Patents

Literature

690 results about "Thiodipropionic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

THIODIPROPIONIC ACID WHEN INJECTED INTO RABBITS IS RAPIDLY ELIMINATED UNCHANGED IN THE URINE (80% EXCRETED IN 2 HOURS) /PRC: LIKE DICARBOXYLIC ACIDS IN GENERAL/ Lefaux, R. Practical Toxicology of Plastics. Cleveland: CRC Press Inc., 1968., p. 402. from HSDB. Human Metabolite Information.

Low-odour polypropylene composite

The invention relates to a low-odour polypropylene compound, the compound comprises (by weight ratio) polypropylene 55-95, talcum powder 0-40, fatty acid ester compound 0.5-3, nano zinc oxide 0.5-3, nano titanium oxide 0.5-3, heat stabilizer DSTP 0.1-1.0, heat stabilizer 3114 0.1-1.0, heat stabilizer 618 0.1-0.5, wherein the fatty acid ester compound being C25-C45 long-chain fatty acid ester, the heat stabilizer DSTP being octadecyl thiodipropionate, the heat stabilizer 3114 being 3,obtaining 5-ditert-butyl-4-hydroxy benzylphosphonate diethylate, the heat stabilizer being dioctadecyl pentaerythritol diphosphite.

Owner:SHANGHAI PRET COMPOSITES +1

Stabilized insulation composition

InactiveUS6187858B1High decomposition temperatureFast curingOrganic chemistryPlastic/resin/waxes insulatorsPropionateAntioxidant

A composition comprising:(a) polyethylene;(b) as a first antioxidant, a thiobisphenol;(c) as a second antioxidant, a compound containing 3-(3,5-di-t-butyl-4-hydroxyphenyl)propionate in the molecule;(d) as a third antioxidant, distearyl thiodipropionate; and(e) an organic peroxide,with the proviso that each antioxidant is present in an amount of about 0.01 to the about 0.2 part by weight and the organic peroxide is present in an amount of about 0.5 to about 3 parts by weight, all per 100 parts by weight of polyethylene.

Owner:NIPPON YUNIKAA

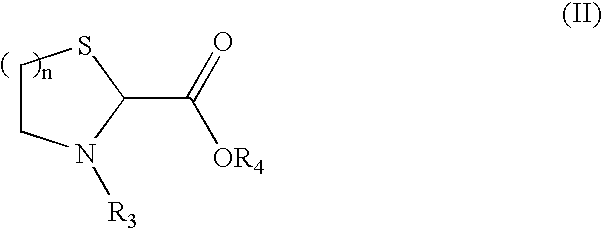

Cosmetic compositions and methods for using same to improve the aesthetic appearance of skin

InactiveUS20040067245A1Treating and preventing and ameliorating sign of dermatological agingImprove aestheticsCosmetic preparationsSalicyclic acid active ingredientsPerilla oilCarboxylic acid

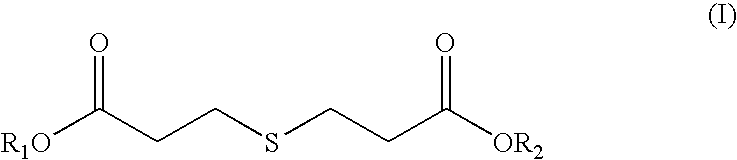

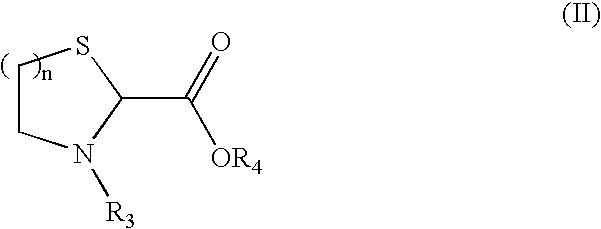

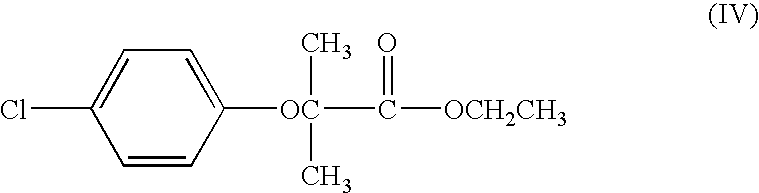

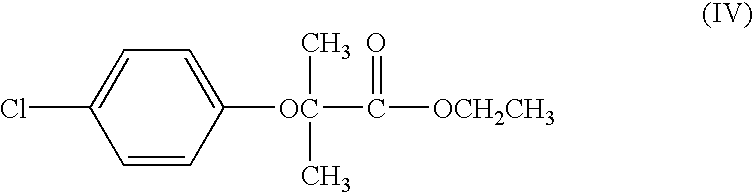

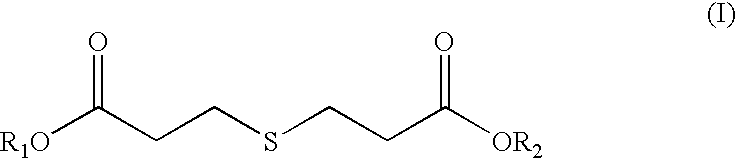

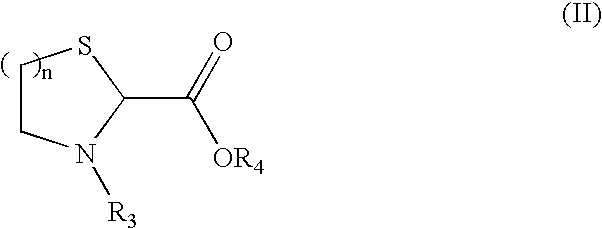

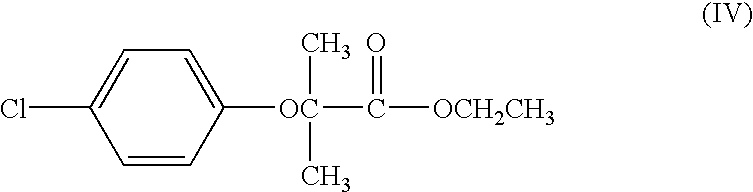

The present invention relates to compositions useful in treating hyperpigmentation and the various signs of dermatological aging in human skin. The present invention also relates to cosmetic compositions and methods of using such compositions that improve the aesthetic appearance of skin. Further, the present invention relates to methods of applying the compositions to the skin to effect treatment and to improve the aesthetic appearance of skin, particularly, by providing anti-aging benefits to the skin. These and other objects of the present invention are achieved by a method and composition that comprises (a) a de-pigmenting agent or anti-aging agent in an amount effective to prevent, treat and / or ameliorate pigmentation or the various signs of aging at an area of skin to which it is applied, and (b) a cosmetically or pharmaceutically acceptable vehicle. Suitable de-pigmenting agents include 3,3'-thiodipropionic acid, thiazolidine-2-carboxylic acid, Kaempferol-7-glucoside, perilla oil, and clofibrate and clofibrate analogs and / or derivatives, as well as those set forth below. Suitable anti-aging agents include 3,3'-thiodipropionic acid and / or its derivatives.

