Patents

Literature

109 results about "Pyroxene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

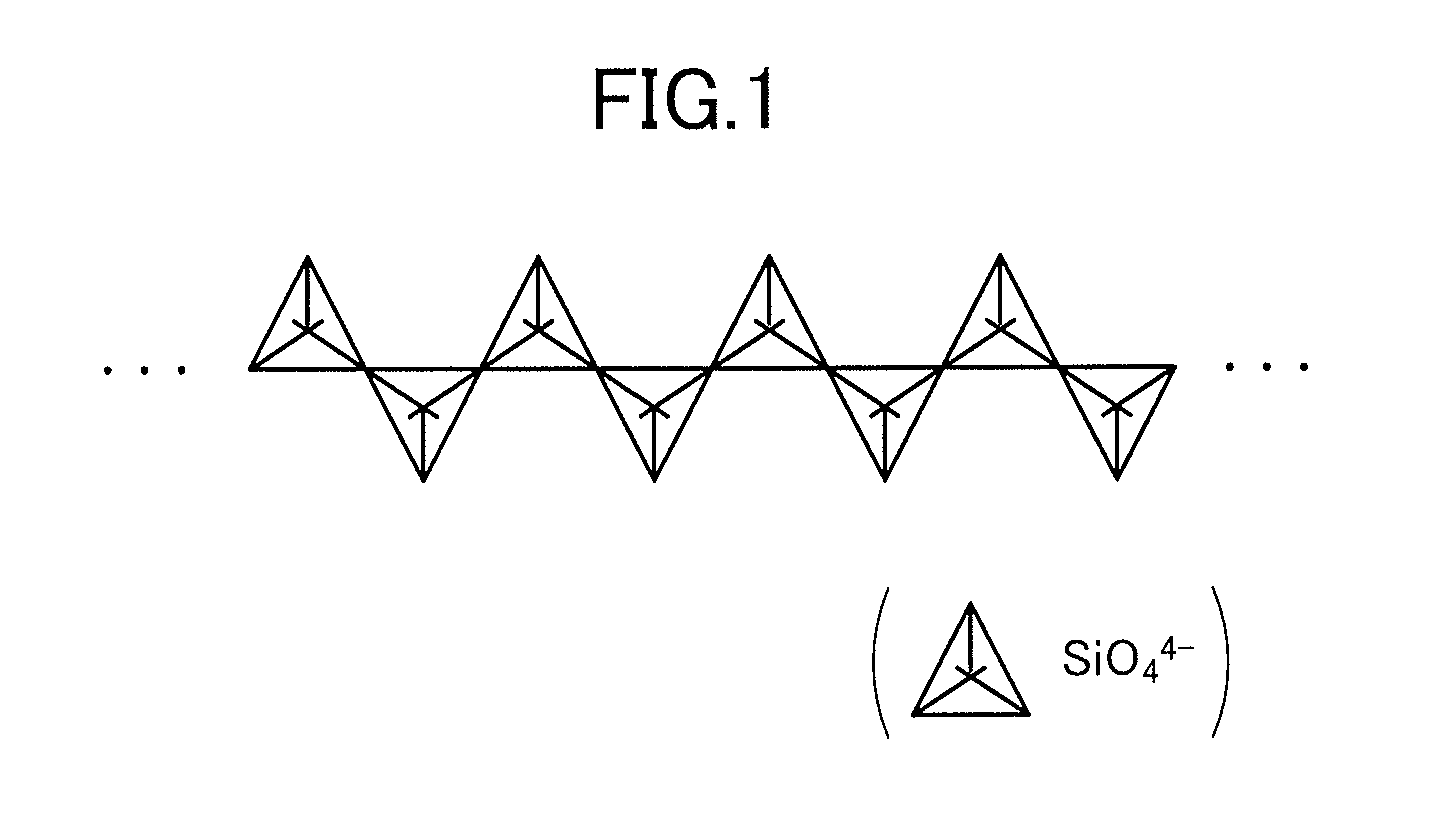

The pyroxenes (commonly abbreviated to Px) are a group of important rock-forming inosilicate minerals found in many igneous and metamorphic rocks. Pyroxenes have the general formula XY(Si,Al)₂O₆, where X represents calcium, sodium, iron (II) or magnesium and more rarely zinc, manganese or lithium, and Y represents ions of smaller size, such as chromium, aluminium, iron (III), magnesium, cobalt, manganese, scandium, titanium, vanadium or even iron (II). Although aluminium substitutes extensively for silicon in silicates such as feldspars and amphiboles, the substitution occurs only to a limited extent in most pyroxenes. They share a common structure consisting of single chains of silica tetrahedra. Pyroxenes that crystallize in the monoclinic system are known as clinopyroxenes and those that crystallize in the orthorhombic system are known as orthopyroxenes.

Method for producing microcrystalline glass-ceramics composite board with novel microcrystalline phase

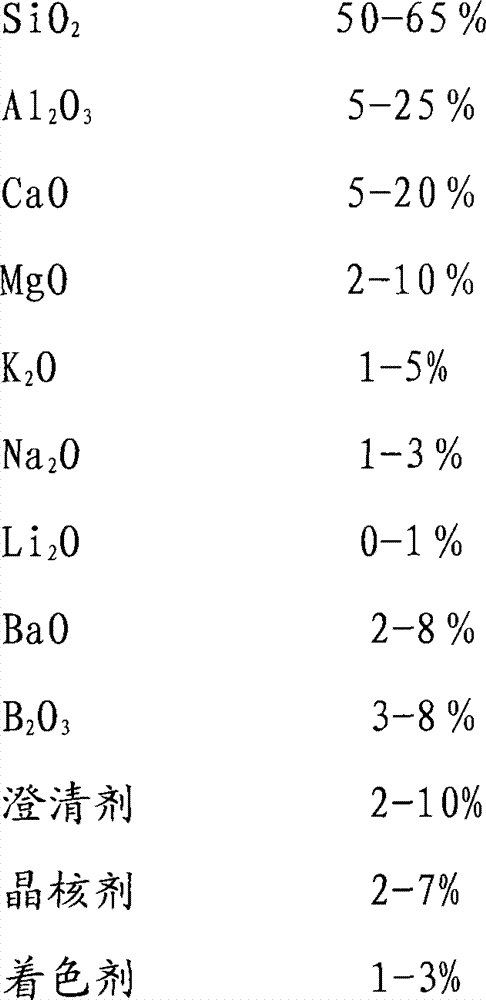

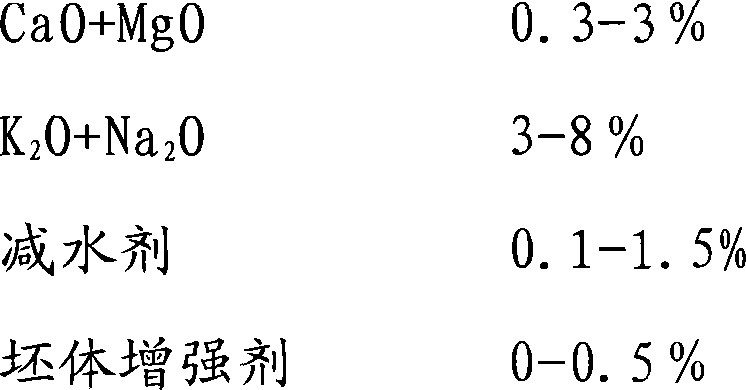

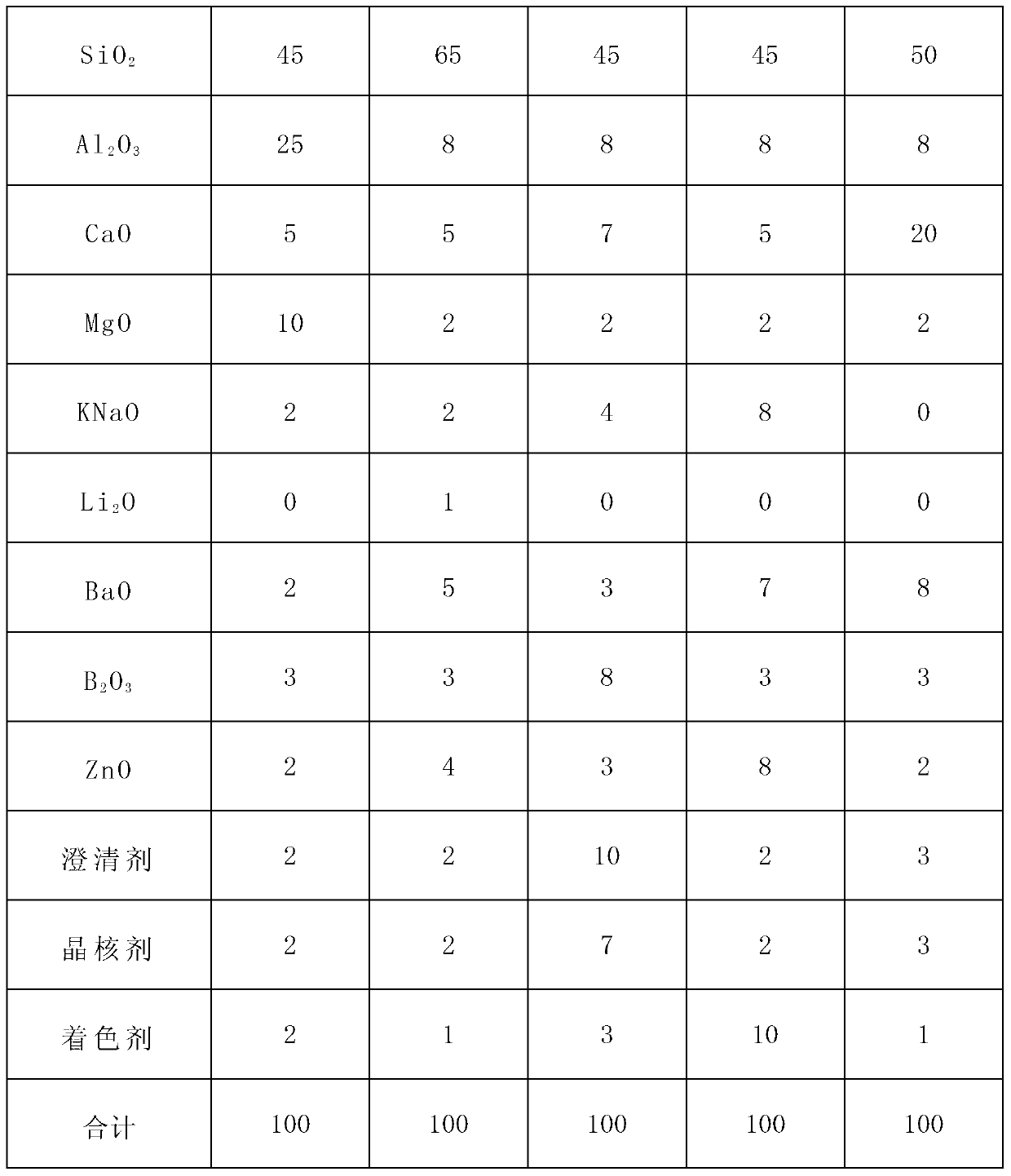

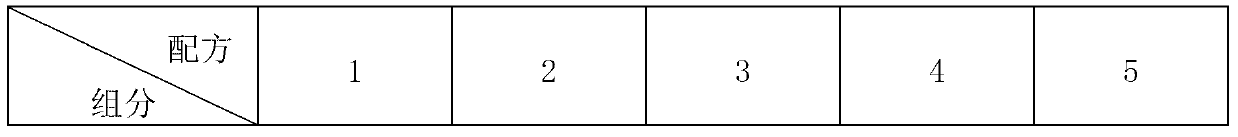

The invention discloses a method for producing a microcrystalline glass-ceramics composite board with novel microcrystalline phase, which is characterized in that the composite board takes diopside-containing pyroxene as microcrystalline phase and the production method thereof comprises the steps as follows: firstly, microcrystalline glass granules are prepared; according to the weight percentage, the microcrystalline glass consist of 50-65% of SiO2, 5-25% of Al2O3, 5-20% OF CaO, 2-10% of MgO, 1-8% of K2O+NaO, 0-1% of Li2O, 0-8% of BaO, 0-8% of B2O3 and the balance of nucleating agent, clarifier and corant with the content ranging from 0 to 20%; secondly, a ceramic palette board is prepared; according to the weight percentage, the ceramic palette board comprises 66-75% of SiO2, 13-23% of Al2O3, 0.3-3% of CaO+MgO, 3-8% of K2O+Na2O and the balance of 0-2% of auxiliary raw material; finally, the raw materials are distributed, sintered and post-processed, thus gaining the finished product of the microcrystalline glass-ceramics composite board. The method has the advantages of low production cost, high product quality, good appearance effect, and the like.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

