Patents

Literature

98results about How to "Low closed cell temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

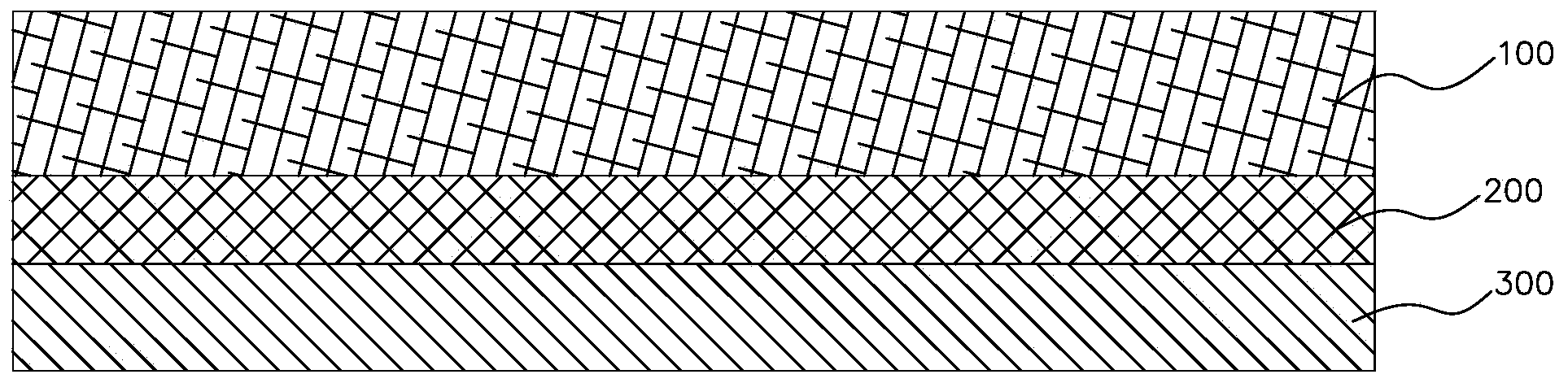

Novel ceramic coating polyolefin composite film and preparation method thereof

ActiveCN103811702AReduced service lifeExtended service lifeSecondary cellsCell component detailsSolventPolyolefin

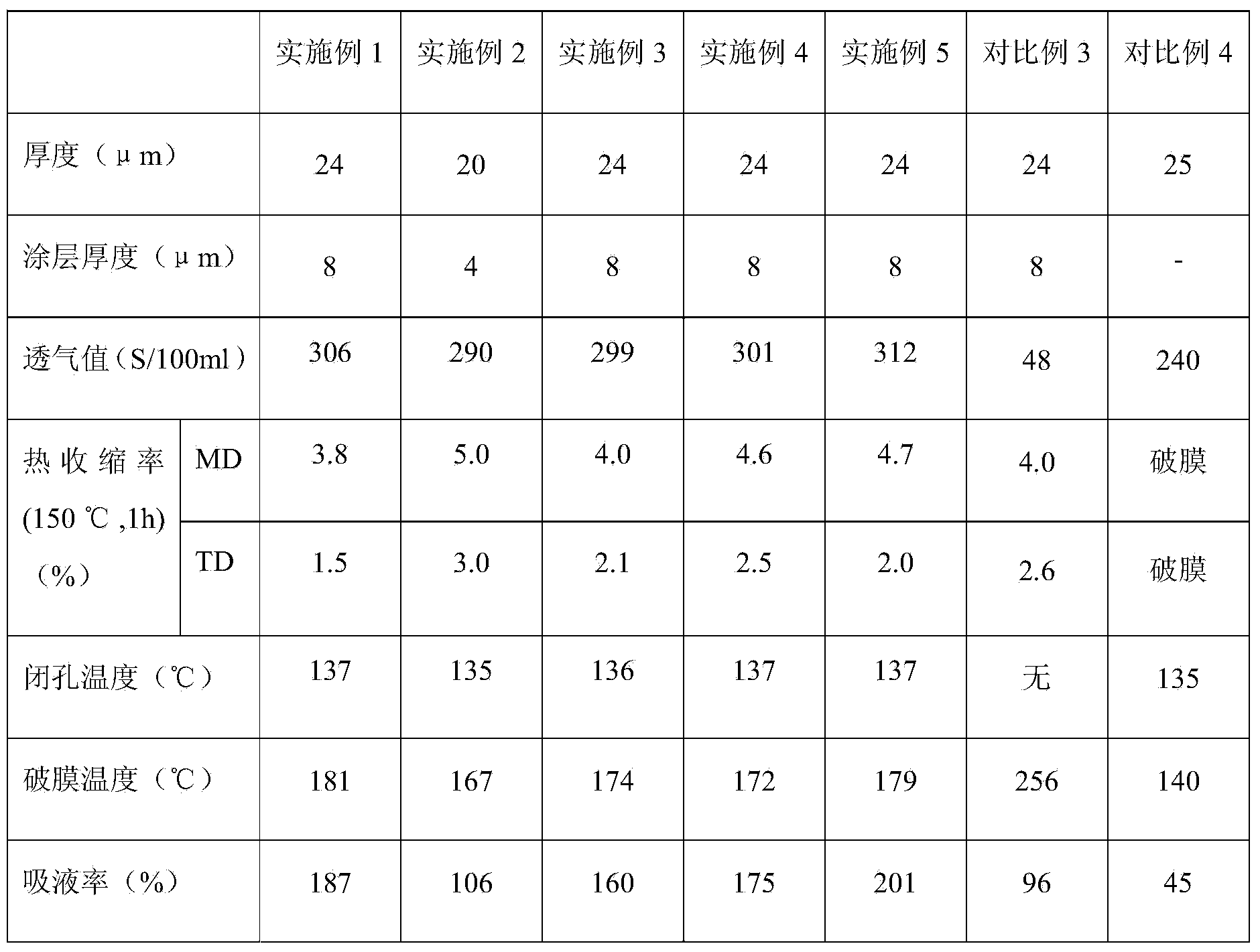

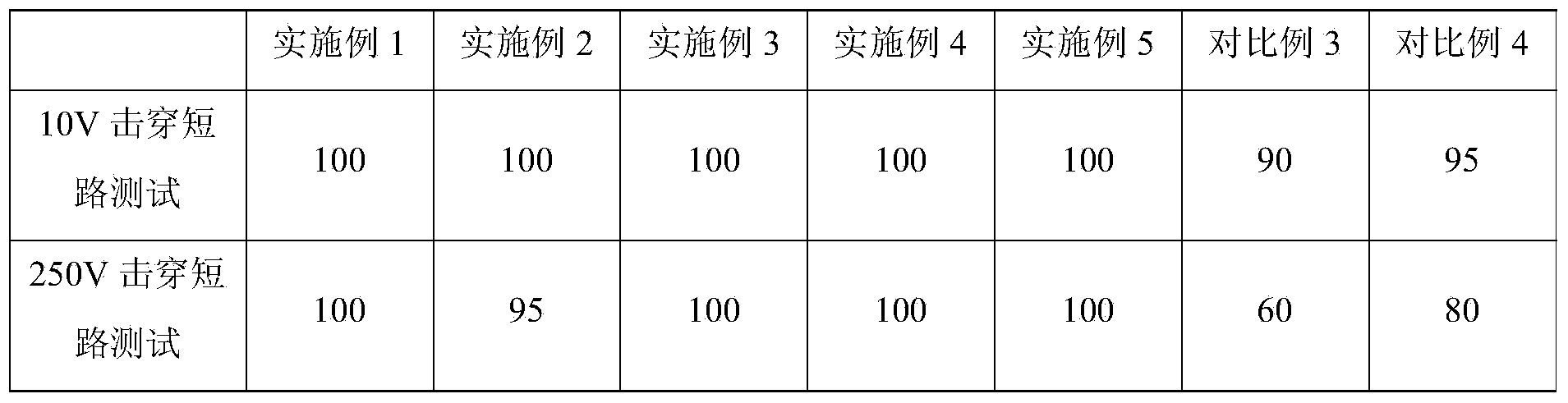

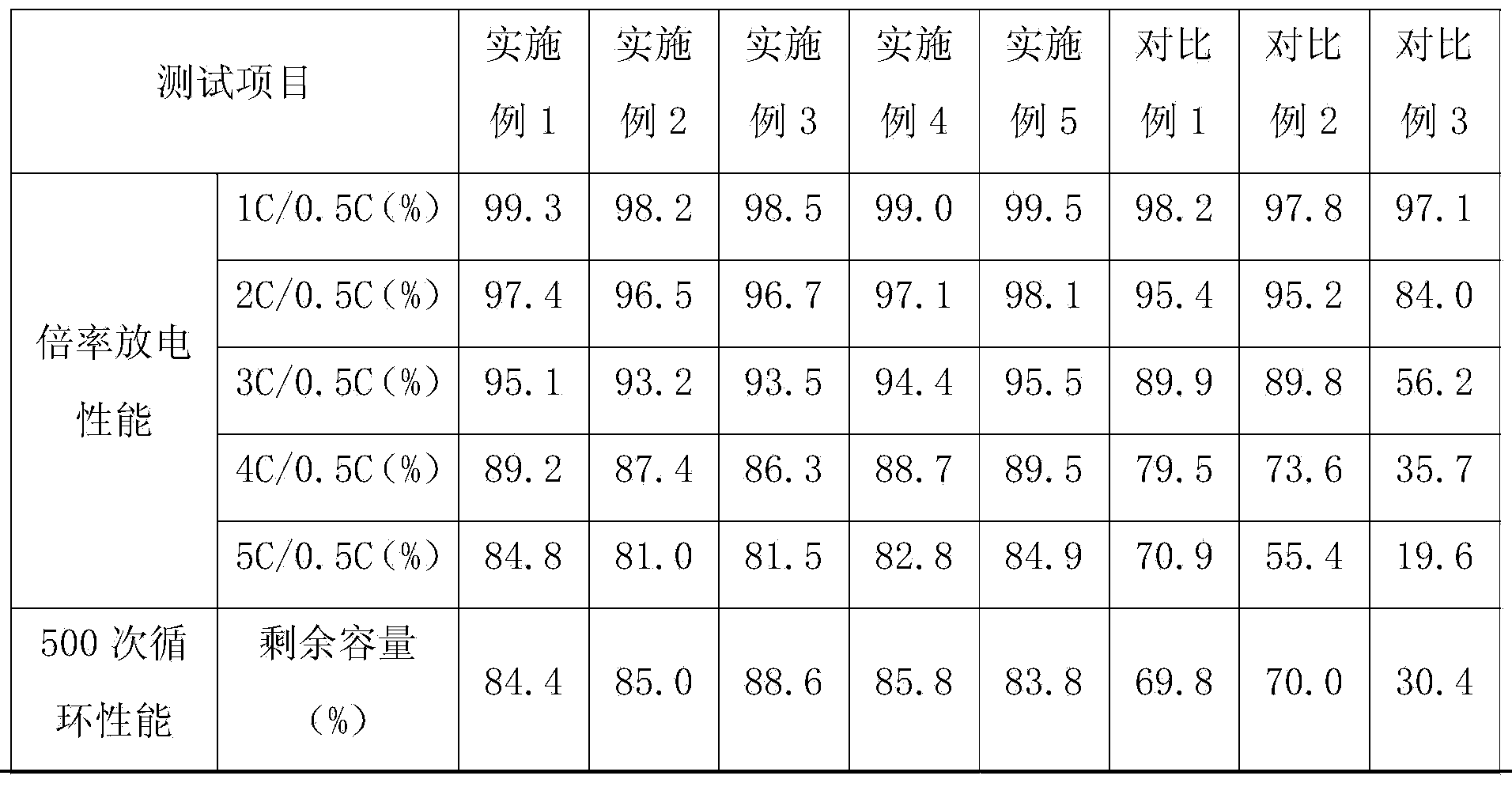

The invention relates to a novel ceramic coating polyolefin composite film which comprises a polyolefin substrate with micro pores, wherein one side or both sides of the polyolefin substrate is / are compounded with ceramic coating(s); the ceramic coating comprises porous ceramic particles, an inorganic filler and an adhesive. The invention also relates to a method for preparing the novel ceramic coating polyolefin composite film. The method comprises the following steps: a, dissolving the adhesive in a solvent, thereby preparing an adhesive solution; b, adding the porous ceramic particles and the functional inorganic filler into the adhesion solution prepared in the step a, and performing dispersing treatment, thereby preparing coating slurry; and c, coating one or two surfaces of the polyolefin substrate with the coating slurry prepared in the step b, and drying and curing to prepare the product. The novel functional composite film has high liquid absorption and retention performance, has the functions of reducing harmful gases inside a battery, improving the performance of the battery and prolonging the service life of the battery, and has the safety characteristics of low closed pore temperature, high melting temperature and low hot-shrinkage rate.

