Patents

Literature

35 results about "Skarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skarns or tactites are hard, coarse-grained metamorphic rocks that form by a process called metasomatism. Skarns tend to be rich in calcium-magnesium-iron-manganese-aluminium silicate minerals, which are also referred to as calc-silicate minerals. These minerals form as a result of alteration which occurs when hydrothermal fluids interact with a protolith of either igneous or sedimentary origin. In many cases, skarns are associated with the intrusion of a granitic pluton found in and around faults or Shear zones that intrude into a carbonate layer composed of either dolomite or limestone. Skarns can form by regional, or contact metamorphism and therefore form in relatively high temperature environments. The hydrothermal fluids associated with the metasomatic processes can originate from either magmatic, metamorphic, meteoric, marine, or even a mix of these. The resulting skarn may consist of a variety of different minerals which are highly dependent on the original composition of both the hydrothermal fluid and the original composition of the protolith.

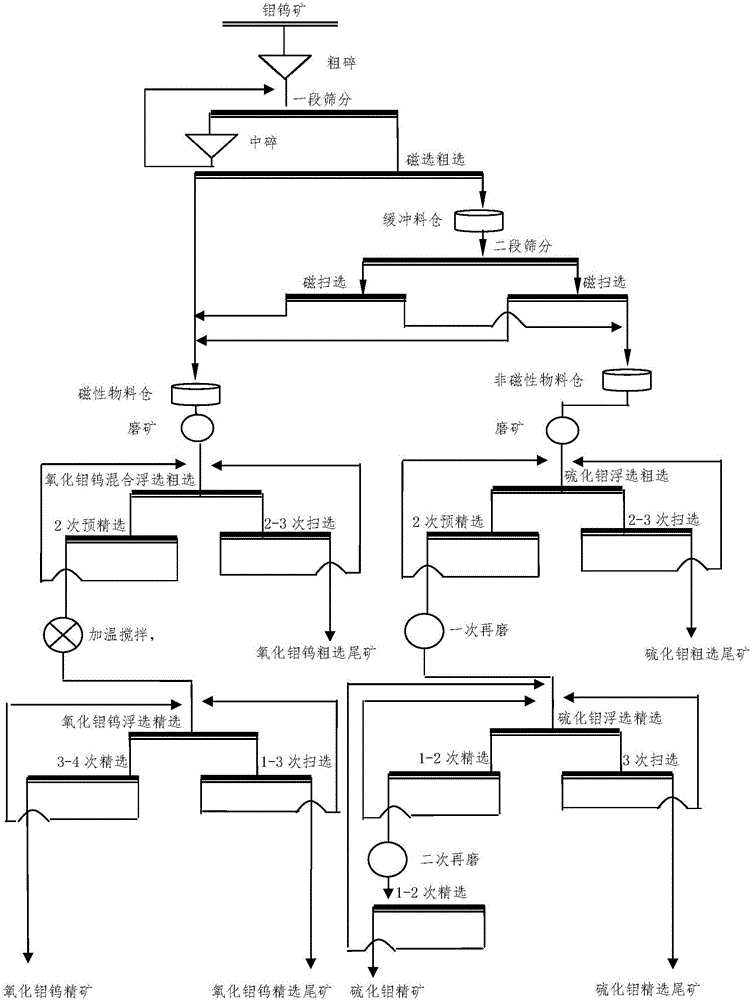

Beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore

InactiveCN106076590AEliminate the need for deslimingThe beneficiation process is simpleFlotationMagnetic separationNon magneticMagnetic characteristic

The invention relates to a beneficiation method for separating molybdenum-tungsten oxide ore and molybdenum sulfide ore from molybdenum tungsten ore. The beneficiation method comprises the steps that magnetic separation is conducted on raw separation molybdenum sulfide ore at least twice, so that the raw separation molybdenum sulfide ore subjected to magnetic separation is divided into magnetic ore containing molybdenum-tungsten oxide and non-magnetic ore containing molybdenum sulfide; and a molybdenum-tungsten oxide flotation process is conducted on the magnetic ore, and a molybdenum sulfide flotation process is conducted on the non-magnetic ore, so that molybdenum-tungsten oxide concentrate and molybdenum sulfide concentrate are obtained. According to the beneficiation method for separating the molybdenum-tungsten oxide ore and the molybdenum sulfide ore from the molybdenum tungsten ore, the magnetic ore containing molybdenum-tungsten oxide and the non-magnetic ore containing molybdenum sulfide are separated out before ore grinding by means of the magnetic characteristic of iron-bearing ore in skarn in a magnetic separation and flotation combined way, so that the floatability of the ore is improved, the beneficiation feed grades of the molybdenum sulfide ore and the and molybdenum-tungsten oxide ore subjected to flotation are increased, and a subsequent flotation technological process is simplified; and in addition, grading index fluctuation caused by the change of the characteristics of the ore is reduced, and the mine production cost can be reduced easily.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

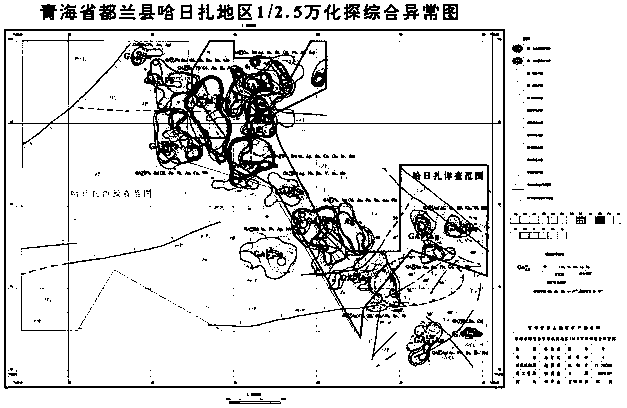

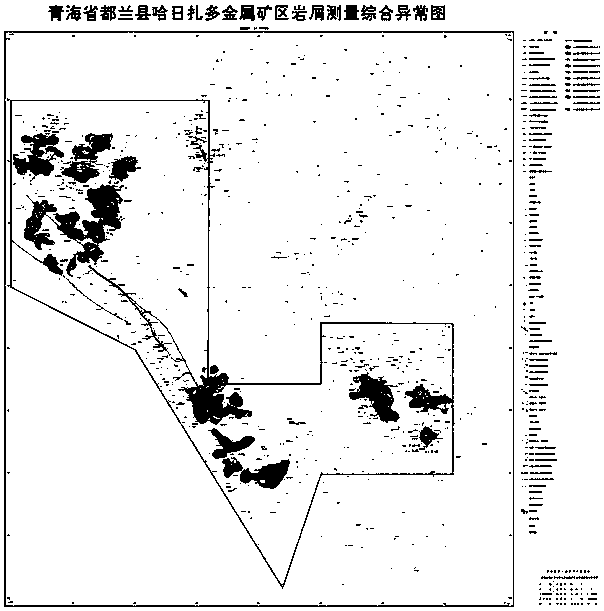

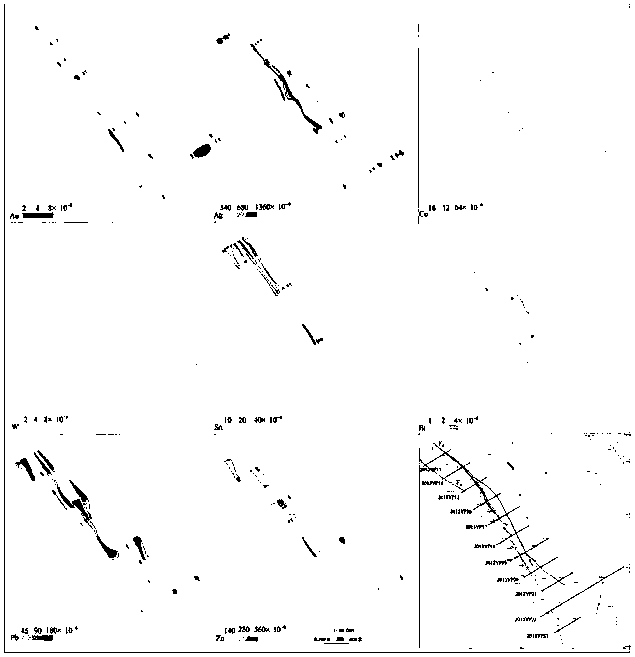

Comprehensive prospecting method for multi-metal minerals

InactiveCN110824582AGreat Prospecting BreakthroughLarge detection depthGeomodellingGeological measurementsMetallogenyGold ore

The invention discloses a comprehensive prospecting method for multi-metal minerals, and provides a prospecting method integrated with a mineralization system, water system sediment measurement, rockdebris measurement, large-scale geophysical and chemical prospecting profile / high-precision magnetic survey and engineering verification, and a huge prospecting breakthrough is obtained in the prospecting process. Through the implementation of the combination method, the limitation of shallow coverage conditions on conventional geological mapping can be effectively avoided, a prospecting target area can be rapidly shrunk in a quaternary coverage area, and spatial positioning of a mineralization alteration zone and an ore-bearing geologic body is achieved, so that the prospecting success rate is increased accordingly, and the method has the advantages of being short in prospecting period, high in efficiency and low in prospecting cost and is suitable for prospecting of shallow vein-shaped copper-lead-zinc-silver-gold ores and skarn-type iron-copper ores; and the wide-area electromagnetic method has the absolute advantage of large detection depth, and is suitable for exploration of deepconcealed porphyry type copper-molybdenum ores by combining an ore prospecting prediction geological model established according to geological characteristics and a speculated concealed ore-bearing porphyry body range.

Owner:马忠元

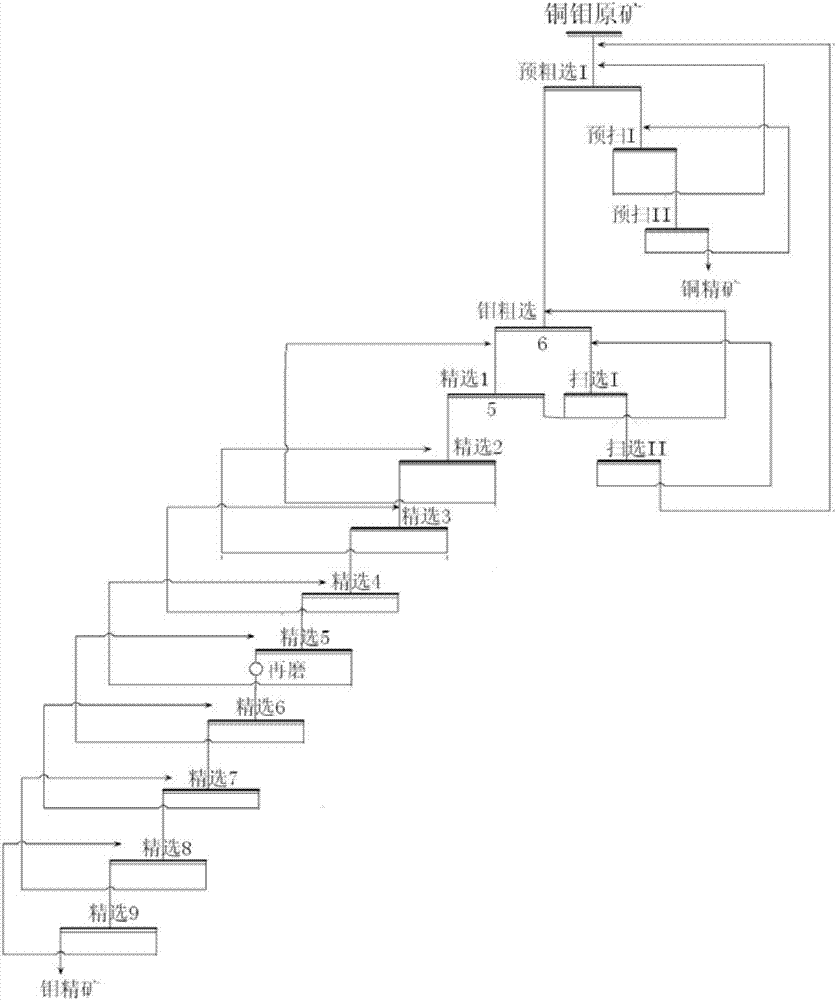

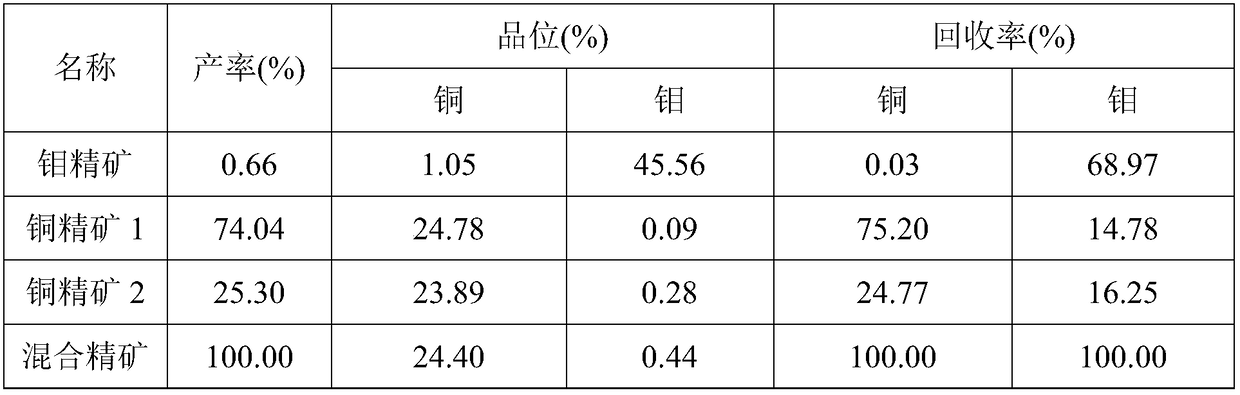

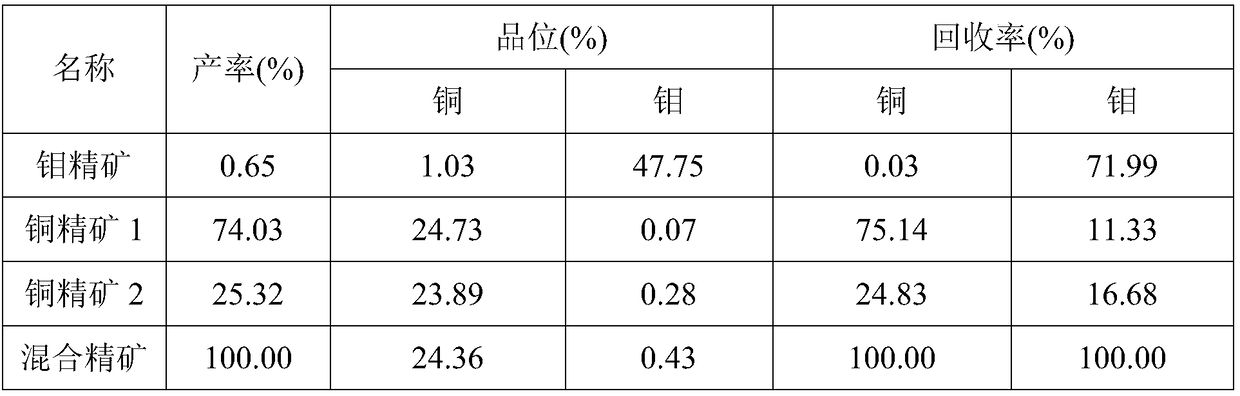

Method for improving grade of copper-molybdenum separated molybdenum concentrate of skarn copper-molybdenum ore

The invention relates to a method for improving the grade of copper-molybdenum separated molybdenum concentrate of skarn copper-molybdenum ore and belongs to a method for copper-molybdenum separation of skarn copper-molybdenum ore to obtain molybdenum concentrate. The method is characterized in that an inhibitor and a dispersant are added into a bulk concentrate regrinding ball mill to improve the monomer separation degree of molybdenum ore, meanwhile, the inhibitor and the dispersant immediately act on fresh surfaces of copper ore and gangue mineral which are produced through regrinding to enhance the chemical function, the milling grade of copper-molybdenum separated molybdenum is improved, and over-ground gangue mineral is thrown out as soon as possible, so that the implementation of copper-molybdenum separation and the grade improvement of the molybdenum concentrate are both facilitated. By adoption of the method, good copper-molybdenum separated floatation indexes are acquired, and the grade of molybdenum is remarkably improved.

