Patents

Literature

120results about "High gradient magnetic separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

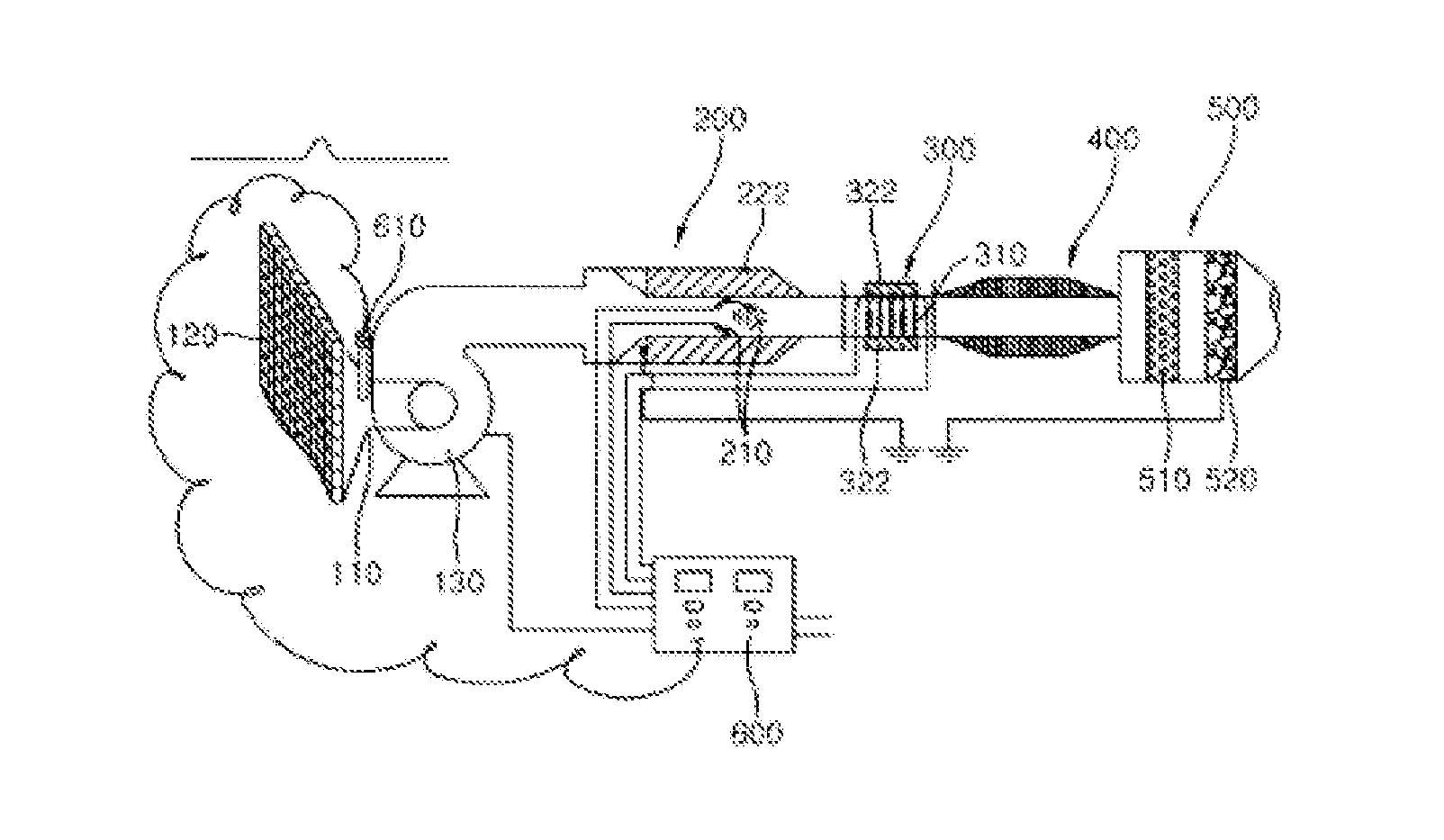

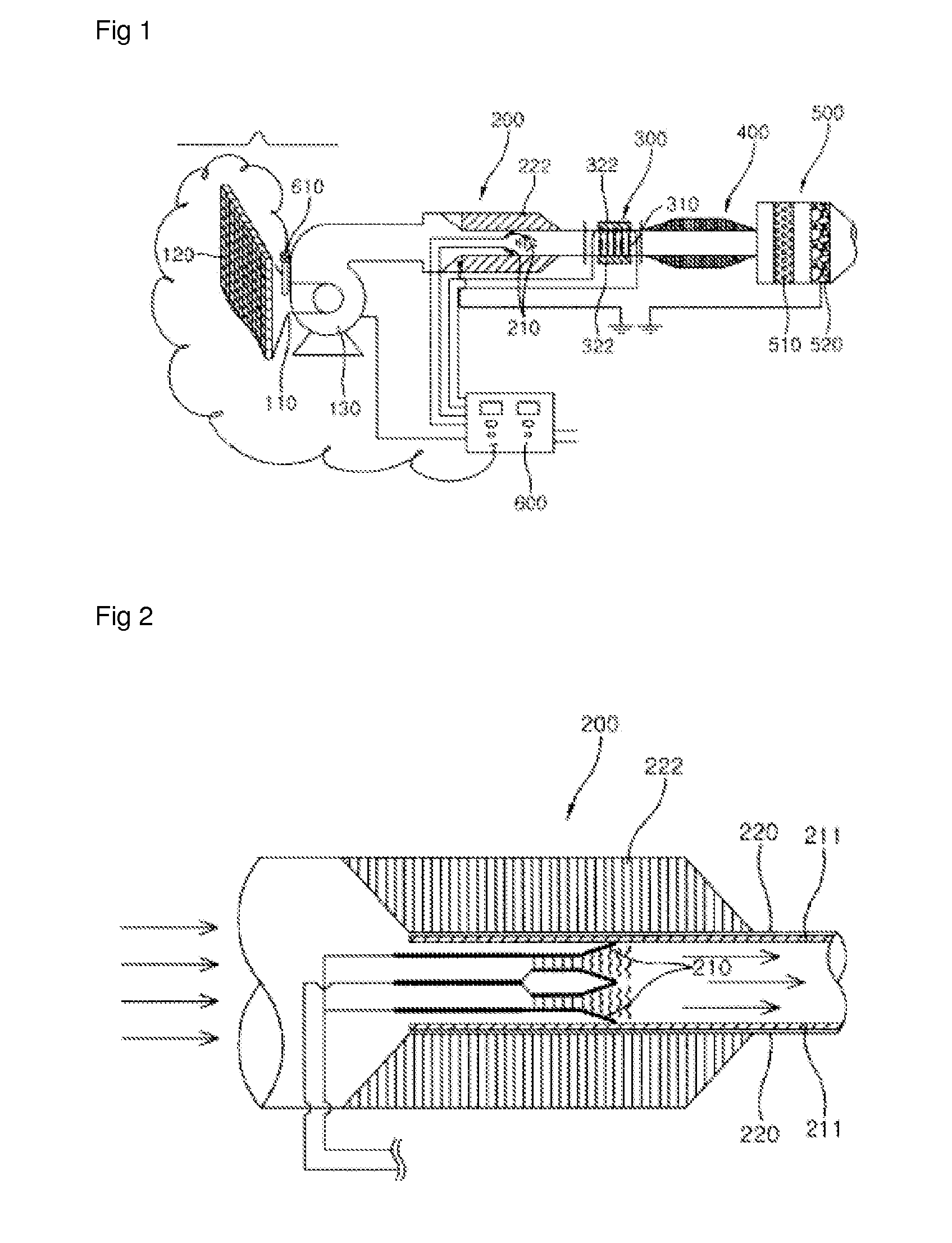

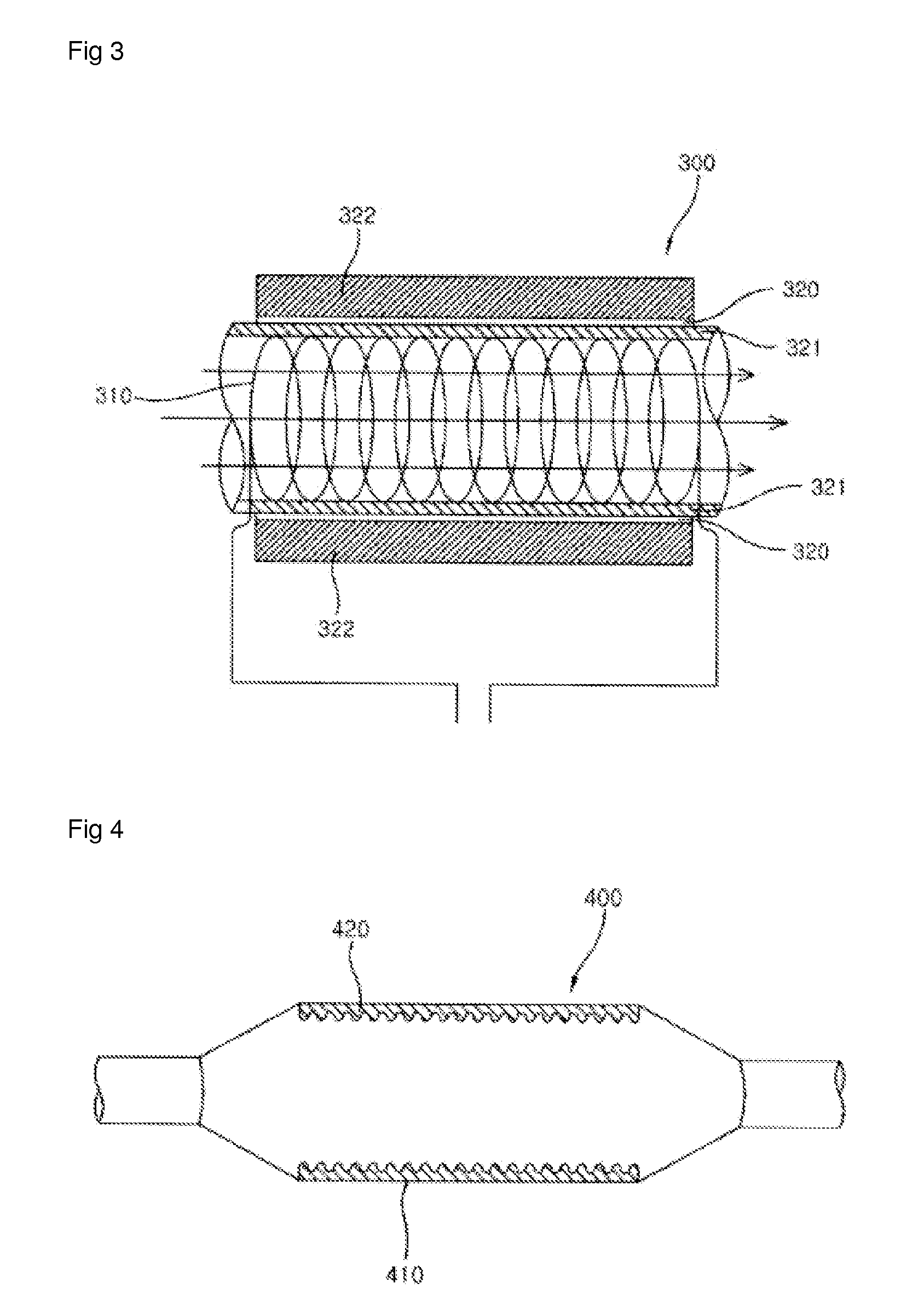

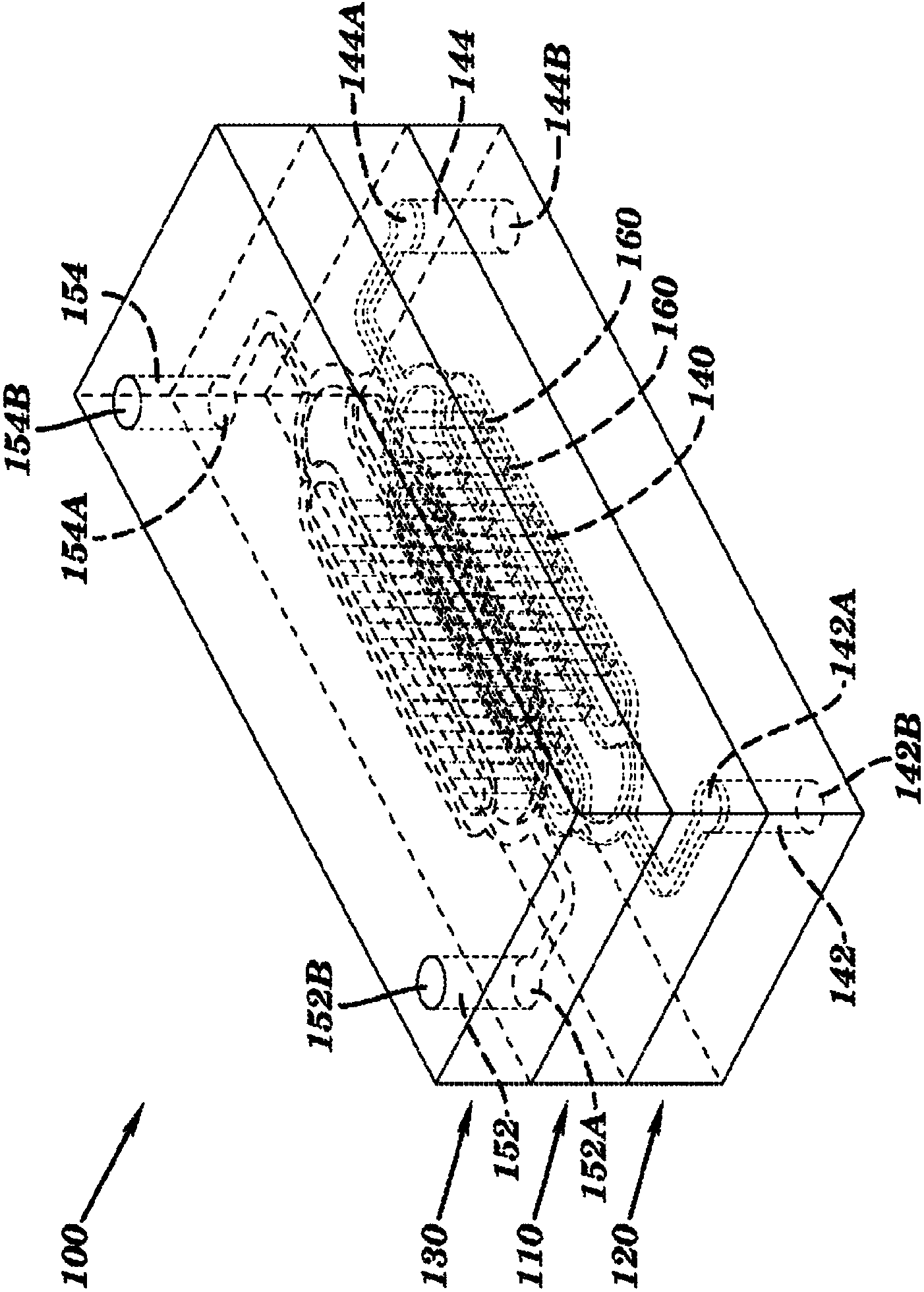

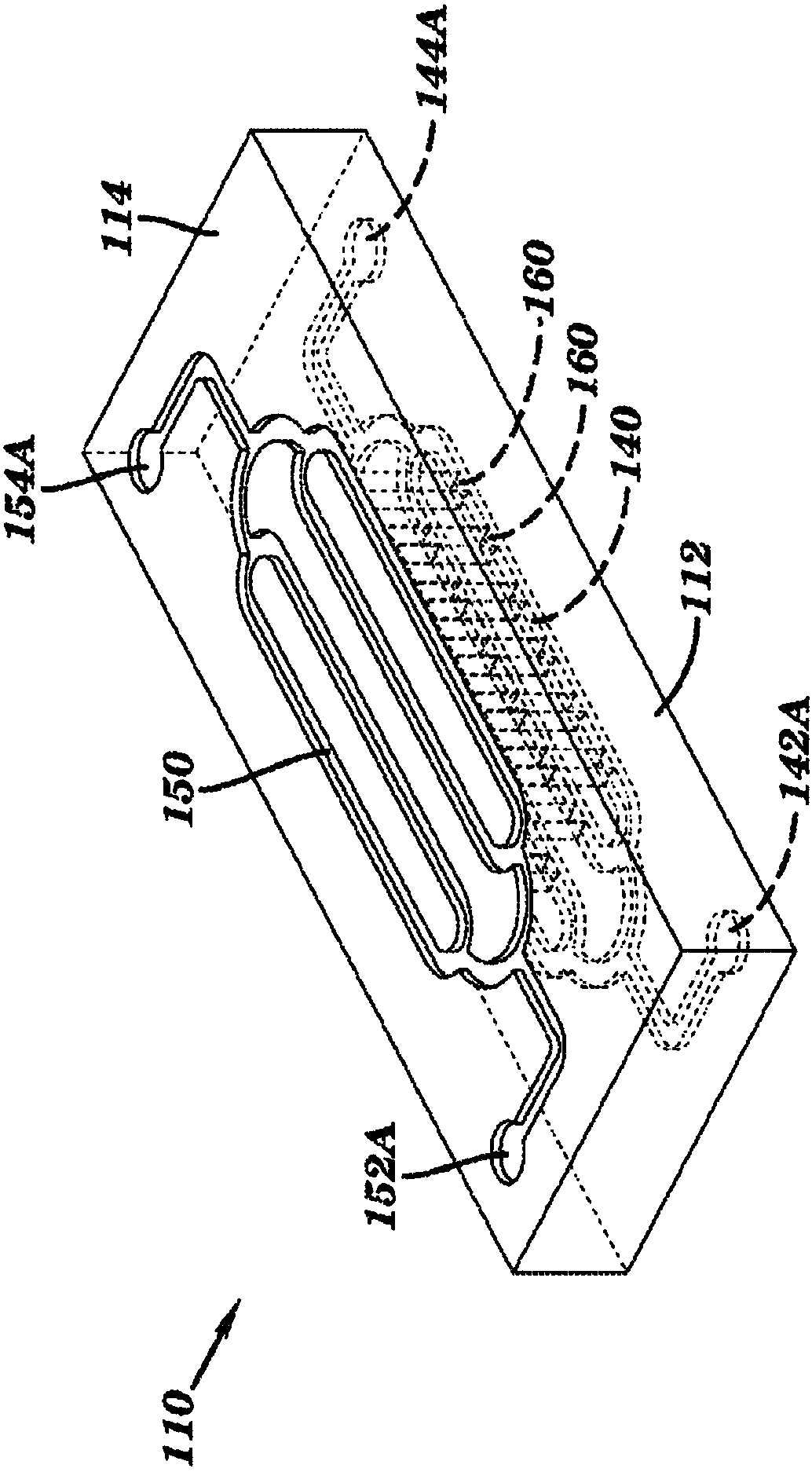

Multiple laminar flow-based particle and cellular separation with laser steering

ActiveUS20090032449A1Improve throughputSave a lot of timeDielectrophoresisMaterial analysis by electric/magnetic meansCellular componentBlood component