Owner:河南惠强新能源材料科技股份有限公司

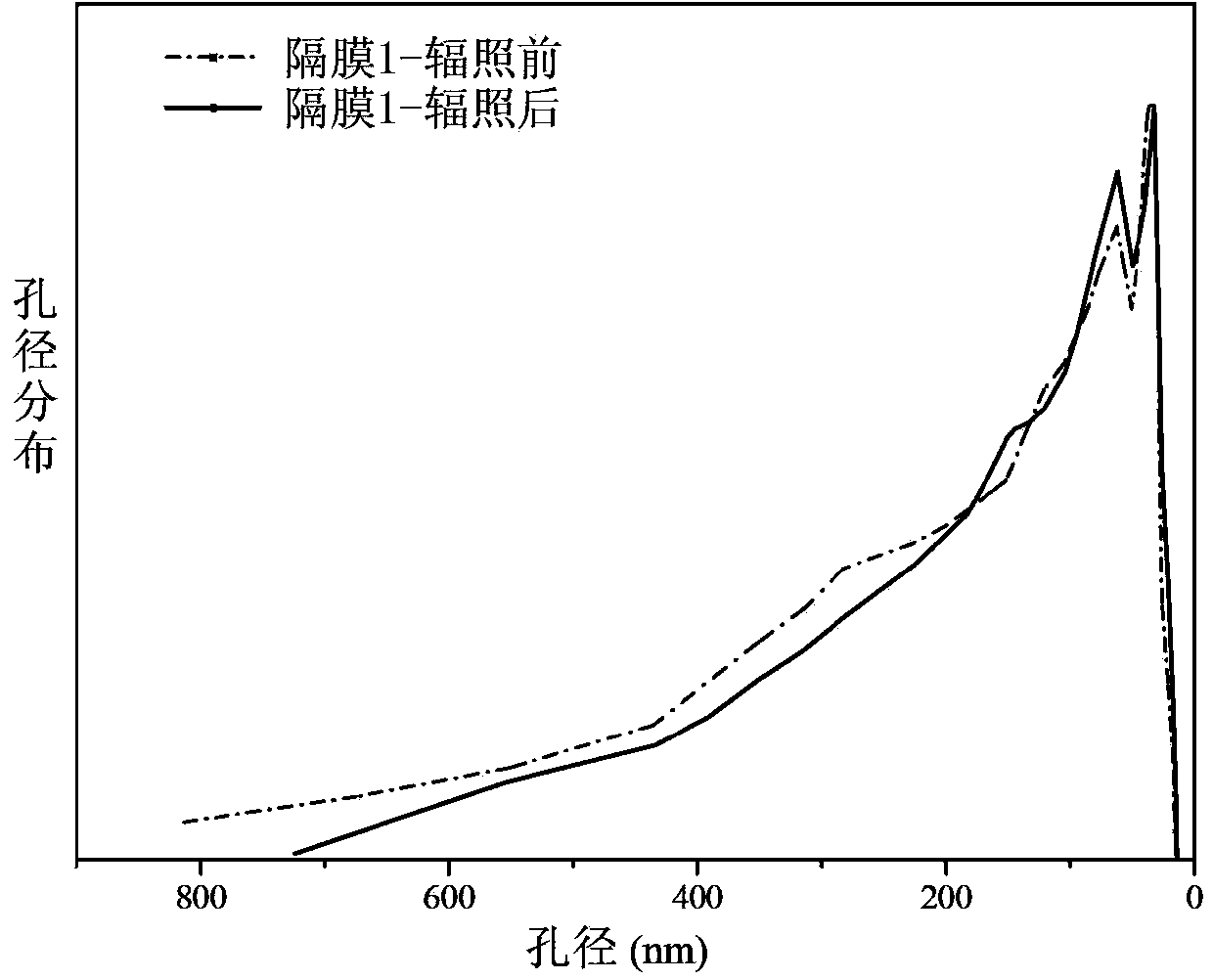

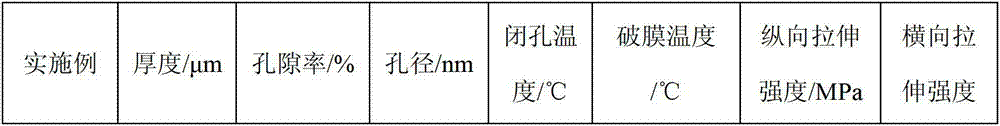

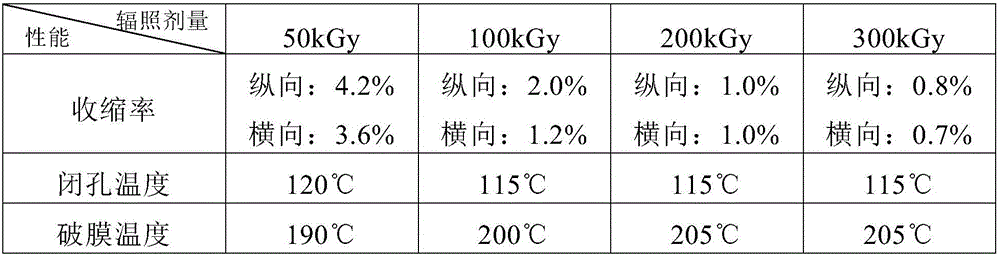

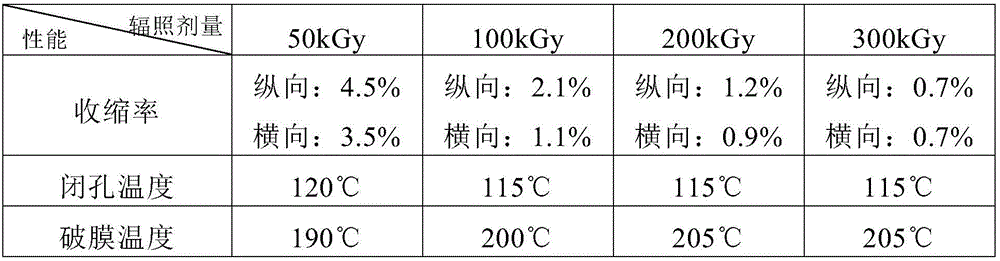

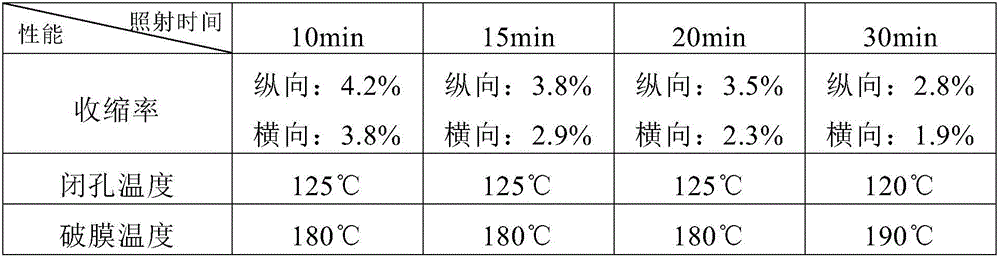

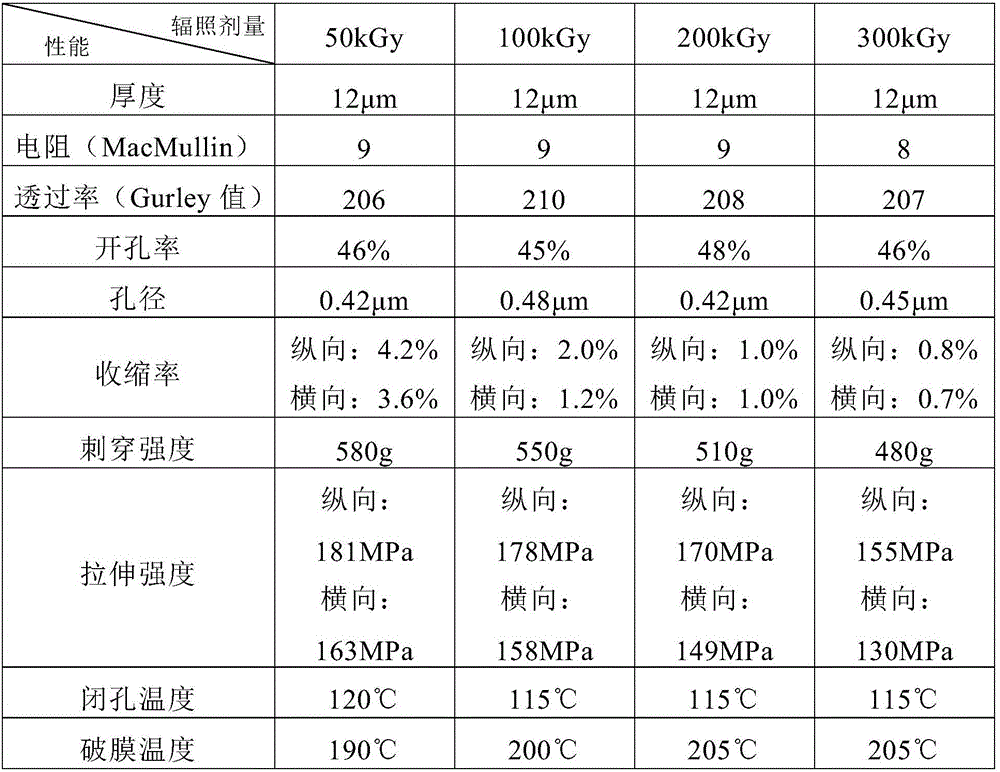

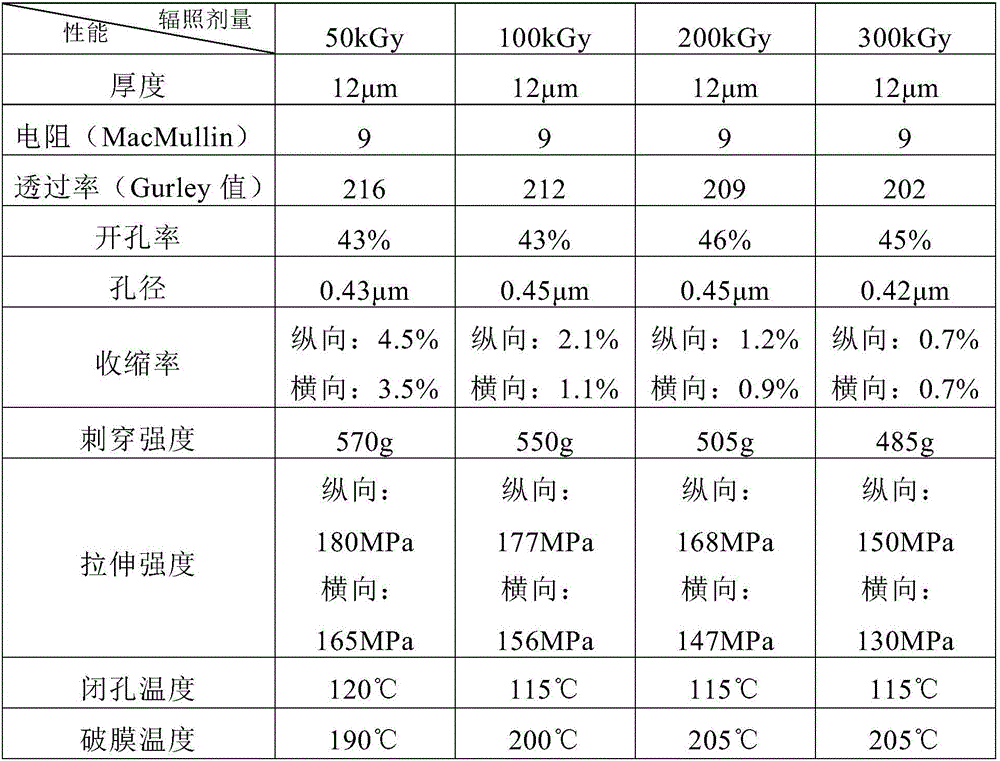

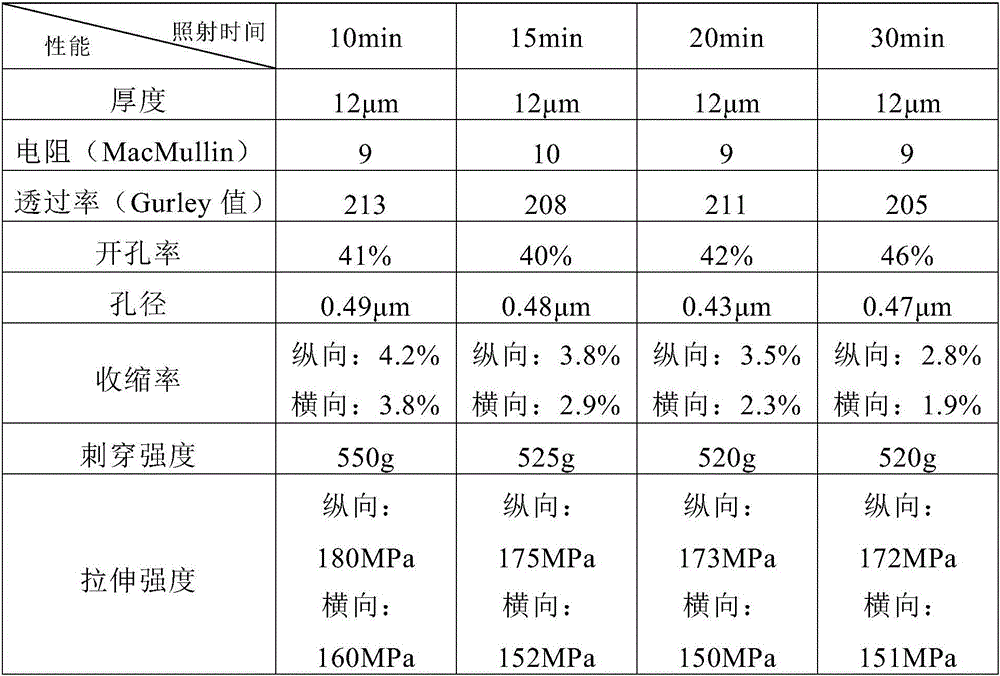

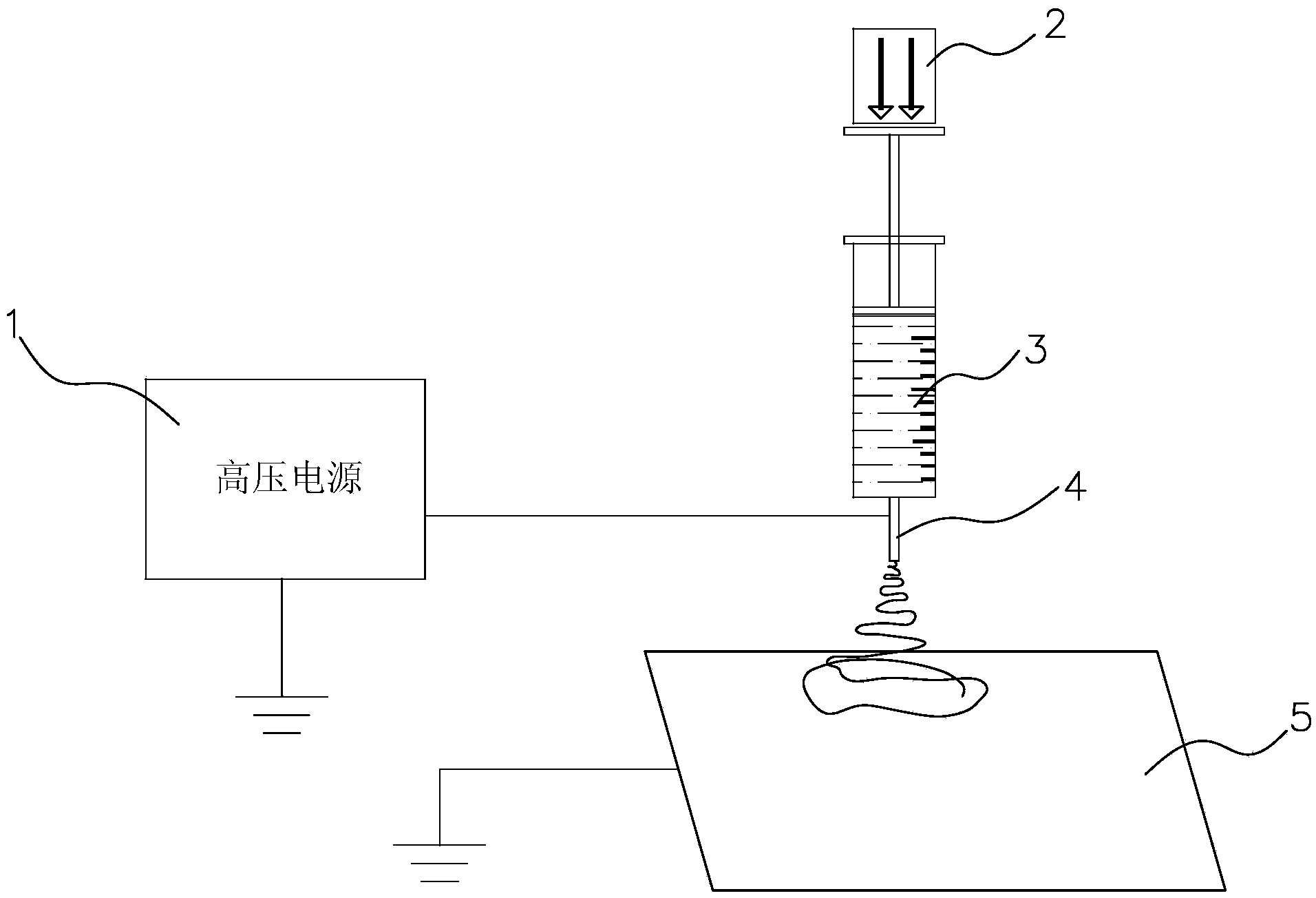

Irradiation cross-linking lithium-ion battery diaphragm and preparation method thereof

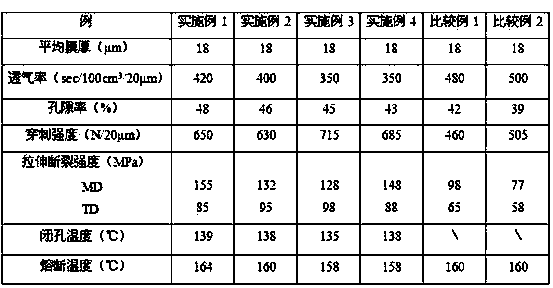

ActiveCN103421208AImprove securityLow closed cell temperatureCell component detailsCross-linkPolymer science

The invention discloses a preparation method of an irradiation cross-linking polyethylene porous diaphragm. According to the method, the polyethylene porous diaphragm is soaked in and adsorbs a volatile solvent containing initiator and cross-linking agent to lead initiator and cross-linking agent into the surface and the interior of the polyethylene porous diaphragm, and is then treated with irradiation cross-linking underwater or under the protection of inert gas, and a locally cross-linked diaphragm is obtained by controlling the cross-linking condition. The irradiation cross-linking lithium-ion battery diaphragm has the advantages that the tensile strength and the hydrophily are greatly improved; the high-temperature hot-shrinkage rate is greatly reduced; the defect of low membrane rupture temperature is overcome; the membrane rupture temperature is greatly raised while the normal hole closing of the diaphragm is guaranteed; the hole closing temperature of the diaphragm is 120 to 140 DEG C; the membrane rupture temperature is raised to be higher than 160 DEG C.

