Patents

Literature

45 results about "Amphibole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amphibole ( /ˈæmfɪboʊl/) is an important group of inosilicate minerals, forming prism or needlelike crystals, composed of double chain SiO₄ tetrahedra, linked at the vertices and generally containing ions of iron and/or magnesium in their structures. Amphiboles can be green, black, colorless, white, yellow, blue, or brown. The International Mineralogical Association currently classifies amphiboles as a mineral supergroup, within which are two groups and several subgroups.

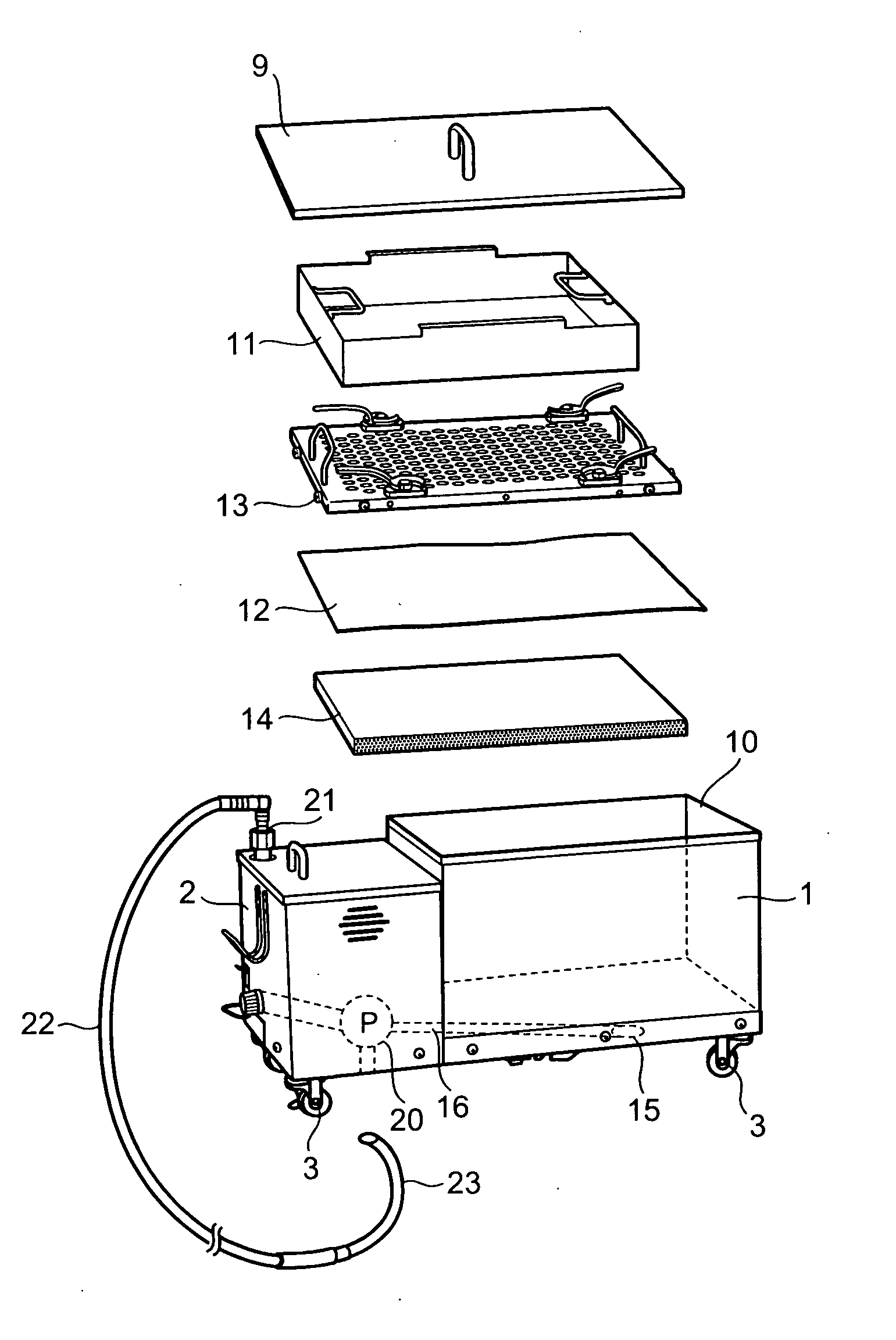

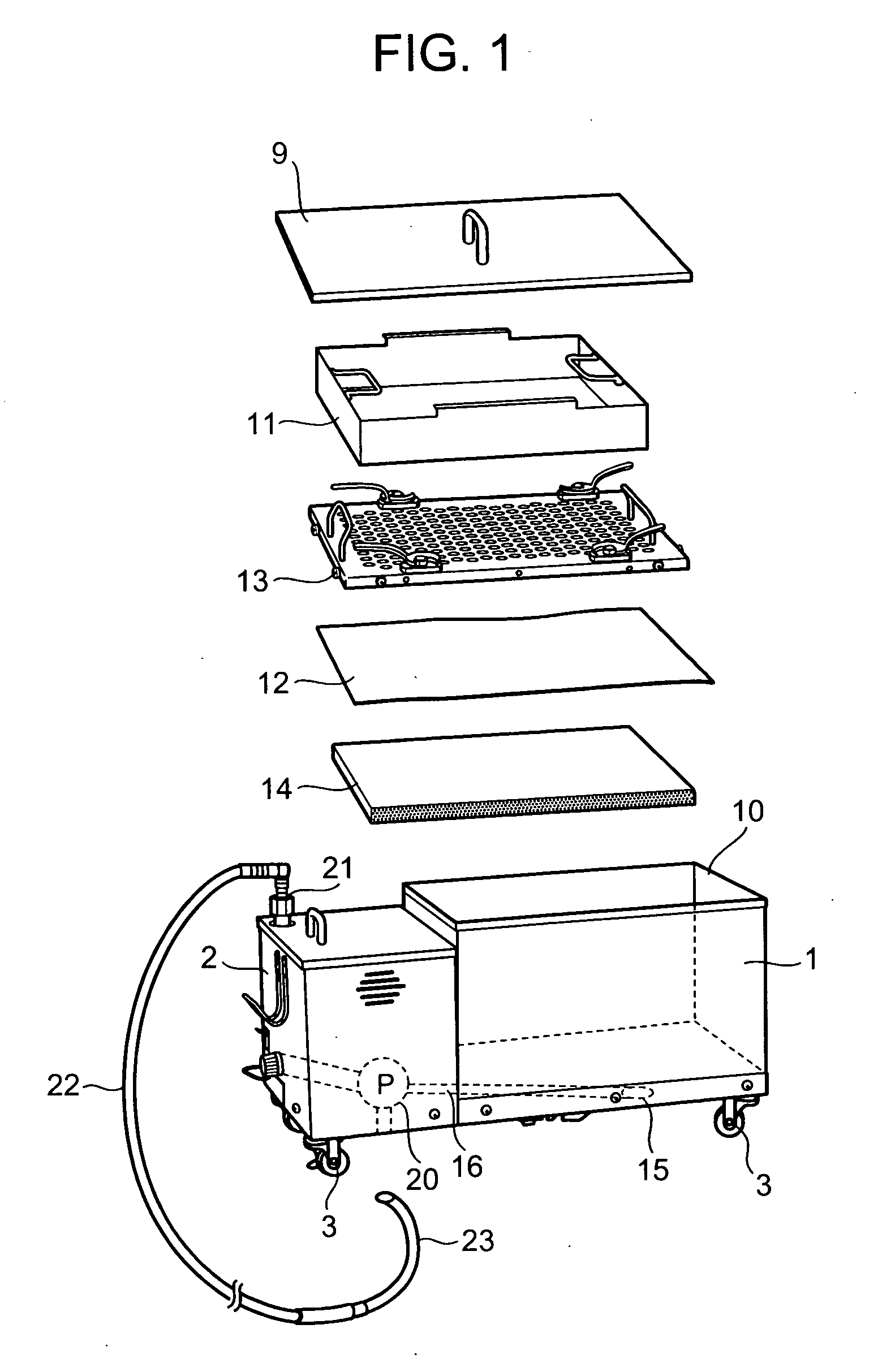

Method for purifying cooking oil and cooking oil filter apparatus

InactiveUS20050223909A1Prevent degradationSuitable materialFatty substance recovery/refiningFiltration separationOxidation resistantFilter material

