High-temperature-resistant crack-resistant flame-retardant cable material and preparation method thereof

A flame retardant cable material, high temperature resistance technology, applied in the field of cable materials, can solve the problems affecting the mechanical properties, easy tearing, toughness, impact resistance and other properties of the cable material, achieve strong physical and chemical adsorption capacity, increase anti- cracking properties, the effect of increasing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

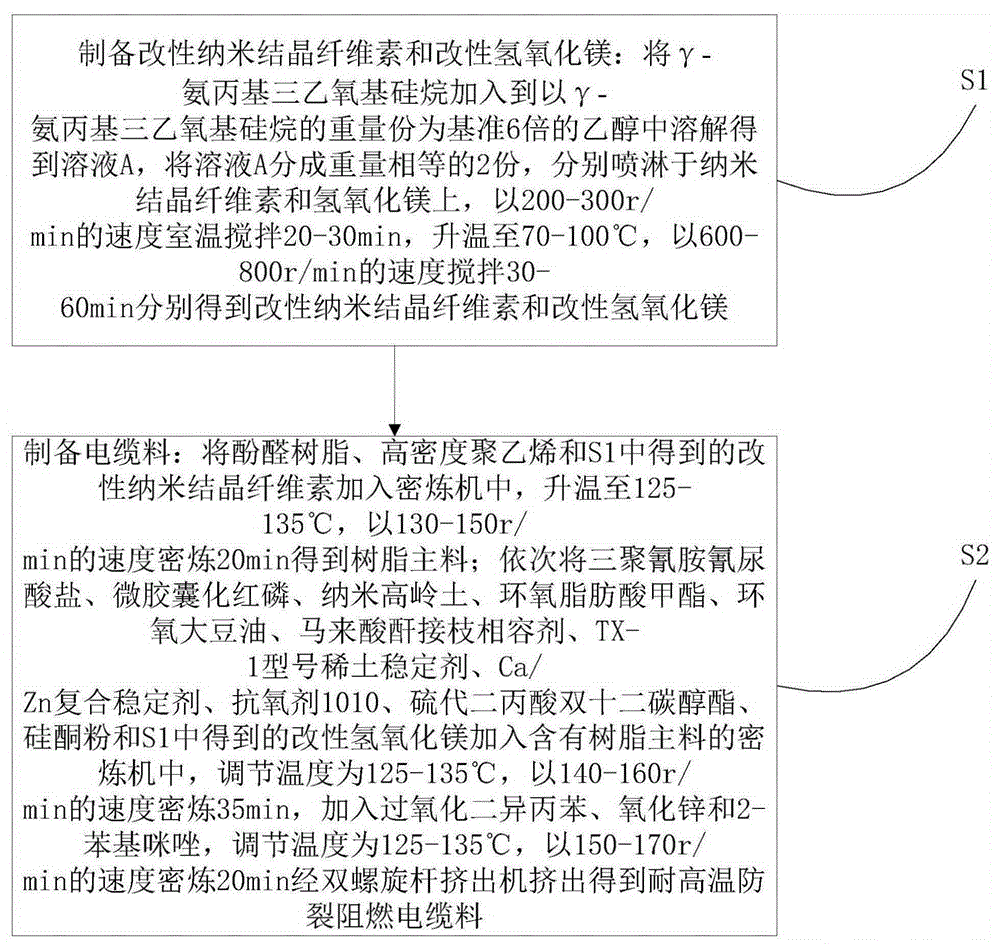

[0024] refer to figure 1 , a kind of preparation method that the present invention proposes high-temperature-resistant crack-resistant flame-retardant cable material, comprises the following steps:

[0025] S1. Preparation of modified nanocrystalline cellulose and modified magnesium hydroxide: adding γ-aminopropyltriethoxysilane to 6 times the ethanol based on the weight part of γ-aminopropyltriethoxysilane Dissolve to obtain solution A, divide solution A into 2 parts with equal weight, spray on nanocrystalline cellulose and magnesium hydroxide respectively, stir at room temperature for 20-30min at a speed of 200-300r / min, and heat up to 70-100°C, Stirring at a speed of 600-800r / min for 30-60min to obtain modified nanocrystalline cellulose and modified magnesium hydroxide respectively;

[0026]S2. Preparation of cable material: add phenolic resin, high-density polyethylene and modified nano-crystalline cellulose obtained in S1 to an internal mixer, heat up to 125-135°C, and b...

Embodiment 1

[0029] A high-temperature-resistant crack-resistant flame-retardant cable material, the raw materials of which include by weight: 50 parts of phenolic resin, 30 parts of high-density polyethylene, 30 parts of nano-kaolin, 10 parts of nano-crystalline cellulose, γ-aminopropyl triethoxy 3 parts of base silane, 40 parts of magnesium hydroxide, 1 part of melamine cyanurate, 7 parts of microencapsulated red phosphorus, 15 parts of epoxy fatty acid methyl ester, 15 parts of epoxy soybean oil, 0.4 part of dicumyl peroxide , 0.5 parts of zinc oxide, 0.5 parts of 2-phenylimidazole, 5 parts of maleic anhydride graft compatibilizer, 2 parts of TX-1 type rare earth stabilizer, 2 parts of Ca / Zn composite stabilizer, 10100.1 parts of antioxidant, 0.1 part of didodecyl thiodipropionate, 2 parts of silicone powder.

[0030] The preparation method of the above-mentioned high-temperature-resistant crack-resistant flame-retardant cable material includes the following steps:

[0031] S1. Prepara...

Embodiment 2

[0034] A high-temperature-resistant crack-resistant flame-retardant cable material, the raw materials of which include by weight: 70 parts of phenolic resin, 50 parts of high-density polyethylene, 50 parts of nano-kaolin, 15 parts of nano-crystalline cellulose, γ-aminopropyl triethoxy 4 parts of base silane, 50 parts of magnesium hydroxide, 3 parts of melamine cyanurate, 9 parts of microencapsulated red phosphorus, 30 parts of epoxy fatty acid methyl ester, 30 parts of epoxy soybean oil, 1 part of dicumyl peroxide , 1.5 parts of zinc oxide, 1.5 parts of 2-phenylimidazole, 10 parts of maleic anhydride graft compatibilizer, 3 parts of TX-1 type rare earth stabilizer, 3 parts of Ca / Zn composite stabilizer, 10100.3 parts of antioxidant, 0.2 part of didodecyl thiodipropionate, 4 parts of silicone powder.

[0035] The preparation method of the above-mentioned high-temperature-resistant crack-resistant flame-retardant cable material includes the following steps:

[0036] S1. Prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com