Patents

Literature

152 results about "Cerium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl sulfonate tinning electrolyte and tinning method of steel strip or steel plate

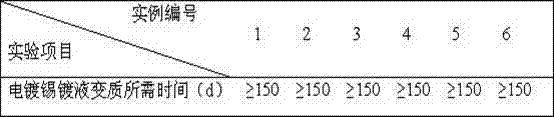

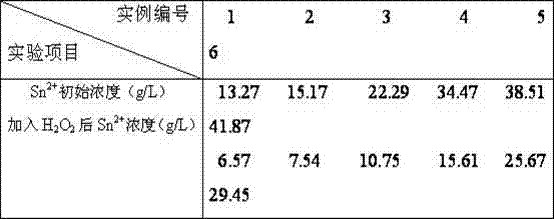

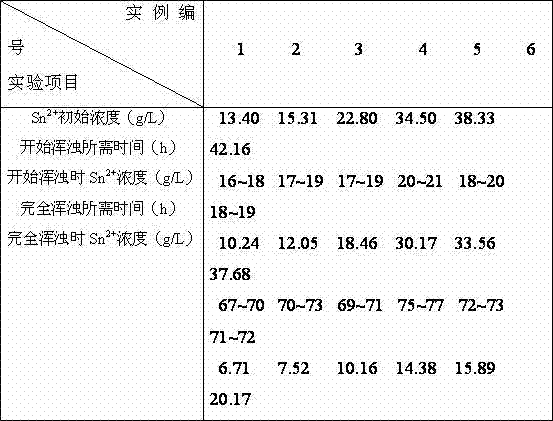

The invention discloses methyl sulfonate tinning electrolyte using cerium salt as an additive. The electrolyte comprises the following components: 30 to 120 g / L of stannous methyl sulfonate, 60 to 180 g / L of methylsulfonic acid, 1 to 10 g / L of cerium sulfate, 0.1 to 2 g / L of antioxidant, 5 to 10 g / L of brightening agent and 5 to 10 g / L of surfactant. The invention also discloses a method for tinning a steel strip or a steel plate by adopting the electrolyte. During plating, the cerium salt in the electrolyte lightens the harm degree of 'hydrogen brittleness', and plays roles of the antioxidant and the brightening agent. On the basis of adaptability to the environment, the electrolyte meets the requirements that the process is simple, the solution is stable, the maintenance is easy and the quality of a coating is high.

Owner:张家港市凤凰科技开发有限公司

Treatment method of electrolytic coloring of black color of aluminium alloy anodic oxidation film

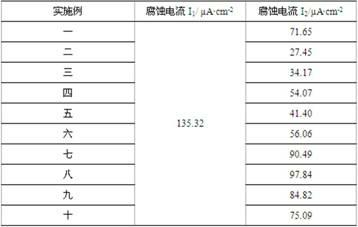

The invention discloses a treatment method of electrolytic coloring of a black color of an aluminium alloy anodic oxidation film, and belongs to the technical field of surface treatment. The method comprises pretreatment, anodic oxidation, AC electrolytic coloring, and sealing; the electrolytic coloring liquid comprises 10-15 g / L of SnSO4, 13-17 g / L of H2SO4, 10-20 g / L of NiSO4, 25-8 g / L of NiCl, 1-2 g / L of tartaric acid, and 0.1-0.2 g / L of cerium sulfate; the coloring technological parameters for the AC electrolytic coloring of a black color are that: the AC voltage is 10-14 V; the coloring liquid temperature is 16-24 DEG C; and the coloring time is 16-22 min. The film with an electrolytic colored black color after anodic oxidation obtained by the method has a pure and uniform color, and is fine and glossy; the fine and glossy black film obtained during electrolytic coloring has a voltage range which is widened nearly twice, and the corrosion resistance to 3.5% sodium chloride of the black film is improved by 30%.

Owner:东莞睿泳五金制品有限公司

Method of purifying exhaust gas and catalyst for purifying exhaust gas

InactiveUS6191061B1Speed up the conversion processReducing and purifying the nitrogen oxides in the exhaust gasMolecular sieve catalystsDispersed particle separationComposite oxideReducing agent

