Patents

Literature

306results about How to "Lower free energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

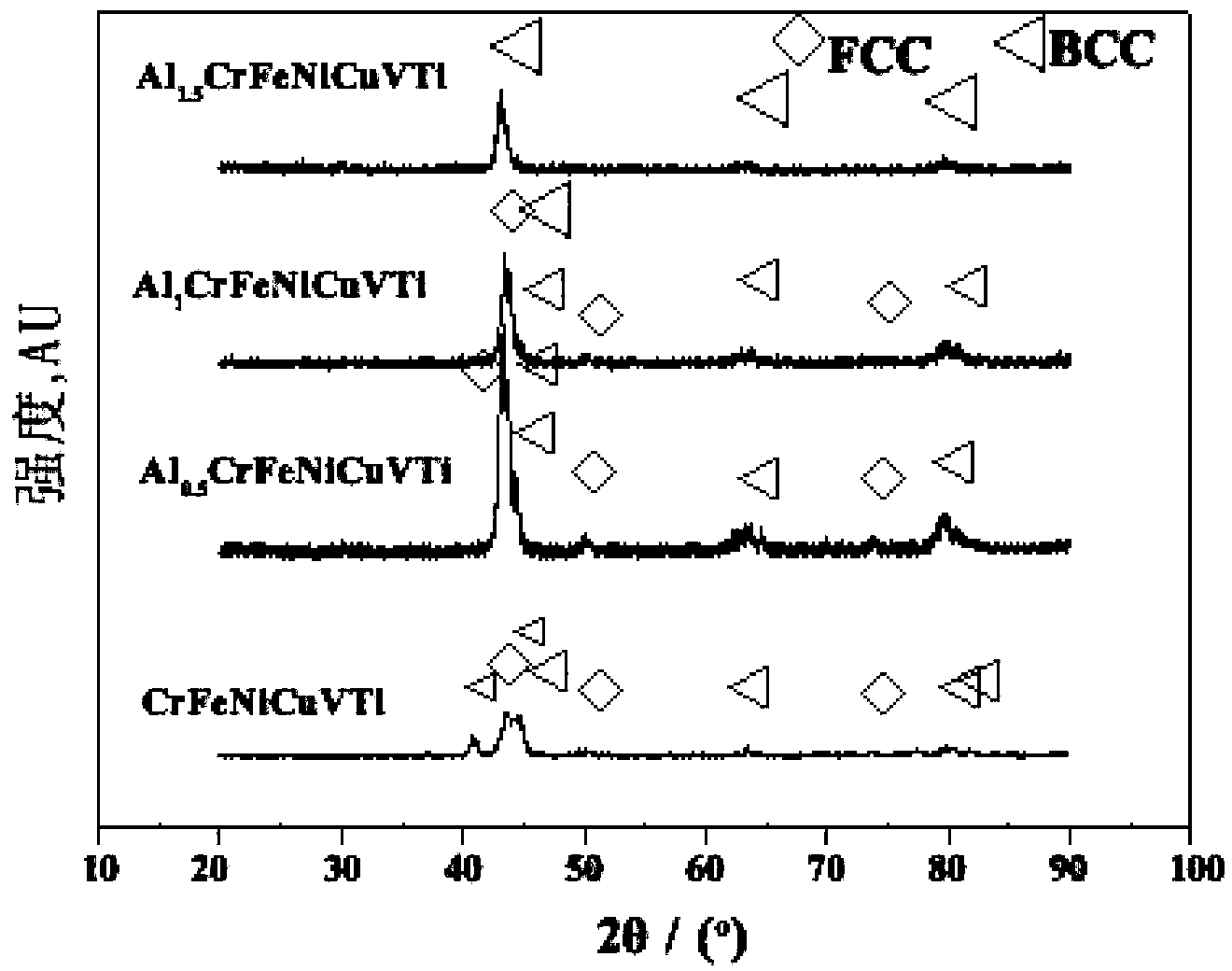

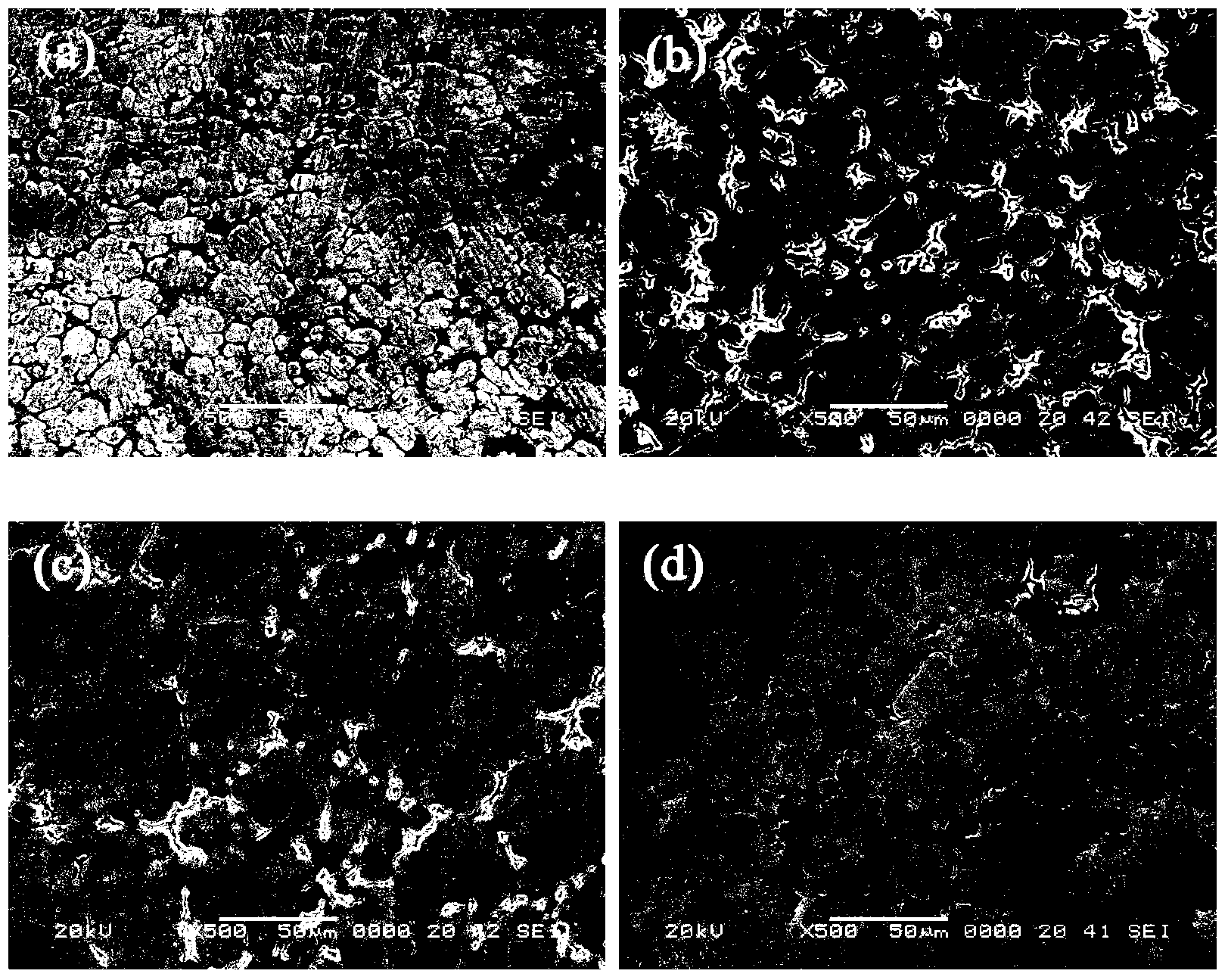

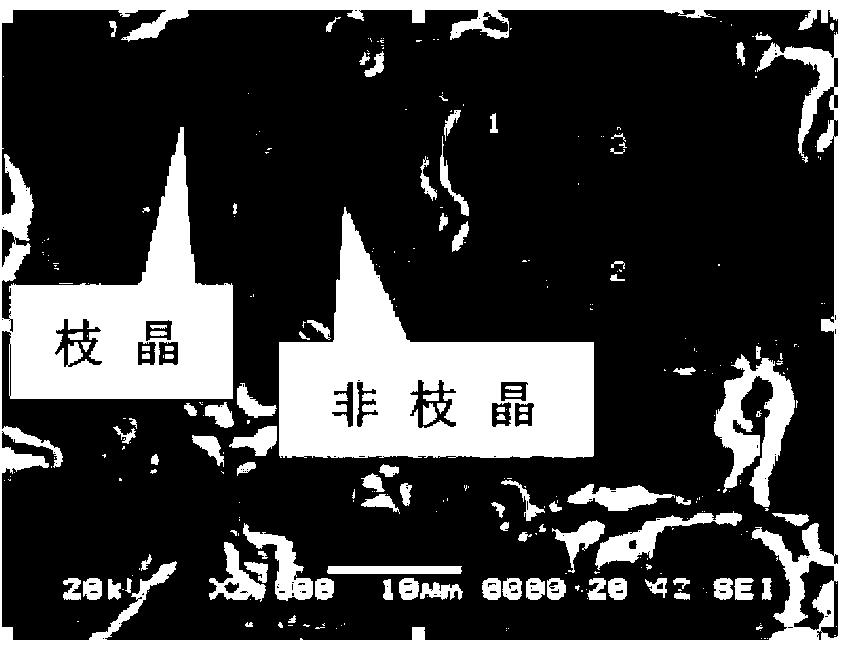

AlxCrFeNiCuVTi high-entropy alloy material and preparation method thereof

The invention relates to an AlxCrFeNiCuVTi high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlxCrFeNiCuVTi, wherein x is a molar ratio, and the value range of x is 0.5-1.5. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the AlxCrFeNiCuVTi high-entropy alloy material has higher hardness, strength, high temperature stability, corrosion resistance and work hardening capacity.

Owner:梧州漓佳铜棒有限公司

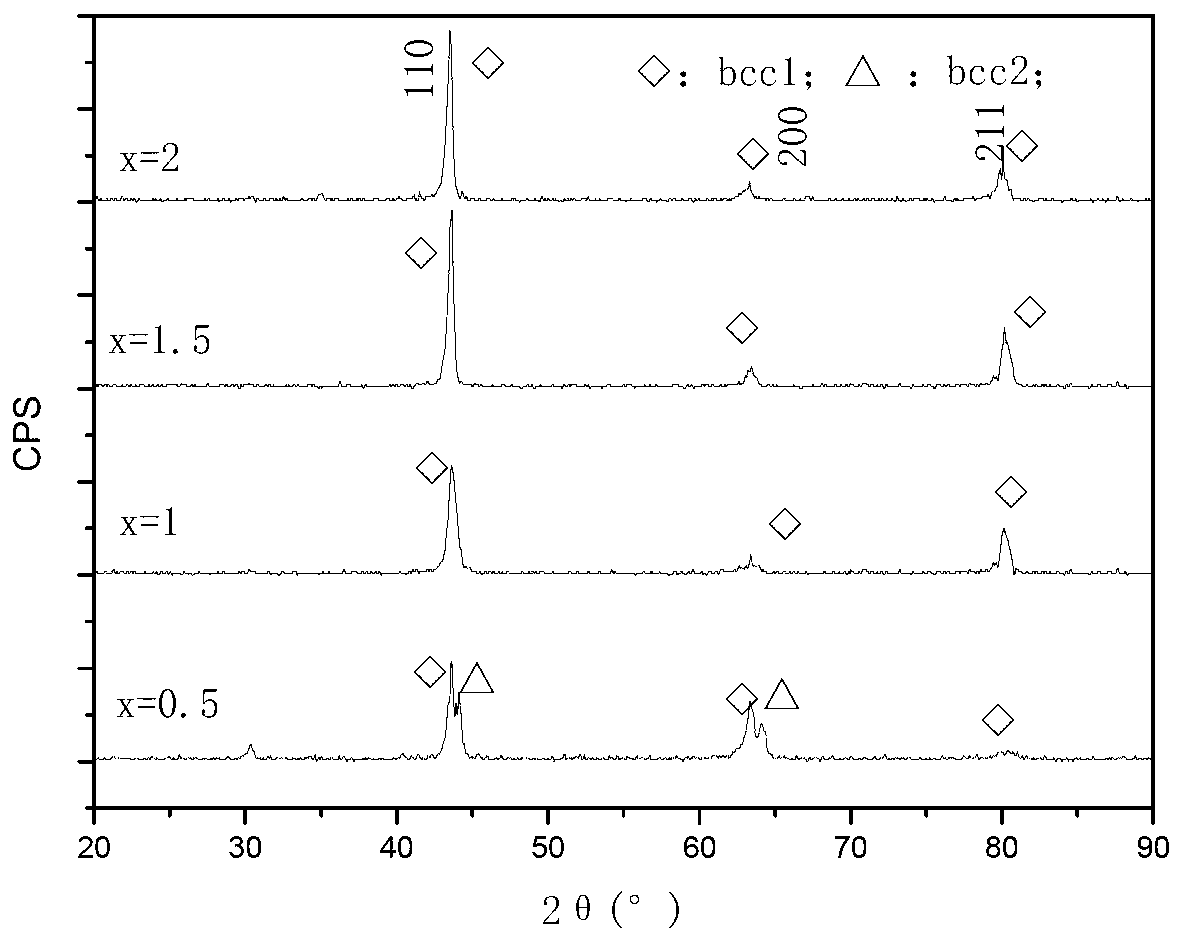

AlFeCoNiCrTiVx high-entropy alloy material and preparation method thereof

The invention relates to an AlFeCoNiCrTiVx high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlFeCoNiCrTiVx, wherein the value range of x is 0.5-2. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the high-entropy alloy material has very good strength, tenacity, elasticity, high-temperature performance and electrochemical performance.

Owner:梧州漓佳铜棒有限公司

No-cleaning leadless solder and preparation method thereof

InactiveCN101391350AAffect physical propertiesImprove liquidityWelding/cutting media/materialsSoldering mediaBenzyl benzoatActive agent

The invention relates to a no-clean lead-free tin welding wire and a preparation method thereof, wherein the lead-free welding wire is composed of 2 to 3 percent of flux and 97 to 98 percent of lead-free solder. The lead-free solder is composed of 0.5 to 0.7 percent of Cu, 0.03 to 0.05 percent of Ni, 0.01 to 0.02 percent of P, 0.005 to 0.01 percent of Ga and the remnant amount of Sn. The No-clean flux is composed of 1.0 to 4.0 percent of organic acid active agent, 0.5 to 5.0 percent of halogenated derivative active solvent, 2.0 to 5.0 percent of heat-resistant resin , 1.0 to 4.0 percent of cosolvent, 2.0 to 5.0 percent of high boiling point solvent and the remnant amount of modified rosin. The cosolvent belongs to ester compound and the high boiling point solvent is the mixed solvent of one or more of the SAF-25, dioctyl sebacate, benzyl benzoate, dioctyl adipate. In the preparation of the welding wire, the key point is first to form the alloys of Sn with other metals, and then the alloys can be added to the tin for melting. The lead-free welding wire of the invention has good heat resistance without halogen, low flux spattering, low odor, non-corrosive flux residue, strong practical feature, good electrical insulation after being welded, crack-free flux residue and high reliability.

Owner:太仓市首创锡业有限公司

Method for preparing iron-free aluminium sulfate and superfine active carbon white utilizing aluminium first-class ore

InactiveCN1850607AConcentration easyDo not reduce the concentrationSilicaAluminium sulfatesSurface-active agentsActive particles

The invention discloses a method for preparing iron-free aluminum sulfate and superfine active white carbon black with bauxite, crushing the bauxite and removing dissociative iron source by magnetic separation, and then reacting with vitriol; adding in dithiocarbamate with medium and high molecular weights and multiple functionalities to remove iron ions by solid phase reaction, and filtering, where the filtrate is iron-free aluminum sulfate; washing filter residue with alkaline water solution, surface active agent water solution, and tap water, respectively, to neutralize it, then after reacting with alkali, filtering, making filtrate, inorganic acid and active particles react mutually, filtering, water-washing, and drying to obtain the superfine active white carbon black. And the method has simple process, and low cost, applied to industrialized production, where the iron content of the prepared aluminum sulfate is less than 15 ppm, and the grain size, specific surface area, tensile strength, added value of the superfine white carbon black are 0.5-5 mum, greater than 200 m2 / g, higher than 17.0 MPa, and high, respectively.