Owner:CHANGCHUN GOLD RES INST

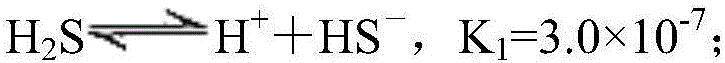

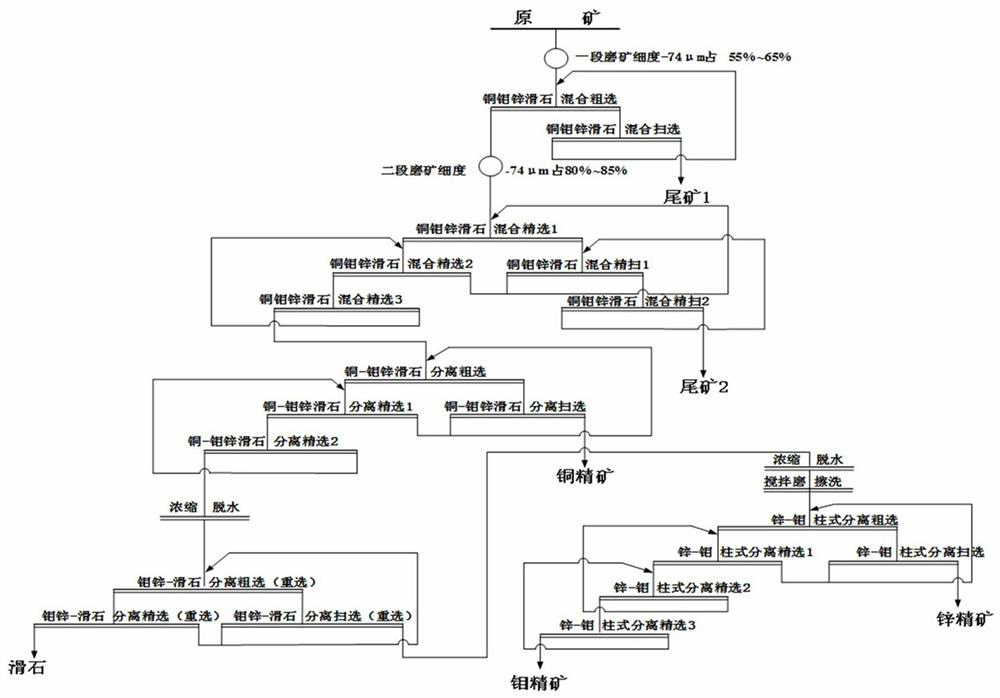

Sorting method of skarn type low-grade copper zinc ore

ActiveCN110328046AHigh degree of comprehensive utilizationEnhanced harvesting capacityWet separationSulfurLower grade

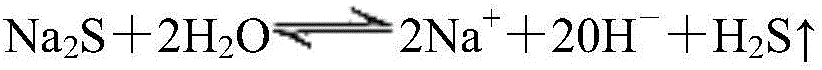

The invention belongs to the technical field of mineral machining, and particularly relates to a sorting method of a skarn type low-grade copper zinc ore. The sorting method comprises the steps of carrying out first ore grinding on raw ore to obtain flotation roughing raw ore; carrying out mixed flotation on the flotation roughing raw ore to obtain copper-zinc-sulfur mixed concentrate; carrying out second ore grinding on the copper-zinc-sulfur mixed concentrate to obtain copper-zinc-sulfur mixed ore pulp; separating the copper zinc mixture and sulfur from the copper-zinc-sulfur mixed ore pulpto obtain copper-zinc mixed concentrate and sulfur crude ore; and carrying out floatation on the sulfur crude ore to obtain sulfur concentrate. According to the sorting method of the skarn type low-grade copper zinc ore, the copper grade of the obtained copper-zinc mixed concentrate is 14.88%, the copper recovery rate is 75.37%, the zinc contained is 9.96%, and the zinc recovery rate is 66.58%; the sulfur grade of the obtained sulfur concentrate is 30.56%, and the sulfur recovery rate is 31.43%; the comprehensive utilization rate of the low-grade copper-zinc ore can be effectively improved; and the use amount of reagent is remarkably reduced, and the pollution degree to the environment can be reduced.

Owner:青海省地质矿产测试应用中心

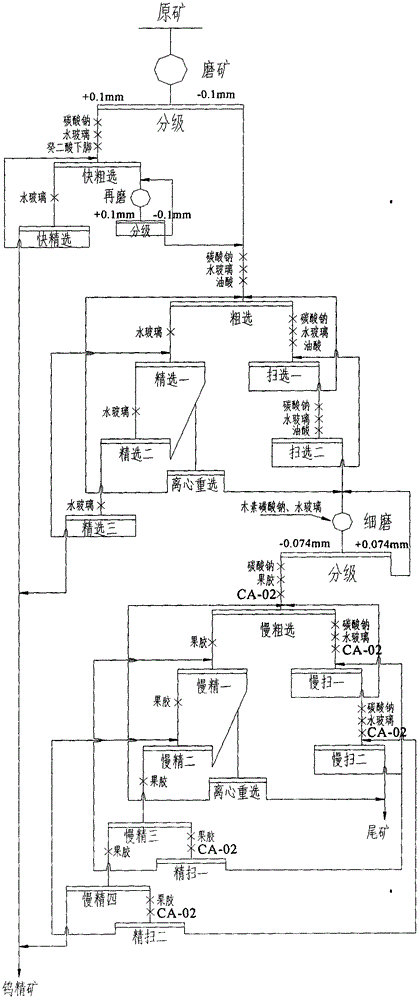

Skarn type tungsten ore beneficiation method

InactiveCN104785355AImprove sorting effectSolve for uniformityWet separationCoarse particleMaterials science

The invention discloses a skarn type tungsten ore beneficiation method. Tungsten concentrates are finally obtained through the steps of raw ore levigation, quick floatation of coarse particles, middling regrinding, quick scheelite flotation, medium grain floatation, fine grinding, fine grain floatation, centrifugal reselection of middlings and the like. Separation indexes of separated skarn type tungsten ore are good, and the grade and recovery rate of the tungsten concentrates are high. The skarn type tungsten ore beneficiation method is stable, efficient, good in separation effect, high in adaptability, high in recovery index, capable of achieving low production cost and suitable for application and popularization.

Owner:JIANGXI UNIV OF SCI & TECH

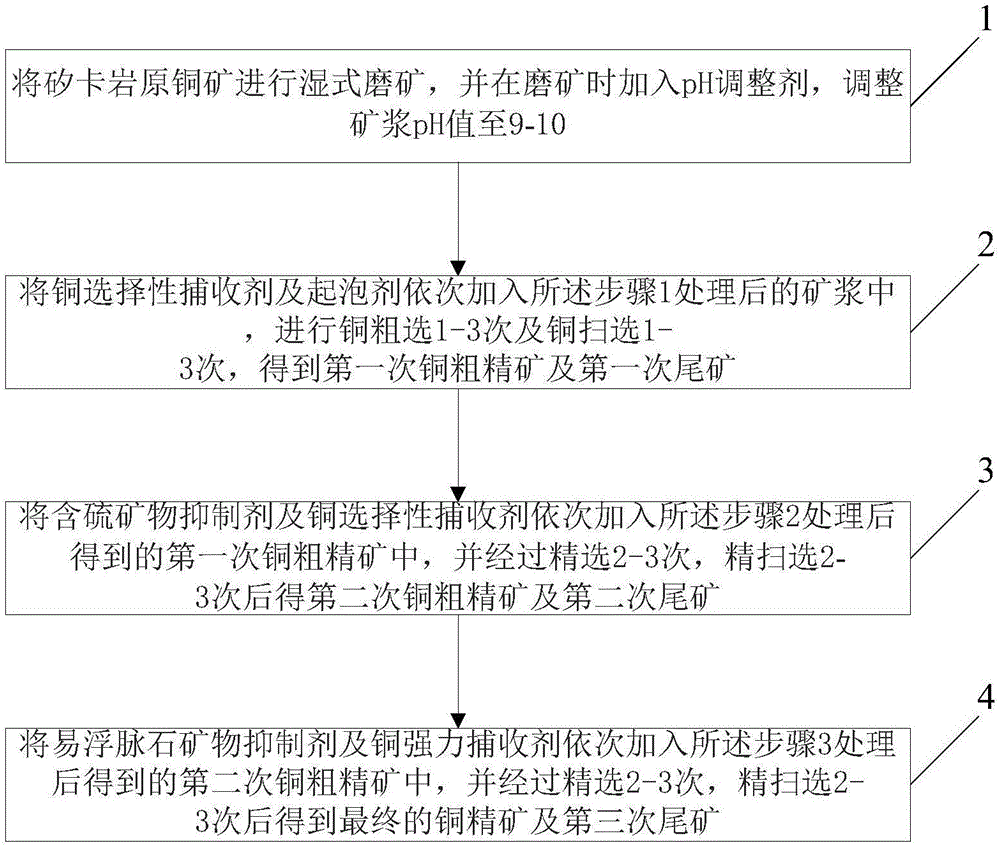

Skarn copper mine beneficiation method

The invention discloses a skarn copper mine beneficiation method. Firstly, raw skarn copper mine is subject to wet type ore grinding, a pH regulator is added during ore grinding, and the pH of ore pulp is adjusted to be 9 to 10; a copper selectivity collector and a foaming agent are sequentially added into ore pulp treated in the step (1), copper roughing is carried out 1 time to 3 times, copper scavenging is carried out 1 time to 3 times, and first-time copper rough concentrate and first-time tailings are obtained; a sulfur-containing mineral inhibitor and a copper selectivity collector are sequentially added into the first-time copper rough concentrate obtained by treatment in the step (2), fine selection is carried out 2 times to 3 times, refined scavenging is carried out 2 times to 3 times, and second-time copper rough concentrate and second-time tailings are obtained; a floatable gangue mineral inhibitor and a copper strong collector are added into the second-time copper rough concentrate obtained through treatment in the step (3), fine selection is carried out 2 times to 3 times, refined scavenging is carried out 2 times to 3 times, and final copper concentrate and third-time tailings are obtained. By means of the method, the using amount of the inhibitors can be effectively reduced, and the copper recovery rate is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

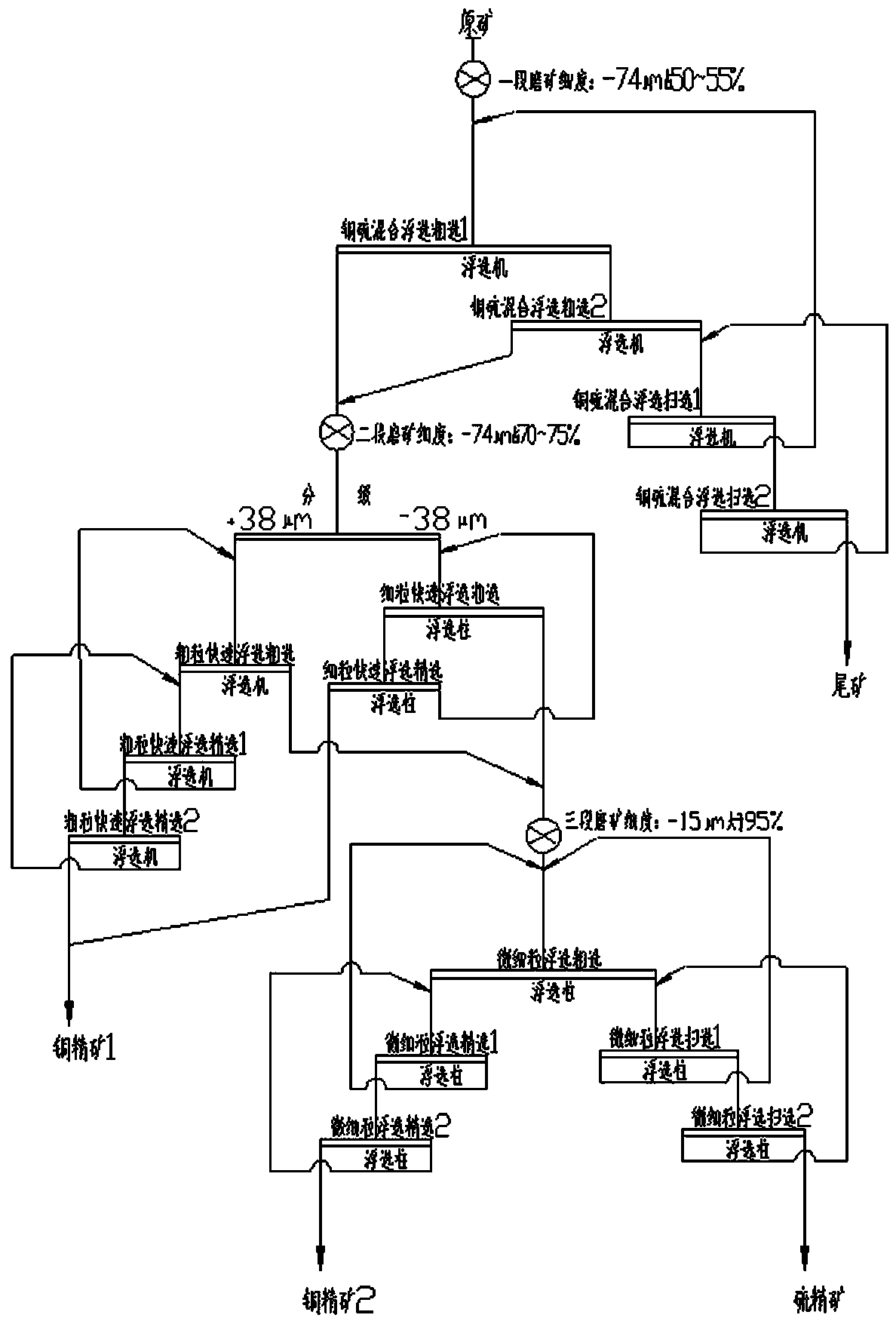

Process for recovering chalcocite and chalcopyrite with non-uniform disseminated grain size from high pyritized skarn copper ores

ActiveCN110841796AHigh recovery rateAvoid excessive muddying and deteriorating flotation processSolid separationPyriteCopper ore

The invention discloses a process for recovering chalcocite and chalcopyrite with the non-uniform disseminated grain size from high pyritized skarn copper ores. The process for recovering chalcocite and chalcopyrite with the non-uniform disseminated grain size from high-pyrite skarn copper ores is characterized by comprising the steps of first-stage grinding, copper-sulfur mixed flotation, second-stage grinding, rapid copper-sulfur flotation, third-stage grinding and copper-sulfur separation column flotation for recovering fine copper particles. The process adapts to the characteristics of thenon-uniform disseminated grain size and different floatability of chalcocite and chalcopyrite, realizes the recovery of ultra-fine grain disseminated chalcocite and chalcopyrite, avoids the adverse effect of a micro-fine grain ore pulp system on the flotation process, and realizes the efficient separation of refractory high-iron copper ores.

