Patents

Literature

1492 results about "Natural stone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

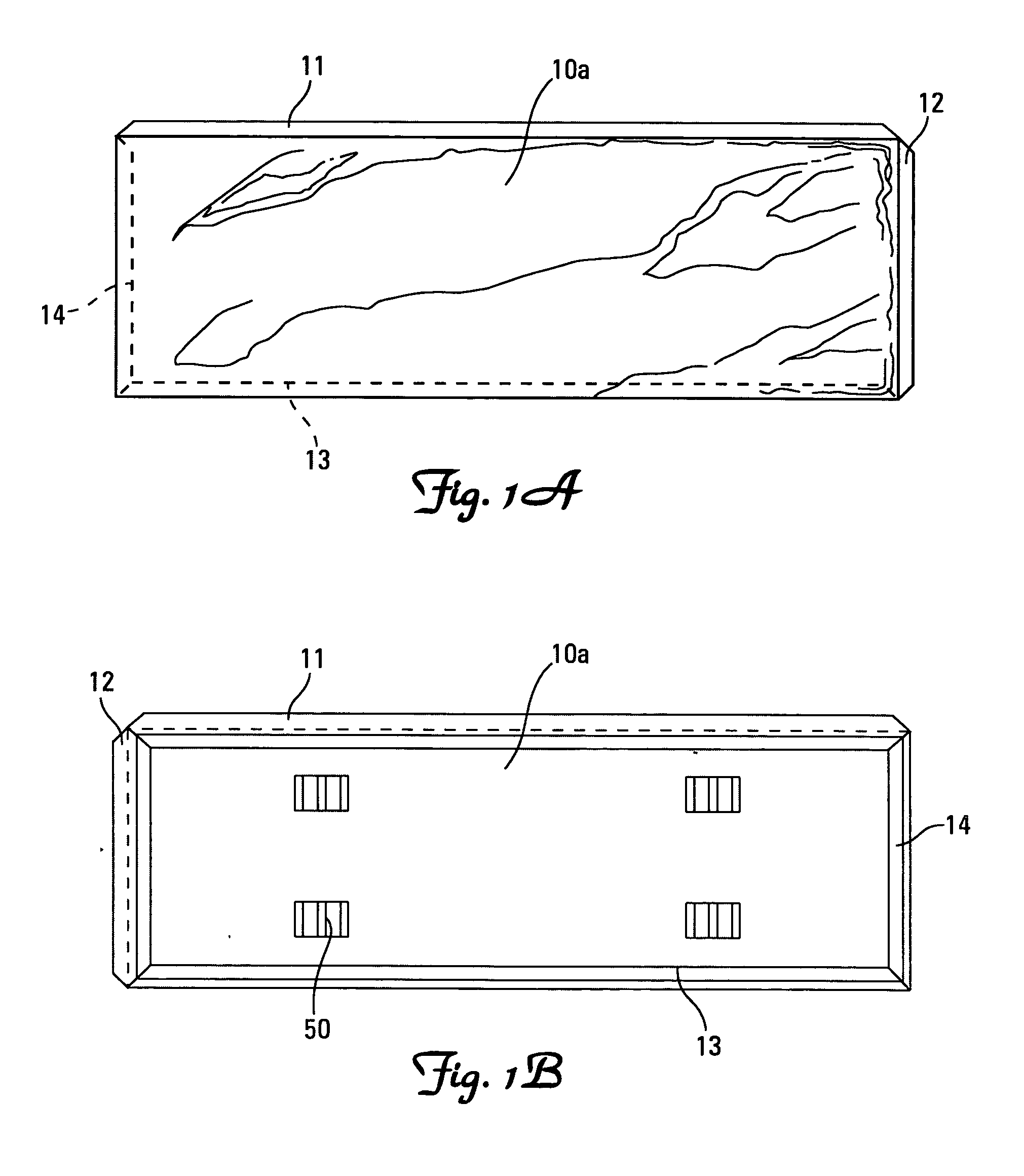

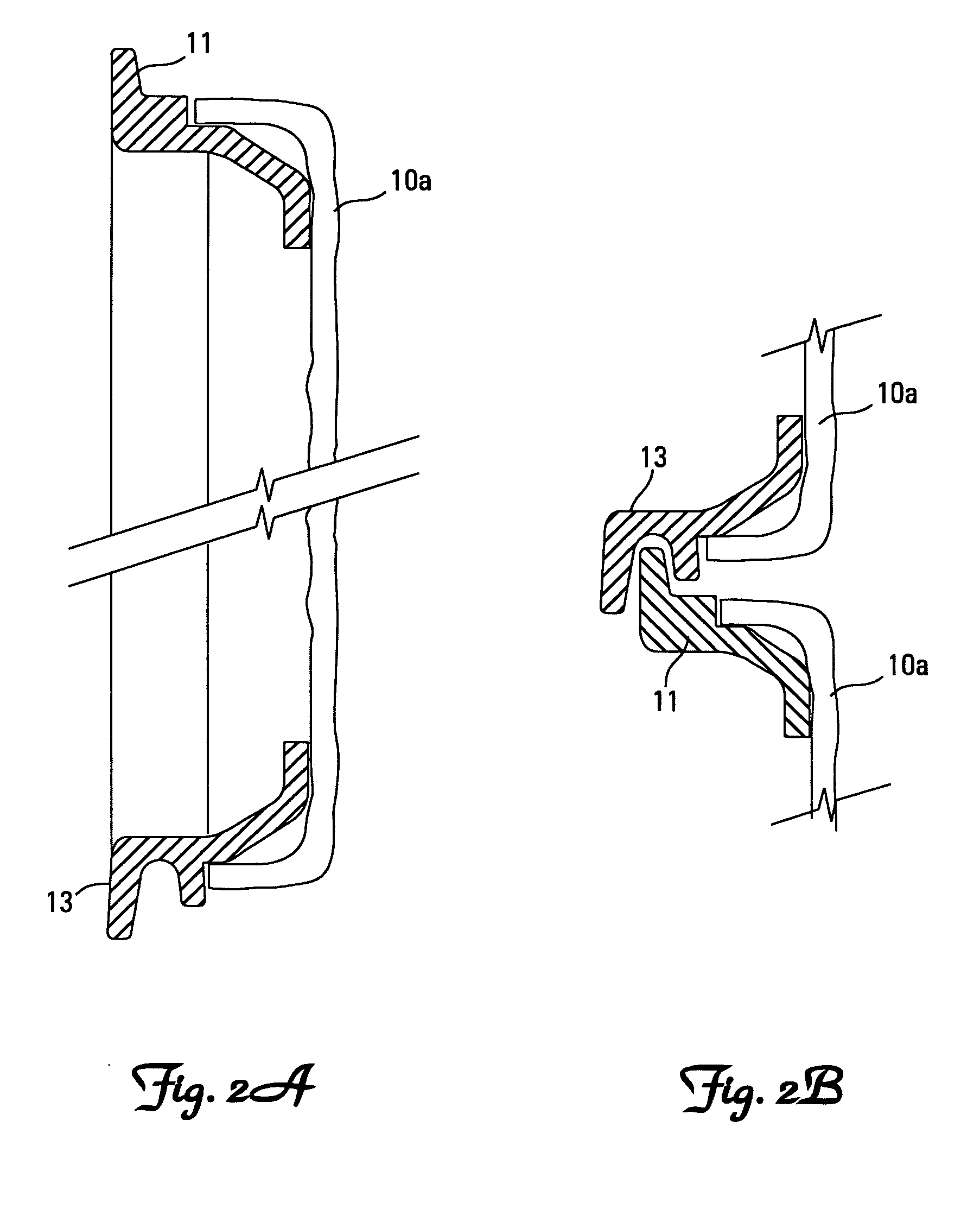

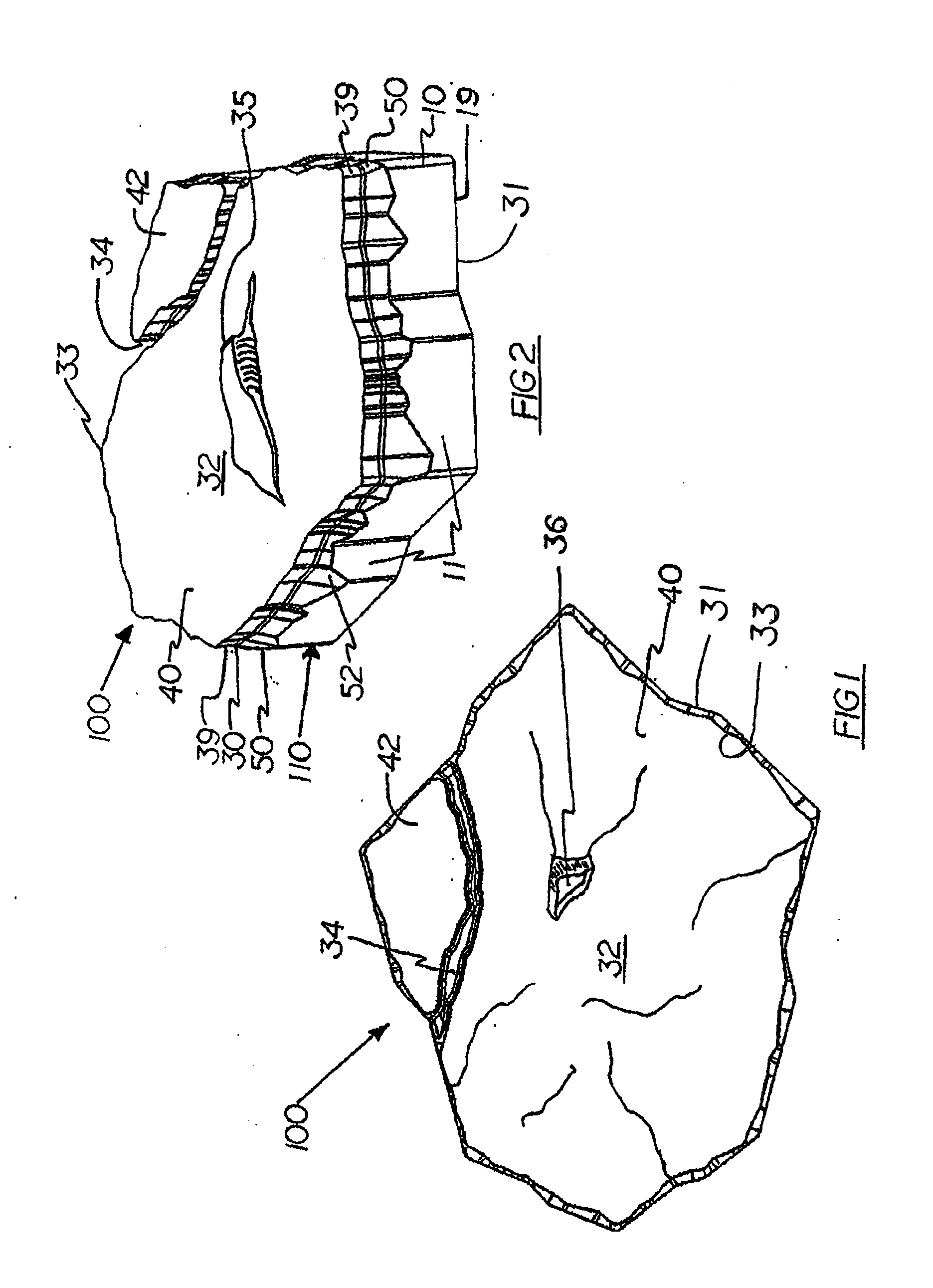

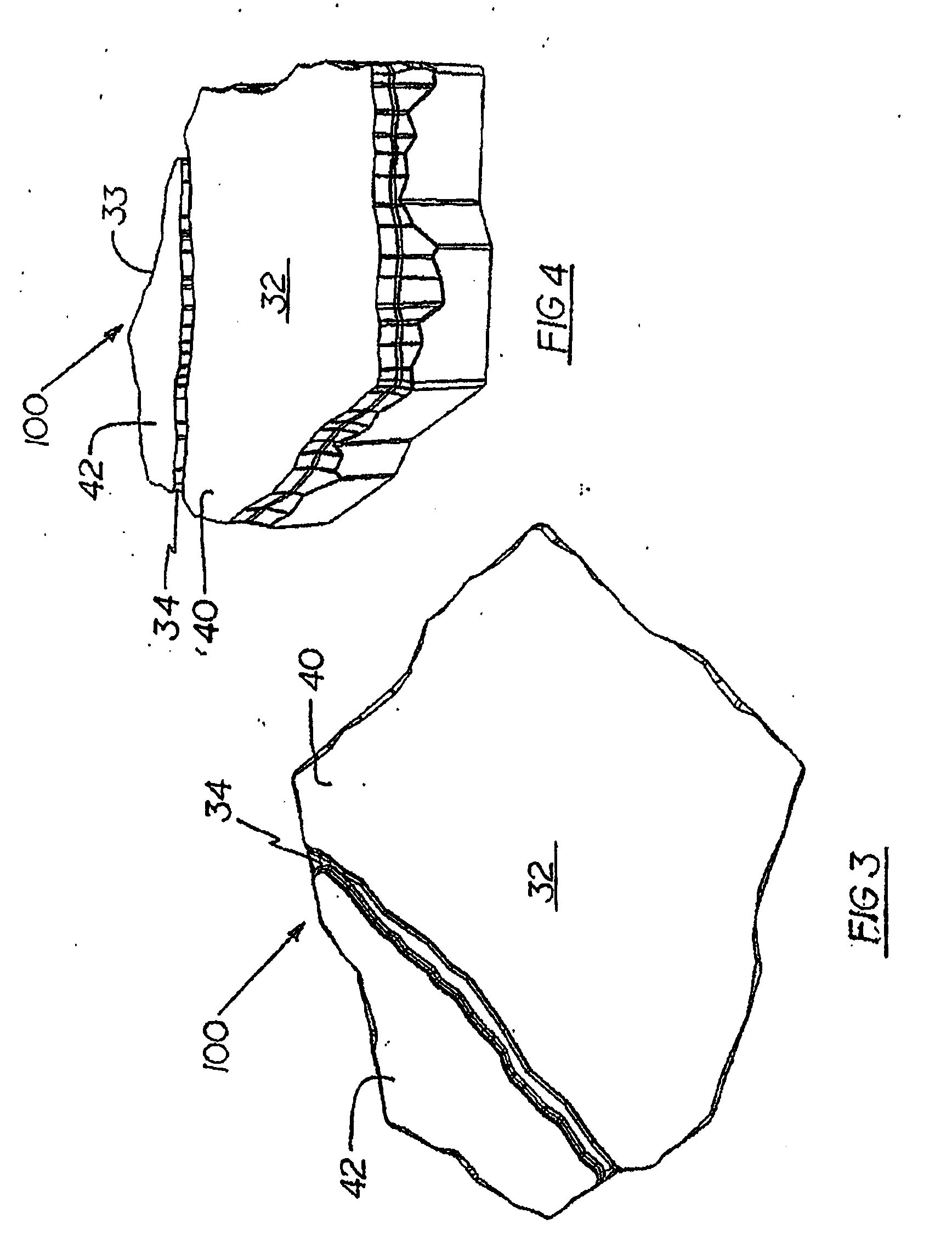

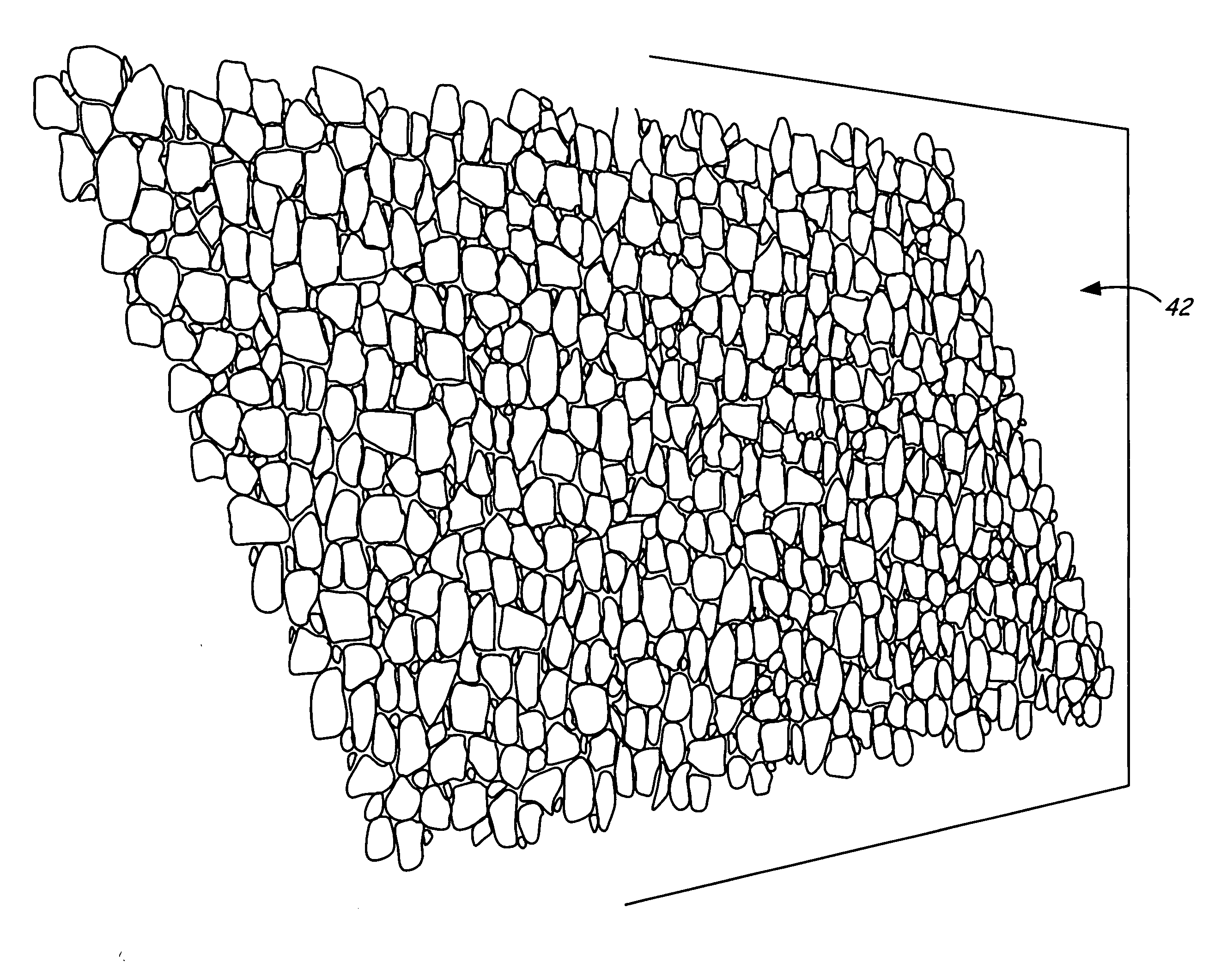

Dry-cast concrete blocks and manufacturing process therefor

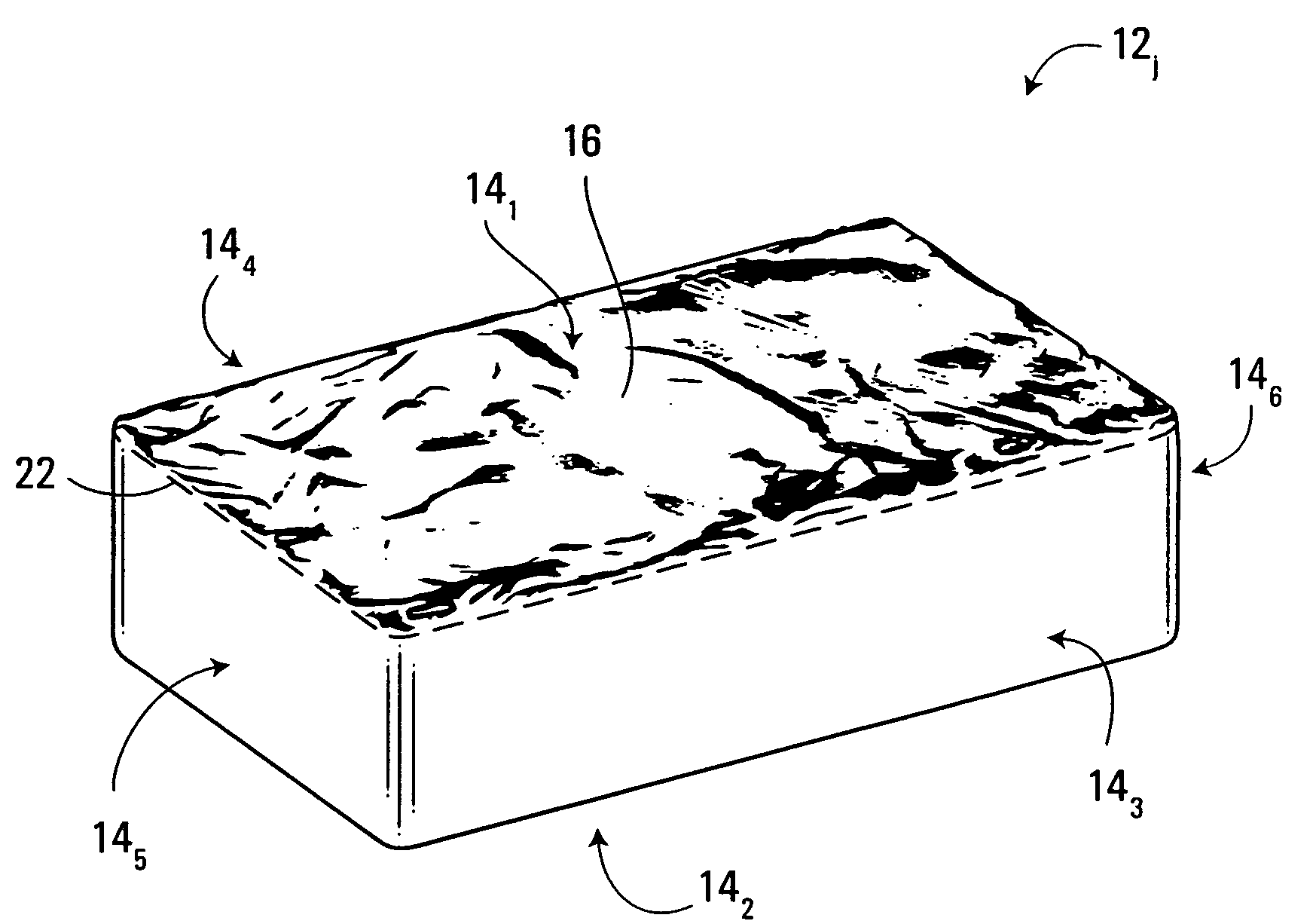

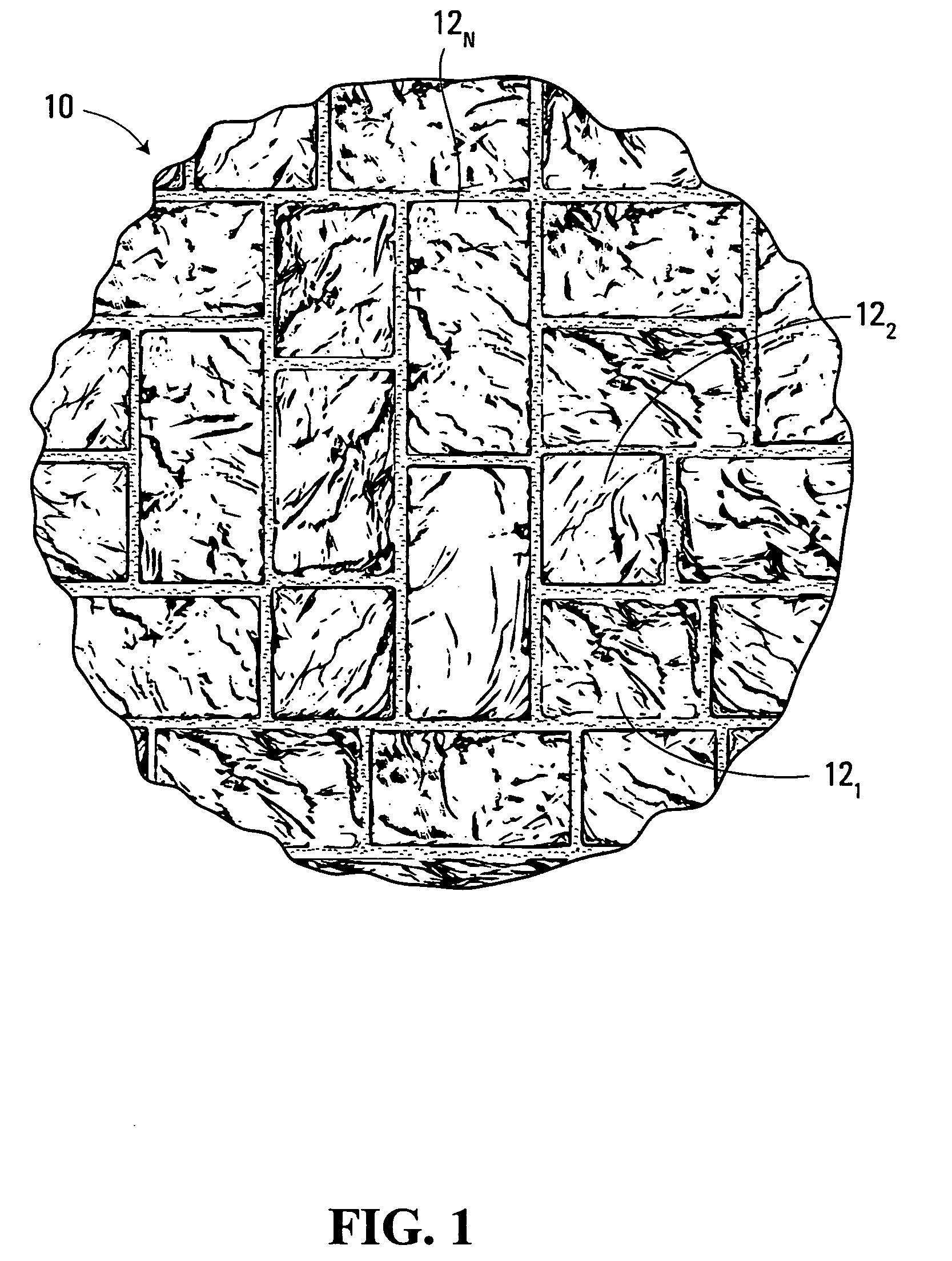

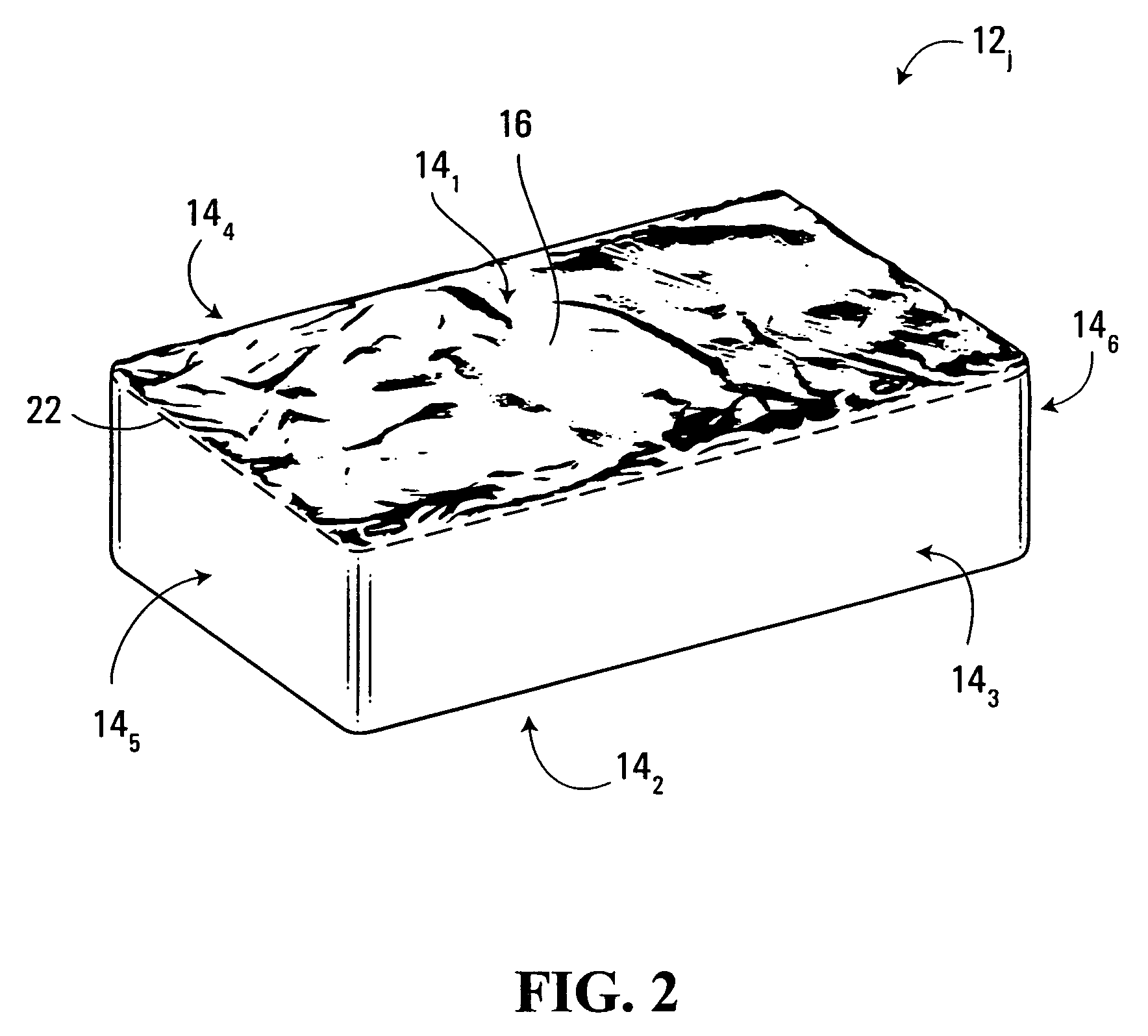

A dry-cast concrete block is provided. The dry-cast concrete block comprises a surface to be exposed, at least a portion of the surface having a cast texture with a natural stone appearance. The cast texture may have a surface level difference of greater than 4 mm. In one example of implementation, the dry-cast concrete block may be a paving unit, in which case the surface level difference may be greater than 6 mm, such as between 6 mm and 12 mm. In another example of implementation, the dry-cast concrete block may be a wall construction unit, in which case the surface level difference may be greater than 15 mm, such as between 15 mm and 25 mm. Each of a plurality of points of the cast texture may define a respective texture angle between 75° and 90°. The cast texture may comprise at least one valley each having a respective depth greater than 4 mm. A process for manufacturing such a concrete block is also provided.

