Patents

Literature

700 results about "Aluminium silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium silicate (or aluminum silicate) is a name commonly applied to chemical compounds which are derived from aluminium oxide, Al₂O₃ and silicon dioxide, SiO₂ which may be anhydrous or hydrated, naturally occurring as minerals or synthetic. Their chemical formulae are often expressed as xAl₂O₃.ySiO₂.zH₂O. It is known as E number E559.

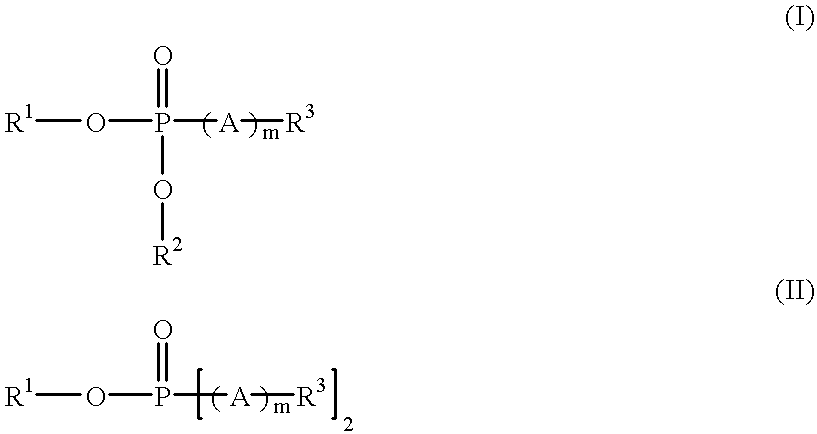

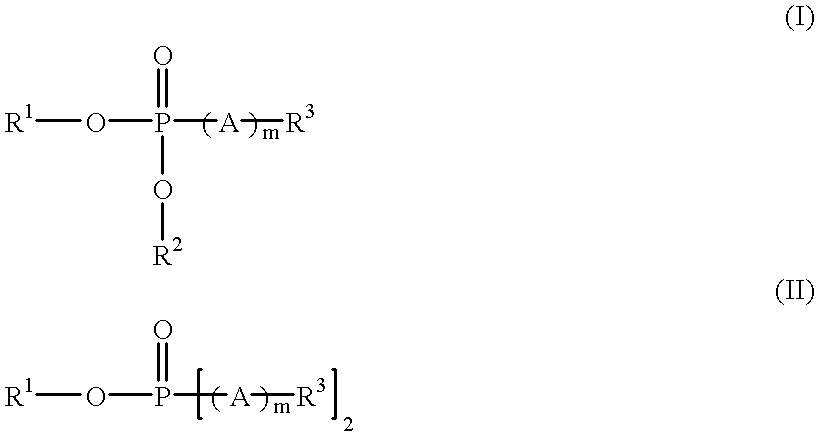

Toner coagulant processes

A process for the preparation of toner comprising mixing a colorant, a latex, optionally a wax and a polyaluminum sulfosilicate.

Owner:XEROX CORP

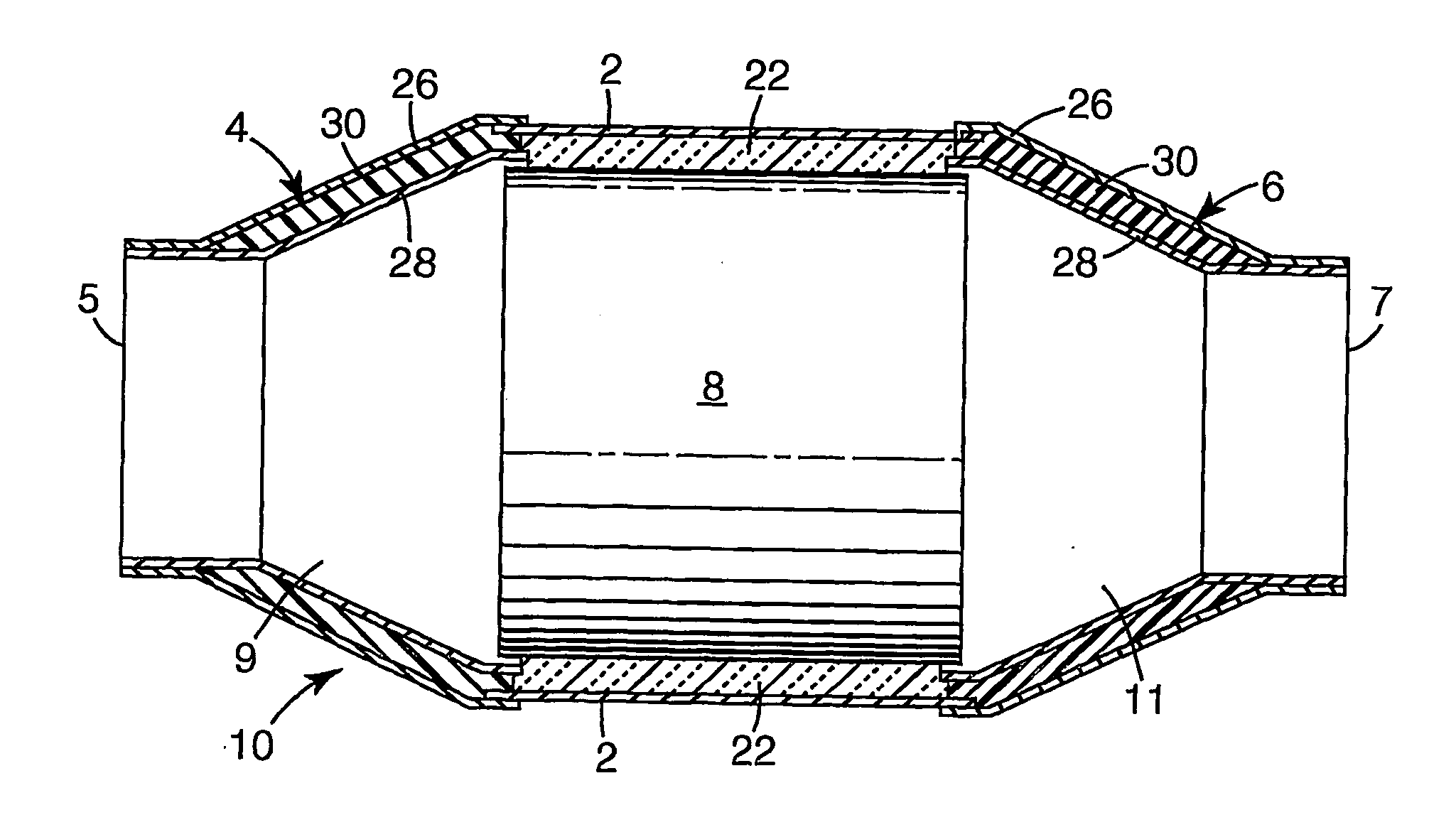

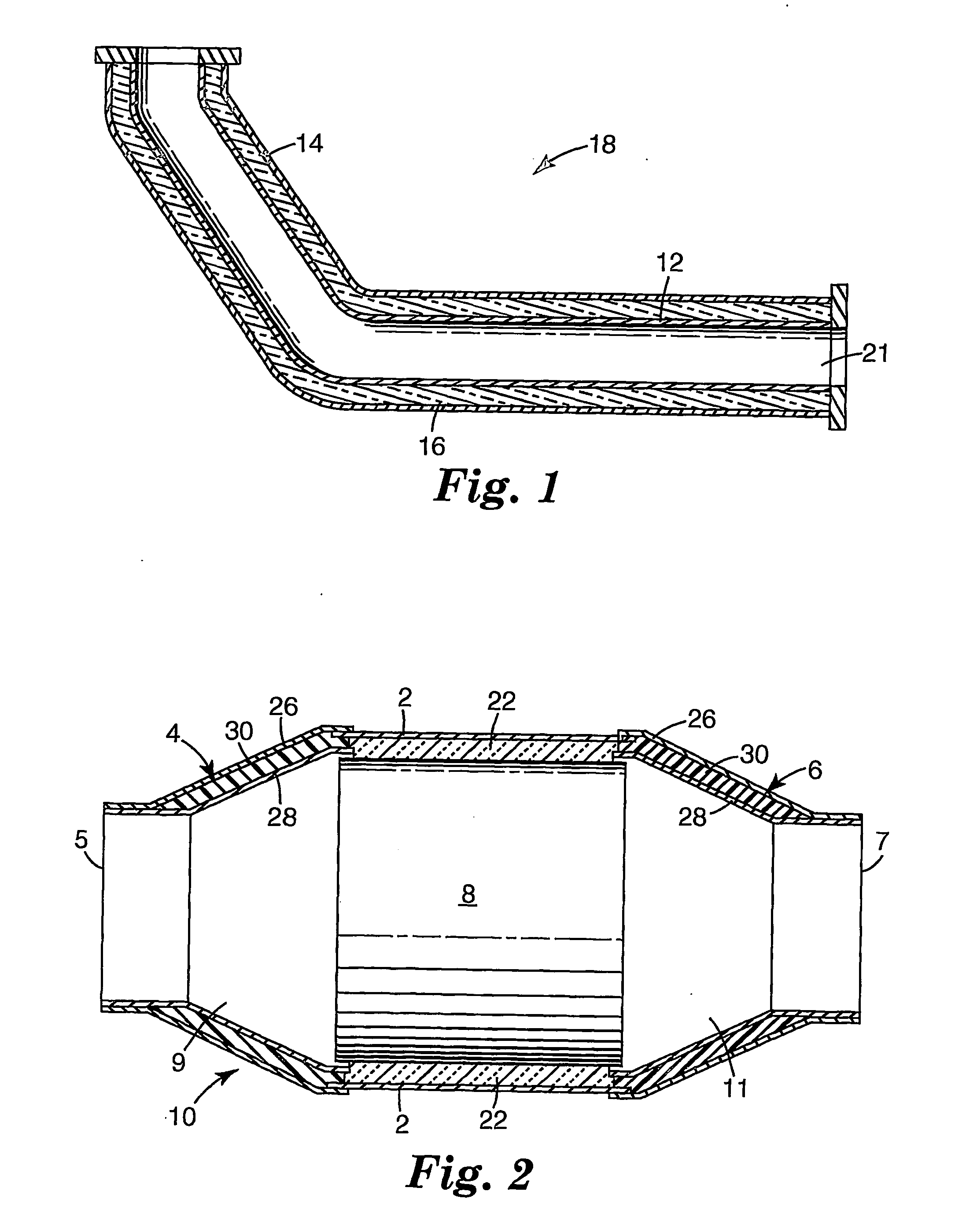

Non-classified end cone insulation for catalytic converter

ActiveUS20070065349A1Improve insulation performanceLow costCombination devicesSilencing apparatusGlass fiberSilicate glass

An exhaust system component (18, 10) for use in an exhaust system of a motor vehicle. The exhaust system component comprises a double wall surrounding a space (9, 11; 21) through which exhaust gas may flow when the exhaust system component is in use in an exhaust system. The double wall is comprised of a first and second metal wall (12, 14; 26, 28) that define between them a gap. The gap comprises an insulation material (16) made of chopped aluminium or magnesium aluminium silicate glass fibers. The insulation material can be in the form of, for example, an end cone perform. The exhaust system component can be an exhaust pipe (18).