Owner:杭州百事特实业股份有限公司

Method for connecting ceramic and metal

The invention discloses a method for connecting ceramic and ceramic, and ceramic and metal. The method comprises the following steps of: 1) forming a compact aluminum or aluminum alloy thin film with thickness of several to tens of microns on a connecting surface of the ceramic to obtain the ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film; and 2) connectingthe ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film and the metal by using the aluminum or aluminum alloy thin film, or connecting the ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film and the ceramic with the connecting surface covered by the aluminum or aluminum alloy thin film by using the aluminum or aluminum alloy thin film. Compared with the prior art, the method has the advantages that: oxide inclusion originated from an aluminum surface oxide film is not formed on the interface between the aluminum film and the ceramic, which is formed by the method, the ceramic is firmly connected with the ceramic or the metal and the ceramic and the metal do not fall off easily, and the separating and peeling strength between the thin film and a ceramic chessboard is greater than or equal to 4.1N / cm. After an aluminum brazing process or an aluminum or aluminum alloy workpiece connection are adopted, defects of the connecting interface of the aluminum or aluminum alloy workpiece and the ceramic are avoided, the 90-degree tear strength of the connection can reach over 12kg / cm, fracture does not occur on the interface, and the ceramic and metal are connected very firmly.

Owner:TSINGHUA UNIV

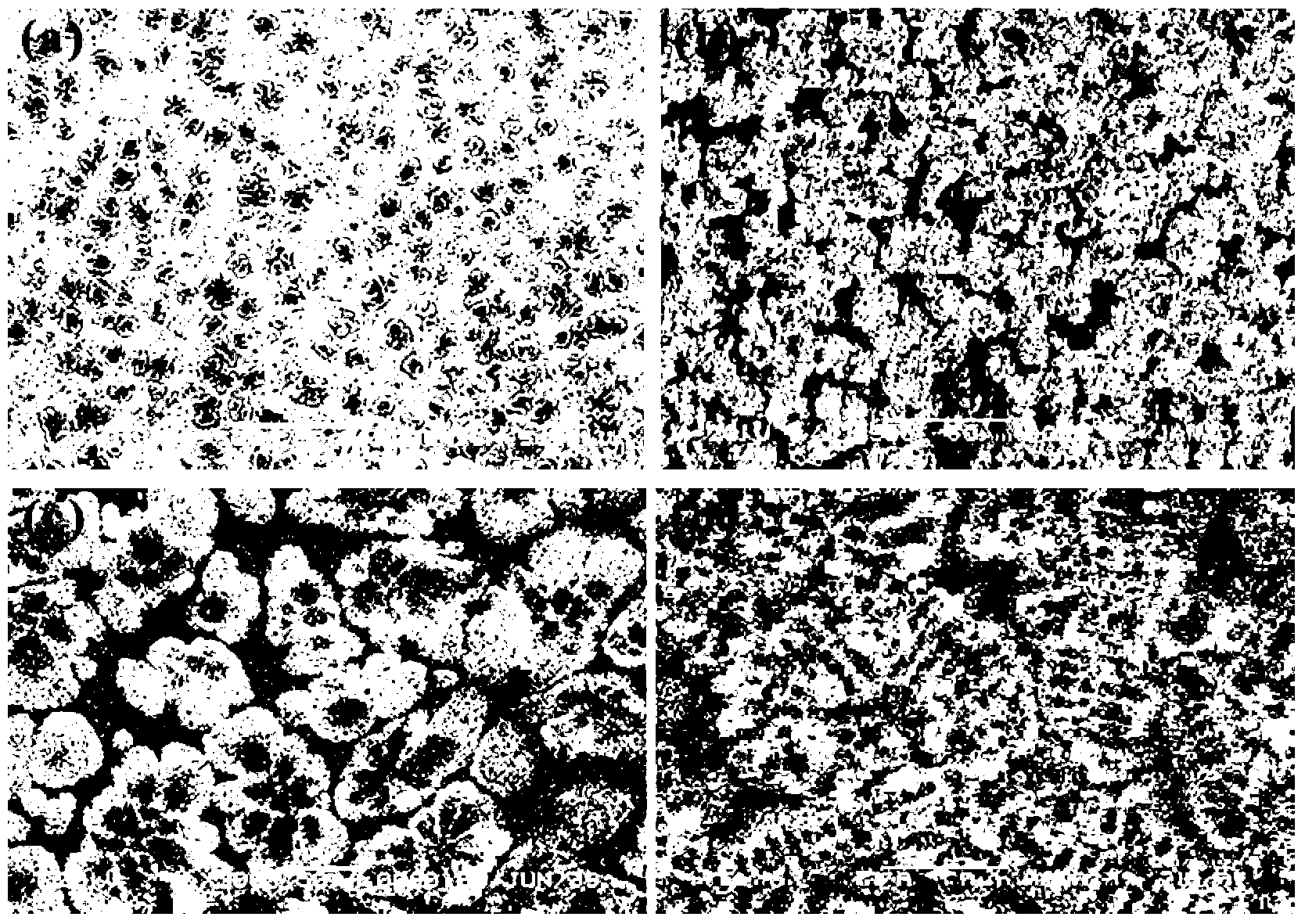

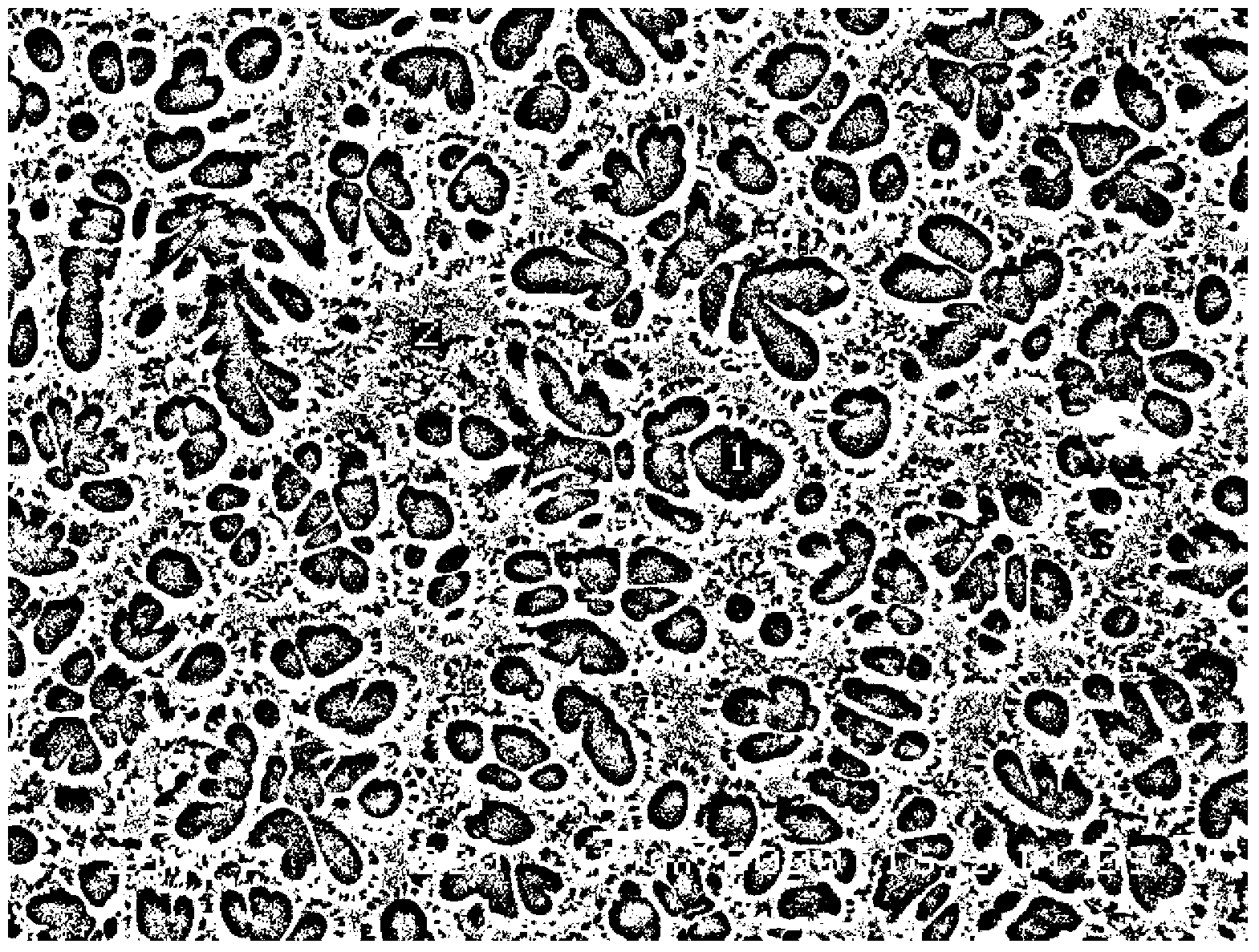

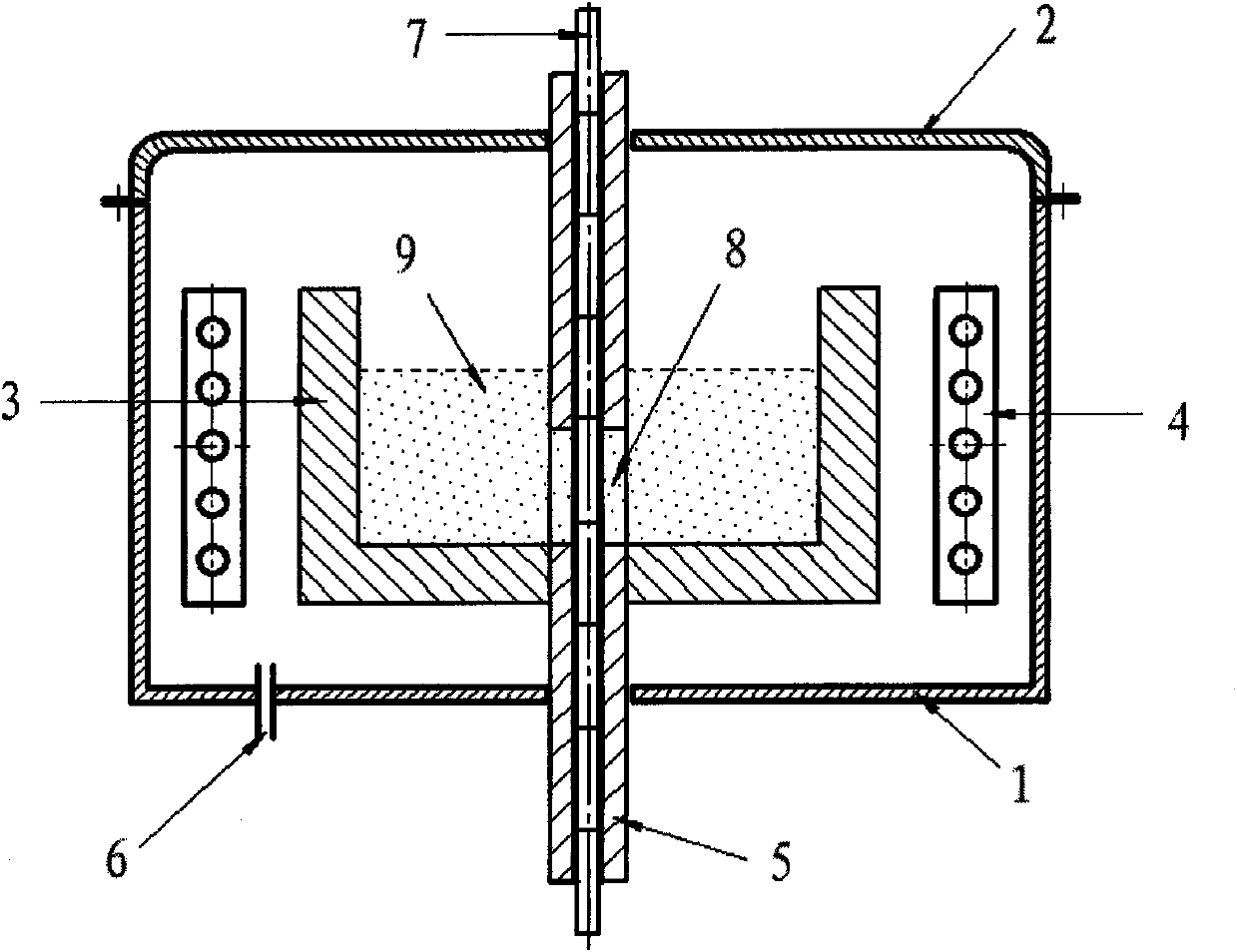

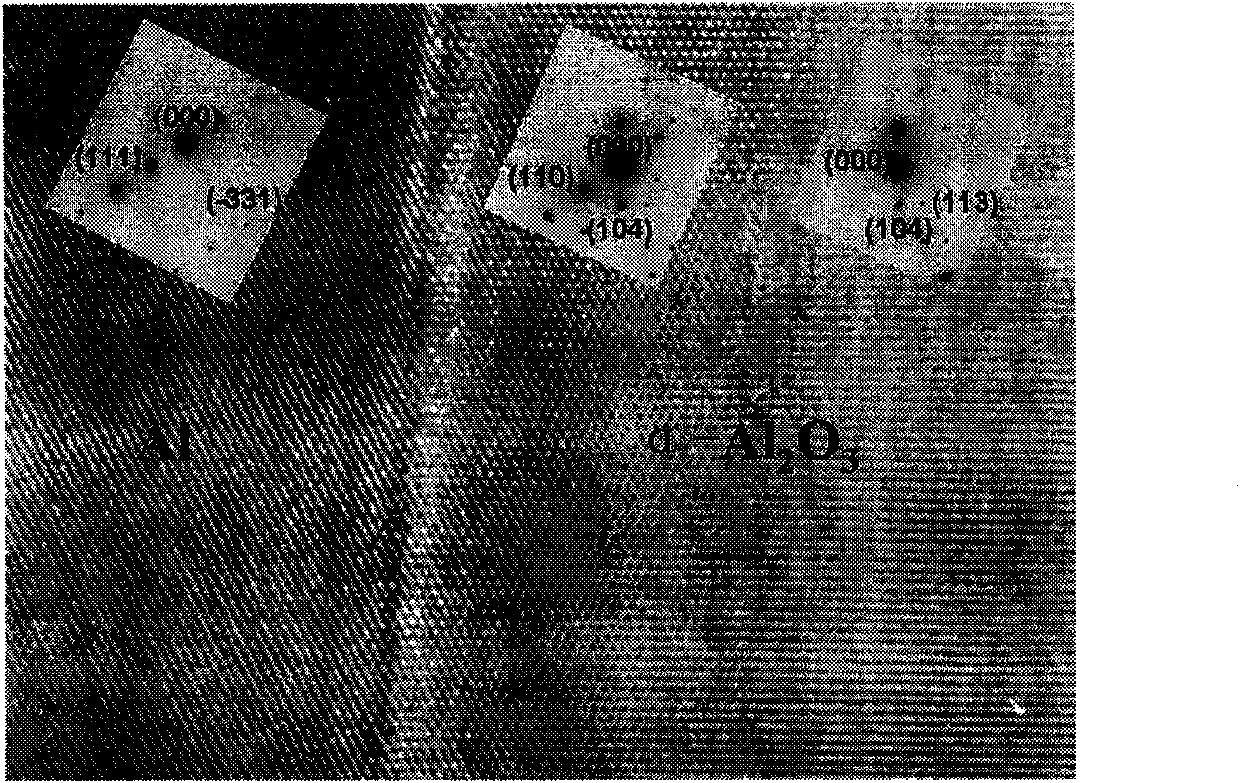

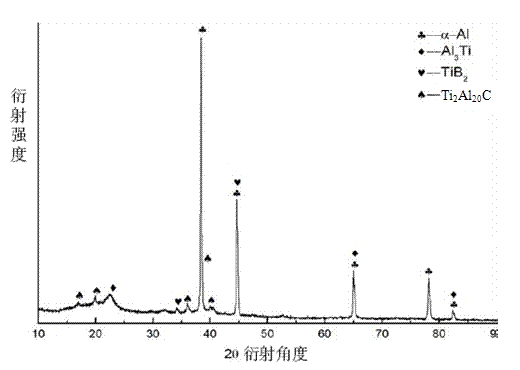

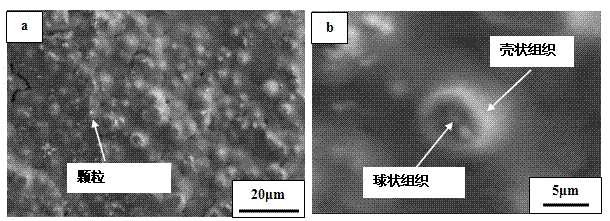

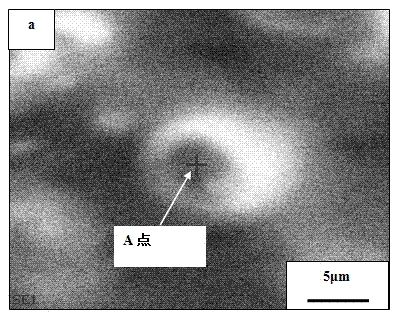

Preparation method of superfine crystal inoculating agent for aluminum alloy grain refinement

