Patents

Literature

2226results about How to "Reduce liquidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for facilitating automated interaction of marketable retail orders and professional trading interest at passively determined prices

InactiveUS7035819B1Increase attractivenessReduce and eliminate traditional remunerationFinancePayment architectureIndication of interestApproaches of management

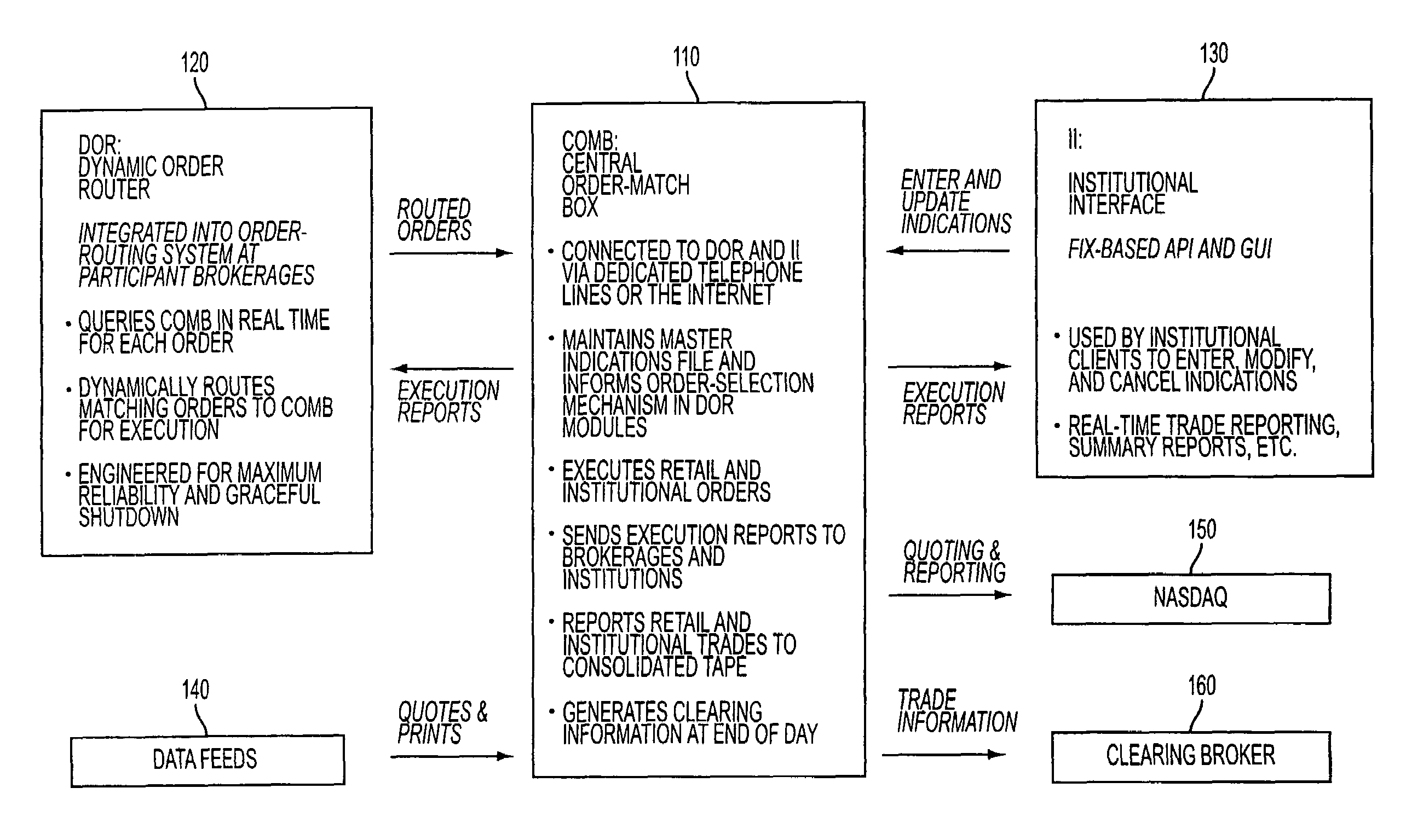

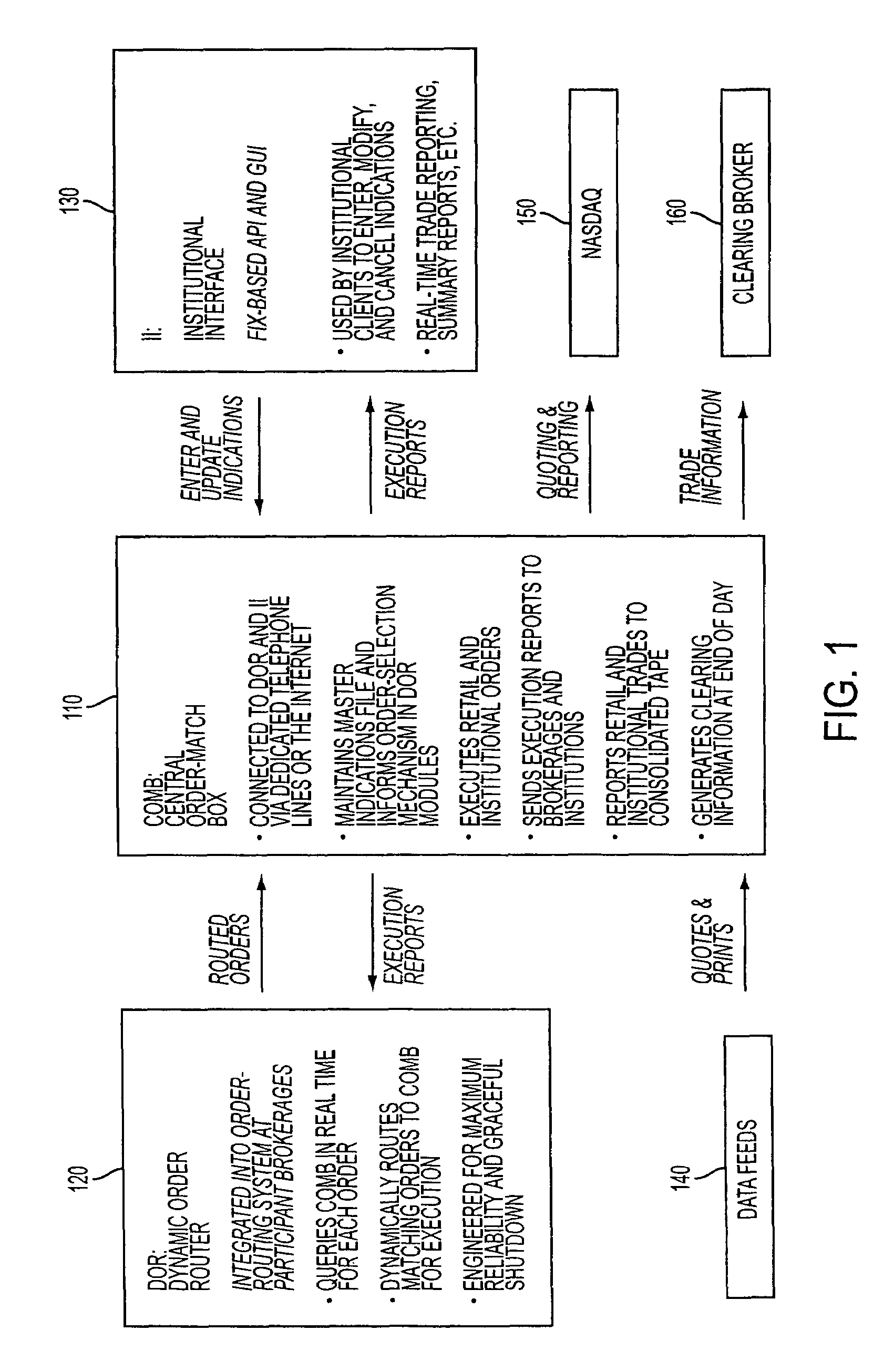

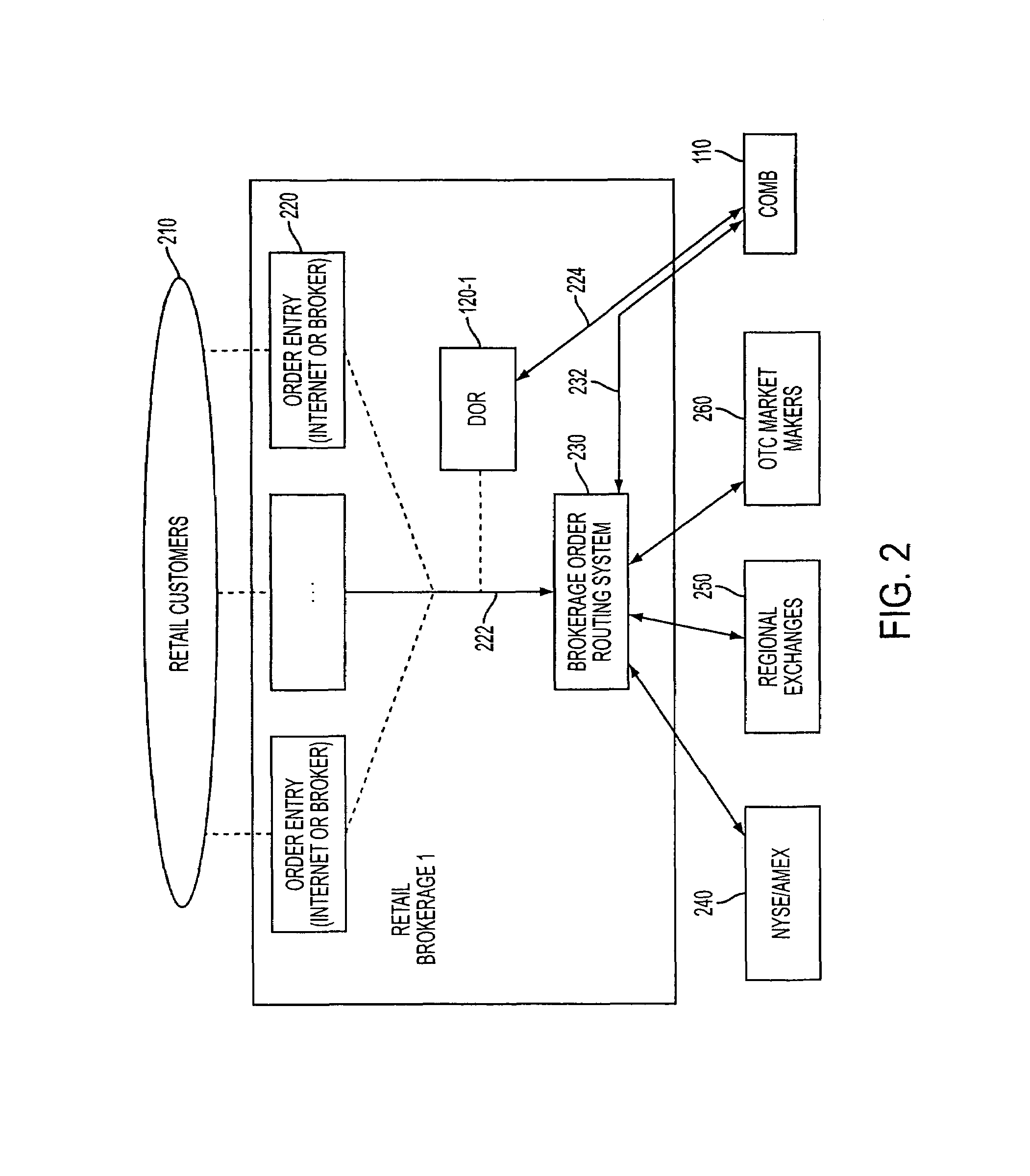

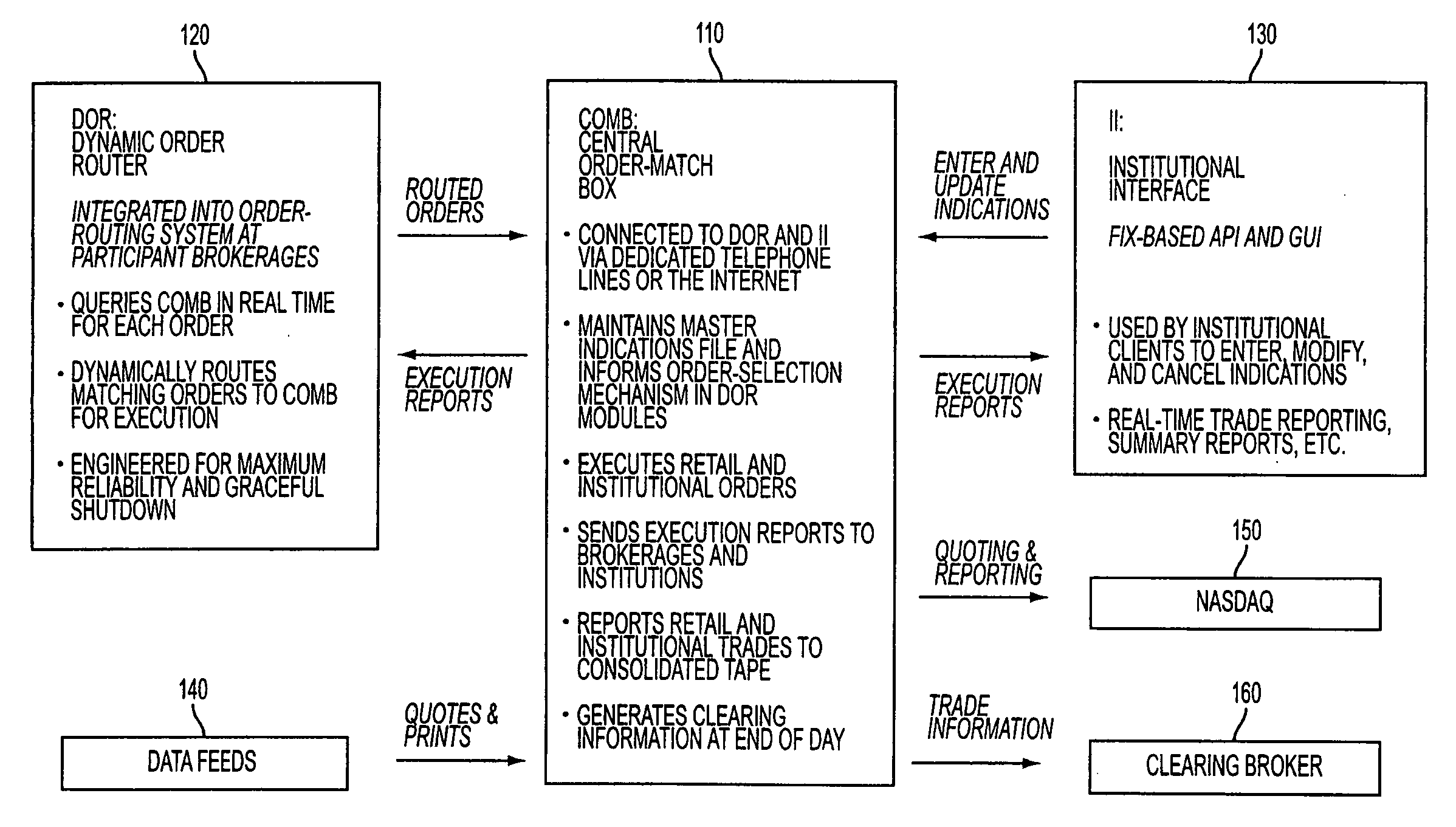

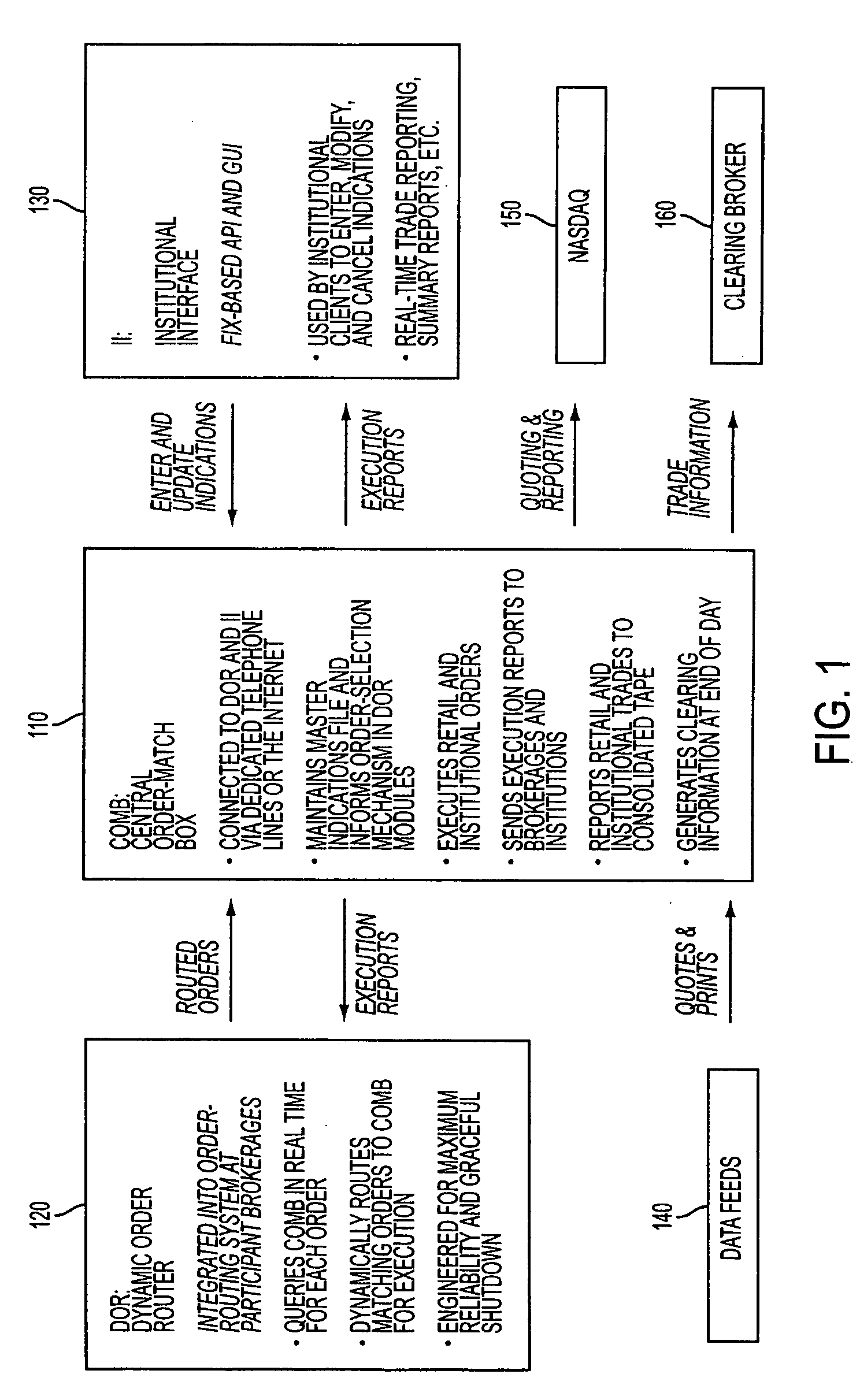

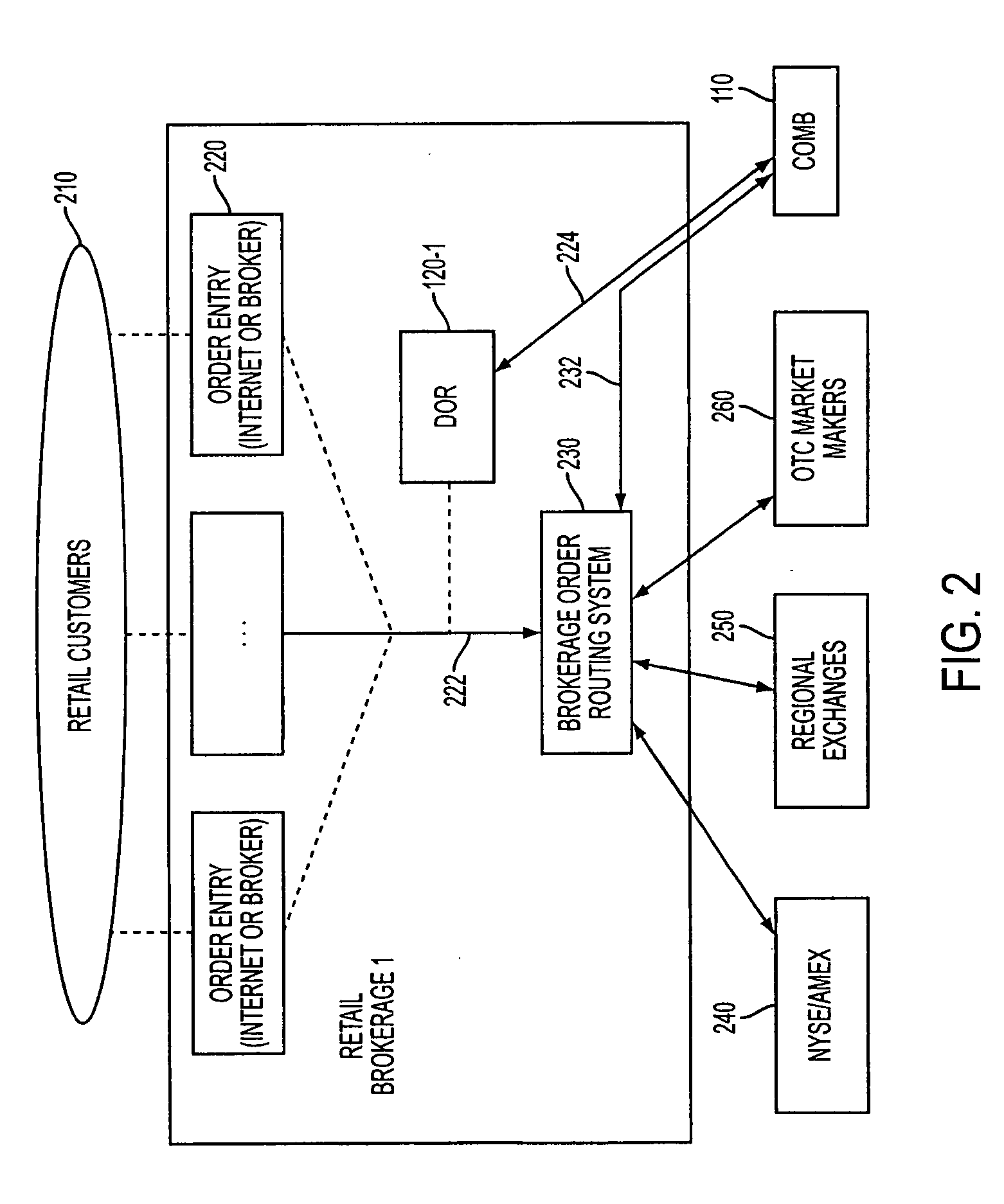

A method and system for an automated trading network that continuously collects invisible, anonymous, binding orders and indications of interest to buy and sell specific equity securities at variable, passively determined prices and, then, executes trades based on these collected orders and indications. In general, the binding orders are collected from retail broker-dealers and the binding indications are collected from institutions. The variable, passively determined, non-discrete prices can be linked to the National Best Bid or Offer (NBBO) for each security, or some other prevailing market indicator, at the time a trade is executed. In an embodiment of the method and system, marketable retail orders which match with one or more collected institutional indications, are routed from a Dynamic Order Router (DOR) at each broker-dealer to a Central Order-Match Box (COMB) to be executed against the one or more matched collected institutional indications. The COMB also manages most other aspects of transactions in the method and system and continuously executes trades against the collected institutional indications at improved prices relative to the NBBO.

