Patents

Literature

85results about How to "Large liquid absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production for gel polymer electrolyte

ActiveCN1645662AHigh mechanical strengthImprove electrochemical stabilityOrganic electrolyte cellsSecondary cellsPolymer electrolytesPolymer science

The method includes following step: two monomers are mixed according to the ratio of 1.0 to 1.0-9.0; then it mixes with thermal booster and liquid lithium ion battery solution to form the fore body of gel polymer dielectric; the fore body is injected into half finished battery. the half finished battery is vacuumized and sealed; the half finished battery is made thermal polymerization reaction, and the gel polymer dielectric is obtained.

Owner:SHENZHEN CAPCHEM TECH

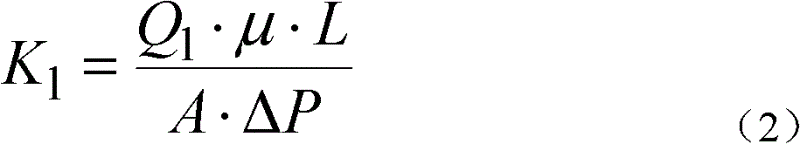

Polymer flooding alternating injection method of heterogeneous oil reservoir

InactiveCN102619492AOil displacement effect is goodReduce dosageFluid removalDrilling compositionSaline waterPolymer science

The invention relates to a polymer flooding alternating injection method of a heterogeneous oil reservoir, which comprises the step of alternatively injecting high-viscosity slug and low-viscosity slug into the heterogeneous oil reservoir, wherein the step of alternating injection is carried out at least for one time. The high-viscosity slug and the low-viscosity slug are solutions provided with different concentrations and obtained by mixing polymers with different molecular weights and saline water. By means of the polymer flooding alternating injection method, the polymer flooding operation in an alternating injection method can inhibit profile reverse rotation, increase liquid absorption amount of a low-permeability layer, control low-efficiency and ineffective circulation, effectively utilize the reserve volume of the low-permeability layer, improve the yield rate and reduce polymer using amount.

Owner:PETROCHINA CO LTD +1

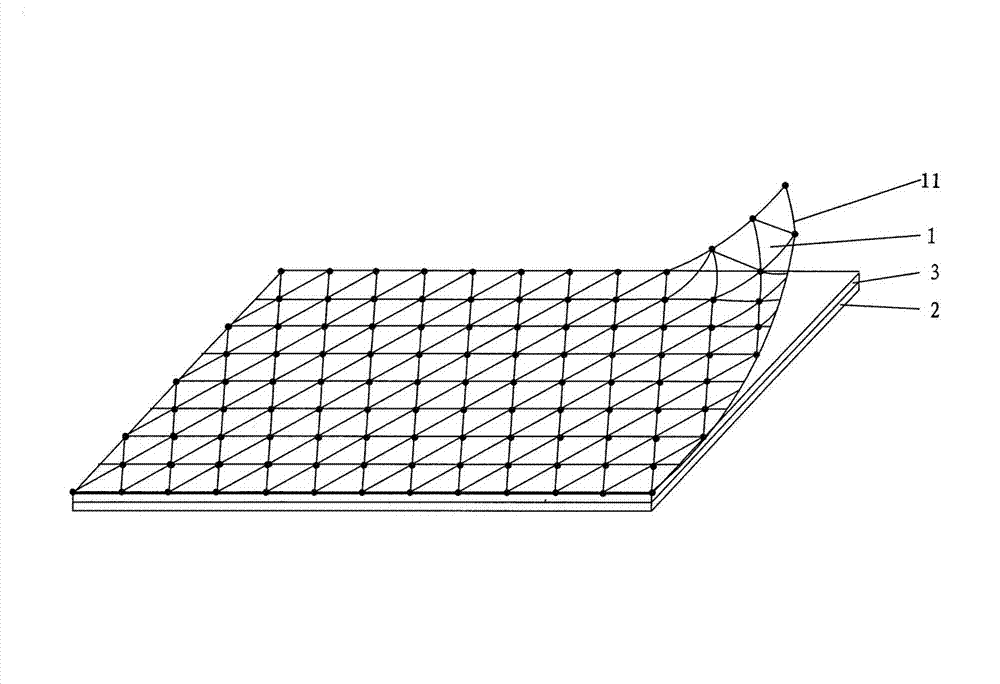

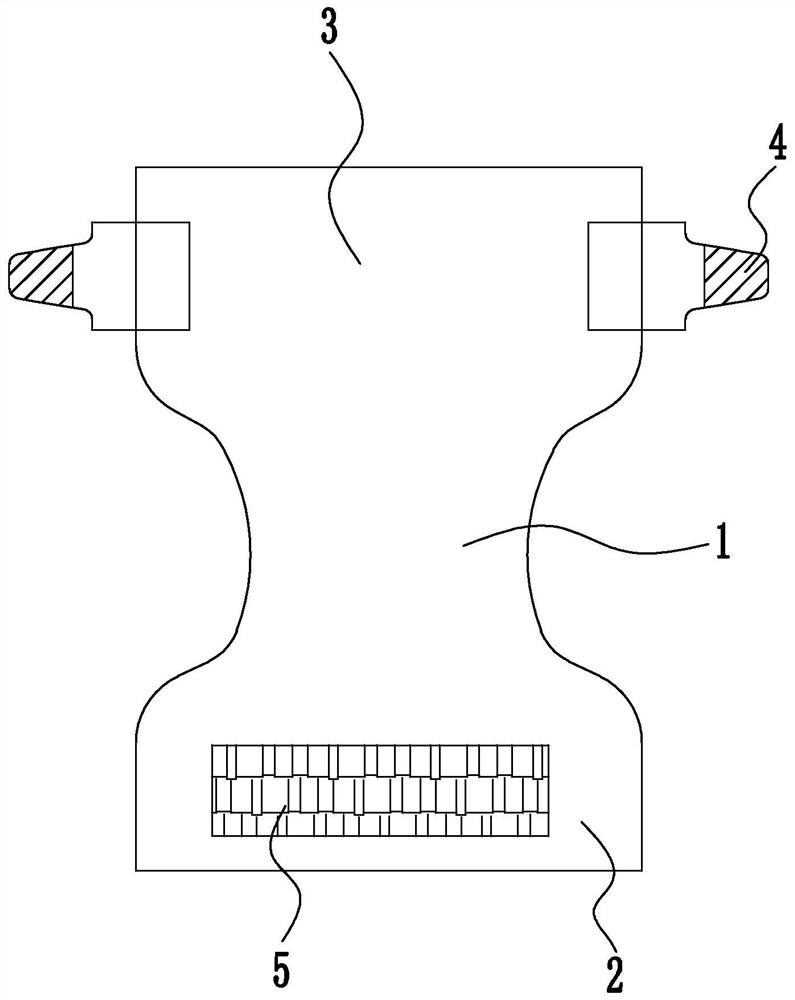

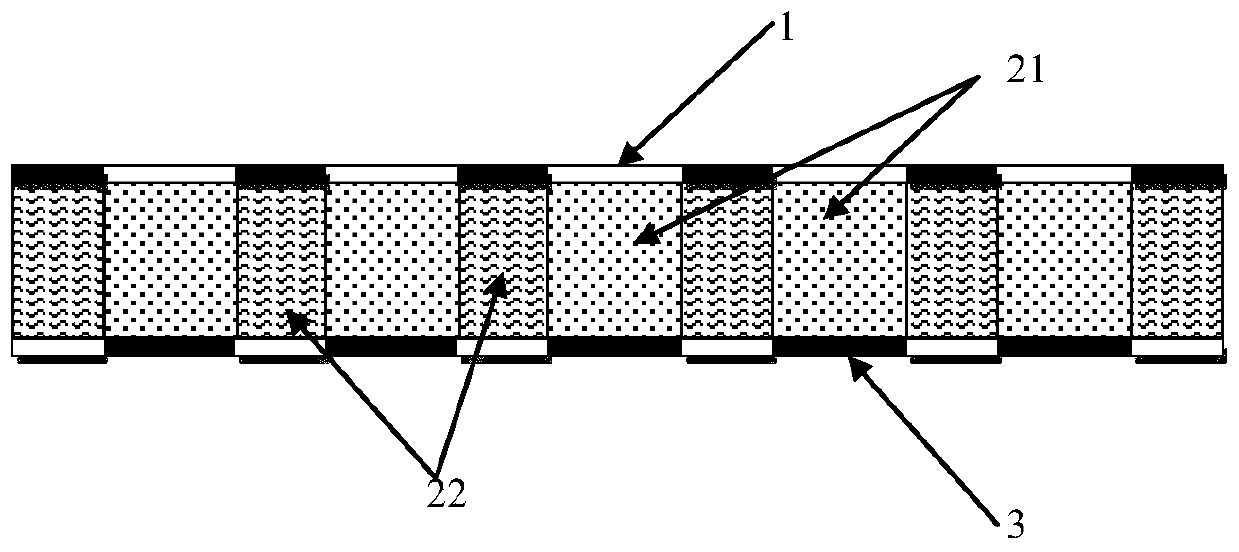

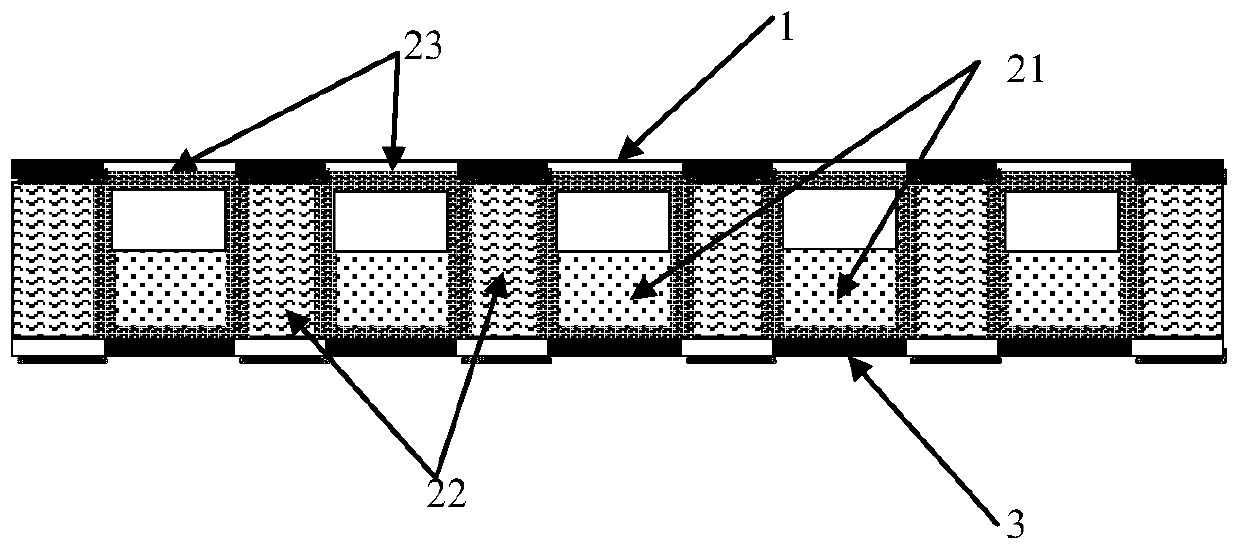

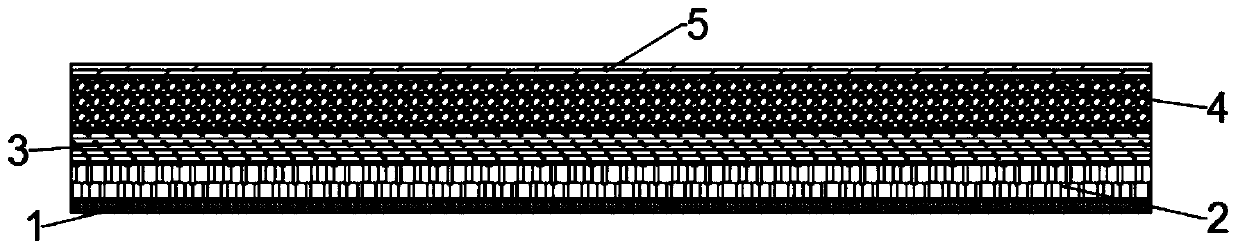

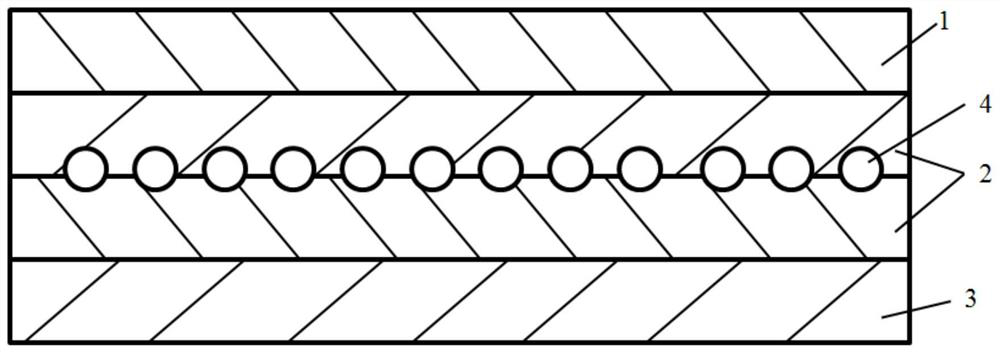

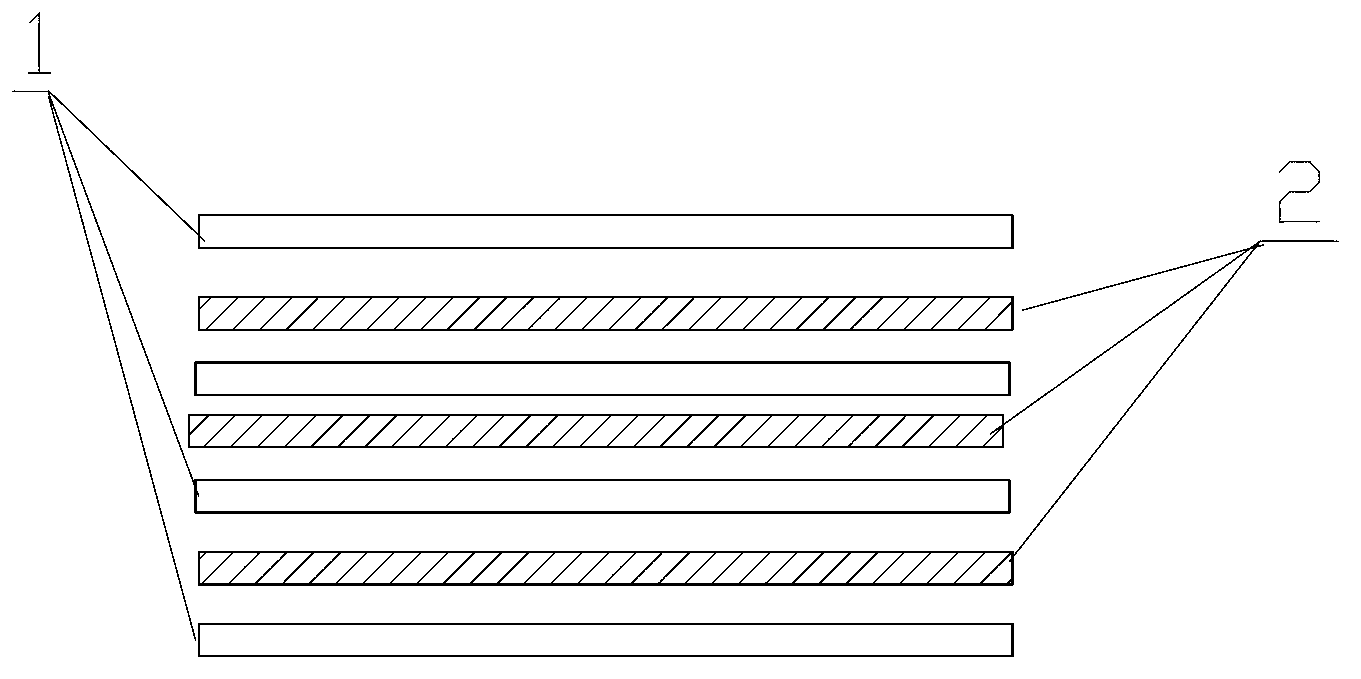

Composite absorption core

ActiveCN104367418ALarge liquid absorptionIncrease filling volumeAbsorbent padsSurface layerEngineering

The invention provides a composite absorption core comprising a surface layer, a bottom layer and a middle absorption layer. The middle absorption layer is arranged between the surface layer and the bottom layer, and is provided with a plurality of vertical through holes. The vertical through holes are filled with macromolecular water-absorbent resin. The composite absorption core has the advantages that the through holes are formed in the middle absorption layer and are filled with the macromolecular water-absorbent resin, filling quantity of the macromolecular water-absorbent resin is increased, and accordingly, liquid absorption quantity of the composite absorption core can be increased.