Owner:3M INNOVATIVE PROPERTIES CO

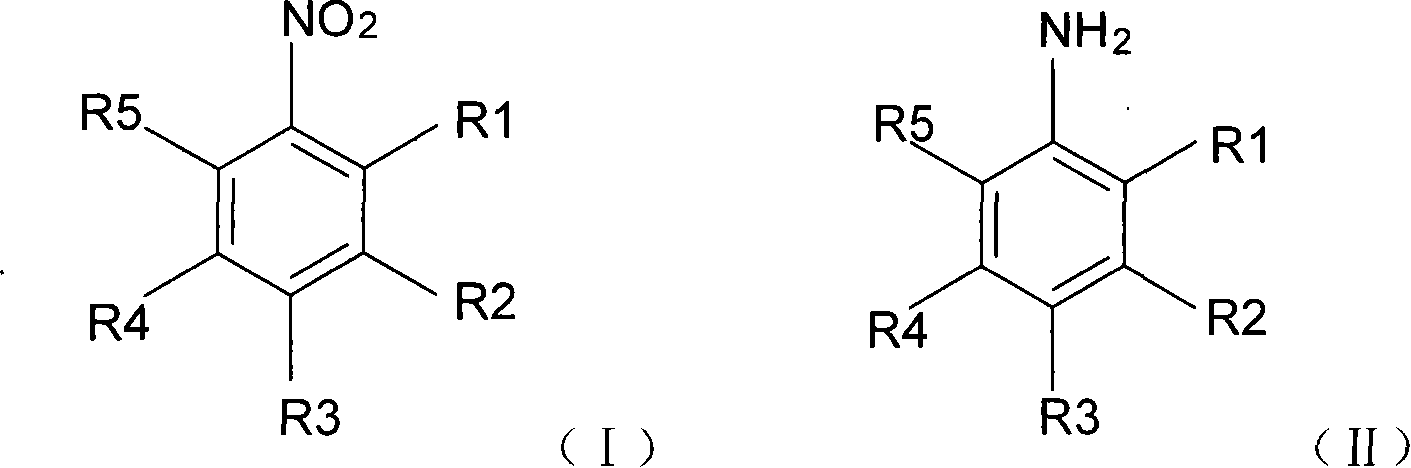

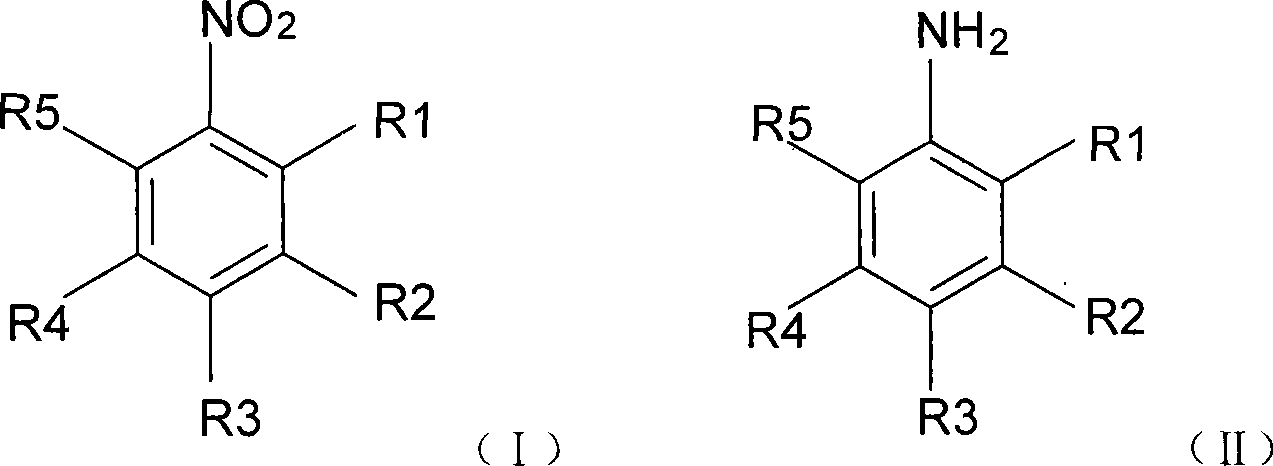

Method for preparation of (substituted radical containted) aminophenol by catalytic hydrogenation of (substituted radical containted) nitrophenol

ActiveCN101041623AOvercoming pollutionSolve problems such as recycling difficultiesMolecular sieve catalystsOrganic compound preparationMolecular sieveNitrophenol

The invention discloses a making method of aminophenol with substituted group through hydrogenating nitrophenol with substituted group, which adopts Ni-A / X typed loaded catalyst, wherein A is one of Co, Mn, Cu, Cr, Mo, Ca, Zn, Fe and W; the carrier X is one of their composition of zeolite molecular sieve, Al2O3, SiO2, TiO2, MgO, active charcoal or amorphic aluminium silicate; the mass percentage of Ni in the catalyst is 2-45% and the mass percentage of component A is 1-40%.

Owner:SHANGHAI HUAYI NEW MATERIAL

Mat for mounting a pollution control element in a pollution control device for the treatment of exhaust gas

InactiveUS20060153746A1Cost optimizationImprove performanceCombination devicesSilencing apparatusGlass fiberFiber

A pollution control device suitable for use with an internal combustion engine (e.g., a diesel engine) and comprising a pollution control element arranged in a casing with non-woven mat disposed between the casing and the pollution control element, said non-woven mat being a non-intumescent mat comprising at least 90% by weight based on the total weight of the mat of chopped magnesium aluminium silicate glass fibers that have a number average diameter of 5μ or more and a length of 0.5 to 15 cm, said glass fibers being needle punched or stitch bonded and said mat being free or substantially free of organic binder.

Owner:3M INNOVATIVE PROPERTIES CO

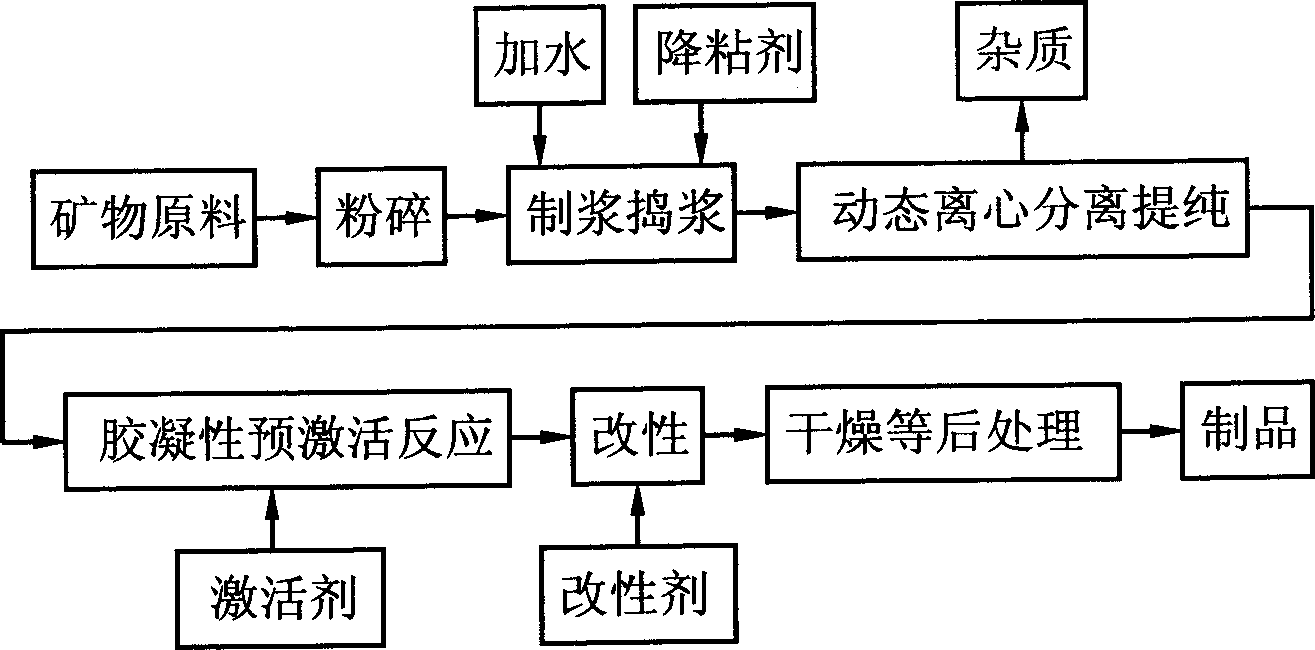

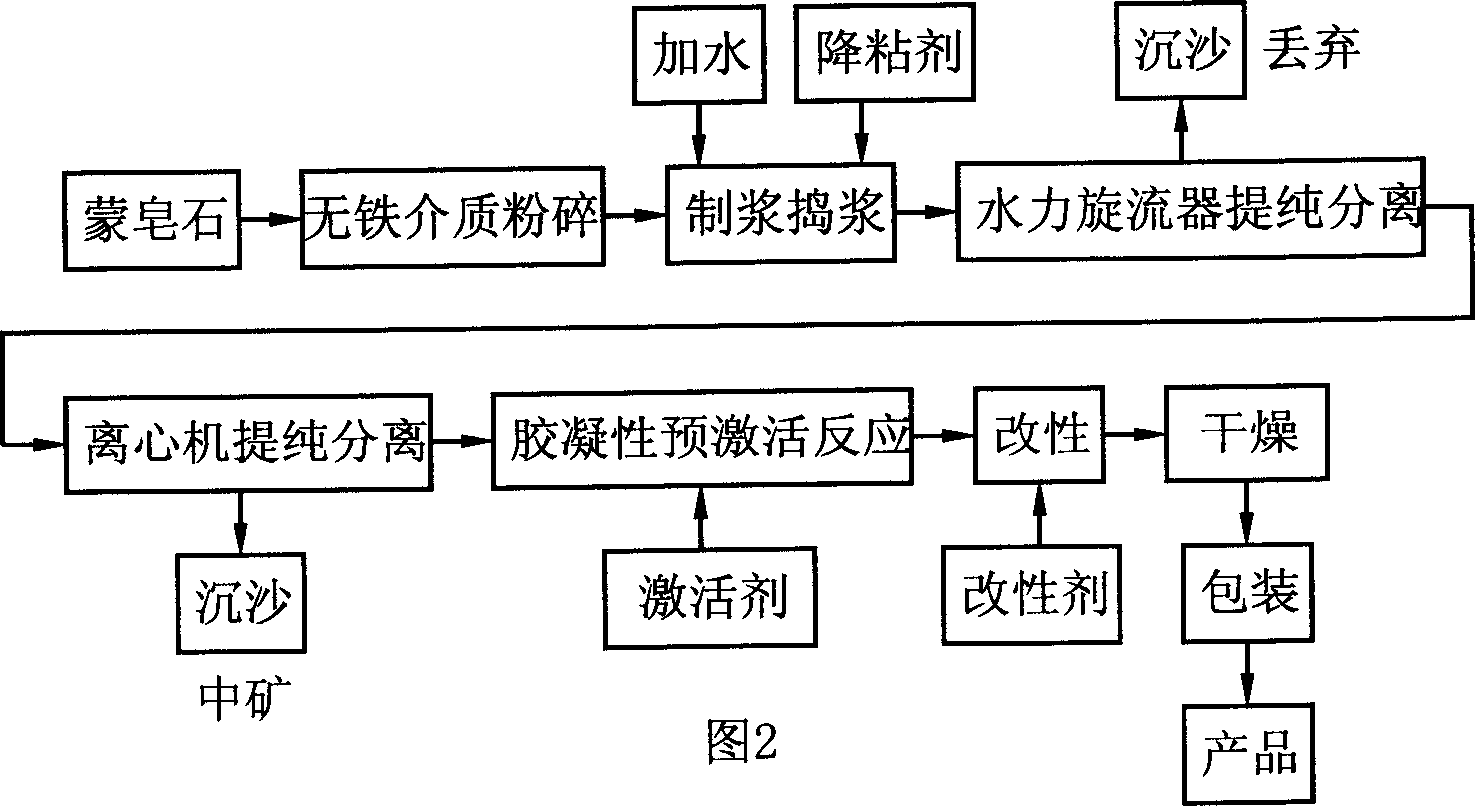

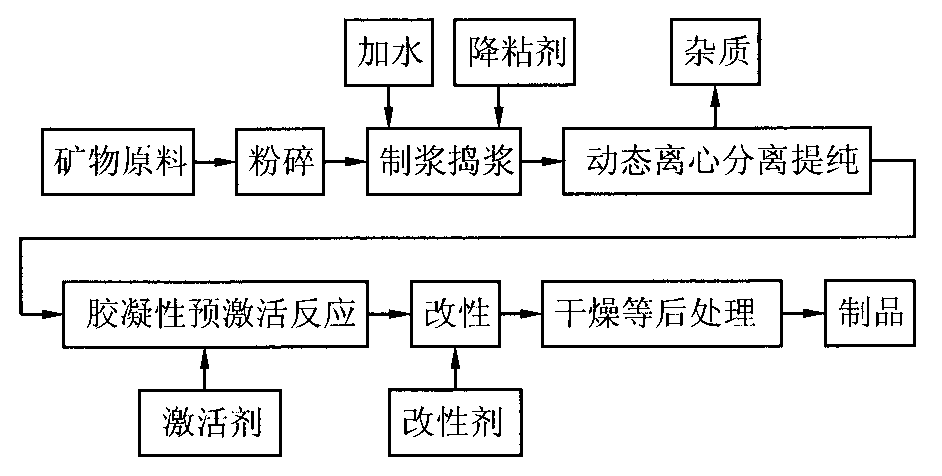

Process for preparing natural magnesium aluminium silicate gel

InactiveCN1363515AAvoid pollutionFe <sub>2</sub> o <sub>3</sub> Low contentAluminium silicatesInorganic saltsSodium Bentonite

A process for preparing natural gel of magnesium aluminium silicate from bentonite, attapulgite, bentone, etc includes such steps as pulverizing, preparing slurry, adding pour depressor, stirring, dynamic centrifugal separation, adding inorganic salt containing one-valence metal ions, stirring, pre-activating, adding organic salt containing at least Na ions, stirring for modifying, and post-treating.