Owner:KUNMING METALLURGY INST

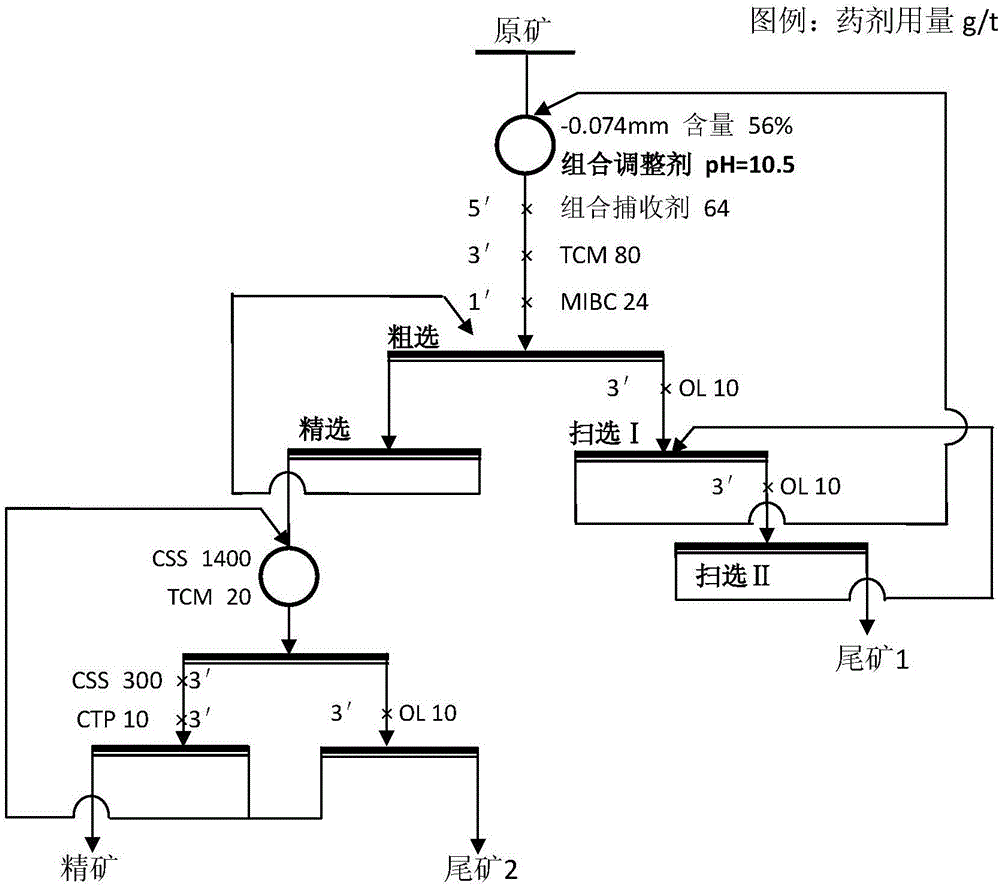

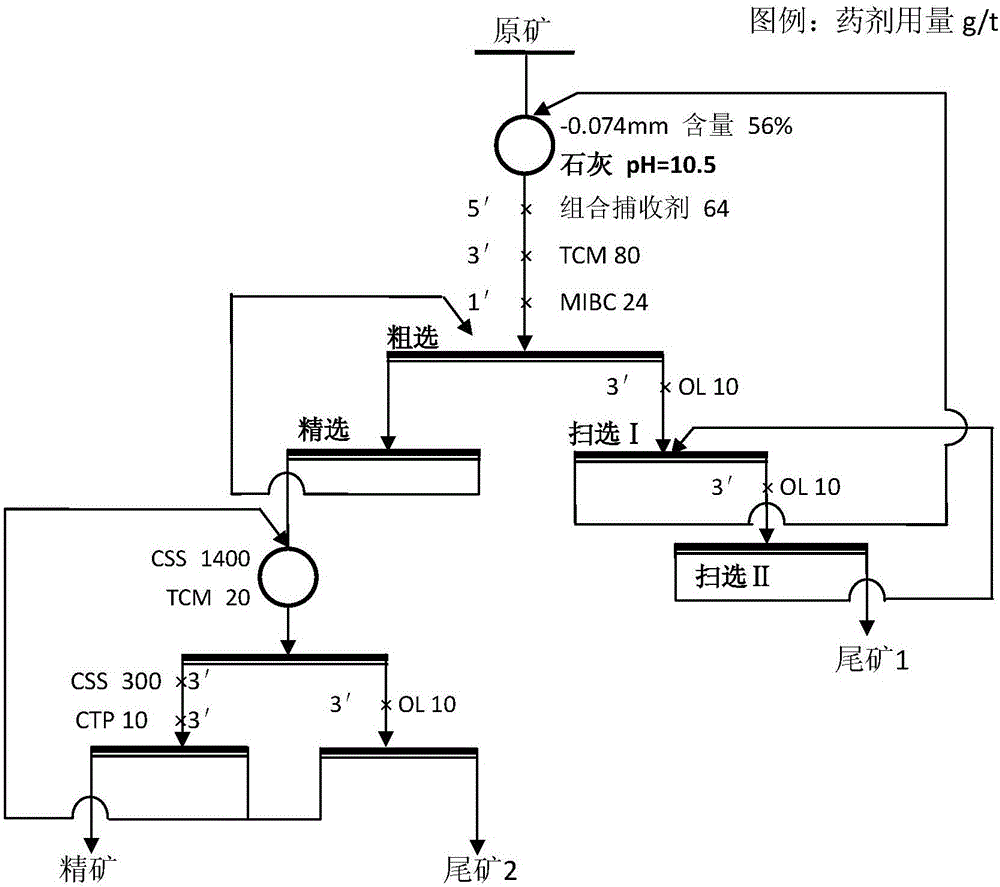

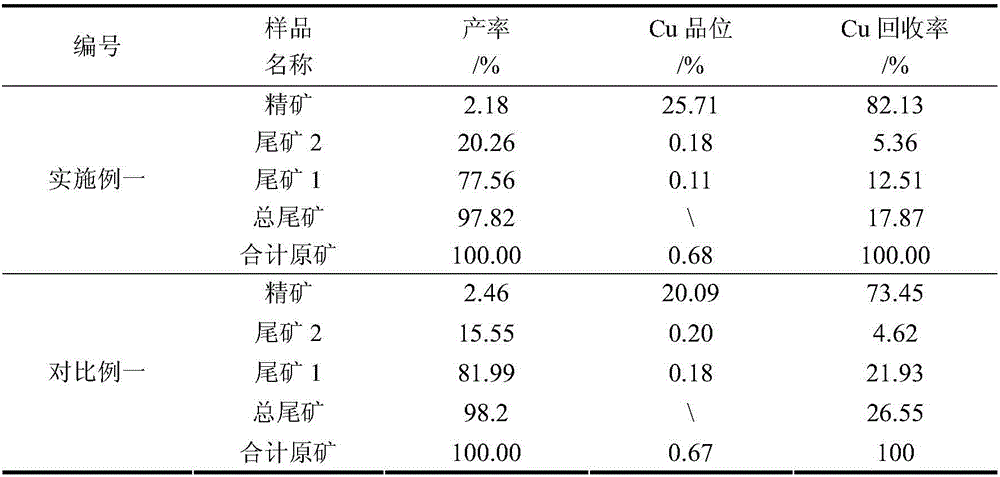

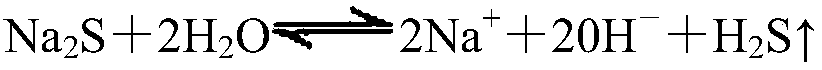

Combined regulator for flotation of magnesian skarn type copper sulfide ore and application thereof

ActiveCN106824551AIncreased selective inhibitionGood for flotation separationFlotationMaceralSodium silicate

The invention discloses a combined regulator for the flotation of magnesian skarn type copper sulfide ore and an application method thereof, and belongs to the technical field of mineral processing engineering. The combined regulator is combined by adopting three agents of caustic soda, sodium sulfide and sodium silicate; the mixing proportion of the three agents is that the ratio of the caustic soda to the sodium sulfide to the sodium silicate is equal to (20 to 40) to (0.5 to 2) to (1 to 5). In comparison with a conventional regulator lime for copper sulfide ore, the three agents are used for synergetic action; the exertion of the performance of an inhibitor and the performance of a collector is more facilitated; the indices of the mineral dressing of copper are greatly improved; the combined regulator has market application value.

Owner:CENT SOUTH UNIV

Method for improving molybdenum concentrate recovery rate during copper-molybdenum separation of low-grade high-argillization skarn ore

InactiveCN107971125AHigh recovery rateSolve the problem of low recovery rateWet separationLower gradeLow graded

The invention relates to a method for improving the molybdenum concentrate recovery rate during copper-molybdenum separation of low-grade high-argillization skarn ore, and belongs to methods for separating molybdenum concentrate from copper-molybdenum ore of the skarn ore during copper-molybdenum separation. The method comprises the steps of beforehand tailing discarding operation of mixed concentrate, rough selection operation of copper-molybdenum separation, rough concentrate re-grinding operation, and molybdenum fine selection operation after re-grinding operation of molybdenum rough concentrate. According to the method for improving the molybdenum concentrate recovery rate during copper-molybdenum separation of the low-grade high-argillization skarn ore, the copper-molybdenum separation operation process is smooth, the molybdenum recovery rate is improved, and the problem that the molybdenum recovery rate is low after the molybdenum concentrate is subjected to repeated fine selection during molybdenum concentrate separation of copper-molybdenum separation of the copper-molybdenum mixed concentrate is solved; and the mixed concentrate is subjected to beforehand tailing discarding operation, and copper concentrate is returned to the beforehand tailing discarding operation again, so that the recovery rate of the molybdenum concentrate is greatly improved.

Owner:CHANGCHUN GOLD RES INST

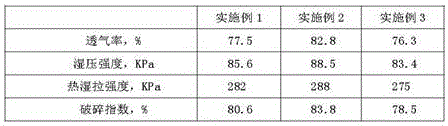

Core sand for automobile engine casting and preparation method of core sand

The invention discloses a core sand for automobile engine casting and a preparation method of the core sand. The core sand is prepared from the following raw materials in parts by weight: 170-180 parts of forsterite sand, 40-55 parts of graphite sand, 35-40 parts of high-magnesium phosphate tailing slag, 40-60 parts of skarn, 25-30 parts of waste foam concrete, 40-50 parts of knar clay, 15-18 parts of coal powder, 16-20 parts of coconut coir, 14-16 parts of blast furnace gas ash, 8-12 parts of high-aluminum fine powder, 10-15 parts of calcium zirconate, 15-17 parts of hollow silica nanospheres, 2-3 parts of sodium silicate, 3-5 parts of aluminum silicate, 3-4 parts of ammonium alginate, 4-6 parts of hydroxyethyl cellulose, 4-7 parts of beta-cyclodextrin and a proper amount of water. The core sand disclosed by the invention is good in performance; in the casting process, the amount of gas evolution is small, the drying time is short, the gas permeability is good, and the wet tensile strength is high; meanwhile, the demolding property of a sand mold can be improved, the sensibility to water during pouring can be lowered, and gas holes in a casting can be prevented; and bentonite and sodium water glass are adopted as binders, so that the mold drawing strength and the collapsibility of the core sand can be improved.

Owner:江阴联华铸造有限公司

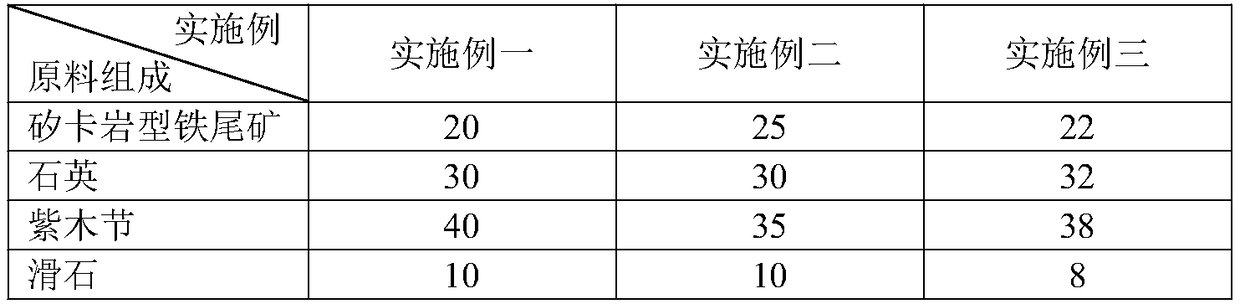

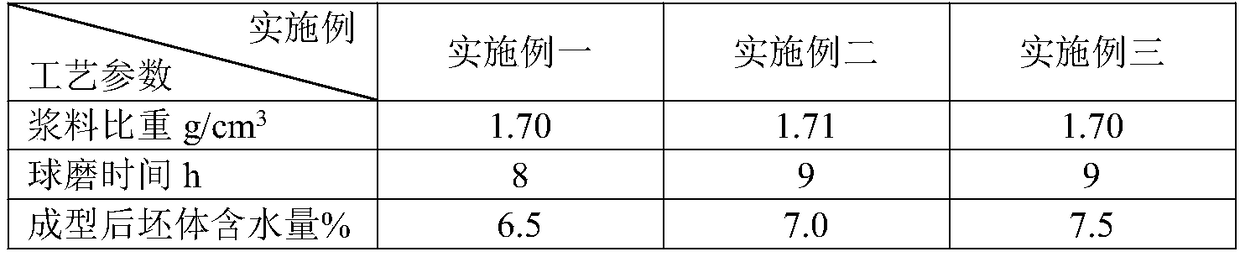

Green archaized brick prepared from iron tailings of skarn with high content of calcium and magnesium and making method thereof

ActiveCN109081677AReduce dependenceReduce manufacturing costCeramic materials productionClaywaresBrickQuartz

The invention discloses a green archaized brick prepared from iron tailings of skarn with high content of calcium and magnesium and a making method thereof. The green archaized brick is prepared from,by weight, 20-25 parts of iron tailings of skarn, 30-40 parts of quartz, 35-45 parts of knar clay, and 6-12 parts of talcum. The invention further discloses a making method of the green archaized brick prepared from iron tailings of skarn with high content of calcium and magnesium. According to the design of preparing the green archaized brick from the iron tailings of skarn with high content ofcalcium and magnesium, product quality and performance is guaranteed, dependence on high-quality raw material resources in production of green bricks is weakened, production cost of building ceramicsis lowered greatly, environmental protection and pollution treatment are both facilitated. The production of the green archaized brick is easy to control and low in cost, and thus the green archaizedbrick is easy to promote and apply and has high practical value and good application prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

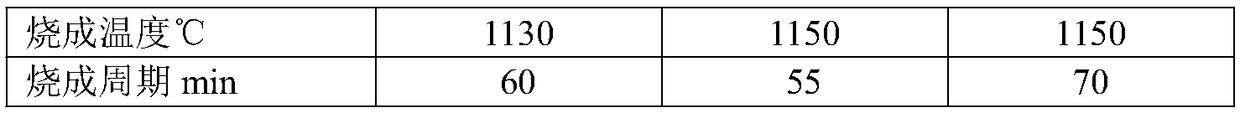

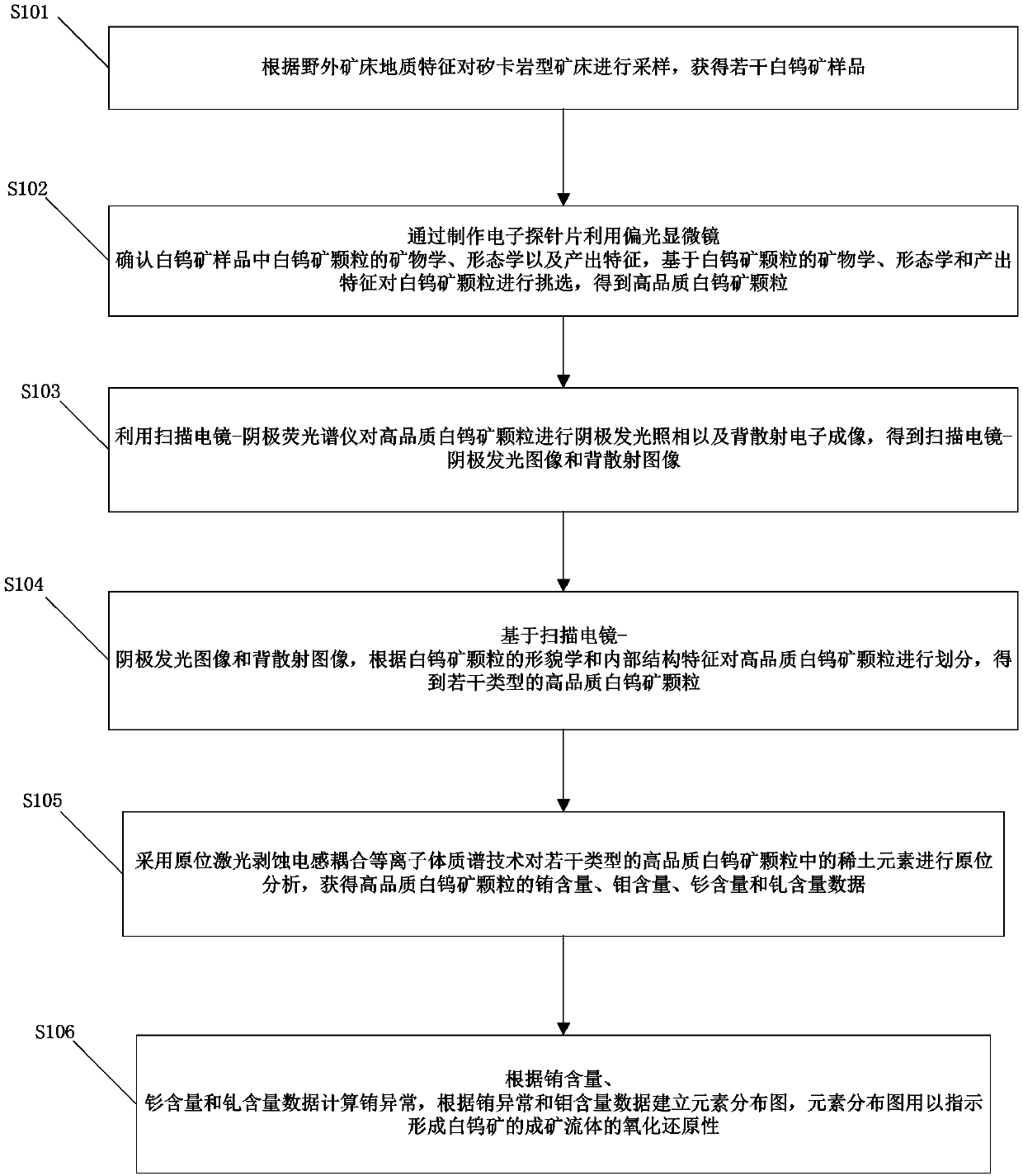

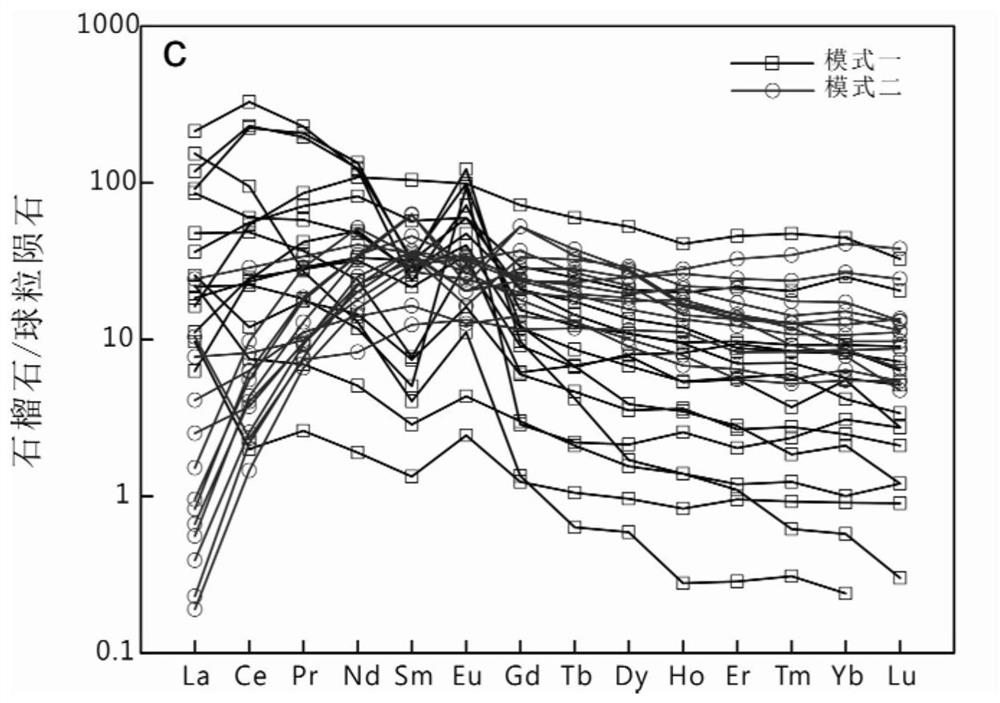

Method based on cathode luminescence feature of scheelite in skarn deposit and used for distinguishing redox properties of ore-forming fluid