Owner:俊富新材料有限公司

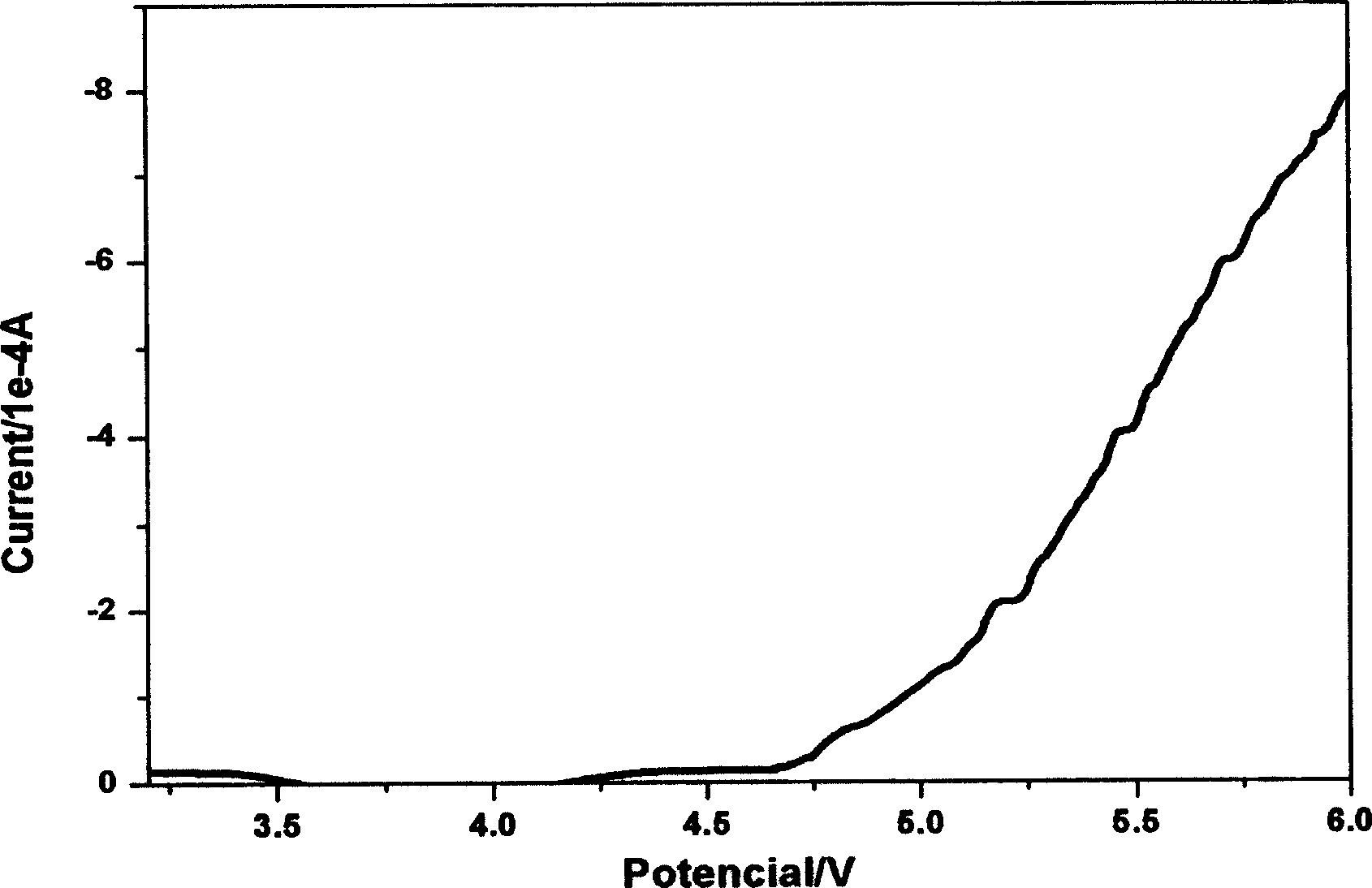

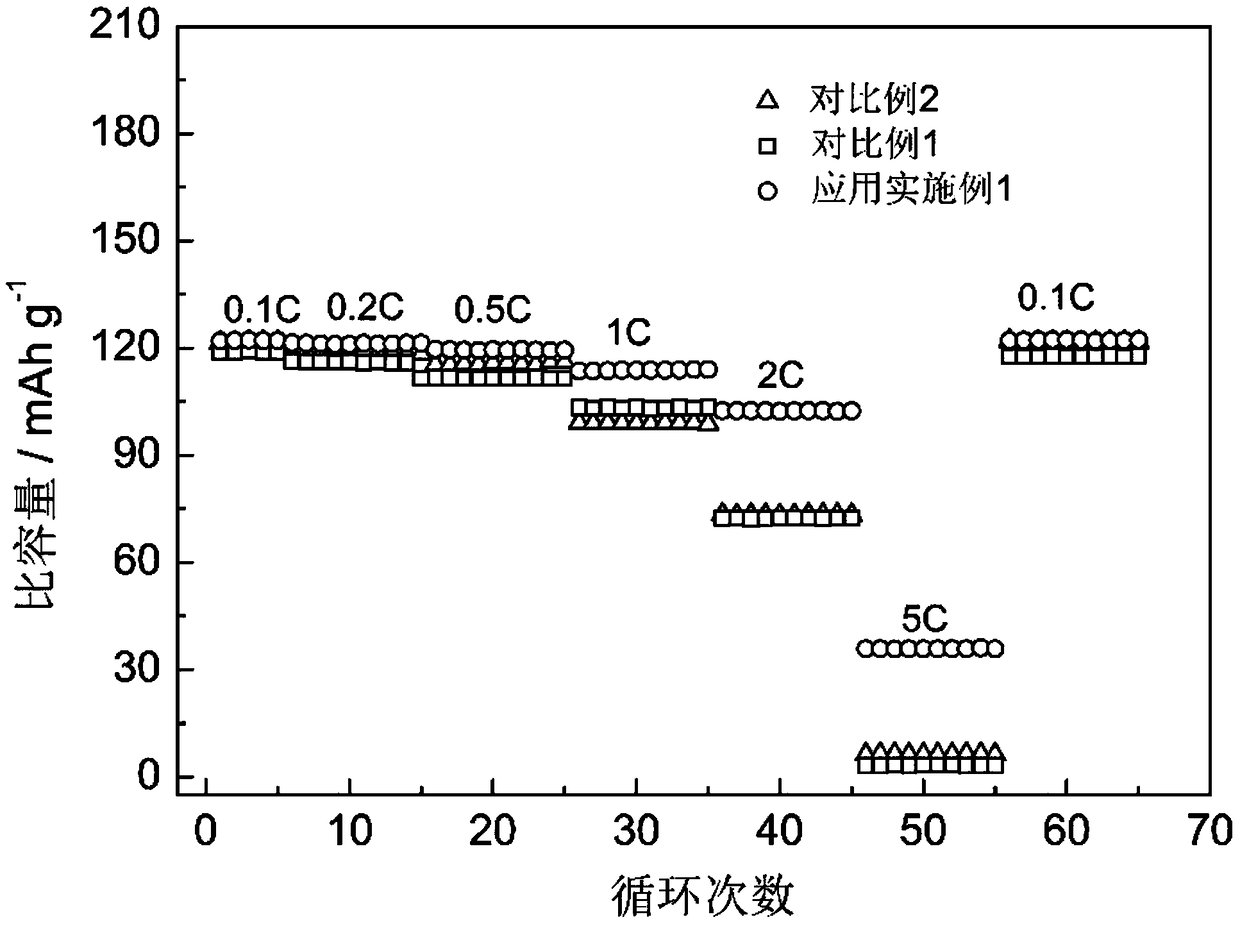

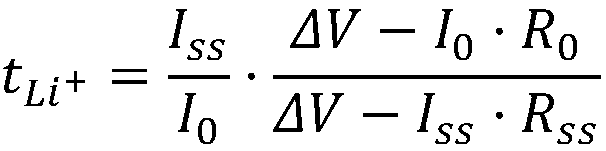

Modified SiO2 nanoparticle, preparation method thereof, nanofiber membrane containing same, gel electrolyte and lithium metal battery

ActiveCN108281705AIncrease the number of transfersIncrease migration resistanceLi-accumulatorsFiberHigh rate

The invention provides a modified SiO2 nanoparticle, a preparation method thereof, a nanofiber membrane containing the modified SiO2 nanoparticle, a gel electrolyte and a lithium metal battery. The modified SiO2 nanoparticle comprises an SiO2 nanoparticle and a specific ionic liquid grafted on the SiO2 nanoparticle. The nanofiber membrane is composed of a vinylidene fluoride-hexafluoropropylene copolymer and fiber consisting of the modified SiO2 nanoparticle. The gel electrolyte comprises the nanofiber membrane and a plasticizer adsorbed inside the nanofiber membrane. An electrolyte of the lithium metal battery is the gel electrolyte. According to the modified SiO2 nanoparticle provided by the invention, the mutual effect of the nanofiber membrane and the plasticizer can be strengthened, the transference number of Li+ is increased, the modified SiO2 nanoparticle is matched with the structure of the nanofiber membrane, and the ionic conductivity and specific capacity of the gel electrolyte and the cycling stability under high rate can be further improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

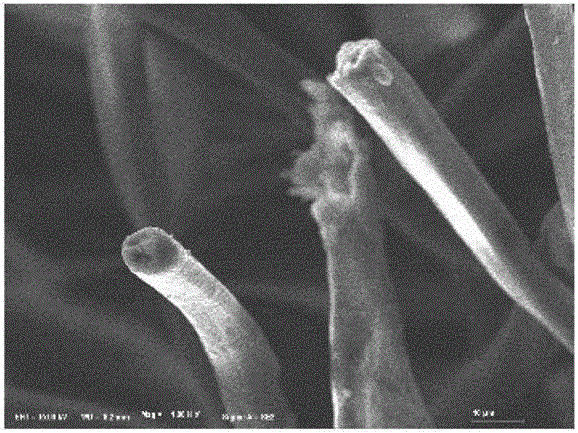

Preparation method of silk fibroin-poly(hydroxybutyrate-hydroxyvalerate) composite fiber membrane

InactiveCN102102278AGood biocompatibilityGood mechanical propertiesFilament/thread formingConjugated cellulose/protein artificial filamentsPorosityFiber

The invention discloses a preparation method of a silk fibroin-poly(hydroxybutyrate-hydroxyvalerate) composite fiber membrane, which comprises the steps of: mixing a prepared silk fibroin solution with a poly(hydroxybutyrate-hydroxyvalerate) solution to prepare a spinning solution, and conducting electrostatic spinning and aftertreatment. Based on the electrostatic spinning method, the composite fiber membrane is prepared, and the fiber membrane has good biocompatibility of the silk fibroin and the excellent mechanical performance of the poly(hydroxybutyrate-hydroxyvalerate) simultaneously, is more applicable to the biomedical field, and is expected to be used as a material for engineering of skin, nerves and cartilaginous tissues. The prepared composite fiber membrane has higher porosity, good mechanical performance, good air permeability and moisture permeability and large liquid absorption amount, can be degraded in human body and can promote tissue repair; and the preparation method has simple process.

Owner:ZHEJIANG SCI-TECH UNIV

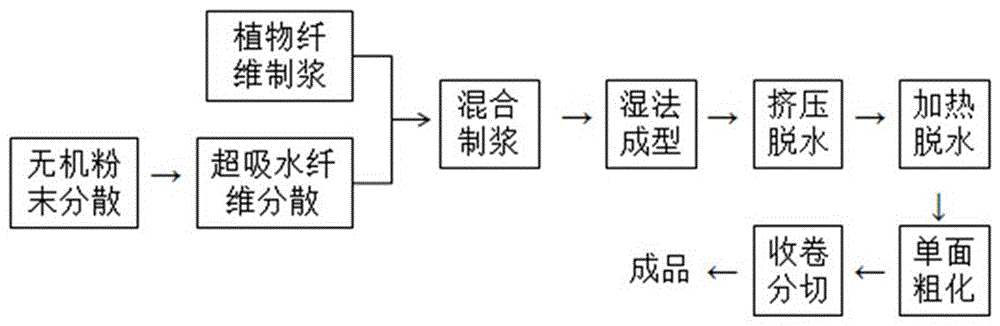

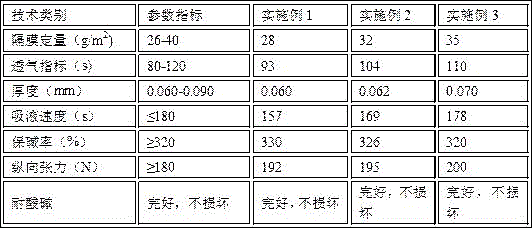

Battery, capacitor diaphragm and preparation method of battery and capacitor diaphragm

InactiveCN105870383ASoft natureImprove toughnessHybrid capacitor separatorsCell component detailsCapacitancePorosity

The invention relates to a battery, a capacitor diaphragm and a preparation method of the battery and the capacitor diaphragm. The diaphragm is prepared from, by weight, 65% to 75% of sulfite wood pulp, 10% to 20% of superabsorbent fibers (SAF), 5% to 30% of attapulgite mineral powder, 0.3% to 0.8% of chitosan, 3% of synthetic fibers and 1.2% to 1.7% of hydrogen storage material ZnO2. The preparation method of the battery and the capacitor diaphragm comprises the step that the finished product is prepared through the steps of plant fiber pulping, inorganic powder dispersing, superabsorbent fiber dispersing, mixed pulping, wet forming, extruding dehydration, heating dehydration, single-face coarsening, rolling and splitting and the like. The defects that in the existing process and technology, the aperture and porosity of a super capacitor diaphragm of a battery are hard to control, the electrolyte retention rate is low, proton passing resistance is large, the gluing process is hard to control, and single-face coarsening of the diaphragm cannot be achieved are overcome, and according to the battery, the capacitor diaphragm and the preparation method of the battery and the capacitor diaphragm, the liquid retention rate is high, gas permeability is good, the physical property is high, internal resistance is low, and the process and technology are more advanced.

