Patents

Literature

1238results about How to "Rich in color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-insulating energy-saving paint for vehicle and method for producing the same

InactiveCN101195725AIncrease reflectionInsulate heat radiationFireproof paintsPolyester coatingsRadiant heatAbsorption rate

The invention relates to heat insulating and energy saving coating used for the vehicle, and the preparation method thereof. The invention takes organic resin film forming material as the main material, the coating at least includes infrared reflection pigment, hollow ceramic micro-spheres and silicon dioxide aerogel, an organic resin film having low sunlight absorption rate is formed in the coating through the organic resin film forming material with high transparency, the visible light and the near infrared ray in the sunlight are reflected through the infrared reflection pigment, the rutile type titanium dioxide and the hollow ceramic micro-spheres, and simultaneously a compact vacuum layer and an inert gas layer are formed on the surface of a coated object through the hollow ceramic micro-spheres and the silicon dioxide aerogel, so as to effectively isolate the radiant heat of the sun, and to reduce the heat conduction of air, and finally the heat insulating and energy saving coating used for the vehicle is formed, which not only can effectively reflect the energy in the sunlight, but also can effectively isolate the radiant heat of the sun and reduce the heat conduction of air, and simultaneously has good weather resistant performance, chemicals resistant performance, mechanical property and decorative property.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

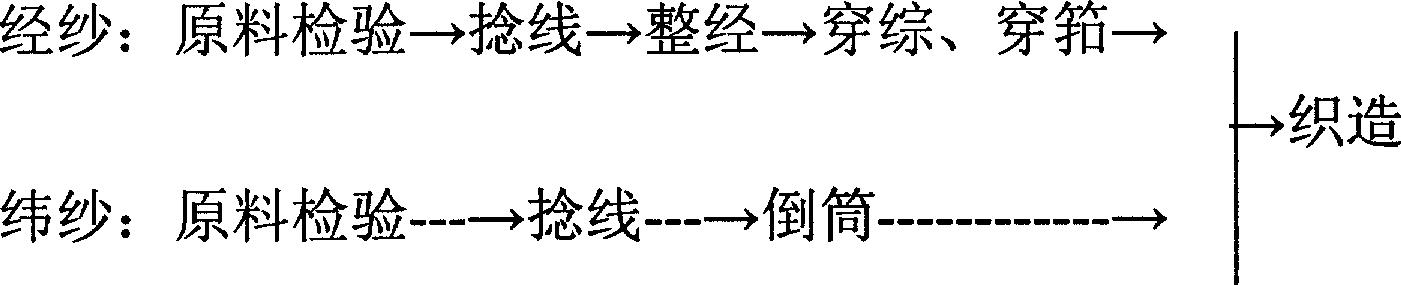

High-strength stretch-proof flame-retardant textile

InactiveCN101748549ASolve the difficulty of weavingSolve not easy to dyeWoven fabricsYarnCompound aEngineering

The invention provides a high-strength stretch-proof flame-retardant textile. The flame-retardant textile is formed by weaving a flame-retardant composite yarn, wherein the flame-retardant composite yarn is formed by compounding a core yarn and a leather yarn and is one of a covering yarn and a fasciated yarn; the core yarn adopts a flame-retardant filament yarn as a raw material; the leather yarn adopts a flame-retardant short fiber as a raw material; and the weight ratio of the flame-retardant filament yarn to the flame-retardant short fiber is 30-90:10-70. Compared with the conventional flame-retardant textile, the high-strength stretch-proof flame-retardant textile has higher strength and overcomes the defects of difficult weaving, difficult dyeing and uncomfortableness of the high-strength fiber; the high-strength stretch-proof flame-retardant textile has permanent flame retardance which cannot decrease after the textile is washed, and better textile strength; the textile has soft and comfortable handfeel, rich color and good strength, meets the requirements of various flame-retardant clothes and related standards; the product has rich and varied appearances and is durable; and the combustion performance of the textile can meet the national standards of flame-retardant products.

Owner:汕头市奥山服饰有限公司

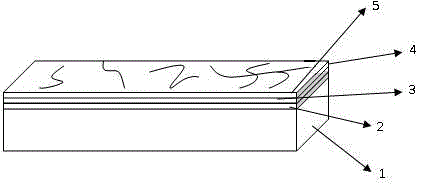

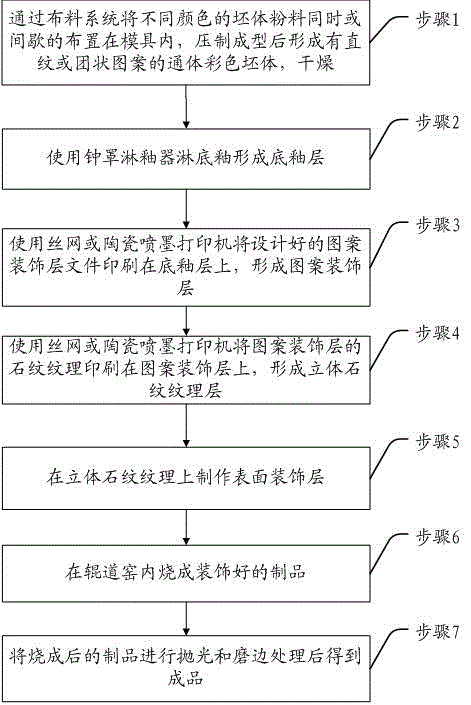

Whole-body polished porcelain tile having three-dimensional stone texture and production method of tile

The invention discloses a whole-body polished porcelain tile having three-dimensional stone texture and a production method of the tile. The tile comprises a whole-body colored blank layer, a ground coat layer, a pattern decoration layer, a three-dimensional stone texture layer and a surface decoration layer. The production method comprises steps as follows: 1) a whole-body colored blank is prepared; 2) the ground coat layer on the blank surface is formed; 3) the pattern decoration layer is formed; 4) ink or glaze having a dent effect is applied to the pattern decoration layer, a pattern corresponds to pattern texture of the decoration layer, and the three-dimensional stone texture layer is formed; 5) the surface decoration layer is formed; 6) a roller kiln is formed through sintering; 7) a finished product is obtained through polishing, edging and packaging. The surface color of the product produced with the scheme is integrated with the color of the blank, the stone texture changes naturally with the pattern texture of the product, the texture layer is protected by the surface decoration layer, and the tile has the decoration effect of natural stone. Properties of the product are superior to those of the natural stone, mining of the natural stone can be effectively reduced, and the natural environment is protected.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