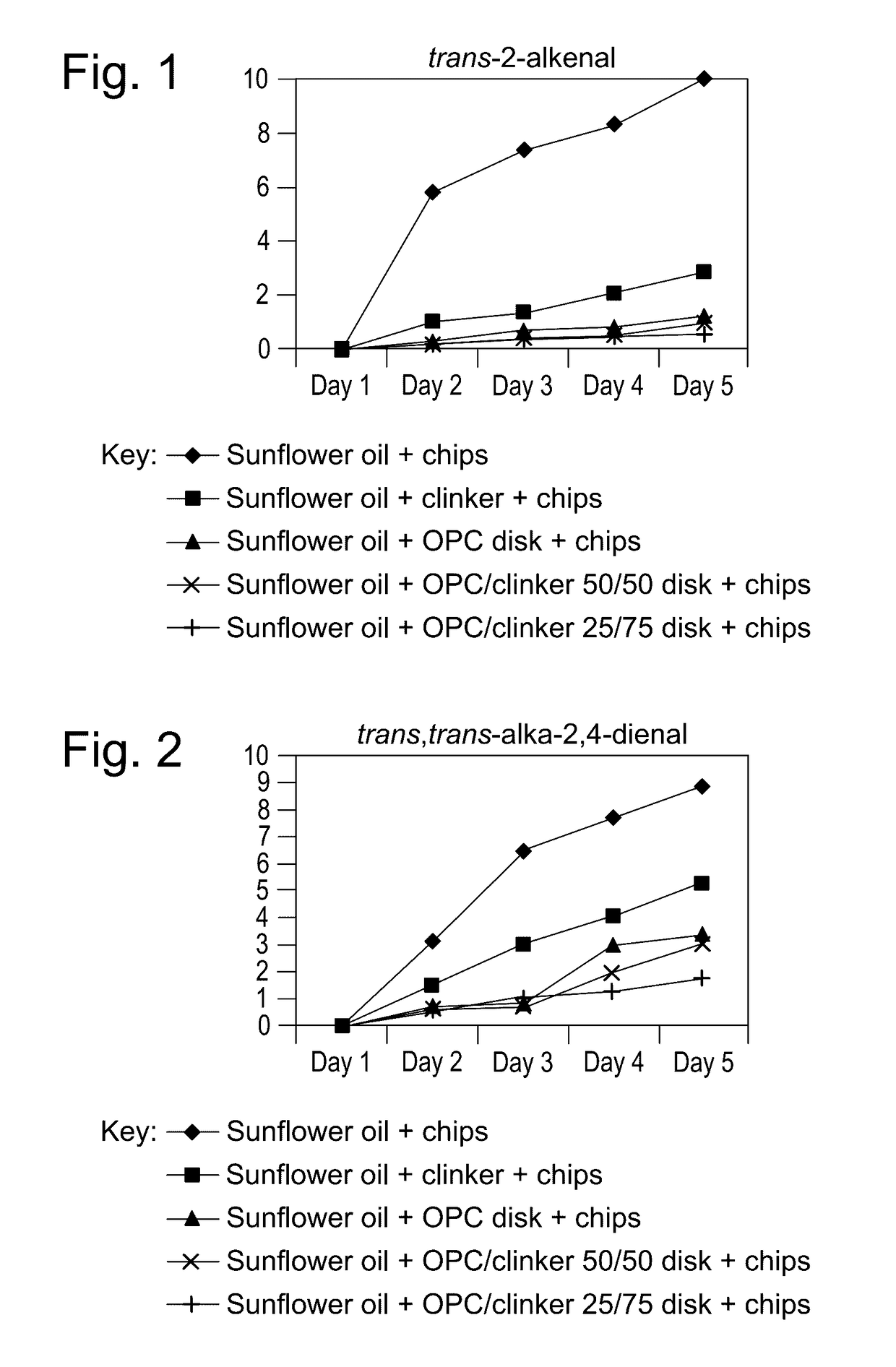

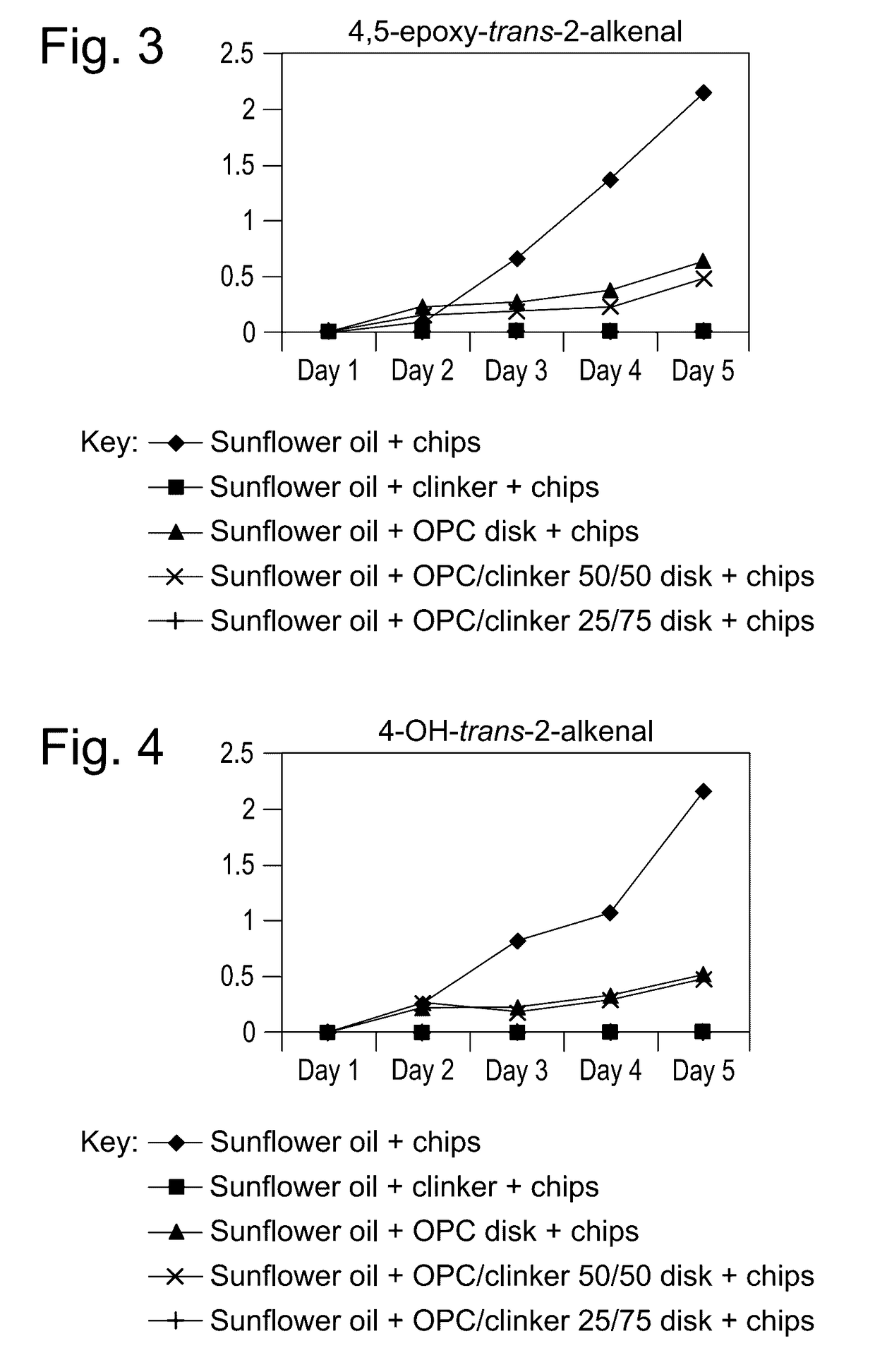

To use cooking oil repeatedly for a long time while maintaining quality of the cooking oil in a good condition, a cooking oil filter apparatus according to this invention filters the cooking oil collected from a fryer in using a filtering material. A fragment of granite porphyry containing amphibole is used as the filtering material. The granite porphyry containing the amphibole indicates a good antioxidant effect against the cooking oil, and the cooking oil is recycled upon contact with the granite porphyry, thereby prevented from degrading. As a structure, for example, the apparatus has a filter cartridge containing the fragment of the granite porphyry containing the amphibole, in which a basket and a paper filter respectively in a mesh form are disposed on the filter cartridge.

Owner:KURATA KATSUHIKO

Oxide/silicate mineral fiber nano composite air-sensitive film and preparation method thereof

InactiveCN101609059AAvoid breakingEnhanced gas adsorption capacityMaterial resistanceFiberPalygorskite

The invention discloses an oxide / silicate mineral fiber nano composite air-sensitive film and a preparation method thereof, belonging to the technical field of functional composite material. The oxide / silicate mineral fiber nano composite air-sensitive film comprises silicate mineral fiber nano material substrate and a nano oxide powder layer coated on the surface of the silicate mineral fiber nano material substrate; wherein silicate mineral fiber nano material is any one in the minerals such as chrysotile, amphibole, meerschaum and palygorskite; and nano oxide powder is any one of nano stannic oxide, nano ferric oxide, nano zinc oxide and nano copper oxide. Compared with the prior art, the oxide / silicate mineral fiber nano composite air-sensitive film obtained by adopting the method has the tensile strength being improved from 10-50MPa to 100-3000MPa and the fracture toughness be enhanced from 3-5MPa.m1 / 2 to 100-500MPa.m1 / 2; the air-sensitive stability and the service life are improved by 80-100%.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Hydraulically set cement body for preservation of organic liquids

