Patents

Literature

741results about How to "High melting temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

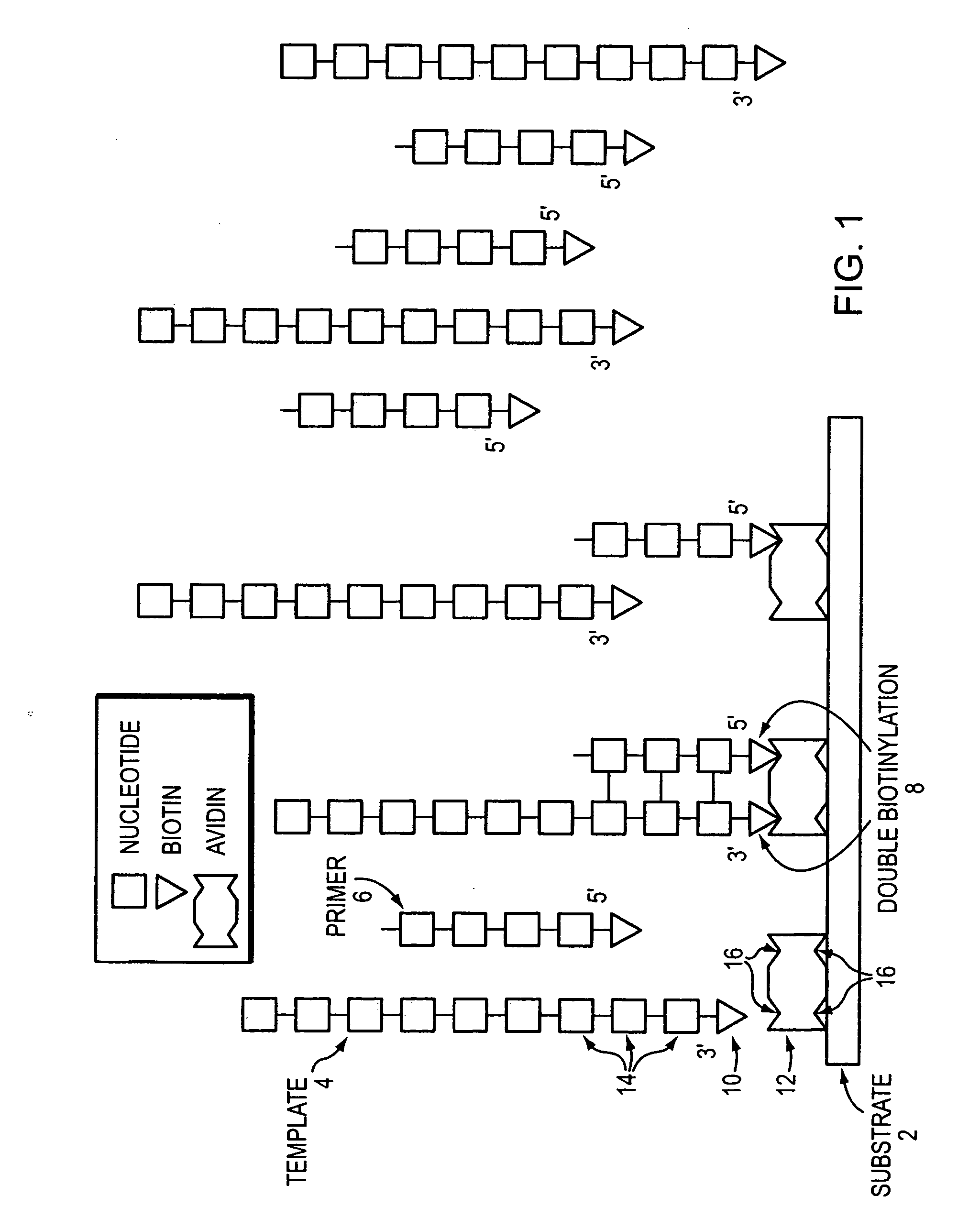

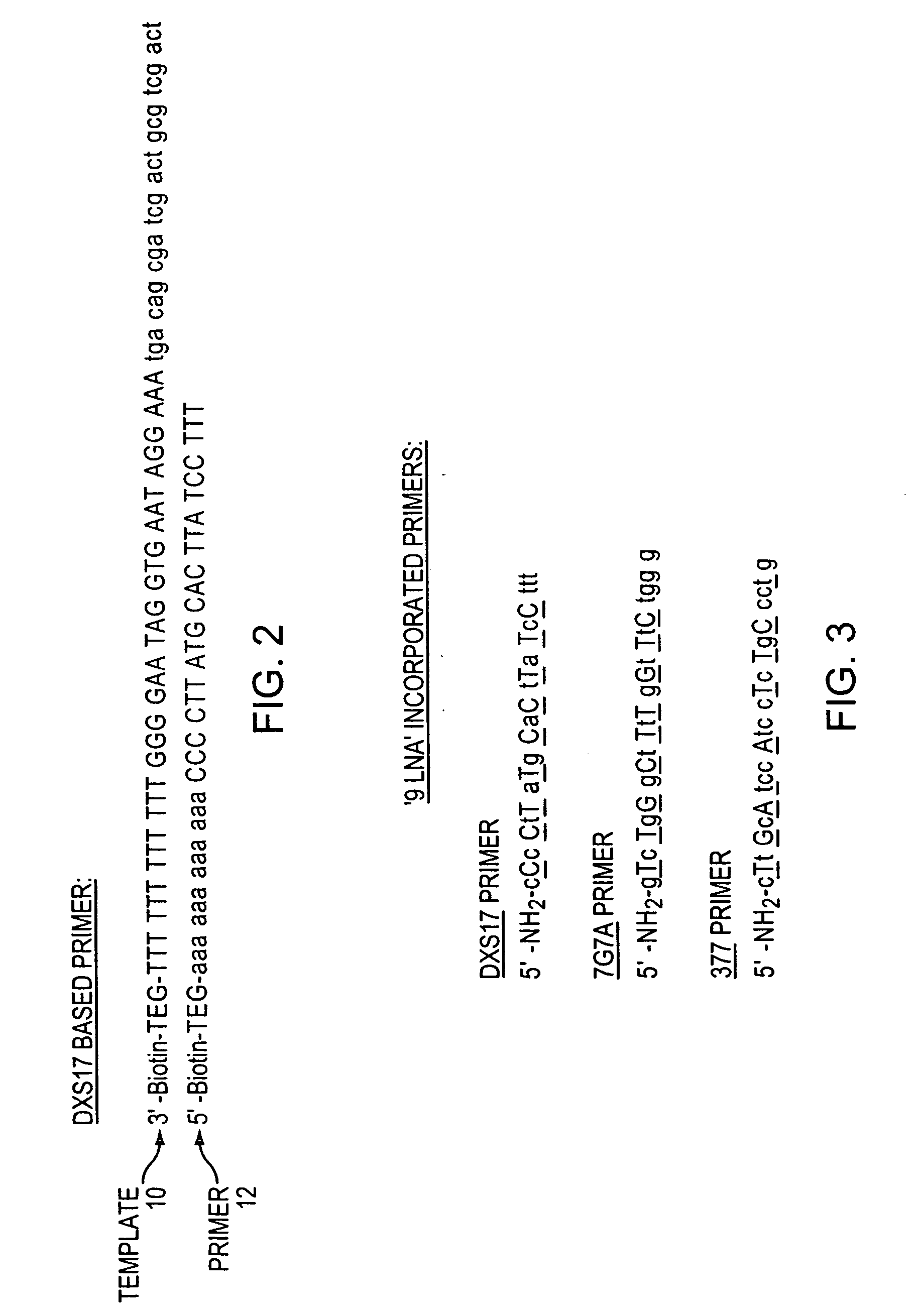

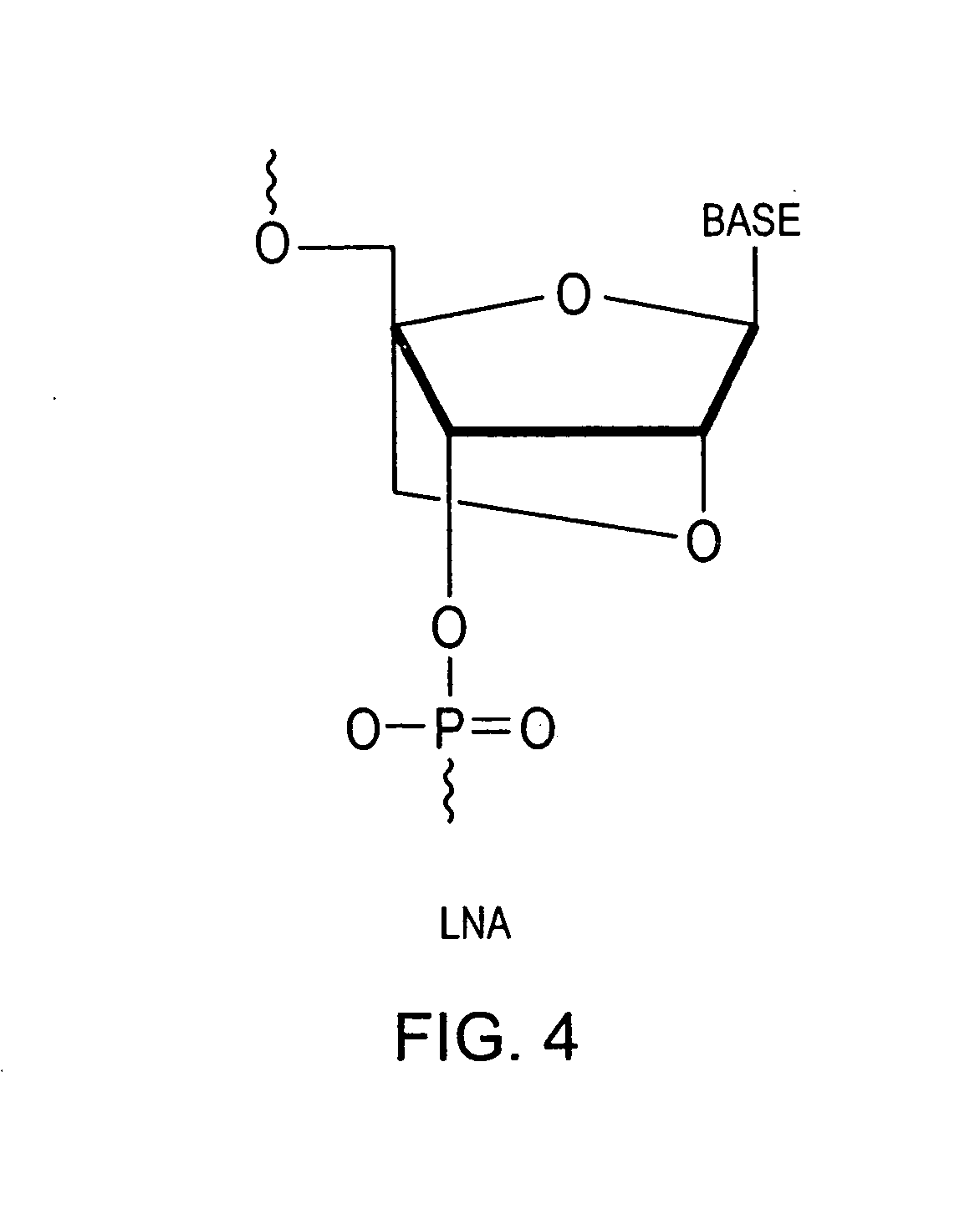

Stabilizing a nucleic acid for nucleic acid sequencing

InactiveUS20060252077A1Reduce lossesHigh affinityBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acid sequencingComputational biology

The invention provides methods for sequencing a nucleic acid comprising stabilizing a primer / target nucleic acid duplex on a substrate. Methods of the invention generally contemplate the use of a dual-anchored primer / target nucleic acid duplex, or a stabilizing molecule in a single molecule sequencing reaction.

Owner:FLUIDIGM CORP

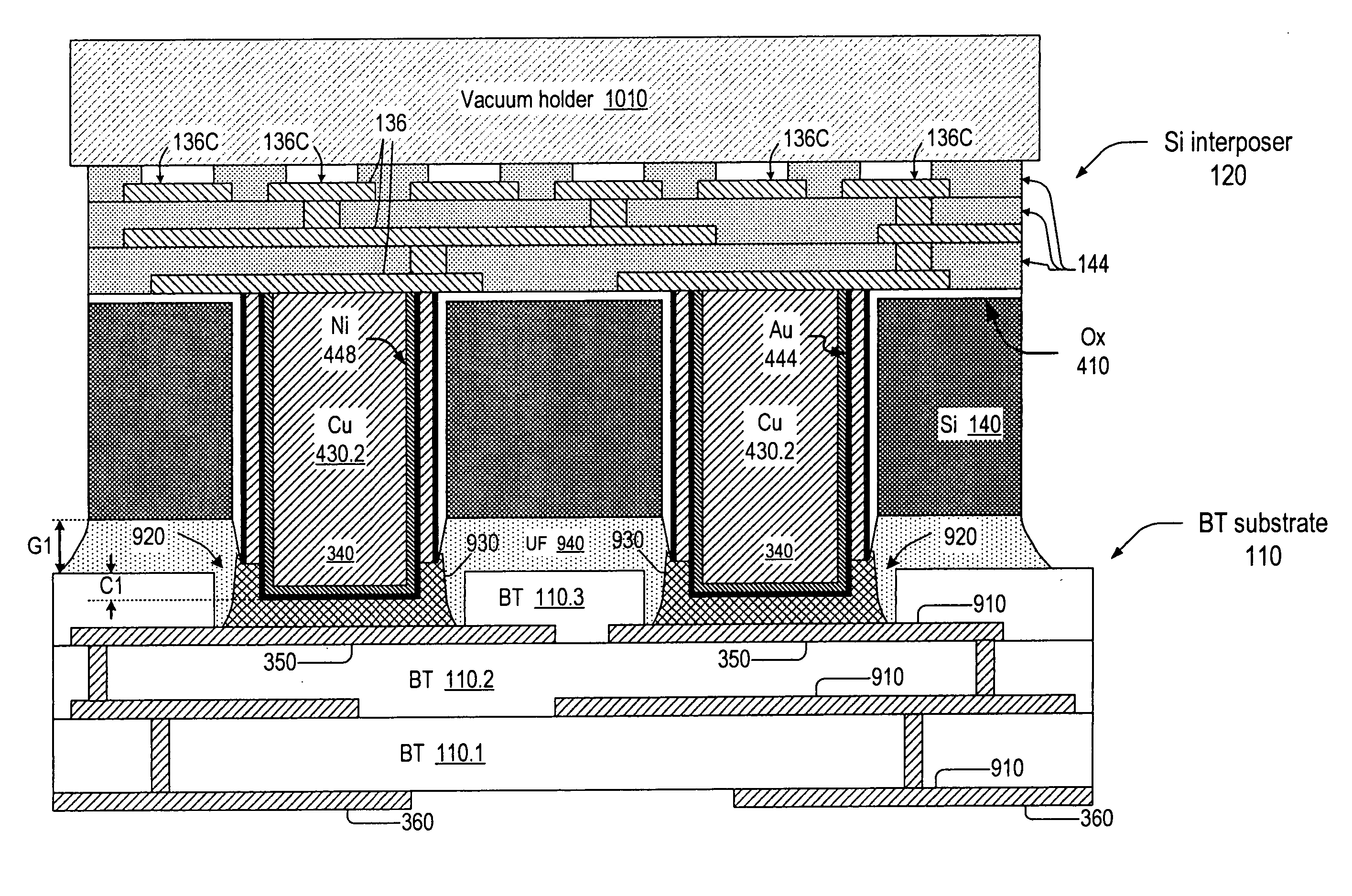

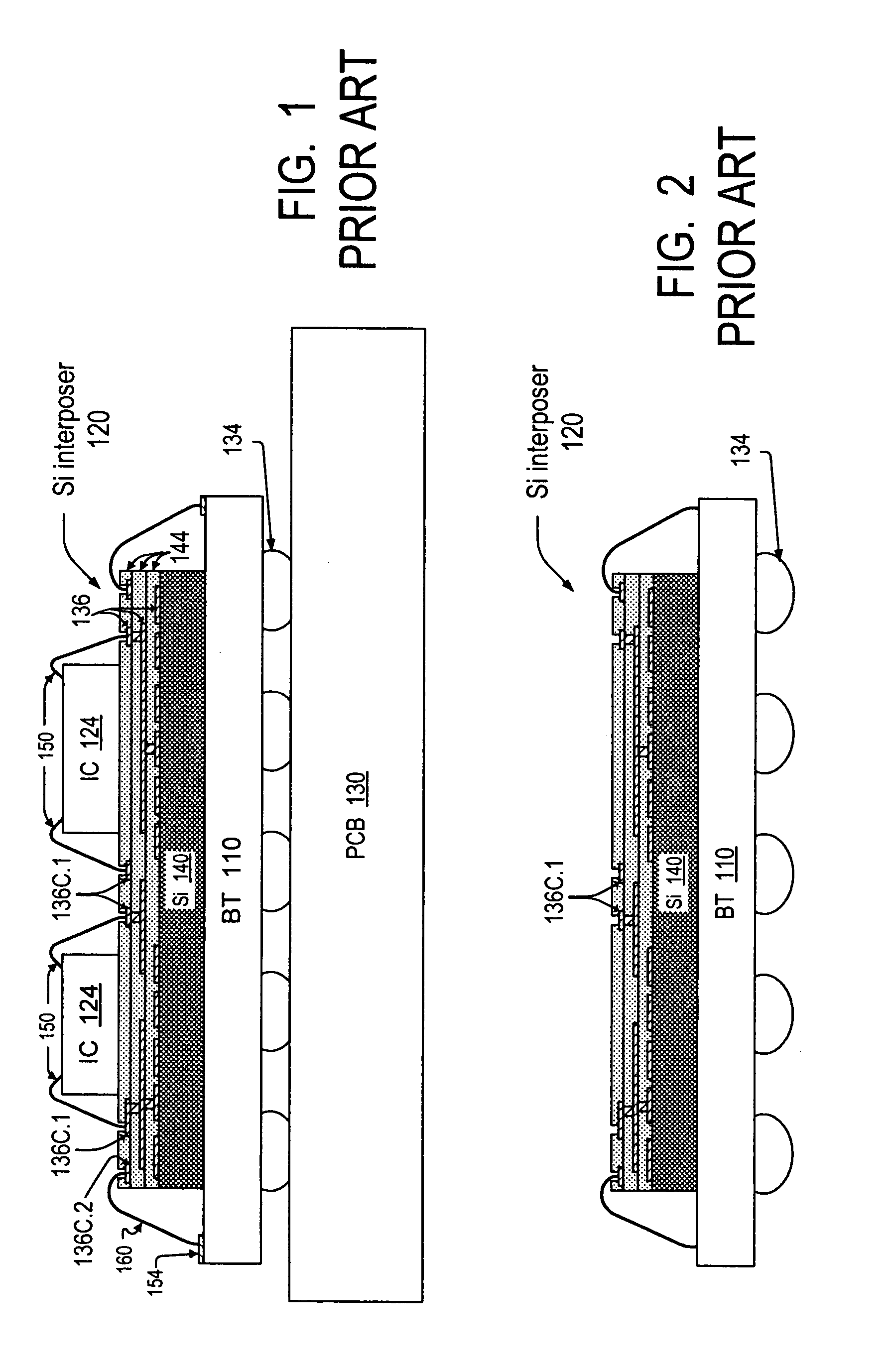

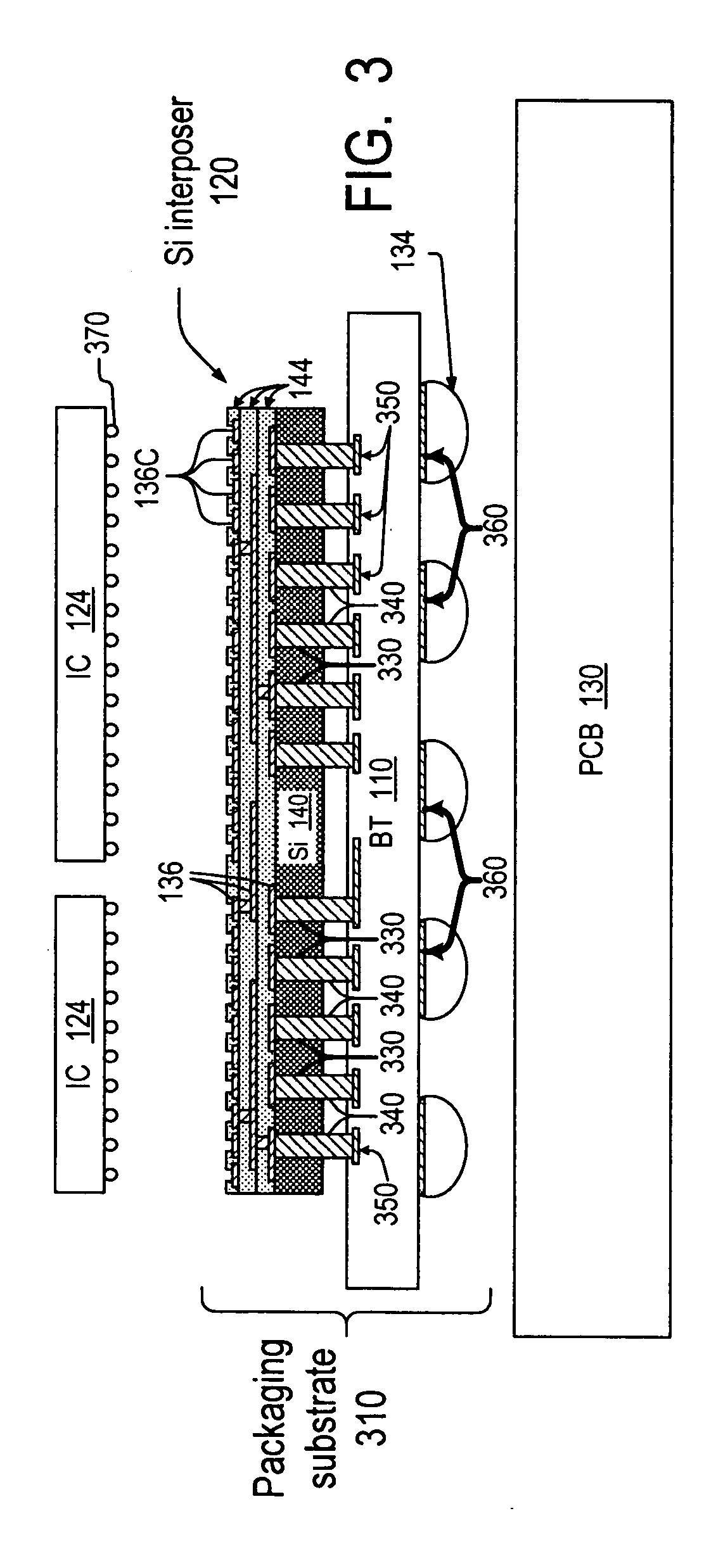

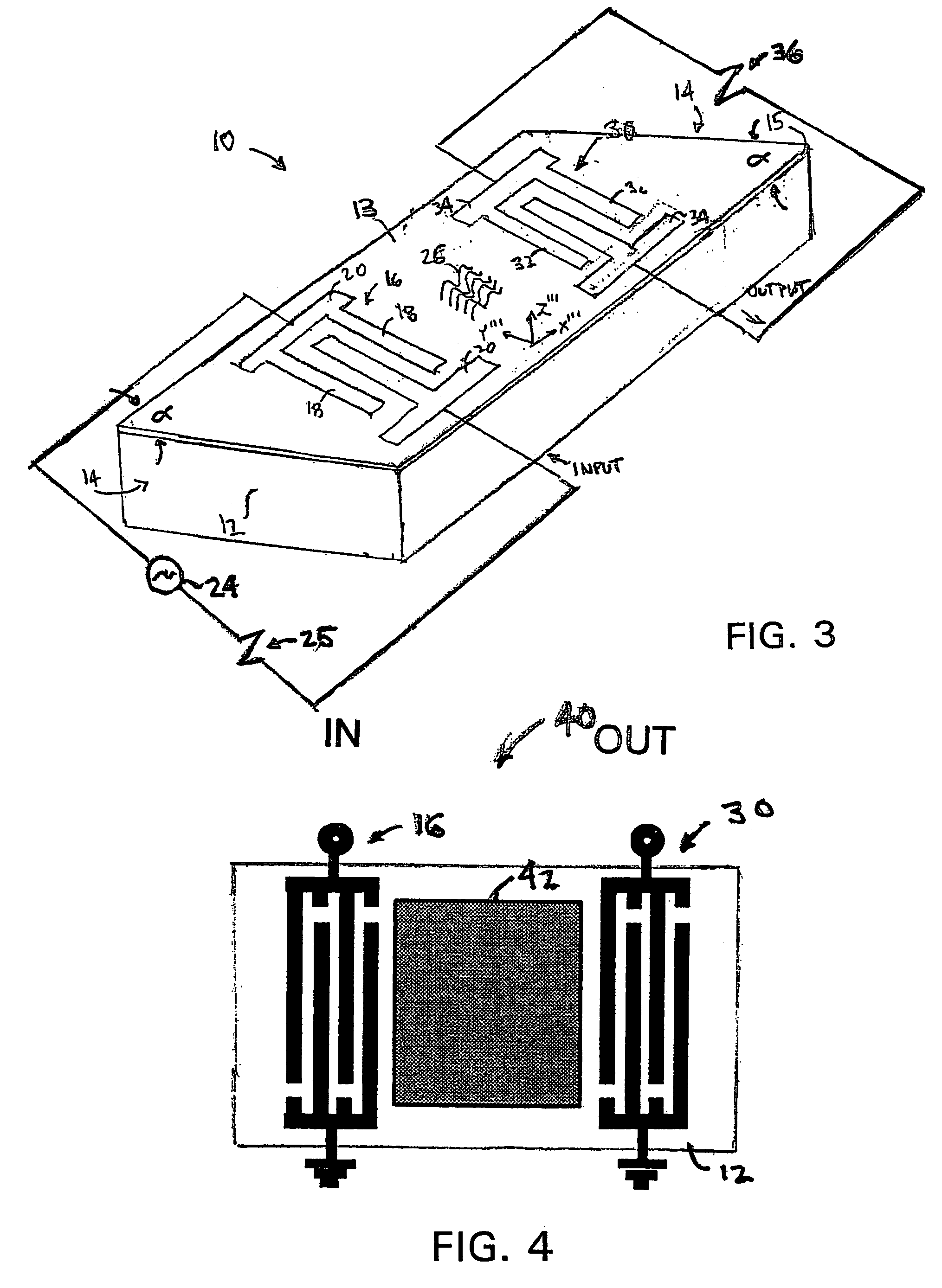

Packaging substrates for integrated circuits and soldering methods

ActiveUS20050133930A1Raise solder melting temperatureEasy maintenancePrinted circuit assemblingSemiconductor/solid-state device detailsContact padInterposer