Owner:王温珏

Manufacturing method of composite medical non-woven fabric absorbent pads

The invention relates to a manufacturing method of composite medical non-woven fabric absorbent pads and belongs to the field of preparation of medical dressing. The manufacturing method includes steps of feeding medical non-toxic polyethylene particles into a screw extruder to fuse and extrude, forming a film through curtain coating, rolling to form anti-adhesive holes, cooling and winding to obtain a medical non-toxic polyethylene film used as an anti-adhesive layer; subjecting blended fibers blended by viscose fibers and high-absorbent fibers to opening by an opener, carding by a carding machine, lapping by a lapping machine and needling by a needle machine, and obtaining non-woven fabric used as a liquid absorbent layer; feeding polyurethane particles into the screw extruder to fuse and extrude, and forming a film by curtain coating, cooling and winding to obtain a polyurethane film used as a waterproof breathable layer; subjecting the anti-adhesive layer and one surface of the liquid absorbent layer to thermal compositing, and subjecting the waterproof breathable layer and the other surface of the liquid absorbent layer to thermal compositing to obtain a composite medical non-woven fabric absorbent pad. The manufacturing method of the composite medical non-woven fabric absorbent pads has the advantages that liquid absorbent quantity is high, leakage to the outside is prevented, contact area of the skin can be remarkably decreased, handling time of medical staff can be shortened, and technical steps are few.

Owner:SUZHOU EMY MEDICAL SUPPLIES

Medical hemostatic sponge for anesthesiology department and preparation method of medical hemostatic sponge

The invention provides medical hemostatic sponge for the anesthesiology department and a preparation method of the medical hemostatic sponge. The method comprises the following steps: preparing high-expansion sponge; and carrying out spray drying on the surface of the prepared high-expansion sponge, wherein the raw materials used in the spray comprise the extract of common bletilla pseudobulb, namely, bletilla mannan. For the medical hemostatic sponge for the anesthesiology department provided by the invention, the extract of common bletilla pseudobulb, namely, the bletilla mannan layer is sprayed to the surface of the high-expansion sponge, so that the sponge prepared by adopting the preparation method disclosed by the invention has large liquid absorption amount, and causes no allergy phenomenon to a patient.

Owner:吴桂生

Method for preparing clean fabrics

InactiveCN101914832ALarge liquid absorptionImprove adsorption capacityWeft knittingLayered productsAbsorption capacityCotton cloth

The invention discloses a method for preparing clean fabrics, which comprises the following steps of: (1) weaving polyester filament yarns serving as ground yarns and poly / nylon filament yarns or polypropylene filament yarns serving as terry yarns into cylindrical grey cloth, wherein the grey cloth consists of base cloth and terry on the single side of the base cloth, and the height of the terry is 0.3 to 0.6cm; (2) opening the grey cloth in an overflow dyeing machine, soaking the grey cloth in an opening washing bath at a bath ratio of 1:70-80 at the temperature of between 70 and 100 DEG C and at normal pressure for 30 to 60 minutes, and drying and sizing the opened grey cloth to form cylindrical smooth grey cloth, wherein the opening washing bath is alkali liquor with the pH value of 13-15; and (3) cutting and sewing the cylindrical smooth grey cloth obtained by the step (2) to obtain the clean fabrics. Compared with the cotton cloth used by soft capsule or pill manufacturers at present, the clean fabrics have the advantages of no hair slip, durability and high liquid absorption capacity.

Owner:QINGDAO UNIV

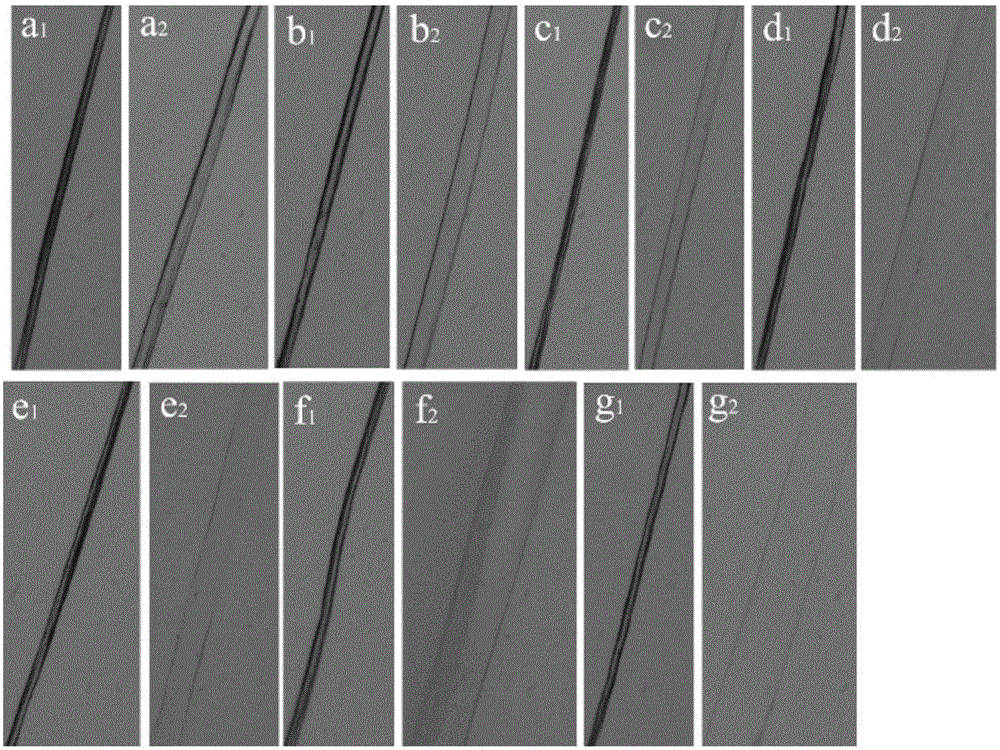

Liquid absorption fiber

The invention aims to provide a liquid absorption fiber. The fiber comprises a polymer represented by the following structural form shown in the description, wherein R is at least one selected from a group consisting of -NH2, -OCH2CH2OH, -OCH2CH2CH2OH, -OH, -ONa, -OK and -OCa; m, n and p respectively represent the quantity percentages of corresponding repeating units in a polymer molecule, and meet the following relational expression: m+n+p=1, p / (m+n+p)=0.05 to 0.30; when the degree of substitution D is defined to be m / (m+n+p): the total degree of substitution of the fiber Ds is 0.09 to 0.8, and the value of the degree of substitution Do of the polymer at the center point of the cross section of the fiber / the degree of substitution Dx of the polymer on the edge of the cross section of the fiber is 0 to 0.98. By the use of a simple process, the antibacterial performance, the liquid absorption property and the like of the fiber are improved by controlling the proportions of the repeating units with different substituent groups in the polymer contained in the fiber and enabling the degree of substitution of the outer side (edge) of the fiber to be greater than that of the inside (center) of the fiber; the fiber suitable for clinical application, particularly applicable in the aspects such as hemostasis, burns and chronic wound treatment, is provided.

Owner:JIANGSU NEWVALUE MEDICAL PROD CO LTD +1

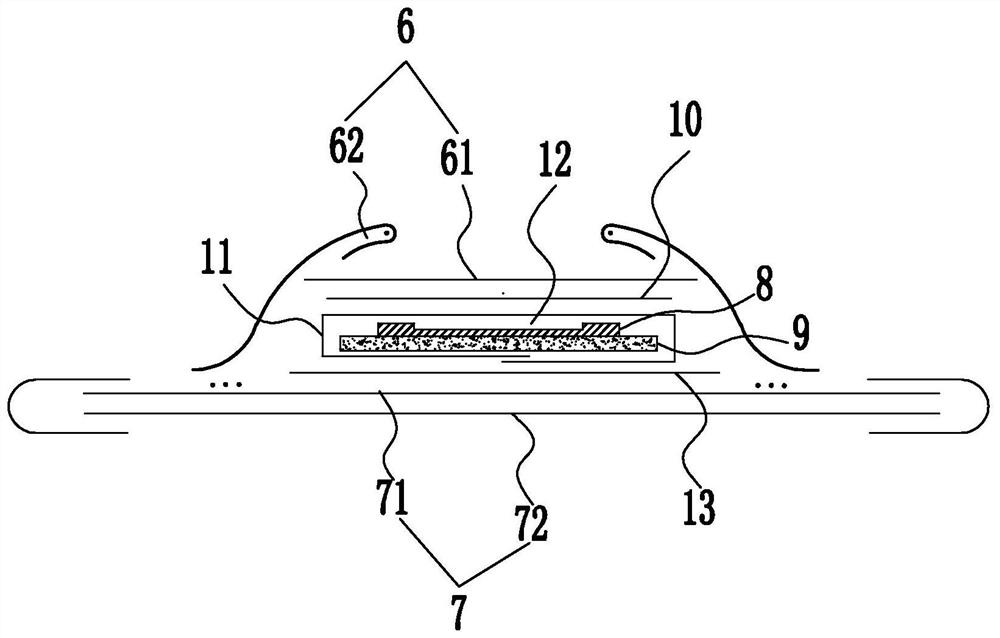

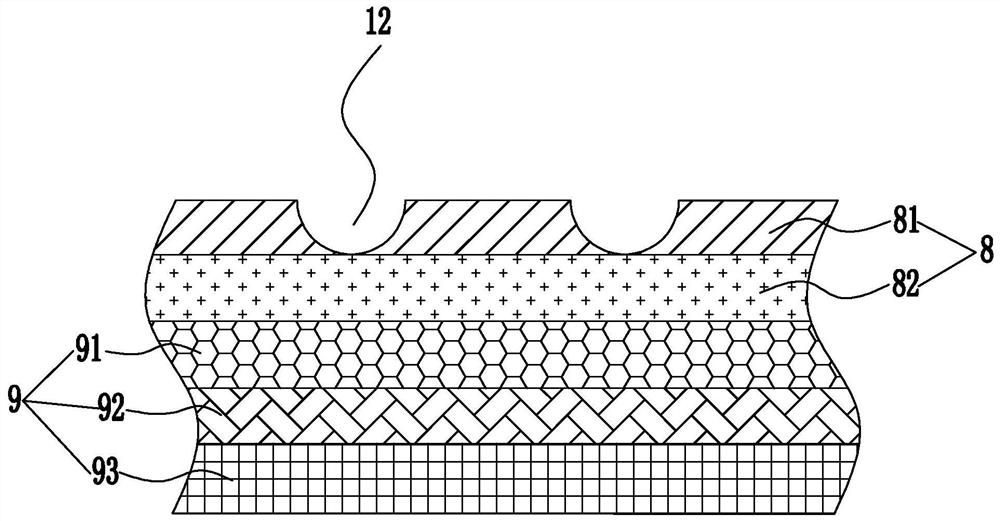

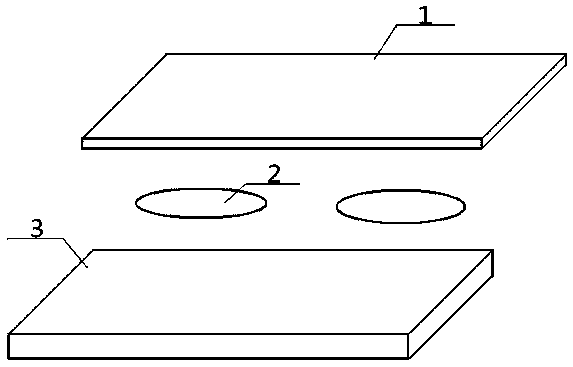

Degradable baby paper diaper

PendingCN112155858AImprove water absorptionPoor water absorptionAbsorbent padsBandagesPolymer scienceNonwoven fabric

The invention relates to the technical field of disposable hygienic products, and provides a degradable baby paper diaper which comprises a paper diaper, the paper diaper comprises a liquid permeablesurface layer, an acquisition layer, an absorption layer and a waterproof bottom layer which are sequentially stacked from top to bottom, the liquid permeable surface layer is composed of polylactic acid non-woven fabric and hydrophobic non-woven fabric, and the absorption layer is composed of polylactic acid non-woven fabric and hydrophobic non-woven fabric. The absorption layer is composed of anabsorption core and a wrapping layer, the absorption core comprises an upper absorption core and a lower absorption core, and the upper absorption core comprises a first macromolecule resin layer anda first fluffy non-woven fabric layer. The lower absorption core is composed of a second fluffy non-woven fabric, a second macromolecule resin layer and a third fluffy non-woven fabric layer which are sequentially stacked from top to bottom, and the waterproof bottom layer is composed of a degradable casting film and a hydrophobic non-woven fabric arranged at the bottom of the degradable castingfilm. The paper diaper solves the problems that paper diapers of the prior art are difficult to be degraded after being used, and affects the health of the ecological environment, and has the advantages of large absorbing capacity and rapid absorbing speed.

Owner:ZHONGTIAN CHINA IND

Wound treatment material

The invention discloses a wound treatment material which comprises a fiber. The wound treatment material is characterized in that the fiber comprises a polymer shown as the following structural formula (please see the formula in the description), wherein R is at least one selected from a group composed of -NH2, -OCH2CH2OH, -OCH2CH2CH2OH, -OH, -ONa, -OK and -OCa, m, n and p represent the quantity percentages of corresponding repetitive units in a polymer molecule respectively and meet the following relational expressions that m+n+p=1 and p / (m+n+p)=0.05-0.30, the substitution degree D is defined to be equal to m / (m+n+p), the overall substitution degree of the fiber is defined as Ds, the substitution degree of the polymer at the center point of the cross section of the fiber is defined as Do, the substitution degree of the polymer at the edge of the cross section of the fiber is defined as Dx, and Ds, Do and Dx meet the following relational expressions that Ds=0.09-0.8 and Do / Dx=0-0.7.