Owner:AVON PROD INC

Montmorillonite/isotactic polypropylene/polylactic acid composite sound absorbing cotton and preparation method thereof

InactiveCN103696127ASimple production processRaw materials are cheap and easy to getSynthetic resin layered productsNon-woven fabricsAdditive ingredientPolypropylene

The invention discloses montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton, which consists of a top surface layer, a back surface layer and a fiber cotton layer, wherein the fiber cotton layer is clamped and arranged between the top surface layer and the back surface layer, and the top surface layer and the back surface layer are made of non-woven fabric materials. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton is characterized in that the non-woven fabric is prepared form the following ingredients in parts by weight by a melt blowing method: 100 parts of isotactic polypropylene, 10 to 12 parts of polylactic acid, 10 to 12 parts of montmorillonite powder, 5 to 7 parts of dilauryl thiodipropionate, 2 to 3 parts of zinc oxide, 12 to 15 parts of diethylene glycol dibenzoate, 4 to 6 parts of triethyl citrate, 2 to 3 parts of zinc chloride, 5 to 7 parts of chitosan, 2 to 3 parts of molecular sieves, 12 to 15 parts of yellow cinnamon leaf, 2 to 3 parts of rhizoma gastrodiae, 2 to 3 parts of mint, 2 to 3 parts of radix angelicae pubescentis and 4 to 5 parts of auxiliary agents. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton has the advantages that the montmorillonite, the isotactic polypropylene and the polylactic acid are compounded for preparing the sound absorbing cotton by the melt blowing method, the production process is simple, the raw materials are easy to obtain, the cost is low, and the prepared product has the advantages that the air permeability and the oxygen permeability are good, the tensile strength and the extension degree are high, the sound absorbing effect is obvious, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Fiber glass enhanced polypropylene material with high ageing ressistance of anti heat and oxygen

InactiveCN1696187AExcellent thermal and oxidative aging resistanceImproved resistance to thermo-oxidative agingDiethyl phosphatePolypropylene composites

A glasls fibre reinforced polypropene material with high refractory, antioxidizing and antiageing performance is prepared proportionally from polypropene, maleic anhydride grafted polypepen, glass fibres, stabilizer DSTP, stabilizer '3114' and stabilizer '618'.

Owner:SHANGHAI PRET COMPOSITES

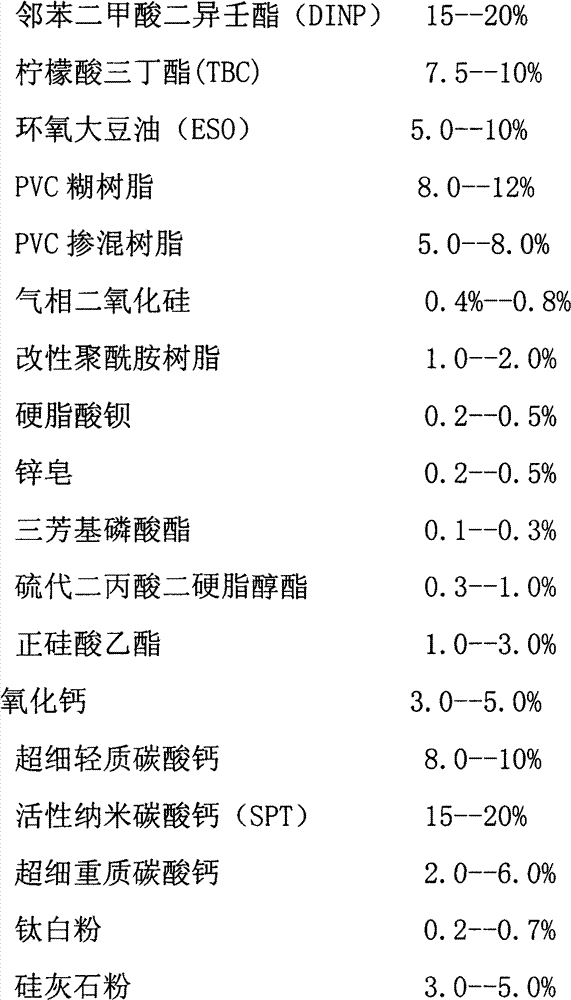

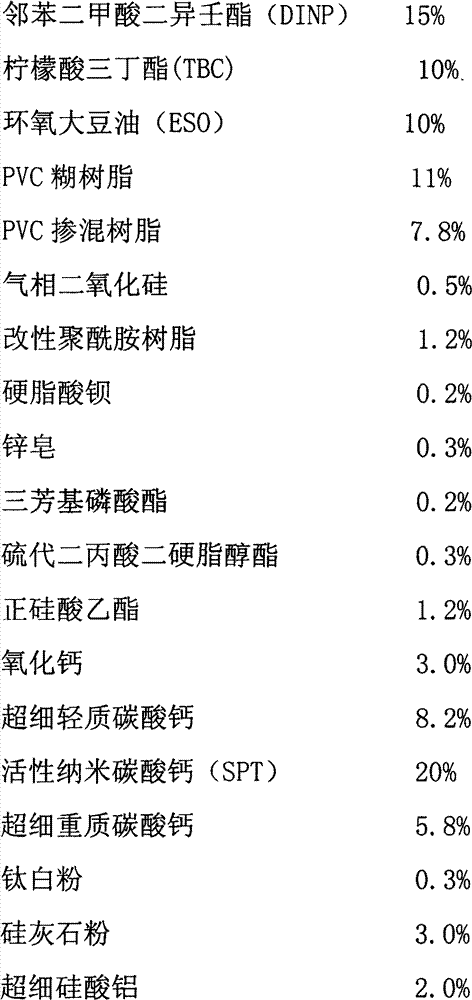

Environment-friendly PVC (Poly Vinyl Chloride) weld joint sealant for vehicle

ActiveCN102757746AGood compatibilityReduce usageNon-macromolecular adhesive additivesOther chemical processesPhosphateTributyl citrate

The invention relates to an environment-friendly PVC (Poly Vinyl Chloride) weld joint sealant for a vehicle. The environment-friendly PVC weld joint sealant mainly comprises the components of diisononyl phthalate (DINP), tributyl citrate (TBC), epoxidized soybean oil (ESO), PVC paste resin, PVC blend resin, fumed silica, modified polyamide resin, barium stearate, zincsoap, triaryl phosphate, thiodipropionic acid distearate alcohol ester, tetraethoxysilane, calcium oxide, ultrathin light calcium carbonate, active nano-calcium carbonate (SPT), ultrathin heavy calcium carbonate, titanium dioxide, wollastonite in powder, ultrathin aluminium silicate and the like. According to the environment-friendly PVC weld joint sealant provided by the invention, the technologies of raw material compounding, nontoxic additive adding and the like are adopted so as to reduce the curing temperature of the sealant; and a 'wet-to-wet' technology is achieved during coating the vehicle. Through the adoption of the environment-friendly PVC weld joint sealant, the energy consumption is reduced, and the volatizing of harmful gases is reduced. The environment-friendly PVC weld joint sealant has the characteristics of nontoxicity, environmental protection, fireproof performance, energy conservation, easiness in construction and the like The environment-friendly PVC weld joint sealant is an energy-conservation environmental-protection PVC weld joint sealant.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

Preparation method of rubber for outer glue layer of power steering tube of automobile

The invention discloses a preparation method of rubber for an outer glue layer of a power steering tube of an automobile and belongs to the technical field of rubber parts for automobiles. The preparation method comprises the following steps: mixing chlorosulfonated polyethylene, fast extruding furnace black, carbon black prepared by a cracking process, magnesium oxide, zinc diethyl dithiocarbamate, dilauryl thiodipropionate, zinc stearate, 2,2'-dithiodibenzo thiazole, trioctyl trimellitate and strong magnesium powder in an external mixer, and after mixing, discharging rubber under a condition that the rubber temperature is 160 DEG C to prepare masterbatch; and putting the prepared masterbatch into the external mixer, adding trithiocyanuric acid and sulfur in the raw materials and mixing; and after mixing, sequentially extruding at a certain temperature interval to prepare the rubber for the outer glue layer of the power steering tube of the automobile. Compared with the rubber for the outer glue layer of the power steering tube of the automobile prepared in the prior art, the rubber prepared by the preparation method has the advantage that the heat resistance of the rubber is effectively improved by mutual synergistic effect among the raw materials and matching corresponding extrusion temperatures.

