Patents

Literature

293results about How to "Promote oxidation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biosensor

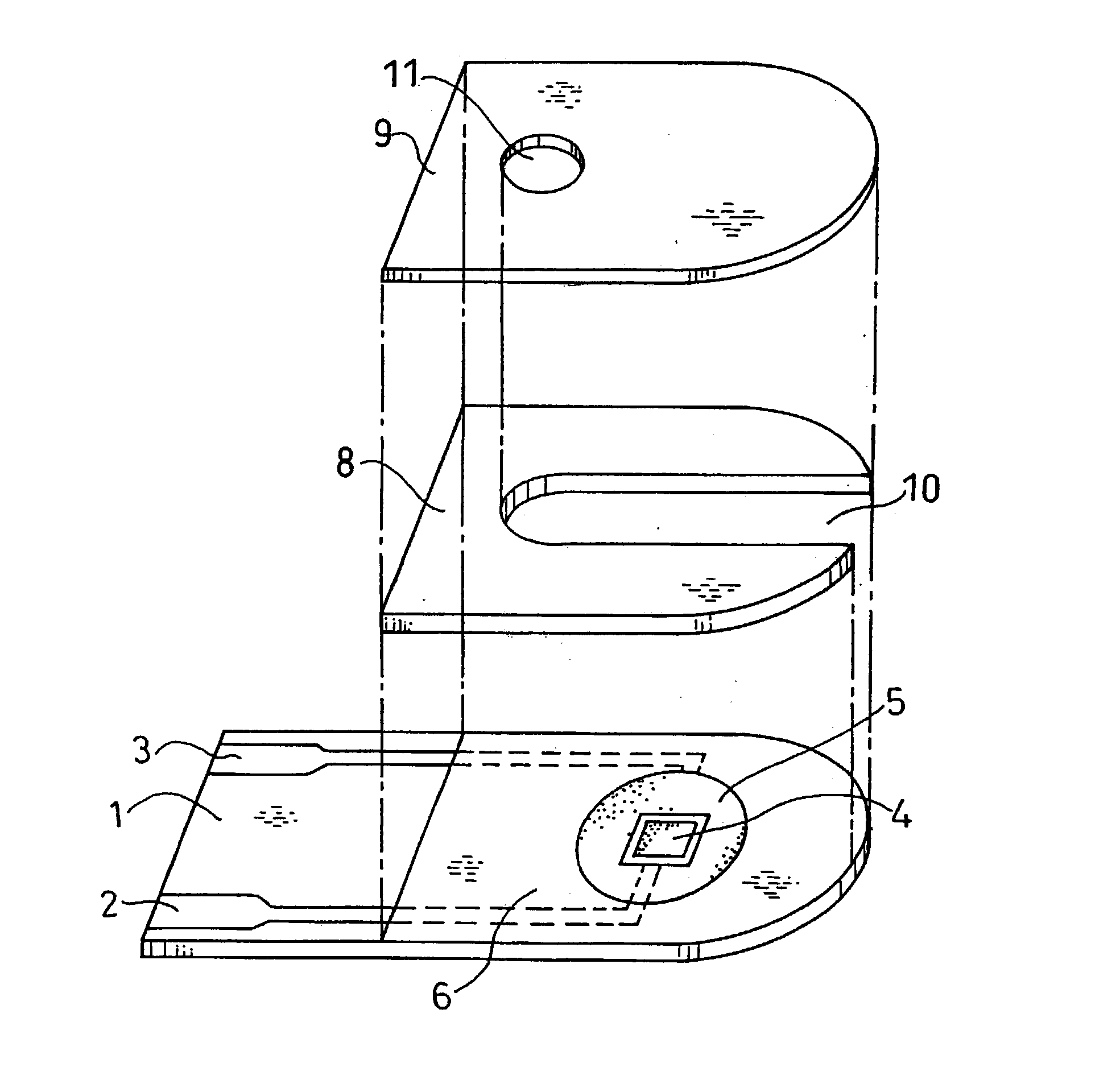

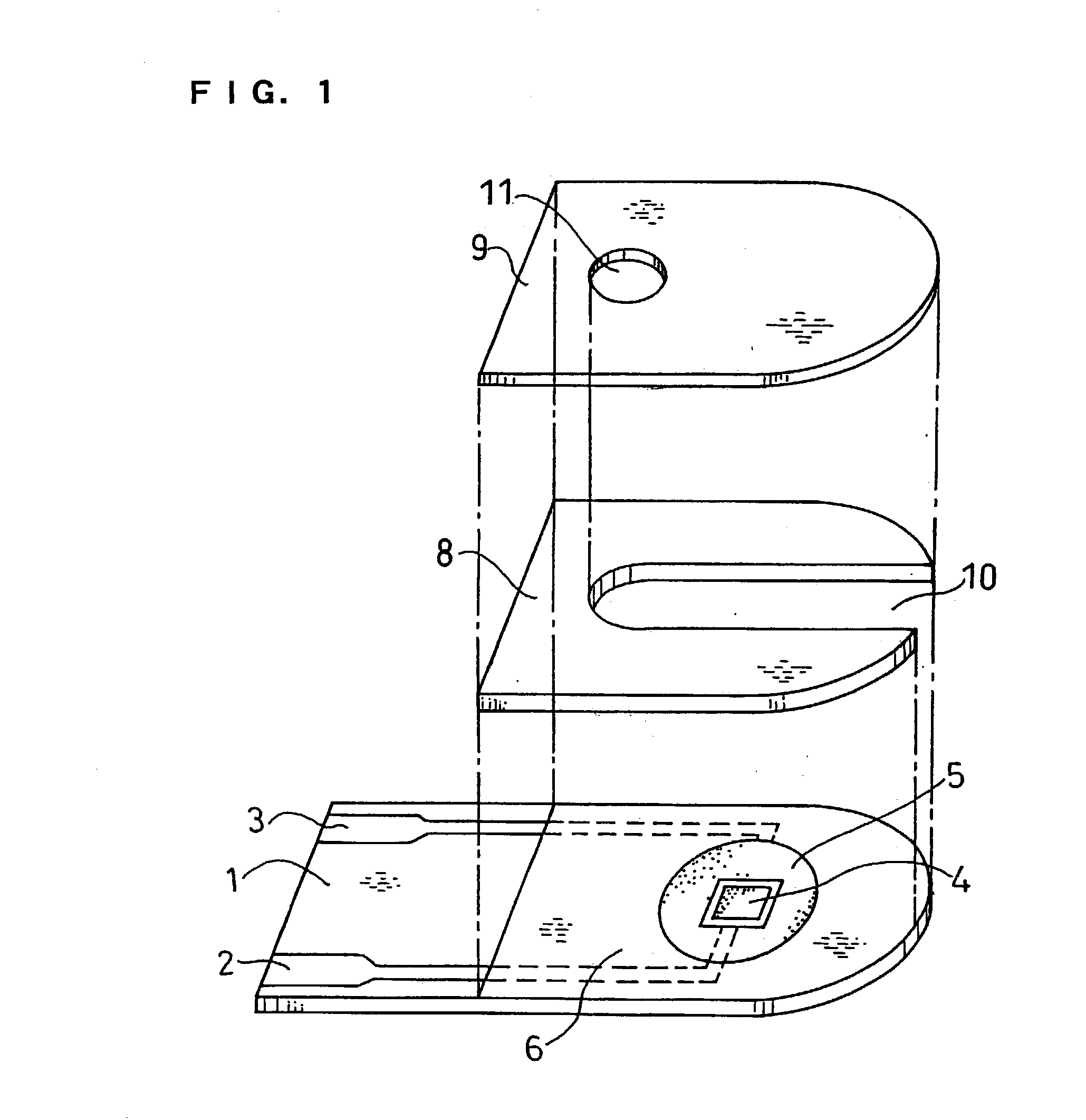

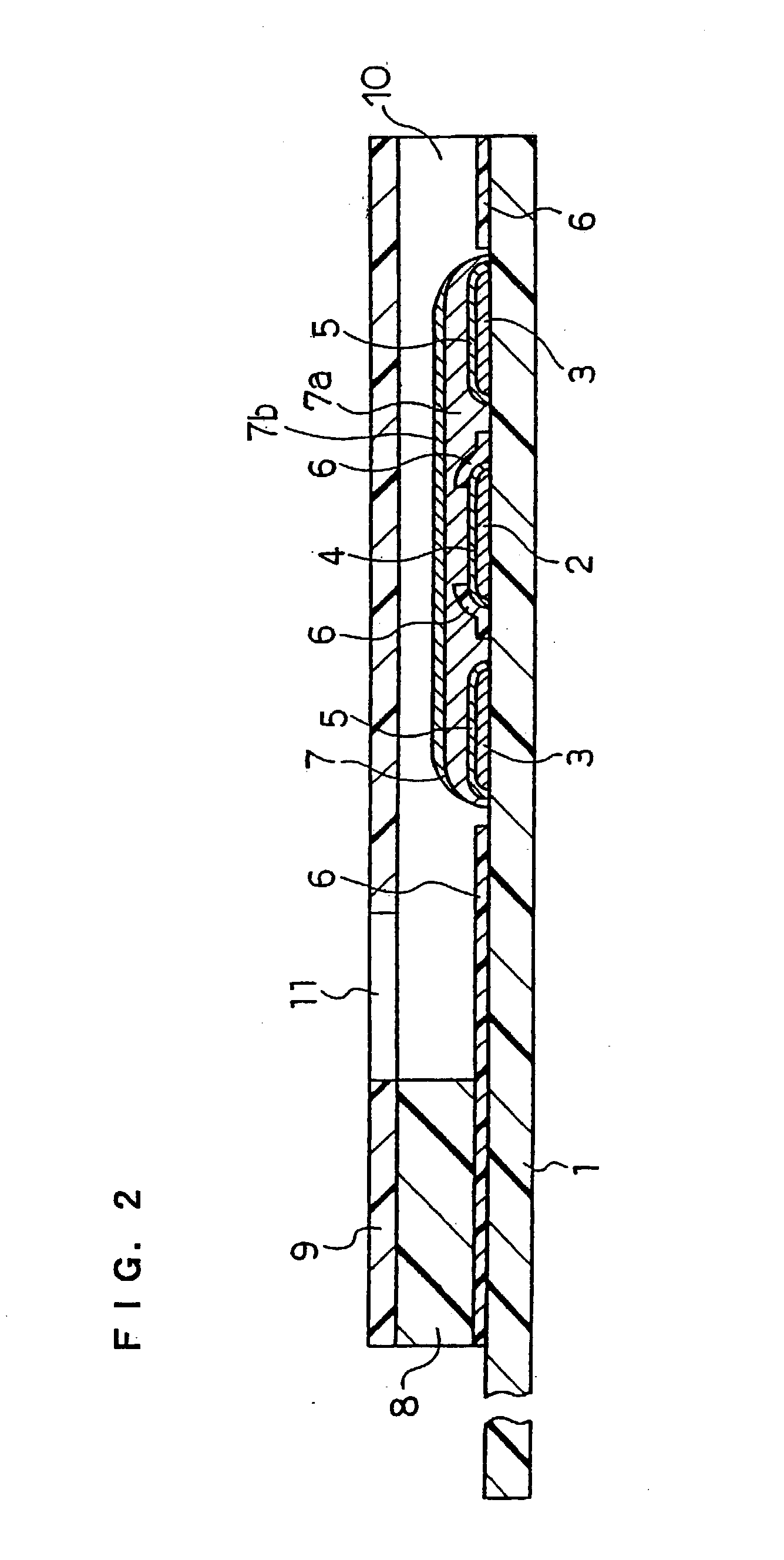

InactiveUS20030175841A1Avoid influenceReduce solubilityImmobilised enzymesBioreactor/fermenter combinationsGluconolactonaseSuccinic acid

A biosensor that is highly responsive and capable of rapid and highly sensitive quantification of a specific component contained in a sample is provided. The biosensor of this invention comprises: an electrically insulating base plate; an electrode system comprising a working electrode and a counter electrode disposed on the base plate; and a reagent system comprising an oxidoreductase which catalyzes the oxidation reaction of glucose, gluconolactonase and a buffer. The buffer is selected from the group consisting of phthalic acid and its salts, maleic acid and its salts, succinic acid and its salts, phospholic acid and its salts, acetic acid and its salts, boric acid and its salts, citric acid and its salts, glycine, tris(hydroxymethyl)aminomethane, piperazine-N,N'-bis(2-ethane sulfonic acid) and the like.

Owner:PHC HLDG CORP

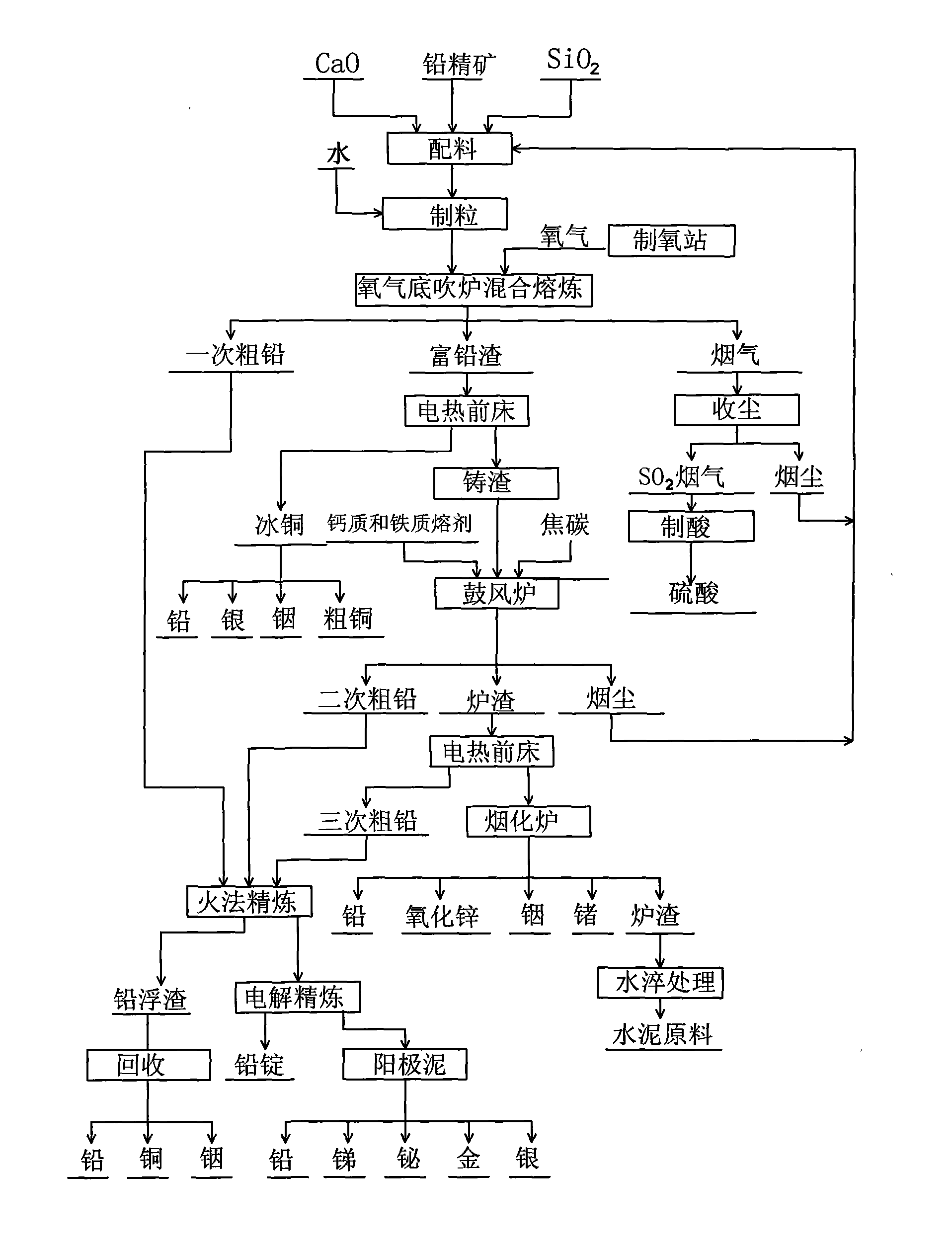

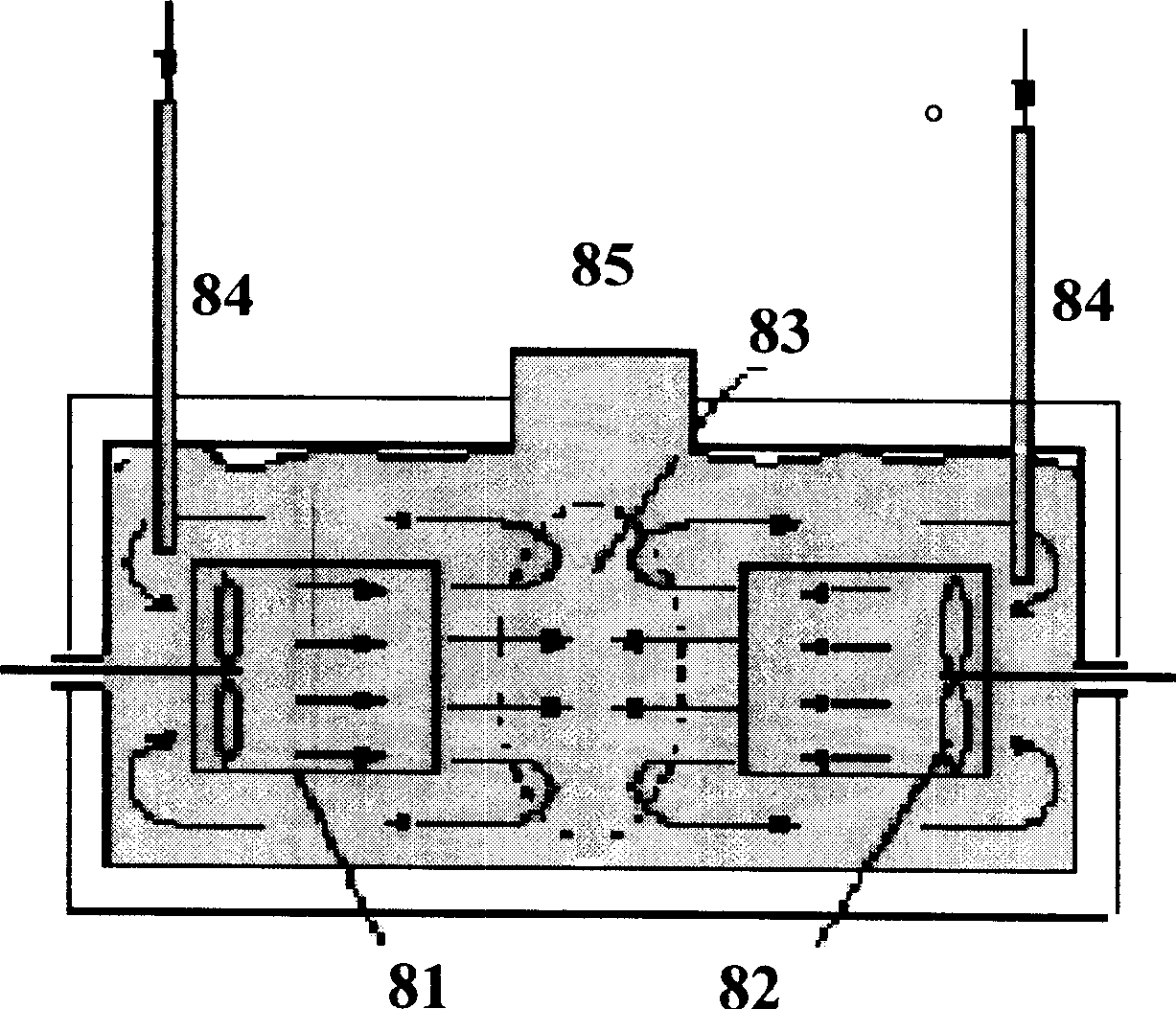

Balancing lead smelting process for comprehensive resource utilization and device thereof

