Sorting method of skarn type low-grade copper zinc ore

A low-grade, skarn technology, used in chemical instruments and methods, solid separation, wet separation, etc., can solve the problem of unsuitable use of chemicals, equipment or mineral processing technology, affecting the recovery rate of target minerals, and increasing slurry viscosity and other problems, to achieve the effect of improving the comprehensive utilization rate, improving the comprehensive recovery rate of minerals, and reducing the dosage of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

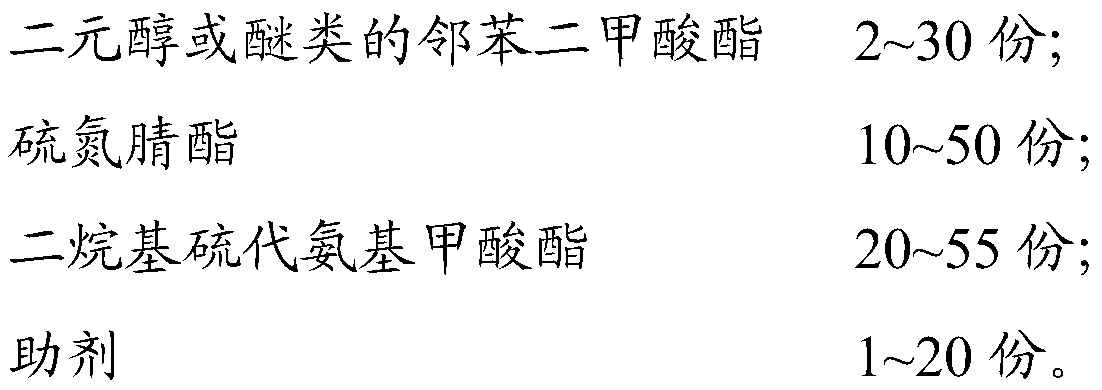

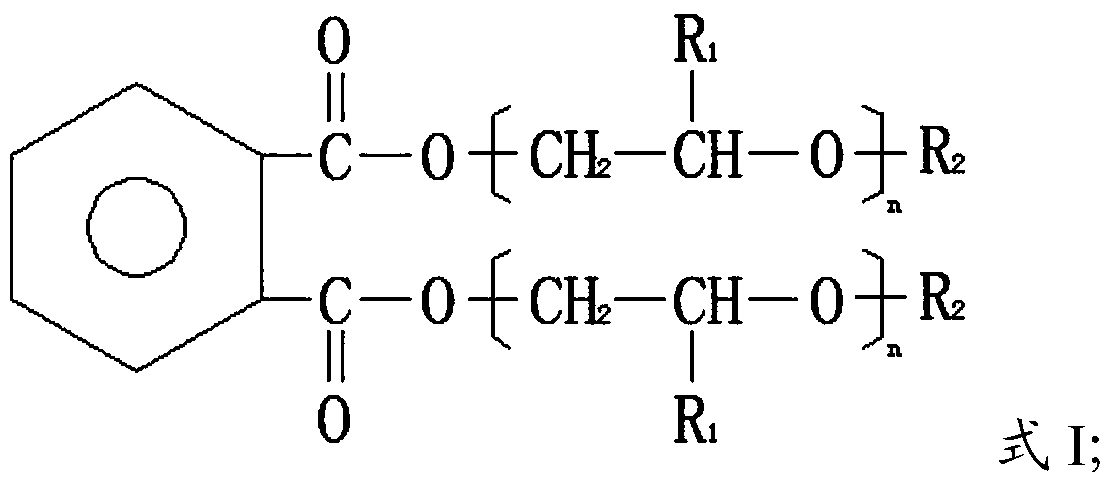

[0056] In the present invention, the preparation method of the low-temperature-resistant composite collector preferably includes the following steps: adding glycol or ether phthalate, thionitrile, and dialkylthiocarbamic acid The ester is mixed with the auxiliary agent to obtain a low temperature resistant composite collector. In the present invention, the mixing order of the phthalate, thionitrile, dialkylthiocarbamate and auxiliary agent of the glycol or ether is not particularly limited, and any mixing order can be adopted. The present invention does not specifically limit the mixing method, and it is sufficient to use a mixing method well known to those skilled in the art. In the present invention, the mixing method is preferably stirring; the mixing time is preferably 8-15 min. Through the mixing, the present invention forms a homogeneous, transparent, oily low-temperature resistant composite collector, ensuring the homogeneity and stability of the low-temperature resista...