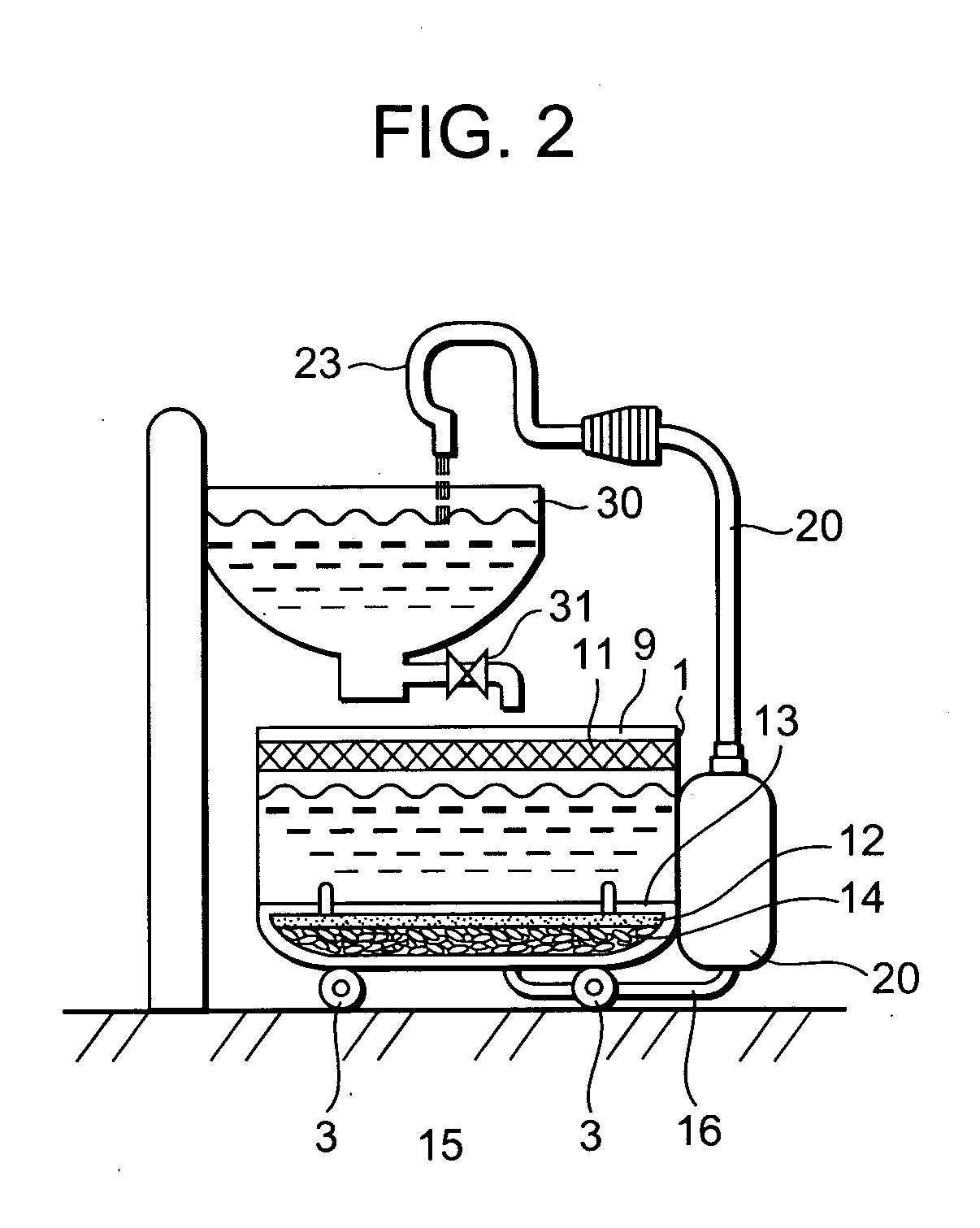

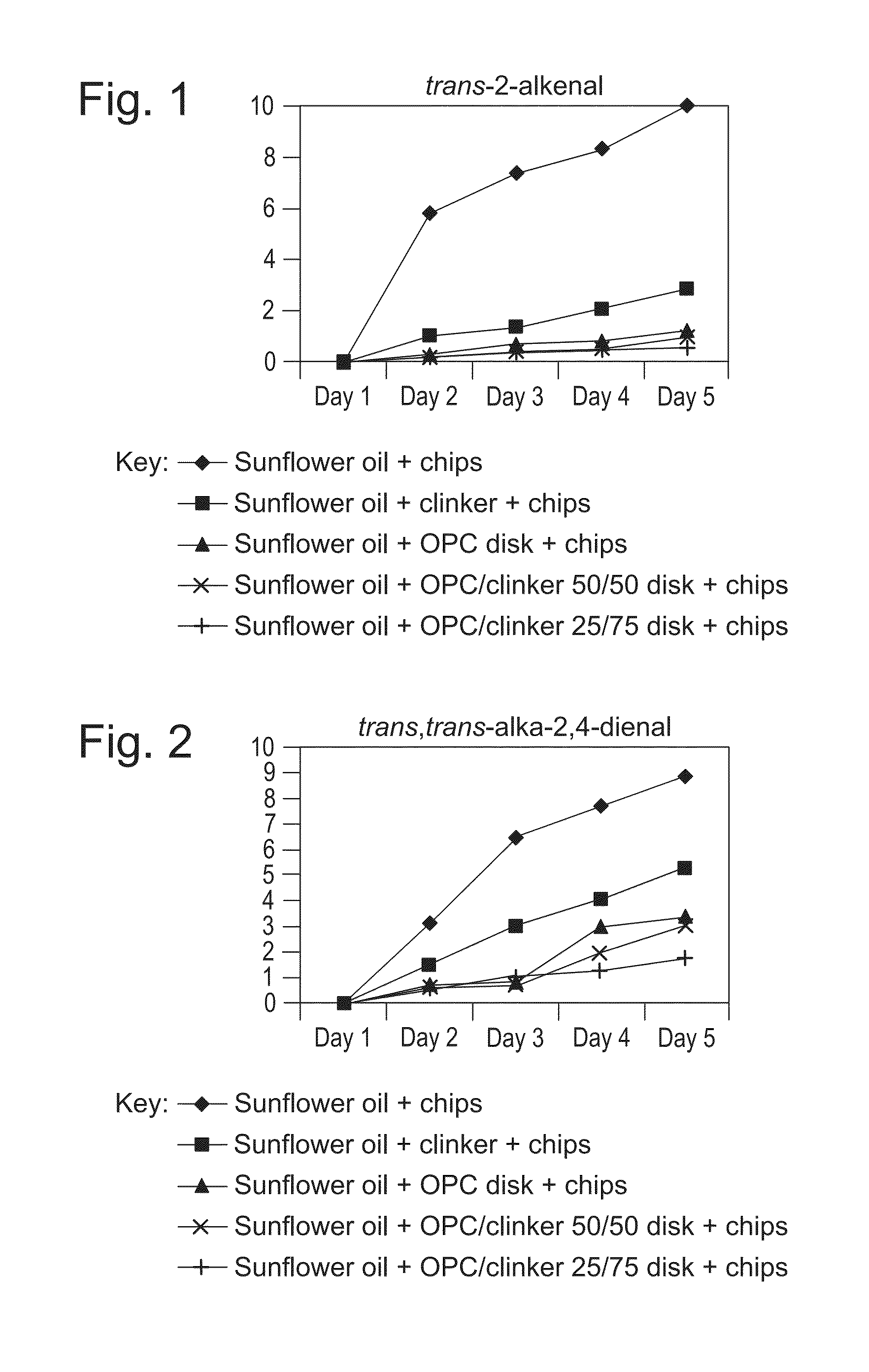

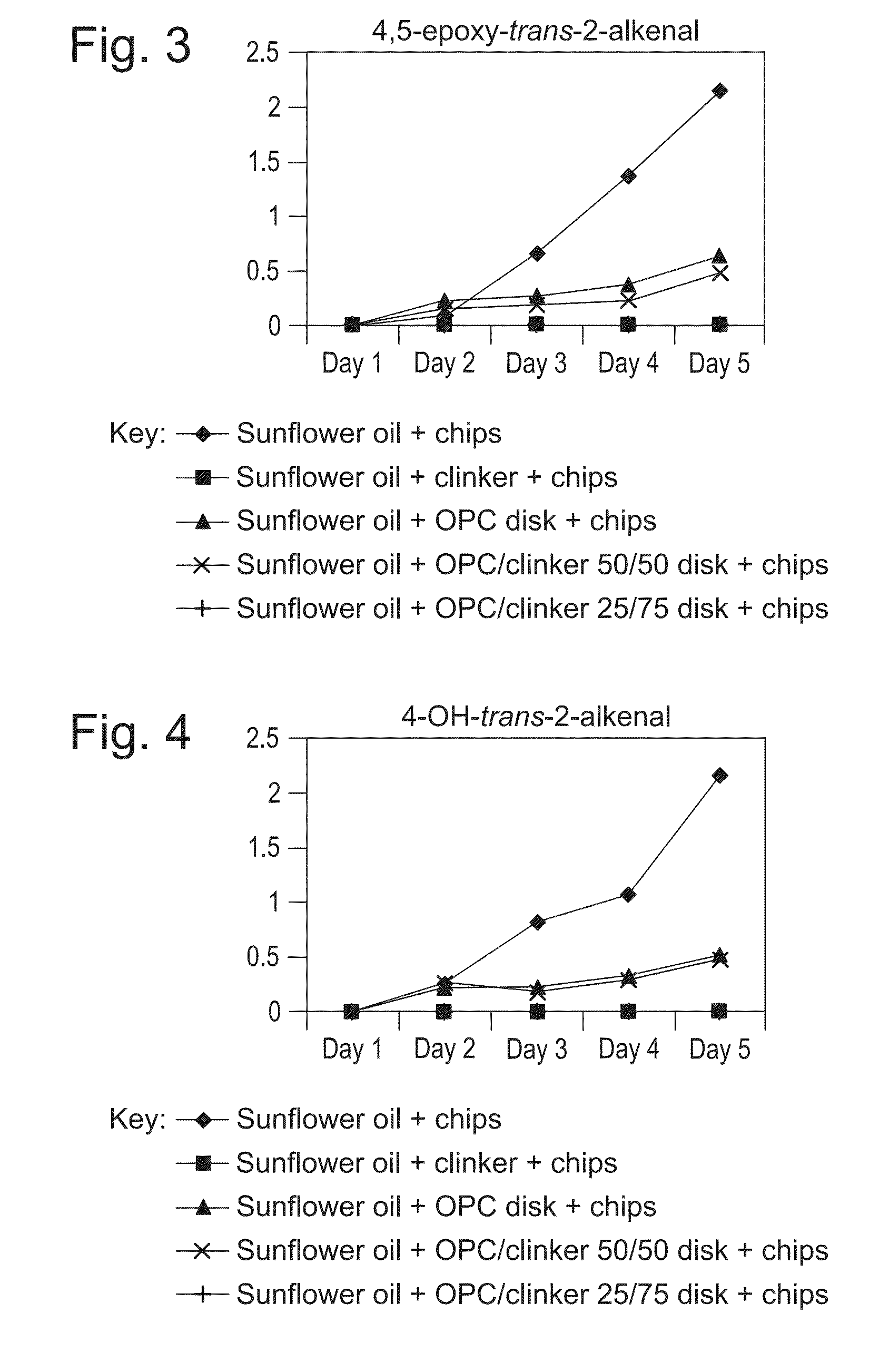

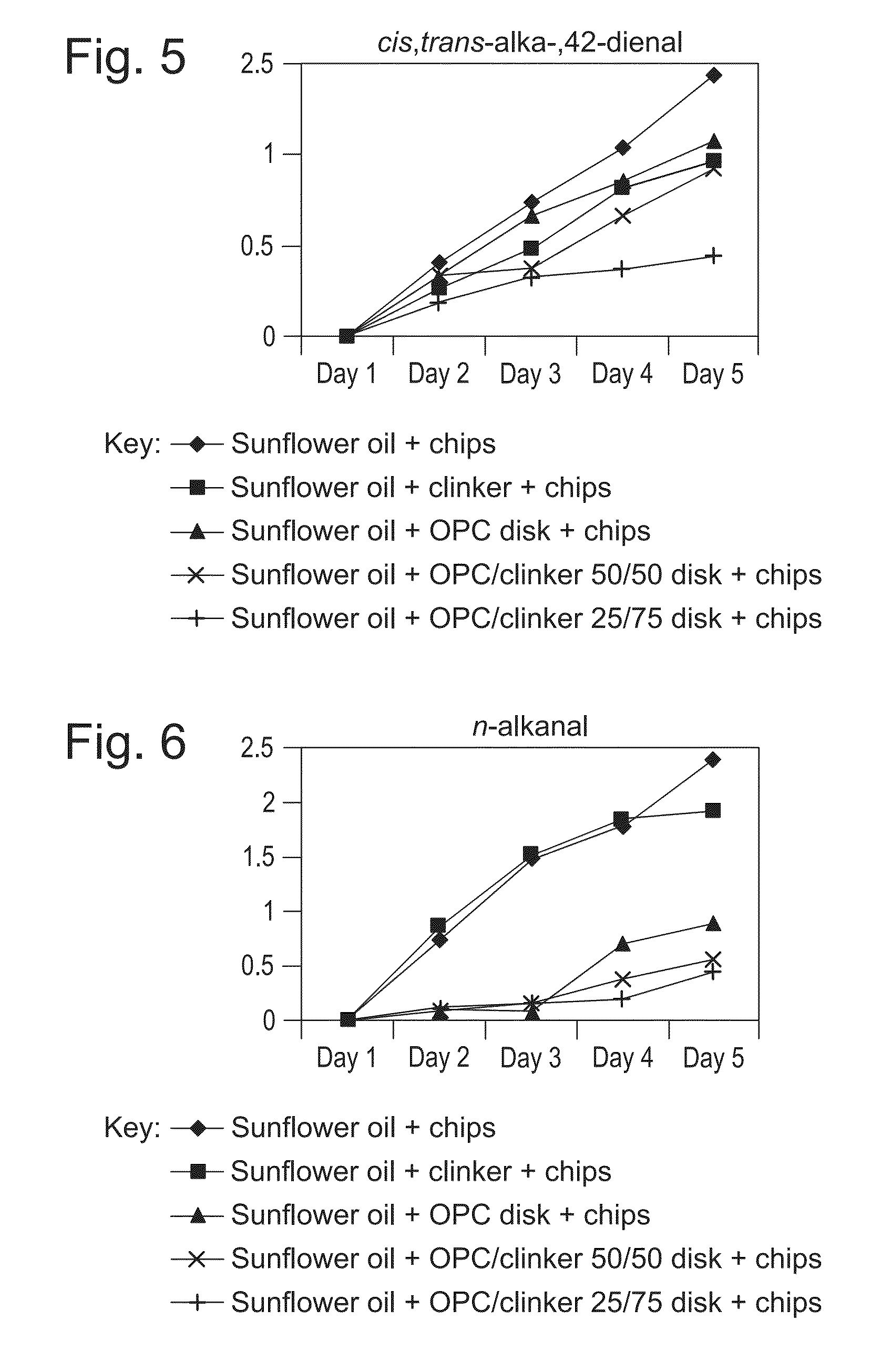

ActiveUS20130112607A1Promote formationNo free waterOther chemical processesEdible oils/fatsCalcium silicateScolecite

