Patents

Literature

3817results about How to "Fine grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for wound, cavity, and bone treatment

InactiveUS20100030132A1Quicker wound closureSafer wound care environmentElectrolysis componentsCannulasNeed treatmentBiomedical engineering

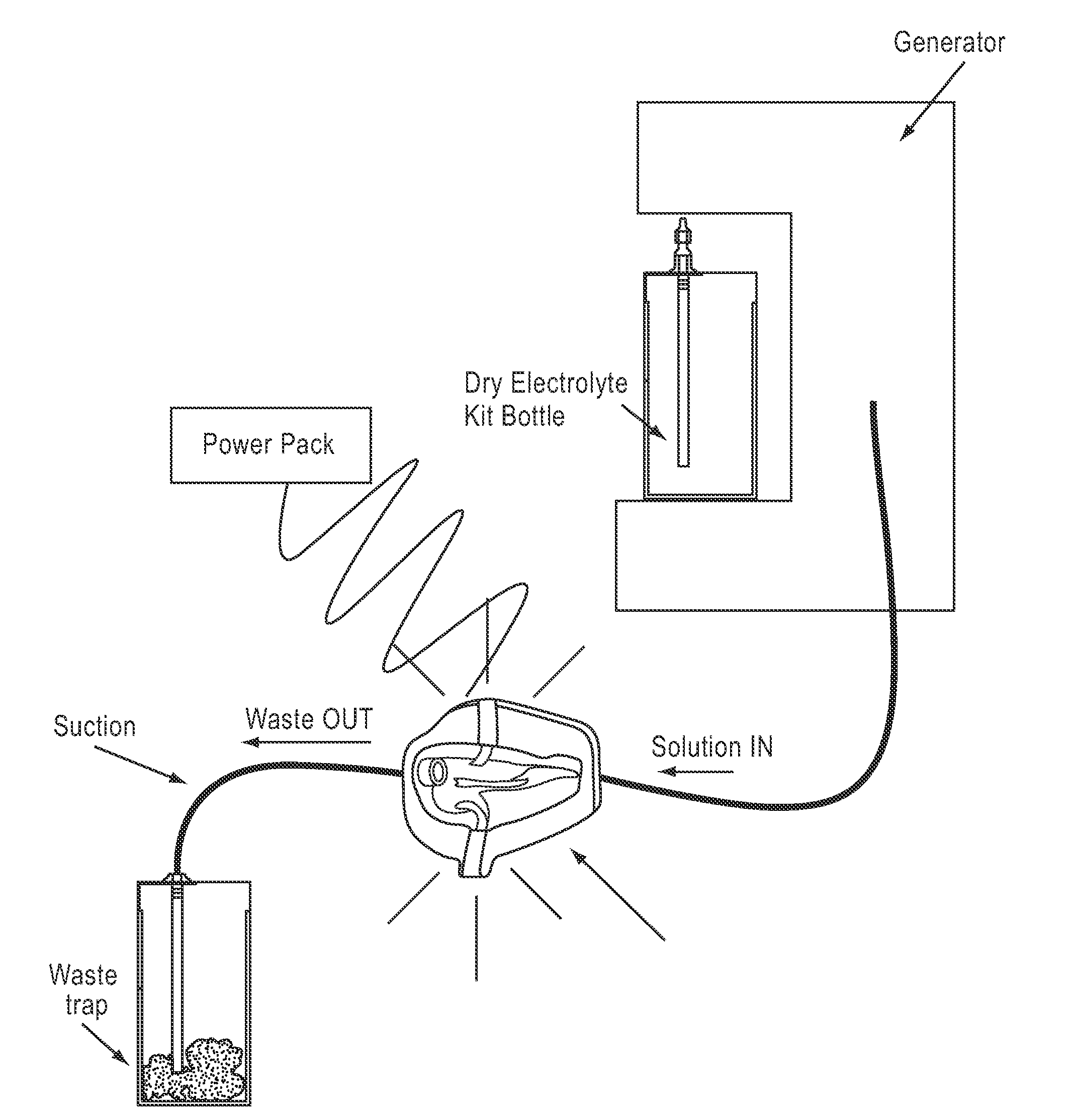

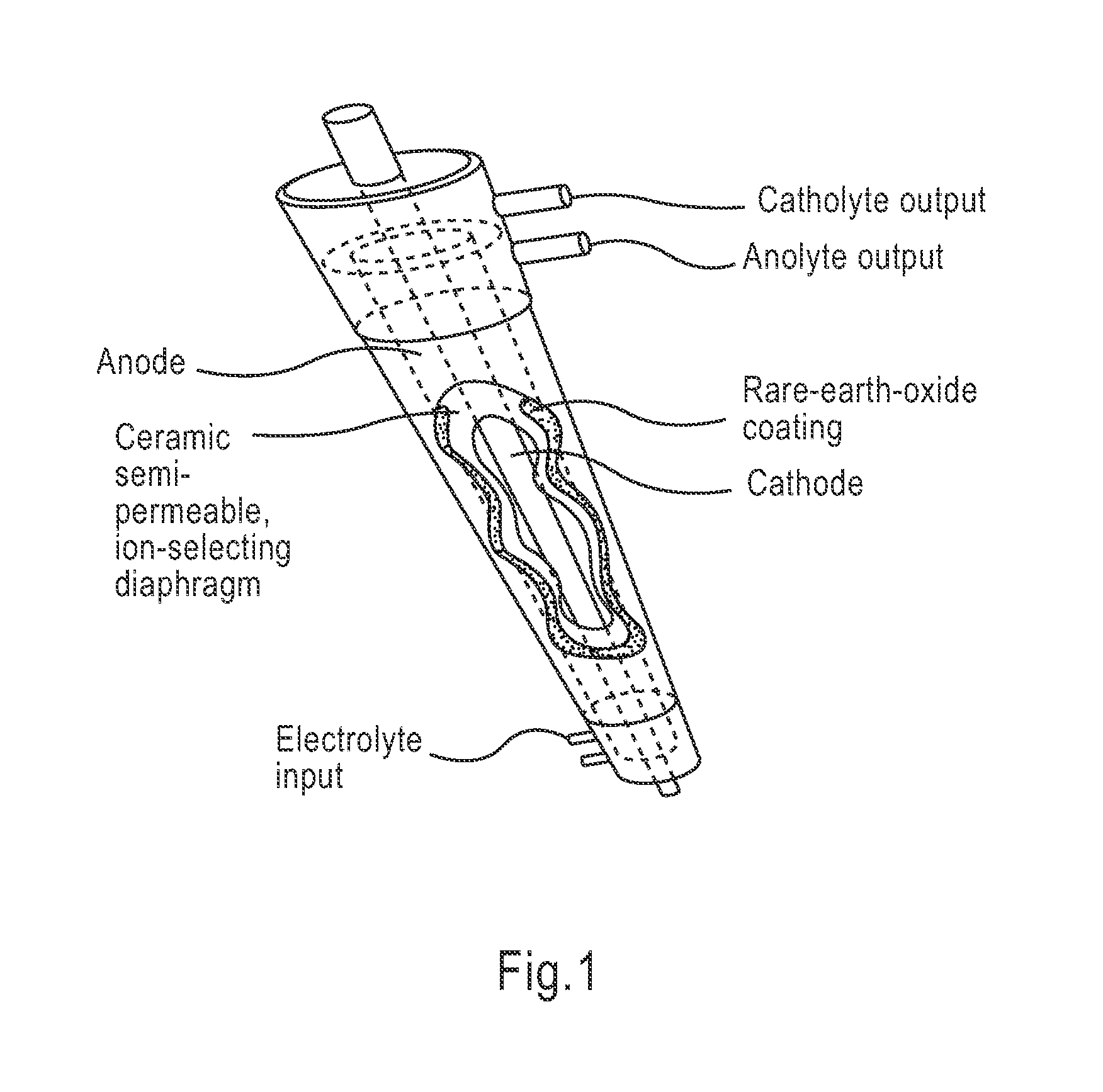

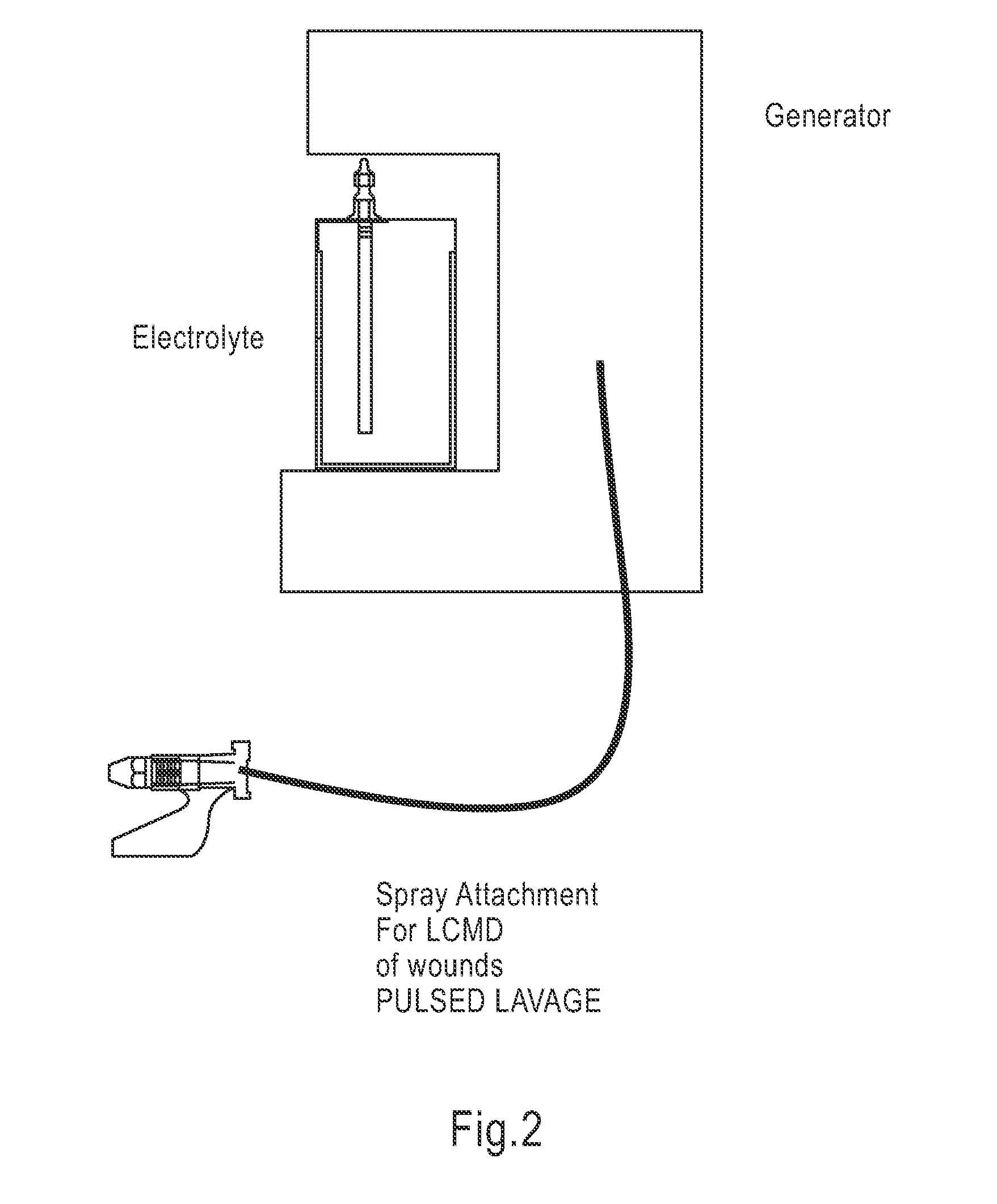

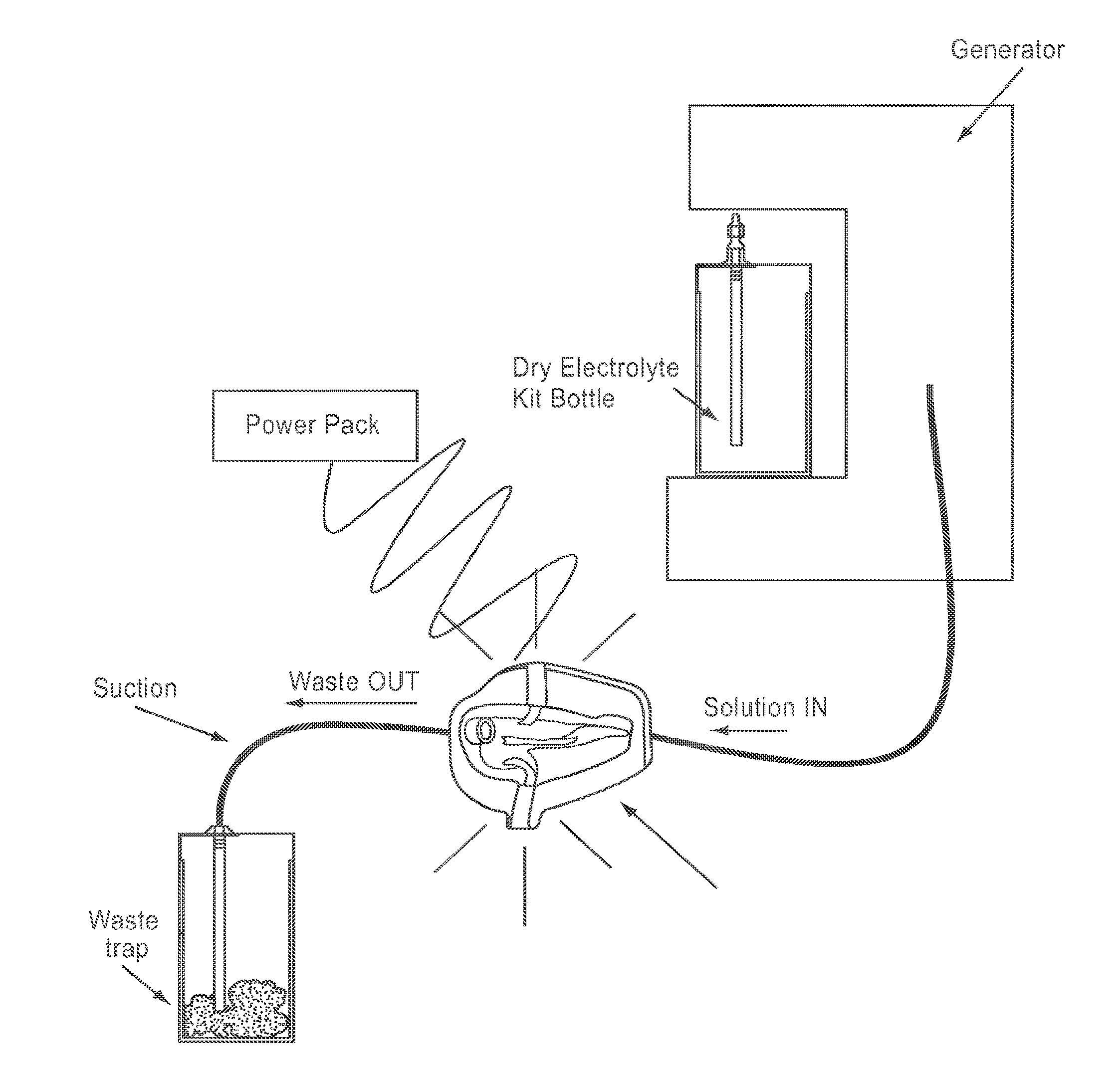

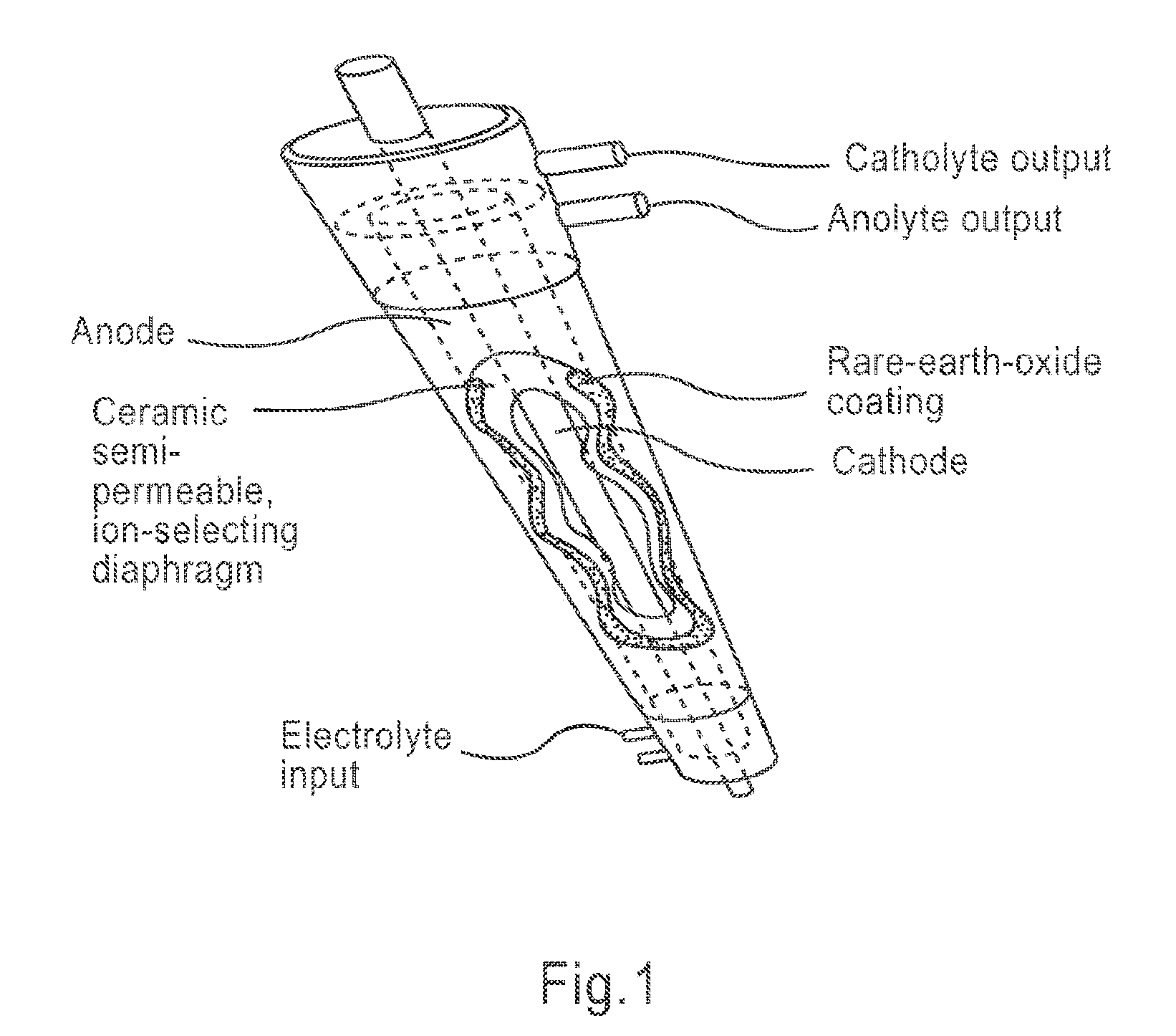

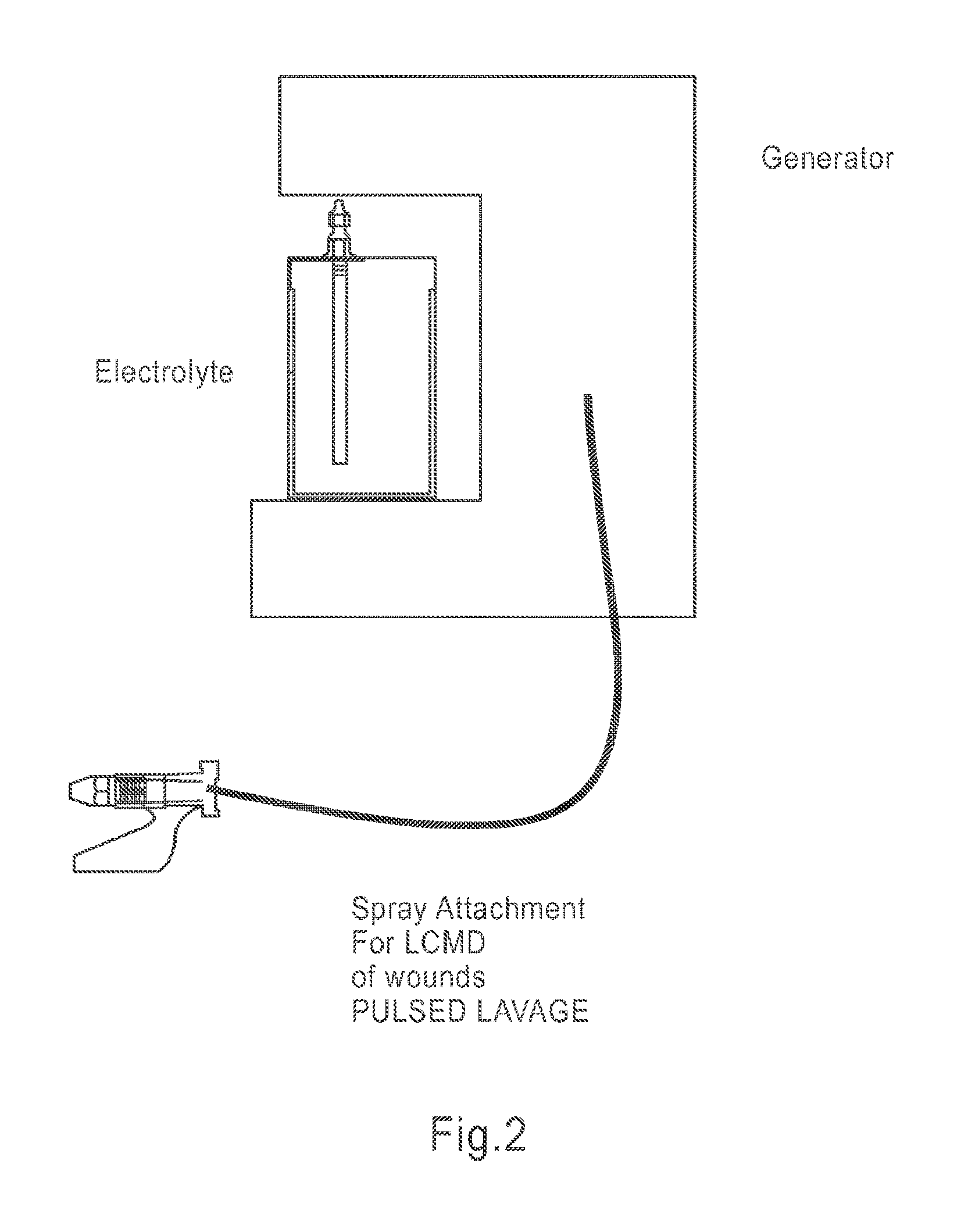

The present invention provides a treatment apparatus. The apparatus contains a reservoir or generator for a treatment solution, a mechanism for delivering the treatment solution to a wound site, and a mechanism for applying the solution to a wound, tissue, bone or surgical cavity for treatment. The apparatus may apply the solution (e.g., a solution containing hypohalous acid) with, for example, an occlusive wound dressing, pulsative lavage device, hydrotherapy, hydrosurgical device, and / or ultrasound. A waste container may be operably connected to the apparatus for collecting waste from the wound by run-off, or by applying negative pressure (e.g. a vacuum). Because the apparatus of the invention can optionally be portable or mobile, the invention is suitable for use in hospitals and nursing homes, as well as for home wound care. The invention also provides a method for treating a wound (or other area needing treatment), and / or for reducing wound bioburden, by supplying a hypochlorous acid solution to the site, such as a wound colonized or infected with drug resistant bacteria, before, during, or after negative pressure wound therapy.

Owner:PURICORE

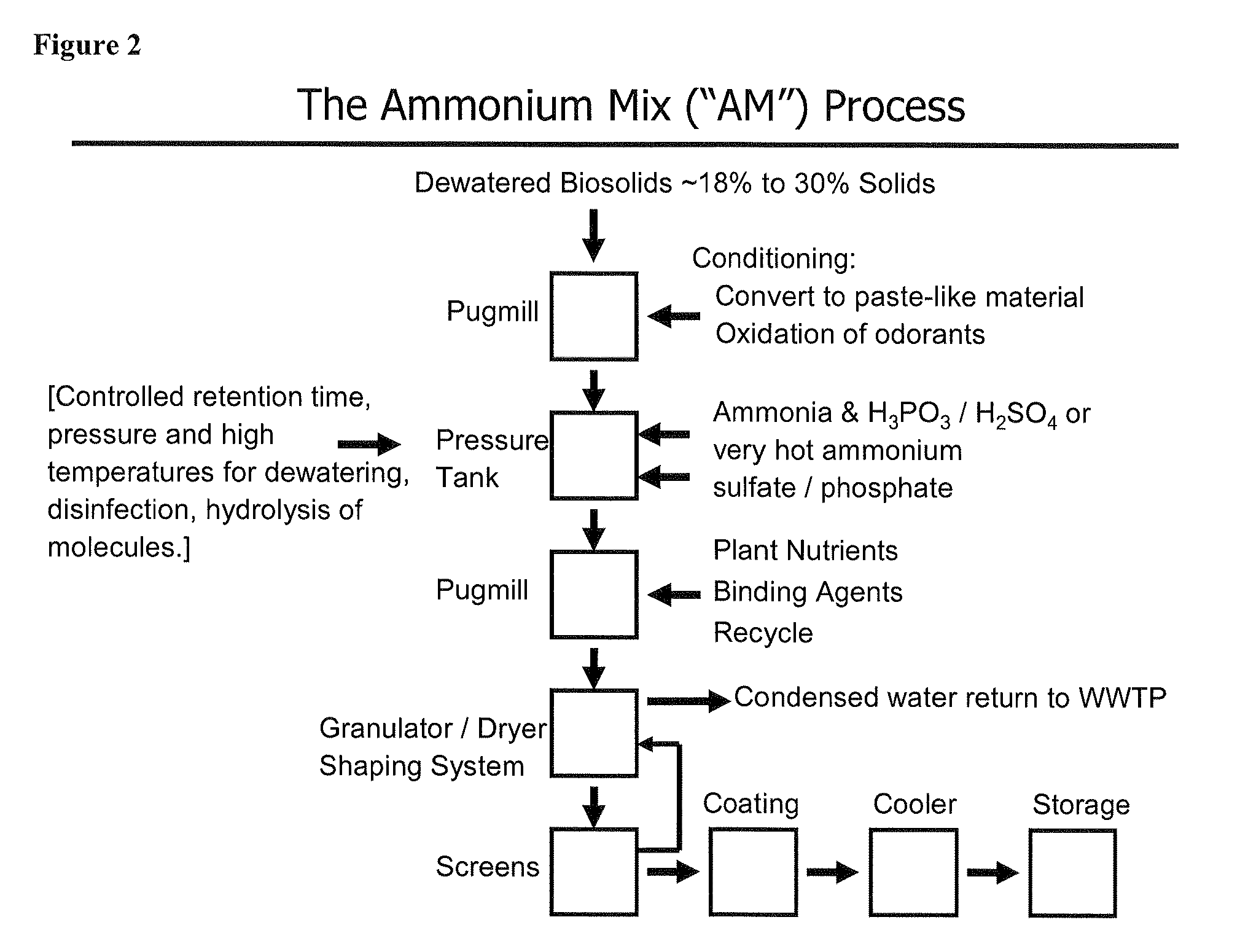