Owner:ZHEJIANG UNIV +2

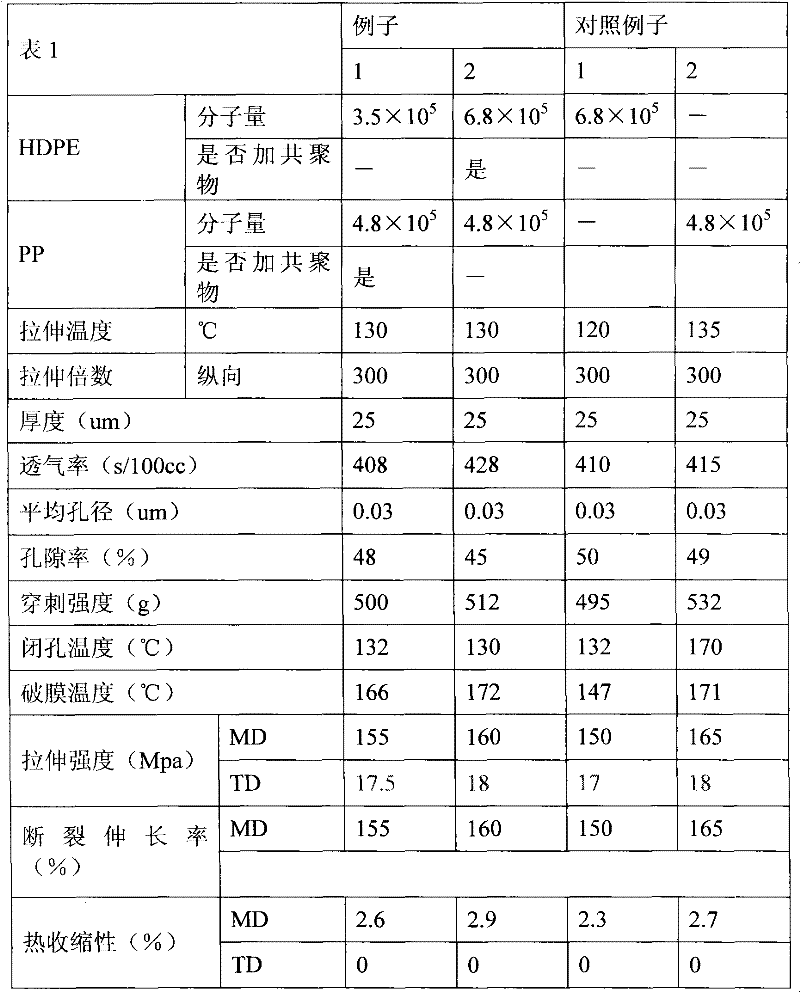

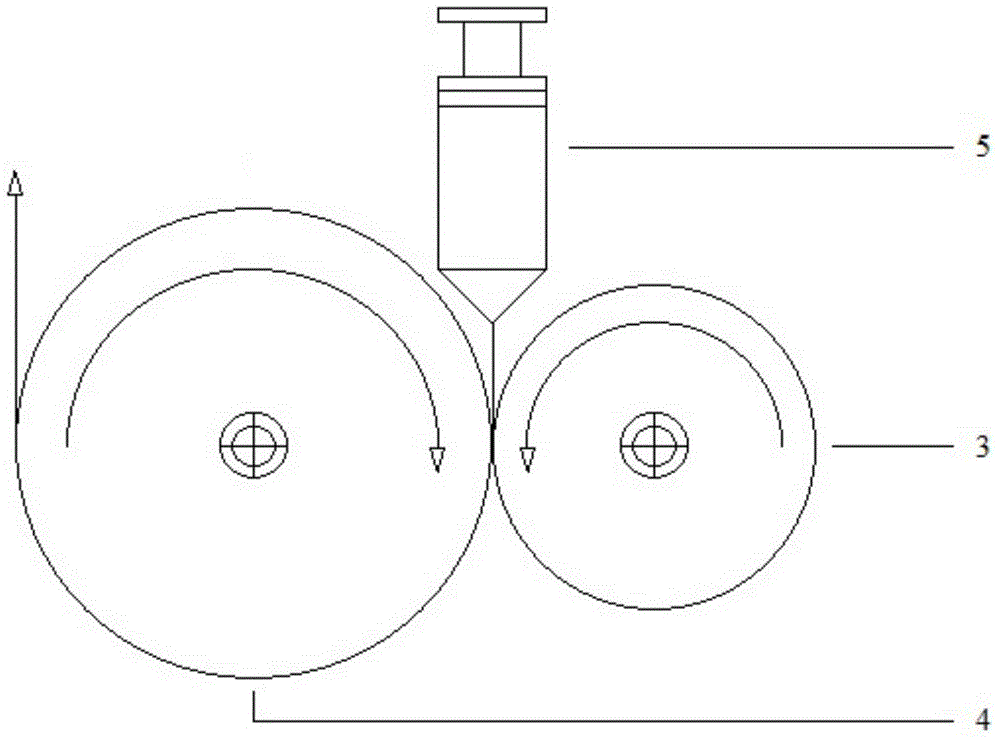

Microporous polyolefin laminated diaphragm for lithium-ion battery and its production

InactiveCN1897329ALow closed cell temperatureHigh membrane rupture temperatureCell component detailsPolyolefinBoiling point

The invention is concerned with the poly tiny porous multilayer septa for lithium ion battery, including several polyethylene layers and several polypropylene layers that cling at the polyethylene layers. The poly tiny porous multilayer septa manufacture method for lithium ion battery includes the following steps: mixes the polyethylene and the polypropylene with the high boiling-point small molecular weight compound solvent respectively, fusing plastifies the solution; extrudes the filming slice from the solution respectively using the double screw by the multi-layer die-head altogether, the cooling film forms the multi-layer gelatinous compound; heats and stretches the compound bidirectionally, cleans the solvent in the compound, dries the compound, and processes the heating finalize the design. The invention uses the whole structure compounding by the multi-layer poly film, the film is with the lower closing temperature by the low melting point polyethylene layer, the film is with the higher breaking temperature by the high melting point polypropylene layer.

Owner:SHENGCHAO AUTOMATION SCI & TECH SHANGHAI

Inorganic composite microporous membrane serving as lithium ion battery diaphragm and preparation method thereof

InactiveCN102738427AImprove integrityWon't fall offMaterial nanotechnologySynthetic resin layered productsPolyolefinSilicon oxide

The invention relates to an inorganic composite microporous membrane serving as a lithium ion battery diaphragm and a preparation method of the inorganic composite microporous membrane. The inorganic composite microporous membrane is a co-extruded inorganic composite microporous membrane, and includes an intermediate layer and two outer layers, wherein the intermediate layer is mainly made of polyethylene, or the copolymer of ethylene and other olefins, or the mixture of polyethylene and other polyolefin; the two outer layers is mainly made of the mixture of polypropylene and inorganic nanoparticles; and the inorganic nanoparticles are selected from at least one of aluminum oxide, magnesium oxide, calcium oxide and silicon oxide. The inorganic composite microporous membrane provided by the invention has good unity, and can prevent shedding of the inorganic nanoparticles so as to ensure the stability of the battery performance during application of the inorganic composite microporous membrane. The preparation method provided by the invention can form the multilayer structure of the inorganic composite microporous membrane in one step by adopting co-extrusion method, thereby simplifying the production process, improving the production efficiency and improving the performance of the inorganic composite microporous membrane.

Owner:HENAN YITENG NEW ENERGY TECH

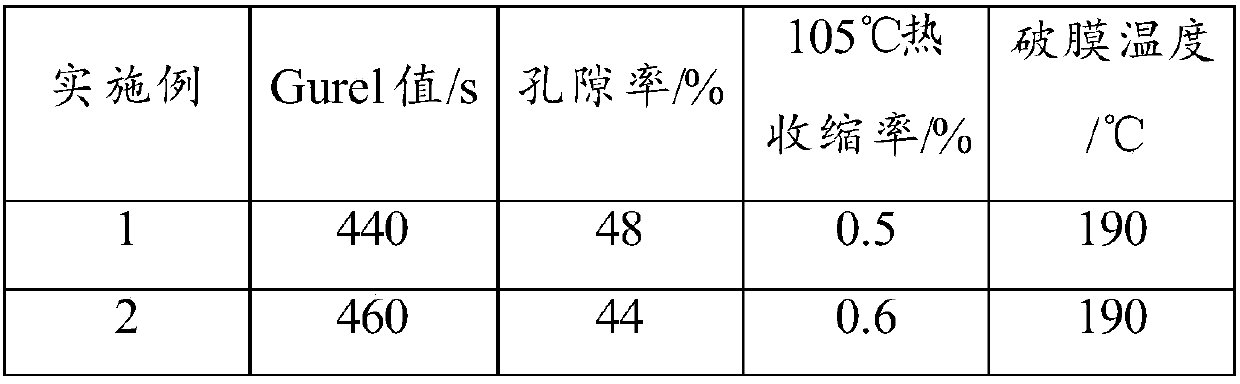

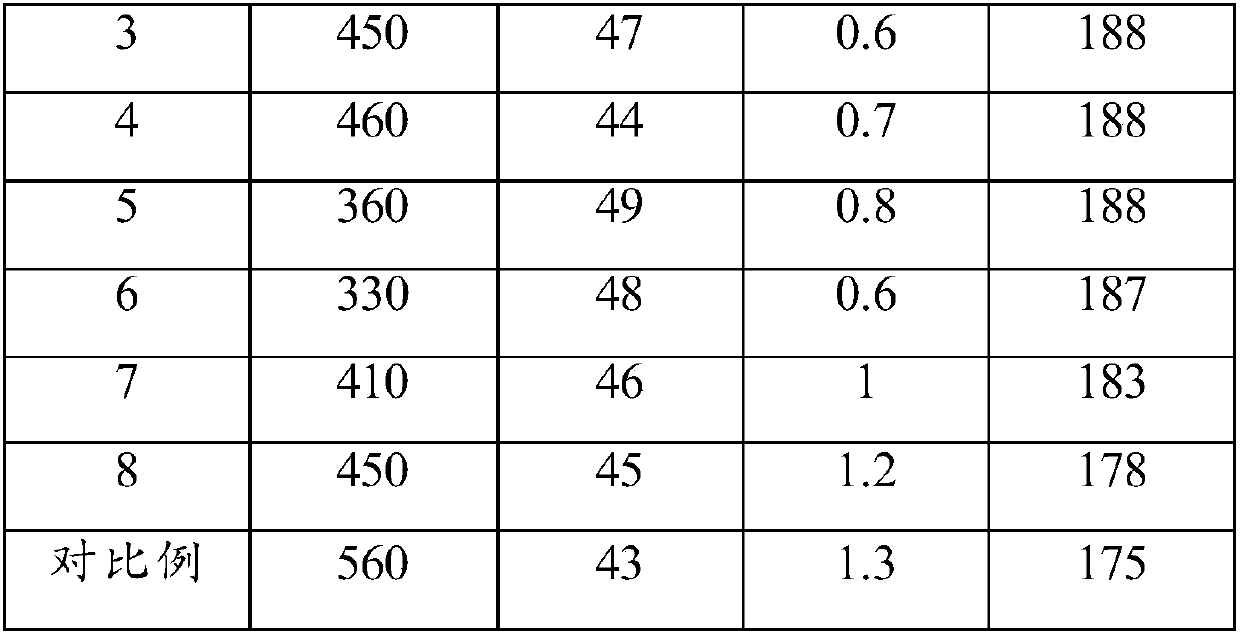

Polyolefin multilayer micro porous diaphragm for lithium ion battery and preparation method of polyolefin multilayer micro porous diaphragm

ActiveCN103531735AWith ion acceleration functionExcellent Adhesive FunctionCell component detailsPolyolefinHigh diaphragm

The invention relates to a polyolefin multilayer micro porous diaphragm for a lithium ion battery and a preparation method of the polyolefin multilayer micro porous diaphragm. The polyolefin multilayer micro porous diaphragm comprises a polyethylene micro porous layer, wherein an ion acceleration layer is arranged on each of the upper surface and the lower surface of the polyethylene micro porous layer, and a polypropylene micro porous layer is arranged on the outer surface of each ion acceleration layer. According to the polyolefin multilayer micro porous diaphragm, due to the adoption of a five-layer structure, a low hole closing temperature and a high diaphragm breaking temperature of the diaphragm can be provided, thus a safety window of the diaphragm is increased and the good safety performance is provided; and meanwhile, the ion acceleration layers provide low resistance, high electron conduction rate and good solution absorption performance and solution maintaining performance of the diaphragm, thus the charge-discharge power and the cycle service life of the lithium ion battery can be improved; and the ion acceleration layers have micro porous net-shaped structures and have excellent lyophilic performance and adhering performance, the ion transmission performance of the diaphragm is improved when all layers of the multilayer micro porous diaphragm are well compounded, and good gas permeability is kept.