An hydraulically set oil-permeable cement body is provided in the form of a stand-alone block or briquette for preserving cooking oil during deep fat frying, said body. It has substantially no free water or having a low free water content for resisting damage on immersion in cooking oil and initial heating and is enclosed in packaging that resists ingress of water or water vapour The block or briquette consists of >50 wt % of a mixture of milled white OPC clinker and white OPC, optionally silica 1-2 wt % and / or titania (TiO2) 1-2 wt % and optionally further ingredients selected from calcium silicate, magnesium silicate, aluminium silicate, natural feldspars, natural sodium zeolites, natural calcium zeolites, synthetic sodium zeolites, synthetic calcium zeolites, wollastonite, calcium hydroxide, clays, pillared clays, activated clays / earths, talcs / kaolinite, amphiboles, granite porphyry, rhyolite, agalmatolite, porphyry, attapulgite and diatomaceous earth. It has the properties that calcium and magnesium substantially do not leach into the oil and that it is porous so that oil can diffuse into it and contaminants can be deposited on and within it.

Owner:BBM TECH LTD

Method for producing spinel glass ceramic with aluminum ash as main raw material

The invention discloses a method for producing spinel glass ceramic with aluminum ash as the main raw material. The method includes the following steps of firstly, selecting raw materials; secondly, mixing the raw materials; thirdly, melting the mixed materials; fourthly, conducting roll-forming; fifthly, conducting annealing; sixthly, conducting crystallizing. When the glass ceramic is prepared with aluminum ash as the main raw material, the utilization rate reaches 50% or above, waste is turned into wealth, and the environmental hazards caused by the aluminum ash are effectively solved. Spinel serves as the principal crystalline phase of the prepared glass ceramic, amphibole serves as the auxiliary crystalline phase of the prepared glass ceramic, the Moh's hardness can reach the 8th level at most, the wear resistance is excellent, and the glass ceramic can be used as a wear-resistant and anti-corrosion material. The produced spinel series glass ceramic has the product tensile strength of 400-500 MPa and the bending strength of 70-90 MPa.

Owner:四川一名微晶科技股份有限公司

High-strength ceramic chopsticks and preparation technology thereof

The invention provides high-strength ceramic chopsticks and a preparation technology thereof. Each high-strength ceramic chopstick comprises a chopstick blank body and glaze, wherein the chopstick blank body is prepared from the following raw materials in parts by weight: 15 to 22 parts of potassium feldspar, 20 to 25 parts of vermiculite powder, 45 to 53 parts of quartz, 12 to 15 parts of serpentine, 5 to 8 parts of shale, 6 to 10 parts of amphibole, 3 to 5 parts of medical stone powder, 2 to 4 parts of Kanuma soil, 5 to 7 parts of lanthanum oxide, 1 to 3 parts of calcium nitride and 2 to 5 parts of magnesium carbonate; the glaze is prepared from the following raw materials in parts by weight: 35 to 42 parts of transparent frit, 10 to 15 parts of red halloysite, 25 to 30 parts of Dehua quartz, 12 to 18 parts of sodium feldspar, 8 to 12 parts of dolomite, 5 to 8 parts of lepidolite, 3 to 5 parts of molybdenum ore powder, 4 to 6 parts of phosphorus slag powder, 5 to 7 parts of volcanic soil and 1 to 3 parts of a dispersant; the transparent frit is prepared from the following chemical components in percentage by mass: 42 percent to 48 percent of SiO2, 17 percent to 23 percent of Al2O3, 2 percent to 3 percent of K2O, 5 percent to 8 percent of Na2O, 8.6 percent to 9.8 percent of MgO, 5.6 percent to 6.4 percent of Fe2O3, 2.2 percent to 4.6 percent of Ca3N2, 1.5 percent to 2.8 percent of Dy2O3, 3 percent to 3.7 percent of La2O3 and 1.2 percent to 2.6 percent of CaF2.

Owner:德化县如瓷生活文化有限公司

Hydraulically set cement body for preservation of organic liquids

ActiveUS9636657B2Reduce contentPromote formationOther chemical processesAlkali metal oxides/hydroxidesCalcium silicateAdditive ingredient

An hydraulically set oil-permeable cement body is provided in the form of a stand-alone block or briquette for preserving cooking oil during deep fat frying, said body. It has substantially no free water or having a low free water content for resisting damage on immersion in cooking oil and initial heating and is enclosed in packaging that resists ingress of water or water vapor The block or briquette consists of >50 wt % of a mixture of milled white OPC clinker and white OPC, optionally silica 1-2 wt % and / or titania (TiO2) 1-2 wt % and optionally further ingredients selected from calcium silicate, magnesium silicate, aluminum silicate, natural feldspars, natural sodium zeolites, natural calcium zeolites, synthetic sodium zeolites, synthetic calcium zeolites, wollastonite, calcium hydroxide, clays, pillared clays, activated clays / earths, talcs / kaolinite, amphiboles, granite porphyry, rhyolite, agalmatolite, porphyry, attapulgite and diatomaceous earth. It has the properties that calcium and magnesium substantially do not leach into the oil and that it is porous so that oil can diffuse into it and contaminants can be deposited on and within it.

Owner:BBM TECH LTD

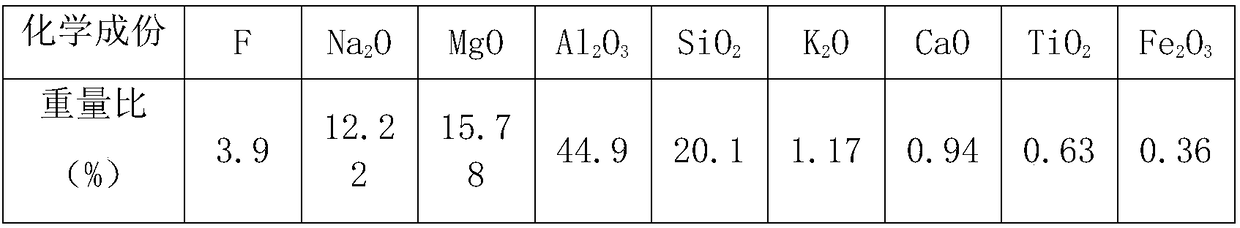

Method for preparing fluorine amphibole glass ceramic by using reactive crystallization-sintering method

InactiveCN101844869ASolve the shortcomings of strict ingredient restrictionsSolve the disadvantages of strict restrictionsPolyvinyl alcoholEnergy conservation

The invention relates to a method for preparing fluorine amphibole glass ceramic by using a reactive crystallization-sintering method. The method comprises the following steps of: separating waste glass, cleaning and pulverizing to prepare glass powder; adding silicate crystals and fluoride powder with a certain proportion, uniformly mixing and then adding PVA (Polyvinyl Alcohol) adhesive with a weight ratio of 2-10 percent to the mixed powder for mould pressing and molding; and sintering by using an ordinary electric furnace in normal pressure atmosphere to prepare the fluorine amphibole glass ceramic. Compared with the prior art, the method has the advantages of low production cost, simple production process, no need of melting fluosilicate glass with specific components, low sintering temperature, energy saving, and the like. The fluorine amphibole glass ceramic produced by the method has the compressive strength of 150-250 MPa, the bending strength of 50-70 MPa, the density of 2.2-2.4g / cm<3> and good processability, can be drilled and turned by using ordinary machining equipment and provides a novel approach for recycling the waste glass.