Owner:国家非金属矿深加工工程技术研究中心

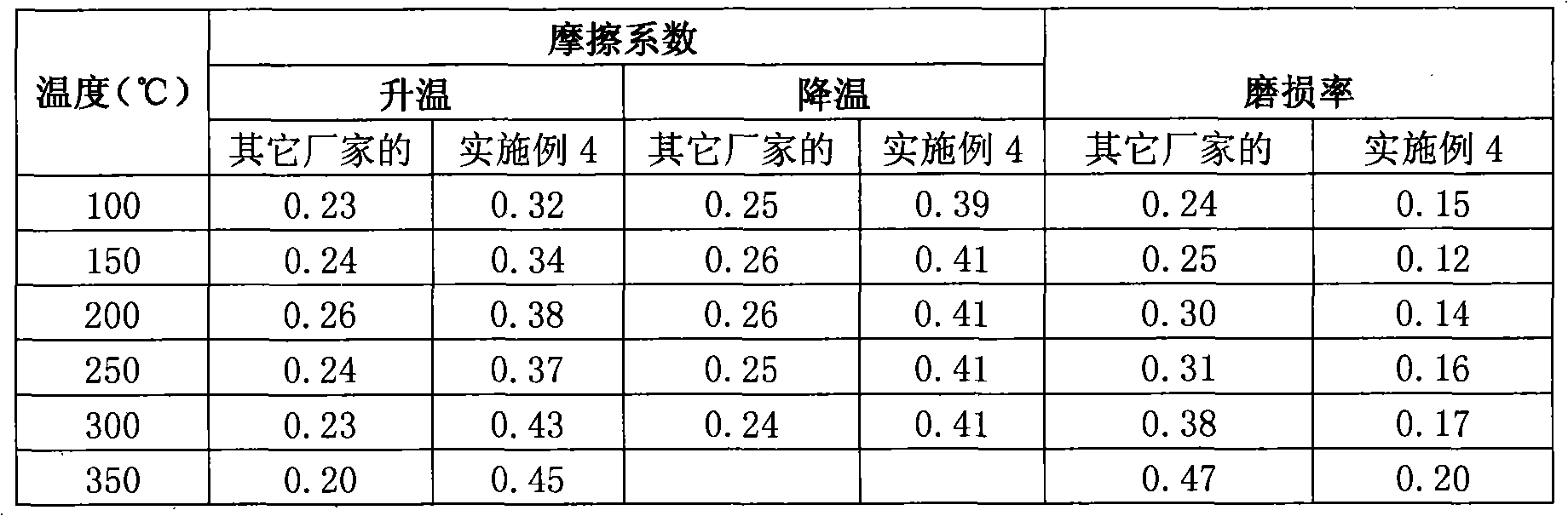

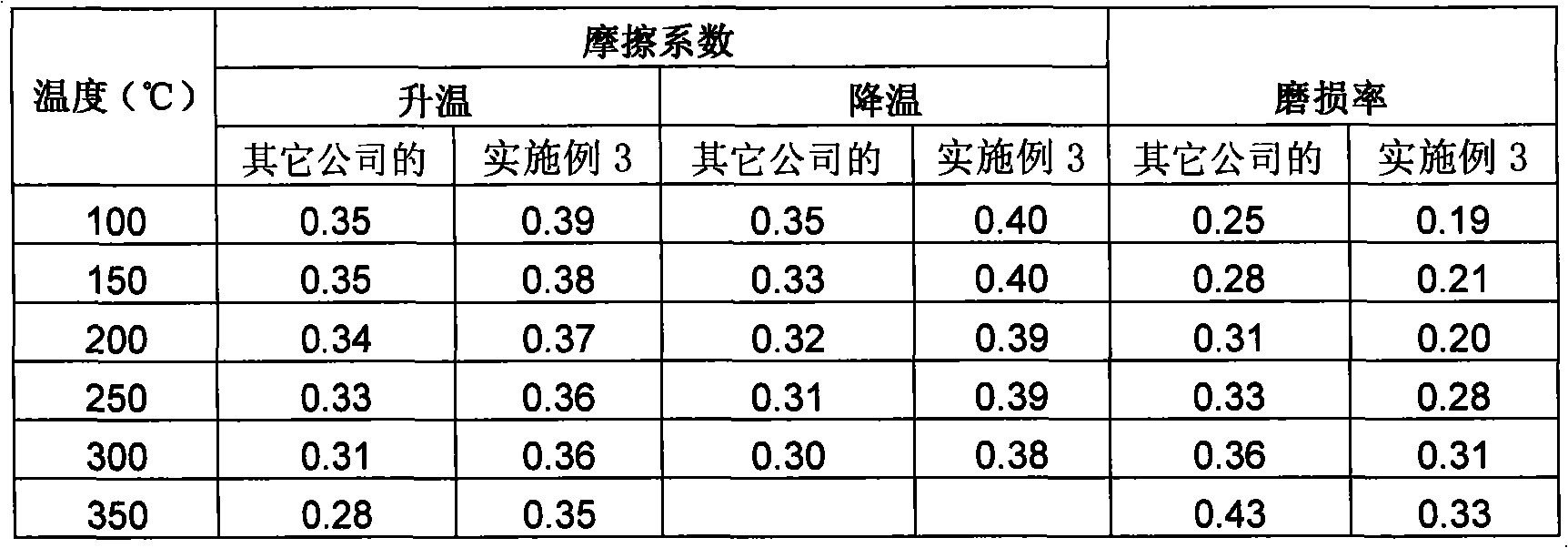

High-performance semi-metallic brake pad

ActiveCN101555915ASensitive brakesReduce brake noiseFriction liningGraphite particleAluminium silicate

A high-performance semi-metallic brake pad comprises the following components according to weight percentages: 4-6% of nitrile rubber powder, 2-4% of tyre powder, 3-5% of crystalline flake graphite, 6-9% of foam iron powder, 9-13% of boron containing phenolic resin, 8-12% of chopped steel fibre, 2-4% of alumina fibre, 8-11% of red copper fibre, 2-5% of cashew nut oil friction powder, 2-3% of graphite particle, 2-3% of calcined petroleum coke, 7-13% of barite, 3-4% of chromite, 2-3% of magnetite, 2-4% of diatomite, 7-10% of glued aluminium silicate fibre, 3-5% of flake aluminium powder, 2-4% of molybdenum disulfide, 0.2-0.5% of zinc stearate, 0.7-1% of antimony sulphide, 0.5-1% of copper sulphide, and 0.3-0.5% of tungsten carbide. After the brake pad is used, the car brake is sensitive, brake noise is low and comfort performance is good. The brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