Owner:南京中配橡塑制品有限公司

Nylon composite material special for electric wire and cable jacket and preparation method thereof

ActiveCN102020842AImprove heat resistanceImprove light aging resistanceInsulated cablesInsulated conductorsPropanoic acidPhenol

The invention provides a nylon composite material special for an electric wire and cable jacket, which is prepared from the following components by mass percent: 86-100% of nylon 6, 0.1-2.0% of main antioxygen, 0.1-2.0% of auxiliary antioxygen, 0.1-2.0% of lubricant release agent, 0.1-2.0% of light stabilizer, 0.1-2.0% of lubricant, 0.1-2.0% of nucleating agent and 0.3-2.0% of tackifier, wherein the main antioxygen is a hindered phenol antioxygen, the auxiliary antioxygen is thiodi-propionic acid diester or phosphite ester, the lubricant release agent is calcium stearate, the light stabilizer is a hindered amine light stabilizer, the lubricant is ethylene double hard ester amide (EBS), silicone powder or a compositor of the ethylene double hard ester amide (EBS) and silicone powder, the nucleating agent is nano talcum powder, and the tackifier is nylon 6 containing reactive groups. The nylon composite material has the advantanges of simple formula and cheap, easily available components and low cost, and the electric wire and cable jacket prepared from the nylon composite material can prevent white ants and mousse, has abrasion resistance and corrosion resistance, is durable in use and is non-toxic and environment-friendly.

Owner:辰东意普万新材料(广东)有限公司

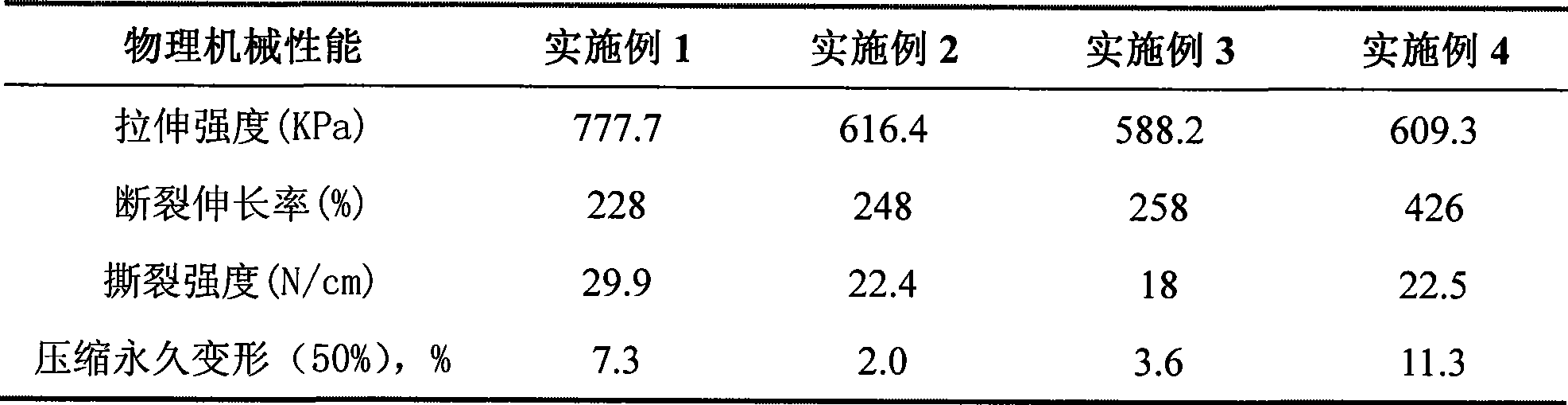

Duprene rubber foamed sheet and preparation method thereof

ActiveCN101392076AImprove flame retardant performanceHigh tensile strengthPolymer sciencePropanoic acid

The invention relates to a neoprene foaming board and a preparation method thereof. The neoprene foaming board is prepared by the following materials according to weight parts: 100 portions of neoprene, 15 portions to 200 portions of kaolin or calcium carbonate, 15 portions to 45 portions of carbon black, 10 portions to 20 portions of a vulcanizing agent, 0 portion to 2 portions of an accelerant, 5 portions to 15 portions of a vesicant, 0 portion to 5 portions of urea resin, 1 portion to 4 portions of olefin, 0 portion to 3 portions of dilauryl thiodipropionate, 0 portion to 2 portions of 2, 2'-methylene-bis(4-methyl-6- tert-butylphenol), 0 portion to 1 portion of nickel dibutyldithiocarbamate, 0 portion to 2 portions of stearic acid, 8 portions to 30 portions of black factice, 0 portion to 4 portions of vaseline, 10 portions to 20 portions of naphthenoid oil, 20 portions to 40 portions of perfume oil, and 1 portion to 4 portions of a dispersant. The preparation method thereof includes the steps of first-time mixing of a pressurizing milling machine, first-time mixing of a mixing mill, second-time mixing of the pressurizing milling machine, second-time mixing of the mixing mill, extrusion of an extruder, first-time foaming vulcanization, second-time foaming vulcanization, cooling and the like. The neoprene foaming board and the preparation method have the advantages of good flame resistance, high tensile strength, high extensibility, good performance of tear resistance, small compression set, good abrasion resistance and skidproof effect, good effect of shock absorption and the like.

Owner:常州美利晟高分子科技有限公司

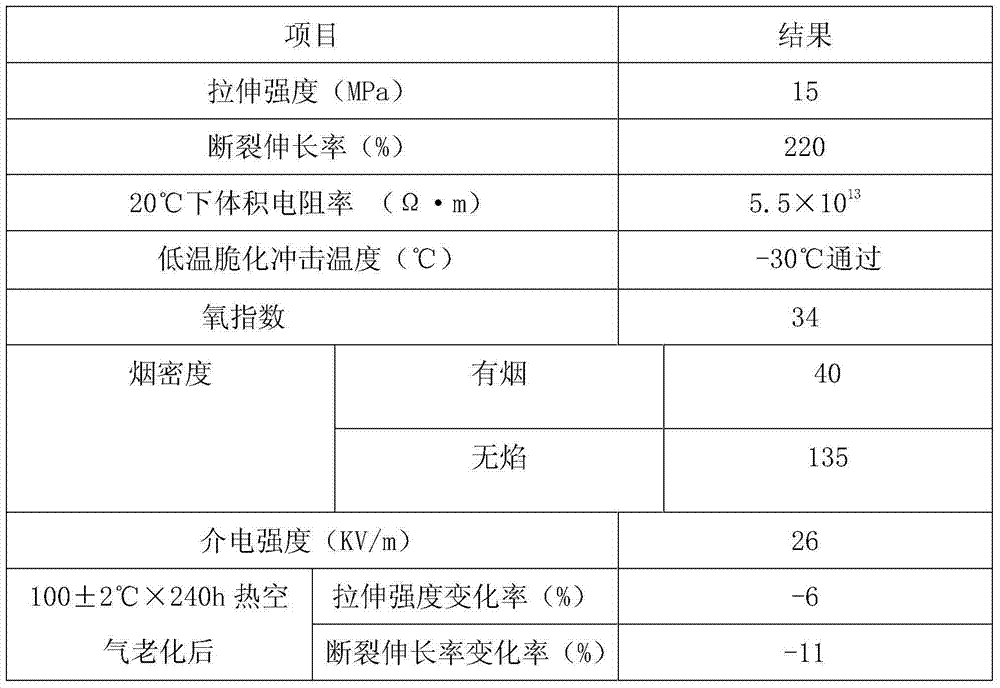

Low-smoke halogen-free flame-retardant cable material

InactiveCN105037899ASoft textureHigh tensile strengthPlastic/resin/waxes insulatorsInsulated cablesEpoxyAntioxidant

The invention discloses a low-smoke halogen-free flame-retardant cable material, and belongs to the field of materials. The low-smoke halogen-free flame-retardant cable material solves the problem that an existing cable material is poor in mechanical property and electrical property. The low-smoke halogen-free flame-retardant cable material is composed of 50-60 parts of high density polyethylene, 20-30 parts of ethylene-ethyl acrylate copolymers, 20-30 parts of methyl vinyl silicone rubber resin, 1-3 parts of magnesium stearate, 2-5 parts of novolac epoxy resin, 15-25 parts of isopropyl phenyl diphenyl phosphate, 1-2 parts of dilauryl thiodipropionate, 10-20 parts of dimellitate, 1-2 parts of antioxidants 1010, 1-1.5 parts of antioxidants CA, 10-20 parts of maleic anhydride grafting ethylene-octylene copolymers, 5-10 parts of polysiloxane, 20-30 parts of nano magnesium hydroxide, 13-18 parts of nano clay, 3-7 parts of zinc oxide, 5-10 parts of polyethylene wax and 3-8 parts of calcium stearate. The low-smoke halogen-free flame-retardant cable material can be widely used as insulation and sheathing materials of various electric wires and cables.

