Patents

Literature

663results about How to "Increase filling volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

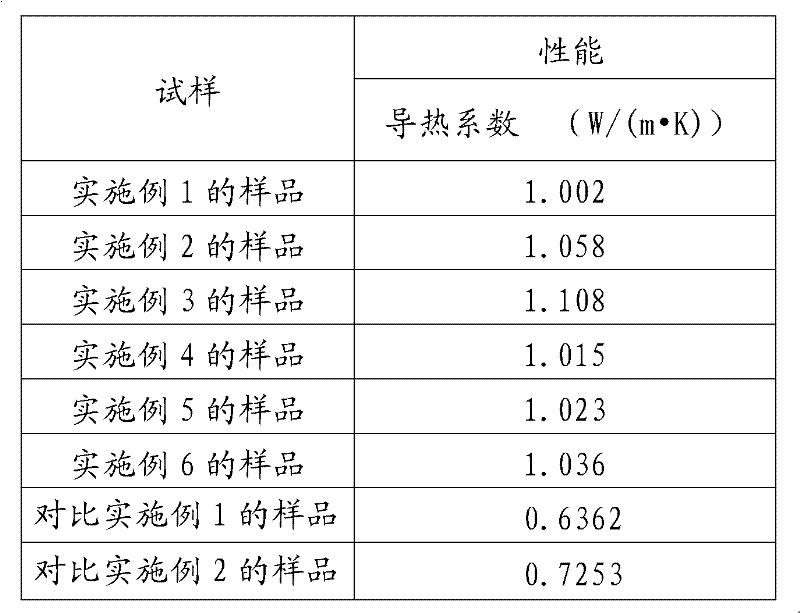

Highly heat-conducting insulation engineering plastic and preparation method thereof

InactiveCN102174254AIncrease China UnicomImprove thermal conductivityPlastic/resin/waxes insulatorsHeat-exchange elementsFiberAntioxidant

The invention discloses highly heat-conducting insulation engineering plastic, which consists of the following components in part by weight: 100 parts of plastic substrate, 100 to 900 parts of heat-conducting filler, 1 to 45 parts of compatibilizer, 1 to 90 parts of toughening agent, 1 to 45 parts of reinforcing agent, 1 to 36 parts of lubricating agent and 0.3 to 5.4 parts of antioxidant. The invention also discloses a preparation method of the engineering plastic, which comprises the following steps of: drying the plastic substrate and the heat-conducting filler in a 60 to 100 DEG C air dry oven for 4 to 8 hours; putting the components into a high-speed mixer and mixing for 3 to 5 minutes; performing internal mixing on the mixture in an internal mixer for 10 to 30 minutes; and uniformly grinding the mixture in a grinder, transferring to a charging hopper of a double-screw extruder, feeding fiber fillers through a fiber inlet of the double-screw extruder, melting, mixing, extruding, cooling, drying, and pelletizing. The prepared material has high heat-conducting property and mechanical property, and is easily subjected to injection molding.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Production of liquid center filled confections

InactiveUS20050260329A1Reduce the amount requiredLow viscosityMeat/fish preservationConfectioneryEngineeringSignificant difference

Liquid center filled confections, such as gummy or jelly candies or fruit snacks are continuously produced by co-deposition into a mold without candy tailing to obtain products with substantially uniform top and bottom walls and little, if any, shell breakage and liquid filling leakage or bleed-out problems. Excessive vertical decentering of the filling caused by substantial differences in specific gravity between the liquid filling component and the shell component and its accompanying production of thin or weak shell walls is substantially reduced or eliminated. A non-gellable liquid filling is deposited vertically off-center within a gellable shell, and the amount of sinking or floating is controlled so as to achieve an at least substantially centered product. The filling migration is limited by rapidly cooling the shell component below its gelling or setting temperature by use of a much colder filling component which itself does not gel or set at low temperatures.

Owner:WM WRIGLEY JR CO

Epoxy resin embedding glue and method for producing the same

The invention relates to an epoxy resin potting adhesive which consists of component A and component B. By weight portion, the component A consists of 90-130 portions of bisphenol A type epoxy resin, 240-320 portions of filling, 15-25 portions of thinner, 10-25 portions of toughener, 1-2.5 portions of defoamer and 0.8-2 portions of black pigment, and the component B consists of 60-130 portions of estolide and 1-3 portions of imidazole accelerator. The mixing proportion of the component A and the component B is (3-5):1. The invention also provides a preparation method of the epoxy resin potting adhesive. The epoxy resin potting adhesive provided by the invention has low cost and long resting period; after being mixed, the component A and the component B have low viscidity, good wetting quality, good heat resistance, good defoaming performance, good fluidity and long operating time and are solidified between 70 DEG C and 160 DEG C; a product after solidifying has bright surface, good mechanical performance and insulating performance and high glass transition temperature; and the quality of a potting component is stable.

Owner:NICHE TECH KAISER SHANTOU

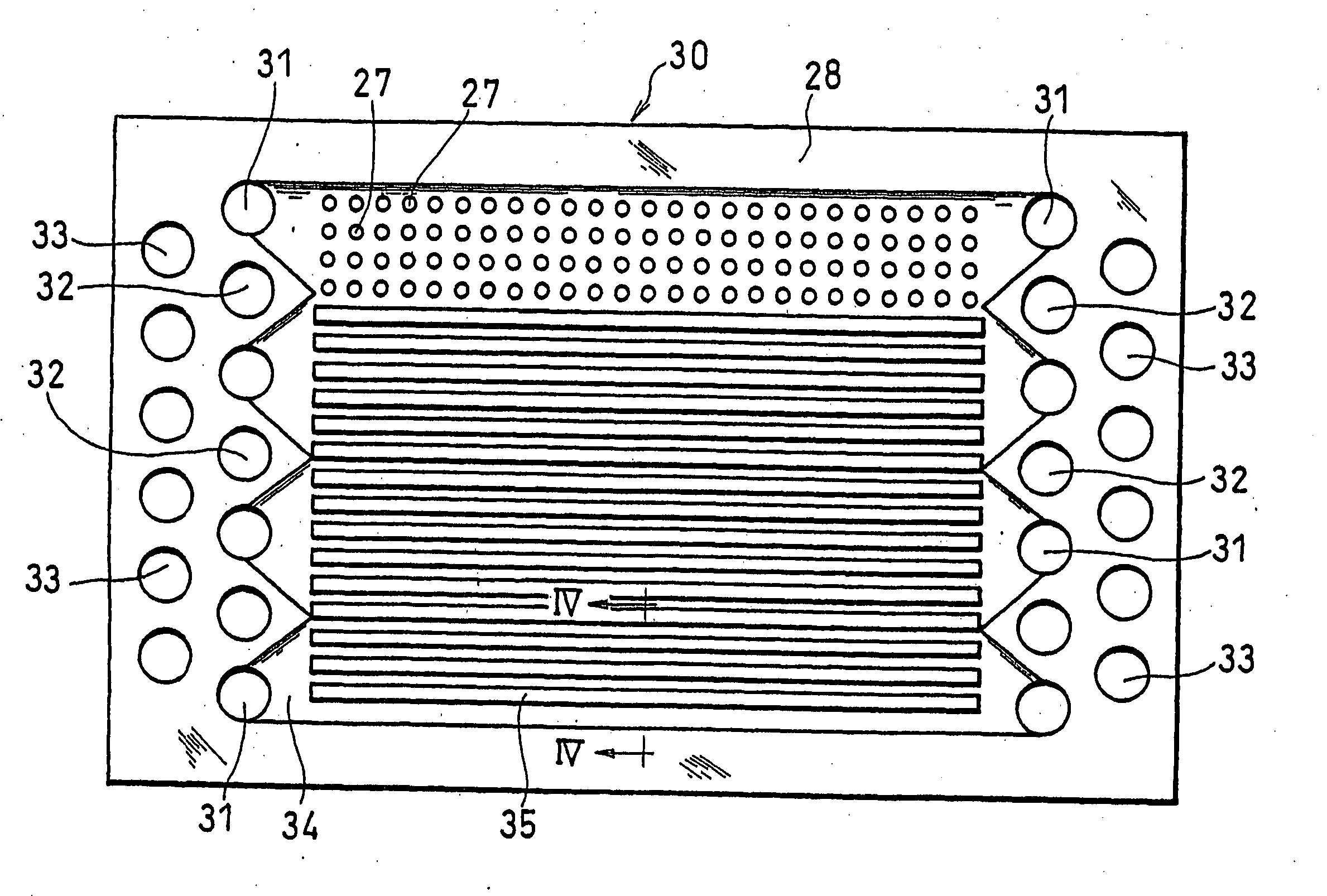

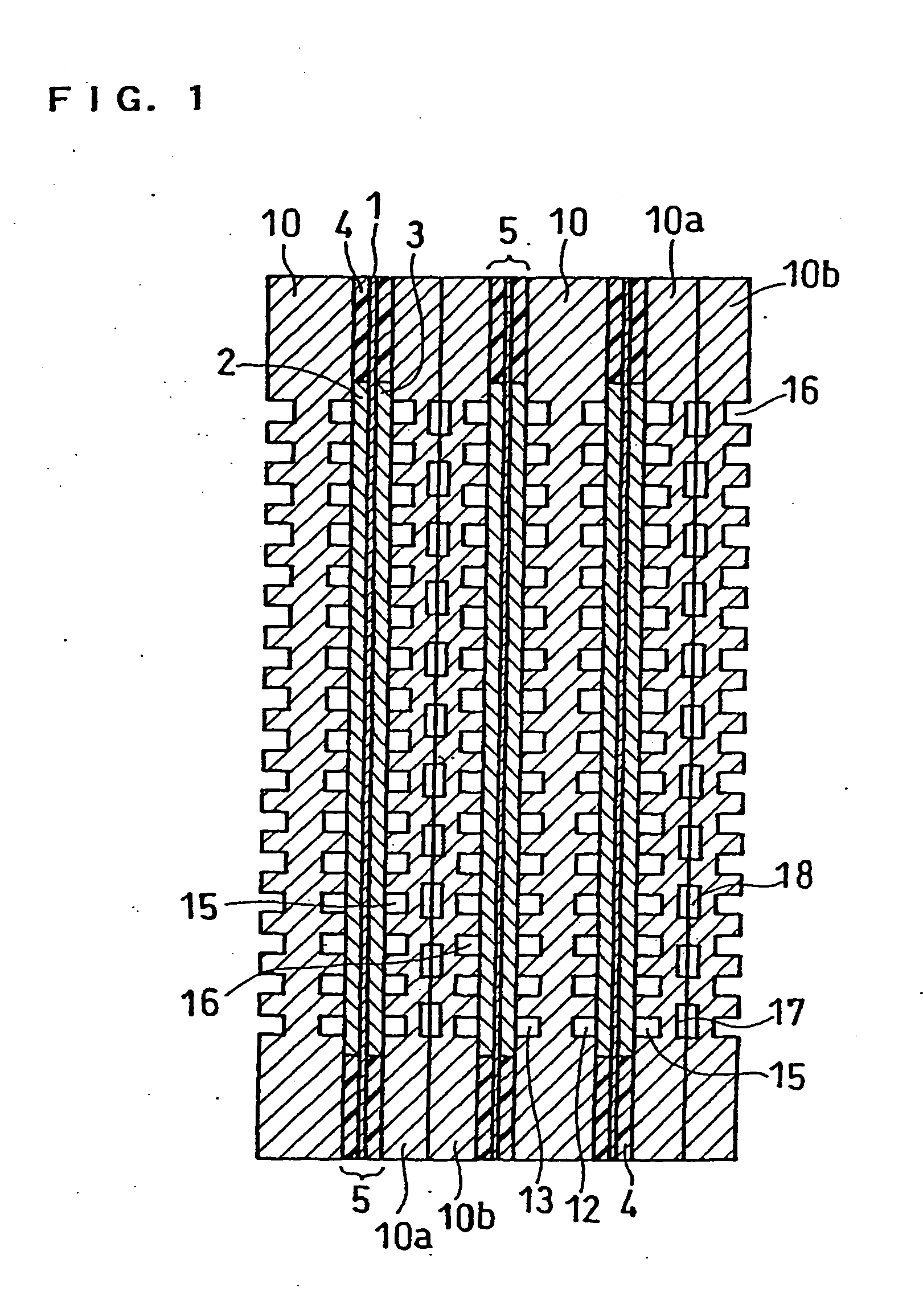

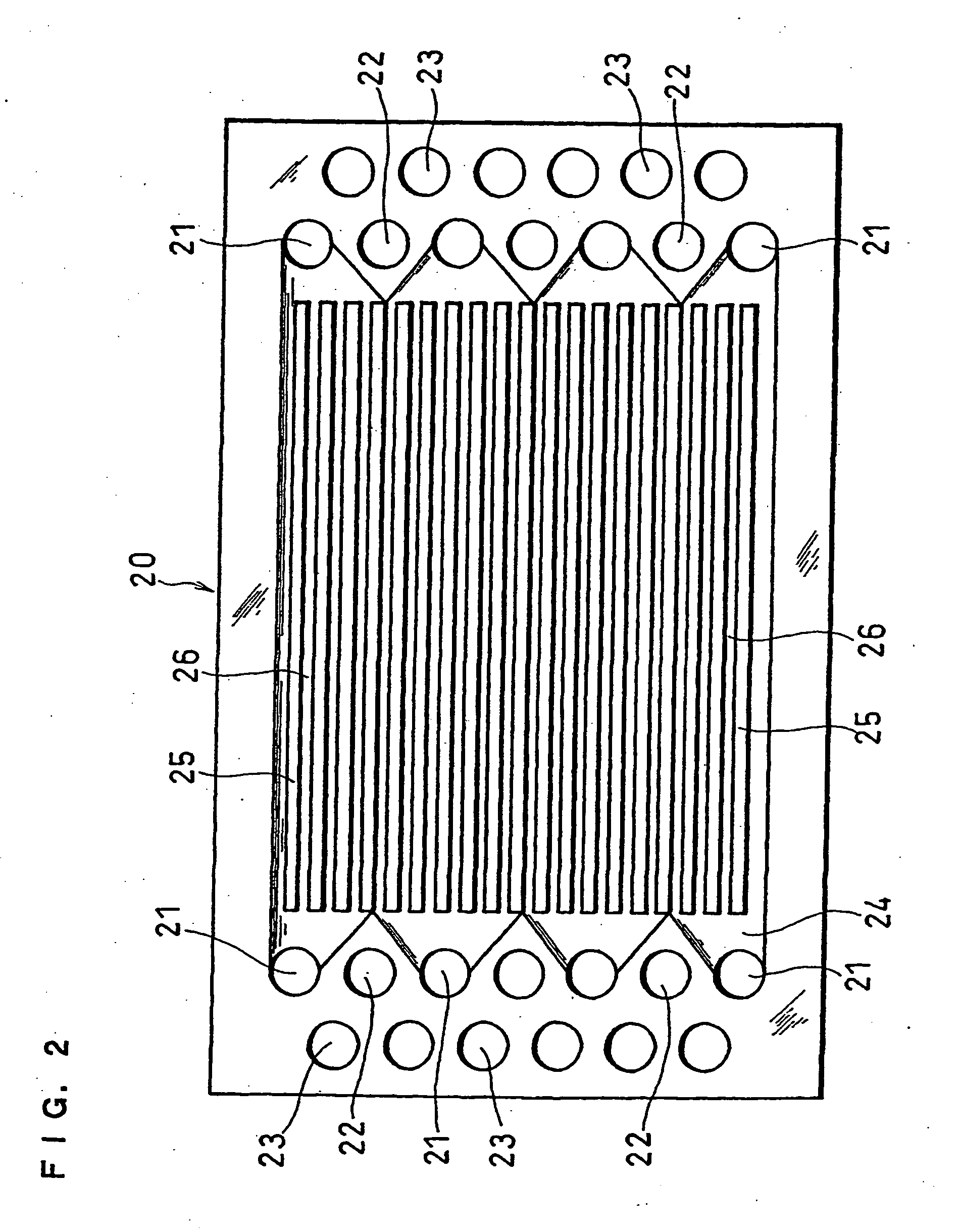

Polymer electrolyte fuel cell and method of manufacturing the same

InactiveUS20040197633A1Improves product water-removal efficiencyEvenly distributedFuel cell heat exchangeFinal product manufacturePolymer electrolytesFuel cells

The present invention relates to a polymer electrolyte fuel cell comprising: an electrolyte membrane-electrode assembly including an anode, a cathode and a polymer electrolyte membrane interposed therebetween; an anode-side conductive separator plate having a gas flow channel for supplying a fuel gas to the anode; and a cathode-side conductive separator plate having a gas flow channel for supplying an oxidant gas to the cathode. A conductive separator plate made of carbon has poor wettability with water. This has posed the disadvantage that variations in performance are induced by nonuniform gas distribution among cells due to the accumulation of product water or humidifying water in the gas flow channel on the surface of the separator plate. The present invention employs a conductive separator plate comprising a conductive carbon having a hydrophilic functional group, at least in a portion of the gas flow channels, thereby preventing water from accumulating in the gas flow channels.