Owner:OLDCASTLE BUILDING PROD CANADA INC

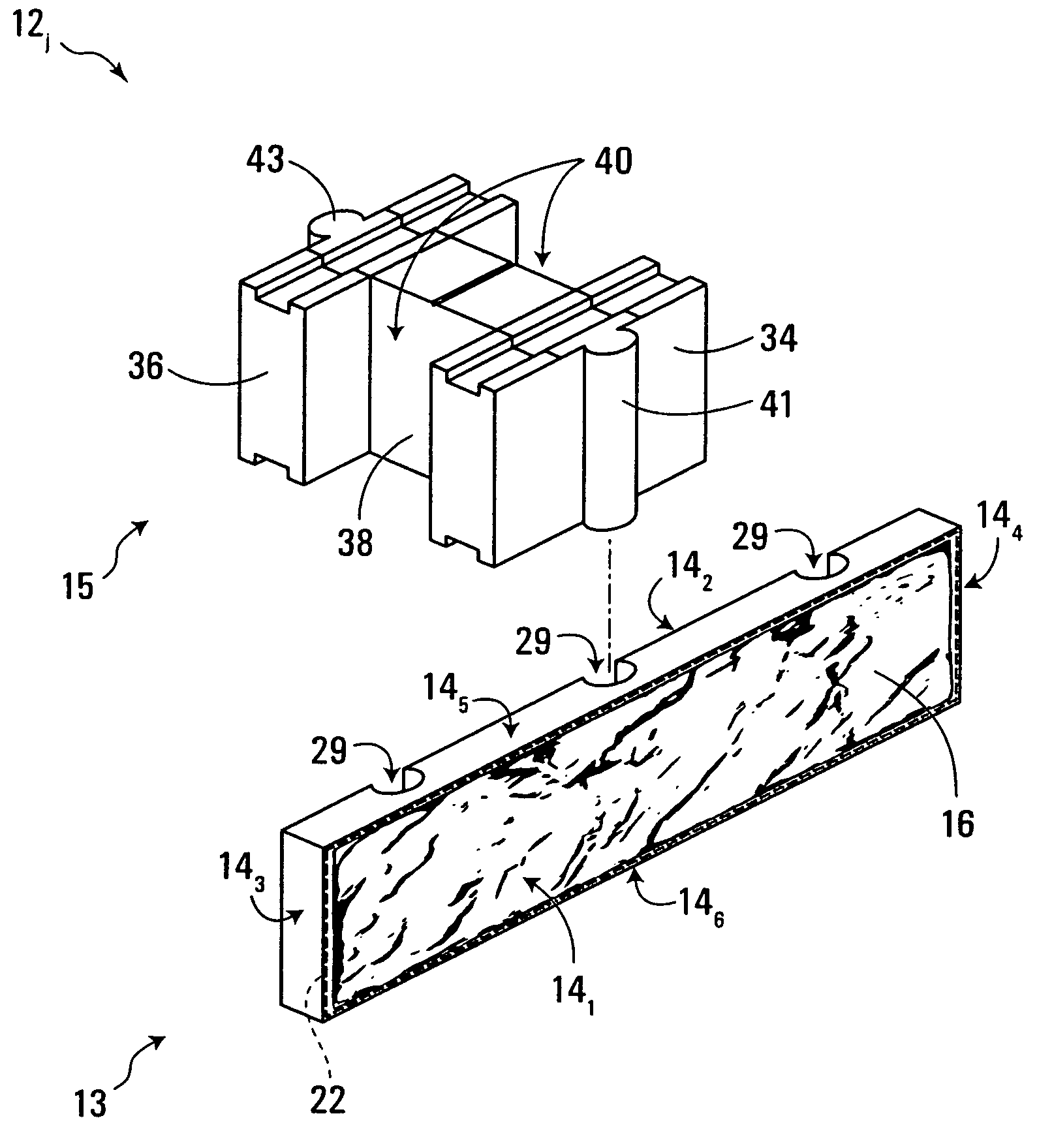

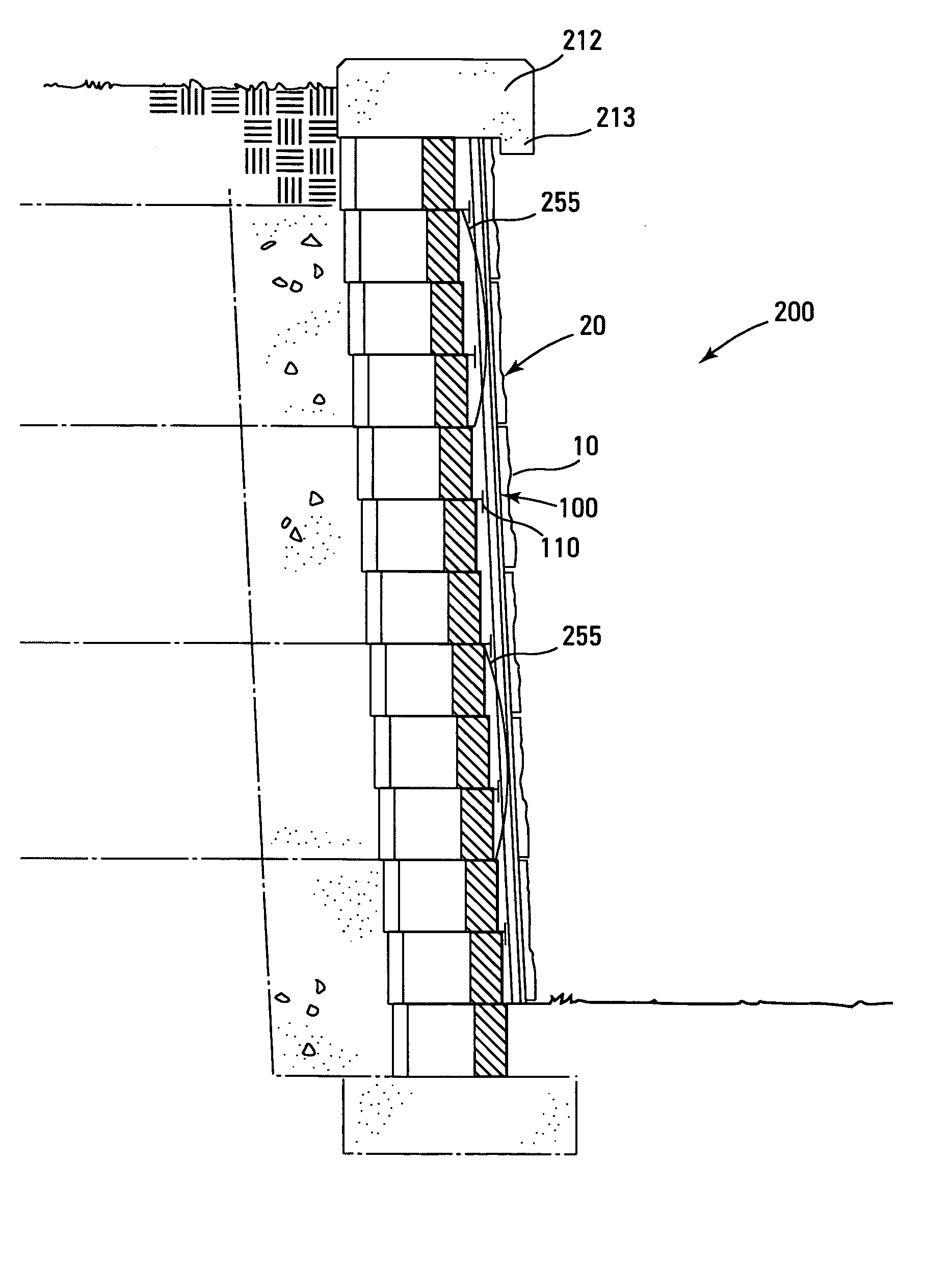

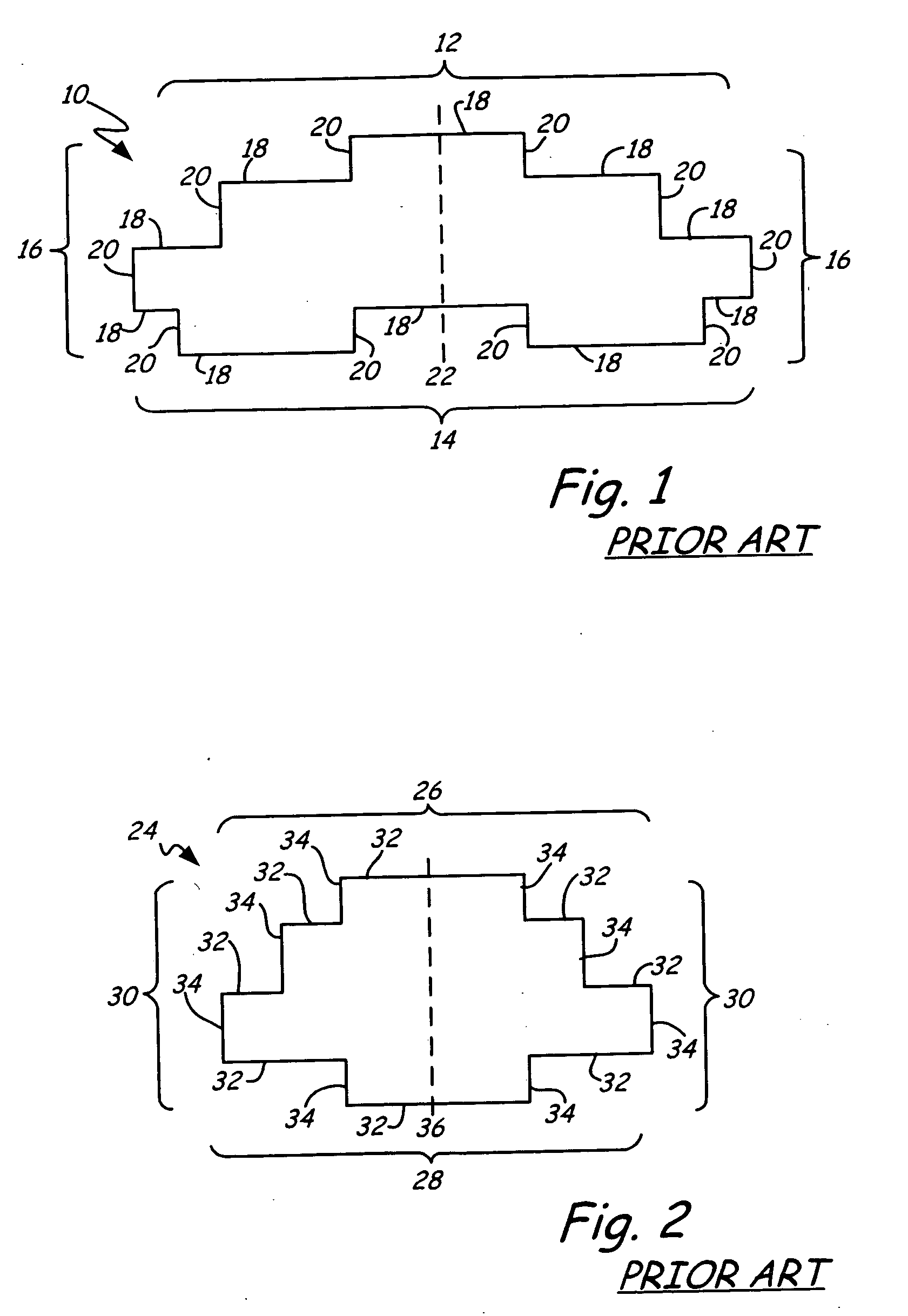

Concrete block system

A dry-cast concrete block system for use in a structure. The dry-cast concrete block system comprises a support block comprising a first coupling part and a face block comprising a second coupling part. The first coupling part and the second coupling part enable the face block to be coupled to the support block. The face block comprises a surface adapted to be exposed when the face block is coupled to the support block and the dry-cast concrete block system is positioned in the structure. In one embodiment, at least a portion of the surface has a cast texture with a natural stone appearance. In one embodiment, the structure is a wall and the concrete block system is a wall block system. For example, the wall may be a retaining wall and the wall block system may be a retaining wall block system. In another embodiment, the structure is a column and the concrete block system is a column block system. In yet another embodiment, the structure is steps and the concrete block system is a steps block system.

Owner:OLDCASTLE BUILDING PROD CANADA INC

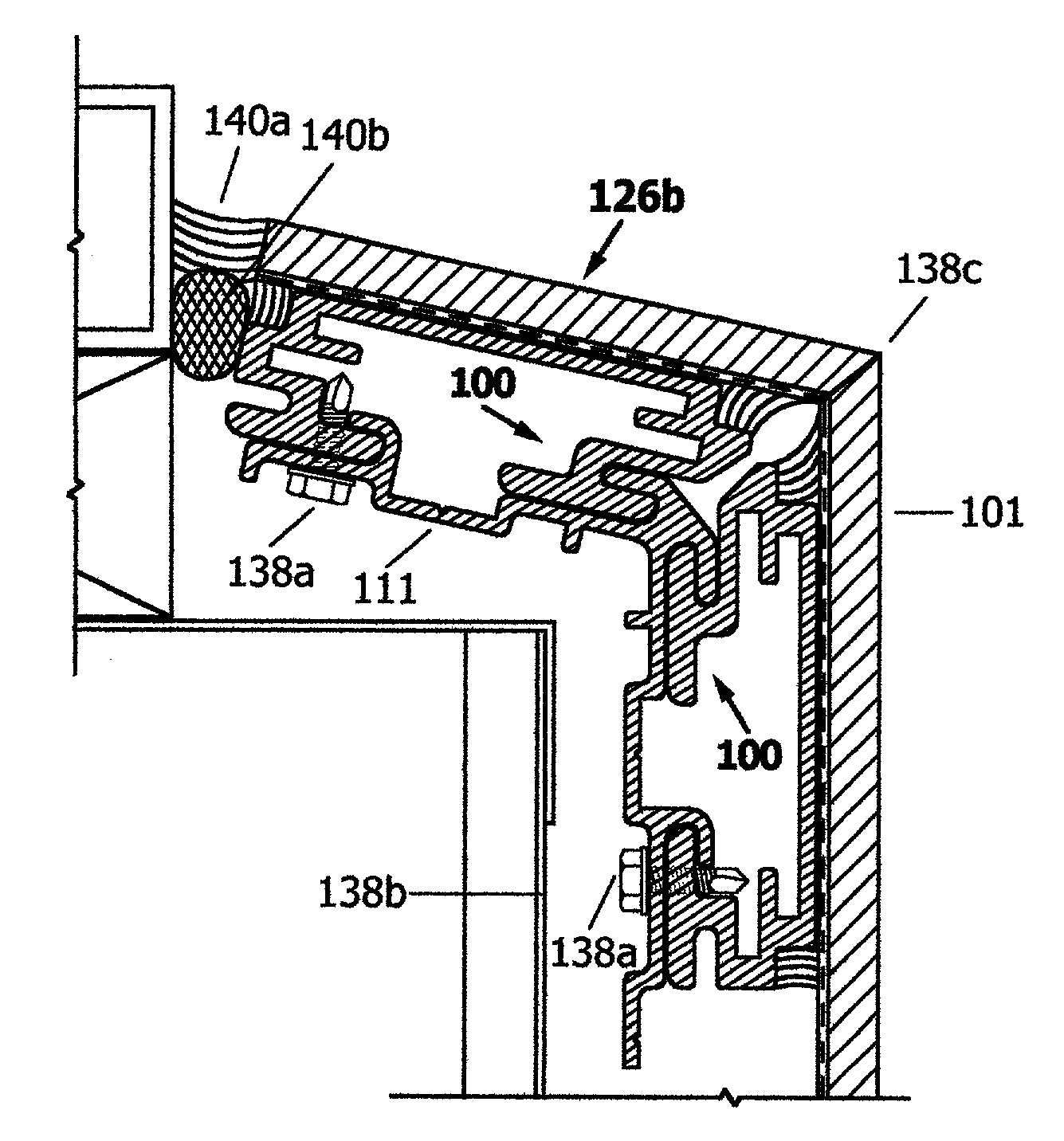

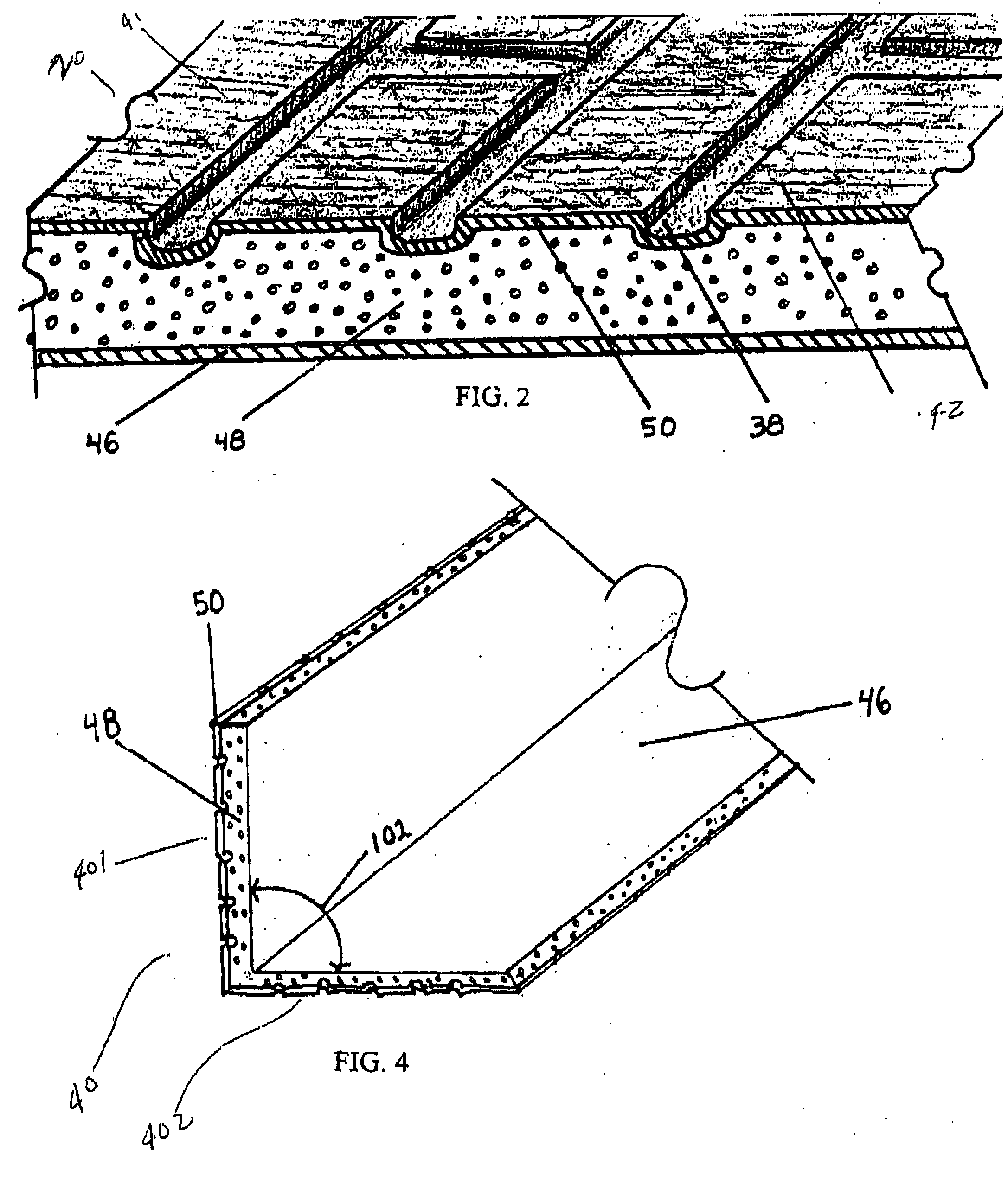

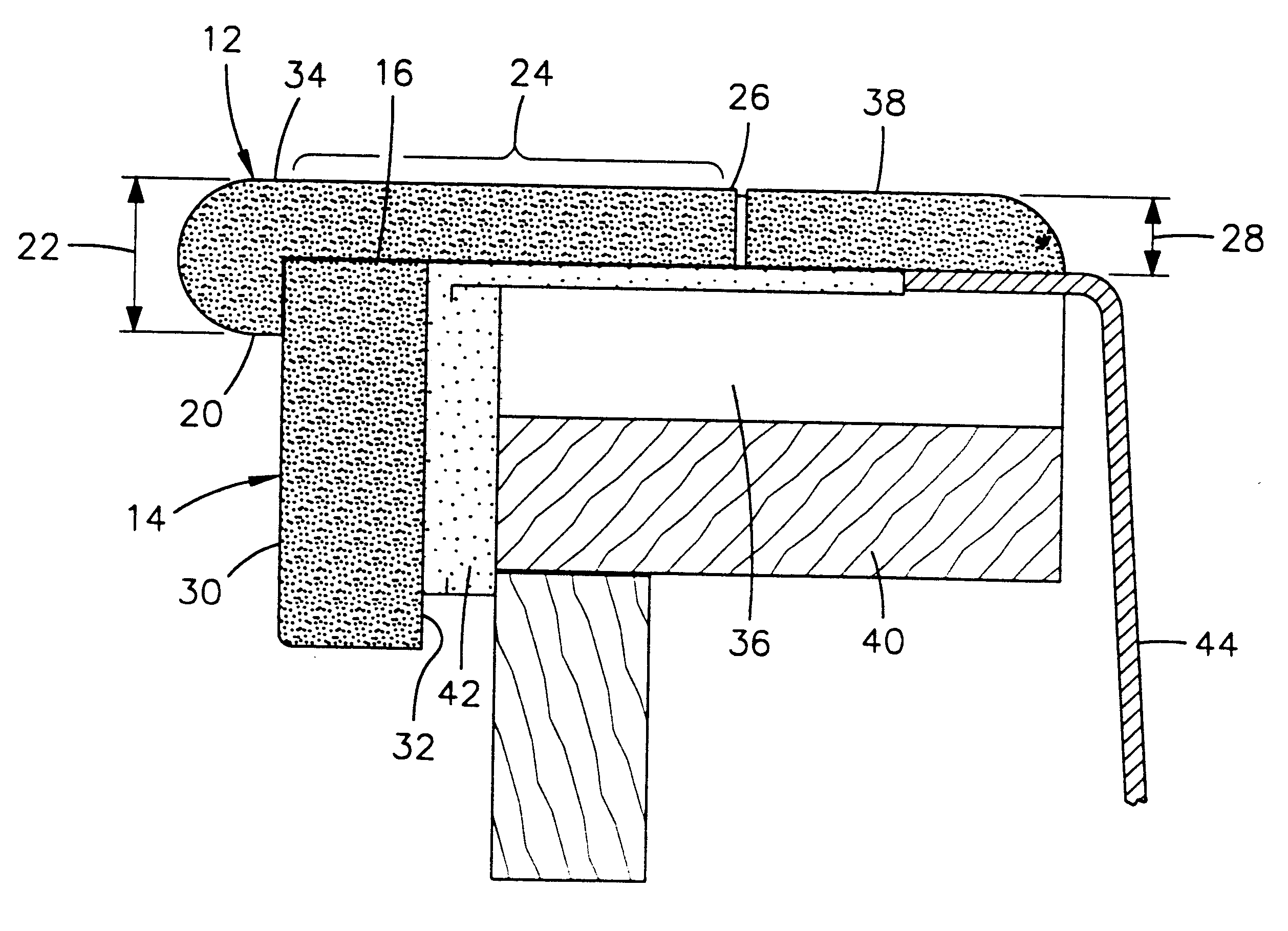

Exterior wall cladding system for panels of thin reinforced natural stone

An installation system designed specifically for thin reinforced natural stone panels used as exterior cladding, re-cladding, or over-cladding of buildings is comprised of a series of extruded aluminum shapes which, when properly applied to the back side of the thin reinforced stone panels, provide structural support for the thin panels and facilitate their installation and will also provide the means for the panels to be pre-assembled in order to obtain desired shapes or profiles and to be easily installed on the building. The series, or family, of extruded aluminum shapes are designed to mate or interlock to perform a variety of tasks such as perimeter frames, structural stiffeners, corner angle supports, interlocking sleeves, runner clips which facilitate attachment to various substrates of a building such as steel stud framing, aluminum curtain wall frames, brick or concrete walls or plywood sheathing.

