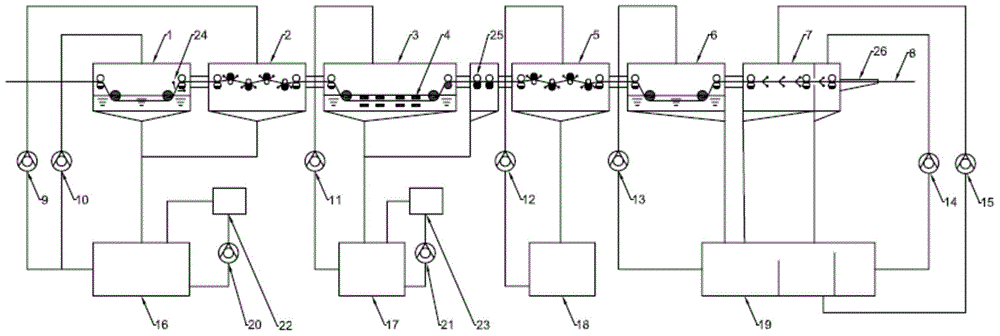

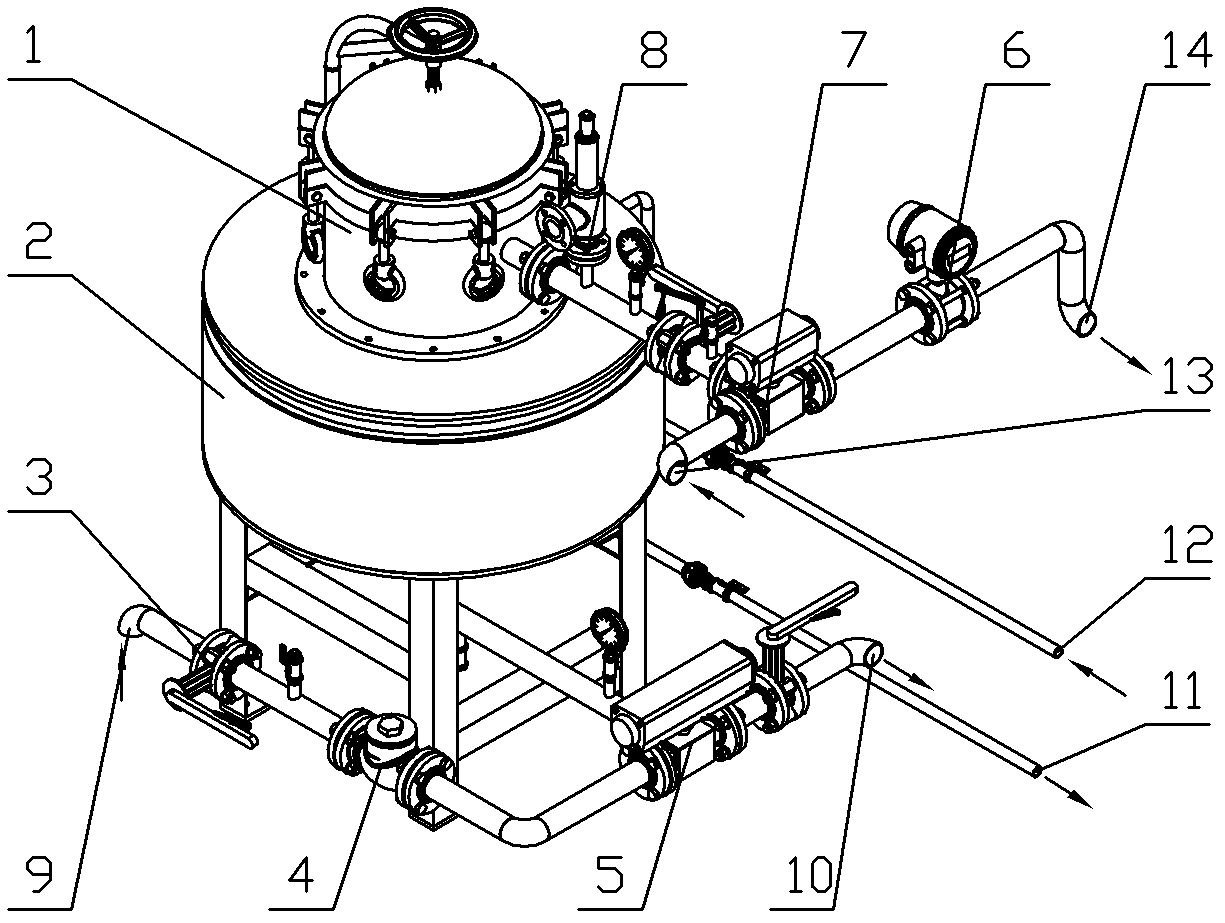

Method for filtering and purifying hydraulic oil

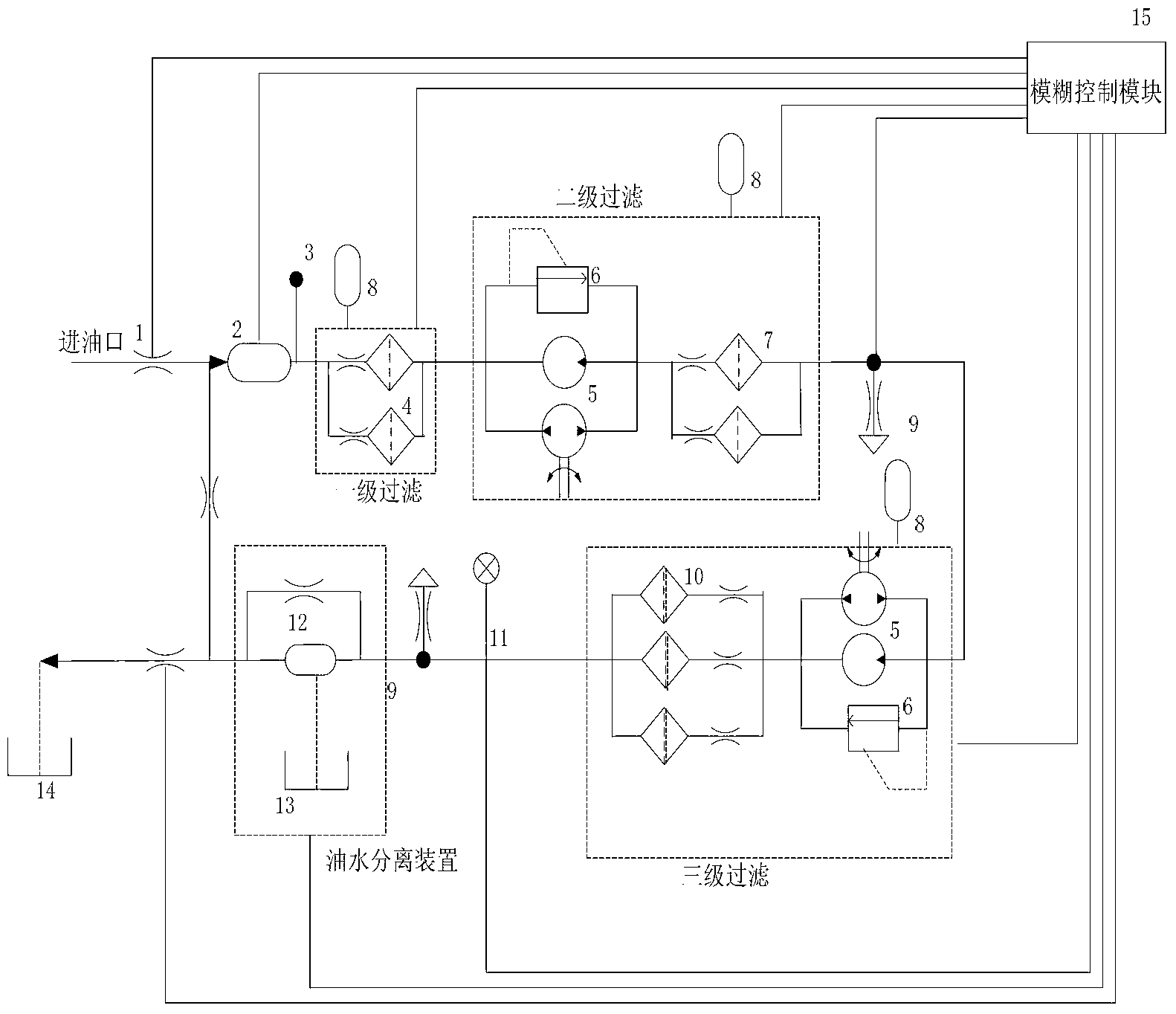

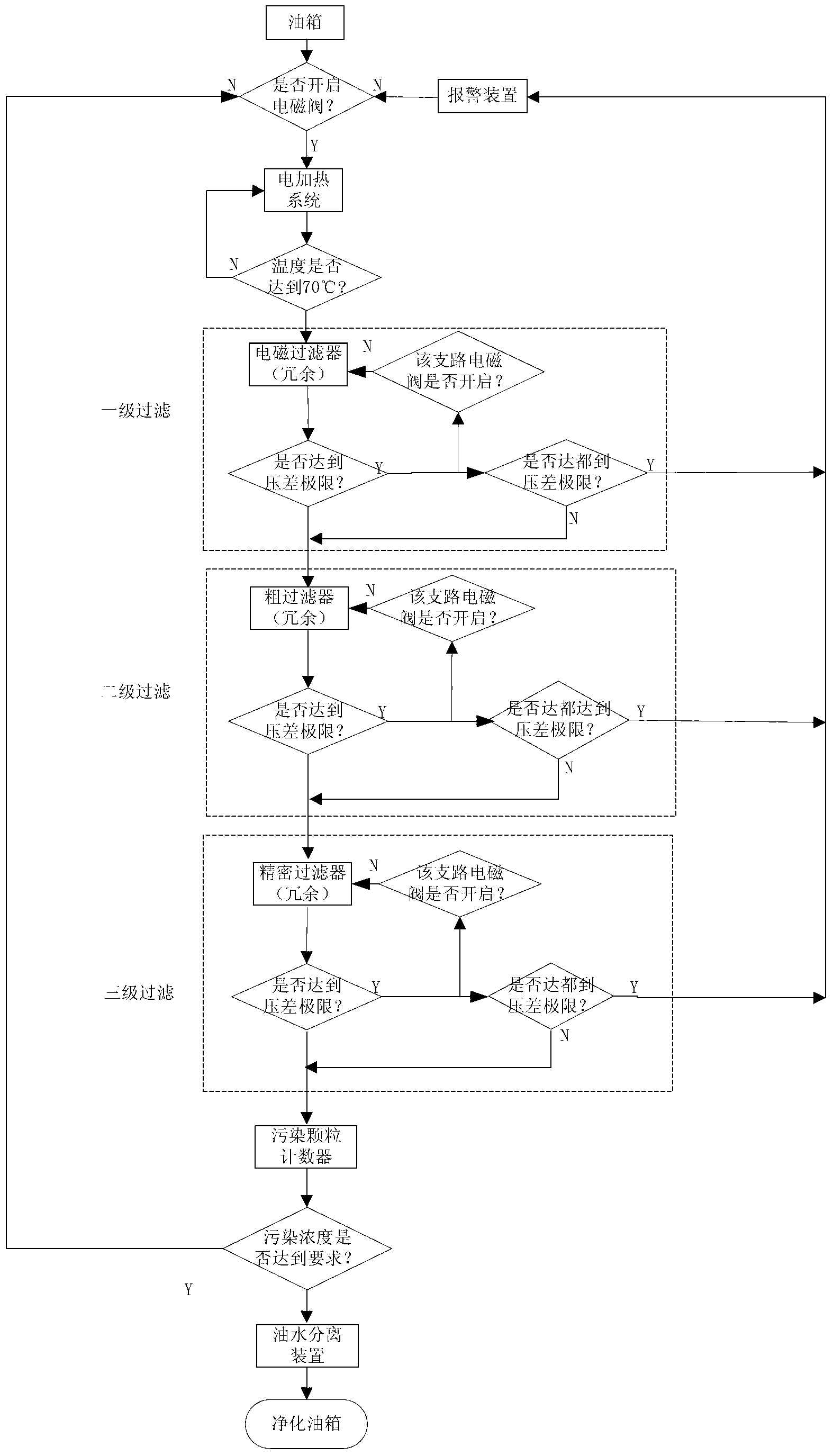

InactiveCN103321988AImprove reliabilityHigh reliabilityFluid-pressure actuator componentsExhaust valveSolenoid valve

A method for filtering and purifying hydraulic oil comprises the steps of (1) using an electrical heating system for heating oil to 60 DEG C; (2) performing primary filtering through a first filtering device which comprises novel high-gradient electromagnetic filters connected in parallel so as to filter ferromagnetic corrosion products in the oil and macromolecules generated by oxidation during usage of the hydraulic oil; (3) performing secondary filtering through a second filtering device to remove large solid particles; (4) subjecting the oil to tertiary filtering through a third filtering device which comprises common parallelly-connected filters high in filtering accuracy to form redundancies; (5) opening exhaust valves which are mounted after filtering of all stages to remove gas impurities in the oil and bubbles generated during filtering; (6) removing moisture in the oil through an oil-water separation system; (7) monitoring the oil cleanliness class in real time through a contamination particle counter, and closing a solenoid valve of an oil return pipe when the purification class requirement is reached.