Owner:PANASONIC CORP

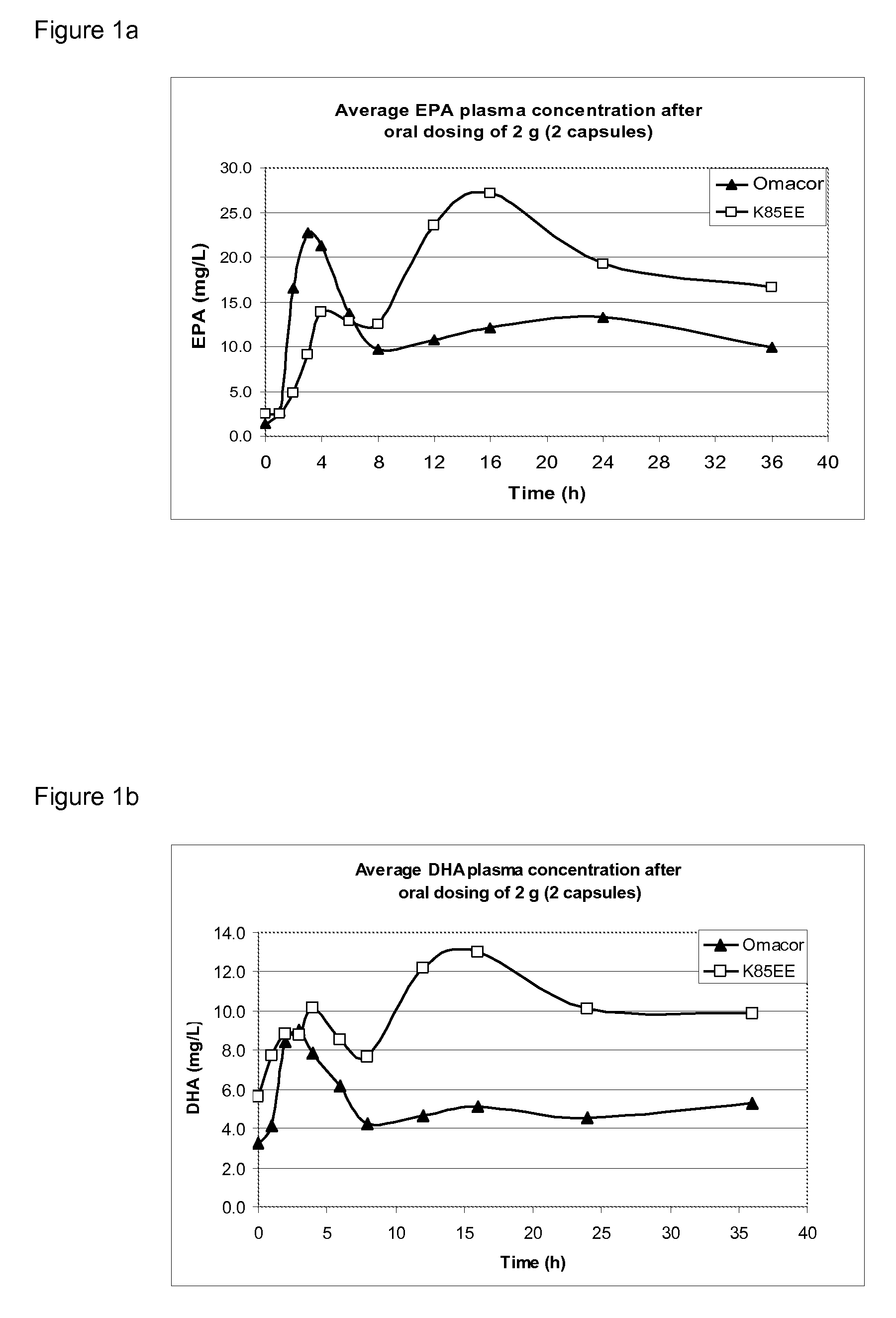

Formulation

InactiveUS20100062057A1Increase volumeIncrease filling volumeOrganic active ingredientsSenses disorderBiomedical engineering

Owner:FMC BIOPOLYMER AS

Industrial lignin reinforcing rubber and preparation method of industrial lignin reinforcing rubber

The invention relates to industrial lignin reinforcing rubber and a preparation method of the industrial lignin reinforcing rubber. The industrial lignin reinforcing rubber is characterized in that 1, the industrial lignin reinforcing rubber comprises lignin dispersoid, rubber latex, a small number of plasticizers and operation oil or comprises multi-component lignin dispersoid, rubber latex, a small number of plasticizers and operation oil; 2, the lignin dispersoid is suspension of lignin in water, the weight part of the lignin is 5 to 30 percent, the multi-component lignin dispersoid is suspension of the lignin and inorganic fillers in water, and the weight proportion of the lignin to the water is (5-30):(95-70); and 3, in the lignin dispersoid and the multi-component lignin dispersoid, the lignin is hydroxymethylation modified dispersoid. The preparation method comprises the steps of 1. lignin preparation, 2, lignin dispersoid preparation, 3, rubber latex preparation, 4, cosedimentation and solidification and 5, industrial lignin reinforcing rubber obtaining. The industrial lignin reinforcing rubber and the preparation method have the advantages that the physical and mechanical properties of the rubber are not reduced, meanwhile, the drying processes in the lignin and rubber production process are combined, and the motive power consumption of rubber mixing is reduced.

Owner:广西合山林格高分子材料科技有限公司

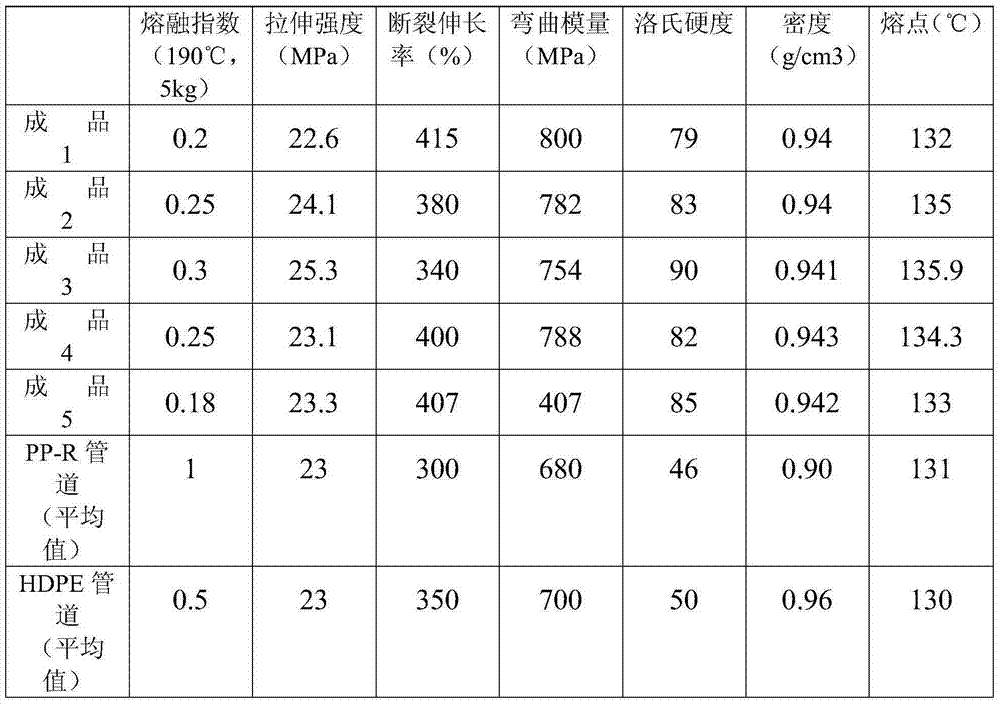

High-temperature, temperature-resisting and wear-resisting polyethylene pipe

The invention discloses a high-temperature, temperature-resisting and wear-resisting polyethylene pipe. The high-temperature, temperature-resisting and wear-resisting polyethylene pipe sequentially comprises a micron-grade modified ultra-high molecular weight polyethylene layer, a high molecular weight modified material layer of high density polyethylene and inorganic minerals and a polyethylene felt layer from inside to outside. The polyethylene felt layer is composed of the following raw materials: 100 parts of the polyethylene, 10-20 parts of nano materials, 1-3 parts of a compatilizer, 1-3 parts of a toughening agent, 1-2 parts of a coupling agent, 1-1.5 parts of a processing lubricant and 1-1.5 parts of an antioxidant. The high-temperature, temperature-resisting and wear-resisting polyethylene pipe has the advantages that nano particles are sufficiently dispersed in plastic resin so that the heat resistance, the weather resistance, the wear resistance and the like of the plastic are effectively improved.

Owner:NINGBO BOER PIPE IND DEV

Low-viscosity and high-heat conduction epoxy resin electronic potting adhesive

InactiveCN101974302AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention relates to a low-viscosity and high-heat conduction epoxy resin electronic potting adhesive which is formed by mixing a component A with an amine curing agent according to the weight ratio of 100:5-12, wherein the component A comprises the following raw materials in weight ratio: 70-85 parts of spherical alumina powder, 10-20 parts of epoxy resin, 2-4 parts of active thinner, 2.5-5 parts of toughening agent and 0.1-0.5 parts of coupling agent. The invention has the advantages that the spherical alumina of the potting adhesive has higher filling amount compared with non-spherical alumina, the viscosity is less affected, the fluidity is favorable and the construction is convenient; the potting adhesive has good dispersibility and is difficult to sedimentate; a condensate has high heat conductivity and can quickly dissipate accumulated heat of heating parts and components; a high-filling filler can reduce a thermal expansion coefficient and a volumetric shrinkage rate and is very suitable for potting parts and components; and the price is cheaper compared with boron nitride and aluminum nitride, and the cost is low.