Owner:THIN STONE SYST

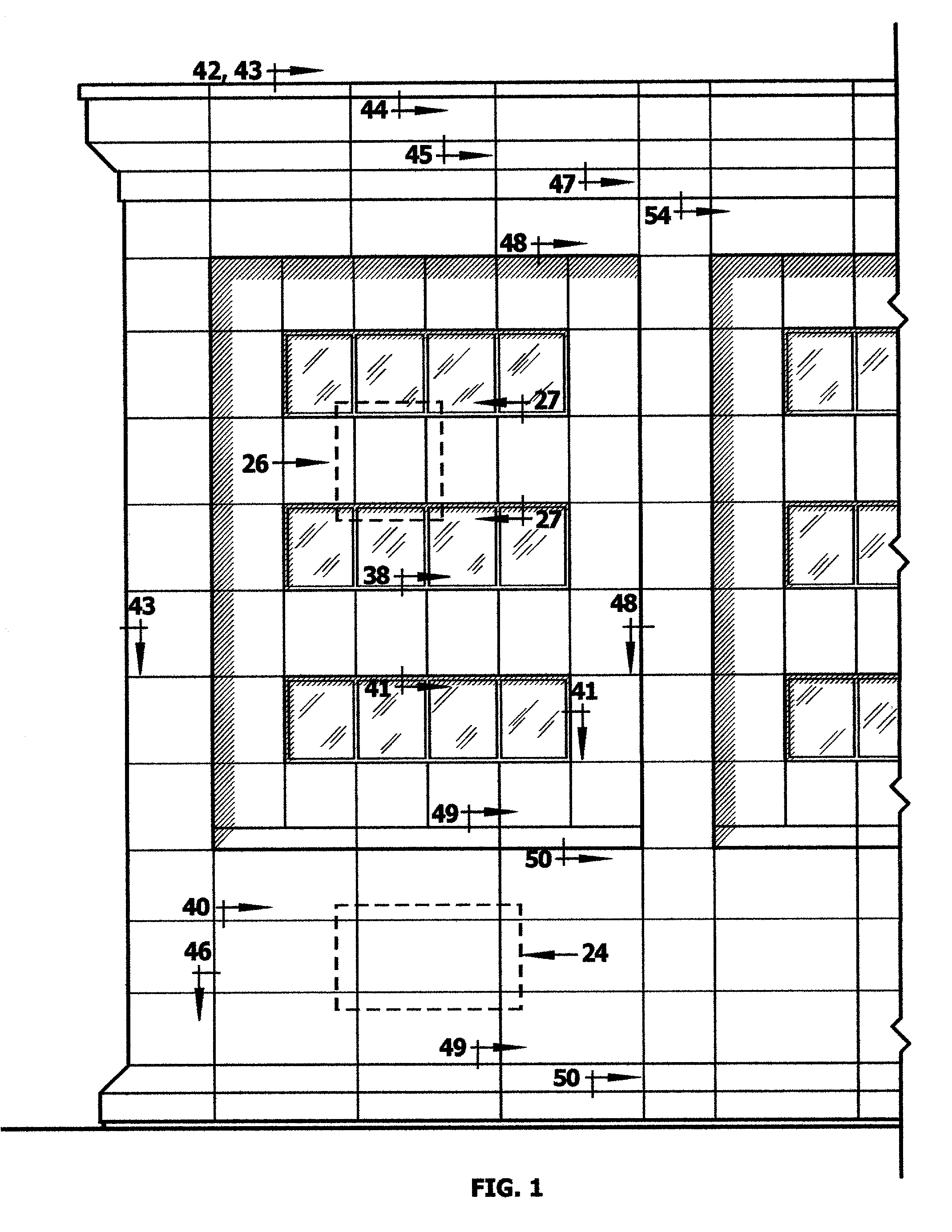

Method and apparatus for forming building panels and components which simulate man-made tiles and natural stones

InactiveUS20050064128A1Easy to handleEasy to removeCovering/liningsNatural patternsArchitectural engineeringNatural stone

Owner:LANE JOHN CLINTON +2

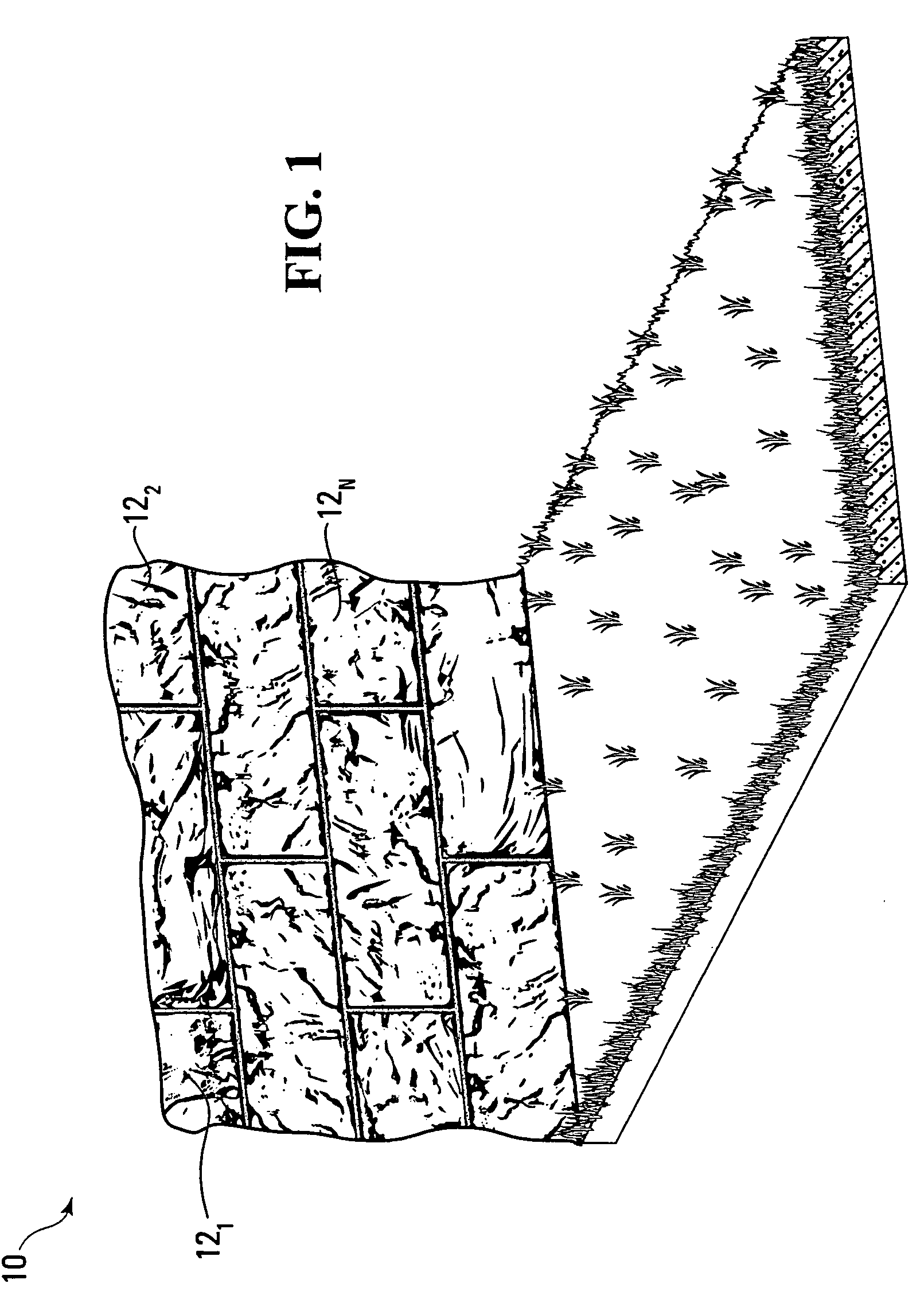

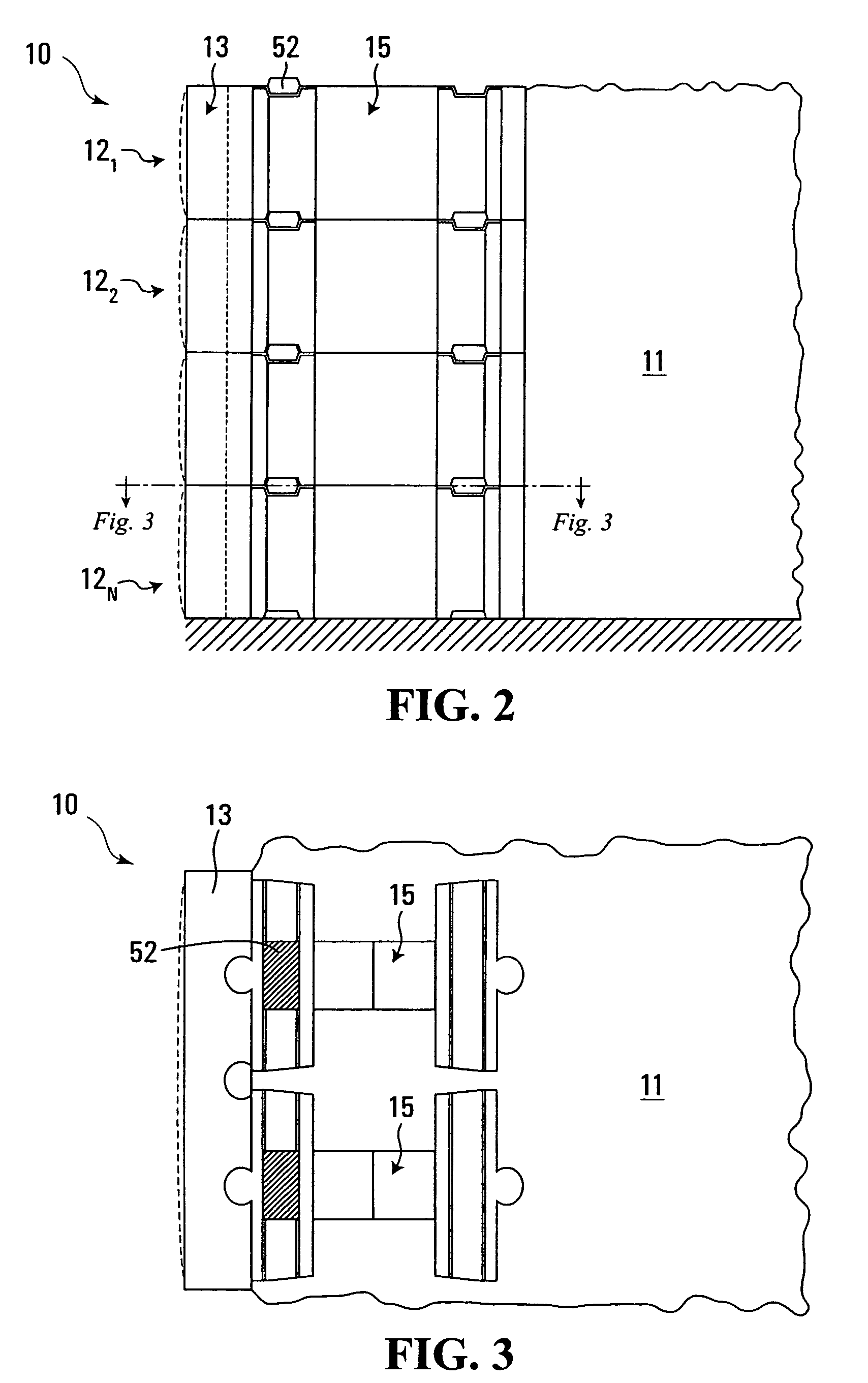

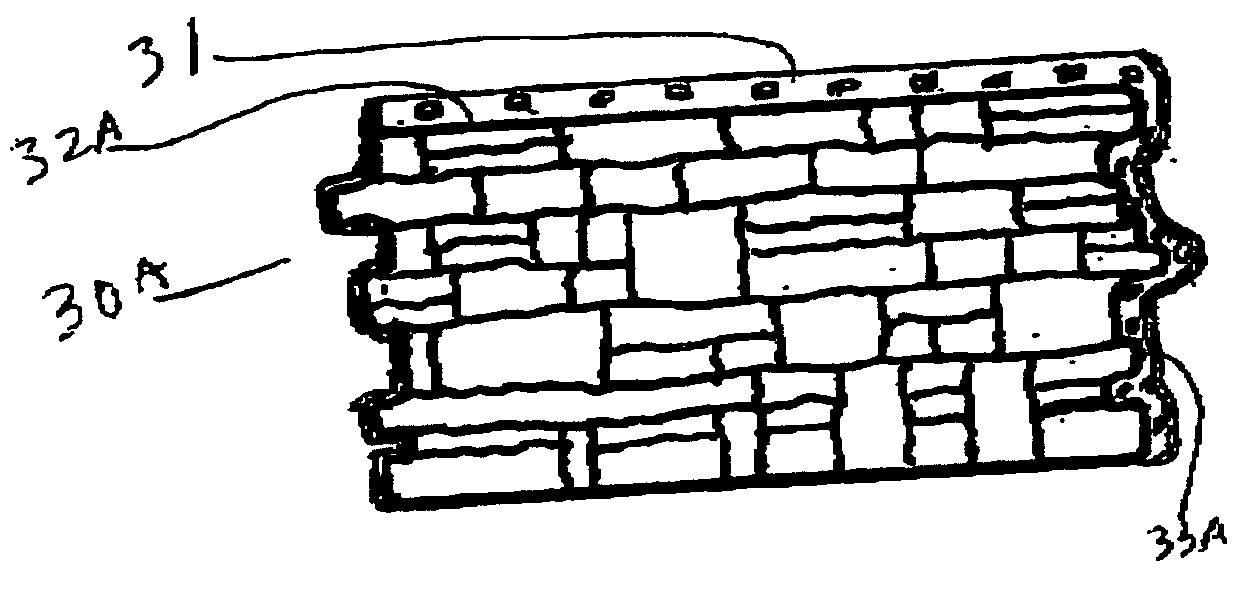

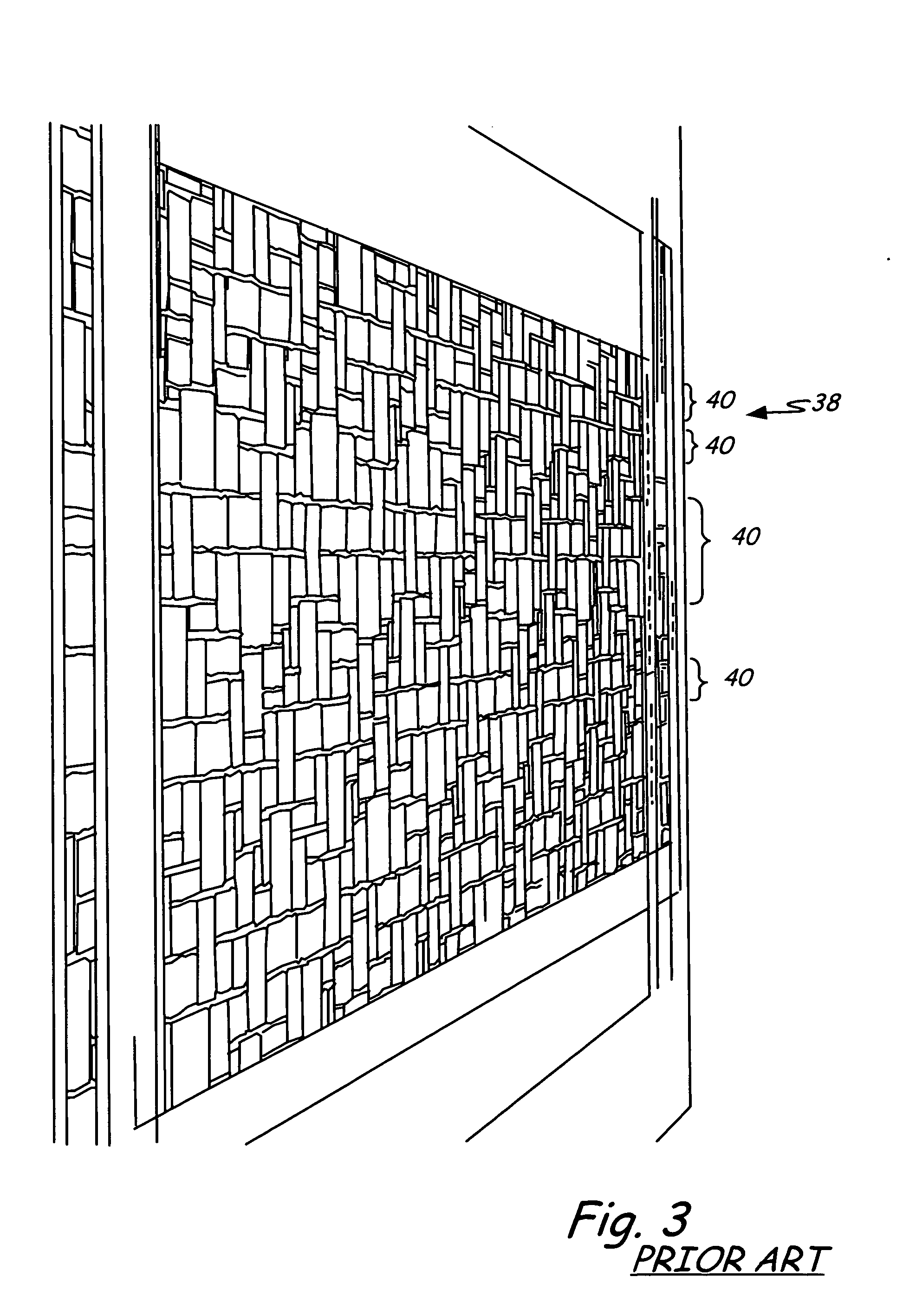

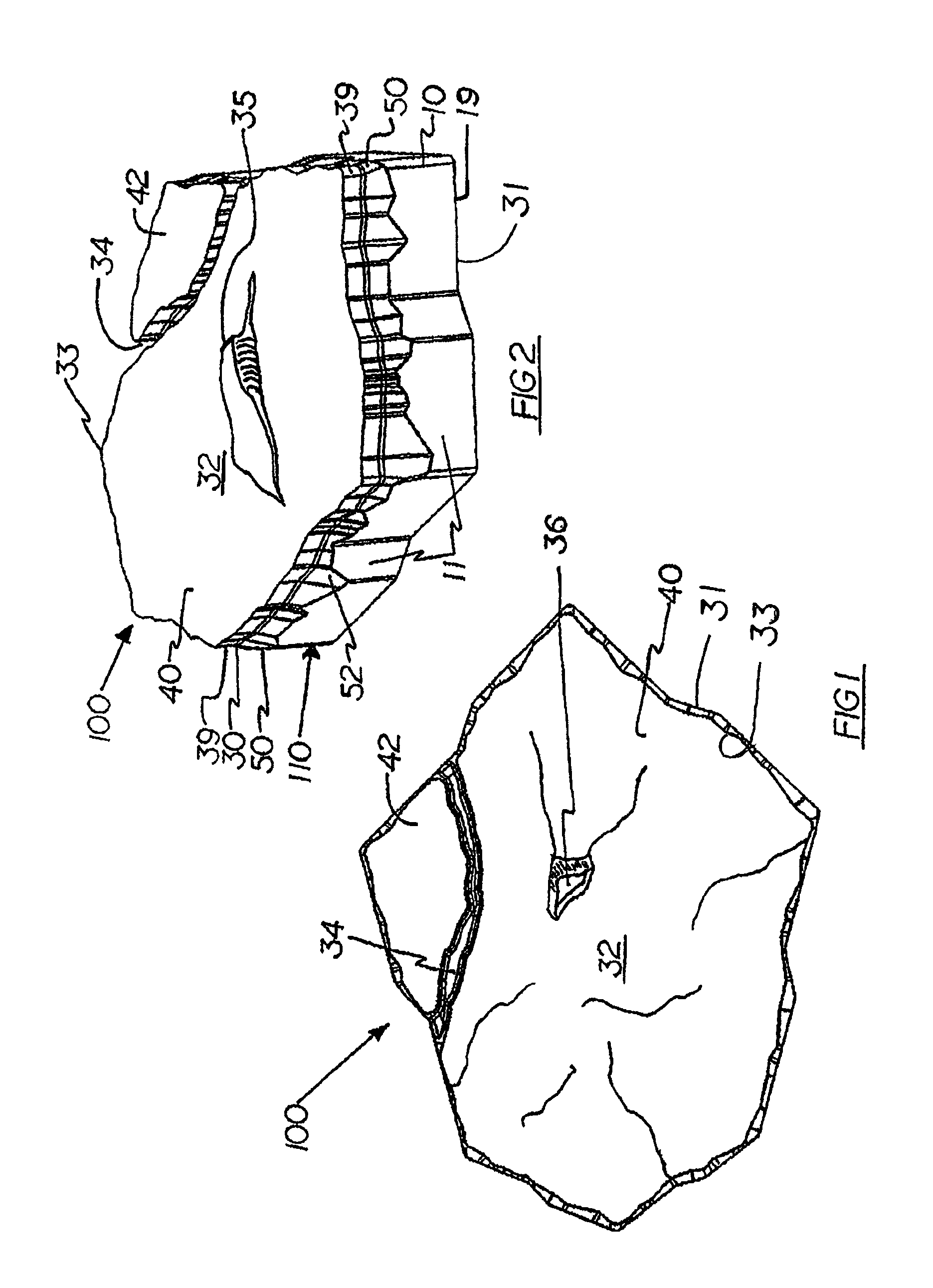

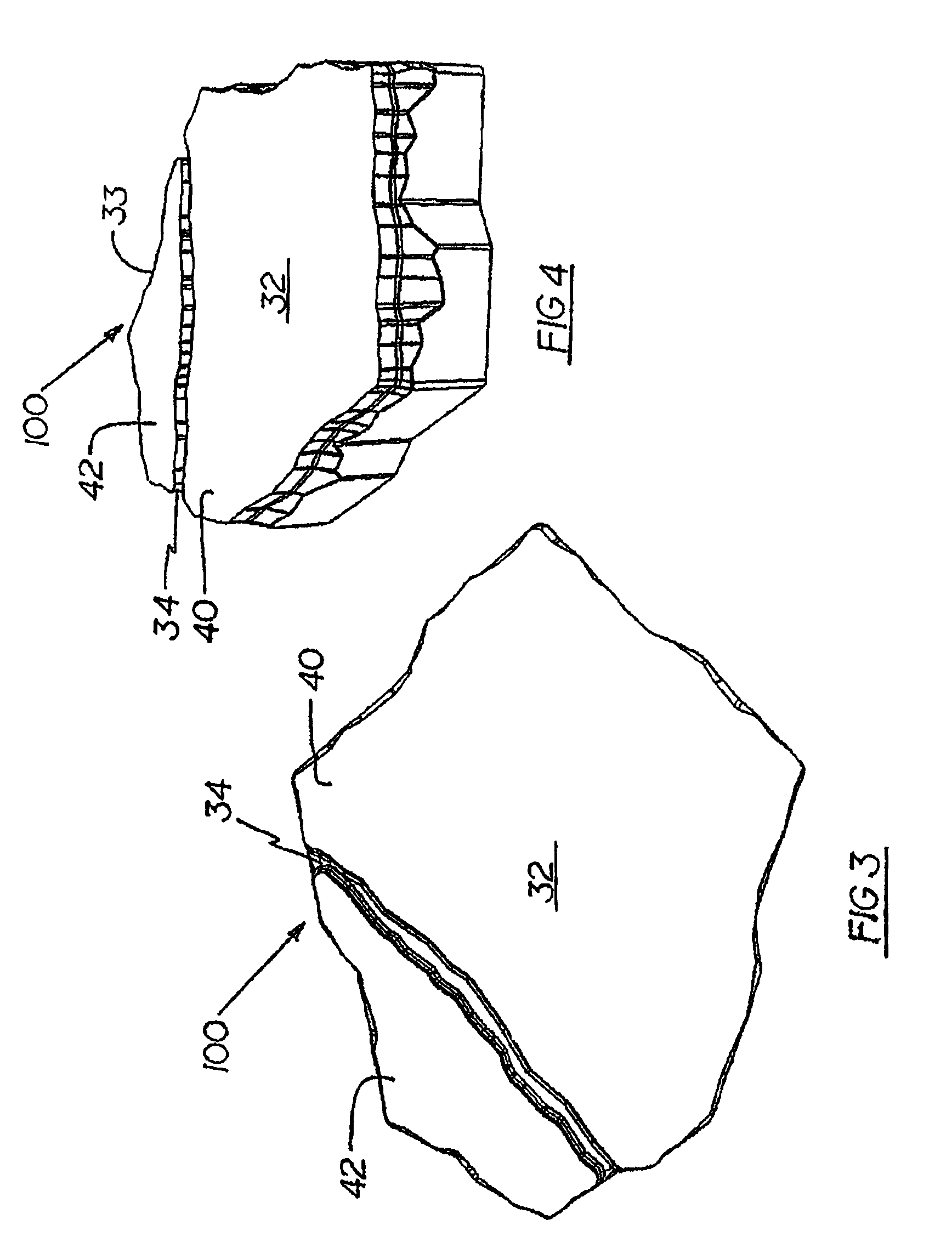

Veneers for walls, retaining walls and the like

InactiveUS20050252144A1Good lookingCost effectiveArtificial islandsConstruction materialEngineeringNatural stone

A veneer panel system is used with a wall or a retaining wall to provide a natural stone appearance and / or to improve the appearance of an existing wall. Panels can be interlocked to form a stable veneer structure. The structure is attached to a wall by various attachment means.

Owner:KEYSTONE RETAINING WALL SYST

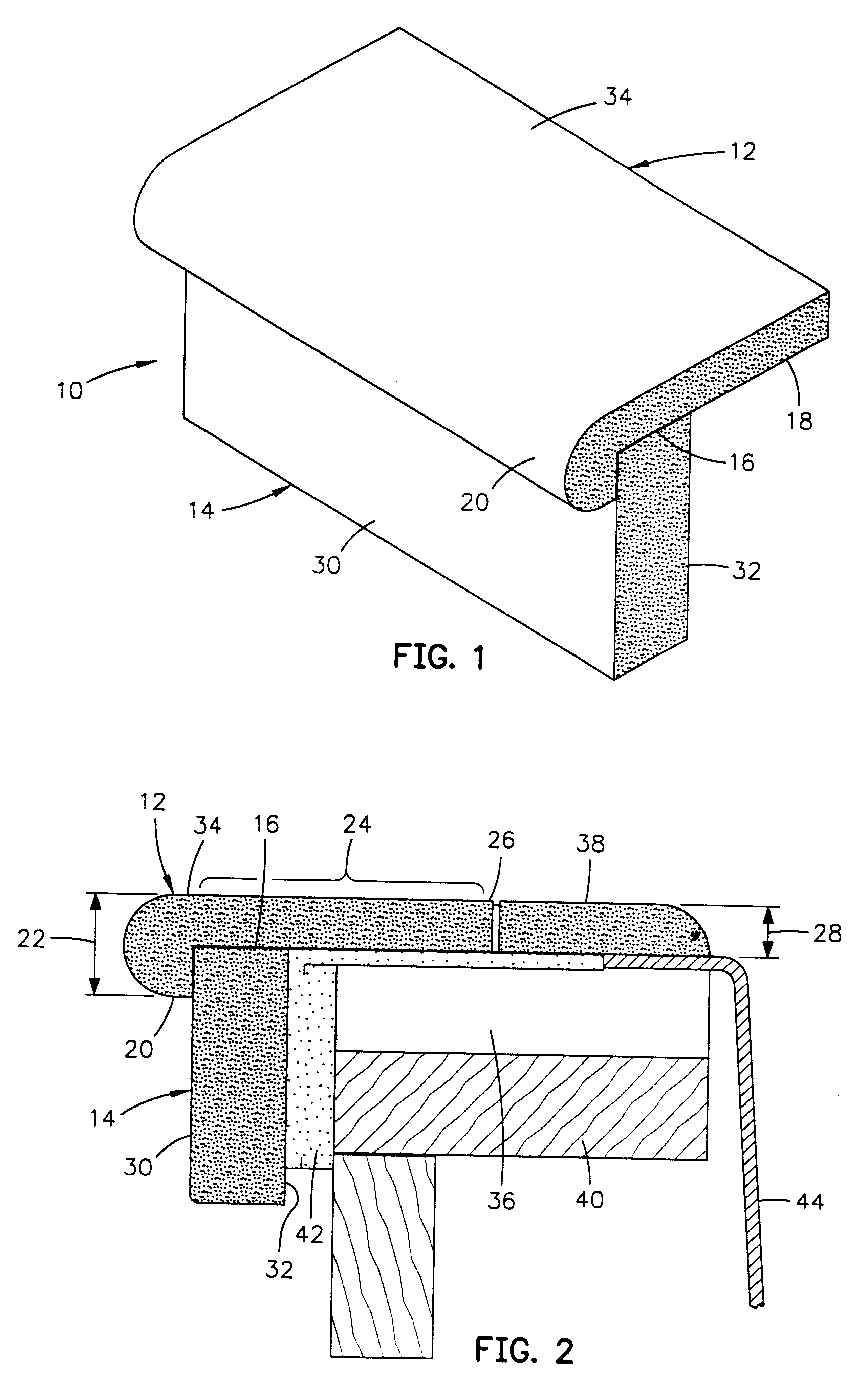

Natural stone tile edging

A natural stone edging tile having a top portion and a generally perpendicular facing portion can be mounted on the forward edge of a countertop substrate and has a portion extending rearward of the forward edge that is approximately half as thick as the forward edge and the same thickness as conventional stone tiles that can be mounted rearward of the edging tile. The conventional tiles have a thickness that is approximately half as thick as a typical stone slab countertop, but to a person viewing the countertop, the entire appears to have the substantial thickness of a typical slab countertop because the forward edge of the edging tile has such a thickness.