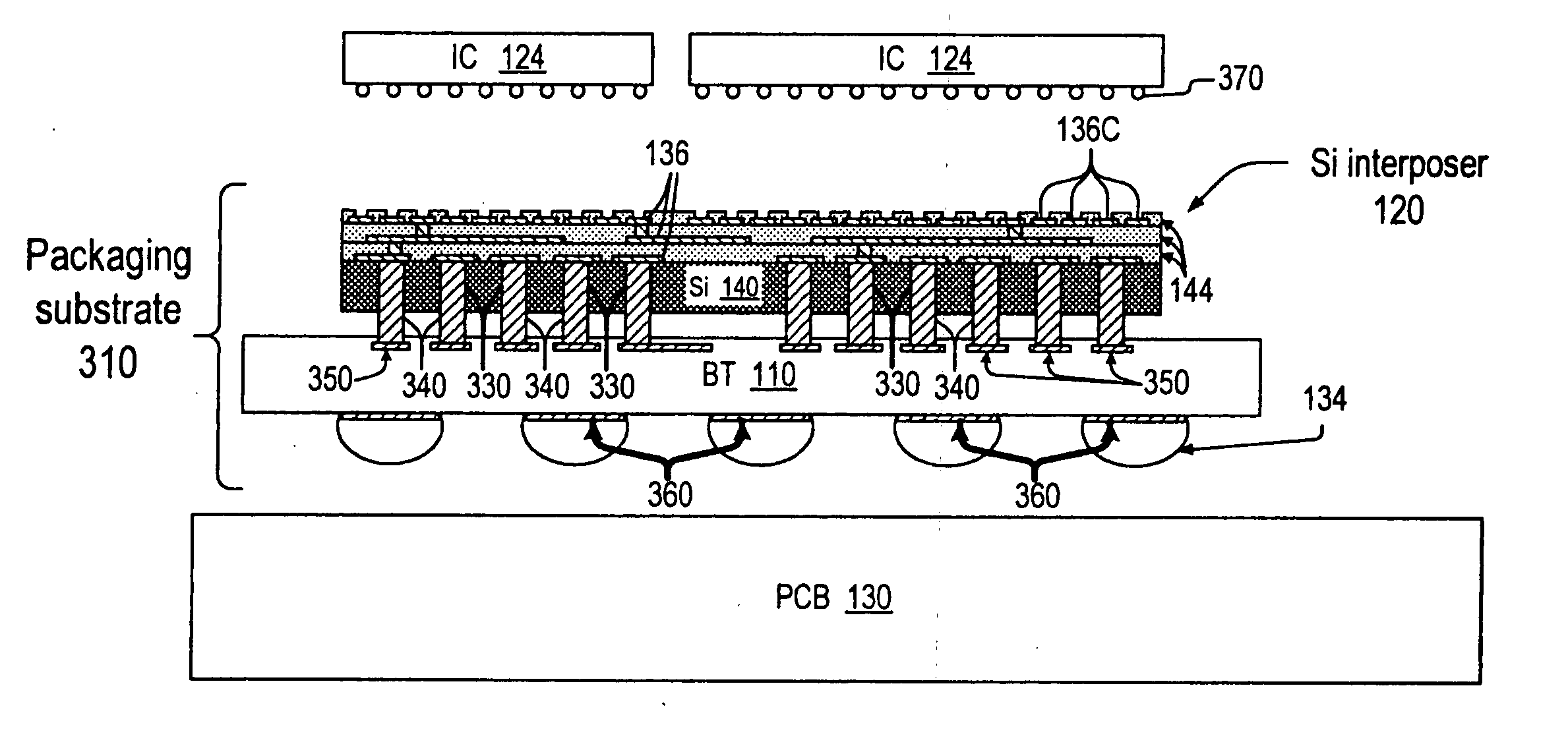

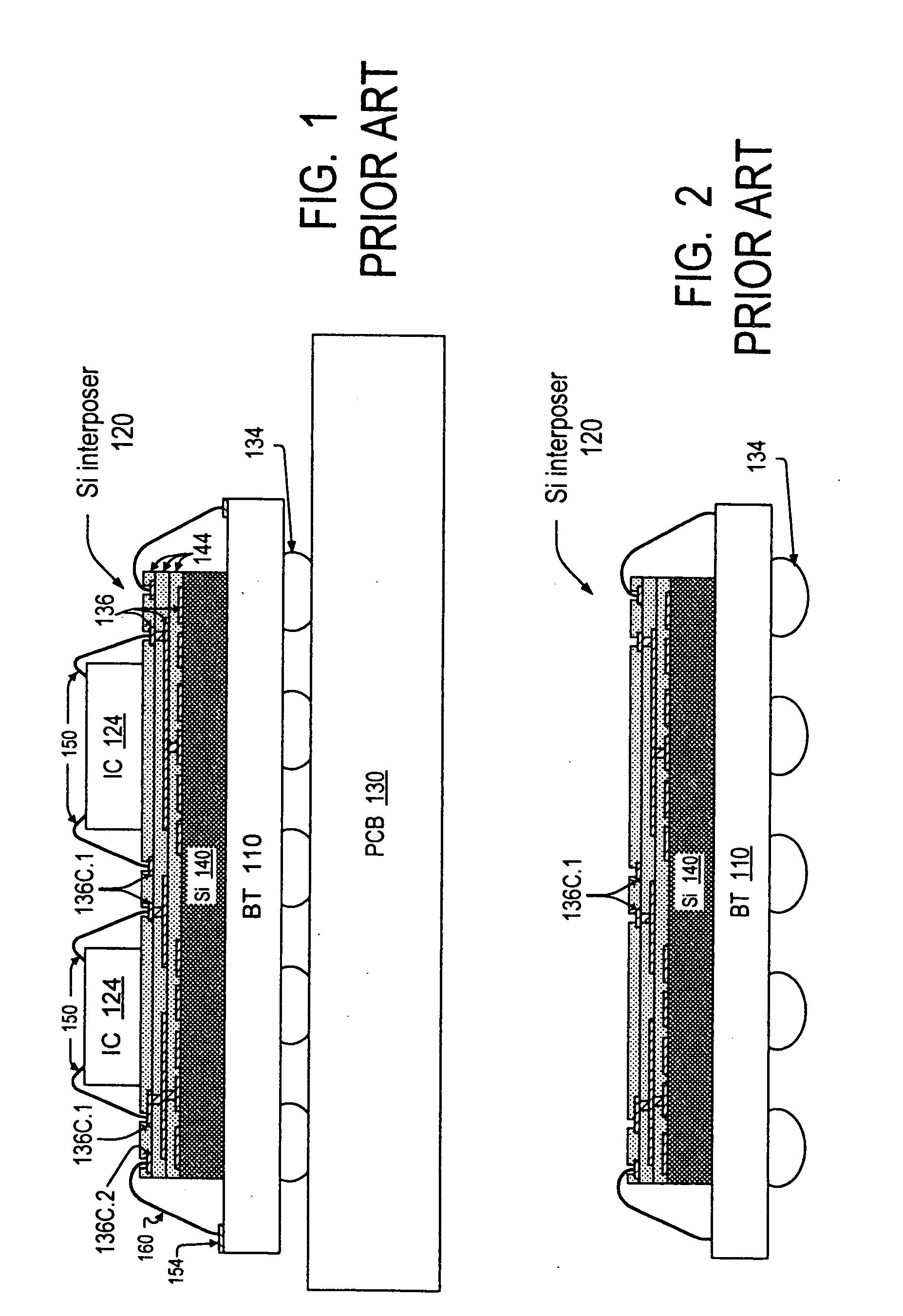

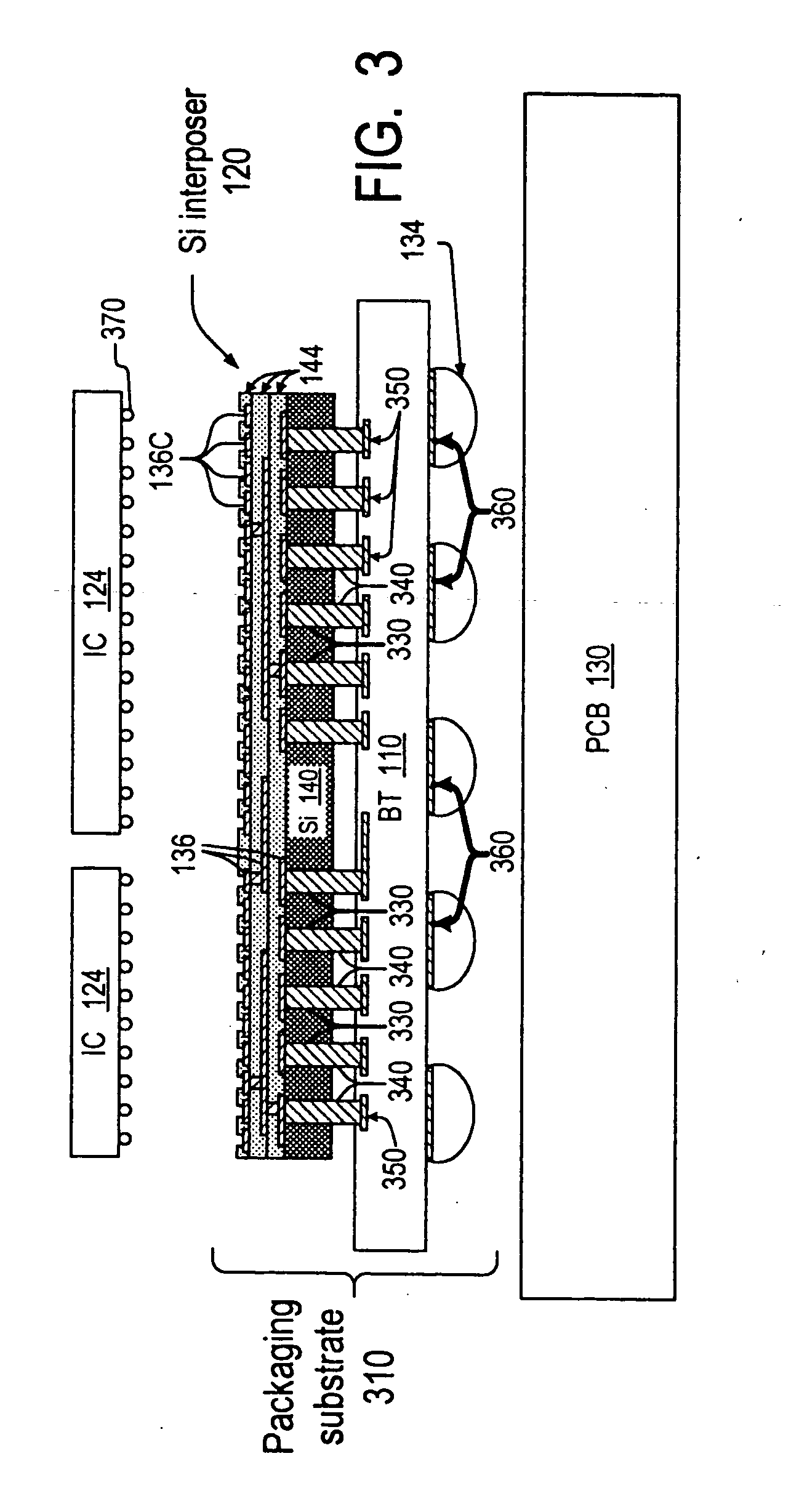

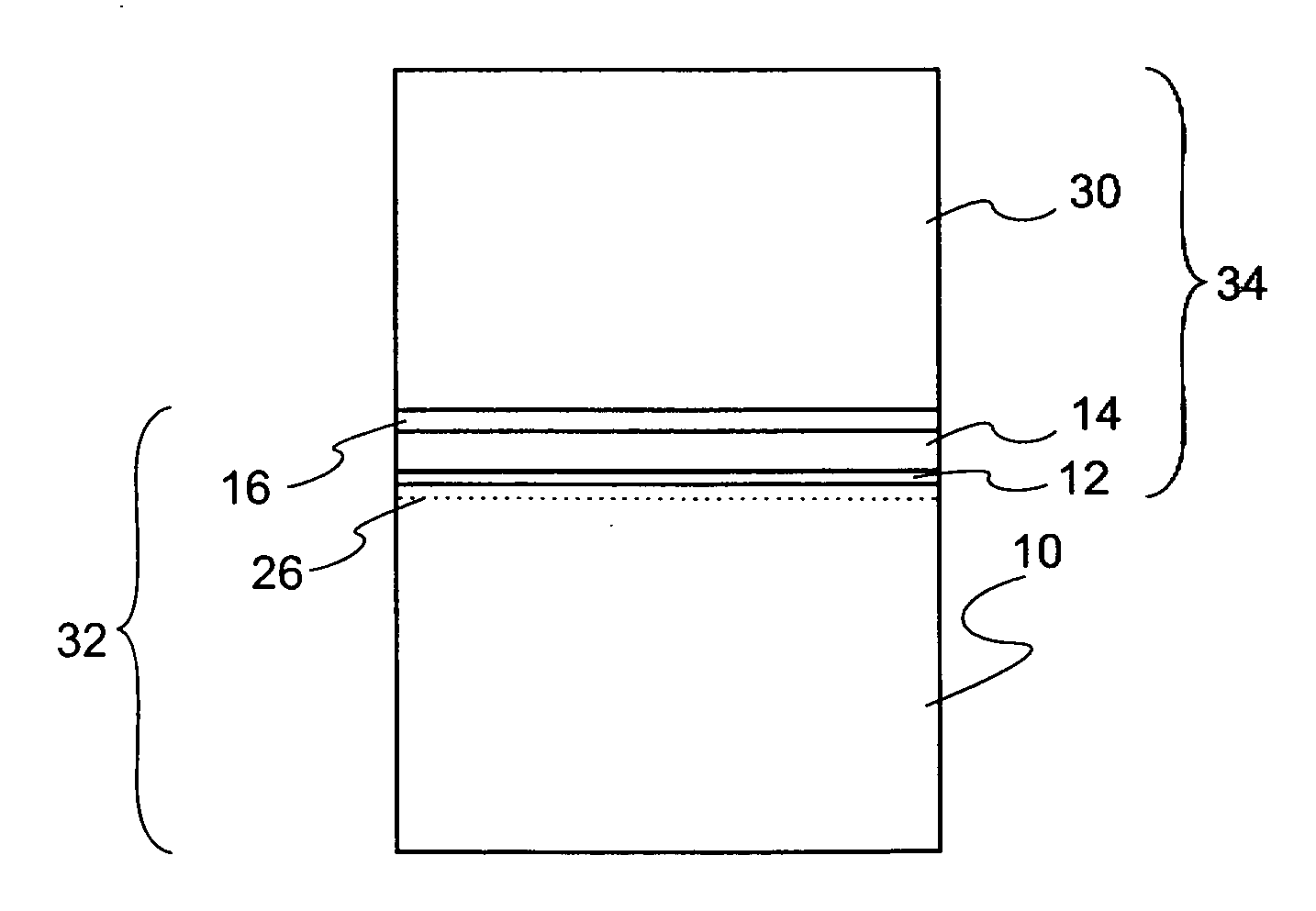

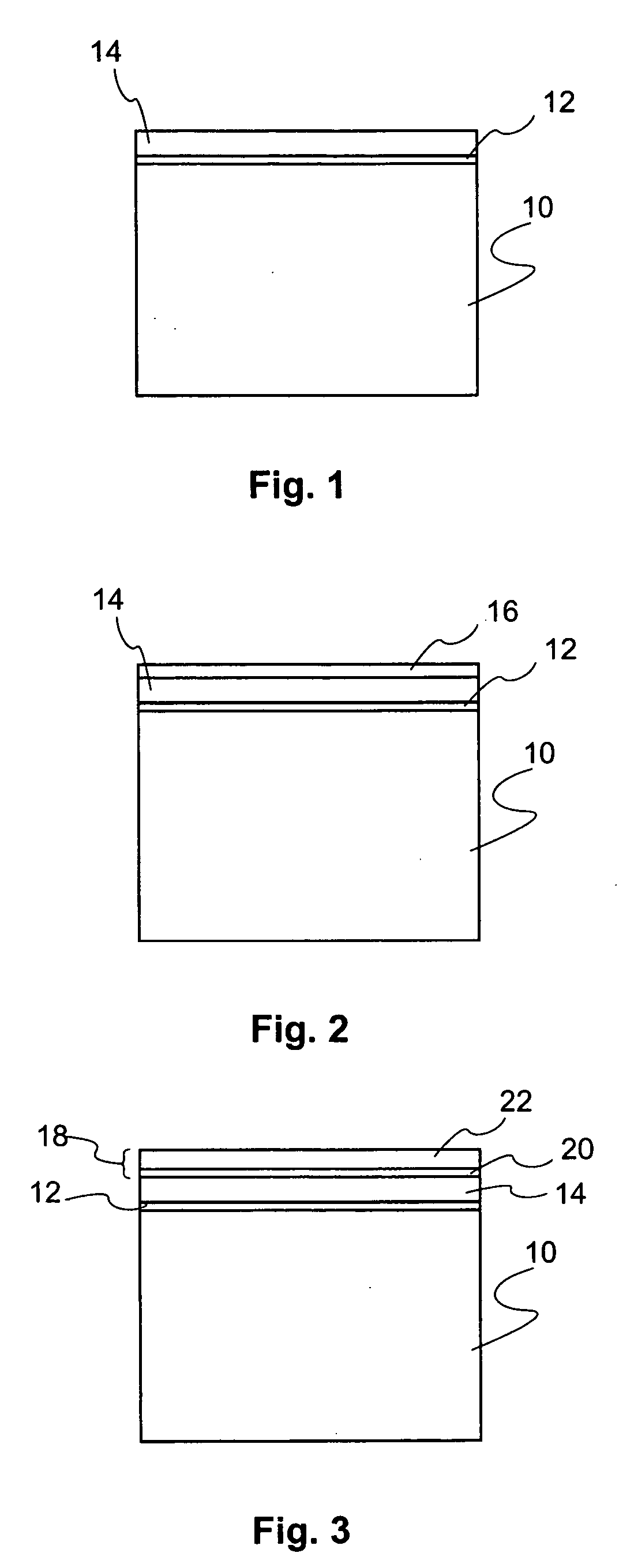

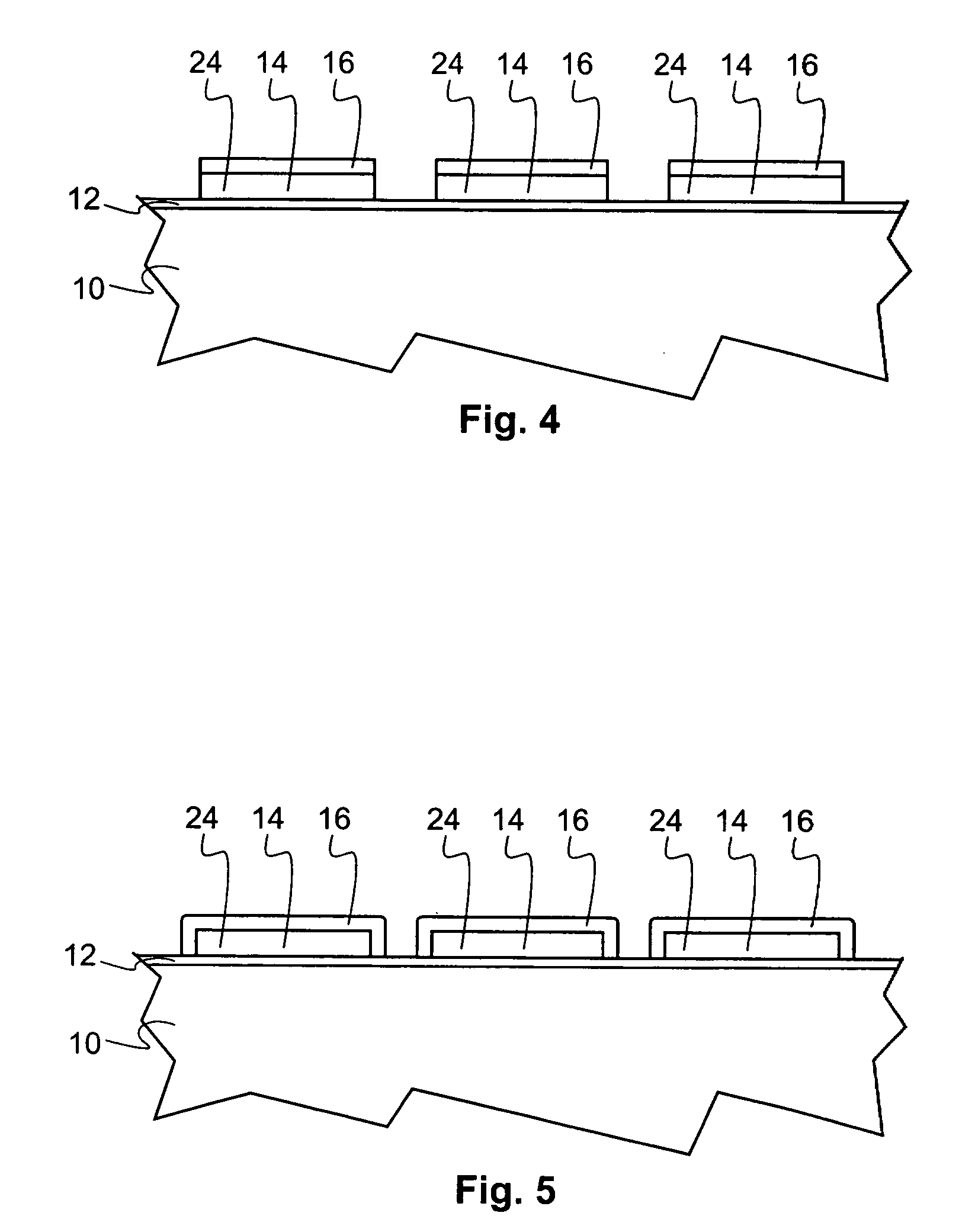

A packaging substrate (310) includes a semiconductor interposer (120) and at least one other intermediate substrate (110), e.g. a BT substrate. The semiconductor interposer has first contact pads (136C) attachable to dies (124) above the interposer, and second contact pads (340) attachable to circuitry below the interposer. Through vias (330) are made in the semiconductor substrate (140) of the interposer (120). Conductive paths going through the through vias connect the first contact pads (136C) to the second contact pads (340). The dies (124) are attached to the interposer after the attachment of the interposer to the BT substrate. In sequential soldering operations, the solder hierarchy is maintained by dissolving some material (e.g. copper) in the solder during soldering to raise the solder's melting temperature. For example, all of the solders may initially have the same melting temperature, but each solder's melting temperature is increased during soldering to prevent the solder from melting in the subsequent soldering operations.

Owner:INVENSAS CORP

Non Proliferating Thorium Nuclear Fuel Inert Metal Matrix Alloys for Fast Spectrum and Thermal Spectrum Thorium Converter Reactors

InactiveUS20080144762A1Improve heat transfer performanceRobust assemblyOptical rangefindersNuclear energy generationHigh energyEpithermal neutron

A set of alloy formulations is disclosed to use with thorium based nuclear fuels in a fast spectrum reactor; with thorium based nuclear fuels in existing thermal spectrum power reactors; for medical isotope production in the epithermal, the fast, the fission spectrum and the thermal spectra; and to use as fuel in test and experimental reactors that are non proliferative. The alloys form inert metal matrixes to hold fine particles of dispersed thorium containing fuel. The formulations also are useful for the production of medical and commercial isotopes in the high energy, fast and epithermal neutron spectra.

Owner:RGT UNIV OF CALIFORNIA

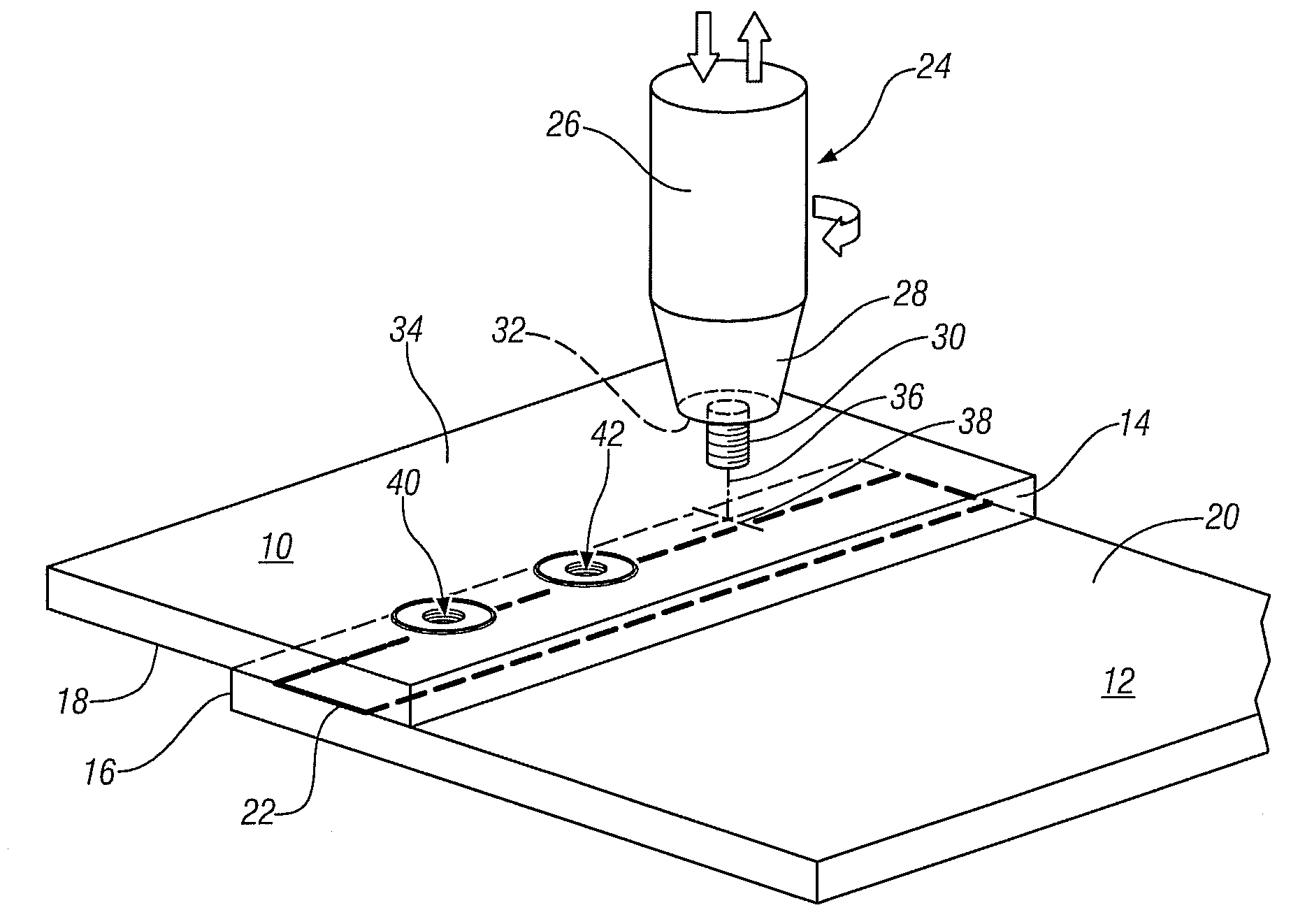

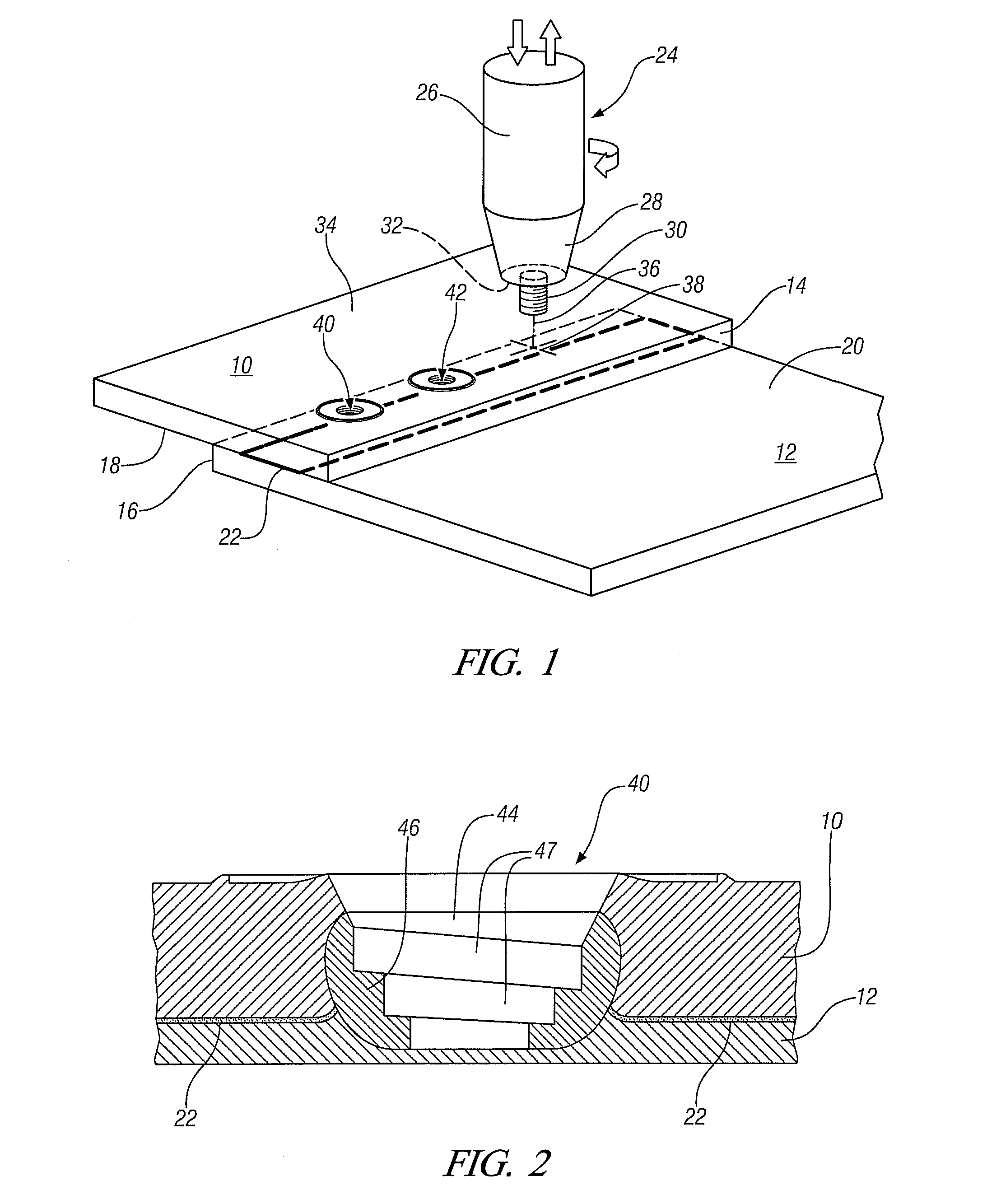

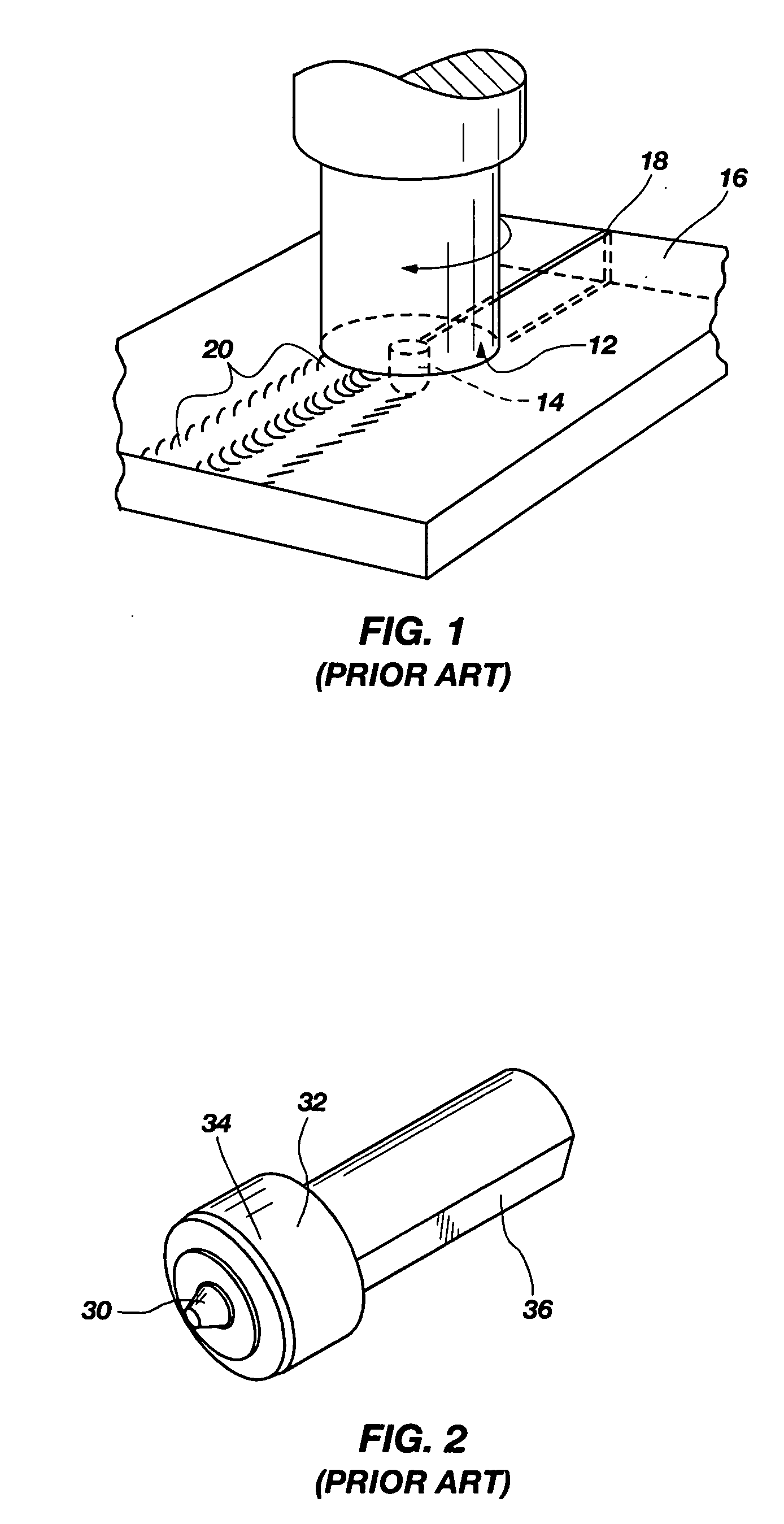

Friction stir welding of dissimilar metals

InactiveUS20100089977A1Improve mechanical propertiesHigh viscosityWelding/soldering/cutting articlesNon-electric welding apparatusFriction stir weldingTin

When a friction stir weld tool penetrates the interface of two workpieces of dissimilar metal alloy materials, the resultant weld of the different alloy materials may produce a weak weld joint. Such weak joints are often experienced, for example, when attempting to form spot welds or other friction stir welds between a magnesium alloy sheet or strip and an aluminum alloy sheet or strip. It is discovered that suitable coating compositions placed at the interface of assembled workpieces can alter the composition of the friction stir weld material and strengthen the resulting bond. In the example of friction stir welds between magnesium alloy and aluminum alloy workpieces, it is found that combinations of copper, tin, and zinc, and other powders can strengthen the magnesium-containing and aluminum-containing friction stir weld material.