InactiveCN107655914AGuide the direction of prospectingIntuitiveMaterial analysis using wave/particle radiationMaterial analysis by electric/magnetic meansRare-earth elementScanning electron microscope

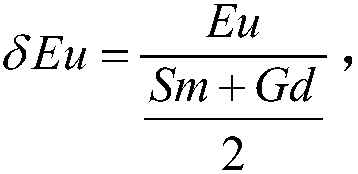

The invention provides a method based on the cathode luminescence feature of scheelite in a skarn deposit and used for distinguishing the redox properties of an ore-forming fluid. The method includes:acquiring a plurality of scheelite samples; selecting scheelite particles on the basis of the mineralogy, morphology and production features of the scheelite particles in the scheelite samples to obtain high-quality scheelite particles; acquiring the scanning electron microscope-cathode luminescence image and back scattering image of the high-quality scheelite particles; based on the scanning electron microscope-cathode luminescence image and the back scattering image, dividing the high-quality scheelite particles according to the morphology and internal structural features of the scheelite particles to obtain a plurality types of high-quality scheelite particles; performing in-situ analysis on rare-earth elements in the plurality types of high-quality scheelite particles to obtain europium content and molybdenum content data; calculating europium anomaly according to the europium content data, and building an element distribution diagram according to the europium anomaly and the molybdenum content data, wherein the element distribution diagram is used for indicating the redox properties of the ore-forming fluid of the scheelite.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

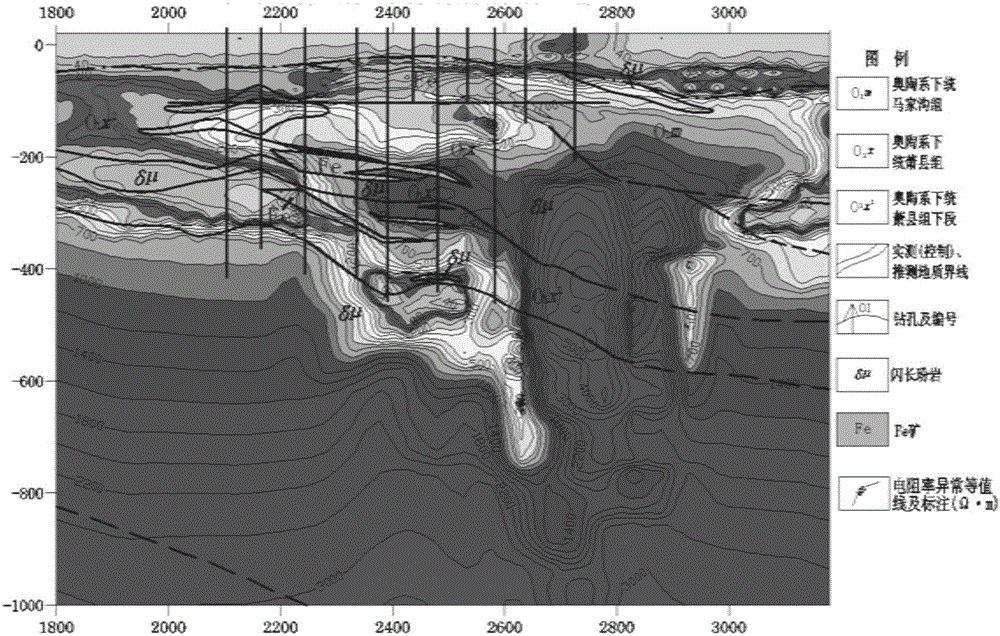

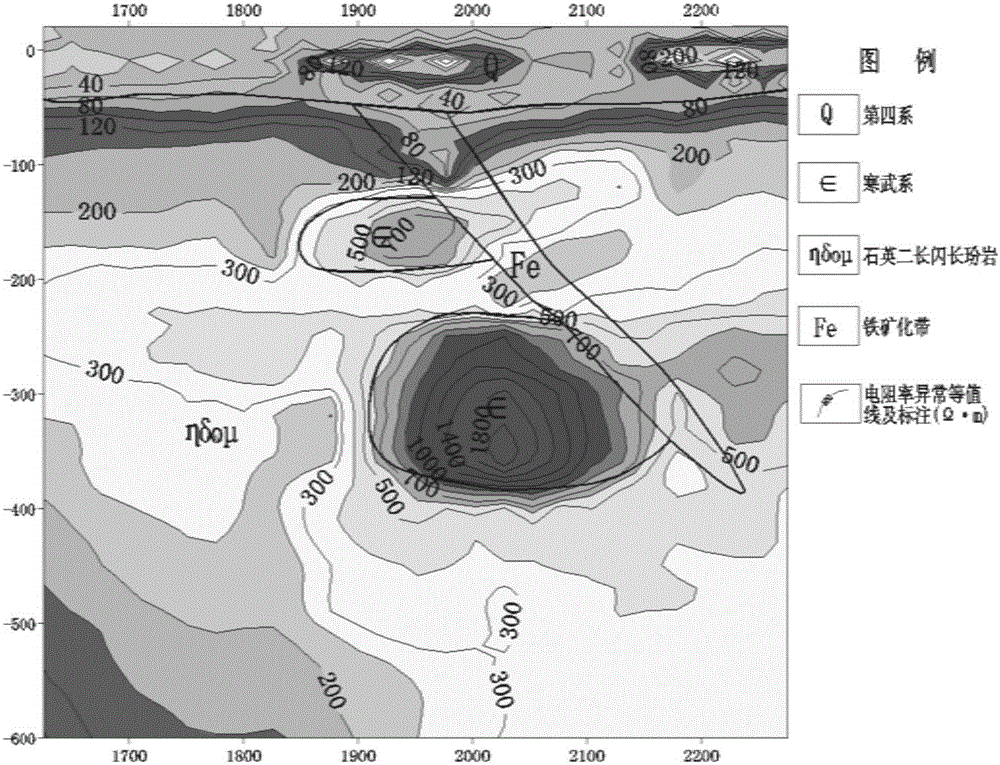

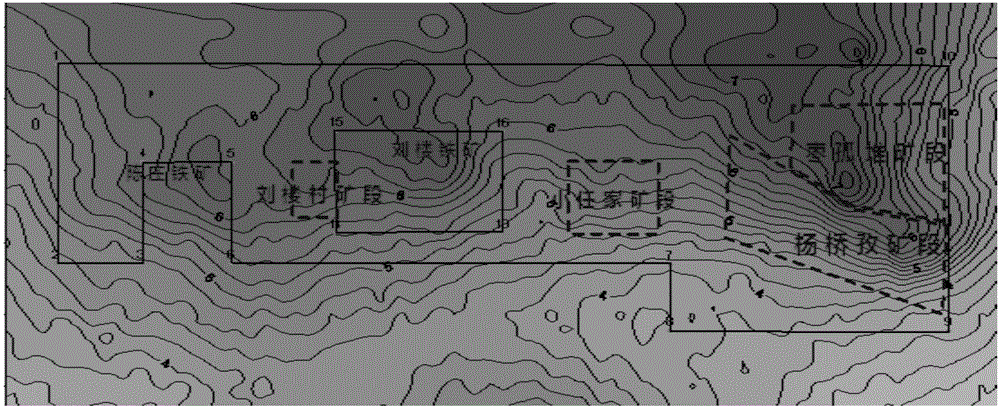

Method for exploring overlay area skarn type iron-copper-gold deposit

InactiveCN106772677ARealize the purpose of indirect prospectingGeological measurementsGold depositFerric

The invention discloses a method for exploring overlay area skarn type iron-copper-gold deposit. According to the method, through steps of analyzing a metallogenetic geological condition and compiling an exploration area metallogenetic structural map; screening an ore finding target area; performing CSAMT method section measurement, determining positions of mineralized marble xenoliths and performing drilling verification, positioning of the mineralized marble xenoliths is realized, thereby realizing a purpose of searching the overlay area skarn type iron-copper-gold deposit. Compared with the prior art, the method is advantageous in that a technical solution of searching the marble xenoliths by means of a CSAMT method is presented according to a resistivity high-low-high difference among marble, ore (mineralized rock) and rock body; and the method is an effective method for deposit exploring in an overlay area.

Owner:安徽省勘查技术院

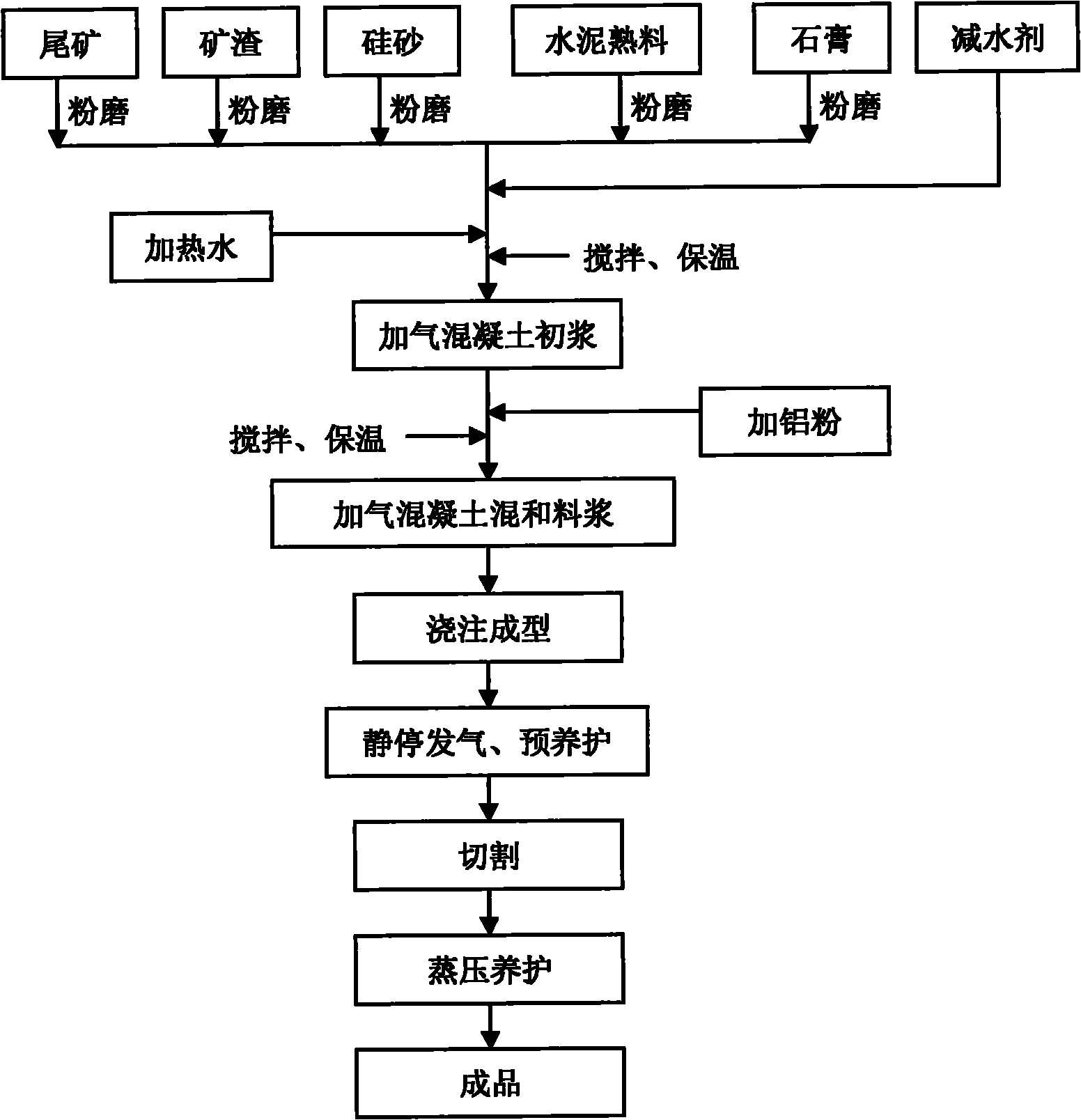

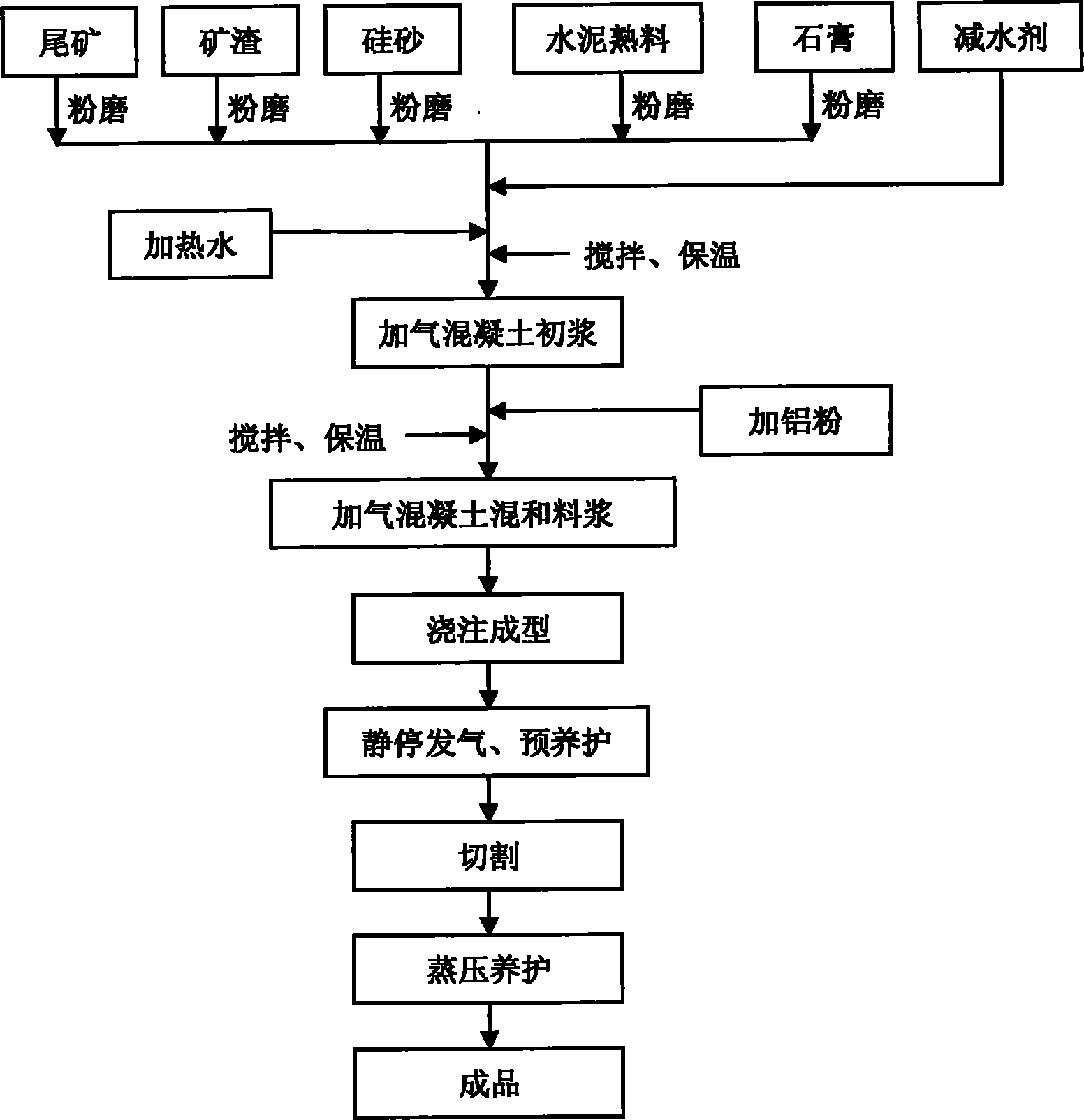

Method for preparing steaming pressure aeroconcrete by skarn type mine tailings

InactiveCN101870568ASolve difficult problems that are not easy to comprehensively utilizeReduce management costsSolid waste managementCeramicwareSteam pressureWarm water

The invention relates to a method for preparing steaming pressure aeroconcrete by skarn type mine tailings, which belongs to the field of ore mine environment protection and the field of building materials and comprises following ingredients in percentage by weight: 25 to 45 percent of skarn type mine tailings, 25 to 35 percent of water quenching blast furnace slag, 15 to 30 percent of silica sand, 6 to 12 percent of cement clinker, 3 to 6 percent of natural gypsum, water reducing agents accounting for 0.6 to 0.9 percent of the total mass of the mixed dry materials, 0.06 to 0.12 percent of aluminum powder and 35 to 45 percent of warm water at the temperature between 48 and 55 DEG C. The aeroconcrete prepared by the invention has the moisture pressure-resistance intensity higher than 3.5 MPa, the absolute dry pressure-resistance intensity higher than 5 MPa and the dry body density between 550 kg / m<3> and 650 kg / m<3>, the requirement of the national standard on the performance indexes of the steaming pressure aeroconcrete can be met, and the invention provides a novel utilization path for the skarn type mine tailing resources with difficult utilization, and is favorable for solving the problems of ground resource occupation and environment pollution of the piling storage of the skarn type mine tailings.