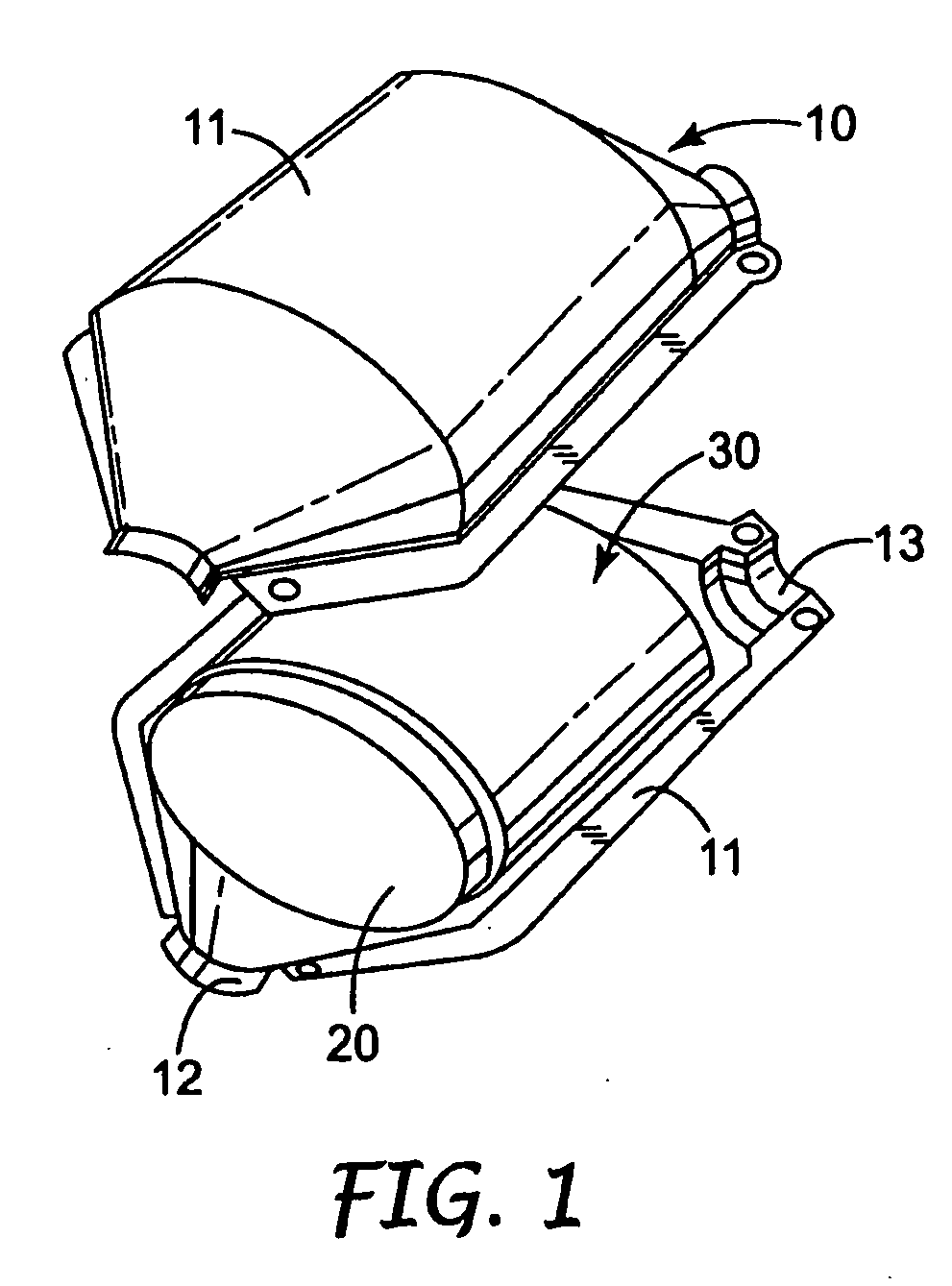

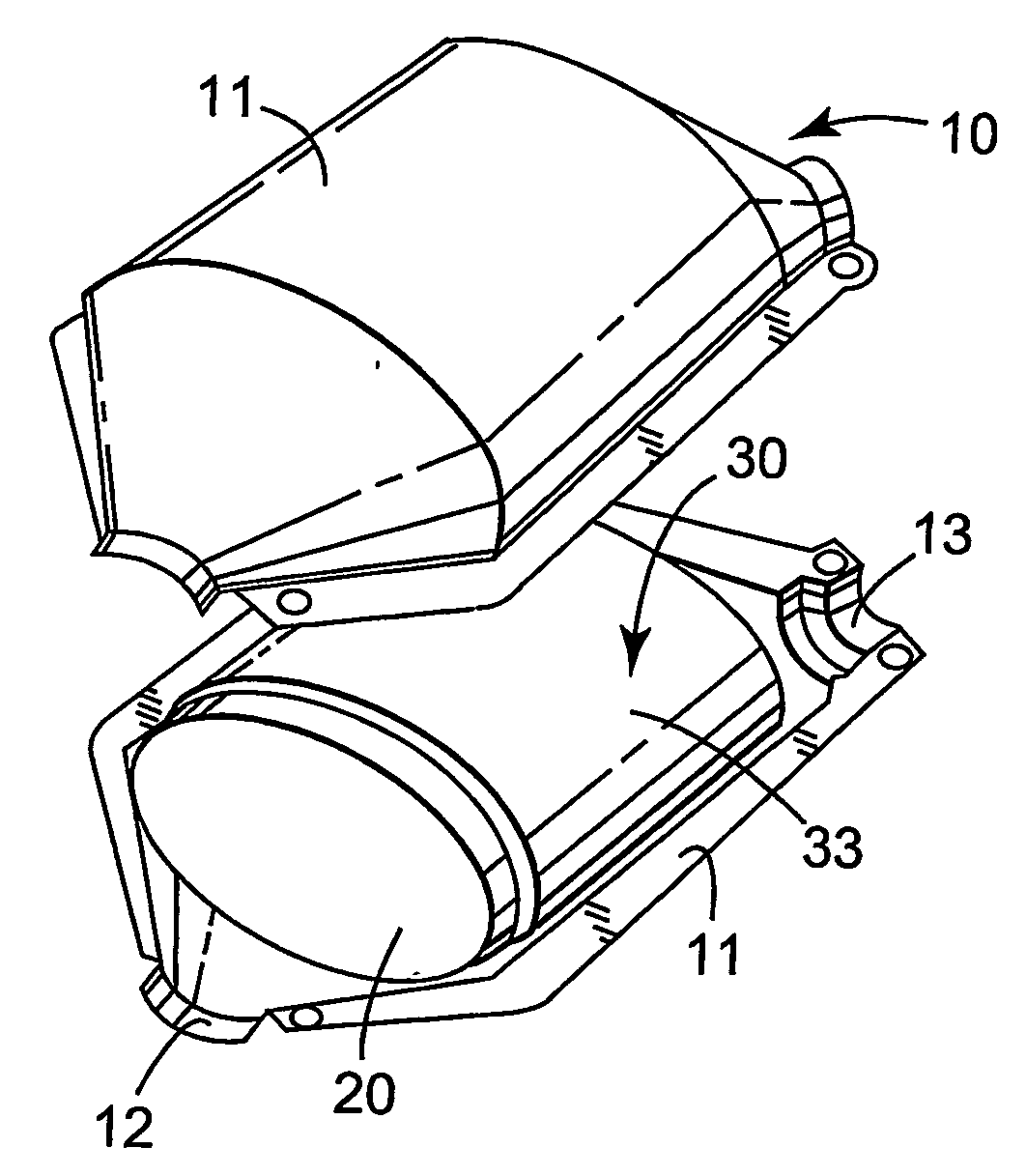

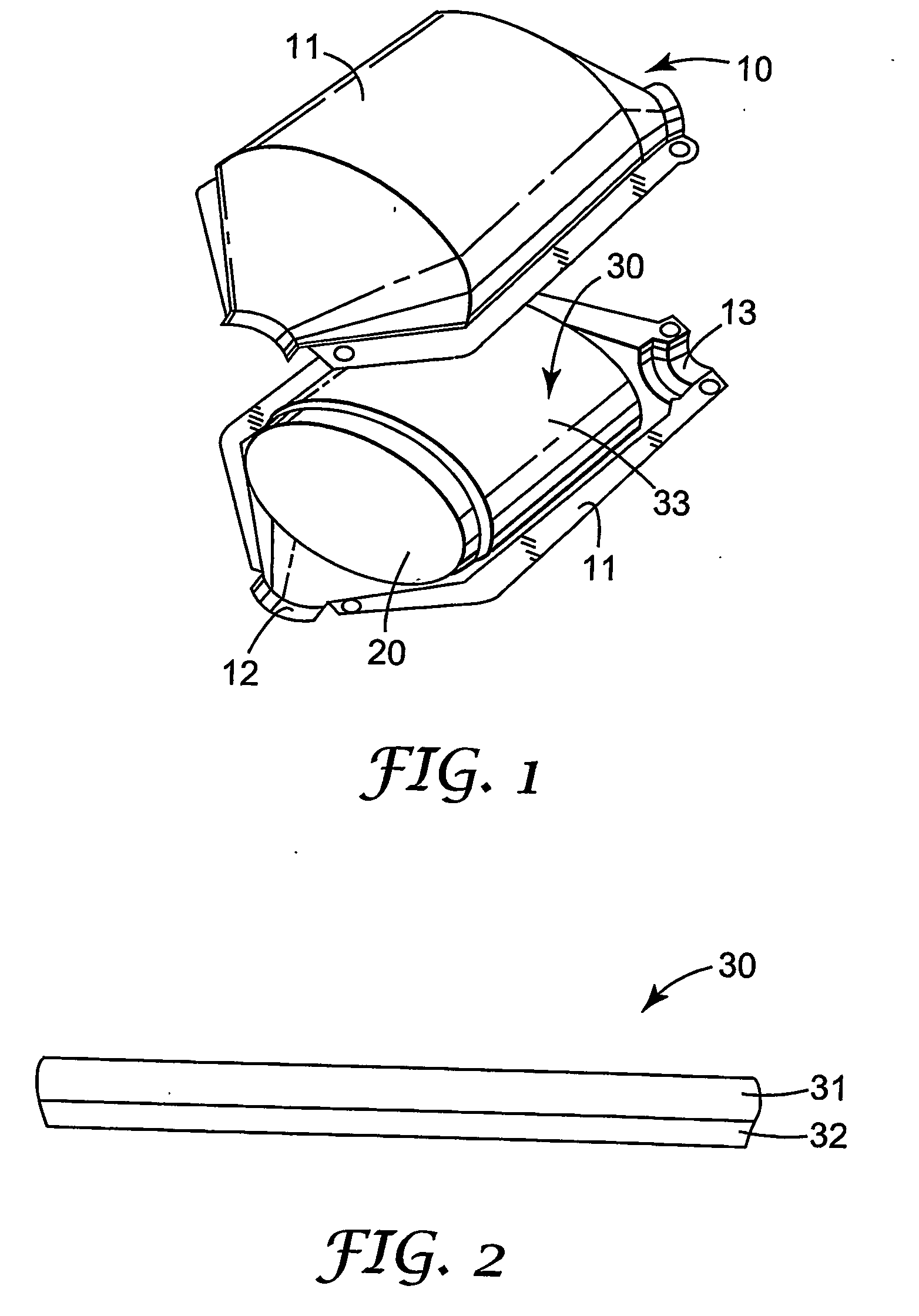

Mounting mat for a catalytic converter

InactiveUS20060257298A1Low costSufficient holding forceCombination devicesGas treatmentFiberGlass fiber

The present invention provides a mounting mat (30) for mounting a pollution control monolith (20) in a pollution control device (10). The mounting mat has a bulk density of 0.12 to 0.3 g / cm3 and comprises (i) a layer of chopped magnesium aluminium silicate glass fibers and (ii) a layer of ceramic fibers obtainable from a sol-gel process. Preferably, the layer of chopped magnesium aluminium silicate glass fibers and the layer of ceramic fibers define opposite major surfaces of the mat. The present invention further provides a pollution control device (10), comprising a pollution control monolith (20) arranged in a metallic casing (11) with the mounting mat (30) disposed between the metallic casing (11) and pollution control monolith (20).