Owner:GM GLOBAL TECH OPERATIONS LLC

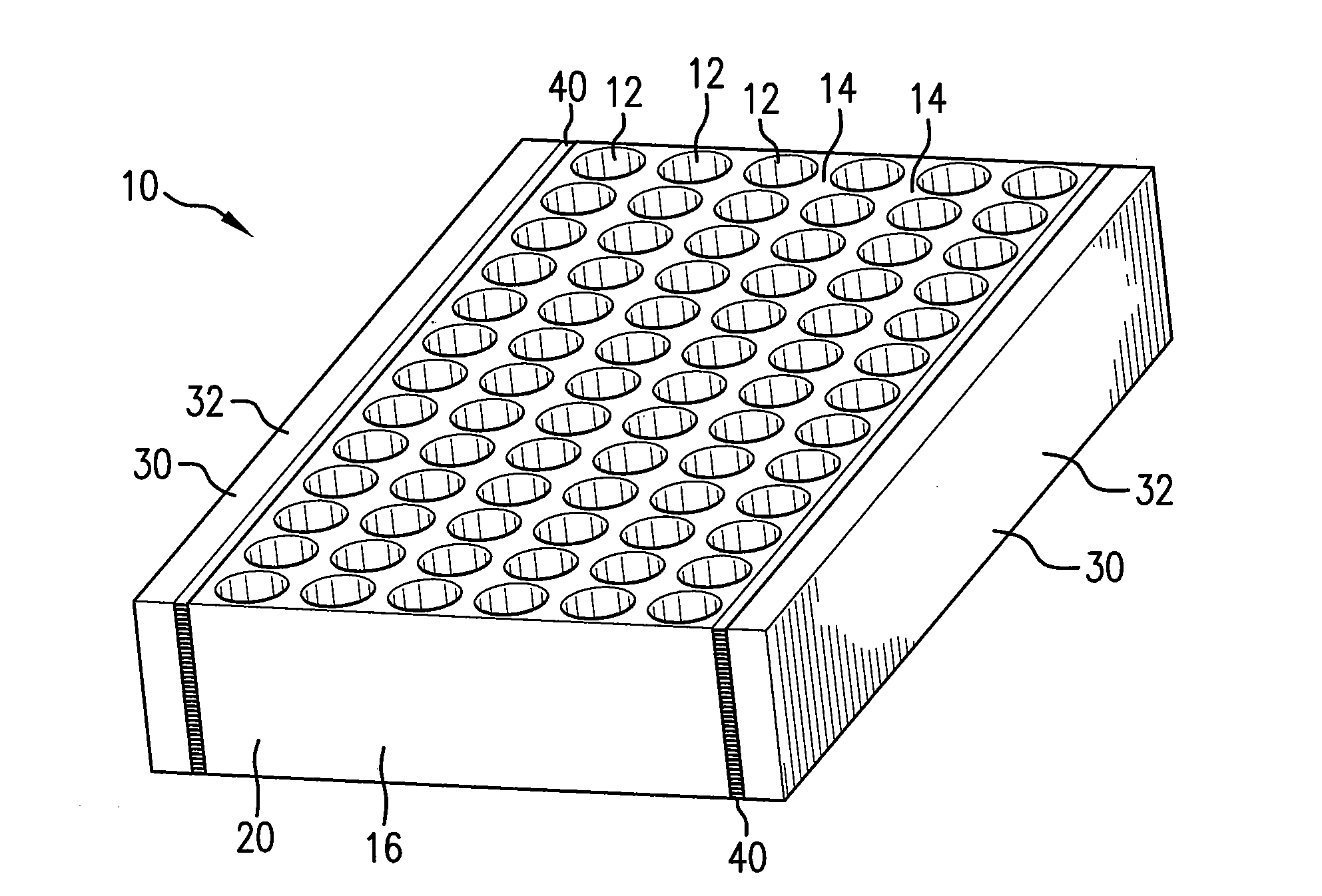

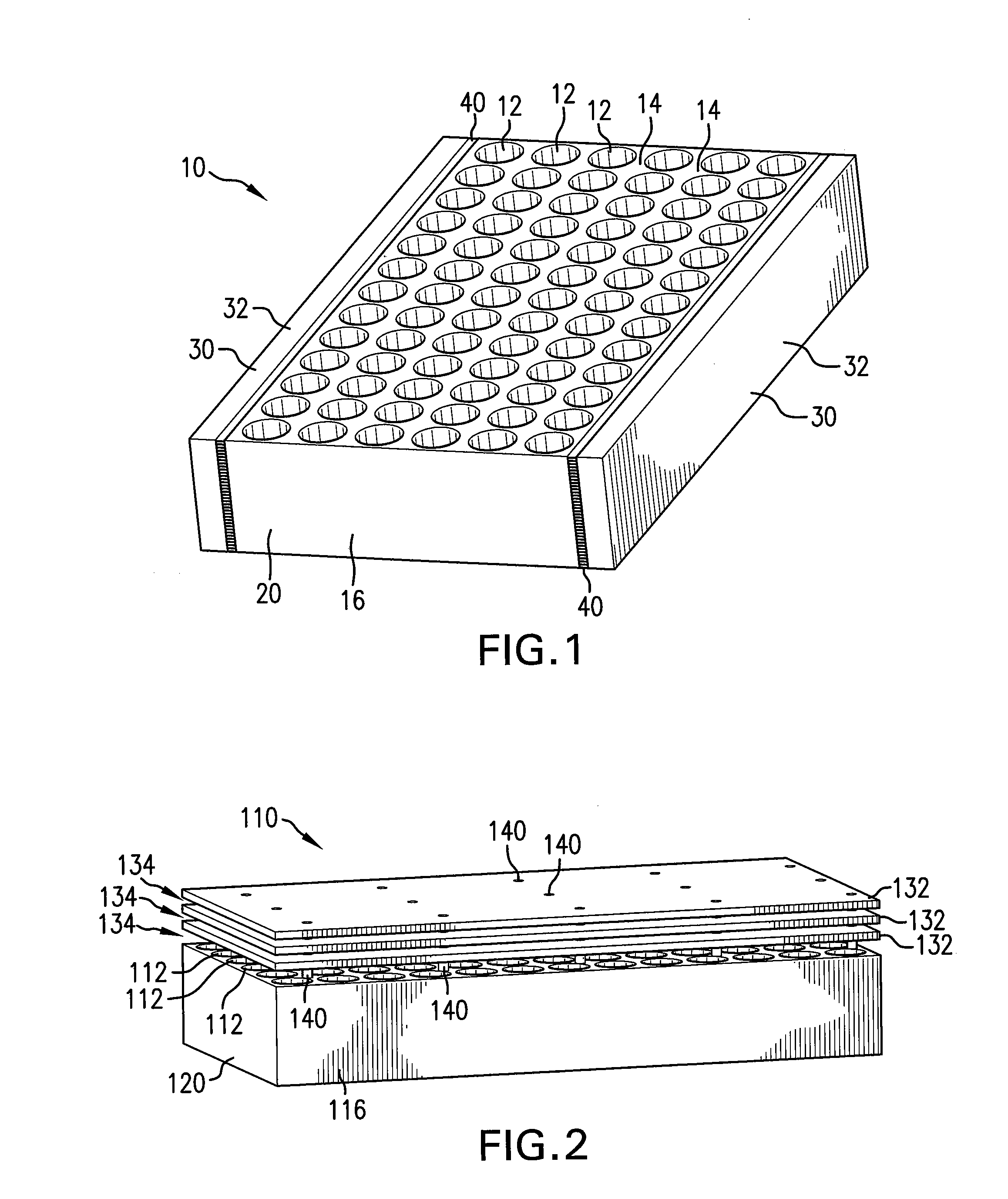

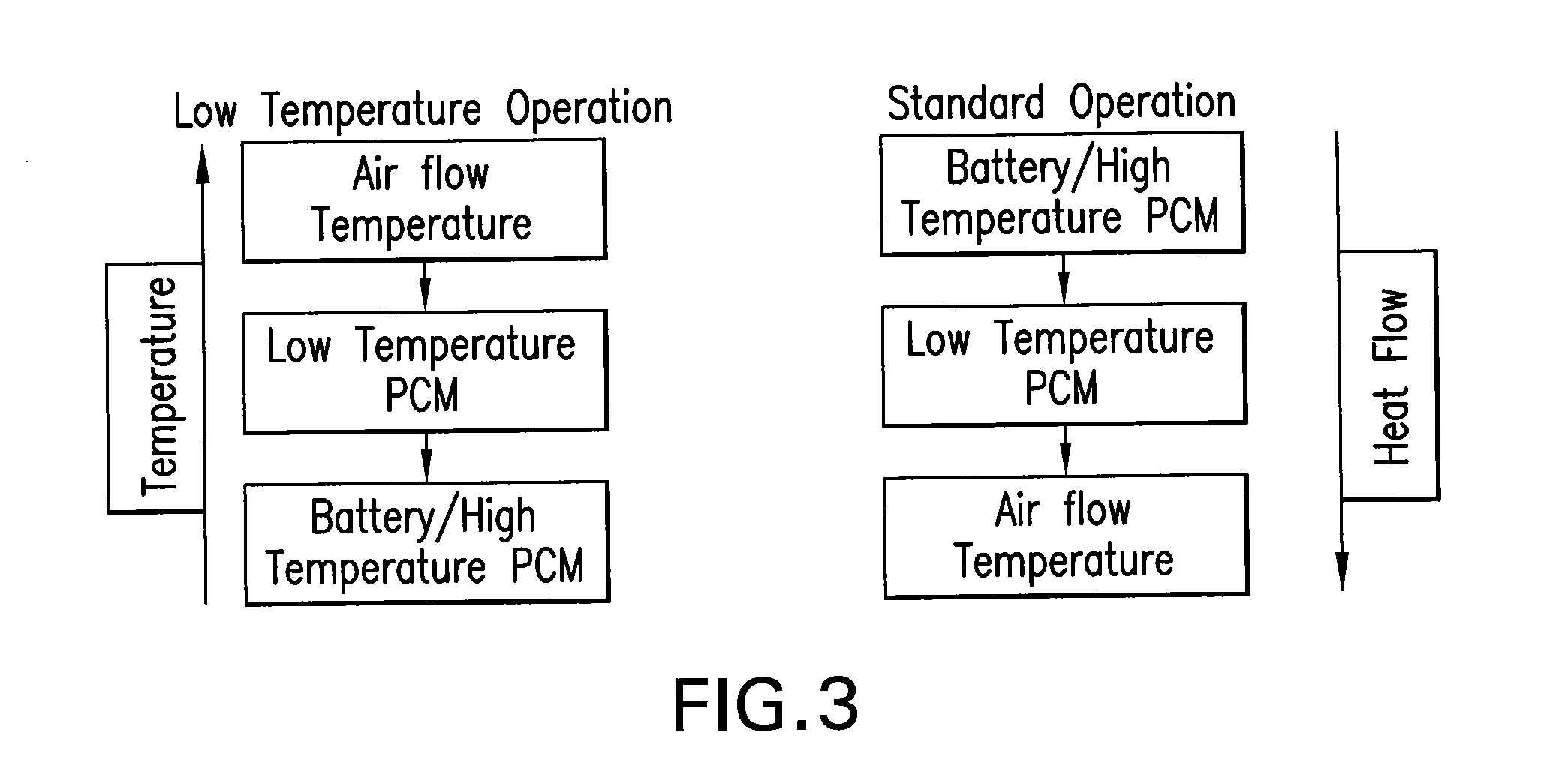

Energy storage thermal management system using multi-temperature phase change materials

ActiveUS20140079978A1Improve efficiencyHigh melting temperatureCell temperature controlElectrical batteryEngineering

A thermal management method and system for energy storage devices, such as devices including an array of electro-chemical cell elements. A first phase change material is in heat-transferring thermal contact with the electrochemical cell elements. A second phase change material in heat-transferring thermal contact with the first phase change material. A heat exchange path can be disposed between the first phase change material and the second phase change material.

Owner:BEAM GLOBAL

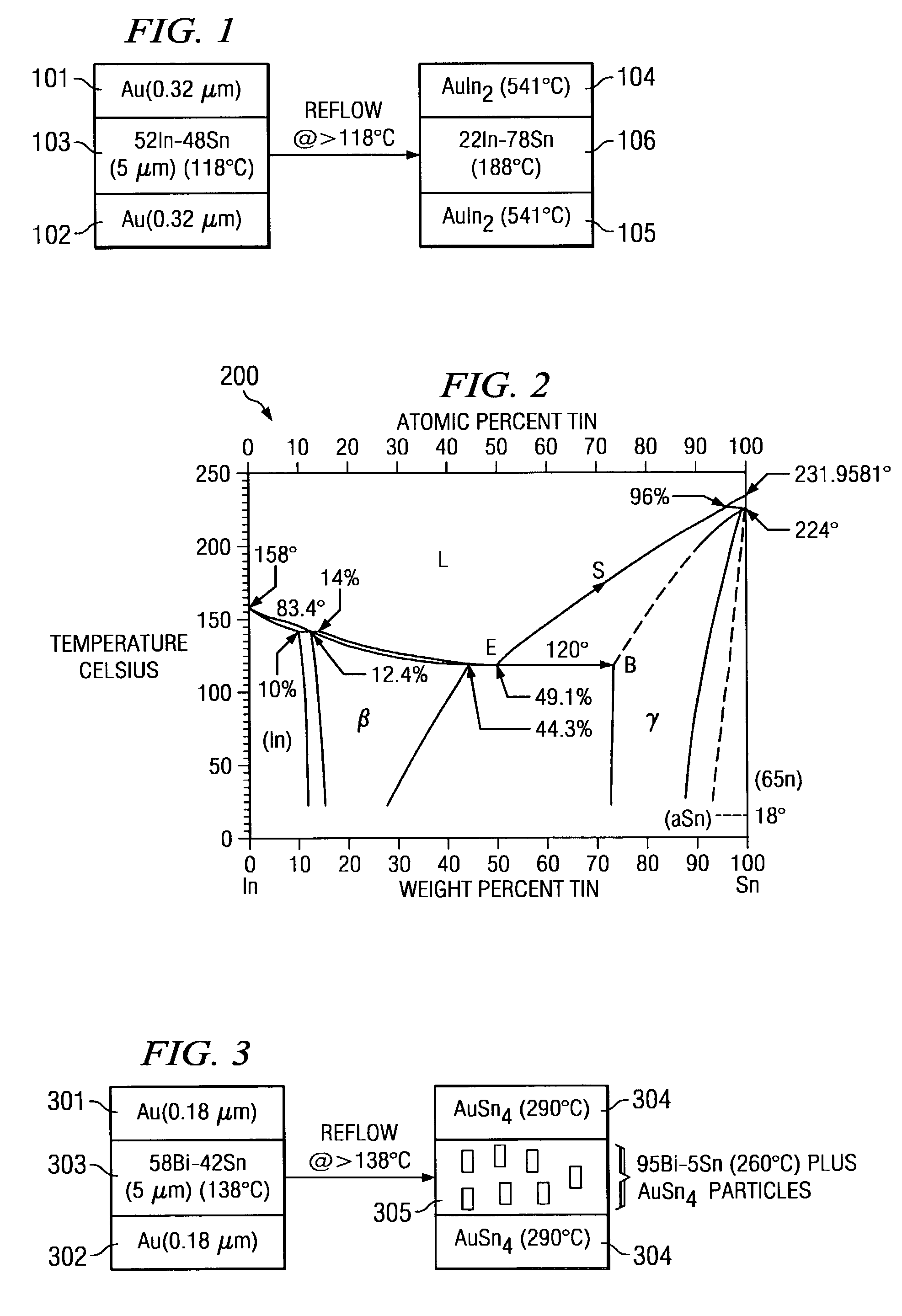

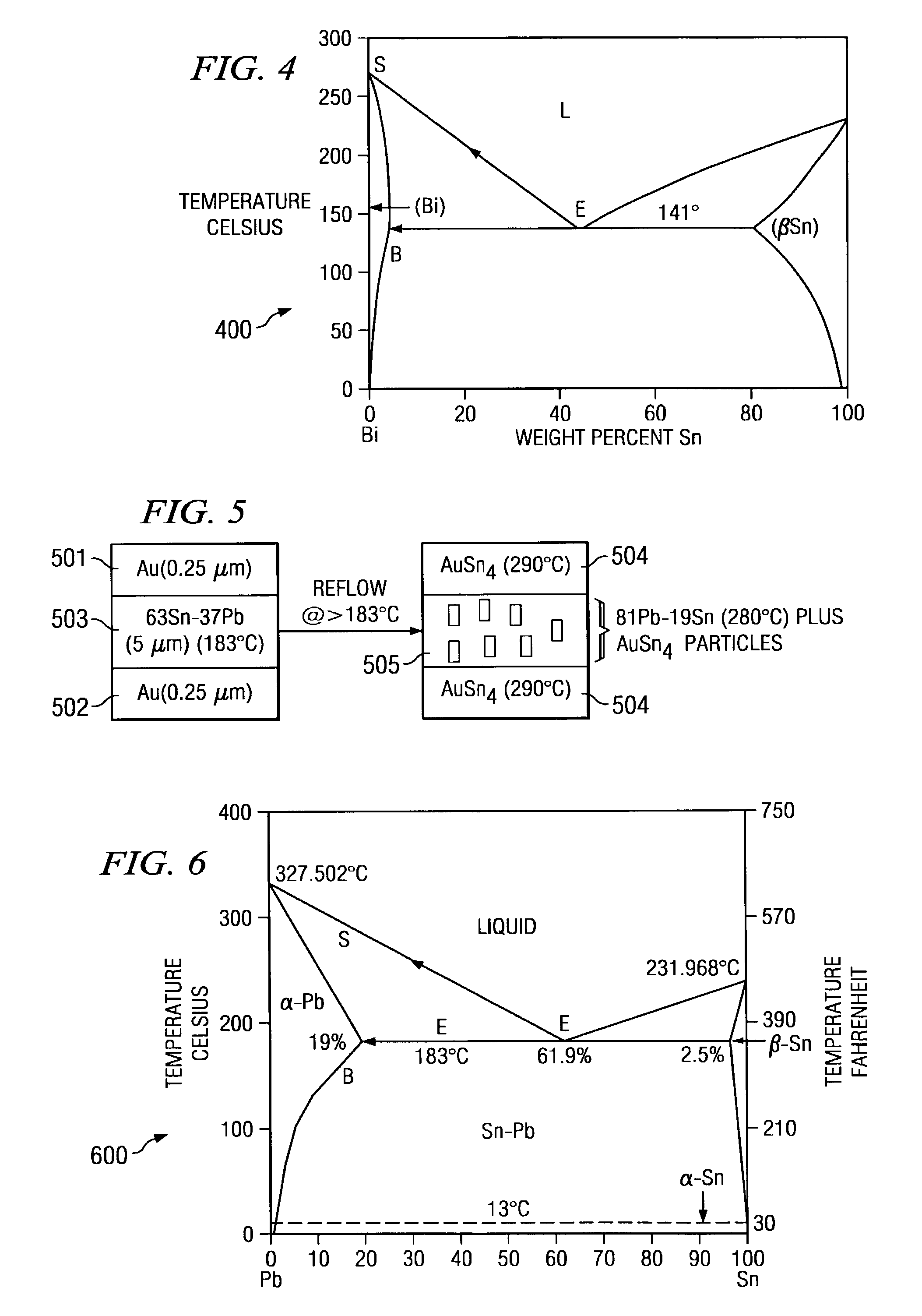

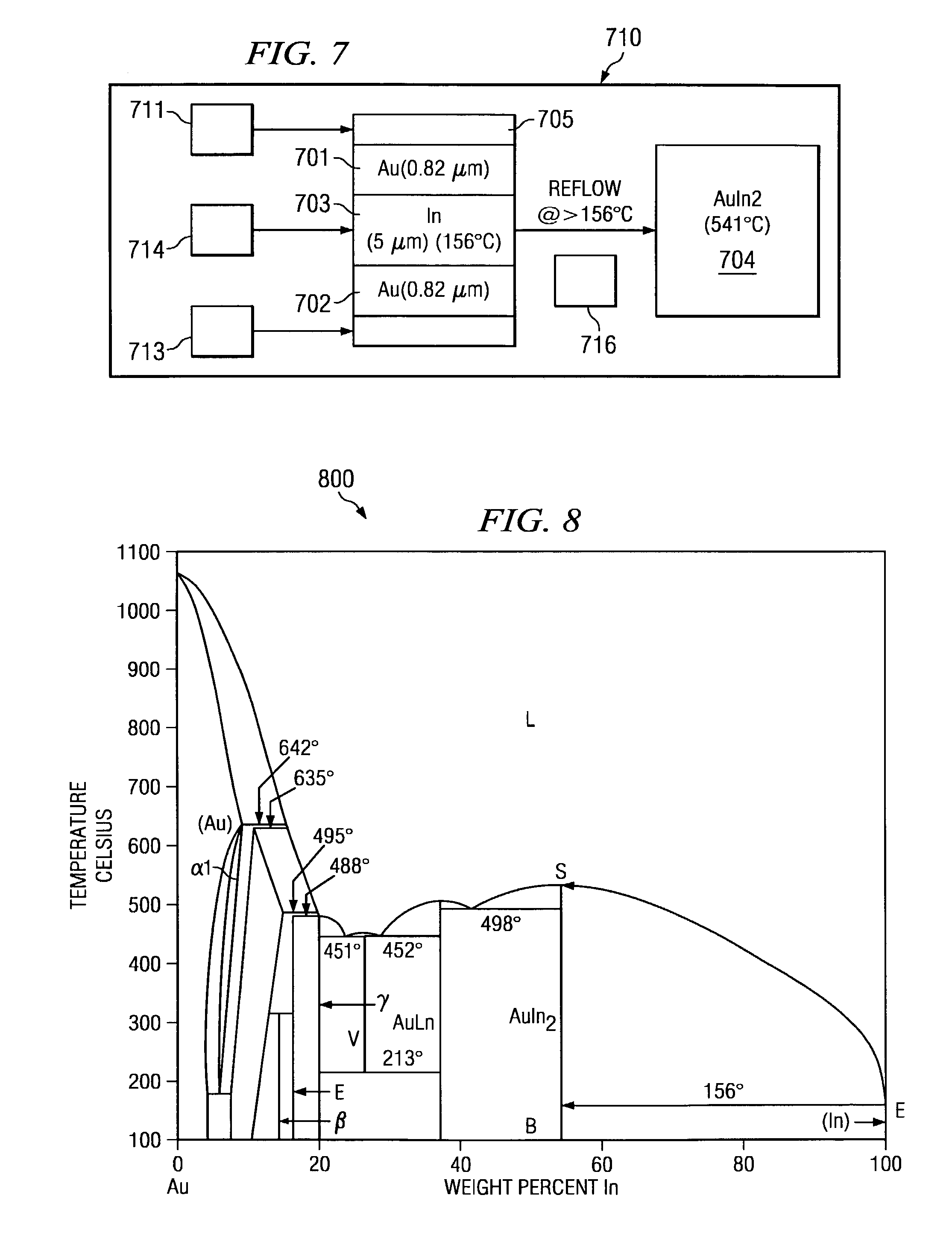

System and method for hermetic seal formation

InactiveUS7168608B2High melting temperatureMinimize thermal induced warpageEngine sealsSolid-state devicesMetallurgyHermetic seal

System and method for formation of a hermetic seal with an significantly greater melting temperature than the melting temperature of the solder employed. The hermetic seal is formed from a solder with a low melting point and a metal having a predetermined thickness that corresponds to the solder. The solder and metal combination undergoes reflow for a period of time relative to the solder thickness. The resultant seal has a melting point at a temperature significantly greater than the melting temperature of the solder.

Owner:AVAGO TECH INT SALES PTE LTD

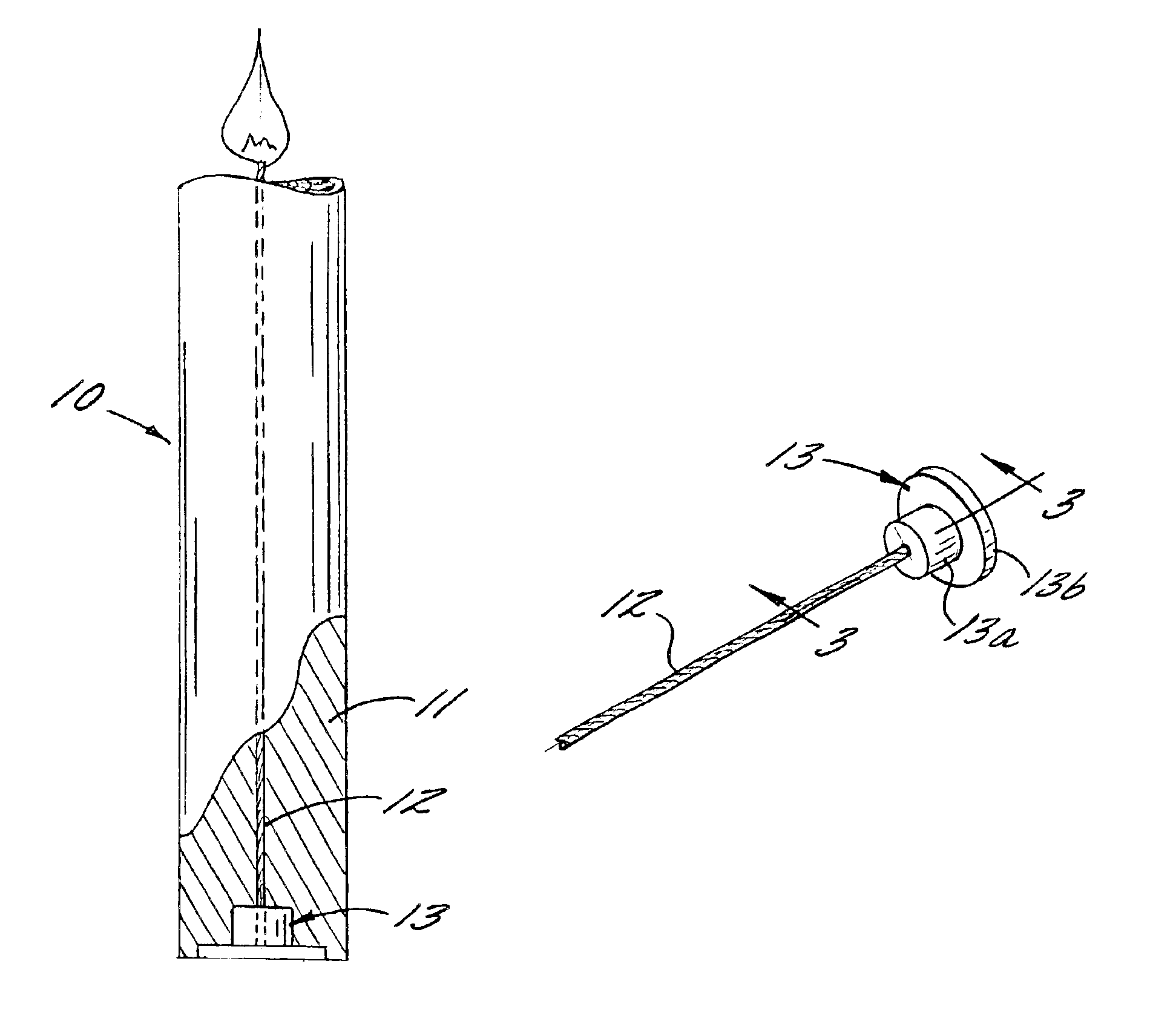

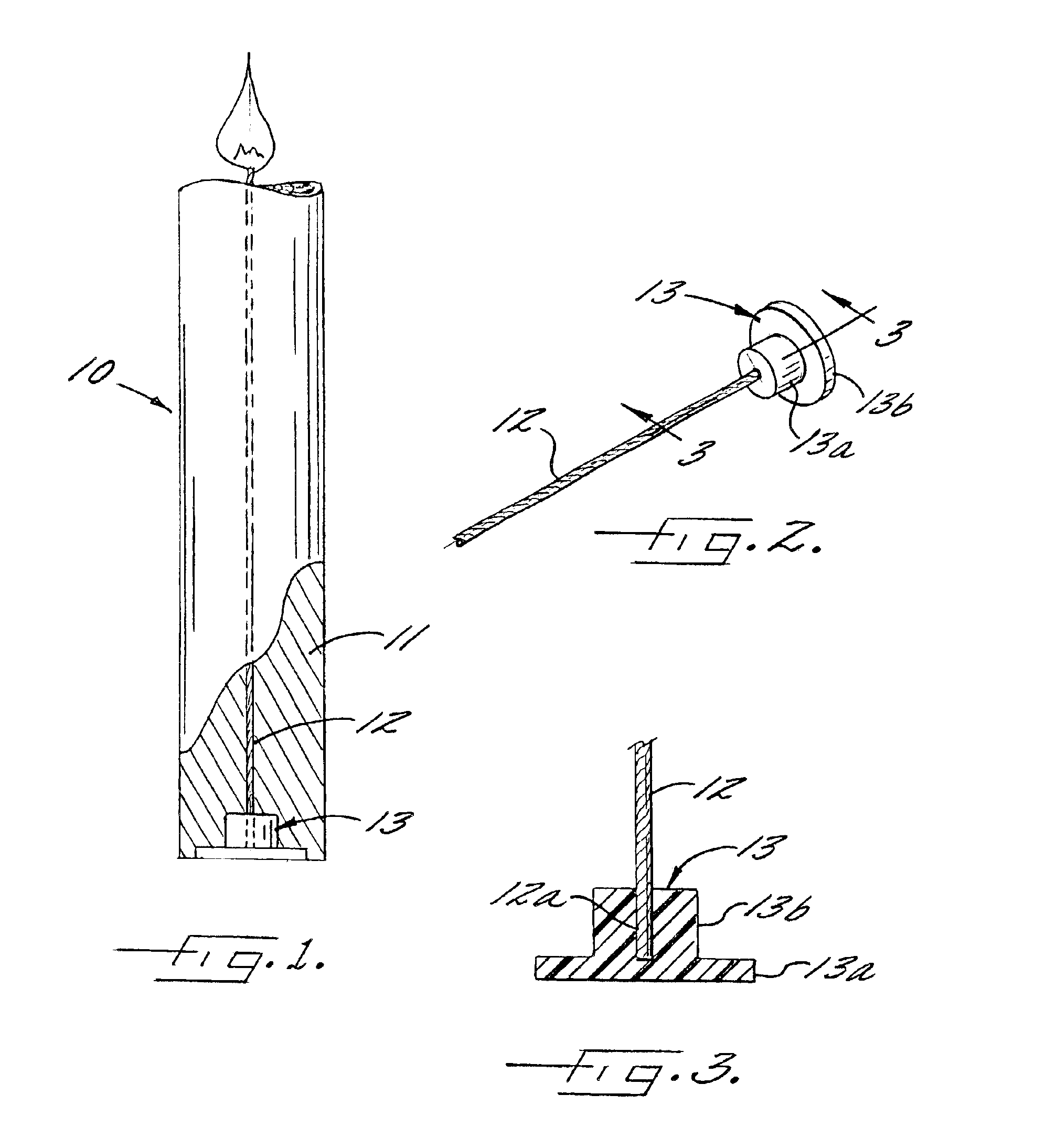

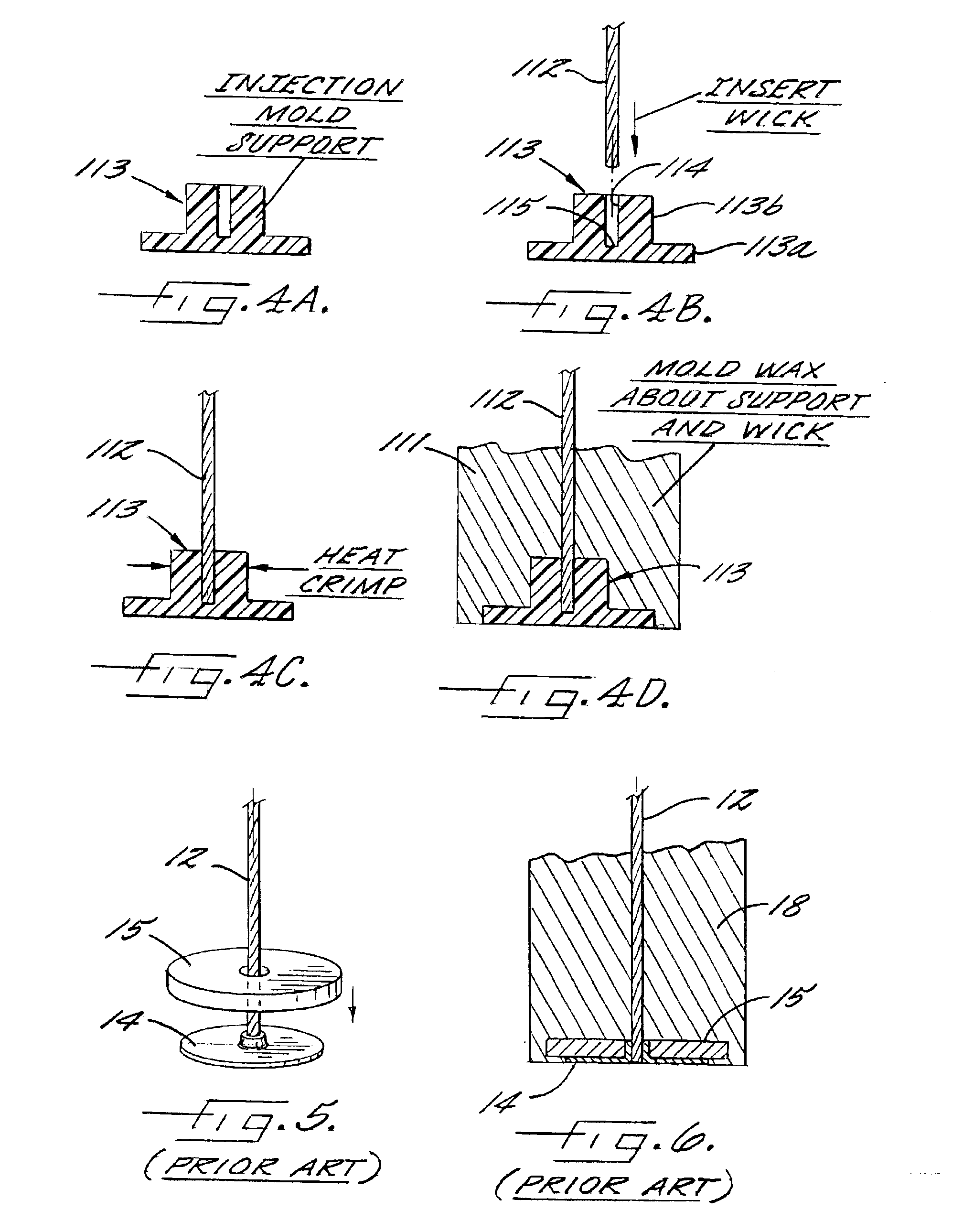

Safety candle and method of forming same

InactiveUS6863525B2High melting temperatureReduce disadvantagesWater heating stoves/rangesCapillary burnersCandleEngineering

A safety candle and a method of forming the same which includes a coaxial wick having its lower end portion fixedly secured in an injection molded, thermoplastic wick support. The wick support may incorporate a flame retardant which can be mixed with the thermoplastic material of the support to aid in snuffing the flame. The wick support is preferably formed of a high melt polypropylene or a clear polycarbonate.

