Hierarchical porous pole piece and preparation method and application thereof

A layered and pole piece technology, applied in the field of lithium ion battery pole piece and its preparation, can solve the problems of pole piece active material falling off, affecting the pole piece bonding performance, etc., to increase liquid absorption, ensure energy density, and increase energy effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

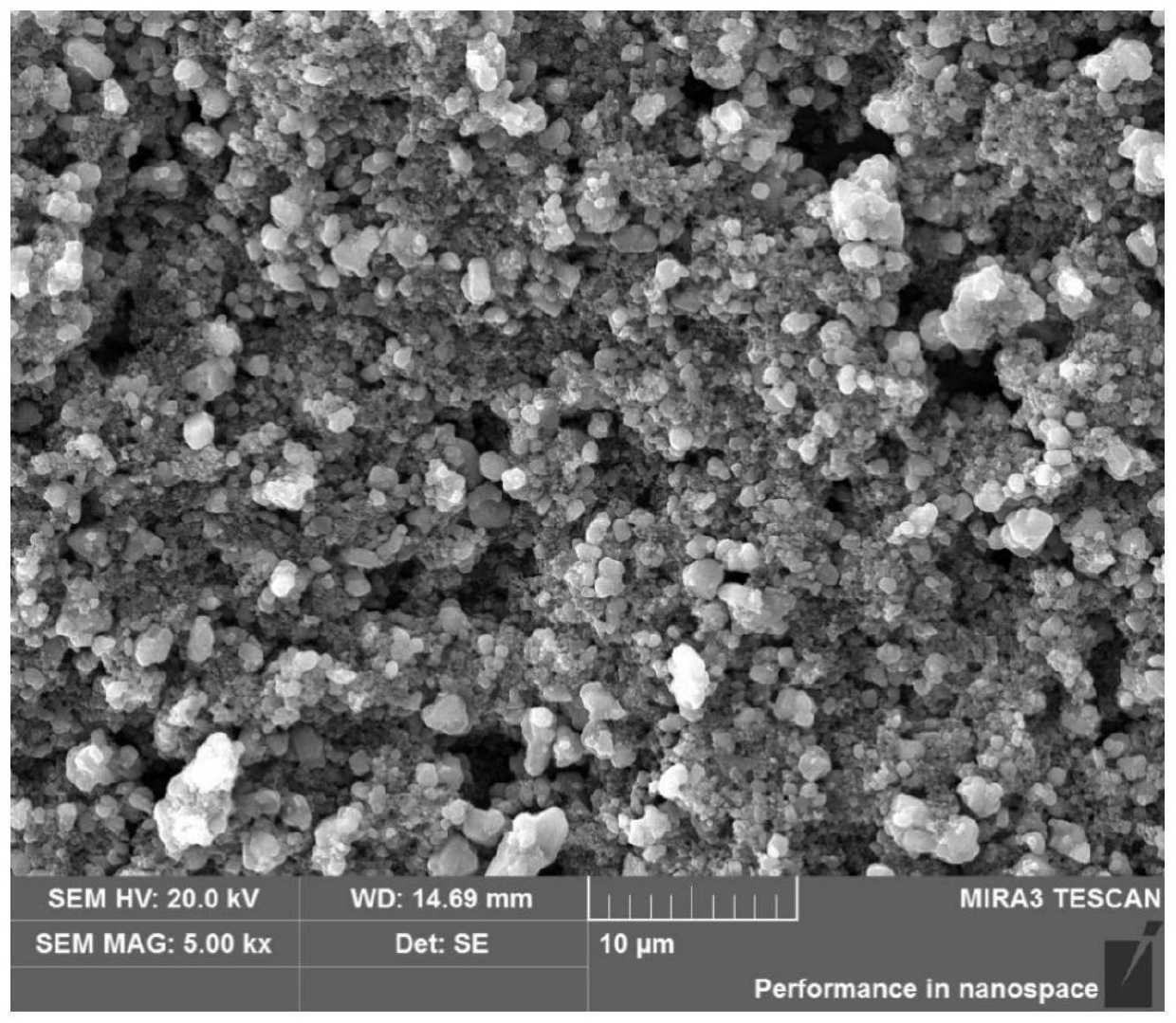

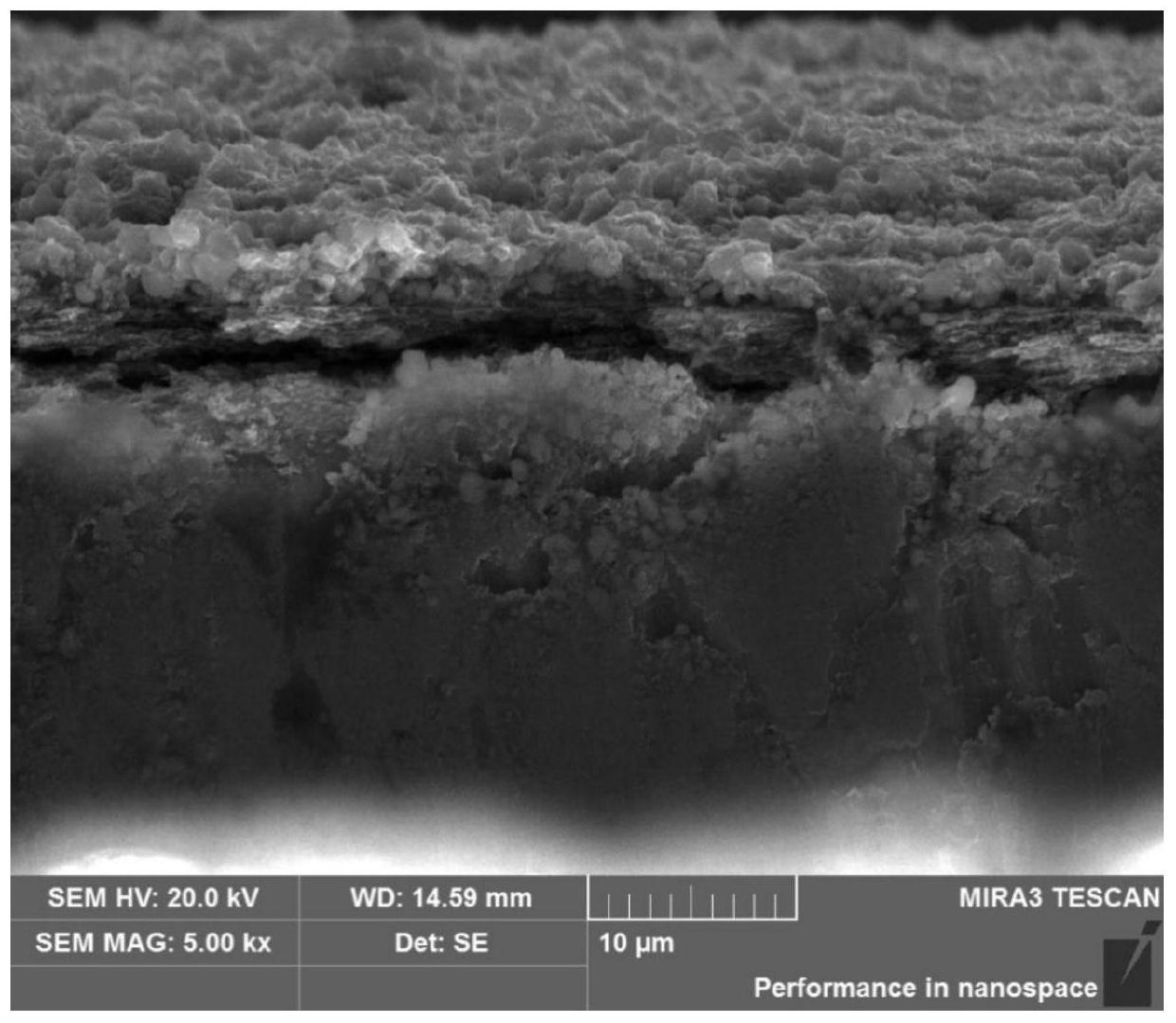

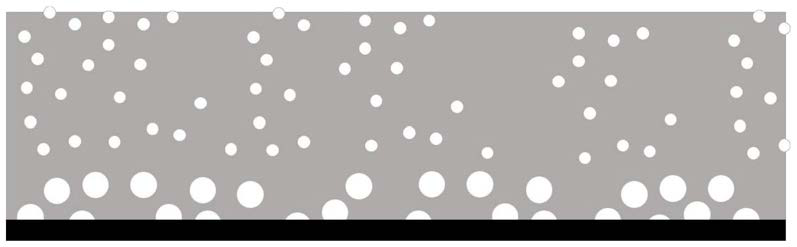

Image

Examples

Embodiment 1

[0097] LiFePO 4 , PVDF, acetylene black, and NMP agent are mixed according to 8:1:1, and 0.8% (as LiFePO 4 , PVDF, the total weight of acetylene black as a benchmark) has an average particle size of 1000nm elemental sulfur powder (particle size standard deviation σ=5nm). Mix evenly to be slurry A (in slurry A, NMP content is 70wt.%);

[0098] LiFePO 4 , PVDF, acetylene black, and NMP agent are mixed according to 8:1:1, and 1.5% (as LiFePO 4 , PVDF, the total weight of acetylene black as a basis) has an average particle size of 100nm elemental sulfur powder (particle size standard deviation σ=5nm). Mix evenly to form slurry B (in slurry B, the NMP content is 70wt.%).