Owner:YANTAI DARBOND TECH

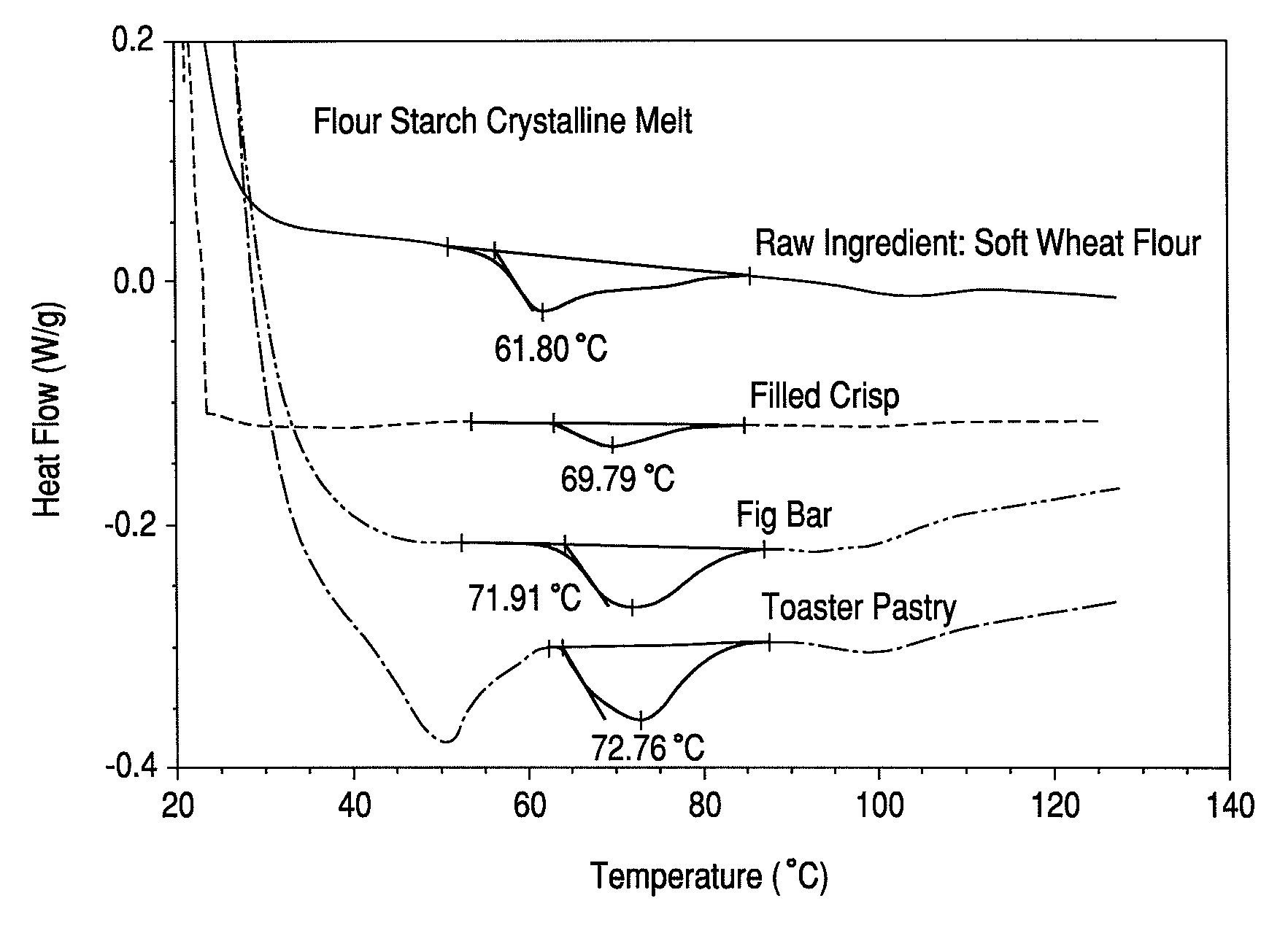

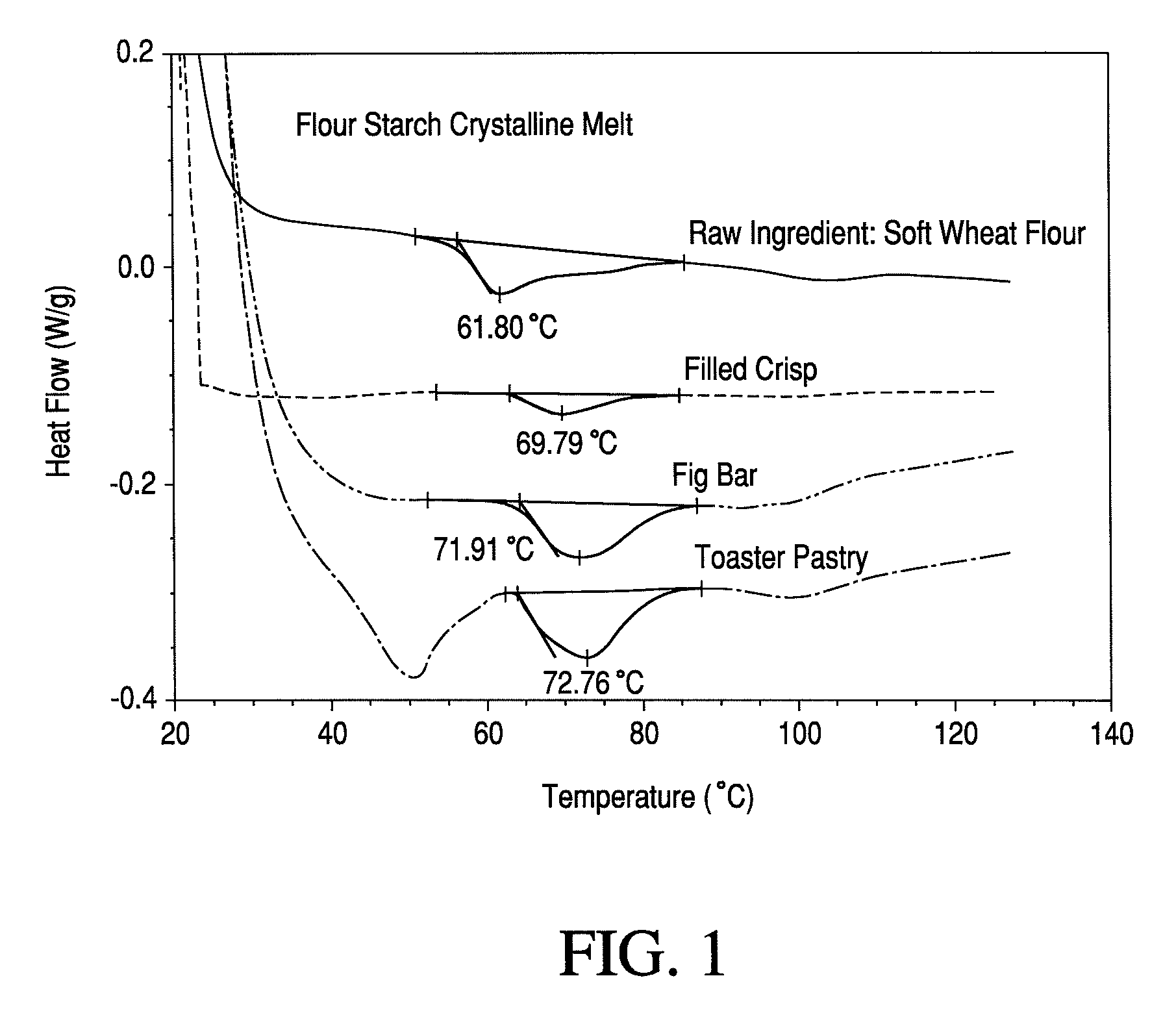

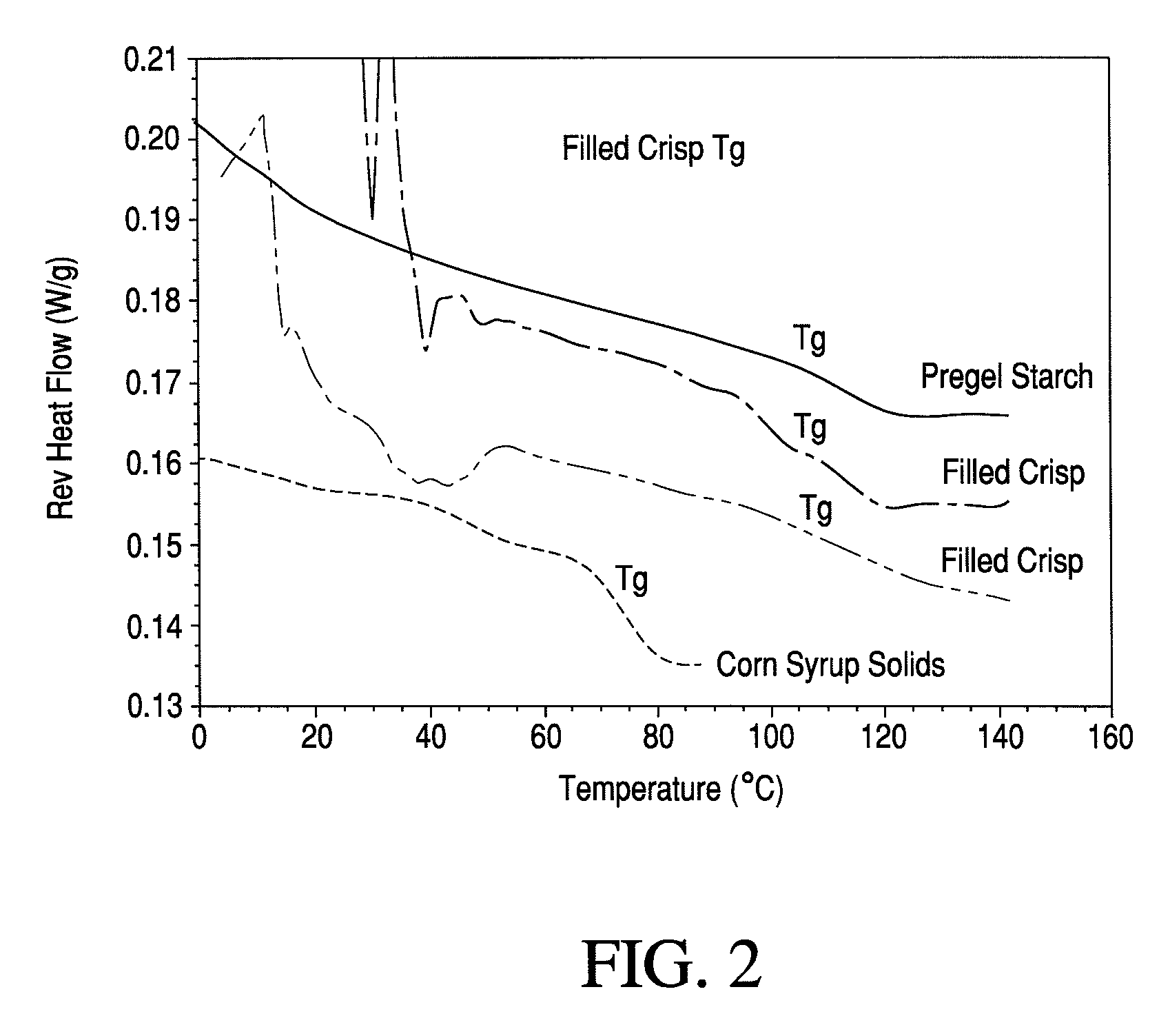

Filled, baked crispy snack having a high moisture content

ActiveUS20090220654A1Improve gelatinizationIncreased TgDough treatmentConfectioneryHigh resistanceReady to eat

A shelf-stable, filled, baked crispy snack which possesses a crispy textured casing and a moist, soft textured filling over a prolonged period of time is obtained by formulating a casing which when baked has a high glass temperature (Tg) at a high moisture content. Increasing the degree of starch gelatinization to increase the Tg may be achieved during baking and by the addition of a pregelatinized starch. The high Tg baked casing permits the use of a high moisture content filler in high amounts to provide a shelf-stable substantial textural dichotomy in the filled, baked, crispy snack. The filled, baked snack exhibits an unexpectedly high resistance to deformation or peak force at high baked casing moisture contents. The baked snack is ready-to-eat out of the packaging and does not have to be toasted, microwaved or further baked, cooked, or heated for consumption, or to achieve a crisp textured casing.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

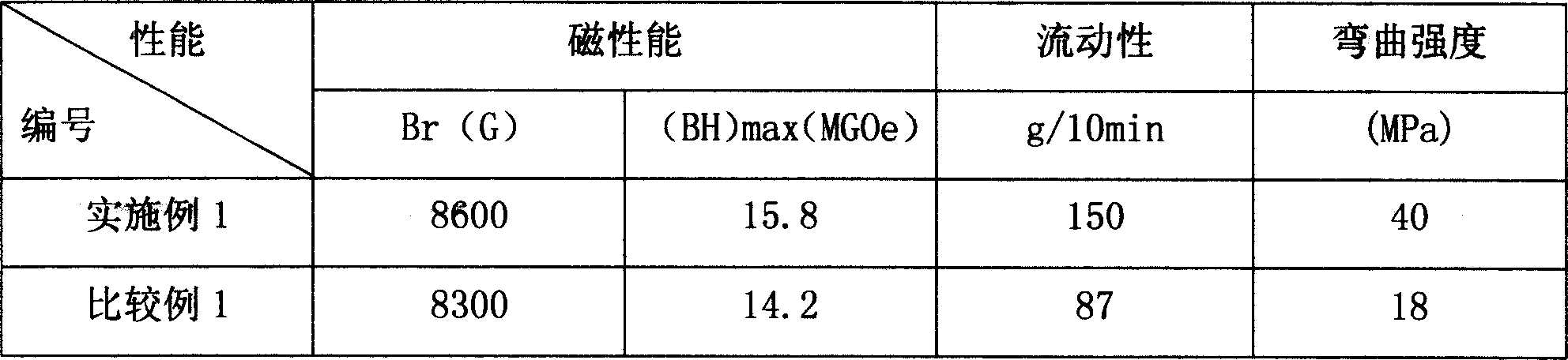

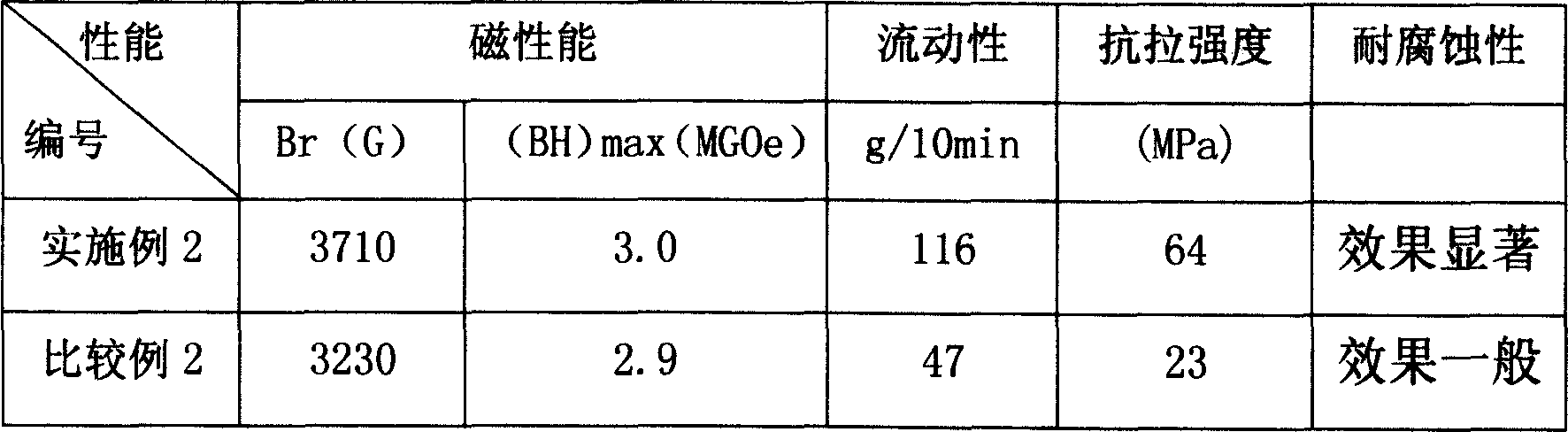

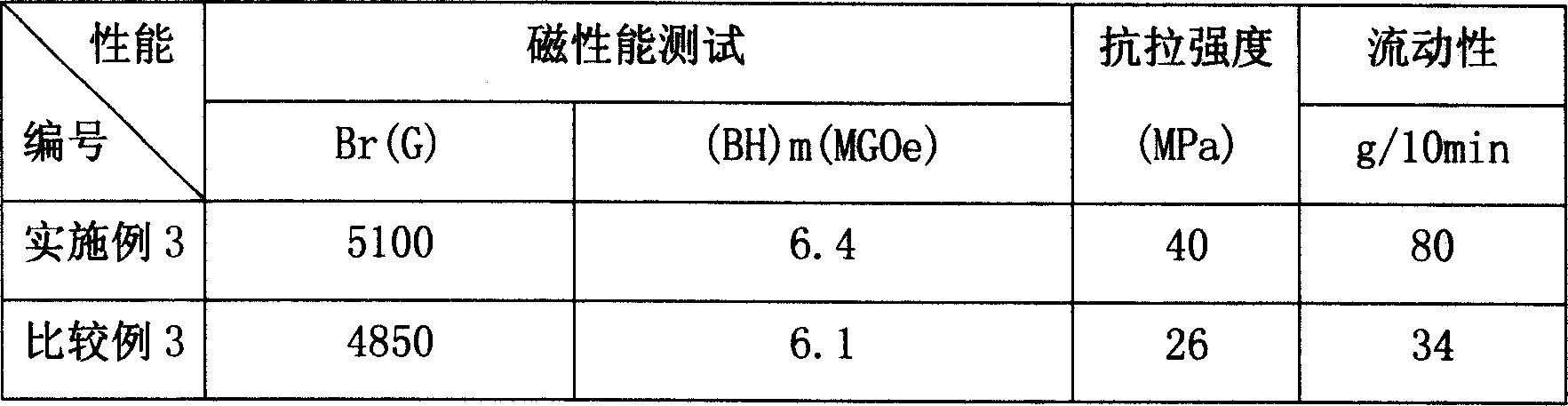

Formula of compoiste adhering magnet

ActiveCN1645525AImprove liquidityLow molding temperatureInorganic material magnetismMetallurgyAdditive ingredient

The invention is related to a permanent magnet consisting of more than two kinds of permanent magnetic powder, special binder, organic or inorganic lubricant, and other additives. The invention has following features: 1) the organic or inorganic lubricant makes the ingredient have good fluidity, low forming temperature, and high loading level of magnetic powder; 2) the production cost is low and the application of magnetic property is wide.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Preparation method of polyvinyl chloride (PVC) low-foaming wood plastic composite

The invention discloses a preparation method of a polyvinyl chloride (PVC) low-foaming wood plastic composite. The wood plastic composite comprises the following raw materials in parts by weight: 100 parts of PVC resin, 40-80 parts of wood fiber, 4-5 parts of stabilizer, 5-15 parts of plasticizer, 5-10 parts of modifier, 2-4 parts of lubricant and 0.2-1.0 part of AC foaming agent. The preparation method comprises the following steps: mixing the raw materials with a high-speed mixer, and pelletizing to realize extrusion molding. By adopting the preparation method, the higher filling volume of wood fiber can be ensured and the product has lower production cost and higher operational performance; in the preparation method, the formula of raw materials is configured reasonably and the calcium zinc composite stabilizer is used; and hydrotalcite can also be used for optimization, thus the mechanical properties of the material and the stability of the product can be further increased.

Owner:SHANGHAI BESTON PLASTICS

Flame retardant high-heat-conductivity epoxy resin electronic adhesive glue

InactiveCN102533192AImprove thermal conductivityDisperse quicklyNon-macromolecular adhesive additivesEpoxynovolac adhesivesHalogenAdhesive glue

The invention relates to flame retardant high-heat-conductivity epoxy resin electronic adhesive glue, which is formed by mixing ingredients A with amine curing agents according to the weight ratio of 100:(5-12), wherein the ingredients A comprises the following ingredients in parts by weight: 50 to 60 parts of spherical alumina powder, 20 to 30 parts of flame retardant fillings, 10 to 20 parts of epoxy resin, 1.5 to 2.5 parts of reactive diluents, 2 to 3 parts of halogen-free liquid flame retardants, 2 to 3 parts of toughening agents, 0.2 to 0.8 parts of thixotropic agents and 0.1 to 0.5 parts of coupling agents. According to the adhesive glue provided by the invention, the adhesive glue filled by the spherical alumina has higher condensate heat conductivity when being compared with the adhesive glue filled by the non-spherical alumina, and the heat accumulation of heating devices can be fast dispersed.