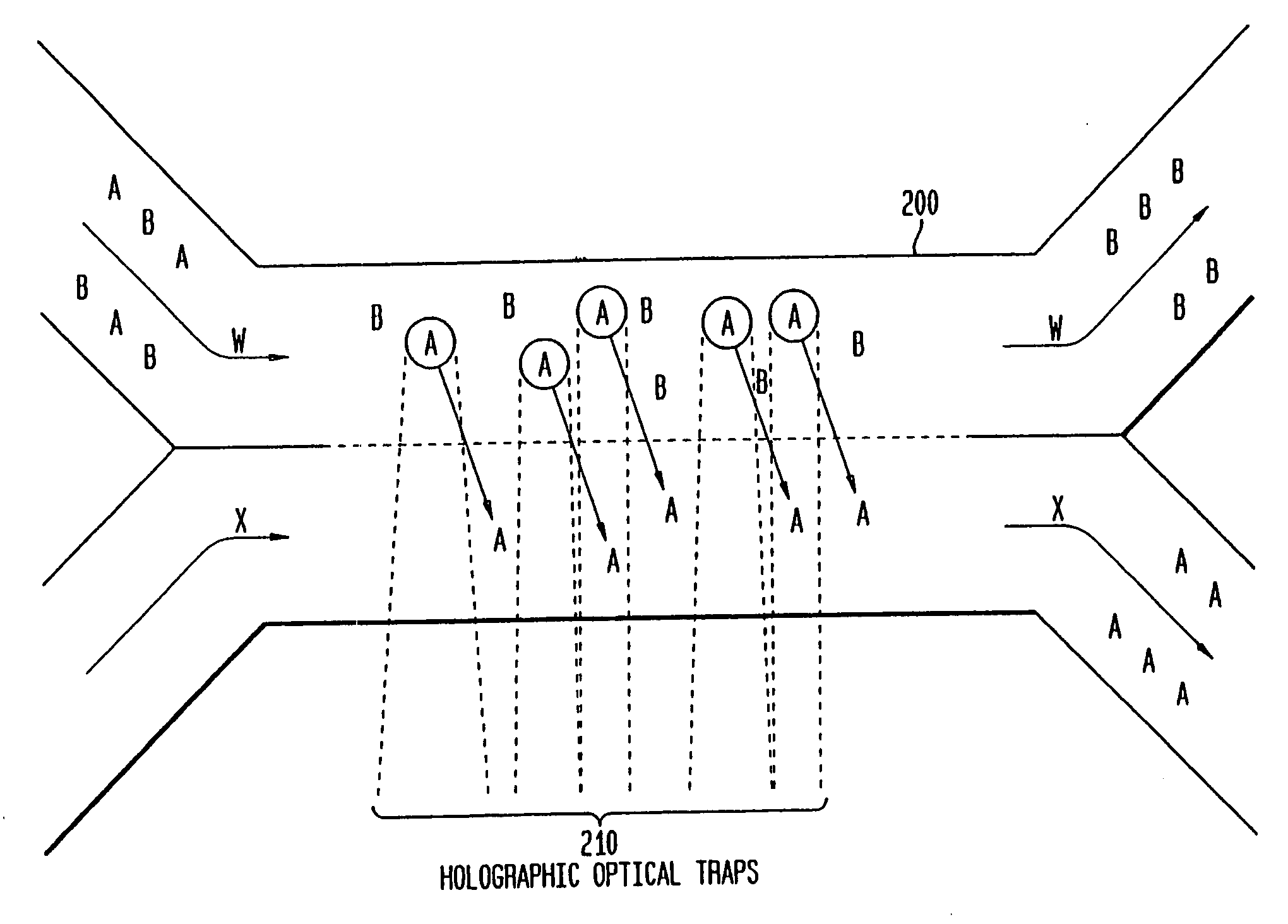

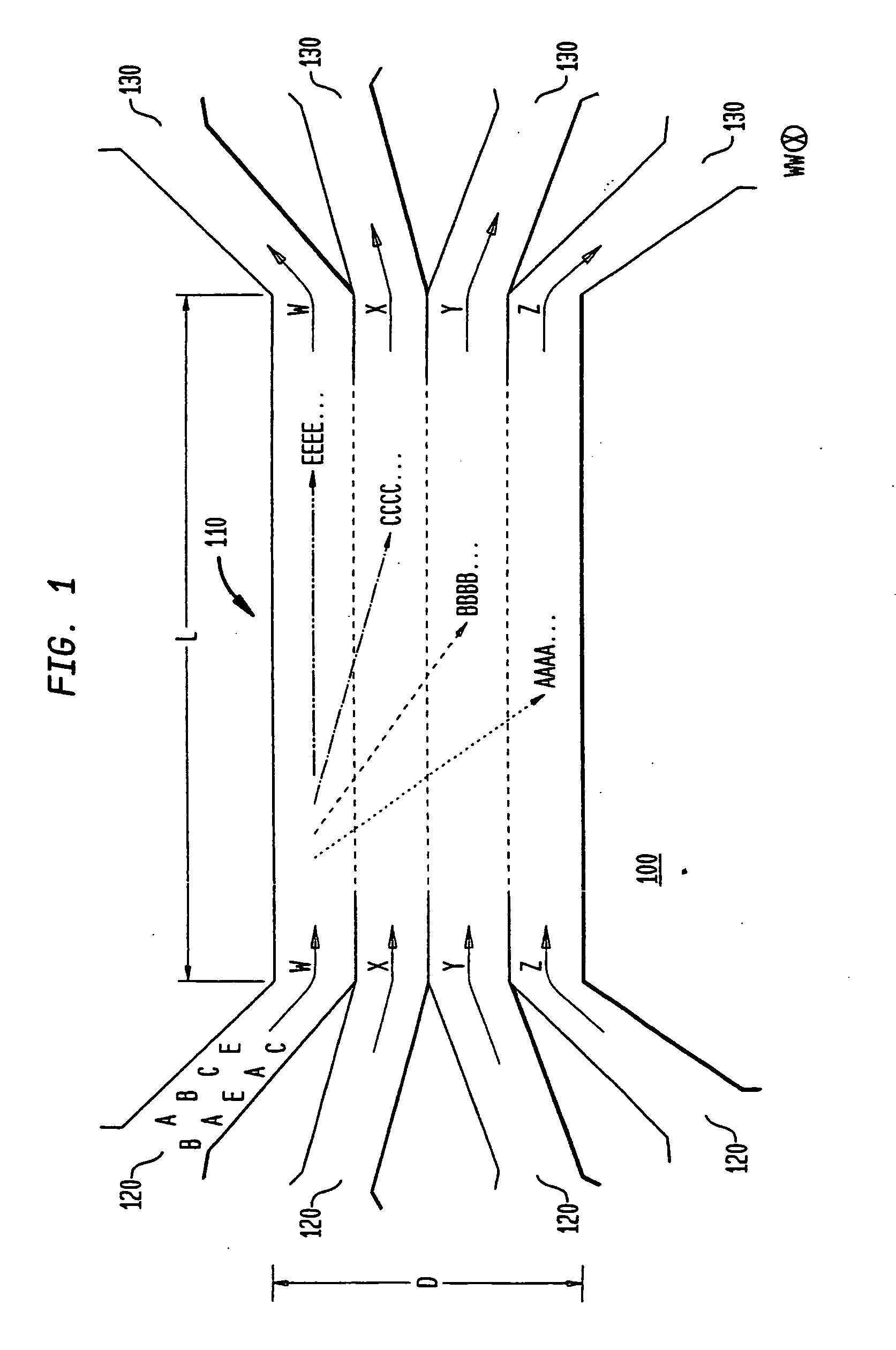

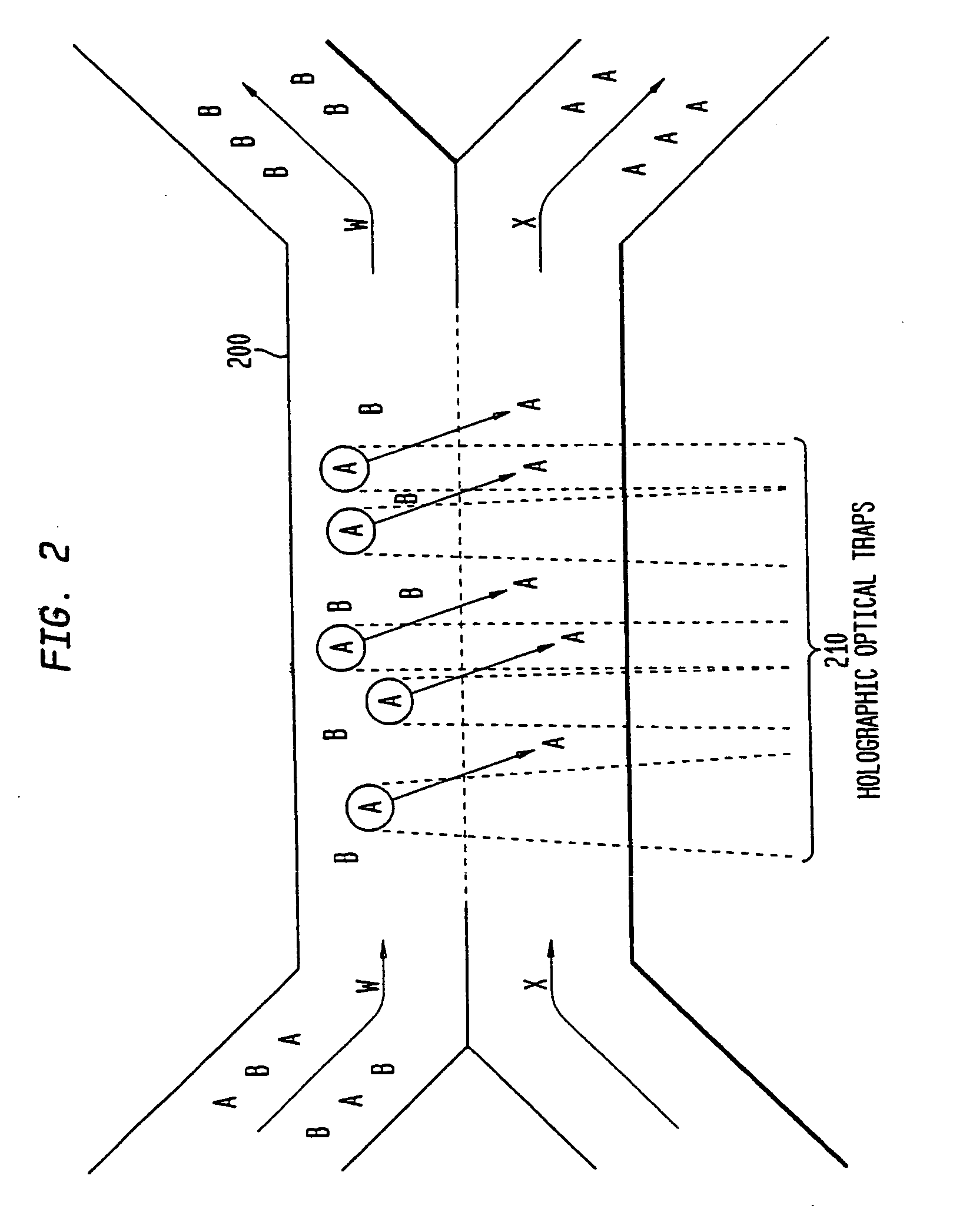

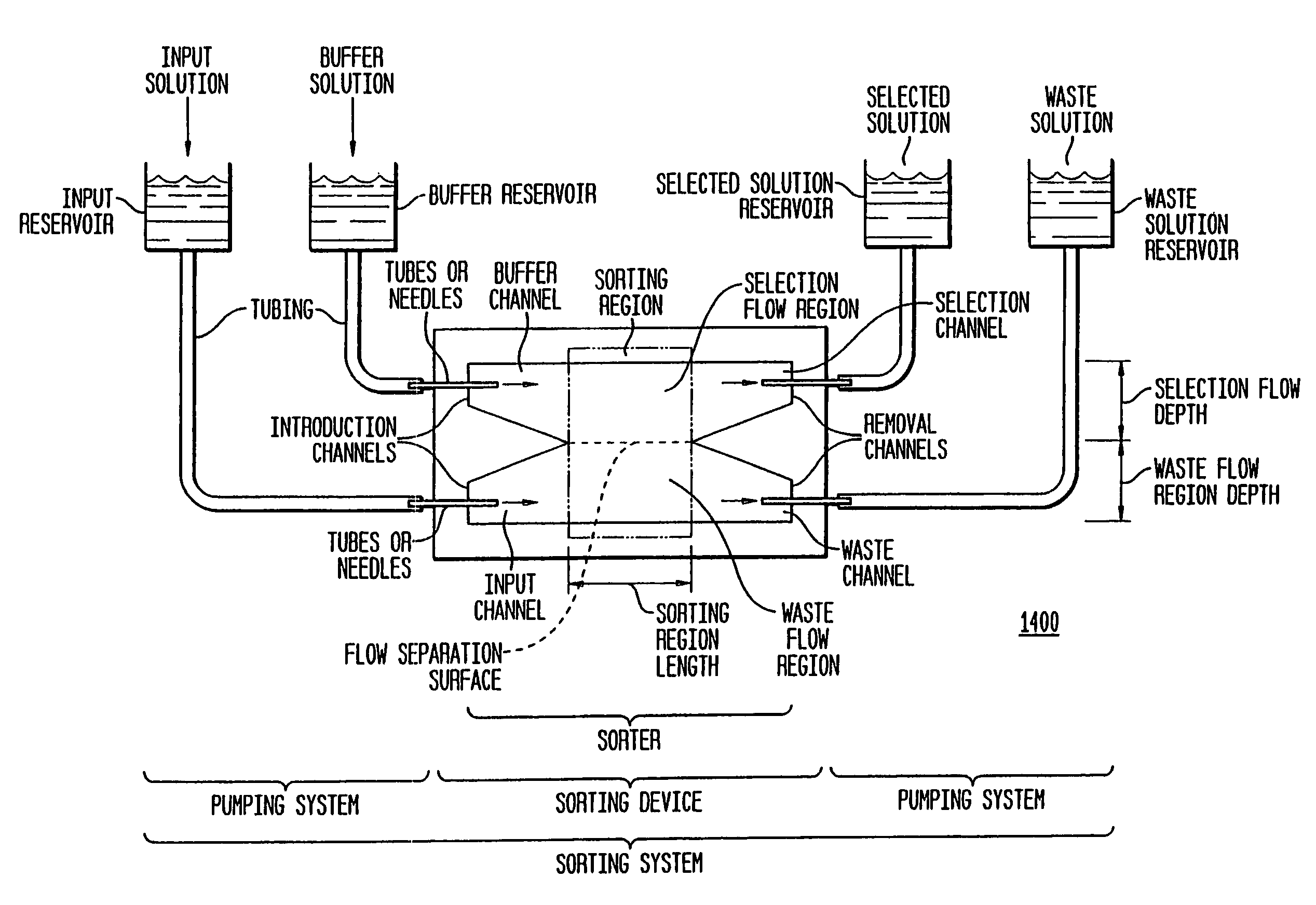

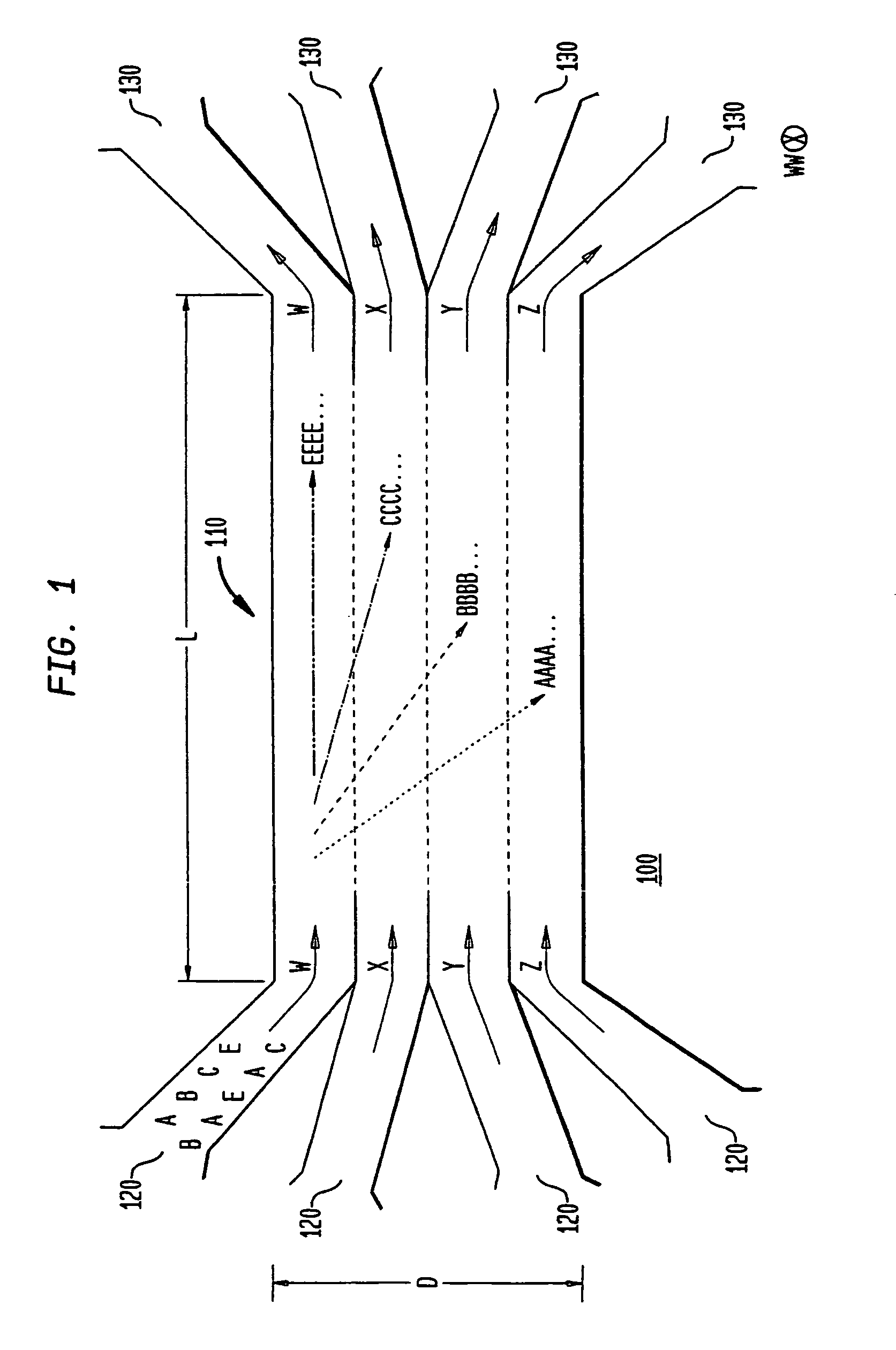

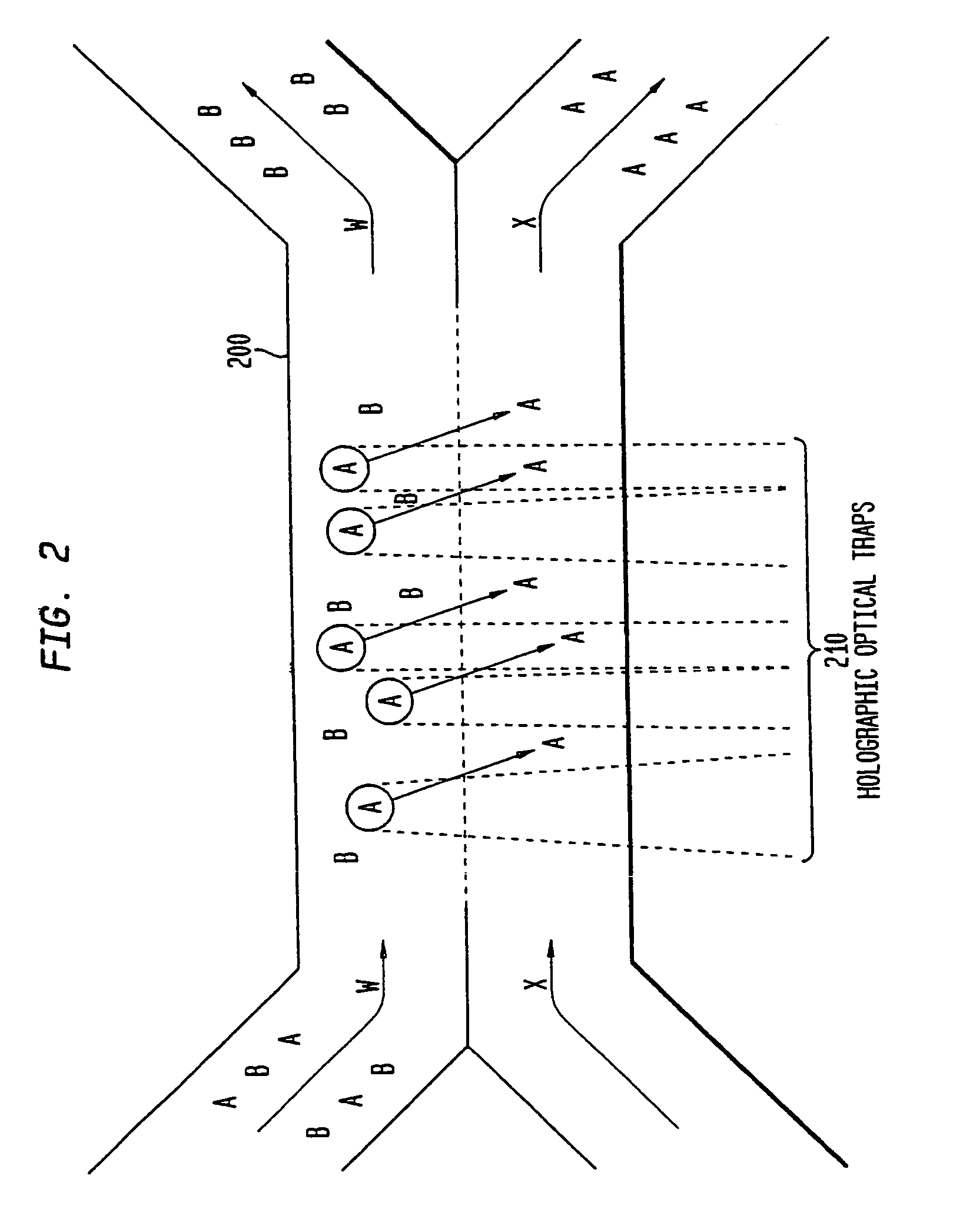

The invention provides a method, apparatus and system for separating blood and other types of cellular components, and can be combined with holographic optical trapping manipulation or other forms of optical tweezing. One of the exemplary methods includes providing a first flow having a plurality of blood components; providing a second flow; contacting the first flow with the second flow to provide a first separation region; and differentially sedimenting a first blood cellular component of the plurality of blood components into the second flow while concurrently maintaining a second blood cellular component of the plurality of blood components in the first flow. The second flow having the first blood cellular component is then differentially removed from the first flow having the second blood cellular component. Holographic optical traps may also be utilized in conjunction with the various flows to move selected components from one flow to another, as part of or in addition to a separation stage.

Owner:ABS GLOBAL

Multiple laminar flow-based particle and cellular separation with laser steering

InactiveUS7699767B2Save a lot of timeImprove throughputDielectrophoresisMaterial analysis by electric/magnetic meansCellular componentBlood component

The invention provides a method, apparatus and system for separating blood and other types of cellular components, and can be combined with holographic optical trapping manipulation or other forms of optical tweezing. One of the exemplary methods includes providing a first flow having a plurality of blood components; providing a second flow; contacting the first flow with the second flow to provide a first separation region; and differentially sedimenting a first blood cellular component of the plurality of blood components into the second flow while concurrently maintaining a second blood cellular component of the plurality of blood components in the first flow. The second flow having the first blood cellular component is then differentially removed from the first flow having the second blood cellular component. Holographic optical traps may also be utilized in conjunction with the various flows to move selected components from one flow to another, as part of or in addition to a separation stage.