Owner:SCIARRINO PETE A +1

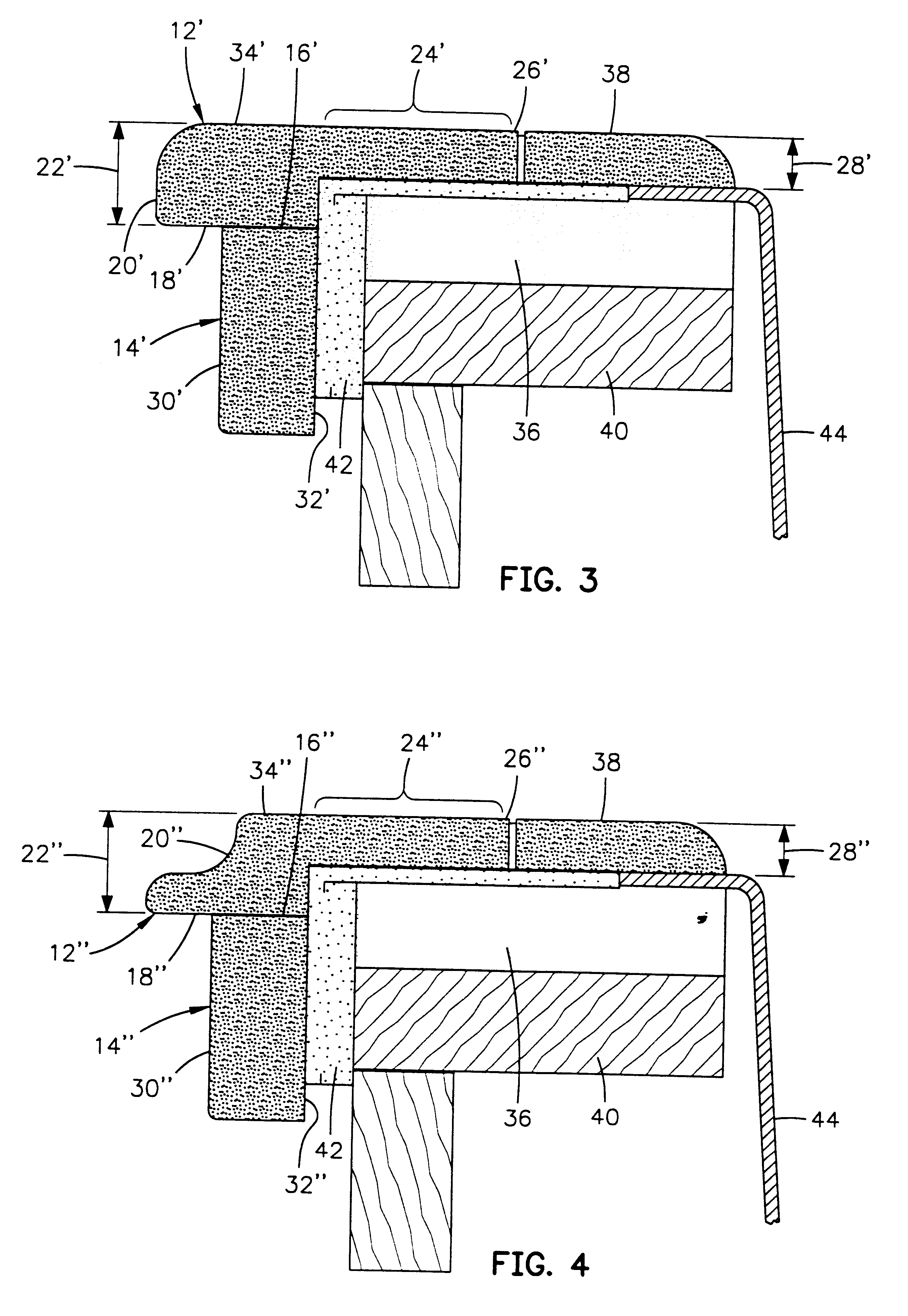

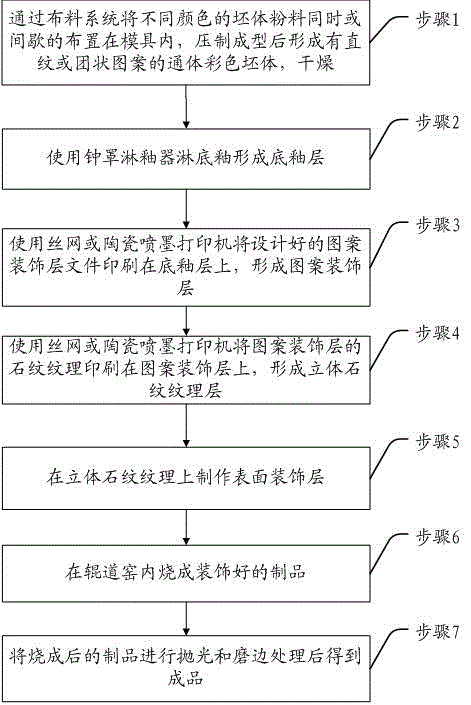

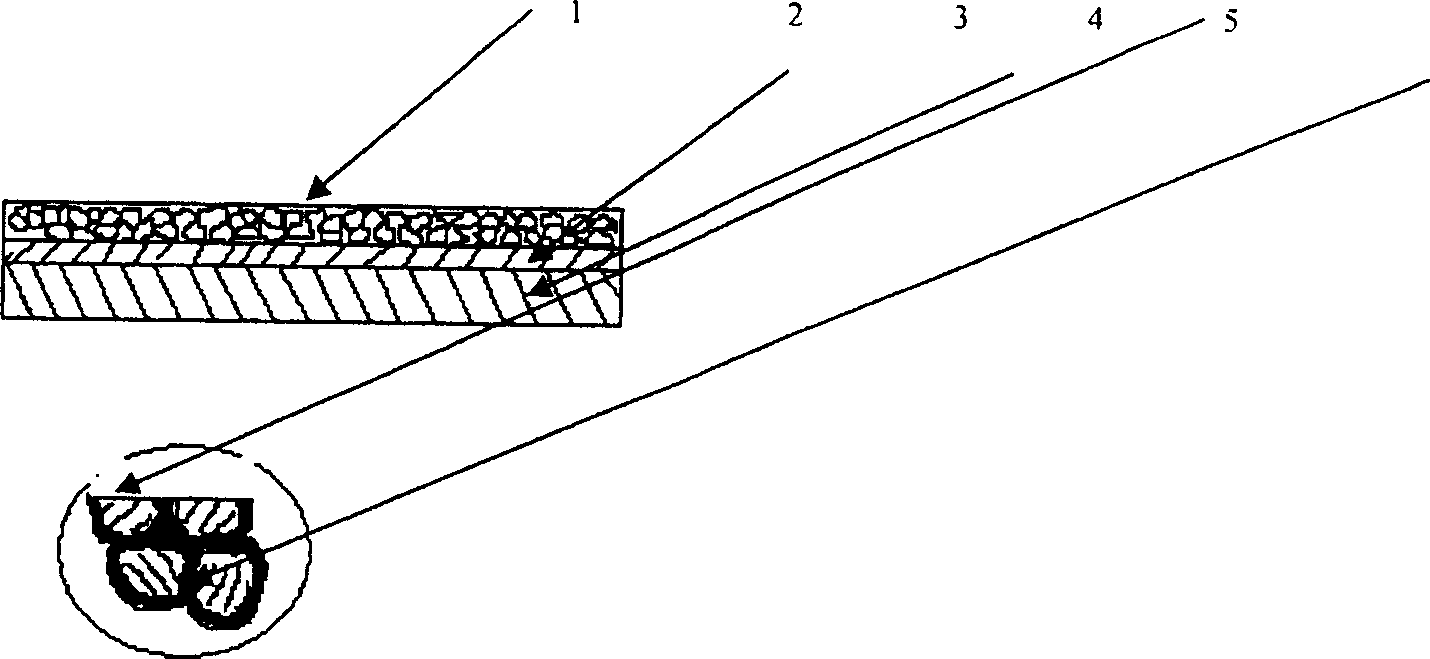

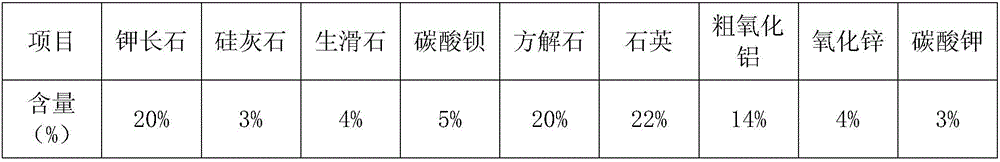

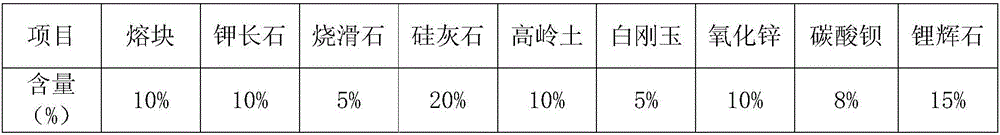

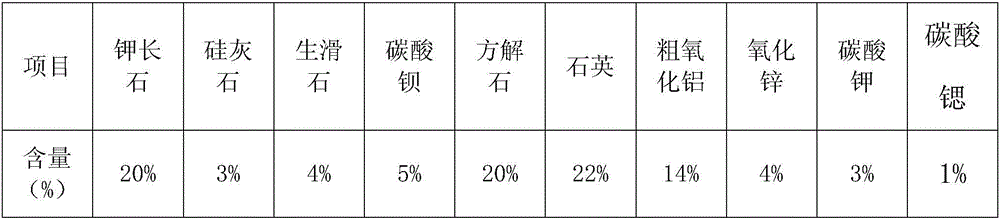

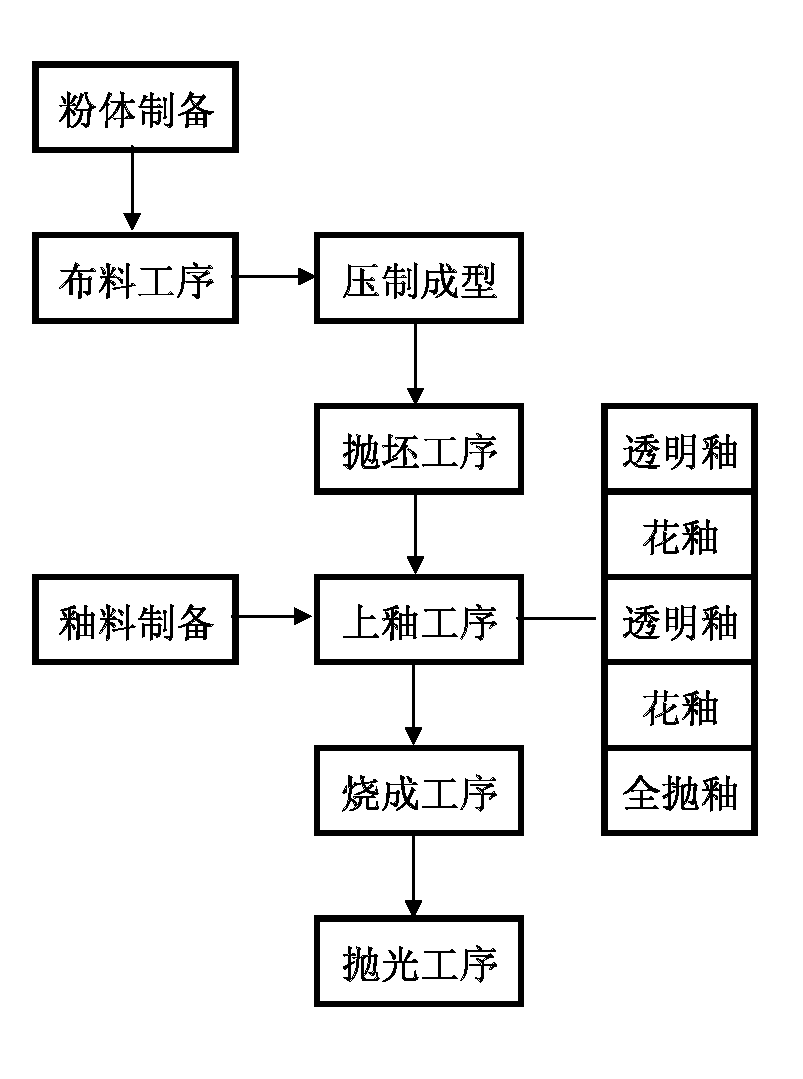

Whole-body polished porcelain tile having three-dimensional stone texture and production method of tile

The invention discloses a whole-body polished porcelain tile having three-dimensional stone texture and a production method of the tile. The tile comprises a whole-body colored blank layer, a ground coat layer, a pattern decoration layer, a three-dimensional stone texture layer and a surface decoration layer. The production method comprises steps as follows: 1) a whole-body colored blank is prepared; 2) the ground coat layer on the blank surface is formed; 3) the pattern decoration layer is formed; 4) ink or glaze having a dent effect is applied to the pattern decoration layer, a pattern corresponds to pattern texture of the decoration layer, and the three-dimensional stone texture layer is formed; 5) the surface decoration layer is formed; 6) a roller kiln is formed through sintering; 7) a finished product is obtained through polishing, edging and packaging. The surface color of the product produced with the scheme is integrated with the color of the blank, the stone texture changes naturally with the pattern texture of the product, the texture layer is protected by the surface decoration layer, and the tile has the decoration effect of natural stone. Properties of the product are superior to those of the natural stone, mining of the natural stone can be effectively reduced, and the natural environment is protected.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Preparation method of glazed ceramic brink with stone imitation pattern based on fused block wrapping pigment

Owner:广东高微晶科技有限公司

Real stone paint, and preparation method and construction method thereof

The invention provides a real stone paint. The real stone paint comprises, by weight, 90-130 parts of water, 2-5 parts of hydroxyethyl cellulose, 2-5 parts of a dispersant, 1-3 parts of a wetting agent, 4-8 parts of an antifoaming agent, 2-3 parts of an antiseptic, 100-150 parts of an emulsion, 5-12 parts of a film forming assistant, 1-3 parts of a pH adjusting agent, 5-20 parts of an antifreeze agent and 400-900 parts of a color sand component, wherein the color sand component comprises two or more than two natural stone flours with similar color. The invention further provides a preparation method of the real stone paint. The natural stone flowers with similar color in raw materials are blended in the embodiment of the invention to balance the color difference of all the natural stone flours, so even the color of one of the natural stone flours changes, the color difference of real stone paint products in batches is very small under the contrast of other natural stone flours with similar color, thereby the color difference change of the real stone paint is well controlled.

Owner:DRAGON BRAND COATINGS (BEIJING) CO LTD

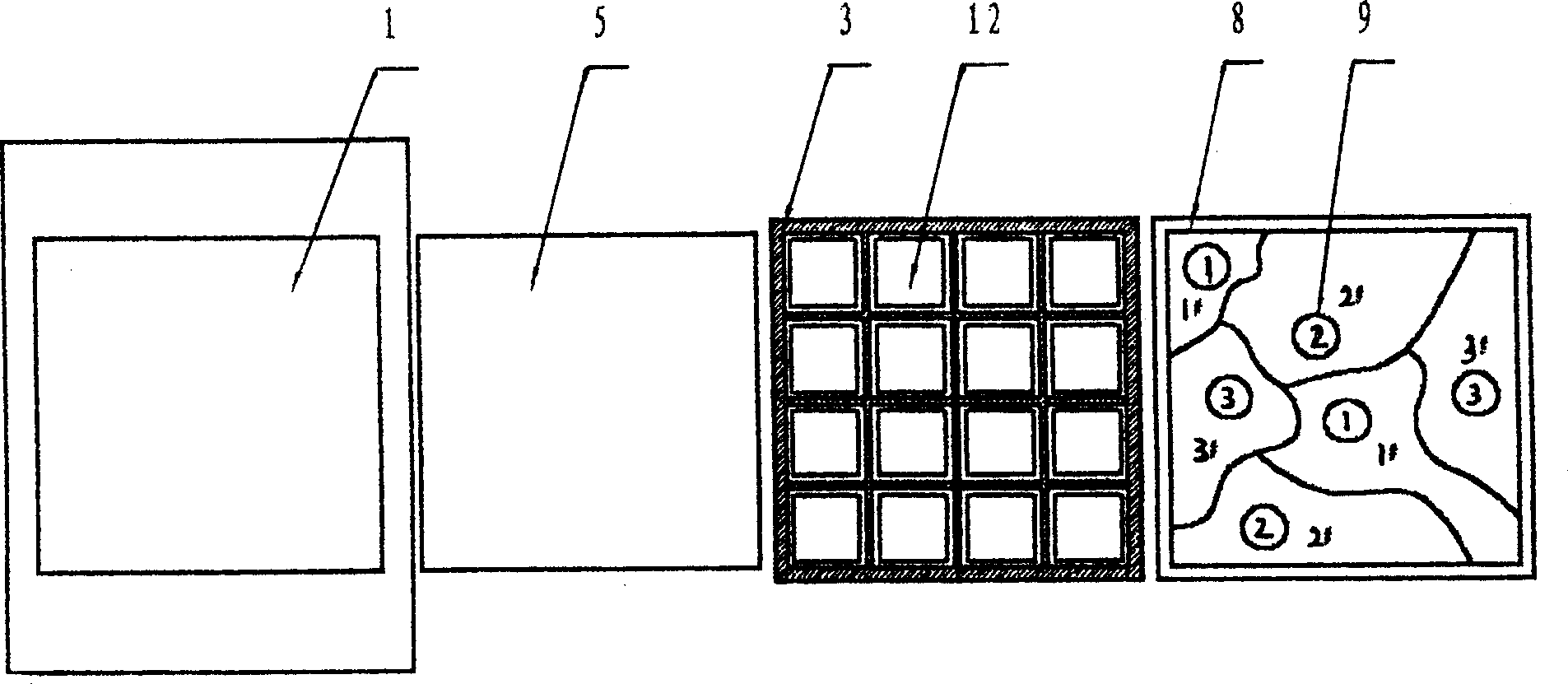

Distributing method for ceramic tile

InactiveCN1586851ADelicate and rich colorsThe pattern is natural and smoothFeeding arrangmentsSurface patternBrick

The material distributing method for ceramic tile is one back side forming process including first distributing powder material and then distributing base material. Fine powder, granular material and their mixture are loaded one layer by one layer onto the conveying belt, added into specially designed lattice via bin to complete the first material distribution; and the base material then falls from the movable bin to fill the mold cavity to complete the second material distribution. During the twice material distribution, the lattice is filled with the fine powder or the mixture of fine powder and the granular material. The present invention has the features of multiple tube material distribution and lattice material distribution, and can form natural and fluent patterns and grains similar to that of natural stone material. The present invention has raised material distribution speed and the back side formation process has no influence on the surface pattern of the returned lattice.

Owner:TEDI CERAMIC FOSHAN CITY

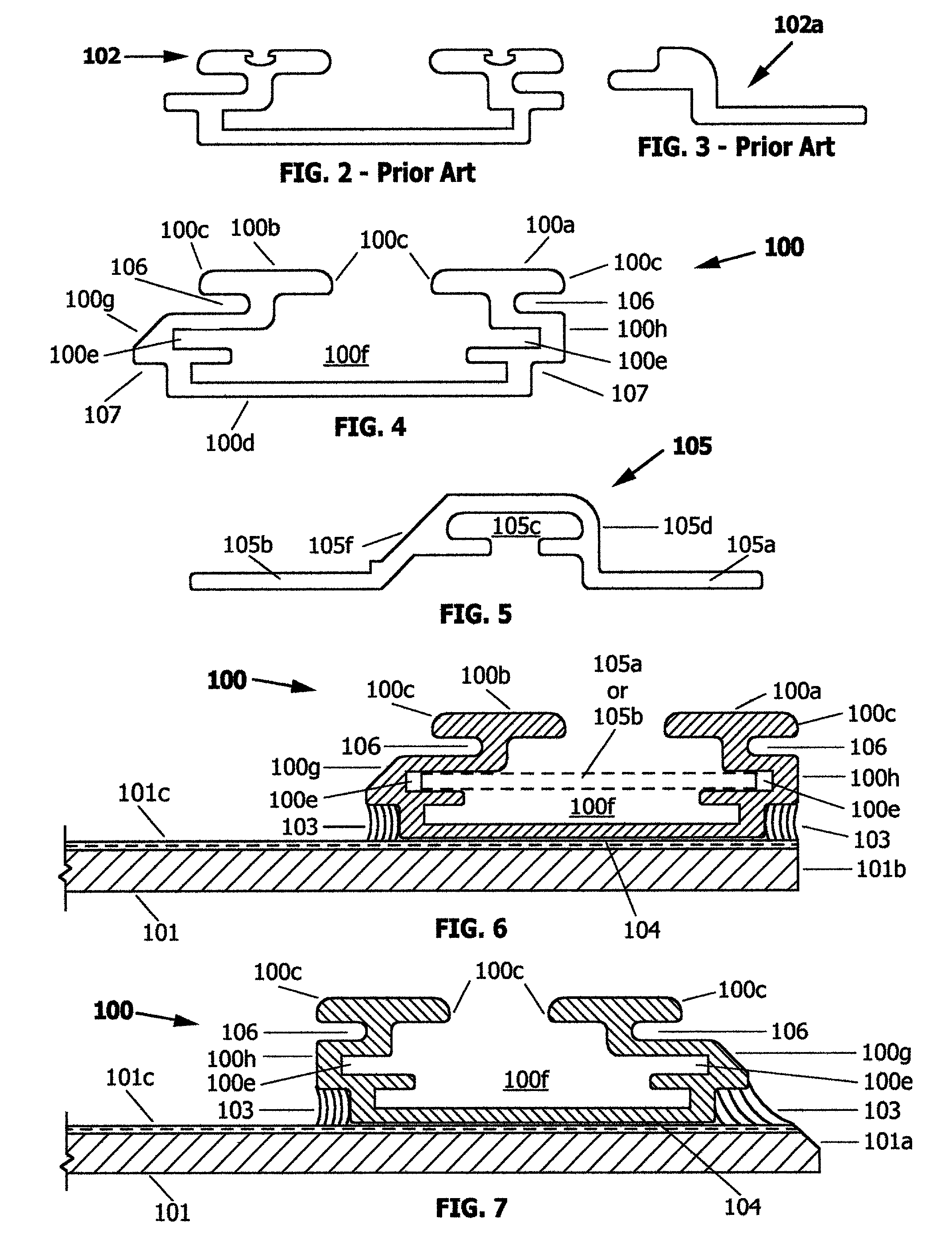

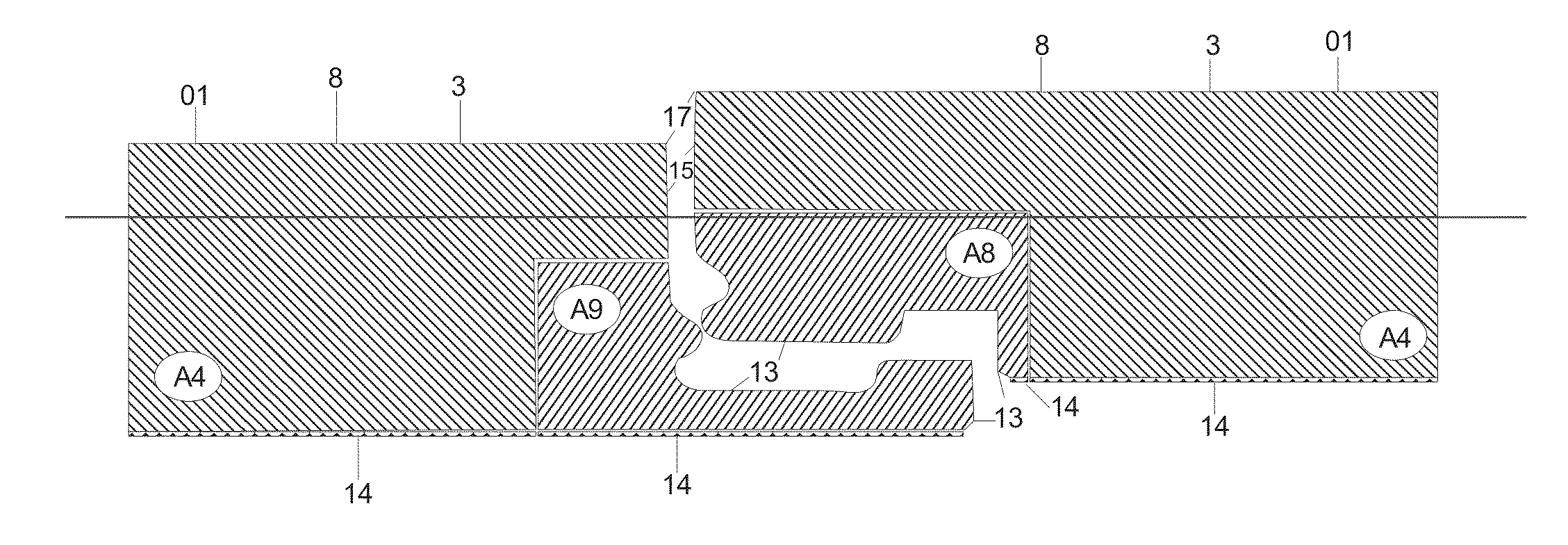

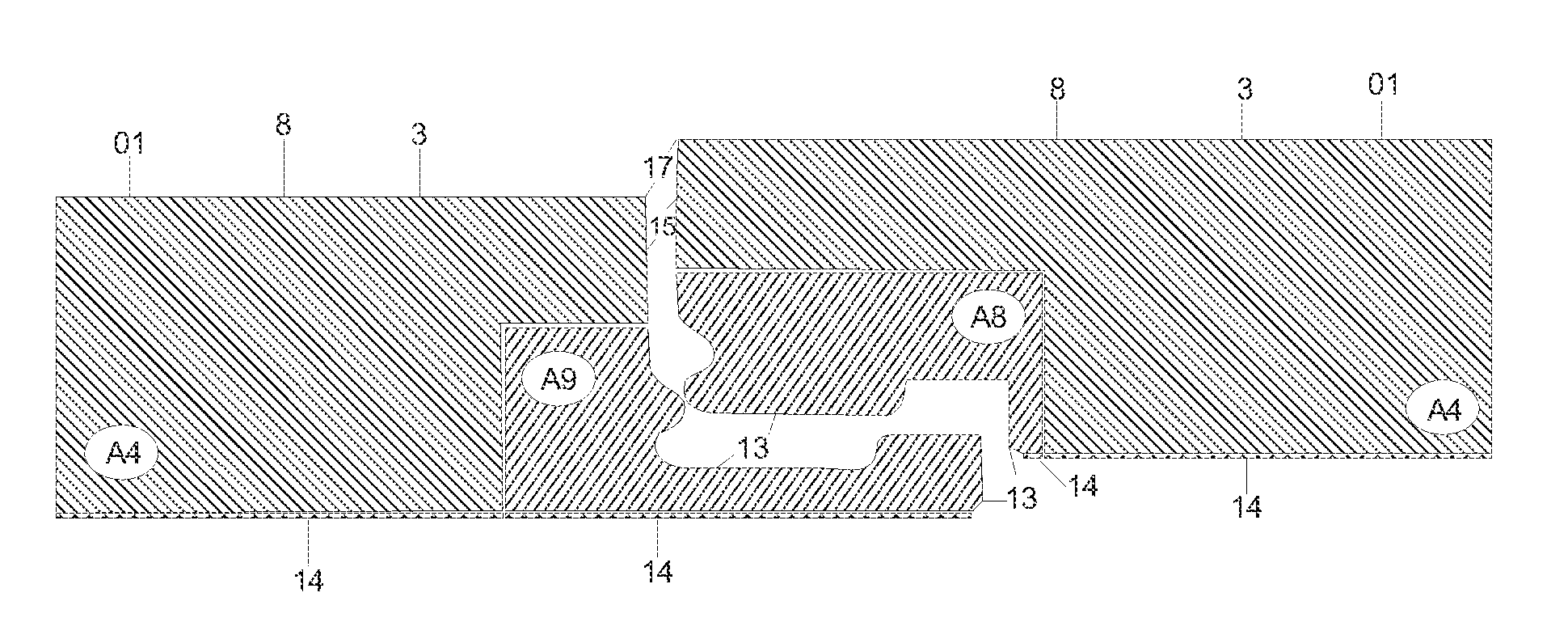

Stone Click Floor Coverings

ActiveUS20130042558A1Precise alignmentSimple preparation processConstruction materialFloorsCouplingAdhesive