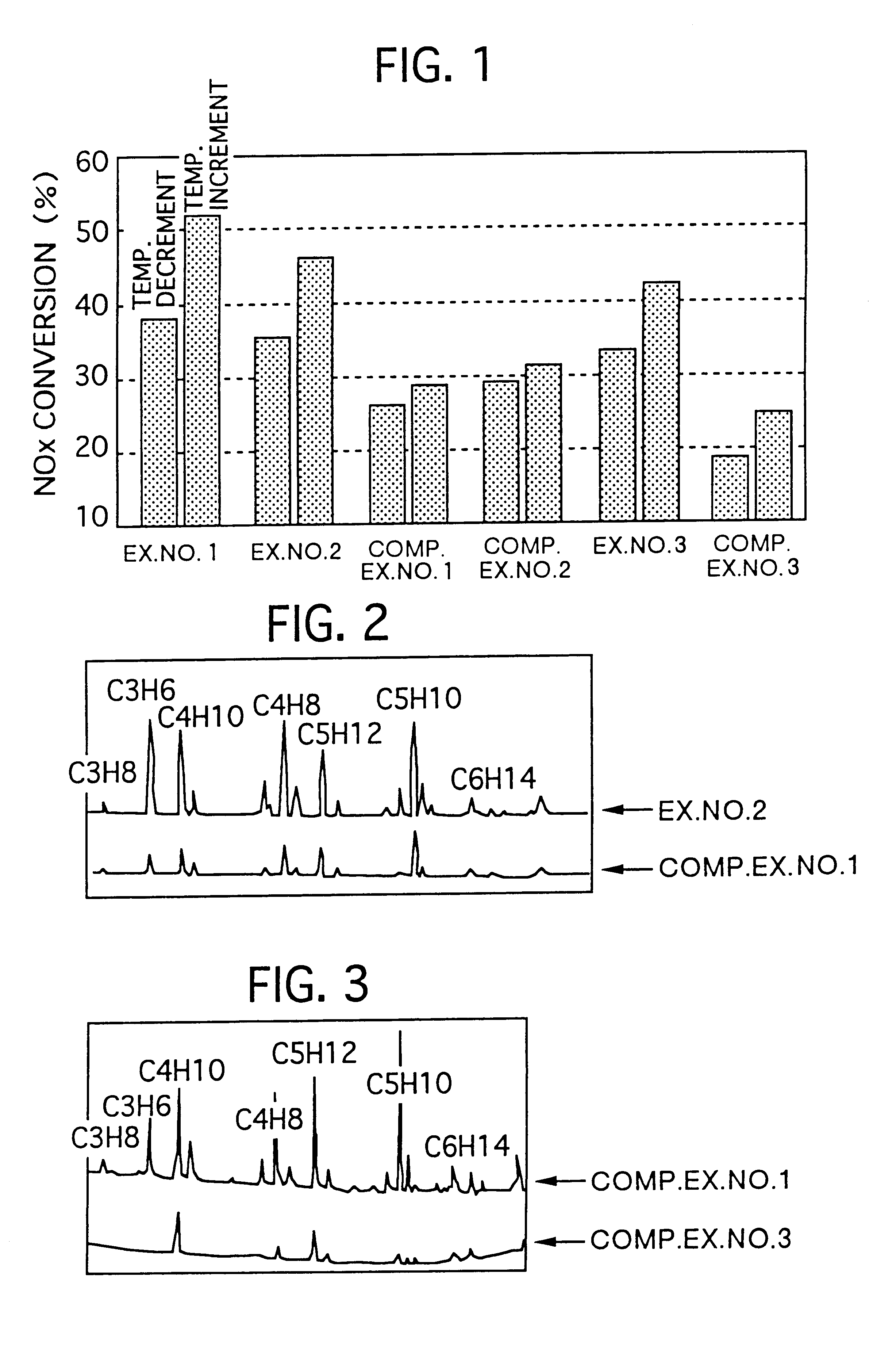

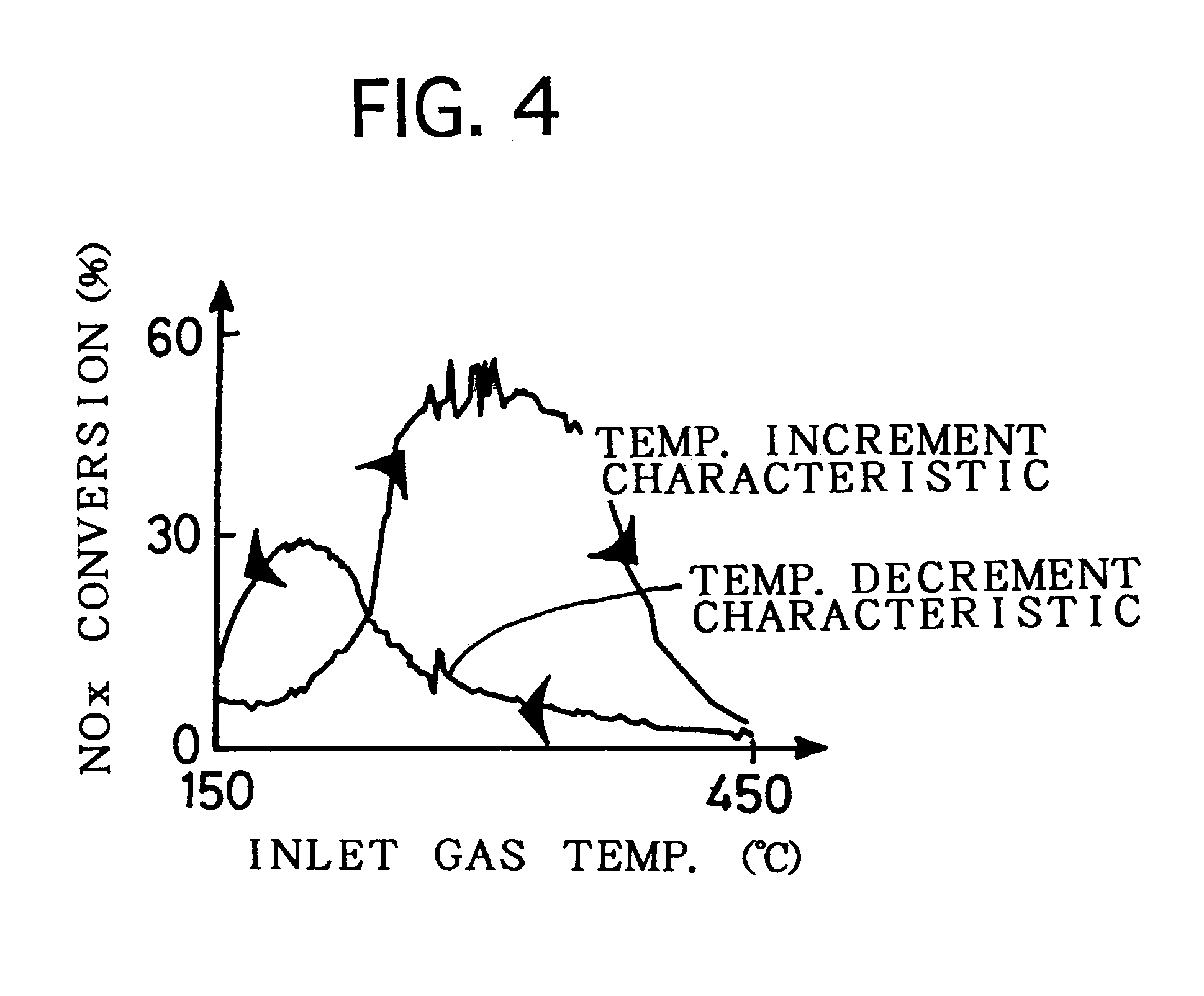

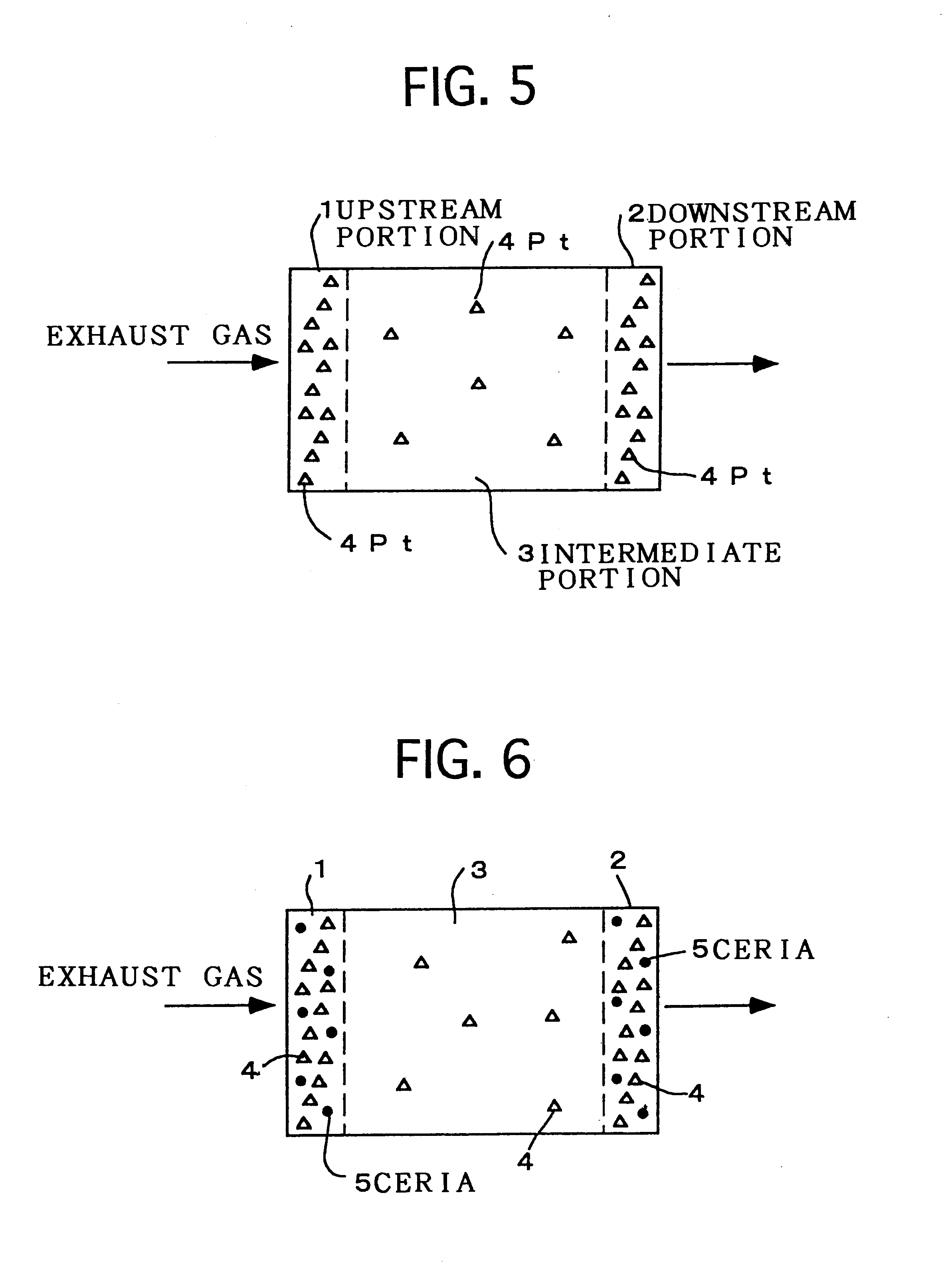

In an exhaust gas in an oxygen-rich atmosphere, a method of purifying an exhaust gas and a catalyst for purifying an exhaust gas, which can exhibit a high NOx conversion securely, are provided. Disclosed is a method of purifying an exhaust gas that reduces and purifies NOx in an exhaust gas in an oxygen-rich atmosphere. Here, as a catalyst for purifying an exhaust gas, a loading layer comprising zeolite is loaded with alumina sulfate and cerium sulfate-zirconium composite oxide, and Pt is loaded on these. And, in a temperature range where HC are not oxidized, the HC are adsorbed and held by the zeolite, the HC, which the zeolite releases at the temperature increment, are subjected to cracking by the zeolite, the alumina sulfate and the cerium sulfate-zirconium composite oxide, and the thus produced low-grade HC are turned into reducing agents, thereby reducing and purifying the NOx in the exhaust gas.

Owner:TOYOTA JIDOSHA KK

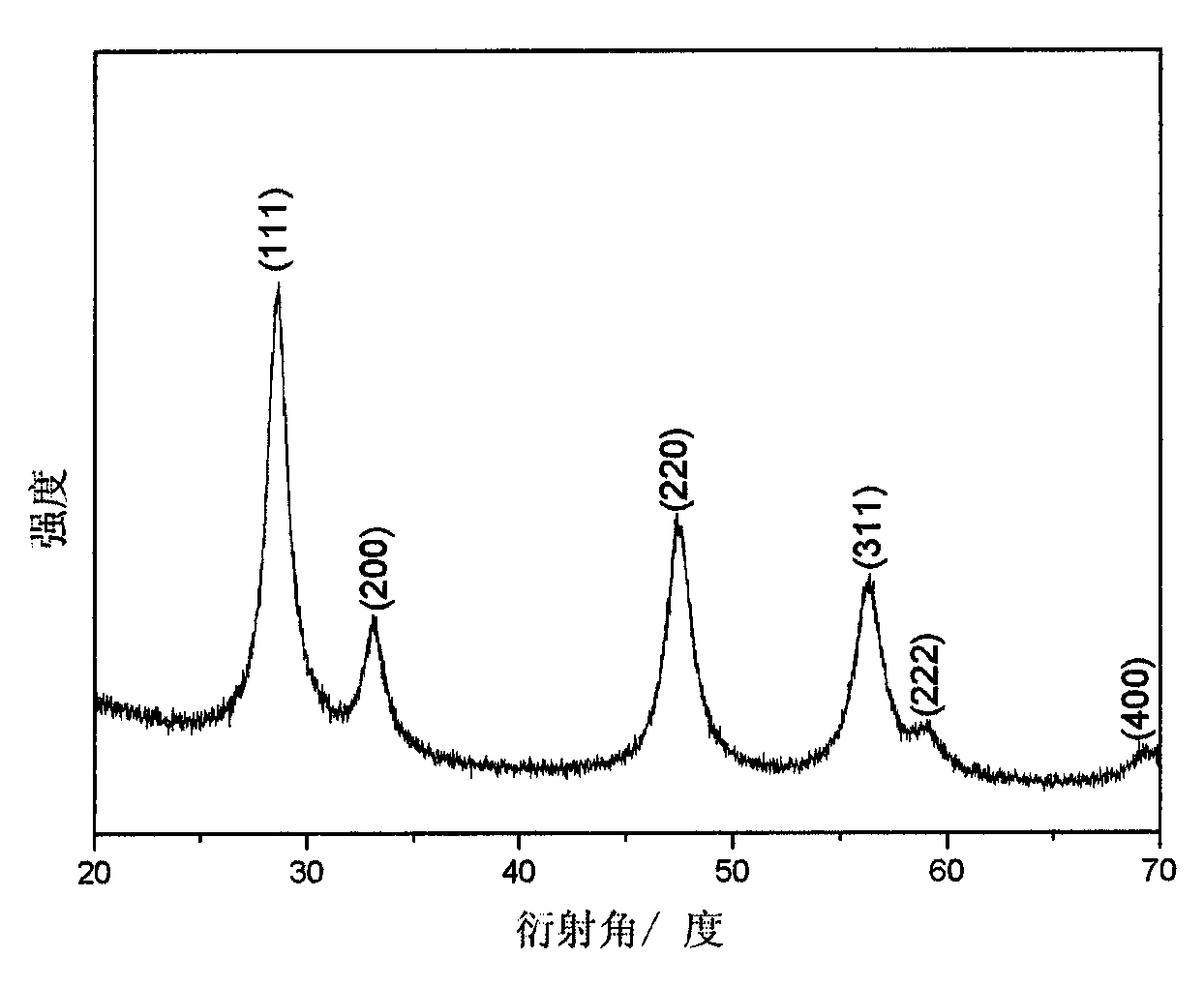

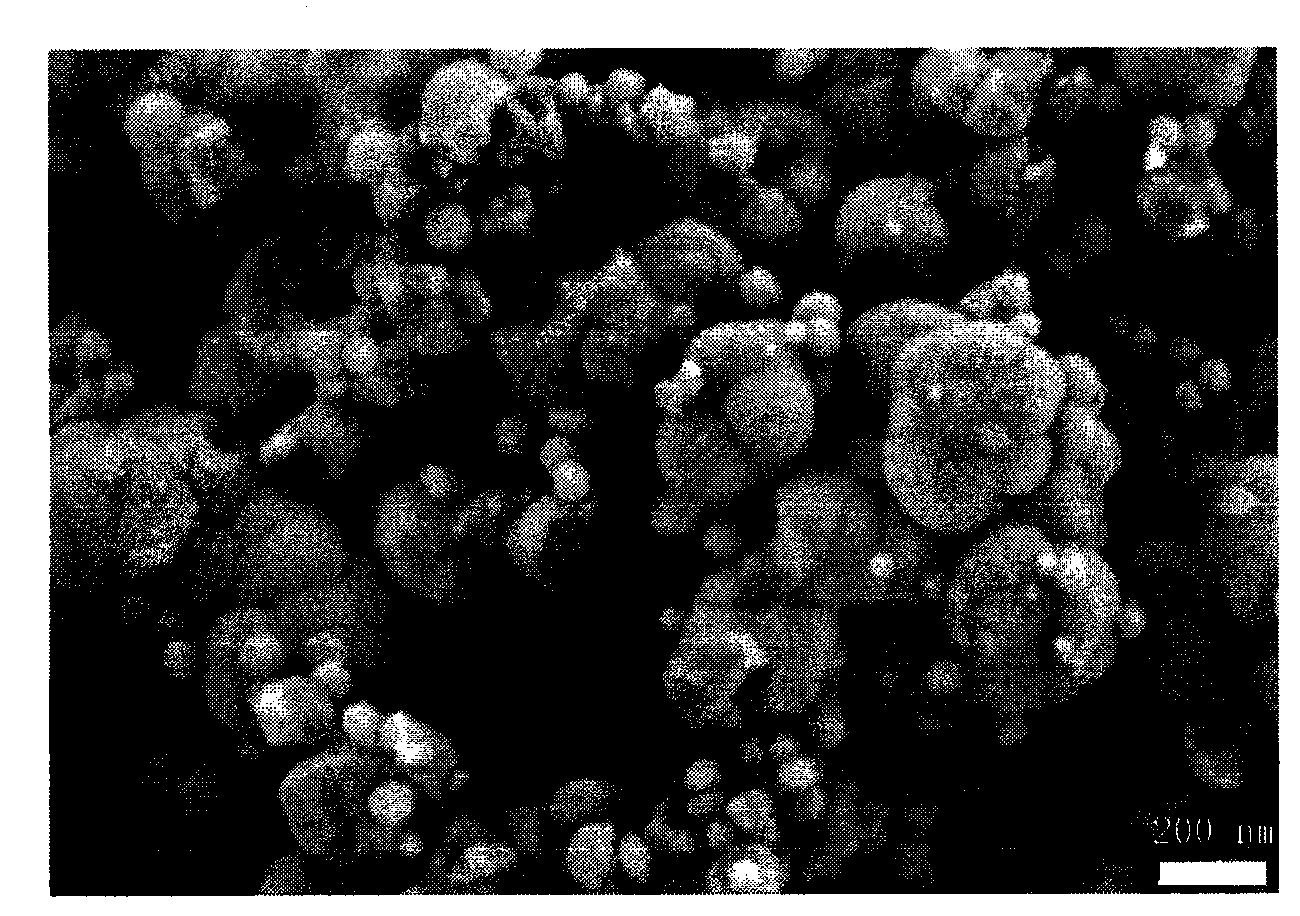

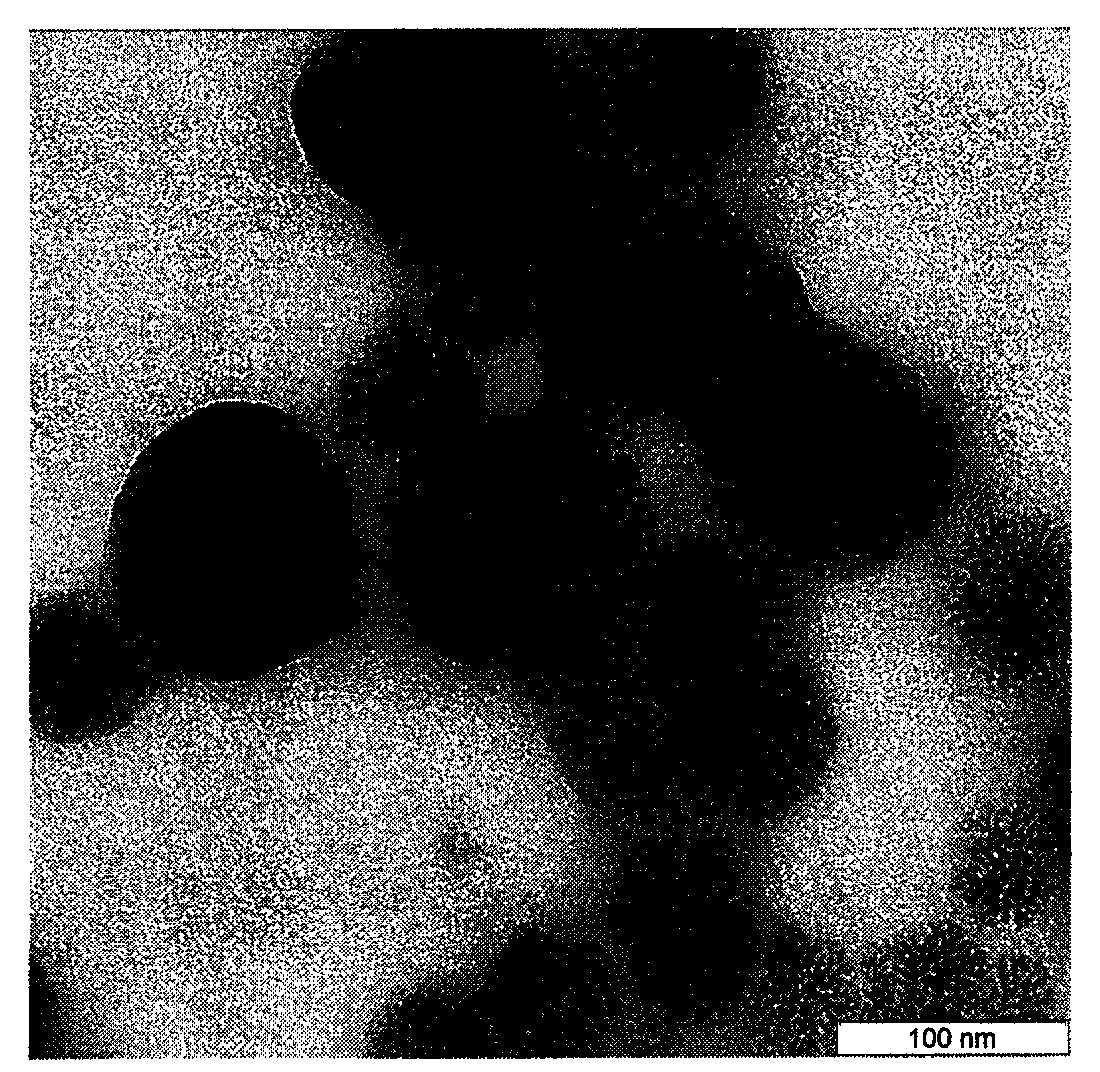

Low-temperature preparation method of ceria nano-crystalline microsphere of graduation structure