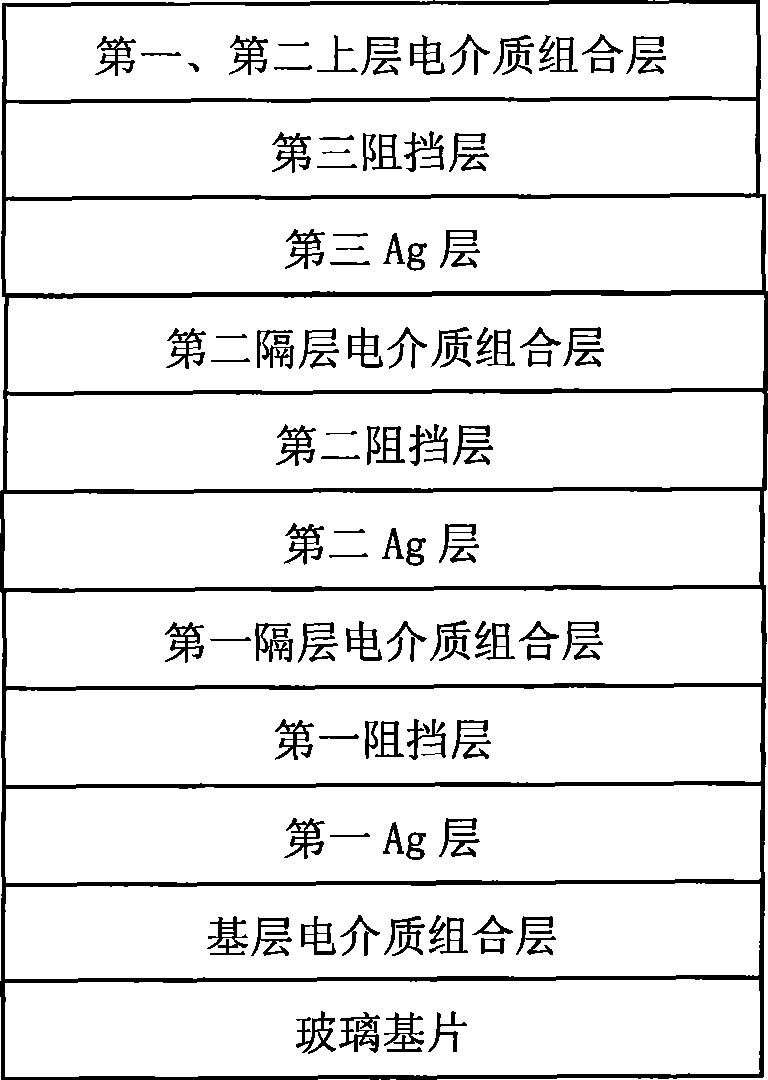

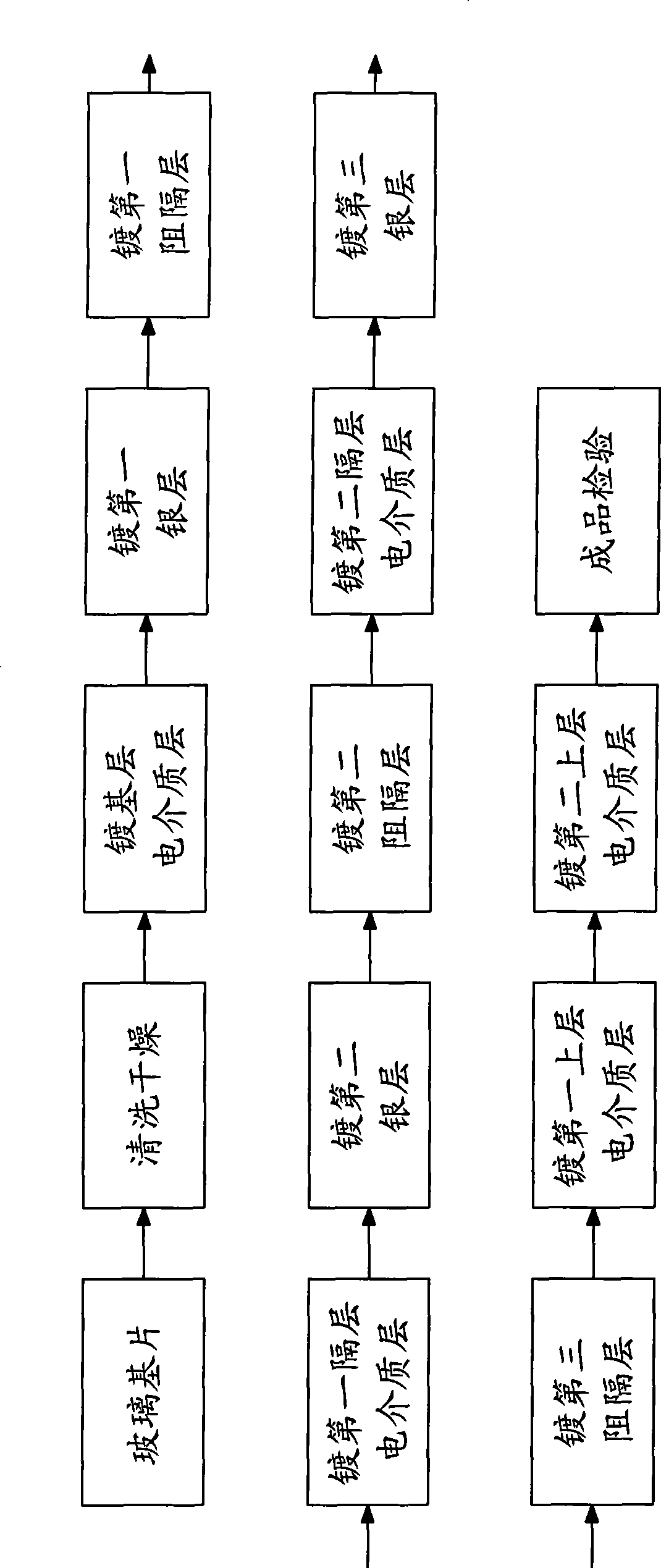

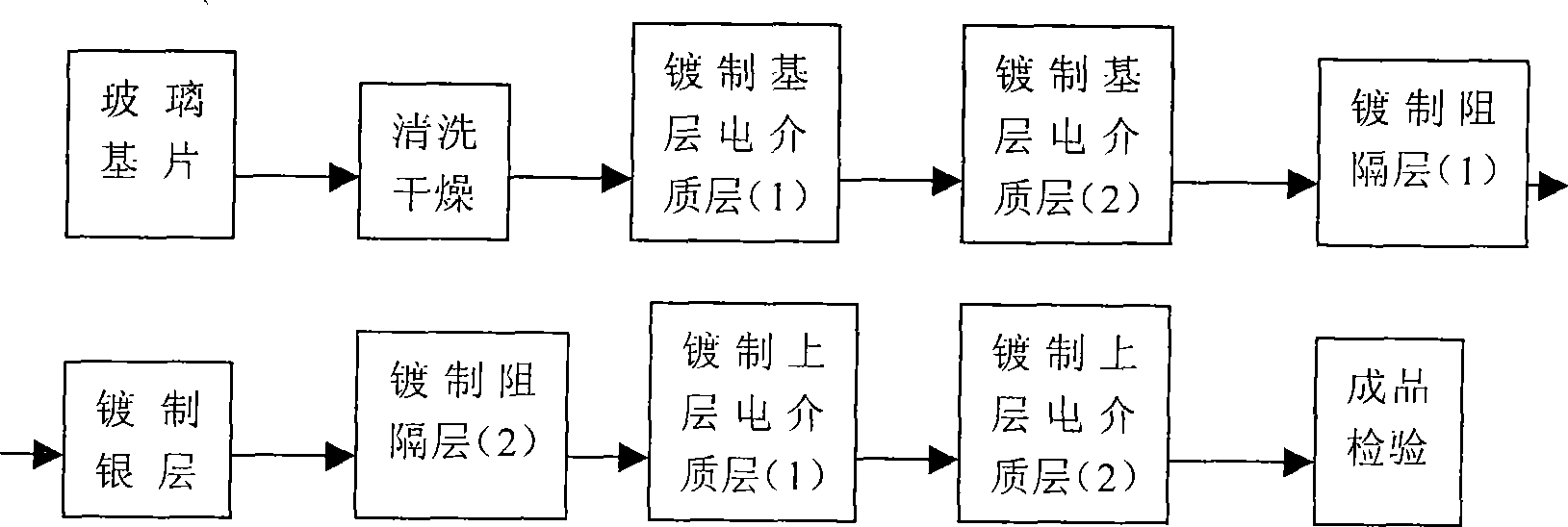

Three-silver low radiation film glass

The invention provides a three-silver low radiation film glass. The film layer structure of the glass comprises glass, a first base layer dielectric combination layer, a first Ag layer, a first blocking layer, a first interlayer dielectric combination layer, a second Ag layer, a second blocking layer, a second interlayer dielectric combination layer, a third Ag layer, a third blocking layer, a first upper layer dielectric combination layer, and a second upper layer dielectric combination layer. The invention also provides a process for producing the glass. The three-silver low radiation film glass and the producing process thereof adopt a unique film layer configuration, the process and a method improve the prior low radiation film glass so that the product has low radiance and good selectivity coefficient Lsg; the indoor and outdoor colors of the glass are close to neutral color without interference colors; and the glass has excellent optical performance, various colors, weather resistance, and the like, and can be widely popularized and applied to vehicle glass and civil architecture glass.

Owner:CSG HOLDING

Method for electroplating magnesium and magnesium alloy

The present invention provides an electroplating method of magnesium and magnesium alloy. The technology comprises dehydrogen, chemical degreasing, shining, neutralization, activation, pre-plating, functional plating, decorative plating and post treatment. The cast workpiece must be water-washed between every two procedures. The current density of pre-plating is 5-15 A / dm2, cell voltage 4-12 V, pH value of pre-plating solution 1.0-1.2, and Baume degree at room temperature is 30-35. Pre-plating solution recipe contains: copper fluoborate, fluoboric acid, alanine, polyethylene glycol and alizarin dye, mixture of itaconic acid and MBT, 3-S isothiourea onium salt propane sulfonate ,R-S-S(CH2)SO3Na and deionization water. The pre-plating solution of the present invention is cyanogen free, non-toxic and non-hazardous. Bond strength between pre-plating layer and substrate material and between pre-plating layer and the post functional plating layer or decorative plating layer is good. The plating layer is bright and has good corrosion resistance, wear resistance and decorative effect.

Owner:SHENYANG POLYTECHNIC UNIV

Colored solar heat reflection and heat-insulation coating, as well as preparation method thereof

InactiveCN104673038AHigh infrared reflectanceGood infrared reflectanceReflecting/signal paintsMulticolor effect coatingsIr reflectionKaolin clay

The invention discloses a colored solar heat reflection and heat-insulation coating. The coating is prepared from the following raw materials: polymer emulsion, titanium dioxide, functional fillers, an infrared reflection pigment, kaolin, ground calcium carbonate, a dispersing agent, a wetting agent, a defoaming agent, a thickening agent, a film-forming additive, a preservative, and water. The colored solar heat reflection and heat-insulation coating provided by the invention has the advantages that a coating film with a high reflectivity is prepared through adoption of the components, addition of the functional fillers (glass microbeads, ceramic microbeads and floating beads) which are large in refraction coefficient and high in scattering capability and reflectivity, as well as the pigment which is large in infrared reflection ratio, and application of film-forming matters and the film-forming additive, so that the coating achieves good heat-insulation performance, multiple selectable colors, excellent elasticity, high stain resistance, as well as large solar and near-infrared reflection ratios.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Inorganic powder texture coating, and its applying method

ActiveCN1757688AEasy constructionUnique texturePowdery paintsCement coatingsInorganic pigmentsMaterials science

A inorganic dry powder paint with good mass sensation is prepared proportionally from cement, color sand, re-dispersed emulsoid powder, hydrophobic agent, inorganic pigment and filler. Its advantages are high adhesion to concrete, high weatherability, good air permeability, and no pollution. Its application method is also disclosed.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