Owner:D E SHAW & CO

Method and system for facilitating automated interaction of marketable retail orders and professional trading interest at passively determined prices

InactiveUS20060031157A1Minimize near-term disruptionEnhanced interactionFinancePayment architectureIndication of interestComputer science

A method and system for an automated trading network that continuously collects invisible, anonymous, binding orders and indications of interest to buy and sell specific equity securities at variable, passively determined prices and, then, executes trades based on these collected orders and indications. In general, the binding orders are collected from retail broker-dealers and the binding indications are collected from institutions. The variable, passively determined, non-discrete prices can be linked to the National Best Bid or Offer (NBBO) for each security, or some other prevailing market indicator, at the time a trade is executed. In an embodiment of the method and system, marketable retail orders which match with one or more collected institutional indications, are routed from a Dynamic Order Router (DOR) at each broker-dealer to a Central Order-Match Box (COMB) to be executed against the one or more matched collected institutional indications. The COMB also manages most other aspects of transactions in the method and system and continuously executes trades against the collected institutional indications at improved prices relative to the NBBO.

Owner:D E SHAW & CO

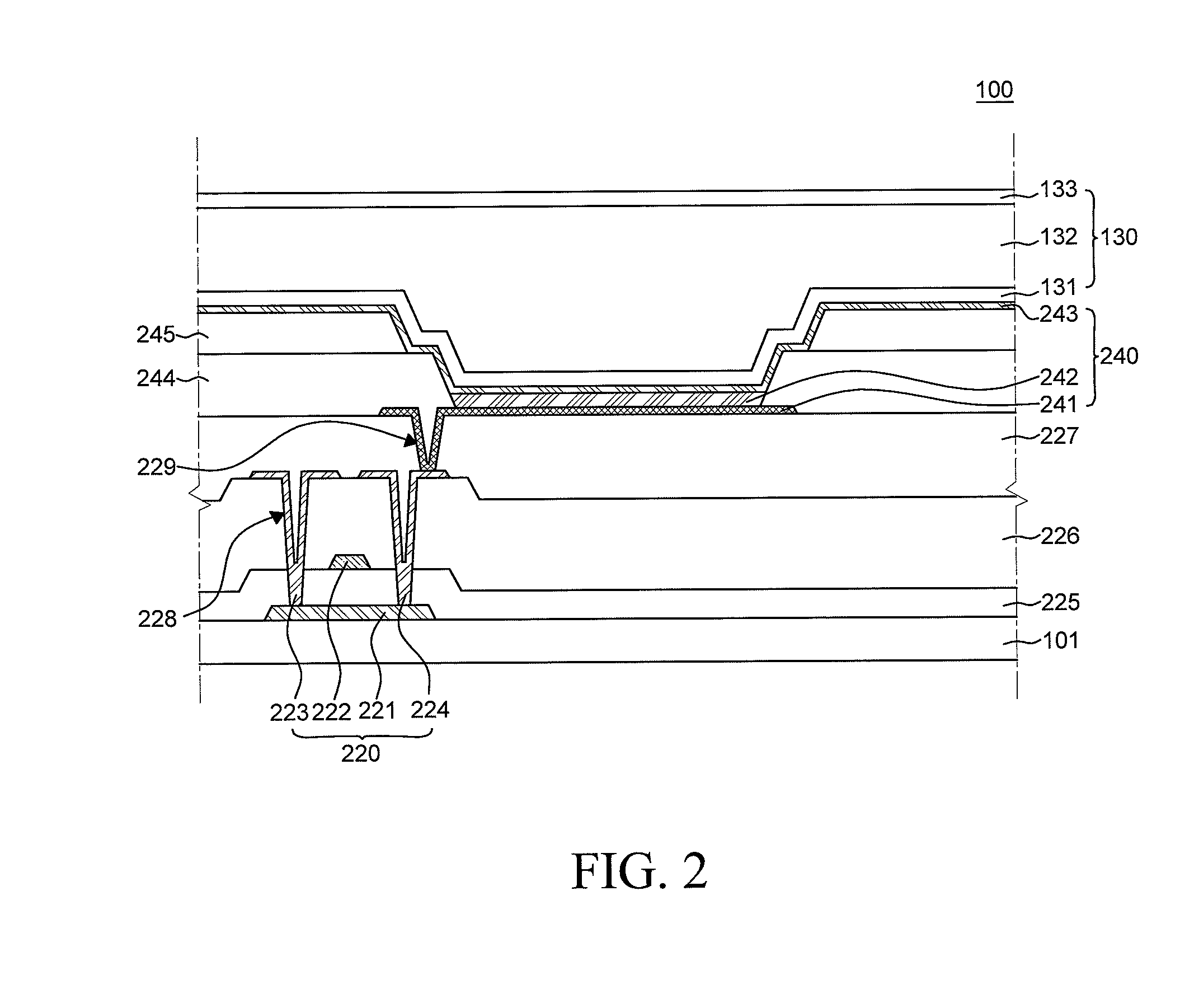

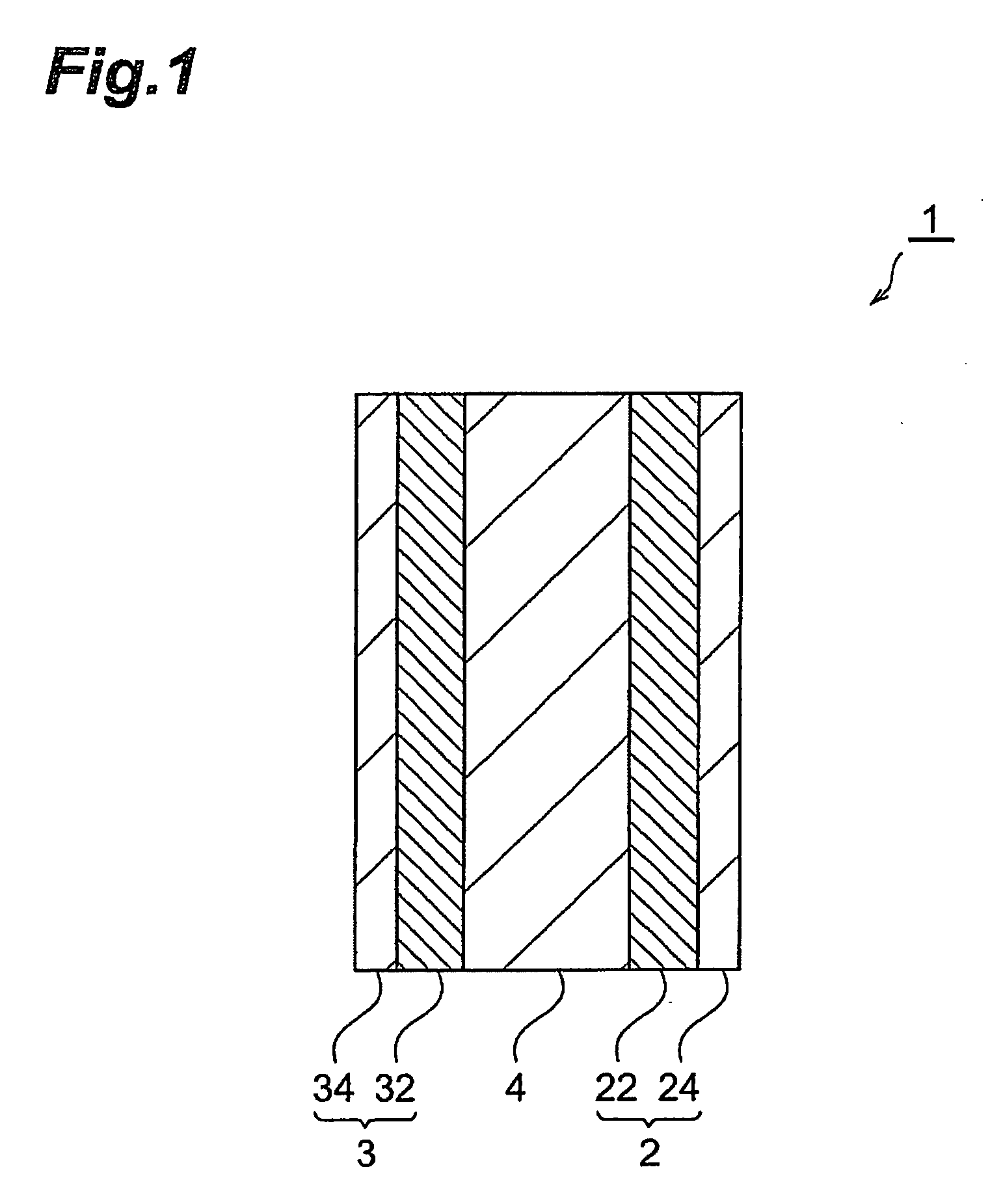

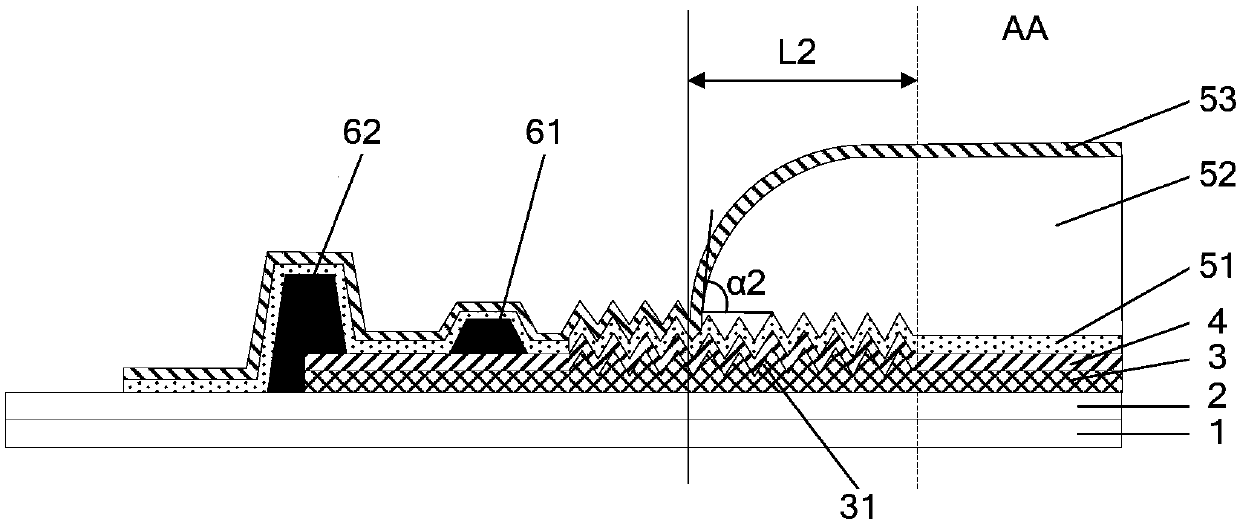

Organic light emitting display apparatus

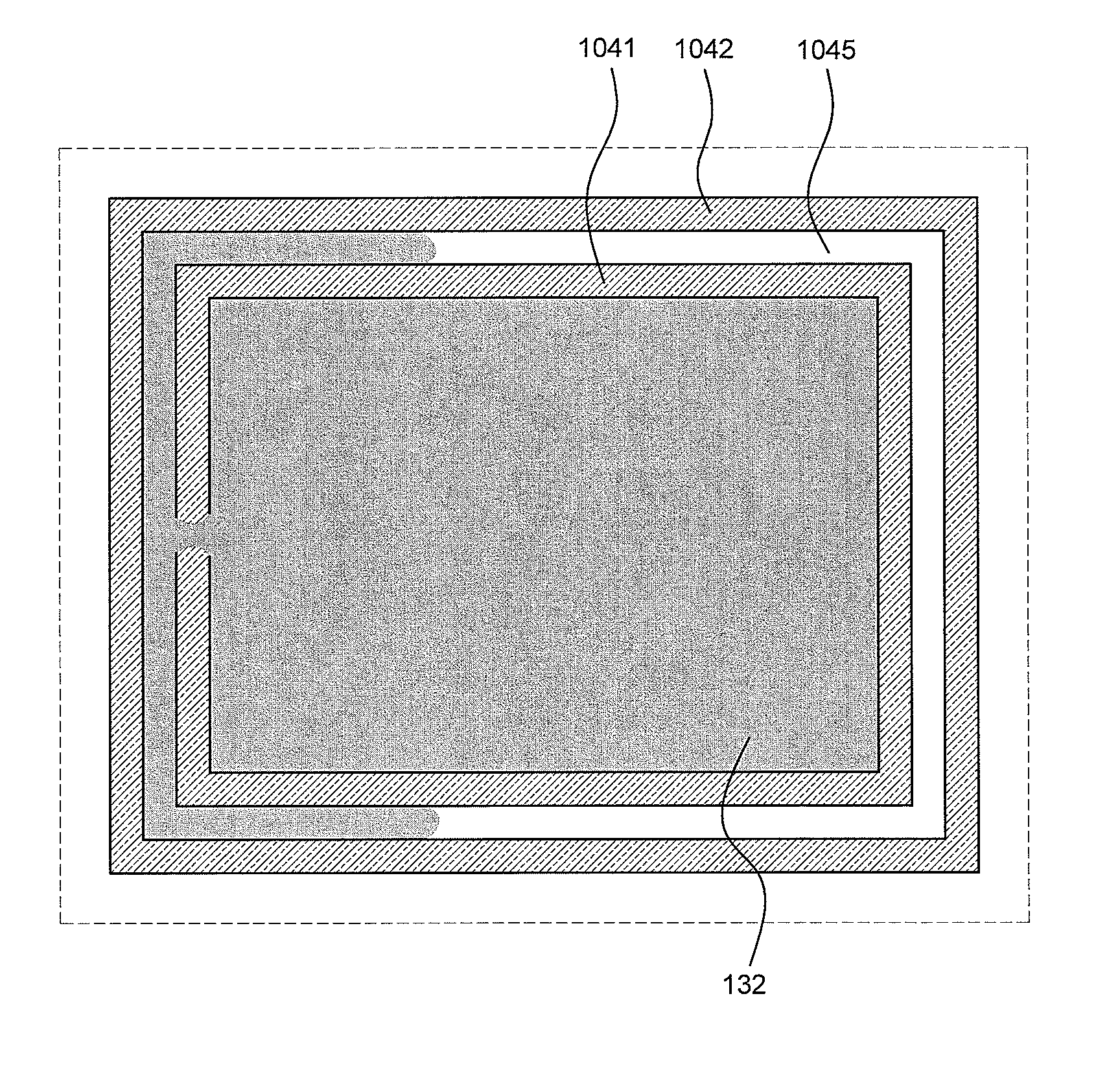

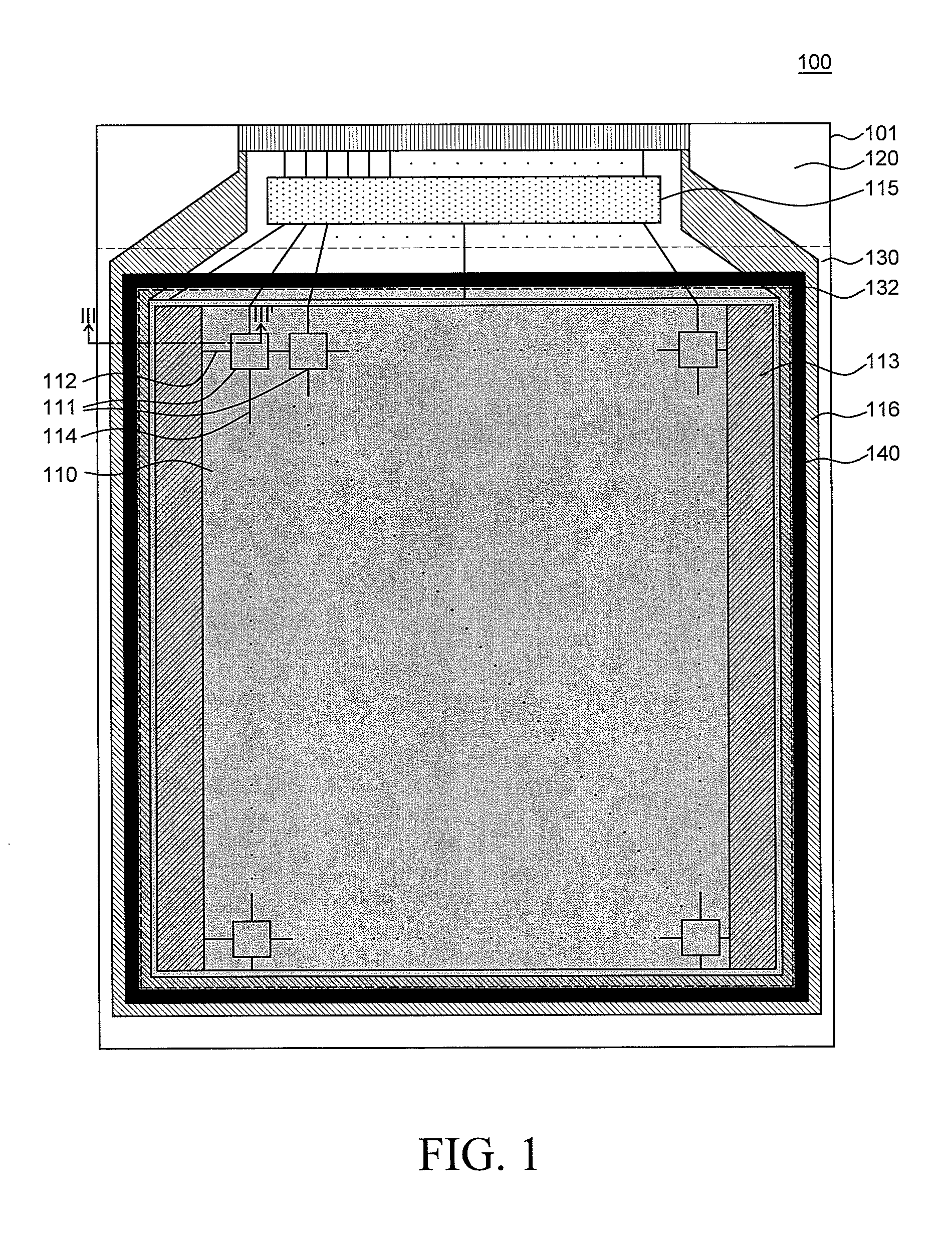

ActiveUS20150380685A1Reduce liquidityEasy to crackSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsGate driver

An organic light-emitting display (OLED) device includes: a pixel area defined by a plurality of pixels on a flexible substrate; a non-pixel area around the pixel area; a gate driver in the non-pixel area; a structure in the non-pixel area configured to surround the pixel area; a first encapsulation layer covering the plurality of pixels, the gate driver and the structure; and a particle cover layer covering the pixel area and suppressed from being excessively spread by the structure.

Owner:LG DISPLAY CO LTD

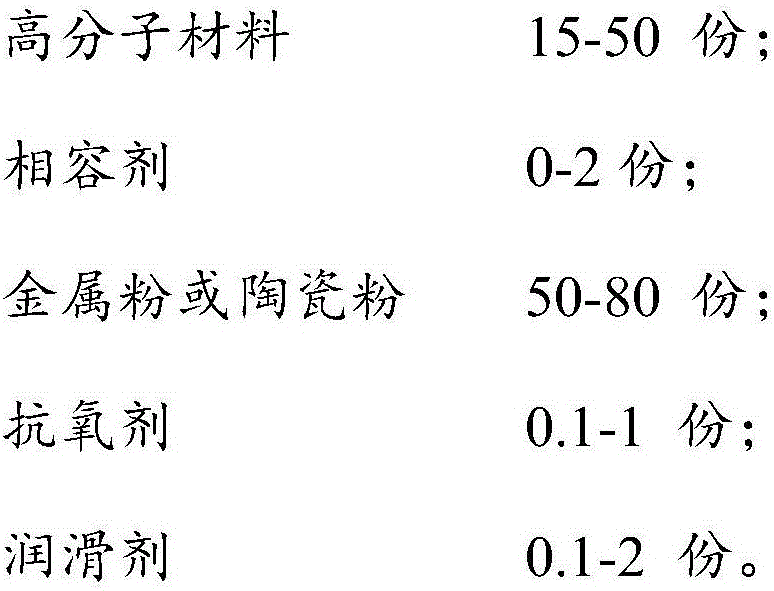

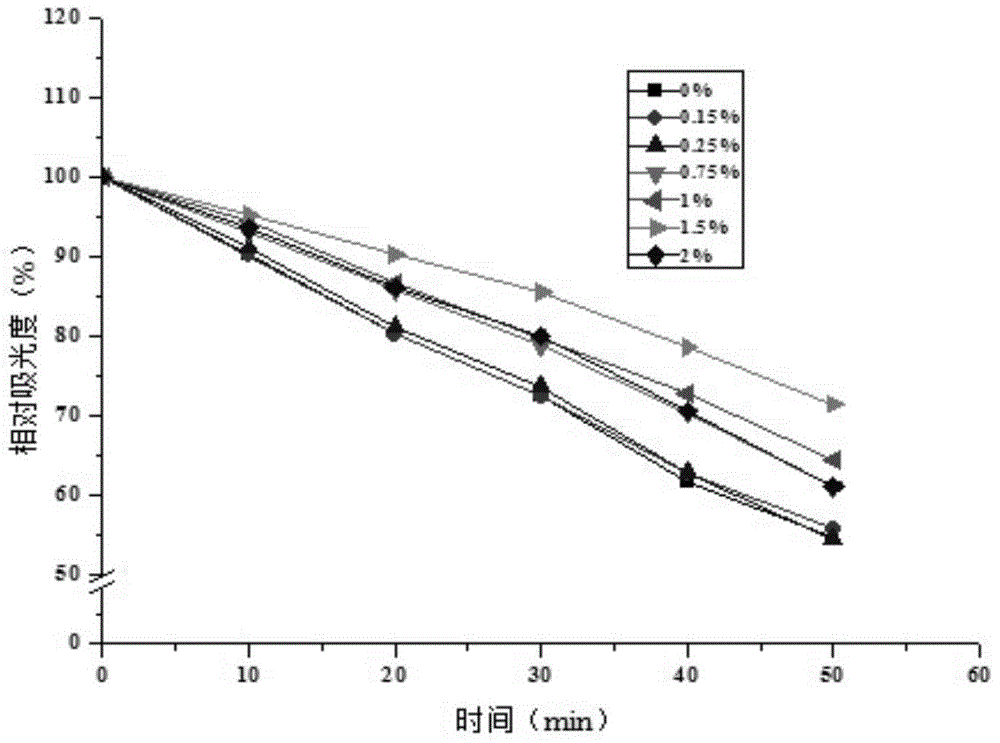

Metal or ceramic consumable item for FDM 3D printing, preparation method for metal or ceramic consumable item and finished product printing method

InactiveCN105665697AEasy to handleUnlimited structureAdditive manufacturing apparatusTransportation and packagingMiniaturizationVolumetric Mass Density

The invention discloses a metal or ceramic consumable item for FDM 3D printing, a preparation method for the metal or ceramic consumable item and a finished product printing method. The metal or ceramic consumable item comprises, by weight, 15-50 parts of a high polymer material, 0-2 parts of a compatilizer, 50-80 parts of metal powder or ceramic powder, 0.1-1 part of an antioxygen and 0.1-2 parts of a lubricating agent. The cost for equipment, the materials and machining is low; a printing structure is free of limitation, collapsing conditions do not exist in the printing process, supports can be removed before fusion sintering of the product, and treatment is easier compared with a manner that the supports are removed after SLS or EBAM fusion sintering; the requirements for the sphericity degree, the size distribution, the mobility and the like are relatively low; the types of metal and ceramic capable of being printed are wider; and the density of the finished products is higher, the strength is high, the degree of finish is higher, the miniaturization capacity is high, the thin-wall capacity is high, the complexity is high, the design tolerance level is high, and the material adaption scope is wide.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and preparation method thereof

ActiveCN101602589AWide variety of sourcesSimple preparation processSolid waste managementMixing operation control apparatusNeutral phPre stress

The invention discloses a preformed material for post-tensioned prestressing pipeline vacuum grouting or mudjacking and a preparation method thereof. The preformed material includes the following components by weight percent: 65 to 95 percent of silicate cement, 0.01 to 3 percent of high-range water-reducing agent, 0 to 1 percent of stabilizing agent, 0.05 to 5 percent of retarding agent, 1 to 20 percent of expanding agent, 0.2 to 2 percent of corrosion inhibitor, 0.01 to 1 percent of air entraining agent and 0 to 30 percent of mineral materials, wherein by uniformly and proportionally mixing the silicate cement, the high-range water-reducing agent, the stabilizing agent, the retarding agent, the expanding agent, the corrosion inhibitor, the air entraining agent and the mineral materials, the post-tensioned prestressing pipeline vacuum grouting or mudjacking preformed material can be obtained. After being uniformly mixed and stirred with water with neutral pH value according to the water cement ratio ranging from 0.24 to 0.32, the preformed material can be used, the obtained grouting material has the advantages of low water cement ratio, favorable flowability, no water bleeding and delamination, and favorable pumpability; meanwhile, the preparation method of the preformed material is simple and the raw material sources of the preformed material are wide.