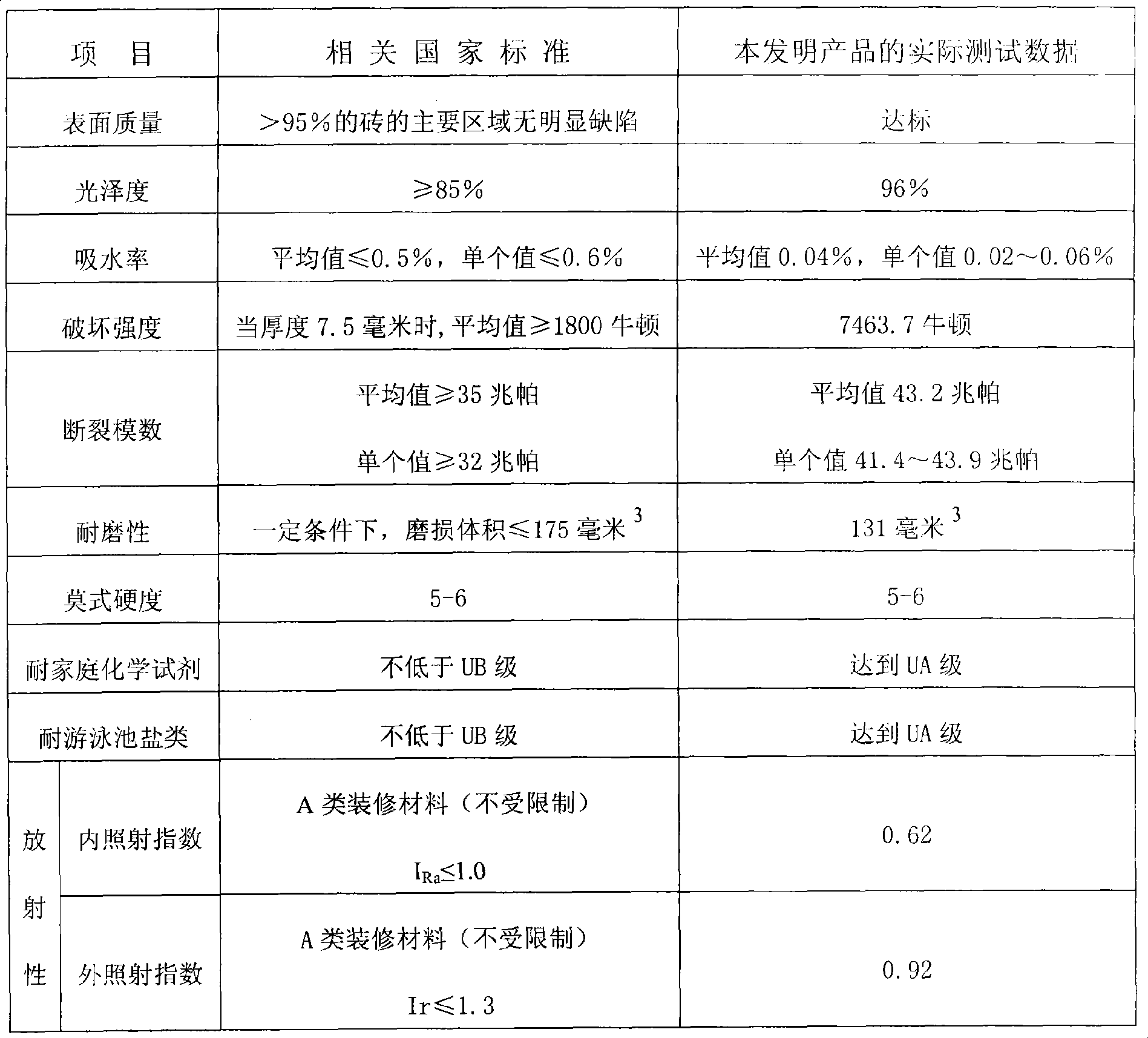

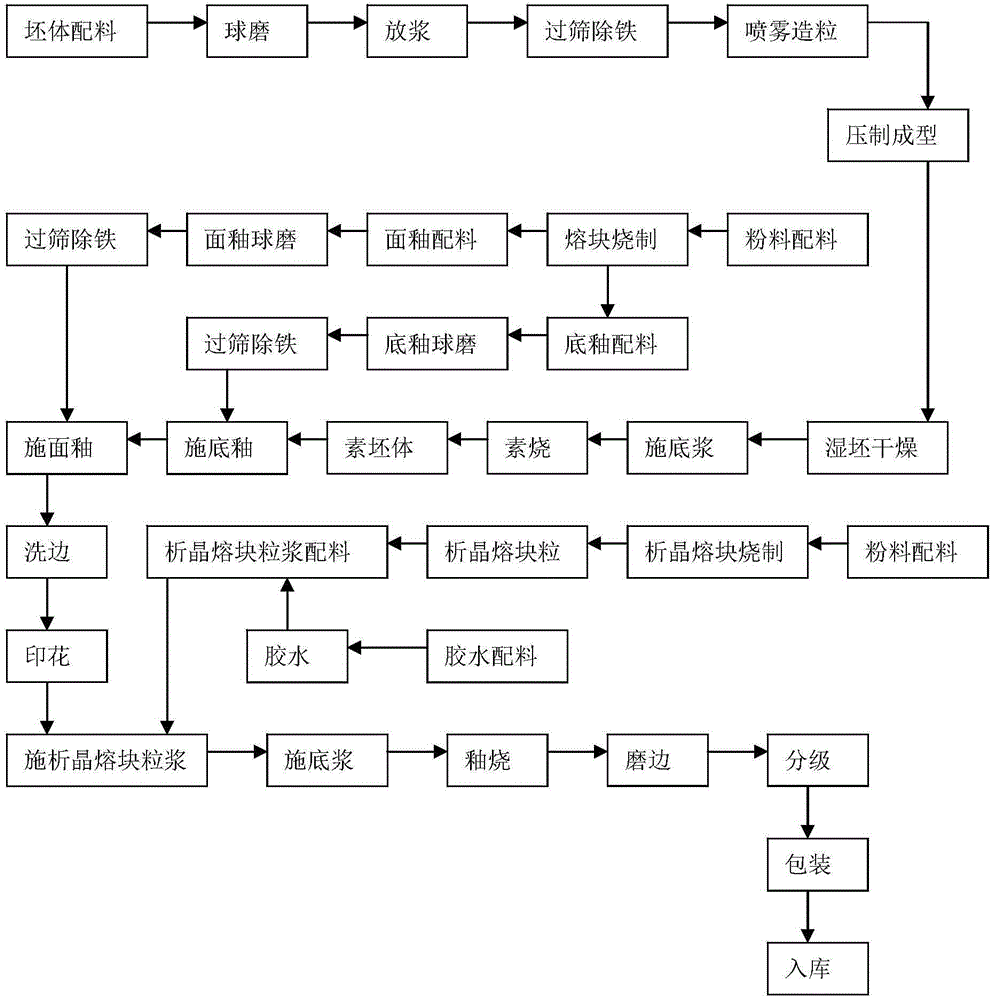

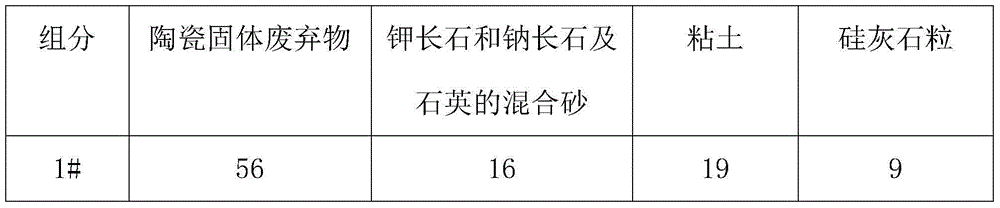

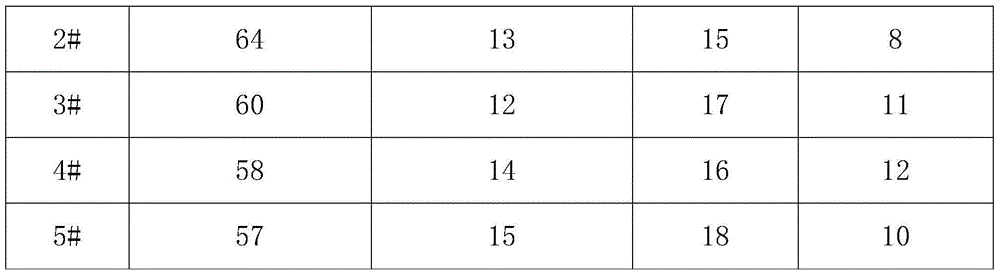

Glazed tile manufactured by using ceramic waste and having broken diamond sand flashing starlight on surface, and preparation method thereof

The present invention relates to a glazed tile manufactured by using ceramic waste and having broken diamond sand flashing starlight on the surface, and a preparation method thereof. According to the present invention, on the base of no major change on the existing glazed tile production process, the green body formula composition, the bottom glaze clinker composition, the surface glaze clinker composition, the bottom glaze formula composition, the surface glaze formula composition, the crystallization clinker composition, the particle size optimizing, the glue formula composition, the crystallization clinker particle slurry formula composition, and process parameters for applying bottom glaze, applying surface glaze and applying crystallization clinker particle slurry are importantly adjusted and optimized, such that the glaze surface of the prepared the glazed tile product likes the matte state through being viewed under the natural light, the slight concave-convex feeling is provided when touching through finger, the glaze surface is smooth and likes jade, the glaze surface crystal such as small quartz grains, pyroxene particles, fine mica sheets and the like in the granulated sugar-like aplite can emit broken diamond sand flashing starlight under side light or light irradiation so as to provide the poetry and painting feeling, the printing pattern texture is delicate, the stimulated stone is vivid, the visual effect is unique, and the whole art sense is strong; and the technology has strong universal property, and is easy to spread in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

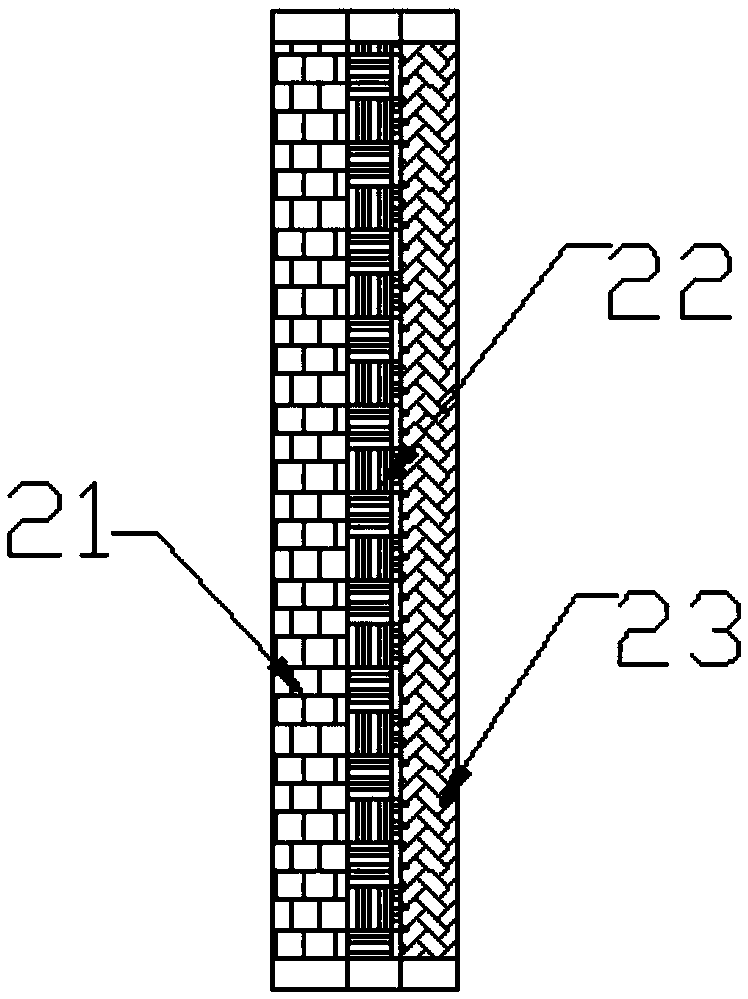

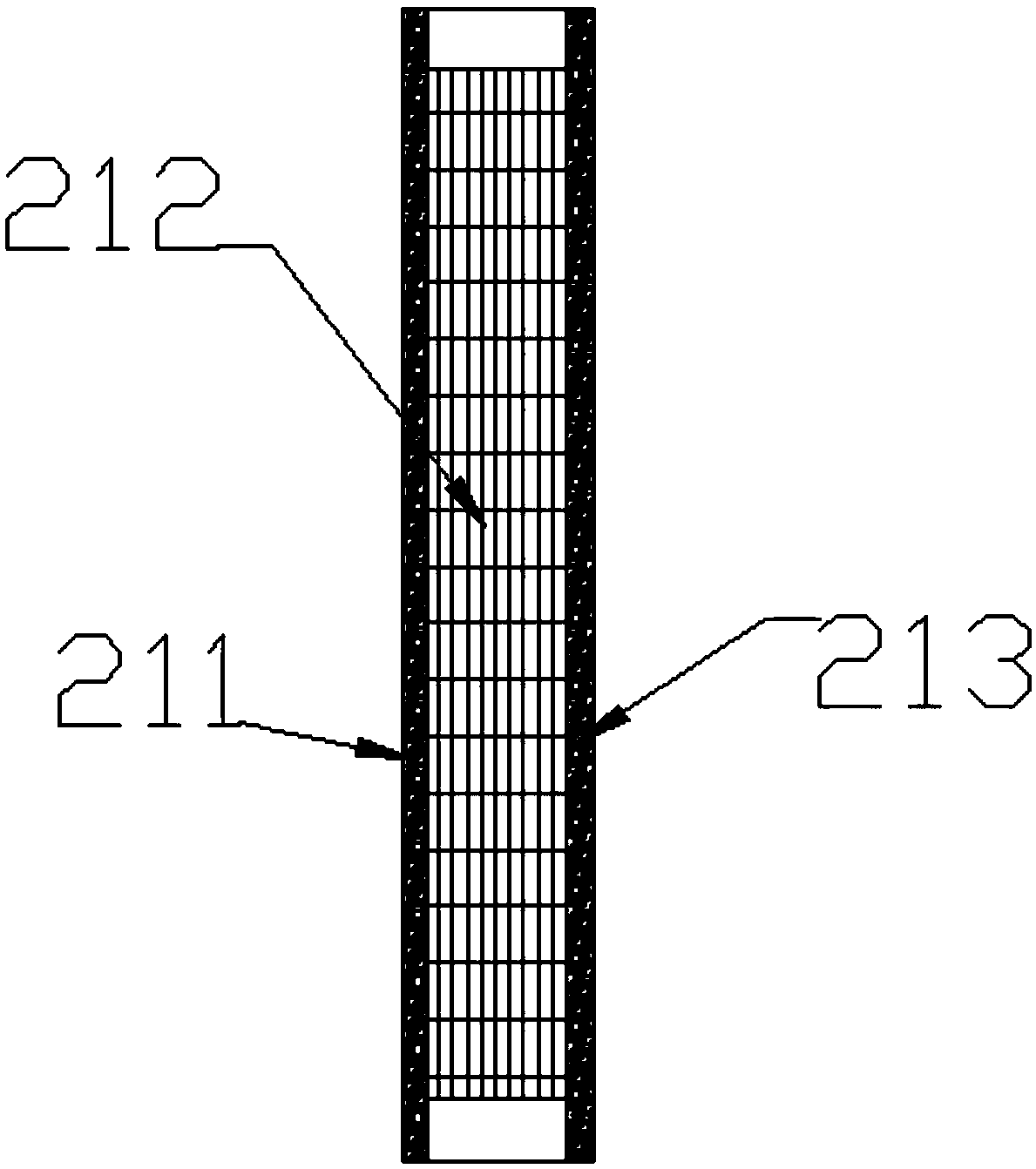

Novel microcrystal glass ceramic composite board and preparation method thereof

The invention discloses ingredients, manufacturing techniques and technological parameters of a novel microcrystal glass ceramic composite board. The novel microcrystal glass ceramic composite board is characterized in that the ingredients contain no zinc oxide. The ingredients comprise 50-65% of SiO2, 5-20% of Al2O3, 5-20% of CaO, 5-20% of MgO, 2-8% of K2O+Na2O, 0-1% Li2O, 2-8% of NaO, 3-8% B2O3 and balanced 5-20% of clarifying agent, nucleation agent and coloring agent. A pyroxene microcrystal phase is separated out from glass ceramics, the devitrification breaks through particle boundaries, and crystallization textures in various patterns are grown. The novel microcrystal glass ceramic composite board achieves purposes of low cost and high decorative art levels.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

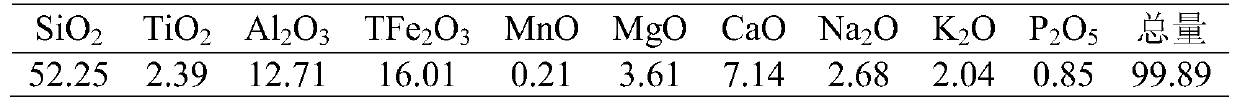

Production method for continuous basalt fiber

ActiveCN106396421AImprove accuracyImprove rapid effectivenessGlass furnace apparatusTO-18Chemical composition

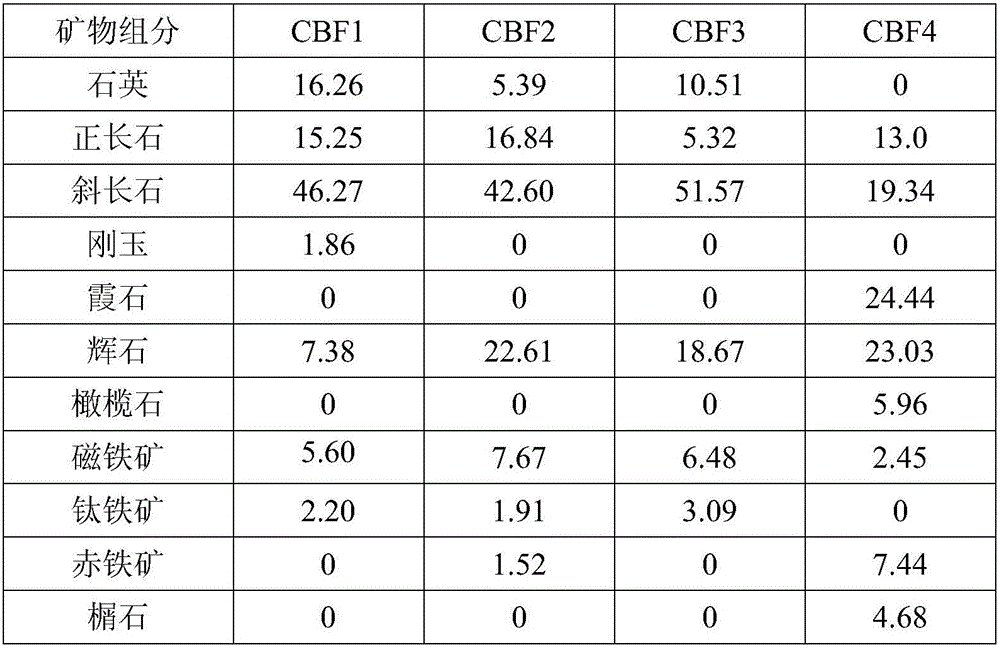

The invention discloses a production method for continuous basalt fiber. The production method is characterized by comprising the following steps: 1) material selection, i.e., comprehensive determination of raw basalt materials for production of the continuous basalt fiber based on the chemical components and mineral components of basalt: analyzing the content of SiO2 in the chemical components of basalt, selecting basalt with SiO2 content of 48 to 63% and with saturated or oversaturated SiO2, analyzing the mineral component of basalt, removing basalt containing olivine and selecting basalt with mineral components consisting of, by weight, 15 to 27% of quartz, 10 to 18% of orthoclase, 30 to 50% of plagioclase or 45 to 60% of plagioclase, and 15 to 30% of pyroxene; and 2) fusing and fiber molding of the selected raw basalt materials so as to obtain the continuous basalt fiber. The production method provided by the invention can substantially improve accuracy in basalt selection and optimize the fusing process and fiber molding process of a basalt melt, enables the basalt melt to be easy to homogenize and provides effective bases and criteria for production of the continuous basalt fiber.