Owner:ABS GLOBAL

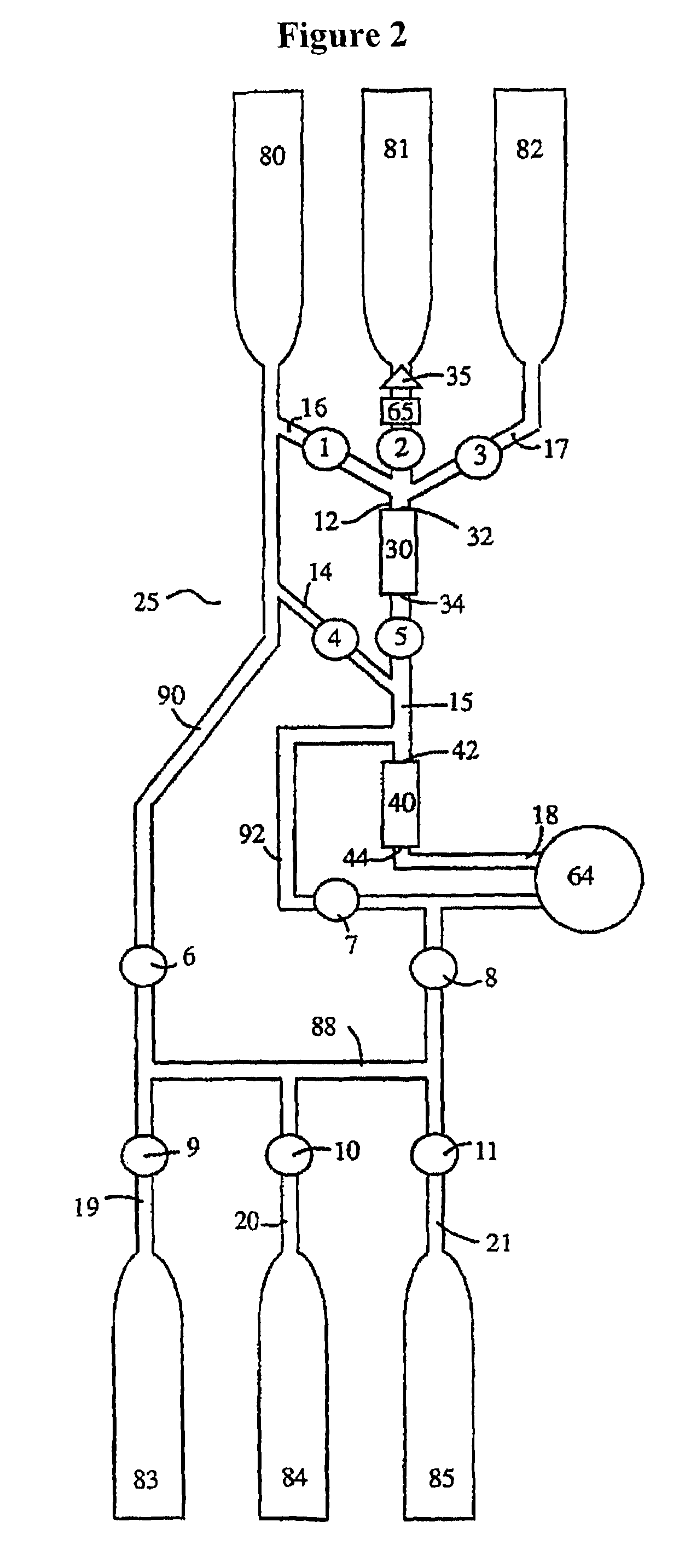

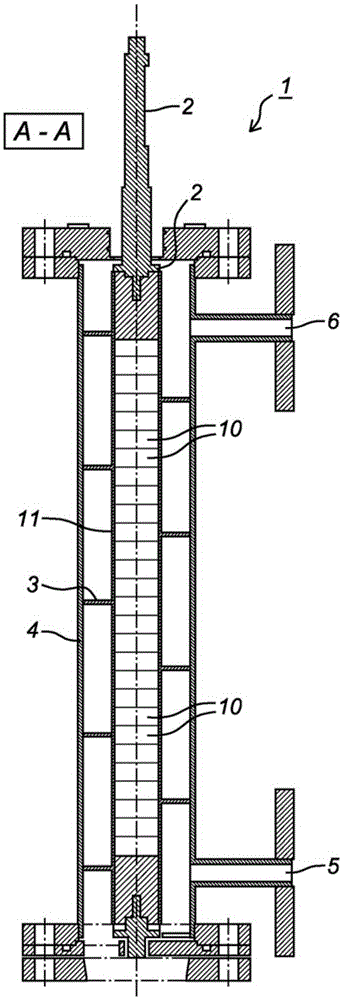

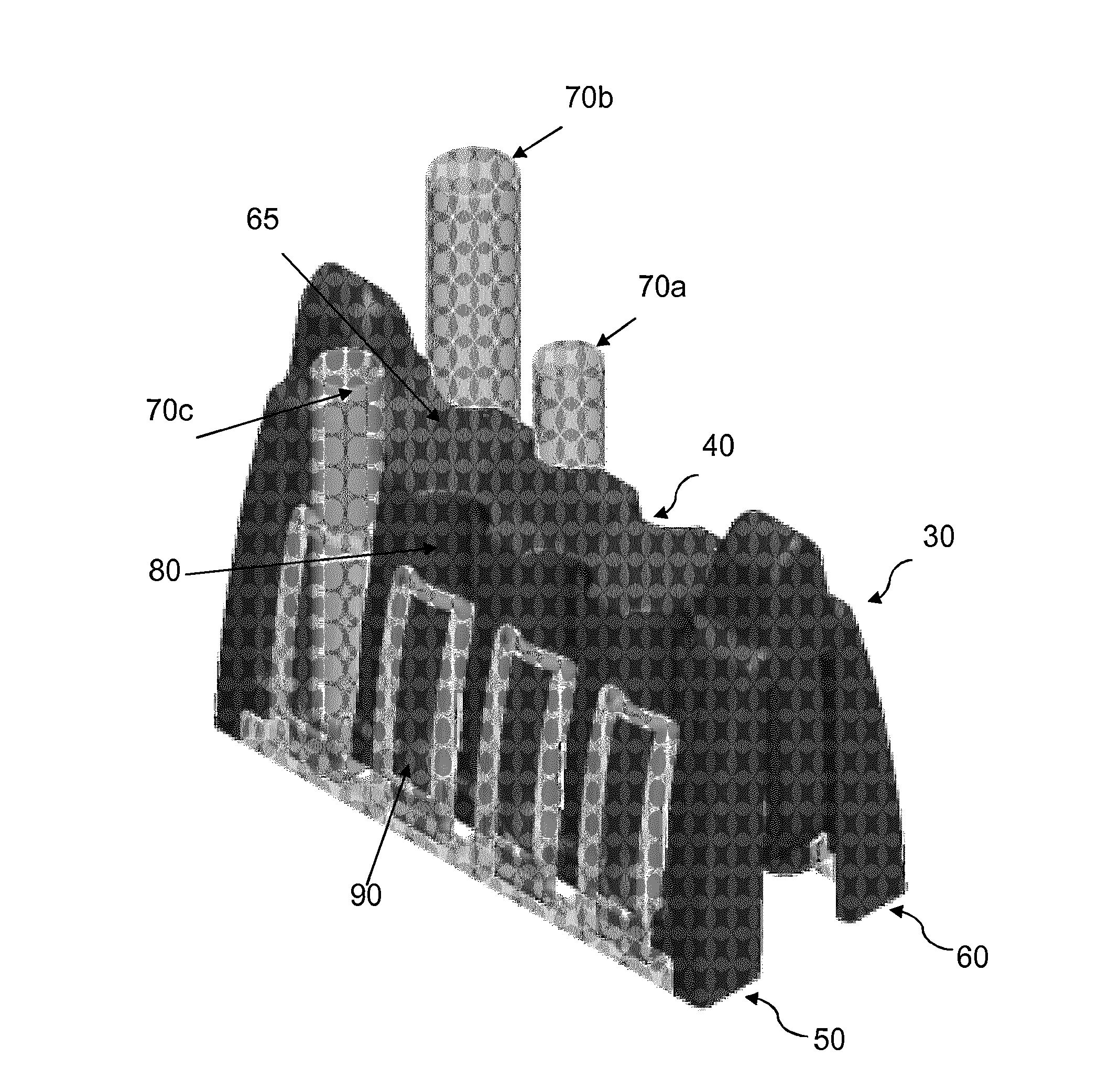

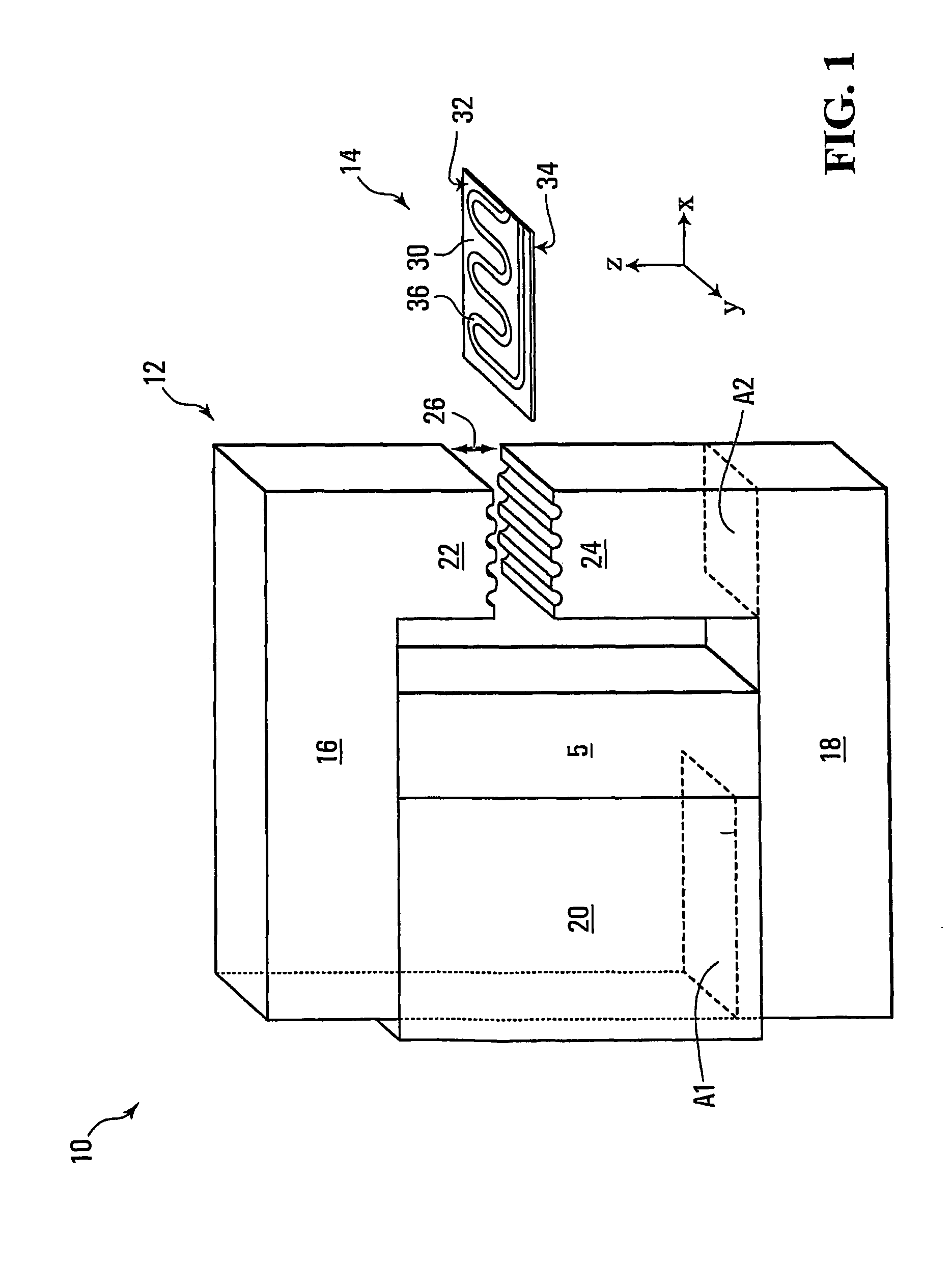

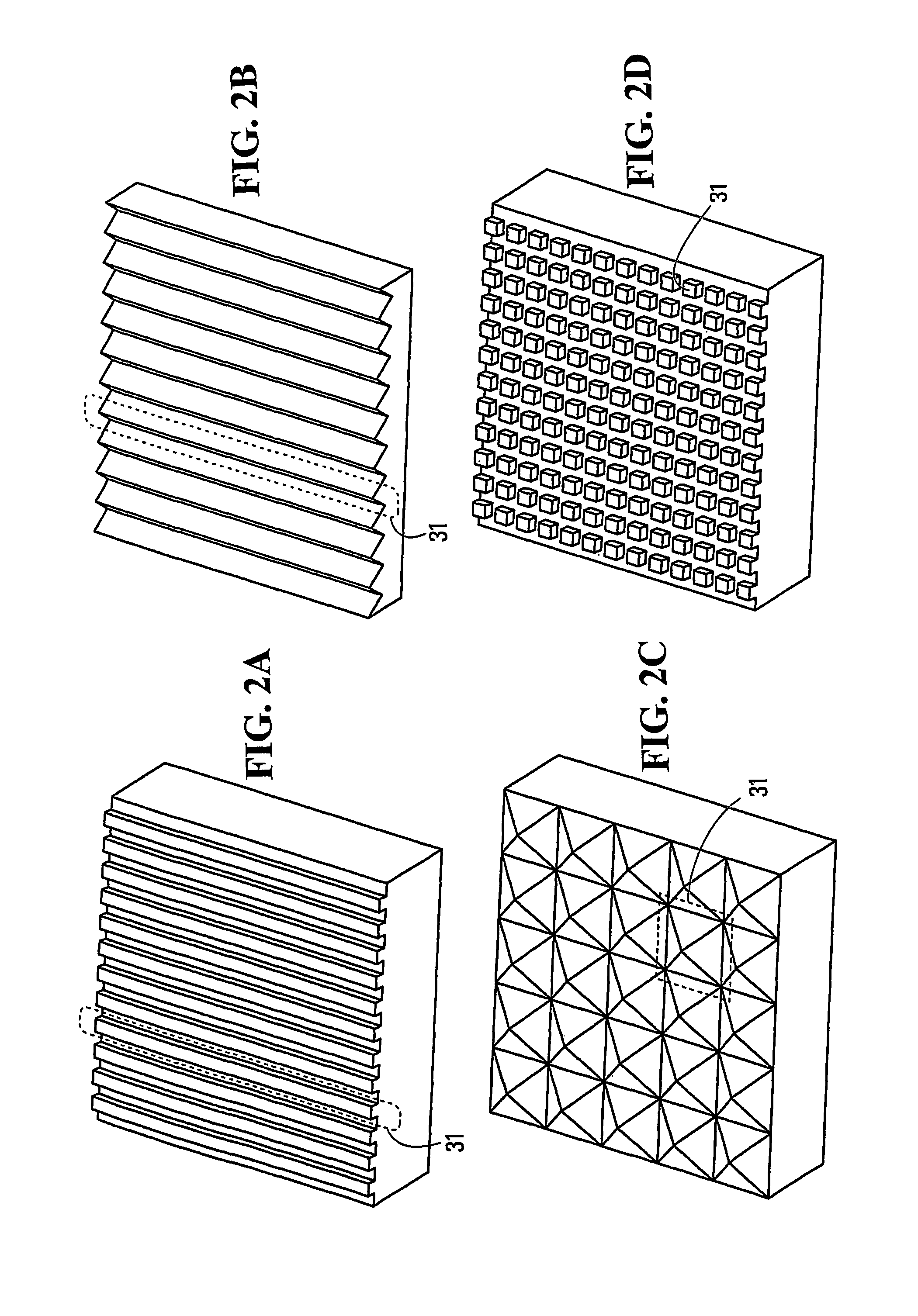

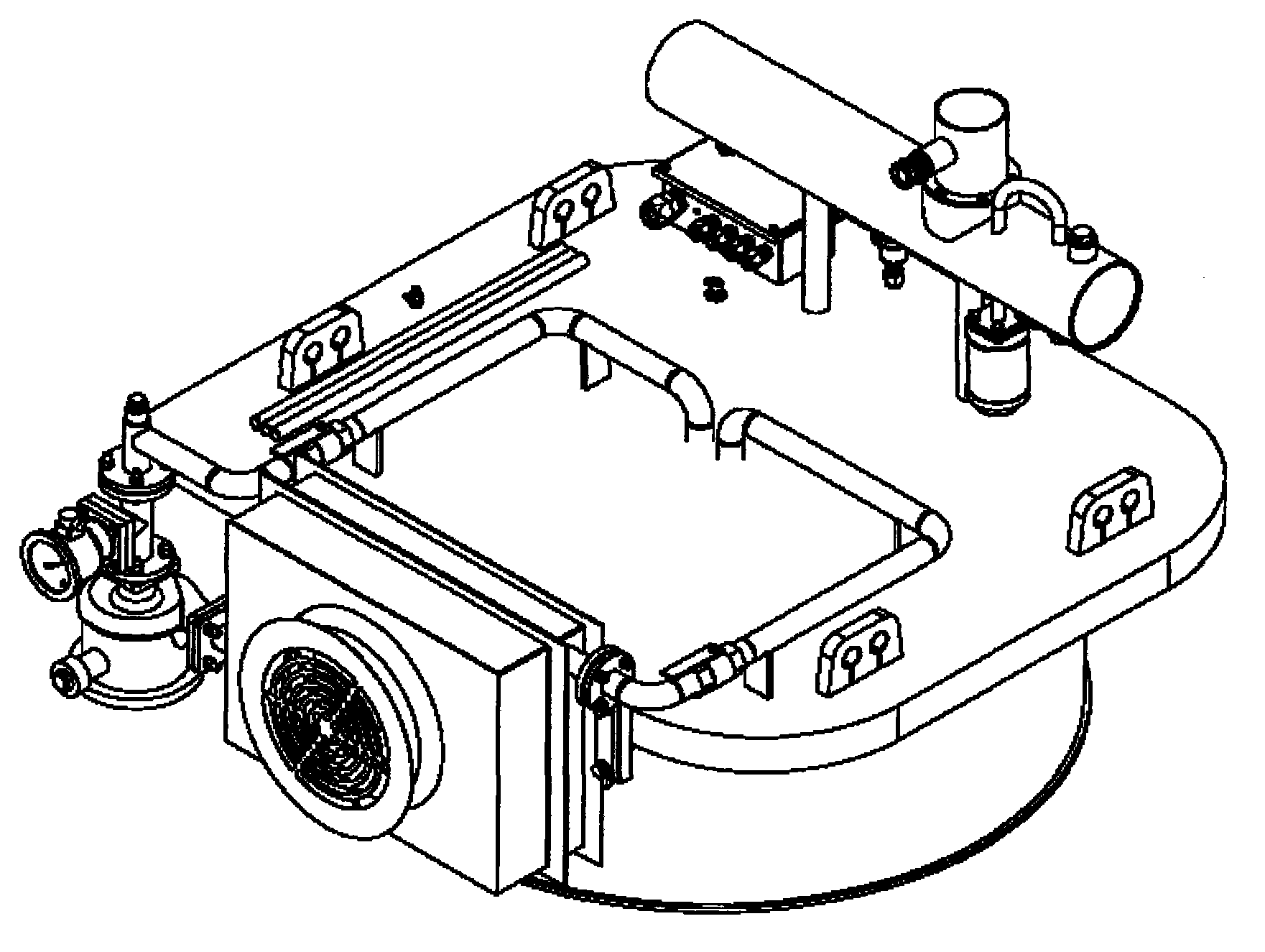

Sample processing system and methods

ActiveUS8727132B2High magnetic separationImprove efficiencyOther blood circulation devicesElectrostatic separationEngineeringCentrifugal force

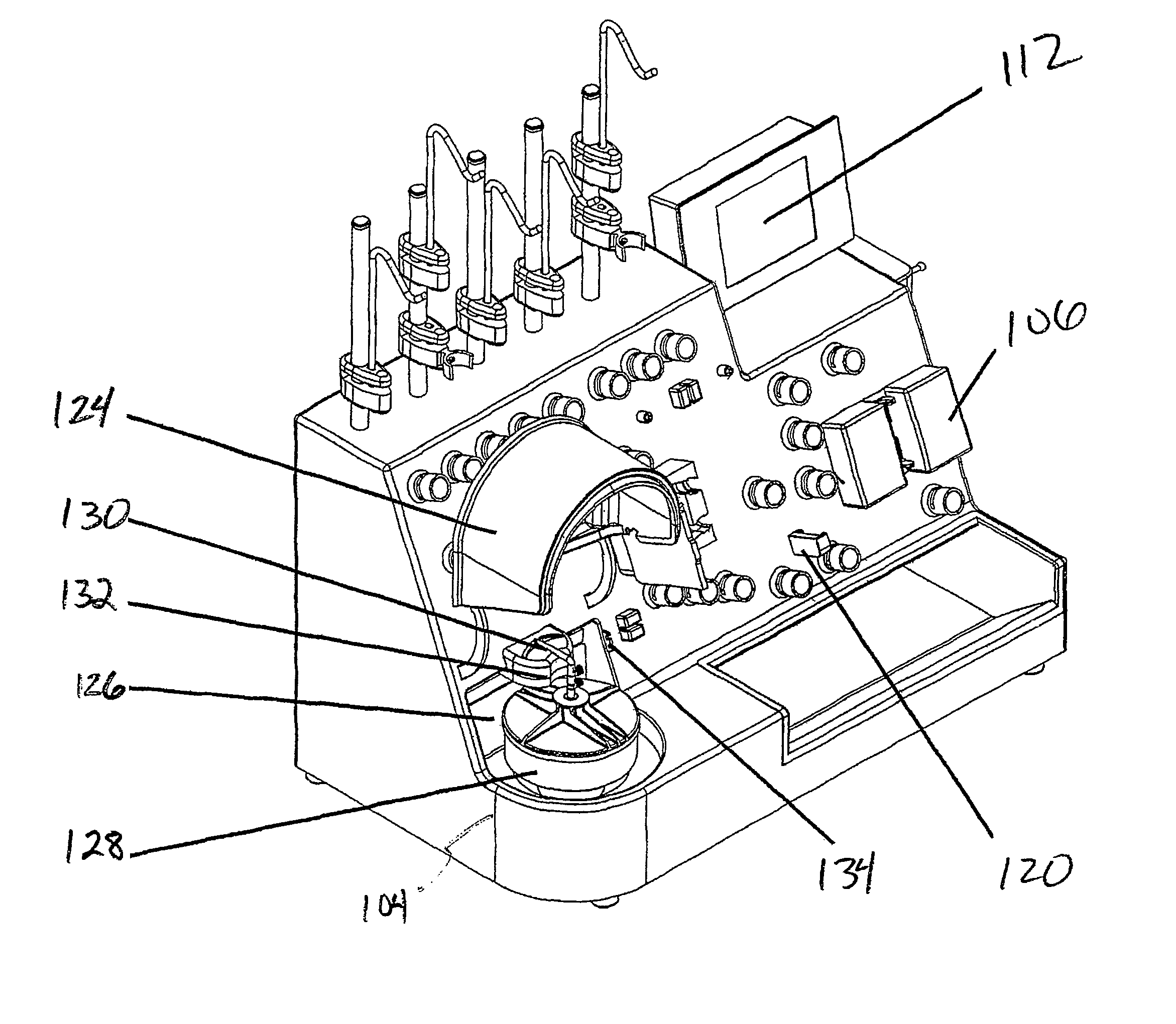

The invention relates to a system, comprising: a) a sample processing unit, comprising an input port and an output port coupled to a rotating container having at least one sample chamber, the sample processing unit configured provide a first processing step to a sample or to rotate the container so as to apply a centrifugal force to a sample deposited in the chamber and separate at least a first component and a second component of the deposited sample; and b) a sample separation unit coupled to the output port of the sample processing unit, the cell separation unit comprising separation column holder (42), a pump (64) and a plurality of valves (1-11) configured to at least partially control fluid flow through a fluid circuitry and a separation column (40) positioned in the holder, the separation column configured to separate labeled and unlabeled components of sample flowed through the column.

Owner:MILTENYI BIOTEC B V & CO KG

Device for indoor air purification and sterilization

ActiveUS20120207647A1Improve purification effectImprove the bactericidal effectLighting and heating apparatusExhaust apparatusExcited stateContact time

The present invention relates to a device for indoor air purification and sterilization which excites indoor air by arc discharge to decompose bad odor and sterilize air, wherein an excited state is maintained by applying a magnetic field and the contact time between molecules activated by arc and pollutants is extended, thereby improving air purification and sterilization effects, and the noise generated by arc discharge is reduced by a silencer and ozone and static electricity are removed by a filter which removes ozone and a metal filter for removing static electricity, respectively, thereby enabling very suitable configuration for indoor air purification and sterilization.