Owner:BYRD RALPH DWAYNE

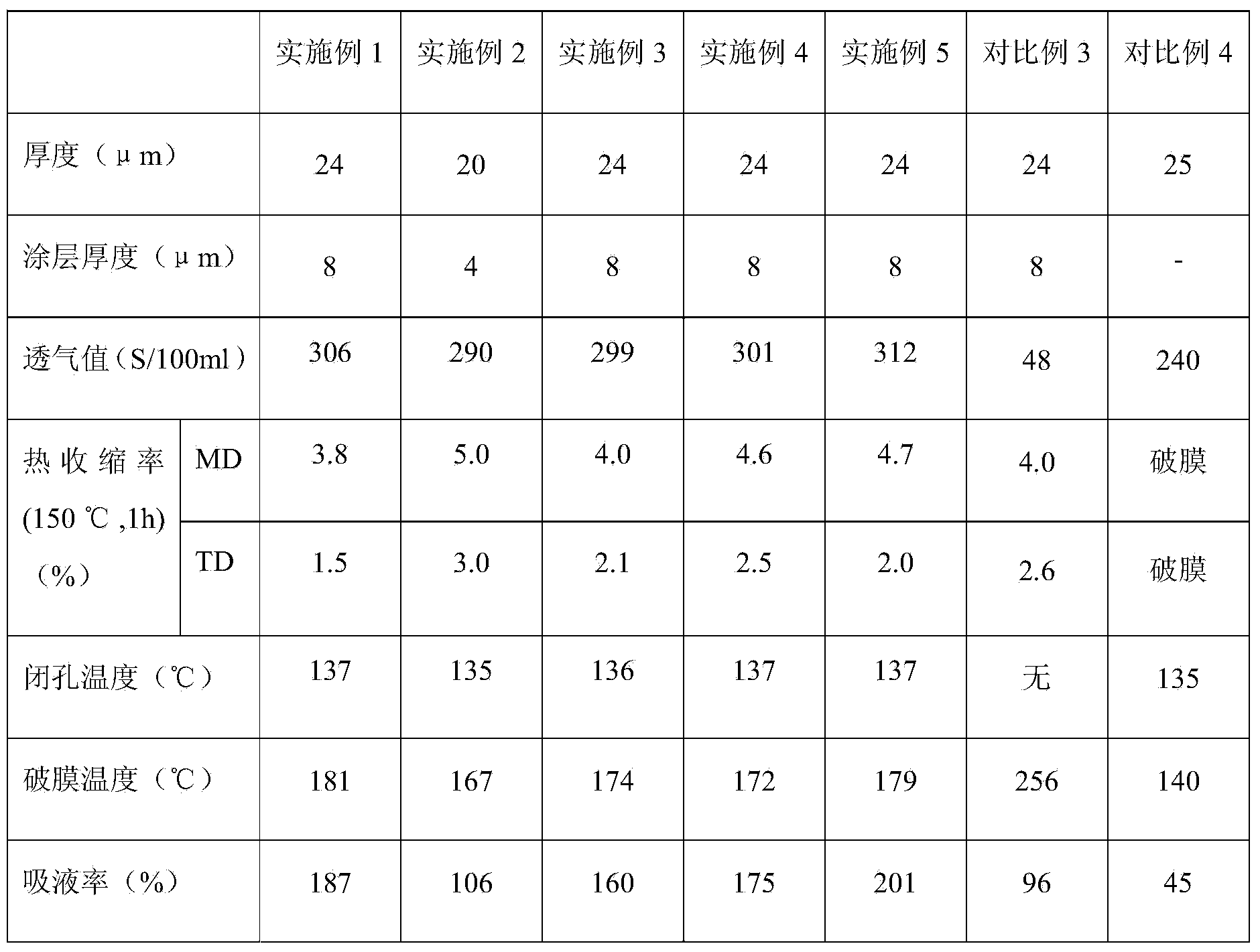

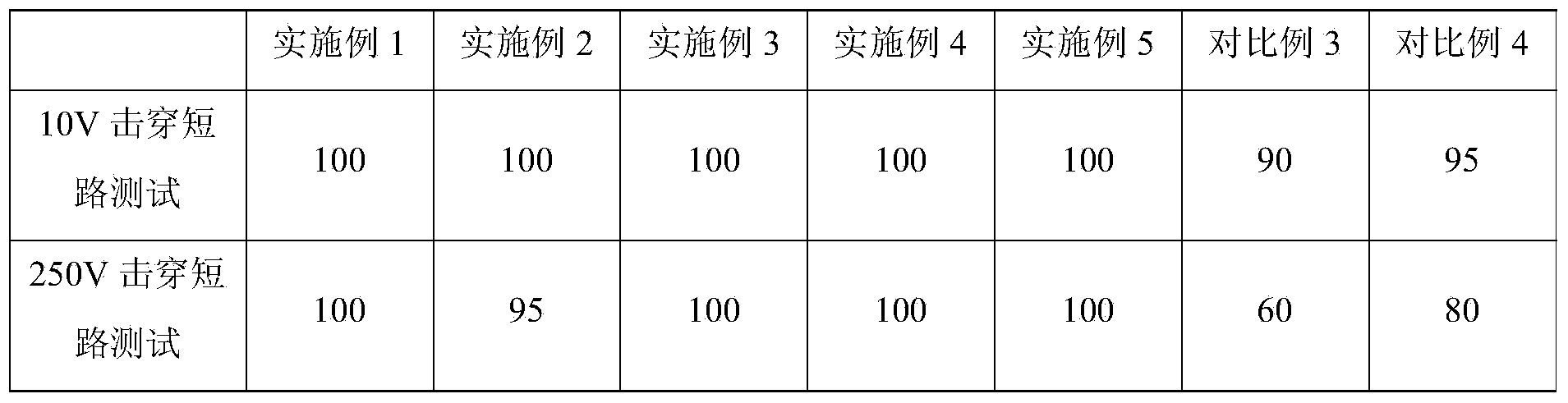

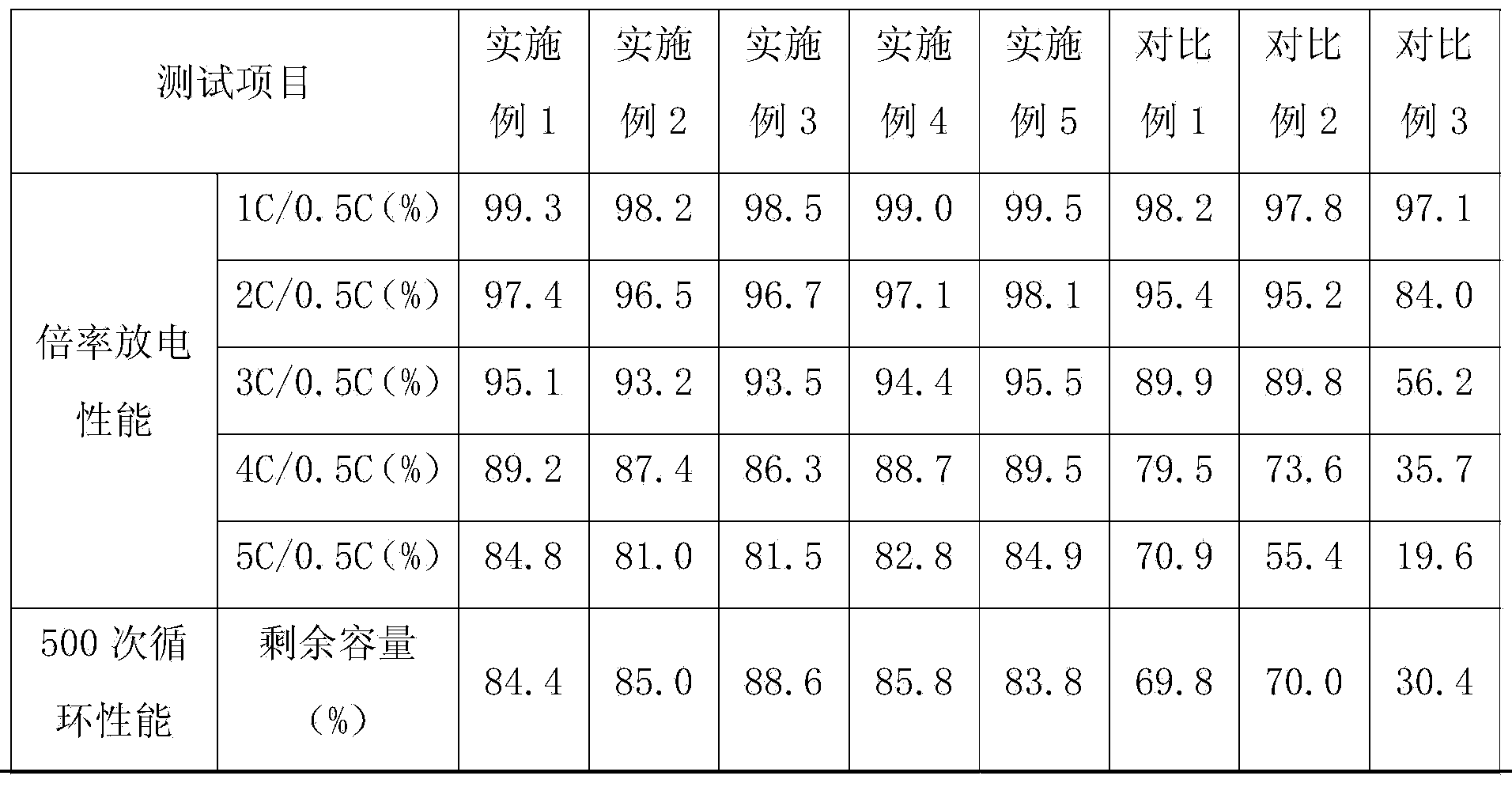

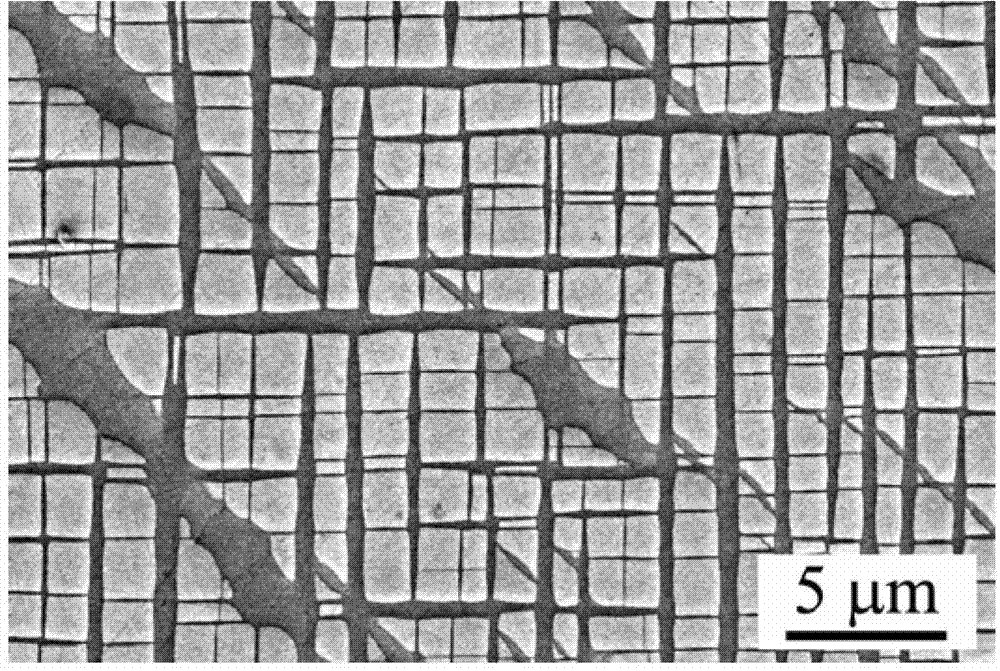

Novel ceramic coating polyolefin composite film and preparation method thereof

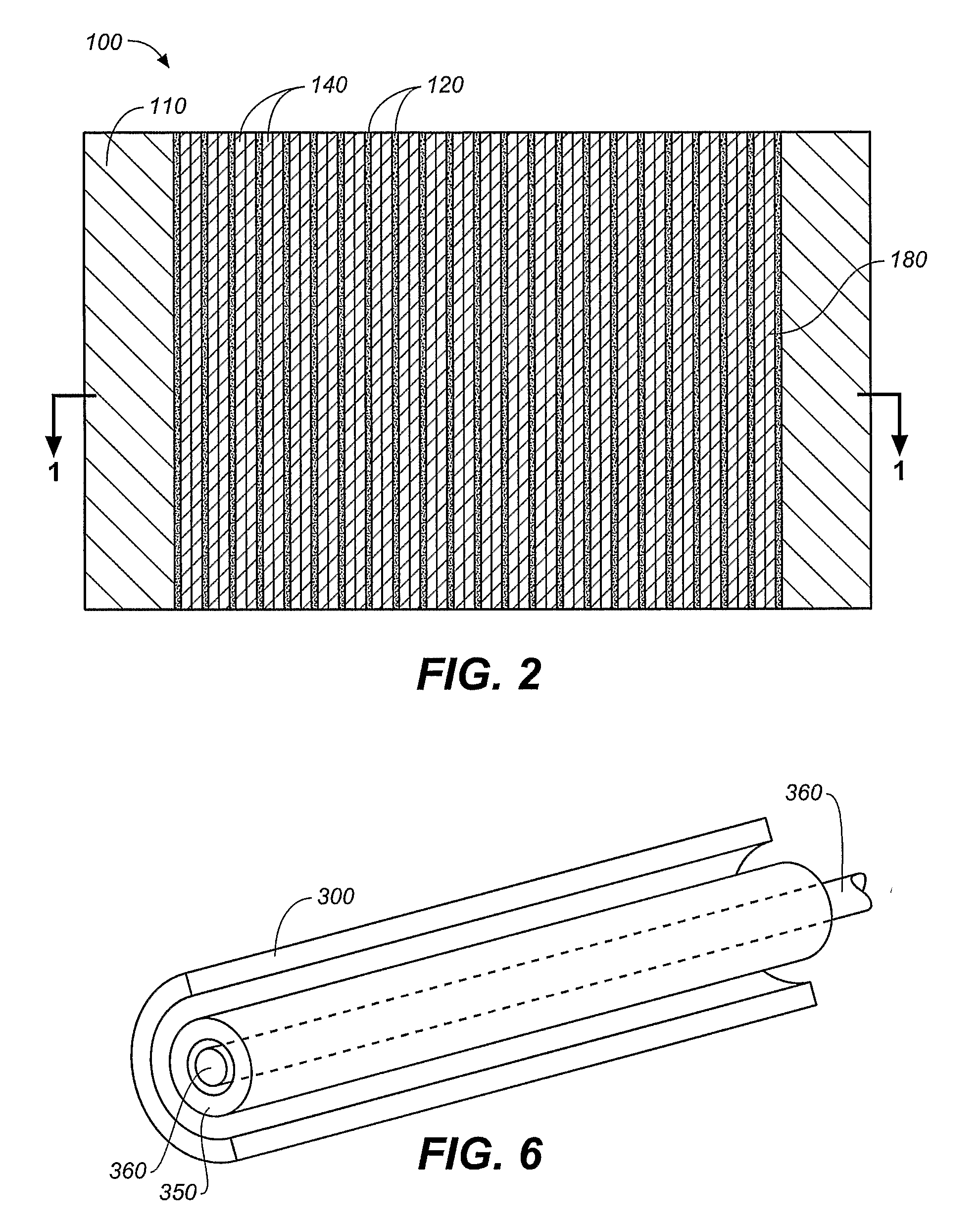

ActiveCN103811702AReduced service lifeExtended service lifeSecondary cellsCell component detailsSolventPolyolefin

The invention relates to a novel ceramic coating polyolefin composite film which comprises a polyolefin substrate with micro pores, wherein one side or both sides of the polyolefin substrate is / are compounded with ceramic coating(s); the ceramic coating comprises porous ceramic particles, an inorganic filler and an adhesive. The invention also relates to a method for preparing the novel ceramic coating polyolefin composite film. The method comprises the following steps: a, dissolving the adhesive in a solvent, thereby preparing an adhesive solution; b, adding the porous ceramic particles and the functional inorganic filler into the adhesion solution prepared in the step a, and performing dispersing treatment, thereby preparing coating slurry; and c, coating one or two surfaces of the polyolefin substrate with the coating slurry prepared in the step b, and drying and curing to prepare the product. The novel functional composite film has high liquid absorption and retention performance, has the functions of reducing harmful gases inside a battery, improving the performance of the battery and prolonging the service life of the battery, and has the safety characteristics of low closed pore temperature, high melting temperature and low hot-shrinkage rate.

Owner:河南惠强新能源材料科技股份有限公司

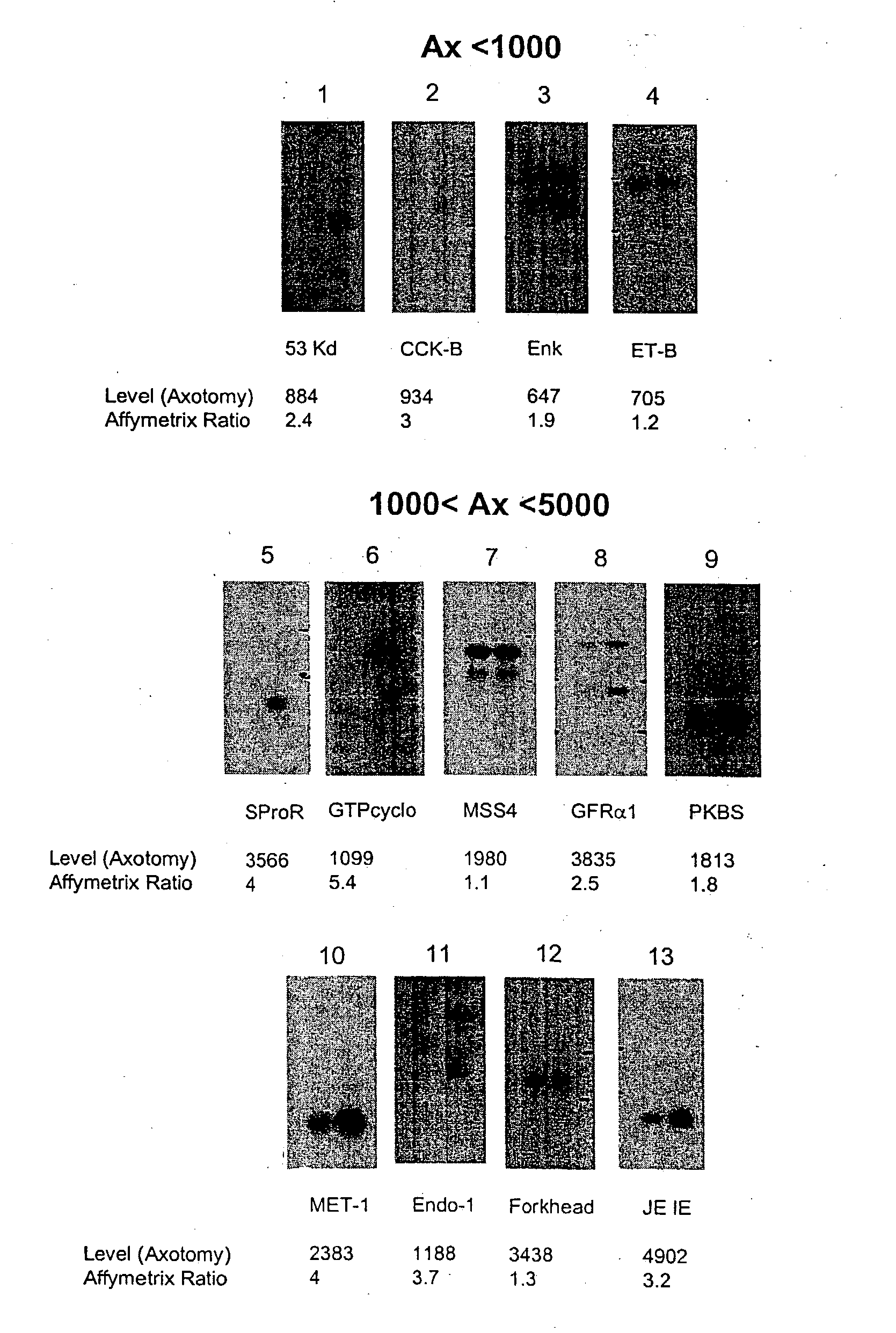

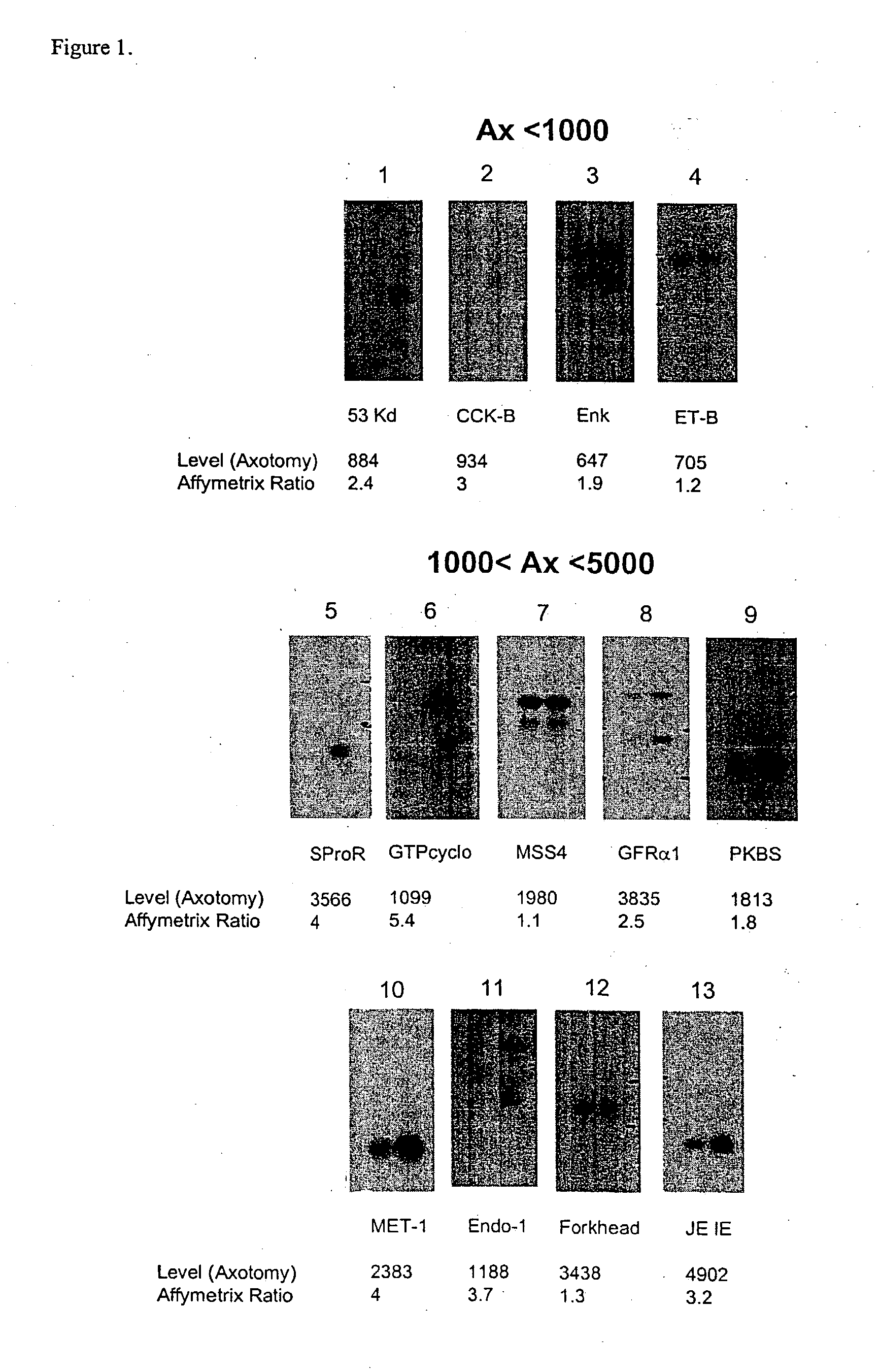

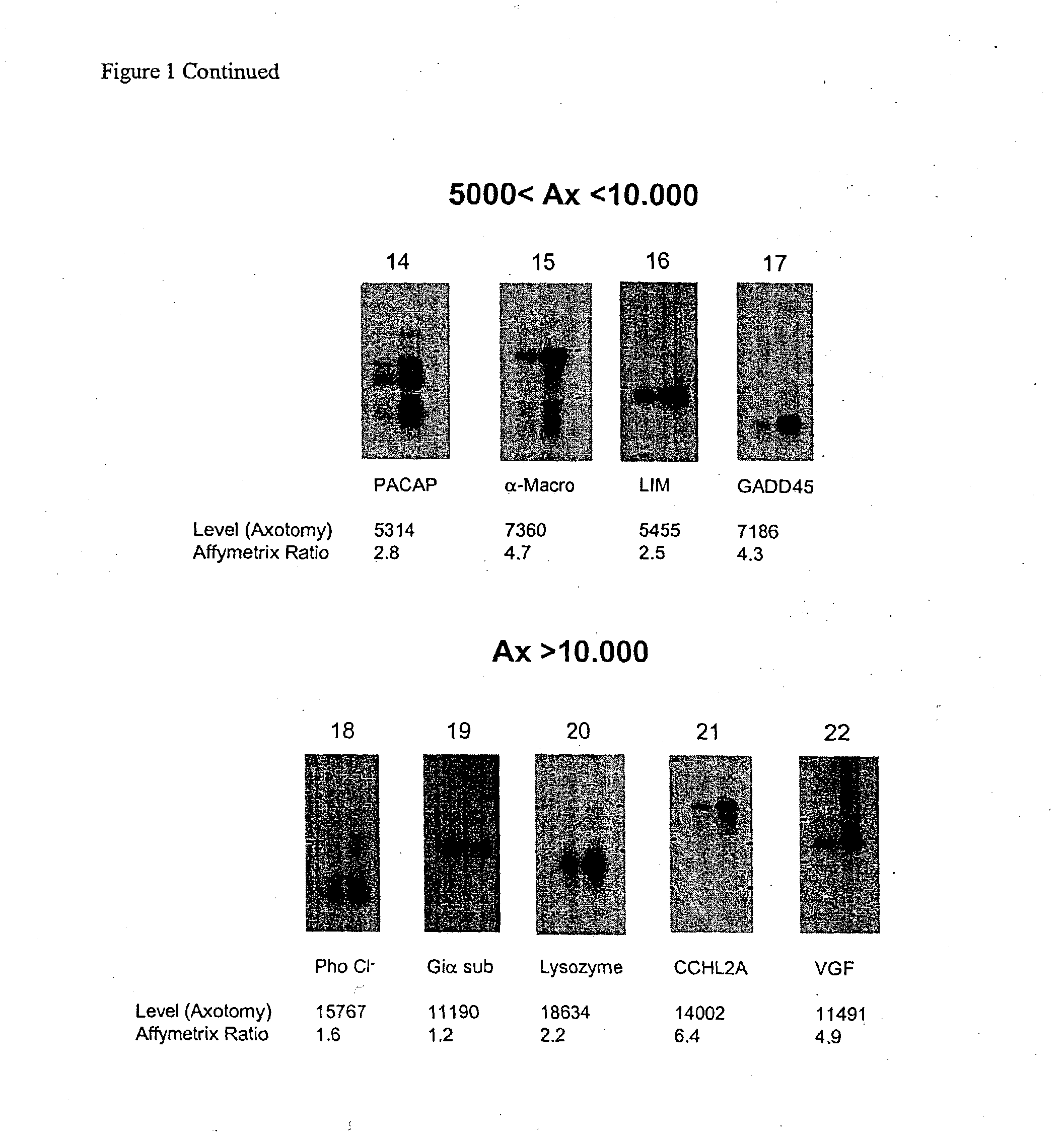

Nucleic acid and amino acid sequences involved in pain

InactiveUS20070015145A1High melting temperatureMinimizing hybridizationBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acid sequencingCell biology

The present invention relates to nucleic acid sequences which are related to pain and which are differentially expressed during pain. The invention further relates to methods of identifying nucleic acid sequences which are differentially expressed during pain, microarrays comprising such differentially expressed sequences and methods of screening agents for the ability to regulate the expression of such differentially expressed sequences.