Owner:SOUTHEAST UNIV

Light-color cast iron paint with high aluminium polycrystalline composite aggreagte

InactiveCN101088660AImprove densification performanceIncrease viscosityFoundry mouldsFoundry coresMulliteStone dust

The light-color cast iron paint with high aluminum polycrystalline composite aggregate consists of high alumina powder with 70-85 wt% Al2O3 20-40 wt%, mullite powder 10-25 wt%, magnesia powder 3-10 wt%, superfine flux of pyroxene or La / Sr RE of 100-500 micron granularity 6-10 wt%, crystal nucleus agent of nanometer level Al, Zr or Cr powder 0.5-3.5 wt%, organic adhesive rosin or resin 1-3 wt%, bentonite as suspending agent 1-6 wt% and solvent of ethanol or isopropanol 30-40 wt% mixed together. The paint of the present invention is coated to cast iron parts for machine tool, and can obtain surface quality higher than that of black graphite paint and improve operation environment.

Owner:SHENYANG RES INST OF FOUNDRY

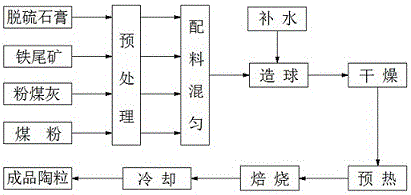

Desulfurized gypsum and iron tailings ceramsite and preparation method thereof

InactiveCN105669243AIncrease the ratio of ingredientsHigh strengthCeramic materials productionCeramicwareCalcium silicateResource utilization

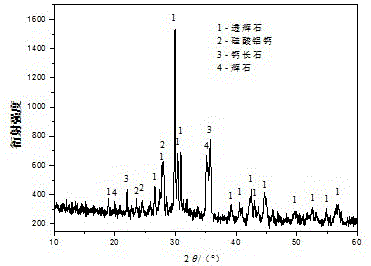

The invention relates to desulfurized gypsum and iron tailings ceramsite and a preparation method thereof. The preparation method comprises the following steps: pretreatment of raw materials, uniform mixing of burdens, pelletizing, drying, preheating, calcination, and cooling. The raw materials comprise 10-20 parts of desulfurized gypsum, 50-60 parts of iron tailings, 20-30 parts of fly ash, and 0-6 parts of coal dust; the main phases of the prepared ceramsite are diopside (CaMgSi2O6), aluminum calcium silicate (CaAl2Si2O8), anorthite (CaMgSi2O6) and pyroxene (Ca4Mg3FeSi8O24); and the diopside and anorthite crystals are in a plate shape or a plate cylindrical shape. According to the invention, burden proportion of the desulfurized gypsum is increased, resource utilization rate is increased; at the same time, the ceramsite intensity is increased, the ceramsite water absorption rate is reduced, the preparation method is simple, operation is convenient, and production cost is low.

Owner:WUHAN UNIV OF SCI & TECH

Precursor compositions for ceramic products

InactiveUS7648934B2Broad sinteringIncrease resistanceFluid removalDrilling compositionPhysical chemistryUltimate tensile strength

A precursor composition for the production of granulated ceramic material to be used as hydraulic fracture proppant, comprises 20 to 55% pyroxene, and 15 to 50% olivine. The remaining component is quartz and / or feldspar. The precursor composition can be sintered in a broader temperature range. The resulting proppant material shows high mechanical strength and resistance to acids, and also higher stability under hydrothermal conditions than the prior art.

Owner:ILEM RES & DEV ESTAB

Medium-temperature matte glaze and preparation method thereof

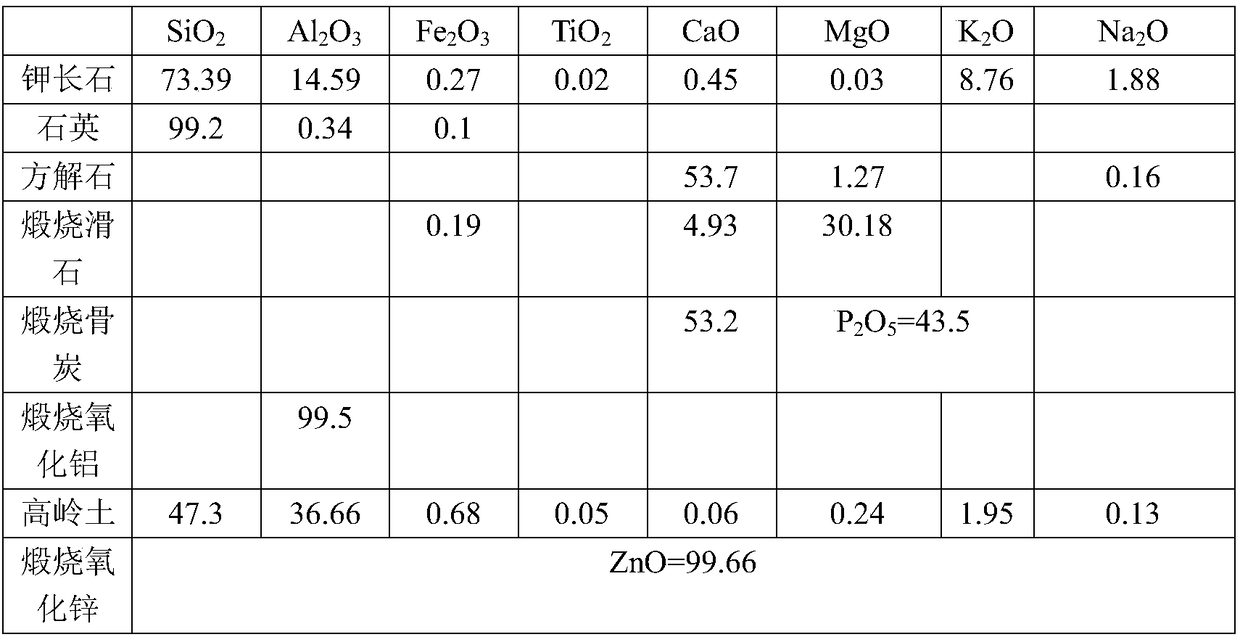

The invention discloses medium-temperature matte glaze. The medium-temperature matte glaze is prepared from the following components: potassium feldspar powder, quartz powder, calcite powder, calcinedtalc powder, calcined zinc oxide, calcined bone carbon powder, calcined alumina, kaolin and a colorant. A preparation method of the medium-temperature matte glaze comprises the following steps: materials are prepared in accordance with the components in parts by mass, wet ball milling is preformed, and glaze is obtained; the glaze is treated by a 120-mesh sieve after being discharged from a ballmill, glaze slurry is obtained, and water and an electrolyte are added to adjust the concentration and thixotropy of the glaze slurry respectively; a glaze body is immersed in the glaze slurry and dried and enters a roller kiln to be sintered. According to the medium-temperature matte glaze, dense pyroxene crystals are prepared from the raw materials under the condition of medium temperature to generate matt; besides, phosphorus pentoxide introduced by adding the bone carbon powder can form a silicate glass phase and a phosphate glass phase with silicon dioxide and metal oxide, the two phasesare not soluble mutually and have different dissolving capacities to the colorant, color differences are produced, and ceramic products of various colors can be obtained.

Owner:HUNAN HUALIAN CHINA IND

Process for extracting lithium from lithium pyroxene concentrate by using fluorine chemistry

InactiveCN102417995AReduce production energy consumptionHigh Lithium Extraction RateProcess efficiency improvementSlagPotassium

The invention provides a process for extracting lithium from lithium pyroxene concentrate by using fluorine chemistry. The process comprises the following steps of: firstly, uniformly mixing raw materials, such as alpha-lithium pyroxene concentrate powder, an additive and sulfuric acid according to weight ratio of 1:(0.1-2):(0.5-5); secondly, feeding the uniformly-mixed raw materials into a reactor and finishing the reaction and timely extracting gas generated in the reaction process; thirdly, leaching reaction slag retained in the reactor with water and carrying out solid-liquid separation on the reaction slag to obtain a sulfate solution and remove ionic impurities in the solution, such as potassium, sodium, aluminum, magnesium, calcium, ferrum and the like; and fourthly, after the impurities are filtered, concentrating residual solution to obtain a precipitation containing lithium ions, filtering to obtain a rough lithium salt product and producing refined lithium salt according to the requirement. The process disclosed by the invention has the advantages of low reaction temperature, low production energy consumption and high lithium extraction rate; the lithium can be directly extracted from alpha-lithium pyroxene without crystal form transformation; and various valuable components of the lithium pyroxene can be integrally utilized while the lithium salt is produced.

Owner:SHANDONG RUIFU LITHIUM IND

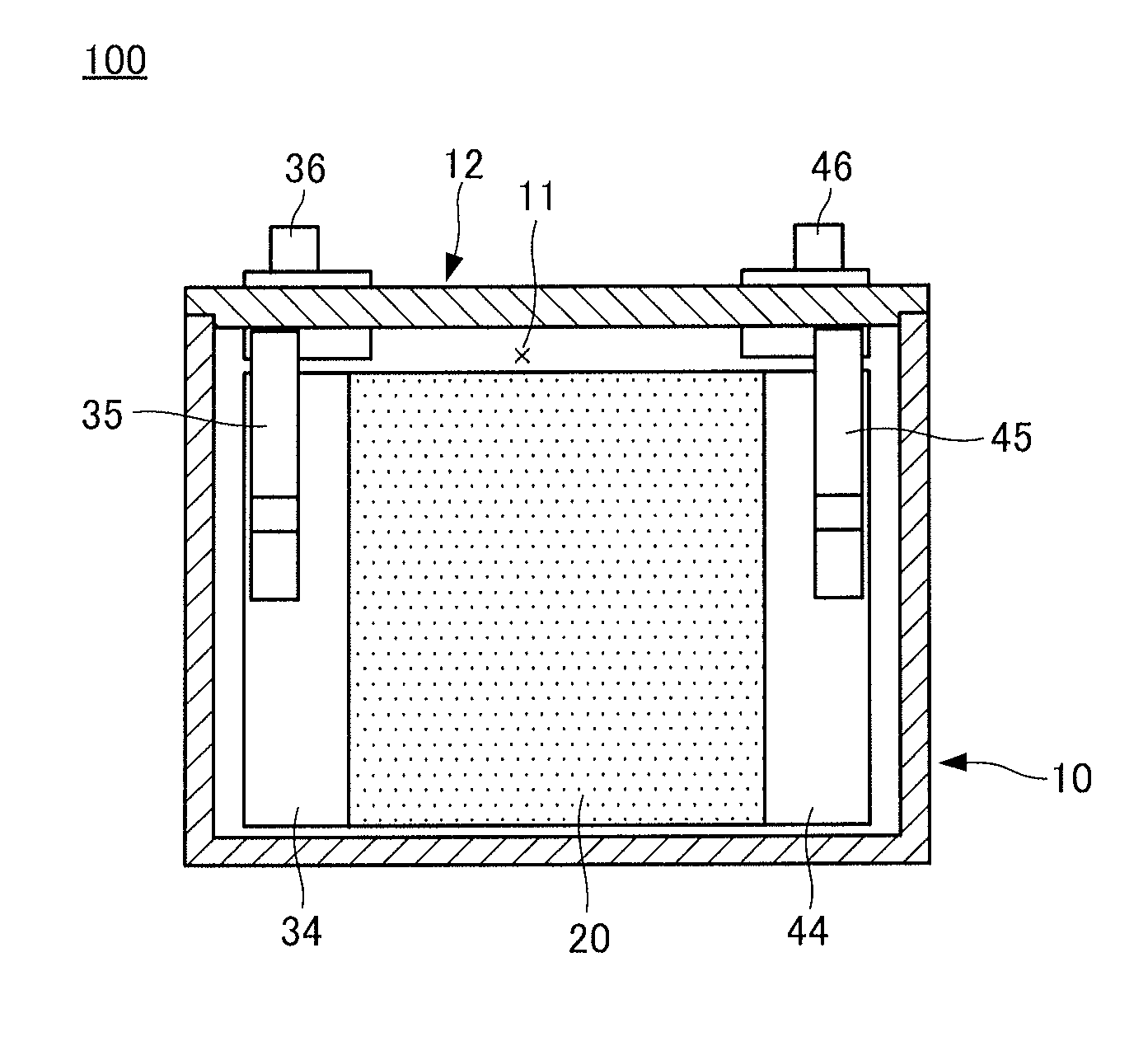

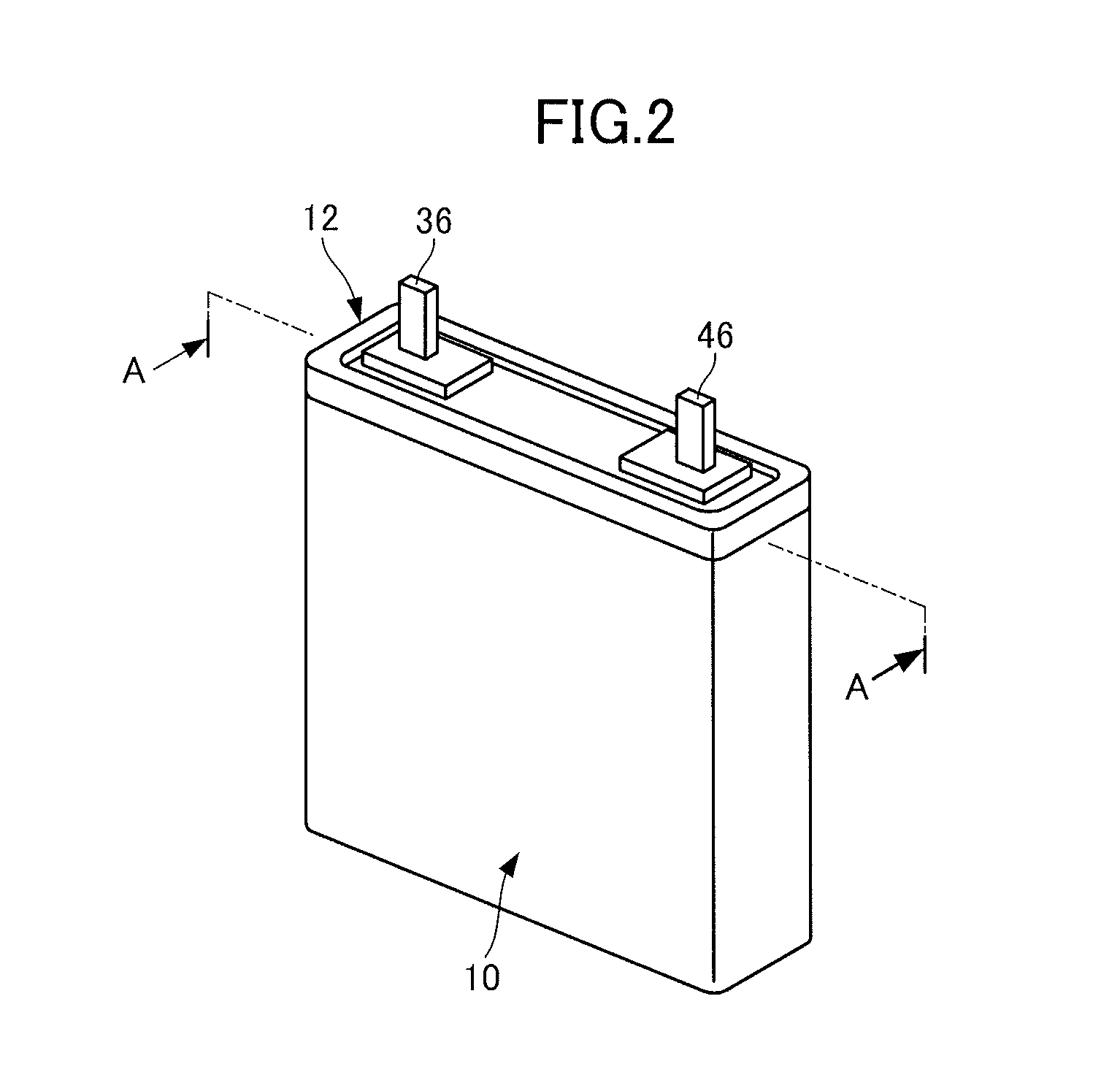

Negative electrode for a secondary battery, a secondary battery, a vehicle and a battery-mounted device

