Preparation technology for improving emulsibility and emulsion stability of desugared egg white powder

A technology of emulsification stability and preparation technology, which is applied in the field of technological transformation of egg white powder functional properties processing, to achieve the effects of enhancing hydrophobicity, reducing interfacial free energy, and reducing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

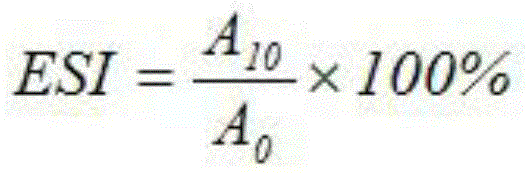

Image

Examples

Embodiment 1

[0029] A preparation process for improving the emulsification and emulsification stability of desugared egg white powder is characterized in that it is prepared according to the following steps:

[0030] (1) Pretreatment of egg white liquid: take commercially available fresh eggs, wash them, carefully crack the shell, separate the egg yolk and leave the egg white part, stir at room temperature for 1-2 hours, filter out the frenulum and impurities for later use;

[0031] (2) Pasteurization of egg liquid: the egg white liquid obtained in step (1) was heated in a water bath at 50° C. for 30 minutes and then rapidly cooled to room temperature;

[0032] (3) Yeast pretreatment: take commercially available Angel yeast, the mass is 0.2% of the total amount of egg white liquid, add water at 30-35°C, the amount of water added is 70%, and fully stir until the yeast is completely dissolved;

[0033] (4) Egg liquid desugar treatment: heat up the egg white liquid obtained in step (2) to 25°...

Embodiment 2

[0040] (1) Pretreatment of egg white liquid: take commercially available fresh eggs, wash them, carefully crack the shell, separate the egg yolk and leave the egg white part, stir at room temperature for 1-2 hours, filter out the frenulum and impurities for later use;

[0041] (2) Pasteurization of egg liquid: the egg white liquid obtained in step (1) was heated in a water bath at 50° C. for 30 minutes and then rapidly cooled to room temperature;

[0042] (3) Yeast pretreatment: take commercially available Angel yeast, the mass is 0.4% of the total amount of egg white liquid, add water at 30-35°C, the amount of water added is 80%, and fully stir until the yeast is completely dissolved;

[0043] (4) Egg liquid desugar treatment: heat the egg white liquid obtained in step (2) to 28°C, add the yeast solution obtained in step (3) to the egg white liquid, keep the temperature at 28°C for 2 hours, Obtain sugar-free egg white liquid;

[0044] (5) adding soybean lecithin: adding comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com