Owner:JIANGSU NEWVALUE MEDICAL PROD CO LTD +1

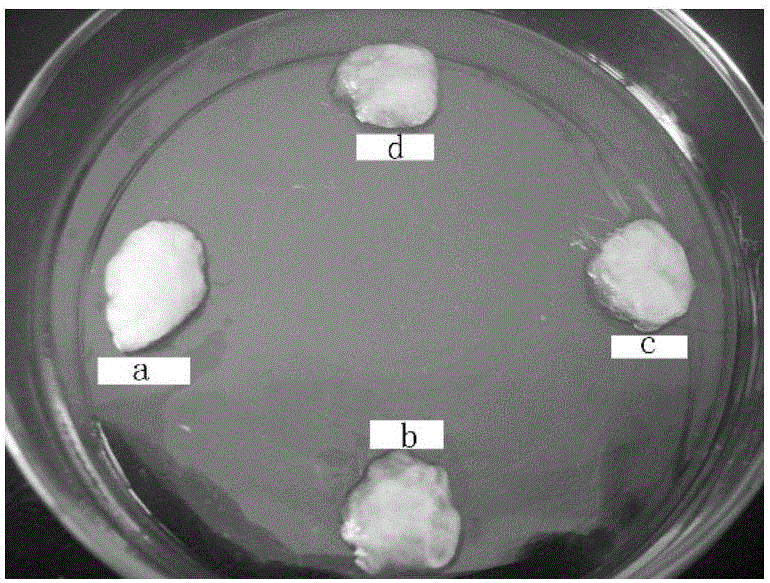

Chitose nanometer ultrafine fibre film material and its preparation method

InactiveCN1238061CLarge liquid absorptionImprove cell affinityProsthesisTissue repairPolyethylene oxide

A nanometer superfine chitosan fibrous membrane material and its preparation process are disclosed. It belongs to tissue repair material technology. The film material with the diameter being 10 mu m-50 mu m, is made by chitosan with mass percent of 10-90% and polyvinyl alcohol or polyethylene oxide superfine fiber with diameter of 50nm -500nm The preparation process is: dissolving chitosan to acetic acid solution, adding PVA pr PEO into the solution, the mass ratio of chitosan with PVA / PEO being 10 / 90-90 / 10, injecting the prepared 4%-8% spinning solution to the electrostatic spinning device for spinning to film material, therein, voltage being 5kV-30kV, liquid inventory being 0.1mL / h-0.5mL / h, receiving range being 5cm-25cm. The advantages of the invention: large volume absorbing ability, favorable cell affinity, capable of degrading in vivo and promoting defect tissue repairing when the film material is utilized as artificial skin or artificial cartilage. In addition, the preparation process is simple.

Owner:TIANJIN UNIV

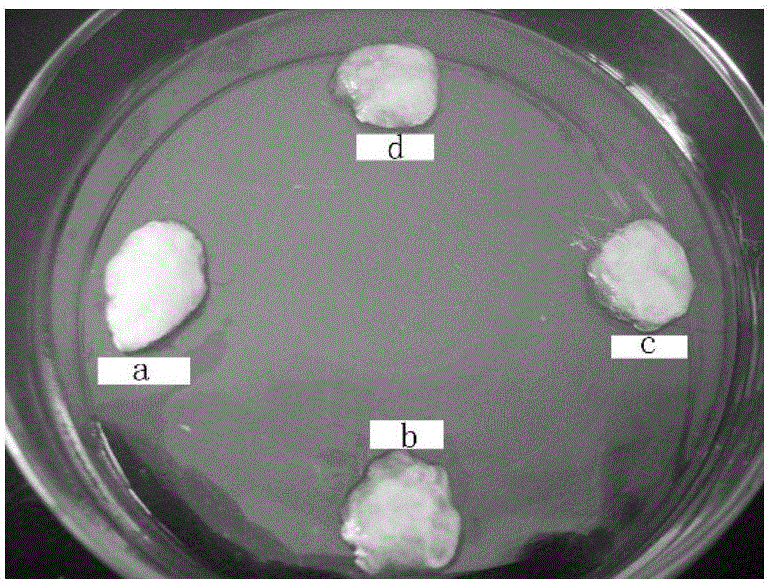

Preparation method of high-expansion liquid absorption sponge

InactiveCN102585273AUniform pore structureSoft textureAbsorbent padsBandagesForeign matterPolyvinyl alcohol

The invention relates to a preparation method of a high-expansion liquid absorption sponge, which belongs to the field of preparation of biomedical materials. The preparation method comprises the following steps of: mixing two polyvinyl formal reaction solutions with different degrees of reaction, then reacting continuously and performing pouring, curing, demolding, cleaning and other steps for getting a final product. According to the preparation method disclosed by the invention, polyvinyl formal with higher depth of pre-reaction is utilized for making a hole-forming core so as to prepare a sponge material, and the material has the characteristics of regular hole structure, no residue of foreign matters, soft texture, immediate expansion when the material meets with water and the like, and is suitable for surgical hematophagia, liquid absorption and other purposes in the medical field.

Owner:NANCHANG UNIV

Konjac glucomannan fiber wet tissue and method for preparing same

InactiveCN103407205AImprove water holding capacityStrong water absorptionPaper/cardboard articlesPolymer sciencePlant fibre

The invention relates to a konjac glucomannan fiber wet tissue and a method for preparing the konjac glucomannan fiber wet tissue. The method for preparing the konjac glucomannan fiber wet tissue comprises the preparation of konjac glucomannan acrylic ester, acrylic ester esterification modification, the preparation of konjac glucomannan spinning solution and the preparation of the konjac glucomannan fiber wet tissue. The konjac glucomannan fiber wet tissue is made of natural fibers like konjac glucomannan and corn starch and other plasticizers, wherein the natural fibers are used as main raw materials of the konjac glucomannan fiber wet tissue. The konjac glucomannan is a natural plant polysaccharide, has good water binding capacity, hydroscopicity and antibacterial property and is large in tension strength, good in toughness, and high in tensile strength and bursting strength. Compared with a traditional synthetic fiber wet tissue, the konjac glucomannan fiber wet tissue is made of 100% natural plant fibers, has the advantages of being high in tensile strength, large in liquid absorbing amount, high in liquid maintaining amount, exquisite and soft in hand feeling, sterile, sanitary, low in production cost and free of environmental pollution and doing no harm to human bodies, and accords with modern consumption concepts and market requirements.