InactiveCN101514399AHigh melting temperaturePromote oxidation reactionPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention relates to a balancing lead smelting process for comprehensive resource utilization and a device thereof. The process comprises the following steps: granulating a raw material containing lead and a fluxing agent after proportioning, sending to an oxygen bottom-blown smelting furnace for smelting to produce primary crude lead, lead ash and flue gas of SO2; sending the flue gas of SO2 to a sulfuric acid system for acid making after recovering waste heat by a waste heat boiler and duct collection by a dust arrester installation; adjusting form of the lead ash and adding the lead ash to a blast furnace together with coking coal for reducing smelting to produce secondary and third crude lead; electrorefining the crude lead to obtain refined lead and anode slime, treating and recovering the anode slime to obtain lead, stibium, bismuth, gold and silver metals; and separating slag of the blast furnace from the crude lead and sending to a fuming furnace to recover zinc oxide, the lead, indium and germanium. A system for realizing the process comprises the oxygen bottom-blown smelting furnace, an oxygen lance, an electrically-heated settler, a slag casting device, the waste heat boiler with a vertical ascending segment of membrane wall structure, the blast furnace, the fuming furnace and a ventilating device. The process design and system improvement help realize balancing optimized recovery of Pb, Zn, Au, Ag, Bi, Cu, In, Sb and S elements.

Owner:CHENZHOU YUTENG CHEM IND

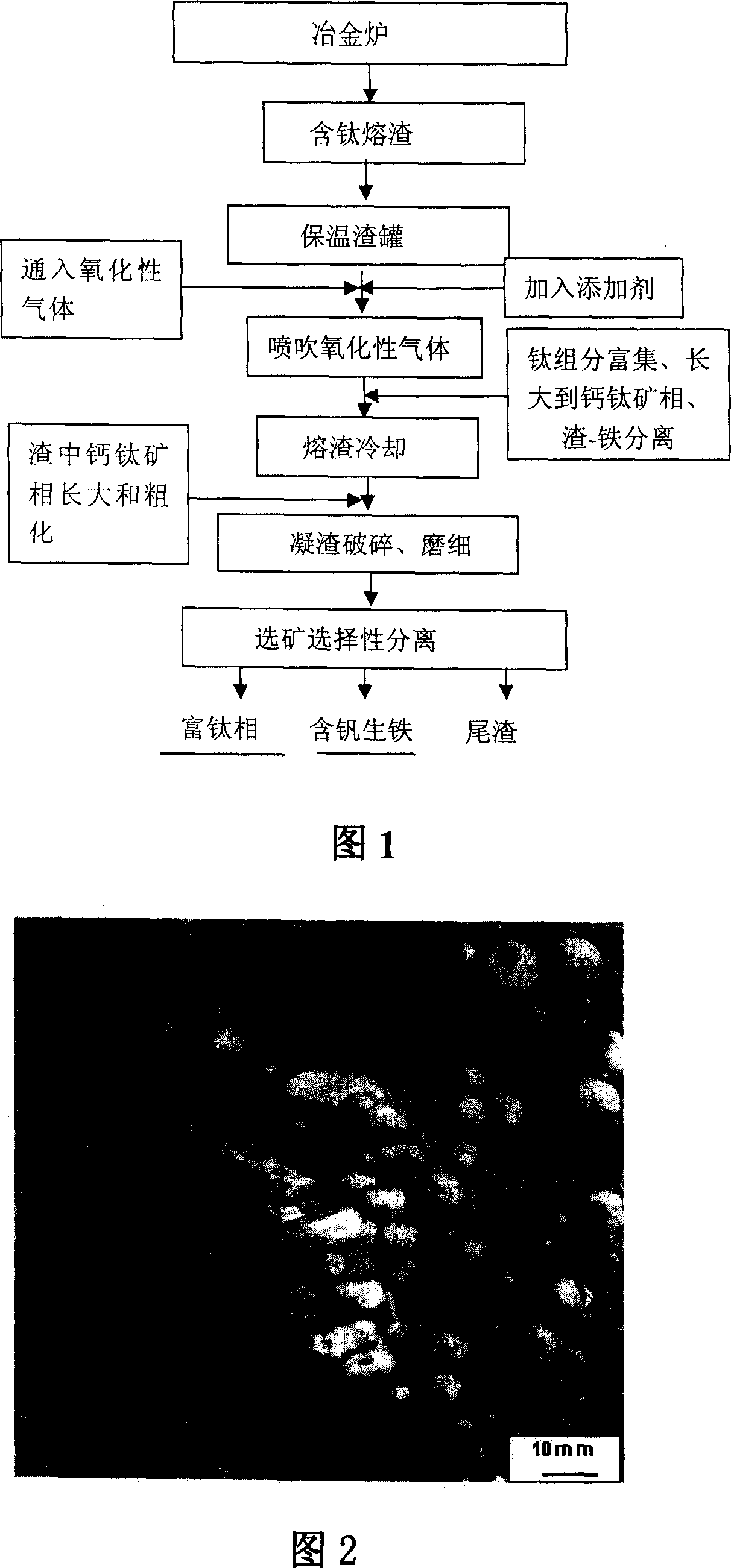

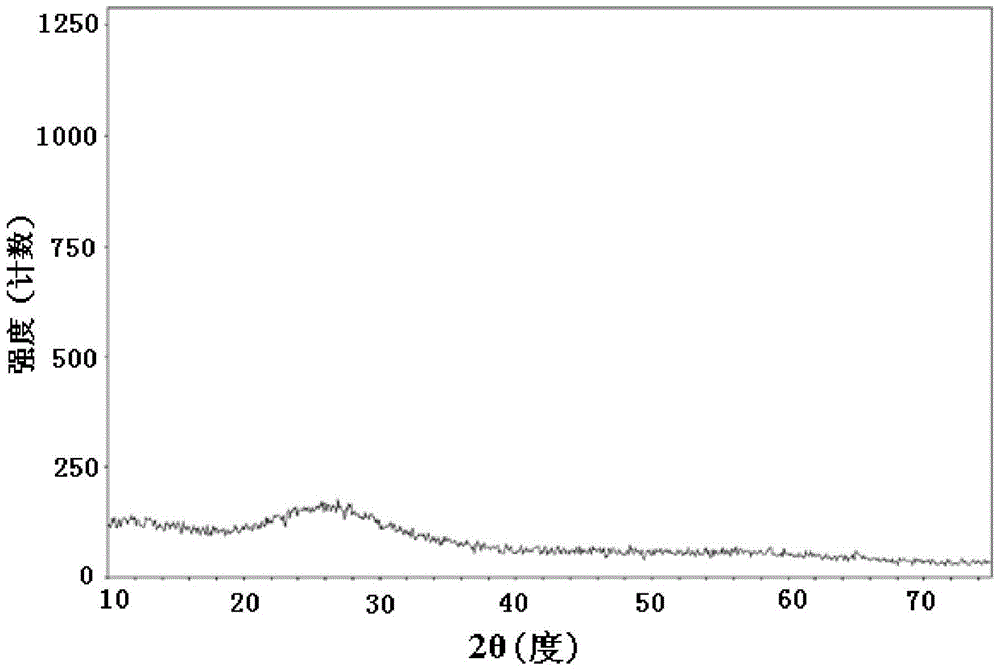

Process for separation and production of titanium-rich materials from titanium-containing blast furnace slag

InactiveCN1952188AFacilitate the realization of comprehensive utilizationRealize comprehensive utilizationProcess efficiency improvementMagnetic beadRoom temperature

A method for separating titanium from the slag containing titanium component, contains the following three steps: heating the slag in the slag tank, adding additives at the same time or after that, blowing oxidizing gases into the tank, stirring the slag constantly, causing titanium components selectively to enrich in perovskite phase, then controlling cooling rate for the slag cooling to room temperature, perovskite phase selectively growing up, finally, crushing the cooling condensate residue grinding and ore dressing perovskite to obtain titanium-rich material, magnetic-separating iron magnetic beads deposited on the metal slag to obtain vanadiferous iron. The process is reasonably designed with practical equipment easy to operate and can make use of the own energy of the slag to regulate the slag temperature, promote oxidation reaction in the slag, has high thermal efficiency, facilitate the promotion of selective enrichment of various titanium scattered in the phase of titanium for the deposition of ironic beads entrained in the slag, and is profit to the realization of comprehensive utilization of titanium, vanadium resources, and is easy for industrial production, is energy-saving and pollution-free.

Owner:隋智通

Preparation method for scented tea of tea tree

ActiveCN104904885AHigh nutritional valuePromote oxidation reactionPre-extraction tea treatmentChemistryBitter taste

The invention discloses a preparation method for scented tea of a tea tree. The method comprises the following steps: picking; cleaning (with an ultrasonic wave); carrying out enzyme wall-breaking; heating and withering; cooling flowers; carrying out enzymatic fermentation; baking; removing impurities; sterilizing; and packaging. Through the enzymolysis wall-breaking effect, a cell wall of tea tree pollen can be destroyed; nutrition health materials are leached; the functional role is enhanced; meanwhile, tea polyphenol is transformed through withering and fermenting; the bitter taste of the scented tea of the tea tree is relieved; and the taste of the scented tea of the tea tree is improved, so that the preparation method can be widely applied to the field of preparation of the scented tea of the tea tree.

Owner:黄山光明茶业有限公司

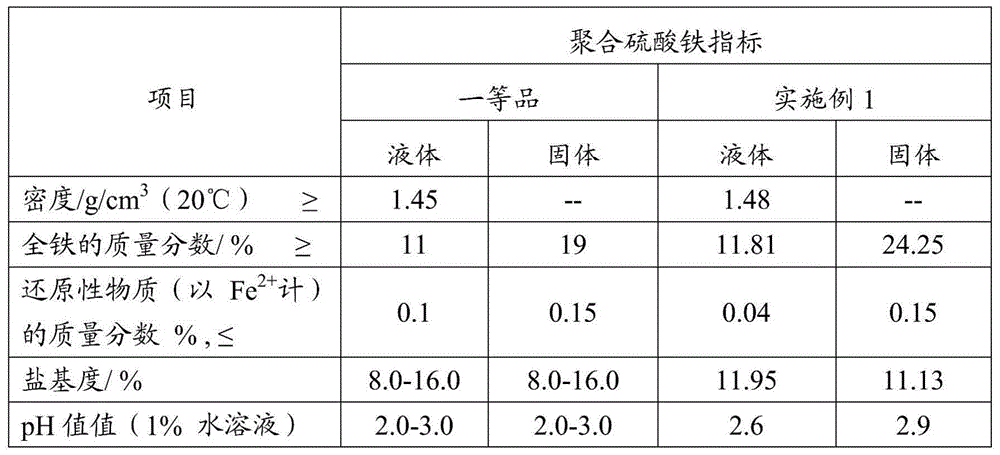

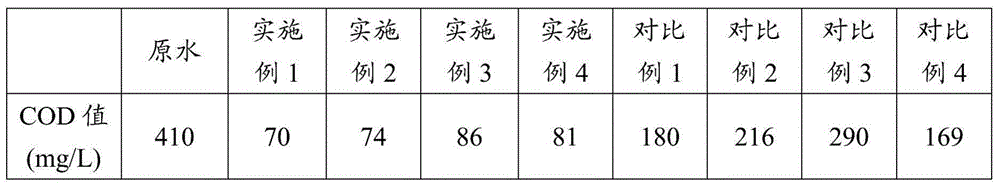

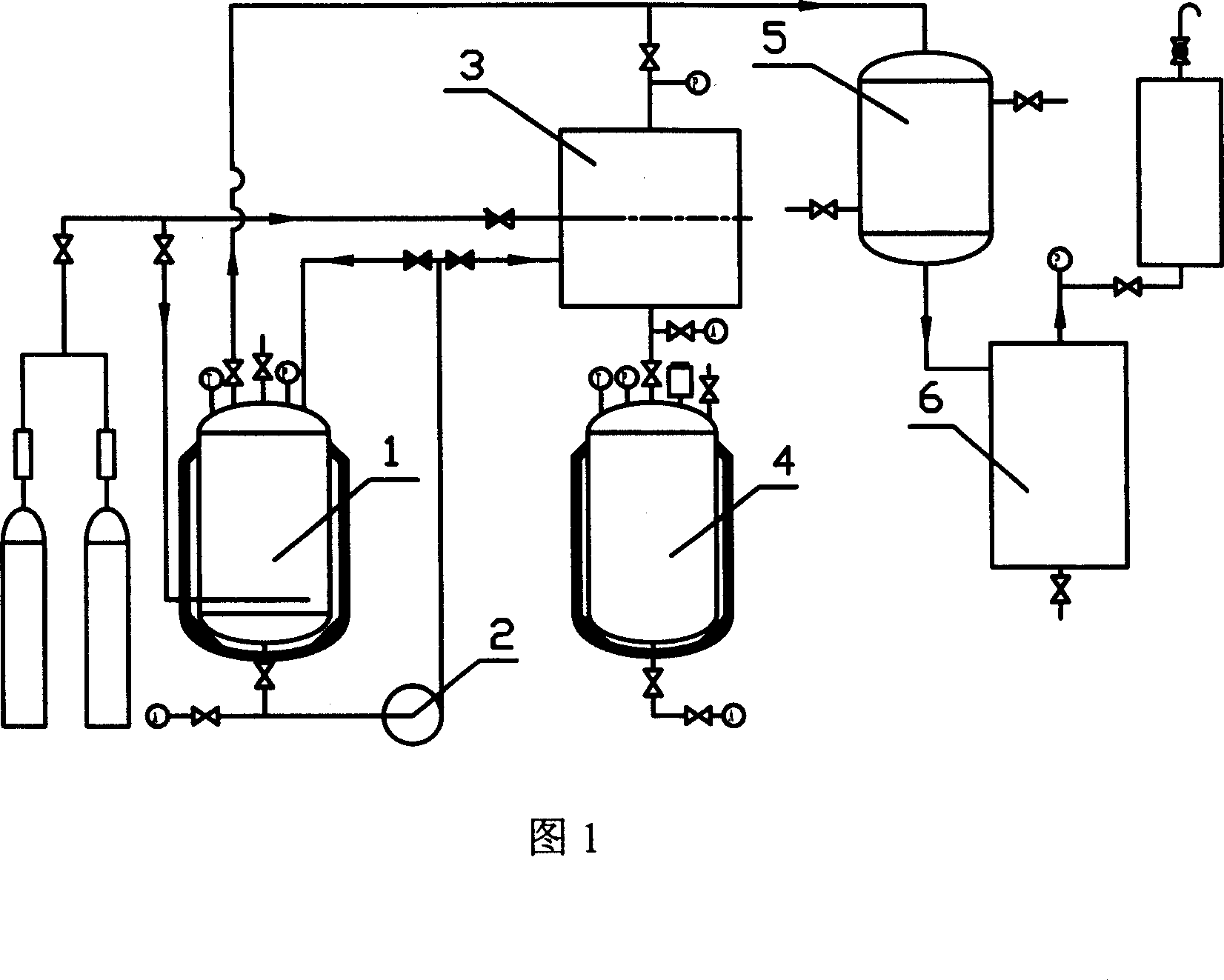

Preparation method of polyferric sulfate

ActiveCN104692467AImprove oxidation capacityReduce dosageIron sulfatesWater/sewage treatment by flocculation/precipitationIron sulfateStrong acids

The invention provides a preparation method of polyferric sulfate. The method is that a sulfuric acid aqueous solution and ferrous sulfate are mixed to obtain a mixing solution of which the pH is 0.5 to 1.5; the mixing solution and hydrogen peroxide respectively individually flow through independent flowing channels and then are synchronously poured into a reaction system to react to obtain polyferric sulfate. With the adoption of the method, the oxidizing capacity of hydrogen peroxide can be improved, the rate of converting ferrous ions into ferric ions can be increased, and moreover, ferrous ions and hydrogen peroxide can fully contact and rapidly react; therefore, the problem of decomposing of hydrogen peroxide at a high temperature or strong acid condition in the prior art can be effectively solved, the dosage of hydrogen peroxide can be reduced, the cost input can be decreased, the operation process is simplified, and the reaction time is greatly reduced. The quality of polyferric sulfate prepared by the method meets indicators as specified by national standard on top quality goods; with the adoption of the polyferric sulfate to treat wastewater, the COD of drained water can be stabilized to be less than or equal to 86mg / L, so that the method is applicable to industrial production.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Production of anone by cyclohexane liquid-phase oxidation

InactiveCN1982273ASolve the problem of reduced selectivityGood choiceOrganic compound preparationCarbonyl compound preparationCyclohexanoneMixed oxide

Production of cyclohexanone by cyclohexane liquid-phase oxidation is carried out by oxidation inductive reacting, inducing oxy-gas and mixed oxide liquid with cyclohexanone, cyclohexanol and cyclohexyl-hydrogen peroxide into super-gravity reactor, continuous oxidation reacting for cyclohexanone and decomposing for cyclohexyl-hydrogen peroxide under cyclohyexanone oxidation. It's efficient, has better selectivity and no environmental pollution.