Owner:河南惠强新能源材料科技股份有限公司

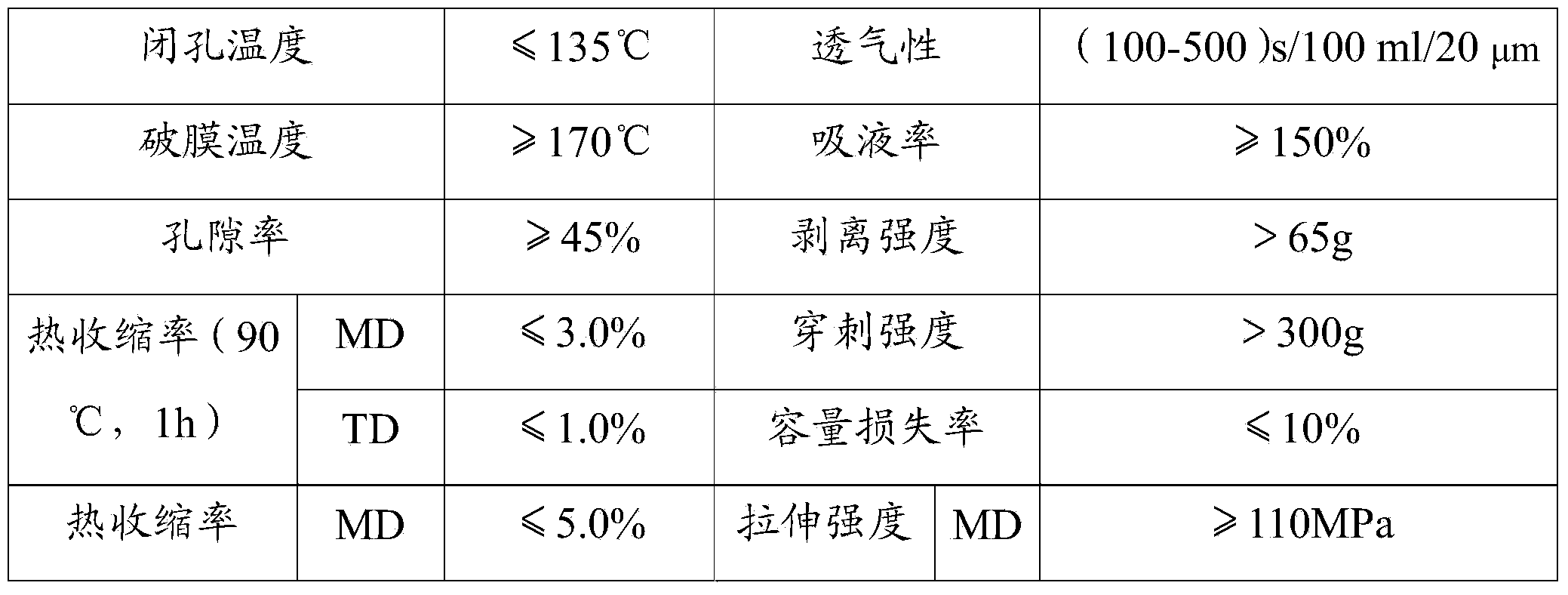

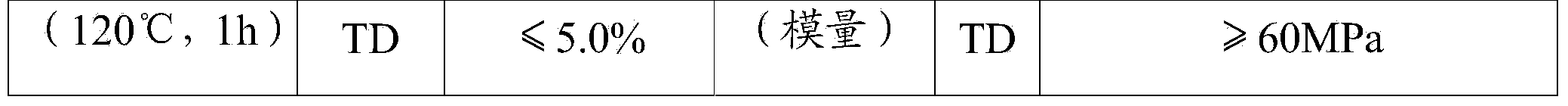

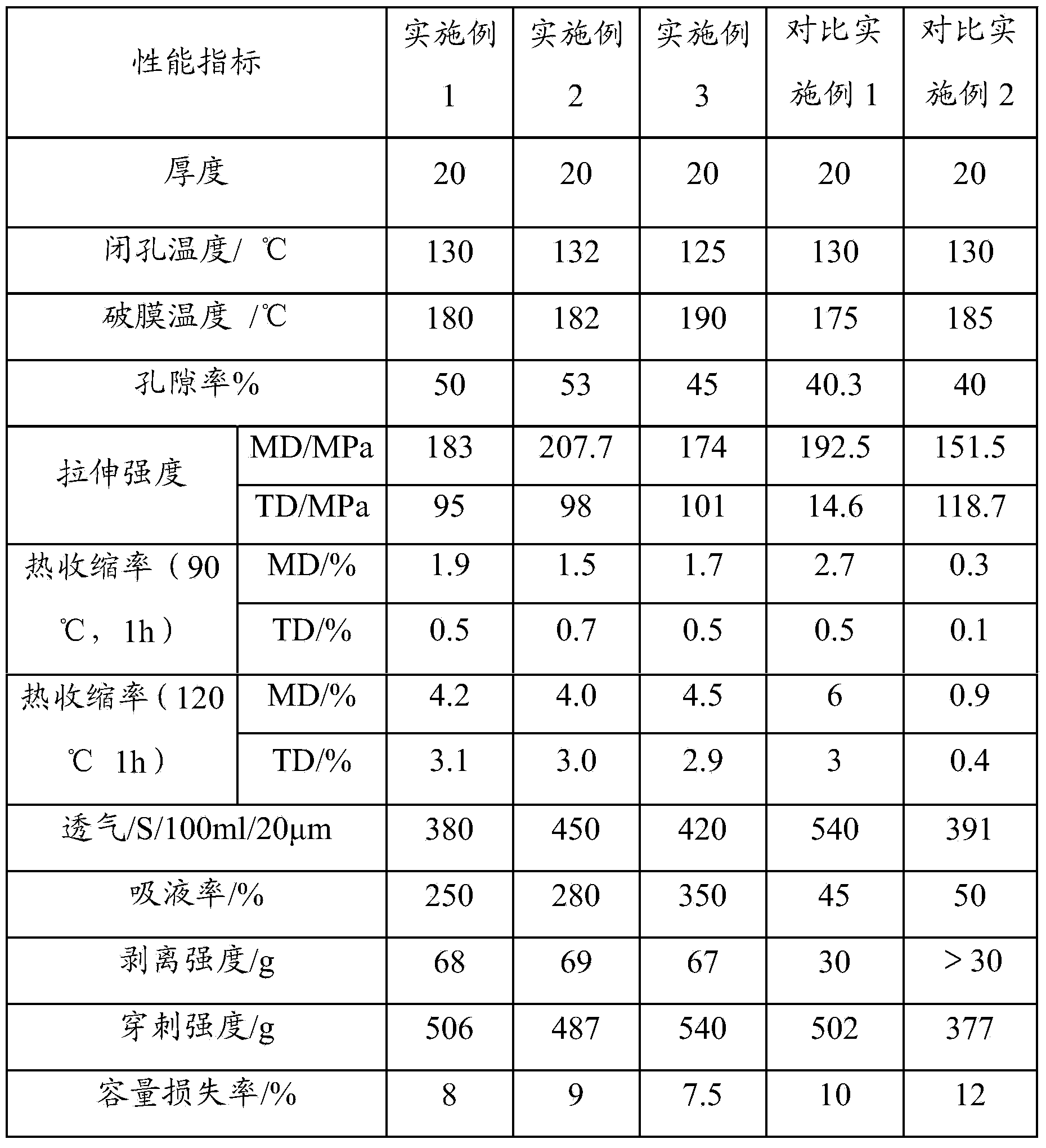

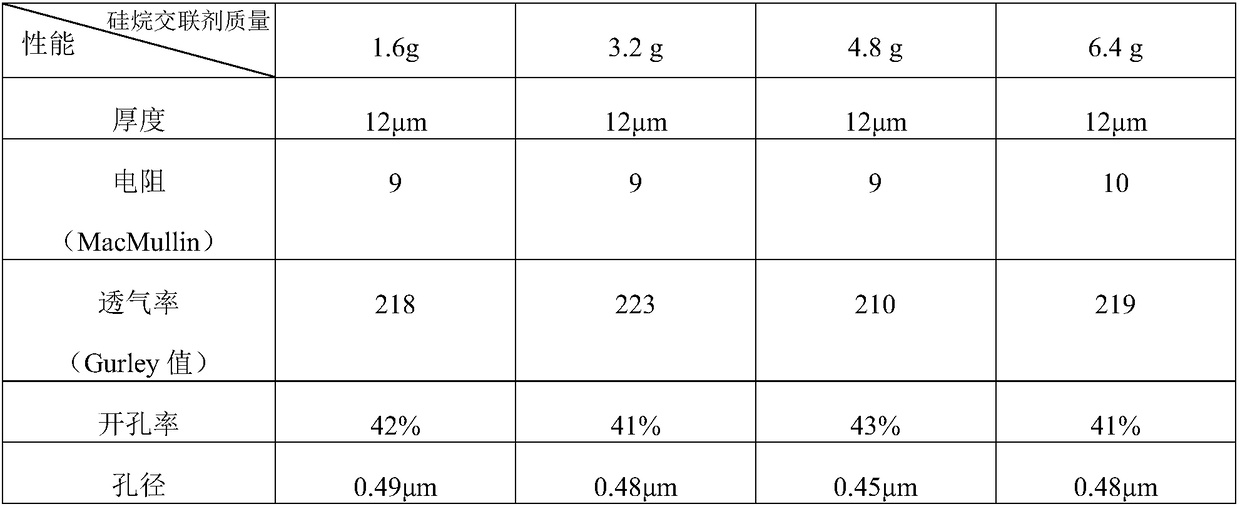

Silane crosslinked polymer separation film and preparation method thereof

InactiveCN108198986AReduce processing costsLow heat shrinkageCell seperators/membranes/diaphragms/spacersHigh densityAntioxidant

The invention provides a silane crosslinked polymer separation film, which comprises crosslinked polymerized ultrahigh molecular weight polyethylene, high-density polyethylene, an antioxidant, an assistant crosslinker and a silane crosslinking agent, wherein the molecular weight of the ultrahigh molecular weight polyethylene is 1.0*10<6> to 10.0*10<6>; the density of the high-density polyethyleneis 0.940-0.976g / cm<3>; and on the basis of 100 parts by weight of a mixture of the ultrahigh molecular weight polyethylene and the high-density polyethylene, the weight of the antioxidant is 0.5-20 parts, the weight of the assistant crosslinker is 0.1-10 parts and the weight of the silane crosslinking agent is 0.1-10 parts. The separation film is prepared through a chemical crosslinking method, sothat a difference value between the film rupture temperature and the obturator temperature of the prepared silane crosslinked polymer separation film and the hot shrinkage rate are improved and the safety performance of a battery is higher.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Battery diaphragm and fabrication method thereof

ActiveCN102820444ALow orientationUniform surface pore size distributionSynthetic resin layered productsSecondary cellsLow-density polyethyleneLinear low-density polyethylene

The invention provides a battery diaphragm. The base material of the diaphragm is a polyvinylidene fluoride non-woven fabric, coating layers are arranged on two sides of the polyvinylidene fluoride non-woven fabric, and the material of the coating layers includes an ultra high molecular weight polyethylene and a linear low density polyethylene. A fabrication method of the battery diaphragm is further provided. According to the battery diaphragm and the fabrication method thereof, the provided battery diaphragm has the advantages that the air permeability is remarkably improved, the closed pore temperature is remarkably lowered, the puncture strength and diaphragm breaking temperature are remarkably improved, a safe protective property is provided for a battery, and the battery diaphragm is applicable to power batteries.

Owner:BYD CO LTD

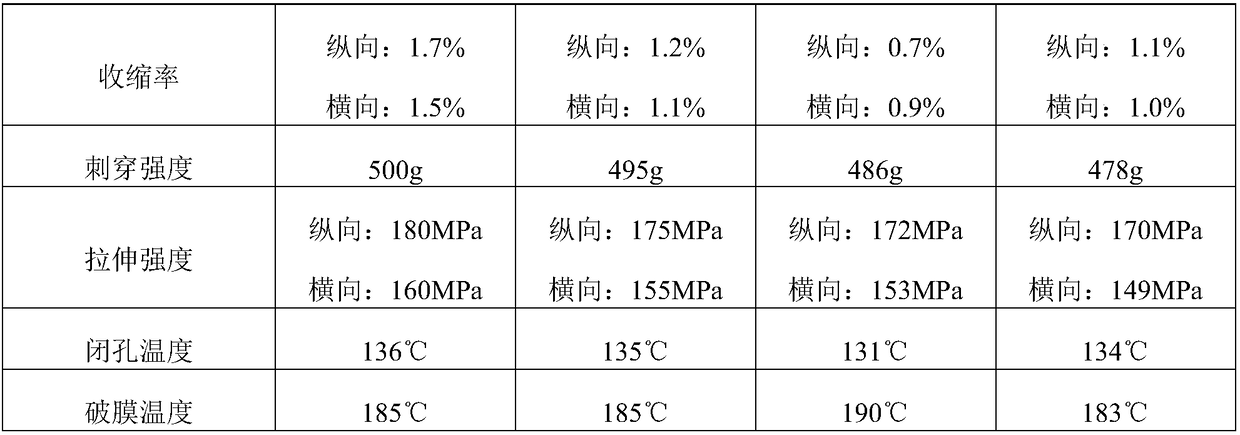

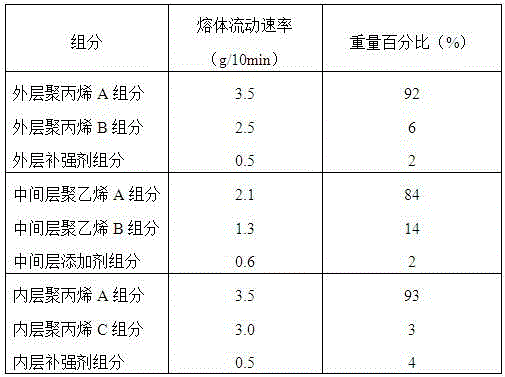

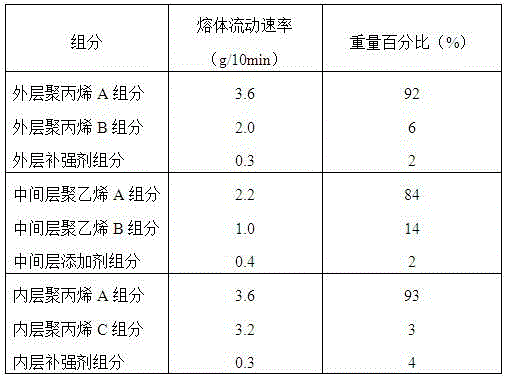

Three-layer lithium battery diaphragm and preparation method thereof

ActiveCN104022249ALow closed cell temperatureResolve Longitudinal WrinklesSynthetic resin layered productsCell component detailsPolymer sciencePolypropylene

The invention discloses a three-layer lithium battery diaphragm and a preparation method thereof. The diaphragm is prepared by adopting a three-layer coextrusion technology, and comprises an outer layer, a middle layer and an inner layer, wherein the outer layer is prepared from 92-93% of polypropylene A, 5-6% of polypropylene B and 1-3% of a reinforcing agent which are taken as raw materials; the middle layer is prepared from 83-86% of polypropylene A, 13-14% of polypropylene B and 1-4% of an additive which are taken as raw materials; the inner layer is prepared from 93-95% of polypropylene A, 3-4% of polypropylene C and 1-4% of a reinforcing agent which are taken as raw materials. The preparation method comprises the following steps of a) mixing and absorbing materials; b) extruding and stretching; c) baking; and d) stretching. The middle layer of the three-layer lithium battery diaphragm provided by the invention is a polypropylene layer, and the three-layer lithium battery diaphragm is prepared from the polypropylene layers of the outer layer and the inner layer in a three-layer coextrusion mode. The obturator temperature decreases greatly and reaches 138 DEG C minimally.