Owner:YANTAI DARBOND TECH

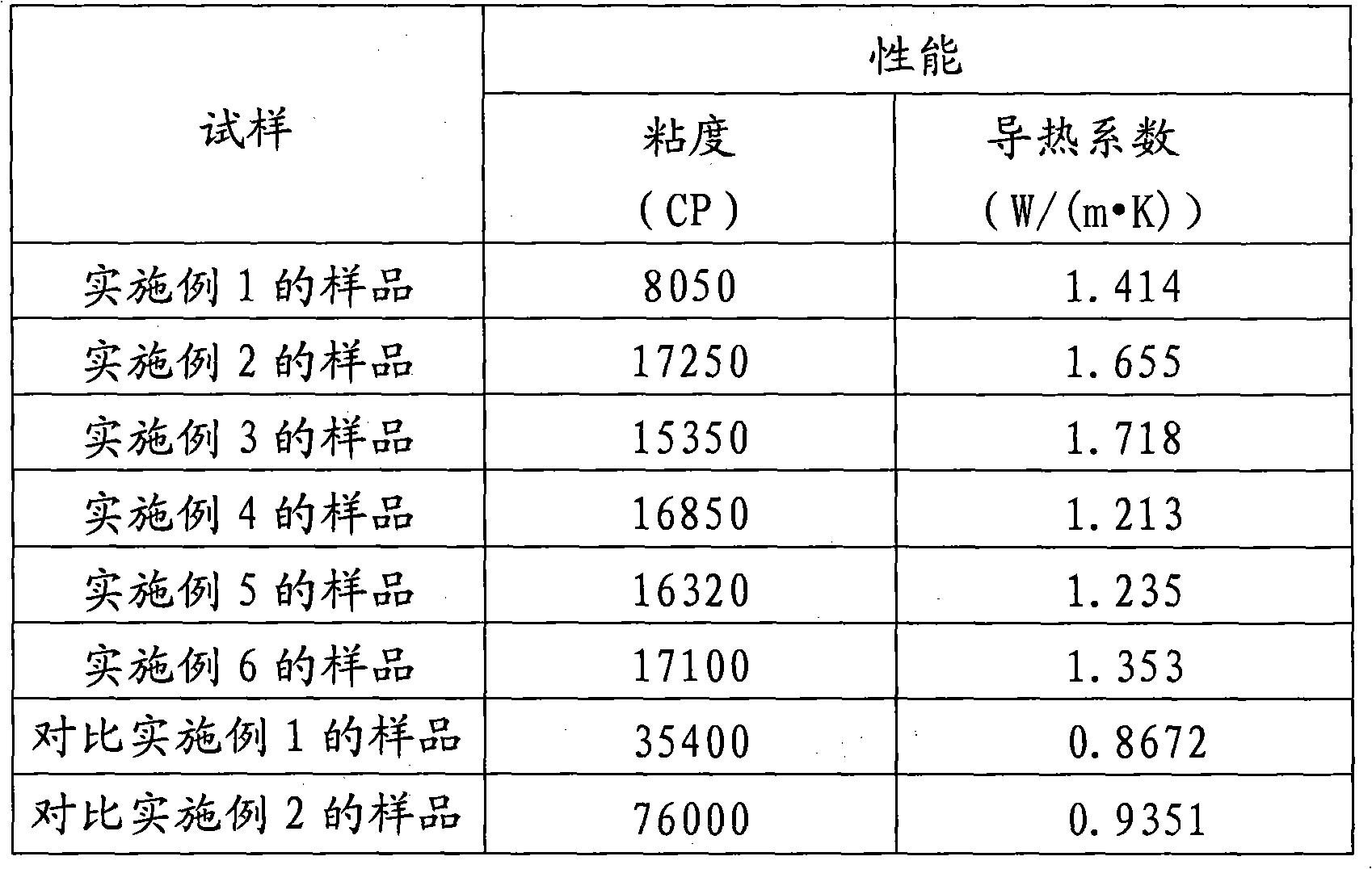

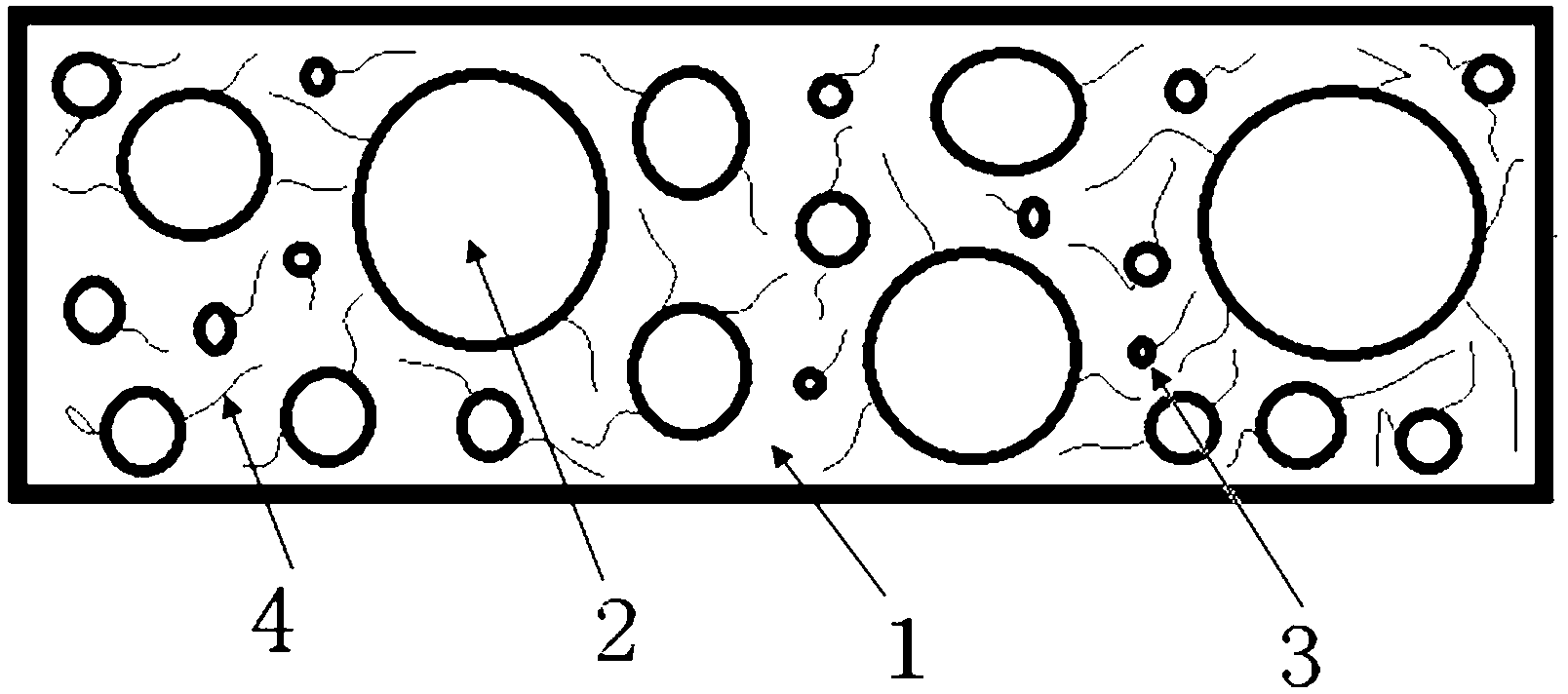

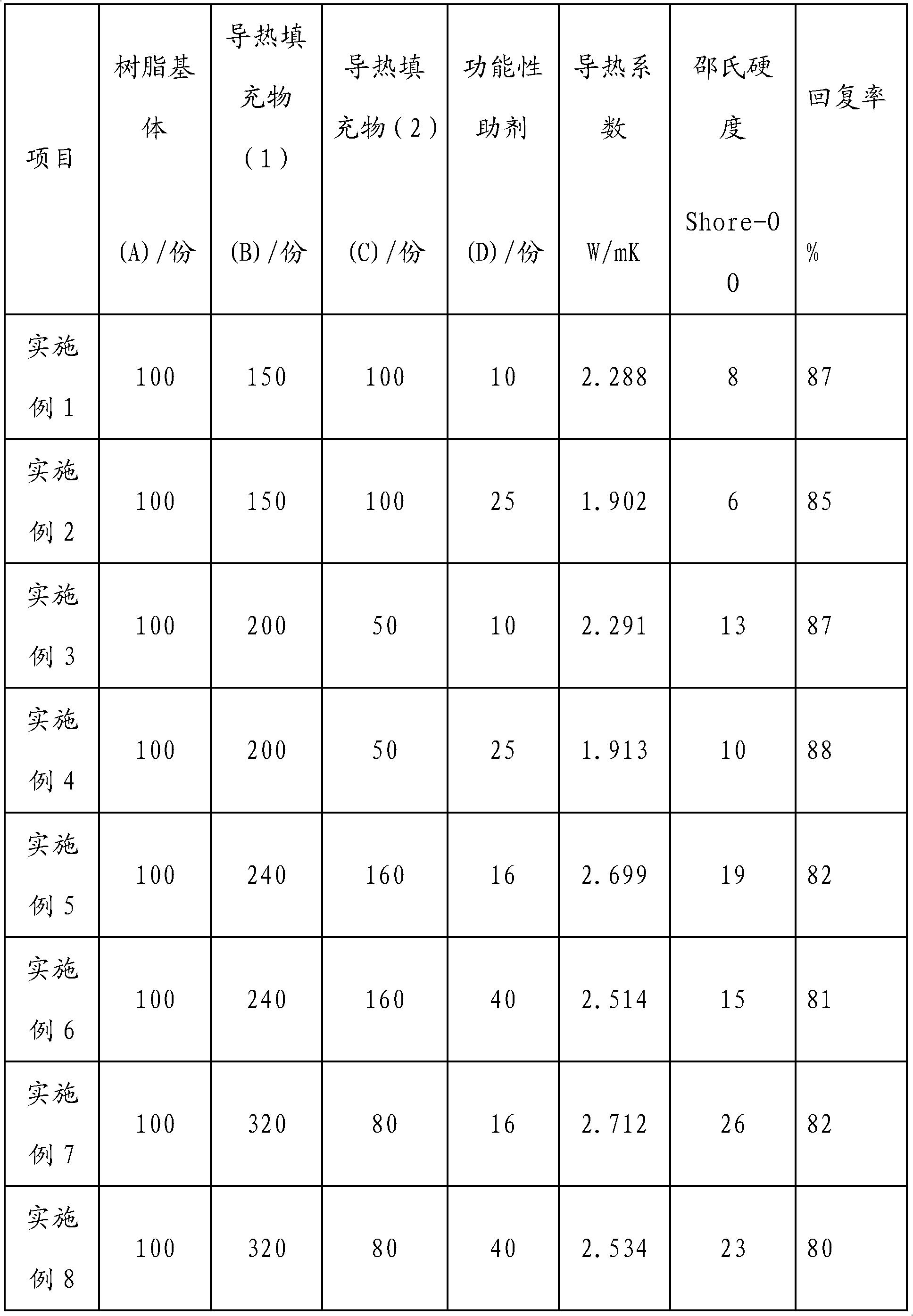

Heat-conductive gap interface material and preparation method thereof

The invention relates to a heat-conductive gap interface material and a preparation method thereof. The heat-conductive gap interface material comprises 100 parts by weight of a resin matrix and 250-400 parts by weight of heat-conductive fillers, and also comprises an assistant; and the preparation method comprises the following steps: adding the assistant and the resin matrix into a stirrer, and carrying out first stirring to obtain a mixture; and adding a heat-conductive filler (2), carrying out second stirring, adding a heat-conductive filler (1), carrying out third stirring, and curing to obtain the heat-conductive gap interface material. The heat-conductive gap interface material has a small hardness, can avoid damages caused in the assembling process of microelectronic components, and can also fully fill the gaps of the microelectronic components.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

High-performance acidic transparent silicone sealant

ActiveCN101982516AImproves strength and hardnessIncrease filling volumeNon-macromolecular adhesive additivesOther chemical processesChemistryDibutyl tin dilaurate

A high-performance acidic transparent silicone sealant belongs to the technical field of the adhesive. The sealant comprises the following components in parts by weight: 90-130 parts of hydroxyl-terminated polydimethylsiloxane, 10-60 parts of alkyl-terminated polydimethylsiloxane, 5-15 parts of crosslinking agent, 20-90 parts of silicon dioxide, 0.01-0.9 part of anti-yellowing agent and 0.005-0.15 part of catalyst, wherein crosslinking agent is the mixture of methyltriacetoxysilane and ethyltriacetoxysilane; anti-yellowing agent is one or more of ultraviolet absorbent and light stabilizer; and catalyst is dibutyltin diacetate or dibutyltin dilaurate. The invention does not depend on the foreign product and provides the high-performance acidic sealant so as to fills the gap that neutral transparent silicone sealant can not be used in the glass fishbowl; and the sealant has good bonding property to the substrate, and can not have blushing and yellowing and can have no pollution to the environment. The sealant can satisfy the demands of the specific curtain wall, glass roof and glass fishbowl.

Owner:ZHEJIANG TIME NEW MATERIAL

Preparation method of orderly porous matrix shaping composite phase change material

InactiveCN103923614AImprove thermal stabilityHigh porosityHeat-exchange elementsMesoporous silicaVolumetric Mass Density

The invention provides a preparation method of an orderly porous matrix shaping composite phase change material, and belongs to the field of a composite phase change material. The preparation method comprises the following steps: firstly preparing an orderly mesoporous silica carrier, and designing, adjusting and controlling the porous-channel structure, pore size and surface property of the carrier; secondly, using a phase change core material for preparing corresponding liquor, dispersing the prepared porous carrier in prepared phase change core material liquor, adsorbing the phase change core material by using the relatively strong capillary action, surface tension and the like of the porous carrier material so as to realize the high-efficiency filling of the core material in combination of the bonding effects of functional groups on the surface of the carrier on the core material, and drying so as to obtain the composite phase change material with relatively good heat storage capacity and relatively high stability. The composite phase change material has the advantages that the carrier is large in specific surface area, high in porosity and small in pore diameter, has orderly porous-channels and strong immobilization capacity on the phase change core material and is difficult to leak, the filling quantity of the core material is large, and the composite phase change material is high in energy storage density, good in heat stability, widely applied, difficult to burn, green and safe in use.

Owner:UNIV OF SCI & TECH BEIJING

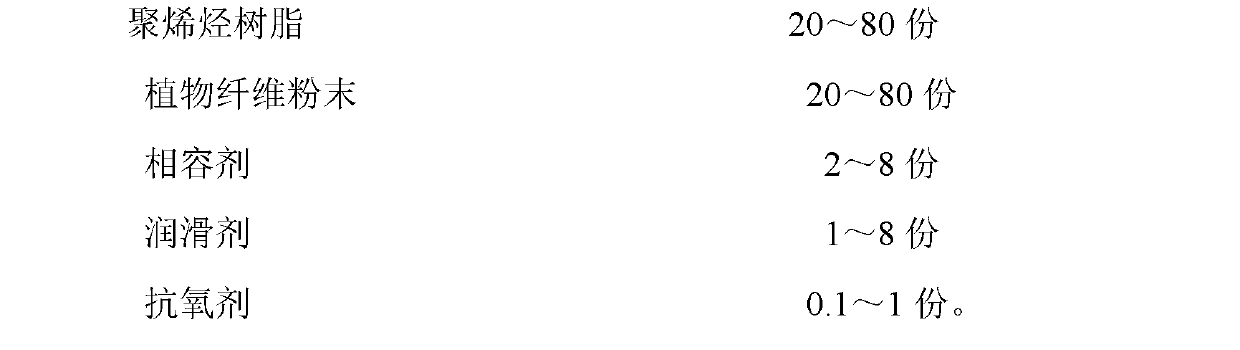

Polyolefin wood-plastic composite material and preparation method thereof

The invention discloses a polyolefin wood-plastic composite material. The polyolefin wood-plastic composite material is prepared by blending and extruding the following components in parts by weight: 20 to 80 parts of polyolefin resin, 20 to 80 parts of plant fiber powder, 2 to 8 parts of compatilizer, 1 to 8 parts of lubricant, and 0.1 to 1 part of antioxygen, wherein the lubricant includes pentaerythritol tetra-benzoate. The composite material has the balance torque of 3.2 to 8.4N.M, bending strength of 30.1 to 66.3MPa, and bending modulus of (0.80-22.6)*10<4>MPa. The invention also discloses a preparation method of the polyolefin wood-plastic composite material. The ester bond of the pentaerythritol tetra-benzoate contained in the wood-plastic composite material and the hydroxyl of the plant fibers can produce high hydrogen bond effect, so that the plant fibers can be promoted to be uniformly dispersed, the filling amount can be increased, the product cost is reduced, the defect on the appearance of the product is avoided, the melting and extruding efficiency is improved, and the bending performance and water absorbing performance of the material are improved; and the polyolefin wood-plastic composite material can be used as the high-level polyolefin wood-plastic composite material to be widely applied in the fields such as indoor and outdoor decoration and construction industry.