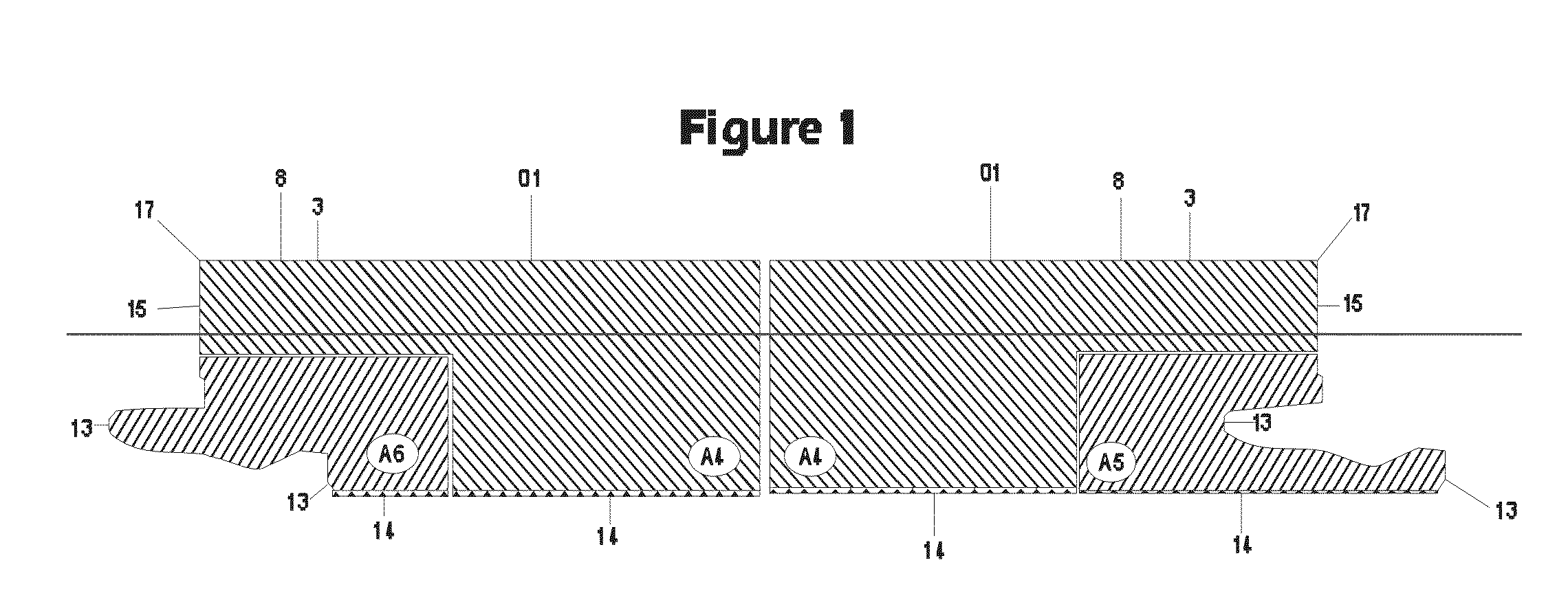

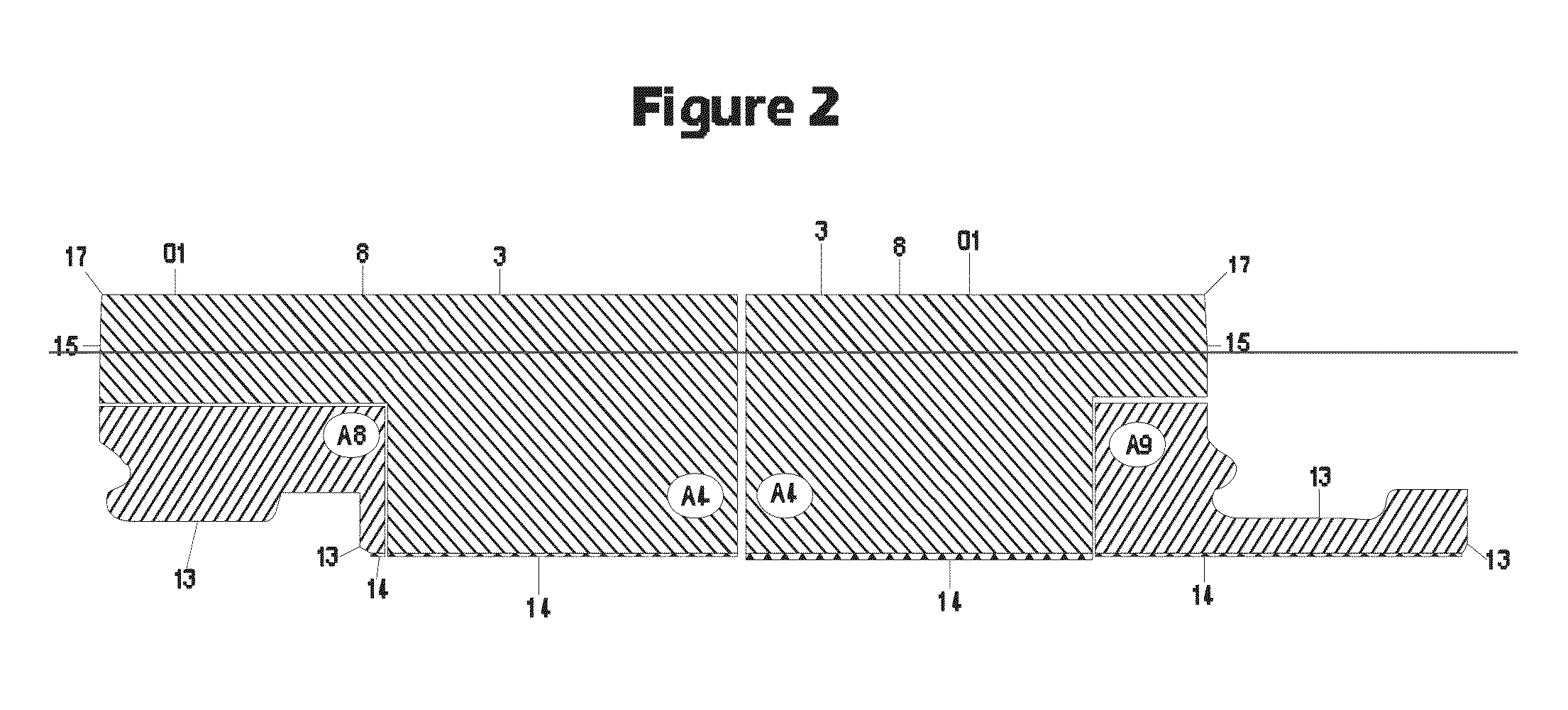

Floor covering (01) material, consisting of Natural Stones, i.e. Marble, Granite, Limestone, Onyx, Travertine and Sandstone, in format of tile slabs, in which the thickness is between 4 mm and 35 mm, in which at the two opposite edges or sides are jointed together and interlocked by mechanical locking means, by connecting or inserting (A6 to A5) and connecting or pressing downward (A8 to A9) using Polyvinyl Chloride (PVC) couplings, connecting in the form of a tongue and a groove which will prevent shifting of two interlocked tiles and or slabs into the opposed direction of each section tile or slab, with an integrated backing layer consisting of cork and / or syntactic foam material, The invention relates to a natural stone core tile slab, allowing for an installation without the use of cement, adhesives or grout, provided with such a mechanical locking system jointed to the core (A4) according to the invention.

Owner:CORDEIRO EURICO JANUARIO

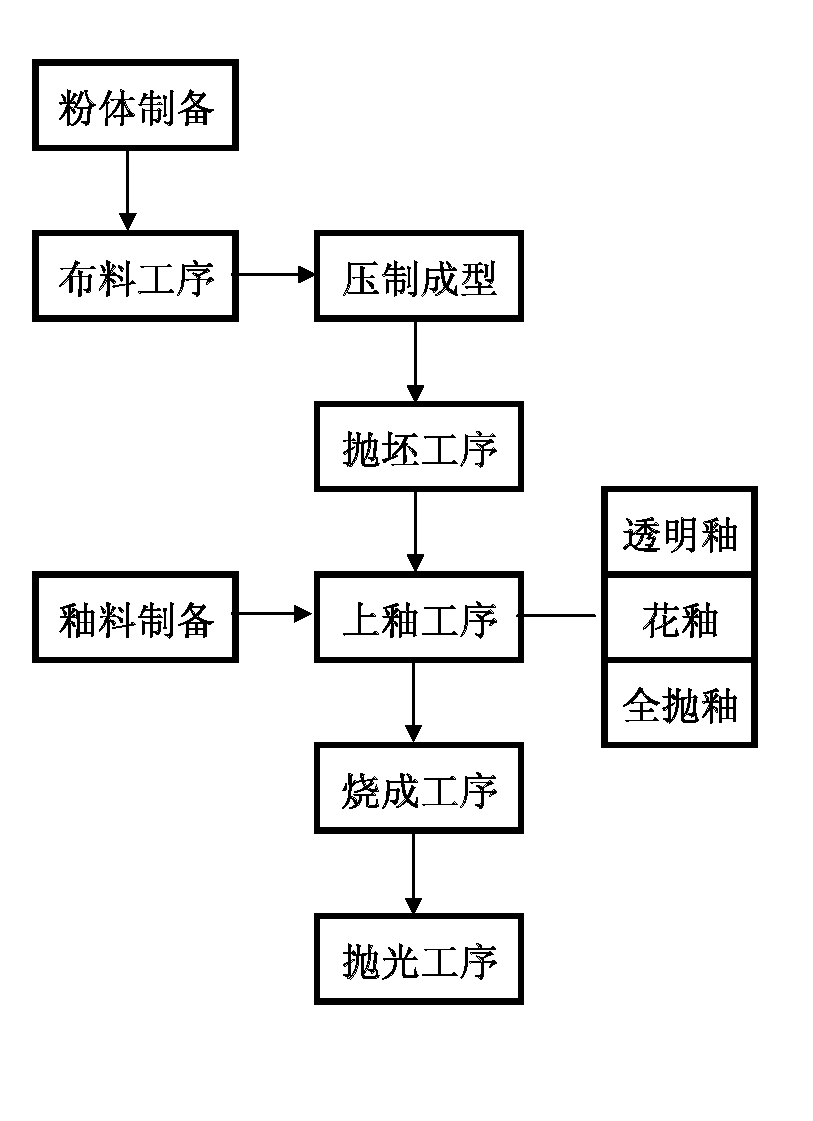

Production method of imitated natural marble polished glazed brick

The invention provides a production method of an imitated natural marble polished glazed brick. The method comprises the following steps: 1, mixing a widely-known rough body raw material with a pigment, and granulating the obtained mixture to obtain granular colored powder; 2, mixing and distributing the colored powder and the widely-known rough body powder, and carrying out stamping forming to make a green ceramic brick wholly having finishing texture; 3, applying a transparent glaze to the green brick obtained in step 2; and 4, adding the glazed green brick to a kiln, sintering the glazed green brick, and polishing the sintered brick to obtain the imitated natural marble polished glazed brick. The production method of the imitated natural marble polished glazed brick allows the green brick with a whole texture effect to be formed through mixing the widely-known green body raw material with the pigment to prepare slurry, granulating the slurry to obtain the granular colored powder, and mixing and distributing the colored powder and the rough body raw material, and allows the texture of the cross section of the produced polished glazed brick to be same to that of natural stones.

Owner:FOSHAN DONGPENG CERAMIC +3

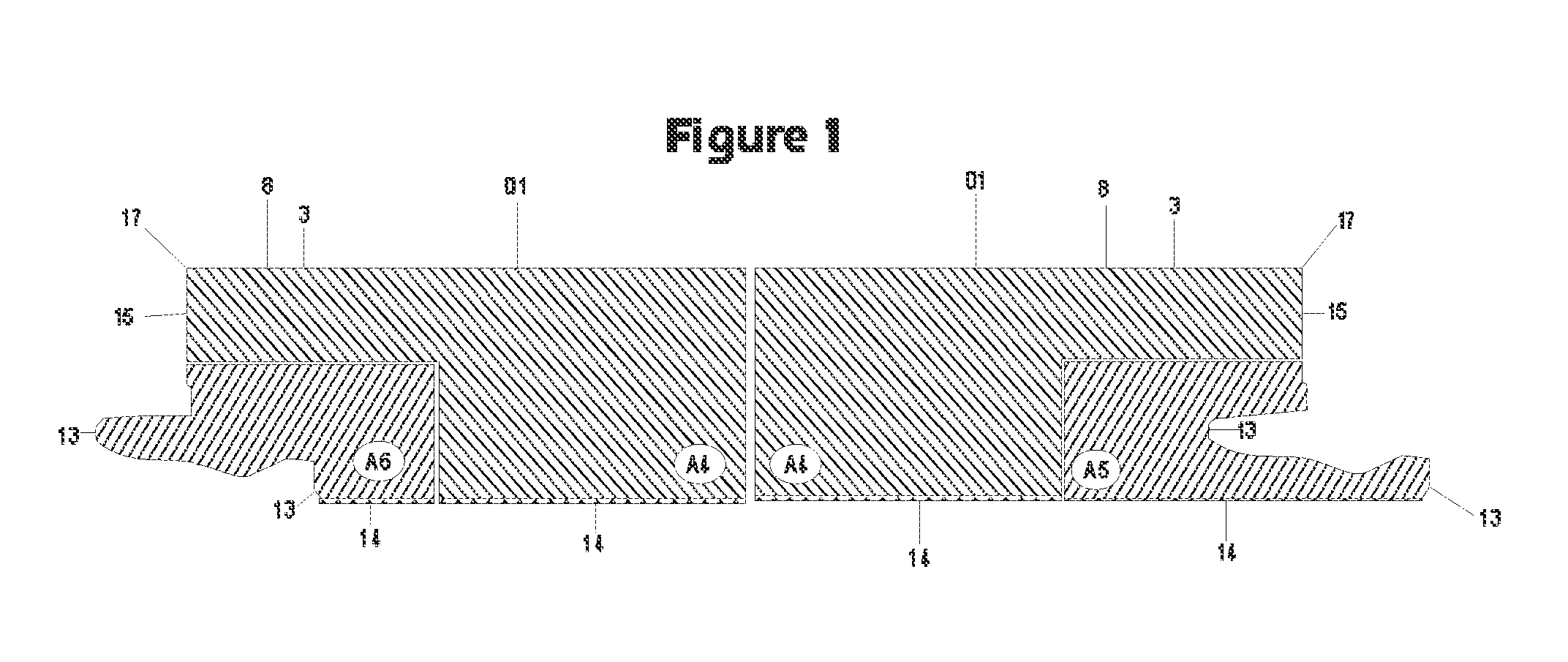

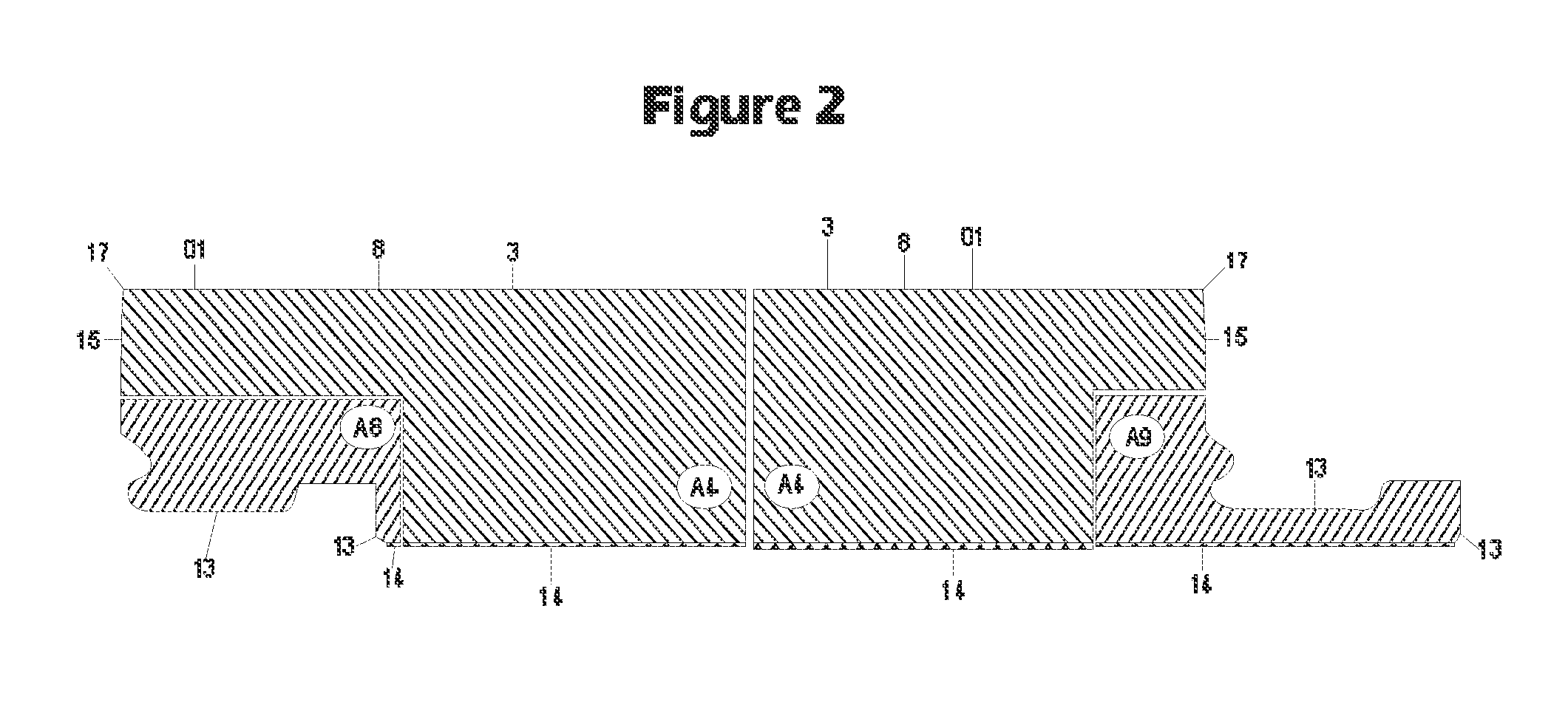

Groutless Tile System

InactiveUS20130212971A1Comfortable feetAcoustical and thermal advantageCovering/liningsFiberAdhesive

Floor, ceiling and wall covering (01) material, consisting of natural stones, i.e. marble, granite, limestone, onyx, travertine and sandstone, cement based tiles, softwood and hardwood, wood fiber HDF, MDF, agglomerated cork, rubber, and composite tile materials, such as stone, quartz or vinyl composition tiles, in format of tile slabs. Which the thickness is between 4 mm and 35 mm in which at the two opposite edges or sides are jointed together and interlocked by mechanical locking means, by connecting or inserting, (A6 to A5) and connecting or pressing downward (A8 to A9) using polyvinyl chloride (PVC) couplings, connecting in the form of a tongue and a groove which will prevent shifting of two interlocked tiles and or slabs into the opposed direction of each section tile or slab, with an integrated backing layer consisting of cork syntactic foam material, The invention relates to a natural stone core tile slab, allowing for an installation without the use of cement, adhesives or grout, provided with such a mechanical locking system jointed to the core (A4) according to the invention.