Owner:BEIJING UNIV OF CHEM TECH

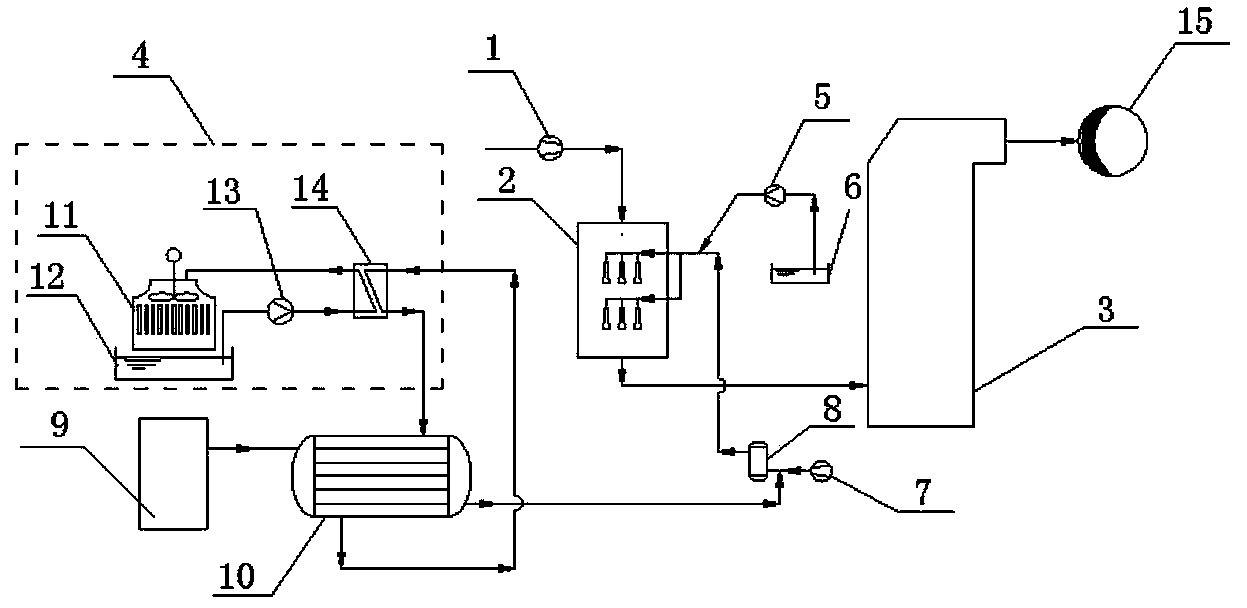

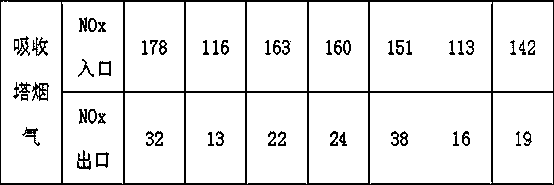

Treatment method for removing nitrogen oxides by virtue of ozone function

InactiveCN104128079AEffective oxidationImprove oxidation efficiencyDispersed particle separationOzone generatorFlue gas

The invention relates to a treatment method for removing nitrogen oxides by virtue of an ozone function. The method comprises the following steps: (1) flue gas containing the nitrogen oxides is introduced into a flue and an ozone adding distributor is additionally arranged; (2) a gas source is introduced into an ozone generator, ozone is generated and diluted and then is mixed in a mixer to obtain ozone diluted uniformly, and the ozone diluted uniformly enters the ozone adding distributor; (3) the ozone diluted uniformly and the flue gas containing the nitrogen oxides are mixed in the ozone adding distributor and are subjected to oxidation reaction, NO in waste gas is converted into high-valent nitrogen oxides and then the high-valent nitrogen oxides enter an absorption tower; and (4) the flue gas is absorbed by the absorption tower and absorption liquid and is purified to obtain tail gas, and the tail gas is exhausted from a chimney. The treatment method for removing the nitrogen oxides has the high efficiency, the low energy consumption and the convenience in use.

Owner:山西易通环保技术有限公司

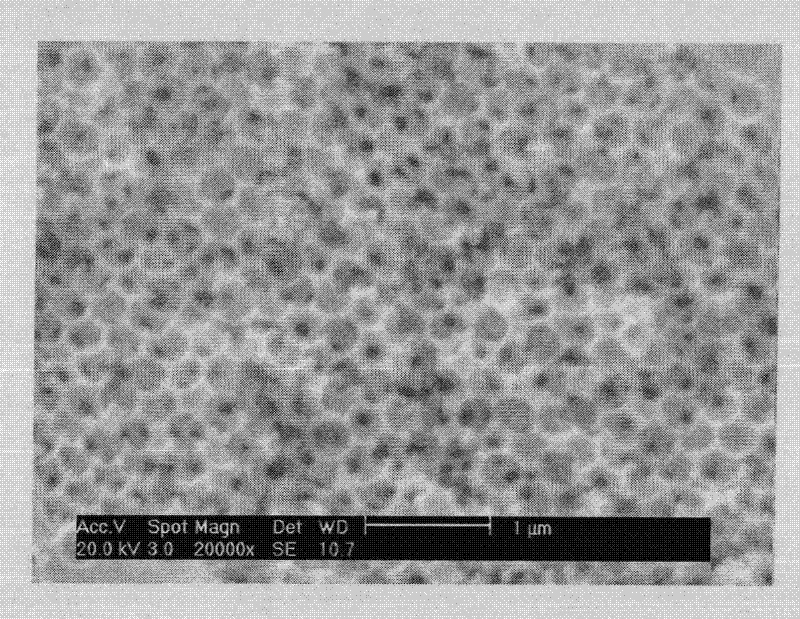

Oxygen carrier of chemical-looping combustion and preparation method and application thereof

ActiveCN102443454AImprove stabilityFacilitated DiffusionFuel additivesActive componentEmulsion polymerization

The invention discloses an oxygen carrier of chemical-looping combustion and preparation method and application thereof; the oxygen carrier uses CeO2 as carrier and Fe2O3 as active component; the weight percentage of the active component Fe2O3 in the oxygen carrier is 5-30%; and the aperture of the oxygen carrier is 500nm-50um. The preparation method of the oxygen carrier comprises the following processes of: preparing template by emulsion polymerization method, preparing the macroporous CeO2 and loading the active component and the like. The oxygen carrier is applied to the chemical-looping combustion, wherein the reaction temperature in the air reactor is 500-1000 DEG C, the reaction temperature of the fuel reactor is 500-1000 DEG C, and the reaction pressure is constant pressure. The oxygen carrier of the invention has three-dimension ordered macroporous structure, uniform distribution of the active component and simple preparation method; and the oxygen carrier in the chemical-looping combustion has the advantages that the lamination of the reaction bed is reduced, the activity of the reaction bed is high and the diffusion effect of the reaction bed is good and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