Owner:3M INNOVATIVE PROPERTIES CO

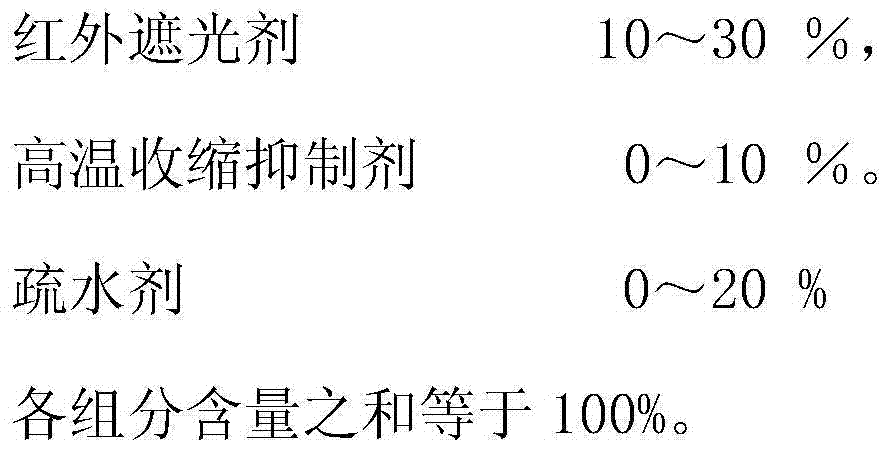

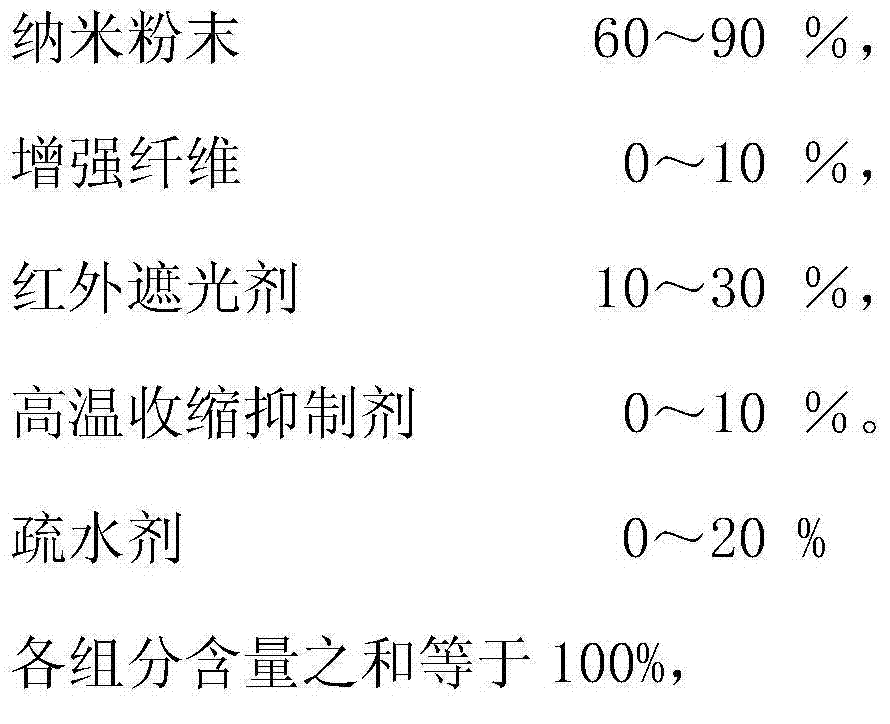

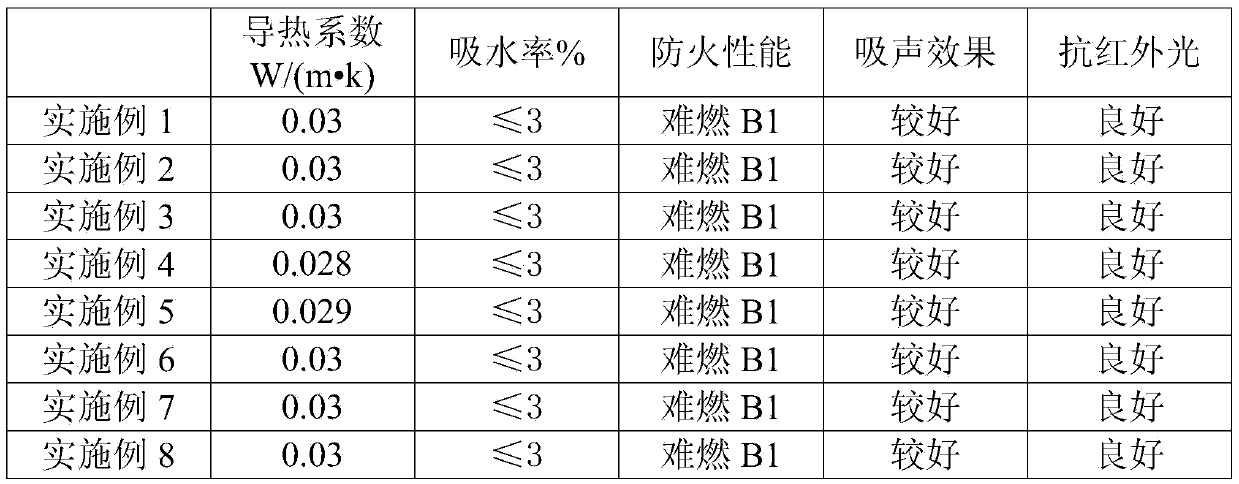

Preparation method of nanopowder-based composite thermal insulation material

The invention provides a preparation method of a nanopowder-based composite thermal insulation material. The preparation method comprises the following steps: by using nanopowder as a base material and alkali-free ultrafine glass fibers, aluminium silicate fibers, zirconia fibers, multicrystal mullite fibers and the like as reinforcing materials, adding infrared opacifiers (potassium hexatitanate whiskers, SiC, ZrSiO4 and rutile or anatase TiO2), adding a high-temperature contraction inhibitor and a hydrophobe as required and carrying out dispersion, blending, compression forming and the like, thus preparing the nanopowder-based composite thermal insulation material. The preparation method belongs to the dry forming preparation process and is simple in preparation process and safe and reliable in operation process. The press-formed thermal insulation material has good mechanical property, thermal insulation property, high-temperature thermal stability and hydrophobicity and can meet the requirements of the fields such as aerospace, the high-temperature industry and the like for efficient thermal insulation materials.

Owner:GUANGXI UNIV

Carbon-based polymer composite material capable of being ceramized and preparation method thereof

The invention relates to a carbon-based polymer composite material capable of being ceramized and a preparation method thereof. The carbon-based polymer composite material is formed by mixing and pressing carbon-based resin, a fiber-reinforced material, a high temperature-resistant coupling agent, aluminium silicate mineral powder and non-oxide ceramic powder, and the carbon-based polymer composite material specifically comprises the following components in parts by weight: 20-50 parts of the carbon-based resin, 10-40 parts of the fiber-reinforced material, 0.5-2 parts of the high temperature-resistant coupling agent, 10-50 parts of the aluminium silicate mineral powder and 1-10 parts of the non-oxide ceramic powder. Compared with the prior art, the composite material disclosed by the invention has the advantages of good thermal protection performance and anti-scour performance; a forming process of the composite material is simple, and aerobic thermal protection and ceramic formationare integrated; the ceramization temperature is lower and the ceramic conversion rate is higher; and the polymer composite material further has the advantages of capability of being formed by the polymer composite material process, strong designability, good mechanical properties at medium and low temperature, high ceramic conversion rate, low thermal weight loss rate, high retention rate of high-temperature strength and the like.

Owner:WUHAN UNIV OF TECH

Method for manufacturing aluminium silicate ceramic fiber using coalgangue and its use

InactiveCN1422820AImprove the level of comprehensive utilizationReduce pollutionGlass making apparatusFiberAluminium silicate

The invention refers to a method of making aluminum silicate ceramic fibery by gangue and the application. It uses the gangue as raw material and is produced by calcinations, melting, spray-blow or centrifugal swinging to make thread. The gangue chemical components: Al2O3>=43.00%, SiO2+Al2O3>=85.00%, Fe2O3 <=1.00%, K2O+Na2O<=0.50 and burning loss quantity<=15.00%, firstly calcining the gangue at 1000-1600 C degree for 300-360h, then melting in at 2100-2300 C degree.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Steelwork fire-retardant paint using self-crosslinking silicone-acrylic compound emulsion as substrate and preparation thereof

InactiveCN101205441AGood thermal oxidation resistanceGood cohesive energyFireproof paintsFiberMelamine phosphate

The invention relates to the fire retardant coating technical field, in particular to steel-structure fire retardant coating taking self-crosslinkable silicone-acrylate composite emulsion as substrate as well as a preparation method thereof. The invention adopts polysiloxanes and self-crosslinkable polyacrylate composite emulsion as film-forming materials; moreover, based on the commonly used composite fire retardant comprising ammonium polyphosphate, melamine and pentaerythritol, melamine phosphate and early stage foaming agent with excellent carbonizing and foaming performances are added in the fire retardant coating, thereby greatly increasing the foaming capacity of the coating with the thickness of the foaming layer 20 times to 35 times of the prior coating; meanwhile, titanium pigment, sepiolite and aluminium silicate fiber are adopted as high temperature resistant filler, and propylene glycol is adopted as film-forming auxiliary agent; in addition, the fire endurance of the formed fire retardant coating can reach 90min (when coating thickness is 2mm). The coating has simple preparation method, no pollution, low cost and wide application.

Owner:TONGJI UNIV

Powderlike mold-releasing agent for die-casing

The invention discloses a powdery release agent for die casting, which is composed of component A and component B with particle diameter n<=10 mu m, in which, the component B is one or more of polyethylene, polypropylene, polyethylene wax, micropowder wax, epoxy resin, silicone resin, phenol-formaldehyde resin or polystyrene, the weight per cent is 10-20%, the component A is one or more of talc, graphite, alumina, supramoly, aluminium nitride, boron nitride or aluminium silicate. The release agent of the invention is difficult to react even being heated, because of having powdery or particle-shaped form and with good chemical stability. In addition, after being used, without polluting the water quality and waste water releasing and processing problem, without polluting the environment, also reducing energy sources consuming. In a word, using the release agent of the invention can settle traditional problems of release agent, the invention improves quality of the casting, prolongs lifetime of the mould and reduces environmental pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

Production of TiO2 naometer light catalyzing net from foam metal carrier

InactiveCN1712131AStable chemical propertiesImprove breathabilityPhysical/chemical process catalystsPhoto catalyticWater quality

A foam metal carried nano-TiO2 photocatalyst mesh with high chemical stability, air permeability, specific surface area and photo catalytic activity is prepared through dipping the foam metal substrate in the sol of SiO2, Al2O3 or aluminium silicate, drying, calcining to generate a transition layer, immersing in the sol of tetrabutyl titanate, TiCl4, or TiCl3, drying, and calcining.

Owner:SHANGHAI JIAO TONG UNIV

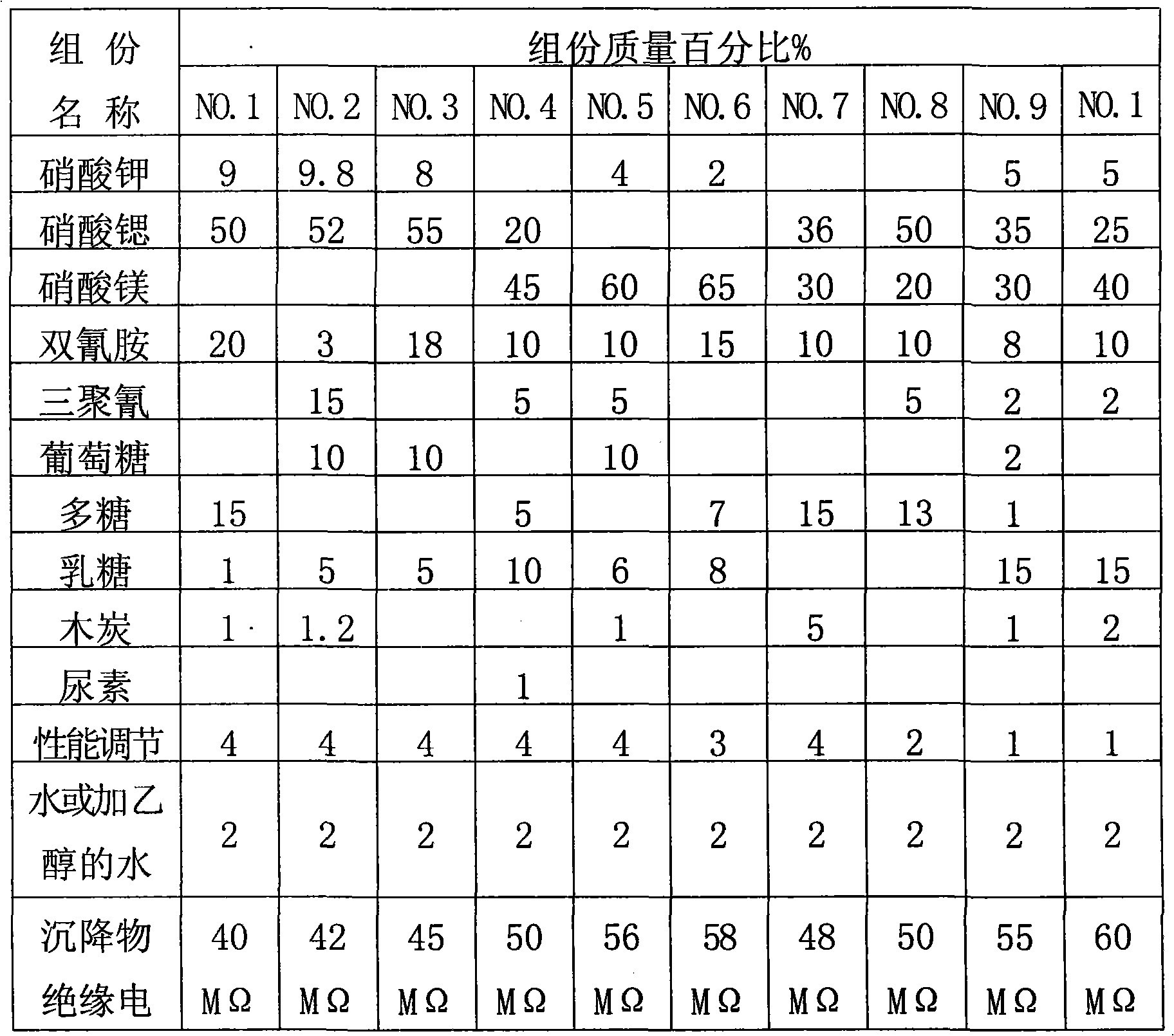

Compound type aerosol extinguishing agent

InactiveCN101862517ALow fire extinguishing concentrationImprove corrosion resistanceFire extinguisherSucroseNuclear chemistry

The invention discloses a compound type aerosol extinguishing agent comprising the following components in percentage by weight: 30-75 percent of oxidizing agent, 20-50 percent of reducing agent, 2-15 percent of performance regulating agent and no more than 2 percent of binding agent. The oxidizing agent is prepared by matching any two or three matched components selected from potassium nitrate, strontium nitrate and magnesium nitrate; the reducing agent is prepared by matching two or more components selected from polyhexose, glucose, starch, sorbitol, xylitol, lactose, dicyandiamide, melamine, carbamide and sucrose; the performance regulating agent is prepared by matching one or more component selected from carbon powder, light magnesium carbonate, magnesium stearate, aluminium nitrate, hexamethylenetetramine, aluminium oxide, magnesium oxide and light metal oxide; and the binding agent is prepared by matching water or 20-30 percent of ethanol added into the water. In the invention, production raw materials have a wide source and low cost, can be constantly obtained and are safe and reliable, and burnt residues have no toxicity and good environmental protection performance.