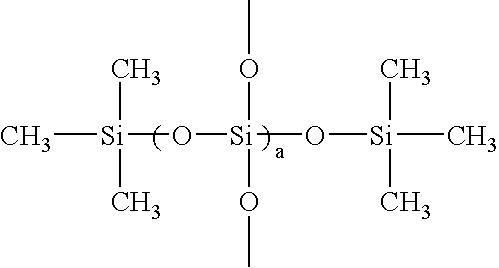

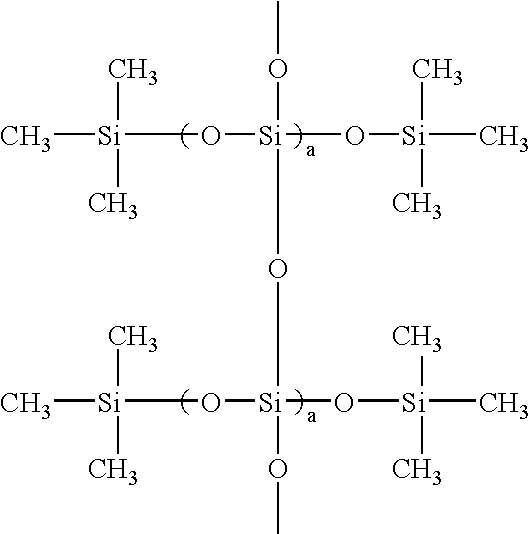

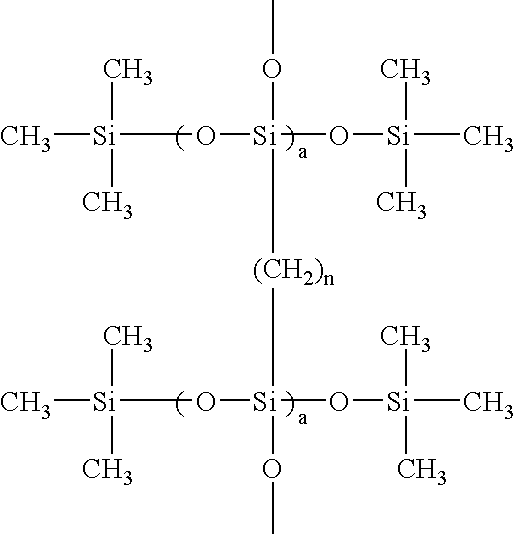

Linear silicone resins in personal care applications

InactiveUS20070196309A1Easy to wearImprove adhesionCosmetic preparationsBiocideHydrogenCompound (substance)

The present invention relates to the use in personal care products of a series of novel silicone polymers (referred to as linear silicone resin) that by are made by the hydrosilylation reaction of a terminal vinyl silicone and a terminal silanic hydrogen polymer. The properties make the compounds very useful in a variety of personal care applications including personal care.

Owner:SILTECH

Low radiation glass capable of being post-treated and its production process

InactiveCN101066845AOptical performance is stableRich in colorVacuum evaporation coatingSputtering coatingSilicon nitrideLow emissivity

The low radiation glass capable of being post-treated is prepared through cleaning glass substrate, drying and coating film, and features that the vacuum magnetically controlled sputtered film on the glass substrate includes Si3N4 film, ZnSnOx film, NiCrOx film, Ag film, NiCrOx film, ZnSnO film and Si3N4 film successively coated. The coated glass has low radiation, stable optical performance, different colors, capacity of being toughened and / or bent at high temperature up to 700 deg.c, and capacity of being cut and treated in other modes.

Owner:SHENZHEN CSG APPLIED TECH CO LTD

Method for transferring patterns on fiber fabric

InactiveCN102797172AReduce investment riskLess investmentTransfer printing processDyeing processTextile printerFiber

The invention relates to a printing method of fabrics, and in particular relates to a method for transferring patterns on a fiber fabric. The method comprises the steps of (1) coating a transfer layer: coating a prepared coating adhesive on a film or paper by a photogravure press or a coating machine so as to form the transfer layer on the surface of the film or the paper, drying, and then printing the surface of the transfer layer by utilizing dye base ink to prepare a transfer printing film or transfer printing paper; (2) starching the fiber fabric: coating fixation slurry for transfer printing on the surface of the fiber fabric; (3) transferring the patterns; and (4) evaporating and fixing: after the transfer, stripping the transfer printing film or the transfer printing paper, drying, evaporating and fixing the fiber fabric. According to the method, the difficulties that the dye base ink can not be directly printed on the film, and the transfer rate of the dye on the paper is not high can be solved, and also the transfer layer, the dye, the film and the paper with an isolation layer are not compatible, so that more than 98% of dye can be transferred, and the transfer rate and the color rate of the printing are improved greatly.

Owner:沈翰宇

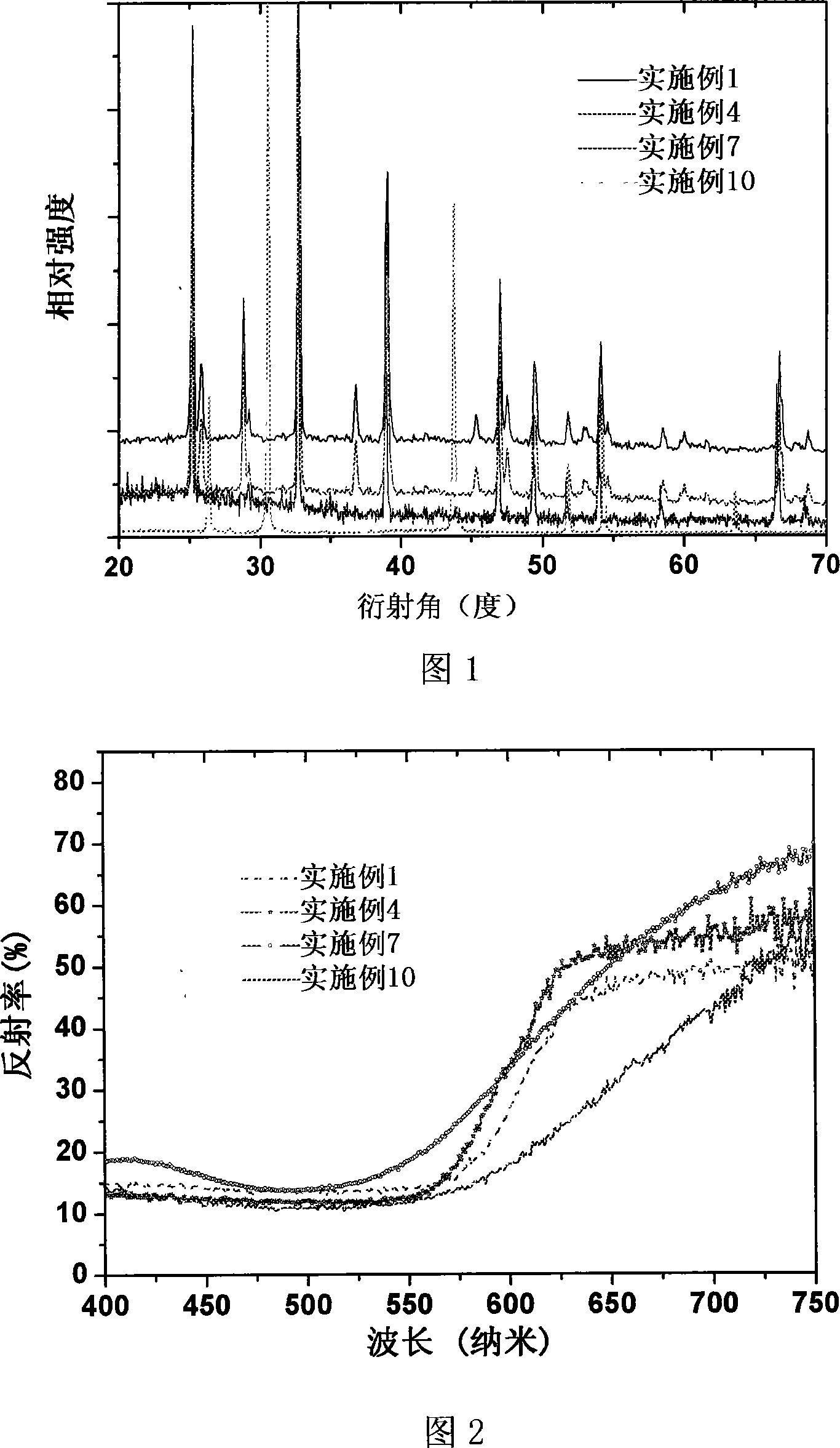

Red rare-earth lanthanum cerium sulfide dye and preparation method thereof

The invention relates to a rare earth lanthanum and cerium sulfate which can be used as a red paint and a preparation method of the rare earth lanthanum and cerium. The chemical formula of the paint is: AxLayCe1-yS(3+x) / 2, wherein, A stands for one of alkali metals lithium, sodium and potassium, x is equal to or bigger tan 0 and is equal to or smaller than 1, and y is equal to or bigger tan 0 and is equal to or smaller than 1. The alkali metal elements are doped into the rare earth lanthanum and cerium sulfate matrix to prepare rare earth sulfide paints in different red color systems through adjusting the doped amount of the alkali metal elements and different proportions of the lanthanum and cerium in high temperature solid-state reaction with mixed sulfate source gas produced by ammonium thiocyanate being heated and melted as reaction gas under the conditions of unoxidizing atmosphere with inert gas being input and the heating temperature of 400 to 1000 DEG C. The structure of a series of rare earth lanthanum and cerium sulfate doped with the alkali metal elements is NaC1type or Th3P4 type of gamma type in single cubic crystal system. The preparation method is safer and more environment protecting, the paint is non-toxic, so that the paint can be used for coloring for plastic, oil paint, coating, rubber, leather, ceramic, ink, paper, cosmetic and construction material like cement.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Integrally formed 3D flyknitted vamp and making method thereof