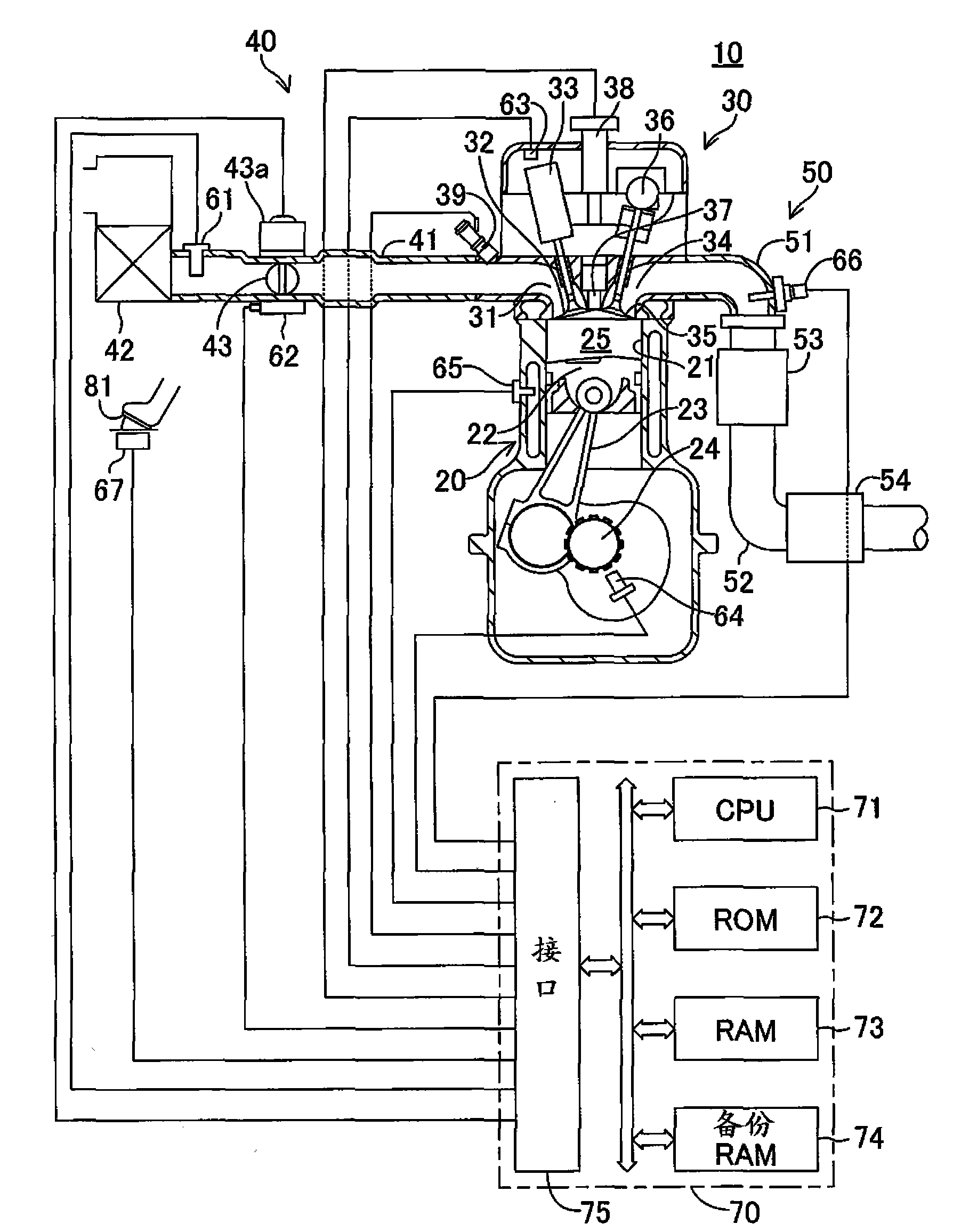

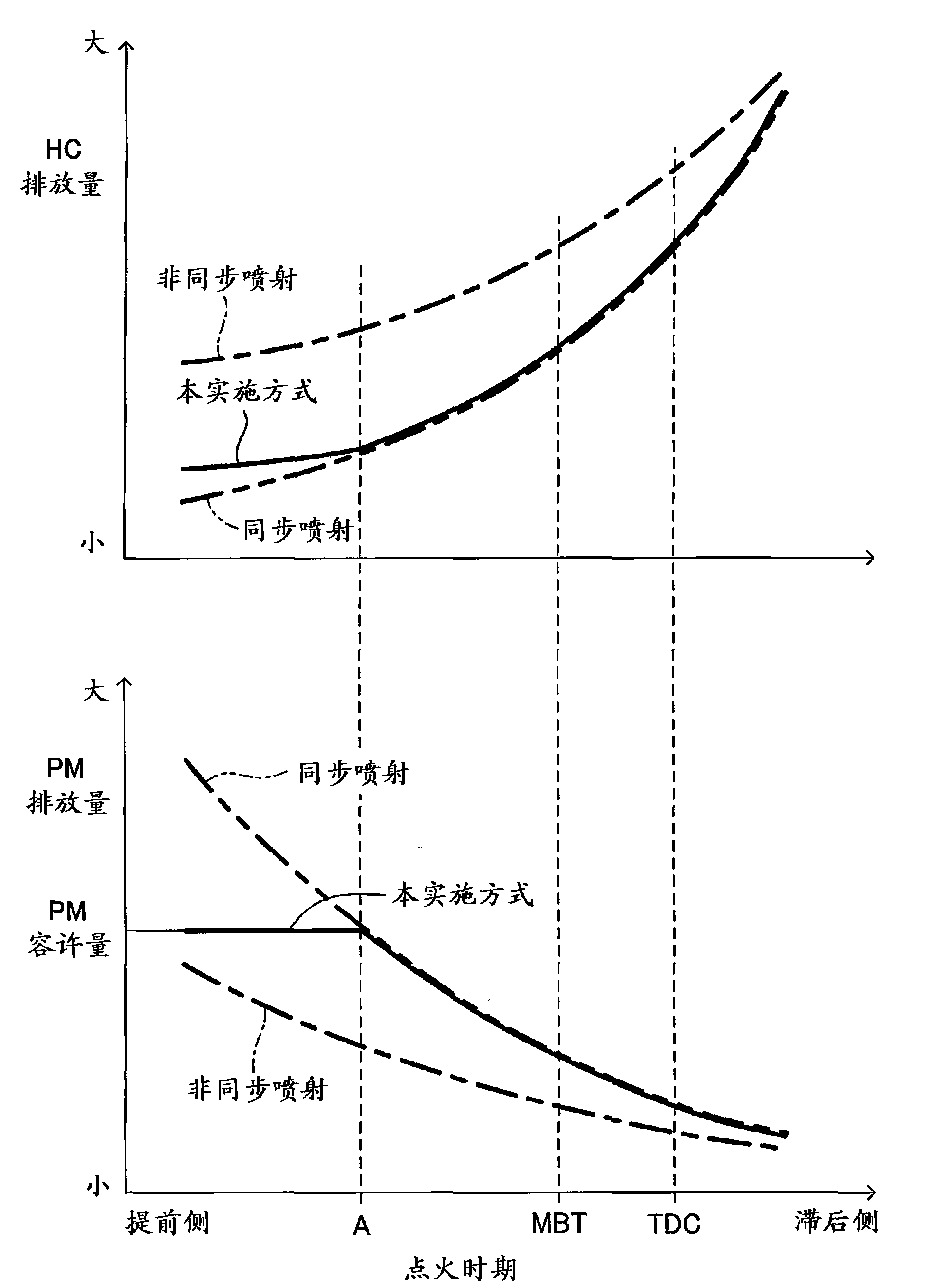

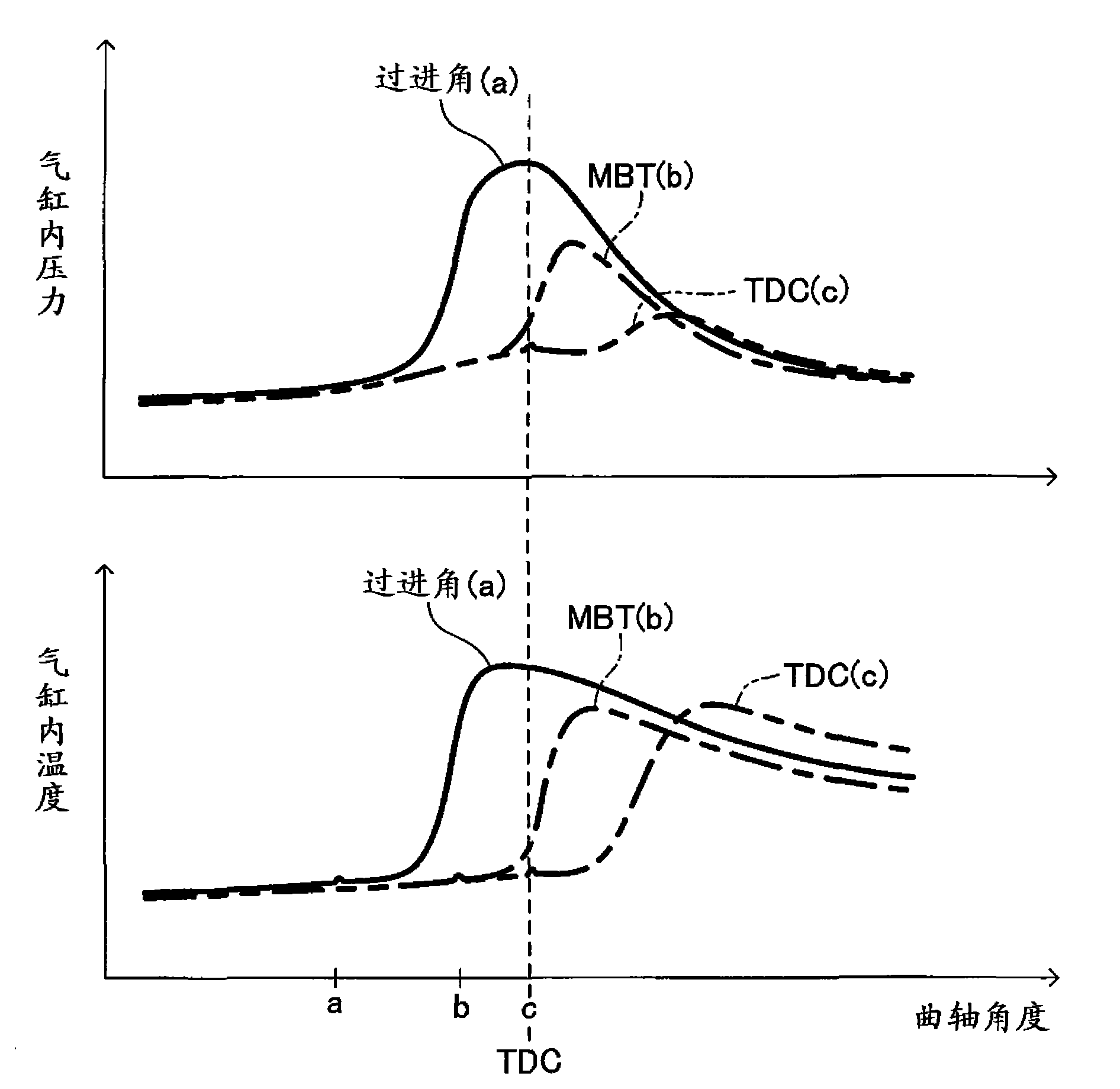

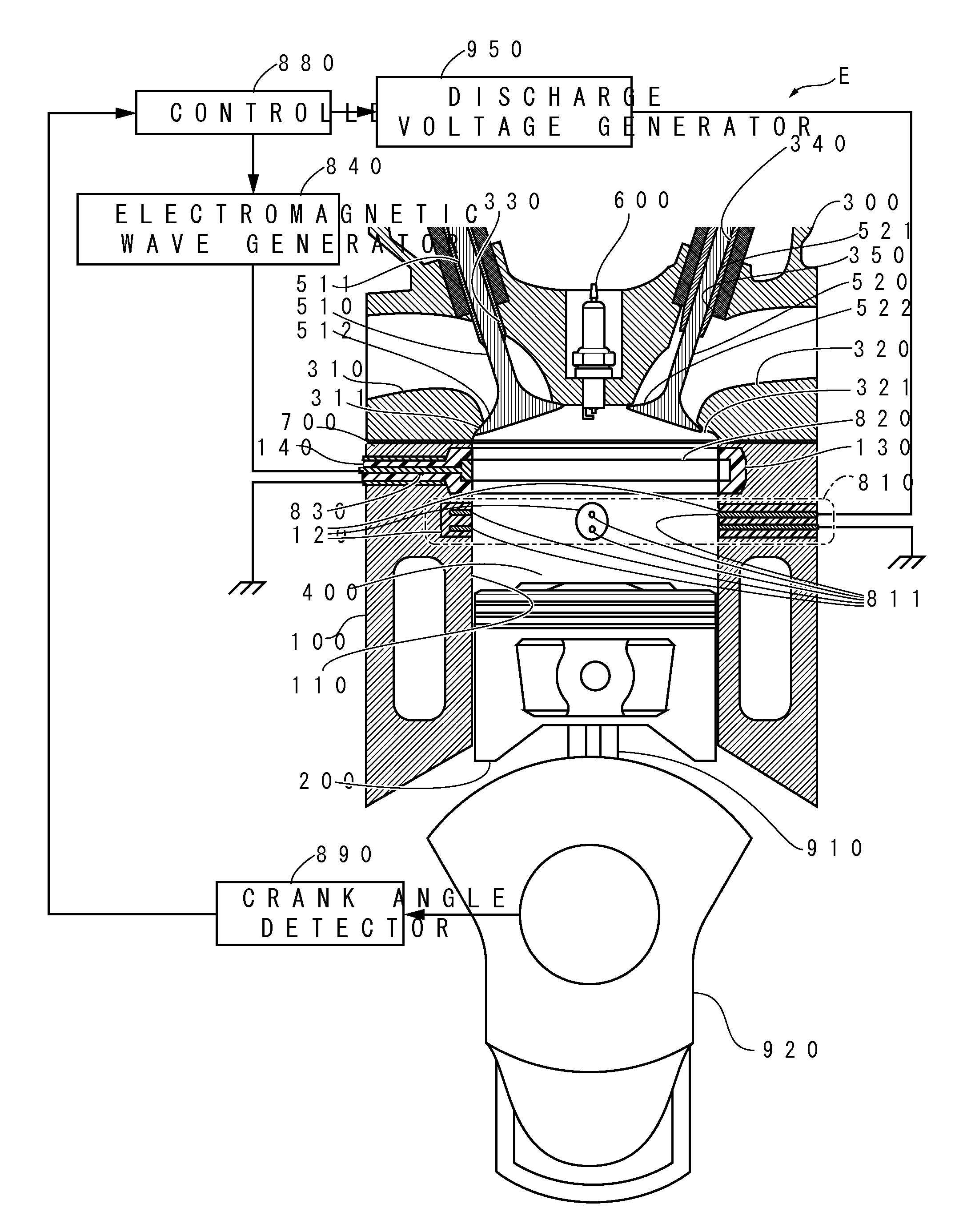

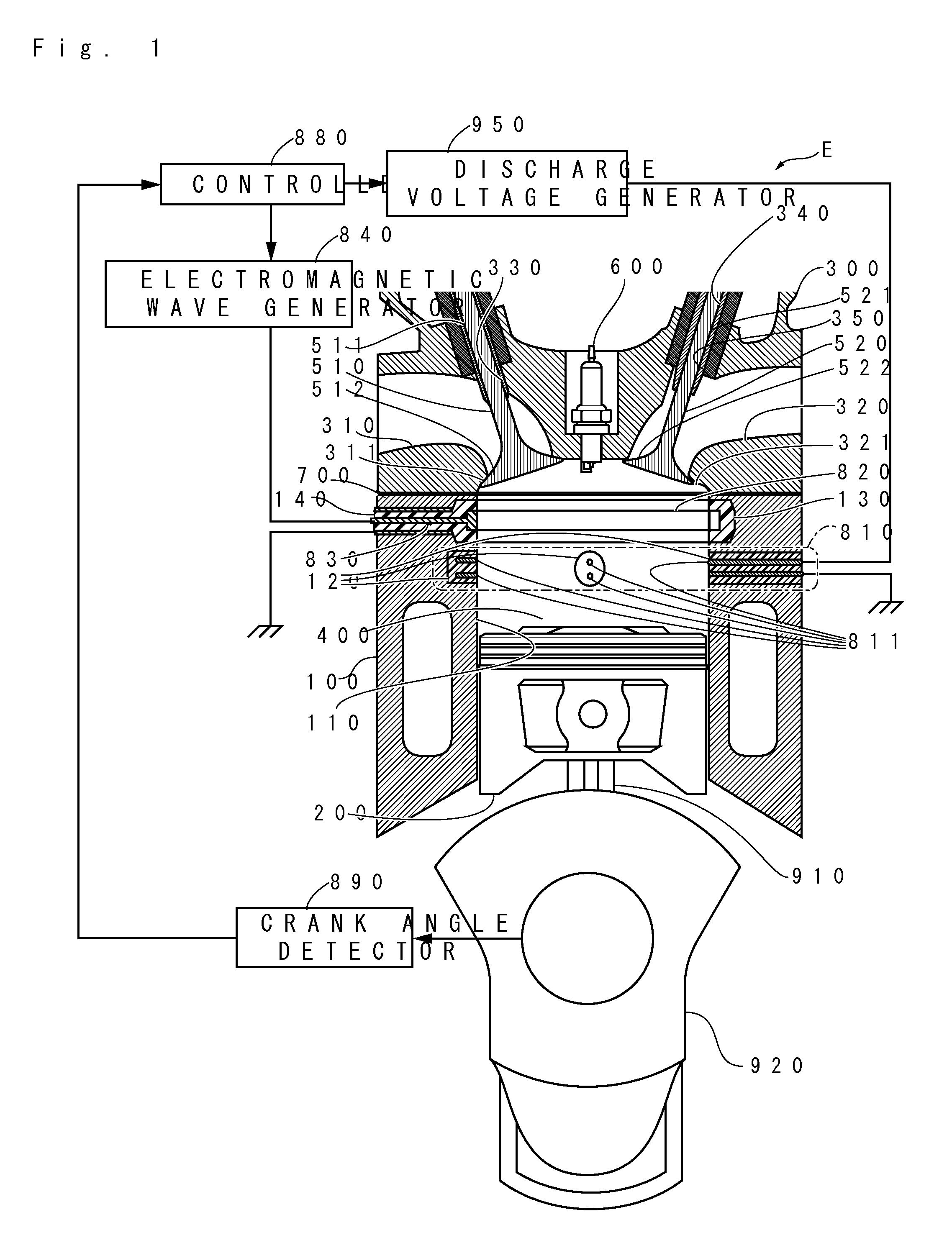

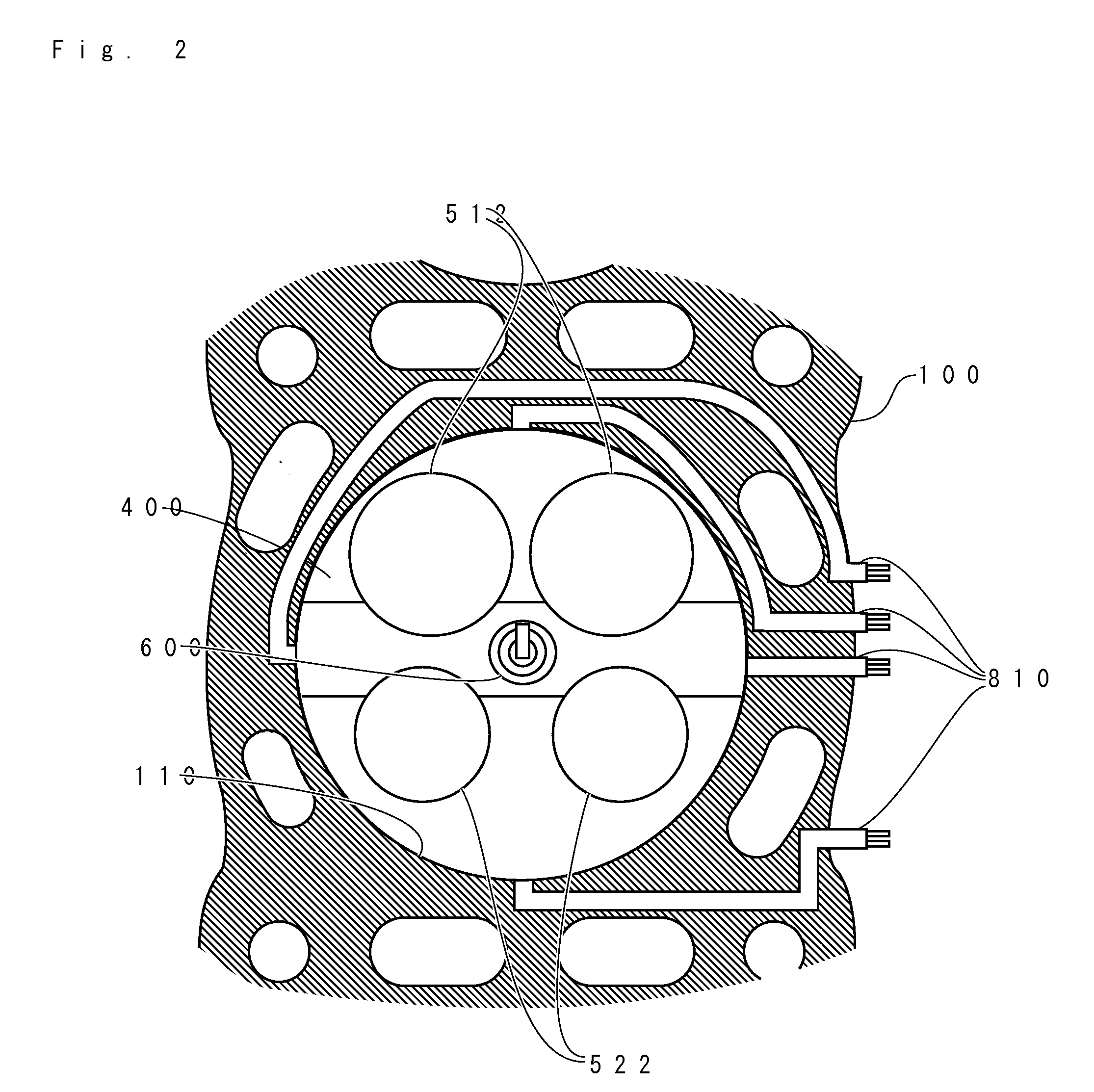

Internal combustion engine controlling apparatus

InactiveCN101668943APromote oxidation reactionElectrical controlMachines/enginesPartial oxidationEngineering

Owner:TOYOTA JIDOSHA KK

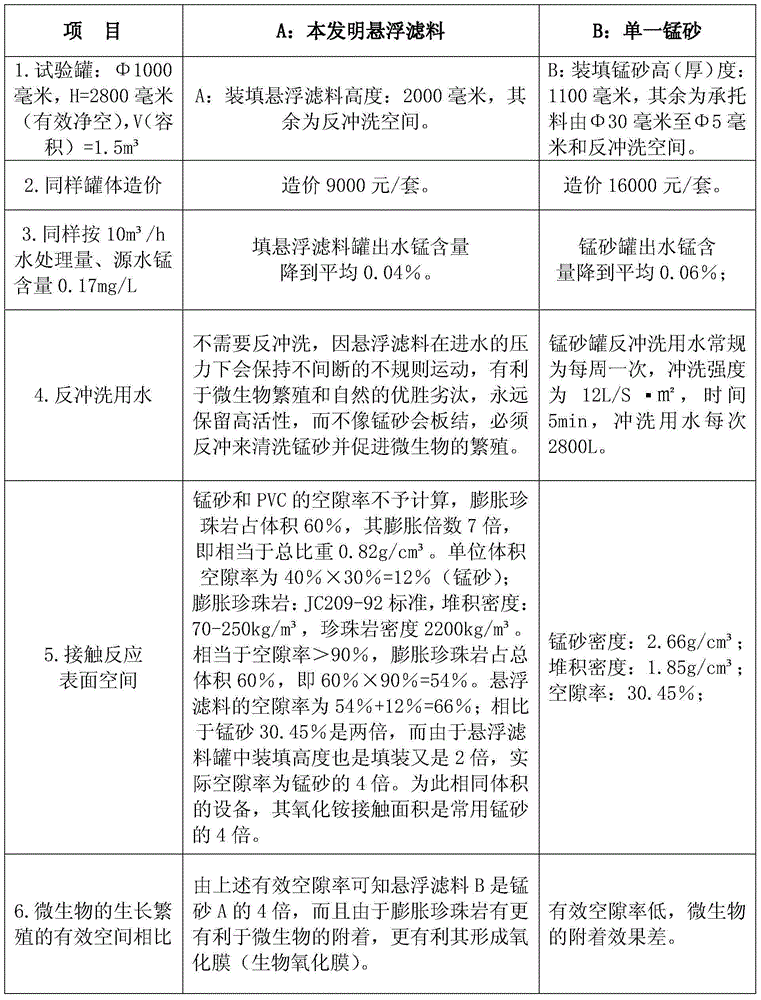

Iron-removing and manganese-removing suspended filter material and preparation method thereof

ActiveCN104150587ALight weightFacilitate direct communicationSustainable biological treatmentBiological water/sewage treatmentManganeseWater resources

The invention discloses an iron-removing and manganese-removing suspended filter material. The iron-removing and manganese-removing suspended filter material is characterized by comprising the following components in parts by weight: 650-700 parts of manganese sand, 80-90 parts of expanded perlite and 20-40 parts of plastic particles; the suspended filter material is prepared by weighing, crushing, uniformly mixing, melting, extruding, granulating and cooling. The iron-removing and manganese-removing suspended filter material has the advantages as follows: (1) the suspended filter material is low in specific weight, is suspended in water, and is conducive to direct exchange contact of water and the manganese sand for sufficient reaction; (2) the expanded perlite is very large in grain space, so that formation of a biofilm is facilitated, and oxidation reaction of iron ions and manganese ions is improved; (3) the iron-removing and manganese-removing suspended filter material improves the backwashing capability and saves water resources; (4) a supporting material is not needed, so that pressure on equipment is reduced and the equipment cost is reduced.