Owner:BEIHANG UNIV

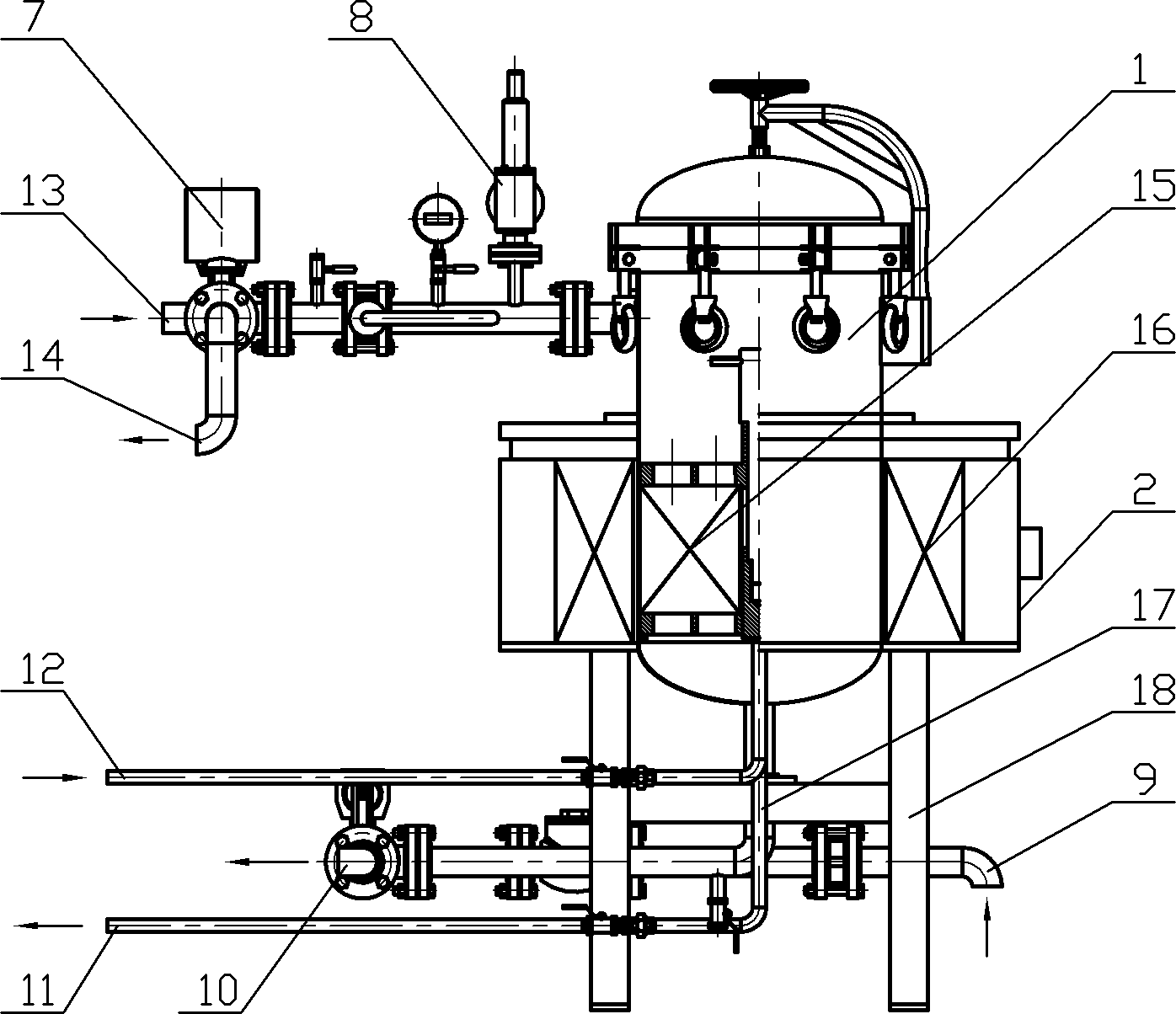

Improved silicon steel plate belt surface cleaning device and cleaning method

InactiveCN104962942AAvoid cloggingAvoid Poor Surface CleaningCleaning using toolsCleaning using liquidsElectrolysisSurface cleaning

The invention discloses an improved silicon steel plate belt surface cleaning device and cleaning method, and aims at providing a cleaning device and cleaning method which can effectively prevent the situation that alkaline leaching liquid flotage is brought in an alkaline washing tank to block nozzles and can avoid the situations that the silicon steel plate belt surface cleaning quality is poor due to the fact that high-speed running belt steel brings alkaline liquid in an electrolysis cleaning tank into a water washing tank, and much inconvenience is brought to equipment maintenance and field safety environment due to water overflowing of the outlet side of a water rinsing tank. The cleaning device comprises an alkaline leaching tank, an alkaline washing tank, an electrolysis cleaning tank, a water washing tank, a water leaching tank, a water rinsing tank, a circulating system and a magnetic filter system. The alkaline leaching tank, the alkaline washing tank, the electrolysis cleaning tank, the water washing tank, the water leaching tank and the water rinsing tank are connected in sequence and matched with the circulating system and the magnetic filter system. The cleaning device is characterized in that a pair of nozzles is arranged in a belt steel upgoing area on the outlet side of an inner cavity of the alkaline leaching tank.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Electromagnetic filter

ActiveCN102512868AImprove adsorption capacityHighly AbsorptiveFiltration separationMagnetic tension forceElectromagnetic interference

The invention relates to an electromagnetic filter which comprises a filter with a liquid inlet and a liquid outlet; a magnetic conductive grid is arranged in the cylinder body of the filter; an electromagnetic coil casing is sleeved outside the cylinder body of the filter; and an electromagnetic coil is mounted in the electromagnetic coil casing, and surrounds the periphery of the magnetic conductive grid. In the invention, the magnetic conductive grid is taken as a filter element, a gradient magnetic filed is formed inside the magnetic conductive grid under the action of the electromagnetic coil, an electromagnet is formed, the magnetic filed intensity is high, the magnetic force distribution is uniform, the adsorbability of the filter element is strong, and the filtering efficiency is high.