Owner:KIM BU YEOL

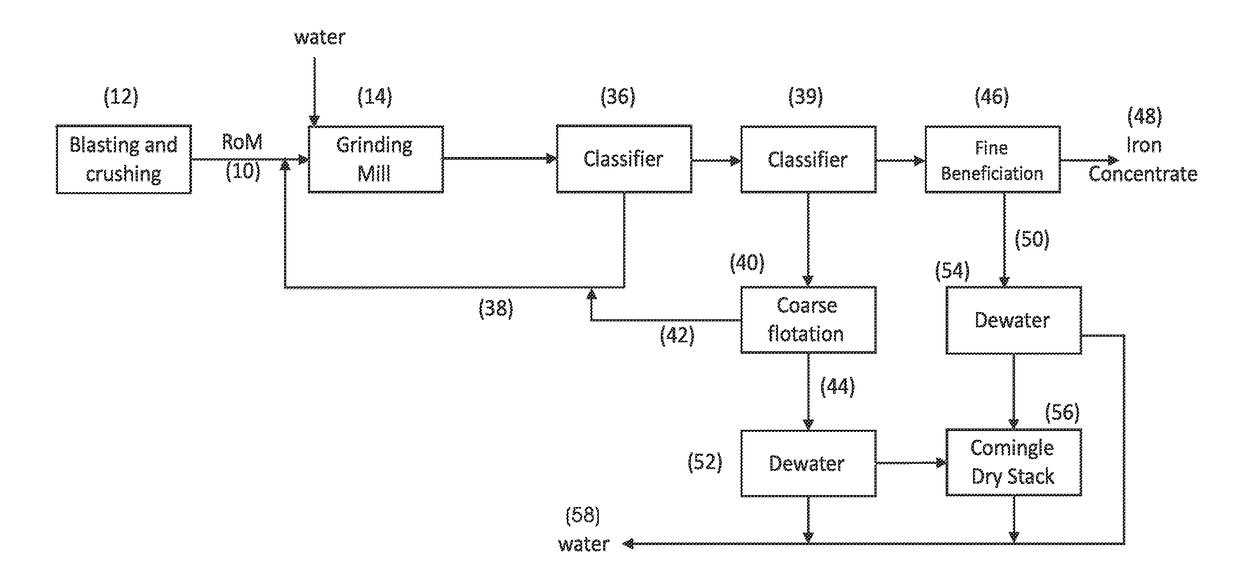

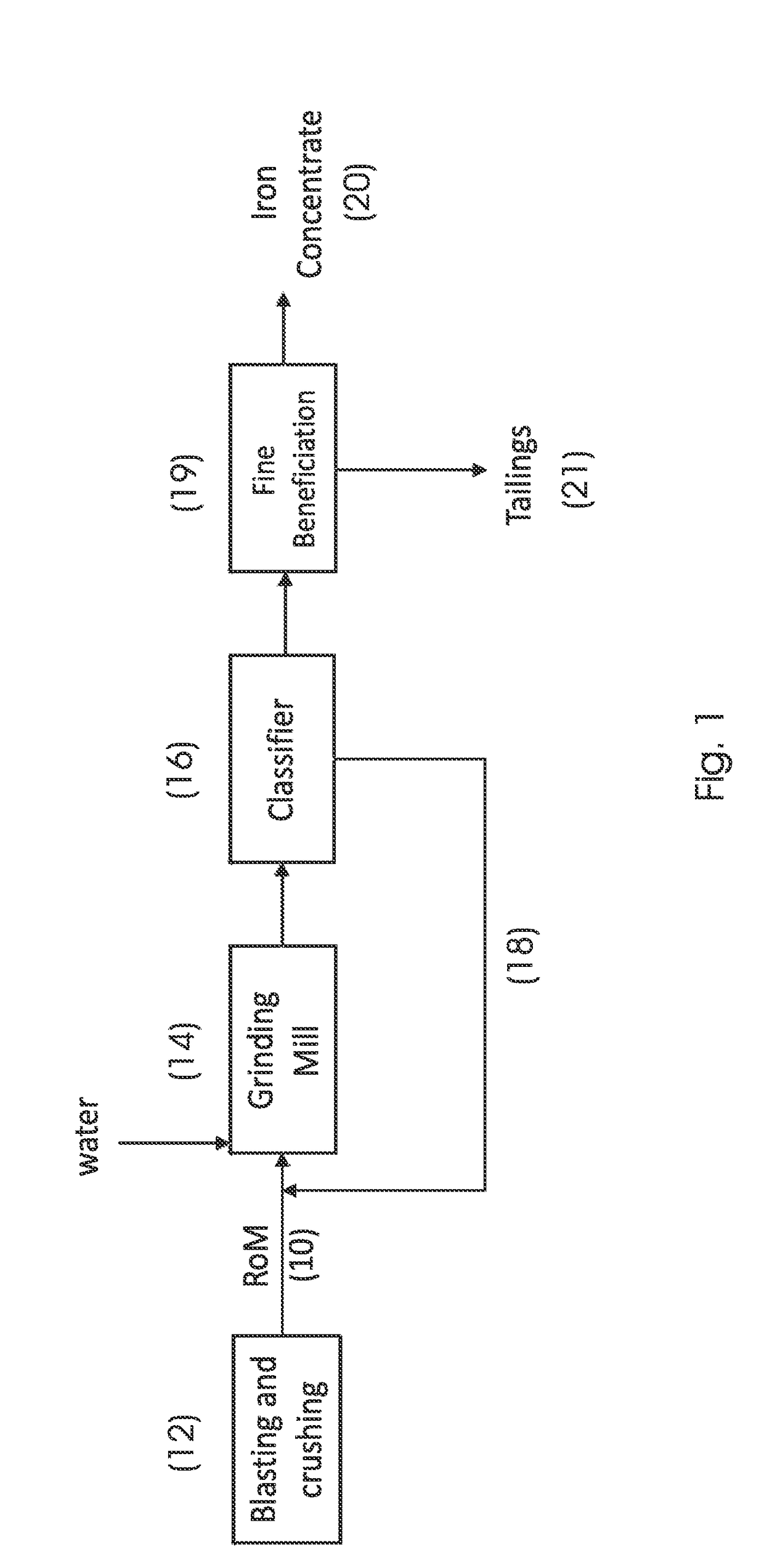

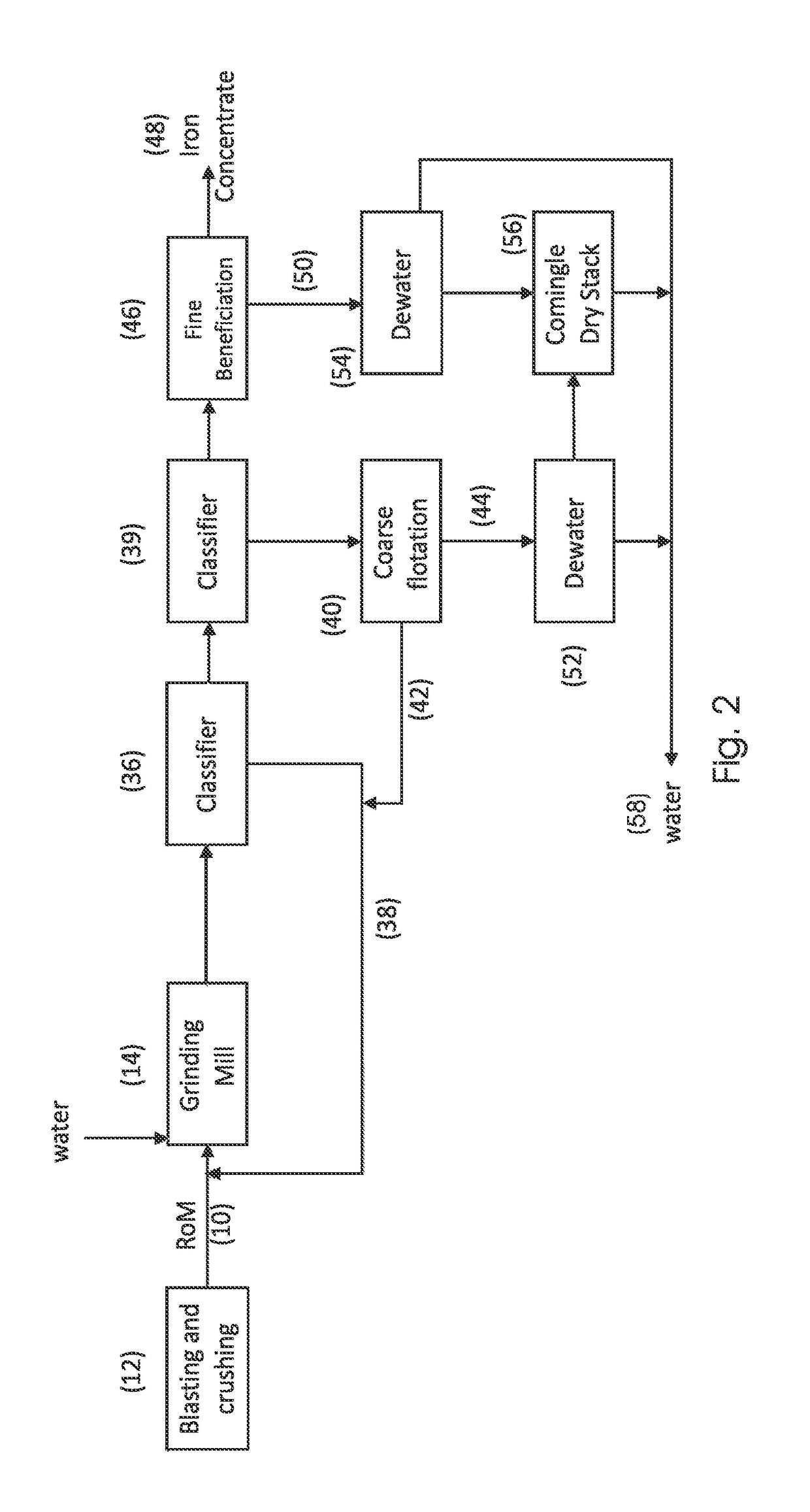

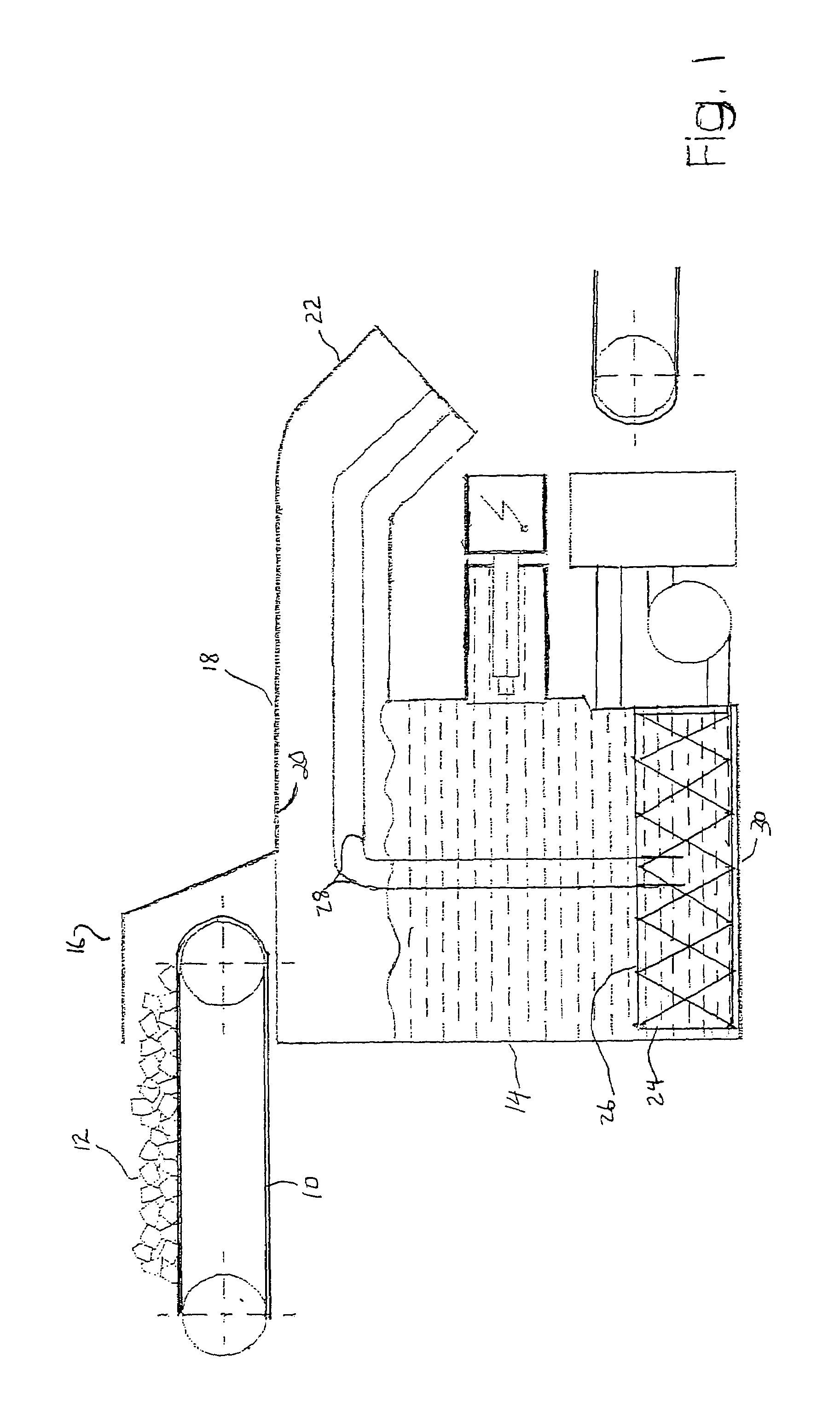

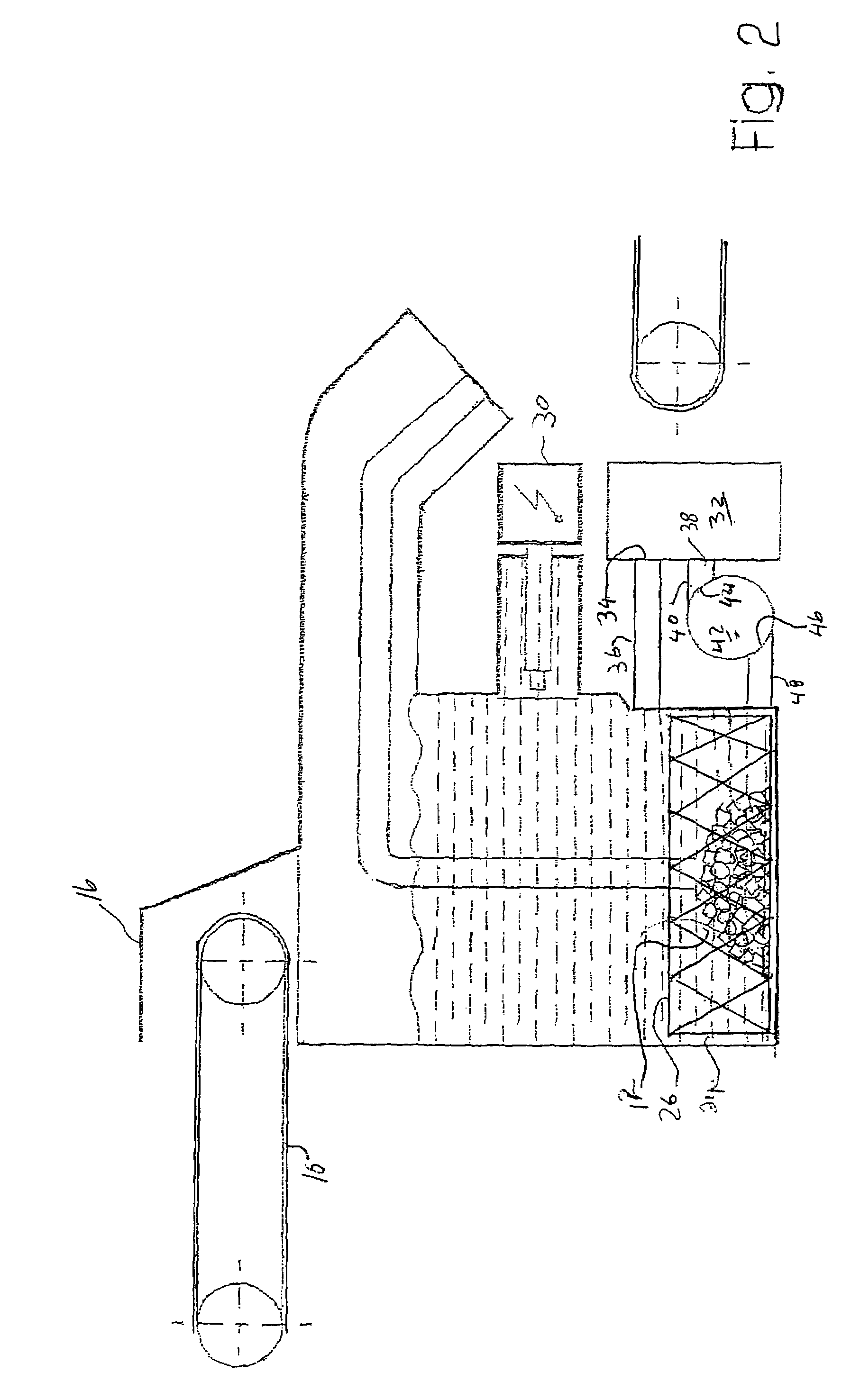

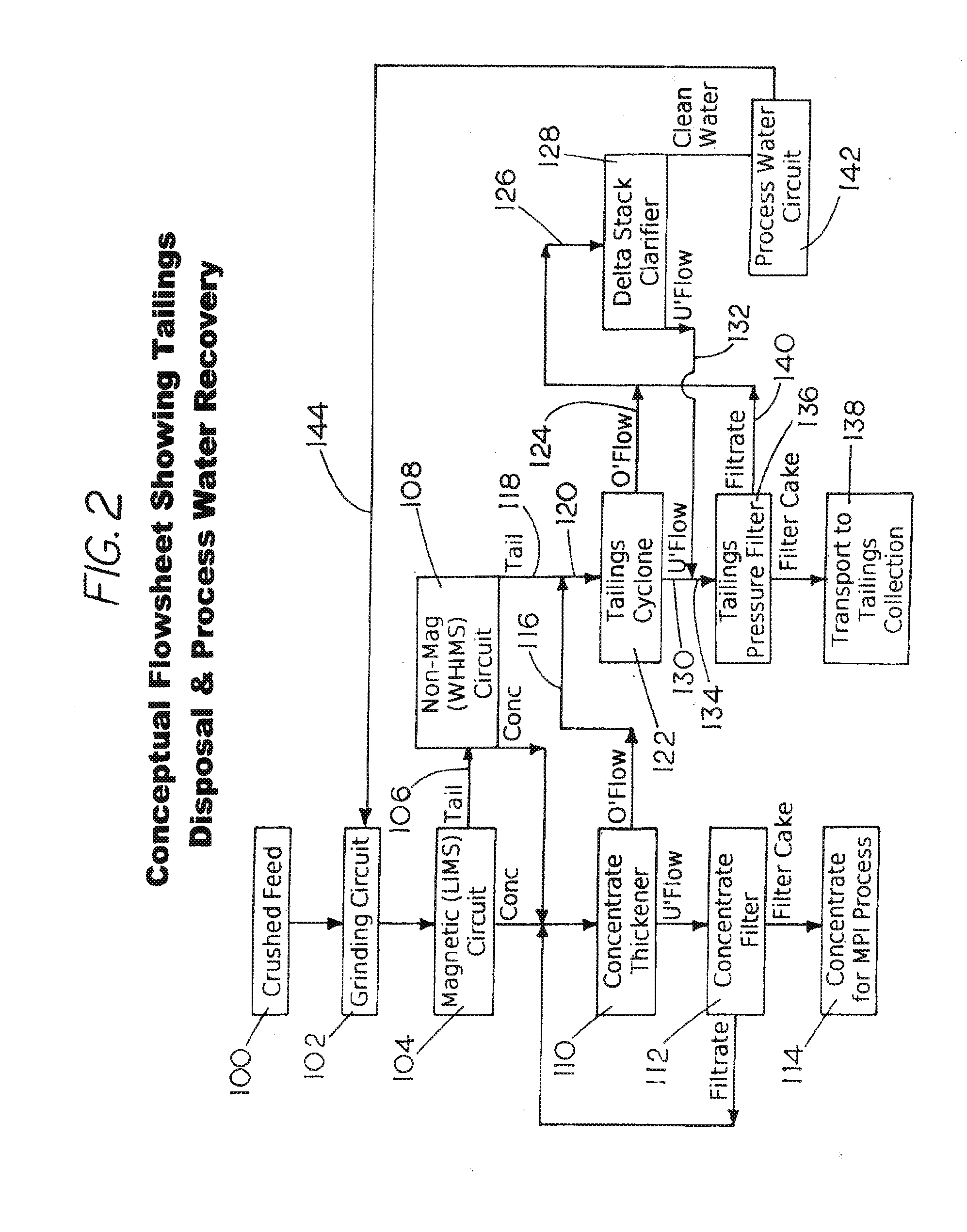

Reducing the need for tailings storage dams in the iron ore industry

ActiveUS20180111131A1Lower unit costImprove throughputHigh gradient magnetic separationFlotationIronstoneLower grade

THIS invention relates to an integrated process for recovering the valuable iron fraction from low grade iron ore, including the steps of: comminution 14 and classification 36 / 39 to obtain a classified fraction suitable for coarse flotation and classified fraction suitable for fine beneficiation; subjecting the fraction suitable for coarse flotation to coarse flotation40 to obtain an intermediate iron concentrate 42 and a coarse sand residue 44; grinding the intermediate concentrate to a size suitable for fine beneficiation; and subjecting the fractions suitable for fine beneficiation to fine beneficiation 46 and obtaining a final iron concentrate 48 and a fine tailings 50.

Owner:ANGLO AMERICAN TECH & SUSTAINABILITY SERVICES LTD

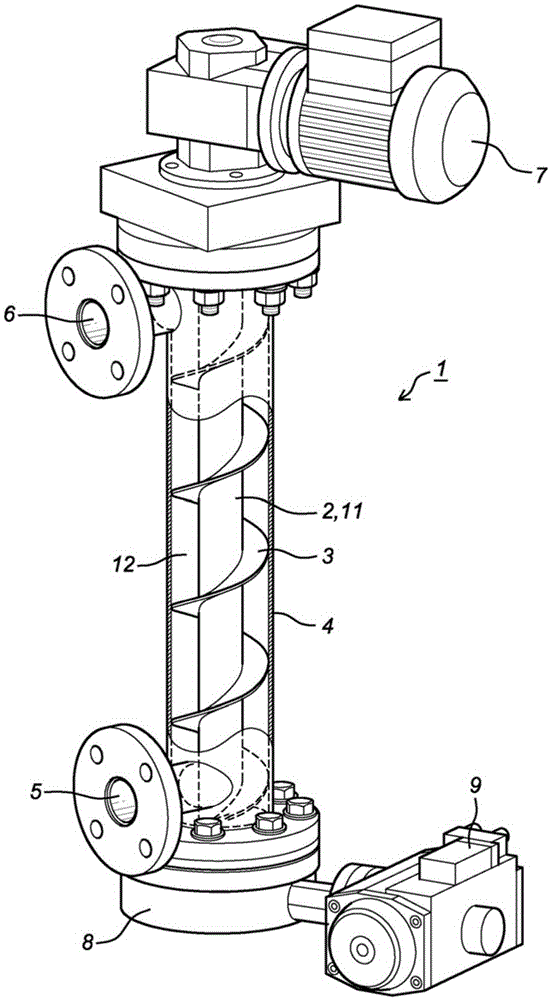

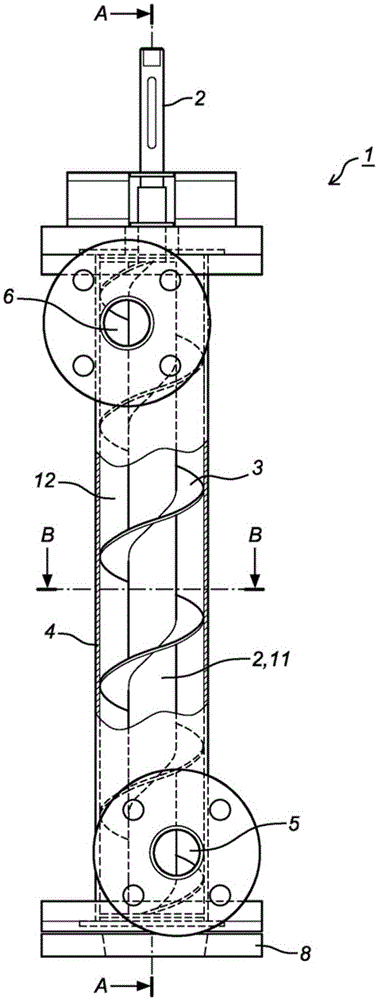

Filter device and method for removing magnetizable particles from a fluid

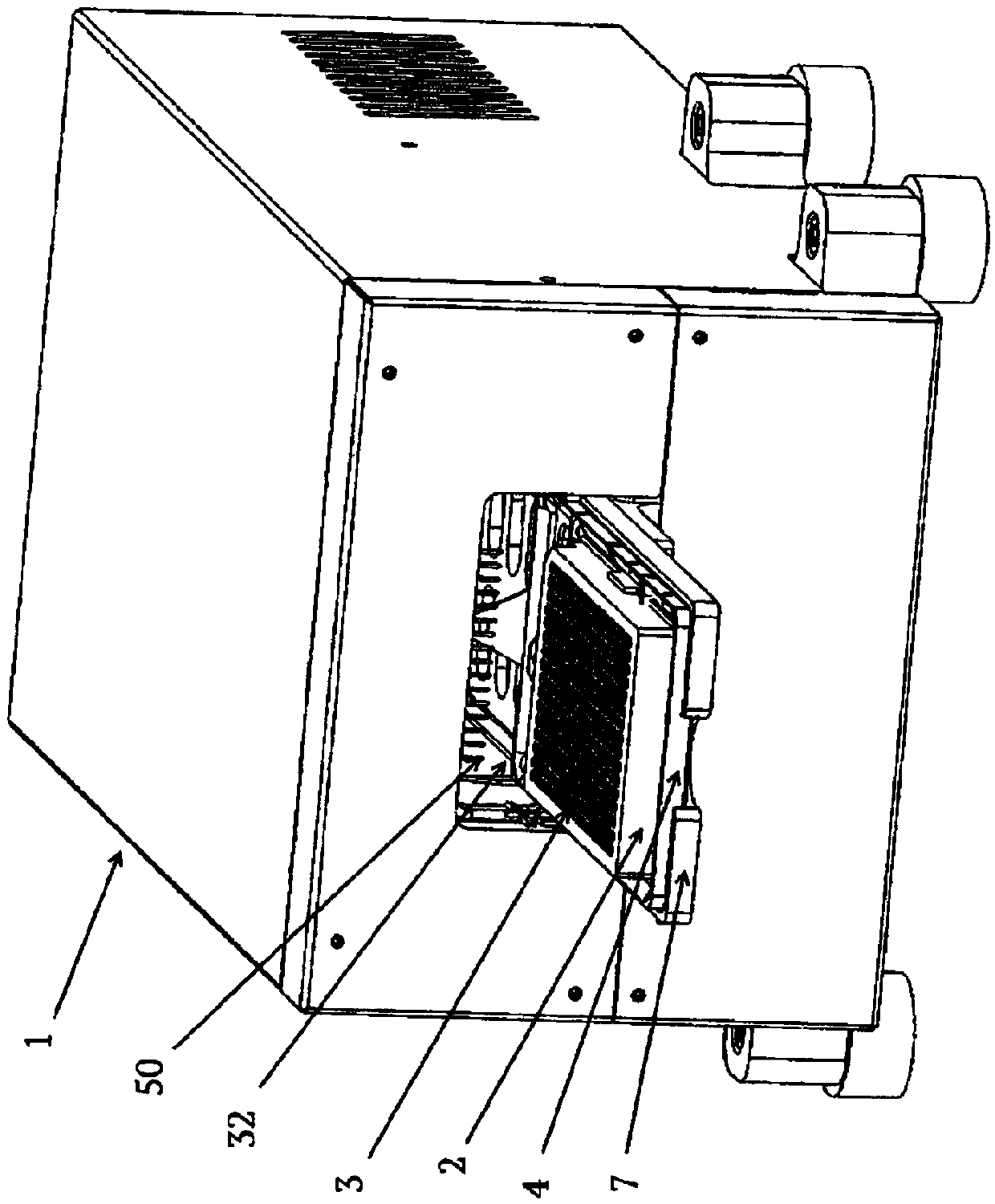

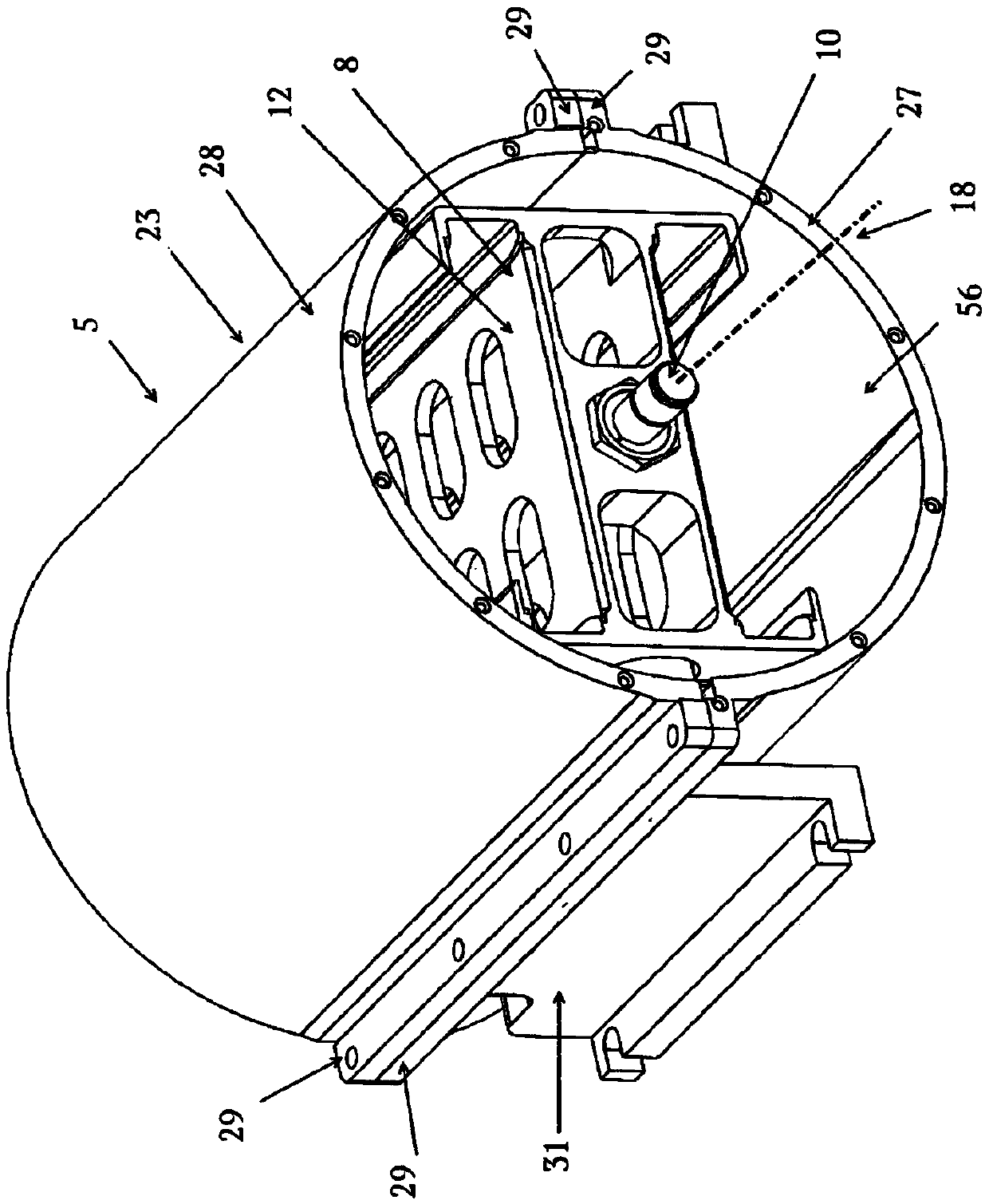

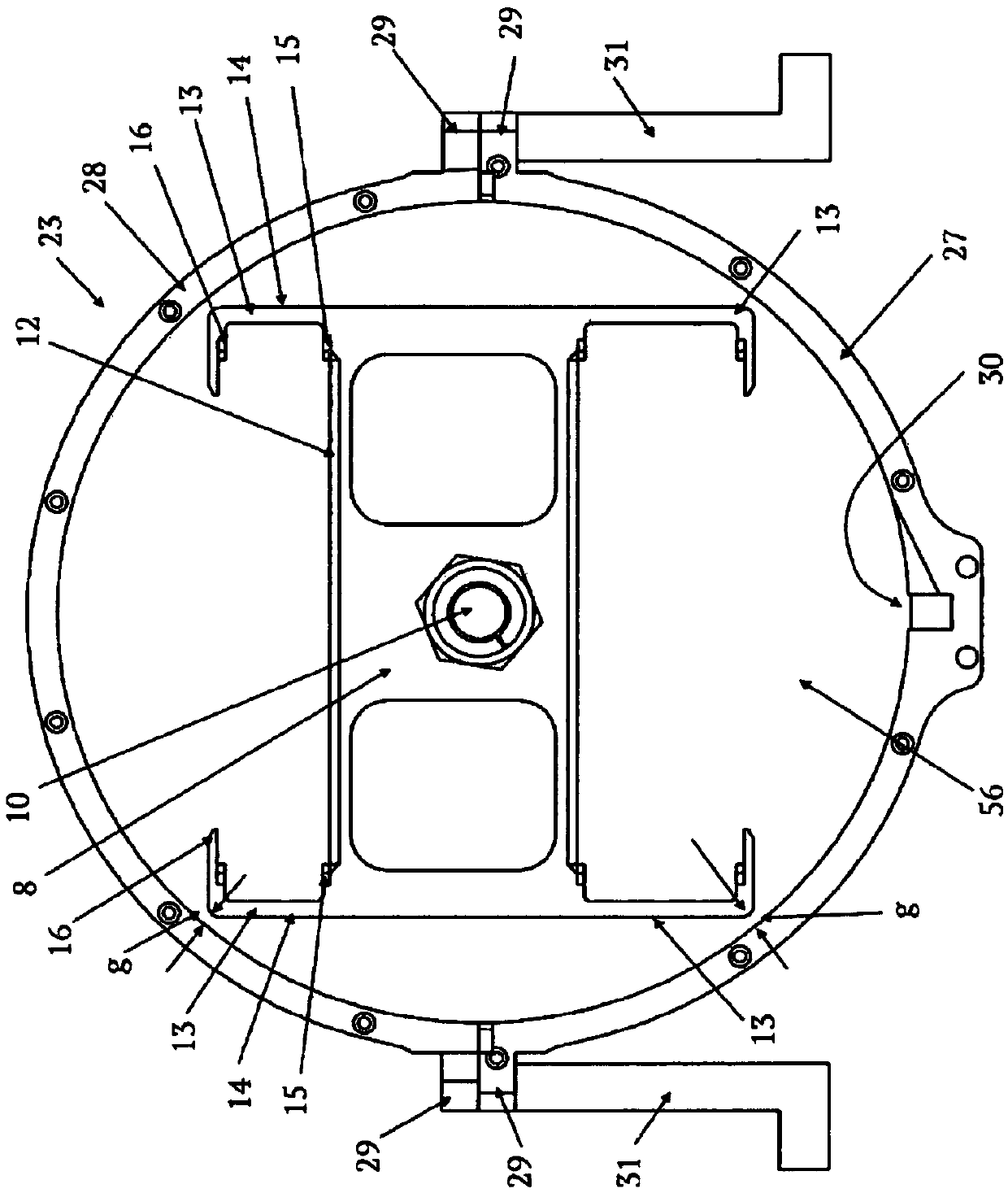

ActiveCN105392566AEasy to joinSimple structureHigh gradient magnetic separationElectrostatic separationEngineeringMagnetic filter

The invention relates to an improved magnetic filter device (1) for separating a fluid and magnetizable particles. The invention also relates to a method for separating a fluid and magnetizable particles, particularly by making use of a device (1) according to the invention.

Owner:艾瑟林解决方案责任有限公司

Sample Holder with Magnetic Base and Magnetisable Body

ActiveUS20150090664A1High gradient magnetic separationElectrostatic separationEngineeringNon magnetic

Owner:LIFE TECH AS

Precious metal recovery

A pulse of over six kilovolts with a duration of 200 nanoseconds causes an explosion that fragments a mineral deposit with metals embedded therein. The fragmentation separates the metals from the mineral. A conditioning electromagnet temporarily magnetizes the metals. A sorting magnet attracts one of the magnetized metals.

Owner:HESSABI IRADJ

Dialysis like therapeutic (DLT) device

InactiveCN103907025AHeating or cooling apparatusOther blood circulation devicesMagnetic field gradientFluidics

A dialysis like therapeutic (DLT) device is provided. The DLT device includes at least one source channel connected at least one collection channels by one or more transfer channels. Fluid contacting surface of the channels can be an anti-fouling surface such as slippery liquid-infused porous surface (SLIPS). Fluids can be flown at high flow rates through the channels. The target components of the source fluid can be magnetic or bound to magnetic particles using an affinity molecule. A source fluid containing magnetically bound target components can be pumped through the source channel of the microfluidic device. A magnetic field gradient can be applied to the source fluid in the source channel causing the magnetically bound target components to migrate through the transfer channel into the collection channel. The collection channel can include a collection fluid to flush the target components out of the collection channel. The target components can be subsequently analyzed for detection and diagnosis. The source channel and the collection channels of the microfluidic device are analogous to the splenic arterioles and venules, respectively; the transfer channels mimic the vascular sinusoids of the spleen where opsonized particles are retained. Thus, the device acts as a dialysis like therapeutic device by combining fluidics and magnetics.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

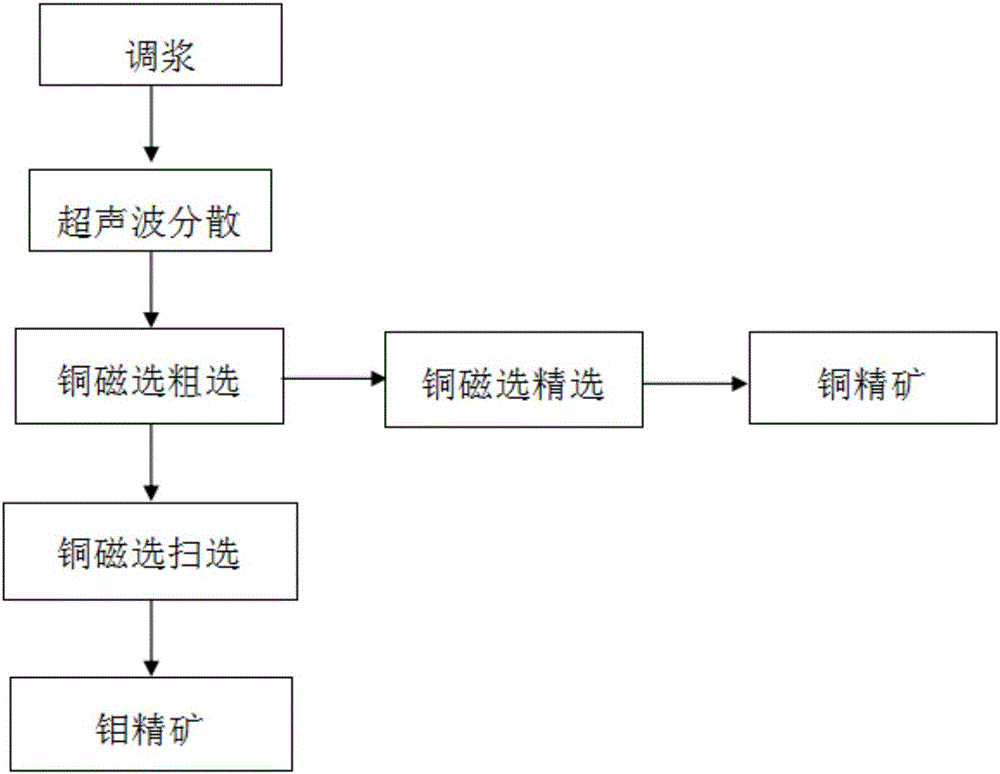

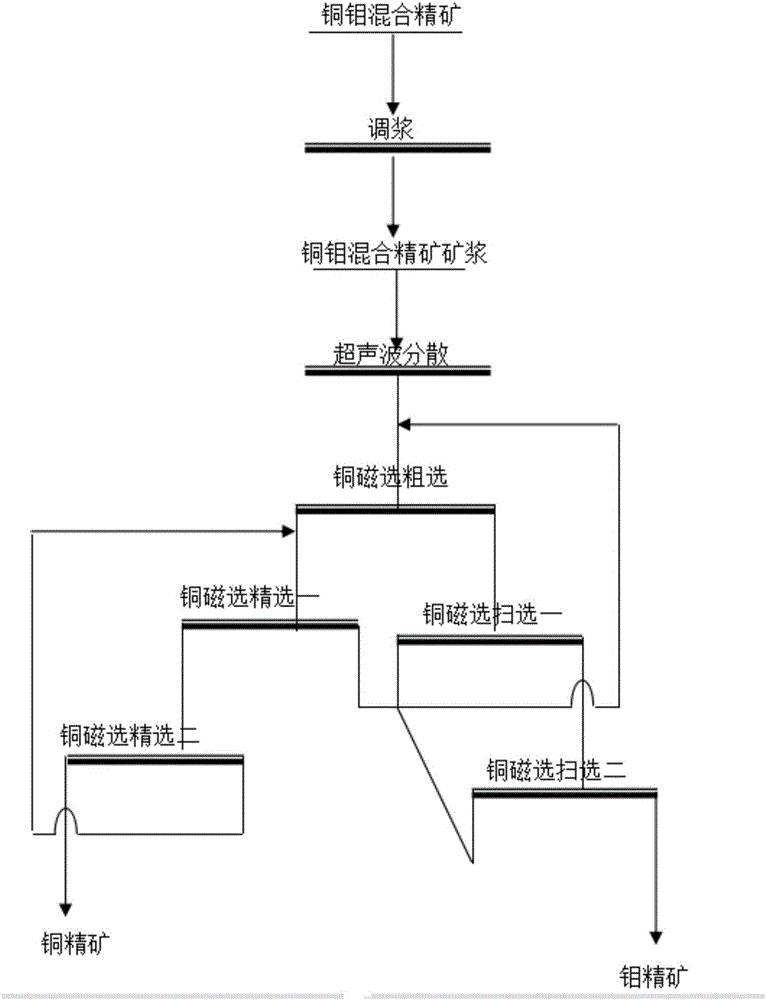

Ultrasonic dispersing-magnetic separating process for copper-molybdenum bulk concentrate

InactiveCN106492982AReduce mutual inclusionEliminate hazardsHigh gradient magnetic separationHigh gradient magnetic separatorsMagnetic separatorCopper

The invention discloses an ultrasonic dispersing-magnetic separating process for copper-molybdenum bulk concentrate. The ultrasonic dispersing-magnetic separating process for the copper-molybdenum bulk concentrate includes the following steps that a, pulp conditioning is conducted, specifically, the copper-molybdenum bulk concentrate is subjected to pulp conditioning to obtain copper-molybdenum bulk concentrate pulp; b, ultrasonic dispersing is conducted, specifically, an ultrasonic dispersing instrument is used for conducting ultrasonic dispersing on the copper-molybdenum bulk concentrate pulp, so that copper-molybdenum ore particles in the copper-molybdenum bulk concentrate pulp are dispersed, and agglomeration among the copper-molybdenum ore particles is eliminated; c, magnetic separation and roughing of copper are conducted, specifically, a magnetic separator is used for conducting magnetic separation and roughing of copper on the copper-molybdenum bulk concentrate pulp after the particle dispersing step, so that copper roughing concentrate and copper roughing tailings are obtained; d, magnetic separation and scavenging of copper are conducted, specifically, the magnetic separator is used for conducting magnetic separation and scavenging of copper on the copper roughing tailings, so that copper scavenging concentrate and copper scavenging tailings are obtained, and the copper scavenging tailings are molybdenum concentrate; and e, magnetic separation and concentration of copper are conducted, specifically, the copper roughing concentrate is subjected to magnetic separation and concentration of copper, so that copper middling and copper concentrate are obtained.