Owner:DALIAN JIAOTONG UNIVERSITY

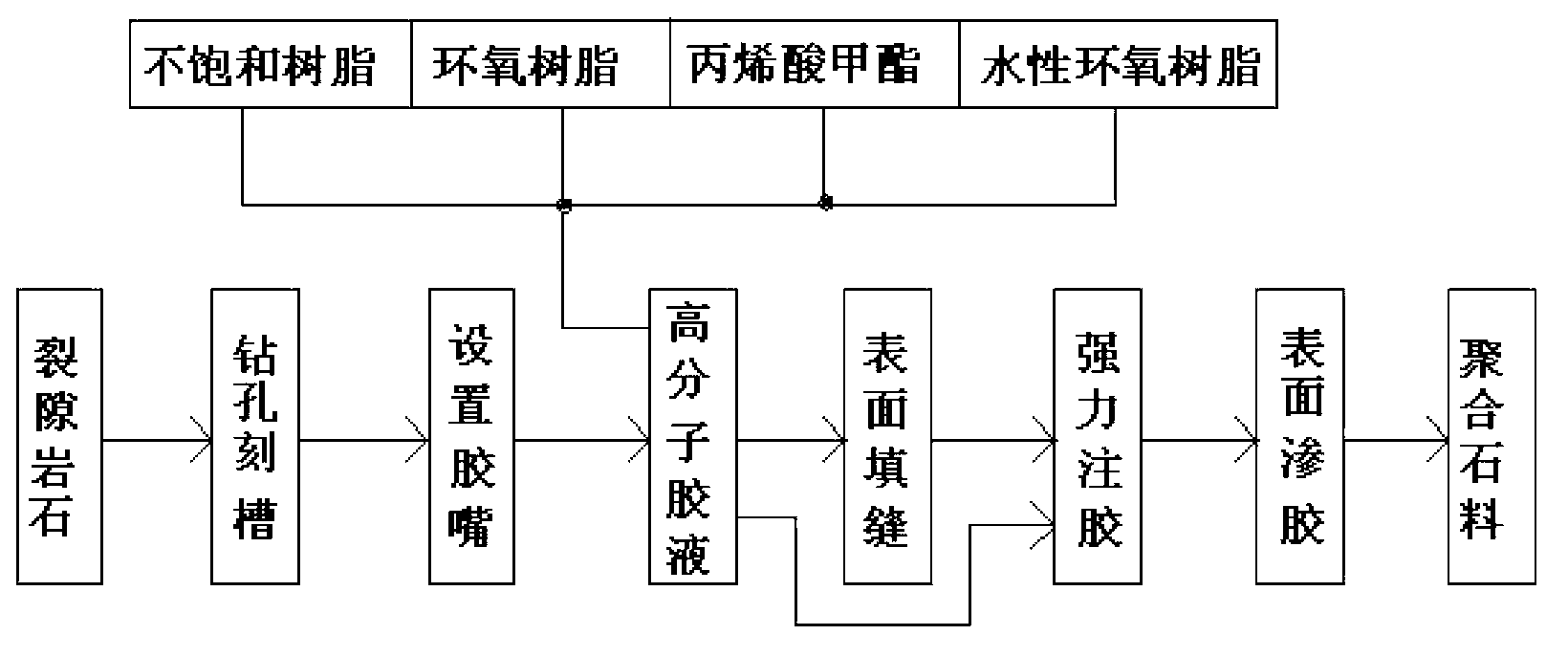

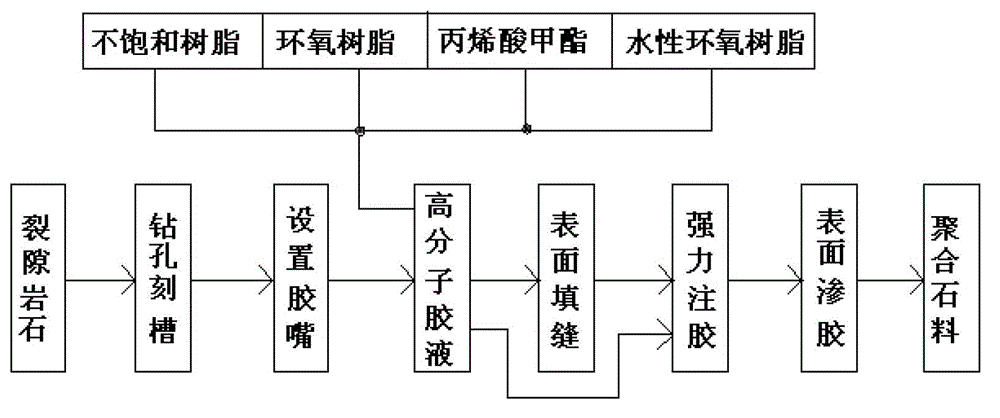

Punching injection type fractured stone material mining and processing method

The invention belongs to the field of stone materials and mining, and particularly relates to a punching injection type fractured stone material mining and processing method. The method mainly solves the problems that minerals such as siliceous jades, amphiboles, granites, quartz stones, stromatolites, serpentine-jades, marbles and the like are difficult to mine and have low yield. The technical scheme is that a macromolecule glue solution and an injection device are adopted, deep holes are used for high-pressure injection, the stone material is spalled under the high pressure of 20-100 MPa, and adhersion bonding healing and injection spalling of joint fissure rocks are achieved through a drilling and grooving process, a rubber nozzle arranging process, a macromolecule glue solution configuration process, a surface joint filling process, a high-pressure injection process and a surface glue permeation process. The method has the advantages that mining can be performed easily, and the yield is high.

Owner:STATE GRID CORP OF CHINA +1

Processing method of punching injection type fractured stone material mining

The invention belongs to the field of stone materials and mining, and particularly relates to a punching injection type fractured stone material mining and processing method. The method mainly solves the problems that minerals such as siliceous jades, amphiboles, granites, quartz stones, stromatolites, serpentine-jades, marbles and the like are difficult to mine and have low yield. The technical scheme is that a macromolecule glue solution and an injection device are adopted, deep holes are used for high-pressure injection, the stone material is spalled under the high pressure of 20-100 MPa, and adhersion bonding healing and injection spalling of joint fissure rocks are achieved through a drilling and grooving process, a rubber nozzle arranging process, a macromolecule glue solution configuration process, a surface joint filling process, a high-pressure injection process and a surface glue permeation process. The method has the advantages that mining can be performed easily, and the yield is high.

Owner:STATE GRID CORP OF CHINA +1

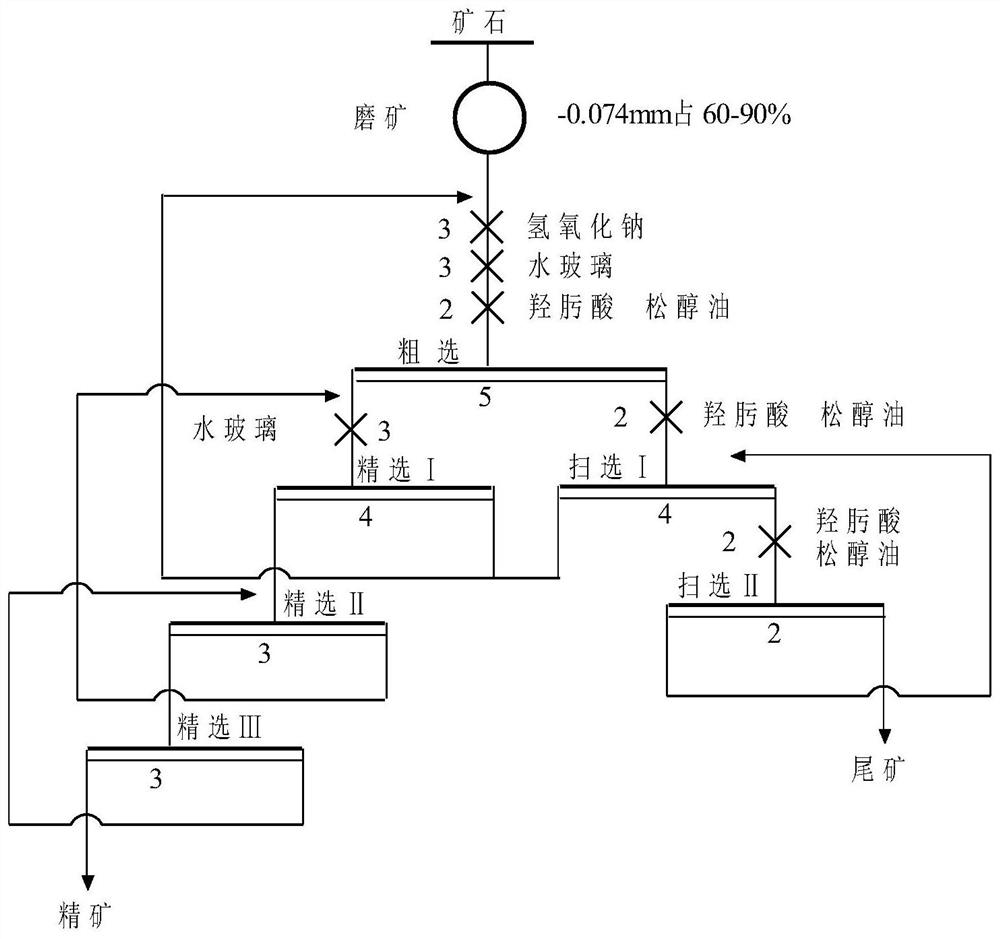

Mineral separation process of high-iron nepheline ores

InactiveCN105964401AReduce contentEmission reductionFlotationMagnetic separationNephelineNon magnetic

The invention provides a mineral separation process of high-iron nepheline ores, and particularly relates to a mineral separation process of nepheline ores with high harmful impurity iron content and finer iron-bearing mineral dissemination size. The mineral separation process provided by the invention comprises the steps of (1) utilizing low intensity magnetic separation to separate magnetic iron minerals from crude ores; (2) utilizing flotation to float aegirine-augite, black mica and amphiboles in low-intensity magnetic separation tailings in the step (1); (3) carrying out high intensity magnetic separation, and obtaining non-magnetic products as ore concentrates. The mineral separation process of the high-iron nepheline ores provided by the invention has the beneficial effects that the content of the harmful impurity iron in the nepheline ore concentrates can be remarkably reduced, the comprehensive utilization value of the nepheline ores is improved, and the emission load of the tailings is greatly reduced.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