Owner:FOSHAN YINGBOLAI TECH

Battery isolating membrane preparation method

InactiveCN106450112AImprove performanceHigh membrane rupture temperatureCell component detailsHigh densityAntioxidant

The invention discloses a battery isolating membrane preparation method. Mixed raw materials are extruded, cooled, formed, extracted, stretched and heat-set to obtain a battery isolating membrane. The raw materials include ultra-high molecular weight polyethylene, high-density polyethylene, antioxidants and pore-forming agents, the molecular weight of the ultra-high molecular weight polyethylene is 1.0*10<6>-10.0*10<6>, the density of the high-density polyethylene ranges from 0.940g / cm<3> to 0.976g / cm<3>, and the method includes cross-linking.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Polyene microporous multilayer diaphragm and manufacturing method thereof

ActiveCN102248713AImprove securityRaise the temperature differenceSynthetic resin layered productsPolyeneEthylene propylene copolymer

The invention provides a polyene microporous multilayer diaphragm and a manufacturing method thereof. The diaphragm is formed by combing three or more than three polyene layers, wherein in a plurality of polyene layers, at least one polyene layer is a polyethylene layer, and at least one polyene layer is a polypropylene layer; the polyethylene layer and the polypropylene layer are tightly attached to each other; and in adjacent polyethylene and polypropylene layers, at least one layer is a polymer blend layer which contains a certain amount of ethylene-propylene copolymer. The invention has the advantages that: in the integrated structure of the polyene microporous multilayer diaphragm, the properties of porosity, puncture strength, pore size, ventilation ratio, tensile strength, breaking elongation and the like are also identical to the high properties of a single-layer diaphragm; simultaneously, the defects of the single-layer diaphragm is overcome, namely the safety of the diaphragm is improved.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

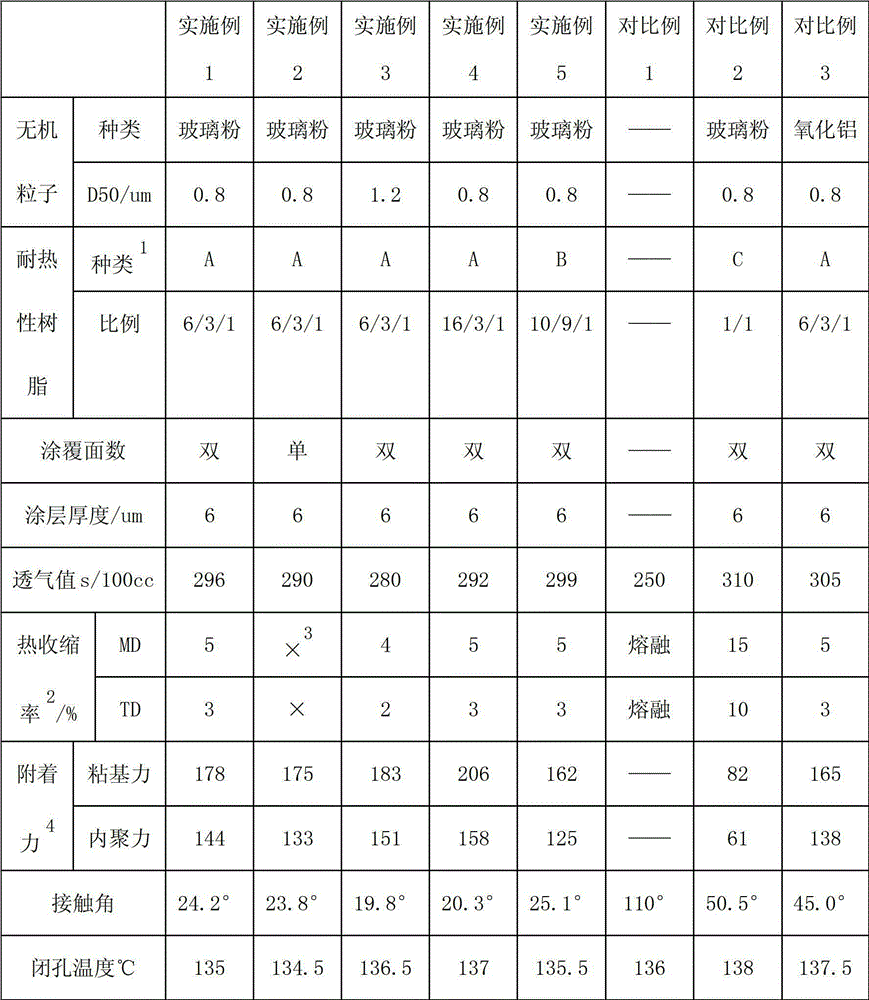

Coating composite for lithium ion secondary battery membrane and method for manufacturing membrane

ActiveCN102942831AHigh temperature resistantLow densityCell seperators/membranes/diaphragms/spacersSecondary cellsCoated surfaceLithium

The invention discloses a coating composite for a lithium ion secondary battery membrane and a method for manufacturing the membrane. The coating composite comprises heat resistant resins and inorganic non-conducting insulation particles, molecular chains of the heat resistant resins comprise oleophylic structural units, hydrophilic structural units and functional group structural units, and a thermal decomposition temperature is larger than 250 DEG C. The inorganic non-conducting insulation particles have the advantages of being high temperature resistant, low in density, rigidity and water absorption and the like; composite micro porous membranes prepared through the coating composite has the advantages of being low in hole closing temperature, high in membrane breaking temperature, low in thermal shrinkage rate, high in combining force between a heat resistant coating and a substrate, good in wettability of the heat resistant coating surface and the like simultaneously; and the membrane used for manufacturing a lithium ion secondary battery has good comprehensive properties and reliable safety performances.

Owner:河南惠强新能源材料科技股份有限公司

Polyolefin multilayer micro-porous membrane and preparation method thereof

ActiveCN102501419ALow closed cell temperatureHigh membrane rupture temperatureCell seperators/membranes/diaphragms/spacersSynthetic resin layered productsPolyolefinSurface layer

The invention discloses a polyolefin multilayer micro-porous membrane and a preparation method thereof. The middle layer of the polyolefin multilayer micro-porous membrane is a polyethylene micro-porous membrane; both surface layers of the polyolefin multilayer micro-porous membrane are micro-porous membranes which respectively contain polypropylene and polyethylene with super-high molecular weight; the polyethylene of the middle layer has the molecular weight of 1*105 to 6*105; the polypropylene of the surface layers has the molecular weight of 1*105 to 1*106; and the polyethylene of the surface layers has the molecular weight of 5*105 to 5*106. The preparation method comprises the following steps: firstly, respectively fusing to mix the raw auxiliary material of the middle layer and the raw auxiliary materials of the surface layers; putting the raw auxiliary materials of the middle layer and the surface layers into a twin-screw extruder; extruding through a multilayer co-extrusion die head; cooling; and then, drawing to manufacture the membrane, extracting and shaping to obtain the polyolefin multilayer micro-porous membrane.

Owner:河南惠强新能源材料科技股份有限公司

High fused mass strength compound isolating film and preparation method and application thereof

InactiveCN101222034ASuperior performanceImprove securityCell component detailsMembrane rupturingPolyolefin

The invention relates to a battery polyolefin isolating membrane. The composite isolating film with high fused mass strength of the invention is a microporous membrane which takes the structure of B / A two-layer or B / A / B three-layer, wherein, A layer is a copolymer membrane of polyethylene or ethylene and 5 to 50 percent other olefins or a mixture membrane of the polyethylene or the ethylene and the 5 to 50 percent other olefins, and B layer is a copolymer membrane of propylene and 0.1 to 10 percent other olefins. The invention has the advantages that: a polymer A which provides low obturator temperature and a polymer B which provides high membrane rupture temperature and high fused mass strength are led in a formulation for preparation of the polyolefin composite microporous isolating membrane, thereby the isolating membrane with low obturator temperature, high membrane rupture temperature, high fused mass strength and high use safety is obtained.

Owner:SHENZHEN SENIOR TECH MATERIAL

Polypropylene microporous membrane with three-layer compound structure and preparation method thereof

InactiveCN103990388AHigh melting temperatureLow closed cell temperatureSemi-permeable membranesCompound structureCo extrusion

The invention discloses a polypropylene microporous membrane with a three-layer compound structure and a preparation method of the polypropylene microporous membrane. The polypropylene microporous membrane with the three-layer compound structure comprises surface layers A and C and a core layer B, wherein the surface layers A and C are made from beta crystal form homo-polypropylene and the core layer B is made from beta crystal form co-polypropylene; or, the surface layers A and C are made from beta crystal form co-polypropylene and the core layer B is made from beta crystal form homo-polypropylene. The preparation method comprises the following steps: (1) respectively melting and mixing the beta crystal form homo-polypropylene and the beta crystal form co-polypropylene, carrying out co-extrusion via a three-layer compound die head and cooling the extruded molten membrane; and (2) stretching the three-layer compound beta crystal form polypropylene membrane. The polypropylene microporous membrane with the three-layer compound structure, disclosed by the invention, has high fusing temperature and low closed pore temperature simultaneously and has the advantages that when the membrane is used for battery diaphragms, closed pores can be timely molten to terminate the battery reaction and the internal short caused by fusing can be avoided, so that the safety is greatly increased.

Owner:昆明云天化纽米科技有限公司

A compound diaphragm for lithium ion battery and its making method

InactiveCN101241984ALow closed cell temperatureHigh membrane rupture temperatureSynthetic resin layered productsLaminationHigh fluxLithium-ion battery

The present invention discloses a composite isolating film used by the lithium cell which is the microporous film with B / A / B three-layer structure, wherein layer A is a copolymer film of ethene and other alkene for 1-25(weight percentage); layer B is a copolymer film of propylene and other alkene for 1-5(weight percentage). The originator of the invention adopts the copolymer film of ethene and other alkene, and adopts the copolymer film of propylene and other alkene for a minute quantity in the other layer for preparing a microporous film with B / A / B three-layer sandwich. The copolymer of ethene and other alkene provides a low pore closing temperature, the copolymer film of propylene and minute-quantity other alkene provides high film breaking temperature, high flux strength and adhesive force in the layer A formed by polythene or vinyl copolymer, thereby obtaining an isolating film which has the advantages of low pore closing temperature, high film breaking temperature, high flux strength and high using security.

Owner:SHENZHEN SENIOR TECH MATERIAL

Battery isolating membrane and preparing method thereof

InactiveCN106486632AImprove performanceAverage pore sizeCell component detailsThermoformingUltrahigh molecular weight polyethylene

The invention discloses a battery isolating membrane and a preparing method thereof. The preparing method includes the steps that extrusion, cooling molding, extraction, stretching and thermoforming are carried out on mixed raw materials to obtain the battery isolating membrane. The raw materials include ultrahigh molecular weight polyethylene with the molecular weight of 1.0*10<6>-10.0*10<6>, high-density polyethylene with the density within the range of 0.940-0.976 g / cm<3>, antioxidant and a pore-forming agent. The method includes the step of crosslinking.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Modified homo-polypropylene/high-density polyethylene/modified homo-polypropylene three-layer co-extrusion lithium battery diaphragm and preparation method therefor

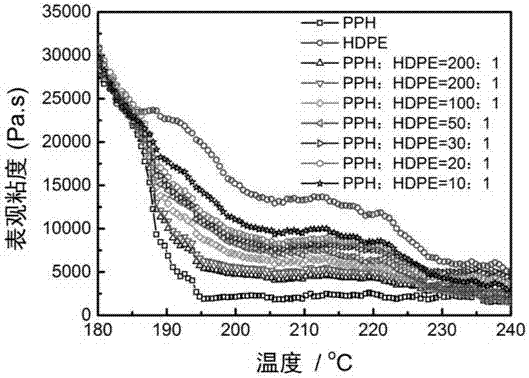

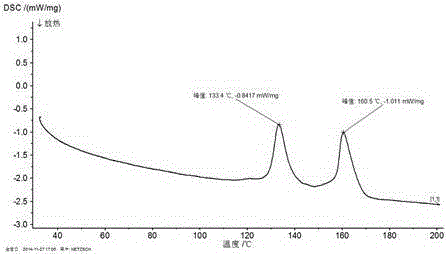

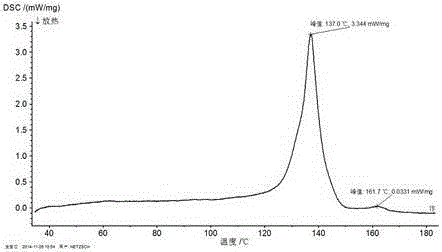

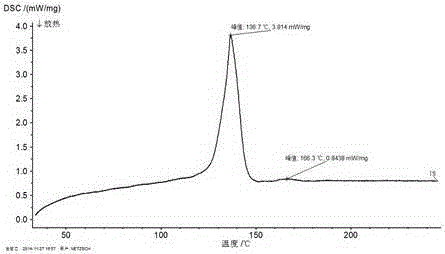

ActiveCN107316964AHigh melting temperatureLow closed cell temperatureCell seperators/membranes/diaphragms/spacersSecondary cellsLow-density polyethyleneApparent viscosity

The invention relates to a homo-polypropylene / high-density polyethylene / homo-polypropylene three-layer co-extrusion lithium battery diaphragm, wherein the diaphragm adopts an A<1> / B / A<2> three-layer structure; the surface layers A<1> and A<2> are both porous structures formed by modified homo-polypropylene; the modified homo-polypropylene is homo-polypropylene doped with high-density polyethylene, wherein the doping amount of the high-density polyethylene is equal to the doping amount corresponding to a melting temperature point which is proximal to an apparent viscosity difference value when the modified homo-polypropylene and high-density polyethylene are in a melting temperature section of 190-240 DEG C; and the middle layer B is a porous structure formed by high-density polyethylene. The prepared lithium battery diaphragm has the relatively low hole-closing temperature in the middle layer and higher melting temperature on the surface layers, so that the diaphragm melt completeness and battery safety of the lithium battery in an extreme high-temperature condition can be improved.

Owner:襄阳惠强新能源材料科技有限公司

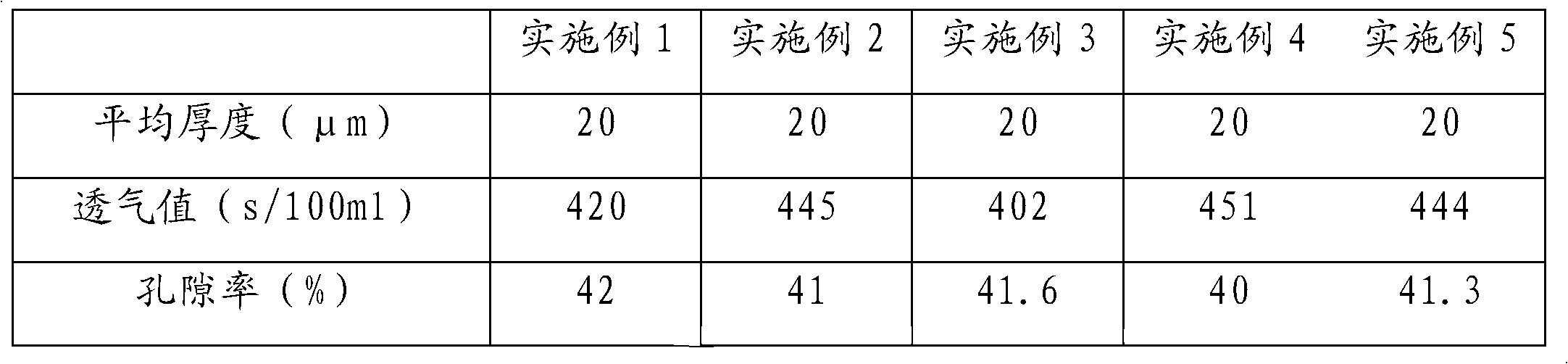

Polyolefin microporous membrane, making method thereof, and lithium ion battery

ActiveCN105355811AIncrease temperatureImprove integrityCell seperators/membranes/diaphragms/spacersSecondary cellsPolymer sciencePolyolefin

The invention relates to a polyolefin microporous membrane, a making method thereof, and a lithium ion battery. The skeleton structure of the microporous membrane is formed by a polypropylene and polyethylene two-phase continuous phase, wherein the mass percentage of polypropylene resin is 50-65%, the mass percentage of polyethylene resin is 35-50%, the intrinsic viscosities of the polypropylene resin and the polyethylene resin are 200-1000ml / g respectively, and a difference between the intrinsic viscosities of the polypropylene resin and the polyethylene resin is 100ml / g. The microporous membrane has the advantages of large safety window, excellent integrity of a high temperature melt, and great improvement of the safety performance of the battery when the microporous membrane is used in the lithium ion battery.