InactiveCN101584981ASimple processEasy to controlOther chemical processesRare earth metal compoundsCerium nitrateHigh absorption

The invention discloses a low-temperature preparation method of ceria nano-crystalline microsphere of graduation structure. The non-aqueous system low-temperature preparation method is used and cerium chloride, ammonium ceric nitrate, cerium nitrate or cerium sulfate is used as the precursor and benzyl alcohol is used as solvent and surfactant and the raw materials react for a certain time in oil-bath heating condition to obtain the ceria nano-crystalline microsphere powder of graduation structure. The prepared ceria has three-dimensional graduation spheroidal structure. The ceria nano-crystalline microsphere powder of graduation structure can quickly and effectively absorb the inorganic and organic pollutant in waste water at room temperature with very high absorption capacity. The low-temperature preparation method has features of simple technology, low cost, friendly environment, high yield, accordance with the practical production requirement.

Owner:XUANCHENG JINGRUI NEW MATERIAL CO LTD

Mixed glue electrolytic liquid of plumbous acid accumulator and production thereof

InactiveCN1747216AIncrease capacityExtended deep discharge cycle lifeLead-acid accumulatorsSilicon dioxidePolypropylene

The mixed gelling electrolyte comprise sulfuric acid, SiO2, sodium sulphate, polyacrylamide, polypropylene sodium, lanthanum sulfate, cerium sulfate, tungsten oxide, molybdenum oxide and deionized water.

Owner:江苏华富能源有限公司

Chromium-free passivation solution for tin plate and method for using same

InactiveCN101638804ALow costSimple processSurface reaction electrolytic coatingChromium freeRare-earth element

The invention relates to an acid metal passivation solution and a method for using the same, in particular to a chromium-free passivation solution for a tin plate and a method for using the same. Thepassivation solution comprises the following components in portion by weight: 5 to 30 portions of inorganic salt of a rare earth element Ce or La, 5 to 40 portions of inorganic salt of ammonium and 1,000 portions of water; the pH value of the passivation solution is between 2 and 7 and can be adjusted by dilute nitric acid or dilute sulfuric acid; the inorganic salt of the rare earth element Ce orLa may be cerous nitrate, cerous sulfate, lanthanum nitrate or lanthanum sulfate; and the inorganic salt of ammonium may be ammonium nitrate or ammonium sulfate. The method for using the passivationsolution comprises that: the tin plate is soaked in the passivation solution for electrochemical processing, and during the processing, the cathodic current density is between 0.1 and 20A / dm<2>, the processing time is between 0.1 and 10s, and the temperature is between 30 and 65 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing lanthanum cerium oxalate from rare earth polishing powder waste residue

ActiveCN102659559ANo pollution in the processScientific and rational useCarboxylic acid salt preparationHydrogen fluorideCerium oxalate

The invention relates to the technical field of material preparation, in particular to a method for preparing lanthanum cerium oxalate from rare earth polishing powder waste residue. The method comprises the following steps: reacting to leach the recovered rare earth polishing powder waste residue in concentrated sulfuric acid to obtain a lanthanum cerium sulfate solution; separating the lanthanum cerium sulfate solution from solid residue, and adding oxalic acid to obtain a lanthanum cerium oxalate precipitate; and filtering and separating the lanthanum cerium oxalate precipitate, washing to neutrality, and drying to obtain the finished lanthanum cerium oxalate product. Fluorides such as hydrogen fluoride are not required, the polishing powder waste residue is scientifically and reasonably utilized comprehensively, and the whole recovery process is environment-friendly. The method has the characteristics of small investment, low recovery cost, simple process flow, high recovery rate, environment friendliness and the like.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

Sealing treatment method used in aluminum alloy surface treatment and sealing liquid used thereby

ActiveCN104005071AImprove corrosion resistanceUniform surfaceSurface reaction electrolytic coatingMetallic material coating processesLanthanum nitrateMaterials science

The invention discloses a sealing treatment method used in aluminum alloy surface treatment and a sealing liquid used in the sealing treatment method. The sealing treatment method comprises the following steps: soaking an aluminum alloy after surface treatment in the sealing liquid, taking out, washing in water and drying, wherein the sealing liquid is prepared from the following components in concentration: 5-25g / L cerium sulfate tetrahydrate, 1-5g / L lanthanum nitrate hexahydrate and 0.5-2.5g / L ammonium persulfate, the soaking time is 50-70 minutes, and the temperature of the sealing liquid is 40-60 DEG C. The sealing liquid disclosed by the invention is not only friendly to environment and human bodies, but also capable of greatly improving the corrosion resistance of an oxidation film after the sealing treatment.

Owner:JIANGSU UNIV OF TECH

Plating solution formula of lead tin plating process for electronic components and lead tin plating process

ActiveCN107099825AImprove antioxidant capacityGive full play to the strong reducibilitySuperimposed coating processTin platingPolyethylene glycol

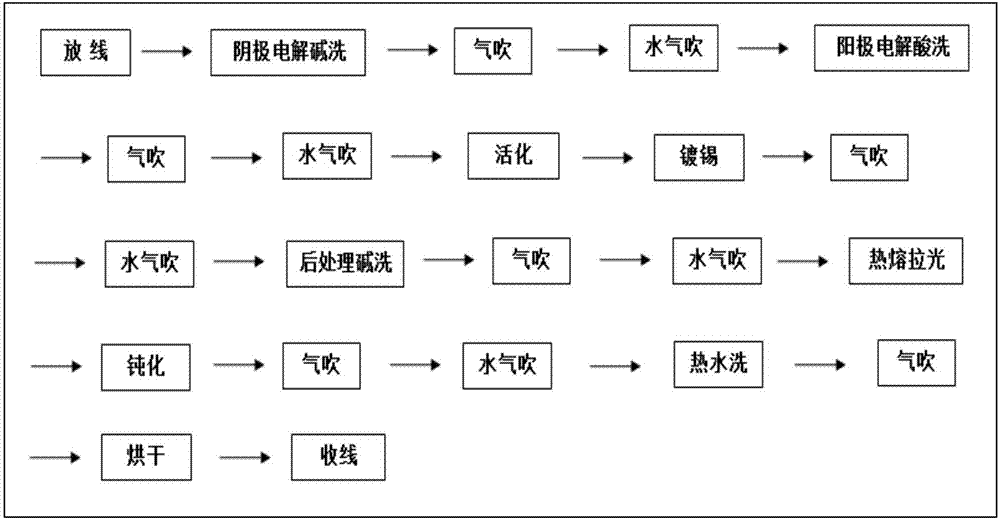

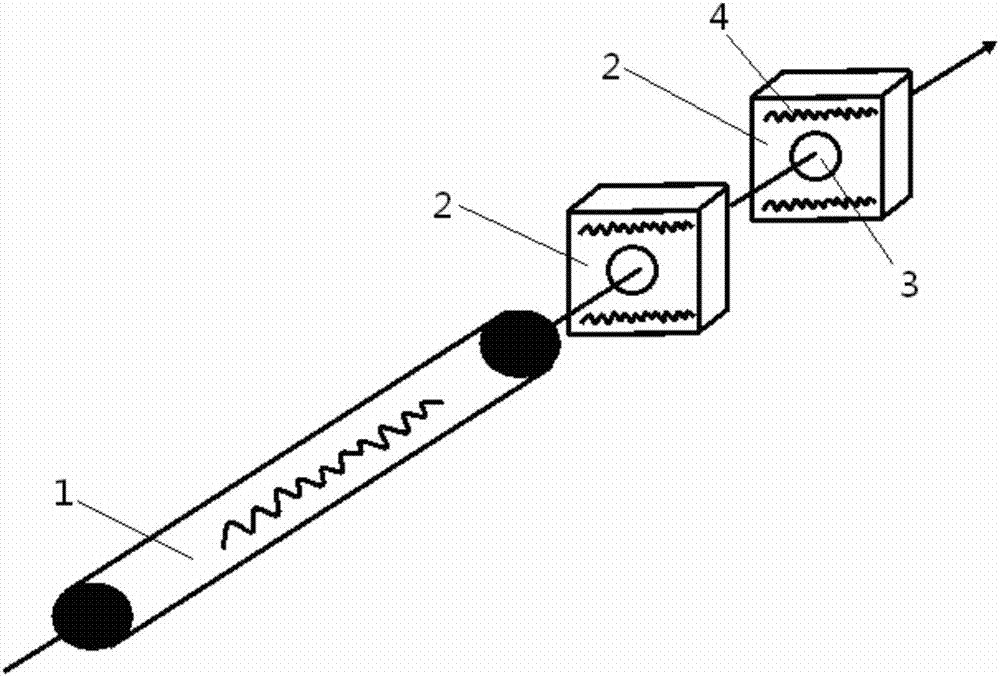

The invention provides a plating solution formula of a lead tin plating process for electronic components and the lead tin plating process. The plating solution formula comprises the following components by mass-volume concentration: 70-120 g / L sulfuric acid (AR), 45-60 g / L stannous mono-sulphate, 0.2-0.8 g / L sodium hypophosphite, 0.5-1.5 g / L ascorbic acid, 2-6 g / L of polyethylene glycol, 1-1.5 g / L catechol, 1-1.5 g / L beta-naphthol, 3-6 g / L cerium sulfate, an 8-10 g / L OP-10 emulsifier, 10-30 g / L phenolsulfonic acid and pure water. According to the lead tin plating process, hot-melt drawing passivation treatment is adopted after tin plating. A tin plating layer of a product produced by adoption of both the formula and the production process is greatly improved in compactness, so that the tin whisker growth prevention performance, the high temperature resistance, the anti-tarnishing capability and the neutral salt spray resistance of the product are improved.

Owner:烟台东牧精密线材有限公司

Natural organic high-molecular flocculant and its preparation method

InactiveCN101007668ALow priceGood environmental acceptabilityWater/sewage treatment by flocculation/precipitationAcetic anhydrideWater quality

The invention discloses a making method of new-typed natural organic macromolecular flocculant, which comprises the following steps: adopting corn starch as main raw material and cerium sulfate as initiator; using the copolymer of ammonium chloride and acetic anhydride with weight rate at 2: 1-1: 2 as cation monomer modifier to react under 10-45 deg.c for 20-50min; setting the weight rate of corn starch and cation monomer at 10:1-1:1; setting the starch alkalizing temperature at 35-55 deg.c for 50-60 min; making the grafting modifying temperature at 30-60 deg.c for 60-120min.