Owner:国网山东莒南县供电公司 +2

Method for preparing antibacterial fiber membrane

ActiveCN105839295AUniform pore sizeExcellent stable membrane fluxHollow filament manufactureElectro-spinningYarnCellulose diacetate

The invention discloses a method for preparing an antibacterial fiber membrane. The method comprises the following steps: preparing a complex antibacterial agent by using N-(4-hydroxy-3-methoxybenzyl)acrylamide, 2-hydroxypropyl methacrylate, N, N- (dimethylamino)ethyl methacrylate, and vinyltriethoxysilane-modified nano zinc oxide; adding polyacrylonitrile, cellulose diacetate and glucose to a mixed solvent to obtain a mixed solution; adding the complex antibacterial agent, poly vinyl alcohol, laponite, silver ion loaded zeolite molecular sieve, nano titanium dioxide, alumina sol, calcium chloride and dilauryl thiodipropionate to water to be uniformly mixed, adding the mixed solution and then conducting electrostatic spinning to obtain a raw yarn, putting the raw yarn in water to be soaked and dried. The method for preparing the antibacterial fiber membrane provided by the invention has the advantages of simple process, mild conditions, good antibacterial properties, excellent stain resistance, high mechanical strength and toughness, and long service life.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

Oil resistant rubber material and preparation method thereof

The invention provides an oil resistant rubber material. The oil resistant rubber material comprises the following components in parts by weight: 60-70 parts of butadiene-acrylonitrile rubber, 25-35 parts of fluororubber, 5-10 parts of dioctyl tin maleate, 2-3 parts of glass fibers, 1-2 parts of stearic acid, 0.5-0.8 part of light calcium carbonate, 3-5 parts of magnesium dimethacrylate, 2-3 parts of drying oil alkyd resin, 1-2 parts of paraffin, 3-5 parts of dilauryl thiodipropionate, 1-2 parts of diacetyl peroxide, 0.8-1.2 parts of zinc oxide, 8-10 parts of aluminium oxide, 6-8 parts of white carbon black, 0.8-1.5 parts of anti-aging agent and 1-3 parts of sulfur. The invention also provides a preparation method of the oil resistant rubber material. The oil resistant rubber material has good sealability, high temperature resistance and oil resistance and is suitable for sealing automobile gearboxes.

Owner:LIUZHOU YINGHANG AUTO PARTS

Radiation crosslinked polyolefin high-elasticity foam and preparation method thereof

The invention provides radiation crosslinked polyolefin high-elasticity foam and a preparation method thereof. The radiation crosslinked polyolefin high-elasticity foam comprises a main material and an auxiliary material, wherein the main material comprises the following components in percentage by weight: 60-65 percent of ethylene-octene copolymer, 25-30 percent of ethylene-vinyl acetate copolymer and 5.0-10.0 percent of foaming agent; the auxiliary material comprises the following components in percentage by weight: 1-2 percent of sensitizing agent, 1-2 percent of antioxidant and 0.5-1.0 percent of lubricating agent; the foaming agent is selected from azodicarbonamide; the sensitizing agent is selected from zinc stearate; the antioxidant is selected from a mixture of tetra-[beta-(3,5-di-tert-butyl-4-hydroxy phenyl)metacetonic acid] pentaerythritol ester and distearyl thiodipropioante; the lubricating agent is selected from polyethylene wax; and the mass ratio of the tetra-[beta-(3,5-di-tert-butyl-4-hydroxy phenyl)metacetonic acid] pentaerythritol ester to the distearyl thiodipropioante is 1:2. The radiation crosslinked polyolefin high-elasticity foam has the beneficial effects of lower foaming energy consumption in comparison to the conventional polyolefin foam, smooth surface, fine foam holes, higher flexibility, smaller hardness, greatly-improved mechanical property and particular increase in the elongation percentage by 2-3 times.

Owner:湖州长园特发科技有限公司

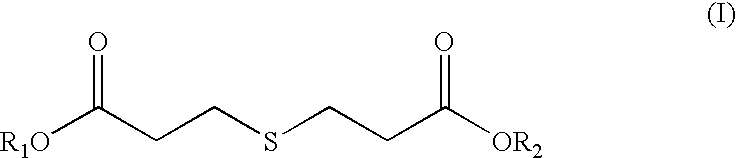

Compositions and methods for treating hyperpigmentation

InactiveUS6562321B2Reduce retention timeImprove shipping rateCosmetic preparationsBiocidePerilla oilCarboxylic acid

There is provided a topical composition for treating, preventing or ameliorating hyperpigmentation in human skin. The composition has a de-pigmenting agent in an amount effect to reduce or diminish pigmentation at an area of skin to which it is applied, and a cosmetically or pharmaceutically acceptable vehicle. Suitable de-pigmenting agents include 3,3'-thiodipropionic acid, thiazolidine-2-carboxylic acid, kaempferol-7-glucoside, perilla oil, and clofibrate and clofibrate analogs and derivatives. There is also provided methods for treating, preventing or ameliorating hyperpigmentation in human skin.

Owner:AVON PROD INC

Irradiation crosslinking low-temperature-resistant flexible oil-resistant halogen-free flame-retardant cable material for locomotive cables at 125 DEG C

ActiveCN106009447AEasy to processGood oil resistancePlastic/resin/waxes insulatorsInsulated cablesSilanesCarvacryl acetate

Provided is an irradiation crosslinking low-temperature-resistant flexible oil-resistant halogen-free flame-retardant cable material for locomotive cables at 125 DEG C. The cable material is characterized by being prepared from, by weight, 25-40 parts of ethylene-vinyl acetate copolymer with high vinyl acetate content, 15-30 parts of ethylene-vinyl acetate copolymer with low vinyl acetate content, 15-30 parts of carboxylated nitrile rubber, 15-25 parts of EVA-g-PU copolymer, 5-15 parts of maleic anhydride grafted ethylene-propylene-diene monomer copolymer, 90-110 parts of aluminum hydroxide, 30-50 parts of magnesium hydroxide, 3-5 parts of zinc borate, 0.8-1.2 parts of methacryloxy propyl trimethoxyl silane, 3-6 parts of silicone master batches, 0.8-1.2 parts of pentaerythrite tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate], 0.5-2 parts of dilauryl thiodipropionate and 1.5-2.5 parts of triallylisocyanurate. The cable material has the advantages of being prominent in oil resistance, super flexible, easy to lay, good in low temperature resistance, good in flame retardance, low in smoke, free of toxicity and the like.