Owner:BAYER CORP +1

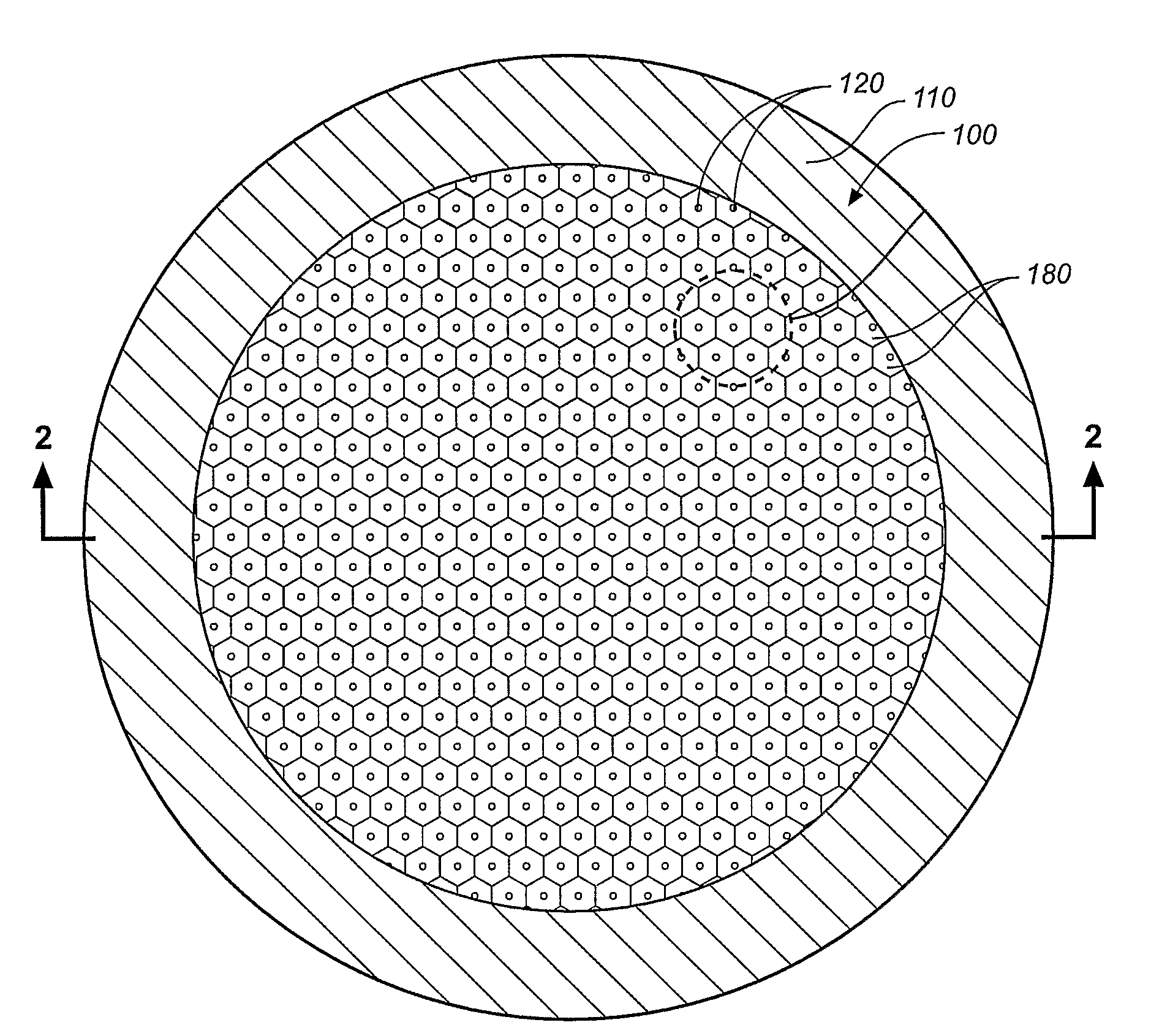

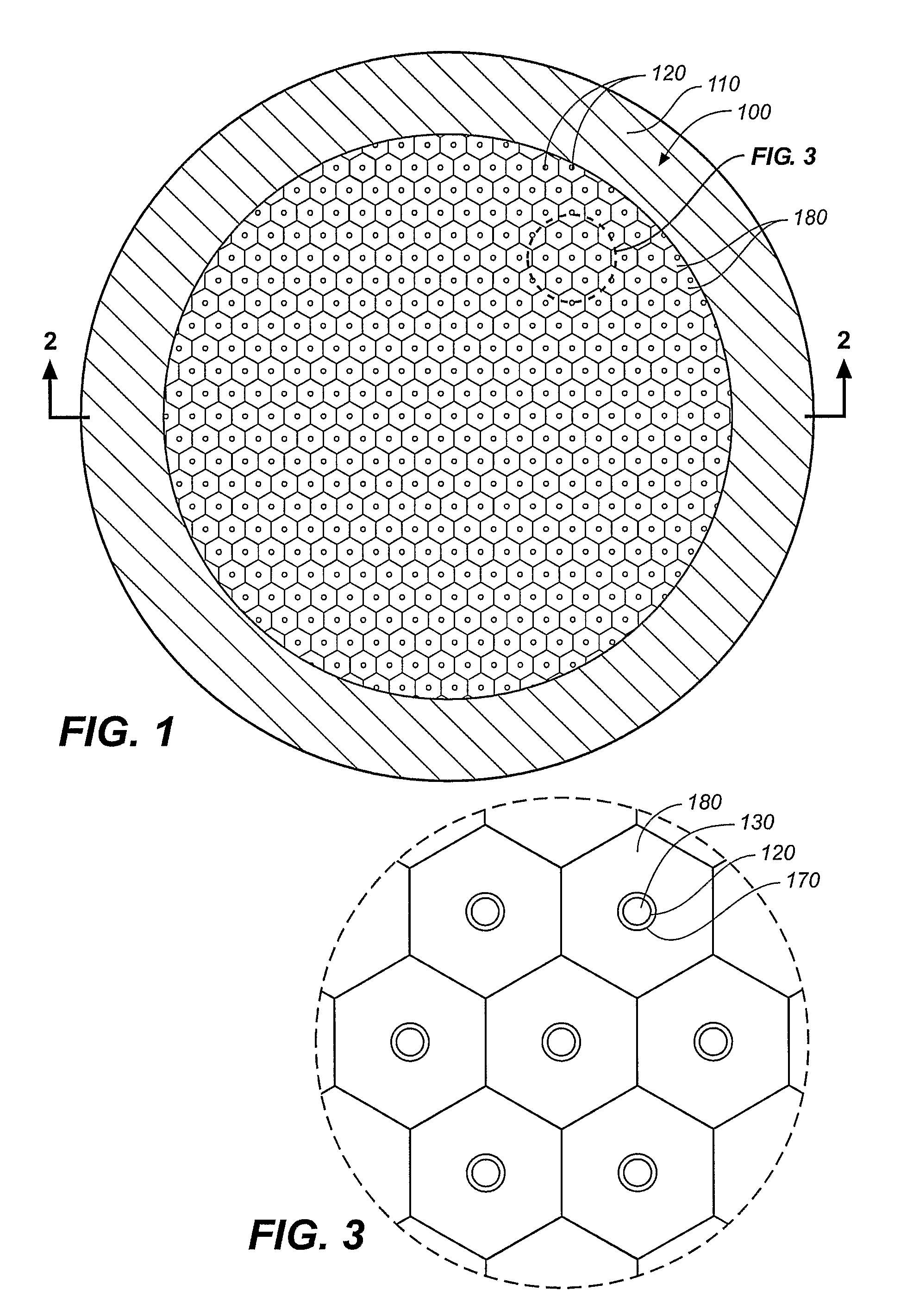

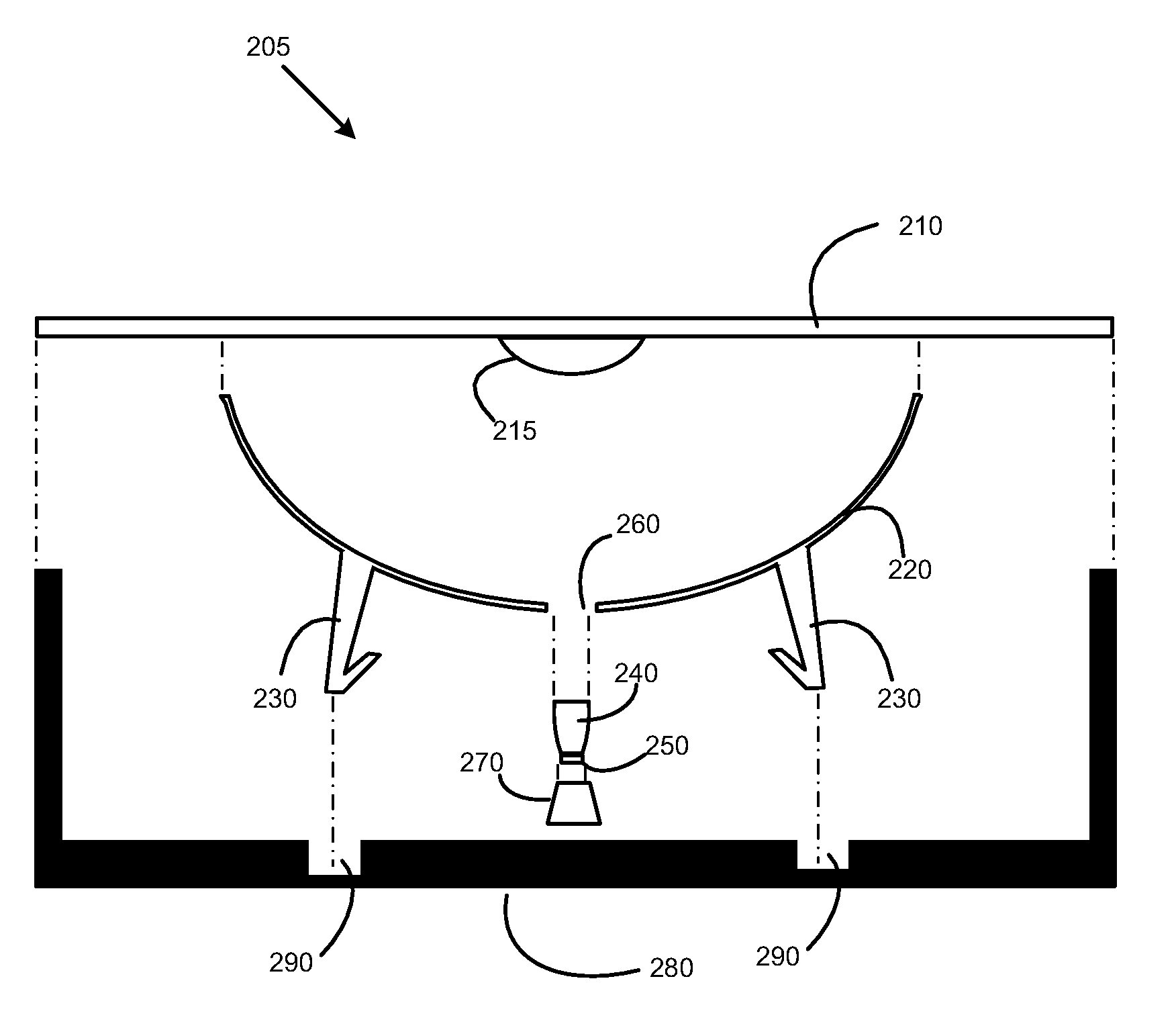

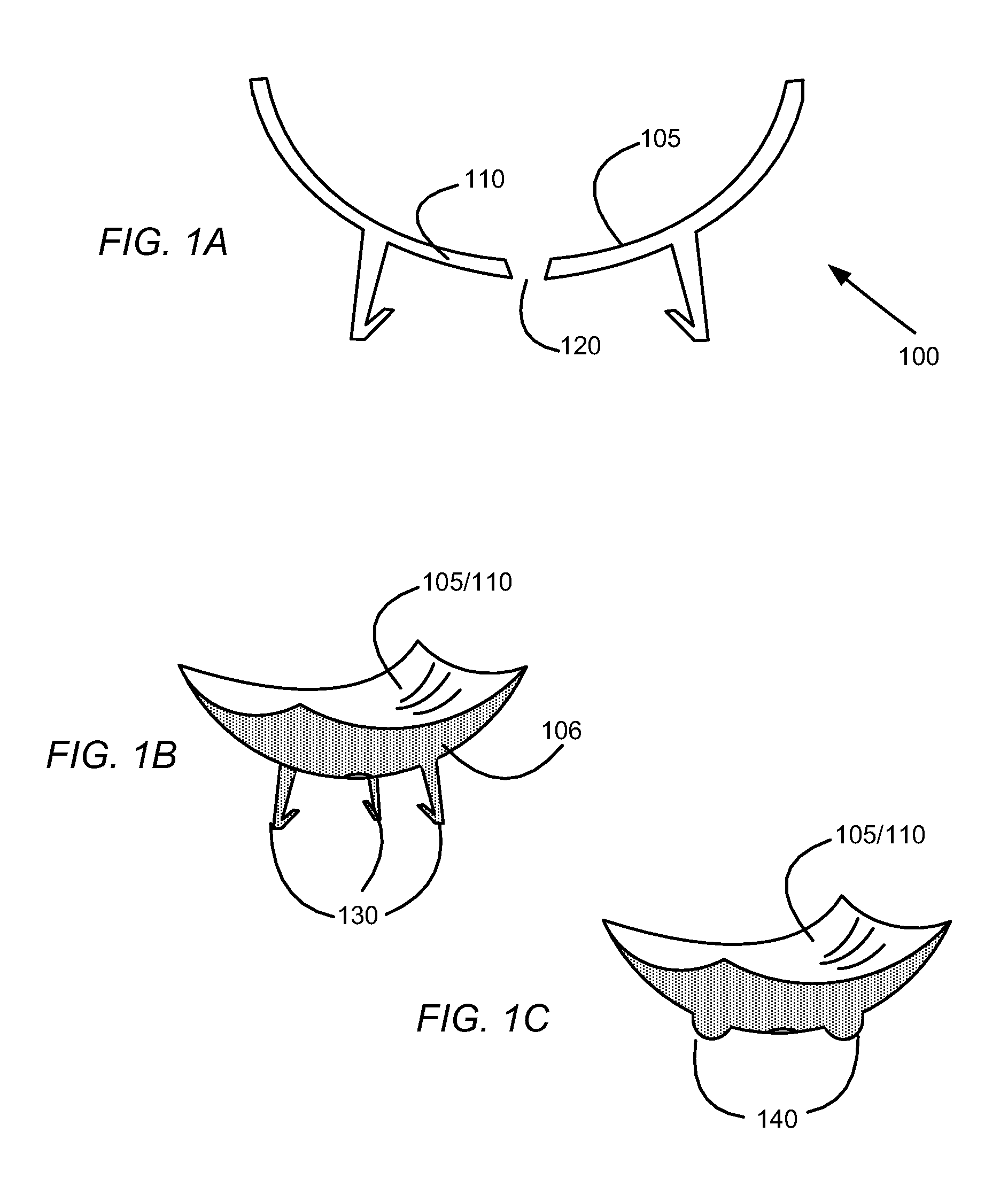

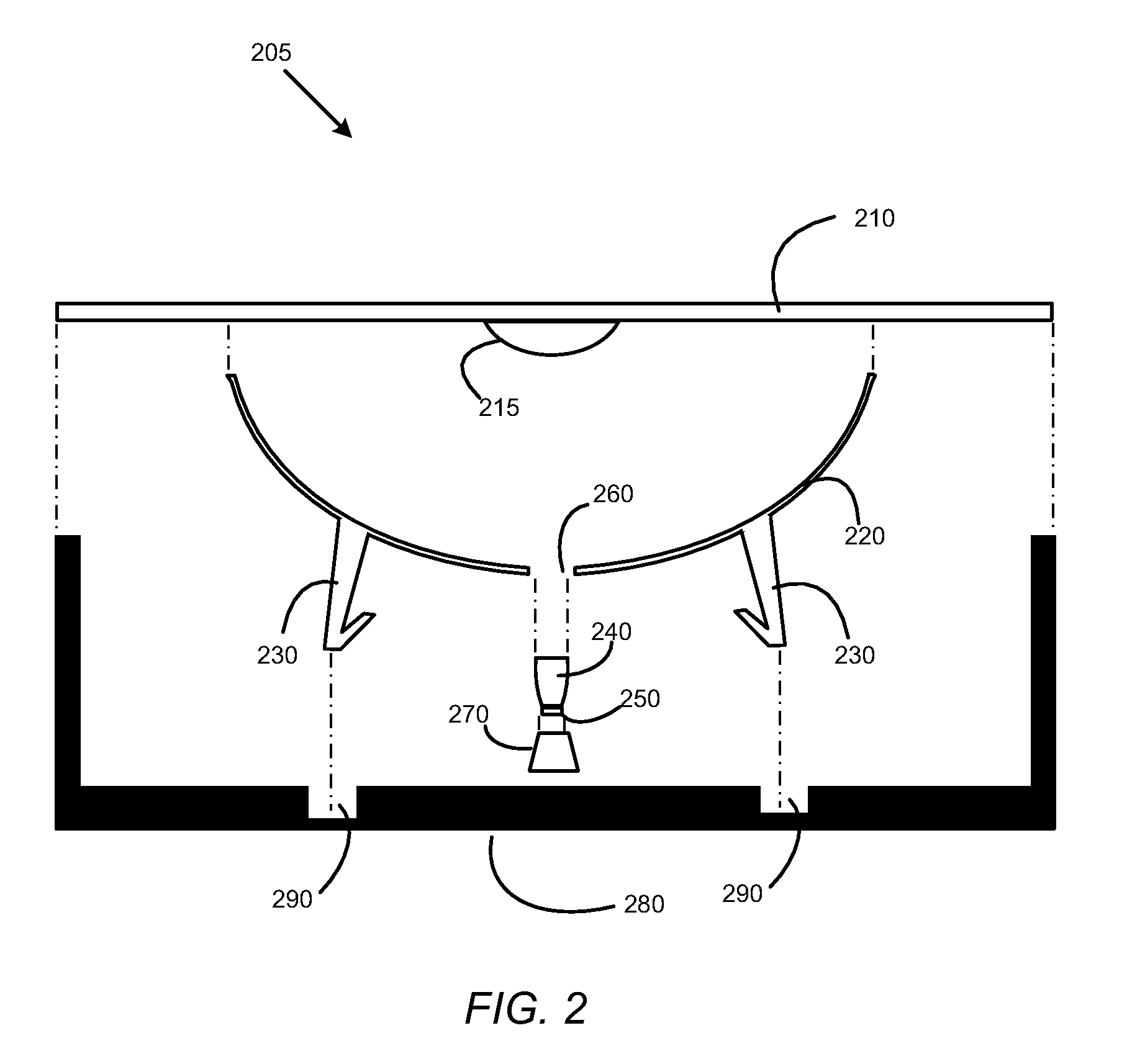

Monolithic Mirror Array

InactiveUS20090056790A1Easy to optimizeLow production costSolar heating energyMirrorsEngineeringThermal stability

The present invention is an improved solar concentrator array utilizing a monolithic array of primary mirrors fabricated from a single sheet of formable material. The material may include glass, plastic, and metal of a high thermal stability to be able to withstand a broad range of temperature conditions. The monolithic array of this invention may include integral alignment or attachment features for attachment to a supporting structure.

Owner:SOLFOCUS

Scuff resistant compositions comprising ethylene acid copolymers and polyamides

InactiveUS20050020762A1Improve toughnessHigh transparencyProtective equipmentSynthetic resin layered productsAlkaline earth metalPolyamide

Disclosed are compositions of ethylene acid copolymers and polyamides that are useful for fabricating films, sheets and molded articles for scuff and scratch resistant material and their application as decorative and protective films, comprising (1) from about 30 to about 65 weight % of a polyamide; and (2) from about 70 to about 35 weight % of a copolymer of (a) ethylene; (b) from about 5 weight % to about 15 weight % of an α,β-unsaturated C3-C8 carboxylic acid; (c) from about 0.5 weight % to about 12 weight % of at least one comonomer that is an ethylenically unsaturated dicarboxylic acid; and (d) from 0 weight % to about 30 weight % of monomers selected from alkyl acrylate and alkyl methacrylate, wherein the alkyl groups have from one to twelve carbon atoms; at least partially neutralized by one or more alkali metal, transition metal, or alkaline earth metal cations. Articles prepared from these compositions, such as films, show high toughness, good mechanical properties, excellent scratch and scuff resistance and, most importantly, good optical properties. More particularly, the compositions of ethylene copolymers and polyamides of the present invention can be used as protective coatings or layers on scuff- and scratch-exposed objects.

Owner:PERFORMANCE MATERIALS NA INC

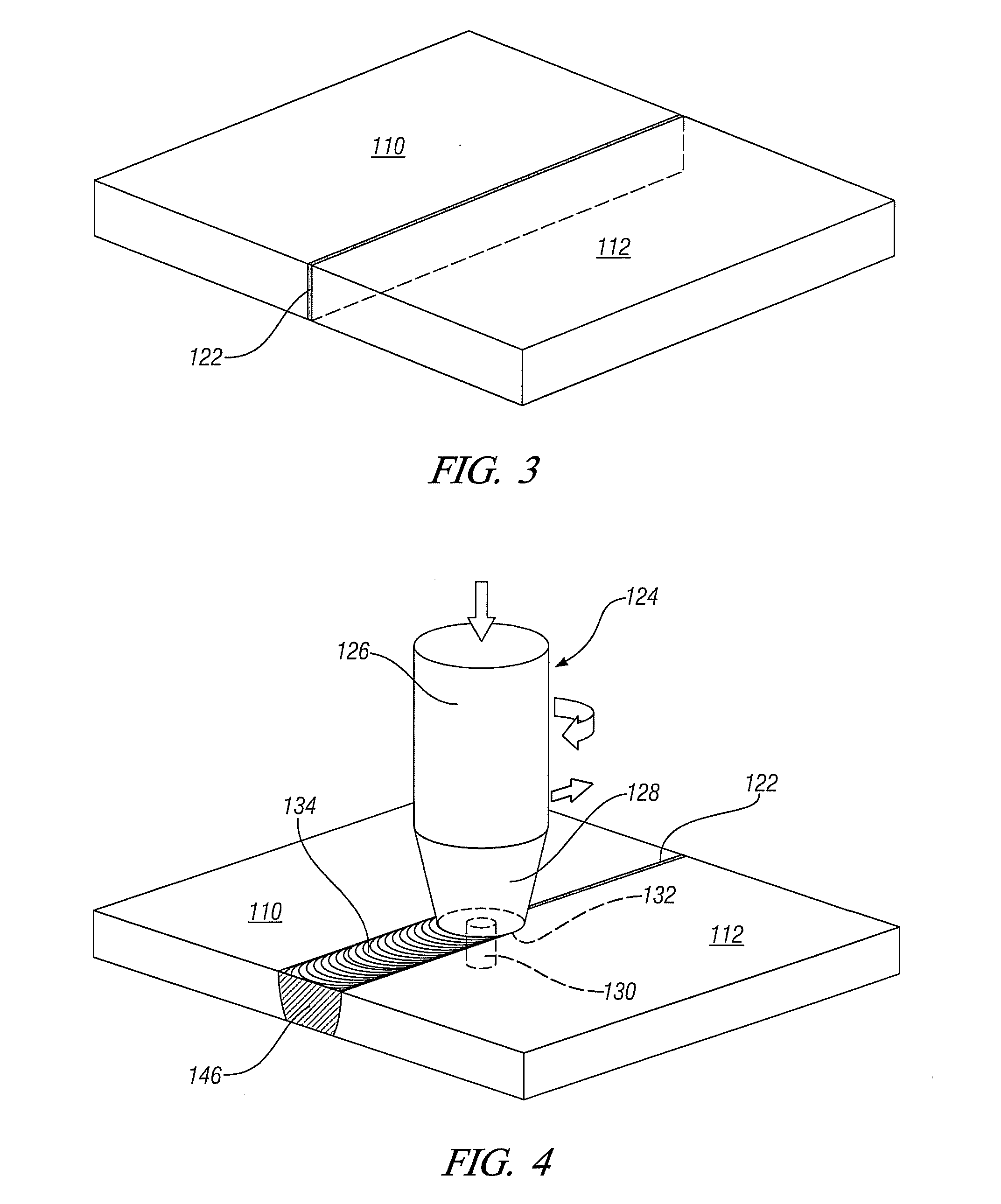

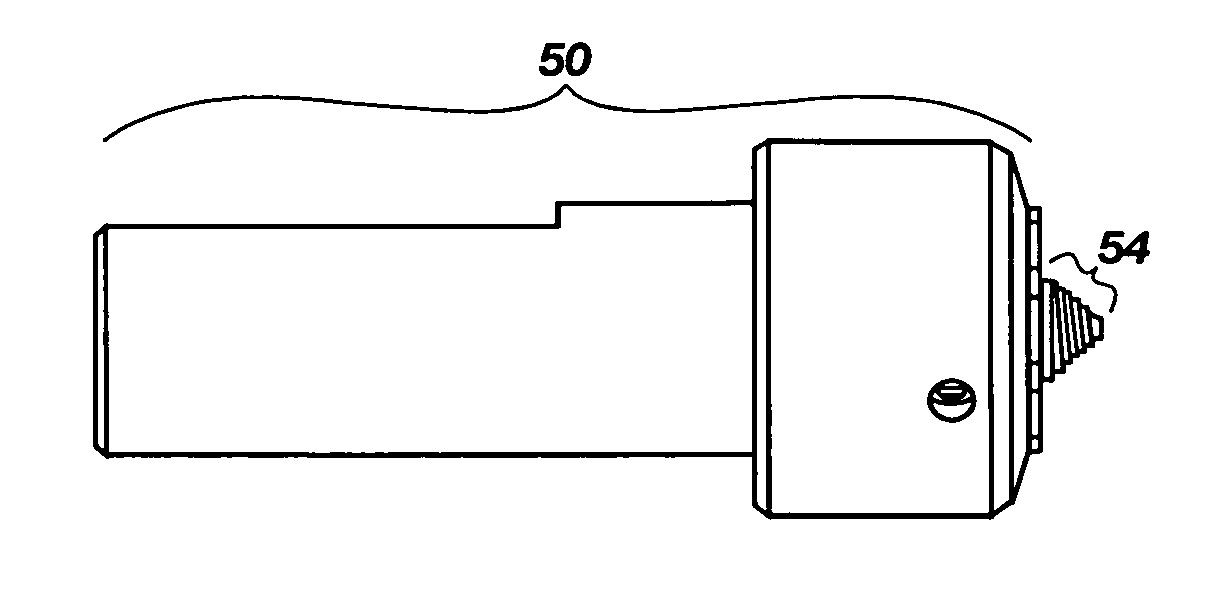

Tool geometries for friction stir spot welding of high melting temperature alloys

InactiveUS20060175382A1Well mixedEnable FSSWWelding/cutting auxillary devicesAuxillary welding devicesAlloySpot welding

A tool for friction stir spot welding of high melting temperature materials, wherein the tool geometry includes a short pin and broad shoulder to enhance mixing of high temperature materials, and wherein the tool includes a superabrasive coating to thereby enable FSSW of high melting temperature materials.

Owner:MAZAK CORP +2

Packaging substrates for integrated circuits and soldering methods

InactiveUS20050189636A1Easy maintenanceHigh melting temperaturePrinted circuit assemblingSemiconductor/solid-state device detailsContact padInterposer

A packaging substrate (310) includes a semiconductor interposer (120) and at least one other intermediate substrate (110), e.g. a BT substrate. The semiconductor interposer has first contact pads (136C) attachable to dies (124) above the interposer, and second contact pads (340) attachable to circuitry below the interposer. Through vias (330) are made in the semiconductor substrate (140) of the interposer (120). Conductive paths going through the through vias connect the first contact pads (136C) to the second contact pads (340). The dies (124) are attached to the interposer after the attachment of the interposer to the BT substrate. In sequential soldering operations, the solder hierarchy is maintained by dissolving some material (e.g. copper) in the solder during soldering to raise the solder's melting temperature. For example, all of the solders may initially have the same melting temperature, but each solder's melting temperature is increased during soldering to prevent the solder from melting in the subsequent soldering operations.

Owner:INVENSAS CORP

In-mold coating compositions for optical lenses

InactiveUS20070138667A1Desirable functional propertyMolding temperature is highOptical articlesCoatingsMethacrylateOptical surface

A composition adapted for use in an in-situ coating process for coating an optical surface for ophthalmic applications. A coating composition according to the present invention includes at least one multifunctional acrylate compound which is cured onto a heated surface with controlled coating distribution in an ophthalmic injection mold. For example, the composition may include an acrylic base cured with an initiator, e.g., t-butyl perbenzoate, and may further include at least one catalyst and at least one metal salt. An acrylic base according to the present invention may include a combination of monofunctional and / or multifunctional acrylate and / or methacrylate compounds.