Owner:CORDEIRO EURICO JANUARIO

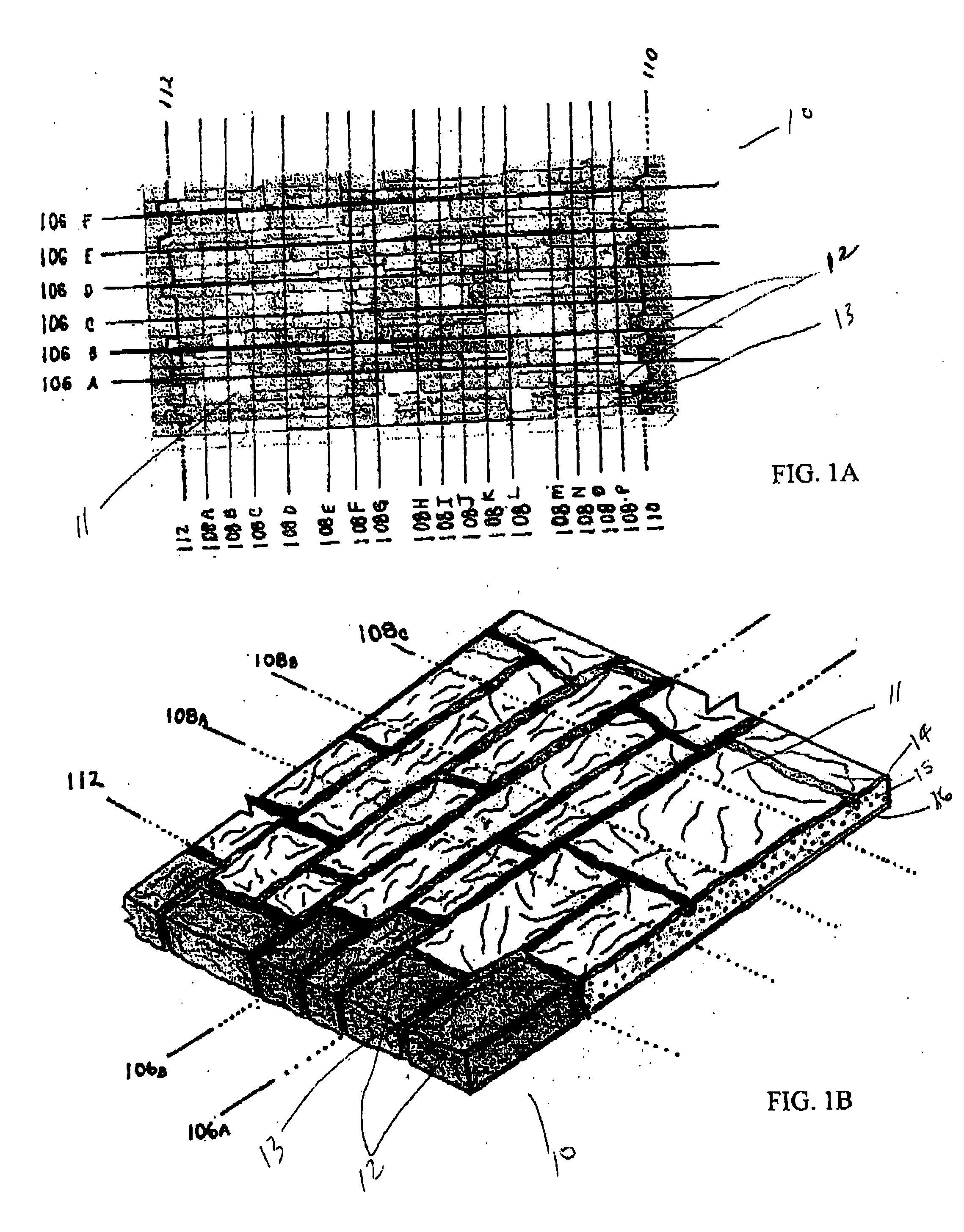

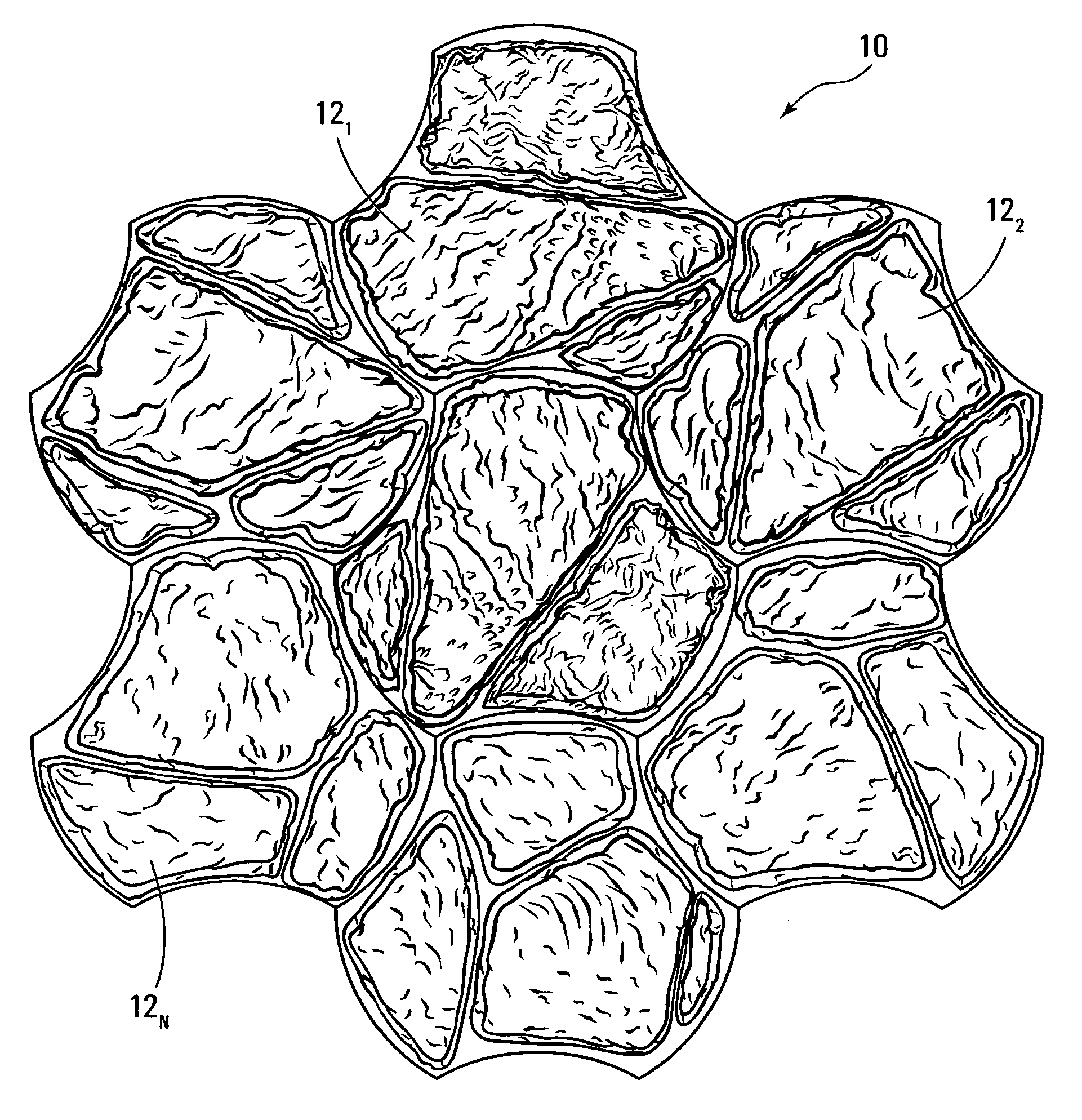

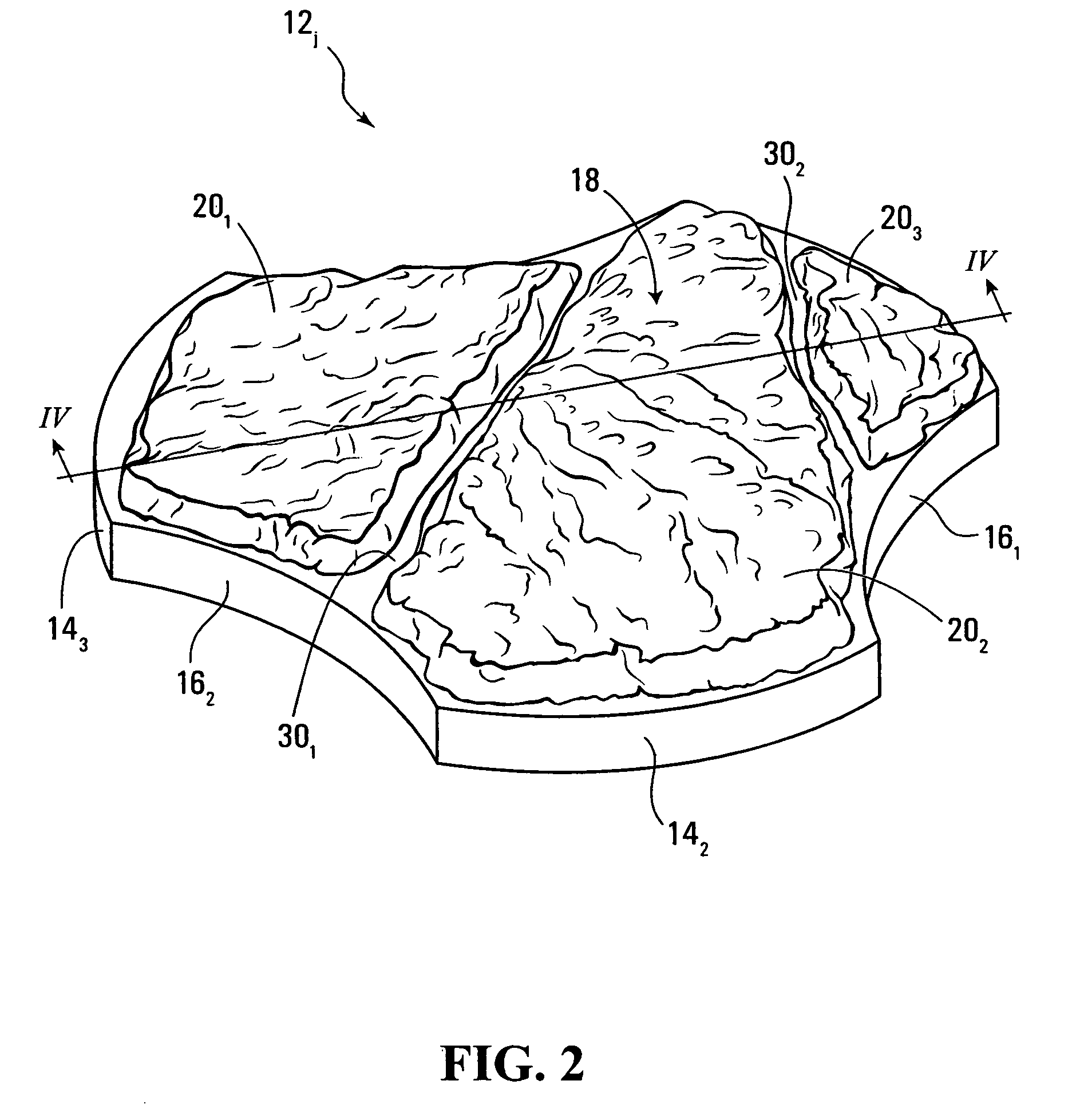

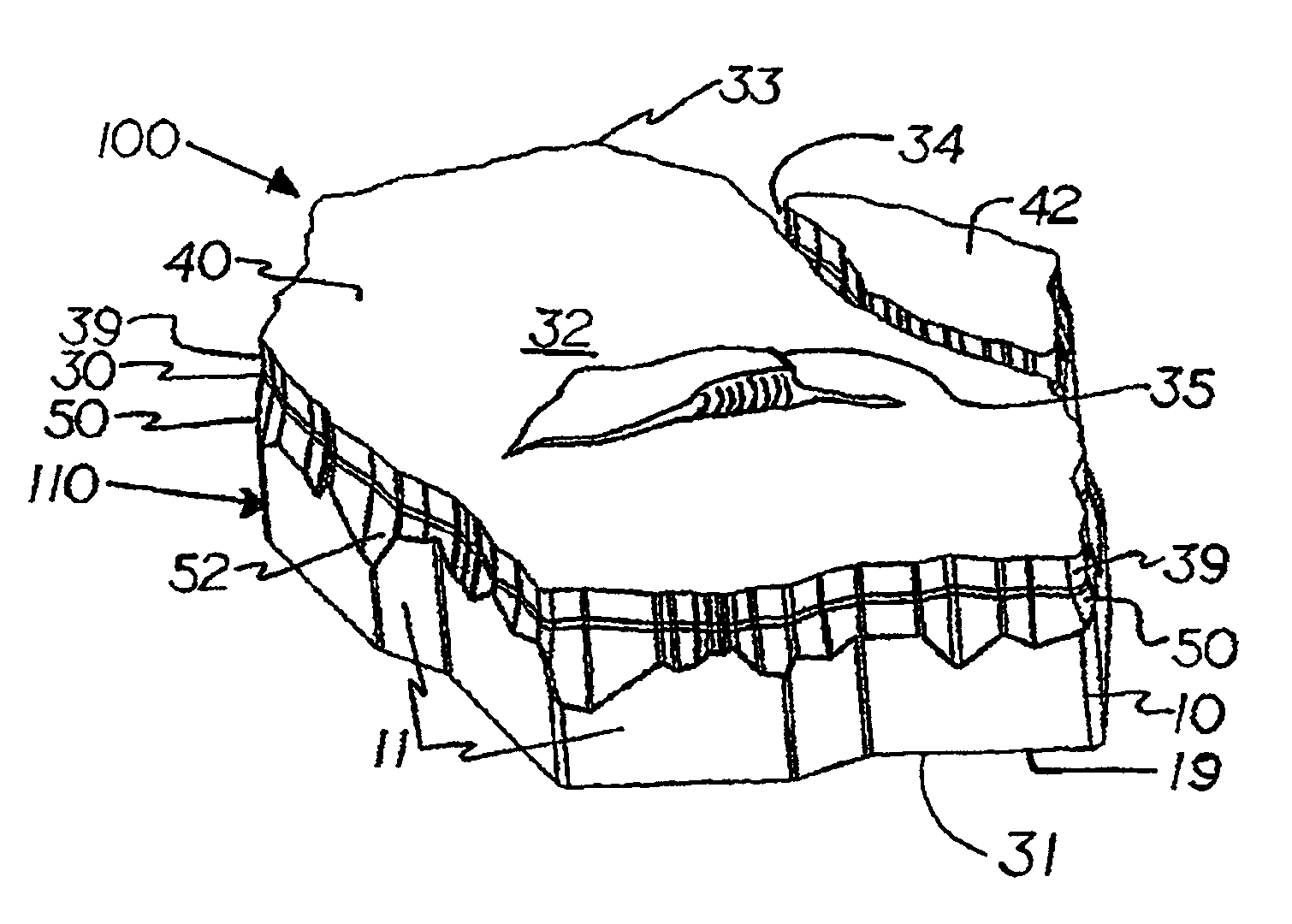

Artificial stone

ActiveUS20110067333A1Enhance natural appearanceLarge widthCovering/liningsNatural patternsRepeat patternEngineering

An artificial stone is disclosed for use in creating a covering for a supporting surface. The artificial stone includes a body for placement on the supporting surface, which is shaped for mating engagement with like stones with intermediate perimeter joints to produce a continuous surface covering. The stone has a facing surface on the body, which facing surface has a contour defining a surface area and is subdivided by at least one simulated joint into a major surface portion and at least one minor surface portion. The major surface portion is free of simulated joints and extends over at least about 60% of the total surface of the facing surface. The stone further includes at least one perimeter recess in the body for generating a gap between the stone and another like stone in mating engagement therewith, which gap is wider than adjacent the adjoining perimeter joint. Stones of this construction can easily be arranged in a regular, repeated pattern to generate a continuous covering for the supporting surface with the surface of the resulting covering having an irregular, natural appearance. The irregular top contours of the stones, the uneven division of the facing surface and the perimeter recesses and the resulting gaps between mating stones simulate the appearance of a natural stone surface covering for walkways, roadways, pavements or walls.

Owner:OLDCASTLE BUILDING PROD CANADA INC

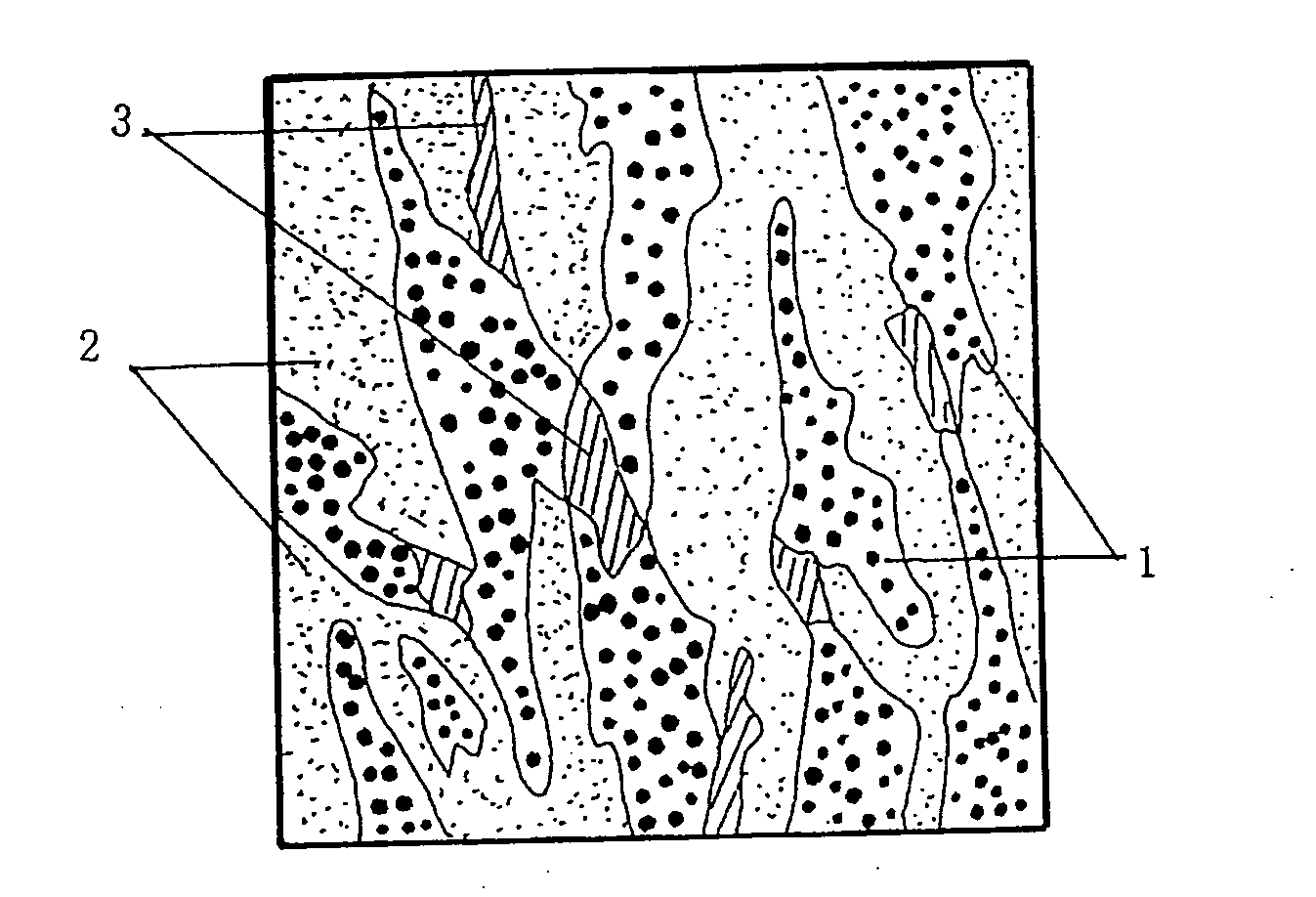

Inorganic artificial combining stone and preparation method thereof

InactiveCN102557571AExpand raw material resourcesLow costCeramic shaping apparatusCement productionFiberKaolin clay

The invention discloses inorganic artificial combining stone and a preparation method thereof. The artificial combining stone uses silicon acid-base solution to arouse metakaolin to react and generate geopolymer to serve as an inorganic cementing agent, and the artificial combining stone mainly contains the metakaolin, the silicon acid-base solution, natural stone aggregate, decoration aggregate, a thickening time control agent, inorganic pigment and fibers. The preparation method is firstly enabling the thickening time control agent and the inorganic pigment to be dissolved in the silicon acid-base solution to obtain mixed serous fluid, evenly blending the metakaolin, the natural stone aggregate, the decoration aggregate, the fibers and the mixed serous fluid, preparing the artificial combining stone through model entering or material distribution, vibration under the vacuum condition, molding in a pressing mode, maintaining, cutting, polishing, burnishing and surface protection. The artificial combining stone not only has decoration features which can be equal to that of resin artificial stone, but also is non-toxic, environment-friendly, low in cost, resisting in corrosion of most majority of acid-base salts, durable in high temperature and excellent in durable performance, obviously avoids whiting and saltpetering phenomena after a long time use, and is strong in pollution resisting capability.

Owner:SOUTH CHINA UNIV OF TECH

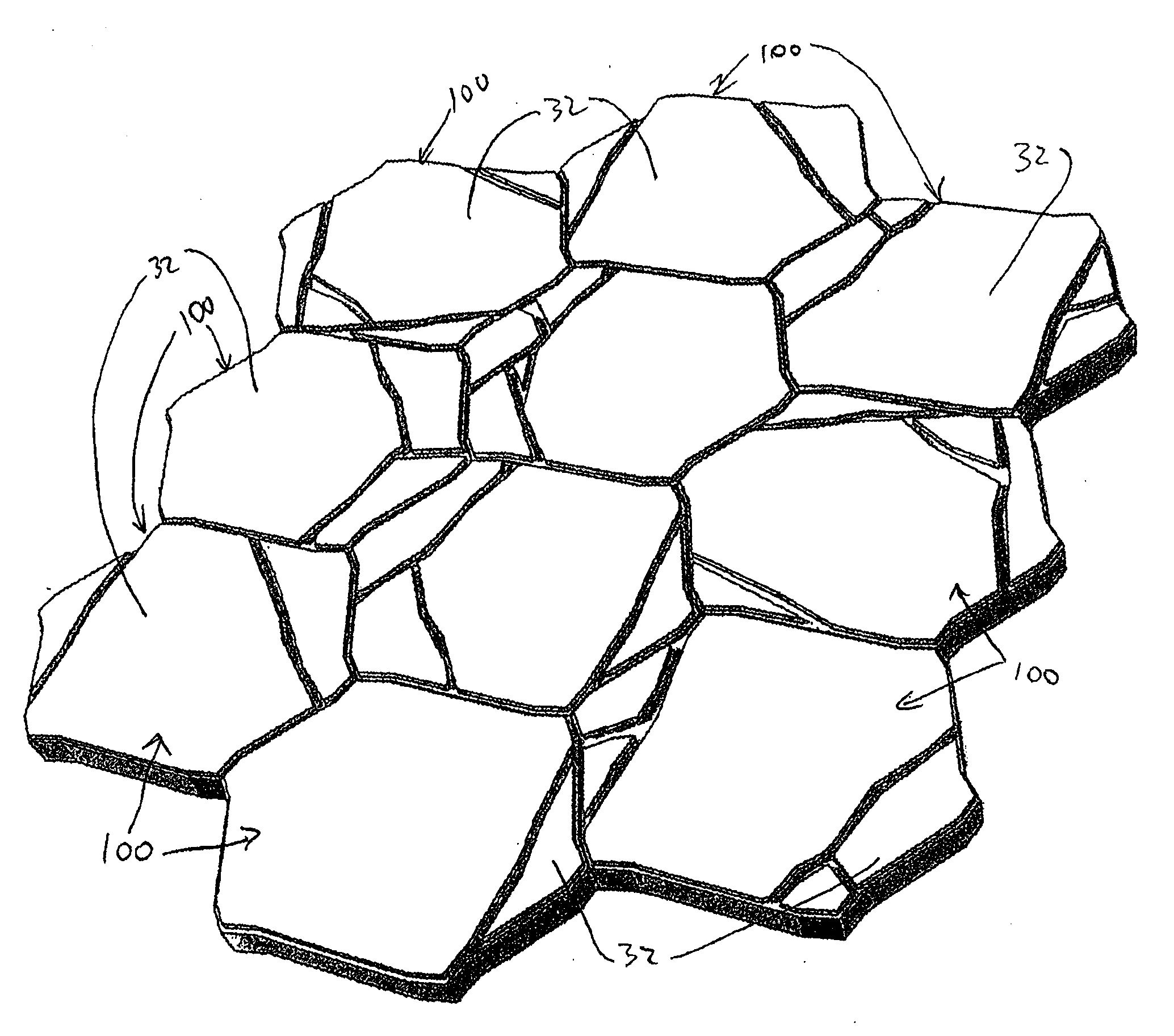

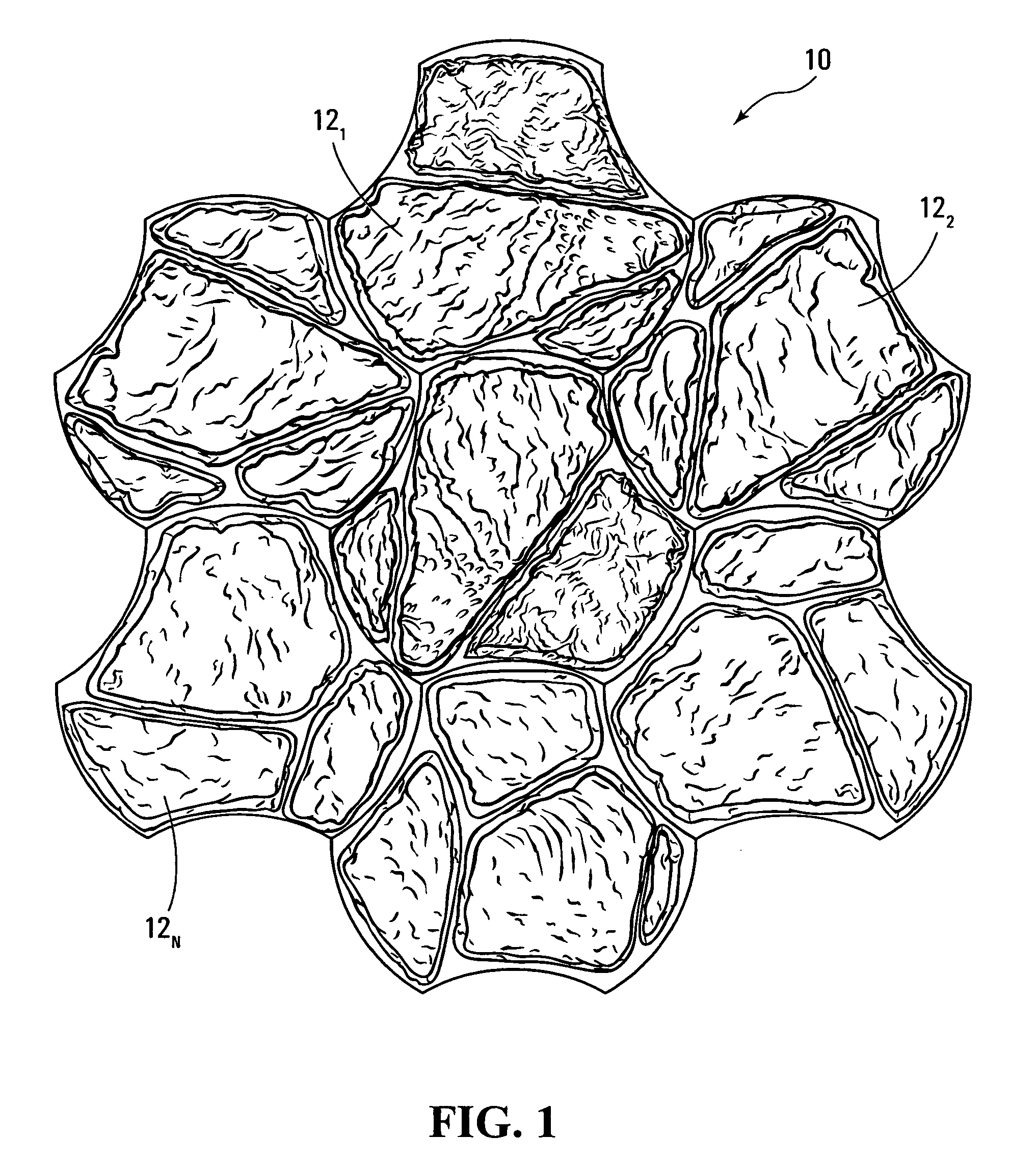

Dry-cast concrete block

A dry-cast concrete block for use in a structure comprising a plurality of concrete blocks. The dry-cast concrete block comprises three convex sides and three concave sides alternating with the three convex sides. The dry-cast concrete block also comprises a surface located between the three convex sides and the three concave sides and comprising at least one portion having a cast texture with a natural stone appearance. Each of the three convex sides is adapted to register with either one of three concave sides of an adjacent one of the concrete blocks to enable positioning of the dry-cast concrete block in different positions relative to the adjacent one of the concrete blocks.

Owner:OLDCASTLE BUILDING PROD CANADA INC

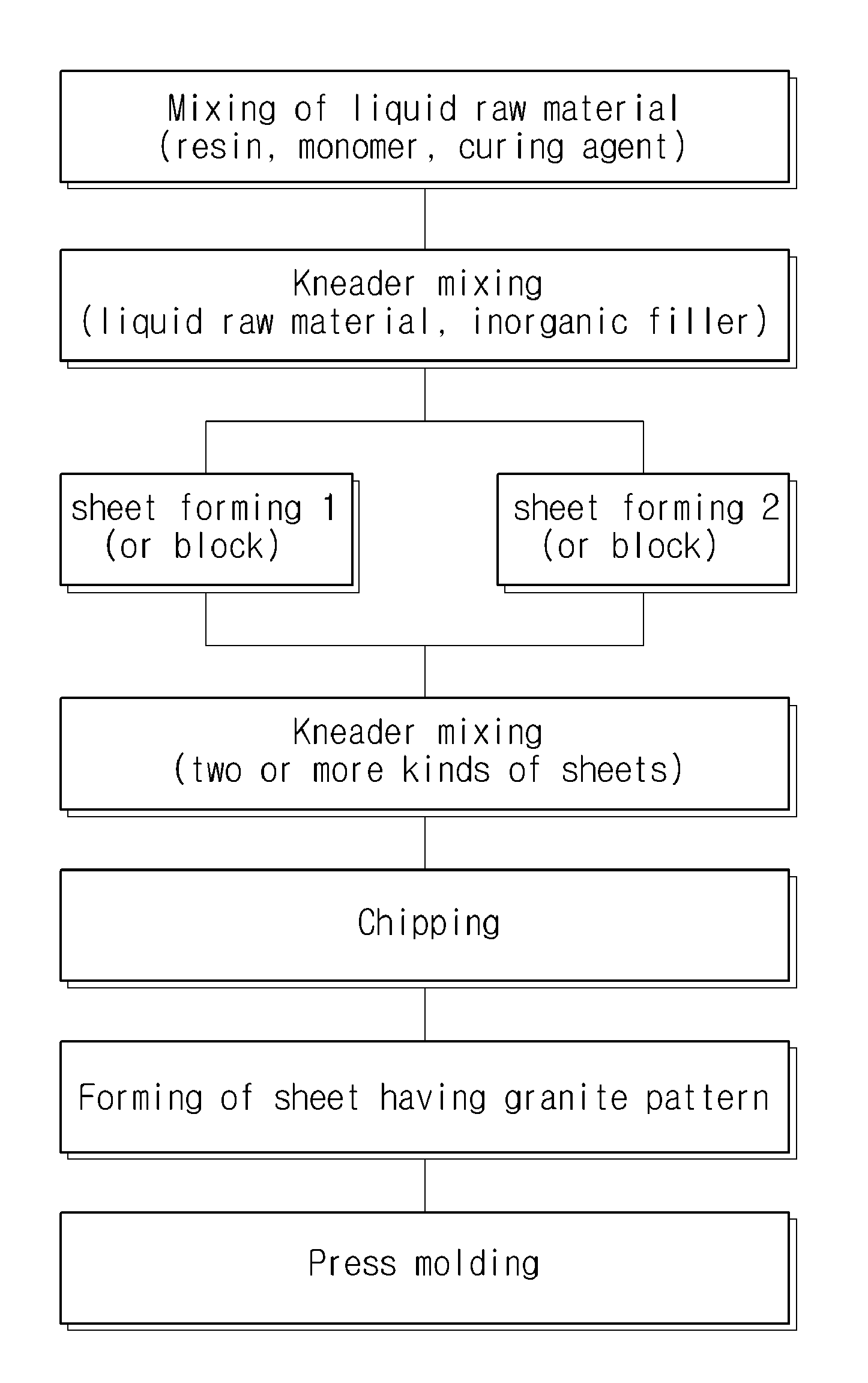

Acrylic artificial marble having granite pattern and method of manufacturing the same

InactiveUS20130137810A1Well mixedDesired patternNatural patternsNon-woven fabricsShell moldingGranolithic

The present invention relates to an acrylic artificial marble having a granite pattern and a method of manufacturing the same, which can provide a natural marble effect by mixing and molding two or more compounds having different colors and thus can obtain a granite pattern in which patterns of the two or more compounds are smoothly mixed, and which can obtain a desired pattern remarkably similar to a pattern of natural stone by using a multicolor chip sheet.