Owner:UNIV OF SCI & TECH BEIJING

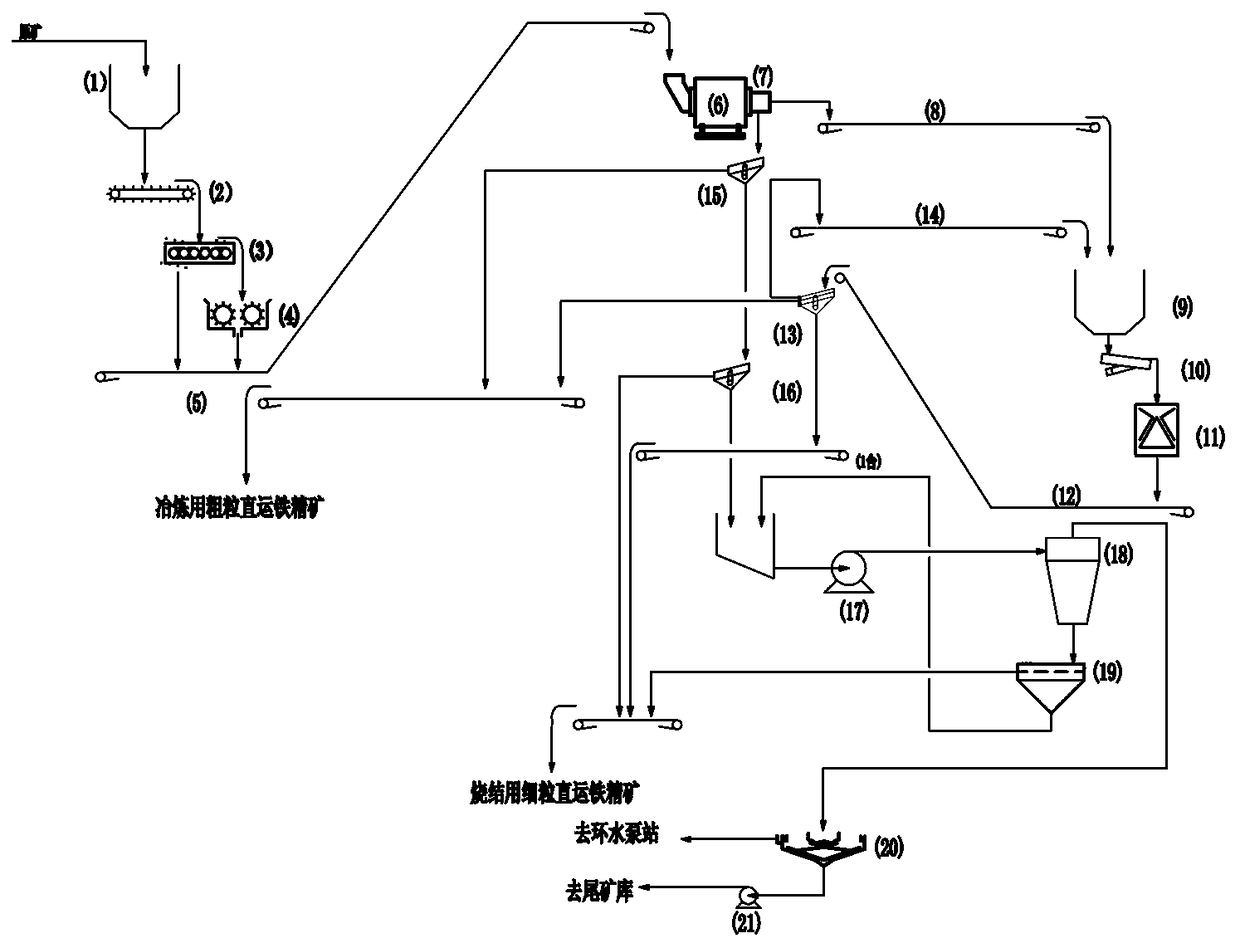

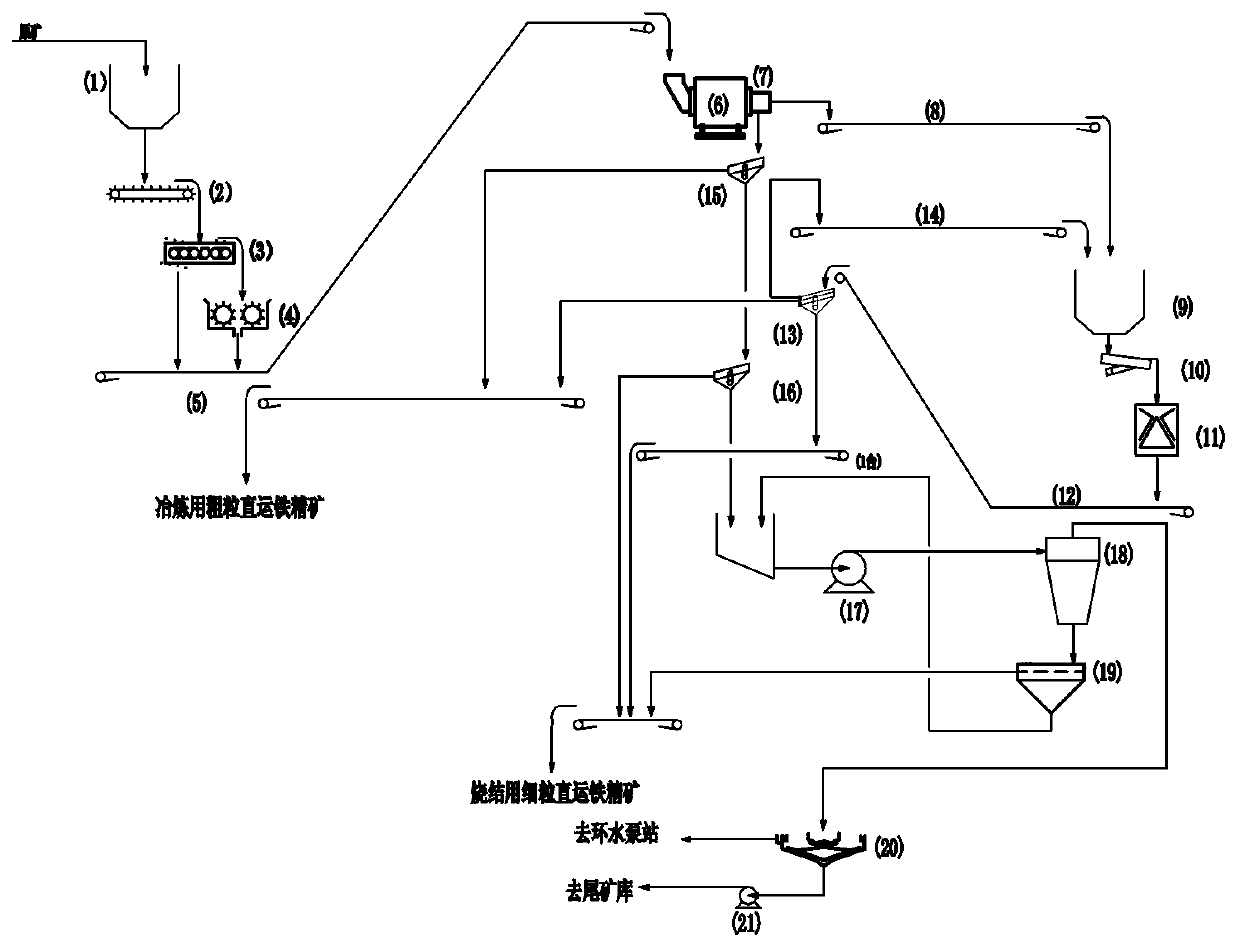

Separation technology of ground surface skarn type hematite

ActiveCN109013077AIncrease incomeGood beneficiation indexSievingGas current separationSeparation technologyEngineering

The invention relates to a separation technology of ground surface skarn type hematite. The technology is characterized by comprising coarse breaking work, ore washing desliming and dry and wet separation work, medium breaking work, wet type screening work and continuous two-segment water removal and grading work. According to the technology, grade of raw ore with 53 to 55% iron grade can be improved to 58% successfully without grinding and separation, the comprehensive concentrate recycling rate can reach 73 to 77%, the comprehensive iron recovery rate is much higher than the 70% recovery rate of traditional hematite mineral separation, the good mineral separation index is obtained, and in order to obtain the higher earnings, the guarantee is provided. The raw ore is subject to effectivedesliming, the slurry blockage problem can be solved, and two kinds of produced raw materials of smelting and sintering ores can be directly transported outwards.

Owner:中冶北方(大连)工程技术有限公司

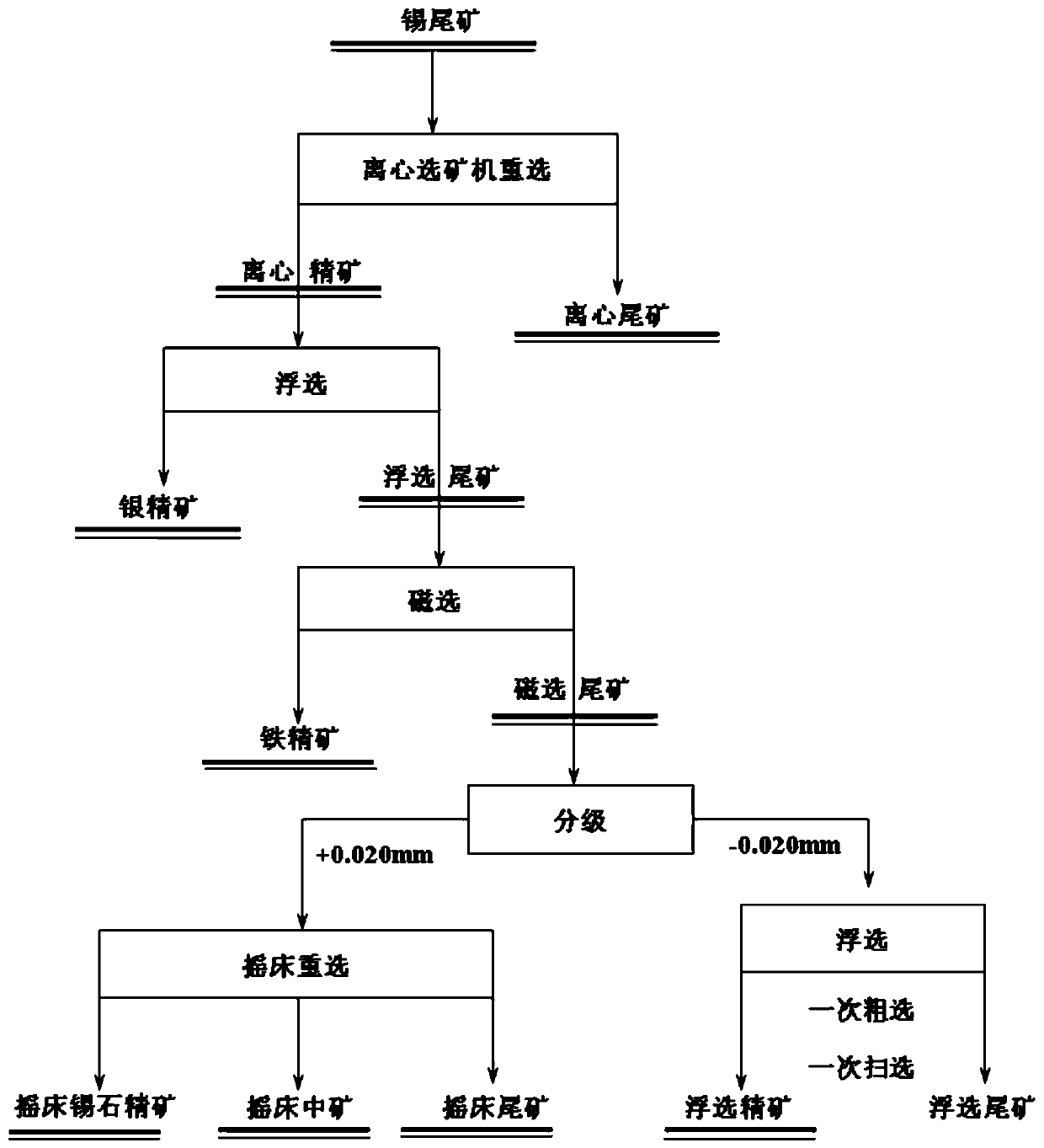

Beneficiation method for recovering tin and silver from skarn type low-grade tin tailings

ActiveCN110479498AEnhanced adhesion effectHigh recovery rateFlotationMagnetic separationGravity separationMaterials science

The invention relates to a beneficiation method for recovering tin and silver from skarn type low-grade tin tailings. The beneficiation method comprises the following steps that: S1, ore samples are subjected to gravity separation and tailing discarding, the centrifugal gravity separation concentrates are subjected to primary flotation roughing, primary scavenging and primary blank concentration,and silver concentrates and flotation tailings are obtained; S2, the magnetic separation flotation tailings are subjected to centrifugal gravity separation, and magnetic separation concentrates and magnetic separation tailings are obtained; grading the magnetic separation tailings into a +A size fraction and a -A size fraction; S3, +A size fraction gravity separation is conducted, and cassiteritetable concentrates and the like are obtained; S4, cassiterite shaking table concentrate is collected for size mixing and the like to serve as carrier minerals; S5, size mixing is conducted on the sizefraction A, and a micro-fine particle cassiterite ore sample is obtained; S6, carrier minerals are added into the micro-fine particle cassiterite ore sample, a collecting agent and the like are added, and ore pulp is obtained; and S7, the ore pulp obtained in the S6 is subjected to flotation, and flotation concentrate and flotation tailings are obtained. The beneficiation method provided by the invention is simple in technological process, low in production cost, low in flotation reagent dosage, capable of remarkably improving the recovery rate of the micro-fine particle cassiterite and highin adaptability.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