Owner:海南甘泉实业有限公司

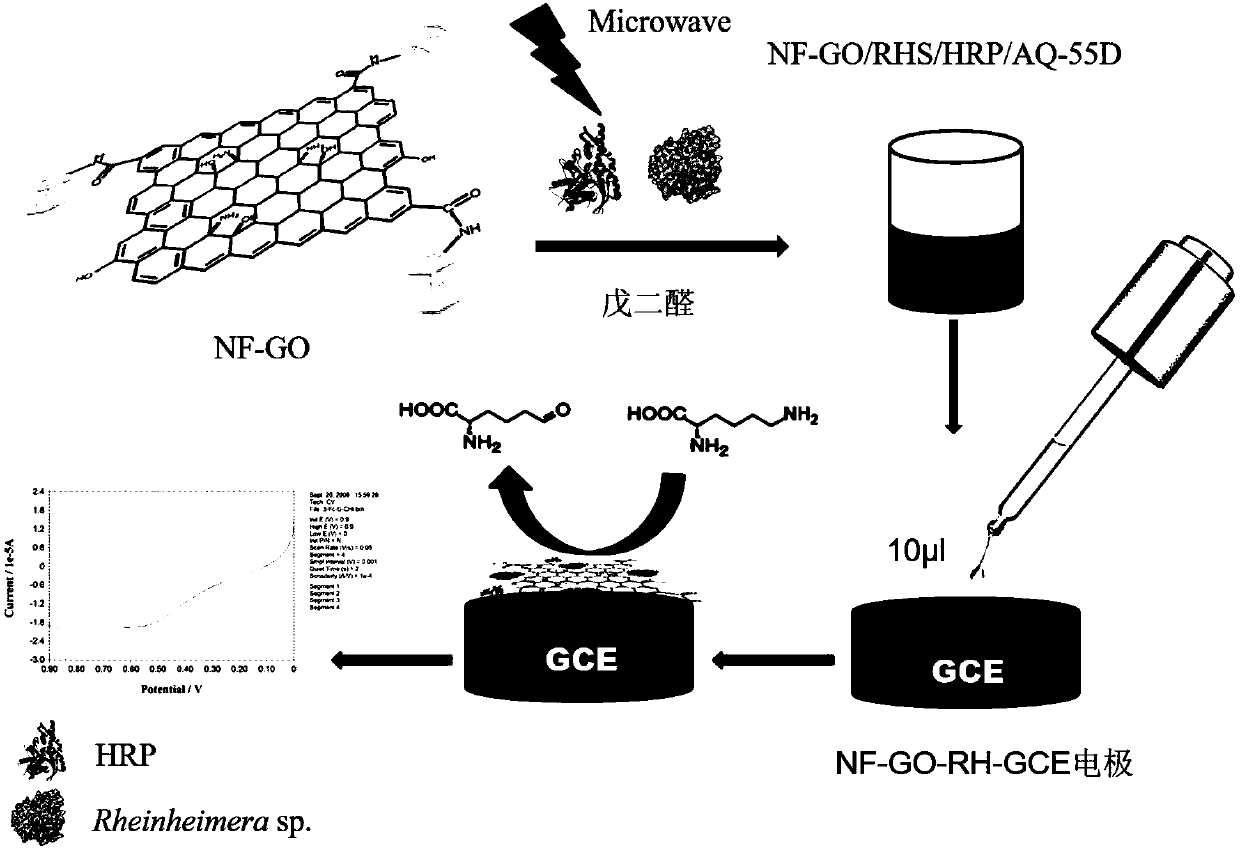

Electrochemical L-lysine sensor based on graphene material and preparation method thereof

PendingCN108051490AEasy to passPlay a closed roleMaterial electrochemical variablesAuxiliary electrodeHigh selectivity

The invention relates to an electrochemical L-lysine sensor based on a graphene material and a preparation method thereof. The preparation method comprises the following steps: modifying a glassy carbon electrode with L-lysine oxidase, with the graphene material as a sensitizing material; and separately arranging the modified glassy carbon electrode used as a working electrode, a saturated calomelelectrode used as a reference electrode and a platinum electrode used as an auxiliary electrode in an electrolytic bath to form a three-electrode system so as to prepare the electrochemical L-lysinesensor. The invention also relates to application of the electrochemical L-lysine sensor based on the graphene material to detection of L-lysine in food or medicines. The electrochemical L-lysine sensor based on the graphene material has the advantages of simple and rapid detection, high sensitivity and low cost and can achieve the purpose of high-selectivity identification and detection of L-lysine.

Owner:SHAOGUAN COLLEGE

Reaction method for preparing corresponding lactone, hydroxy acid and dicarboxylic acid through cyclic ketone oxidation

ActiveCN103373978AIncrease profitAvoid thermal decompositionOrganic compound preparationChemical recyclingMolecular sieveDicarboxylic acid

The invention relates to a reaction method for preparing corresponding lactone, hydroxy acid and dicarboxylic acid through cyclic ketone oxidation. The reaction method is characterized by comprising the following steps of: enabling reaction materials which include cyclic ketone, hydrogen peroxide, an entrainer and water to contact under the condition of oxidation reaction in the presence of a catalyst to obtain a product; and continuously adding and extracting the reaction materials and the product in a reaction device, wherein the entrainer generates azeotropism with the water, an azeotrope formed under a reaction condition is continuously removed and separated, the reaction materials and the entrainer are recycled, and the catalyst is a nano beta molecular sieve and / or a metal modified nano beta molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

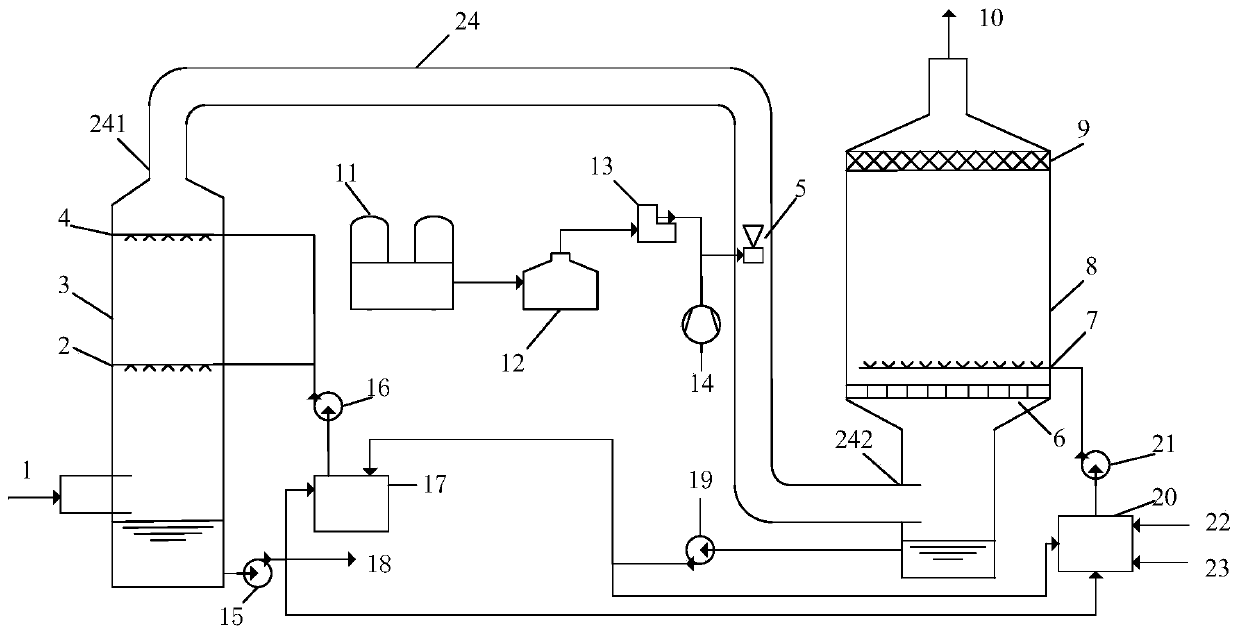

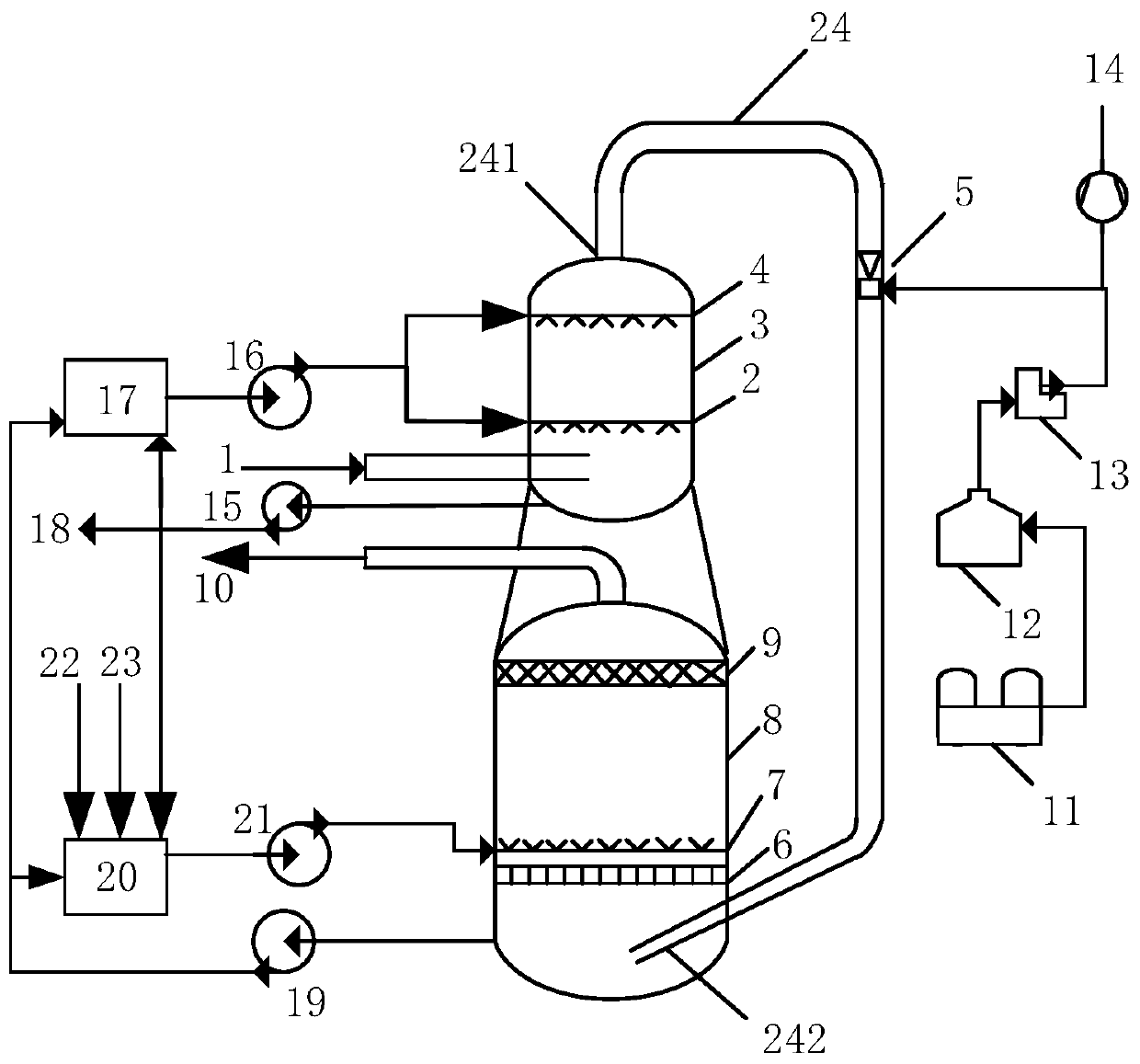

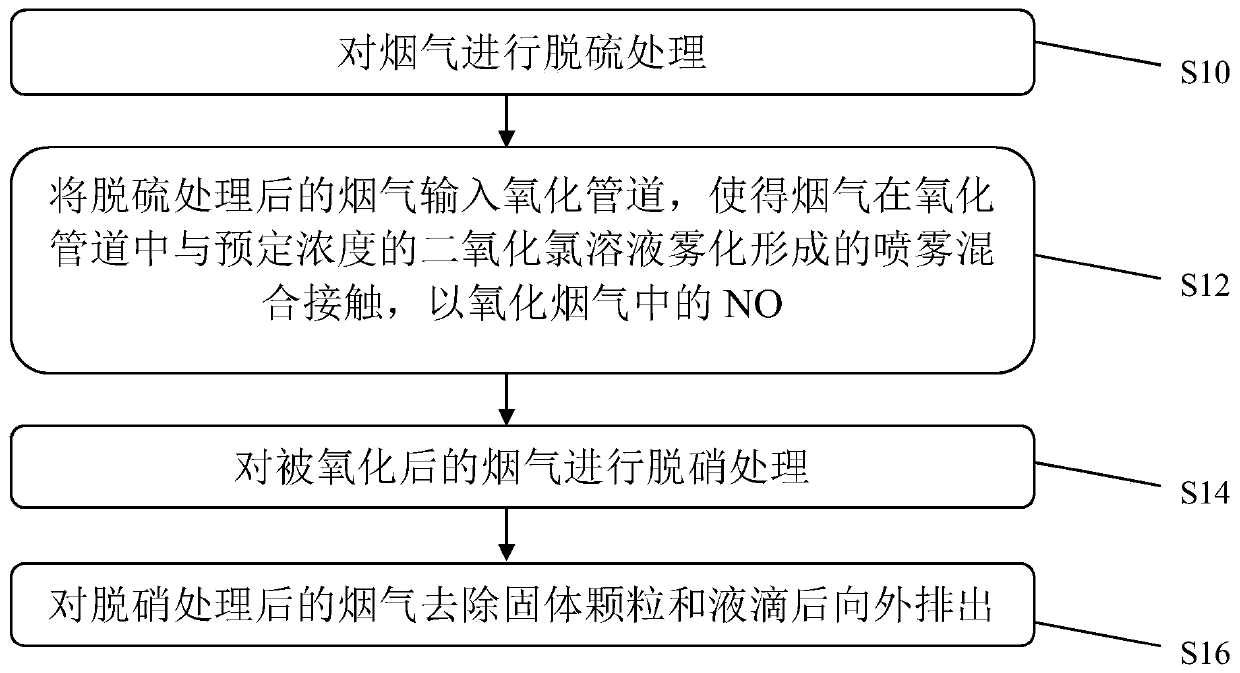

Flue gas desulfurization and denitration device and method

ActiveCN109718653AHigh gas velocityOxidation achievedDispersed particle separationChlorine dioxideFlue gas

The invention discloses a flue gas desulfurization and denitration device and method. The device comprises: a desulfurization container, the bottom of which is equipped with a desulfurization liquid material storage area, above which a flue gas inlet is disposed, with a flue gas washing and desulfurization structure being arranged above the flue gas inlet; a denitration container, the bottom of which is equipped with a denitration liquid material storage area, above which a flue gas washing and denitration structure is arranged, with a separation structure for removing solid particles and liquid drops being disposed above the flue gas washing and denitration structure, and a gas outlet being disposed at the top of the denitration container; an oxidization pipeline for communicating the desulfurization container and the denitration container; an atomization spray structure that is disposed in the oxidization pipeline and capable of providing structure connection together with chlorine dioxide, with the chlorine dioxide mist sprayed by the atomization spray structure being mixed with the flue gas in the oxidization pipeline. The flue gas desulfurization and denitration device and method provided by the invention can realize high efficiency and high utilization oxidation of ClO2 to NO, are safe and convenient to operate, and are convenient for industrial application.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

After-treatment apparatus for exhaust gas in a combustion chamber

InactiveUS20110023458A1Promote oxidation reactionConstant finding about the mechanismExhaust apparatusElectric ignition installationDielectricElectricity

An after-treatment apparatus for exhaust gas in a combustion chamber includes a discharge device with an electrode exposed to the combustion chamber and installed in at least one of members constituting the combustion chamber, an antenna installed in at least one of the members constituting the combustion chamber so as to radiate electromagnetic waves into the combustion chamber, an electromagnetic wave transmission line installed in at least one of the members constituting the combustion chamber and with one end connected to the antenna and the other end covered with an insulator or dielectric and extending to a portion, in at least one of the members constituting the combustion chamber, distant from the combustion chamber, and an electromagnetic wave generator for feeding electromagnetic waves to the electromagnetic wave transmission line. The after-treatment apparatus is configured such that discharge is generated with the electrode of the discharge device and the electromagnetic waves fed from the electromagnetic wave generator through the electromagnetic wave transmission line are radiated from the antenna, while the exhaust gas remains in the combustion chamber after the exhaust gas is produced during the explosion stroke.