Embodiment 1

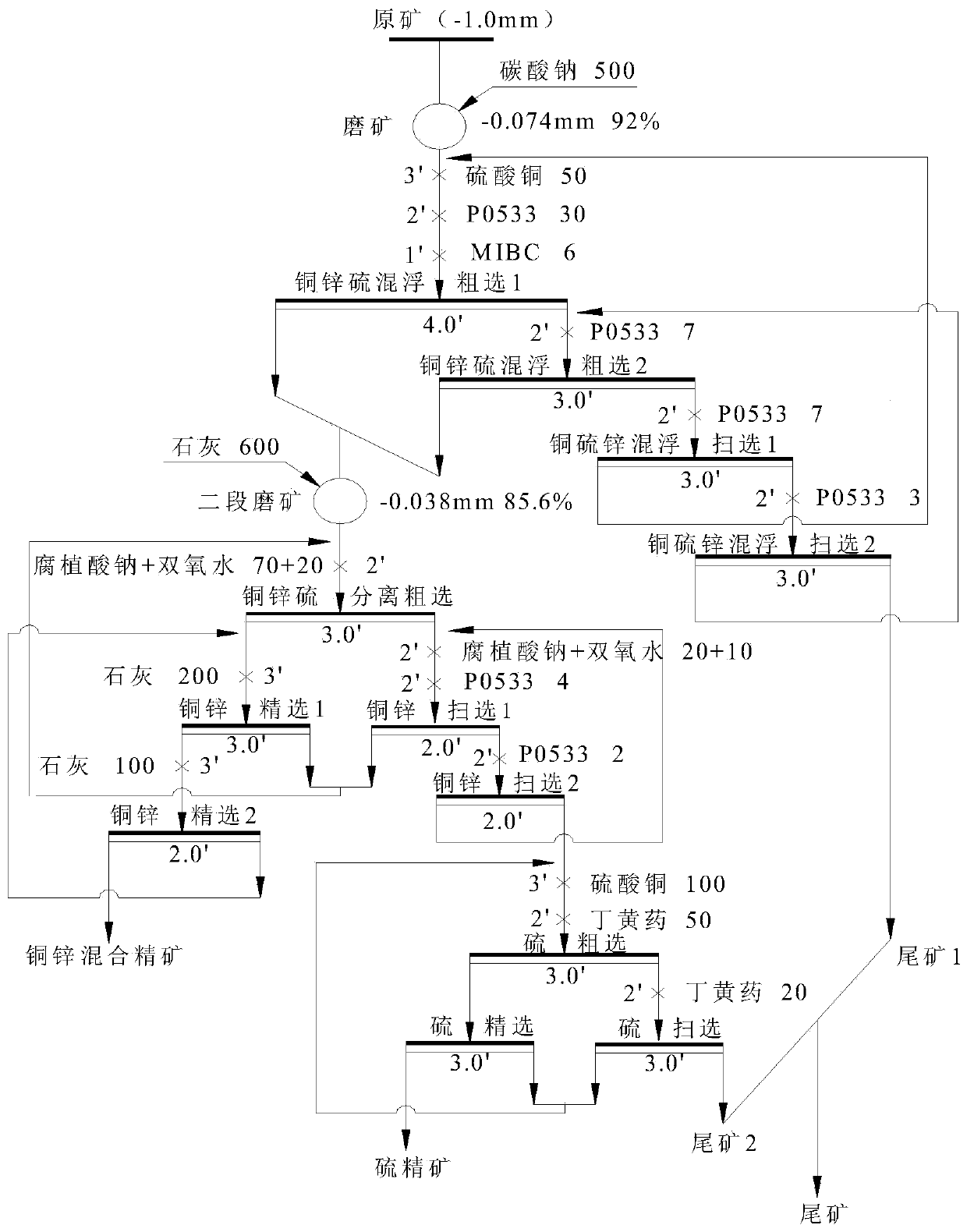

[0076] Grind the raw ore (skarn type low-grade copper-zinc ore), control the mass concentration of the ore to 67%, add sodium carbonate (500g / t) during the grinding process, and grind to a particle size of more than 92% It is less than 0.074mm to obtain the rough flotation ore;

[0077] The rough flotation raw ore is subjected to copper-zinc-sulfur mixed flotation: 50g / t copper sulfate is added to the rough flotation raw ore and stirred for 3min, 30g / t P0553, stirred for 3min, and 6g / t MIBC (methyl isobutyl Base methanol), set the mass concentration of the coarse beneficiation slurry to 30%, perform the first roughing to obtain a copper-zinc-sulfur mixed concentrate 1, and add 7g / tP0553 to the tailings obtained from the first roughing for the second roughing, Obtain the copper-zinc-sulfur mixed concentrate 2 and the copper-zinc-sulfur mixed coarse beneficiation tailings, combine the copper-zinc-sulfur mixed concentrate 1 and the copper-zinc-sulfur mixed concentrate 2 to obtain a ...

Embodiment 2

[0084] Grind the raw ore (skarn type low-grade copper-zinc ore), control the mass concentration of the ore to 67%, add sodium carbonate (500g / t) during the grinding process, and grind to a particle size of more than 92% It is less than 0.074mm to obtain the rough flotation ore;

[0085] Perform mixed flotation of the rough flotation ore: add 50g / t copper sulfate to the rough flotation ore and stir for 3min, add 25g / t P0553, stir for 3min, add 6g / t MIBC, set the rough ore slurry The first roughing process is carried out to obtain a copper-zinc-sulfur mixed concentrate 1, and 10g / t P0553 is added to the tailings obtained from the first roughing process for the second roughing process to obtain a copper-zinc-sulfur mixed concentrate 2. And copper-zinc-sulfur mixed coarse-dressing tailings; combining the copper-zinc-sulfur mixed concentrate 1 and copper-zinc-sulfur mixed concentrate 2 to obtain a copper-zinc-sulfur mixed concentrate; adding the copper-zinc-sulfur mixed coarse-dressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com