The invention provides a preparation method of a superfine crystal inoculating agent for aluminum alloy grain refinement and relates to aluminum-based alloy and is a method for preparing nano-crystalline Al-Ti-B-Re thin-strip intermediate alloy by a rapid solidification technology of metal, wherein the method comprises steps as follows: proportioning 5-5.4% of Ti, 1-1.04% of B, 1-1.2% of Ce, 0.05-0.2% of La and the balance of Al according to determined ingredients; weighing raw materials Al-5Ti-1B intermediate alloy and lanthanum cerium alloy to proportion the materials; melting in vacuum to obtain blocky Al-5Ti-1B-1Re intermediate alloy; carrying out rapid solidification to obtain the superfine crystal inoculating agent for the aluminum alloy grain refinement, wherein the superfine crystal inoculating agent is the nano-crystalline Al-5Ti-1B-1Re intermediate alloy. With the adoption of the method provided by the invention, adverse impact of needlelike TiAl3 on the matrix structure is eliminated, nucleating particles TiAl3 with thinner size and more dispersed distribution are obtained, and superfine nucleating particles are realized.

Owner:HEBEI UNIV OF TECH

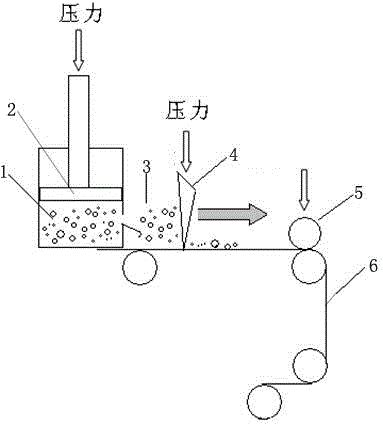

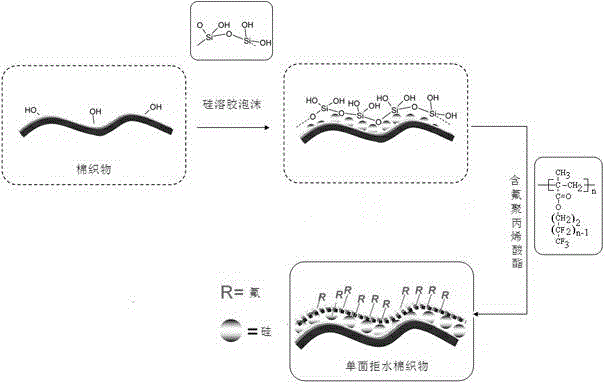

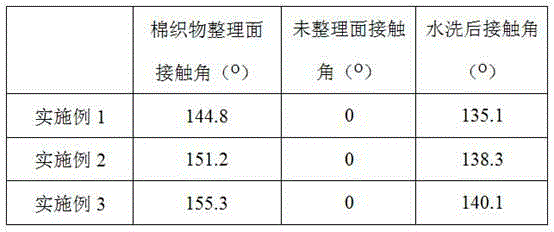

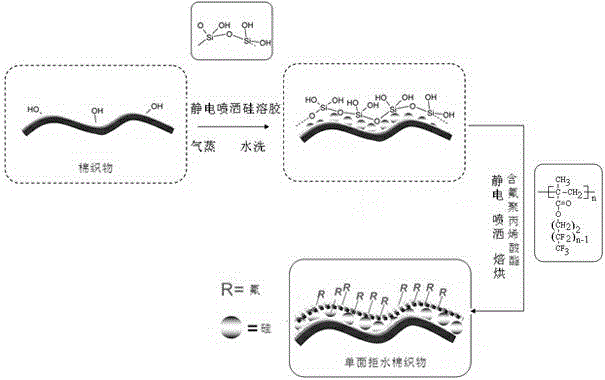

Arranging method of single-faced super-hydrophobic cotton fabrics

ActiveCN104878592AReduce liquid volumeReduce the liquid carrying rateVegetal fibresFree energiesALLYL SUCROSE

The invention discloses an arranging method of single-faced super-hydrophobic cotton fabrics. The method comprises the steps of preparing a silica sol foam finishing agent and an aqueous fluorine-containing polyacrylic acid water-repellency foam finishing agent, sequentially and uniformly scrapping and coating the silica sol foam finishing agent and the aqueous fluorine-containing polyacrylic acid water-repellency foam finishing agent on the surfaces of the fabrics, keeping a low liquid carrying ratio, controlling the finishing agent on the single faces of the cotton fabrics only without permeation, and then carrying out gas steam-roasting-washing, and forming coatings on one surfaces of the cotton fabrics so that the single faces of the fabrics are roughened, the surface free energy of the cotton fabrics can be greatly reduced and the single face super-hydrophobicity can be endowed to the cotton fabrics. The arranging method of the single-faced super-hydrophobic cotton fabrics is practical, environmental-friendly and efficient because the cotton fabrics still have better hydrophobic effects after washing for multiple times; furthermore, the arranging method is convenient to operate, low in water consumption, simple in process and low in energy consumption; in addition, the liquid carrying ratio of the cotton fabrics is very low so that the arranging method is applicable to the single face water-repellency of uneven thick cotton fabrics, and the single-faced super-hydrophobic cotton fabrics can be prepared to meet the specific requirements on functionality and comfort by people, therefore the arranging method has a good application prospect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

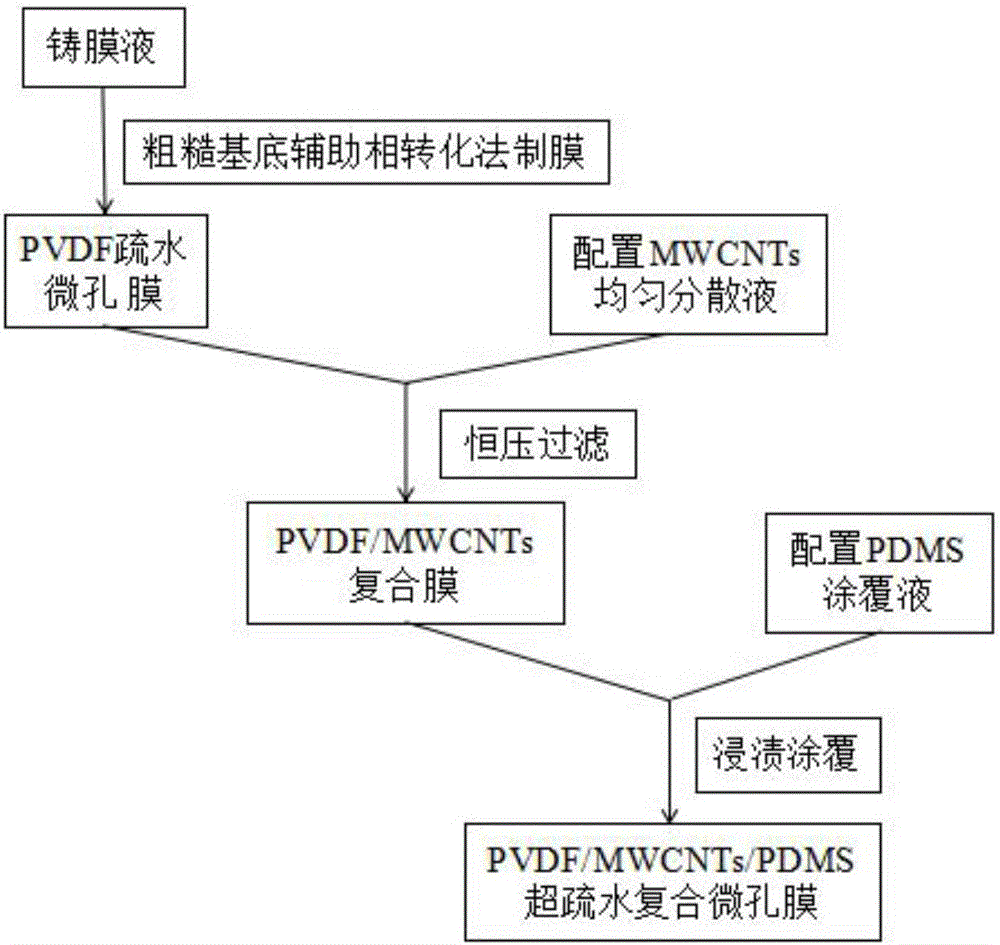

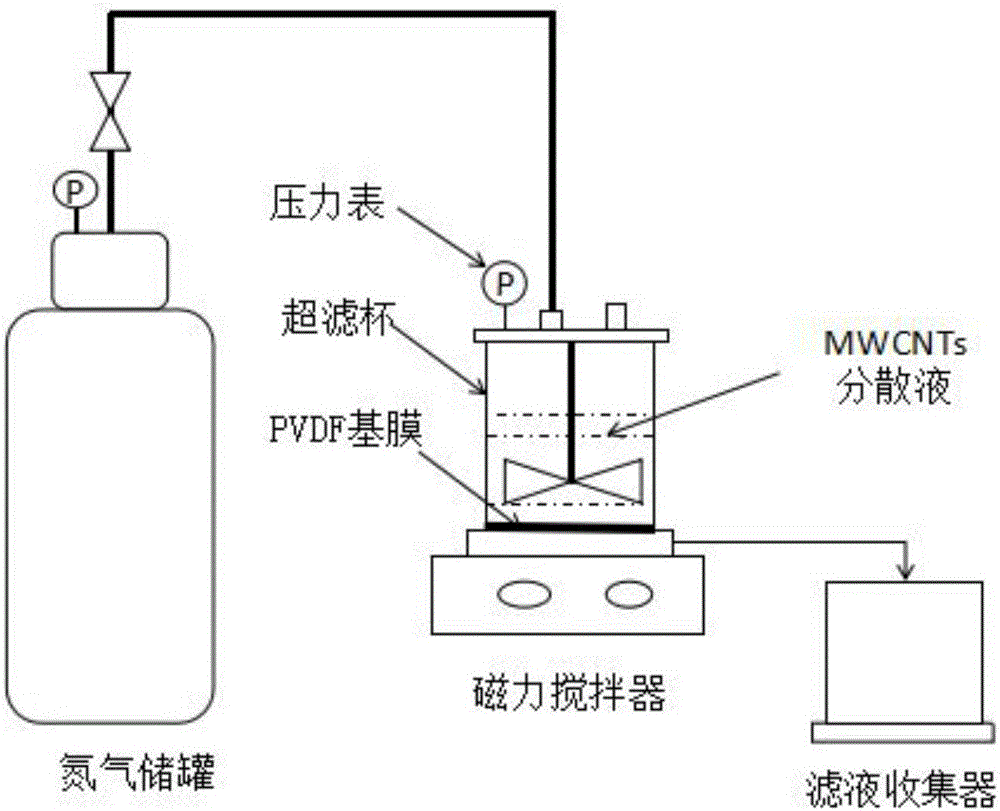

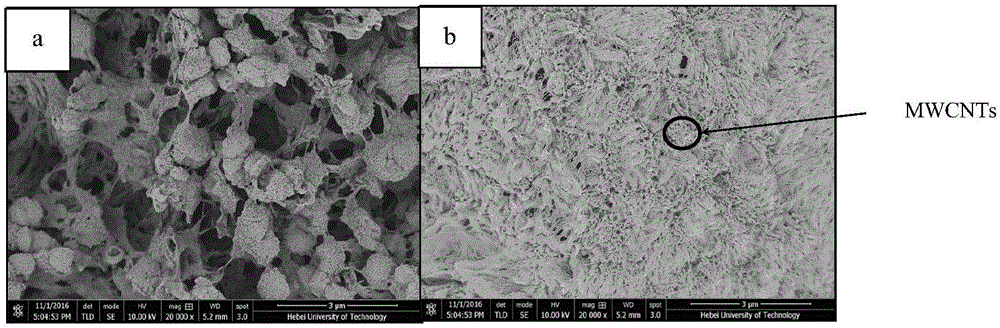

Method for preparing superhydrophobic composite microporous membrane

ActiveCN106582332ASuperhydrophobicLower free energySemi-permeable membranesPolyvinylidene fluorideChemistry

The invention relates to a method for preparing a superhydrophobic composite microporous membrane. The method comprises the following steps: firstly, preparing a polyvinylidene fluoride (PVDF) high-hydrophobic microporous membrane as a basal membrane by a coarse substrate assisted phase inversion method, then, preparing a multi-walled carbon nanotube (MWCNTs) uniform dispersion solution, filtering the MWCNTs dispersion solution with the prepared PVDF basal membrane at constant pressure by adopting a constant-pressure filtering method so as to prepare a PVDF / MWCNTs composite membrane, and carrying out coating with an n-hexane solution of polydimethylsiloxane (PDMS), thereby preparing the PVDF / MWCNTs / PDMS superhydrophobic composite microporous membrane. According to the composite microporous membrane obtained by the method, the static water contact angle can reach 162 degrees, the angle of roll is 10 to 20 degrees, the nitrogen gas flux at the pressure of 100kPa is greater than 0.3m<3> / (m<2>.s), the tensile strength is higher than 2.6MPa, and the elongation at break is higher than 96%, so that the superhydrophobic composite microporous membrane can be applied to membrane contact procedures such as membrane distillation and membrane absorption.