Owner:MAGINEERING INC

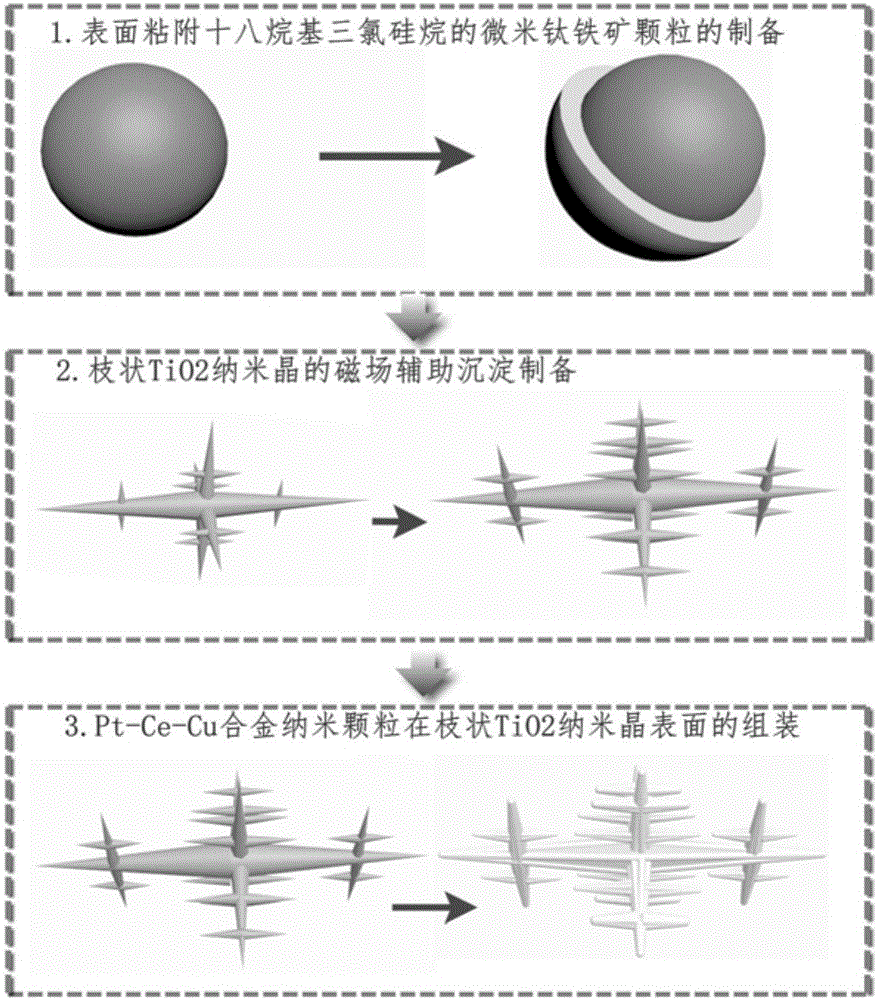

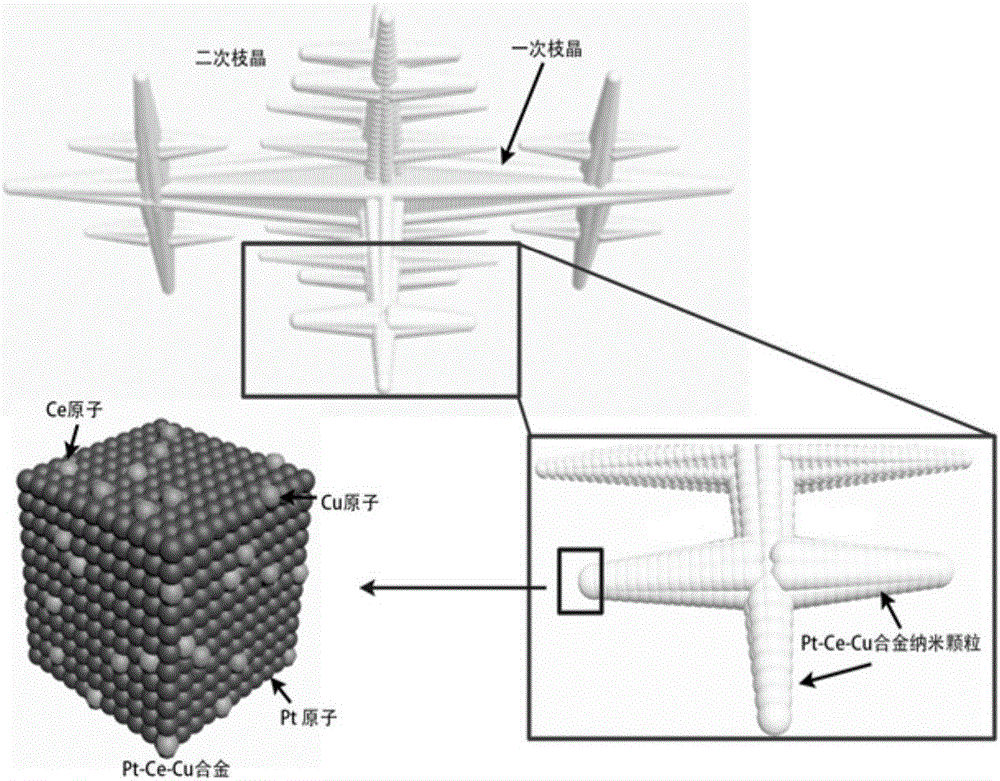

Preparation method of dendritic nanocrystal-loaded ternary alloy nanoparticle photocatalysis material

ActiveCN106378148ALower work functionPromote oxidation reactionMaterial nanotechnologyOrganic compound preparationOctadecyltrichlorosilaneBenzaldehyde

The invention relates to a preparation method of a dendritic TiO2 nanocrystal-loaded Pt-Ce-Cu alloy nanoparticle benzaldehyde photocatalysis material. The preparation method comprises the following steps: preparation of micrometer ilmenite particles with octadecyl trichlorosilane adhered to the surface, preparation of dendritic TiO2 nanocrystal magnetic-assisted precipitate and assembling of Pt-Ce-Cu alloy nanoparticles on the surface of dendritic TiO2 nanocrystal. The prepared dendritic TiO2 nanocrystal-loaded Pt-Ce-Cu alloy nanoparticle material has remarkable selective photocatalysis characteristic for benzyl alcohol catalytic oxidation reaction for production of benzaldehyde.

Owner:海门市创豪工业设计有限公司

Preparation of low-resistance / high-resistance composite film through ultrasonic spray pyrolysis

InactiveCN1544691APromote decompositionPromote oxidation reactionLiquid/solution decomposition chemical coatingHigh resistanceElectrical resistance and conductance

The invention prepares transparent low-distance and high-distance films by ultrasonic spray thermolysis technique. It uses a technique of ultrasonic spray deposition, and has the characters of large area and high deposition ratio. By improving the film forming device by ultrasonic spray thermolysis, it changes the spout from one point to one slot, which makes gas uniformly ejected on a line. The sample moves at uniform speed in the direction of the vertical spraying slot so that the thickness of the deposited film can be made uniform and consistent. It can be used in preparation of the transparent low-resistance films and transparent intrinsic high-resistance films of solar energy batteries and LCDs.

Owner:SICHUAN UNIV

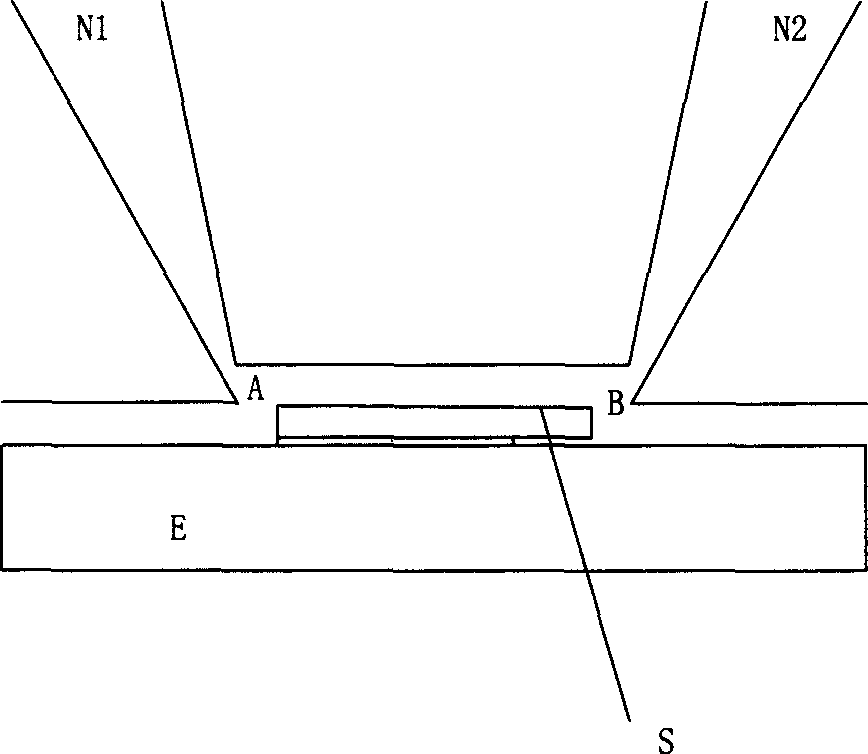

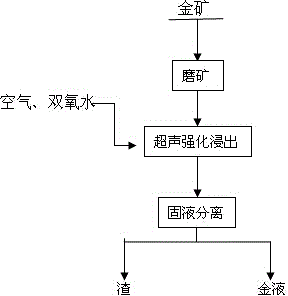

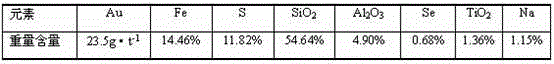

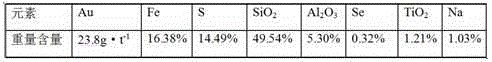

Method for collaboratively leaching gold in refractory gold ores by virtue of ultrasonic enhancement, chlorination and oxidization

InactiveCN104630466AImprove leaching rateShorten the leaching timeProcess efficiency improvementOxidation-Reduction AgentRedox

The invention discloses a method for collaboratively leaching gold in refractory gold ores by virtue of ultrasonic enhancement, chlorination and oxidization, and belongs to the field of hydrometallurgy. The method comprises the following steps: firstly, crushing gold ores into ore powder, thoroughly mixing the ore powder with sodium hydroxide, sodium hypochlorite and water to obtain ore pulp, introducing air into the ore pulp, and performing ultrasonic enhanced leaching under a stirring condition; periodically adding hydrogen peroxide in the enhanced leaching process. According to the method, at the same time of ultrasonic enhancement, a redox reaction is performed by virtue of the synergistic effect of hydrogen peroxide and sodium hydroxide; the synergistic effect of the hydrogen peroxide and the sodium hydroxide is far better than the independent oxidization effect of each of the hydrogen peroxide and the sodium hydroxide. The ultrasonic enhancement is capable of improving the gold leaching effect while shortening the reaction time, and therefore, the reagent cost can be saved and the gold ore leaching efficiency also can be improved; as long as the method is adopted for leaching, the leaching rate can be above 98%; in addition, the sodium hypochlorite is adopted as a leaching agent for the method and no pressure is caused on the environment; besides, the method is capable of realizing one-step enhanced leaching of the gold ores and shortening the leaching steps.

Owner:KUNMING UNIV OF SCI & TECH

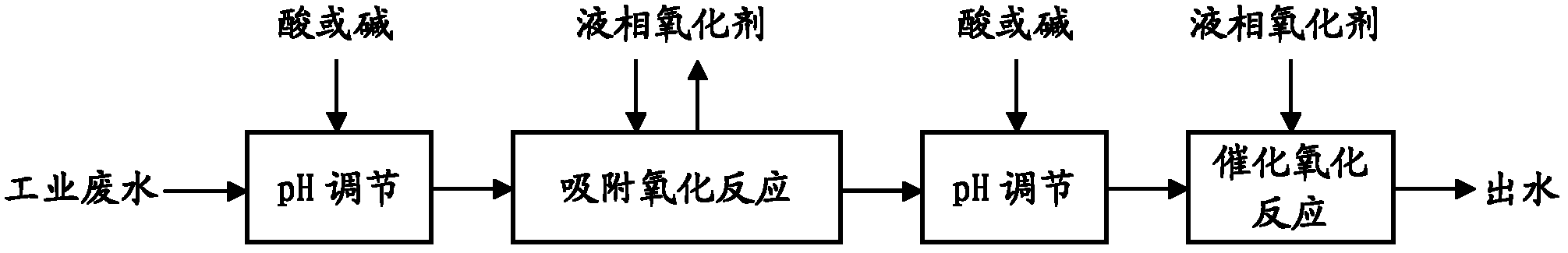

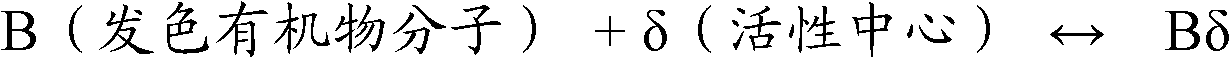

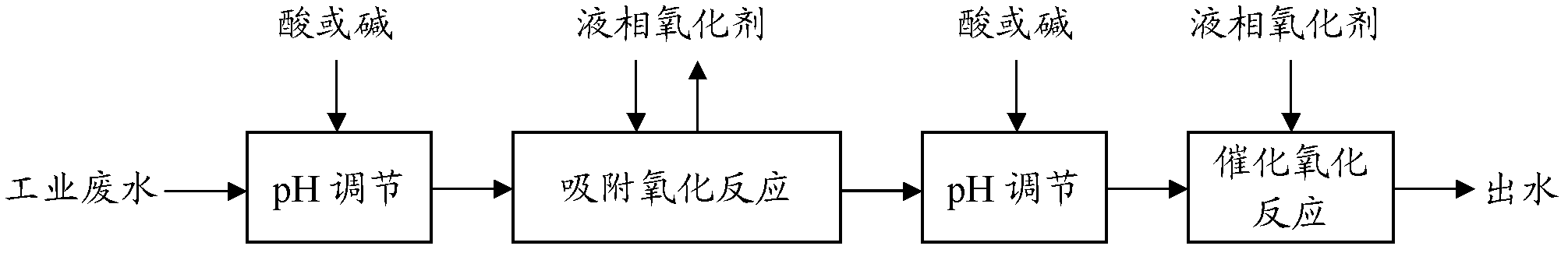

Industrial wastewater decoloring treatment process

ActiveCN102276084AExtend your lifeLower activation energyMultistage water/sewage treatmentIndustrial effluentCatalytic oxidation

The invention discloses an industrial wastewater decoloring treatment process. The process comprises the following steps: the pH value of wastewater is adjusted, an adsorption and oxidation reactor filled with adsorption resin is introduced, a lot of chormophoric organics are adsorbed in the resin, when the chroma removal rate is less than 60%, drainage is performed, a liquid-phase oxidant is added in the adsorption resin to perform oxidative decoloration, the resin is activated and regenerated; and after the pH value of the discharged water of the adsorption and oxidation reactor is adjusted, the discharged water enters a catalytic oxidation reactor, the adsorption resin loaded with a transition metal catalyst is filled in the reactor, and the liquid-phase oxidant is added to perform heterogeneous catalytic oxidation decoloration and remove the small molecules and nonpolar chormophoric organics which are difficult to be adsorbed by the adsorption and oxidation unit. By adopting the method, the polar and nonpolar chormophoric organics with wide molecular weight range can be removed and the effects of efficient decoloring and wide applications can be achieved.

Owner:杭州浙大易泰环境科技有限公司

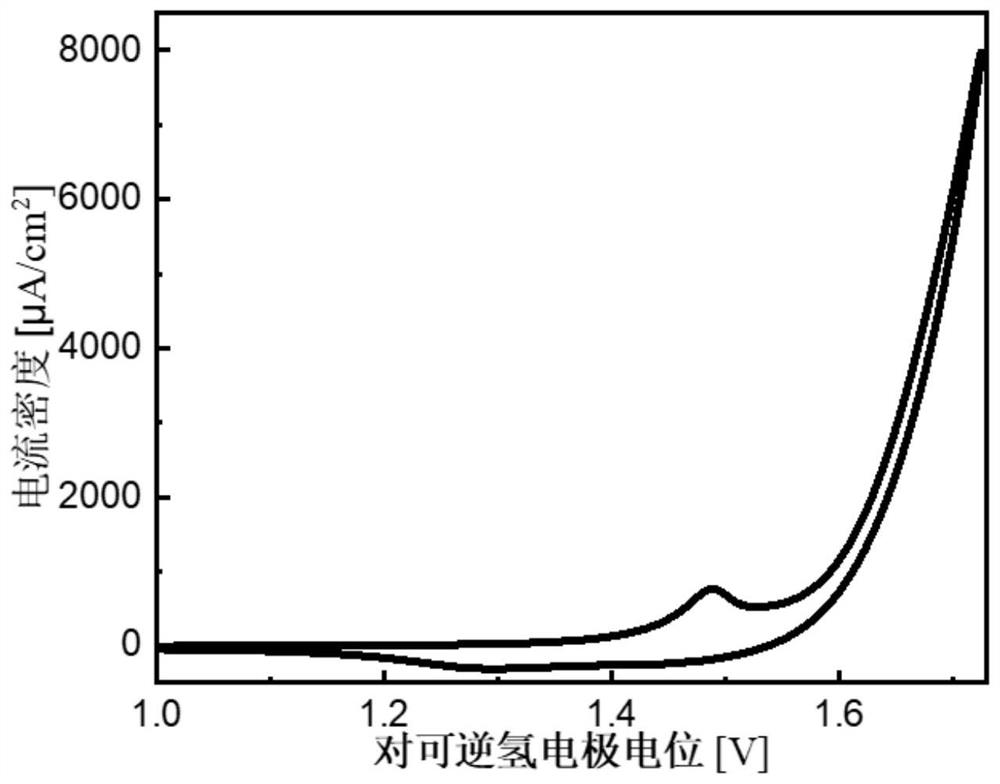

Amorphous lanthanum nickelate film composite electrode, and preparation method and application thereof