Owner:SICHUAN UNIV

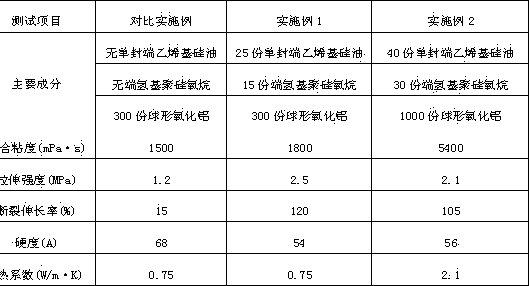

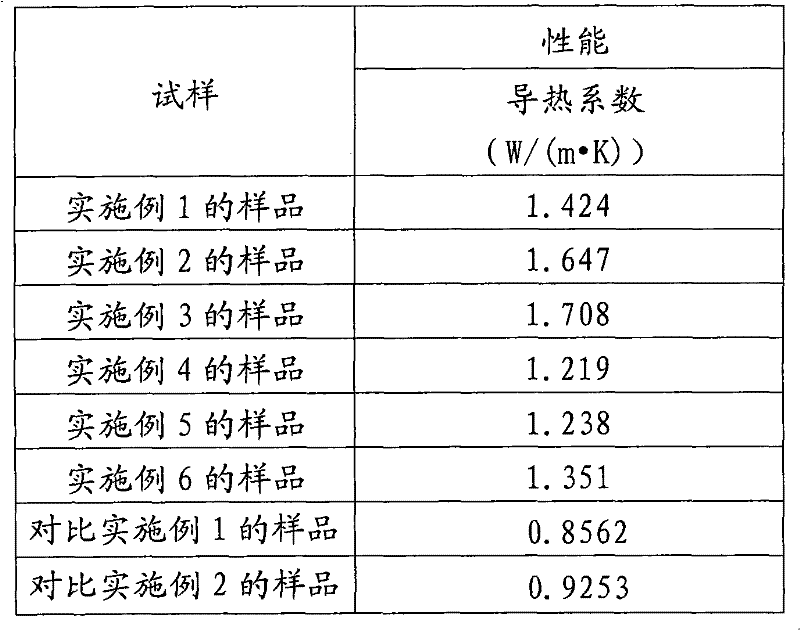

Double-component high heat-conducting pouring sealant with excellent mechanical properties and preparation method thereof

ActiveCN103834352AIncrease filling volumeGood mechanical propertiesNon-macromolecular adhesive additivesOther chemical processesHydrogenCrack resistance

The invention relates to a double-component high heat-conducting pouring sealant with excellent mechanical properties and a preparation method thereof. The pouring sealant comprises components A and B in a weight mixing ratio: 1:1, wherein the component A comprises 100-120 parts of polysiloxane, 15-45 parts of mono-blocked vinyl silicone oil, 0.1-5 parts of catalyst and 200-1200 parts of heat-conducting filler; the component B comprises 100 parts of polysiloxane, 10-40 parts of hydrogen-containing polysiloxane, 5-25 parts of hydrogen-terminated polysiloxane, 0.05-1 part of inhibitor and 200-1200 parts of heat-conducting filler. According to the sealant provided by the invention, spherical heat-conducting filler is selected, and the loading level of the heat-conducting filler is increased under the premise of not affecting the flowability through grain size compounding, so that a higher heat-conducting performance is obtained. The mono-blocked vinyl silicone oil and hydrogen-terminated polysiloxane are added into the system, and the mechanical properties (hardness and elongation at break) can be adjusted by changing the content of the mono-blocked vinyl silicone oil and hydrogen-terminated polysiloxane, so that performances such as impact resistance and crack resistance are further improved. Finally, the high heat-conducting pouring sealant with excellent mechanical can be obtained.

Owner:TONSAN ADHESIVES INC

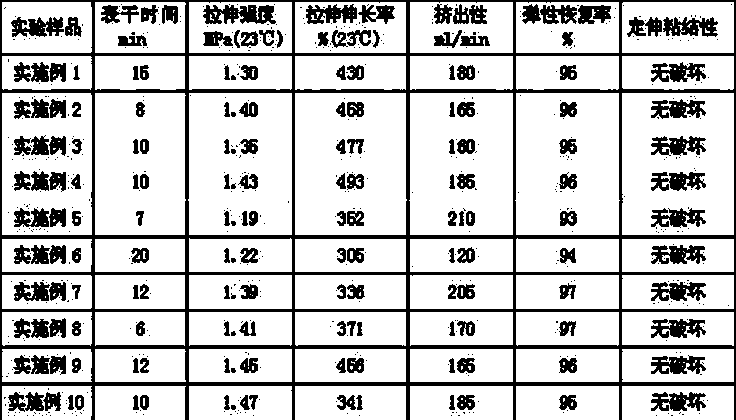

Method for preparing silicone sealant

ActiveCN103642452AIncrease the amount addedImprove stabilityNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePtru catalyst

The invention discloses a method for preparing silicone sealant. The method comprises the following steps: adding alpha,omega-dyhydroxy polydimethylsiloxane, filler and dimethyl silicon oil into a vacuum kneading machine, vacuuming, heating and mixing for 2-5 hours; stopping heating, introducing nitrogen to change the vacuum state, adding a silane coupling agent, mixing for 0.5-1 hour at the vacuum degree of -0.06 to -0.1Mpa, introducing nitrogen to change the vacuum state; sealing and cooling to room temperature, subsequently transferring into a stirring machine, adding a cross-linking agent, a thickening agent and a catalyst, vacuuming, and uniformly stirring and mixing so as to obtain the silicone sealant. According to a product of the silicone sealant, the addition amount of the filler is increased, the product stability and the surface smoothness are improved, the thixotropy and the deep curing are also improved, the curing homogeneity is good, the tensile strength, the elasticity and the cohesiveness are greatly improved, expensive white carbon black can be replaced, the filling amount is large, the curing time is short, the construction efficiency is improved, the process is simple and feasible, the production cost is low, and good economic benefits and social benefits are achieved.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Modified silicon dioxide powder/silicon dioxide nanofiber composite aerogel material and preparation method thereof

The invention provides a modified silicon dioxide powder / silicon dioxide nanofiber cross-gradient composite aerogel material and a preparation method thereof. The modified silicon dioxide powder / silicon dioxide nano fiber cross-gradient composite aerogel material is characterized in that silicon dioxide nano fibers serve as a three-dimensional framework structure of aerogel, modified nano silicondioxide powder is uniformly filled in gaps formed among single nano fibers, the whole composite material is divided into three layers of different nano silicon dioxide powder filling densities in thickness, and by the three-dimensional framework formed by the silicon dioxide nanofibers, good compression resilience and strength are achieved. The three-dimensional silicon dioxide powder / silicon dioxide nanofiber aerogel material has a bulk density of 10-1000 mg / cm<3> and the average pore size of 0.05-1000 mu m, a tensile strength of 20-50 kPa, and a compression resilience is greater than or equal to 85%. According to the inner structure of the obtained aerogel material, silicon dioxide powder is uniformly dispersed in meshes of a three-dimensional frame formed by silicon dioxide fibers, thefibers are mutually staggered and penetrated to form pores, the mechanical strength of the aerogel material is improved, meanwhile, the aerogel material has a high porosity and small pore size structure, and has wide application prospects in the fields of heat insulation, sound absorption, noise reduction and the like.

Owner:黄金龙

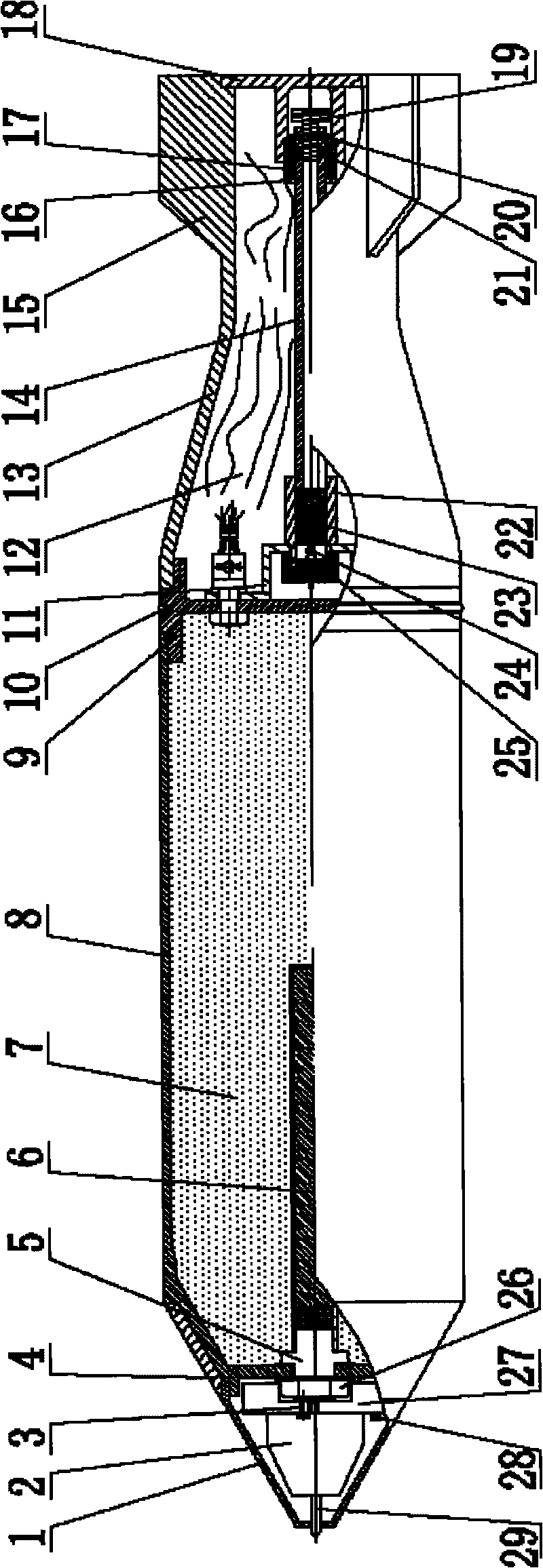

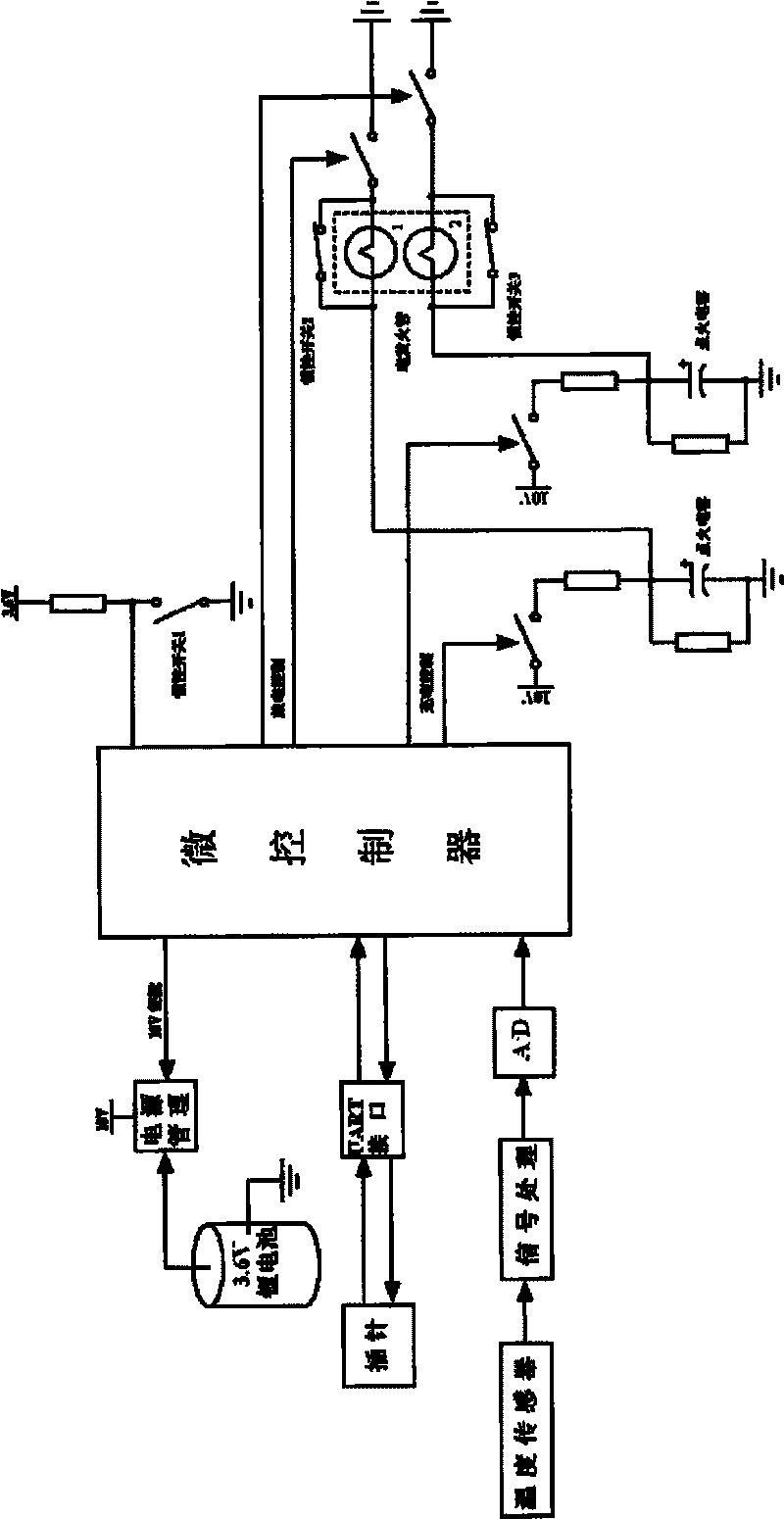

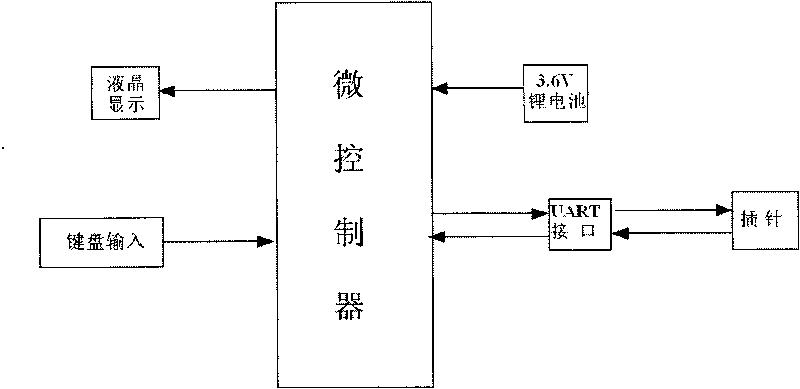

Pneumatic emission-type forest extinguishing cannonball

InactiveCN101703830AGood fire extinguishing effectReduce volumeAmmunition projectilesFire rescueFuzeEngineering

The invention provides a pneumatic emission-type forest extinguishing cannonball, which mainly comprises a ballistic cap, a fuze, a cylindrical shell, a fire-extinguishing agent, a central nonel tube, an umbrella cabin shell, a brake parachute and an umbrella throwing disengagement structure, wherein, the ballistic cap is connected with the front end of the cylindrical shell; the cylindrical shell is connected with the umbrella cabin shell through a connecting plate; the fuze is fixed at the front end of the cylindrical shell; the central nonel tube is fixed in the cylindrical shell and is connected with the fuze through a wire; the umbrella cabin shell is provided with the umbrella throwing disengagement structure and the brake parachute; the fire-extinguishing agent is filled in the cylindrical shell. The pneumatic emission-type forest extinguishing cannonball of the invention can scatter the fire-extinguishing agent and can achieve the optimal extinguishing effect.