Owner:ESSILOR INT CIE GEN DOPTIQUE

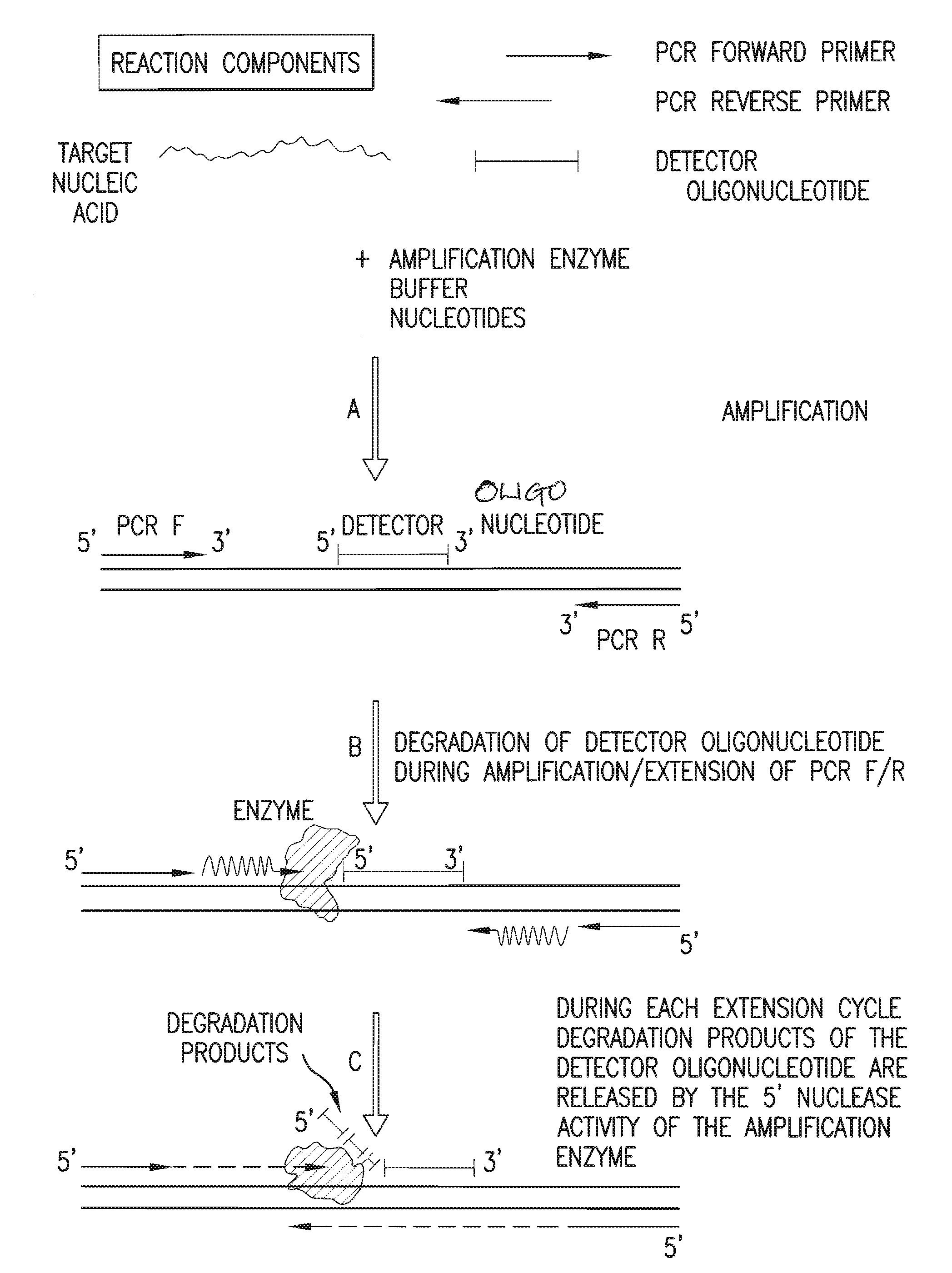

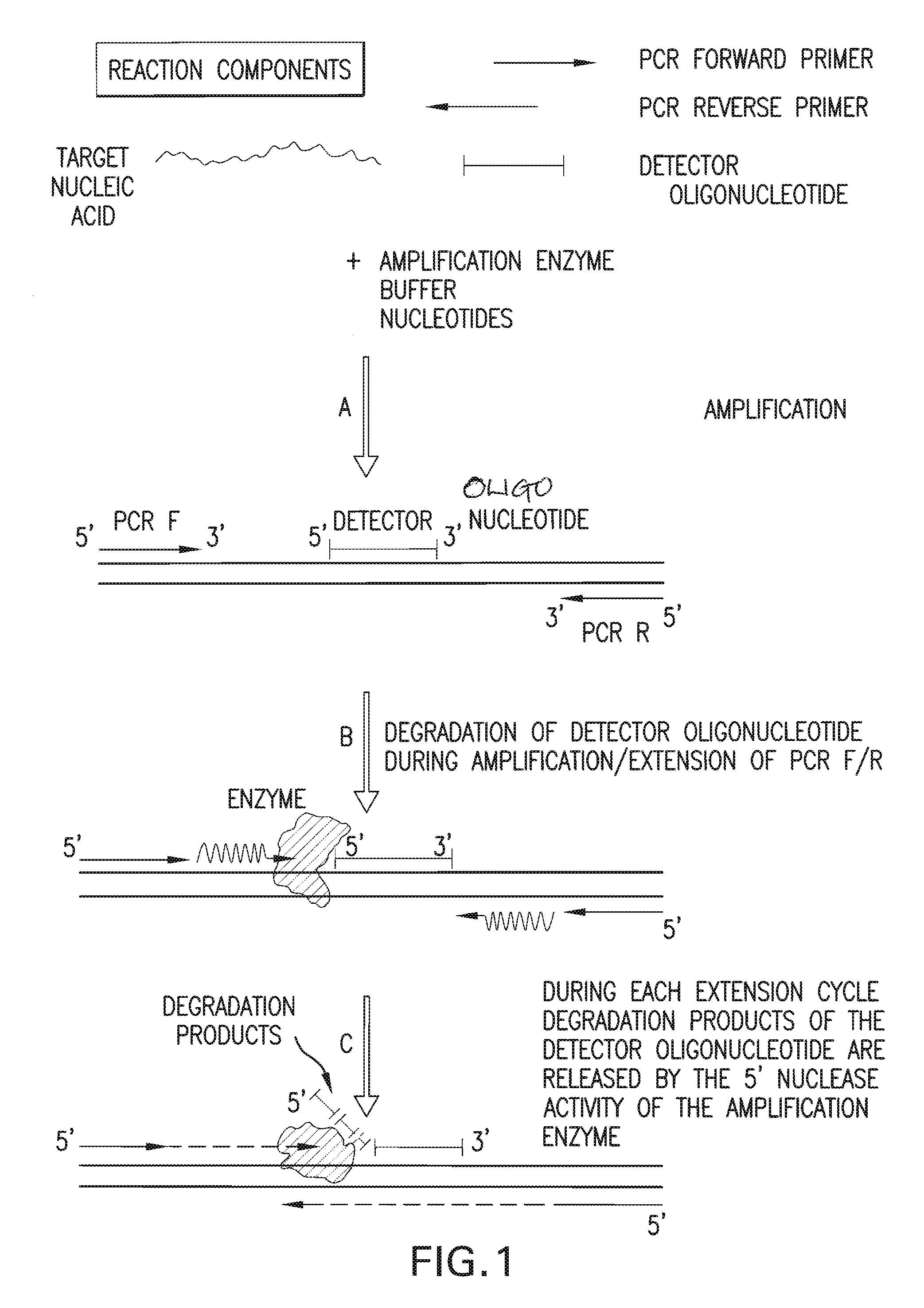

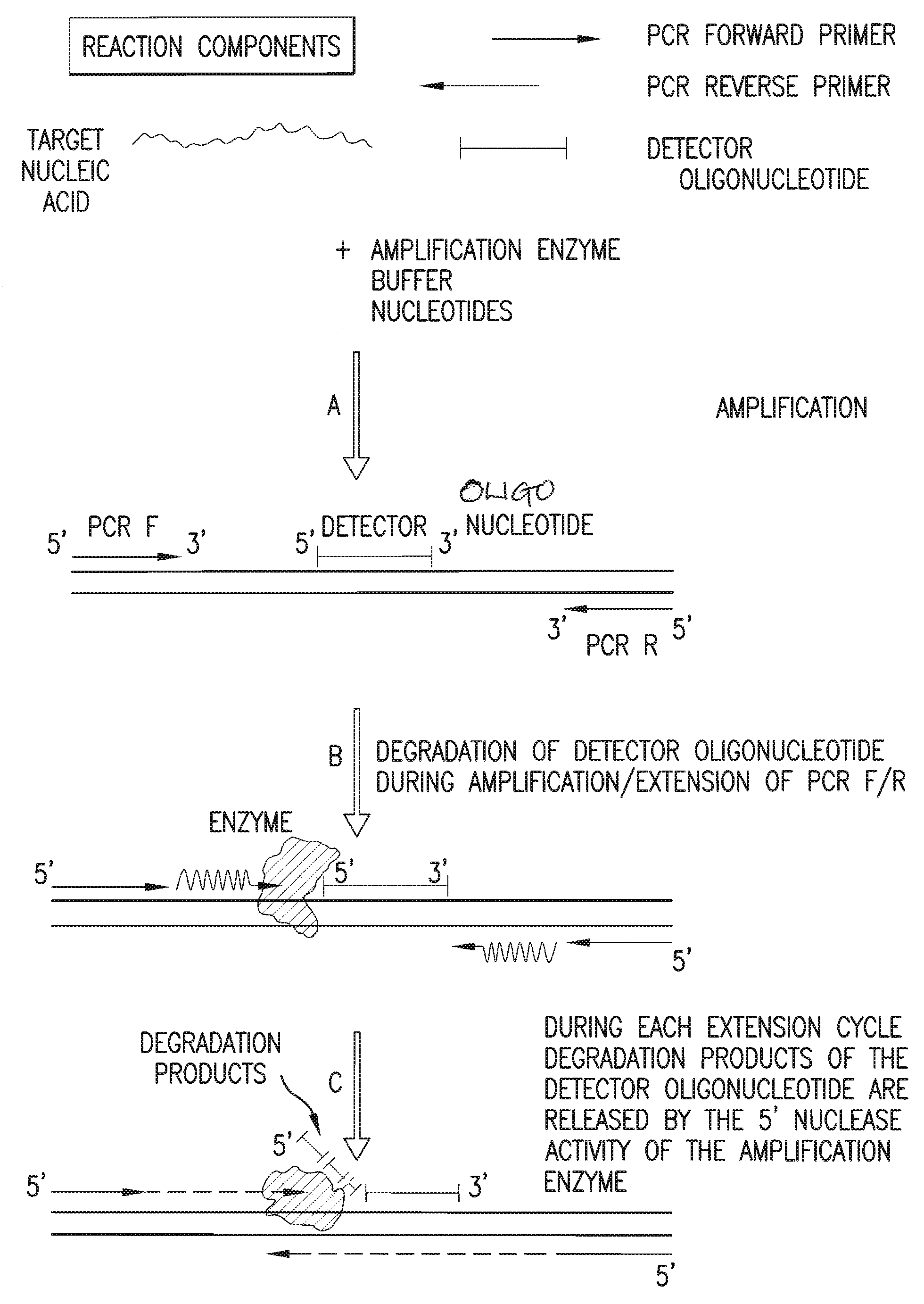

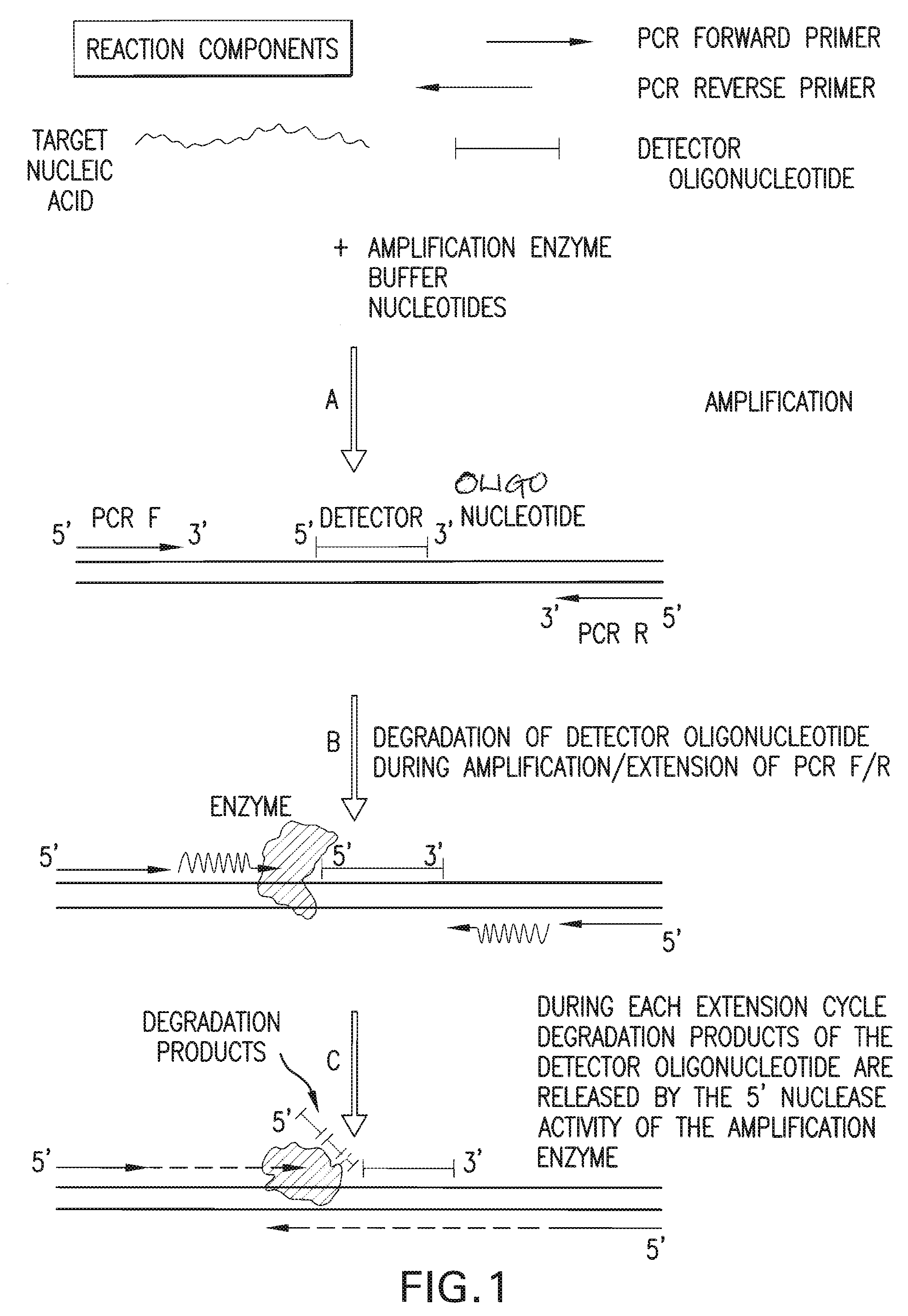

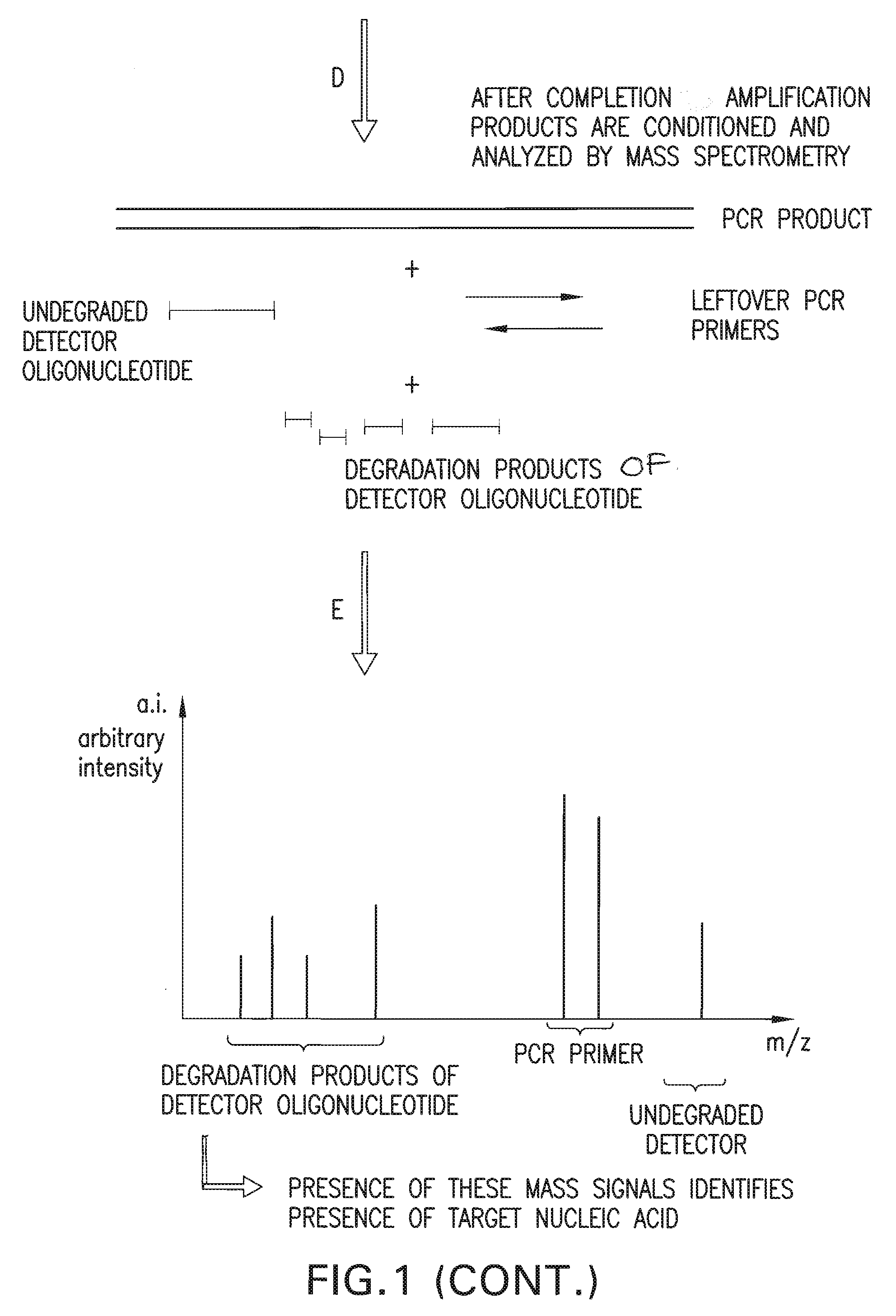

Detection and quantification of biomolecules using mass spectrometry

InactiveUS20110160093A1Reduce processing stepsReduce rateSugar derivativesNucleotide librariesPolymerase LMass Spectrometry-Mass Spectrometry

The present invention is directed in part to a method for detecting a target nucleic acid using detector oligonucleotides detectable by mass spectrometry. This method takes advantage of the 5′ to 3′ nuclease activity of a nucleic acid polymerase to cleave annealed oligonucleotide probes from hybridized duplexes and releases labels for detection by mass spectrometry. This process is easily incorporated into a polymerase chain reaction (PCR) amplification assay. The method also includes embodiments directed to quantitative analysis of target nucleic acids.

Owner:AGENA BIOSCIENCE INC

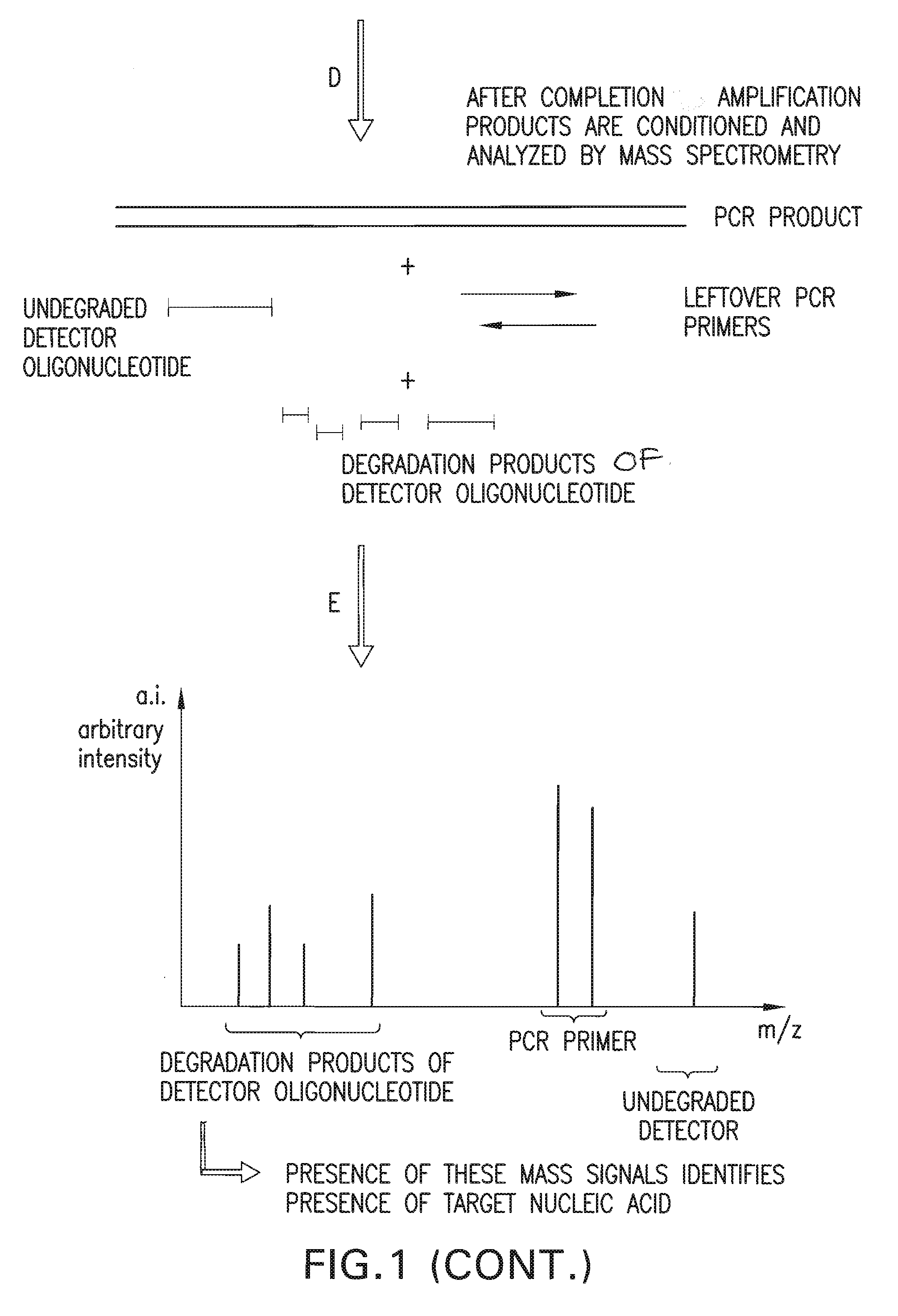

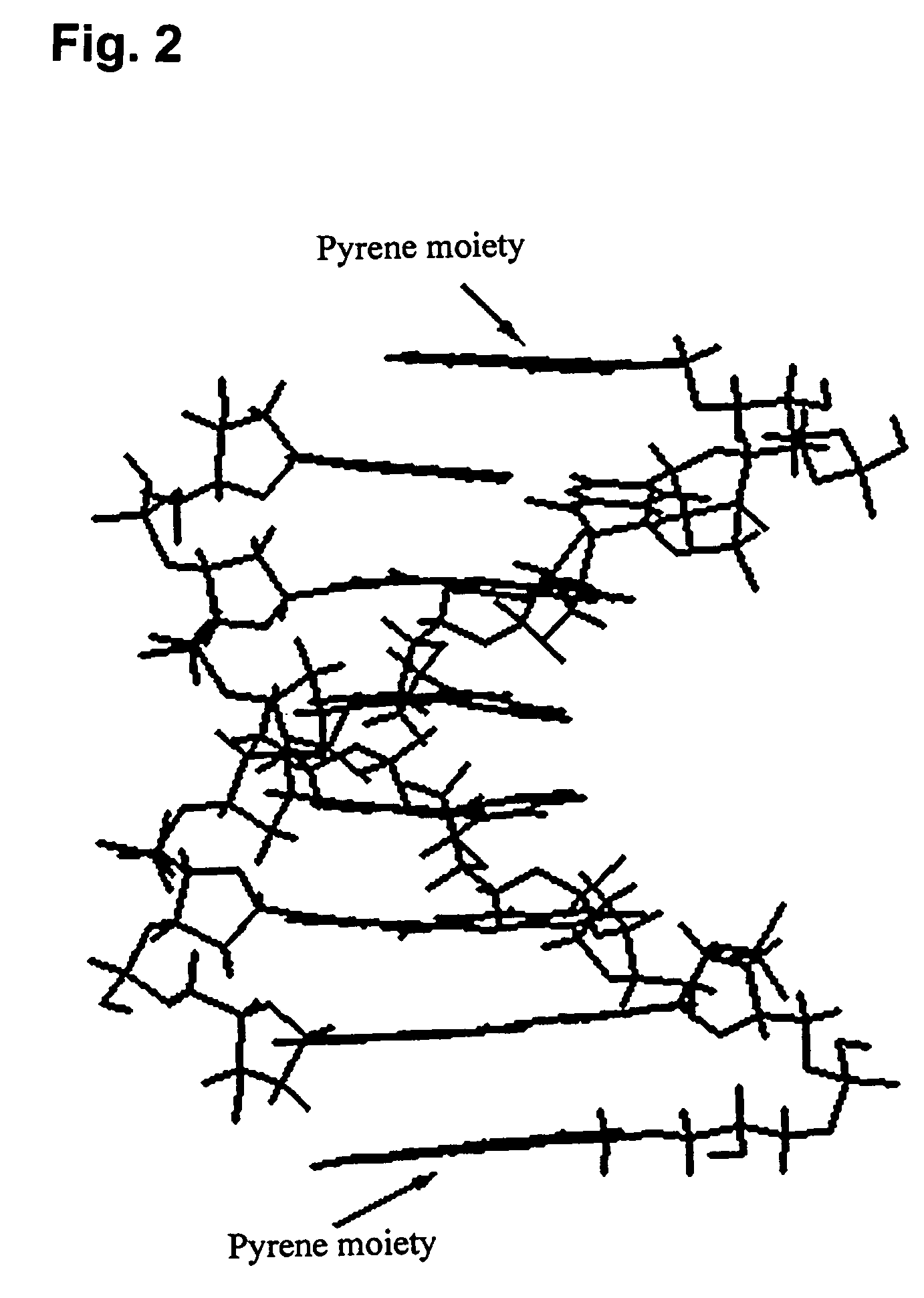

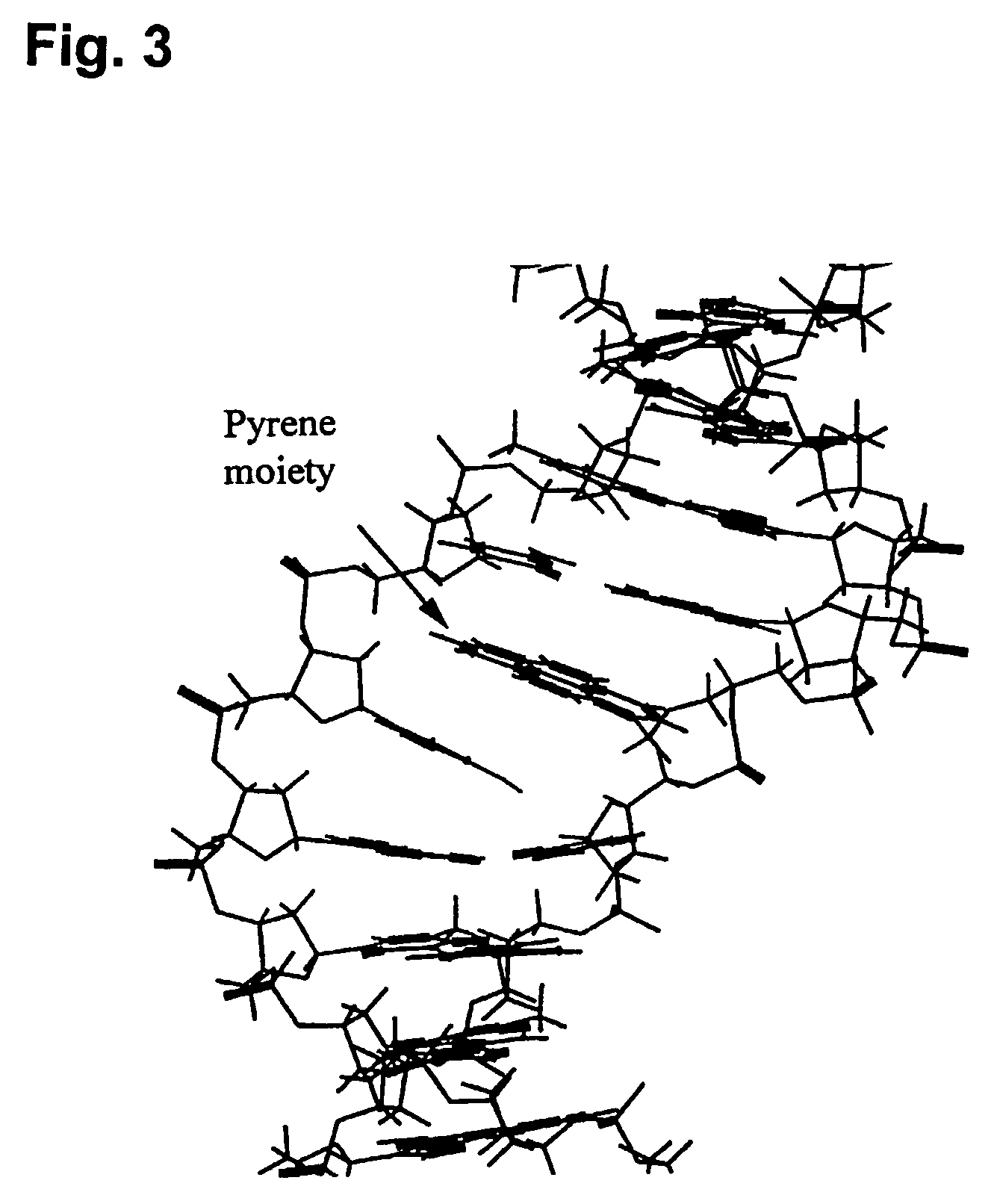

Pseudonucleotide comprising an intercalator

InactiveUS20060014144A1Strong specificityHigh melting temperatureSugar derivativesMicrobiological testing/measurementNucleobaseNucleic acid analogue

The present invention relates to intercalator pseudonucleotides. Intercalator pseudonucleotides according to the invention are capable of being incorporated into the backbone of a nucleic acid or nucleic acid analogue and they comprise an intercalator comprising a flat conjugated system capable of co-stacking with nucleobases of DNA. The invention also relates to oligonucleotides or oligonucleotide analogues comprising at least one intercalator pseudo nucleotide. The invention furthermore relates to methods of synthesising intercalator pseudo nucleotides and methods of synthesising oligonucleotides or oligonucleotide analogues comprising at least one intercalator pseudonucleotide. In addtition, the invention describes methods of separating sequence specific DNA(s) from a mixture comprising nucleic acids, methods of detecting a sequence specific DNA (target DNA) in a mixture comprising nucleic acids and / or nucleic acid analogues and methods of detecting a sequence specific RNA in a mixture comprising nucleic acids and / or nucleic acid analogues. In particular said methods may involve the use of oligonucleotides comprising intercalator pseudo nucleotides. The invention furthermore relates to pairs of oligonucleotides or oligonucleotide analogues capable of hybridising to one another, wherein said pairs comprise at least one intercalator pseudonucleotide. Methods for inhibiting a DNAse and / or a RNAse and methods of modulating transcription of one or more specific genes are also described.

