Modified homo-polypropylene/high-density polyethylene/modified homo-polypropylene three-layer co-extrusion lithium battery diaphragm and preparation method therefor

A high-density polyethylene, homopolypropylene technology, applied in the direction of separator/film/diaphragm/spacer element, secondary battery, battery pack components, etc., can solve problems such as affecting the stability of the diaphragm, and achieve good strength , Improve the integrity and battery safety, the effect of good surface plasticization uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A modified homopolypropylene / high-density polyethylene / modified homopolypropylene three-layer co-extruded lithium battery diaphragm, which is A 1 / B / A 2 Three-layer structure with a total thickness of 12 μm; surface layer A 1 、A 2 Both are porous structures formed by modified homopolypropylene, which is homopolypropylene (PPH) doped with high-density polyethylene (HDPE), and the weight ratio of PPH / HDPE in modified homopolypropylene =30:1; the middle layer B is a porous structure formed by high-density polyethylene (HDPE); and the surface layer A 1 、A 2 The thicknesses are all 3 μm, and the thickness of the middle layer B is 6 μm.

[0032] The preparation method of the above-mentioned modified homopolypropylene / high-density polyethylene / modified homopolypropylene three-layer co-extruded lithium battery diaphragm, the specific steps are as follows:

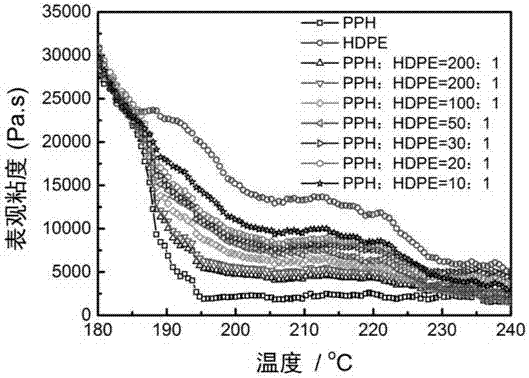

[0033] 1) Preparation of surface material modified homopolypropylene: Homopolypropylene (PPH, Daehan Petrochemical, S...

Embodiment 2

[0042] A modified homopolypropylene / high-density polyethylene / modified homopolypropylene three-layer co-extruded lithium battery diaphragm, which is A 1 / B / A 2 Three-layer structure with a total thickness of 35 μm; surface layer A 1 、A 2 Both are porous structures formed by modified homopolypropylene, which is homopolypropylene (PPH) doped with high-density polyethylene (HDPE), and the weight ratio of PPH / HDPE in modified homopolypropylene =45:1; the middle layer B is a porous structure formed by high-density polyethylene (HDPE); and the surface layer A 1 、A 2 The thicknesses are all 10 μm, and the thickness of the middle layer B is 15 μm.

[0043] The preparation method of the above-mentioned modified homopolypropylene / high-density polyethylene / modified homopolypropylene three-layer co-extruded lithium battery diaphragm, the specific steps are as follows:

[0044] 1) Preparation of surface material modified homopolypropylene: Homopolypropylene (PPH, Yanshan Petrochemical...

Embodiment 3

[0053] A modified homopolypropylene / high-density polyethylene / modified homopolypropylene three-layer co-extruded lithium battery diaphragm, which is A 1 / B / A 2 Three-layer structure with a total thickness of 9 μm; surface layer A 1 、A 2 Both are porous structures formed by modified homopolypropylene, which is homopolypropylene (PPH) doped with high-density polyethylene (HDPE), and the weight ratio of PPH / HDPE in modified homopolypropylene =90:1; the middle layer B is a porous structure formed by high-density polyethylene (HDPE); and the surface layer A 1 、A 2 The thicknesses are all 2 μm, and the thickness of the middle layer B is 5 μm.

[0054] The preparation method of the above-mentioned modified homopolypropylene / high-density polyethylene / modified homopolypropylene three-layer co-extruded lithium battery diaphragm, the specific steps are as follows:

[0055] 1) Preparation of surface material modified homopolypropylene: Homopolypropylene (PPH, Yanshan Petrochemical, F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com