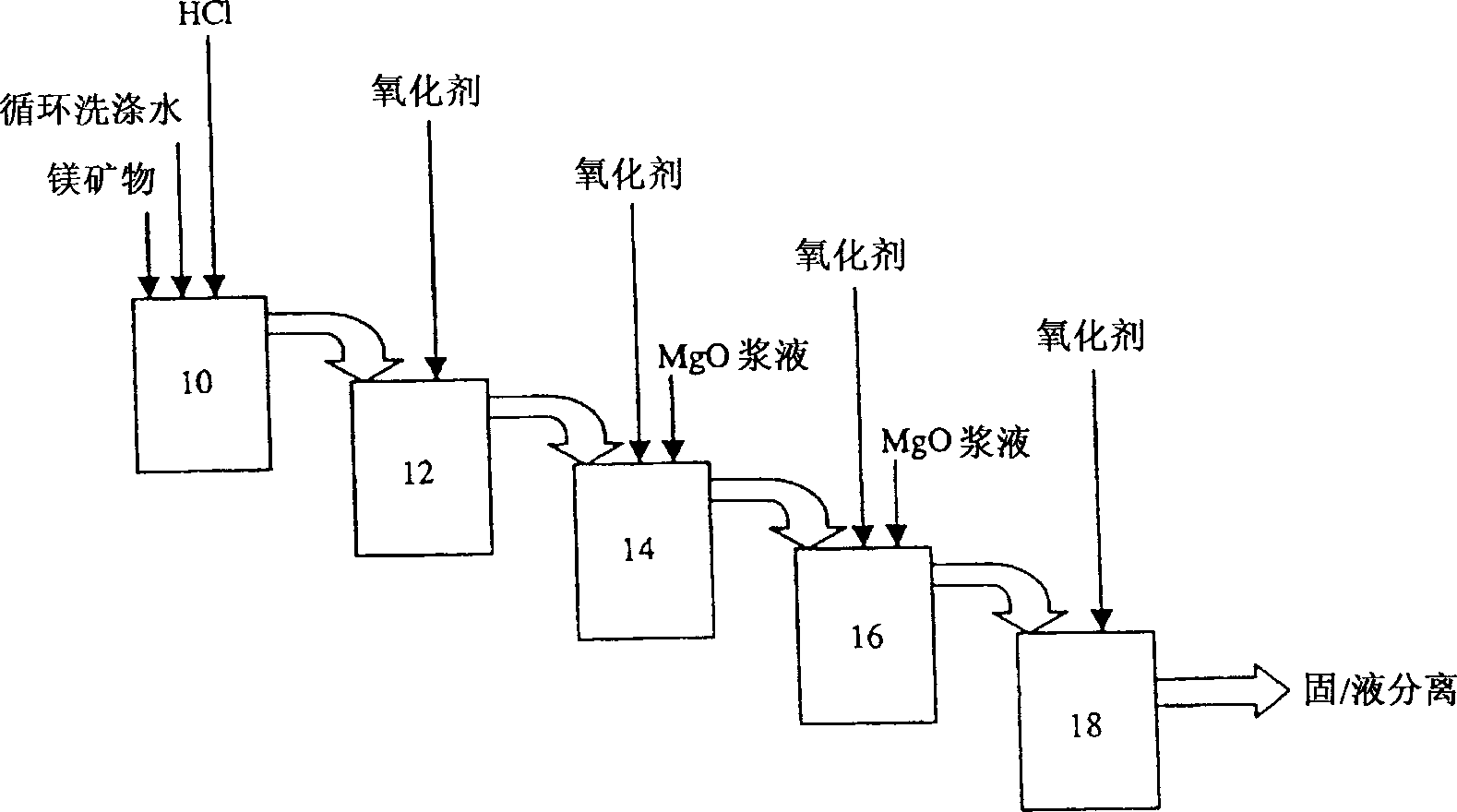

Method for production of high-purity concentrated magnesium chloride solution

The present invention is concerned with a method for the extraction of magnesium from magnesium-containing materials such as magnesite, dolomite and silicates materials like serpentine residues, products from the amphibole or pyroxene group. The magnesium-containing material is first leached in at least one leaching reactor, and subsequently submitted to a series of neutralizing steps in separate reactors under controlled pH and oxydo-reduction potentials. The slurry produced is filtered to produce a substantially pure magnesium chloride solution containing less than 1 ppm of each contaminant present therein.

Owner:NORANDA MINES

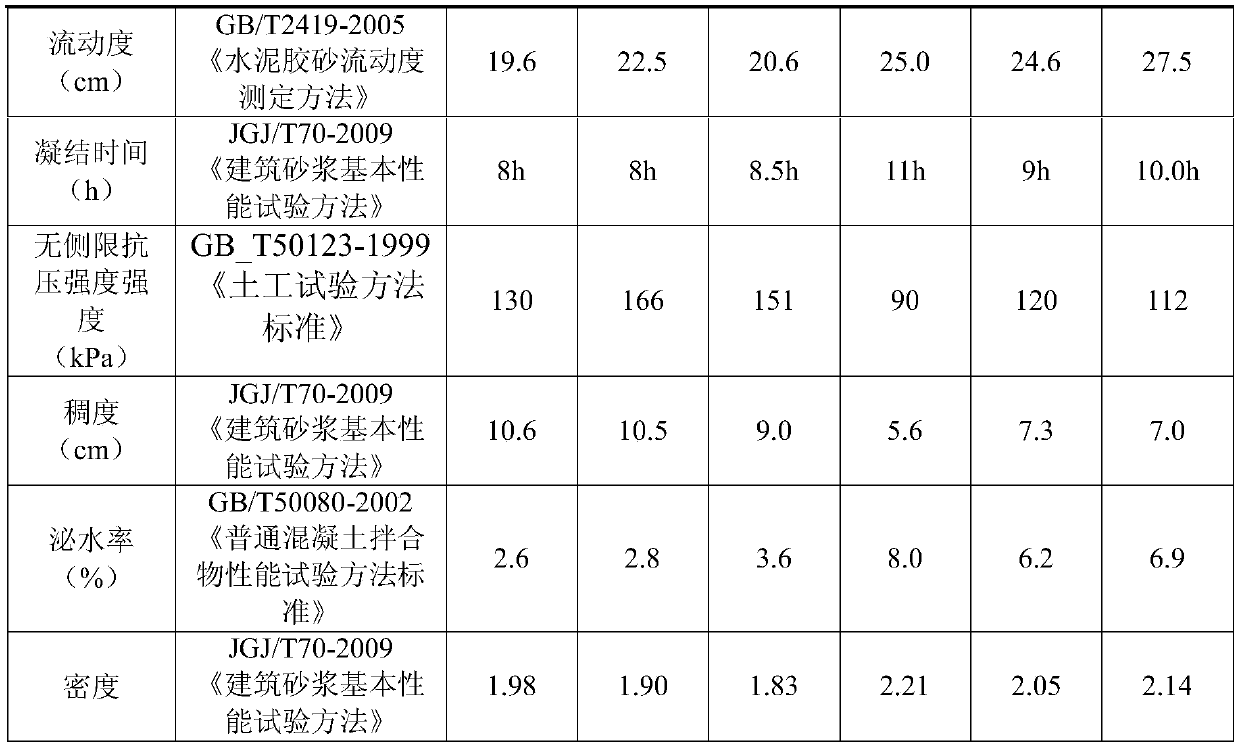

Method for preparing post-wall grouting material by utilizing waste amphibole muck through earth pressure shield

ActiveCN111072347ALow costSolve procurement difficultiesUnderground chambersTunnel liningEnvironmental engineeringAmphibole

The invention relates to a method for preparing a post-wall grouting material by utilizing waste amphibole muck through earth pressure shield. The method comprises the following steps: (1) cleaning and drying muck discharged during shield excavation of a amphibole stratum; (2) conveying the muck treated in the step (1) to a screening machine for screening to remove large particles; and (3) replacing part of medium sand in the original post-wall grouting material with the sieved muck, and then adding bentonite, fly ash, cement and water to prepare the post-wall grouting material. The grouting material comprises cement, coal ash, bentonite and screened muck, the treated muck replaces part of river sand in traditional materials, the problem that sand in the Jinan area is difficult to purchaseis solved, and the muck recycling process method is economical and environmentally friendly.

Owner:HOHAI UNIV +2

Method for producing photovoltaic glass by utilizing recycled glass bottles

The invention discloses a method for producing a photovoltaic glass by utilizing recycled glass bottles. The method comprises the following steps: cleaning: soaking glass in neutral bleaching powder with the concentration of 5% for 3 hours, and then washing with clear water until the impurities of the glass are removed; crushing: crushing the glass bottles into glass sheets by a crusher, wherein the particle size of the crushed glass sheet is less than 50 meshes; material preparation: weighting the raw materials in parts by weight: 100 parts of glass sheets, 130 parts of silica sand, 50 parts of sodium carbonate, 40 parts of limestone, 1 part of alumina powder, 0.5 part of sodium nitrate, 1 part of Amphibole, 0.2 part of cerium oxide, 0.4 part of antimony trioxide and 1 part of antimony oxide; melting: heating the mixed raw materials at 1550-1600 DEG C in a melting furnace; molding: performing calendering molding; heat treatment. The method is environment-friendly, energy-saving and low in cost, and the produced glass process is simple and convenient to control. Dust is not easy to adhere to the surface of the glass and is very easy to scour out by rain. The invention relates to the technical field of glass production and processing.

Owner:安徽省金志新能源科技有限公司

Method for producing glass by using recycled glass bottles

The invention provides a method for producing a glass by using recycled glass bottles relates to the technical field of glass production processing. The method comprises the following steps: carrying out washing: firstly, soaking glass with neutral bleaching powder with the concentration of 5% to 10% for 3 to 10 hours, and then, flushing the glass with clean water until impurities are removed from the glass; carrying out crushing: crushing the glass bottles with a crushing machine so as to obtain glass pieces, wherein the grain size of the crushed glass pieces is smaller than 50 meshes or less; carrying out material preparing: preparing the materials in parts by weight: 100-120 parts of glass pieces, 130-140 parts of silica sand, 50-58 parts of sodium carbonate, 20-30 parts of calcium oxide, 1-5 parts of alumina powder, 5-8 parts of magnesia, 3-5 parts of sodium oxide, 1-2 parts of potassium oxide and 1-2 parts of amphibole; carrying out melting: heating the raw material, obtained after mixing the prepared materials, in a melting furnace at the high temperature of 1,500 DEG C to 1,600 DEG C, so as to form uniform liquid glass; carrying out shaping: carrying out shaping by a blowing method; and carrying out heat treatment. The method is environmentally friendly and energy-saving and is low in cost, and the glass production process is simple and is convenient to control.

Owner:TIANHAO GLASSWARE GRP CO LTD

Glass sheet for optical lens and preparation method thereof

InactiveCN106587615AImprove compactnessHigh strengthOptical surface grinding machinesGlass rolling apparatusN dimethylformamidePolyethylene glycol

The invention provides a glass sheet for an optical lens, and relates to the technical field of optical glass production. The glass sheet is prepared from the following ingredients in percentage by mass: silica sand, sodium carbonate, quartzite, alumina powder, sodium nitrate, amphibole, cerium oxide, diantimony trioxide, tetrabutyl titanate, N,N-dimethylformamide, polyethyleneglycol, a decolourant, a flatting agent and an additive. The produced optical lens has the advantages that the glass strength is high; the compactness is high; the optical performance is good; fragmentation cannot easily occur.

Owner:ANHUI CHANGGENG OPTICS TECH CO LTD

Acid and alkali resisting craft glass and preparation method thereof

InactiveCN108585486AAcid and alkali resistance hasGood acid and alkali resistanceGlass fiberAntimony trioxide

The invention provides acid and alkali resisting craft glass and a preparation method thereof. The craft glass is characterized in that an existing craft glass formula is adjusted and improved; the craft glass is specifically prepared from quartz sand, feldspar powder, asbestos section, dodecanedioic acid, fiberglass mineral powder, ethyltrimethoxysilane, amphibole powder, antimony trioxide and antimony oxide; the raw materials are matched according to the ratio disclosed by the invention, and then are subjected to burdening, melting, molding, tempering and cooling treatment, and thus the acidand alkali resisting craft glass is prepared.