Owner:HUBEI CHIDGE TECH

Low melting point glass and glass ceramic composition

InactiveUS6355586B1Essential and effective for stabilizing the glassIncreased durabilityTube sealing materialsGlass-ceramicLow melting point

A low melting point glass consisting essentially of, as represented by mol % based on the following oxides:wherein SnO+ZnO+P2O5+B2O3 is at least 76 mol %, Li2O+Na2O+K2O is from 0 to 9 mol %, MgO+CaO+SrO+BaO is from 0 to 35 mol %, and the molar ratio of SnO to ZnO is less than 1.

Owner:ASAHI GLASS CO LTD

Epoxy resin embedding glue and method for producing the same

The invention relates to an epoxy resin potting adhesive which consists of component A and component B. By weight portion, the component A consists of 90-130 portions of bisphenol A type epoxy resin, 240-320 portions of filling, 15-25 portions of thinner, 10-25 portions of toughener, 1-2.5 portions of defoamer and 0.8-2 portions of black pigment, and the component B consists of 60-130 portions of estolide and 1-3 portions of imidazole accelerator. The mixing proportion of the component A and the component B is (3-5):1. The invention also provides a preparation method of the epoxy resin potting adhesive. The epoxy resin potting adhesive provided by the invention has low cost and long resting period; after being mixed, the component A and the component B have low viscidity, good wetting quality, good heat resistance, good defoaming performance, good fluidity and long operating time and are solidified between 70 DEG C and 160 DEG C; a product after solidifying has bright surface, good mechanical performance and insulating performance and high glass transition temperature; and the quality of a potting component is stable.

Owner:NICHE TECH KAISER SHANTOU

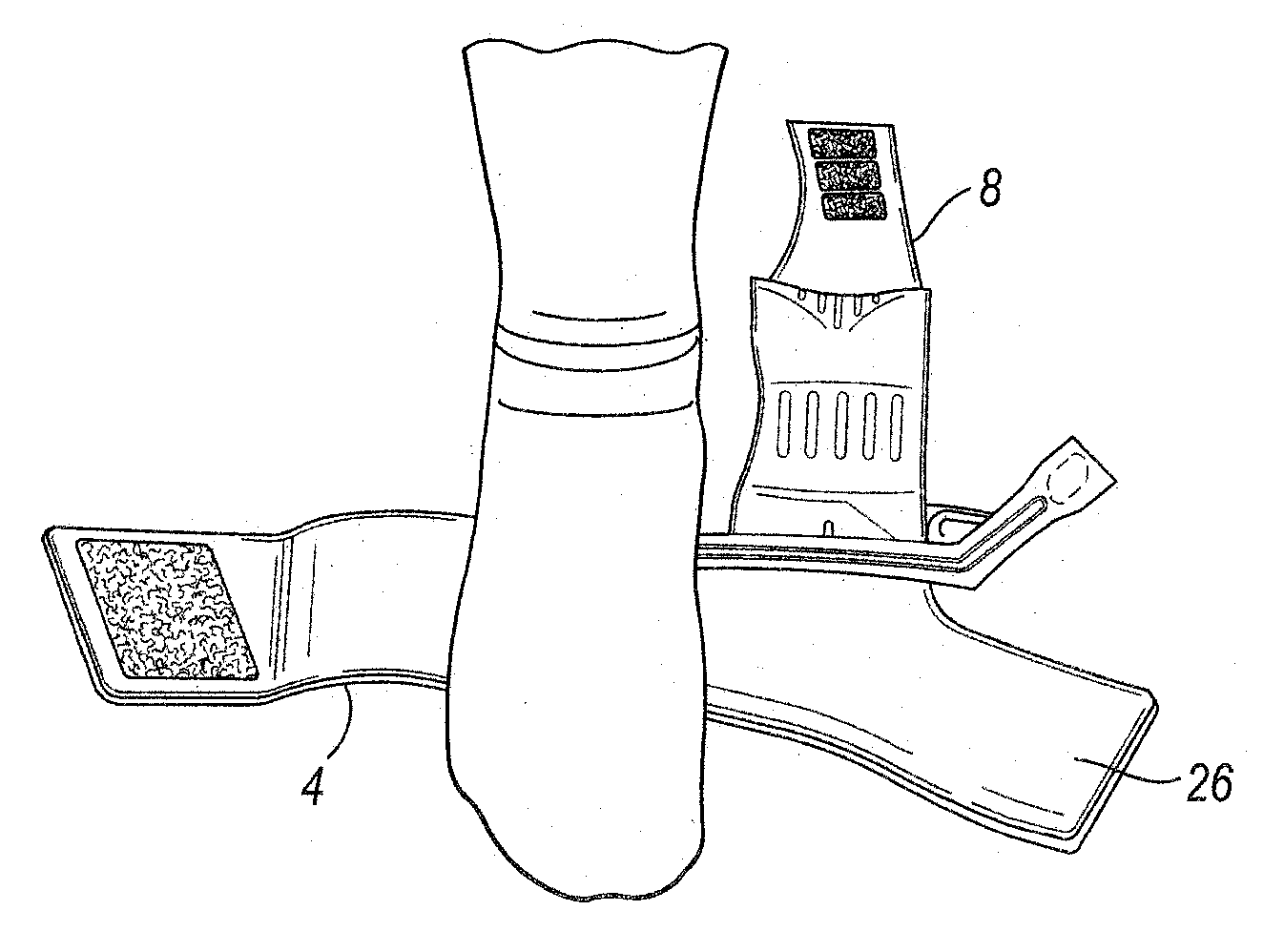

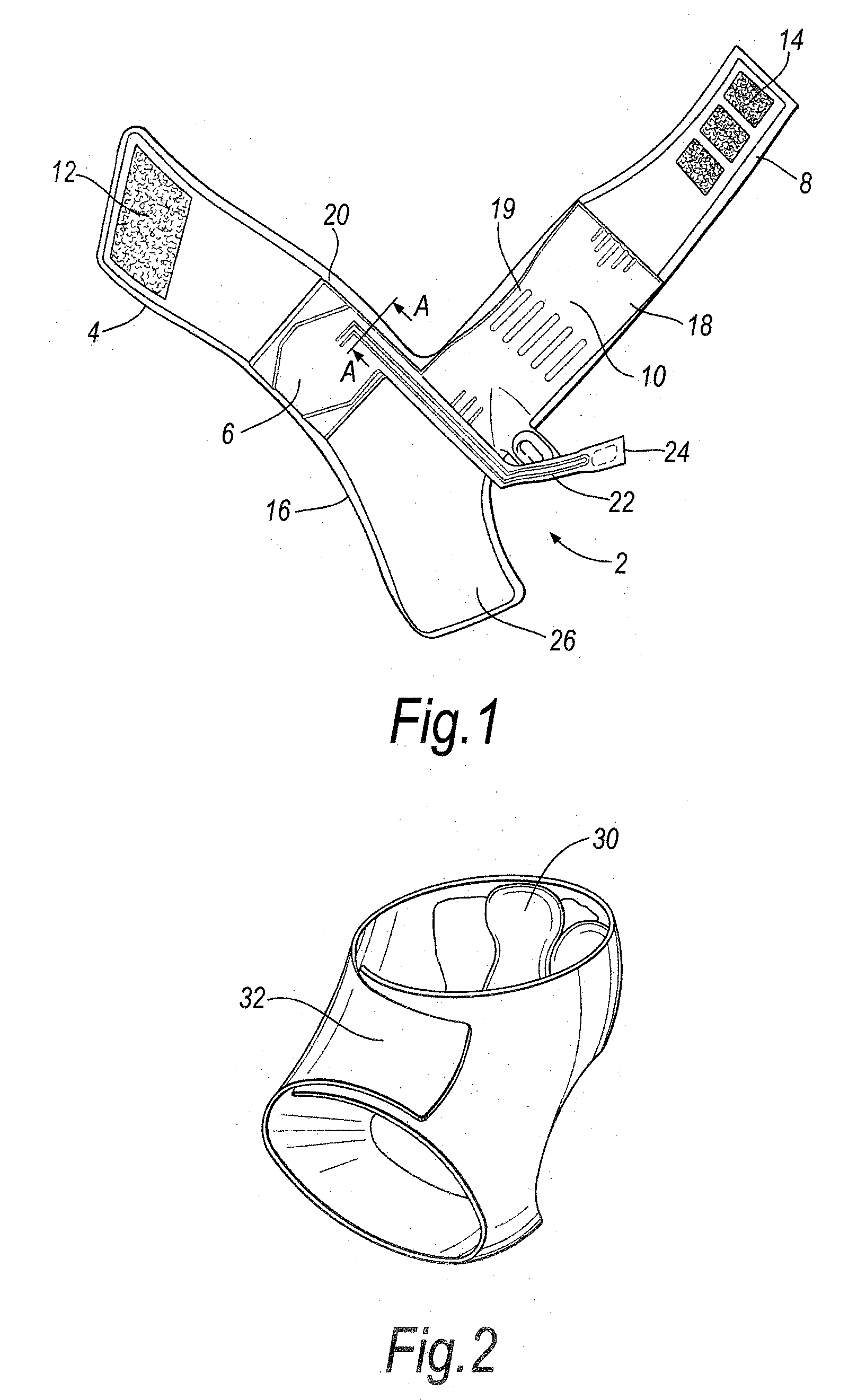

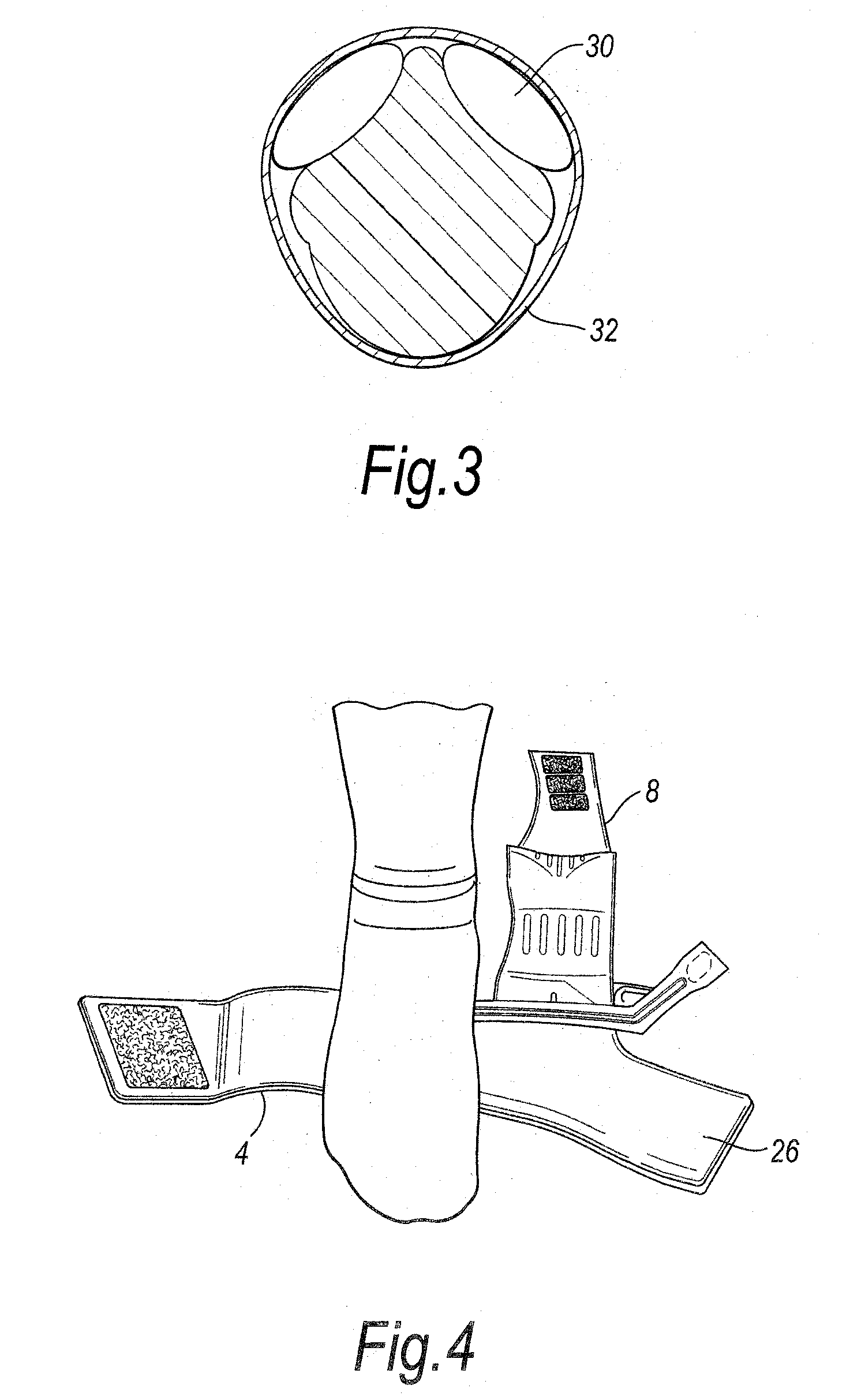

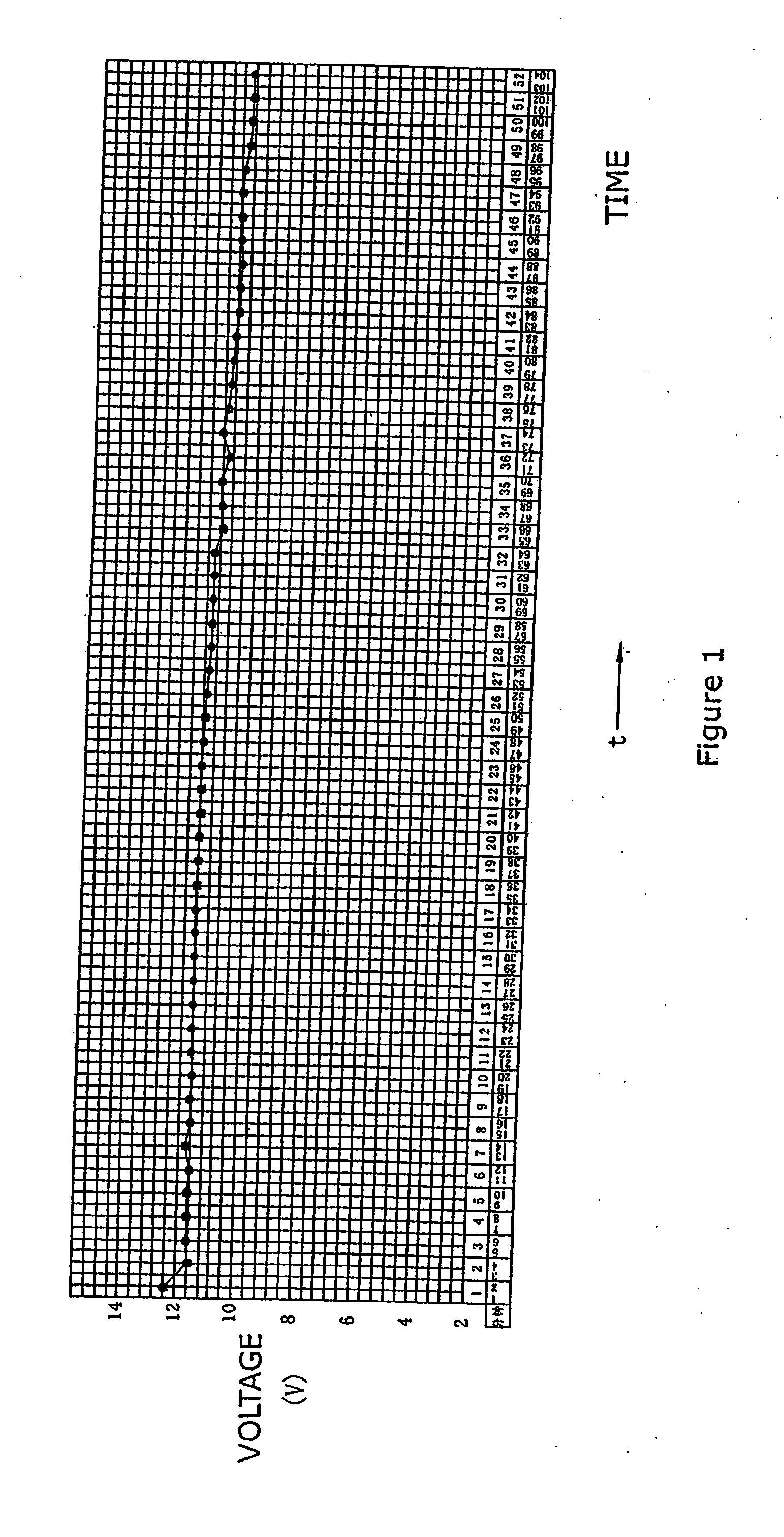

Compression device for the foot

ActiveUS20070038167A1Reduce liquidityPneumatic massageGenitals massagePhysical medicine and rehabilitationCompression device

A compression device for the foot comprising: a wrap adapted to surround the foot, the wrap comprising at least two bladders which when inflated conform to the shape of the foot to provide compression, the bladders being positioned on the wrap so that a first bladder focuses compression on the heel of the foot and a second bladder focuses compression on the arch of the foot; a channel attached to each bladder for independently delivering fluid to each bladder; and a controller attached to the channels that generates and independently controls the flow of fluid to the bladders.

Owner:SWELLING SOLUTIONS

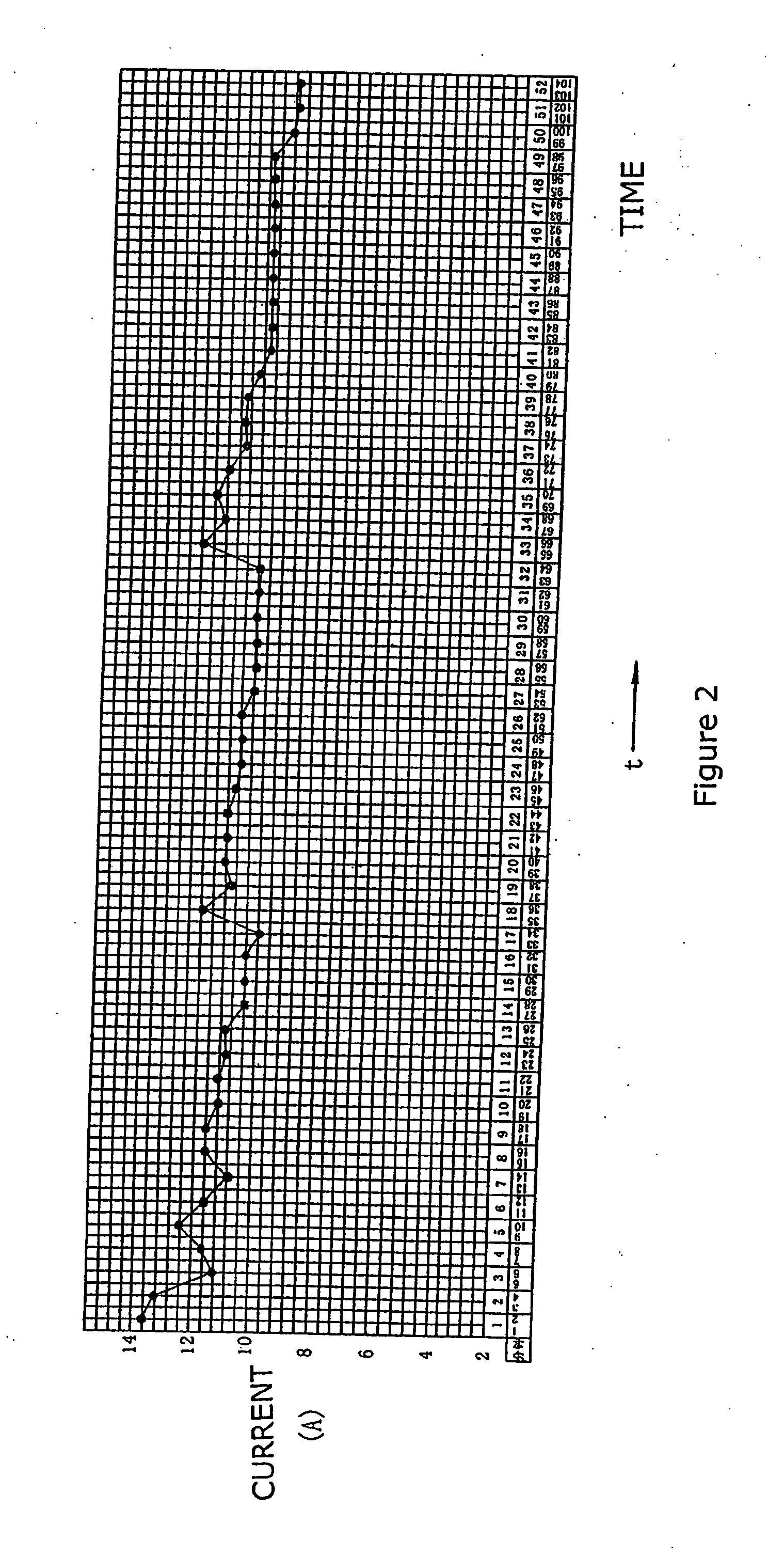

Liquid low-sodium silicate electrolyte used for a storage battery and manufactured by magnetization process, and the usage thereof

InactiveUS20080044726A1Improve liquidityHigh viscosityOther chemical processesMagnetic paintsMagnetizationBiological activation

A liquid low concentration sodium-containing silicate solution as electrolyte for lead-acid storage batteries and its applications, is prepared by mixing a silica gel containing 40˜60 wt % SiO2, the weight units of such a silica gel are 5˜15; add 15-25 weight units water and stir until the concentration of the mixture is 0.65˜0.85 0Be′ measured by a Baum densimeter, adjusting the pH value of this mixture to 1-4 using inorganic acid and magnetizing the mixture under 1000-6000 Gauss magnetic field for 5-10 minutes, stir the magnetized mixture until the viscosity of the mixture is less than 0.02 poise and finally obtain a liquid low concentration sodium-containing silicate solution. The electrolyte can be used as electrolyte or activation solution for common or special lead-acid storage batteries.