InactiveUS20150228965A1Large capacityAluminium silicatesAlkaline-earth metal silicatesEngineeringBattery cell

The present invention provides a negative electrode for a secondary battery having a higher capacity than conventional batteries and the secondary battery having the negative electrode incorporated therein. The negative electrode for the secondary battery includes a silicate having a pyroxene structure and represented by a general formula ApM2-pX2O6, wherein “A” represents at least one species selected from among a group of Na, Ca, Fe, Zn, Mn and Mg, “M” represents at least one species selected from among a group of transition metal elements, Al and Mg, where one of the transition metal elements being an indispensable element of “M”, “A” and “M” represent same elements or different elements, “p” represents a number satisfying 0<p<2, “X2” represents Si2 or AlqSi2-q, and “q” represents a number satisfying 0<q<2.

Owner:TOYOTA JIDOSHA KK

Process and apparatus for hot-forging synthetic ceramic

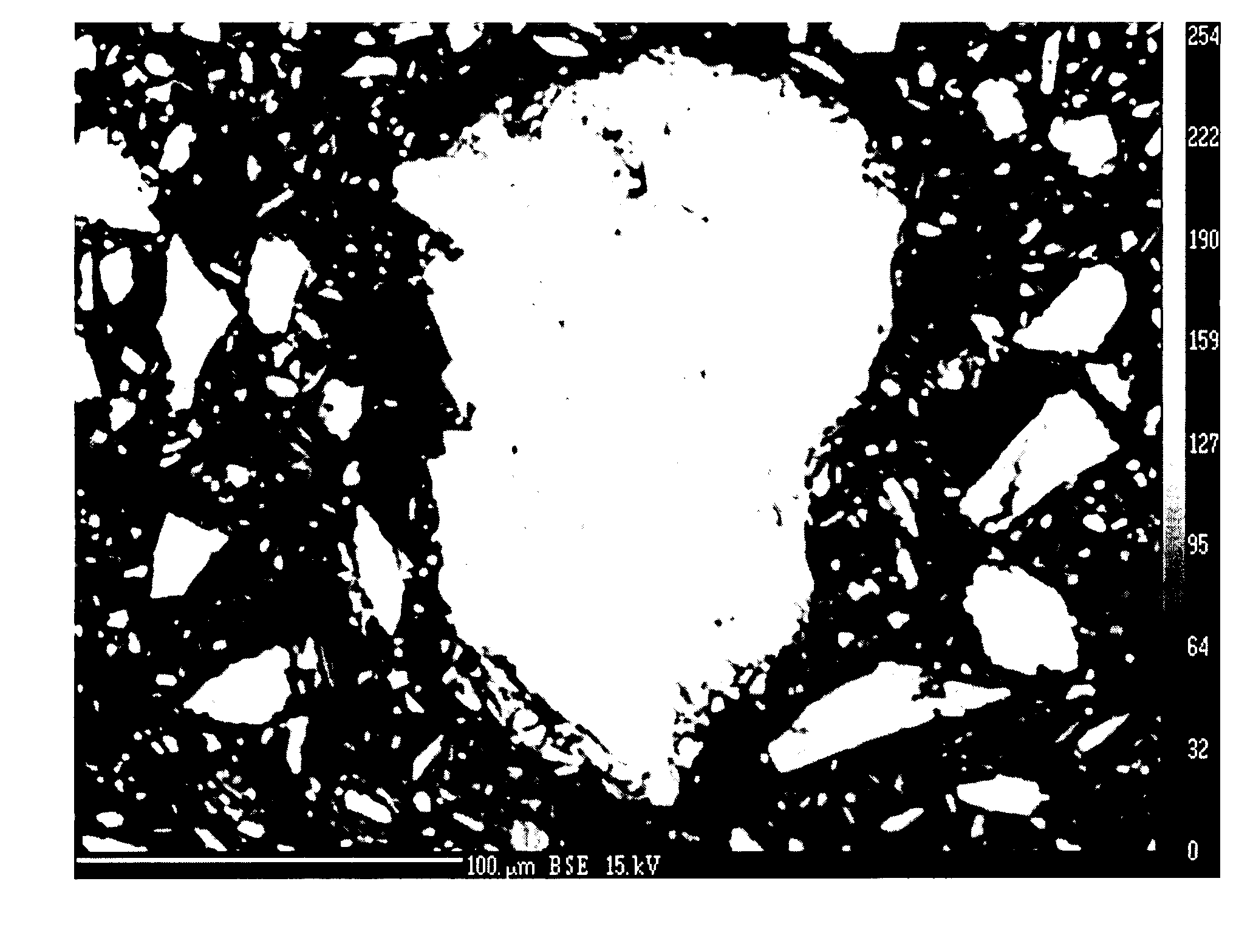

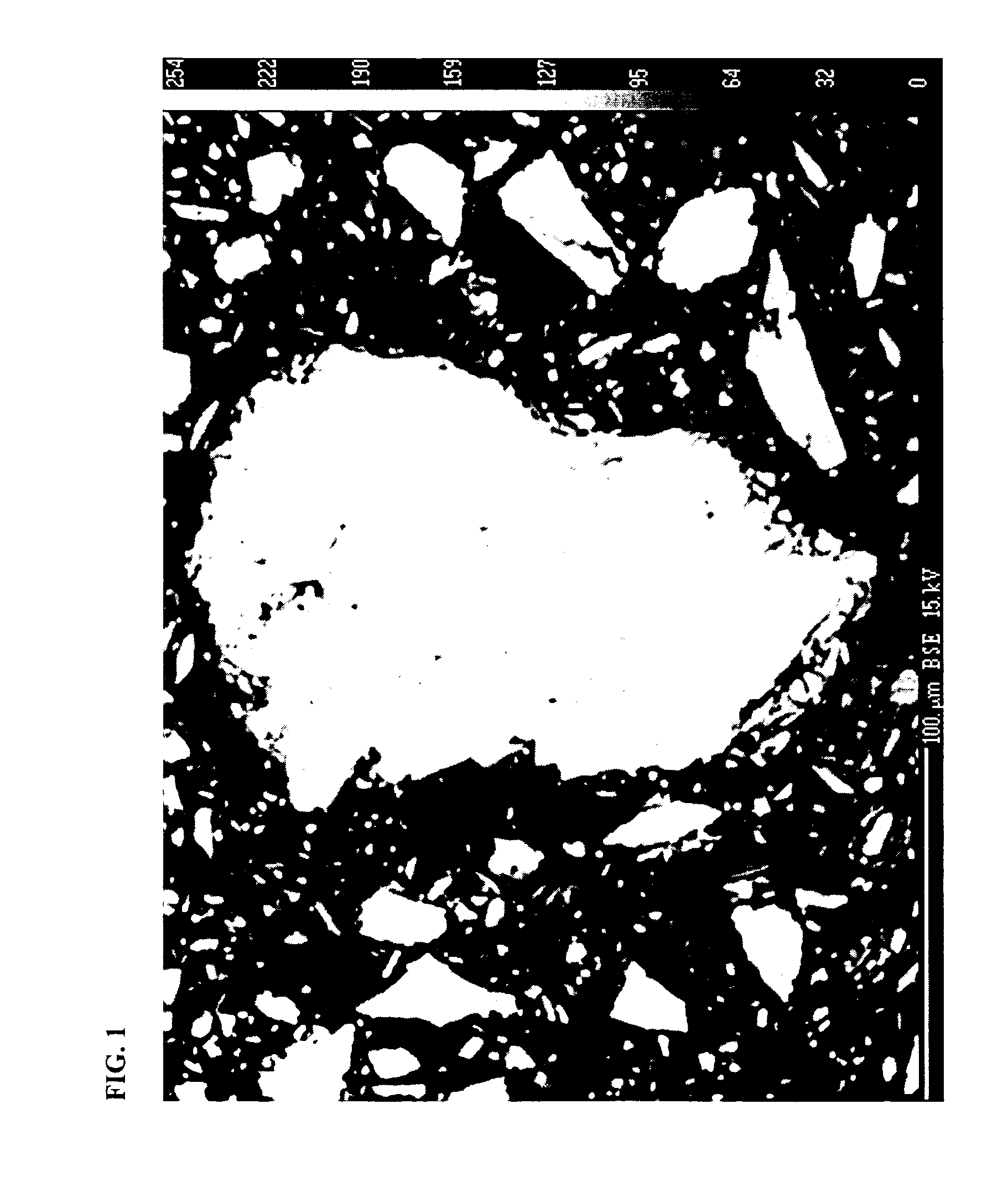

InactiveUS20080090720A1Less porous and more impermeableLight weightPolycrystalline material growthCeramic materials productionCeramicCrystallization

The embodiments of the invention are directed to a synthetic ceramic comprising pyroxene-containing crystalline phase, a clast, and a glass phase, wherein at least a portion of the synthetic ceramic is plastically deformable in a certain temperature range. Other embodiments of the invention relate to a method of making a synthetic ceramic, comprising heating a green ceramic material to 900-1400° C., to a temperature sufficient to initiate partial melting of at least a portion of the green ceramic material, transferring the heated green ceramic material to a press, pressing the heated green ceramic material in a die at 1,000 to 10,000 psi, and transferring the heated, pressed green ceramic material to a furnace for cooling to form the synthetic ceramic.

Owner:CERAMEXT LLC

Novel microcrystalline glass ceramic composite board and preparation method thereof

The invention relates to the technical field of building materials and discloses a novel microcrystalline glass ceramic composite board and a preparation method thereof. Calcium oxide and magnesium oxide are introduced into microcrystalline glass and simultaneously a small amount of zinc oxide is added. The microcrystalline glass precipitates a pyroxene crystalline phase and simultaneously remains a crystalline phase of zinc silicate, the crystallization breaks through the grain boundary, and crystallized textures with various patterns are grown. The cost is reduced, and simultaneously air holes in the surface of the microcrystalline glass ceramic composite board are easily controlled and greatly reduced by utilizing the characteristics of large surface tension and low viscosity of the zinc oxide, so that the defect of poor exhausting property of the microcrystalline glass adopting pyroxene as the crystalline phase is avoided; since the novel microcrystalline glass ceramic composite board adopts once firing, the firing period can be shortened to be 60 minutes, the bottleneck of twice firing and long firing period in the traditional process is broken through, the energy consumption is greatly reduced, and the current low-carbon and environment-friendly slogans are responded.

Owner:佛山瑭虹釉料科技有限公司

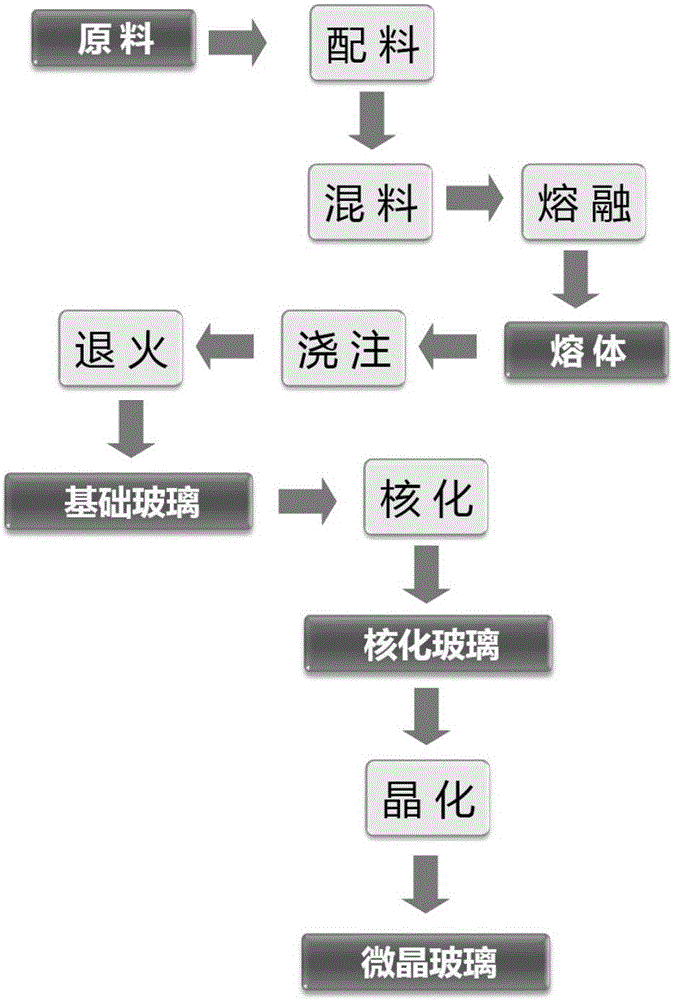

Method for compounding microcrystalline glass materials by means of ferrochrome slags

The invention relates to the technical field of synthesis of inorganic nonmetal materials, and aims at providing a method for compounding pyroxene-type microcrystalline glass materials by means of solid waste such as ferrochrome slags and waste glass, limestone, sodium carbonate and fluorite. The raw materials used for compounding mainly adopt the solid waste, and the ferrochrome slags belong to waste with severe toxicity and need to be treated individually. The waste microcrystalline glass materials are compounded only by means of normal pressed sintering, all performances meet needs of industrial production, the problem that the environment is polluted due to the fact that a large amount of solid waste is stacked is solved, the compounded waste slag type microcrystalline glass materials can be applied to building decoration materials, the method for compounding the pyroxene-type microcrystalline glass materials by means of the solid waste such as the ferrochrome slags and the waste glass, the limestone, the sodium carbonate and the fluorite accords with the industrial policy of circular economy advocated by the nation, and higher economic value and environmental significance are achieved.