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS20080230484A1Reduce logisticsReduces liabilityByproduct vaporizationExcrement fertilisersPhosphateRetention time

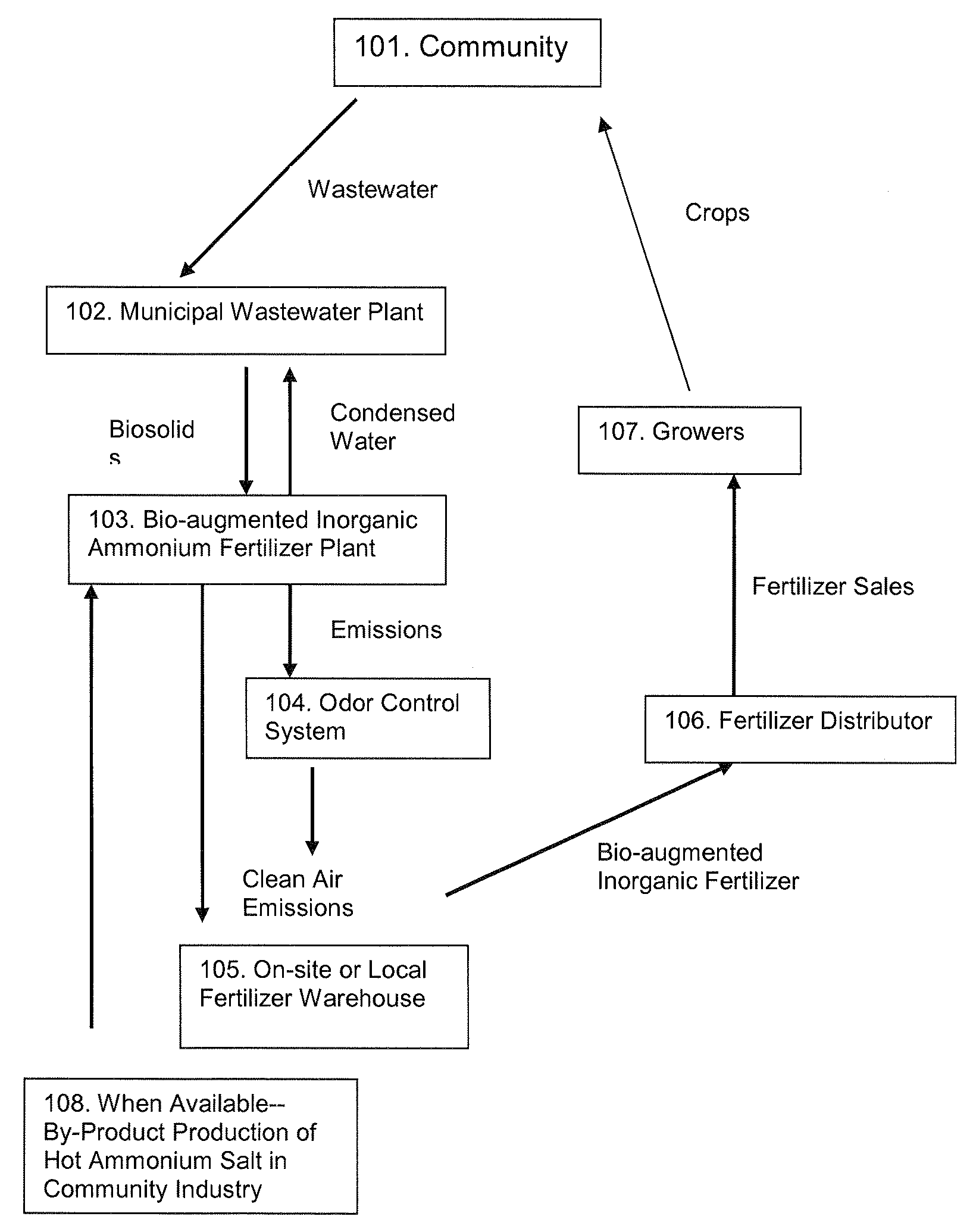

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

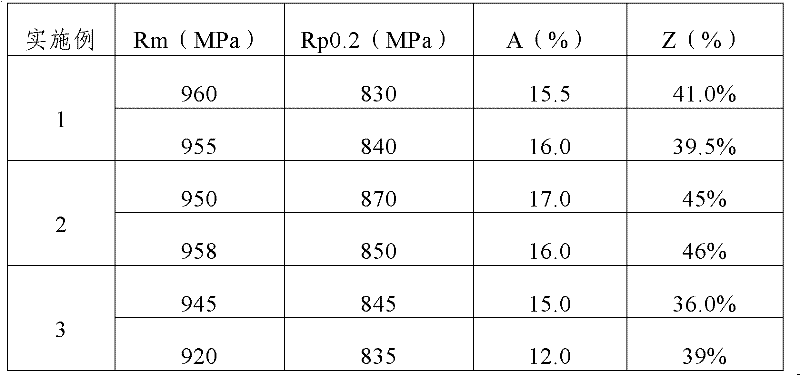

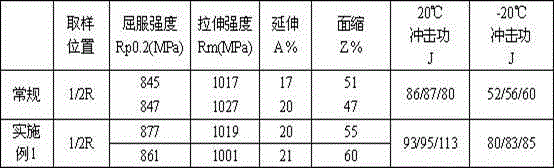

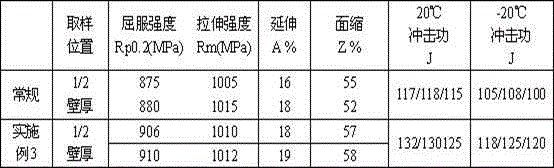

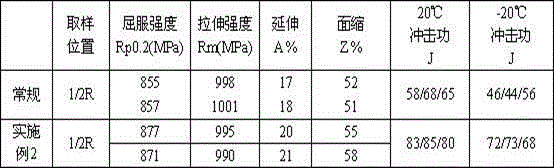

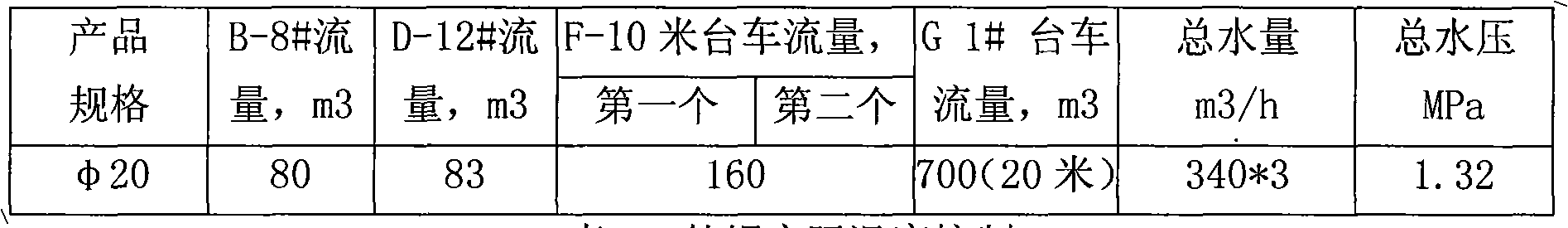

Processing method for TC4 titanium alloy large-sized bar

The invention discloses a processing method for a TC4 titanium alloy large-sized bar. The method comprises the following steps of: cogging and forging TC4 titanium alloy ingots for 2 to 3 heating times to obtain forging billets; 2, upsetting the forging billets repeatedly and performing drawing-out forging for 2 to 3 heating times; 3, upsetting the forging billets subjected to forging repeatedly and performing drawing-out forging for 3 to 5 heating times; and 4, performing chamfering round forging on the forging billets subjected to forging for 2 heating times to obtain the TC4 titanium alloy large-sized bar with the diameter of 200 to 400 mm and length of not less than 2,500 mm. The TC4 titanium alloy bar processed by the method has uniform and fine grains, few internal defects and high safety and accords with the domestic advanced level of the like products. In the processed TC4 titanium alloy bar, the room-temperature tensile strength is 920 to 960 MPa; the yield strength is 830 to 870 MPa; the elongation percentage is not less than 12 percent; the contraction ratio of the cross section is not less than 36 percent; flaw detection clutter reflects small signals; and the flaw detection level is high.