Owner:HUMAN GENETIC SIGNATURES PTY LTD

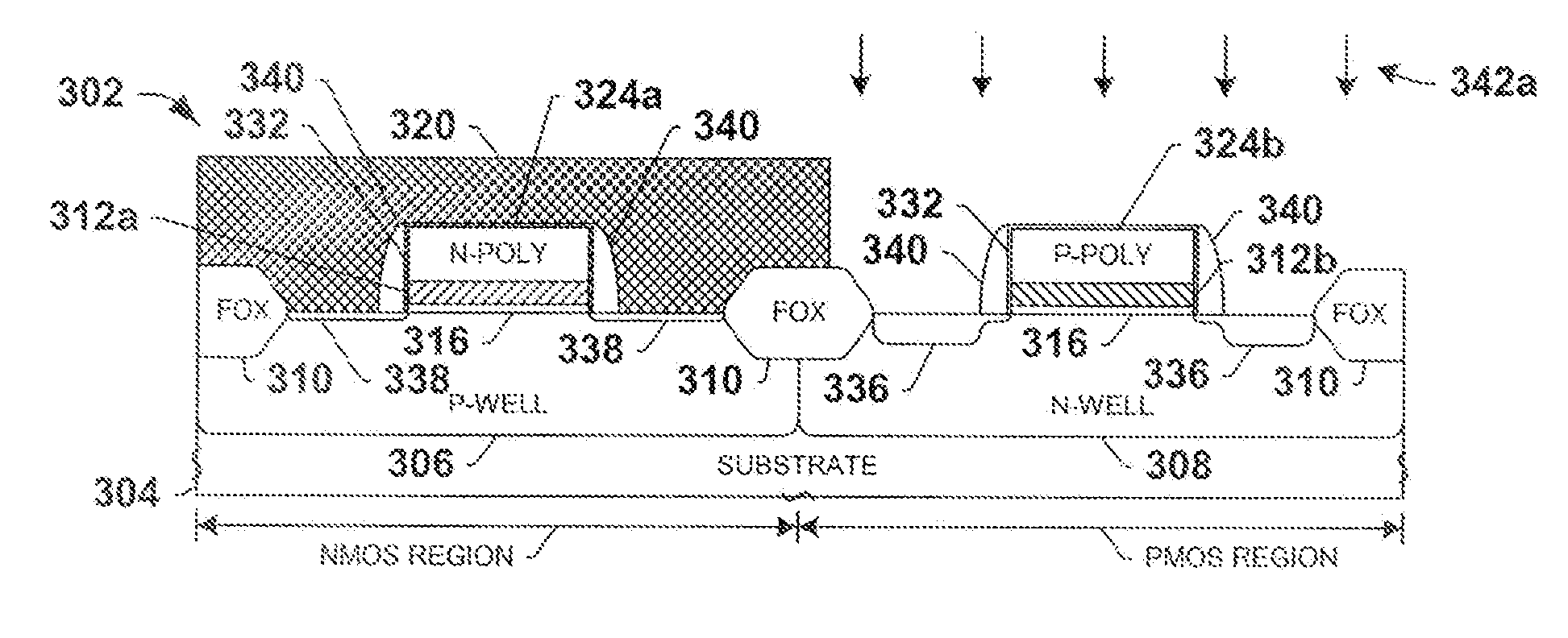

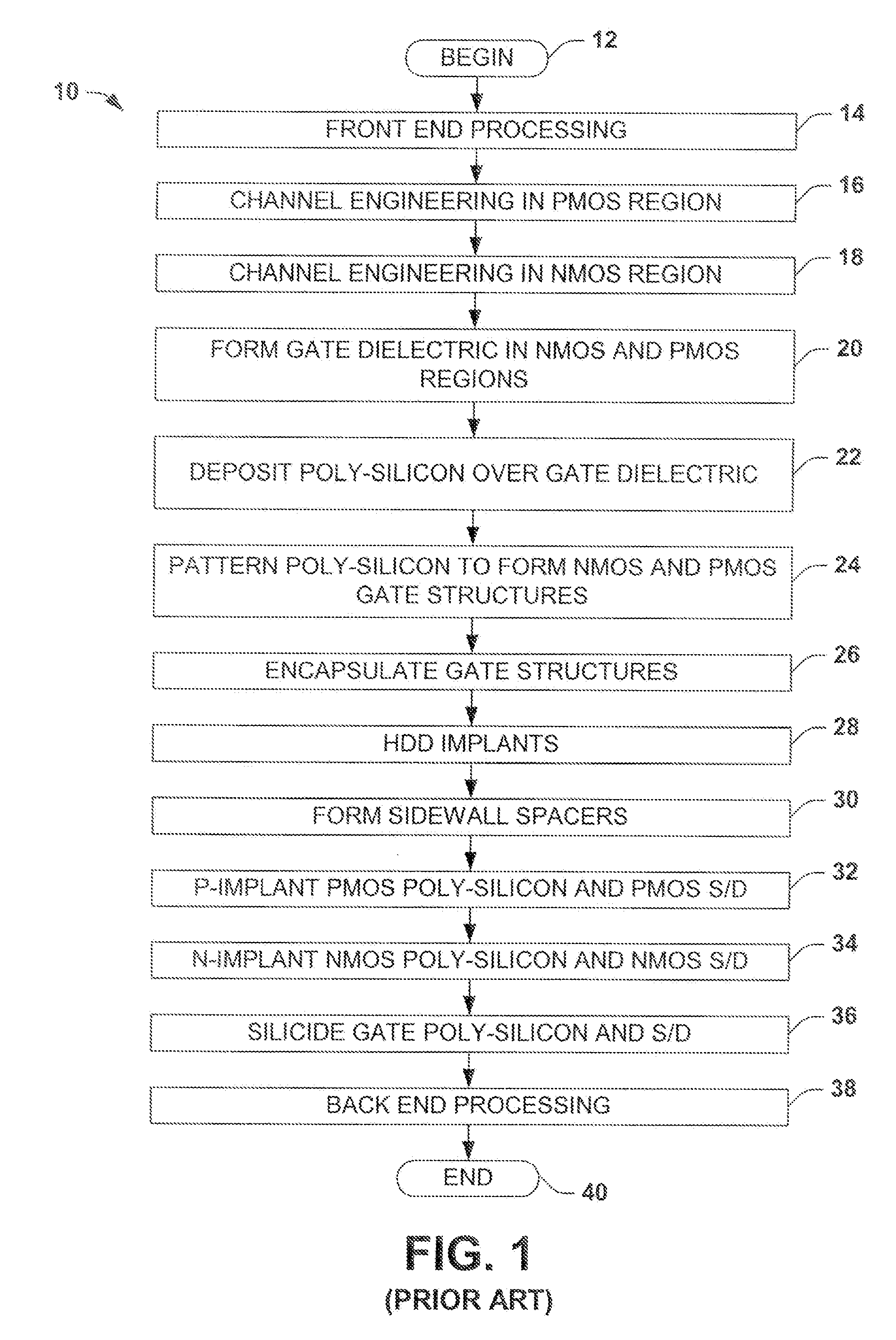

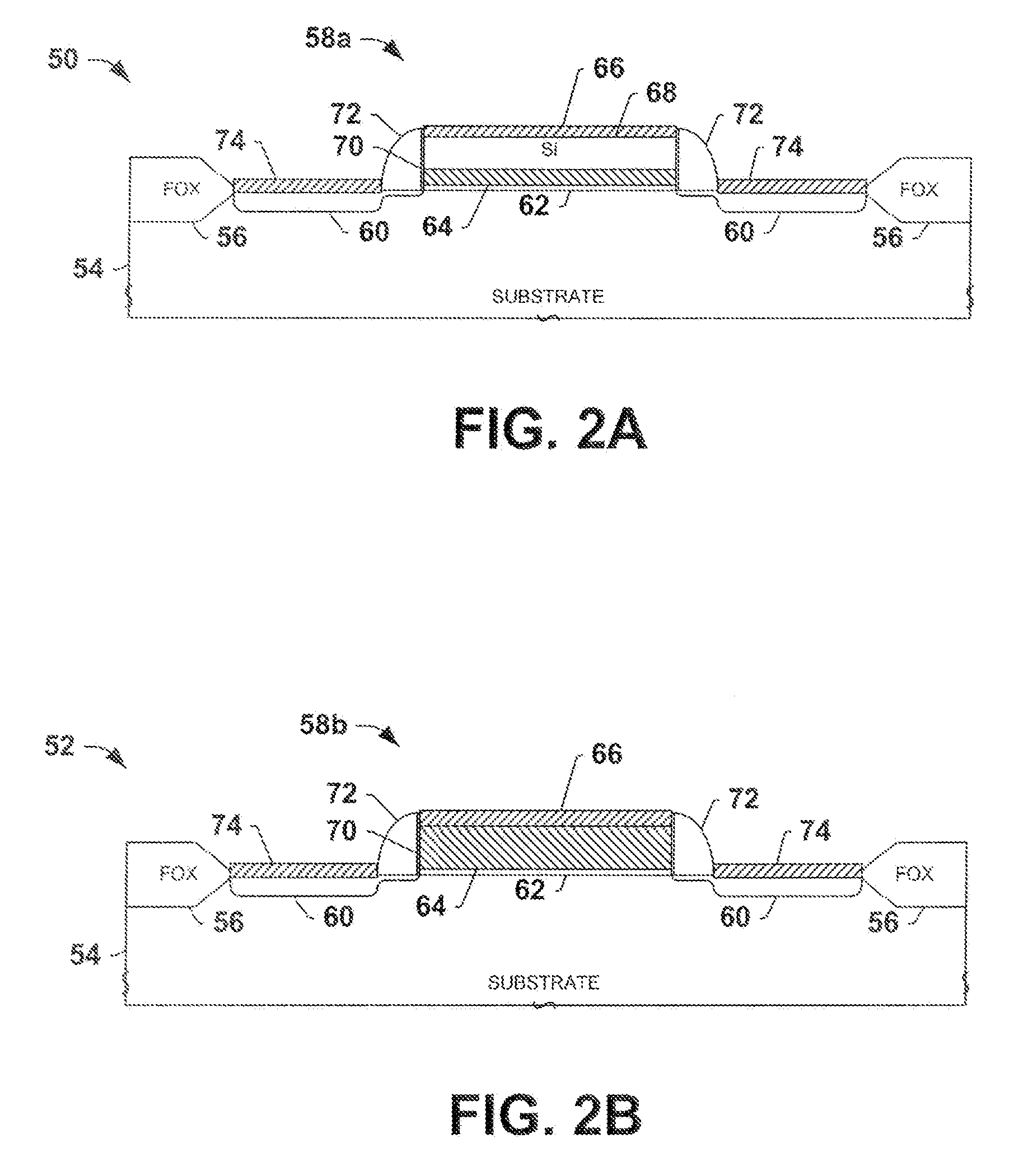

MOS Transistor Gates with Doped Silicide and Methods for Making the Same

InactiveUS20060244045A1Facilitating elimination and simplificationHigh melting temperatureTransistorSemiconductor/solid-state device manufacturingGate dielectricDevice material

Owner:VISOKAY MARK +1

Detection and quantification of biomolecules using mass spectrometry

InactiveUS20090111712A1Reduce processing stepsReduce rateSugar derivativesNucleotide librariesPolymerase LMass Spectrometry-Mass Spectrometry

The present invention is directed in part to a method for detecting a target nucleic acid using detector oligonucleotides detectable by mass spectrometry. This method takes advantage of the 5′ to 3′ nuclease activity of a nucleic acid polymerase to cleave annealed oligonucleotide probes from hybridized duplexes and releases labels for detection by mass spectrometry. This process is easily incorporated into a polymerase chain reaction (PCR) amplification assay. The method also includes embodiments directed to quantitative analysis of target nucleic acids.

Owner:AGENA BIOSCI

Glaze for fast-fired crystal glaze ceramic tile, and preparation method and applications of ceramic tile

ActiveCN104829268AReduce granularity requirementsSimple manufacturing processManufacturing technologyBrick

The invention provides a glaze for fast-fired crystal glaze ceramic tile and a preparation method and applications of ceramic tile. The glaze comprises basic crystal glaze and a color developing agent, wherein the basic crystal glaze comprises the following raw materials: zinc oxide, titanium dioxide, quartz, cryolite, zinc phosphate, kaolin, and lead frit. A proper amount of zinc phosphate is introduced into the glaze to avoid the raw material frit treatment, which is carried out to ensure the residual amount of nucleating agent, the requirements on the glaze granularity are reduced, the manufacture technologies of crystal glaze and ceramic tiles are simplified, and the technical difficulties that the crystal glaze sintering technology is complicated, the crystal patterns are difficult to control, and the production cost is high are solved. Moreover, the addition amount of quartz and lead frit is precisely controlled to obtain crystal glaze art ceramic tiles which have the advantages of good crystallization effect, strong three-dimensional effect, and good artistic effect. The provided preparation method has the advantages of simpleness, lower sintering temperature, shorter period, and suitability for massive industrial production.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

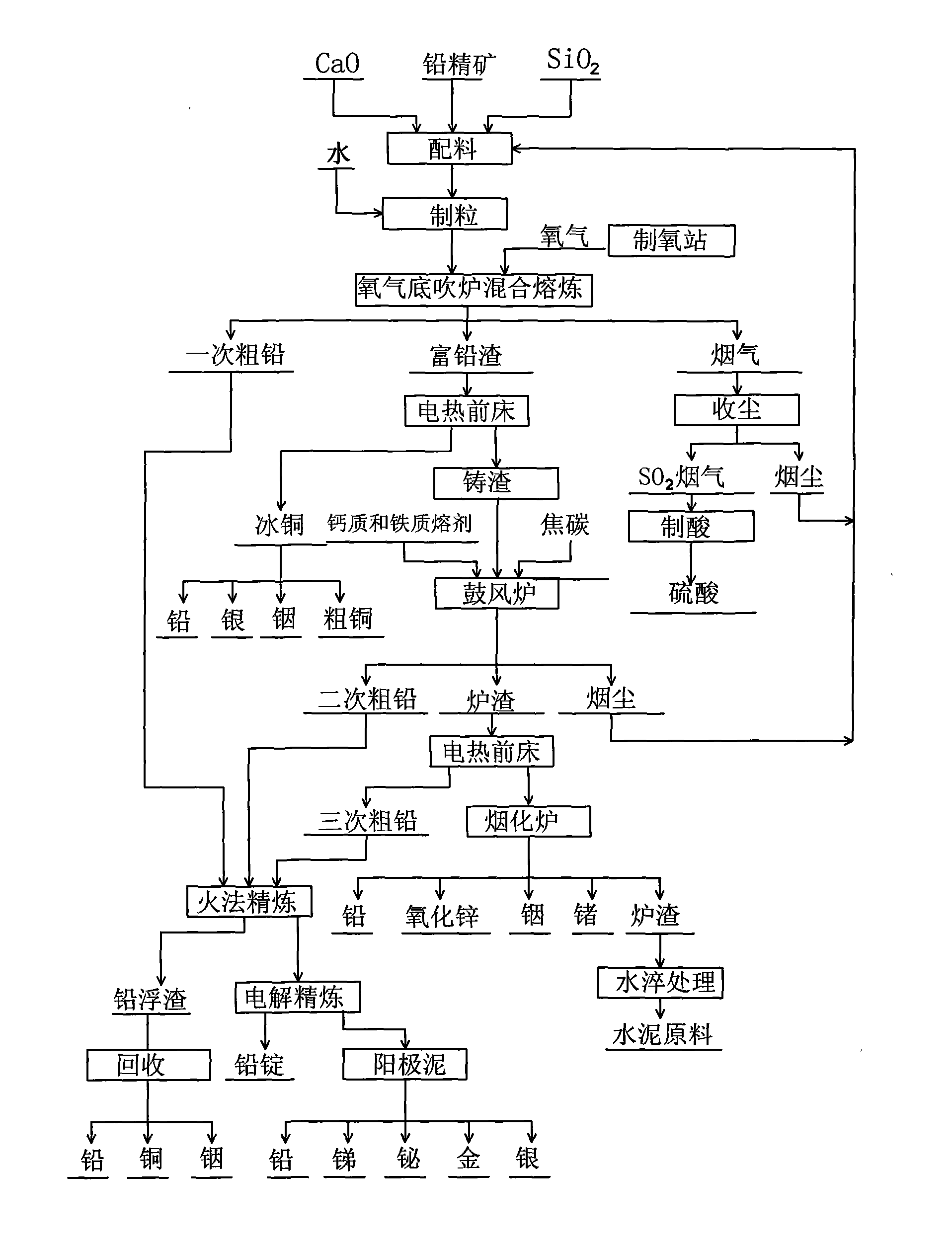

Balancing lead smelting process for comprehensive resource utilization and device thereof

InactiveCN101514399AHigh melting temperaturePromote oxidation reactionPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention relates to a balancing lead smelting process for comprehensive resource utilization and a device thereof. The process comprises the following steps: granulating a raw material containing lead and a fluxing agent after proportioning, sending to an oxygen bottom-blown smelting furnace for smelting to produce primary crude lead, lead ash and flue gas of SO2; sending the flue gas of SO2 to a sulfuric acid system for acid making after recovering waste heat by a waste heat boiler and duct collection by a dust arrester installation; adjusting form of the lead ash and adding the lead ash to a blast furnace together with coking coal for reducing smelting to produce secondary and third crude lead; electrorefining the crude lead to obtain refined lead and anode slime, treating and recovering the anode slime to obtain lead, stibium, bismuth, gold and silver metals; and separating slag of the blast furnace from the crude lead and sending to a fuming furnace to recover zinc oxide, the lead, indium and germanium. A system for realizing the process comprises the oxygen bottom-blown smelting furnace, an oxygen lance, an electrically-heated settler, a slag casting device, the waste heat boiler with a vertical ascending segment of membrane wall structure, the blast furnace, the fuming furnace and a ventilating device. The process design and system improvement help realize balancing optimized recovery of Pb, Zn, Au, Ag, Bi, Cu, In, Sb and S elements.

Owner:CHENZHOU YUTENG CHEM IND

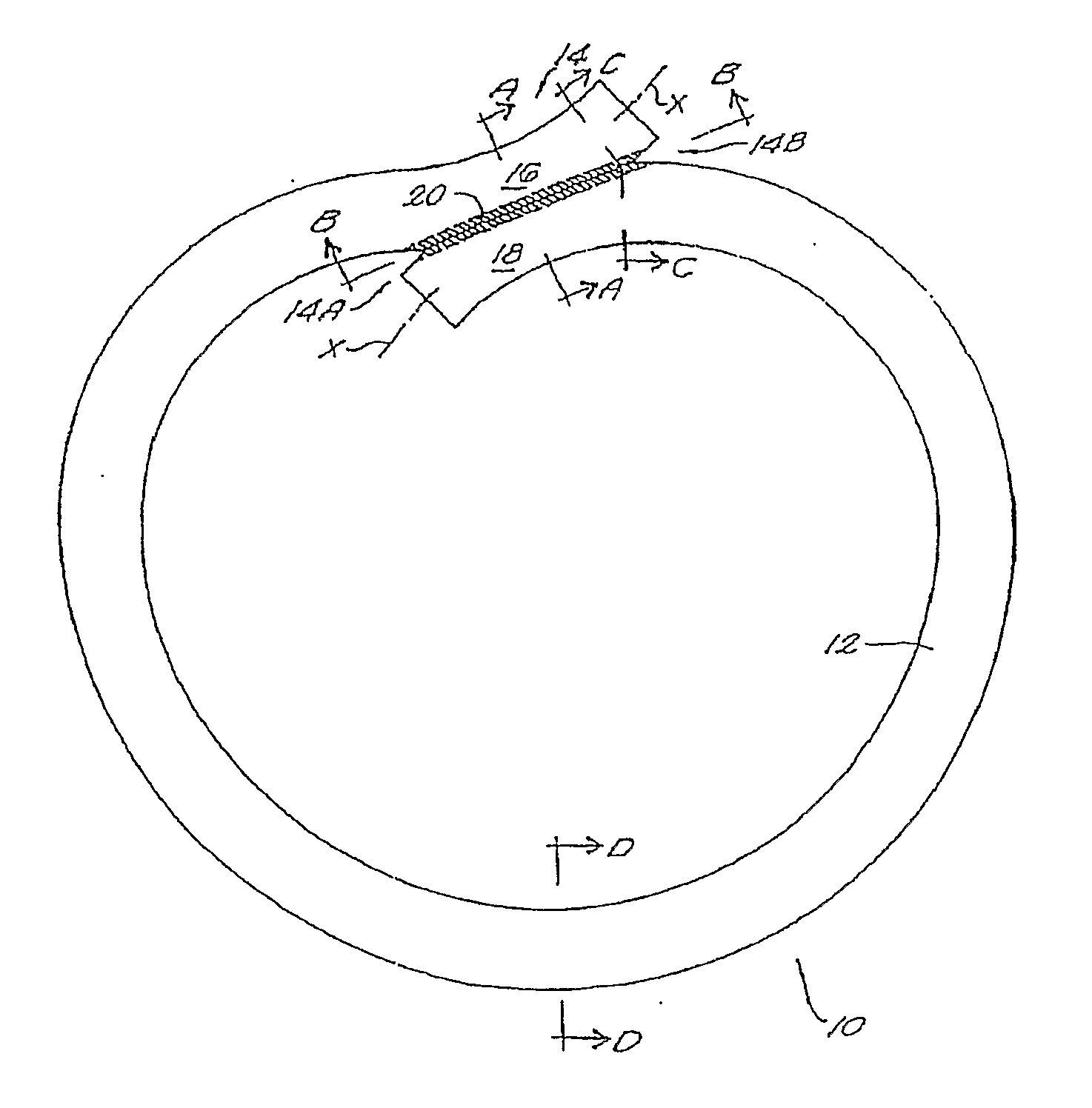

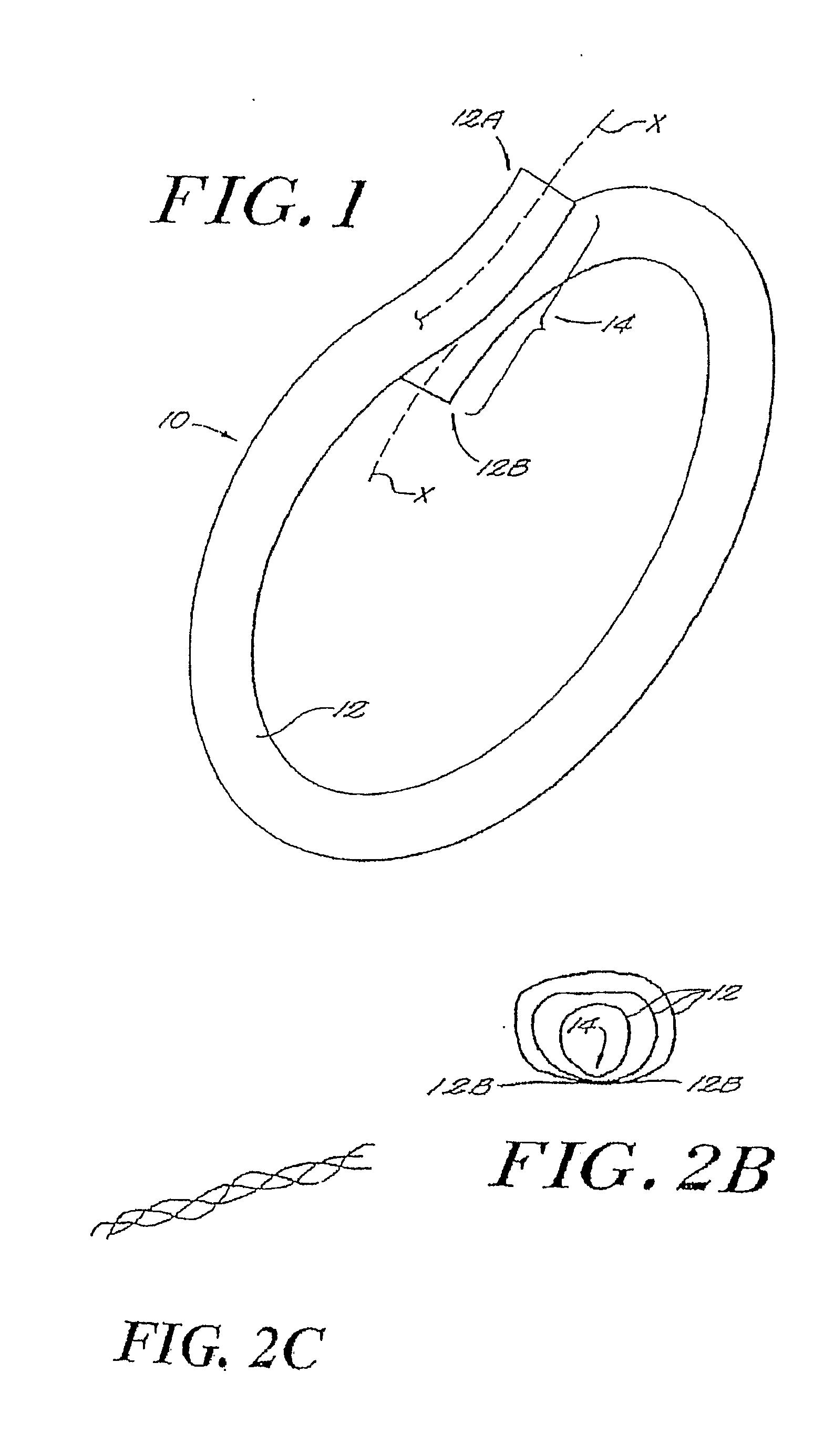

Multicomponent fused suture loop and apparatus for making same

InactiveUS20090216269A1Easy to weldImprove the immunitySuture equipmentsMechanical working/deformationFiberUltrasonic welding

A fused loop of an elongated material, such as a surgical suture, and apparatus for making the loop are described. Portions of one or more segments of elongated material may be fused in an ultrasonic welding process to form a welded joint. Multiple materials each with different a different melting point may be used for one or more fibers within the elongated material. The elongated material may include a sheath, which may be used to protect a core within the elongated material. A fused region of the fused loop may be formed when a material with a lower melting temperature, compared to one or more other materials in the elongated material, is caused to melt. A related ultrasonic welding apparatus may include a temperature sensor for control of the welding process.

Owner:TORNIER INC

Relaxation of a strained layer using a molten layer

ActiveUS20060175608A1Freeze fastLarge diffusionSemiconductor/solid-state device manufacturingSemiconductor devicesInterface layerComputer science

A method for making a crystalline wafer, in which an interface layer is associated with a support substrate. A first layer is associated with the interface layer in a strained state. The interface layer is melted sufficiently to substantially uncouple the first layer from the support substrate to relax the first layer from the strained to state to a relaxed state. The interface material is solidified with the first layer in the relaxed state to obtain a first wafer.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

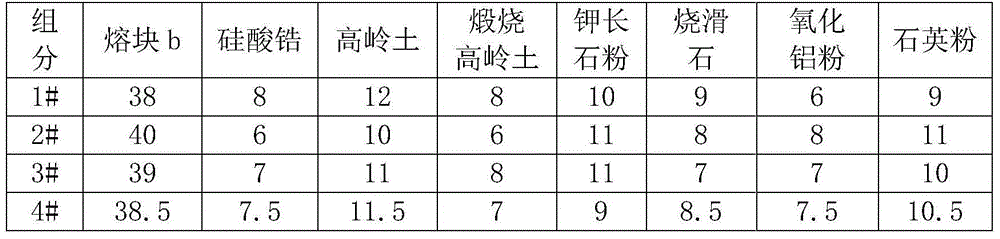

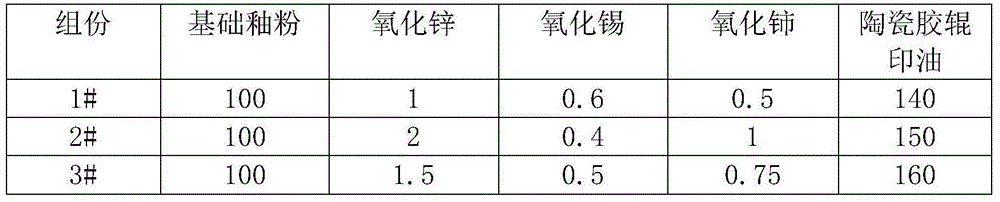

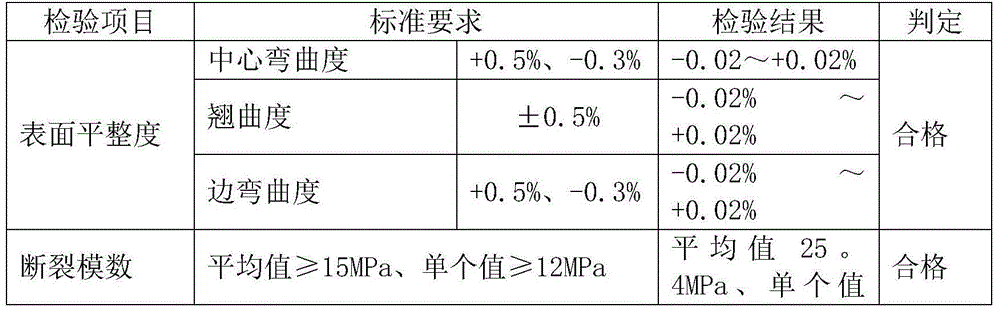

Glaze and preparation of embossment phantom glazed brick

The invention discloses a glaze and preparation of an embossment phantom glazed brick. The glaze comprises a ground glaze, a surface glaze and an embossment phantom printing glaze, wherein the ground glaze is prepared from a frit b, zirconium silicate, kaolin, calcined kaolin, potassium feldspar powder, fired talc, aluminum oxide powder, quartz powder, carboxymethyl cellulose, sodium tripolyphosphate and water; the surface glaze is prepared from a frit, the frit b, a frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water; the embossment phantom printing glaze is prepared from parent glaze powder, zinc oxide, tin oxide, cerium oxide and ceramic adhesive roll-printing oil; the parent glaze powder is prepared from the frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water. The preparation method comprises the following steps: sequentially applying the ground glaze and the surface glaze on a green brick, then printing the embossment phantom printing glaze, performing inkjet printing, and finally firing to obtain the embossment phantom glazed brick. The product disclosed by the invention has unique decorative effect and visual aesthetic feeling; moreover, each indicator can reach the standard requirements, so that the product has relatively strong universality, and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

Slag splashing method for converter high-oxidisability furnace residue

InactiveCN101177720AHigh melting temperatureAdjustable viscosityManufacturing convertersComing outSlag

The invention pertains to the metallurgy field and relates to a method of slag splashing for converter maintenance, in particular to a method of the slag splashing for the converter maintenance of converter high oxide slag. After steel come out from a converter, the slag is left inside the converter, a converter top oxygen lance is used for insufflating nitrogen; after the nitrogen is insufflated into the converter through the converter top oxygen lance, a slag modifier compounded by anthracite and magnesia is added into the converter, and the addition quantity of the slag modifier is: 30-100 kilograms slag modifier is added to every ton of the slag. Terminal slag of the converter ironmaking is splashed and bonded on the converter wall to form slag splashing layers. By actualizing the slag splashing for the converter maintenance of the invention, the effect of the slag splashing for the converter maintenance of the converter with high oxidation slag production when smelting the high additional value steel can be obviously improved, and the service life of a converter liner of the converter can be greatly prolonged.

Owner:NANJING IRON & STEEL CO LTD +1

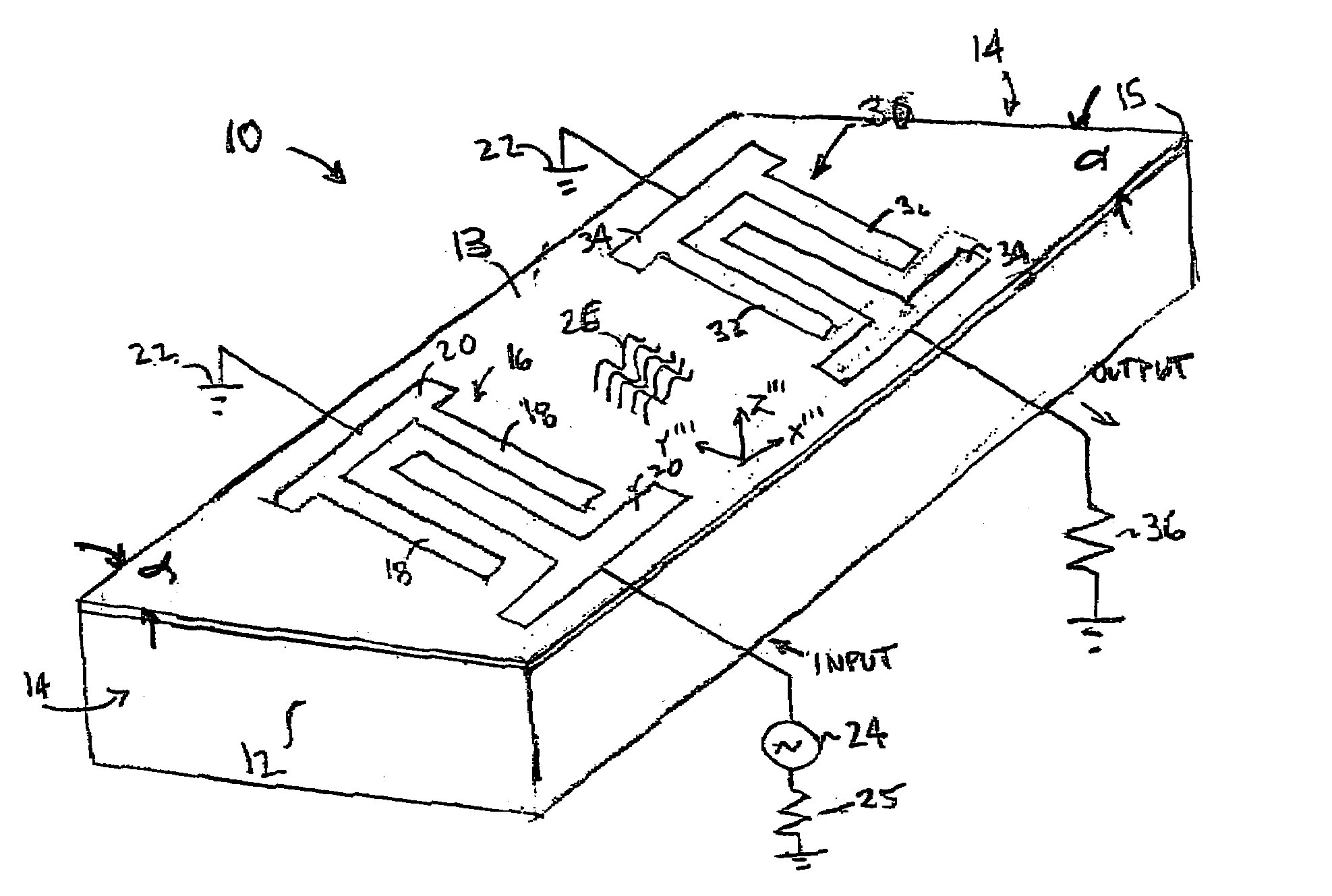

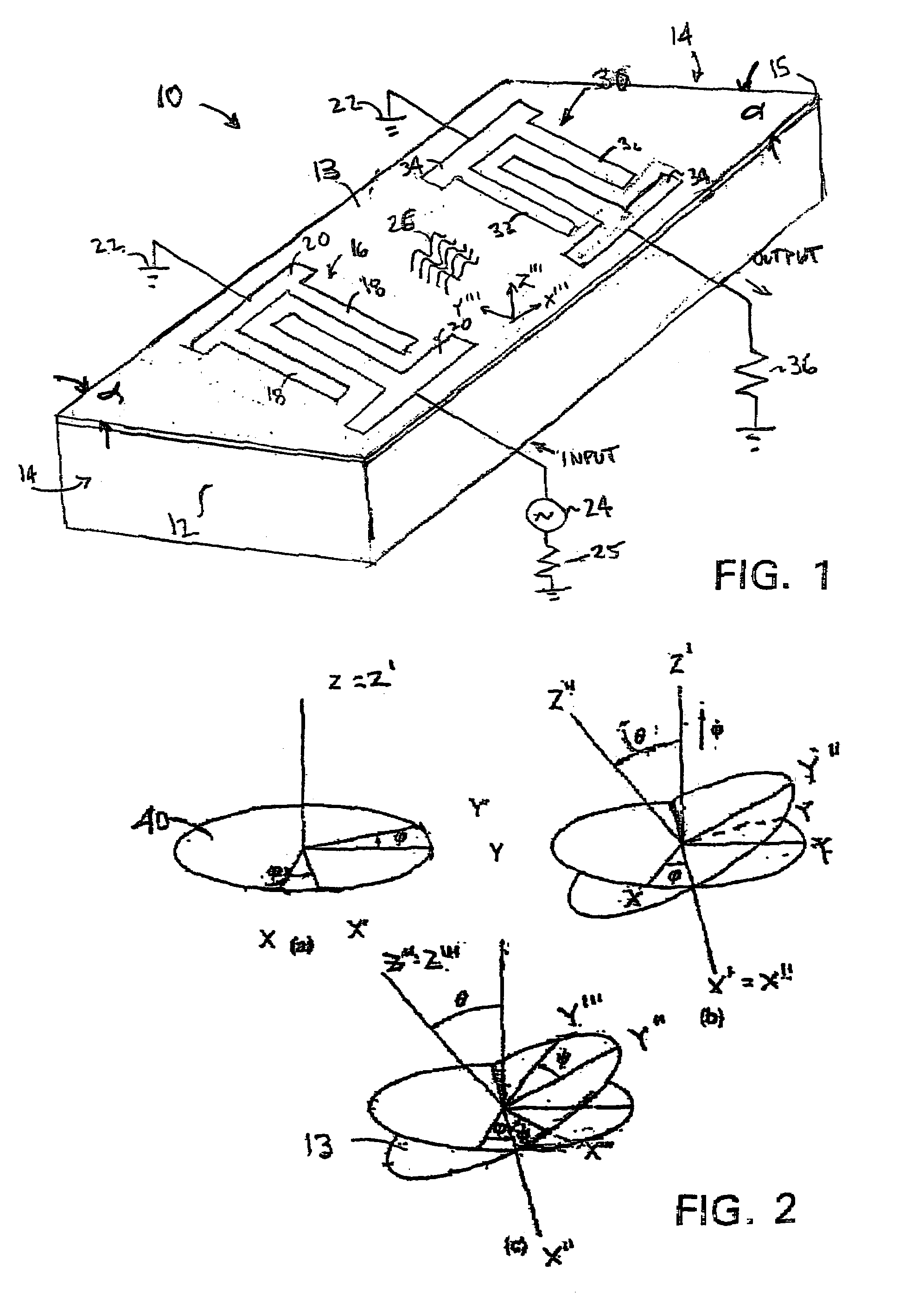

Surface acoustic wave devices for high temperature applications

ActiveUS7285894B1High melting temperatureImpedence networksPiezoelectric/electrostriction/magnetostriction machinesConductive materialsAcoustic wave

A Surface Acoustic Wave device including a resonator or a delay line formed from an electrically conductive material having a high melting temperature disposed upon the surface of a substrate formed from one of the LGX family of crystals or gallium phosphate. The Surface Acoustic Wave Device is operative as a sensor at high temperatures.