Owner:FUJIAN AGRI & FORESTRY UNIV

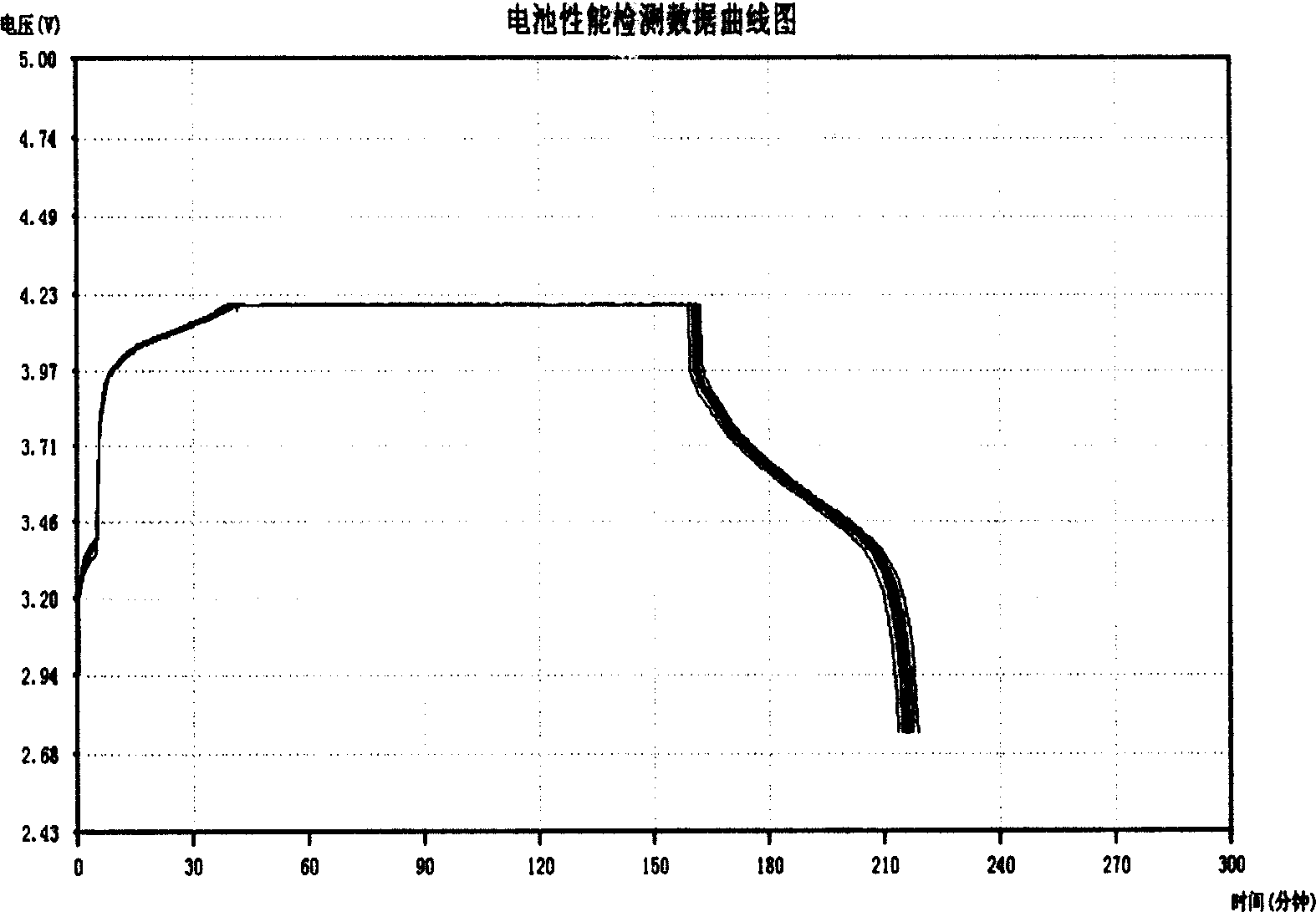

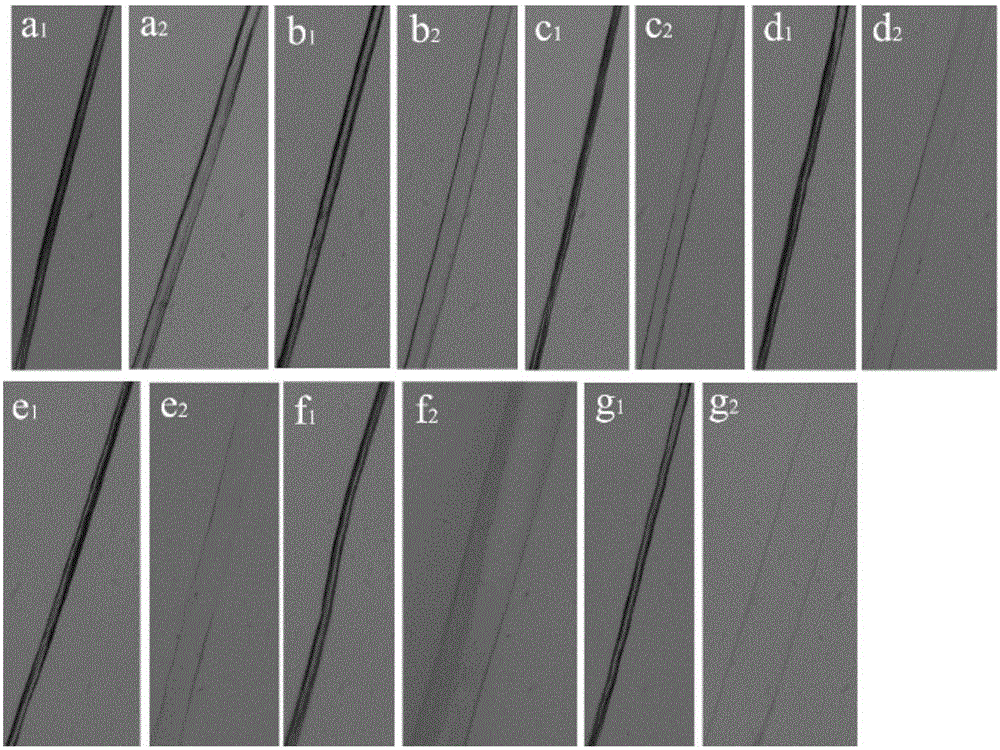

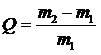

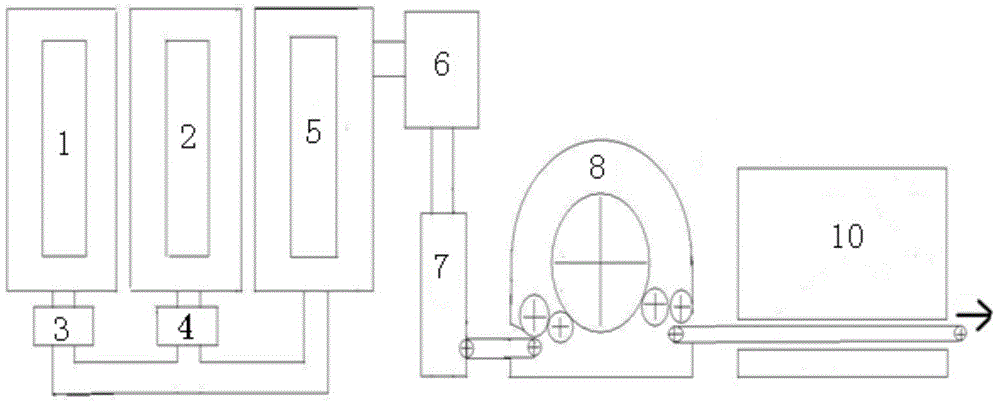

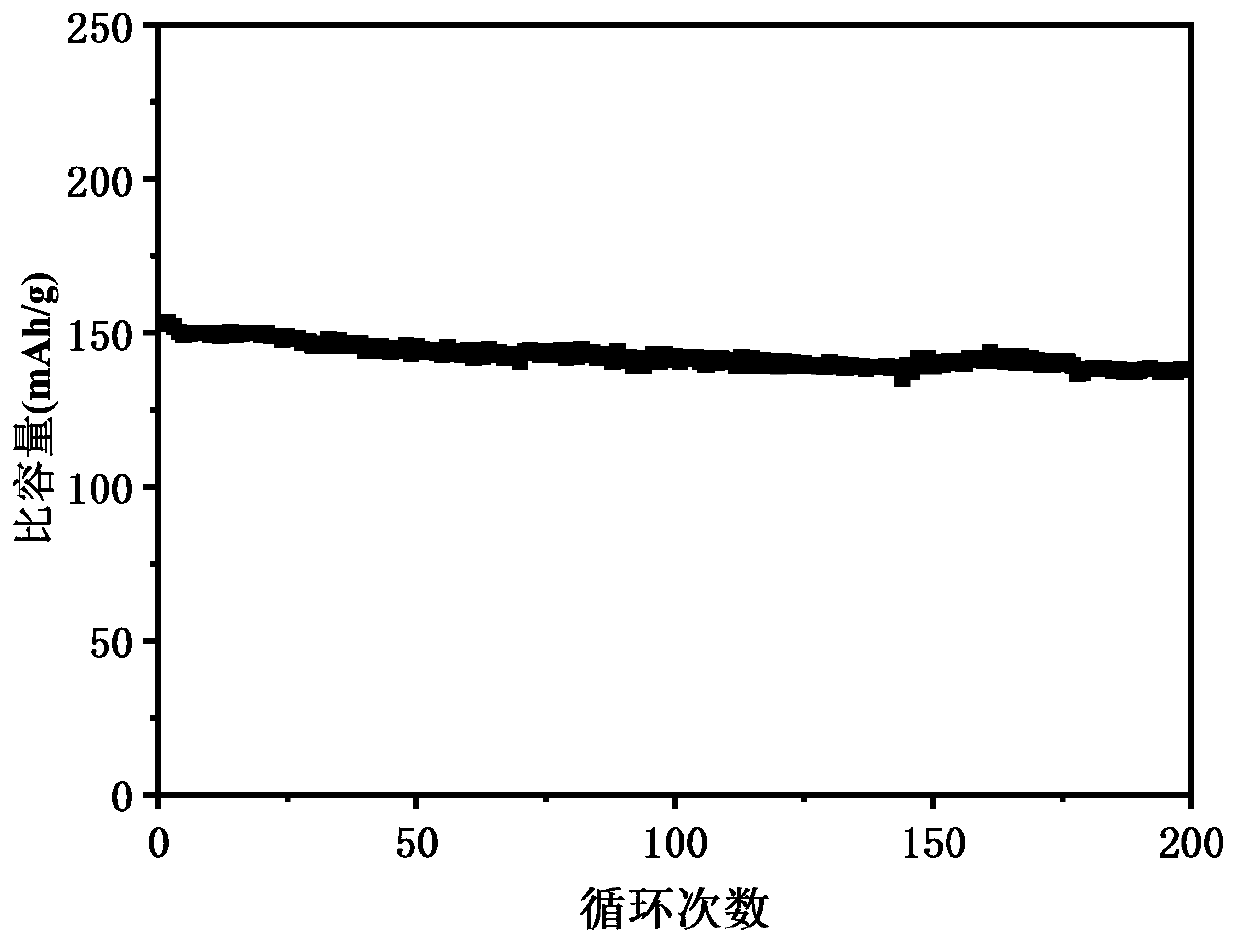

Hierarchical porous pole piece and preparation method and application thereof

ActiveCN111490225AIncrease liquid absorptionImprove electrochemical performanceElectrode thermal treatmentSecondary cellsButton batteryElectrical battery

The invention discloses a hierarchical porous pole piece and a preparation method thereof. Grading coating and pore forming agent addition are utilized to perform grading regulation and control on thepore structure of the pole piece, thereby enhancing the liquid absorption capacity of the pole piece, ensuring the maximization of the active substances, and ensuring the energy density of the battery on the basis of enhancing the electrochemical properties of the pole piece. The pole piece and a lithium piece are assembled into a button cell, it is proved that the material shows excellent electrochemical performance, the electrode polarization can be effectively reduced, and the energy density and the cycling stability of the cell are improved.

Owner:CENT SOUTH UNIV

Graphene absorbing object and preparation method thereof

InactiveCN106890354AIncrease surface areaReduce contentAbsorbent padsBaby linensSurface layerFluff pulp

The invention relates to the field of sanitation supplies, and provides a graphene absorbing object and a preparation method thereof with an aim to solve problems about poor liquid absorption effect, slow liquid absorption speed and no antibacterial efficacy in the prior art. The graphene absorbing object comprises a permeable surface layer, an absorber and an impermeable bottom layer which are laminated sequentially from top to bottom, the absorber is formed by wrapping an absorbing core with non-woven fabric, and the absorbing core is formed by mixing fluff pulp, super absorbent polymer and graphene powder.

Owner:泉州信和石墨烯研究院有限公司

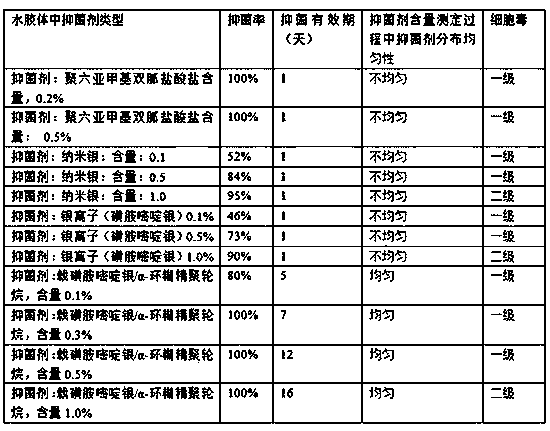

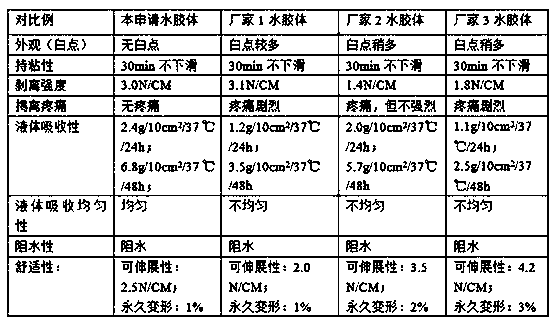

Silver-containing medical hydrocolloid dressing and preparation method thereof

ActiveCN109395155AOvercome stabilityOvercome bacteriostasisAbsorbent padsMicrocapsulesPolyrotaxaneIrritation

The invention belongs to the technical field of medical and sanitary auxiliary materials and particularly relates to a silver-containing medical hydrocolloid dressing and a preparation method thereof.The hydrocolloid dressing includes CMC / PEG / PAA particles, thermoplastic rubber, liquid paraffin, tackifying resin, a plasticizer, alpha-cyclodextrin polyrotaxane / silver sulfadiazine serving as an antibacterial agent and the like. In general, by optimizing and adjusting relevant components, the hydrocolloid dressing which is safe, free of irritation, uniform in liquid absorption, excellent in antibacterial performance and lasting in antibacterial effect is prepared, and the antibacterial agent is uniformly dispersed. The dressing is great in waterproof and antibacterial performance and capableof absorbing a large amount of exudate and toxic substances of a wound and maintaining a wet healing environment for the wound for a long time without being bonded to the wound and has other excellent performance. Therefore, the dressing has a high practical value for wound repairing and wound healing.

Owner:HENAN HUIBO MEDICAL CO LTD

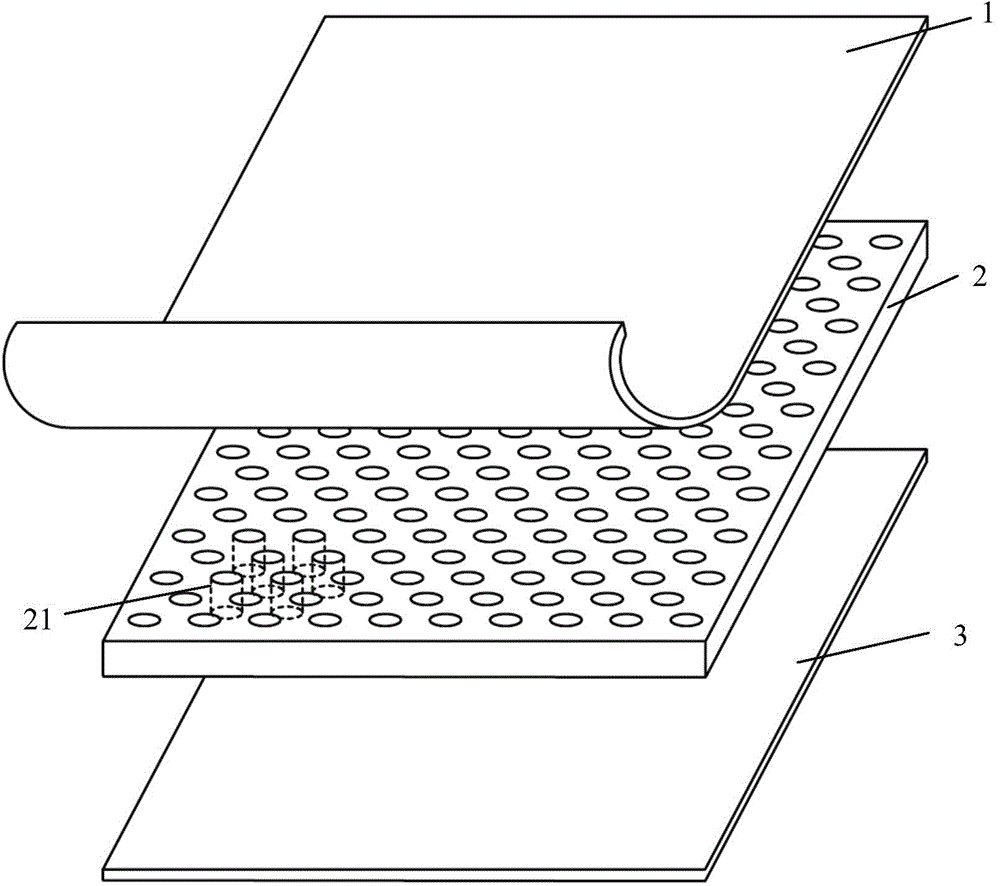

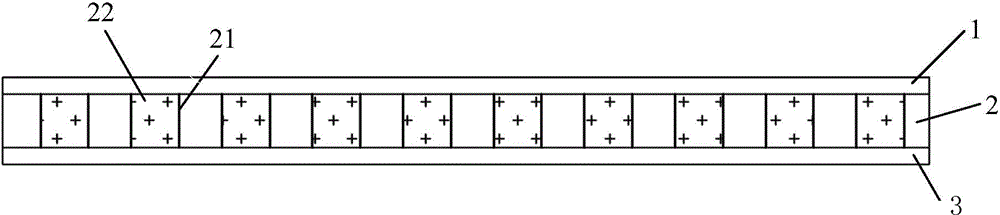

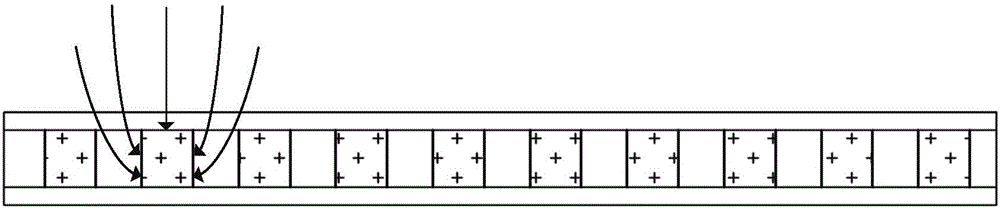

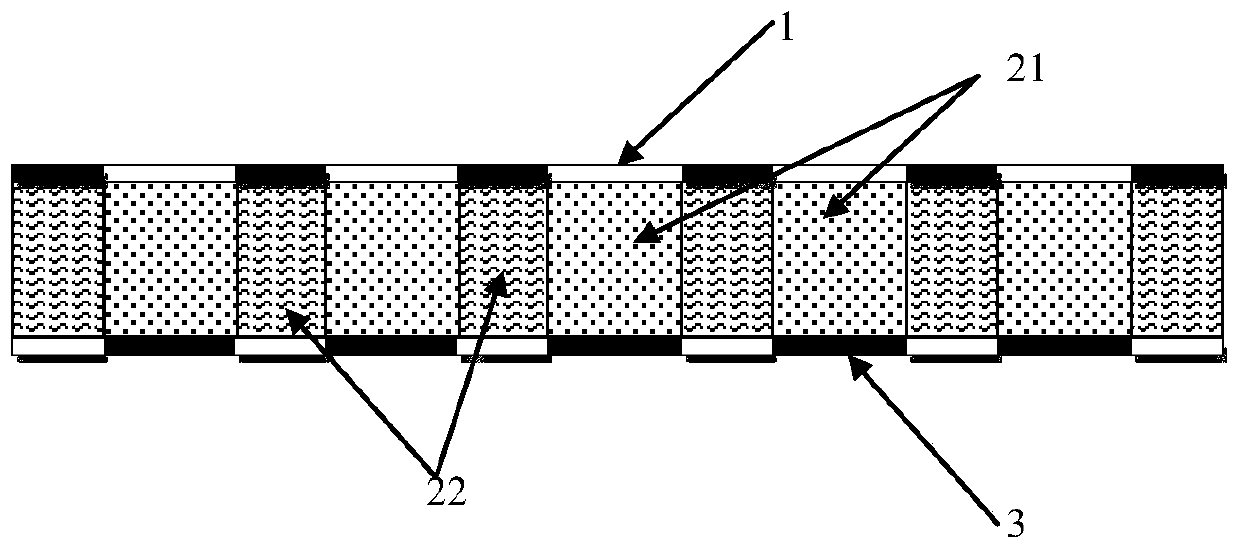

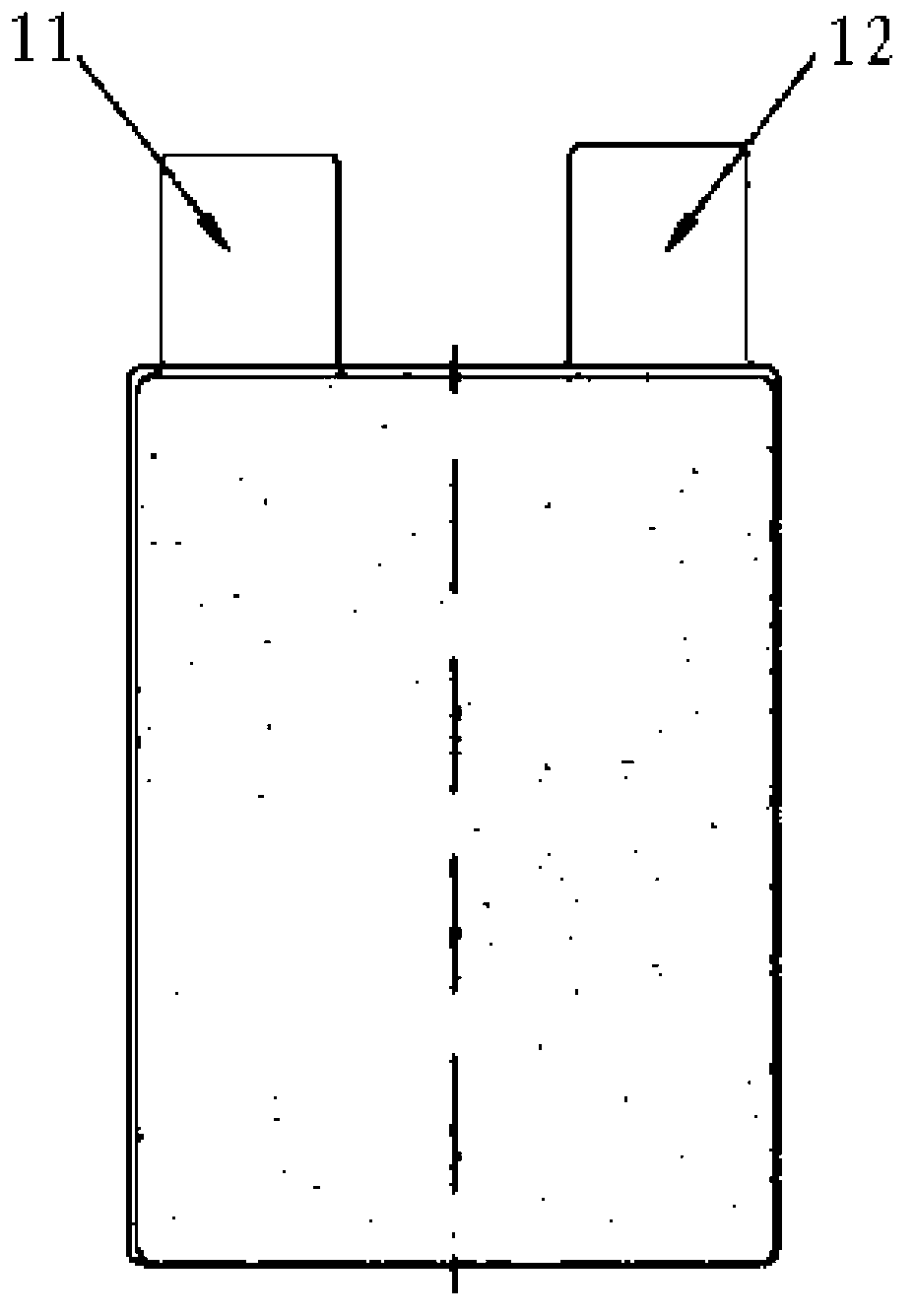

Absorption core and preparation method of absorption core

ActiveCN110801349AReduce areaGuaranteed infiltrationAbsorbent padsBaby linensPhysical chemistryReverse osmosis