Owner:HEBEI UNIV OF TECH

Modified soyabean protein adhesive and preparation method thereof

InactiveCN103013436ALower free energyImprove hydrophobicityNon-macromolecular adhesive additivesProtein adhesivesIce waterAdhesive

The invention provides a modified soyabean protein adhesive and a preparation method thereof. The adhesive comprises the following components in percentage by weight: 5 to 10 percent of soy isolation protein, 5 to 14 percent of soy protein modification agent, 0.1 to 5 percent of plant nano cellulose and the balance of water. The preparation method comprises the steps of preparing 5 to 30 percent of microcrystalline cellulose water suspension; putting the microcrystalline cellulose water suspension into an ice water bath; inserting a thermometer; dropping concentrated sulfuric acid until the sulfuric acid concentration is 50 percent; stirring at the temperature of 40 DEG C for reaction for 1.5 hours; centrifugating at the speed of 12,000 rpm for 10 minutes, repeating for 3 to 5 times, and performing ultrasonic for 0.5 hour to obtain the plant nano cellulose suspension; and adding the soy isolation protein, the soy protein modification agent and the plant nano cellulose into the water according to the weight percentage, stirring at the temperature of 50 DEG C for 1 hour, and performing ultrasonic for 0.5 hour to obtain the modified soyabean protein adhesive. The modified soyabean protein adhesive is high in adhering strength and high in water resistance.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

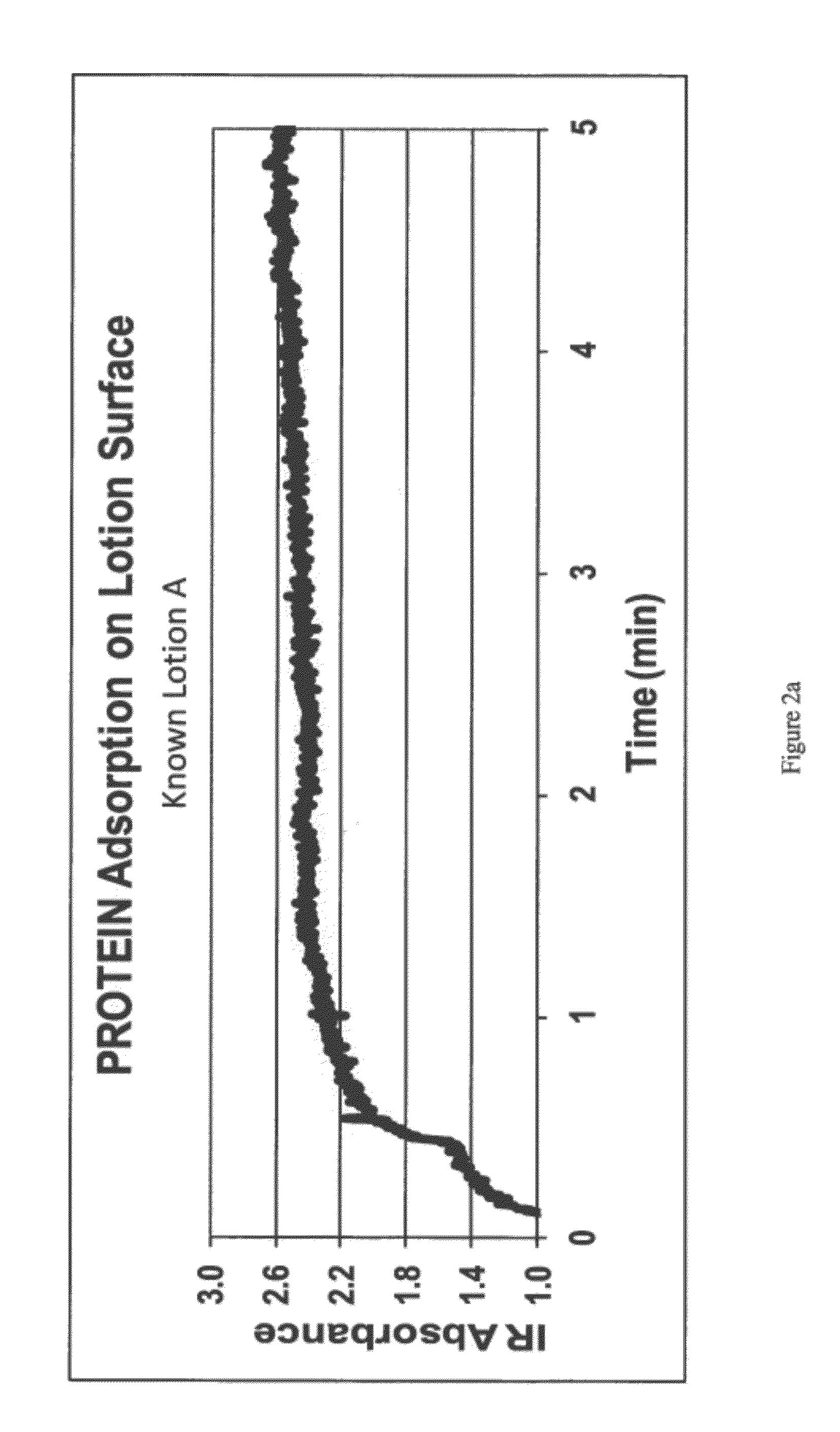

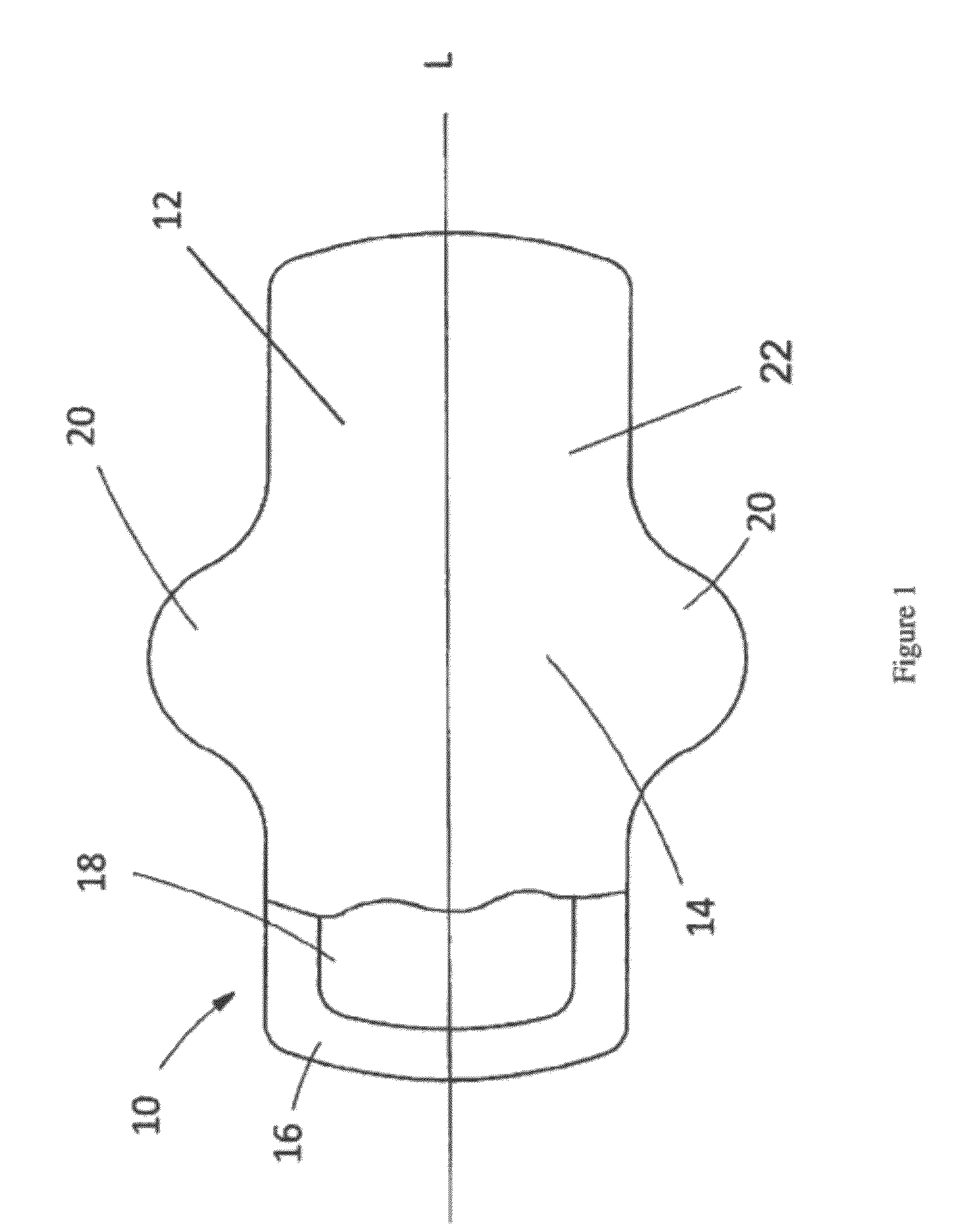

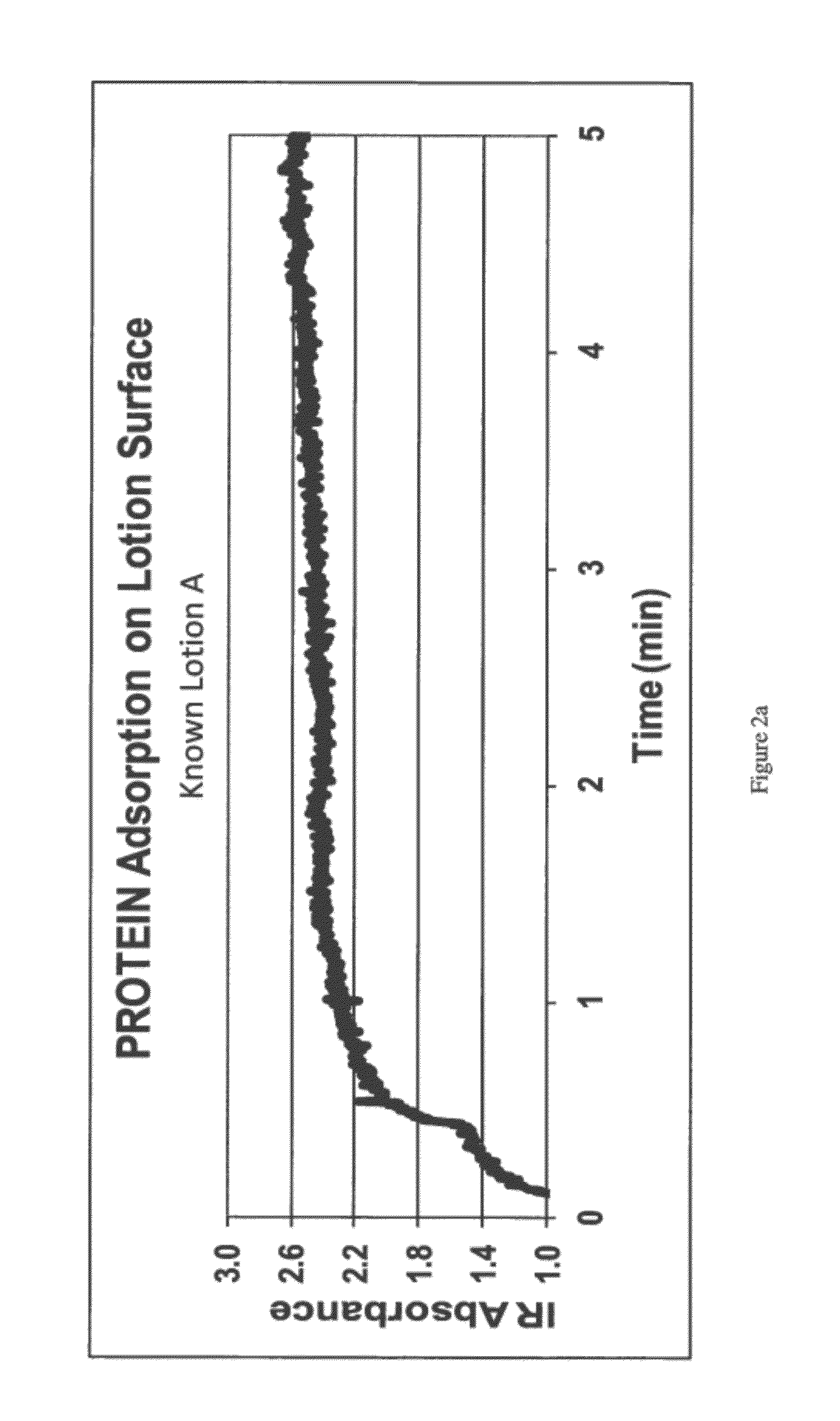

Absorbent Article with Philic Anhydrous Lotion

ActiveUS20120123365A1Superior fluid handling propertyEffectively coat surfaceAntibacterial agentsCosmetic preparationsMicrocrystalline waxLotion

A lotion composition is provided. The lotion composition can comprise a) about 0.1% to about 90%, by weight, of a microcrystalline wax; b) about 0.1% to about 25%, by weight, of POE-4 monolaurate; c) about 0.1% to about 50%, by weight, of POE-8 monostearate; and d) a carrier.

Owner:THE PROCTER & GAMBLE COMPANY

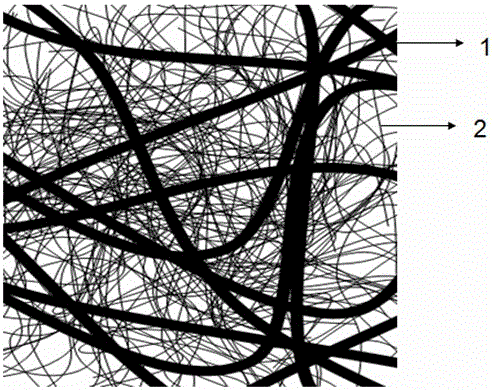

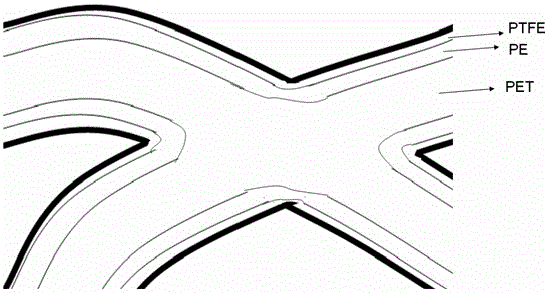

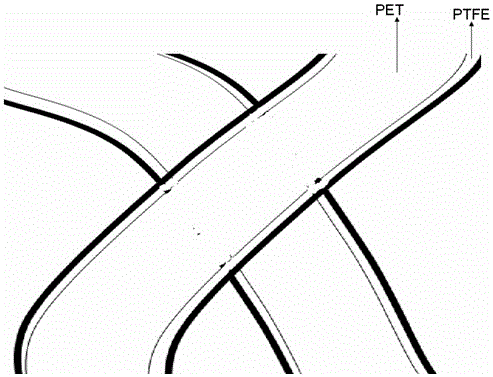

Electret non-woven filter material for air filtering

ActiveCN105771427AHigh strengthDimensionally stableFilament/thread formingHeating/cooling textile fabricsFiberPorosity

The invention discloses an electret non-woven filter material for air filtering.An evenly-distributed three-dimensional spatial network structure is formed by 0.06D PET superfine fibers and 30D PE / PET skin core complex fibers, linkage joints are formed by the skin core complex fibers and the fibers in contact with the skin core complex fibers, and PTFE coatings are arranged on the surfaces of the superfine fibers and the skin core complex fibers.A preparation method of the electret non-woven filter material comprises the steps that the PET / PET figured sea-island staple fibers and the PE / PET skin core complex short fibers are mixed according to a certain mass ratio and carded, and the electret non-woven filter material is formed through needling net forming, alkali liquor melting, roll compacting and washing, PTFE emulsion dipping, tentering heat shaping and cooling curing.The electret non-woven filter material has the advantages of being high in strength, stable in size and small in resistance.The filter material is high in porosity, small and even in aperture and good in breathability.The electron work function is high, the dielectric constant is small, and the static adsorption effect on PM2.5 dust is good.Super-hydrophobic performance is achieved, and the static adsorption function of the filter material cannot be weakened by damp air.