The invention discloses an integrally formed 3D flyknitted vamp and a making method thereof.Low-melting yarn and dyed yarn are adopted as raw materials, an upper layer of double-faced jacquard vamp body and a lower layer of double-faced jacquard vamp body with the edges interwoven together are woven on a bidirectional jacquard double-faced loop transfer computer flat knitting machine, openwork figured texture weave is primary weave, different weave structures are adopted in functional zones of the vamp, and then the integrally formed 3D flyknitted vamp is made through hot pressing shaping.The temperature of hot pressing shaping ranges from 170 DEG C to 200 DEG C, and the time of hot pressing shaping ranges from 20 s to 80 s.Each double-faced jacquard vamp body comprises a dyed yarn layer and a low-smelting yarn layer which are interwoven together through yarn coils, and the integrally formed 3D flyknitted vamp is formed by bonding and combining the two layers of double-faced jacquard vamp bodies according to the wave structure of one dyed yarn layer, one low-melting yarn layer, the other low-melting yarn and the other dyed yarn layer through the upper low-melting yarn layer and the lower low-melting yarn layer in a hot pressing and melting mode.The integrally formed 3D flyknitted vamp has the advantages of being soft, comfortable, durable, colorful, attractive, low in cost and the like.

Owner:厦门翔鹭化纤股份有限公司

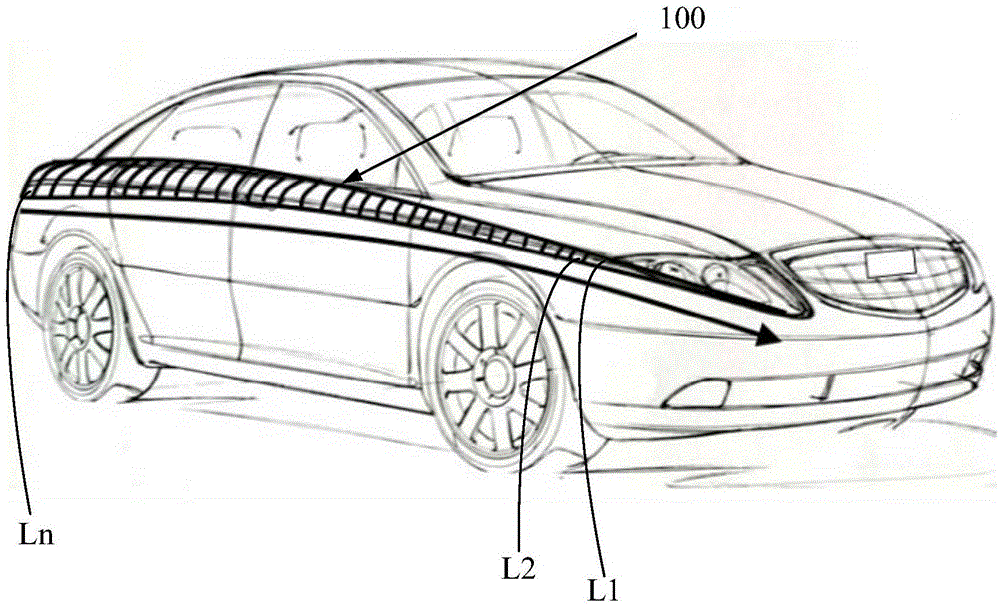

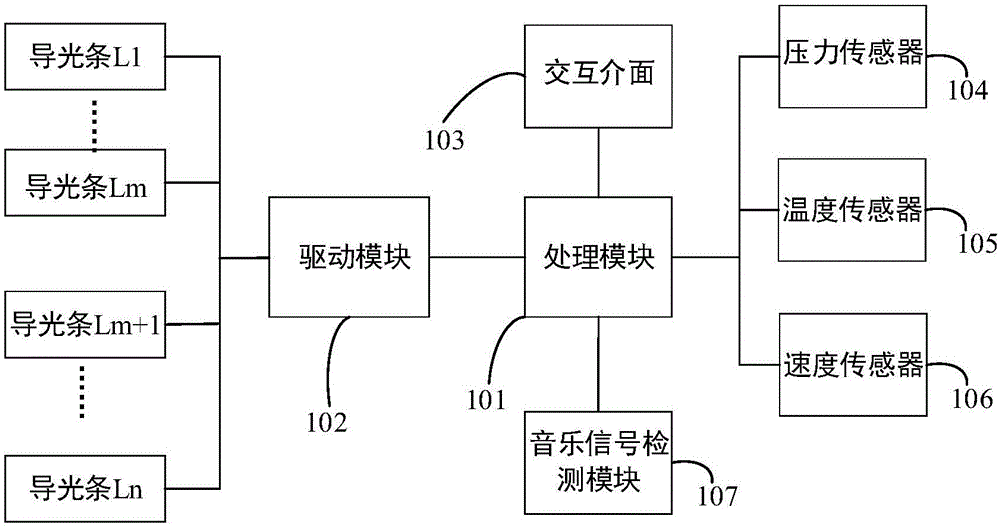

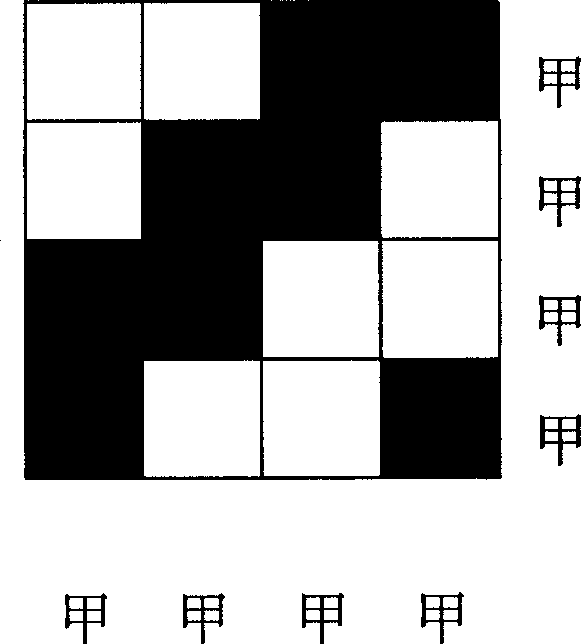

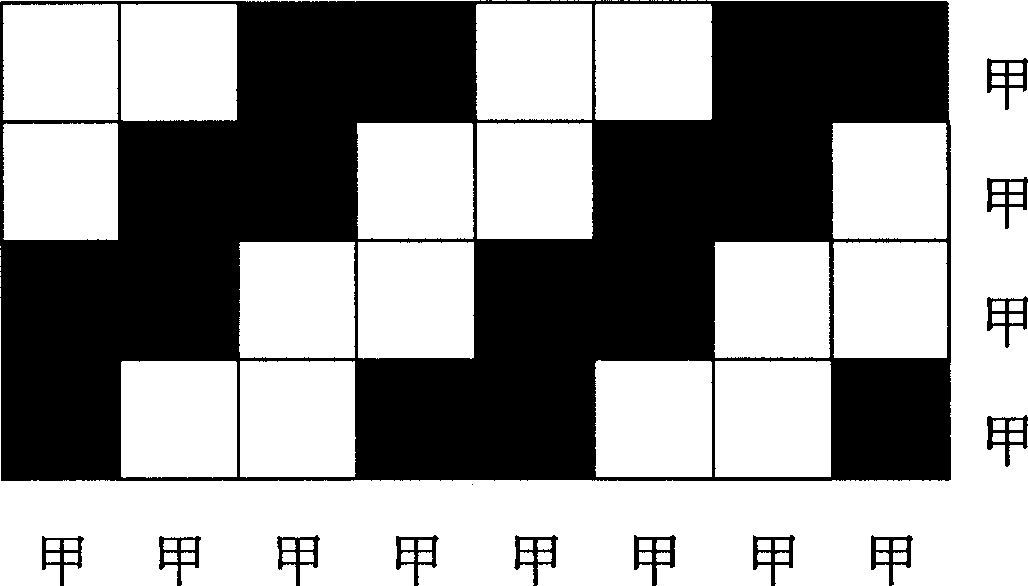

Atmosphere lamp and adjusting method thereof

InactiveCN104999957ARich in colorVarious adjustment methodsVehicle interior lightingElectric light circuit arrangementLight guideHue

The invention discloses an atmosphere lamp and an adjusting method thereof. Parts of light guide strips of the atmosphere lamp are arranged outside a vehicle body, and the other parts of light guide strips of the atmosphere lamp are arranged inside the vehicle body. According to a series of parameter values such as parameter values of the pressure at the pedaling position of a pedal accelerator, parameter values of the temperature outside the vehicle body and parameter values of the traveling speed of a vehicle, the luminance and the hue of the light guide strips outside the vehicle body can be automatically adjusted, and the luminance and the hue of the light guide strips inside the vehicle body can be automatically adjusted according to the amplitude and the frequency of music signals detected by a music signal detecting module.