Owner:LIDU WANG

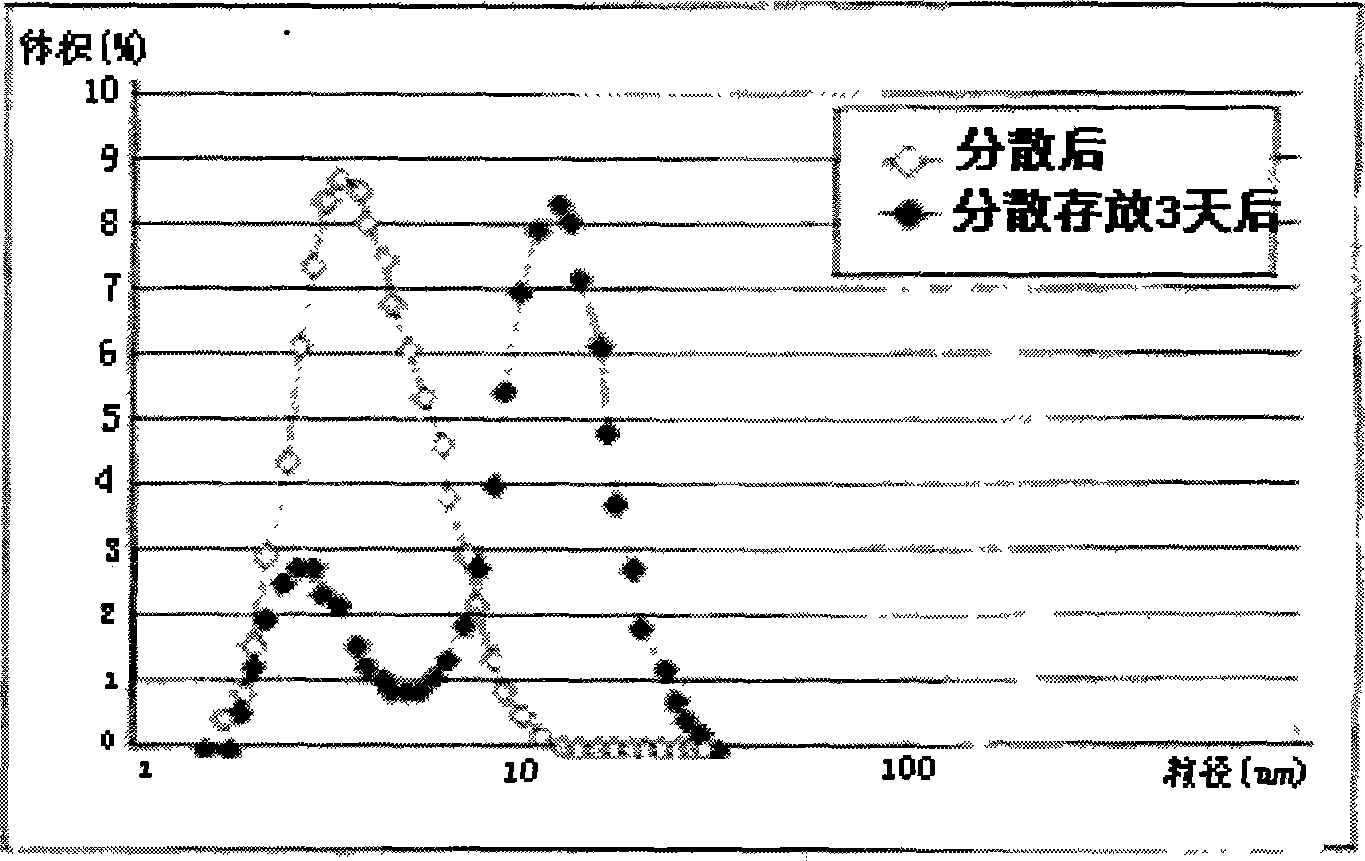

Pulp for lithium ionic cell electrode and manufacturing method thereof

ActiveCN101393978AEasy to useReduce dosageElectrode manufacturing processesActive material electrodesAdhesiveColloid

A sizing material for electrodes of a lithium ion battery mainly comprises an active material, a conductive agent, an adhesive and a solvent, and is characterized in that the distribution ratio of the active material, the conductive agent, the adhesive and the solvent is 100 : 0-4 : 1-7 : 35-100. The preparation process thereof comprises the following steps: 1) mixing the adhesive with partial solvent to prepare a glue body with the viscosity of 1 to 10 percent; 2) mixing the conductive agent weighed according to the distribution ratio with the glue body prepared in the step 1) and stirring to form a conductive glue; 3) mixing the active material and the rest solvent weighed according to the distribution ratio with the conductive glue and stirring to form a premixed sizing material; 4) introducing the premixed sizing material into a dispersion machine rotating at a high speed to conduct dispersion; 5) cooling and vacuumizing the dispersed sizing material to form the sizing material for the electrodes of the lithium ion battery. The sizing material has the better use performance, and the preparation method thereof solves the defect in the traditional mixture that the layering of the conductive agent is easily caused by a larger density difference when the conductive agent is mixed with the active material and the like, thereby ensuring the uniform distribution of each ingredient of the sizing material.

Owner:ZHENGZHOU BAK BATTERY CO LTD

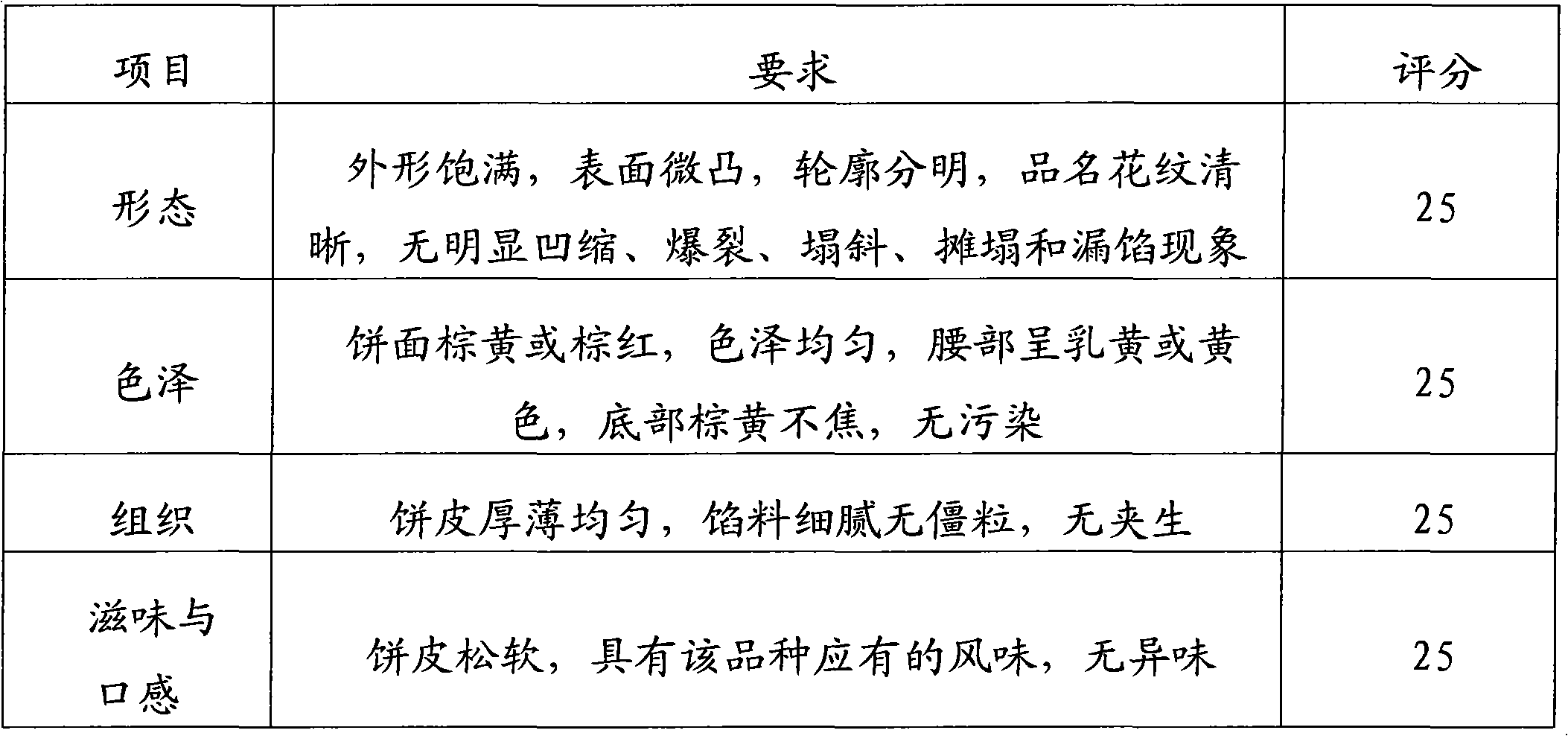

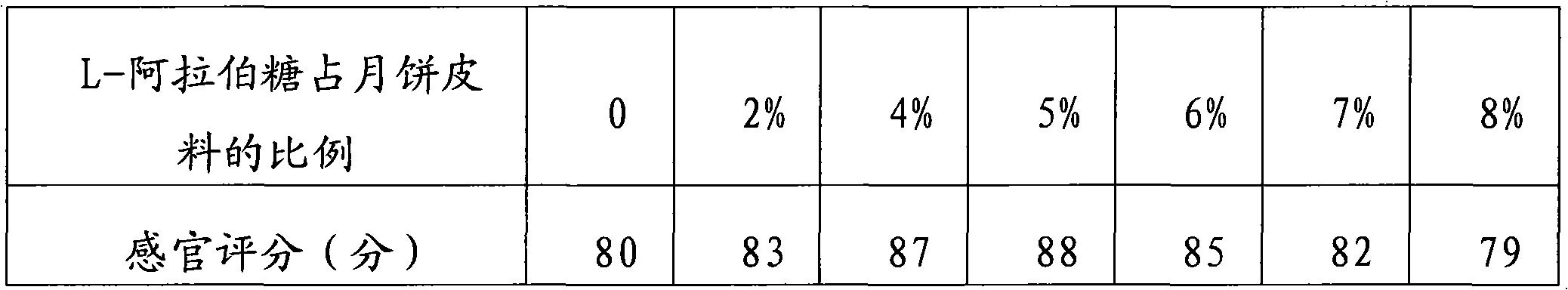

Moon cake

ActiveCN101889600AEasy to shapeImprove plasticityDough treatmentBakery productsAlkaline waterVegetable oil

The invention discloses a moon cake. The moon cake comprises a moon cake cladding and a moon cake filling, wherein the moon cake cladding comprises the following raw materials: 40 to 70 percent of wheat flour, 20 to 45 percent of sugar alcohol, 2 to 8 percent of L-arabinose, 5 to 20 percent of animal and vegetable oil or hydrogenated animal and vegetable oil and 0.2 to 2 percent of alkaline water. The technical problems of soft cladding and poor plasticity caused by the low viscosity of a sugar-free moon cake which takes maltitol solution as a cladding in the prior art are solved. Therefore, the moon cake has the characteristics of easily-shaped cladding, high plasticity and stable texture in baking process.

Owner:SHENGQUAN HEALTANG

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

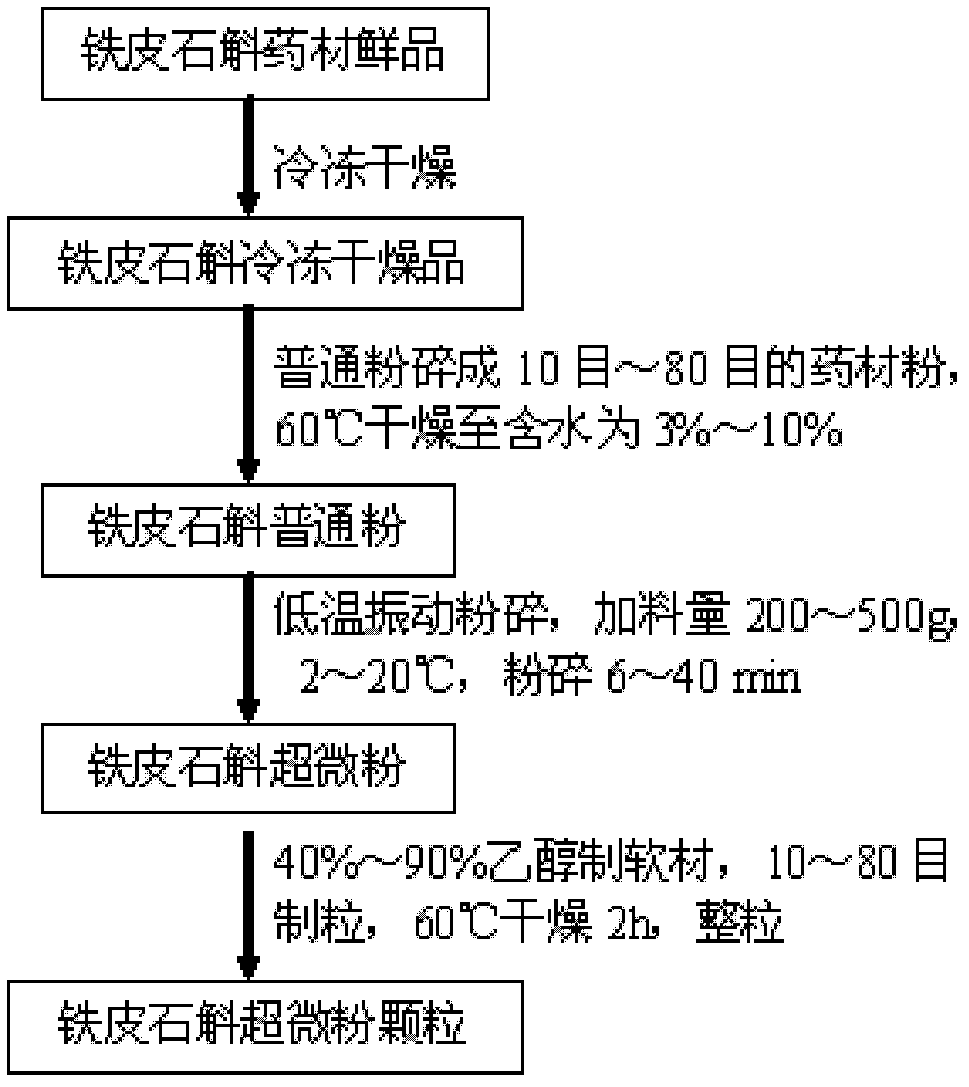

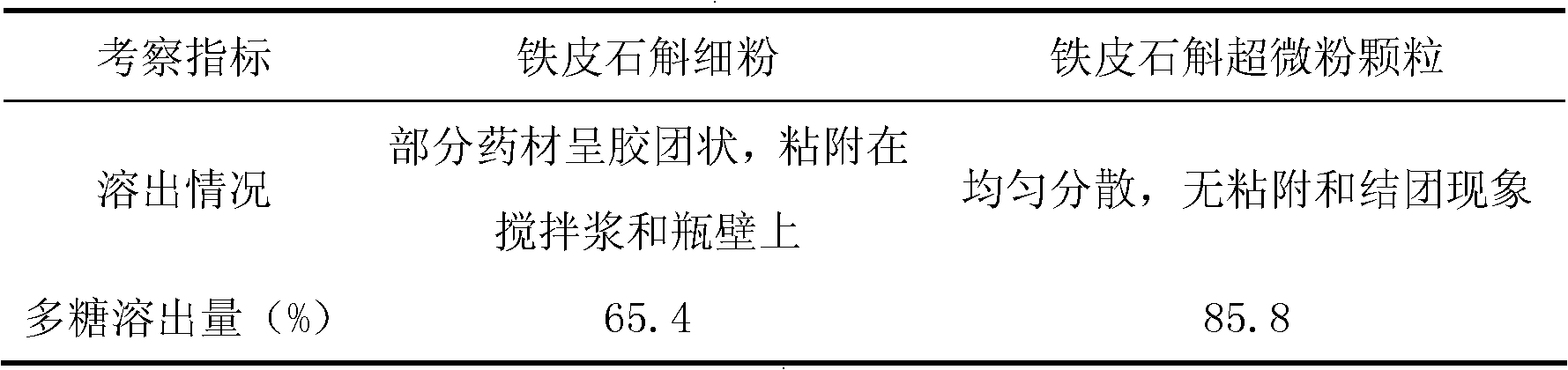

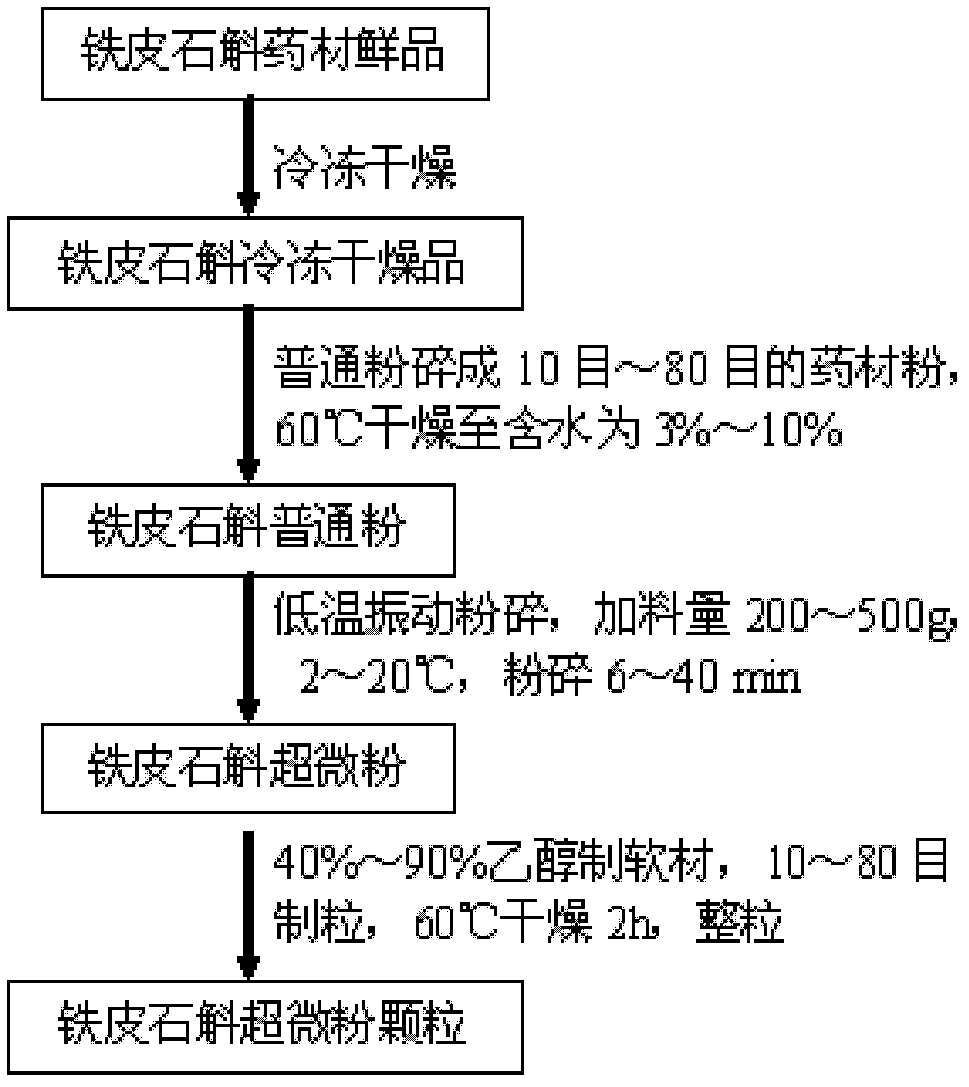

Processing method capable of reserving all components of dendrobium officinale

The invention provides a processing method capable of reserving all components of dendrobium candidum. The processing method comprises the following steps: (1) preliminarily processing the medicinal material; (2) freeze-drying in vacuum; (3) preparing common powder; (4) preparing ultrafine powder; and (5) preparing ultrafine particles, wherein the step of freeze-drying in vacuum comprises the following three processes: pre-freezing; sublimation drying; and desorption drying. The product produced by the method has the advantages of fresh color, aromatic flavor and fully reserved nutrient components without loss, and is convenient to serve; meanwhile, the product is thoroughly dewatered, thus being convenient for long-term preservation, reprocessing and transportation at normal temperature.

Owner:蔡光先 +3

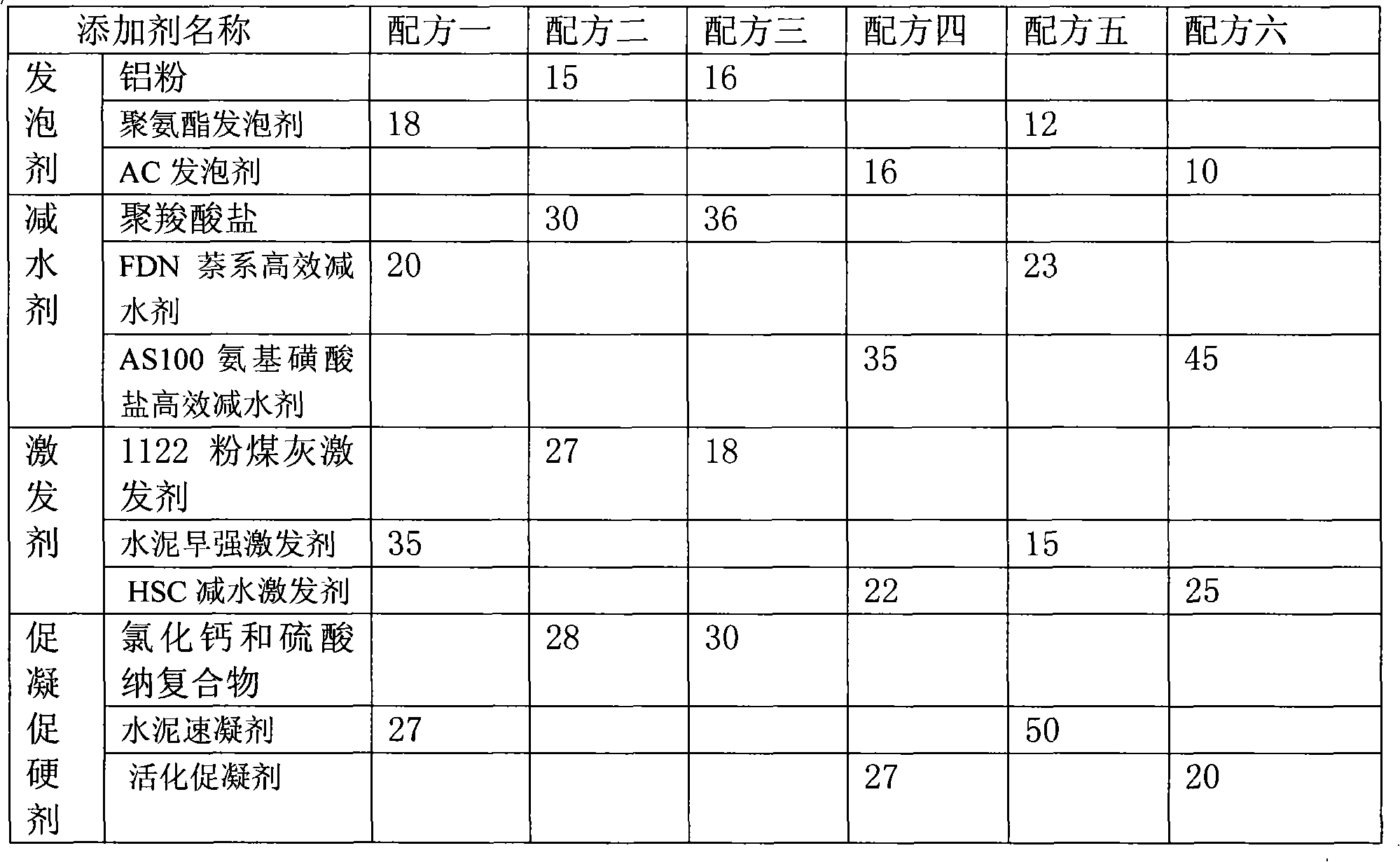

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

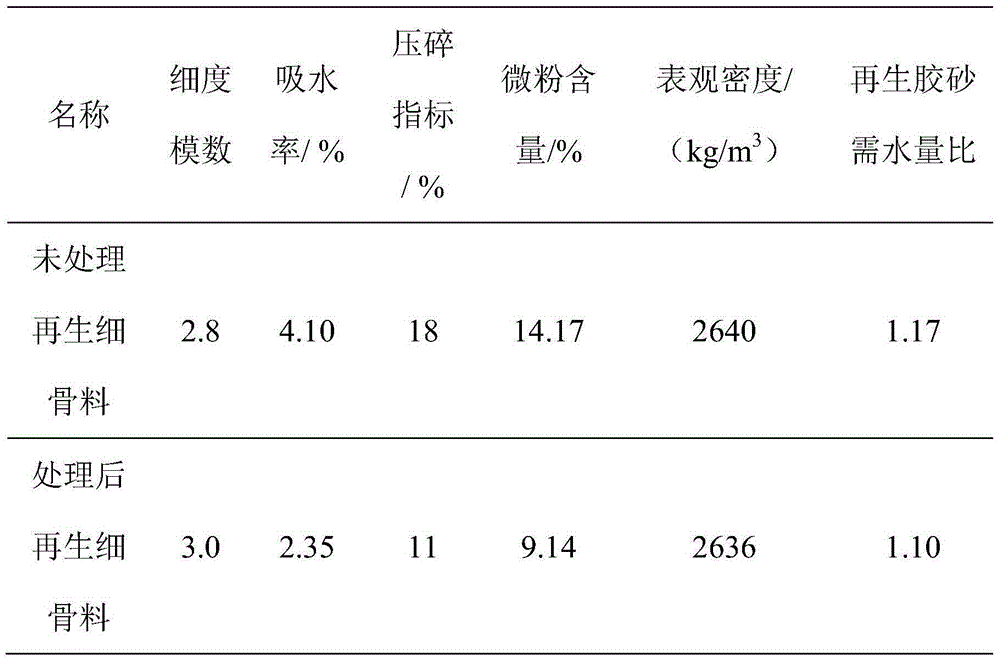

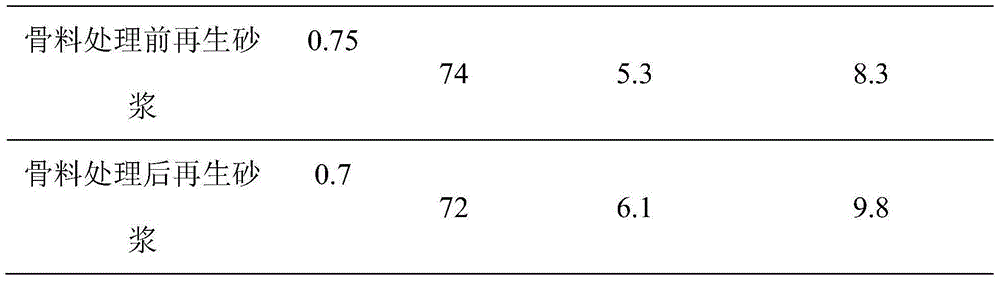

Method for reinforcing recycled concrete fine aggregate by using carbon dioxide

ActiveCN105174766AImprove water absorptionLow water absorptionSolid waste managementCALCIUM HYDROXIDE SOLUTIONCalcification

The invention discloses a method for reinforcing recycled concrete fine aggregate by using carbon dioxide, which comprises the following steps: (1) calcium hydroxide solution or calcium salt calcification treatment: spreading recycled fine aggregate prepared from construction waste on a tray, spraying a calcium hydroxide or calcium salt solution, and stirring uniformly; (2) CO2 curing: putting the recycled fine aggregate subjected to calcium hydroxide solution or calcium salt calcification treatment in a closed carbonization box, and carrying out carbonization curing until the surface is completely carbonized; and (3) recycled mortar preparation: preparing recycled mortar with the substitution rate of 100% by using the treated recycled fine aggregate. Compared with the unreinforced recycled aggregate, the crushing value of the recycled fine aggregate prepared by the method is lowered by nearly 45%, and the water absorptivity is lowered by nearly 53%. Compared with the recycled mortar prepared from the unreinforced recycled aggregate, the consistency of the recycled mortar prepared by the method is enhanced by 42% or so, the 7d strength of the mortar is enhanced by 15-26%, and the 28d strength can be enhanced by 17-24%.