Owner:中广核三角洲(江苏)塑化有限公司

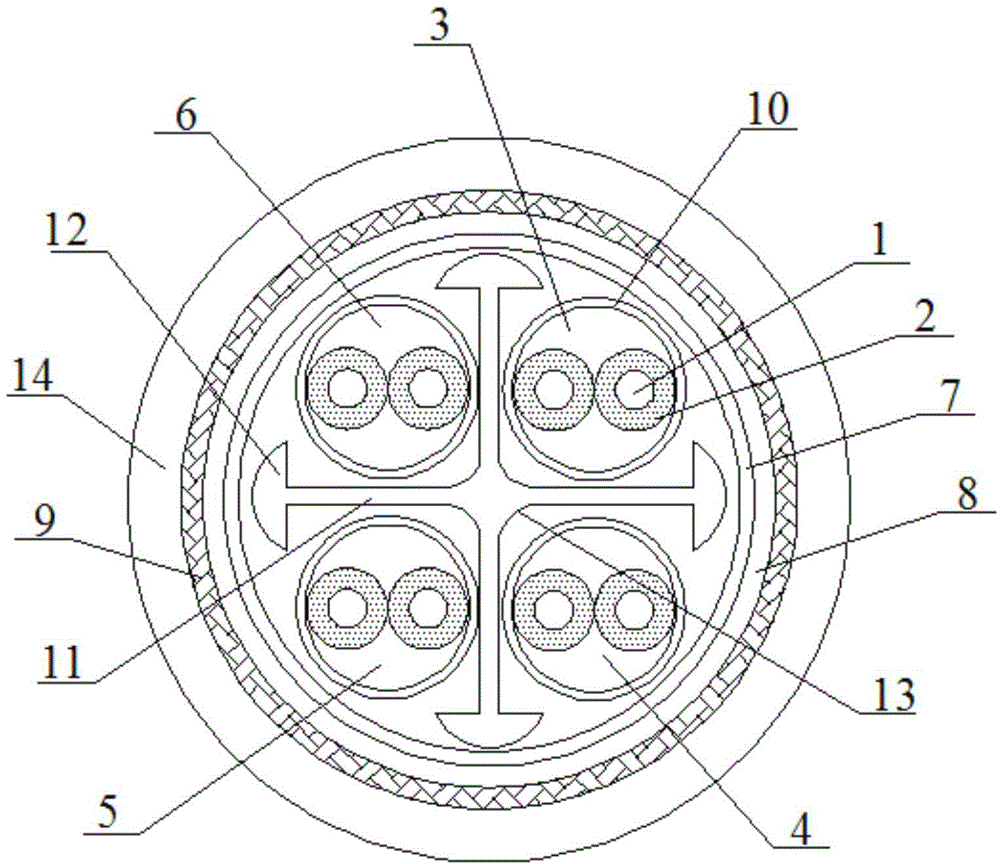

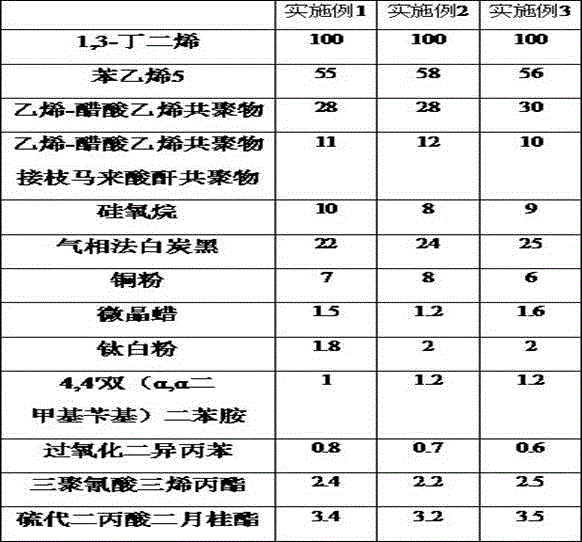

Shielding high-speed enhanced CAT 7 type data communication cable

ActiveCN104867607AReduce bulk resistivityIncrease reflectionInsulated cablesInsulated conductorsMicrocrystalline waxCopper wire

The invention discloses a shielding high-speed enhanced CAT 7 type data communication cable which comprises eight copper leads and a cross skeleton. A sheath layer wraps a tinned copper wire braided layer. The sheath layer comprises 100 parts by weight of 1,3-butadiene, styrene, ethane-vinyl acetate copolymer, ethane-vinyl acetate copolymer grafted maleic anhydride copolymer, siloxane, vapor-phase-method white carbon black, cooper powder, microcrystalline wax, titanium white, 4,4'-bis(alpha,alpha-dimethylbenzyl)diphenylamine, dicumyl peroxide, triallyl cyanurate and dilauryl thiodipropionate. The pitches of first, second, third and fourth twisted pairs are 15.2, 13.7, 14.4 and 12.9 mm respectively. The shielding high-speed enhanced CAT 7 type data communication cable improves reflection and absorption of high-frequency electromagnetic waves, reduces crosstalk and signal attenuation, broadens the bandwidth of adsorption frequency, and enhances the stability of product performance.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Antibacterial PPR (polypropylene random copolymer) water supply pipe of high low-temperature toughness

InactiveCN104927207AWide range of usesImprove low temperature toughnessFlexible pipesAntioxidantPolyamide

The invention discloses an antibacterial PPR (polypropylene random copolymer) water supply pipe of high low-temperature toughness, made from, by weight, 80 to 100 parts of PPR, 20 to 30 parts of polyisocyanurate, 15 to 25 parts of PA66 (polyamide 66), 3 to 10 parts of antioxidant, 2 to 8 parts of light stabilizer, 5 to 15 parts of organic antibacterial agent, 1 to 5 parts of dispersant, 4 to 8 parts of color masterbatch, and 1 to 5 parts of clay nano-composite. The antioxidant is one of 2, 6-tert-butyl-4-methylphenol and distearyl thiodipropionate. The light stabilizer is a combination of light stabilizer LQ-292 and light stabilizer 765 in any proportion. The organic antibacterial agent is one of vanillin and ethyl vanillin. The dispersant is vinyl distearamide. The clay nano-composite is phyllosilicate nano-material. The antibacterial PPR water supply pipe has excellent low-temperature toughness, oxidation resistance and light stability, is high in strength, can inhibit and kill germs in the pipe, is safe and environment friendly and high in cost performance and has promising market prospect.

