Beneficiation method for low-grade scheelite rich in hedenbergite and andradite

A technology of calcite and calcite, applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve the difficulty in obtaining sorting indexes and economic benefits, and the difficulty in separating scheelite from gangue containing calcium , the problems of unsatisfactory production and operation benefits, etc., to improve the selection conditions and environmental impact, reduce the consumption of chemicals and production costs, reduce the amount of selection and the consumption of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

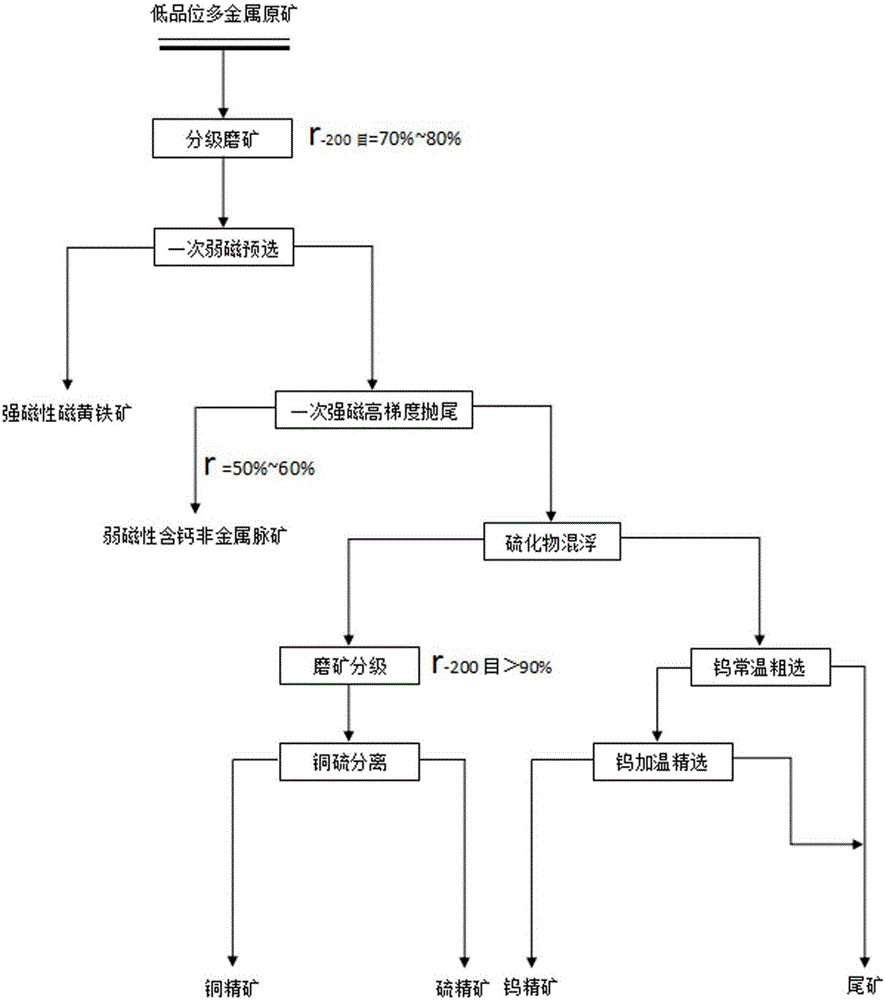

[0023] The polymetallic scheelite ore containing 0.2% of tungsten, 0.07% of copper, and 55.21% of magnetic gangue minerals such as andandrite and andandrite is crushed, and the ore is ground to a fineness of r-200 mesh (-0.074 mm) accounted for 70%, and the pulp concentration was 40%. A permanent magnet wet magnetic separator is used for permanent magnet pre-selection under the magnetic field strength of 240 (mT), and the strong magnetic pyrrhotite accounting for 6-8% of the mass of scheelite ore is selected, and the impurity removal rate is 5%. Afterwards, using an electromagnetic high-gradient strong magnetic separator, under a magnetic field strength of 700 (mT), a strong magnetic tailing is used to obtain the scheelite ore, which accounts for 48.61% of the quality of the scheelite ore. Non-metallic weak magnetic products and non-magnetic products, magnetic products are discarded as tailings, the throwing yield accounts for 56.73%, the tungsten content is 0.026%, and the tu...

Embodiment 2

[0028] The polymetallic scheelite ore containing 0.14% of tungsten, 0.081% of copper, and 51.03% of magnetic gangue minerals such as andandrite and andandrite is crushed, and the ore is ground to a fineness of r-200 mesh (-0.074 mm) accounted for 70%, and the pulp concentration was 35%. A permanent magnet wet magnetic separator is used for permanent magnet pre-selection under a magnetic field strength of 300 (mT), and the strong magnetic pyrrhotite accounting for 9-10% of the mass of scheelite ore is selected, and the impurity removal rate is 8.95%. Afterwards, using an electromagnetic high-gradient strong magnetic separator, under a magnetic field strength of 800 (mT), a strong magnetic tailing is used to obtain the scheelite ore, which accounts for 49.34% of the quality of the scheelite ore. Non-metallic weak magnetic products and non-magnetic products, magnetic products are discarded as tailings, and the discarding yield accounts for 58.29%, containing 0.03% tungsten, and t...

Embodiment 3

[0032] The polymetallic scheelite ore containing 0.22% tungsten, 0.089% copper, and 66.22% magnetic gangue minerals such as andandrite and andandrite is crushed, and the ore is ground to a fineness of r-200 mesh (-0.074 mm) accounted for 70%, and the pulp concentration was 35%. A permanent magnet wet magnetic separator is used for permanent magnet pre-selection under the magnetic field strength of 400 (mT), and the strong magnetic pyrrhotite accounting for 9-10% of the mass of scheelite ore is selected, and the impurity removal rate is 9.35%. Afterwards, using an electromagnetic high-gradient strong magnetic separator, under a magnetic field strength of 1000 (mT), a strong magnetic tailing is used to obtain scheelite ore, which accounts for 50.43% of the ore quality, including andartite, andandrite, feldspar Non-metallic weak magnetic products and non-magnetic products, magnetic products are discarded as tailings, the throwing yield accounts for 59.78%, the tungsten content is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com