Process for preparing natural magnesium aluminium silicate gel

A technology of magnesium aluminum silicate and magnesium silicate, which is applied in the direction of aluminum silicate and silicate, can solve the problems of reducing the purification and separation effect, poor pulp dispersion effect, and poor purification effect, so as to improve the concentration of pulping operation, Achieve large-scale production and avoid iron pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

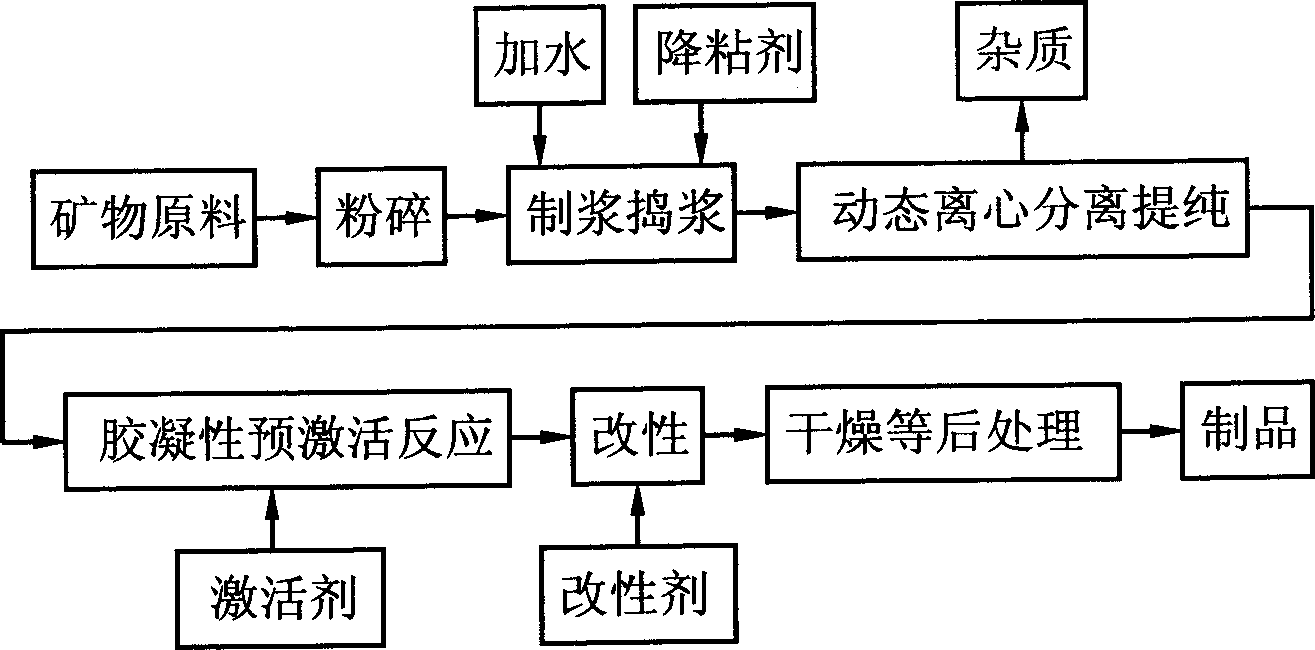

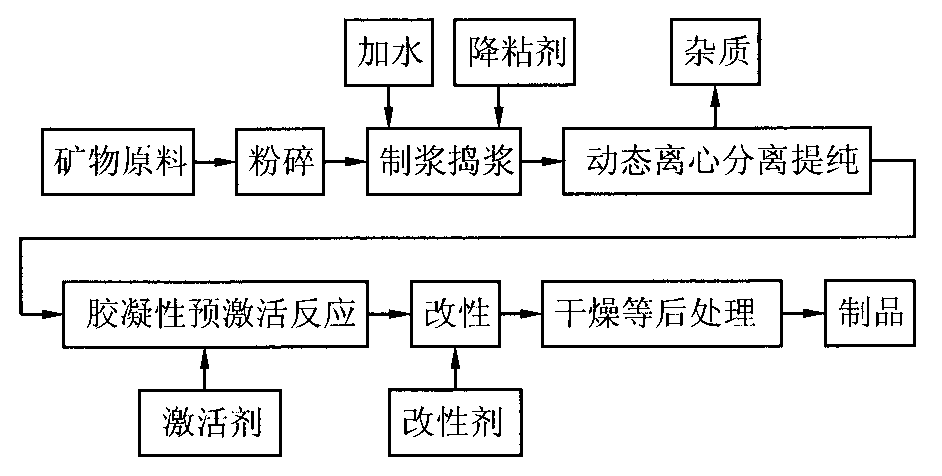

Method used

Image

Examples

Embodiment

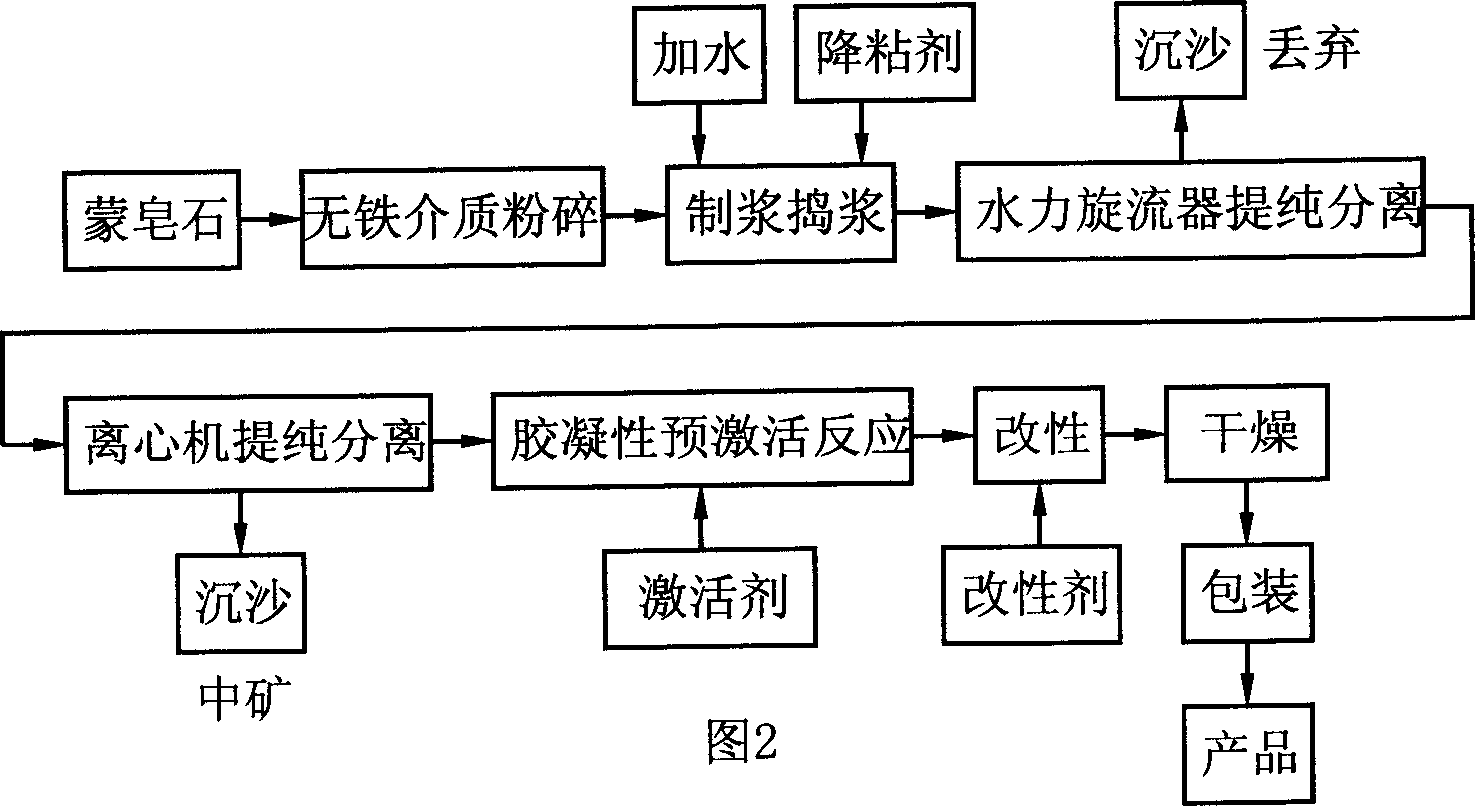

[0030]Embodiment: referring to shown in accompanying drawing 2, a kind of preparation method of natural magnesium aluminum silicate gel, take natural smectite mineral as raw material, prepare according to the following steps:

[0031] 1. The smectite ore (mainly composed of MgO 7.0% CaO 13.70% Al 2 o 3 9.32% Fe 2 o 3 2.64%) is crushed to a fineness of 100-200 mesh mineral powder through an iron-free medium.

[0032] 2. Add water to the ore powder to make a slurry with a concentration of 20-30% by weight, and pound it for 40 minutes. When pounding, add 0.5-10% of dry ore weight to the slurry. Sodium hexametaphosphate.

[0033] 3. The ore pulp obtained from the pulping operation is sorted by the secondary hydrocyclone, and the ore feeding pressure is 0.1-0.5Mpa (MPa), and the overflow ore pulp obtained is then purified by a centrifugal classifier under the condition of a separation factor of 600-2000 Separation to obtain purified pulp with a concentration of 4% to 5%. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com