Owner:SOUTHEAST UNIV +1

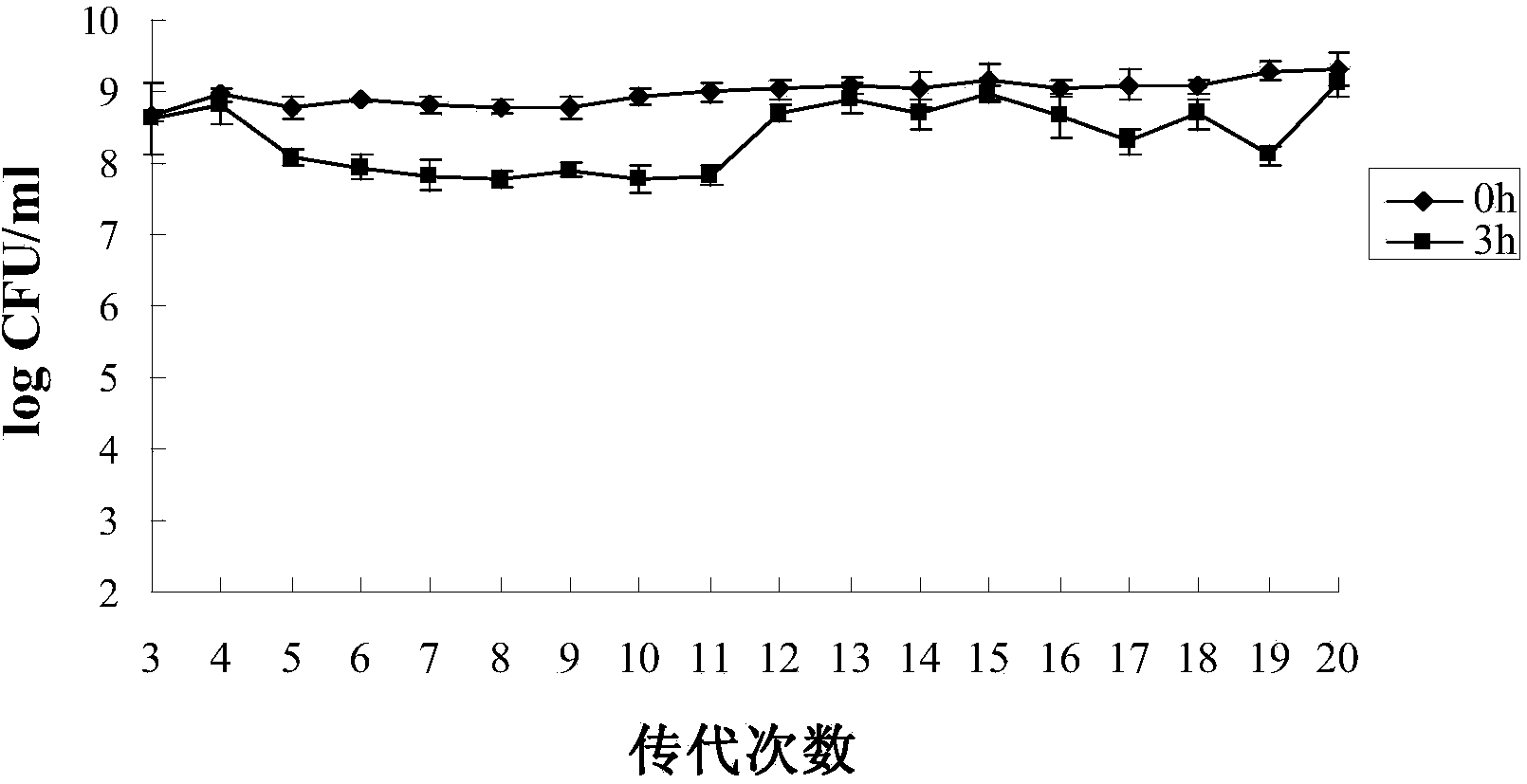

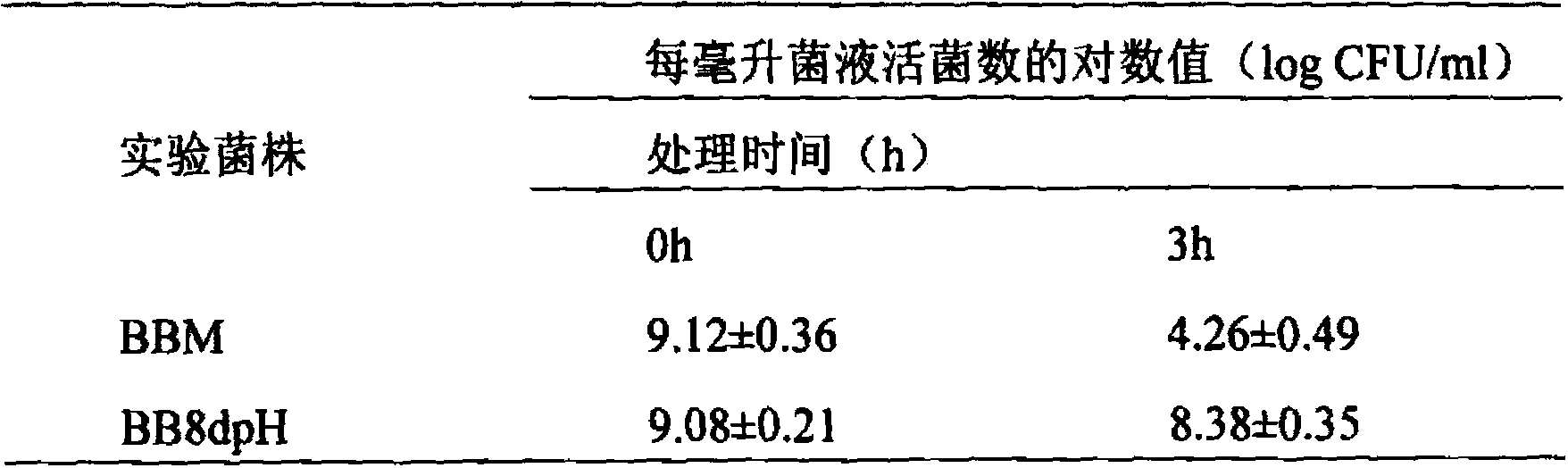

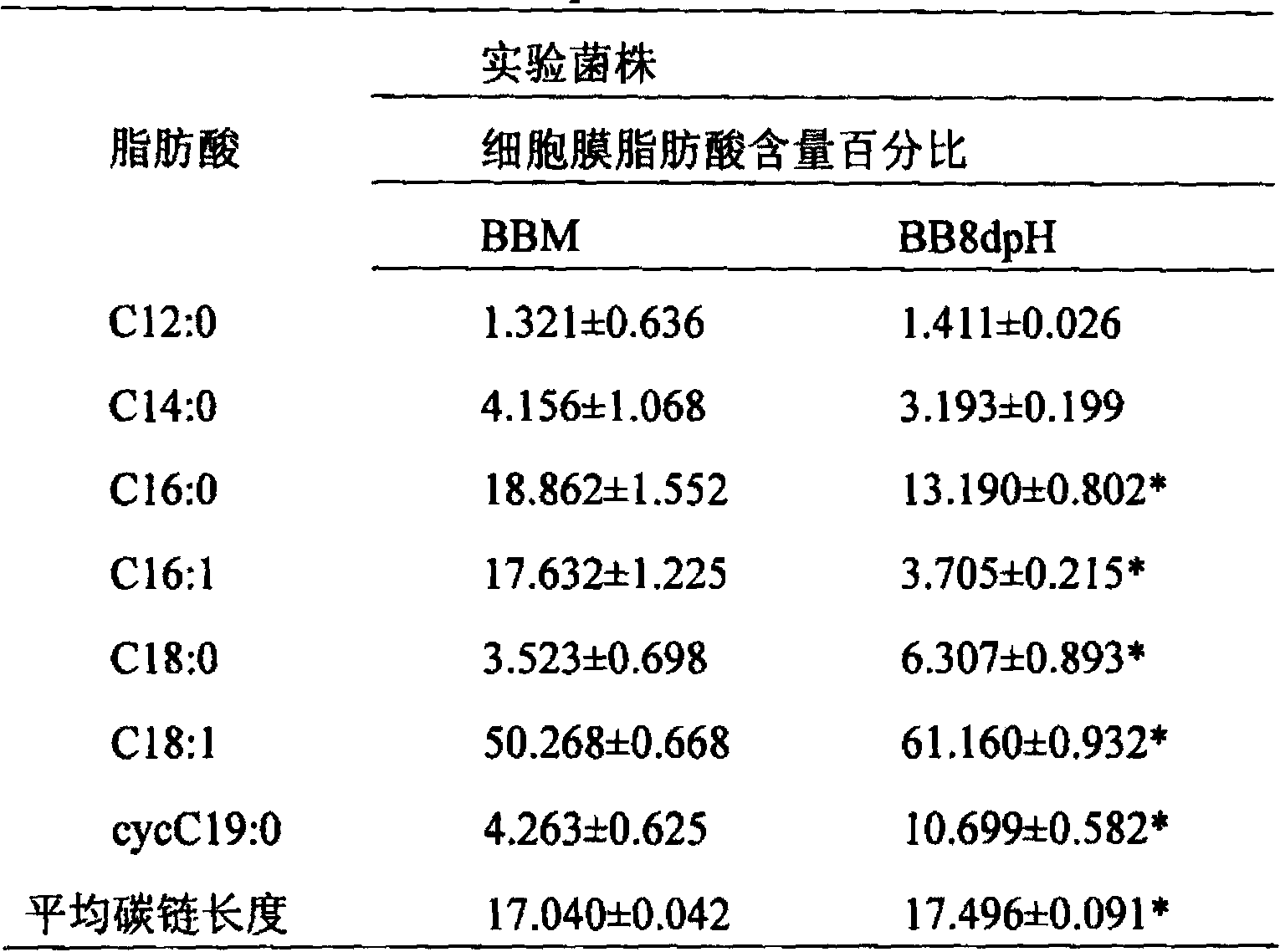

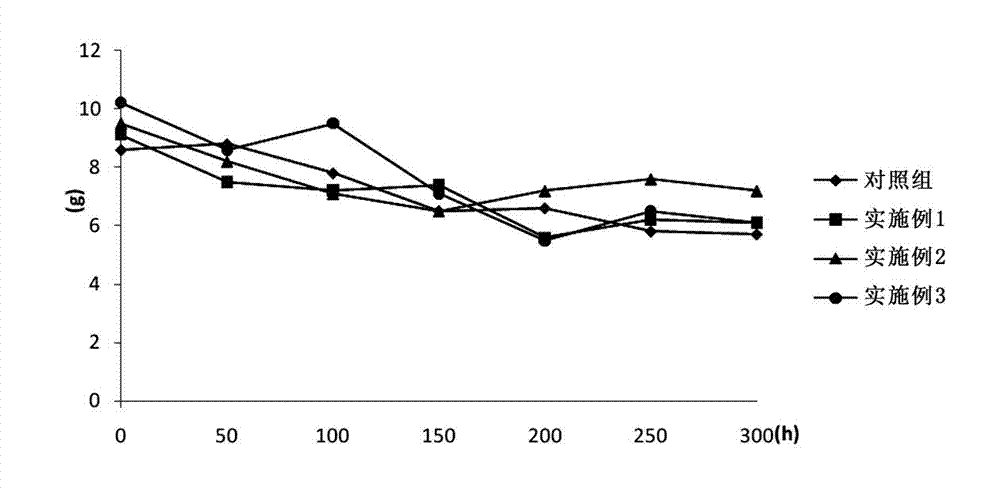

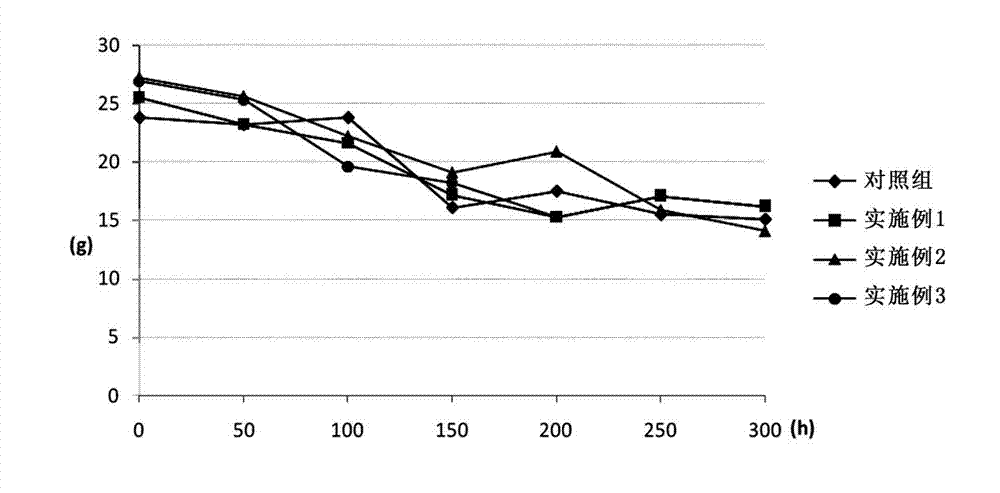

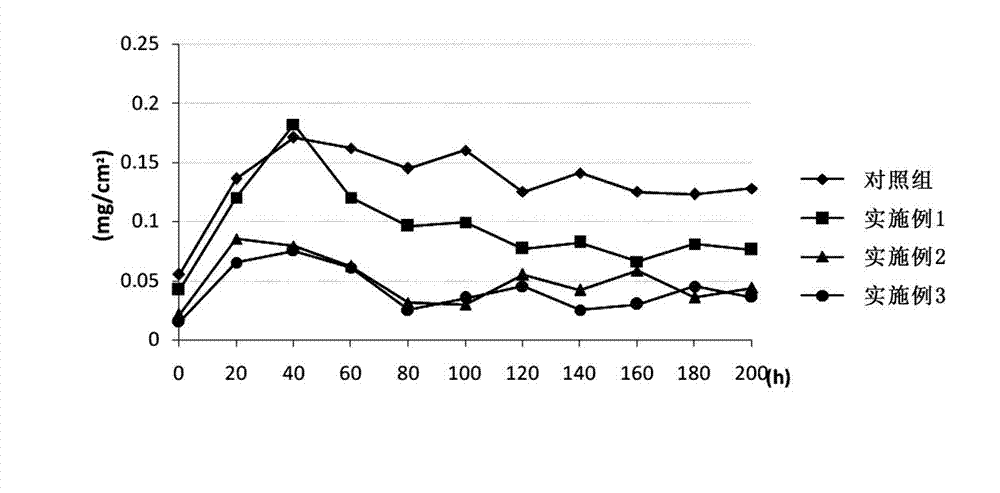

Acid-resistant bifidobacterium breve BB8dpH and application thereof

InactiveCN103849590AExcellent acid resistanceGenetically stableBacteriaMicroorganism based processesFecesCell membrane

The invention provides an acid-resistant bifidobacterium breve BB8dpH and an application thereof. The nucleotide sequence of the 16SrRNA gene part of the bifidobacterium breve BB8dpH is shown in SEQ ID NO.1, and is stored with the preservation number of CGMCCNo.8370. The bifidobacterium breve BB8dpH is a strain obtained by separating from the dejecta of healthy young people and further screening under the pH 3.2 acid condition. According to the fermentation and culturing process, anaerobic culture at 37 DEG C is carried out in a BL liquid substrate (containing 0.05% cysteine hydrochloride) for 24 hours. The bifidobacterium breve BB8dpH has remarkably better acid resistance than the common strains, and the acid resistance has genetic stability; the bifidobacterium breve BB8dpH has different percent contents of cell membrane fatty acids from the common strains, the average carbon chain length of the bifidobacterium breve BB8dpH is remarkably longer than that of the common strains, and the cell membrane fluidity of the bifidobacterium breve BB8dpH is remarkably lower than that of the common strains; and the bifidobacterium breve BB8dpH is used in the production field of daily fermented food, health-care food and medicines.

Owner:SHANGHAI JIAO TONG UNIV

Silver alloy wire and preparation method thereof

The invention relates to a silver alloy wire and a preparation method thereof. The silver alloy wire is prepared from the following components of 0.5-10 percent of Au, 0-1 percent of Pt, 1-6 percent of Pd, 0-1 percent of Rh, 0-1 percent of Cu, 0-500ppm of Ln, 0-200ppm of Ce, 0-0.5 percent of Al, 0.7-3 percent of Ti, 0-0.2 percent of Si, 0-0.3 percent of Zn, 0-1 percent of Sn, 0-10 percent of Be and the balance of Ag. A directional continuous casting process is adopted. The prepared silver alloy wire overcomes the problem that the bonded silver wire is easily subjected to sulfur corrosion in the prior art, and has a series of other excellent characteristics.

Owner:YANTAI YINUO SEMICON MATERIAL CO LTD

Karst grouting reinforcement water-stop constructing method

The invention discloses a karst grouting reinforcement water-stop constructing method, which is to construct according to sizes of karst caves by adopting a principle of from big to small regarding a certain area, construct by adopting a principle of from outside to inside for the karst caves with the same size, and construct by adopting a principle of from the bottom to the top in a vertical direction. On the basis of the construction principles, the method comprises the following steps of: (1) forming grouting holes by adopting a core drill; (2) forming construction exhaust and drainage pressure relief holes; (3) inserting grouting pipes into the grouting holes, wherein the grouting pipes comprise steel pipes, grouting shock pipes and sleeve valve pipes; (4) cleaning the holes, wherein when the step (3) is completed, the grouting pipes are cleaned with clean water; (5) grouting; and (6) drawing out the grouting pipes after the grouting is completed, and blocking the grouting holes with cement mortar or concrete. By adopting the constructing method, the pertinence to karst caves is strong, the grouting quantity is small, the engineering work amount is small, the cost is low, and the effect of filling and reinforcing is good.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