Owner:乐凯胶片股份有限公司

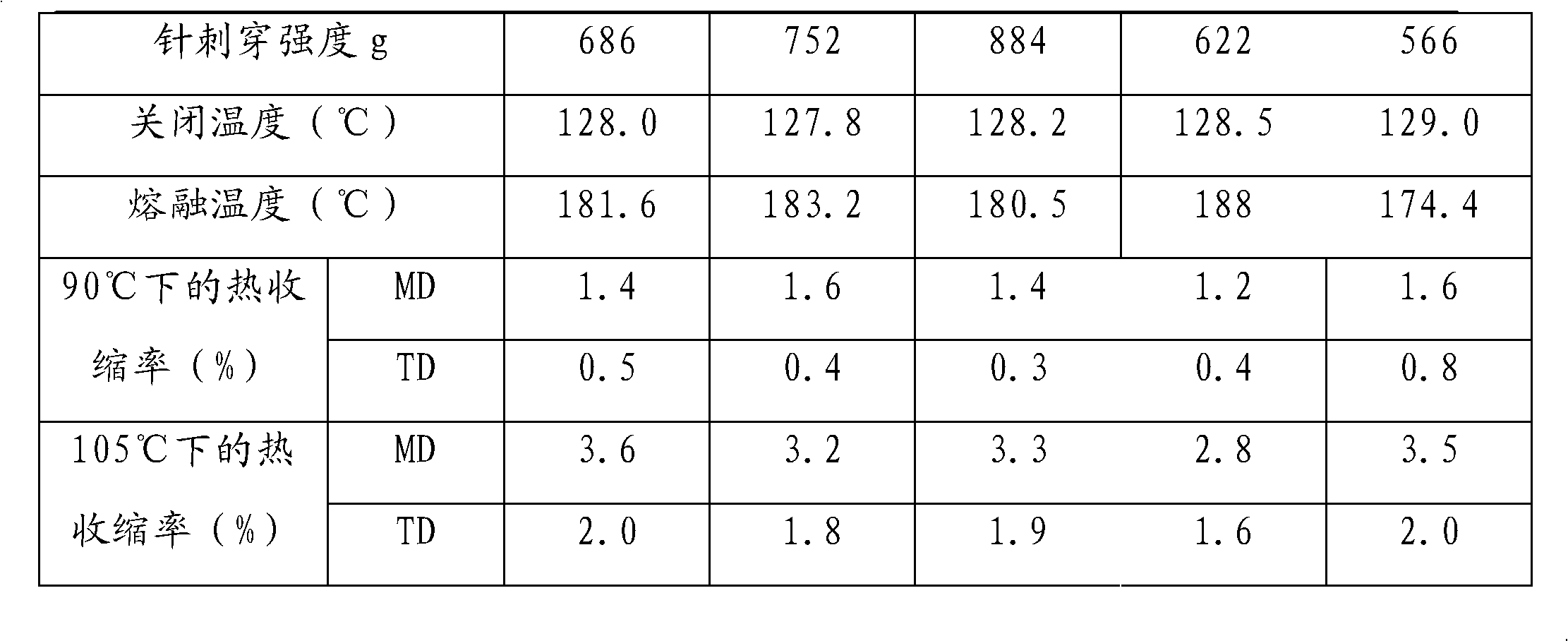

Preparation method of power lithium battery diaphragm

InactiveCN102569699ALow closed cell temperatureHigh melting temperatureCell seperators/membranes/diaphragms/spacersLi-accumulatorsPorosityPolymer science

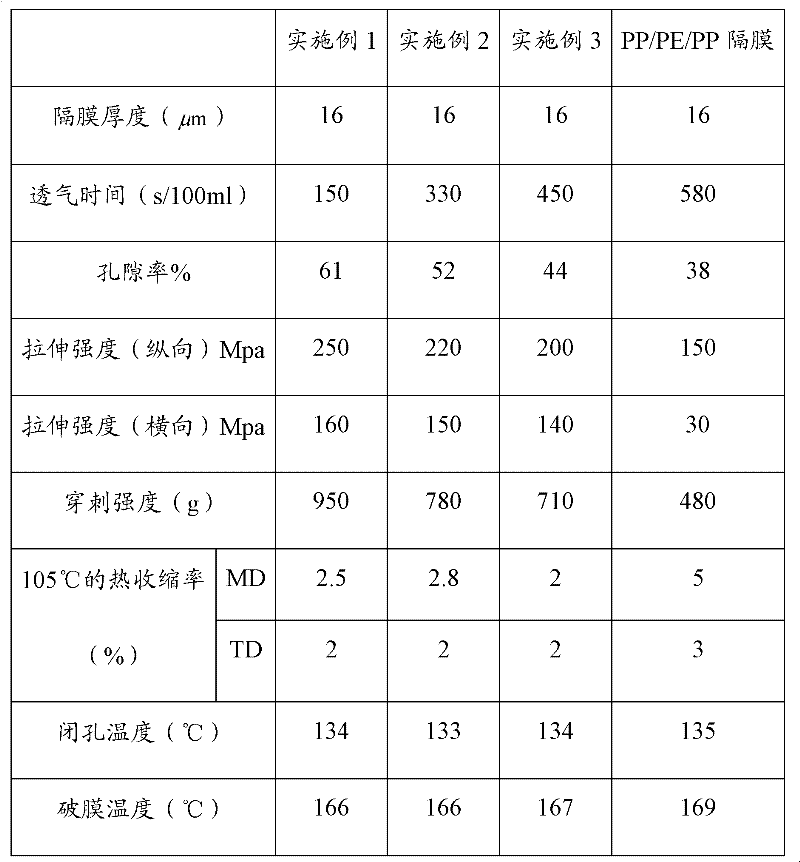

The invention relates to the technical field of lithium batteries, in particular to a preparation method of a power lithium battery diaphragm. The preparation method comprises the following steps of dissolving, assistant adding, extruding, sheeting casting, diaphragm forming by drawing, shaping and the like, and a polyolefin resin microporous membrane, namely a lithium battery diaphragm, is formed finally. The diaphragm prepared by the method is 10-25 mu m thick, has a preferential porosity being 40-70%, and 105 DEG C heat shrinkage rate below 5%. The prepared diaphragm has the advantages of low closed-pore temperature, high fusing temperature, low heat shrinkage rate, good mechanical properties and has excellent safety performance when used as a power lithium battery diaphragm. In addition, the power lithium battery diaphragm is a polyolefin resin microporous sinlge-layer membrane which has good heat stability after being subjected to process steps such as drawing and shaping.

Owner:FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

Preparation method of special composite coating diaphragm for lithium battery

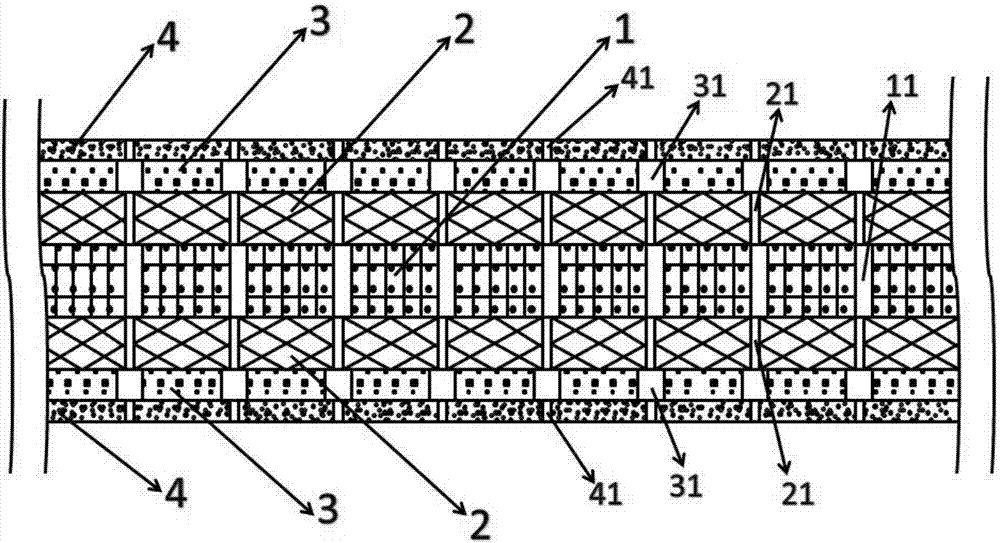

ActiveCN107994183ALow closed cell temperatureHigh membrane rupture temperatureCell seperators/membranes/diaphragms/spacersBoehmiteSurface modification

The invention discloses a special composite coating diaphragm for a lithium battery. The special composite coating diaphragm comprises a microporous membrane, resin layers, ceramic layers and acrylicadhesive layers; the special composite coating diaphragm is characterized in that the resin layers coat the upper surface and the lower surface of the microporous membrane; one ceramic layer coats theouter side of each resin layer; one acrylic adhesive layer coats the outside of each ceramic layer; first micropores are formed in the microporous membrane; second micropores are formed in each resinlayer; third micropores are formed in each ceramic layer; and fourth micropores are formed in each acrylic adhesive layer. A preparation method of the special composite coating diaphragm for the lithium battery comprises the following steps of surface modification of boehmite alumina, preparation of the microporous membrane, preparation of a polymer composite membrane, preparation of modified boehmite alumina slurry, coating of the modified boehmite alumina slurry and bonding forming of an acrylic adhesive, thereby obtaining the special composite coating diaphragm for the lithium battery. According to the composite coating diaphragm, the security problem of a high-energy density battery core can be well solved.

Owner:桑顿新能源科技(长沙)有限公司

Coating slurry for diaphragm, composite heat resisting diaphragm and preparation method of composite heat resisting diaphragm

ActiveCN106252570ALow closed cell temperatureEasy to aggregateCell seperators/membranes/diaphragms/spacersSecondary cellsMetallurgySlurry

The invention provides coating slurry for a diaphragm, a composite heat resisting diaphragm, and a preparation method of the composite heat resisting diaphragm, wherein the coating slurry for the diaphragm comprises and is prepared from the following materials: organic particles, ceramic particles, a binder and water; by solid content, the organic particles account for 24.5%-99.5% by weight, the ceramic particles account for 0-75% by weight, and the binder accounts for 0.5%-15%; the solid content is 20%-50% of the total weight of the coating slurry. Compared with a diaphragm in the prior art, the closed pore temperature in an electrolyte / battery is lower, and a current is cut off before the accelerated heat release of the battery.

Owner:TIANJIN ENERGIES

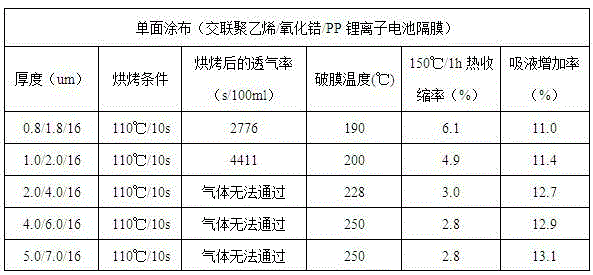

Lithium ion battery diaphragm and preparation method

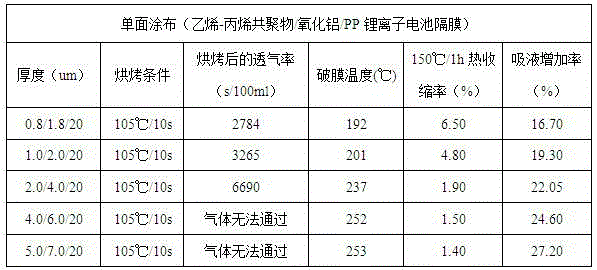

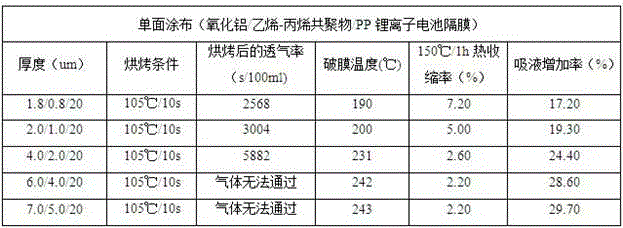

ActiveCN104022250ALow closed cell temperatureAvoid thermal runawayCell component detailsPolyolefinPhysical chemistry

The invention discloses a lithium ion battery diaphragm and a preparation method thereof. The ion battery diaphragm comprises a diaphragm base material, wherein the surface of the diaphragm base material is coated with a polyolefin coating, and the coating thickness of the polyolefin coating is 1 to 4 micrometers. The diaphragm base material is coated with the polyolefin coating, and an effect for reducing the obturator temperature can be realized, so that the worsening of a thermal runaway can be prevented, when the temperature in a lithium ion battery reaches the obturator temperature, current can be disconnected at the first time, an effect for protecting the lithium ion battery can be realized, the thermal shrinkage rate of the lithium ion battery diaphragm after being roasted for 1h under the temperature of 150DEG C is less than 5 percent; compared with a non-coated lithium ion battery diaphragm, for the lithium ion battery diaphragm disclosed by the invention, the liquid absorption addition rate is 10 to 28 percent, and the charging-discharging cycling efficiency of the lithium ion battery can be further improved.

Owner:FOSHAN YINGBOLAI TECH

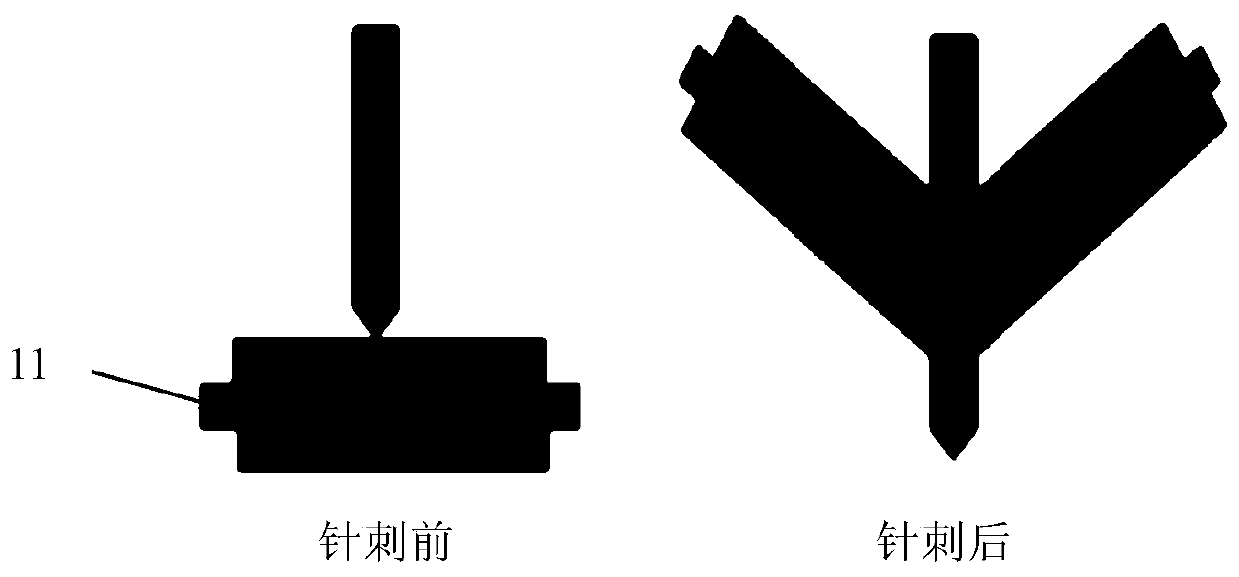

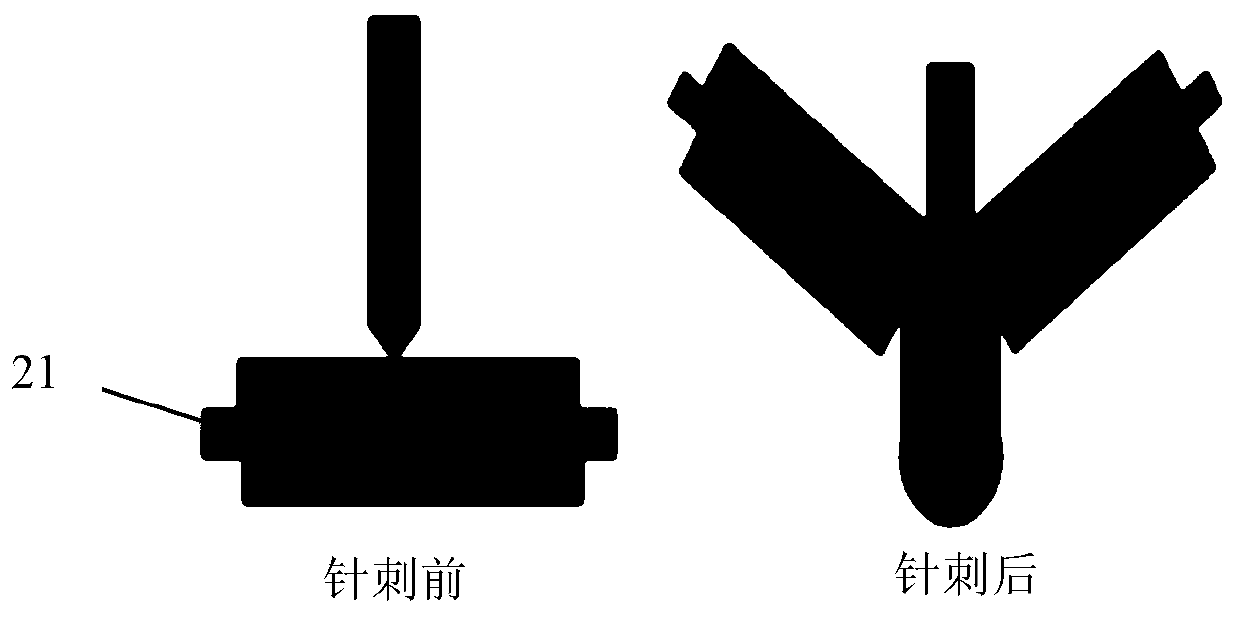

Battery diaphragm and preparation method thereof, battery and terminal

ActiveCN111416086AReduced puncture riskReduce the probability of positive and negative short circuitLi-accumulatorsCell component detailsPolyolefinPolymer chemistry