Owner:UNIVERSITY OF MAINE

Novel high-temperature-resisting diaphragm of lithium battery and preparation process of diaphragm

ActiveCN103618054AHigh melting temperatureSynthetic resin layered productsLi-accumulatorsBiochemical engineeringLithium-ion battery

The invention discloses a novel high-temperature-resisting diaphragm of a lithium battery and a preparation process of the diaphragm, which belong to the field of a battery diaphragm, and solve the problem in the prior art that the lithium battery diaphragm which is prepared by adopting a wet-method process is low in fuse temperature. The high-temperature-resisting diaphragm of the lithium battery is prepared by adopting a wet-method process. The diaphragm comprises an inner layer, an intermediate layer and an outer layer, wherein both the inner layer and the outer layer are prepared by adopting polyethylene and white oil as raw materials; the intermediate layer is prepared by adopting polyethylene, white oil and nanometer inorganic oxide as raw materials. The preparation process comprises the following steps of mixing, extrusion, compounding through a die head, casting, cooling and molding, bidirectional synchronous stretching, extraction, drying, transversely stretching and expanding and thermal setting. The fuse temperature of the diaphragm prepared through the process is detected to be 50 to 70 DEG C higher than that of the diaphragm with a single PE (polyethylene) component.

Owner:QINGDAO LANKETU MEMBRANE MATERIALS CO LTD

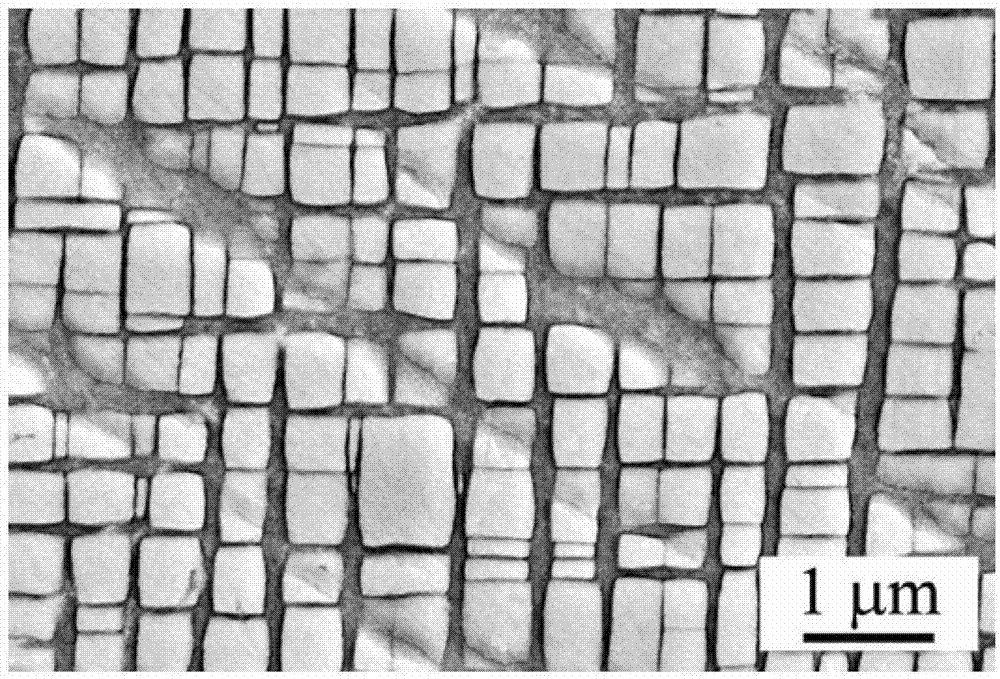

High-temperature-stability gamma'-phase-reinforced cobalt-base high-temperature alloy and preparation method thereof

The invention belongs to the technical field of new materials, and relates to a gamma'-phase high-temperature-stability cobalt-base high-temperature alloy with gamma / gamma' two-phase structure, which is a candidate material for high-temperature hot end components of gas turbines for aviation, spaceflight, vessels, power generation and the like. The alloy comprises the following components in atomic percentage: 4-12% of Al, 4-12% of W, 1-4% of Ta, 1-6% of Ti, 0-10% of Cr, 0-3% of Mo, 0-2% of Hf, 0-1% of C, 0-1% of B and the balance of Co. The preparation method comprises the following steps: smelting in a vacuum induction furnace, carrying out solid solution heat treatment at 1250-1300 DEG C, and carrying out aging heat treatment at 1000-1100 DEG C. After carrying out L12-type gamma'-phase high-temperature reinforcement, the gamma' shape is cubic, the volume percent is higher than 60%, and the gamma'-phase is uniformly distributed in the gamma-phase. Compared with the traditional cobalt-base high-temperature alloy, the alloy provided by the invention has higher application temperature; and compared with the recently developed similar cobalt-base alloys, the alloy provided by the invention has higher gamma'-phase solution temperature and gamma / gamma' two-phase structure stable existence temperature.

Owner:UNIV OF SCI & TECH BEIJING

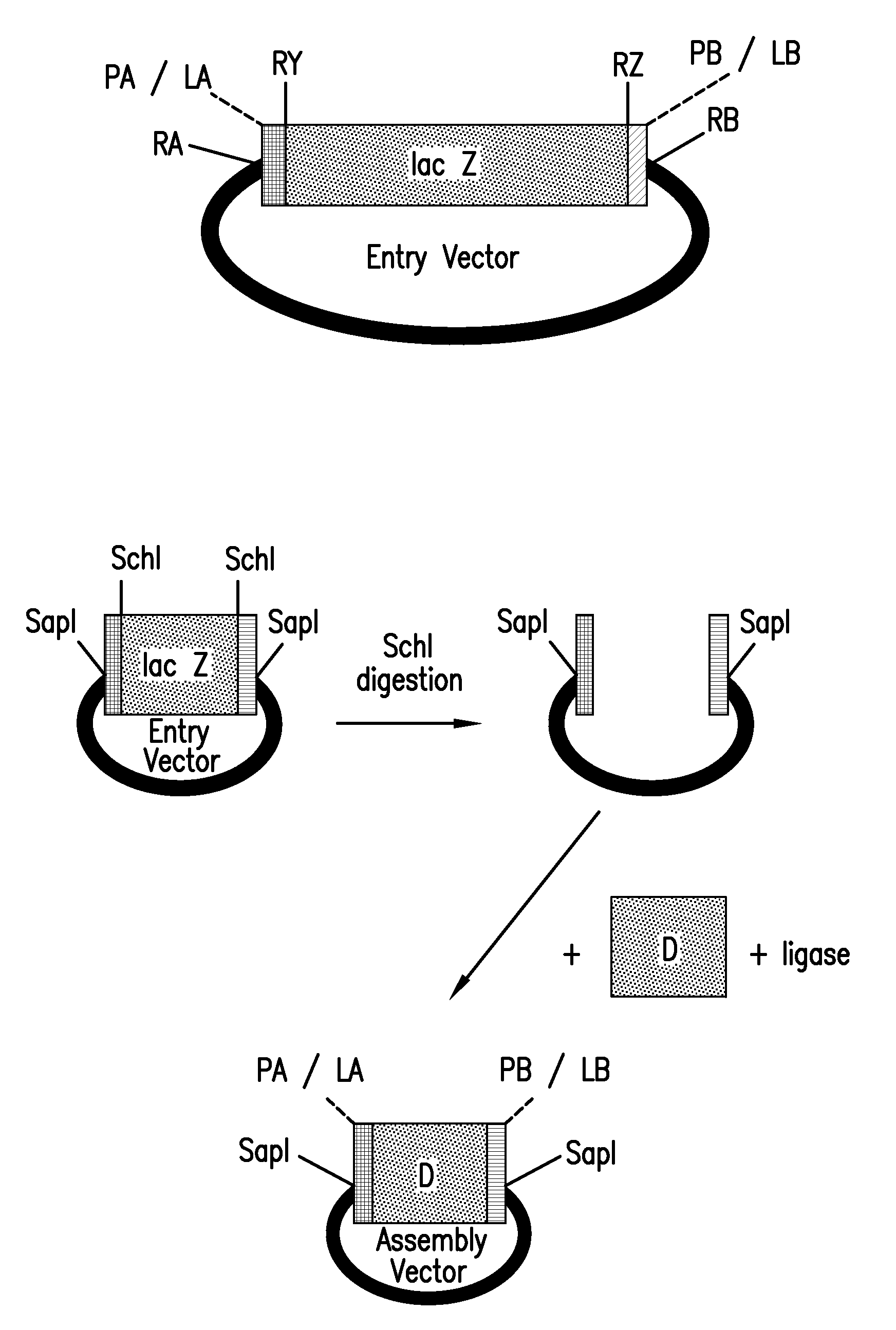

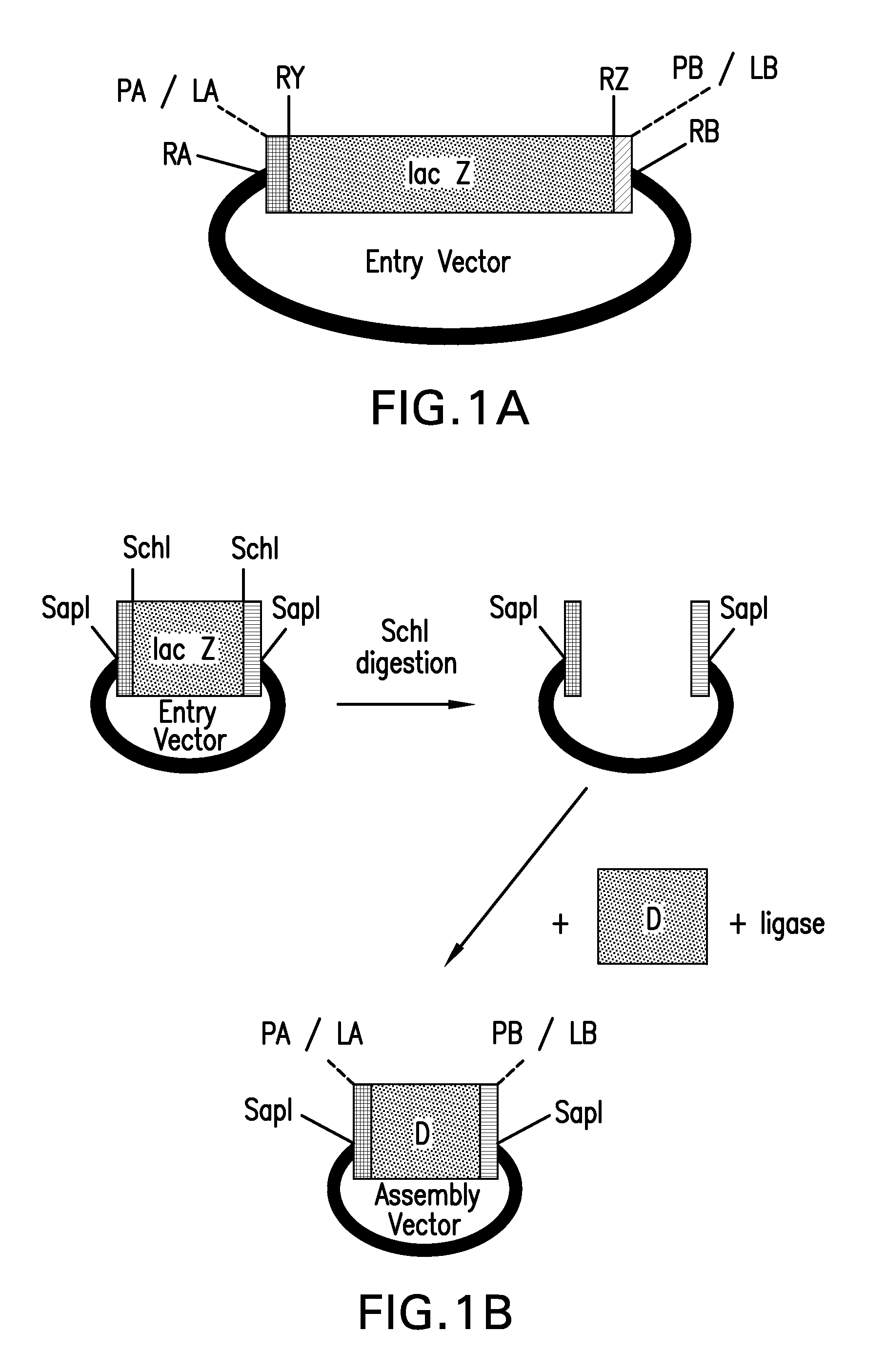

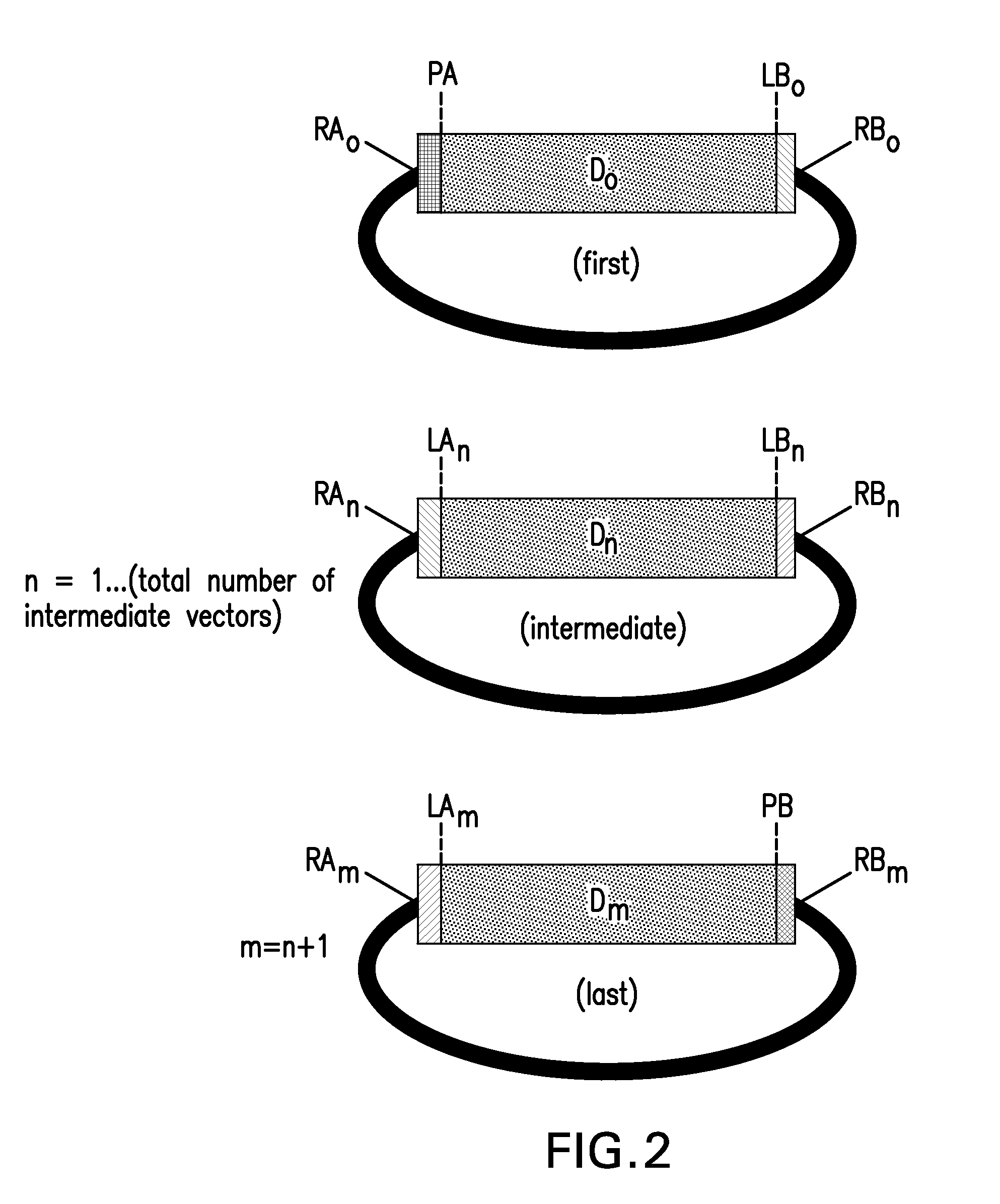

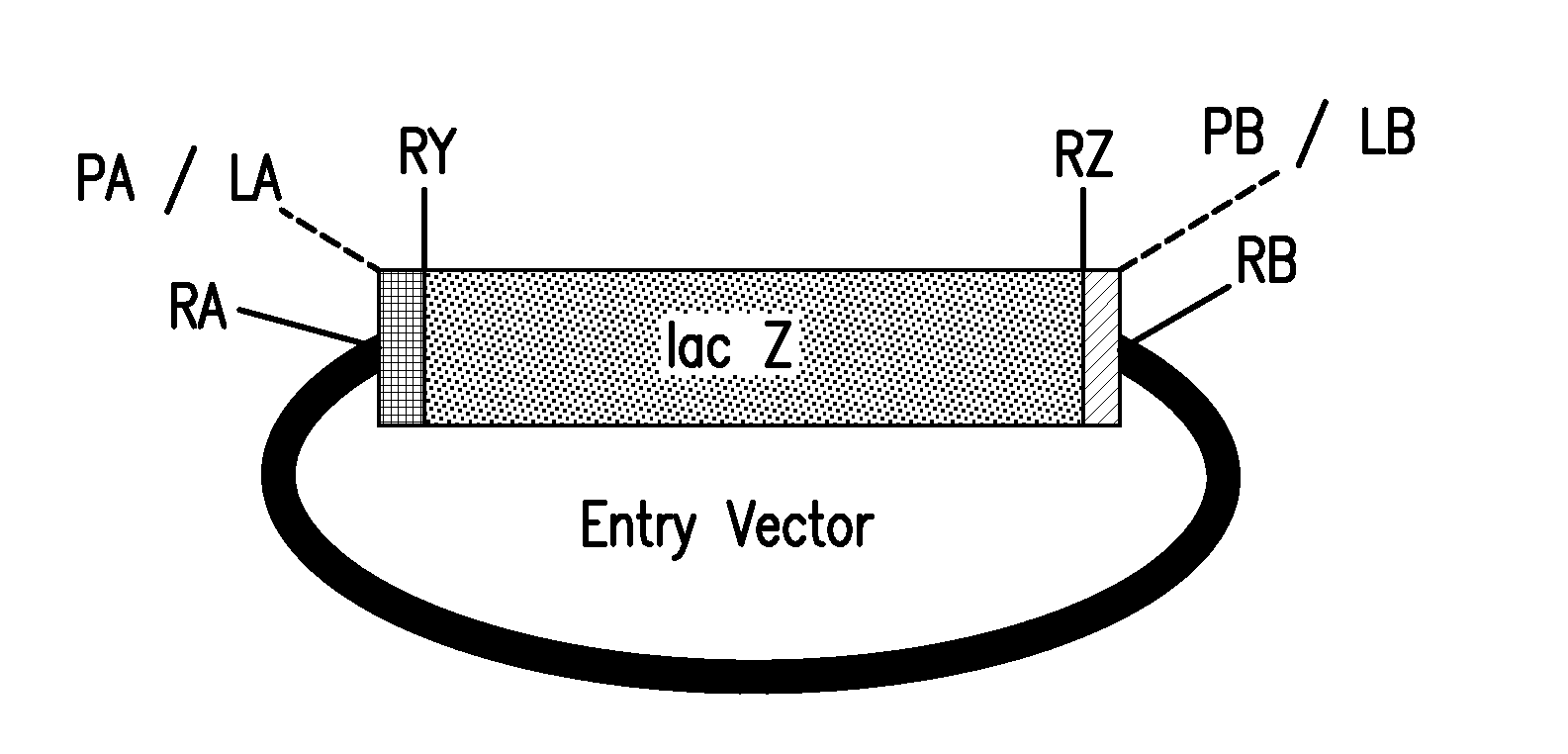

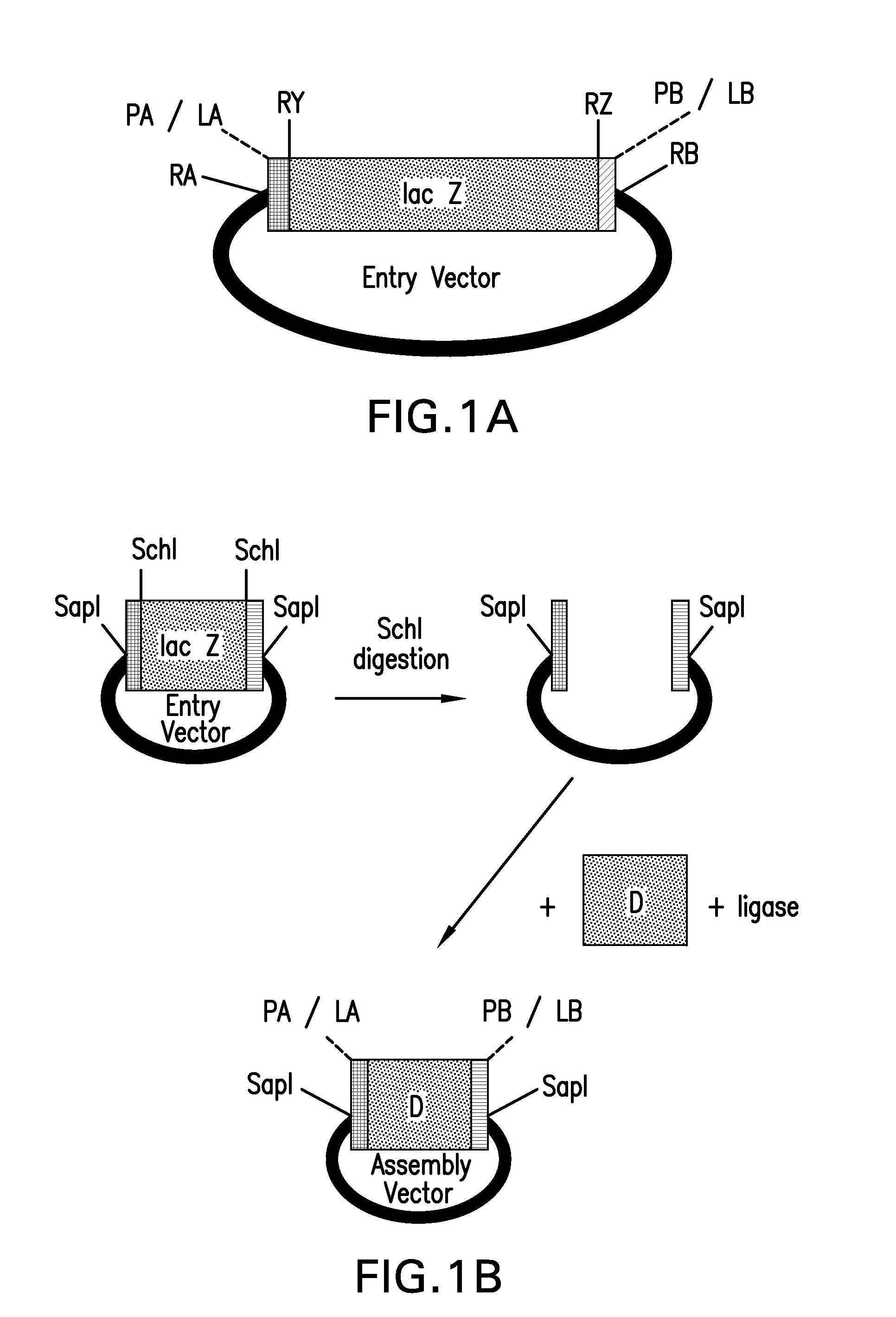

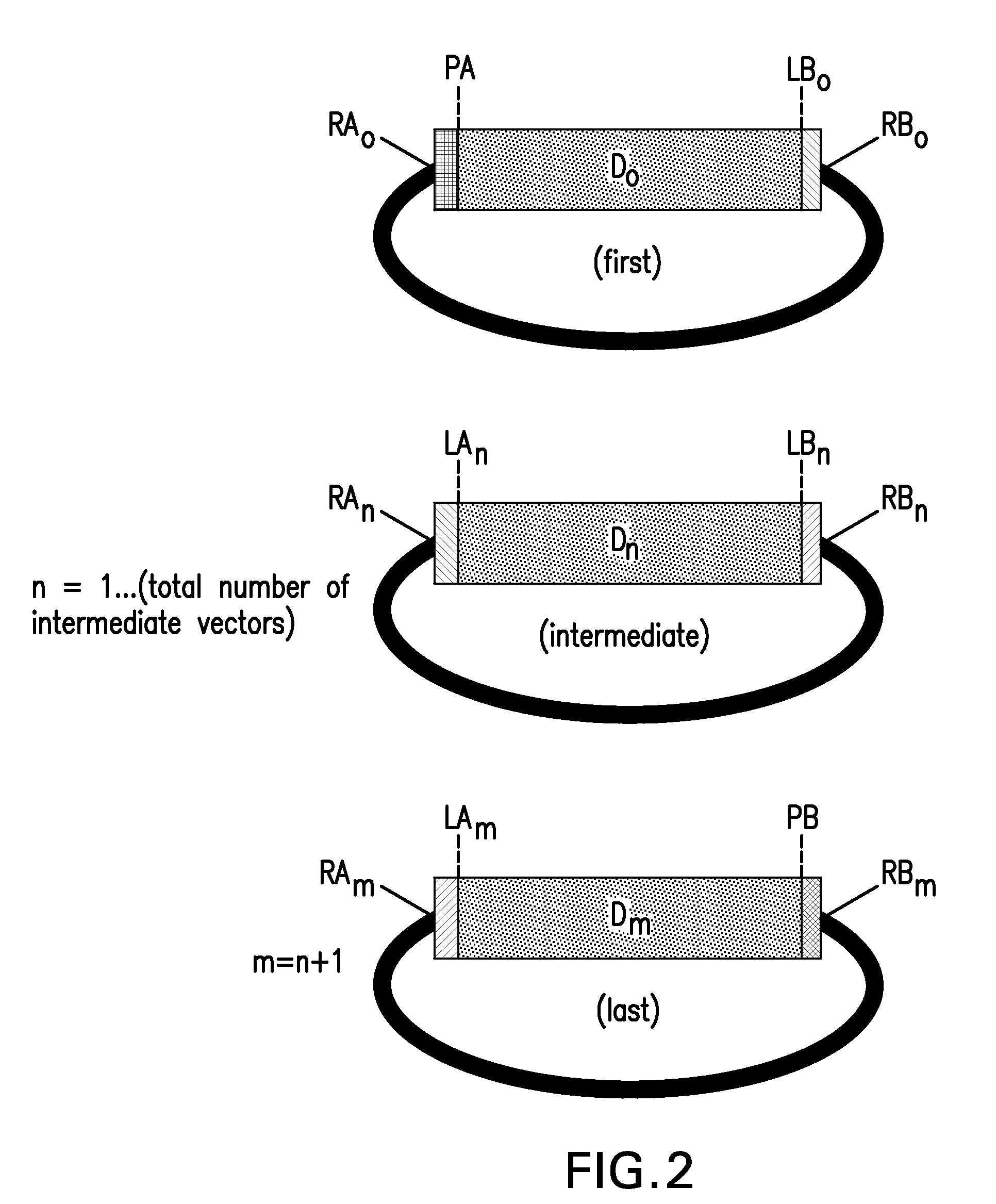

Compositions and methods for the assembly of polynucleotides

ActiveUS20100124768A1Efficient assemblyHigh melting temperatureFungiSugar derivativesNucleotidePolymerase L

The present invention provides compositions and methods for rapid assembly of one or more assembled polynucleotides from a plurality of component polynucleotides. The methods of the invention utilize circular nucleic acid vectors that comprise a DNA segment D flanked by an annealable linker sequence, annealable linker sequence pairs LA and LB, or annealable linker sequence / primer binding segment pairs LA and PB or PA and LB. Restriction endonuclease digestion of a plurality of vectors containing the DNA segments to be assembled generates a plurality of DNA fragments comprising the elements PA-D-LB, LA-D-LB, and LA-D-PB or D-LB, LA-D-LB, and LA-D. The sequences of annealable linker sequences LA and LB provide complementary termini to the DNA fragments, which are utilized in host cell mediated homologous recombination or together with primer binding segments PA and PB in a polymerase cycling assembly reaction for the ordered assembly of the various DNA segments into one or more assembled polynucleotides.

Owner:AMYRIS INC

Compositions and methods for the assembly of polynucleotides

ActiveUS20100136633A1Efficient assemblyHigh melting temperatureFungiSugar derivativesNucleotidePolymerase L

The present invention provides compositions and methods for rapid assembly of one or more assembled polynucleotides from a plurality of component polynucleotides. The methods of the invention utilize circular nucleic acid vectors that comprise a DNA segment D flanked by an annealable linker sequence, annealable linker sequence pairs LA and LB, or annealable linker sequence / primer binding segment pairs LA and PB or PA and LB. Restriction endonuclease digestion of a plurality of vectors containing the DNA segments to be assembled generates a plurality of DNA fragments comprising the elements PA-D-LB, LA-D-LB, and LA-D-PB or D-LB, LA-D-LB, and LA-D. The sequences of annealable linker sequences LA and LB provide complementary termini to the DNA fragments, which are utilized in host cell mediated homologous recombination or together with promer binding segments PA and PB in a polymerase cycling assembly reaction for the ordered assembly of the various DNA segments into one or more assembled polynucleotides.

Owner:AMYRIS INC

Prepared foods containing triglyceride-recrystallized non-esterified phytosterols

InactiveUS6638547B2Reduce fat oxidationDecrease in levelOrganic active ingredientsBiocideRoom temperatureTriglyceride

A prepared food product for ingestion by mammals is described and methods for preparing such products. The food product includes an oxidation-resistant fat-based composition substantially free of exogenous solubilizing and dispersing agents for phytosterols. The fat-based composition includes between 75% and 98% by weight of at least one triglyceride-based edible oil or fat, and between 2% and 25% by weight of non-esterified phytosterols. Typically, approximately 1.5% by weight of phytosterols remain soluble at room temperature, and between 0.5% and 23.5% by weight are converted to triglyceride-recrystallized phytosterols (TRPs). The fat-based composition which has been partially oxidized in the prepared food by exposure to air (and typically heat), contains a reduced amount of oxidative by-products compared to a similar fat-based composition lacking these non-esterified phytosterols.

Owner:BRANDEIS UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com