Owner:WESTERN TITANIUM TECH

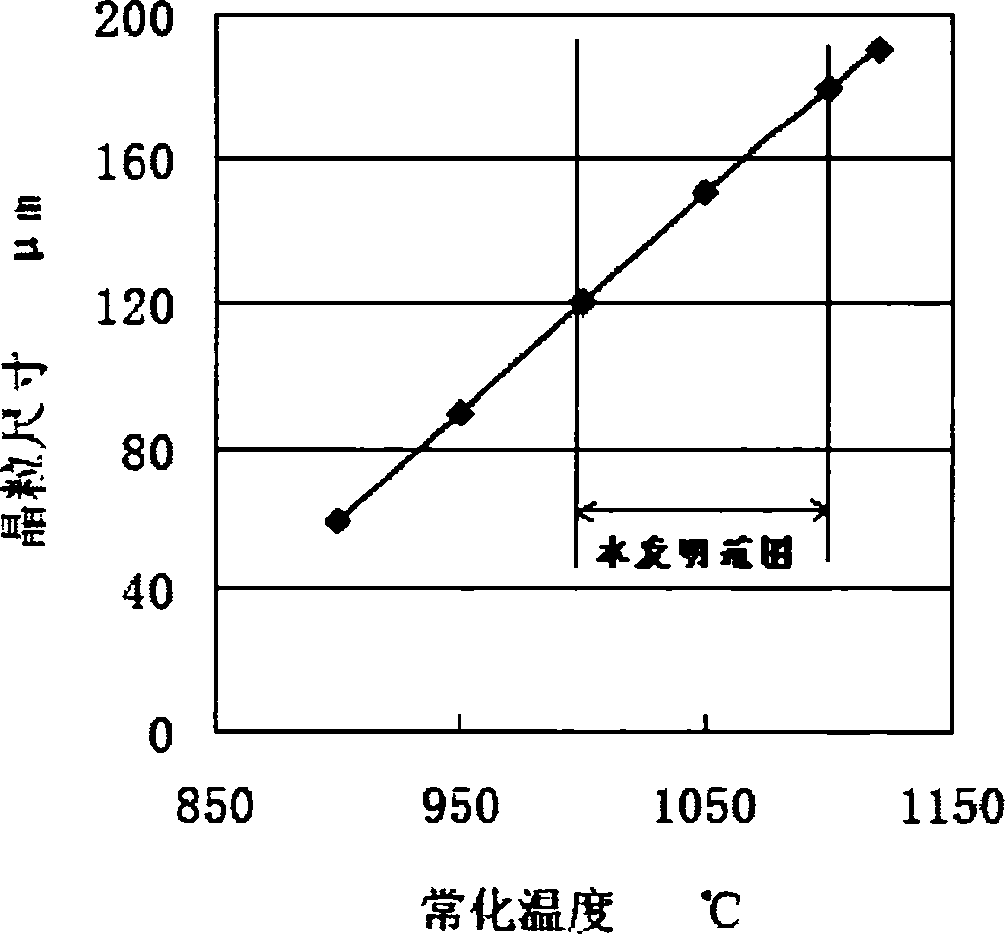

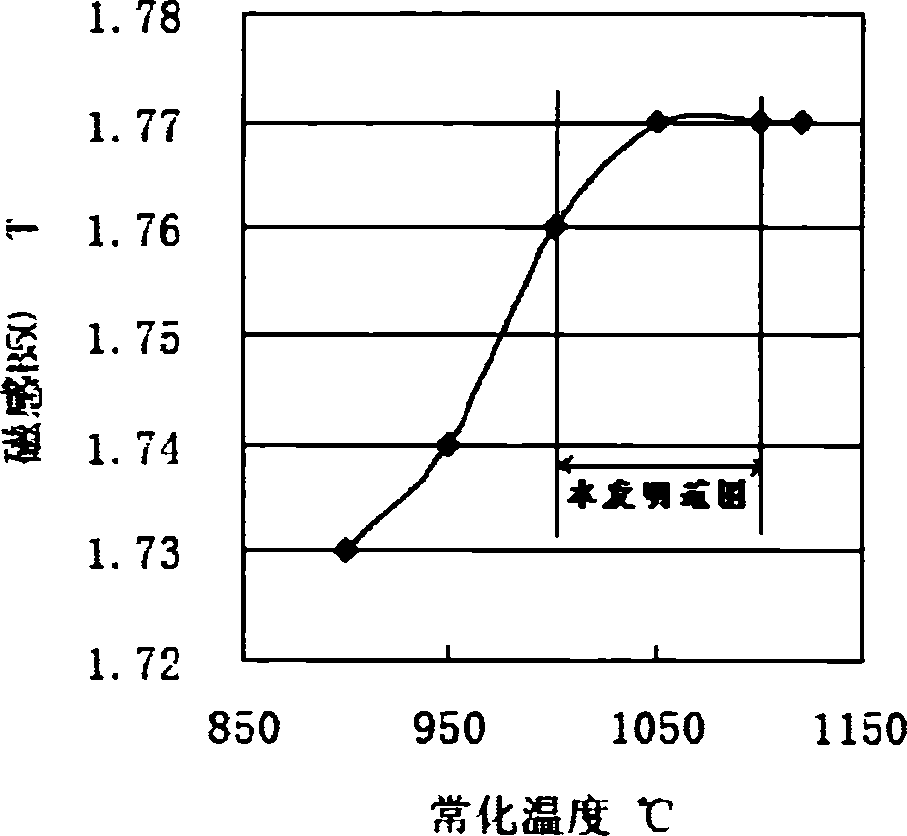

Production process of cold rolled orientation-free electrical steel plate with low iron loss and high magnetic induction

ActiveCN1887512ALow investment costReduce operating costsOther manufacturing equipments/toolsElectrical steelImpurity

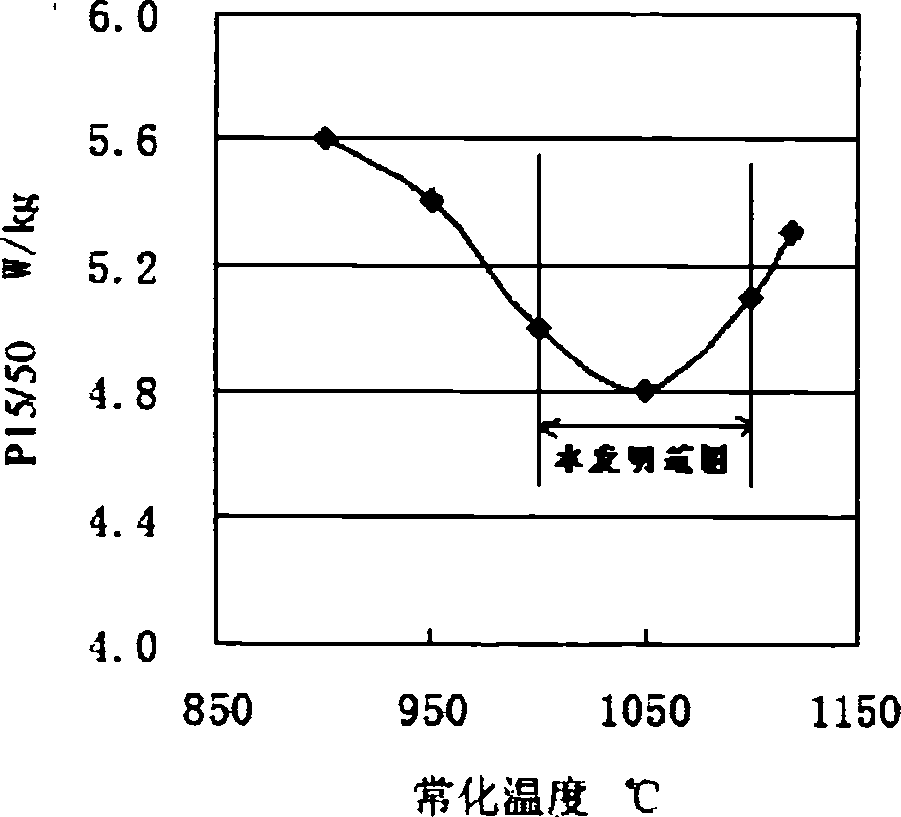

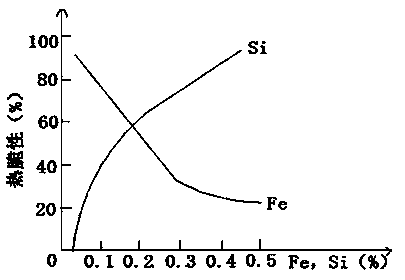

The production process of cold rolled non-orientation electric steel plate comprising C not more than 0.0050 wt%, Si not more than 2.50 wt%, Al not more than 1.0 wt%, Si+2Al not more than 2.50 wt%, Mn 0.10-1.50 wt%, P not more than 0.20 wt%, S not more than 0.005 wt%, N not more than 0.0025 wt%, Sn+Sb not more than 0.2 wt%, and Fe and inevitable impurities for the rest includes the following steps: 1. smelting, continuous casting and rolling; 2. normalizing treatment of the hot rolled plate through heating at heating rate of 5-15 deg.c / s to over Ac1, heat soaking at 1100 deg.c below for 10-90 s, cooling in two stages including cooling at the cooling rate belw 15 deg.c / s to below 650 deg.c and cooling at the cooling rate capable of ensuring the plate form to below 80 deg.c; 3. cold rolling; and 4. final annealing to form the cold rolled non-orientation electric steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and making method thereof

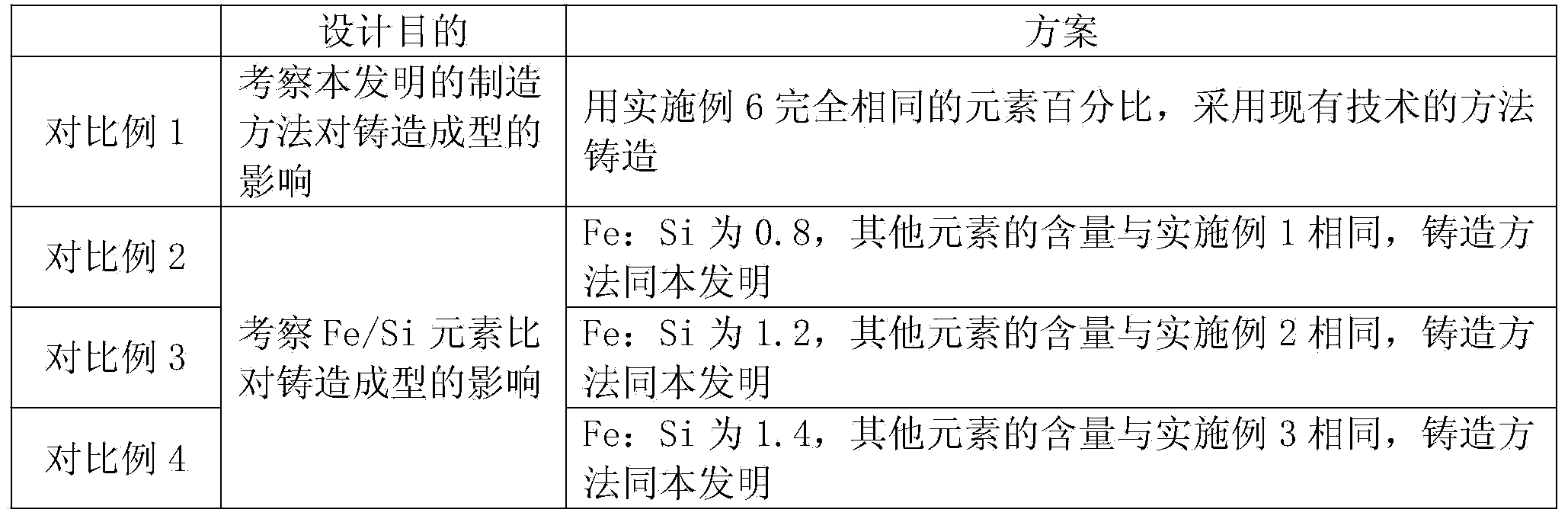

The invention discloses an ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and a making method thereof, and belongs to the aluminum alloy making field. The flat cast ingot comprises, by mass, 2.0-2.4% of Cu, 1.95-2.5% of Mg, 5.5-9.0% of Zn, 0.08-0.15% of Zr, 0.0003-0.0015% of Be, below 0.06% of Ti, below 0.04% of Cr, below 0.10% of Mn, 0.085% or less of Si, 0.14% or less of Fe, and the balance Al and inevitable elements, wherein the content of each of the inevitable elements is lower than 0.05%, the total amount of the inevitable elements is lower than 0.15%, and a content ratio of Fe to Si is not less than 1.6. The making method disclosed in the invention improves traditional making methods, and does not need pure aluminum bottoming, and the flat cast ingot made in the invention has the advantages of large size, high strength, no cracks, and high casting success rate.