Owner:合肥钢骨玻璃制品有限公司

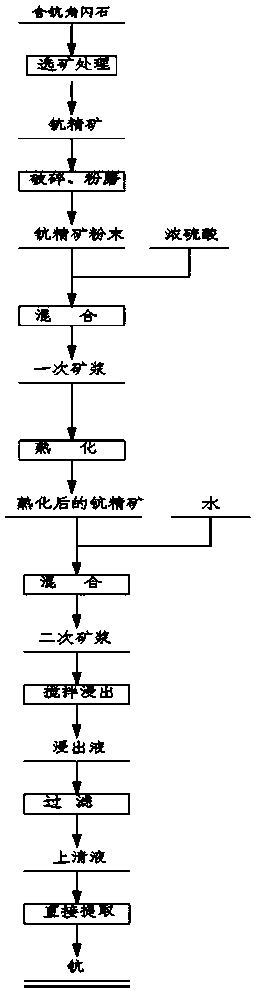

Method for extracting scandium from Sc-containing amphibole concentrates

PendingCN110129590AImprove decomposition rateEasy extractionProcess efficiency improvementRare earthAmphibole

The invention relates to a method for extracting scandium from Sc-containing amphibole concentrates. The method comprises the following steps: carrying out ore dressing treatment on Sc-containing amphibole to obtain scandium concentrates; crushing the scandium concentrates, and grinding the scandium concentrates into powder to obtain scandium concentrate powder; mixing the scandium concentrate powder and concentrated sulfuric acid to obtain primary ore pulp; curing the primary ore pulp at certain temperature to obtain cured scandium concentrates; mixing the cured scandium concentrates and water to obtain secondary ore pulp; mixing and leaching the secondary ore pulp at certain temperature to obtain leachate; and filtering the leachate to obtain supernatant and directly extracting scandiumfrom the supernatant. In the process of extracting the scandium, baking treatment does not need to be additionally carried out on rare earth ores, and the extracting of the scandium no longer needs touse mineral acid as a leaching agent in the leaching process, so that the production procedure is simplified, and the production cost is reduced. The method is clean, simple, easy to operate and suitable for large-scale application and popularization.

Owner:CENT SOUTH UNIV

Decorating plate for interior architecture and preparation method thereof

The invention discloses a decorating plate for interior architecture and a preparation method thereof. The decorating plate is prepared from the following raw materials in parts by weight: 40-70 partsof diatomaceous earth, 16-24 parts of sepiolite, 6-10 parts of attapulgite, 10-20 parts of quartz slit filler, 45-54 parts of river sands, 60-90 parts of straws, 3-6 parts of light calcium carbonate,12-17 parts of water-based epoxy resin, 2-5 parts of a curing agent, 2-4 parts of methylcellulose, 6-20 parts of pulverized fuel ash, 15-20 parts of white cement, 5-12 parts of amphibole, 2-4 parts of ross quartz, 0.3-0.8 part of azodicarbonamide, 3-4 parts of adhesive, 2-5 parts of cinnamon and 1.2-2 parts of astragalus membranaceus. The decorating material is wide in raw material sources, woodconsumption can be reduced since saw dust is not required, the preparation process is simple, components in the decorating plate are synergized, and the prepared finished product has good comprehensive mechanical performance.

Owner:陈勇

Organic composite nano-diameter amphibole fiber reinforced concrete rust inhibitor, preparation method and application thereof

The invention relates to an organic composite nano-diameter amphibole fiber reinforced concrete corrosion inhibitor, and a preparation method and application thereof. The corrosion inhibitor is obtained by the steps of stirring an organic corrosion inhibitor and inorganic nano-diameter amphibole fibers in high speed, and homogenizing; the mass ratio of the organic corrosion inhibitor to the inorganic nano-diameter amphibole fibers is (1-1.5):(2.0-2.5); the invention solves the problem of low penetration resistance capacity of concrete in the prior art; and a comparison experiment result showsthat the organic composite nano-diameter amphibole fiber reinforced concrete corrosion inhibitor has rust resistance capacity under the conditions of choride ions and carbonization, improves the corrosion limit content of reinforcing steel bars, the anti-permeability capacity of a reinforced concrete protection layer, and the performance of an interfacial zone of concrete and reinforcing steel bars, and ensures that the reinforced concrete has high durability and long engineering service life, and various electrochemistry parameters completely meet the rust and corrosion resistance requirements of reinforced steel bars in the reinforced concrete.

Owner:LANZHOU UNIVERSITY +1

Self-cleaning photovoltaic glass production process

InactiveCN106566296AWith self-cleaning functionReduce adhesionGlass rolling apparatusCoatingsAntimony trioxideSilica gel

The invention discloses a self-cleaning photovoltaic glass production process, and relates to the technical field of photovoltaic panel production. The production process comprises the following steps: preparing the raw materials in parts by weight: 130-140 parts of silica sand, 50-58 parts of sodium carbonate, 40-50 parts of limestone, 1-5 parts of aluminum oxide powder, 0.5-0.8 part of sodium nitrate, 1-2 parts of Amphibole, 0.2-0.3 part of cerium oxide, 0.4-0.5 part of antimony trioxide and 1-3 parts of antimony oxide; melting; molding: performing calendering molding; heat treatment: spraying a layer of self-cleaning coating on the surface of glass through annealing and quenching processes, wherein the self-cleaning coating comprises the following components in parts by weight: 10-20 parts of shell powder, 4-6 parts of a binding agent, 4-5 parts of starch, 1-2 parts of chlorite schist powder, 1-3 parts of antimony oxide, 4-6 parts of octadecyl silane bonded silica gel and 3-6 parts of peach gum. The photovoltaic glass disclosed by the invention has a self-cleaning function, and dust is not easy to adhere to the surface of the photovoltaic glass and is easy to wash away under the rain, and a large amount of manpower and physical resources can be saved.

Owner:安徽省金志新能源科技有限公司

Composition of a cement additive material as an additive to cementitious mineral admixtures, and utilised as latent hydraulic binders to improve the outcome of cementitious products

ActiveUS10774001B2Easy to addImprove performanceSolid waste managementCement productionHydration reactionSilicic acid

A composition of a cement additive material to improve durability of cementitious structures, was disclosed. The cement additive composition includes an admixture of one or more of divalent magnesium metal silicates with capacity to act as a latent hydraulic binder in said composition activated by a hydration process under aqueous conditions, and in particular the divalent metal silicate is magnesium-dominated silicate, preferably comprising mineral groups of olivines, orthopyroxenes, amphiboles, talc and serpentines or mixtures thereof. The composition also includes chloride ions or brine. Applications of the compositions are also disclosed, in particular to utilize a property of hydration as a major trigger for the latent hydraulic reaction of magnesium silicates, particularly for said olivines, when exposed to water and brines, in order to obtain a cementitious material becoming self healing.

Owner:RESTONE AS

Organic composite nano-diameter amphibole fiber reinforced concrete corrosion inhibitor, and preparation method and application thereof

The invention relates to an organic composite nano-diameter amphibole fiber reinforced concrete corrosion inhibitor, and a preparation method and application thereof. The corrosion inhibitor is obtained by the steps of stirring an organic corrosion inhibitor and inorganic nano-diameter amphibole fibers in high speed, and homogenizing; the mass ratio of the organic corrosion inhibitor to the inorganic nano-diameter amphibole fibers is (1-1.5):(2.0-2.5); the invention solves the problem of low penetration resistance capacity of concrete in the prior art; and a comparison experiment result showsthat the organic composite nano-diameter amphibole fiber reinforced concrete corrosion inhibitor has rust resistance capacity under the conditions of choride ions and carbonization, improves the corrosion limit content of reinforcing steel bars, the anti-permeability capacity of a reinforced concrete protection layer, and the performance of an interfacial zone of concrete and reinforcing steel bars, and ensures that the reinforced concrete has high durability and long engineering service life, and various electrochemistry parameters completely meet the rust and corrosion resistance requirements of reinforced steel bars in the reinforced concrete.

Owner:LANZHOU UNIVERSITY +1

A method for preparing saponite crystals under hydrothermal conditions

Owner:NORTHEASTERN UNIV LIAONING

Anti-static tile and preparing method thereof

The invention provides an anti-static tile and a preparing method thereof, and relates to the field of building and ornament materials. The preparing method of the anti-static tile comprises the following steps of heating amphibole suspension liquid in water bath to 70 DEG C, stirring and then dropping a mixed hydrochloric acid solution in the amphibole suspension liquid, keeping the system pH value at 1.0, after reaction is completed, conducting suction filtration, and then washing, drying and calcining precipitate to obtain conductive powder; taking epoxy resin E51 and N-methyl pyrrolidone,conducting stirring and dissolving, then adding the conductive powder, a water reducing agent and distilled water, and conducting slow ball-milling and ultrasonic agitation to obtain a sizing agent for use; mixing the obtained sizing agent and a glaze material to be uniform, conducting ball-milling on the mixture to the mesh size of 80, conducting dry pressing on the mixture, and then drying and calcining the mixture to obtain the anti-static tile. The prepared anti-static tile has good static resistance, fracture resistance and stain resistance.

Owner:深圳市欧科力科技有限公司

Method for preparing crystallized building materials from tailings

ActiveCN103864307AAvoid process problemsAvoid the problem of high porosity of productsPorosityHigh rate

The invention relates to a method for preparing crystallized building materials. The crystal components of building materials are designed according to the tailing components, the crystal components are one or a mixture of two or more of wollastonite, diopside, amphibole, olivine, spinel, feldspar, spodumene and mullite stone crystalline phases. The crystallized glass having natural stone texture and spot effect, which is difficult to obtain by a direct crystallization method, is prepared by the method disclosed by the invention and the problems of high energy consumption and high rate of porosity of the product in a sintering crystallization method are solved. Furthermore, production costs can be greatly reduced by using 70-99% of the tailings to achieve the purpose of turning waste into treasure. Either aesthetics or performance indicators of crystallized building materials prepared by the invention are better than those of the natural stone, cost is only 1 / 3-1 / 2 of that of the natural stone, and the sales prices of crystallized building materials are comparable to domestic imported natural marbles, thus having broad market prospects.

Owner:承德华富玻璃技术工程有限公司

Production process of self-cleaning optical lens glass

InactiveCN106698936AWith self-cleaning functionReduce adhesionAntifouling/underwater paintsPaints with biocidesAntimony trioxideSilica gel

The invention relates to a production process of self-cleaning optical lens glass. The process is characterized by including the following steps: material compounding: by weight, compounding 130-140 parts of silica sand, 50-58 parts of sodium carbonate, 40-50 parts of quartz stone, 1-5 parts of alumina powder, 0.5-0.8 part of boron oxide, 1-2 parts of amphibole, 0.2-0.3 part of cerium oxide, and 0.4-0.5 part of antimony trioxide; melting; molding: performing calendaring molding at 800-1000DEG C; heat treatment, grinding and polishing; spraying: spraying a layer of self-cleaning coating on the glass surface, wherein the self-cleaning coating comprises the following components: 10-20 parts of shell powder, 4-6 parts of a binder, 1-2 parts of chlorite schist powder, 1-3 parts of antimony oxide, 4-6 parts of octadecyl silane bonded silica gel, and 3-6 parts of peach gum. The photovoltaic glass provided by the invention has self-cleaning function, dust does not adhere to the glass surface easily, and the photovoltaic glass has high strength, high compactness, and good optical properties.