Owner:广西金滩管业科技有限公司

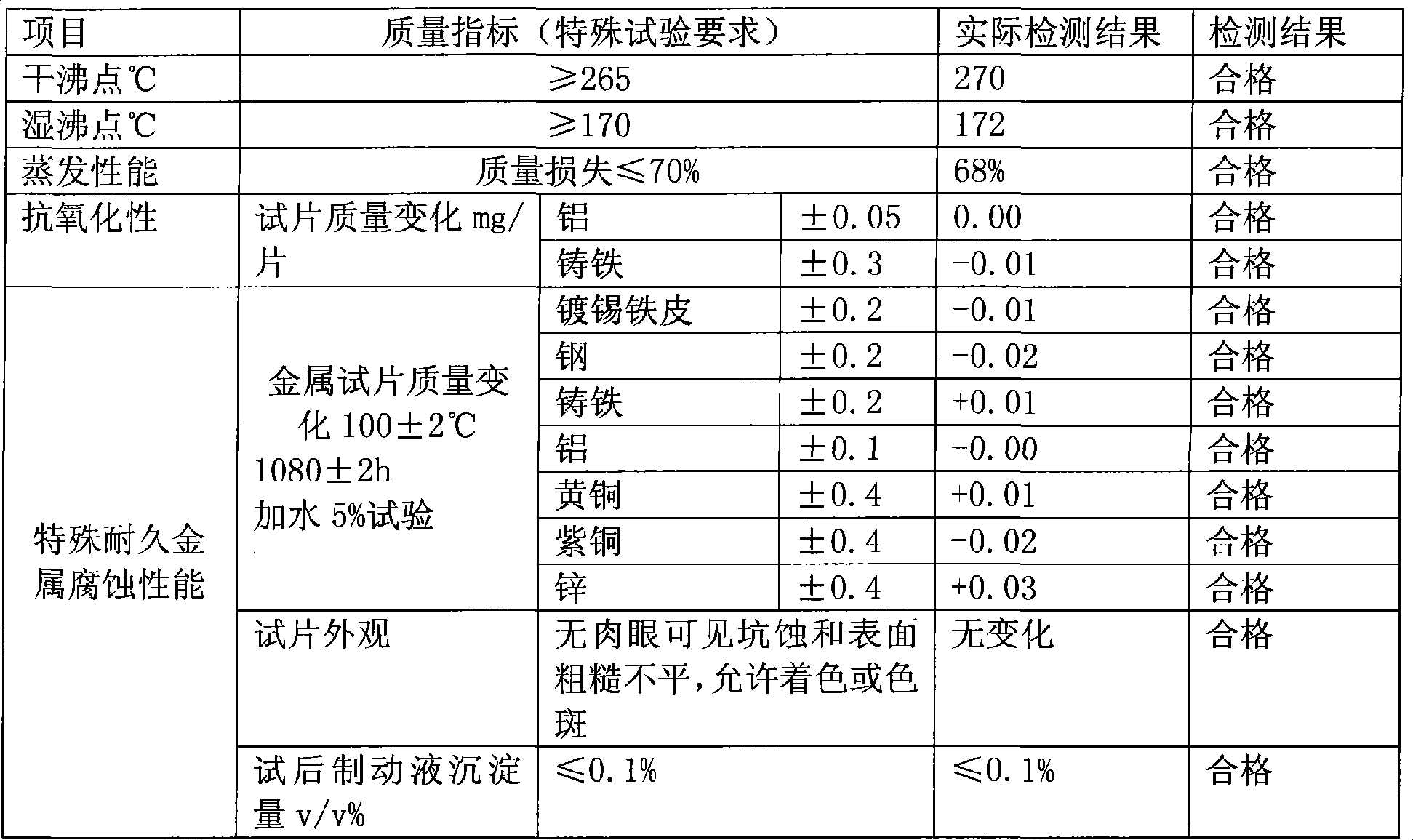

DOT4 boric acid ester type brake fluid

ActiveCN101418249ASolve the problem of long-term storage hydrolytic stabilityAdditivesBase-materialsMorpholinePhenol

The invention discloses a DOT4 boric acid ester type brake fluid, which comprises the following components in weight percentage: 4.3 to 4.7 percent of triethylene glycol methyl ether, 15 to 17 percent of tetraethylene glycol methyl ether, 1.9 to 2.1 percent of diethylene glycol, 74 to 76 percent of alcohol ether borate, 0.19 to 0.21 percent of benzotriazole, 0.33 to 0.37 percent of N-phenyl morpholine, 0.76 to 0.84 percent of tri-n-butylamine, 0.57 to 0.63 percent of 2, 2-di (4-hydroxyl phenyl) propane (bisphenol A), 0.057 to 0.063 percent of thiodipropionic acid didodecyl alcohol ester, 0.19 to 0.21 percent of 2.6-di-tert-butyl-4-methyl phenol, 0.095 to 0.105 percent of mercapto styrene-acrylic thiazole, and 0.38 to 0.42 percent of dodecatylene butane diacid (T746). The DOT4 boric acid ester type brake fluid has the advantages that the DOT4 boric acid ester type brake fluid can thoroughly solve the problem of hydrolytic stability of boric acid ester for long term storage by using a formulation technology of combining organic substances and additives.

Owner:张家港迪克汽车化学品有限公司

Method for preparing heat-resisting modified polypropylene resin with high glossiness

The invention relates to a method of producing high-gloss heat-resistance modification polypropylene resin, which comprises: polypropylene resin group material is mixed with additive uniformly before granulation is produced by melting and mixing. The polypropylene resin group material is isotactic and homopolymerized polypropylene with fused mass flowing speed of 3-26g / 10min and 98.5-99.5 percent of isotactic index. The additive comprises nucleating agent 2, 2-methylene-di (4, 6-di-tert-butylphenoxyl) sodium phosphate and 3MgO2.4SiO2.H2O; lubricant is monopalmitin; antioxidant is four (3, (3, 5-di-tert-buty-4-hydroxyphenyl)) propionate pentaerythritol ester, phosphorous acid three (2, 4-tert-butylphenyl) ester and thiodipropionate bisoctadecanol ester. The modified polypropylene resin produced by the invention not only has good heat resistance, but also has excellent luster of products, which can reach above 98 GU20 degrees.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Anticorrosive paint containing dimethyl sulfoxide

InactiveCN103173094AGood flexibilityHigh impact strengthAnti-corrosive paintsEpoxy resin coatingsTitanium tetrafluoridePolyacrylamide

The invention discloses an anticorrosive paint containing dimethyl sulfoxide. The anticorrosive paint is composed of a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 84-90 parts of epoxy resin E44, 10-15 parts of high chlorinated polyethylene resin, 10-15 parts of precipitated barium sulfate, 1-2 parts of titanium tetrafluoride, 2-4 parts of sodium monofluorophosphate, 2-4 parts of dimethyl sulfoxide, 2-3 parts of ethylene glycol monobutyl ether, 2-4 parts of ethyl acrylate, 3-5 parts of urea, 2-3 parts of polyacrylamide, 2-3 parts of diethylamine, 2-3 parts of diphenylmethane diisocyanate, 3-5 parts of diisooctyl phthalate, 1-2 parts of ethylene diamine tetra methylene phosphonic acid sodium, 5-7 parts of hydrotalcite, 1-2 parts of dimethylethanolamine, 15-20 parts of compound modifier, 25-30 parts of dimethylbenzene, 10-15 parts of n-butyl acetate, 0.8-1 parts of dilauryl thiodipropionate, 0.8-1 parts of vinyltriethoxysilane and 0.5-1 part of methyl silicone oil. A paint film prepared by the invention has the advantages of good adhesive force to metal, small structure pores, compact structure, good adhesive force, good flexibility, high impact strength and strong corrosion resistance, and plays an efficient protection effect on base metal.

Owner:ANHUI MINGZHU PIGMENT TECH

Preparation method for rubber for inner rubber layer of car power steering hose

The invention discloses a preparation method for rubber for the inner rubber layer of a car power steering hose, and belongs to the technical field of car rubber pieces. The preparation method comprises the following steps: adding chlorosulfonated polyethylene, fast extruding furnace black, cracking carbon black, magnesium oxide, zinc diethyl dithiocarbamate, dilauryl thiodipropionate, zinc stearate, 2,2'-dithio-dibenzo thiazole, trioctyl trimellitate and magnesium strong powder into an internal mixer for banburying; after banburying, discharging rubber at the rubber temperature of 160 DGE C to obtain a master batch; adding the prepared master batch into the internal mixer, and adding in trithiocyanuric acid and sulphur for mixing; after mixing, sequentially squeezing out within a certain temperature range to obtain rubber for the inner rubber layer of the car power steering hose. Compared with that manufactured rubber for an inner rubber layer of a car power steering hose in the prior art, the rubber adopts the synergistic effects of the raw materials and the corresponding squeezing temperatures to effectively improve the heat resistance property of the rubber.

Owner:南京中配橡塑制品有限公司

Halogen-free non-red-phosphorus flame-retardant thermal shrinkable tube and preparation method thereof

InactiveCN102585329AHigh tensile strengthFlat surfacePlastic/resin/waxes insulatorsInsulated cablesLow-density polyethylenePhosphoric Acid Esters

The invention relates to a halogen-free non-red-phosphorus flame-retardant thermal shrinkable tube which consists of the following components by weight: 100 parts of base resin, 60 to 80 parts of melamine phosphate ester, 10 to 20 parts of melamine cyanuric acid, 10 to 20 parts of pentaerythritol, 1 to 3 parts of complex antioxidant and 2 to 5 parts of lubricant. The base resin is a mixture of one or a plurality of the following substances: low-density polyethylene, ethylene methyl acrylate copolymer, ethylene-ethyl acrylate copolymer, ethylene-butyl acrylate copolymer, ethylene-vinyl acetate copolymer, ethylene-octene copolymer and ethylene-propylene-diene monomer; and the complex antioxidant is formed by compounding pentaerythrite tetra [beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate] with disteaxyl thiodipropionate according to a ratio of 1:1. The halogen-free non-red-phosphorus flame-retardant thermal shrinkable tube disclosed by the invention does not contain red phosphorus. The flame-retardant performance of the halogen-free non-red-phosphorus flame-retardant shrinkable tube can pass through the VM-1 test.