Owner:SHANGHAI XIUYUAN NETWORK TECH

High elastic wool-like fabric and production method thereof

The invention discloses a high-elasticity wool-like fabric and a method for producing the same. The method comprises the following steps: selecting two yarns with different fiber components and different blending ratios; using a folded yarn of a yarn A interlacing with a yarn B as a First warp to form a warp yarn arrangement First; using the folded yarn of the yarn A interlacing with the yarn B as a Fist weft to form a weft yarn arrangement First, wherein the fabric comprises two upper twill structures and two lower twill structures. A drafting method adopts pathwise penetration of four pieces or pathwise penetration of eight pieces, wherein the portie is between No.10 and No.11, the penetration is 2 heddles per reed, and the width of the fabric on a machine is 205 centimeters. Through dyeing the same color on an anode dyeable terylene and a viscose staple fiber, the elastic property of wool fiber and PTT fiber can be embodied sufficiently. Through the selection of a yarn combination with different fiber components, and according to selecting the prior product process flow, the produced bamboo joint color wool-like fabric has the advantages of abundant colors, gentle color and luster, and strong woolly handfeel.

Owner:富丽达集团控股有限公司

Flame-retardant antibacterial artificial wig hairline

ActiveCN106245156AWith temperature and weather resistanceRich in colorWigsFlame-proof filament manufacturePolyesterMasterbatch

The invention discloses a flame-retardant antibacterial artificial wig hairline, which comprises, by weight, 80-90% of a polyester material, 5-11% of a flame retardant agent, 2.5-6% of an antibacterial agent, 0.3-3% of a dispersing agent, 0.2-0.5% of an antioxidant, and 2-5% of color masterbatch. According to the present invention, the flame-retardant antibacterial artificial wig hairline has characteristics of high simulation degree, flexible hairline, diverse color, flame retardant property, antibacterial property, no fused drop, environmental protection and the like, and can replace the expensive human hairline. The invention further discloses a manufacturing method of the flame-retardant antibacterial artificial wig hairline, wherein the manufacturing method comprises: pre-treating a polyester raw material, carrying out blending granulation on the polyester material, the antibacterial agent, the flame retardant agent, the dispersing agent and the stabilizer by using a double-screw extruder to obtain a flame-retardant antibacterial slice, carrying out melt spinning on the slice, carrying out high-temperature shaping treatment, carrying out washing and drying, and carrying out other steps.

Owner:见喜新材料股份有限公司

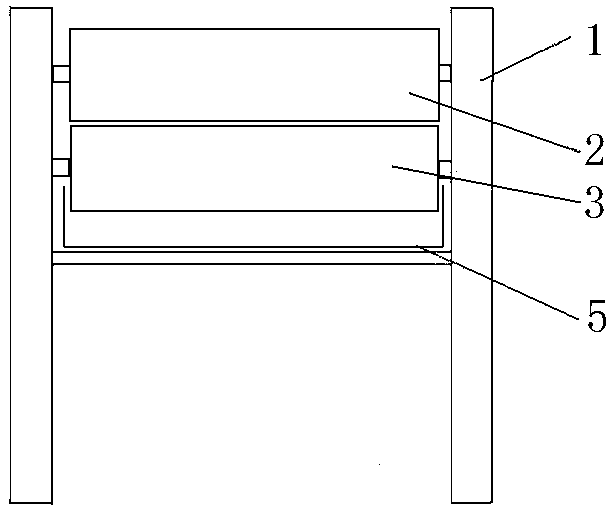

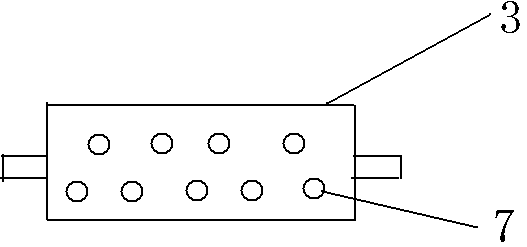

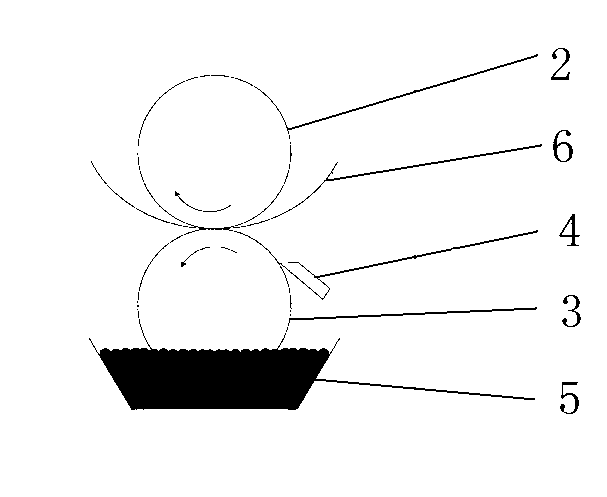

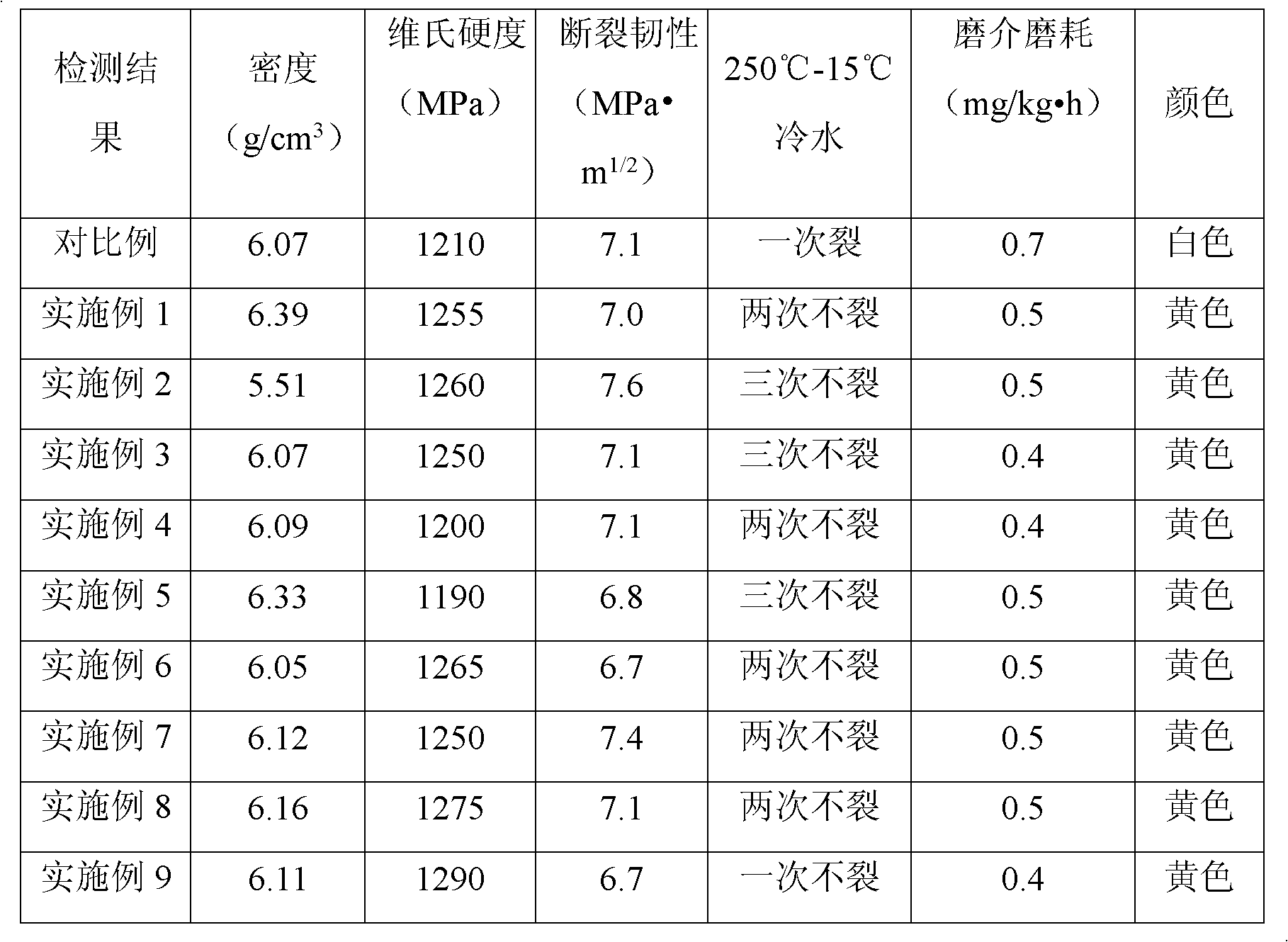

Ceramic and preparation method and application thereof

The invention discloses ceramic and a preparation method and application thereof and relates to zirconia ceramic. By adding cerium oxide and yttrium oxide into zirconia, the zirconia ceramic with performance not inferior to the performance of yttrium zirconium structural ceramic is prepared at lower temperature. The ceramic comprises the following oxides in percent by weight: 7-30 percent of CeO2, 0.1-12 percent of Y2O3 and 50-92 percent of ZrO2. The density can reach 6.4g / cm<3>. The colors of zirconia products are enriched. The ceramic product can work in environments with the temperature being 250 DEG C, the grinding efficiency of the ceramic grinding medium during dry-process grinding and viscous material grinding is improved, the grinding loss is smaller, a new product is added to zirconia structural ceramic and the application scope of the zirconia structural ceramic is widened.