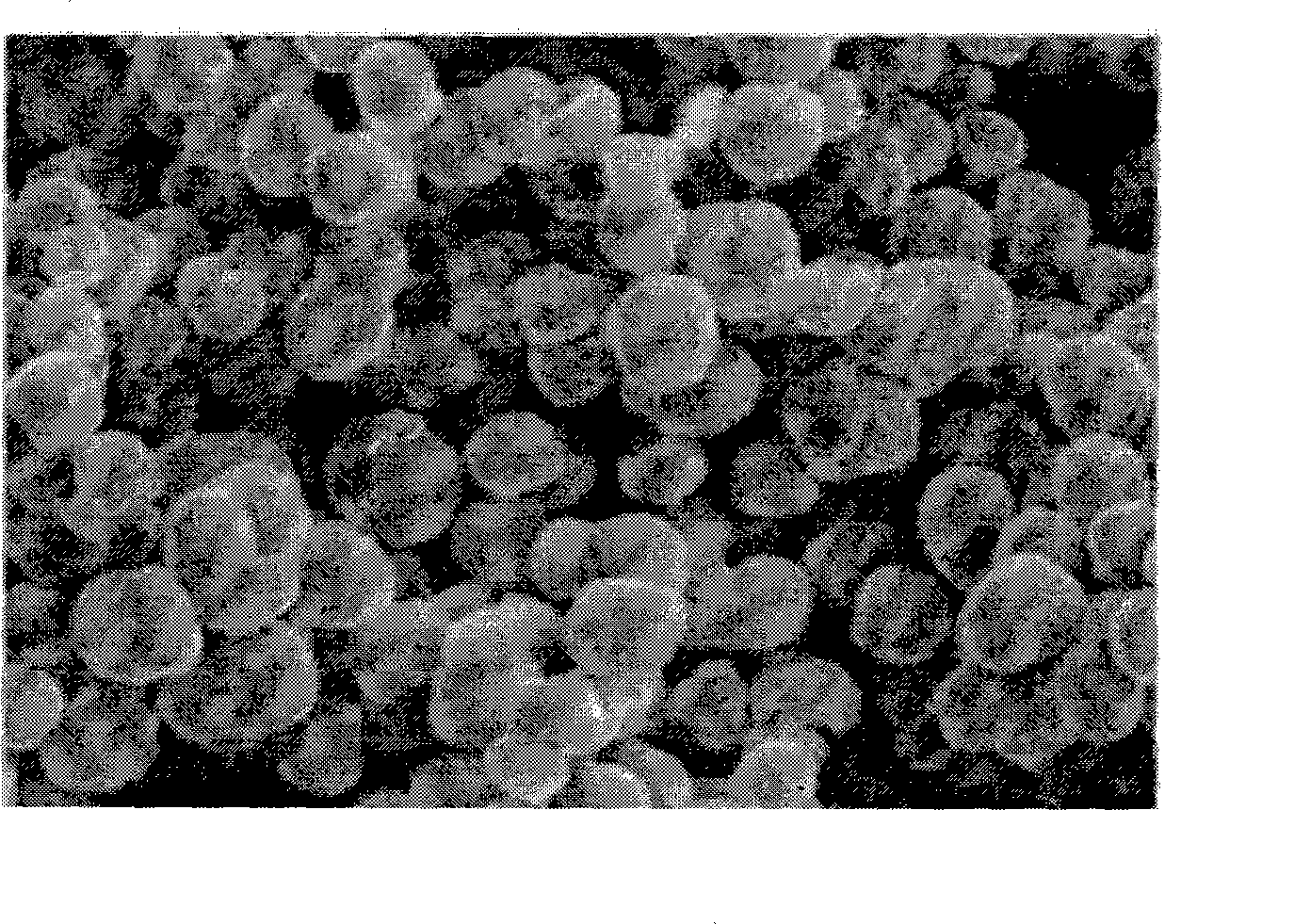

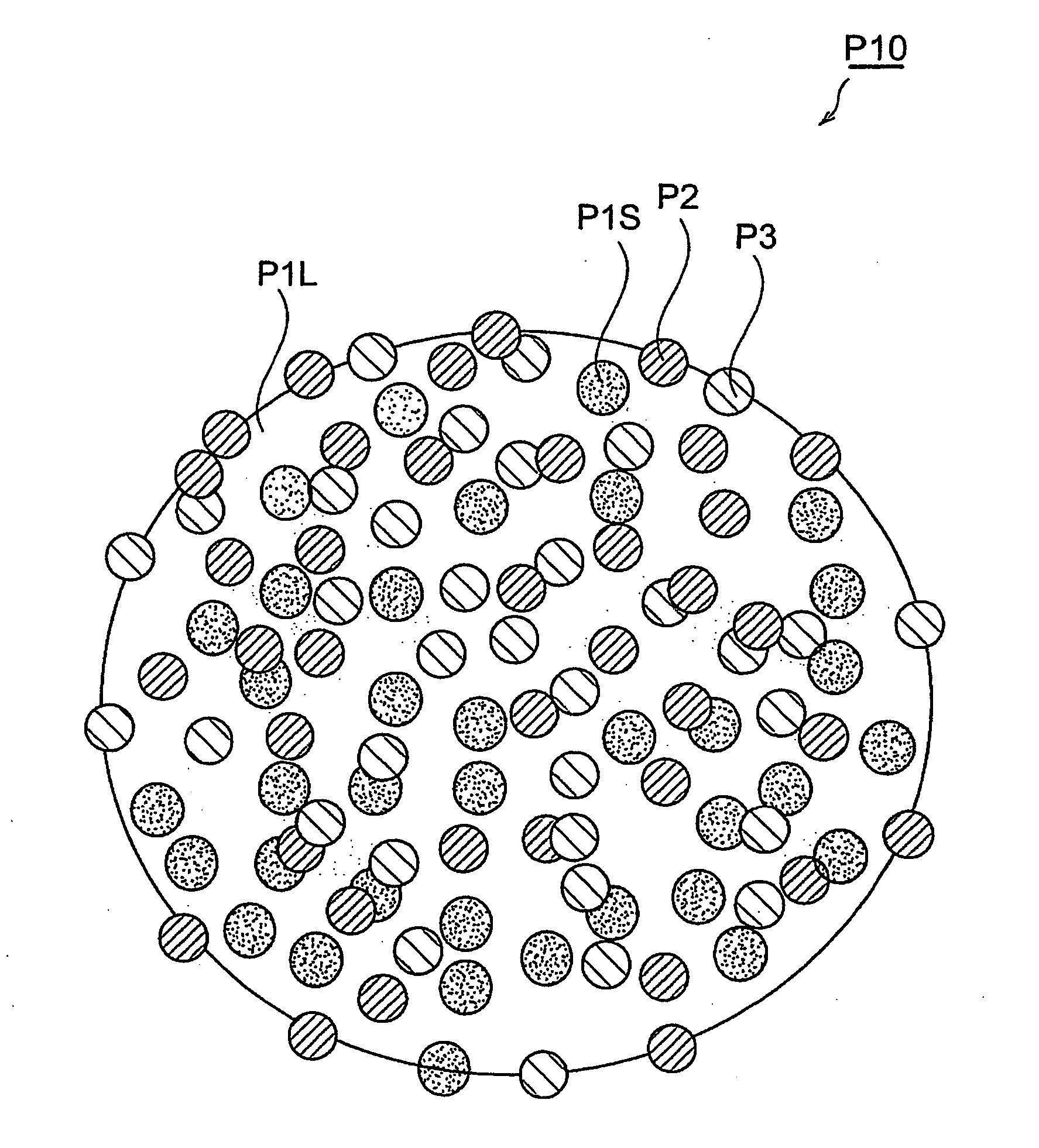

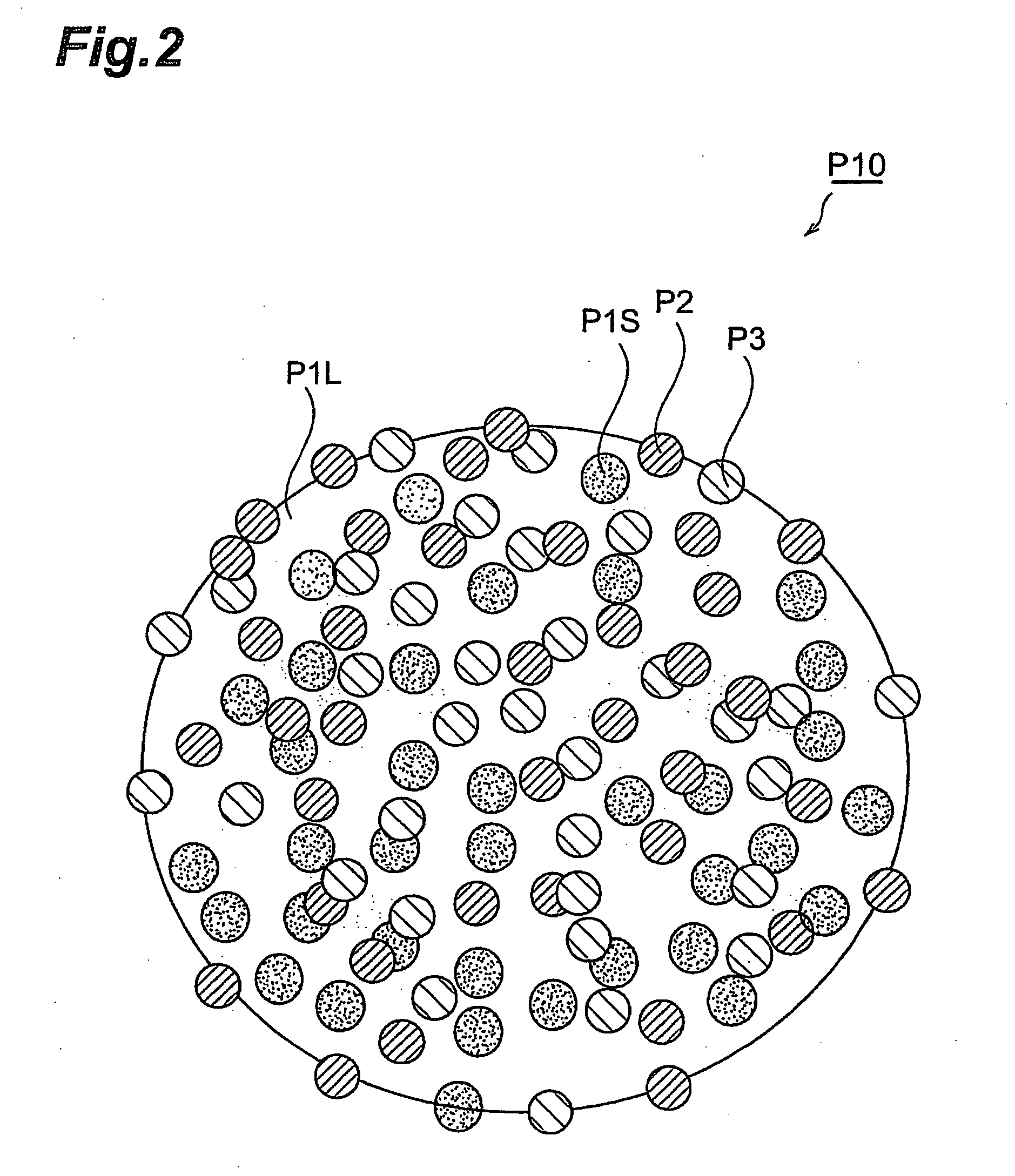

Electrode composite particles, electrode and electrochemical element, method of manufacturing the electrode composite particles, electrode manufacturing method, electrochemical element manufacturing method

InactiveUS20050285080A1Large capacityIncrease surface areaFixed capacitor electrodesNon-aqueous electrolyte accumulatorsMetallurgyElectrochemistry

The electrode composite particles of this invention comprise an electrode active substance, an conductive auxiliary agent having electron conductivity, and a binder which binds the electrode active substance with the conductive auxiliary agent. The particles of electrode active substance contain large diameter particles and small diameter particles which simultaneously satisfy conditions expressed by the relations: 1 μm≦R≦100 μm (1) 0.01 μm≦r≦5 μm (2) ( 1 / 10000)≦(r / R)≦(⅕) (3) R is the average particle diameter of the large diameter particles, and r is the average particle diameter of the small diameter particles.

Owner:TDK CORPARATION

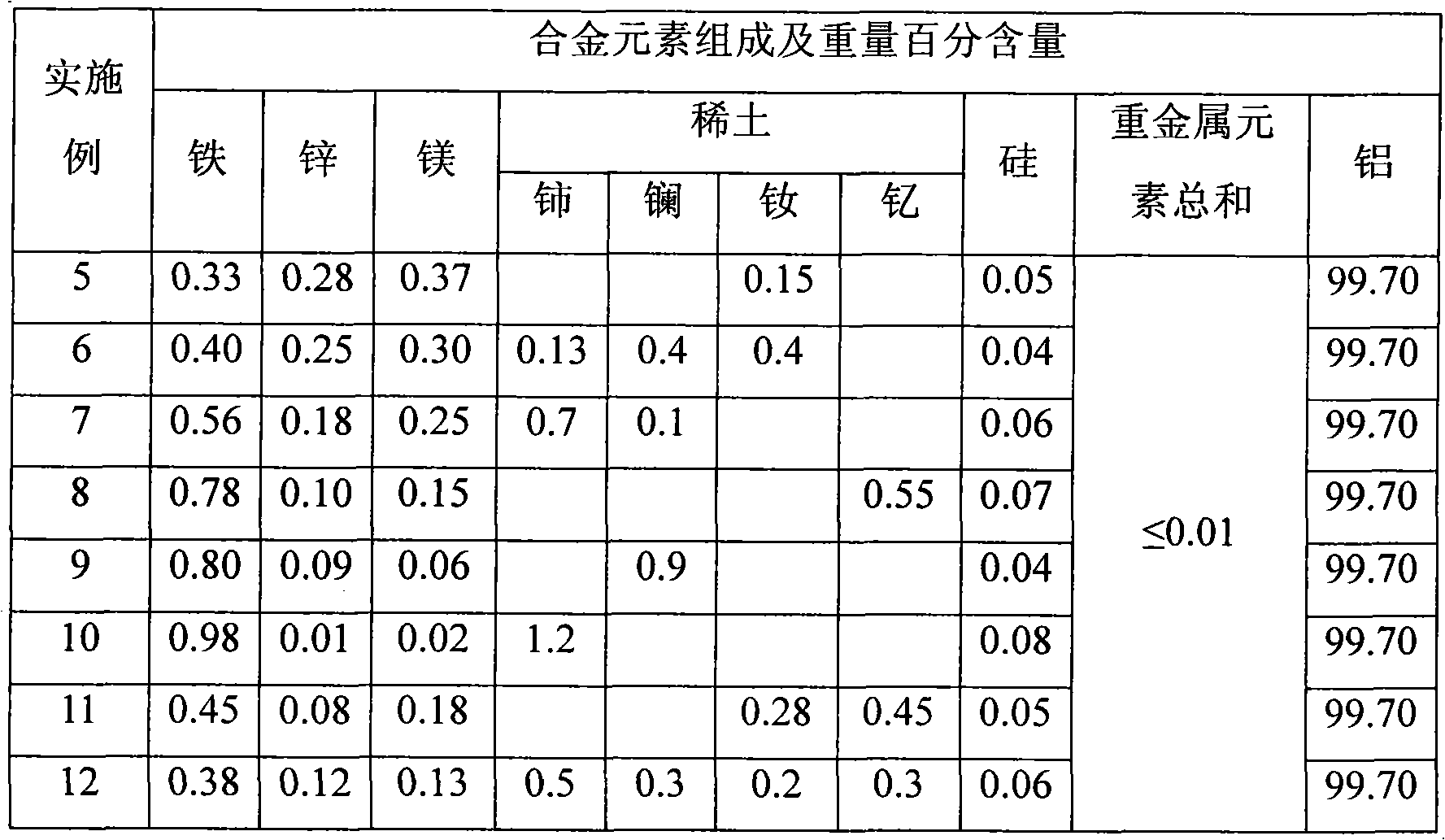

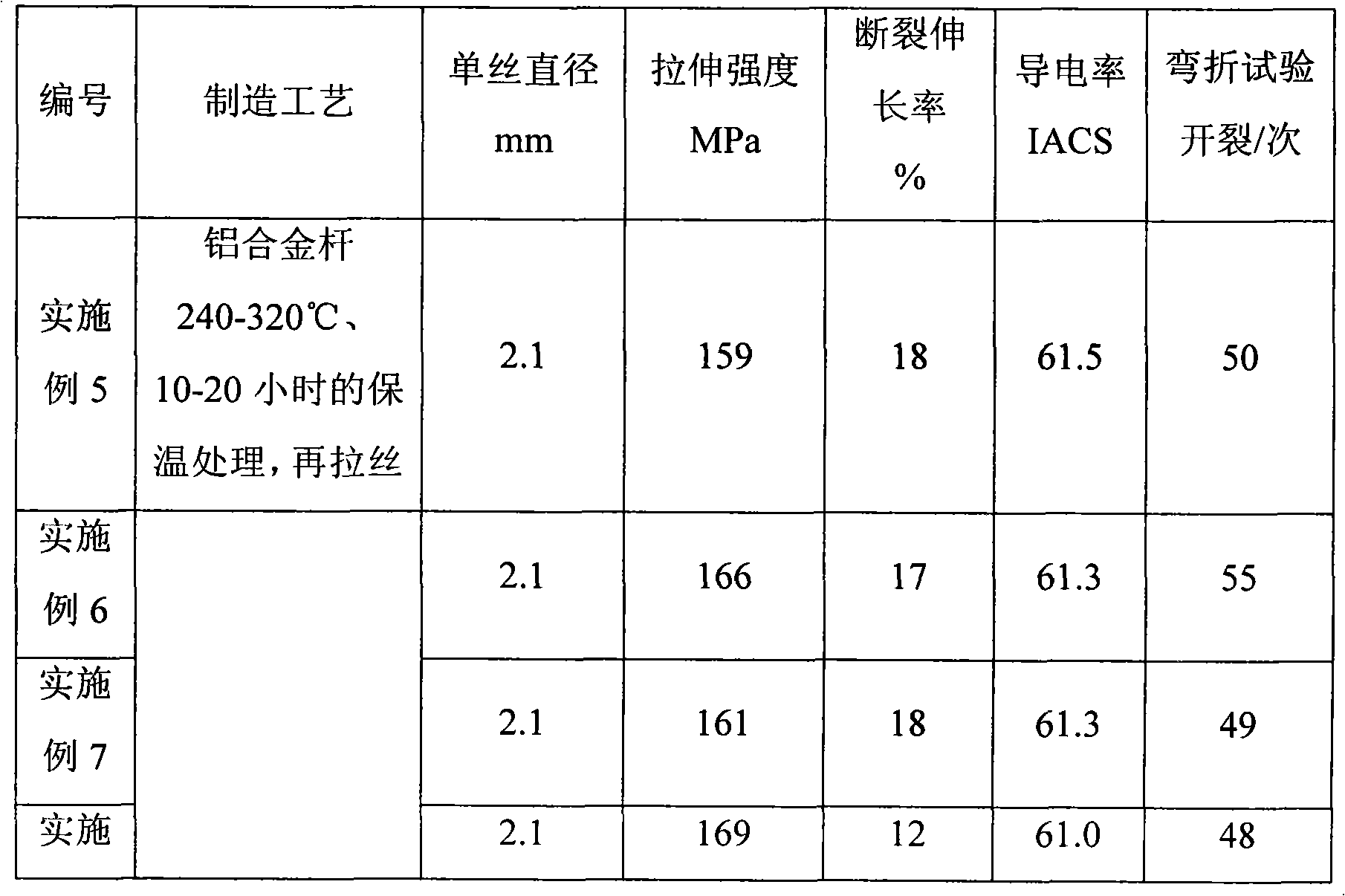

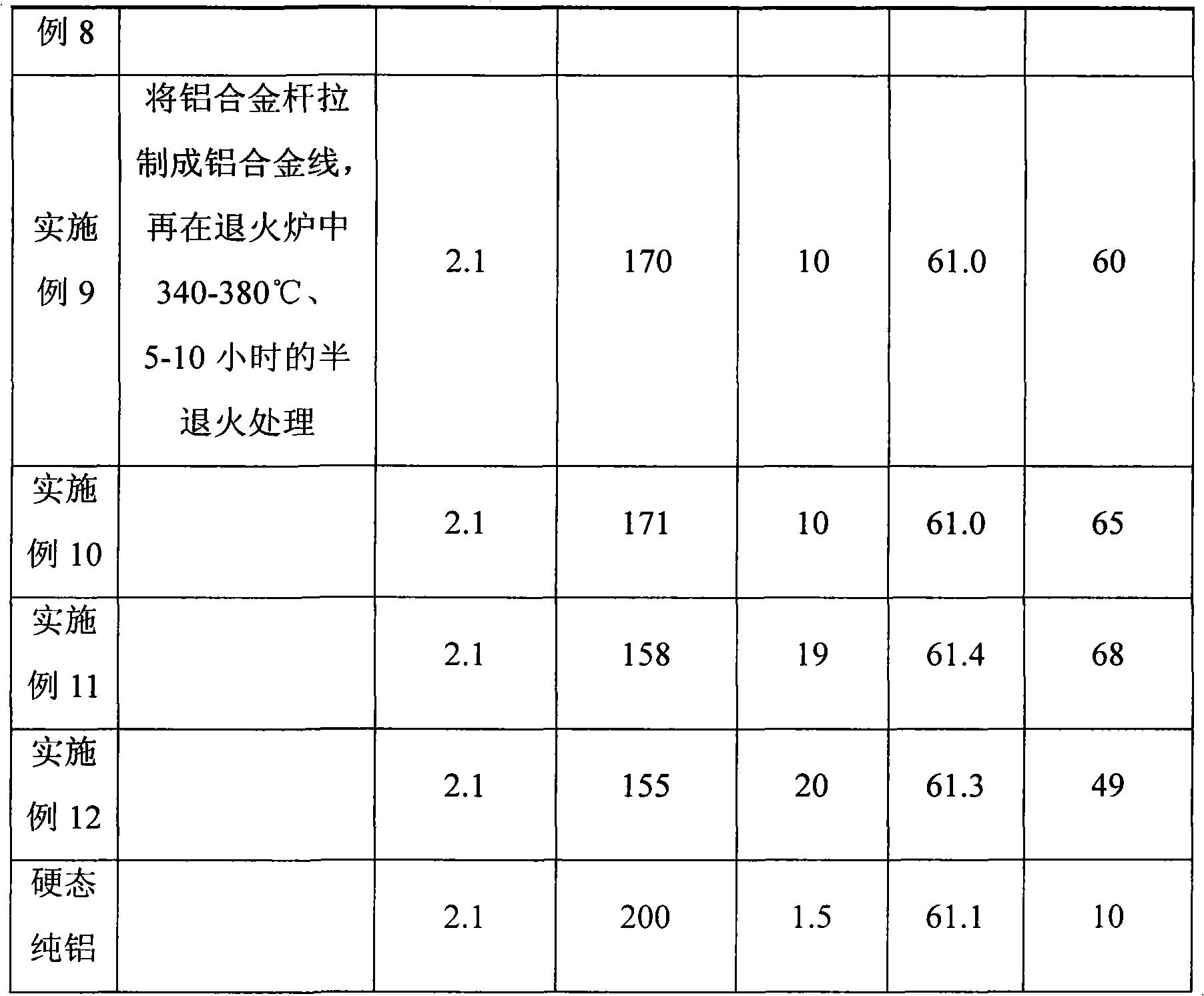

Al-Fe-Zn-Mg rare earth alloy wire and preparation method thereof

InactiveCN101880799AReduce defect densityGood match of strength and toughnessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsAlloy elementRare-earth element

The invention discloses an Al-Fe-Zn-Mg rare earth alloy wire and a preparation method thereof. The aluminum alloy comprises the following elements: 0.3-1.2wt% of Fe, 0.01-0.3wt% of Zn, 0.01-0.4wt% of Mg, 0.1-1.5wt% of rare earth element and the balance of Al and inevitable impurities, wherein the rare earth element is composed of one or more of cerium, lanthanum, neodymium and yttrium. The preparation method of the aluminum alloy wire comprises the following steps: preparing an aluminum alloy rod through smelting, casting and rolling, performing insulation treatment in a heat holding cover at 240-320 DEG C for 10-20 hours, wiredrawing and extruding insulating material on the wire; or preparing an aluminum alloy rod through smelting, casting and rolling, drawing the aluminum alloy rod to prepare the aluminum alloy wire, performing semi-annealing treatment in an annealing furnace at 340-380 DEG C for 5-10 hours, and finally extruding insulating material on the wire. The aluminum alloy wire prepared by the method of the invention has excellent electrical property, mechanical property and corrosion resistance and can be used in the wire and cable conductors.

Owner:ANHUI JOY SENSE CABLE

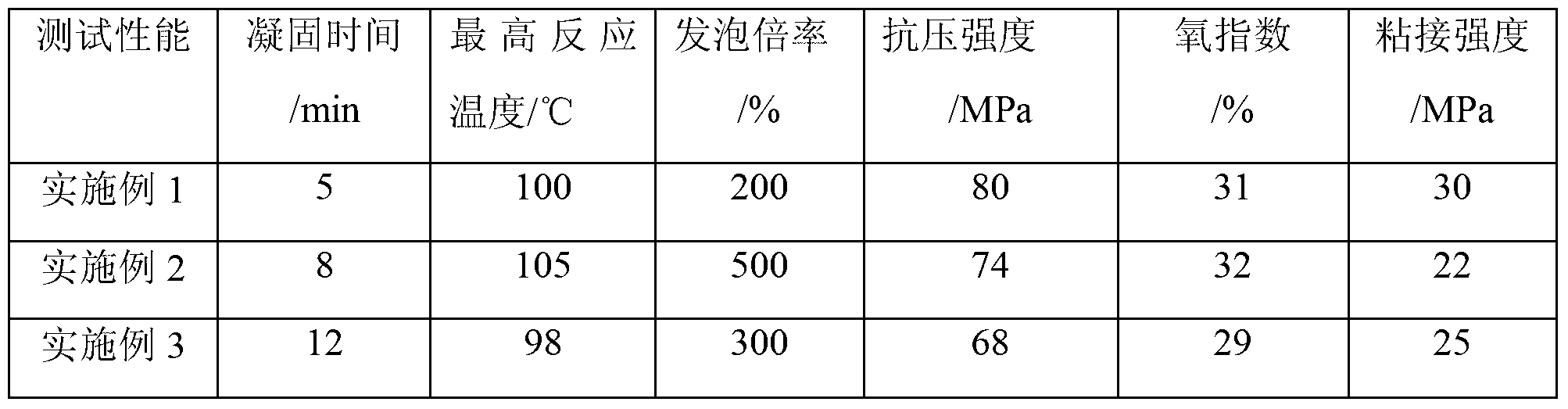

High-strength low-heat-release mining flame-retardant grouting reinforcement material and preparation method thereof

The invention discloses a high-strength low-heat-release mining flame-retardant grouting reinforcement material and a preparation method thereof. The flame-retardant grouting reinforcement material is obtained through mixing and solidifying a component A and a component B which are two low-viscosity liquids, the component A is obtained through mixing 60-80 parts of an isocyanate prepolymer, 10-38 parts of a flame retardant and 2-3 parts of an antistatic agent, and the component B is obtained through mixing 30-40 parts of polyether polyol, 0.1-0.5 parts of a catalyst, 10-25 parts of a diluting agent, 10-30 parts of an epoxy resin and 10-25 parts of a phenolic resin. The flame-retardant grouting reinforcement material has a low reaction heat release during solidification and has a highest reaction temperature of below 110DEG C, the obtained reinforcement has a high strength and a good caking property with coal rocks, the bonding strength, the sand consolidating strength and the compressive strength of the material are not below 30MPa, not below 8MPa and not below 60MPa, and the grouting reinforcement material has an obviously higher flame retardation property than a simple polyurethane grouting material.