Owner:广西南南铝加工有限公司

Method for smithing GH4169 alloy plate shaped forgeable piece in air at an approximately equal temperature

ActiveCN101036931AGrain refinementHigh strengthForging/hammering/pressing machinesWheelsRoughcastCrystallite

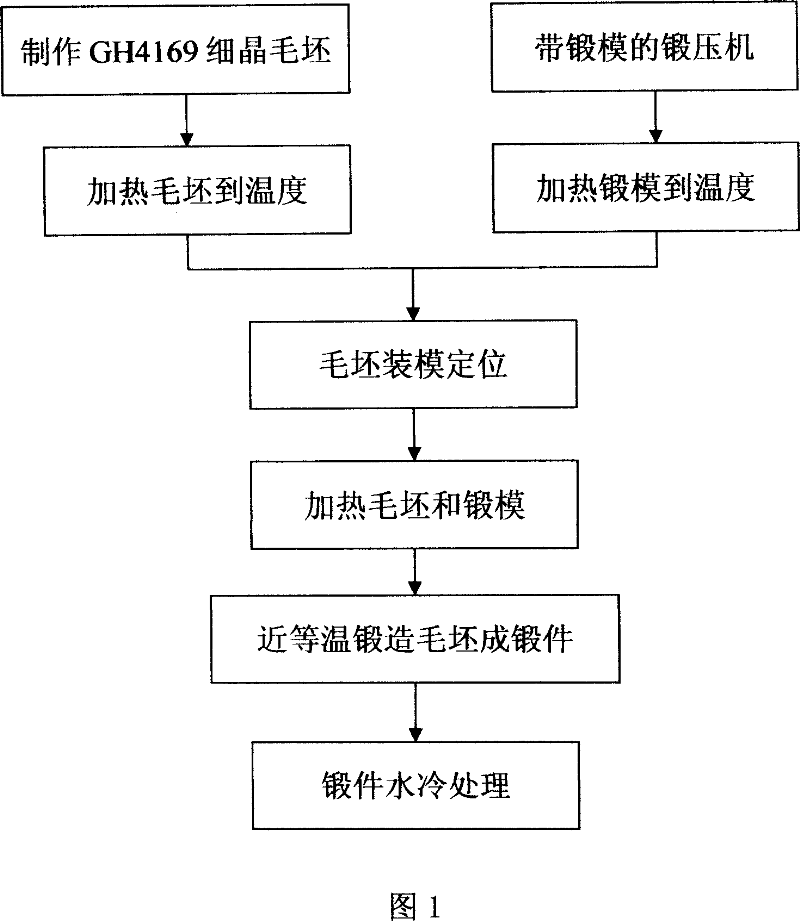

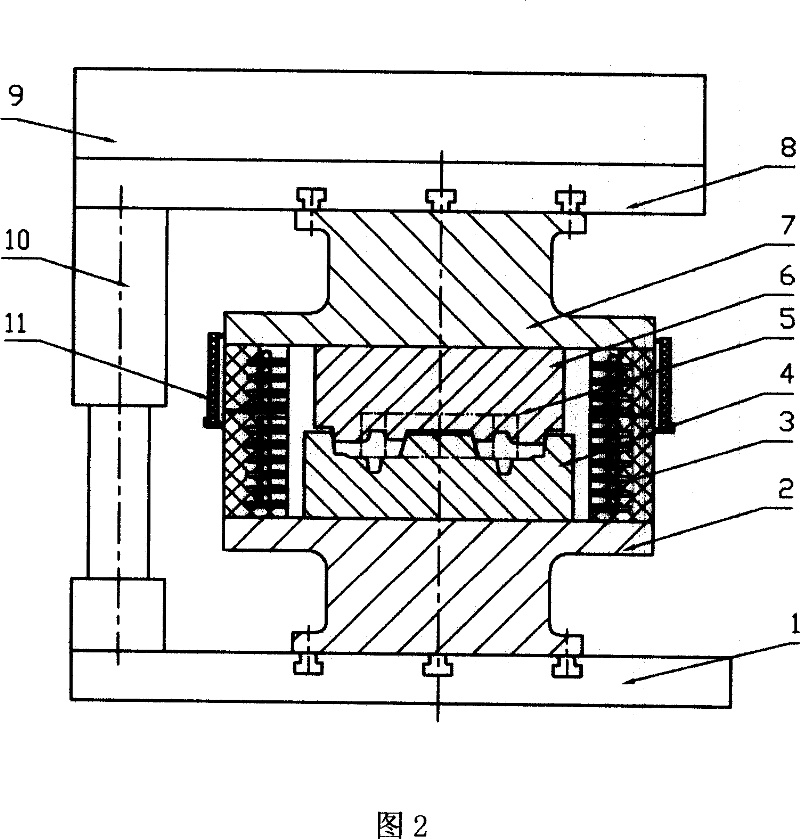

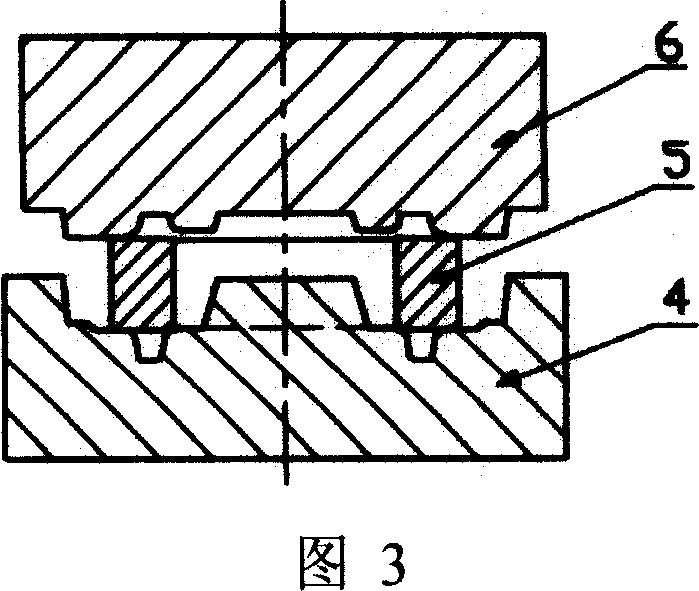

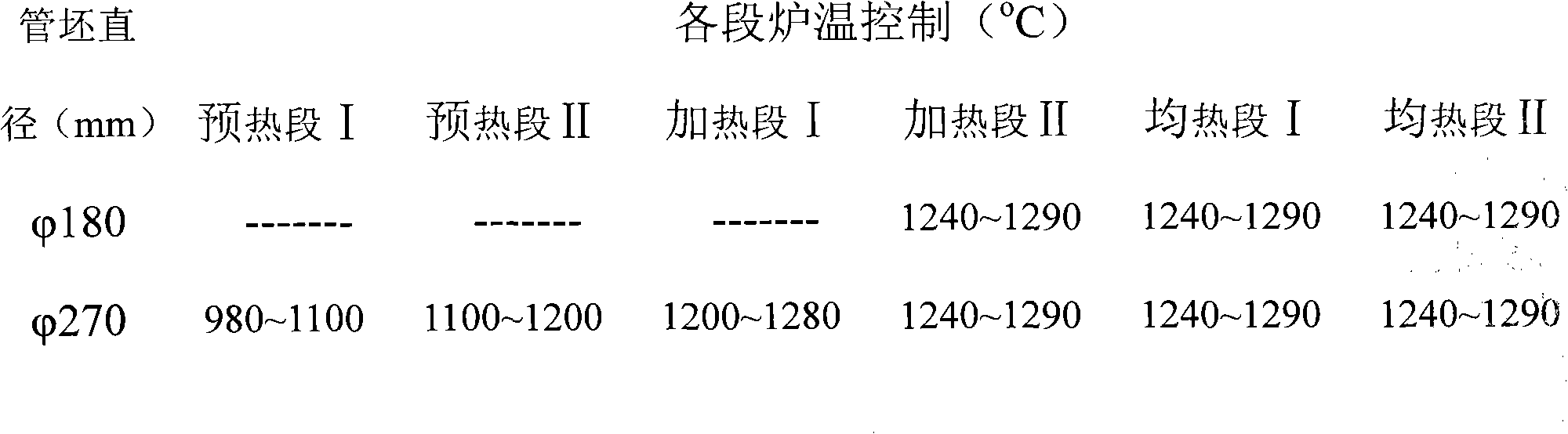

The invention discloses a close isothermal forging method of GH4169 alloy tray-shaped forging in the air, the technological process is that: making GH4169 finegrain roughcast adopting method of upsetting, punching and rolling after heating GH4169 alloy original rod material to 995-1005 DEG C; respectively heating the finegrain roughcast to 995-1005 DEG C and forging die to 950-965 DEG C; diefilling and positioning the finegrain roughcast; while heating finegrain roughcast and forging die to keep the heating warm humidity; forging die and forging press the finegrain roughcast forming under the 55MN to 65MN forging pressure and 0.01s-1 to 0.05s-1 strain rate; obtaining the tray-shaped forging; water-cool processing the tray-shaped forging. Adopting forging method of the invention can realize forming of the GH4169 alloy material tray-shaped forging difficult to deform and obtain the GH4169 alloy tray-shaped forging with weensy crystal grain, high intensity and complicated shape.

Owner:GUIZHOU ANDA AVIATION FORGING

Rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and production method thereof

InactiveCN102251180ALow elemental contentReduce residual stressDrilling rodsProcess efficiency improvementRare earthFlame cutting

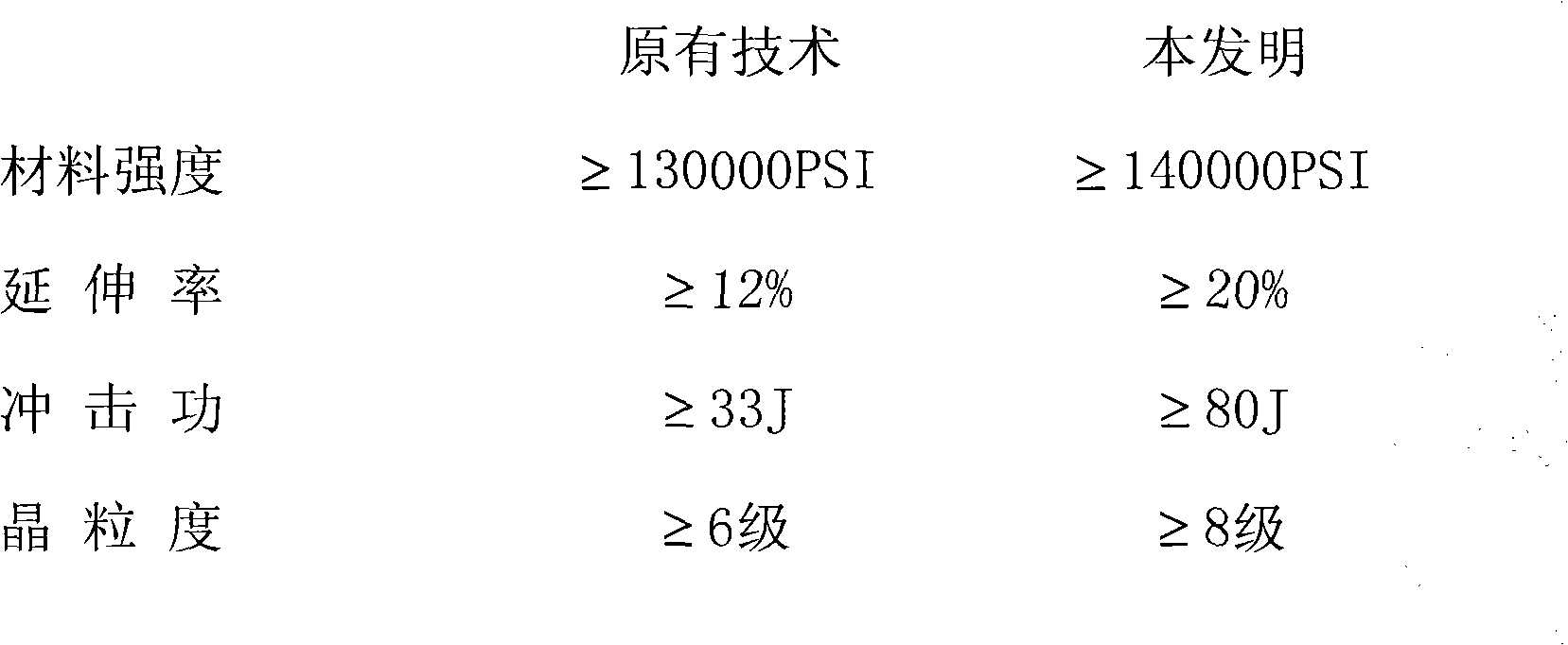

A rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and a production method thereof belong to the technical fields of ferrous metal smelting and metal press working. The petroleum casing comprises the following raw materials by weight percent: 90% of blast furnace molten iron and 10% of high quality steel scrap. The casing blank comprises the following chemical components by weight percent: 0.18-0.35% of C, 0.10-0.35% of Si, 0.55-1.10% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.60-1.10% of Cr, 0.15-0.50% of Mo, 0.01-0.03% of Al, 0.0005-0.0100% of RE ( RE is the mixed rare earth metals of Ce and La and the weight percents of Ce and La are 67% and 33% respectively), less than 0.10% of Cu, less than 0.10% of Ni and the balance of Fe and trace elements. The process flow of the production method is as follows: pretreating molten iron, smelting in a top-bottom blowing converter, refining in a ladle furnace (LF), performing VD vacuum treatment, performing continuous casting of round billets, performing flame cutting, heating the casing blanks, boring, performing continuous rolling, performing sizing and diameter reducing, cooling, performing saw cutting, performing heat treatment, straightening, performing flaw inspection and lathing screw threads. The mechanical properties of the petroleum casing are as follows: the strength is no less than 140000PSI, the residual stress is no more than 80MPa, the impact power is no less than 80J and the grain size is no less than the grade 8. The product is characterized in that the residual stress is low, the content of harmful elements is low, the impact toughness is high, the grains are small, and the product resists extrusion and is difficult to damage.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