Owner:LG HAUSYS LTD

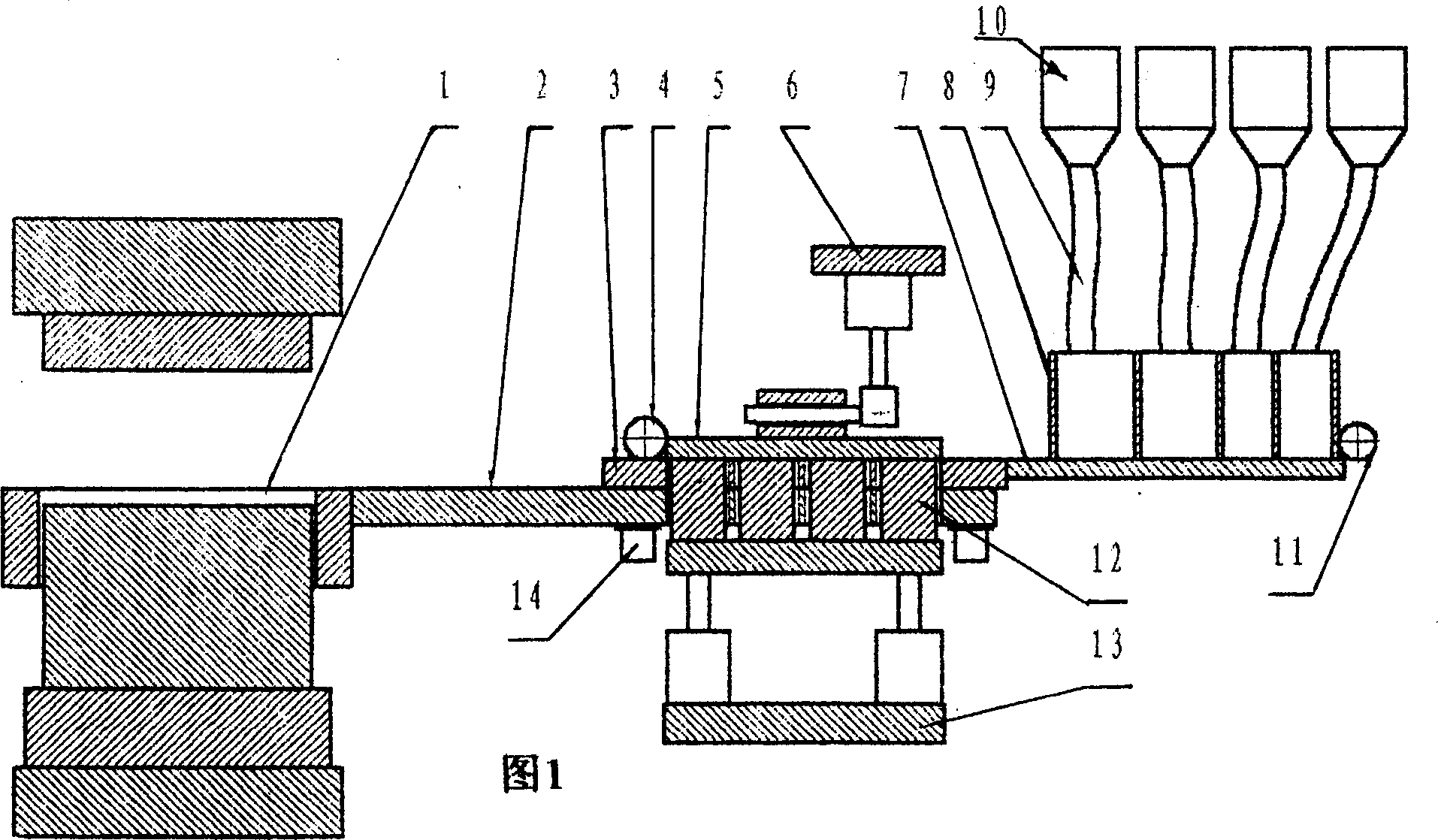

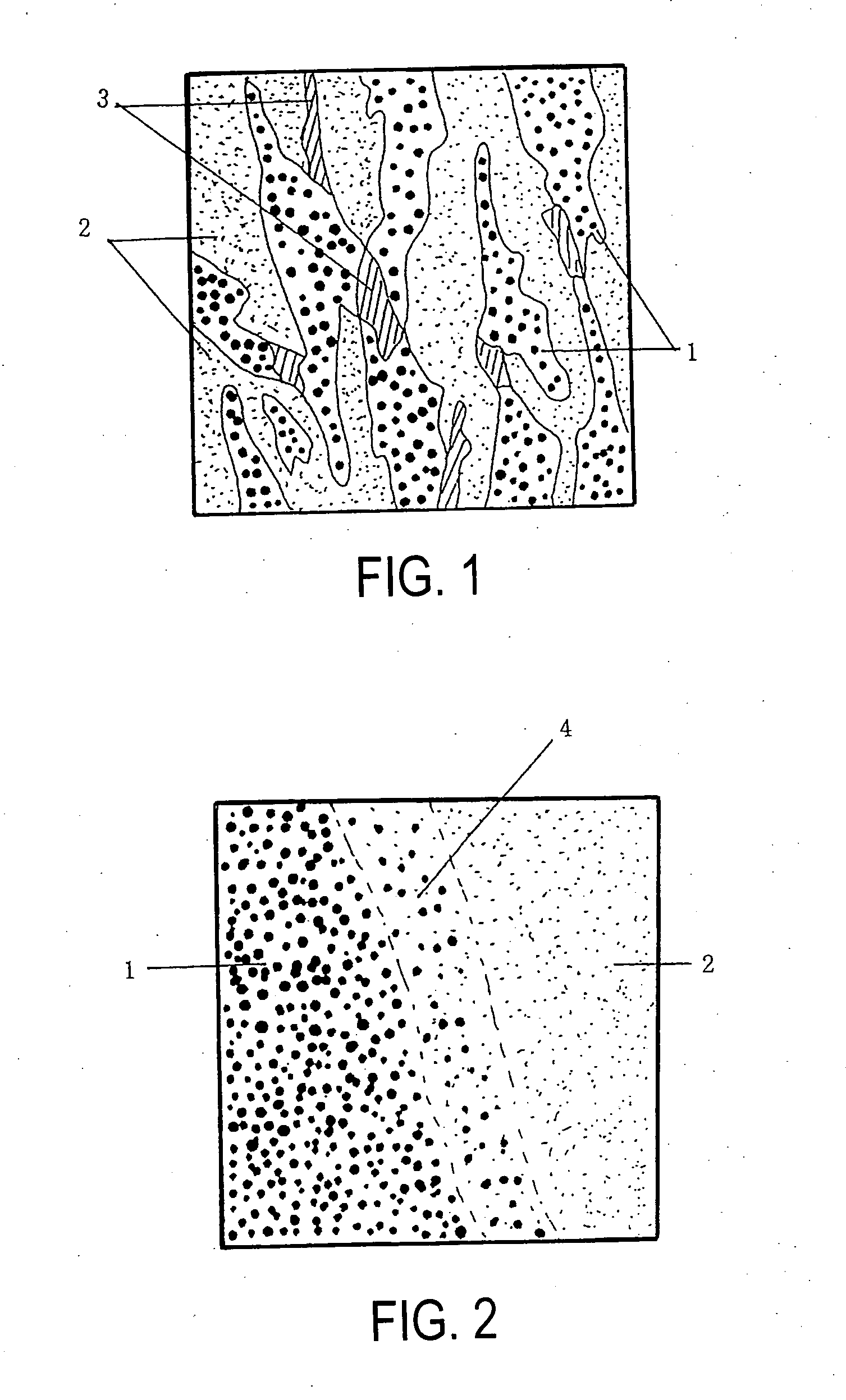

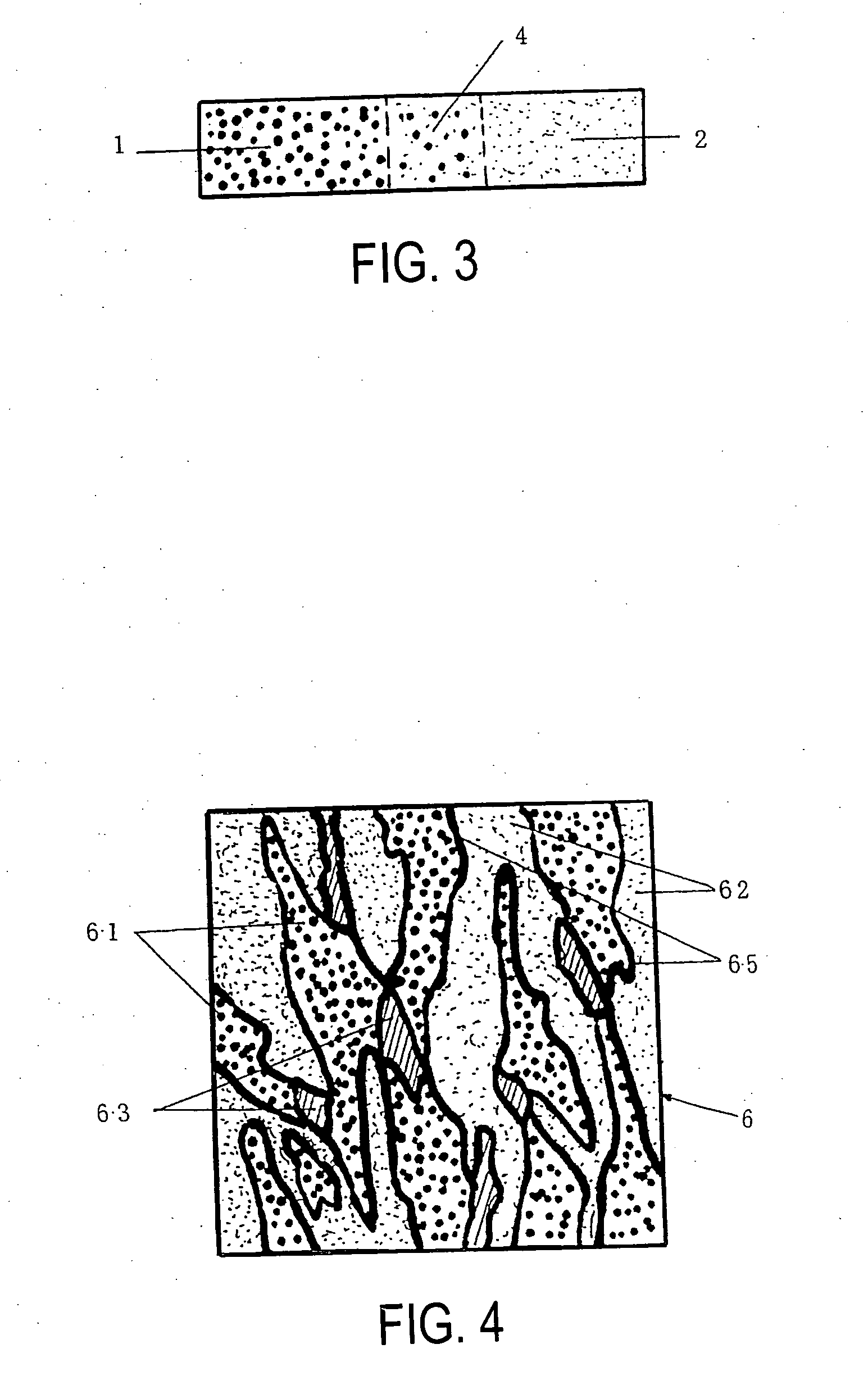

Apparatus and method for moulding porcelain with artificial natural stone patterns

InactiveCN1424190AMeet different needsSolve unforeseen and uncontrollable technical problemsCeramic shaping apparatusEngineeringMechanical engineering

An apparatus for preparing the ceramics with simulative natural stone pattern is composed of die frame for press, small copy die, small die core, lattice, pattern materials box, hopper, feed tube and electric controller. Said ceramics is made up through forming pattern in said box, locating lattice and small copy die, lifting up the small die core to come in lattice, moving the box above the lattice, lowering down the small die core to make the pattern come in the lattice, removing the box, pressing the pattern, and die pressing. Its advantages are lifelike pattern, and high productivity.

Owner:GUANGDONG DONGPENG CERAMIC CO LTD

Colorful transparent polished-glazed brick and production method thereof

The invention discloses a colorful transparent polished-glazed brick and a production method thereof. The production method for the colorful transparent polished-glazed brick comprises the following steps: enameling a dried ceramic blank, spreading one or more glazes in different colors and with different burning temperature and different refractive indexes on the brick blank, and performing calcining and profiling soft polishing treatment to obtain the brick. According to the colorful transparent polished-glazed brick and the production method thereof, the layering effects and transition of the surface of the colorful transparent polished-glazed brick are closer to those of a natural stone, and the grade of the product is improved to a certain extent; original color effects can be achieved without adding a coloring material, so that process complexity is reduced, the labor intensity of a worker is reduced, and the production efficiency is favorably improved, and the colorful transparent polished-glazed brick and the production method thereof are suitable for popularization and application.

Owner:GUANGDONG JIA MEI CERAMIC

Form liner for creating a realistic stone wall pattern

The form liner of the present invention simulates a natural stone wall having a random pattern. The form liner comprises an outer edge and a surface that is contoured to resemble a plurality of stones held together by an adhesive substance. The outer edge of the form liner has six connection regions made up of multiple linear segments. No two adjacent connection regions are connected at a ninety degree angle and no linear segment of the fifth connection region lies along the same linear path as any linear segment of the sixth connection region.

Owner:NASVIK PAUL C

Novel material capable of imitating multiple ornamental sculpture stone materials and manufacturing process of novel material

ActiveCN104478390AGuaranteed dockingGuaranteed aestheticsNatural patternsOrnamental structuresPrillPlasticizer

The invention discloses a novel material capable of imitating multiple ornamental sculpture stone materials. The novel material is prepared from a coagulation material and natural stone sand in percentage by weight, wherein the coagulation materials comprises the following raw materials in percentage by weight: sulfate aluminum cement clinker, white stone, calcium carbonate powder, high-class talcum powder, a super plasticizer, color powder and a thickening time control agent; the natural stone sand comprises the following raw materials in percentage by weight: pure white sand with the grain fineness of 1-2 mm, pure white sand with the grain fineness of 0.2-0.5 mm and colored sand with the grain fineness of 1-2 mm; the colored sand comprises one or two or more of pure red sand, pure pulp sand, pure blue sand and sand of other colors. The raw materials are finely grinded and compounded to obtain a coagulation material which is white in color, short in coagulation time and high in strength, various stone surface effects are achieved when various natural stone sands are compounded, the novel material can be produced in batch, and compared with a manner that sculptures are directly carved on stone materials, the novel material is much excellent in working efficiency, good in consistency of sculpture products, good in pattern abutting of finished products and low in production cost.

Owner:广州新尚艺术股份有限公司

Artificial stone

Owner:OLDCASTLE BUILDING PROD CANADA INC

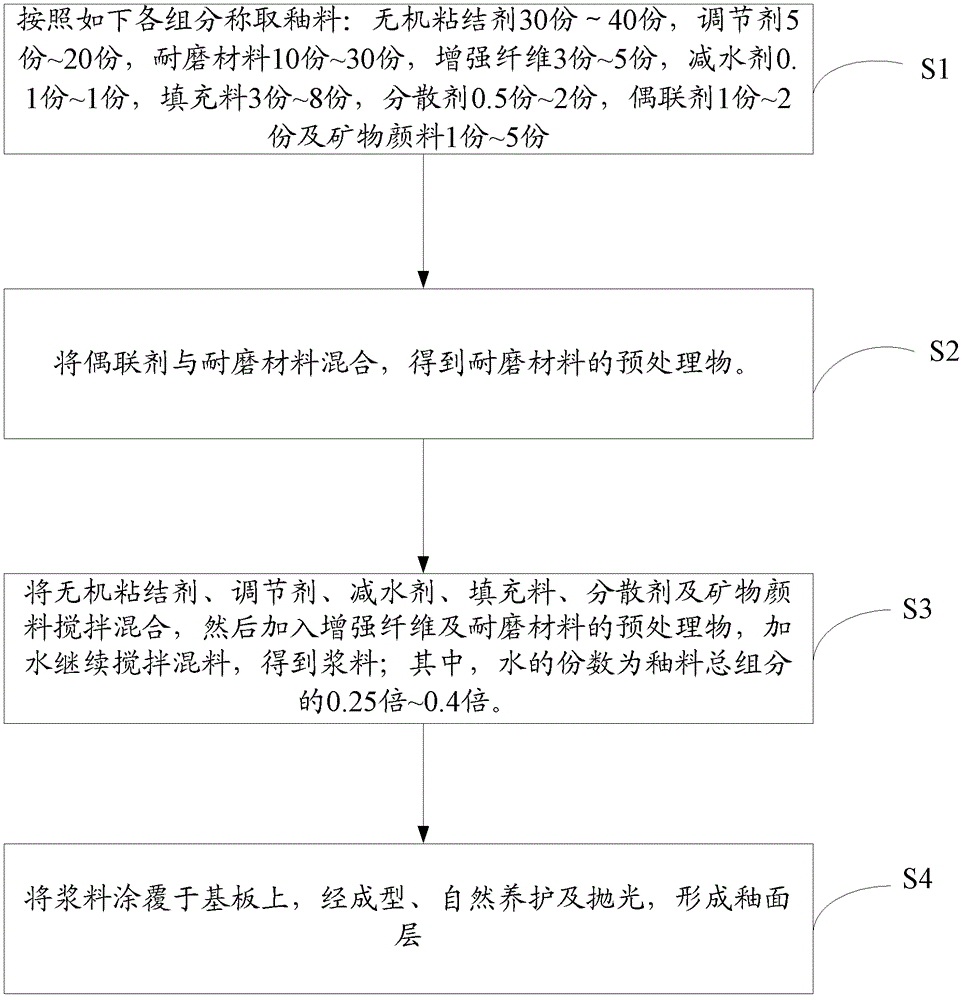

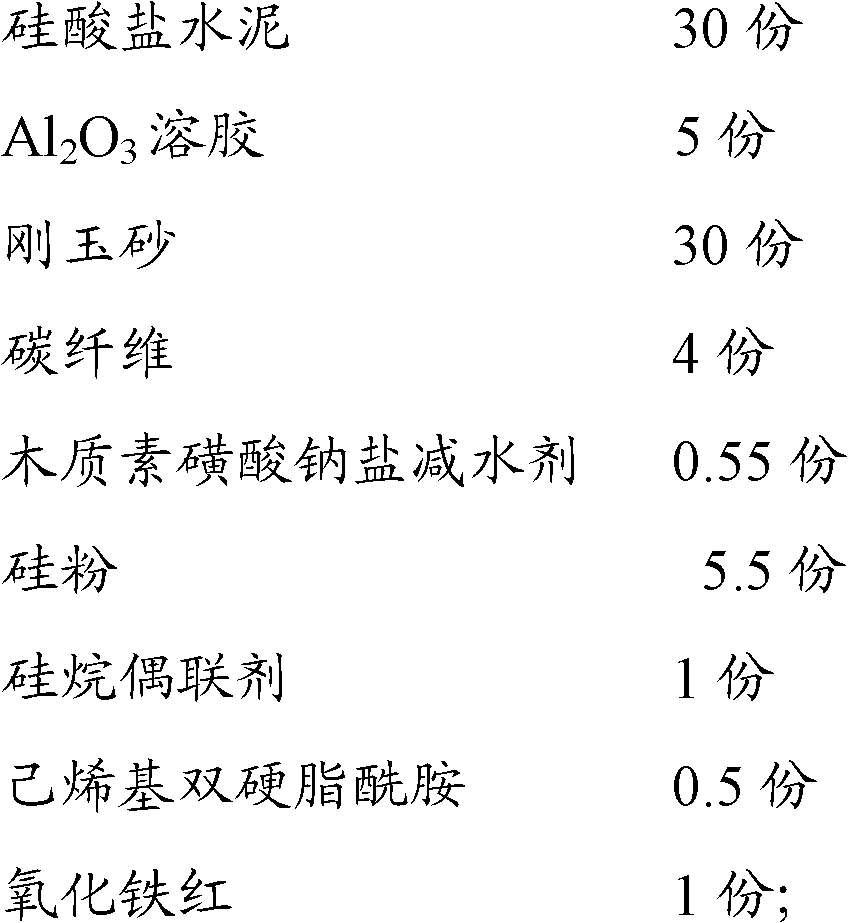

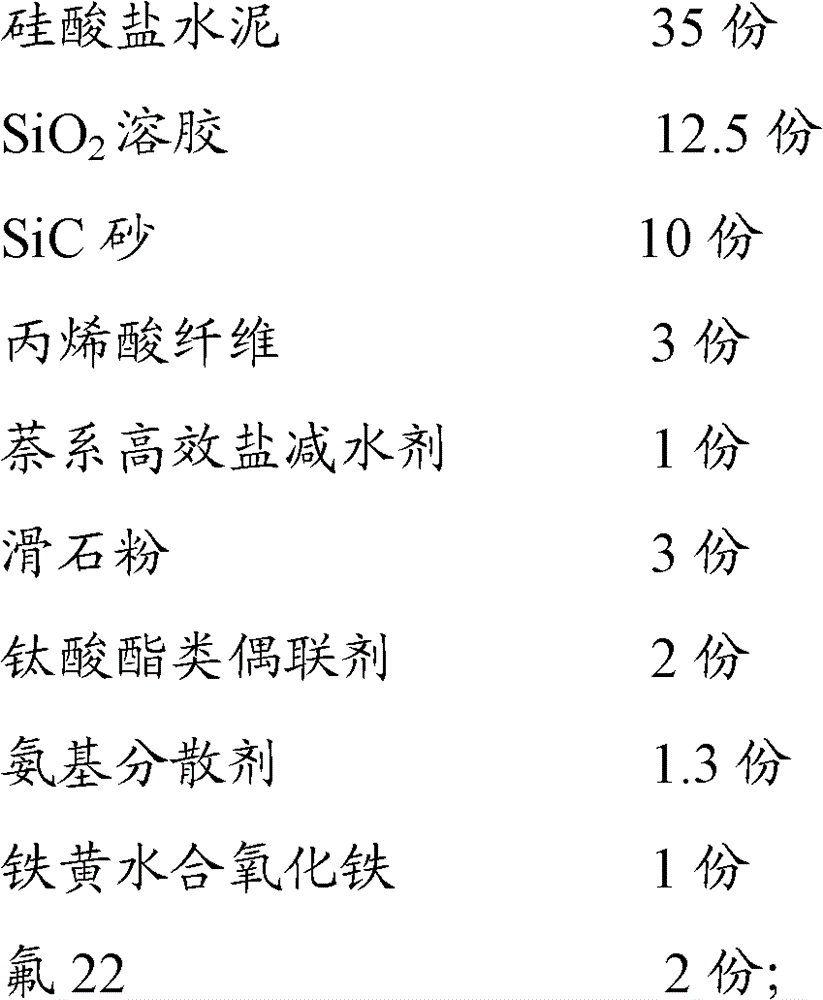

Glaze and method for forming glaze layer

A glaze comprises the following components: 30-40 parts of an inorganic binder, 5-20 parts of regulators, 10-30 parts of wear-resistant material, 3-5 parts of reinforced fiber, 0.1-1 part of a water-reducing agent, 3-8 parts of filling material, 0.5-2 parts of a dispersing agent, 1-2 parts of a coupling agent and 1-5 parts of a mineral pigment, wherein the regulator is at least one selected from Al2O3 sol, SiO2 sol, ZrO2 sol, water glass and aluminum sulfate; the wear-resistant material is at least one selected from emery, silicon carbide sand, quartz sand and steel grit; the filling material is at least one selected from silicon powder, talcum powder and calcium carbonate powder. The glaze layer formed by the glaze containing the above components has a similar color and luster with that of a natural stone and can replace decorative effect of the natural stone; further, the glaze layer formed by the glaze mostly adopts commonly used inorganic materials whose cost are lower compared with that of the natural stone. In addition, it is necessary to provide a method for forming the glaze layer.

Owner:深圳市爱思宝科技发展有限公司

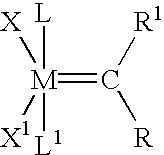

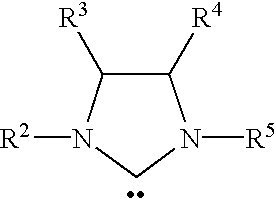

Metathesis-active adhesion agents and methods for enhancing polymer adhesion to surfaces

InactiveUS7339006B2Synthetic resin layered productsPaper/cardboard layered productsPolyolefinDouble bond

Owner:MATERIA

Three-dimensional colour pattern slabs which formed by sintering ceramic powder

InactiveUS20050013991A1Overcome defectsLess color differenceDead plant preservationArtificial flowers and garlandsCeramic sinteringMetallurgy

This invention relates to a the 3D color pattern slab formed by sintering ceramic powder, which is formed by pressing and sintering ceramic powders with minimum diameter of 0.1 mm-0.8 mm to provide a 3D color pattern slab formed by sintering ceramic powder, which is characterized in that, the ceramic product includes clear cut ceramic sintered pattern regions having 2-10 various kinds of colors or different shades of a single or mixed colors; at least 2 types of pattern regions each occupies 10%-90% of the total area of the ceramic product, in which at least each pattern region having at least one type of colored ceramic powder uniformly distributed in 80%-100% of the pattern area and 70%-100% from surface to the inside 70%-100% of the thickness of the ceramic product; also, in a 1 mm-20 mm intersecting region between said two types of colored pattern regions, the mixture ratio of the different colored powder material between two different color pattern regions can reach from 1:50 to 50:50. In this way imitation stone slab imitating natural stone in 3D space, with virtues of lower water absorption, less color difference, and higher degree of smoothness, and free of radioactive contamination etc.

Owner:YANG DENING

Method for preparing jade type microcrystalline glass with high-temperature furnace slag

The invention discloses a method for preparing jade type microcrystalline glass with high-temperature furnace slag, which comprises the steps of: taking molten furnace slag as main materials; adding auxiliary materials such as fluxing clarifying agent and additive, and the like; further melting and clarifying in a high-temperature furnace to form glass liquid; pouring or calendaring the glass liquid to form basic glass; heat processing the basic glass by means of crystallization to obtain the rough product of the jade type microcrystalline glass; and finish machining to obtain the finished product of the jade type microcrystalline glass. The method not only effectively utilizes the molten high-temperature furnace slag, but also sufficiently utilizes heat energy stored in the high-temperature furnace slag, and prevents the high-temperature furnace slag from generating huge amounts of corrosive hot steam in the process of discharging. The jade type microcrystalline glass prepared by the method is in the status of semitransparent wax, exactly looks like natural jade, has good cutting performance, high intensity and good tenacity, can be used for replacing natural stones in construction industry, and can be used for replacing natural rare jades in machining artware.