Owner:QINGDAO JINMEISHENG NON WOVEN CO LTD

Method for preparing white carbon black and manganese fertilizer from manganese leaching residue

The invention discloses a method for preparing white carbon black and manganese fertilizer from manganese leaching residue. The method comprises the following steps: 1, washing the manganese leaching residue with dilute sulphuric acid solution and running water in turn to obtain the residue; 2, conducting reaction between the residue and 25 to 40% strong base solution by mass at 90 to 120 DEG C for 2 to 5 h, and filtering to obtain filtrate; 3, decoloring the filtrate with active carbon and then carboxyl-terminated hyperbranched polyester at 100 to 120 DEG C to obtain the aqueous solution of silicate; 4, adding water and then inorganic acid and carboxyl-terminated hyperbranched polyester for reaction at 40 to 90 DEG C for 0.5 to 2 h to obtain the white carbon black; and 5, drying and dehydrating the residue obtained in step 2 and adding into a high-speed mixer, adding phosphoric acid, anticaking agent and manganese sulfate into the high-speed mixer, and mixing at room temperature for 10 to 20 min to obtain the manganese fertilizer. The method is simple in process and low in cost and is suitable for industrial production; and the silicon dioxide content of the prepared white carbonblack is more than 95% by mass, the specific area is more than 270 m<2> / g and the particle size is less than 50 nm.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Microwave-assisted aqueous two-phase extraction and separation method of kudzu root total flavones

The invention relates to a microwave-assisted aqueous two-phase extraction method for separating kudzu root total flavone, which comprises the following steps: 1) preparation of an aqueous two-phase system: taking an inorganic salt, adding water to dissolve the inorganic salt, and adding an organic solvent to obtain a aqueous two-phase extractant; and 2) microwave-assisted aqueous two-phase extraction: adding kudzu root powder into the aqueous two-phase extractant obtained in the step 1), carrying out microwave-assisted extraction, and carrying out vacuum filtration to obtain an obvious phase-separated kudzu root flavone extracting solution. Compared with the prior art, the method provided by the invention has the following advantages: (1) the method is simple to operate and does not need to wait for phase separation; 2) the process is integrated; 3) the extraction process is quick and efficient; 4) the extraction solvent is low in toxicity; 5) the interfacial tension is small, thereby being beneficial to mass transfer between the two phases; 6) abundant impurities can be removed along with solid matters, thereby being beneficial to purifying the sample; and 7) the extraction method does not have obvious scale-up effect, can easily implement technique amplification and continuous operation, and can be directly connected with the subsequent purification procedure without special treatment.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

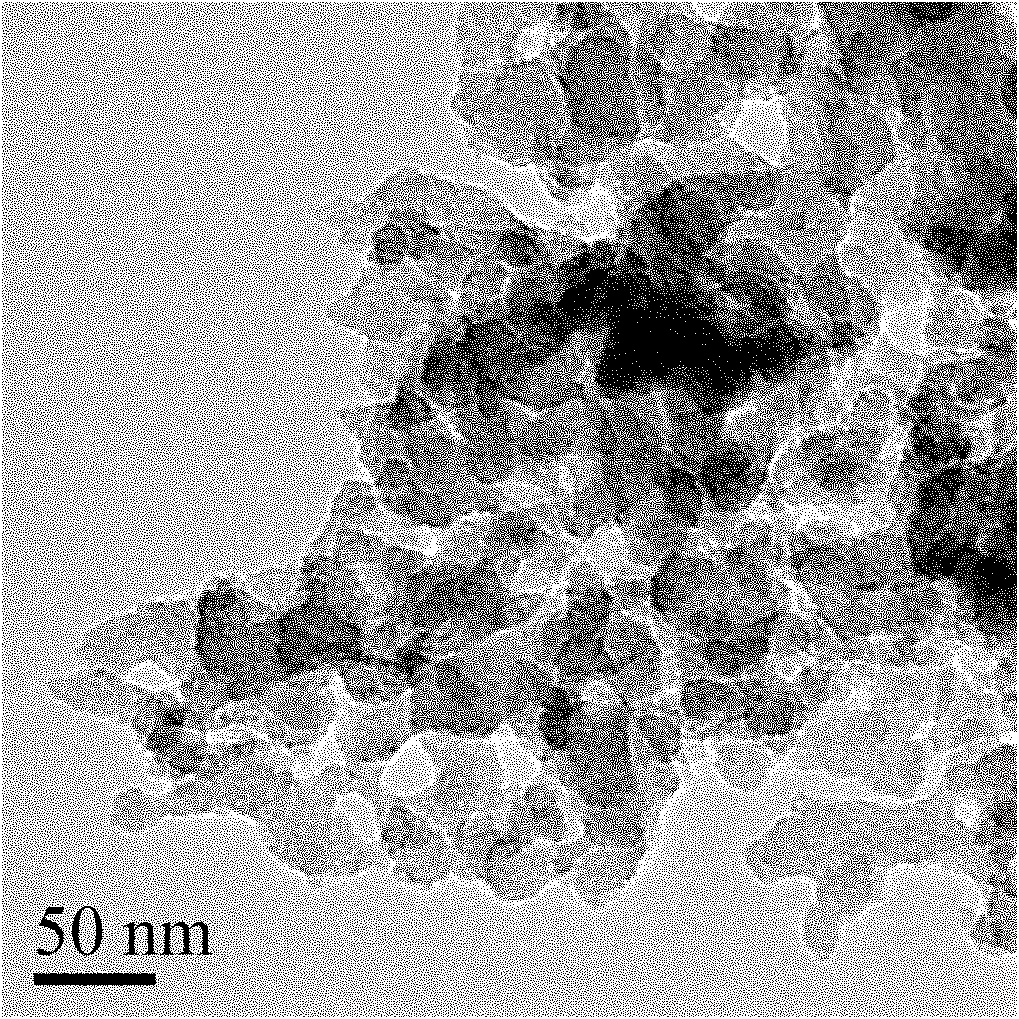

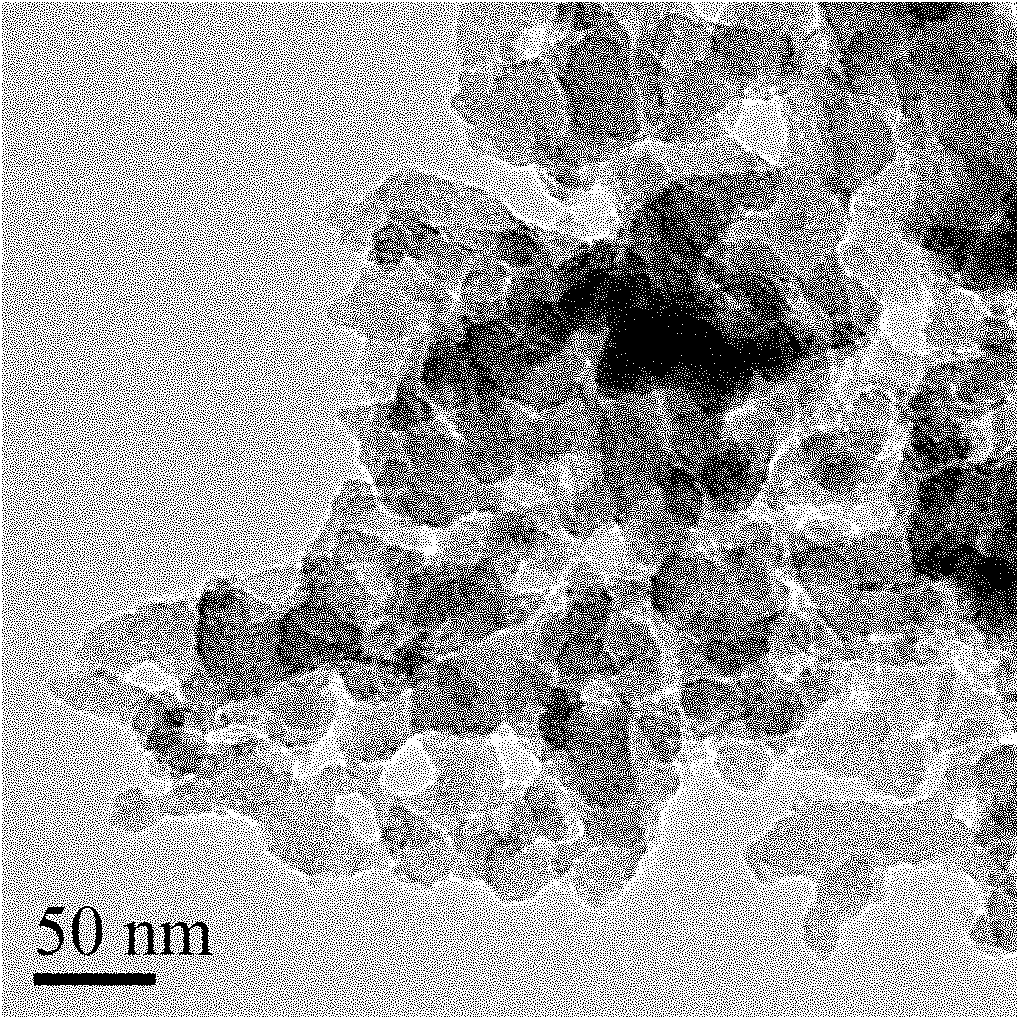

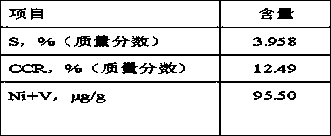

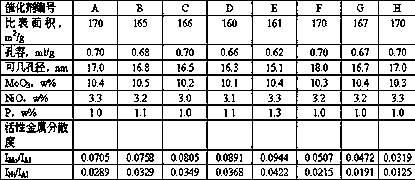

Residue oil hydrogenation catalyst and preparation method thereof

ActiveCN109833890AReduce polarityLower free energyCatalyst activation/preparationHydrocarbon oil crackingOrganic solventHigh activity

The invention discloses a residue oil hydrogenation catalyst and a preparation method thereof, wherein the preparation method comprises: (1) carrying out spray impregnating on a residue oil hydrodemetallization catalyst carrier with an organic solvent containing a Span surfactant, and drying; and (2) impregnating the dried carrier with an active metal solution containing polyacrylate radicals, drying, and calcining to obtain the catalyst. According to the present invention, the residue oil hydrogenation catalyst prepared by the method has advantages of high metal utilization rate, high metal dispersion degree, high activity and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for nano composite porous netty superhydrophobic textile

InactiveCN107513863AExcellent superhydrophobic propertiesLower free energyLiquid repellent fibresVegetal fibresNanoparticleSolvent

The invention relates to a preparation method for a nano composite porous netty superhydrophobic textile; with adopting of a sol-gel method, a three-dimensional porous SiO2 aerogel is prepared through acid-base two-step catalysis, aging, solvent replacement and atmospheric drying; the SiO2 aerogel is mixed with polysiloxane to prepare a polysiloxane / SiO2 aerogel nanocomposite material; a textile is finished with the polysiloxane / SiO2 aerogel nanocomposite material by a one-step method; through cooperation of the characteristic of low surface energy of polysiloxane and a three-dimensional network nanoporous micro rough structure of the SiO2 aerogel, and combination of the crosslinked adhesion effect between polysiloxane and aerogel particles and the crosslinked adhesion effect between the aerogel particles and the textile, the durable nano composite porous netty superhydrophobic textile is obtained. The preparation method is different from a method for constructing a superhydrophobic textile through close packed arraying structure of nanoparticles, the preparation process is simple, the superhydrophobic property is excellent, stable and durable, and the product is suitable for mass production.

Owner:SHANGHAI UNIV OF ENG SCI

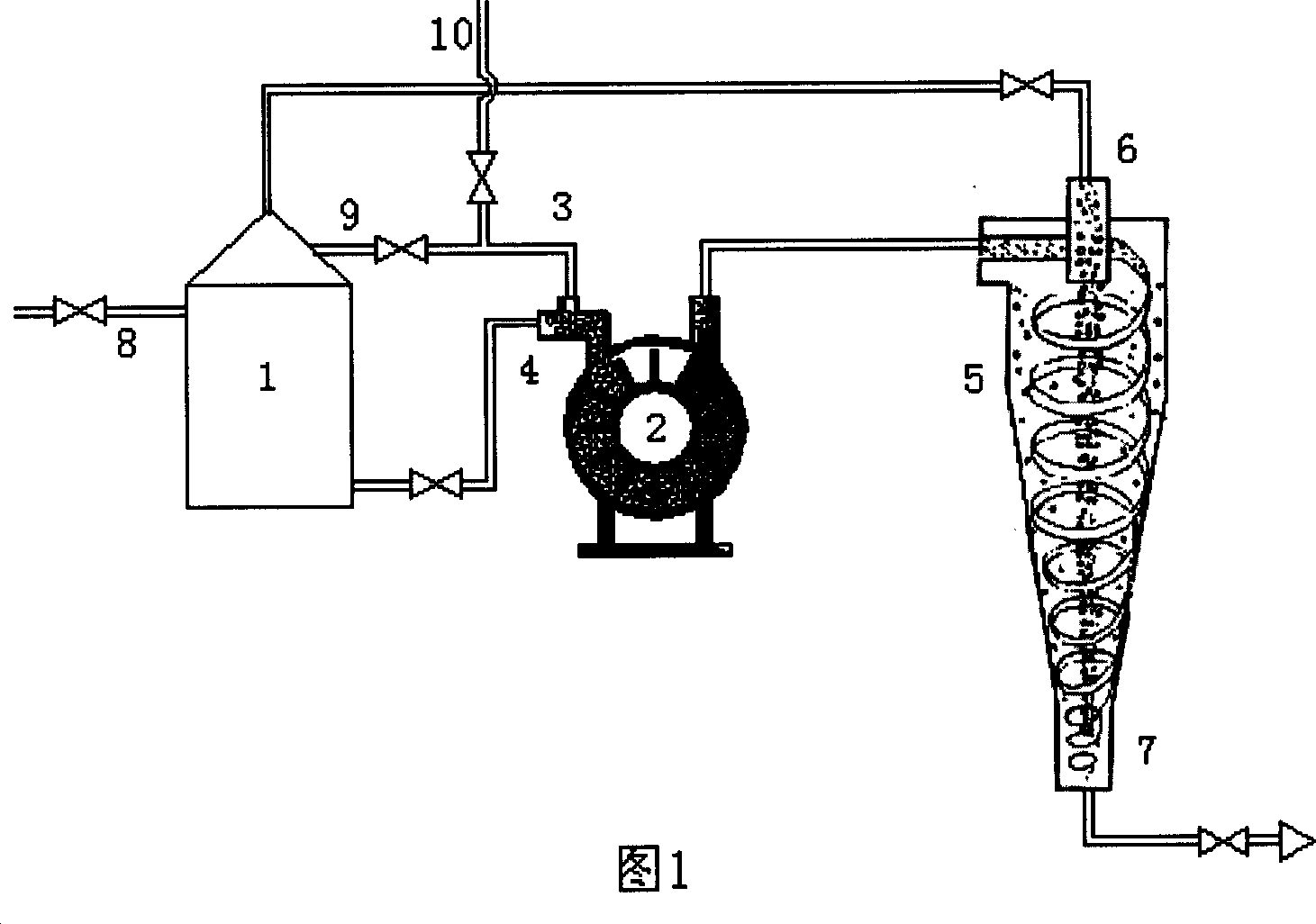

Oil-containing sewage floatation cyclone coupling separation method

InactiveCN1470461ALower free energyIncrease density differenceWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesCycloneSewage

The present invention discloses a floatation cyclone couping separation method of oil-containing sewage, and is characterized by that because of the special stirring function of the vortex pump, the vortex pump suck oil-containing sewage while sucking air, and the sewage and air are stirred and mixed, the pressure is increased to the greater than or equal to 0.20 MPa, then pumped into the oil-removing cyclone with special structure. Because pressure is suddenly reduced, lots of microfine air bublbes are quickly released out, and the air bubbles and microsmall oil drops can be automatically adhered together under the action of interfacial tension in the cyclone centrifugal force field, because the density of oil drop and air bubble adhered body is greatly less than that of oil phase, so that the small oil drops can be separated out by adopting floatation cyclone combined equipment, and its cleaning rate can be up to above 99%.

Owner:EAST CHINA UNIV OF SCI & TECH

Antifoaming agent for flue gas desulphurization system and preparing method thereof

InactiveCN106334349AIncrease surface tensionLower free energyDispersed particle separationFoam dispersion/preventionEmulsionFlue gas

The invention discloses an antifoaming agent for a flue gas desulphurization system. The antifoaming agent is prepared from, by mass, 30%-60% of antifoaming components, 10%-20% of foam inhibition components, 5%-10% of an emulsion stabilizer, 5%-10% of a synergist and the balance deionized water. The antifoaming agent is suitable for a thermal-power-plant limestone-gypsum wet flue gas desulfurization system adapting to high chlorine, fluorion and solid-content slurry liquid and aeration, and has the advantages of being good in antifoaming effect and long in foam inhibition time; the foaming characteristic of desulfuration slurry liquid can be improved, the stability of a slurry-liquid oxidation zone is effectively controlled, the foam content of the slurry liquid is reduced, losses of the slurry liquid of a circulating pump are reduced, the circulation amount of the slurry liquid is increased, and it is avoided that foam overflows to a pipe zone, the slurry liquid is deposited in a pipe, and scale formation corrosion is caused.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Polyvinylalcohol composite film, preparation method thereof and method of preparing nano composite powder for preparing the polyvinylalcohol composite film

InactiveCN101016397AImprove mechanical propertiesIncrease production capacityComposite filmPolyvinyl alcohol

The invention discloses a preparing method of polyvinyl alcohol coextruded film and nanometer composite powder body for preparing coextruded film, which comprises the following steps: resolving defect of current adding amidon; allocating 120-180 wt polyvinyl alcohol, 30-90 wt amidon, 2.0-2.2 wt nanometer ZnO / SiO2 composite powder and 85-95 wt glycerin; mixing polyvinyl alcohol, amidon, nanometer ZnO / SiO2 composite powder and glycerin; cooling; melting; squeezing thin film; getting the thin film; adding polyacrylic acid, poly-sodium acrylate or triethanolamine, wetting agent-436, defoaming agent-50A and nanometer ZnO into distilled water; emulsifying; pre-dispersing; dipping into Na2SiO3 and sulfuric acid; aging; depositing; drying; grinding; getting the nanometer ZnO / SiO2. The tensile strength of thin film can reach at 17.5-30.48MPa and elongation at break at 406.25%-462.50%.