Owner:盛力

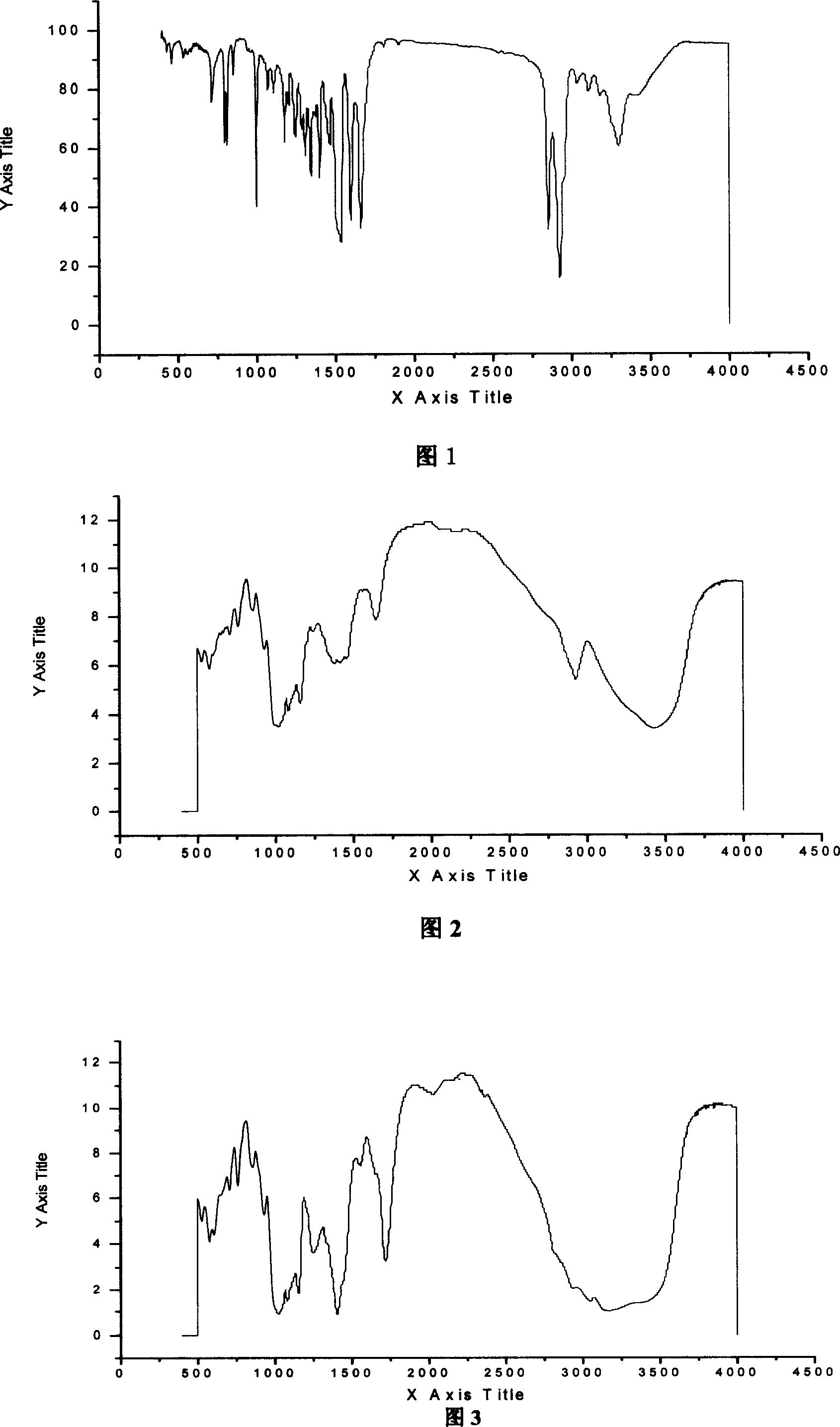

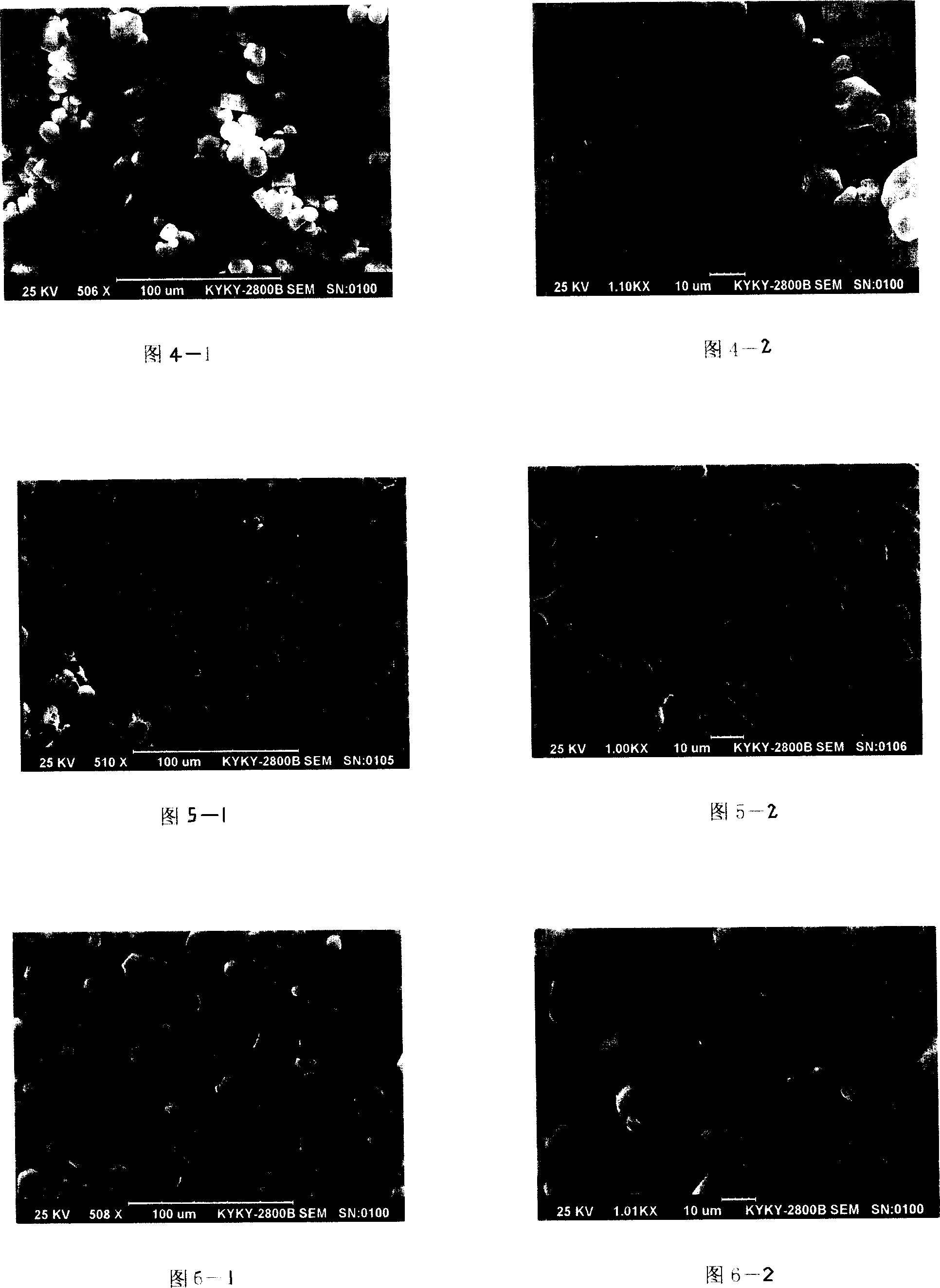

Preparation process of chemical plating rare earth cerium Ni-P-PTFE (Polytetrafluoroethylene) composite coating

ActiveCN104419919ASimple processLow costLiquid/solution decomposition chemical coatingActive agentPtfe composite

The invention relates to a preparation method of a chemical sedimentation rare earth cerium Ni-P-PTFE (Polytetrafluoroethylene) composite coating. Based on a chemical Ni-P-PTFE composite plating process and the characteristics of a rare earth cerium atom, the Ni-P-PTFE composite coating is prepared on a steel 20 matrix by virtue of a mechanical stirring method. The method comprises the following specific steps of pretreating a sample; preparing a plating solution containing 10-15g / L nickel sulfate, 10-15g / L sodium hypophosphite, 5-10g / L citric acid and 2-8g / L cerium sulfate; preparing a mixed solution of 4-11g / L PTFE emulsion and 0.2-0.8g / L an active agent FC-134; mixing the plating solution with the mixed solution; cleaning the sample; activating with hydrochloric acid; washing with water; plating; and washing with water and drying. The Ni-P-PTFE composite coating prepared by the preparation method, which is disclosed by the invention, has the advantages of small friction coefficient, good wear resistance and antifouling property and the PTFE particles in the coating are evenly distributed.

Owner:PETROCHINA CO LTD +1

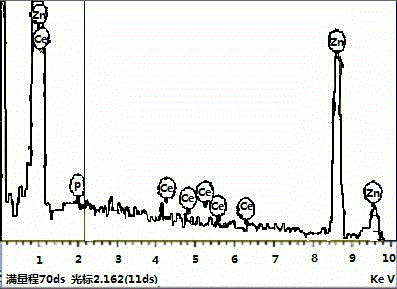

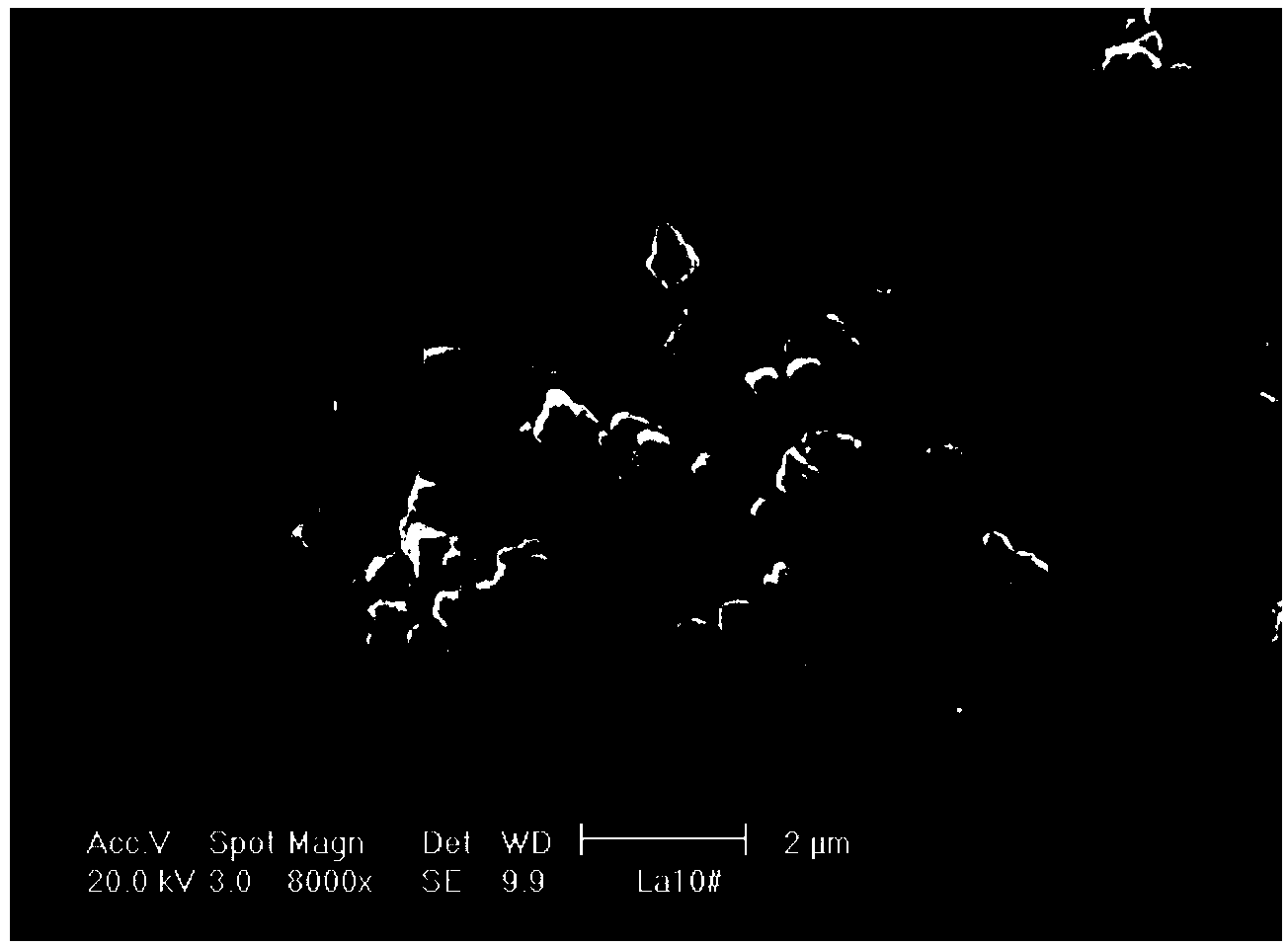

Method for preparing cerium-containing zinc coating

InactiveCN102719864AEasy maintenanceChanged cathodic polarization behaviorPhosphorous acidDC - Direct current

The invention discloses a method for preparing cerium-containing zinc coating. The method comprises the following main steps: (1) sulfate plating solution for ions to be plated is prepared, wherein the concentration of zinc sulfate is 50-300g / L, and the concentration of cerium sulfate is 0.2-4g / L; sodium citrate serving as rare earth complexing agent, with the concentration of 5-60g / L is added, and sodium hypophosphite with the concentration of 5-60g / L is added; dilute sulfuric acid is adopted to adjust the pH value of the plating solution to be 1-4; the temperature of the plating solution is controlled to be 15-60 DEG C; (2) the direct current electrodeposition method is adopted for plating; in a plating bath containing the plating solution, carbon steel used as the plated material is used as the cathode, a platinum sheet is adopted as the anode, direct current is introduced to the plating bath, the current density is 0.6-4 A / cm<2>, and the plating time is 1-6 min; and finally, the concentration of cerium in the prepared coating is 0.05-0.3 wt%. Aiming at the sulfate system of the DC (direct current) electrodeposition zinc coating, the sodium citrate and the sodium hypophosphite as the substances are adopted for promoting the deposition of cerium, so that the cathodic polarization behavior of cerium in deposition can be improved, the zinc coating containing trace cerium is finally obtained, and the corrosion resistance of the coating is obviously improved.