Owner:TSINGHUA UNIV

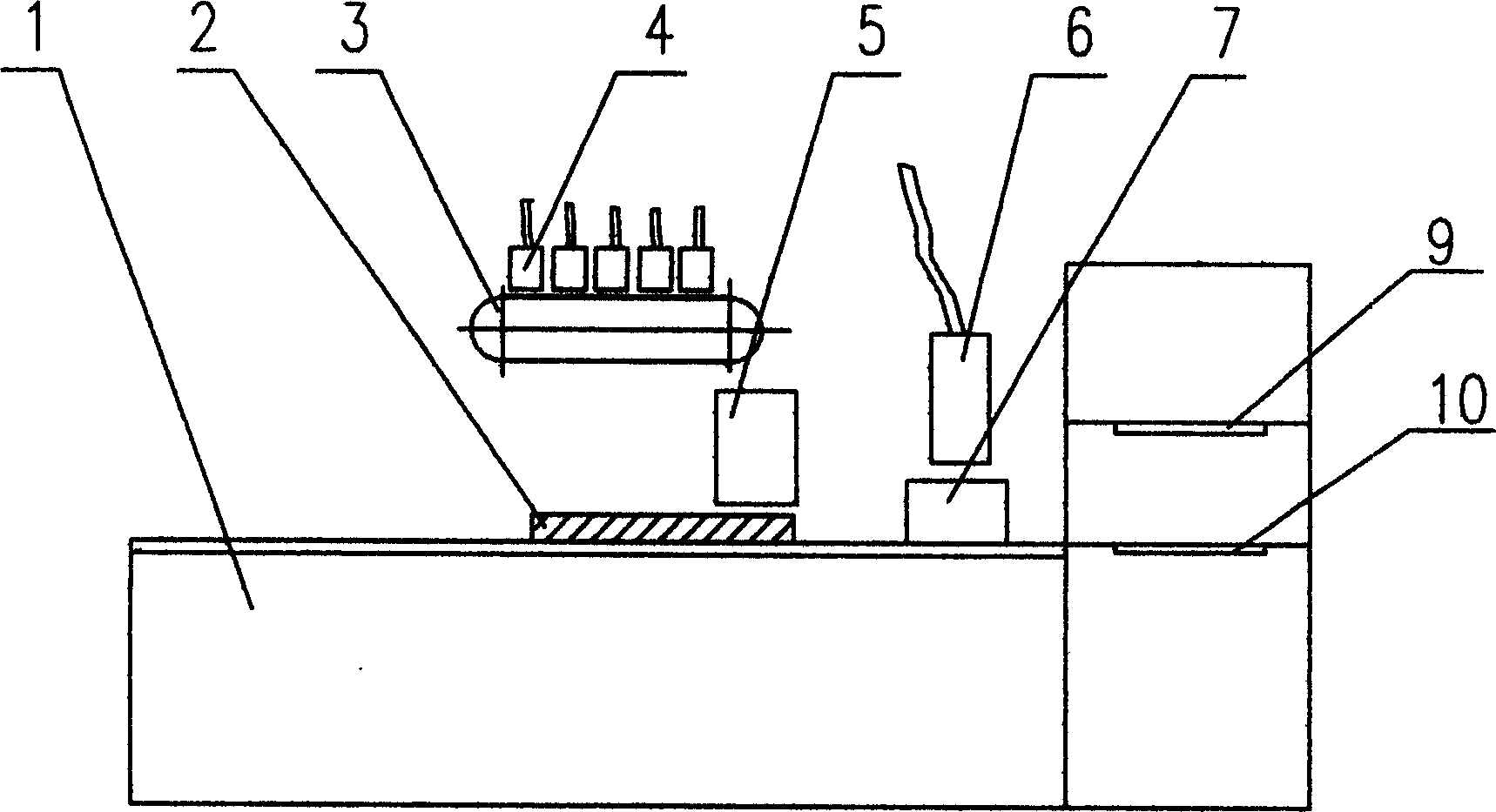

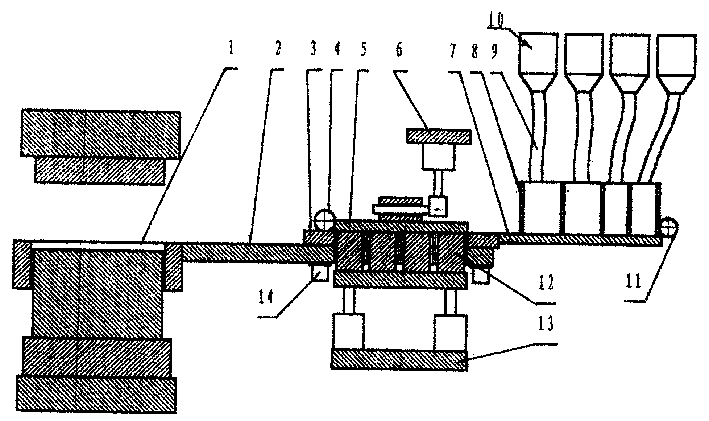

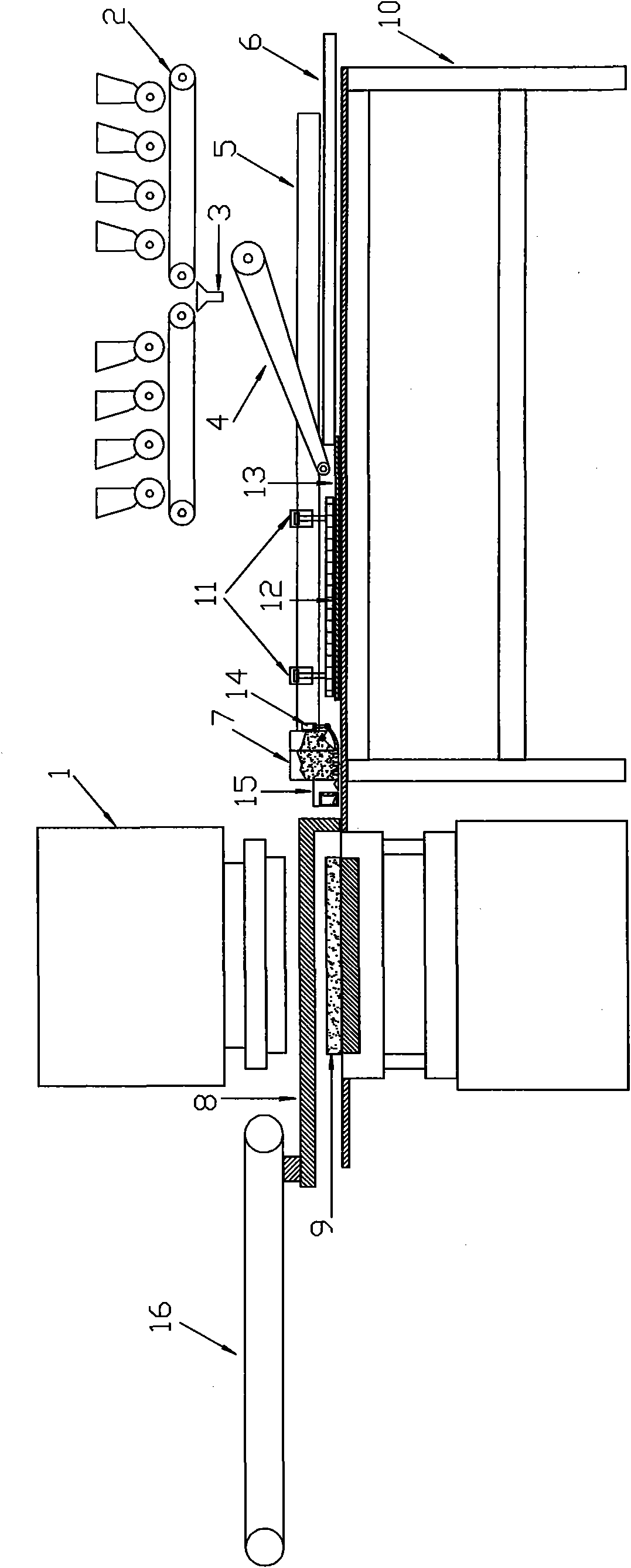

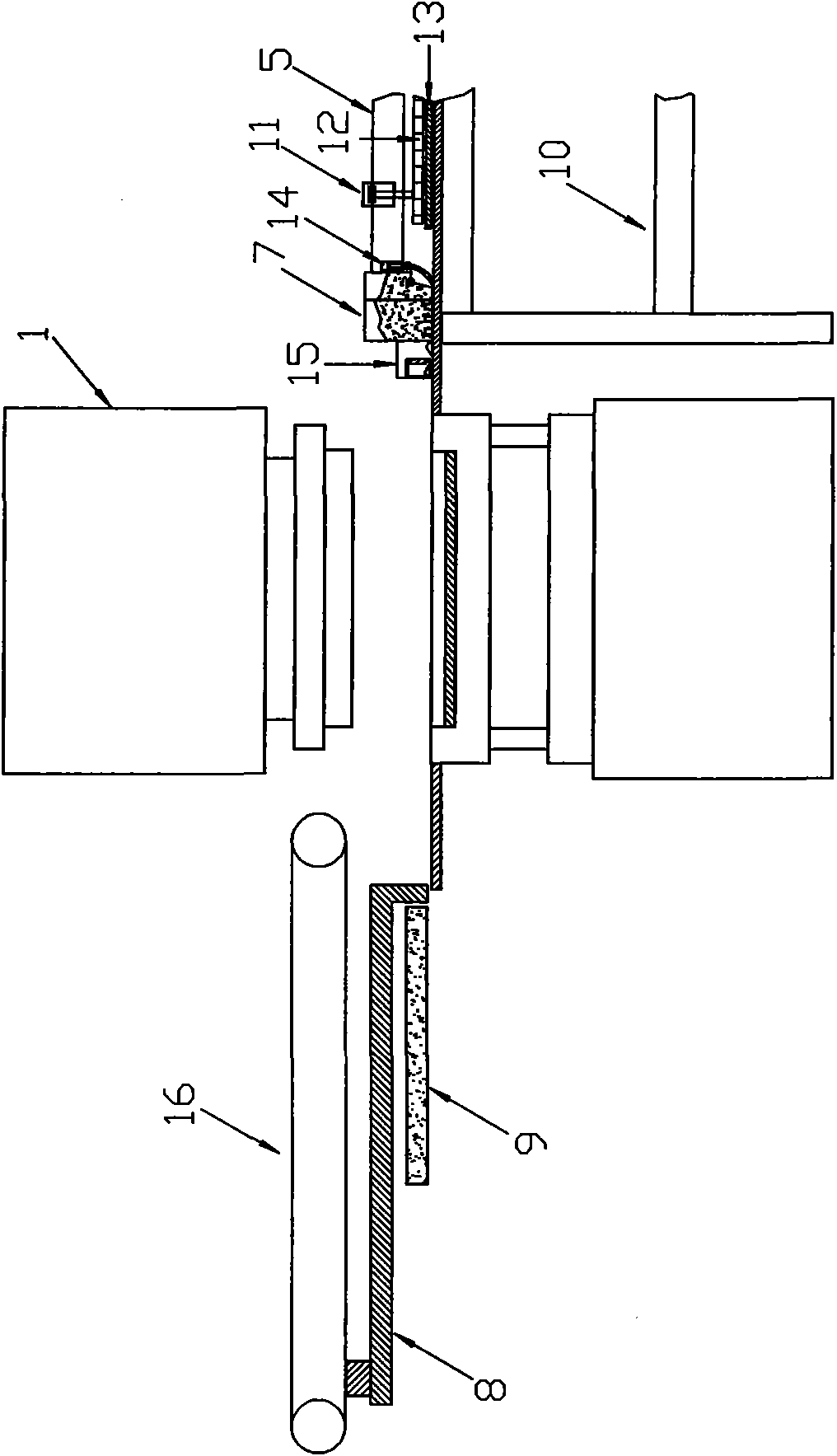

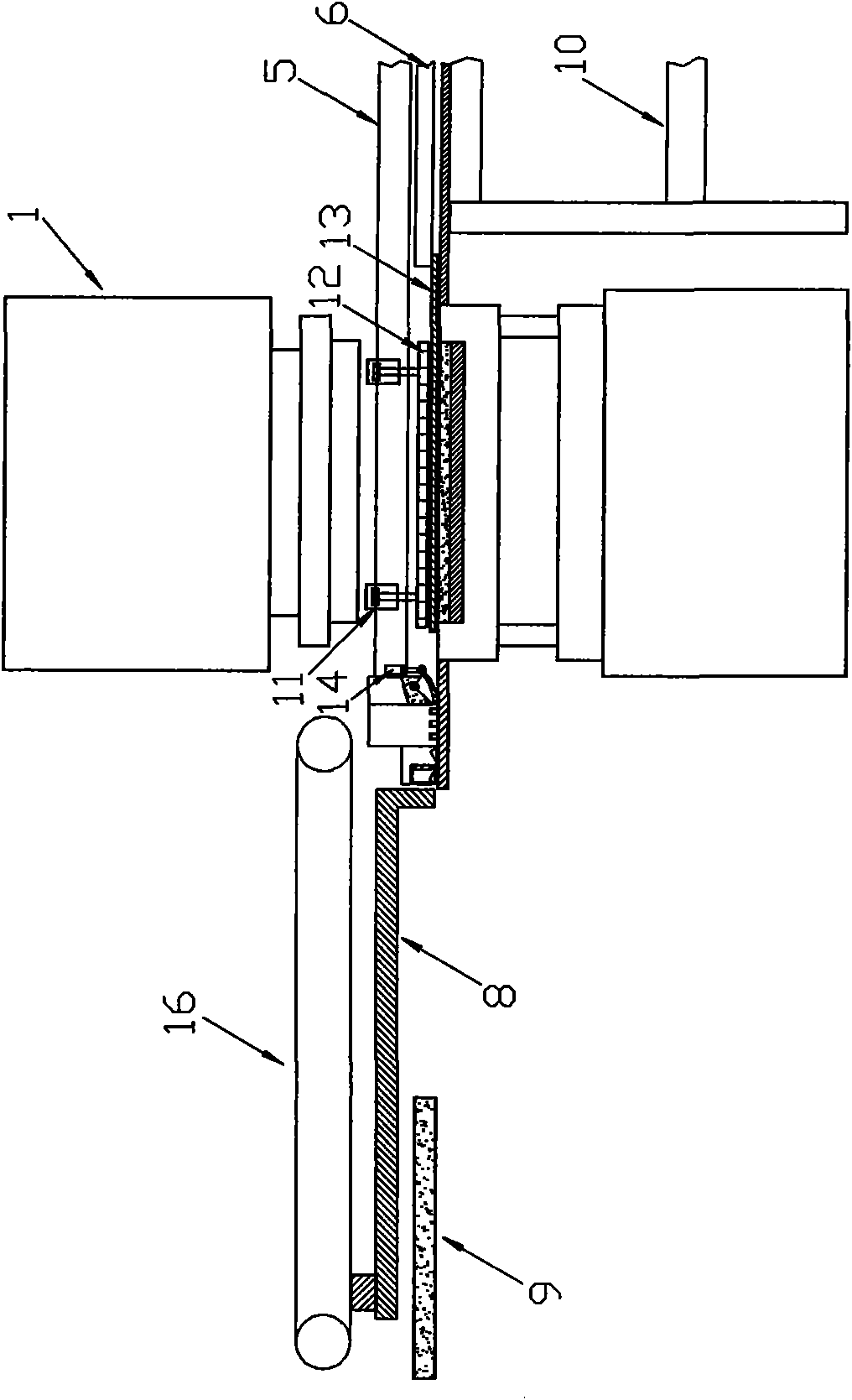

Equipment and method for producing imitation stone-texture ceramic tile

The invention relates to equipment and a method for producing an imitation stone-texture ceramic tile. The equipment comprises a hydraulic machine, a tile pulling rod, a material pushing frame of a secondary material spreader and a composite base material hopper, wherein the tile pulling rod is arranged at the front end of the composite base material hopper on the material pushing frame of a secondary material spreader and consists of two tile pulling arms and a transverse rod. The equipment is characterized by also comprising a tile pulling mechanism driving the tile pulling rod and a powder removing mechanism which is used for removing powder and arranged between the hydraulic machine and the composite material hopper. The invention also provides a secondary material spreading device and a method thereof, which not only can solve the problem of directly producing a ceramic tile with a clear texture effect pattern imitating a natural stone without a polishing working procedure difficult to be realized in a counter steer mode, particularly a rough surface or dull surface micro powder ceramic tile with the texture effect pattern imitating the natural stone, but also can ensure that the texture effect pattern imitating the natural stone in a micro powder material can be kept more complete.

Owner:GUANGDONG NEWPEARL CERAMIC GRP CO LTD

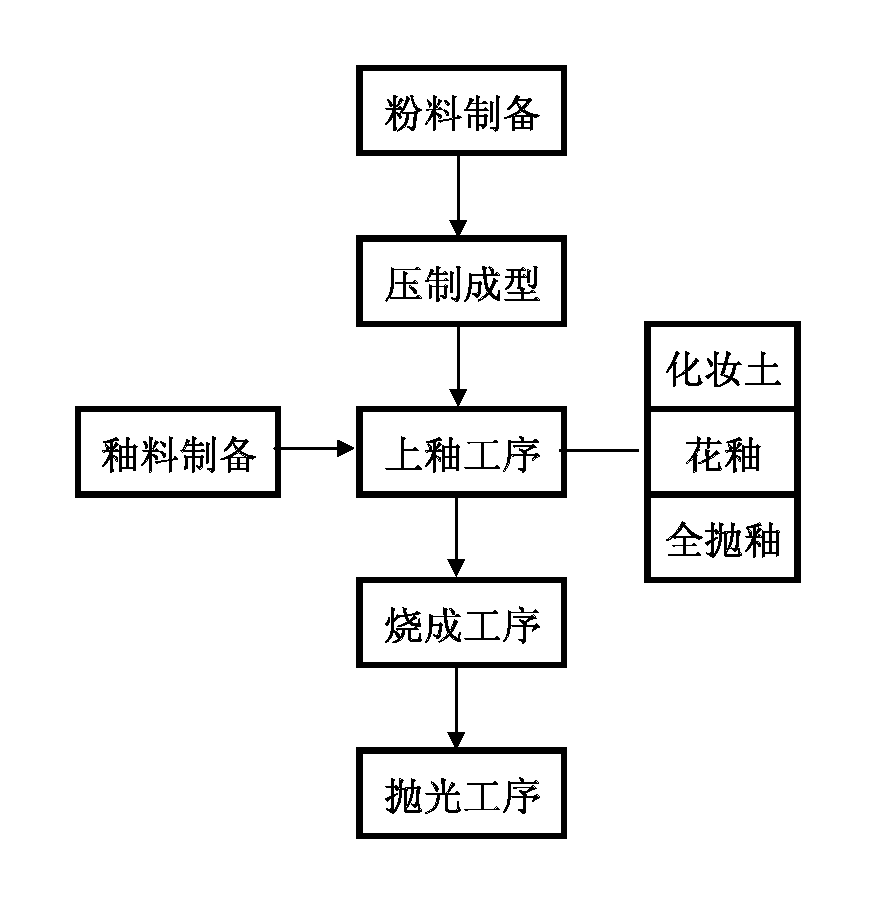

Stereoscopic magical-color ceramic product and preparation method thereof

The invention relates to a stereoscopic magical-color ceramic product and a preparation method thereof, and the preparation method comprises the following steps: distributing a designed pattern by prepared green brick powder through a powder multi-pipe material-distributing device, then pressing a green brick by a pressing machine; performing polishing treatment of the dried green brick by a polishing machine; spraying a layer of transparent ground glaze on the polished green brick surface; printing on the ground glaze according to the designed pattern to form a fancy glaze layer; coating a layer of completely polished transparent glaze on the fancy glaze layer to obtain a green body product; drying the green body product, performing high temperature sintering in a kiln, and polishing to obtain the stereoscopic magical-color ceramic product. The method of the invention adopts multi-step decoration means, and combines the characteristics of rough pattern and real texture of powder with the characteristics of abundant and fine pattern of glaze; therefore, the product has a clear and abundant pattern, a fine texture as natural stone, a definite gradient, and strong stereo perception.

Owner:MONALISA GRP CO LTD

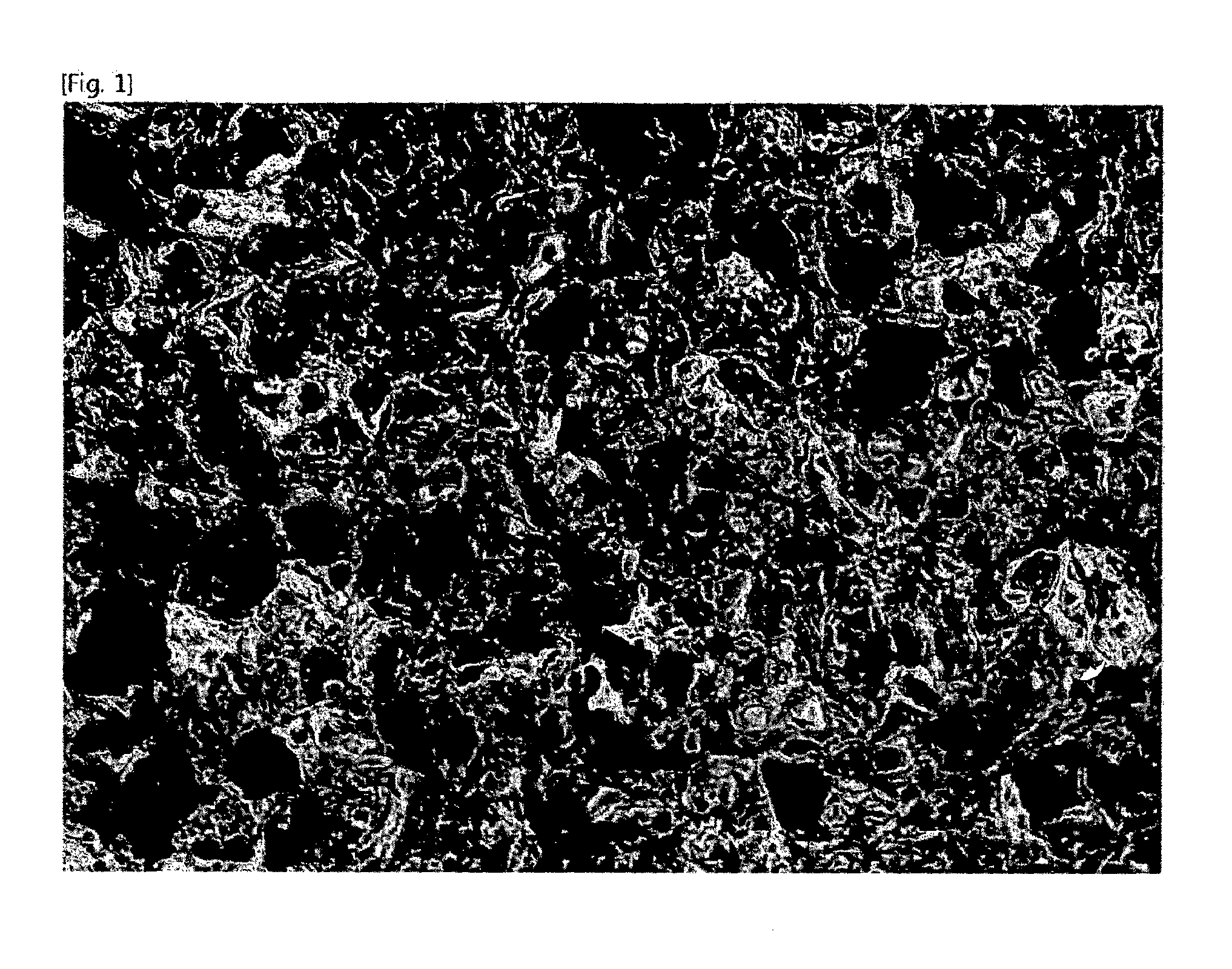

Composite material having the appearance of natural stone

ActiveUS20060270758A1Easy to operateProcessing speedCovering/liningsNatural patternsNatural stonePolymer

Disclosed is a composite material having the appearance of natural stone that made from a polymer and natural aggregate. The composite material also has an antimicrobial material incorporated into it that resists the proliferation of microbes on the surface of the material. A method for producing this material is also disclosed.

Owner:COSENTINO SA

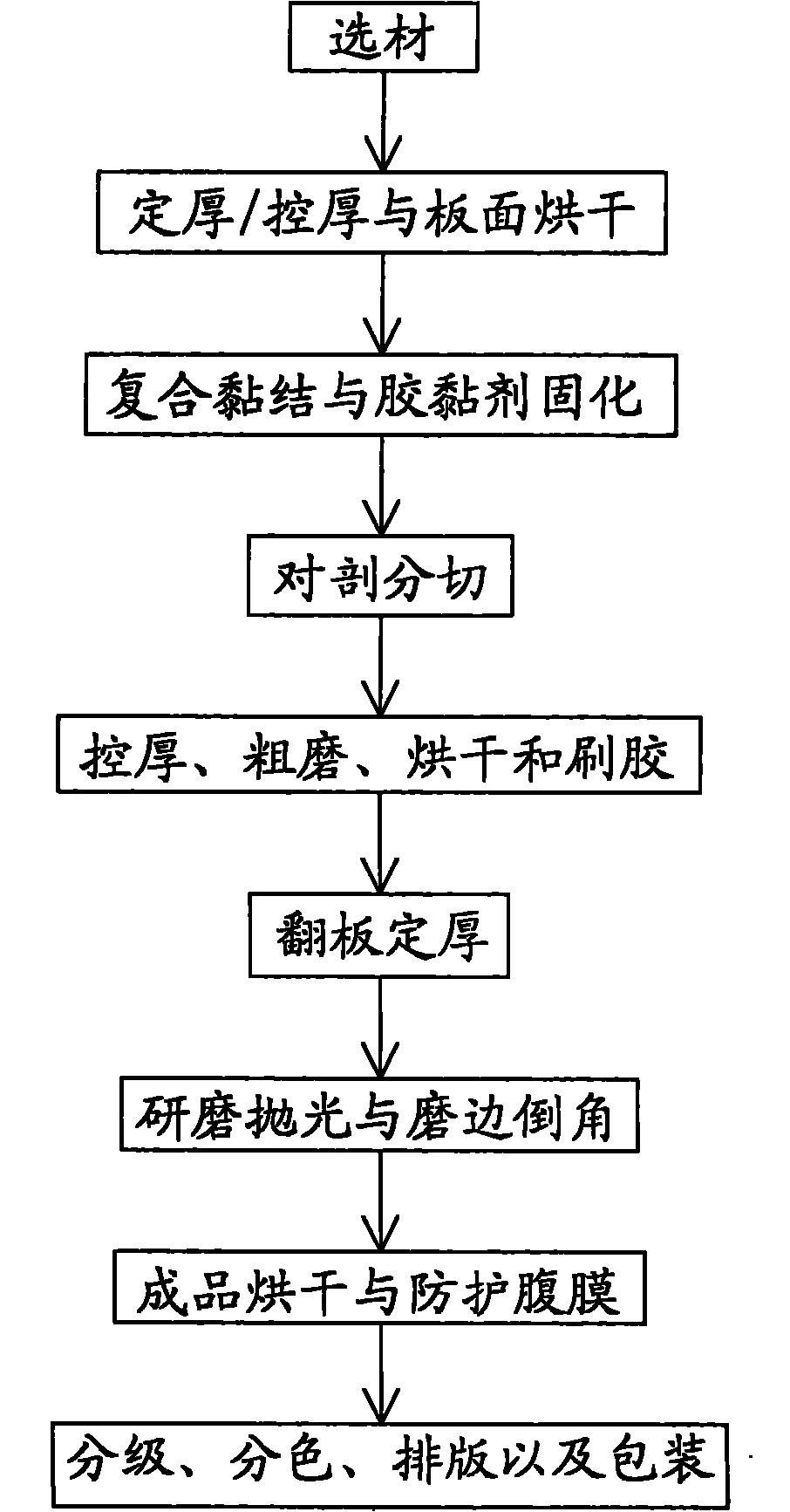

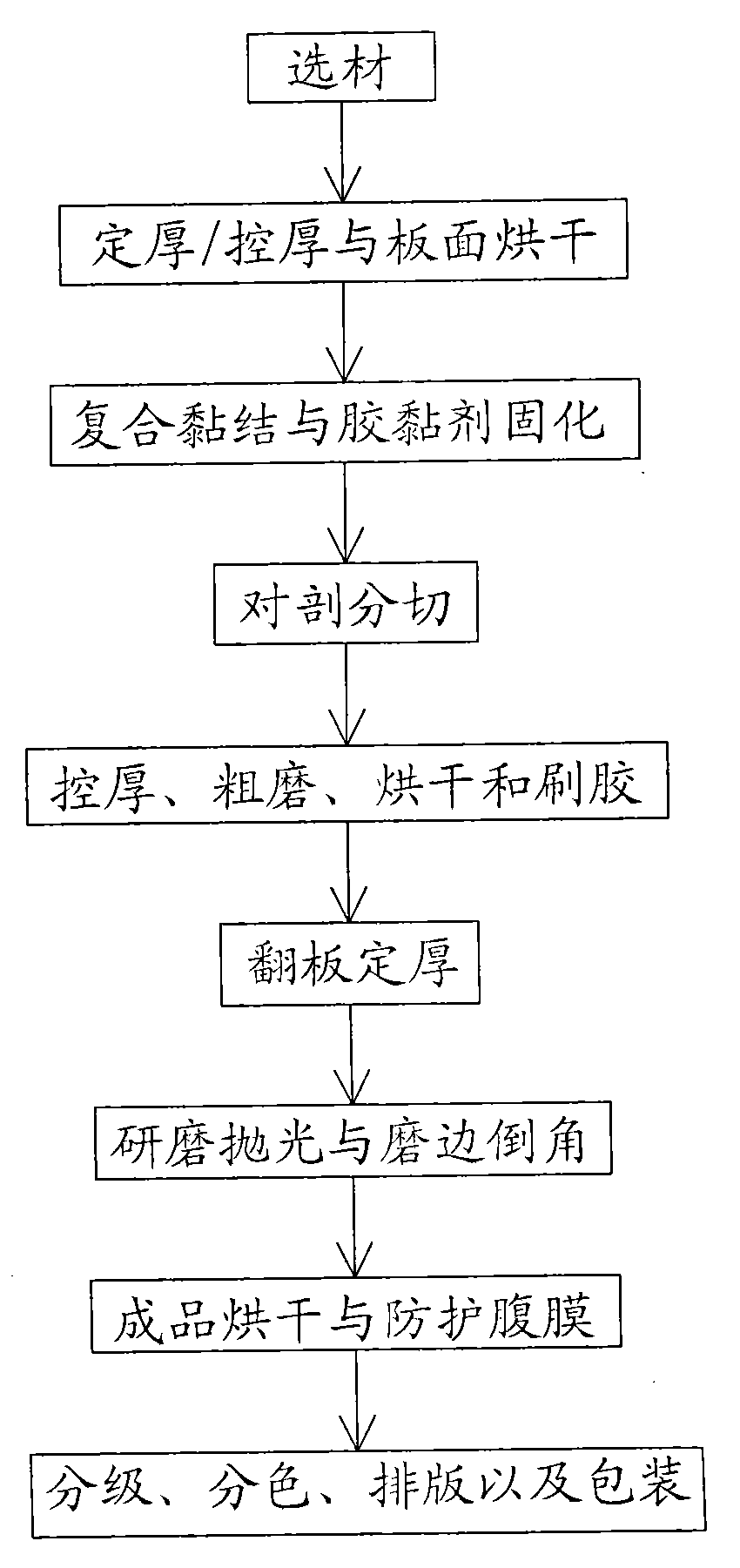

Technology for producing natural stone composite board

InactiveCN101966719AGuaranteed decorative effectHigh strengthLaminationLamination apparatusEngineeringNatural stone

The invention discloses technology for producing a natural stone composite board, which comprises the following steps of: (1) selecting materials; (2) fixing and controlling the thickness and drying a board; (3) performing composite bonding and adhesive curing; (4) halving and slitting; (5) controlling the thickness, coarsely grinding, drying and cementing; (6) turning the board and fixing the thickness; and (7) grinding and polishing and chamfering so as to form the finished product of the natural stone composite board. The natural stone composite board produced by the technology has the characteristics of high efficiency, high yield and high strength.

Owner:FUJIAN NANAN XINDONGYUAN STONE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com