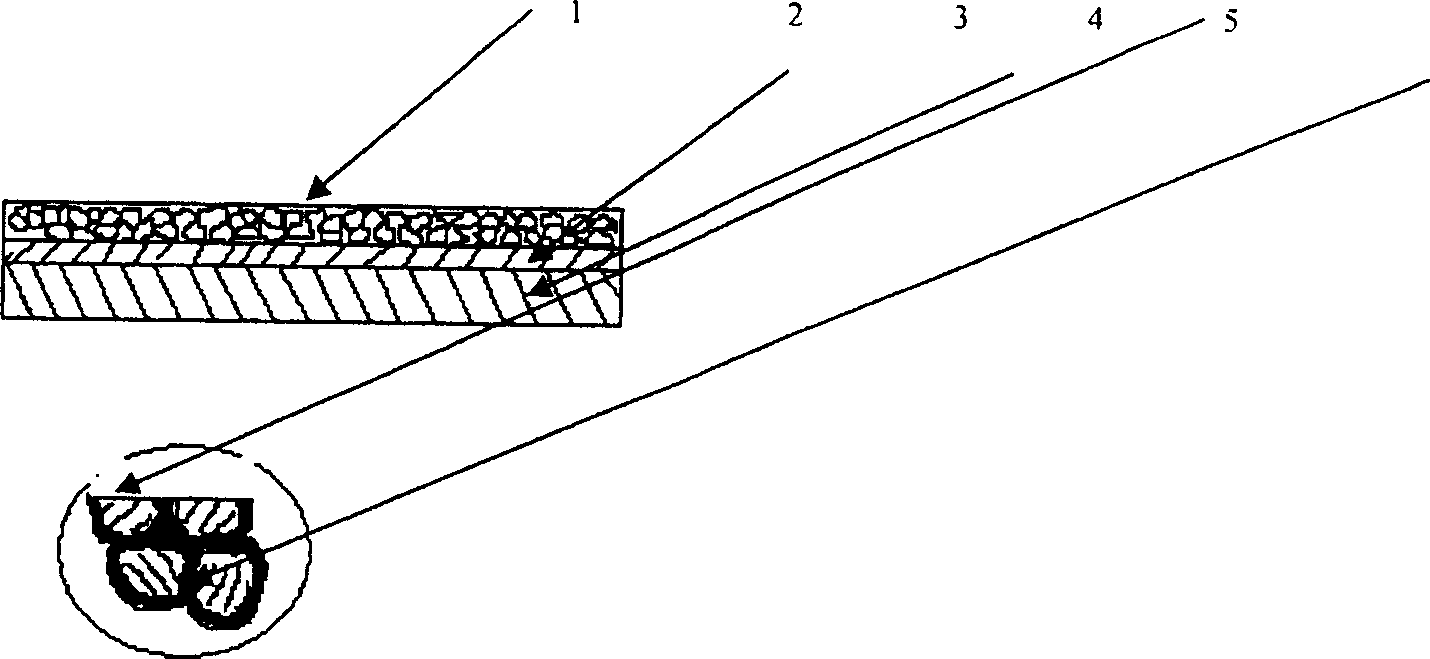

Preparation method of glazed ceramic brink with stone imitation pattern based on fused block wrapping pigment

A manufacturing method and technology of imitating stone, applied in the field of beautiful decorative patterns, can solve the problems of unsatisfactory, low score, and inability to achieve bright coloring and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] For the following examples 1 to 5, the preparation of the samples is carried out according to the aforementioned standard steps ①-⑤: in the 5 operating steps, step ② includes two options: one is that the adobe bottom The base material is processed in advance through pre-adding background color background (belowmarked as step ② a), and its second is that the described adobe substrate has not been processed in advance through pre-adding background color background (marked as step ② b below); step 3. includes two steps: The selection of three types: the first type is, for the purpose of imitating the typical pattern of granite particles, the basic measure for selecting and determining is to make the color diversification of the frit formed by wrapping and coloring (marked as step 3.( i)), diversifying the types of frit (hereinafter marked as step ③ (ii)), compounding two types of ceramic pigments (opaque type and transparent type) used in the encapsulation coloring techniqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com