Owner:SHANGHAI FINETAC PRECISION TECH CO LTD

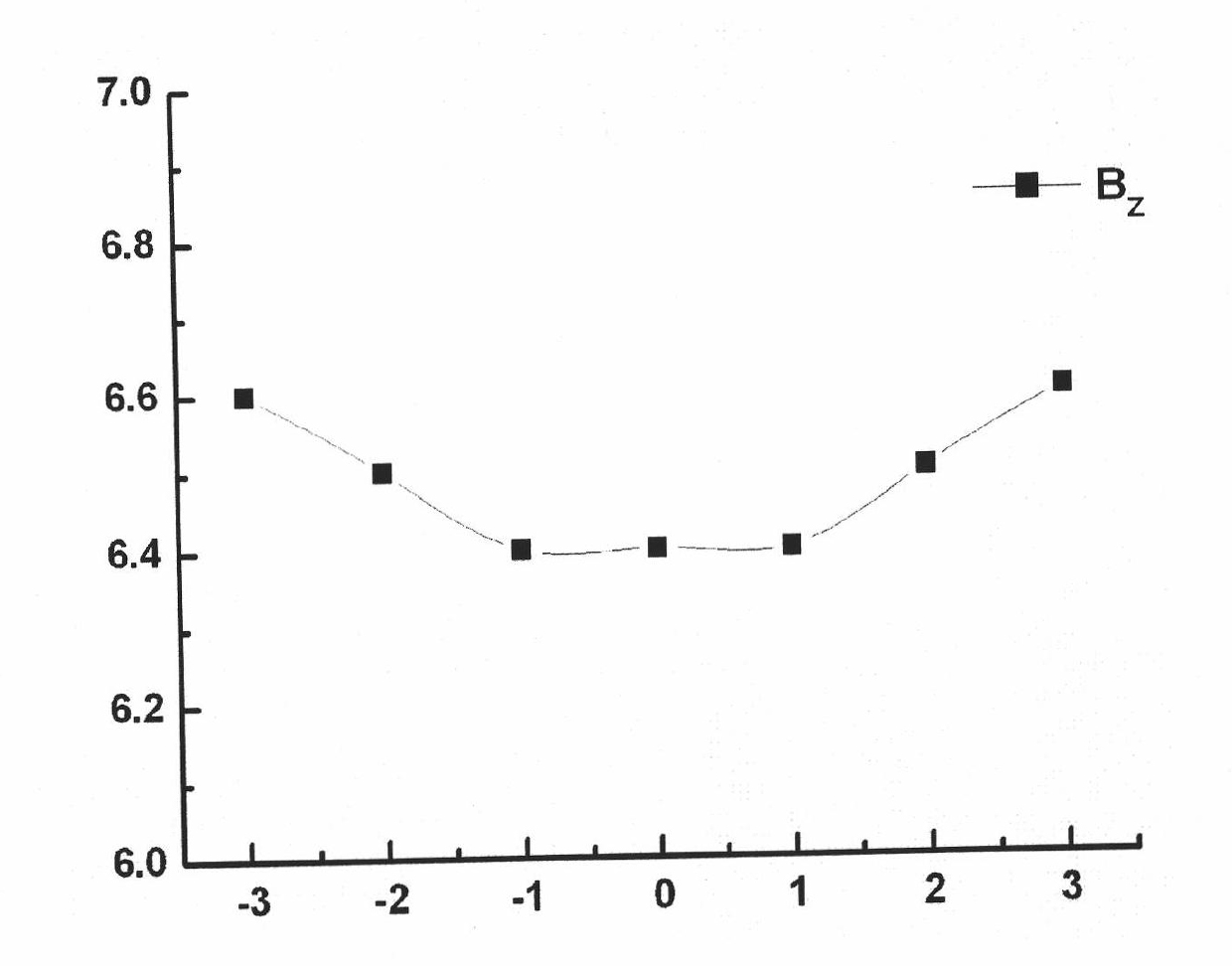

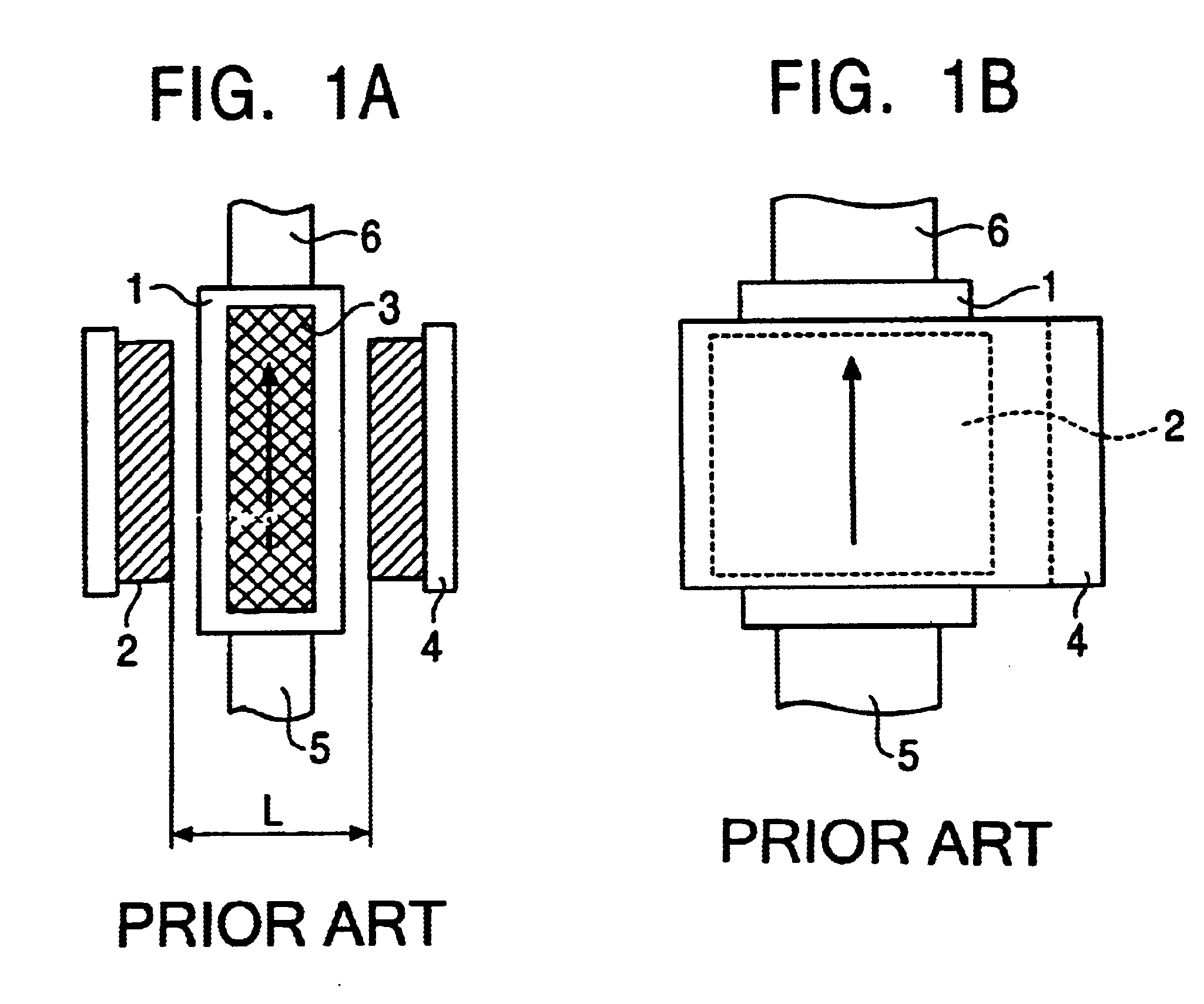

Magnetic filter device

InactiveUS6649054B2Small sizeLow costHigh gradient magnetic separatorsWater/sewage treatment by magnetic/electric fieldsGeneral purposeNeodymium magnet

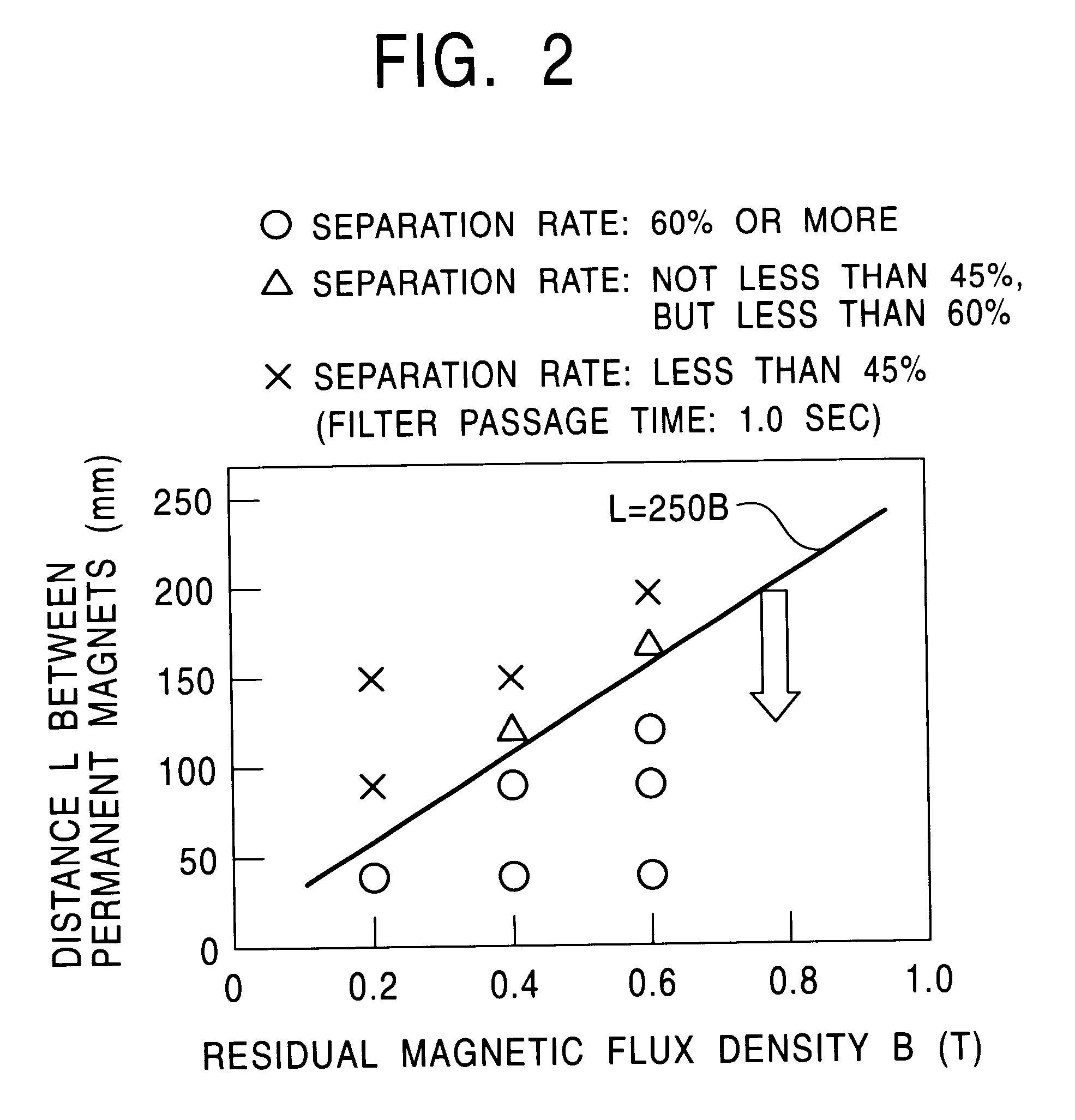

In a magnetic filter apparatus in which permanent magnets are arranged to oppose each other with a container therebetween so as to generate a magnetic line of force in a direction substantially orthogonal to the moving direction of the fluid in the interior of the container, while regulating a filter passage time of the fluid in the range of 0.5 to 1.5 seconds, the permanent magnets are arranged so that the distance L (mm) between the permanent magnets in relation to the residual magnetic flux density B (T) of the permanent magnets satisfies the relationship:In this manner, the highest possible performance can be obtained from the filter using general-purpose permanent magnets such as ferrite or neodymium magnets, thereby achieving size reduction of the apparatus at low equipment cost.