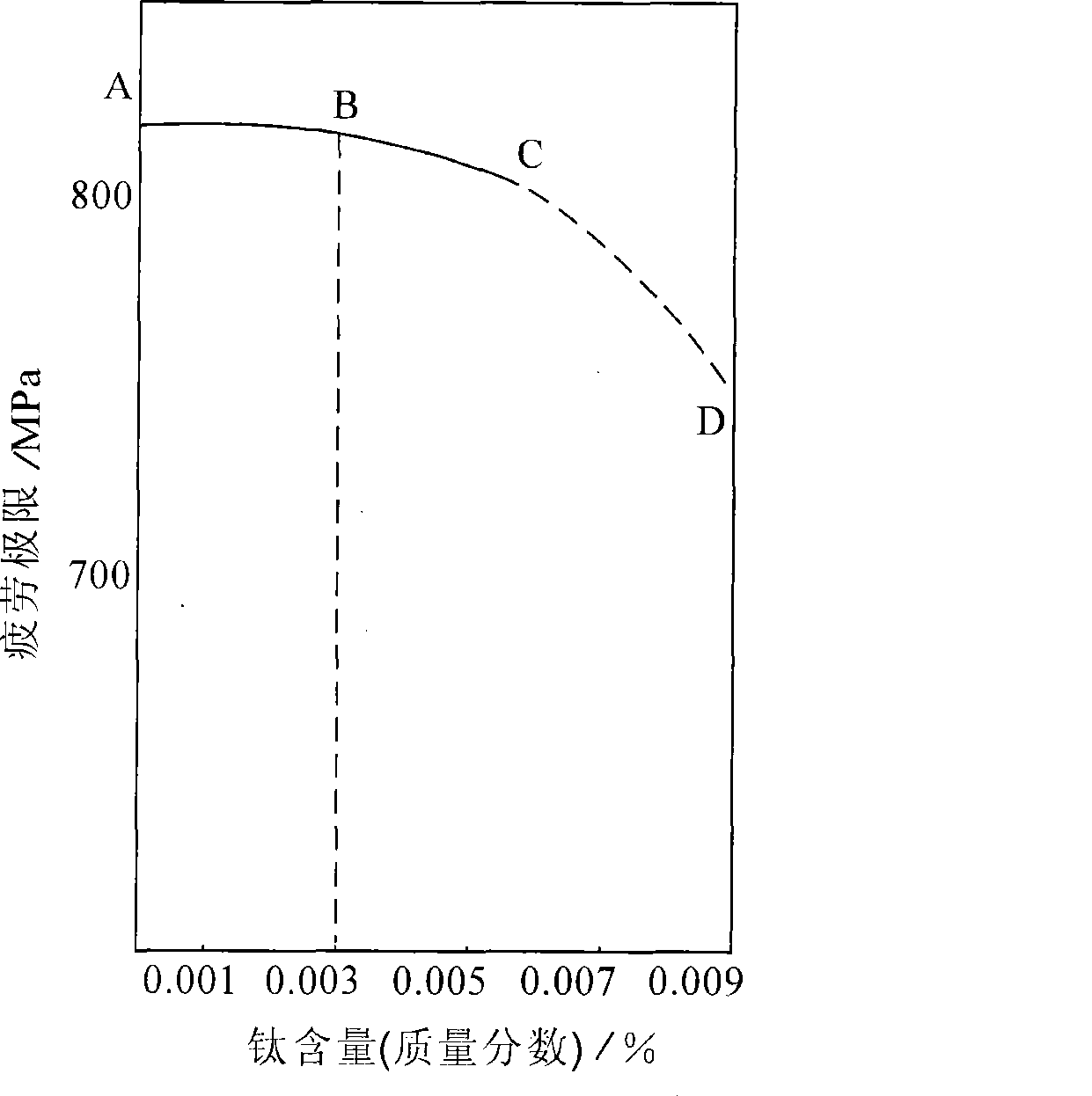

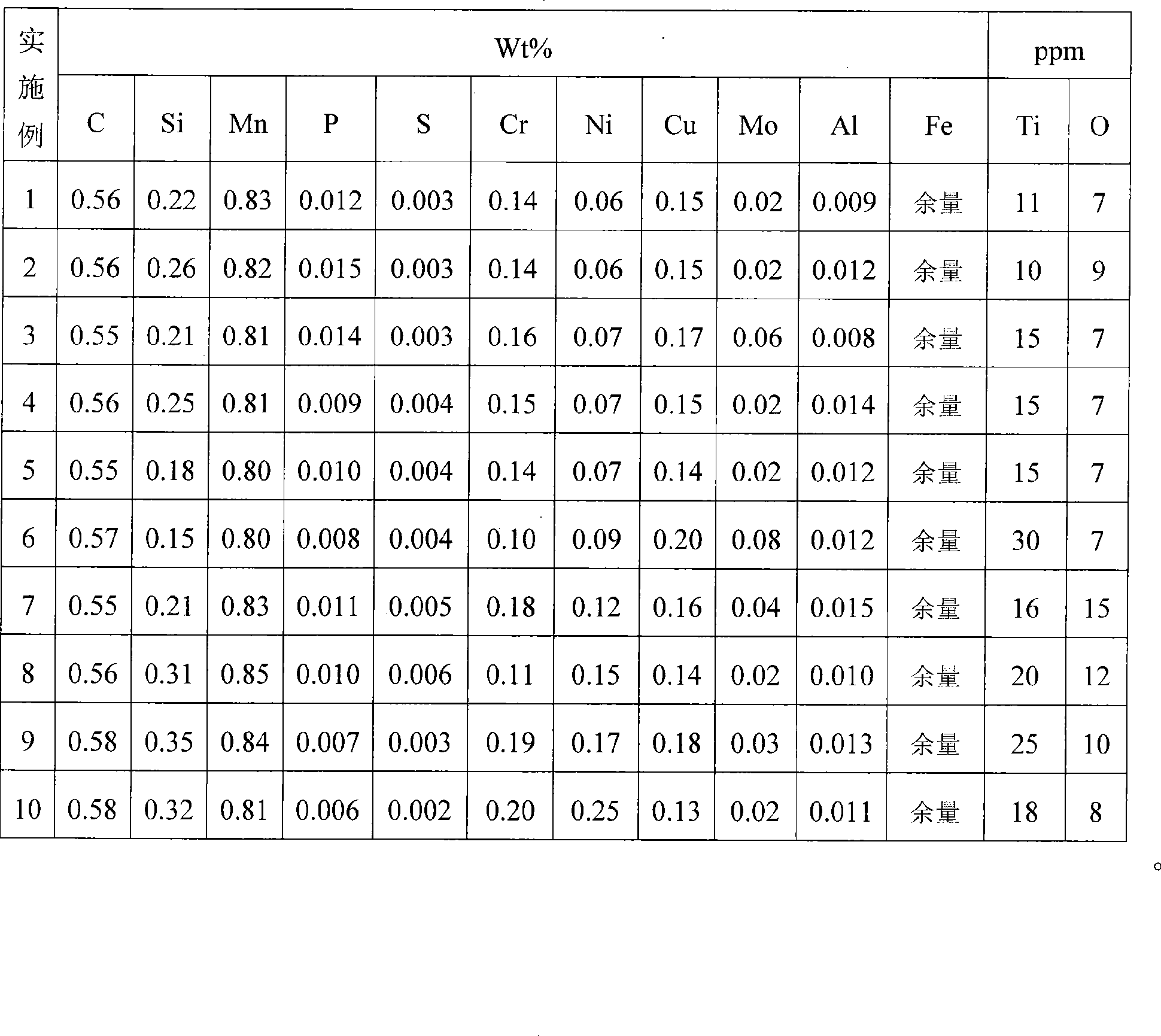

Low-cost high-purity medium carbon bearing steel for automobile hub and manufacturing method thereof

The invention discloses a manufacturing method of low-cost and high-purity medium-carbon bearing steel used for automobile hubs; the manufacturing method comprises the following steps: (a) the mass percentage of the components of the bearing steel is as follows: C: 0.55 percent to 0.58 percent, Si: 0.15 percent to 0.35 percent, Mn: 0.80 percent to 0.85 percent, P: less than or equal to 0.030 percent, S: less than or equal to 0.015 percent, Cr: 0.10 percent to 0.20 percent, Ni: less than or equal to 0.25 percent, Cu: less than or equal to 0.20 percent, Mo: less than or equal to 0.08 percent, Al: 0.008 percent to 0.015 percent, Ti: less than or equal to 30ppm, O: less than or equal to 15ppm, and the rest are Fe and inevitable impurities; (b) smelting, electric furnace initial melting+ ladle furnace refined melting+ vacuum degassing; (c) continuous casting into steel billet; (d) rolling. Compared with the prior art, the technological process has obviously shorter process and lower production cost; the impact resistance, torsion resistance, wear resistance and fatigue endurance of the produced automobile hub bearing are good.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Method for manufacturing high-strength 7055 aluminum alloy forge piece formed by spraying

The invention belongs to a manufacturing technology of aluminum alloy and relates to a method for manufacturing a high-strength 7055 aluminum alloy forge piece formed by spraying. The method sequentially comprises the following steps: (a) melting components of 7055 alloy in an intermediate frequency furnace; (b) degassing, deslagging, refining and filtering an aluminum alloy fusant; (c) forming the filtered fusant by spraying to obtain a columnar aluminum alloy ingot blank; (e) carrying out hot extrusion on the aluminum alloy ingot blank formed by spraying; (f) constantly cutting the extrusion ingot as required and then carrying out free forging; (g) carrying out blocker-type forging and / or stamp forging on the blank after the free forging to obtain a stamp forging piece; and (h) carrying out T6 heat treatment on the stamp forging piece. A large-specification and high-property 7055 product can be obtained by using the method which is suitable for industrial production.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

High-toughness medium-carbon quenched and tempered round steel of grade 120 KSI and manufacturing method thereof

The invention discloses high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI. The high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI comprises, by mass, 0.35%-0.50% of C, 0.15%-0.40% of Si, 0.60%-1.30% of Mn, equal to or less than 0.015% of P, equal to or less than 0.040% of S, 0.75%-1.30% of Cr, 0.15%-0.35% of Mo, equal to or less than 0.25% of Ni, equal to or less than 0.25% of Cu, 0.015%-0.040% of Alt, equal to or less than 0.10% of V, equal to or less than 0.10% of Nb, equal to or less than 0.05% of Ti, equal to or less than 0.008% of N, equal to or less than 0.0010% of B and the balance Fe and unavoidable impurity elements, wherein the content of V, the content of Nb and the content of Ti are not equal to or less than 0.010% at the same time. The round steel with the maximum specification reaching 260 mm is manufactured through Kanbara reactor (KR) pretreatment, basic oxygen furnace (BOF) smelting, ladle furnace (LF) refining, Ruhrstahl Heraeus (RH) vacuum degassing, continuous casting, heating, continuous rolling, and hardening and tempering, so that the requirements for high specifications and toughness are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

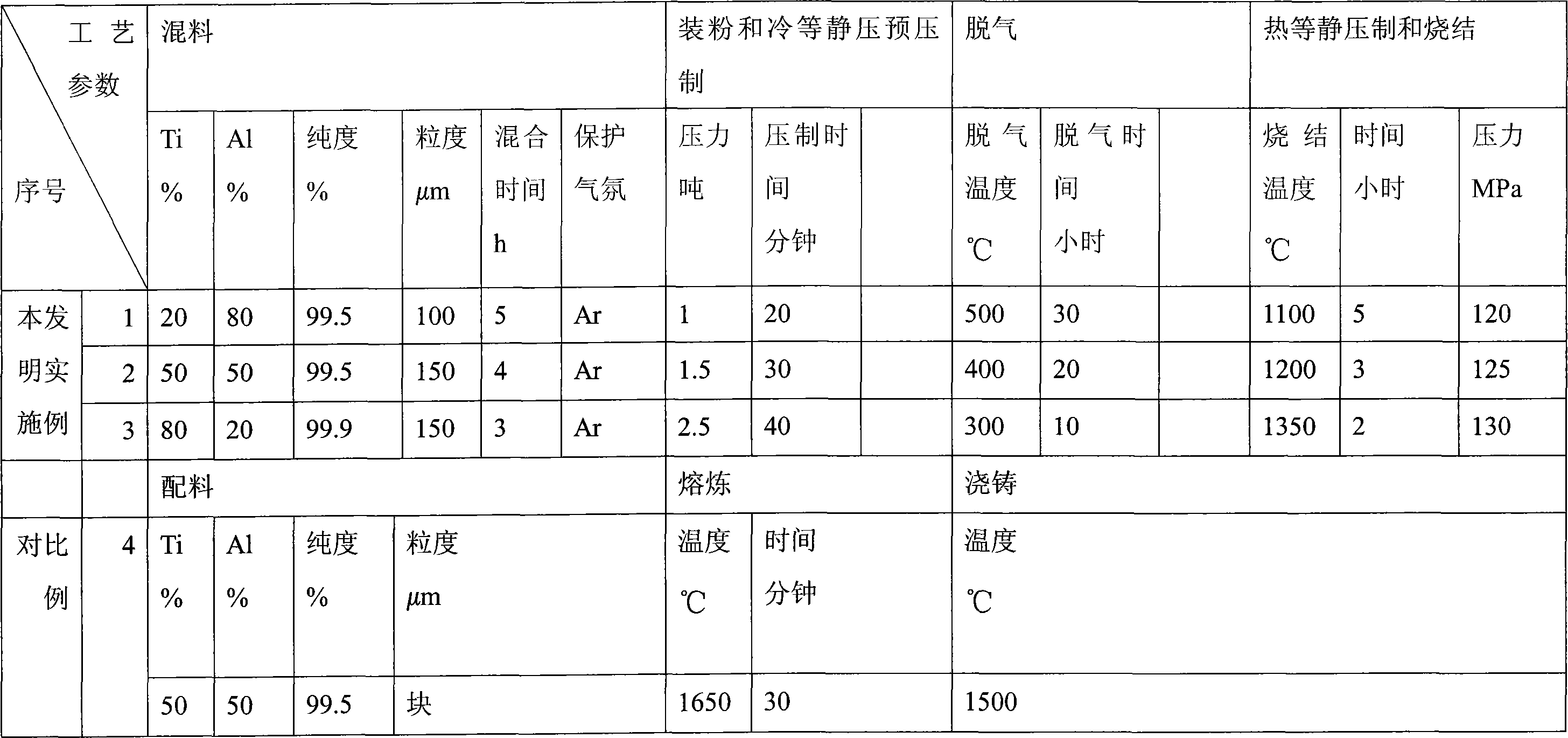

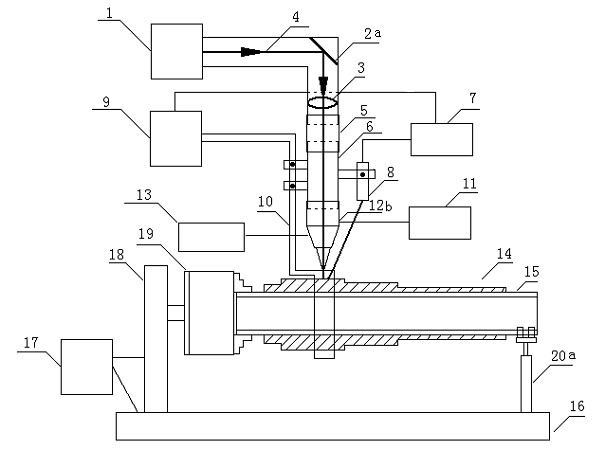

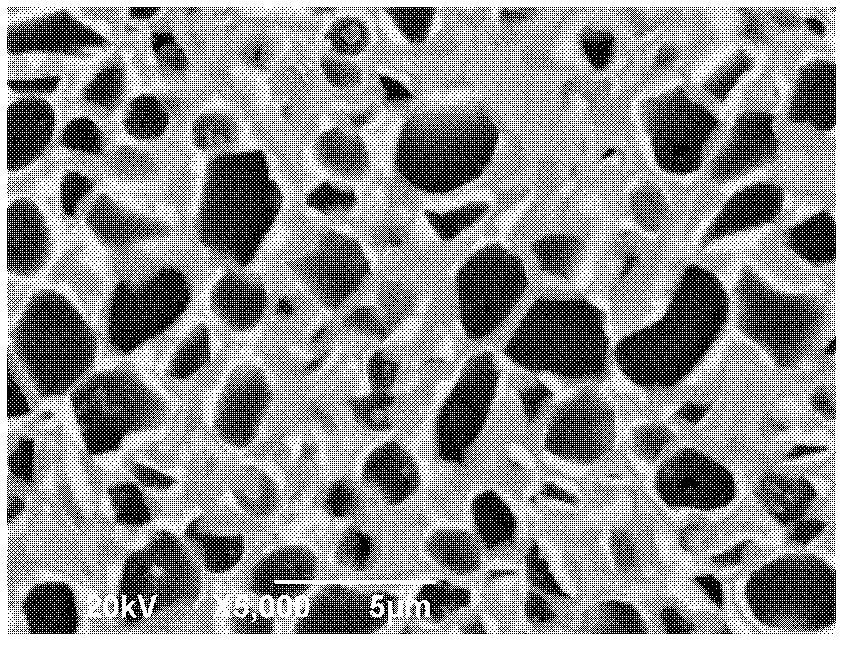

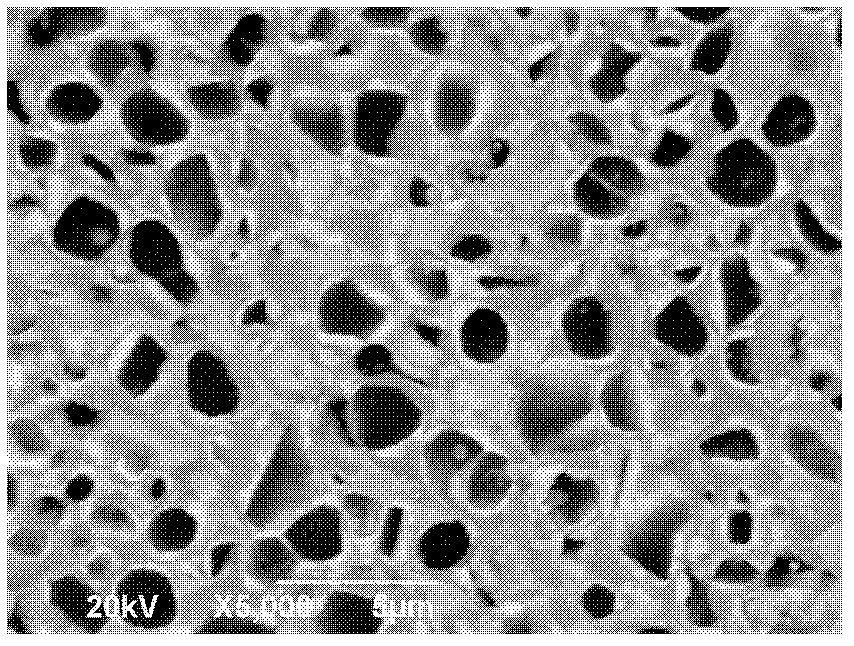

Method for preparing powder metallurgy of titanium-aluminium alloy target material

The invention belongs to the preparing field of powder metallurgy, in particular to the powder metallurgy preparing method for titanium aluminum alloy target material. The components of the titanium aluminum alloy target material relates to: Ti to Al is equal to 80 percent to 20 percent or Ti to Al is equal to 20 to 80 percent. The powder metallurgy preparing method for the titanium aluminum alloy target material is to adopt a pulverization method to acquire the titanium aluminum alloy or mix the titanium powder and the aluminum powder and then pre-pressing through powder mounting and isostatic cool pressing, and then carries out hot isostatic pressing forming after the technique of desaeration and finally carries out sintering process and machining to acquire the titanium aluminum alloy target material. Compared with the exiting casting target material, the titanium aluminum alloy target material of the invention has the advantages of good compactness, no air holes, no loosening and aliquation, uniform component, petty crystal particle, big specification dimension, etc., and is suitable for hard coat needed by various tools and dies.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