Owner:HUNAN RES INST FOR NONFERROUS METALS

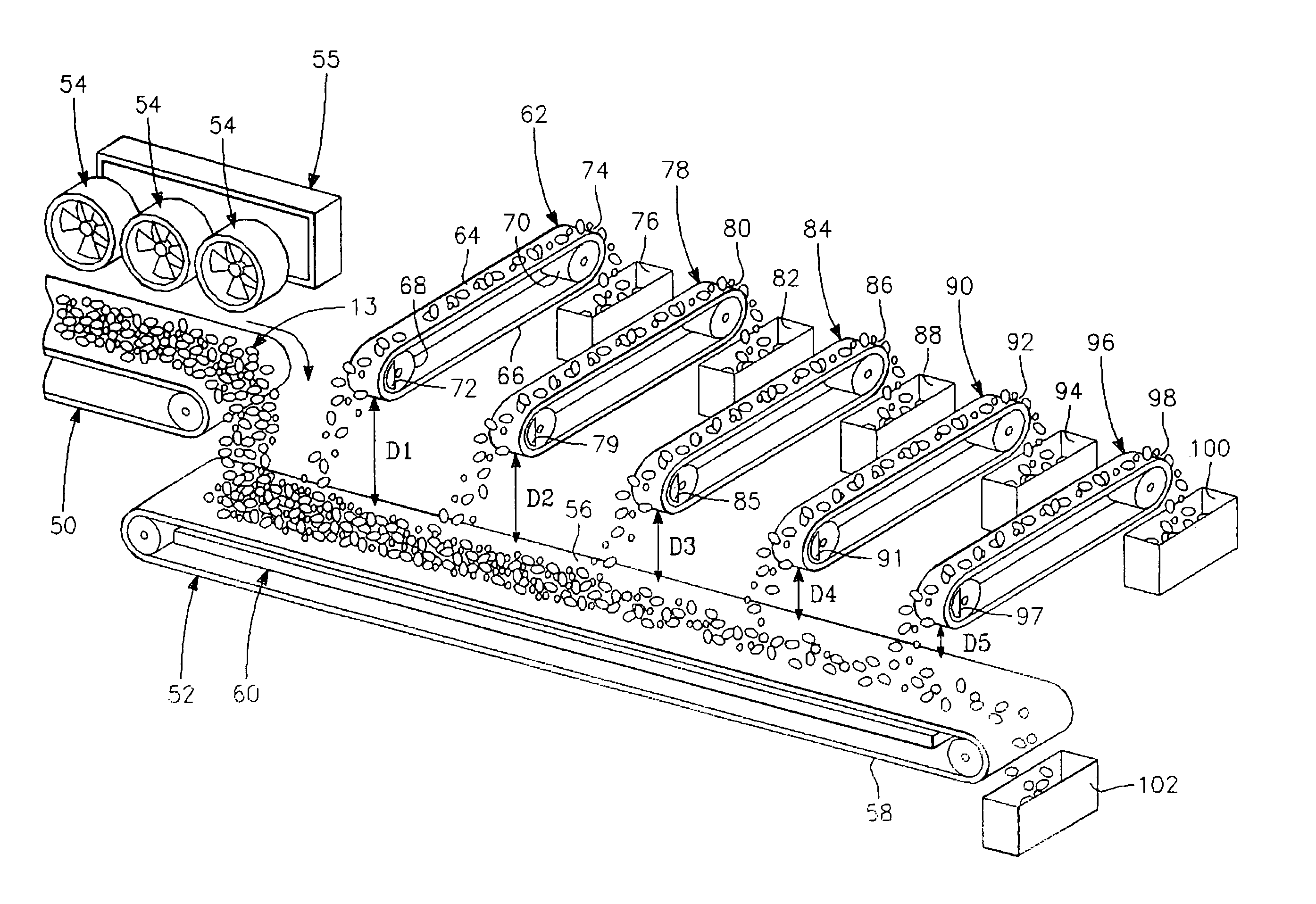

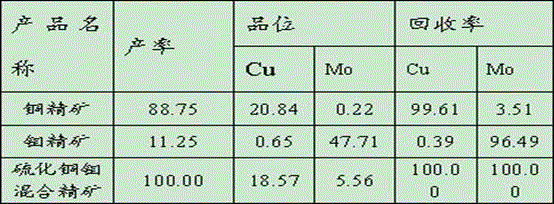

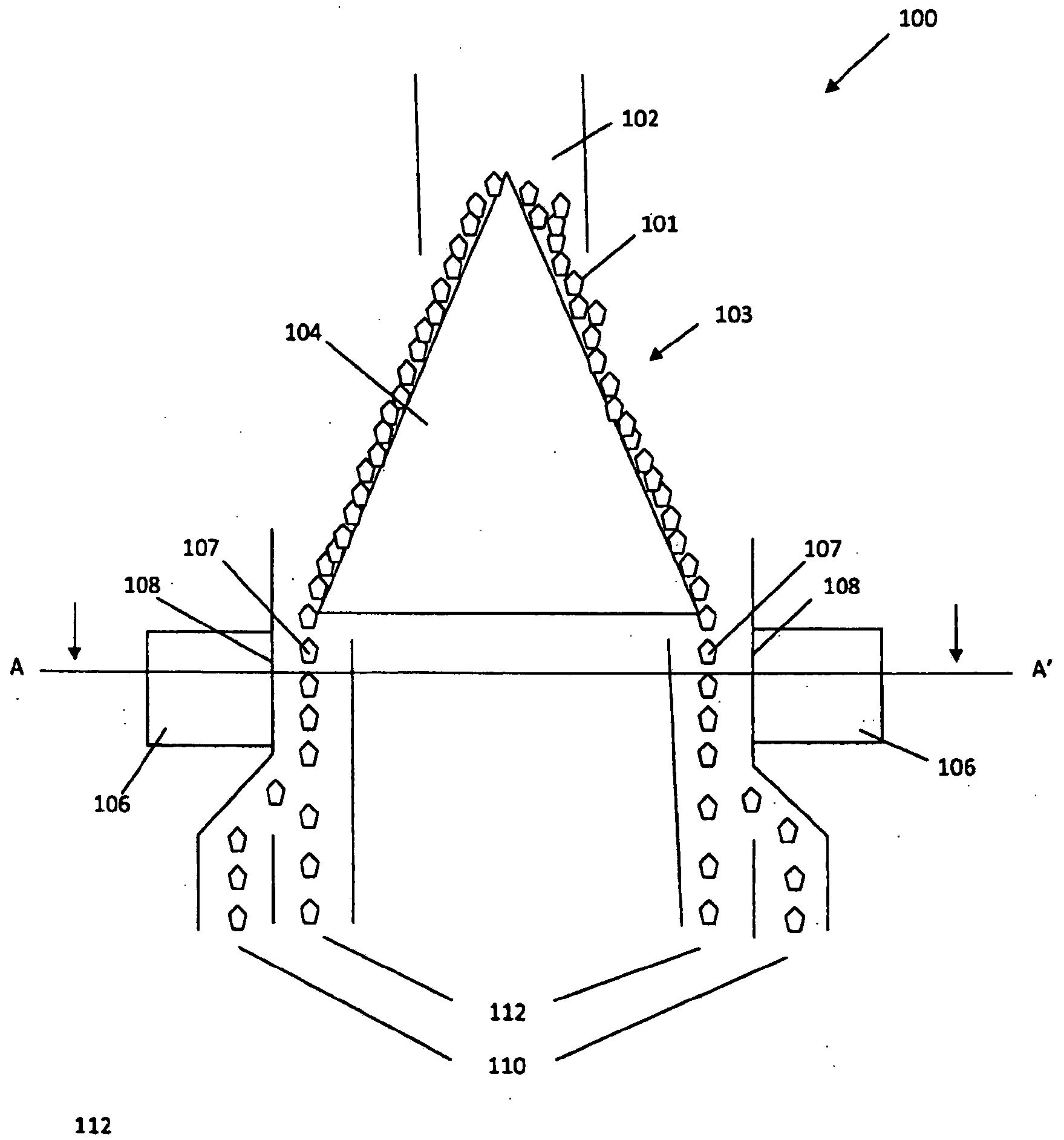

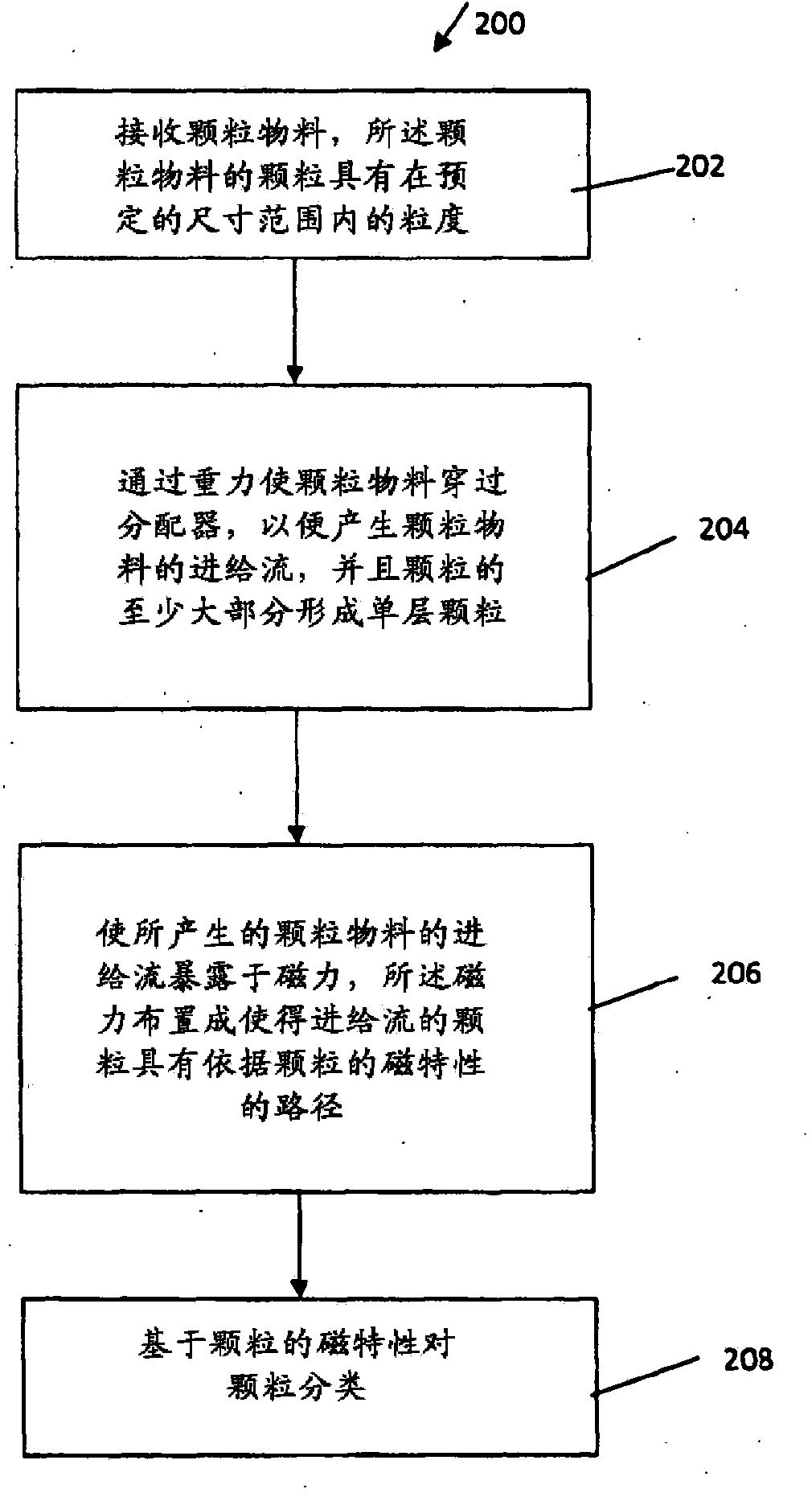

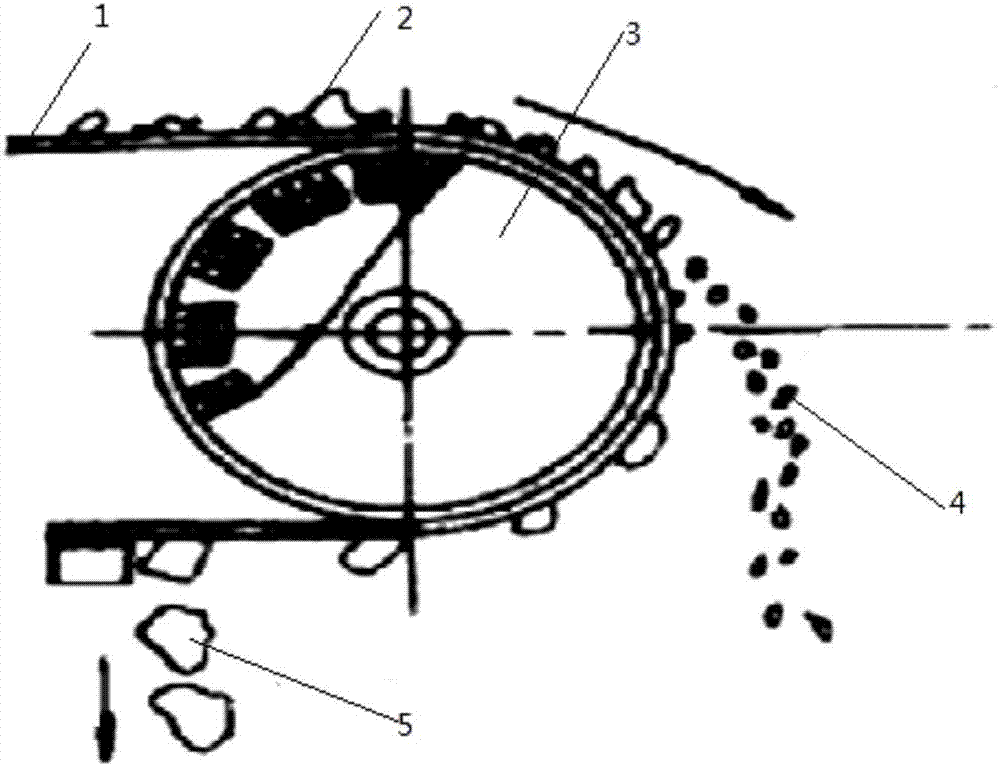

An apparatus and a method for sorting a particulate material

InactiveCN104136127AIncrease in sizeHigh mechanical reliabilityHigh gradient magnetic separationHigh gradient magnetic separatorsMagnetic tension forceMagnetic characteristic

The present disclosure provides an apparatus for sorting a particulate material. The apparatus comprises a receiving portion for receiving the particulate material having a particle size within a predetermined range of sizes. The apparatus also comprises a distributor for receiving the particulate material at an upper end thereof and having a sloped distribution surface along which, in use, the particulate material passes substantially by gravity. A surface area of the sloped distribution surface increases towards a lower end of the distributor to facilitate a monolayer feed stream of the particles exiting and falling from a lower end of the distributor distributed as a curtain-like stream of particles. The apparatus further comprises a magnetic element for generating a magnetic force that is directed such that the particles of the falling feed stream that exit the lower end of the distributor have pathways that depend on magnetic properties of the particles. The apparatus also comprises sorting portions for sorting the particles based on the pathways of the particles.

Owner:CURTAIN UNIV OF TECH

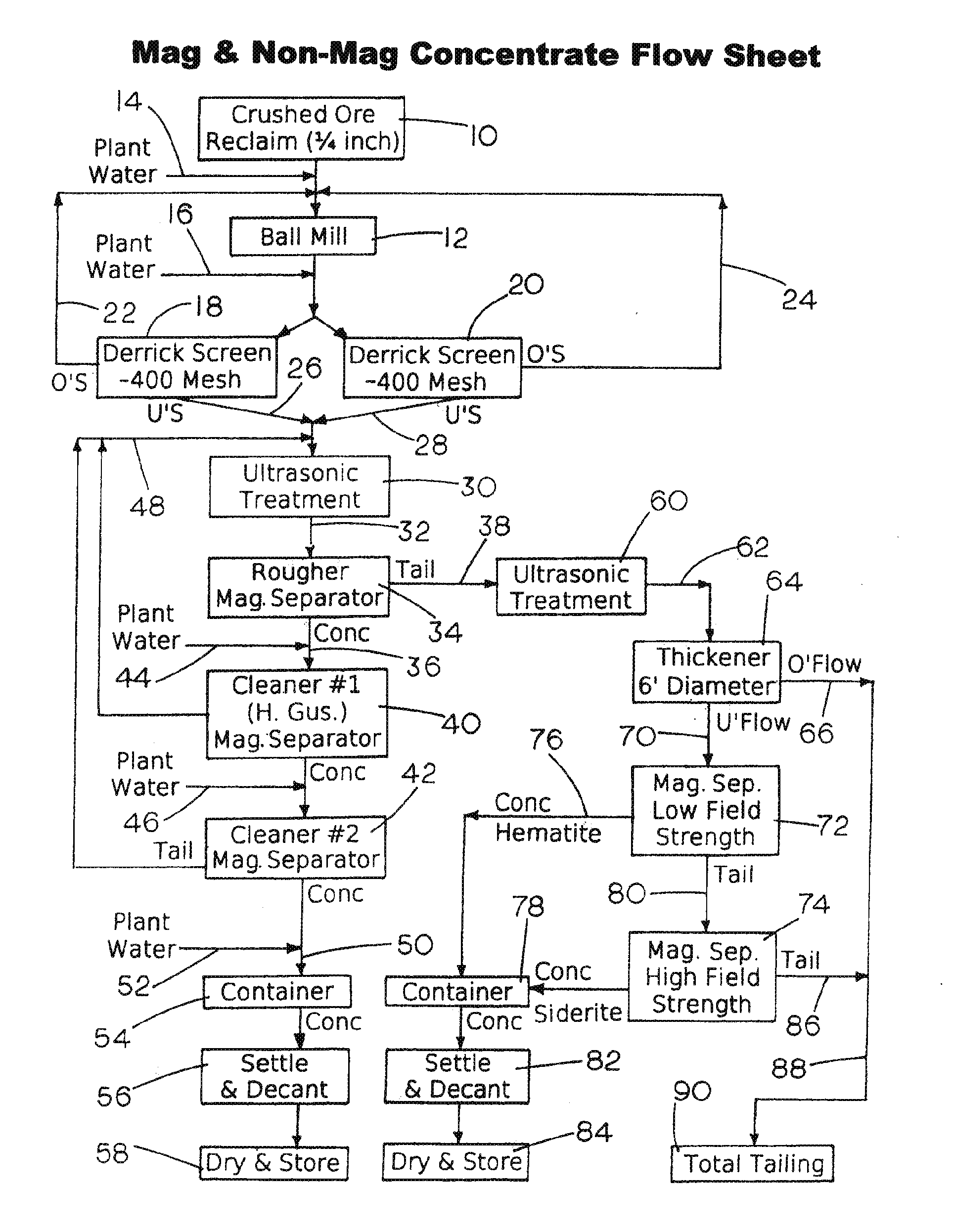

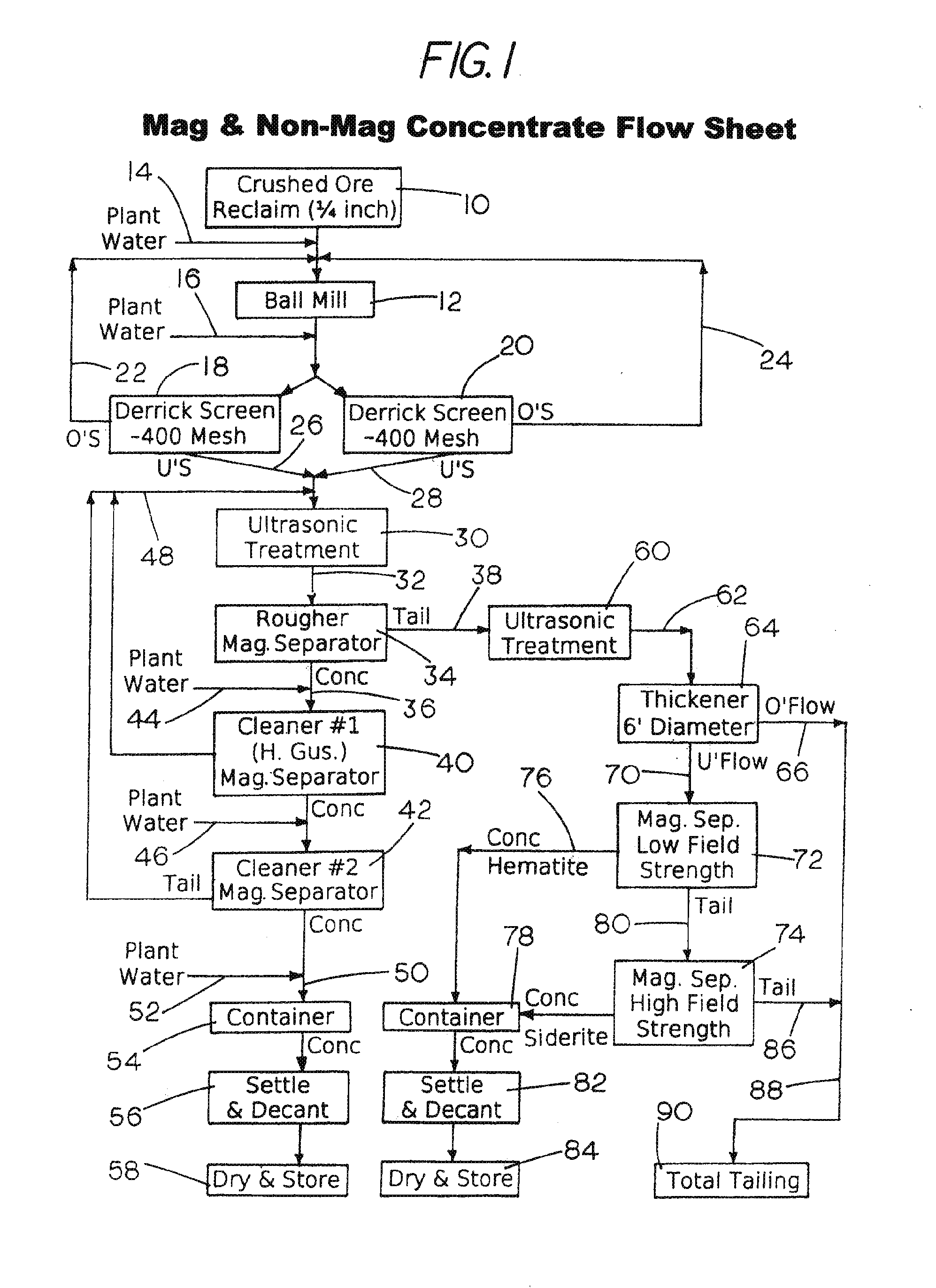

Ore beneficiation

A method of enriching the iron content of low-grade iron-bearing ore materials has been developed which produces a high iron ore concentrate suitable for processing into pig iron and steel. The process includes reducing the low-grade iron-bearing ore materials to a fine particulate form and treating a water slurry of this material by applying a combination of ultrasonic treatments in a plurality of high and low intensity magnetic separation operations to remove interfering materials and concentrate magnetic and paramagnetic iron-bearing materials into a high-grade ore stock.