[0099] Coat the slurry A on the aluminum foil, control the coating thickness to 20 μm, and dry at 110°C for 3 hours; after drying, apply the slurry B on the pole piece, control the coating thickness to 60 μm, set Dry at 110°C for 3 hours; after drying, compact it, then place the pole piece at 180°C and dry f...

Embodiment 2

[0103] LiCoO 2 , PVDF, acetylene black, and NMP agent are mixed according to 9:0.5:1, and 0.5% (as LiCoO 2 , PVDF, the total weight of acetylene black as a basis) has an average particle size of 700nm elemental sulfur powder (standard deviation of particle size σ=5nm). Mix evenly to be slurry A (in slurry A, NMP content is 72wt.%);

[0104] LiCoO 2 , PVDF, acetylene black, and NMP agent are mixed according to 9:0.5:1, and 2% (as LiCoO 2 , PVDF, the total weight of acetylene black as a basis) has an average particle size of 10nm elemental sulfur powder (standard deviation of particle size σ=5nm). Mix evenly to form slurry B (in slurry B, the NMP content is 72wt.%).

[0105] Coat the slurry A on the aluminum foil, control the coating thickness to 10 μm, and dry at 80°C for 3 hours; after drying, apply the slurry B on the pole piece, control the coating thickness to 100 μm, and place Dry at 80°C for 3 hours; after drying, compact it, then place the pole piece at 200°C and dr...

Embodiment 3

[0108] LiFePO 4 , PVDF, carbon nanotubes, and NMP agent are mixed according to 9:1:1, and 1.5% (as LiFePO 4 , PVDF, based on the total weight of carbon nanotubes) with an average particle size of 500nm elemental sulfur powder (standard deviation of particle size σ=5nm). Mix evenly to be slurry A (in slurry A, NMP content is 80wt.%);

[0109] LiFePO 4 , PVDF, carbon nanotubes, and NMP agent are mixed according to 9:1:1, and 1.8% (as LiFePO 4 , PVDF, based on the total weight of carbon nanotubes) with an average particle size of 300nm elemental sulfur powder (standard deviation σ=5nm of particle size). Mix evenly to form slurry B (in slurry B, the NMP content is 80wt.%).

[0110] Coat the slurry A on the aluminum foil, control the coating thickness to 15 μm, and dry at 120°C for 3 hours; after drying, apply the slurry B on the pole piece, control the coating thickness to 80 μm, and place Dry at 120°C for 3 hours; after drying, place the pole piece at 190°C for 50 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com