Owner:HARBIN ENG UNIV

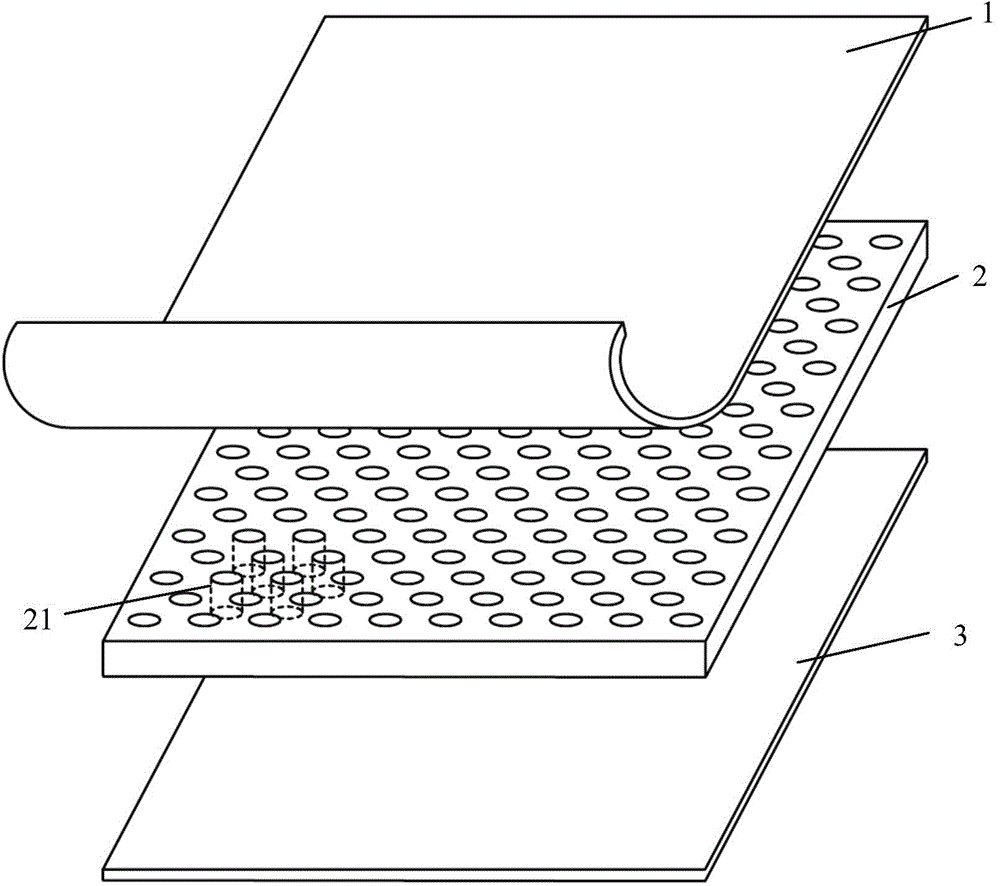

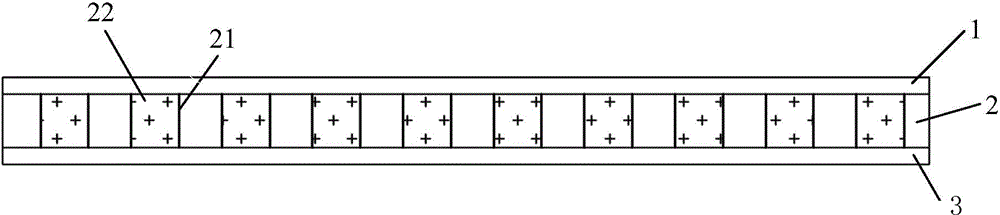

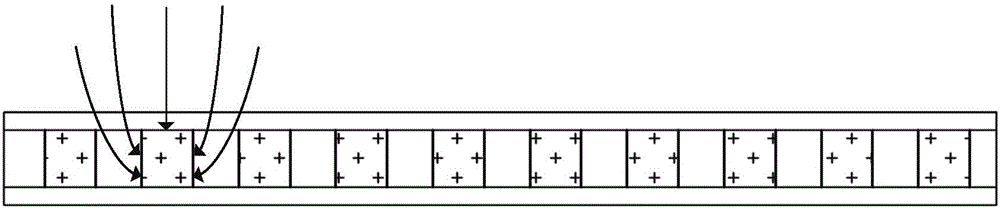

Composite absorption core

ActiveCN104367418ALarge liquid absorptionIncrease filling volumeAbsorbent padsSurface layerEngineering

The invention provides a composite absorption core comprising a surface layer, a bottom layer and a middle absorption layer. The middle absorption layer is arranged between the surface layer and the bottom layer, and is provided with a plurality of vertical through holes. The vertical through holes are filled with macromolecular water-absorbent resin. The composite absorption core has the advantages that the through holes are formed in the middle absorption layer and are filled with the macromolecular water-absorbent resin, filling quantity of the macromolecular water-absorbent resin is increased, and accordingly, liquid absorption quantity of the composite absorption core can be increased.

Owner:俊富新材料有限公司

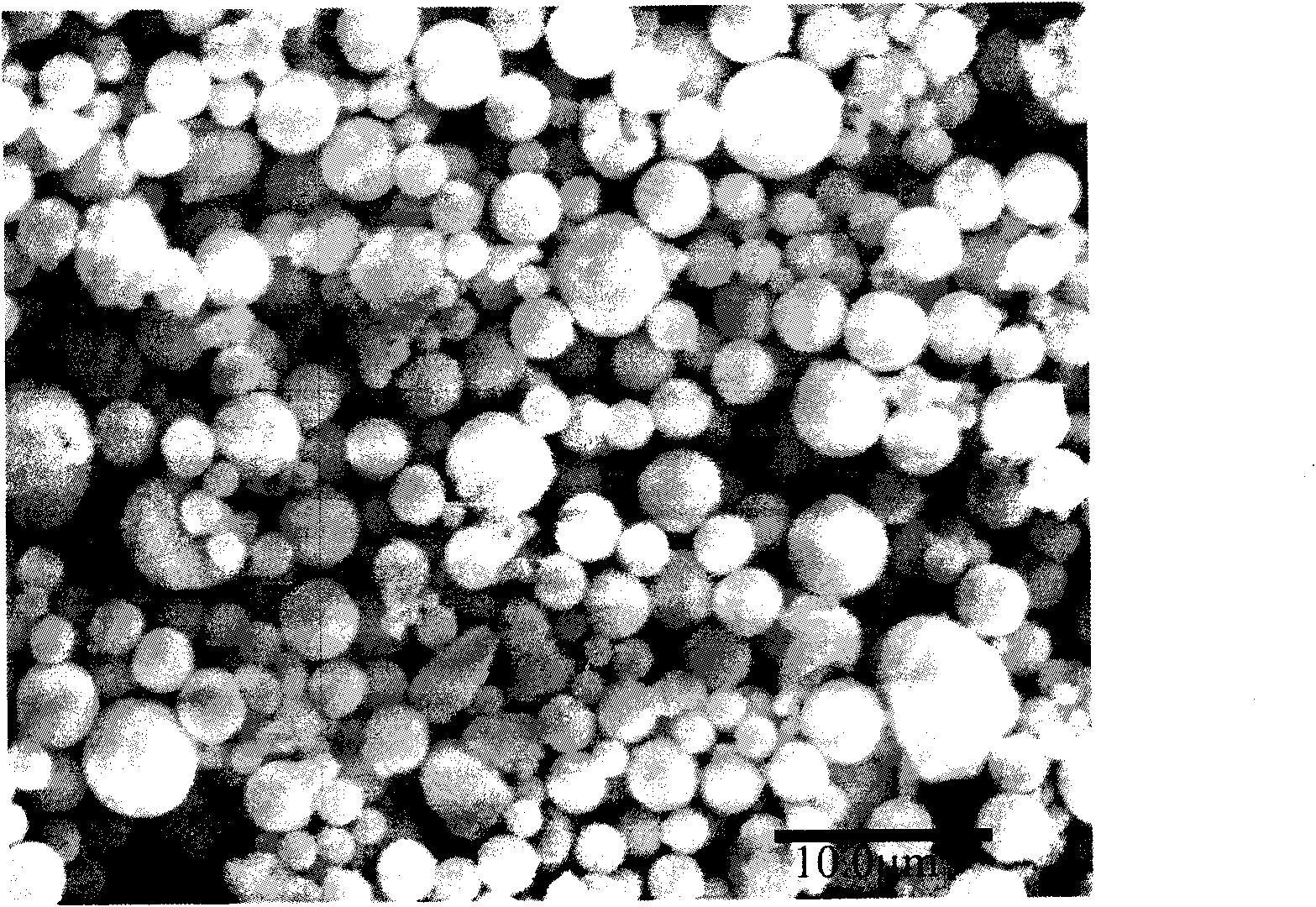

High-purity low-radioactivity spherical silicon micropowder and preparation method thereof

The invention discloses high-purity low-radioactivity spherical silicon micropowder. In the silicon micropowder, the content of SiO2 is not lower than 99.90 percent, the content of radioelement U is less than or equal to 1*10g / g, sphericization ratio is between 90 and 100 percent, and non-crystalline ratio is between 99 and 100 percent. The method for preparing the silicon micropowder comprises the following steps: preparing stable silica sol which has purity not lower than 99.90 percent and the ion content of an arbitrary impurity less than or equal to 5*10g / g by a silicon source with the content of radioelement U being less than or equal to 1*10g / g; concentrating the silica sol to lead the solid content of the silica sol to be between 41 and 70 percent; granulating the concentrated silica sol to lead grain diameter of the silica sol to be between 0.5 and 60 mu meters; roasting the granulated silicon oxide micropowder at a temperature of between 500 and 1,100 DEG C; and carrying out sphericization treatment on the micropowder in a flame burner and a sphericizing furnace, and classifying and collecting the micropowder after cooling to obtain the high-purity low-radioactivity spherical silicon micropowder. The spherical silicon micropowder of the invention can meet the requirement of a large-scale integrated circuit on capsulation packing, and the invention has simple process, low cost, simple required equipment, and is applicable to industrial production.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

High-heat-conductivity epoxy resin electronic binding glue

InactiveCN102127382AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesEpoxynovolac adhesivesReactive diluentThermal expansion

The invention relates to a high-heat-conductivity epoxy resin electronic binding glue. The invention is characterized in that the high-heat-conductivity epoxy resin electronic binding glue is prepared by mixing 100 parts by weight of a component A and 5-12 parts by weight of an amine curing agent; and the component A is prepared from the following raw materials in parts by weight: 70-85 parts of spherical aluminum oxide powder, 10-20 parts of epoxy resin, 2-3.5 parts of reactive diluent, 2.5-5 parts of toughener, 0.2-1 part of thixotropic agent and 0.1-0.5 part of coupling agent. The spherical aluminum oxide of the binding glue provided by the invention has higher filling volume than non-spherical aluminum oxide, and high heat conductivity for solids, and can quickly dissipate heat accumulated in the heating components; the filler with high filling volume can lower the thermal expansion coefficient and volume shrinkage, and thus, the binding glue is very suitable for binding electronic components; and the price of the spherical aluminum oxide is lower than that of boron nitride (BN) or aluminium nitride (ALN), and thus, the binding glue provided by the invention has the advantage of low cost.

Owner:YANTAI DARBOND TECH

Reflective thermal-insulation exterior wall coating

InactiveCN103555102AKeep the decorative functionKeep the protection functionReflecting/signal paintsCelluloseThermal insulation

A reflective thermal-insulation exterior wall coating is characterized in that based on the total weight of the coating, components of the coating contain, by weight, 40-50% of waterborne acrylic resin, 10-20% of water, 10-15% of silica powder, 5-8% of expanded perlite, 3-5% of hollow ceramic microsphere, 2-5% of vermiculite powder, 3-5% of sericite powder, 5-8% of coal ash, 1-2% of an antifreeze agent, 4-6% of titanium dioxide, 4-6% of barium sulfate, 0.1-0.15% of aluminium titanate, 0.1-0.15% of silicon carbide, 0.1-0.15% of cordierite, 0.3-0.8% of an antifoaming agent, 0.1-0.15% of a bactericide, 0.1-0.4% of a dispersant, 1-1.5% of an alkali swelling thickener, 0.1-0.2% of a cellulose thickener, 0.1-0.15% of a wetting agent and 0.5-1% of an film-forming additive.

Owner:苏州富莱希涂料有限公司

Foaming water discharge agent and its preparation

ActiveCN101492599ANo wasteWill not affect the use effectDrilling compositionBorehole/well accessoriesWater dischargeDiethylenetriamine

The invention discloses a foam dewatering agent. The foam dewatering agent is prepared by the following raw materials by weight percentage: 5-10% of triethylene tetramine, 10-20% of diethylenetriamine, 1-30% of oleic acid, 2-10% of glacial acetic acid, 5-15% of maleic anhydride, 5-10% of acrylic acid, 2-7% of citric acid, 5-30% of imidazoline, 5-30% of LAS, 5-10% of HCl aqueous solution with the mass percentage concentration of 20%, 5-10% of NaOH aqueous solution with the mass percentage concentration of 30% and 10-30% of water. The foam dewatering agent integrates foam dewatering, corrosion inhibiting and antiscaling functions, as one potion has the functions such as foam dewatering, corrosion inhibiting and antiscaling and the like at the same time, so that one-time filling-up can replace the traditional three-time respective filling-up, thus reducing the cost, simplifying the process without affecting the functions and prolonging the period of validity. The invention also discloses a method for preparing the foam dewatering agent.

Owner:成都孚吉科技有限责任公司 +2

High-filling bentonite foaming stone paper and preparation method thereof

The invention relates to high-filling bentonite foaming stone paper and a preparation method thereof. The stone paper comprises the following constituents mixed in parts by weight: 75-85 parts of bentonite, 15-25 parts of polymer resin, 0.5-1 part of surfactant, 0.5-2 parts of coupler, 0.5-1 part of lubricant, 0.1-0.2 parts of antioxidant and 0.2-0.5 parts of antistatic agent. The preparation process for the stone paper comprises the following steps: modifying bentonite; compounding modified bentonite with resin and auxiliaries; processing and forming composite particles. The preparation method for the high-filling bentonite foaming stone paper disclosed by the invention gives a foaming function to the system by virtue of the bound water of bentonite while increasing a filling amount, and can be used by replacing a chemical foamer, thus reducing the raw material cost, improving the environment-friendly characteristic of the stone paper, and giving the functions of silencing and reducing noise, adsorbing impurities and purifying air to the stone paper simultaneously.

Owner:宋旭

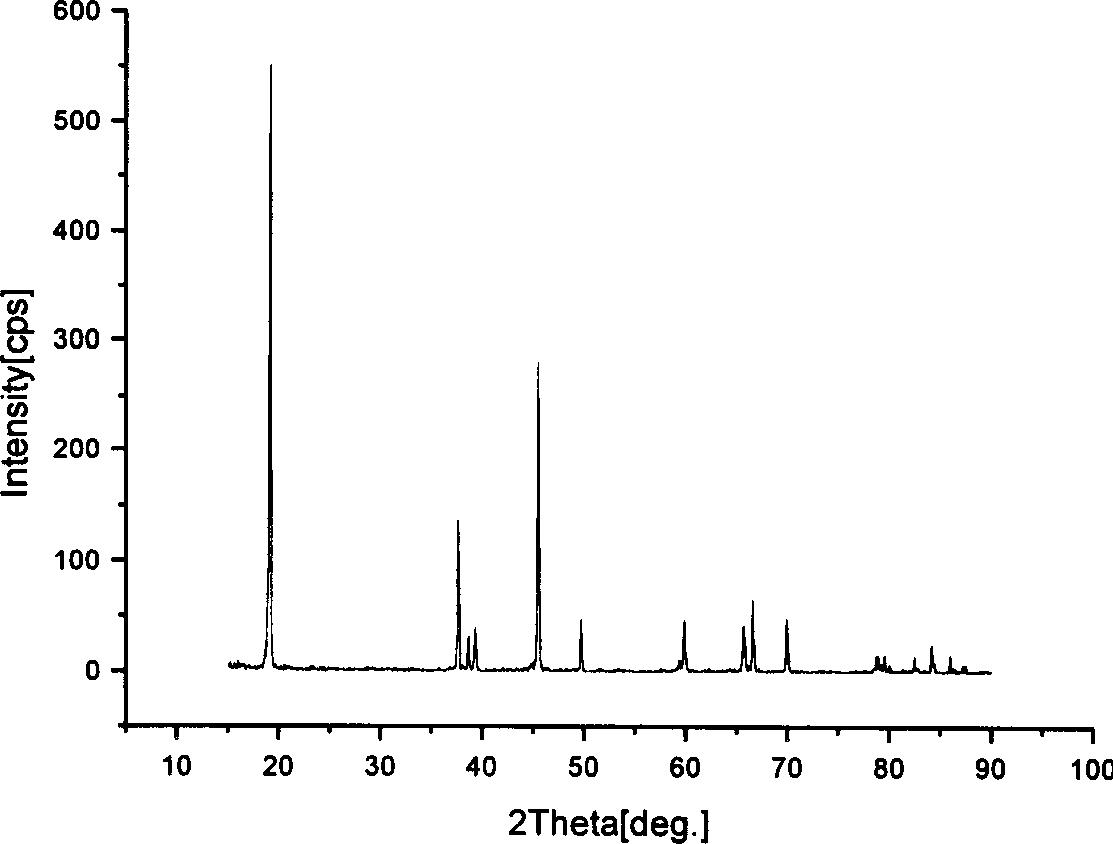

Method for preparing spherical positive pole active material for lithium ion position

