Ultrahigh-malleability tunnel supporting anchor rod steel of converter continuous cast billet and production method

A roadway support and anchor steel technology, which is applied in the manufacture of converters, etc., can solve the problems that the chemical composition range cannot meet the actual performance index requirements of ultra-high strength, the steel used for anchor support in coal mines is chaotic, and the strength level is low. Excellent comprehensive mechanical properties, improved safety and reliability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

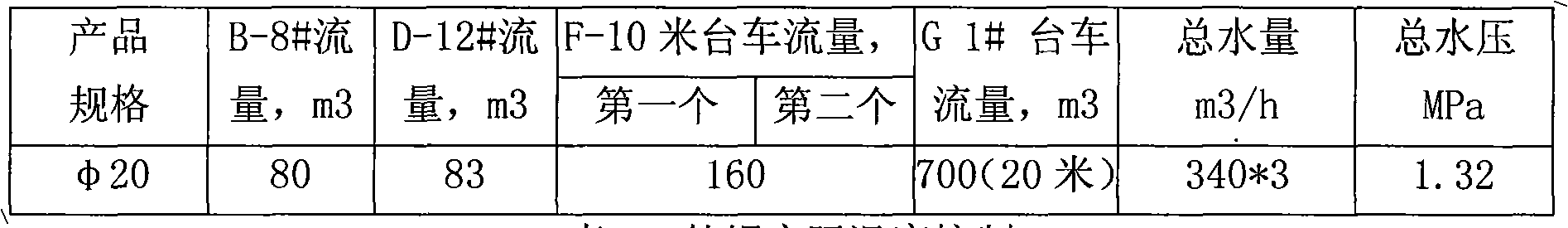

Image

Examples

Embodiment 1

[0016] 1.1 Addition amount of steelmaking alloy:

[0017] Add L08 (brand) hot metal and Class 1 steel scrap into the converter, and the ratio of hot metal to scrap steel is 195:12. Add composite deoxidizer alloy in sequence: AlFe (49% Al), the addition amount is 0.5kg / t; SiAlBaCa (45% Si, 8% Al, 18% Ba, 7% Ca, Fe balance), the addition amount is 1.5kg / t ; Iron alloy: ferromanganese: (68% Mn), the addition amount is 24.56kg / t; ferrosilicon (75% Si), the addition amount is 15.47kg / t; ferrosilicon (52% V), the addition amount is 0.88kg / t.

[0018] 1.2 Main process parameters of converter smelting:

[0019] Double slag operation is adopted to dephosphorize the slag early. End point control End point C of molten steel: 0.10-0.15%, P content qualified. Tapping temperature is 1665-1685°C. Tapping time is 4-7min. The steel is tapped with slag blocking, and the slag thickness is ≤70mm.

[0020] 1. Main process parameters of 3LF furnace smelting:

[0021] The molten steel is refi...

Embodiment 2

[0032] 2.1 Addition amount of steelmaking alloy:

[0033] Add L08 (brand) hot metal and Class 1 steel scrap into the converter, and the ratio of hot metal to scrap steel is 195:12. Add composite deoxidizer alloy in sequence: AlFe (49% Al), the addition amount is 0.5kg / t; SiAlBaCa (45% Si, 8% Al, 18% Ba, 7% Ca, Fe balance), the addition amount is 1.5kg / t ; Iron alloy: ferromanganese (68% Mn), the addition amount is 23.62kg / t; ferrosilicon (75% Si), the addition amount is 10.81kg / t; vanadium iron (52% V), the addition amount is 3.21kg / t.

[0034] 2.2 Main process parameters of converter smelting:

[0035] Double slag operation is adopted to dephosphorize the slag early. End point control End point C of molten steel: 0.06-0.10%, P content qualified. Tapping temperature is 1665-1685°C. Tapping time is 4-7min. The steel is tapped with slag blocking, and the slag thickness is ≤70mm.

[0036] 2.3 Main process parameters of LF furnace smelting:

[0037]The molten steel is refin...

Embodiment 3

[0048] 3.1 Alloy addition amount:

[0049] Add L08 (brand) hot metal and Class 1 steel scrap into the converter, and the ratio of hot metal to scrap steel is 195:12. Add composite deoxidizer alloy in turn: SiAlBaCa (45% Si, 8% Al, 18% Ba, 7% Ca, Fe balance), adding amount 2kg / t; iron alloy: low carbon ferrochrome (65% Cr), adding amount 7.86kg / t; low-carbon ferromanganese (68% Mn) addition amount 23.31kg / t addition amount; ferrosilicon (75% Si): addition amount 13.1kg / t; niobium ferromanganese (63% Nb) addition amount 0.71kg / t; vanadium iron (52% V), the addition amount is 0.85kg / t; AlFe (49% Al), the addition amount is 1kg / t; titanium iron (29% Ti), the addition amount is 0.61kg / t; boron iron (24 %B) The addition amount is 0.17kg / t.

[0050] 3.2 Main process parameters of converter smelting:

[0051] Double slag operation is adopted to dephosphorize the slag early. End point control The end point of molten steel is C<0.04%, and the P content is qualified. Tapping temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com