Owner:HARBIN INST OF TECH

Absorbent Article with Lotion

ActiveUS20120089110A1Superior fluid handling propertyEffectively coat surfaceAntibacterial agentsBiocidePolymer scienceDimethyl siloxane

An absorbent article, such as a catamenial device, having a liquid pervious topsheet, a backsheet joined to the topsheet, and an absorbent core disposed between the topsheet and the backsheet is disclosed. The absorbent article has a lotion composition applied to at least a portion of the outer surface of the topsheet, the lotion composition including a rheology structurant selected from the group consisting of microcrystalline wax, alkyl dimethicone, ethylene glycol dibehenate, ethylene glycol distearate, glycerol tribehenate, glycerol tristearate, and ethylene bisoleamide.

Owner:THE PROCTER & GAMBLE COMPANY

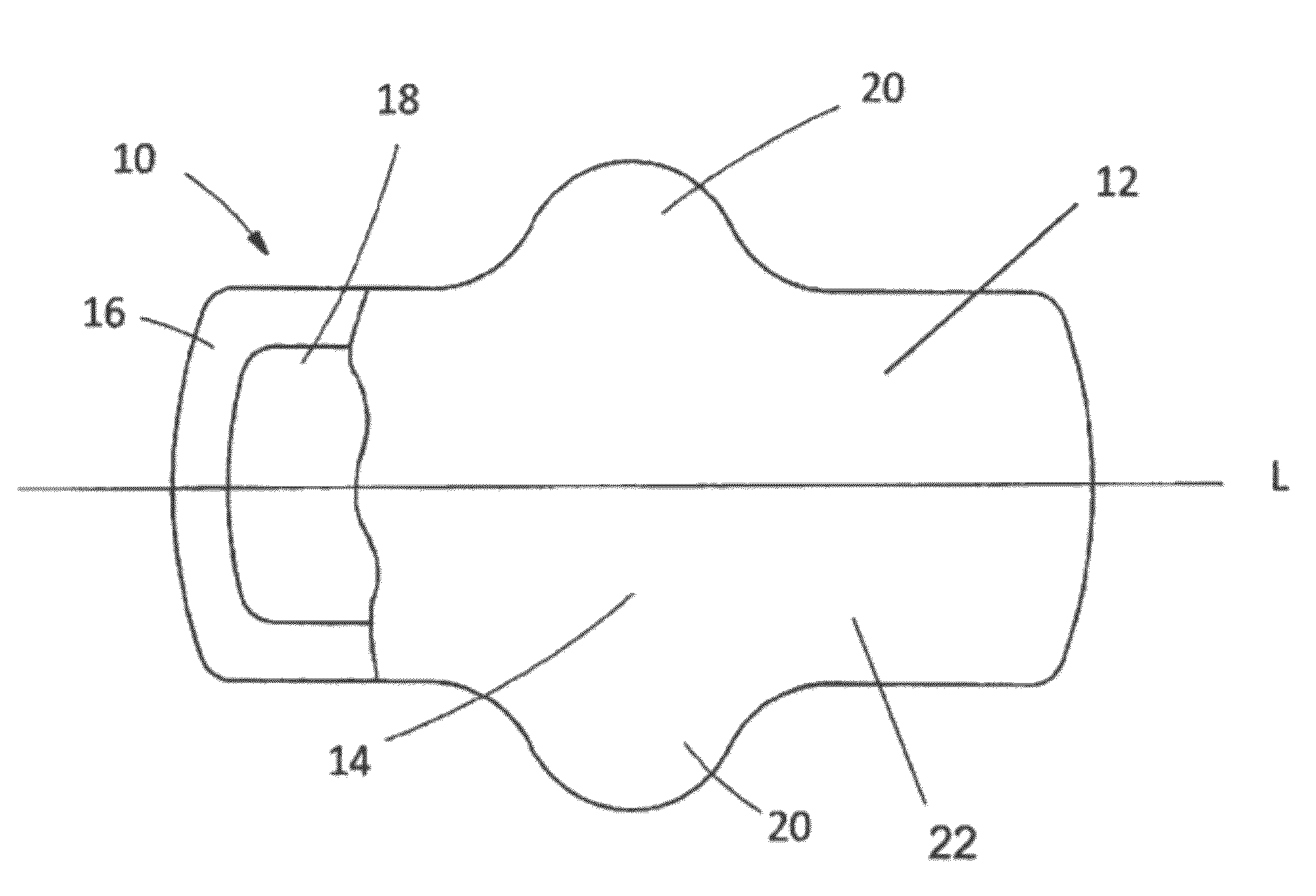

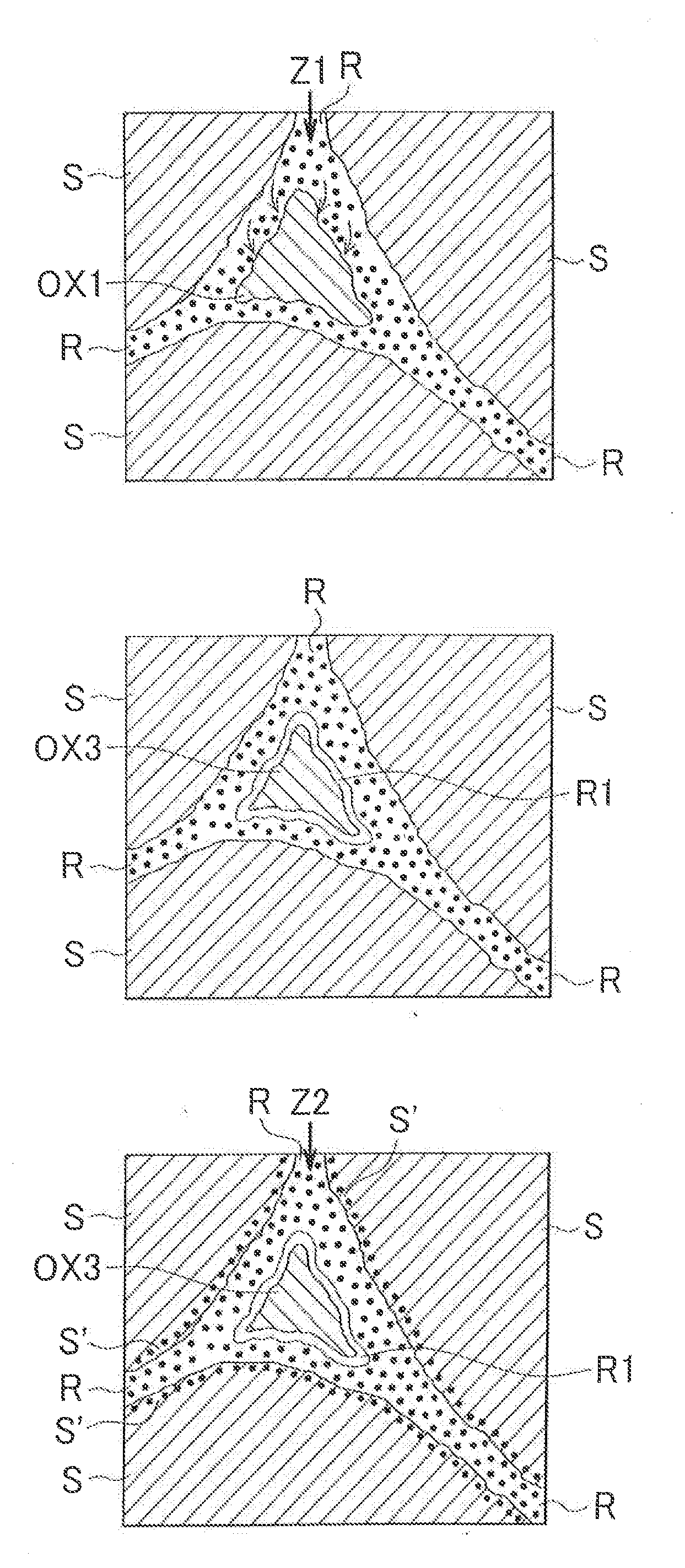

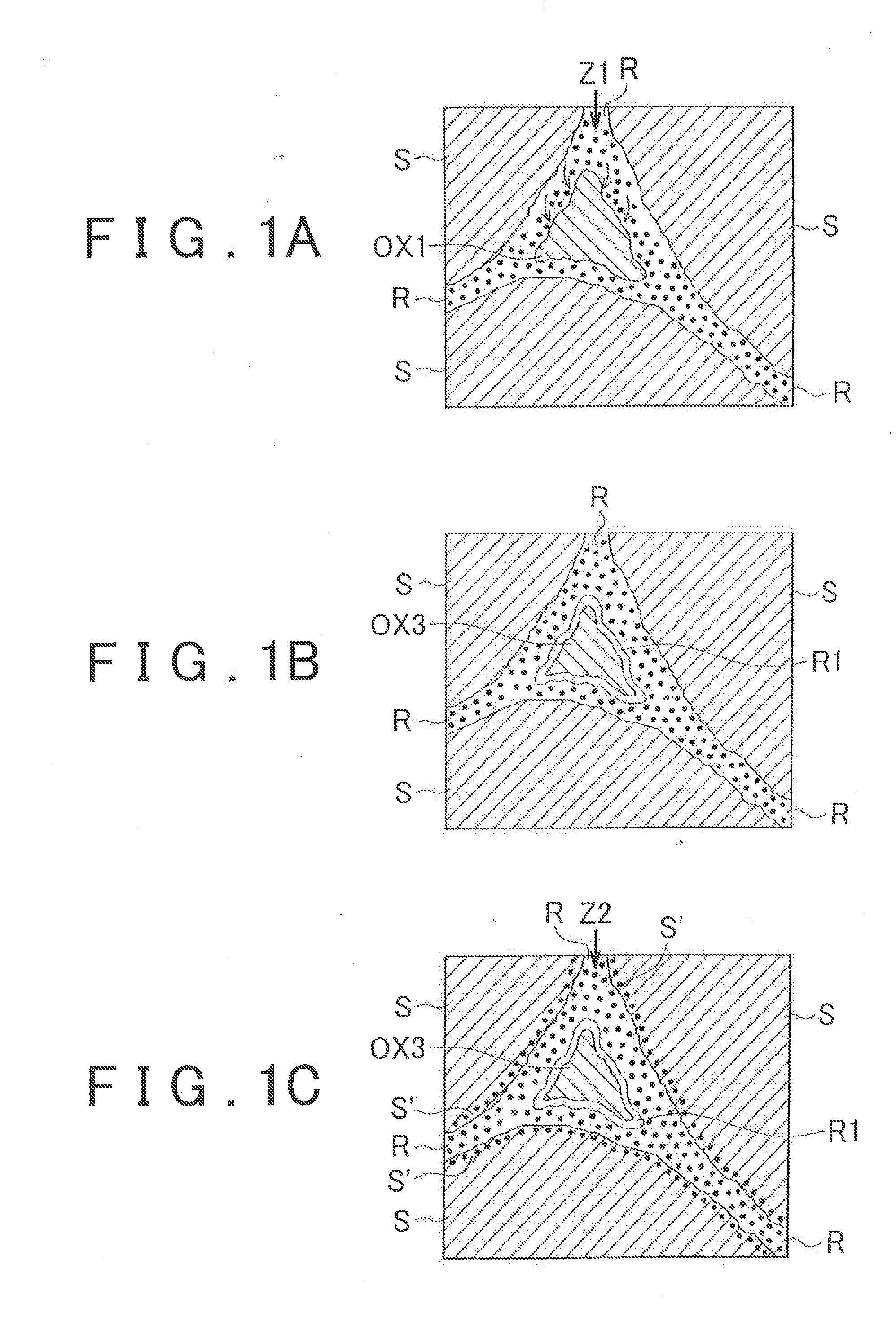

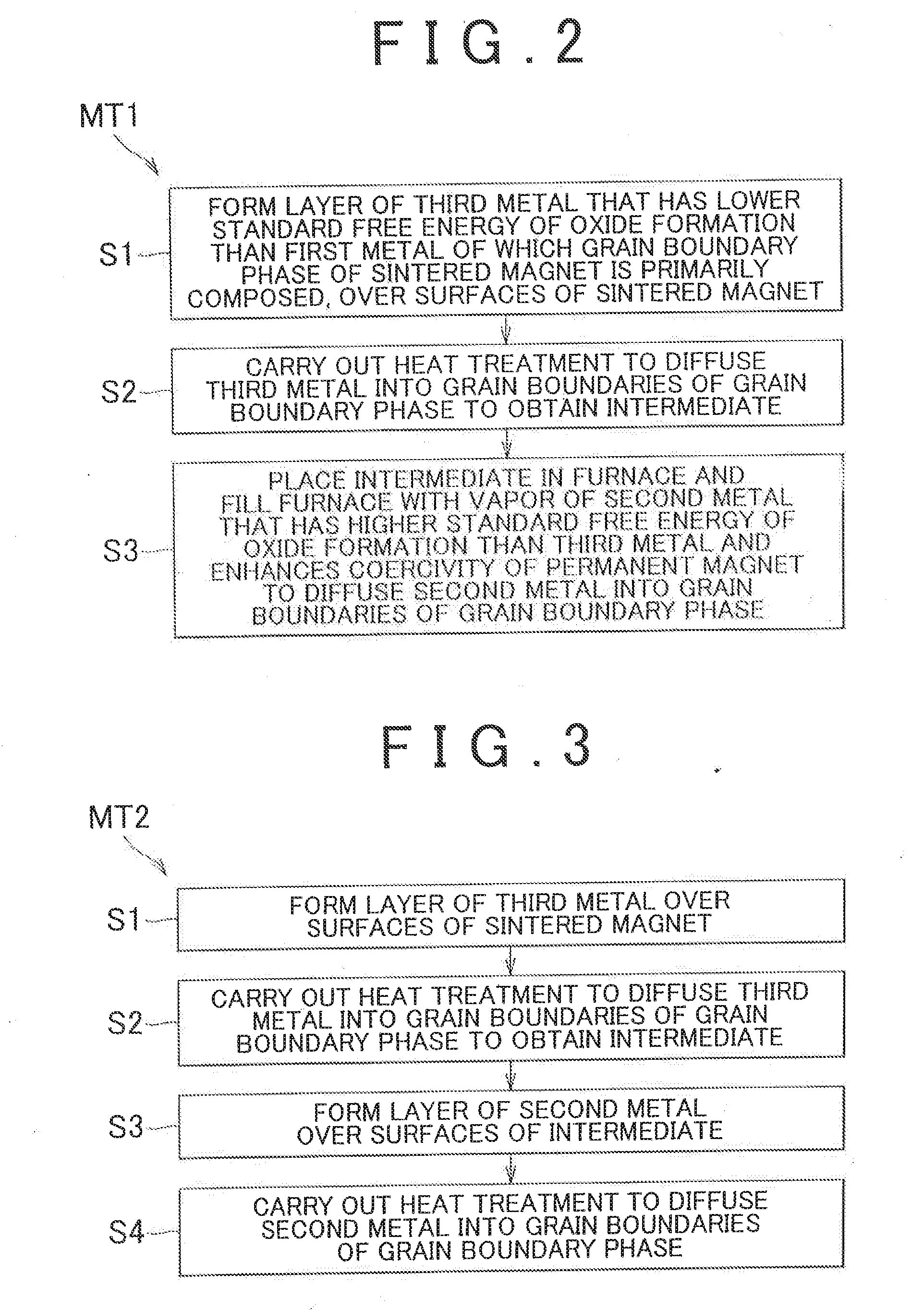

Permanent magnet and method of producing permanent magnet

ActiveUS20130135069A1Increase output powerLow production costVacuum evaporation coatingSputtering coatingFree energiesGrain structure

A permanent magnet has a grain structure that includes a main phase and a grain boundary phase that is primarily composed of a first metal. A second metal that enhances the coercivity of the permanent magnet and a third metal that has a lower standard free energy of oxide formation than the first metal and the second metal are diffused in the permanent magnet, and the third metal is present in the form of an oxide in the grain boundary phase.