InactiveCN1392621AHigh densityLarge capacityElectrode thermal treatmentActive material electrodesDecompositionLithium-ion battery

This invention provides a method for preparing anode active material of spherical micron order powder for Li-ion battery including the following steps: firstly compounding soluble Co, Mn or Ni salts with LI salt in to a solution to be sprayed with inlet temperature at 300-450 deg.C, and outlet temperature at 200-305 deg.C and dried to form precursor powder, then decomposing in a thermo decomposition furnace at a controlled temperature of 850-1000 deg.c to be gathered by cyclone separation. The powder is calcinated again for 5-25 hours at 750-8000 deg.C under perturbation, and finally the spherical Li-ion battery anode active material is obtained.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

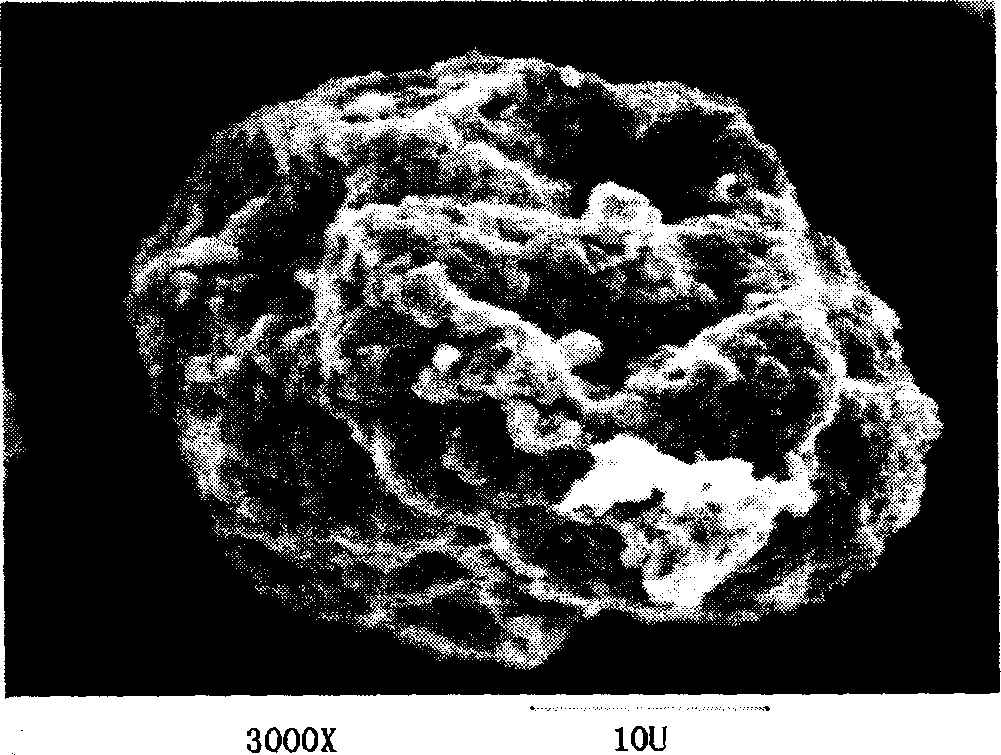

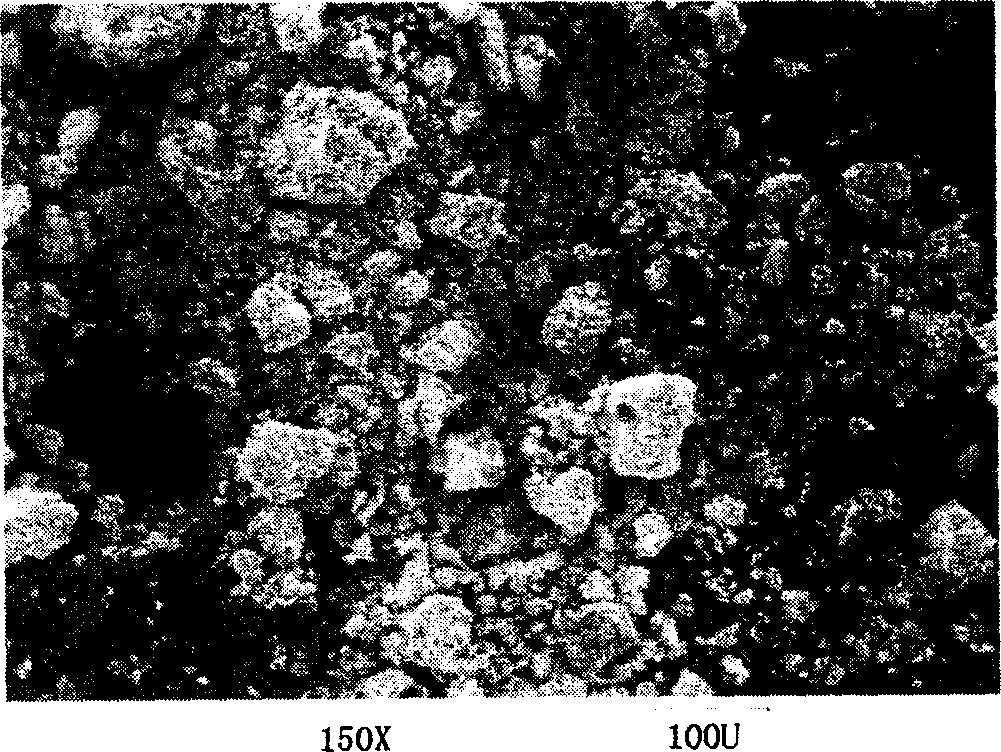

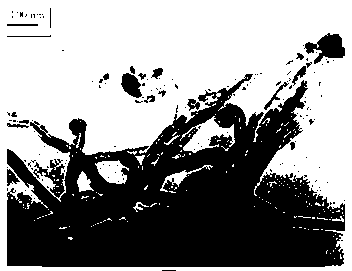

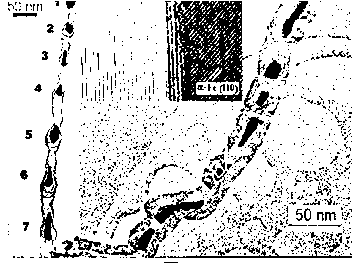

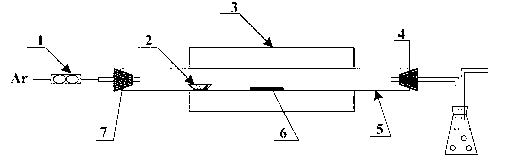

Preparation method of iron filled carbon nano tube and reaction device

InactiveCN103288072AImprove fill rateIncrease filling volumeMaterial nanotechnologyCarbon compoundsPtru catalystIron(III) chloride

The invention provides a preparation method of an iron filled carbon nano tube and a reaction device. The preparation method of the iron filled carbon nano tube comprises the following steps of: preparing the iron filled carbon nano tube by adopting an inorganic covalent compound of iron namely ferric chloride anhydrous as a catalyst precursor and selecting different carbon sources through floating catalysis chemical vapor deposition method, wherein the iron filled carbon nano tube comprises a non-nitrogen-doped iron filled carbon nano tube or a nitrogen-doped iron filled carbon nano tube. The preparation method of the iron filled carbon nano tube disclosed by the invention is simple and scientific in steps and can prepare a high-iron filled carbon nano tube. The invention further discloses a reaction device of the preparation method of the iron filled carbon nano tube. According to the preparation method of the iron filled carbon nano tube and the reaction device, a plurality of disadvantages in the prior art can be overcome; and the advantages that the preparation method is simple and the obtained iron filled carbon nano tube has high iron filling rate are realized.