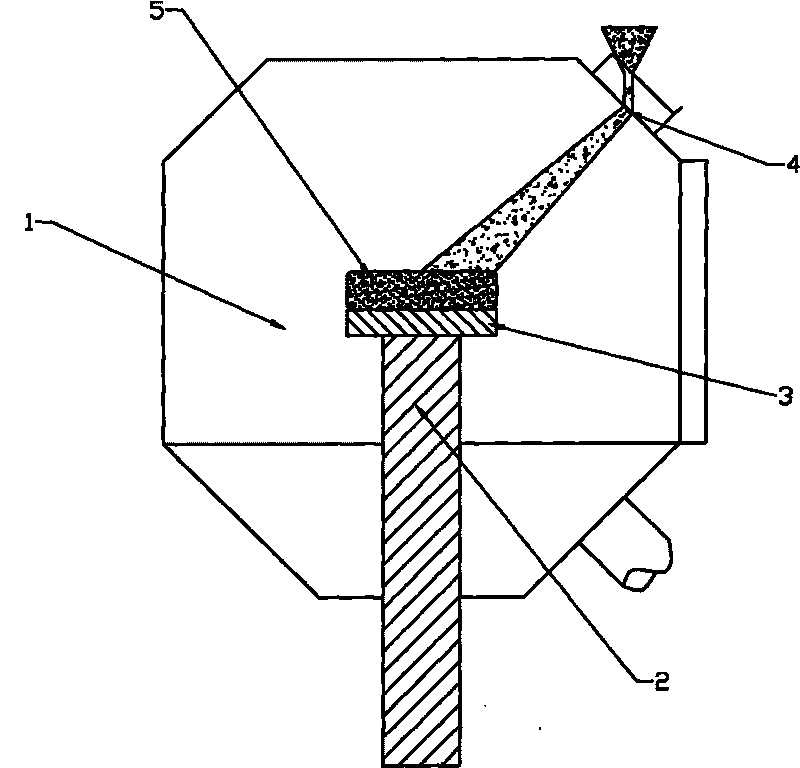

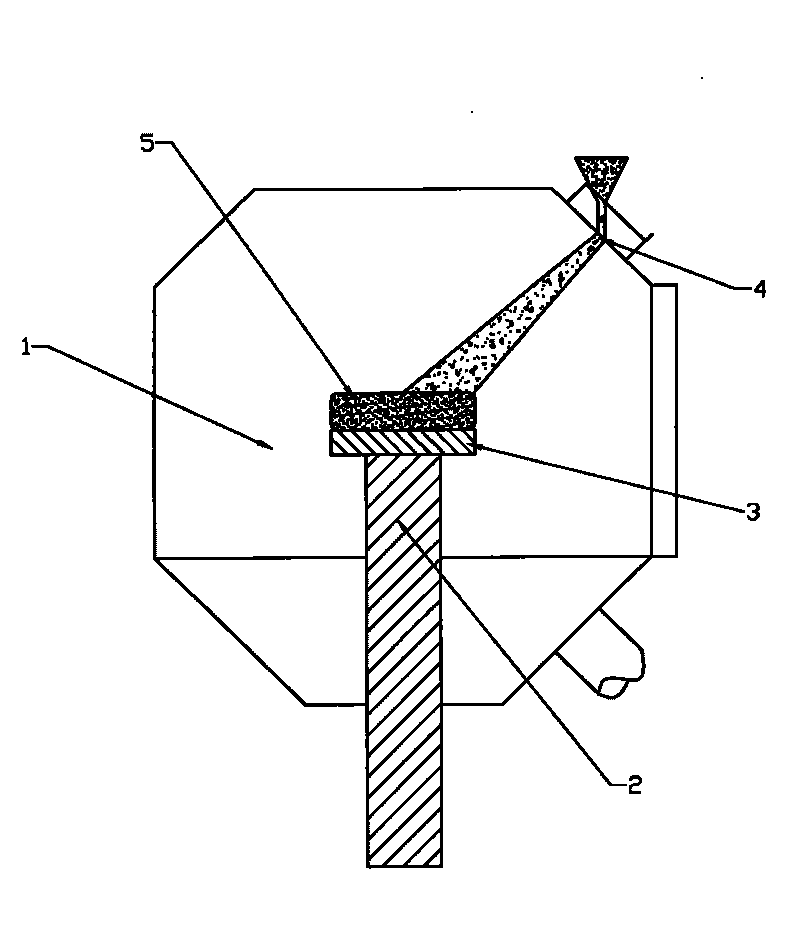

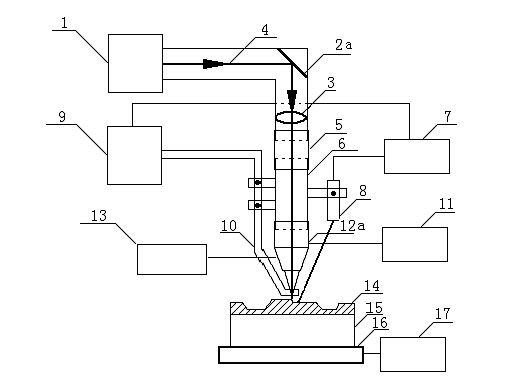

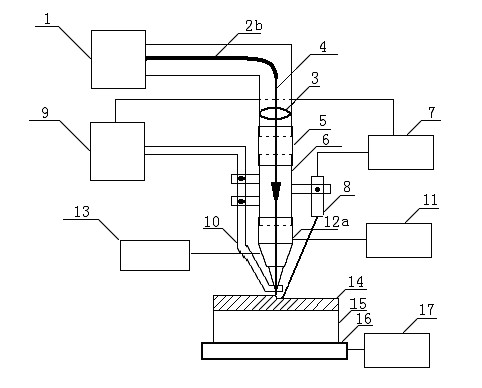

Laser-induction hybrid melting direct forming method and device

The invention discloses a laser-induction hybrid melting direct forming method and device. The laser-induction hybrid melting direct forming method comprises the following steps of: generating a three-dimensional model of a part through CAD (Computer-Aided Design) software, and then slicing the three-dimensional model and generating a G code to drive a numerical control system and a base body to move; and melting synchronously fed metal or metal / ceramic hybrid powder through a high-power laser beam and an induction heat source, and depositing the three-dimensional part in a designed shape layer by layer, wherein a temperature controller is used for monitoring and controlling the temperature of the base body in the processing process. The device for realizing the laser-induction hybrid melting direct forming method comprises a laser, a light path system, an induction heating and temperature control system, a powder feed system and the numerical control system. The device can be used for directly generating large and medium size three-dimensional parts on various metal base bodies, has the advantages of high processing efficiency, compact part structure, fine crystalline grain, excellent mechanical property, less residual stress without deformation or cracking phenomenon, high processing flexibility without tools and moulds, high material utilization ratio, cleanness without pollution and capability of designing the components of a metal-ceramic hybrid layer as required and even changing the components in a gradient manner.

Owner:HUAZHONG UNIV OF SCI & TECH

Apparatus and method for wound, cavity, and bone treatment

InactiveUS20130261534A1Environment safetyPromote formationElectrolysis componentsCannulasWound dressingWound care

Owner:PURICORE

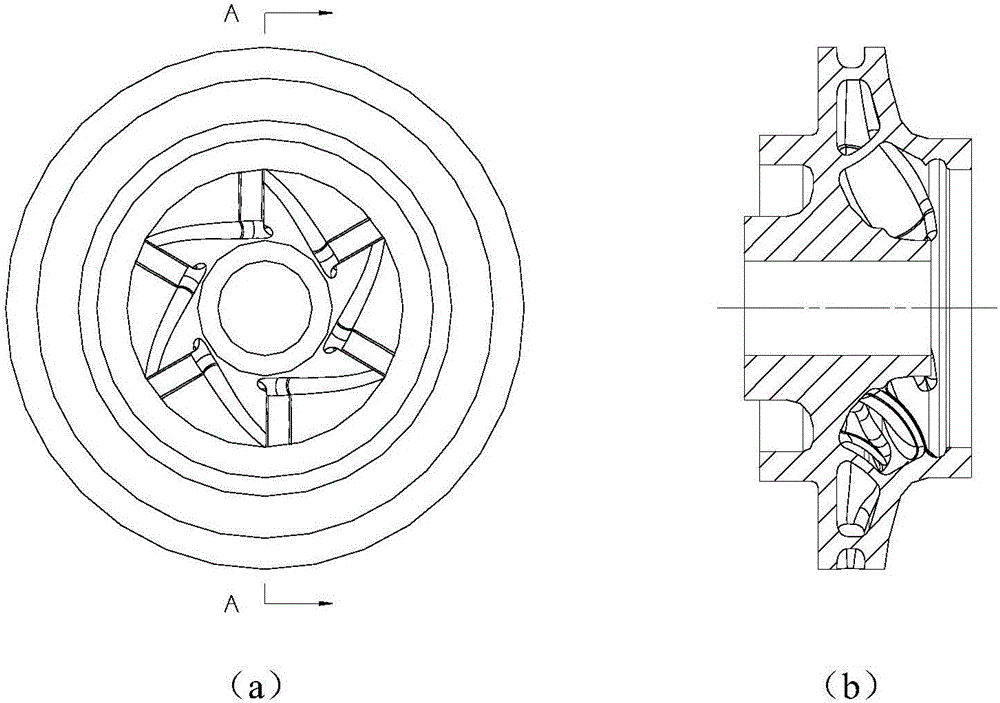

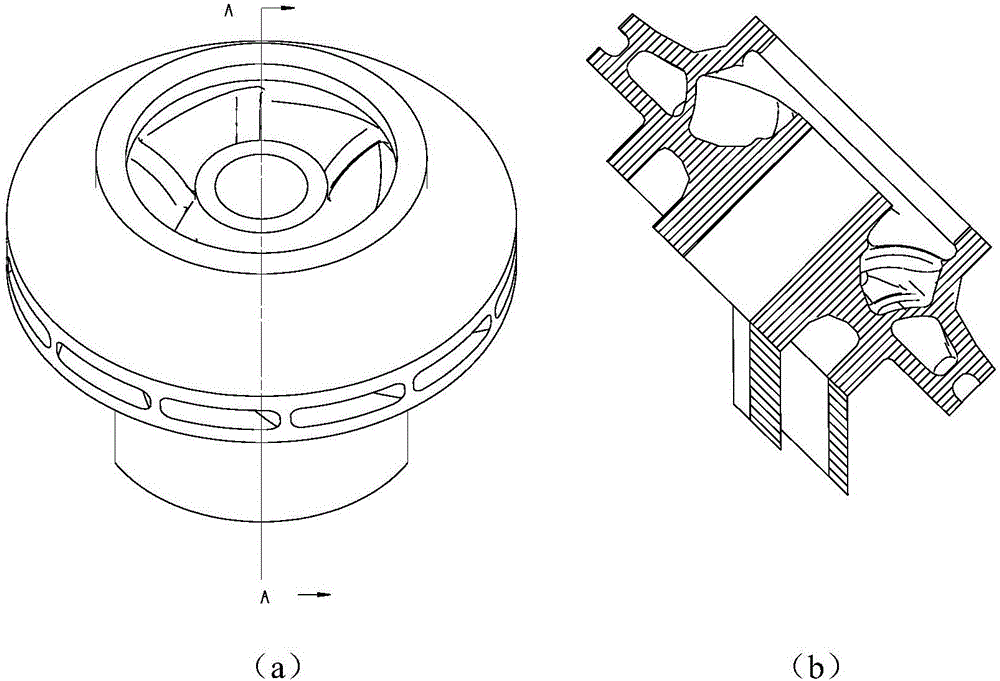

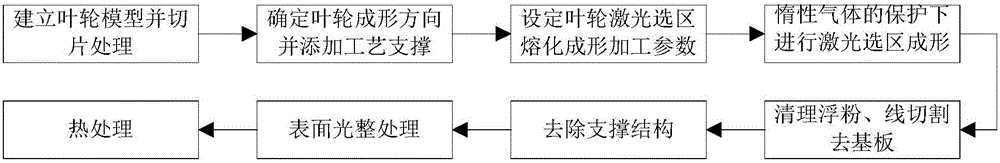

Integral manufacturing method of S-04/S-08 high-strength stainless steel three-dimensional flow shrouded impeller

ActiveCN106077643AShorten the manufacturing cycleCompact structureAdditive manufacturing apparatusEngine manufactureMaterials scienceAustenitic stainless steel

The invention provides an integral manufacturing method of an S-04 / S-08 high-strength stainless steel three-dimensional flow shrouded impeller. The integral manufacturing method comprises the steps of firstly, establishing an impeller three-dimensional model, and carrying out slicing treatment; determining the forming direction and support adding positions according to structural characteristics of the impeller; setting parameters of a laser selective melting forming processing technology according to characteristics of a high-strength stainless steel material; forming under protection of an inert gas; after forming, cleaning floating powder, removing a base plate through linear cutting, and removing supports; and finally, carrying out follow-up treatment such as surface treatment and thermal treatment on the impeller. According to the integral manufacturing method, complex cutters or fixtures do not need to be designed, materials can be directly added for part manufacturing only through the three-dimensional model of the impeller, the manufacturing cycle is greatly shortened, and the integral manufacturing method is applicable to trial manufacturing and middle and small-batch production in the development stage.

Owner:XIAN SPACE ENGINE CO LTD

Aluminum alloy and aluminum alloy extruded profile machining method

The invention discloses aluminum alloy and an aluminum alloy extruded profile machining method. The aluminum alloy comprises, by weight, 0.6-1.4% of Si, 0.7-1.3% of Mg, 0.1-1% of Cu, 0.1-1% of Mn, 0.01-0.15% of Ti, 0-0.2% of Zr, 0-0.5% of Cr, 0-0.4% of Fe, 0-0.25% of Zn and the balance Al. The aluminum alloy also meets the requirements that the weight percentage range of Mg+Si+Cu is 1.4-3.7%, themole ratio of Mg to Si is 0.7-1.5, and the weight percentage range of Mn+Cr+Zr is 0.1-1.5%. The machining method comprises the steps that (1) a cast ingot of the alloy is subjected to homogenization treatment; (2) the cast ingot is extruded into aluminum profile; (3) extrusion production is conducted; (4) on-line quenching is conducted; (5) tension leveling is conducted; and (6) artificial aging is adopted. According to the aluminum alloy and the aluminum alloy extruded profile machining method, the technology is simple, and the production cost is low.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

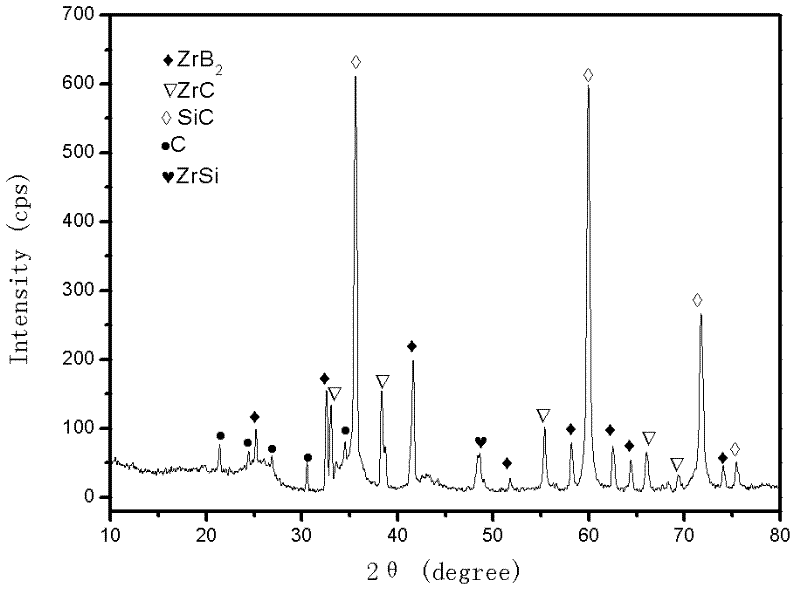

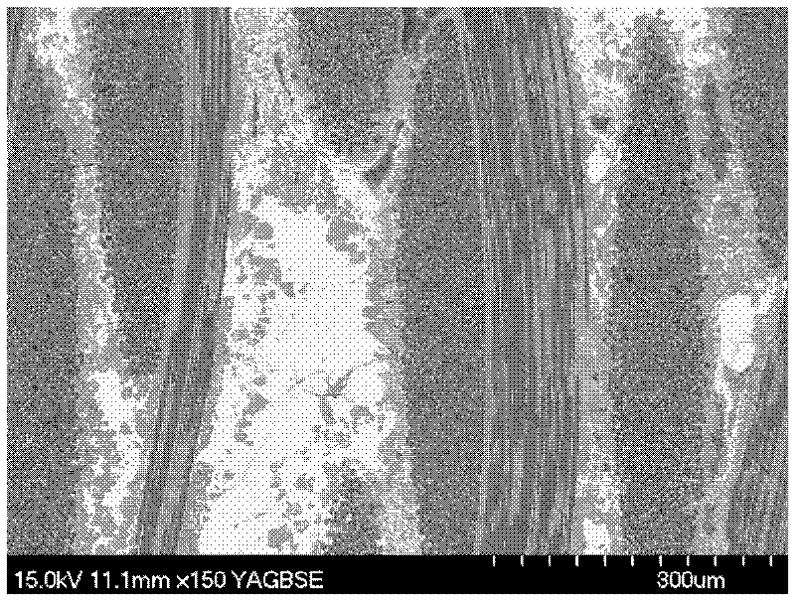

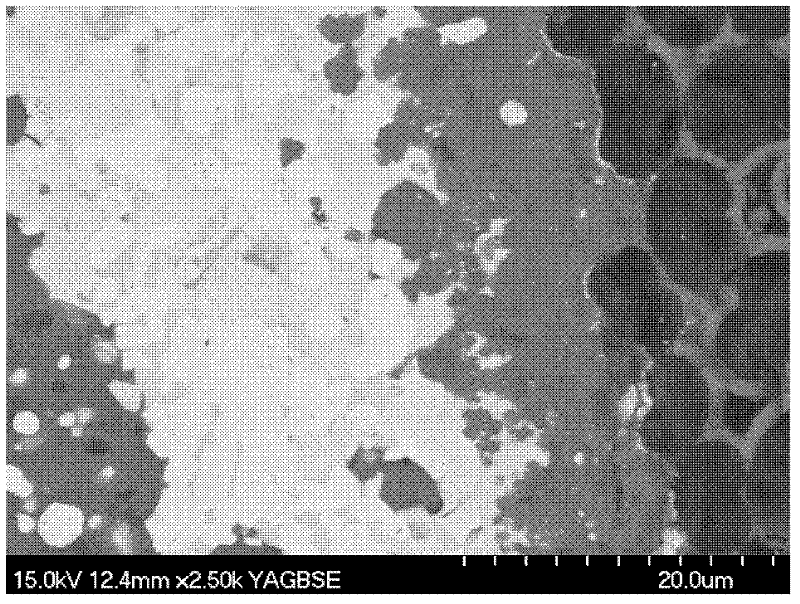

Preparation method of C/SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material