Owner:UNIV OF SCI & TECH BEIJING

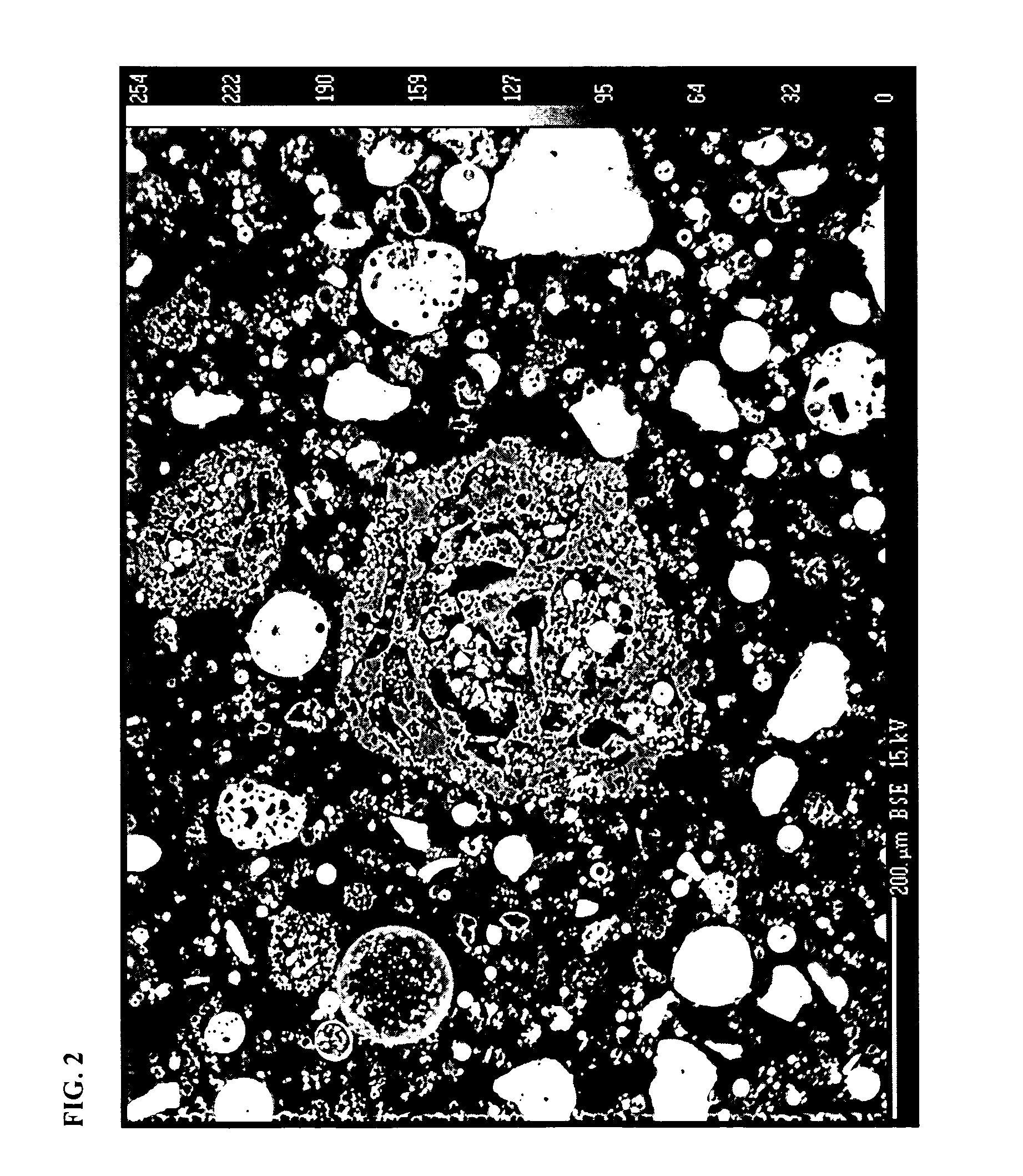

Precursor compositions for ceramic proppants

InactiveUS20080073083A1Broad sinteringIncrease resistanceFluid removalDrilling compositionAlkali feldsparHydraulic fracturing proppants

A precursor composition for the production of granulated ceramic material to be used as hydraulic fracture proppant, comprises 20 to 55% pyroxene, and 15 to 50% olivine. The remaining component is quartz and / or feldspar. The precursor composition can be sintered in a broader temperature range. The resulting proppant material shows high mechanical strength and resistance to acids, and also higher stability under hydrothermal conditions than the prior art.

Owner:ILEM RES & DEV ESTAB

Precursor compositions for ceramic products

InactiveUS20090192059A1Broad sinteringIncrease resistanceCleaning apparatusFlushingAlkali feldsparHydraulic fracturing proppants

Owner:ILEM RES & DEV ESTAB

Red porcelain ceramic product

The invention discloses a red porcelain ceramic product which is prepared from the following raw materials and components in parts by weight: 50-80 parts of red porcelain mud, 30-40 parts of argil, 20-30 parts of mica, 30-35 parts of feldspar powder, 25-30 parts of quartz powder, 20-25 parts of calcite powder, 20-25 parts of pyroxene powder, 15-20 parts of zeolite powder, 5-10 parts of montmorillonite powder, 8-10 parts of limonite powder, 3-5 parts of aluminum oxide, 2-5 parts of water reducing agents, 2-3 parts of magnesium oxide, 2-3 parts of copper oxide, 5-10 parts of boric acid, 30-35 parts of purple soil, 5-8 parts of titanium oxide, 2-5 parts of sodium metasilicate pentahydrate and 6-8 parts of polyvinyl alcohol. The red porcelain ceramic product disclosed by the invention has the advantages of wide raw material sources, material cost saving, good quality of a produced product, low cost, high benefit, high heat stability and suitability for cold and hot environments, and meets the requirement for various indices.

Owner:梁胜光

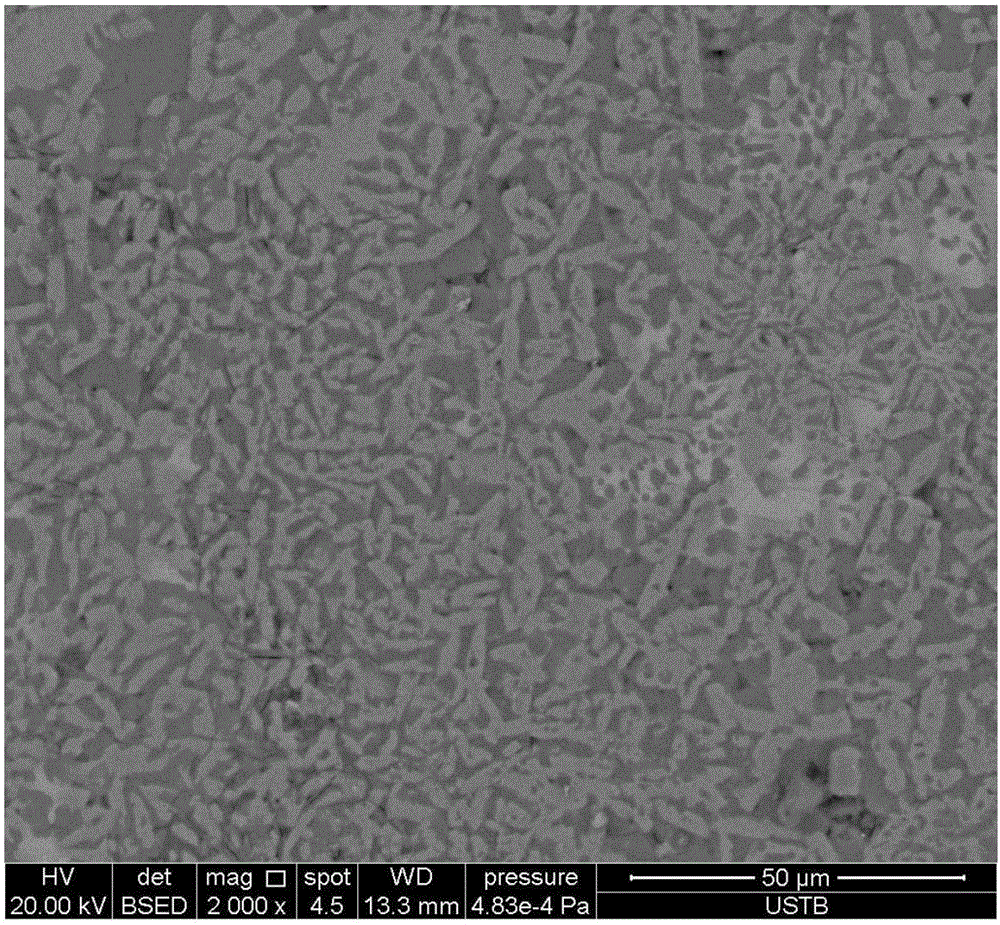

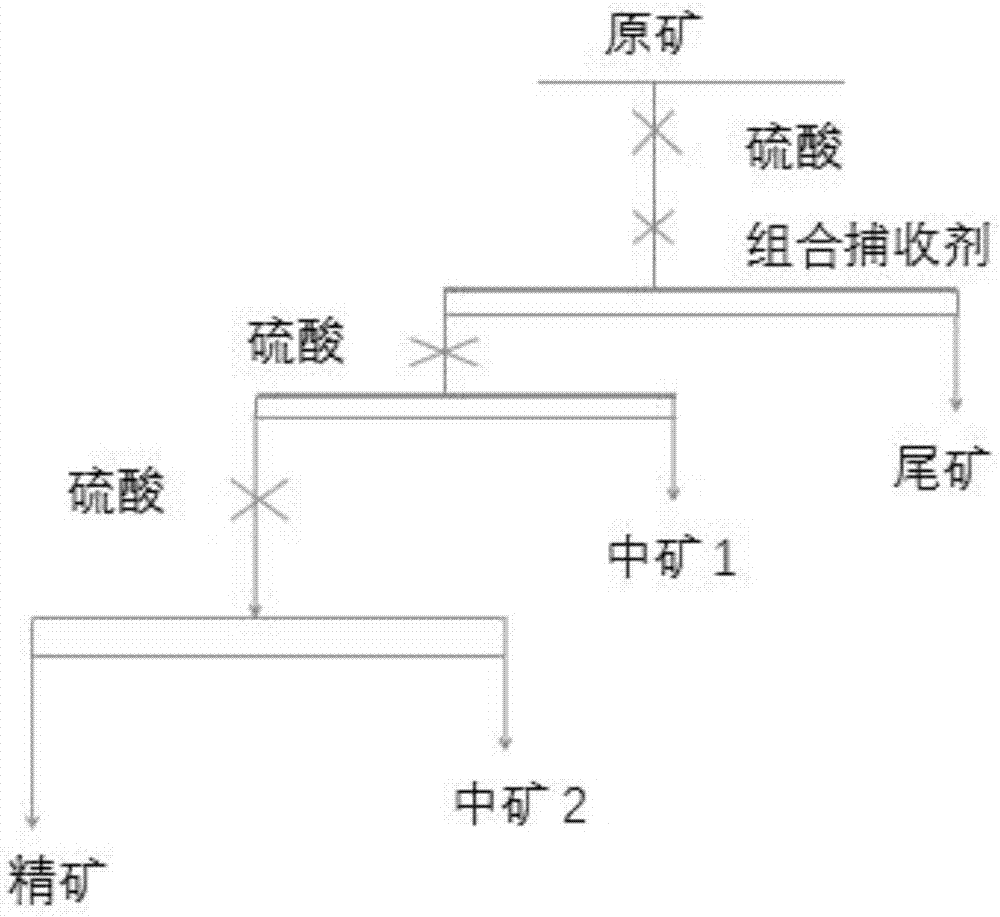

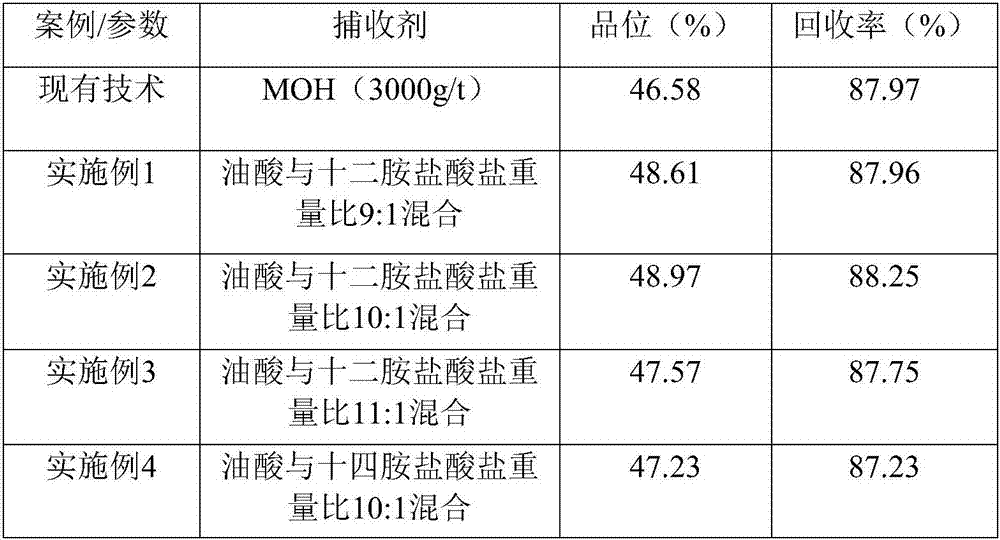

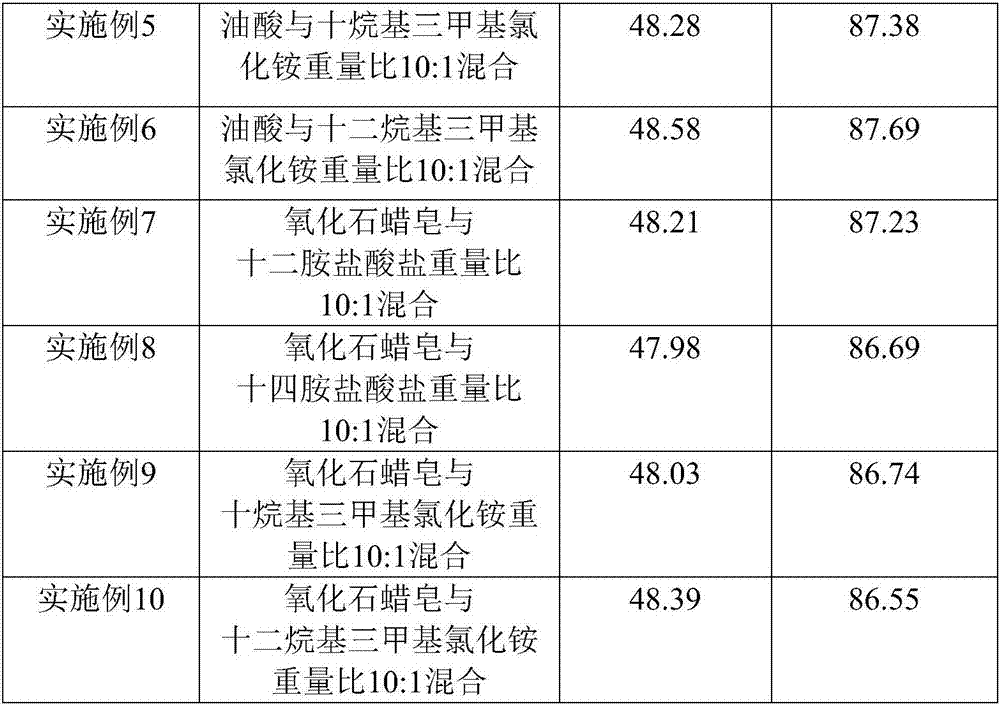

Combined collecting agent used for conducting flotation on pyroxene peridotite type ilmenite, preparation method and application

The invention provides a combined collecting agent used for conducting flotation on pyroxene peridotite type ilmenite. The combined collecting agent is composed of a component A, a component B and water. The component A is oleic acid or oxidized paraffin soap. The component B is primary amine hydrochloride or quaternary ammonium salt. The weight ratio of the component A to the component B ranges from 9:1 to 12:1. The weight ratio of the sum of the weight of the component A and the weight of the component B to the weight of the water is 1:(4-19). The raw ore grade of the pyroxene peridotite type ilmenite is not higher than 18%. The invention further provides a preparation method and application of the combined collecting agent. The flotation index achieved through the combined collecting agent is good, the number of required concentration times is small, and the quantity of the agent which is used is small; and meanwhile the requirement of the collecting agent for flotation conditions is loose, and the combined collecting agent has good hard water resistance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Sewage treatment agent, preparation method thereof and method for processing sewage

The invention discloses a sewage treatment agent and a preparation method thereof, and a method for processing sewage by using the sewage treatment agent, wherein the preparation method of the sewage treatment agent comprises the following steps of: crushing pyroxene andesite-prophyrite powder to powder with the fineness being smaller than 2mm; and mixing the crushed pyroxene andesite-prophyrite powder with sodium chloride powder according to ratio of weight parts of 10: 0.5 to 10: 1 and evenly stirring to prepare sewage treatment agent product. In the preparation process of the sewage treatment agent disclosed by the invention, the pyroxene andesite-prophyrite and the sodium chloride are needed to be crushed and evenly mixed only. Compared with the prior art, the invention has the advantages that: the production speed of the product is improved; in the scheme of the invention, every 10t of pyroxene andesite-prophyrite only needs 0.5t to 0.1t sodium chloride, and due to the reduction of use level of the sodium chloride, the raw material cost of the product is reduced to the greater extent and further the production cost of the product and the cost for sewage treatment are reduced.