Owner:DALIAN UNIV OF TECH

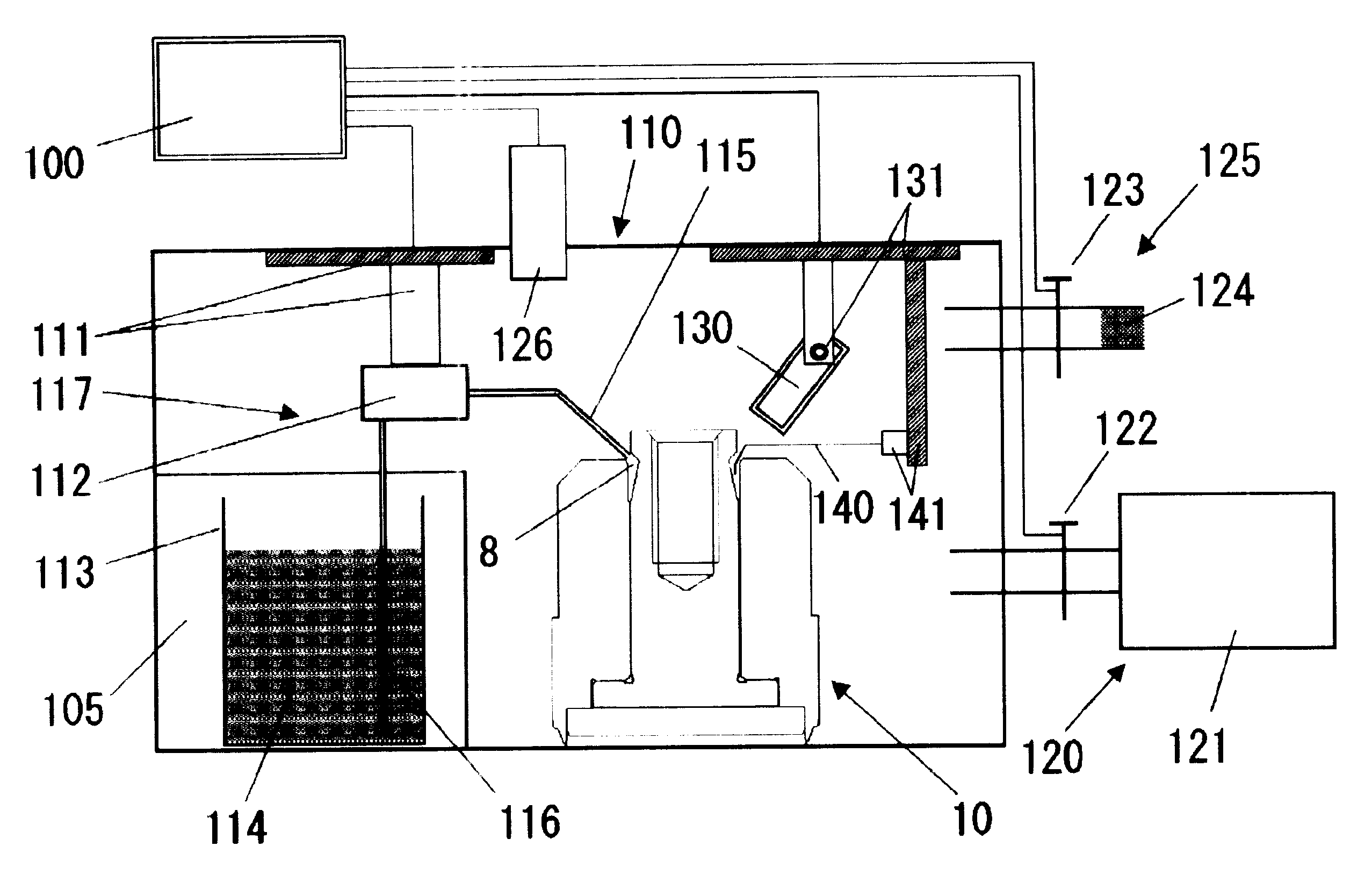

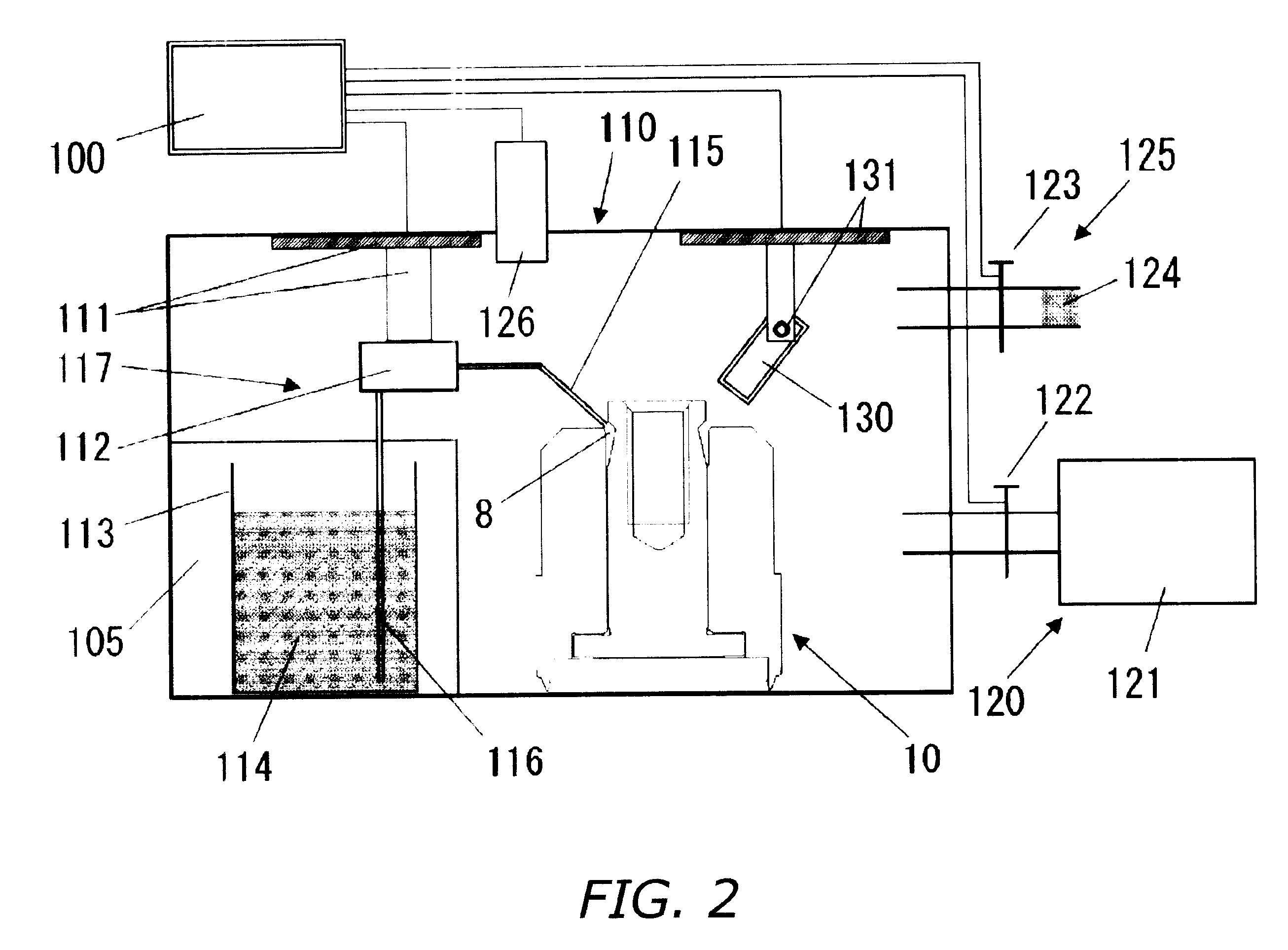

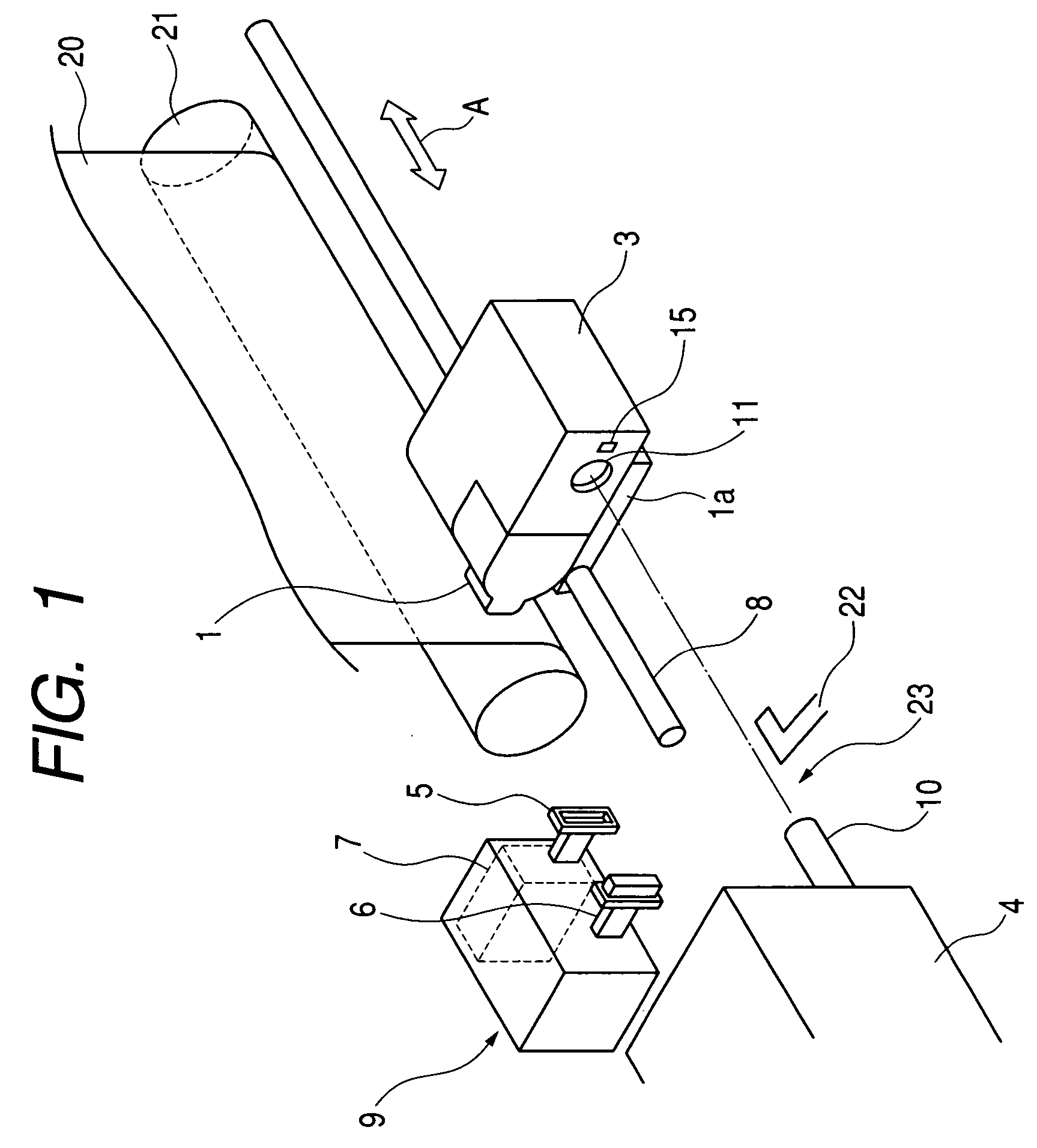

Method and apparatus for charging oil into fluid-dynamic-pressure bearings, spindle motor utilizing fluid-dynamic-pressure bearings, and signal record-and-playback device utilizing fluid-dynamic-pressure bearings

InactiveUS20040107577A1Extended service lifeImprove performanceBearing assemblyShaftsEngineeringPressure reduction

Manufacturing method enabling optimal volume oil-fill even where differing from bearing to bearing due to machining fluctuations in volume-production dynamic pressure bearings. In a first charging method, injection of oil is divided into two cycles. The first is carried out under reduced pressure, following which the pressure is raised a predetermined amount to force the oil into the bearing gap. The oil-fill status is thereupon checked, the shortage is reckoned, and in the second cycle the shortage is injected. In a second charging method, in a first cycle a surplus volume is injected under reduced pressure and the pressure is raised a predetermined amount to force the oil into the bearing gap. Following that, what is in excess of the appropriate amount is removed from the bearing. The first cycle of injection and the pressure elevation may be implemented multiple times, in between which repeat pressure-reduction can be carried out.

Owner:NIPPON DENSAN CORP

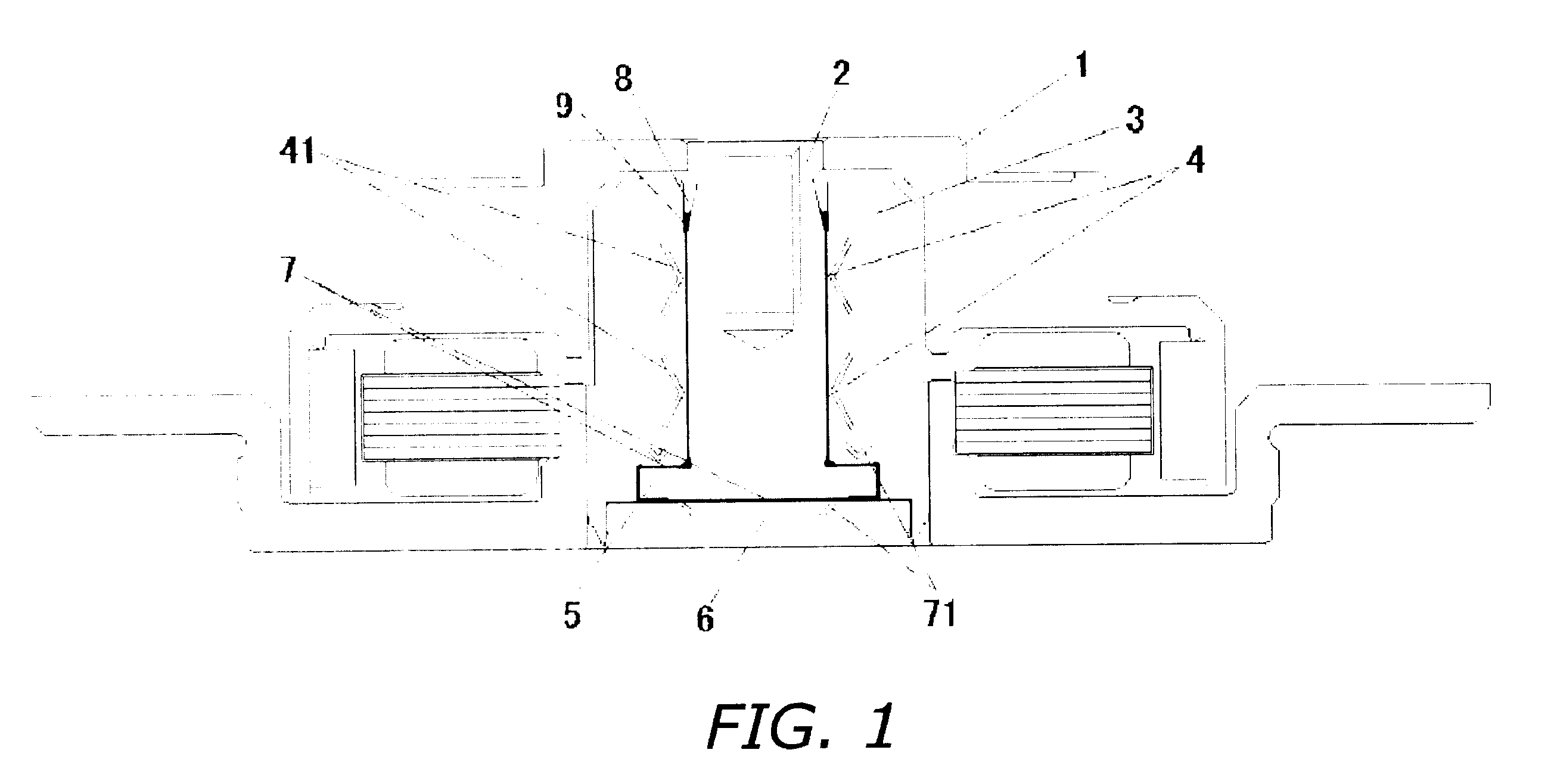

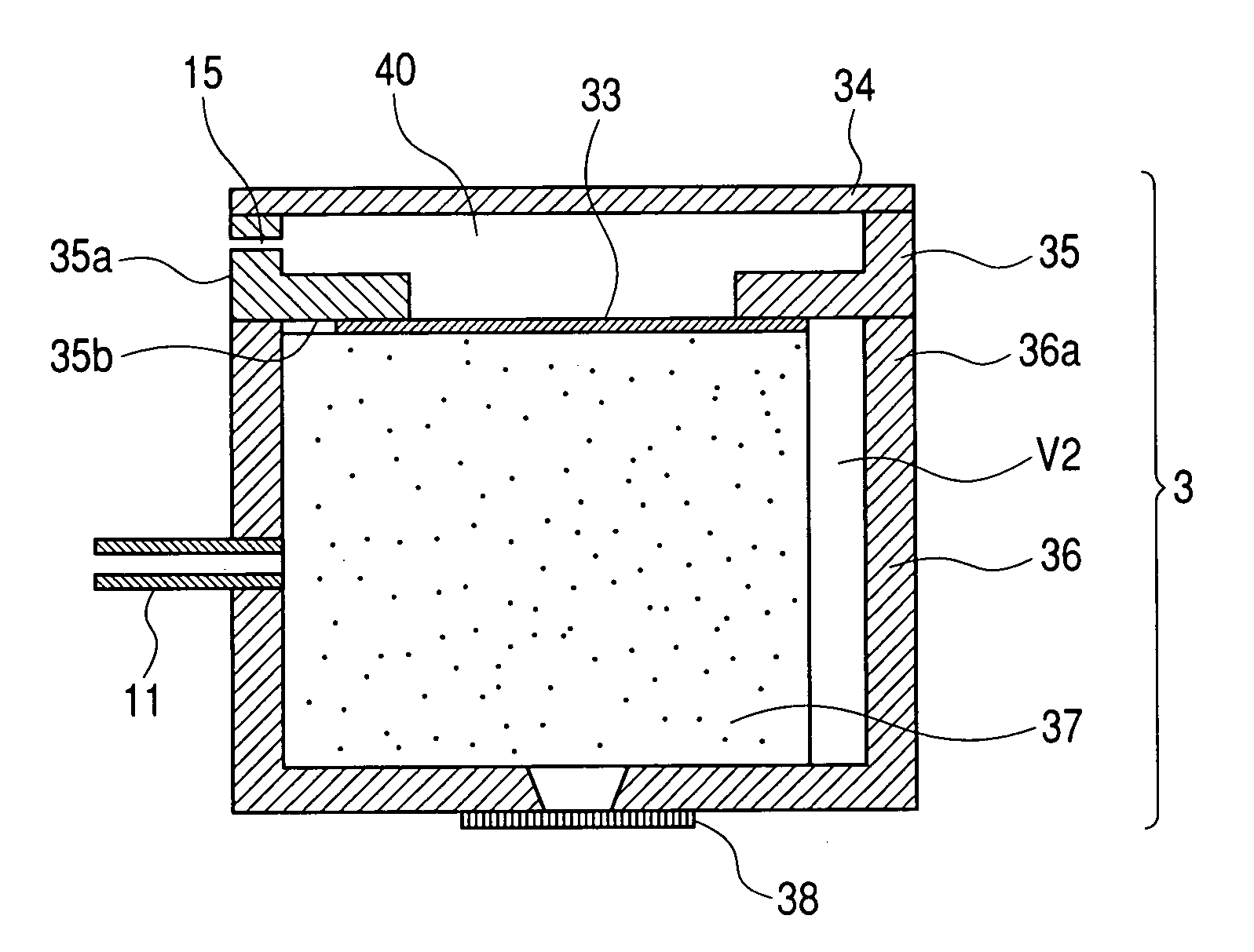

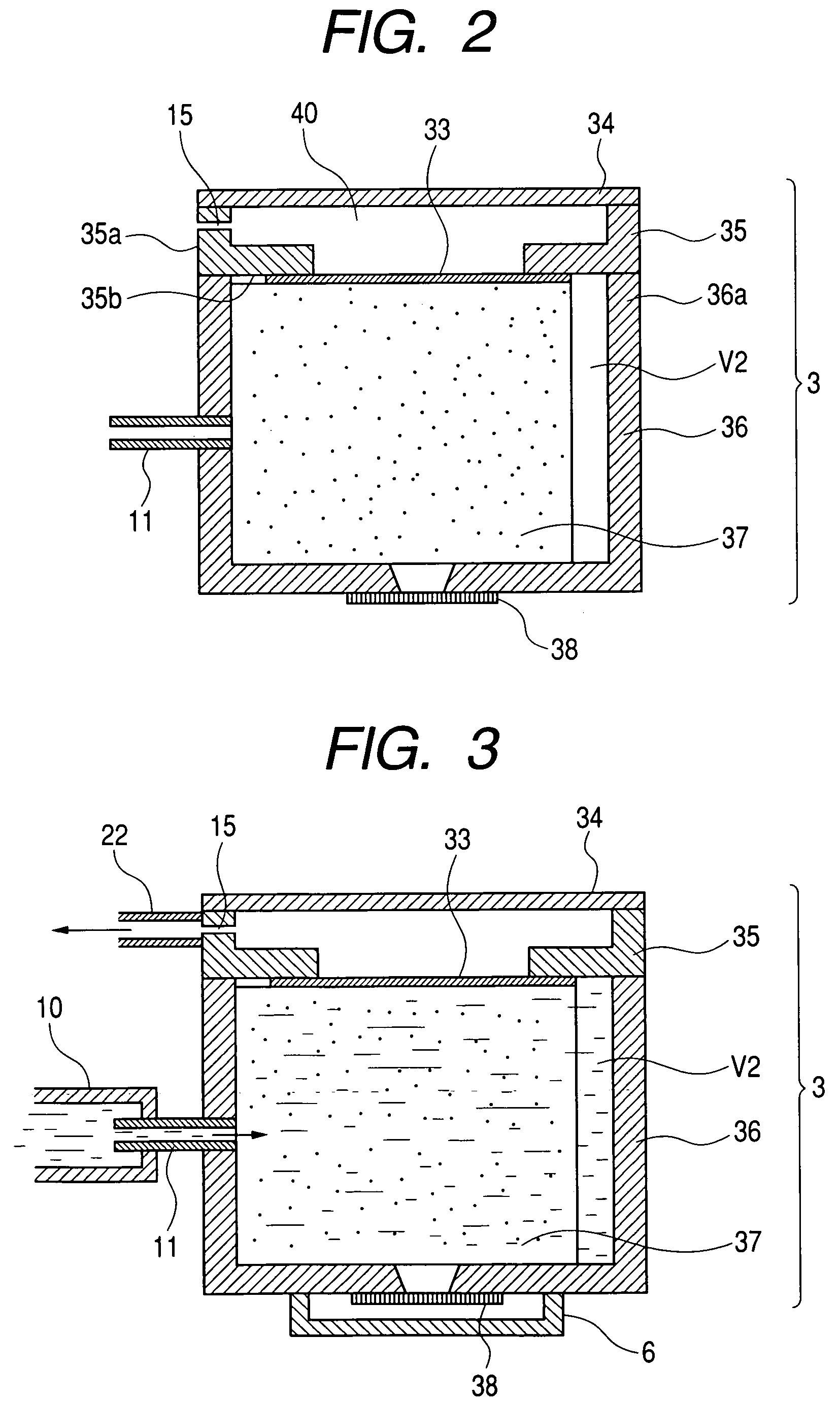

Ink reservoir, ink jet head structure including ink reservoir, and ink jet recording apparatus including ink reservoir

InactiveUS6966641B2Reduce the amount requiredIncrease filling volumePrintingEngineeringElectrical and Electronics engineering

In a sub-tank of an ink jet recording head, an ink absorbing member capable of being impregnated with and holding an ink is arranged and a space V2, which is an area formed by a first wall surface of an ink reservoir and the ink absorbing member and in which the ink absorbing member is not present, is formed. A gas-liquid separation member made of a porous member, transmitting a gas but shutting off a liquid such as the ink is provided in a cap member in which an air hole is formed. A volume of the space V2 and a total volume V2 of an amount of the ink by which the ink is discharged from a discharge port of an ink jet recording element in one recovery operation and an initial pre-discharge amount hold a relationship of 0.7V1≦V2≦V1.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com