Owner:湖南省金鼎消防器材有限公司

Special synthesis process of poly ferrum aluminium silicate

InactiveCN1594082AShort synthesis timeLong storage timeAluminium silicatesWater/sewage treatment by flocculation/precipitationSlagAluminium silicate

The invention discloses a special synthesis process of poly ferrum aluminium silicate which comprises the steps of raw material selection, pulverized coal ash sintering, sintered coal ash handling, filtering sediment treatment, treatment of pickle liquor for iron-making waste slag, preparation of polymerized aluminum-ferrum, preparation of polymeric silicon acid and polyaluminum-ferric-silicate. The process can greatly shorten synthesizing time for finished product, and lower the fabrication cost and waste water treatment cost.

Owner:TAIYUAN INST OF TECH

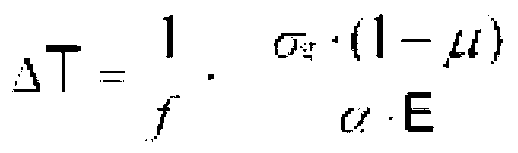

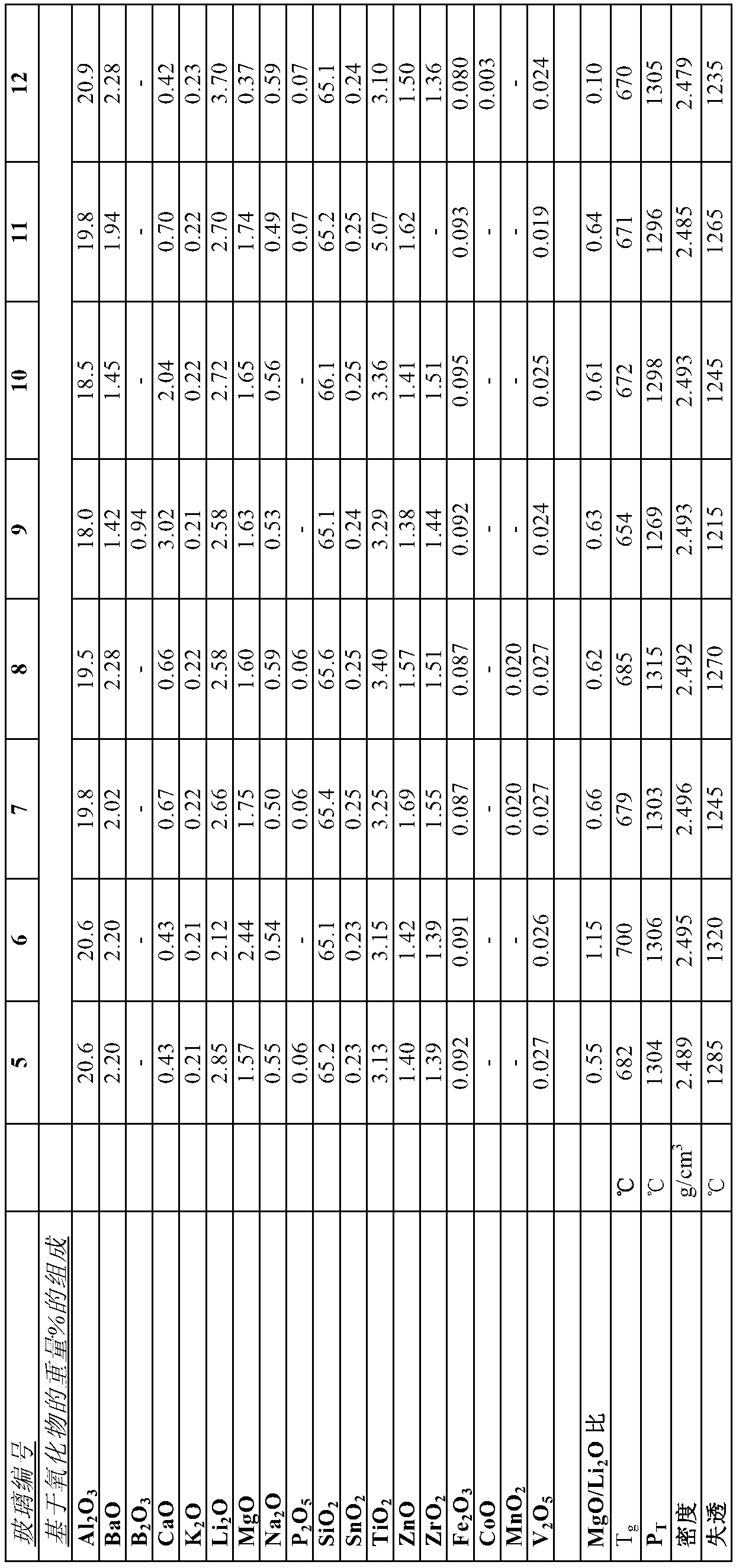

Transparent or transparent dyed lithium aluminium silicate glass ceramic material having adapted thermal expansion and use thereof

The invention relates to transparent or transparent dyed lithium aluminium silicate (LAS) glass ceramic material having an adapted thermal expansion, consisting of a glass ceramic material comprising high-quartz mixed crystals as the predominant crystalline phase, and a thermal expansion between room temperature and 700 DEG C from 1.0 to 2.5 10-6 / K, preferably from 1.3 to 1.8 10-6 / K.

Owner:SCHOTT AG

Ceramic brake pad of high-performing automobile

InactiveCN101555920AExtended service lifeImprove the lubrication effectFriction liningBoron nitrideCopper

A ceramic brake pad of high-performing automobile comprises the following components according to weight percentages: 7%-11% of ceramic fibre, 7-9% of glued aluminium silicate fibre, 5-8% of polyacrylonitrile fibre, 2-3% of aramid fibre 7-9% of red copper fibre, 7-10% of acicular aedelforsite fibre, 7-12% of barite, 7-9% of chromite, 1-2% of butyronitrile rubber, 7-11% of graphite particle, 0.2-0.5% of zinc oxide, 5-8.5% of calcined petroleum coke, 1-3% of expansion graphite, 6-10% of boron containing phenolic resin, 3-5% of magnetite, 1-1.5% of heavy-burned magnesia, 0.3-0.5% of modified whiten bead of resin acceptor, 3-5% of boron nitride and 0.3-0.5% of alumina; the invention can form excellent friction layer and transmission film in using process, thereby having good lubricating effect without damaging the couple plate; therefore, the service life of the friction material is greatly prolonged.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

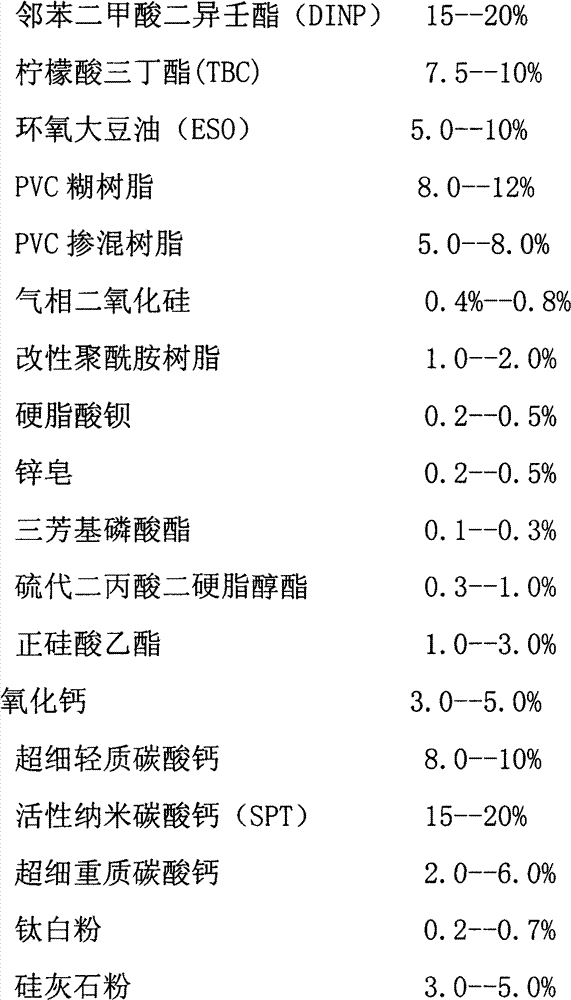

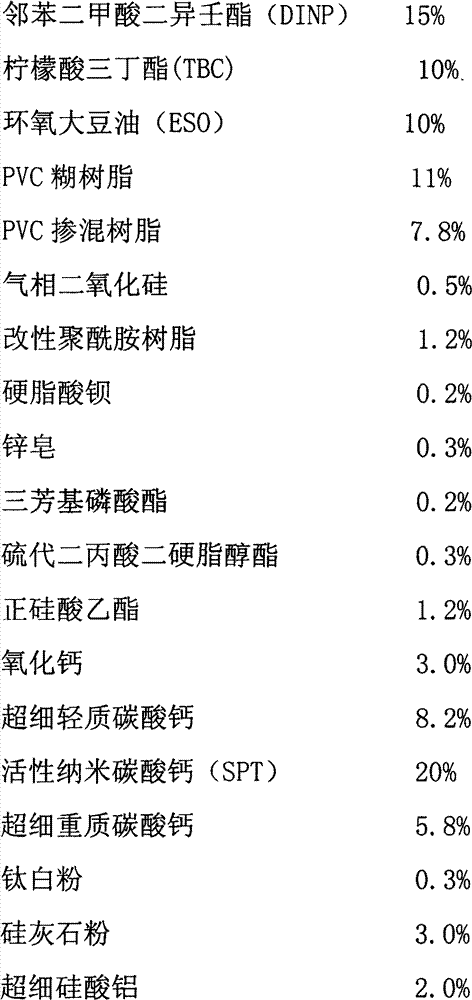

Environment-friendly PVC (Poly Vinyl Chloride) weld joint sealant for vehicle

ActiveCN102757746AGood compatibilityReduce usageNon-macromolecular adhesive additivesOther chemical processesPhosphateTributyl citrate

The invention relates to an environment-friendly PVC (Poly Vinyl Chloride) weld joint sealant for a vehicle. The environment-friendly PVC weld joint sealant mainly comprises the components of diisononyl phthalate (DINP), tributyl citrate (TBC), epoxidized soybean oil (ESO), PVC paste resin, PVC blend resin, fumed silica, modified polyamide resin, barium stearate, zincsoap, triaryl phosphate, thiodipropionic acid distearate alcohol ester, tetraethoxysilane, calcium oxide, ultrathin light calcium carbonate, active nano-calcium carbonate (SPT), ultrathin heavy calcium carbonate, titanium dioxide, wollastonite in powder, ultrathin aluminium silicate and the like. According to the environment-friendly PVC weld joint sealant provided by the invention, the technologies of raw material compounding, nontoxic additive adding and the like are adopted so as to reduce the curing temperature of the sealant; and a 'wet-to-wet' technology is achieved during coating the vehicle. Through the adoption of the environment-friendly PVC weld joint sealant, the energy consumption is reduced, and the volatizing of harmful gases is reduced. The environment-friendly PVC weld joint sealant has the characteristics of nontoxicity, environmental protection, fireproof performance, energy conservation, easiness in construction and the like The environment-friendly PVC weld joint sealant is an energy-conservation environmental-protection PVC weld joint sealant.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