ActiveCN102515870AGuaranteed mechanical propertiesHigh volume contentVacuum pressureUltrahigh temperature ceramics

The invention relates to a preparation method of a C / SiC-ZrB2-ZrC ultrahigh-temperature ceramic-based composite material. According to the invention, B4C and a C organic precursor are introduced into a C / SiC composite material with a vacuum pressure impregnation method; the obtained material is cured and is subject to a heat treatment, such that the C organic precursor is cracked, and pores sealed by the C organic precursor are opened; with a reactive melt infiltration method, under a condition that a temperature is higher than that of silicozirconium alloy, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized, and the C / SiC-ZrB2-ZrC composite material is prepared. According to the invention, with the vacuum pressure impregnation method, B4C and the C organic precursor are introduced into the C / SiC composite material; with the reactive melt infiltration method, silicozirconium alloy is subject to a reaction with B4C and C, such that in-situ productions of SiC, ZrB2, and ZrC are realized. The produced ZrB2 and ZrC are advantaged in fine grains and high volume content. The ablation resistance and mechanical properties of the composite material are effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Special saline-alkali-soil improvement fertilizer prepared by modification with flue gas desulfurization gypsum and preparation method thereof

ActiveCN104355943ASolve the problem of difficult mechanized applicationSimple production processCalcareous fertilisersMagnesium fertilisersAlkali soilPhosphate

The invention discloses a special saline-alkali-soil improvement fertilizer prepared by modification with flue gas desulfurization gypsum and a preparation method thereof. The special improvement fertilizer comprises the following components in parts by weight: 40-80 parts of flue gas desulfurization gypsum, 1-3 parts of citric acid, 0.5-1.5 parts of magnesium sulfate, 1-5 parts of aluminum sulfate, 1-5 parts of ferrous sulfate, 10-30 parts of weathered coal, 10-20 parts of cattle manure or chicken manure, 1-5 parts of urea, 0.5-2.5 parts of ammonium sulfate, 1-3 parts of potassium sulfate, 1-3 parts of monoammonium phosphate, 0.1-0.5 part of zinc sulfate, 0.1-0.5 part of manganese sulfate and 3-10 parts of bentonite. The fertilizer is reasonable in design, provides an effective solution for inland saline-alkali soil of China, and has higher practical value and wide market prospects.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

Chrome-free tannage producing technique for goat glove leather

The invention relates to a processing technique of leather, in particular to a chrome-free tannage manufacturing technique of goat glove leather, aims at solving the problem of heavy environment pollution caused by the chrome sewage in the prior art of chrome tannage. The processing technique of leather adopts a technical proposal that the chrome-free tannage manufacturing technique of goat glove leather comprises a plurality of successively steps as followings: softening, dipping in acid, organophosphor tanning, oxidation, stacking, sammying and extension, shaving, washing, degreasing, rinse, washing, retanning and stuffing, washing, and routine following chrome tanning technique. The processing technique of leather has the advantages of eliminating the environment pollution caused by the heavy metal chrome, reducing the cost of sewage treatment, producing environment-friendly goat glove leather with soft, plumpy, highly resilient, and flowing hand feeling, smooth grain, brilliant color, qualified formaldehyde content as ecological leather, over 88 DEG C shrinkage temperature, and completely same mechanical property as routine chrome tannage leather.

Owner:HAINING SHANGYUAN LEATHER

Rare earth alloy powder-modified Ti(C,N)-based metal ceramic and preparation method thereof

The invention discloses a rare earth alloy powder-modified Ti(C,N)-based metal ceramic and a preparation method of the metal ceramic. The metal ceramic comprises Co and Ni or at least two of components selected from Co, Ni as well as Fe as a bonding phase, Ti(C,N) as a basic hard phase and optionally at least one of metallic carbides; and a rare earth alloy powder modifier 0.1-3wt% of the total mass of the metal ceramic. The preparation method comprises treating a raw material through a wet-grinding and mixing process, a die-forming process, a vacuum-degreasing process and a low-pressure sintering process to prepare the rare earth alloy powder-modified Ti(C,N)-based metal ceramic. On the premise of keeping high hardness and high wear resistance, the Ti(C,N)-based metal ceramic prepared according to the invention has excellent comprehensive performance, can be greatly improved in strength and tenacity and can also be widely applied to various cutting tools and wear-resistant parts.

Owner:SICHUAN UNIV

Halogen-free cleaning-free rosin flux, and preparation and application thereof

ActiveCN102513732ALess corrosiveSlow growth rateWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention discloses a halogen-free cleaning-free rosin flux, and preparation and application thereof, and particularly relates to a flux suitable for surface mount lead-free welding paste, preparation of the flux and application of the flux. The flux comprises 20-50% (mass fraction, the same below) of rosin, 5-25% of film-forming agent, 30-50% of high boiling solvent, 3-8% of activator and 2-5% of thixotropic agent, and the flux does not contain any halogen. In order to control growth of interface IMC (intermediate compound) during welding, 0.3-1% of combined inhibitor is added. The welding paste prepared with the flux and lead-free tin-silver-copper powder has the advantages of excellent printing performance, fine weldability, less post-weld residue, thin and even welding spot interface IMC and excellent mechanical property, and is capable of meeting the requirement of high-end electronic products on packaging.

Owner:CENT SOUTH UNIV

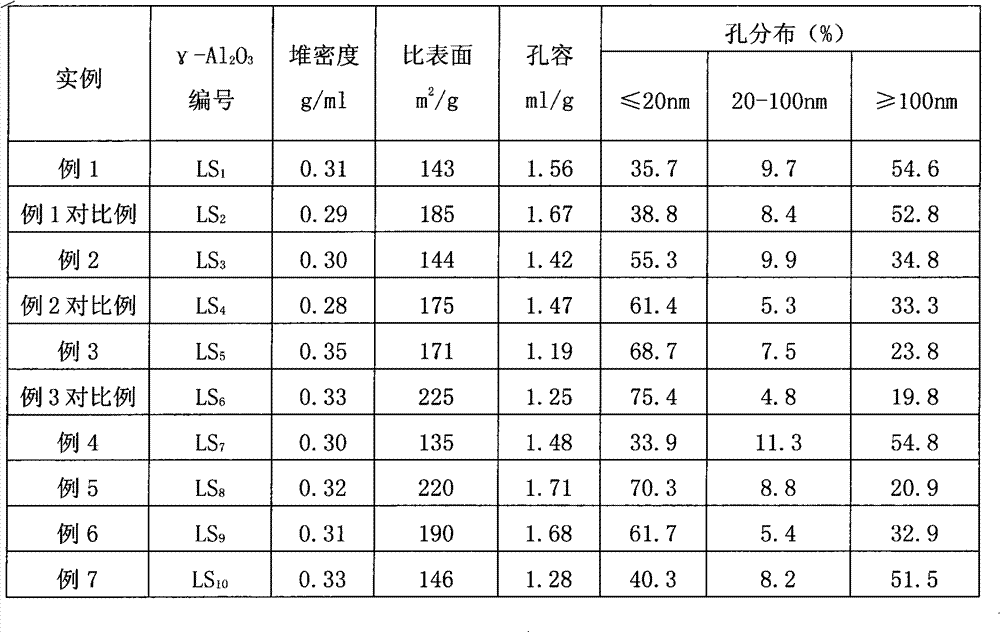

Preparation process for large pore volume and light bulk density activated alumina

InactiveCN102730724AChange the stacking methodFine grainAluminium oxides/hydroxidesWater vaporSodium aluminate

The invention relates to a preparation process for large pore volume and light bulk density activated alumina, and belongs to the technical field of activated alumina preparation. According to the process, an aluminum sulfate solution and a sodium aluminate solution form a glue in a stainless steel neutralization kettle through a continuous co-current flow method; then an aging treatment is performed for a certain time in a stainless steel aging washing tank; the resulting material is pressed to a plate and frame filter press with a material pressing pump to carry out continuous washing to prepare primary pseudo-boehmite particles with large grains; the removed filter cake is acidified, and proper amounts of a pore expanding agent and a surfactant are added during the acidification process to carry out forming; the formed wet balls are placed in a drying box to carry out drying; and the dried small balls are loaded into a calcination activation furnace to carry out high temperature calcination and pore expanding. The process of the present invention has characteristics of low cost and low equipment corrosion, can performs continuous washing cycle, and has advantages of low wastewater discharging, less pollution, and the like. With the process of the present invention, the production cycle can be reduced, the labor intensity can be reduced, and various performance indicators of the prepared gamma-Al2O3 can meet the international advanced level after pore expanding by water vapor.

Owner:JIANGSU JINGJING NEW MATERIALS

Ultrahigh-malleability tunnel supporting anchor rod steel of converter continuous cast billet and production method

The invention relates to ultrahigh-malleability tunnel supporting anchor pile steel of converter continuous cast billet and a production method, which belongs to the technical field of a mine anchor rod. The anchor rod steel comprises the following components by weight percent: 0.5 to 0.70 percent of carbon, 0.15 to 1.20 percent of silicon, 0.5 to 2.5 percent of manganese, less than or equal to 0.045 percent of phosphorus, less than or equal to 0.045 percent of sulfur, 0 to 1.00 percent of chrome, 0 to 1.00 percent of nickel, 0 to 1.00 percent of molybdenum, 0 to 0.30 percent of copper, 0.03 to 0.40 percent of vanadium, 0.01 to 0.2 percent of aluminum, 0 to 0.10 percent of titanium, 0 to 0.10 percent of boron, 0.001 to 0.0 percent of niobium, 0.004 to 0.020 percent of nitrogen, and iron for the surplus; the yield strength Rel is larger than or equal to 600 MPa, the percentage elongation delta 5 is larger than or equal to 20 percent, the impact strength is 20 DEG C, Akv is larger than or equal to 27 J, and the breaking load is larger than or equal to 300 KN. By adopting the production process flow of converter crude metallurgy, LF furnace fine metallurgy and full protection continuous casting, the steel grade has the advantages that the purity is high, the structure is dense, the grain is fine, the physical chemistry properties of the steel are stable, the over-all mechanical property is good, the production operation and process flow are simple, and the rolled metal finished product can be directly used without heat treatment to the rear part.

Owner:SHOUGANG CORPORATION

Electric power generator, steam turbine rotor spindle repaired by laser and repairing method thereof

InactiveCN1674408AMeet working conditionsHigh creep limitMagnetic circuit rotating partsPump componentsOptoelectronicsCobalt

The present invention provides a laser repaired power generator and turbine rotor shaft, on its matrix surface on alloy covering layer which can be mutually merged with matrix surface and is different from matrix completely in components is formed, and on the surface where the matrix and alloy layer are connected a micromolten layer whose thickness is 0.05-0.1 mm is formed, and said alloy covering layer is nickel base, cobalt base or iron base alloy. Said invention also provides a laser repairing method of the described power generator and turbine rotor shaft. It adopts a pre-set laser melt-covering mode, and its technological parameters are: laser power 1200-2000 W, spot diameter 2-6 mm and spot moving speed 2-20 mm / s.

Owner:SHENYANG DALU LASER TECH

Porous phosphorus removing ceramic granules with function of slowly releasing alkali and preparation method thereof

ActiveCN101935195AImprove plasticityLarge specific surface areaSilicon compoundsWater/sewage treatment by sorptionFiberPorosity

The invention discloses porous phosphorus removing ceramic granules with a function of slowly releasing an alkali and a preparation method thereof. The prepared ceramic granules are an environmental material for efficiently removing phosphorus from municipal sewage and industrial wastewater. Based on the basic chemical properties of the phosphorus in water and a phosphorus removing mechanism by chemical absorption, the preparation method of the ceramic granules comprises the following steps of: mixing 20 to 40 mass percent of ordinary portland cement (42.5 level), 10 to 20 mass percent of bentonite, 10 to 20 mass percent of fly ash, 10 to 15 mass percent of calcium oxide, 15 to 25 mass percent of nitrocellulose, 14 to 30 mass percent of xonotlite fiber particle and 0.1 to 0.5 mass percent of pore-creating agent; adding water for stirring the mixture according to a water-solid ratio of 0.35 to 0.45; granulating the mixture into granules with required grain sizes; and after the granules are foamed and solidified, curing the granules by using high-temperature steam to obtain the ceramic granules. The method has the advantages of simple preparation process, readily available raw materials, low cost and wide application prospect in the field of the removing of the phosphorus in water bodies. The prepared ceramic granules have the characteristics of capacity of slowly releasing the alkalis, silicic and calcareous textures, porosity, capacity of continuously and efficiently absorbing and removing the phosphorus and suitability for phosphorus removing systems of the municipal sewage and the industrial wastewater.

Owner:郑俊 +1

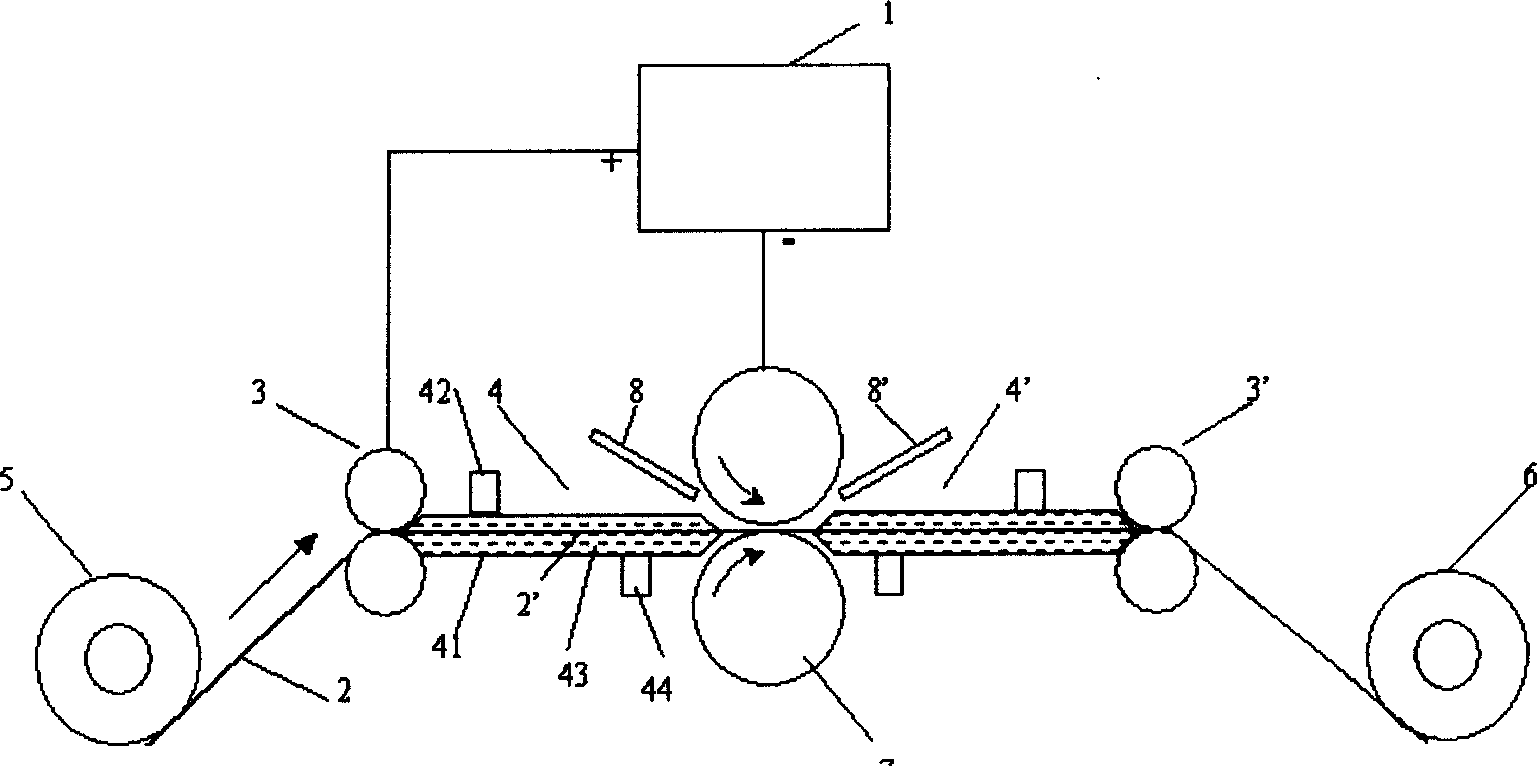

Electroplastic rolling method and apparatus for deformable magnesium alloy sheet, band and wire rod