Owner:SHANGHAI UNIV

Process for preparing fluorine reducing ion sieve of aquatic body

InactiveCN1724362AImprove adsorption capacityHigh mechanical strengthCrystalline aluminosilicate zeolitesWater/sewage treatment by sorptionZirconium oxychlorideAqueous solution

A process for preparing the ionic sieve used to de-fluorinate water includes such steps as dripping sulfuric acid to the aqueous solution of sodium silicate while stirring to generate silicate acid gel, ageing to form porous skeleton structure, dripping the aqueous solution of zirconium oxychloride or cerium sulfate to said gel while stirring to obtain de-fluorinating gel, filtering for dewatering, washing, baking, calcining and holding the temp for a certain time. Its advantage is high adsorptive speed and capacity.

Owner:TIANJIN UNIV

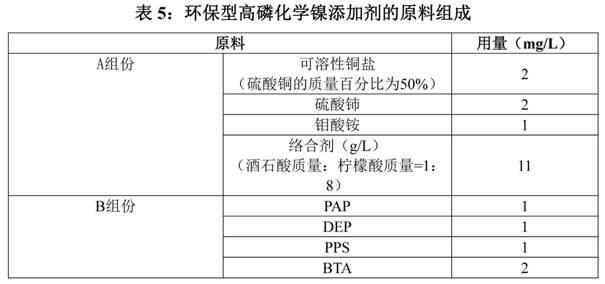

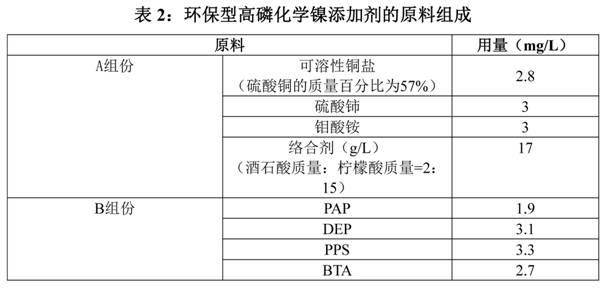

Environment-friendly high-phosphorus chemical nickel additive

ActiveCN102140631AGood resistance to nitric acidReduce porosityLiquid/solution decomposition chemical coatingPyridiniumEngineering

The invention discloses an environment-friendly high-phosphorus chemical nickel additive which consists of component A and a component B. The component A comprises the following raw materials based on concentration: 2-5mg / L soluble copper salt, 2-4mg / L cerous sulfate, 1-4mg / L ammonium molybdate and 11-23g / L complexing agent. The component B comprises the following raw materials based on concentration: 1-4mg / L PAP (propargyl alcohol propoxy compound), 1-3mg / L DEP (N, N-diethyl-propyne ammonium), 1-4mg / L PPS (pyridinium-1-pmpane-3-sulfonate) and 2-4mg / L BTA (benzotriazole). The formula of the environment-friendly high-phosphorus chemical nickel additive provided by the invention does not contain lead, cadmium and other heavy metal ions, thus the additive is non-toxic, harmless and environment-friendly. The additive is applied to a chemical nickel plating liquid to enable the plating liquid to be stable, thus the obtained plating is dense, has low porosity and good nitric acid resistance, and can achieve the effect that the nickel plating does not change color after being immersed in concentrated nitric acid for 5 minutes.

Owner:广州市二轻研究所股份有限公司 +1

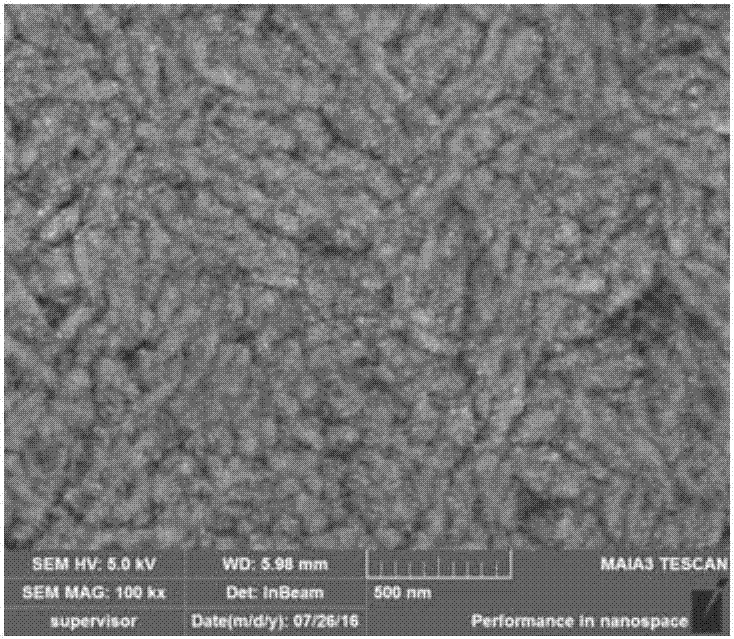

Cerate composite additive and solidification liquid for copper foil surface solidification treatment and application method of cerate composite additive and solidification liquid

The invention discloses a cerate composite additive and a solidification liquid for copper foil surface solidification treatment, and an application method of the cerate composite additive and the solidification liquid. The additive is characterized by comprising cerium sulfate, ammonium sulfate and ammonium hydroxide, wherein the addition amount of cerium sulfate in each liter of the solidification liquid is 0.1-1.0g, the addition amount of ammonium sulfate is 10-60g, and the addition amount of ammonium hydroxide is 5-20mL with the concentration of 20%. According to the additive, the characteristic absorption function of rare earth ions is utilized, a cladding layer grains are refined, the surface is smooth, the inoxidizability and the corrosion resistance of a copper coil are improved, and conditions are provided for continuous development of the industry. The composite additive also has the characteristics of low cost and conduction easiness, the conventional process is convenient and feasible to transform, no extra processes are needed to be added, and any great process route transformation is not needed.

Owner:JIANGSU MINGFENG ELECTRONIC MATERIALS CO LTD +1

Surface treatment method of rear-earth magnesium alloy casting product

ActiveCN103215584ASolubility product is smallMetallic material coating processesTectorial membranePre treatment

The invention relates to a surface treatment method of a rear-earth magnesium alloy casting product. The surface treatment method sequentially comprises the following steps of: immersing the rear-earth magnesium alloy casting product in 0.02mol / L-0.12mol / L of cerium sulfate aqueous solution in an ultrasonic precipitating-crystallizing device after carrying out oil-removing and impurity-removing pre-treatment onto the rear-earth magnesium alloy casting product; adding a magnesium hydroxide solution to regulate the pH value to 8-11; adding hydrogen peroxide to generate cerium hydroxide, wherein the mass percentage concentration of the hydrogen peroxide is 5%-20%, and the weight ratio of the using amount of the hydrogen peroxide to the cerium hydroxide aqueous solution is (1-5):100; generating a precipitated and crystallized compact tetravalent cerium protective film on the surface of the rear-earth magnesium alloy casting product by the cerium hydroxide under the ultrasonic action; and getting out the rear-earth magnesium alloy casting product from the precipitating-crystallizing device, and drying at 120 DEG C to 240 DEG C after water-washing to obtain the rear-earth magnesium alloy casting product coated with cerium dioxide on the surface. The surface treatment method of the rear-earth magnesium alloy casting product can be used for forming a compact tetravalent cerium protective film on the surface of the rear-earth magnesium alloy casting product; moreover, the process is simple and reliable.

Owner:YANGZHOU FENG MING METAL PROD

Alcoholic clean fuel

The invention discloses an alcoholic clean fuel which comprises the following components in percentage by weight: 65-75% of methanol, 1-3% of petroleum ether or naphtha, 15-30% of gasoline, 0.1-0.2% of ETBE, 0.5-1.5% of tween-80 or benzotriazole, 0.5-2% of quinoline, 1-3% of oleic acid, tween-20 or triethanolamine, 0.3-1.5% of tertiary butanol or isobutanol, 0.1-1% of butyldiglycol, 0.1-2% of cyclohexanone and 0.1-1% of cerium sulfate. The fuel disclosed by the invention is great in incorporated amount of methanol and is not layered in use, and air resistance can be avoided, and the fuel is enough in power and small in metal corrosion and low in swelling property of a sealing ring of an engine. A vehicle engine needs not to be changed, and the engine is easy to start in a low-temperature state in use.

Owner:GUOHAO BEIJING NEW ENERGY TECH DEV CO LTD

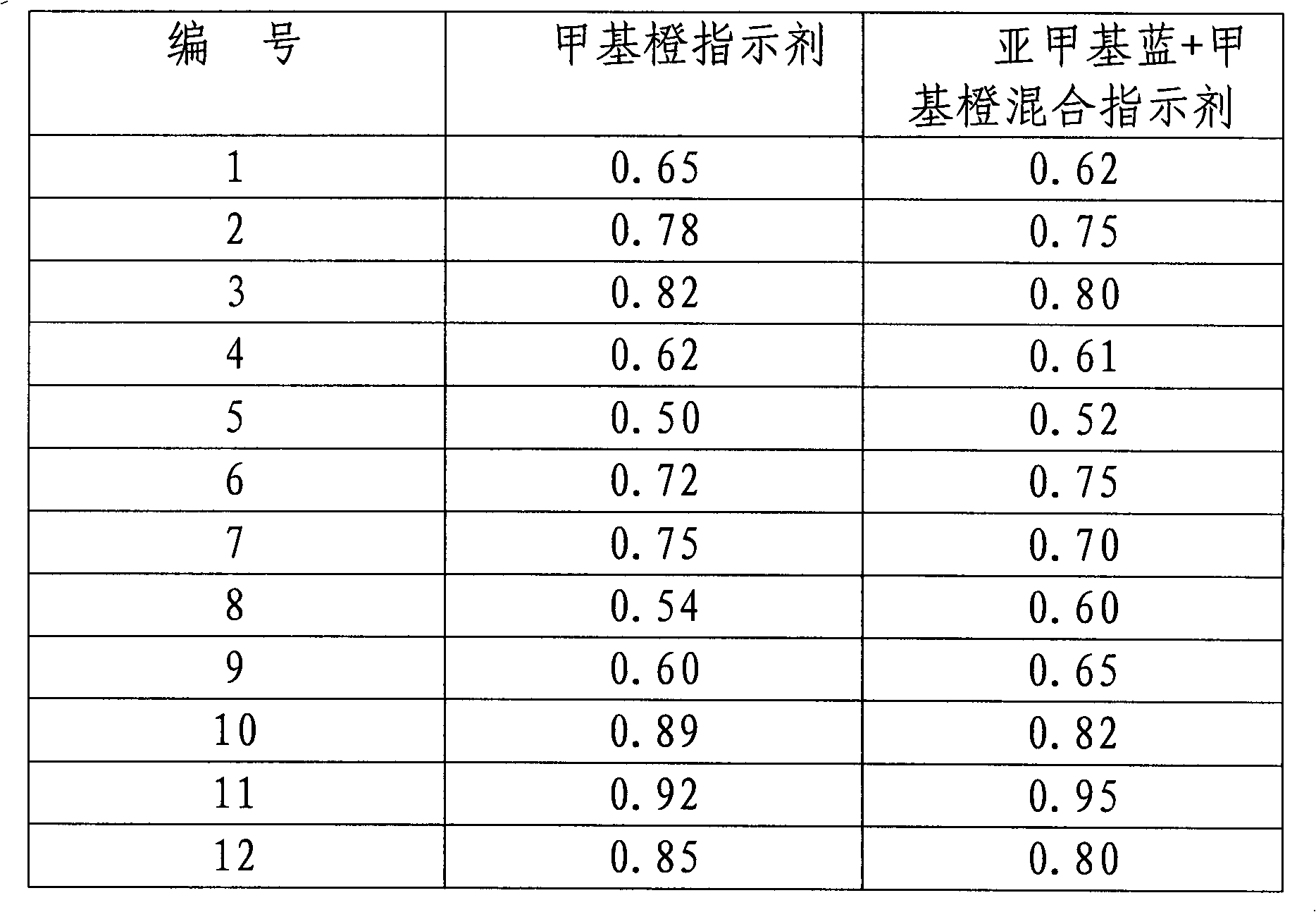

Method for determination of antimony content in smelting slag

InactiveCN102914618AEasy to operateReal reaction real tasteChemical analysis using titrationPreparing sample for investigationPotassium fluorideDecomposition

The present invention discloses a method for determination of the antimony content in a smelting slag, which comprises the following steps: (1) weighing a certain amount of a slag sample, and placing in a conical flask; (2) adding a certain amount of potassium sulfate, potassium fluoride dehydrate, and a sulfuric acid solution to dissolve the sample, and then heating the test sample on an electric hot plate for decomposition; and after most of the sulfur is expelled, covering by a watch glass, and further heating on the electric hot plate, so that the sample was dissolved completely; (3) taking down the test sample and cooling a little, adding a certain amount of hydrazine sulfate and heating continuedly for 10-15 minutes; (4) taking down and cooling the test sample; adding a certain amount of water, and hydrochloric acid, mixing uniformly; adding a certain amount of phosphoric acid, and mixing uniformly in on the electric hot plate for continue heating, temperature controlled at 80 DEG C to 90 DEG C; (5) taking down the test sample, adding a little methylene blue and a little methyl orange, mixing as an indicator; titrating with the cerium sulfate standard solution; and calculating the content of antimony ions according to the consumption of the cerium sulfate standard solution. By using the method, the result is easy to judge, and the determination is rapid and accurate.