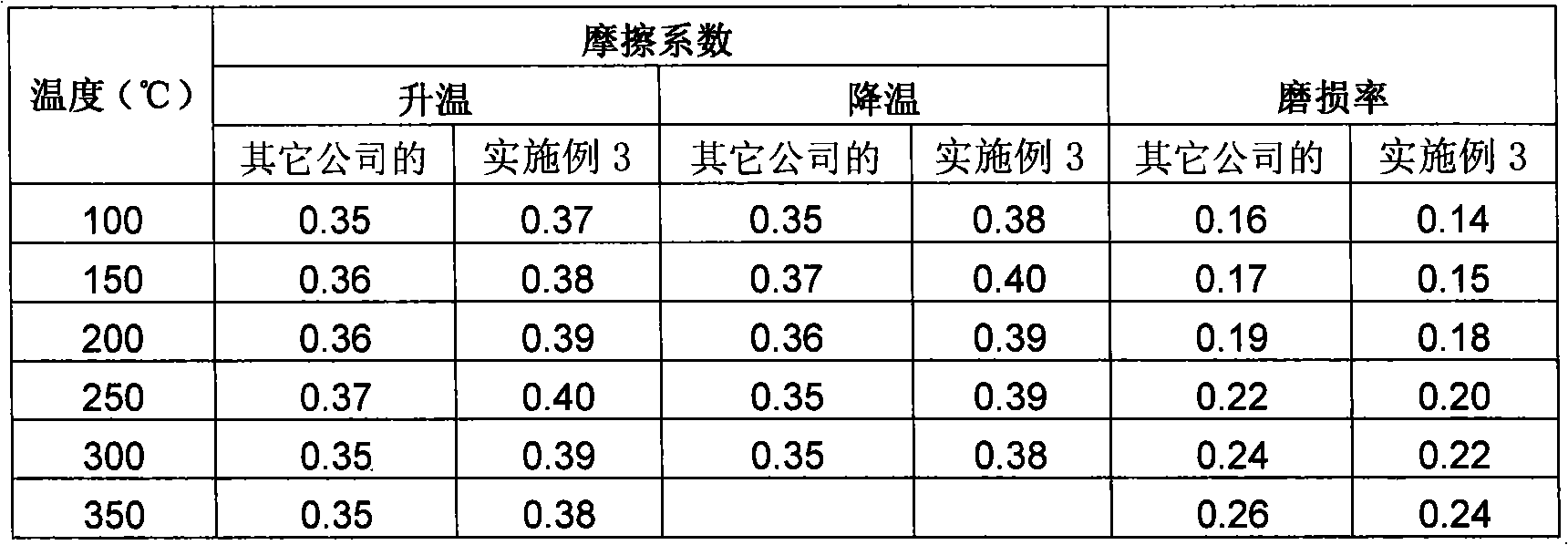

High-performance organic fibre brake pad

ActiveCN101555918AStable coefficient of frictionSmall thermal expansionFriction liningLow noiseCellulose

A high-performance organic fibre brake pad comprises the following components according to weight percentages: 5-9% of cashew nut oil friction powder, 4-8% of chromite, 7-10% of barite, 4-7% of calcined petroleum coke, 3-7% of crystalline flake graphite, 3-6% of sepiolite fibre, 4-7% of ceramic fibre, 1.5-3% of antimony sulphide, 4-7% of red copper fibre, 3-5% of glued aluminium silicate fibre, 1-2% of alumina fibre, 8-11% of vermiculite powder, 9-13% of organosilicone phenol-formaldehyde resin, 1-2% of carbon fibre, 5-7% of bastose, 1-2.5% of wood pulp cellulose, 3-6% of viscose fibre, 6-9% of bamboo carbon fibre, 3-5% of nitrile rubber and 0.3-0.5% of zinc oxide. The invention has the advantages of light weight, strong wear resistance, good flexibility, low noise and long service life, and the like, and the friction performance is stable at operating temperature between 100 DEG C and 450 DEG C.

Owner:摩擦一号制动科技(仙桃)有限公司

Ceramic fiber back lining board

A backing ceramic-fibre board as refractory is prepared from aluminium silicate fibre, organic fibre, mineral wool, expanded pearlite, clay, starch, polyacrylamide, and polymerized aluminium chloride through proportional mixing, preparing paste, shaping, drying and post-processing.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Repairing method of coking chamber of coke oven by using silica bricks

ActiveCN101974339AAvoid damageReduce outputCoke oven brickworkBrickwork leakage repair/preventionFiberBrick

The invention discloses a repairing method of a coking chamber of a coke oven by using silica bricks, comprising the following steps of: burning silica bricks or coking silica bricks according to the size of a coke oven silica brick; preparing the specific fireclay by adopting a coke oven hot-patch specific high-temperature binder, wherein added materials comprise high alumina powder and fireclay; manufacturing a thermal insulation material by adopting an aluminium silicate fiber felt with a certain thickness, evenly coating glass liquid on the aluminium silicate fiber felt and pasting the aluminium silicate fiber felt to a high-temperature silica brick wall surface for insulating; insulating heat by adopting an asbestos cloth as a fire curtain; manufacturing an insulating cage and squeezing the insulating cage into the coking chamber to form an insulating seal wall; and arranging buffer ovens with 1-2 holes on both sides of the coking chamber to be repaired and discontinuously heating burning chambers of both sides of the coking chamber to be repaired to control the temperature of the silica bricks. Due to the adoption of the technical scheme, the invention realizes oven wall restoration under a heat-state condition, greatly reduces the destroy to the coke oven silica bricks in a repairing process and the influence on coke over output and overcomes the defects of short use period, frequent repair, destroy of new oven wall bricks, and the like of the traditional repairing method.

Owner:WUHU XINXING DUCTILE IRON PIPES

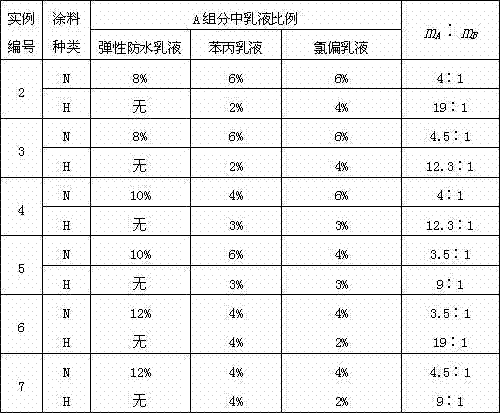

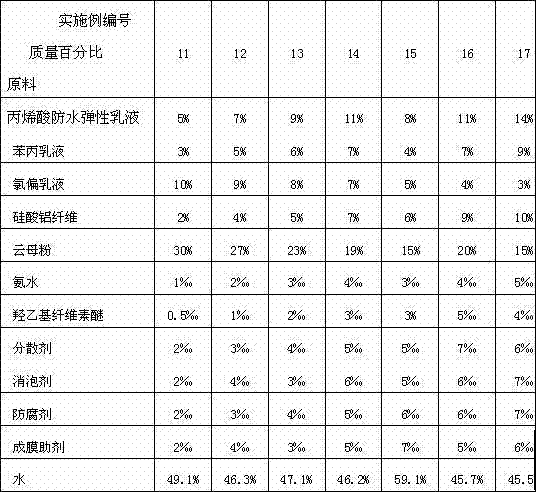

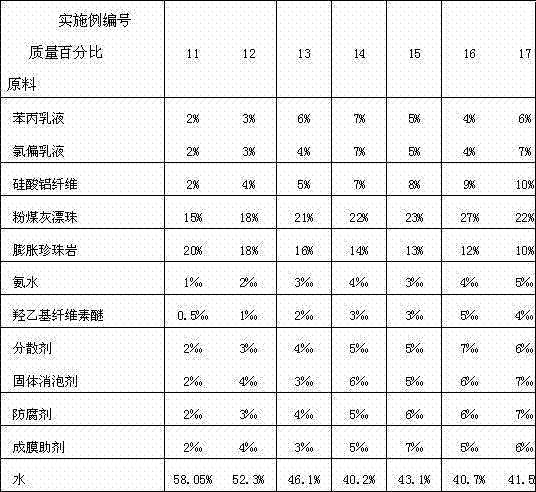

Preparation method for anti-corrosion and flameproof integrated coating for thick-type steel structure

The invention discloses a preparation method for an anti-corrosion and flameproof integrated coating for a thick-type steel structure. The coating is characterized by: preparing an anti-corrosion primer for a fire resistant-type steel structure, wherein the primer is prepared through mixing a component A and silicate cement, wherein the component A comprises emulsions such as acrylic acid waterproof elastic emulsion and the like, aluminium silicate fiber, mica powder, an assistant agent and water; preparing a flameproof coating for a thick-type steel structure, wherein the coating is preparedthrough mixing a component C and the silicate cement, wherein the component C comprises emulsions such as styrene-acrylate emulsion and the like, the aluminium silicate fiber, fly ash floater, expanded perlite, an assistant agent and the water; carrying out steps of cleaning process, the anti-corrosion primer coating, burnishing, the flameproof coating coating and the like for the surface of the steel structure to obtain the anti-corrosion and flameproof integrated coating for the thick-type steel structure, wherein the integrated coating is a system comprising the emulsion, the cement and the aluminium silicate fiber. The prepared coating provided by the present invention has characteristics of low comprehensive cost, anti-corrosion and flameproof integrated coating, and is applicable for the corrosion prevention and the flame protection for load-bearing steel structure components of various buildings in the industries of spaceflight, petroleum, chemical engineering, electric power, metallurgy, national defense, textile and the like.

Owner:四川金和时代建筑工程有限公司

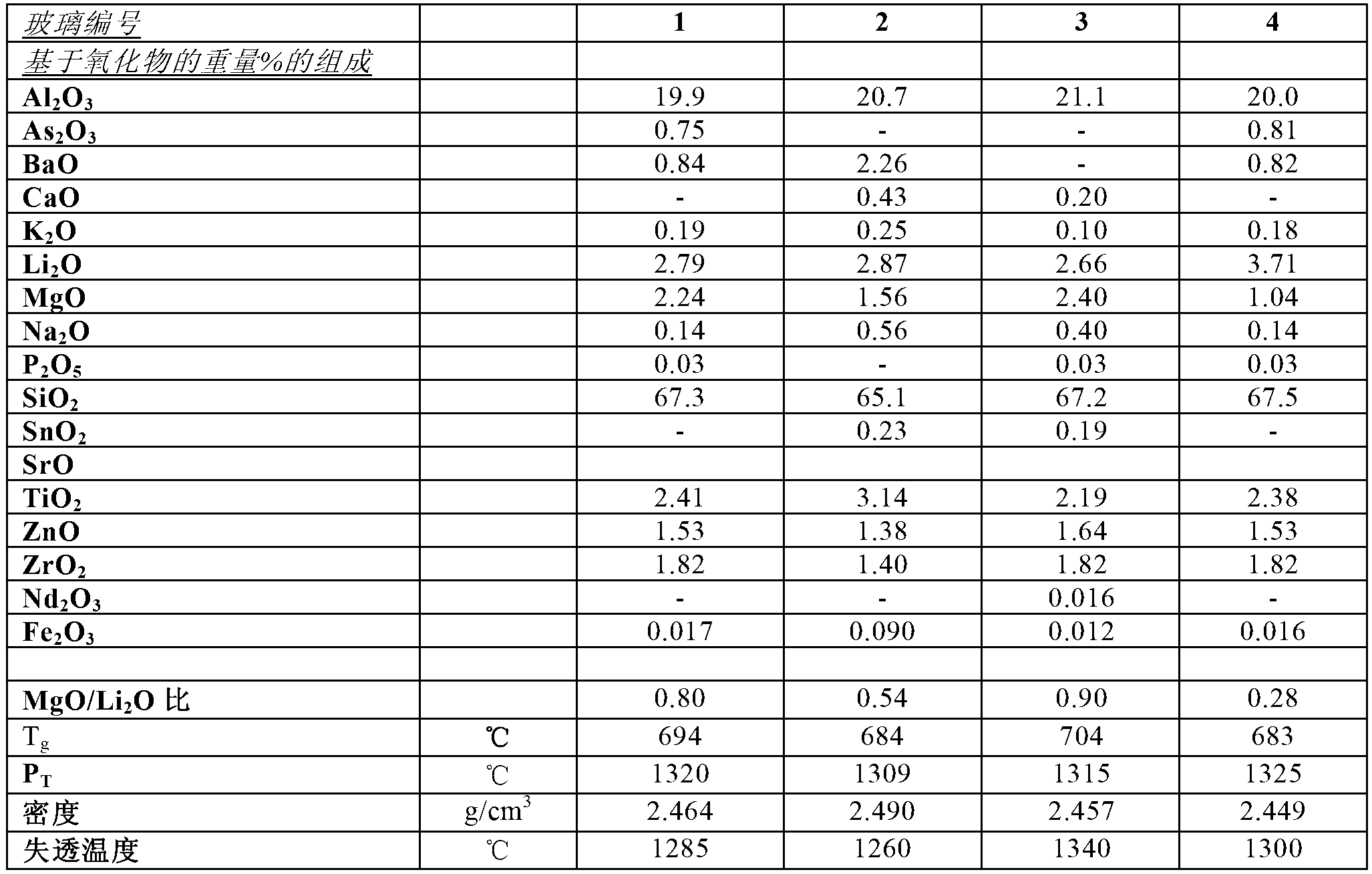

Method for environmentally friendly melting and refining a glass melt for an initial glass of a lithium-aluminium silicate (las) glass ceramic

The method of environmentally friendly melting and refining a glass melt of a crystallizable glass, which is used for making a lithium aluminium silicate (LAS) glass ceramic, includes the steps of providing a glass batch with a main batch composition within a lithium aluminium silicate (LAS) glass system, in which tin oxide has been added as main refining agent, but which does not contain arsenic oxide and / or antimony oxide as refining agent, formulating a raw material mixture for the glass batch for restricting the proportion of quartz sand of raw material, which is used for introducing the glass component SiO2, and refining a glass melt formed from the glass batch at temperatures of at least 1600 DEG C.