Owner:长园科技集团股份有限公司

Compositions and methods for treating hyperpigmentation

InactiveUS20020141953A1Reduce retention timeImprove shipping rateBiocideCosmetic preparationsPerilla oilCarboxylic acid

There is provided a topical composition for treating, preventing or ameliorating hyperpigmentation in human skin. The composition has a de-pigmenting agent in an amount effect to reduce or diminish pigmentation at an area of skin to which it is applied, and a cosmetically or pharmaceutically acceptable vehicle. Suitable de-pigmenting agents include 3,3'-thiodipropionic acid, thiazolidine-2-carboxylic acid, kaempferol-7-glucoside, perilla oil, and clofibrate and clofibrate analogs and derivatives. There is also provided methods for treating, preventing or ameliorating hyperpigmentation in human skin.

Owner:AVON PROD INC

Low-smoke halogen-free silicane natural cross-linked polyolefin cable material and preparation method thereof

ActiveCN103571030ALow smoke hasGood weather resistanceInsulated cablesInsulatorsElastomerPolyvinyl chloride

The invention disclose a low-smoke halogen-free silicane natural cross-linked polyolefin cable material, which is prepared from the following raw materials in parts by weight: 20-40 parts of linear low-density polyethylene, 10-20 parts of high-density polyethylene, 20-40 parts of polyethylene octylene elastomer, 10-20 parts of ethylene-vinyl acetate copolymer, 10-15 parts of PVC (polyvinyl chloride) paste resin, 2-3 parts of dilauryl thiodipropionate, 1-2 parts of dibutyltin laurate maleate, 20-25 parts of aluminum hypophosphite, 1-2 parts of melamine pyrophosphate, 10-15 parts of magnesium hydroxide, 5-10 parts of zinc borate, 1-3 parts of di(3, 5-tert-butyl-4-hydroxyl phenyl) thioether, 2-4 parts of polyethylene wax, 1-2 parts of polytetrafluoroethylene, 5-10 parts of modification filler, 3-5 parts of vinyltris(2-methoxyethoxy)silane, 1-2 parts of N-salicyloylamino-phthalimide and 1-3 parts of dibenzoyl peroxide. In comparison with the normal low-smoke halogen-free polyolefin cable material, the low-smoke halogen-free silicane natural cross-linked polyolefin cable material has the advantages that temperature resistance level of products is improved, mechanical property is improved, and the problem that the normal low-smoke halogen-free polyolefin cable material is easy to crack is eliminated.

Owner:常州超越特种电缆有限公司

Stabilizer for food contact and medical grade PVC

Disclosed is a composition of matter which provides heat and color stability to polyvinyl chloride resins, especially of the flexible type, said composition consists essentially of (A) about 10 to about 40 parts by weight of a zinc carboxylate; (B) about 50 to about 80 parts by weight of an alkyl ester of thiodipropionic acid; and (C) abqut 5 to about 20 parts by weight of a phenolic antioxidant. A PVC resin containing the above composition of matter is also disclosed.

Owner:CK WITCO

Method for preparing blade of cooling fan of automobile engine

The invention discloses a method for preparing blade of a cooling fan of an automobile engine, and belongs to the technical field of automobile engine parts. The blade of the cooling fan is prepared from polypropylene, elastic bodies, ultrathin SiO2, organosilicone coupling reagent, alkaline-free short glass fiber, beta nucleation agent, anti-oxidization agent CA, dilauryl thiodipropionate and ultraviolet absorption agent by the steps of secondary extrusion, cooling, granulation, melting injection molding, cooling and forming, demolding and inspection. The polypropylene is used as basic resin; the beta nucleation agent controls crystallization of polypropylene; the organosilicone coupling reagent modifies the alkaline-free short glass fiber into an enhancement material; the elastic bodiesPOE and SiO2 are compounded to enhance the flexibility; the heat resistance is increased by 145 to 150 DEG C, so that the blade cannot be aged and cracked after bearing the high temperature for 750 to 1,000 hours, and the impact flexibility and the stress cracking performance are improved greatly; furthermore, the mechanical performance, the heat resistance and the anti-aging performance of the fan are improved, and the environment adaptability is improved; and moreover, the manufacturing cost, the noise and the power consumption are low; and the blade is deformed and broken difficultly.

Owner:临海市四通制管有限公司

Medical composite antimicrobial tube and preparation method thereof

The invention discloses a medical composite antimicrobial tube and a preparation method thereof. The composite antimicrobial tube comprises the following components in parts by weight: 40-50 parts of PVC (polyvinyl chloride), 10-20 parts of polycarbonate, 30-40 parts of PE (polyethylene), 8-15 parts of PET (polyethylene terephthalate), 3-7 parts of silver powder, 0.8-2 parts of potassium phosphate, 1-4 parts of calcium oxide, 1-4 parts of bis thiodipropionate, 5-10 parts of butyl rubber, 0.8-2 parts of stearic acid, 3-8 parts of titanium dioxide, 3-7 parts of polyethylene wax, 1-5 parts of epoxy soybean oil, 0.8-2 parts of barium stearate, 1-5 parts of polyester fiber and 2-6 parts of maleic anhydride. The preparation method comprises the following steps: uniformly mixing the components in a stirrer according to parts by weight, adding into a grinder, grinding, discharging, and carrying out extrusion molding by an extruder. The medical composite antimicrobial tube disclosed by the invention has favorable mechanical properties and mold resistance, and can be widely used in the field of medical treatment.