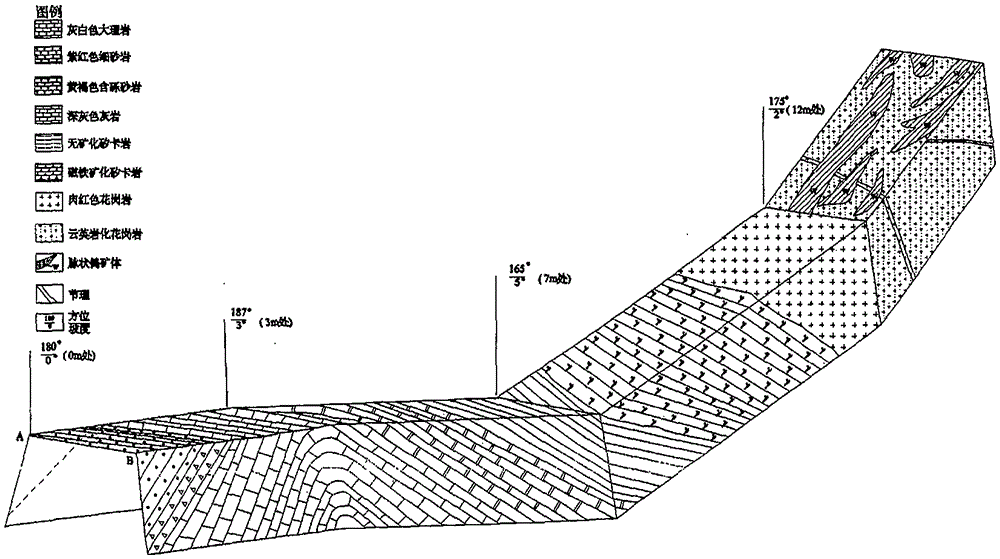

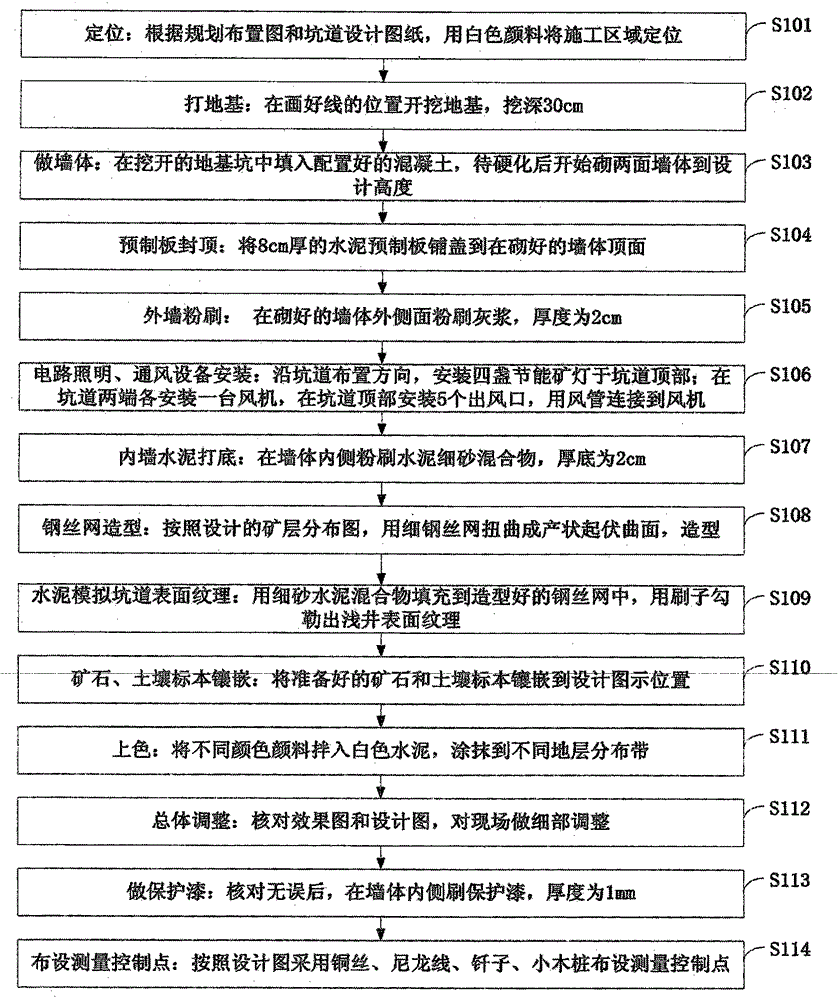

Campus underground sap engineering situation teaching area implementation method

The invention discloses a campus underground sap engineering situation teaching area implementation method, and simulation saps are divided into transverse drift saps and following-vein drift saps. A transverse drift sap bottom plate employs an extending artificial slope, and is provided with a small corner and a big corner. The rocks in the saps are sequentially clastic rocks, limestone, marble, skarn and granitic mass; the interiors of the saps are provided with true rocks and ore mineral samples in an inset manner; two walls are provided with bulged rock stratum surfaces in a molding manner according to different lithologic sections. The method solves problems in geological specialty, geotechnical engineering specialty and measurement specialty better that the time and space of the theory and practice teaching of underground engineering measurement and geological record cannot be unified and the theory and practice teaching of underground engineering measurement and geological record cannot be carried out at the same time, combines with the characteristics of specialties and regions in a construction process, creates typical and true ore deposits, rock stratums and constructions which facilitate the teaching, and enables a large-area and large-scale geological background to be represented in a more microcosmic and stereoscopic manner.

Owner:HUNAN ENG POLYTECHNIC

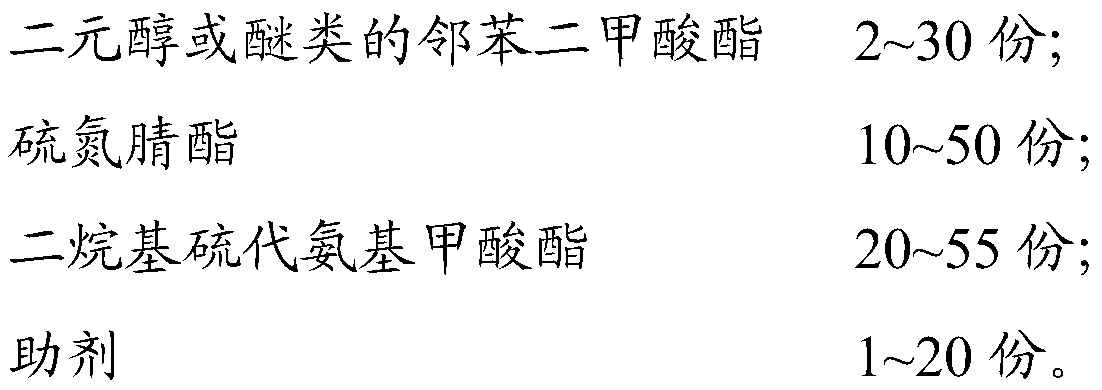

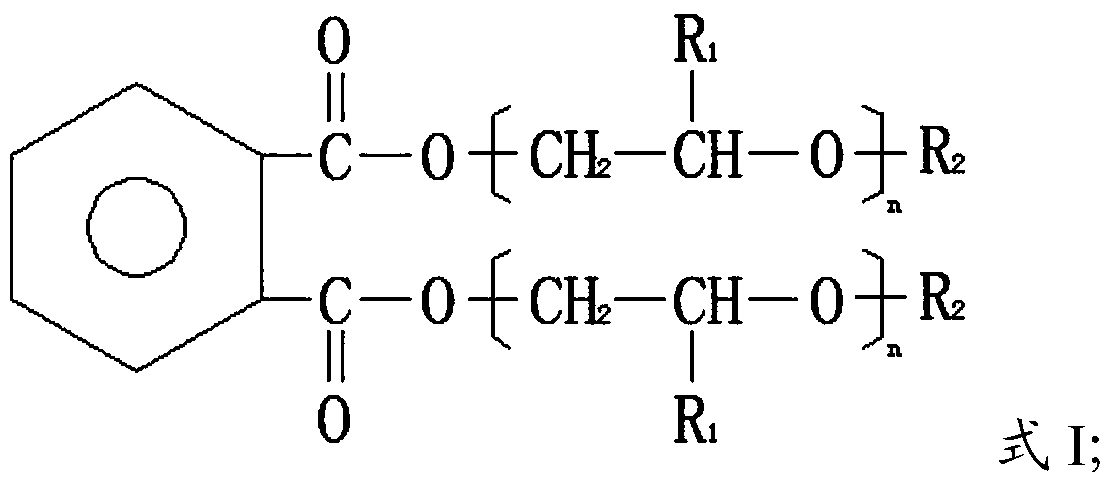

Gangue inhibitor of high-argillization low-grade skarn copper molybdenum ore

The invention provides a gangue inhibitor of high-argillization low-grade skarn copper molybdenum ore, and belongs to the field of copper-molybdenum separation flotation for skarn copper molybdenum ore. The gangue inhibitor comprises the following substances by mass percent: 85% to 95% of water glass, 0.1% to 1% of carboxymethyl cellulose, 1% to 5% of sodium fluoride and 1% to 10% of sodium metabisulfite. The preparation concentration of the inhibitor is 0.1% to 1%, stirring time is larger than or equal to 30 min, and dosage is 2 kg / t to 4 kg / t. The gangue inhibitor has the advantages that water glass, carboxymethyl cellulose, sodium fluoride and sodium metabisulfite are combined into inorganic colloid, the gangue inhibitor has a good inhibition function on high-argillization gangue minerals like calcite, wollastonite, dolomite, quartz and silicate during the practice process, a preparation method is easy and convenient, cost is low, muddy gangue minerals during the copper-molybdenum separation flotation process can be effectively inhibited, and the grade of molybdenum concentrate is improved.

Owner:CHANGCHUN GOLD RES INST

Method for searching covered-area skarn-type copper-gold deposit by means of high-precision gravitational prospecting

InactiveCN106772651ATo achieve the purpose of indirect prospectingGravitational wave measurementGravity anomalyGold deposit

The invention discloses a method for searching covered-area skarn-type copper-gold deposit by means of high-precision gravitational prospecting. The method comprises the steps of compiling a metallogenic formation construction drawing through analyzing a metallogenetic geological condition; defining an ore searching target area; performing 1 / 10000 high-precision gravity measurement, and defining a skarn alteration area range; performing steps such as drilling and mineral reserve verifying for gradually reducing a target range, and realizing accurate ore searching. Compared with the prior art, the method is advantageous in that the skarn range of the covered area is defined according to residual gravity abnormity, thereby realizing a purpose of indirect ore searching. The invention provides the method for searching the covered-area skarn-type copper-gold deposit for filling related gaps. According to a gravitational prospecting principle, the invention provides the method for searching the covered-area skarn-type copper-gold deposit by means of a high-precision gravimetric prospecting method. According to the residual gravity abnormity, the skarn range is defined. The method for searching covered-area skarn-type copper-gold deposit by means of the high-precision gravimetric prospecting method is firstly realized in China.

Owner:安徽省勘查技术院

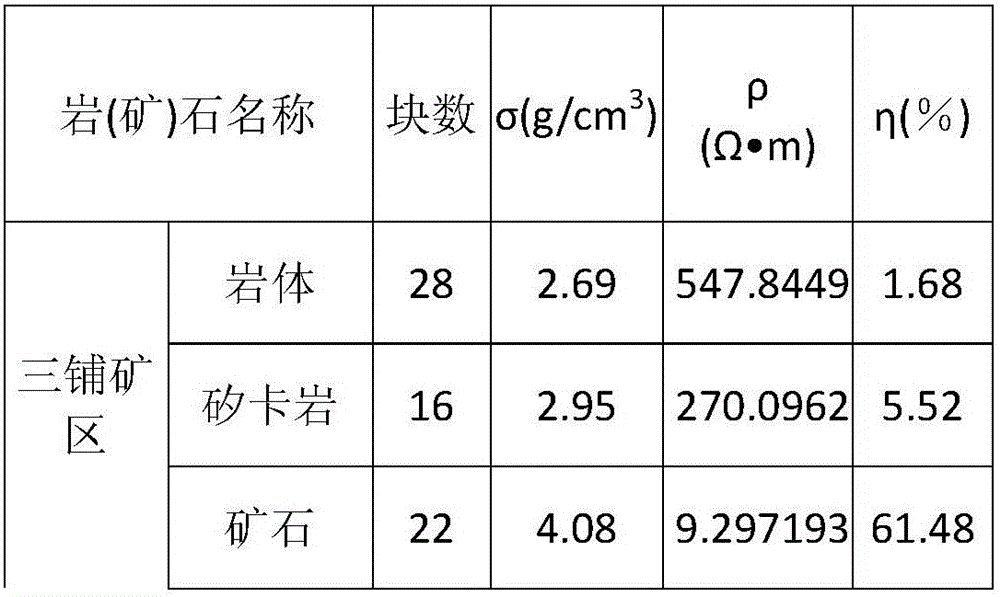

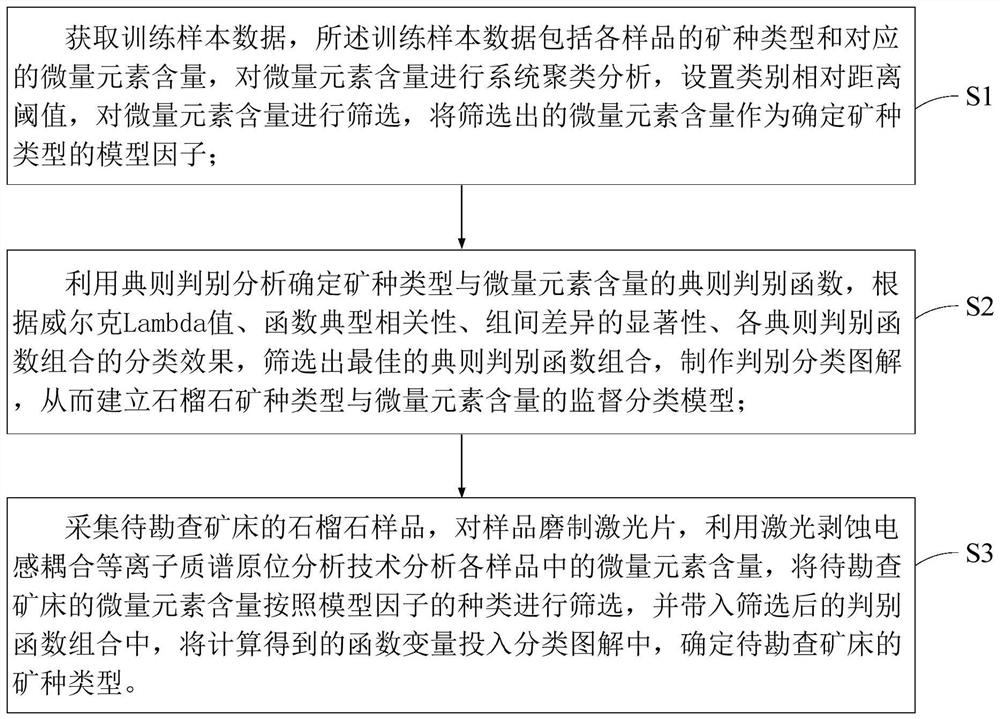

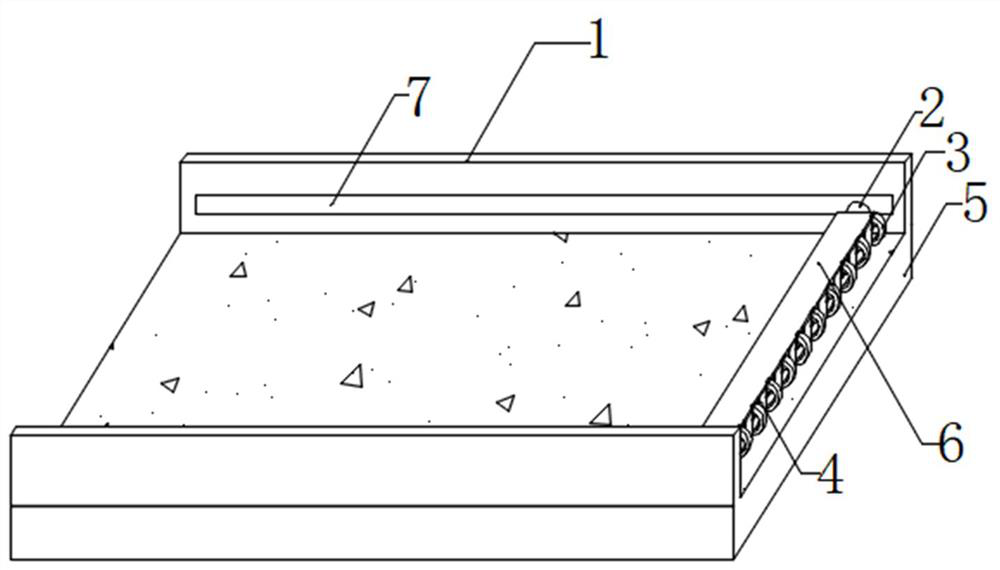

Method for discriminating mineral types based on garnet micro-area chemical components