Owner:SUPERIOR MINERAL RESOURCES

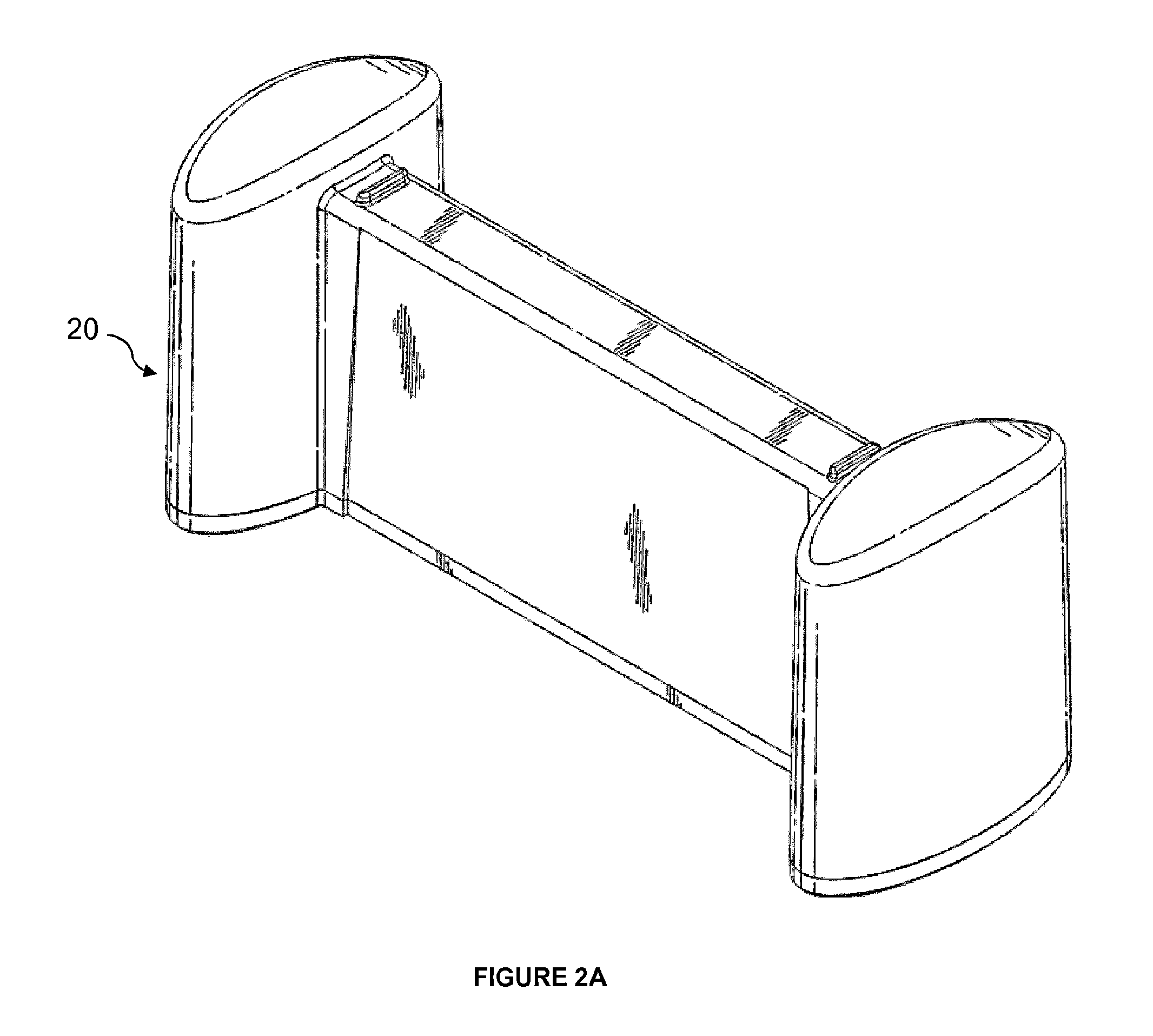

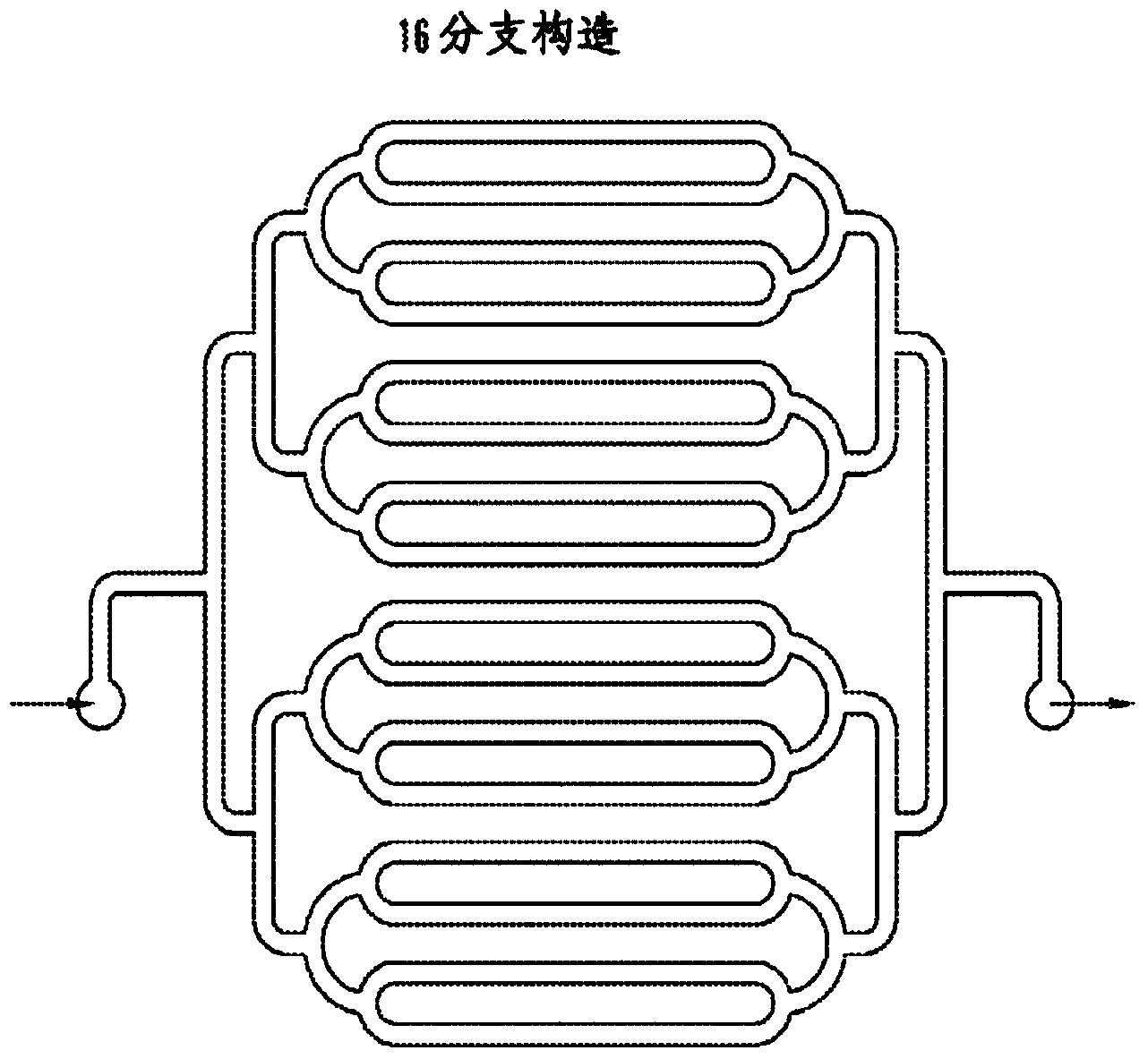

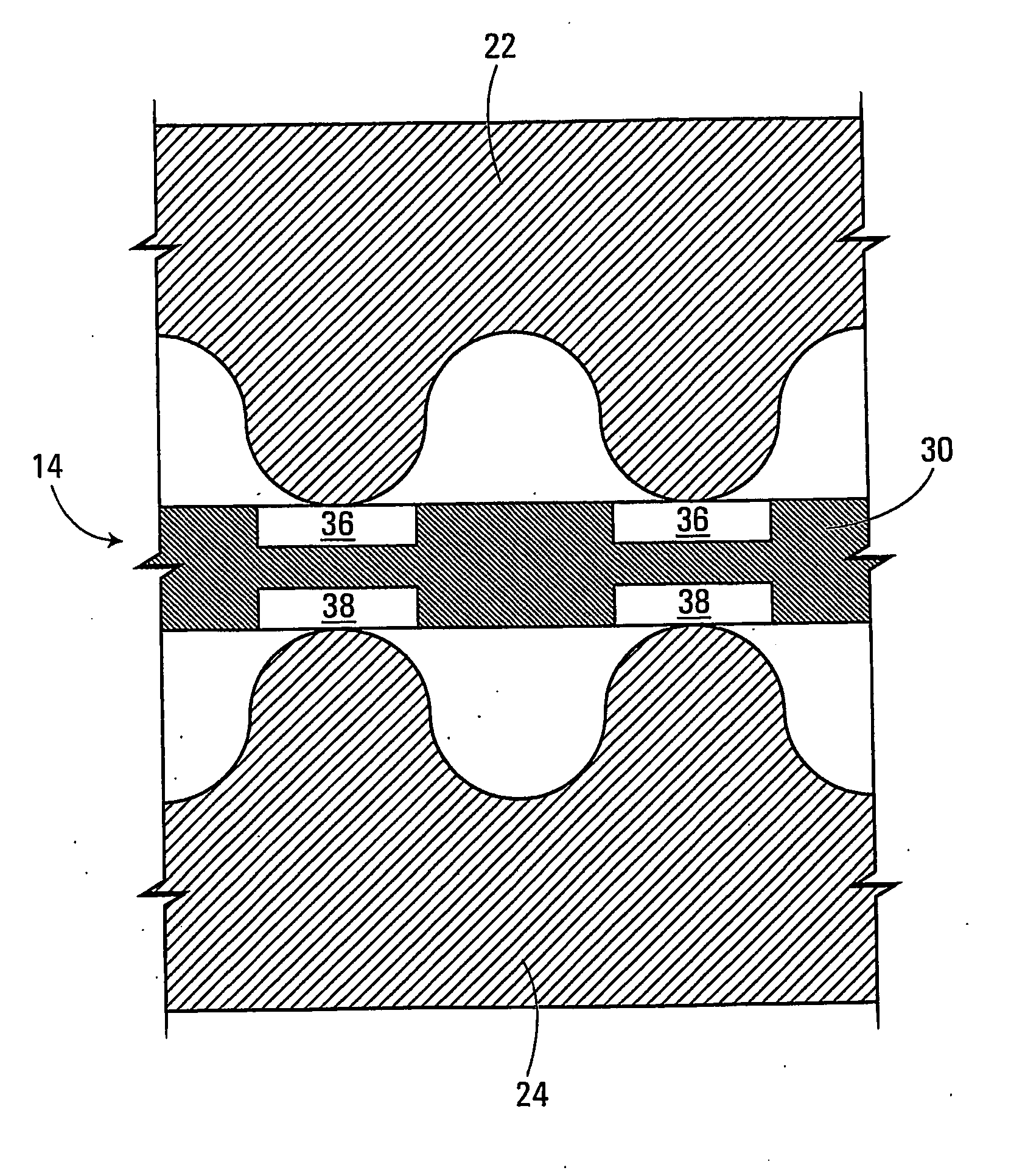

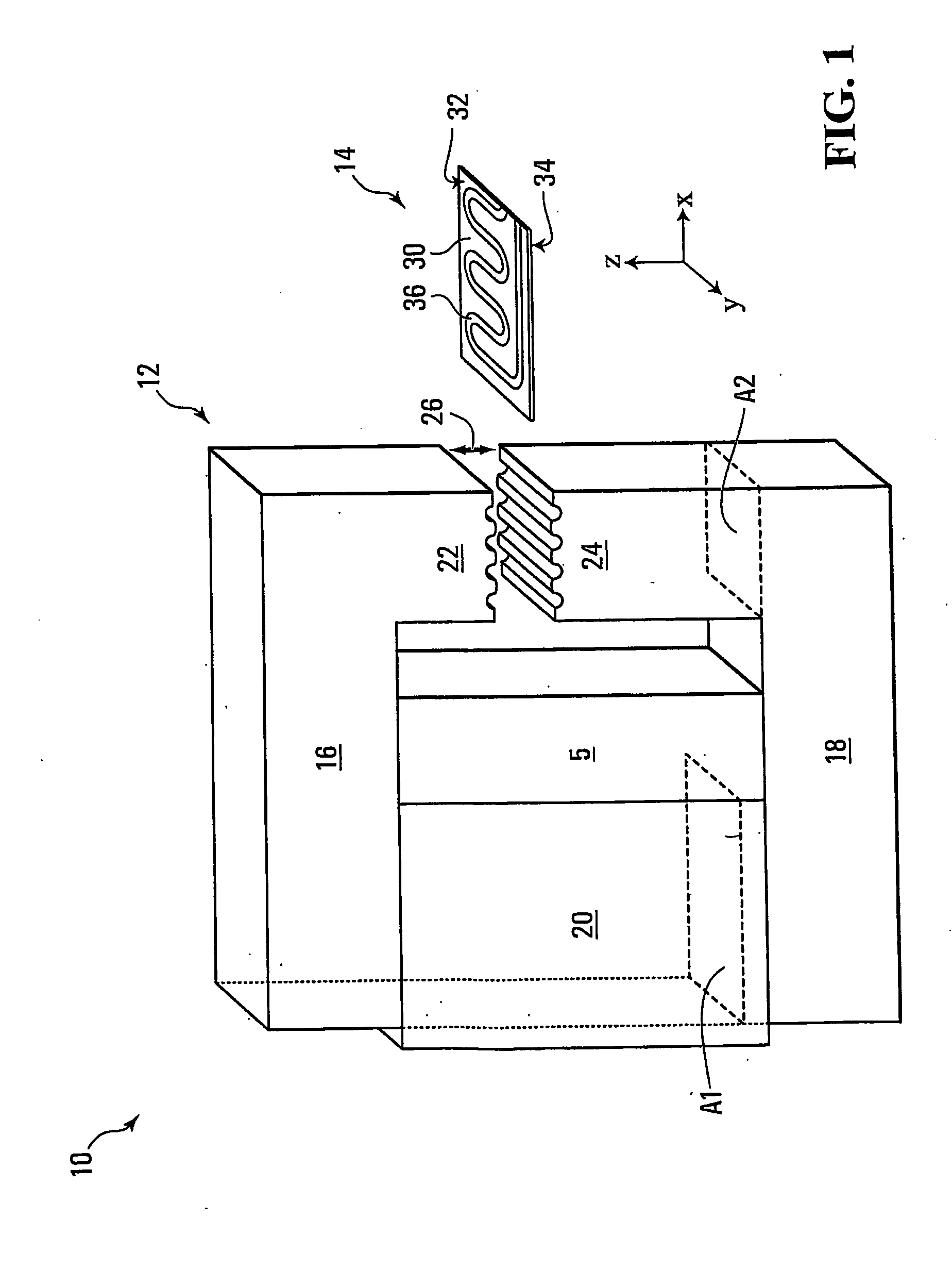

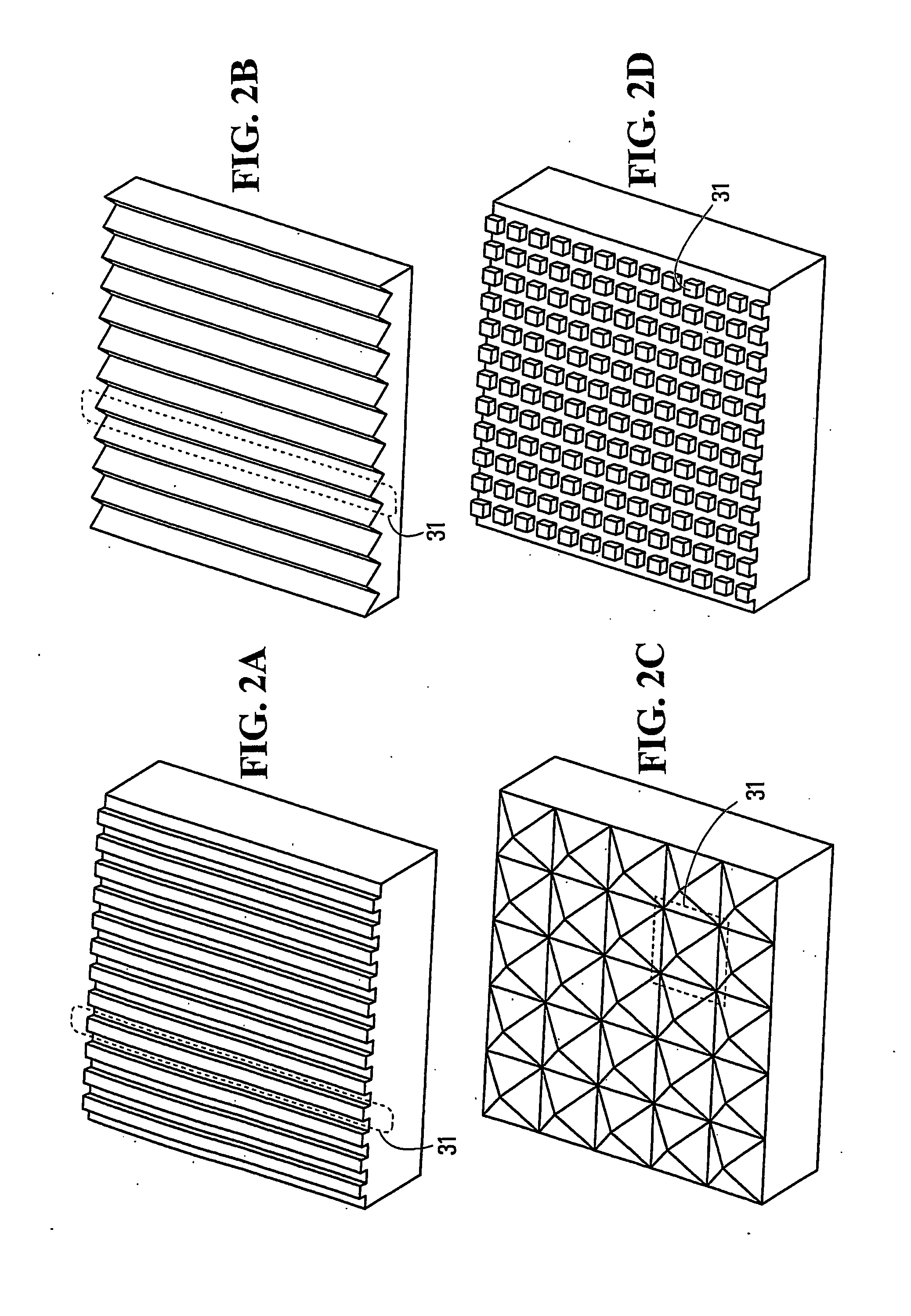

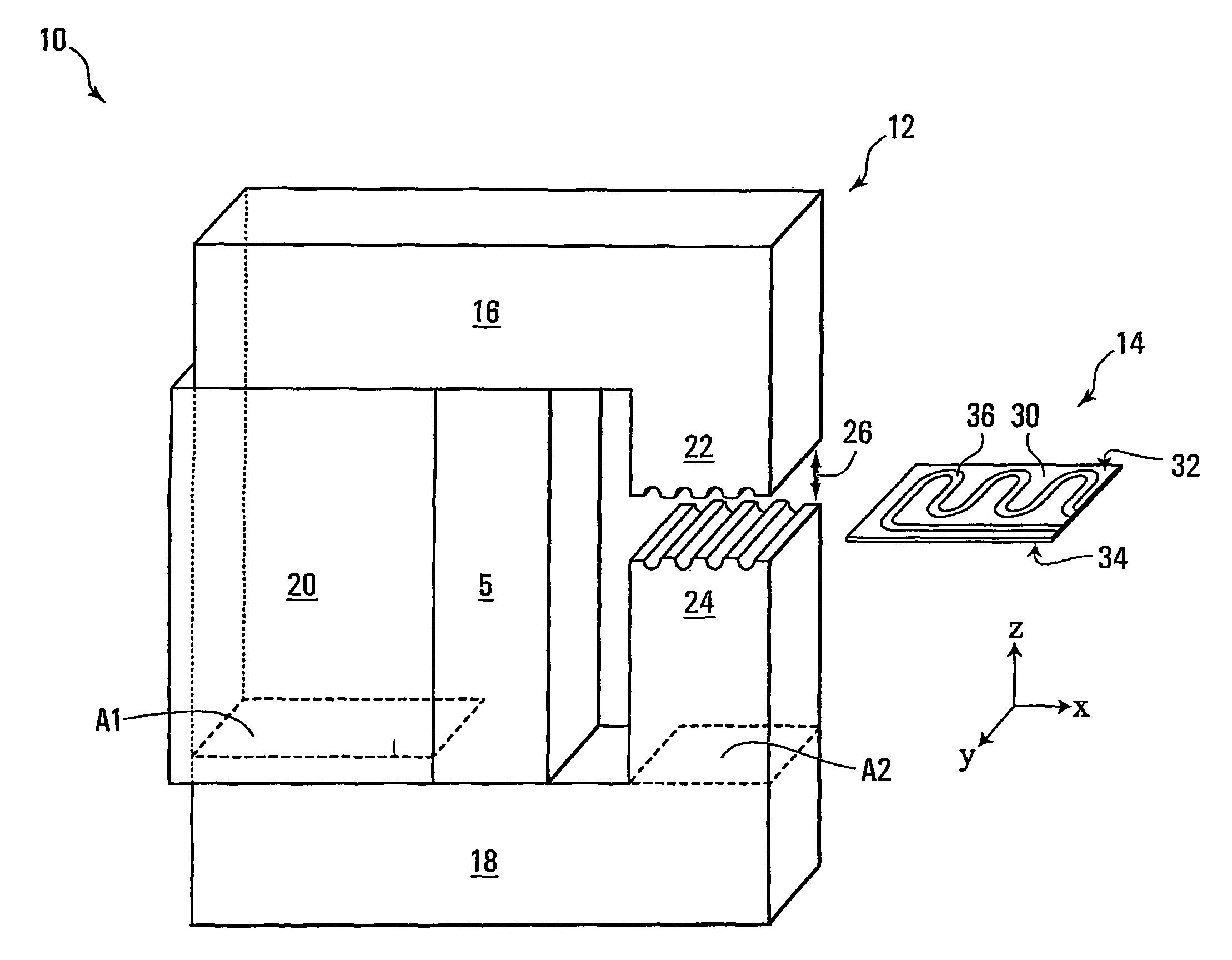

Microfluidic separation system

InactiveUS20120024770A1Bioreactor/fermenter combinationsBiological substance pretreatmentsTest sampleMagnetic separator

A microfluidic separation system, which comprises a magnetic separator, which itself comprises a magnetic energy source; first and second magnetically conductive members leading from the magnetic energy source and having respective terminal ends that are separated by a gap over which a magnetic field is applied due to the magnetic energy source. The separation system further comprises a microfluidic chip for insertion into the gap, which comprises a body defining channels on respective faces of the body; and an exterior lining that seals the plurality of channels to allow separate test sample volumes to circulate in at least two of the channels. Upon insertion of the chip into the gap, a first test sample volume is confined to circulating closer to the terminal end of the first member and a second test sample volume is confined to circulating closer to the terminal end of the second member.

Owner:AGENCY FOR SCI TECH & RES

Recovery method of high-iron highly-argillaceous alkaline gangue refractory oxide copper ore

InactiveCN104815746AIncrease costIncrease consumptionHigh gradient magnetic separationFlotationSulfidationCopper oxide

The invention relates to a recovery method of a high-iron highly-argillaceous alkaline gangue refractory oxide copper ore, and belongs to the technical field of ore processing. A raw oxide copper ore is ground for mixed flotation by sulfur and oxygen to obtain a sulfur-oxygen mixed flotation concentrate and a flotation tailing; through high-gradient magnetic separation of the flotation tailing, a refractory oxide copper magnetic separation rough concentrate and a magnetic separation tailing are obtained; the open selection is performed for the oxide copper magnetic separation rough concentrate obtained through the high-gradient magnetic separation for 2-3 times to obtain an oxide copper magnetic separation concentrate and a magnetic separation middling; and wet leaching is performed for the magnetic separation middling. The recovery rate of the recovery method is increased by 15-25% compared with single floatation. The recovery method solves the problems of low recovery rate of conventional vulcanization flotation to high-iron-content oxide copper minerals, high agent consumption, low leaching rate, high energy consumption, easy hardening and high production cost in the process of wet leaching of highly-argillaceous alkaline gangue oxide copper and low recovery rate of single magnetic separation to copper minerals. The recovery method guarantees high-efficiency recovery of high-iron highly-argillaceous alkaline gangue refractory oxide copper. The recovery method is stable in process flow, strong in adaptability and low in production cost, and facilitates the industrial implementation.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Microfluidic separation system

InactiveUS8268177B2Bioreactor/fermenter combinationsFixed microstructural devicesTest sampleMagnetic separator

A microfluidic separation system, which comprises a magnetic separator, which itself comprises a magnetic energy source; first and second magnetically conductive members leading from the magnetic energy source and having respective terminal ends that are separated by a gap over which a magnetic field is applied due to the magnetic energy source. The separation system further comprises a microfluidic chip for insertion into the gap, which comprises a body defining channels on respective faces of the body; and an exterior lining that seals the plurality of channels to allow separate test sample volumes to circulate in at least two of the channels. Upon insertion of the chip into the gap, a first test sample volume is confined to circulating closer to the terminal end of the first member and a second test sample volume is confined to circulating closer to the terminal end of the second member.

Owner:AGENCY FOR SCI TECH & RES

Sand ilmenite tailing-selecting treatment system and treatment process

ActiveCN107377196AHigh recovery rateRaise the gradeHigh gradient magnetic separationHigh gradient magnetic separatorsEngineeringSlurry

The invention relates to a sand ilmenite tailing-selecting treatment system and a treatment process. The system comprises two mineral benefication parts, namely a vertical-ring pulsation high-gradient magnetic separator and a staged concentration tank as well as two tailing treatment assemblies, namely a tailing slurry concentration tank and a strong belt type dehydration press. The process comprises the following steps of: magnetic separation and graded concentration of the high-gradient magnetic separator, graded reselection, tailing concentration and strong belt type dehydration extrusion. According to the mineral benefication system and the mineral benefication process disclosed by the invention, technical indexes are greatly superior to those of a conventional process, a recovery rate of iron is increased by 20% or more, a recovery rate of titanium is increased by 25% or more, and grade of iron ore concentrates and titanium iron concentrates is separately improved by 2% or more. After tailing pulp is treated by equipment, moisture content is about 20%, and an emission process is free of dust, pollution, leakage and any harmful chemical element, and reaches the relevant national environment-friendly standards; and water can be continuously recycled, so that water can be saved by 20-30% relative to a conventional process.