Owner:QIANDONG RARE EARTH GRP

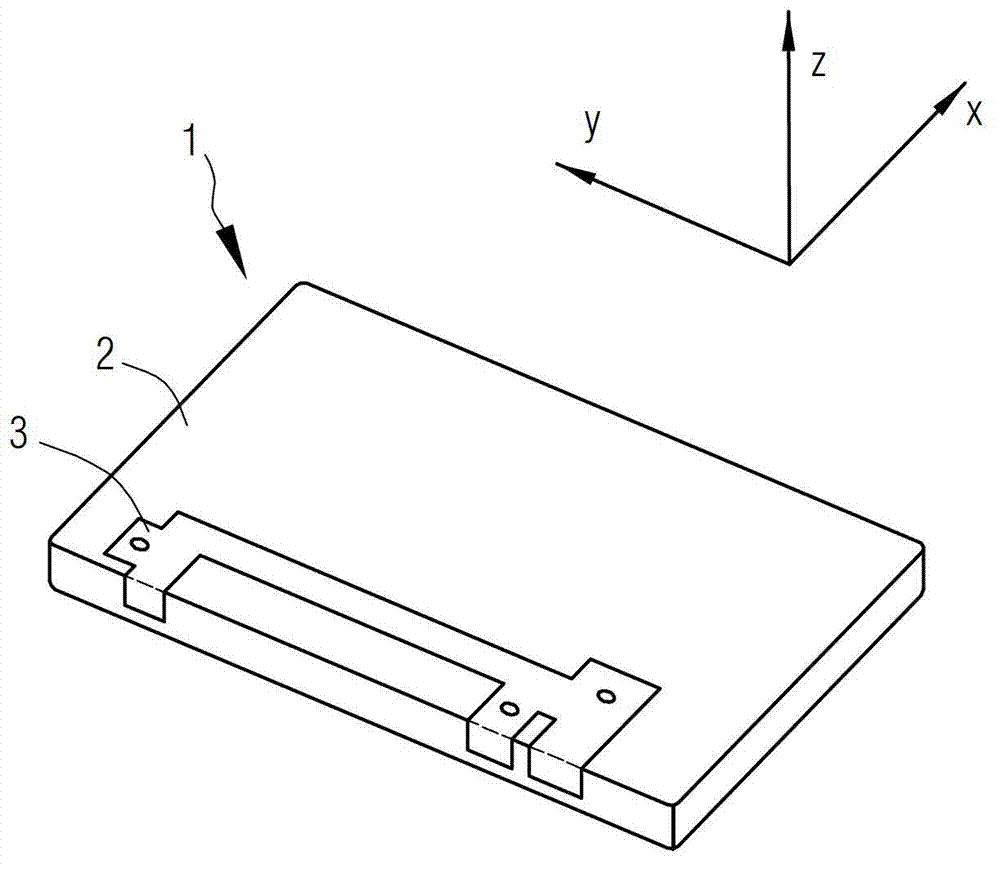

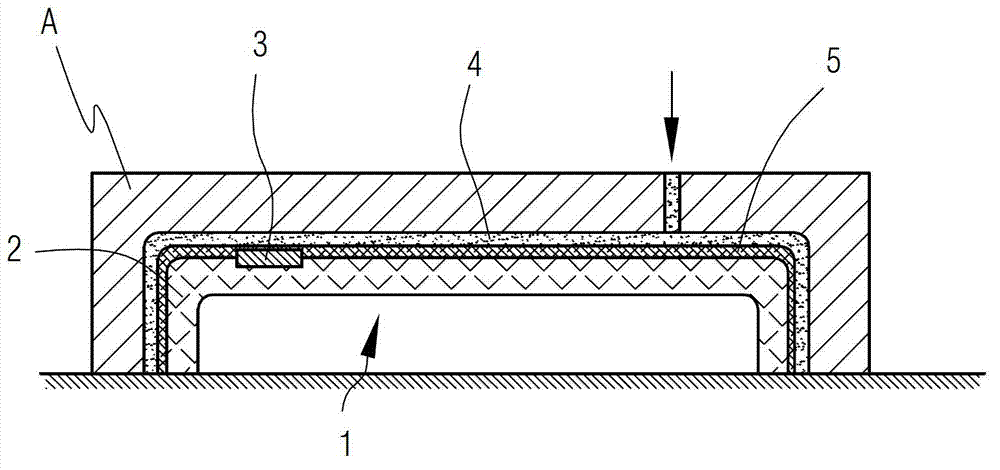

Electronic device housing and manufacturing method therefor

ActiveCN102781187AStrong tear resistanceHigh tensile strengthAntenna supports/mountingsCasings/cabinets/drawers detailsEngineeringSilica gel

The invention discloses an electronic device housing and a manufacturing method for the electronic device housing. The manufacturing method comprises the following steps: forming a metal antenna on the surface of an active plastic layer of the electronic device housing by an LDS (Laser Direct Structuring) technology; spraying a layer of bottom coating agent on the surface of the active plastic layer and the surface of the metal antenna; moulding a layer of liquid silica gel on the surface of the active plastic layer sprayed with the bottom coating agent and the surface of the metal antenna in an injection way, drying the liquid social gel to form a silica gel protective layer. According to the electronic device housing and the manufacturing method for the electronic device housing, the silica gel protective layer is moulded on the surface of the electronic device housing in an injection way by liquid silica gel, and can be suitable for various different using environments for the electronic device housing, can be manufactured to be very soft or relatively hard, and has high anti-tearing and anti-stretching strength; simultaneously, the product is diversified in colour, smudginess-resistant, chemical-resistant, and soft and smooth in hand feeling.

Owner:LOVEPAC CONVERTING BEIJING +1

Production method for ready-to-eat instant nutritive edible fungus soup

The invention discloses a production method for ready-to-eat instant nutritive edible fungus soup, which belongs to the technical field of deep processing of agricultural products. The production method mainly comprises the steps of selecting, cleaning, precise cutting, mixed boiling, spreading, pre-freezing and microwave vacuum freeze drying on screened raw materials such as edible fungi, thus obtaining the product which is subjected to nitrogen-filled packaging after being taken out of storage. The raw materials of the edible fungus soup is dewatered by a microwave vacuum freeze drying technology according to a modern food nutrition principle, so that the original color, aroma, taste and nutrients of the product are kept to the hilt, and compared with those of a conventional process, the drying efficiency is remarkably improved, the production cycle is shortened, the production cost is effectively reduced, and the special sterilizing effect of microwaves further guarantees the product quality at the same time. The edible fungus soup produced by the method is flat in shape, bright in color and luster, rich in nutrition, good in water regaining effect and long in storage time, and a feasible new way is provided for deep processing and utilization of the edible fungi.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Heat transfer digital printing method for natural fibers and regenerated cellulose fibers

InactiveCN102677492ALess investmentReduce investment riskDyeing processDigital printingNatural fiber

The invention relates to a printing method for textiles, in particular to a heat transfer digital printing method for natural fibers and regenerated cellulose fibers. The heat transfer digital printing method comprises the following steps of: spreading and printing a film or a composite film which is subjected to coating treatment and textiles subjected to sizing by using an ironing press at the temperature of between 40 and 100 DEG C for 30 to 90 seconds; stripping the film or the composite film; and drying the textiles subjected to printing, and ageing for color fixing. By the heat transfer digital printing method, the problem that a digital printing machine and a computer photogravure press cannot perform jet printing on the film directly is solved, and the obtained printing textiles have the characteristics of high resolution ratio of printing patterns and distinct gradation of flower types and can achieve a photo effect; and a process is easy to operate and low in production cost.

Owner:沈翰宇

Production method of color carbon fibers

ActiveCN104862948AEasy to prepareThe deposition process is easyCarbon fibresTitanium dioxide thin filmMegasonic cleaning

The invention relates to a production method of color carbon fibers and belongs to the technical fields of inorganic non-metallic materials and surface treatment. The production method comprises the following steps of removing an adhesive layer and other attachment materials on the surface of the carbon fibers after ultrasonic cleaning through an organic solvent and depositing a layer of nanometer titanium dioxide thin film on the surface of the carbon fibers by an atomic layer deposition method so as to develop the carbon fibers. According to the production method of the color carbon fibers, the production process is simple and the deposition process is easy to control; the surface the nanometer titanium dioxide thin film deposited carbon fibers is rich in color, the color maintenance durability is good, and the oxidation resistance and the environmental erosion resistance of the carbon fibers are greatly improved; the cost is low, the pollution to the ecological environment is not produced, and the application prospect is broad.

Owner:WUHAN TEXTILE UNIV

Ceramic colorful sand and its preparation process

The invention relates to a kind of colored sand with ceramic coating and its preparing process, wherein the sand mainly comprises skeletal material, coloring agent and bonding agent, characterized in that, the skeletal material is 12-40 mesh basalt ore whose chemical compositions being Al2O3 10-18%, SiO2 40-70%, FeO 34-13% and CuO+MgO 1-5%.