The invention discloses an absorption core and a preparation method of the absorption core. The absorption core comprises an upper layer spunbond nonwoven, a lower layer spunlace nonwoven and an absorption layer arranged between the two layers of the nonwovens, wherein the absorption layer consists of a high-water-absorption resin column and a super water absorbent fiber column which are arrangedalternatively; the part corresponding to the high-water-absorption resin column, on the upper layer nonwoven is a water repellency treatment column, and the part corresponding to the super water absorbent fiber column is the hydrophilic treatment column; and on the lower layer nonwoven, at least the part corresponding to the high water absorption resin column is a hydrophilic treatment column, andthe part corresponding to the super water absorbent fiber column is the water repellency treatment column. Hydrophilic treatment and water repellency treatment are performed alternatively, liquid infiltration can be guaranteed, the hydrophilic area can be reduced, and reverse osmosis is reduced. Because liquid is uniformly distributed in the absorption core, emergence of local nuggets can be avoided, and high softness can be obtained.

Owner:FUJIAN HENGAN HLDG CO LTD +3

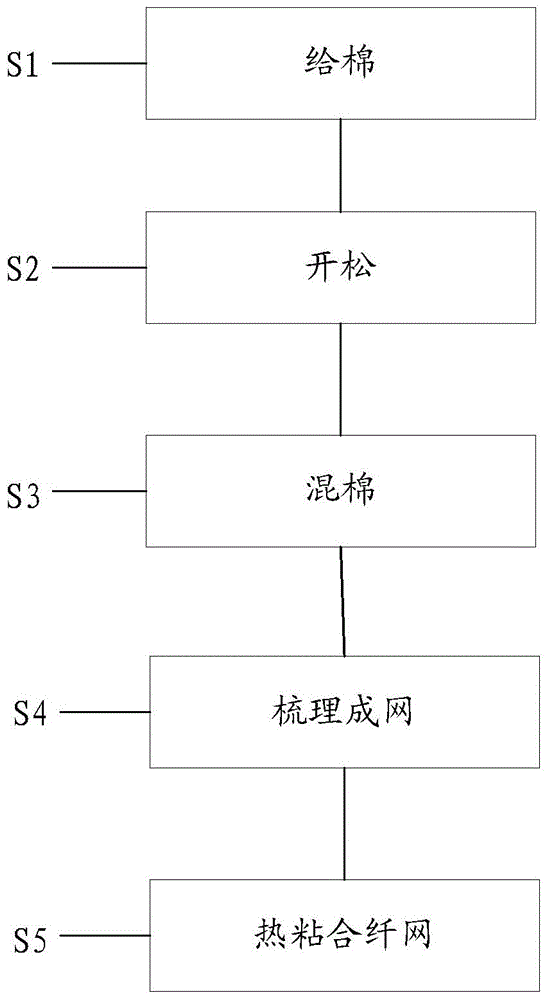

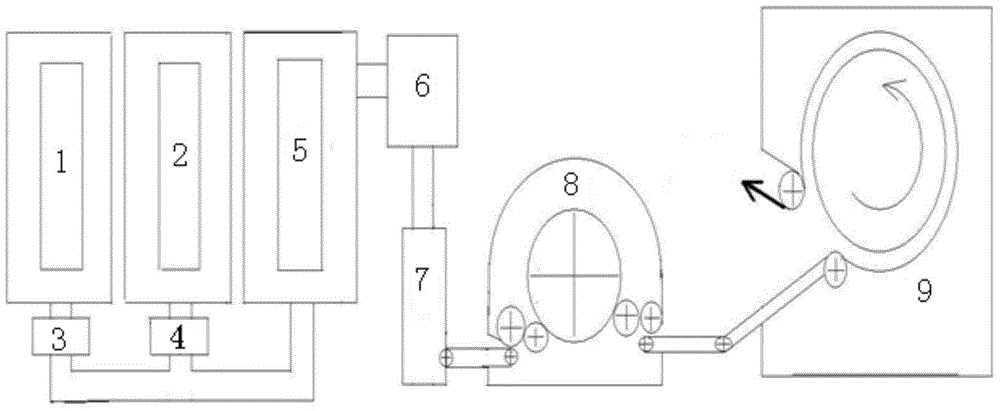

Manufacturing method of basal body bearing super absorbent resin, water absorption core body and disposable sanitary product

InactiveCN104800004APromote environmental protectionDiffusion speed can be controlledSanitary towelsBaby linensGreen environmentFiber

The invention discloses a manufacturing method of basal body bearing super absorbent resin. The method comprises the following steps: supplying cotton: respectively supplying terylene low-melting-point short fiber and terylene short fiber; opening: respectively debonding terylene low-melting-point short fiber and terylene short fiber; mixing cotton: mixing the terylene low-melting-point short fiber and terylene short fiber into the base material, the ratio is 10-90%: 90-10%; combing into web: combing the base material through a combing machine and processing the material into the fibre web; hot sticking the fibre web: transferring the fibre web to a drying machine, adopting hot wind technology for executing hot sticking process on the fibre web for forming the basal body with 100% terylene material. The basal body prepared by the basal body manufacturing method is 100% terylene material, compared with the basal body comprising ES short fiber material, the space of the basal body prepared by the method is big, the super absorbent resin can be evenly distributed on the basal body for forming water absorption core body, thus the liquid through performance of the water absorption core body is improved, the basal body is made of 100% terylene material, so that the basal body can be recycled for 100% and the green environment protection performance is further improved.

Owner:肇庆天富新合纤有限公司

Preparation method for organic/inorganic fiber composite diaphragm

ActiveCN105428573AHigh porosityImprove high temperature resistanceCell component detailsPorosityEmulsion

The invention relates to a preparation method for an organic / inorganic fiber composite diaphragm, and belongs to the technical field of lithium ion battery composite diaphragms. The preparation method comprises the following process steps: (1) acid cleaning: cleaning a sepiolite mineral material of a natural fiber structure with an acid solution, so as to remove soluble impurities and realize bundle separation; (2) ball milling: dispersing the sepiolite mineral material cleaned with the acid solution in an water solution, and carrying out ball milling by a milling ball to prepare a uniformly mixed slurry; (3) dispersion: adding a water-soluble organic emulsion as a bonding agent for uniform dispersion; (4) diaphragm preparation: feeding the slurry into a casting machine, carrying out heating and drying to remove moisture and form a thin film, and conducting rolling, slitting and winding on the thin film by adopting a finishing roll of which the surface is coated with polytetrafluoroethylene, so as to prepare the organic / inorganic fiber composite diaphragm. The preparation method has the advantages of being stable in process, convenient to operate, safe and reliable; the prepared organic / inorganic fiber composite diaphragm is relatively high in porosity, relatively thin, and not only resistant to high temperature but also soft; the preparation method can be widely applied to manufacture of various lithium ion batteries.

Owner:TIANJIN XIANZHONG SCI & TECH

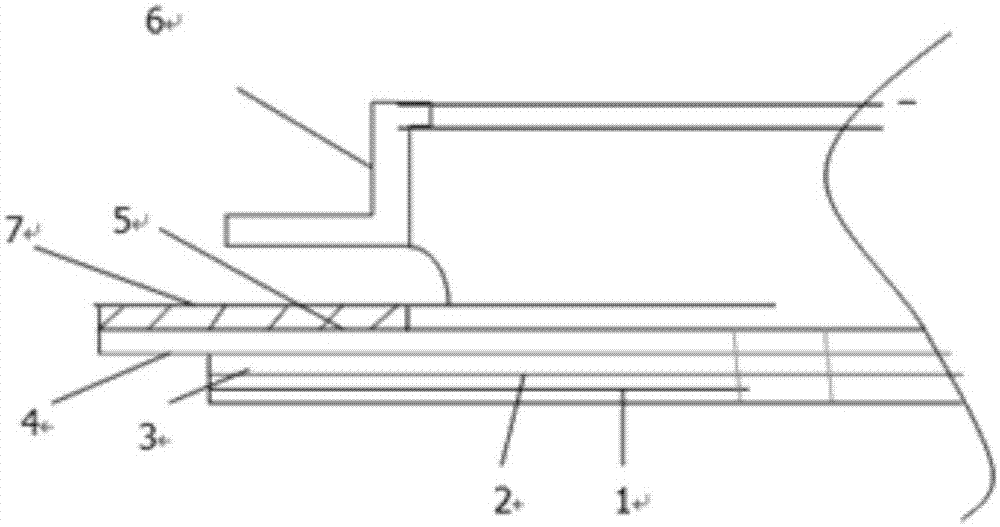

Silica gel application and using method and application thereof

The invention relates to a silica gel application and a using method and application thereof, belongs to the field of medical applications, and particularly relates to a silica gel application and a using method and application thereof. The silica gel application comprises release paper; a wound contact layer, a flow guide layer, a middle water absorption layer and a waterproof protection layer, wherein the wound contact layer is made of silica gel material; the flow guide layer is made of SS non-woven fabrics; the middle water absorption layer is made of a PAS water absorption material; the waterproof layer is made of SMS; and silica gel and the flow guide layer as well as the periphery of the flow guide layer and the periphery of the waterproof layer are bonded together in an ultrasonicheat sealing mode. The silica gel application can be specially used for nursing acute and chronic wounds with moderate to severe exudation. Besides, the silica gel application can be used together with alginate for a cavity hole type wound in the using process, and can be combined with a pressure bandage for pressure therapy for leg ulcer. The silica gel application is rapid in seepage conduction,high in liquid absorption rate, capable of being repeatedly pasted, free of deformation, displacement and falling, transparent, easy to fix and beneficial to wound healing.

Owner:JILIN UNIV +1

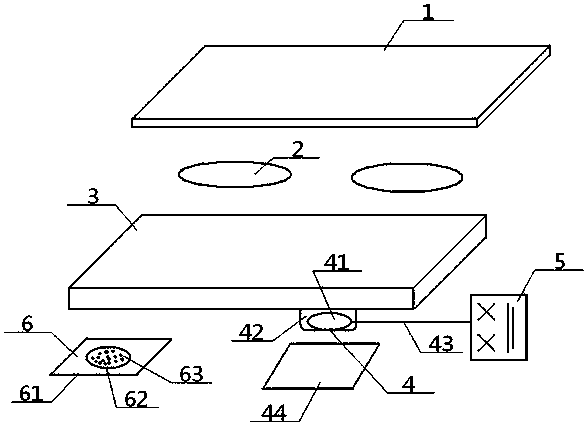

Healing-promoting biologically environmentally-friendly medical dressing and manufacturing method thereof

ActiveCN109512577APromote healingFacilitate spontaneous healingElectrotherapyAdhesive dressingsRare earthMoisture

A healing-promoting biologically environmentally-friendly medical dressing comprises a moisture-absorbing top layer, a magnetic therapy moisture-absorbing layer and a carrier layer, the bottom surfaceof the moisture-absorbing top layer is connected with the top surface of the magnetic therapy moisture-absorbing layer, the bottom surface of the magnetic therapy moisture-absorbing layer is connected with the top surface of the carrier layer, the moisture-absorbing top layer is formed by cutting a chitosan nanofiber membrane, the chitosan nanofiber membrane is manufactured through electrospinning raw materials comprising acetic acid, chitosan and polyoxyethylene, and the magnetic therapy moisture-absorbing layer comprises a magnetic substance and a moisture-absorbing substance which form anintegrated structure, wherein the magnetic substance comprises neodymium-iron-boron-rare earth magnetic powder, and the moisture-absorbing substance comprises silk fibroin, sodium alginate and glycerin. The dressing has the advantages of strong moisture-absorbing effect, magnetic therapy function, facilitation of wound healing, good green and environmentally-friendly property, good sterilization effect, high manufacturing efficiency and low cost.