Owner:湖南东港锑品有限公司

Medium-deep well crosslinked polymer gel plugging agent and preparation method thereof

The invention relates to a medium-deep well crosslinked polymer gel plugging agent and a preparation method thereof. The plugging agent comprises the raw materials of, by weight, 120 parts of a refined cotton sodium salt solution, 75-85 parts of acrylamide, 13-17 parts of ammonium persulfate, 2-5 parts of cerium sulfate, 4 parts of beta-D-mannuronic acid (M), 1-1.5 parts of ammonium dihydrogen phosphate, 100 parts of composite Portland cement slurry, and 150-200 parts of hybrid microfiber. The water-cement ratio of the composite Portland cement slurry is 0.44. According to the invention, acrylamide, ammonium persulfate and cerium sulfate particles are sequentially added into refined cotton sodium salt solution, such that crosslinked polymer gel is obtained; the beta-D-mannuronic acid (M) is added; the composite Portland cement slurry and the hybrid microfiber are added; the ammonium dihydrogen phosphate is added, and the mixture is well mixed, such that the medium-deep well crosslinked polymer gel plugging agent is obtained. The medium-deep well crosslinked polymer gel plugging agent has high high-temperature resistance and high compressive strength, and is reliable in plugging.

Owner:SINOPEC SSC +1

Plating solution for electroless plating of Ni-W-Zn-P alloy coating and coating process thereof

ActiveCN105039943AStrong corrosion resistanceLiquid/solution decomposition chemical coatingLead nitrateAlloy coating

The invention discloses a plating solution for electroless plating of a Ni-W-Zn-P alloy coating and a coating process thereof. The plating solution comprises 15-30 g / L of nickel sulfate, 30-60 g / L of sodium tungstate, 3-10 g / L of zinc sulfate, 80-120 g / L of sodium citrate, 15-25 g / L of sodium hypophosphite, 30-50 g / L of ammonium chloride, 10-20 mg / L of lead nitrate, 3-10 mL / L of lactic acid, and 0.15-0.3 g / L of cerium sulfate. In the experimental process, PH is regulated to be at 8.5-9.5 by ammonium hydroxide; the plating temperature is 70-90 DEG C; and plating time is 2 hours. A coating obtained through the coating process is 20-30 [mu] m in thickness and up to 600 HV0.1 in microhardness. The zinc sulfate is added to the plating solution, so that the obtained coating contains zinc, and corrosion resistance of the coating can be improved to a large extent. After heat treatment, a zinc-phosphorus alloy phase is separated out, so that texture is refined and a dispersion strengthening function is achieved. The cerium sulfate is added, so that not only is the plating speed increased, but also the coating is more even and compact.

Owner:UNIV OF SCI & TECH BEIJING

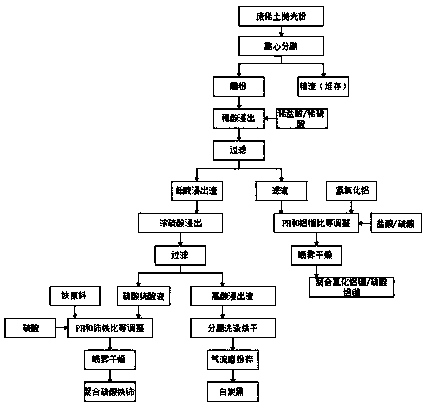

Method for extracting white carbon black and rare-earth water purifying agent from waste rare-earth polishing powder

The invention discloses a method for extracting white carbon black and a rare-earth water purifying agent from waste rare-earth polishing powder. The method comprises the following steps of conducting centrifugal separation of the waste rare-earth polishing powder; leaching and filtering separated fine powder dilute acid; adjusting the pH value and the aluminum-lanthanum ratio of the filtered filtrate, and then drying to obtain polyaluminum lanthanum chloride or aluminum sulfate; leaching filtered filter slag with concentrated sulfuric acid, and then filtering to obtain a cerium sulfate solution and high-acid leaching slag; adjusting the pH value and the cerium-iron ratio of the cerium sulfate solution, and then drying to obtain polymerized ferric sulfate; and separating, washing and drying the high-acid leached slag, and then carrying out jet milling to obtain the white carbon black. According to the method for extracting the white carbon black and the rare-earth water purifying agent from the waste rare-earth polishing powder, the low-content waste rare-earth polishing powder can be prepared into white carbon black and a water purifying agent, and a large part of valuable substances are comprehensively utilized, so that the comprehensive recovery and utilization of the low-content waste rare-earth polishing powder are realized.

Owner:湖南景翌湘台环保高新技术开发有限公司 +1

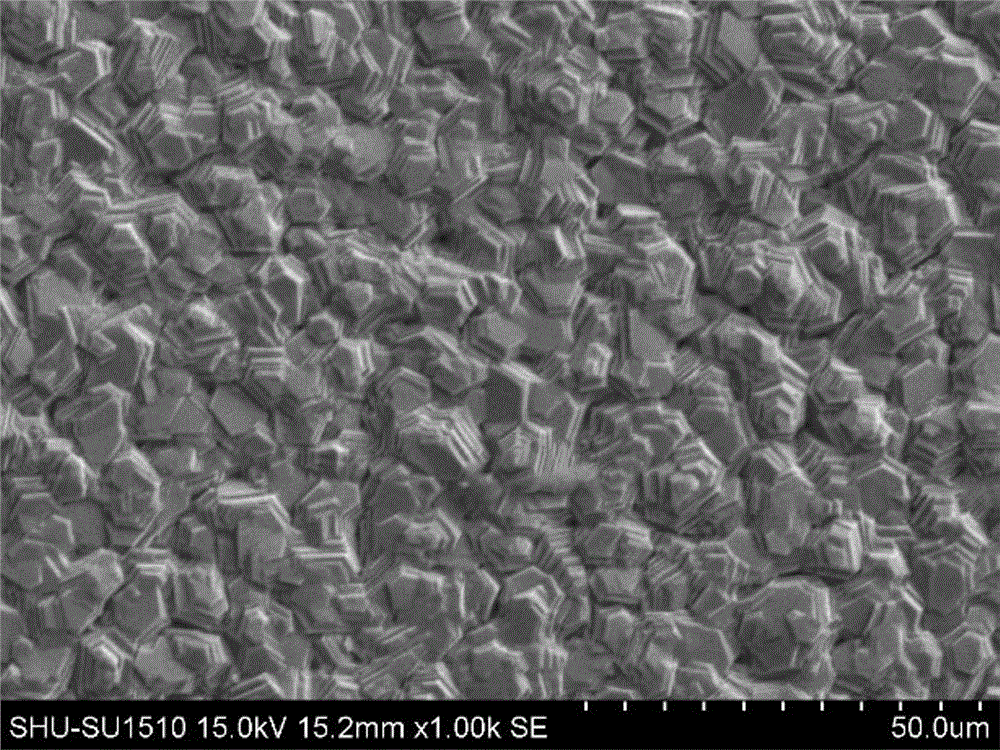

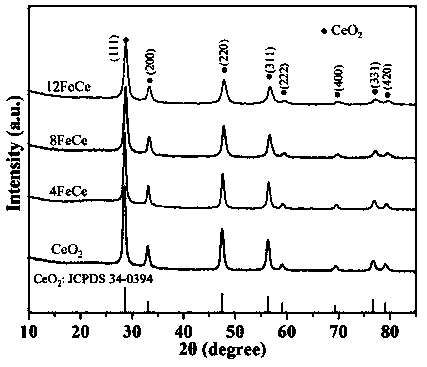

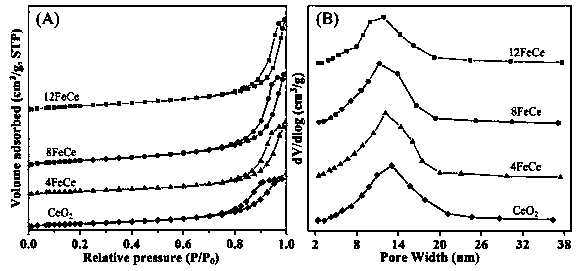

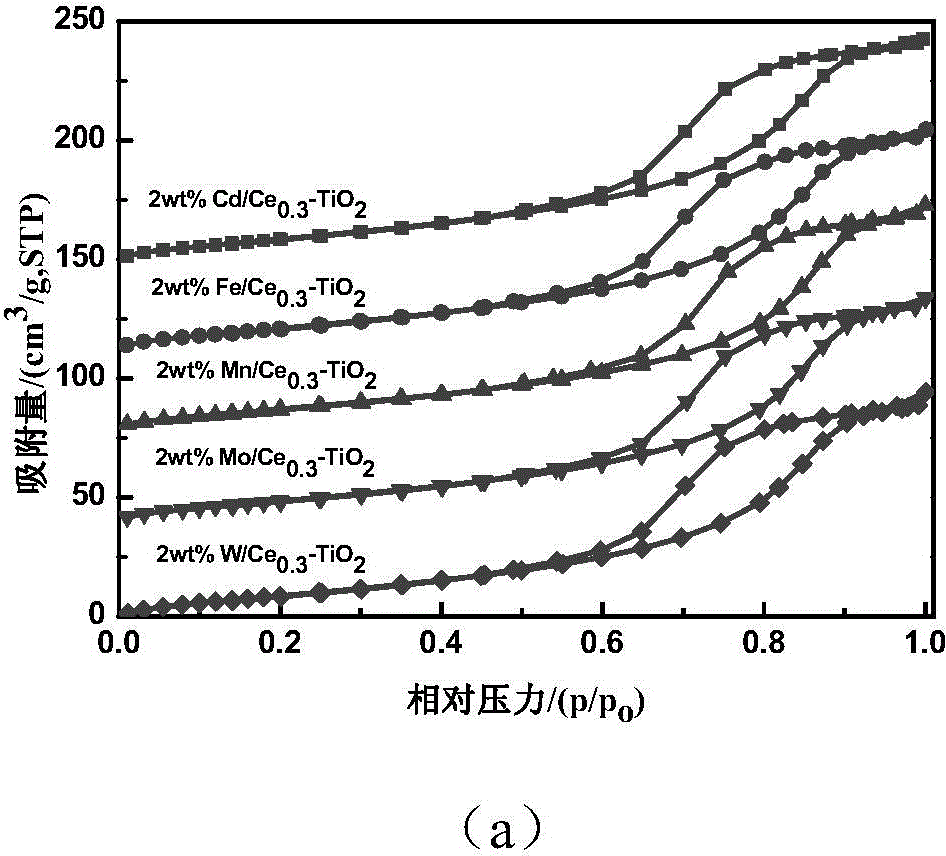

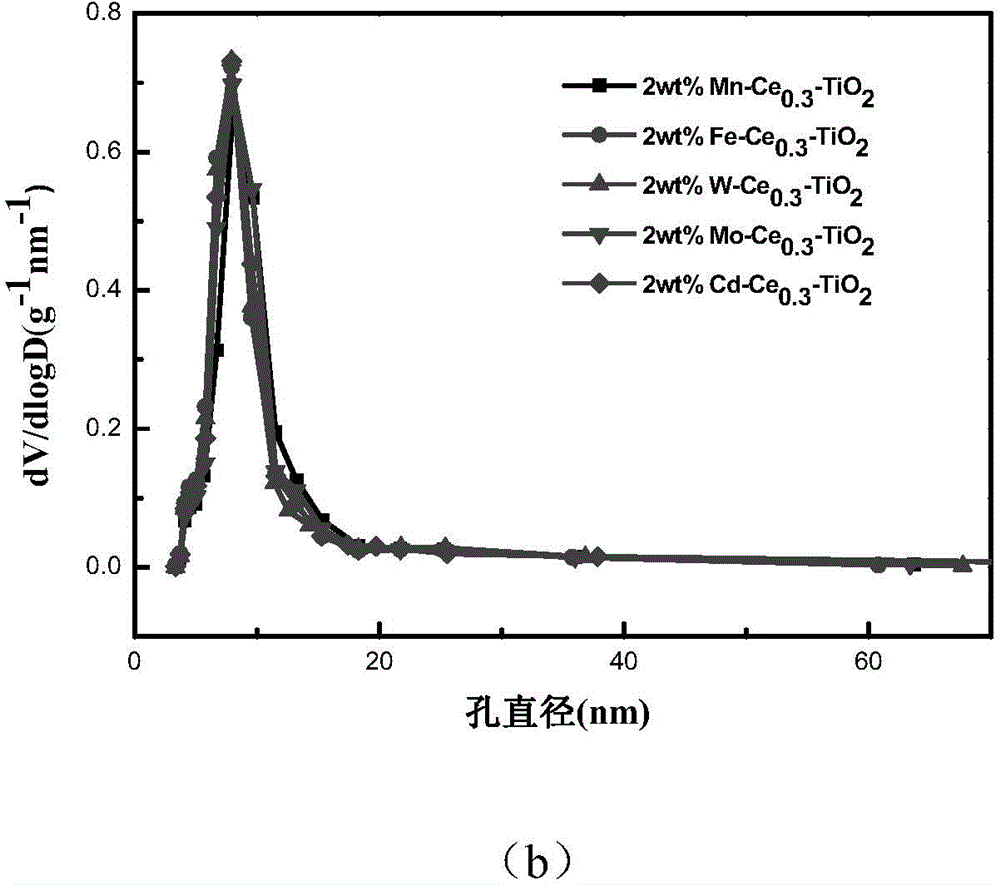

Preparation and desulfurization applications of flower-like iron-doped cerium dioxide with porous structure