Owner:江苏欧文斯彩砂科技有限公司

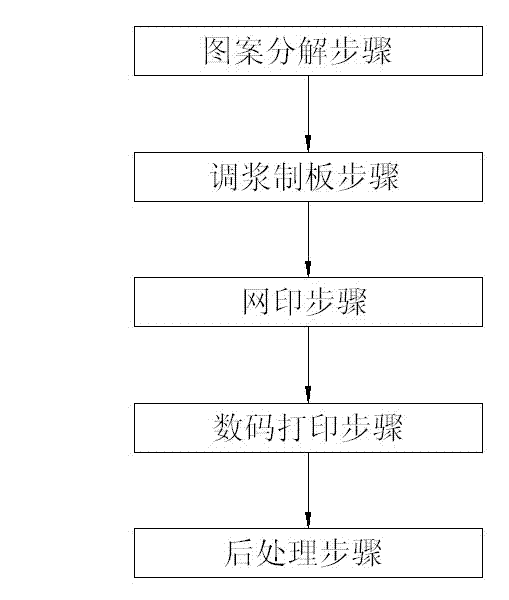

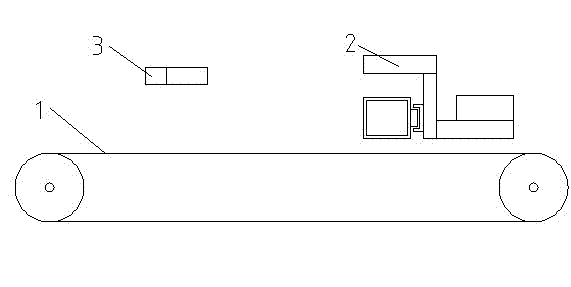

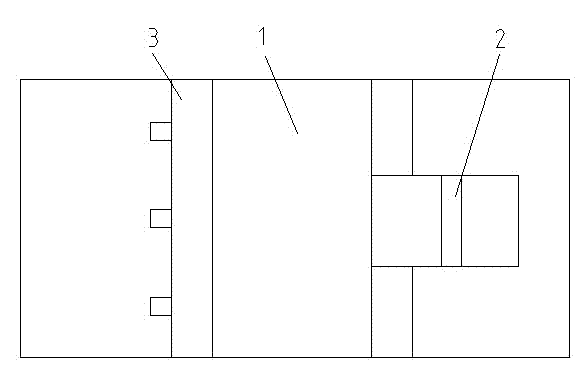

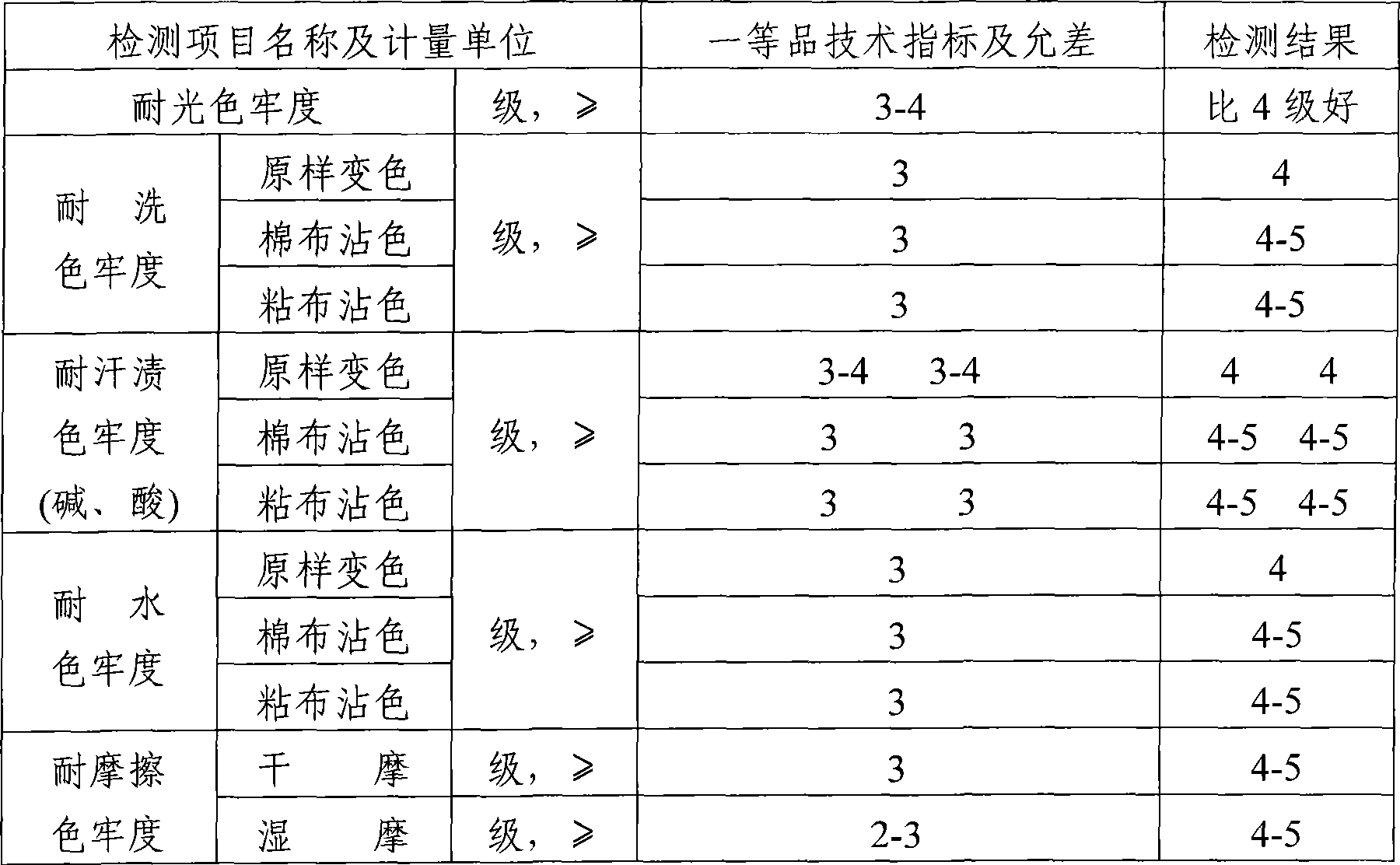

Printing method of combining conventional printing with digital printing

ActiveCN103171319AFlexible printingRich in colorDuplicating/marking methodsTypewritersDigital printingEngineering

The invention relates to a printing method of combining conventional printing with digital printing. At present, no printing method is capable of really and effectively combining conventional printing with digital printing. The printing method sequentially comprises the following steps of:1. decomposing a pattern, namely, decomposing a pattern needing being printed into a conventional printing pattern and a digital printing pattern; 2. mixing size and making plate, namely, carrying out dye blending and making a digital printing screen; 3. carrying out screen printing, namely, carrying out conventional printing and digital printing pretreatment; 4. carrying out digital printing, namely, carrying out digital jet printing on a printing medium by adopting a digital jet printing system with a pre-detection device according to the digital printing pattern, determining a digital printing position on the printing medium, printing the digital printing pattern on the printing medium to ensure that the digital printing pattern is coincident with the conventional printing pattern; and 5. carrying out post-treatment to prepare a finished product. The printing method is good in printing effect and low in production cost, and is capable of really and effectively combining the conventional printing with the digital printing.

Owner:HANGZHOU HONGHUA DIGITAL TECH

Antistatic blended yarn and application thereof

The invention provides an antistatic blended yarn, which is prepared from 20 to 45 percent of polyester fiber, 35 to 70 percent of cotton fiber and 10 to 30 percent of stainless steel fiber by weight percentage through blended spinning. The invention also provides an antistatic sweater produced by adopting the antistatic blended yarn and a method for producing the same. The product of the antistatic blended yarn has antistatic and electromagnetic shielding functions, does not have special requirement on washing, is not influenced by the environment, has complete colors and solid texture, is sweat-resistant and corrosion-resistant, can be applied to special industries such as anti-microwave clothes and radiation-resistant clothes, can effectively prevent human body from being radiated by computers and the like, and particularly protect pregnant women. The antistatic blended yarn can be processed into clothes worn in spring, autumn and winter and the clothes are comfortable to wear with excellent performance.

Owner:JIANGYIN XIANGFEI APPAREL

Low-wool-content multi-component chemical fiber blended fabric and preparing method thereof

ActiveCN103835048AImprove perceptionEasy to takeSucessive textile treatmentsWoven fabricsPolyesterPolymer science