Owner:WUHAN TEXTILE UNIV

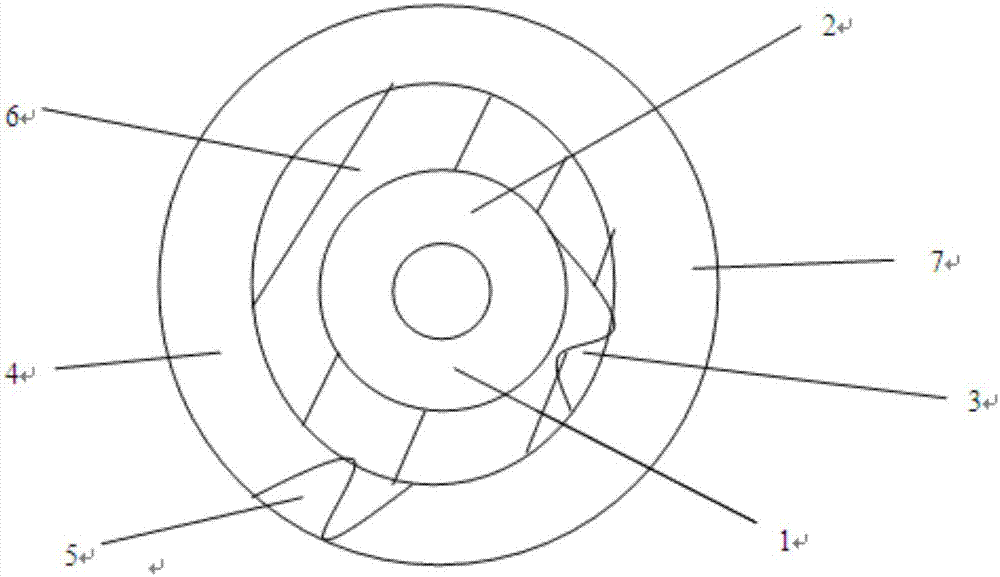

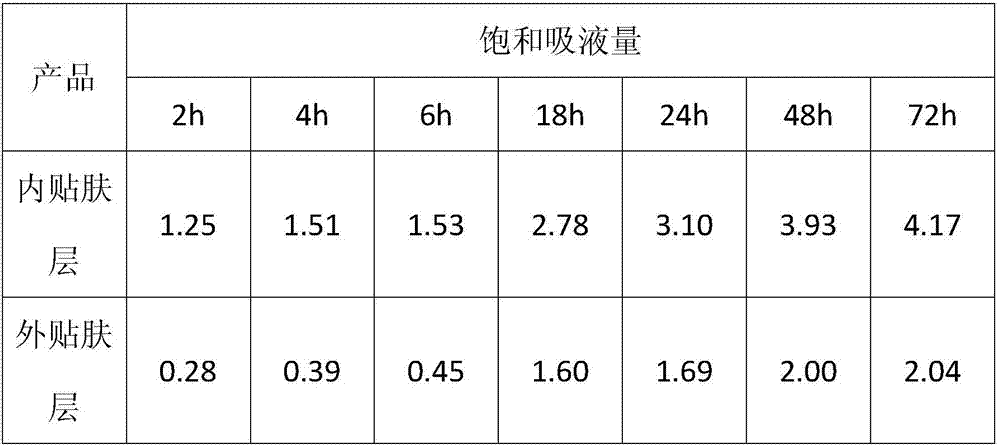

Ostomy base plate with smell removal function and excellent adaptability

InactiveCN107280843AEffective absorptionAvoid damageSurgeryBodily discharge devicesBiochemical engineeringRetaining ring

The invention relates to the technical field of medical instruments, in particular to an ostomy base plate with a smell removal function and excellent adaptability. The ostomy base plate is characterized in that the ostomy base plate is provided with a scale film layer, a release film layer, an internal skin-affinity layer, a release paper layer, an external skin-affinity layer and a lining film layer; the top of the lining film is provided with a retaining ring connected to an ostomy bag; the internal skin-affinity layer is made by medical hydrocolloid with smell removal function and high liquid absorptivity; the area of the external skin-affinity layer is larger than that of the internal skin-affinity layer; and the external skin-affinity layer is made by transparent medical hydrocolloid. The ostomy base plate with a smell removal function and excellent adaptability has the following obvious advantages such as simple and reasonable structure and convenient operation and application.

Owner:WEIHAI JIERUI MEDICAL PRODUCTS CO LTD

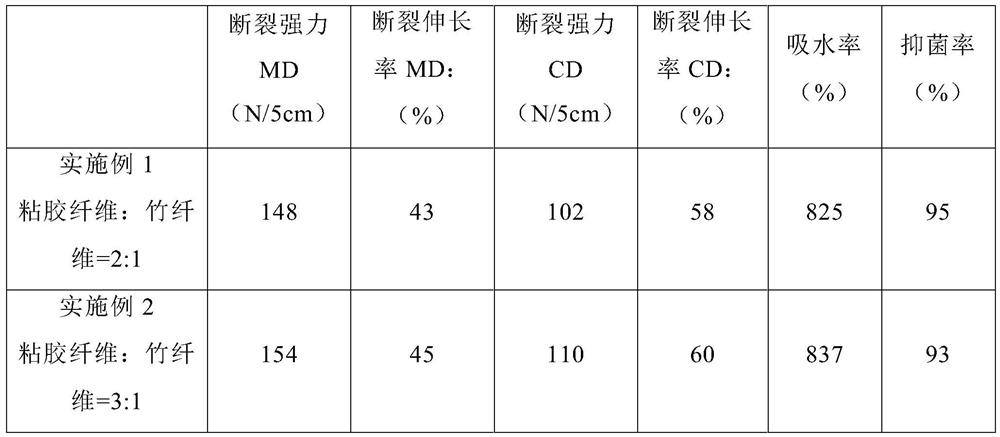

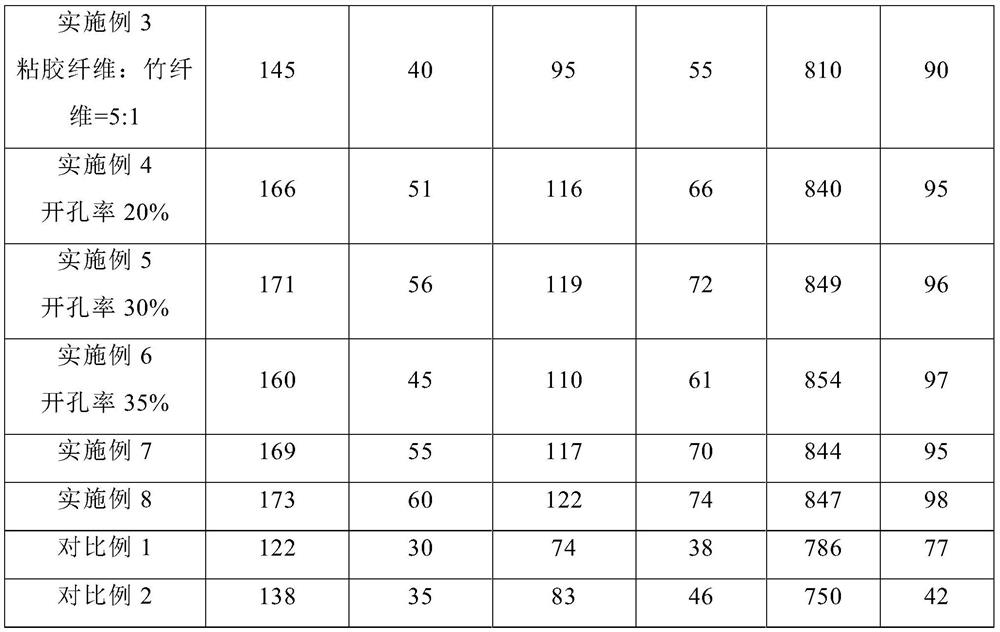

Method for ventilation and antibiotic finishing of viscose non-woven cloth for medical treatment and public health

InactiveCN108951129ALarge liquid absorptionImprove breaking strengthBiochemical fibre treatmentVegetal fibresCarboxylic acidChloroacetic acids

The invention discloses a method for ventilation and antibiotic finishing of viscose non-woven cloth for medical treatment and public health. The method comprises the following steps: dipping a clothsample into a sodium hydroxide solution, adding chloroacetic acid for generating etherification reaction, neutralizing by virtue of an ethanol solution of acetic acid, washing with an ethanol-water mixed solution, and drying; adding a silver nitrate into a protecting agent, namely a beta-cyclodextrin solution in the same volume, dropwise adding a reducing agent, namely a sodium borohydride solution, and magnetically stirring for reaction, so as to obtain a beta-cyclodextrin-nano-silver water solution; adding a cross-linking agent, namely butane tetracarboxylic acid into the obtained beta-cyclodextrin-nano-silver water solution, and uniformly stirring and mixing, so as to obtain antibiotic finishing liquid; and carrying out carboxymethylation on viscose non-woven cloth, dipping the viscosenon-woven cloth into the antibiotic finishing liquid, carrying out pre-baking and baking, washing with hot water, washing with cold water, and finally, drying.

Owner:安徽利通达纤维新材料有限公司

Fresh-keeping pad containing spunlaced composite fiber layers and preparation method thereof

ActiveCN111705421AStrong water absorptionHigh strengthFlexible coversWrappersPolymer scienceNonwoven fabric

The invention relates to a fresh-keeping pad containing spunlaced composite fiber layers and a preparation method thereof. The fresh-keeping pad is obtained by pressing spun-bonded non-woven fabric, two layers of spunlaced composite fiber layers, and a plastic film, wherein the raw materials for the preparation of the spunlaced composite fiber layers comprise viscose fiber and bamboo fiber with amass ratio of (1-5): 1, the spunlaced composite fiber layers are obtained by preparation with pearl grain spunlaced process, and water absorbing material and a preservative are filled between the twolayers of spunlaced composite fiber layers. The preparation method comprises the steps of opening and mixing, carding and laying, spunlace reinforcement, pressing, filling, trimming and winding. The fresh-keeping pad has the advantages of high strength, strong water absorption, prolonged food fresh-keeping time, safety and environmental protection.

Owner:ZHEJIANG WANGJIN NONWOVENS CO LTD

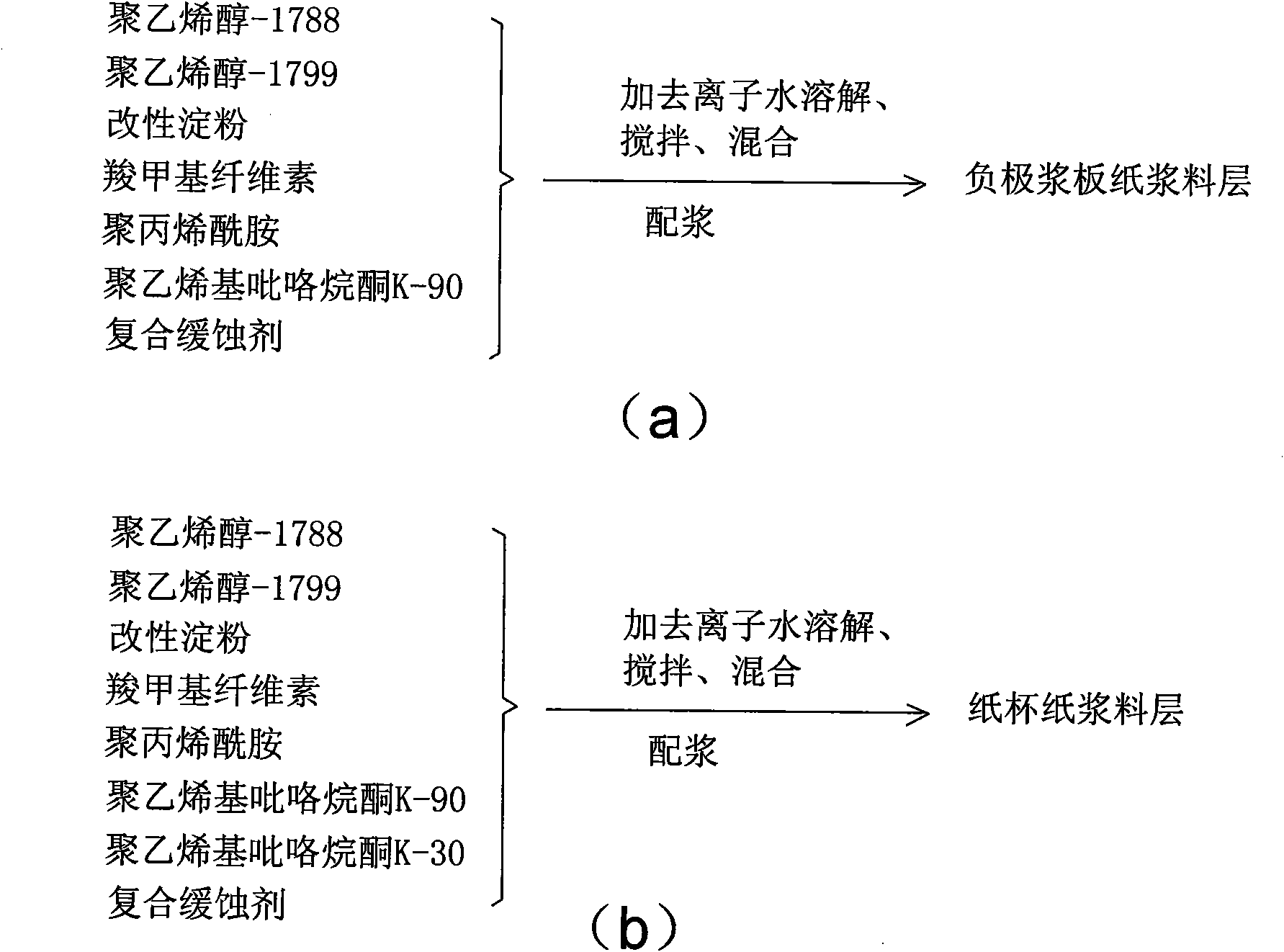

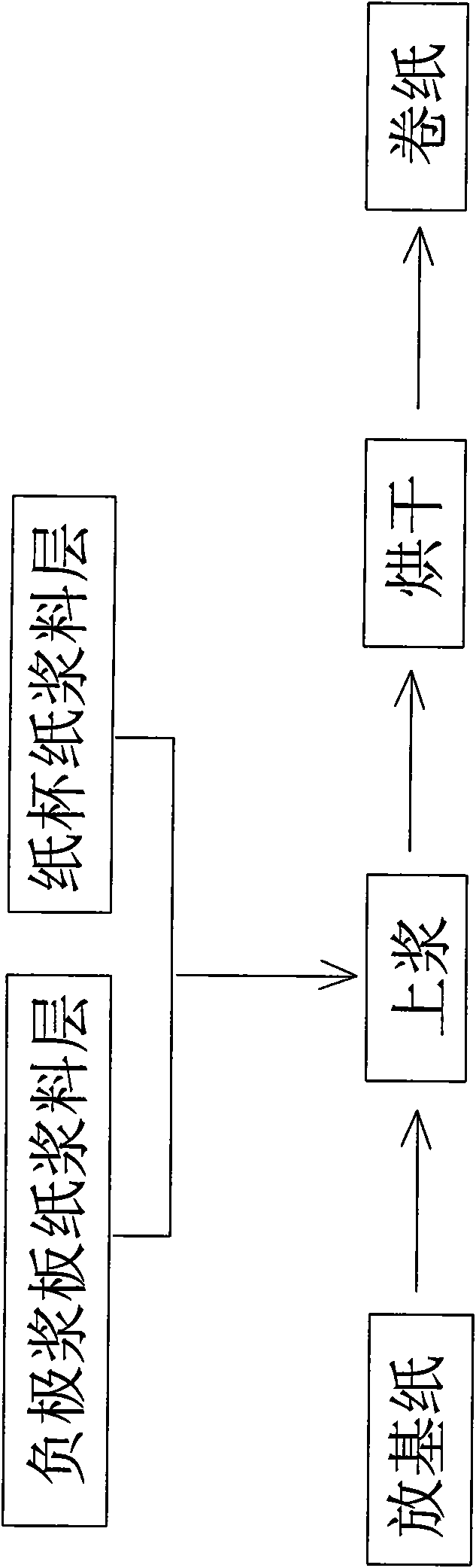

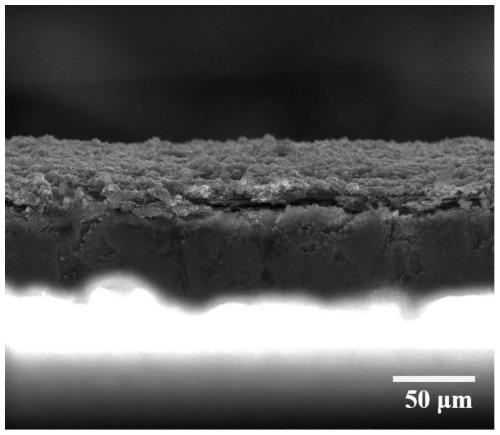

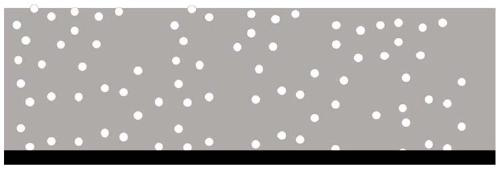

Coated paper for stacked battery and preparation method thereof

InactiveCN101671975AClose contactReduce storage timePaper coatingPaper/cardboardPolyvinyl alcoholManganese

The invention provides coated paper for a stacked battery and a preparation method thereof, wherein, the coated paper comprises base paper and a coating layer coated at the front of the base paper, i.e. single-side coating; and the coating layer is composed of modified starch, polyacrylamide, polyvinyl alcohol, a composite corrosion inhibitor, polyvinyl pyrrolidone and the like. The coated paper for the stacked battery is composed of negative pulp board paper and cup paper (i.e. carbon-clad paper), wherein, the negative pulp board paper has good liquid keeping performance and high isolation performance; and the cup paper has large liquid absorption amount and fast liquid absorption speed, thus meeting the electrical property requirement of high open circuit voltage and low short-circuit current for the stacked zinc-manganese dry cell. The coated paper can meet the industrial production requirement of the stacked battery.