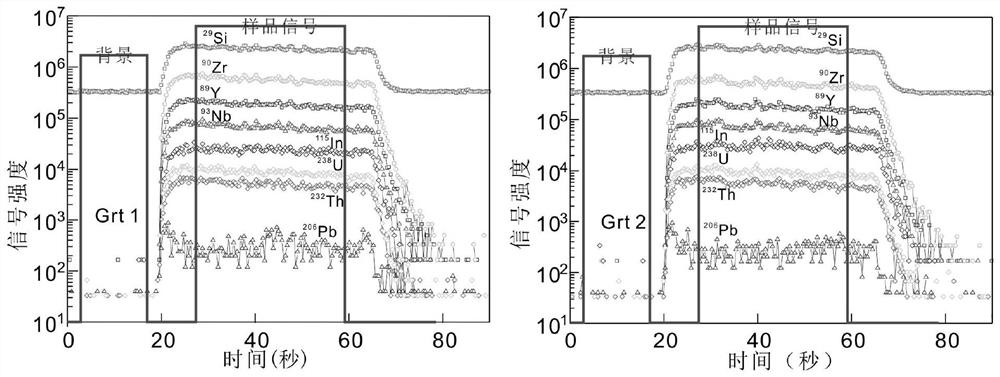

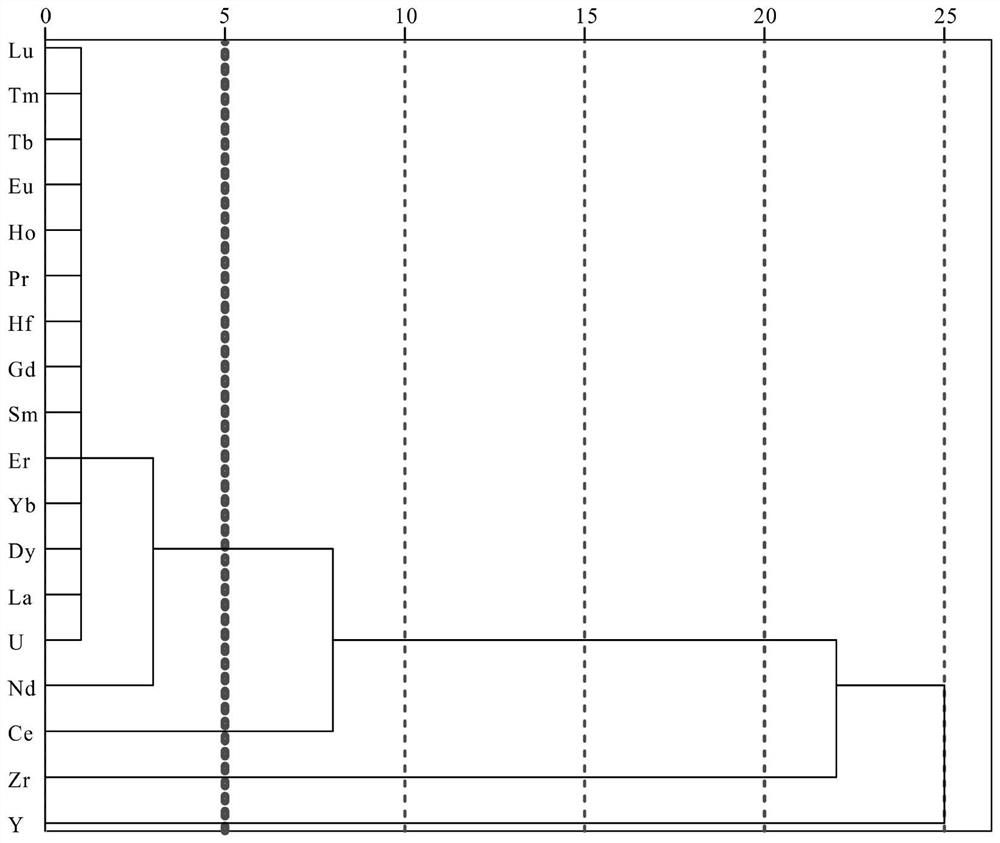

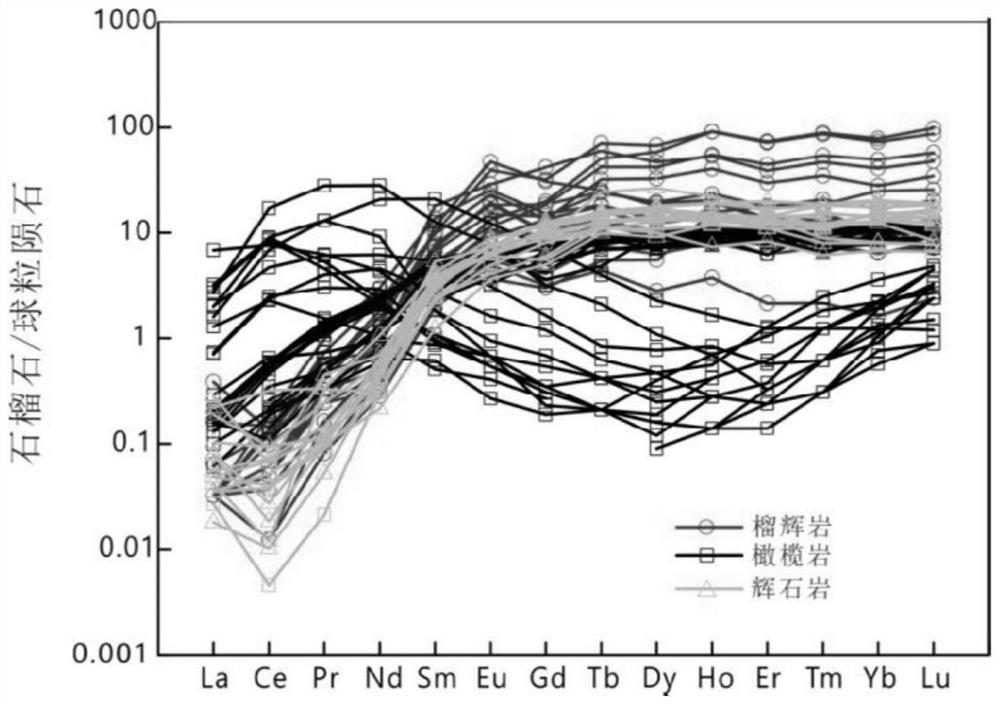

PendingCN114813903AShorten the exploration cycleShort test timeMaterial analysis by electric/magnetic meansCharacter and pattern recognitionChemical compositionTrace element

The invention provides a method for distinguishing ore types based on garnet micro-area chemical components, which comprises the following steps of: acquiring training sample data, and screening trace element contents by utilizing system clustering analysis to serve as model factors for determining ore types; determining a canonical discriminant function of the mineral type and the trace element content by utilizing canonical discriminant analysis, and screening out an optimal canonical discriminant function combination to establish a supervised classification model; and determining the ore type of the to-be-explored ore deposit by using the supervised classification model. The technical scheme provided by the invention has the beneficial effects that the method for judging potential ore types by utilizing the components of the garnet in the skarn type ore deposit provides a garnet trace element quantitative index and formula for quickly judging the ore types, so that the accuracy of quickly judging the ore types and predicting the target region can be greatly improved; the method overcomes the difficulties of low efficiency, long period and high cost of a traditional mineral type discrimination method in the early stage of mineral exploration.

Owner:西藏鑫湖矿业有限公司 +1

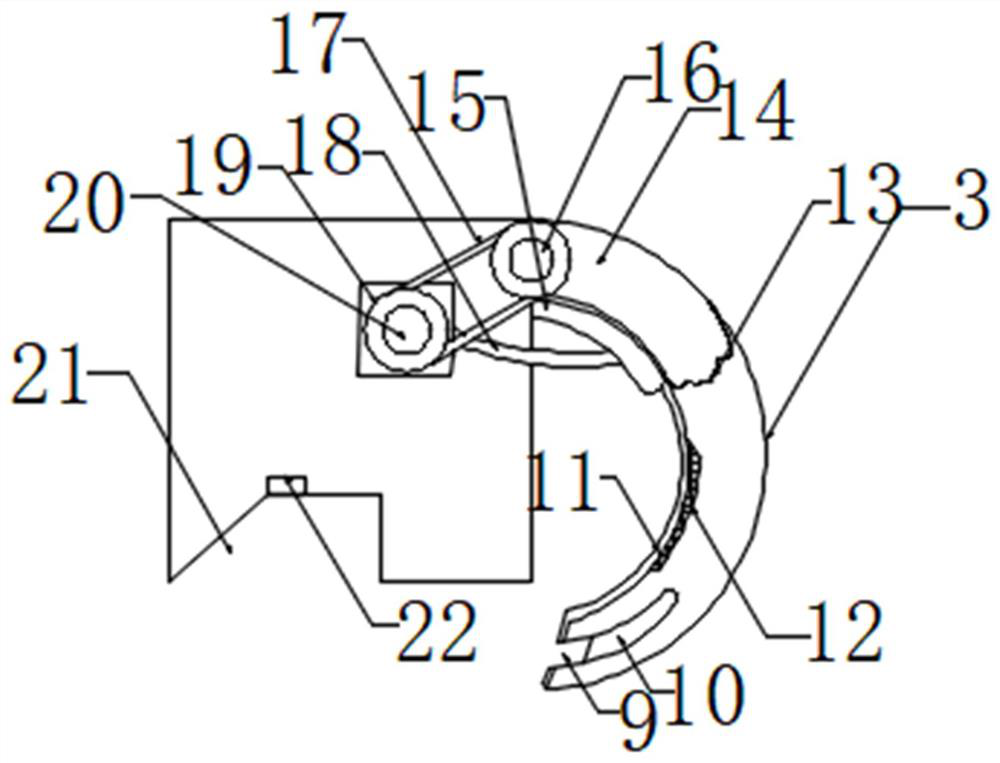

Method and device for determining lithology of clastic garnet mineral parent rock

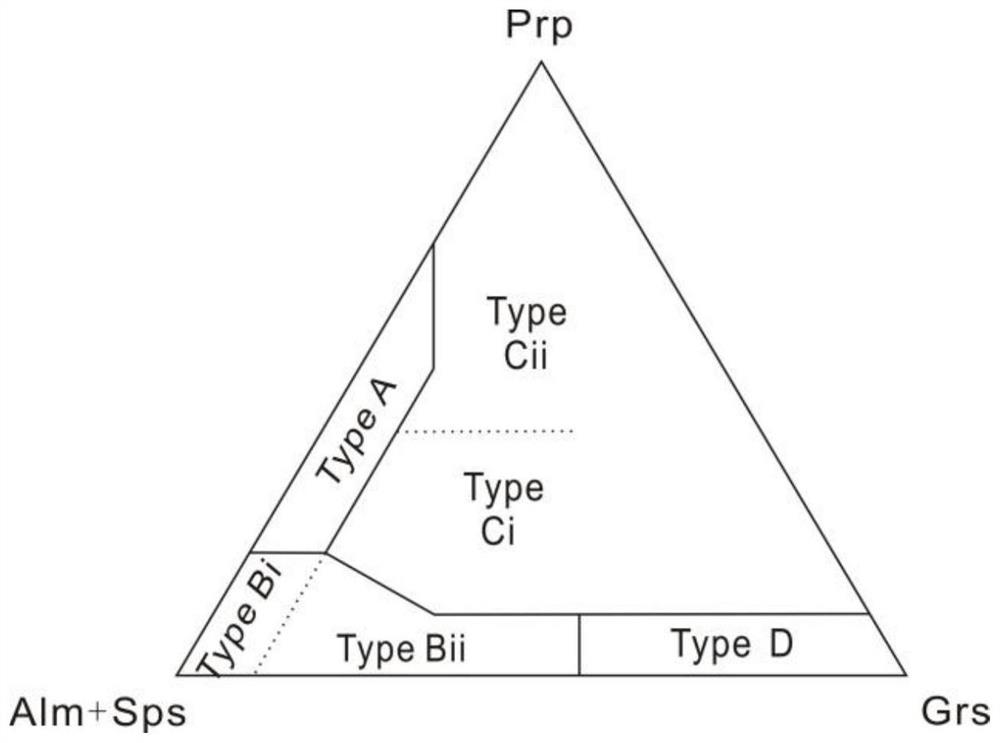

ActiveCN112395729ASystem distinctionAccurate distinctionDesign optimisation/simulationLithologyElement analysis

The invention provides a method and device for determining lithology of clastic garnet mineral mother rock. The method comprises steps of preliminarily determining the lithology of the clastic garnetmineral mother rock through employing a garnet Mg-Fe+Mn-Ca main element discrimination graph according to a main element analysis result of a to-be-detected clastic garnet mineral; and when the main element analysis result of the to-be-detected chip garnet mineral falls in the Type A, Type B or Type D region of the discrimination graph, further determining the parent rock lithology of the to-be-detected chip garnet mineral by utilizing the trace element analysis result of the to-be-detected chip garnet mineral. According to the method, garnets from a basic rock source and a variable basic rocksource can be more systematically and accurately distinguished, garnets from different types of skarn sources can be distinguished, and garnets from a granite source, a high-grade granite phase-change argillaceous rock source and a medium-low-grade hornstone phase-change argillaceous rock source can be distinguished; and therefore, the method plays an important role in the aspects of material source recovery research, even basin-mountain coupling relationship research and the like.

Owner:PETROCHINA CO LTD

Beneficiation process of skarn type magnetite containing copper and gold

The invention discloses a beneficiation process of skarn type magnetite containing copper and gold. The beneficiation process of the skarn type magnetite containing copper and gold comprises the following steps that firstly, the dimension of ores is made to reach less than 12mm through three-stage closed-circuit crushing, sorting is conducted through a permanent magnet wet magnetic separator, magnetic separation concentrates directly enter a ball mill, and magnetic separation tailings enter a linear vibrating screen to be screened; secondly, bulk flotation is performed after ore grinding to obtain copper-sulfur bulk concentrates, and the copper-sulfur bulk concentrates are subjected to copper-sulfur separation to obtain qualified copper concentrates and sulfur concentrates; and thirdly, the bulk flotation tailings enter a one-roughing two-concentration one-scavenging magnetic separation process to obtain qualified iron ore concentrate products. According to the beneficiation process ofthe skarn type magnetite containing copper and gold, after the ores are crushed, special metal distribution with a low copper grade in non-magnetic ores in coarse fraction is fully utilized, a pre-selection process before grinding is added, discarded waste coarse particles can be sold as building materials to generate economic benefits, and meanwhile, the grinding and separation cost and the tailing treatment cost of the discarded waste coarse particles are reduced; and fine-fraction materials in the non-magnetic materials do not enter the ball mill any more.