The embodiment of the invention provides a battery diaphragm. The diaphragm comprises a polyolefin porous diaphragm base material, wherein the polyolefin porous diaphragm base material comprises polyethylene resin, the elongation of the polyolefin porous diaphragm base material in the MD direction is greater than 120%, the polyolefin porous diaphragm base material has an elongation rate of more than 120% in the TD direction, the polyolefin porous diaphragm base material has a primary heating crystallinity of less than 65% and a secondary heating crystallinity of less than 55%, which are measured by a differential scanning calorimeter, and the difference between the primary heating crystallinity and the secondary heating crystallinity is less than 12%. The battery diaphragm has the characteristics of high elongation and low hole closing temperature, and by implementing the embodiment of the invention, the diaphragm rupture risk can be reduced when a battery cell is mechanically abused,and meanwhile, diaphragm pores are closed in advance when the battery cell is thermally abused, so the safety of the battery cell is improved. The embodiment of the invention further provides a preparation method of the battery diaphragm as well as a battery and a terminal adopting the battery diaphragm.

Owner:HUAWEI TECH CO LTD

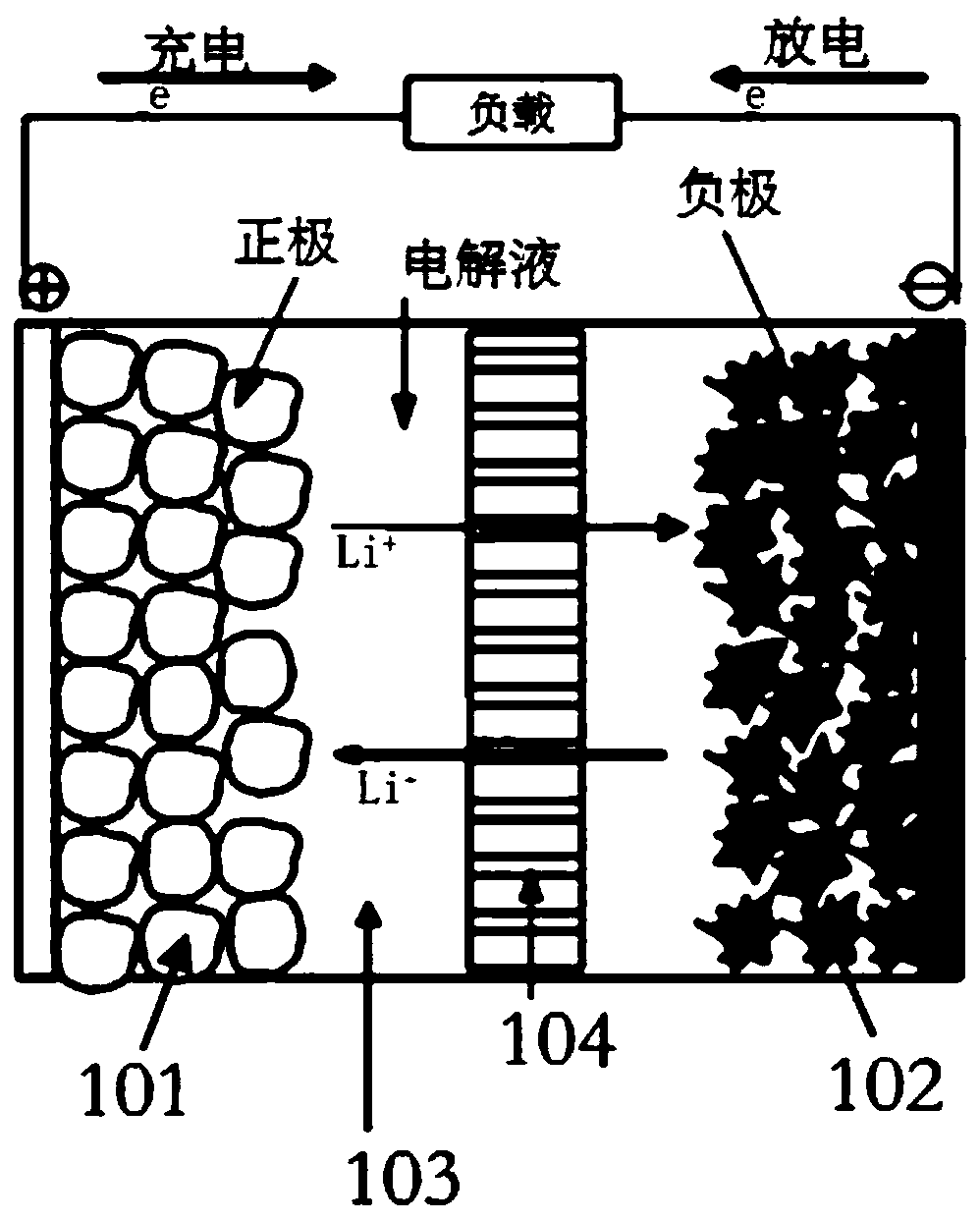

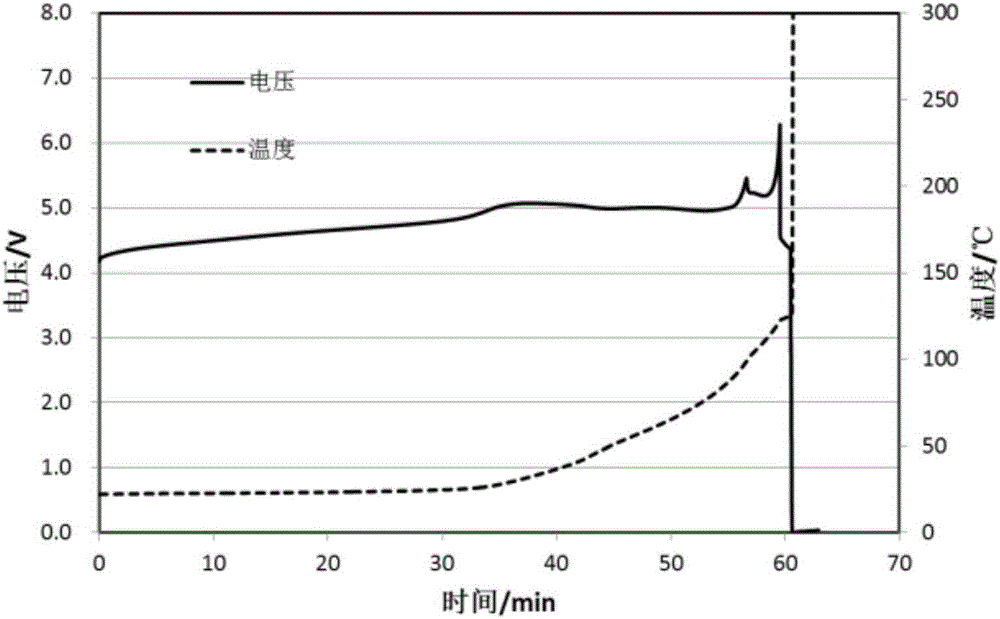

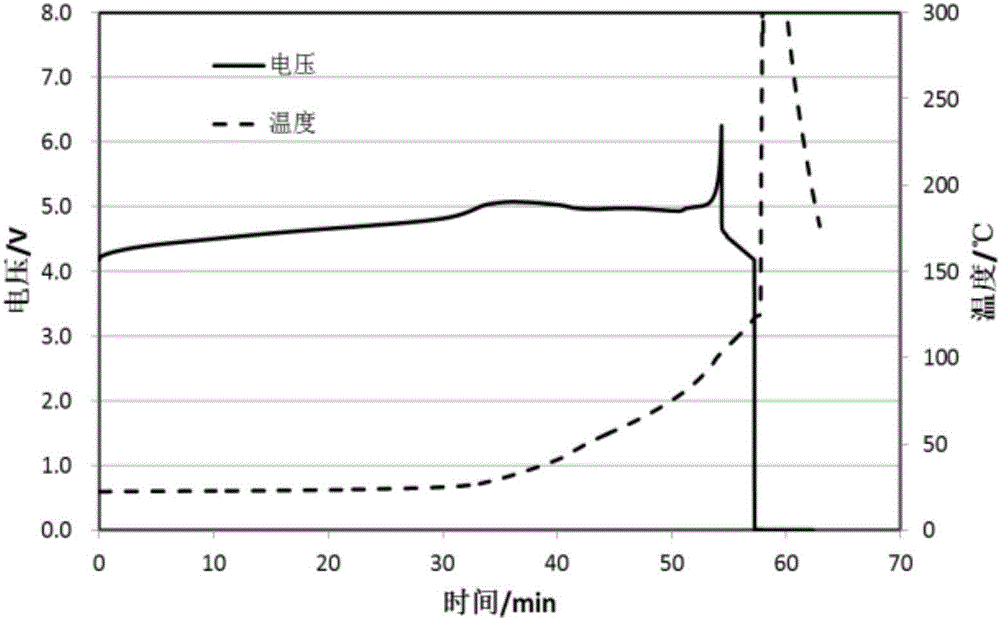

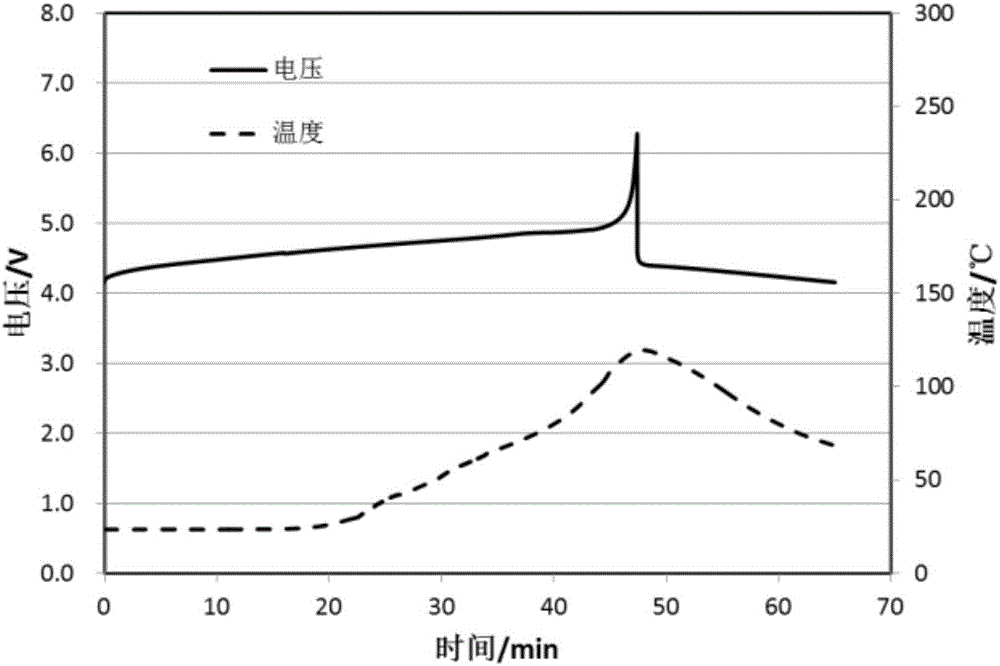

Secondary battery

ActiveCN106848162ALow closed cell temperaturePrevent thermal runaway from occurringCell component detailsSecondary cells servicing/maintenanceDecompositionVoltage

The invention relates to the field of energy storage materials, in particular to a secondary battery which comprises an anode piece, a cathode piece, a diaphragm and electrolyte. The diaphragm comprises diaphragm matrixes and coatings, the coatings are arranged on the surfaces of the diaphragm matrixes and comprise polymer micro-spheres, and the softening temperatures of the polymer micro-spheres are 50-120 DEG C; the electrolyte comprises additives, and the decomposition voltages of the additives are 4.4V-4.8V. The secondary battery has the advantages that sufficient hole closing of the diaphragm can be synergistically promoted by the diaphragm with the polymer micro-sphere coatings and the additives, the polymer micro-spheres with the low softening temperatures are coated on the surfaces of the diaphragm, and accordingly the hole closing temperature of the diaphragm can be lowered; the voltages can be increased, accordingly, the reactive additives can be triggered, self-reaction can be quickly carried out at over-charge initial phases to generate heat, and melting of the polymer micro-spheres and large-area hole closing of the diaphragm can be promoted.

Owner:JIANGSU CONTEMPORARY AMPEREX TECHNOLOGY LIMITED

Heat-shrinkage-resistant lithium ion battery diaphragm and polyethylene composition adopted by same

ActiveCN106328859ALow costWide variety of sourcesCell seperators/membranes/diaphragms/spacersSecondary cellsHigh diaphragmPhysical chemistry

The invention provides a polyethylene composition for preparing a heat-shrinkage-resistant lithium ion battery diaphragm. The composition comprises high-molecular polyethylene, ultra-high-molecular polyethylene and an optional additive. The lithium ion battery diaphragm prepared from the composition has high heat shrinkage resistance, high tensile strength, high puncture strength, relatively high diaphragm-rupture temperature and relatively low closed-hole temperature, thereby ensuring safety in preparation and usage of the lithium ion battery.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

High-temperature resistant diaphragm material of lithium ion battery and preparation method of high-temperature resistant diaphragm material

ActiveCN105374972AImprove the heat absorption effectLower operating temperatureCell seperators/membranes/diaphragms/spacersSecondary cellsBoPETLithium-ion battery

The invention discloses a high-temperature resistant diaphragm material of a lithium ion battery and a preparation method of the high-temperature resistant diaphragm material. The diaphragm material comprises a modified nylon membrane and a cooling coating layer, wherein the two surfaces of the modified nylon membrane are coated with the cooling coating layer. The preparation method of the diaphragm material comprises the following steps of 1, taking the modified nylon membrane as a base membrane, and coating the two surfaces of the modified nylon membrane with a cooling coating to form the cooling coating layer and obtain a composite membrane; 2, carrying out vacuum drying on the composite membrane in the step 1, and then carrying out bidirectional stretching on the composite membrane; and 3, carrying out plasma processing on the stretched composite membrane in the step 2 to obtain the finished diaphragm. The diaphragm material has the characteristics of uniform pore distribution, excellent cooling performance, low high-temperature thermal shrinkage rate, high liquid absorption rate and high application safety.