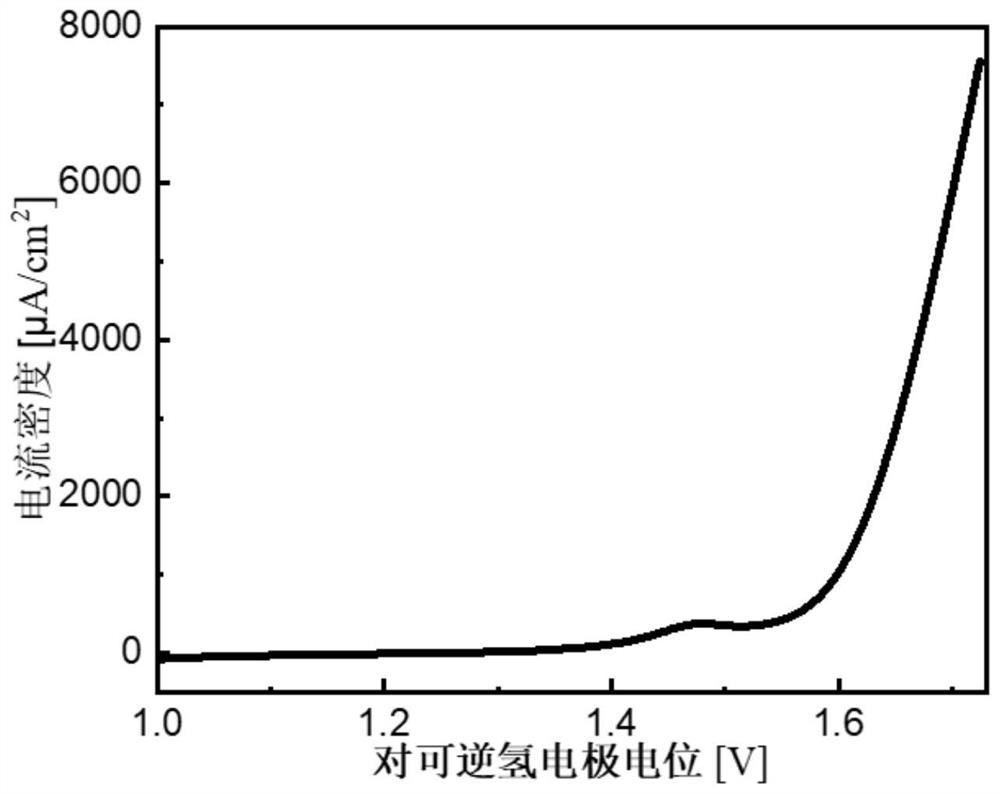

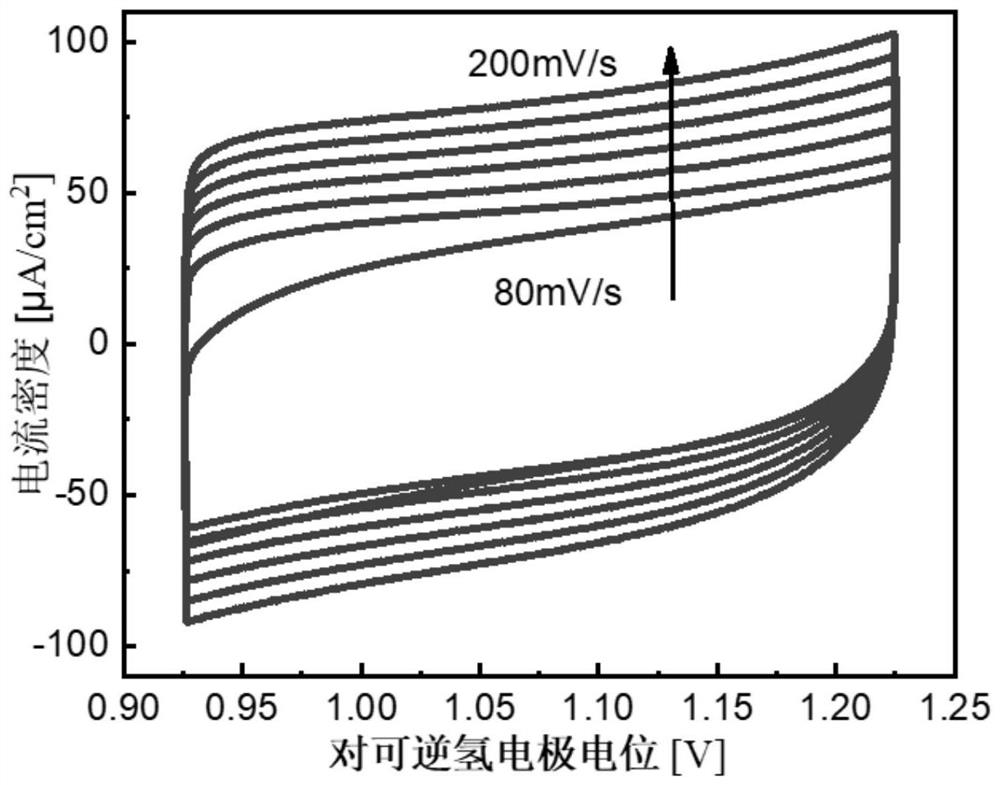

ActiveCN113073353ARich sourcesLow priceVacuum evaporation coatingSputtering coatingComposite electrodePhysical chemistry

The invention discloses an amorphous lanthanum nickelate film composite electrode, and a preparation method and application thereof. The preparation method comprises the following steps: (1) preparing a lanthanum nickelate target material; (2) pretreating a substrate; and (3) preparing the composite electrode. By preparing the amorphous lanthanum nickelate film, more active sites can be provided; and the amorphous lanthanum nickelate film covers the glassy carbon sheet substrate, so that conductivity can be provided. When the composite electrode covered with the amorphous lanthanum nickelate film is applied to an OER electro-catalysis system, the catalytic activity and durability in an alkaline solution can be effectively improved, and the OER reaction is effectively catalyzed and promoted.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for treating selenium-containing wastewater

ActiveCN104556540ASolving Tolerance IssuesReduce the burden onWater treatment parameter controlWater contaminantsWastewaterSelenate ion

The invention discloses a method for treating selenium-containing wastewater. The method comprises the following steps: adjusting the pH of the selenium-containing wastewater to be 7-9, performing ozone oxidization in an ozone reactor, oxidizing selenious acid radical ions (SeO3<2->) into selenate radical ions (SeO4<2->), then performing aerobic biological treatment, putting the wastewater into a flocculating settling pool, adding a flocculating agent, stirring and performing solid-liquid separation to obtain wastewater subjected to selenium removal. The method disclosed by the invention is high in removal rate of selenium from the wastewater, wide in application range, easy and convenient to operate and particularly suitable for high-concentration selenium-containing wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

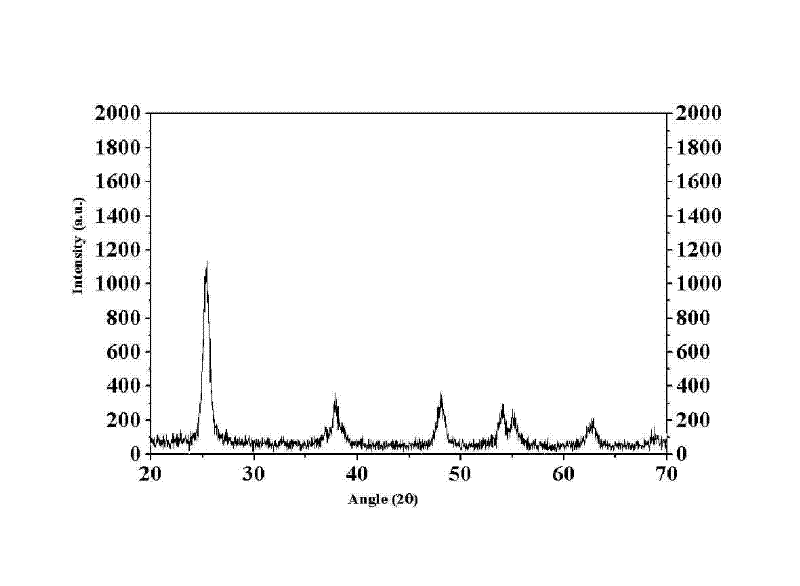

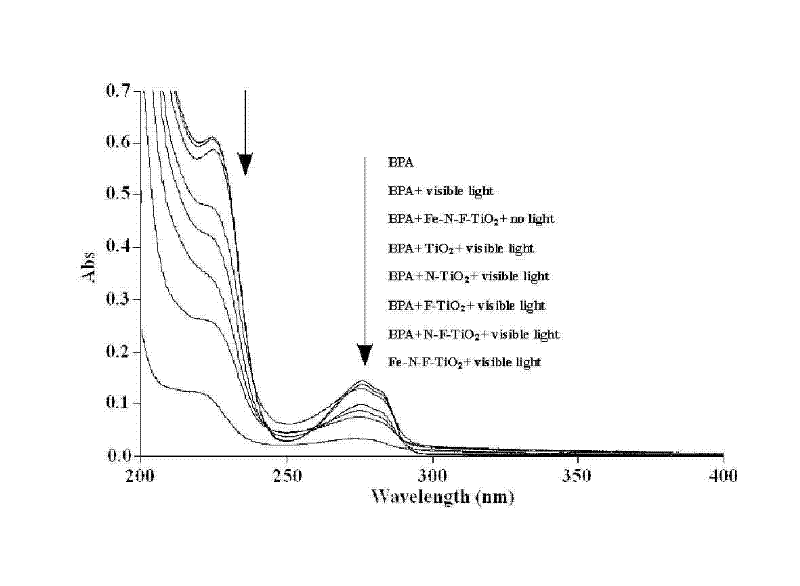

Iron, nitrogen and fluoride co-doped titanium dioxide (TiO2) photocatalyst and application thereof in degrading organic pollutants in visible light

ActiveCN102500406AImprove photocatalytic performancePromote absorptionPhysical/chemical process catalystsWater/sewage treatment by irradiationHYDROSOLTitanic acid

The invention relates to an iron, nitrogen and fluoride co-doped titanium dioxide (TiO2) photocatalyst and the application thereof in degrading organic pollutants in visible light. The invention adopts the technical scheme that: butyl titanate is stirred and slowly dripped into the mixed solution of ethanol and glacial acetic acid; after the mixed solution is stirred uniformly, hydrofluoric acid solution is added drip by drip and stirred, and transparent mixed solution A is formed; ammonia and the ethanol are mixed, ferric nitrate is added in, the pH value is regulated to be 2, and solution B is prepared; the solution B is slowly dripped into the solution A, and uniform and transparent sol is obtained; the sol stays and is aged in the air, and solid gel is obtained; and the solid gel is dried and ground into powder, put into a Francesca furnace to be roasted for 40min to 1.5h at 400DEG C to 500DEG C, and the iron, nitrogen and fluoride co-doped TiO2 photocatalyst is prepared. The photocatalyst and the application thereof expand the visible light response scope of the TiO2 and reduce the composition of electrons and cavities, so that the utilization rate of TiO2 to the solar energy and the light catalysis activity of the TiO2 are improved.

Owner:LIAONING UNIVERSITY

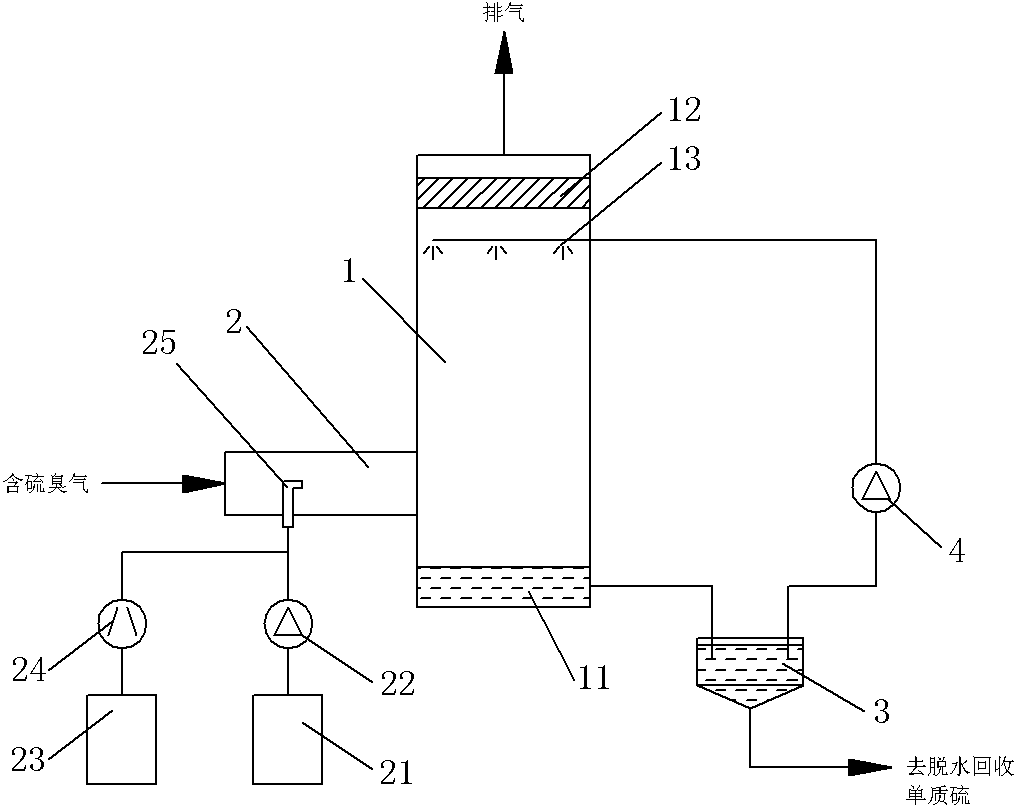

Wet oxidation desulfurization method and device

InactiveCN104275086AAchieve recyclingSolve technical problems with increased loadDispersed particle separationPollutionHydrogen peroxide

The invention discloses wet oxidation desulfurization method and device capable of removing hydrogen sulfide pollutants generated by a biochemical pool and the like. The wet oxidation desulfurization method disclosed by the invention comprises the following steps: (1) supercharging an ozone gas through a compressor, and supercharging a hydrogen peroxide solution through a booster pump; (2) mixing the supercharged ozone gas with hydrogen peroxide and then atomizing through an ejector; (3) spraying an odor gas containing hydrogen sulfide into a mixing pipe, simultaneously, spraying the atomized ozone gas and hydrogen peroxide mixture into the mixing pipe and mixing the mixture with the odor gas containing hydrogen sulfide; and (4) introducing a mixture of the odor gas containing hydrogen sulfide, the ozone gas and hydrogen peroxide into a spray tower for spraying through the mixing pipe. According to the wet oxidation desulfurization method, green and pollution-free ozone and hydrogen peroxide free of alkali are adopted as oxidants, and hydrogen sulfide can be oxidized into elemental sulfur by the oxidants, so that cyclic utilization of a sulfur element can be achieved, a by-product polluting the environment is not generated in the overall desulfurization process, and no brine waste is generated after the spray tower is washed.

Owner:NANJING UNIV

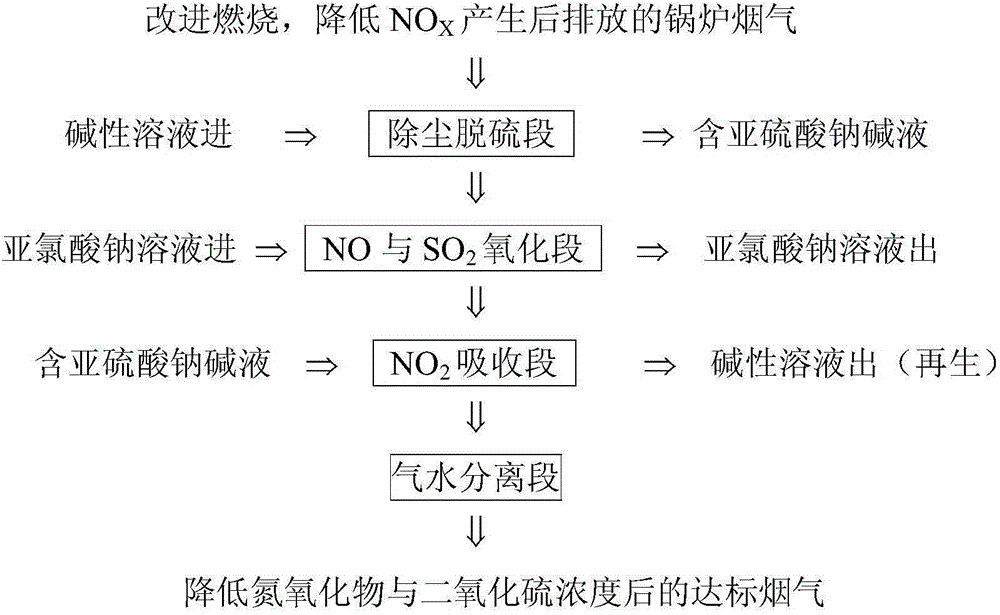

Method for reducing nitrogen oxides in flue gas of medium and small sized industrial coal burning boiler through combination with wet-method sulfur removing technology

InactiveCN104801160ALess investment in equipment transformationLow running costDispersed particle separationChemistryEnvironmental standard

The invention provides a method for reducing nitrogen oxides in flue gas of a medium and small sized industrial coal burning boiler through a wet-method sulfur removing technology. The method comprises the following steps: conducting dust removing and primary sulfur removing on flue gas generated by the coal burning boiler; collecting alkali liquor comprising sulfur removing product sodium sulfite of primary desulfuration according to a dual-alkali method; conducting oxidation treatment on the pretreated flue gas to integrally oxidize NO and residuary sulfur dioxide in the pretreated flue gas; utilizing the oxidized flue gas to get in contact with an alkali liquor, thereby removing nitrogen dioxide and sulfur oxide generated after oxidation in the oxidized flue gas to obtain purified flue gas; conducting gas-water separation to discharge flue gas which meets the environmental standard. Compared with the conventional dry-process flue gas denitration technology, the method provided by the invention has the advantages that desulfurization and denitrification can be simultaneously realized only by additionally arranging an oxidation reactor section in a conventional dual-alkali method absorbing system, so that the economic performance is very high.

Owner:BEIJING YANJING BREWERY

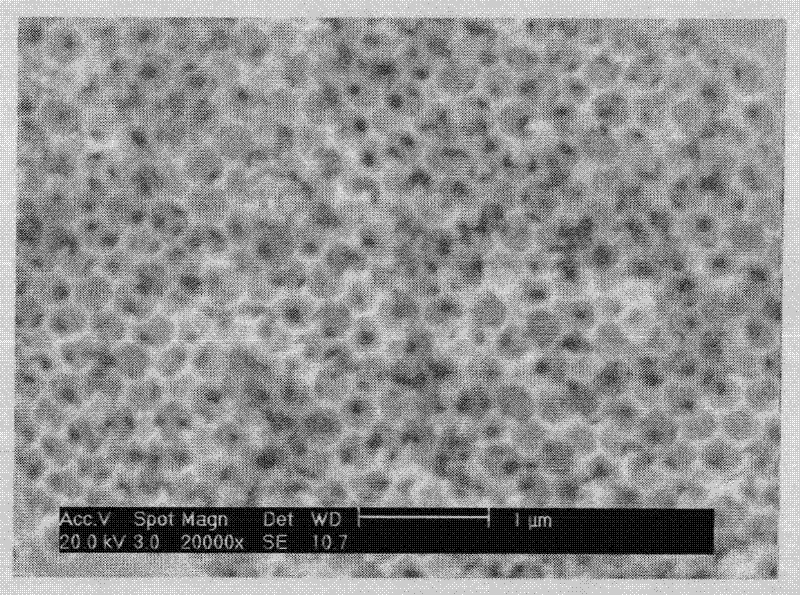

Oxygen carrier, preparation method therefor, and applications thereof

ActiveCN103374431AFacilitated DiffusionSmall pressure dropHydrogen productionFuel additivesActive componentHigh activity

The invention discloses an oxygen carrier. The oxygen carrier employs CeO2-Al2O3 as a carrier and NiO as an active component. CeO2 is coated on the surface of Al2O3 in the carrier CeO2-Al2O3. CeO2 weighs 10-50% of the total weight of the carrier, the preference being 20-40%. According to the final weight content of the oxygen carrier, the content of the active component NiO in the oxygen carrier is 1-20%, the preference being 1-10%. The oxygen carrier has a pore size of 10-100 nm. The oxygen carrier is advantaged by mesoporous structure, and small particle size and homodisperse of the active component. The oxygen carrier has advantages of high activity, good stability and the like during chemical looping combustion and hydrogen production.