Owner:孙和光 +1

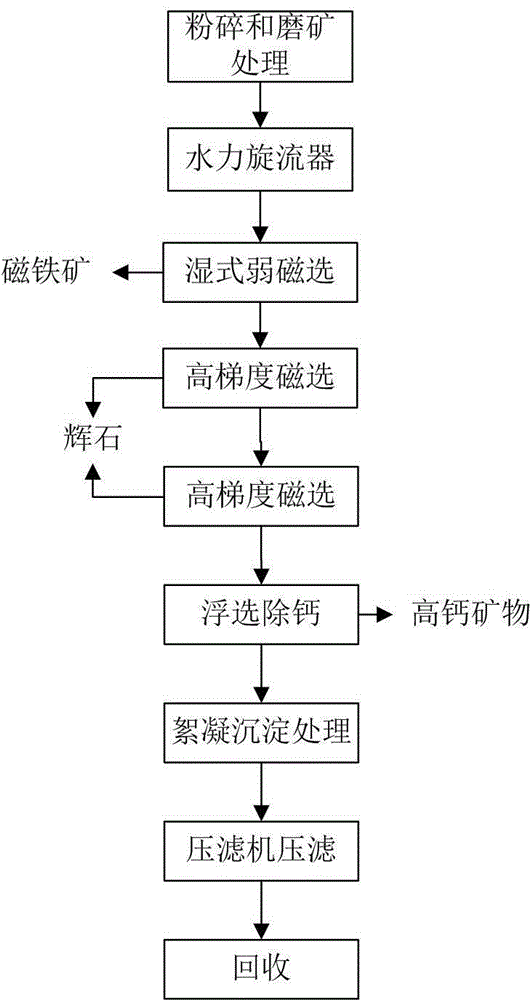

Method for recovering nepheline ore in nepheline ore tailings

The invention discloses a method for recovering nepheline ore in nepheline ore tailings. The method includes the steps that the nepheline ore tailings are smashed and ground to obtain tailing primary pulp; a hydrocyclone is used for classifying the tailing primary pulp; the tailing primary pulp classified by the hydrocyclone is concentrated, so that the concentration of the tailing primary pulp is made to at least reach 3.5%; iron removal and pyroxene removal treatment is carried out on the concentrated tailing primary pulp by the adoption of wet-type low-intensity magnetic separation and at least one level of high-gradient magnetic separation; flocculating agents are added to the tailing primary pulp subjected to iron removal and pyroxene removal treatment in a stirring mode; the tailing primary pulp with the added flocculating agents is conveyed to a settling pond through a pipeline to be subjected to standing treatment; supernatant in the settling pond is discharged in an overflowing mode, and pulp flocculating constituents are fed into a filter press to be filter-pressed into filter cakes; and the filter cakes fall freely under the effect of gravity, and are dispersed under an impact effect and then conveyed to a dry storage yard through a vehicle to be recovered.

Owner:四川南江新兴矿业有限公司

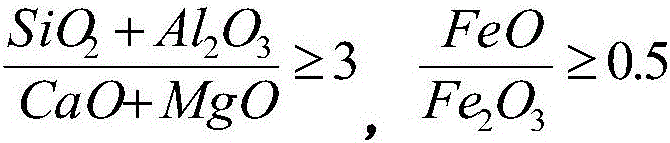

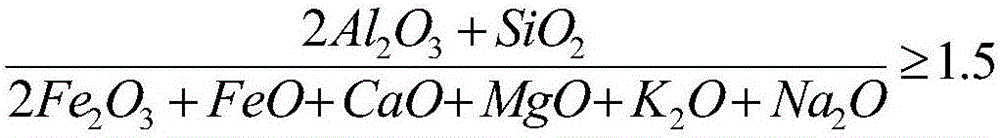

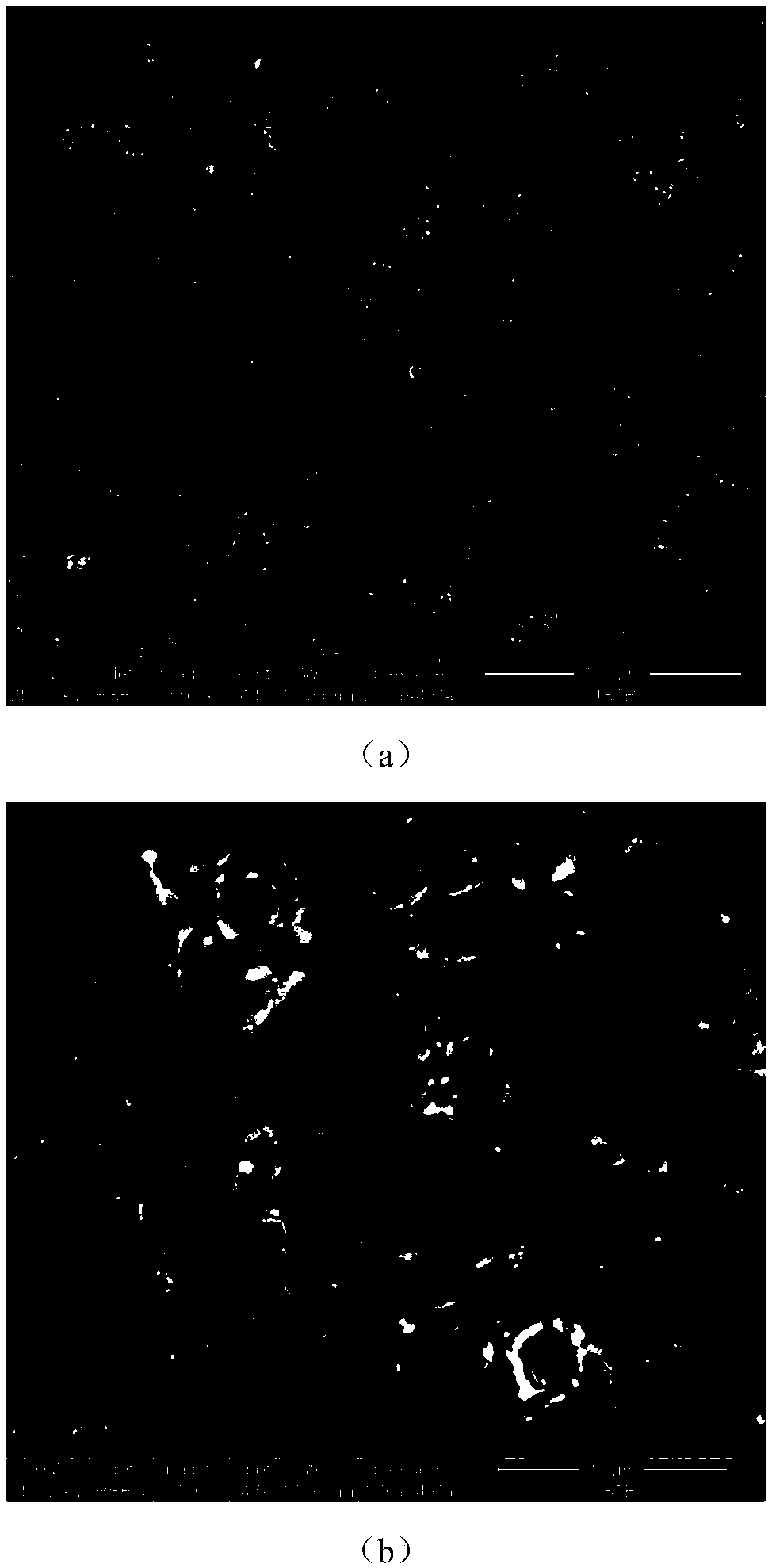

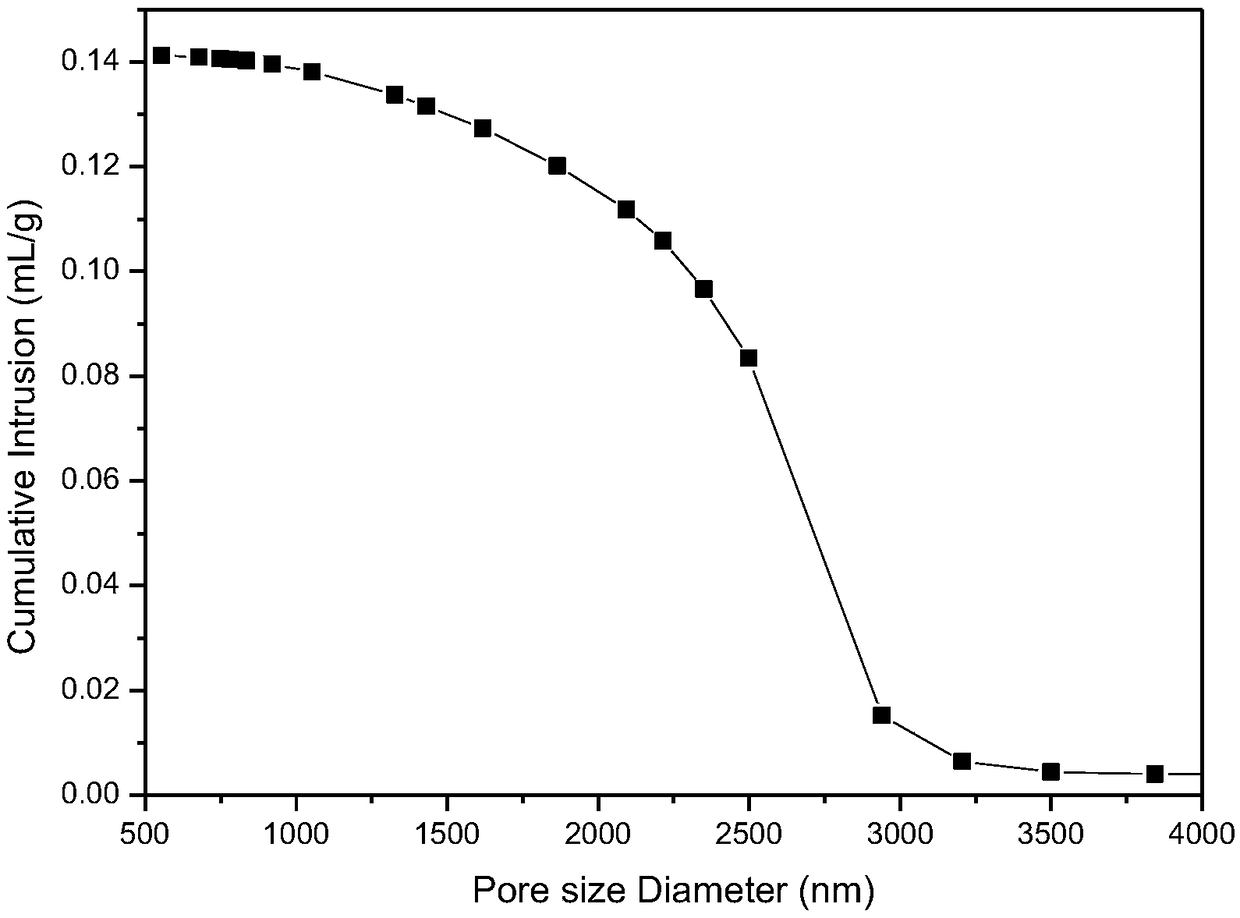

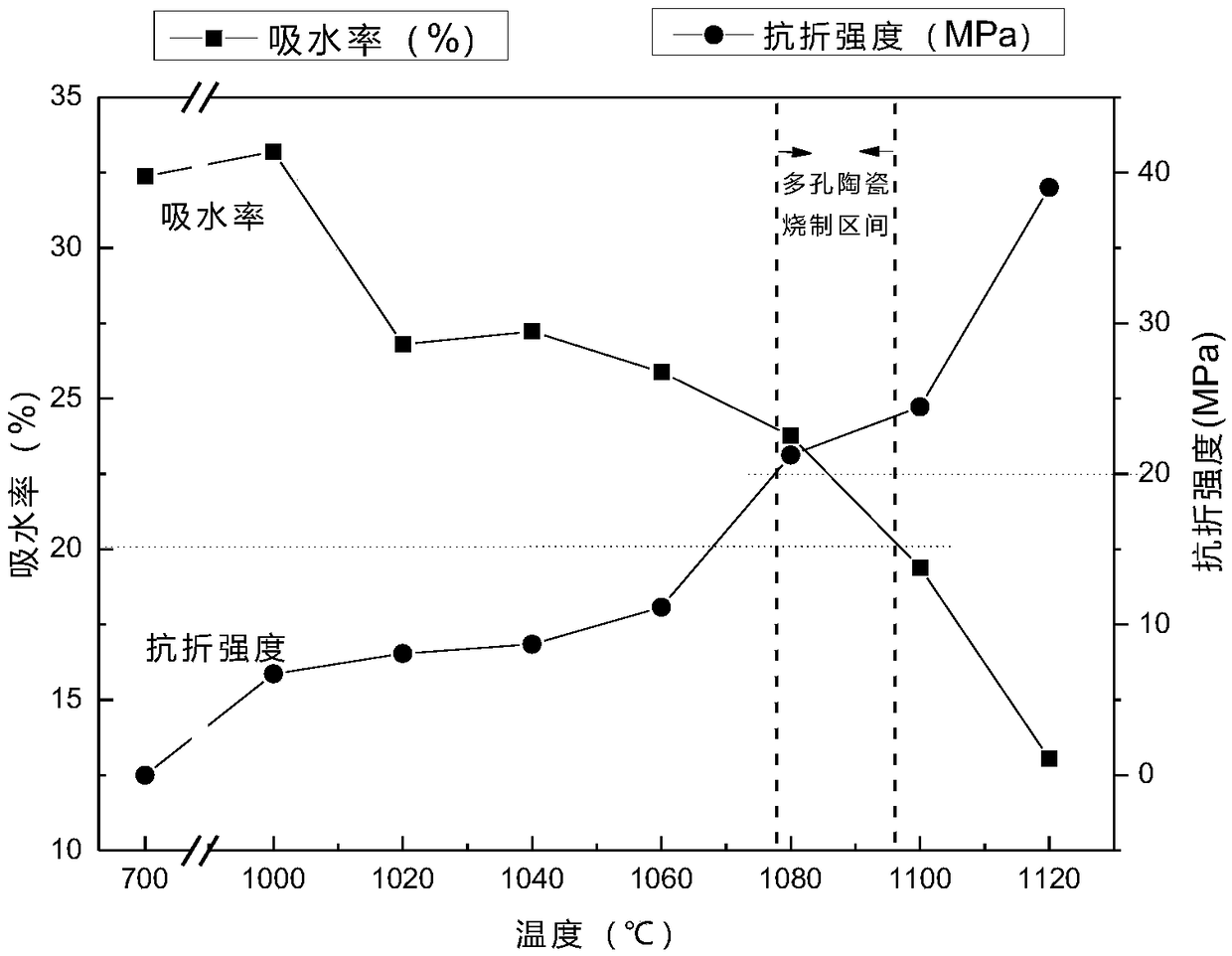

Porous ceramic material preparation method with intrinsic pore formation

The invention provides a porous ceramic material preparation method with intrinsic pore formation and belongs to the technical field of solid waste comprehensive utilization. The method comprises thefollowing steps of mixing different raw materials according to the mass percentage without adding a pore-forming agent, processing a mixture into a green body according to the traditional ceramic preparation method, and performing drying and sintering to acquire a porous ceramic material. The raw materials do not include a pyroxene crystal phase; a chemical composition of the ceramic material prepared after mixing of the raw materials is as follows: SiO2 is larger than 35 percent and smaller than 65 percent, CaO is larger than 10 percent and smaller than 30 percent, Al2O3 is larger than 3 percent and smaller than 31 percent, MgO is larger than 3 percent and smaller than 20 percent, Fe2O3 is larger than 0 percent and smaller than 10 percent, and Na2O+K2O is larger than 0 percent and smallerthan 3 percent; and the sintering temperature is in a range from 1020 DEG C to 1260 DEG C. The porous ceramic material preparation method provided by the invention is simple in technology and liableto control and is an effective way of producing the porous ceramic material; and the porous ceramic material can be used as functional materials with a function of adsorption or filtering, various carrier materials or functional building materials and is widely applied.