Owner:TOYOTA JIDOSHA KK

Energy-saving environment-protective methanol gasoline for vehicle and preparation thereof

InactiveCN101372636ACurb emissionsLower free energyLiquid carbonaceous fuelsGasolinePollutant emissions

The invention relates to an energy-saving and environment-friendly vehicle methanol gasoline and a preparation method thereof, belonging to the technical field of alternative energy sources. The vehicle methanol gasoline is prepared by the following materials by weight percentage: 30-88.5% of white gasoline component oil, 10-55% of methanol and 1.5-15% of composite additive; the composite additive is composed of the following components: 60-77.5% of latent solvent, 17-30% of heat value enriching substance, 0.08-1.3% of power synergistic agent, 3.5-10% of homogeneous catalysis combustion improver, 0.6-3.0% of corrosion and swelling inhibitor and 1.5-3.5% of vapor pressure regulator, after being evenly mixed, the materials are added into 10-55% of methanol, after being slightly stirred, the mixture is filled in 30-85.5% of white gasoline, evenly stirred and is subject to static reaction for 4-8 hours. The methanol gasoline can effectively solve the technical difficult problems of power reduction, high gasoline consumption, corrosiveness, swelling, difficult cold start, high-temperature air resistance, and the like, when the content of methanol gasoline is 10-55%; the vehicle methanol gasoline can be directly used on automobiles, while engines do not need to be modified; the vehicle methanol gasoline can also be mixed or interchanged with white gasoline and ethanol gasoline for application. The invention has the advantages of easily available raw materials, low cost, simple preparation technique and significant energy-saving benefit, and can greatly reduce tail gas pollutant emission.

Owner:TIANJIN LANDUN PETRO CHEM TECH

Silicon dioxide-based CMP (Chemical Mechanical Polishing) solution and preparation method thereof

ActiveCN102796460AReduce surface activityLower free energyPolishing compositions with abrasivesElectrical conductorUltrasonic dispersion

The invention provides silicon dioxide-based CMP (Chemical Mechanical Polishing) solution which is applied to global planarization of a very large scale integrated circuit silicon substrate and an interlayer medium and a preparation method of the silicon dioxide-based CMP solution. The polishing solution contains the following components in percentage by weight: 10-50 percent of nano silicon dioxide grinding material, 0.1-10 percent of dispersant, 0.1-10 percent of wetting agent, 0.1-10 percent of chelating agent, 0.01-1 percent of pH (Potential of Hydrogen) regulator and the balance of de-ionized water. The polishing solution is prepared through the means of: modifying with a surfactant, strongly and mechanically stirring, performing high-shear grinding, performing ultrasonic dispersion and the like, and the problem of extreme easiness in flocculation and agglomeration of nano-scale grinding material particles is solved. Since the particle size distribution of the grinding material is narrow, the range is selectable, the polishing rate is easy to adjust and control and the polishing solution is alkaline, equipment is not corroded, less damage is caused, cleaning is easy and the environment is not polluted. The silicon dioxide-based CMP solution can be used for chemical mechanical polishing of the very large scale integrated circuit silicon substrate, the interlayer medium, a shallow trench isolation isolator, conductor and damascene metal.

Owner:ANTEDI TIANJIN TECH

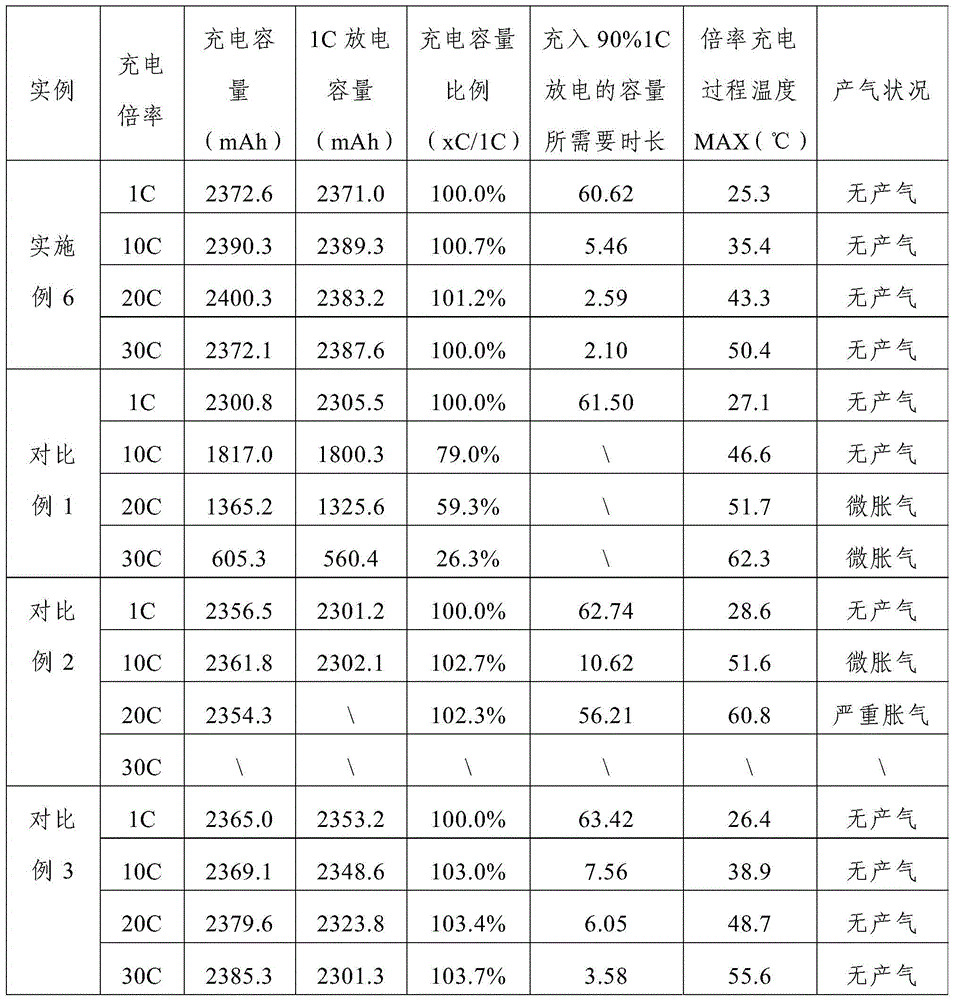

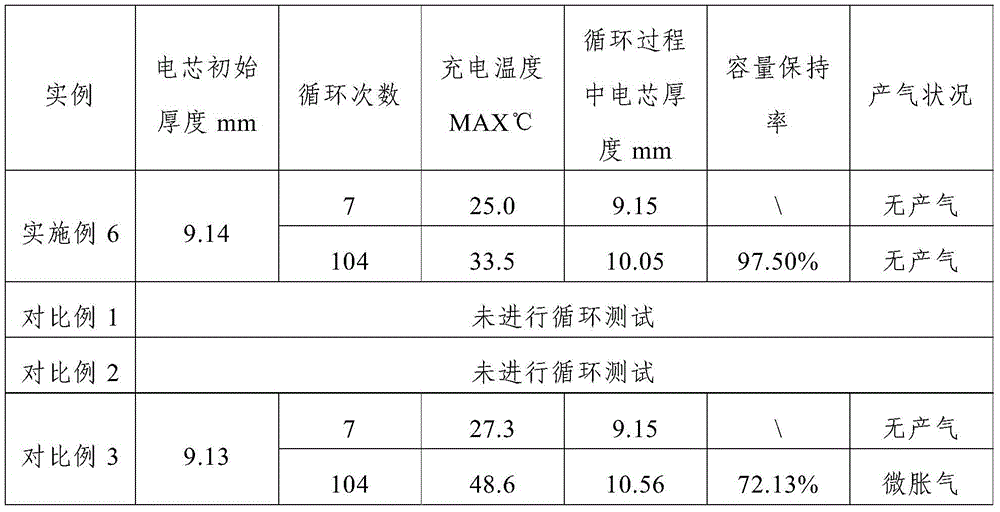

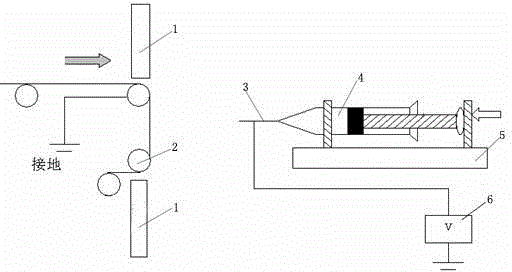

Quick charging lithium-ion battery

The invention discloses a quick charging lithium-ion battery, which comprises a positive plate, a negative plate, a diaphragm, an electrolyte, a positive tab, a negative tab and a package shell, wherein the negative plate is prepared by coating two surfaces of copper foil with a negative paste containing a negative active material; and the negative active material is modified graphite of which the mean particle size D<50> is 3microns to 20microns. The lithium-ion battery disclosed by the invention can be used at super high rate, and has 30C continuous charging capability; the charging capacity can reach over 95% of 1C low-current charging capacity; over 90% of battery capacity can be charged for 2 minutes at 30C; quick charging can be achieved; and the charge capacity retention ratio is over 97.31% through charging at 30C and 100 discharge cycles at 1C.

Owner:XIAN SAFTY ENERGY TECH

Arranging method of super-hydrophobic and hydrophilic double-faced heterologous cotton fabric

The invention discloses an arranging method of a super-hydrophobic and hydrophilic double-faced heterologous cotton fabric. The method comprises the steps of spraying a silicon dioxide sol finishing agent and a water-based fluorine-containing polyacrylic acid water repellent finishing agent on the surface of the cotton fabric by using a high voltage static field, keeping low amounts of condensing liquids, controlling the finishing agent only on the single face of the cotton fabric without permeation, then steaming, baking and washing, forming a coating on one surface of the cotton fabric to rough on the single face of the fabric, reducing the surface free energy of the cotton fabric and endowing the super-hydrophobicity of single face of the cotton fabric; on the other side, the good inherent hygroscopicity can be kept to obtain the super-hydrophobic and hydrophilic double-faced heterologous cotton fabric; furthermore, the arranging method provided by the invention is convenient to operate, simple in process and good in operability; meanwhile, the amounts of condensing liquids of the cotton fabric are low, therefore the method is applicable to the single water repellent finish of uneven heavy cotton fabrics, and the prepared super-hydrophobic and hydrophilic double-faced heterologous cotton fabric can meet the special requirements on functionality and comfort.