Owner:JFEENG CORP

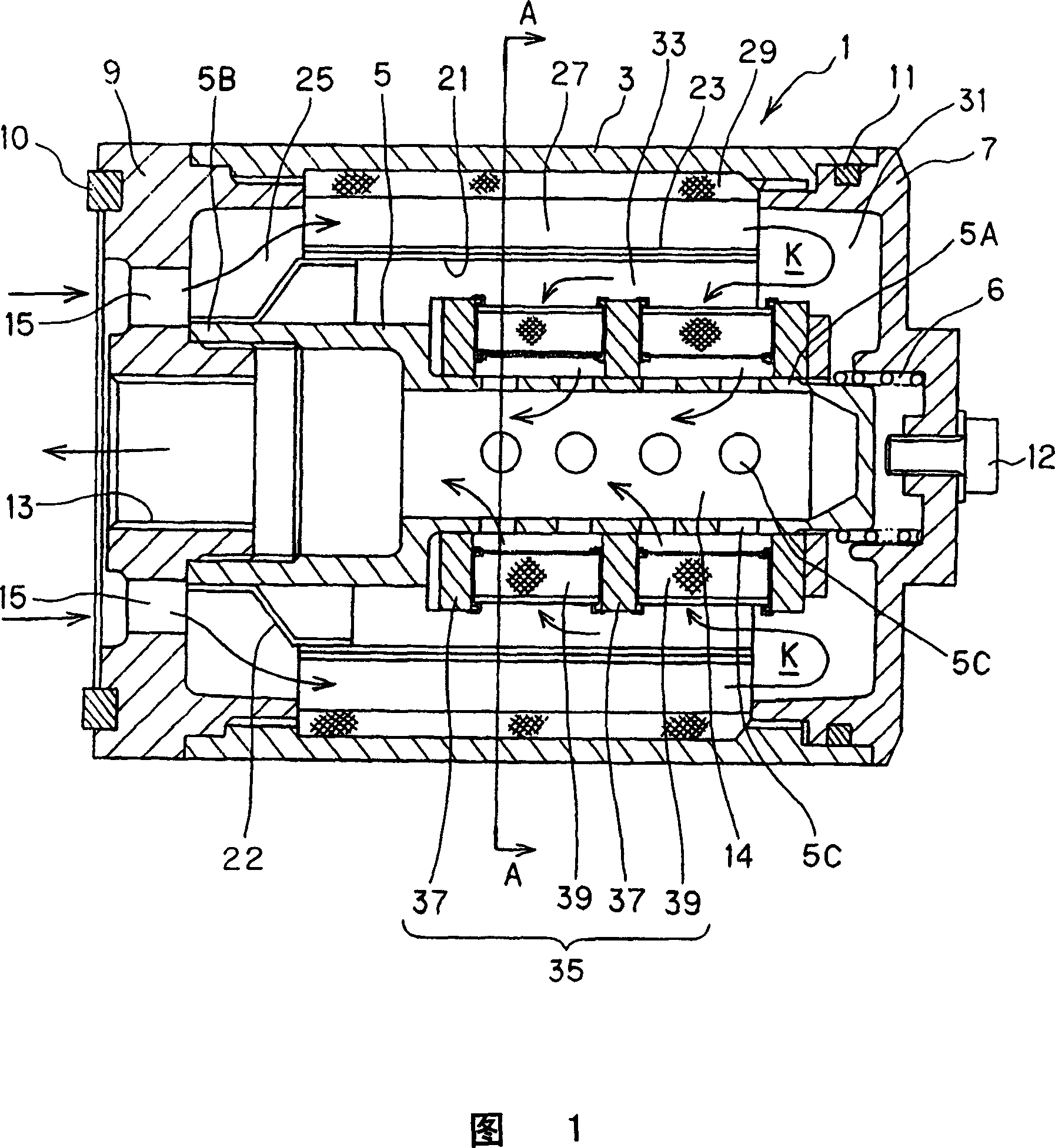

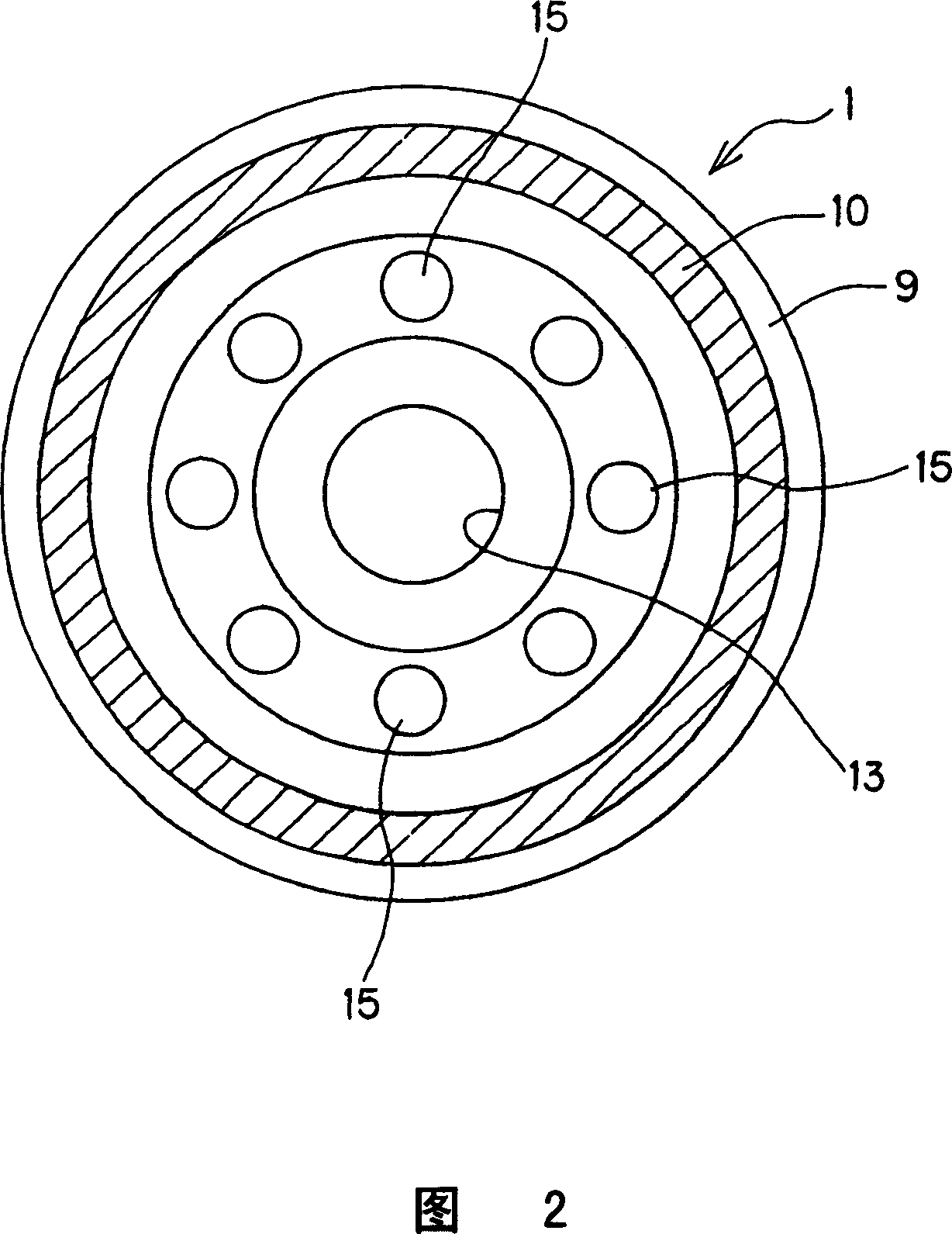

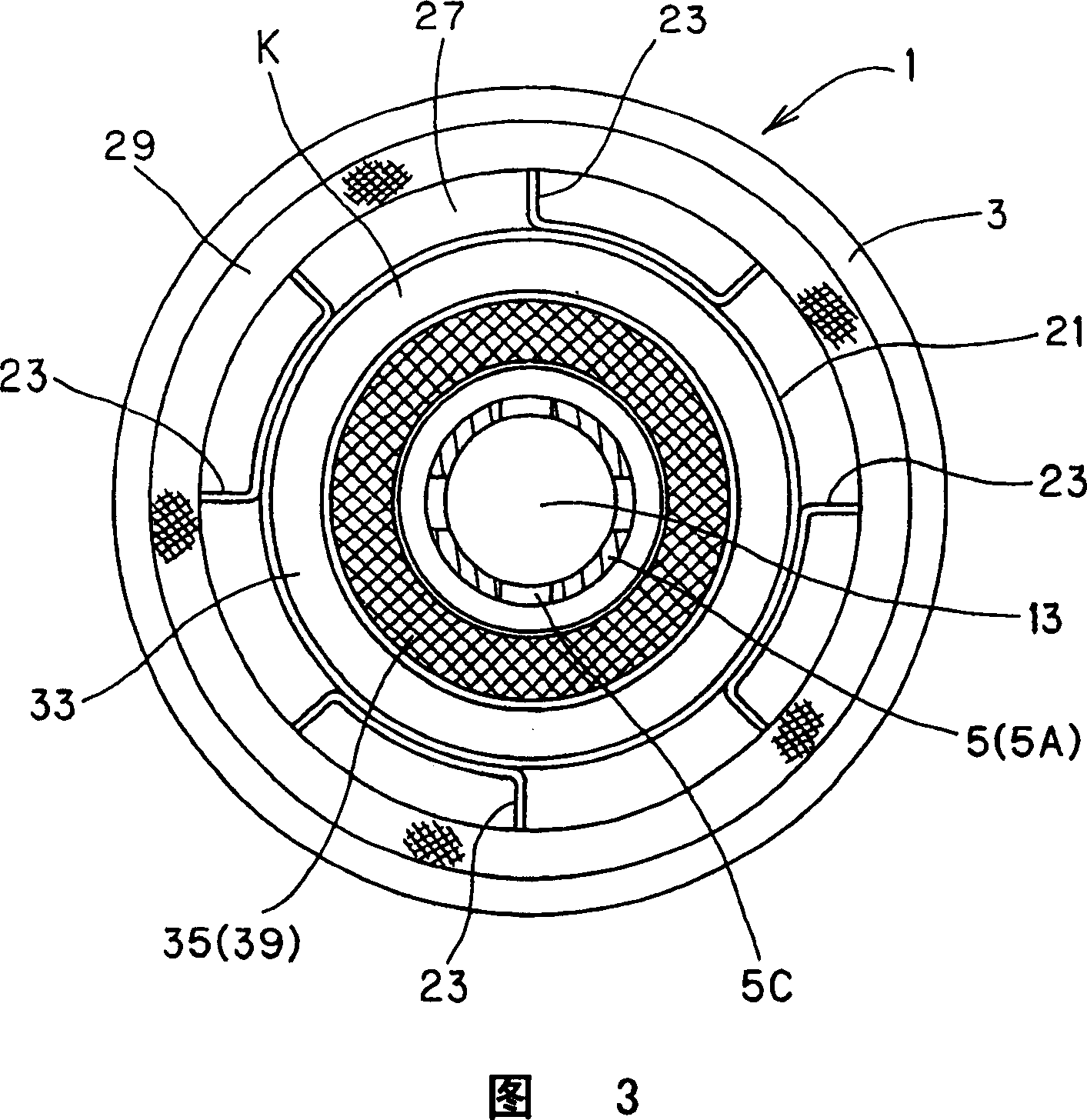

Oil filter

InactiveCN1919467AEfficient removalExtended maintenance cycleCentrifugesMagnetic separationForeign matterOil sludge

An oil filter capable of efficiently removing foreign matter, such as carbon, oil sludge and metal powder, and prolonging maintenance timing is provided. The oil filter body (1) integratively has an oil passage (27) for applying a centrifugal force on flowed-in oil, a collecting bag (29) for collecting foreign bodies with a large proportion which is throwed outwards by the centrifugal force, and a magnetic filter (35) mounted at the downstream side of the oil passage (27) and capable of removing metal powders.