Owner:ANHUI UNIVERSITY +2

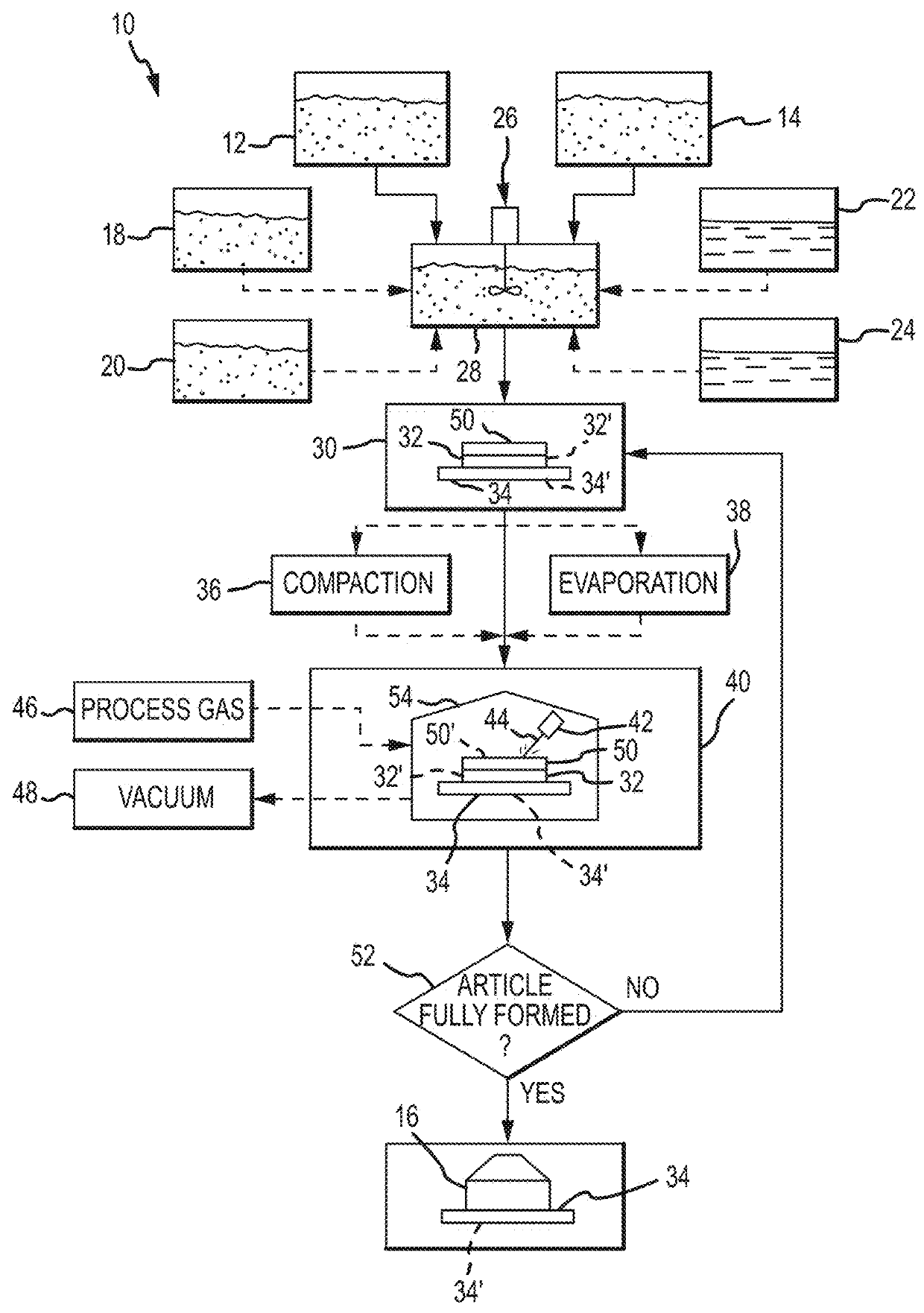

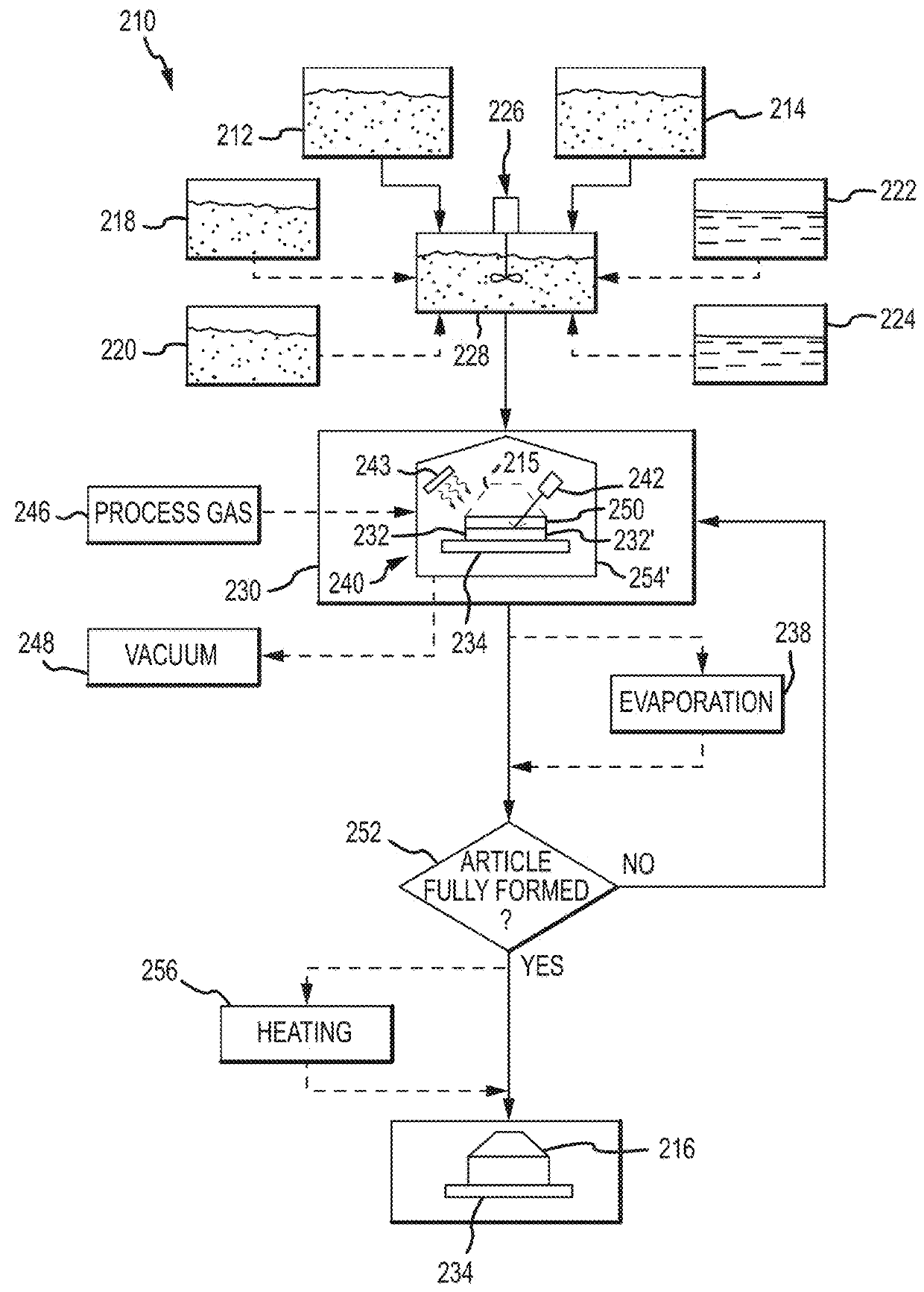

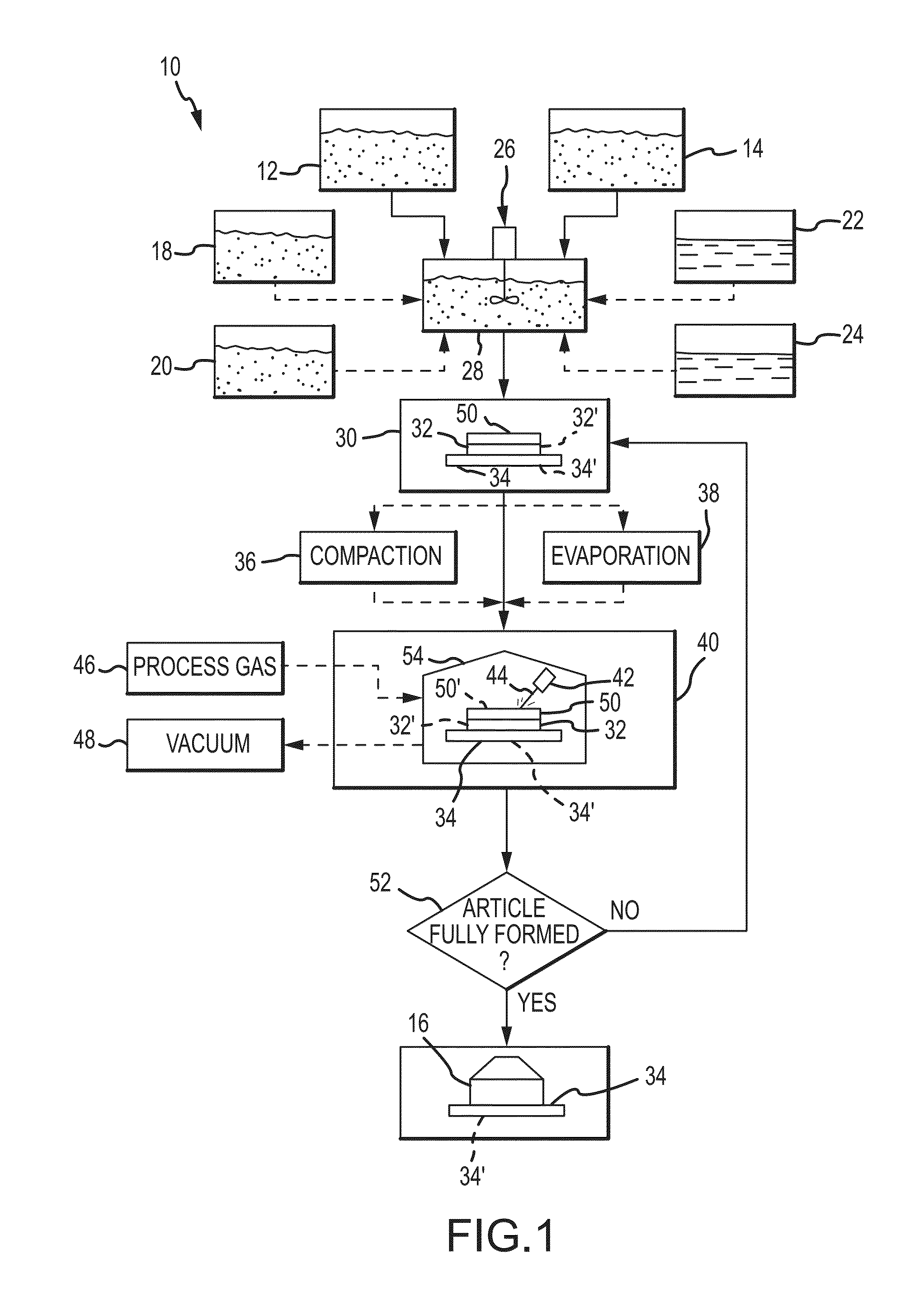

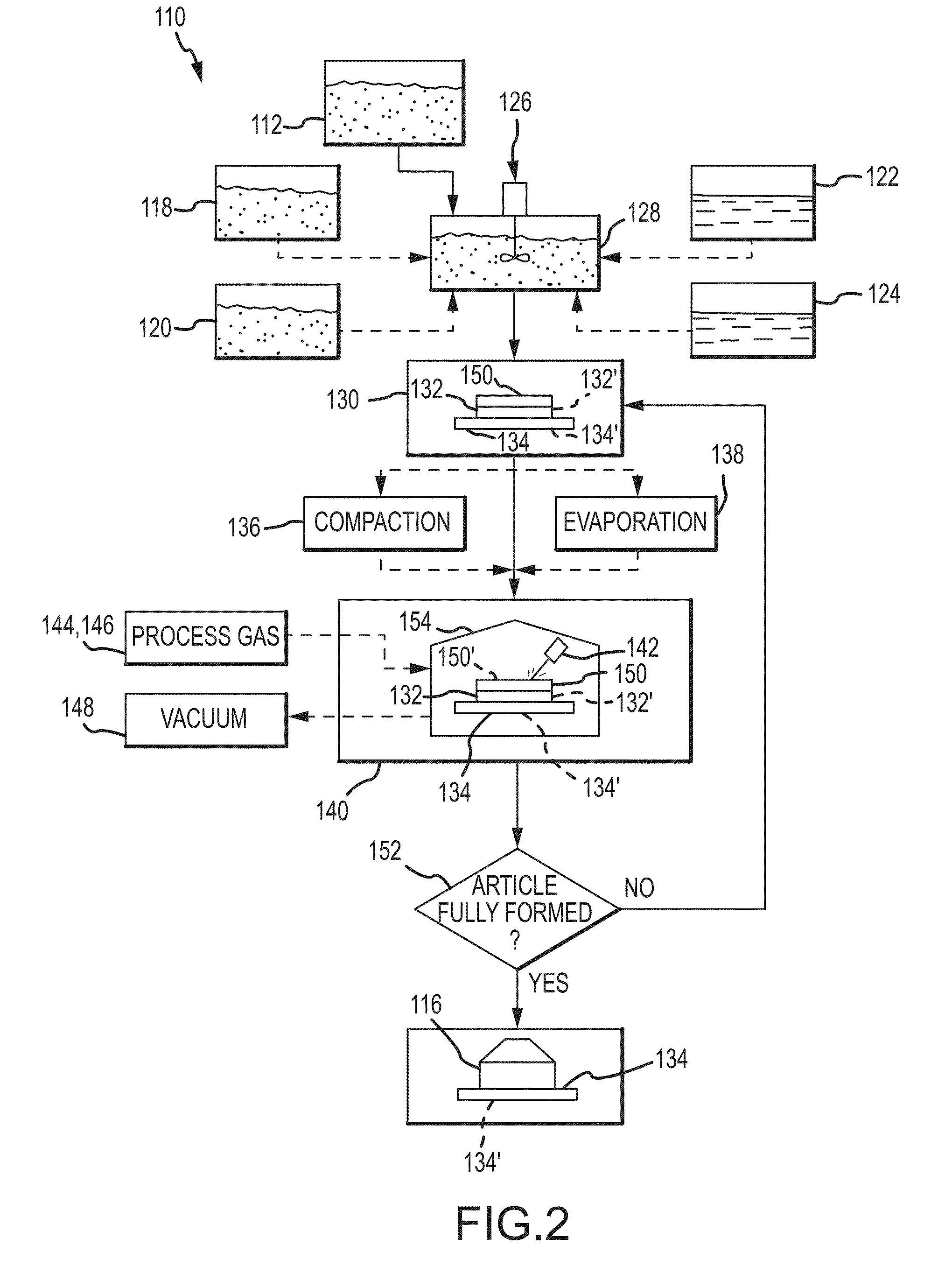

Additive manufacturing of metal alloys and metal alloy matrix composites

ActiveUS20180161874A1High strengthPrevent partial lowAdditive manufacturing apparatusTitanium carbideMetal alloyNucleation

An additive manufacturing method of producing a metal alloy article may involve: Providing a supply of a metal alloy in powder form; providing a supply of a nucleant material, the nucleant material lowering the nucleation energy required to crystallize the metal alloy; blending the supply of metal alloy powder and nucleant material to form a blended mixture; forming the blended mixture into a first layer; subjecting at least a portion of the first layer to energy sufficient to raise the temperature of the first layer to at least the liquidus temperature of the metal alloy; allowing at least a portion of the first layer to cool to a temperature sufficient to allow the metal alloy to recrystallize; forming a second layer of the blended mixture on the first layer; and repeating the subjecting and allowing steps on the second layer to form an additional portion of the metal alloy article.

Owner:ELEMENTUM 3D INC

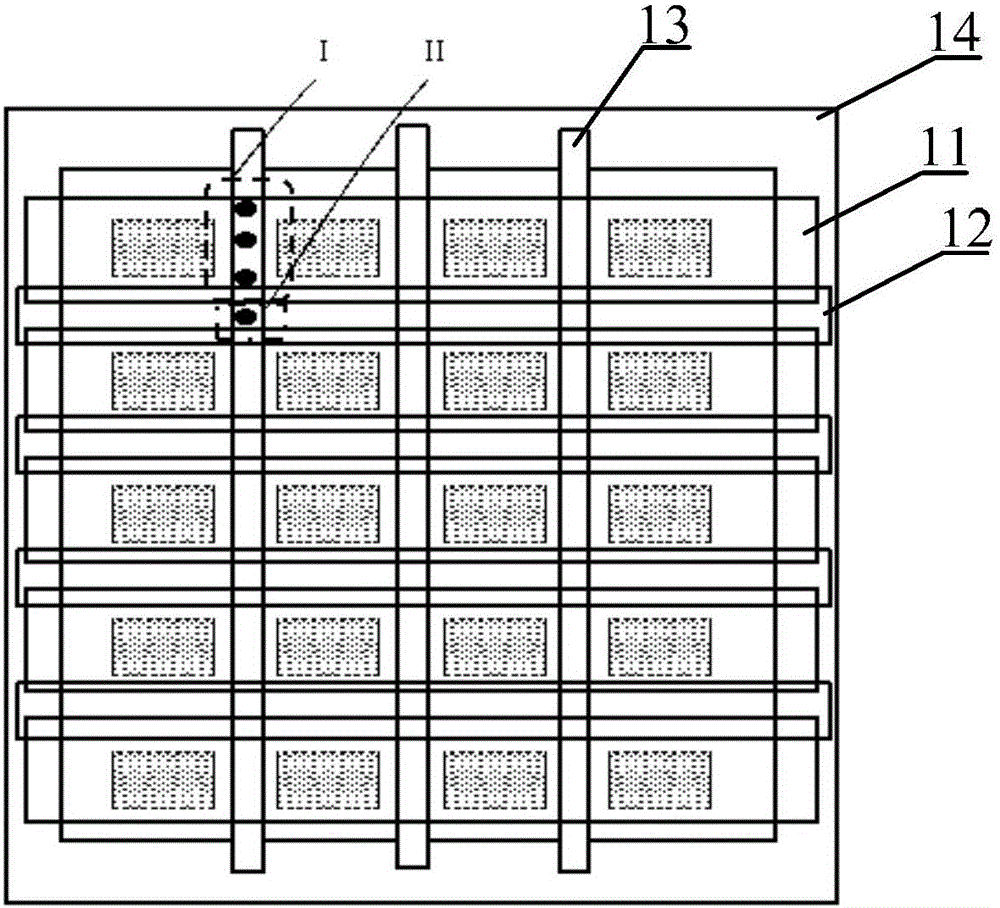

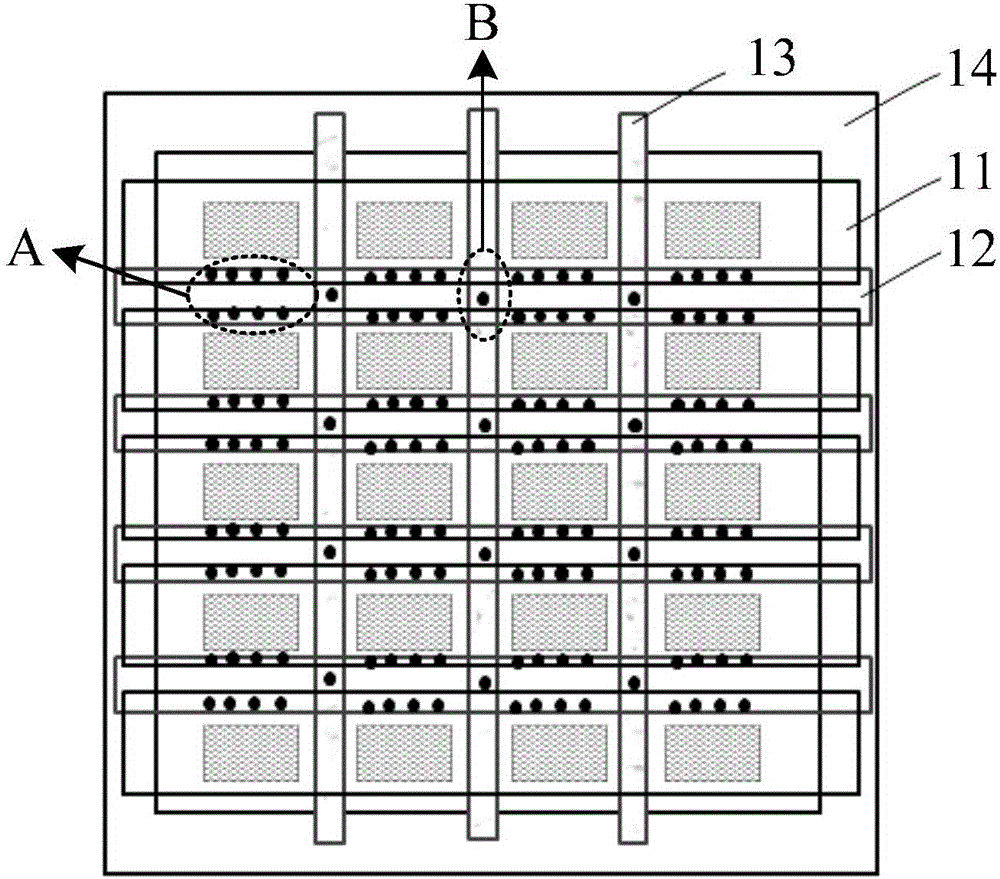

Mask plate and manufacturing method thereof

ActiveCN105951042ATo achieve the reinforcement effectReduced risk of vibration damageVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses a mask plate and a manufacturing method thereof, and relates to the field of display. According to the mask plate, the fluidity of components of a conventional mask plate can be reduced, the problems that color mixing of a panel is poor and the rate of good products is decreased are solved, the vibration damage risk of the mask plate during the transportation, cleaning, alignment and lamination processes is reduced, the service life is prolonged, and the production cost is reduced. The mask plate comprises a frame, mask sticks with effective openings, cover sticks and howling sticks used for supporting the mask sticks, wherein the mask sticks are mutually spliced; the cover sticks cover the mutual splicing parts of the mask sticks and are used for preventing an evaporation plating material from permeating; the howling sticks are arranged vertical to the mask sticks and the cover sticks; overlapping regions of the cover sticks and the mask sticks are connected; and overlapping regions of the howling sticks and the cover sticks are connected.