Owner:GUANGDONG ZHAOQING MINGZHU PAPER

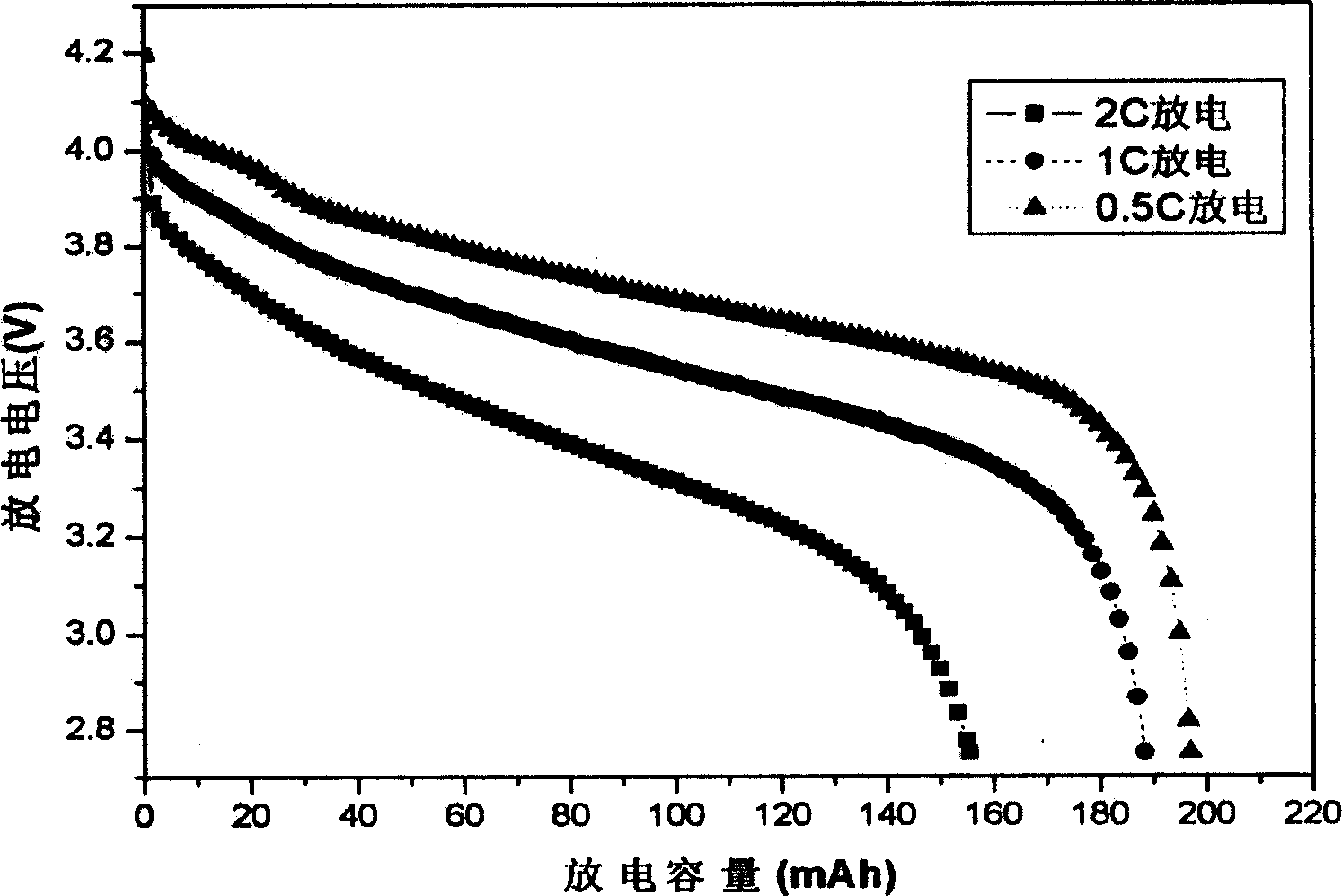

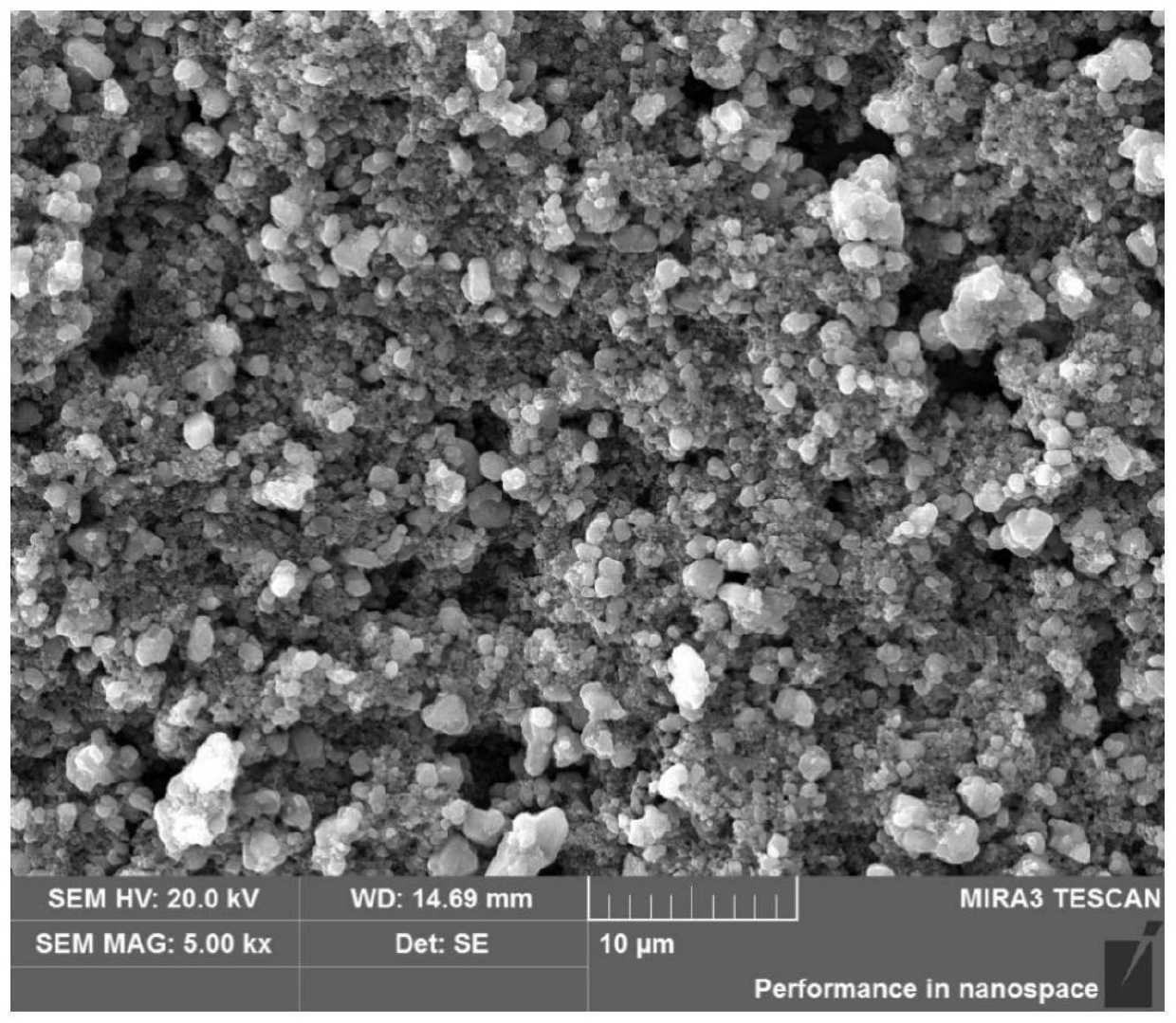

Porous composite pole piece and preparation method and application thereof in all-solid-state lithium battery

ActiveCN111490227AImprove performanceReduce interface impedanceSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrolytic agentButton battery

The invention belongs to the technical field of solid batteries, and particularly discloses a porous composite pole piece which comprises a current collector and an active material layer compounded onthe surface of the current collector, wherein the active material layer has a porous structure, the porous structure being filled with an electrolyte / polymer composite material. The invention also discloses a preparation method of the porous composite pole piece. The preparation method comprises the following steps: firstly, compounding on the surface of the current collector to form the active material layer with the porous structure; then, soaking the obtained product in a solution containing an electrolyte and a polymer synthesis raw material; carrying out curing reaction on the polymer synthesis raw material, and filling an electrolyte / polymer composite material in pores of the active layer; and obtaining the porous composite pole piece. The pole piece and a lithium piece are assembled into a button cell, it is proved that the material shows excellent electrochemical performance, the electrode polarization can be effectively reduced, and the energy density and the cycling stability of the cell are improved.

Owner:CENT SOUTH UNIV

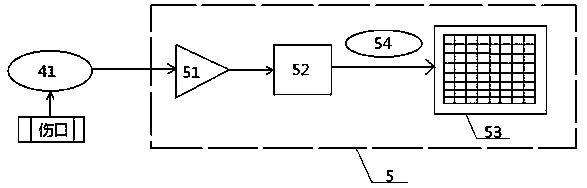

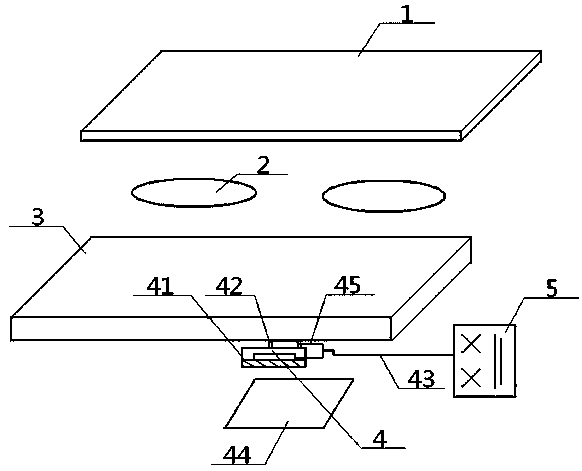

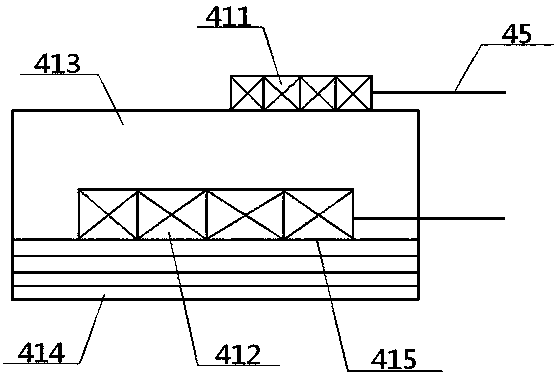

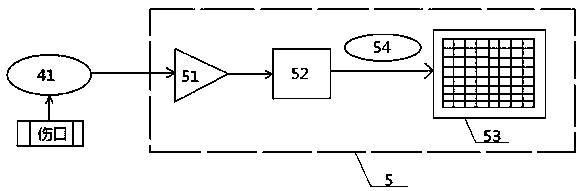

Wet control type magnet therapy environment-friendly dressing facilitating wound healing and manufacturing method thereof

InactiveCN109453000APromote healingEasy to control in real timeElectrotherapyAdhesive dressingsFiberRare earth

The invention discloses a wet control type magnet therapy environment-friendly dressing facilitating wound healing. The dressing comprises a wet absorption top layer, a magnet therapy wet absorption layer, a sensor monitoring layer and a carrier layer, wherein a moisture sensitive sensor inside the sensor monitoring layer comprises an upper electrode, a lower electrode, a moisture sensitive film and an insulation base material, the top face of the moisture sensitive film makes contact with the bottom face of the carrier layer, the upper electrode and the lower electrode are connected with a humidity monitoring system located outside the environment-friendly dressing through a signal line, the wet absorption top layer is formed by cutting a chitosan nanometer fiber membrane, the chitosan nanometer fiber membrane is obtained by electrostatic spinning of acetic acid, chitosan and polyoxyethylene, the magnet therapy wet absorption layer comprises a magnetic substance and a wet absorption substance of the integrated structure, wherein the magnetic substance includes neodymium iron boron rare earth magnetic powder, and the wet absorption substance includes silk fibroin, sodium alga acidand glycerinum. The dressing has the wet control and magnet therapy function, wound healing is facilitated, and the dressing is good in environmentally friendliness, low in cost and high efficiency.

Owner:WUHAN TEXTILE UNIV

Novel liquid polymer lithium ion battery

InactiveCN102709594AReduce thicknessHigh porositySecondary cellsCell component detailsPorosityEngineering

The invention relates to the technical field of a lithium ion battery, and specifically discloses a novel liquid polymer lithium ion battery which comprises an aluminum shrinkage film, wherein a pole group is arranged in the aluminum shrinkage film, and consists of a positive plate and a negative plate; both the surfaces of the current collectors of the positive plate and the negative plate are coated with electrode sizing agent; and the two positive plate surfaces coated with the electrode sizing agent are respectively provided with a polyvinylidene fluoride (PVDF) / XB film. The novel liquid polymer lithium ion battery has the advantages that the PVDF / XB film is adopted to produce the battery, the film has small characteristic thickness, high porosity, small ion resistance, no shrinkage at high temperature, and excellent air permeability; and the novel liquid polymer lithium ion battery has excellent antioxidant and anti-polluting performances, has good affinity to the electric liquid, large imbibition amount, strong coating capability, better electrochemical performance, high efficiency, large capacity and good cycle performance, the power batter capacity can be increased by times, and moreover, the battery resistance is small, and accordingly, the whole electrical property of the lithium ion battery is greatly improved.

Owner:TIANJIN LISHEN BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com