Owner:UNIV OF SCI & TECH BEIJING

Pyroxene peridotite type ilmenite depressing agent and preparation method thereof

InactiveCN103721853AResolve recovery rateSolve the technical problem of low concentrate gradeFlotationPhysical chemistryIlmenite

The invention belongs to the ilmenite flotation technology, and particularly relates to a pyroxene peridotite type ilmenite depressing agent and a preparation method of the pyroxene peridotite type ilmenite depressing agent. The preparation method of the pyroxene peridotite type ilmenite depressing agent comprises the step of carrying out oscillation, stir and curing on a mixed solution formed by sodium silicate, ferric nitrate and sulfuric acid to obtain the pyroxene peridotite type ilmenite depressing agent, wherein oscillation, stir and curing are carried out for 30-40min. The obtained pyroxene peridotite type ilmenite depressing agent comprises, by weight, 5-15 parts of the sodium silicate, 5-15 parts of the ferric nitrate and 1-10 parts of the sulfuric acid. The pyroxene peridotite type ilmenite depressing agent obtained through the preparation method has a good selective depressing effect on olivine and pyroxene, and has extremely important significance in obtaining of good technical indexes of titanium flotation of pyroxene peridotite type ilmenite.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

Plastic inner film of rice packaging bag

InactiveCN105885166AAvoid the phenomenon of puncturing the packaging bagImprove the preservation effectLow-density polyethylenePolyethylene glycol

The invention discloses a plastic inner film of a rice packaging bag, and relates to the technical field of plastic packaging materials. The plastic inner film of the rice packaging bag is prepared from the following raw materials in parts by weight: 35-40 parts of low-density polyethylene, 10-13 parts of polyester resin, 6-10 parts of carnauba wax, 6-10 parts of polycarbonate, 5-8 parts of montmorillonite, 4-6 parts of water pyroxene powder, 4-6 parts of wood powder, 3-5 parts of rosin glycerin ester, 3-5 parts of dampproof and insect-resistant agent, 2-3 parts of titanate coupling agent, 2-3 parts of polyethylene glycol 400, 1-2 parts of sldium lauryl sulfate, 1-2 parts of sodium abietate and 0.5-1 part of nano rubber powder. The plastic inner film of the rice packaging bag has an excellent preservation effect, and is capable of effectively preventing rice from mildewing and breeding insects, thus prolonging the shelf life of rice.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

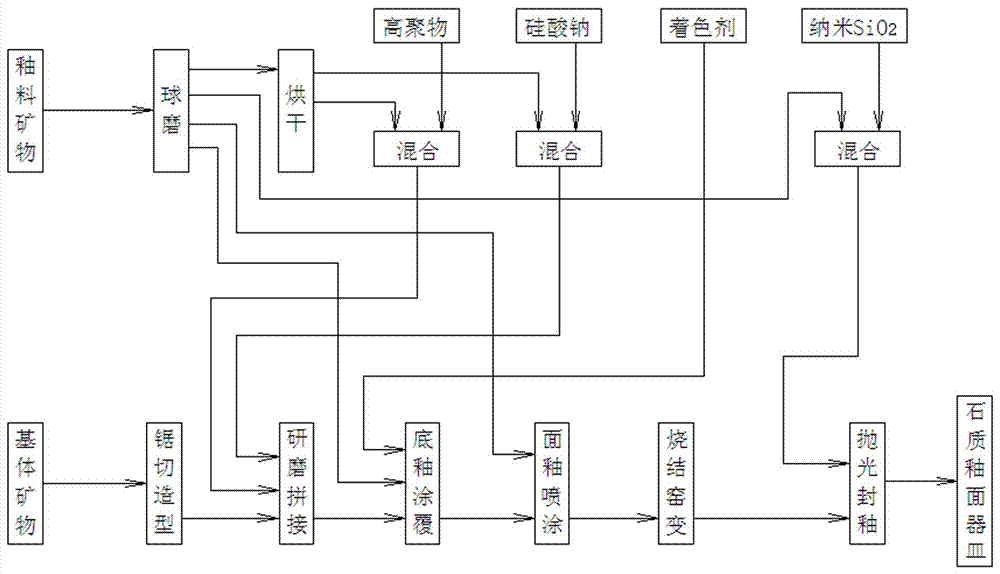

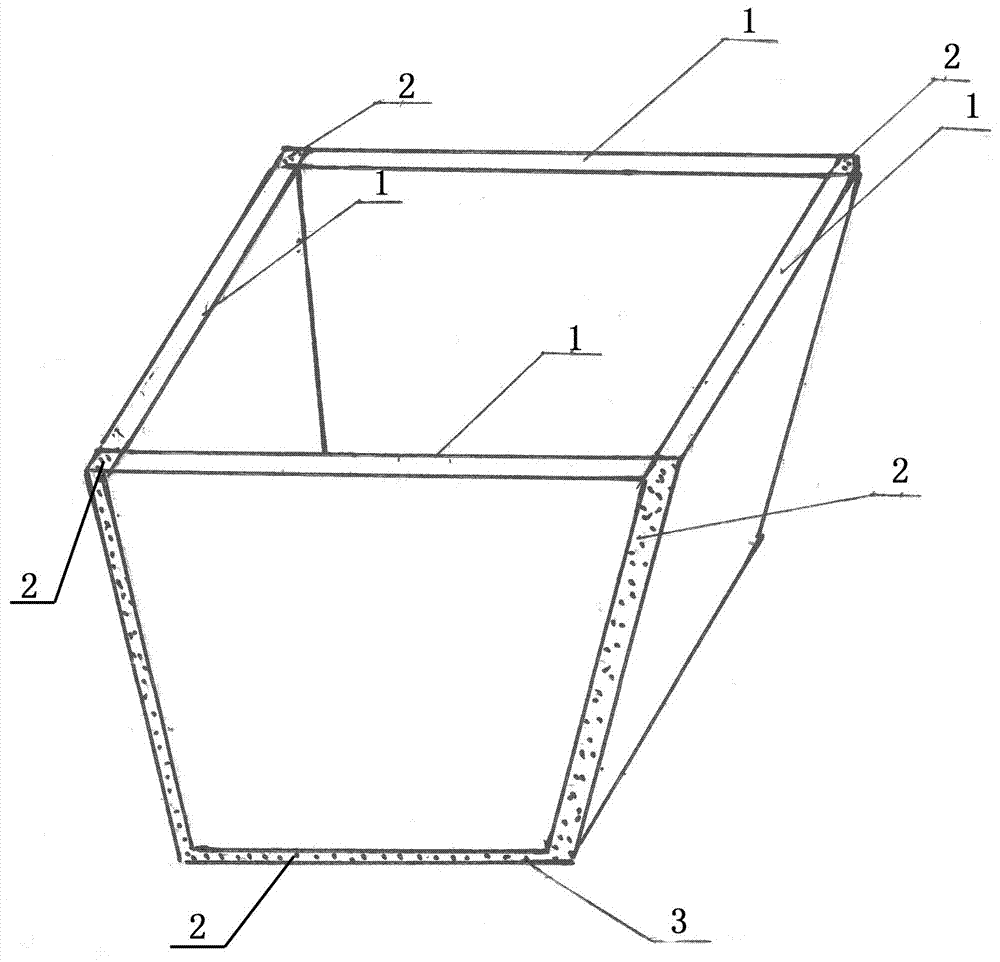

Method for preparing stony glazed vessel by using ophiolite

The invention belongs to the technical field of silicate materials and ceramics, and in particular relates to a method for preparing a stony glazed vessel by using ophiolite. The method comprises basic process steps of saw-cutting moulding, grinding and splicing, bottom glaze coating, surface glaze spraying, sintering furnace transmutation and polishing glaze sealing and auxiliary processes of grinding and glaze drying, the stony glazed vessel or device is prepared from the ophiolite as a matrix mineral by the method. Olivine, serpentine and pyroxene minerals with good appearance and transparency are used as a stony matrix, the purification and the electromagnetic performance both can be kept, the difficult-to-solve problem of cracks of the stony glazed vessel can be solved by surface glazing, filling of silicic acid cement gum in joint cracks and the micro-melting effect of high-temperature sintering, and by use of the mineral micro-melting process, wettability and color of the stony glazed vessel can be changed.

Owner:景德镇祥玉聚美陶瓷有限公司

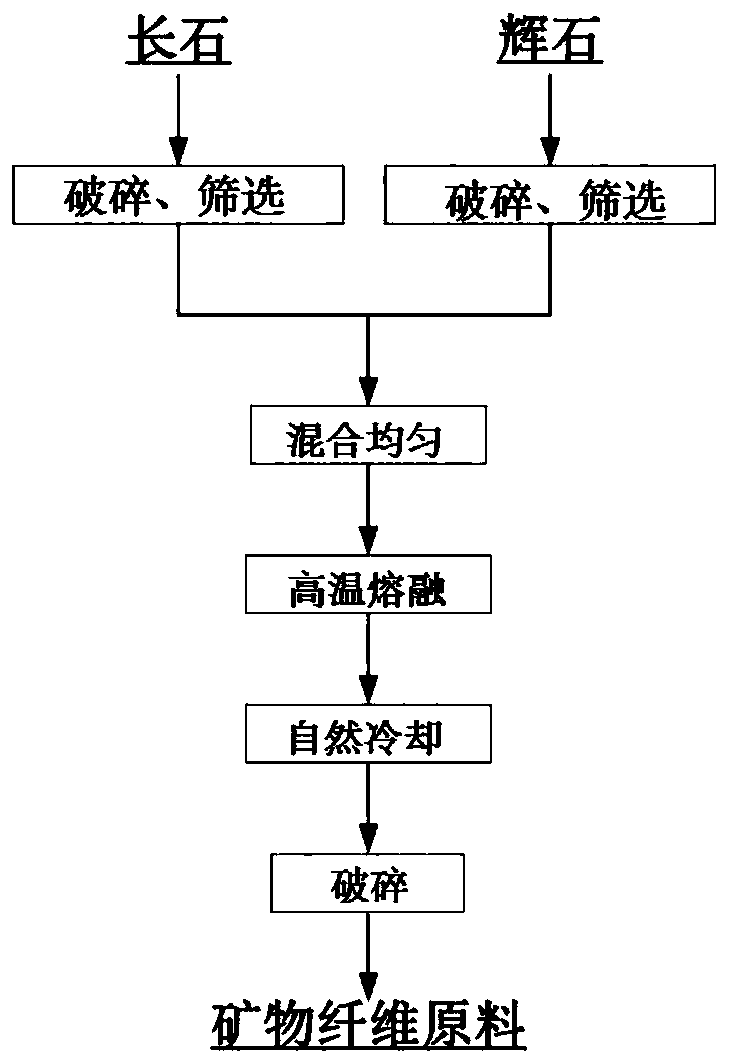

Preparation method of mineral fiber raw material and obtained mineral fiber raw material

The invention relates to a preparation method of a mineral fiber raw material and the mineral fiber raw material prepared by the method, and the method comprises the following steps of: (1) mixing feldspar and pyroxene particles according to a certain proportion, so that the mass fraction of feldspar is 50-70%, the mass fraction of pyroxene is 25-35%, the total mass fraction of feldspar and pyroxene is more than 85%, and the mass fraction of associated minerals is not more than 15%; (2) putting the mixture into a platinum crucible and heating and melting at high temperature to obtain a uniformsilicate melt; and (3) taking out the melt from the furnace, placing the melt in air and naturally cooling to obtain an amorphous silicate solid product, and crushing the solid to obtain the mineralfiber raw material.

Owner:河北地质大学

Craft porcelain with raised particle effect on glaze surface and preparation method thereof

The invention discloses a craft porcelain with a raised particle effect on a glaze surface and a preparation method thereof. The craft porcelain with a raised particle effect on a glaze surface comprises a green body and overglaze arranged on the green body, the overglaze comprises a glaze slurry and frit dry particles, the glaze slurry comprises the following raw materials: Dehua quartz, halloysite, Dehua feldspar, montmorillonite, sepiolite, dickite, pyroxene, aluminum oxide and lanthanum oxide, during preparation of the craft porcelain, the overglaze is uniformly applied to the surface of the green body, then the green body is sent into a kiln for firing, the surface of the fired craft porcelain has the decoration effect of naturally fused convex bumped artistic patterns, and bump points are clear, vivid, full and rich in layering sense, thus further improving the aesthetic sense of the craft porcelain.

Owner:FUJIAN DEHUA JIASHUN CRAFTS

Ceramic pug

InactiveCN104086157AAvoid deformationExtended temperature rangeClaywaresAluminium hydroxideExpanded clay aggregate

The invention discloses ceramic pug. The ceramic pug is prepared from the following raw material components in parts by weight: 30-40 parts of kaolinite powder, 1-2 parts of nanosilicon dioxide, 2-3 parts of aluminium oxide, 2-5 parts of montmorillonite powder, 10-20 parts of mica powder, 15-20 parts of vermiculite powder, 5-10 parts of ceramsite powder, 3-5 parts of turf, 5-10 parts of zeolite powder, 10-15 parts of pyroxene powder, 10-15 parts of hornblende powder, 2-5 parts of magnesium oxide, 2-3 parts of ferric oxide, 3-5 parts of aluminium hydroxide, 5-8 parts of limestone, 2-3 parts of sodium metaaluminate, 3-5 parts of Na[Al(OH)4] and 5-8 parts of polycarboxylate water reducing agent. The ceramic pug has the advantages that the defects of easy deformation and unstable shrinkage ratio in a firing process are overcome, the shrinkage ratio is controlled under the synergistic effect of all the components in a formula, so that a product has small possibility of deformation in the firing process; meanwhile, firing shrinkage ratio is controlled to be 14-15%, the range of firing temperature of the product can be expanded, so that yield of fired products is high, and the requirement of large-scale industrial production is met.