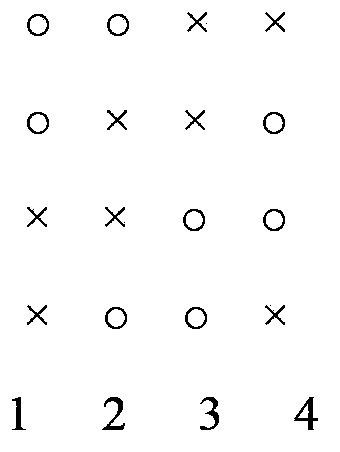

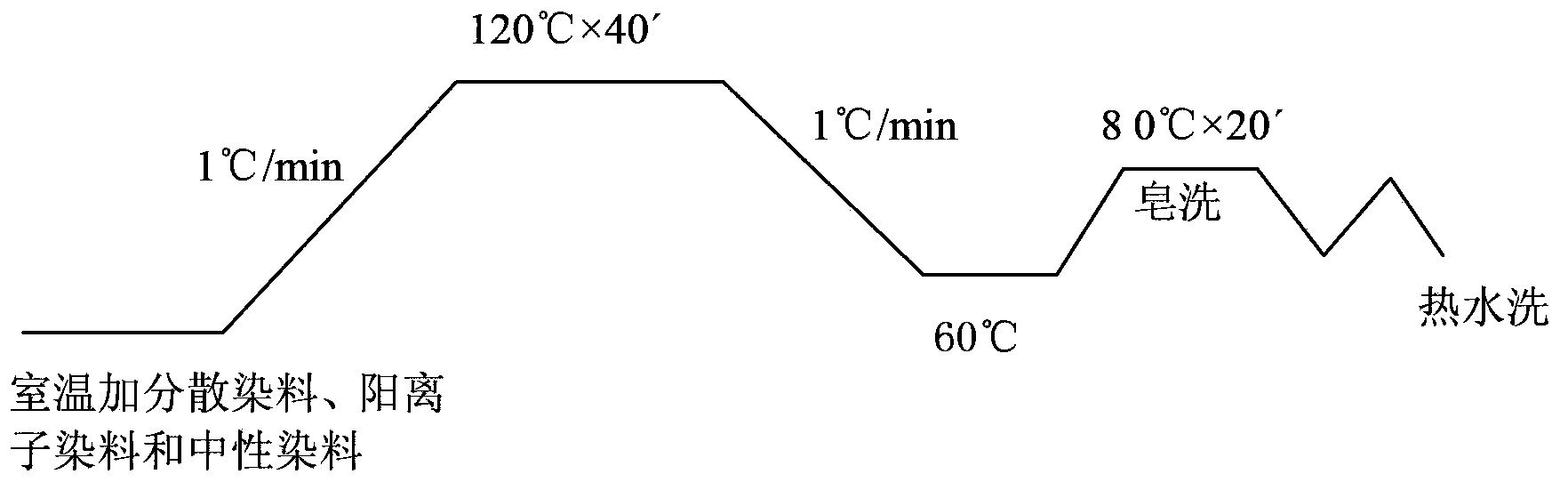

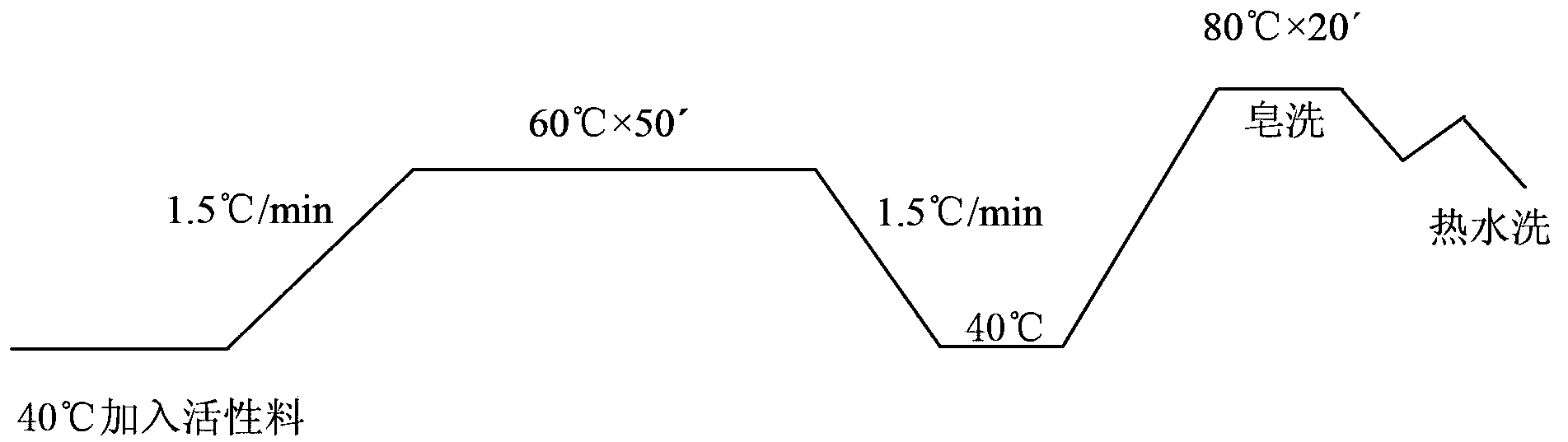

The invention provides a low-wool-content multi-component chemical fiber blended fabric and a preparing method of the low-wool-content multi-component chemical fiber blended fabric and belongs to the field of spinning dyeing and finishing. Wool is added to multi-component chemical fibers and the low-wool-content multi-component chemical fiber blended fabric comprises, by weight, 30% to 40% of polyester staple fibers, 20% to 30% of modified polyester fibers, 10% to 20% of mucilage glue, 5% to 15% of Tencel, 8% to 30% of the wool and 0.1% to 0.6% of conductive fibers. The wool content of a traditional product is changed, wool fibers with the content smaller than 30% are blended with the polyester staple fibers, the modified polyester fibers, the mucilage glue, the Tencel and the conductive fibers in the chemical fibers in a combined mode, so that mutual advantage complement of the various fibers is achieved, and multiple colors, the high comfort degree and the easy-maintenance performance of the fabric are achieved with the low wool content. The technology is reasonable, the technical purpose of one bath dyeing of the wool and the multi-component chemical fibers is effectively achieved, and a new path is created for upgrading orientation and the comfort of chemical fiber fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

Bamboo waterproof antiseptic coloring plate and preparation method thereof

The invention discloses a bamboo waterproof antiseptic coloring plate and a preparation method thereof. The preparation method of the bamboo waterproof antiseptic coloring plate comprises the steps of cutting off bamboo materials, slicing, coarsely planing, drying, vacuum high-temperature high-pressure antiseptic coloring carbonization treatment, secondary drying, precision planing, sorting, gluing and thermal pressing, polishing and planing on four sides. The bamboo material is processed in the vacuum high-temperature high-pressure antiseptic coloring carbonization manner, the process is novel, the manipulability is strong, the produced bamboo board has a waterproof function, an antiseptic function and rich colors and can be used as an outdoor building material and indoor decoration material, and the application range is wide.

Owner:福建省祥福工艺有限公司

Glaze composition for redware products

The invention provides a glaze composition for redware products and relates to the technical field of redware. The glaze composition is prepared from the following components in parts by weight: 1-3 parts of copper oxide, 5-9 parts of barium oxide, 4-6 parts of silicon carbide, 25-35 parts of quartz, 10-20 parts of borax, 0.1-0.5 part of graphene, 0.005-0.03 part of ferric oxide, 0.01-0.06 part of titanium carbide, 10-20 parts of dolomite, 5-15 parts of shell and 0.1-1 part of glass. According to the invention, lead material is removed and the quartz and glass are added, the quartz is used for increasing the surface strength of glazing color, the glass is used for increasing smoothness, and the hand feeling is good. The graphene and titanium carbide are added, so that the adsorption capacity among materials is great, and a layer of mesh structure can be formed on the surface of a green body and cannot fall off after firing.

Owner:卢群山

Solution in use for plating trivalent chromium, and plating method for using the plating solution

This invention provides a plating solution for trivalent chrome electroplating. The plating solution comprises make-up agent, stabilizer, wetting agent, complexing agent and FeCl3. This invention also provides a method for trivalent chrome electroplating by using the plating solution. The coordination effect of FeCl3 with the other components can improve the covering performance of the plating solution, and can adjust the darkness of the plating layer so that the colors of the product are abundant.

Owner:BYD CO LTD

Multi-sensor fusion low-illumination video image enhancement method

ActiveCN105809640AMeet real-time requirementsTo achieve the effect of real-time displayImage enhancementImage analysisIlluminanceImage resolution

The invention relates to a multi-sensor fusion low-illumination video image enhancement method and belongs to the video image processing field. According to the method, matching is carried out according to characteristic similarities between videos from different sources; registration is performed on images from different sources by adopting a multi-scale SIFT algorithm; an accurate transformation matrix can be obtained based on the combination of the multi-scale SIFT algorithm and a RANSAC algorithm; the transformation matrix is utilized to perform interpolation on each frame in infrared video images and visible light video images, and therefore, images with different resolutions can be transformed into images with the same resolution, and problems in the registration of images with different resolutions can be solved; and fast fusion of the images is realized by using an alpha-based weighting algorithm, the fusion time of the images satisfies the real-time requirement of the videos, and therefore, real-time display of the videos can be realized. With the multi-sensor fusion low-illumination video image enhancement method adopted, the definition of the videos can be improved, and information contained by the clear videos is also rich and colorful, and follow-up processing can be facilitated.

Owner:CHANGCHUN UNIV OF SCI & TECH

Low-glycemic alcoholic beverages and methods for making same

InactiveUS20060110519A1Favorable organoleptic qualityStrong natural flavorAlcoholic beverage preparationFood preparationGlycemicAlcoholic spirits

Owner:ATKINS NUTRITIONALS

Preparation method of stone-pattern-simulating glazed brick

The invention discloses a preparation method of a stone-pattern-simulating glazed brick. The preparation method comprises the following steps of: 1) laying and accumulating colored dry particles on the surface of a blank body according to the pattern requirement with the thickness being 1-3mm; 2) after drying the blank body laid with the dry particles, burning the blank body for 90-150 minutes in a kiln at the temperature of 1150-1230 DEG C; and 3) edging and polishing the burnt brick body to obtain the stone-pattern-simulating glazed brick. The preparation method is simple in process and low in production cost; and the obtained glazed brick is strong in stereoscopic impression and vivid in stone-simulating effect, and meets the requirements of consumers better.

Owner:广东道氏陶瓷材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com