Owner:ANHUI CHANGGENG OPTICS TECH CO LTD

Bastnaesite beneficiation method

The invention provides a method for beneficiating bastnaesite. The ore beneficiation method includes a step of adjusting the pH value of the ore pulp and a rare earth flotation process in sequence; wherein, the step of adjusting the pH value of the ore pulp includes adjusting the pH of the ore pulp to 8.5-9.5 by adding alkaline substances. Applying the technical solution of the present invention, by adjusting the pH value of the flotation system, the sodium-iron amphibole is effectively suppressed, and the problem of low-grade rare earth concentrate and high iron content is solved; in addition, because only alkali substances need to be added Adjusting the pH value of the slurry is easy to operate and the index is stable; thus, the rare earth concentrate can be obtained with good quality and significant economic benefits through the inhibitor of sodium amphibole.

Owner:CHINA ENFI ENGINEERING CORPORATION

A kind of beneficiation process of high iron nepheline mine

InactiveCN105964401BReduce contentEmission reductionFlotationMagnetic separationNephelineNon magnetic

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Method for preparing fluorine amphibole glass ceramic by using reactive crystallization-sintering method

InactiveCN101844869BImprove machinabilityReduce manufacturing costPolyvinyl alcoholEnergy conservation

The invention relates to a method for preparing fluorine amphibole glass ceramic by using a reactive crystallization-sintering method. The method comprises the following steps of: separating waste glass, cleaning and pulverizing to prepare glass powder; adding silicate crystals and fluoride powder with a certain proportion, uniformly mixing and then adding PVA (Polyvinyl Alcohol) adhesive with a weight ratio of 2-10 percent to the mixed powder for mould pressing and molding; and sintering by using an ordinary electric furnace in normal pressure atmosphere to prepare the fluorine amphibole glass ceramic. Compared with the prior art, the method has the advantages of low production cost, simple production process, no need of melting fluosilicate glass with specific components, low sintering temperature, energy saving, and the like. The fluorine amphibole glass ceramic produced by the method has the compressive strength of 150-250 MPa, the bending strength of 50-70 MPa, the density of 2.2-2.4g / cm<3> and good processability, can be drilled and turned by using ordinary machining equipment and provides a novel approach for recycling the waste glass.

Owner:DALIAN JIAOTONG UNIVERSITY

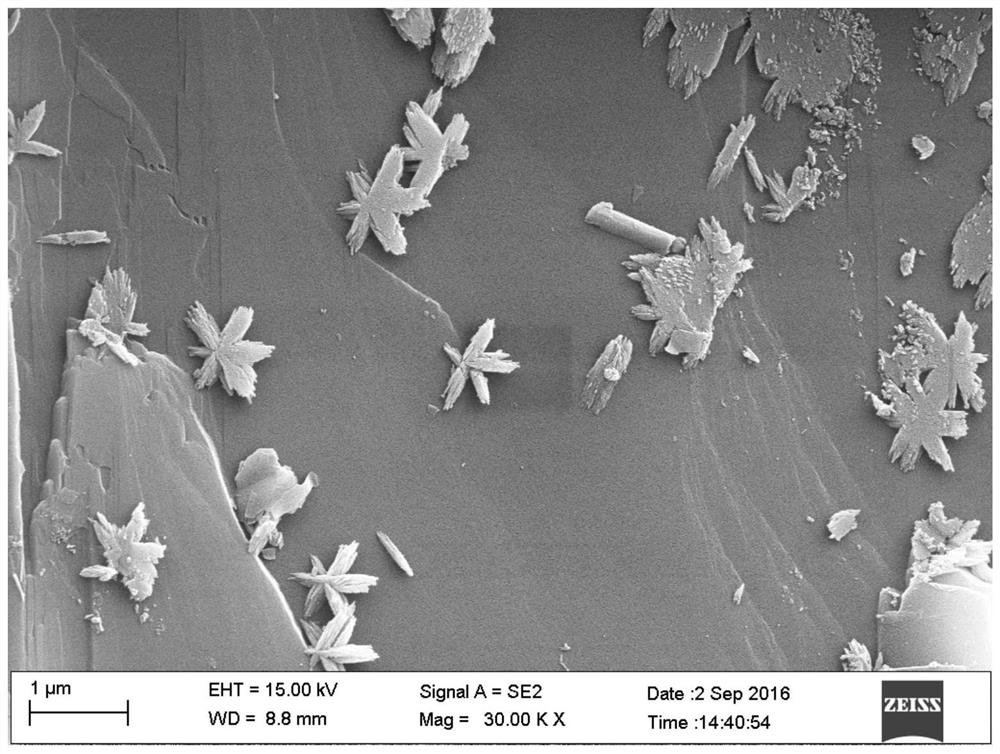

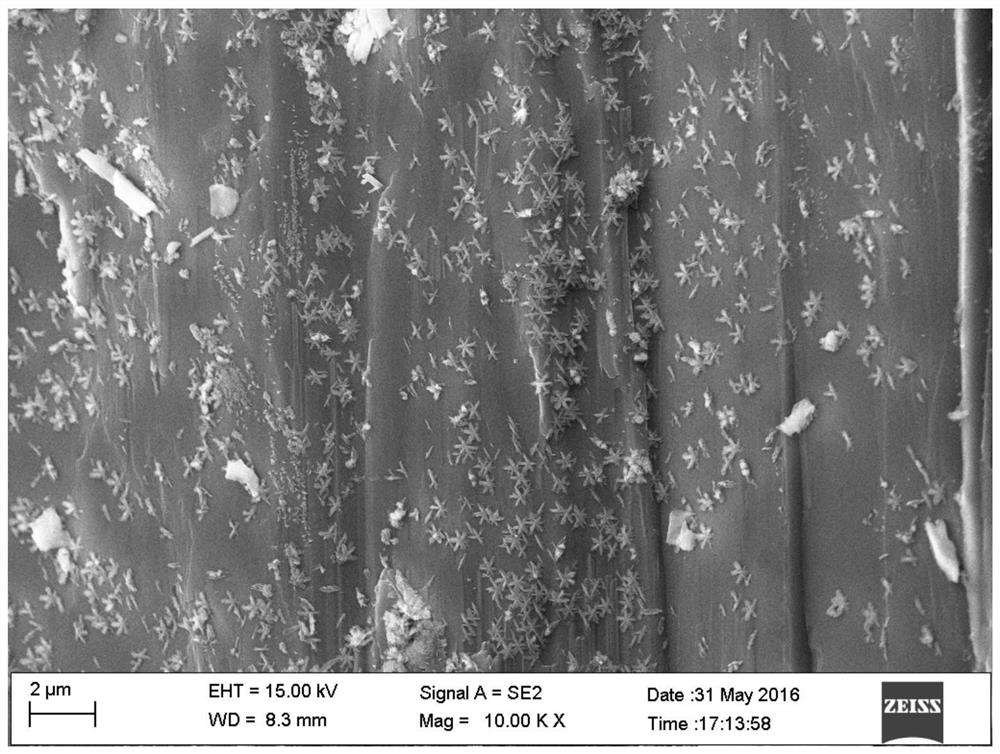

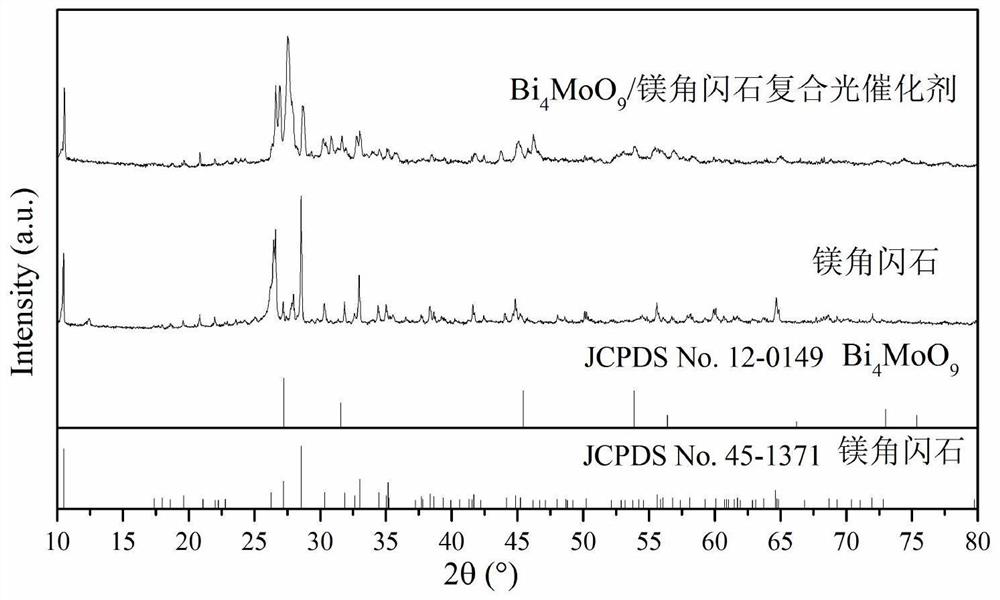

a bi 4 moo 9 Preparation method of amphibole composite photocatalyst

ActiveCN110314679BHigh yieldImprove solubilityWater/sewage treatment by irradiationWater treatment compoundsPhysical chemistryGlycerol

The invention provides a Bi 4 MoO 9 / the preparation method of amphibole composite photocatalyst, comprises: (1) Bi(NO 3 ) 3 ·5H 2 O was mixed with glycerol to obtain solution A; (2) ultrasonically dispersed amphibole in deionized water to obtain solution B; (3) (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in deionized water to obtain solution C; (4) NH 4 HCO 3 Dissolve in deionized water to obtain solution D; (5) slowly add solution B to solution A to obtain solution E; (6) mix solution C and solution D to obtain solution F; (7) add solution F to solution E , after the water bath reaction, the reaction solution was post-treated to obtain Bi 4 MoO 9 / amphibole composite photocatalyst. Bi prepared by the inventive method 4 MoO 9 / amphibole composite photocatalyst, amphibole as Bi 4 MoO 9 carrier material, significantly improving the Bi 4 MoO 9 Natural sedimentation rate and high yield (more than 90%), adopt the Bi prepared by the inventive method 4 MoO 9 / Amphibole composite photocatalyst has excellent visible light catalytic performance.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com