Owner:CHINA PETROLEUM & CHEM CORP +1

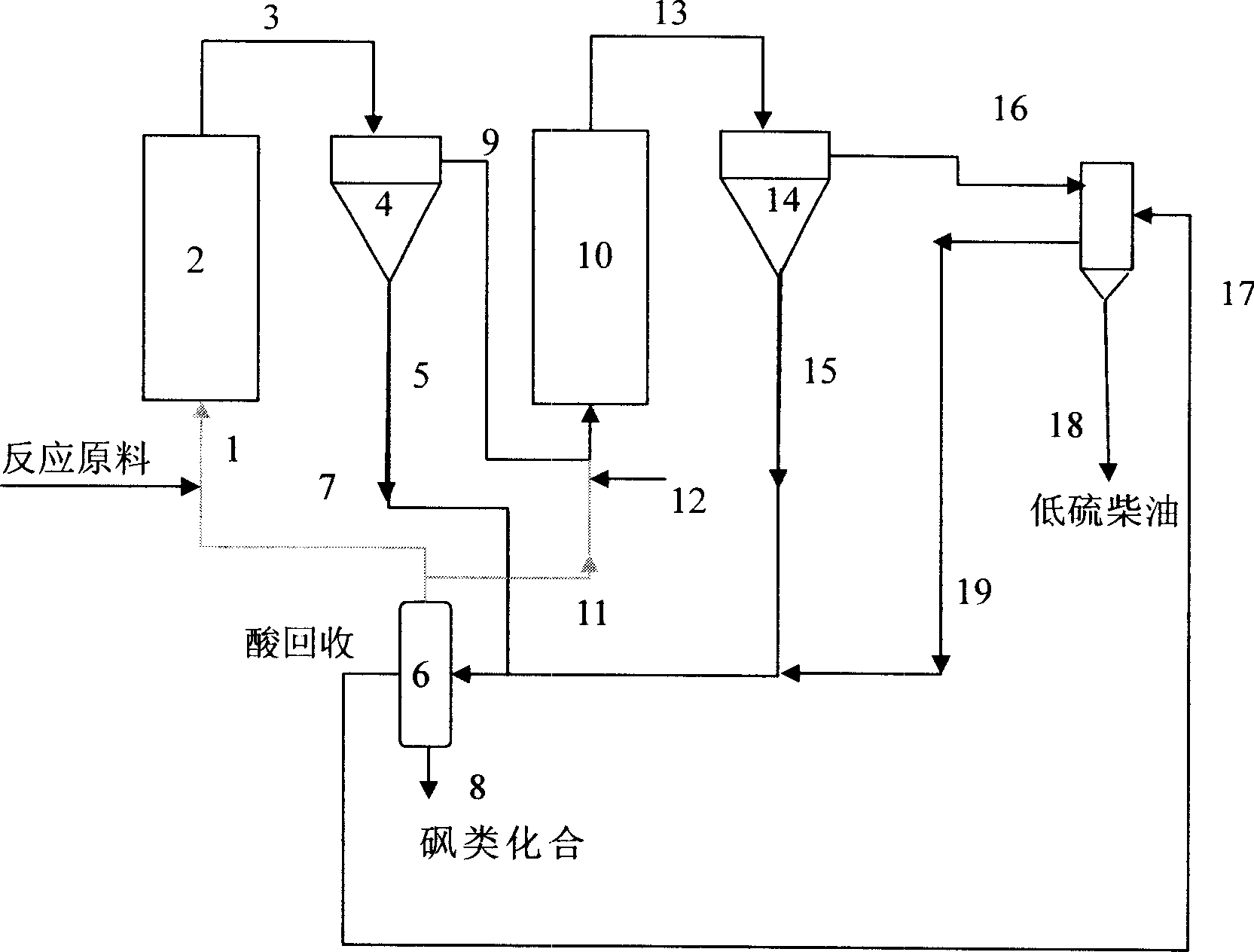

Method for producing low-sulfur diesel-oil by oxidation desulfurization

ActiveCN1814710AReduce adsorptionIncreased oxidation depthRefining with oxygen compoundsOrganic acidSulfur product

This invention discloses an oxidizing and desulfurizing method for fraction oil including that the fraction oil and hydrogen peroxide are reacted in a multi-stage reactor where low level organic acid catalyst exists, the product in each stage reactor is separated in oil-water phase, the water phase product is recovered after the organic acid is removed and the oil phase product is taken as the feed of the next stage reactor, apart from the raw material oil from the above stage, the feed of each stage is added with organic acid and hydrogen peroxide, different reacting stages are determined according to the needs on sulfur by a product and its content and the fraction oil from the last stage is taken as the low sulfur product directly after being dehydrated, which leaves out the process of solvent extraction or adsorption to the oil phase products after the oxidizing reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

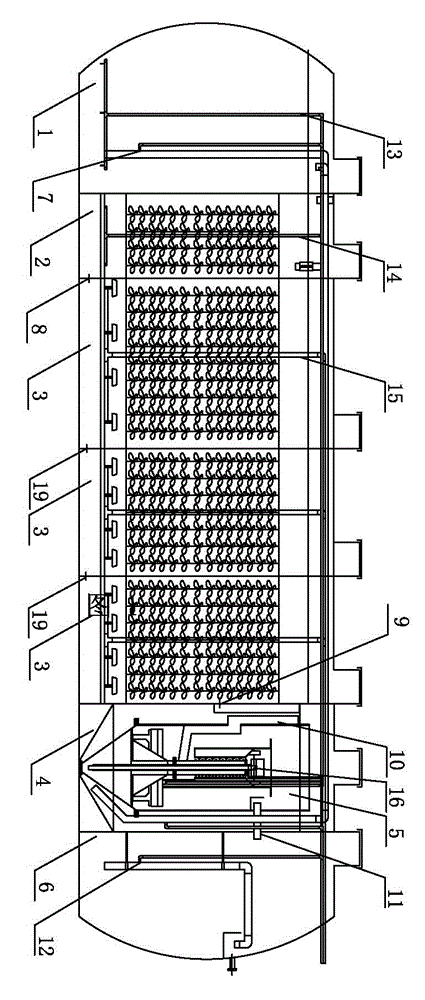

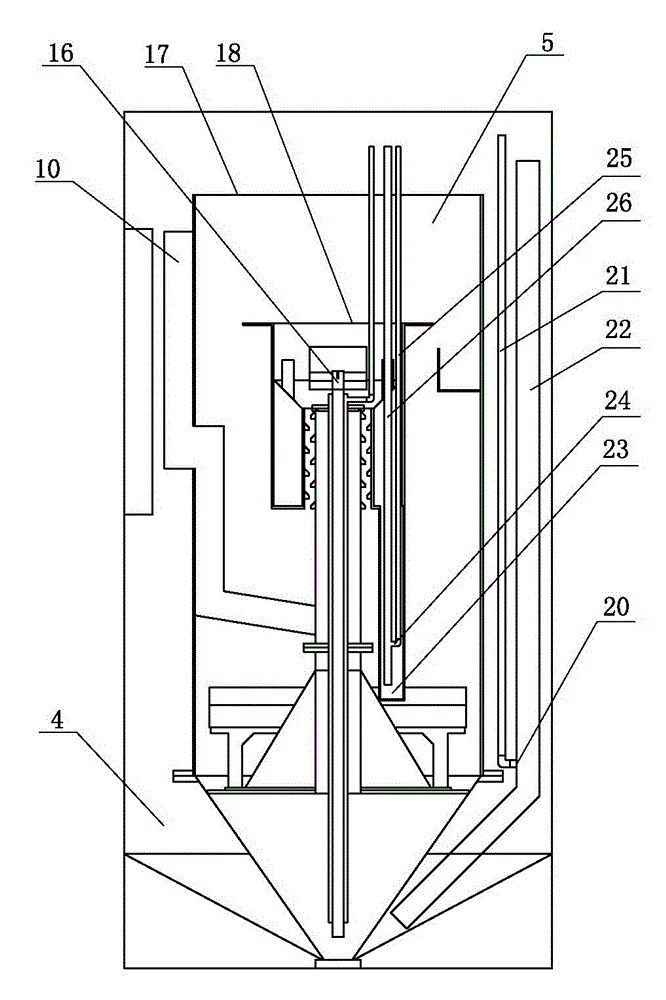

Pump-free integrated wastewater deep treatment equipment

ActiveCN104961303AEasy to handleImprove processing levelMultistage water/sewage treatmentPower cycleTherapeutic effect

The invention provides pump-free integrated wastewater deep treatment equipment, in order to solve the problems that current wastewater treatment equipment is large in occupied area, heavy in the energy consumption and the like. The equipment belongs to the technical field of wastewater treatment equipment, and comprises an adjusting tank, an anoxic tank, aerobic tanks, a secondary sedimentation tank, a sand filter and a clean water tank, wherein the sand filter is arranged in the secondary sedimentation tank, the adjusting tank is communicated with the anoxic tank through an adjusting tank stripping tube, the anoxic tank is communicated with the adjacent aerobic tank through an anoxic tank water passing hole in the bottom of an adjacent baffle plate of the anoxic tank and the adjacent aerobic tank, the third aerobic tank is communicated with the secondary sedimentation tank through a secondary sedimentation tank water passing hole in an adjacent baffle plate of the third aerobic tank and the secondary sedimentation tank, the secondary sedimentation tank is communicated with the sand filter through a sand filtration diversion trench, the sand filter is communicated with the clean water tank through a clean water tube, and the clean water tank is internally provided with a clean water tank stripping tube. According to the equipment provided by the invention, a plurality of wastewater treatment tanks are developed and designed into a whole, so that the occupied area is small, and the land source is saved, a gas stripping manner is adopted to replace a pump to provide power cycle, so that the energy consumption is greatly reduced, and through multilevel oxidation treatment, the wastewater treatment effect is increased.

Owner:青岛绿水清源环保技术有限公司

Methane catalytic oxidation catalyst for natural gas vehicle and preparation method of methane catalytic oxidation catalyst

ActiveCN104549213AHigh content of active ingredientsPromote oxidation reactionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationRare earth

The invention relates to a methane catalytic oxidation catalyst for natural gas vehicle exhaust aftertreatment and a preparation method of the methane catalytic oxidation catalyst. The methane catalytic oxidation catalyst is a stannum-zirconium composite oxide solid solution catalyst, wherein the stannum / zirconium atomic ratio is at least 1.1, the general equation is Sn(1-x)ZrxM0.10O2, M is at least one of rare earth and transition metal, and x is a coefficient; the methane catalytic oxidation catalyst is prepared from the following components in percentage by weight: 50-70% of a stannic oxide (SnO2) precursor, 15-40% of a zirconium dioxide (ZrO2) precursor and the balance being a stabilizer oxide precursor. The preparation method sequentially comprises the following steps: (1) preparing mixed salt; (2) adding a precipitant-urea; (3) carrying out homogeneous precipitation reaction; and (4) roasting to obtain a finished product. The methane catalytic oxidation catalyst has the high active component content and can completely oxidize methane at about 500 DEG C, and the catalytic oxidation ability of a stannum-zirconium composite oxide solid solution on the methane, propane and carbon monoxide can be remarkably improved; and besides, the preparation method is simple, can be operated easily and is low in cost.

Owner:韩霜

Preparation technology for improving emulsibility and emulsion stability of desugared egg white powder

ActiveCN105326021AEnsure safetyThe total amount added is smallFood ingredient as antioxidantFood thermal treatmentYolkEmulsion

A preparation technology for improving emulsibility and emulsion stability of desugared egg white powder specifically comprises steps as follows: yolks are separated after fresh eggs are pretreated, an egg white liquid is desugared, then soybean lecithin is added to the egg white liquid, and the emulsibility of egg white powder obtained after spray drying can be significantly improved; besides, an antioxidant is added to the obtained egg white powder, and a lipid oxidation reaction can be avoided in the hot chamber treatment process of subsequent industrial production. Compared with other kinds of egg white powder, the prepared egg white powder has the advantages that the emulsibility can be significantly improved, the egg white powder has the uniform and stable pure white color, the method adopts the simple technology, other devices are not required to be added, and industrial production is facilitated.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Uterus warming sanitary towel

InactiveCN112156219AEvenly heatedStable feverElectrotherapySanitary towelsSodium bicarbonatePyrrolidinones

The invention relates to the field of hygienic products, and provides a uterus warming sanitary towel. The uterus warming sanitary towel comprises a surface layer, a uterus warming layer, an absorption layer and a leakage-proof bottom layer which are sequentially laminated from top to bottom, wherein the uterus warming layer comprises a sealing bag formed by hot pressing of two layers of polypropylene non-woven fabrics, and a heating composition and a plant extract microcapsule which are filled in the sealing bag, the plant extract microcapsule and the heating composition are separated by a PEbreathable film, the heating composition is pressed into a sheet shape and comprises the following raw materials in parts by weight: 60-80 parts of iron powder, 5-15 parts of activated carbon, 3-5 parts of potassium nitrate, 10-20 parts of water, 2-4 parts of vermiculite, 0.5-1.5 parts of sodium alginate, 1.5-3 parts of starch, 1-2 parts of polyvinylpyrrolidone and 0.4-0.8 part of sodium bicarbonate, and the plant extract microcapsule is prepared by taking a chitosan quaternary ammonium salt and sodium alginate as wall materials and taking a plant extract as a core material. The uterus warming sanitary towel solves the problems that sanitary towels in the prior art are relatively single in function and cannot meet various requirements of female users for sanitary towels.

Owner:泉州市嘉佰利卫生材料有限公司

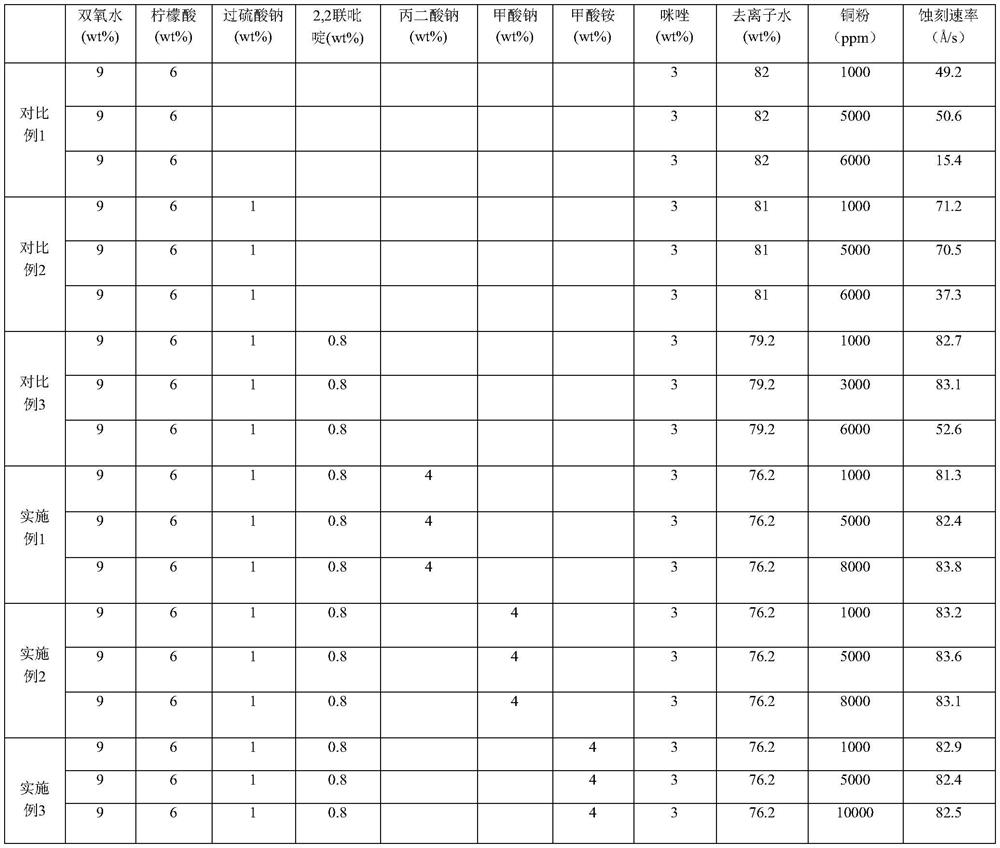

Copper etching solution with long etching life

The invention relates to a copper etching solution with high stability and long etching life. The etching solution is composed of hydrogen peroxide, organic acid, a secondary oxidant, chelating agentsand a pH regulator. In the etching solution, the synergistic effect of the hydrogen peroxide and the secondary oxidant overcomes the defects of low etching rate, too fast oxidant consumption, short etching life and the like; citric acid and other organic acid can promote the dissolution process of copper oxide in the etching solution, and meanwhile, the organic acid can also be used as a pH buffer agent to keep the pH of the etching solution changing in a small range and improve the stability; and a variety of chelating agents are combined for use, different coordination atoms are fully and quickly combined with divalent copper ions to generate a more stable metal chelate, the copper ions are prevented from promoting the decomposition of the hydrogen peroxide, and the service life of thecopper etching solution is prolonged. The copper etching solution provided by the invention can keep stable and uniform in a long etching time, the service life of the etching solution is prolonged, and the etching cost is reduced.

Owner:湖北兴福电子材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com