Owner:SCHOTT AG

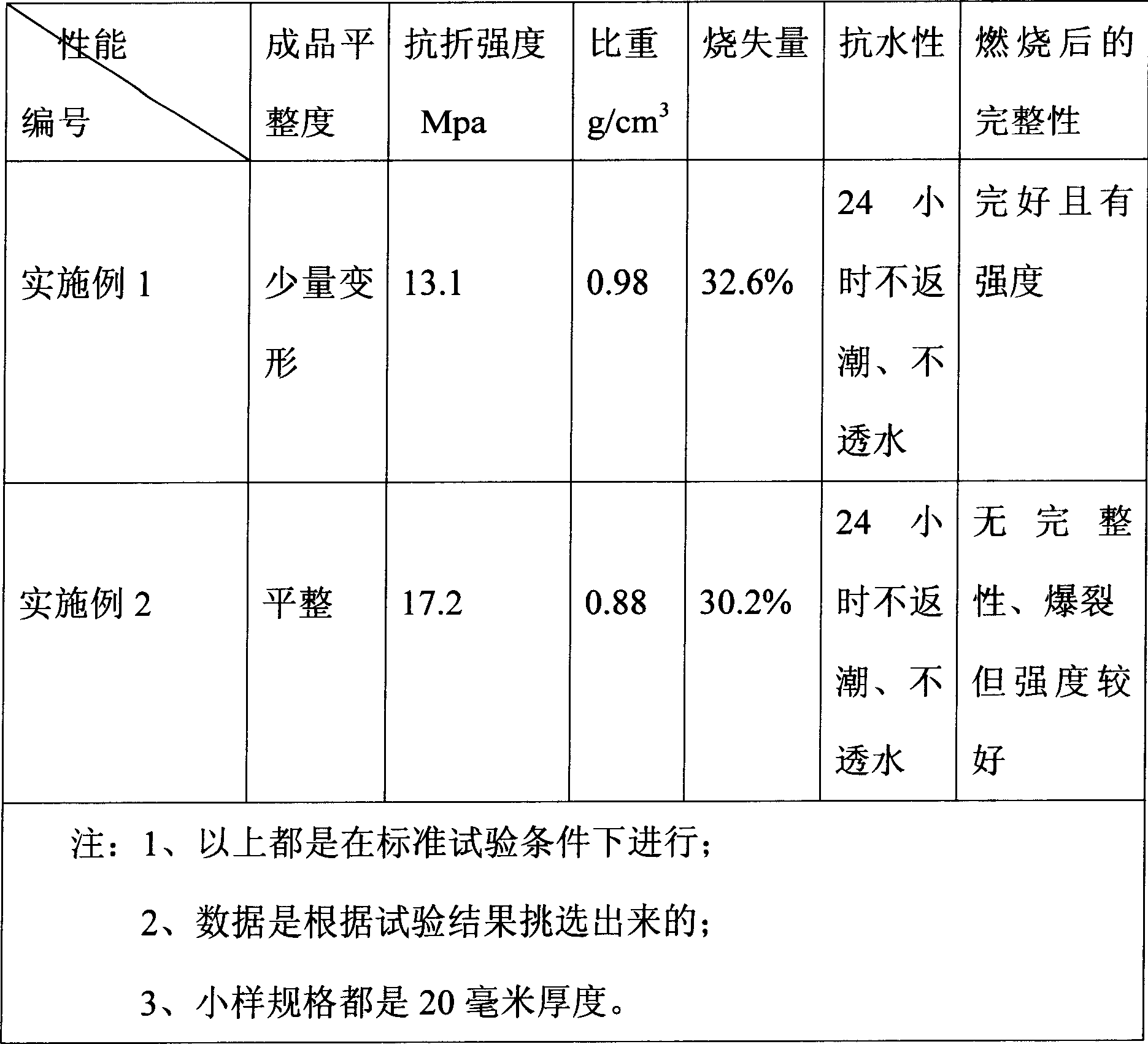

Organic and inorganic composite insulation material

ActiveCN102219460ARaw materials are easy to getReduce pollutionCement productionCombustionThermal insulation

The invention discloses an organic and inorganic composite insulation material which is a composite material prepared from an organic material as aggregate and an inorganic material as a bonder by stirring in a mixed way, moulding and forming at normal temperature or extruding and forming at high temperature. The proportion of the organic material to the inorganic material in parts by weight is (5-25): (75-95). The organic material is polystyrene foam or polyvinyl chloride foam or polyurethane foam. The inorganic material is aluminium silicate geological polymer material. The organic and inorganic composite insulation material prepared by the invention not only has good thermal insulation performance but also is advantageous for bonding to the inorganic material, such as a wall body and the like and is simple for construction and low in cost; and compared with the traditional organic insulation material, the organic and inorganic composite insulation material has the advantages of high strength, difficult combustion, low water absorption, low deformation, air permeability, light weight and the like.

Owner:GUANGXI UNIV

Fire-proof plate for tunnel

The invention relates the tunnel flame-resistant plate, comprising the following steps: using magnesium chloride and magnesium oxide as binder, using porcelain clay, volcanic ash, tabular spar, diatom earth and aluminium silicate as main material, using organic and inorganic compound salt as modified contaminant, using fortifying fiber (glass fiber) as reinforced materials, stirring, extrusion forming, and getting high-strength material.

Owner:张志明

Preparation method of titanium dioxide pigment with high covering power, weather resistance and whiteness

ActiveCN106497147AHigh whitenessGood average particle sizeCoatingsPigment physical treatmentFiltrationSlurry

The invention provides a preparation method of a titanium dioxide pigment with high covering power, weather resistance and whiteness. The preparation method includes: adopting a titanium dioxide primary product, beating in water to prepare slurry, adding water-soluble silicate solution as a dispersant, and performing curing prior to grinding treatment; heating up the slurry, adding in the water-soluble silicate solution, adopting mineral acid to regulate pH value, and performing curing prior to forming a dense, hydrated and unformed silica membrane; adding the water-soluble silicate solution again, maintaining the pH value of the slurry with an acidic aluminium compound, and performing curing prior to forming a loose and porous membrane layer taking aluminium hydrosilicate as a main ingredient so as to assure high covering power and whiteness; wrapping the loose hydrated alumina membrane to assure excellent dispersibility; performing filtration washing, drying, gasification and pulverization, and recovering with a bag filter to obtain the finished product. The preparation method has the advantages that the titanium dioxide pigment prepared with the method has high weather resistance and whiteness besides excellet covering power, is high in production cost, and can be widely applied to the fields of flat and matt building coatings, printing ink and the like with requirements on high dry covering power.

Owner:中信钛业股份有限公司

Hydrocracking catalyst and preparation method thereof

InactiveCN103007999AHigh activitySmall cell constantMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveHazardous substance

The invention relates to a hydrocracking catalyst and a preparation method thereof. The hydrocracking catalyst consists of hydrogenation active metal and a carrier structured by a modified composite molecular sieve and amorphous aluminium silicate; the hydrogenation active metal is molybdenum and / or tungsten, and / or cobalt, and / or nickel; the molybdenum and / or the tungsten accounts for 15.0-30.0% of the weight of the catalyst as weighed by oxide; the cobalt and / or the nickel accounts for 4.0-8.0% of the weight of the catalyst as weighed by oxide; the balance is the carrier structured by the modified composite molecular sieve and amorphous aluminium silicate; and the modified composite molecular sieve accounts for 10-20% and the amorphous aluminium silicate accounts for 80-90% by metering as the weight of the catalyst. The catalyst has the advantages that the raw materials are cheap and easy to buy; the preparation process is simple and easy to operate and has no generation of poisonous and harmful substances; the adaptability directing at the feature change of the raw materials; and the catalyst is suitable for experiment research on the existing hydrocracking process technology, can effectively solve the laboratory research difficulty and provides a reliable guarantee for the research and implementation of the hydrocracking process technology.

Owner:PETROCHINA CO LTD

Heat-preserving material for outer wall

The present invention discloses a heat-preserving material for an outer wall which comprises the following raw materials in parts by weight: 45-55 parts of coal ash silicate cement, 15-20 parts of white floating beads, 1.5-2 parts of nano TiO2, 0.5-1.2 parts of ceramic cotton fiber, 5-10 parts of aluminium silicate fiber cotton, 0.2-0.6 part of a water repellent, 3-7 parts of an elastic emulsion, 6-9 parts of swelled vitrified microbead heat-preserving slurry, 3.5-4.5 parts of polypropylene fiber, 2-5 parts of an inorganic nano coating, 0.05-0.1 part of foam filaments, 0.05-0.1 part of bamboo fiber and 10-15 parts of a flame retardant. The heat-preserving material for the outer wall has the characteristics of good heat preservation, thermal insulation, sound insulation, self-cleaning, ray resistance, water resistance, energy conservation and environment protection and high strength.

Owner:NANYANG INST OF TECH

Emulsification type car cleaning polish and preparation method of emulsification type car cleaning polish

InactiveCN102703232AEasy to cleanNo harmInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsParaffin waxAluminium silicate

The invention discloses an emulsification type car cleaning polish and a preparation method of the emulsification type car cleaning polish and belonging to the field of fine chemicals. The emulsification type car cleaning polish is characterized in that the emulsion is prepared by using paraffin wax, carnauba wax and methylsilicone oil as the polish, mineral oil as a penetrating agent, fatty alcohol-polyoxyethylene (7) ether and fatty alcohol-polyoxyethylene (10) ether as an emulsifier, coconutt diethanol amide and coconut fatty alkanolamide as a washing detergent and a synergist, aluminium silicate as a grinding material and water as the medium and adding essences. The emulsification type car cleaning polish disclosed by the invention is an emulsification type car cleaning polish with integration of cleaning, polishing, anti-static, dustproof and waterproof and the like functions; the cleaning capacity to oil strains is very strong and the brightness can be maintained for a long timeafter use; and the emulsification type car cleaning polish is an energy-saving and environmental-friendly product and has no harm to human bodies and no pollution to the environment.

Owner:邹庆

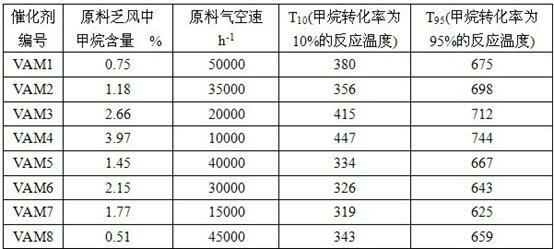

Ventilation air methane combustion catalyst and preparation method thereof

InactiveCN101947457AEasy to prepareLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSilicic acid

The invention discloses a ventilation air methane combustion catalyst and a preparation method thereof. The catalyst consists of the following components in percentage by weight: 1 to 50 percent of active ingredient, 1 to 30 percent of active aid and the balance of porous carrier, wherein the active ingredient is one or two of oxides of manganese and cobalt or soluble salts of manganese and cobalt; the active aid is any one of cerium compounds or lanthanum compounds; and the porous carrier is one or more of aluminium oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon dioxide, aluminium silicate and magnesium silicate. The catalyst is applied to ventilation air methane combustion and has the advantages of simple preparation method, low cost, relatively low methane ignition point and complete combustion temperature, and the like.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com