This invention relates to an electro-plastic rolling method and a device for deformed Mg alloy thin plates, strips and wires including: inducing the deformed Mg alloy plates, strips and wires in single-way instant high energy continuous pulse current directly in the process of rolling, the current passes through a pair of electric contact devices with their distance adjustable to apply on the moving Mg materials, and the roller is the negative in it, necessary cooling and lubrication measures should be taken when rolling, this time, the rolling deformation ability of the Mg material is increased greatly and the resistance is reduced to avoid high temperature oxidation and poor accuracy in size.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

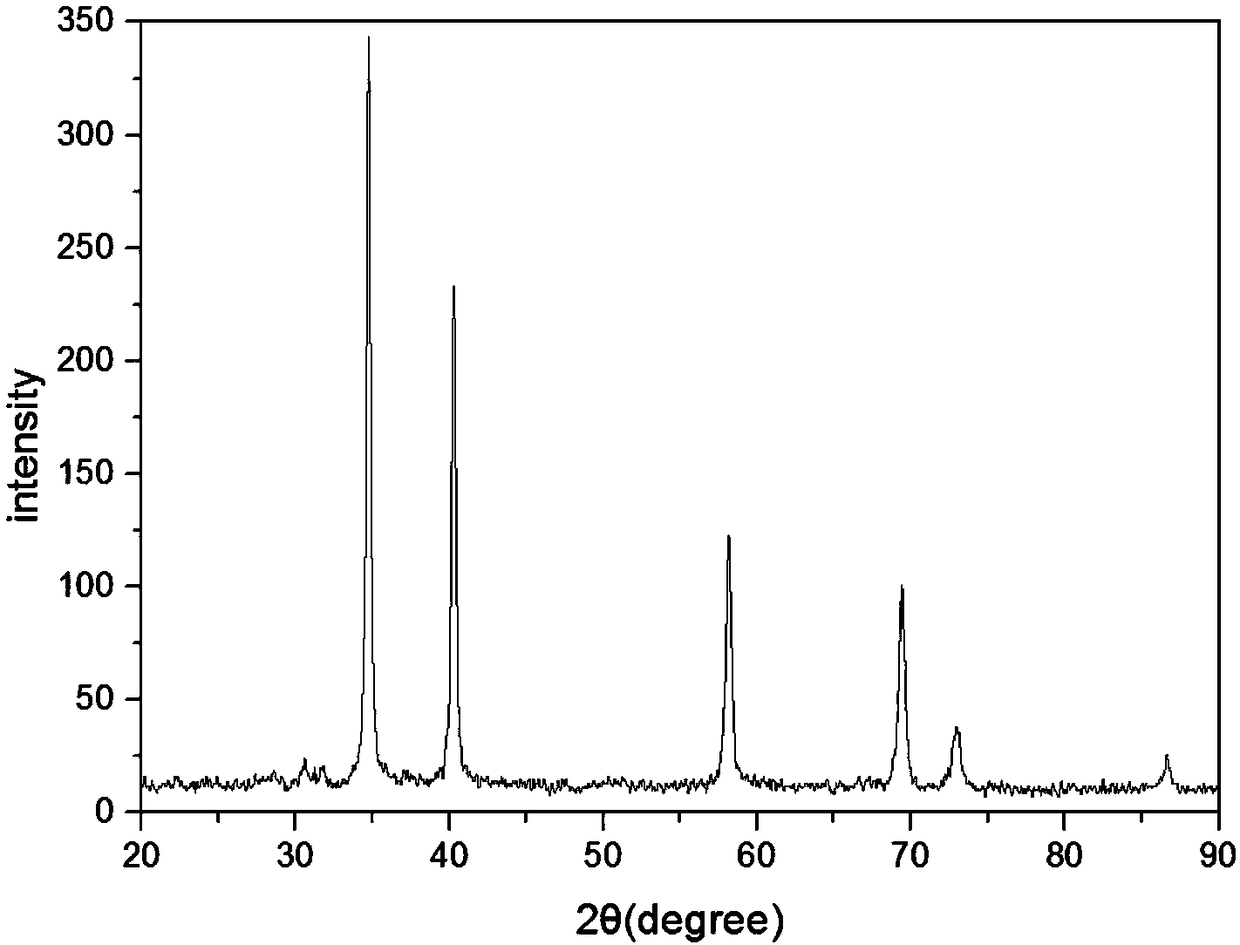

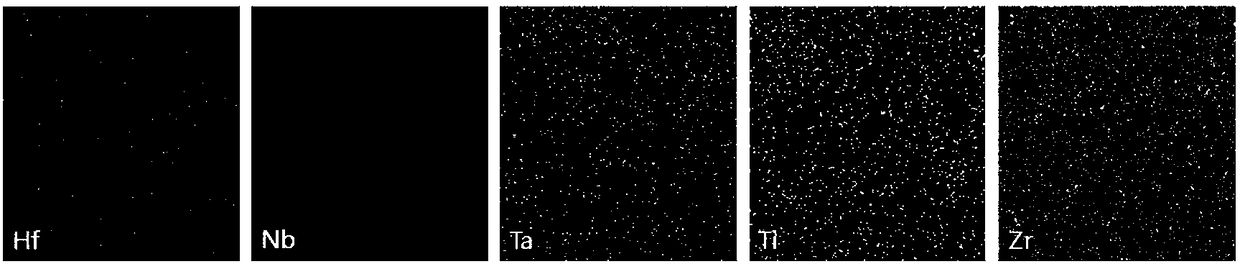

(HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of high-entropy ceramic powder and high-entropy ceramic blocks

The invention relates to (HfTaZrTiNb) C high-entropy ceramic powder and preparation methods of the high-entropy ceramic powder and high-entropy ceramic blocks. Five-face centered cube (FCC) carbonizedpowder is made into ceramic powder through a high-energy ball milling method, then a discharging plasma method is adopted to realize preparation of the high-entropy ceramic blocks, and quick sintering of ceramic within a temperature range of 1700-2350 DEG C can be realized to obtain high-entropy ceramic with single-phase-face centered cube (FCC) structure. The preparation method of (HfTaZrTiNb) Chigh-entropy block ceramic is solved; the high-entropy ceramic with the FCC structure is finally obtained by strictly controlling parameters of a discharging plasma sintering furnace or a hot press furnace and characterizing XRD, so that the ceramic material system is enriched.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Magnesium-bearing wound-covering material

InactiveUS20060018954A1Reduce sensitivityFine grainBiocideAbsorbent padsWound careAntiproliferative effect

The invention concerns a biocompatible and bioabsorbable wound covering material. The object of the present invention is to improve wound care by a biocompatible, biodegradable wound covering material. In that respect body-specific defense and healing mechanisms are to be assisted and antimicrobial and antiproliferative effects are to be achieved. That is attained in that the wound covering material contains elementary magnesium.

Owner:BIOTRONIK VI PATENT

A kind of rapid start-up method of anaerobic ammonium oxidation reactor

ActiveCN102259976AEnsure anaerobic environmentUnobstructed exhaustWaste based fuelTreatment with anaerobic digestion processesChemistrySubstrate concentration

The invention provides a method for quickly starting an anaerobic ammonia oxidation reactor. A small amount of anaerobic ammonia oxidation sludge subjected to enrichment culture successfully is regularly added into a reactor for starting an anaerobic ammonia oxidation process by using non-anaerobic ammonia oxidation sludge (such as nitrification sludge, denitrification sludge, methane-producing sludge and the like) to provide certain growth factors for the reactor, so that the starting condition of the anaerobic ammonia oxidation process is improved, and a part of bacterium sources can be increased to accelerate the enrichment of anaerobic ammonia oxidation bacteria in the sludge in the reactor; and substrate concentration and hydraulic retention time are timely adjusted on the basis to avoid substrate lack and accelerate the growth of the anaerobic ammonia oxidation bacteria and the process of granulating the sludge, so that the starting time of the anaerobic ammonia oxidation reactor is greatly shortened, and the popularization and application of the anaerobic ammonia oxidation process are facilitated.

Owner:江苏清材智能制造有限公司

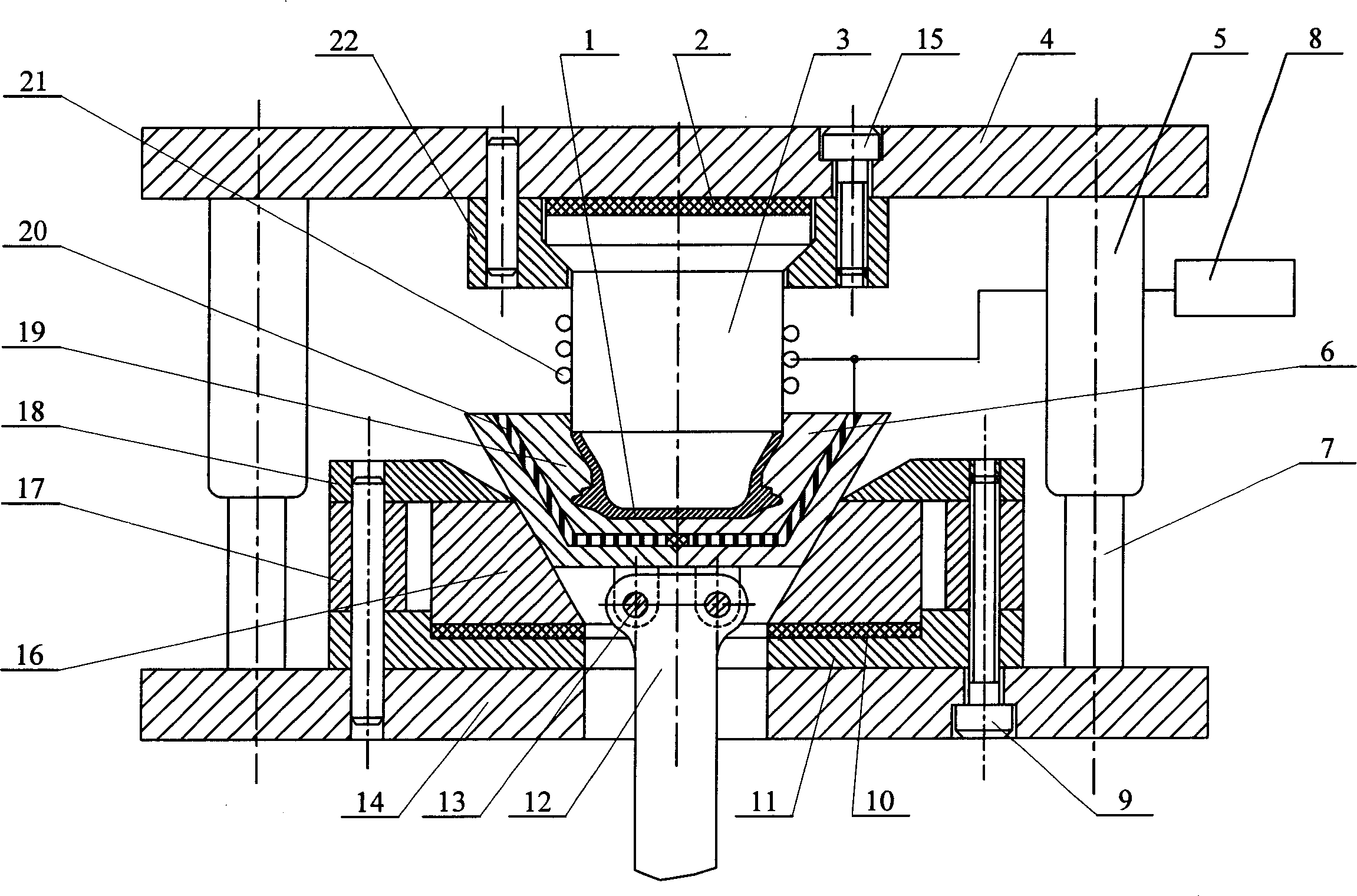

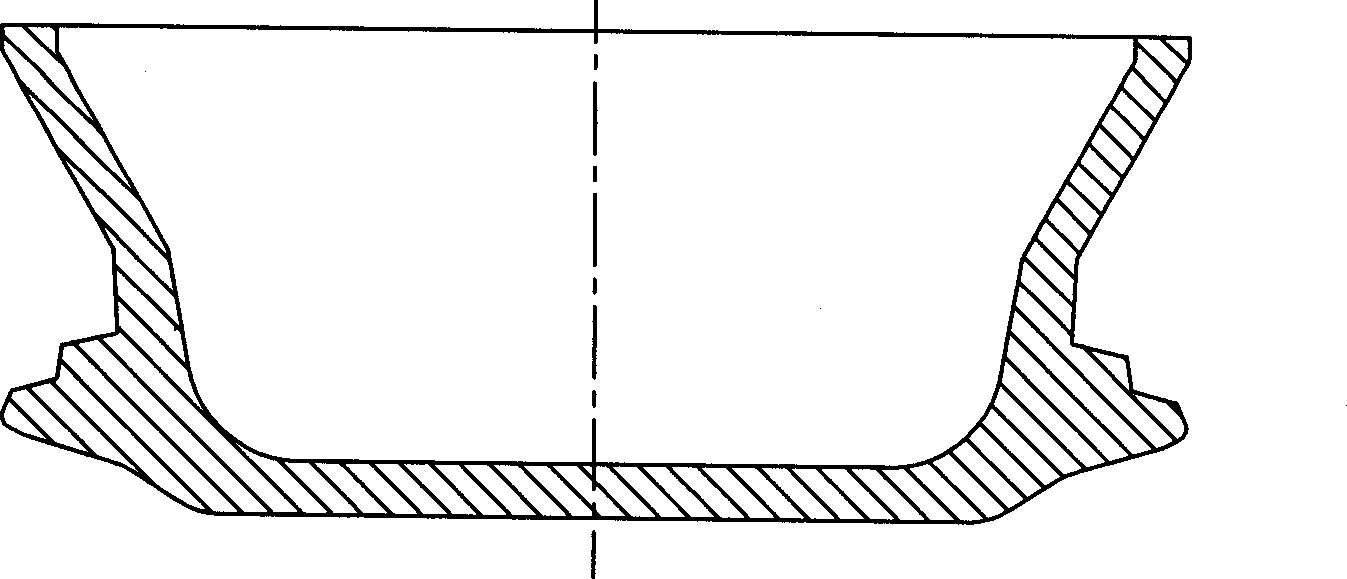

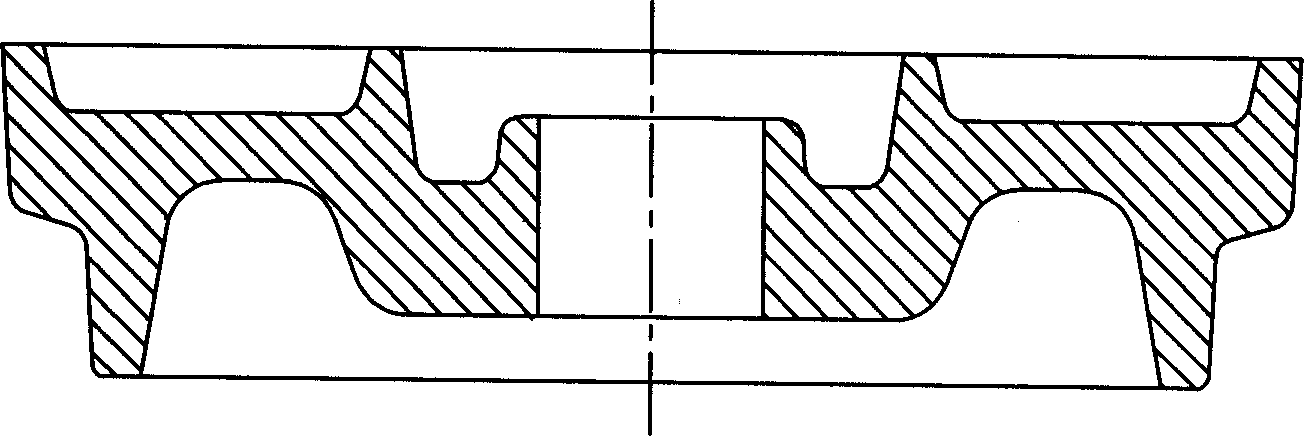

Shaping device of solid hot extrusion magnesium alloy wheel hub and shaping method thereof

A solid-state hot squeezing apparatus for shaping the Mg-alloy wheel hub is composed of upper die plate, male die and its heater, heat isolating plate between said upper die plate and male die, moulding cavity heater for left and right moulding cavities, heat isolating plate between female die and its die plate, push-out rod, and temp controller. Its shaping method includes such steps as blanking, heating, holding temp, preheating die set squeezing cutting, surface treating and ageing treating.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com