Owner:云南中钛科技有限公司

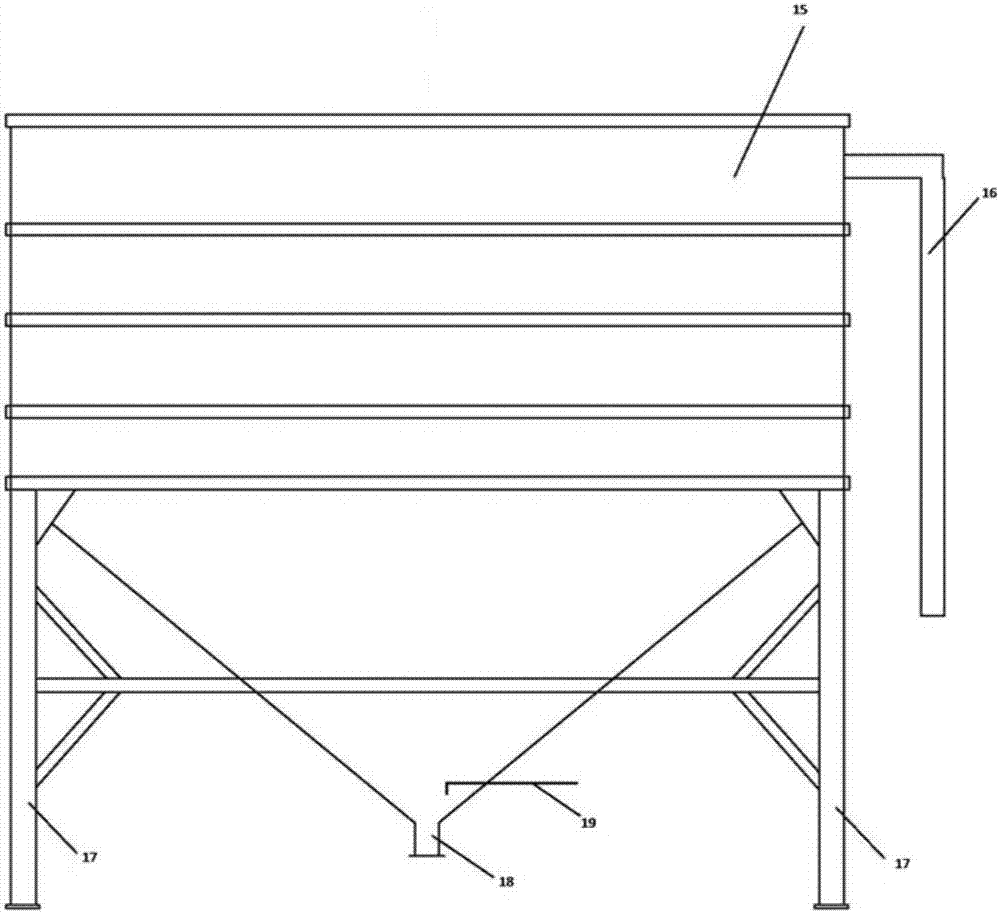

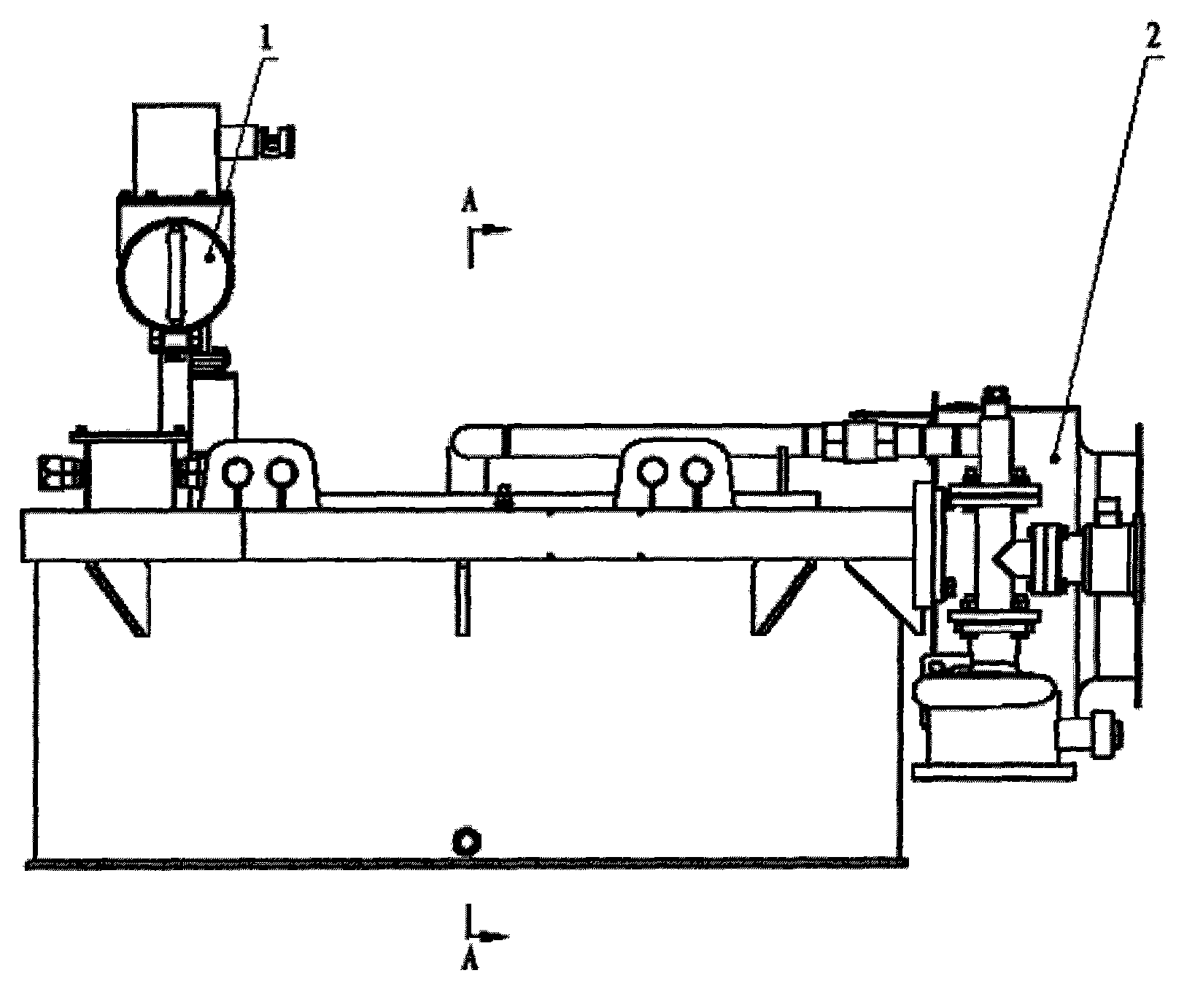

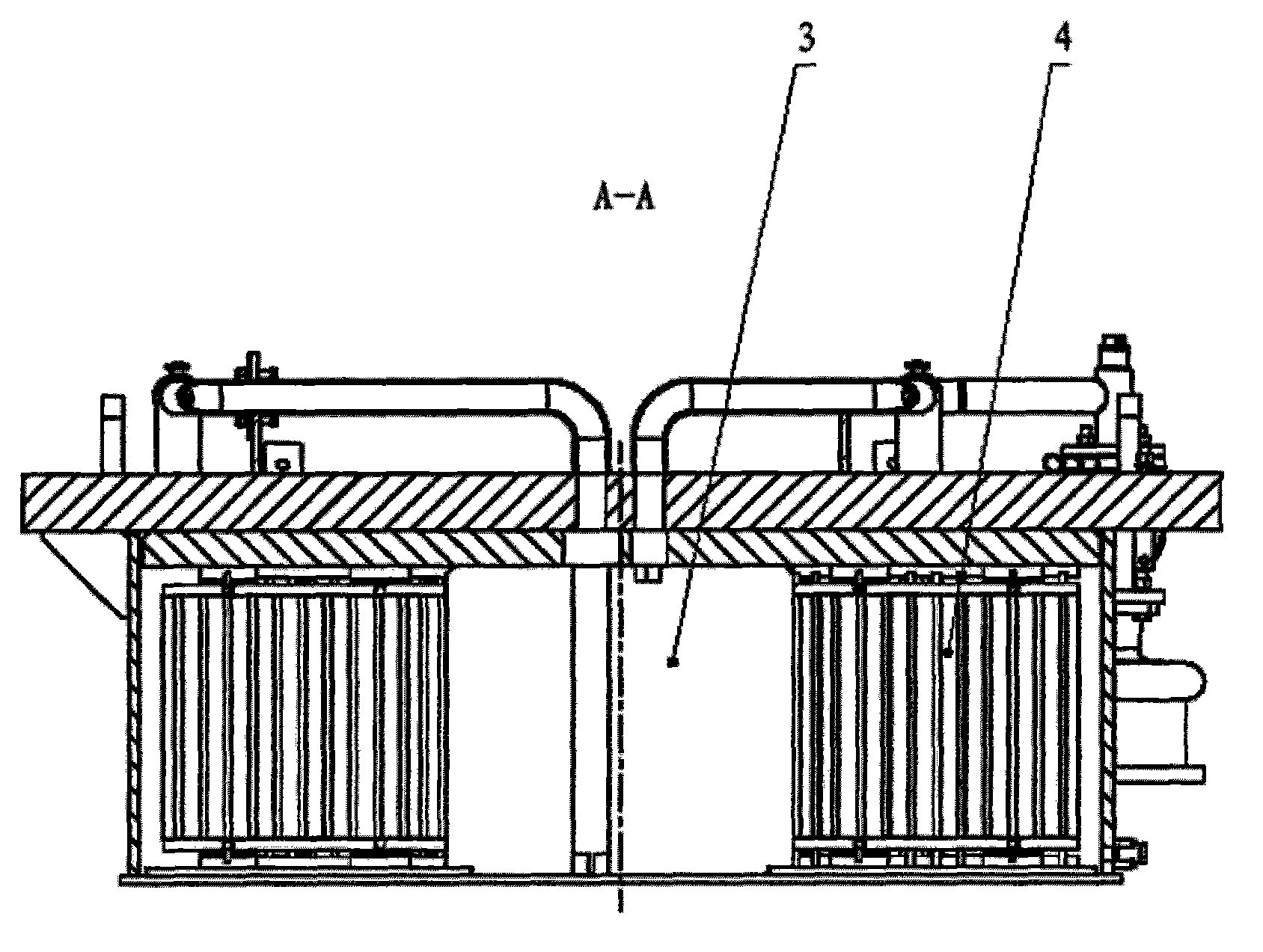

Novel high-efficiency inner circulation oil-cooling iron remover

InactiveCN102553711AWork lessReduce temperature riseHigh gradient magnetic separationTransformers/inductances coolingReturn channelIron removal

The invention discloses a novel high-efficiency inner circulation oil-cooling iron remover which comprises a shell formed by a yoke plate, a support plate and a magnetic conductive plate, and a magnetic system arranged in the shell, wherein the magnetic system comprises an iron core and a coil which is wound at the outer side of the iron core and is provided with an oil duct; an oil inlet pipe, an oil outlet pipe and an oil conservator are arranged at the upper side of the yoke plate; the iron core is internally provided with an oil injection channel; an oil return channel and an oil inlet channel are respectively arranged in the yoke plate arranged at the upper part of the iron core and at the bottom of the iron core; and the oil inlet pipe is communicated with the oil outlet pipe through the oil injection channel, the oil inlet channel and the oil return channel. After an inner circulation structure is adopted by the novel high-efficiency inner circulation oil-cooling iron remover, an external circulation pipeline is simplified, the leakage of a welding spot can be reduced, the iron remover can be guaranteed to normally work, and the iron removal efficiency can be improved. Meanwhile, due to the inner circulation structure, the oil way circulation is evener and more reasonable, the temperature rise of the iron remover is effectively reduced and guaranteed to be lower than 40 DEG C, the iron removal performance is improved, and the performance of the iron remover is far higher than the industry standard.

Owner:LONGI MAGNET CO LTD

Centrifuge and method for centrifuging a reaction vessel unit

ActiveCN105517711AHigh gradient magnetic separationElectrostatic separationCentrifugal forceCentrifuge

A centrifuge for cleaning a reaction vessel unit, having a rotor for holding at least one reaction vessel unit with its opening(s) directed outwardly, a motor for rotating the rotor around a rotation axis, a housing having a substantially cylindrical inner surface, wherein a drain is provided for discharging fluid expelled from the reaction vessel unit, wherein a gap is provided between the inner surface and the rotor so that by rotating the rotor a wind is generated which drives the expelled fluid on the inner surface to the drain wherein an aspiration pump is connected to the drain for discharging fluid.

Owner:YANTAI AUSBIO LAB

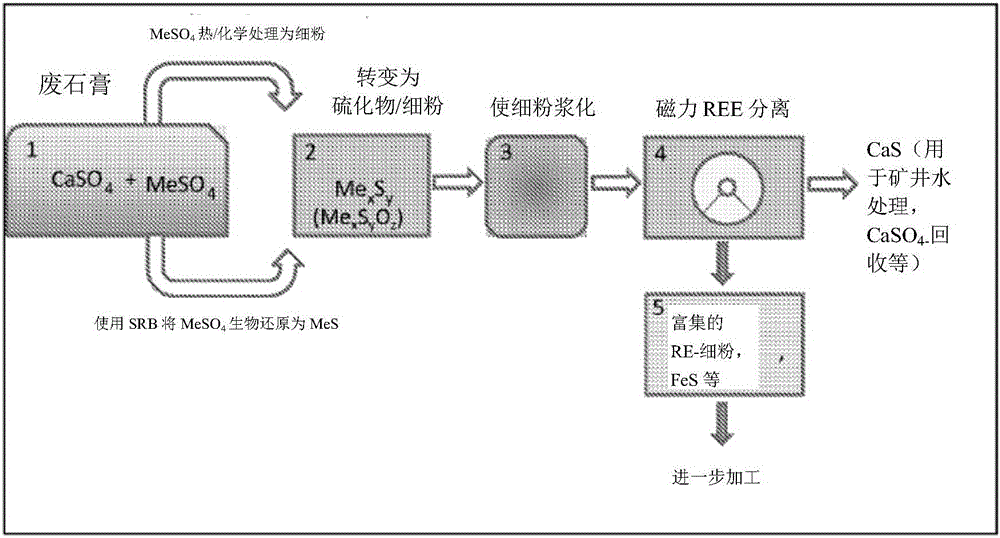

Method for recovering rare earth metals from waste sulphates

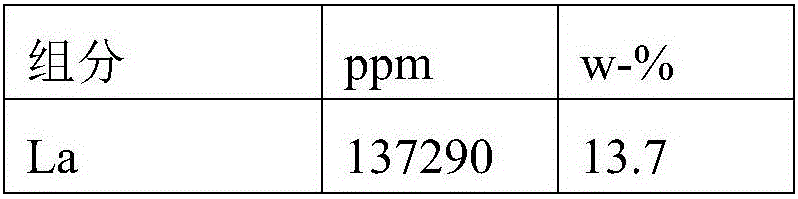

InactiveCN105765091ALow costHigh gradient magnetic separationRare earth metal sulfidesRare-earth elementMagnetic susceptibility

The present invention relates to a method for recovering rare earth metals from waste sulphate materials, such as waste gypsum, which is a known secondary resource of rare earth metals and widely present e.g. in areas, where industrial phosphate production takes place. The present invention combines sulphate reduction treatment, such as bioreduction with sulphate reducing bacteria, and magnetic separation, which is based on an exceptionally high magnetic susceptibility of rare earth compounds compared to e.g. calcium compounds in such reductively pretreated gypsum precipitate.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

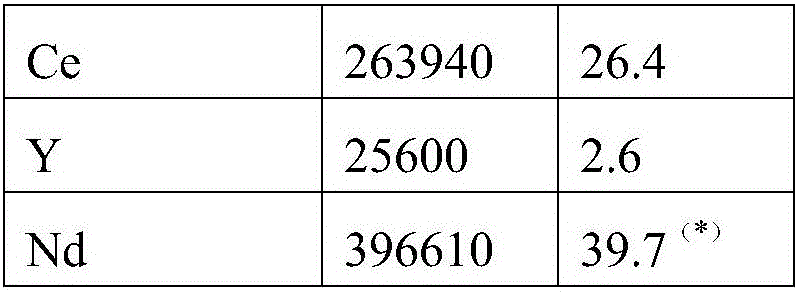

Beneficiation method for low-grade scheelite rich in hedenbergite and andradite

InactiveCN106583028AOptimizationImprove the environmentHigh gradient magnetic separationFlotationAndraditeMaterials science

The invention discloses a beneficiation method for low-grade scheelite rich in hedenbergite and andradite. The benefication method comprises the following steps of: crushing multi-metal scheelite ores which contain 0.10-0.25% of tungsten, 0.05-0.09% of copper, hedenbergite, andradite and feldspar, and performing ore grinding until a mass ratio of cores with fineness r being 200 meshes is 70-80%; performing magnetic separation and flotation, wherein magnetic separation comprises once permanent magnet pre-selection and once strong-magnet tailings discarding magnetic separation, 5-10% of strong-magnetism pyrrhotite products are produced through permanent magnet pre-selection, and 45-50% of nonmetal weak-magnetism minerals comprising hedenbergite, andradite and feldspar are selected out through strong-magnet tailings discarding magnetic separation; separating the non-magnetic products by floating, and performing mixed flotation on sulfides, producing copper concentrate and sulfur concentrate by performing reagent-removal ore grinding and copper-sulfur separation on mixed flotation foam products; and producing tungsten concentrate by performing low-grade multi-metal scheelite flotation on flotation tailings. The beneficiation method disclosed by the invention can obtain relatively good separation effect, and greatly reduces production and management cost.

Owner:YUNNAN TIN

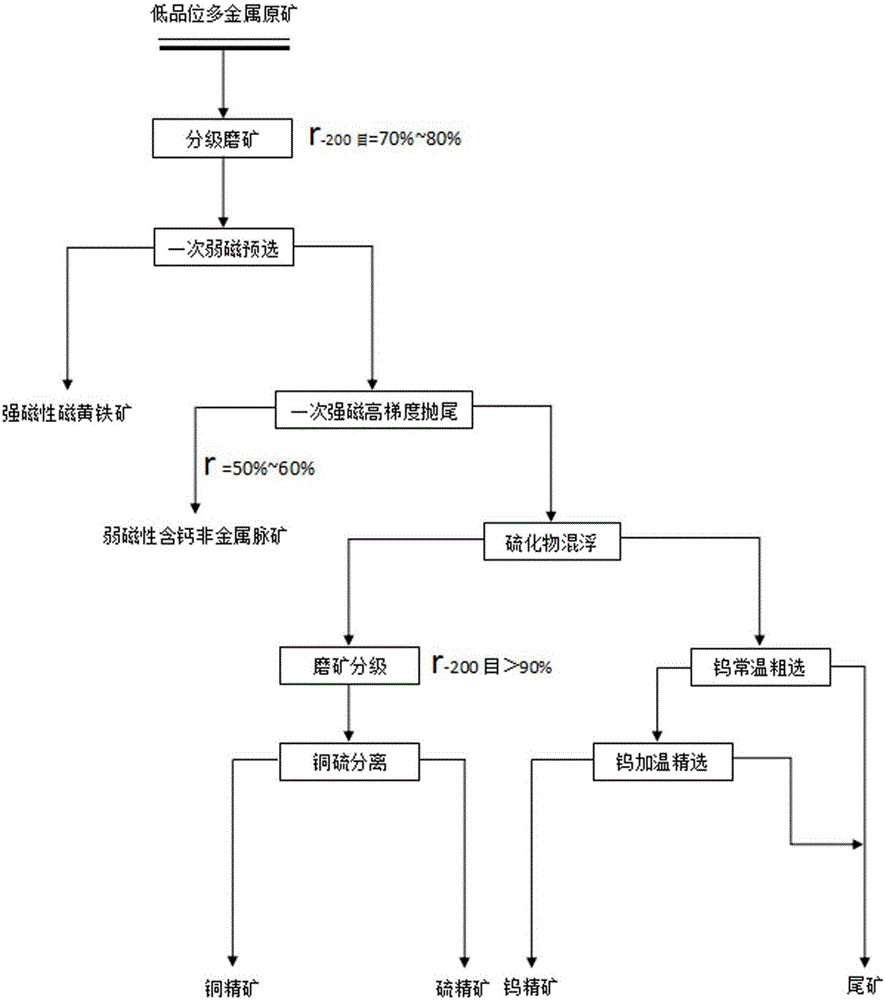

Technology of extracting lepidolite from lithium porcelain stone ore

ActiveCN108014901AIncrease production capacityLess investmentHigh gradient magnetic separationHigh gradient magnetic separatorsLepidoliteMaterials science

The invention belongs to the technical field of lepidolite extraction and particularly discloses a technology of extracting lepidolite from lithium porcelain stone ore. The technology comprises the steps that (1) naturally dissociation of the lithium porcelain stone ore is carried out, concretely, screw-thread steel in a sand making machine carries out four stages of rapid impact on ore grains sothat ore crystals are naturally disassembled, and after screening, a mixture of gangue quartz and lepidolite crystals, feldspar and lepidolite are obtained; (2) efficient gravity difference floatationis carried out, concretely, the mixture of the gangue quartz and the lepidolite crystals is subjected to ball milling, magnetic separation, swirling, liquid separation and floatation and thus a lepidolite concentrate and fine silica powder are obtained; and (3) the feldspar and the lepidolite are subjected to continuous high-gradient strong magnet purification, and thus the lepidolite concentrateand albite are obtained. With the adoption of the technology, after the lithium porcelain stone ore is subjected to lithium extraction, the low-grade feldspar is turned into the fine silica powder and fine albite powder after the lithium porcelain stone ore is subjected to lithium extraction, and the industrial recovery rate of the lepidolite is increased from 60% to 90%. In addition, neither tailings or tailing mud are / is generated in the entire technological process, the productive capacity is high, the investment is low, and the technology is suitable for popularization and application.

Owner:江西九岭锂业股份有限公司

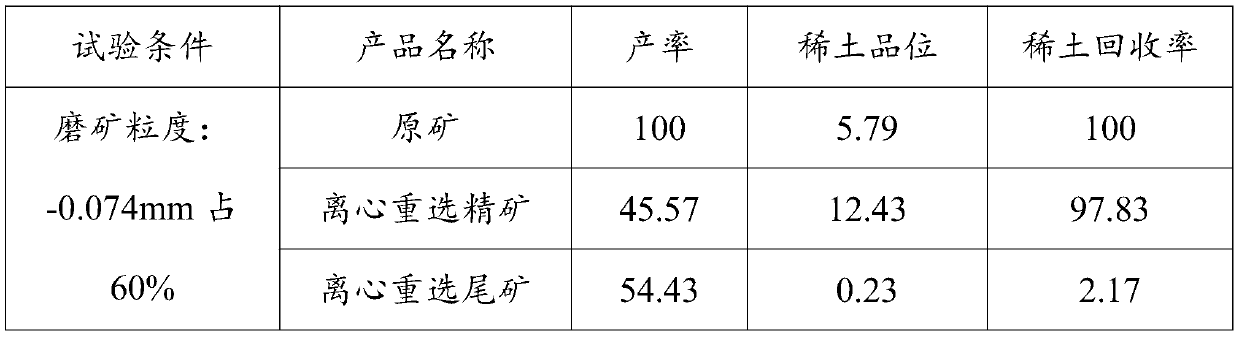

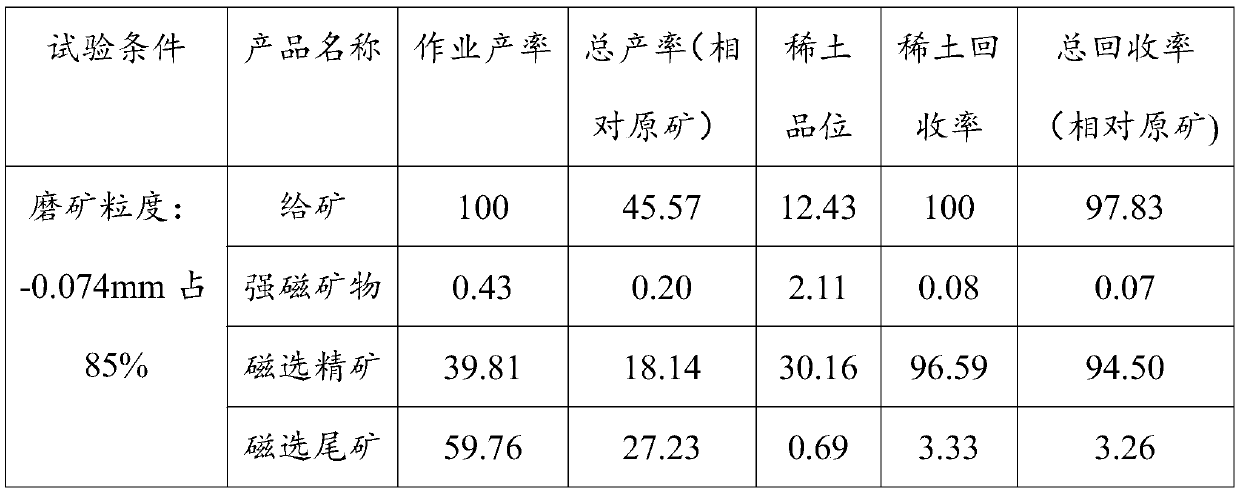

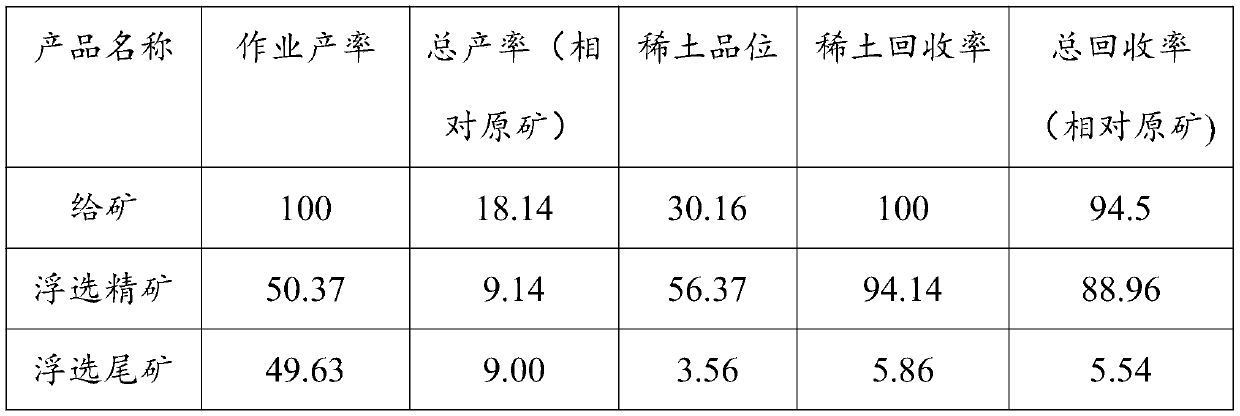

Beneficiation method applied to superconduction magnetic separation of rare earth ore

InactiveCN111346742AReduce the amount of oreReduce volumeHigh gradient magnetic separationCentrifugesMining engineeringWater resources

The invention discloses a beneficiation method applied to superconduction magnetic separation of a rare earth ore, and aims to solve the technical problems of higher economical loss and resource wastecaused by lower recovery rate of a rare earth resource in a traditional rare earth beneficiation process. The substantial process of the beneficiation method is as follows: firstly, a raw ore of therare earth ore is crushed and grinded; the tailing discarding is performed on the rare earth ore in advance by centrifugal reselection; then, a reselected concentrate is grinded, and a superconductionmagnetic separator is used for superconduction weak magnetic separation to remove high-magnetism mineral impurities; then, superconduction strong magnetic separation is performed to obtain a rare earth rough concentrate; and finally, flotation is performed on the rare earth rough concentrate to obtain a high-grade rare earth concentrate. The beneficiation method greatly improves the sorting precision and efficiency, and reduces consumption of a total flotation medicament and consumption of a water resource through a breakthrough-developed reselection-superconduction magnetic separation-flotation process, so that the energy consumption and the operation cost are reduced, efficient sorting and utilization of the rare earth resource are implemented, and the grade and recovery rate of the rare earth ore are greatly improved.