ActiveCN110813303AAperture adjustableGood dispersionGaseous fuelsDispersed particle separationIron saltsPtru catalyst

The invention discloses a preparation method of flower-like iron-doped cerium dioxide with a porous structure, and belongs to the technical field of catalyst preparation, wherein the flower-like iron-doped cerium dioxide with the porous structure is synthesized by using a cerium salt, an iron salt and an ammonia water solution as raw materials and adding polyvinylpyrrolidone, citric acid and different pore-enlarging agents. According to the invention, the catalyst has a porous structure; the method is simple in process and high in repeatability compared with the template method; by doping withiron ions, the lattice distortion of cerium dioxide can be caused, so more lattice defects and oxygen vacancies appear in material lattices, and the oxygen storage capacity and the oxidation-reduction capacity are further improved; the electron transfer of iron ions and cerium ions can inhibit the oxidation of a by-product SO2 into SO3, so that the generation of cerium sulfate is reduced; and theporous structure exposes abundant active sites, so that the reaction is effectively promoted, and the catalyst shows high catalytic activity, high elemental sulfur selectivity and high stability in aselective catalytic oxidation H2S reaction.

Owner:FUZHOU UNIV

Stainless steel surface passivation treatment solution and method

ActiveCN106637353AImprove corrosion resistanceExtended service lifeAnodisationMetallic materialsRare earth

The invention provides a stainless steel surface passivation treatment solution and method, and belongs to the field of surface treatment of metal materials. The passivation treatment solution comprises rare earth metal salt, silicate and an oxidizing agent, wherein the rare earth metal salt is cerium sulfate, the silicate is sodium silicate, and the oxidizing agent is potassium permanganate; and the above substances are added into a certain amount of distilled water and fully stirred until the solid substances are completely dissolved. According to the stainless steel surface passivation treatment solution and method, stainless steel is used as a working electrode, is placed in the passivation treatment solution, and forms a three-electrode system along with a reference electrode and a counter electrode, the working electrode is subjected to anodic oxidation, a passivation film layer is formed on the surface of the stainless steel, and passivation treatment on the surface of the stainless steel is realized. The passivation treatment solution does not contain hexavalent chromium or highly corrosive acids such as sulfuric acid, nitric acid and hydrochloric acid, is simple in preparation process, low in cost, good in reproducibility and free of large expensive equipment. The prepared passivation film layer can be applied to the fields of stainless steel product surface treatment and the like, the corrosion resistance of the stainless steel is obviously improved, and the service life of the stainless steel is prolonged.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

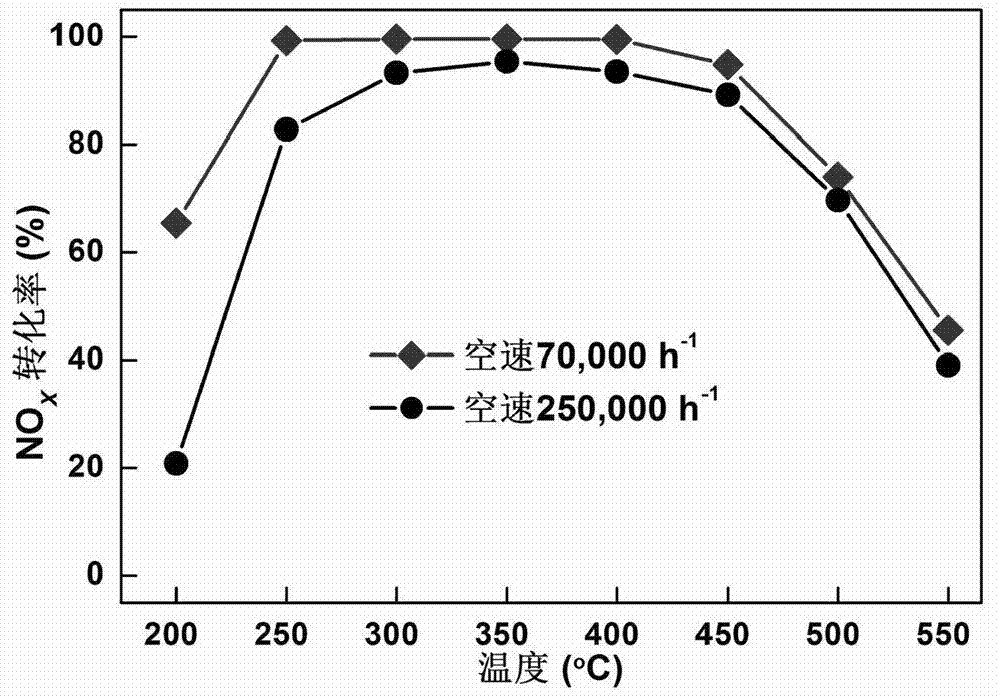

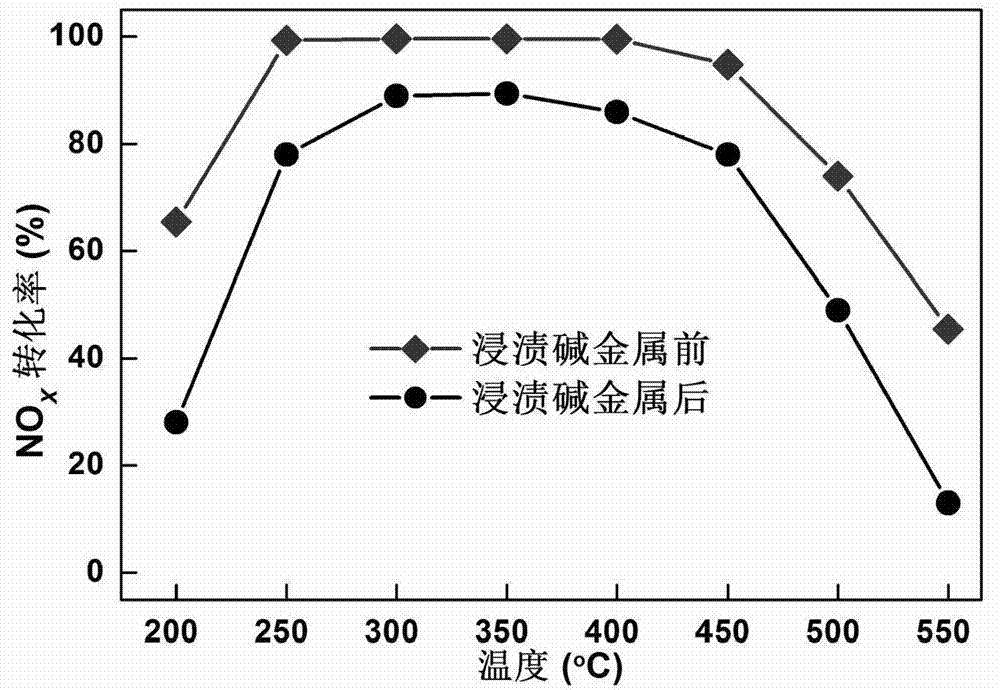

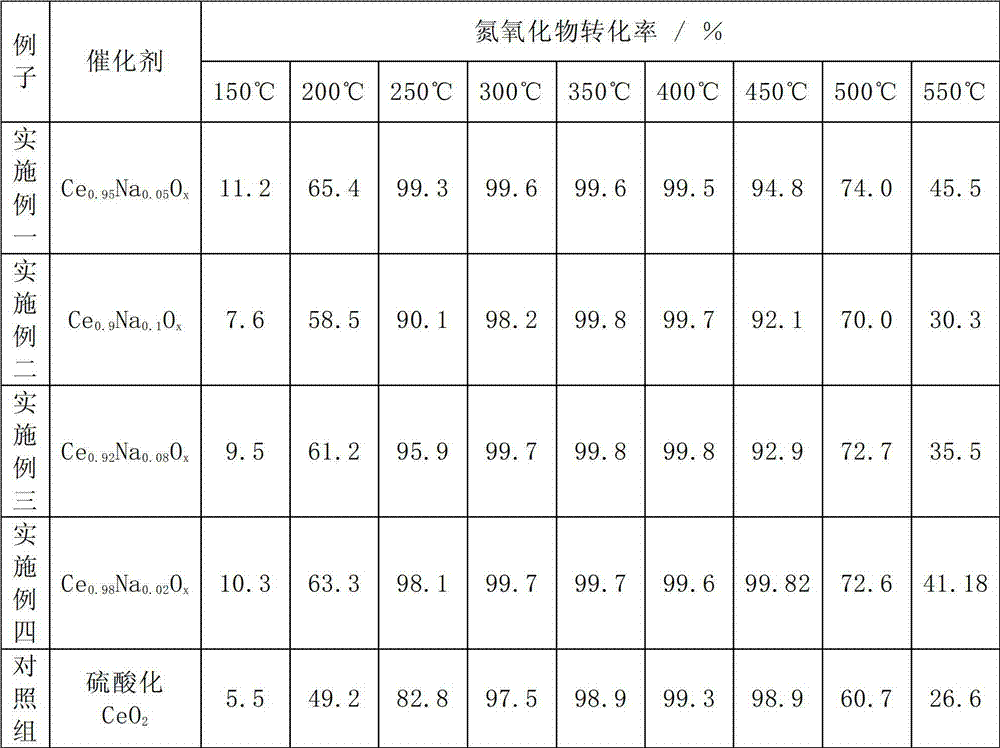

Novel cerium oxide denitration catalyst and preparation method thereof

ActiveCN103007919BImprove efficiencyLow running costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfate radicalsSodium phosphates

The invention discloses a novel cerium oxide denitration catalyst. The novel cerium oxide denitration catalyst has the expression formula of CeNaOx, wherein the molar ratio of Ce to Na is (90-98):(10-2), and x is balanced and determined by positive and negative valence electrons in each atom. The preparation method of the catalyst comprises the following steps of: 1, dissolving cerous sulfate, sodium phosphate and cerium sulfate in water at normal temperature, and stirring to form a transparent solution; 2, transferring the prepared solution into a hydrothermal reaction kettle, and adding deionized water; 3, sealing the hydrothermal reaction kettle and transferring the hydrothermal reaction kettle to an oven for heating and reacting, reducing the temperature, performing centrifugal separation, and cleaning until no sulfate radical is detected by using deionized water; and 4, drying and roasting the centrifuged precipitate, thereby obtaining the catalyst. The metallic oxide catalyst is in the range of 200-500 DEG C, and the purification efficiency of nitric oxide is 71-100 percent; and the composite oxide catalyst has high high-altitude-resistant speed and good alkali-resistant metal poisoning performance, the efficiency is greatly improved, and the operating cost can be obviously reduced.