Owner:BOE TECH GRP CO LTD +1

Method for improving fermentability and nutritional property of gluten protein-free dough

ActiveCN104146020AImprove fermentation effectImproved ability to hold gasDough treatmentPre-baking dough treatmentNutritive valuesFermentation

The invention provides a method for improving fermentability and nutritional property of gluten protein-free dough. The method includes the steps of 1) activating glutamic acid transaminase, protease A and yeast; 2) peptizing food in water with temperature 50-100 degrees to be evenly mixed with whole flour free of gluten protein, proteins, starches, sugars and salts; 3) adding the activated glutamic acid transaminase and protease A to the mixture for evenly mixing; 4) adding and stirring the activated yeast in the mixture to form the dough; 5) fermenting the mixture within 40-90mins at the temperature of 36-40 degrees and at the humidity of 70-85%. The method is simple and greatly improves the nutritional property and the fermentability of the gluten protein-free dough at the same time. Thus fermentation size of the dough is increased by 1-3 times, contents of vitamin, protein, dietary fiber, mineral elements and the like are remarkably increased, structures and sizes of fermented products such as breads, steamed breads and steamed sponge cakes are improved, and nutritional value of the fermented products is increased.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

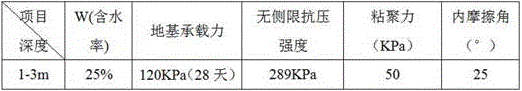

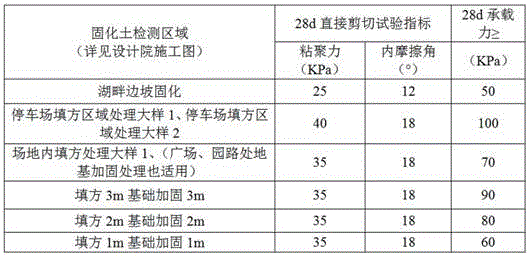

Silt solidification soil construction technology

The invention discloses a silt solidification soil construction technology which comprises the steps of surface cleaning drainage, silt sampling, detection analysis, excavation stacking, stirring and mixing, filling and grinding and stabilized soil maintenance. Through solidification soil in-situ solidification, silt and a curing agent are stirred and mixed to form silt solidification soil, and the curing agent is prepared through expanded graphite, activated carbon, cement, quick lime, gypsum, lignocelluloses, coal ash, granulated blast-furnace slag powder, coal gangue, caustic dross, hydroxypropyl methyl celluloses, furfural residues, medical stone and smectite clay. By means of the silt solidification soil construction technology, original flowing high-water-content low-strength high-compressibility silt is converted into high-compressive-strength excellent-entire-board-performance, good-durability and environment-friendly solidification soil, and the requirement of shallow ground earthwork materials for roads, storage yards, ports, reclamation projects, afforesting and the like can be met.

Owner:福建港湾岩土工程集团有限公司

Light-weight corundum-spinel castable and preparation method thereof

The invention relates to a light-weight corundum-spinel castable and a preparation method thereof. The preparation method includes following steps: (A) employing 60-75 wt% of equal-diameter micro-porous corundum spheres as an aggregate, and employing 8-12 wt% of electric-fused white corundum fine powder, 2-8 wt% of electric-fused magnesite fine powder, 2-8 wt% of magnesium aluminate spinel fine powder, 6-12 wt% of [alpha]-Al2O3 micro powder, 0.5-2.5 wt% of chromium oxide powder and 3-7 wt% of an aluminum silicone gel powder as substrate materials, wherein the aggregate and the substrate materials form a raw material in total; (B) employing organic fibers accounting for 0.02-0.08 wt% of the raw material and a polycarboxylate water reducer accounting for 0.05-0.12 wt% of the raw material as additive materials, pre-mixing the substrate material with the additive materials and adding the aggregate with uniform mixing; (C) adding water accounting for 3-5 wt% of the raw material, stirring the mixture and performing cast moulding; and (D) maintaining the temperature at 110-200 DEG C for 12-48 h, roasting the moulded product at 800-1200 DEG C for 24-72 h to obtain the light-weight corundum-spinel castable. The light-weight corundum-spinel castable is low in apparent porosity, is low in volume density, is low in heat conductivity, is strong in anti-slag-erosion capability and is long in service life.

Owner:WUHAN UNIV OF SCI & TECH

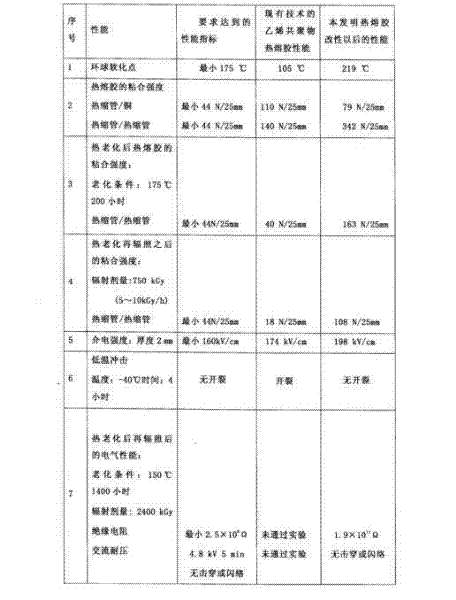

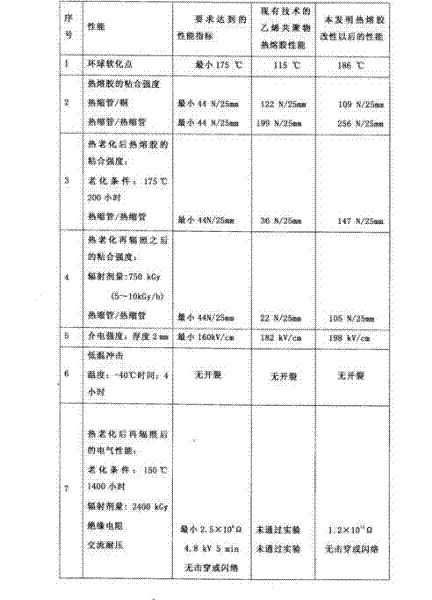

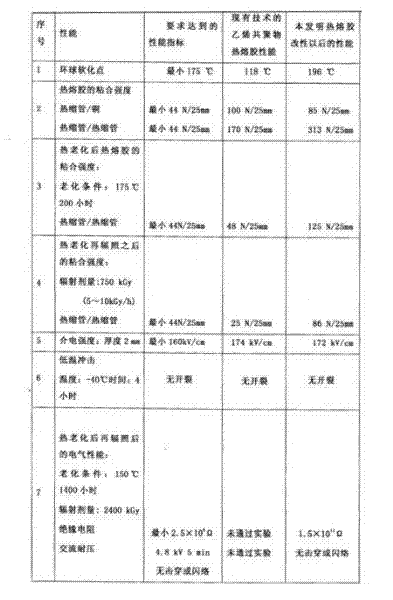

Hot melt adhesive for cable accessories in nuclear island of nuclear power plant and preparation method thereof

ActiveCN102250563AImprove performanceReduce liquidityNon-macromolecular adhesive additivesElastomerPolyolefin

The invention relates to a hot melt adhesive for cable accessories in a nuclear island of a nuclear power plant, and the hot melt adhesive is composed of the following components in parts by weight: 100 parts of ethylene copolymer hot melt adhesive, 30-100 parts of polyolefin elastomer and 5-10 parts of composite antioxidant, wherein the ethylene copolymer hot melt adhesive comprises one or more of ethylene-vinyl acetate copolymer hot melt adhesive, ethylene-ethyl acrylate copolymer hot melt adhesive, and ethylene-methyl acrylate copolymer hot melt adhesive; the polyolefin elastomer is a molecular-chain-saturated ethylene and C3-C20 alpha-olefin copolymer; and the composite antioxidant is one or more of a hindered phenolic antioxidant, a sulfur-containing antioxidant and an ester antioxidant. The hot melt adhesive provided by the invention can be applied to the cable accessories in the nuclear island of the nuclear power plant, and can also be used in aviation, shipping, nuclear submarine and other fields with higher performance requirements on the hot melt adhesive.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +1

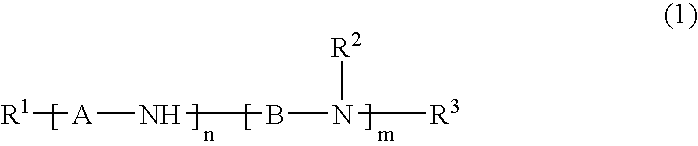

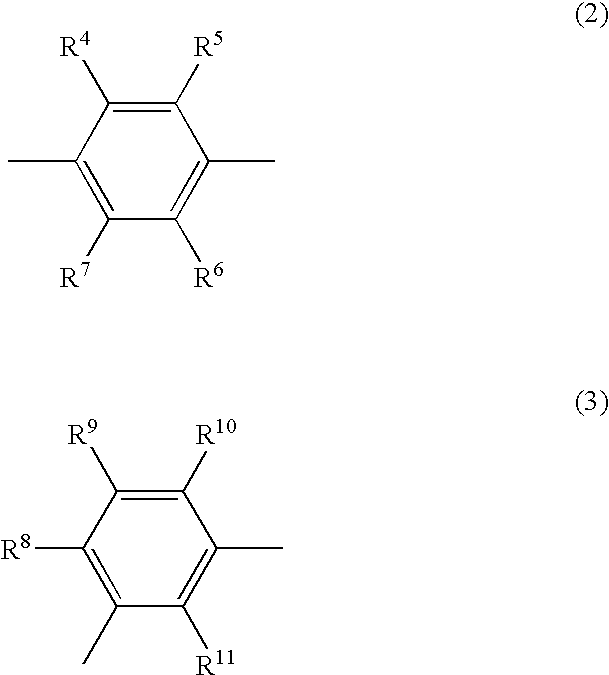

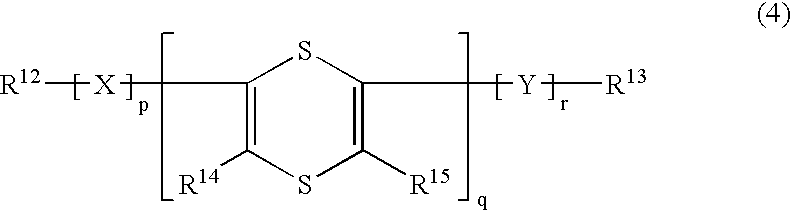

Charge-transporting varnish

ActiveUS20060115652A1Sufficient viscosityReduce the driving voltageLayered productsElectroluminescent light sourcesOligomerLacquer

A varnish containing a charge-transporting organic material and a solvent is used as a charge-transporting varnish. The charge-transporting organic material is composed of a charge-transporting substance comprising a charge-transporting monomer, or charge-transporting oligomer or polymer having a number average molecular weight of 200 to 500,000, or is composed of such a charge-transporting substance and an electron- or hole-accepting dopant substance. The solvent contains at least one type of high-viscosity solvent having a viscosity of 10 to 200 mPa·s at 20° C. The charge-transporting substance or the charge-transporting organic material is dissolved or uniformly dispersed in the solvent. The varnish has a high uniform film forming capability even in a system using a charge-transporting substance of low molecular weight and a charge-accepting dopant substance. When the varnish is used in, particularly an OLED device or PLED device, excellent EL device characteristics, namely a low drive voltage, a high luminance efficiency, and a long life are realized.

Owner:NISSAN CHEM IND LTD

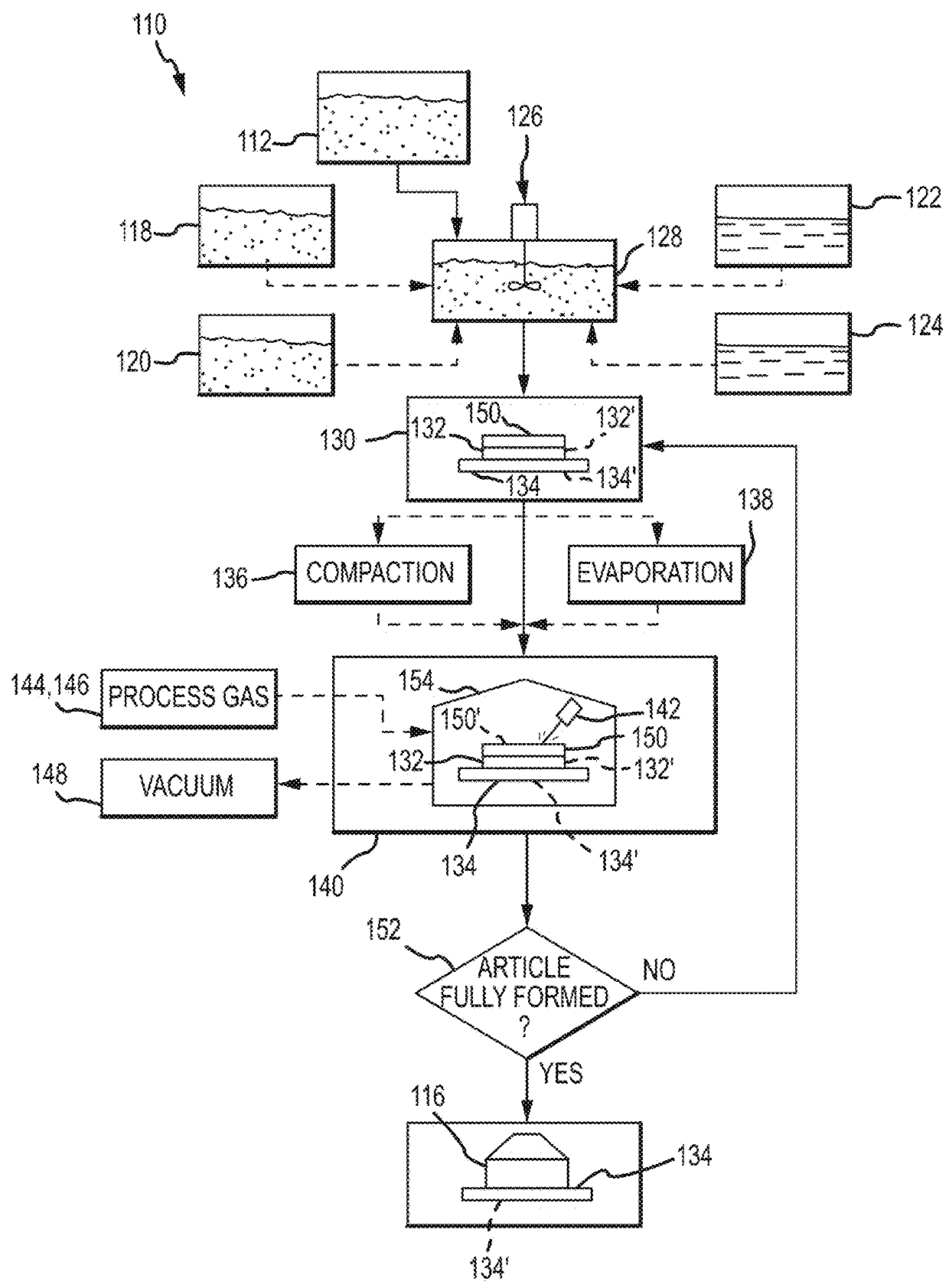

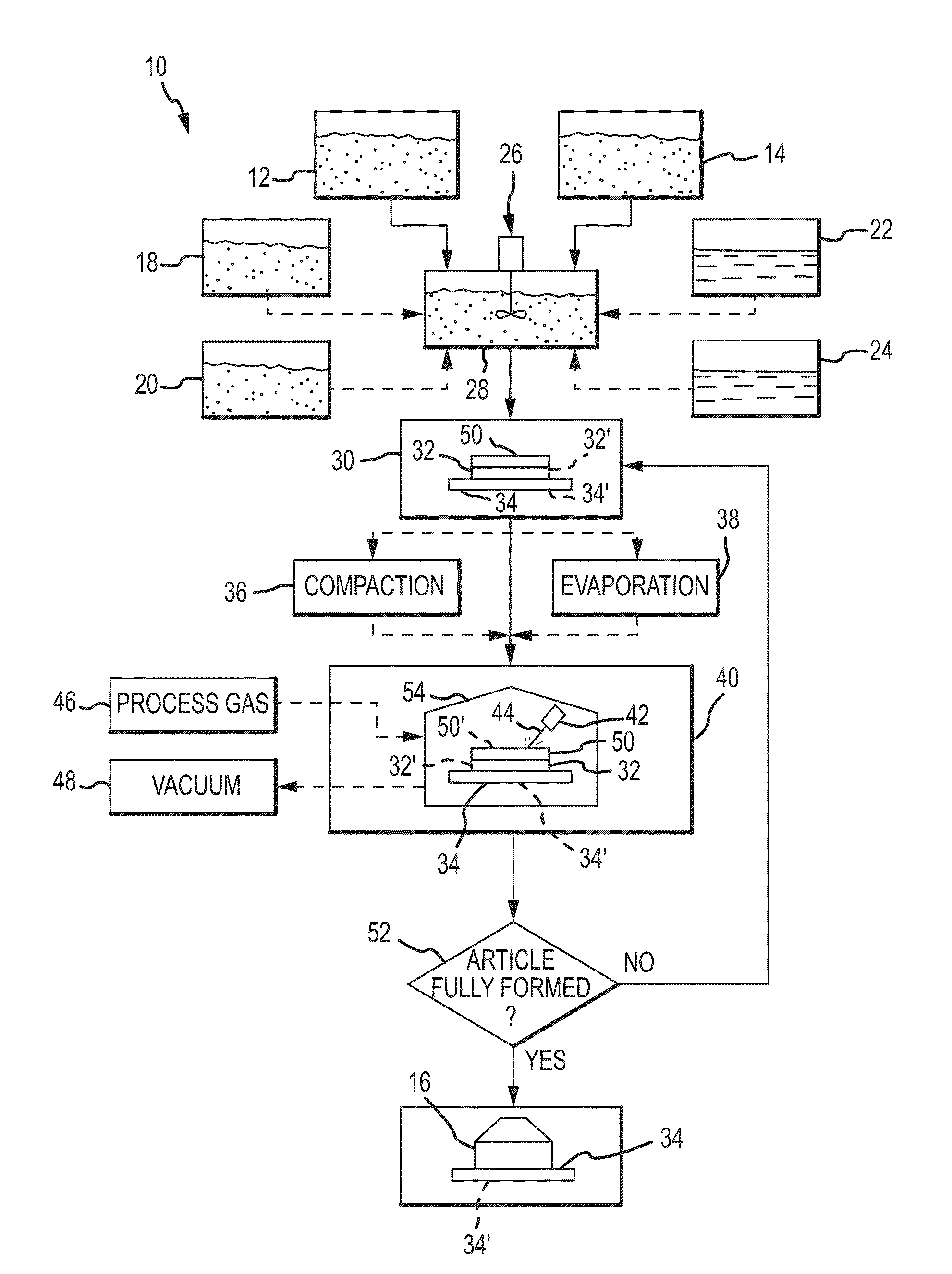

Reactive additive manufacturing

ActiveUS20160271878A1High quality partHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceReaction product

An additive manufacturing method may involve: Providing a first and a second material, the second material capable of reacting with the first material to form a reaction product; forming at least the first material into a first layer; subjecting at least a portion of the first layer to energy in the presence of the second material, the energy being sufficient to initiate a reaction between at least the first and second materials to form a portion of the article, the portion of the article comprising the reaction product; forming a second layer of at least the first material on the first layer; and subjecting at least a portion of the second layer to energy in the presence of the second material, the energy being sufficient to initiate a reaction between the first and second materials to form an additional portion of the article.

Owner:ELEMENTUM 3D INC

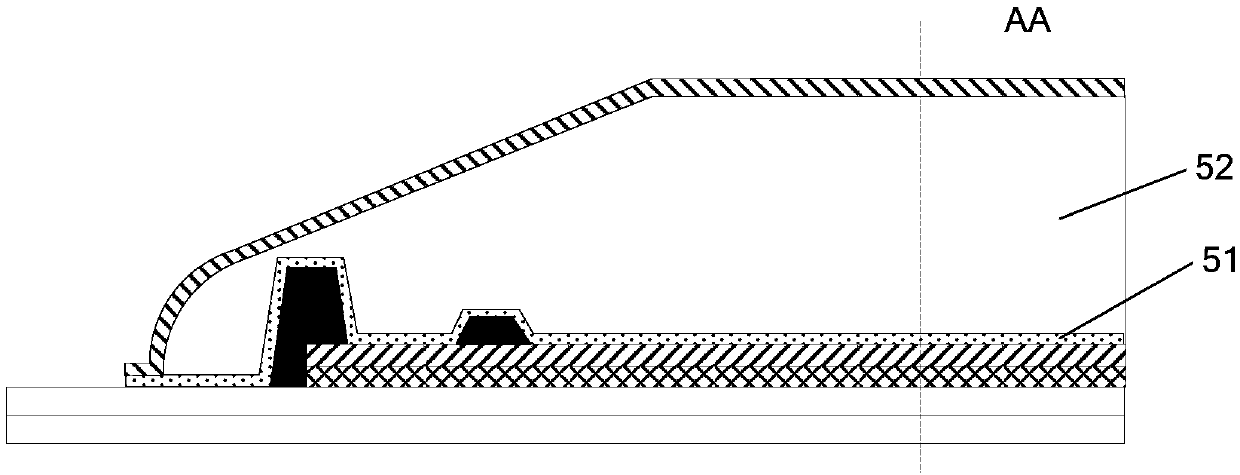

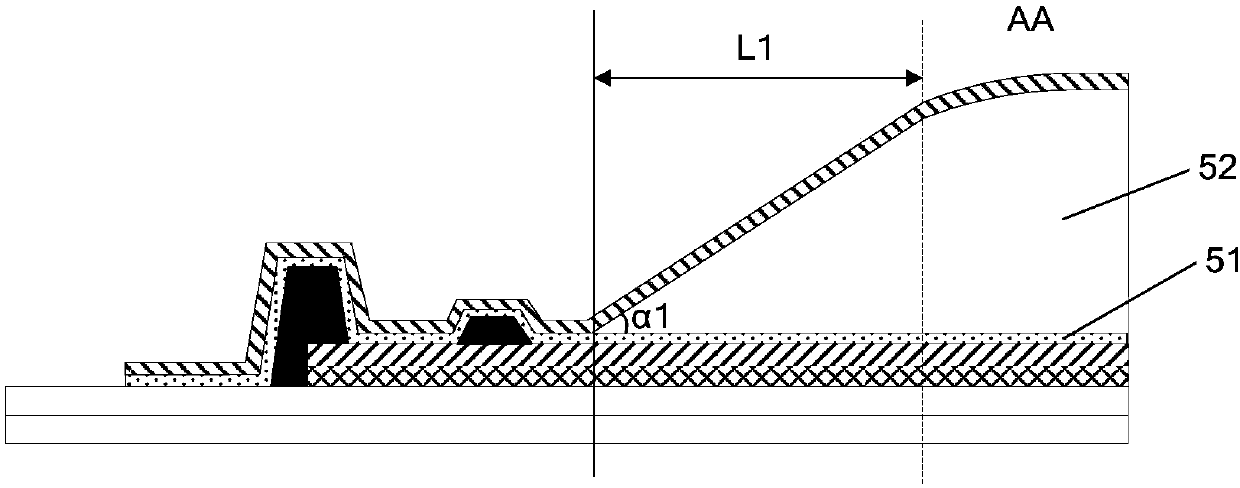

OLED display panel and a method for manufacturing same, and OLED display device

PendingCN109860411ABlock the flowReduce climbing distanceSolid-state devicesSemiconductor/solid-state device manufacturingConvex structureDisplay device

The present invention provides an OLED display panel and a method for manufacturing the same, and an OLED display device. A concave-convex structure is arranged at one side, far away from a substrate,on a planarization layer, after an organic light-emitting functional layer and an inorganic first package layer are formed on the planarization layer, positions of the organic light-emitting functional layer and the first package layer corresponding to the concave-convex structure are non-flat surfaces, namely concave-convex structures with the same shapes are formed at the positions, corresponding to the concave-convex structure, on the organic light-emitting functional layer and the first package layer; when an organic second package layer is formed, the non-flat surface of the first package layer can block the flow of the second package layer to a certain extent to reduce the liquidity of the second package layer, reduce the climbing distance of the edge of the second package layer andincrease the edge stress and an angle of gradient so as to achieve the product narrow-frame design, improve the thickness uniformity of the edges of the second package layer, avoid bad mura of a non-display area and ensure the package effect.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com