Owner:SUZHOU VIVOTIDE BIOTECH

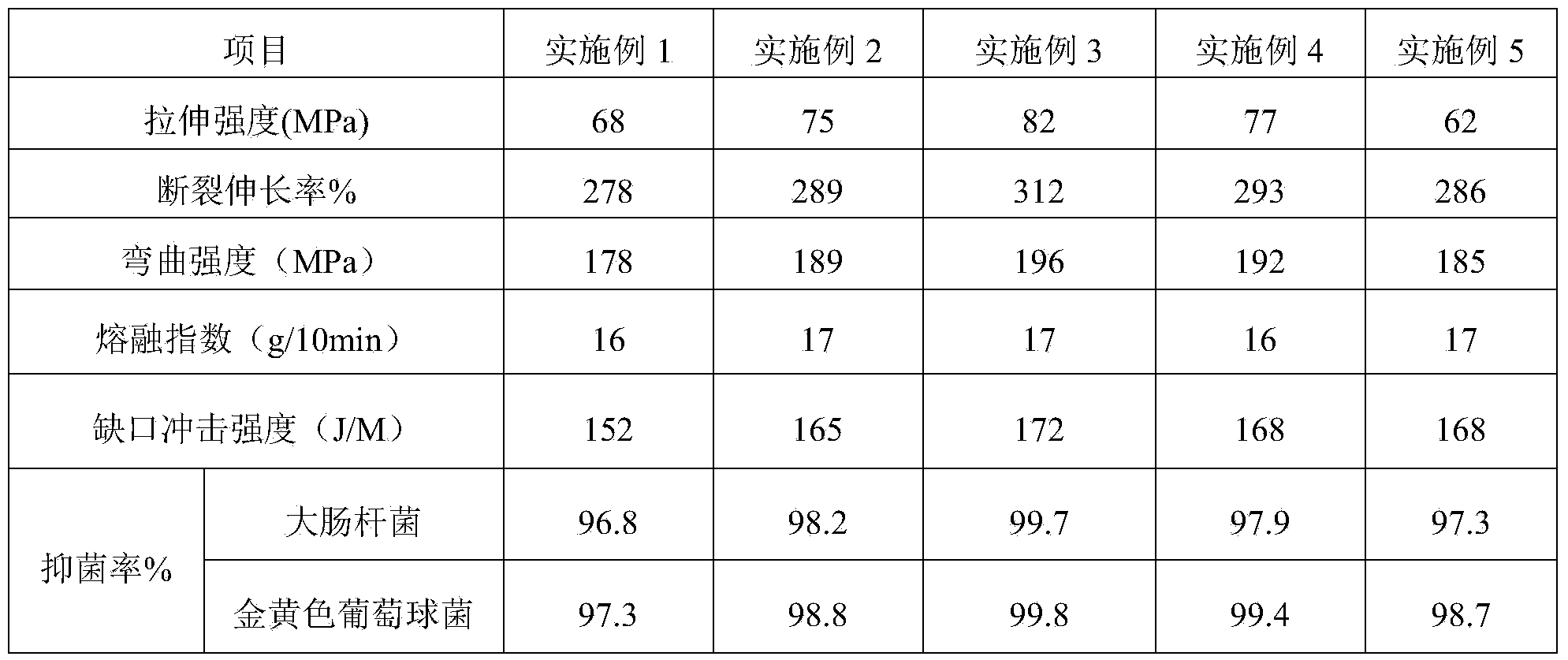

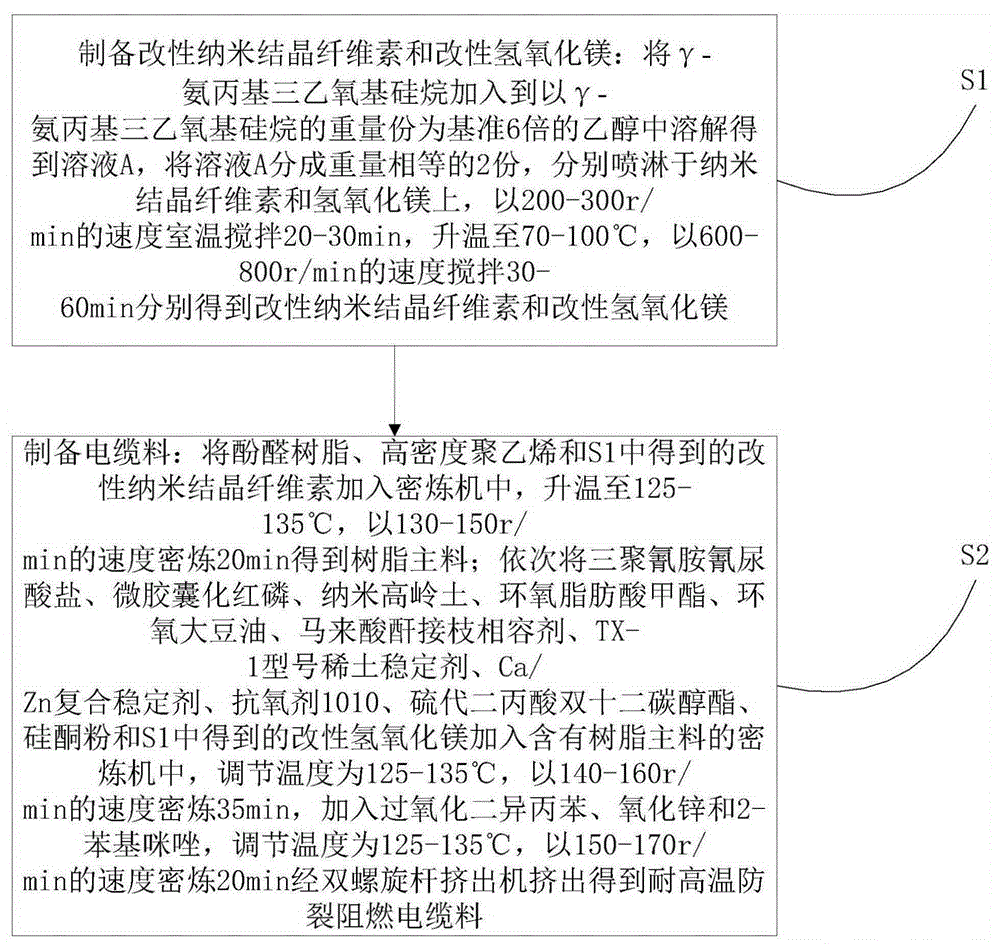

High-temperature-resistant crack-resistant flame-retardant cable material and preparation method thereof

The invention discloses a high-temperature-resistant crack-resistant flame-retardant cable material which is prepared from the following raw materials in parts by weight: 50-70 parts of phenolic resin, 30-50 parts of high-density polyethylene, 30-50 parts of nano kaolin, 10-15 parts of nano crystalline cellulose, 3-4 parts of gamma-aminopropyltriethoxy silane, 40-50 parts of magnesium hydroxide, 1-3 parts of melamine cyanurate, 7-9 parts of microcapsulated red phosphorus, 15-30 parts of epoxy fatty acid methyl ester, 15-30 parts of epoxy soybean oil, 0.4-1 part of dicumyl peroxide, 0.5-1.5 parts of zinc oxide, 0.5-1.5 parts of 2-phenyl iminazole, 5-10 parts of maleic anhydride graft compatilizer, 2-3 parts of TX-1 rare-earth stabilizer, 2-3 parts of Ca / Zn composite stabilizer, 0.1-0.3 part of antioxidant 1010, 0.1-0.2 part of bisdodecanol thiodipropionate and 2-4 parts of silicone powder. The invention also discloses a preparation method of the high-temperature-resistant crack-resistant flame-retardant cable material.

Owner:无为县茂林电缆材料有限公司

Viscosity stabilizer for oil-displacing polymer solution and preparation method of stabilizer

PendingCN110724513AGood viscosity stabilityEliminate the effect of viscosityDrilling compositionPropanoic acidAntioxidant

The invention discloses a viscosity stabilizer for an oil-displacing polymer solution and a preparation method of the viscosity stabilizer. The stabilizer composition includes a solvent and additives;the additives are at least two selected from the group consisting of an antioxidant, an anti-salt agent and a bactericide; the antioxidant is at least one selected from the group consisting of thioethanol, thiourea, thiodipropionic acid, sodium thiosulfate, potassium iodide, 2-hydroxyethylamine and acetone; the anti-salt agent is at least one selected from the group consisting of ethylenediaminetetraacetic acid or a salt thereof, 1-hydroxyethylidene-1,1-diphosphonic acid or a salt thereof, polyacrylic acid and sodium citrate; and the bactericide is at least one selected from the group consisting of N,N-dimethyldithiocarbamic acid sodium salt, methylene dithiocyanate, 2,2-dibromo-3-cyanoacetamide, 2-nitro-2-bromo-1,3-propanediol, glutaraldehyde and isothiazolinone. The stabilizer solves the problem of large viscosity loss of the polymer solution during polymer displacement.

Owner:DAQING PETROLEUM ADMINISTRATION +2

Antibacterial mildew-proof PVC (polyvinyl chloride) wood-plastic composite material

The invention discloses an antibacterial mildew-proof PVC (polyvinyl chloride) wood-plastic composite material, made from, by weight, 30 to 40 parts of wood powder, 10 to 20 parts of butyl acrylate, 0.02 to 0.03 part of benzoyl peroxide, 0.01 to 0.02 part of N, N-dimethylaniline, 3 to 4 parts of polyethylene wax, 1 to 1.2 parts of dilauryl thiodipropionate, 1.5 to 2 parts of calcium stearate, 95 to 100 parts of polyvinyl chloride, 2 to 3 parts of AC foamer, 1 to 2 parts of cell regulator ACR530, 6 to 8 parts of chlorinated polyethylene, 2 to 4 parts of methylisothiazolinone, 3 to 4 parts of nano carbon powder, 3 to 5 parts of chitosan, 3 to 4 parts of ceramic fiber, and 0.3 to 0.4 part of silane coupling agent kh570. A preparation process of the material is simple and highly operable, and the material is good in quality stability, has excellent performances in terms of antibiosis, bacteriostasis, mildew prevention, corrosion resistance and the like, has high cost performance and is worthy of vigorous popularization.

Owner:ANHUI BEIMA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com