Owner:浙江锂盾储能材料技术有限公司

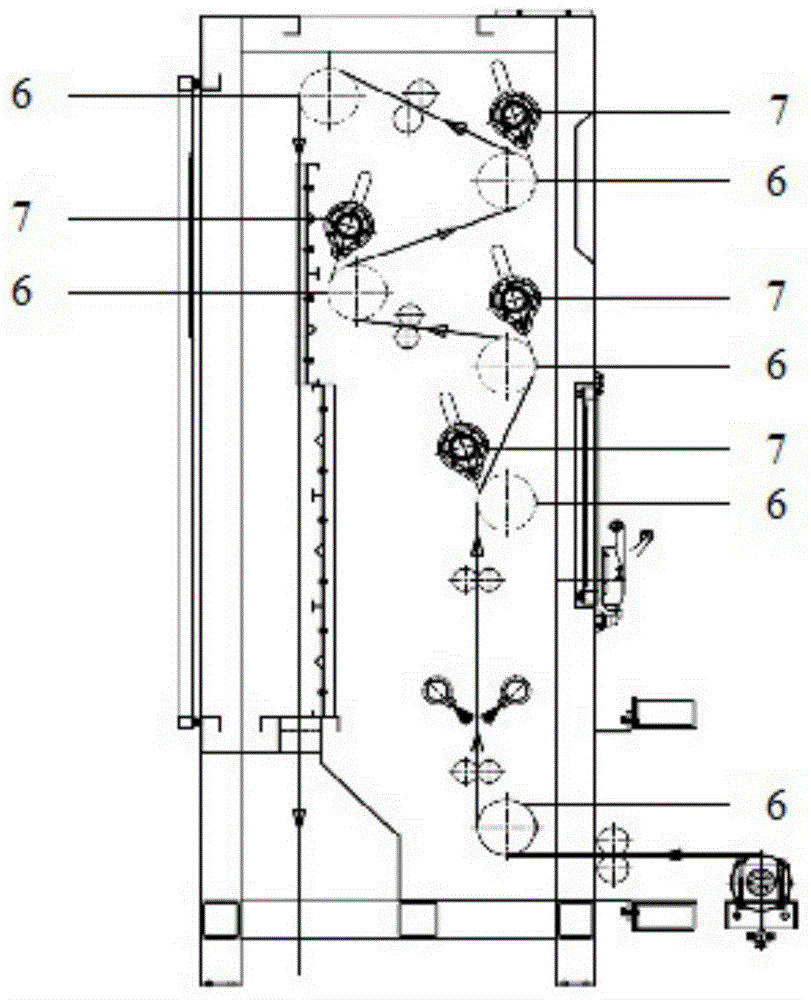

Composite diaphragm with excellent high temperature performance and pore closing performance and preparation method thereof

ActiveCN103915592AImprove thermal safetyImprove heat resistanceCell component detailsCompound aPolypropylene

The invention discloses a composite diaphragm with excellent high temperature performance and pore closing performance. The composite diaphragm is prepared by compounding a polyimide electrostatic spinning layer, a PE (Poly Ethylene) microporous membrane layer and a PP (Polypropylene) microporous membrane layer in sequence. The invention further discloses a preparation method of the composite diaphragm. The composite diaphragm has the advantages of high safety as well as excellent high temperature performance and pore closing performance.

Owner:SENIOR (NANTONG) NEW MATERIAL TECH CO LTD

Multilayer micro-porous polyolefin diaphragm and production method thereof

ActiveCN107808943AHigh porosityImprove uniformitySecondary cellsCell component detailsPolyolefinHeat resistance

The invention provides a production method of a multilayer micro-porous polyolefin diaphragm. The method comprises the following steps: 1, respectively carrying out melt extrusion on polypropylene andinorganic composite polyethylene through adopting three extrusion casting machines, and carrying out multilayer bush die casting to obtain a multilayer composite cast film, wherein the polypropyleneis positioned at the outer layer, and the inorganic composite polyethylene is positioned at the middle layer; 2, carrying out heat treatment on the multilayer composite cast film at 125 DEG C for 0.5h to obtain a multilayer heat-treated film; 3, carrying out cold drawing on the multilayer heat-treated film at -20 DEG C under a drawing ratio of 50% to obtain a heat-treated film having initial porous nucleuses; 4, carrying out hot drawing on the heat-treated film having initial porous nucleuses at 125 DEG C under a drawing ratio of 90%; and 5, fixing the micro-porous film obtained in step 4 at125 DEG C for 20 min in order to obtain the multilayer micro-porous polyolefin diaphragm. The produced micro-porous diaphragm has the advantages of uniform aperture, good heat resistance and good stability.

Owner:GUANGDONG UNIV OF TECH

High-safety diaphragm and battery

PendingCN113054324AIncrease temperatureImprove heat resistanceSecondary cellsCell component detailsPorous substrateHigh diaphragm

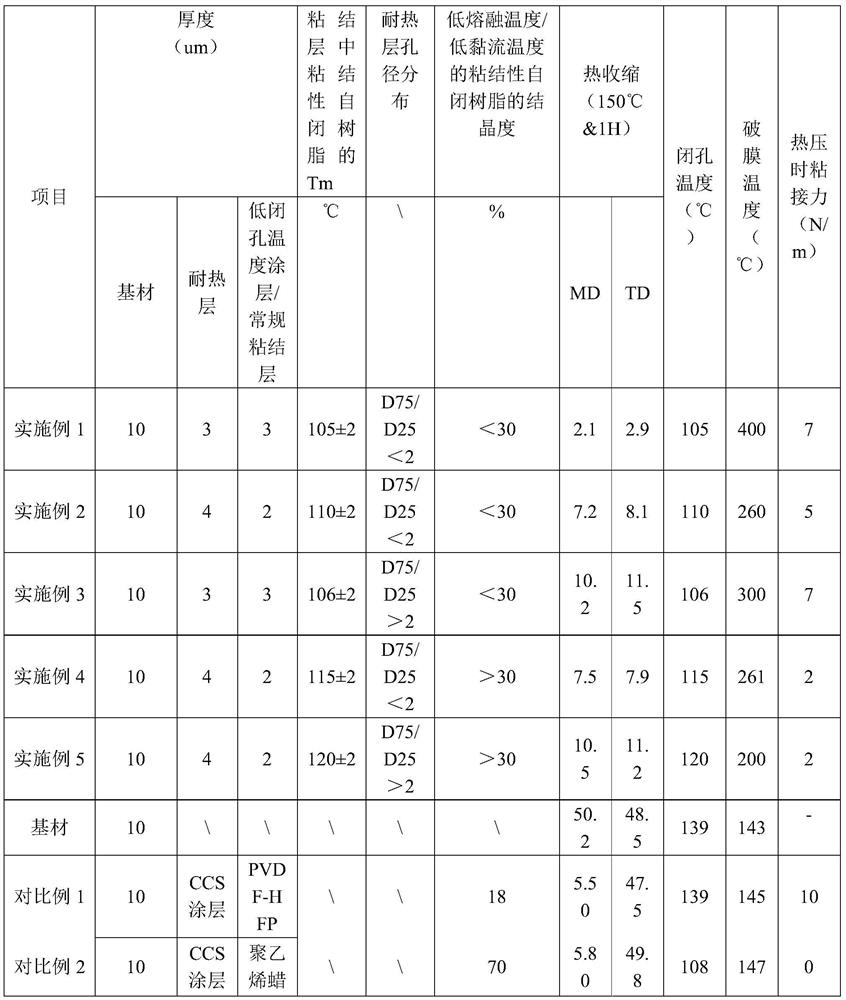

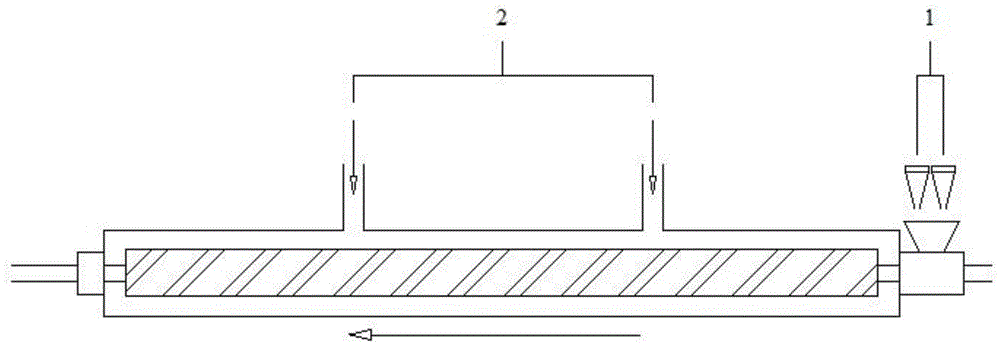

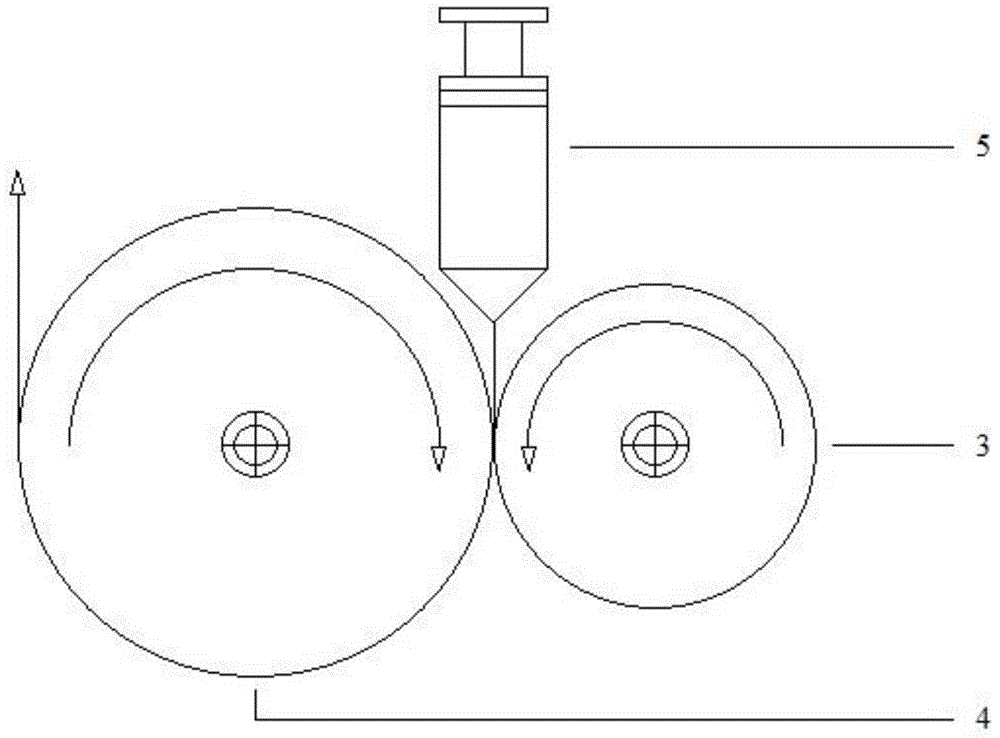

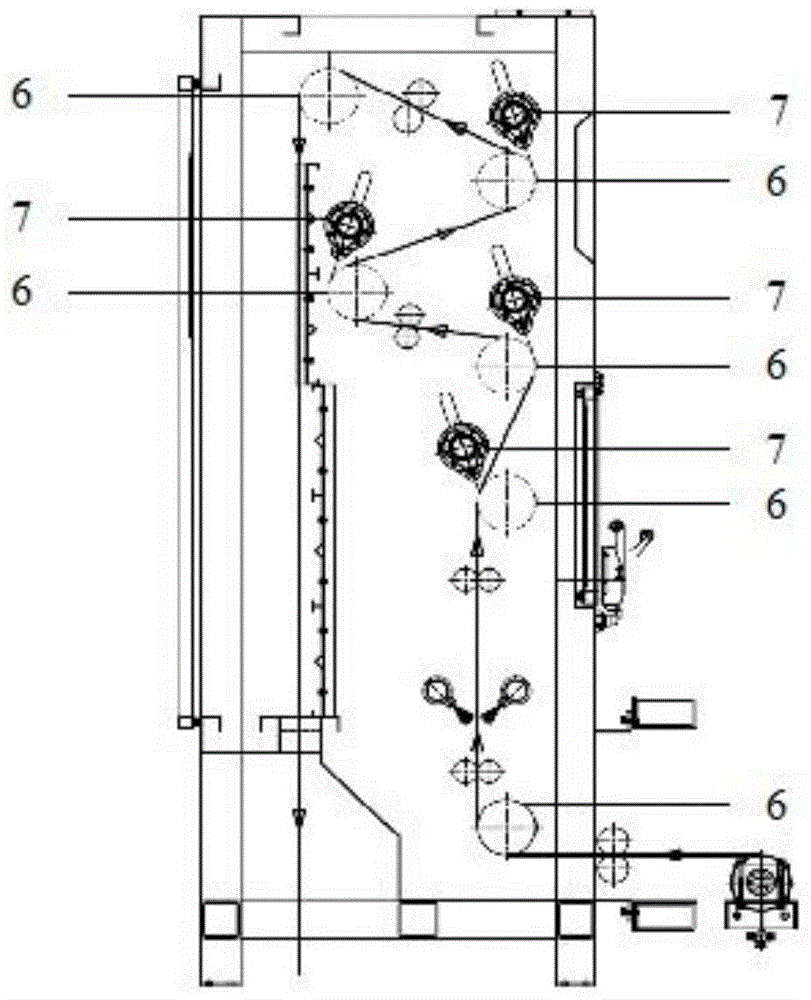

The invention relates to the field of battery diaphragms, in particular to a high-safety diaphragm and a battery, the high-safety diaphragm comprises a porous base material, a heat-resistant coating coated on at least one side of the porous base material, and a low-hole-closing-temperature coating coated on the porous base material or the heat-resistant coating; the heat-resistant coating comprises heat-resistant resin; the low-hole-closing-temperature coating comprises a self-hole-closing material; and the self-closing material comprises cohesive self-closing resin with a low melting temperature or a low viscous flow temperature. The diaphragm rupture temperature and the heat-resistant shrinkage performance of the diaphragm are improved by arranging the heat-resistant coating, meanwhile, the low-pore-closing-temperature coating is introduced, and cohesive self-closing resin with low melting temperature or low viscous flow temperature can be rapidly melted or softened at a certain temperature to close pores of the porous base membrane, so that the purpose of reducing the pore closing temperature is achieved, the difference value between the hole closing temperature and the membrane breaking temperature is increased, and the high-safety diaphragm is obtained, so that the safety of the battery is enhanced.

Owner:ZHUHAI ENERGY NEW MATERIALS TECH CO LTD

Heat shrinkage-resistant lithium-ion battery separator

ActiveCN106328867AExcellent heat shrinkage resistanceImprove performanceSecondary cellsCell component detailsPorosityInternal resistance

The invention discloses a heat shrinkage-resistant lithium-ion battery separator, which comprises a first outer layer, a second outer layer and an inner layer clamped between the first outer layer and the second outer layer, wherein the first outer layer, the second outer layer and the inner layer have different micropore structures. The heat shrinkage-resistant lithium-ion battery separator disclosed by the invention has excellent heat shrinkage resistance and good overall performance, has high puncture strength and tensile strength when reaching a relatively low thickness, can be applied to a relatively small battery and is not easily damaged in the installation process; a plurality of physical properties are taken into account; meanwhile, the heat shrinkage-resistant lithium-ion battery separator has good air permeability and porosity and small internal resistance; the capacity and the cycle performance of the battery are improved; and furthermore, the heat shrinkage-resistant lithium-ion battery separator also has relatively low closed pore temperature and membrane rupture temperature and high safety.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com