Owner:梁胜光

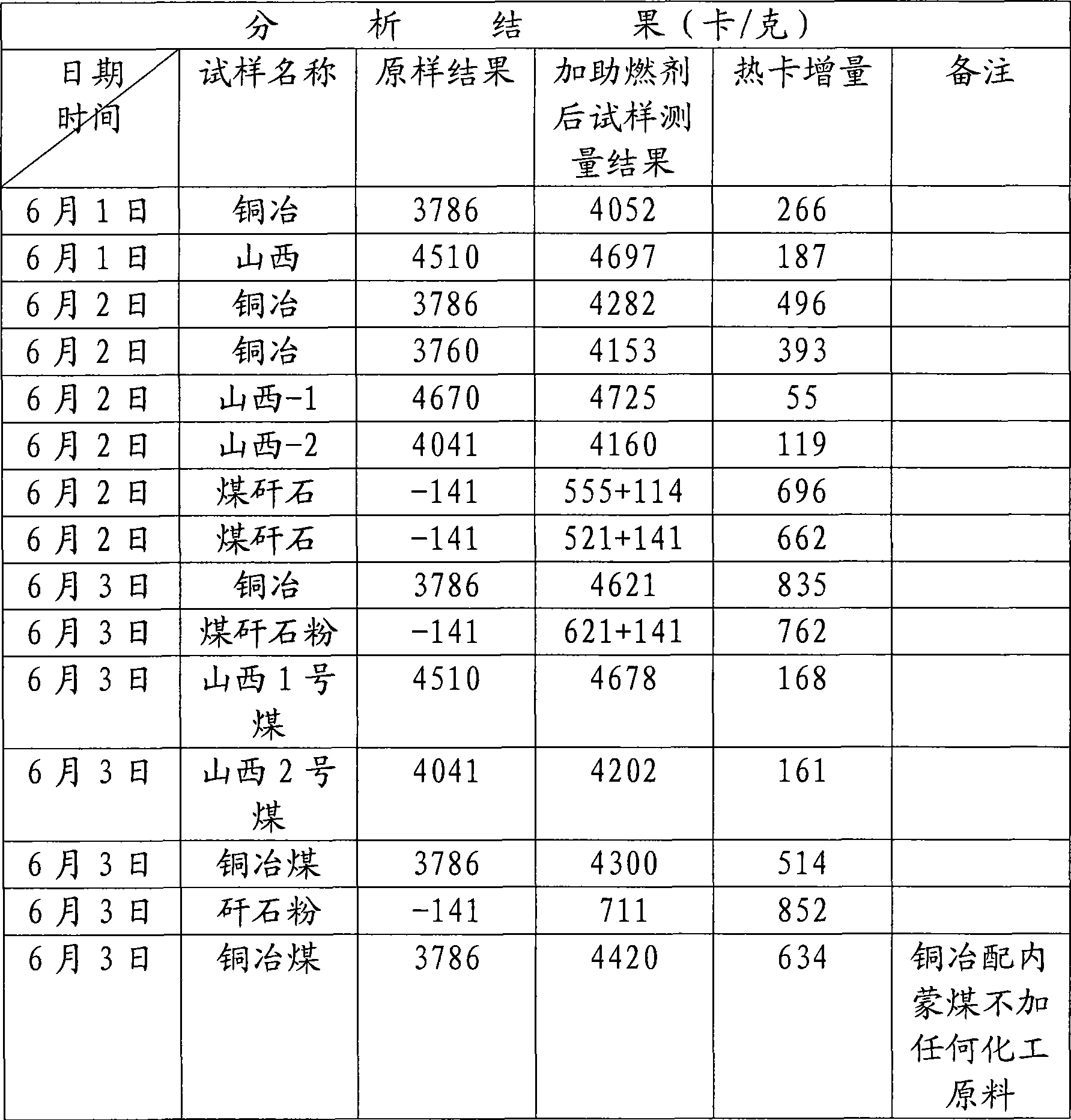

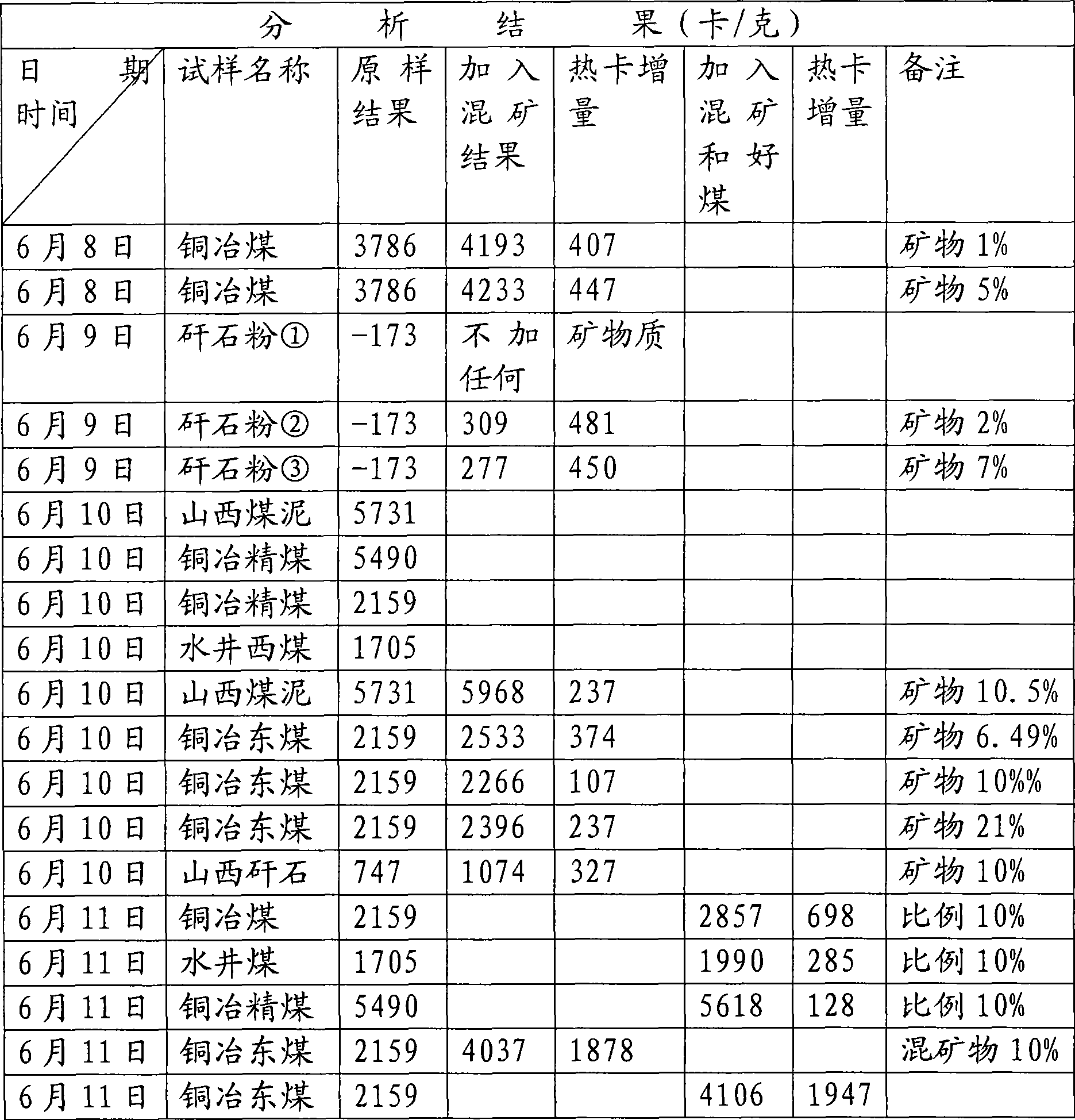

Nano ore coal combustion supporting additive, preparation and use as coal renewable energy source

The invention discloses a nanometer ore coal combustion-supporting additive, a preparation method thereof and application of the additive as renewable energy source of coal. The additive comprises the following raw material ores: 2 to 25 weight portions of saltpeter, 5 to 25 weight portions of marble, 5 to 25 weight portions of talcum, 5 to 20 weight portions of feldspar, 5 to 25 weight portions of picrite, and 1 to 10 weight portions of pyrolusite. The ores are subject to ultrafine grinding and are prepared into a coal combustion-supporting agent according to certain mixture ratio, and then the combustion-supporting agent is prepared into complex coal with coal gangue and coal according to the mixture ratio. The additive can ensure that 30 to 50 percent of standard coal is saved in the power generation industry and the cement industry, can reduce the discharge amount of sulfur dioxide and smoke dust, also reduce the environmental pollution of the coal gangue caused by land occupation spontaneous combustion at the same time, has good social benefit and economical benefit, meets the requirements of energy conservation, environmental protection and emission reduction, and is worthy to be promoted.

Owner:蒋凤亮 +2

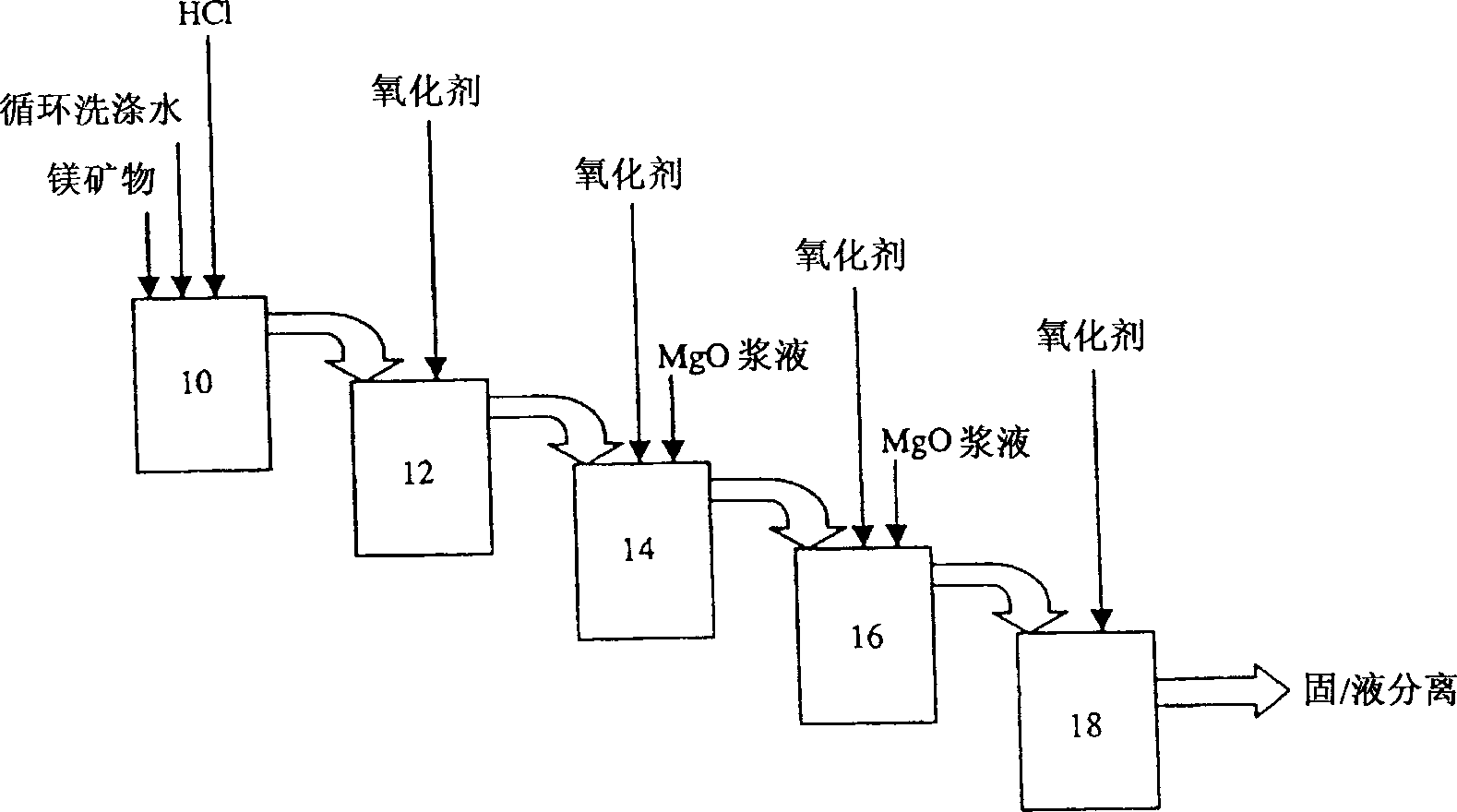

Method for production of high-purity concentrated magnesium chloride solution

The present invention is concerned with a method for the extraction of magnesium from magnesium-containing materials such as magnesite, dolomite and silicates materials like serpentine residues, products from the amphibole or pyroxene group. The magnesium-containing material is first leached in at least one leaching reactor, and subsequently submitted to a series of neutralizing steps in separate reactors under controlled pH and oxydo-reduction potentials. The slurry produced is filtered to produce a substantially pure magnesium chloride solution containing less than 1 ppm of each contaminant present therein.

Owner:NORANDA MINES

Separation method of associated rich fluorite and low-grade cassiterite in tungsten flotation tailings

The invention discloses a separation method of associated rich fluorite and low-grade cassiterite in tungsten flotation tailings. The separation method comprises the steps of directly feeding tungsten flotation tailings containing 16-25% of fluorite CaF2 and 0.1-0.3% of tin SnO2 into a flotation column for rough fluorite flotation, and separating fluorite from calcite and iron-containing pyroxene, so as to obtain rough fluorite concentrate and tin-containing tailings subjected to derichment; carrying out precise flotation on the rough fluorite concentrate for five times, so as to obtain a fluorite concentrate product and fluorite flotation tailings; and carrying out two-stage sorting on the tin-containing tailings subjected to derichment, and carrying out a concentrated back washing shaking table gravity separation technology on secondary concentrate, so as to obtain a rough tin concentrate product and tin flotation tailings. According to the separation method, the technological process is simple, the loss of fluorite and cassiterite in overflow water can be reduced, and the comprehensive recycling rate of fluorite and cassiterite is increased.

Owner:YUNNAN TIN

Organic waste gas treater utilizing attapulgite adsorption and superparamagnetic field magnetolysis

PendingCN108889066AImprove purification rateHydrophobic modification technology is easyGas treatmentDispersed particle separationActivated carbonSimple Organic Compounds

The invention discloses an organic waste gas treater utilizing attapulgite adsorption and superparamagnetic field magnetolysis. The organic waste gas treater comprises a treater body and a fan arranged in the treater body. An air outlet is formed in one side face of the treater body, and an air inflow face is arranged on at least one side face of the treater body. The air inflow face is provided with an attapulgite molecular sieve, modified activated carbon and a superparamagnetic field magnetolysis plate from outside to inside. The attapulgite molecular sieve is provided with three layers ofstructures which sequentially comprise a front-layer fine net, a middle-layer honeycomb flow layer and a rear-layer fine net. The honeycomb flow layer is filled with attapulgite particles and wrappedby the front-layer fine net and the rear-layer fine net. According to the waste gas treater, adsorption filtering of an attapulgite adsorption plate and a modified activated carbon adsorption plate and magnetolysis filtering of the superparamagnetic field magnetolysis plate are combined, the waste gas purification rate is higher, attapulgite serves as an adsorbent and red pyroxene serves as a representing agent in the attapulgite molecular sieve, the hydrophobic modification technology of the attapulgite molecular sieve is simpler and has a better effect, and the selective adsorption capacityof the attapulgite molecular sieve for an organic compound can be improved.

Owner:张诚

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com