Owner:江苏中创清源科技有限公司

Hydrolytic agent for treating wastewater containing tetrafluoroborate and application thereof

ActiveCN102336460BImprove hydrolysis effectWide range of application conditionsWater contaminantsWater/sewage treatmentAluminium chlorideTetrafluoroborate

Owner:CHINA PETROLEUM & CHEM CORP

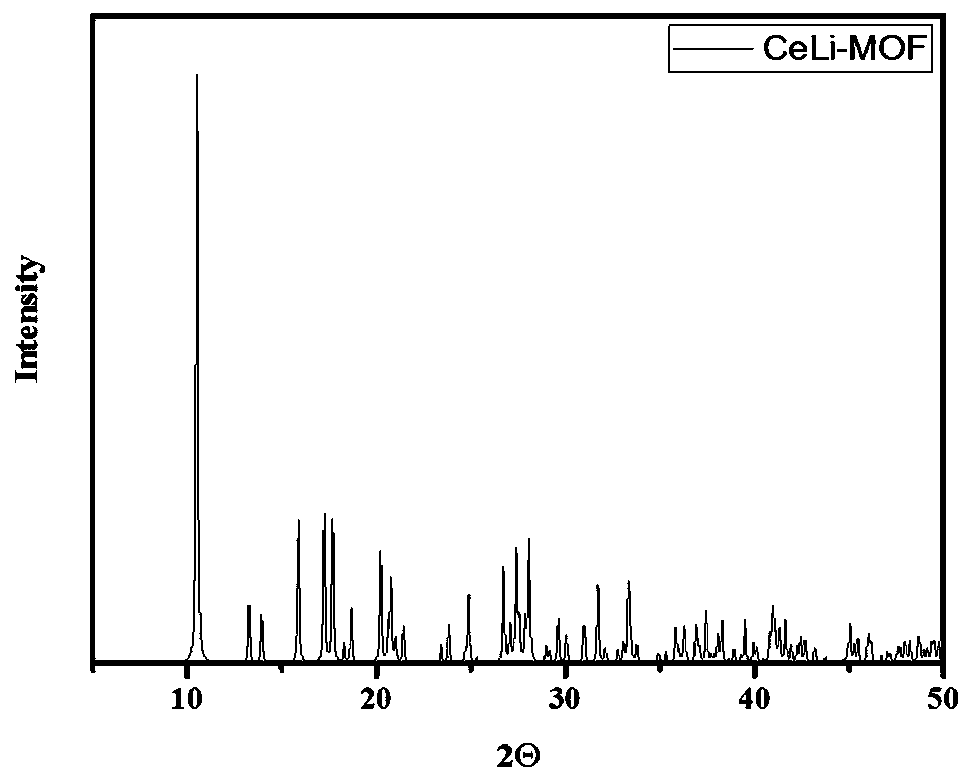

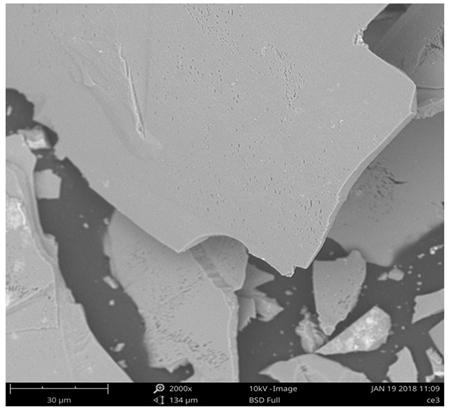

Preparation method of Ce-Li-MOF lithium ion battery negative electrode material and application in lithium ion battery preparation thereof

InactiveCN109867796AStable structureNovel structureFinal product manufactureCell electrodesAir atmosphereLithium hydroxide

The invention belongs to the field of functional material preparation, and specifically relates to a preparation method of a Ce-Li-MOF lithium ion battery negative electrode material and an application in the lithium ion battery preparation thereof. The method is implemented in the following steps: (1) dispersing pyromellitic acid, cerium sulfate and lithium hydroxide in an aqueous solution, placing the above aqueous solution in a reaction kettle, and performing stirring under the air atmosphere at room temperature to obtain an orange-brown slurry material; (2) transferring the product obtained in step (1) to a high pressure reaction kettle, performing a heating reaction, and performing natural cooling to room temperature to obtain pale-yellow transparent crystals; and (3) washing the product obtained in step (2) with deionized water, and performing drying under natural conditions to obtain the Ce-Li-MOF lithium ion battery negative electrode material. The method has good reproducibility, the morphology structure of the target product is ideal, and the prepared button battery has outstanding electrochemical performances.

Owner:SHENYANG POLYTECHNIC UNIV

Catalysts used in production of promoter 2,2'-dithiobisbenzothiazole, and preparation method thereof

InactiveCN102350350AEasy to prepareEasy to industrializeOrganic chemistryMolecular sieve catalystsCerium nitrateCopper nitrate

The invention relates to catalysts used in the production of a promoter 2,2'-dithiobisbenzothiazole, and a preparation method of the catalysts. The catalysts can be one or more selected from metal salts of copper acetate, copper sulfate, copper nitrate, cobalt acetate, cobalt sulfate, cobalt nitrate, cerium acetate, cerium sulfate, cerium nitrate, chrome acetate, chrome sulfate, chrome nitrate, and the like. Carriers of the catalysts can be one or more selected from SiO2, Al2O3, TiO2, mesoporous material molecular sieve, microporous material molecular sieve, and the like. Prepared catalysts are used in a reaction for synthesizing DM by using an oxygen oxidizing method, and the reaction is used for representing performances of the catalysts, wherein a catalyst dosage is 0.01 to 0.1% of the reactant by weight. The catalysts provided by the invention are advantaged in reasonable formulation, low dosage, and good catalytic effect. The catalysts contain active components and carriers. Dispersion areas of the active components are enlarged, such that contact areas between the active components and the reactants are enlarged. Therefore, reaction speed is improved, and the catalyst dosage is reduced. Also, reaction conditions are optimized, such that the yield of DM is higher than 98%.

Owner:KEMAI CHEM

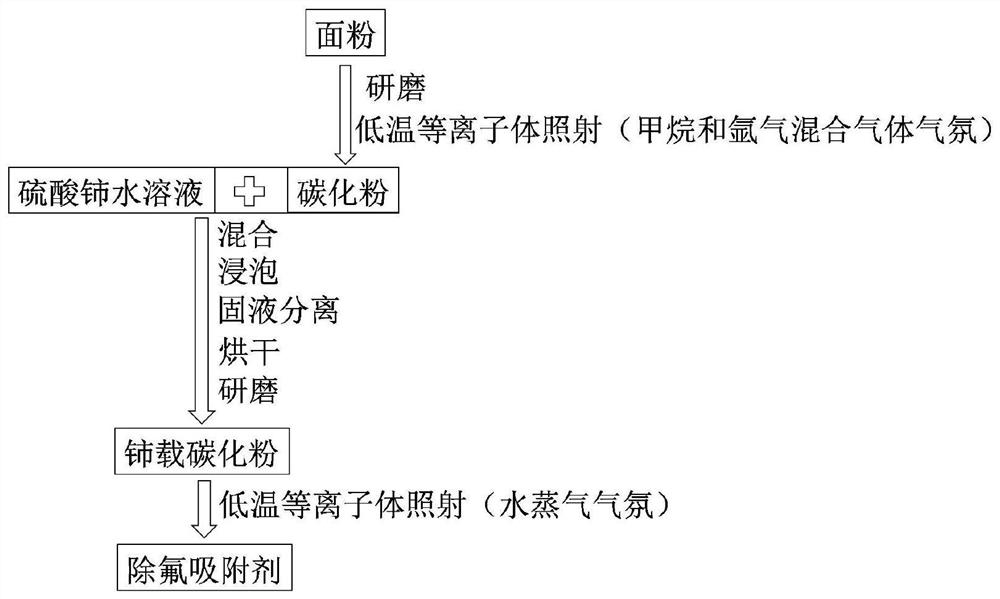

Preparation method of defluorination adsorbent based on flour

ActiveCN111821948AWide pH rangeIncrease optionalityOther chemical processesWater contaminantsSorbentCarbonization

The invention discloses a preparation method of a defluorination adsorbent based on flour. The preparation method comprises the following steps: (1) carrying out low-temperature plasma irradiation onthe flour to obtain carbonized powder; (2) mixing the carbonized powder with a cerous sulfate aqueous solution, soaking, carrying out solid-liquid separation, drying the solid part, and grinding to obtain cerium-loaded carbonized powder; and (3) carrying out low-temperature plasma irradiation on the cerium-loaded carbonized powder to obtain the defluorination adsorbent. The low-temperature plasmatechnology is applied to convert flour into the defluorination adsorbent so that the selectivity of the carbon precursor is broadened, and the method is not limited to selection of biomass materials with certain hardness or relatively stable plant cell wall structures any more; the preparation process is simple, and a stable high-temperature environment does not need to be maintained in the preparation process; the prepared fluorine removal adsorbent is wide in pH application range (1-13) and high in fluorine ion selectivity, and the maximum adsorption capacity can reach 246mg / g.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

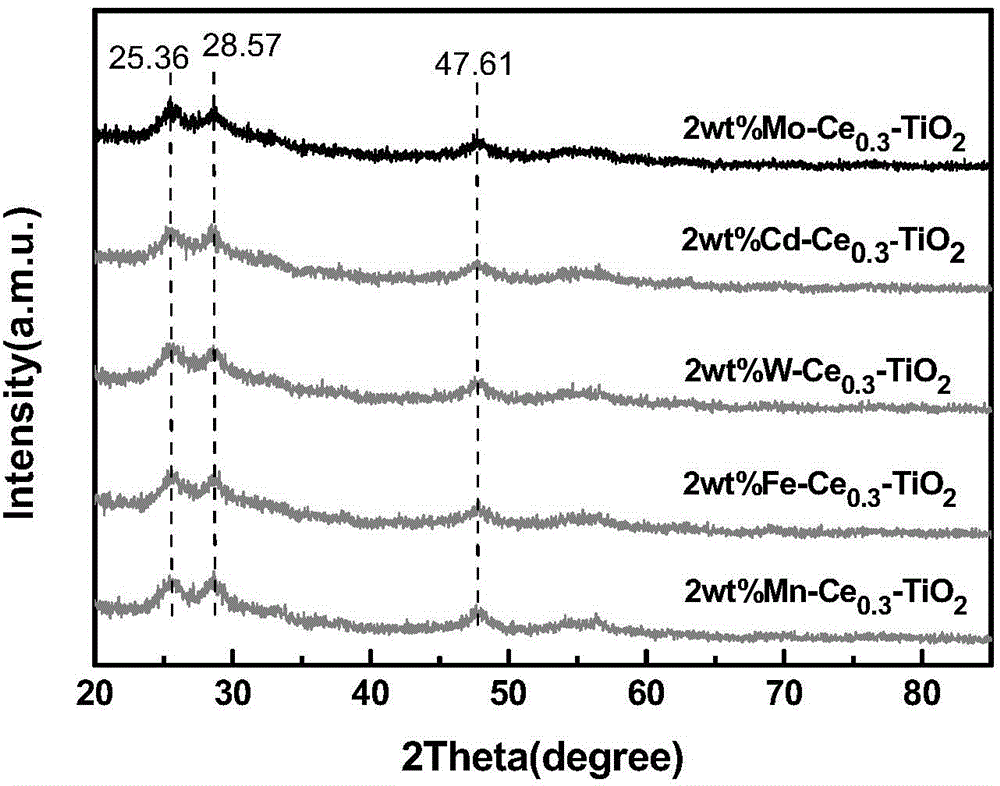

Catalyst for FCC regeneration flue gas denitration, preparation method and application thereof

InactiveCN104645974AGood activity at low temperatureEfficient use ofDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateEvaporation

The invention relates to a catalyst for FCC regeneration flue gas denitration, a preparation method and an application of the catalyst. The catalyst contains a titanium-cerium bimetal composite oxide carrier and an active component transition metal oxide loaded on the surface of the carrier, wherein the molar ratio of cerium to titanium atoms is 0.1-0.5, and the transition metal oxide is any one or a mixture of at least two of manganese oxide, iron oxide, molybdenum oxide, tungsten oxide or cadmium oxide. According to the method, by taking tetrabutyl titanate and the like as a titanium source, cerium nitrate or cerium sulfate and the like as a cerium source, and transition metal salt, deionized water, ethanol and concentrated hydrochloric acid as raw materials simultaneously, the steps of solution stirring and mixing, air evaporation self-assembling, drying and roasting, and the like are carried out, the molding intensity of the catalyst is improved by further adopting an end hardening technology preferably. The catalyst provided by the invention is relatively short in preparation time and relatively high in low temperature reactivity when being used in regeneration flue gas denitration SCR reaction, and is high in dust washing resistance and good in application prospect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

Simultaneous process of electroreducing ytterbium and oxidizing cerium

InactiveCN1986895APrevent volatilizationPrevent dispersalPhotography auxillary processesProcess efficiency improvementCeriumIon-exchange membranes

The present invention is one electrolytic process of reducing Yb, enriching Tu and Lu, and oxidizing Ce simultaneously. The electrolytic process reduces Yb into bivalent Yb ion in the cathode chamber so as to separate out Yb from the enriched Yb, Tu and Lu; oxidizes Ce into four-valent ion so as to separate out Ce. The electrolytic equipment has cathode of metal mercury or amalgam, anode of inert metal, anion exchange membrane to separate the anode chamber from the cathode chamber, cathode solution of sulfuric acid solution of pH 0.1-4.0 with enriched Yb, Tu and Lu, and anode solution of sulfuric acid solution of acidity 0.01-3.0 mol / L with enriched Ce. The present invention has low production cost, best utilization of electrolytic current and other advantages.

Owner:北京方正稀土科技研究所有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com