Methyl sulfonate tinning electrolyte and tinning method of steel strip or steel plate

A technology of methanesulfonate and stannous methanesulfonate, which is applied in the field of methanesulfonate tin plating electrolyte, to achieve the effects of inhibiting crystal growth, enhancing throwing ability, and reducing the degree of harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

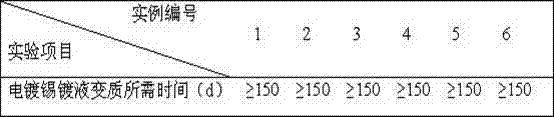

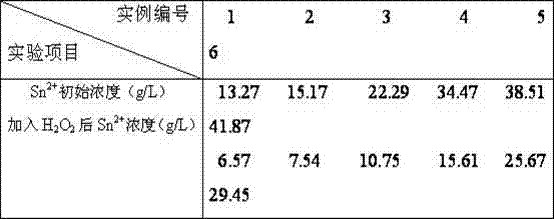

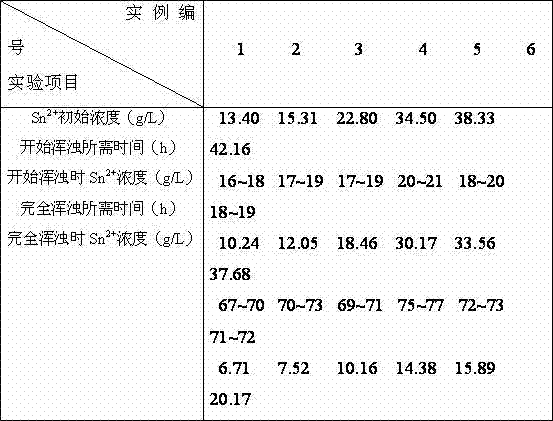

Examples

Embodiment 1

[0021] First, pre-clean and pickle the pre-plated sample (according to the "Ferrostan (Ferrostan)" method). The samples are reflowed, passivated, and the tin layer is oiled after treatment. Plating temperature 20°C, current density 6 A / dm 2 , the speed of the cathode conveyor belt is 3m / s. When preparing the electrolyte, clean the plating tank with tap water and deionized water respectively, then add 1 / 2 volume of deionized water, add methanesulfonic acid, stannous methanesulfonate, cerium sulfate, methanesulfonic acid, Hydroquinone, catechol, benzylidene acetone, glutaraldehyde, OP, sodium dodecylsulfonate; then, add deionized water to the specified volume, stir well and then electroplating. The formula of the electrolyte is as follows:

Embodiment 2

[0023] Plating temperature 25°C, current density 8A / dm 2 , the speed of the cathode conveyor belt is 3m / s, and others are the same as in Example 1. The formula of the electrolyte is as follows:

Embodiment 3

[0025] Plating temperature 30°C, current density 10A / dm 2 , the speed of the cathode conveyor belt is 3m / s, and others are the same as in Example 1. The formula of the electrolyte is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com