Highly-wear-resistant super-hydrophobic composite coating and preparation method thereof

A composite coating, super-hydrophobic technology, applied in the coating and other directions, can solve the problems of easy damage, harsh application conditions, low strength of super-hydrophobic coatings, etc., and achieve the effects of low cost, improved bonding strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

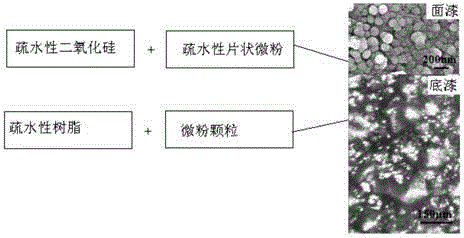

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a highly wear-resistant super-hydrophobic composite coating, the steps are:

[0037](1) Preparation and preparation of the primer: Add the hydrophobic resin to the compatible solvent in a certain proportion, and disperse it for 5-30 minutes under the compound conditions of ultrasonic and 500-1500rpm mechanical stirring until the resin is completely dissolved to obtain a resin solution, and then add a certain proportion The compounded micropowder particles, surfactant and resin curing agent, continue to compound and stir for 5-30 minutes to obtain a uniformly dispersed hybrid primer suspension, and after standing for 3-10 minutes to degas, brush or spray directly on the A uniform coating is formed on the surface of the substrate. Adjust the thickness of the coating to 20-200μm by brushing and spraying. Under the condition of 30-80℃, cure for 1-48h to obtain the required semi-cured primer. According to the characteristics of the resin, It can also b...

Embodiment 1

[0040] Add the fluorocarbon resin into the butyl acetate solvent at a weight ratio of 3:1, compound and disperse it under ultrasonic and 500rpm mechanical stirring for 5 minutes until the resin is completely dissolved, and add 0.1% equal mass compounded 100-mesh and 1500 mesh polytetrafluoroethylene and 0.05% curing agent, then add the polyoxyethylamine whose weight is 0.01% relative to the micropowder particles, and continue compounding and stirring for 5 minutes to obtain a uniformly dispersed hybrid primer suspension, and leave it for 3 minutes to remove After drying, spray a 20 μm thick coating on the surface of the glass substrate, and obtain the desired primer after curing at 30°C for 48 hours.

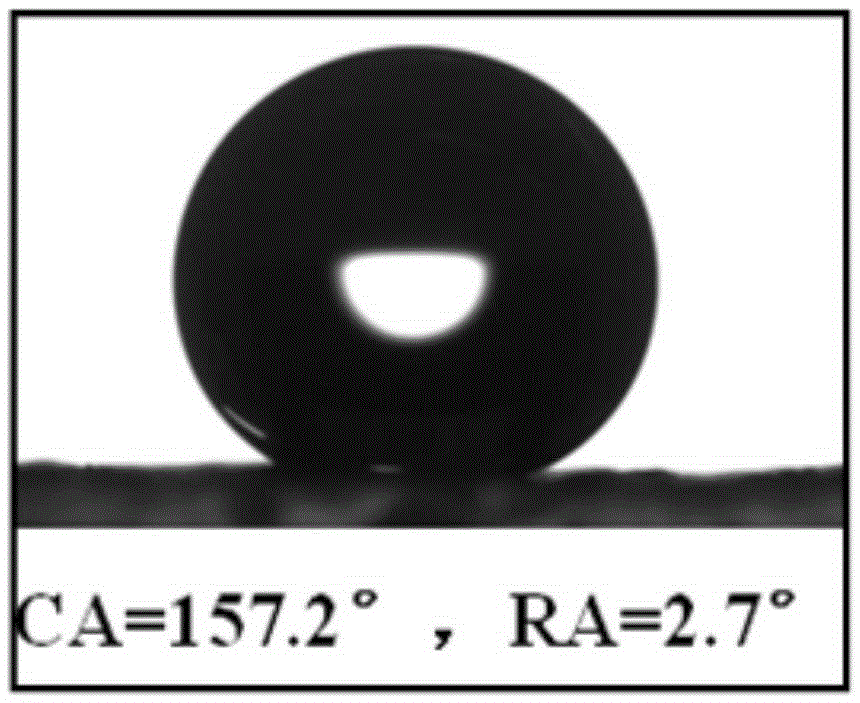

[0041] Add hydrophobic nano-silica particles to ethanol, ultrasonically disperse for 5 minutes, and prepare a 1 mg / mL suspension, then dissolve polyvinylidene fluoride (PVDF) in acetone, stir mechanically at room temperature for 12 hours, and obtain a 0.4 mg / mL solution, mix in e...

Embodiment 2

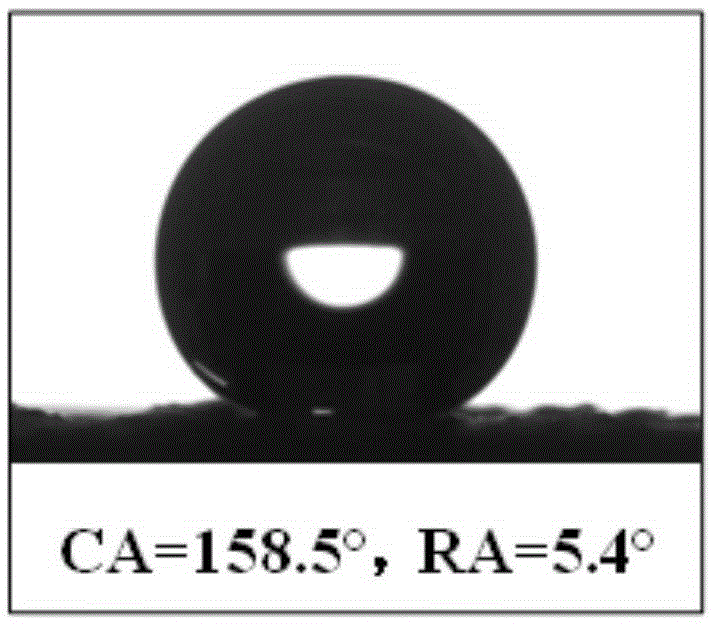

[0043] Add the hydrophobic silicone resin 2:1 into the acetone solvent, compound and disperse for 20 minutes under ultrasonic and 1000rpm mechanical stirring until the resin is completely dissolved, add 0.3% of 250 mesh and 2000 mesh diamonds, 0.05% dodecyl Sodium sulfate and 10% curing agent, continue to mix and stir for 20 minutes to obtain a uniformly dispersed hybrid primer suspension. After standing for 5 minutes to degas, brush a 10 μm thick coating on the surface of the metal (copper, aluminum, stainless steel) substrate, air Put 10mg / mL hydrophobic nano-silica particles on the surface of the primer after 4min, and bake and cure at 50°C for 24h to obtain a wear-resistant super-hydrophobic composite coating with a water contact angle of 158.5°. The angle is 5.4°( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com