Owner:安徽太平矿业有限公司

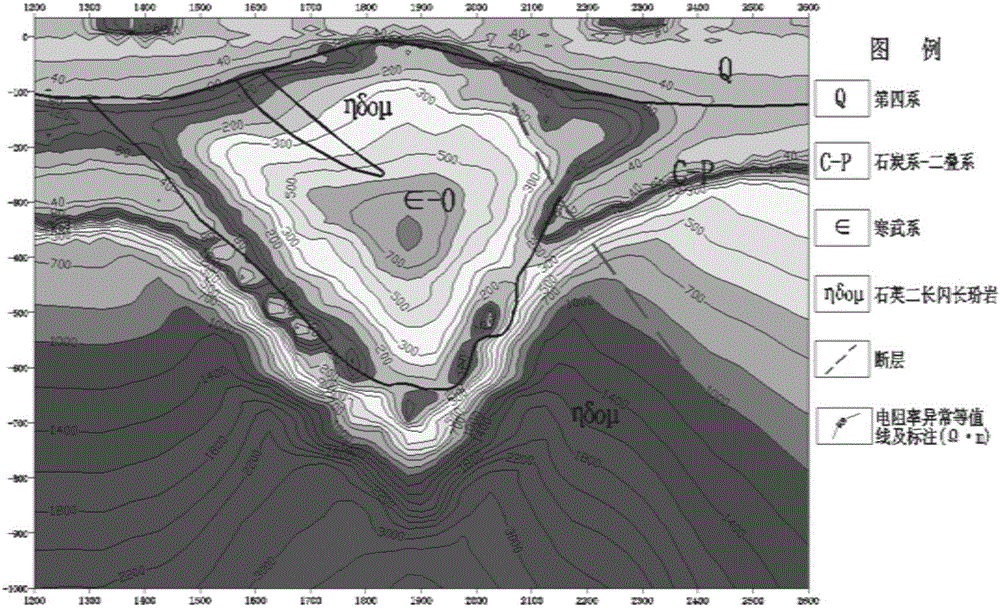

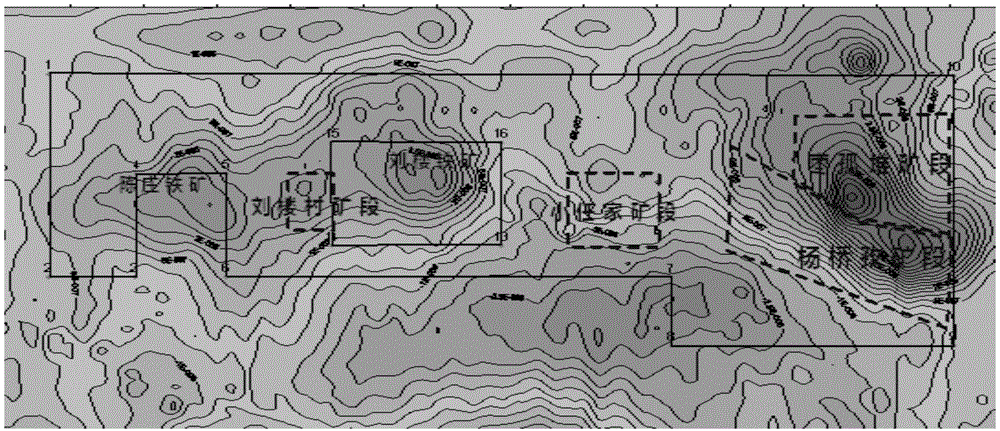

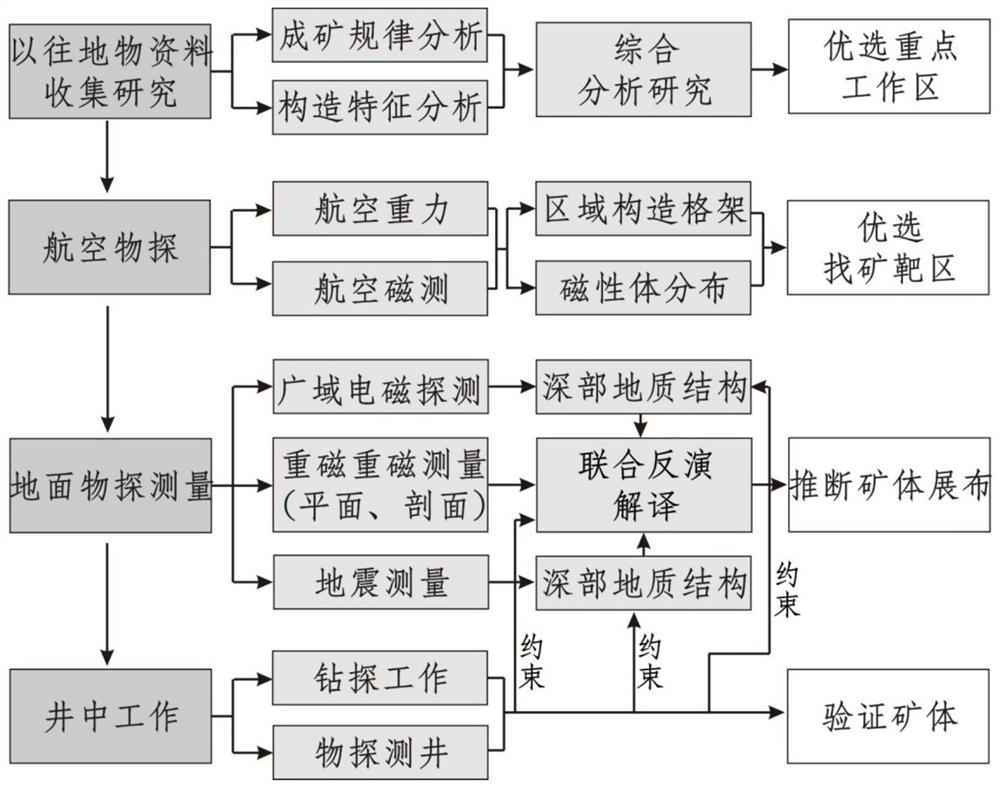

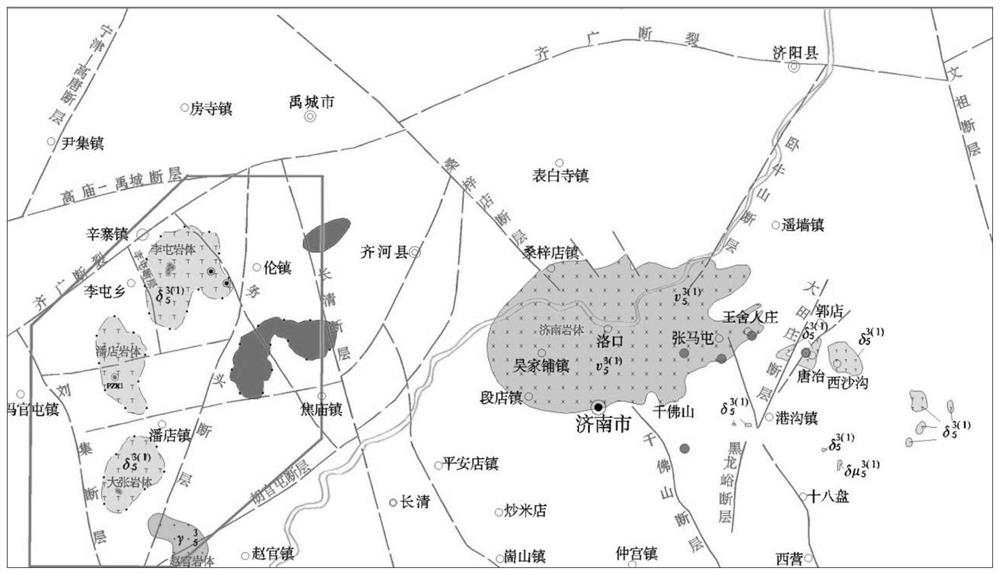

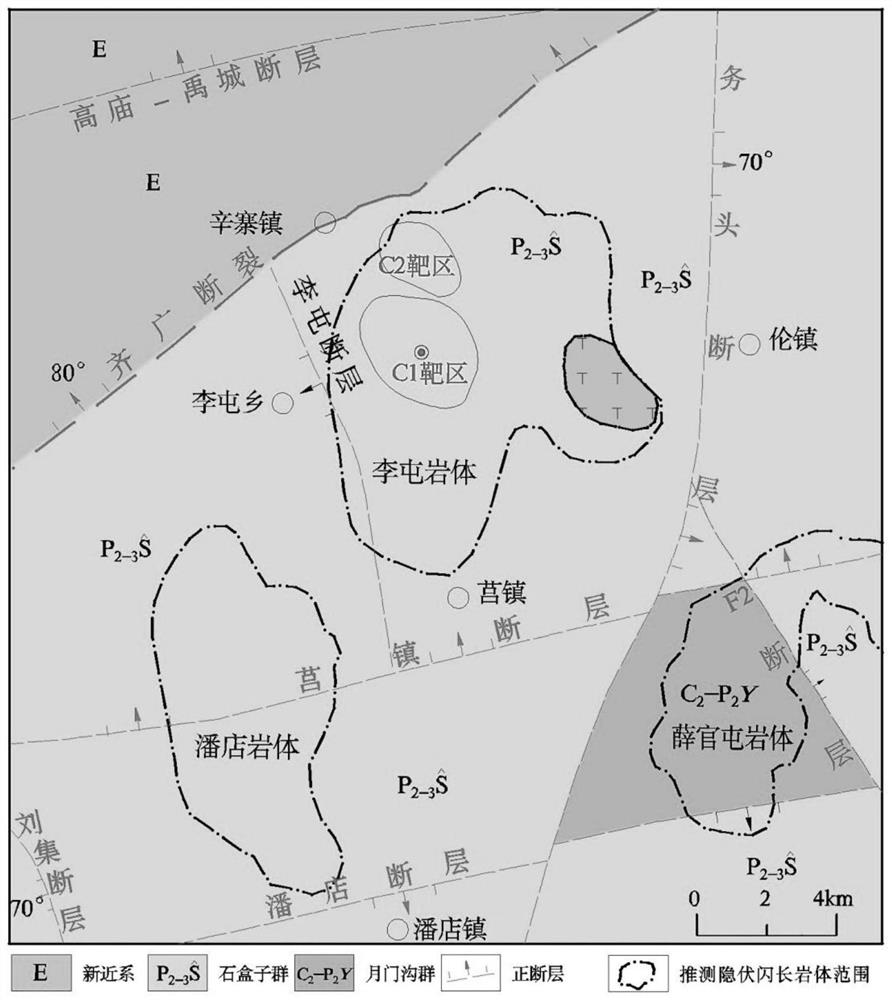

Sarn type iron-rich ore deep exploration method and system based on multi-element geophysics

PendingCN114740538AAchieving a major breakthrough in prospectingCracking the shielding puzzleWater resource assessmentElectric/magnetic detectionWell loggingMagnetite

The invention relates to the technical field of deep prospecting of geological exploration, and provides a skarn type iron-rich ore deep exploration method and system based on multi-element geophysics, the method combines direct prospecting with indirect prospecting, adopts multiple geophysical methods such as gravity, magnetic method, electrical method, earthquake and the like, exerts the advantages of each geophysical method, and improves the exploration efficiency. According to the method, cross constraint and joint interpretation of multi-element geophysical information are carried out, deep ore body extension is deduced, drilling verification is carried out, geophysical well logging is carried out, geophysical interpretation results are repeatedly corrected with drilling and well logging information as constraints, accurate positioning of the hidden magnetite body is achieved, the exploration success rate is increased, and the exploration cost is reduced.

Owner:SHANDONG PROVINCIAL COAL GEOLOGICAL PLANNING EXPLORATION & RES INST

A method for improving the grade of skarn copper-molybdenum ore copper-molybdenum separation molybdenum concentrate

The invention relates to a method for improving the grade of copper-molybdenum separated molybdenum concentrate of skarn copper-molybdenum ore and belongs to a method for copper-molybdenum separation of skarn copper-molybdenum ore to obtain molybdenum concentrate. The method is characterized in that an inhibitor and a dispersant are added into a bulk concentrate regrinding ball mill to improve the monomer separation degree of molybdenum ore, meanwhile, the inhibitor and the dispersant immediately act on fresh surfaces of copper ore and gangue mineral which are produced through regrinding to enhance the chemical function, the milling grade of copper-molybdenum separated molybdenum is improved, and over-ground gangue mineral is thrown out as soon as possible, so that the implementation of copper-molybdenum separation and the grade improvement of the molybdenum concentrate are both facilitated. By adoption of the method, good copper-molybdenum separated floatation indexes are acquired, and the grade of molybdenum is remarkably improved.

Owner:CHANGCHUN GOLD RES INST

Water purifying agent

InactiveCN106241902AGood water purification effectExtended service lifeSpecific water treatment objectivesWater contaminantsWastewaterSewage

The invention relates to a water purifying agent. The water purifying agent is prepared from, by weight, 30-42% of magnesium oxide, 12-36% of calcium oxide, 10-30% of skarn and 6-16% of titanium dioxide. The water purifying agent has the advantages that the water purifying effect is obvious; the service life is long, and the water purifying agent can be repeatedly used; the water purifying agent is convenient to use, low in price and capable of being used for purifying various industrial wastewater, domestic sewage, lake water, river water and tap water.

Owner:李宝全

Recycling process of associated low-grade silver and cobalt in skarn type cupreous magnetite

ActiveCN107626435AAchieve recyclingSolve the problem of easy to entrain slimeWet separationMagnetiteCobalt

The invention discloses a recycling process of associated low-grade silver and cobalt in skarn type cupreous magnetite. The recycling process comprises the following steps of (1) performing bulk flotation on the skarn type cupreous magnetite, so that copper-sulfide mixed concentrate is obtained; (2) finely grinding the copper-sulfide mixed concentrate, so that the degree of dissociation of silverand cobalt carrier minerals is increased; (3) obtaining high-copper concentrate products with high silver content which is greater than 20 g / t by adopting a partial selective floatation process first,and then obtaining low-copper concentrate and sulfur concentrate with low silver content by adopting a separation flotation process, so that the enrichment and recycling of silver in copper and sulfide separation flotation are realized; and (4) deironing the sulfur concentrate, so that cobalt-sulfur concentrate products with the cobalt content which is greater than 0.28% can be obtained. According to the recycling process, the high-copper concentrate products with the silver content which is greater than 20 g / t and the cobalt-sulfur concentrate products with the cobalt content which is greater than 0.28% are obtained, the recycling of the associated low-grade silver and cobalt in the skarn type cupreous magnetite is realized, and the economic benefit of mineral resources is greatly increased.

Owner:武钢资源集团大冶铁矿有限公司

Skarn type iron mine drilling technology for thick-covering areas

The invention discloses a skarn type iron mine drilling technology for thick-covering areas. The technology includes the steps that a drilling tested well site is locked and is subjected to geology exploration; geological data of the well site is investigated and surveyed and estimated whether to drill or not, and drilling equipment is erected; pre-solidification treatment is performed around thedrilling site; and shaft-drilling is performed. The skarn type iron mine drilling technology for thick-covering areas has great significance in searching high-grad iron ore deposit, the areas possiblycontaining of high-grad iron ore deposit are locked, drilling exploitation is performed, the space model of the high-grad iron ore deposit is analyzed and determined, and the technology has great advantages for searching the high-grad iron ore deposit.

Owner:SHANDONG PROVINCIAL COAL GEOLOGICAL PLANNING EXPLORATION & RES INST

A sorting process for surface skarn-type hematite

ActiveCN109013077BIncrease incomeGood beneficiation indexSievingGas current separationSeparation technologyMining engineering

The invention relates to a separation technology of ground surface skarn type hematite. The technology is characterized by comprising coarse breaking work, ore washing desliming and dry and wet separation work, medium breaking work, wet type screening work and continuous two-segment water removal and grading work. According to the technology, grade of raw ore with 53 to 55% iron grade can be improved to 58% successfully without grinding and separation, the comprehensive concentrate recycling rate can reach 73 to 77%, the comprehensive iron recovery rate is much higher than the 70% recovery rate of traditional hematite mineral separation, the good mineral separation index is obtained, and in order to obtain the higher earnings, the guarantee is provided. The raw ore is subject to effectivedesliming, the slurry blockage problem can be solved, and two kinds of produced raw materials of smelting and sintering ores can be directly transported outwards.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Beneficiation method for molybdenum-containing high-zinc complex magnesium silicate altered skarn type copper ore

PendingCN114534906AAvoid inhibitionAvoid filter effectsFlotationMechanical material recoverySulfideTalc

The invention discloses a beneficiation method for molybdenum-containing high-zinc complex magnesium silicate altered skarn type copper ore. The beneficiation method comprises the steps of first-stage ore grinding, copper-molybdenum-zinc-talc mixed roughing, second-stage ore grinding, copper-molybdenum-zinc-talc mixed concentration, copper-molybdenum-zinc-talc flotation separation, molybdenum-zinc-talc reselection separation and molybdenum-zinc column type separation. According to the method, in the full flotation process, talc and other easily-floating magnesium silicate minerals are not inhibited, but are removed through centrifugal reselection, the problems of target sulfide metal mineral inhibition, tailing filtration and the like caused when easily-floating gangue is inhibited by a macromolecular inhibitor in traditional mineral separation are solved, and the recovery rate of target sulfide multi-metal minerals is increased to the maximum extent.

Owner:KUNMING METALLURGY INST

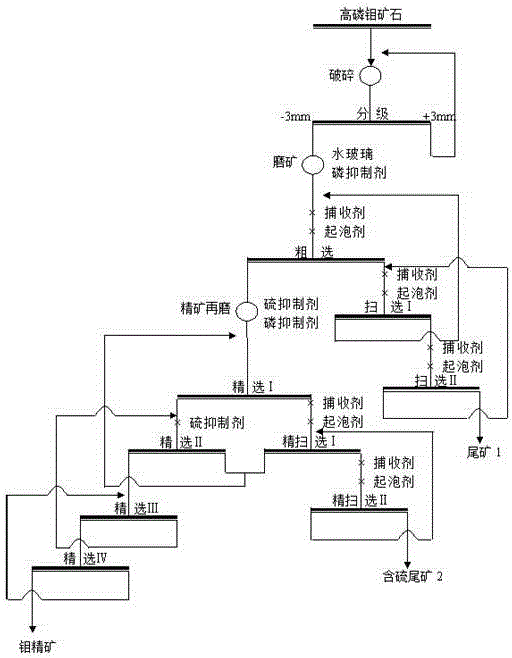

A method for reducing phosphorus by physical beneficiation of skarn-type high-phosphorus molybdenum ore

The invention discloses a physical concentration and phosphorus reduction method for a skarn-type high-phosphorus molybdenum ore. The physical concentration and phosphorus reduction method comprises the following steps of (1) crushing, namely crushing raw ores by using a crusher, sieving, and returning a +3mm-grade raw ore to crush until the particle size of the raw ore is up to the -3mm grade; (2) grinding the ores, namely adding the crushed -3mm-grade raw ore into raw ore grinding equipment to carry out closed-circuit ore grinding operation, meanwhile, adding 500-1000g / t of water glass and 250-800g / t of a phosphate mineral inhibitor into a grinding machine, and grinding the raw ore until the particle size is up to the -0.075mm grade and the phosphorus content is up to 55-75%; (3) carrying out roughing operation; (4) carrying out scavenging operation; (5) regrinding a roughed molybdenum concentrate, namely adding 100-280g / t of a sulfur inhibitor and 150-300g / t of a phosphate mineral inhibitor to regrind the roughed molybdenum concentrate in roughed molybdenum concentrate regrinding equipment until the particle size is up to the -0.045mm grade and the phosphorus content is up to 70-95%; and (6) carrying out fine flotation operation. By using the physical concentration and phosphorus reduction method, the phosphorus content of a molybdenum concentrate product can be reduced to be lower than the standard, and a high-quality molybdenum concentrate product can be obtained.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com