Owner:ZHONGYUAN ENGINEERING COLLEGE

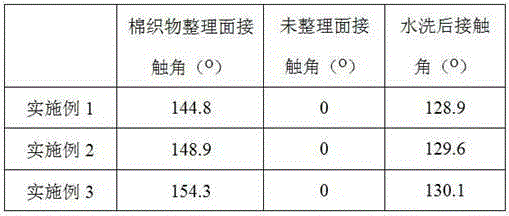

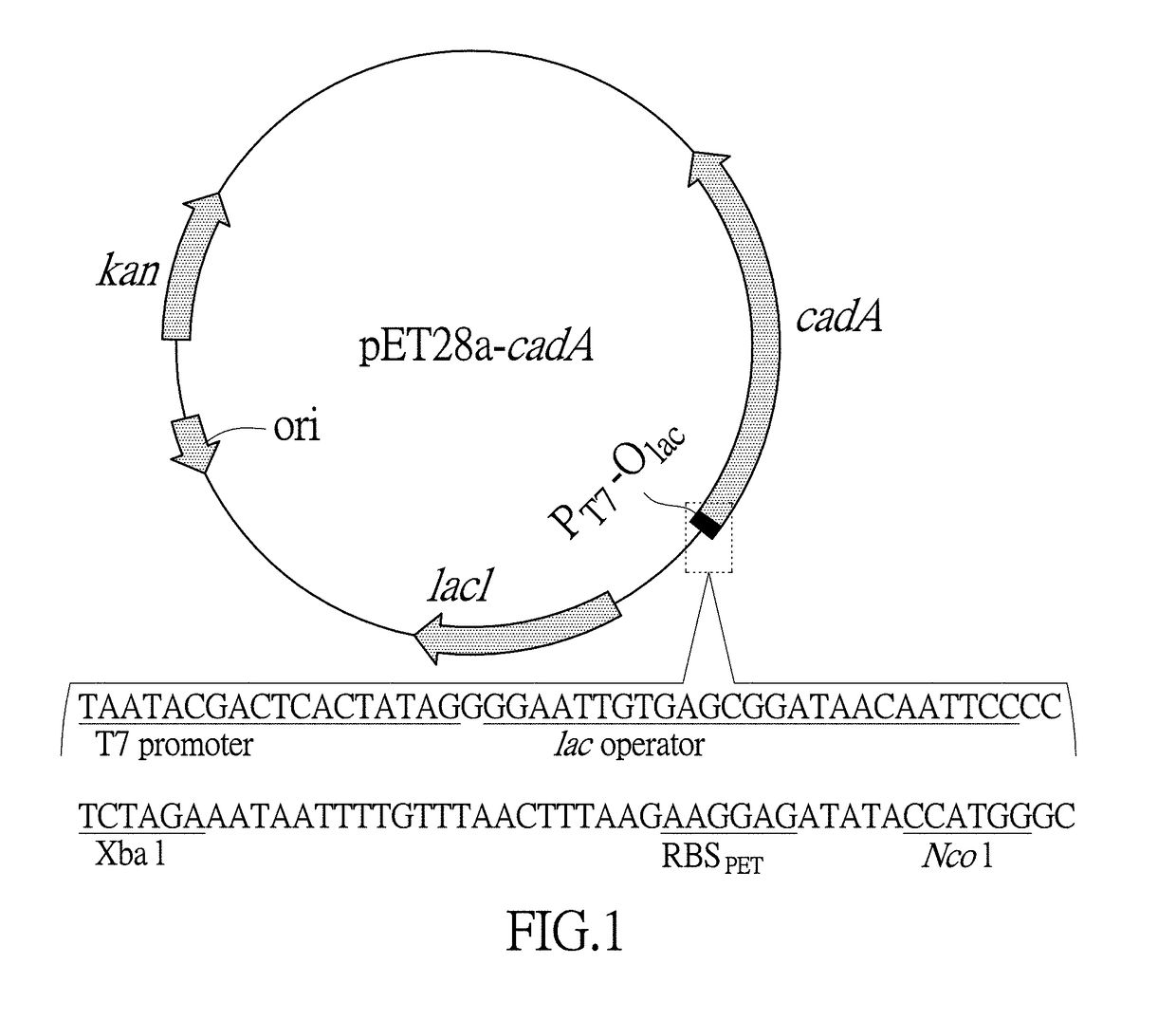

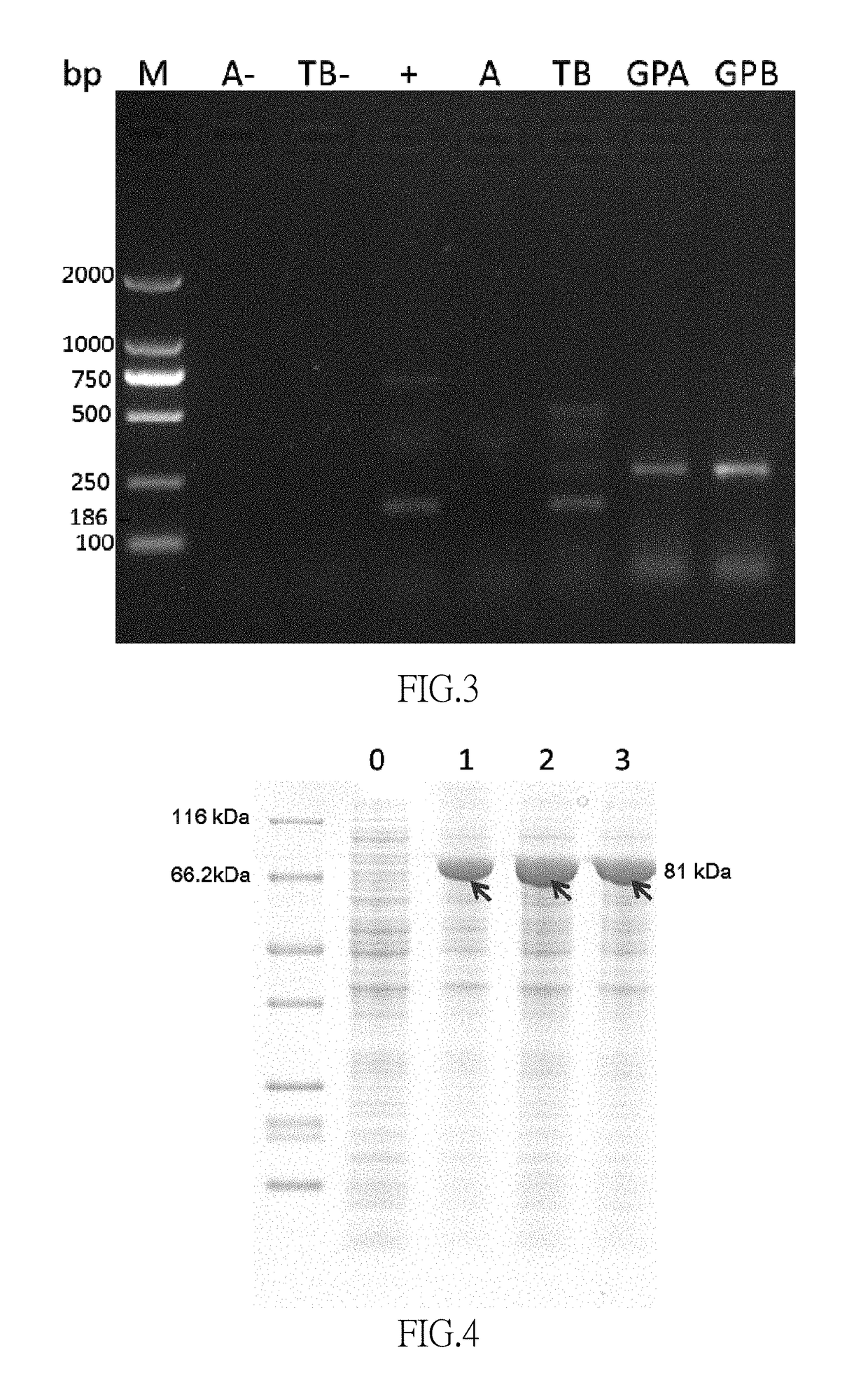

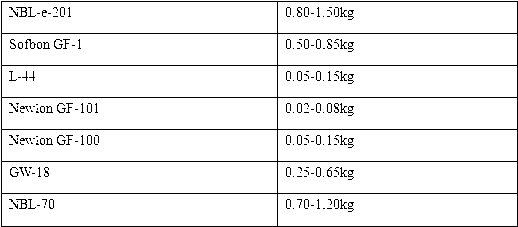

E. coli engineering bacteria producing 1,5-pentanediamine through whole cell catalysis and application thereof

ActiveUS20170226544A1High efficient protein expressionImprove catalytic performanceMicroorganismsMicroorganism based processesEscherichia coliTranslocator protein

The present invention discloses an E. coli engineering bacteria producing 1,5-pentanediamine through a whole cell catalysis and its application. The engineering bacteria according to the present invention, is Escherichia coli (E. coli) strain B or its derivative strains with the overexpression of a lysine decarboxylase gene and a proper expression of a lysine-cadaverine antiporter gene cadB. The engineering bacteria according to the present invention is the engineering bacteria producing 1,5-pentanediamine through the whole cell catalysis constructed from Escherichia coli B derivative strains, which has an overexpression of a lysine decarboxylase gene cadA and a proper expression of the lysine-cadaverine antiporter gene cadB. The present invention further discloses a method of producing a 1,5-pentanediamine catalyzed by the engineering bacteria, the yield and production intensity of 1,5-pentanediamine in bio-based production could be significantly improved through the method, hence it could be applied to mass production and convenient for extending applications.

Owner:HEILONGJIANG EPPEN NEW MATERIALS LTD

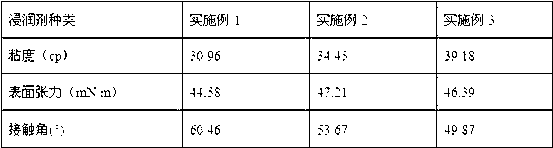

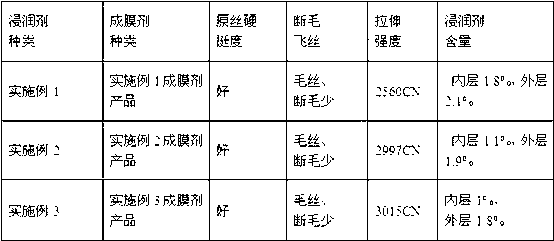

A method for preparing an esterified starch film former for glass fiber wetting

The present invention discloses a method for preparing an esterified starch film former for glass fiber wetting, and the method is characterized in that the product of the esterified starch film former for glass fiber wetting is obtained by: placing corn starch into a reactor, adding water, heating to a temperature of 70-90 DEG C under stirring, reacting for 0.5- 2h, and cooling to 30-60 DEG C; adjusting a pH value to 4-7, adding isoamylase, after reacting for 0.5-6h, heating to a temperature of 80-90 DEG C for 20 min for enzyme deactivation, and filtering to remove the enzyme and obtain a reaction solution; and cooling the reaction solution to a temperature of 25-55 DEG C, adding an acid anhydride, adding an alkaline catalyst, maintaining the pH value being 7-10, reacting for 2-10h, adjusting the pH value to be 6-7, cooling to the room temperature, suction filtering, and drying a solid. The product of the film former has the advantages of a good film forming property and an easy post-treatment process, and has excellent effects of bundling and protecting the glass fiber in the production process of the glass fiber.

Owner:SOUTHWEAT UNIV OF SCI & TECH

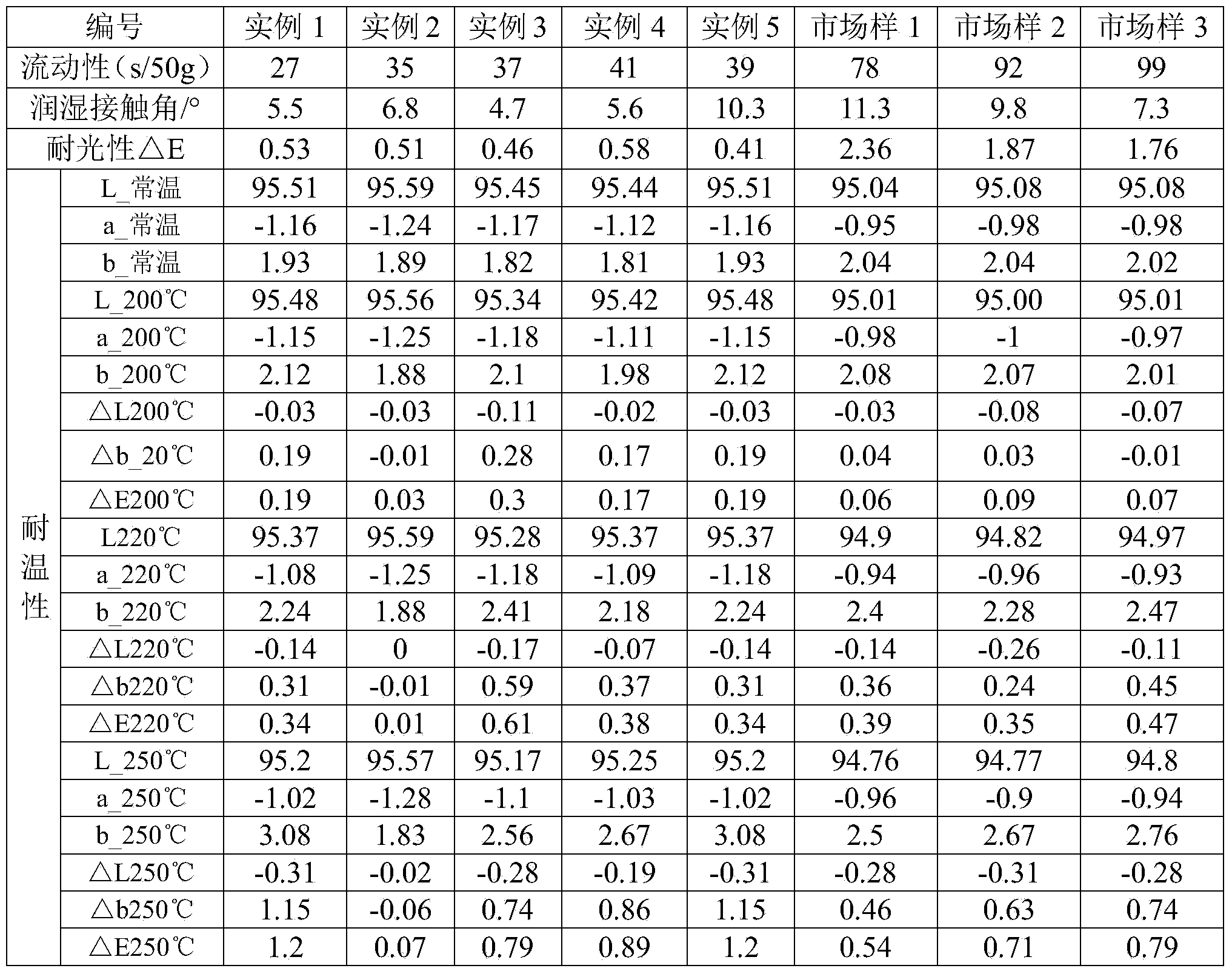

Preparation method of high-fluidity TiO2 and organic surface treatment mechanism thereof

ActiveCN104356692AImprove liquidityEasy to washPigment treatment with organosilicon compoundsSteam pressureFiltration

The invention discloses a preparation method of high-fluidity TiO2 and an organic surface treatment mechanism thereof and belongs to the technical field of TiO2 preparation. The preparation method comprises the following steps: 1, a titanium dioxide crude product is ground and dispersed; 2, inorganic surface treatment is carried out on slurry; 3, suction filtration and washing are carried out on the slurry by the use of deionized water, and the slurry is dried; 4, a cavity in a high-temperature bag filter is preheated, steam pressure is controlled, and steam is conveyed to the high-temperature bag filter; 5, when temperature in the cavity reaches 200-300 DEG C, steam temperature is controlled to 280-300 DEG C; 6, when temperature in the cavity reaches 140-160 DEG C, thermal insulation is carried out on the high-temperature bag filter; and 7, 40-60% of an organosilicone surface treating agent is added into a jet mill, and the dosage is 0.3-0.5 percent; and simultaneously, feeding is conducted to carry out organic surface treatment. In the stage of jet pulverization, organosilicon (silicone oil) is selected to be added so as to carry out organic surfactant coating on TiO2, and by lubrication effect and low surface energy of organosilicon, high fluidity is achieved at macro level.

Owner:ANHUI JXTB GRP

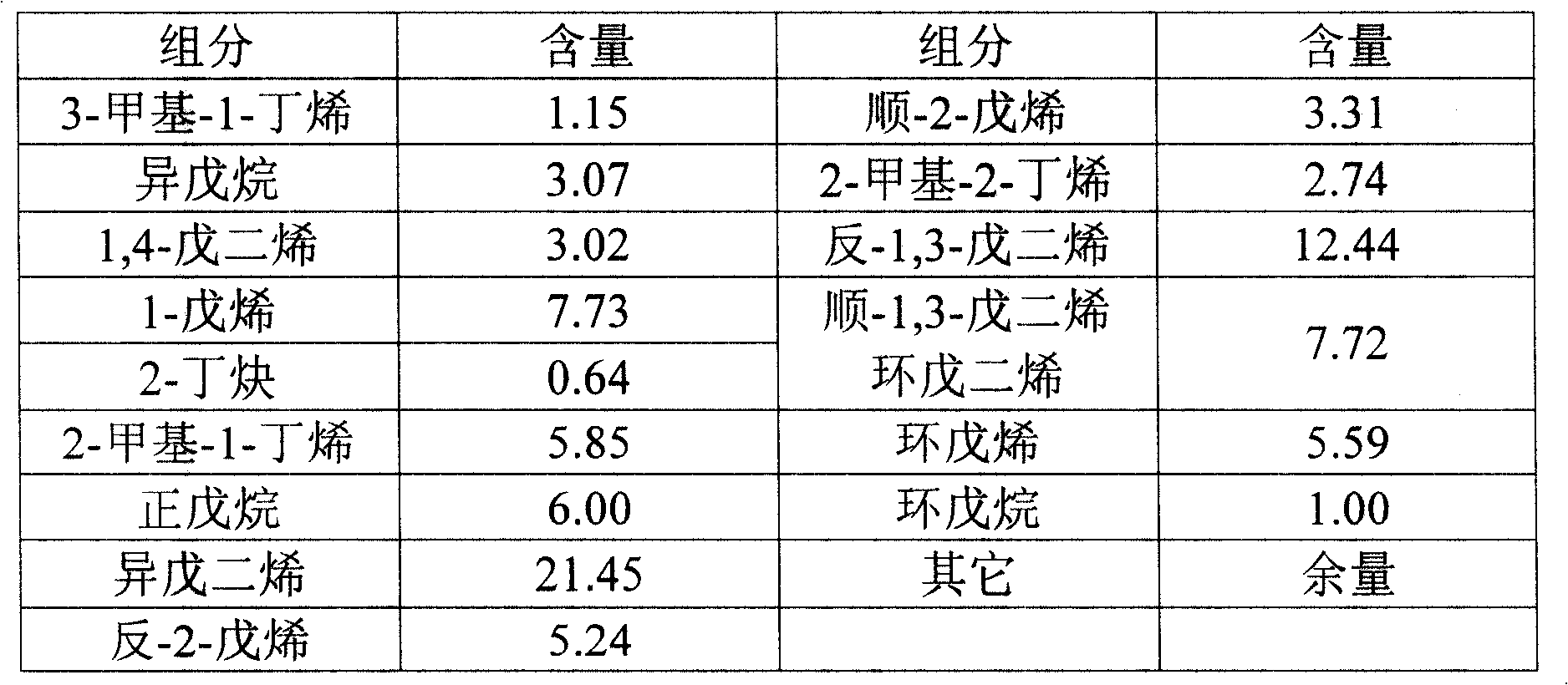

Cracking carbon five selective hydrogenation catalyst

ActiveCN101254465AHigh activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionStrontiumPotassium

The invention relates to a selective hydrogenation catalyst for C5 fraction cracking and belongs to the technology field of hydrogenation catalysts. In order to meet the urgent need of the selective hydrogenation catalysts for the C5 fraction cracking, the invention provides a catalyst for selective hydrogenation in the C5 fraction cracking, which contains the following components in the given mass percentages: Ni 10-35%, La 0.5-3%, Ag 0.3-3% and aluminum oxide carrier 59-89.2%, calculated on basis of the total mass of the catalyst. The catalyst can also contains K and / or Sr or Pb. The catalyst is used for selective hydrogenation in the C5 fraction cracking as well as hydrogenation in the C5 fraction cracking and excellent in conversion rate, selectivity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com