Owner:筱崎隆 +3

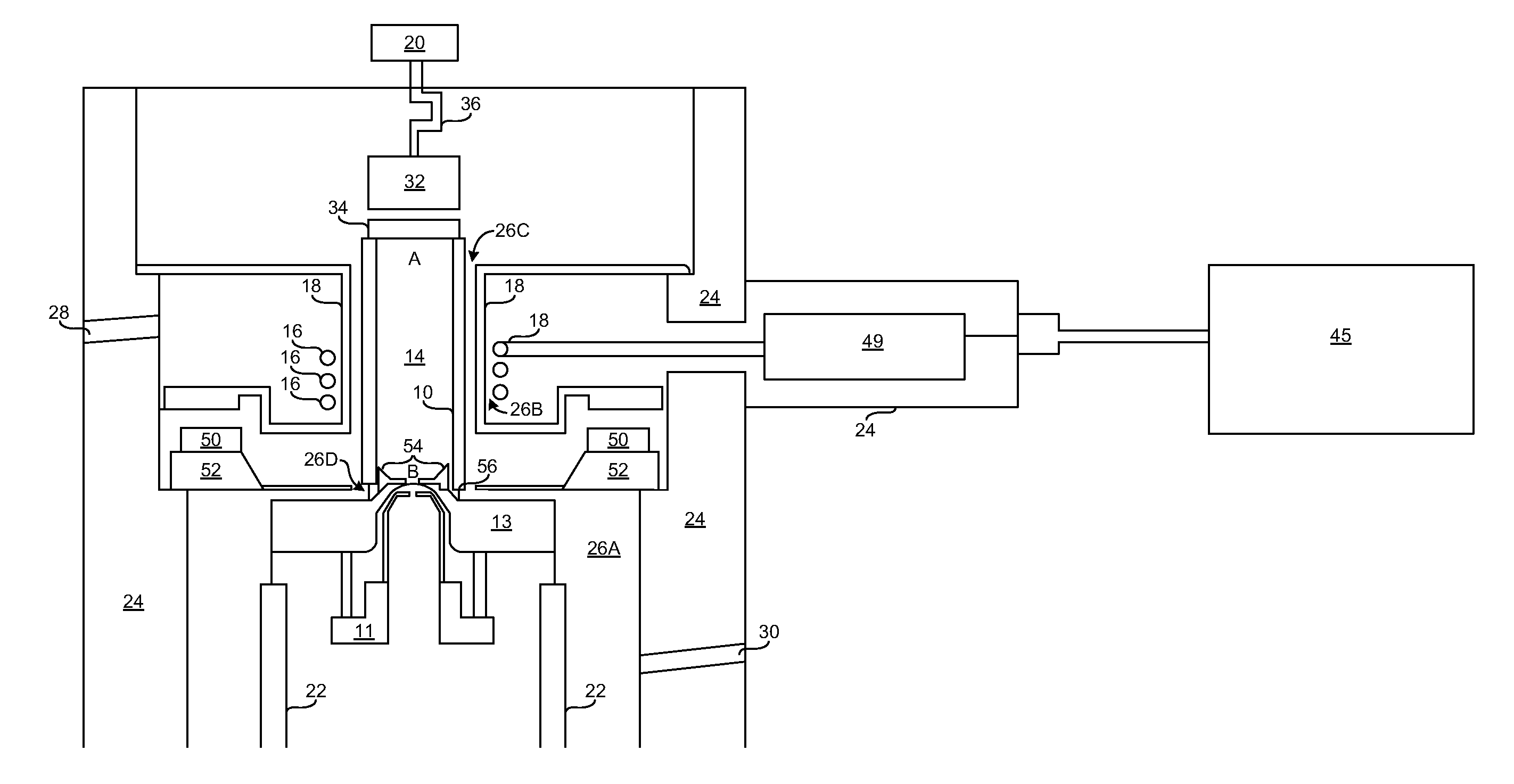

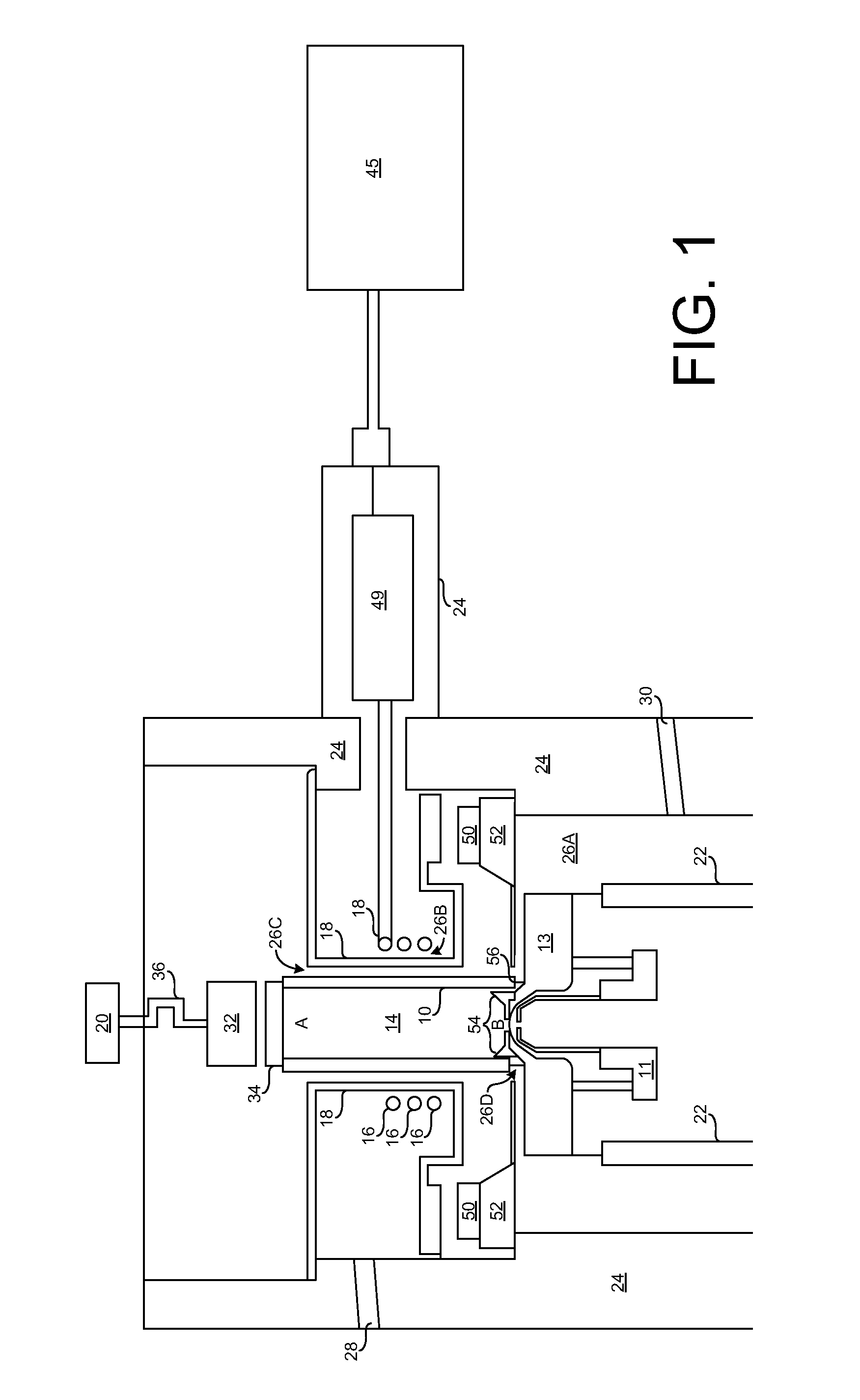

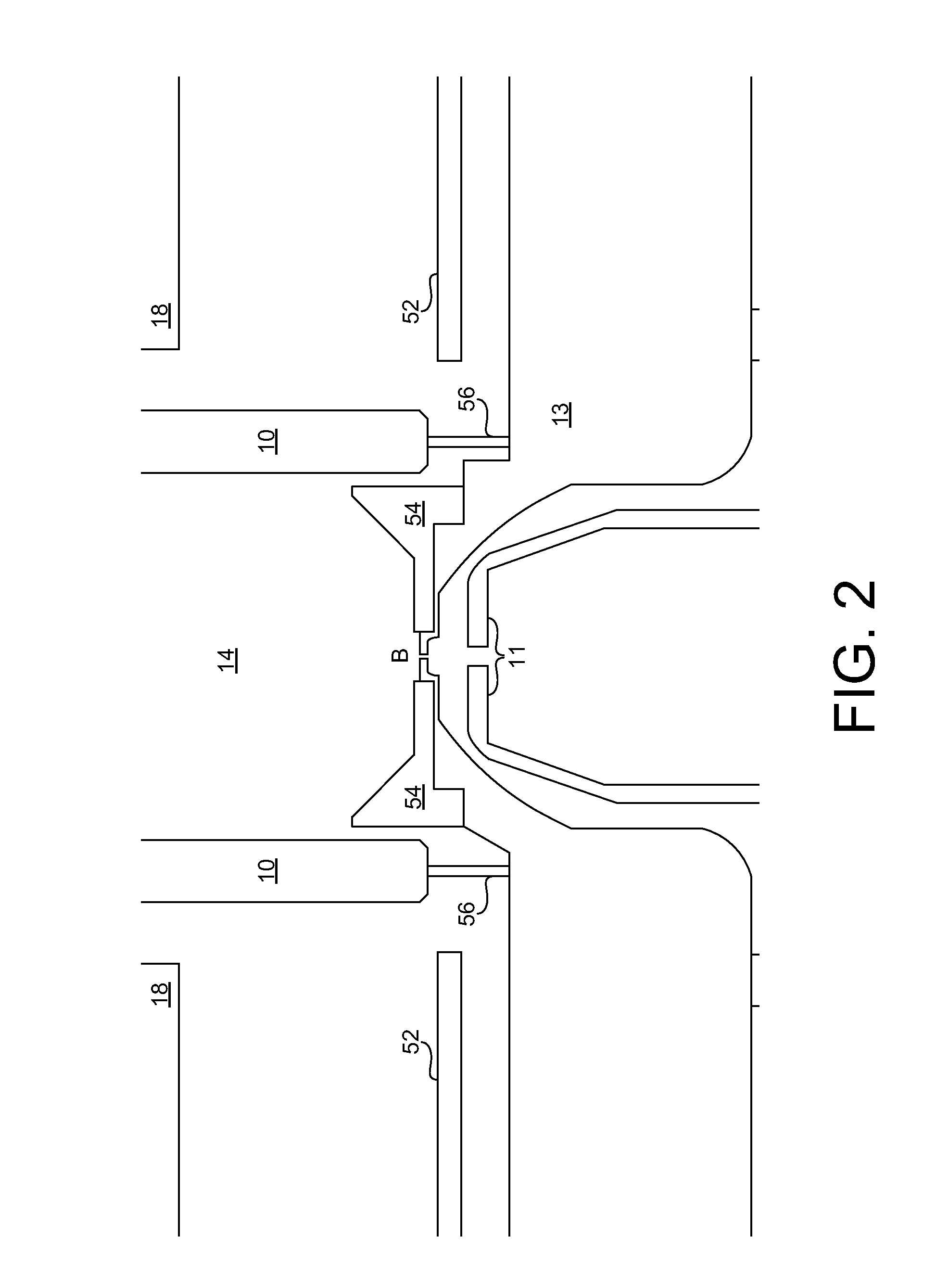

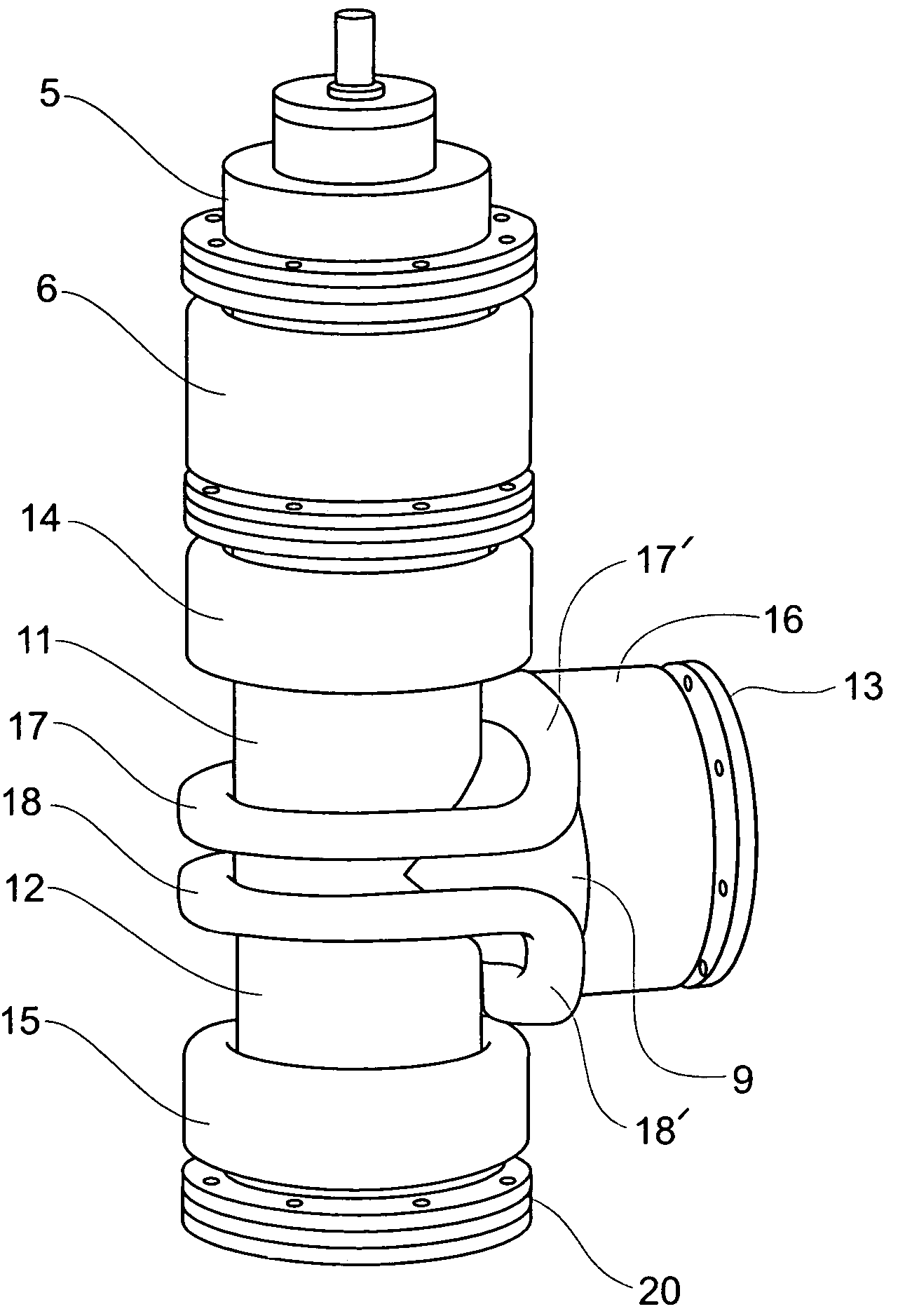

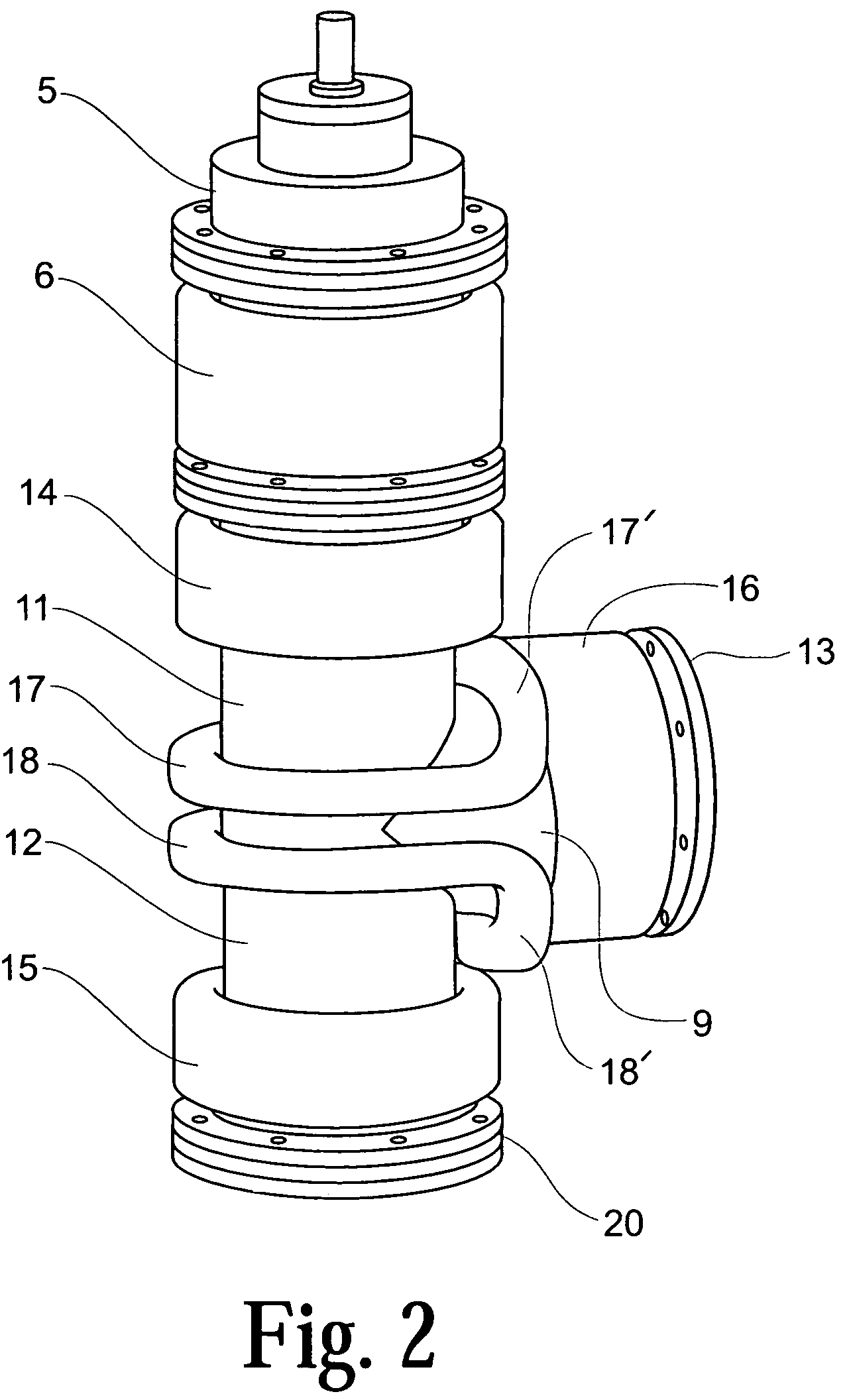

Filtered cathodic-arc plasma source

InactiveUS7381311B2Improve ion transmission efficiencyQuality improvementCellsElectric discharge tubesPlasma currentMagnetic flux

A filtered cathodic-arc plasma source of lower plasma losses and higher output plasma current to input current efficiency is disclosed. Plasma filtering is accomplished in a right angle bend magnetic filter arranged to include the effects of at least three added magnetic coils located at the right angle bend of the filter path. These magnetic coils and other filter attributes, including an array of transverse fins and a magnetic cusp trap in the filter path, achieve desirable magnetic flux paths, lower plasma collision losses and reduced undesired particle output from the plasma filter. Multiple cathode sources, multiple plasma output ports, Larmour radius influence, equipotential magnetic flux lines and electron / ion interaction considerations are also included in the plasma source. Application of the plasma source to film coating processes is included.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com