Owner:JIANGXI UNIV OF SCI & TECH

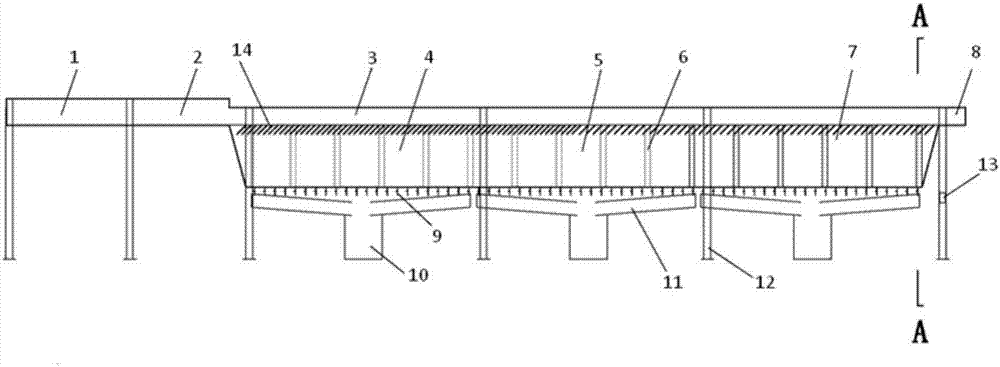

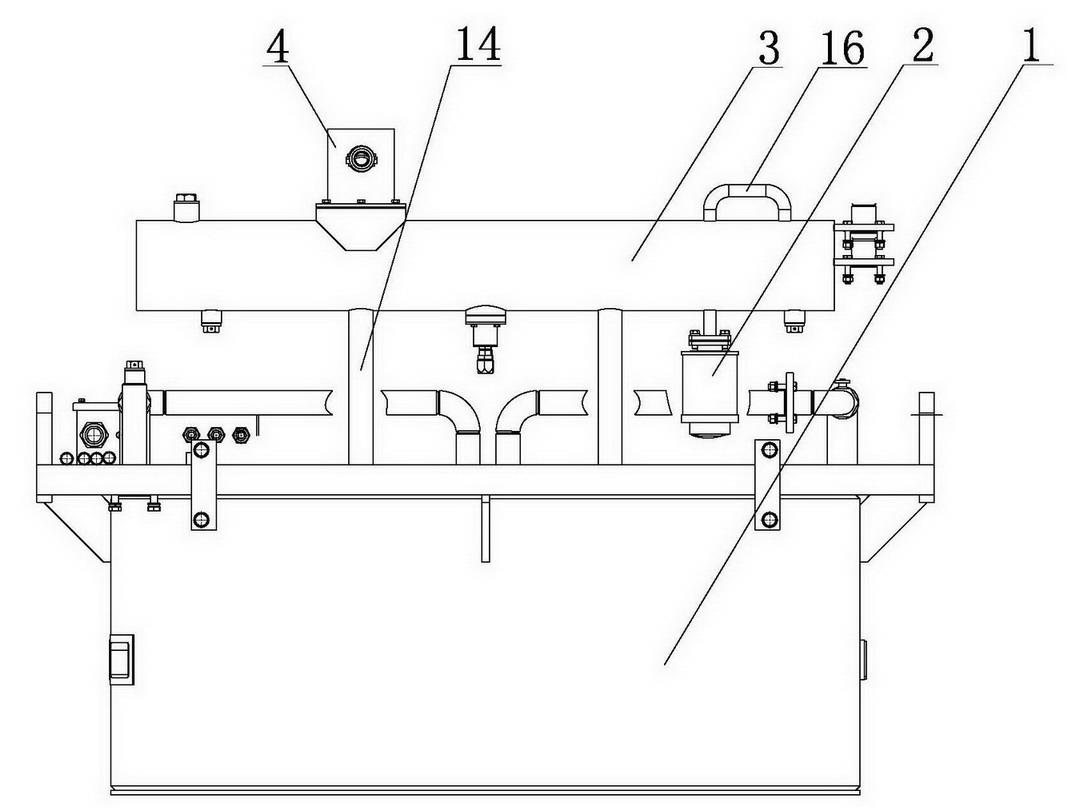

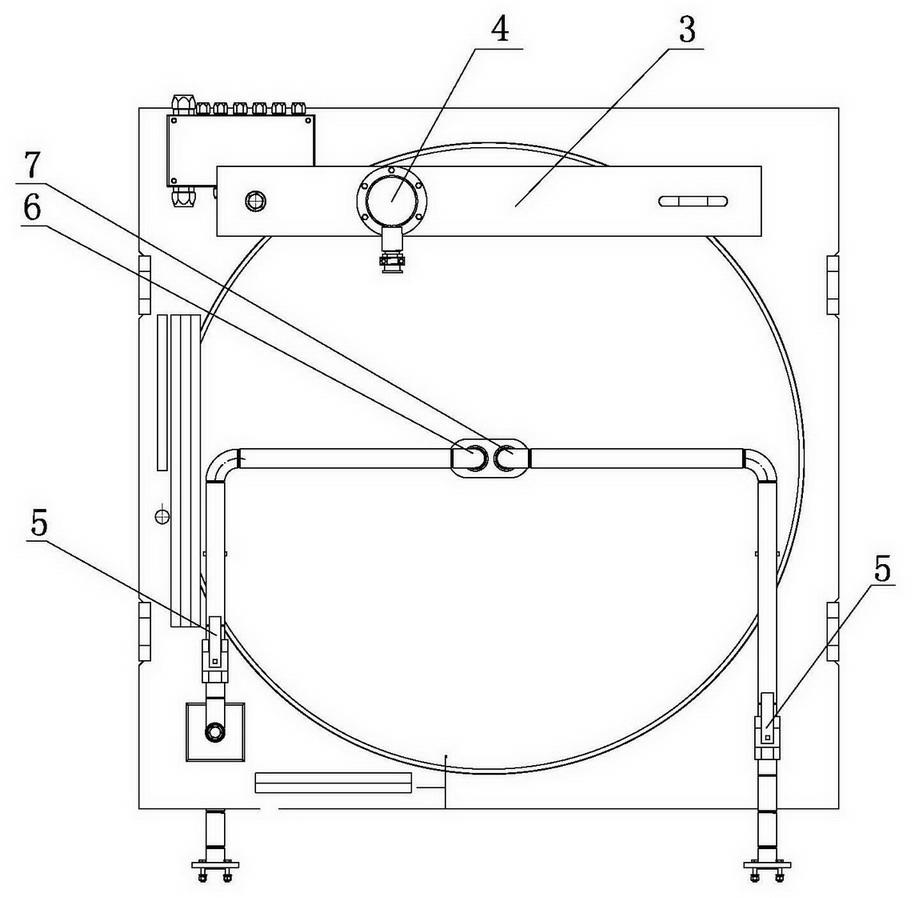

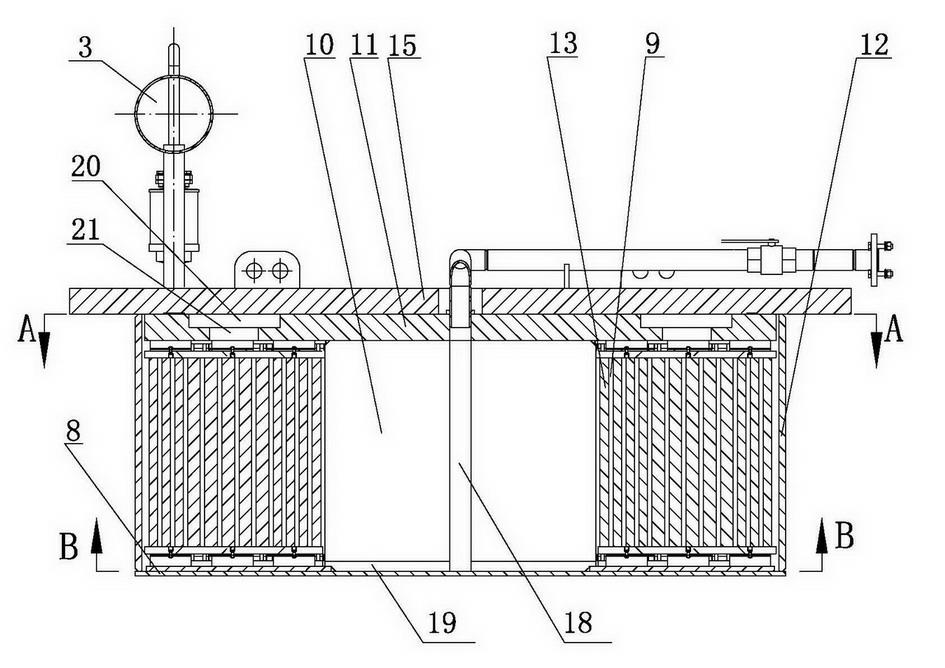

High-gradient internal circulation oil cooling iron remover

ActiveCN103008100ALow circulation resistanceEven and reasonable cycleHigh gradient magnetic separationTransformers/inductances coolingExpansion tankTransformer oil

The invention discloses a high-gradient internal circulation oil cooling iron remover which comprises a magnetic system coil (4), an internal circulation oil path system (3), an external cooling system (2) and an expansion tank (1), wherein the magnetic system coil (4) is used for generating an excitation magnetic field which realizes the iron sucking function of the iron remover; the magnetic path of the magnetic system coil (4) is in an opened magnetic path structure; the internal circulation oil path system (3) is used for distributing, collecting and circulating transformer oil; the external cooling system (2) is used for radiating the heat of the transformer oil so as to realize the heat radiation balance in the high-gradient internal circulation oil cooling iron remover; and the expansion tank (1) is used as a compensation container for the transformer oil expansion when equipment operates. By adopting the internal circulation structure, the external circulation pipeline is simplified, the oil path circulation resistance is reduced, problems that an oil path is complexly arranged with interference, the circulation efficiency is low, a welding spot has leakage and the like are avoided, the normal operation of the iron remover is ensured, and the iron removing efficiency is improved.

Owner:LONGI MAGNET CO LTD

Rectorite impurity removal purification mineral separation process, mineral separation system, rectorite concentrate and application of rectorite concentrate

PendingCN109248778ARaise the gradeLow impurity contentHigh gradient magnetic separationFlotationProduction lineLower grade

The invention discloses a rectorite impurity removal purification mineral separation process, a mineral separation system, a rectorite concentrate and an application of the rectorite concentrate, andrelates to the technical field of mineral separation. The rectorite impurity removal purification mineral separation process includes the steps: performing scrubbing dissociation and separation on crushed middle-low-grade primary or oxidation rectorite raw ores; performing stripping and grinding dissociation, mixing dispersion and roughing separation on dewatered separation materials; performing 1-4-section superfine grading and optionally high-gradient magnetic separation on roughing separation materials to obtain the rectorite concentrate. The rectorite impurity removal purification integrated industrial mineral separation method applicable to middle-low-grade primary or oxidation ores, a process method is economical and effective and can be flexibly adjusted and controlled according todifferent raw ore natures and different requirements for the rectorite concentrate, concentrates with multi-layer specifications and models are outputted on the same mineral separation production line, matched device parameters are suitably adjusted, requirements of process technical indexes can be met, and large-scale rectorite mineral separation industrial production can be easily achieved.

Owner:兰运堂

Preparing method for high-whiteness potash feldspar powder

InactiveCN109127152AHigh whitenessRelieve stressHigh gradient magnetic separationHigh gradient magnetic separatorsHigh concentrationSulfonate

The invention provides a preparing method for high-whiteness potash feldspar powder. The preparing method comprises beneficiation and ore washing, preliminary screening, ball milling, magnetic separation, primary flotation, secondary flotation and water removal. Petroleum sodium sulfonate and sodium oleate are selected as a collecting agent of primary flotation, and lauryl amine, dodecyl trimethylammonium chloride and cetyltrimethylammonium chloride serve as a collecting agent of secondary flotation; and compared with a single collecting agent, the flotation effect can be improved, and the whiteness is improved. Treatment is conducted in a physical method and chemical method combination manner, the whitening efficiency is improved, and the high-whiteness potash feldspar powder is obtained; and the pressure brought to the environment due to usage of high-concentration sulfuric acid is avoided.

Owner:贺州市骏鑫矿产品有限责任公司

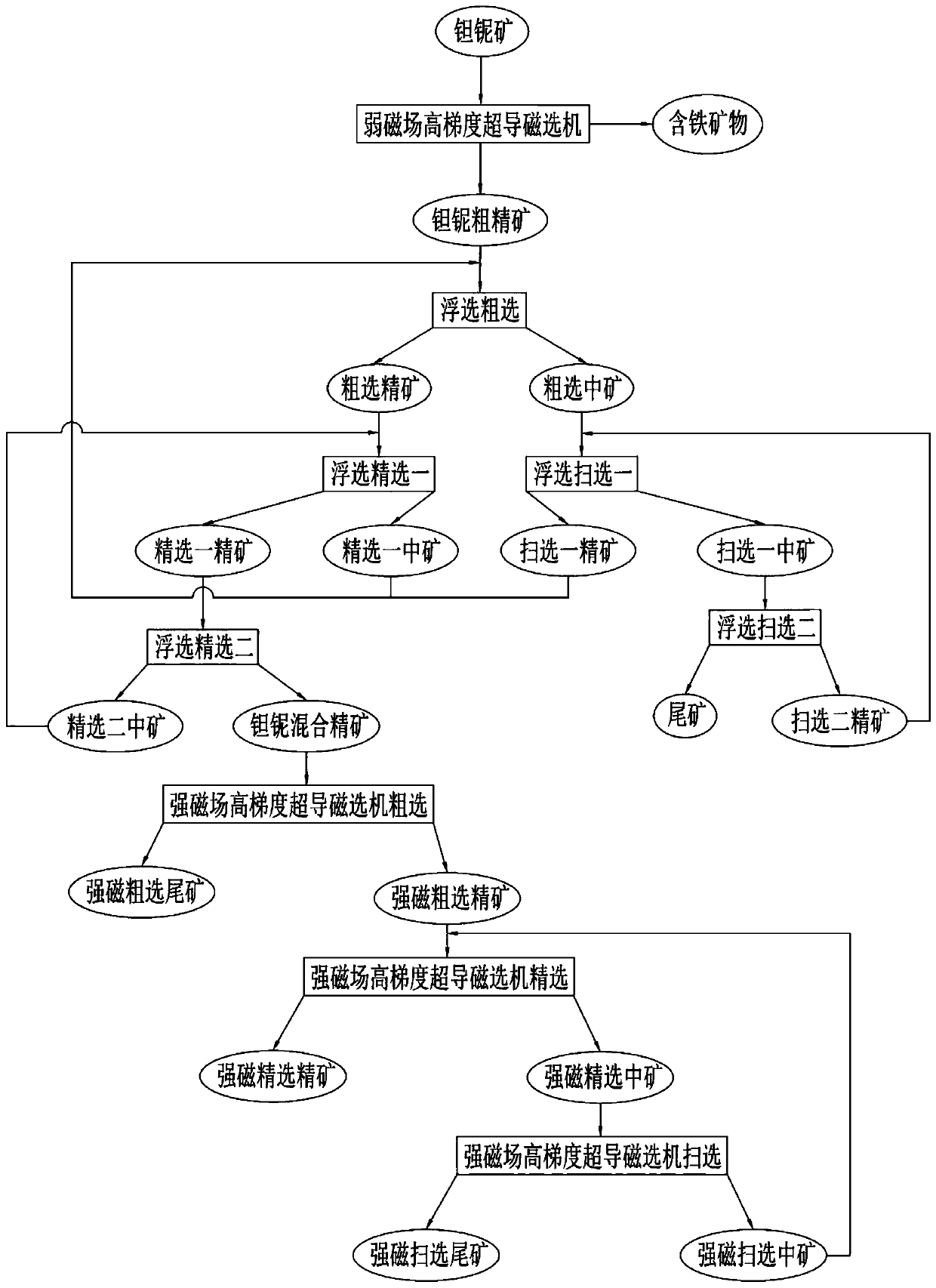

Sorting process of micro-fine particle low-grade tantalum-niobium ore

InactiveCN111346733ASolve complexitySolve technical problems with long processHigh gradient magnetic separationFlotationNiobiumMagnetic separator

The invention discloses a sorting process of micro-fine particle low-grade tantalum-niobium ore. The sorting process aims at solving the technical problems that an existing sorting mode of micro-fineparticle low-grade tantalum-niobium ore is complex in process, long in flow, low in efficiency and high in energy consumption. The rough steps of the sorting process are as follows: performing magnetic separation on tantalum-niobium ore by a high-gradient superconducting magnetic separator under the condition of low magnetic field intensity; removing iron-containing gangue minerals; then enablingthe tantalum-niobium rough concentrate to be subjected to flotation, wherein the flotation process adopts a process of one-time roughing, two-time concentration and two-time scavenging and sequentialreturning of middlings, obtaining tantalum-niobium bulk concentrate through flotation, finally, enabling the tantalum-niobium-tungsten bulk concentrate to be subjected to magnetic separation through ahigh-gradient superconducting magnetic separator under the condition of high magnetic field intensity, wherein the high-intensity magnetic separation adopts a one-time roughing, one-time concentration and one-time scavenging process to obtain tantalum concentrate and niobium concentrate. According to the sorting process, through a magnetic-floating combined separation mode, the process flow is simplified and shortened on the whole, and operation and management are easy, so that the production energy consumption and the production cost are reduced, and the sorting efficiency is improved.

Owner:JIANGXI UNIV OF SCI & TECH +1

Separation method for cathode and anode plates in recovery process of lithium ion batteries

InactiveCN107492695AReduce recycling costsHigh recovery rateHigh gradient magnetic separationWaste accumulators reclaimingAluminium-ion batteryManganese

The invention relates to a separation method for cathode and anode plates in a recovery process of lithium ion batteries and belongs to the technical field of recovery of lithium ion batteries. The separation method includes the steps of: performing magnetic separation to mixed chips, which are composed of cathode chips and anode chips and are formed during the recovery process of lithium ion batteries, in a magnetic field, of which the magnetic inductive intensity is higher than 9000 Gs, thus separating the cathode chips out, wherein a cathode material of the cathode chips includes at least one of cobalt, manganese, iron and nickel. The separation method is simple and high-effective, is low in recovery cost and is free of generation of pollutants. Through the separation method, the separation rate of the cathode chips can reach more than 95% through one-stage magnetic separation and can reach more than 98% through more than two stages of magnetic separation. The method can significantly increase the recovery rate and recovery purity of cathode and anode powders and copper and aluminum granules in subsequent steps.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

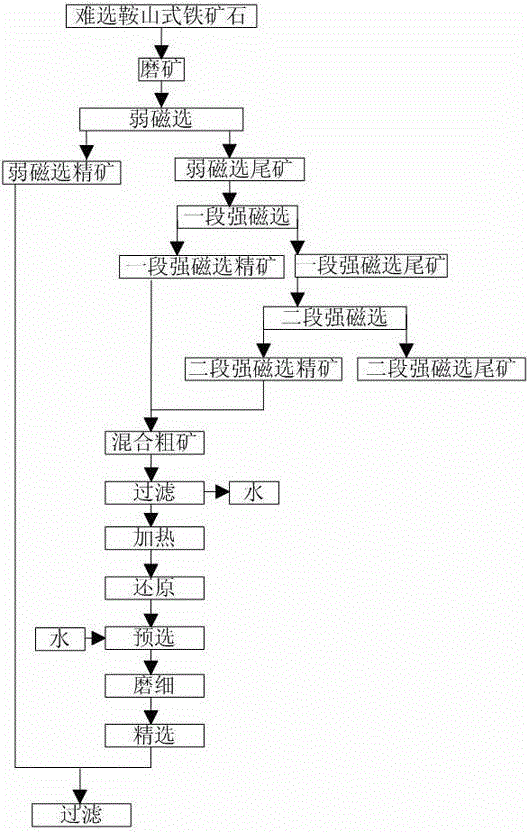

Beneficiation method for complex iron ore

InactiveCN104624361AEfficient use ofIndicators are stableHigh gradient magnetic separationWet separationIronstonePre selection

The invention provides a beneficiation method for complex iron ore and belongs to the technical field of mineral processing. The method includes the following steps that 1 ore grinding is conducted after the complex iron ore is crushed; 2 low intensity magnetic separation, first-stage high intensity magnetic separation and second-stage high intensity magnetic separation are conducted, and first-stage high intensity magnetic separation concentrate and second-stage high intensity magnetic separation concentrate are combined to serve as mixed coarse ore; 3 the mixed coarse ore is filtered, then heated to be dehydrated, placed under a reducing atmosphere condition for heat preservation and air-cooled; 4 water is added to the mixed coarse ore to manufacture ore pulp, and pre-selection is conducted after stirring; 5 fine selection is conducted after fine grinding, and obtained fine selection concentrate and low intensity magnetic separation concentrate are mixed, filtered and dehydrated. Pre-selection, ore grinding and fine selection are conducted after high intensity magnetic separation, low intensity magnetic separation, roasting and reduction, obtained products are stable in index and good in economical efficiency, and resources can be efficiently used.

Owner:ANSTEEL GRP MINING CO LTD

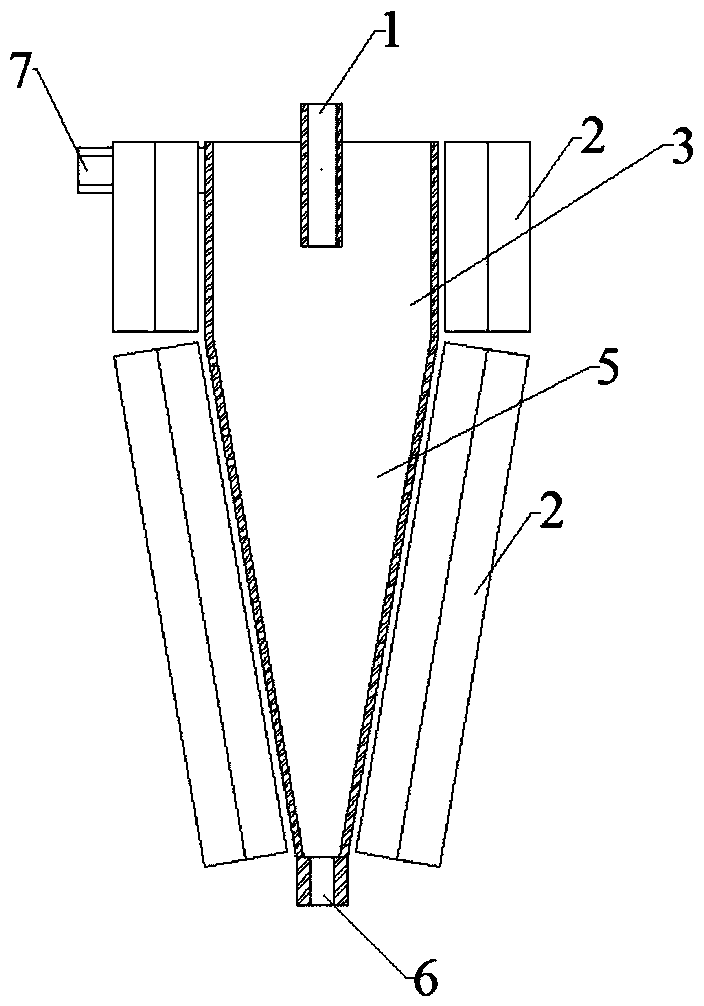

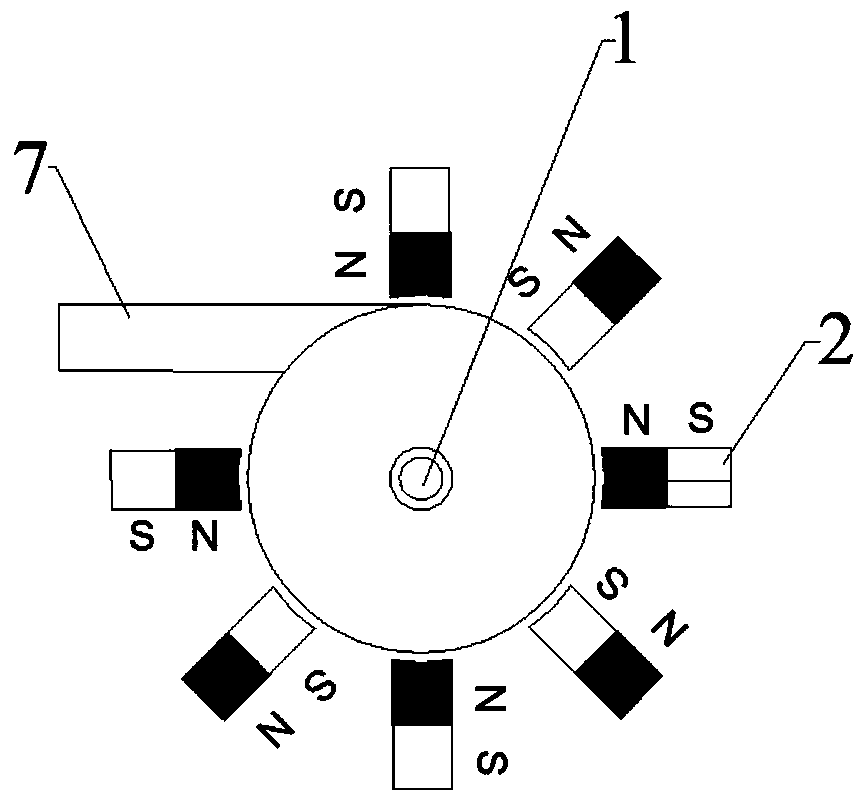

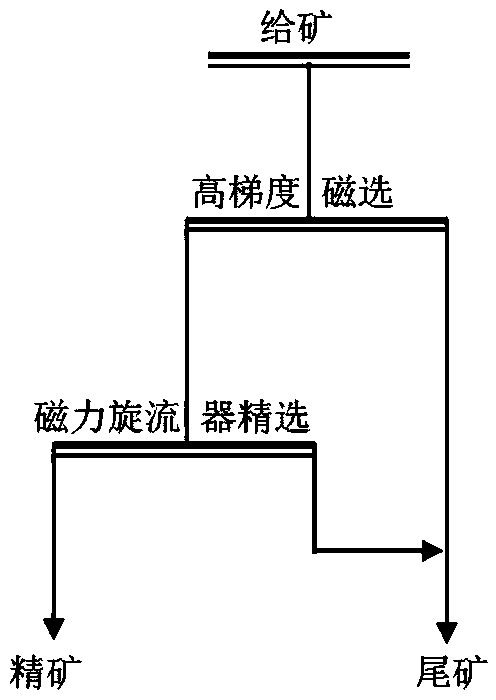

Magnetic hydrocyclone, magneto-gravitational combined separation system and magneto-gravitational combined separation method applied to weakly-magnetic mineral selection

PendingCN109201354AHigh recovery rateReduce energy consumptionHigh gradient magnetic separationVortex flow apparatusMagnetic field gradientHigh intensity

The invention discloses a magnetic hydrocyclone applied to weakly-magnetic mineral selection. The magnetic hydrocyclone comprises a hydrocyclone body, wherein a plurality of permanent magnets used forforming magnetic field gradient are evenly arranged on an outer wall of the hydrocyclone body, and the direction of the magnetic field gradient points from the inside of the hydrocyclone body to theoutside. The invention further provides a magneto-gravitational combined separation system and a method of using the magneto-gravitational combined separation system to perform magneto-gravitational combined separation. The method comprises the following steps: S1, utilizing a high-intensity magnetic separation machine or a high-gradient magnetic separation machine to coarsely select the weakly-magnetic minerals to obtain rough concentrate; S2, sending the rough concentrate in the S1 into the magnetic hydrocyclone to be separated to obtain settled sand and overflow and collecting the settled sand to obtain a concentrate product. According to the magneto-gravitational combined separation method disclosed by the invention, the difference of specific magnetic susceptibility and specific gravity difference between the weakly-magnetic minerals and gangue minerals is fully utilized; the magneto-gravitational combined separation method can be applied to weakly-magnetic mineral selection and has the advantages of low energy consumption, high separation efficiency, low cost, easiness in adjustment and control and the like.

Owner:CENT SOUTH UNIV

Process for recovering zinnwaldite from Ta Nb tailings

InactiveCN111346740AAchieve pre-enrichmentReduce the amount of oreHigh gradient magnetic separationCentrifugesLepidolitePollution

The invention discloses a process for recovering zinnwaldite from Ta Nb tailings. The process aims to solve the problems that for sorting for recovering zinnwaldite from Ta Nb tailings, a large amountof agent is needed by a traditional floatation process at present, so that environmental pollution and equipment corrosion are easily caused, the recovery effect is not good, so that certain resourceloss can be caused, and the process is complex, so that production cost is high. The process specifically includes the steps of performing centrifugal re-sorting on the Ta Nb tailings to remove a small proportion of minerals in the Ta Nb tailings, performing pre-enrichment on the zinnwaldite to obtain a gravity concentrate, and performing superconducting magnetic separation on the gravity concentrate through a superconducting magnetic separation machine to obtain a zinnwaldite concentrate. By means of the process, the re-sorting and superconducting magnetic separation process is adopted innovatively, and the sorting precision and efficiency are greatly improved; sorting indexes are good and stable, and production cost is reduced; and meanwhile no agent needs to be added, energy conservation and environmental protection are realized in the technological process, and the efficient recycling of the zinnwaldite resource is realized.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com